Patents

Literature

35results about How to "Constant operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

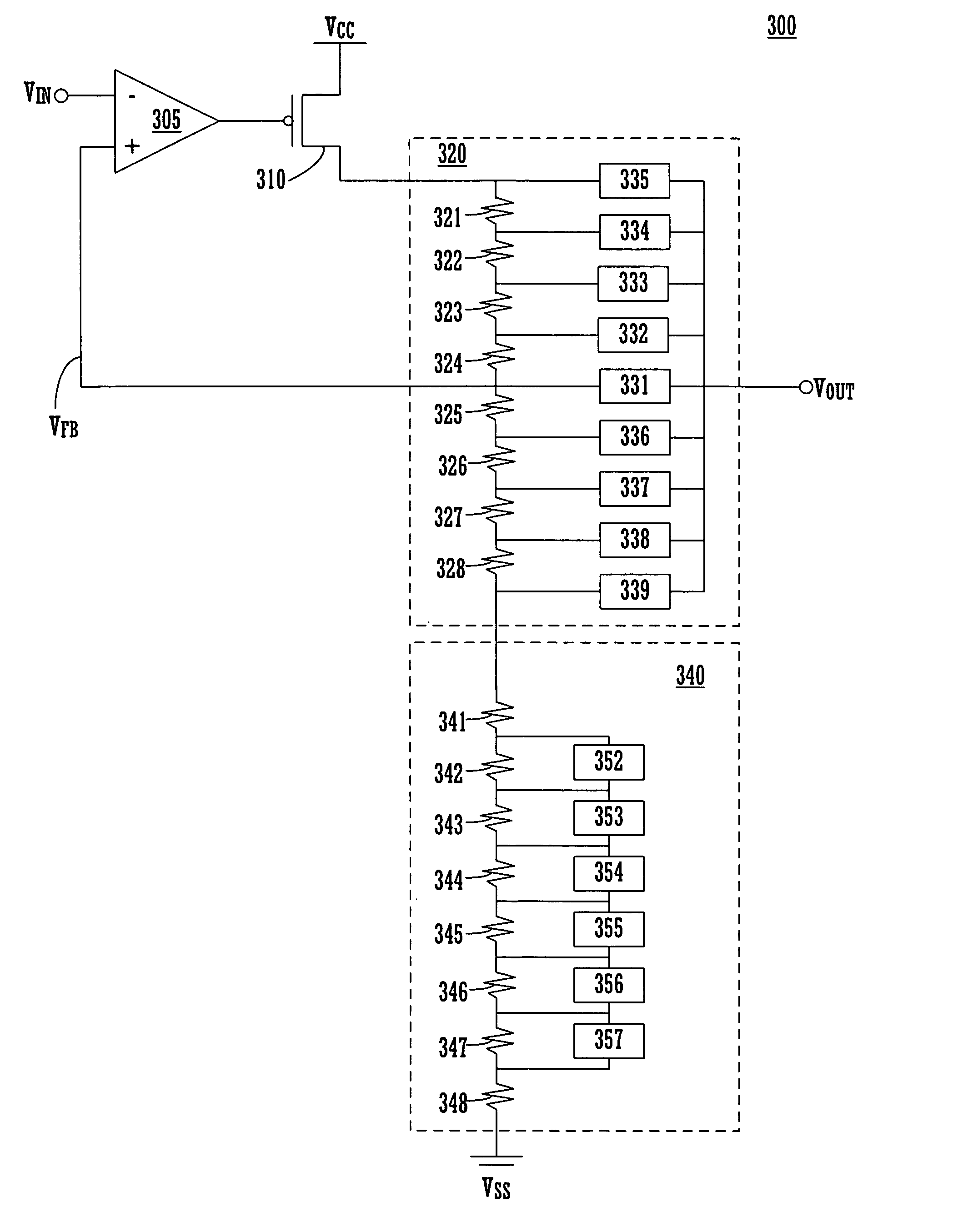

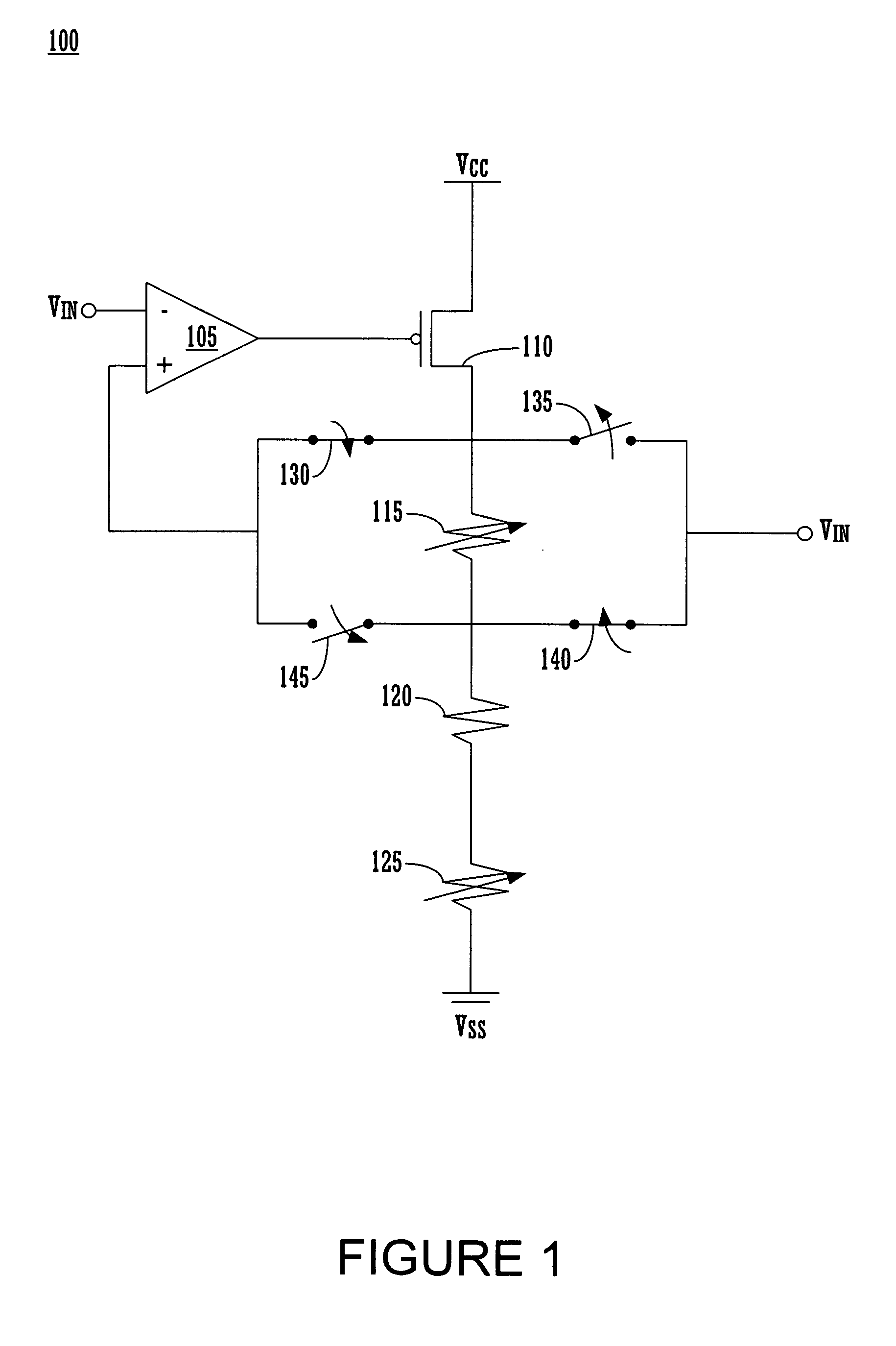

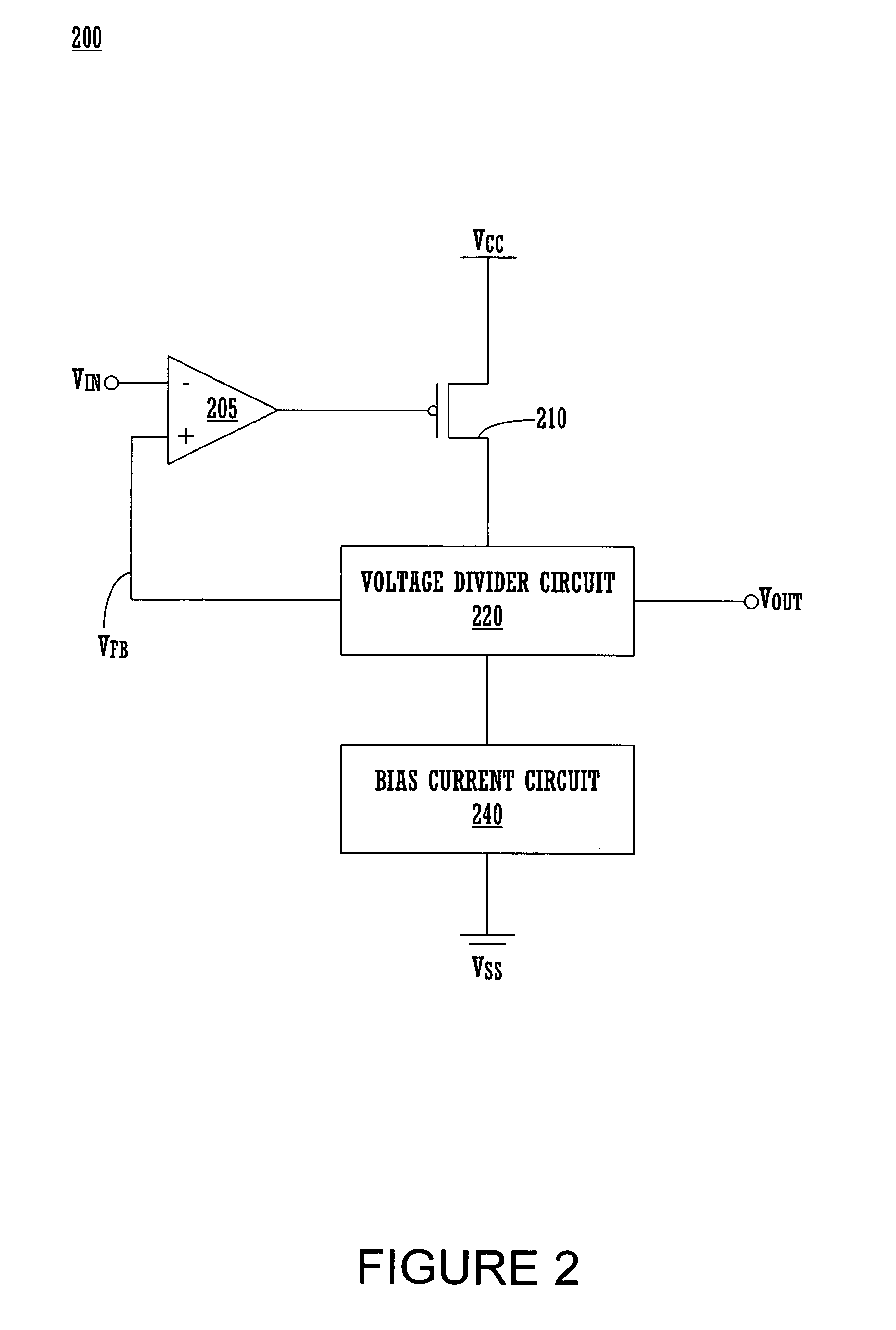

Method and circuit for adjusting a reference voltage signal

ActiveUS7019585B1Improve stabilityConstant operationElectric variable regulationLoad resistanceEngineering

A voltage trim circuit, in accordance with one embodiment of the invention, includes an operational amplifier, a transistor, a voltage divider and a bias current circuit. The operational amplifier is coupled to an input. The transistor is coupled to the operational amplifier and a first potential. The voltage divider circuit is coupled to the operational amplifier, the transistor and an output. The bias current circuit is coupled to the voltage divider circuit and a second potential. The voltage divider generates an output voltage as a function of a selectable divider ratio and provides a substantially constant feedback path to the operational amplifier. The bias current circuit provides for selectively adjusting a load resistance of the transistor to maintain a substantially constant load current through the transistor.

Owner:MONTEREY RES LLC

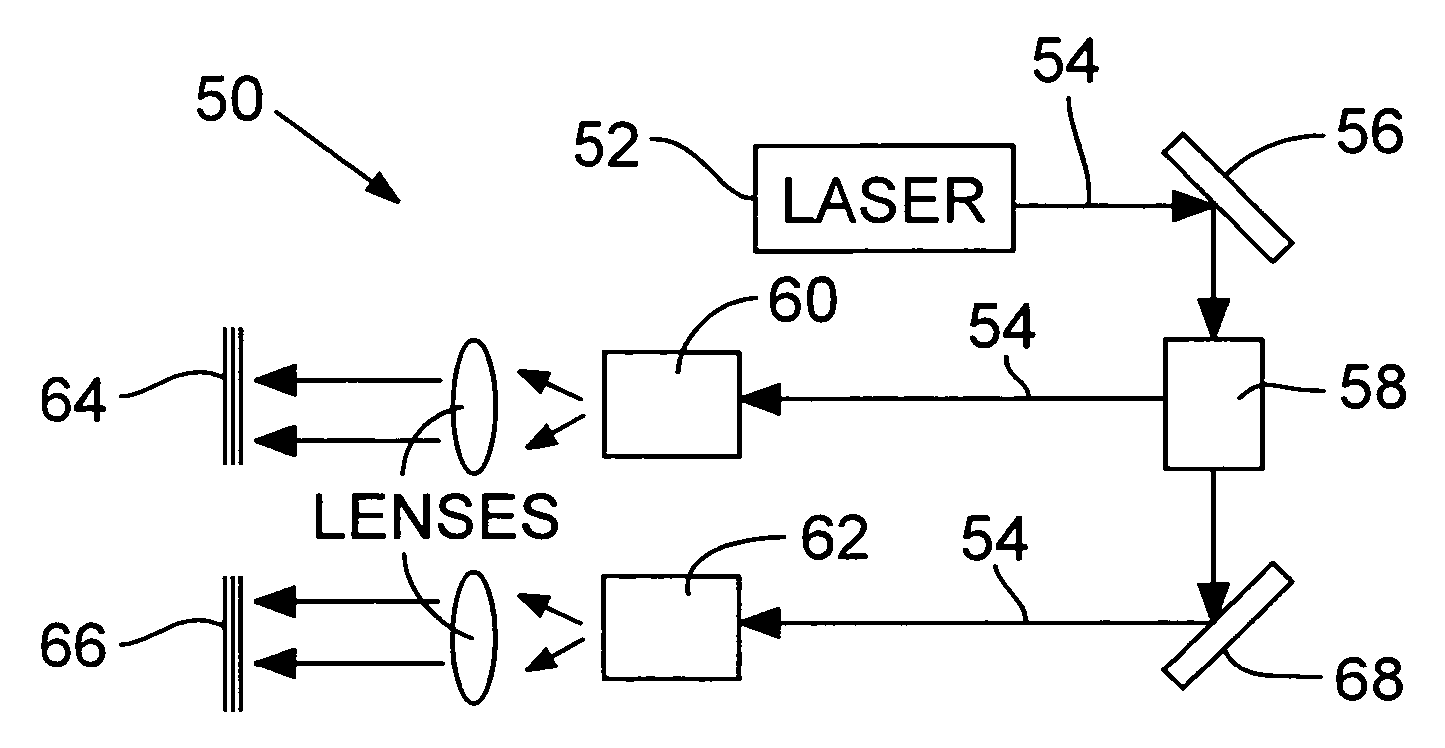

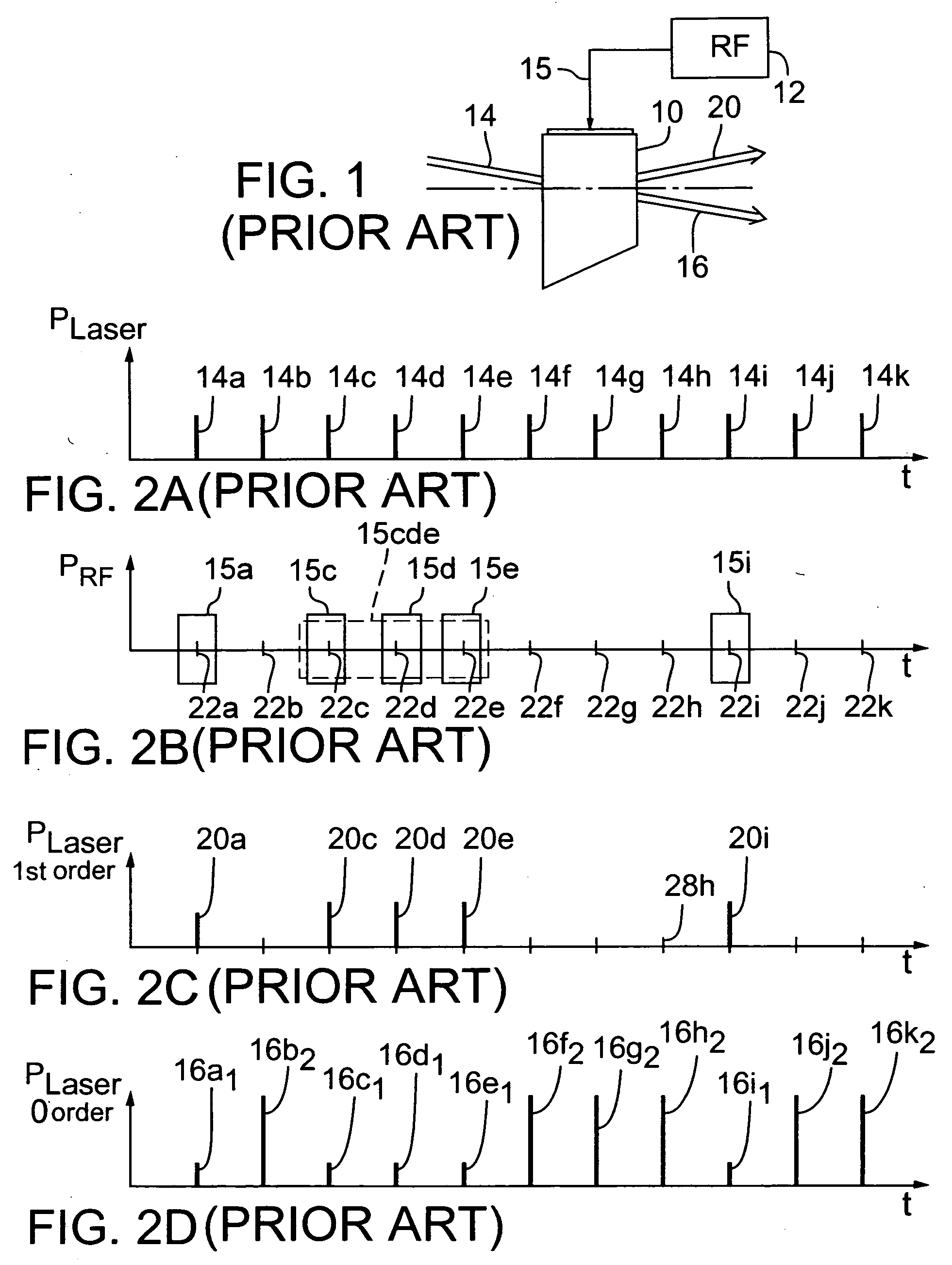

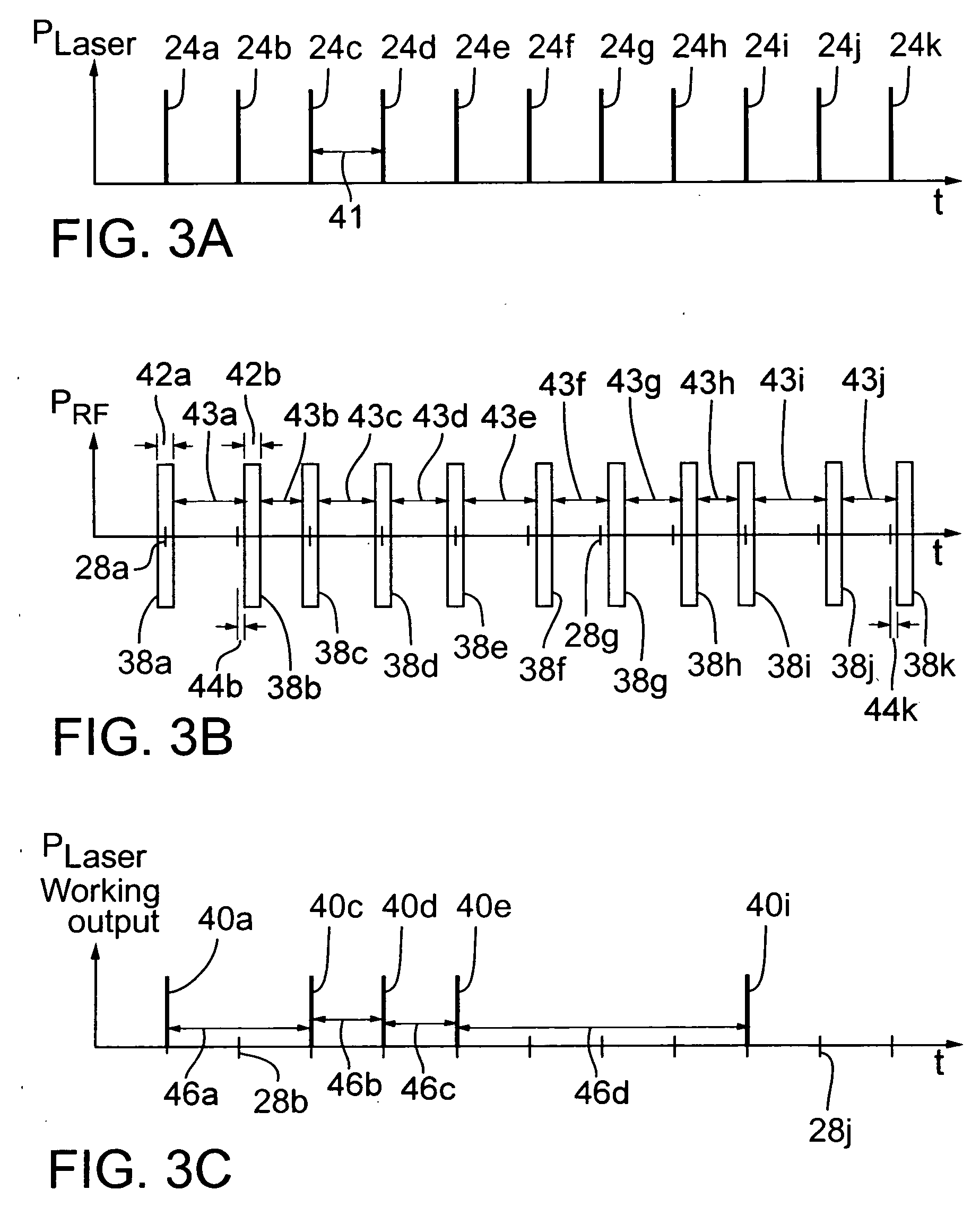

Workpiece processing system using a common imaged optical assembly to shape the spatial distributions of light energy of multiple laser beams

InactiveUS20060114948A1Eliminates thermal drifting of laser outputIncreasing laser beam positioning accuracyOptical resonator shape and constructionLaser beam welding apparatusBeam expanderLight energy

A workpiece processing system employs a common modular imaged optics assembly and an optional variable beam expander for optically processing multiple laser beams. In one embodiment, a laser and a fixed beam expander cooperate to produce a laser beam that propagates through a beam switching device to produce multiple laser beams that propagate along separate propagation path portions and subsequently merge into a common path portion through an imaged optics assembly and optional variable expander. The beam expander sets the shape of the laser beams in the form of a Gaussian spatial distribution of light energy. The imaged optics assembly shapes the Gaussian spatial distribution of the laser beams to form output beams of uniform spatial distribution. In an alternative embodiment, the beam switching device is removed and the laser beams propagate from separate laser sources associated with separate optional beam expanders.

