Patents

Literature

881 results about "Secondary stage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

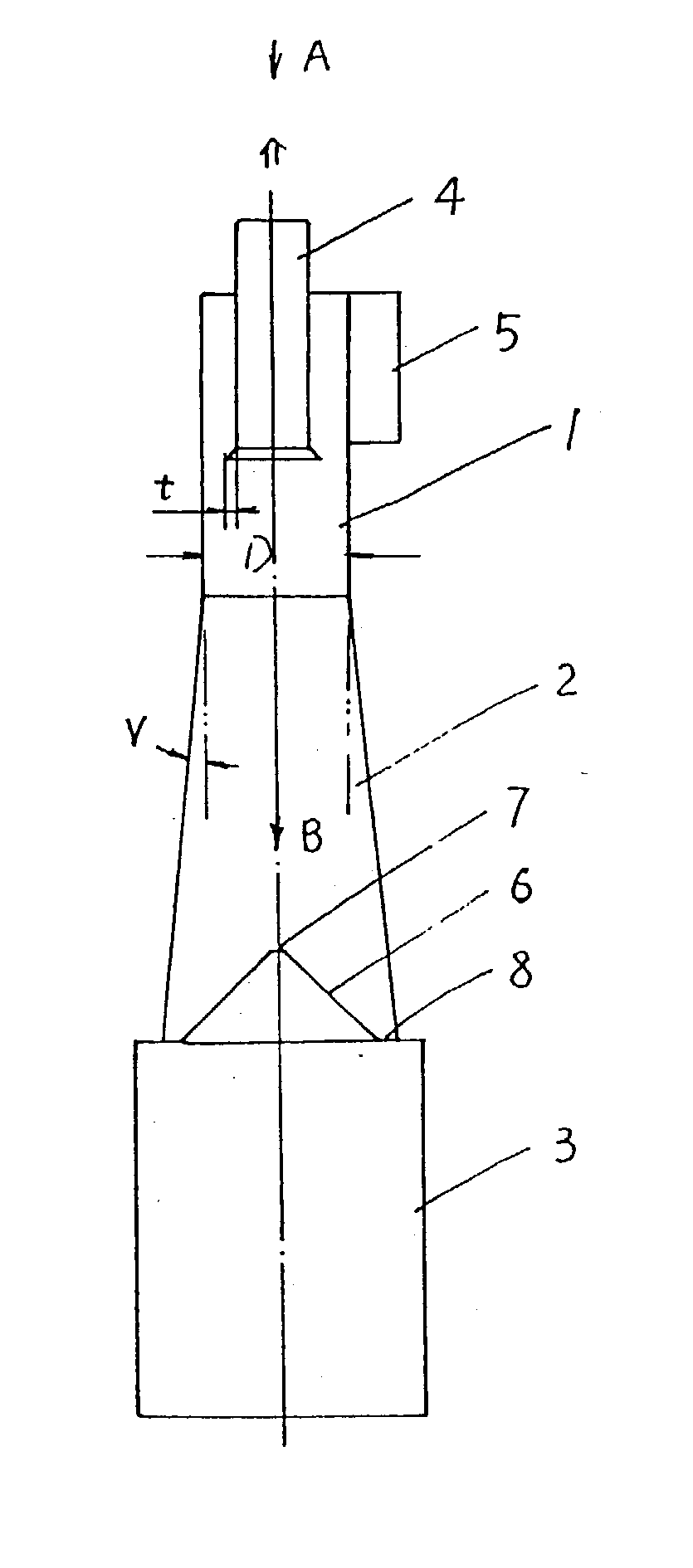

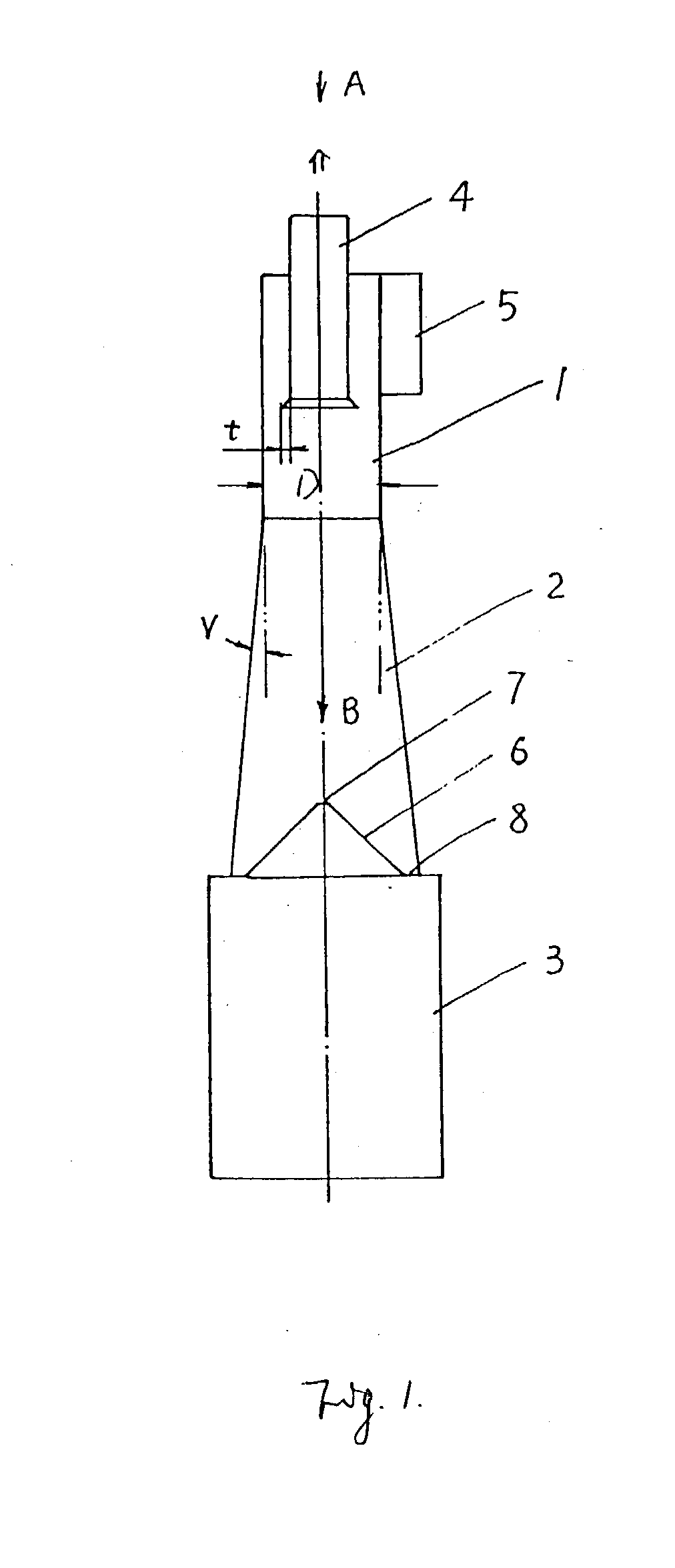

Process for the production of thin semiconductor material films

InactiveUSRE39484E1Uniform and controlled thicknessHigh implantationFluid pressure measurement by electric/magnetic elementsSolid-state devicesIon bombardmentMicrobubbles

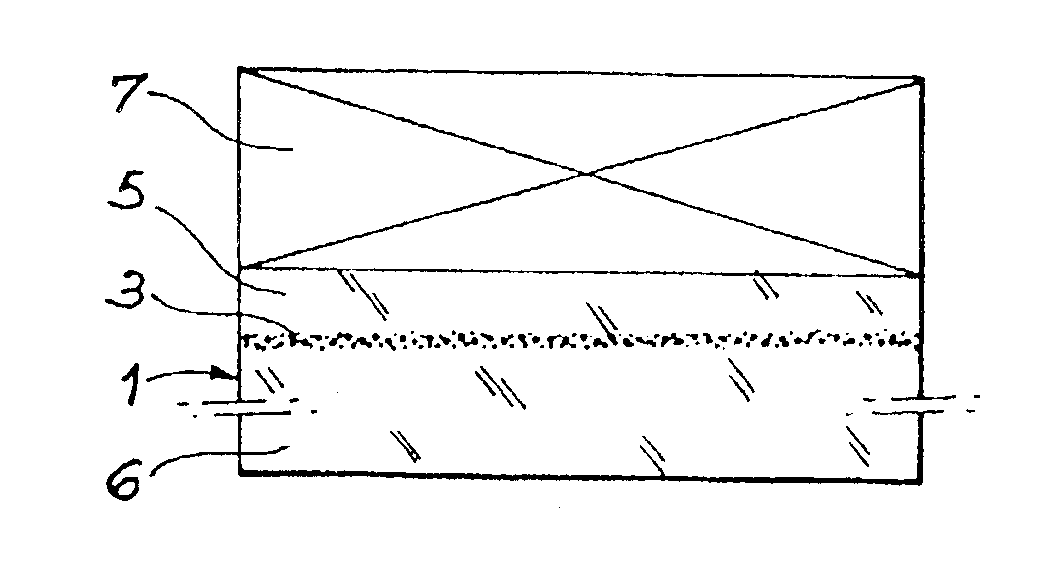

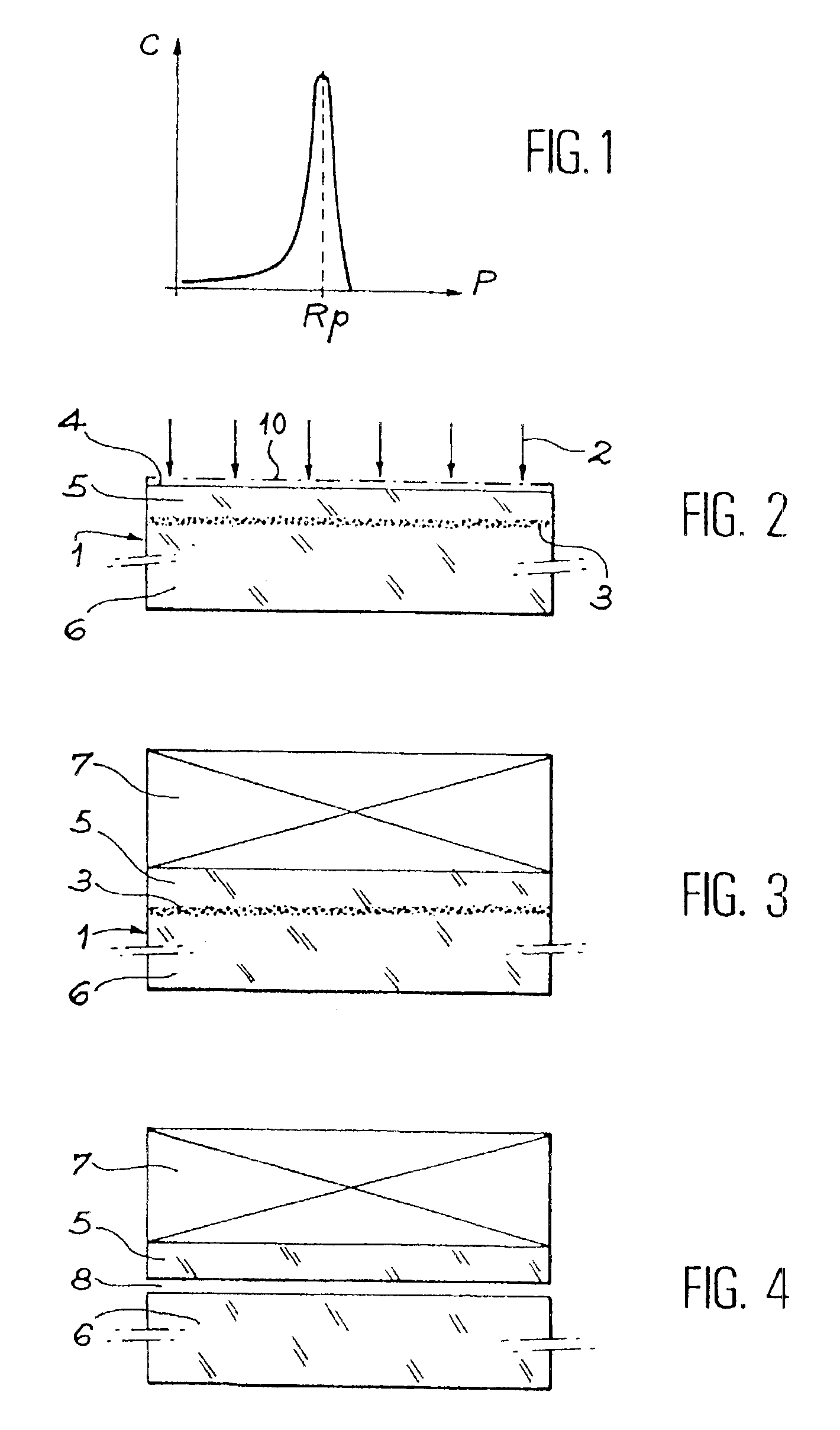

Process for the preparation of thin monocrystalline or polycrystalline semiconductor material films, characterized in that it comprises subjecting a semiconductor material wafer having a planar face to the three following stages: a first stage of implantation by bombardment (2) of the face (4) of the said wafer (1) by means of ions creating in the volume of said wafer a layer (3) of gaseous microbubbles defining in the volume of said wafer a lower region (6) constituting the mass of the substrate and an upper region (5) constituting the thin film, a second stage of intimately contacting the planar face (4) of said wafer with a stiffener (7) constituted by at least one rigid material layer, a third stage of heat treating the assembly of said wafer (1) and said stiffener (7) at a temperature above that at which the ion bombardment (2) was carried out and sufficient to create by a crystalline rearrangement effect in said wafer (1) and a pressure effect in the said microbubbles, a separation between the thin film (5) and the mass of the substrate (6).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

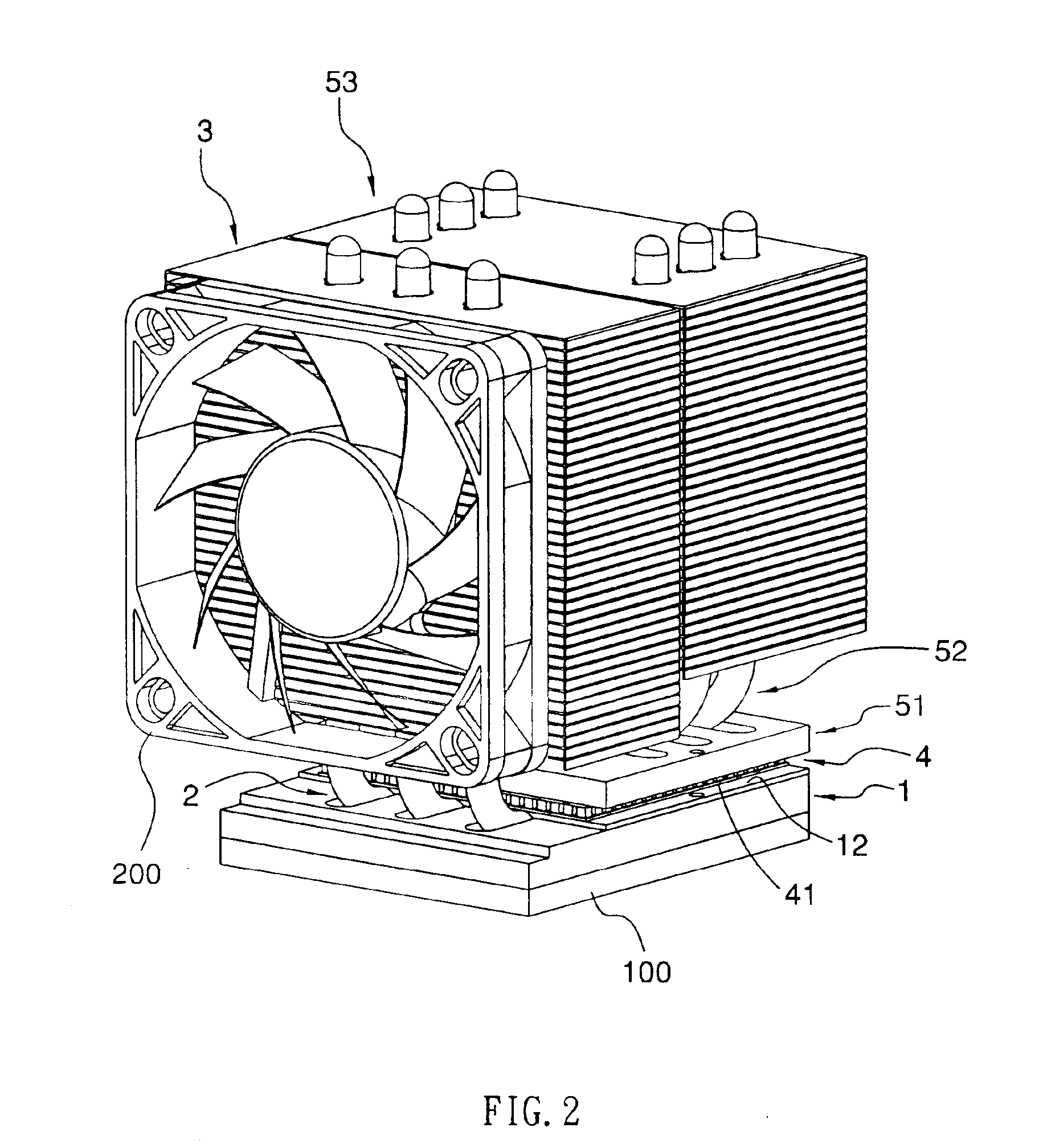

Two stage radiation thermoelectric cooling apparatus

ActiveUS6880346B1Guaranteed to workThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsSecondary stageEngineering

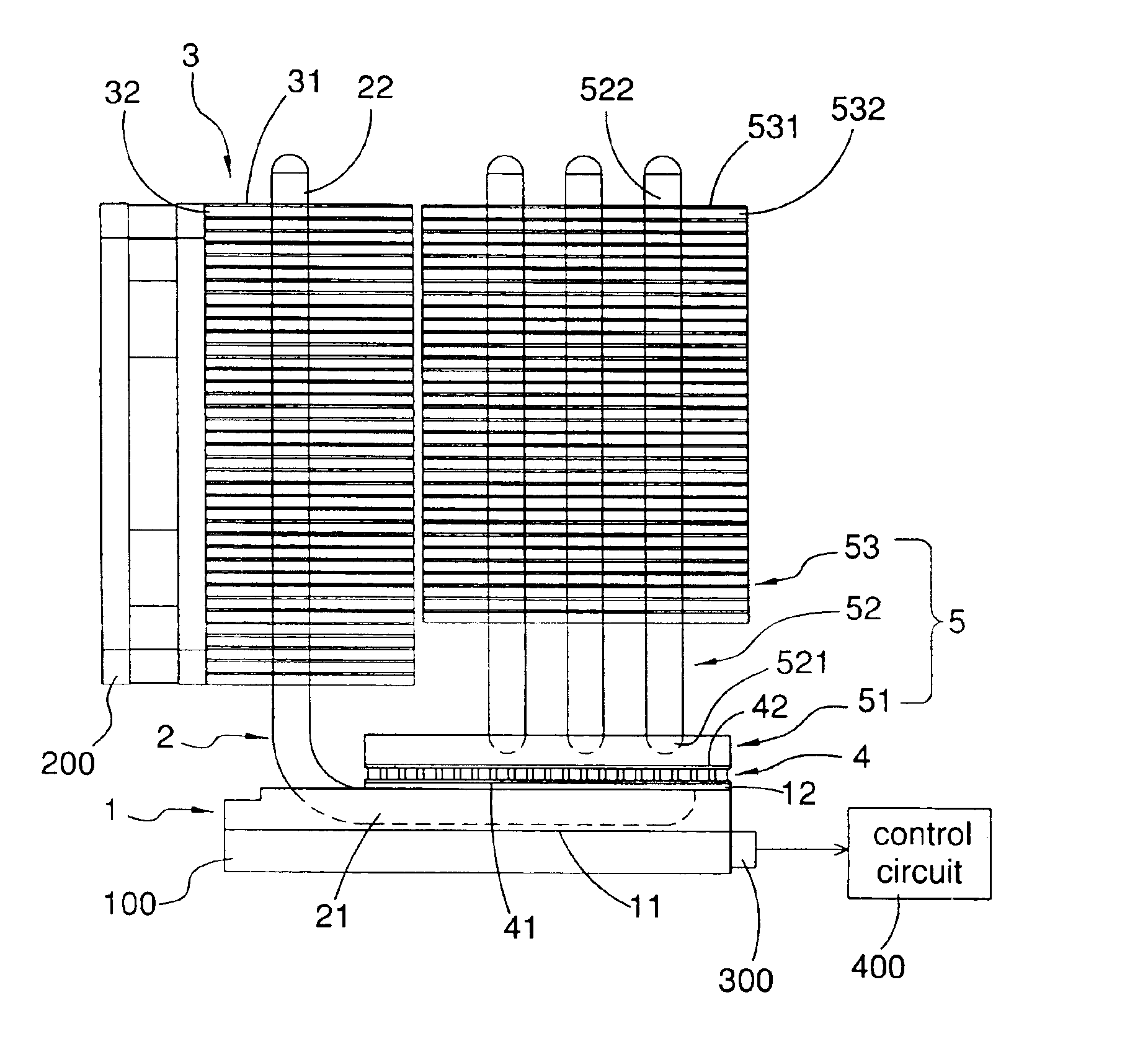

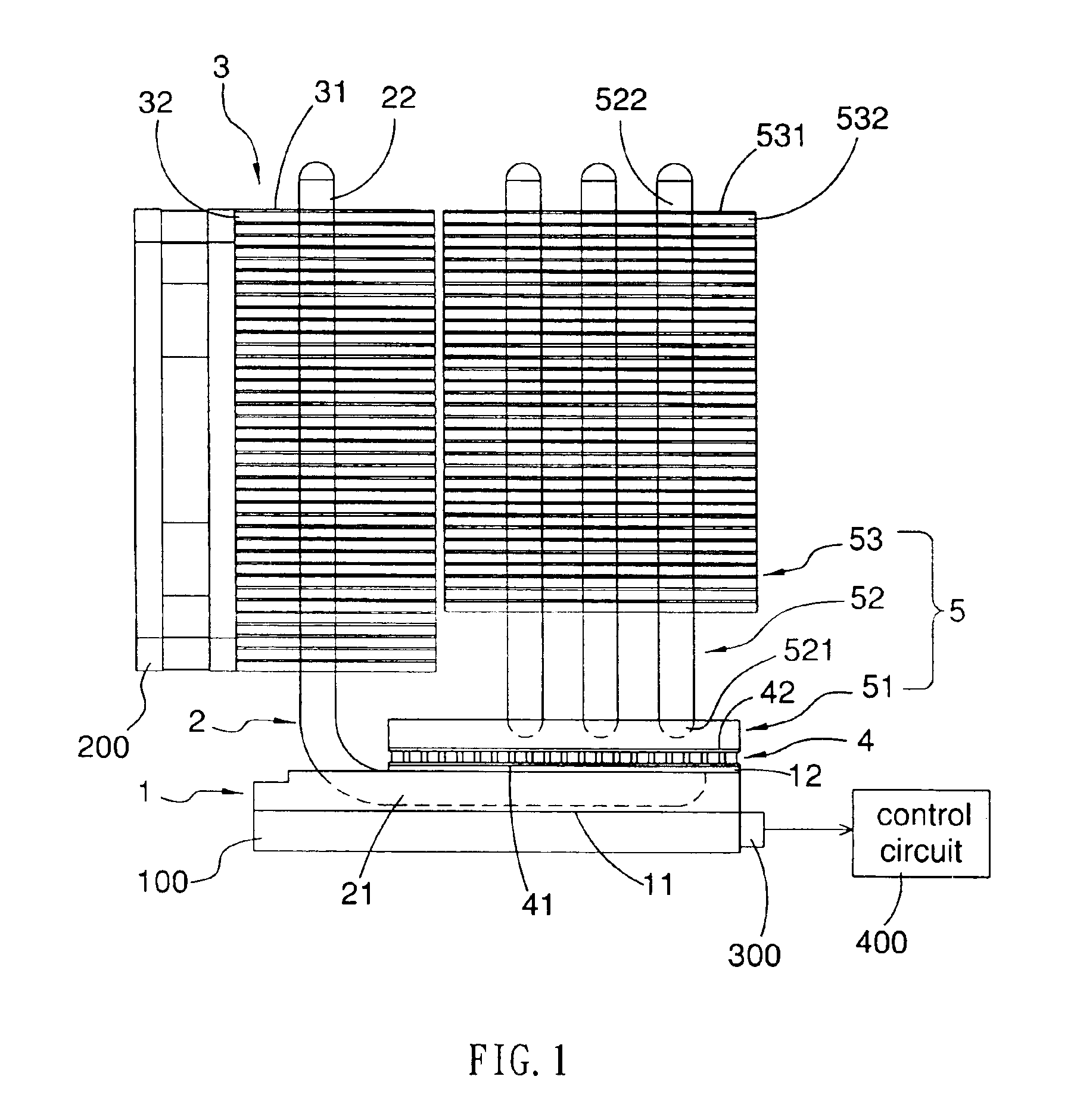

The present invention provides a thermoelectric cooling apparatus for cooling an electronic device such as a CPU, or a computer chip. The apparatus cools the electronic device by two stages. In the first stage, a heat absorbing block collects the heat produced by the electronic device and the apparatus pre-cools the electronic device by dissipating a portion of the collected heat in a distant location through a front heat conductive device and a front radiator. Thereby the heat of the electronic device is reduced to a degree that a TEC can efficiently handle. In the second stage, a TEC of the apparatus dissipate the residual of the heat produced by the electronic device through at least a back heat pipe and a back radiator.

Owner:GIGA BYTE TECH CO LTD

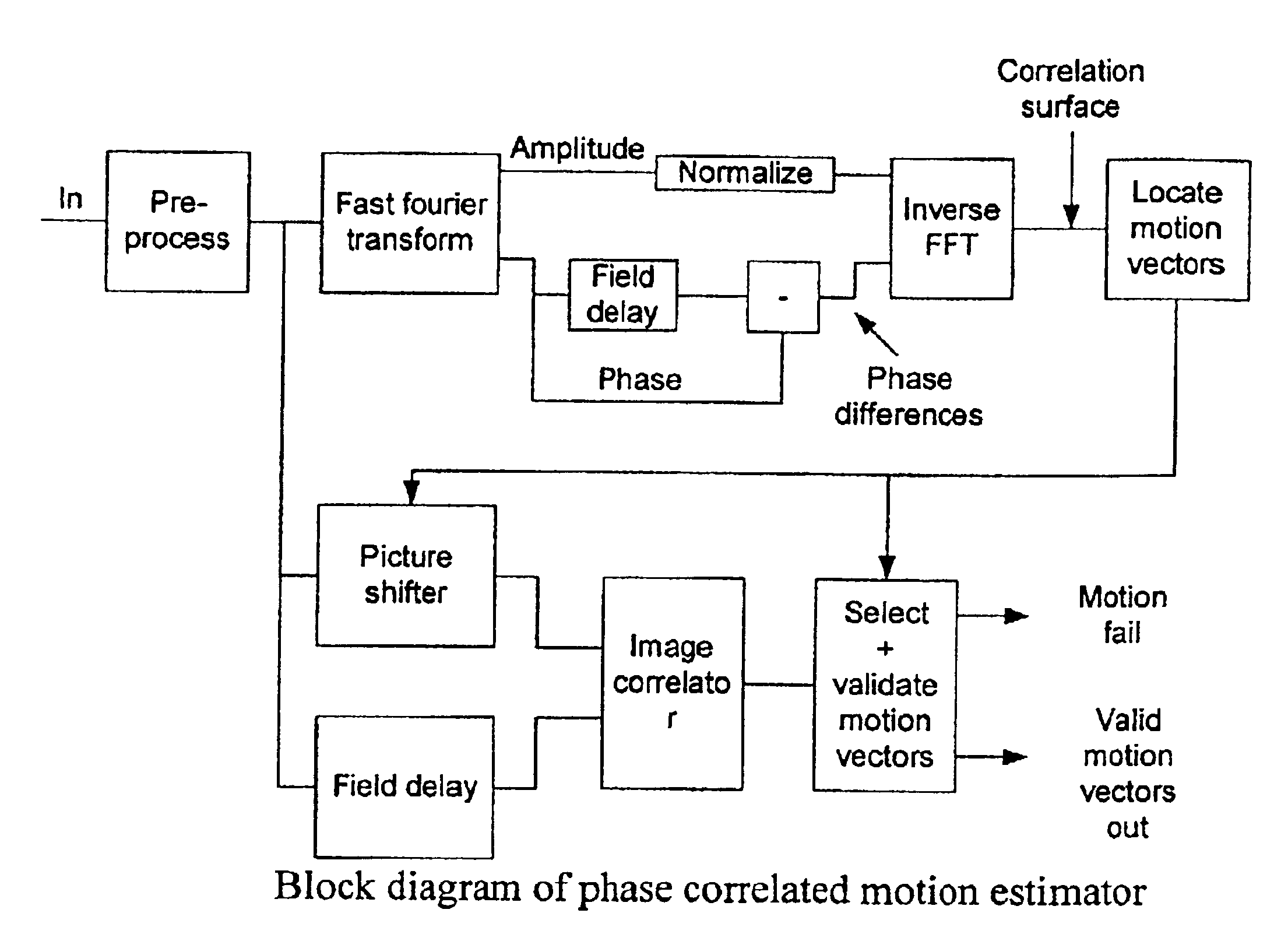

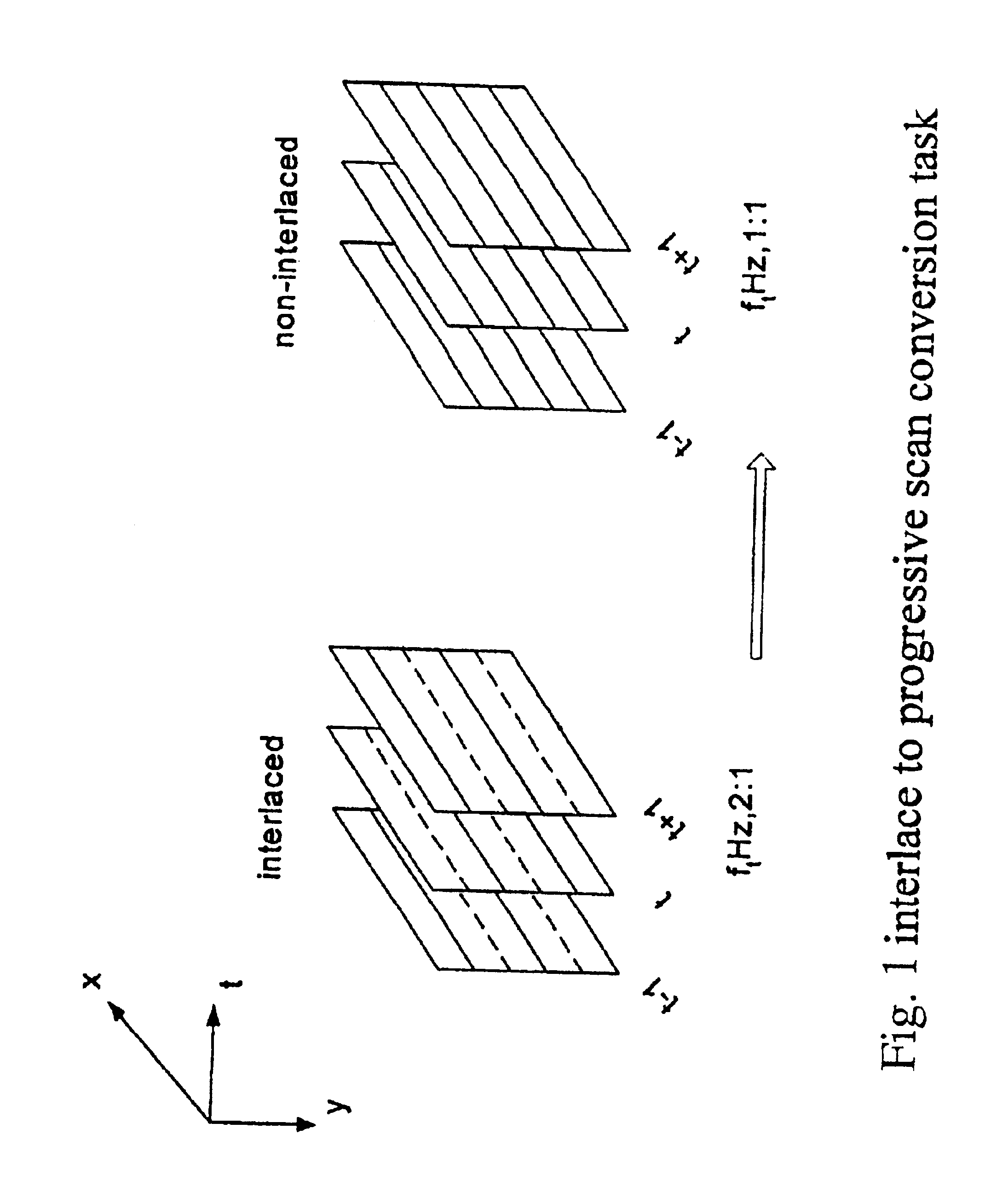

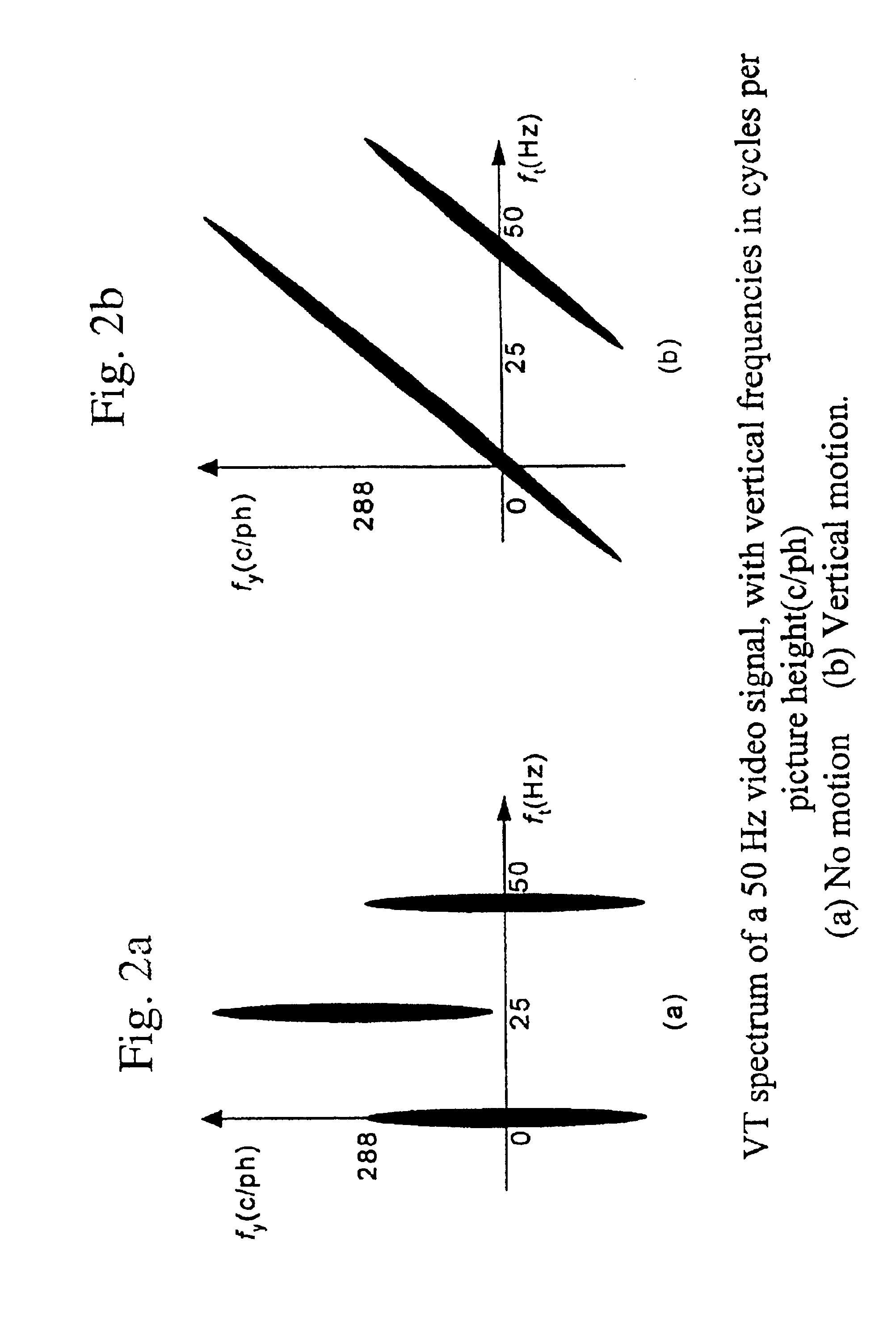

Adaptive interlace-to-progressive scan conversion algorithm

InactiveUS6940557B2Television system detailsColor signal processing circuitsProgressive scanData set

An interlace-to-progressive scan conversion system comprises: a spatial line averaging prefilter; a motion estimator; a three-stage adaptive recursive filter. The motion estimator comprises: a 3-D recursive search sub-component having a bilinear interpolator; a motion correction sub-component having an error-function including penalties related to the difference between a given candidate vector and a plurality of neighboring vectors; a block erosion sub-component. The motion estimator assumes that motion is constant between fields. The three-stage adaptive recursive filter comprises: a first stage that selects between using static pixels data and moving pixels data from a next field; a second stage that selects a more valid set of data between motion compensated data from a previous field and the pixels selected by the first stage; a third stage that combines an intra-field interpolation with the more valid set of data selected by the second stage.

