Patents

Literature

31 results about "Stage determination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

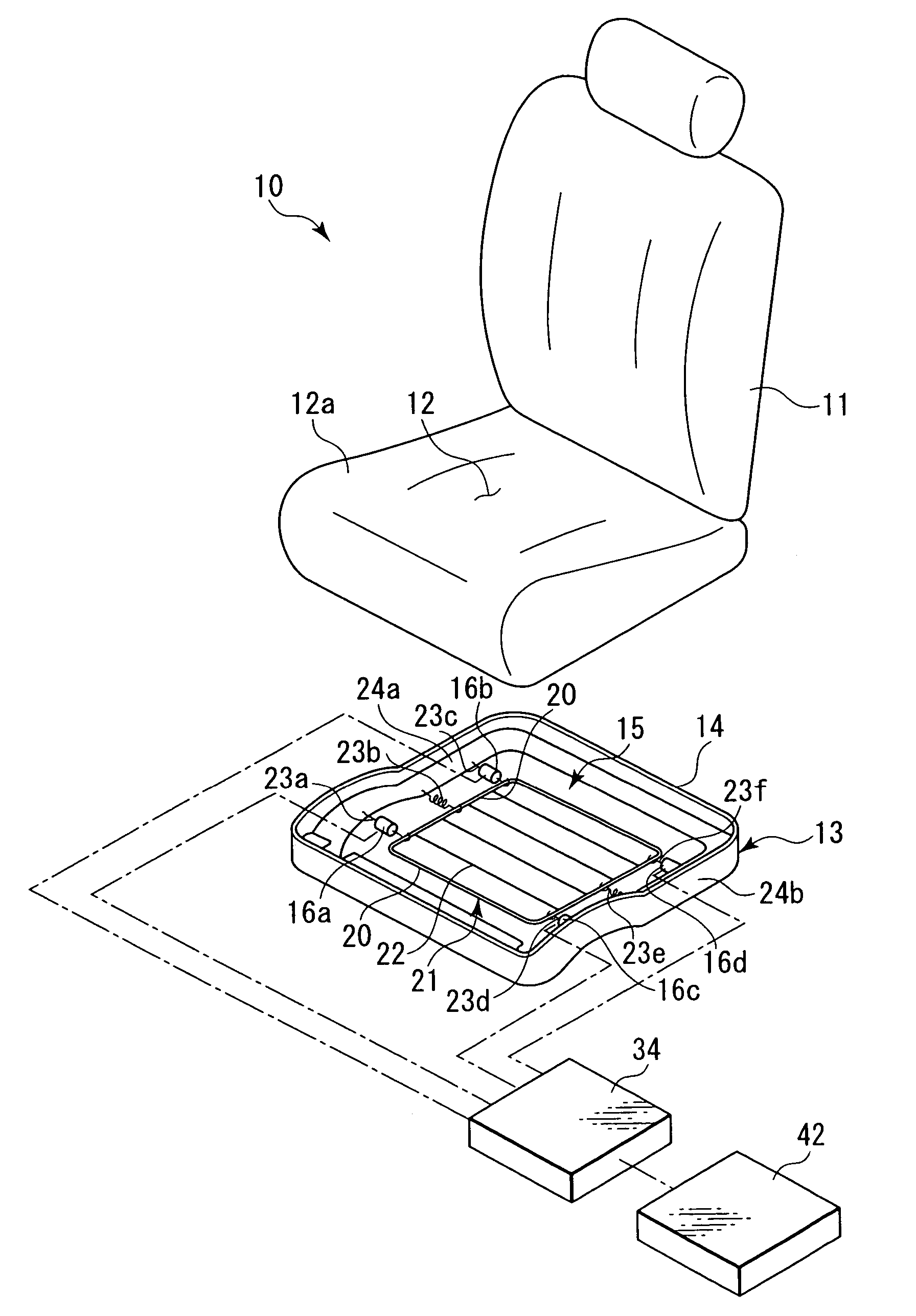

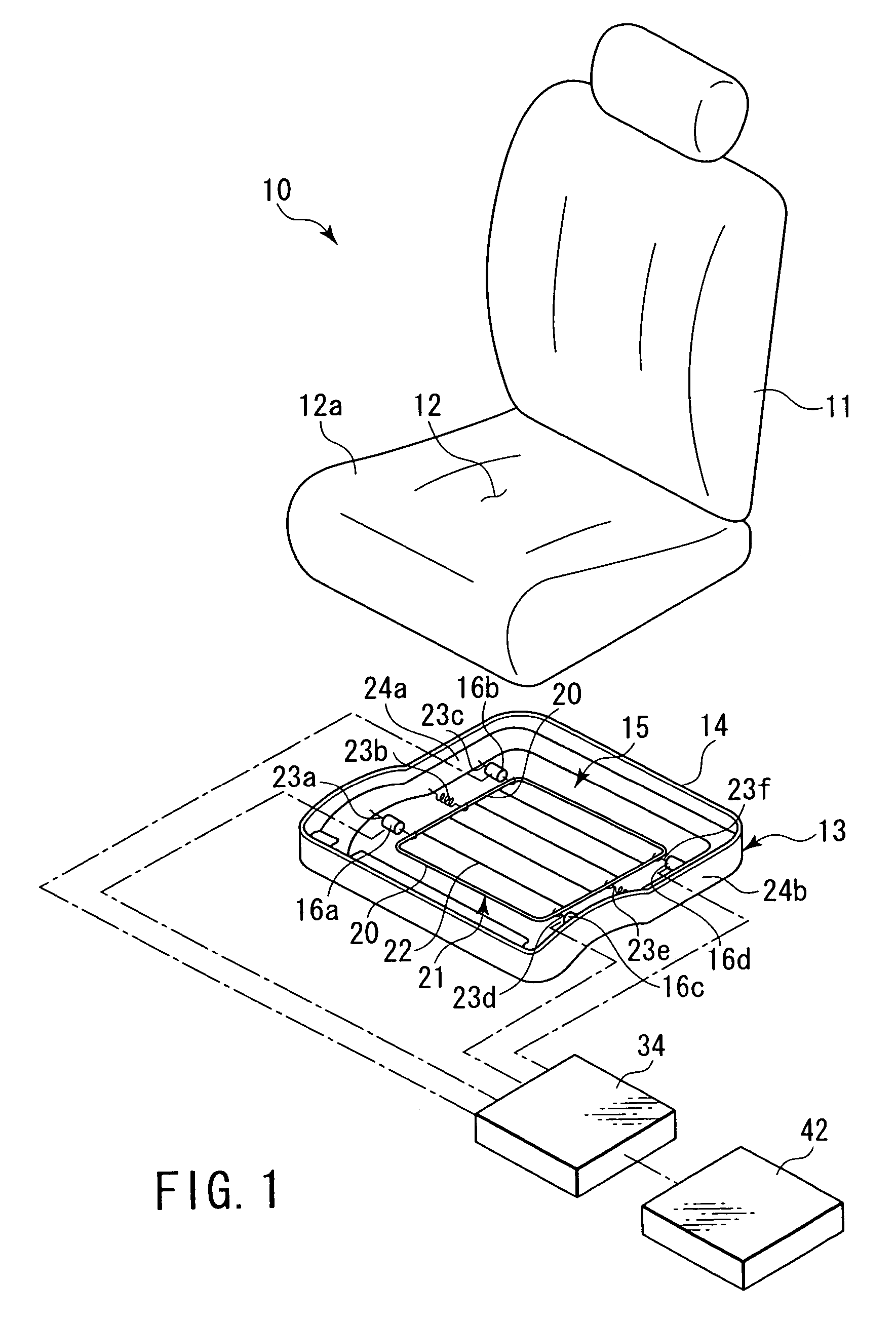

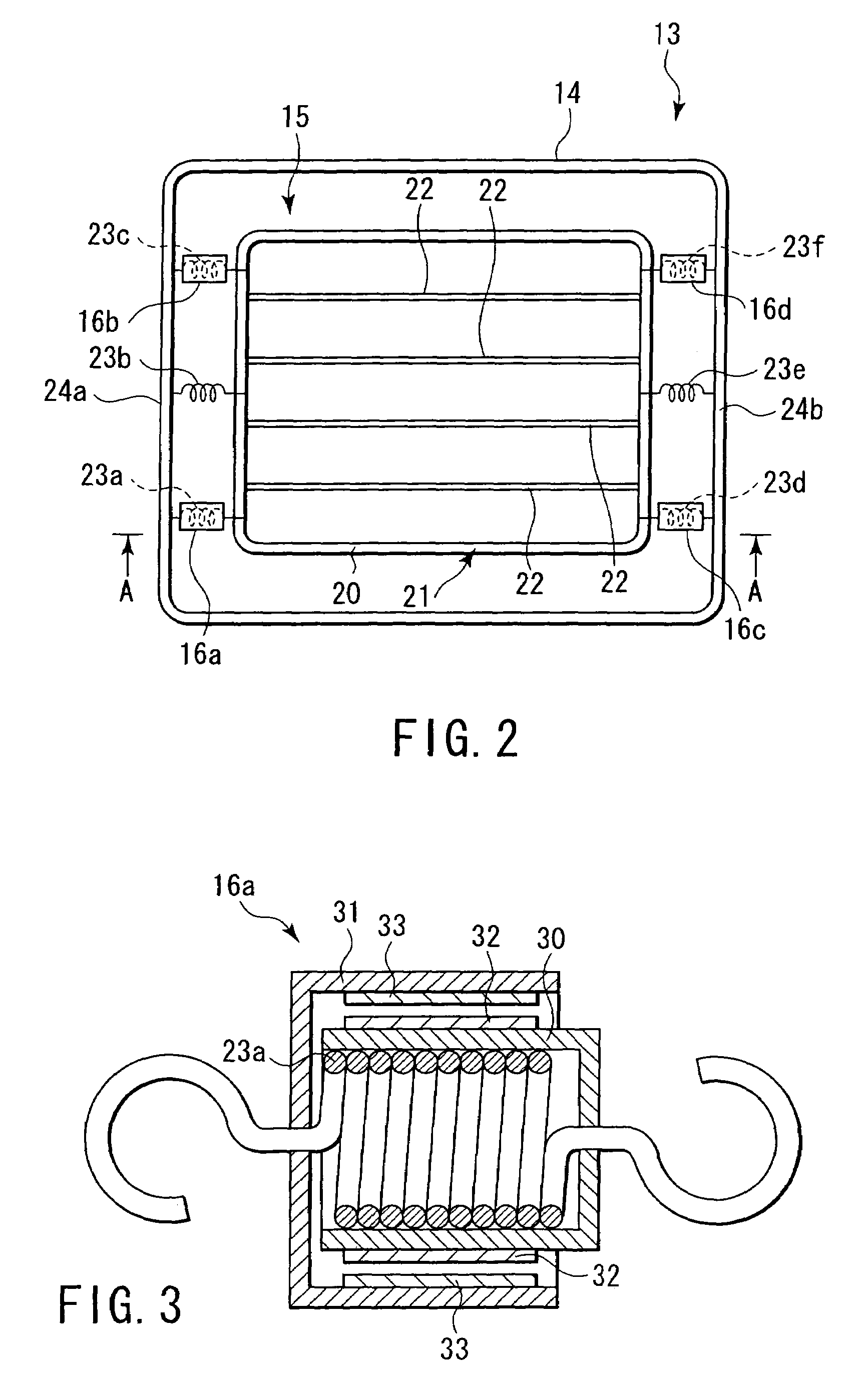

Occupant discriminating method for vehicular seat

InactiveUS7131513B2Incorrect determinationStability determinationVehicle seatsElectric devicesStage determinationEngineering

A flat spring of a vehicular seat is elastically supported by means of supporting springs that extend in accordance with the load of an occupant. The seat has displacement sensors, first-stage determination step, second-stage determination step, and third-stage determination step. The displacement sensors output electrical signals corresponding to the respective elongations of the springs. The first-stage determination step determines the occupant in the seat in accordance with voltage values delivered from the displacement sensors. The second-stage determination step determines whether or not the result of determination by the first-stage determination step is maintained for a given period of time. The third-stage determination step compares the result of determination by the second-stage determination step with the preceding result of determination and specifies the occupant in accordance with the result of the comparison.

Owner:NHK SPRING CO LTD

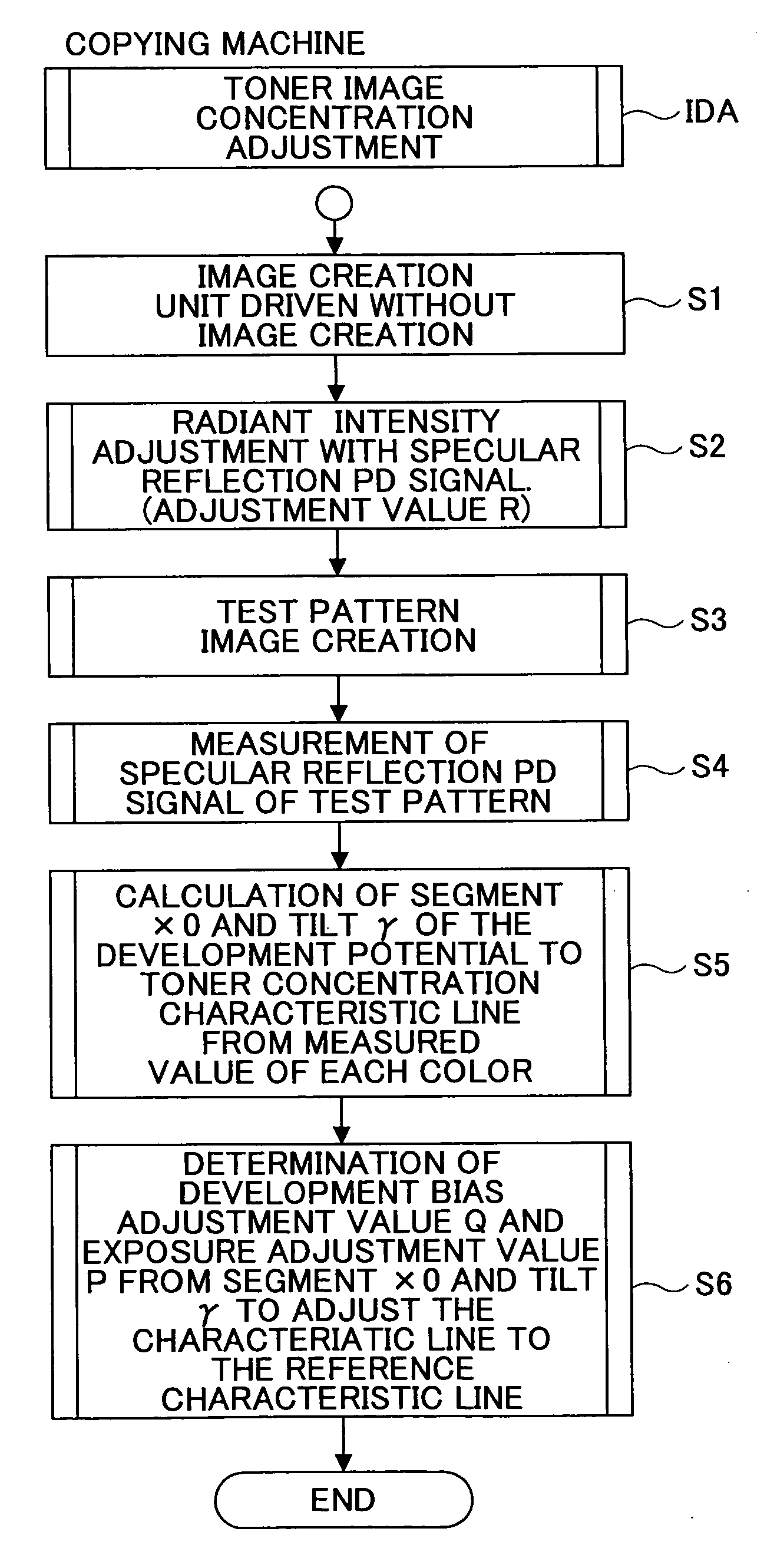

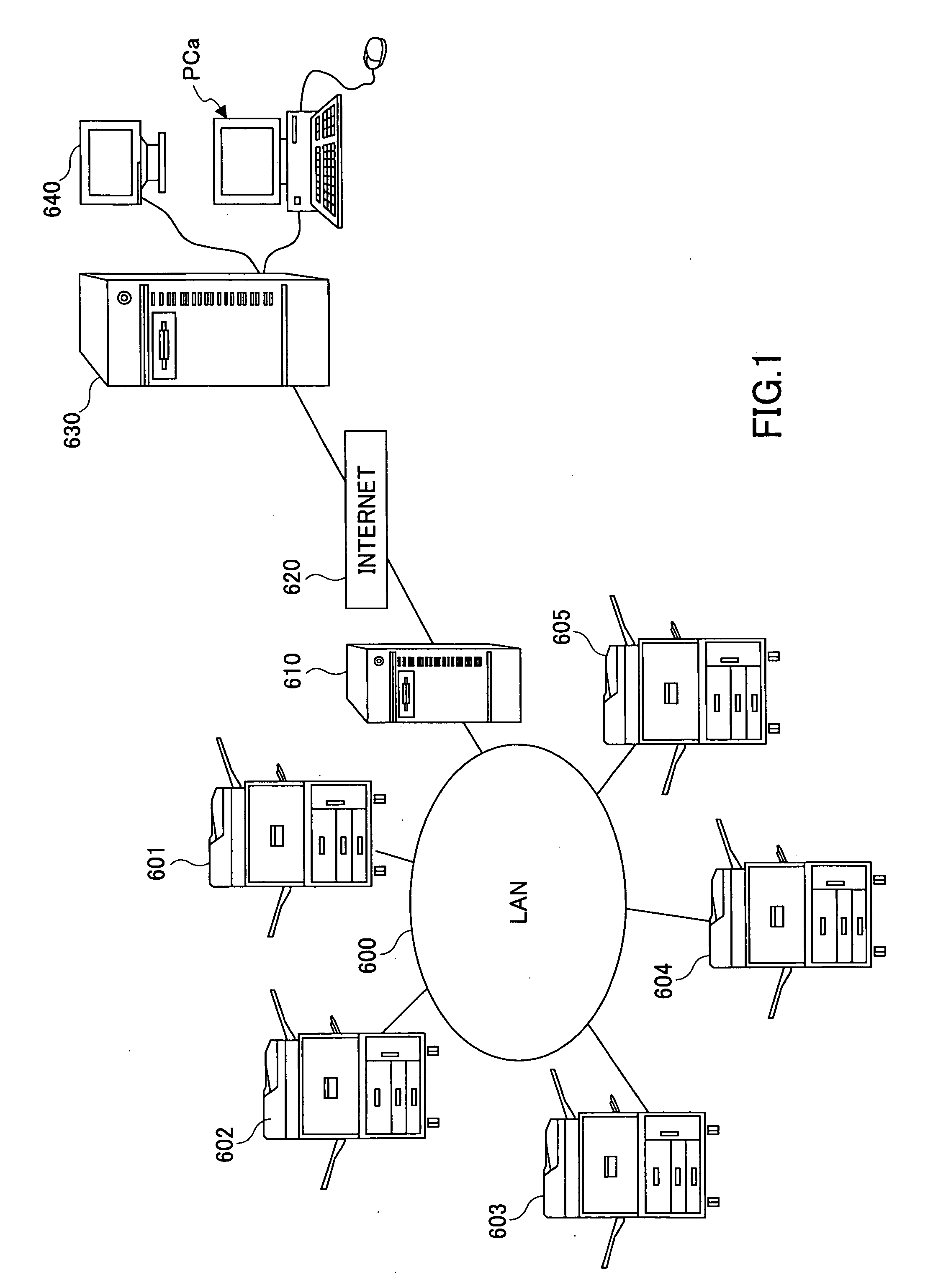

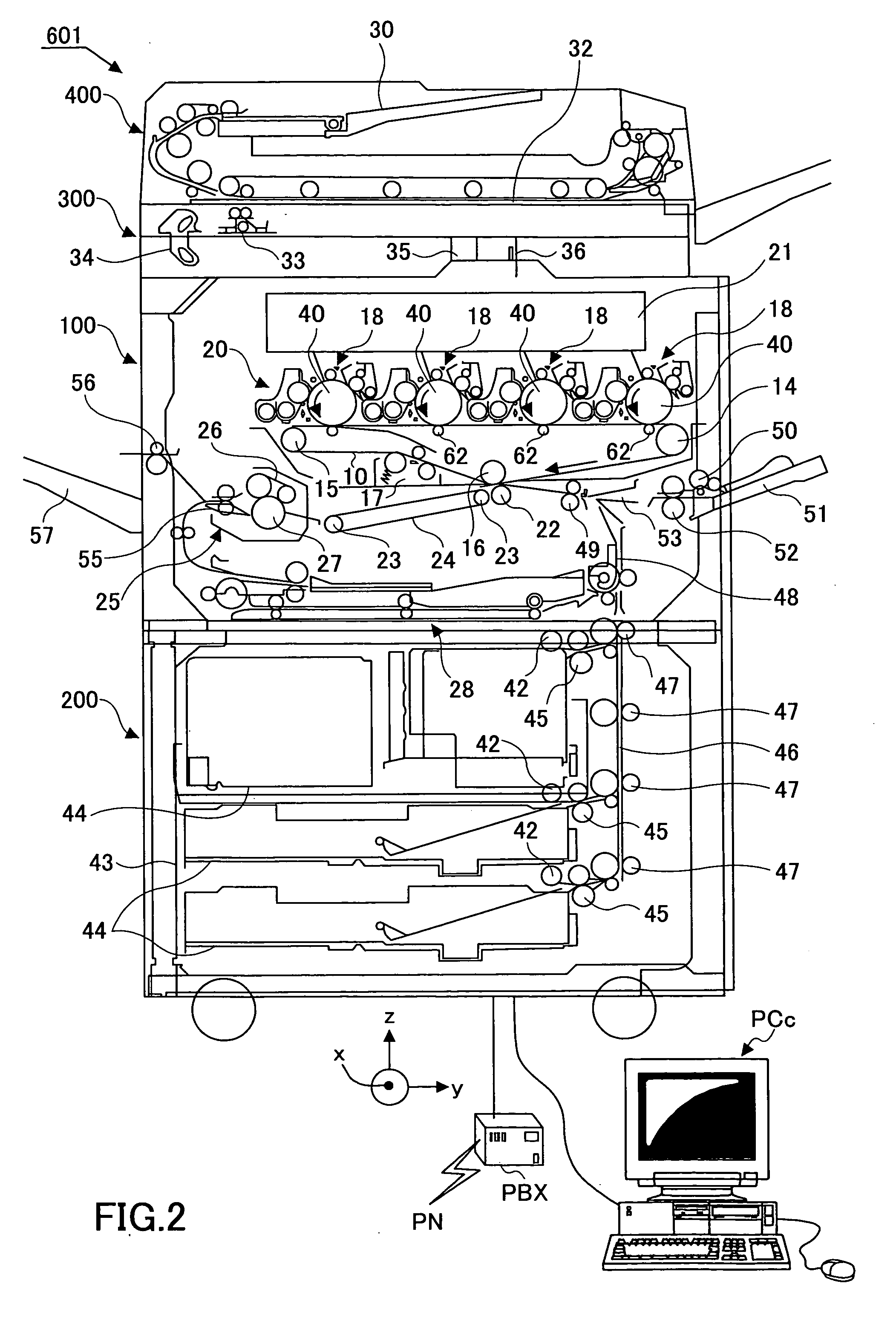

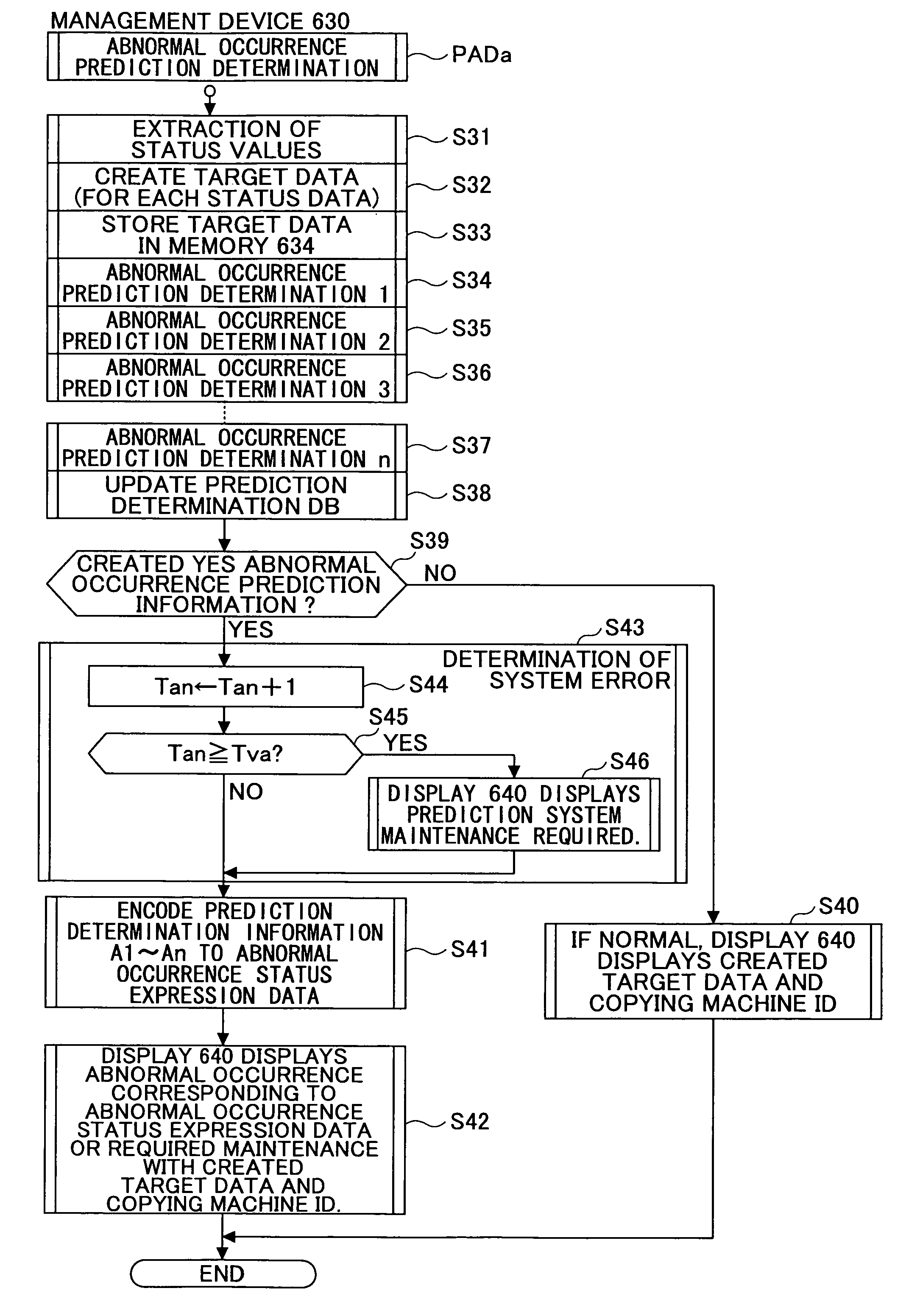

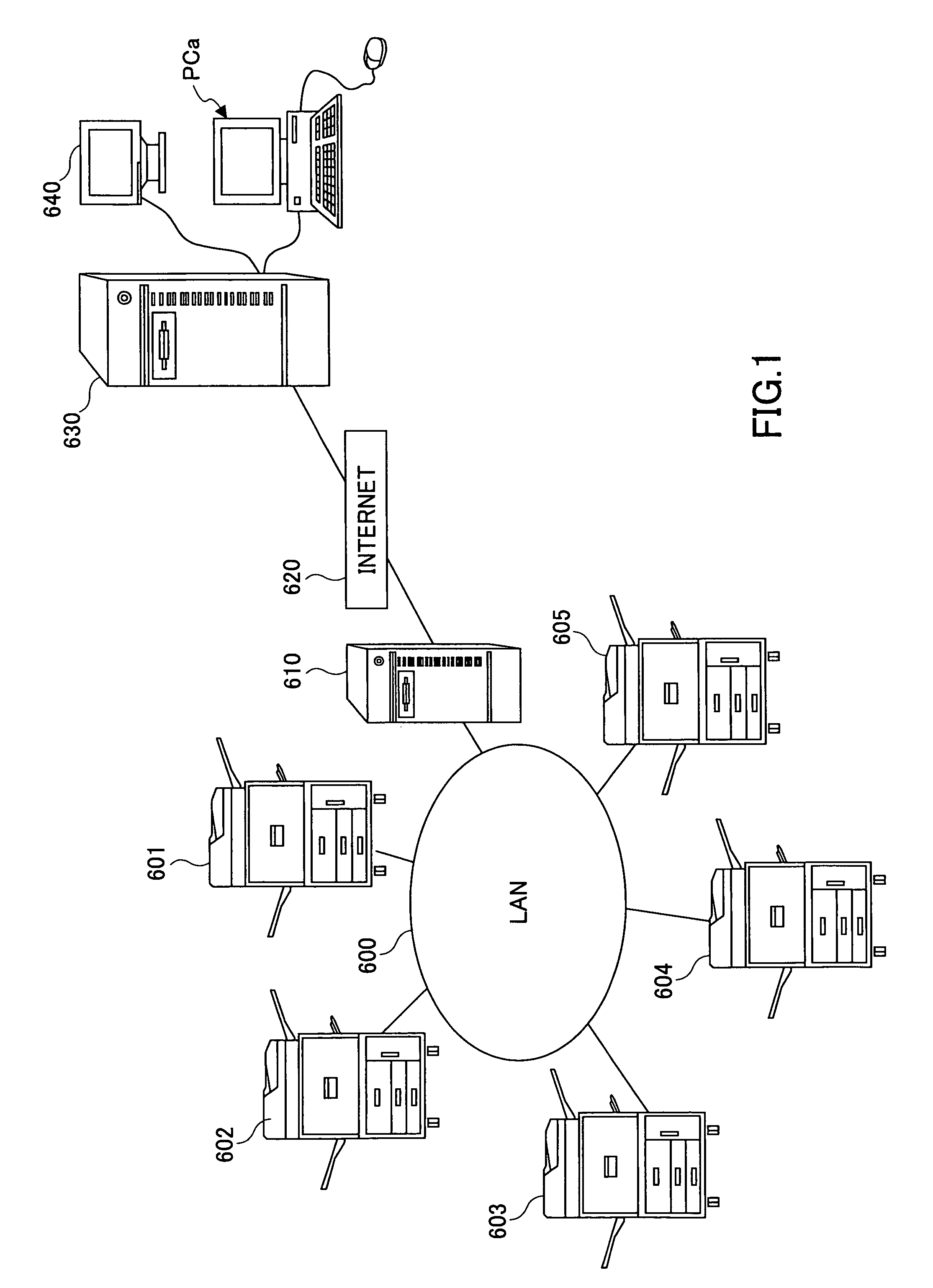

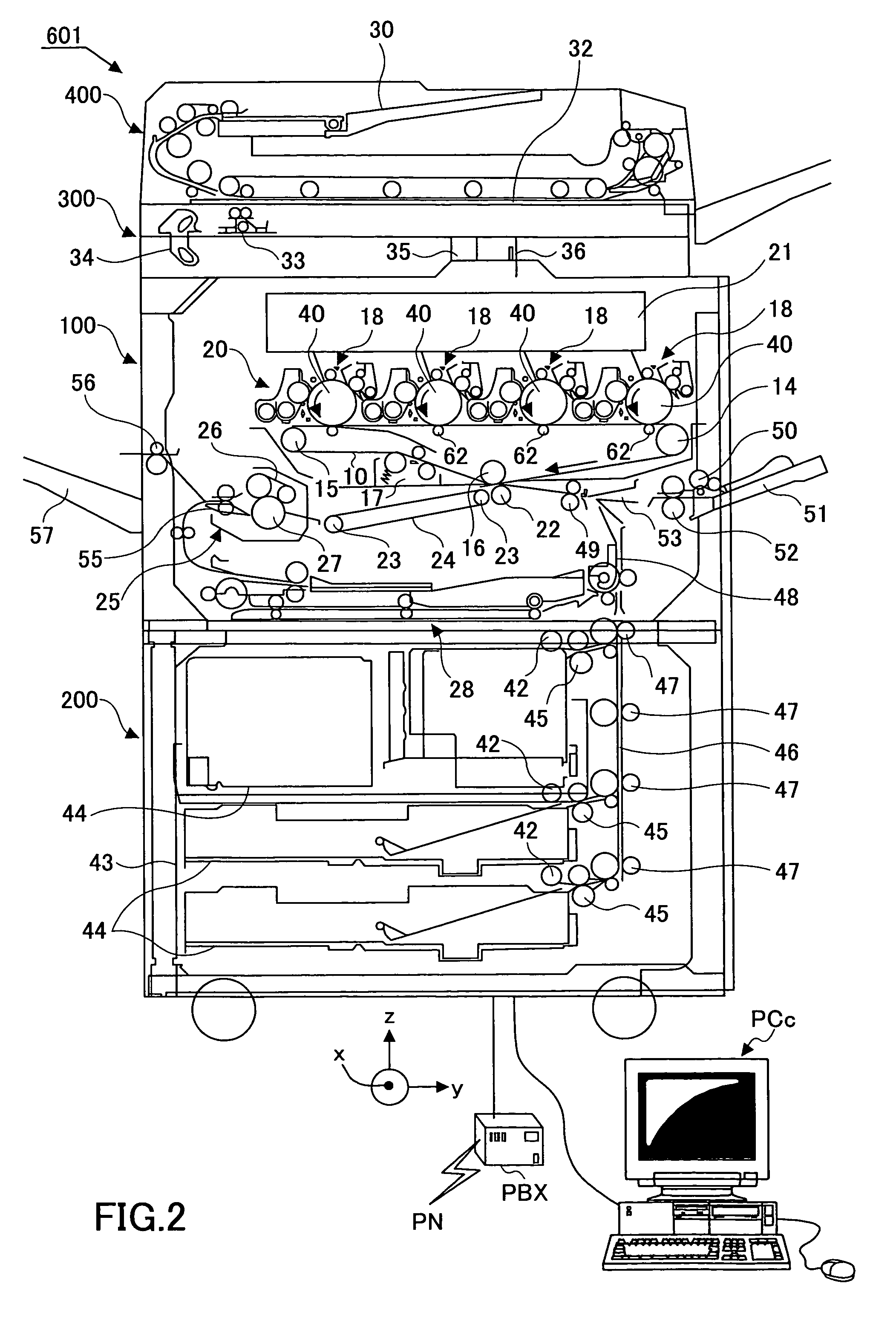

Management device of an image forming apparatus

ActiveUS20090034990A1Improve reliabilitySmall loadElectrographic process apparatusValue setStage determination

A management device for an image forming apparatus including a status data collection unit where multiple types of status data are received from the image forming apparatus and stored in a status database, a target data creation unit where multiple types of target data are created based upon the multiple types of status data, a first stage determination unit where the multiple types of target data are identified as being above or below reference values set for each type, and a second stage determination unit where a weight value set for each status data type is attached to the determination results of the multiple types of status data of the first stage determination unit and as a whole of the multiple types of status data determined with majority logic for abnormal occurrence prediction.