Owner:ELECTRO SCI IND INC

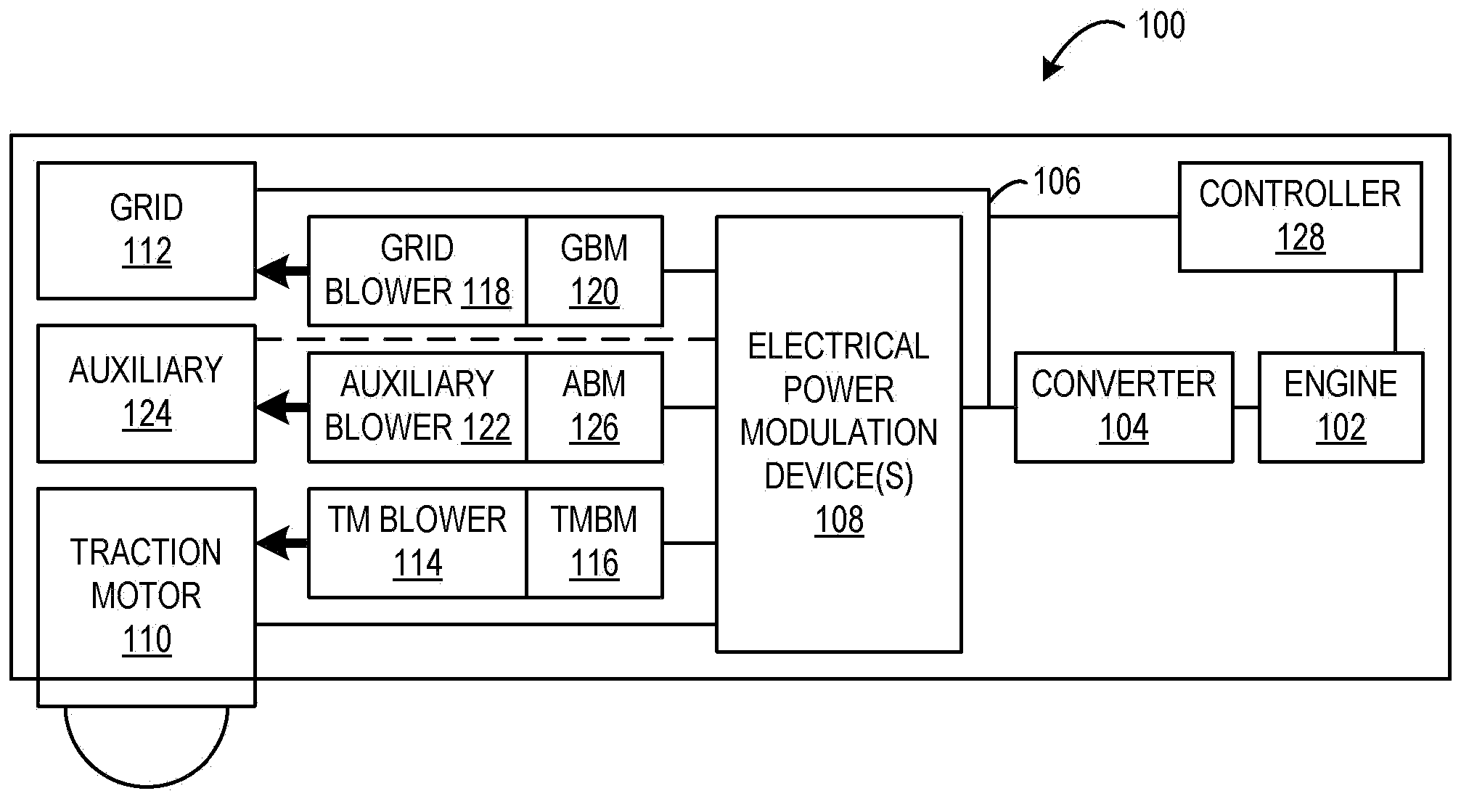

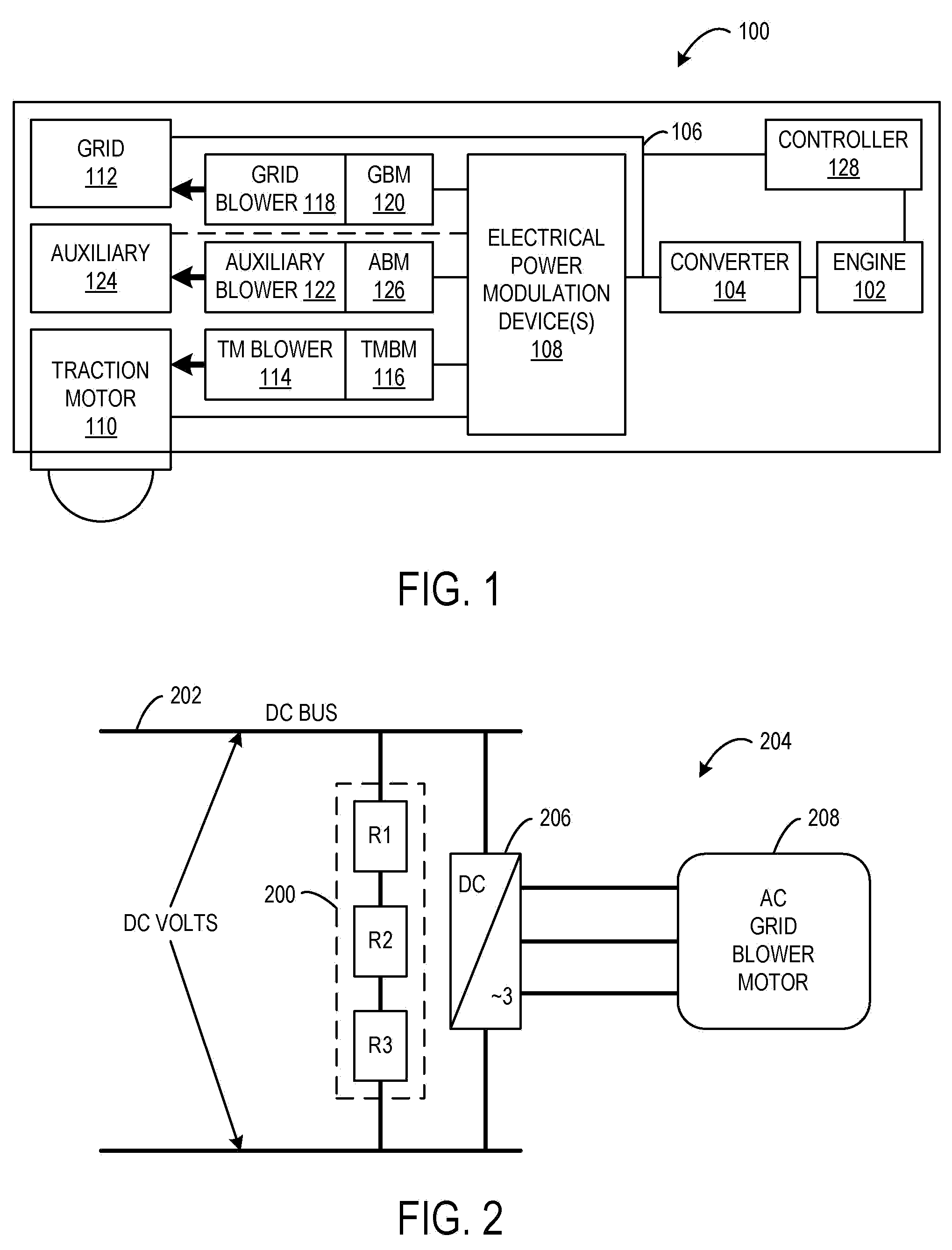

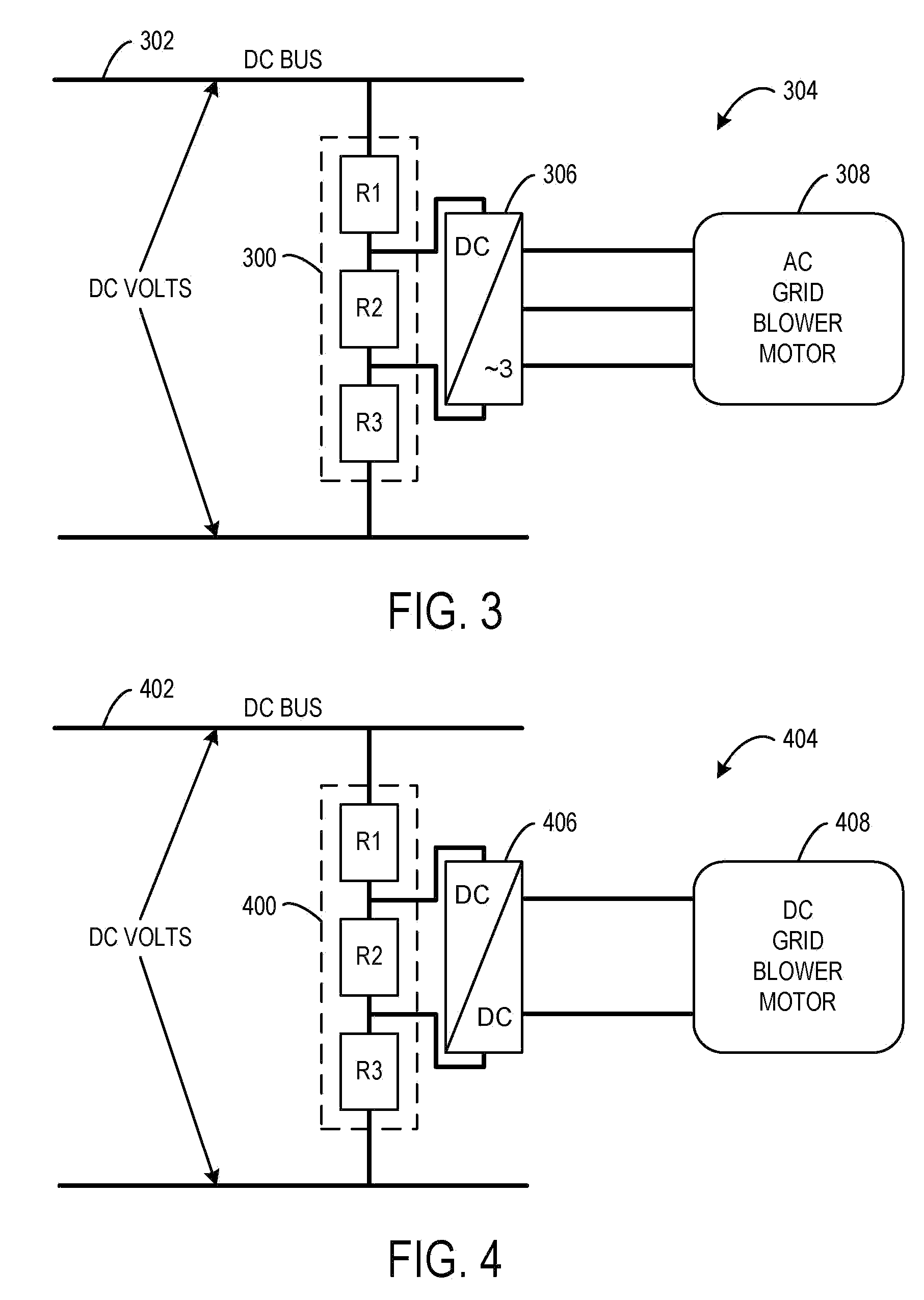

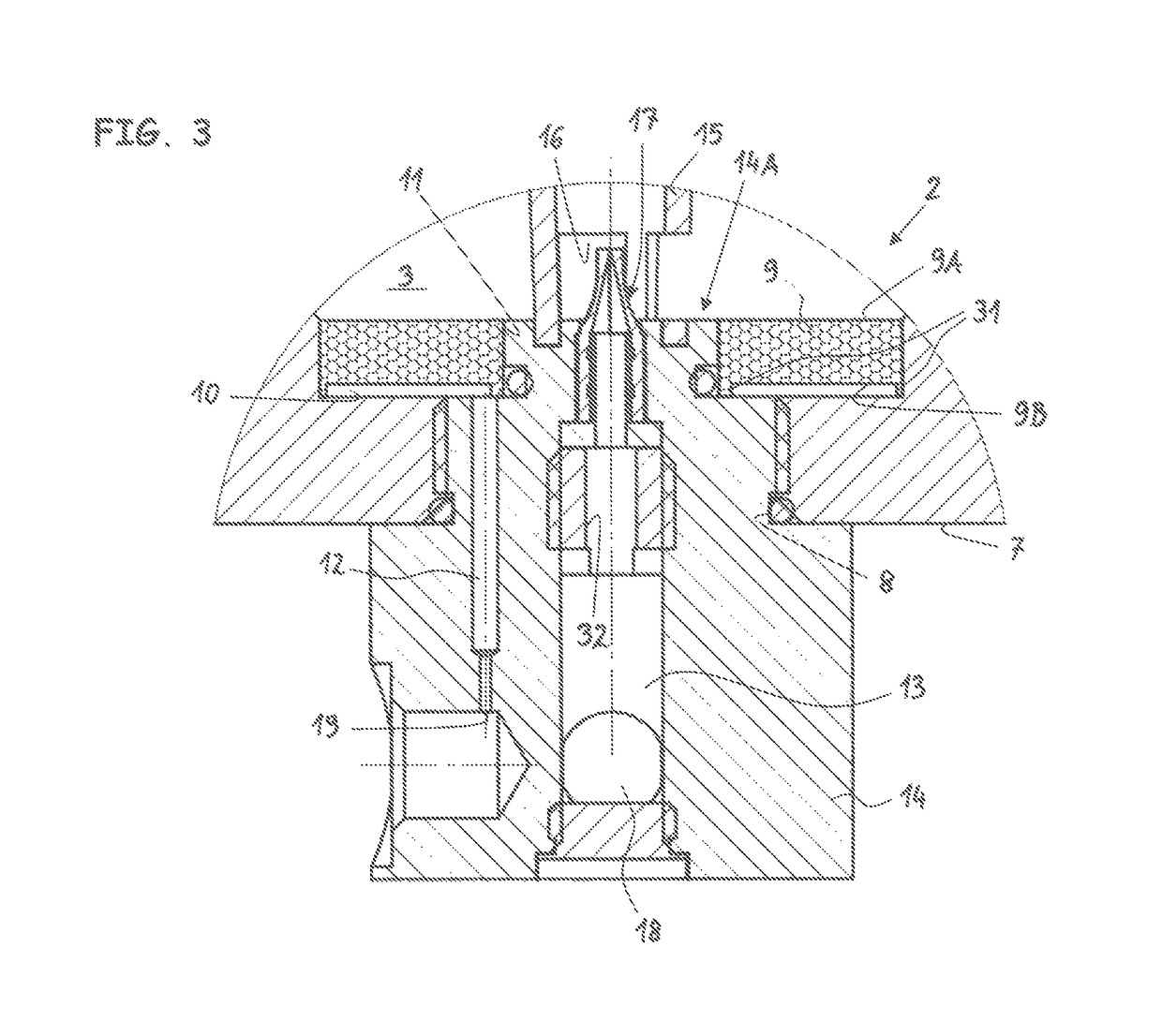

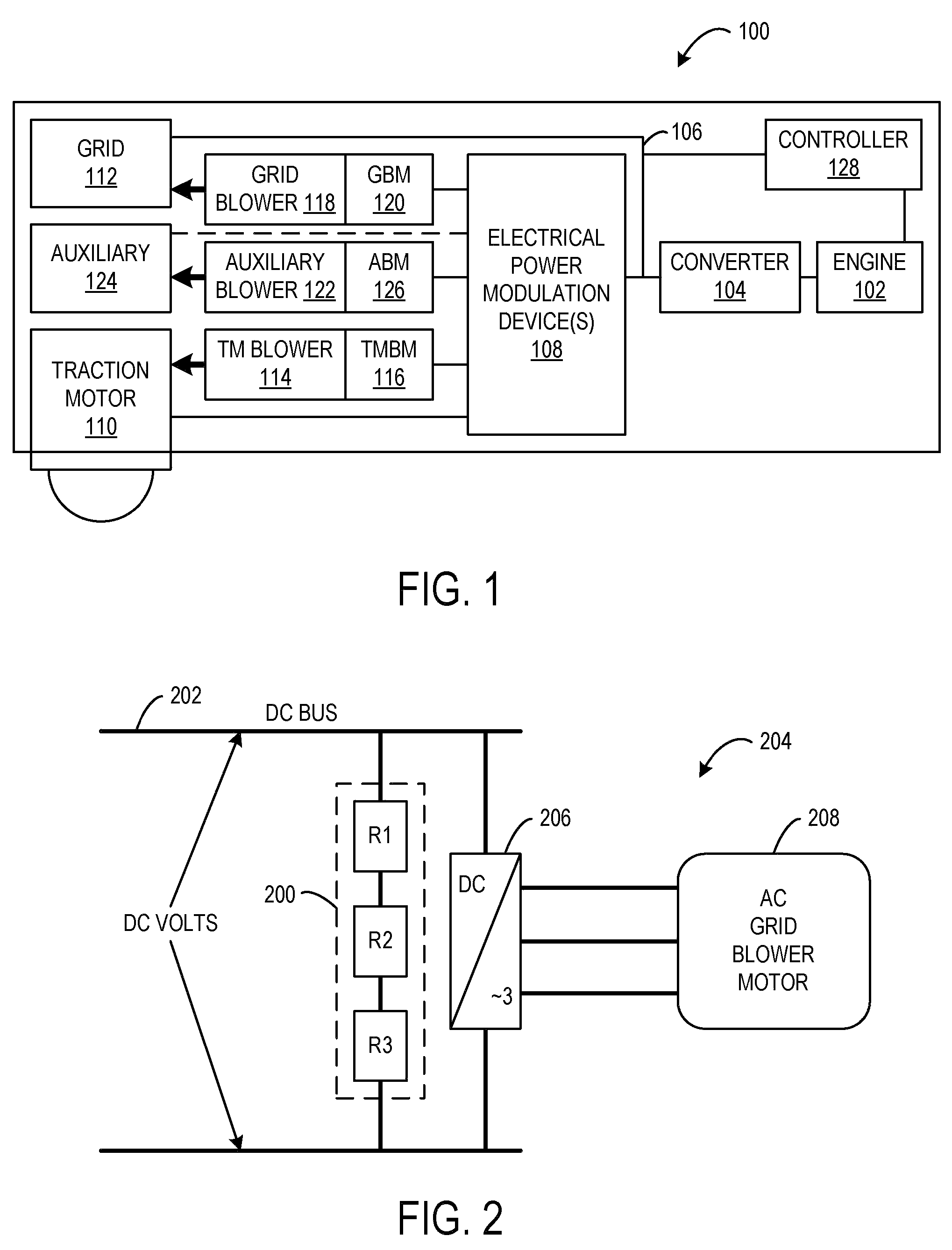

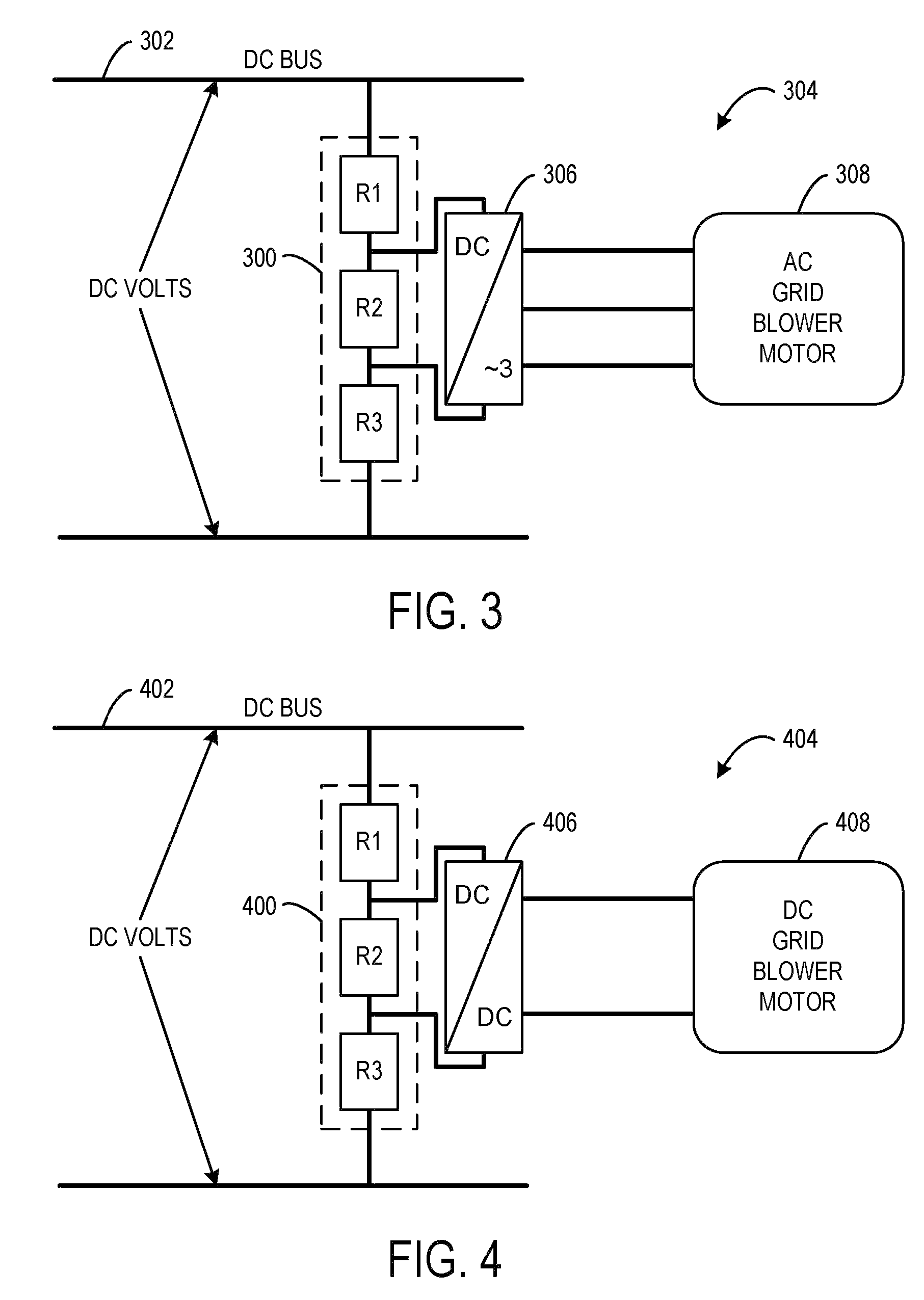

Variable-Speed-Drive System for a Grid Blower

ActiveUS20090293760A1Enhance forced-air cooling effectExtended service lifeDC motor speed/torque controlDigital data processing detailsElectrical resistance and conductancePower modulation

A drive system for a grid blower of a vehicle is provided. The system includes: an electrical bus, a grid of resistive elements connected to the electrical bus, the grid of resistive elements configured to thermally dissipate electrical power generated from braking of the vehicle, the electrical power being transmitted on the electrical bus to the grid of resistive elements, an electrical power modulation device configured to modify electrical power received from at least one of the electrical bus and the grid of resistive elements, and a grid blower motor coupled to an output of the electrical power modulation device, wherein a speed of the grid blower motor varies based on the electrical power that has been modified by the electrical power modulation device.

