X fluorescence spectrum analysis method of siliceous slag conglomeration agent

A technology of fluorescence spectrum and slag gathering agent, which is applied in the field of inspection and testing, can solve the problems of inconsistency in observing the color of the indicator, difficulty in distinguishing the end point of titration, and incomplete dissolution of the sample, so as to shorten the measurement time and improve the accuracy of analysis. Effects with few types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

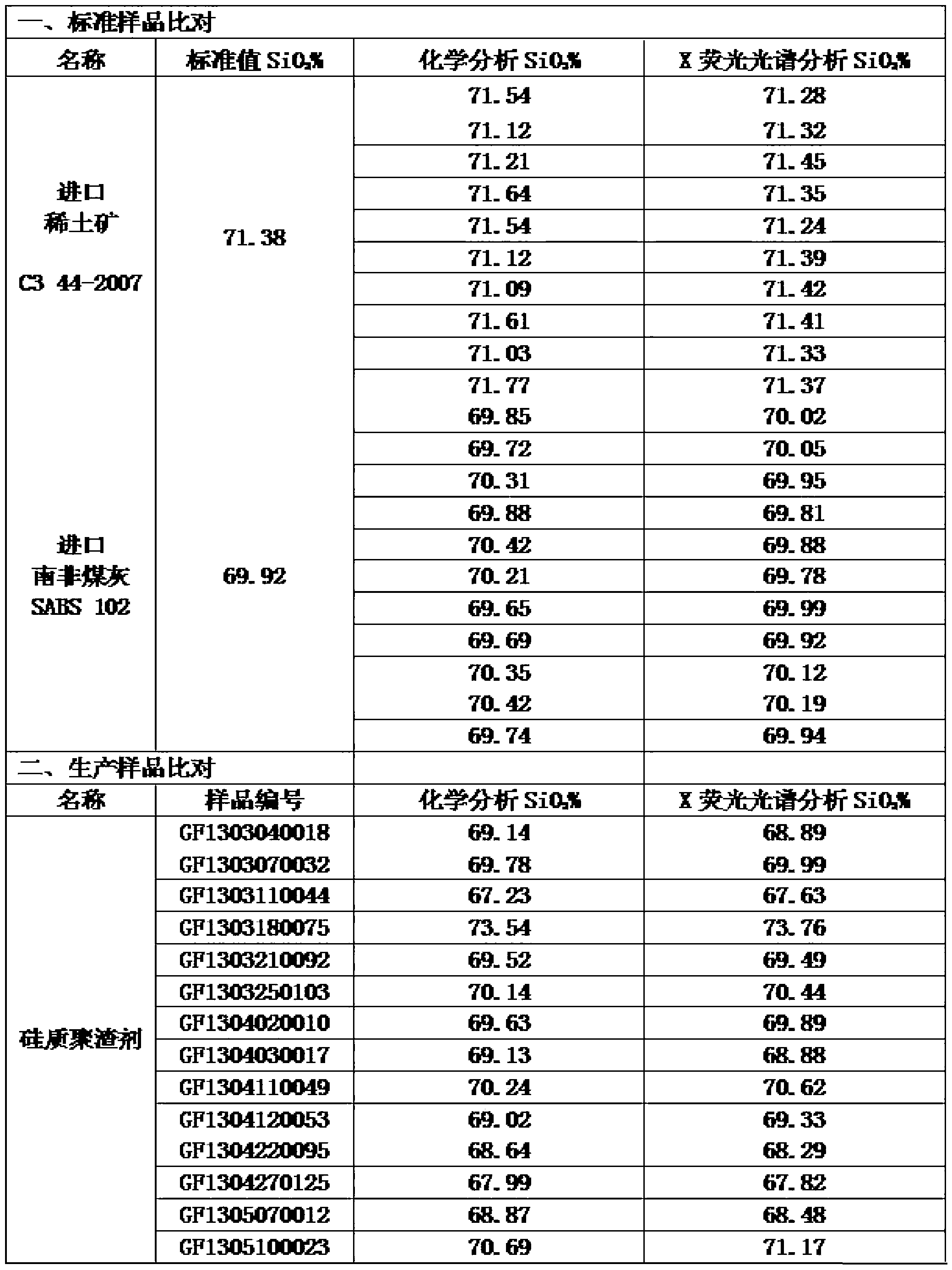

Examples

Embodiment 1

[0026] Sample preparation:

[0027] 1. Weigh 6.0000g lithium tetraborate and 0.1000g lithium fluoride reagent into a clean platinum pot, add 0.2000g sample, stir, add 5 drops of saturated potassium nitrate solution and 5 drops of 40% potassium iodide solution.

[0028] 2. Put the platinum pot containing the sample into the melting furnace and melt at 1145°C for 16 minutes.

[0029] 3. Remove the platinum pot and cool to room temperature.

[0030] Standard curve drawing:

[0031] 1. Select 10 national standard samples with a silica content in the range of 60-85wt% and a certain gradient as analysis samples.

[0032] 2. Follow the three steps of "sample preparation" to melt 10 national standard samples into glass samples.

[0033] 3. Set the analysis parameters of the X-ray fluorescence spectrometer.

[0034] a. X-ray tube voltage 40kV, current 70mA.

[0035] b. The elemental analysis time is 20s.

[0036] c. The selection range of pulse height is: PHA Low Level: 15, PHA H...

Embodiment 2

[0042] Sample preparation:

[0043] 1. Weigh 6.0000g lithium tetraborate and 0.1000g lithium fluoride reagent into a clean platinum pot, add 0.2000g sample, stir, add 5 drops of saturated potassium nitrate solution and 5 drops of 40% potassium iodide solution.

[0044] 2. Put the platinum pot containing the sample into the melting furnace, and melt it at 1150°C for 15 minutes.

[0045] 3. Remove the platinum pot and cool to room temperature.

[0046] Standard curve drawing:

[0047] 1. Select 10 national standard samples with a silica content in the range of 60-85wt% and a certain gradient as analysis samples.

[0048] 2. Follow the three steps of "sample preparation" to melt 10 national standard samples into glass samples.

[0049] 3. Set the analysis parameters of the X-ray fluorescence spectrometer.

[0050] a. X-ray tube voltage 40kV, current 70mA.

[0051] b. The elemental analysis time is 20s.

[0052] c. PHA Low Level: 15, PHA High Level: 130.

[0053] d. Spectro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com