Owner:ENTROPIC COMM INC

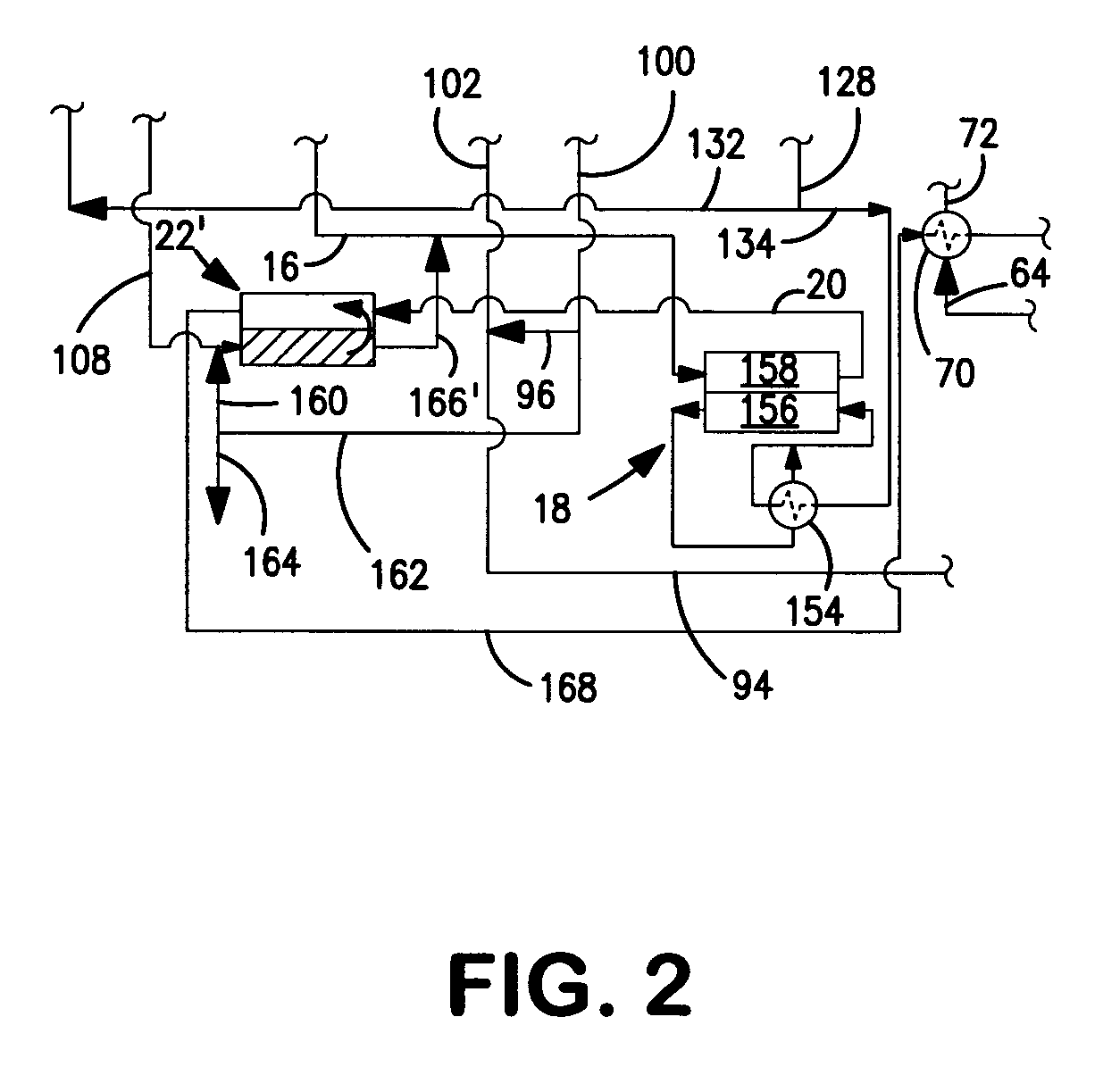

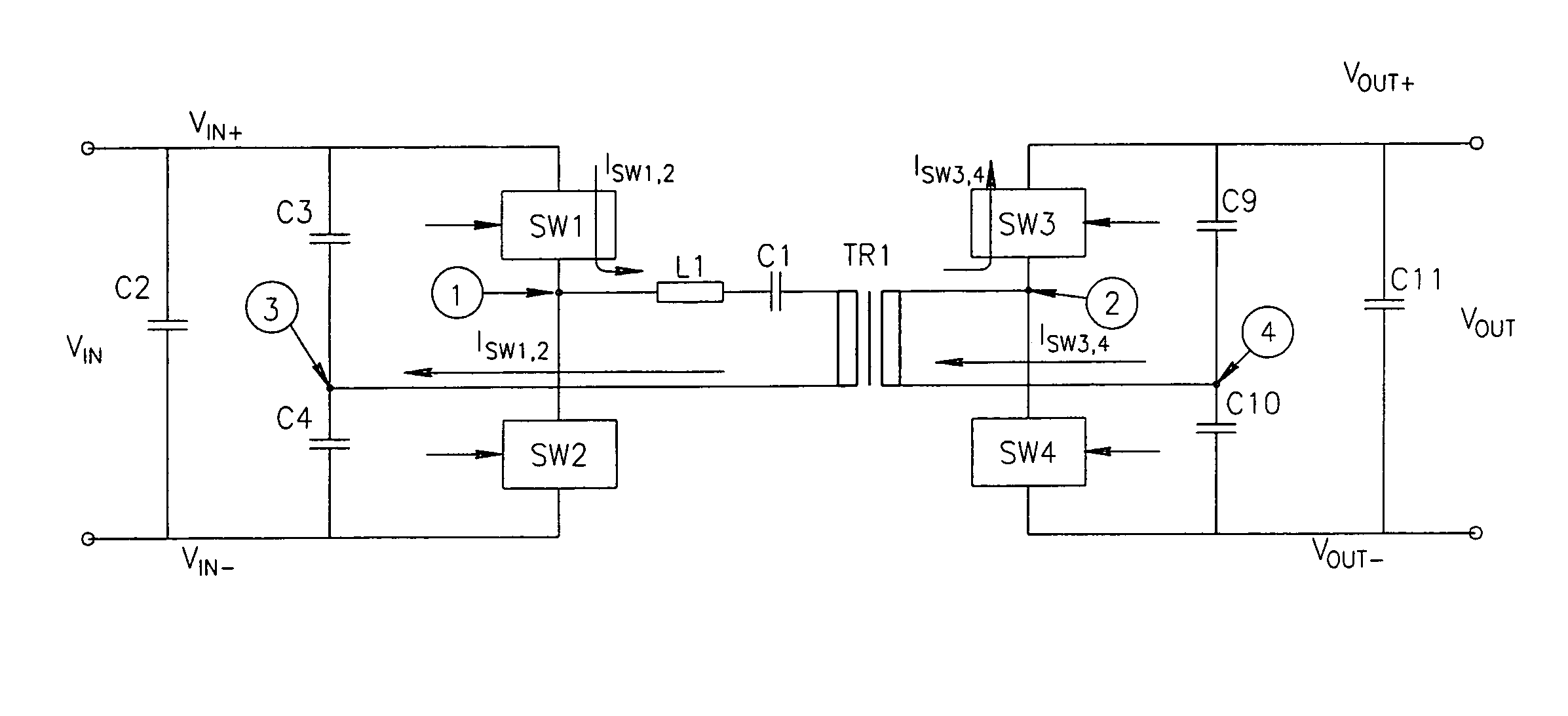

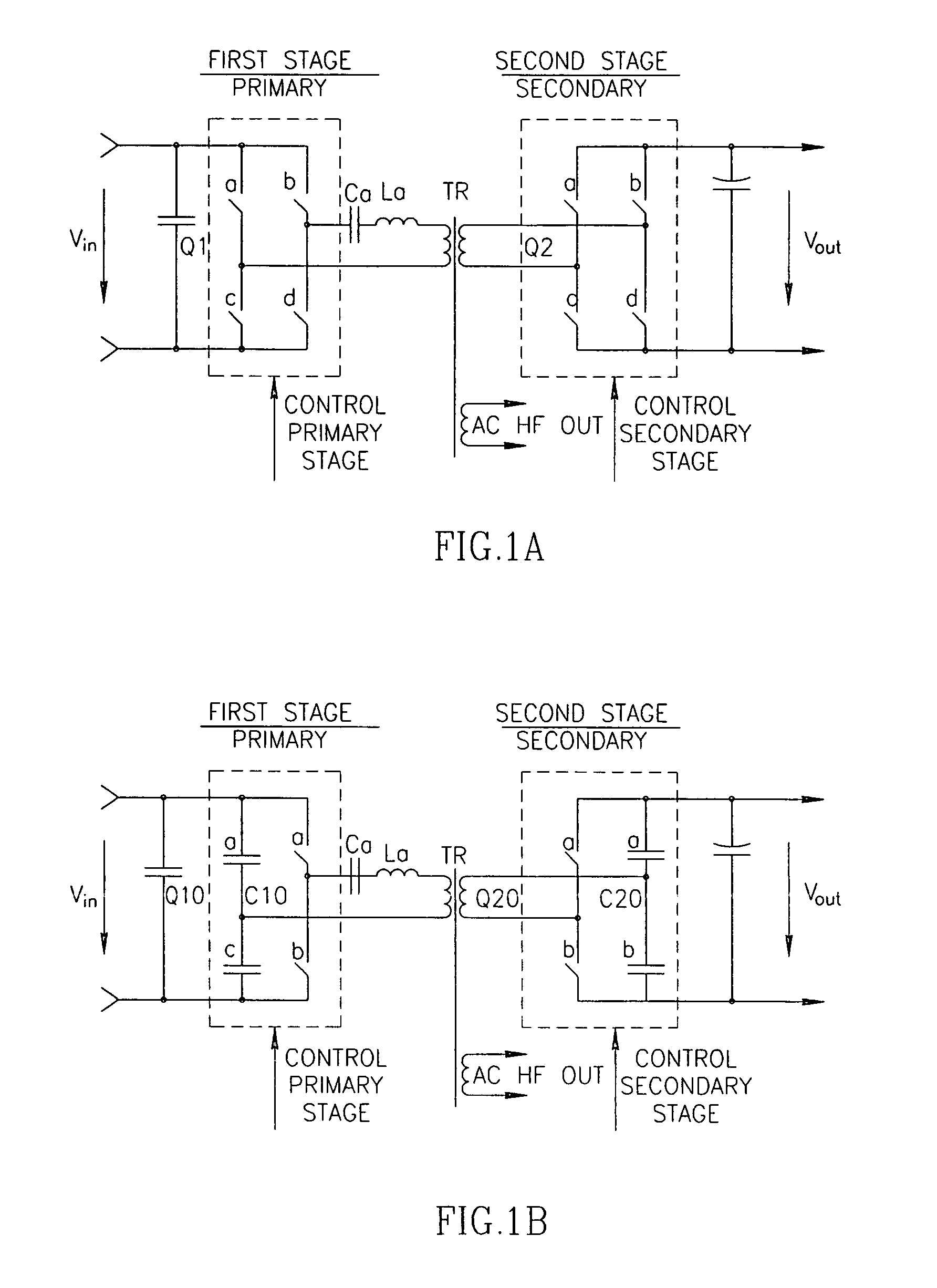

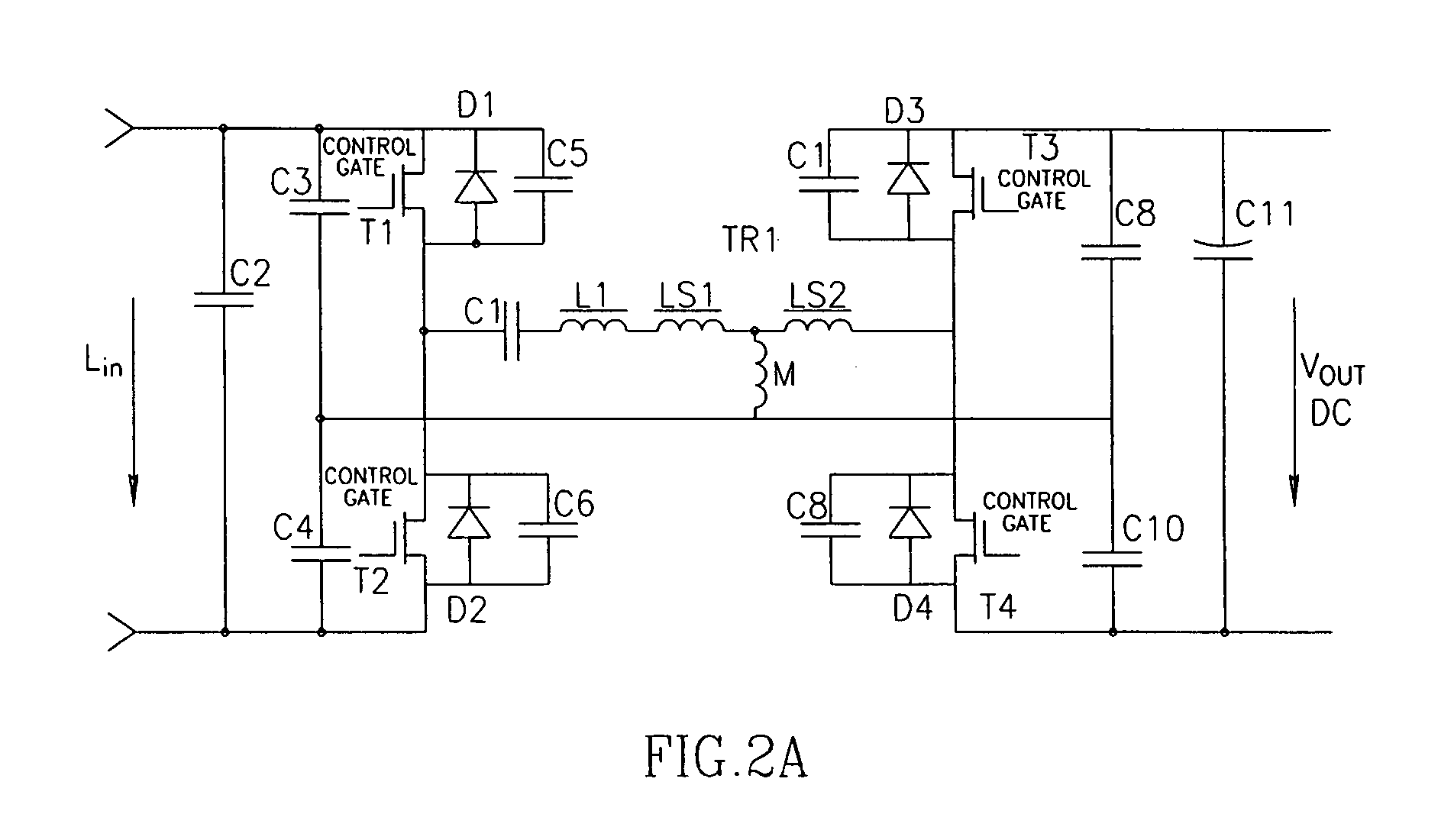

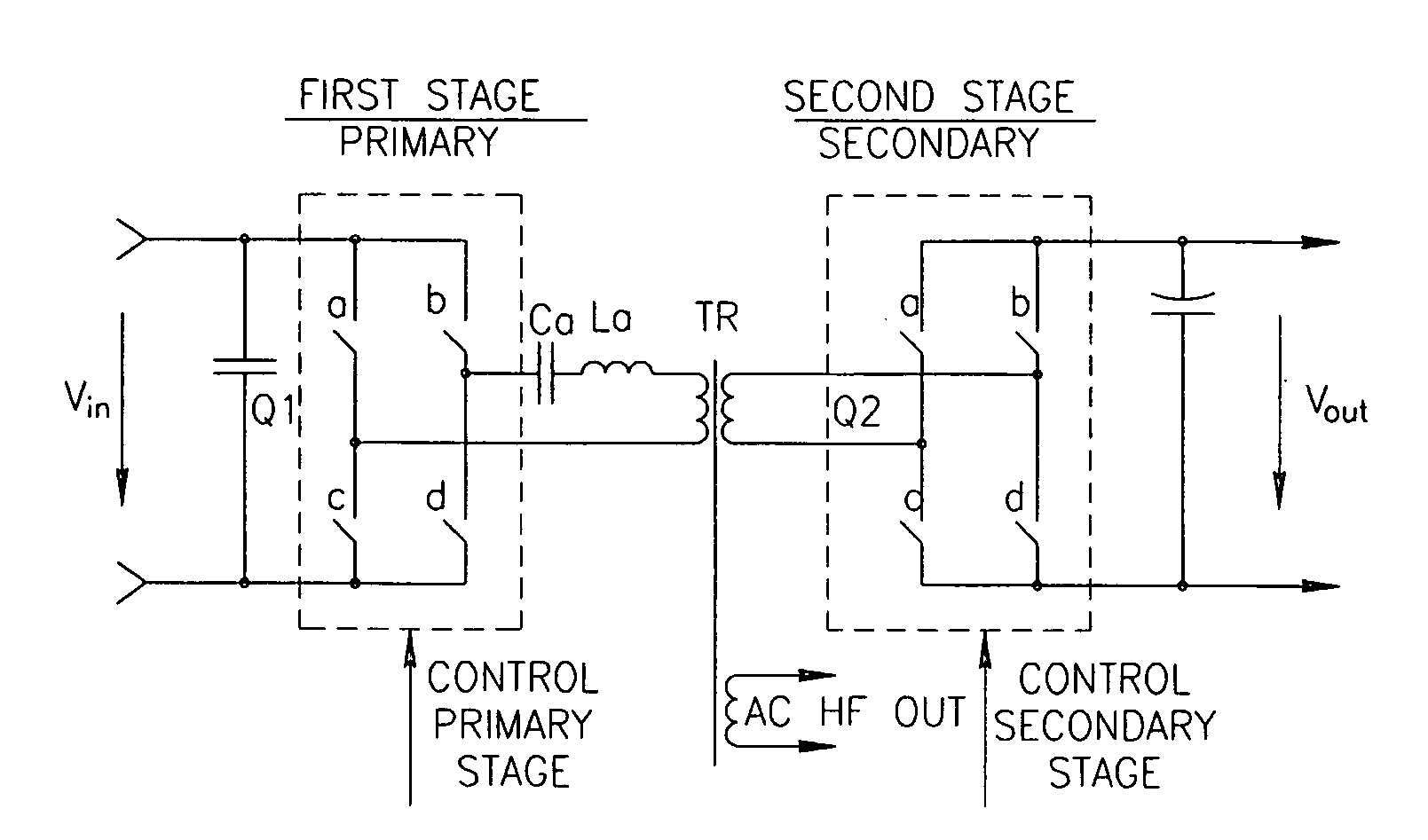

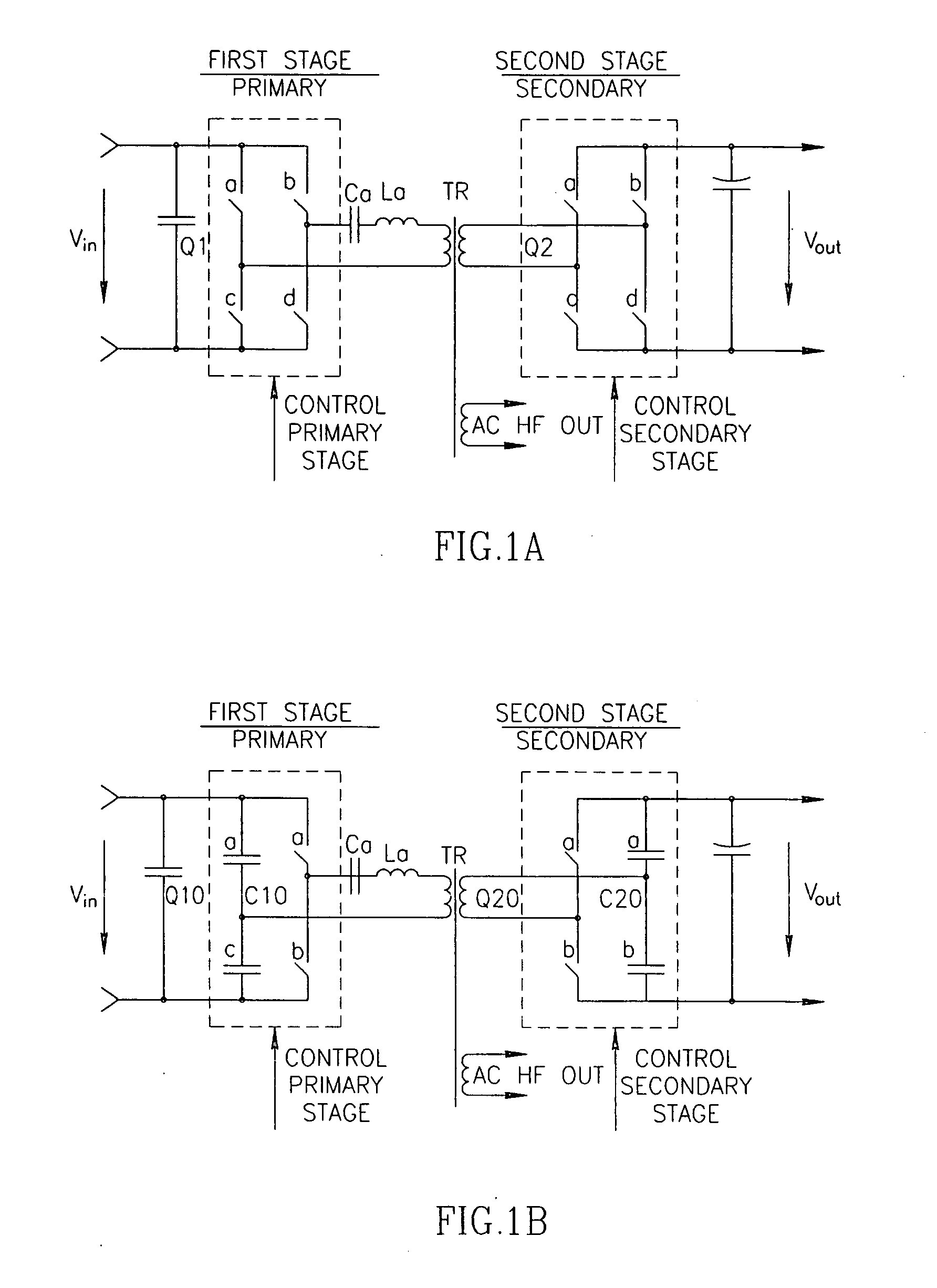

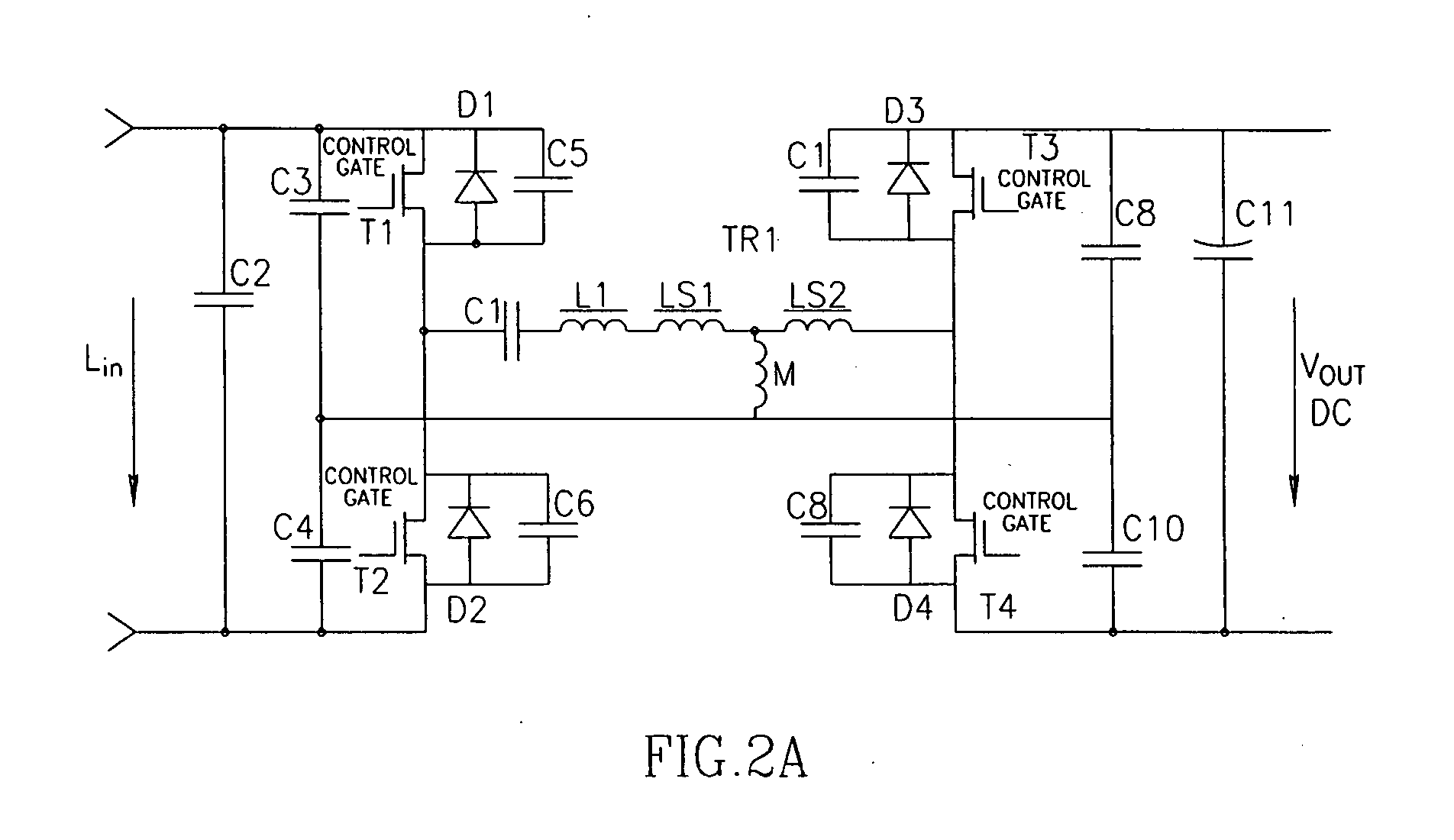

Apparatus and method for high efficiency isolated power converter

InactiveUS20090034299A1Improve efficiencyLow conductiveDc network circuit arrangementsEfficient power electronics conversionDc dc converterFull bridge

A DC-DC converter apparatus comprising half or full bridge, two-stage resonant converter, which may include series resonant (inductor, capacitor) devices. An isolated transformer having primary and secondary winding supplies current to full-wave secondary stage-bridge through the use of primary winding resonant devices employing primary stage-bridge. The magnetizing of said devices employs zero-current, zero-voltage resonant-transition switching technology, which reduces switching losses at all switching frequencies to almost zero. The regulation of output voltage at all loads and input voltages achieved by the control of the switching frequency and the phase between signals for primary and secondary stages. The proper intermittent of the frequency and the phase allows achieving the value of efficiency up to 97%.

Owner:LUMENIS LTD

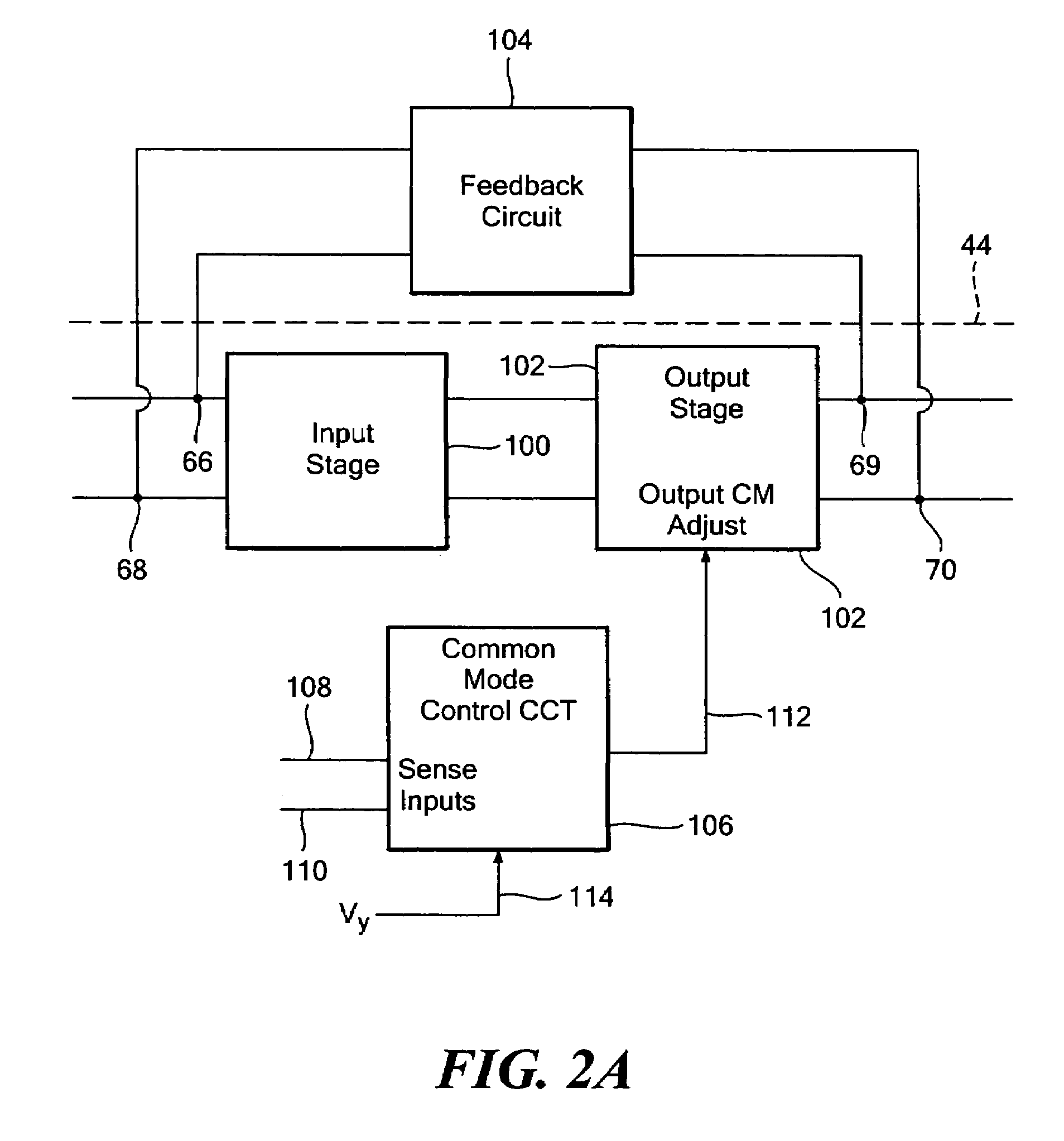

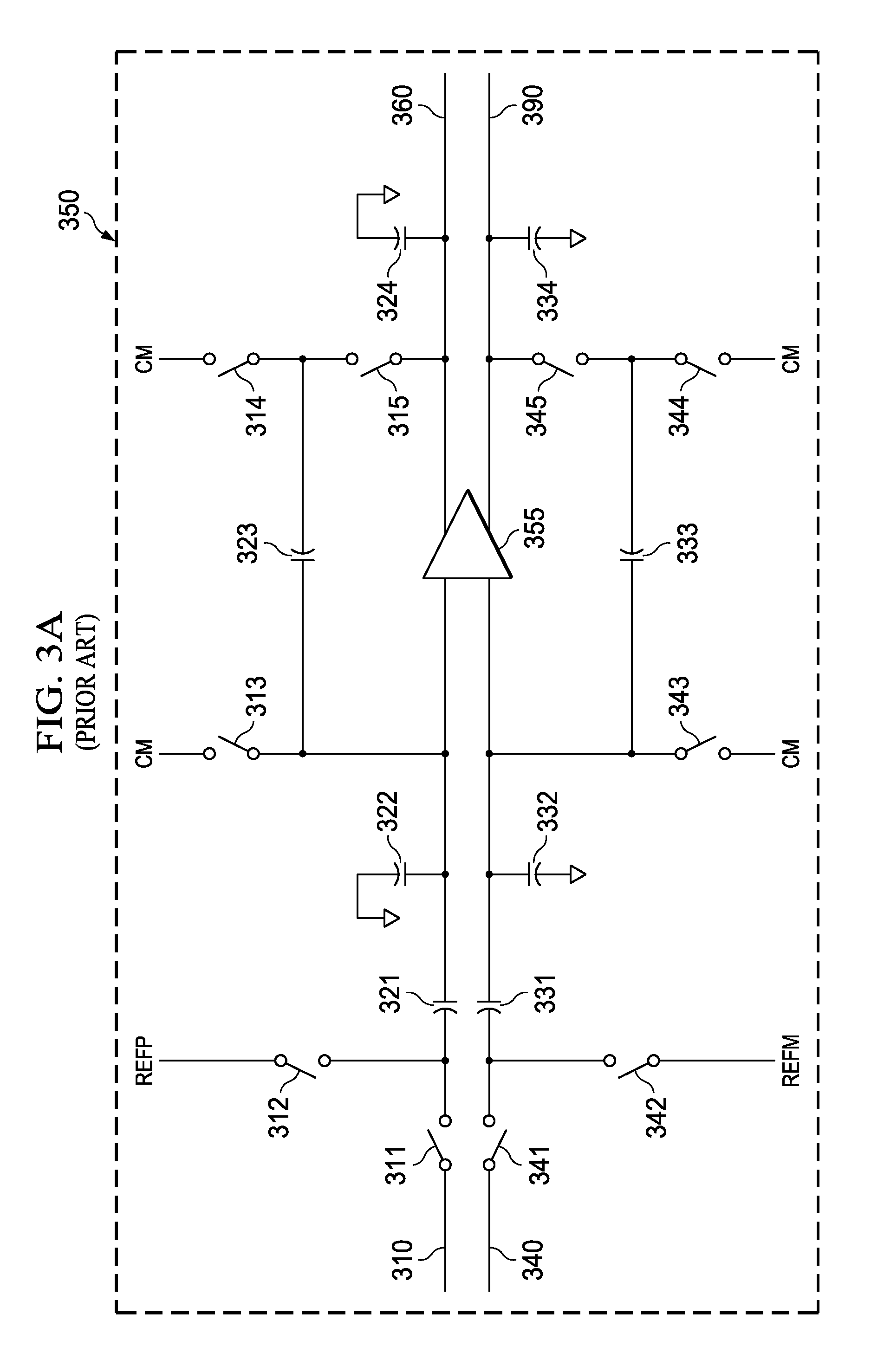

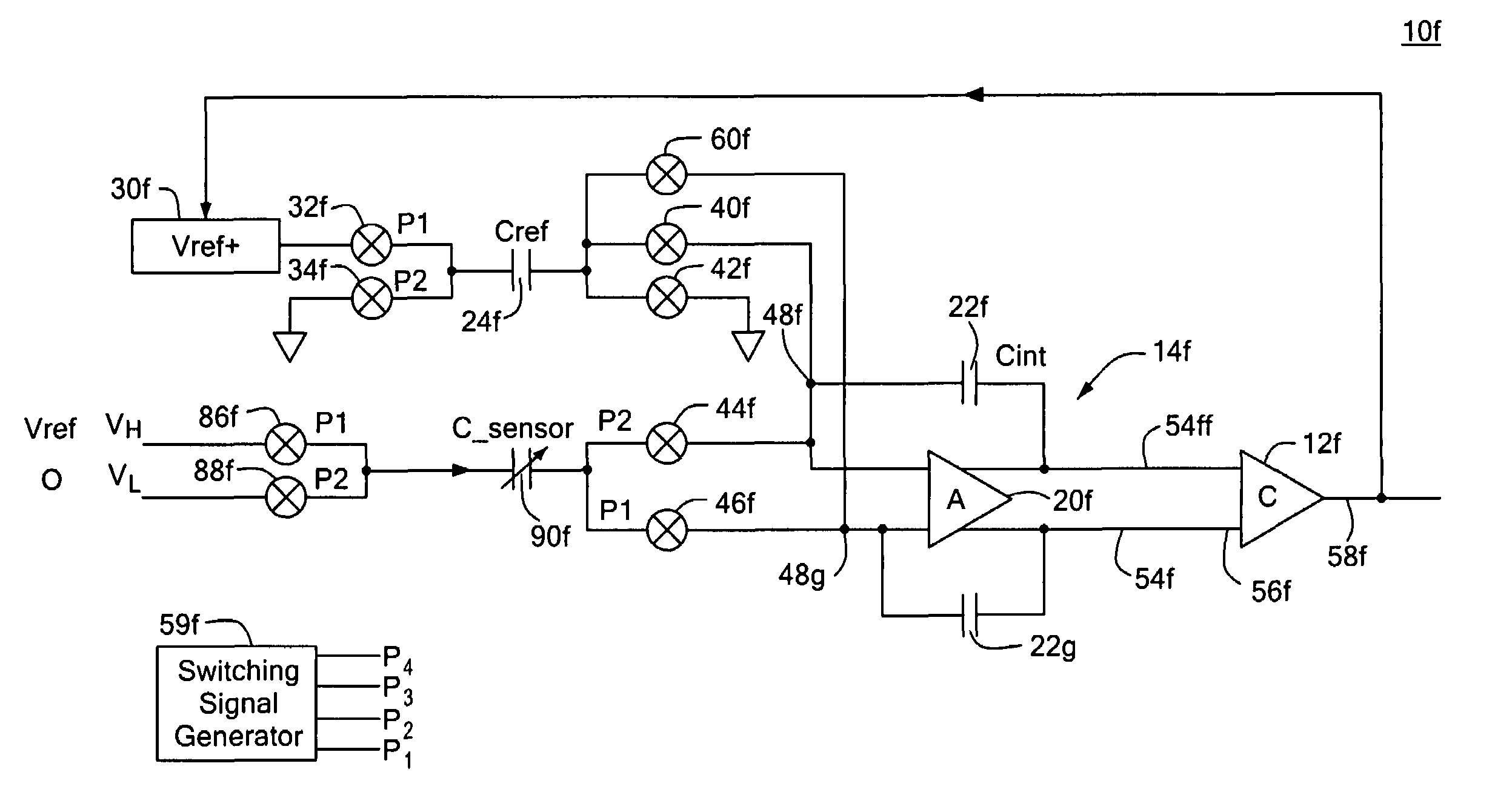

Variable capacitance switched capacitor input system and method

ActiveUS6970126B1Current errorElectric signal transmission systemsDelta modulationCapacitanceIntegrator

A variable capacitance switched capacitor input system and method includes a differential integrator circuit having first and second input summing nodes and a variable sensing capacitor; one terminal of the variable sensing capacitor is connected to one of the nodes in the first phase and to the other of the nodes in the second phase; an input terminal connected to a second terminal of the variable sensing capacitor receives a first voltage level in the first phase and a second voltage level in the second phase for delivering the charge on the variable sensing capacitor to the first summing node in the first phase and to the second summing node in the second phase and canceling errors in a differential integrator circuit output caused by leakage current.

