Patents

Literature

67 results about "Confounding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In statistics, a confounder (also confounding variable, confounding factor, or lurking variable) is a variable that influences both the dependent variable and independent variable, causing a spurious association. Confounding is a causal concept, and as such, cannot be described in terms of correlations or associations.

Method for judging category of failures caused by electrical contact in sealed electromagnetic relay

InactiveCN101806861AEliminate distracting factorsCircuit interrupters testingSpecial data processing applicationsPrincipal component analysisInterference factor

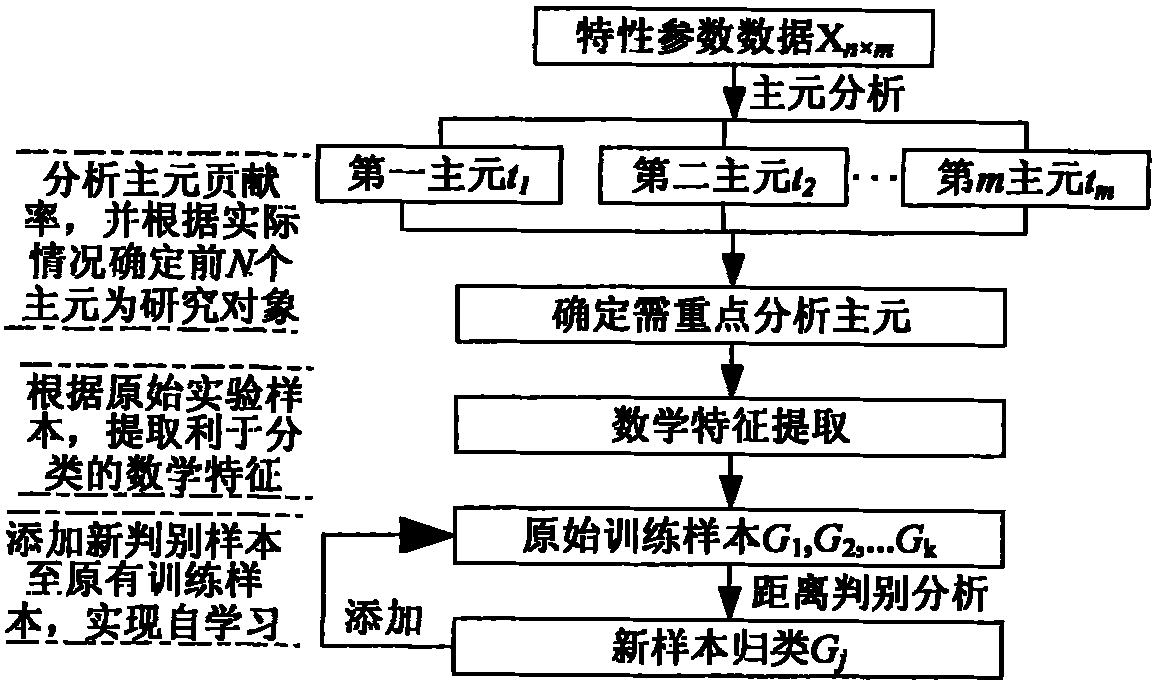

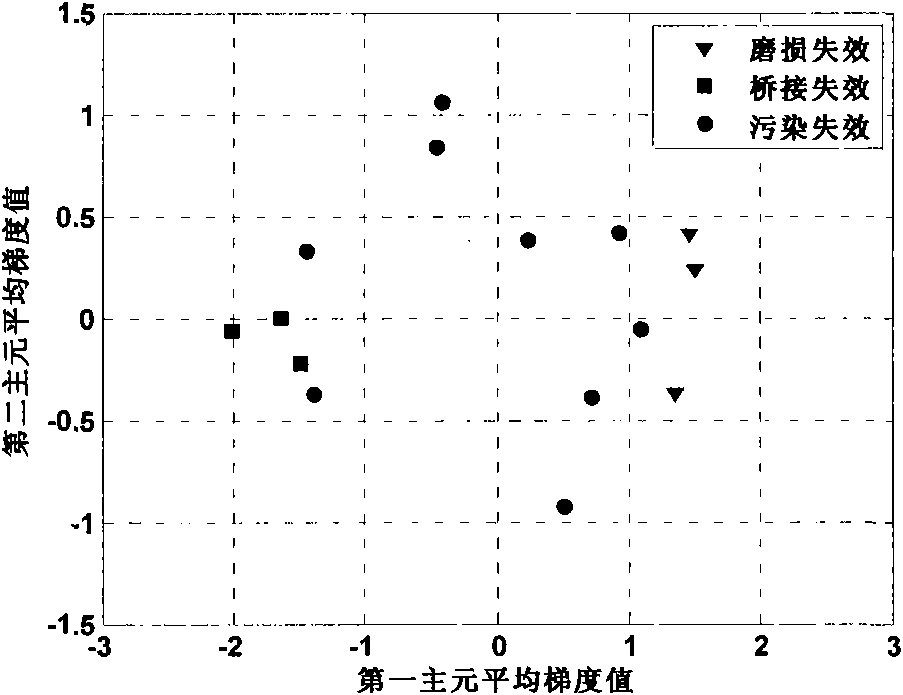

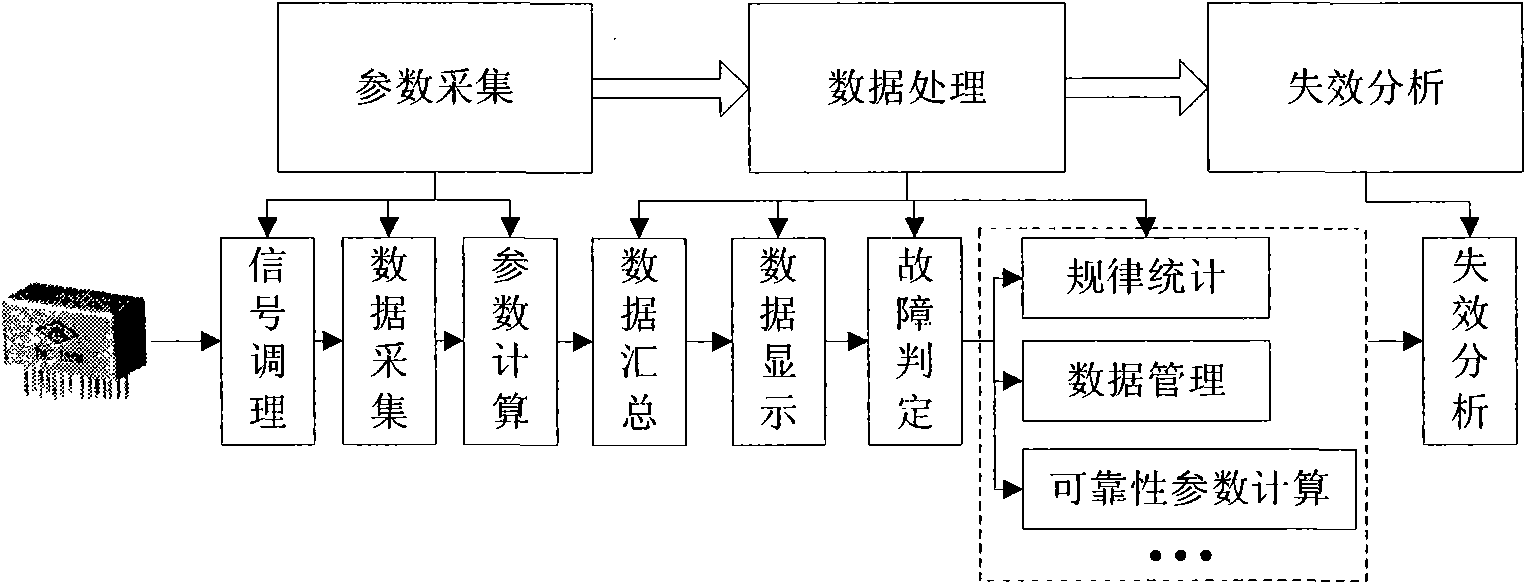

The invention provides a method for judging the category of failures caused by electrical contact in a sealed electromagnetic relay. The method comprises the following steps: firstly, running tests on the reliability life of a plurality of sealed electromagnetic relays as the samples to be tested; recording the relation between the contact resistance and other characteristic parameters of each sample to be tested and the operation frequency thereof in the entire test process; forming a data matrix Xn*6 from the six characteristic parameters, such as the contact resistance; carrying out the dimension reduction pre-processing on the multi-dimension characteristic parameter data by using the principal component analysis method; extracting the corresponding data characteristics from the data subjected to the dimension reduction, and sorting the data characteristics by failure mechanisms; and calculating the Mahalanobis distances between the new sample to be tested and various training samples using the distance discriminant analysis method, and comparing the Mahalanobis distances to judge the category of the failure. Instead of opening a housing and achieving the failure analysis by optical microscopes and other instruments, the invention can eliminate the interference factors caused by other inducements and expose and locate the real causes of failures.

Owner:HARBIN INST OF TECH

Short-term load prediction method based on time sequence

InactiveCN105701559AImprove management levelHighly innovativeForecastingPredictive methodsInterference factor

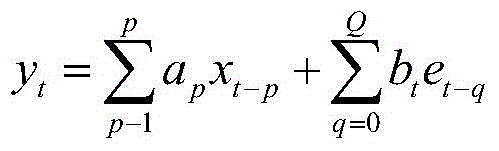

The invention discloses a short-term load forecasting method based on time series, which belongs to the technical field of power supply. It conducts statistical analysis on the historical load of the existing regional power grid, and preprocesses the collected daily power consumption data to obtain a stable, normal, zero-mean time series; establishes a mathematical model based on the historical data of daily power load , use this mathematical model to describe the statistical regularity of the random variable change process of electric load; on the basis of this mathematical model, establish the mathematical expression of daily electric load forecasting, and predict the future load. In this technical solution, the power load to be measured is used as the dependent variable, and the past value of the power load is used as the independent variable. The obtained mathematical model successfully reflects the relationship between the dependent variable and the independent variable as well as the interference factors hidden in it. , especially suitable for short-term daily electricity load forecasting. It can be widely used in the fields of load forecasting and load management in power systems.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

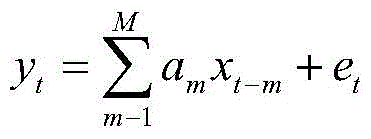

Forward-looking radar imaging sea-surface target key point detection and recognition method

ActiveCN103971127AImplement adaptive selectionStandardization of resultsCharacter and pattern recognitionRadar imagingInterference factor

The invention discloses a forward-looking radar imaging sea-surface target key point detection and recognition method. The method includes the steps that radar echo data are quantized into a gray scale image; a region of interest is extracted from the gray scale image, partition is performed, and a target region partition image is obtained; the radar echo data and the region of interest of the image are used, and a target region peak point information matrix is obtained; information merging is conducted on the target region partition image and the target region peak point information matrix, the number K of peak points in a target region in a merging result is obtained through counting, the previous K peak points are selected and serve as target effective peak points and form a target effective peak point image in a binaryzation mode, target axial features are extracted, and a target position is determined; the center of gravity of target energy is calculated and serves as the target key point. According to forward-looking radar target features, multiple mode identification methods are used comprehensively, the inherent features of a target can be reserved, meanwhile interference factors such as artifacts and side lobes can be restrained, and the recognition accuracy and the positioning precision of radar imaging sea surface target key points are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

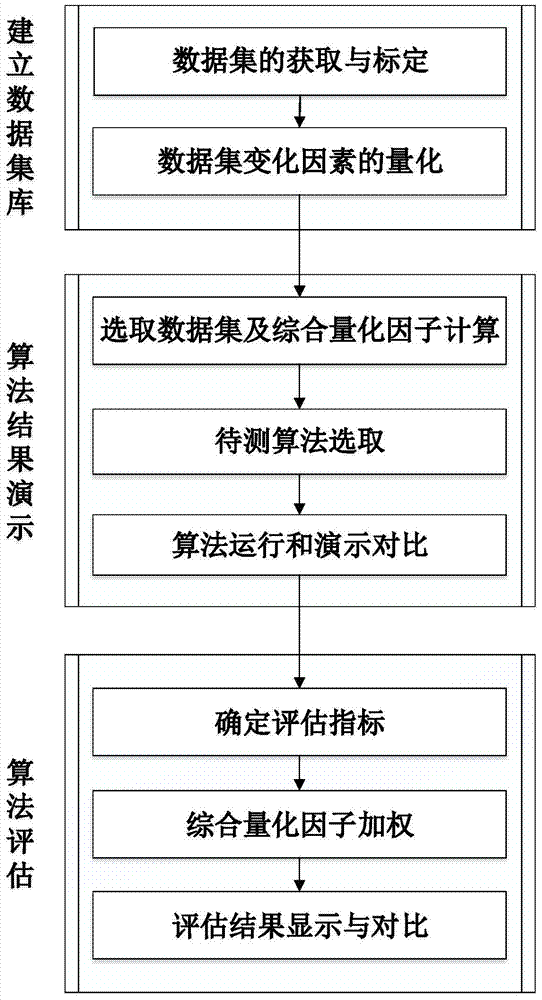

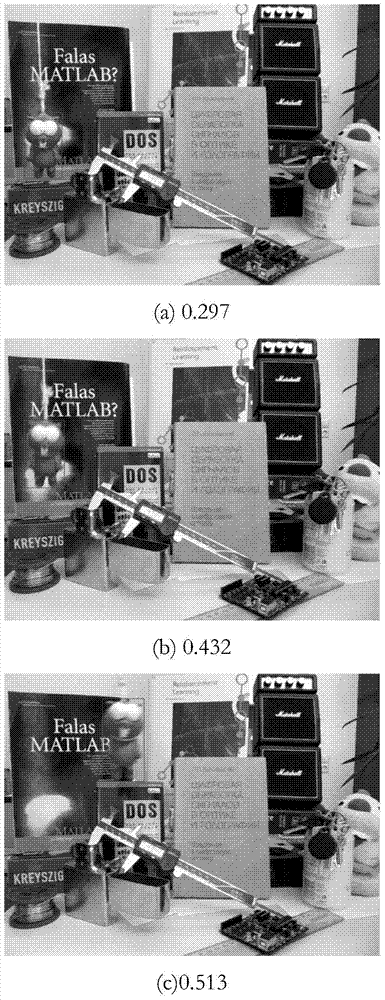

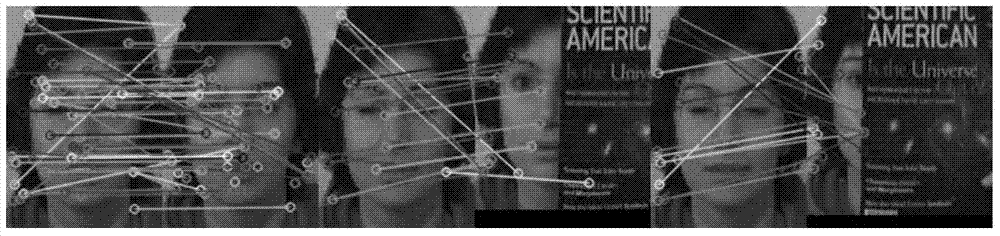

Moving target detecting and tracking algorithm evaluation method based on data set compensation

The invention discloses a moving target detecting and tracking algorithm evaluation method based on data set compensation. The moving target detecting and tracking algorithm evaluation method automatically adds quantification factors of eight performance interference factors for data sets, and allows the user to select variation factors when evaluating an algorithm conveniently; the moving target detecting and tracking algorithm evaluation method can customize weight sizes of the variation factors according to degree of sensitivity of a specific evaluated algorithm to specific variation factors, so that comprehensive quantification factors corresponding to the data sets truly reflect the algorithm application environments, and finally the objectiveness of evaluation results is ensured; at last, since the comprehensive quantification factors are comprehensive quantification embodiments of the variation factors affecting algorithm performances in the corresponding data sets, the comprehensive quantification factors of the data sets are adopted for performing weighted compensation for threshold values used for carrying out success determination of the evaluation index precision OverlapP, can show different influences of the data sets with different variation factors on the algorithm performances in the evaluation result, can simulate results of the algorithm under some interference conditions, and provides certain guidance for the further improvement direction of the algorithm.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

