Energy Conversion Using Rankine Cycle System

a technology of energy conversion and rankine cycle, applied in the field of energy conservation, can solve the problems of large-scale steam turbines with low power generation efficiency and confuse the efficiency of the combined heat and power system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

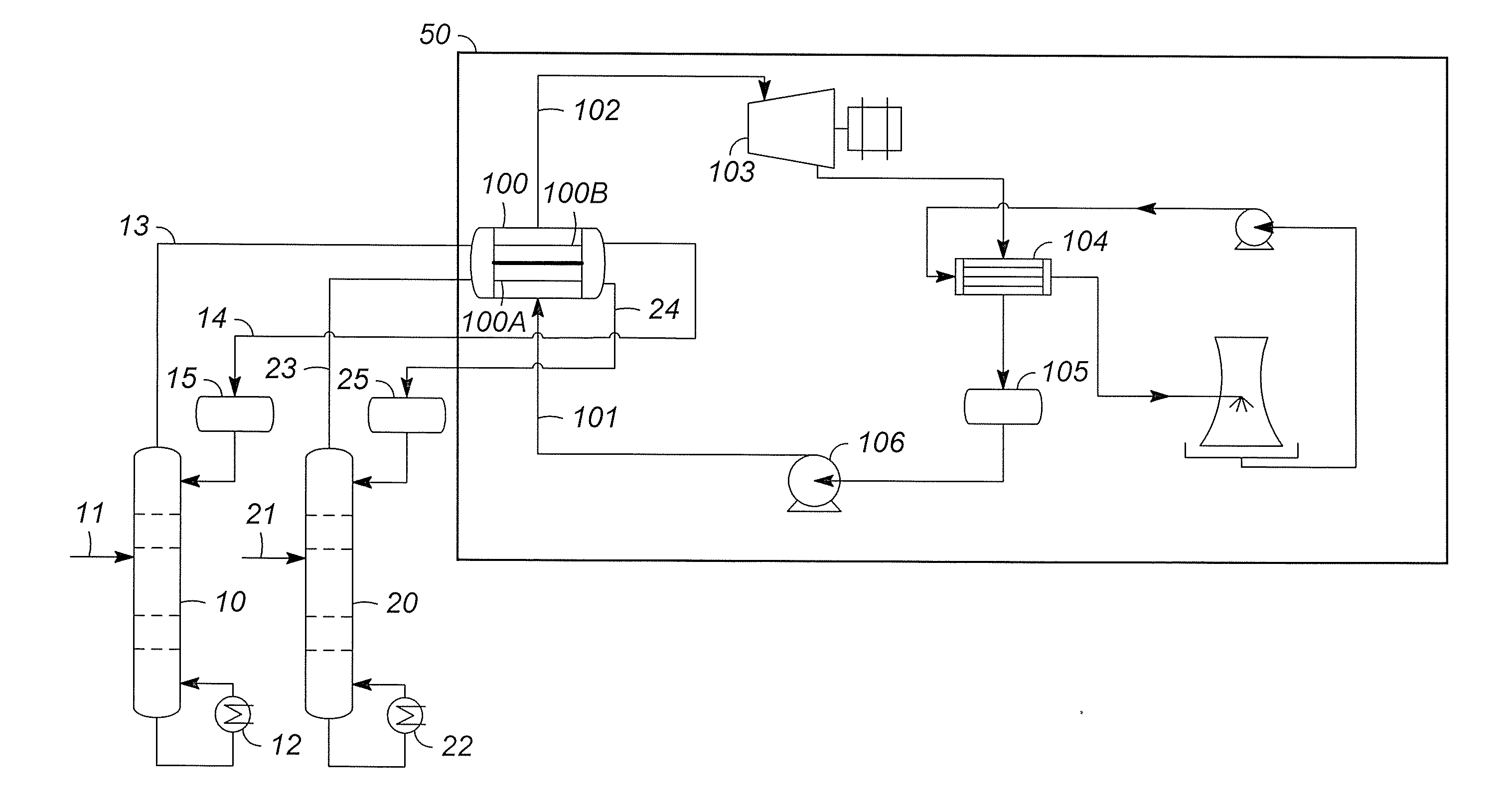

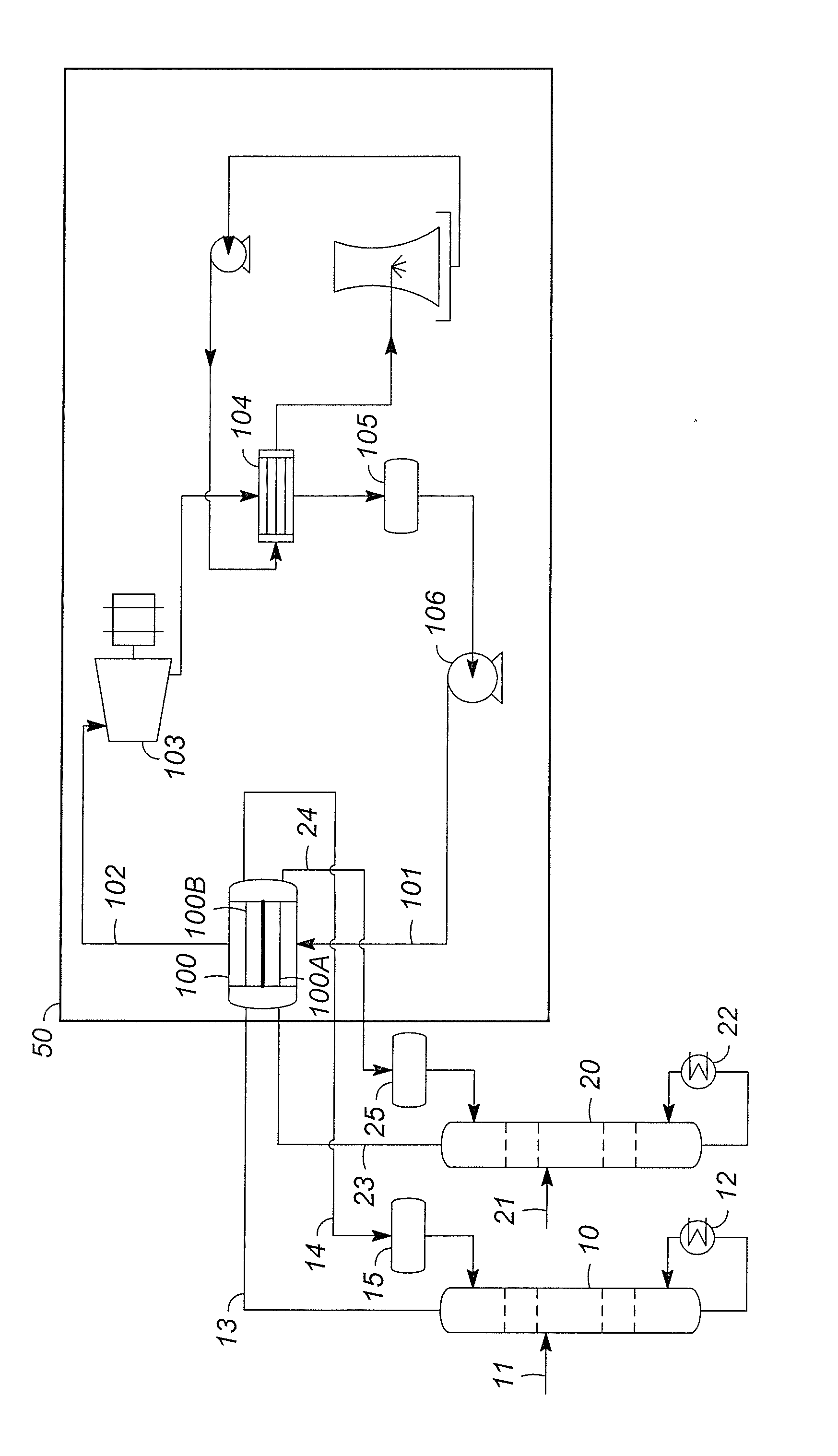

[0023]The following example illustrates the benefits of the invention using ORC in an aromatics complex producing 900,000 tons / year of para-xylene. Aspects of the aromatics complex are described in U.S. Pat. No. 6,740,788 which is incorporated herein by reference. Columns 10 and 20 as described in the FIGURE of the present application are, respectively, distillation columns in an adsorption separation unit separating C8-aromatics raffinate from desorbent and para-xylene-rich extract from desorbent. The raffinate column is, relatively, the high-temperature column and the extract column is the low-temperature column. To compare ORC to air cooling and water cooling, the heat duties are as follows:

Heat Rejected(MW)T-in (° C.)T-out (° C.)Extract Column Overhead34.0151.1128.9Raffinate Column Overhead90.6152.6140.8Total124.6——

[0024]The net power benefit of using ORC relative to air and water condenser cases is calculated using the following equations:

[0025]For Water Cooling:

[0026]Net Power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com