Owner:RICOH KK

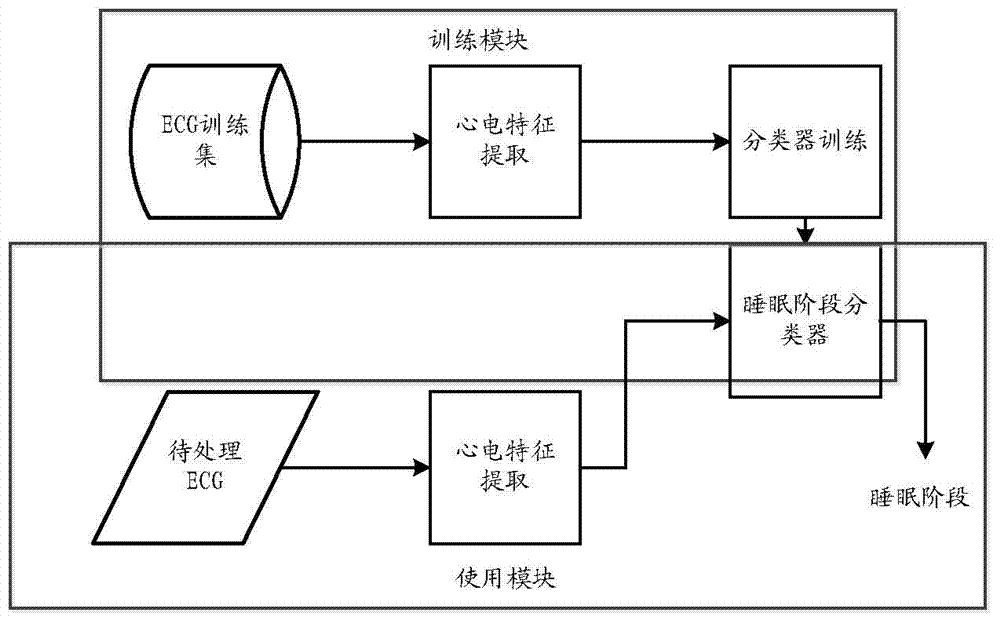

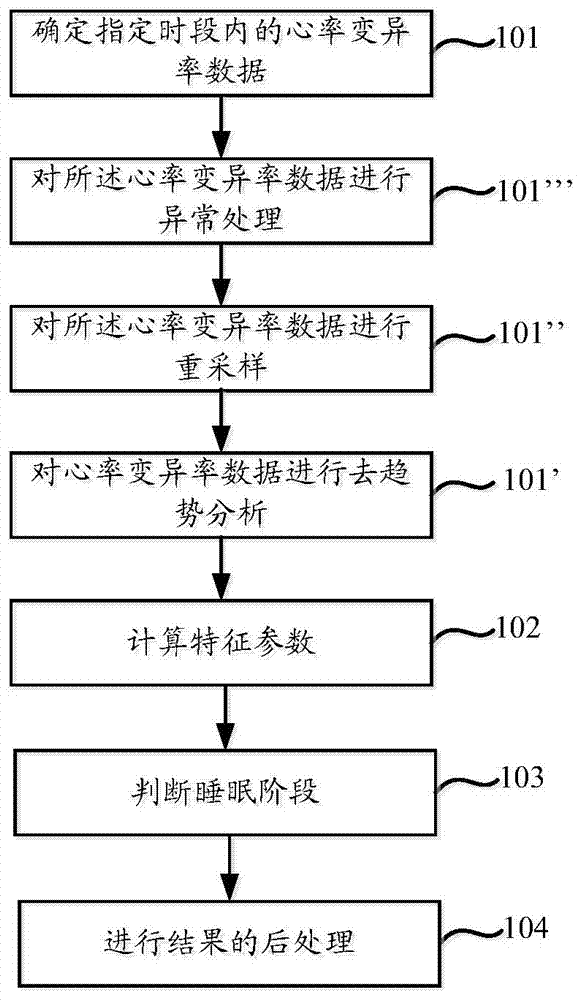

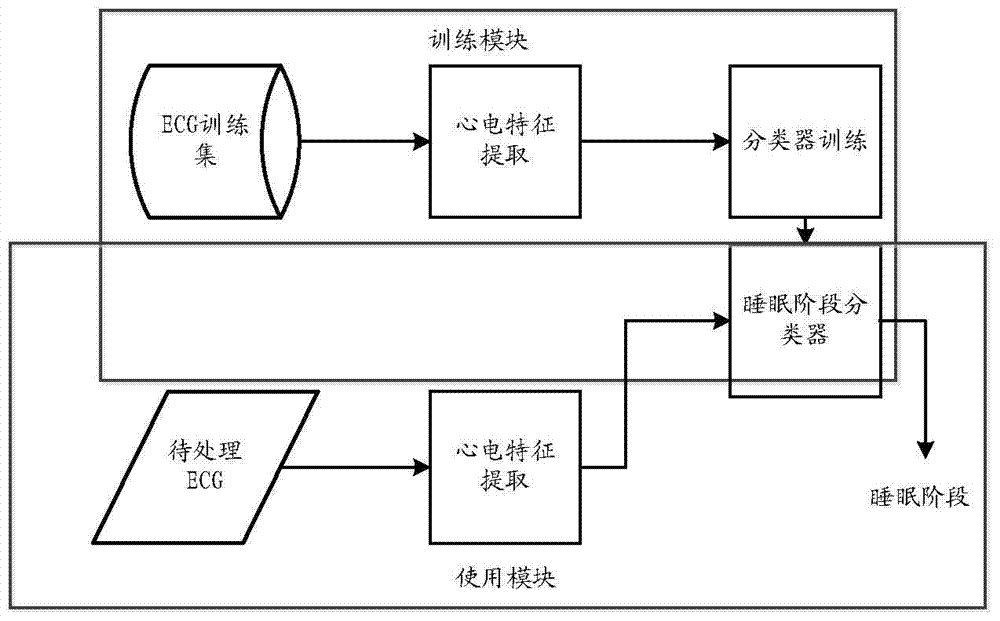

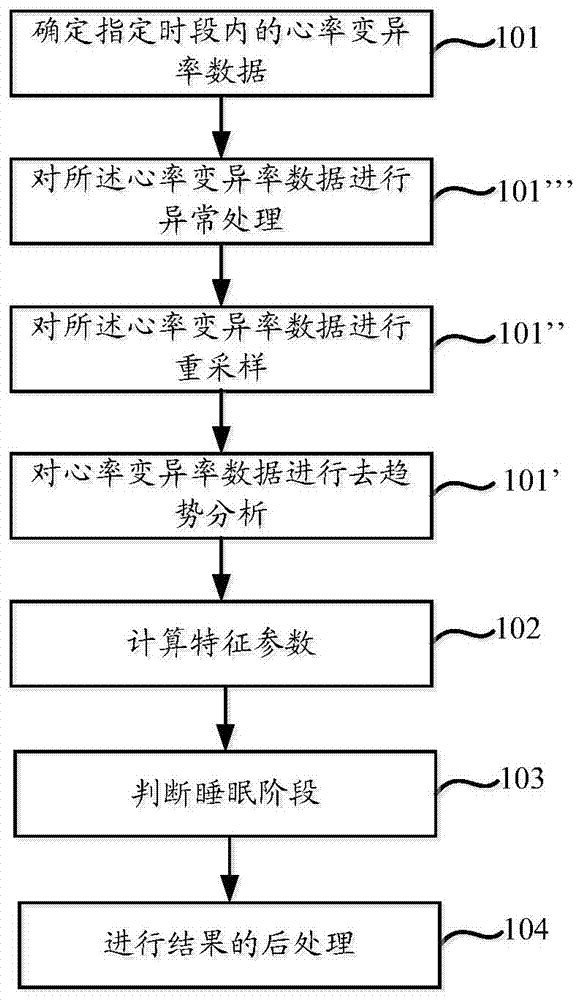

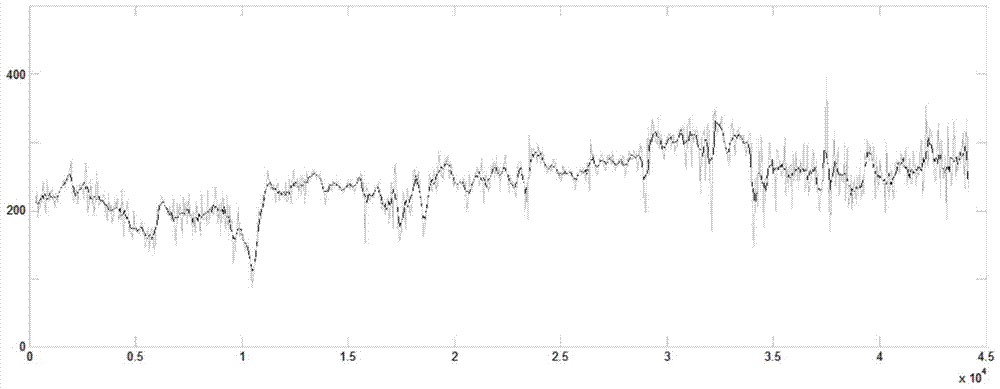

Sleeping stage determination method and system

An embodiment of the invention provides a sleeping stage determination method and system. The sleeping stages can be recognized by means of characteristic parameters of heart rate variability data. Accordingly, after heart rate variability data is obtained, the corresponding sleeping stages within the time section can be determined according to the correspondence of the characteristic parameters of the heart rate variability data corresponding to a time section and the preset rule, so that a sleeping stage classifier is not needed to be trained by acquiring and marking samples, and the problem that sleeping stage determination accuracy is low and the sleeping stage classifier is poor in applicability due to deficiency of training samples is solved.

Owner:CHINA MOBILE COMM GRP CO LTD

Management device of an image forming apparatus

ActiveUS8064782B2Improve reliabilitySmall loadElectrographic process apparatusStage determinationImage formation

A management device for an image forming apparatus including a status data collection unit where multiple types of status data are received from the image forming apparatus and stored in a status database, a target data creation unit where multiple types of target data are created based upon the multiple types of status data, a first stage determination unit where the multiple types of target data are identified as being above or below reference values set for each type, and a second stage determination unit where a weight value set for each status data type is attached to the determination results of the multiple types of status data of the first stage determination unit and as a whole of the multiple types of status data determined with majority logic for abnormal occurrence prediction.

Owner:RICOH KK

HEVC coding size rapid determining method based on texture complexity

InactiveCN103957421AAccurate judgmentHigh precisionDigital video signal modificationPattern recognitionStage determination

Owner:SHANGHAI UNIV +1

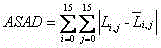

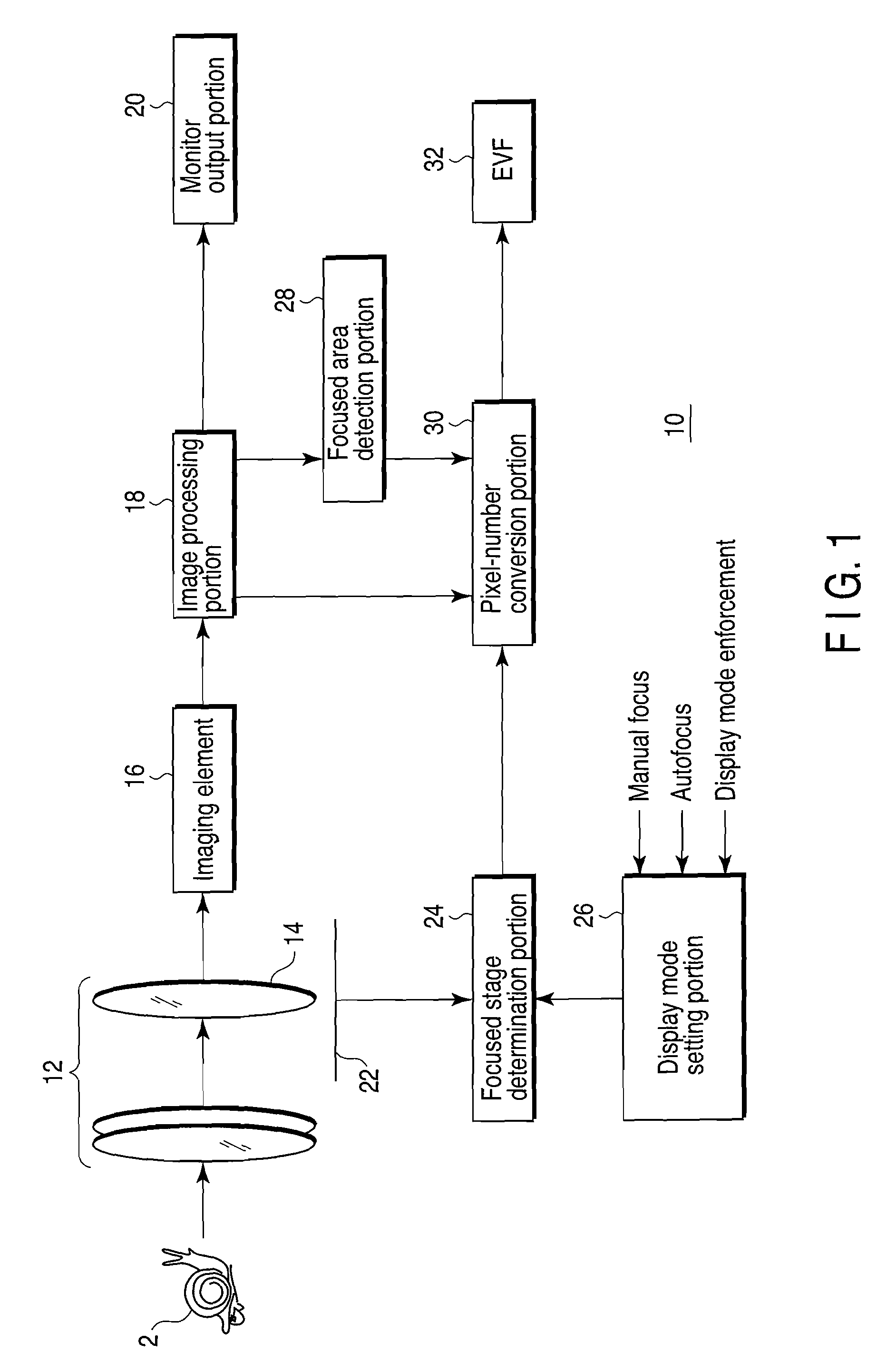

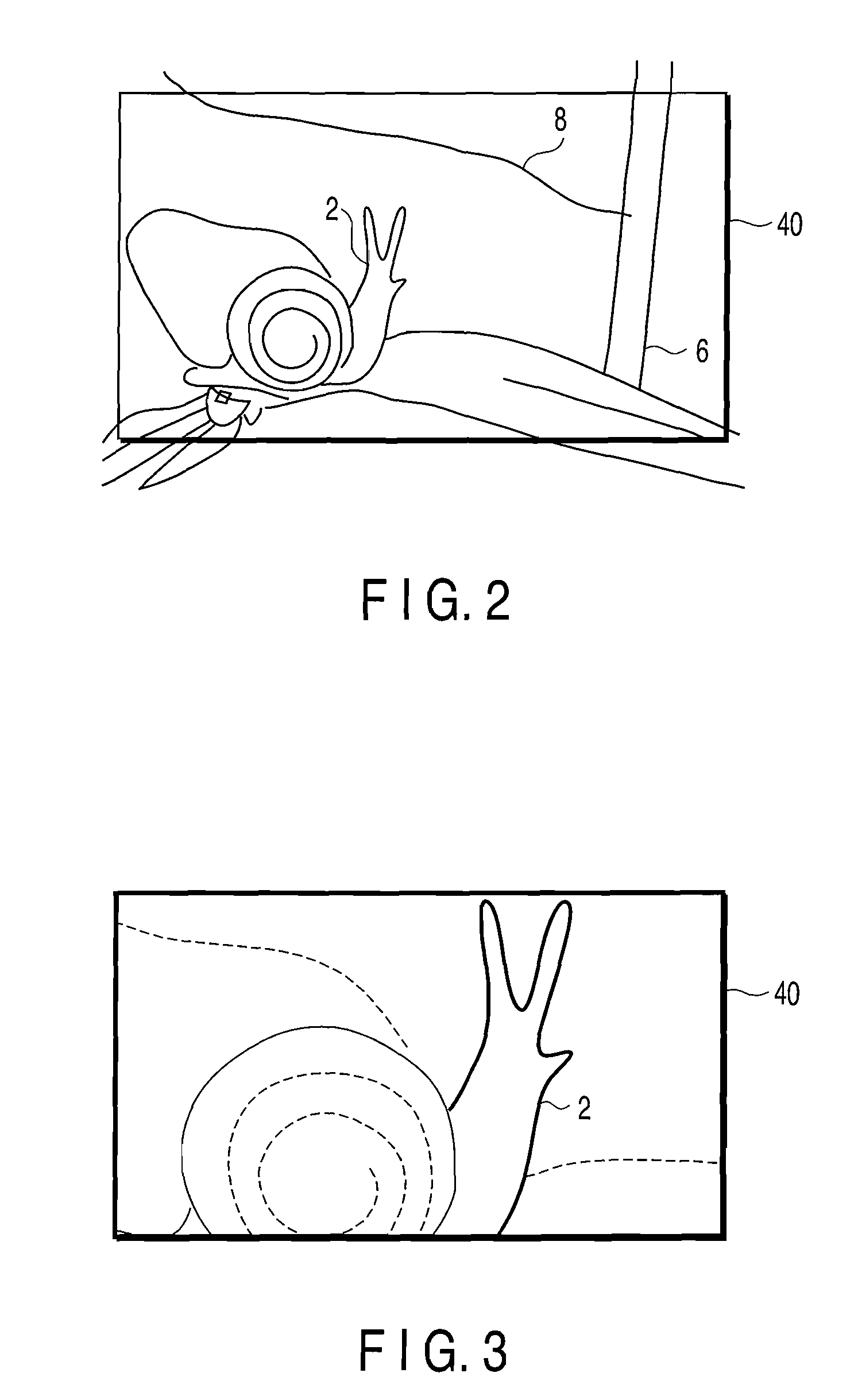

Imaging device

InactiveUS20080278619A1Television system detailsColor television detailsStage determinationImaging equipment

In a present imaging device, an optical image formed through a lens group from a subject is converted into an imaging signal by an imaging element and a focused area is detected by a focused area detection portion. Optical displacement or physical movement of the lens group is detected by a focus lens movement detector and an adjustment stage of the lens group is determined by a focused stage determination portion based on a detection signal output from this. Based on the determination result, the focused area of the imaging signal is automatically enlarged and output.

Owner:OLYMPUS CORP

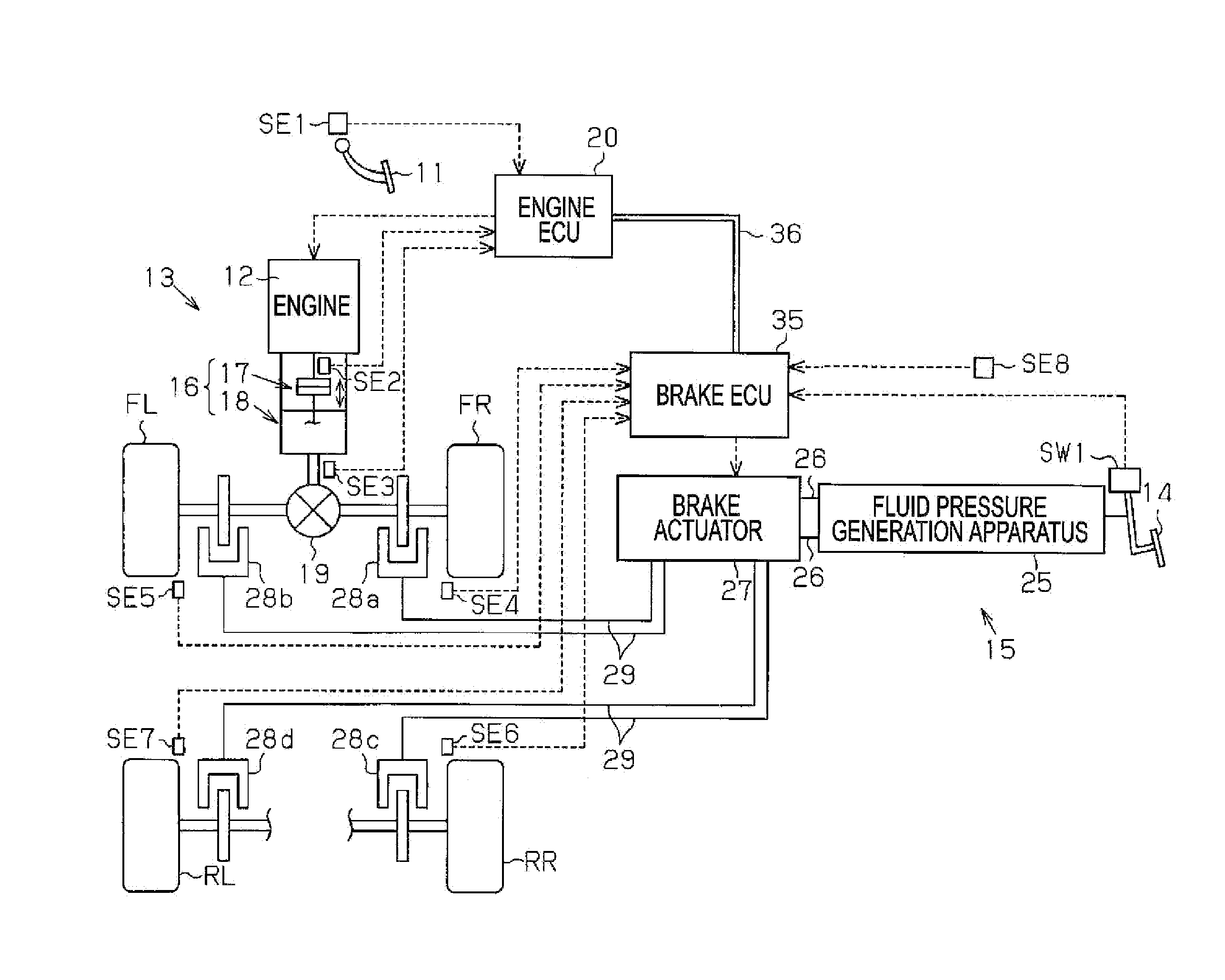

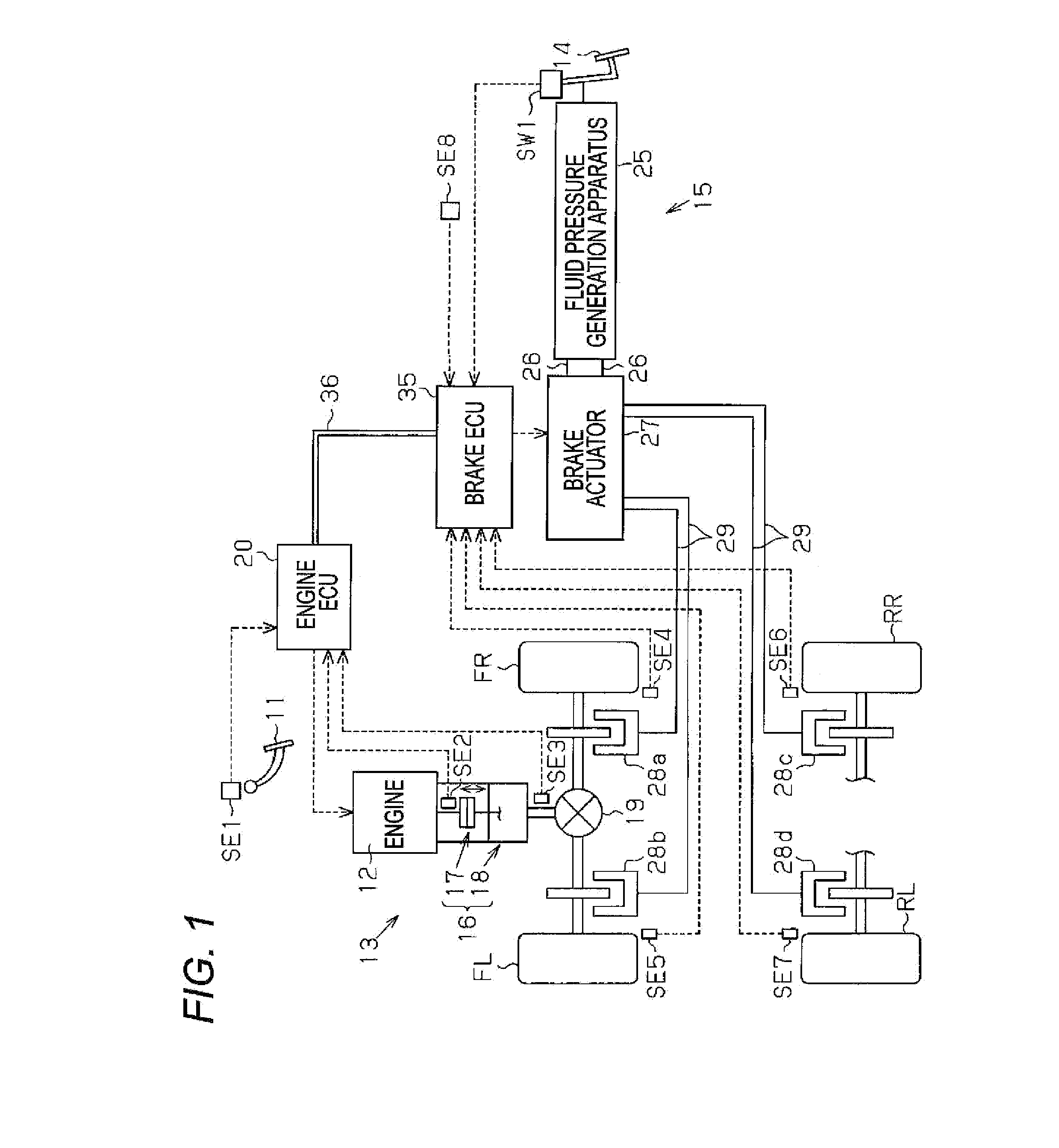

Vehicle forward traveling determination apparatus and vehicle forward traveling determination method

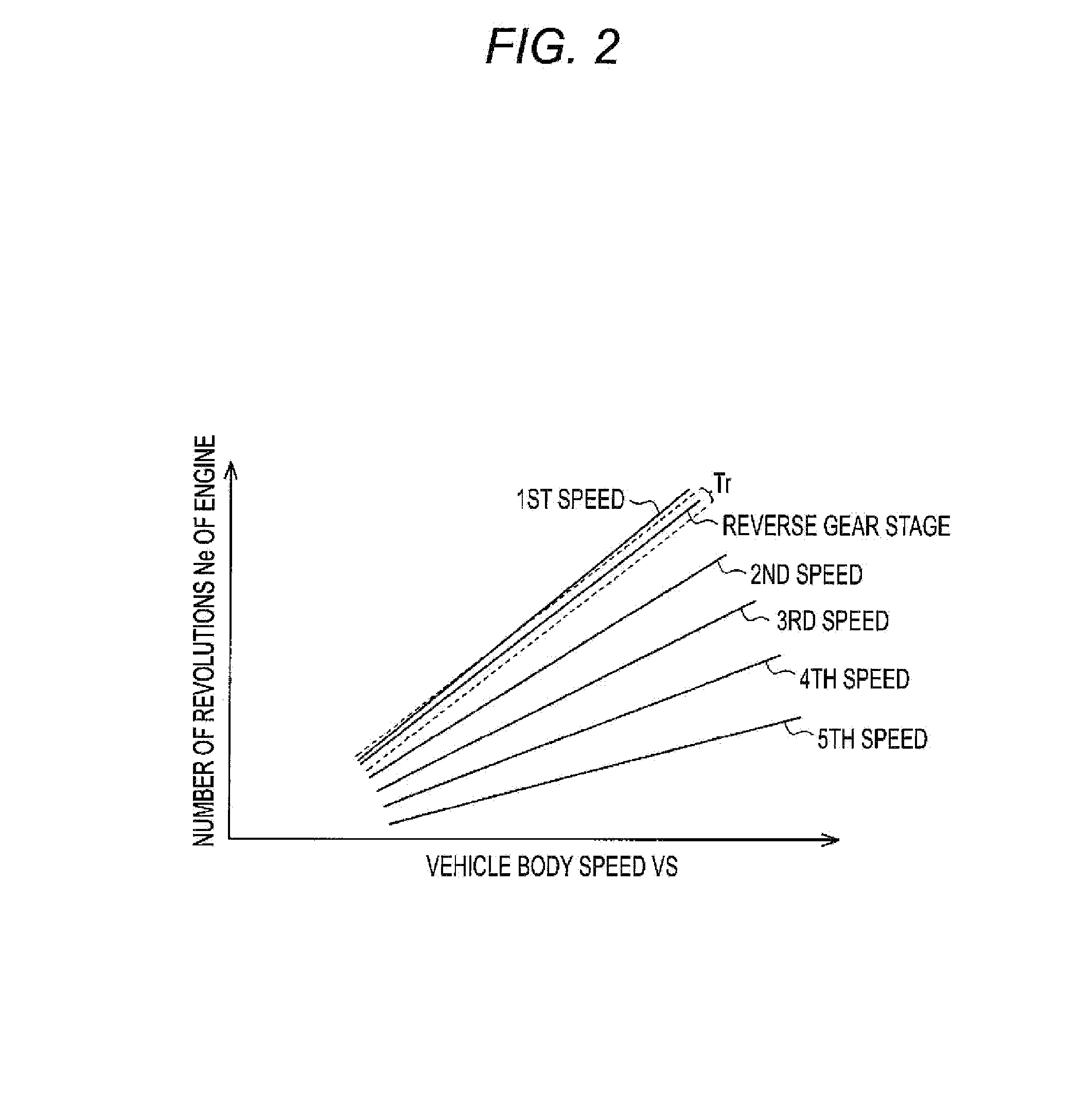

InactiveUS20120053798A1Accurately determineHigh measurement accuracyDigital data processing detailsGearing controlStage determinationGear ratio

A vehicle forward traveling determination apparatus and a vehicle forward traveling determination method are provided. The apparatus includes a transmission gear ratio calculation unit which calculates a transmission gear ratio based on a number of revolutions of a driving source of a vehicle and a value corresponding to a number of revolutions at an output side of a transmission mounted to the vehicle, a gear stage determination unit which determines whether a gear stage of the transmission is set in a forward gear stage based on the calculated transmission gear ratio calculated, an acceleration determination unit which determines whether the vehicle is being accelerated, and a forward traveling determination unit which determines that the vehicle is traveling forward when it is determined that the gear stage of the transmission is set in the forward gear stage and that the vehicle is being accelerated.