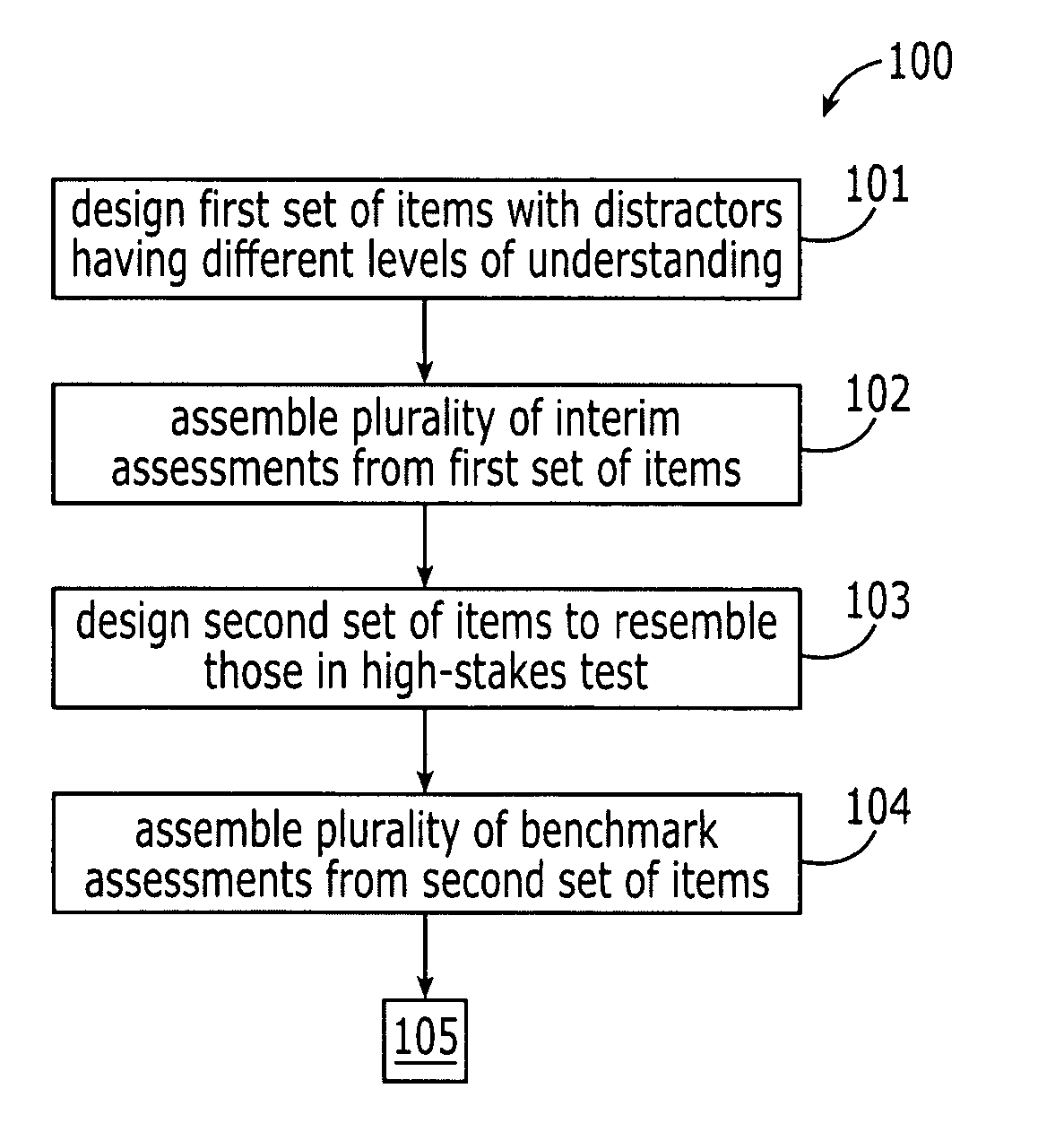

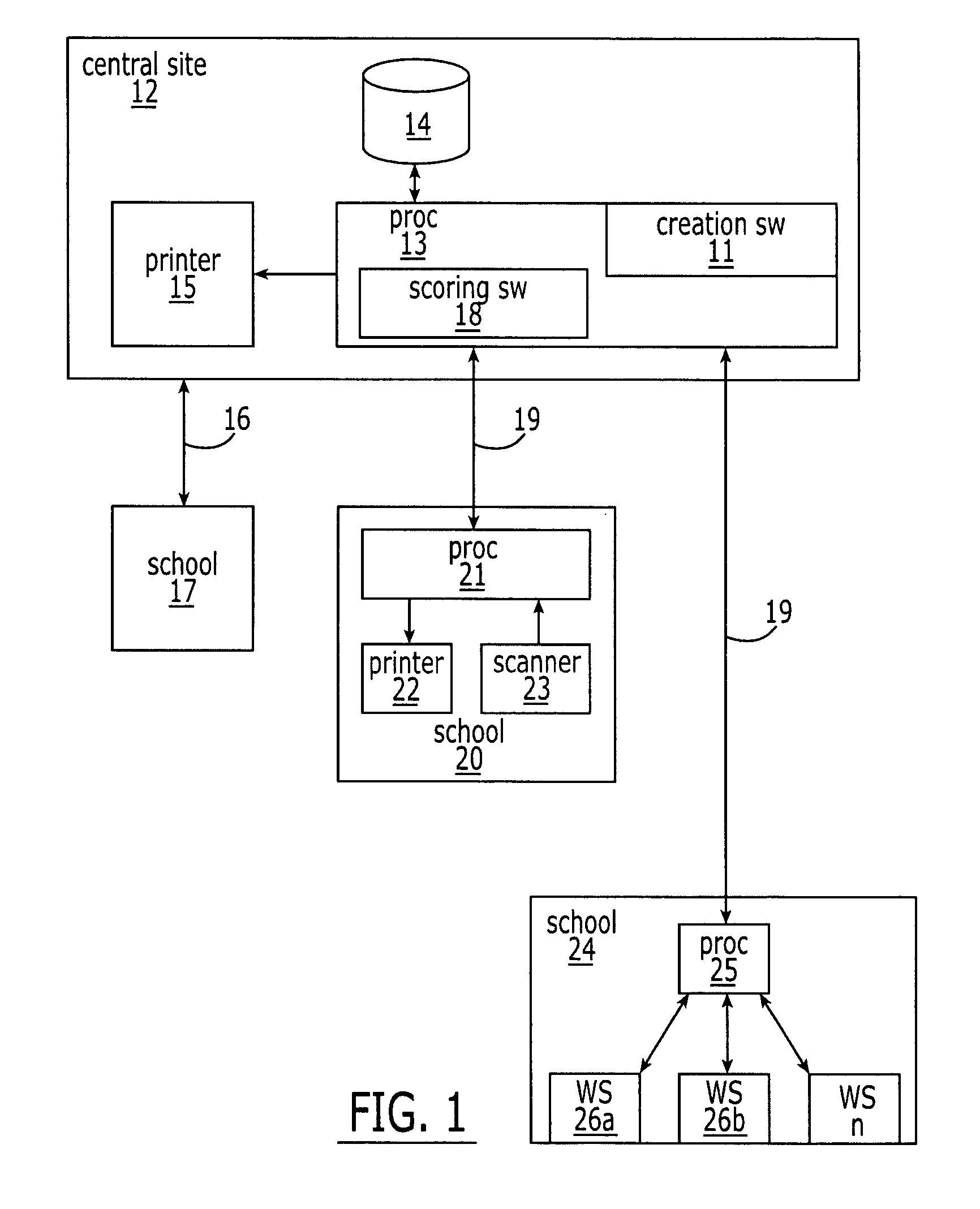

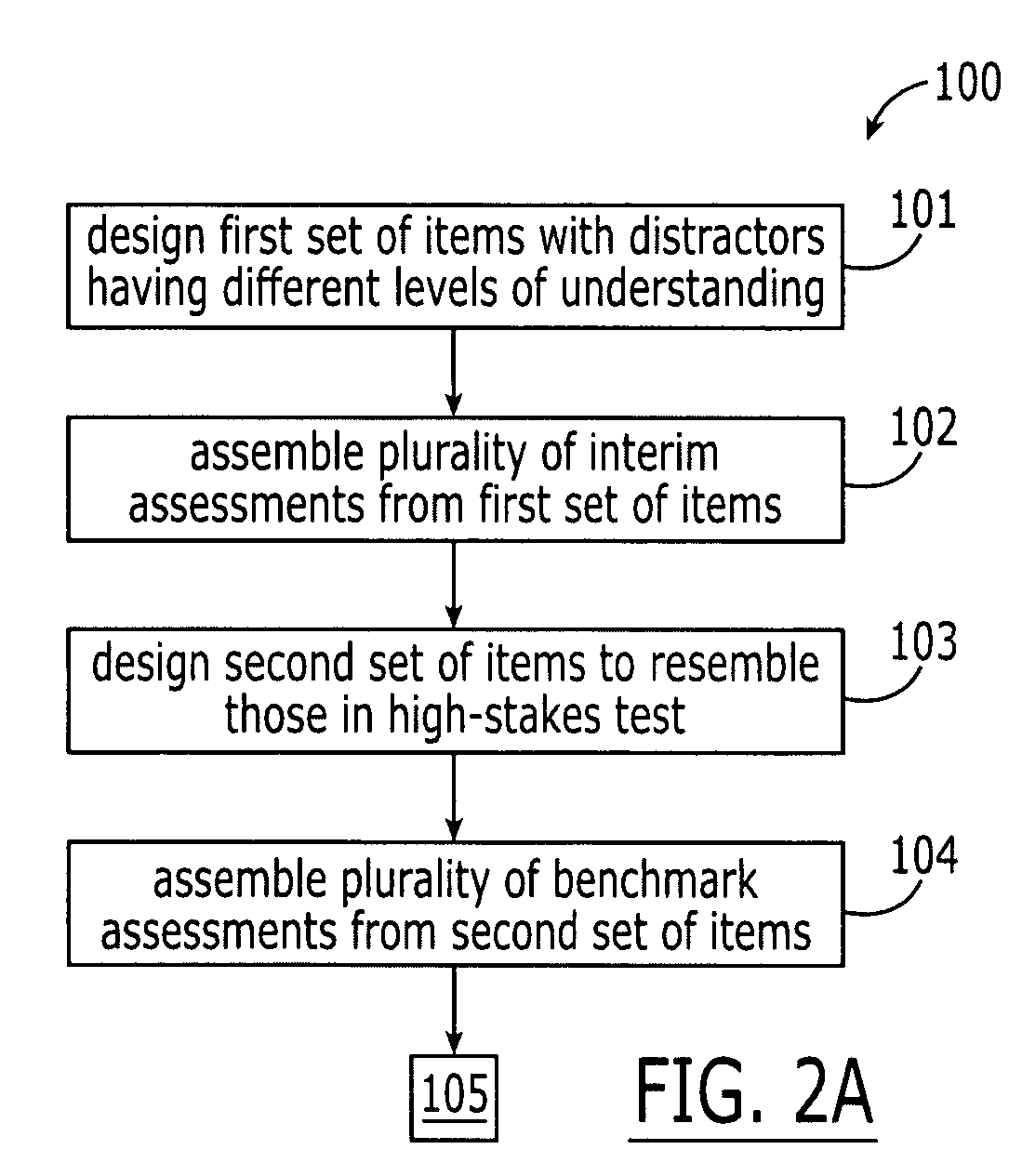

Test item development system and method

An assessment system includes interim tests administered at predetermined intervals. Each assessment is designed to test specific concepts, and includes multiple-choice test items, each having an item stem, a correct answer, and several distractors. Preferably at least two of the distractors are directed to disparate cognitive levels. Any distractors selected are automatically correlated for each student, in order to determine a presence of a possible problem in a particular concept. Then an individual focus can be applied to correcting any problems. Any distractors selected by any of the students are automatically correlated for the teacher, to determine the presence of a possible problem for a number of students, for applying focus to improving the understanding of some or all of a class for any problem identified by the correlation. A benchmark assessment is also administered that has a format substantially identical to that of an upcoming high-stakes test.

Owner:PSYCHOLOGICAL CORPORATION

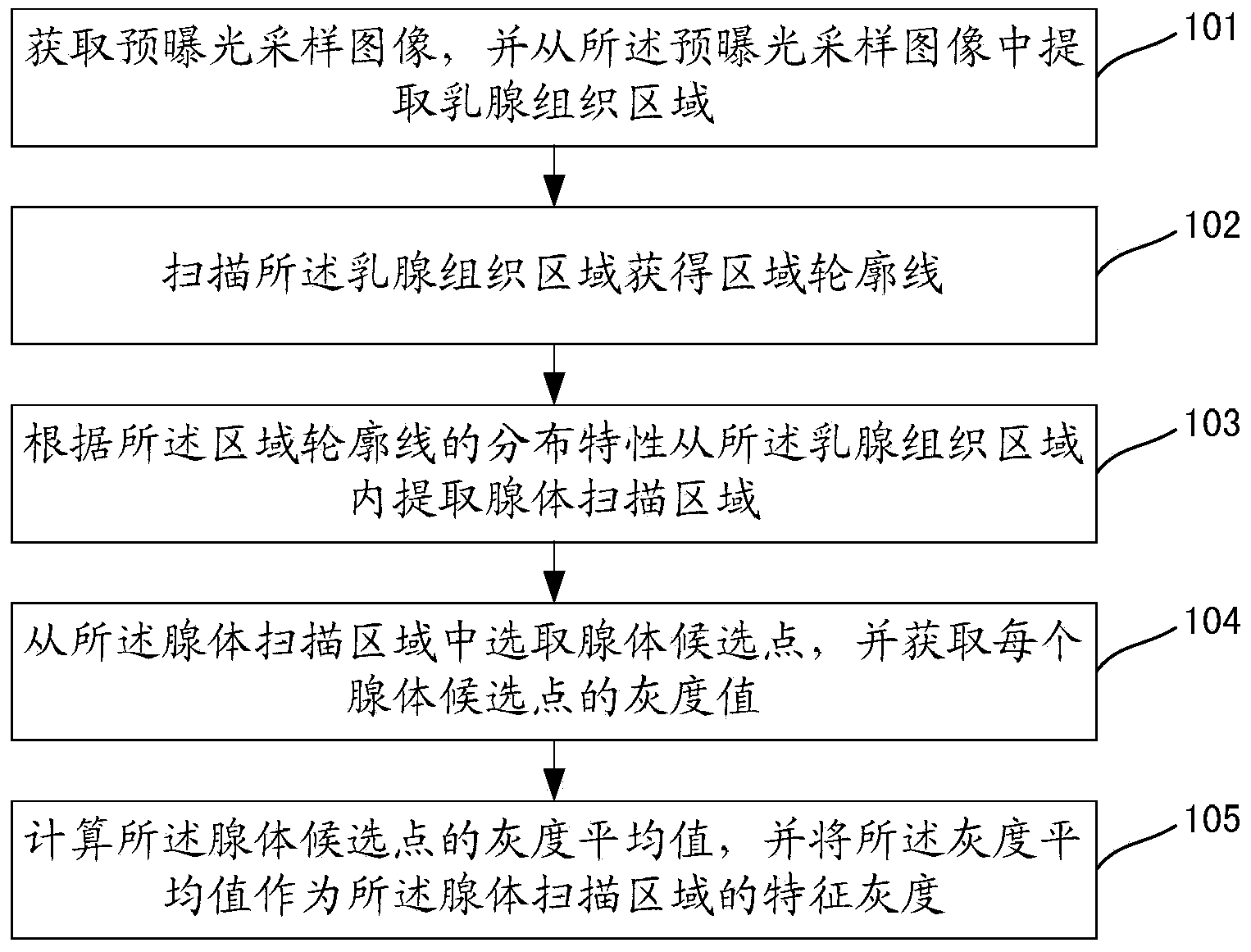

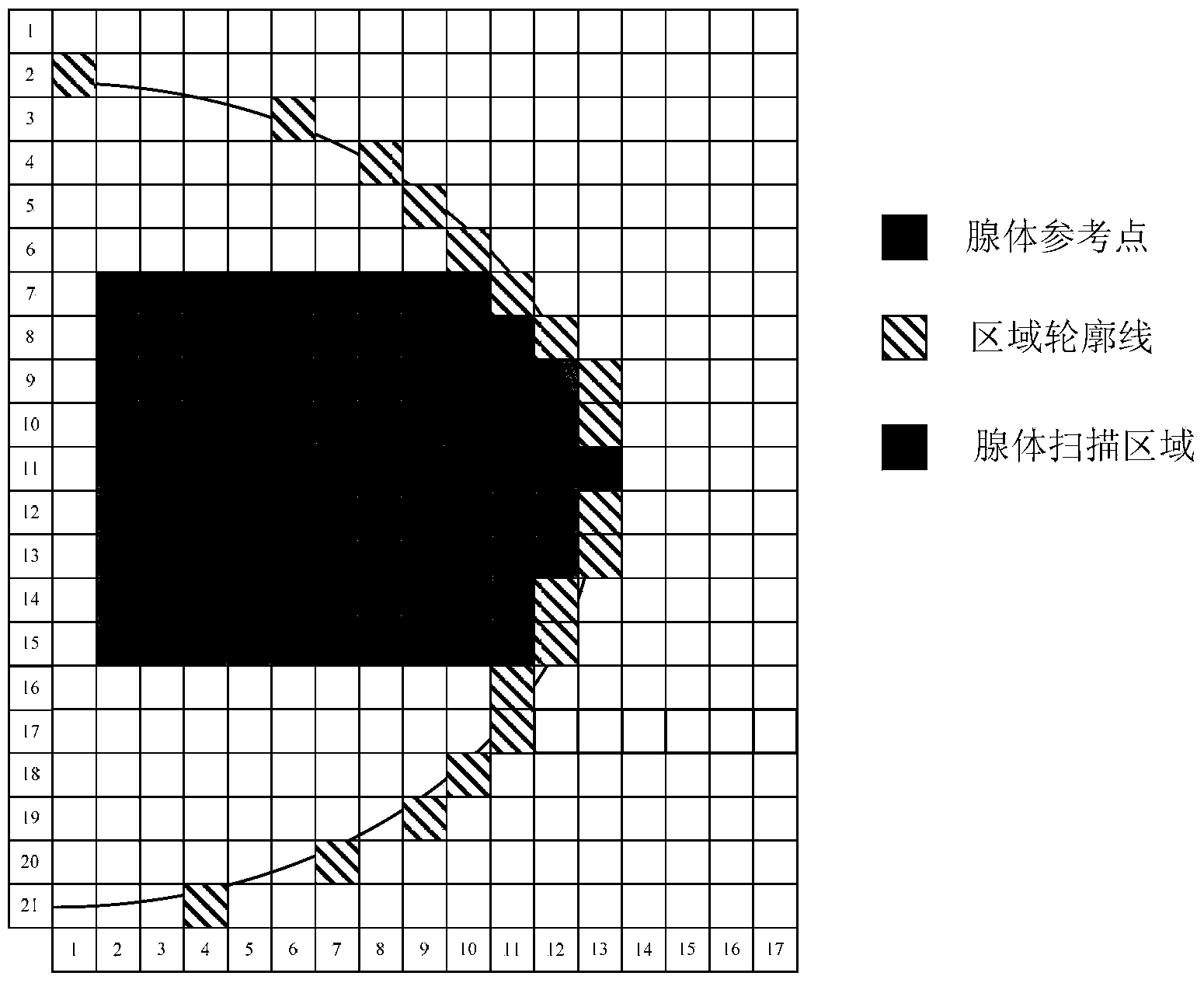

Glandular tissue characteristic gray scale detection method and device

ActiveCN103886576AAvoid the defects of inaccurate and reasonable feature gray scaleReduce the degree of impactImage analysisRadiation diagnosticsPattern recognitionDistribution characteristic

The invention discloses a glandular tissue characteristic gray scale detection method and device. The method comprises that: a pre-exposure sampling image is acquired, and a mammary tissue area is extracted from the pre-exposure sampling image; the mammary tissue area is scanned so that area contour lines are acquired; gland scanning areas are extracted from the mammary tissue area according to distribution characteristics of the area contour lines; gland candidate points are selected from the gland scanning areas, and a gray scale value of each gland candidate point is acquired; and a gray scale mean value of the gland candidate points is calculated, and the gray scale mean value acts as the characteristic gray scale of the gland scanning areas. The process has no participation of personnel so that time and labor are saved, and defects of inaccurate and unreasonable characteristic gray scale caused by artificial factors are also avoided. Besides, the defects in the prior art that secondary exposure dose is increased under the influence of interference factors can be reduced and even avoided by the technical scheme.

Owner:NEUSOFT MEDICAL SYST CO LTD

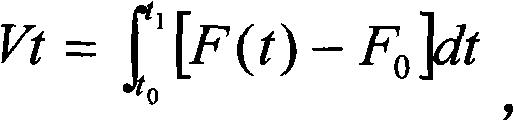

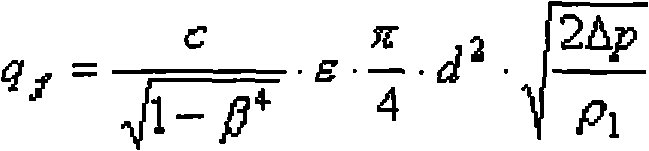

Measuring method of anesthesia apparatus tidal volume

ActiveCN101310678AImprove controllabilityRespiratorsDiagnostic recording/measuringTidal volumeMedicine

The invention discloses a method for measuring the tidal volume of an anaesthetic machine, which can effectively improve the measurement accuracy of medical anaesthetic machine in measuring the tidal volume breathed in or out by patients. The method comprises the following steps: (1) the average value measured by a flow sensor at the prior breathing-out or breathing-in stage is calculated; (2) the flow value of patients at the current breathing-out or breathing-in stage are collected; (3) the flow value of patients at the current breathing-out or breathing-in stage deducts the average value measured by the flow sensor at the prior breathing-out or breathing-in stage and the integration are accumulated in the whole breathing-out or breathing-in stage, thereby obtaining breathing-out or breathing-in tidal volume value; all factors interfering the flow measurement are compensated in real time so as to prevent the measurement results from being affected by the component, the pressure, the temperature, atmospheric pressure and environmental temperature thus achieving the purpose of correctly measuring the breathing-out or breathing-in tidal volume, greatly improving the controllability of anaesthetic effect and realizing the purpose of the method.

Owner:上海力申科学仪器有限公司

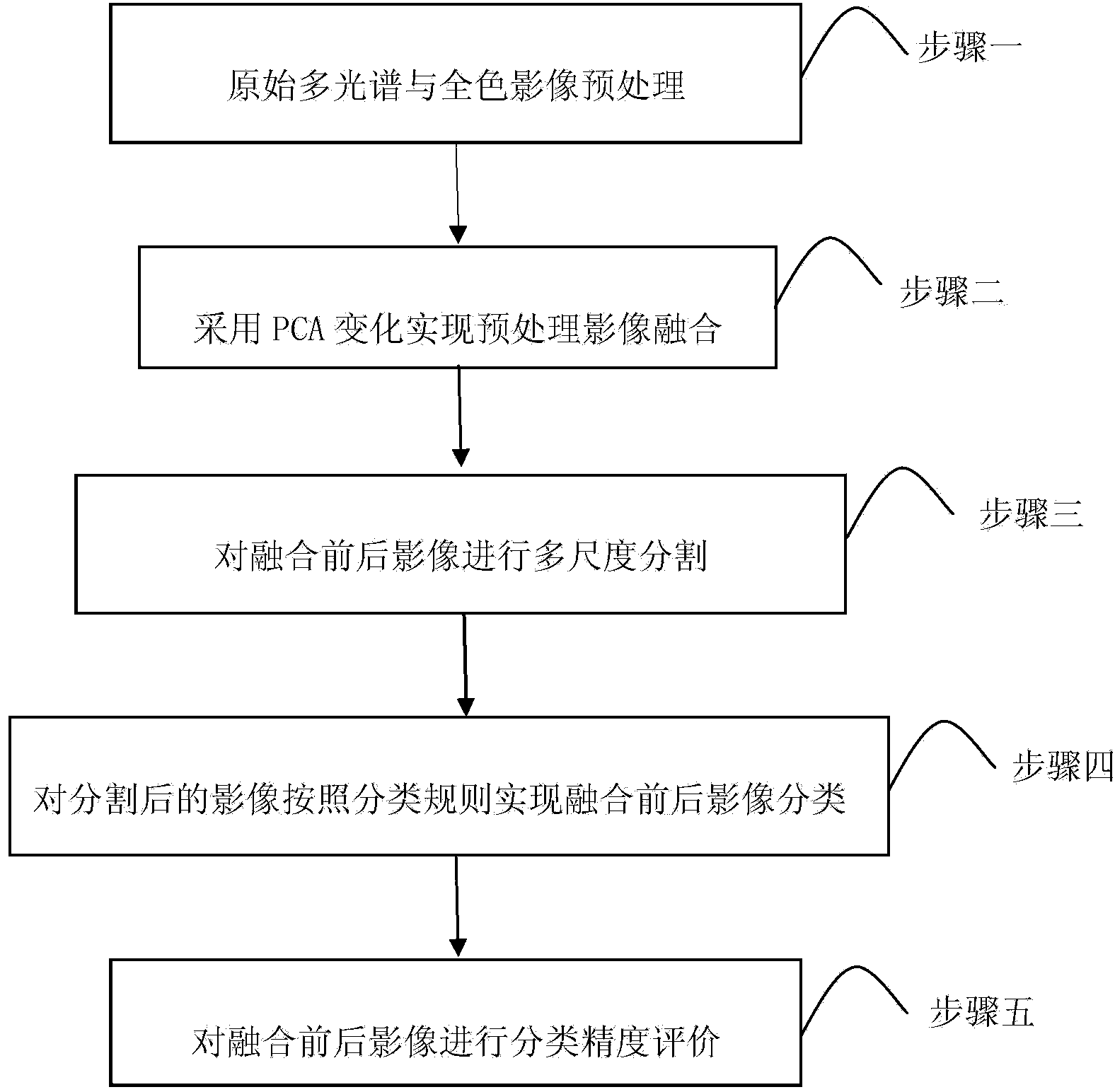

Method for evaluating remote-sensing image fusion effect

InactiveCN103383775AImprove classification accuracyEvaluation results are objectiveImage enhancementImage analysisRemote sensing image fusionImaging quality

The invention relates to remote-sensing image effect evaluation, in particular to a method for evaluating a remote-sensing image fusion effect. The method for evaluating the remote-sensing image fusion effect solves the problems that the man-made interference factor of a main visual effect of an existing method for evaluating the remote-sensing image fusion effect is large, errors can occur easily, a uniform standard does not exist in index selection in an objective mathematical statistic analysis, and image quality is hard to evaluate comprehensively. The method includes the steps that first, an original image to be fused is preprocessed; second, fusion processing is conducted on a preprocessed multispectral image and a panchromatic image; third, object-oriented segmentation is conducted on the images before and after fusion; fourth, a classification rule is used for classifying the segmented remote-sensing image; fifth, the classification result is precisely evaluated from the three aspects of production precision, user precision and a Kappa coefficient, and contrastive analysis is carried out on the classification accuracy of the images before and after fusion so that the fusion effect can be evaluated. The method for evaluating the remote-sensing image fusion effect can be applied to the technical field of remote-sensing image processing.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