Owner:GE GLOBAL SOURCING LLC

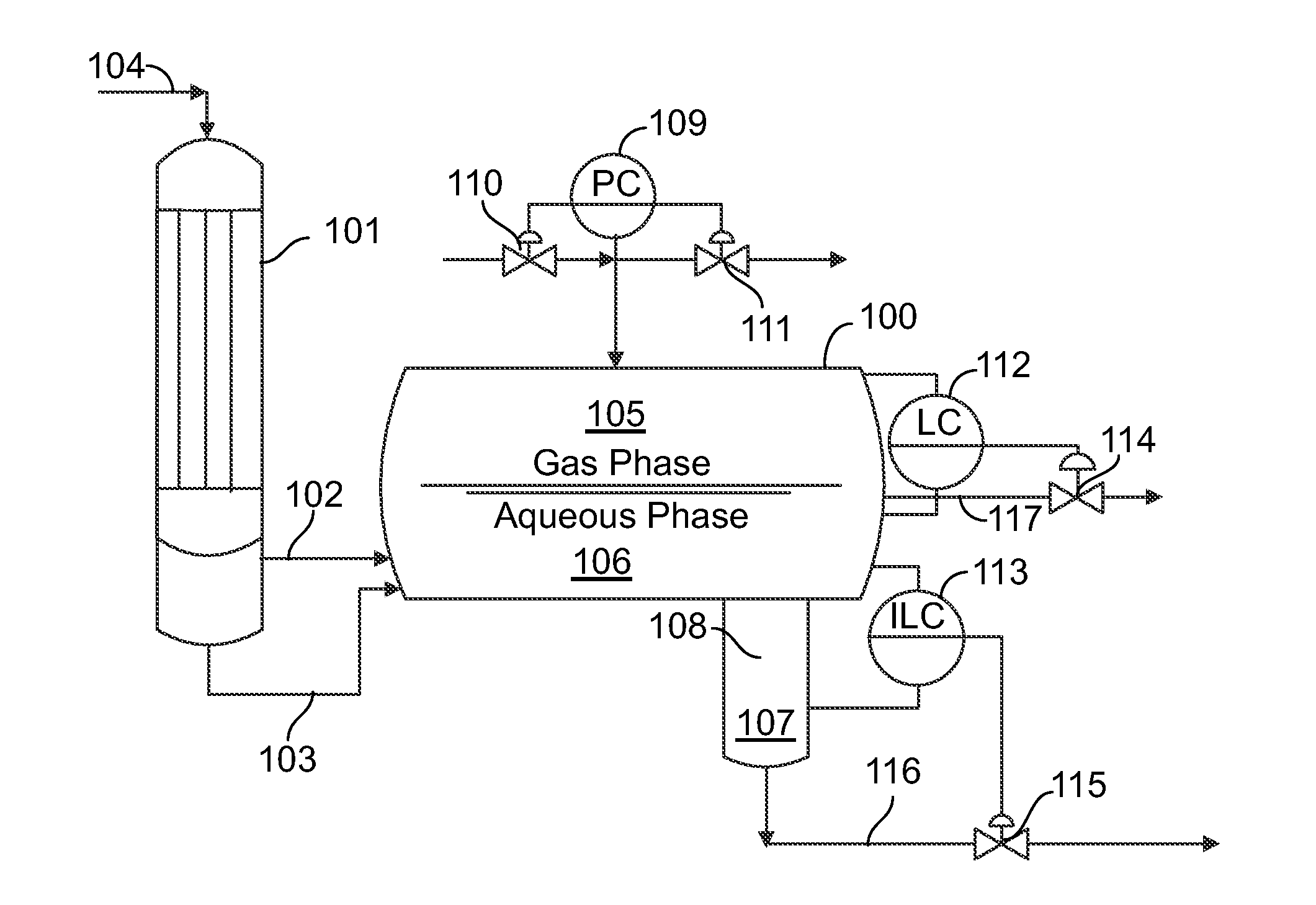

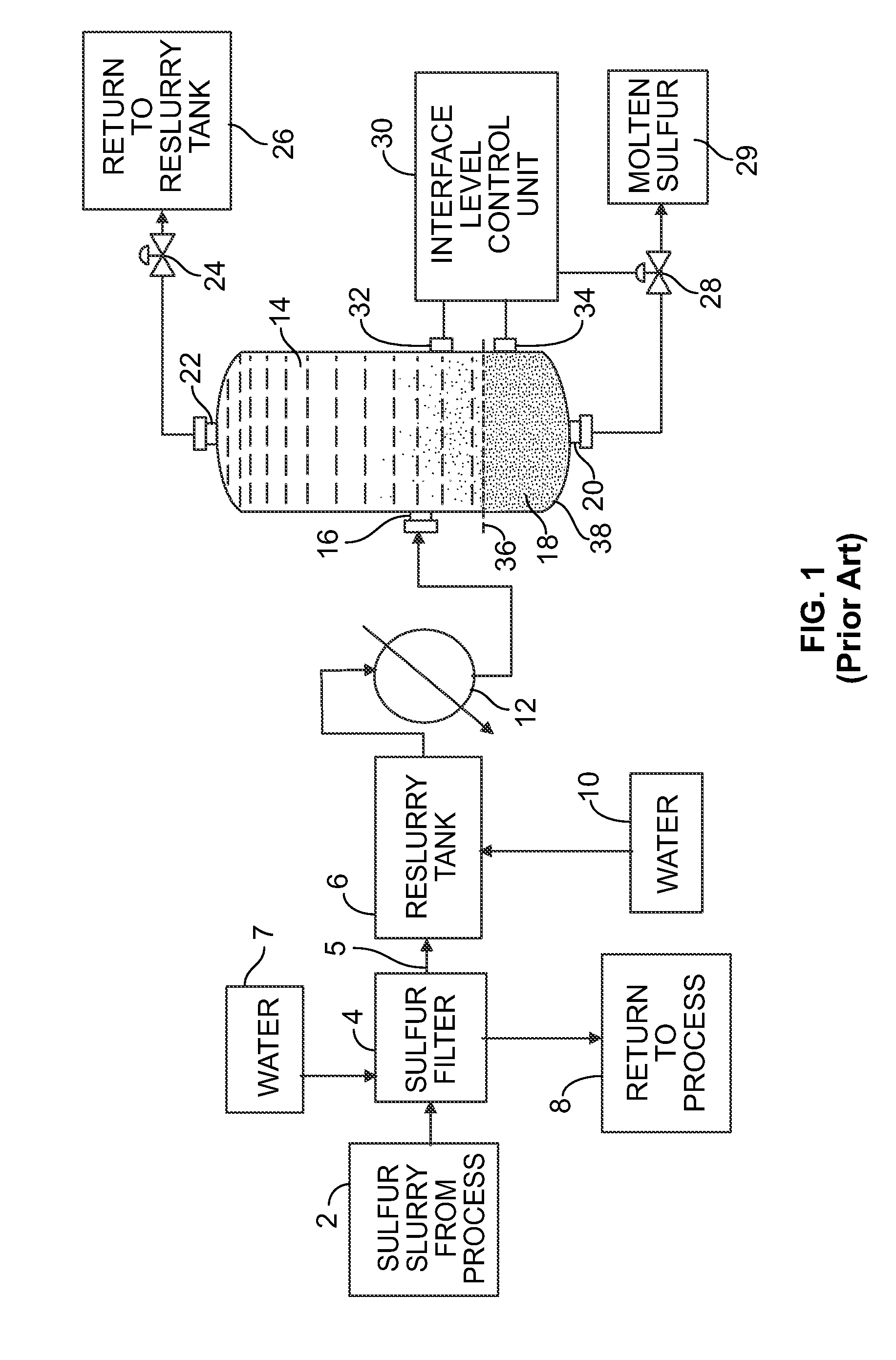

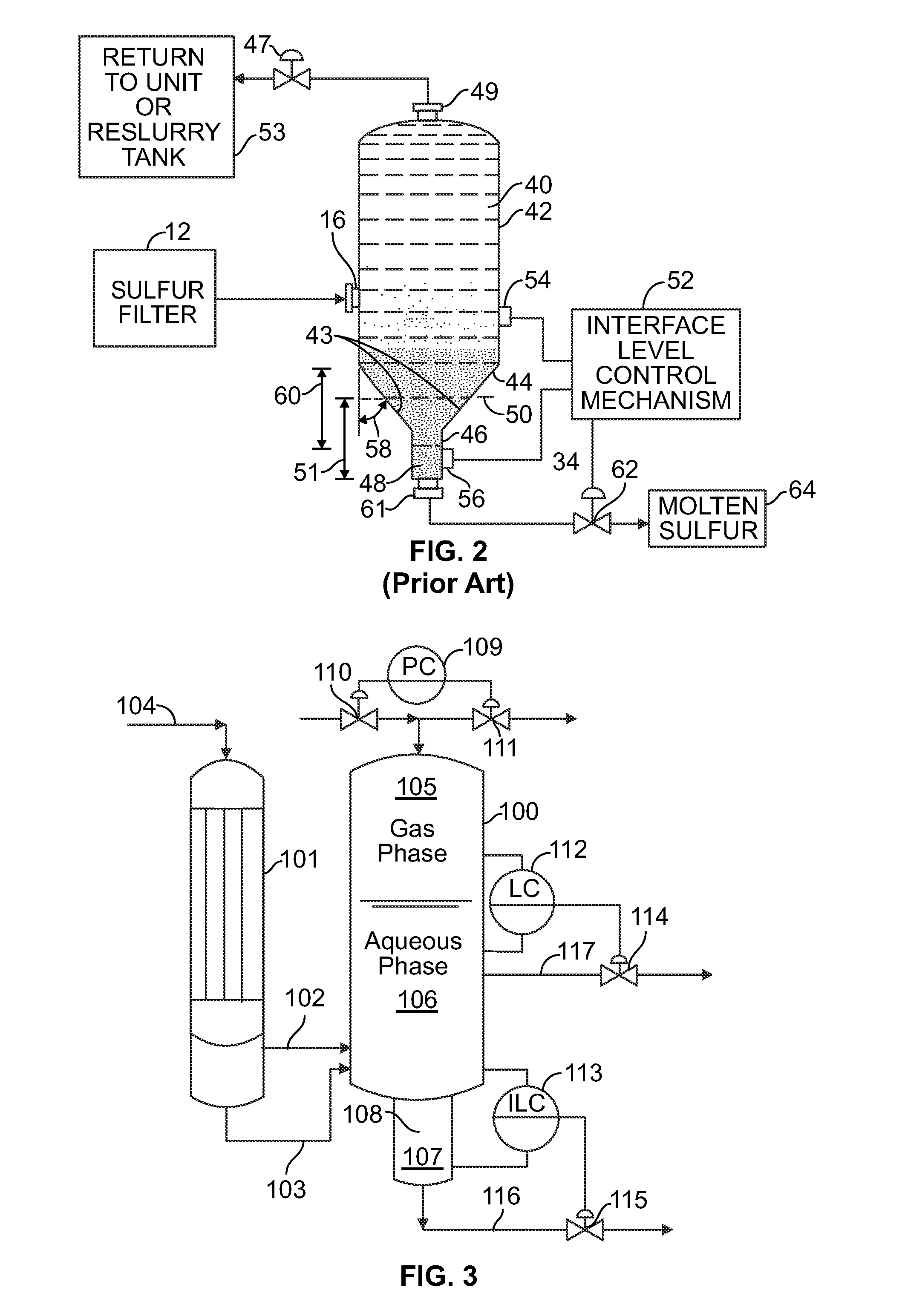

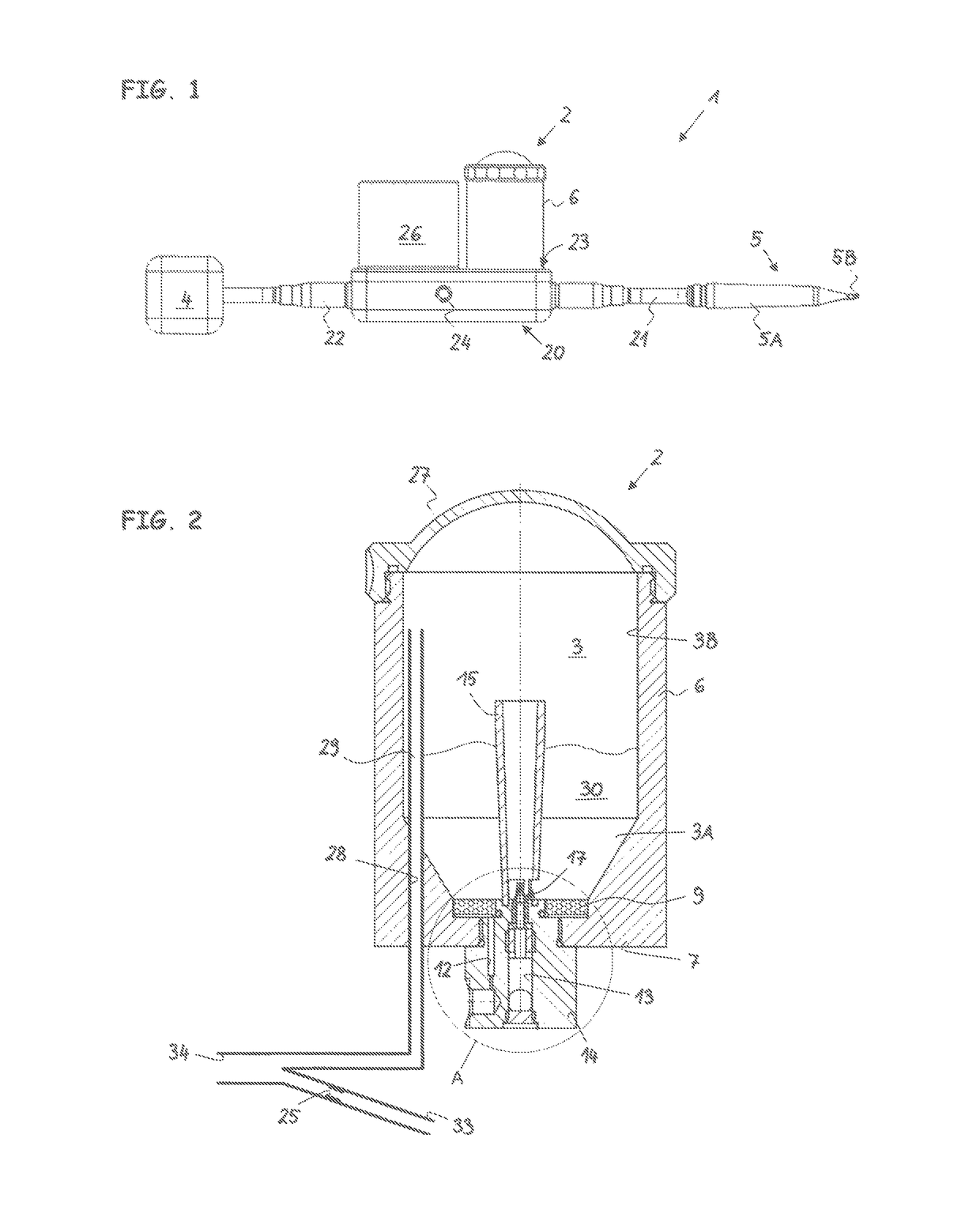

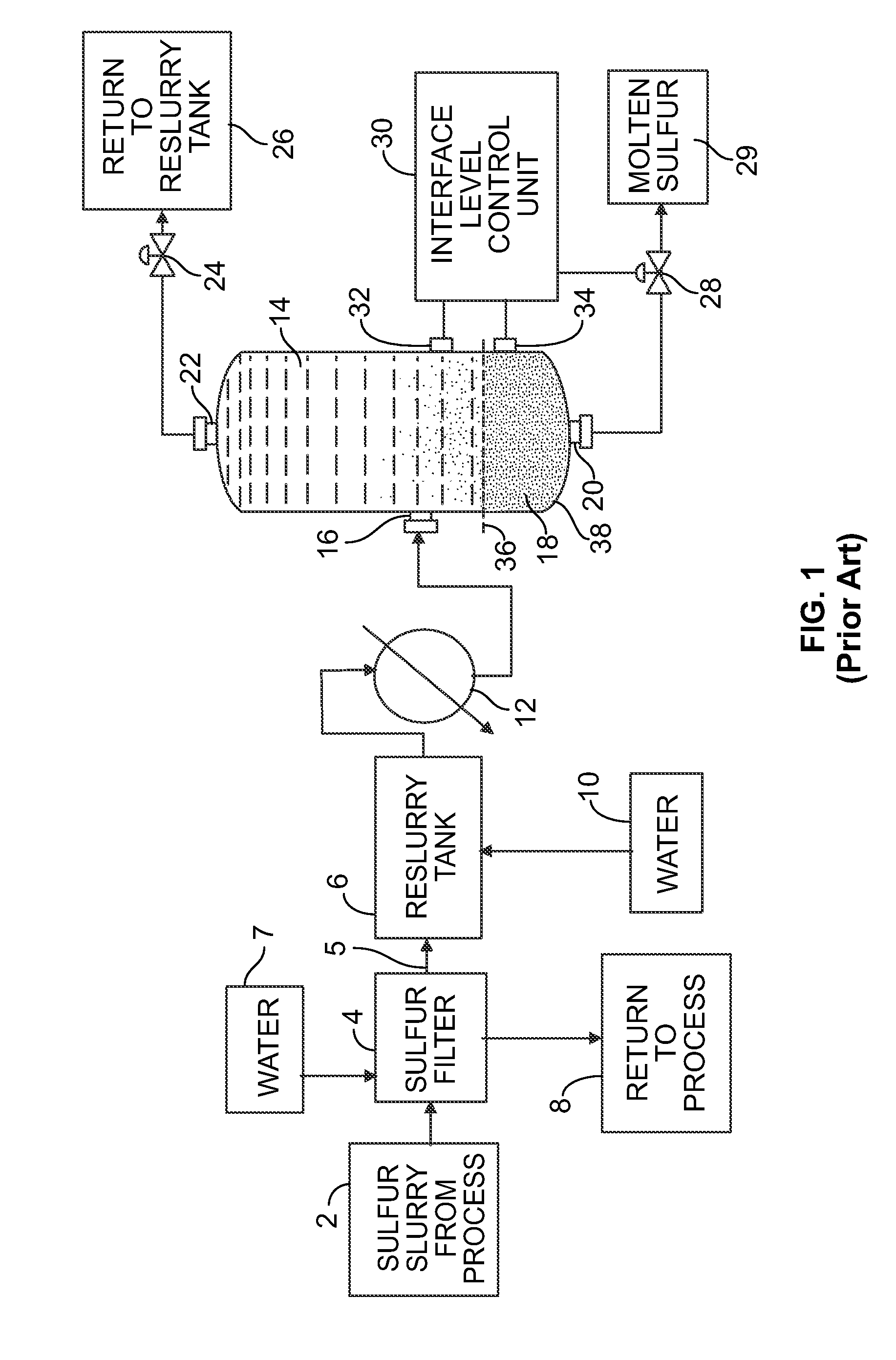

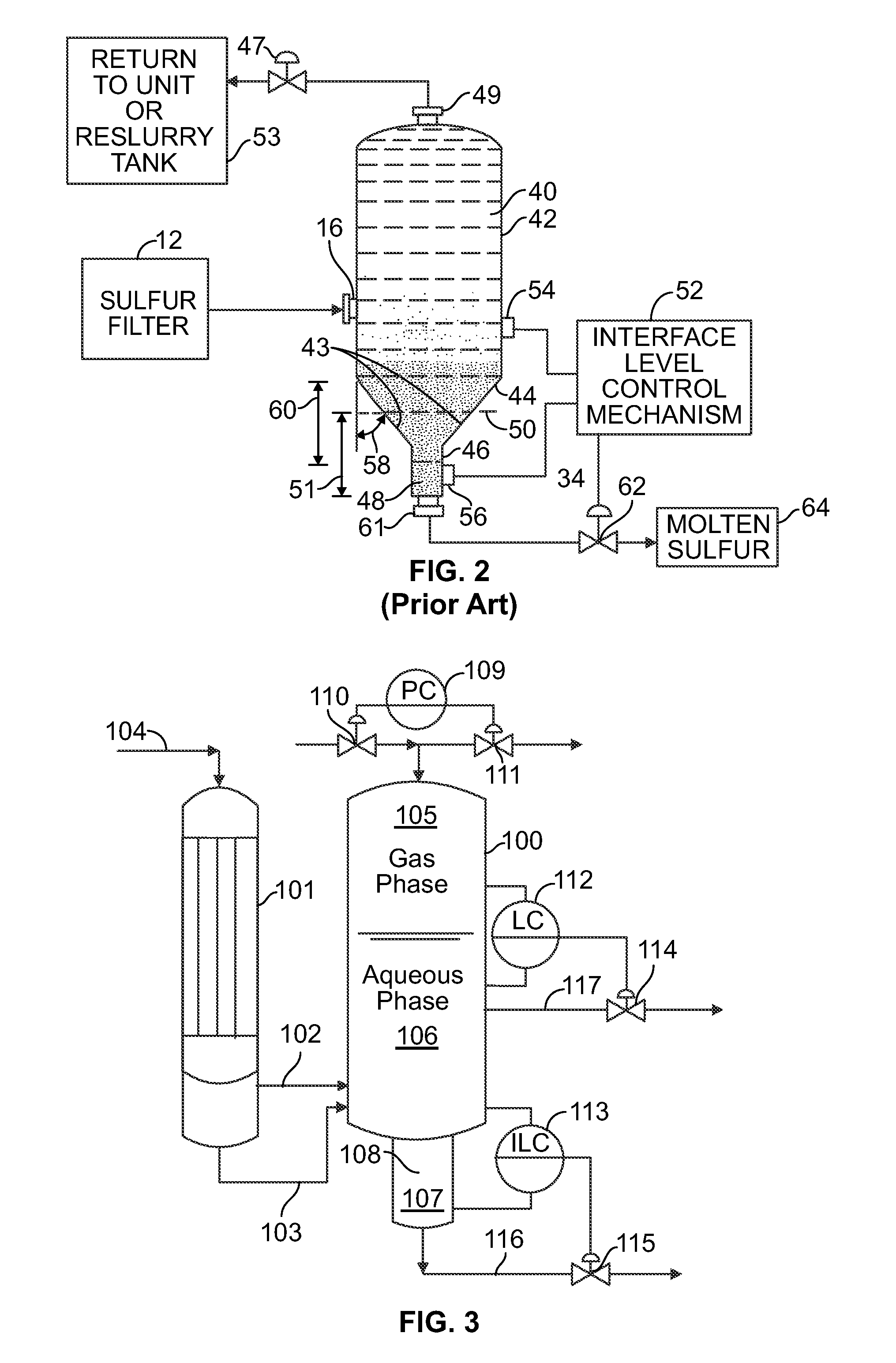

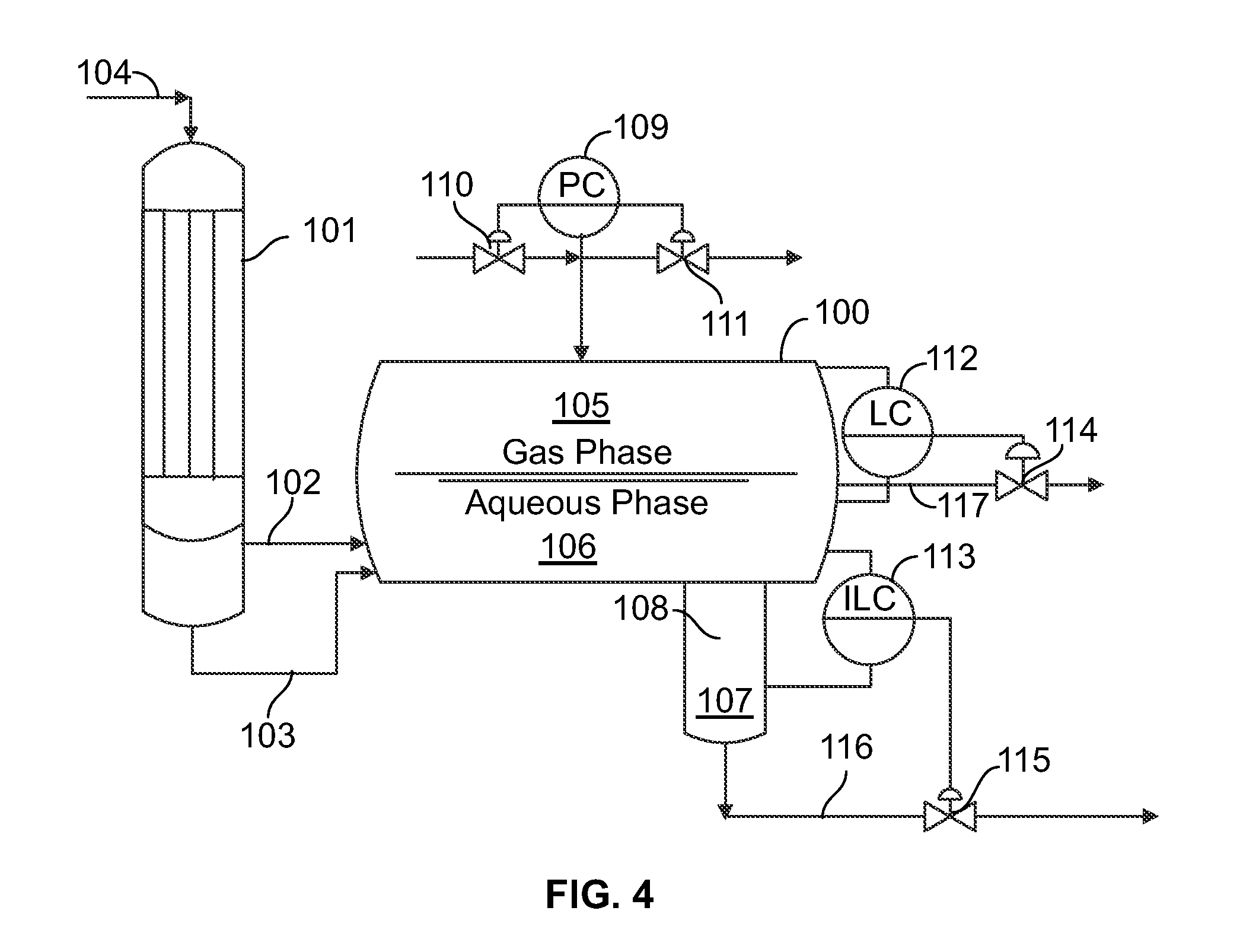

Three phase sulfur separation system with interface control

ActiveUS20110142747A1Quality improvementPrecise interface level controlLevel controlCrystallization separationGas phaseSulfur

A liquid separator system having a gas phase zone, an aqueous phase zone and a denser liquid zone is used to separate mixtures of fluids. The separator can be used for separating molten sulfur from liquid redox solution or reslurry water. The system includes a vessel with a top part and a bottom part. The vessel has a larger diameter at the top part than at the bottom part. The system also includes an inlet for introducing a redox solution or reslurry water and molten sulfur, which is denser than redox solution or reslurry water, into the vessel. An outlet near the bottom part of the vessel allows a flow of the molten sulfur from the vessel. An interface control structure senses an interface level between the redox solution or reslurry water and the molten sulfur, and the interface control structure controls the flow of molten sulfur from the outlet. The interface control structure is adjusted to optimally alter the vertical height of the interface level within the vessel so that the residence time of the molten sulfur in the vessel does not decrease as the sulfur production throughput decreases, and so that the interface area of the molten sulfur and the redox solution is reduced as the sulfur throughput decreases. A pressure controller monitors the pressure in the vessel and adds or removes gas from a gas phase zone in the vessel to maintain a predetermined pressure regardless of the vertical height of the interface.

Owner:MERICHEM CO

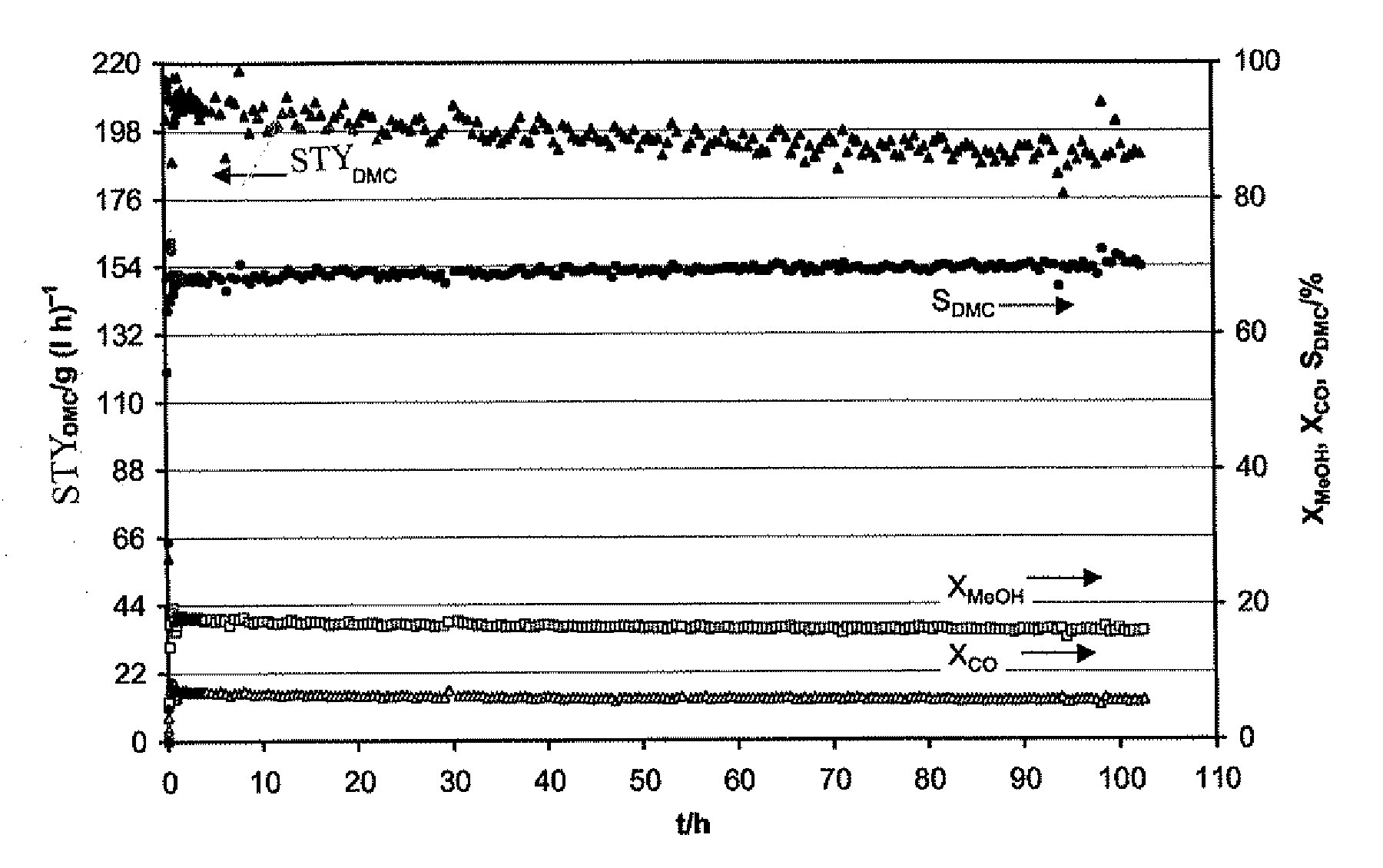

Catalyst for the Synthesis of Dimethyl Carbonate in the Gas Phase

InactiveUS20080249327A1Increased space-time yieldConstant operationAluminium compoundsMolecular sieve catalystsPtru catalystLiquid medium

The invention relates to an improved catalyst for the synthesis of dimethyl carbonate by reacting methanol, carbon monoxide and oxygen in the gas phase and to the use thereof. The catalyst consists of a copper-containing zeolite produced by admixing one or more halide-free copper(II) compounds to a zeolite in a liquid medium, drying the zeolite modified by the admixture, and tempering at 400-900° C. under inert conditions, essentially retaining the crystallinity of the zeolite, said admixing being effected by means of a method selected from the group consisting of impregnation of the zeolite, ion exchange, precipitation of copper(II) hydroxide in the presence of the zeolite, and a combination of these methods. The catalyst shows high space-time yields, is constant over the period of operation and has no corrosive action.