Owner:ADVICS CO LTD

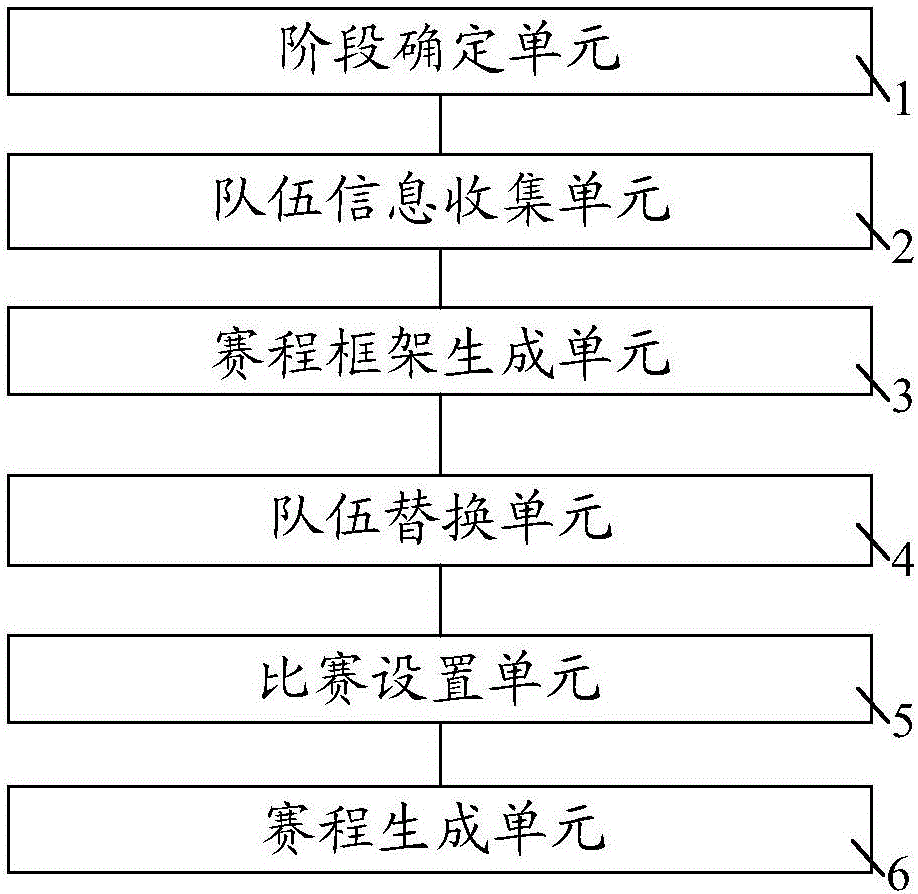

System for generating agenda of sports event

InactiveCN106447543ALow costImprove the efficiency of schedule schedulingData processing applicationsStage determinationSystems engineering

The invention, which relates to the sports event and competition agenda fields, discloses a system for generating an agenda of a sports event, thereby reducing the personnel cost and improving the efficiency for arranging the agenda. The system comprises a stage determination unit for determining sports event stages by a sport event organizer, a team information collection unit for collecting information of teams participating in the sports event and determining the number of the teams, an agenda frame generation unit for generating an agenda frame according to the team number and the determined sports event stages and determining the number of times of a game, a team substitution unit for substituting information of all teams participating the sports event practically for teams expressed by numerical numbers in the agenda frame, a game setting unit for arranging a data, time, and a place of each game, and an agenda generation unit for generating an agenda according to the arranged date, time and place of the sports event as well as the agenda frames of all team information. The system provided by the invention is used for calculating an agenda of a sports event.

Owner:北京河马能量体育科技有限公司

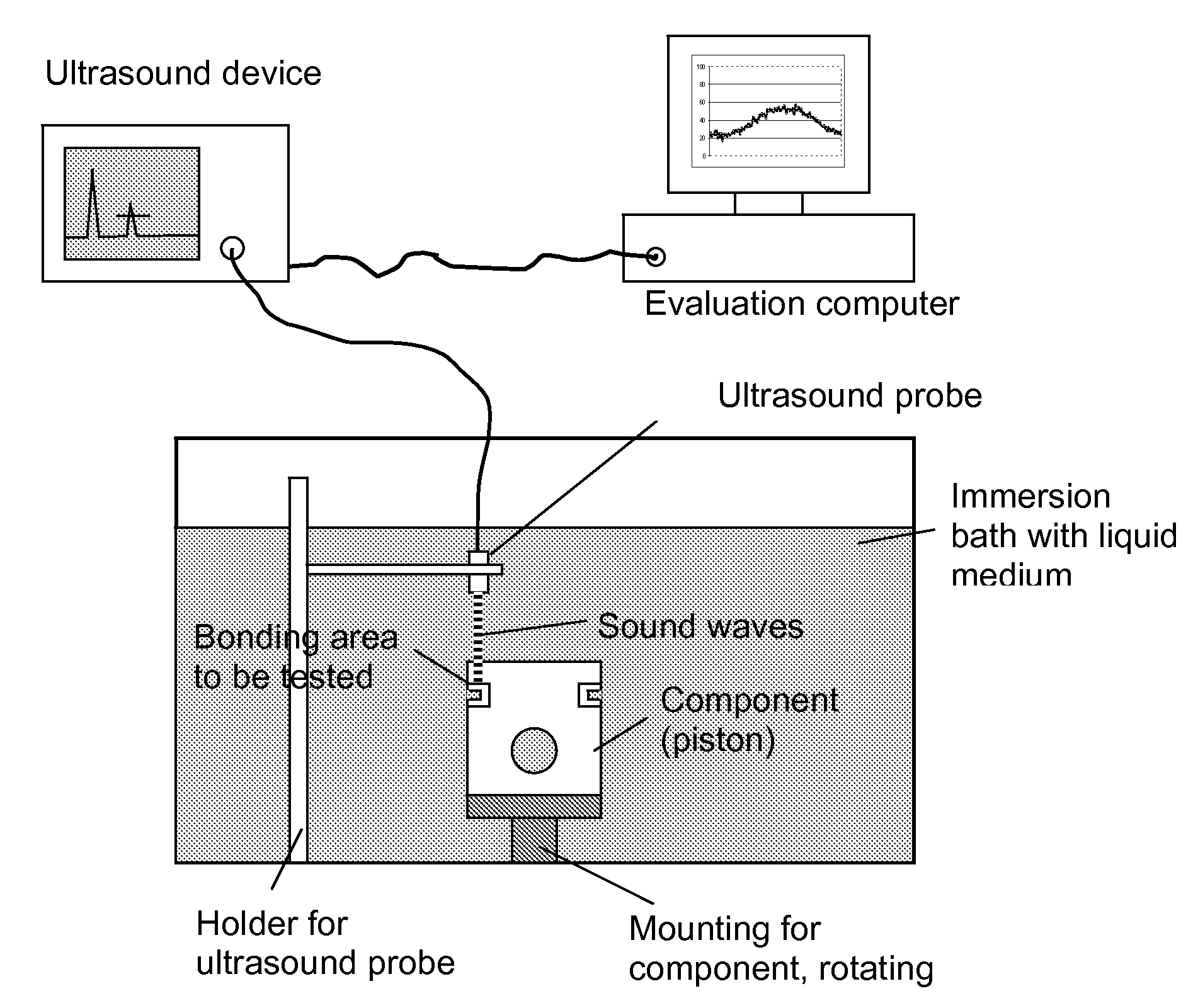

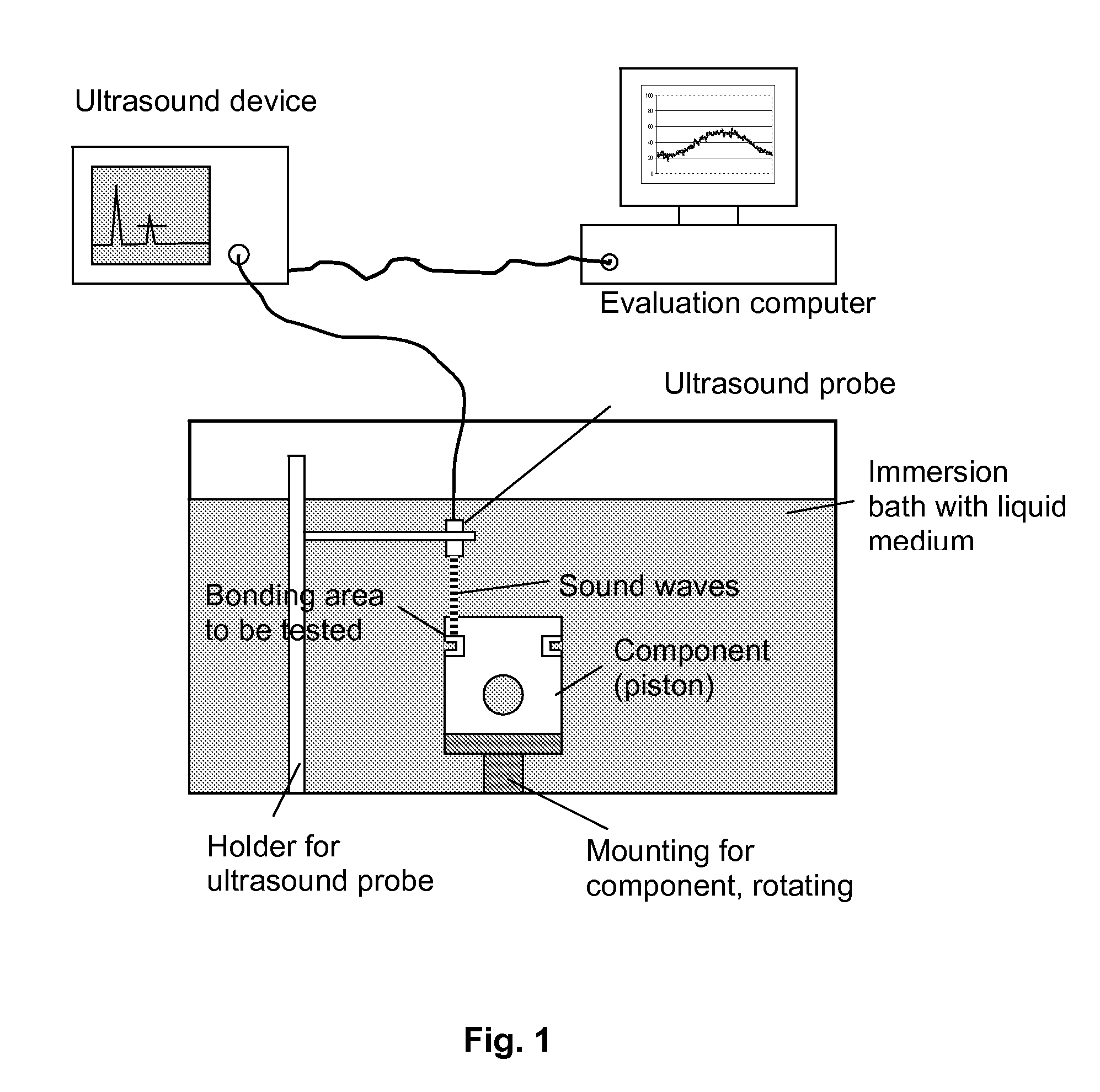

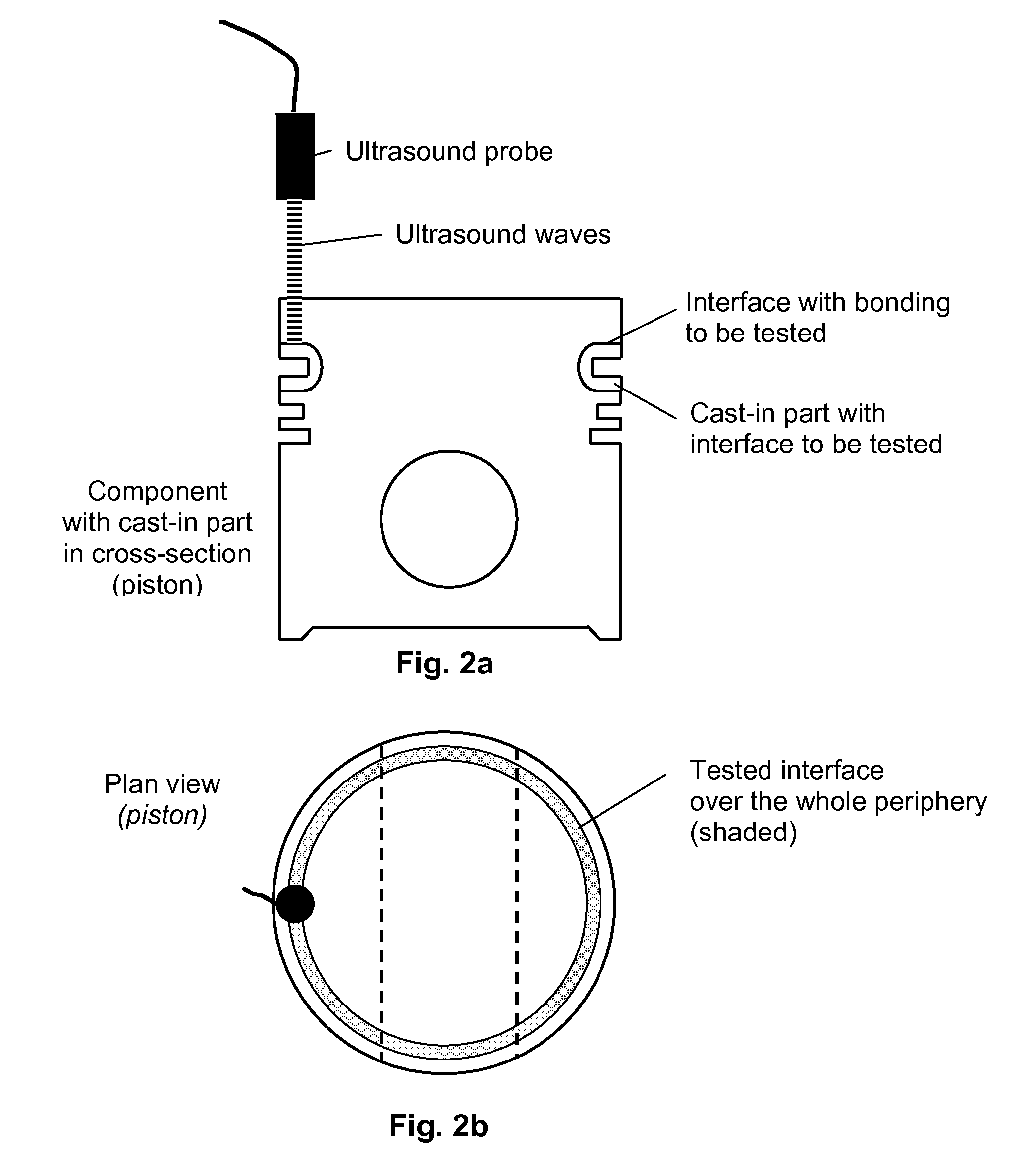

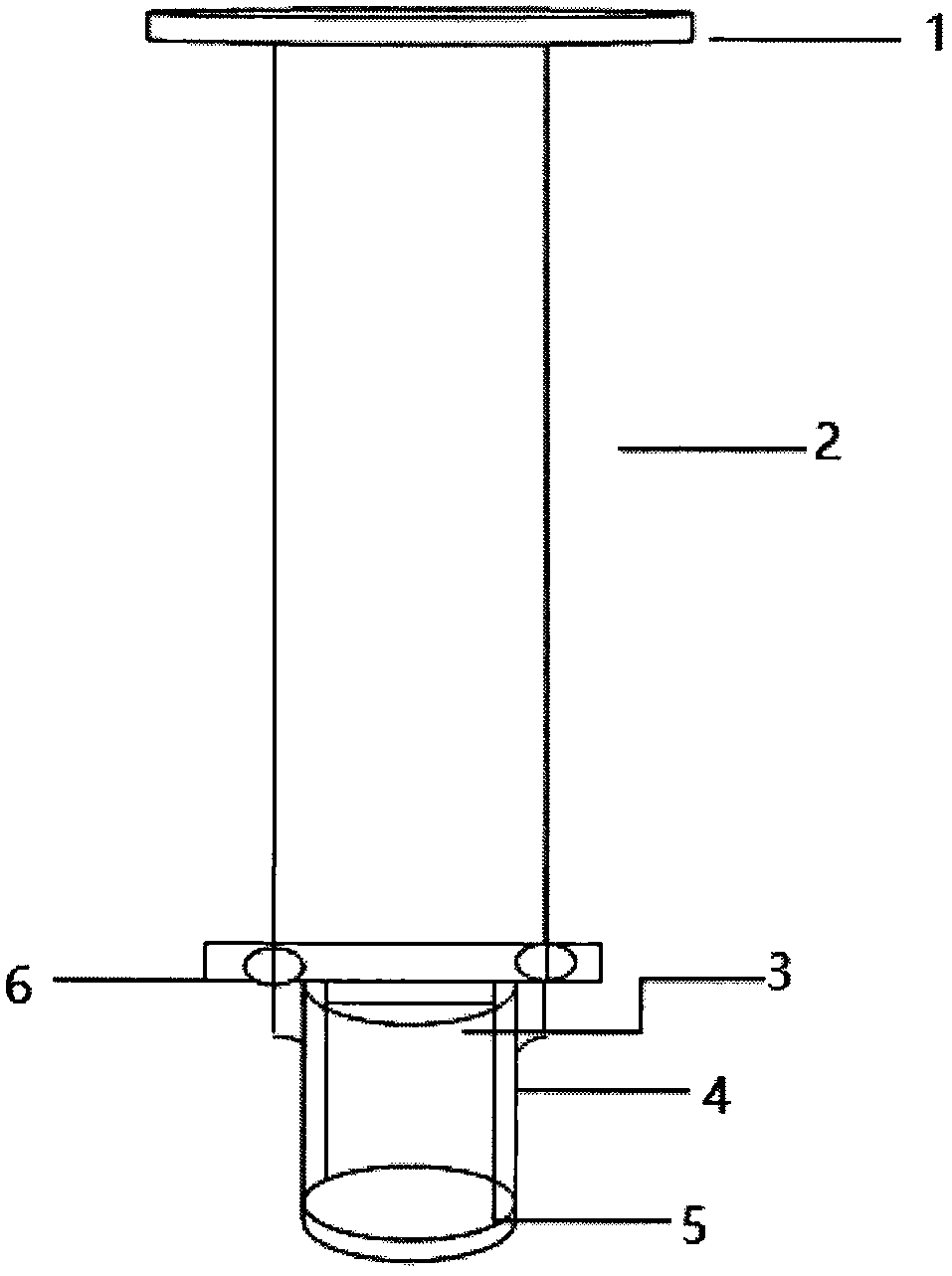

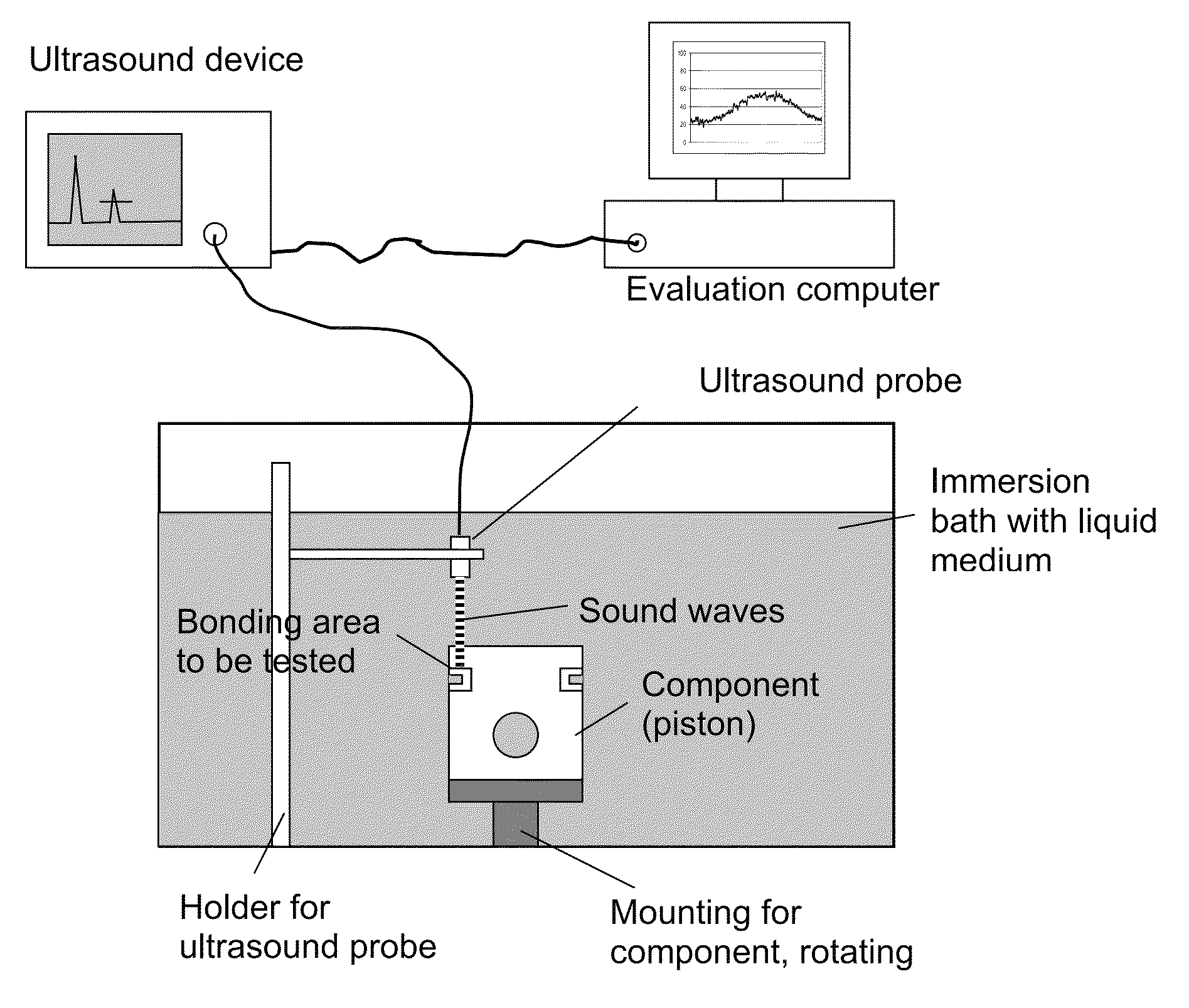

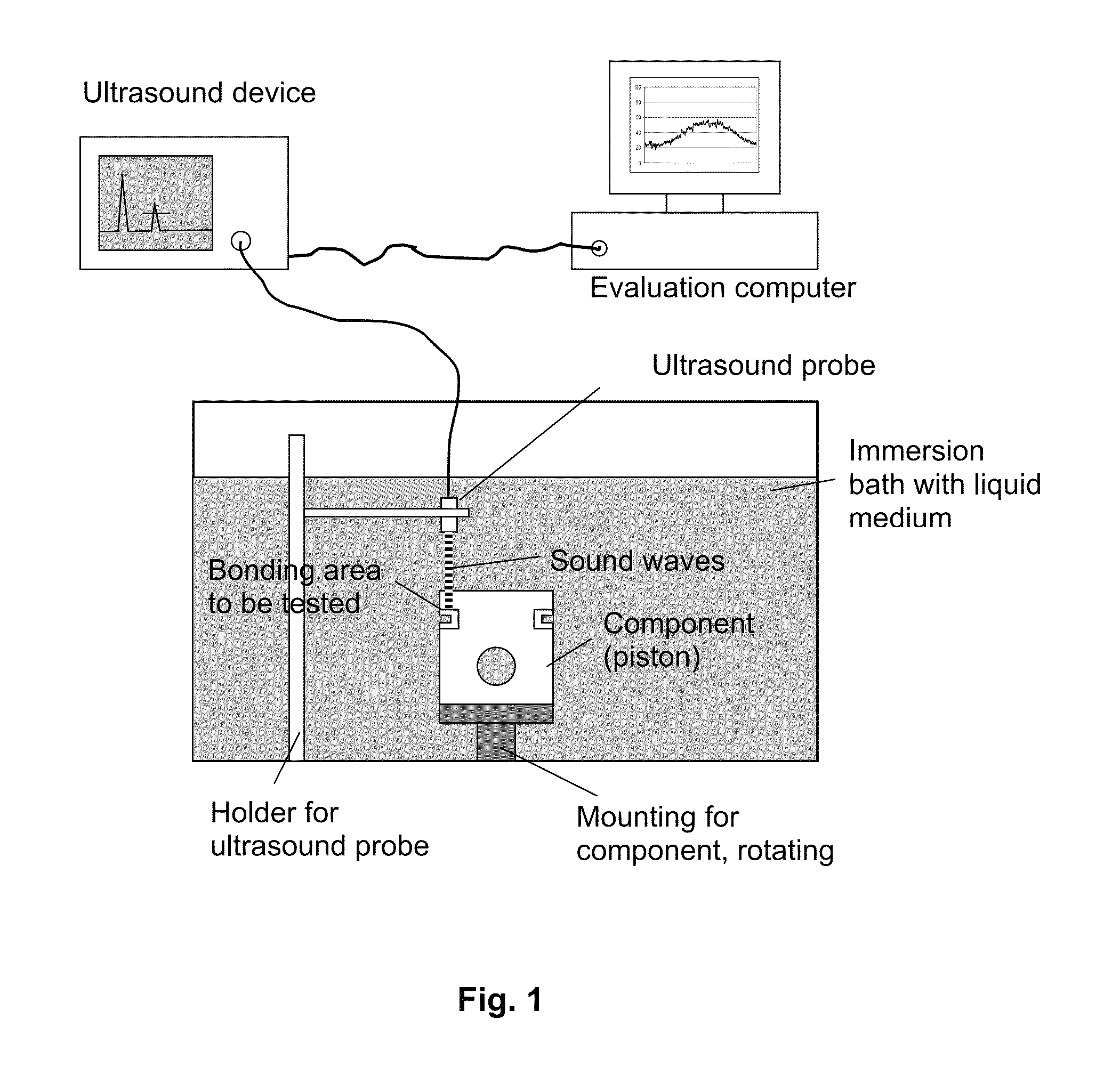

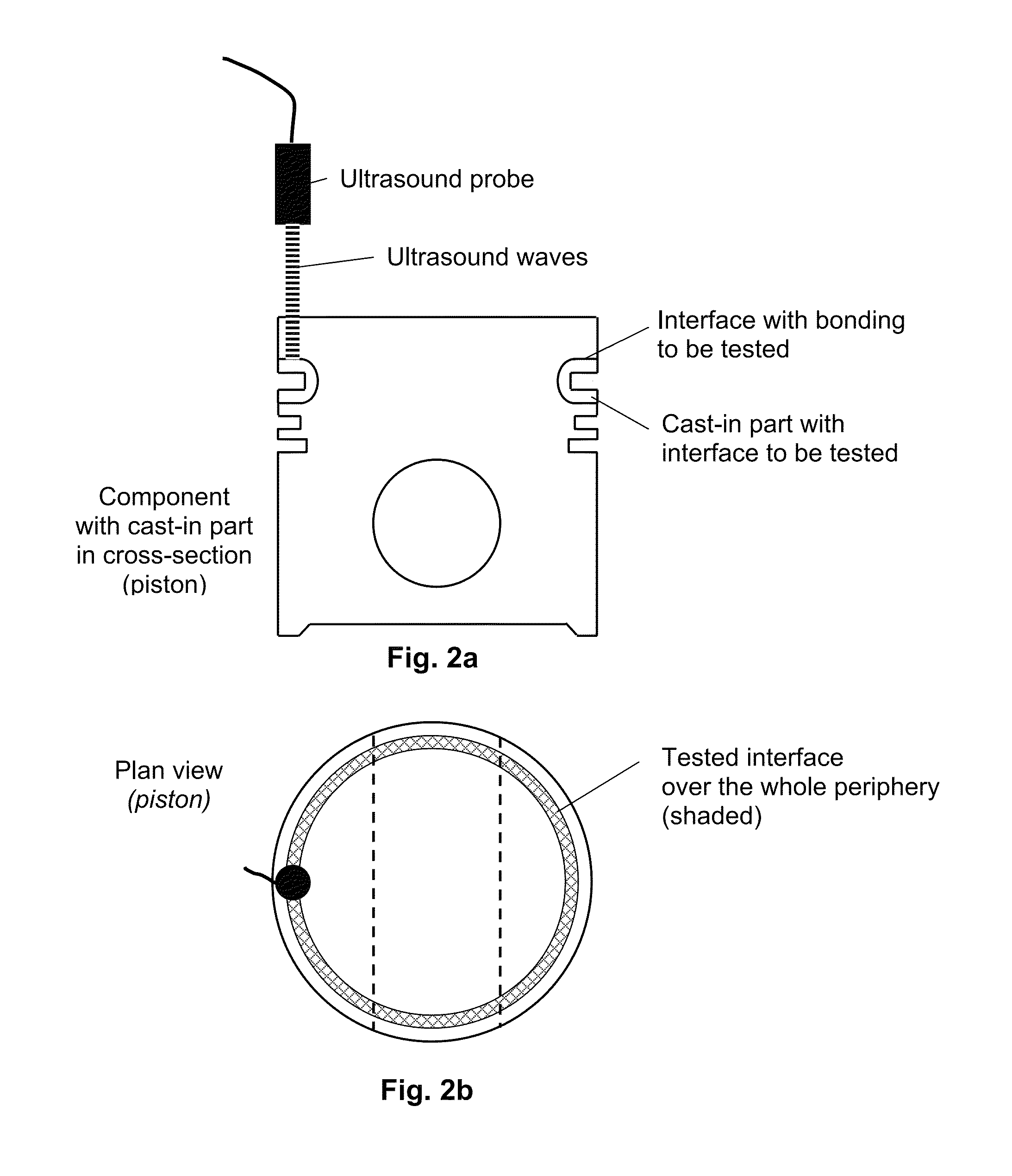

Measuring method and system for components, in particular for pistons and piston engines

ActiveUS20100042337A1Shorten the timeReduce the proportionVibration measurement in solidsInternal-combustion engine testingObservational errorFoundry

The invention relates to the non-destructive measurement of components, in particular the functional assessment of the bonding of cast-in parts, eg. in pistons for internal combustion engines. With such a measurement or functional assessment, it is a question of assessing the function and completeness of the bonding between the base material and the material cast in or otherwise joined. The quality of the component or its suitability for a specific purpose can thus be assessed and / or quality monitoring of the production process, e.g. in the foundry or during production, can take place. According to the invention, this purpose is served by a multi-stage correction procedure, wherein the measured values ascertained by means of a suitably devised measuring arrangement and method, e.g. using ultrasound, are subjected to a multi-stage determination process, which minimises universally and for each individual measurement the disturbing factors which, being inherent in the system, occur in the measurement and ascertains therefrom the desired results. A correspondingly devised system minimises both error influences, which occur in the performance (especially with the setting-up / adjustment) of such a measurement, as well as measurement errors and incorrect assessments in the performance of the measurement, which occur due to geometrical tolerance deviations or differences between a number of components to be measured or due to differences in the material or structural composition, as well as other disturbing influences.