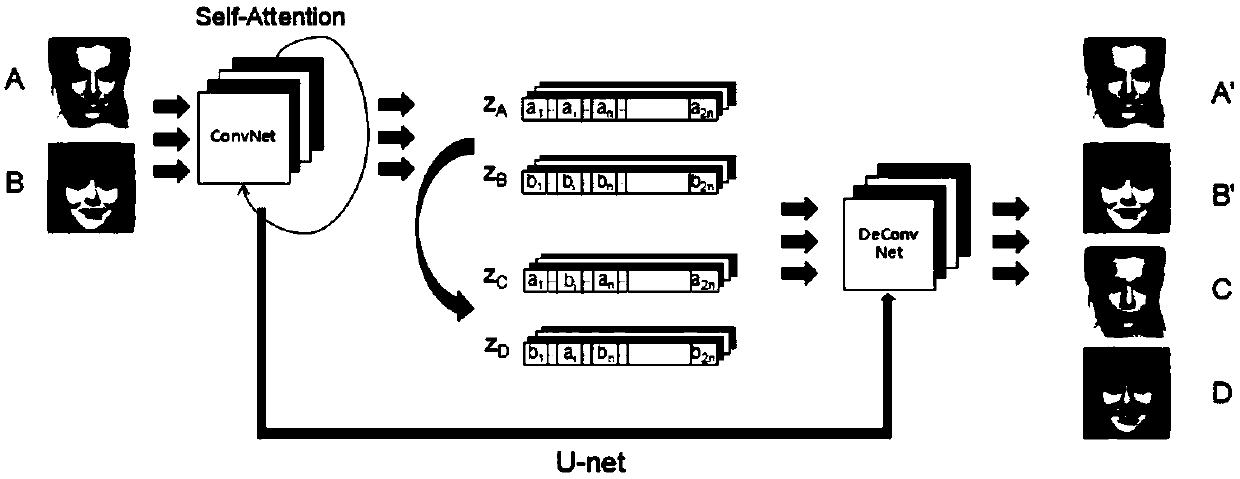

An image local information migration method based on GAN and Self-Attention

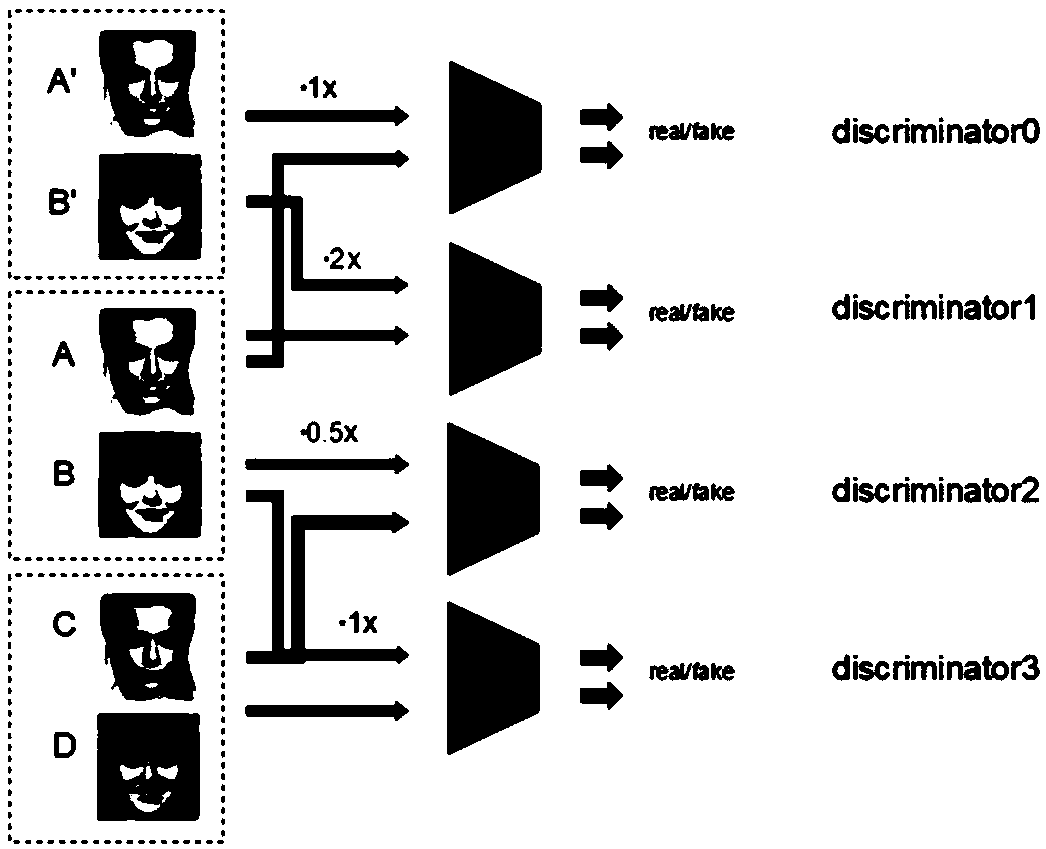

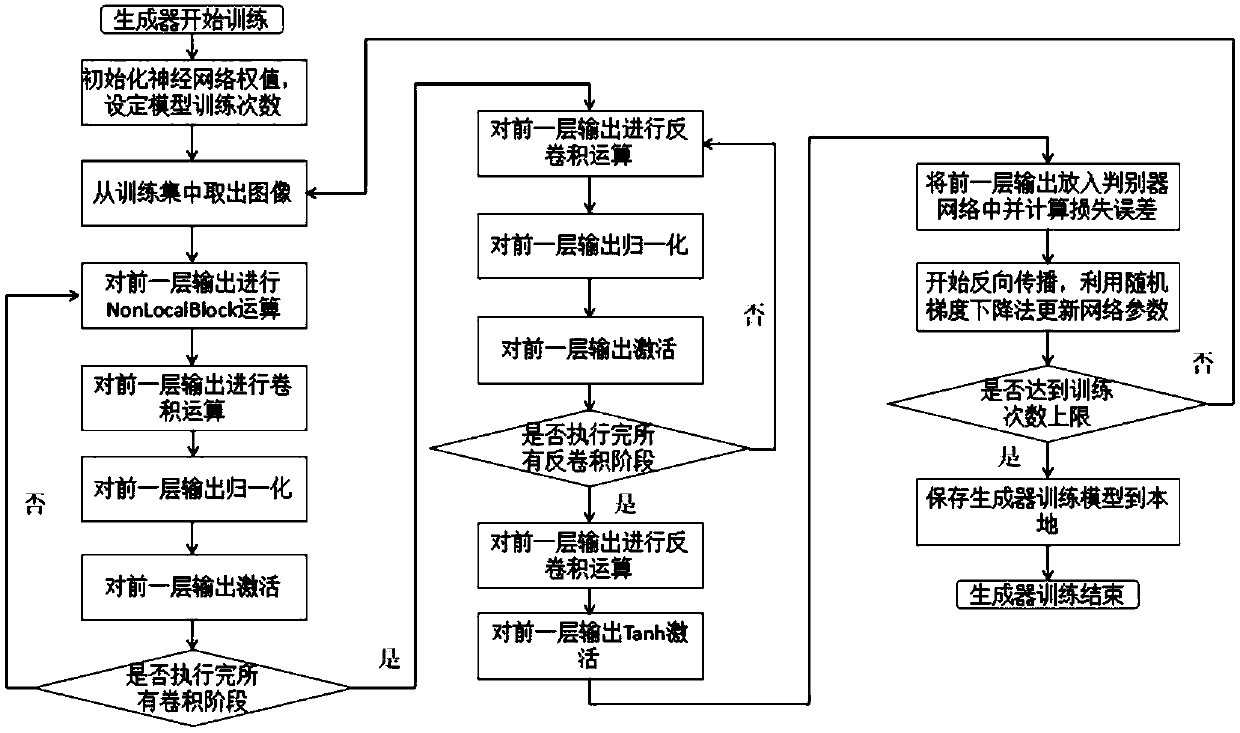

InactiveCN109543742AImprove the effect of local feature transferImprove the ability to locate local feature locationsCharacter and pattern recognitionDiscriminatorNerve network

The invention relates to an image local information migration method based on GAN and Self-Attention, which comprises the following steps: 1) acquiring an image migration task; 2) according to that image migration task, a trained neural network is used for image local information migration, and the migrate image is outputted; The neural network comprises an image generator and a discriminator, wherein the image generator comprises a convolution network and a deconvolution network, wherein the convolution network convolves pictures into hidden feature spaces, andthe Self-Attension model is usedto exchange part of hidden features, and that exchanged features are de-convoluted into new pictures through the de-convolution network so as to realize the feature transfer of local information of an image; The discriminator is used for discriminating the true-false relationship of the generated picture. Compared with the prior art, the invention has the advantages of avoiding the influence of the local migration and the global pixel of the image, solving the interference factors of the local migration of the image to the whole image, etc.

Owner:聚时科技(上海)有限公司

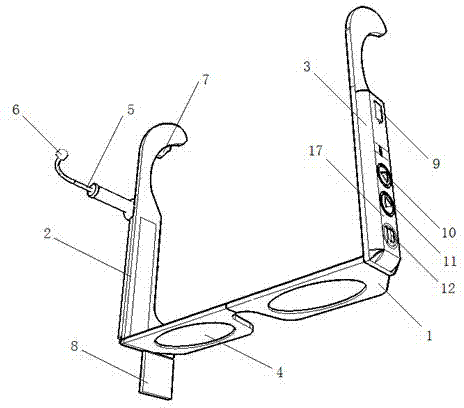

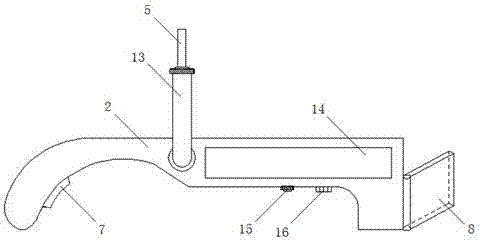

Wearable brain wave attention training instrument

InactiveCN103656833ALow costEasy for secondary developmentDiagnostic recording/measuringSensorsFrequency spectrumVirtual screen

The invention discloses a wearable brain wave attention training instrument. A miniature projector is used for generating a virtual screen at the position 2m away from the human eyes, and video stimulation signals are provided for attention training; audio signals are output through an audio interface, and background music, training instructions and other audio stimulation signals are provided for attention training; a brain wave electrode is arranged on the forehead of the head through a rotary adjusting rod and a telescopic adjusting rod. The brain wave electrode sends collected brain wave signals to an embedded processing unit, and the embedded processing unit carries out spectral analysis on the brain wave signals, extracts beta-wave components reflecting the brain attention focusing degree, carries out neurofeedback on attention training, and transmits data to a human-computer interaction device through a wireless data interface. According to the wearable brain wave attention training instrument, brain waves serve as feedback signals of attention training, and thus efficiency and reliability of attention training are greatly improved; due to the fact that a wearable computer is used, a plurality of unwanted interference factors are eliminated, and the training environment is improved.

Owner:TIANJIN NORMAL UNIVERSITY

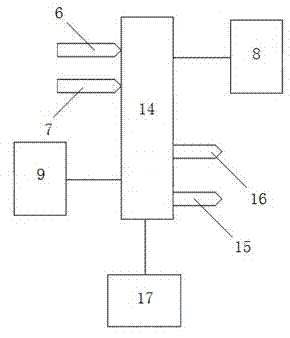

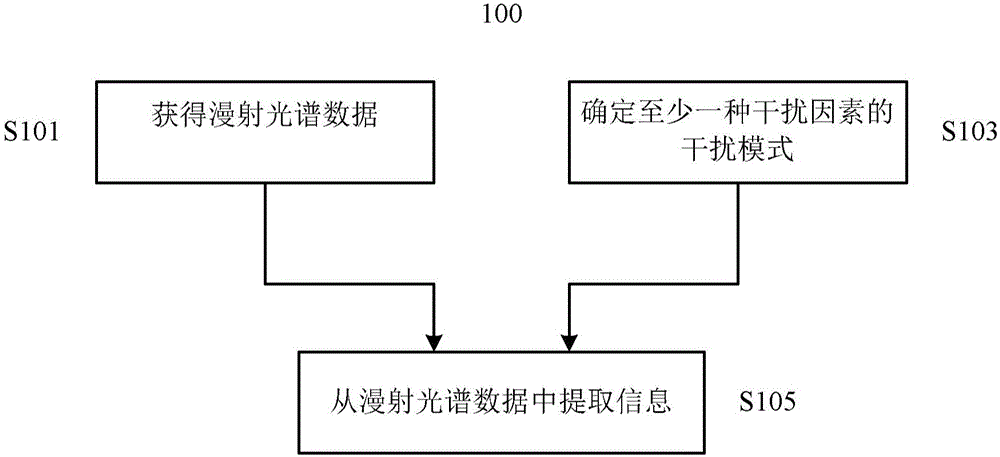

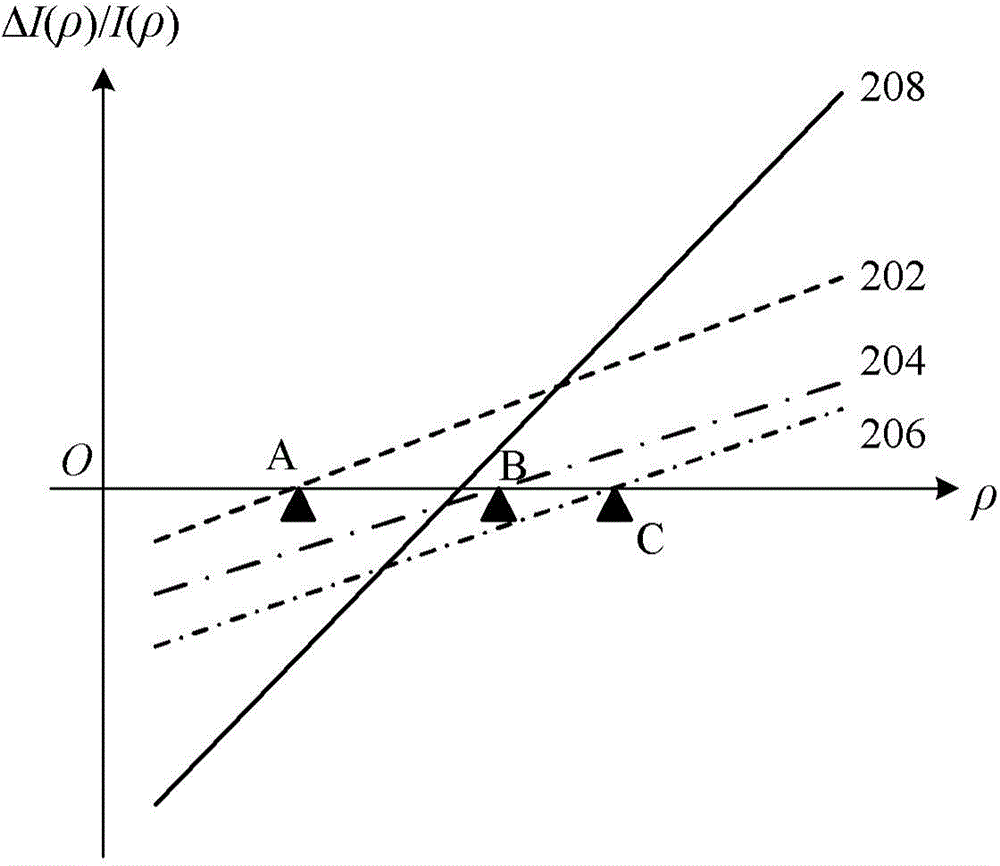

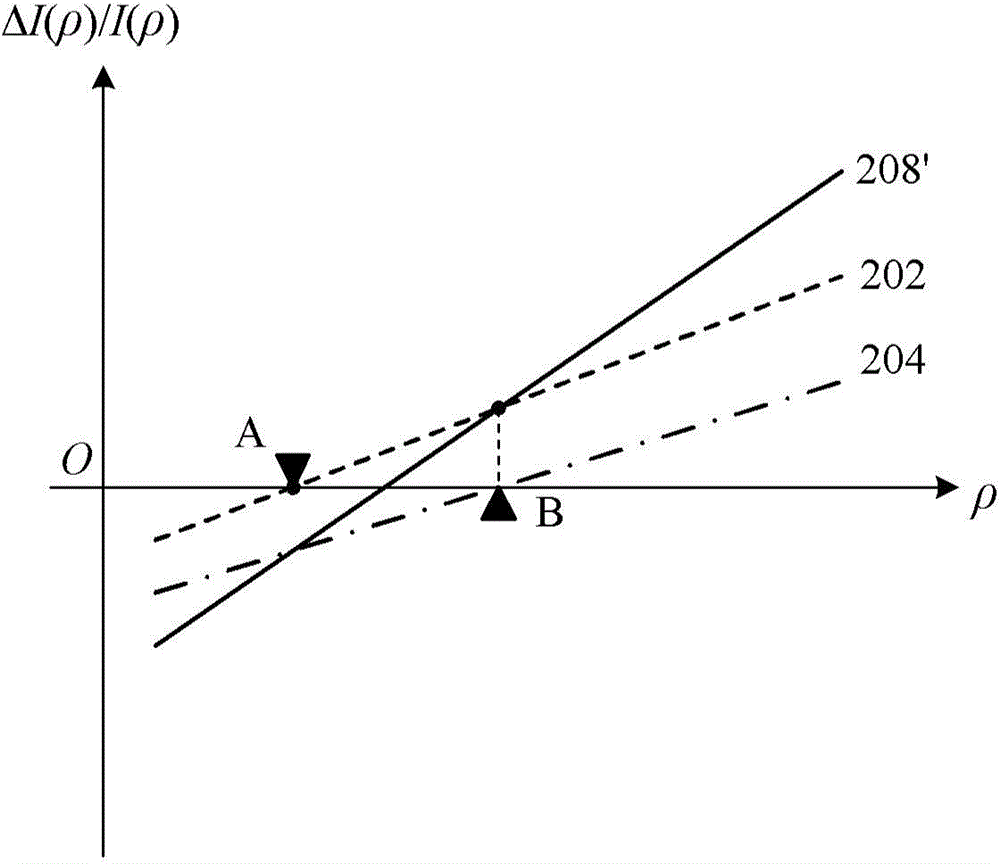

Spectral-data interference suppression method, modeling method, forecasting method and processing device

ActiveCN105987881AIncreased concentration prediction accuracySpectrum investigationColor/spectral properties measurementsDiffusionAdditive ingredient

The invention provides a spectral-data interference suppression method, a modeling method, a forecasting method and a processing device. According to the embodiment, the spectral-data interference suppression method can include the steps that the interference mode of at least one interference factor in spectral measurement is determined, and the interference mode limits interference at multiple radial positions away from a light source; diffusion spectral data of a measured medium containing specific ingredients is obtained; on the basis of the interference mode, information relative to the specific ingredients is extracted from the diffusion spectral data, wherein interference of the at least one interference factor in the diffusion spectral data is inhibited in the extracted information.

Owner:TIANJIN SUNRISE TECH DEV

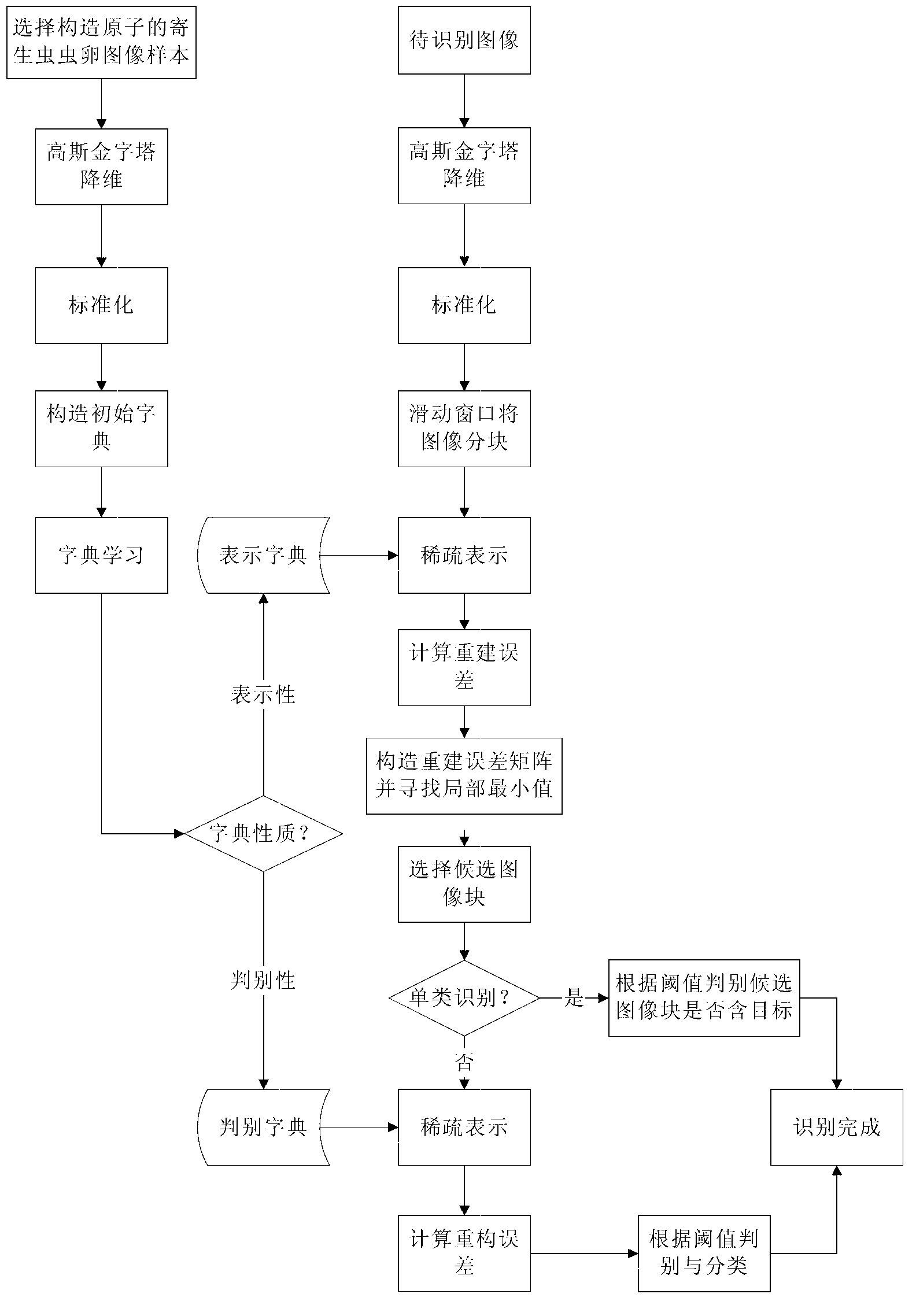

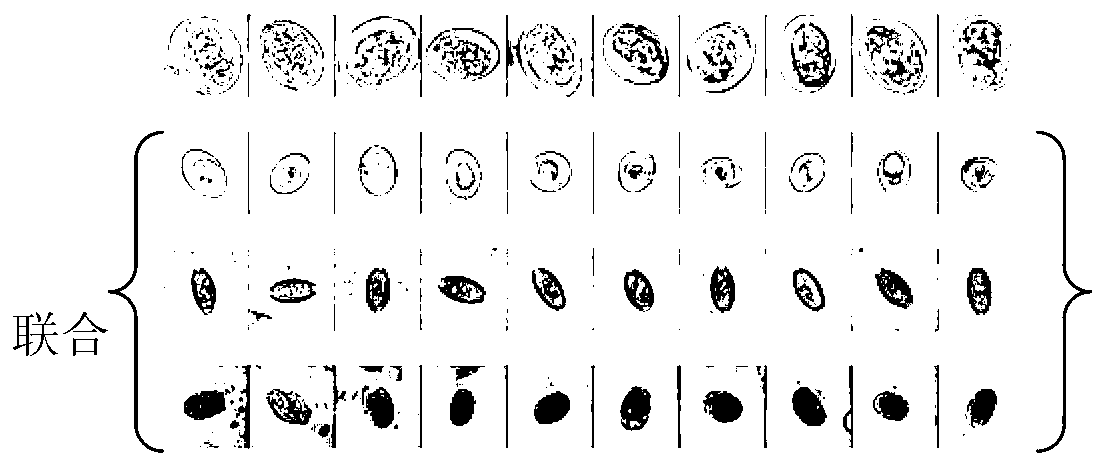

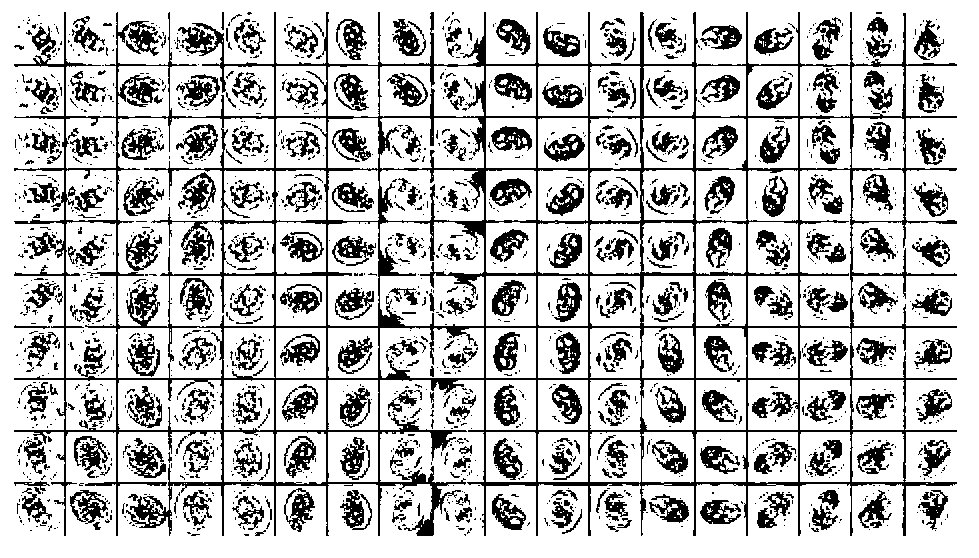

Parasite egg identifying method based on sparse representation

InactiveCN103268494AImprove robustnessImprove recognition efficiencyCharacter and pattern recognitionSorting algorithmDimensionality reduction

The invention belongs to the technical field of image identification, and particularly relates to a parasite egg identifying method based on sparse representation. The method comprises that steps of establishing an initial dictionary; using a K-SVD algorithm to study the dictionary; processing an input image; calculating a reconstructed error matrix; obtaining a candidate image block; identifying the candidate image block. The parasite egg identifying method based on sparse representation introduces a sorting algorithm based on sparse representation, reinforces robustness of the whole parasite egg algorithm to various interfering factors, introduces the Batch-OMP algorithm which is used in the process of large-scale sparse representation, improves identification efficiency, introduces a method that a dictionary is directly established after a sample is subjected to gaussian pyramid dimensionality reduction, avoids the step that egg target characteristics are abstracted, enables the identification process to be simple and convenient, introduces the method for establishing an error matrix and solving the smallest local value of the error matrix, and avoids the situation that different image blocks containing the same target are obtained in the preliminary locating process.

