Modular heat exchanger

a heat exchanger and multi-channel technology, applied in the field of heat exchangers, can solve the problem of limited heat exchangers in the overall siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

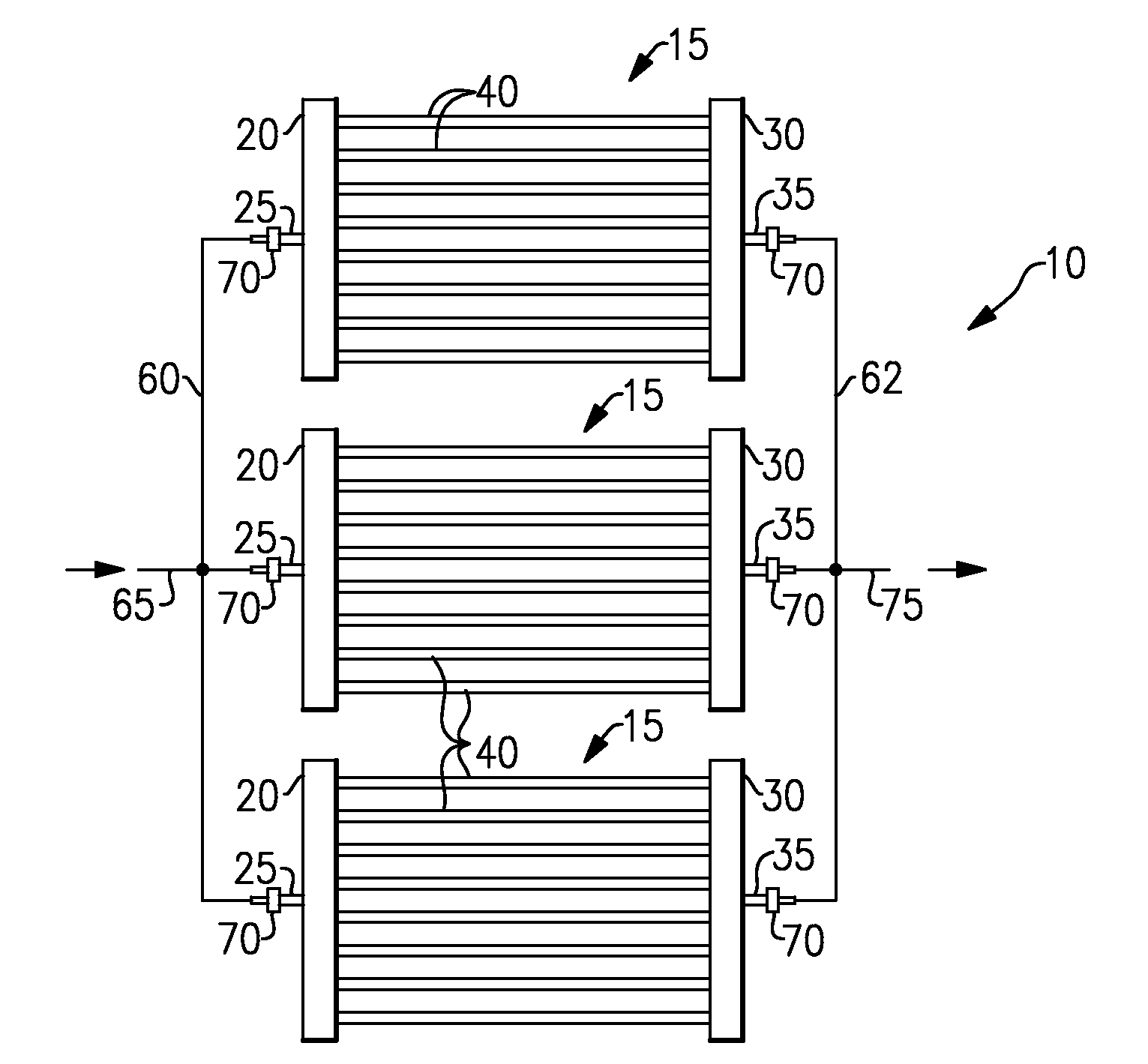

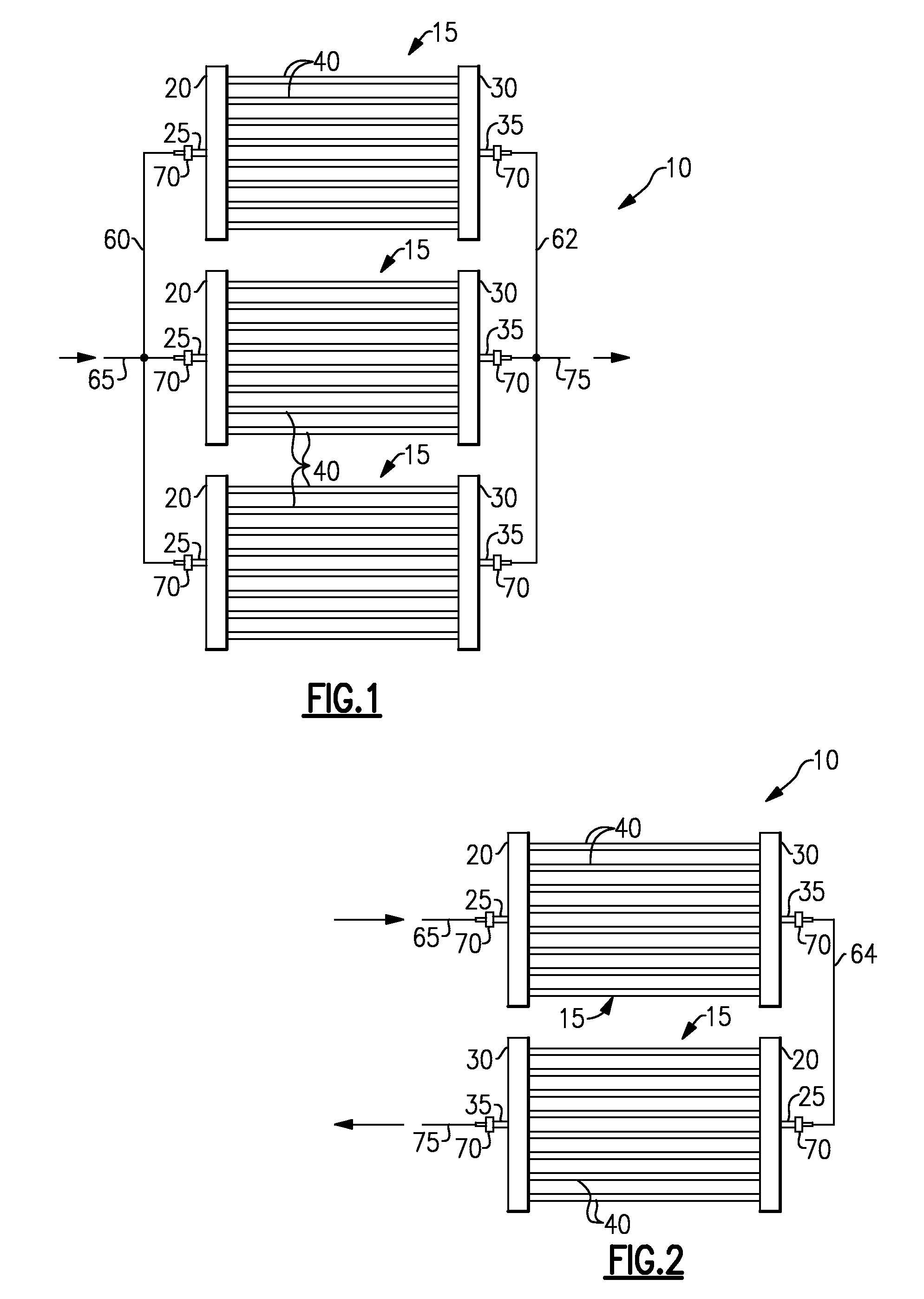

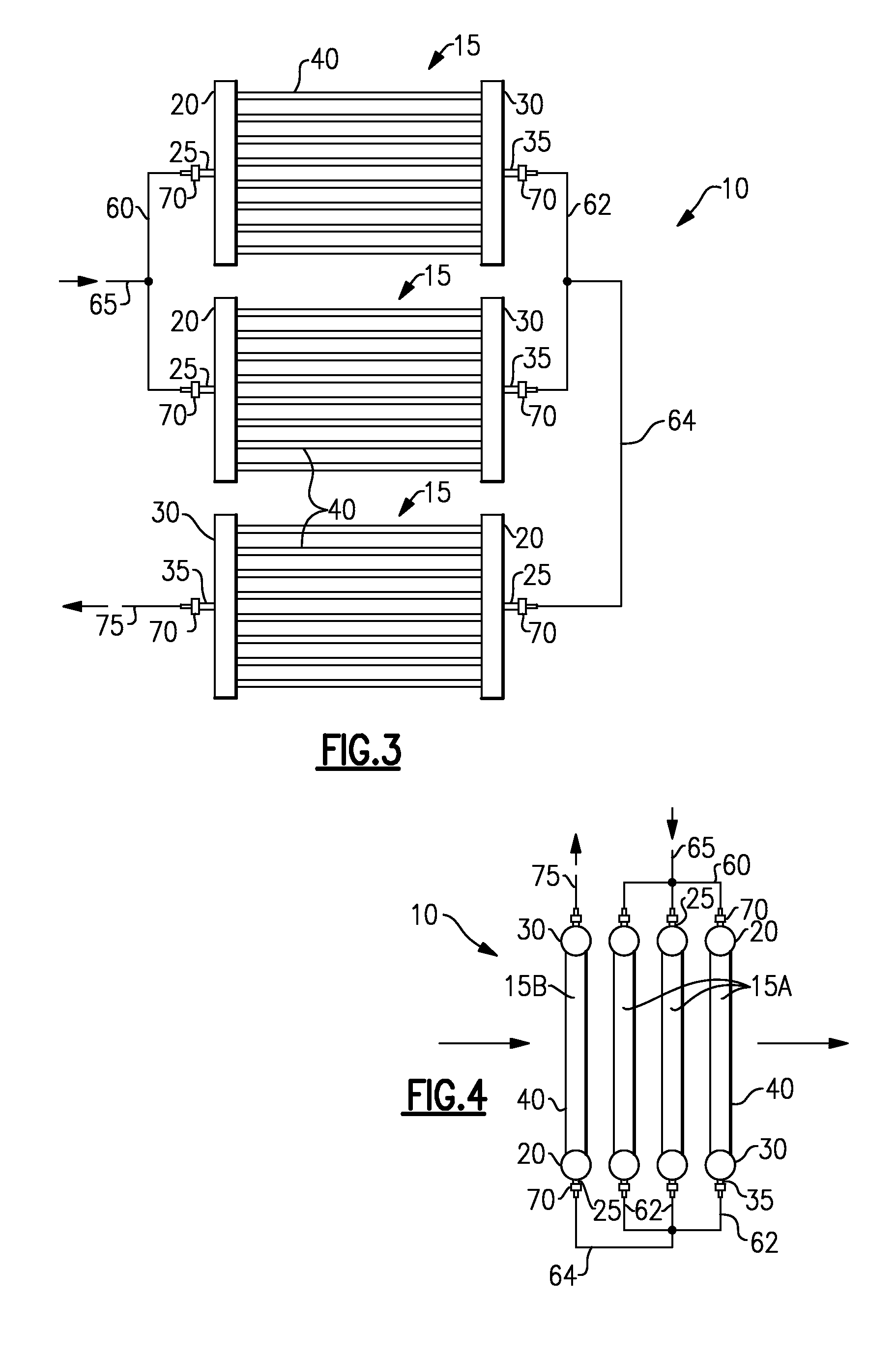

[0023]The modular, multi-channel heat exchanger 10 of the invention will be described in general herein with reference to the various exemplary embodiments depicted in FIGS. 1-8. However, the depicted embodiments are illustrative and are not intended to limit the invention. It is to be understood that the modular, multi-channel tube heat exchanger 10 of the invention may be comprised of any number of a plurality of heat exchanger modules arranged in various configurations.

[0024]In each of the illustrated exemplary embodiments shown in FIGS. 1-4, the heat exchanger 10, in its simplest configuration, includes a plurality, that is two or more, single pass, parallel-tube, multi-channel tube heat exchanger modules 15. In the exemplary embodiment depicted in FIG. 1, the heat exchanger 10 comprises three heat exchanger modules 15 arranged in a parallel configuration, with respect to refrigerant flow. In the exemplary embodiment depicted in FIG. 2, the heat exchanger 10 comprises a pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com