Owner:MAHLE INT GMBH

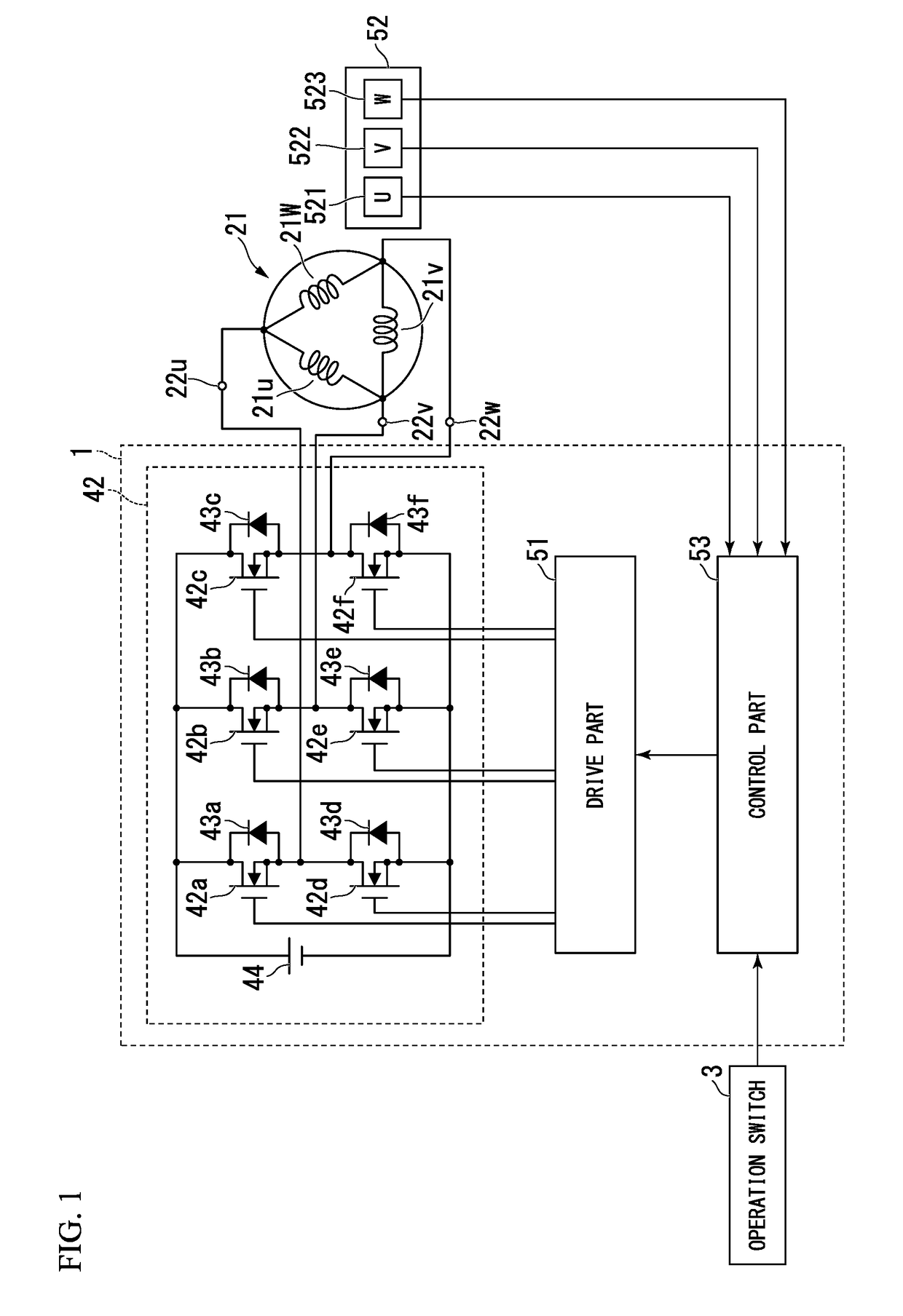

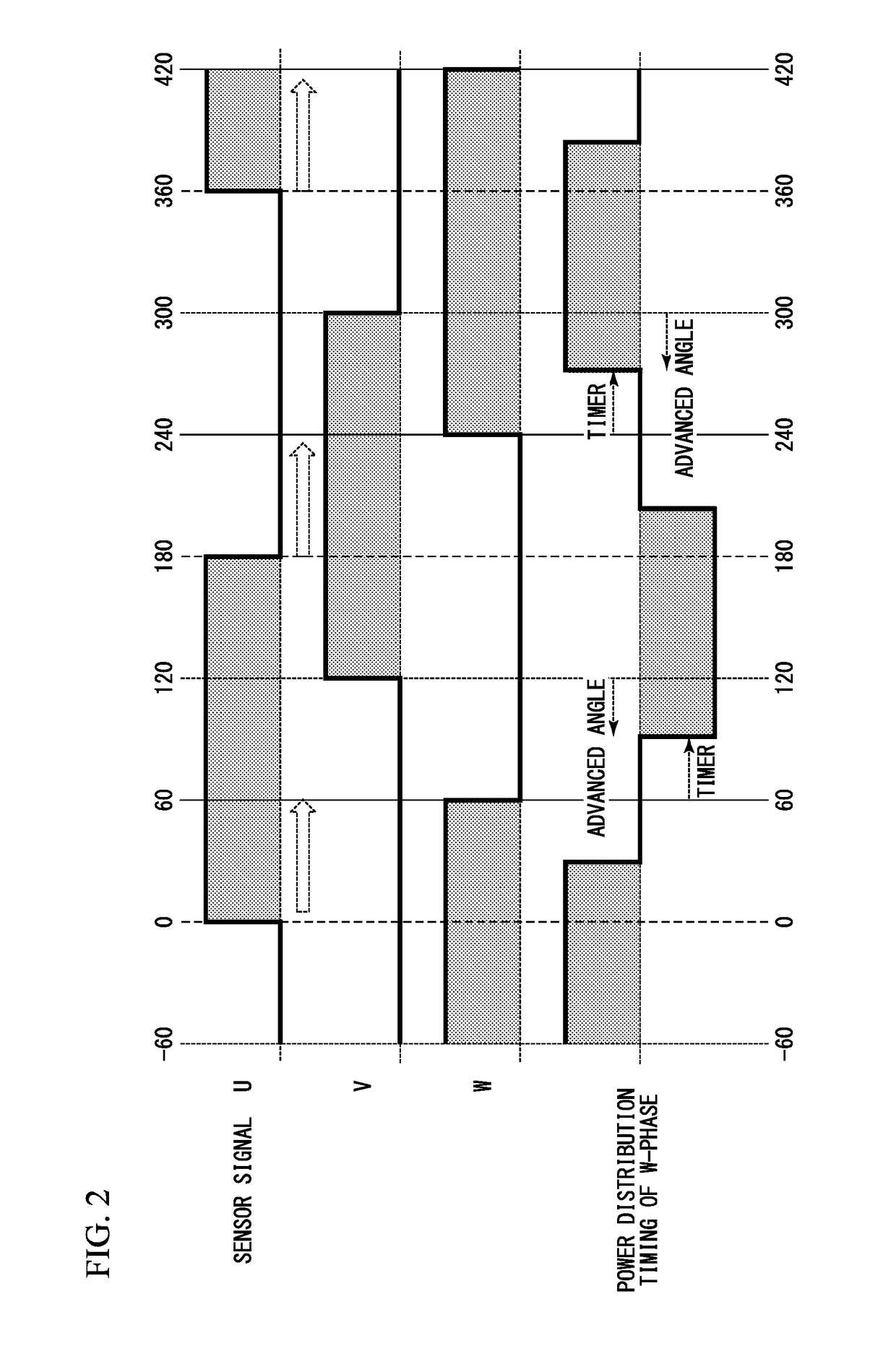

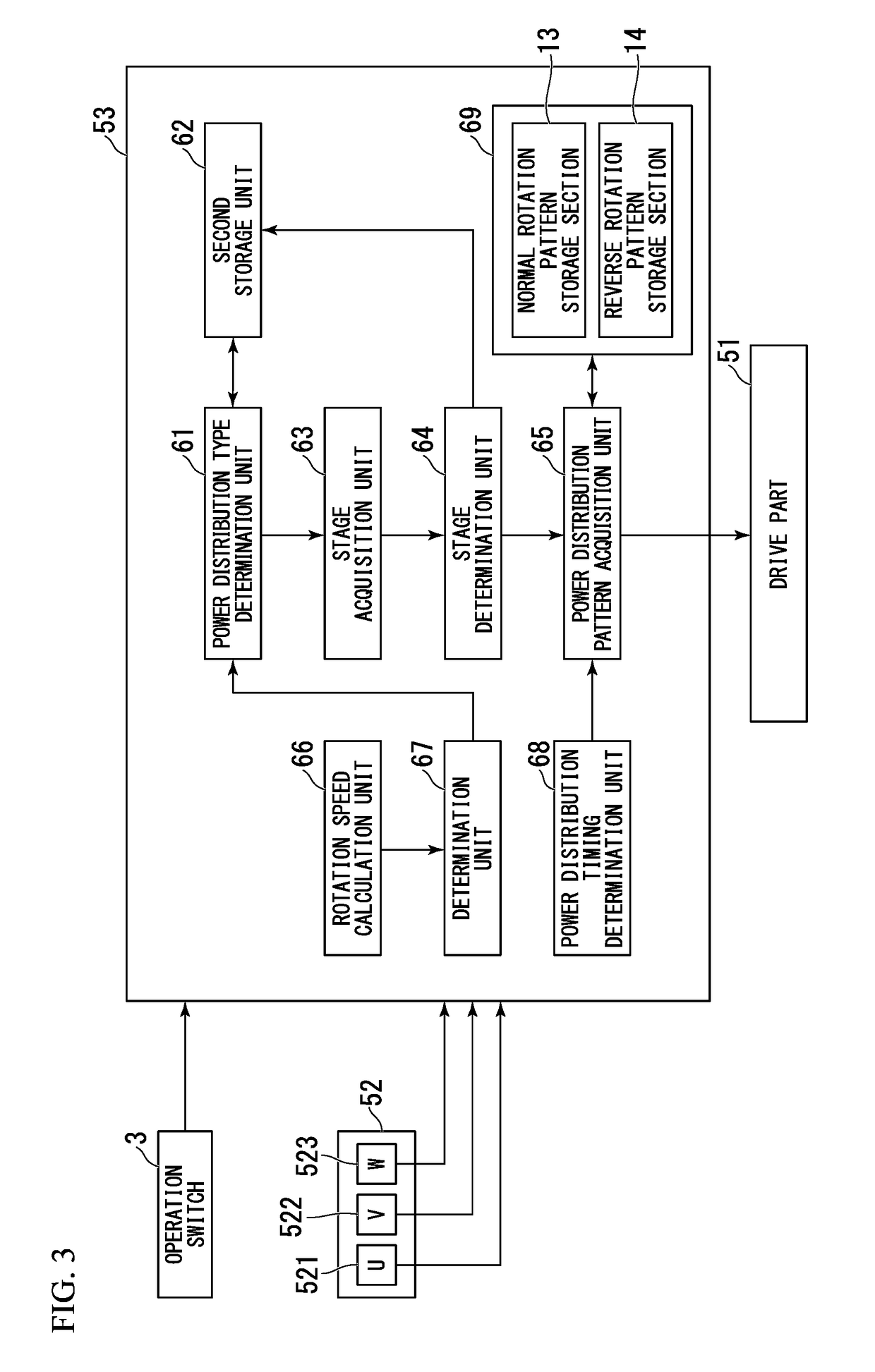

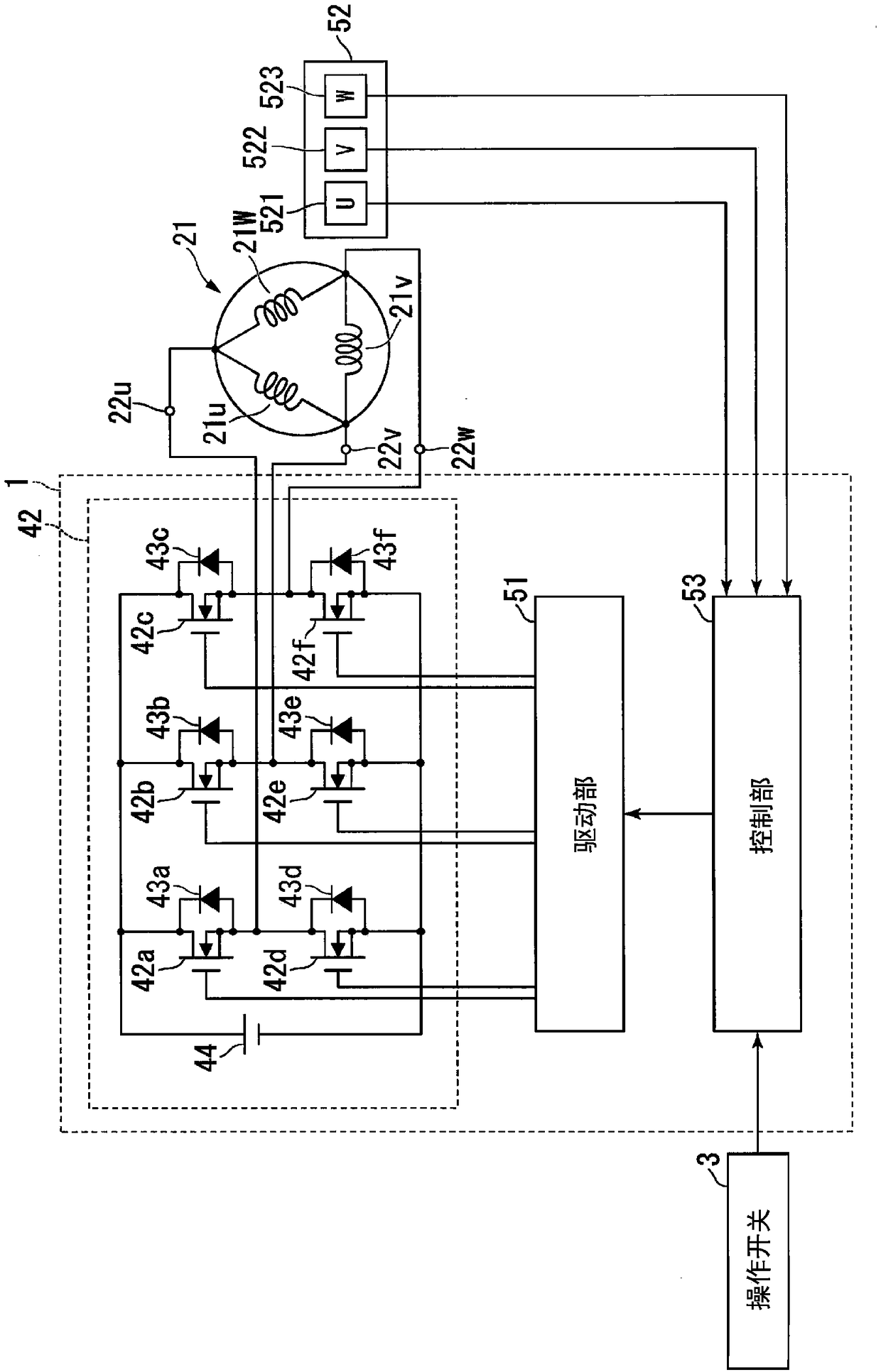

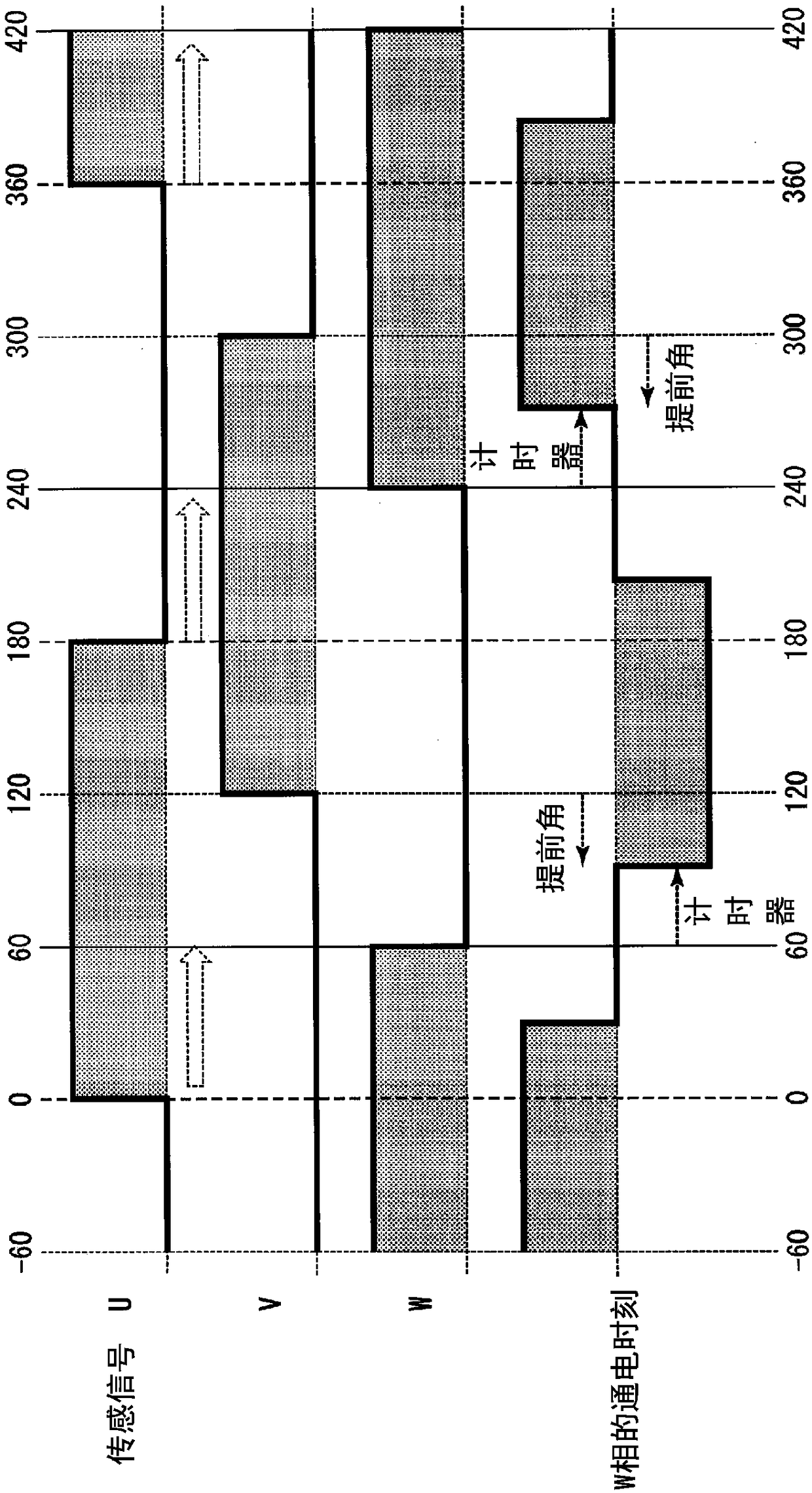

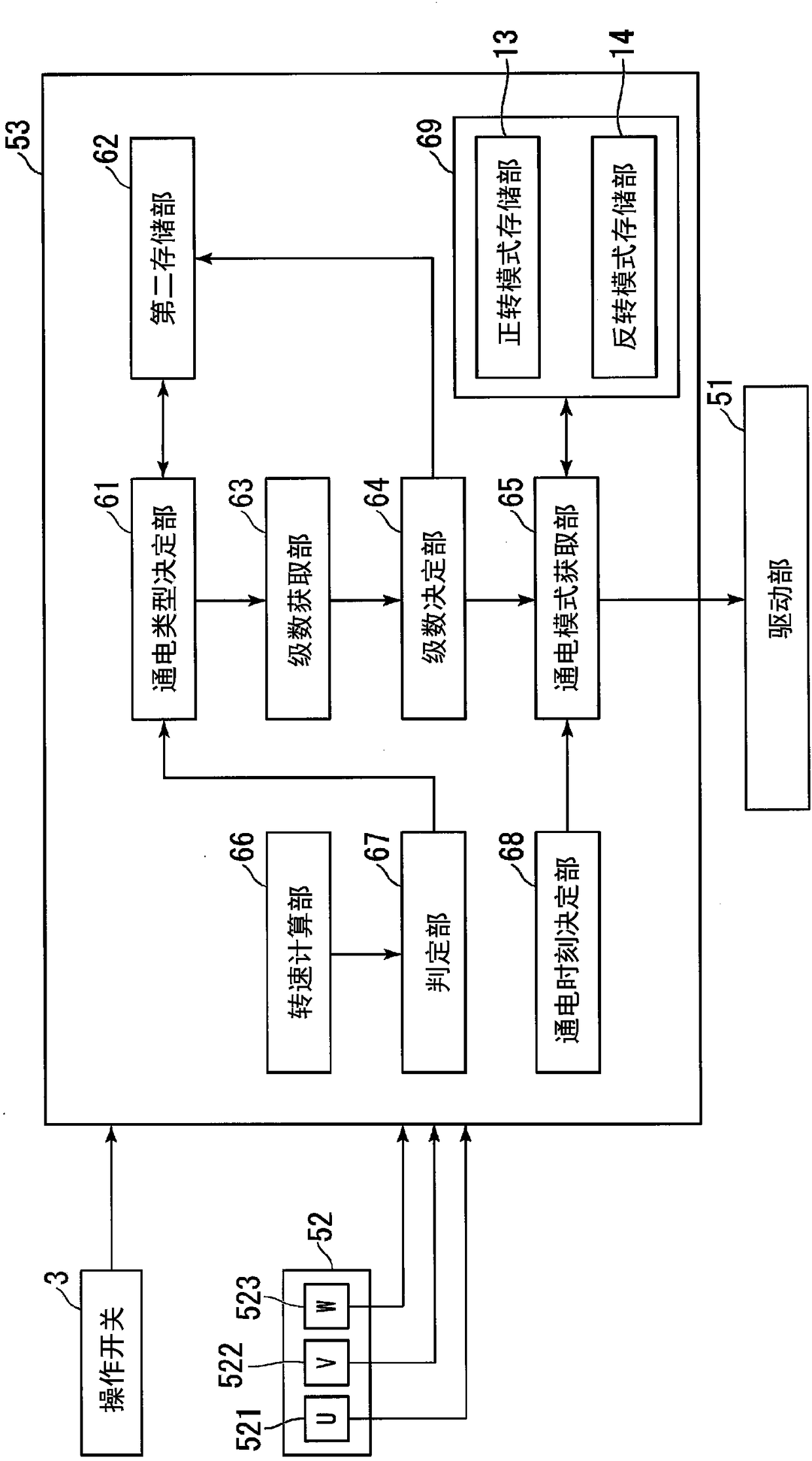

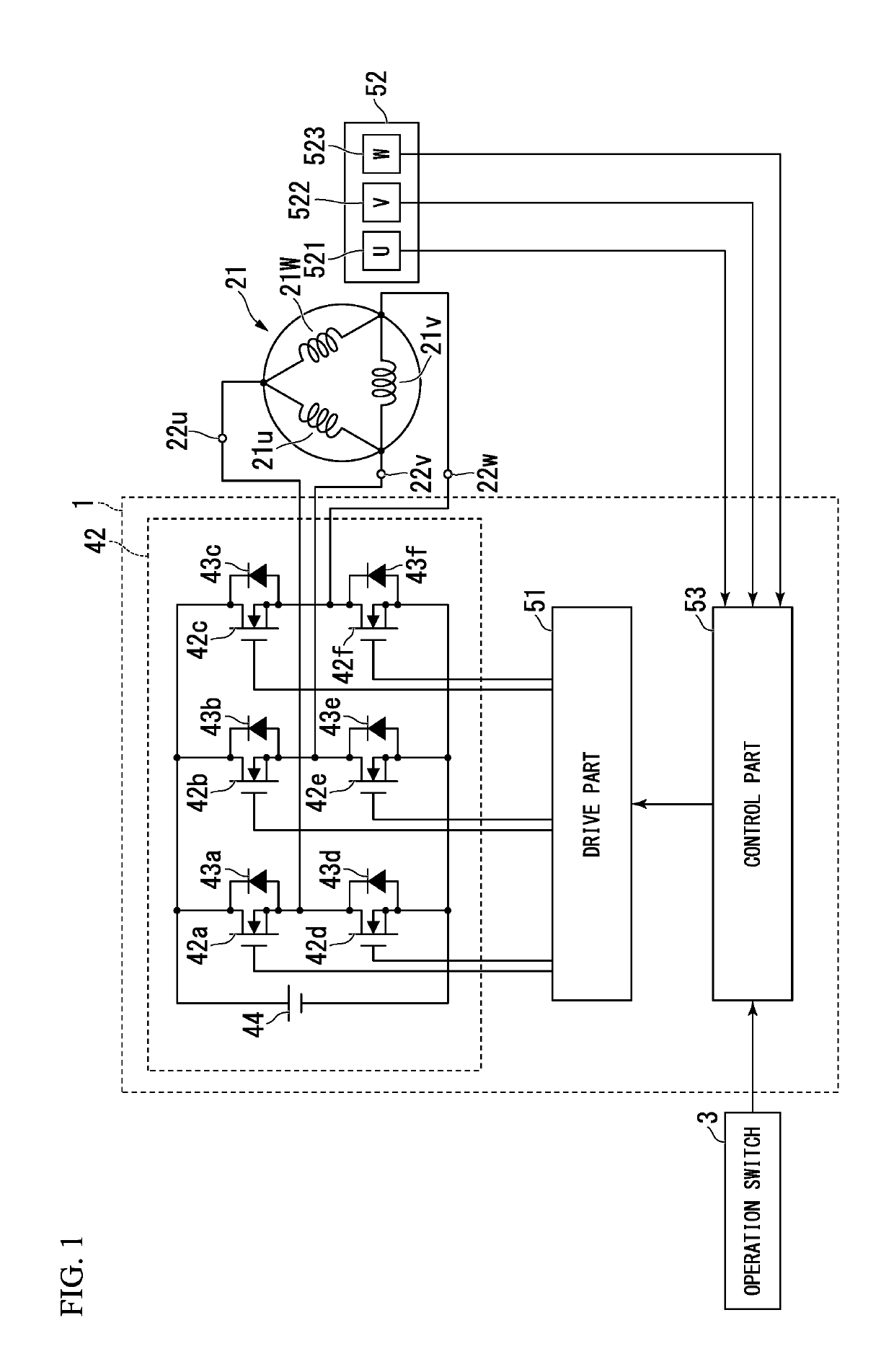

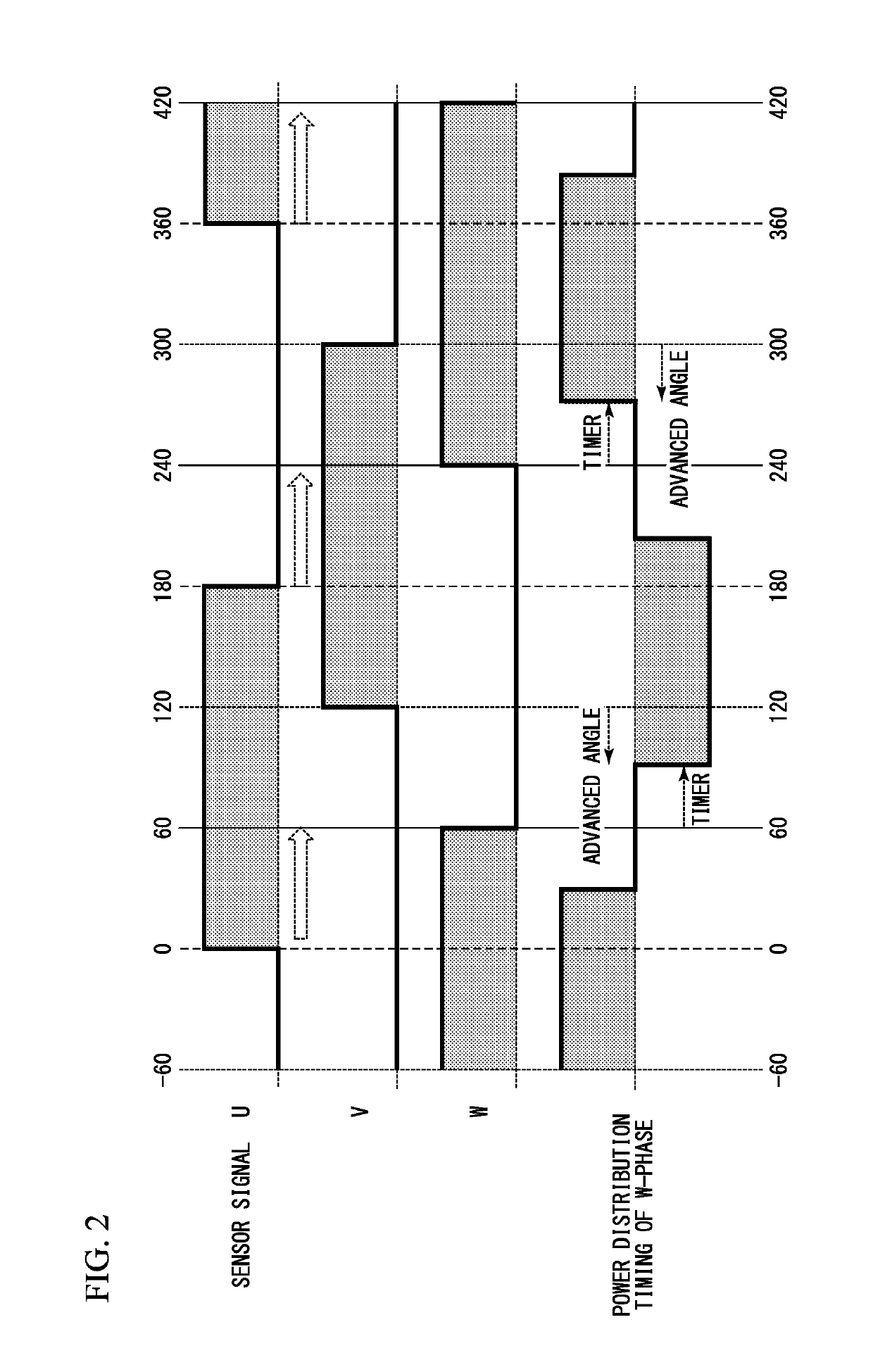

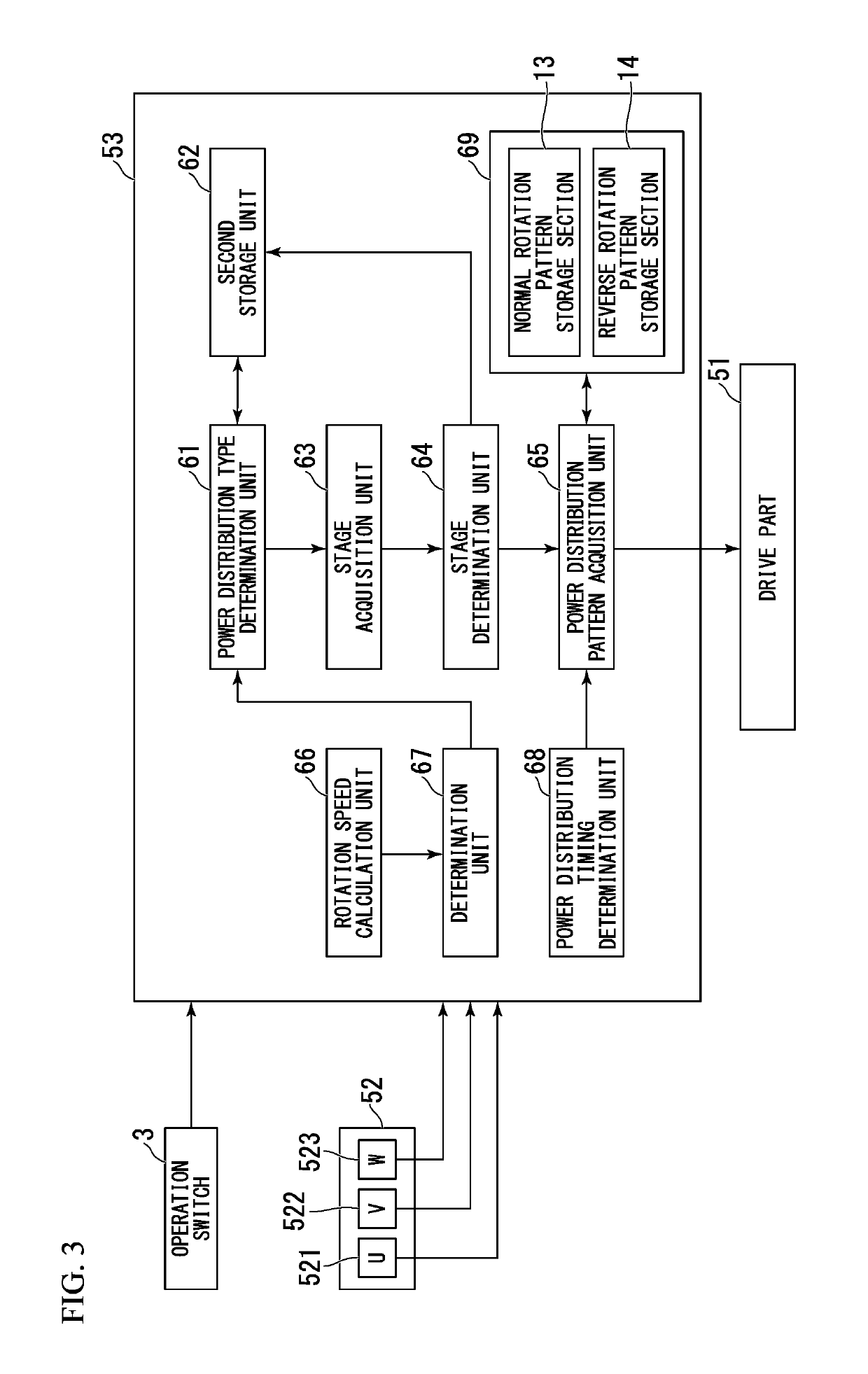

Motor drive apparatus and motor drive method

ActiveUS20180358911A1Reduce in quantityProgramme controlElectric motor controlMotor driveStage determination

A motor drive apparatus includes: a stage determination part that determines a position of the rotor based on a combination of states of a plurality of the output signals; and a power distribution timing determination part which determines that a power distribution timing when power is distributed to the coil is a timing obtained by advancing an angle by an amount that corresponds to a predetermined electric angle in a startup time of the motor, wherein, when a rotation speed of the motor becomes a predetermined rotation speed or more, the power distribution timing determination part determines that a timing when a predetermined period of time elapses since a position of the rotor arrives at a position of an electric angle that corresponds to a displacement amount of an electric angle which is arbitrarily advanced with respect to a predetermined electric angle that is advanced in the startup time is a power distribution timing.

