Method for determining model selection and installation position of steel coil labeling and code spraying six-axis robot

A technology for installation position and determination method, which is applied to instruments, manipulators, image data processing, etc., and can solve the problems of robot selection basis and installation position determination method that have not yet seen relevant research reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

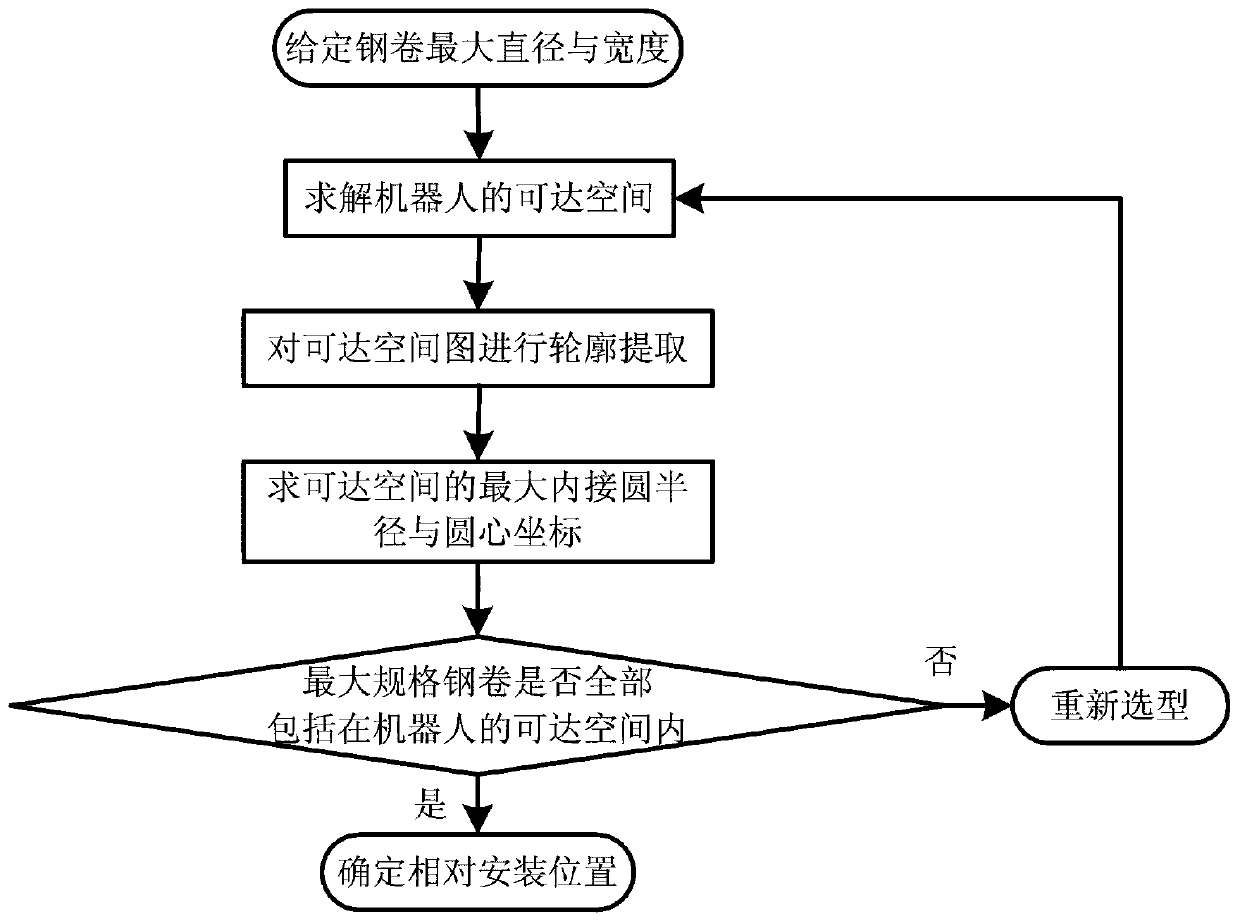

[0051] A method for determining the type selection and installation position of a six-axis robot for labeling and coding on steel coils. The specific implementation methods are as follows:

[0052] Step 1: Give the maximum radius r_max=750mm and the maximum width l_max=1500mm of the steel coil to be labeled and coded;