Owner:SUD CHEM AG

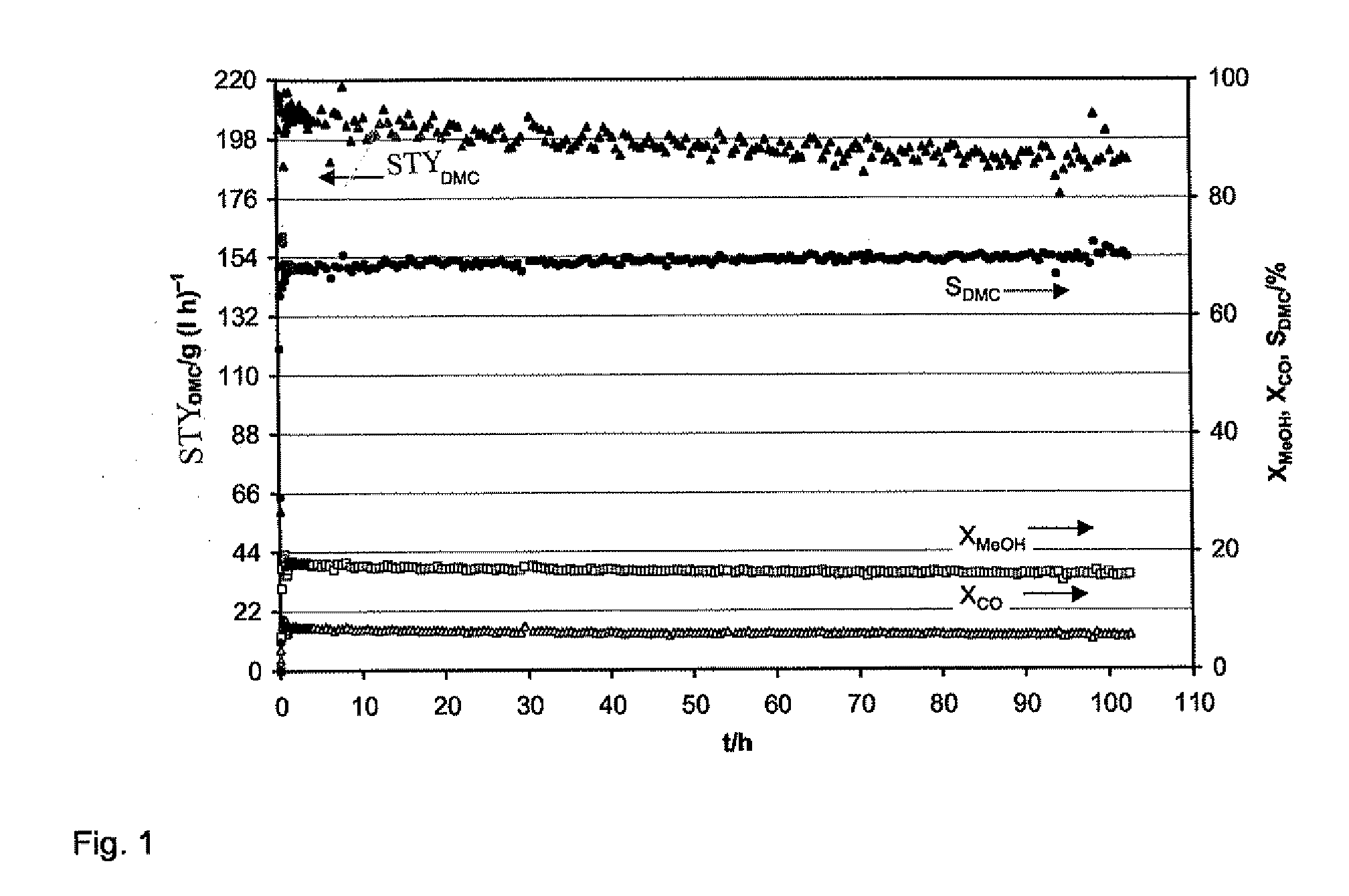

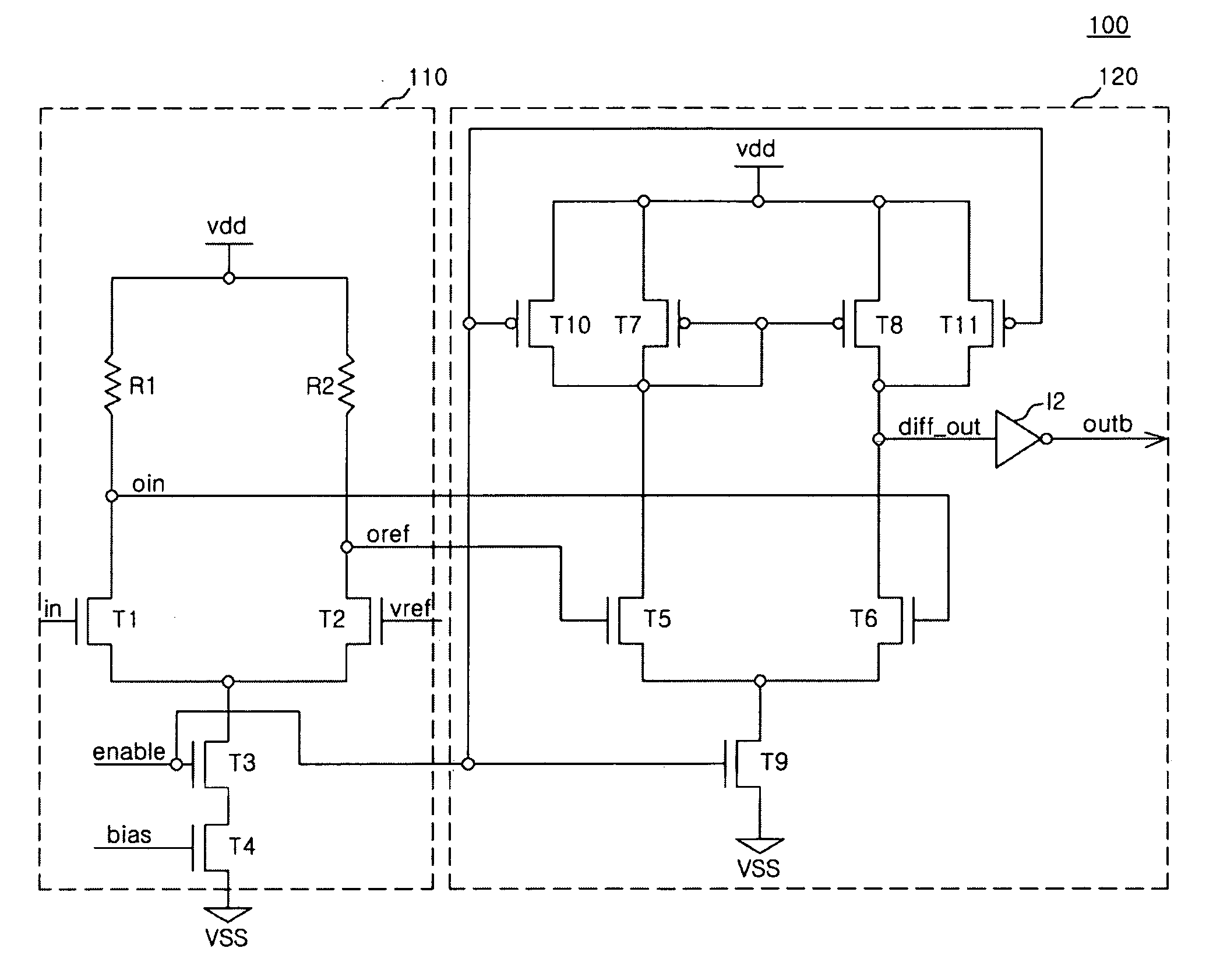

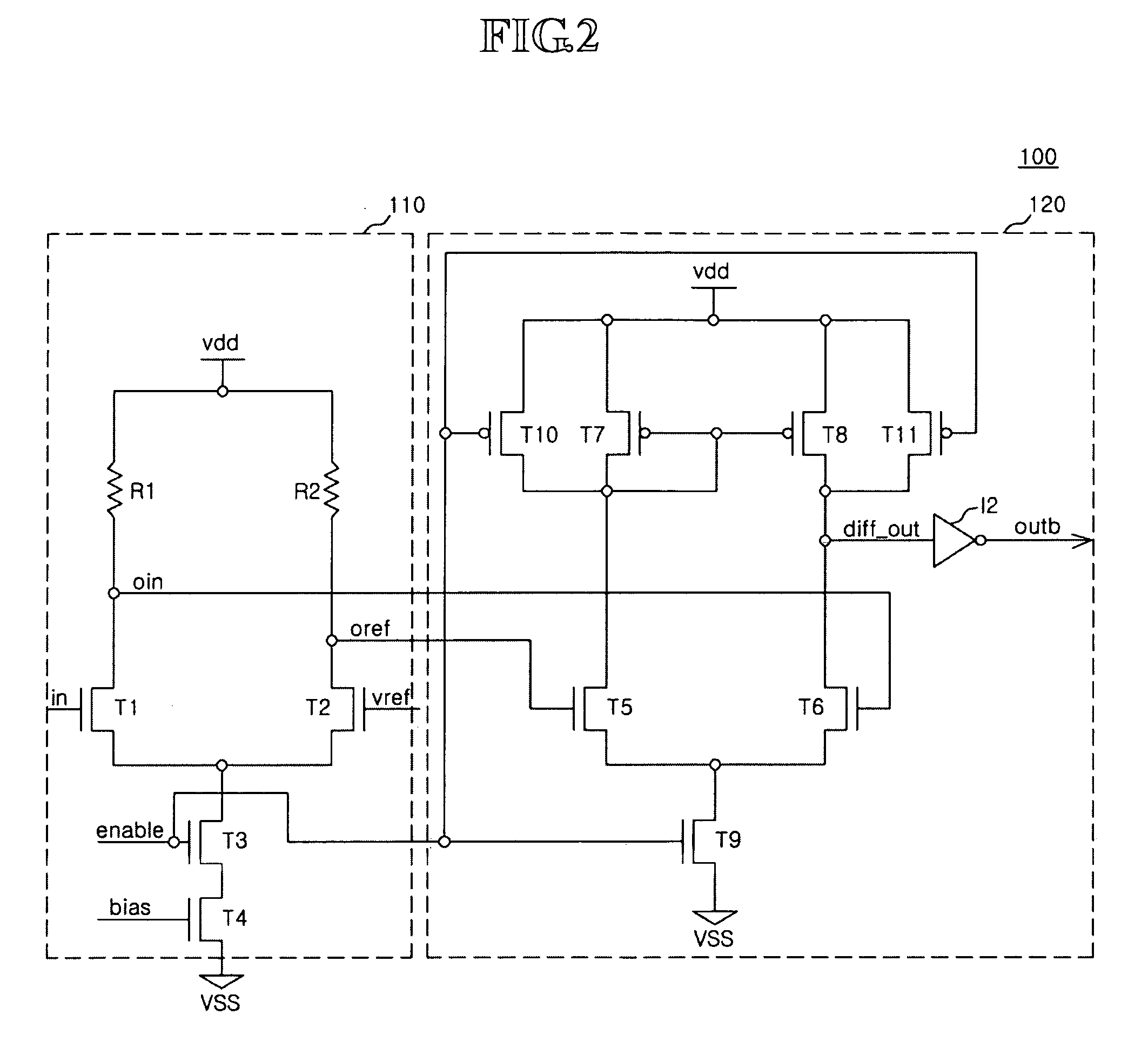

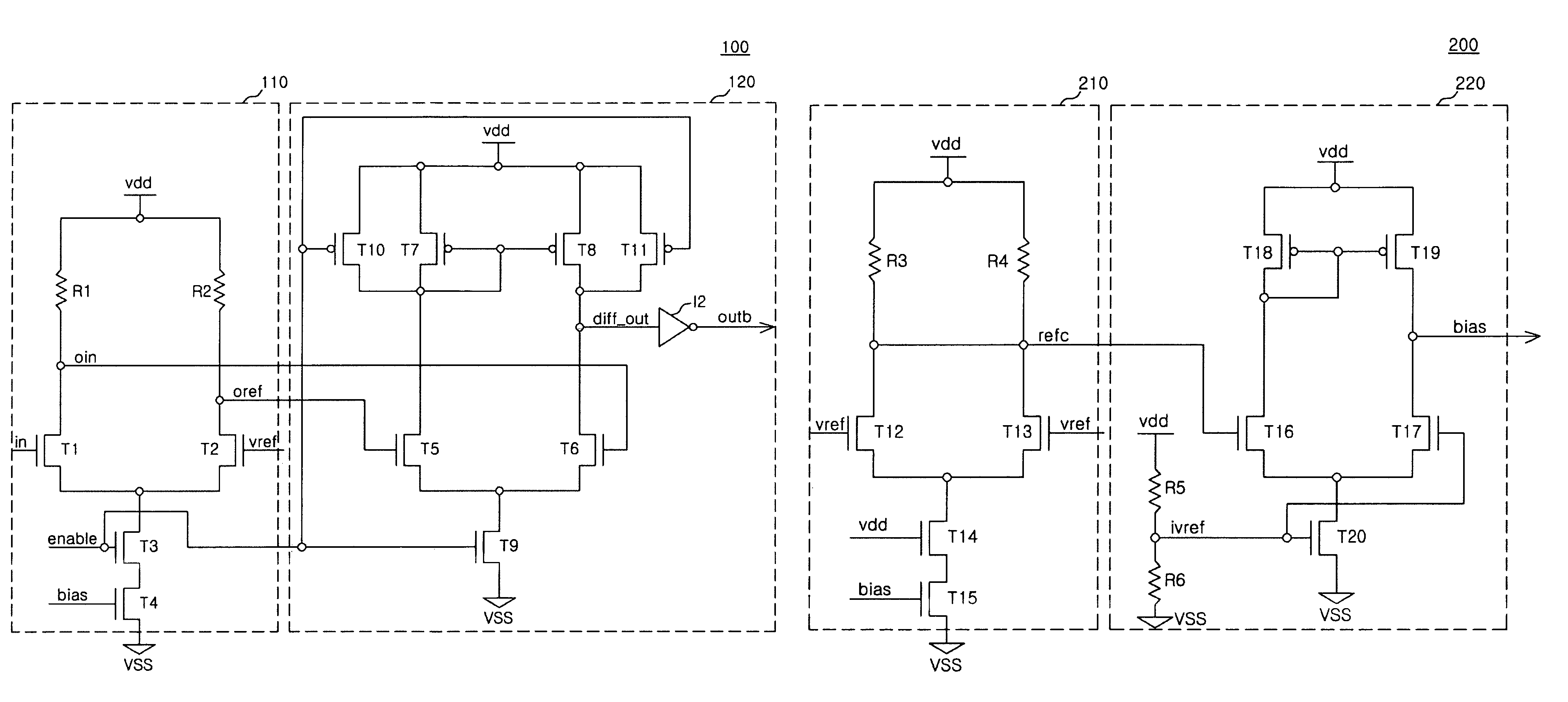

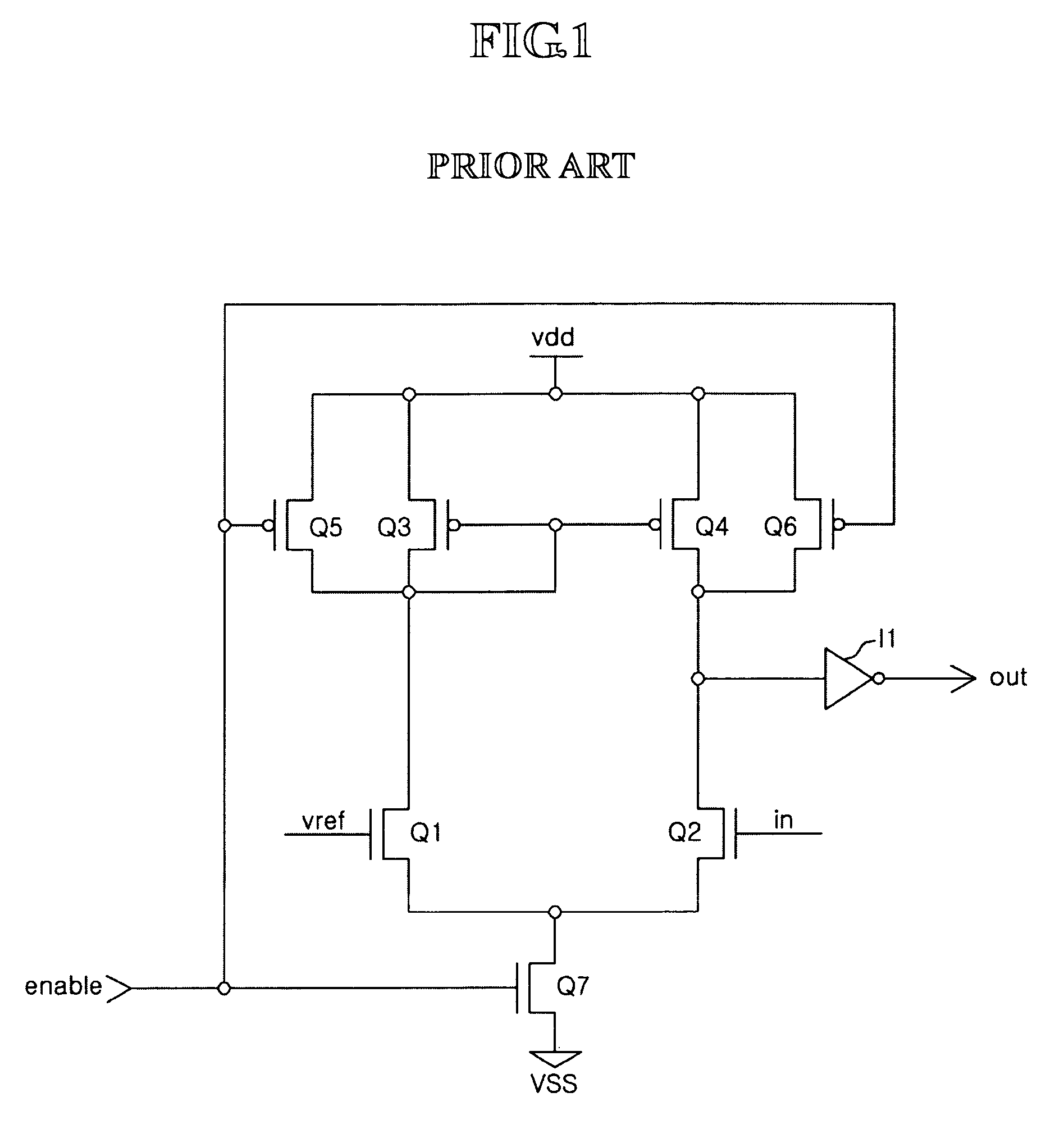

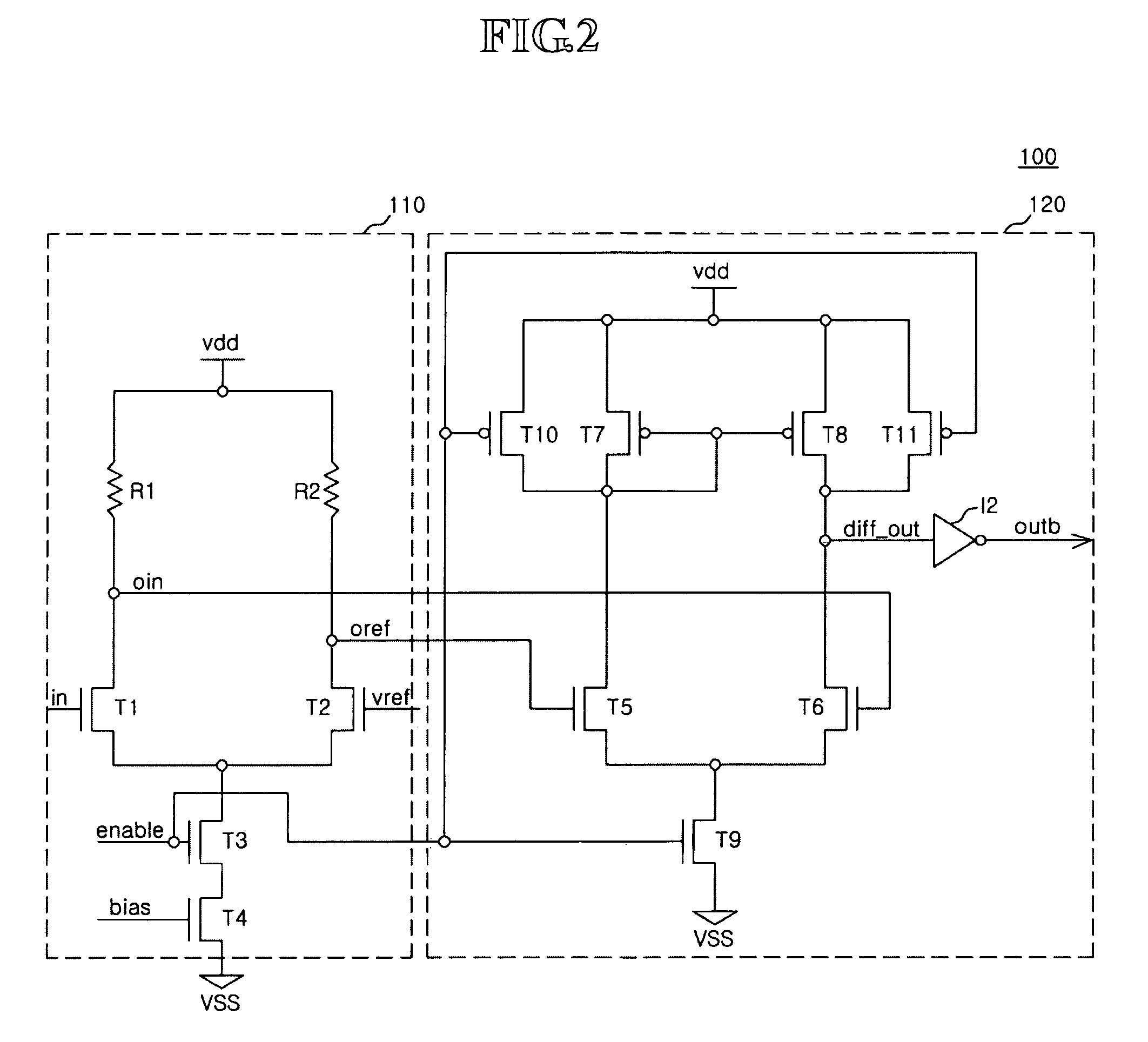

Input circuit for semiconductor integrated circuit

InactiveUS20070273406A1Increasing swing widthHigh voltage gainDigital storageElectric pulse generatorPotential differenceVoltage reference

An input circuit for a semiconductor integrated circuit in which an operational state is constant even when a process condition, a temperature, a voltage, and the like are varied at the time of operation is provided. The input circuit includes a first input unit that performs a first amplifying operation on a potential difference between a reference voltage and an input signal and outputs a result of the amplification, and a second input unit that performs a second amplifying operation on a signal amplified by the first input unit and outputs a result of the amplification.

Owner:SK HYNIX INC

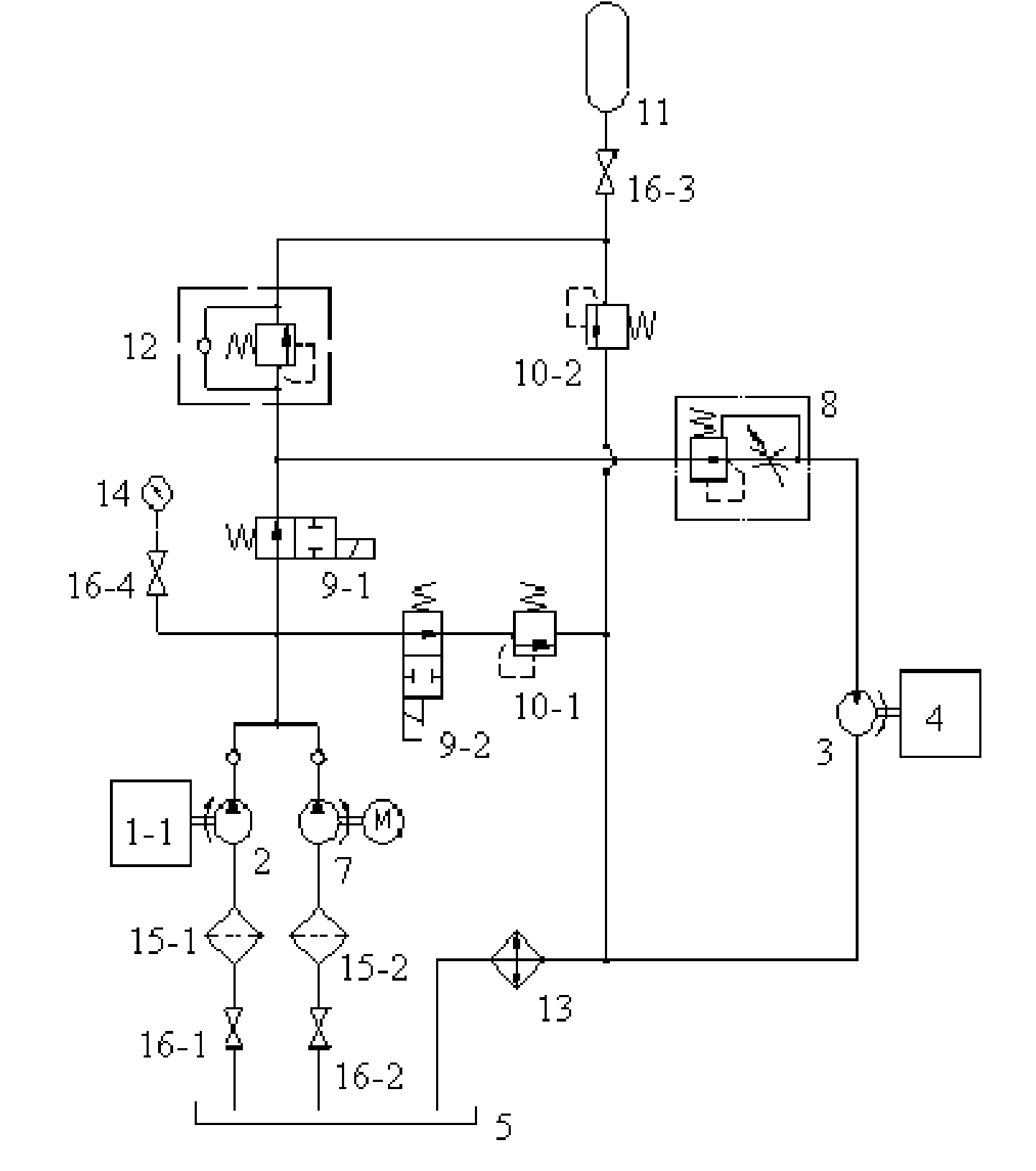

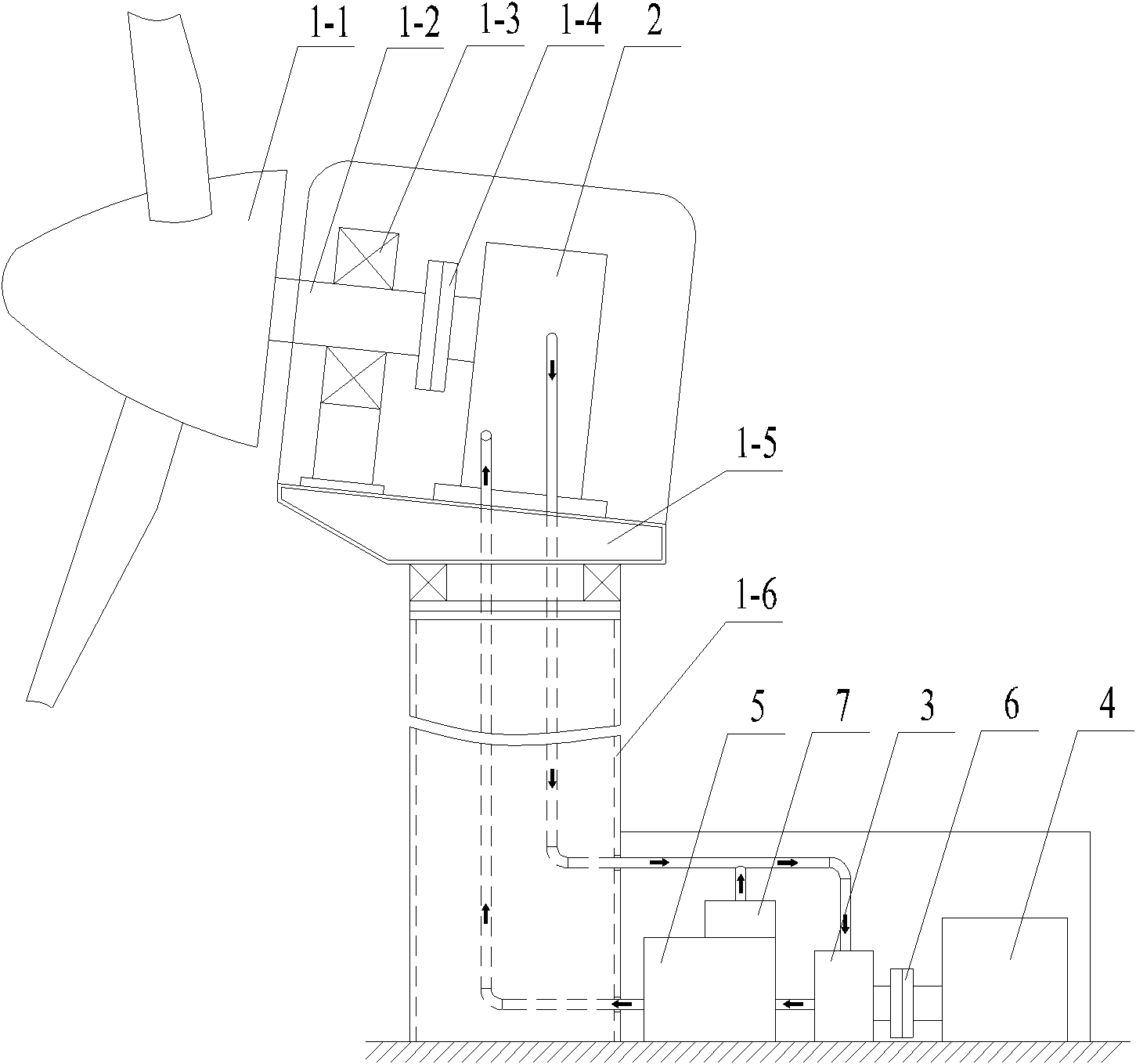

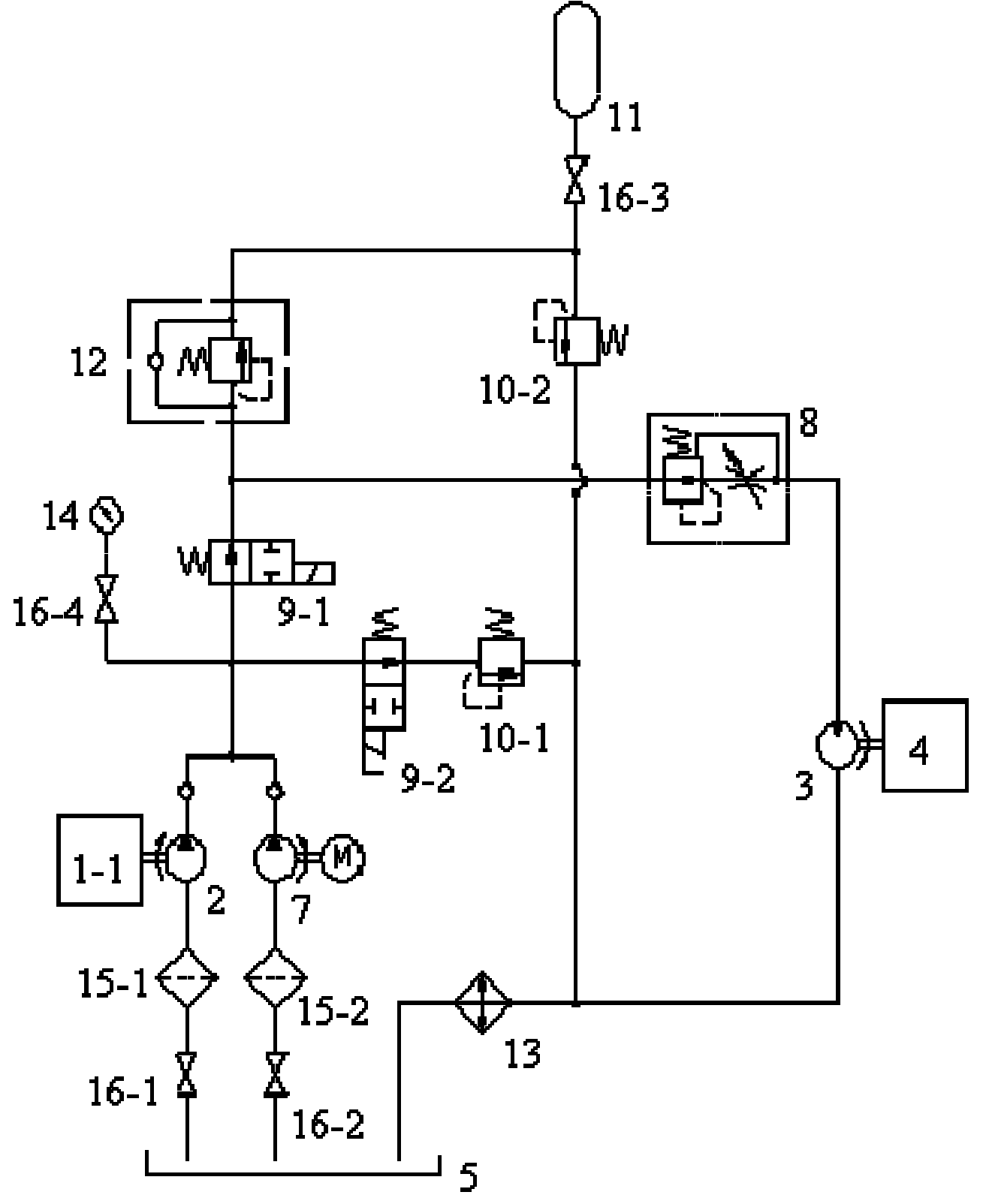

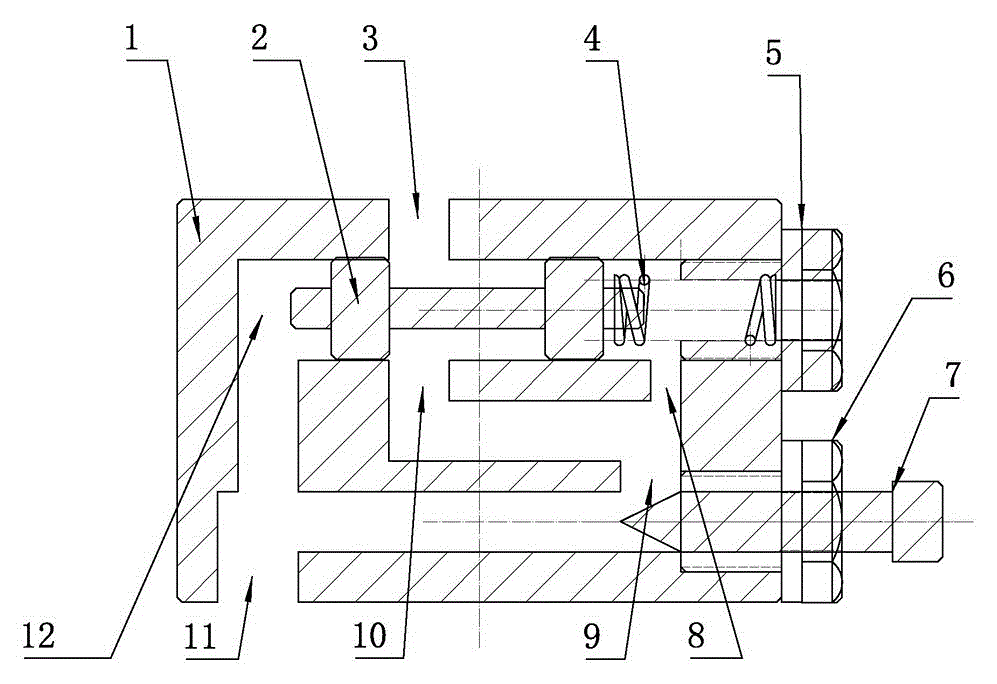

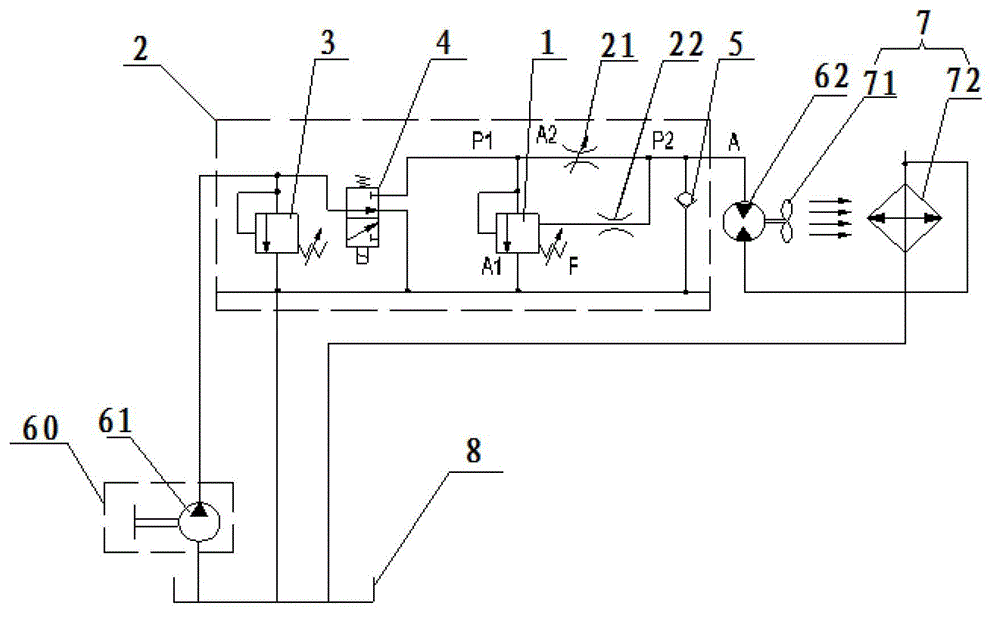

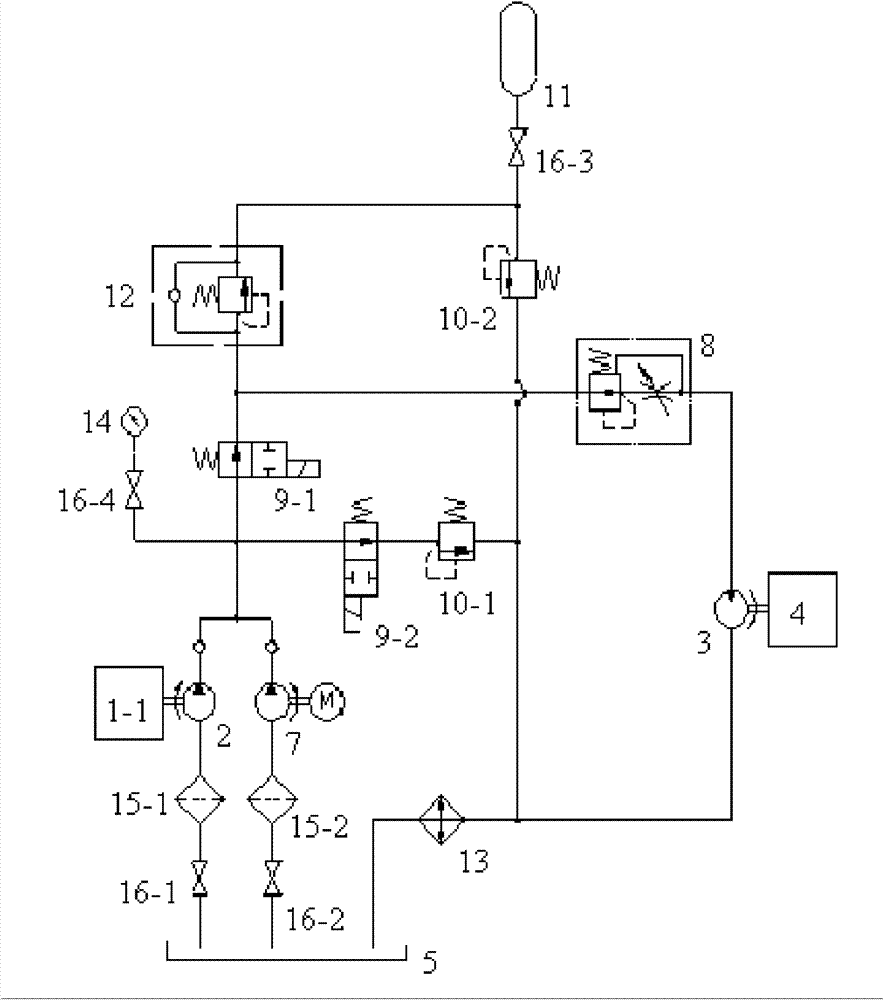

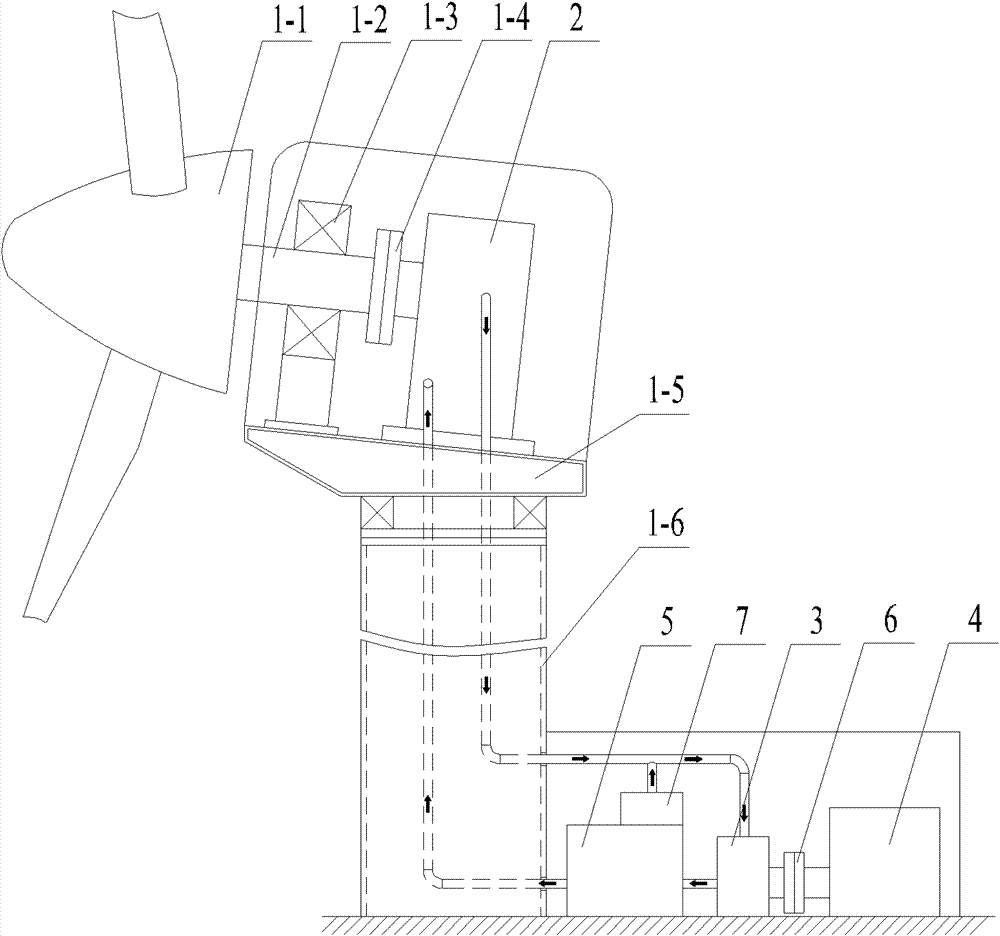

Hydraulic system and wind-driven power generator set

ActiveCN102454555AConstant operationConstant powerEnergy industryMachines/enginesWind drivenFuel tank

The invention relates to the technical field of wind-driven power generator sets, and particularly discloses a hydraulic transmission system for transmitting the power generated by a wind wheel of a wind-driven power generator set to a power generator, wherein the hydraulic transmission system comprises a first hydraulic pump and a hydraulic motor; the power input end of the first hydraulic pump is connected with a wind wheel main shaft; the oil inlet of the first hydraulic pump is communicated with an oil tank, and the oil outlet of the first hydraulic pump is communicated with the oil inlet of the hydraulic motor; the oil outlet of the hydraulic motor is communicated with the oil tank; the power output end of the hydraulic motor is communicated with the power input end of the power generator; and an oil channel between the first hydraulic pump and the hydraulic motor is provided with a speed regulating valve. No matter how the wind speed changes, the transmission system can always enable the power generator to operate always at a constant speed, and can enable the power and frequency of electricity to be constant. The invention also discloses a wind-driven power generator set.