Owner:MITSUBA CORP

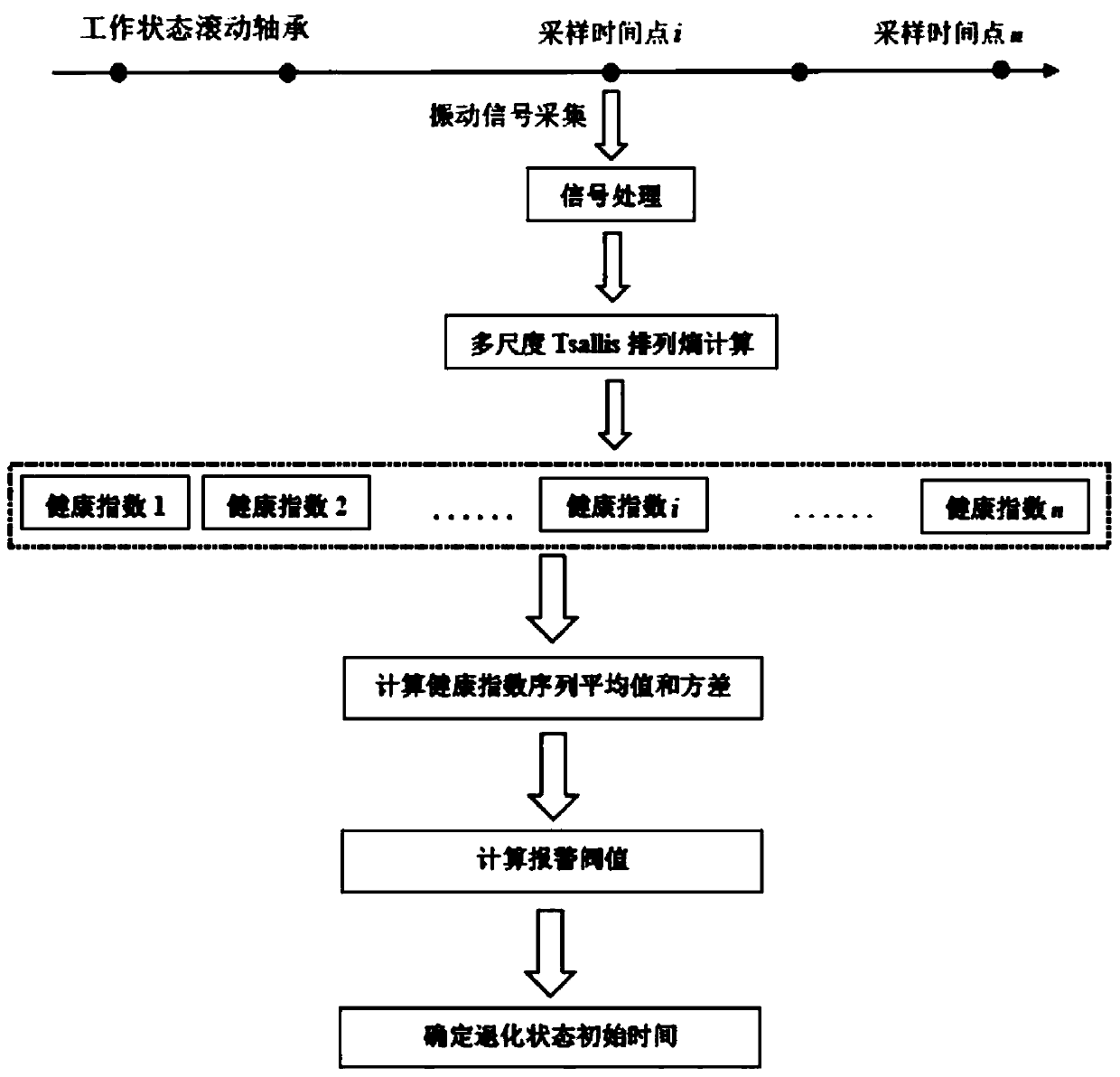

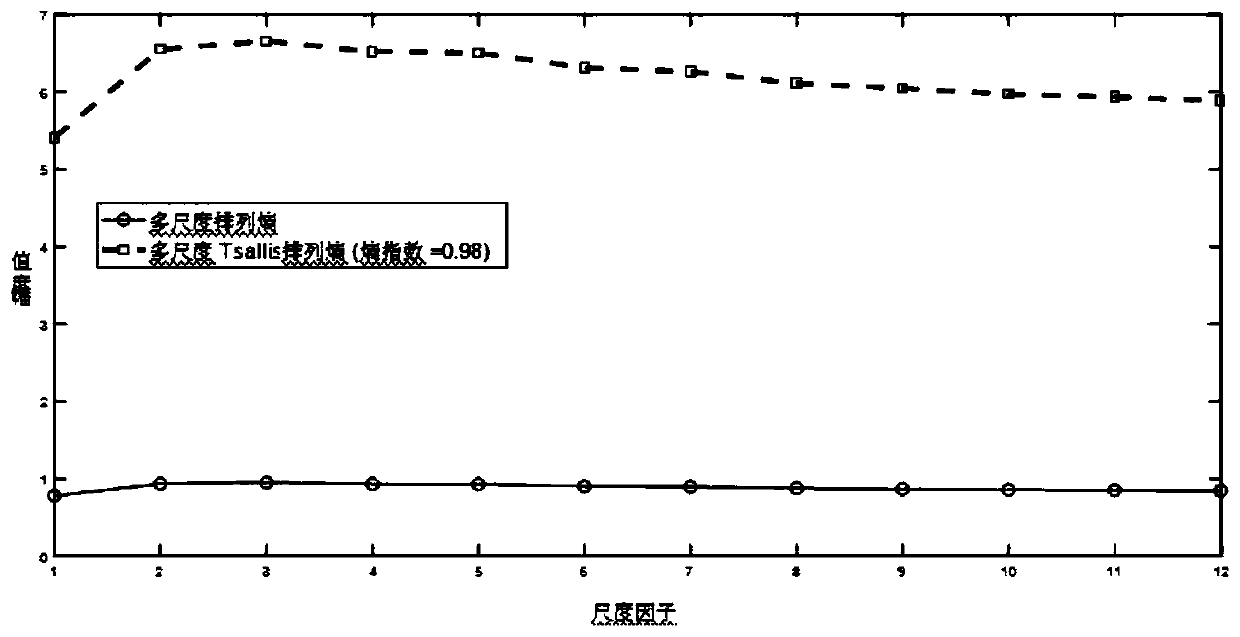

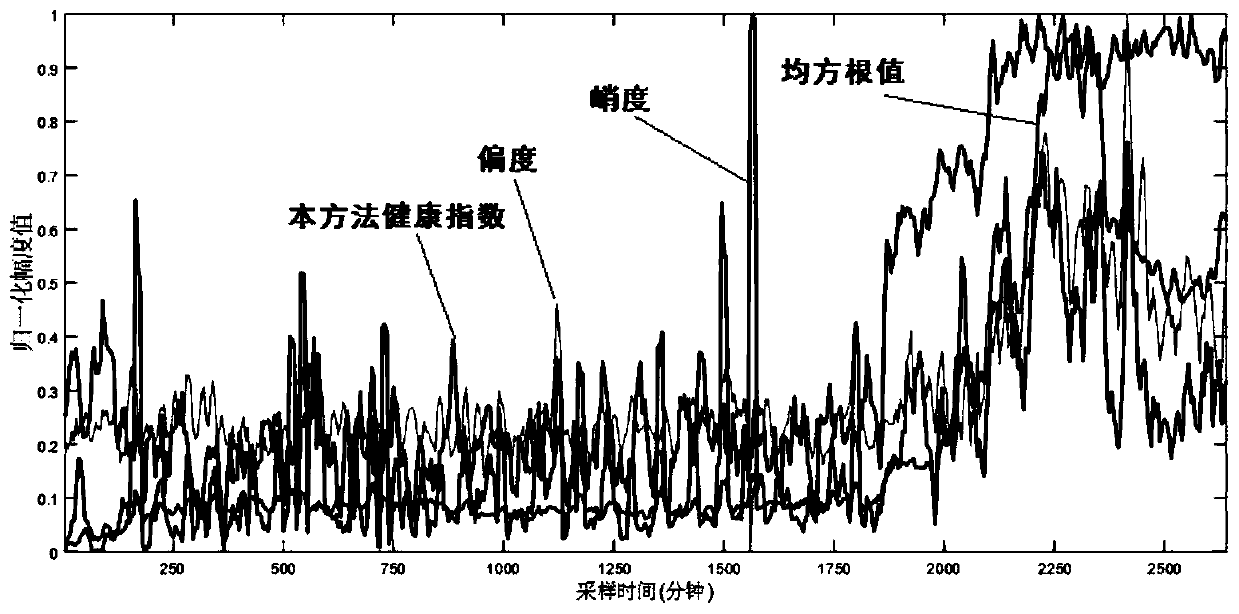

Rolling bearing degradation state stage determination method

The invention provides a rolling bearing degradation state stage determination method, which comprises the following steps: 1, vibration signals representing a stable working state of the rolling bearing are collected and denoised to obtain a useful signal sequence capable of specifically representing a stable working state of the rolling bearing; 2, a multi-scale Tsallis permutation entropy valueof the useful signal sequence is calculated to obtain a health state index time sequence; 3, based on the health state index time sequence, an average value and a variance value are calculated; and 4, an alarm threshold is calculated according to the average value and the variance value, a time sequence change trend is formed according to the multi-scale Tsallis permutation entropy value, and thestarting time point for the rolling bearing degradation stage is recognized. By using the multi-scale Tsallis permutation entropy, the entropy index can be adjusted to adapt to the condition monitoring ability of the mechanical system under various conditions and well sense the mechanical system state change ability, determination of the rolling bearing degradation state stage is realized, the recognition effects are good, and the calculation speed is quick.

Owner:FOSHAN UNIVERSITY

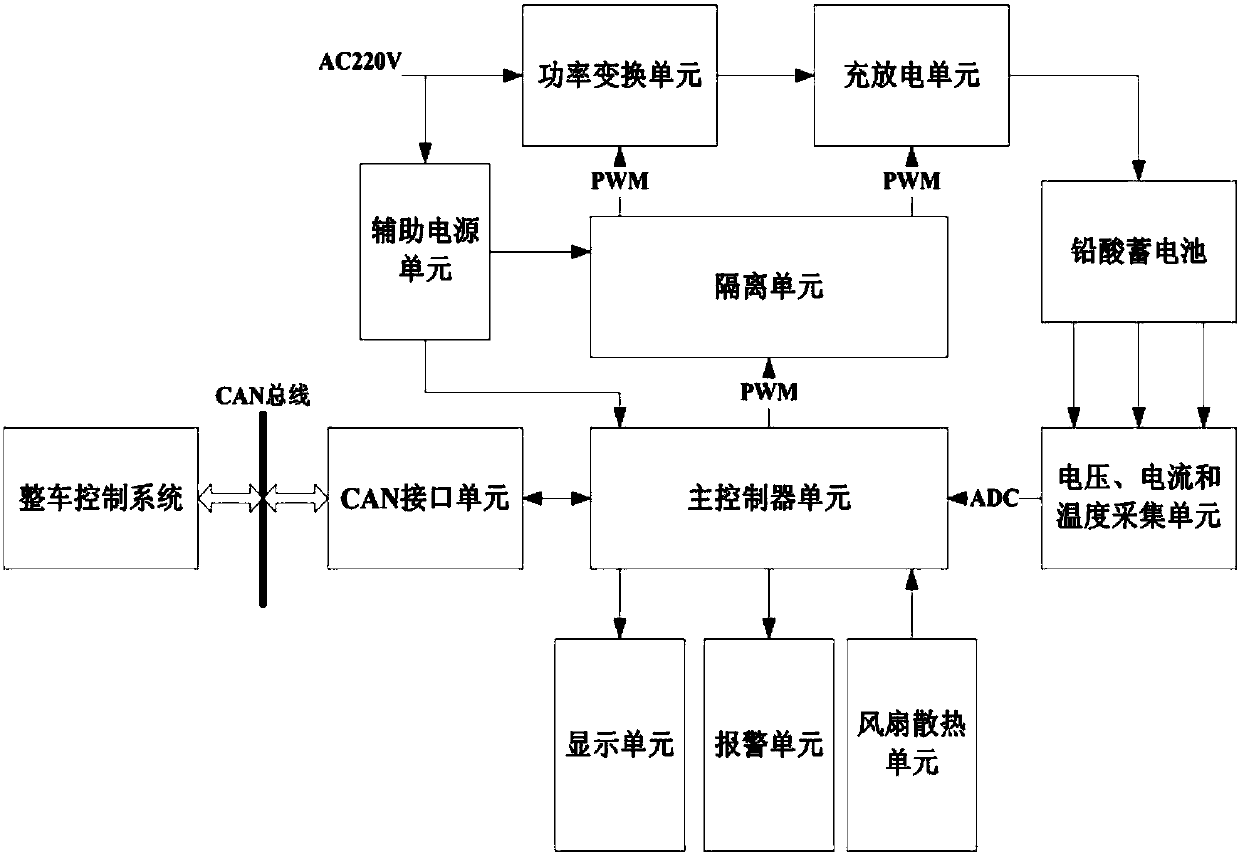

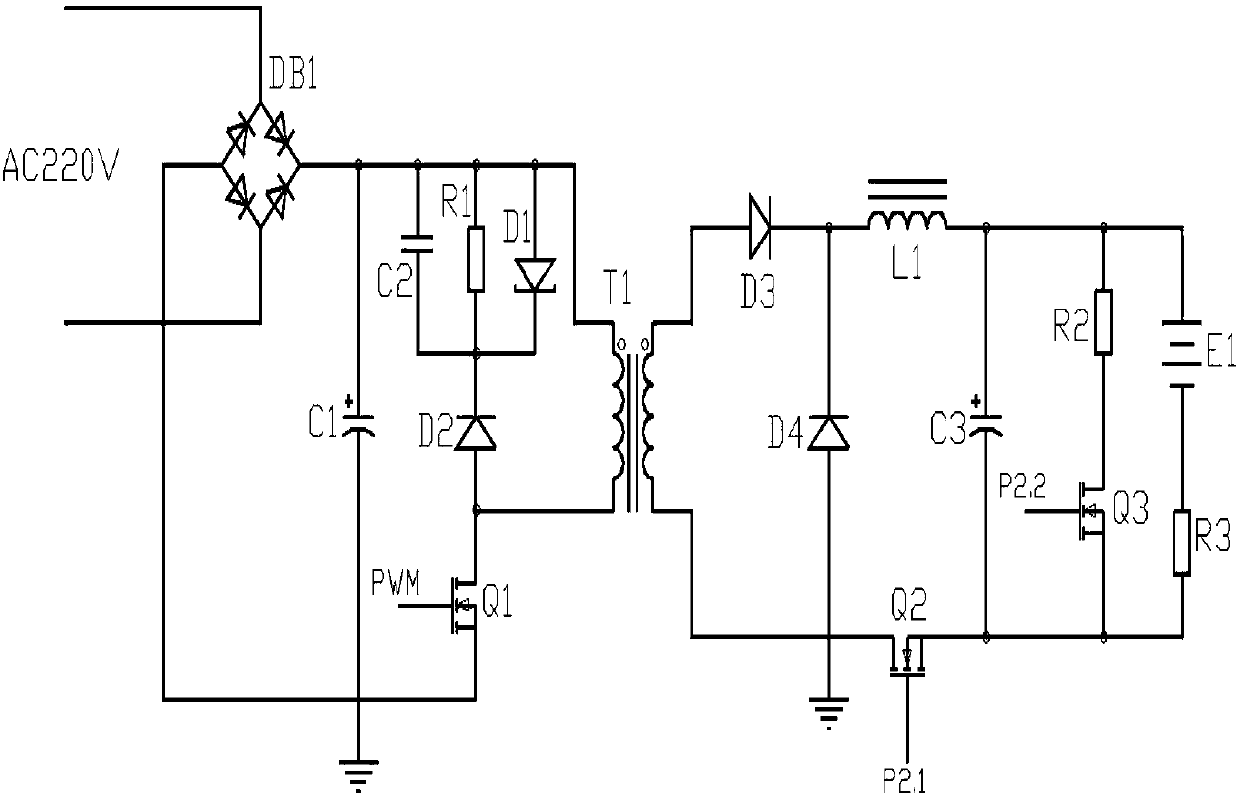

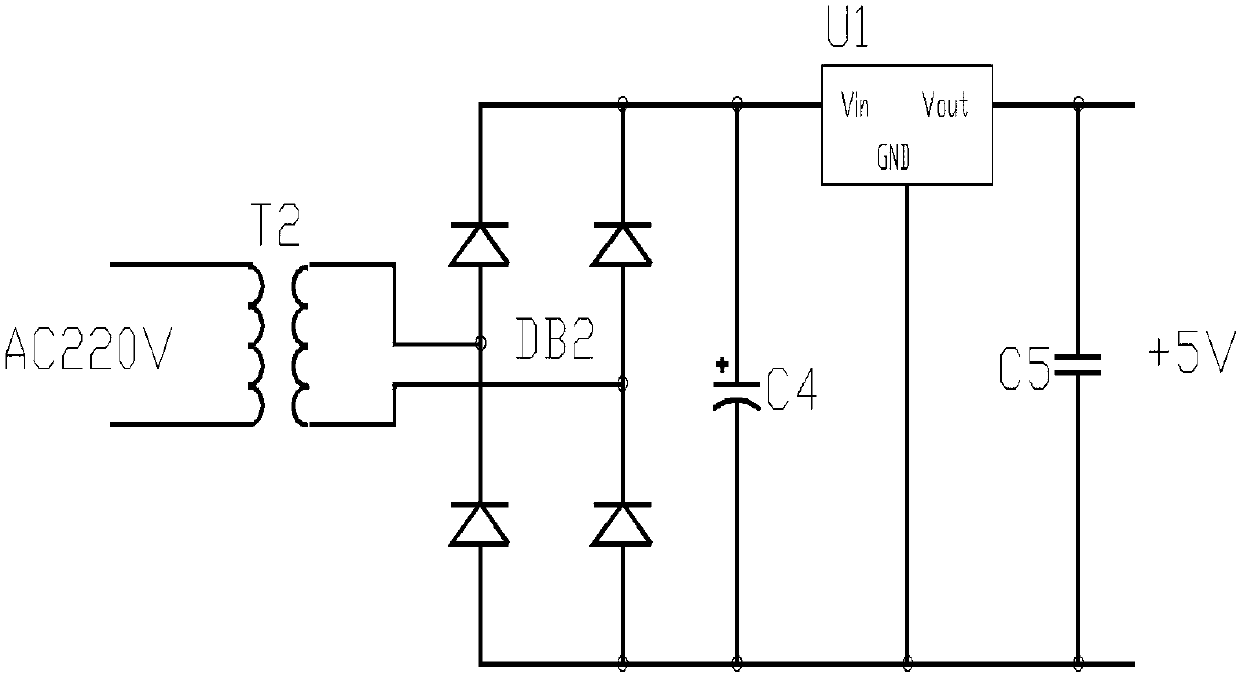

Intelligent charging system of lead acid storage battery of electric automobile

InactiveCN107666173AReduce capacitySolution to short lifeBatteries circuit arrangementsCharging stationsMicrocontrollerStage determination

The invention provides an intelligent charging system of lead acid storage battery of an electric automobile. The system comprises a power conversion unit, a charging and discharging unit, a parameteracquisition unit, an auxiliary power supply unit, an isolation unit, a main controller unit, a CAN port unit, a display unit, an alarm unit and a fan heat radiation unit. According to the invention,by use of a novel charging control strategy in which the staged determination of the current and the positive and negative pulse are combined, and by use of the single-chip microcomputer digital PI control technology and the highly-efficient and low-loss DC-DC conversion circuit, the charging speed is remarkably increased; charging is quite safe; the temperature rise of the battery is small; effects on capacity and service lifetime of the storage battery are reduced; and by using the single-chip microcomputer which is low in cost to replace an expensive power supply to manage the IC, the intelligent monitoring and intelligent management of the storage battery are achieved.

Owner:SINOPOL ELECTRONICS TECH

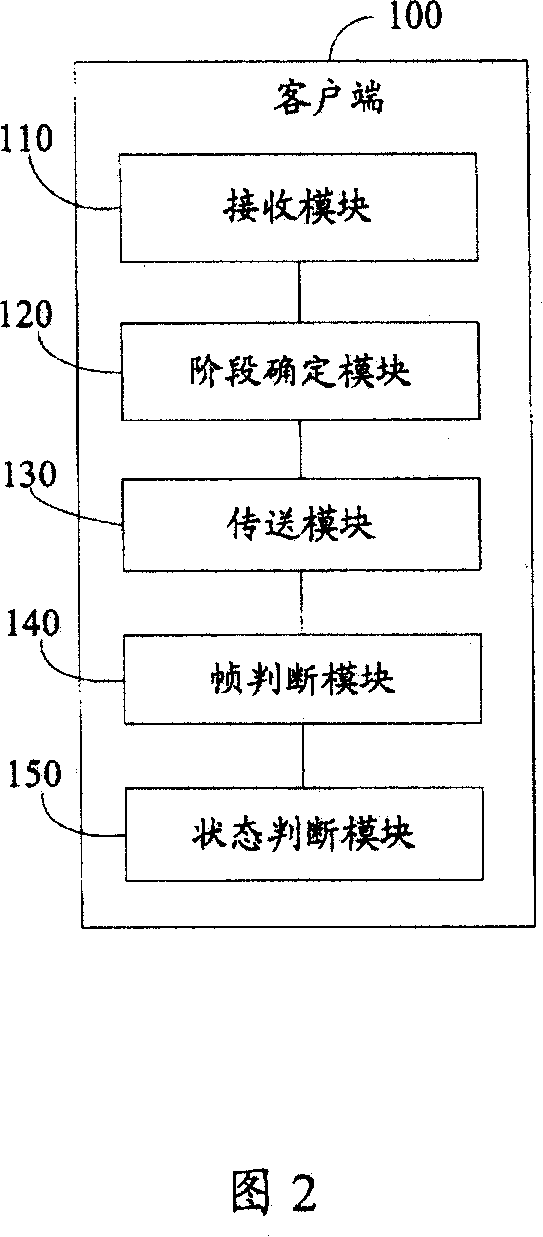

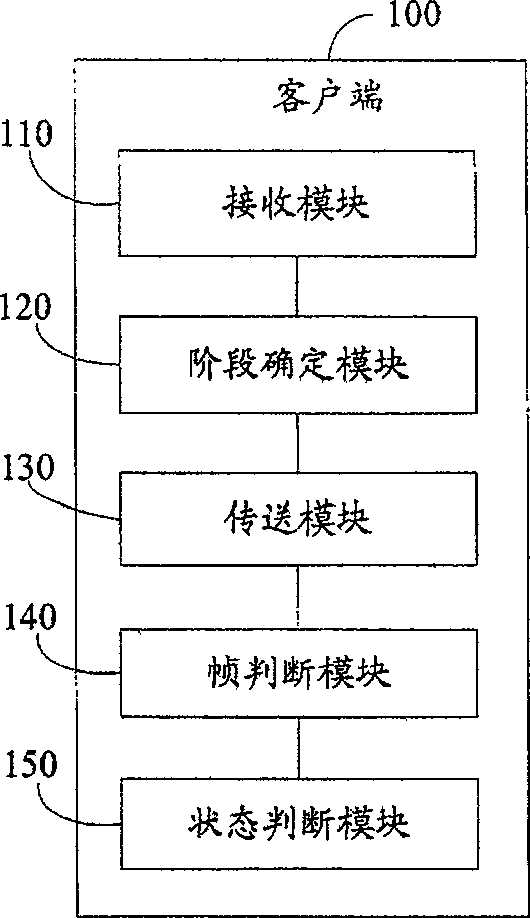

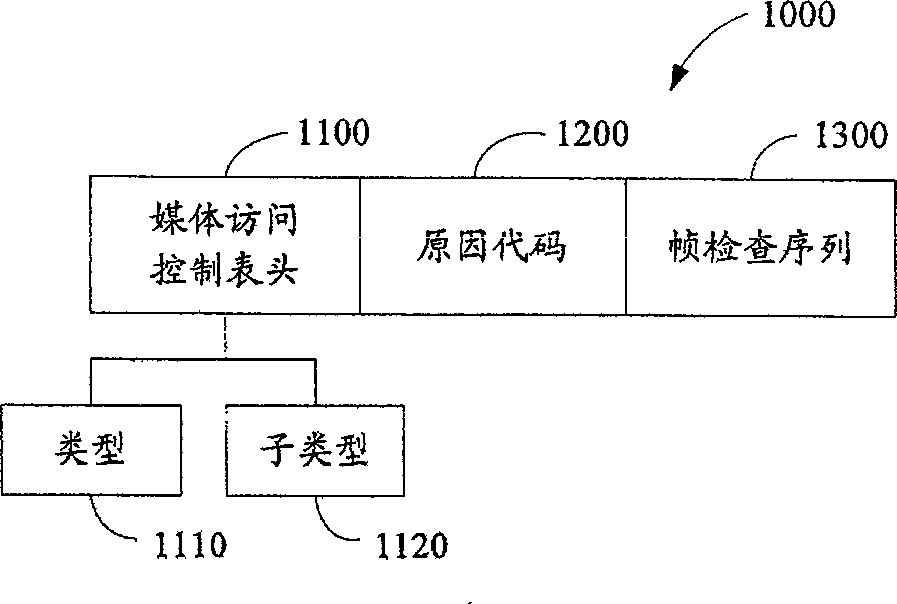

Client terminal and connection detecting method

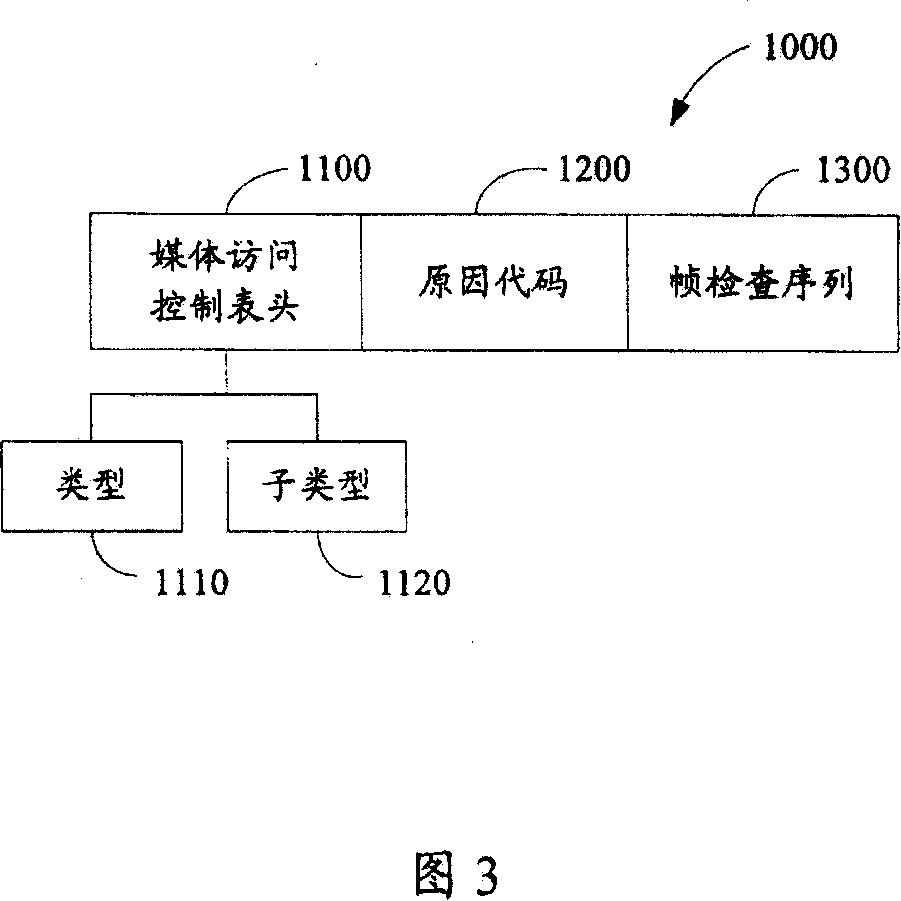

A client end which is connected with a server includes a receiving module, a stage determination module, a transmission module, a frame judgment module and a condition judgment module. The receiving module is used for receiving a management frame and the stage determination module is used for determining the frame stage according to the management frame. The transmission module is used for transmitting the grade frame to the server according to the frame stage, wherein, the frame corresponded by the grade ratio frame stage of the grade frame has a very high grade. The frame judgment module is used for judging whether the expecting frame is received. The condition judgment module is used for judging the connecting condition of the client end and the server according to the judgment result of the frame judgment module. The invention also provides a connection detecting method which is used for detecting the connecting condition of the client end and the server. The client end and the connection detecting method thereof can timely detect the server, the connection of which is cut off to stop the client from transmitting the data to the server, thereby avoiding the loss of the transmission data.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

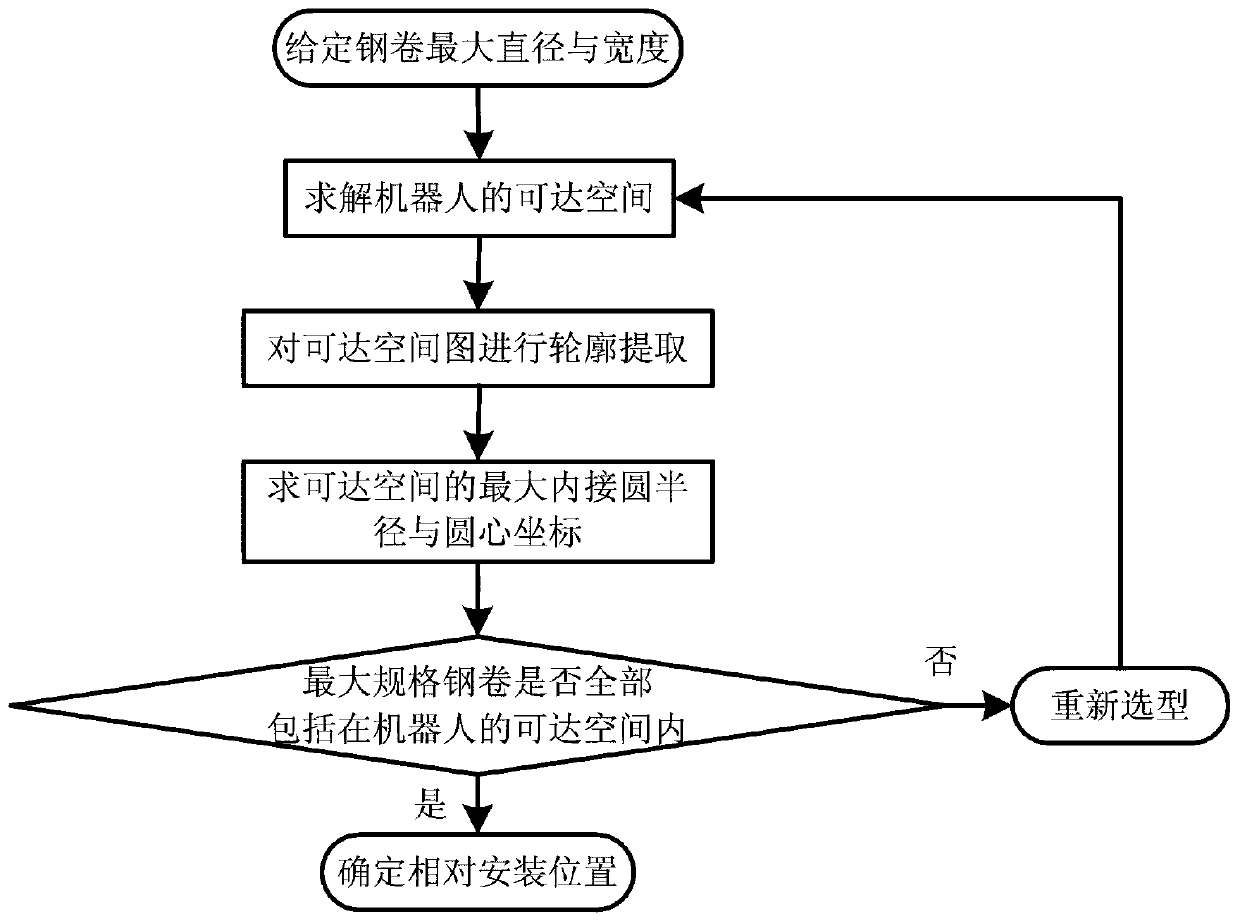

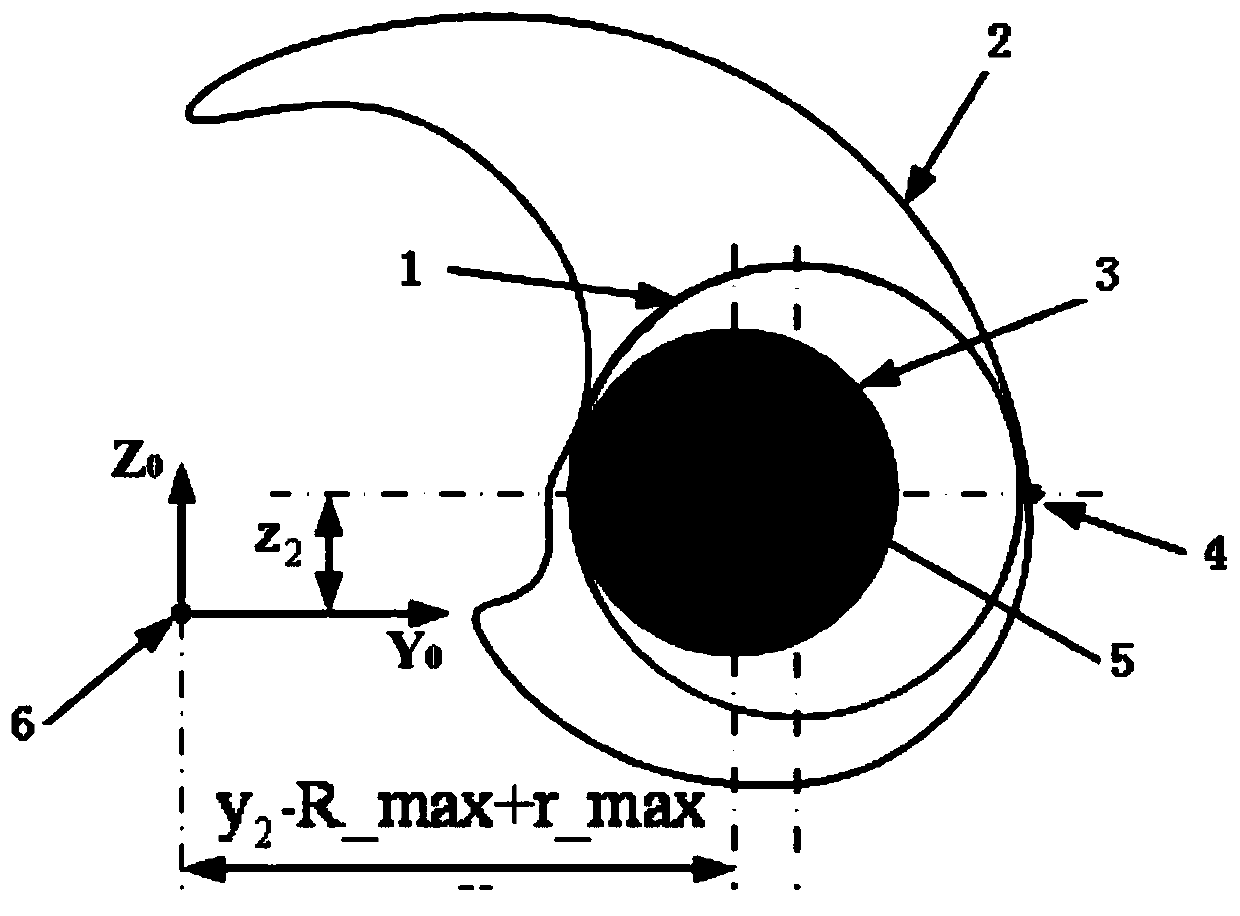

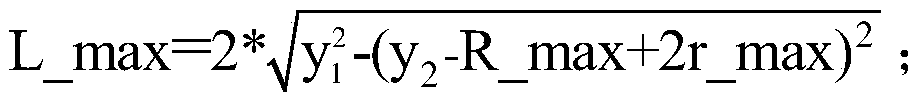

Method for determining model selection and installation position of steel coil labeling and code spraying six-axis robot