Owner:ANALOG DEVICES INC

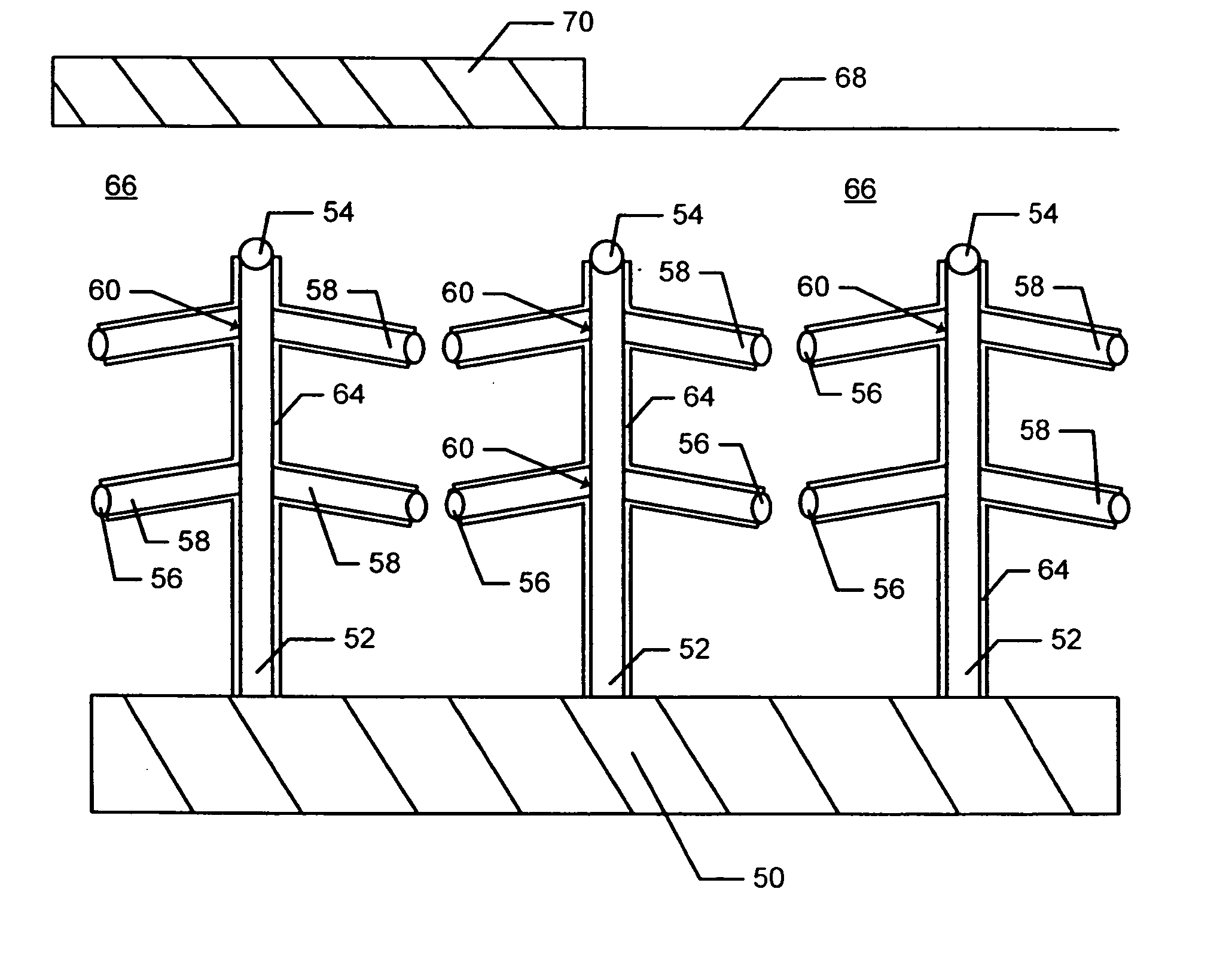

Nanostructures formed of branched nanowhiskers and methods of producing the same

InactiveUS20060057360A1Structure moreMaterial nanotechnologyLiquid surface applicatorsHeterojunctionEngineering

A method of forming a nanostructure having the form of a tree, comprises a first stage and a second stage. The first stage includes providing one or more catalytic particles on a substrate surface, and growing a first nanowhisker via each catalytic particle. The second stage includes providing, on the periphery of each first nanowhisker, one or more second catalytic particles, and growing, from each second catalytic particle, a second nanowhisker extending transversely from the periphery of the respective first nanowhisker. Further stages may be included to grow one or more further nanowhiskers extending from the nanowhisker(s) of the preceding stage. Heterostructures may be created within the nanowhiskers. Such nanostructures may form the components of a solar cell array or a light emitting flat panel, where the nanowhiskers are formed of a photosensitive material. A neural network may be formed by positioning the first nanowhiskers close together so that adjacent trees contact one another through nanowhiskers grown in a subsequent stage, and heterojunctions within the nanowhiskers create tunnel barriers to current flow.

Owner:QUNANO

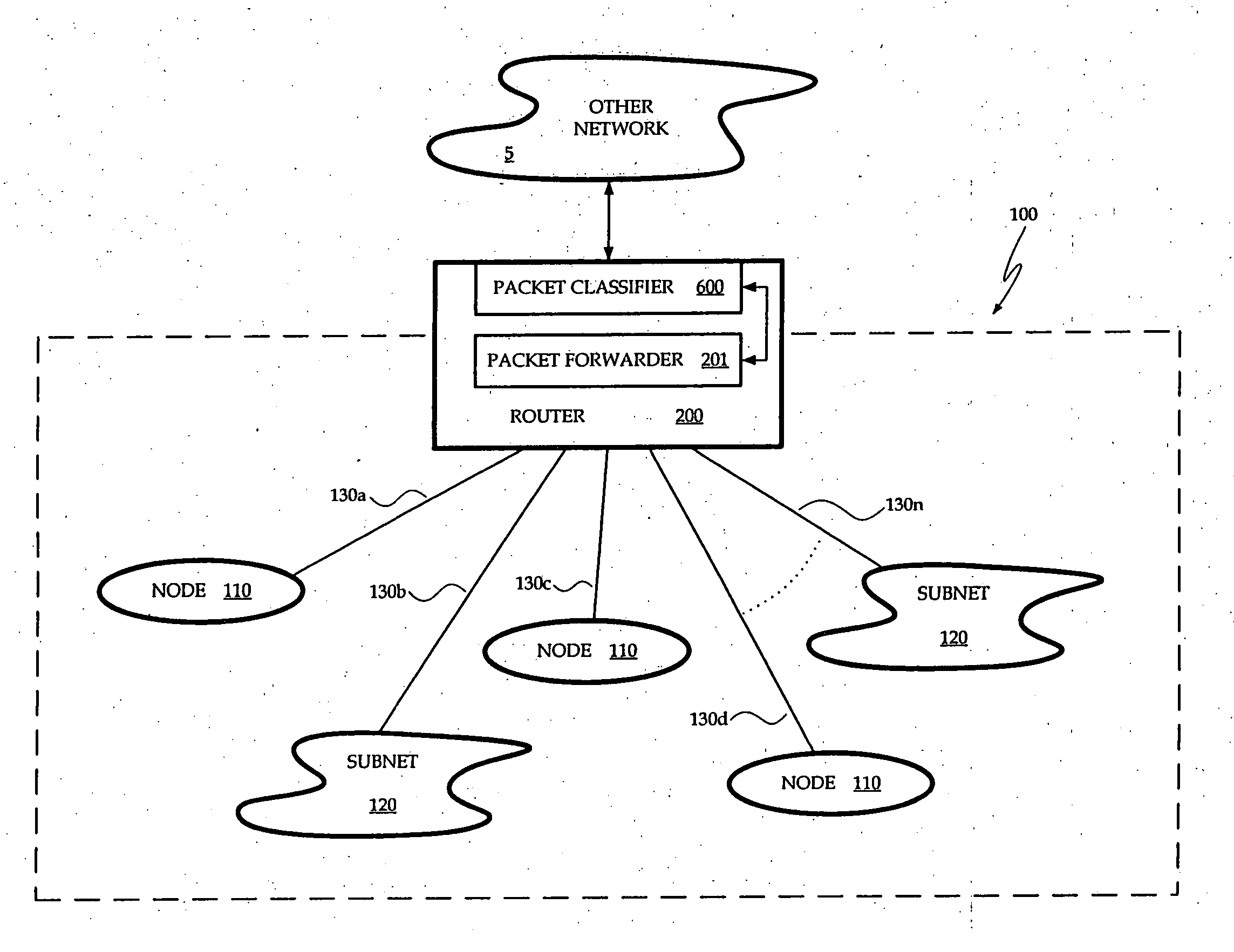

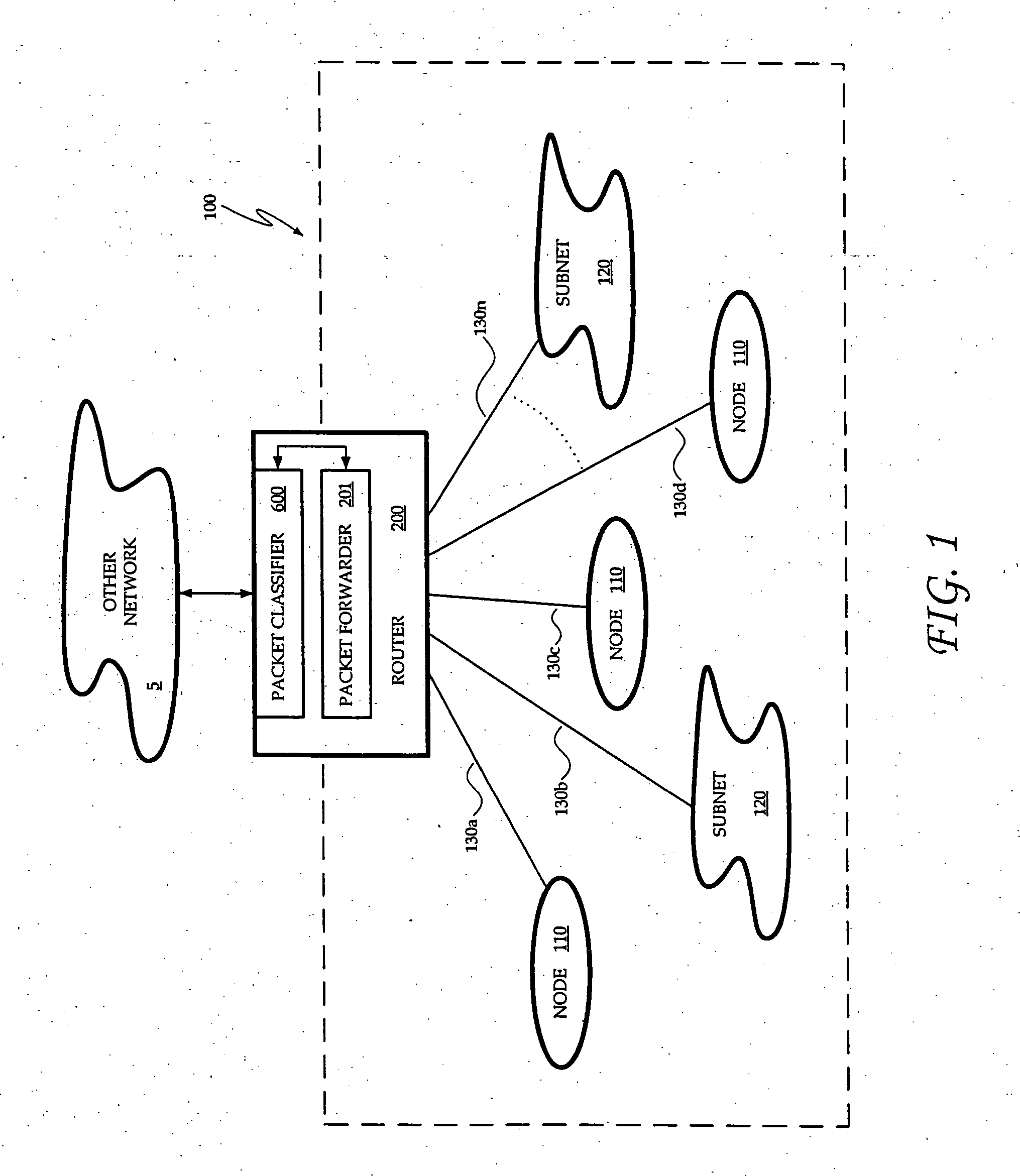

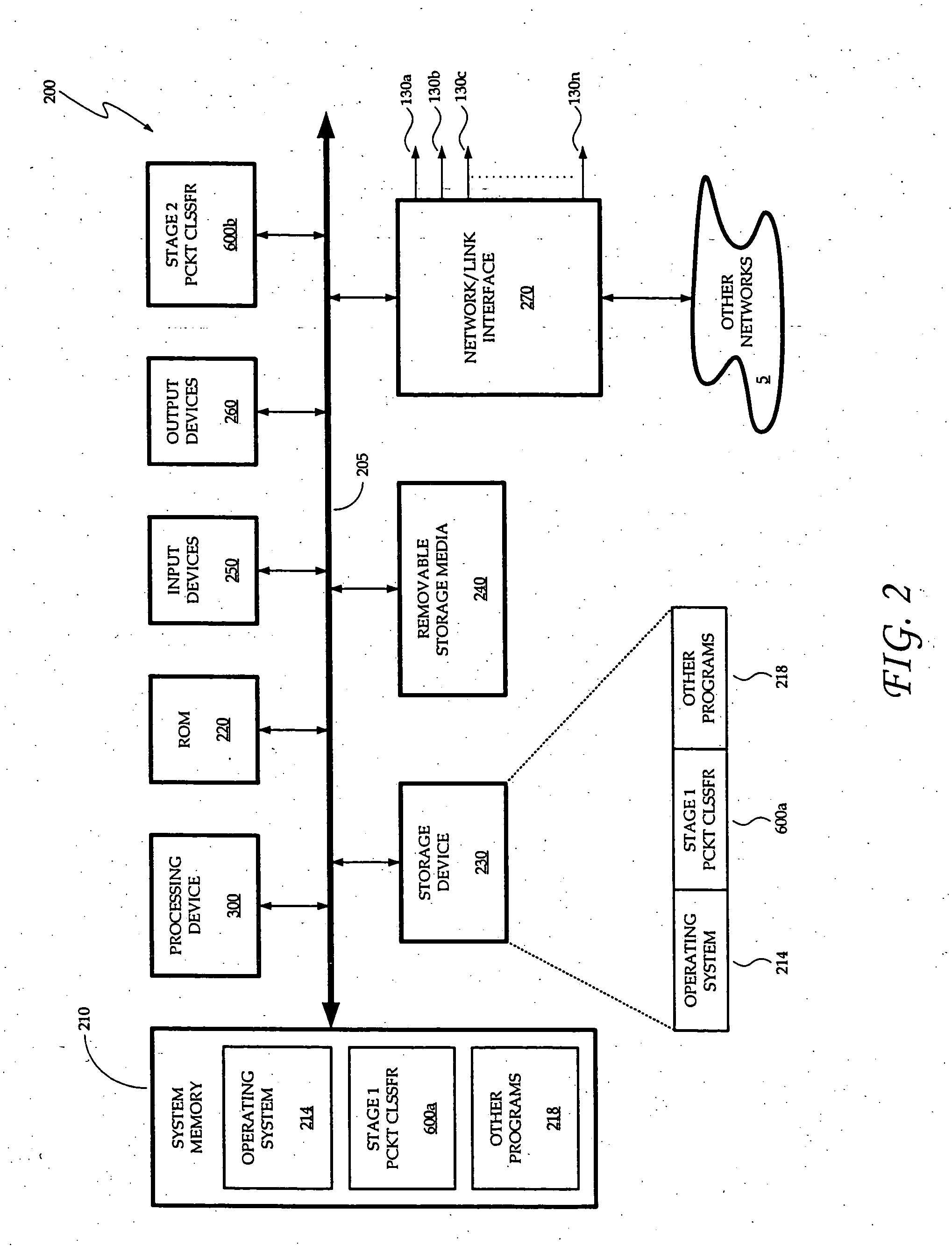

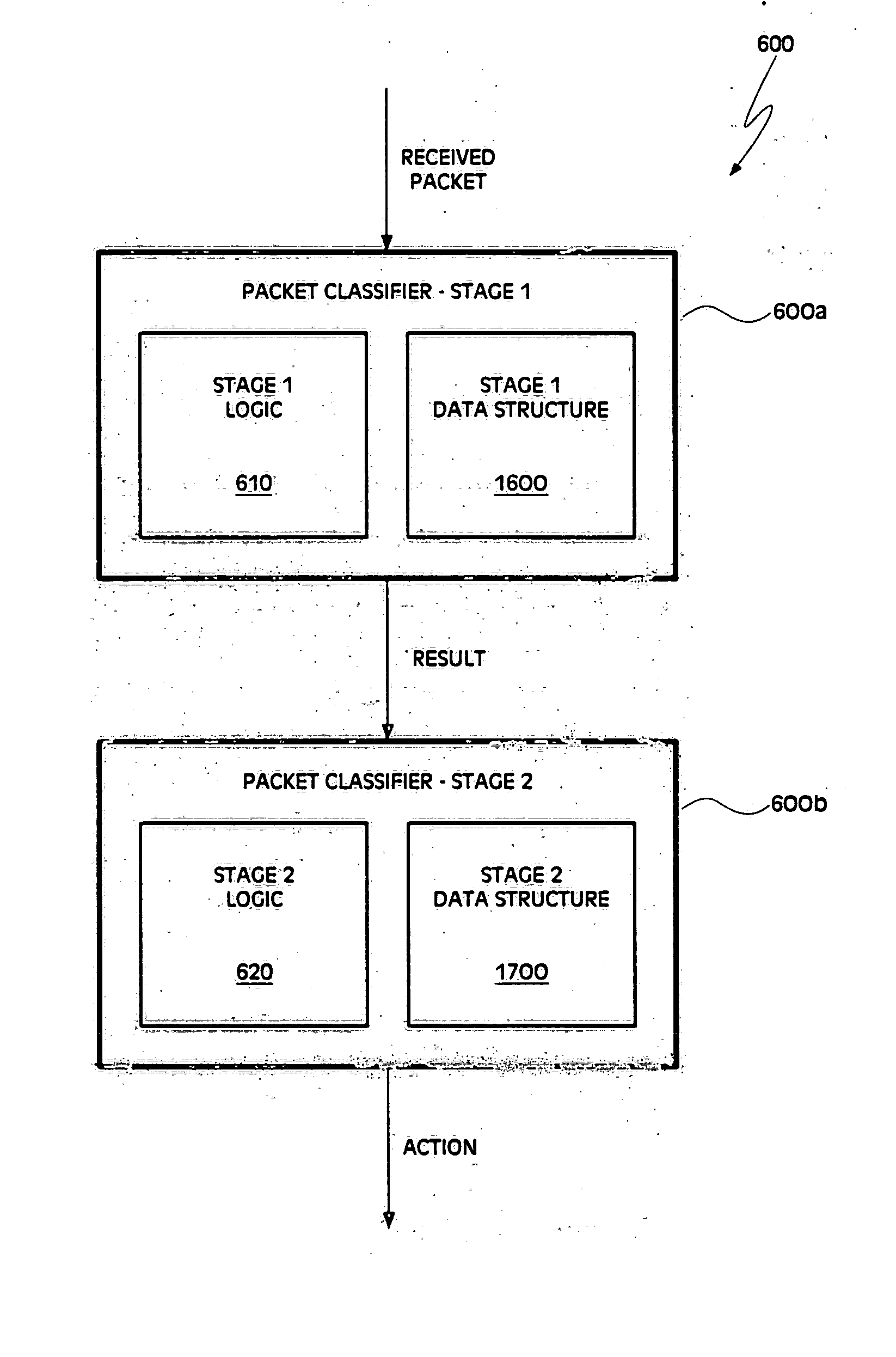

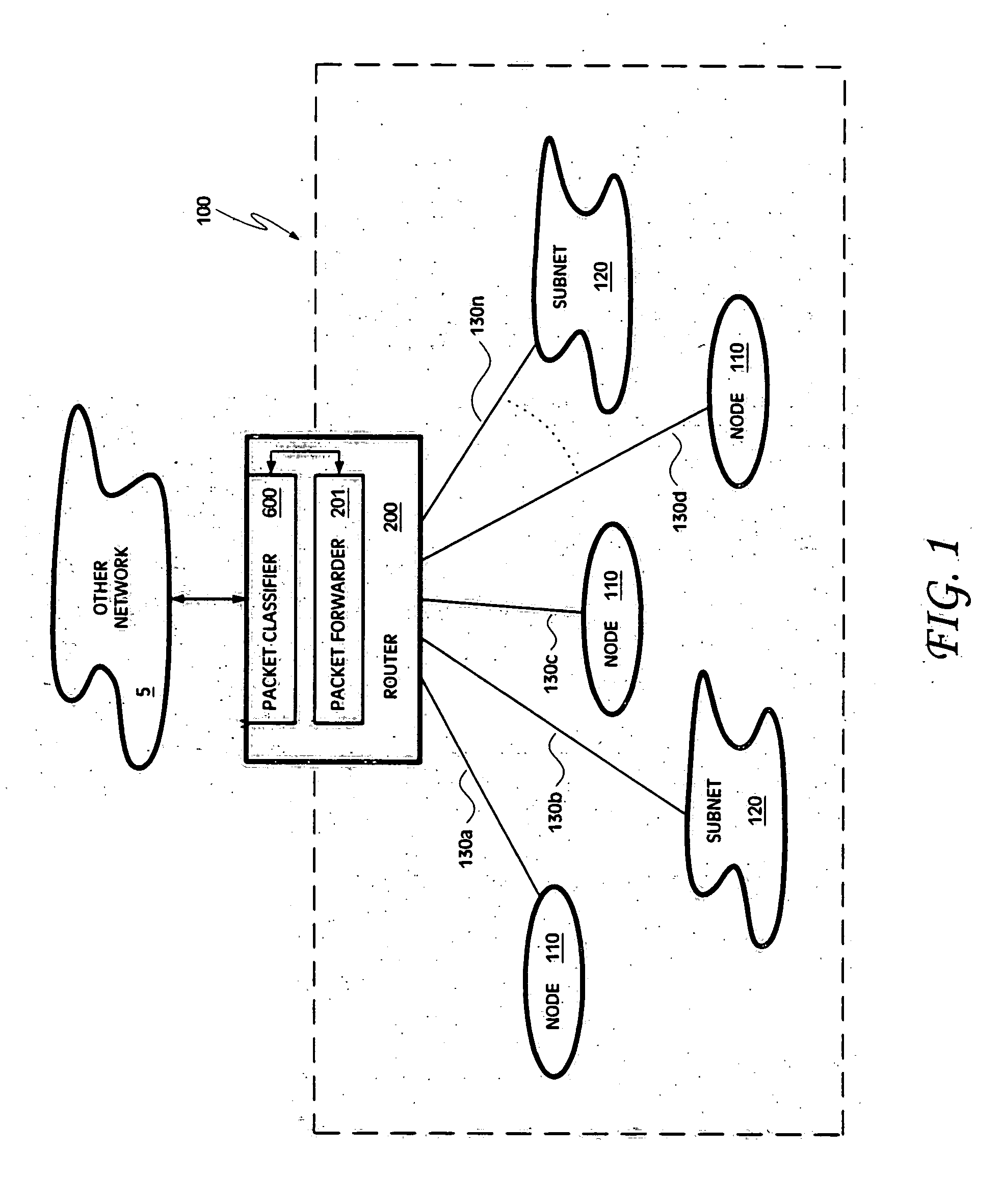

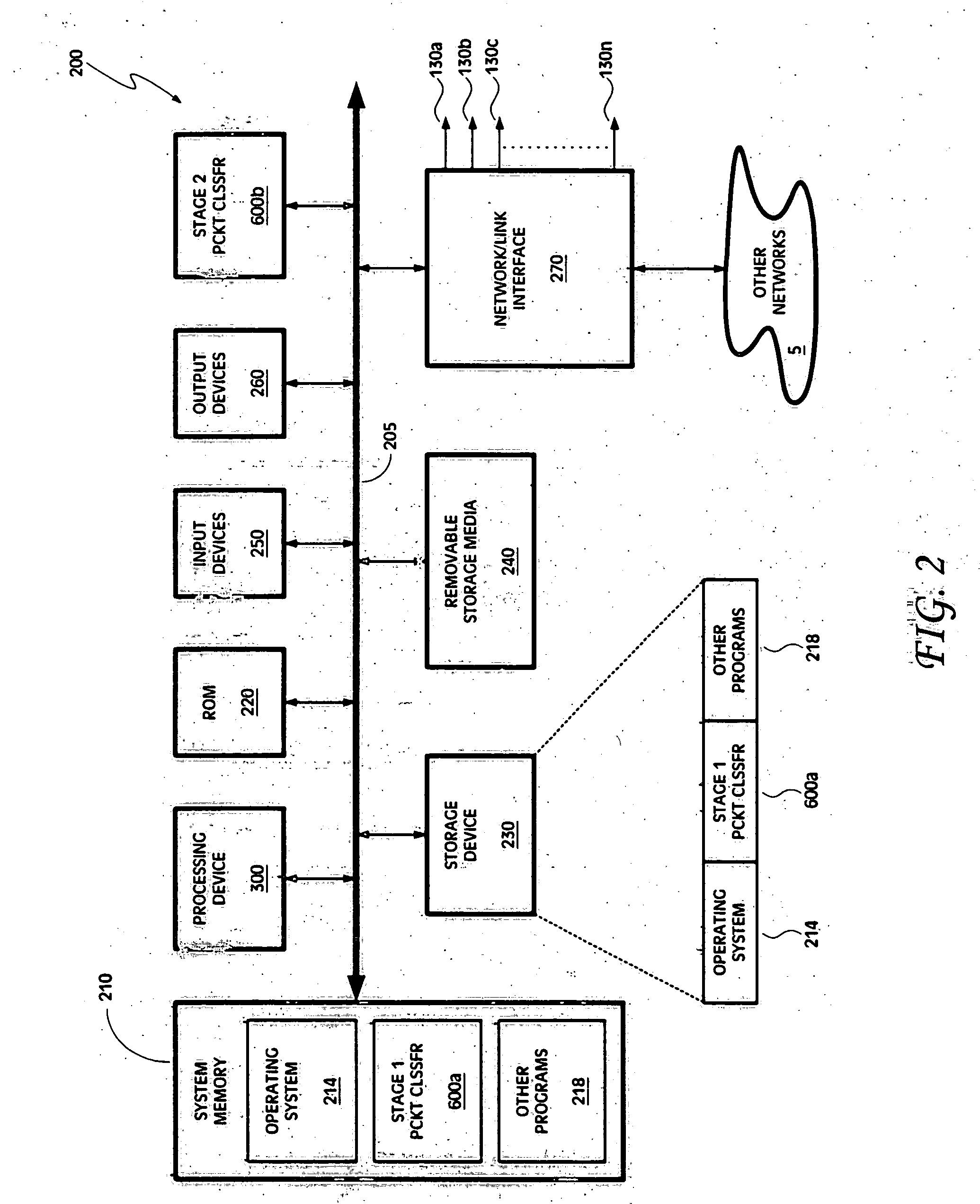

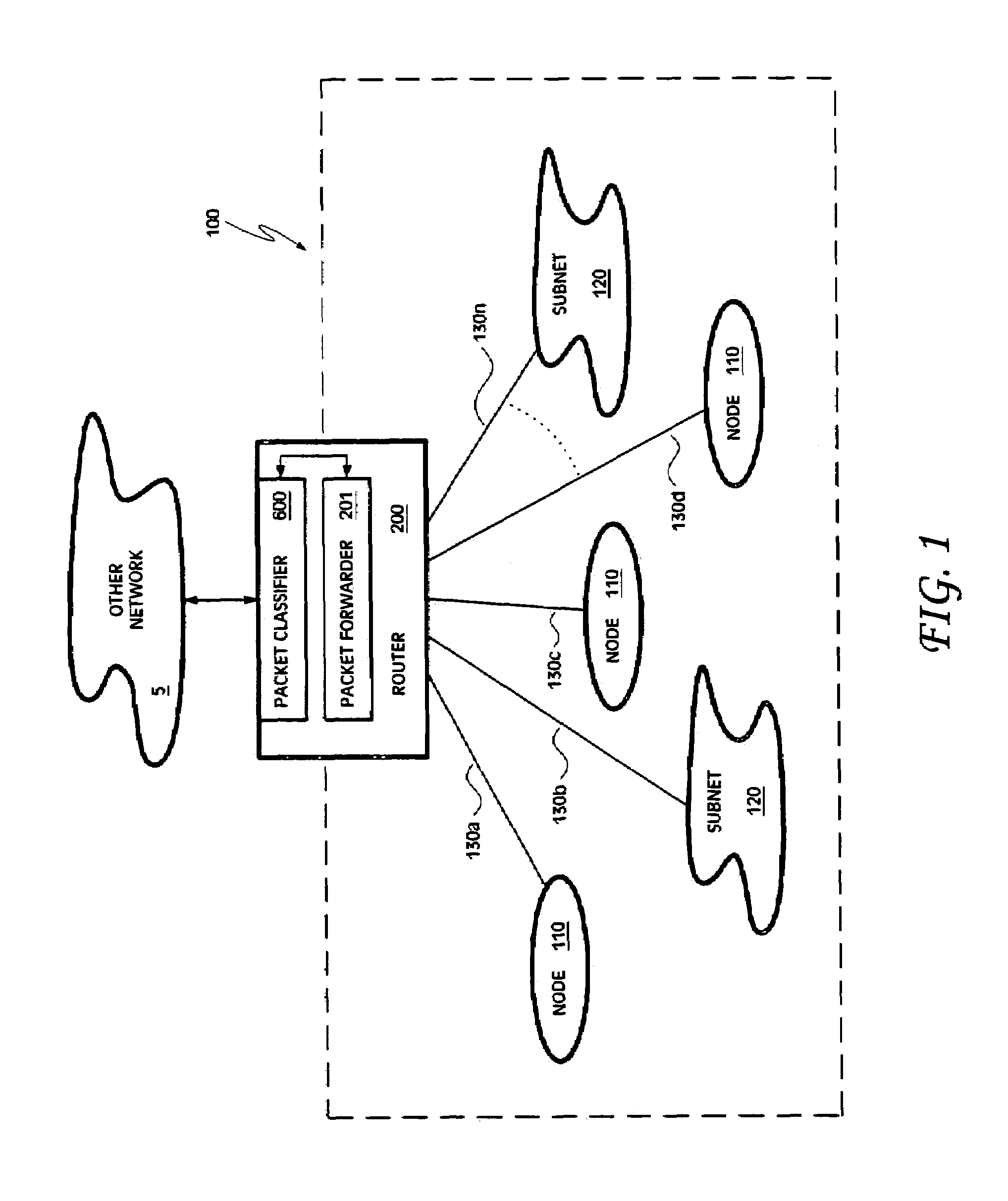

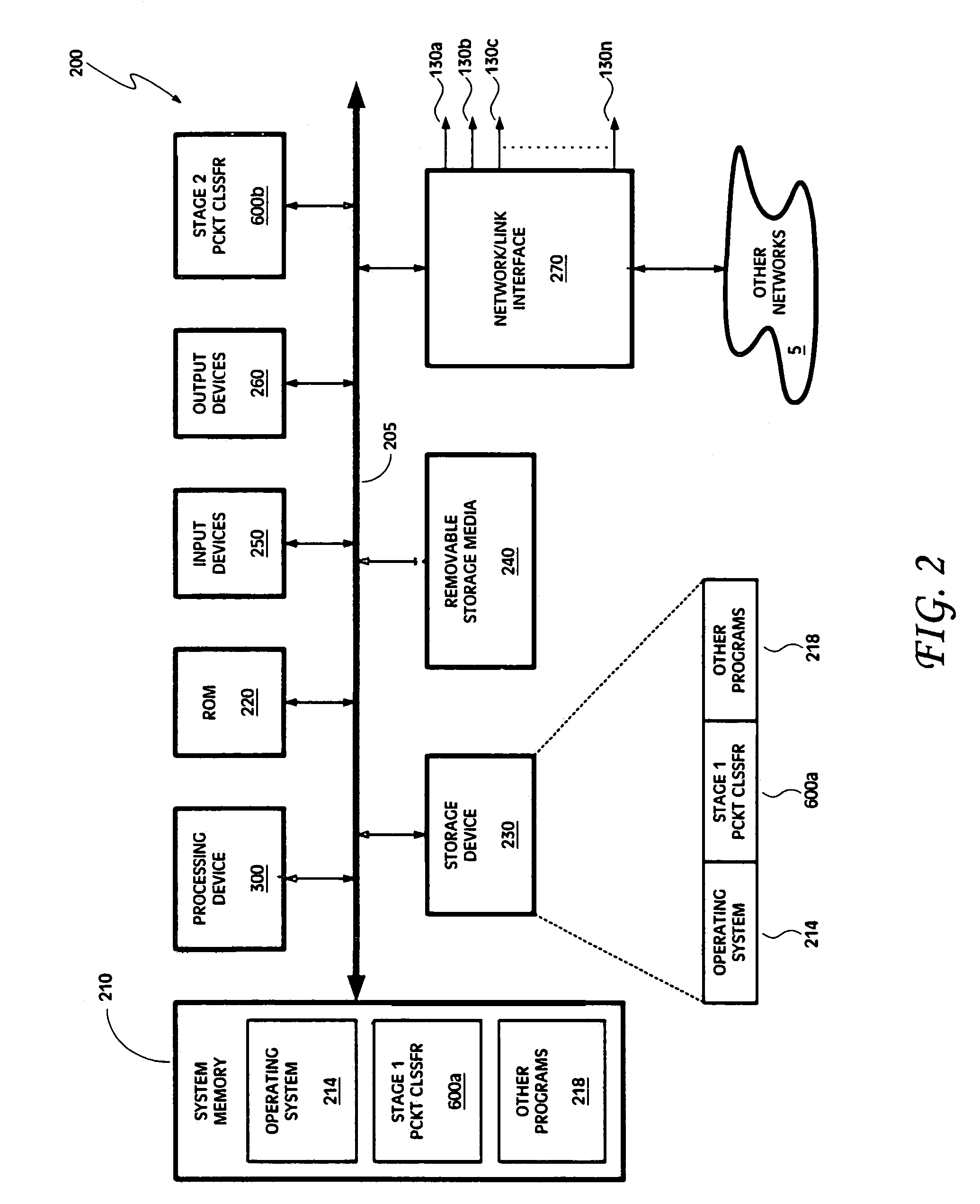

Method and apparatus for two-stage packet classification using most specific filter matching and transport level sharing

ActiveUS20050083935A1Network traffic/resource managementData switching by path configurationSecondary stageDistributed computing

A method and apparatus for two-stage packet classification, the two-stage packet classification scheme including a first stage and a second stage. In the first classification stage, a packet is classified on the basis of the packet's network path. In the second stage of classification, the packet is classified on the basis of one or more transport (or other) fields of the packet. Also disclosed are embodiments of most specific filter matching and transport level sharing, and either one or both of these techniques may be implemented in the two-stage classification method.

Owner:INTEL CORP

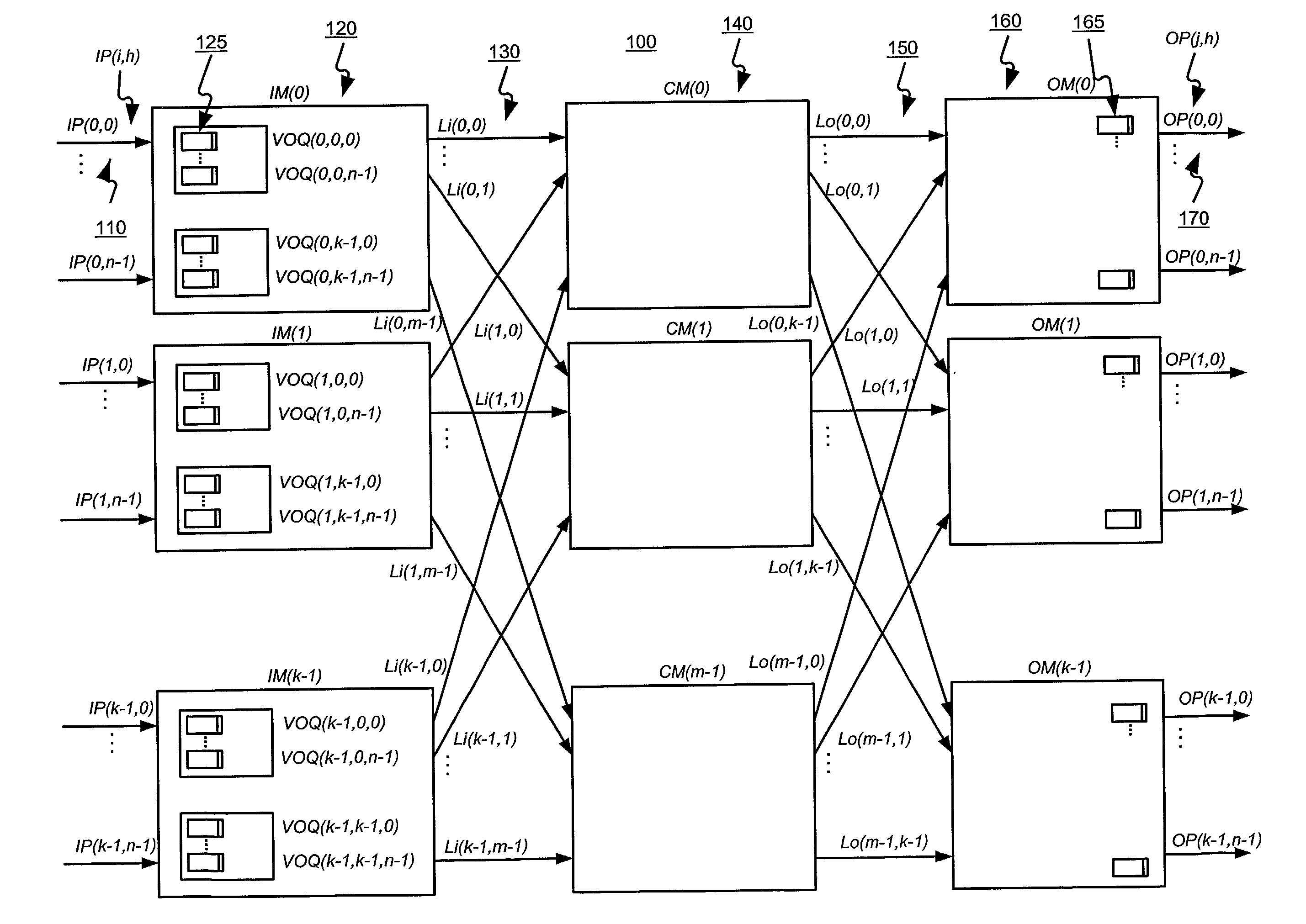

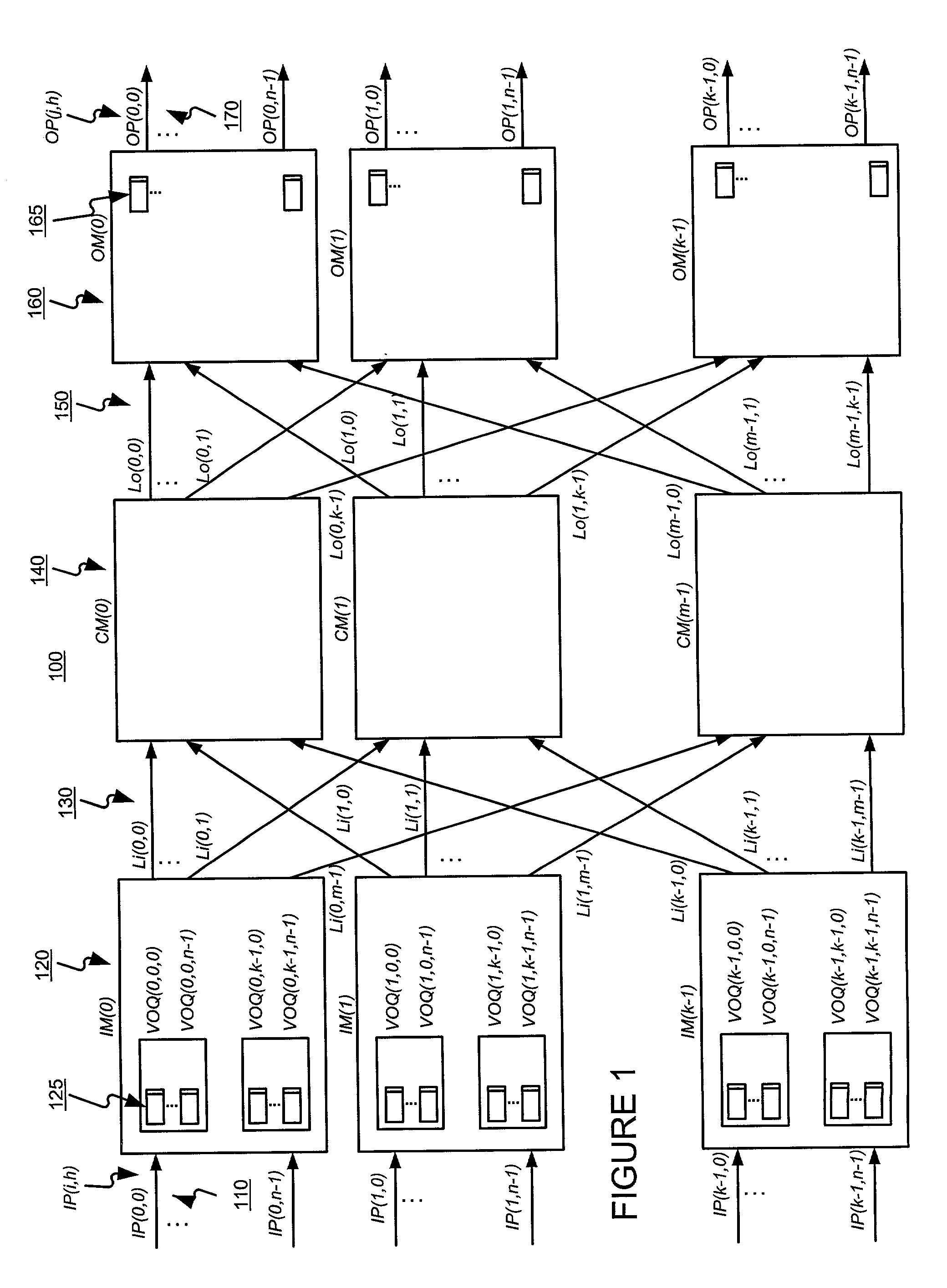

Scheduling the dispatch of cells in multistage switches

InactiveUS7173931B2Improve throughputAvoid switchingTime-division multiplexData switching by path configurationSecondary stageMulti phase

A multiple phase cell dispatch scheme, in which each phase uses a simple and fair (e.g., round robin) arbitration methods, is described. VOQs of an input module and outgoing links of the input module are matched in a first phase. An outgoing link of an input module is matched with an outgoing link of a central module in a second phase. The arbiters become desynchronized under stable conditions which contributes to the switch's high throughput characteristic. Using this dispatch scheme, a scalable multiple-stage switch able to operate at high throughput, without needing to resort to speeding up the switching fabric and without needing to use buffers in the second stage, is possible. The cost of speed-up and the cell out-of-sequence problems that may occur when buffers are used in the second stage are therefore avoided.