Owner:SANY ELECTRIC CO LTD

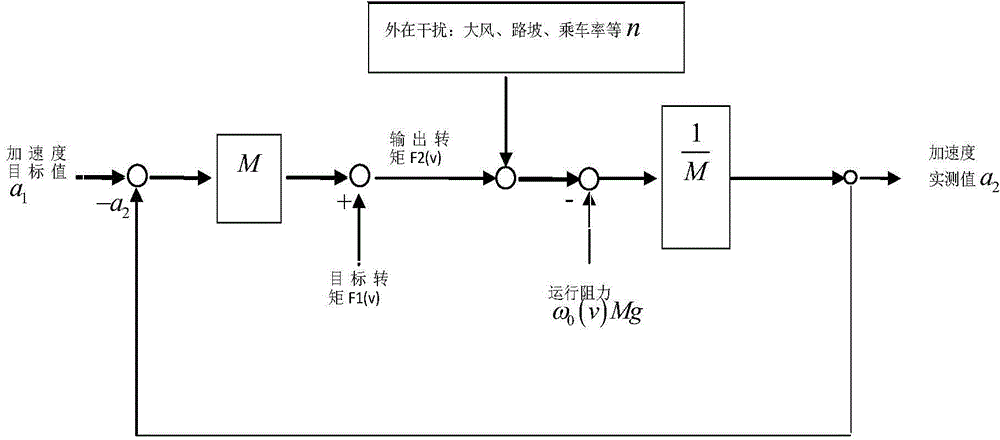

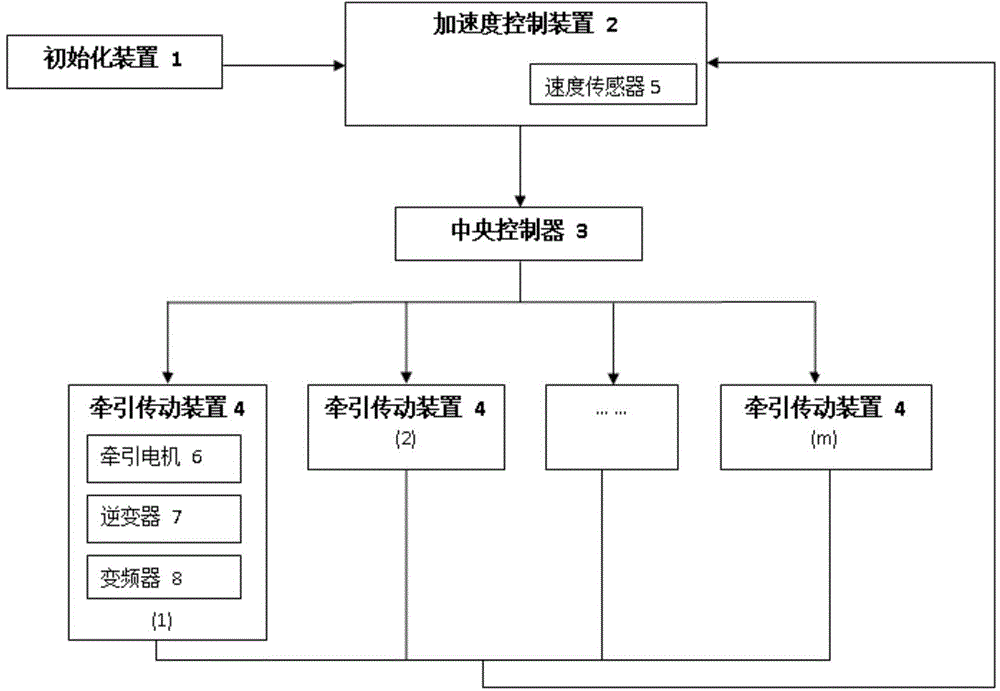

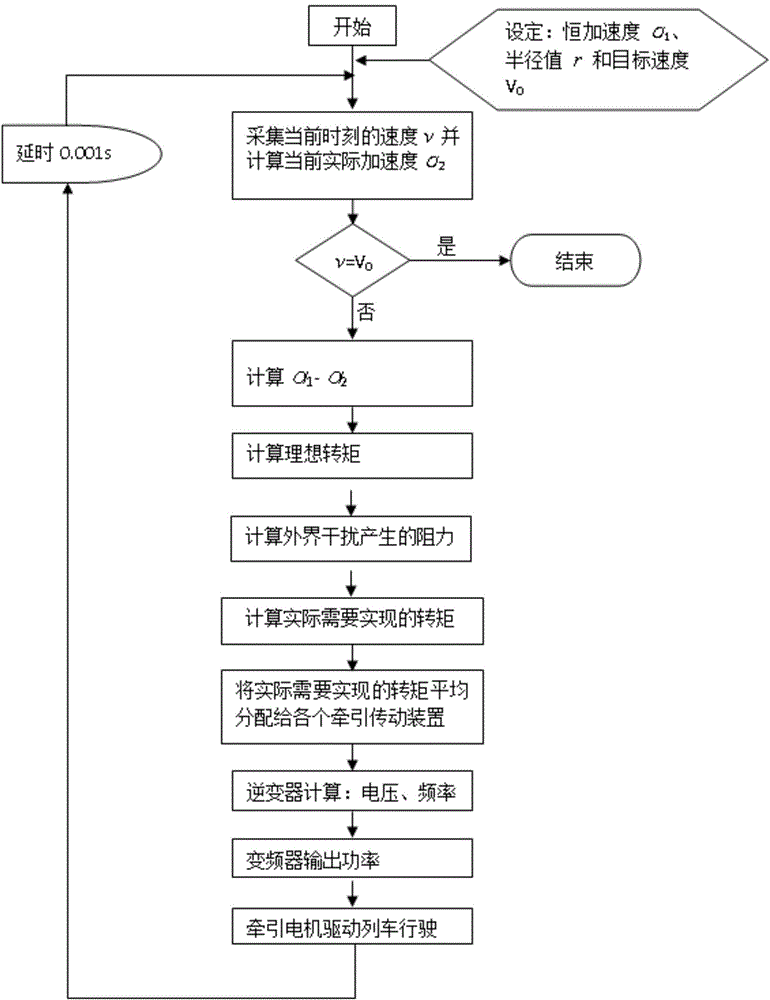

Train traction control method and system

ActiveCN104057980AConstant operationLoss of stationarityAutomatic systemsControl theoryResistance force

The invention provides a train traction control method, which comprises the following steps: firstly, setting a to-be-achieved accelerated speed target value a1 and testing a present speed v of a train; acquiring an ideal torque F1(v) and a practical resistance n suffered by the train according to the accelerated speed target value a1 and the present speed v; calculating and acquiring a traction torque F2(v) practically required by the train for achieving the accelerated speed target value a1 according to F2(v)=F1(v)+nr; distributing the traction torque F2(v) practically required by the train to each traction driving device of the train. Through the process, the output power of a traction motor is continuously adjusted, so that the train can run at a constant accelerated speed, and the stability and comfort loss of the train and the burden of a driver during the running process caused by the continuous change of the accelerated speed are avoided.

Owner:CRRC QINGDAO SIFANG CO LTD

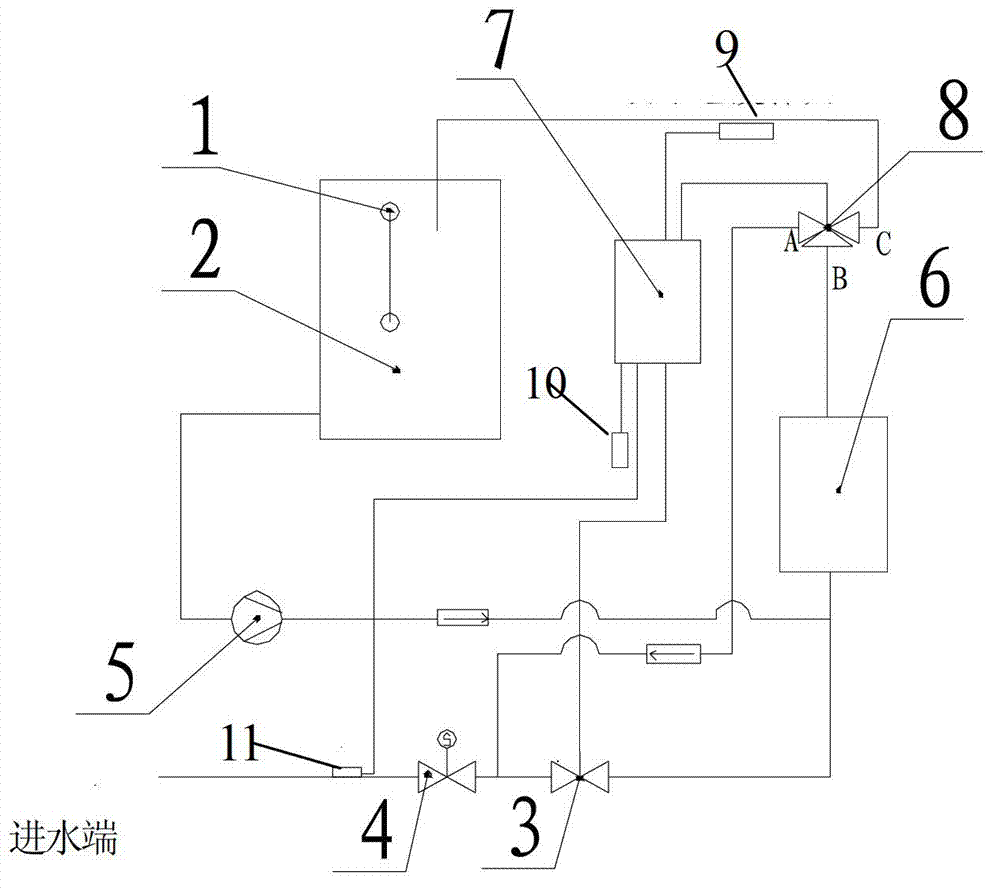

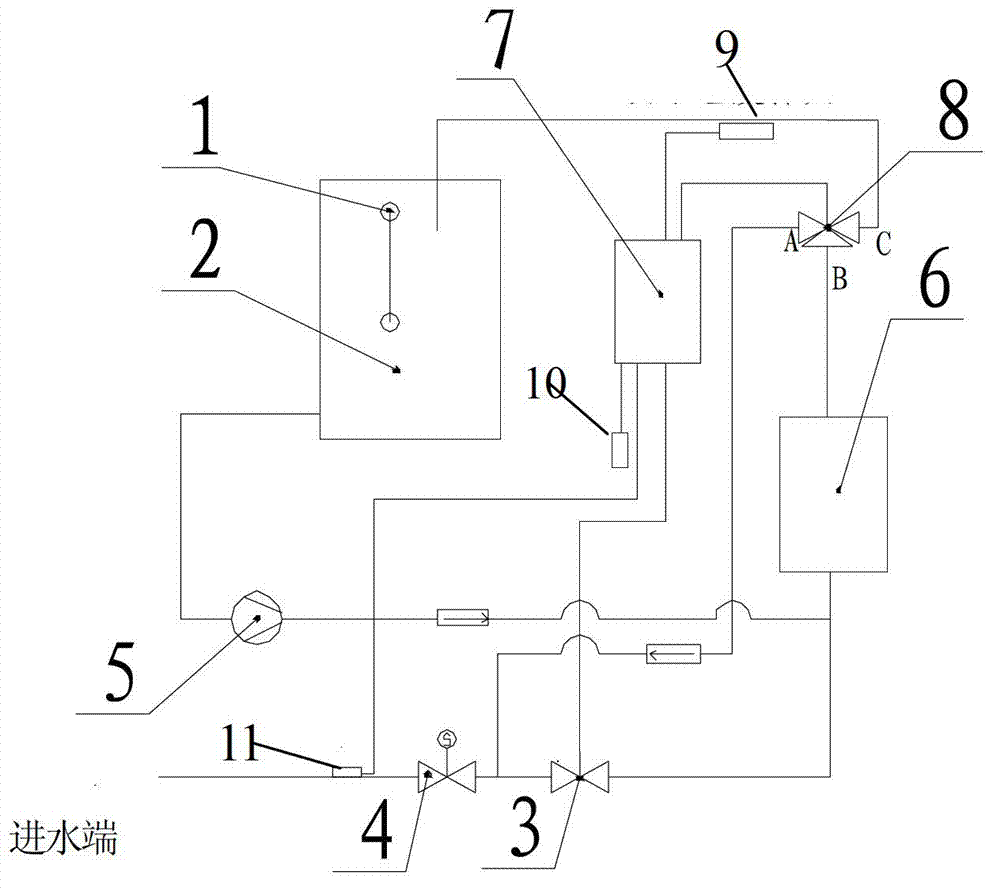

Temperature control device and temperature control method for yielding water of single-heat type heat pump water heater

ActiveCN102818372ASimplify engineering installationLow costFluid heatersProportioning valveHeat pump water heater

The invention discloses a temperature control device for yielding water of a single-heat type heat pump water heater. A pipeline is connected with a heat storage water tank, a tee-joint proportioning valve, a heating water heat exchanger, a water pump and a yielding water constant temperature control module connected with the heat storage water tank, wherein the yielding water constant temperature control module is connected with an ambient temperature probe, and controls the switching on and off of the tee-joint proportioning valve; and an opening in the A-B direction of the tee-joint proportioning valve is communicated with a water inlet end, and an opening in the B-C direction is communicated with the heating water heat exchanger. In addition, the invention also discloses a temperature control method, the temperature of the heat storage water tank, the ambient and the heating water heat exchanger are subjected to sampling detection, and according to different ambient temperatures, different yielding water temperature values can be set, the switching on-off degree of the tee-joint proportioning valve is adjusted, the water feeding amount is adjusted by the temperature control regulating valve, so that the yielding water temperature of the heating water heat exchanger can reach the set value. The temperature control device can run with safety, stability and high efficiency, and meanwhile, the engineering installation is simple, the cost is low, and the supplied hot water is constant.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

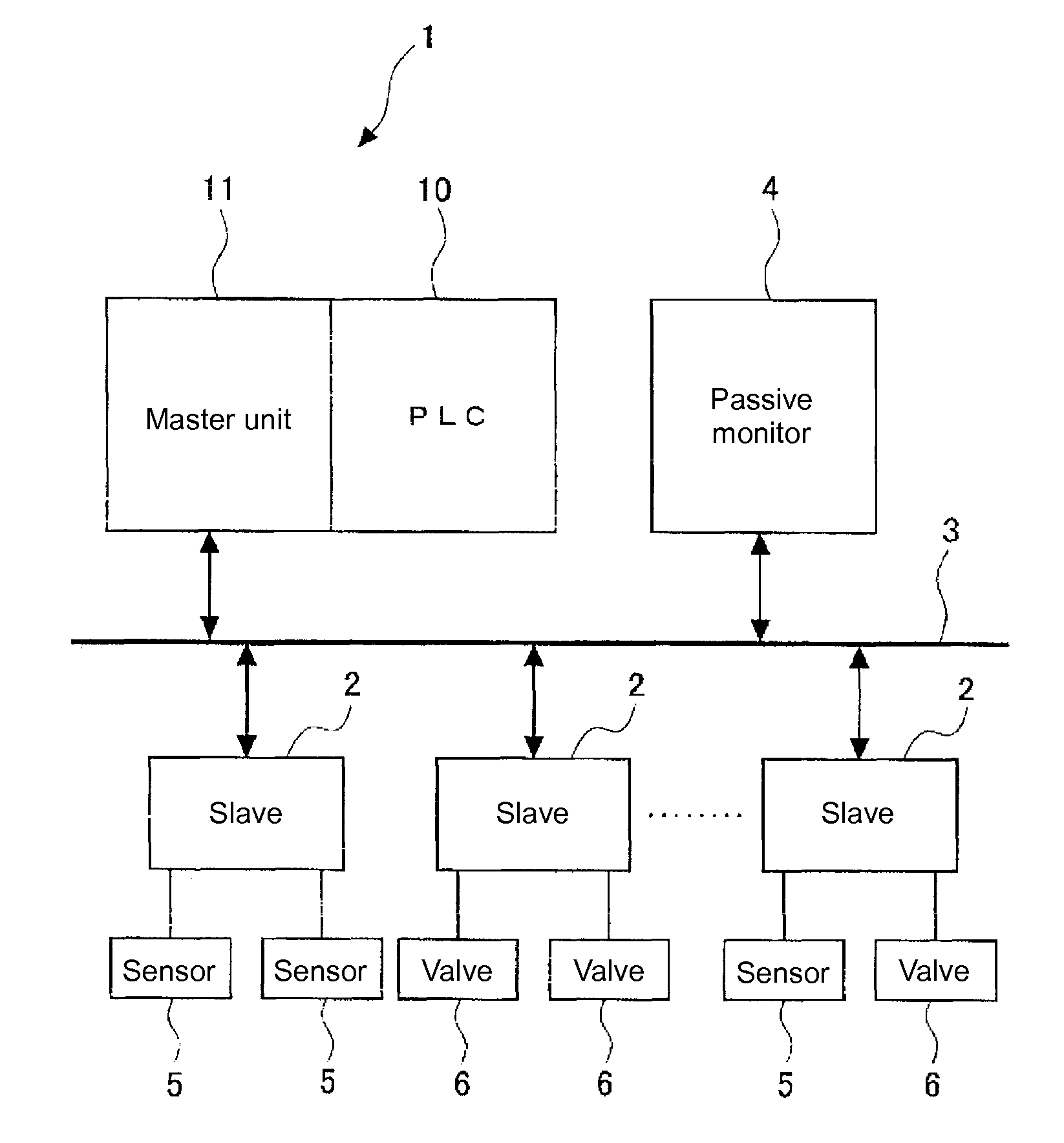

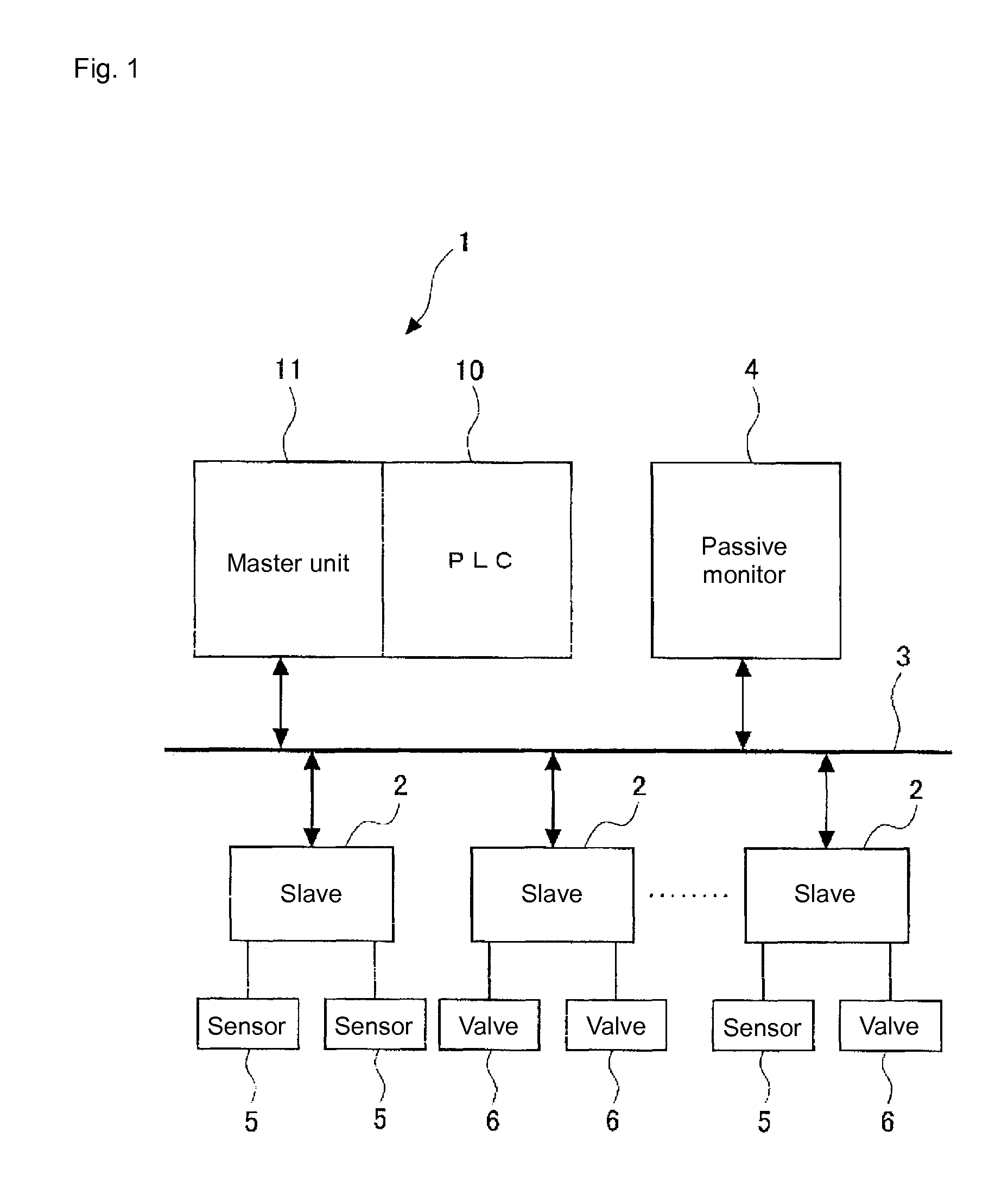

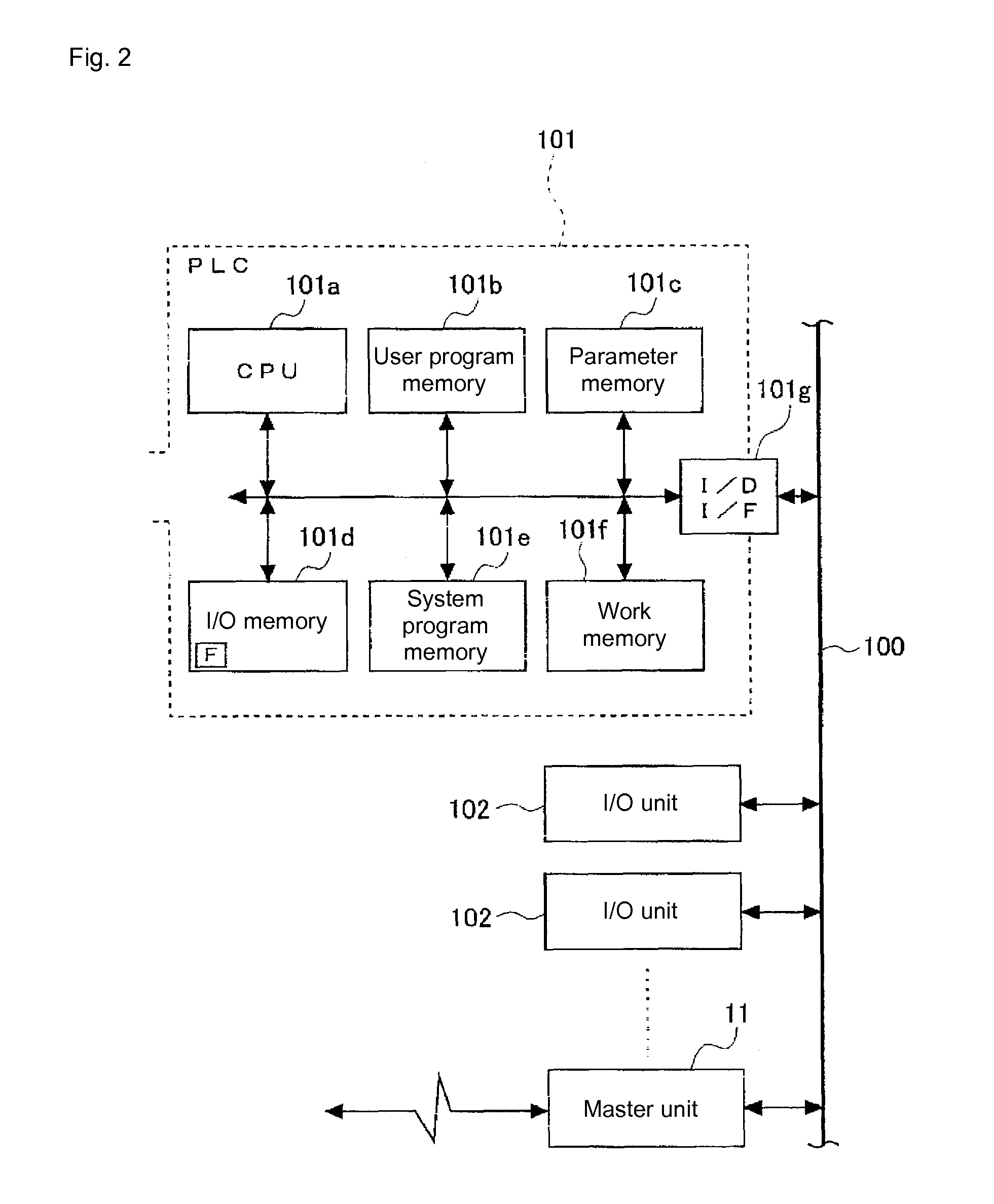

Programmable controller system

ActiveUS20110077906A1Reduce effortConstant operationProgramme controlSafety arrangmentsProgrammable logic controllerOutput device

A programmable controller system includes a programmable controller apparatus, a remote input and output apparatus connected to the programmable controller apparatus via a field bus and a monitoring apparatus configured to be located on a communication path between the programmable controller apparatus and the remote input and output apparatus and to monitor a communication data therebetween. The monitoring apparatus includes a rewritable tag for prescribing a condition for issuing a transmission request command with respect to an external equipment deterioration diagnosis and a command issuing part issues a transmission request command required for the external equipment deterioration diagnosis with reference to the tag. A preferable data logging operation is carried out properly without any PLC operation.