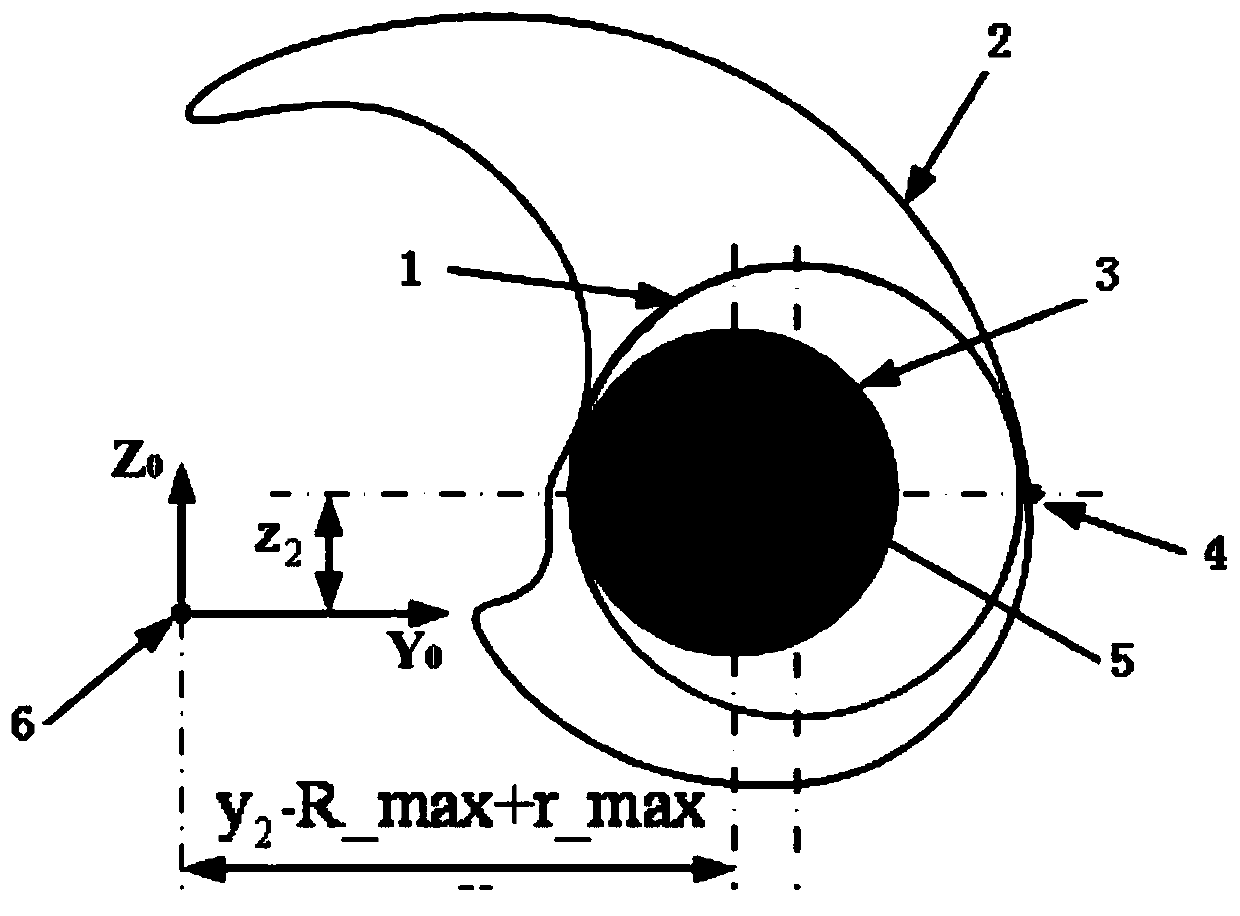

[0053] Step 2: Solve the reachable space of the six-axis robot, including:

[0054] (1) Set a local coordinate system for each link of the robot according to the D-H method, where the coordinate system of link i is X i -Y i -Z i , the value range of i is 0~6, i=0 represents the robot base;

[0055] (2) at X 0 =0 in the plane; the connecting rod parameters of the six-axis robot are:

[0056]

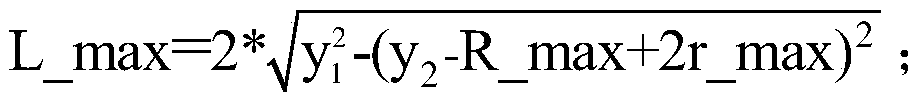

[0057] (3) According to the parameters in step 2 (2) of step 2, the lower limit of lower arm swing θ 下min =-133°, lower arm swing upper limit θ 下max =-10°, lower limit of upper arm swing θ 上min =-57°, upper arm swing upper limit θ 上max =90°, lower limit of wris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com