Owner:POLYTECHNIC INST OF NEW YORK

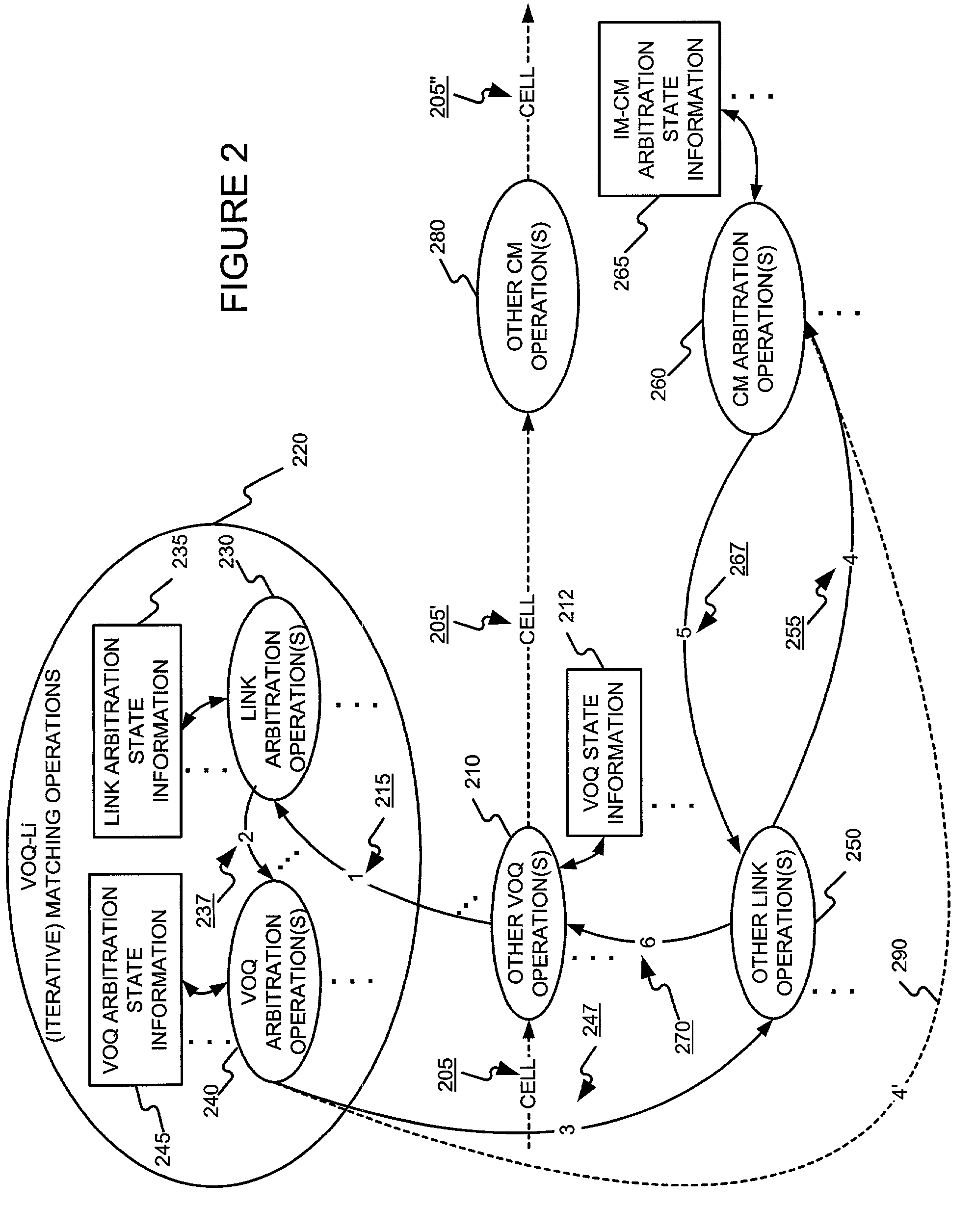

Method and apparatus for two-stage packet classification using most specific filter matching and transport level sharing

ActiveUS7408932B2Network traffic/resource managementData switching by path configurationClassification methodsSecondary stage

A method and apparatus for two-stage packet classification, the two-stage packet classification scheme including a first stage and a second stage. In the first classification stage, a packet is classified on the basis of the packet's network path. In the second stage of classification, the packet is classified on the basis of one or more transport (or other) fields of the packet. Also disclosed are embodiments of most specific filter matching and transport level sharing, and either one or both of these techniques may be implemented in the two-stage classification method.

Owner:INTEL CORP

Decelerated centrifugal dust removing apparatus for dust cleaner

InactiveUS20030200736A1Avoid secondary pollutionSmooth rotationCombination devicesAuxillary pretreatmentLow noiseFilter system

The present invention discloses a decelerated centrifugal dust removing apparatus for a dust cleaner. It comprises a cylinder, a conical cylinder and a dust collector box connected in the given order from the upper part to the lower part, as well as an air outlet pipe and an air inlet pipe on the cylinder body. The conical cylinder has a small upper end and a large lower end. In the conical cylinder, on the lower part of the air outlet pipe (under the air outlet pipe) there is an umbrella-shaped reflector in the center of which is provided a hole for air returning. Between the periphery of the umbrella reflector and the side wall is provided an annular gap for the falling down of dust. The apparatus features small loss of air flow pressure, good effectiveness of air suction, high quality of dust filtering, and low noise. With the apparatus, the secondary pollution of the cleaned air can be effectively prevented, and it is especially suitable for use in a secondary stage filtering system of the dust cleaner and for separating small and fine dust particles.

Owner:SUZHOU KINGCLEAN FLOORCARE

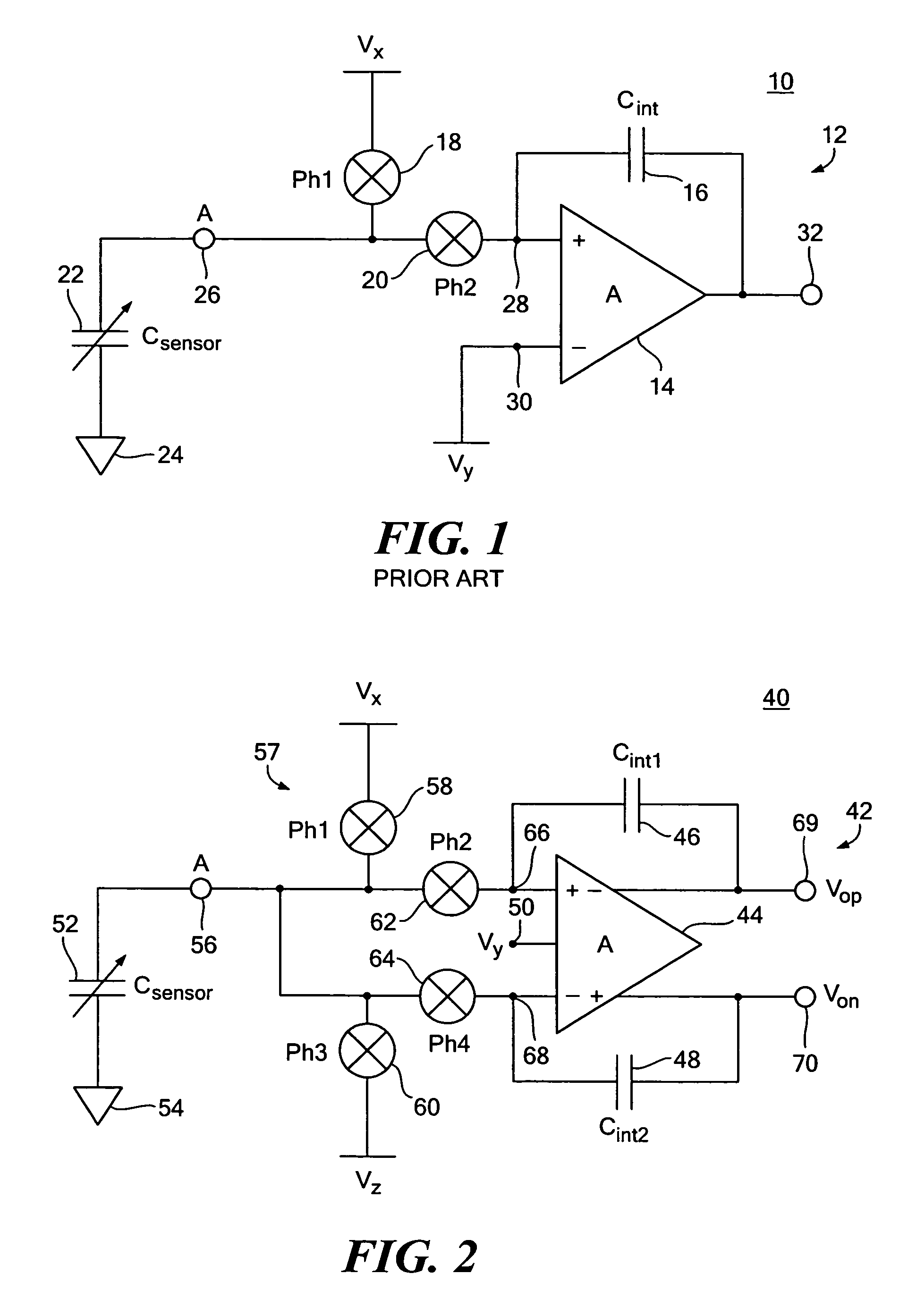

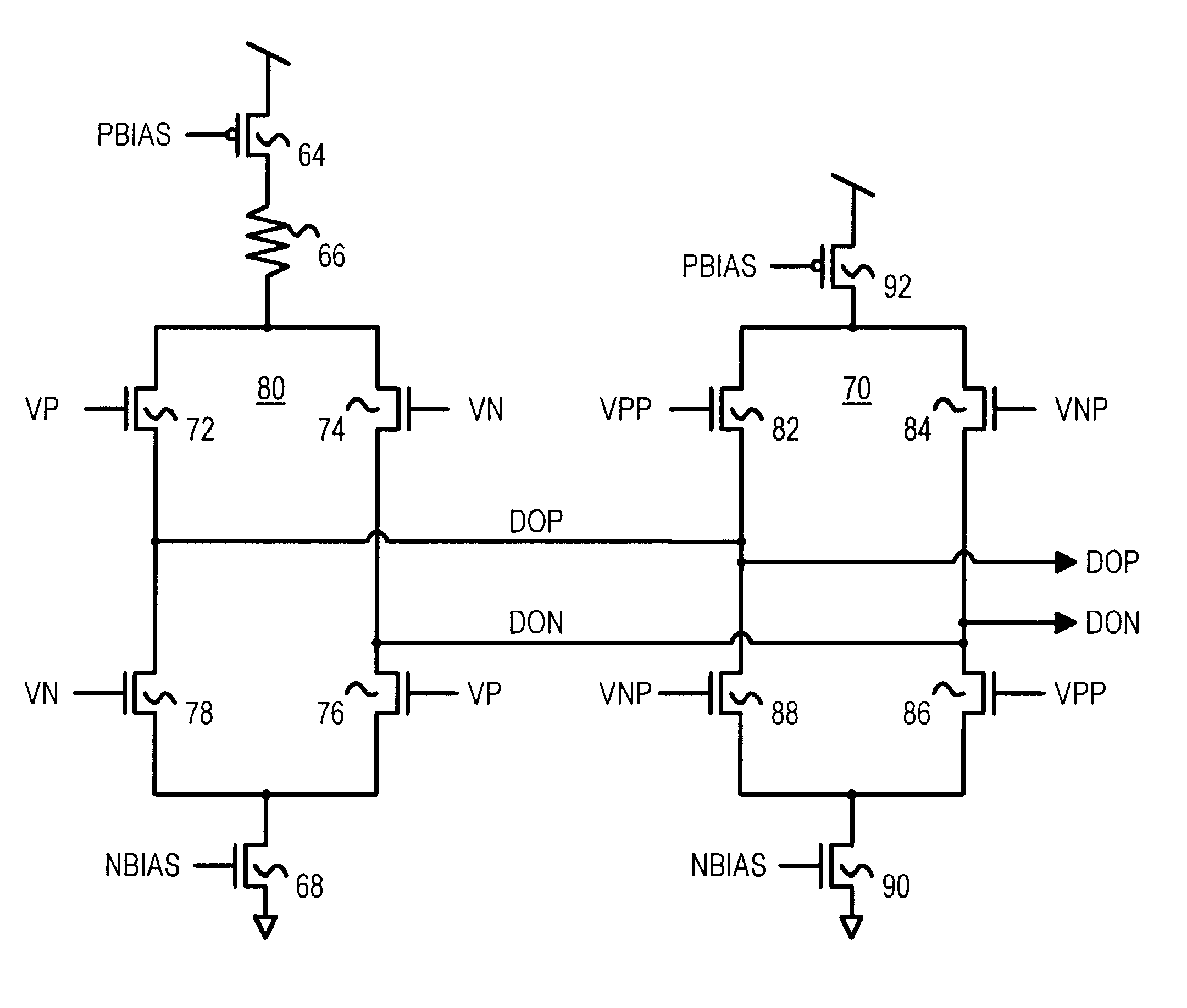

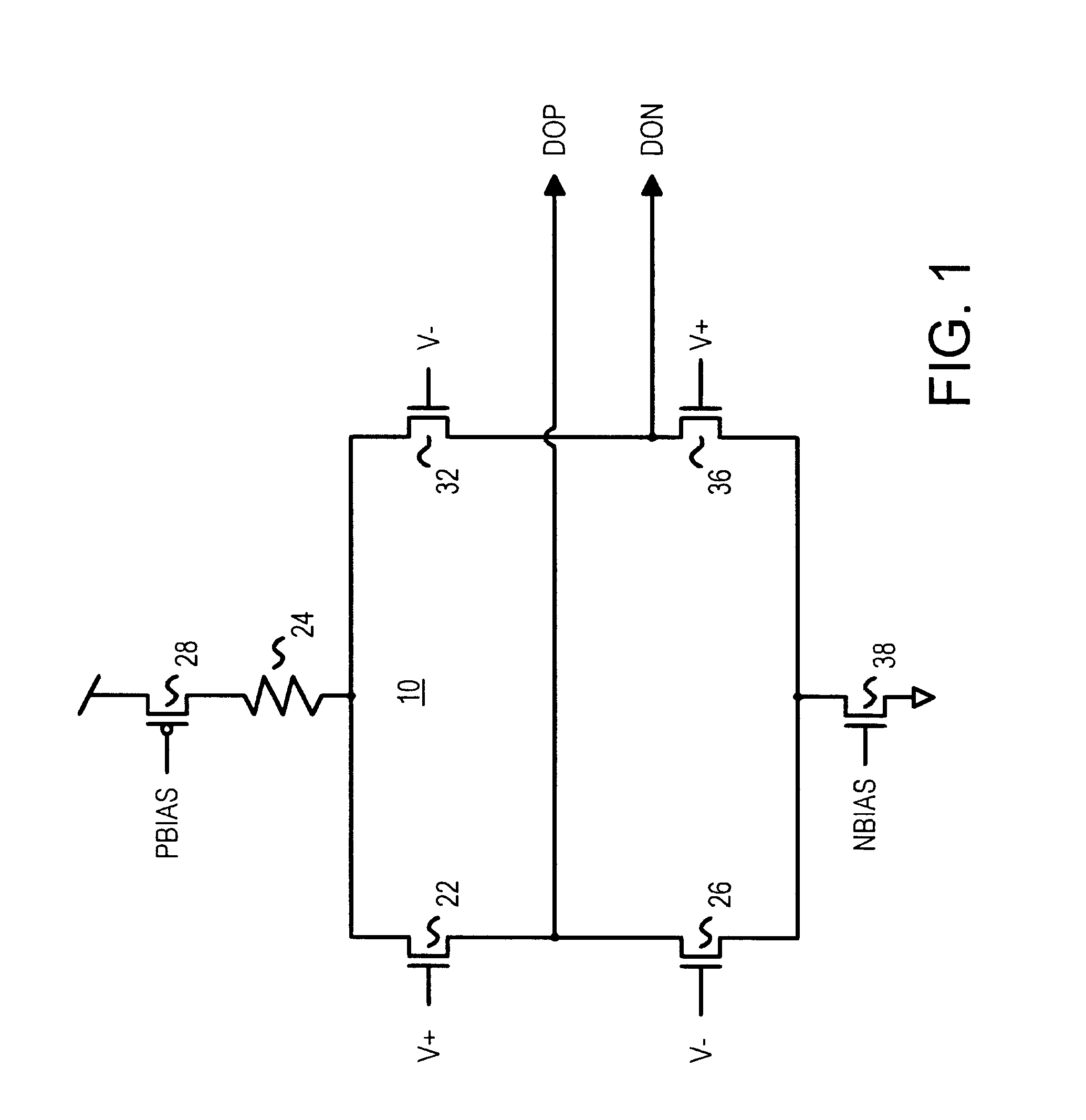

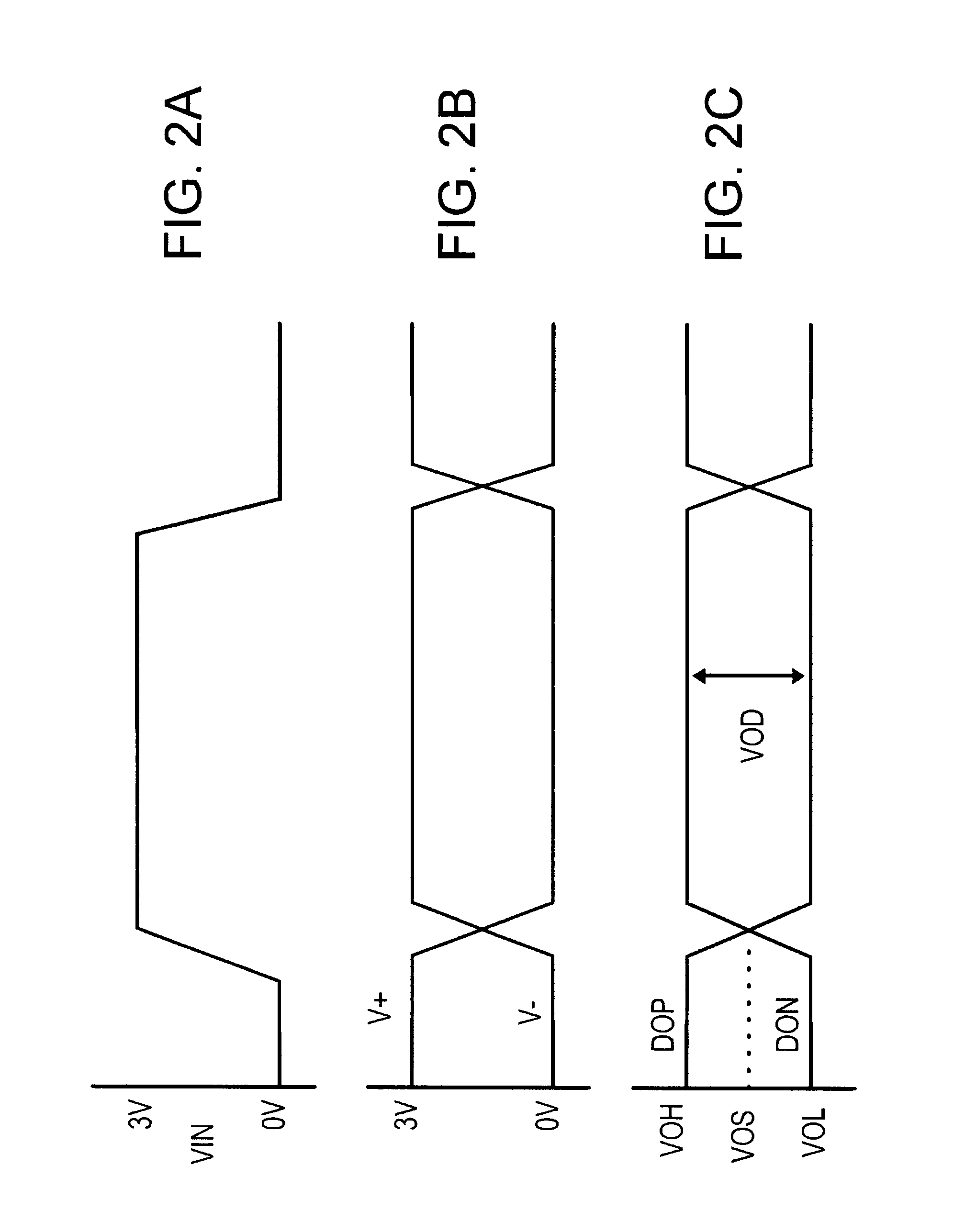

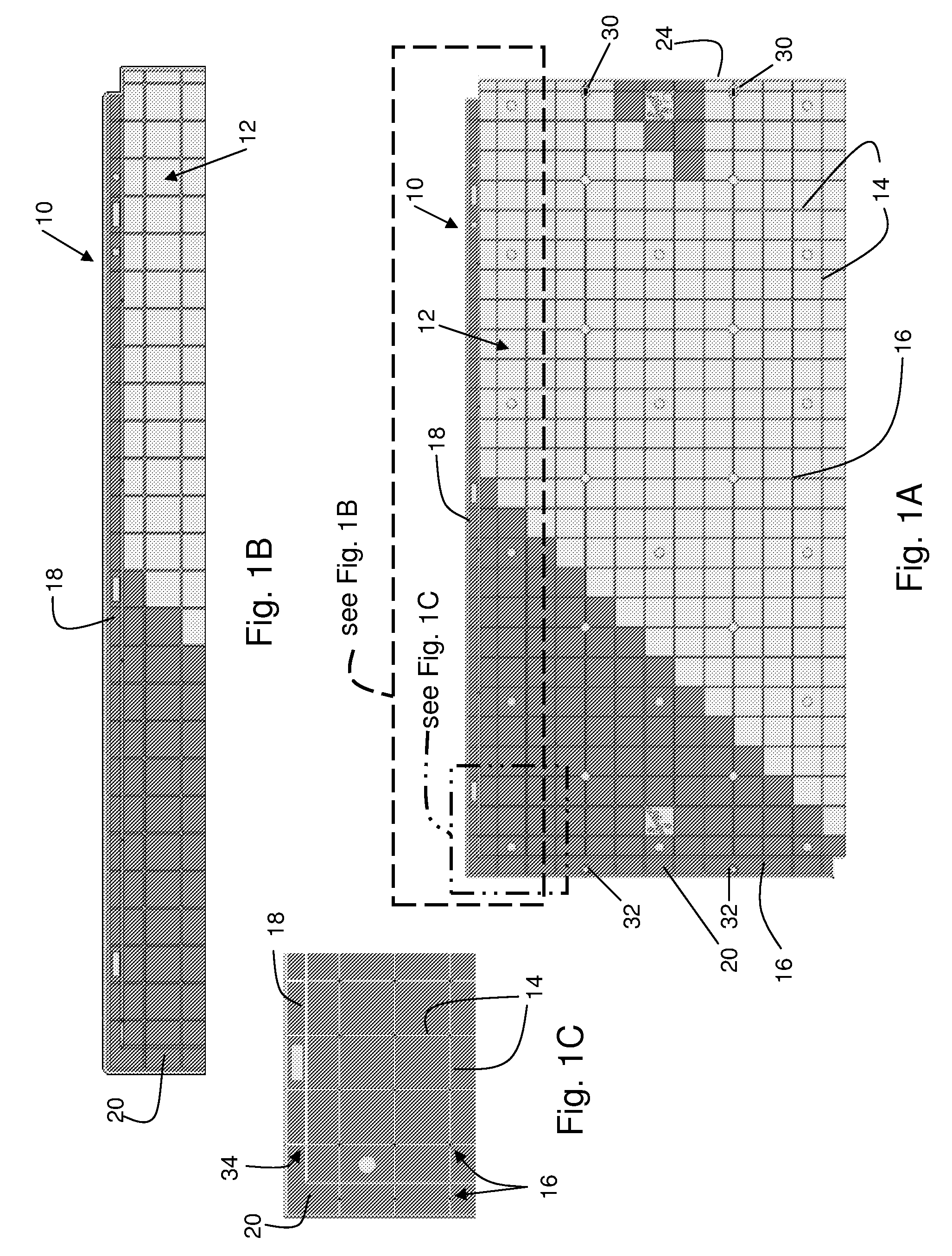

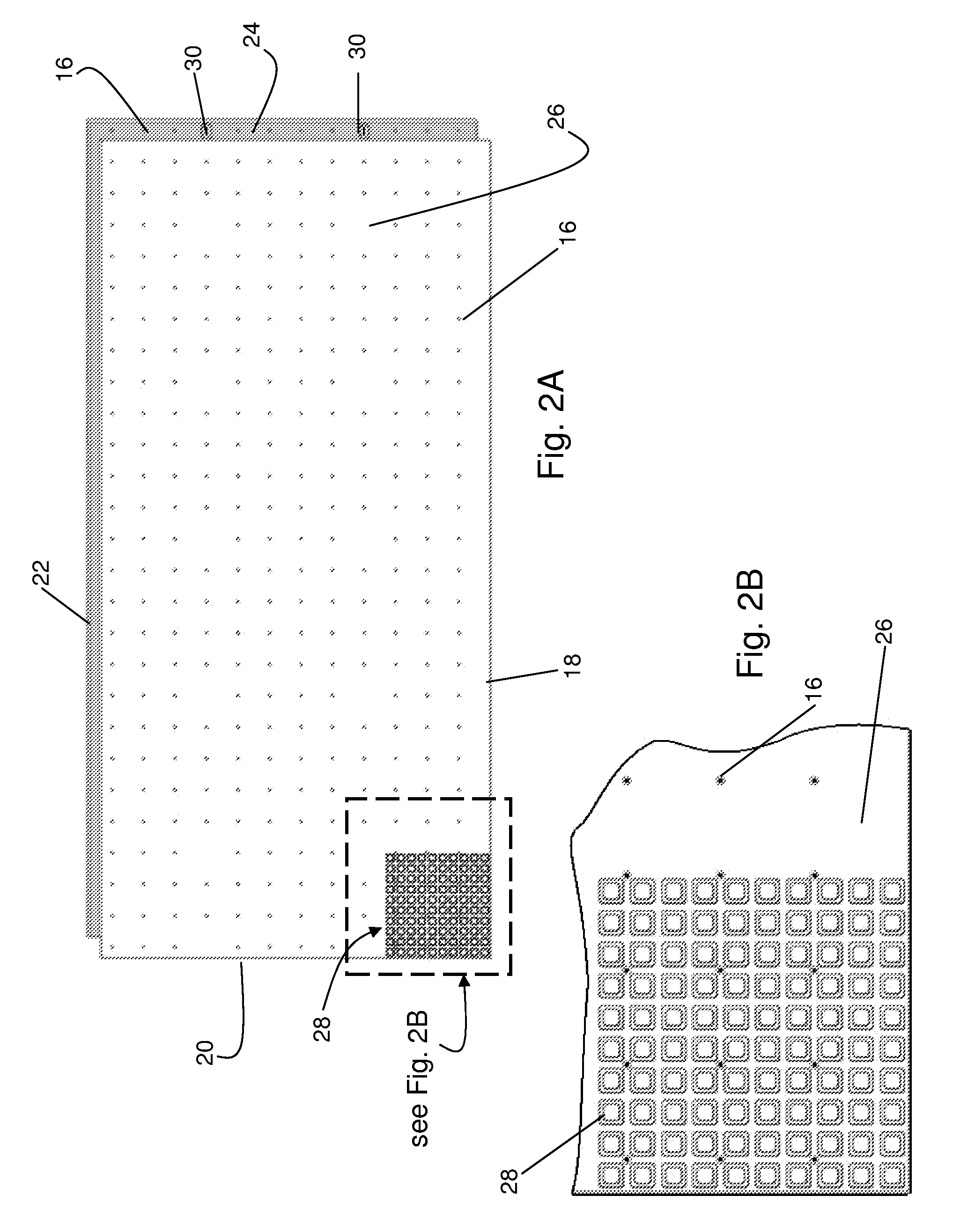

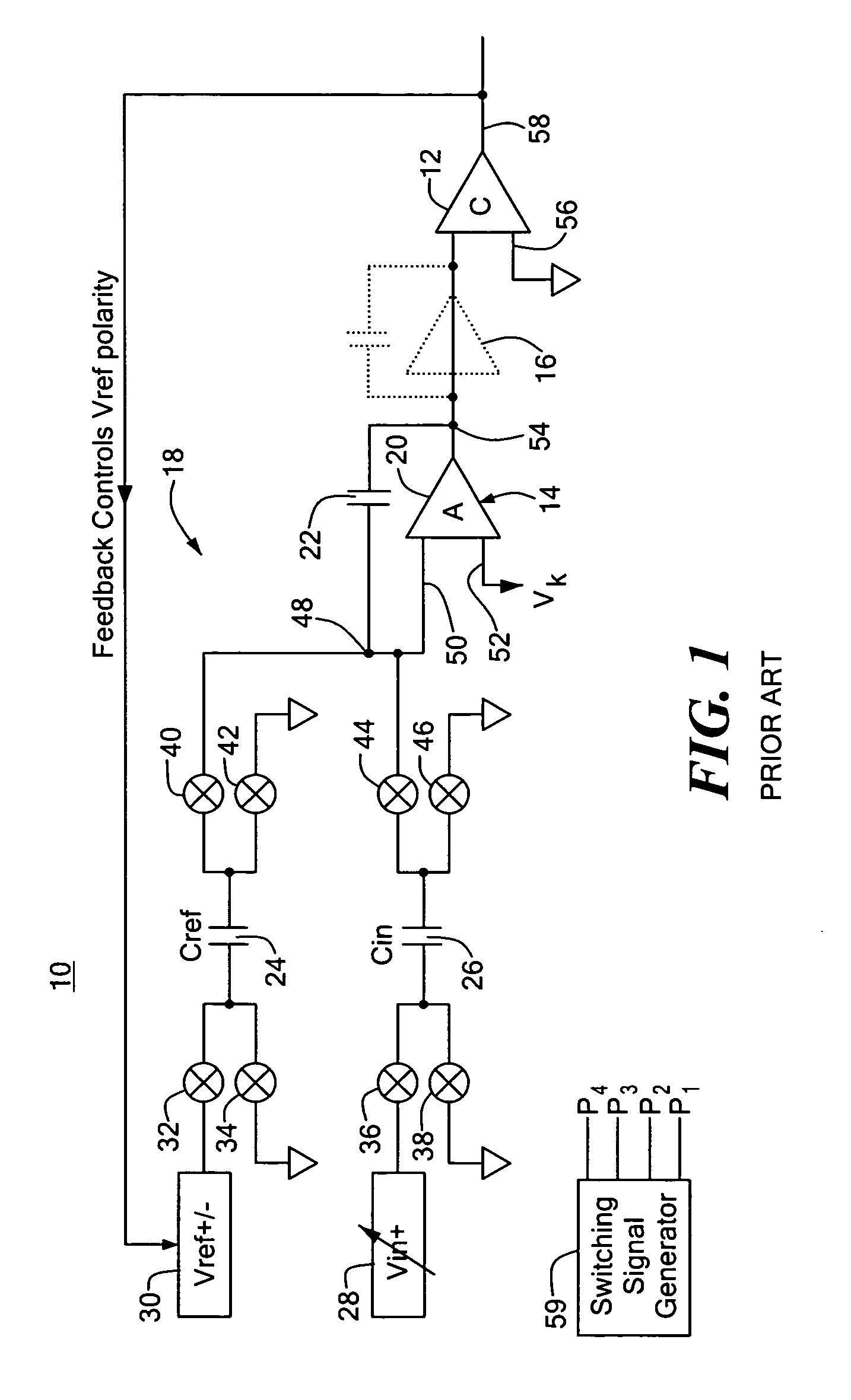

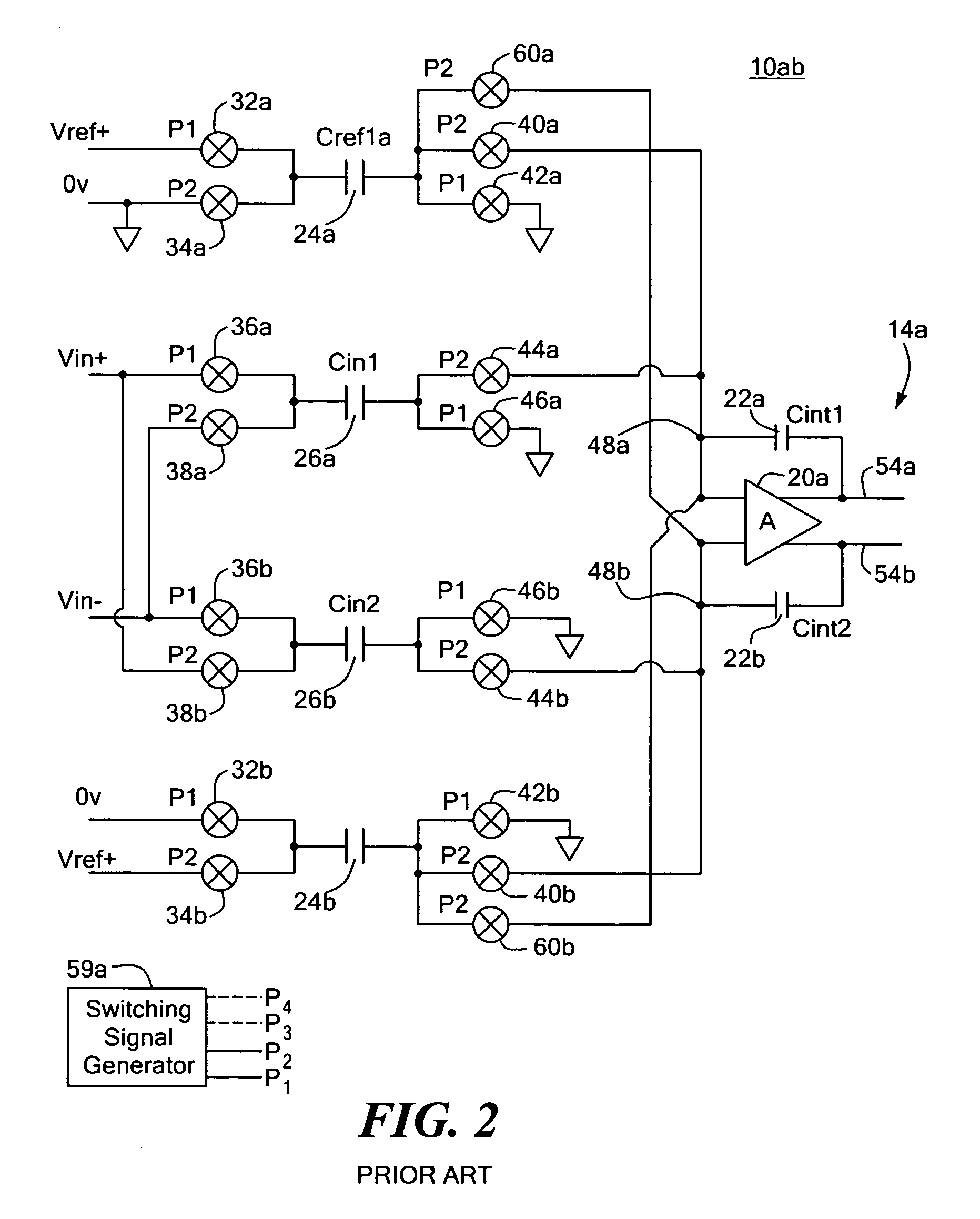

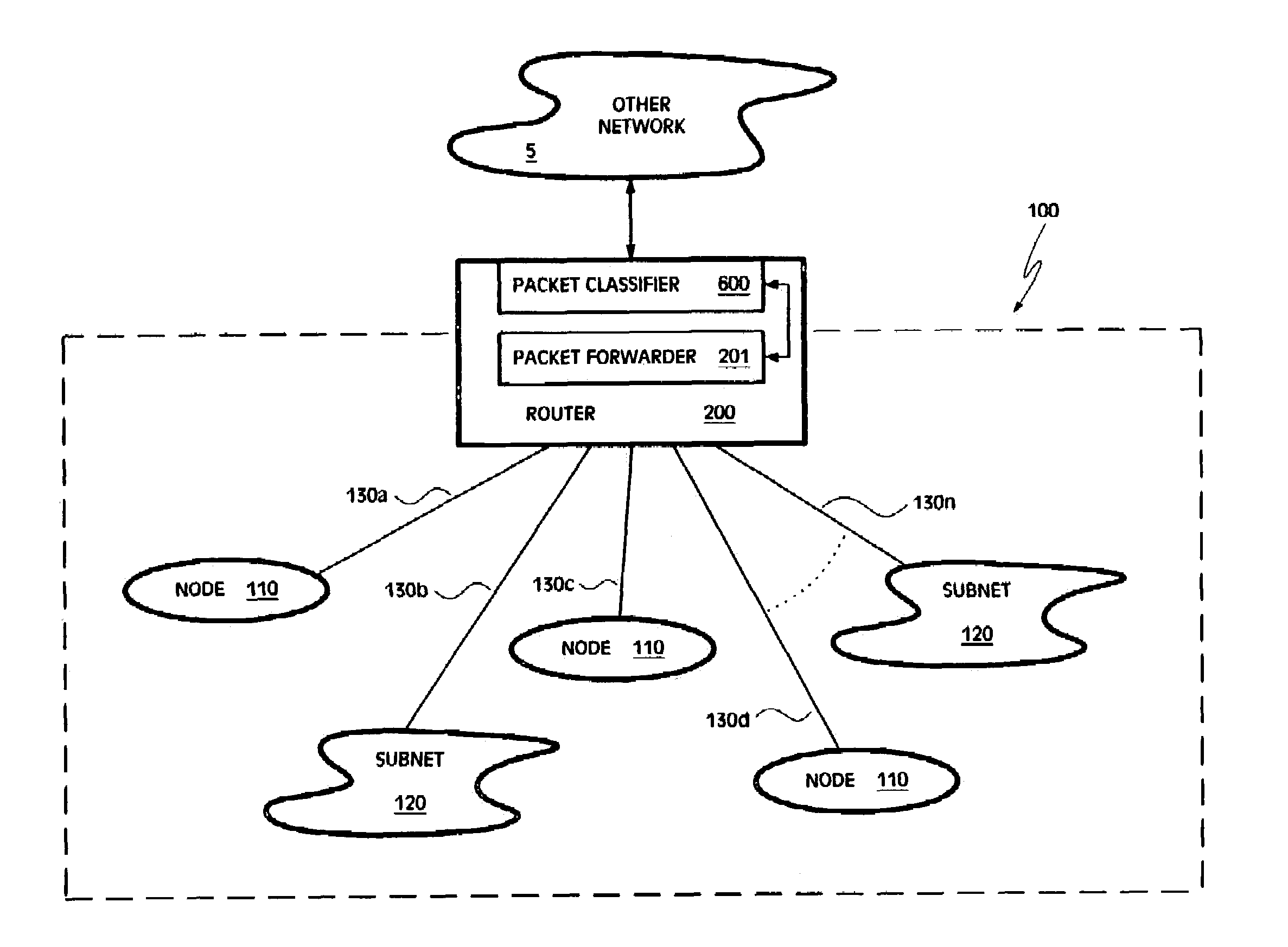

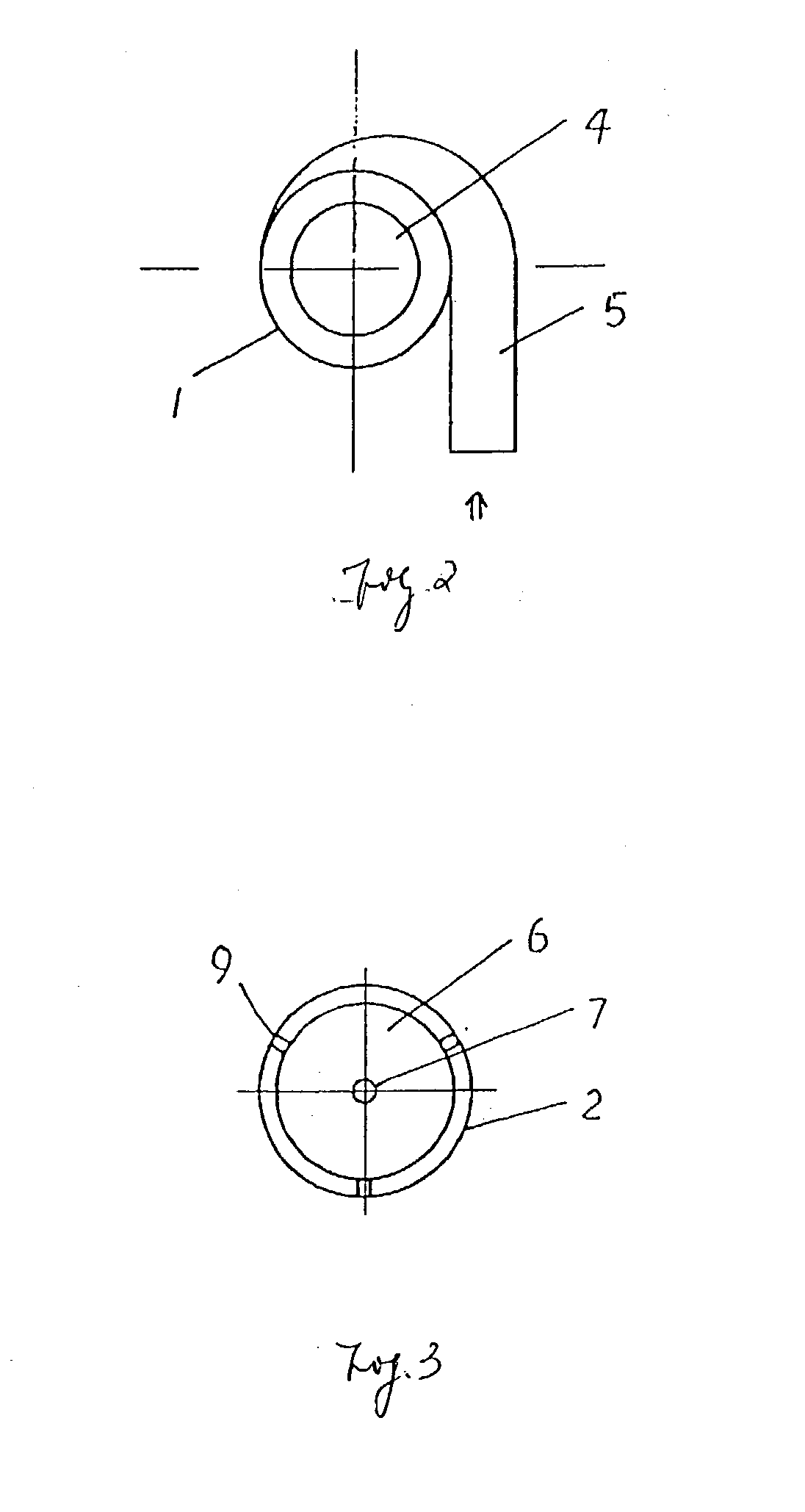

Low voltage differential signaling [LVDS] driver with pre-emphasis

ActiveUS6977534B2Reduce data jitterMultiple input and output pulse circuitsBaseband system detailsControl signalSecondary stage