Owner:JIANGSU UNIV

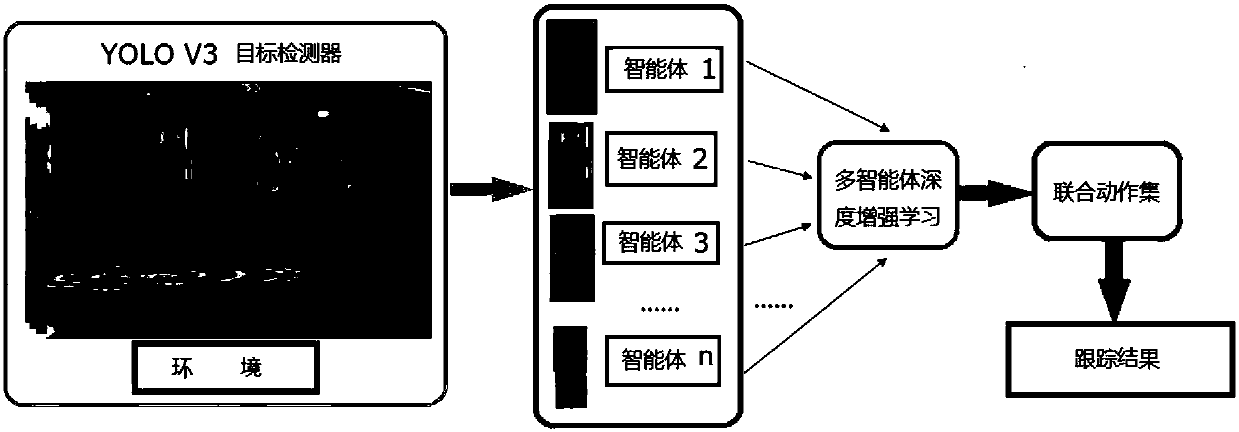

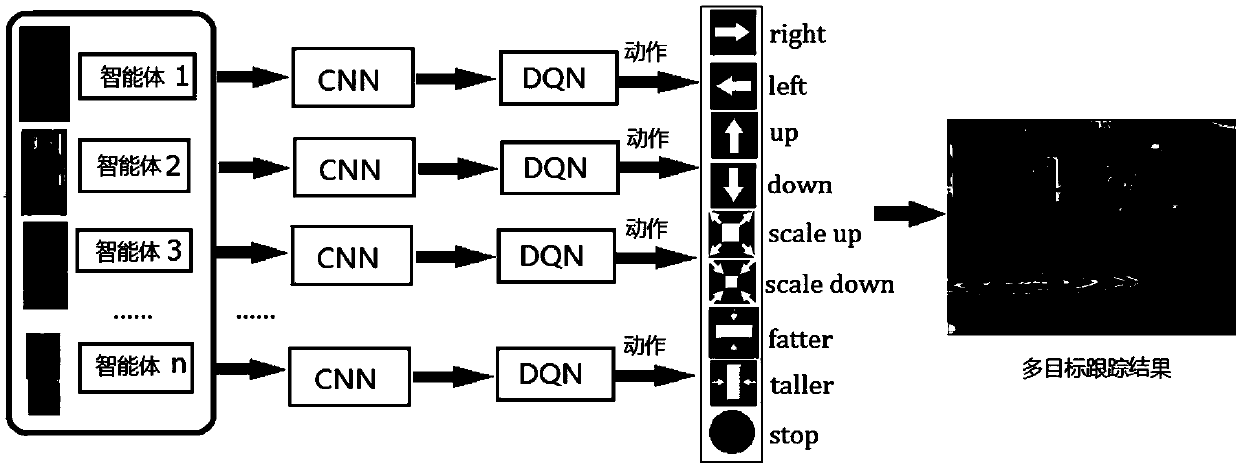

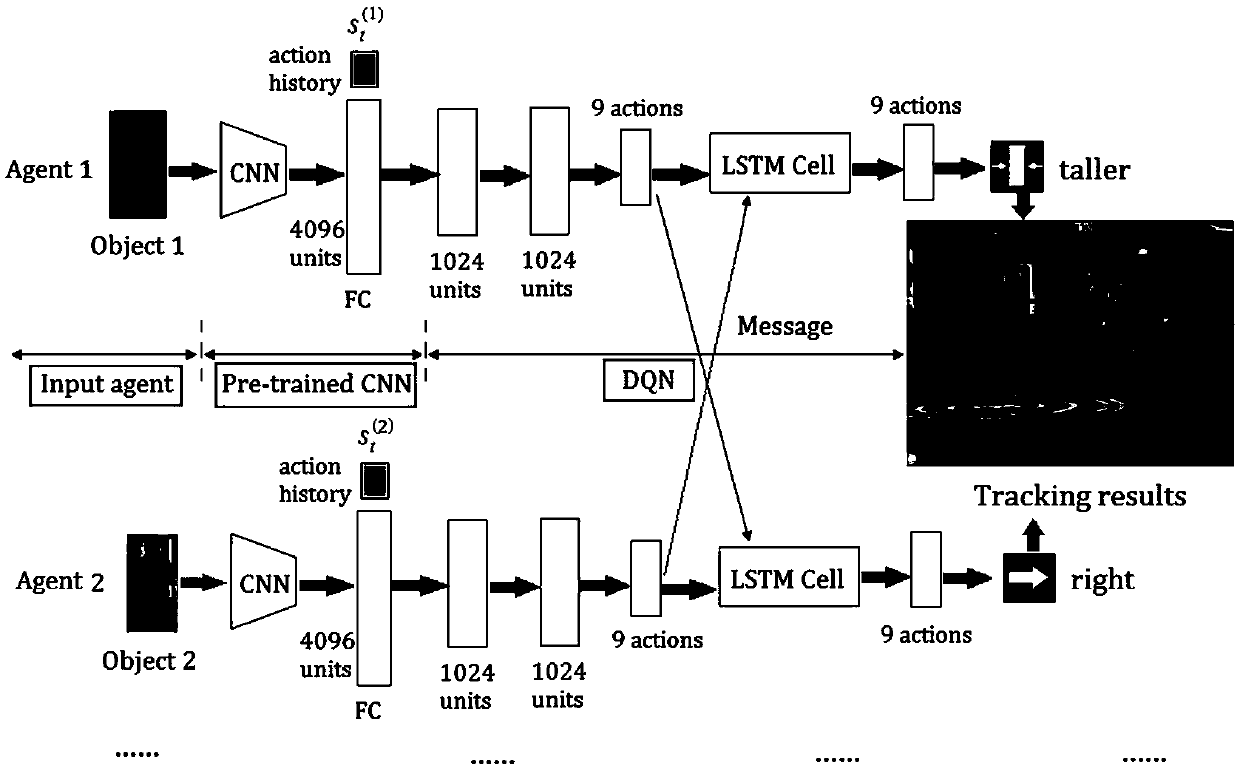

Multi-target tracking method based on multi-agent deep enhancement learning

ActiveCN108898612AHigh multi-target tracking accuracyHigh precisionImage enhancementImage analysisPattern recognitionMulti target tracking

The invention discloses a multi-target tracking method based on multi-agent deep enhancement learning. The method comprises: detecting multiple targets through a target detector, regarding the detected multiple targets as multiple agents, and then using a deep enhancement learning method to obtain a combined action set of the multiple targets, thereby completing multi-target tracking. The method applies a multi-agent deep enhancement learning technology to the multi-target tracking method for the first time, and can overcome technical disadvantages that artificial design features are not comprehensive and not accurate enough, and can improve calculation speed, realize real-time tracking. The method has high multi-target tracking accuracy rate and precision, and the number of misinformationand missing reports is low. The method is less affected by interference factors in a multi-target tracking scene, and tracking results are more accurate.

Owner:NANJING QIANHE INTERNET OF THINGS TECH CO LTD

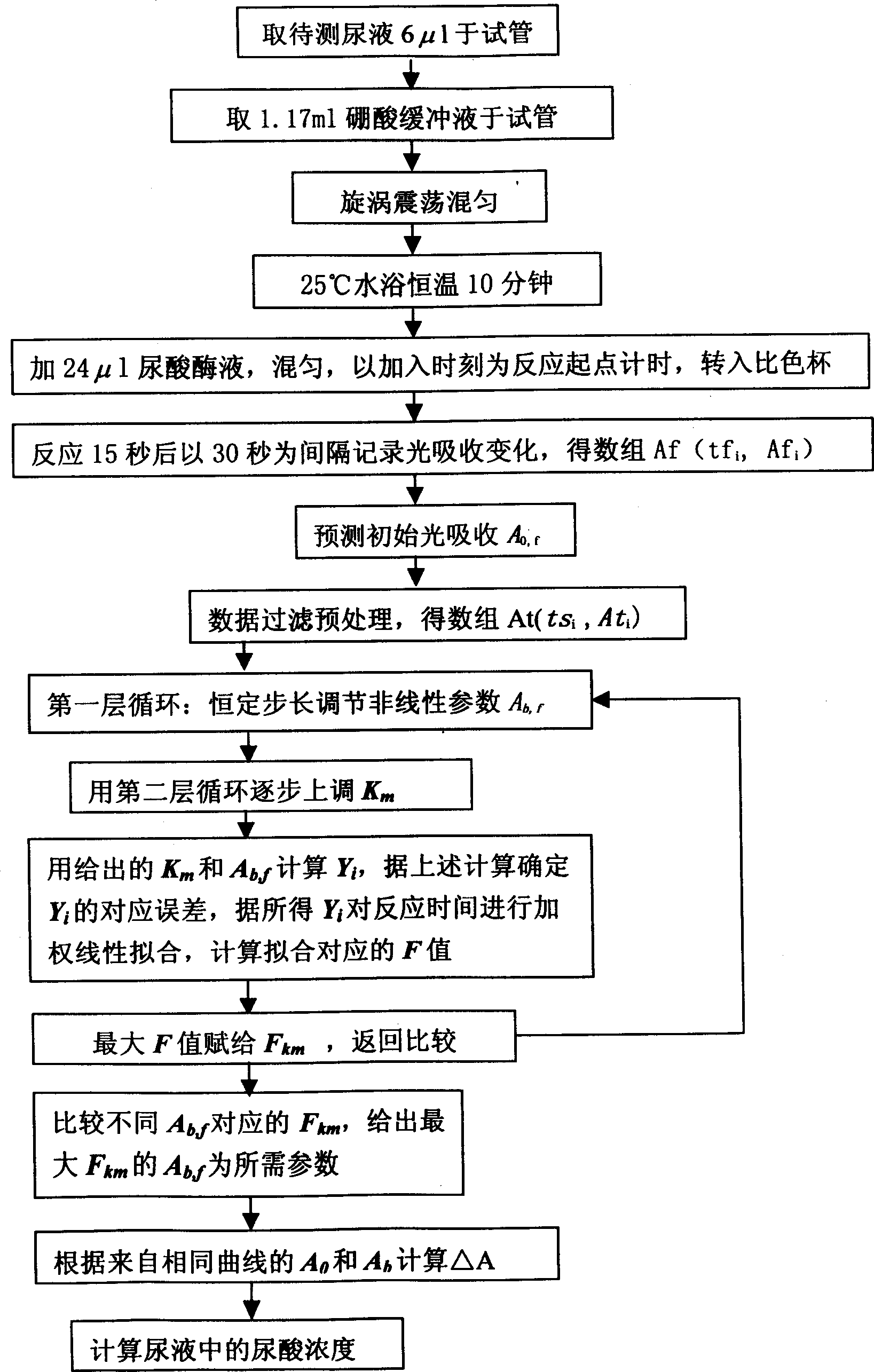

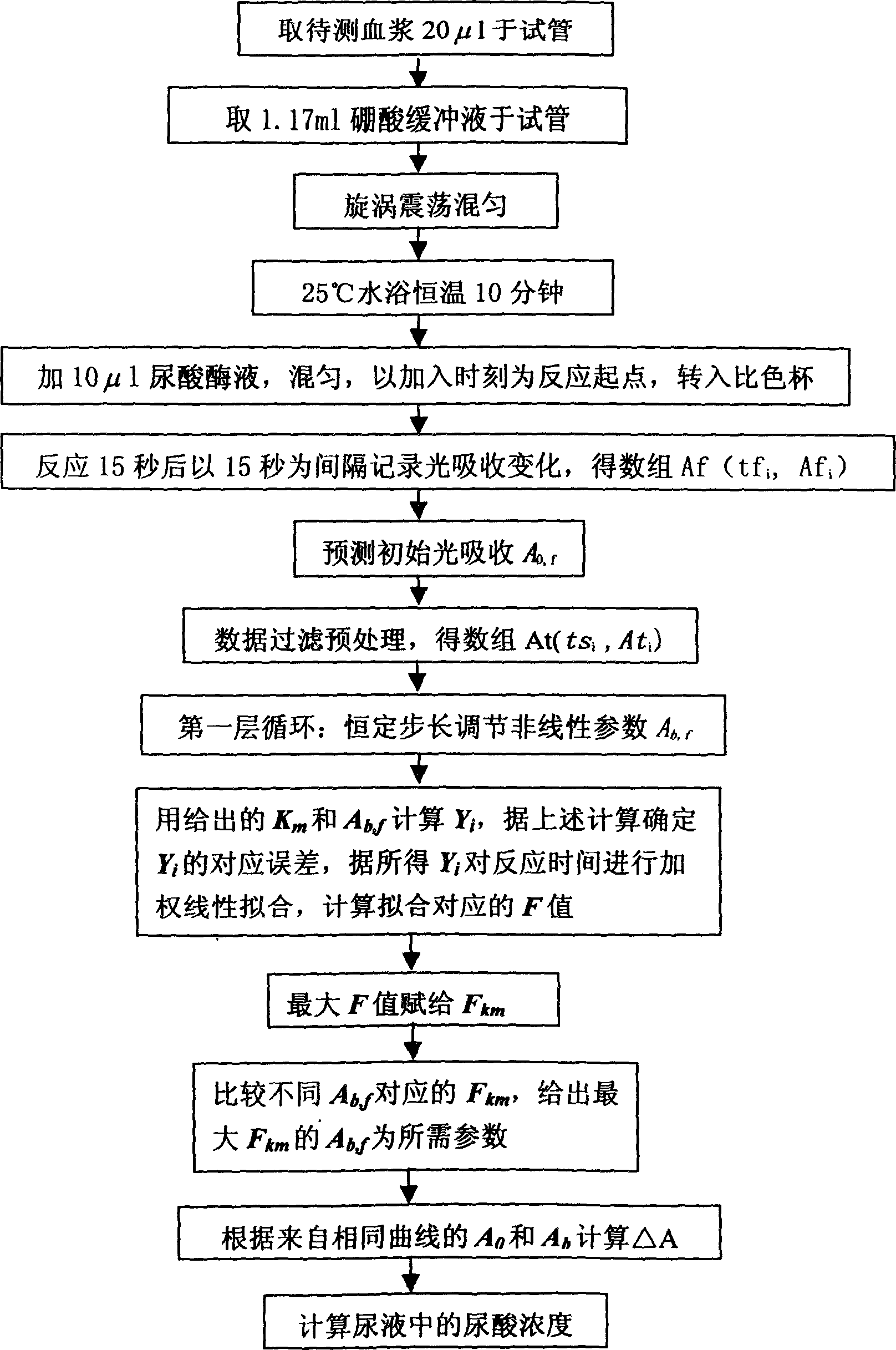

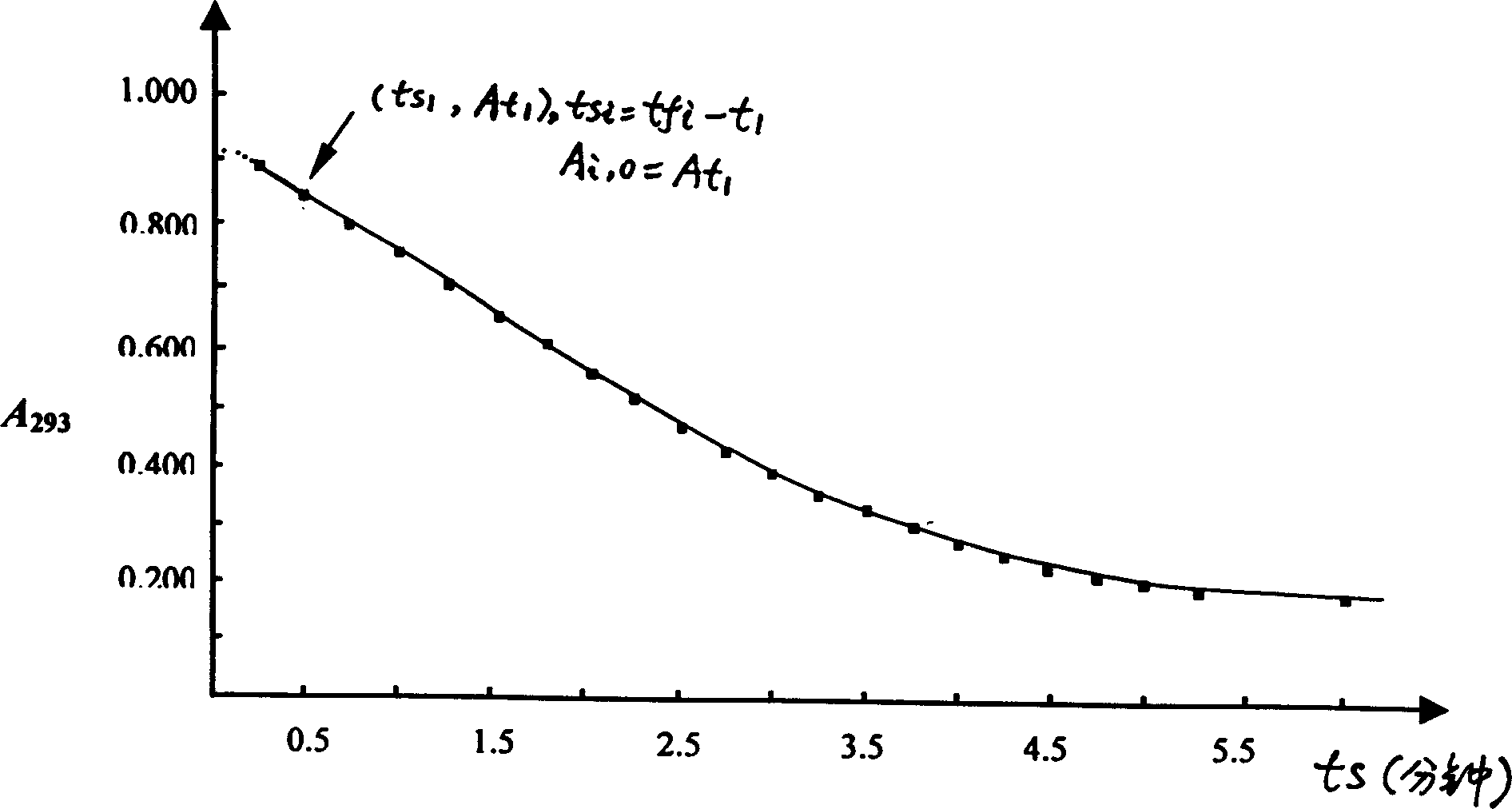

Method for quantitative determination of biochemical substance by enzyme analysis via predicting background

InactiveCN1488762ALow costHigh precisionMicrobiological testing/measurementQuantitative determinationReaction curve

The method for quantitative determination of biochemical substance by means of predetermining background and making enzyme analysis includes the following steps: adding buffer solution and tool enzyme in the sample solution to be determined, measuring the change of light absorption with reaction time, and utilizing integral velocity equation to fit and analyze the negative curve of light adsorption consumed by substrate to predetermine background instead of directly detemining background. It can directly determine body fluid sample, and it has no meed of diluting said sample, and its determination accuracy is high.

