Copper base particle reinforced friction material

A technology of friction materials and particles, applied in the direction of friction linings, mechanical equipment, etc., to achieve the effects of reducing energy consumption, shortening sintering time, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

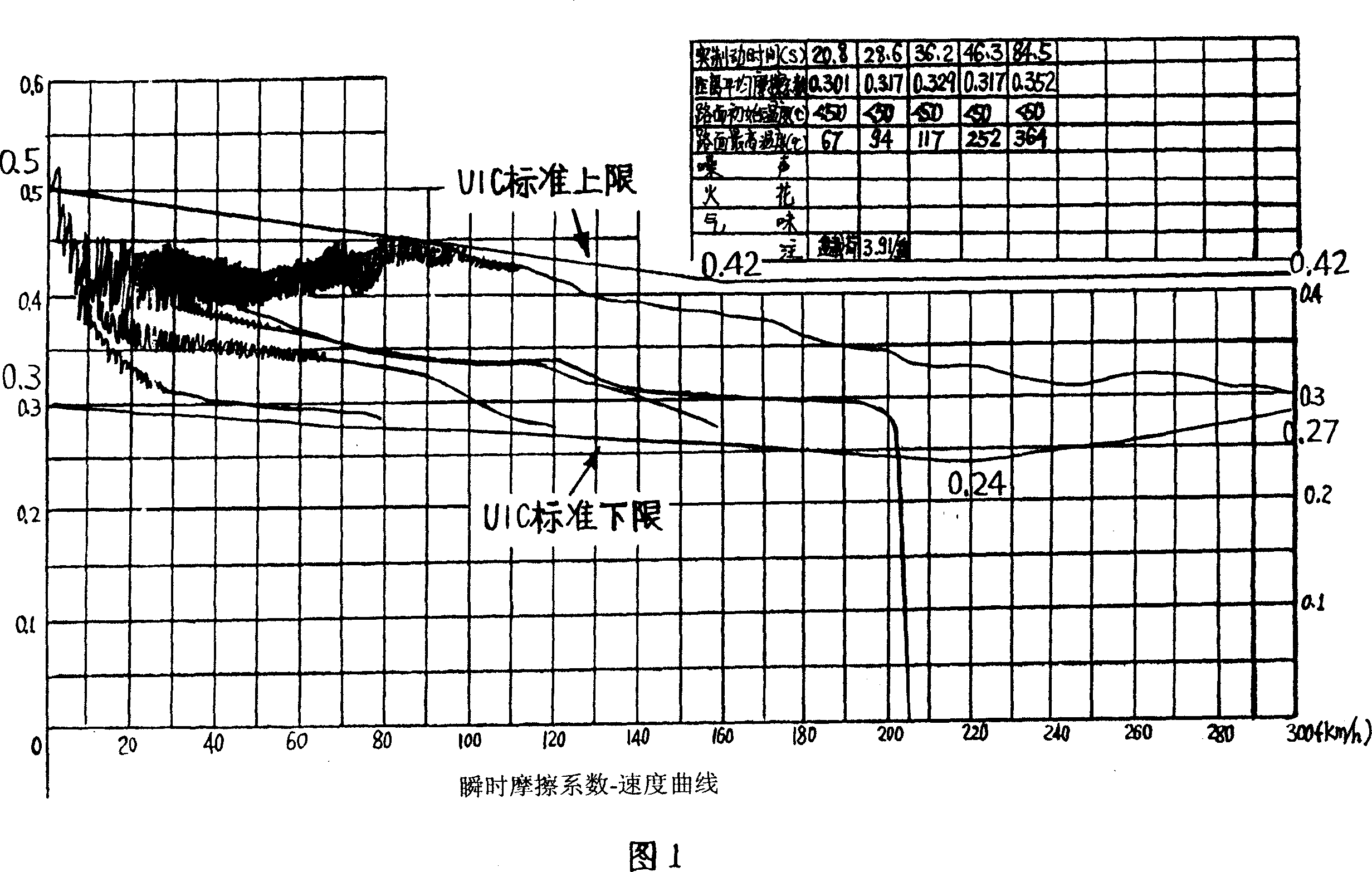

Image

Examples

Embodiment 1

[0020] Copper-based particle reinforced friction material, the weight percentage of each component is as follows: copper powder 54%, tin powder 6%, aluminum powder 3%, iron powder 12%, Al 2 o 3 6%, SiO 2 9%, graphite 10%.

[0021] To manufacture a brake block from the above friction material, firstly weigh the above raw materials in proportion and mix them, add 0.2% kerosene by weight of the mixed powder, and mix until uniform. Put the mixed powder with suitable weight into the mold, press it under the pressure of 500MPa for 5-10 seconds, and take it out to become a cold pressed blank. Put the cold-pressed blank into the hot-pressing mold, start the vacuum system, when the vacuum reaches 70mmHg, apply a pressure of 3MPa to the blank, and at the same time, start the heating current, when the temperature of the blank reaches 800°C, apply a pressure of 50MPa to the blank, and keep it warm for 2 minutes , with the furnace cooling to 100 ℃ out of the furnace, made of brake block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com