A Low Voltage Differential Signaling Driver with Pre-emphasis and including a primary stage having a first switching circuit providing an output representing a sequence of pulses at a predetermined current level, a secondary stage having a second switching circuit arranged to provide an additional current level for the pulses, and a control circuit arranged to provide control signals for controlling the first and second switching circuits. The control circuit detects a difference in level between two consecutive pulses of the sequence and provides accordingly control signals to the first and second switching circuits. The control signals are such that when two consecutive pulses of the sequence are different, the additional current level is added to the predetermined current level, whilst when two consecutive pulses of the sequence are identical, the additional current level is subtracted from the predetermined current level.

Owner:RPX CORP

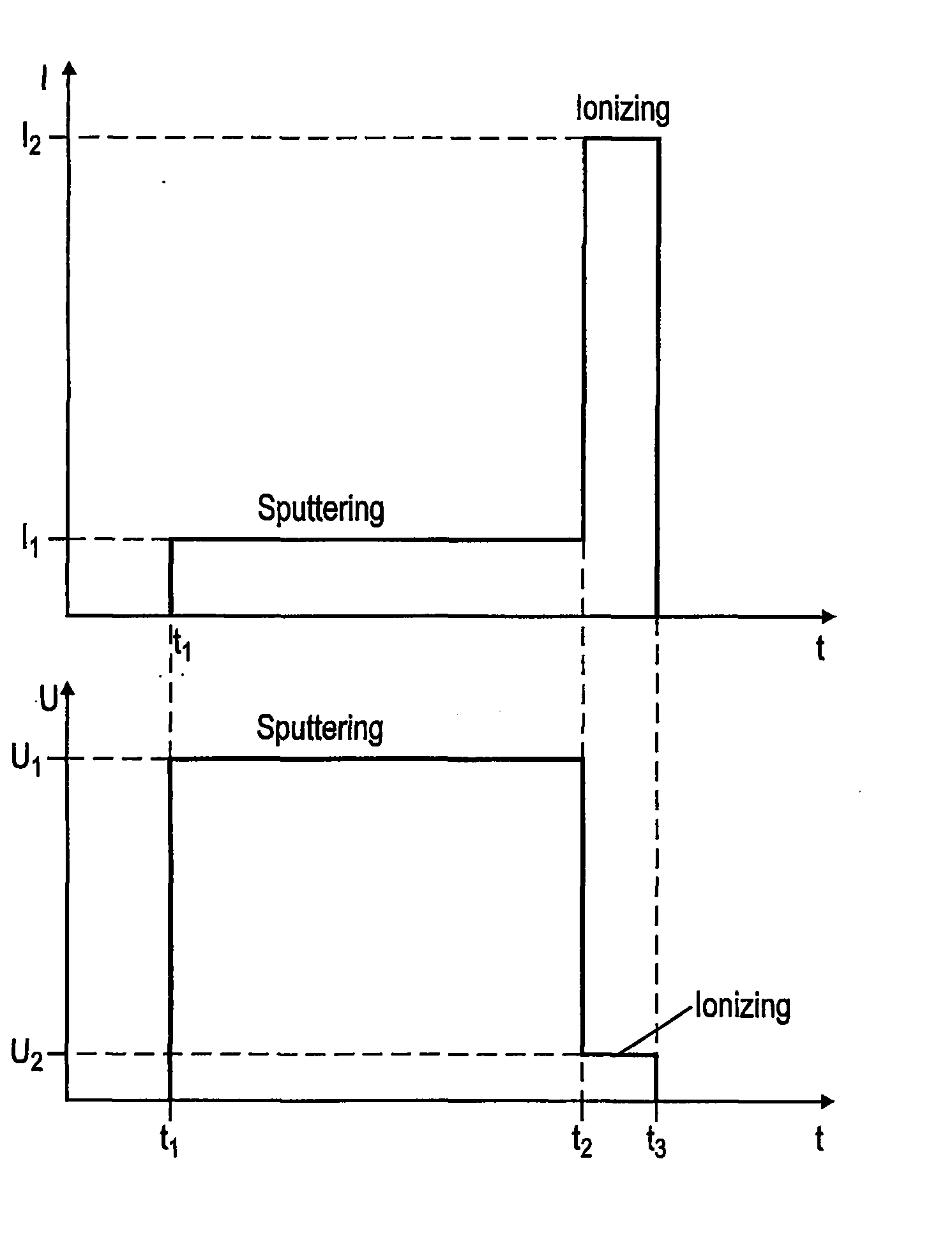

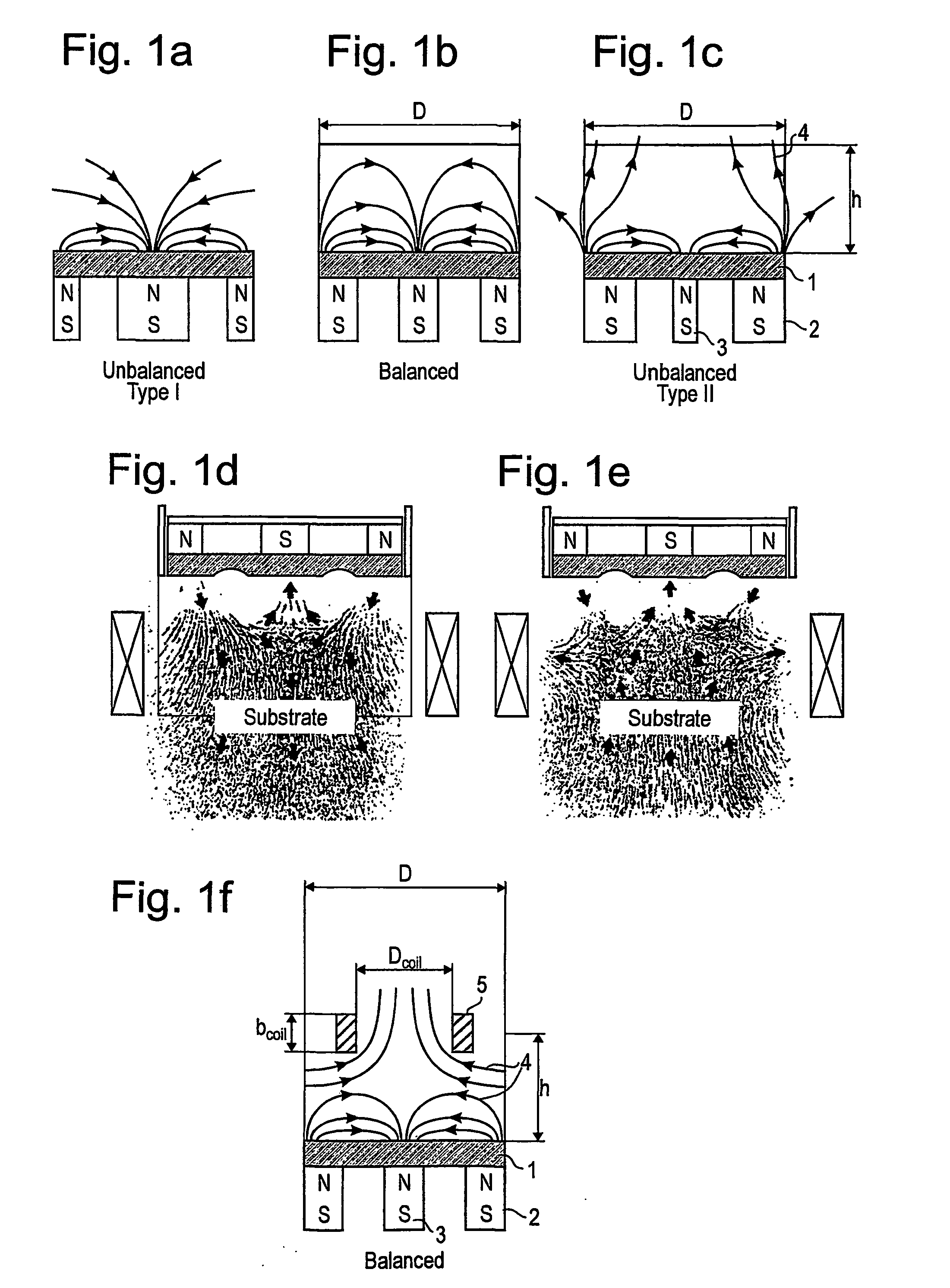

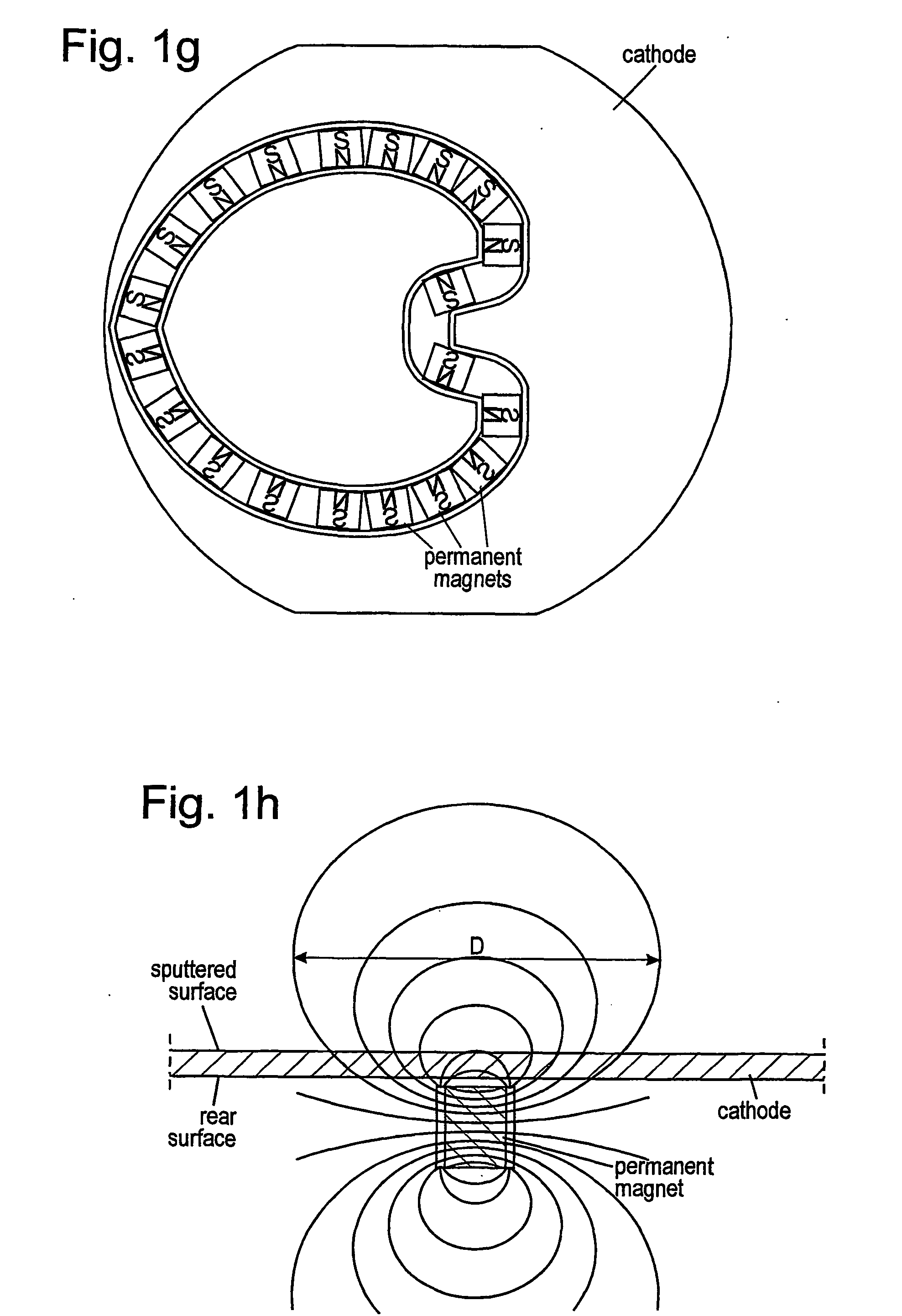

Method and apparatus for plasma generation

ActiveUS20050092596A1Improved plasma confinement propertyIncrease currentElectric discharge tubesVacuum evaporation coatingElectric dischargePlasma flow

In a simple method and device for producing plasma flows of a metal and / or a gas electric discharges are periodically produced between the anode and a metal magnetron sputtering cathode in crossed electric and magnetic fields in a chamber having a low pressure of a gas. The discharges are produced so that each discharge comprises a first period with a low electrical current passing between the anode and cathode for producing a metal vapor by magnetron sputtering, and a second period with a high electrical current passing between the anode and cathode for producing an ionization of gas and the produced metal vapor. Instead of the first period a constant current discharge can be used. Intensive gas or metal plasma flows can be produced without forming contracted arc discharges. The selfsputtering phenomenon can be used.

Owner:CEMECON +1

Apparatus and method for two-stage packet classification using most specific filter matching and transport level sharing

InactiveUS20050226235A1Multiplex system selection arrangementsData switching by path configurationSecondary stageHandling system

Owner:INTEL CORP

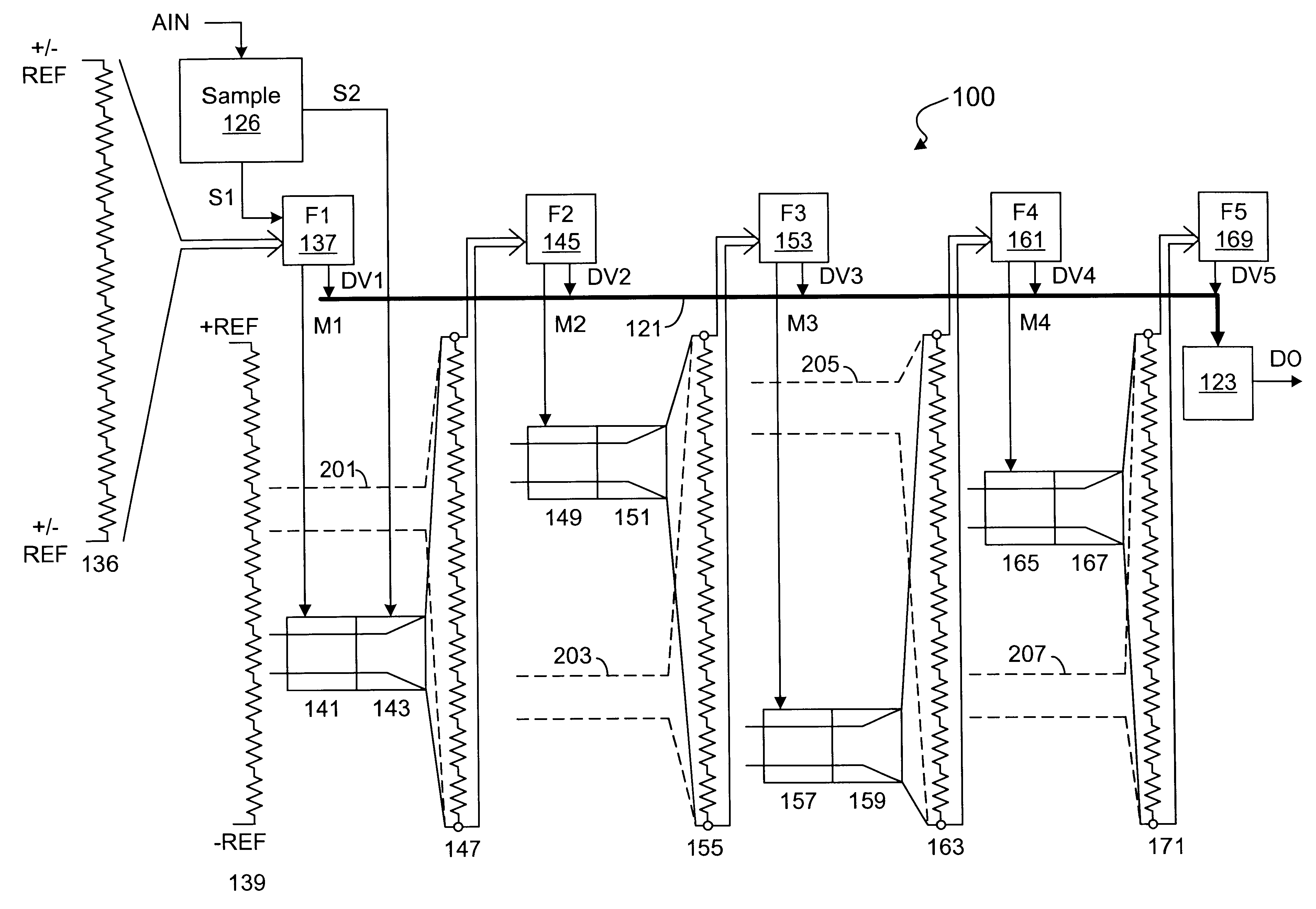

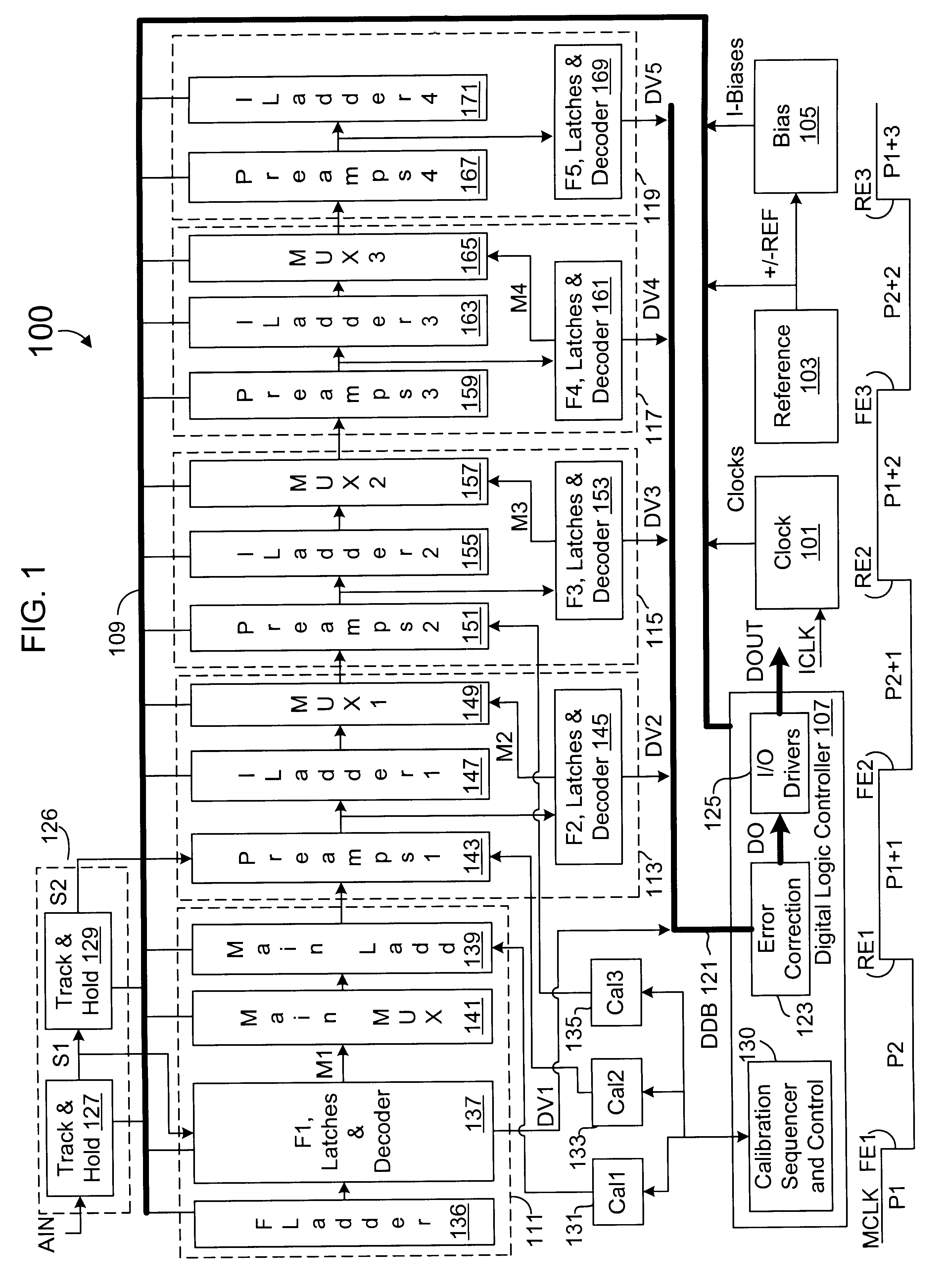

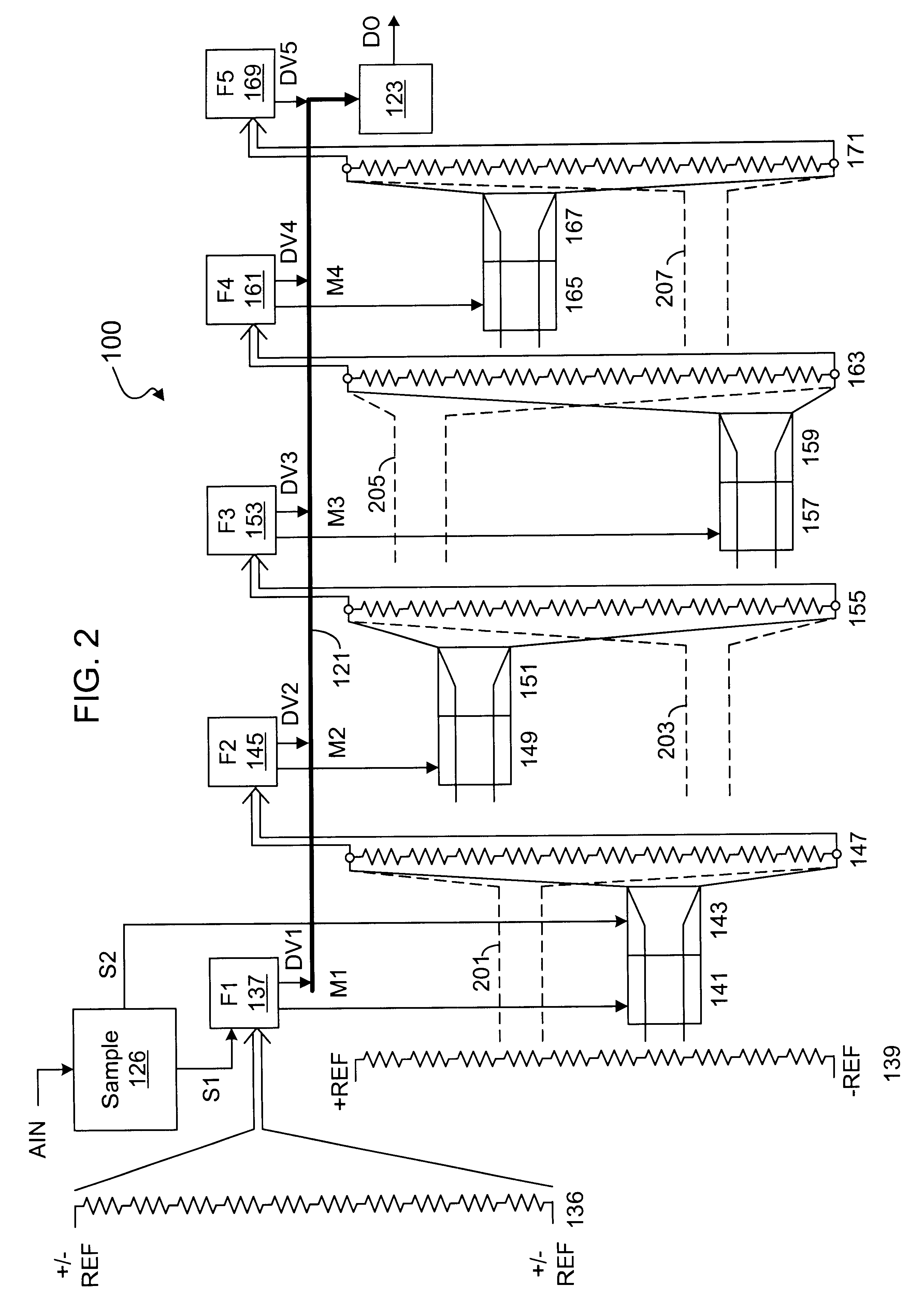

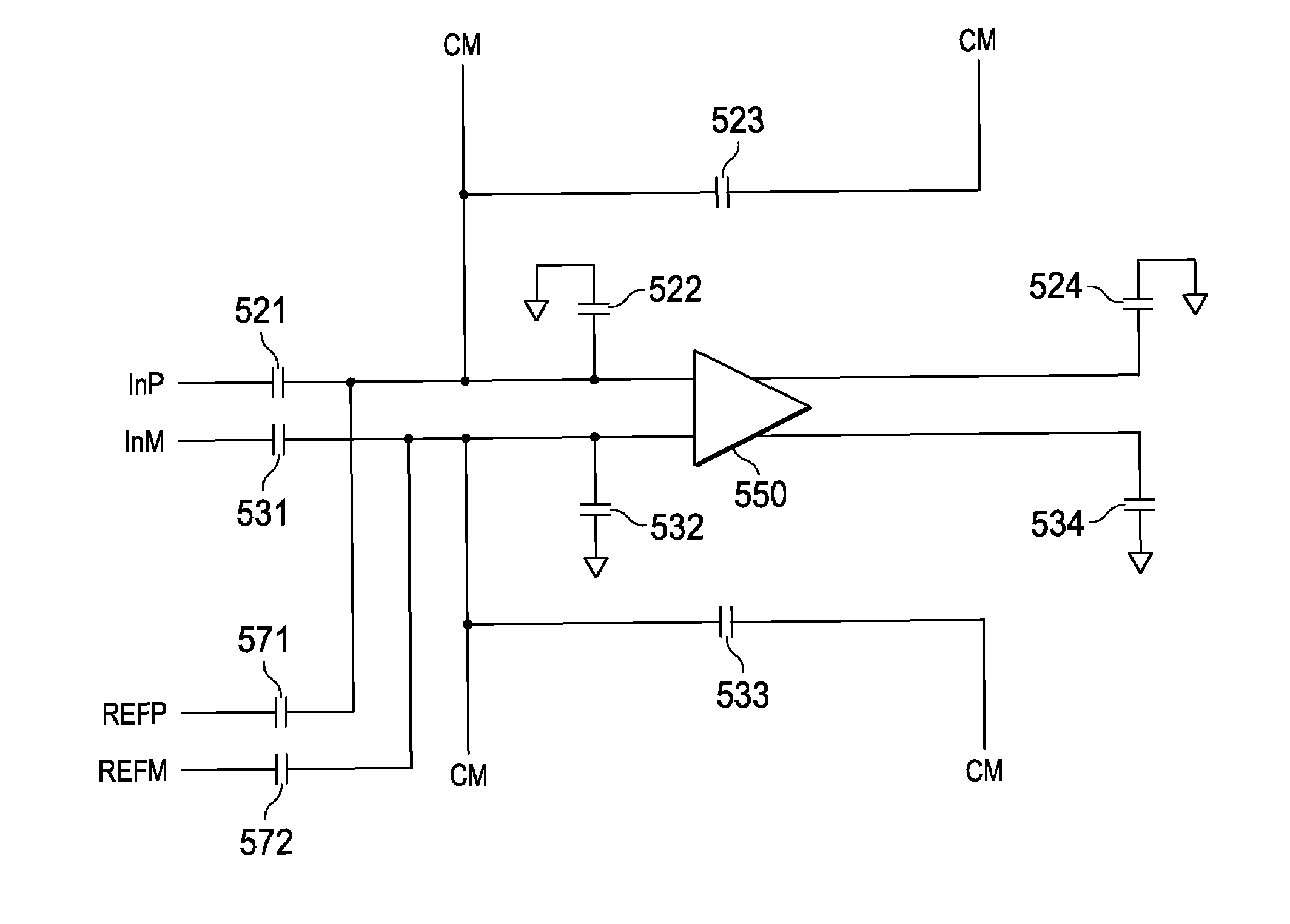

Analog to digital converter using subranging and interpolation

InactiveUS6570523B1Improve signal-to-noise ratioAccurate representationElectric signal transmission systemsAnalogue-digital convertersDigital down converterEngineering

A multistage ADC that subranges and interpolates, and that amplifies selected subranges to convert an analog signal to a stream of digital values. The ADC samples the analog signal and provides a stream of sample signals. A first stage flash converts each sample signal into a first multiple bit value and subranges a reference ladder according to the first multiple bit value into selected reference signals. Each additional secondary stage amplifies a selected subrange of signals from a prior stage, flash converts the amplified residual signals to provide an additional multiple bit value, interpolates each set of amplified residual signals and subranges the interpolated signals according to the corresponding multiple bit value. A final stage amplifies and flash converts to determine a final multiple bit value. An error corrector combines each set of multiple bit values into a digital value.