Owner:廖飞

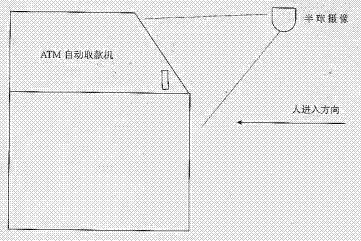

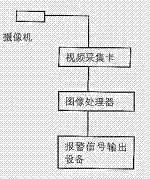

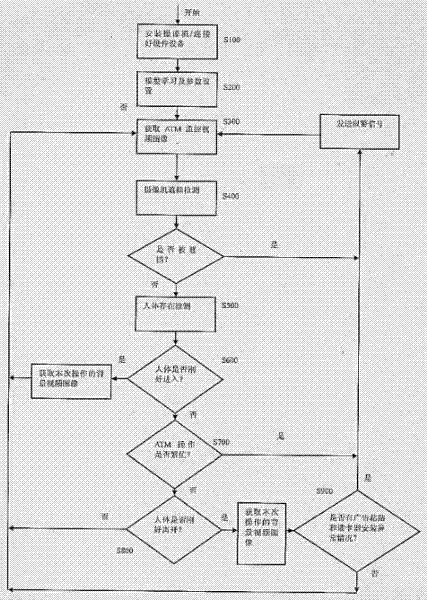

Automatic teller machine (ATM) pre-warning method and system based on computer vision

InactiveCN102542673AMeet early warning needsReduce work intensityBurglar alarmCoin/paper handlersHuman bodyInterference factor

The invention discloses an automatic teller machine (ATM) pre-warning method based on computer vision. The method comprises the following steps of: 1, setting a detection region and a human body entry region of an ATM panel in an ATM monitoring view field, and learning a video without people to acquire a statistical model of a scene; and 2, judging whether ATM operation is frequent by detecting the human body detection region, and judging whether an abnormal situation exists before a human body enters and after the human body enters. The method has the advantages that: such abnormal situations that a camera is shielded, a fraud advertisement is pasted, a card reader is arranged, the ATM operation is frequent and the like can be analyzed timely and reliably through a computer vision technology, so that the working strength and the investment cost for monitoring by workers are reduced effectively; furthermore, interference factors, such as sunshine and the like, can be avoided effectively, the warning accuracy is high, the mis-warning rate is low, the instantaneity is high, and an ATM pre-warning requirement can be well met.

Owner:HAOYUN TECH CO LTD

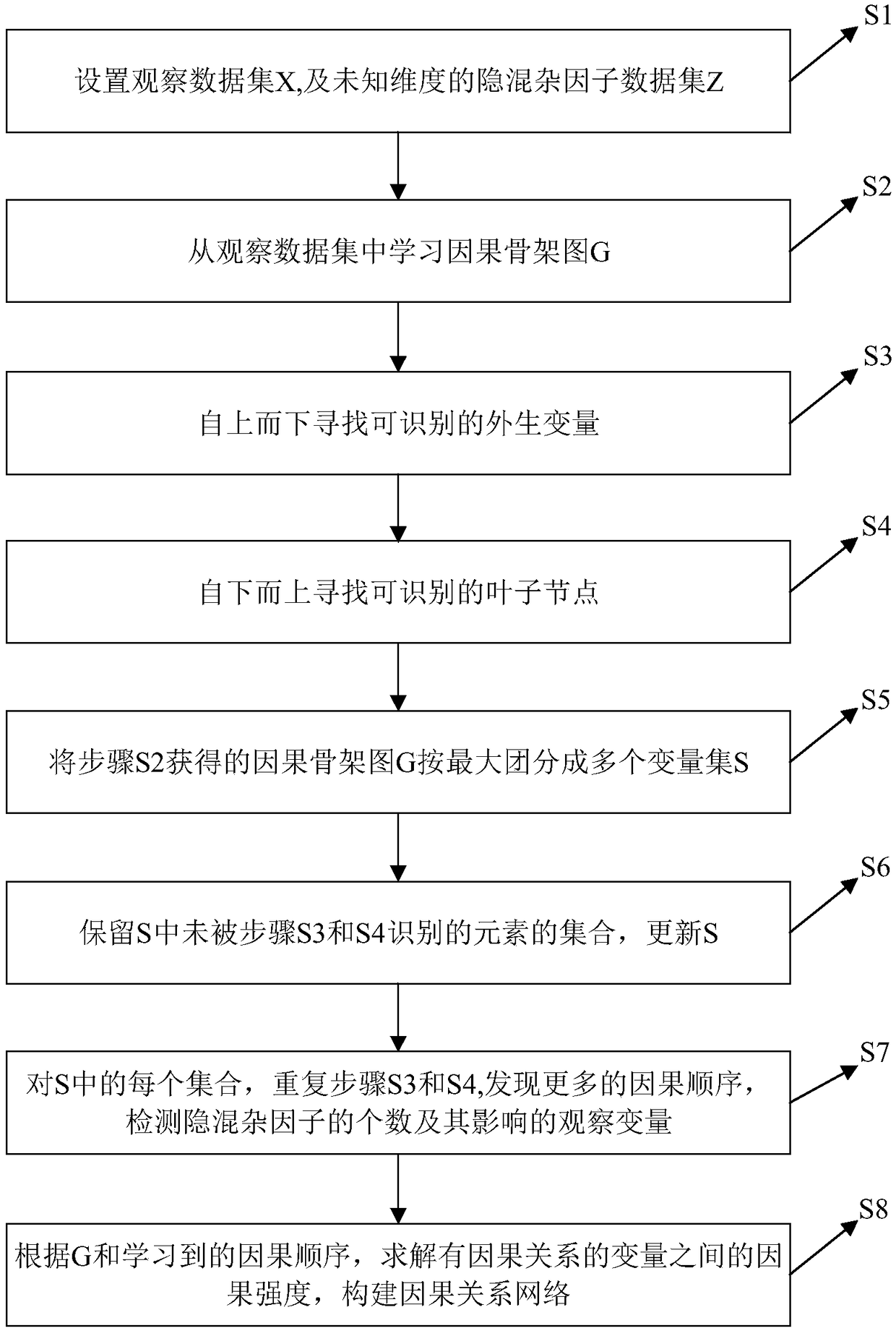

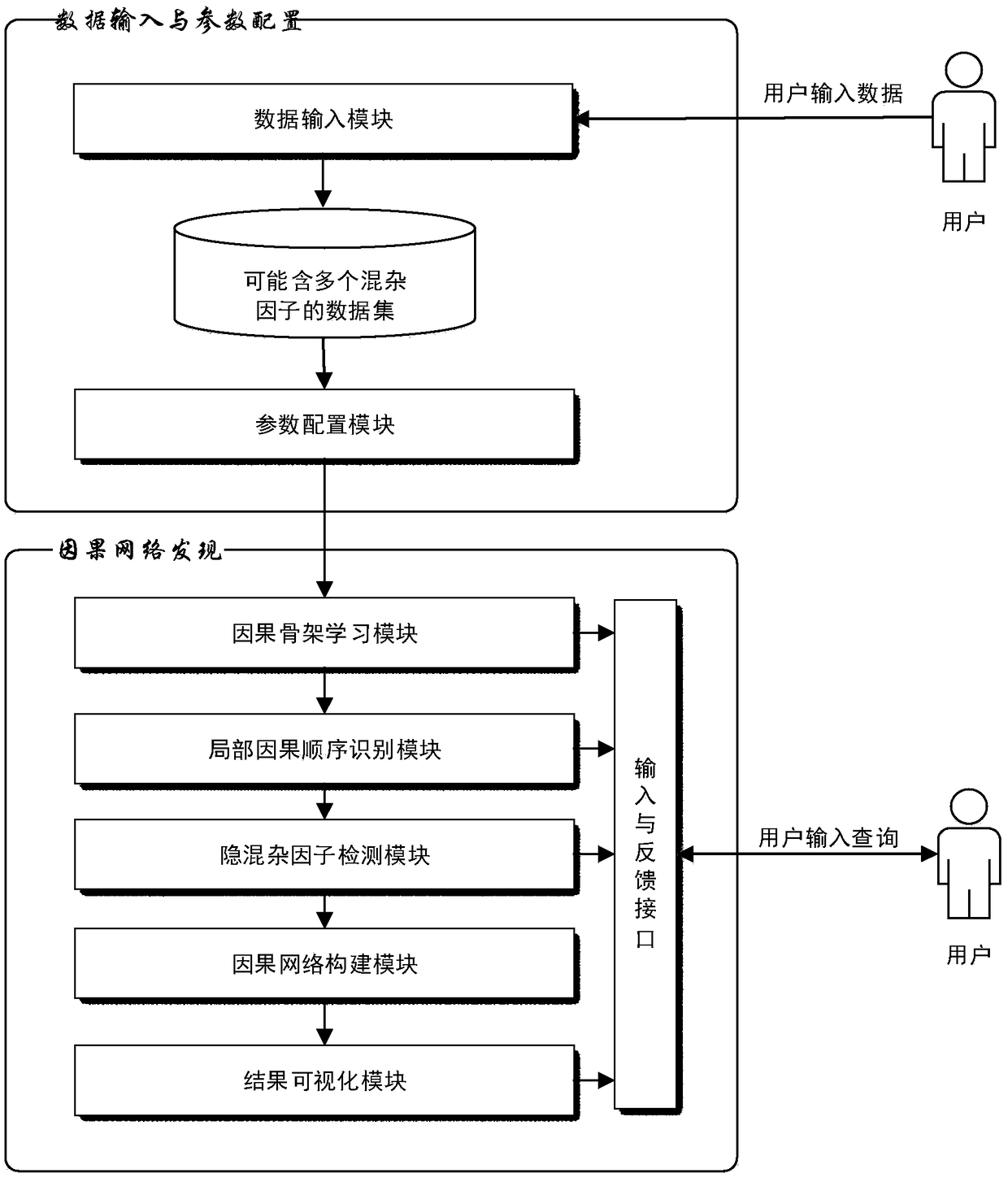

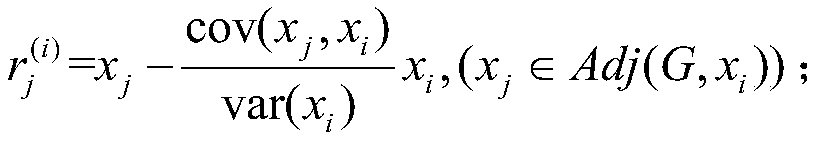

Discovery method and system suitable for a plurality of hidden confounding factor data

InactiveCN109325600AImprove accuracyEasy to identifyOther databases indexingInference methodsUser inputMachine learning

The invention discloses a causal network discovery method and system suitable for a plurality of hidden confounding factor data. The system comprises a user input data module, a parameter configuration module, a causal skeleton learning module, a local causal sequence identification module, a hidden confounding factor detection module, a causal network construction module and a result visualization module. The causal network discovery system suitable for the plurality of hidden confounding factor data can discover the causal network according to the needs of users, and then visually present the causal network between observation variables. The invention takes into account the case of the plurality of hidden confounding factors, the information of causal skeleton can greatly reduce the complexity of solution, and detect the number of implicit confounding factors and the observed variables of their effects, so that the learning and identification accuracy of the causal network are high,and the problem that the causal network can not be found correctly in the case of multiple implicit confounding factors data is solved. The invention is simple in implementation and high in learning accuracy, and has strong practical value and practical significance.

Owner:GUANGDONG UNIV OF TECH

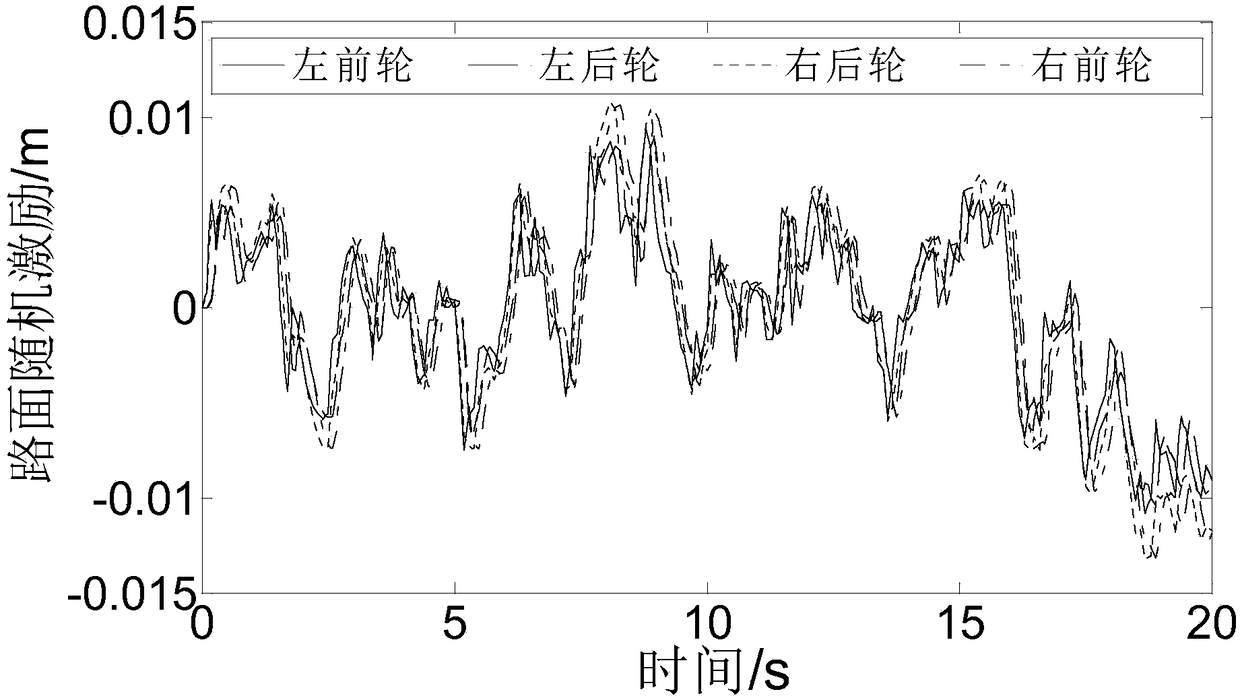

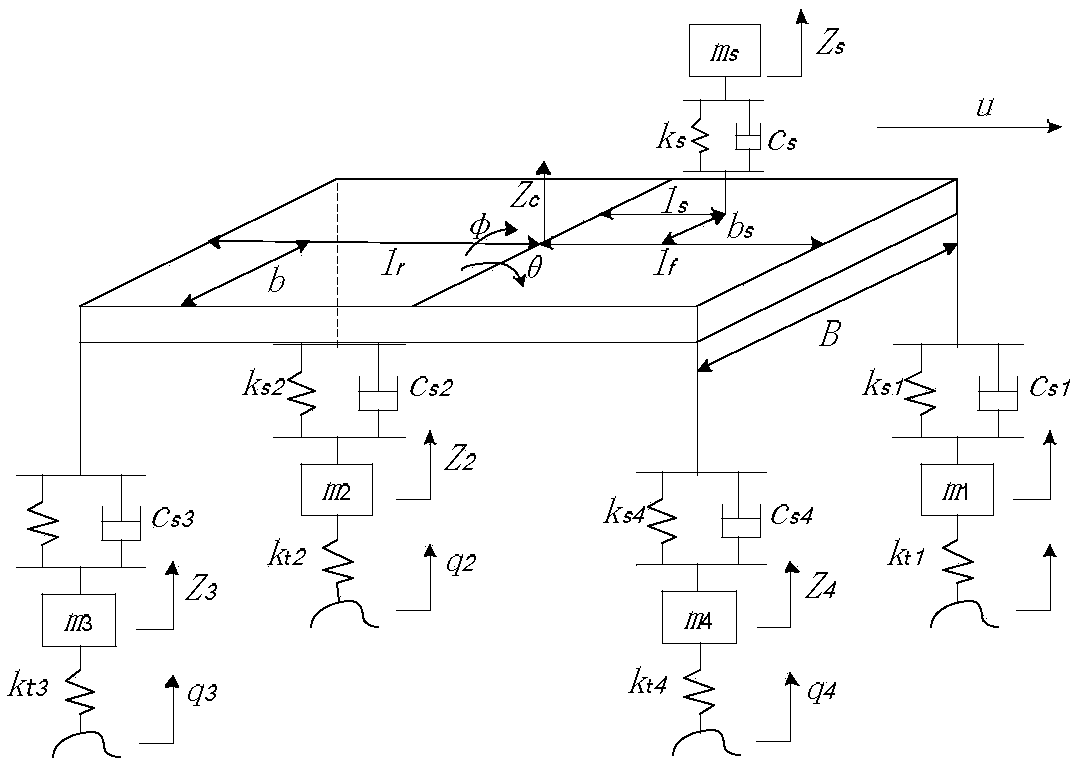

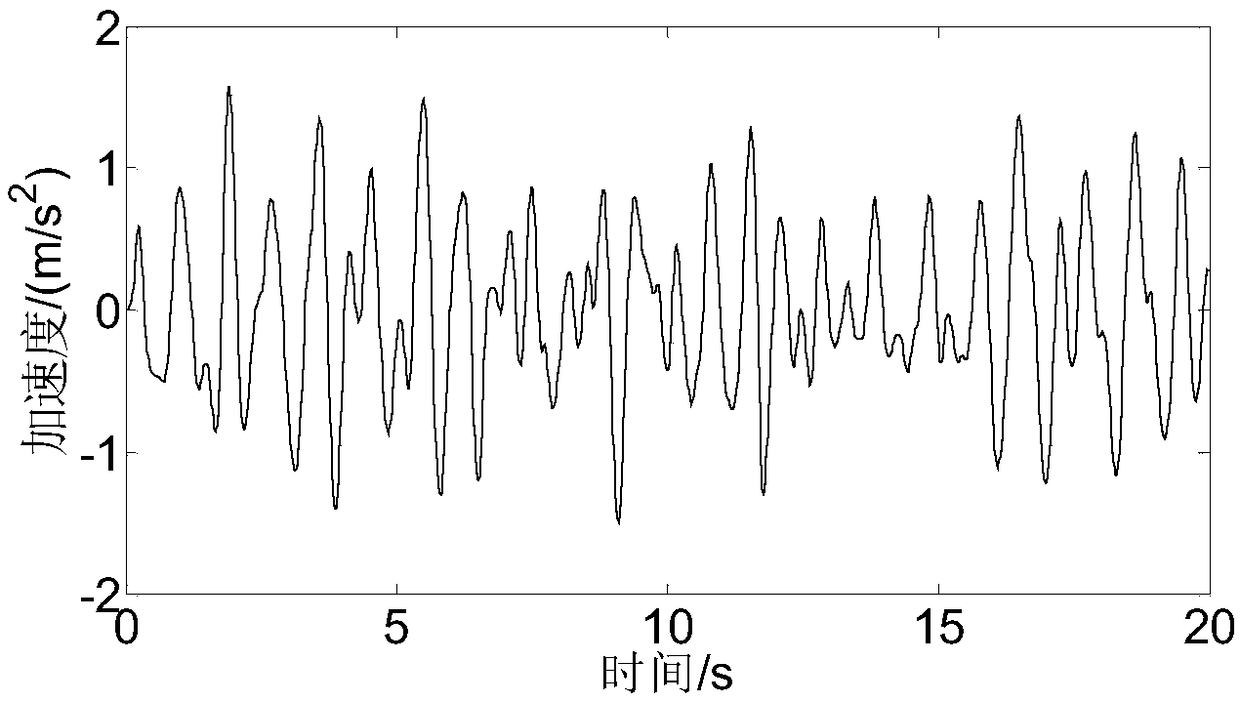

Optimization analysis method of automobile ride comfort based on Taguchi experiment

ActiveCN109002599AImproved normal ride and stabilityGeometric CADDesign optimisation/simulationStatistical analysisEngineering

The invention discloses an optimization analysis method of automobile ride comfort based on the Taguchi experiment, comprising the following steps: S1, based on the Taguchi method experiment, determining controllable factors and noise factors which affect the ride comfort of the automobile to be optimized; S2, generating a header of a combined orthogonal array according to the number of controllable factors and noise factors and the horizontal number thereof; S3, simulating the combination of controllable factors and noise factors in Matlab / Simulink, and calculating the root mean square valueof seat vertical acceleration; 4, carrying out statistical analysis and calculation on that data obtained in the step S3, obtaining a variance analysis table of the signal-to-noise ratio, and calculating the contribution rate of each controllable factor to vehicle ride comfort and robustness. The simulation analysis can be combined with the Taguchi method to analyze the influence of controllable design variables and random disturbance factors on ride comfort, and the best combination of parameters can be selected to improve the normal ride comfort and stability.

Owner:CHONGQING JIAOTONG UNIVERSITY

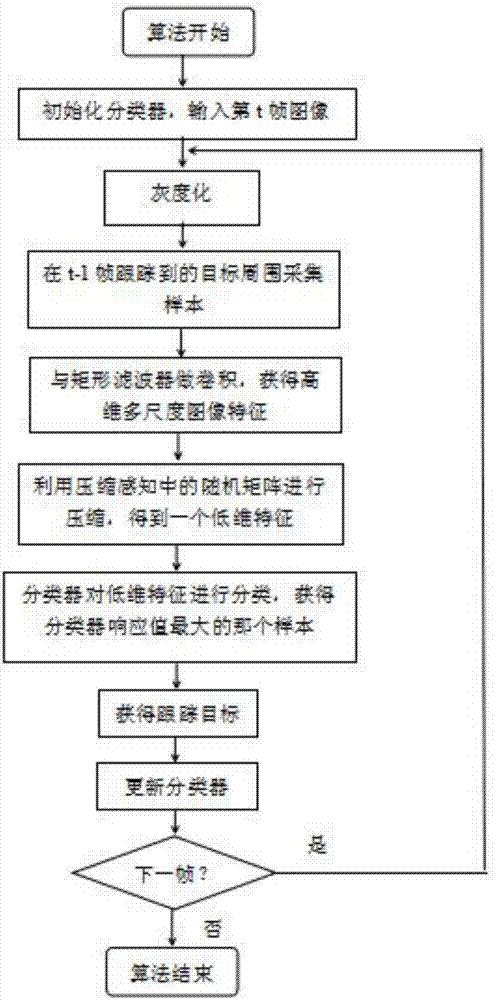

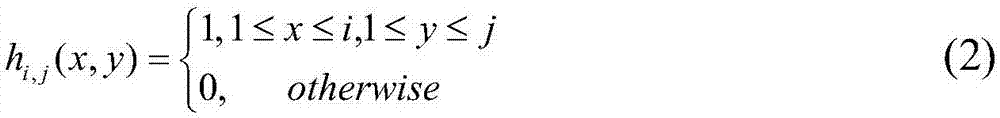

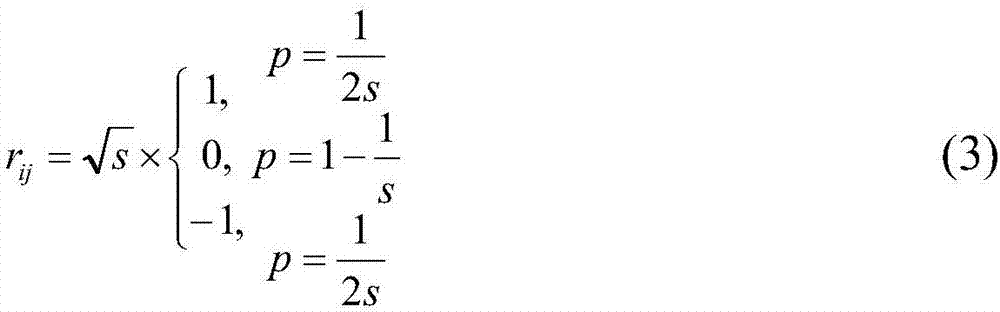

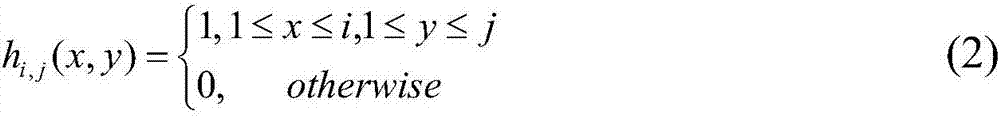

Real-time target tracking algorithm based on compressed sensing

The invention belongs to the vision tracking field, relates to a real-time target tracking algorithm based on compressed sensing and solves problems of low speed, low robustness and inaccurate target tracking existing in a target tracking algorithm in the prior art. The algorithm comprises steps that a tth image is acquired and is grayed, the compressed sensing theory is utilized, a quite sparse random matrix is utilized to map extracted high-dimensional multi-scale image characteristics to a low-dimensional subspace to acquire low-dimensional image characteristics, the characteristics are classified through utilizing a classifier, and a sample with the largest classifier reaction value is selected as a tracking target. The algorithm is advantaged in that disadvantages in the prior art are solved, not only can high robustness and high accuracy under various interference factors be realized, but also an average image processing speed reaches 35 frames per second, the timeliness requirement is realized, and the method is of important reality significance.