Owner:ORMON CORP

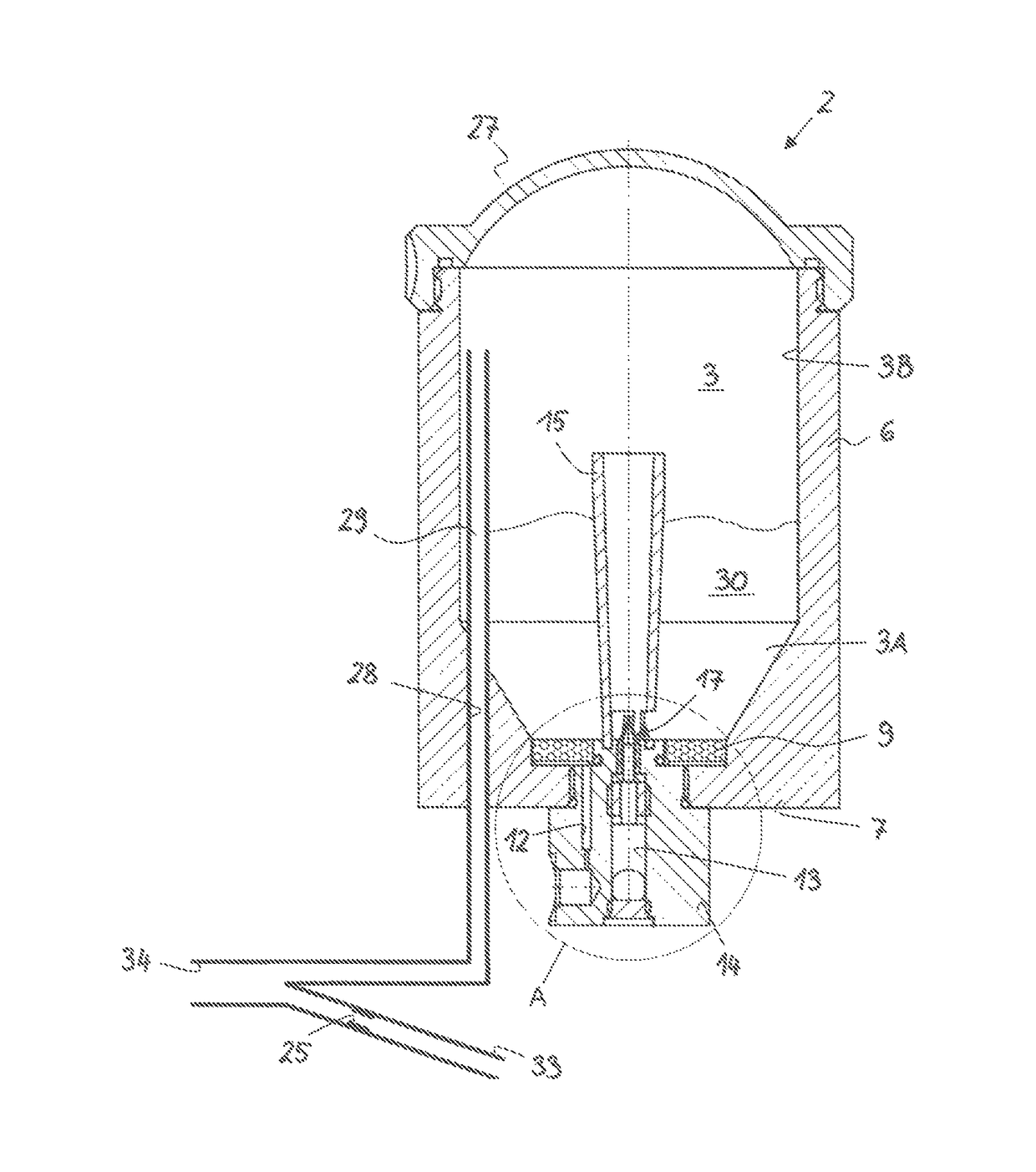

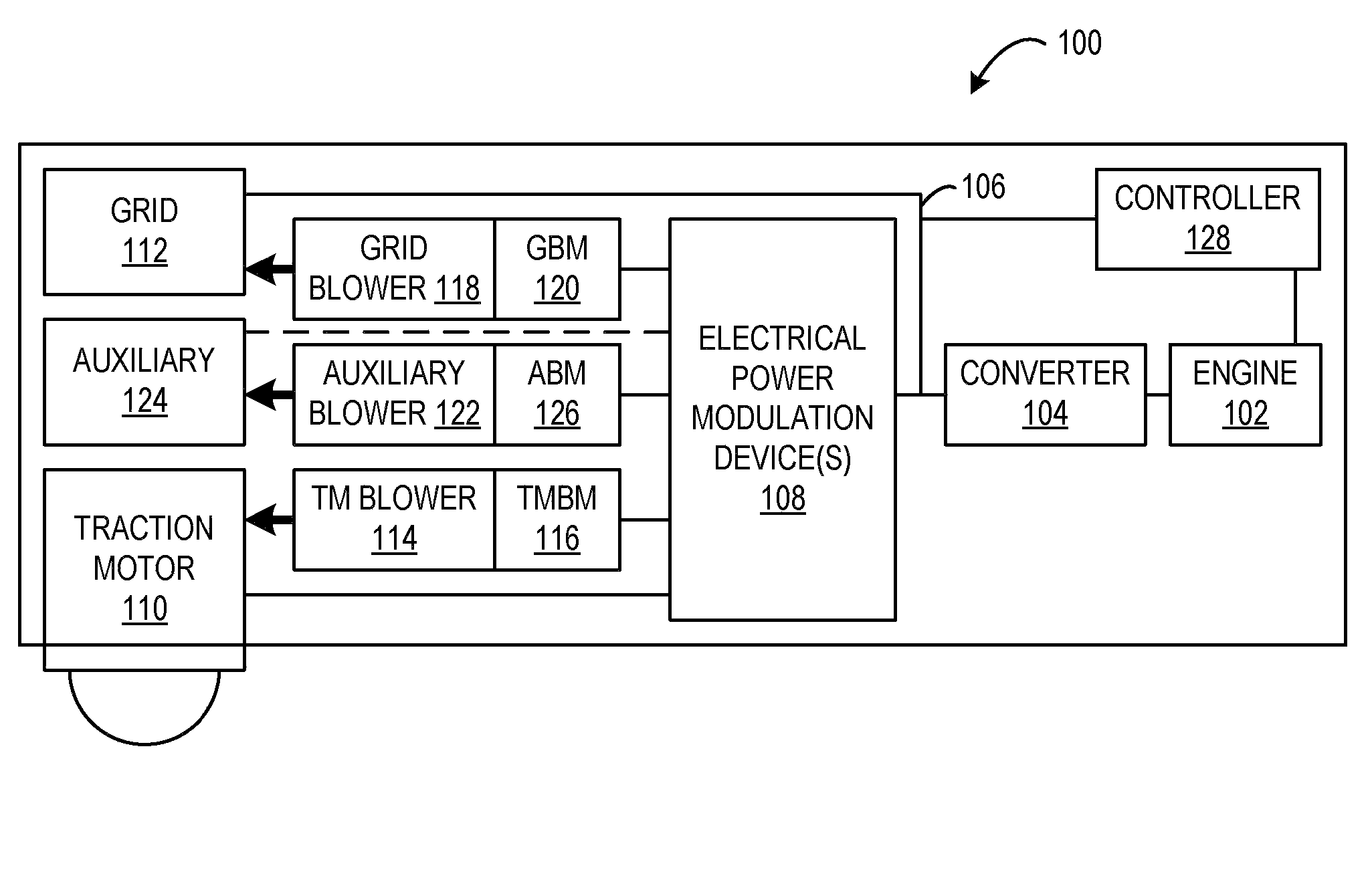

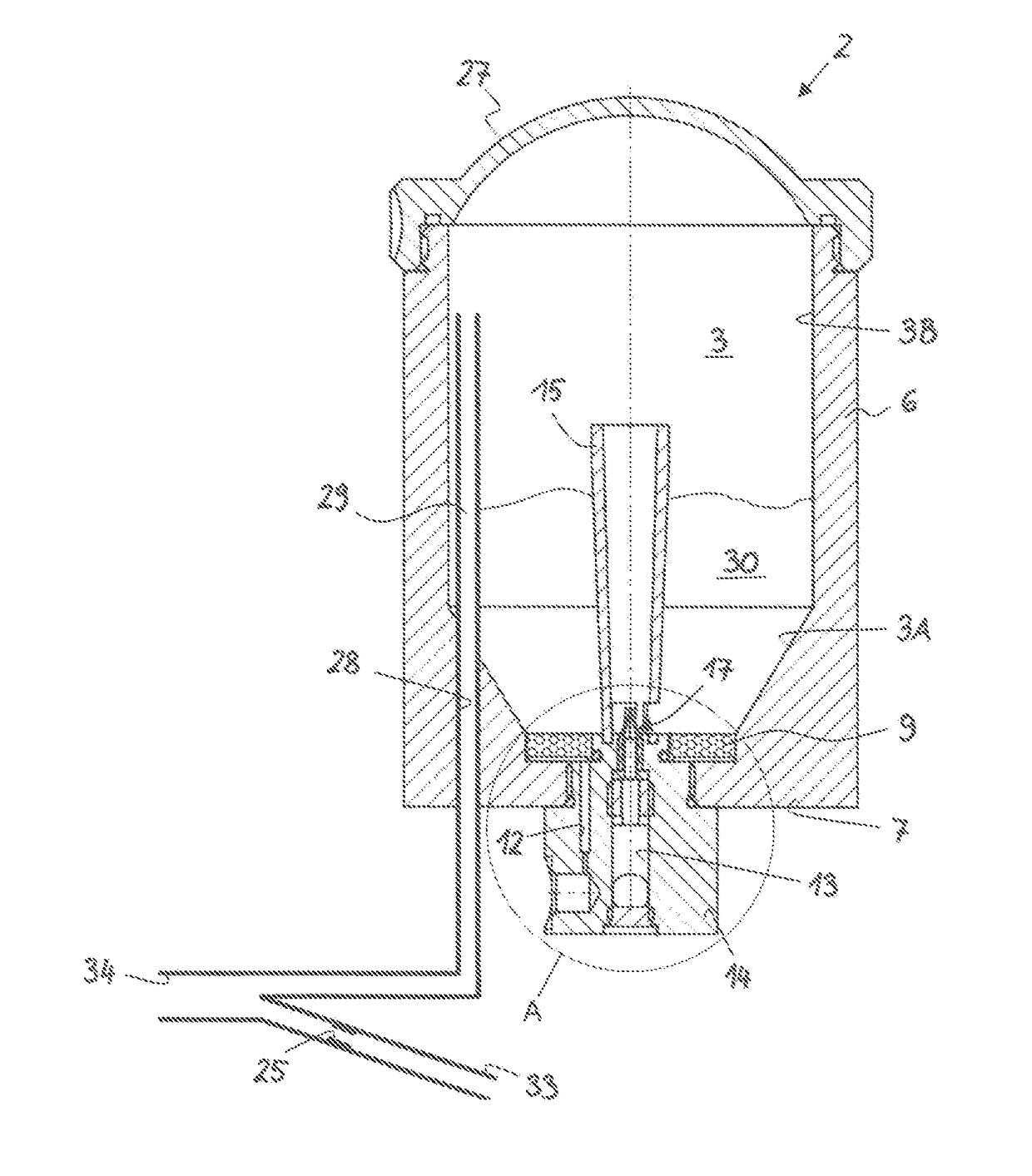

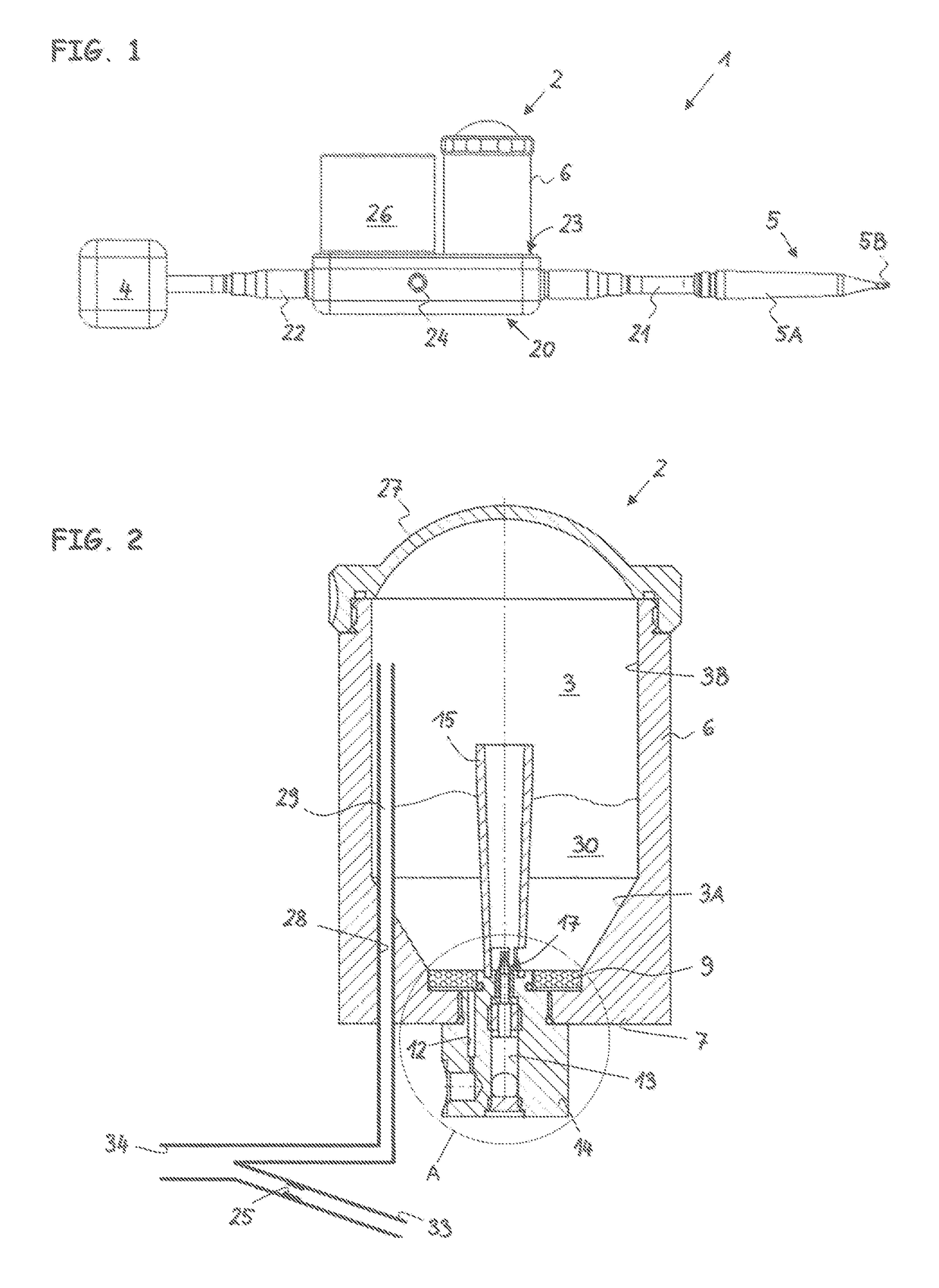

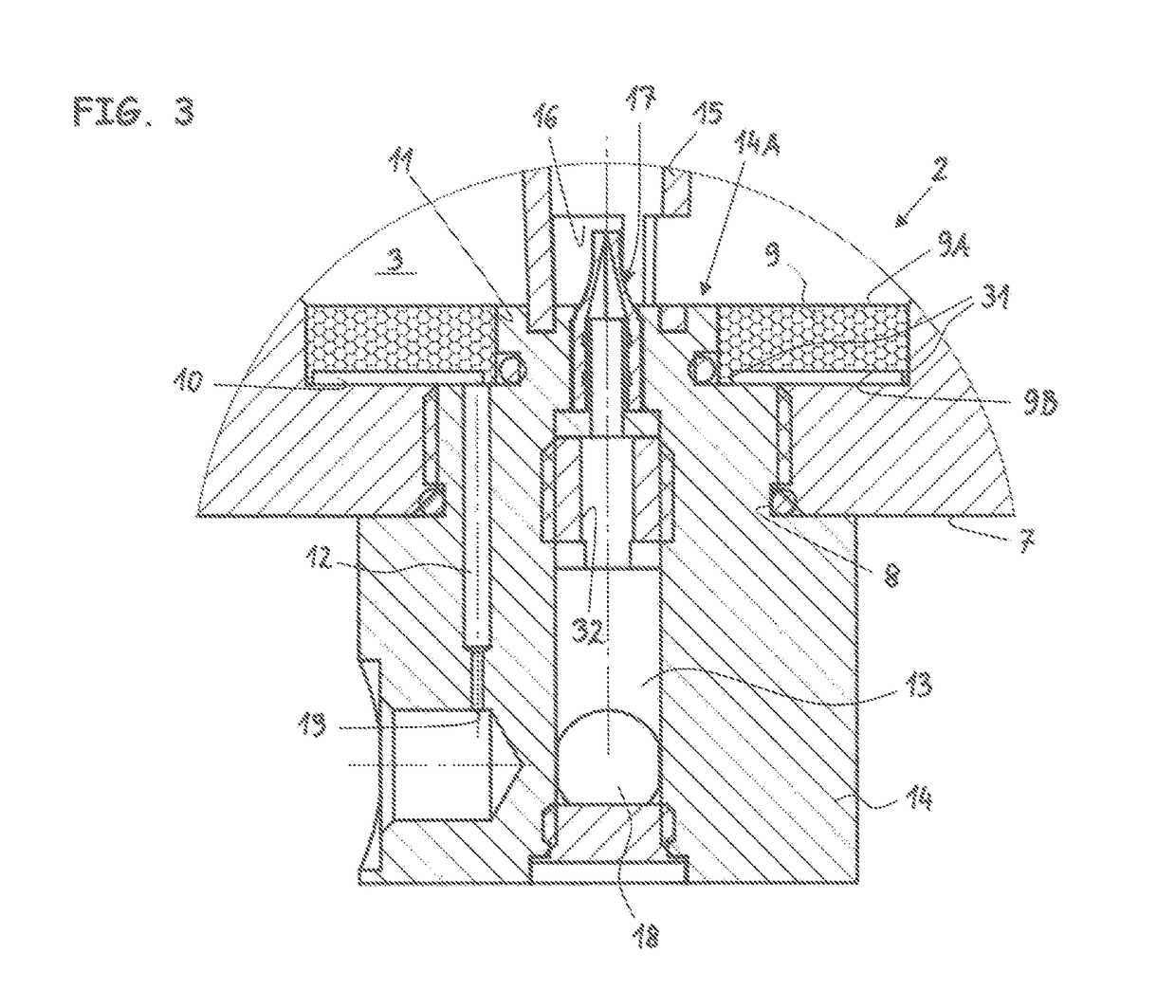

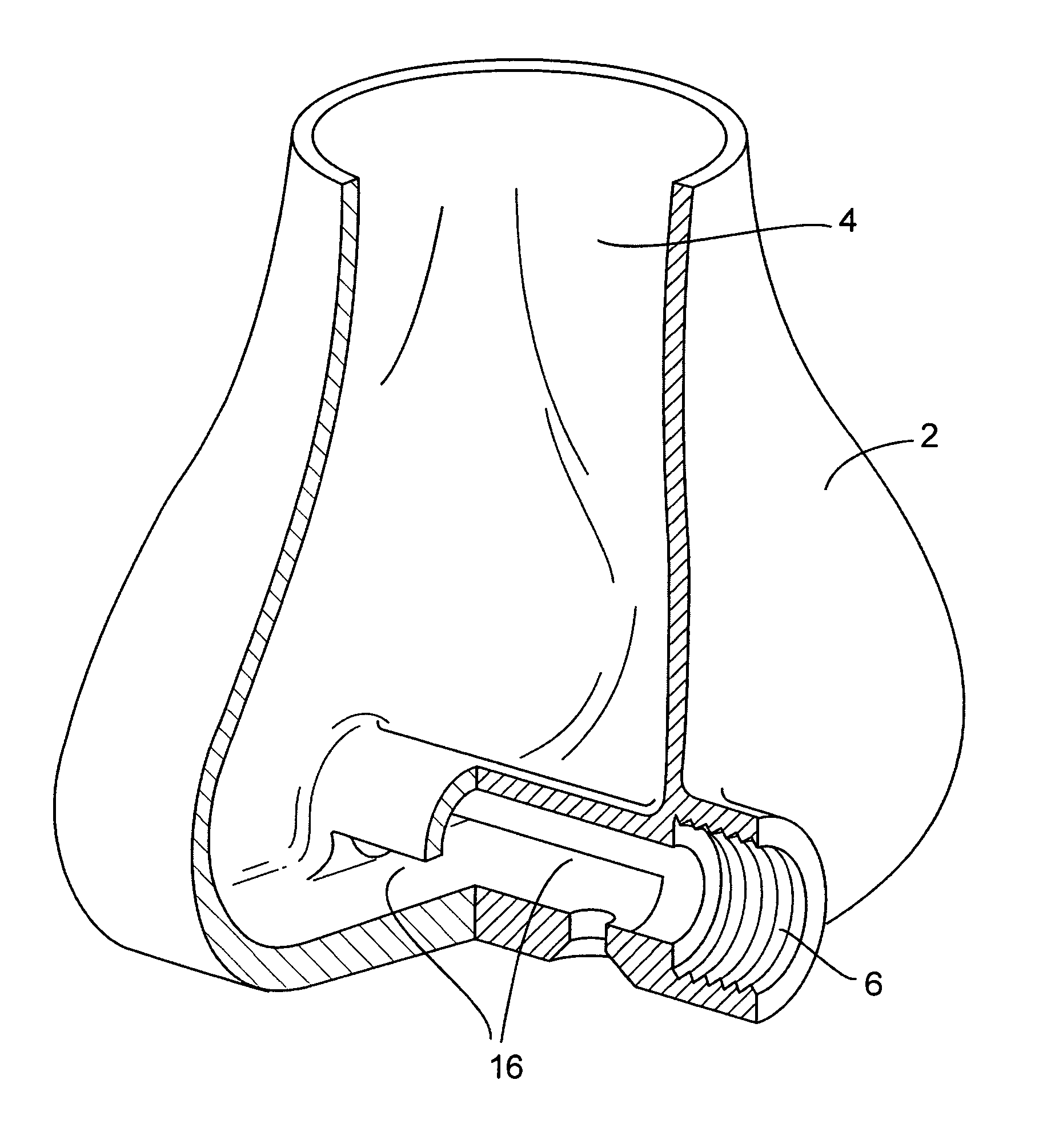

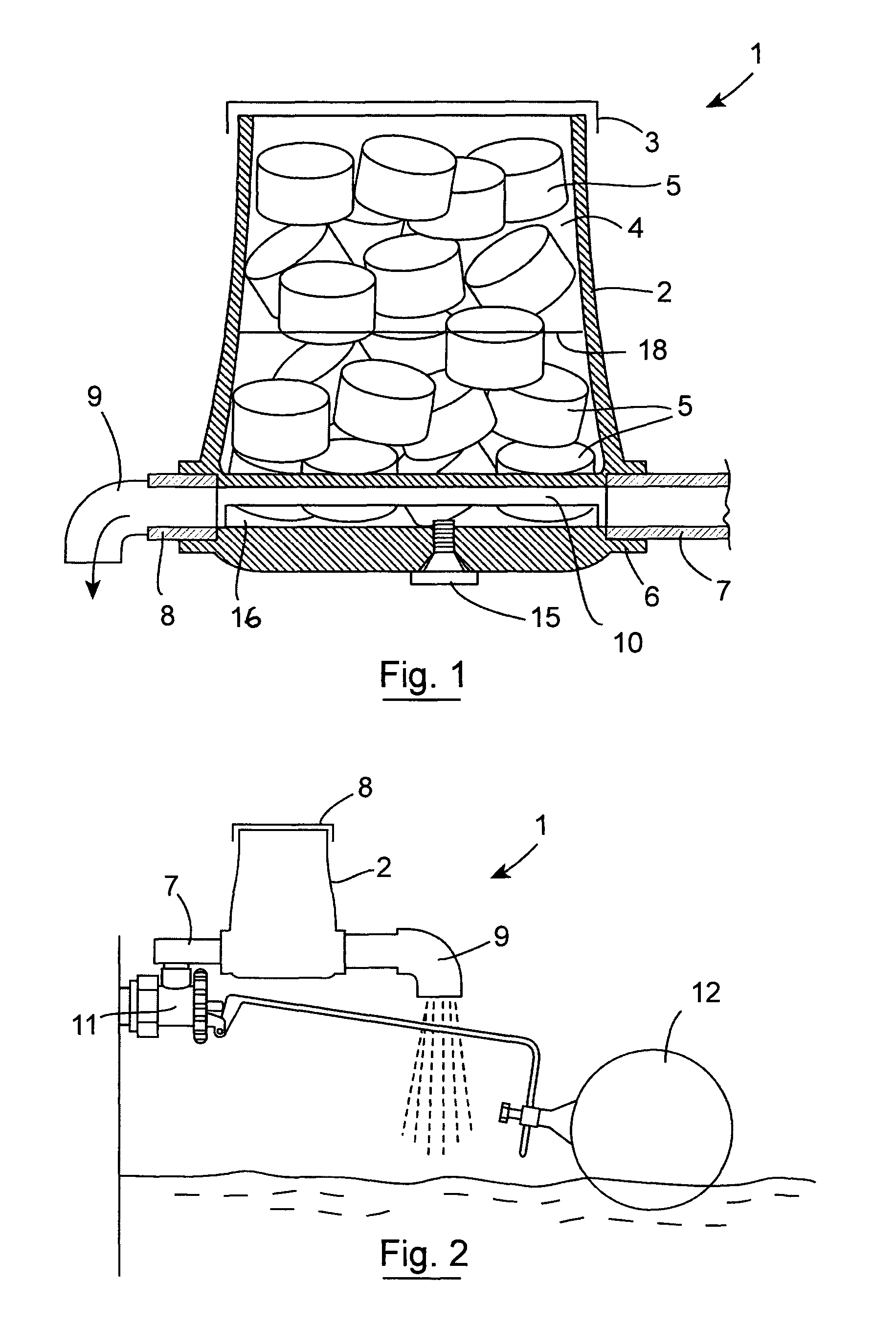

Medical or dental device for dispensing a powdered medium

InactiveUS10065004B2Less variationConstant operationMedical devicesDental toolsInterior spaceDental Equipment

A medical or dental device for dispensing a powdered medium with a container having a container interior space. The container can be connected to a compressed gas source to convey the powdered medium together with the compressed gas out of the interior space, and to a dispensing unit, so that the powdered medium is conveyed with the compressed gas to the dispensing unit. The container comprises: a wall, and a bottom that is connected to the wall and has at least one bore through which compressed gas from the compressed gas source can be conducted into the interior space. A swirl plate made of a porous material is provided at the bottom. Compressed gas can be conducted through the porous swirl plate into the interior space to aerate at least a portion of the powdered medium without conveying the powdered medium out of the interior space to the dispensing unit.

Owner:W&H DENTALWERK

Variable-speed-drive system for a grid blower

ActiveUS8179084B2Enhance forced-air cooling effectExtended service lifeDC motor speed/torque controlDigital data processing detailsElectrical resistance and conductancePower modulation

A drive system for a grid blower of a vehicle is provided. The system includes: an electrical bus, a grid of resistive elements connected to the electrical bus, the grid of resistive elements configured to thermally dissipate electrical power generated from braking of the vehicle, the electrical power being transmitted on the electrical bus to the grid of resistive elements, an electrical power modulation device configured to modify electrical power received from at least one of the electrical bus and the grid of resistive elements, and a grid blower motor coupled to an output of the electrical power modulation device, wherein a speed of the grid blower motor varies based on the electrical power that has been modified by the electrical power modulation device.

Owner:GE GLOBAL SOURCING LLC

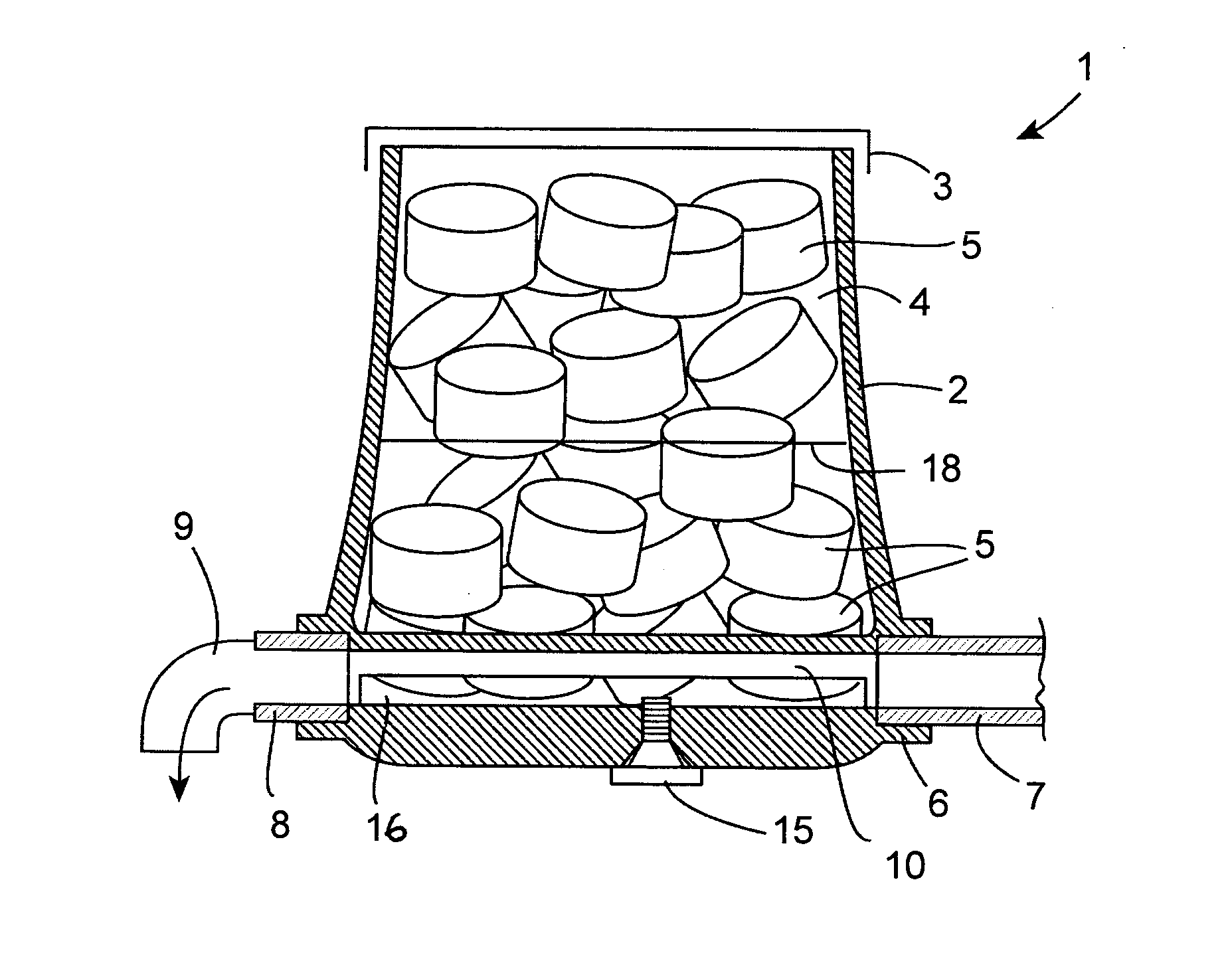

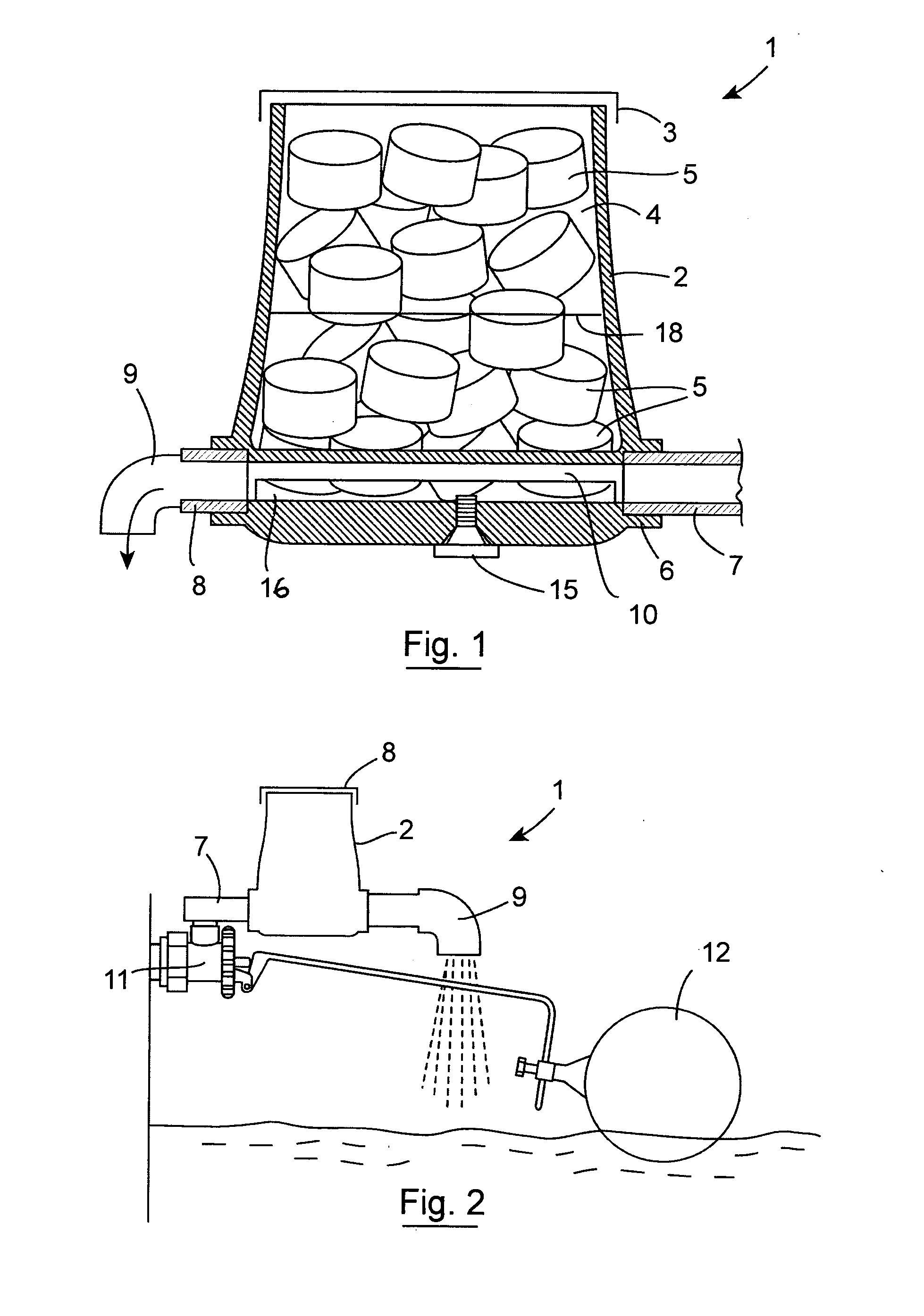

Chlorination device

ActiveUS20120152813A1Increase the cross-sectional areaAvoid accumulationWater treatment parameter controlOther chemical processesEngineeringWater supply

An un-pressurised chlorination device comprises a container having an open top closed by a removable lid. The container defines an inner chamber for a plurality of chlorination tablets. The container has a lower inlet spigot for receiving a water supply inlet pipe. The container also has a lower water outlet through which chlorinated water is delivered. There is a water flow path between the inlet and the outlet. The tablet chamber is not pressurised and the outlet discharges to atmosphere pressure. The device of the invention is useful for dissolving, dispersing and dispensing soluble material in tablet form into a liquid. There is a substantially horizontal fluid path with just enough fall to the outlet to allow the device to drain down out of the outlet when there is no inlet flow.