Owner:INTERSIL INC

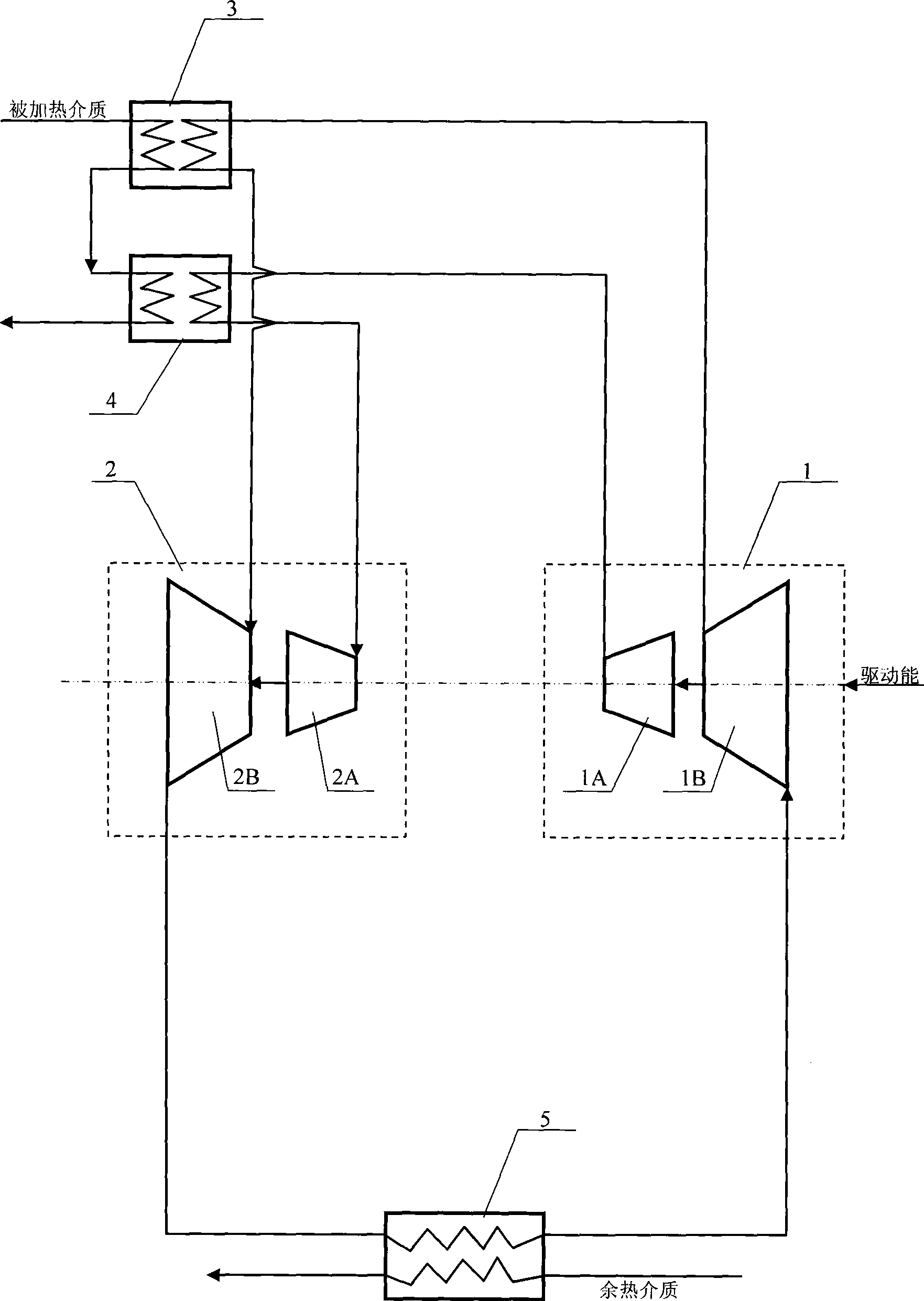

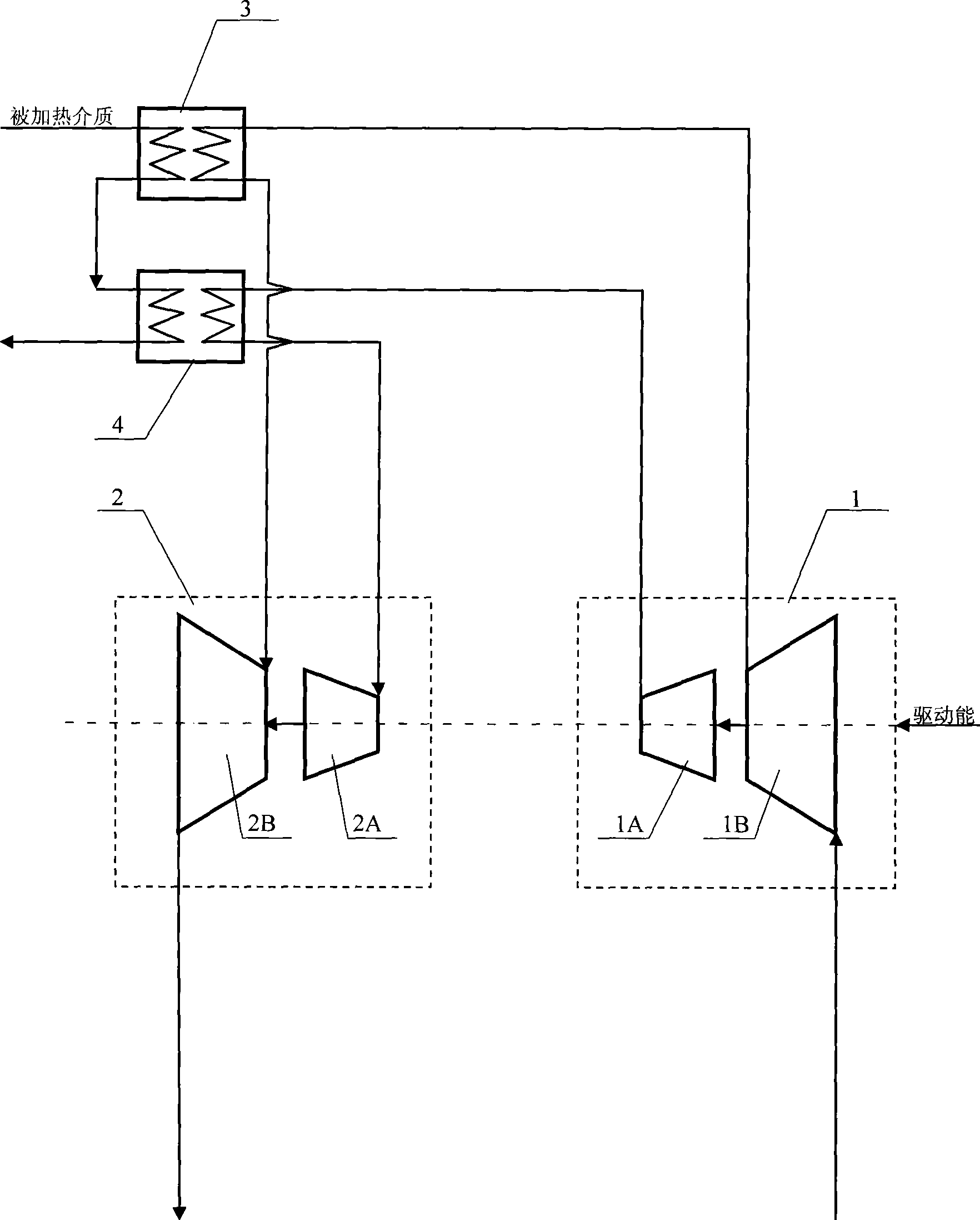

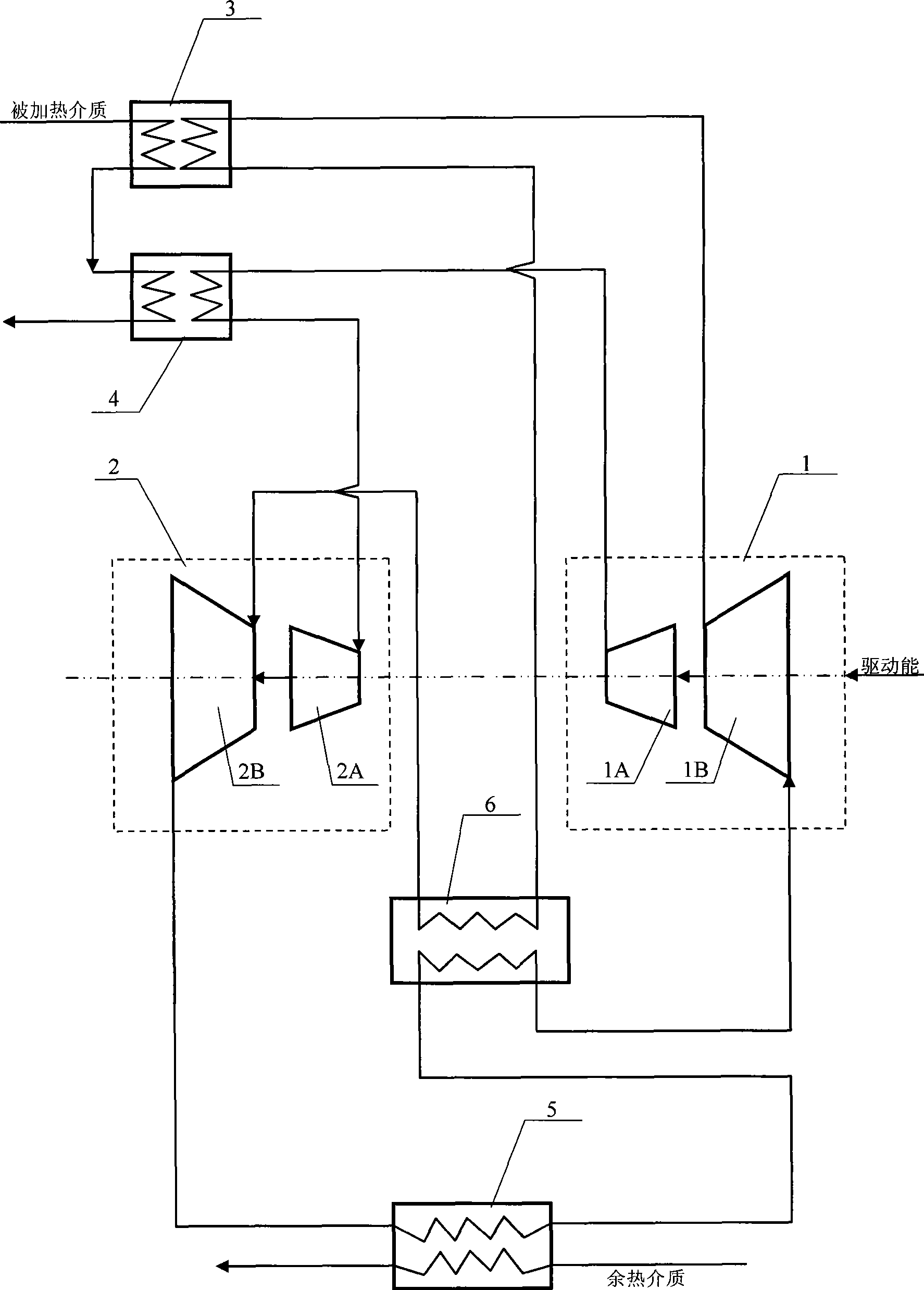

Segmented compression-segmented heat supply-segmented expansion gas compression type units

ActiveCN101504205AReduce power consumptionReduce the compression ratioCompression machines with non-reversible cycleSuperheatersPerformance indexEngineering

A subsection compression-subsection heat supply-subsection gas expanding compression type machine set belongs to the technical field of heat pumps / refrigeration, and consists of a compressor, an expander, a heat exchanger, a second heat exchanger and a low-temperature heat exchanger. Gas working substances absorbing heat from the low-temperature heat exchanger and raising temperature enter the compressor; after the gas working substances are compressed in a low pressure compression section, a part of the gas working substances are provided for the heat exchanger to complete the heating of a heated medium at an initial stage; the part of the gas working substances enter the expander and is expanded at a low pressure expansion section; the other part of the gas working substances are provided for the second heat exchanger to complete the heating of a second stage of the heated medium after continuously passing through the whole compression process and raising temperature, and enter the expander from an inlet of the high pressure expansion section of the expander for expanding; the gas working substances completing the expanding work flow through the low-temperature heat exchanger to absorb the heat and raise the temperature and enter the compressor; and a heat regenerator is added to form a regenerative machine set. The gas expanding compression type machine set reduces temperature difference of heat transmission and improves the performance index; when taken as a heat pump, the gas expanding compression type machine set is particularly suitable for occasions with high heating temperature and wide range; and when used for refrigeration, the gas expanding compression type machine set can reduce power consumption.

Owner:李华玉

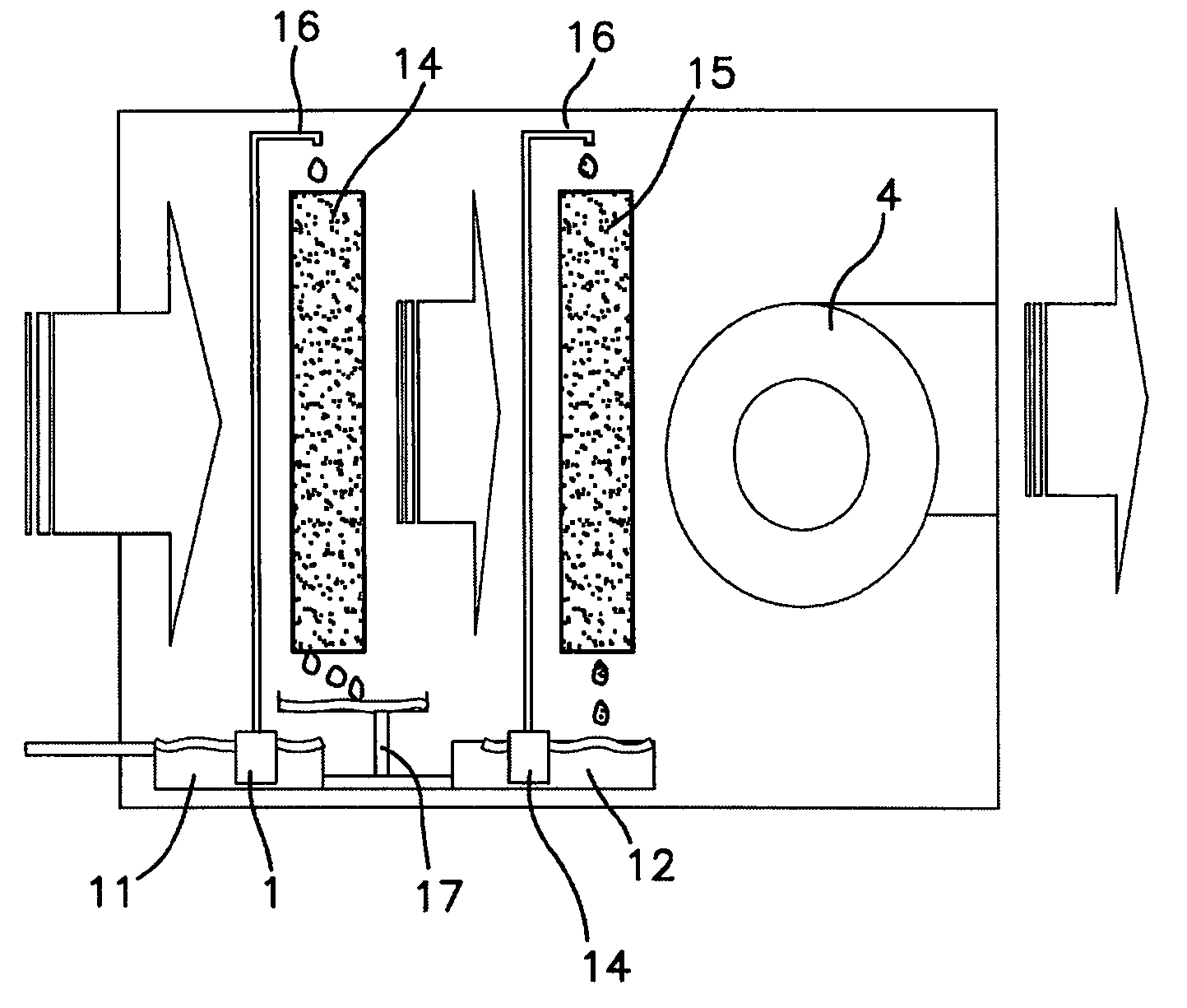

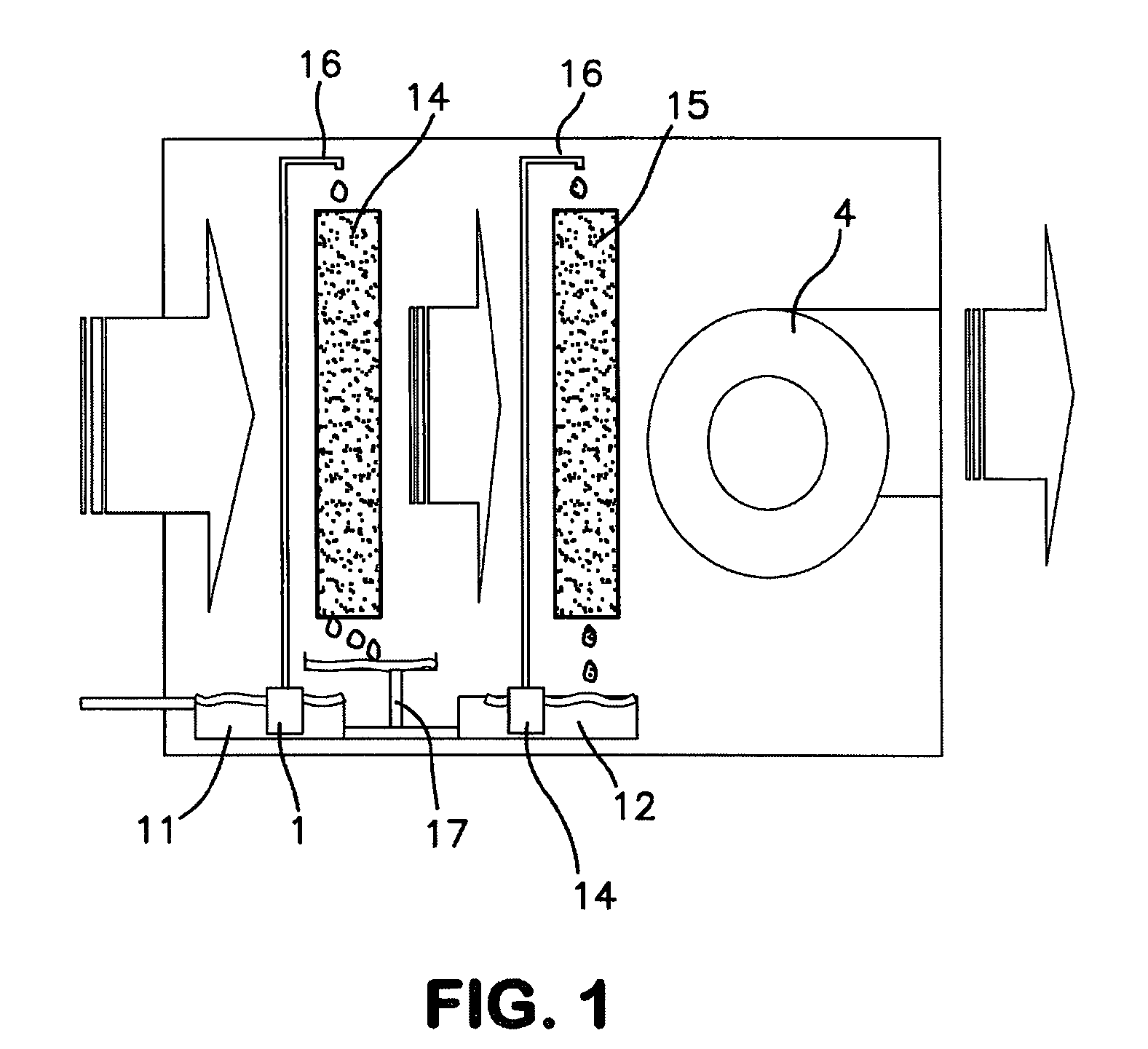

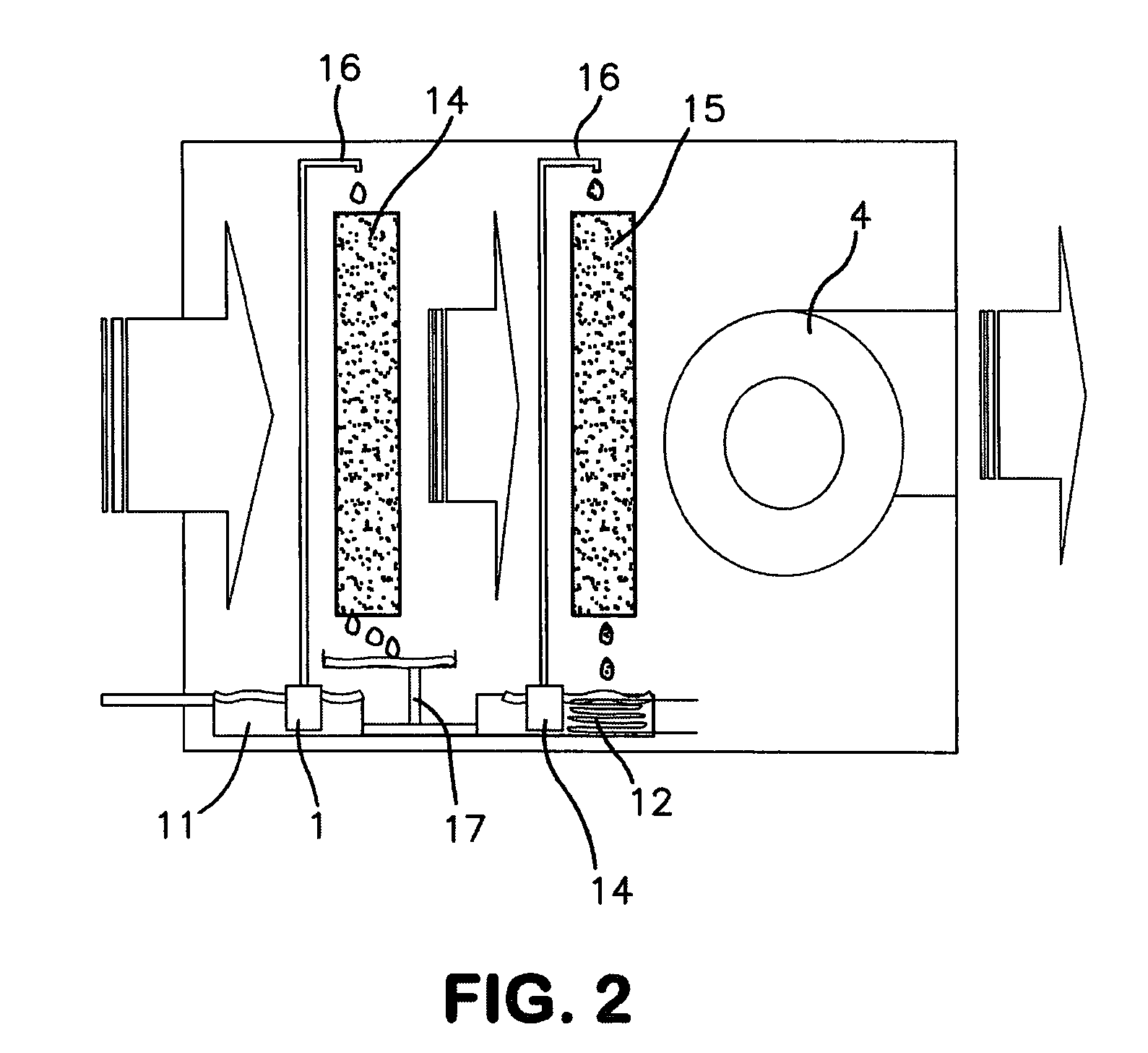

Evaporative Air Cooler With Multi Stages Cooling And Or Heating With Or Without Cooling Coil

InactiveUS20100281896A1Free-cooling systemsStationary conduit assembliesEvaporative coolerCooling coil

An outdoor air cooler with two stages includes a first stage for cooling and humidification with constant wet bulb temperature. The air cooler has a first stage pump circulating water over the first stage evaporative cooling media operating at conditions having a constant adiabatic wet bulb temperature line. The first stage tank is supplied with water from external source. The second stage includes a second set of evaporative cooling media using water from the first stage media, which is equal to or lower than outdoor air wet bulb temperature. The temperature of air leaving the second stage evaporative media follows the adiabatic wet bulb temperature line toward the second stage tank water temperature thereby cooling humidifying the treated air to stable wet and dry bulb temperatures.

Owner:AL WATBAN ALAA ABDULKAREEM

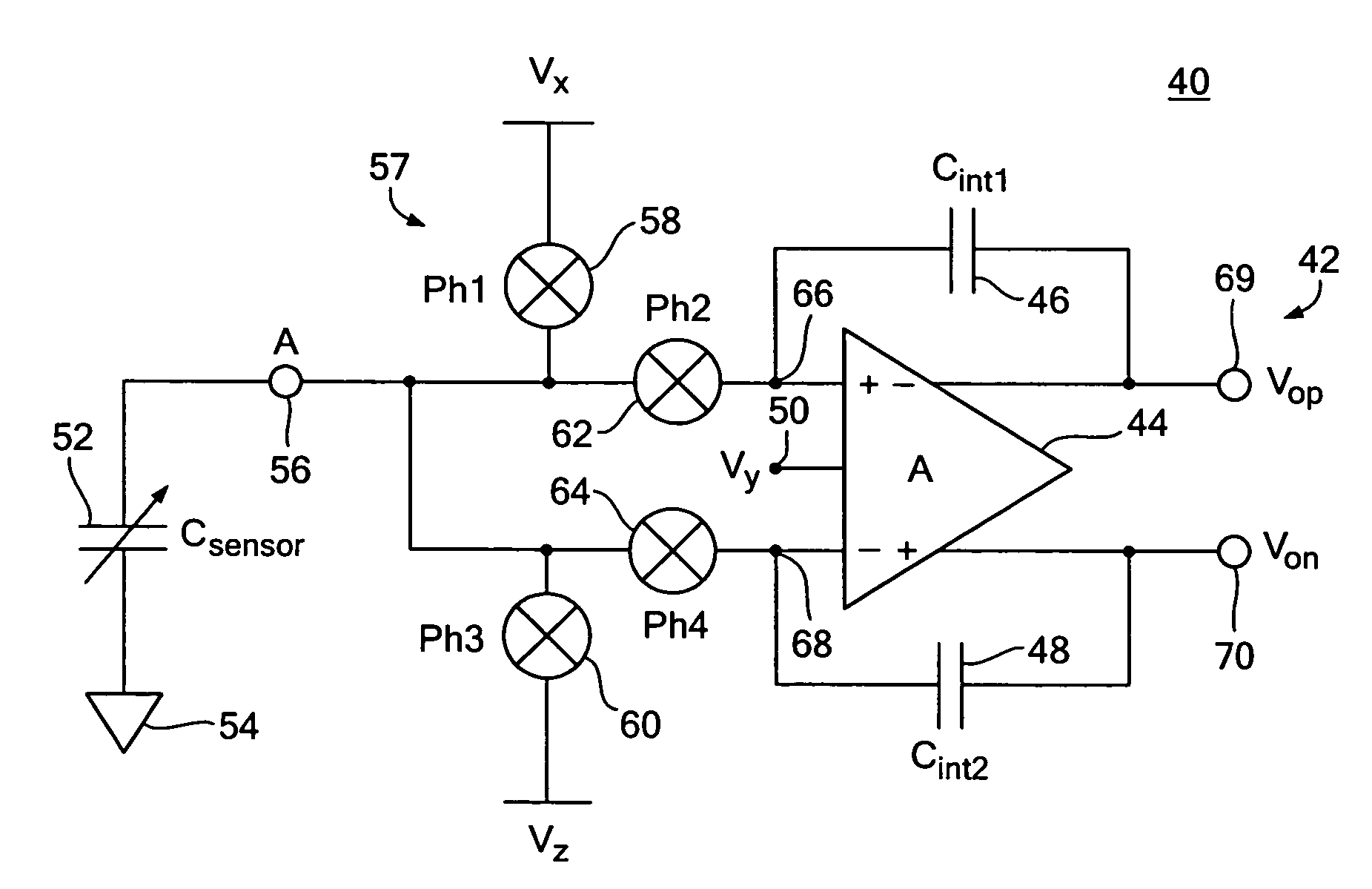

One terminal capacitor interface circuit

ActiveUS7235983B2Offset errorLow frequency noiseResistance/reactance/impedenceAnalogue conversionCapacitanceSecondary stage

A one terminal capacitor interface circuit for sensing the capacitance of a capacitor includes a differential integrating amplifier having an input common mode voltage and two summing nodes whose voltage is substantially equal to the input common mode voltage, a switching circuit for charging the capacitor to a first voltage level in a first phase, connecting, in a second phase, the capacitor to one of the summing nodes of the differential amplifier to provide a first output change substantially representative of the difference between the first voltage level and the input common mode voltage, and also representative of the capacitor; charging the capacitor to a second voltage level in a third phase, and connecting, in a fourth phase, the capacitor to the other summing node of the differential amplifier to provide a second output change substantially representative of the difference between the second voltage level and the input common mode voltage, and also representative of the capacitor; the combined first and second output changes representing the capacitance of the capacitor substantially independent of the input common mode voltage.

Owner:ANALOG DEVICES INC

Low-voltage differential driver with opened eye pattern

A differential output buffer has a primary stage and a secondary stage that each directly drive differential outputs. Link transistors between the secondary stage and the differential outputs are eliminated. The primary stage continuously receives differential inputs applied to gates of n-channel sourcing and sinking transistors. The sources of the sourcing transistors and the drains of the sinking transistors are connected to the true and complement differential outputs. The secondary stage also has n-channel sourcing and sinking transistors directly connected to the differential outputs. Pulsed inputs applied to secondary-stage gates are normally low, disabling the sourcing and sinking transistors in the secondary stage to disable the secondary stage. However, during a switching transient, the pulsed inputs are pulsed on, allowing the secondary stage to drive a boost current to the differential outputs. This boost current sharpens rise and fall edges to compensate parasitic capacitances, opening the eye pattern.

Owner:DIODES INC

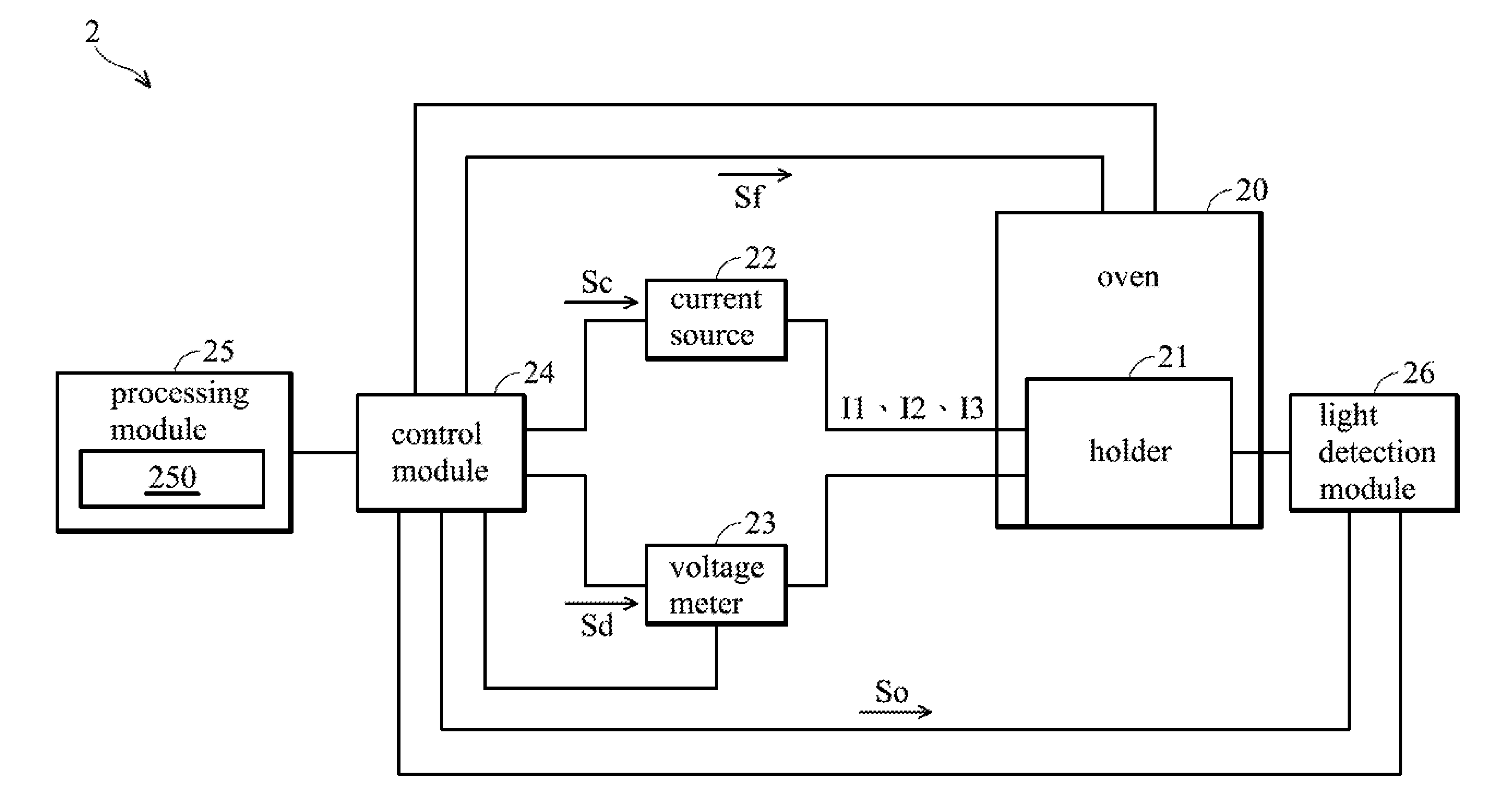

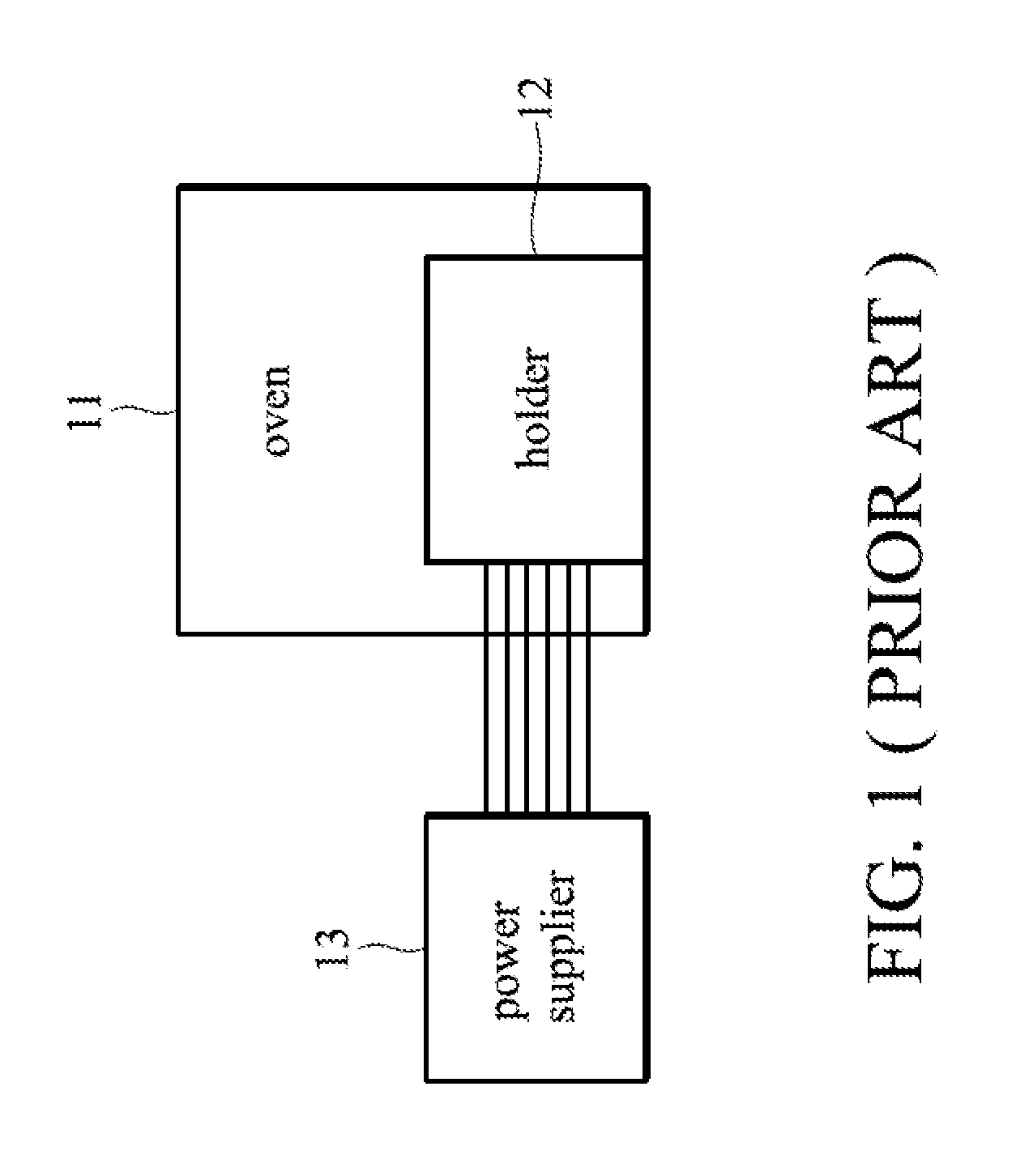

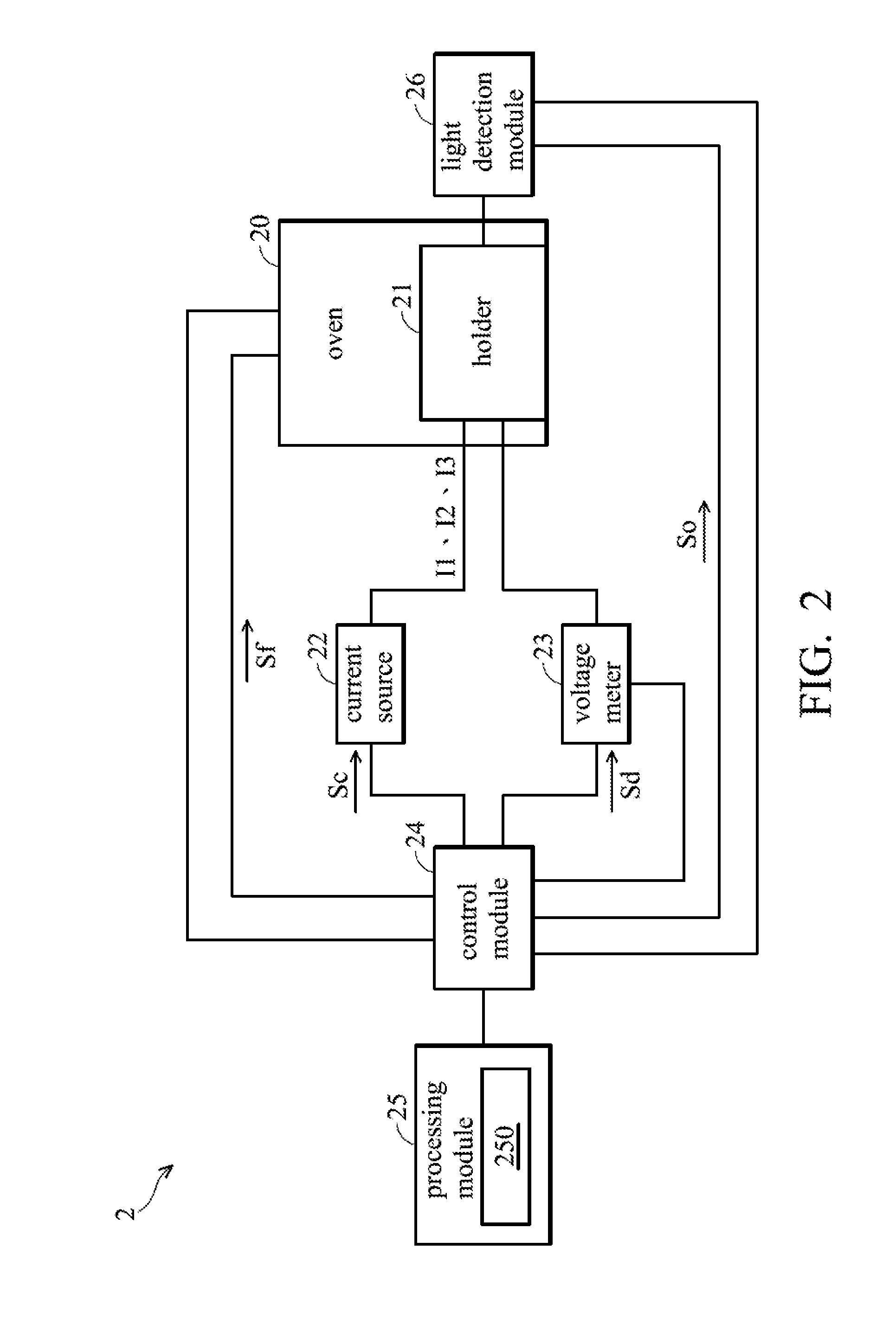

Devices And Methods For LED Life Test

A life test device comprises an oven, a current source, a voltage meter, a control module, and a process module. A light-emitting diode (LED) is disposed in the oven. The temperature of the oven is gradually changed in a first period and remains at a set temperature in a second period. The current source provides a first current and a second current to the LED. The voltage meter measures forward voltages of the LED. The control module controls the current source to output the first or second current to the LED and controls the voltage meter to measure the forward voltages of the LED. The process module calculates a junction temperature of the LED according to the forward voltages and a variation relationship formula between the forward voltages and the temperature of the oven.