Owner:深圳市美好幸福生活安全系统有限公司

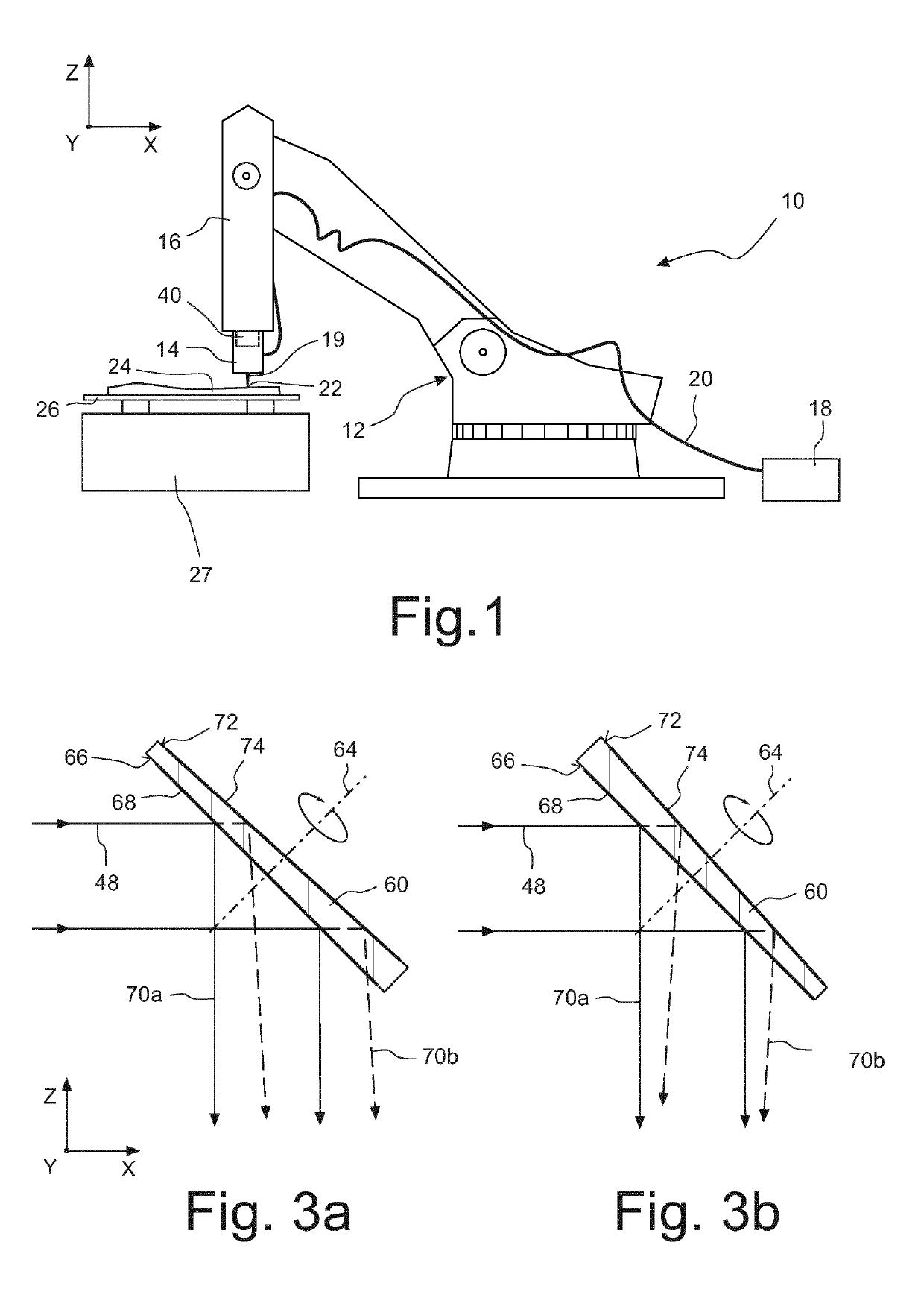

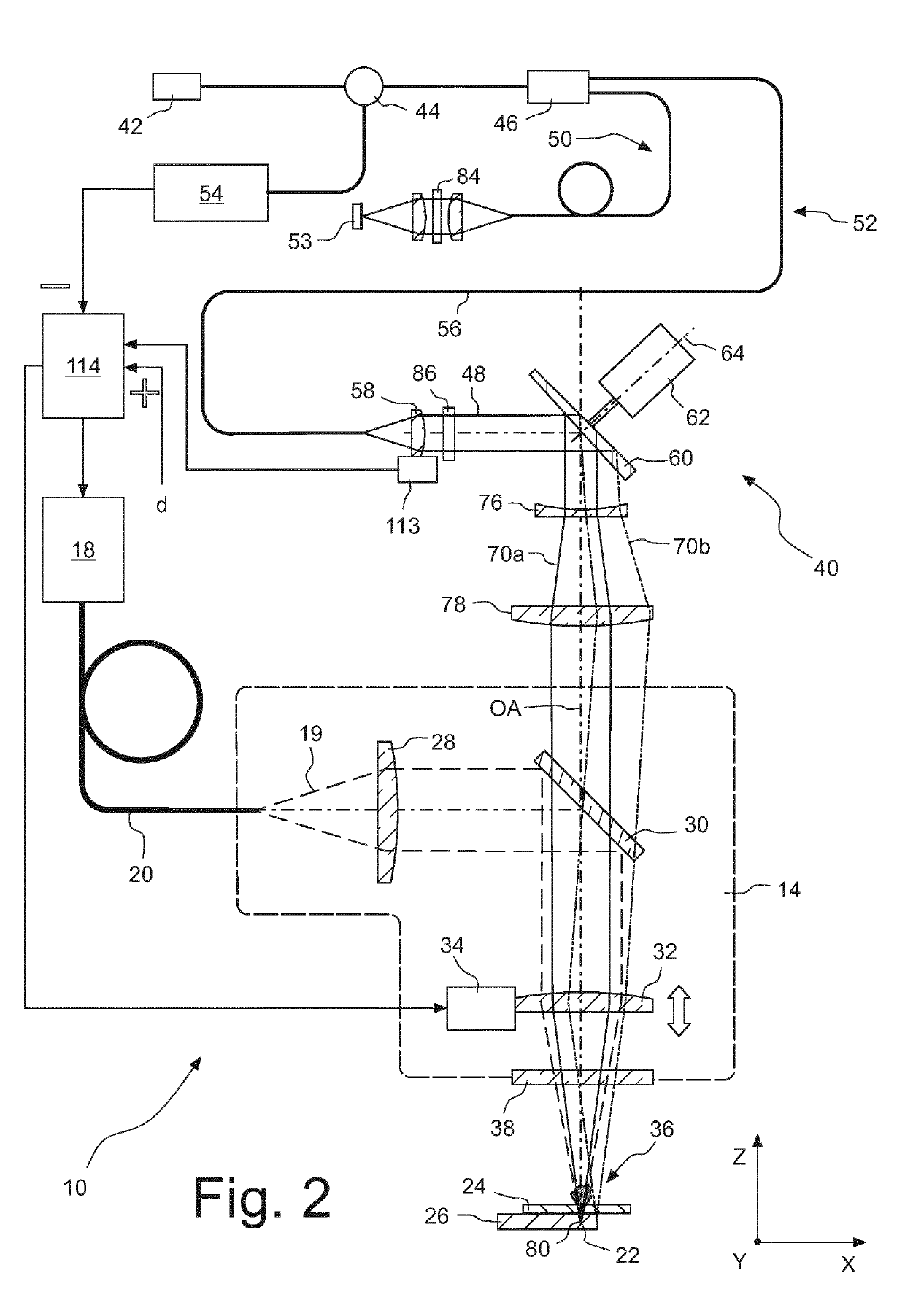

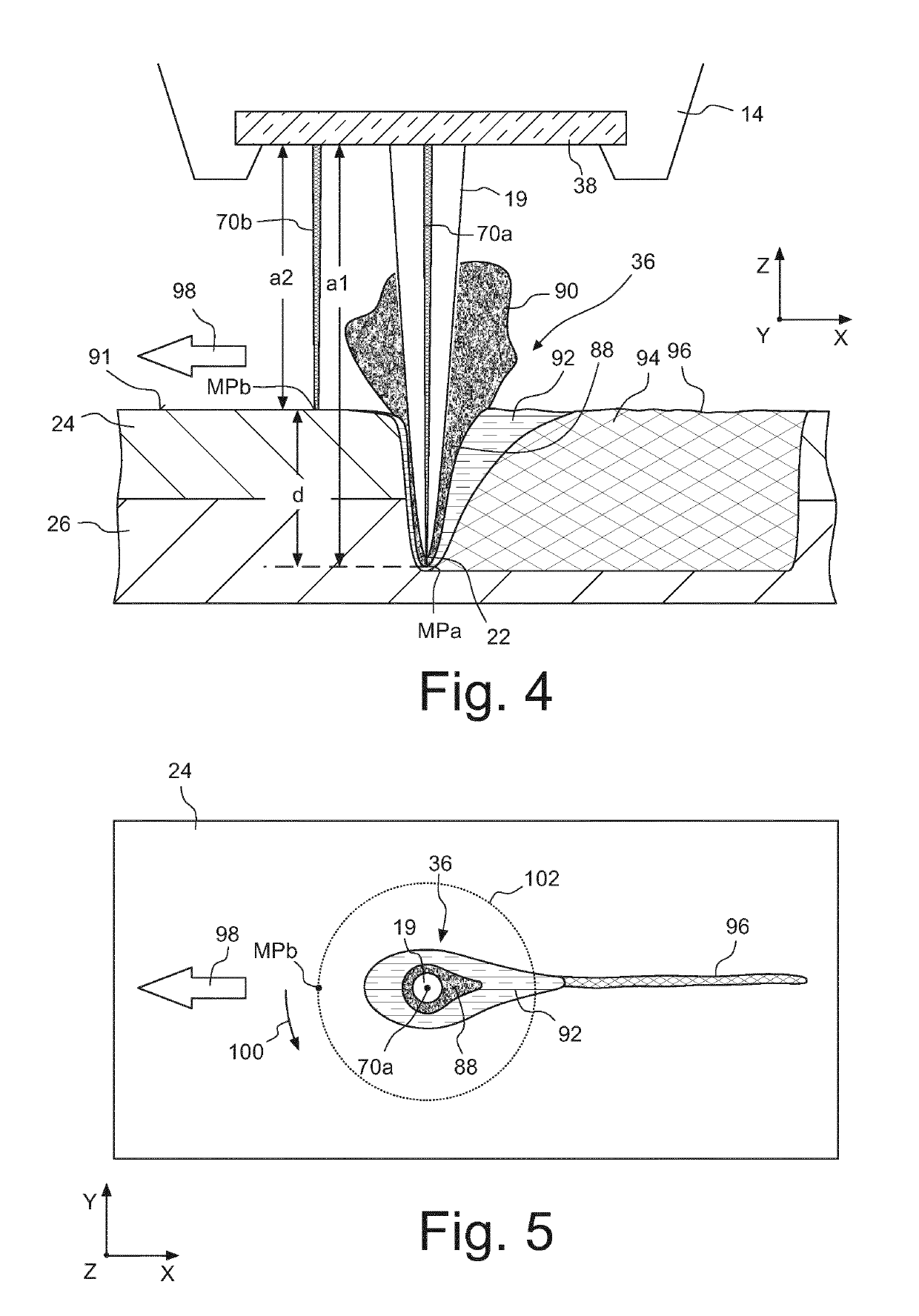

Method and device for measuring the depth of the vapor capillary during a machining process with a high-energy beam

ActiveUS20190091798A1Reliably and accurately determinedMinimizes probabilityInterferometersUsing optical meansLight beamInterference factor

A method for measuring the depth of the vapour cavity during an industrial machining process employs a high-energy beam. An optical measuring beam is directed towards the base of a vapour cavity. An optical coherence tomograph generates interference factors or other raw measurement data from reflections of the measurement beam. An evaluation device generates interference-suppressed measurement data, wherein raw measurement data that is generated at different times is processed together in the course of a mathematical operation. This operation can be a subtraction or a division. Slowly changing interference factors can thus be eliminated. An end value for the distance to the base of the vapour cavity is calculated from the interference-suppressed measurement data using a filter. As a result, the depth of the vapour cavity can be determined, in the knowledge of the distance at a part of the surface of the work piece that is not exposed to the high-energy beam.

Owner:PRECITEC OPTRONIK GMBH

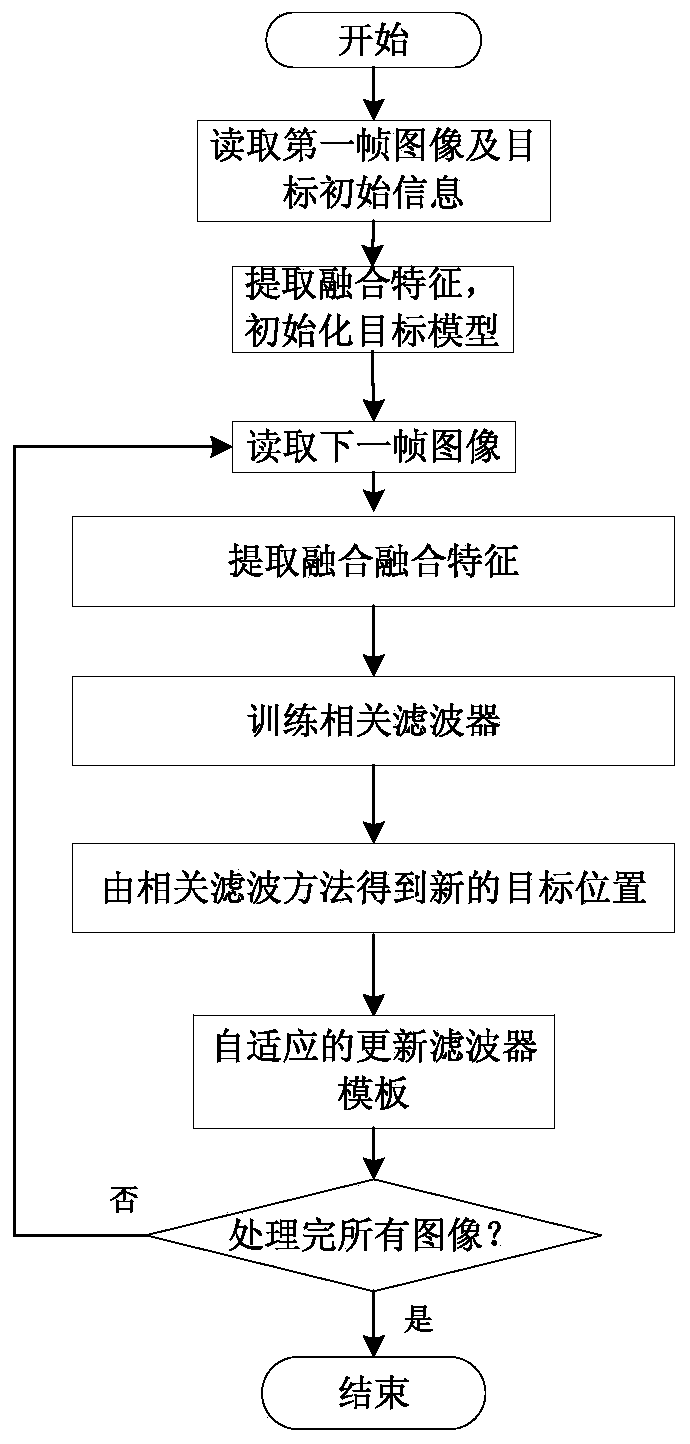

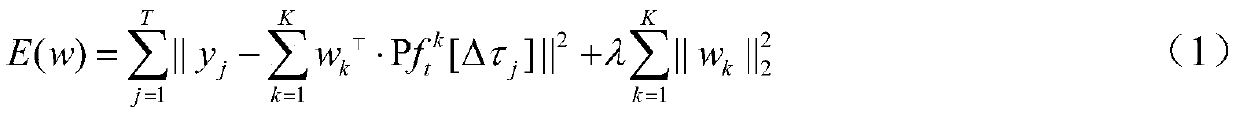

Correlation filtering tracking algorithm based on fusion features and self-adaptive updating strategy

ActiveCN109754424AGuaranteed catchReduce noiseImage enhancementImage analysisPattern recognitionTracking model

The invention relates to a correlation filtering tracking algorithm based on fusion features and a self-adaptive updating strategy. A tracking method based on correlation filtering is adopted, and a robust target model is constructed by using sub-channel fusion features to predict the central position of a target. For the problem that a target is severely shielded, a self-adaptive model updating mechanism is introduced to solve the problem that firstly, the reliability degree of a current response graph is judged according to a confidence coefficient threshold value, and the higher the reliability degree is, the lower the possibility that the target in the image is shielded is. Constructing a self-adaptive updating function on the basis, updating the tracking model according to the function, ensuring that the model is updated at a very low learning rate when the target is severely shielded, and introducing noise as little as possible. When the appearance of the target is clear and interference factors such as shielding deformation do not exist, the model is updated at a very high learning rate, and it is guaranteed that the model can capture the latest target characteristics. By means of the measures, a very robust tracking result can be obtained under different challenging scenes.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Forest fire hazard burning site extraction method based on multi-source remote sensing data

ActiveCN109753936AAccurately determineImprove extraction accuracyCharacter and pattern recognitionInterference factorConfounding

The invention relates to a forest fire hazard burning site extraction method based on multi-source remote sensing data. The method comprises the following steps: S1, calculating a forest fire disturbance index based on high-time resolution remote sensing data, judging a pixel of which the forest fire disturbance index is greater than a first threshold as a burning pixel, determining the burning pixel position as a fire point position, and recording time information of the fire point position; S2, based on high spatial resolution remote sensing data, calculating normalized vegetation index changes of the pixels within a preset distance range around the fire point position before and after a fire disaster by taking the fire point position as a circle center, judging the pixels as burning pixels when the absolute value of the normalized vegetation index changes is greater than a second threshold value, and extracting all the burning pixels to generate burning site data. The method provided by the invention can accurately determine the whole fire occurrence range, improves the information extraction precision based on the remote sensing fire mark, and distinguishes the information fromother interference factors.