ActiveCN110428436AAvoid selection errorsHigh precisionImage enhancementImage analysisMaximum diameterModel selection

The invention discloses a method for determining model selection and installation position of a steel coil labeling and code spraying six-axis robot. The method mainly comprises the following steps: 1, giving the maximum diameter and width of a steel coil; 2, solving a reachable space of a robot; 3, performing contour extraction on the reachable space diagram; 4, solving the maximum inscribed circle radius and circle center coordinates of the reachable space; and 5, judging whether the steel coil with the maximum specification is completely in a reachable space of the robot or not and determining a relative mounting position. The method can determine whether the robot can meet the task requirement in the determination stage, can avoid type selection errors while determining the relative installation position of the robot and the steel coil, can fully utilize the whole reachable space of the robot, and has the advantages of high accuracy, high working efficiency and low production cost.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

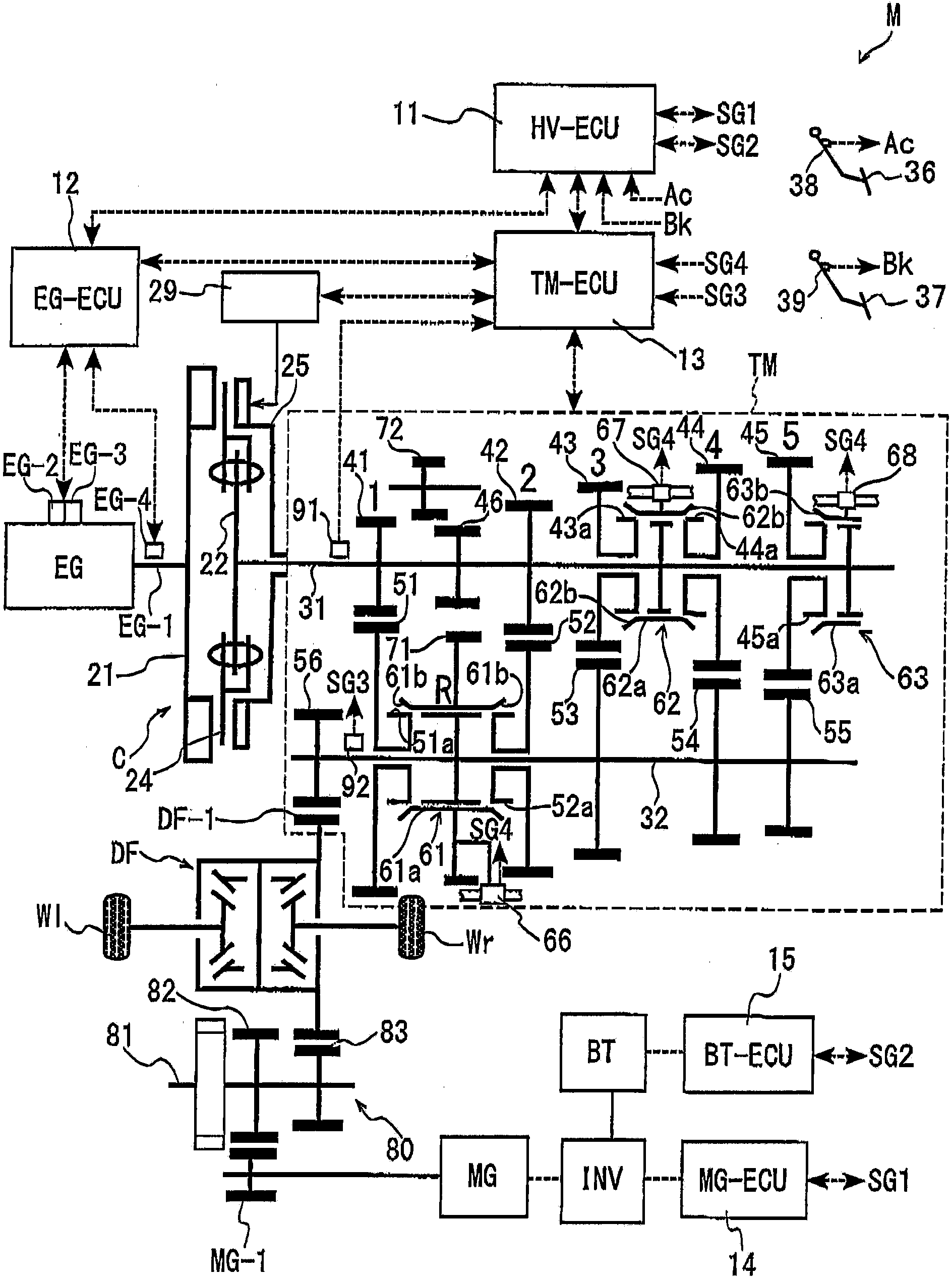

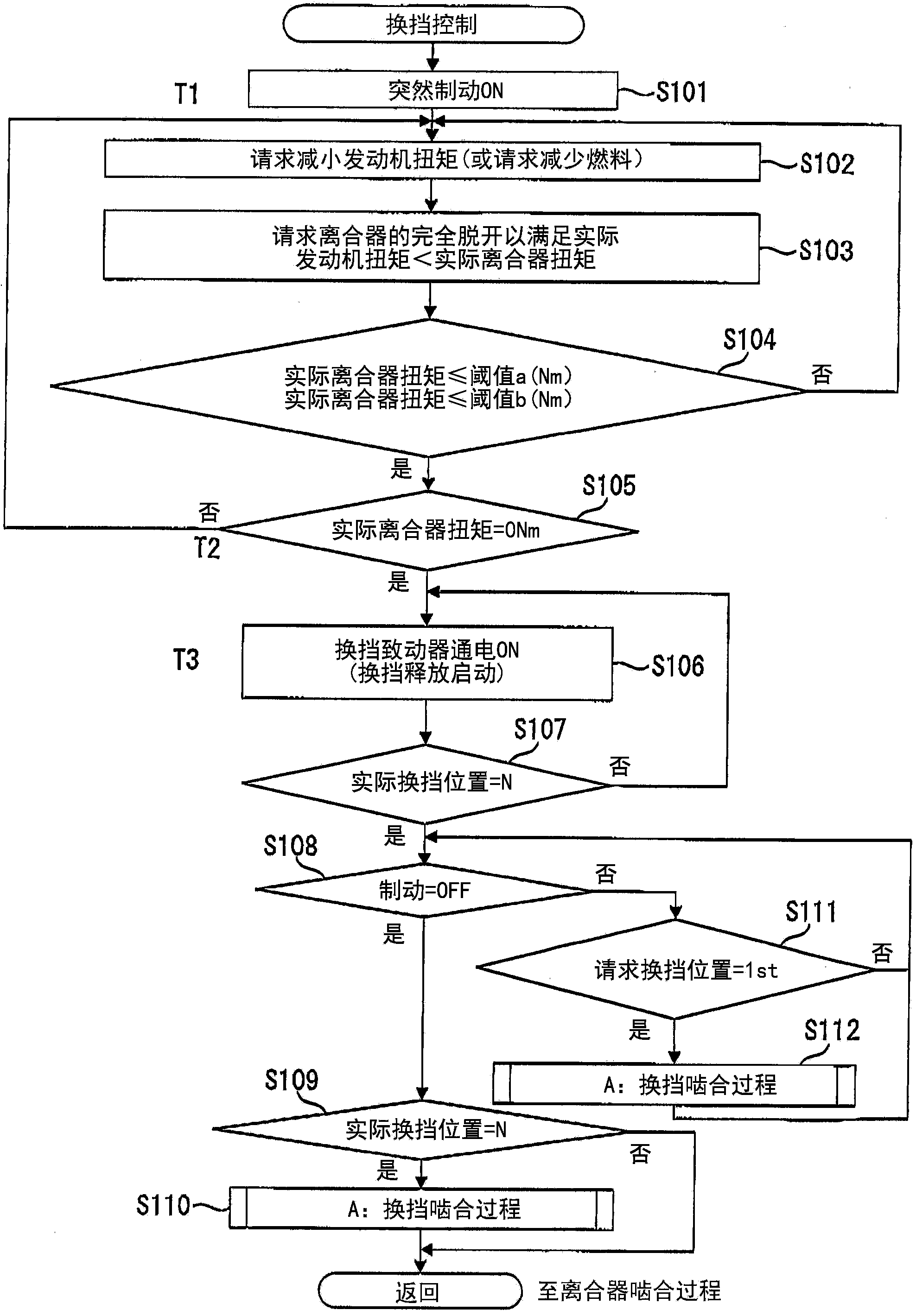

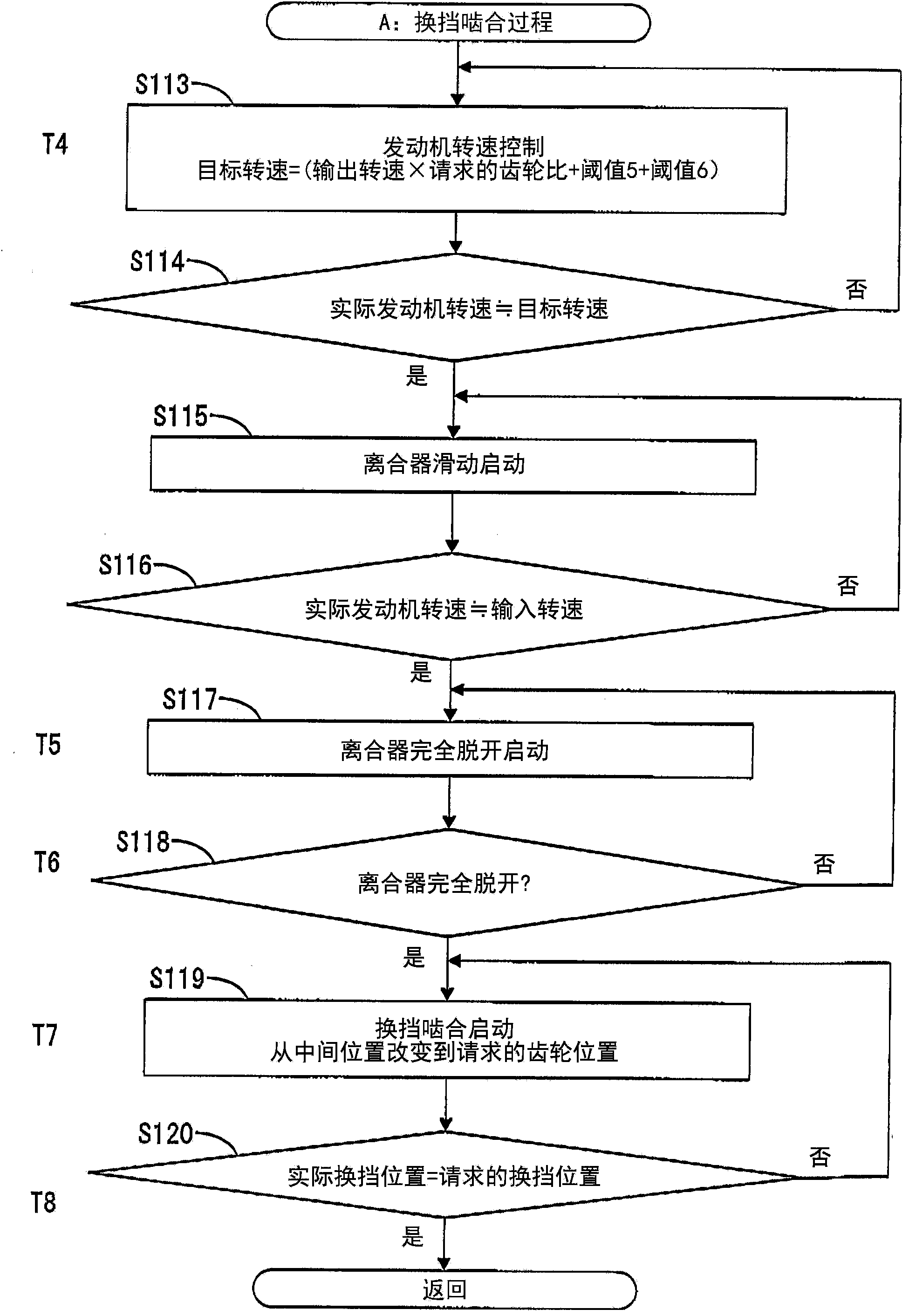

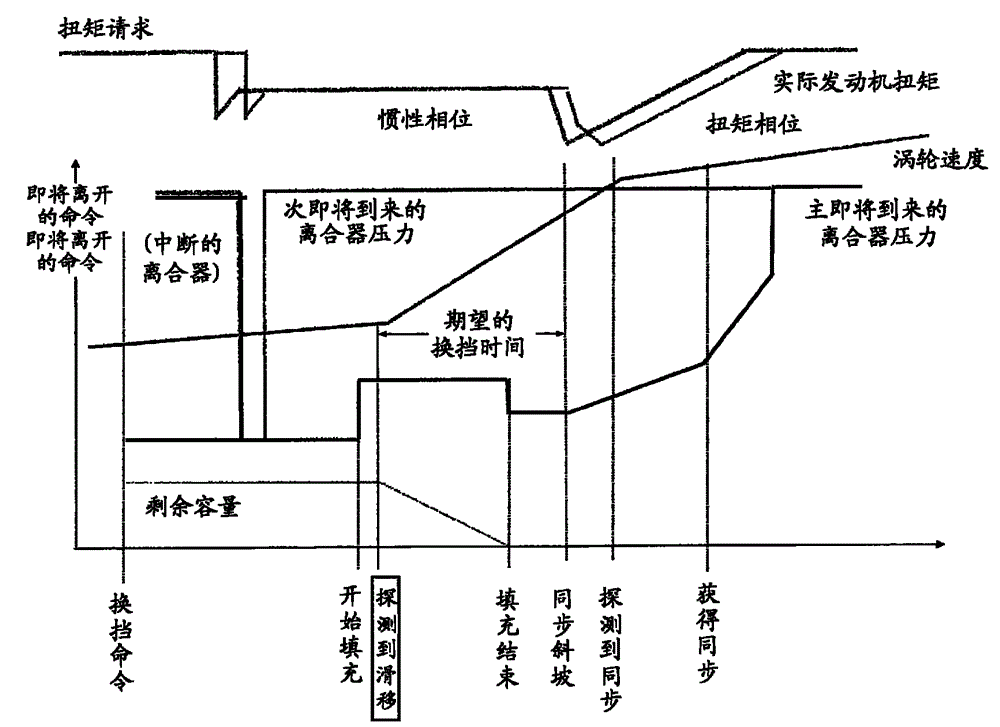

Automated transmission control apparatus

An automated transmission control apparatus includes an accelerated / decelerated travelling determination portion (11) determining a decelerated travelling state and an accelerated traveling state, a gear stage determination portion (13) determining a gear stage to be changed to, on the basis of at least one down-shift curve, on the basis of a travelling state, and a shift operation control portion (13) controlling a clutch actuator (29) in a case where the accelerated / decelerated travelling determination portion determines a sudden braking state, the shift operation control portion controlling the shift actuator to move at least one sleeve (61 a, 62a, 63a) to a neutral position in a case where the gear stage determination portion determines that the down-shift curve is crossed, the shift operation control portion maintaining all the sleeves in a stand-by state at the neutral position while the accelerated / decelerated travelling determination portion maintains the determination of the sudden braking state.