Owner:MEDENTECH

Input circuit for semiconductor integrated circuit

InactiveUS7642810B2Guaranteed uptimeConstant operationDigital storageElectric pulse generatorPotential differenceVoltage reference

Owner:SK HYNIX INC

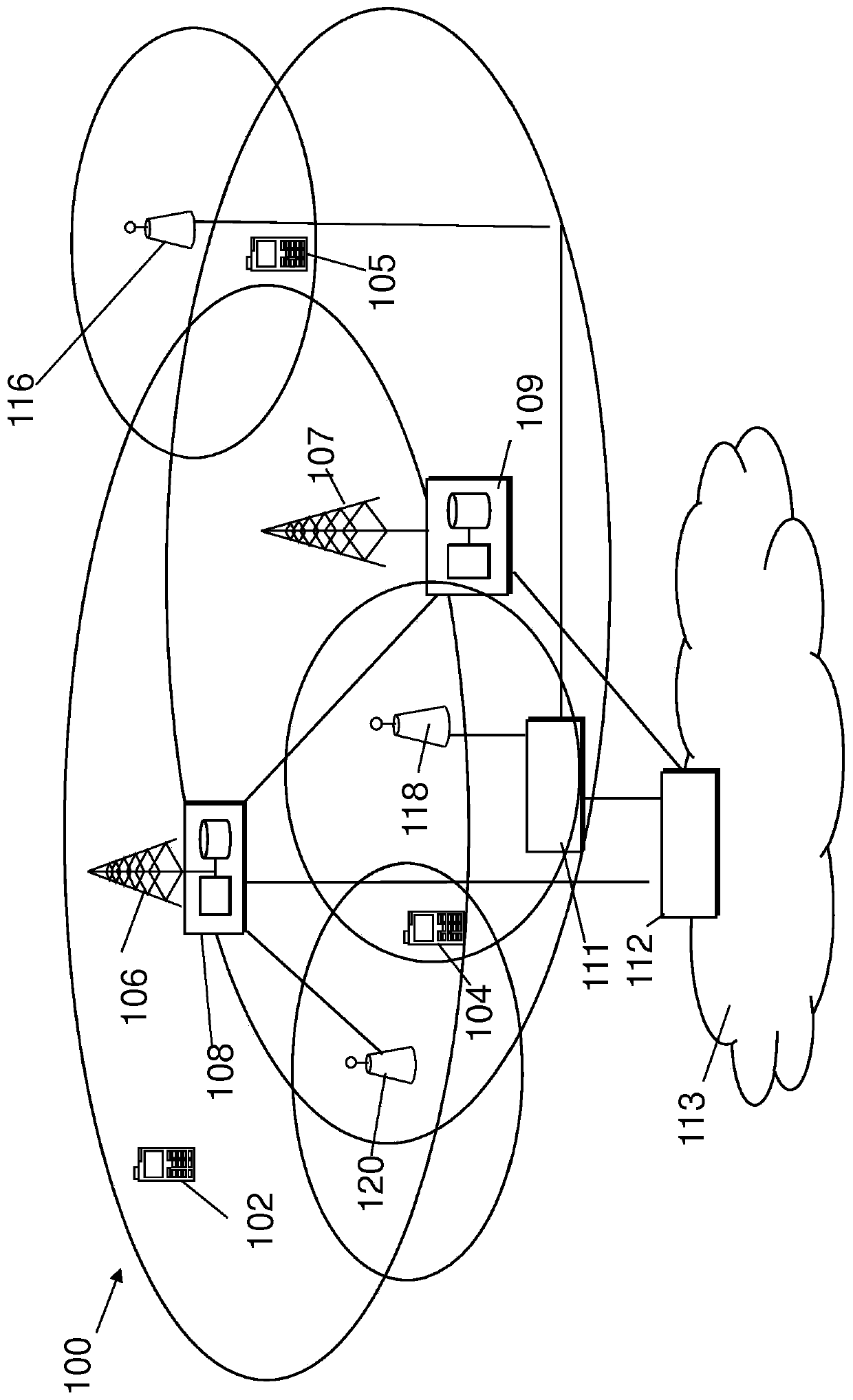

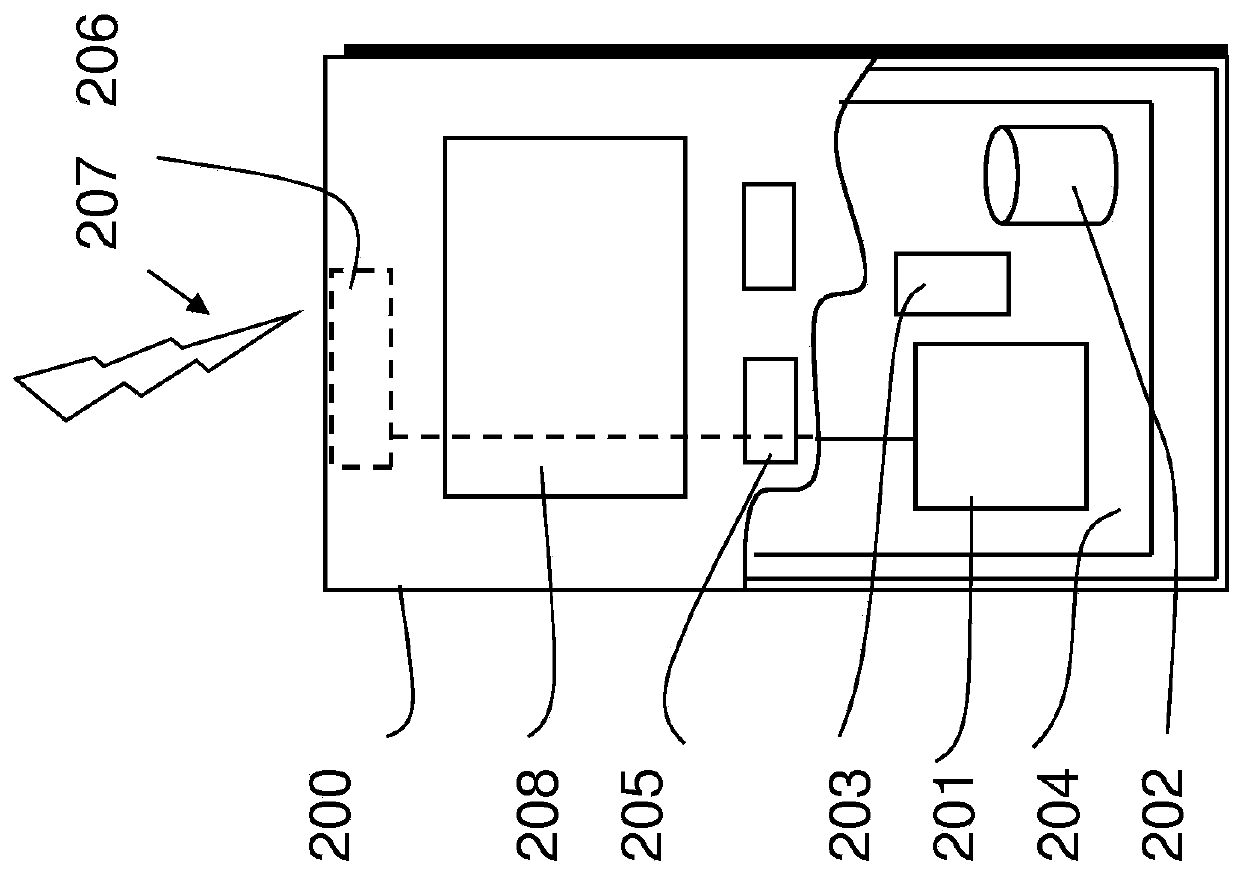

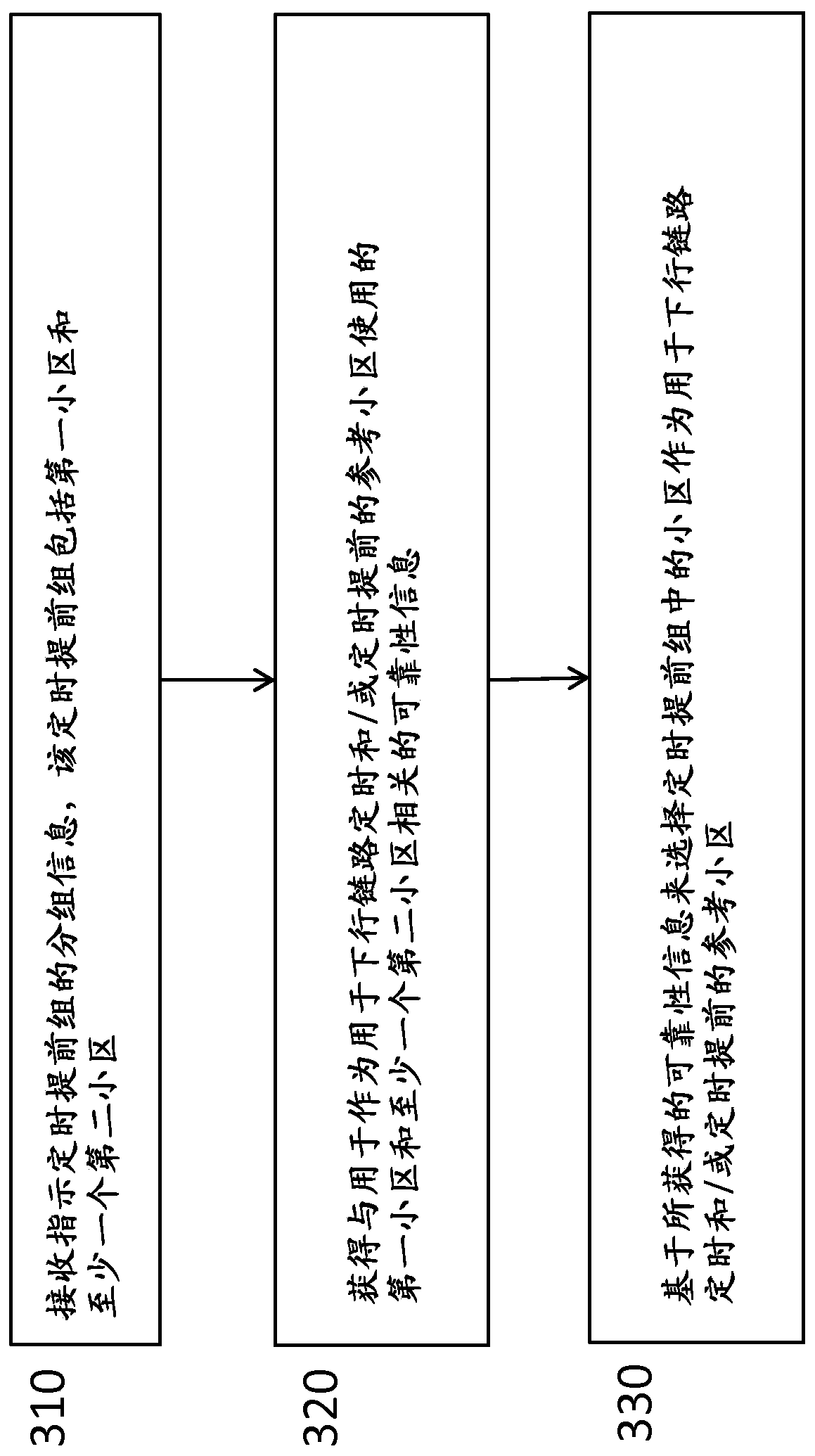

Selection of a reliable cell for downlink timing and timing advance in a timing advance group

A method comprising receiving grouping information indicative of a timing advance group comprising a first cell and at least one second cell obtaining reliability information related to the first celland the at least one second cell for use as reference cell for downlink timing and / or timing advance and selecting a cell in the timing advance group a reference cell for downlink timing and / or timing advance based on the obtained reliability information.

Owner:NOKIA TECHNOLOGLES OY

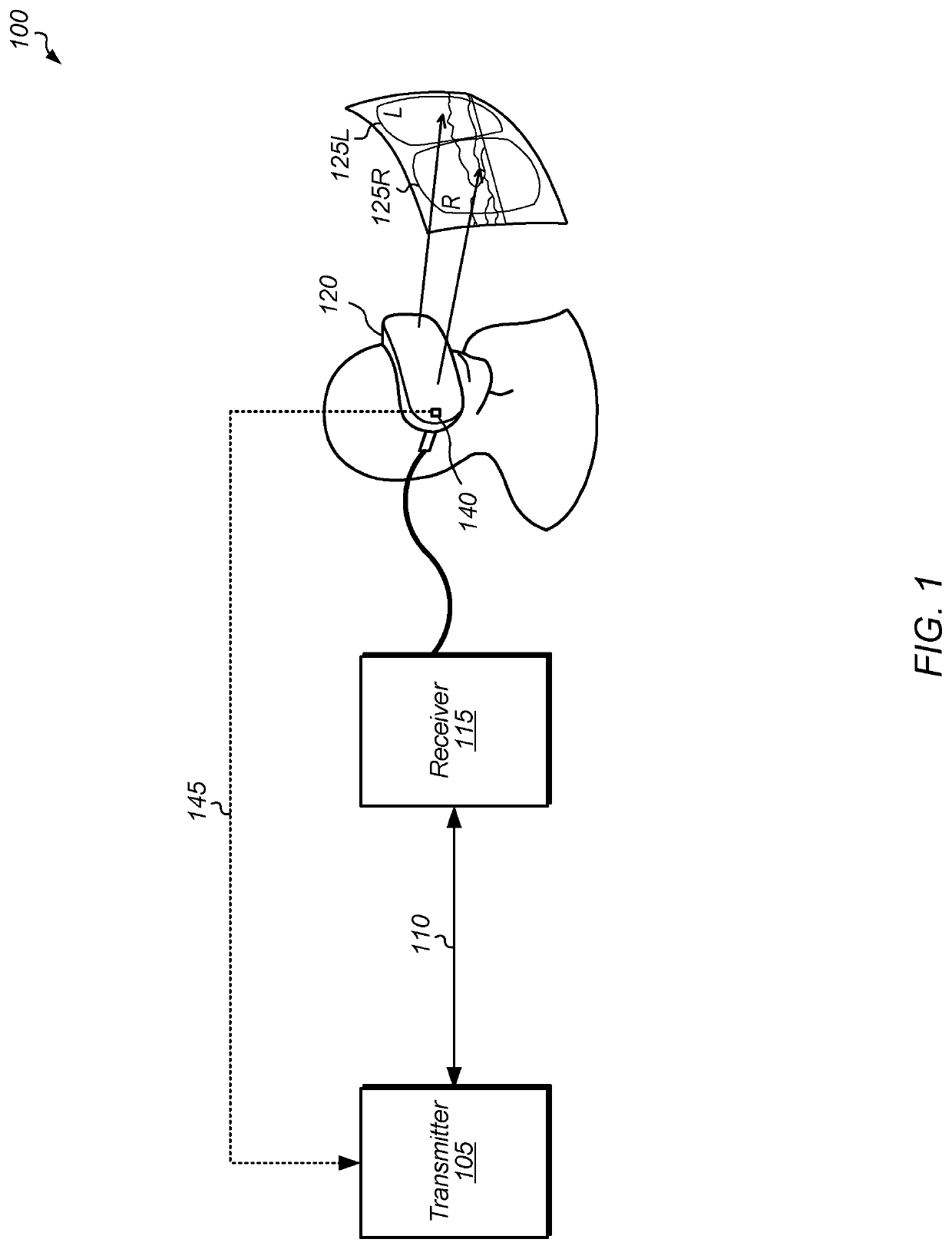

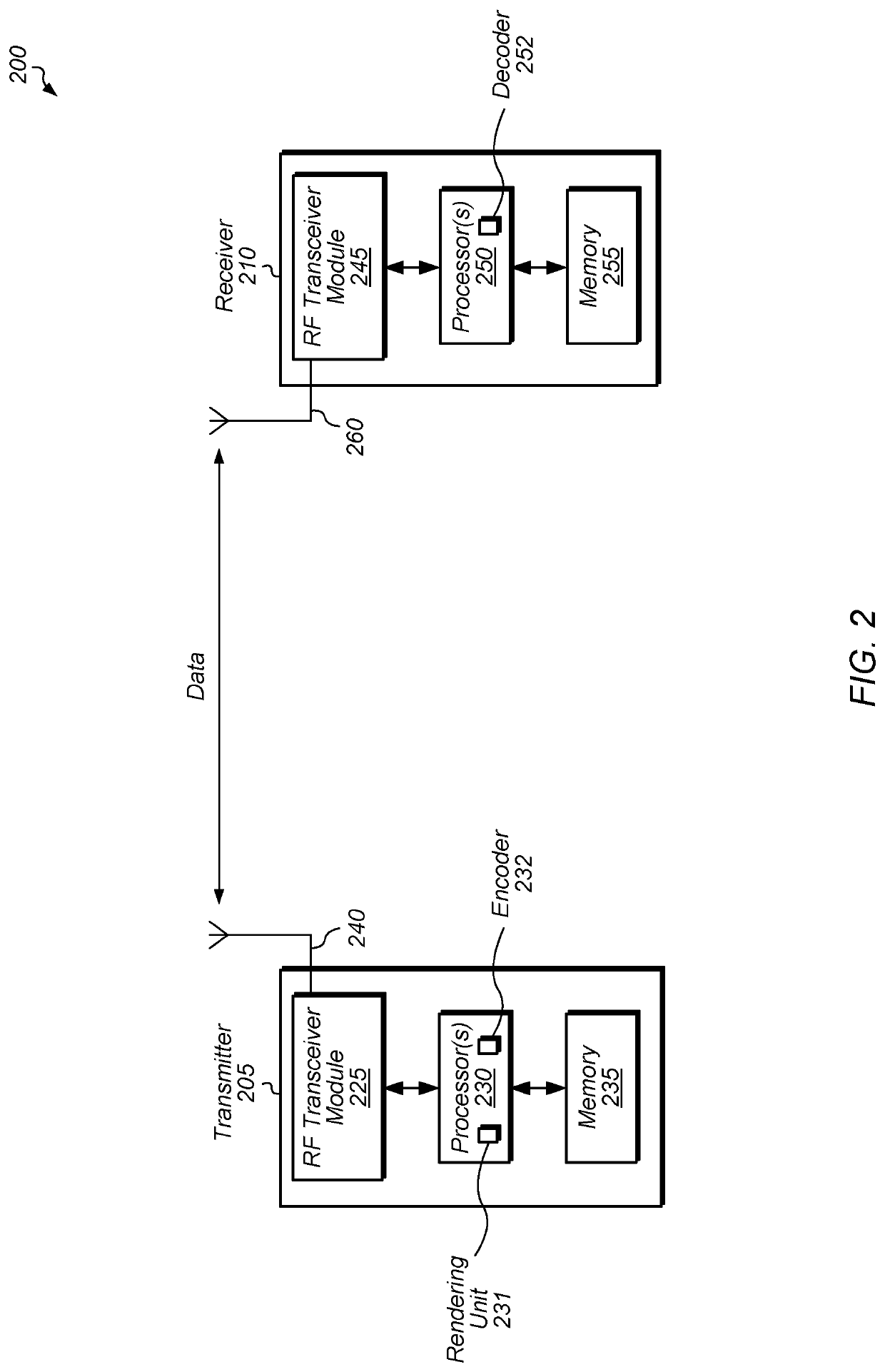

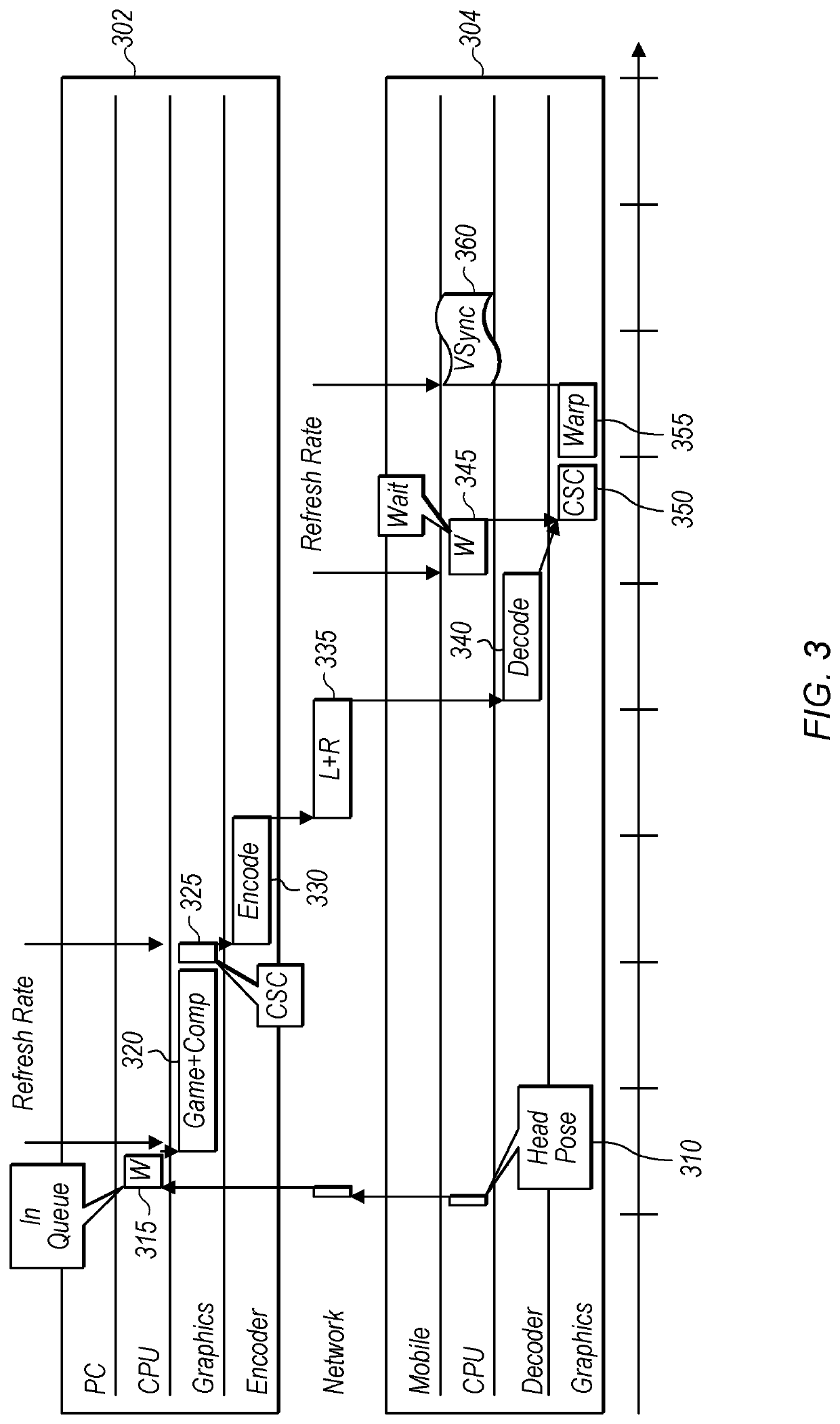

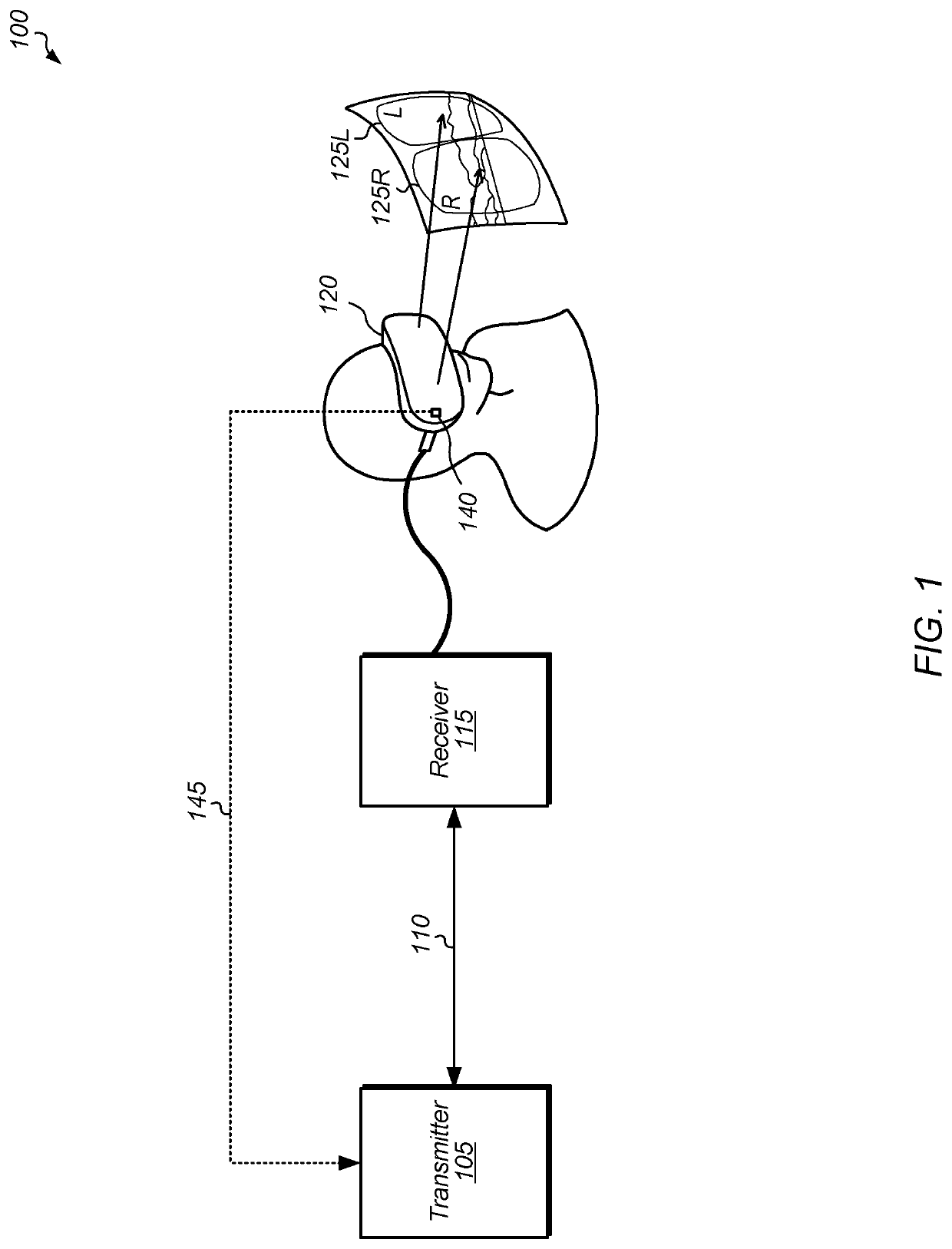

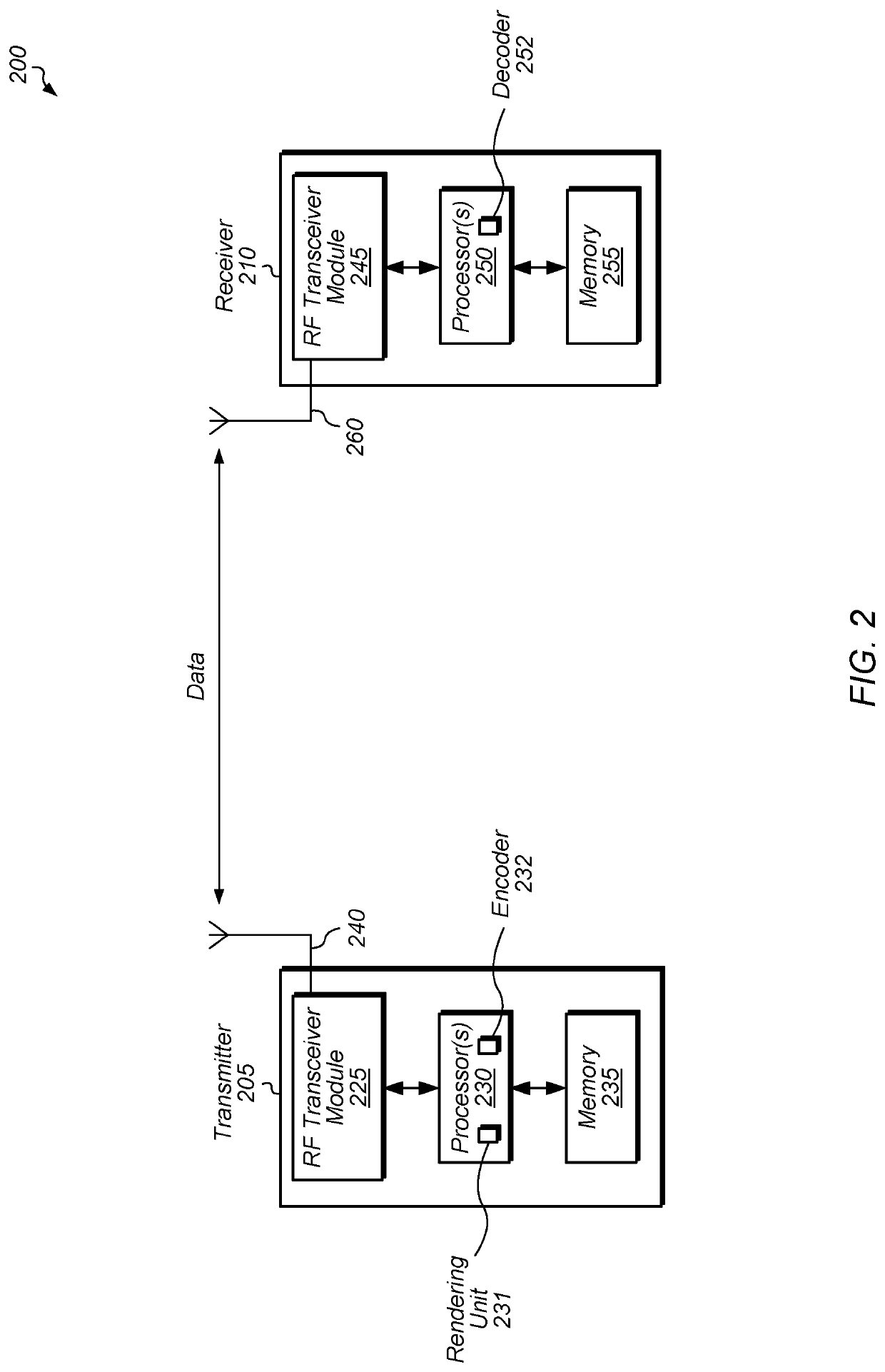

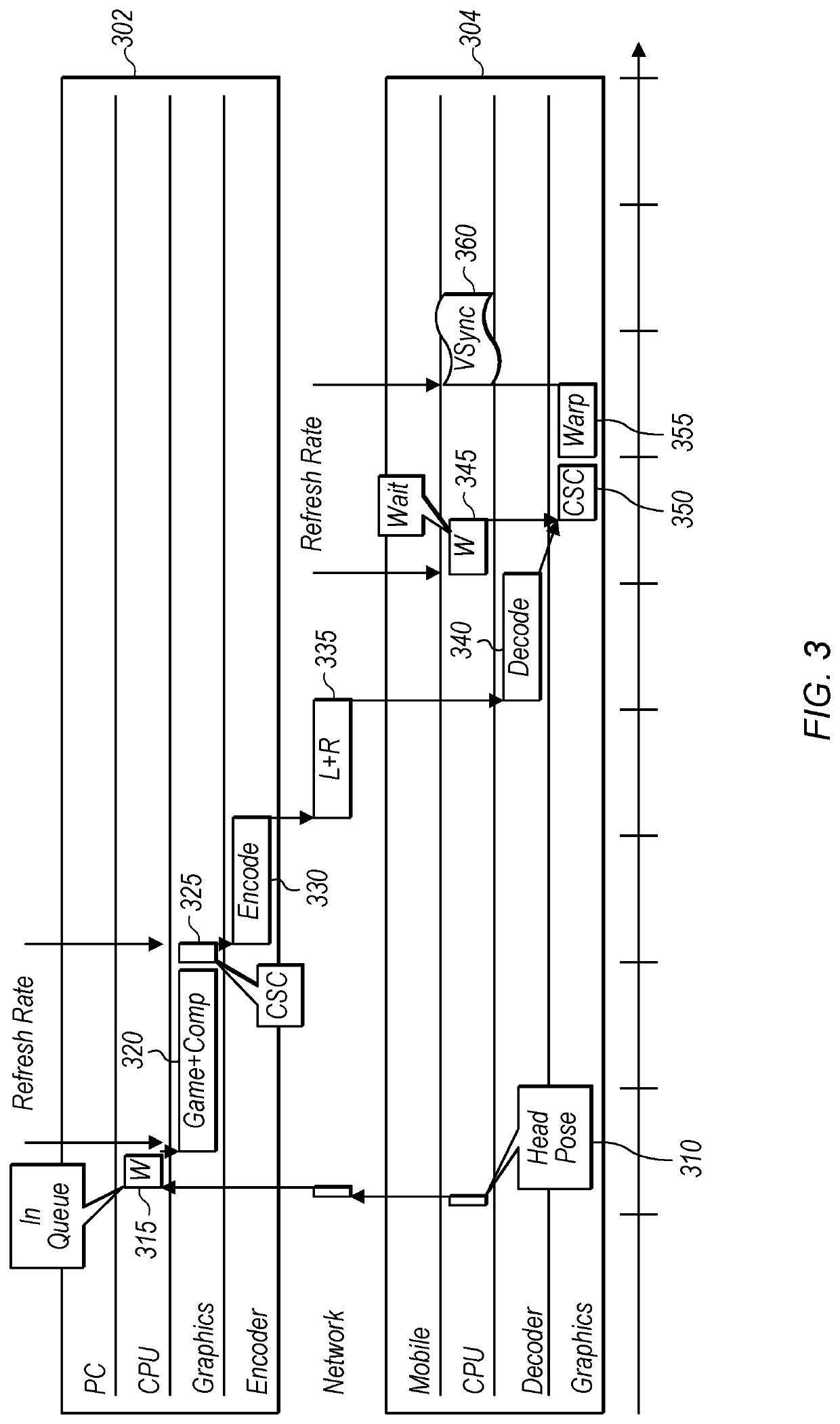

Reducing latency in wireless virtual and augmented reality systems

ActiveUS20210185334A1Excessive latencyConstant operationDigital video signal modificationSteroscopic systemsHead worn displayEngineering

Systems, apparatuses, and methods for reducing latency for wireless virtual and augmented reality applications are disclosed. A virtual reality (VR) or augmented reality (AR) system includes a transmitter rendering, encoding, and sending video frames to a receiver coupled to a head-mounted display (HMD). In one scenario, rather than waiting until the entire frame is encoded before sending the frame to the receiver, the transmitter sends an encoded left-eye portion to the receiver while the right-eye portion is being encoded. In another scenario, the frame is partitioned into a plurality of slices, and each slice is encoded and then sent to the receiver while the next slice is being encoded. In a further scenario, each slice is being encoded while the next slice is being rendered. In a still further scenario, each slice is prepared for presentation by the receiver while the next slice is being decoded by the receiver.