Owner:TAIYUAN NORMAL UNIV

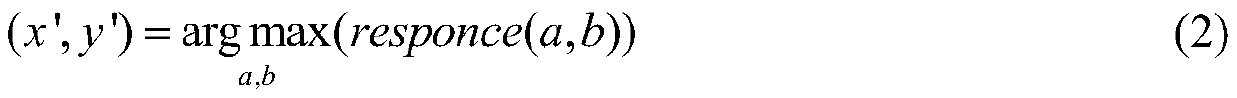

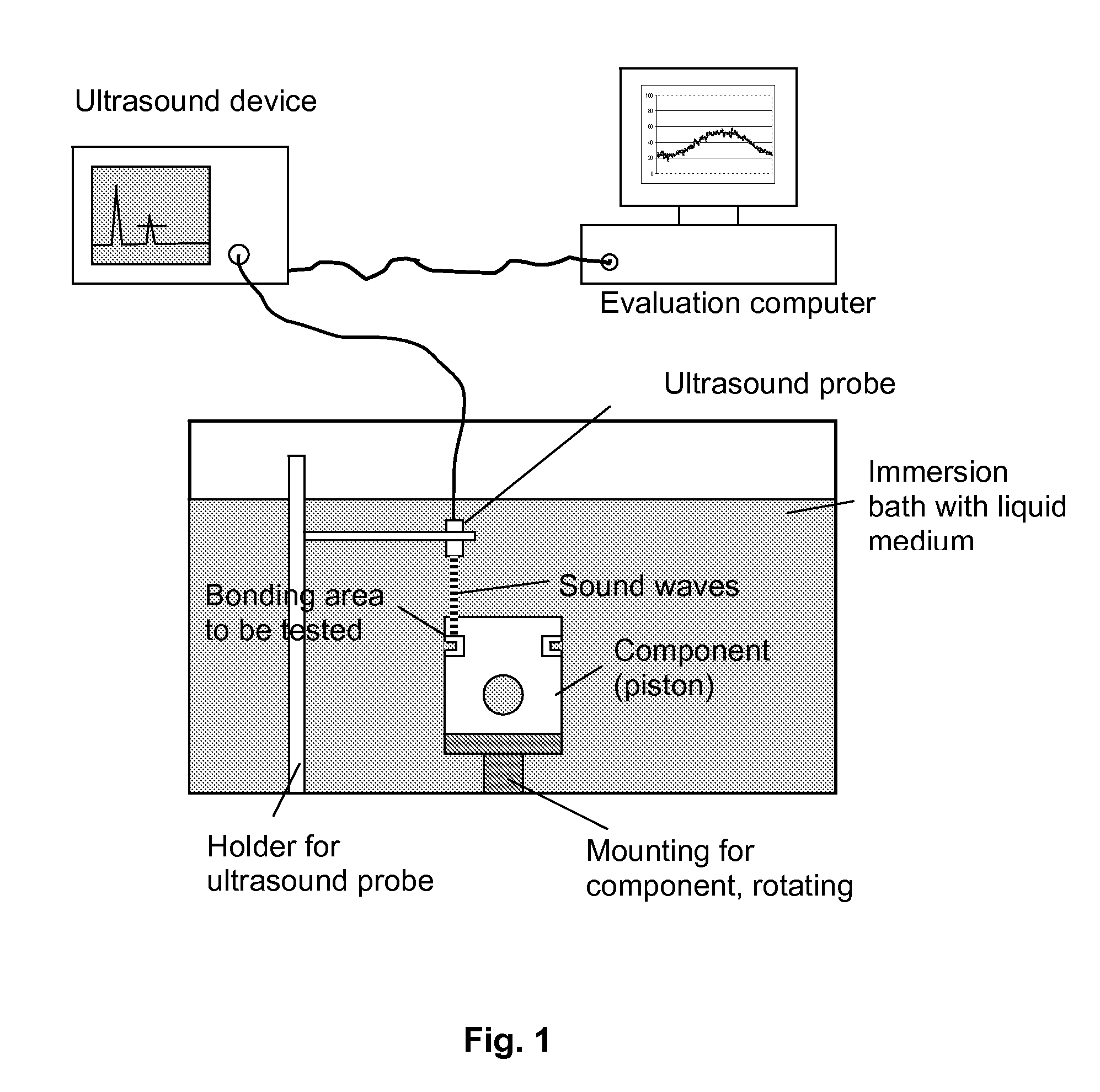

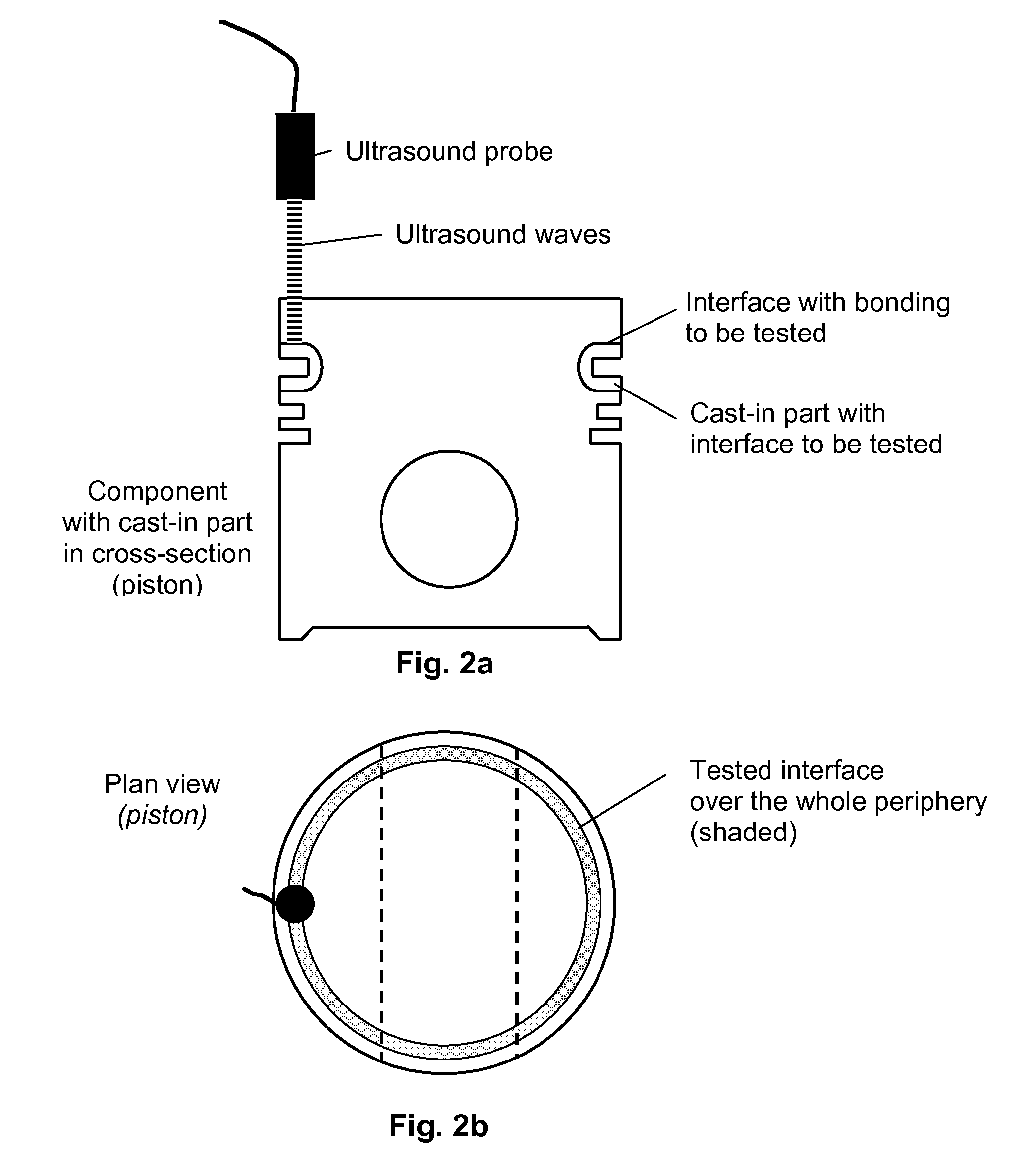

Measuring method and system for components, in particular for pistons and piston engines

ActiveUS20100042337A1Shorten the timeReduce the proportionVibration measurement in solidsInternal-combustion engine testingObservational errorFoundry

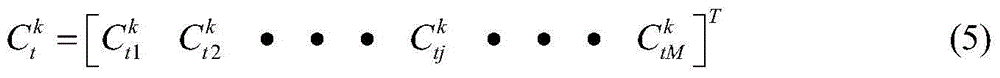

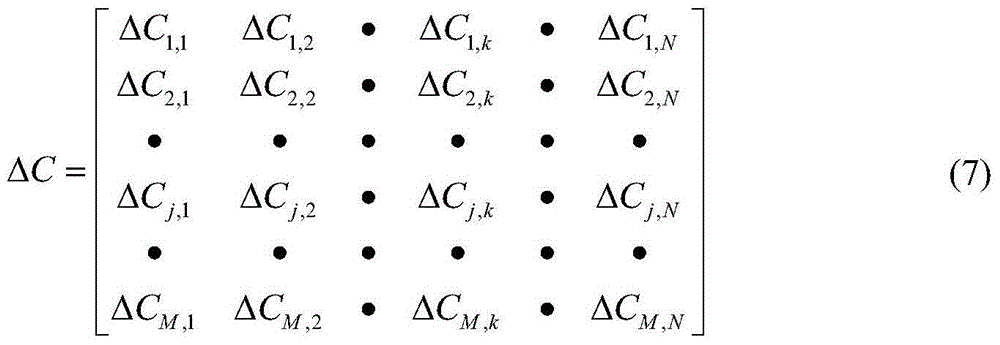

The invention relates to the non-destructive measurement of components, in particular the functional assessment of the bonding of cast-in parts, eg. in pistons for internal combustion engines. With such a measurement or functional assessment, it is a question of assessing the function and completeness of the bonding between the base material and the material cast in or otherwise joined. The quality of the component or its suitability for a specific purpose can thus be assessed and / or quality monitoring of the production process, e.g. in the foundry or during production, can take place. According to the invention, this purpose is served by a multi-stage correction procedure, wherein the measured values ascertained by means of a suitably devised measuring arrangement and method, e.g. using ultrasound, are subjected to a multi-stage determination process, which minimises universally and for each individual measurement the disturbing factors which, being inherent in the system, occur in the measurement and ascertains therefrom the desired results. A correspondingly devised system minimises both error influences, which occur in the performance (especially with the setting-up / adjustment) of such a measurement, as well as measurement errors and incorrect assessments in the performance of the measurement, which occur due to geometrical tolerance deviations or differences between a number of components to be measured or due to differences in the material or structural composition, as well as other disturbing influences.

Owner:MAHLE INT GMBH

Damaged cable and concentrated load recognition method on basis of hybrid monitoring

InactiveCN103604624AAccurate identificationAchieve accurate identificationStructural/machines measurementApparatus for force/torque/work measurementReference modelLinear relationship

The invention relates to a damaged cable and concentrated load recognition method on the basis of hybrid monitoring, which is based on hybrid monitoring. Cable structure temperature and ambient temperature are monitored to determine whether a mechanical calculation reference model of the cable structure needs to be updated, thereby obtaining a mechanical calculation reference model of the cable structure counting in the cable structure temperature and ambient temperature; and the calculation is performed on the basis of the model to obtain unit-damage monitored quantity value change matrix. The noninferior solution of the evaluated object current nominal damage vector is calculated according to the near linear relationship among the monitored quantity current value, monitored quantity current initial value vector, unit-damage monitored quantity value change matrix and unknown evaluated object current nominal damage vector, thereby eliminating the influence of interference factors by utilizing a multiobjective optimization algorithm and the like and recognizing the concentrated load variation and damaged cable in the presence of temperature change.

Owner:SOUTHEAST UNIV

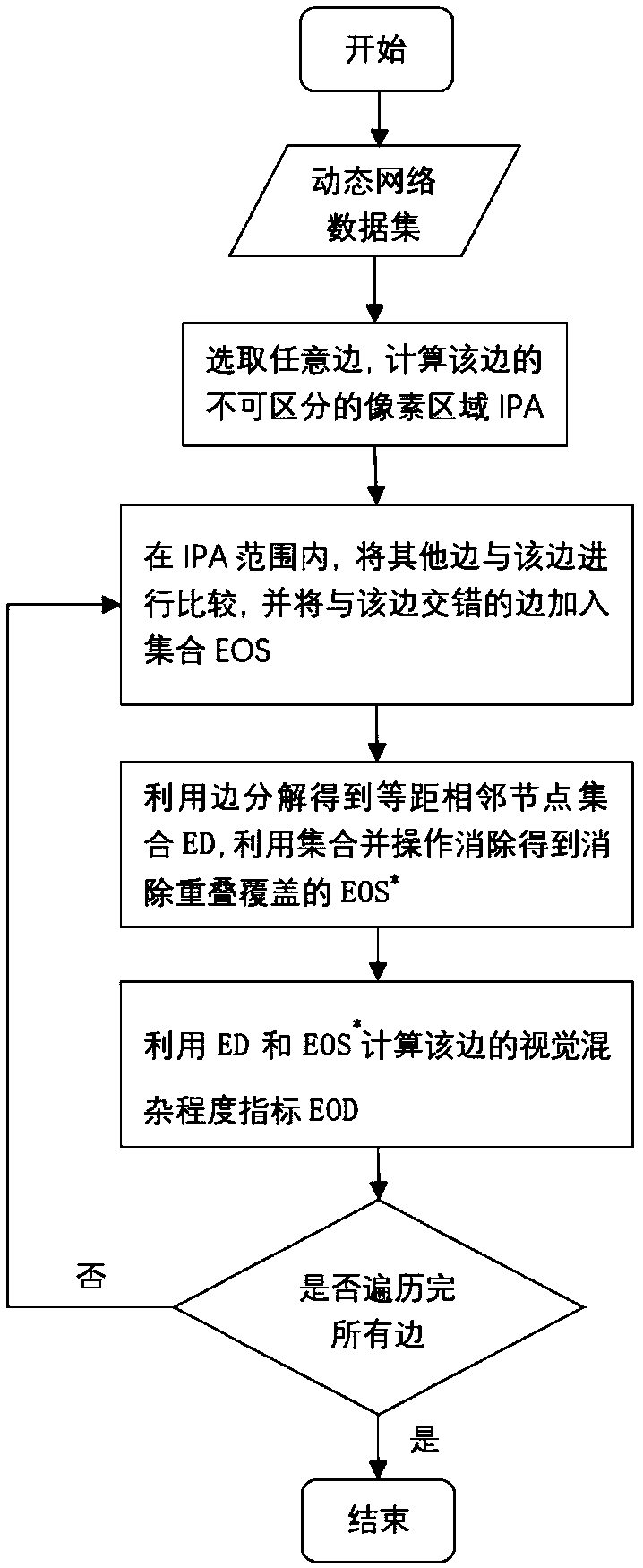

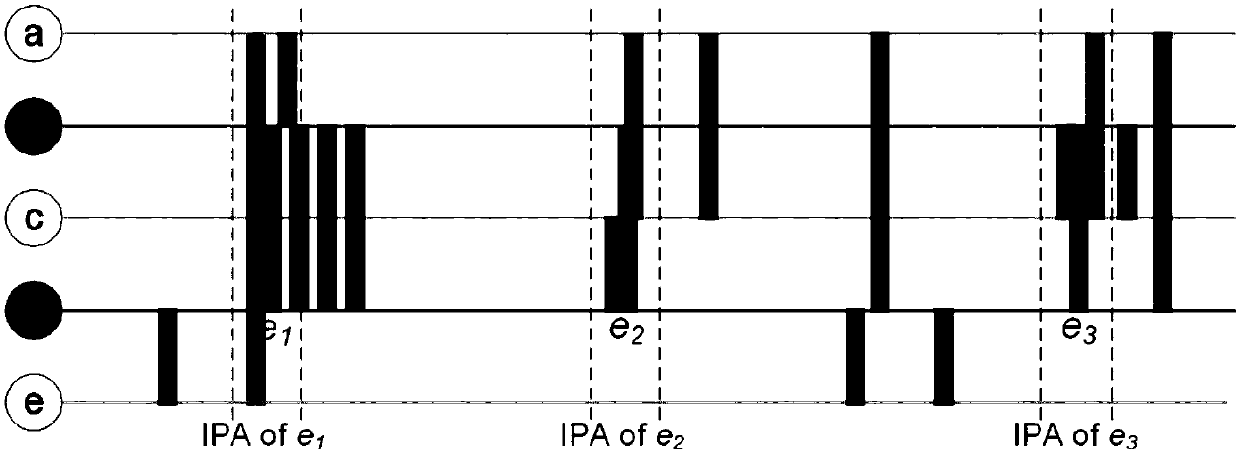

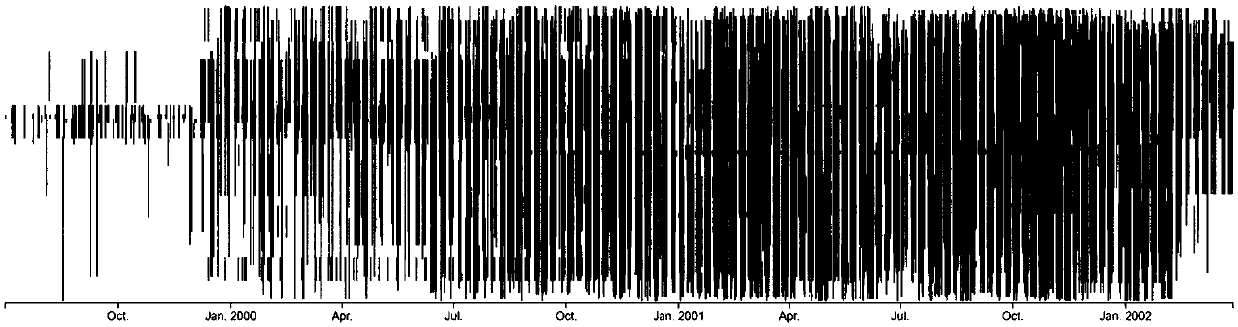

A method for quantitatively evaluating the degree of visual clutter of MSV

ActiveCN109101628AReduce data volume confusionImprove readabilitySpecial data processing applicationsVisual clutterComputer vision

The invention discloses a calculation method for quantitatively evaluating the edge level visual confounding degree index of an MSV, including such steps as 1) obtaining any edge e in MSV, calculatingindistinguishable pixel distance value IPD, respectively extending width of IPD from center position of edge e to left and right direction to form indistinguishable pixel area IPA, and calculating indistinguishable pixel distance value IPD from center position of edge e to left and right direction to form indistinguishable pixel area IPA; 2) adding an edge interleaved with that edge e in the IPAinto an interleaved edge set; 3) decomposing the set of interleaved edge according to the node order to obtain a plurality of equidistant and adjacent node pair sets, eliminating overlap cover by using union operation to obtain the set of interleaved edges eliminating overlap cover; 4) calculating the visual mixing degree index of the edge e according to the set of interlaced edges and node pairsto eliminate coverage. The invention quantitatively evaluates the visual mixing degree of the edges in the MSV, which is helpful to provide reliable basis for the subsequent edge sampling work, further helps to reduce the visual mixing degree in the MSV, and improves the readability of the MSV.

Owner:CENT SOUTH UNIV

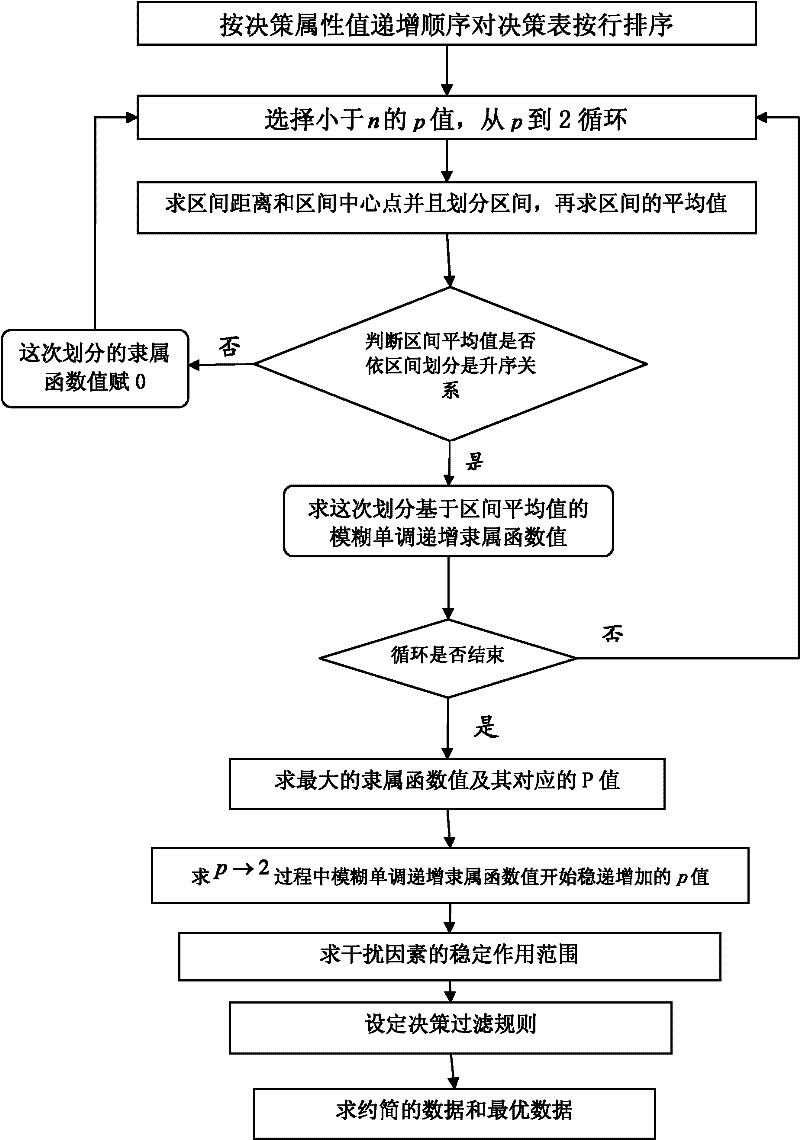

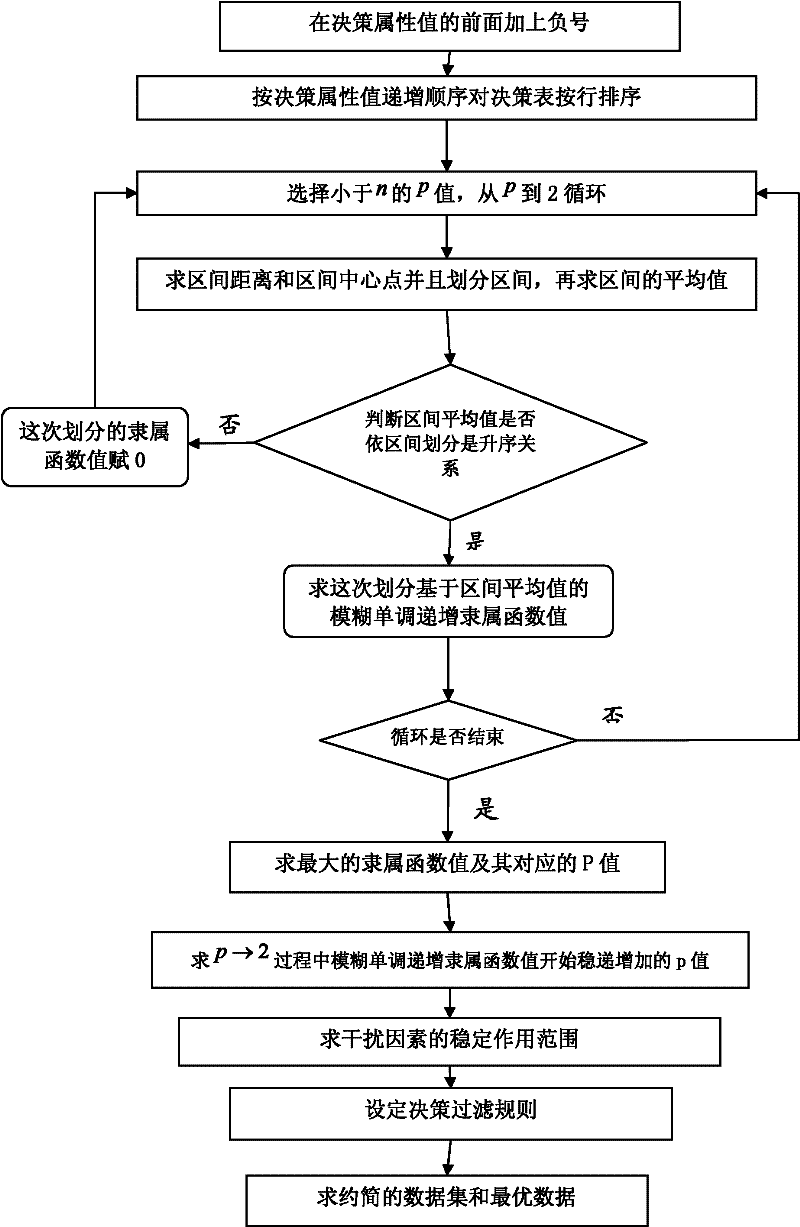

Mining method for fuzzy rough monotonic data based on interval average

InactiveCN102609470AReduce input attributesSpecial data processing applicationsFuzzy rough setsData set

The invention refers to the theory of fuzzy rough set and provides a mining method for fuzzy rough monotonic data based on interval average. The method includes: realigning decision properties and condition attributes; dividing realigned collections into intervals; deciding monotone according to each interval average; determining membership function values of the condition attributes; determining number of divisions according to circular division of the intervals to obtain function range of interference factors; setting filtering rules to filter unsuitable data so as to obtain reduction data collection and optimal data.

Owner:SOUTH CHINA NORMAL UNIVERSITY

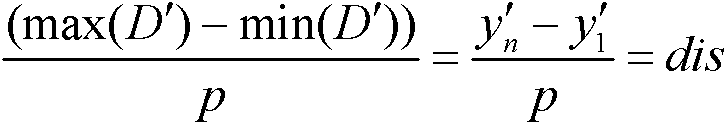

Method for determining linear acceleration and device for its implementation

InactiveUS20090145223A1Harmful influenceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeConfounding

The present technical solution for determining linear acceleration, the vector whereof is considered to be at a tangent to a trajectory of movement of a moving object, is based on determining new differences of accelerations. It is considered to be the basis for efficient, accurate, with the threshold of sensitivity equal to zero in small-size option solving the tasks of autonomous navigation, piloting, stabilization and etc. Said solution is irrespective of disturbance factors, in particular, cross-axis and centrifugal accelerations, vibrations, temperature and others, and can be used without any gyroscopes.