Owner:AISIN SEIKI KK

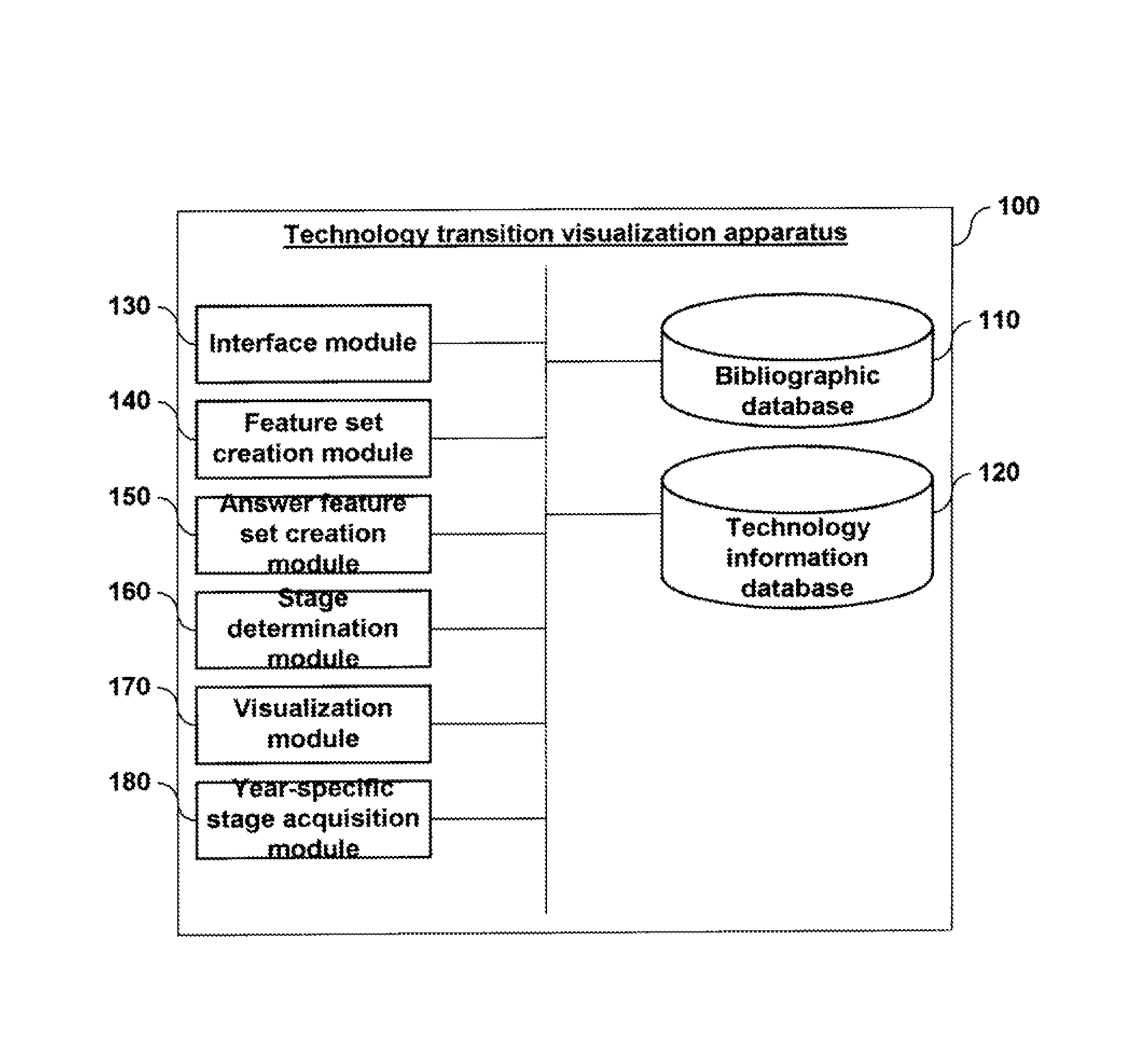

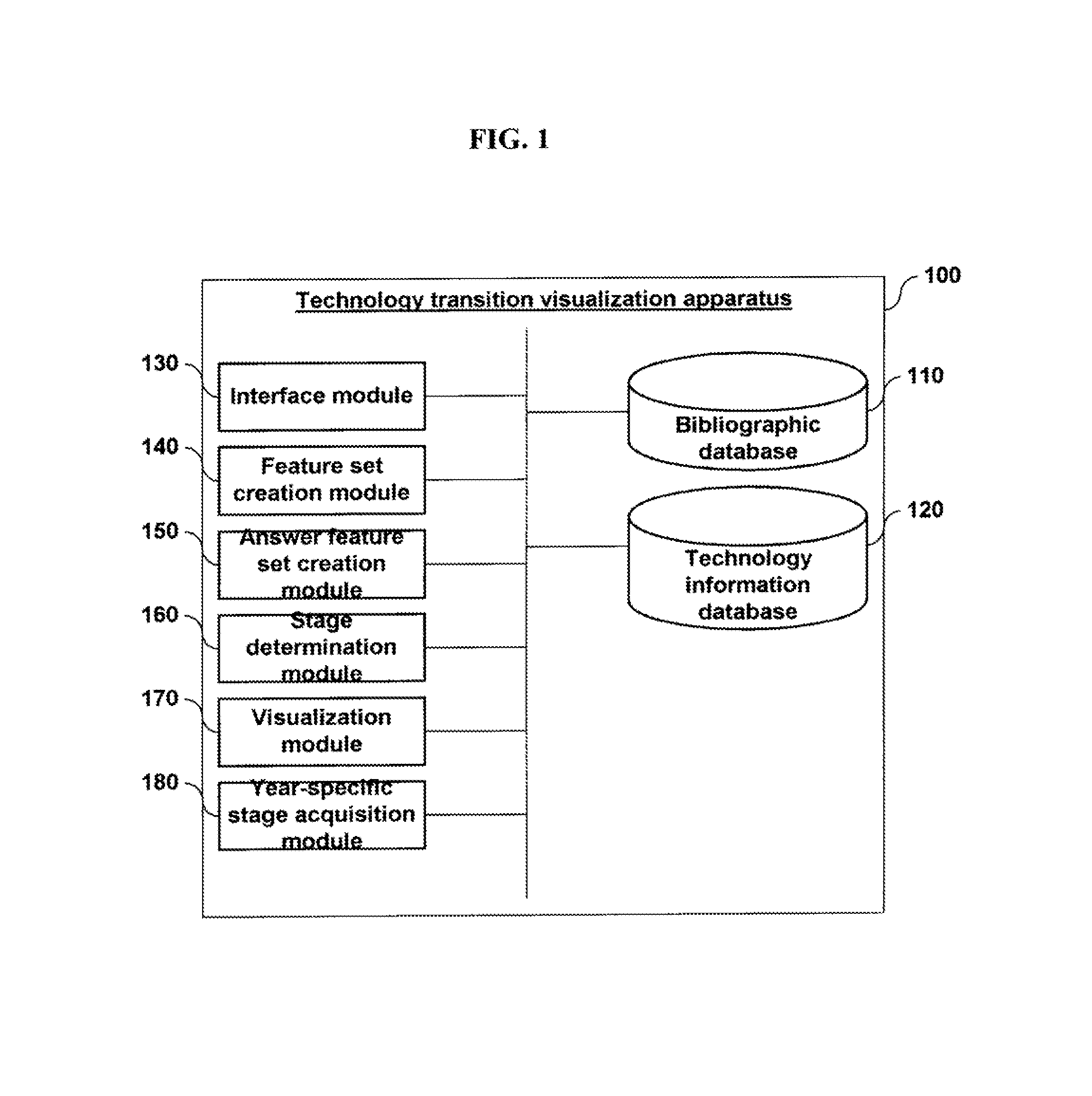

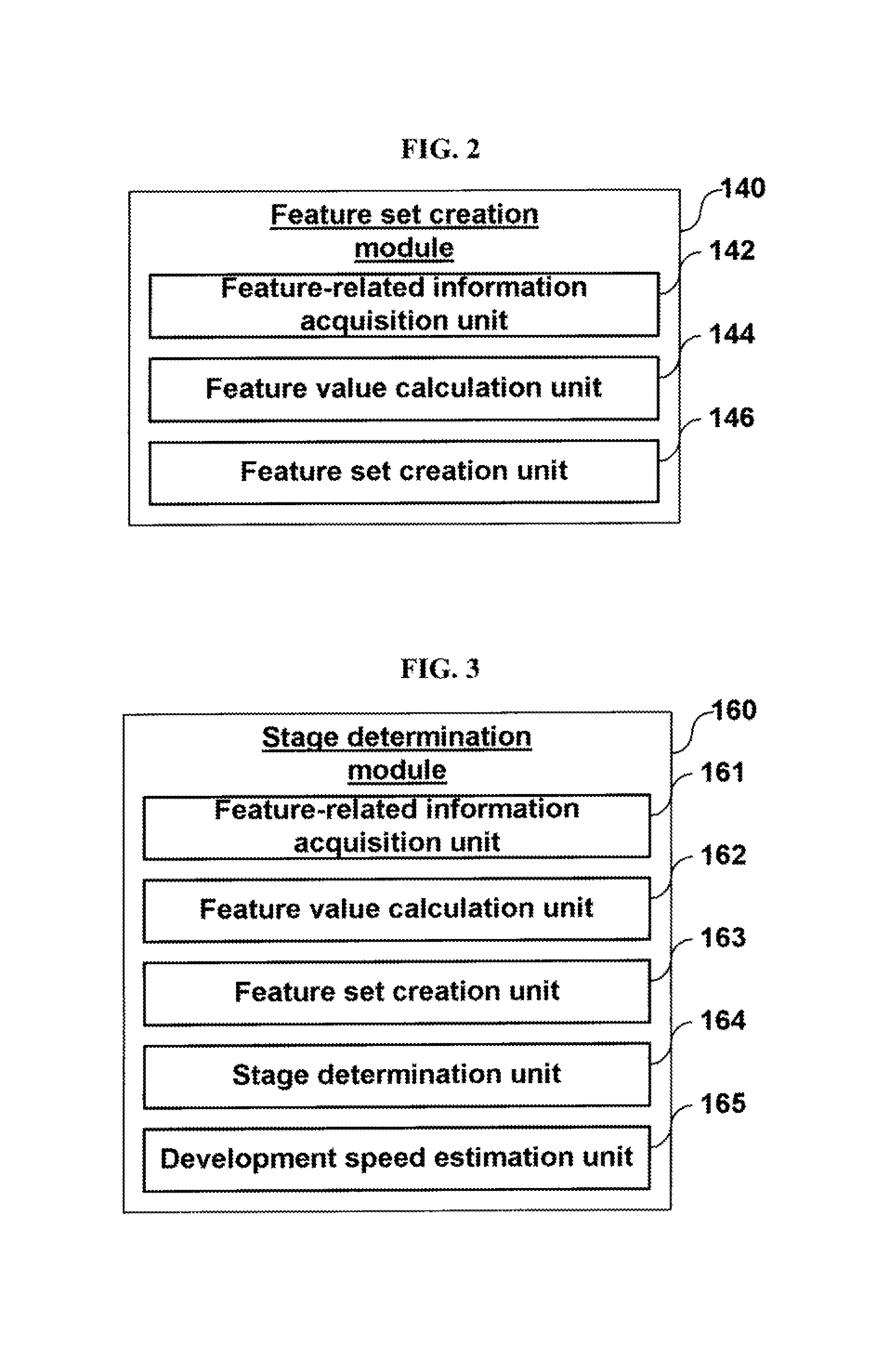

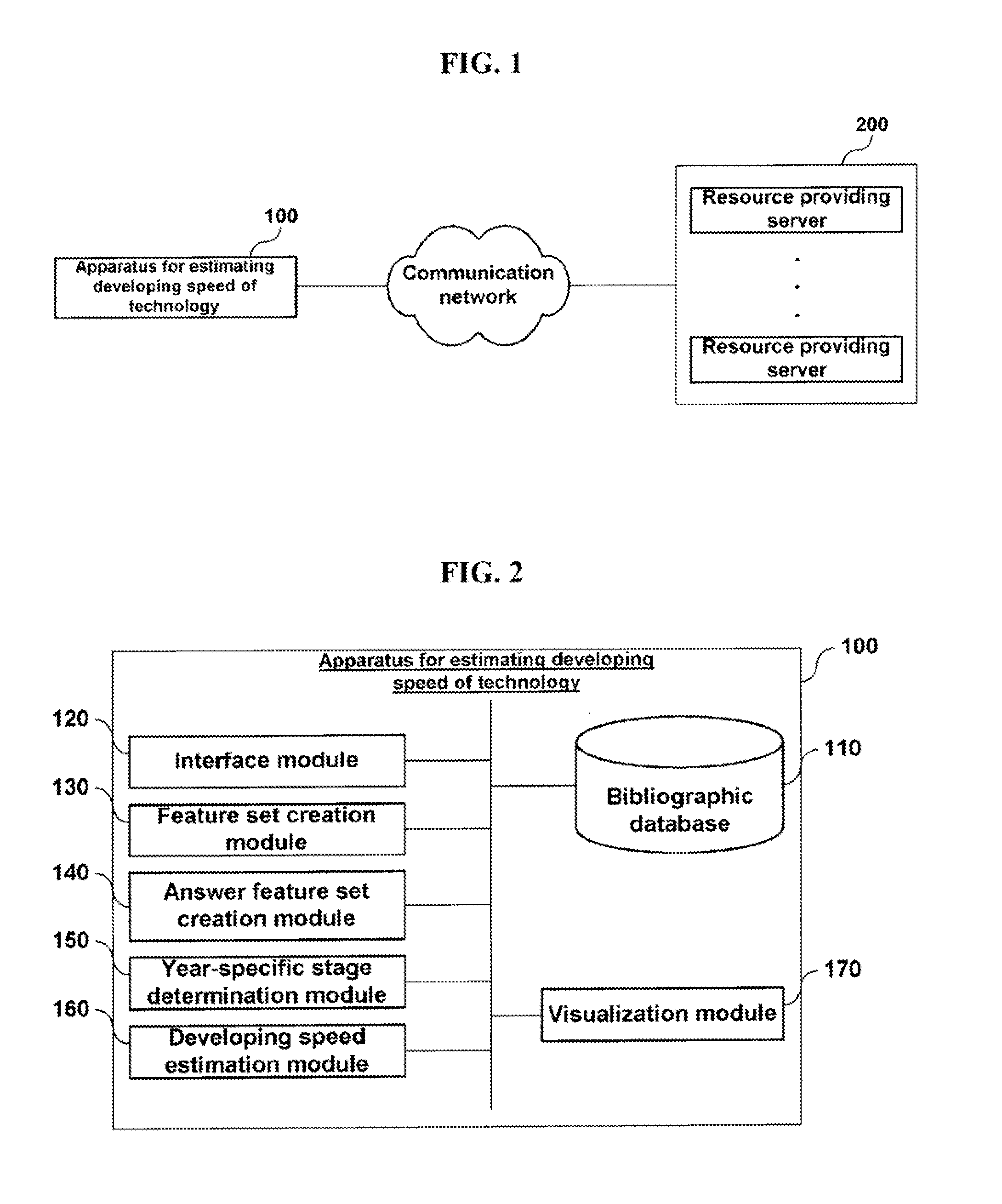

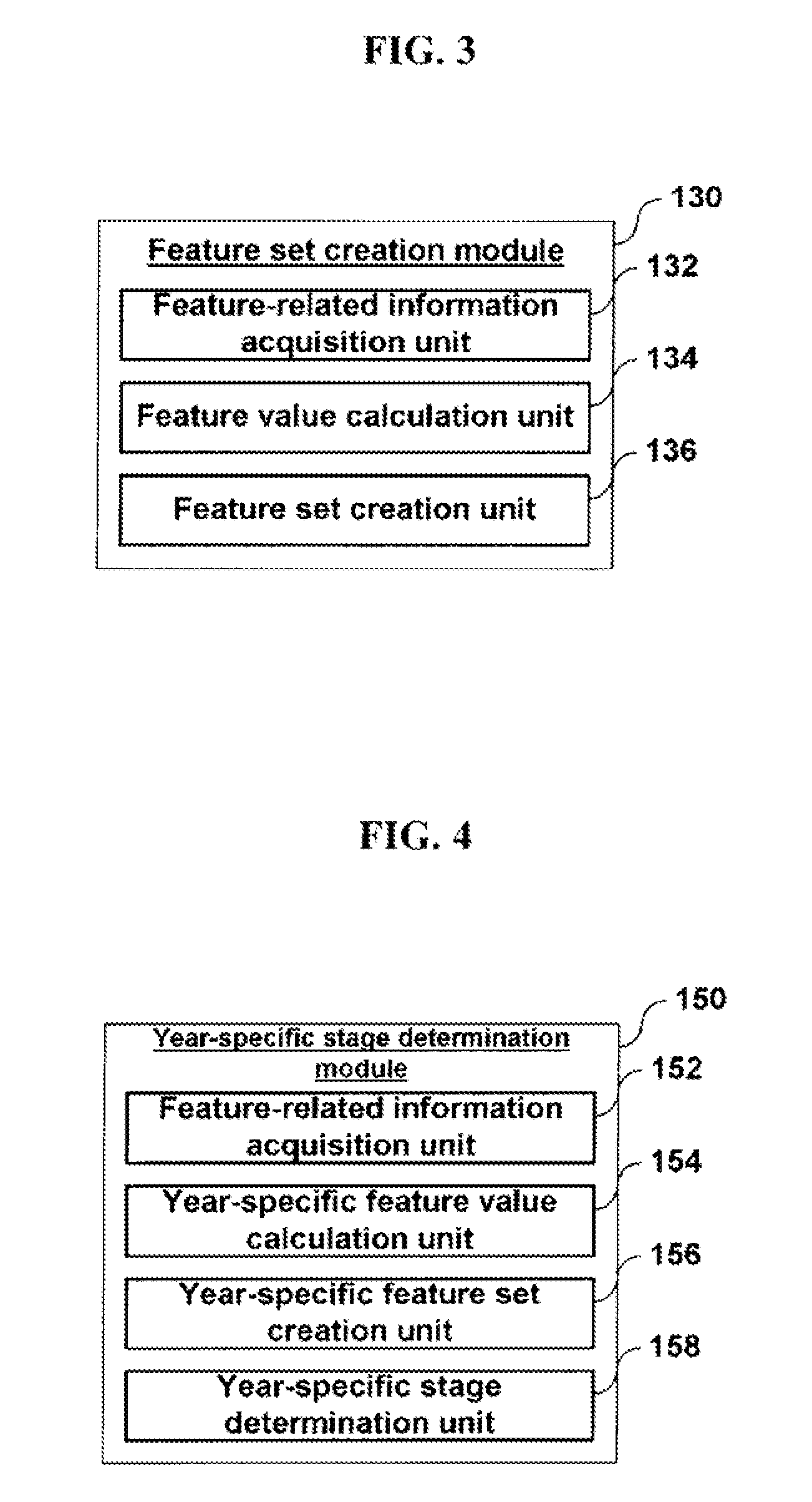

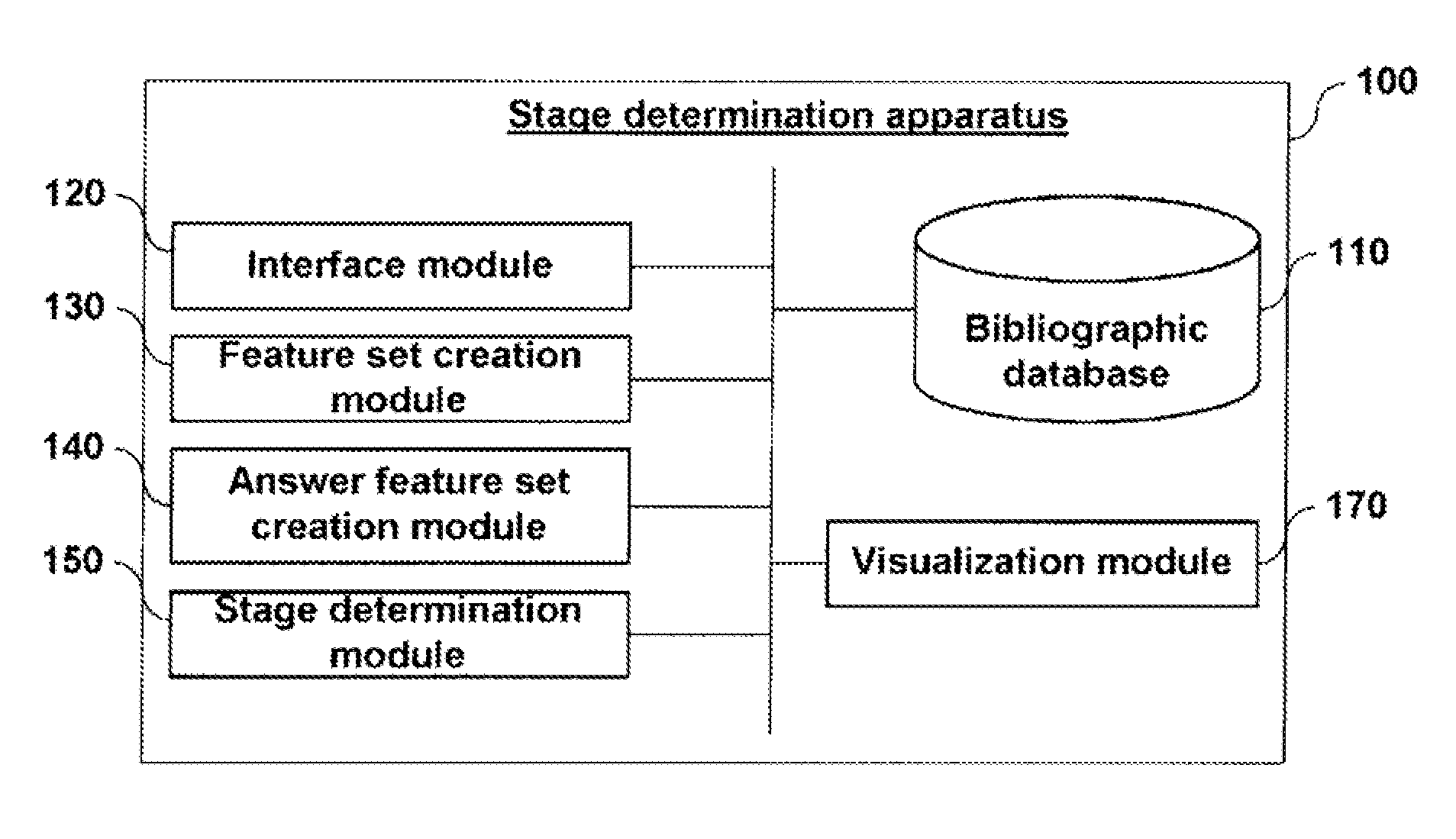

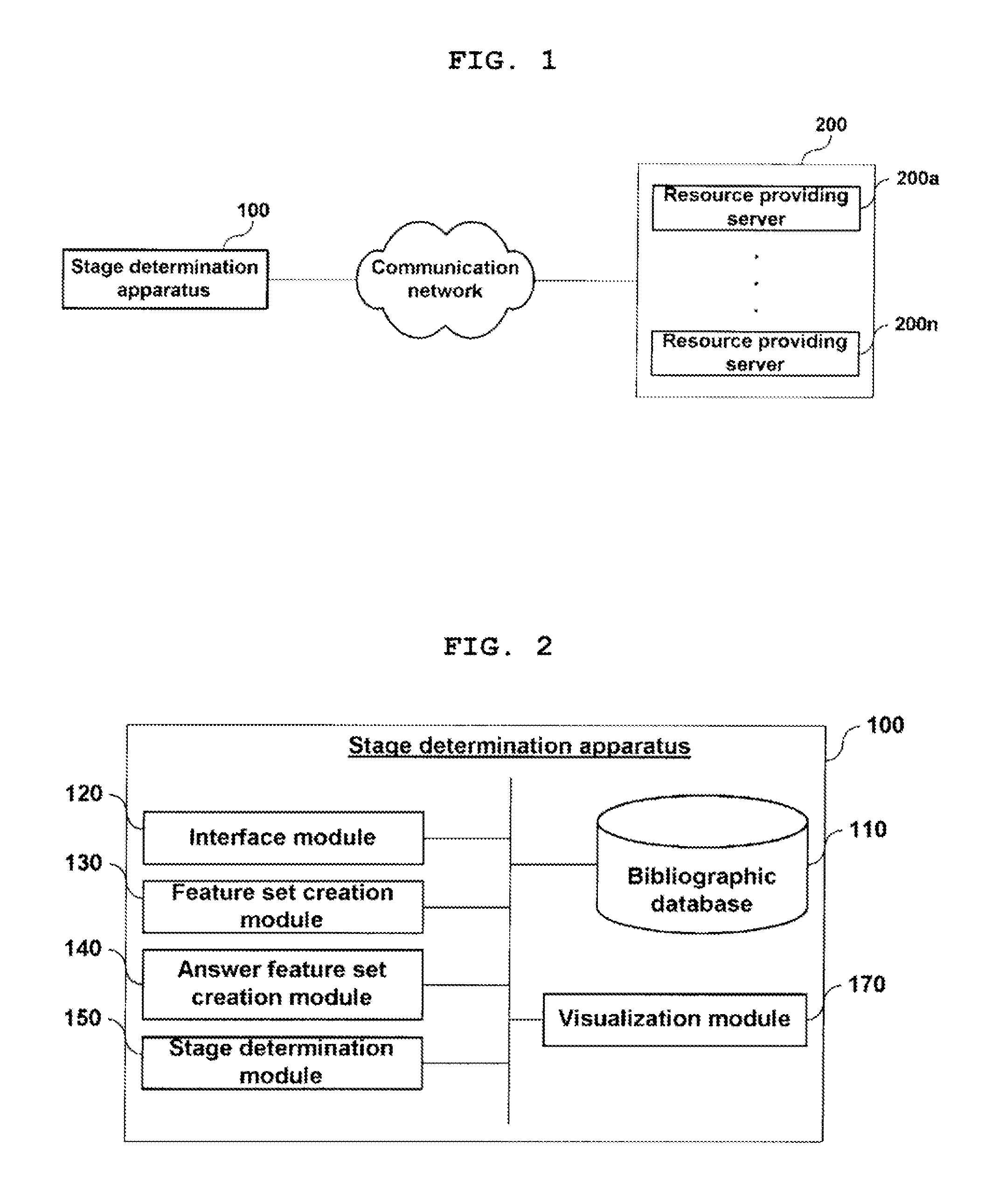

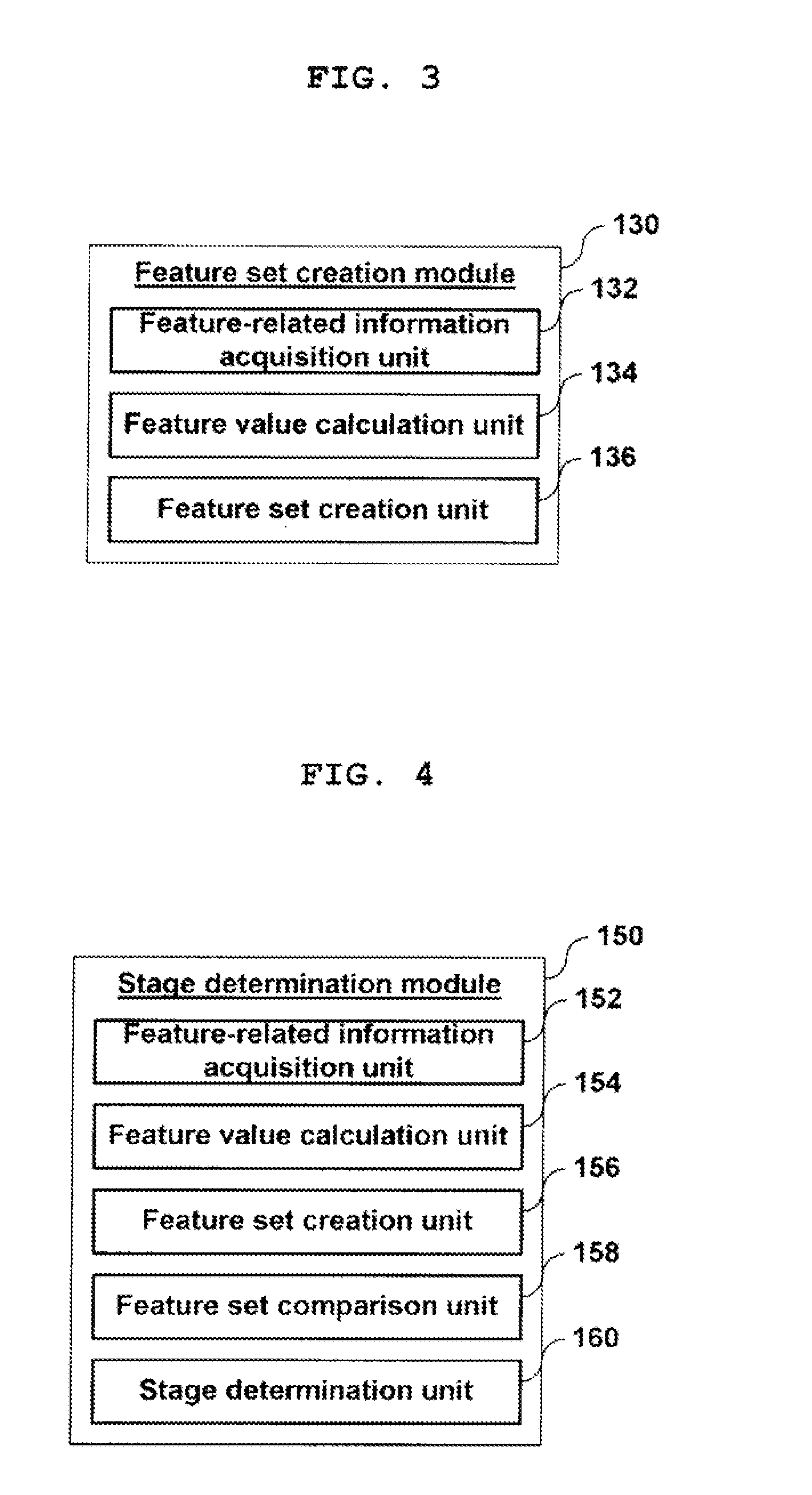

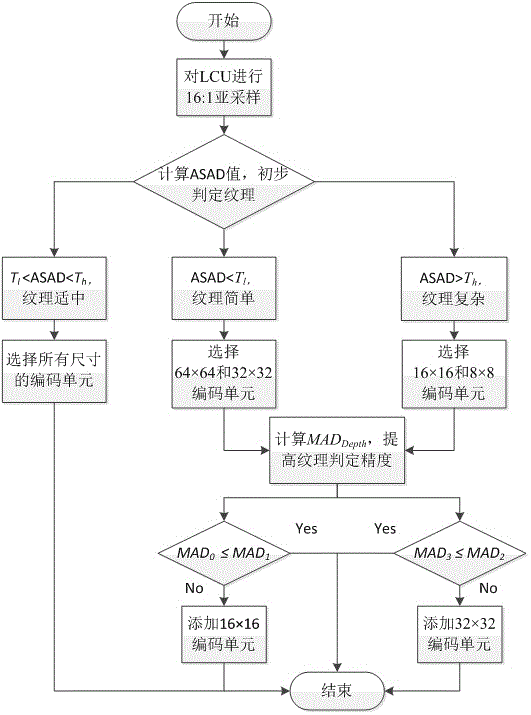

Apparatus and method for visualizing technology change

A technology transition visualization apparatus includes: bibliographic database integrating heterogeneous resources; technology information database storing information in technology lifecycle; interface module receiving technology from user; feature set creation module calculating feature values by searching bibliographic database and creating feature set for each technology; answer feature set creation module calculating common feature value of feature sets of technologies belonging to the same stage in technology lifecycle and creating answer feature set of each stage; stage determination module acquiring feature-related information, creating representative feature set and year-specific feature set of technology, determining representative stage or year-specific stage by comparing the representative feature set or year-specific feature set with the answer feature set, and estimating development speed of the technology; visualization module visualizing the technology lifecycle; and year-specific stage acquisition module acquiring current stage, year-specific stage and estimated next stage of the technology and visualizing the stages.

Owner:KOREA INST OF SCI & TECH INFORMATION

Moringa oleifera seedling growing and field planting method of Beijing-Tianjin-Hebei region

The invention discloses a Moringa oleifera seedling growing and field planting method of the Beijing-Tianjin-Hebei region. The method comprises the following steps of variety selection, seedling growing stage determination, seed treatment, configuration and treatment of a seedling growing matrix and standardizing a seedling growing furrow. According to a seedling growing management method, the matrix is filled into a feeding block, one seedling is sown in each feeding block, the feeding block is placed in the seedling growing furrow after sowing, and watering is carried out under the feeding block; a mulch film is covered after watering, the seedling growing temperature is controlled between 10 and 25 DEG C, and the highest temperature does not exceed 35 DEG C; when the emergence rate of the feeding block reaches 70%, the mulch film is removed before 10 o'clock in the morning or in cloudy day; the humidity in the feeding block needs to be maintained after removal of the mulch film by watering once in the morning or at dusk every day; when the Moringa oleifera seedling is 10cm high, the seedling is hardened, and the seedling can be planted in a field after hardening. Via the seedling growing technology, basis is provided for plantation and development of Moringa oleifera in the Beijing-Tianjin-Hebei region. According to the method, the seedling rate reaches 90% or more, the seedling stage lasts for 20 days, and field planting is allowed then.

Owner:COTTON RES INST HEBEI ACAD OF AGRI & FOREST SCI

Measuring method and system for components, in particular for pistons and piston engines

ActiveUS8660804B2Reduce the ratioImprove reliabilityVibration measurement in solidsVibration measurement in fluidFoundryNon destructive

The invention relates to the non-destructive measurement of components, in particular the functional assessment of the bonding of cast-in parts, eg. in pistons for internal combustion engines. With such a measurement or functional assessment, it is a question of assessing the function and completeness of the bonding between the base material and the material cast in or otherwise joined. The quality of the component or its suitability for a specific purpose can thus be assessed and / or quality monitoring of the production process, e.g. in the foundry or during production, can take place. According to the invention, this purpose is served by a multi-stage correction procedure, wherein the measured values ascertained by means of a suitably devised measuring arrangement and method, e.g. using ultrasound, are subjected to a multi-stage determination process, which minimises universally and for each individual measurement the disturbing factors which, being inherent in the system, occur in the measurement and ascertains therefrom the desired results. A correspondingly devised system minimises both error influences, which occur in the performance (especially with the setting-up / adjustment) of such a measurement, as well as measurement errors and incorrect assessments in the performance of the measurement, which occur due to geometrical tolerance deviations or differences between a number of components to be measured or due to differences in the material or structural composition, as well as other disturbing influences.

Owner:MAHLE INT GMBH

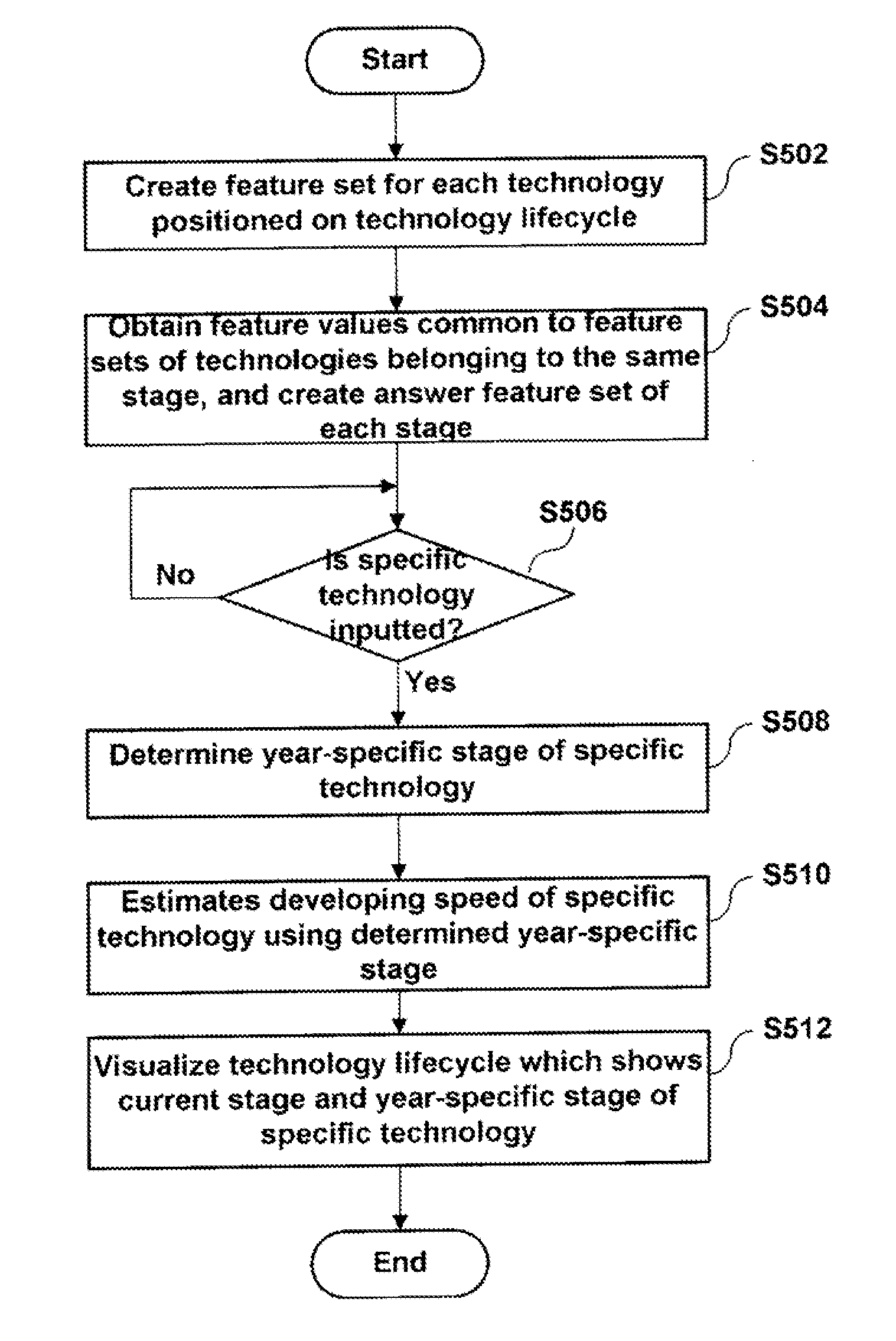

Apparatus and method for prediction development speed of technology

A developing speed estimation apparatus includes: bibliographic database integrating heterogeneous resources; feature-set creation module calculating feature values of predefined features by searching the bibliographic database, and creating a feature-set of each technology using the feature values, for technologies on technology lifecycle; answer feature-set creation module calculating common feature values of feature sets of technologies belonging to the same stage in the technology lifecycle and creating answer feature-set of each stage; year-specific stage determination module that, if specific technology is inputted, acquires feature-related information for predetermined features by searching the bibliographic database for the specific technology, creates year-specific feature-set using the feature-related information, and determines year-specific stage of the specific technology by comparing the year-specific feature-set with the answer feature-set; and developing-speed estimation module estimating the developing speed of the specific technology using the year-specific stage.

Owner:KOREA INST OF SCI & TECH INFORMATION

Motor drive device and motor drive method

ActiveCN108450054AReduce in quantityProgramme controlElectric motor controlMotor driveStage determination

The present invention provides a motor drive device and a motor drive method. This motor drive device is provided with: a stage determination unit which determines the position of a rotor on the basisof the combination of the states of multiple output signals; and an energization timing determination unit which, at the time of start of a motor, sets, as an energization timing at which a coil is energized, a timing advanced by an amount equivalent to a predetermined electrical angle, wherein, when the rotation speed of the motor becomes equal to or higher than a predetermined rotation speed, the energization timing determination unit sets, as the energization timing, a timing when a predetermined period of time has elapsed after the position of the rotor reaches a position for an electrical angle corresponding to a displacement amount of an arbitrarily advanced electrical angle relative to the predetermined electrical angle by which the advancement has been made at the time of the start.