Owner:IND TECH RES INST

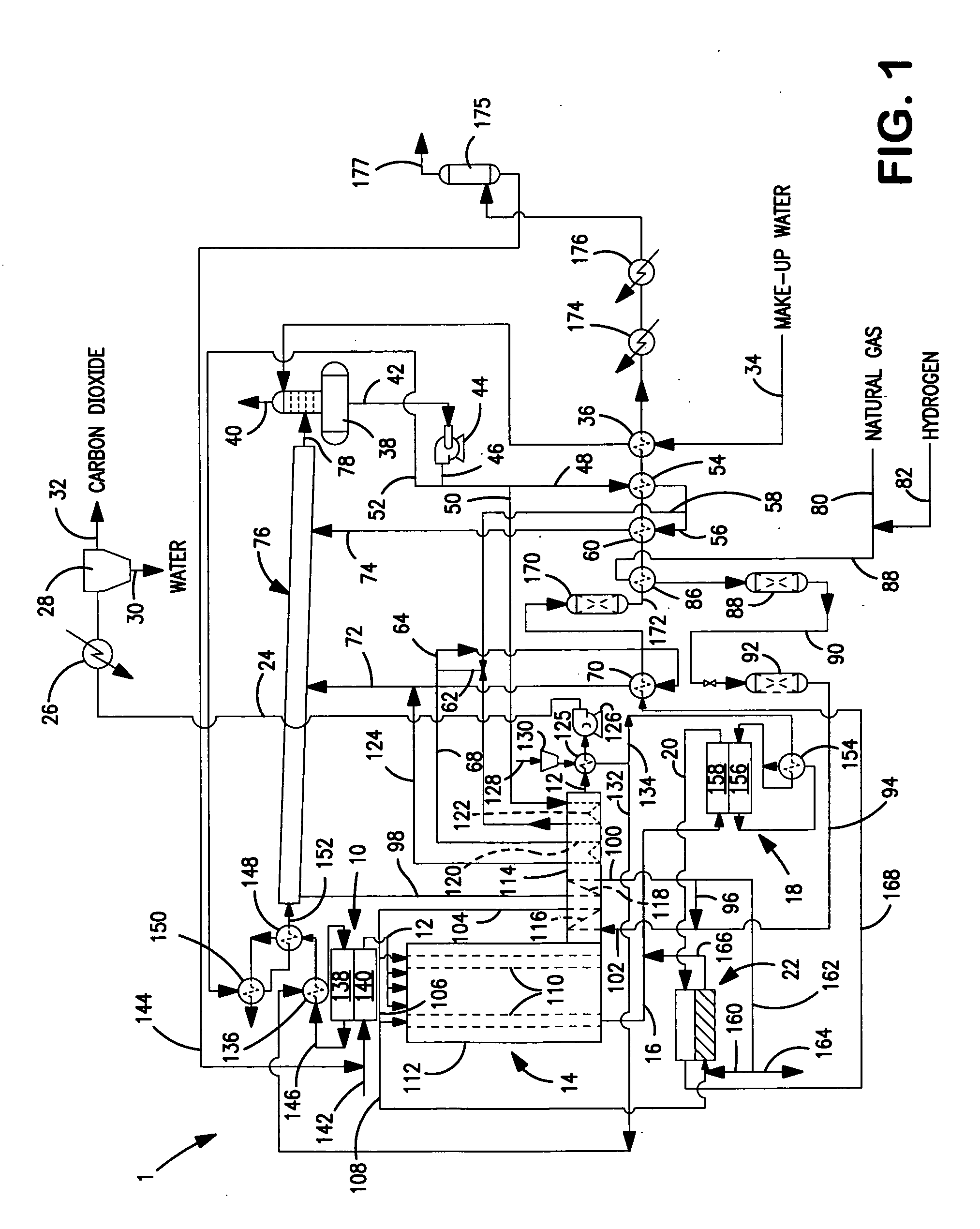

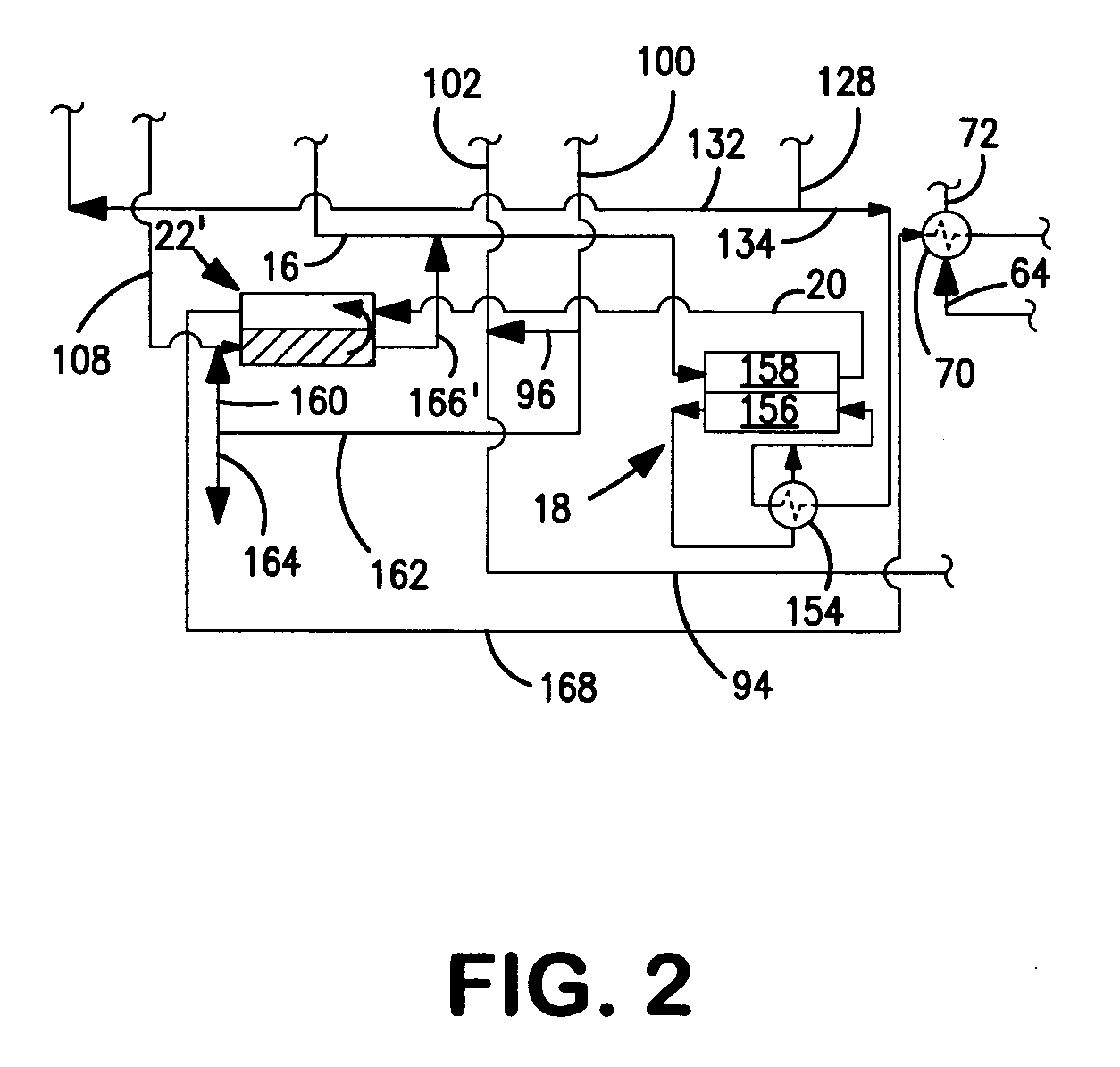

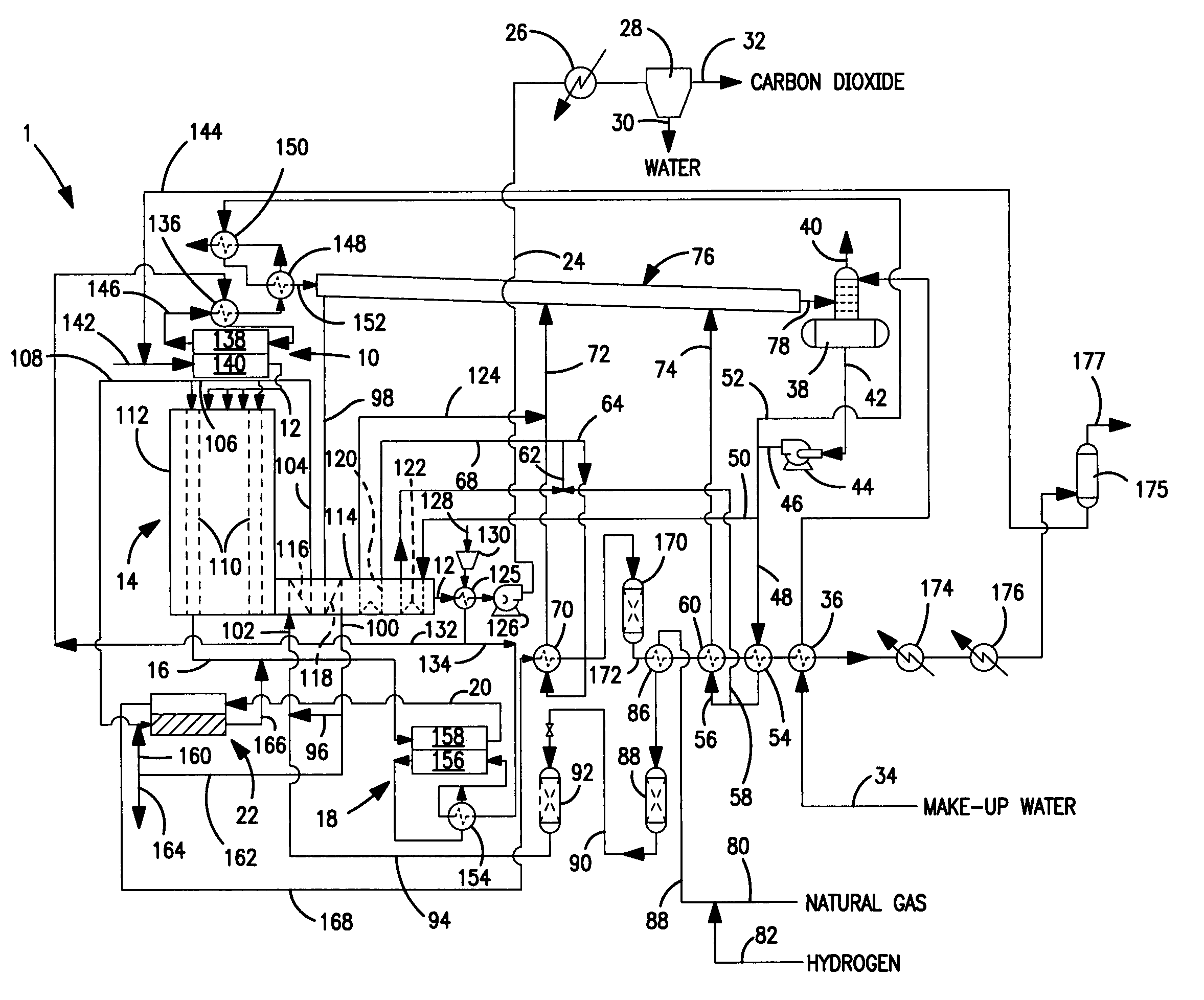

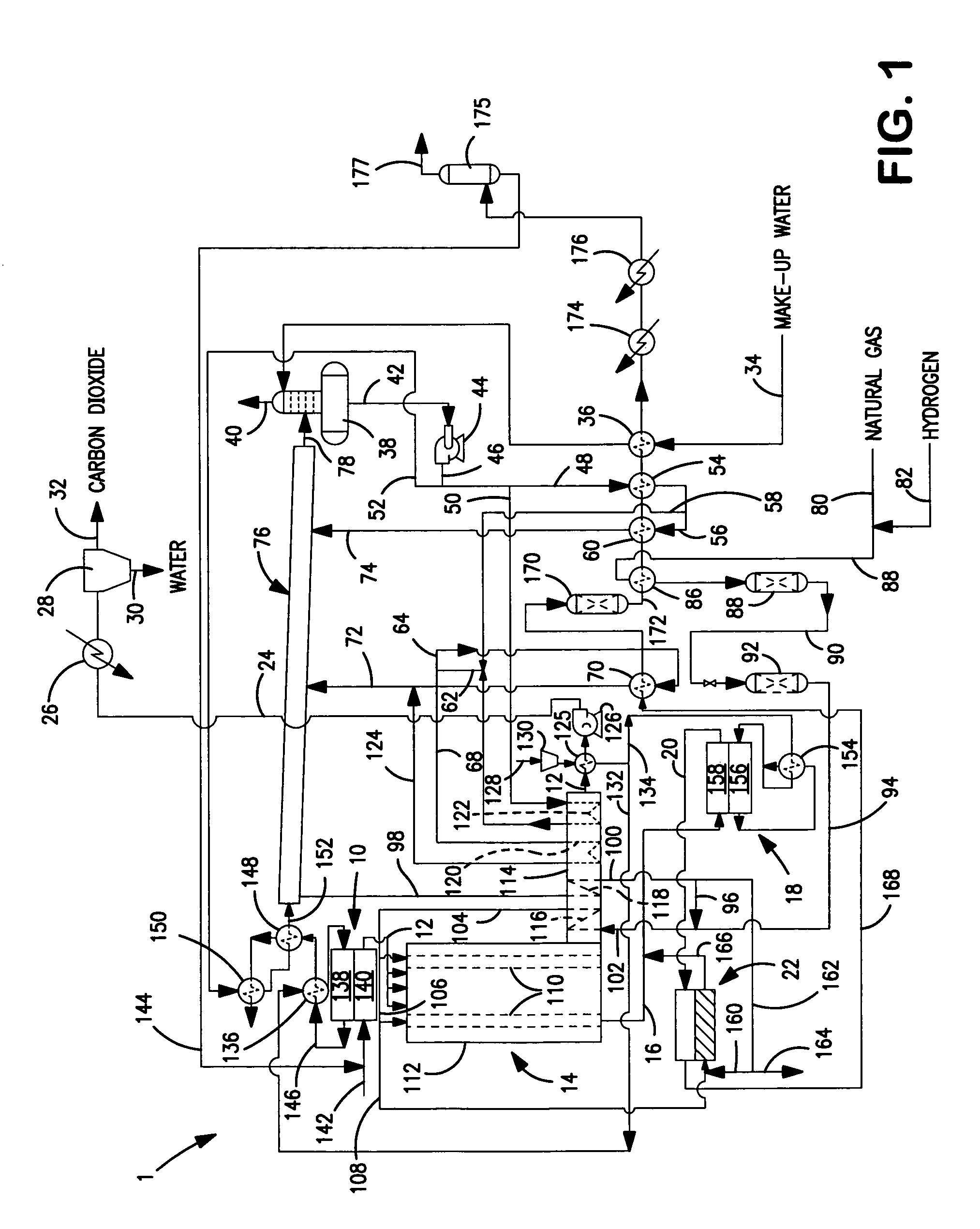

Synthesis gas and carbon dioxide generation method

A method of generating a synthesis gas product stream and carbon dioxide in which a fuel is combusted in an oxygen transport membrane combustor to produce a flue gas stream containing the carbon dioxide and water. Reforming duty is divided between a combined reforming process and a gas heated reformer to produce the product stream. The flue gas stream is used to supply heat to a primary, steam methane reforming stage of the combined reforming process. Residual methane, produced in the primary stage, is reacted in a secondary stage having an oxygen transport membrane reactor. Heat produced in the secondary stage is supplied to the gas heated reactor to support its operation. The flue gas stream is cooled and water is separated therefrom to produce the carbon dioxide at a concentration of at least 85 mol percent.

Owner:PRAXAIR TECH INC

Synthesis gas and carbon dioxide generation method

A method of generating a synthesis gas product stream and carbon dioxide in which a fuel is combusted in an oxygen transport membrane combustor to produce a flue gas stream containing the carbon dioxide and water. Reforming duty is divided between a combined reforming process and a gas heated reformer to produce the product stream. The flue gas stream is used to supply heat to a primary, steam methane reforming stage of the combined reforming process. Residual methane, produced in the primary stage, is reacted in a secondary stage having an oxygen transport membrane reactor. Heat produced in the secondary stage is supplied to the gas heated reactor to support its operation. The flue gas stream is cooled and water is separated therefrom to produce the carbon dioxide at a concentration of at least 85 mol percent.

Owner:PRAXAIR TECH INC

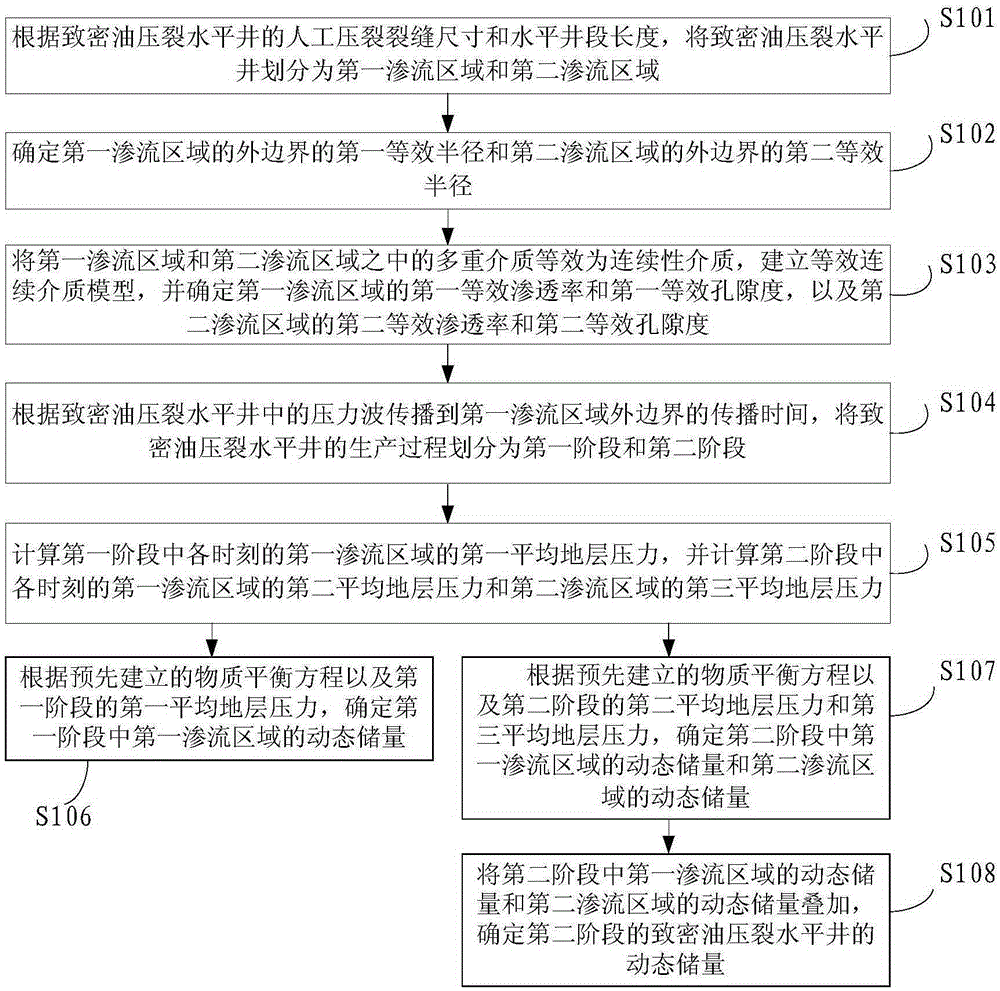

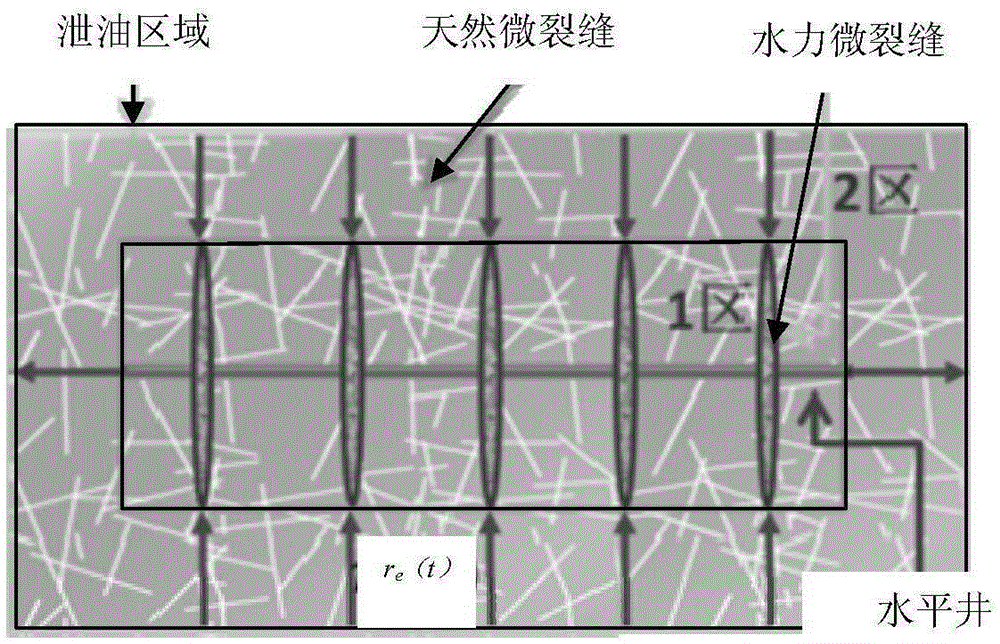

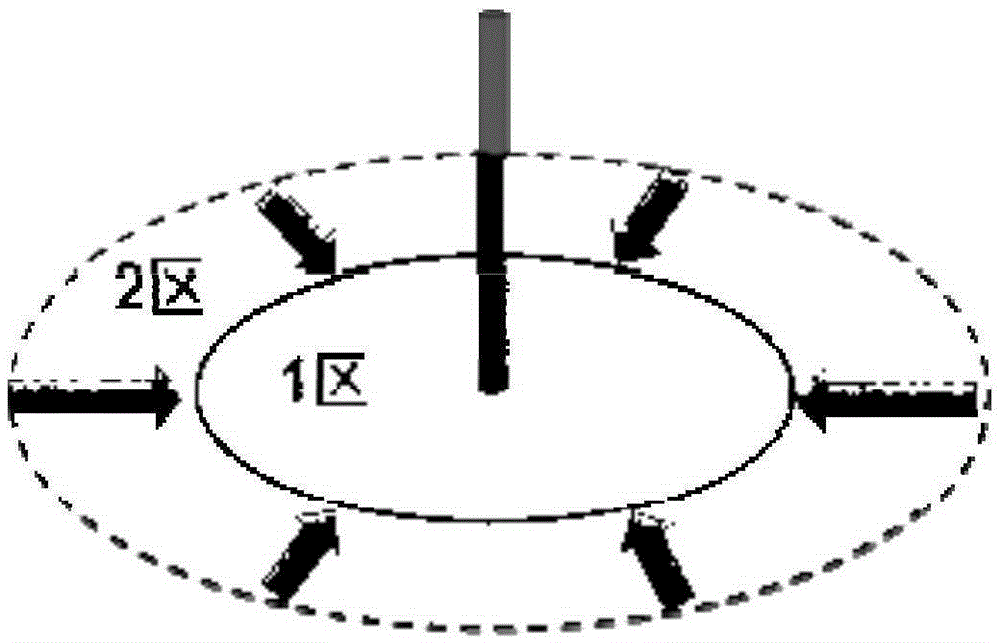

Method for calculating dynamic reserve of dense oil fractured horizontal well

ActiveCN105243182AAccurate predictionSpecial data processing applicationsMaterial balanceHorizontal wells

The present invention provides a method for calculating a dynamic reserve of a dense oil fractured horizontal well, and relates to the technical field of dense oil fractured horizontal wells. The method comprises: dividing a dense oil fractured horizontal well into a first percolation region and a second percolation region; dividing a production process of the dense oil fractured horizontal well into a first stage and a second stage; calculating a first average formation pressure of the first percolation at each time in the first stage, and calculating a second average formation pressure of the first percolation region and a third average formation pressure of the second percolation region at each time in the second stage; according to a pre-established mass balance equation, determining a dynamic reserve of the first percolation region in the first stage as a dynamic reserve of the dense oil fractured horizontal well of the first stage; and according to the pre-established mass balance equation, determining a dynamic reserve of the first percolation region and a dynamic reserve of the second percolation region in the second stage, and determining a sum of the dynamic reserve of the first percolation region and the dynamic reserve of the second percolation region to be a dynamic reserve of the dense oil fractured horizontal well in the second stage.

Owner:PETROCHINA CO LTD

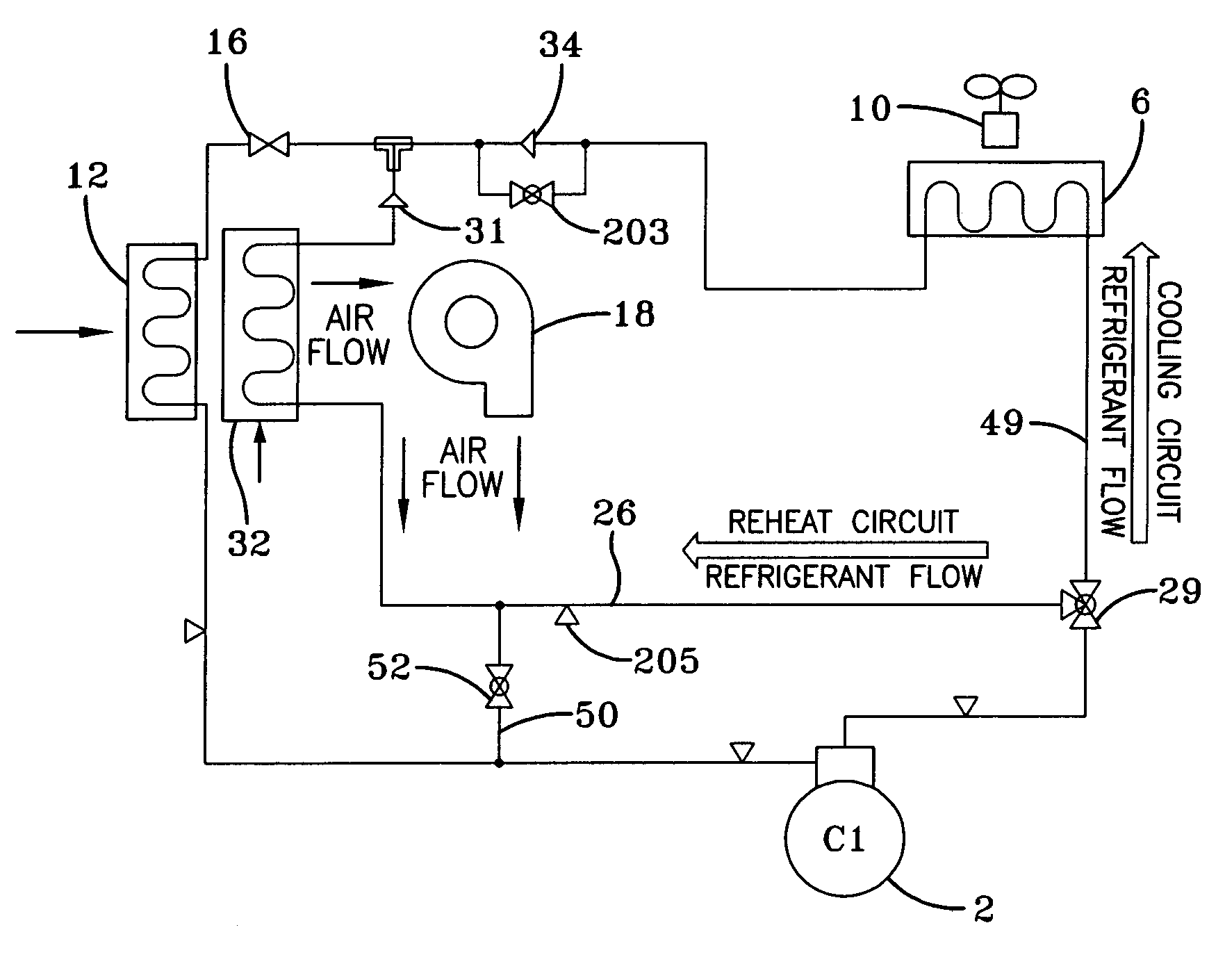

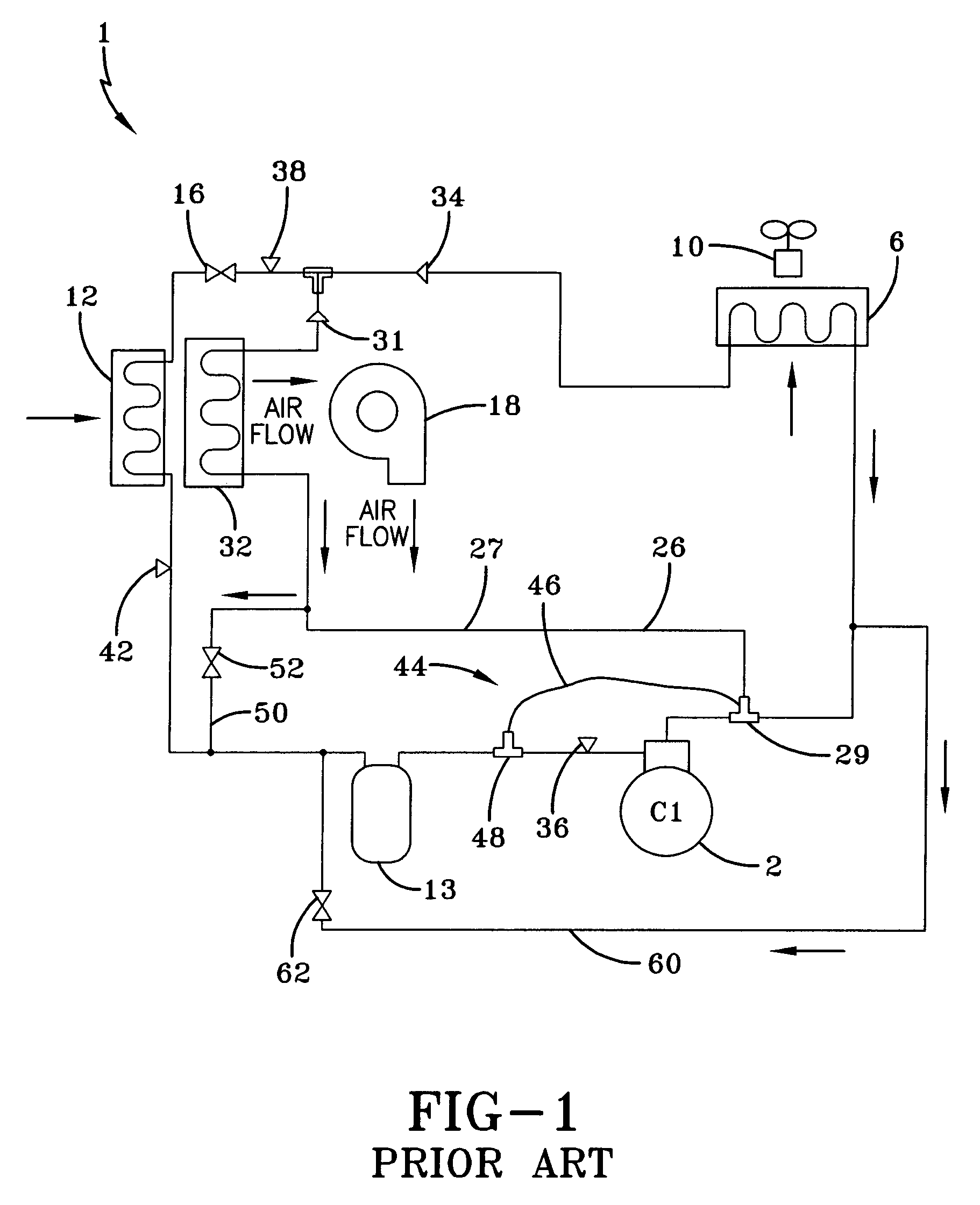

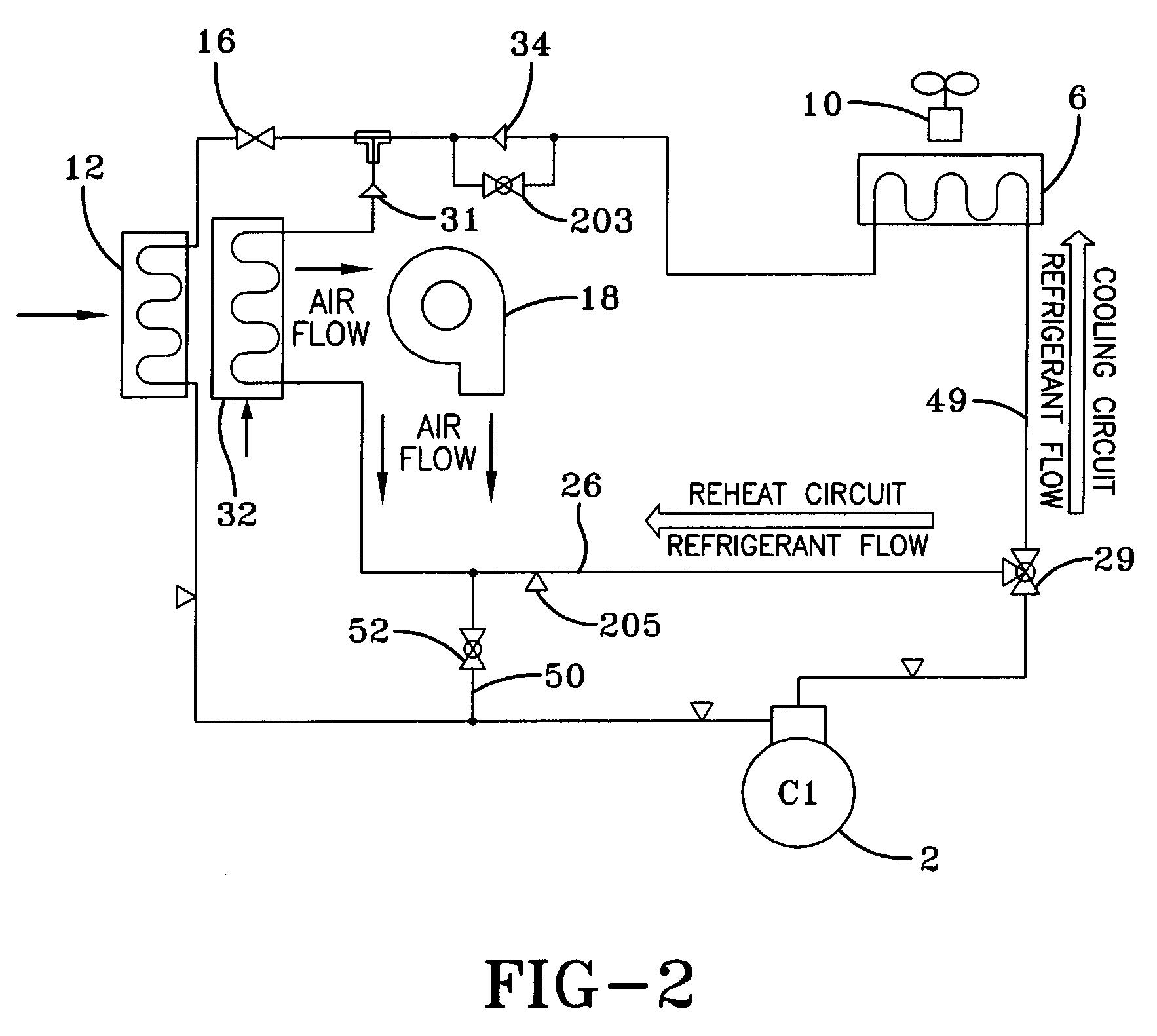

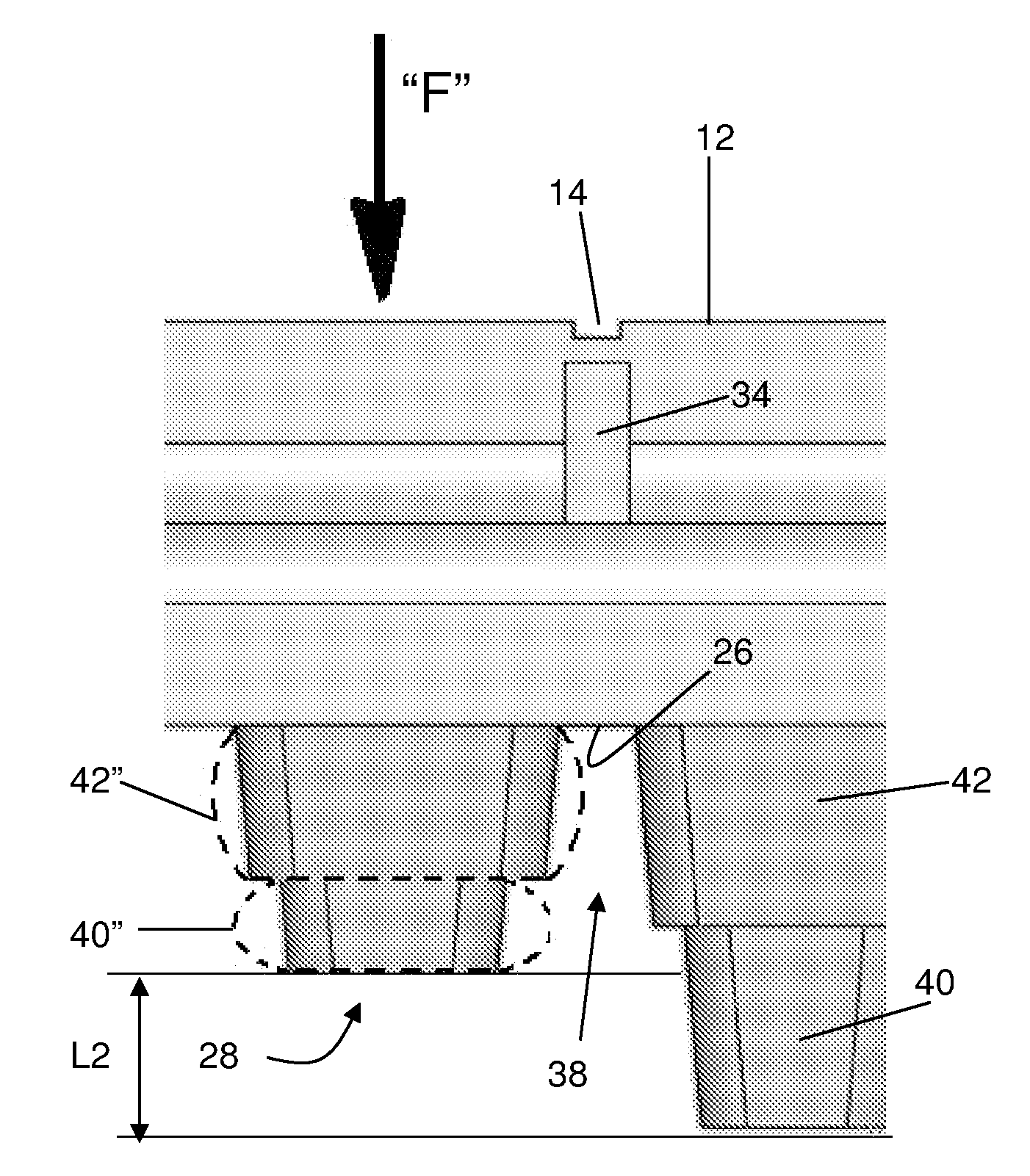

Control stability system for moist air dehumidification units and method of operation

ActiveUS7219505B2Accumulator can be eliminatedSave energyMechanical apparatusFluid circulation arrangementEngineeringSecondary stage

A system and humidity control method is provided for a multi-stage cooling system having two or more refrigerant circuits that balances humidity control and cooling demand. Each refrigerant circuit includes a compressor, a condenser and an evaporator. A hot gas reheat circuit having a hot gas reheat coil is connected to one of the refrigerant circuits and is placed in fluid communication with the output airflow from the evaporator of that refrigerant circuit to provide additional dehumidification to the air when humidity control is requested. The hot gas reheat circuit bypasses the condenser of the refrigerant circuit during humidity control. Humidity control is performed during cooling operations and ventilation operations. During a first stage cooling operation using only one refrigerant circuit and having a low cooling demand, the request for humidity control activates the hot gas reheat circuit for dehumidification and activates a second refrigerant circuit to provide cooling capacity. The hot gas reheat circuit is sized to match the cooling provided by the evaporator so that air cooled by passing through the evaporator can be reheated. Excess refrigerant is passed into the inactive cooling circuit so that proper pressure and temperature can be maintained in the active reheat circuit and so that high head pressure that can damage the compressor can be avoided. During a second stage cooling operation using two or more refrigerant circuit and having a high cooling demand, the request for humidity control is suspended and is initiated only upon the completion of the second stage cooling demand.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Load supporting panel having impact absorbing structure

An impact absorption panel is adapted for playground use and comprises a panel section and a plurality of projections. The panel section is defined by a top surface and a bottom surface. The plurality of projections extend from the bottom surface of the panel section. The plurality of projections have a first stage and a second stage. The first stage is configured to collapse initially when subjected to an impact load. The second stage is configured to provide greater resistance to the impact load than the first stage. The panel section is configured to provide greater resistance to the impact load than the first and second stages. The first stage can also be distinguished from the second stage by virtue of having a comparatively smaller volume.