Owner:NAUMOV MICHAEL

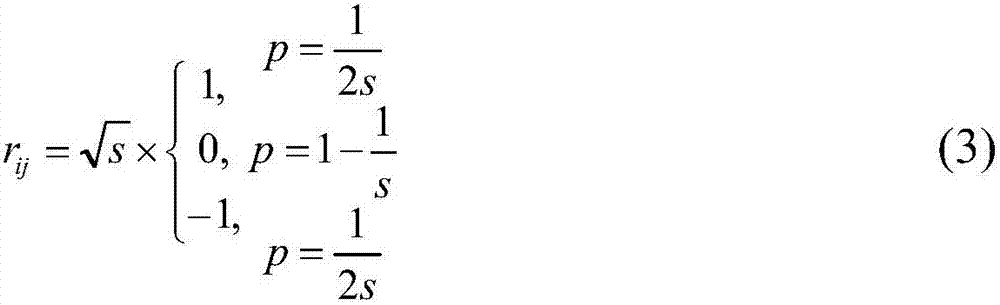

Adaptive compressive tracking algorithm based on multiple features

InactiveCN107122722ARobustAccuracyCharacter and pattern recognitionPattern recognitionAdaptive compression

The invention belongs to the field of visual tracking and discloses an adaptive compressive tracking algorithm based on multiple features. Firstly, a tth frame of image is extracted and is grayed, a compressive sensing theory is used, extracted high-dimensional and multi-scale image features are mapped to low-dimensional subspace respectively through two extremely-sparse random matrixes, two low-dimensional image features are obtained, a classifier is used for classifying the features, and the sample with the maximum reaction value of the classifier is selected to be the tracked target. Then, the Hamming distance between a Hash fingerprint of the current frame of tracked target and a Hash fingerprint of the previous frame of tracked target is calculated, the Hamming distance is compared with a high-low threshold, and the updating degree parameters of the classifier are adjusted adaptively. The algorithm has high robustness and high accuracy under various interference factors, the average speed for image processing can achieve 19.8 frames per second, real-time performance requirements can be achieved basically, and an important practical significance is realized.

Owner:DALIAN UNIV OF TECH

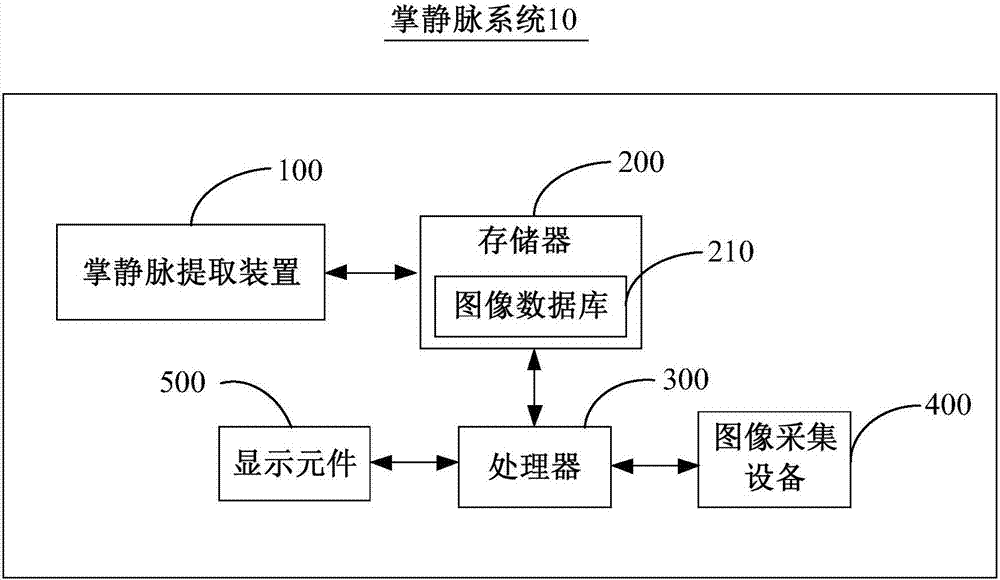

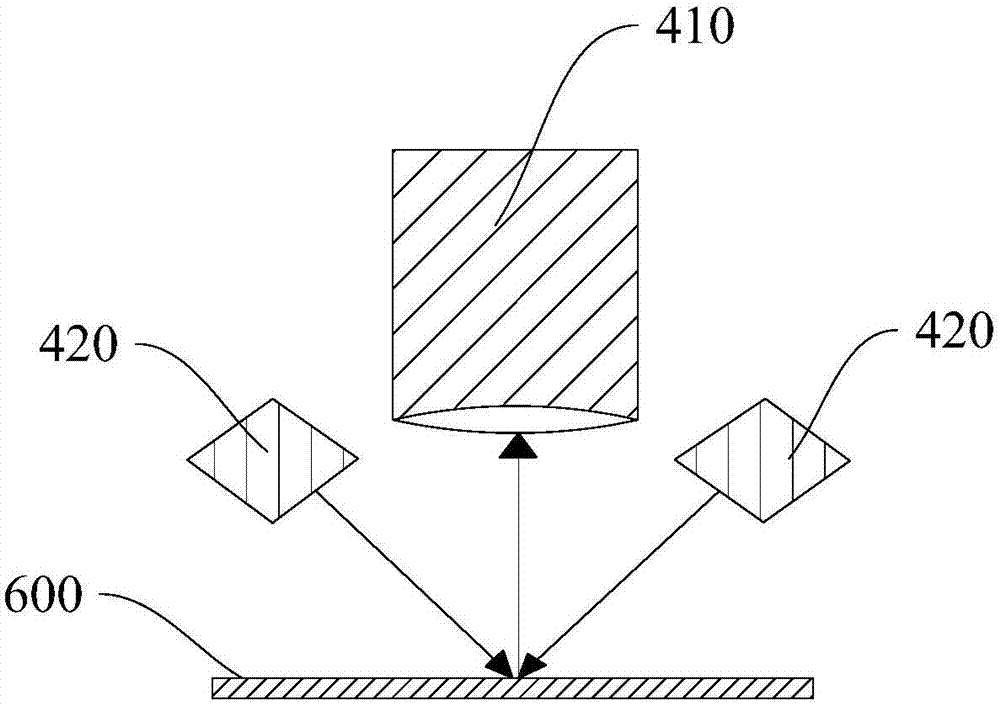

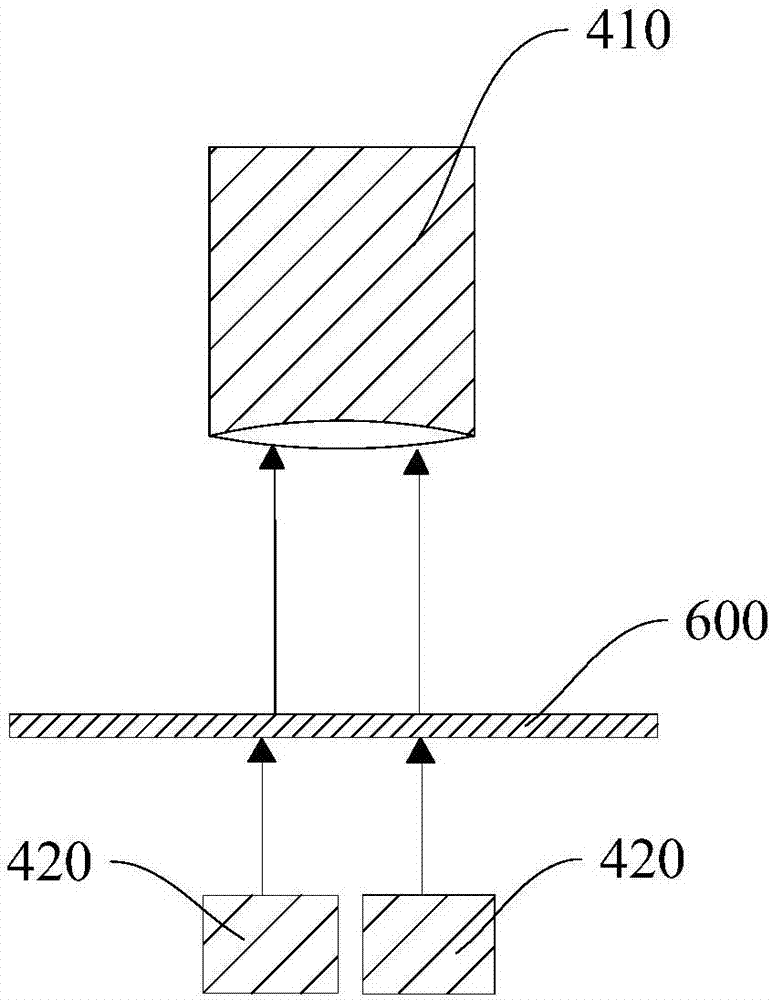

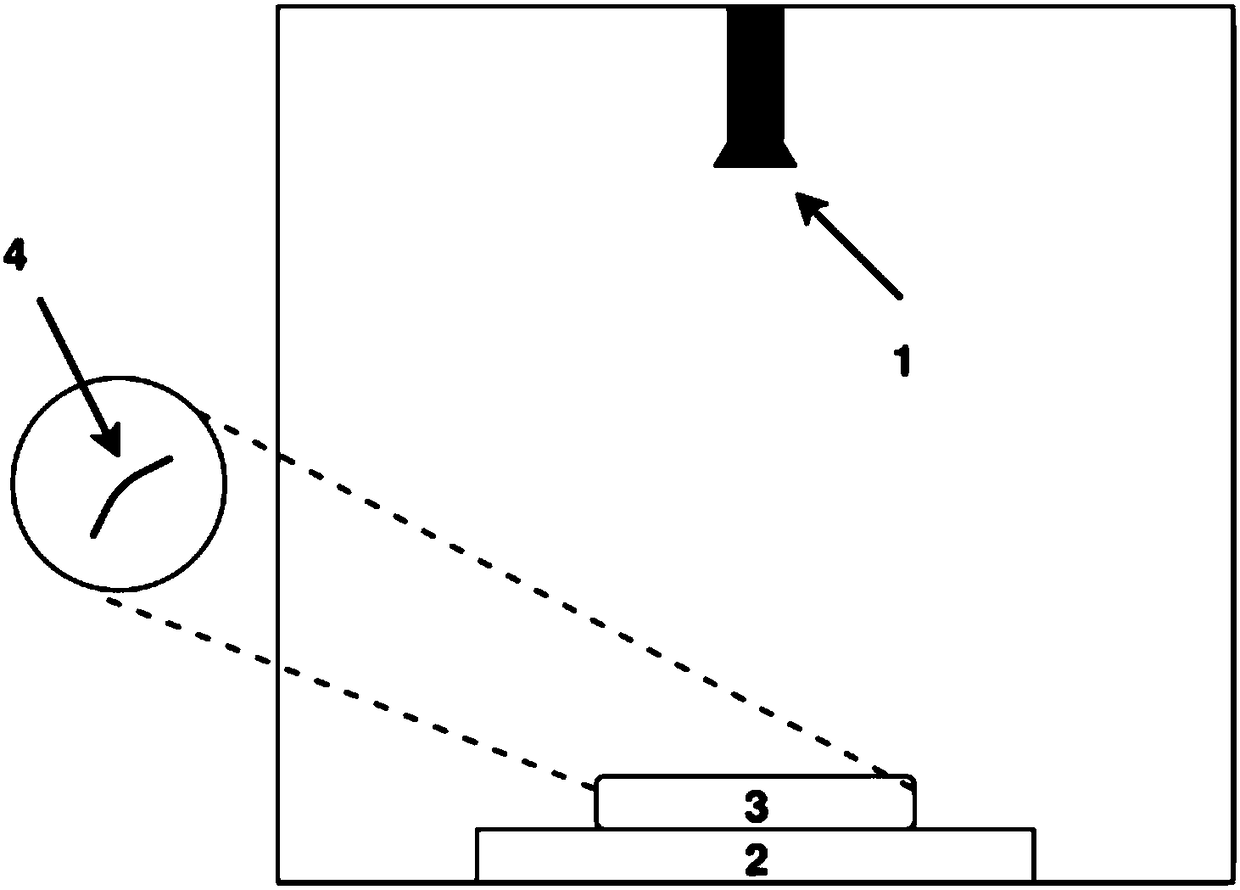

Palmar vein extraction method and device

InactiveCN107256395AReduce adverse effectsLess distracting factorsImage enhancementImage analysisVeinInterference factor

The invention provides a palmar vein extraction method and a palmar vein extraction device. The method comprises the steps of collecting a palmar vein image; pre-processing the palmar vein image to obtain an area-of-interest; and extracting palmar vein characteristics based on the area-of-interest. Therefore, clean and accurate palmar vein characteristic image information can be extracted so as to reduce adverse effect on identification of the palmar vein characteristics, decrease interference factors and improve the identification rate.

Owner:成都芯软科技股份公司

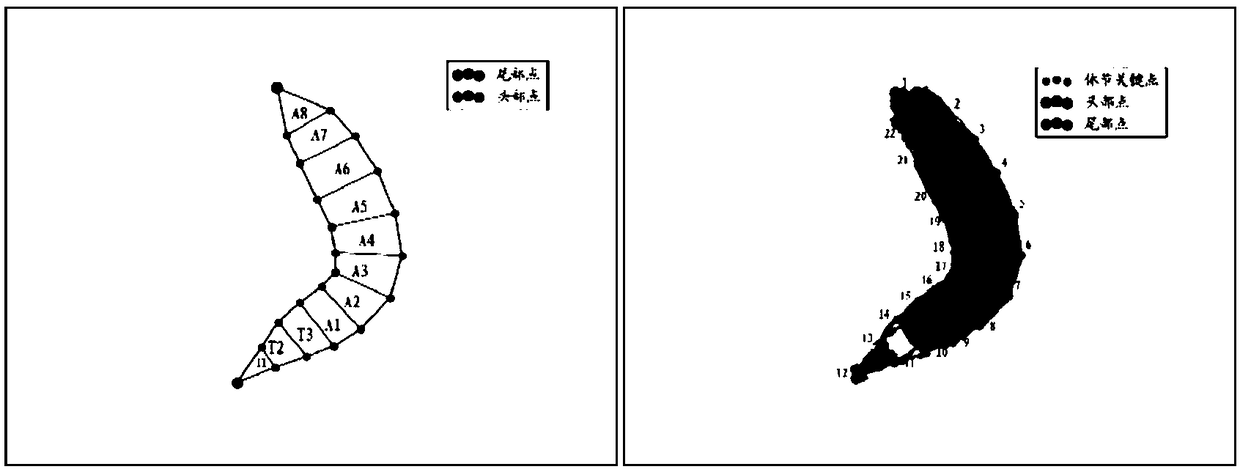

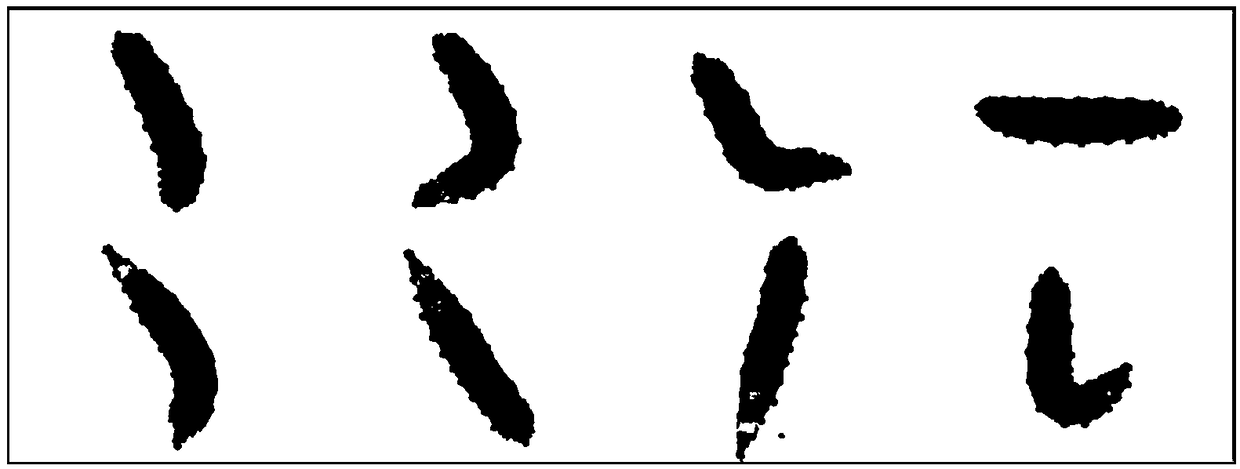

Drosophila larva body segment key point positioning method based on cascade posture regression

ActiveCN108573226AAvoid distractionsConsumption of manpower and material resourcesCharacter and pattern recognitionCrucial pointData set

The invention discloses a Drosophila larva body segment key point positioning method based on cascade posture regression. The behavior data of the movement of a Drosophila larva with clear body segments on a two-dimensional plane are recorded. A body segment key point data set is constructed to train a body segment key point positioning model. According to the characteristics of the Drosophila larva, a body segment key point regression process is designed to automatically acquire the body segment information of the body of the Drosophila larva. According to the invention, the method is combined with a computer vision algorithm to automatically process the data of the Drosophila larva, so as to acquire the representation of the body segment precision of the body of the Drosophila larva; a large number of interference factors on the movement of the Drosophila larva are avoided; a lot of manpower and material resources can be saved; the method can be used for automated behavior analysis of the Drosophila larva, complex movement decomposing and the like; a large amount of data can be processed without manual intervention; and a basis is provided for automatic behavior analysis of bodysegment precision.

Owner:ZHEJIANG UNIV

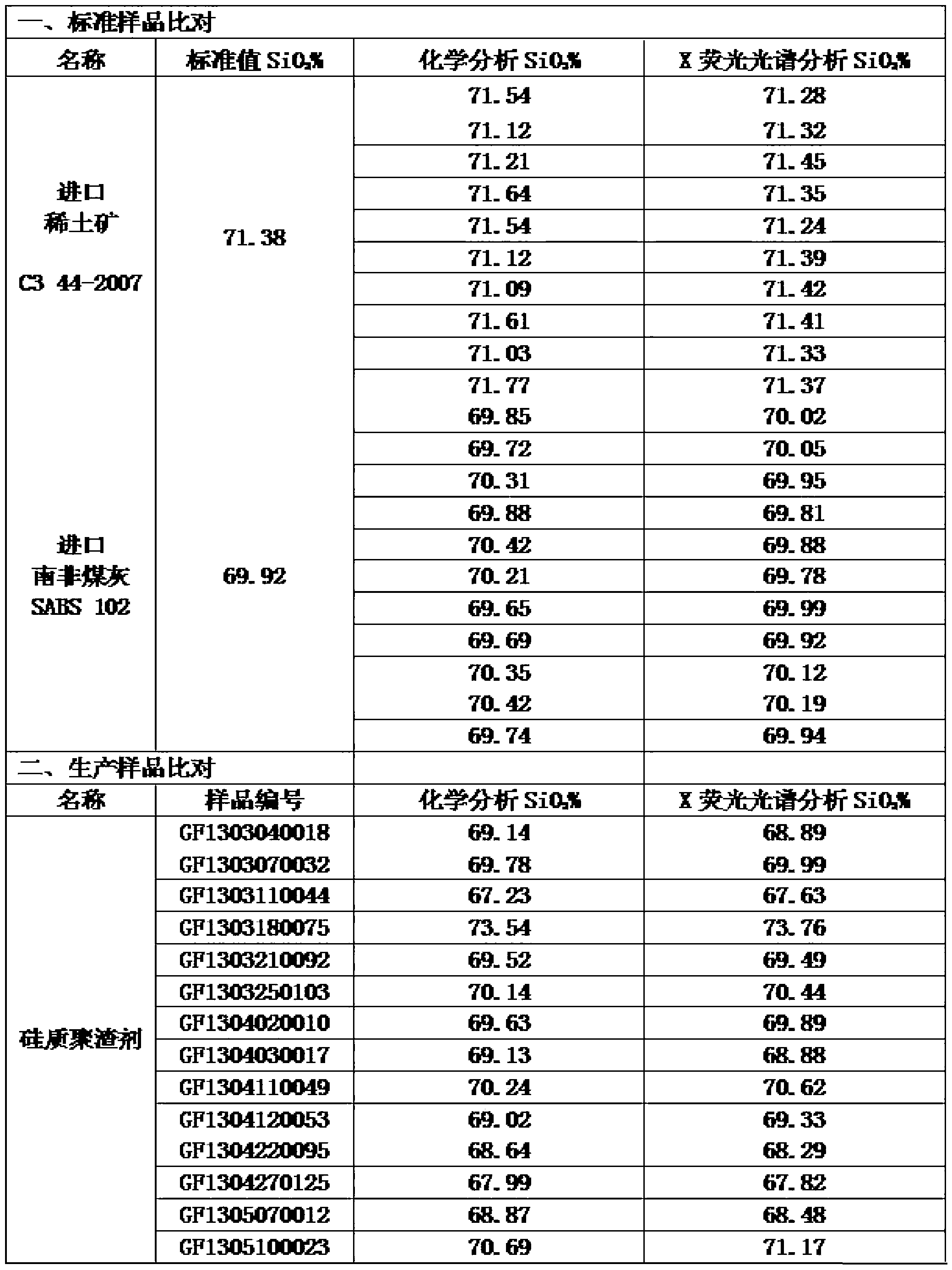

X fluorescence spectrum analysis method of siliceous slag conglomeration agent

InactiveCN103278520AReduce typesMethod procedure simplificationMaterial analysis using wave/particle radiationPreparing sample for investigationFluorescenceSlag

The invention provides an X fluorescence spectrum analysis method of a siliceous slag conglomeration agent. A lithium tetraborate reagent is taken as a fusion agent, samples are melted into glass sample sheets at a high temperature, then an X fluorescence spectrophotometer is used for drawing a national standard sample curve, and the intensity of a to-be-measured element is analyzed, so that the percentage composition of the to-be-measured element is calculated. Compared with a chemical analytical method, the process is simplified, the procedure is simple, the varieties of reagents are few, the detection cost can be reduced, the air quality is purified, and the standard curve can be drawn for one time and then can be used repeatedly; the measurement time can be shortened, the analysis time for each batch of samples can be saved by 3 hours, and the analysis efficiency is greatly improved; and analysis is performed by instruments instead of manual work, the analysis errors can be reduced, the analysis accuracy rate is improved, the interference factors are few, little influence on a machine body is caused, and the stability is good.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com