Owner:MITSUBA CORP

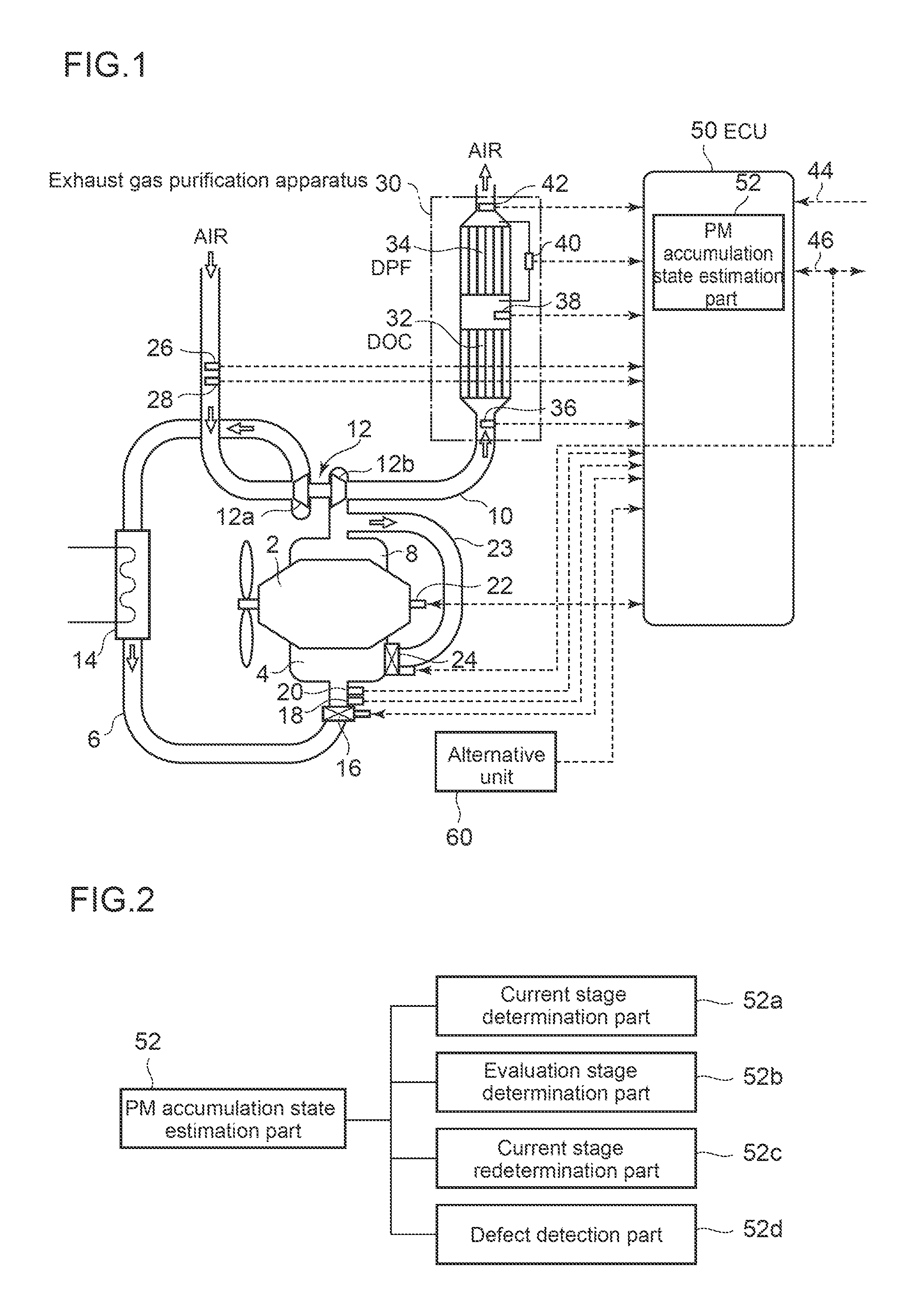

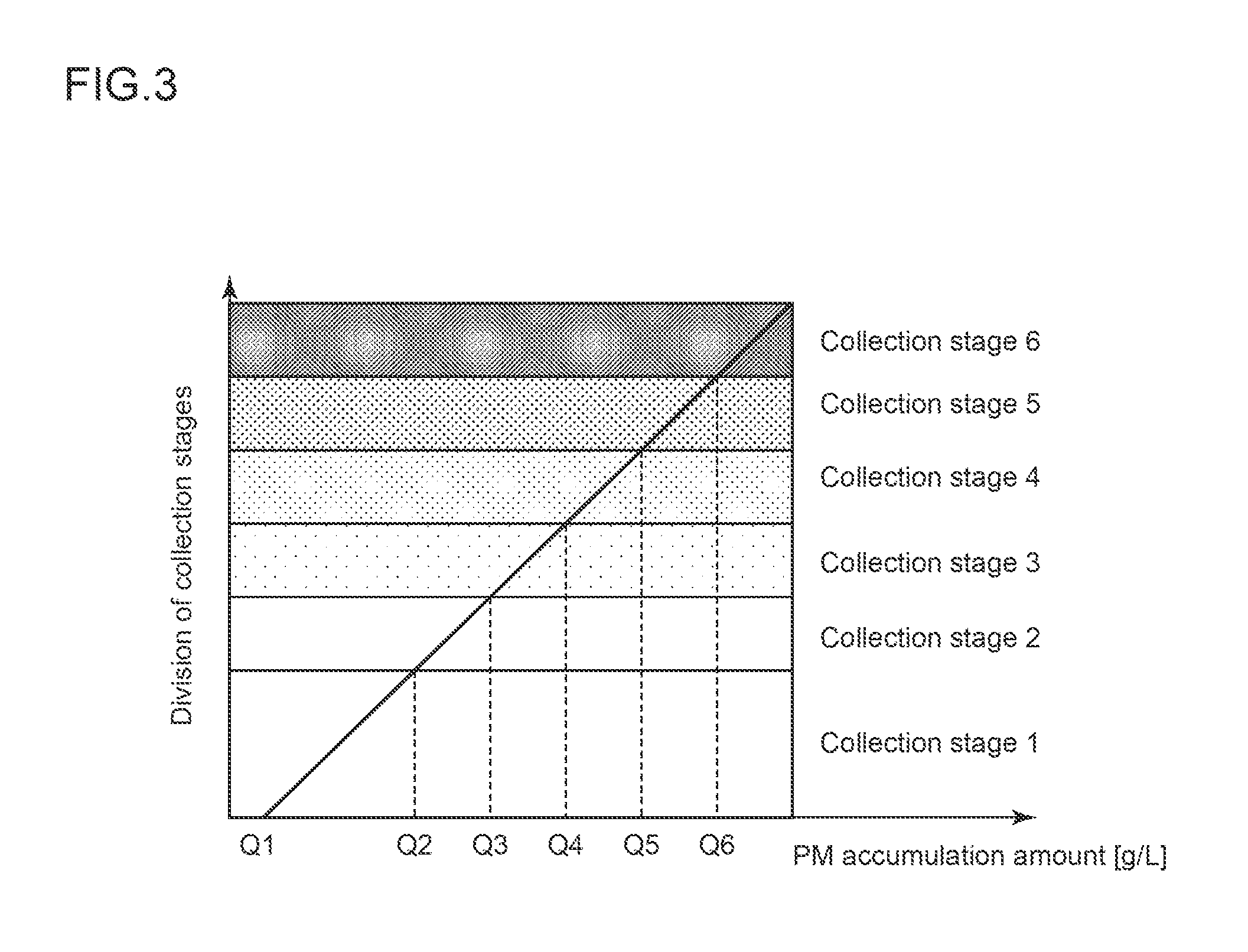

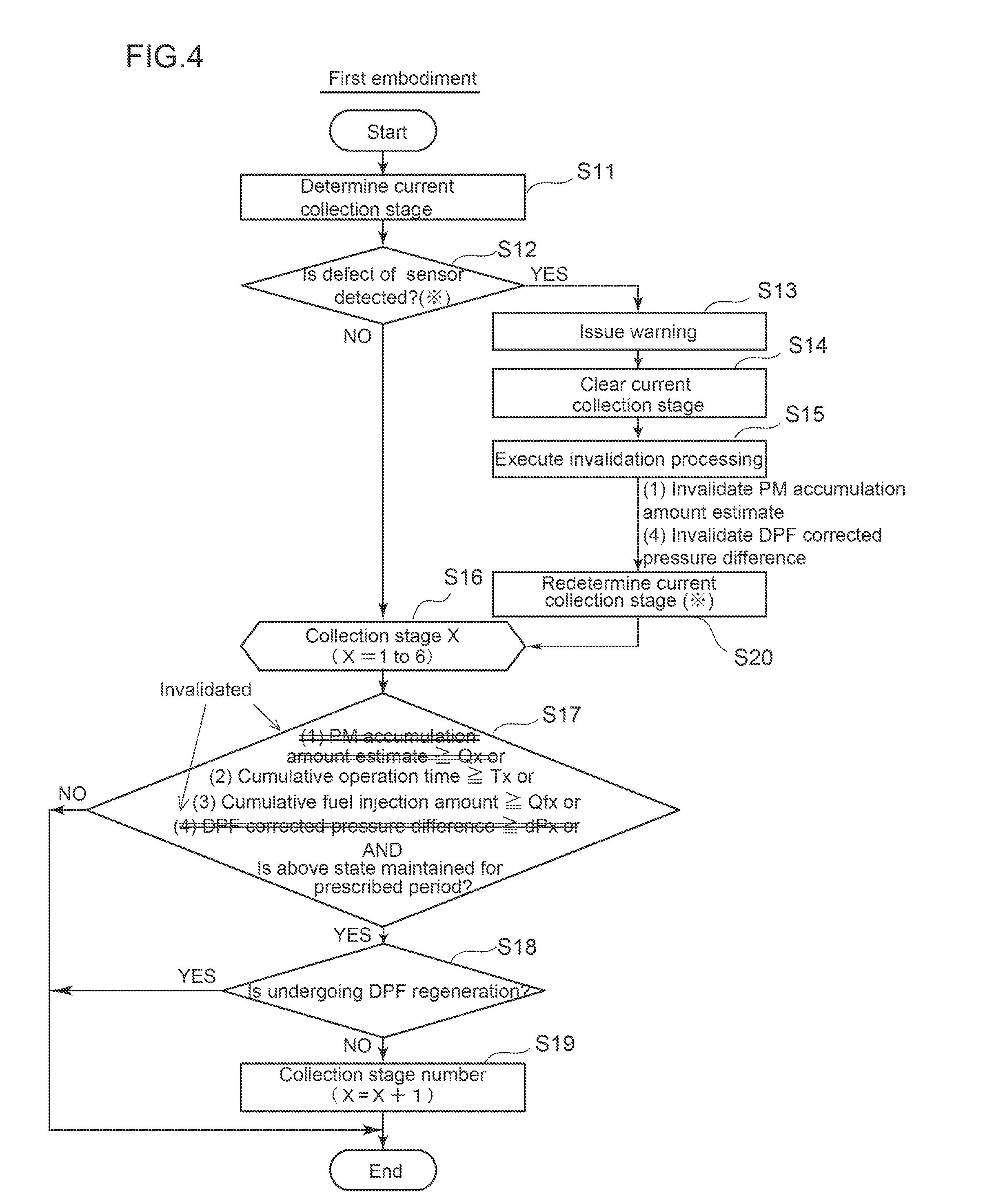

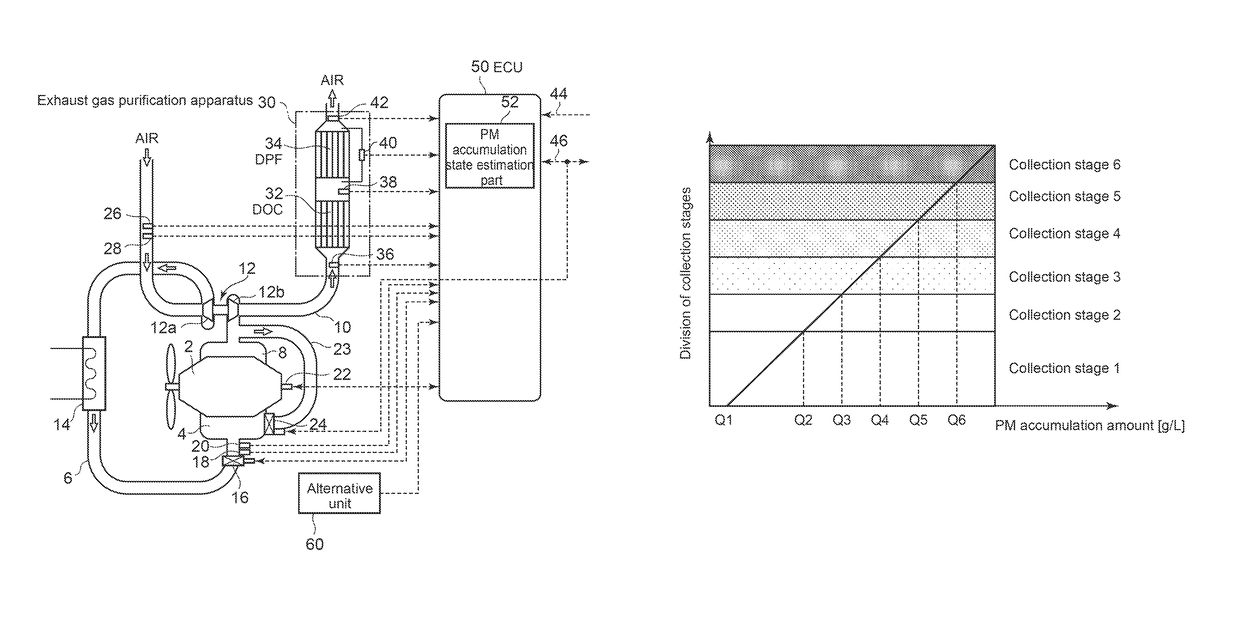

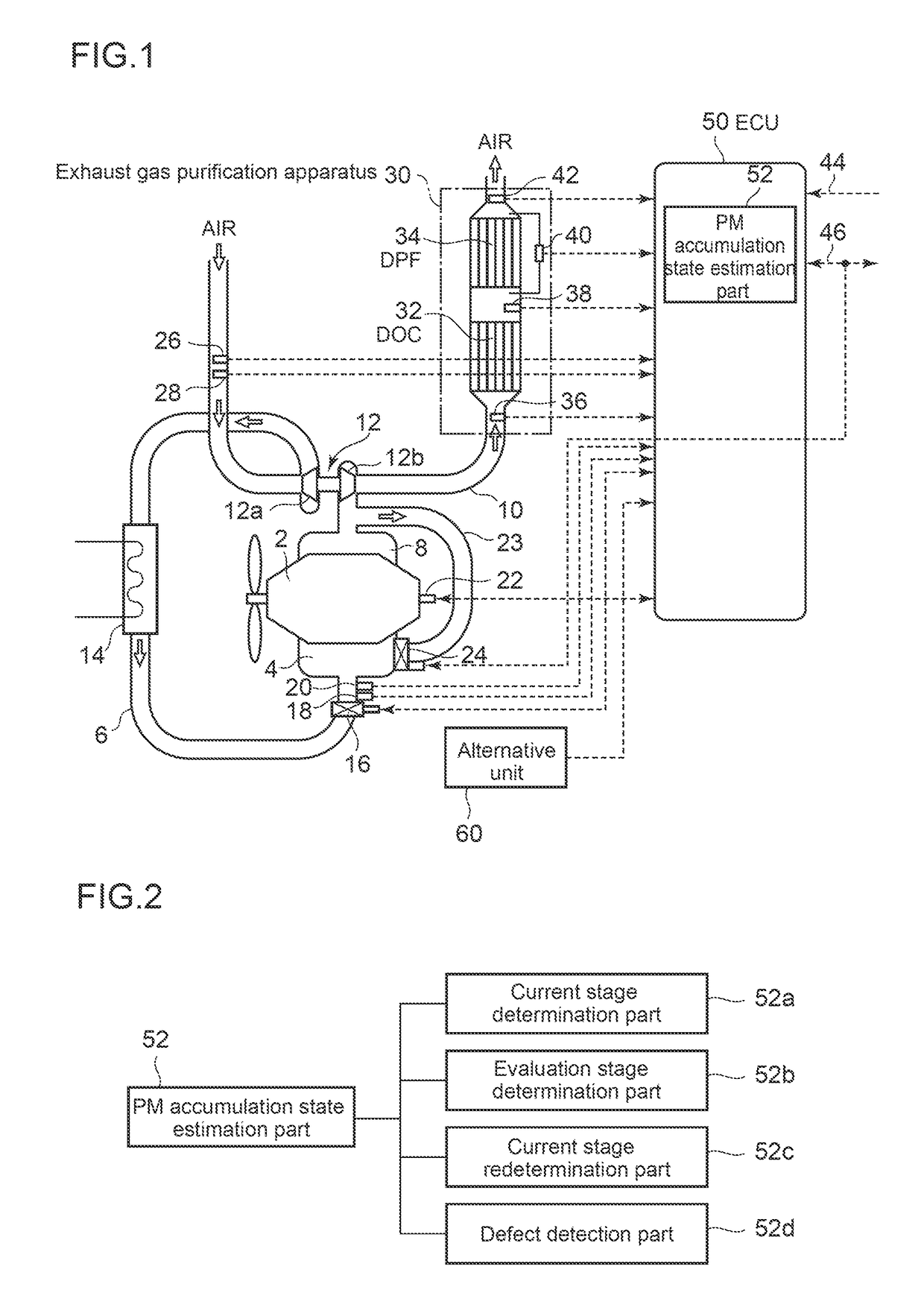

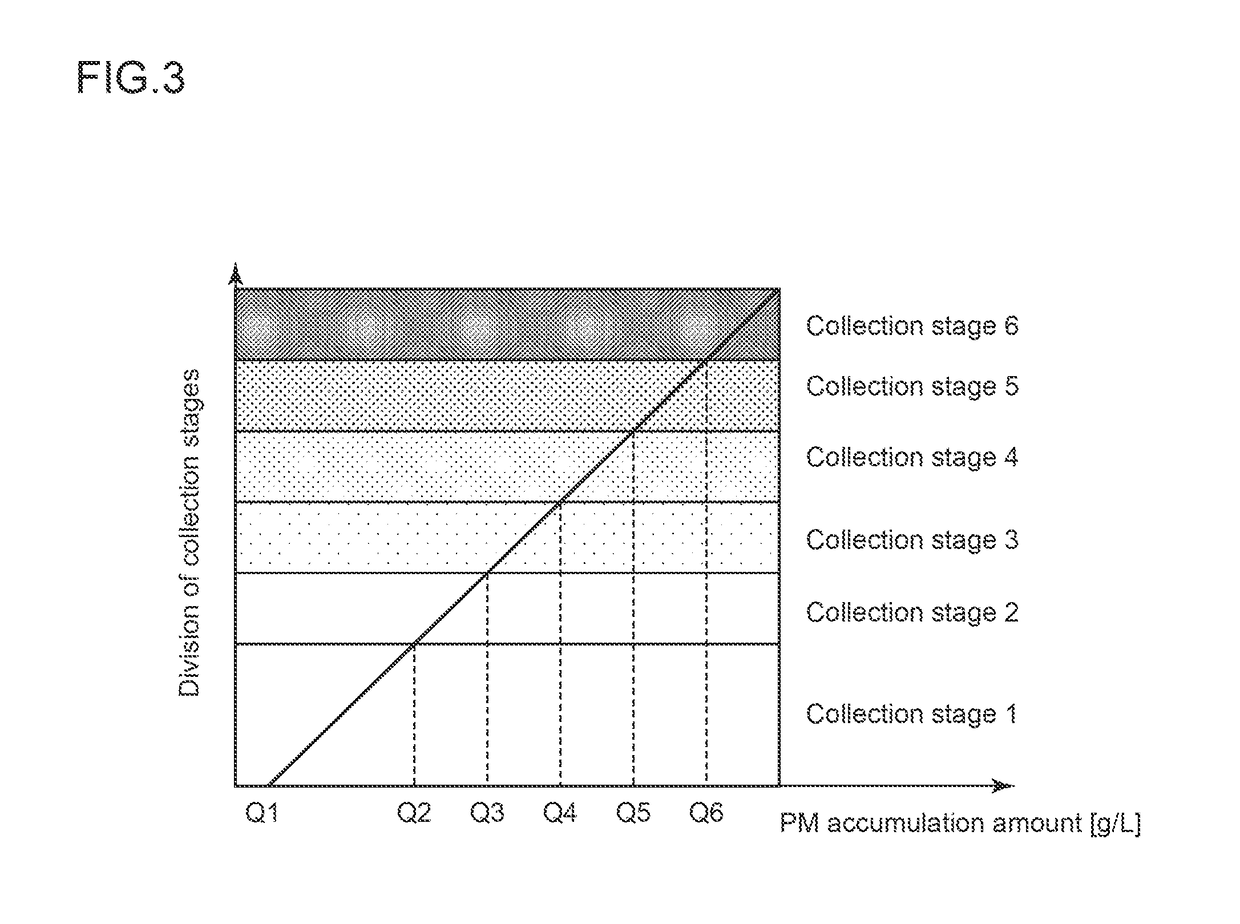

Exhaust gas purification system for engine

An exhaust gas purification system of engine configured to classify a PM accumulation state of DPF into multiple evaluation stages based on a plurality of evaluation indices, and to repeatedly perform determination of the current evaluation stage by the current stage determination part and determination of whether to move up the current evaluation stage to the evaluation stage of the next rank by the evaluation stage determination part, wherein upon a defect of a sensor among different types of sensors being detected by the defect detection part, the current evaluation stage is newly redetermined by the current stage redetermination part as substituted for the current evaluation stage determined by the current stage determination part.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Client terminal and connection detecting method

A client end which is connected with a server includes a receiving module, a stage determination module, a transmission module, a frame judgment module and a condition judgment module. The receiving module is used for receiving a management frame and the stage determination module is used for determining the frame stage according to the management frame. The transmission module is used for transmitting the grade frame to the server according to the frame stage, wherein, the frame corresponded by the grade ratio frame stage of the grade frame has a very high grade. The frame judgment module is used for judging whether the expecting frame is received. The condition judgment module is used for judging the connecting condition of the client end and the server according to the judgment result of the frame judgment module. The invention also provides a connection detecting method which is used for detecting the connecting condition of the client end and the server. The client end and the connection detecting method thereof can timely detect the server, the connection of which is cut off to stop the client from transmitting the data to the server, thereby avoiding the loss of the transmission data.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Exhaust gas purification system for engine

ActiveUS9724643B2Accurate estimateElectrical controlInternal combustion piston enginesStage determinationExhaust gas

An exhaust gas purification system of engine configured to classify a PM accumulation state of DPF into multiple evaluation stages based on a plurality of evaluation indices, and to repeatedly perform determination of the current evaluation stage by the current stage determination part and determination of whether to move up the current evaluation stage to the evaluation stage of the next rank by the evaluation stage determination part, wherein upon a defect of a sensor among different types of sensors being detected by the defect detection part, the current evaluation stage is newly redetermined by the current stage redetermination part as substituted for the current evaluation stage determined by the current stage determination part.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Motor drive apparatus and motor drive method

A motor drive apparatus includes: a stage determination part that determines a position of the rotor based on a combination of states of a plurality of the output signals; and a power distribution timing determination part which determines that a power distribution timing when power is distributed to the coil is a timing obtained by advancing an angle by an amount that corresponds to a predetermined electric angle in a startup time of the motor, wherein, when a rotation speed of the motor becomes a predetermined rotation speed or more, the power distribution timing determination part determines that a timing when a predetermined period of time elapses since a position of the rotor arrives at a position of an electric angle that corresponds to a displacement amount of an electric angle which is arbitrarily advanced with respect to a predetermined electric angle that is advanced in the startup time is a power distribution timing.

Owner:MITSUBA CORP

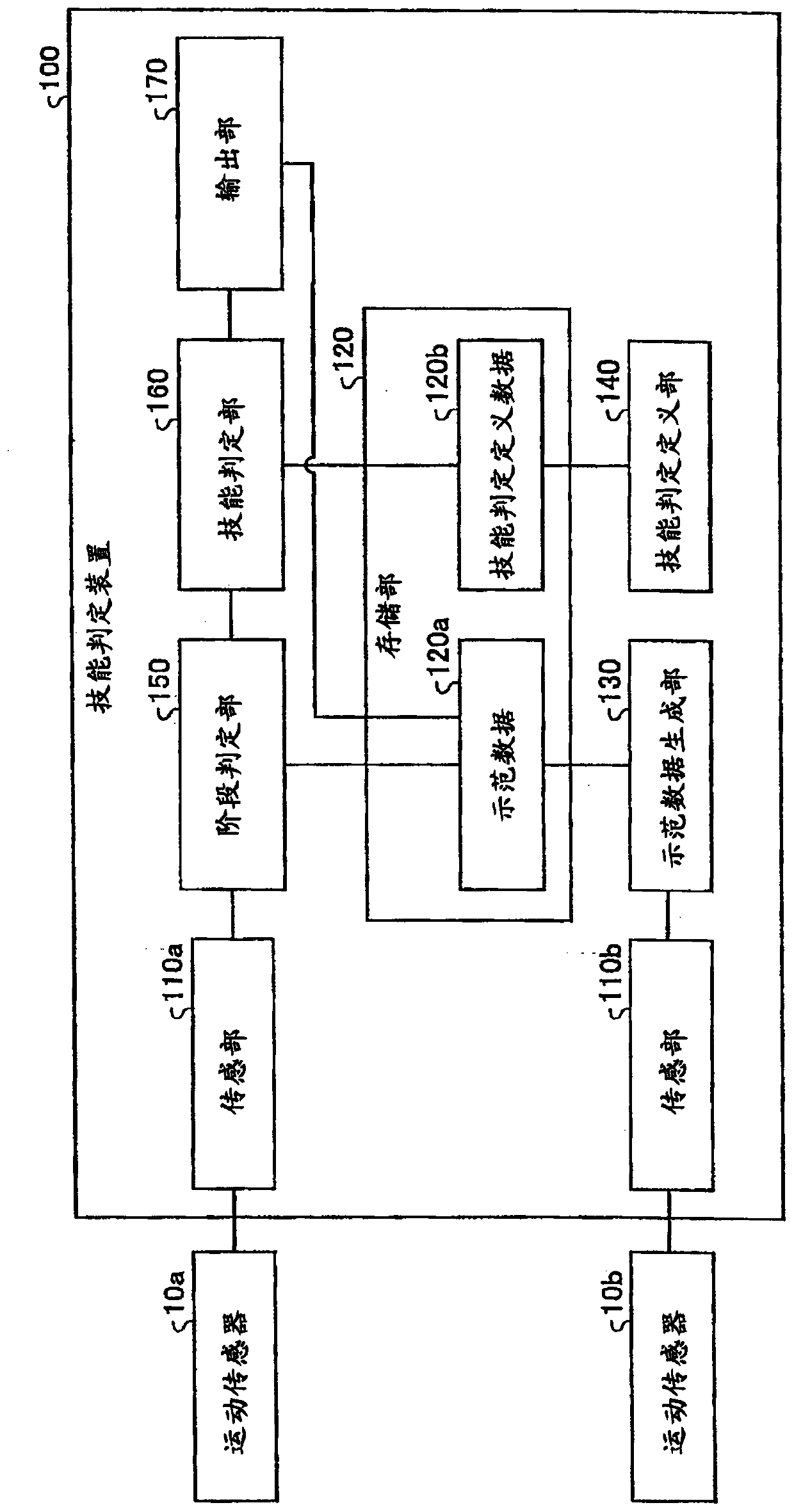

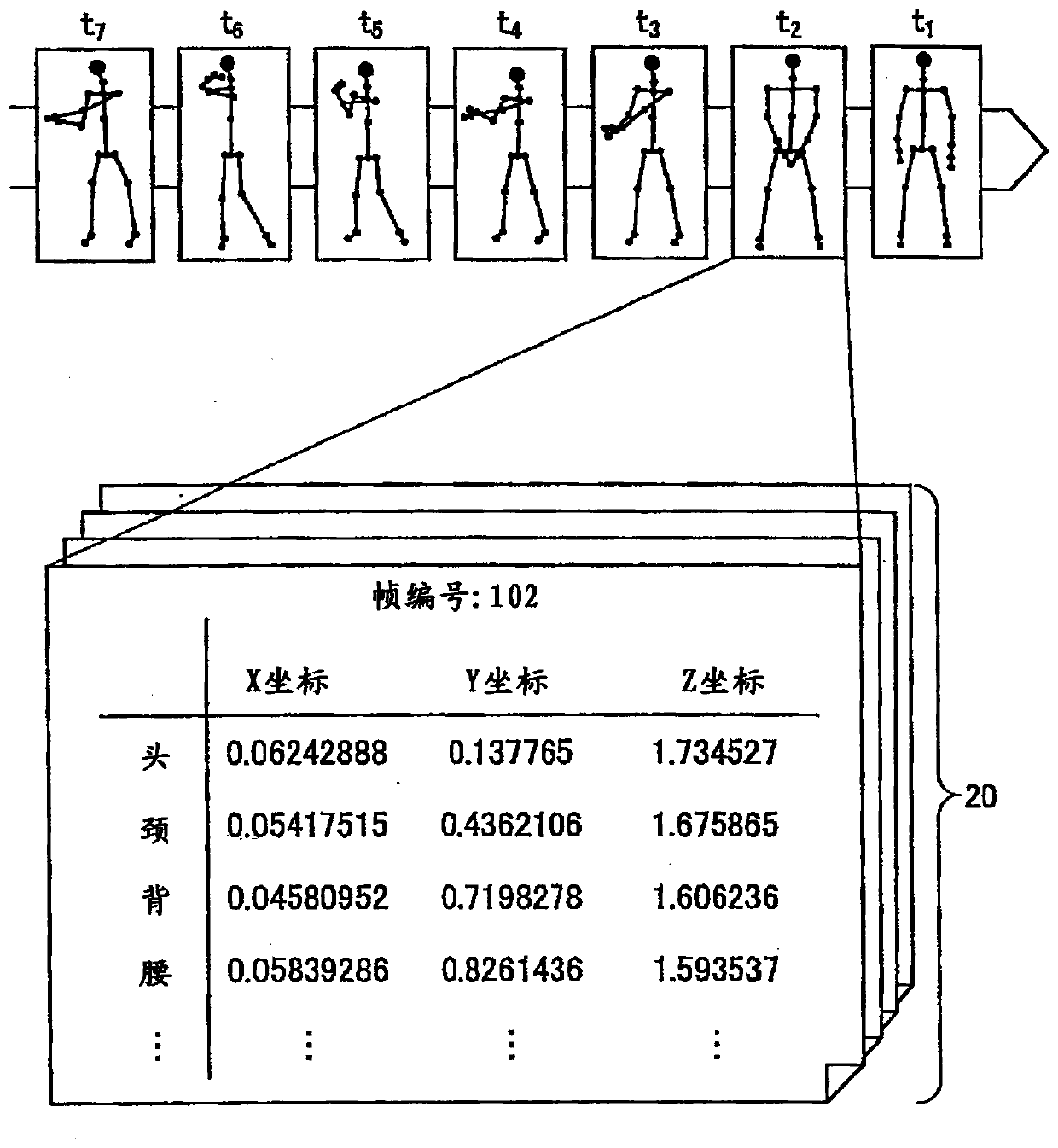

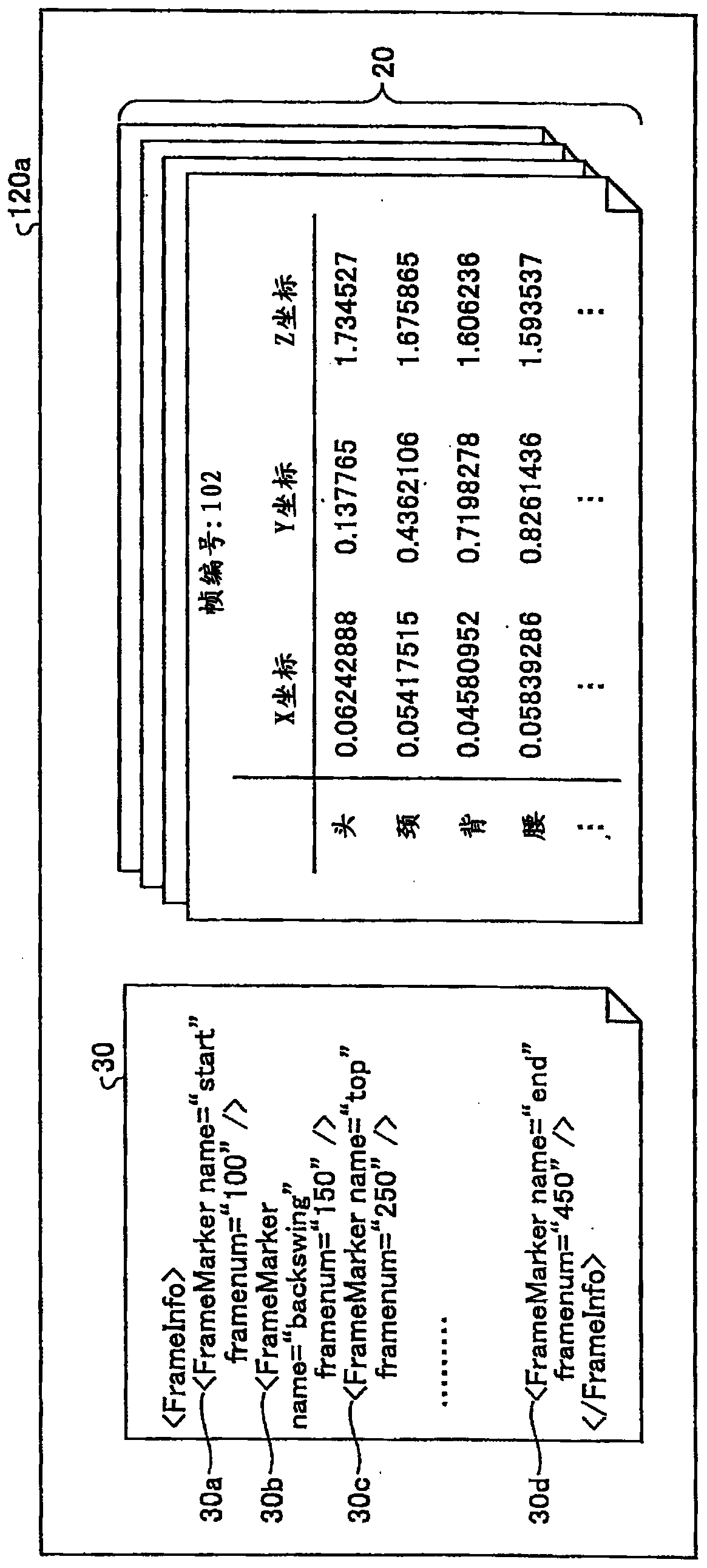

Skill judging method, skill judging device, and server

ActiveCN106794371BAutomatic judgmentPhysical therapies and activitiesAdvertisementsSkill setsStage determination

A skill judging device (100) includes a stage judging unit (150) and a skill judging unit (160). The stage determination unit (150) extracts second frame data for each stage type based on the sample data (120a) and the user's motion data. The skill judging unit (160) judges the user's skill based on the second frame data and the skill judging definition data (120b) for each stage category.

Owner:FUJITSU LTD

A method and system for determining sleep stages

An embodiment of the invention provides a sleeping stage determination method and system. The sleeping stages can be recognized by means of characteristic parameters of heart rate variability data. Accordingly, after heart rate variability data is obtained, the corresponding sleeping stages within the time section can be determined according to the correspondence of the characteristic parameters of the heart rate variability data corresponding to a time section and the preset rule, so that a sleeping stage classifier is not needed to be trained by acquiring and marking samples, and the problem that sleeping stage determination accuracy is low and the sleeping stage classifier is poor in applicability due to deficiency of training samples is solved.

Owner:CHINA MOBILE COMM GRP CO LTD

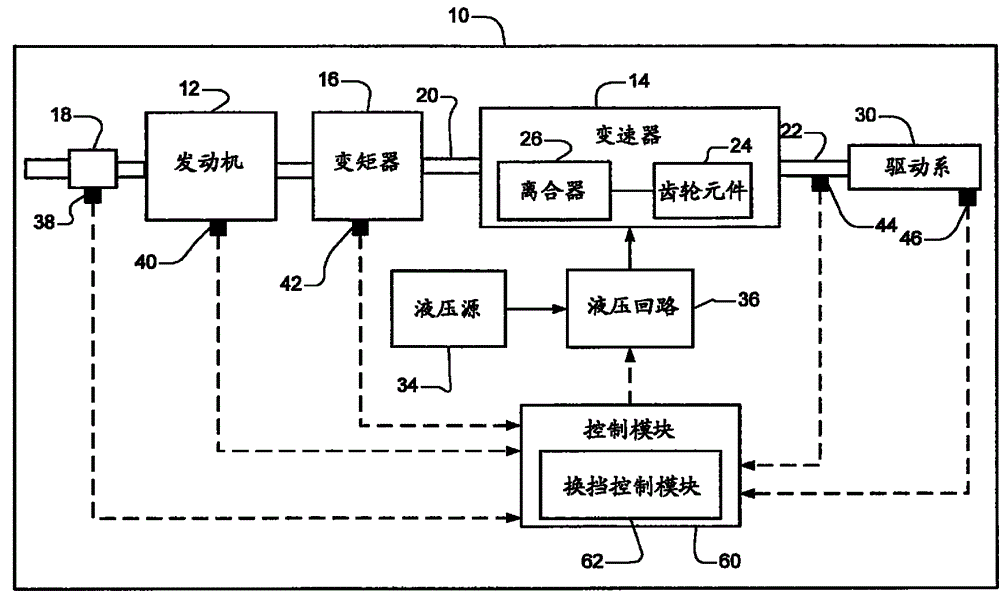

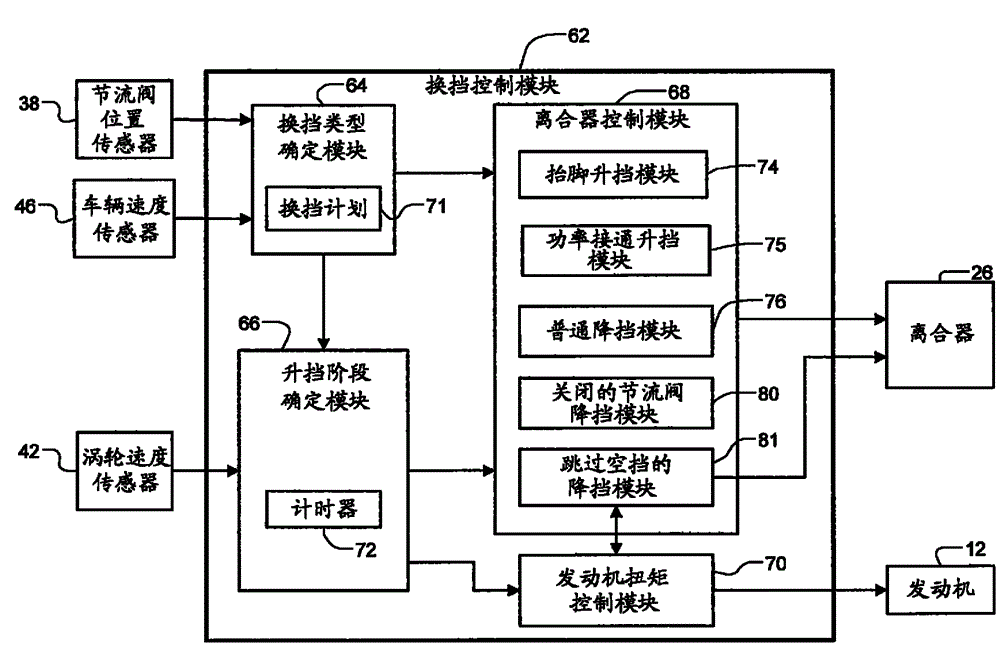

Shift control systems and methods for an automatic transmission

Owner:GM GLOBAL TECH OPERATIONS LLC

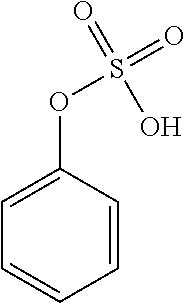

Marker for determining diabetic nephropathy

ActiveUS20180313851A1Avoid seizuresEffective treatmentDisease diagnosisBiological testingNephrosisBacteriuria

An object of the present invention is to provide a biomarker capable of determining the onset risk or the stage of diabetic nephropathy (early-stage diabetic nephropathy in particular). Diabetic nephropathy is determined by measuring or quantitatively determining a concentration of phenyl sulfate or a salt thereof (a phenyl sulfate) contained in a biological sample, preferably plasma or urine, collected from a test subject to detect a phenyl sulfate. The present invention exhibits excellent effects particularly for stage determination for stage 1 (pre-nephropathy stage) to stage 3 (overt nephropathy stage), or for determination of onset risk of diabetic nephropathy (diabetic nephropathy at pre-nephropathy stage).

Owner:TOHOKU UNIV

Apparatus and method for stage judgement using of technology life cycle

A stage determination apparatus including storage and processor includes: a bibliographic database integrating heterogeneous resources; a feature-set creation module calculating feature values of predefined features by searching the bibliographic database, and creating a feature-set of each technology using the feature values, for technologies on technology lifecycle; an answer feature-set creation module calculating a common feature value of feature sets of technologies belonging to the same stage in the technology lifecycle and creating an answer feature-set of each stage; a stage determination module that, if a technology is inputted, acquires feature values and creates a feature-set for predefined features by searching the bibliographic database for the technology, compares a corresponding feature value in the feature-set of the technology with a feature value according to a feature selection flow in a previous decision tree according to the feature selection flow, and determines a stage having a feature value finally selected according to the feature selection flow as a stage where the technology belongs to in the technology lifecycle.

Owner:KOREA INST OF SCI & TECH INFORMATION

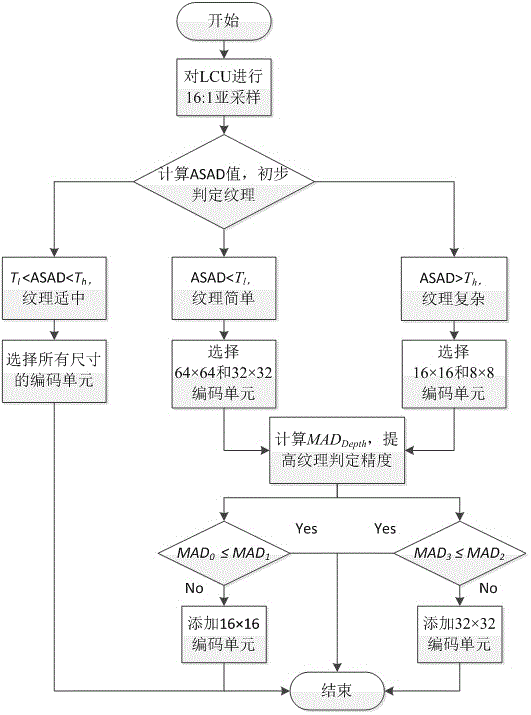

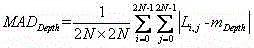

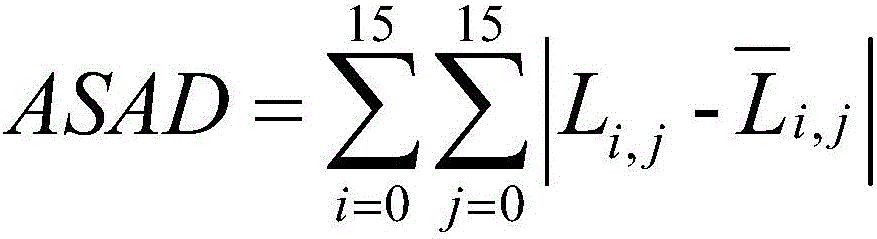

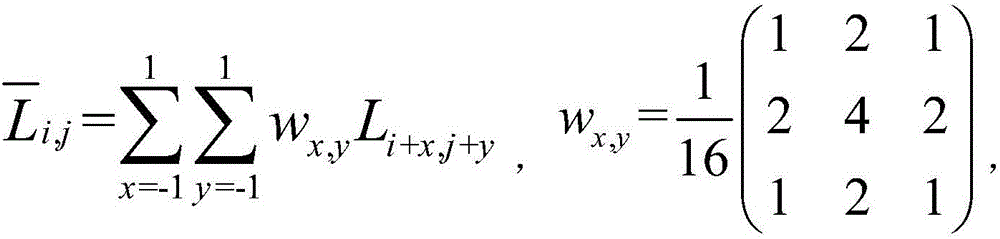

A fast judgment method of hevc code size based on texture complexity

InactiveCN103957421BAccurate judgmentHigh precisionDigital video signal modificationPattern recognitionRound complexity

The invention relates to an HEVC coding size rapid determining method based on texture complexity. According to the method, sub-sampling at the ratio of 16:1 is conducted on LCUs, subsequent time spent in calculating the texture complexity is shortened to 1 / 16 of original time, and then a two-stage determining mechanism is introduced; firstly, an ASAD model is used for preliminarily determining the texture complexity of blocks obtained after sub-sampling is conducted on the LCUs, erroneous judgment is prevented by setting two threshold values, and large-size coding units are adopted for the LCUs with simple texture, and small-size coding units are adopted for the LCU with complex texture; secondly, based on upper-stage determination results, an MAD model is adopted, whether coding units in other sizes are added or not is determined, and the accuracy of texture determining is improved. By means of the HEVC coding size rapid determining method based on the texture complexity, the algorithm complexity can be reduced greatly, the texture can be accurately determined, and the algorithm accuracy is improved.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com