Owner:BROCK USA

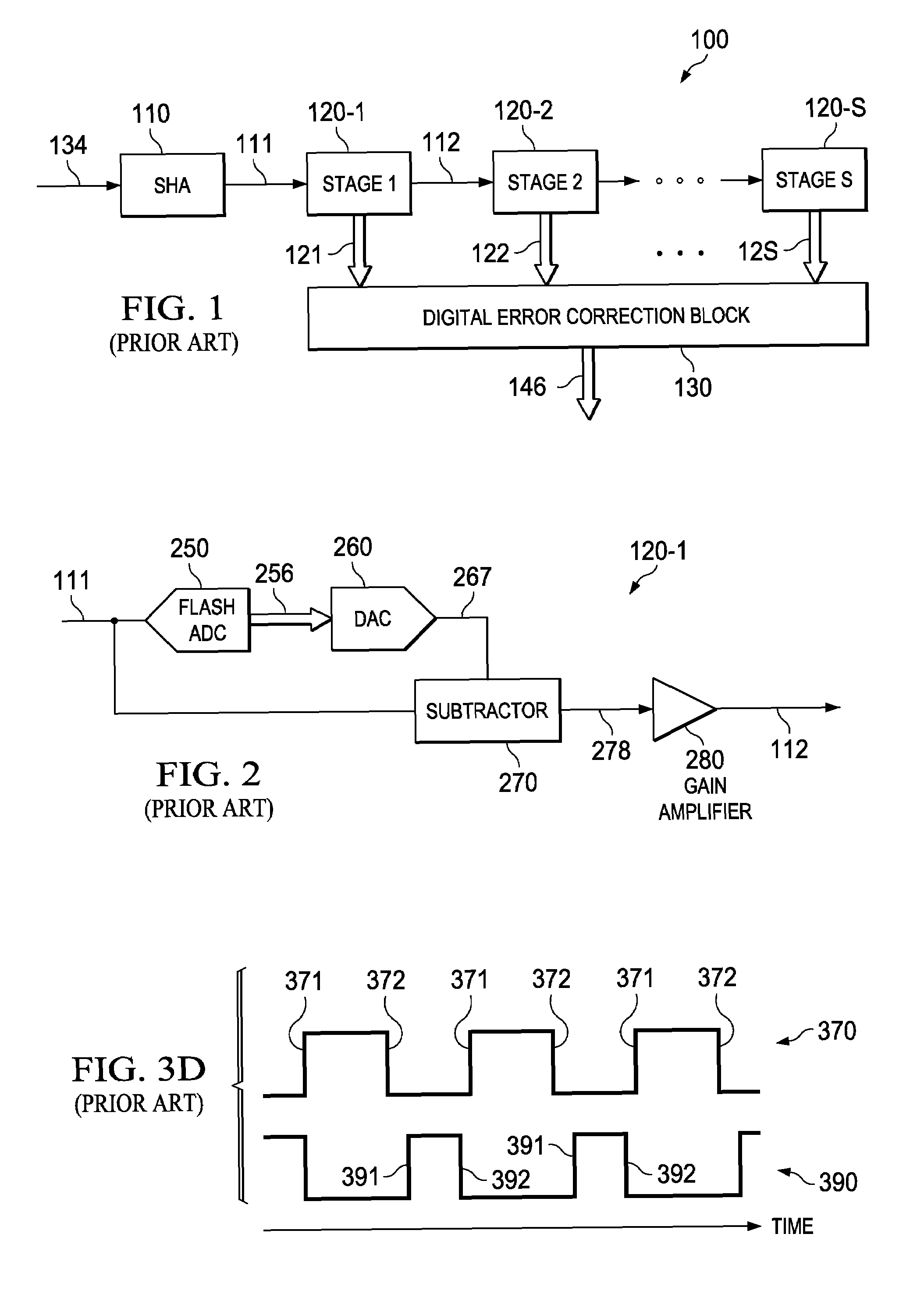

Reducing noise and/or power consumption in a switched capacitor amplifier sampling a reference voltage

ActiveUS7358801B2Amplifier modifications to reduce noise influenceAmplifier modifications to raise efficiencyAudio power amplifierSecondary stage

Owner:TEXAS INSTR INC

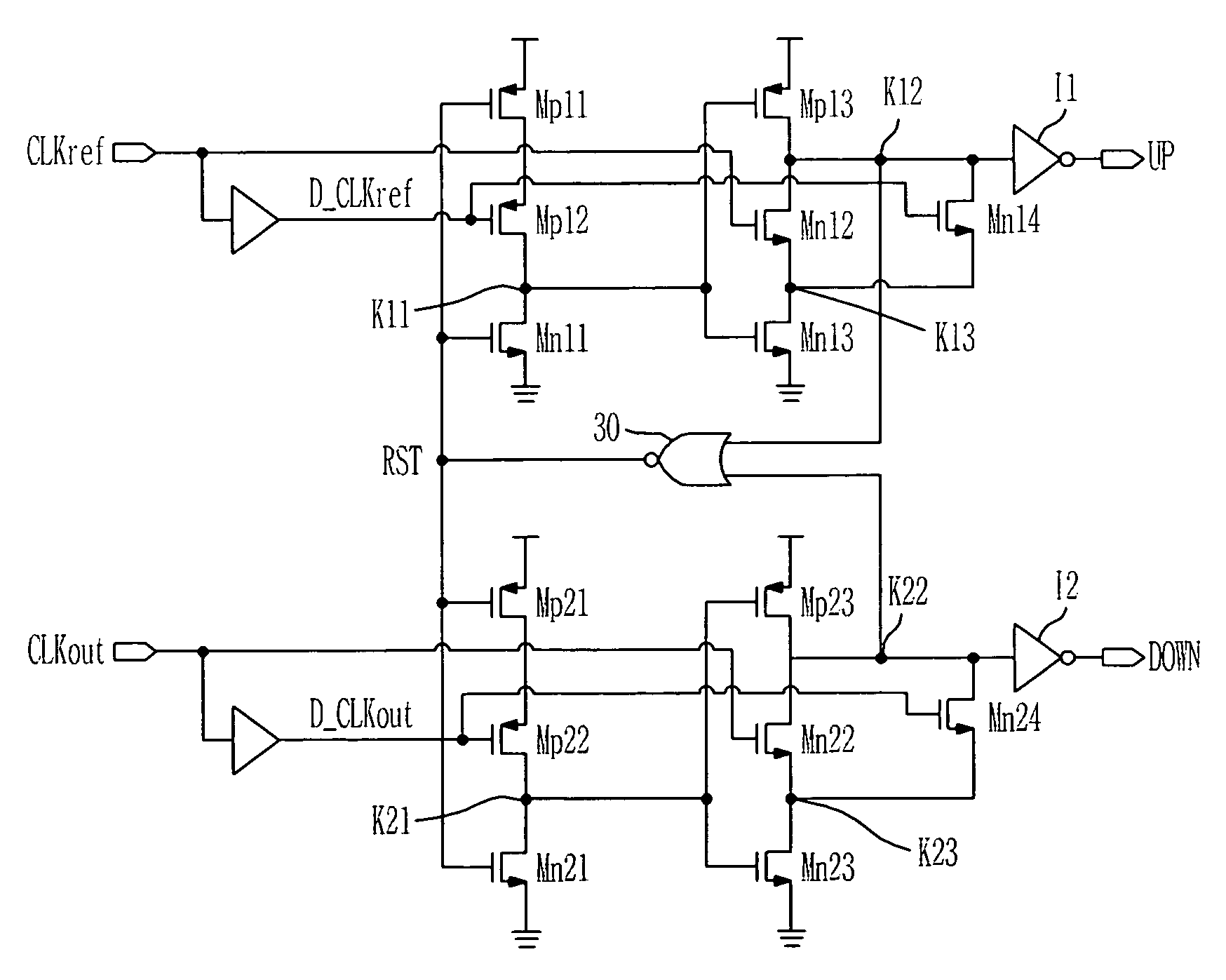

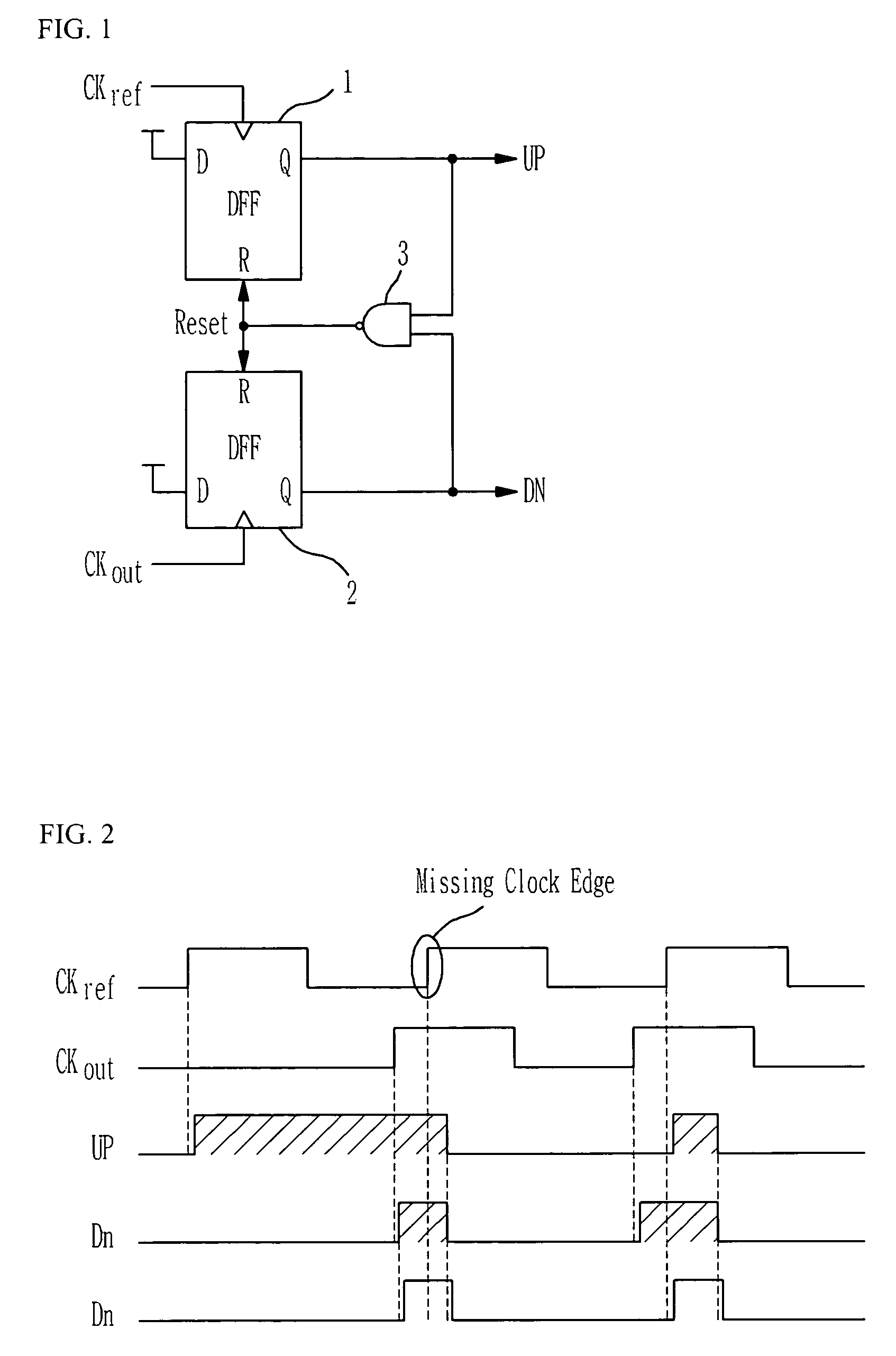

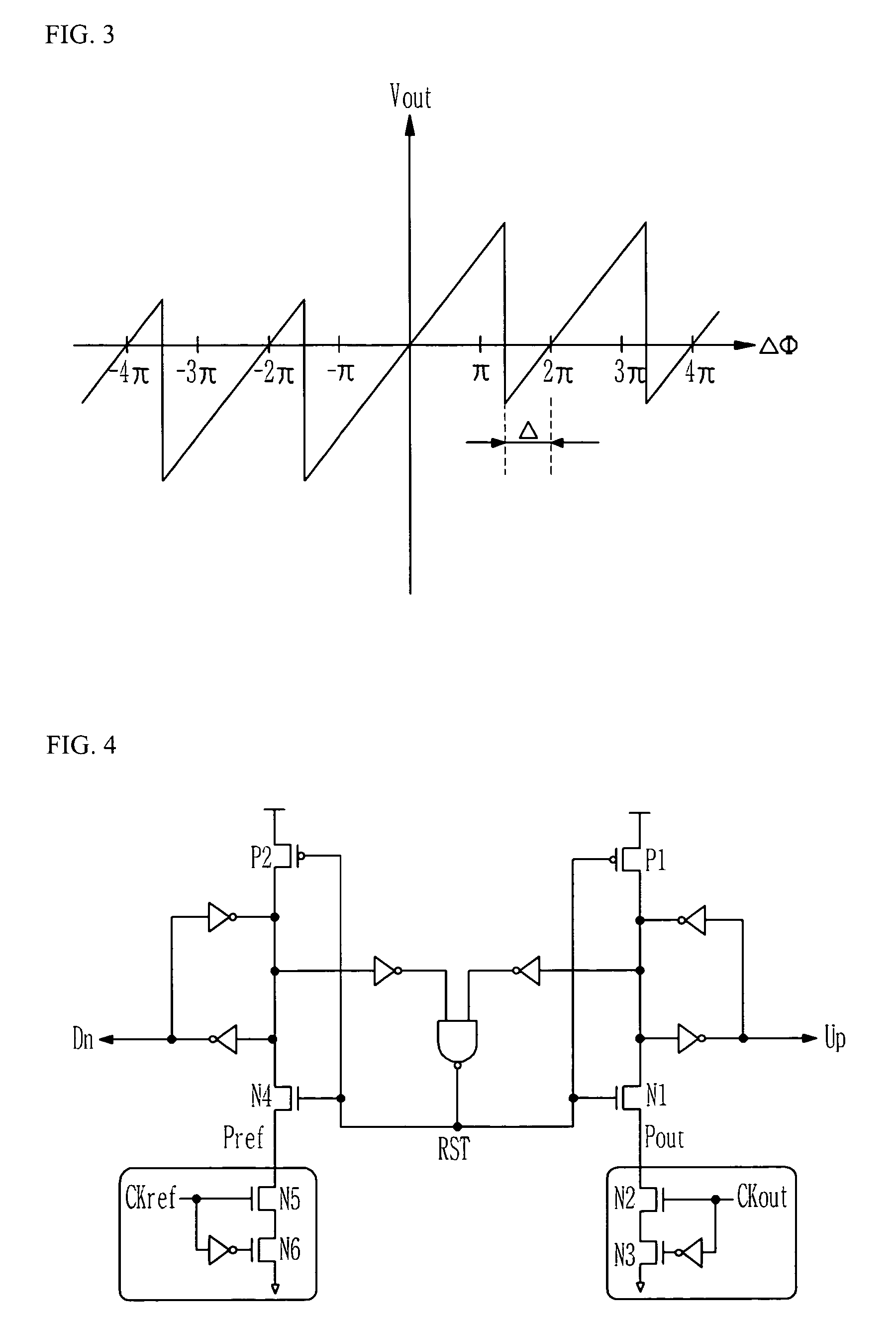

Phase frequency detector

InactiveUS7053666B2Fast phase lockReduce power consumptionPulse automatic controlVoltage-current phase angleLow noiseControl signal

Provided is a phase frequency detector for use in a phase locked loop (PLL) or a delay locked loop (DLL), the phase frequency detector including: an UP signal output unit having a first stage operated according to a reference clock delayed by a predetermined time and a reset signal, a second stage operated according to the reference clock and an output of the first stage, and an inverter for inverting an output of the second stage; a DOWN signal output unit having: a first stage operated according to an outer clock delayed by a predetermined time and the reset signal, a second stage operated according to the outer clock and an output of the first stage, and an inverter for inverting an output of the second stage; and a logic gate logically combining the output of the second stage of the UP signal output unit and the output of the second stage of the DOWN signal output unit to generate the reset signal, thereby a phase range of the input signal with which an effective control signal can be obtained is wide so that low power consumption and low noise characteristics can be obtained due to fast phase lock, low power consumption of a dynamic logic, and fast signal transmission.

Owner:ELECTRONICS & TELECOMM RES INST

Apparatus and method for high efficiency isolated power converter

InactiveUS7796406B2Improve efficiencyLow conductiveDc network circuit arrangementsEfficient power electronics conversionDc dc converterFull bridge

A DC-DC converter apparatus comprising half or full bridge, two-stage resonant converter, which may include series resonant (inductor, capacitor) devices. An isolated transformer having primary and secondary winding supplies current to full-wave secondary stage-bridge through the use of primary winding resonant devices employing primary stage-bridge. The magnetizing of said devices employs zero-current, zero-voltage resonant-transition switching technology, which reduces switching losses at all switching frequencies to almost zero. The regulation of output voltage at all loads and input voltages achieved by the control of the switching frequency and the phase between signals for primary and secondary stages. The proper intermittent of the frequency and the phase allows achieving the value of efficiency up to 97%.

Owner:LUMENIS LTD

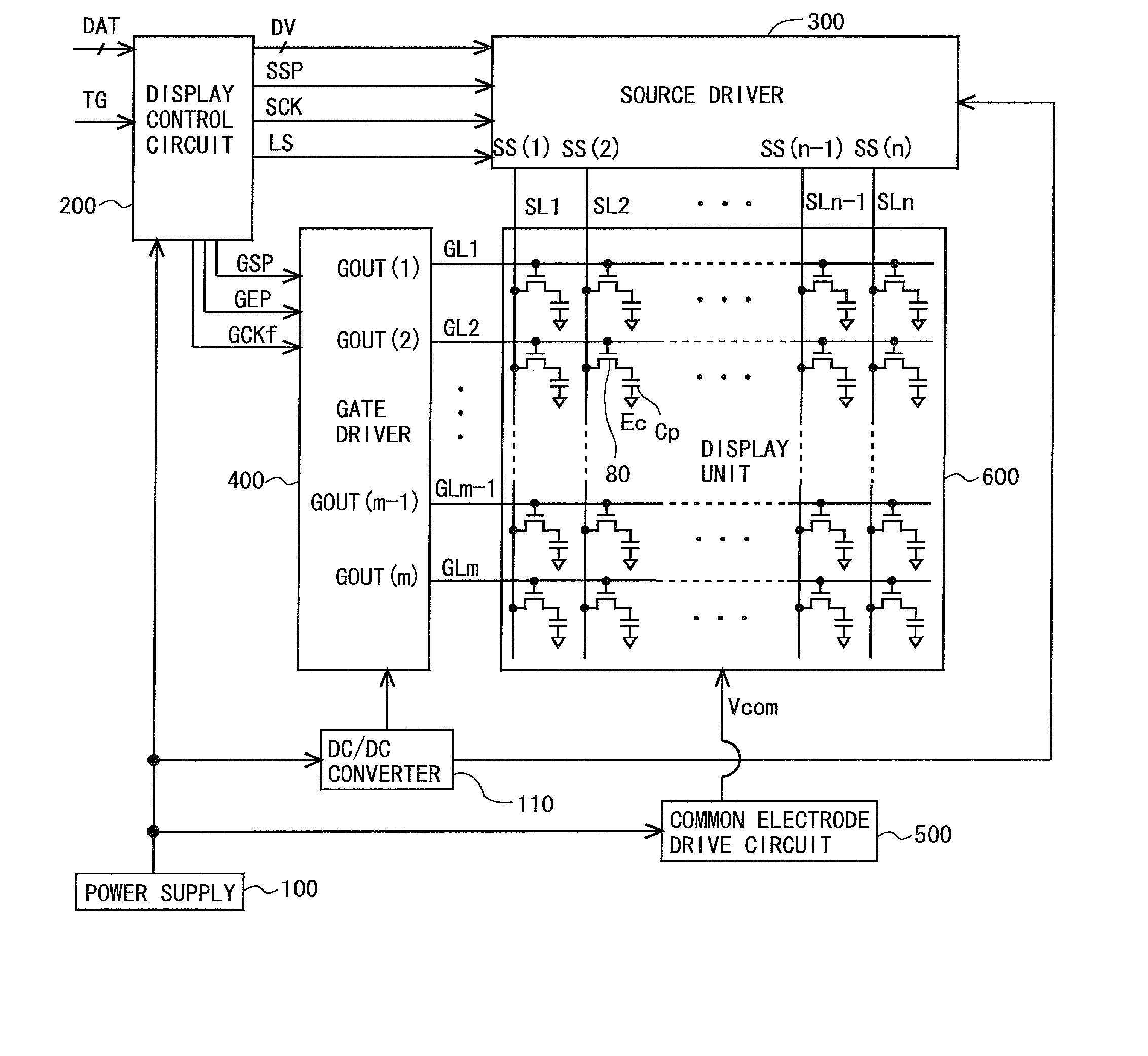

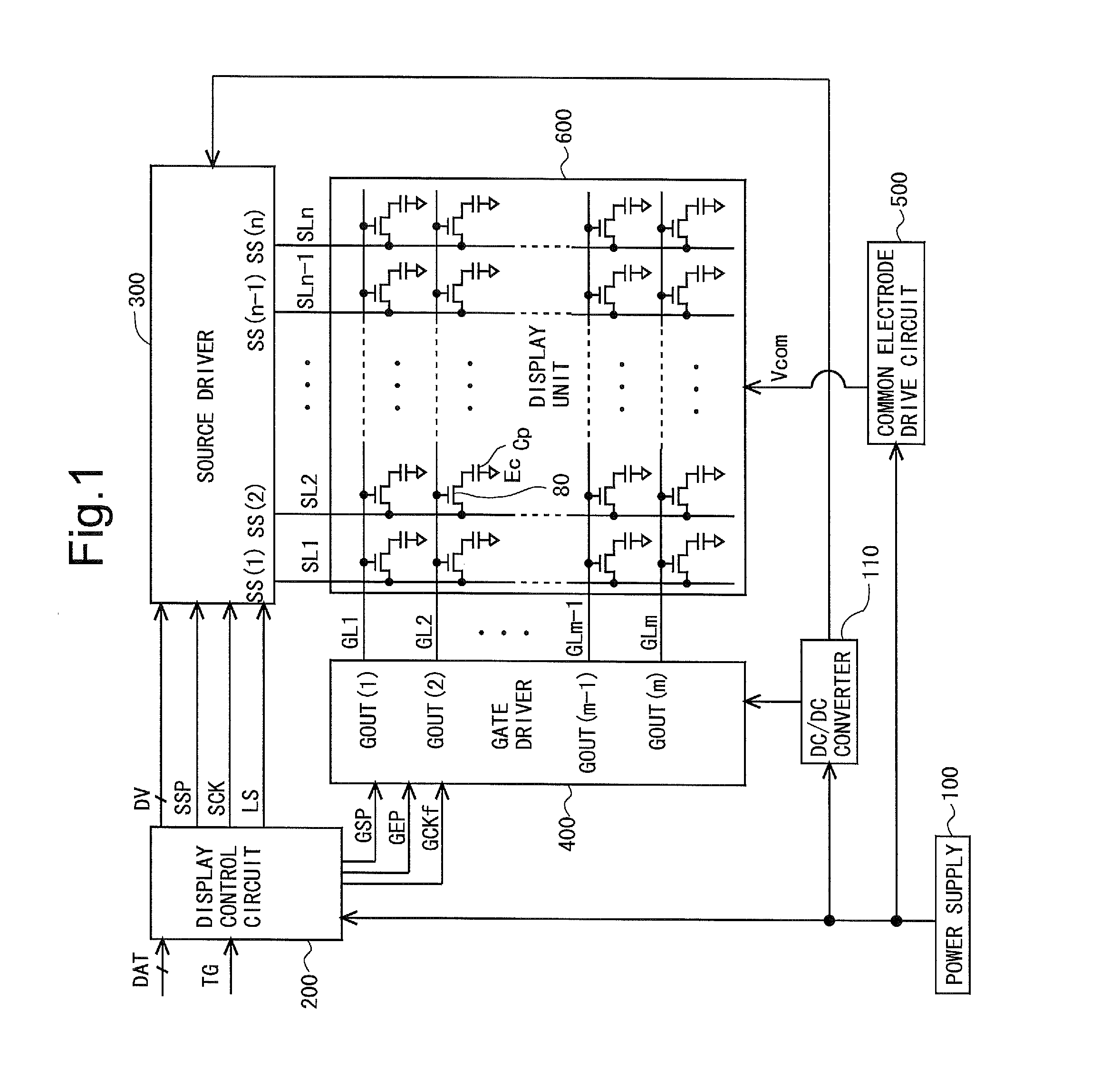

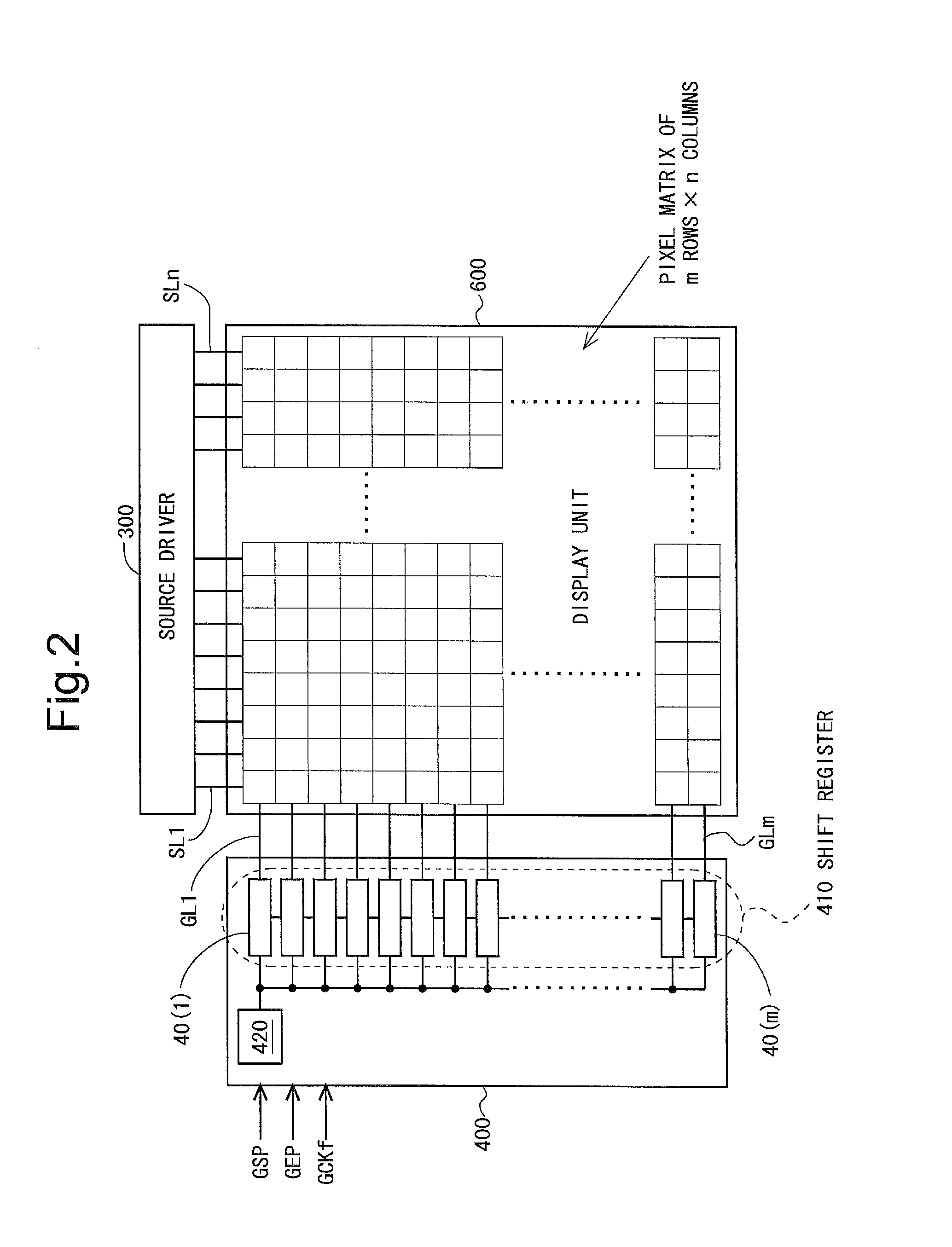

Scanning signal line drive circuit, display device having the same, and driving method for scanning signal line

InactiveUS20140111495A1Small sizeReduce power consumptionCathode-ray tube indicatorsDigital storageShift registerBistable circuits

The purpose of this invention is to increase reliability of a switching element while reducing consumption power. In the vertical blanking period, an end pulse signal (ED) changes from the low level to the high level. The potential of first nodes (N1) in the first stage to (m−1)th stage of cascade-connected m-stage bistable circuits included in a shift register of the scanning signal drive circuit is reliably maintained at the low level, and the potential of second nodes (N2) in the first stage to the (m−1)th stage changes from the high level to the low level. In a bistable circuit in the m-th stage, the potential of the first node (N1) in the m-th stage changes from the high level to the low level, and the potential of the second node (N2) in the m-th stage is maintained at the low level. The supply to a bistable circuit of clock signals (CKA, CKB) is stopped. Until a write period in the subsequent vertical scanning period, the potential of the first node (N1) and the potential of the second node (N2) in each stage are maintained at the low level.

Owner:SHARP KK

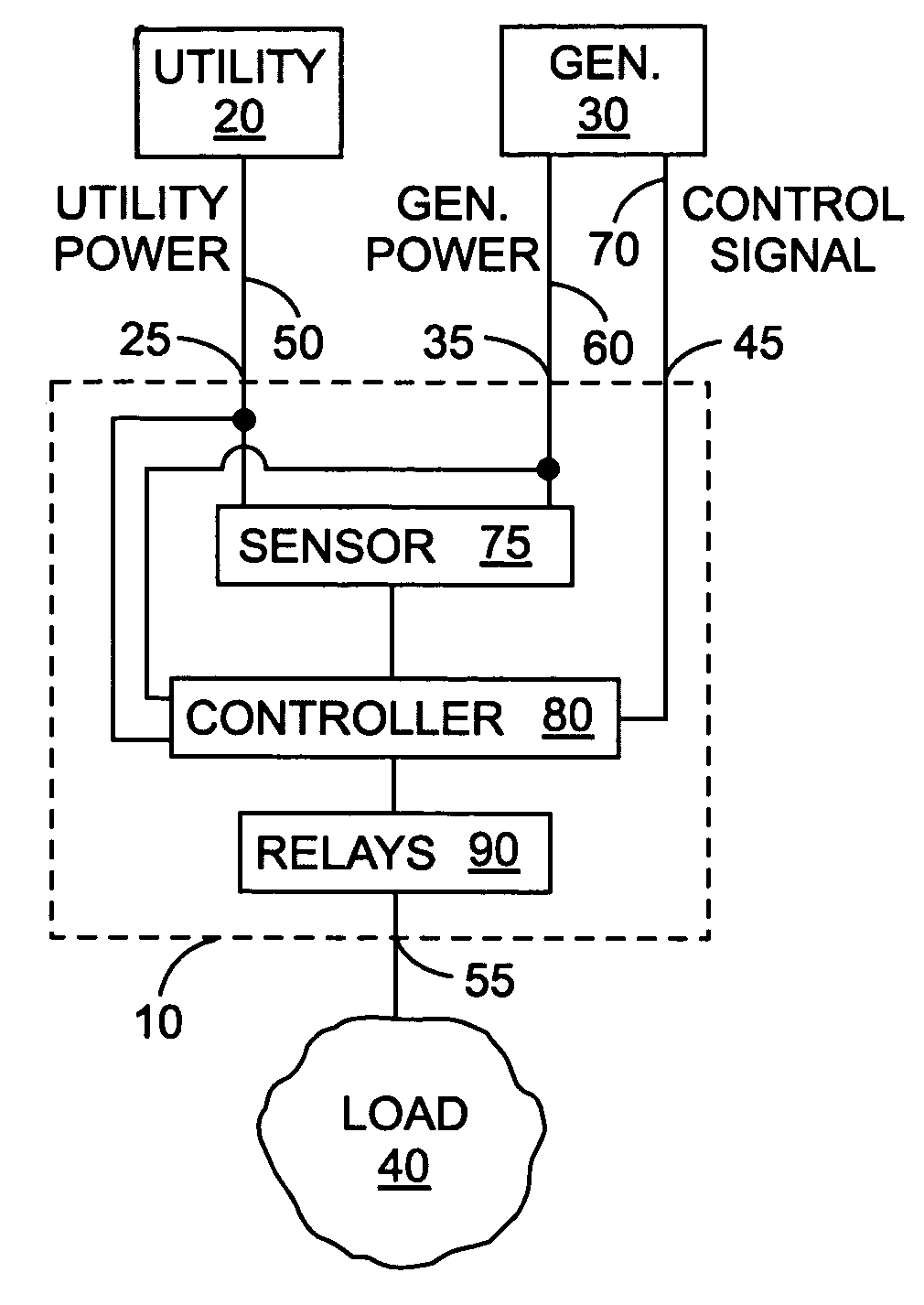

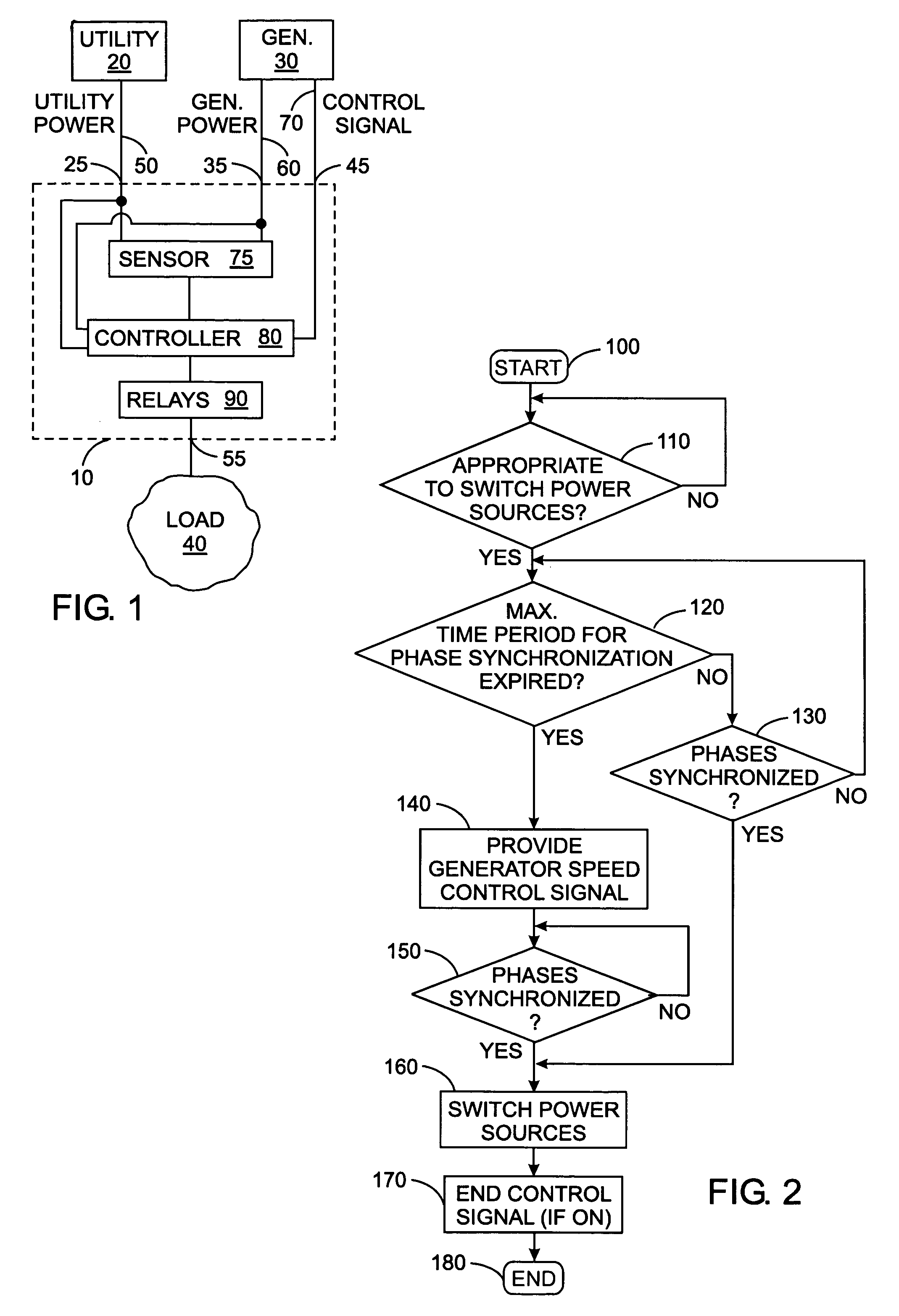

Automatic transfer switch system with synchronization control

InactiveUS6980911B2Constant operationConstant frequencySelective ac load connection arrangementsElectrical testingTime segmentControl signal

An automatic transfer switch (ATS) system and method of operating an ATS system to switch between first and second powers received from respective first and second power supplies, are disclosed. In one embodiment, the method includes sensing a first phase associated with the first power and a second phase associated with the second power, and determining whether the first and second phases have failed to become synchronized within a first time period. The method further includes providing a control signal at a second output port when it is determined that the first and second phases have failed to become synchronized within the time period, determining that the first and second phases have become synchronized in response to the control signal, and switching between the first and second powers once it is determined that the first and second phases have become synchronized.

Owner:KOHLER CO

Process for producing lithium-containing composite oxide for positive electrode of lithium secondary battery

InactiveUS20080135802A1Large volume capacity densityImprove securityFuel cells groupingConductive materialComposite oxideSecondary stage

A process for producing a lithium-containing composite oxide having a large volume capacity density, high safety, excellent durability for charge / discharge cycles, and further, excellent low temperature characteristics, which is suitable for mass production, is provided.A process for producing a lithium-containing composite oxide represented by a general formula LipNxMyOzFa (wherein N is at least one type of element selected from the group consisting of Co, Mn and Ni, M is at least one type of element selected from the group consisting of Al, an alkali earth metal element and a transition metal element other than N, 0.9≦p≦1.2, 0.97≦x≦1.00, 0<y≦0.03, 1.9≦z≦2.2, x+y=1 and 0≦a≦0.02), the process comprising a step of firing a blended product containing a lithium source, an N element source, an M element source and, as the case requires, a fluorine source in an oxygen-containing atmosphere;wherein as the N element source and the M element source, a product produced by impregnating a solution containing the M element source into a powder containing the N element source and drying them, is employed, and as the above firing, a first-stage firing at from 250 to 700° C. is applied and a second-stage firing at from 850 to 1,100° C. is subsequently applied to the fired product of the first-stage firing.

Owner:AGC SEIMI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Low voltage differential signaling [LVDS] driver with pre-emphasis Low voltage differential signaling [LVDS] driver with pre-emphasis](https://images-eureka.patsnap.com/patent_img/74b8f4ad-e594-484b-88fa-38de88ef32f9/US06977534-20051220-D00000.png)

![Low voltage differential signaling [LVDS] driver with pre-emphasis Low voltage differential signaling [LVDS] driver with pre-emphasis](https://images-eureka.patsnap.com/patent_img/74b8f4ad-e594-484b-88fa-38de88ef32f9/US06977534-20051220-D00001.png)

![Low voltage differential signaling [LVDS] driver with pre-emphasis Low voltage differential signaling [LVDS] driver with pre-emphasis](https://images-eureka.patsnap.com/patent_img/74b8f4ad-e594-484b-88fa-38de88ef32f9/US06977534-20051220-D00002.png)