Owner:ATI TECH INC

Three phase sulfur separation system with interface control

ActiveUS8367009B2Reduce interface areaConstant operationLevel controlCrystallization separationGas phaseSulfur

A liquid separator system having a gas phase zone, an aqueous phase zone and a denser liquid zone is used to separate mixtures of fluids. The separator can be used for separating molten sulfur from liquid redox solution or reslurry water. The system includes a vessel with a top part and a bottom part. The vessel has a larger diameter at the top part than at the bottom part. The system also includes an inlet for introducing a redox solution or reslurry water and molten sulfur, which is denser than redox solution or reslurry water, into the vessel. An outlet near the bottom part of the vessel allows a flow of the molten sulfur from the vessel. An interface control structure senses an interface level between the redox solution or reslurry water and the molten sulfur, and the interface control structure controls the flow of molten sulfur from the outlet. The interface control structure is adjusted to optimally alter the vertical height of the interface level within the vessel so that the residence time of the molten sulfur in the vessel does not decrease as the sulfur production throughput decreases, and so that the interface area of the molten sulfur and the redox solution is reduced as the sulfur throughput decreases. A pressure controller monitors the pressure in the vessel and adds or removes gas from a gas phase zone in the vessel to maintain a predetermined pressure regardless of the vertical height of the interface.

Owner:MERICHEM CO

Medical or dental device for dispensing a powdered medium

InactiveUS20170119980A1Less variationConstant operationMedical devicesDental toolsInterior spaceMedical treatment

A medical or dental device for dispensing a powdered medium with a container for storing the powdered medium in a container interior space, wherein the container can be connected to a compressed gas source to convey the powdered medium together with the compressed gas out of the container interior space, and wherein the container can be connected to a dispensing unit, so that the powdered medium is conveyed with the compressed gas to the dispensing unit and can be dispensed by the dispensing unit, wherein the container comprises: a container wall, which defines at least a portion of the container interior space, and a container bottom that is connected to the container wall and has at least one bore through which compressed gas from the compressed gas source can be conducted into the container interior space, wherein a compressed-gas-permeable swirl plate made of a porous material is provided at the container bottom, wherein compressed gas can be conducted through the porous material of the compressed-gas-permeable swirl plate into the container interior space to aerate at least a portion of the powdered medium in the container interior space without conveying the powdered medium out of the container interior space to the dispensing unit.

Owner:W&H DENTALWERK

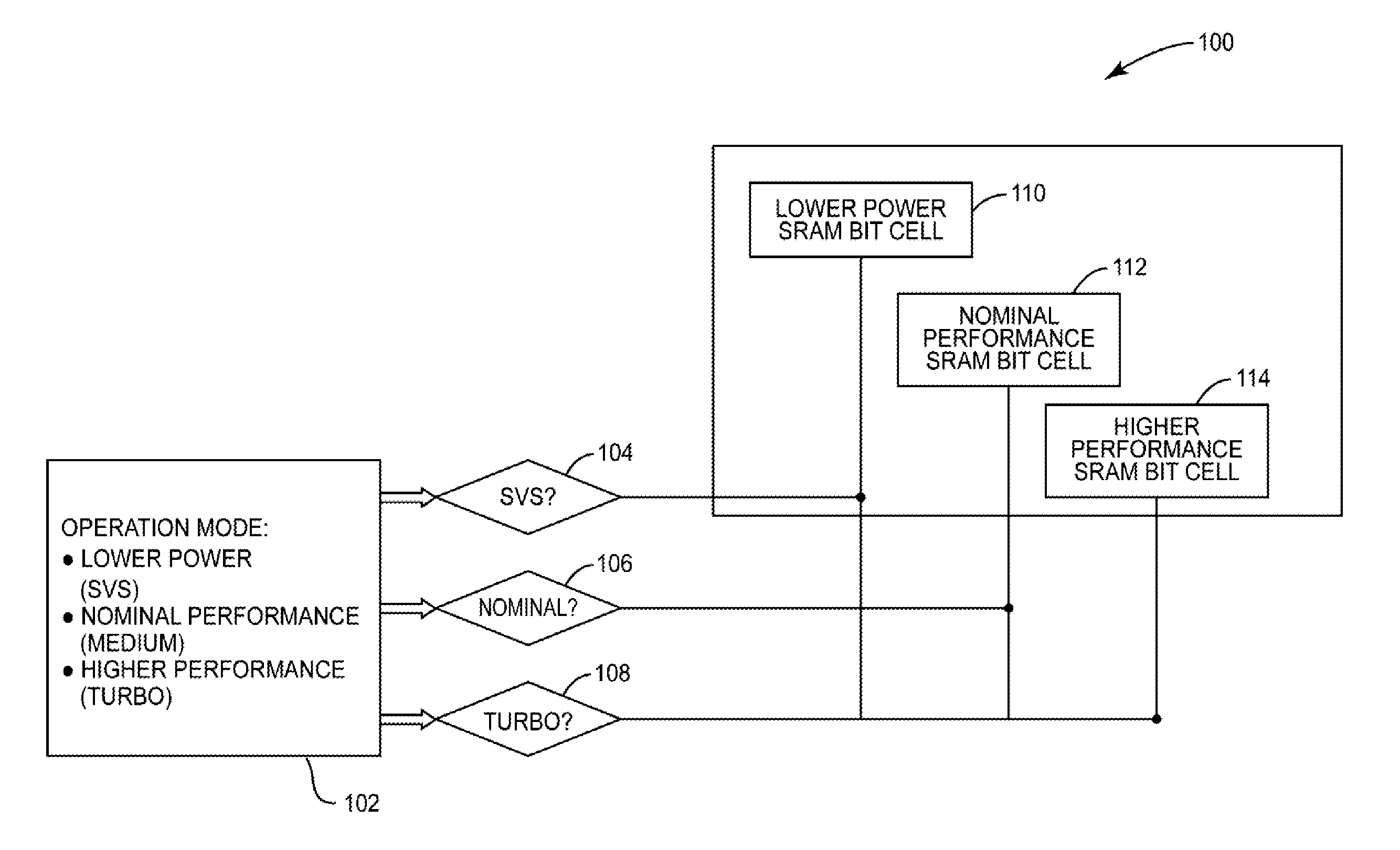

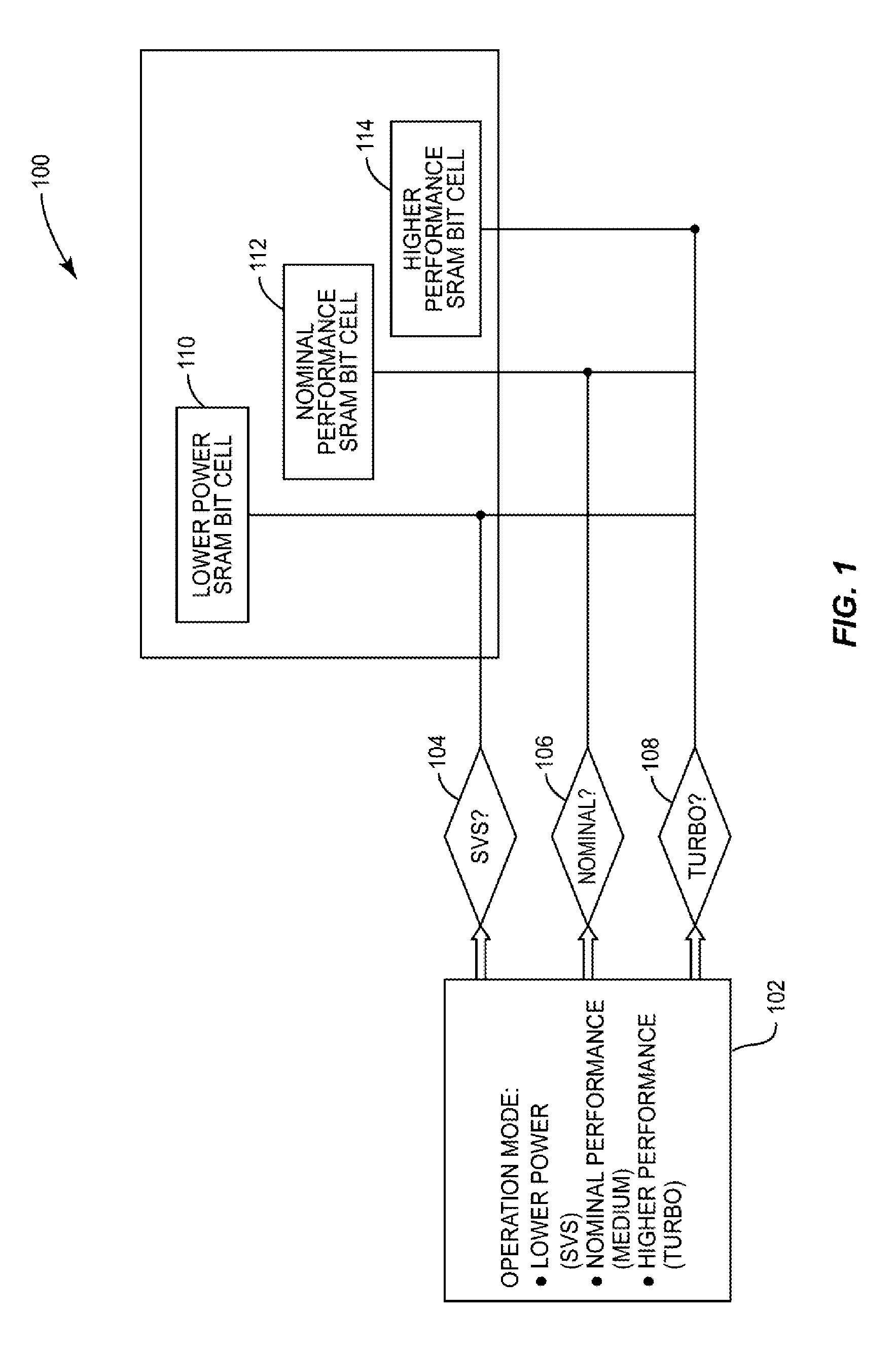

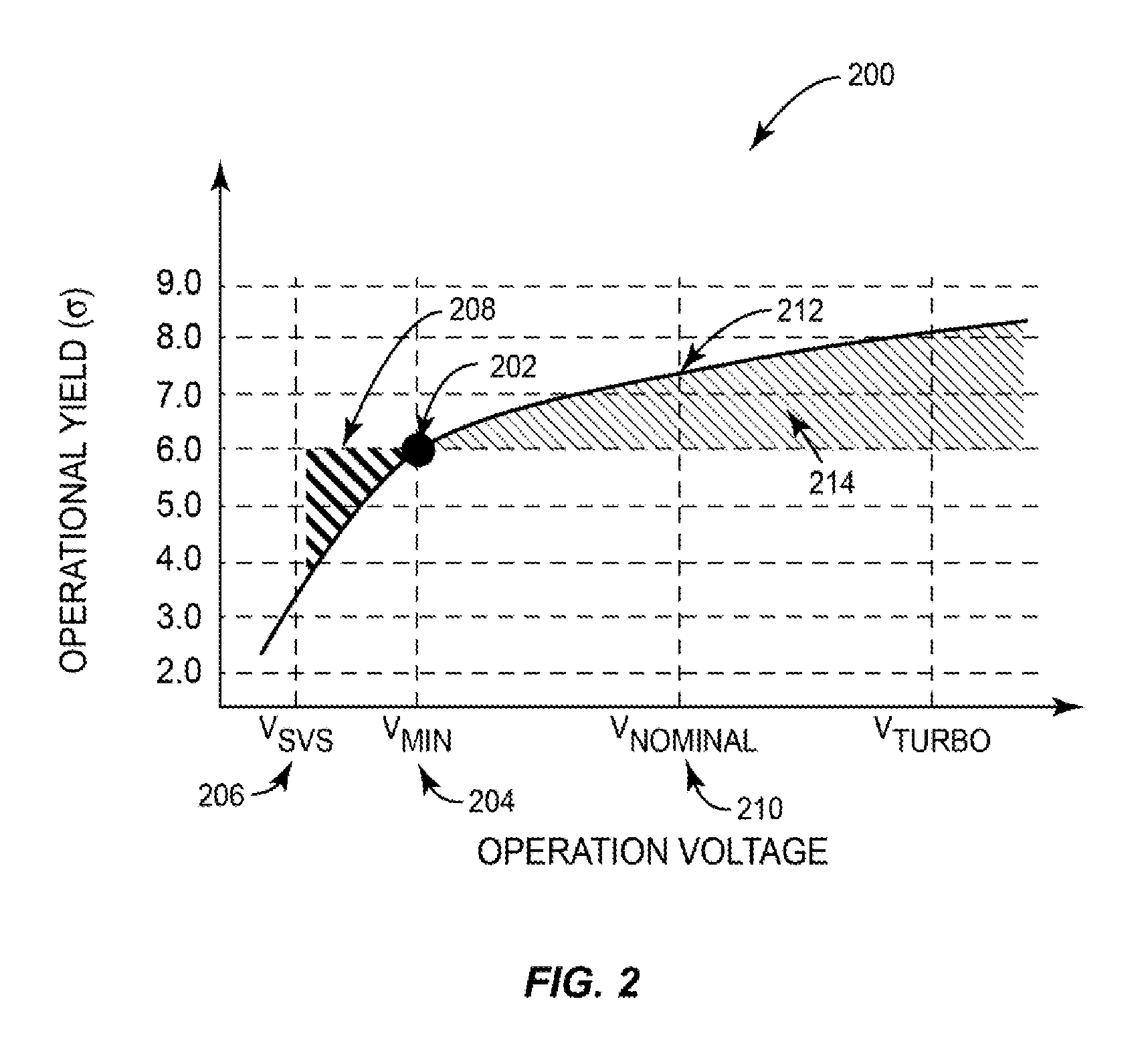

Static random access memory (SRAM) arrays having substantially constant operational yields across multiple modes of operation

ActiveUS9424909B1Constant operational yieldLow costDigital storageCAD circuit designStatic random-access memoryRandom access memory

Aspects disclosed include static random access memory (SRAM) arrays having substantially constant operational yields across multiple modes of operation. In one aspect, a method of designing SRAM arrays with multiple modes operation is provided. The method includes determining performance characteristics associated with each mode of operation. SRAM bit cells configured to operate in each mode of operation are provided to the SRAM array. SRAM bit cells are biased to operate in a mode of operation using dynamic adaptive assist techniques, wherein the SRAM bit cells achieve a substantially constant operational yield across the modes. The SRAM bit cells have a corresponding type, wherein the number of SRAM bit cell types in the method is less than the number of modes of operation. Thus, each SRAM array may achieve a particular mode of operation without requiring a separate SRAM bit cell type for each mode, thereby reducing costs.

Owner:QUALCOMM INC

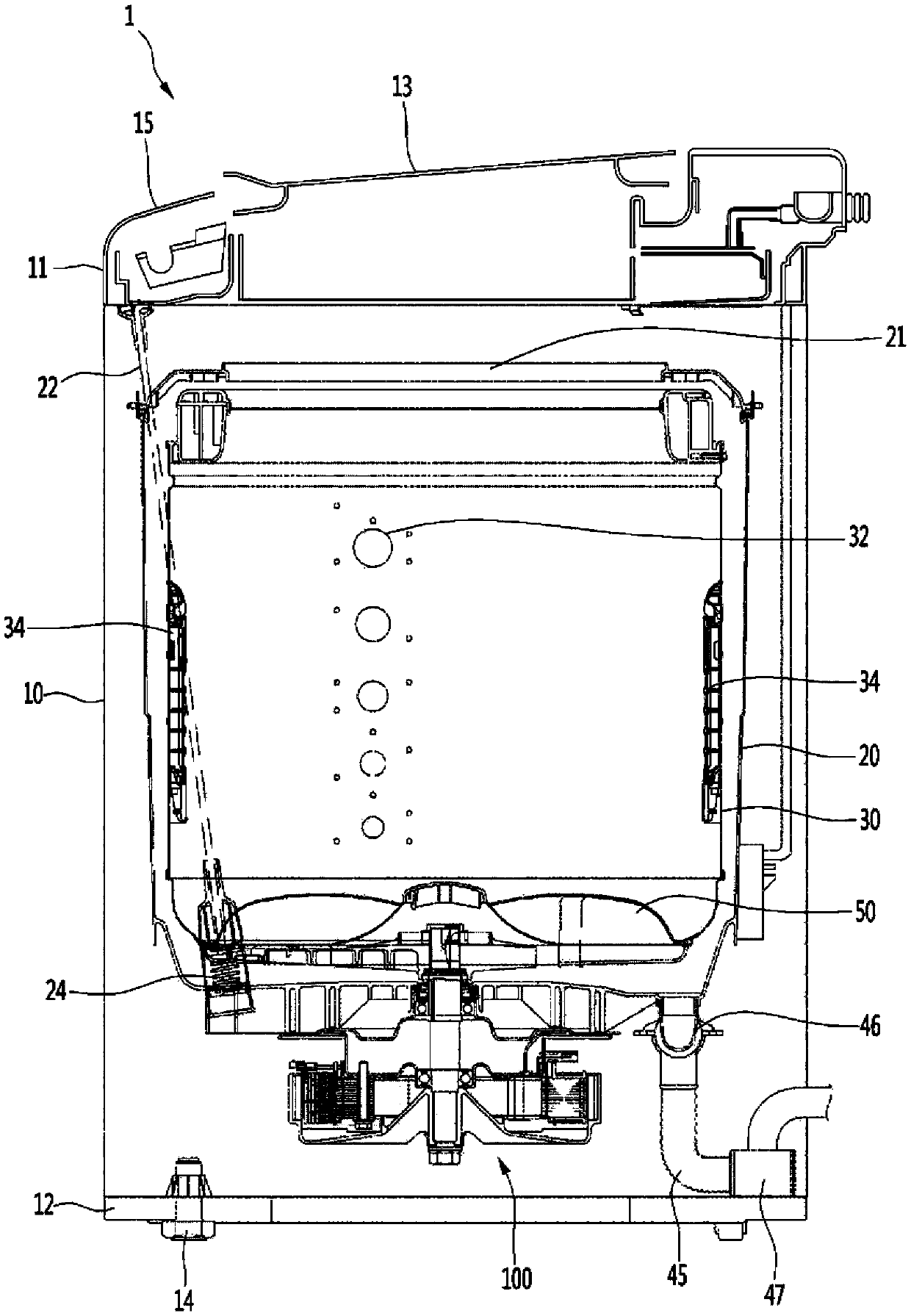

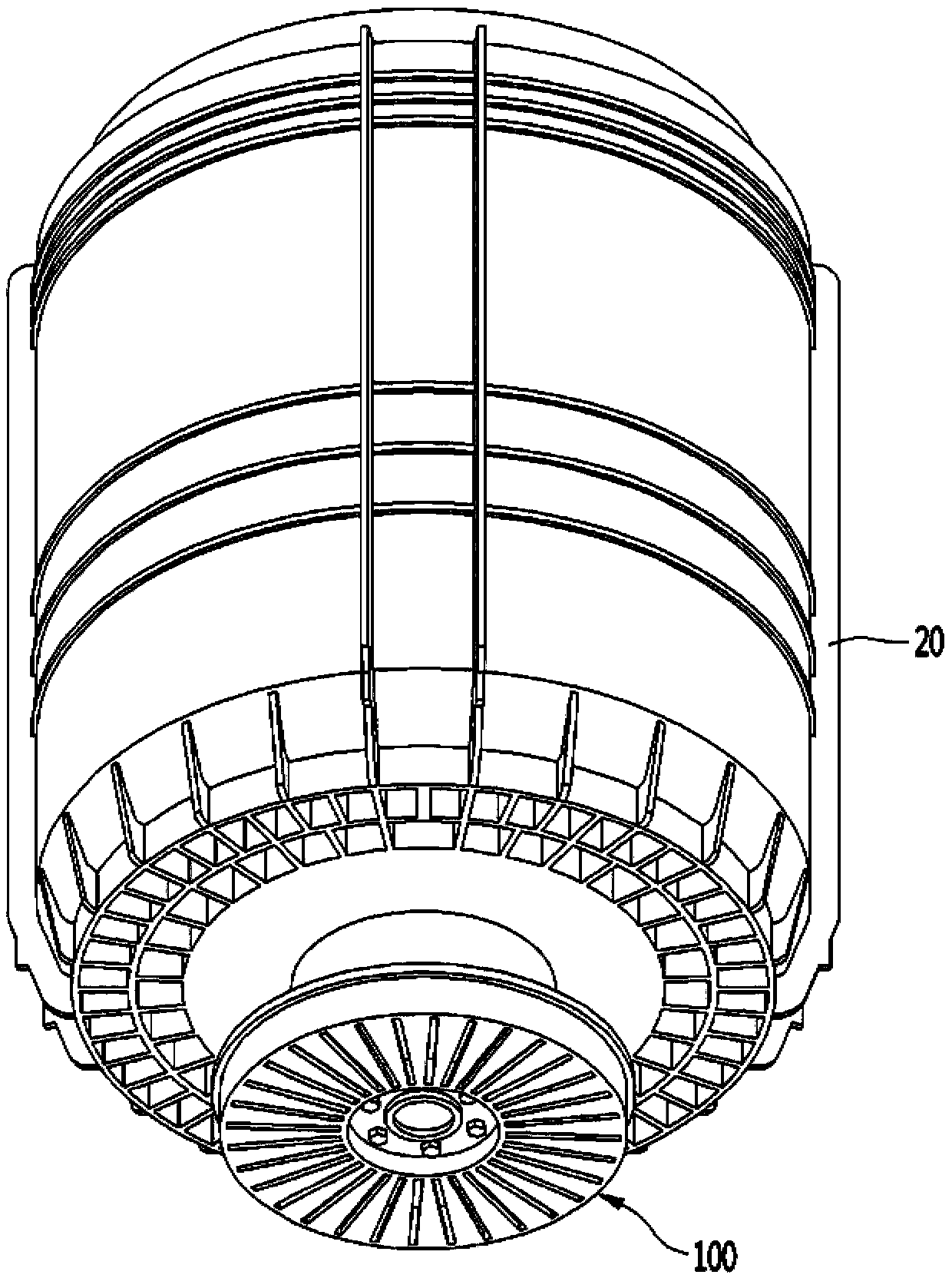

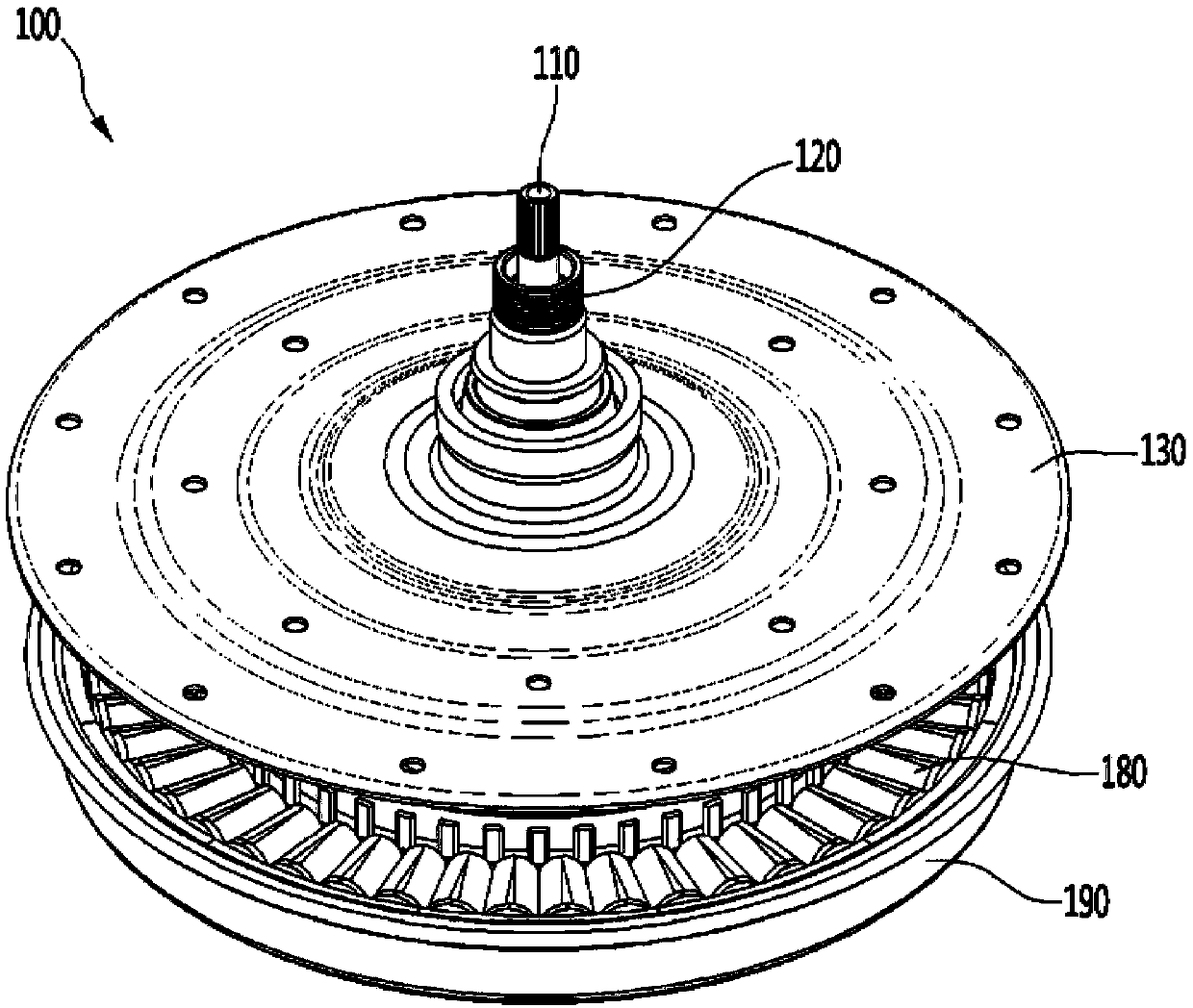

Washing machine

ActiveCN109837701AReduce noiseConstant operationOther washing machinesWashing machine with receptaclesDrive motorClutch

According to the present invention, there is provided a washing machine including a bearing housing which is installed on a bottom surface of an outer tub, a clutch stopper which is installed on a bottom surface of the bearing housing, and a driving motor which includes a stator and a rotor which are coupled to a lower side of the clutch stopper, in which the clutch stopper includes a base portionwhich is disposed on the bottom surface of the bearing housing; and a fastening boss which extends from the base portion to the lower side by a predetermined length and is fastened to stator by a fastening member.

Owner:LG ELECTRONICS INC

Reducing latency in wireless virtual and augmented reality systems

ActiveUS11070829B2Excessive latencyConstant operationDigital video signal modificationSteroscopic systemsComputer graphics (images)Display device

Owner:ATI TECH INC

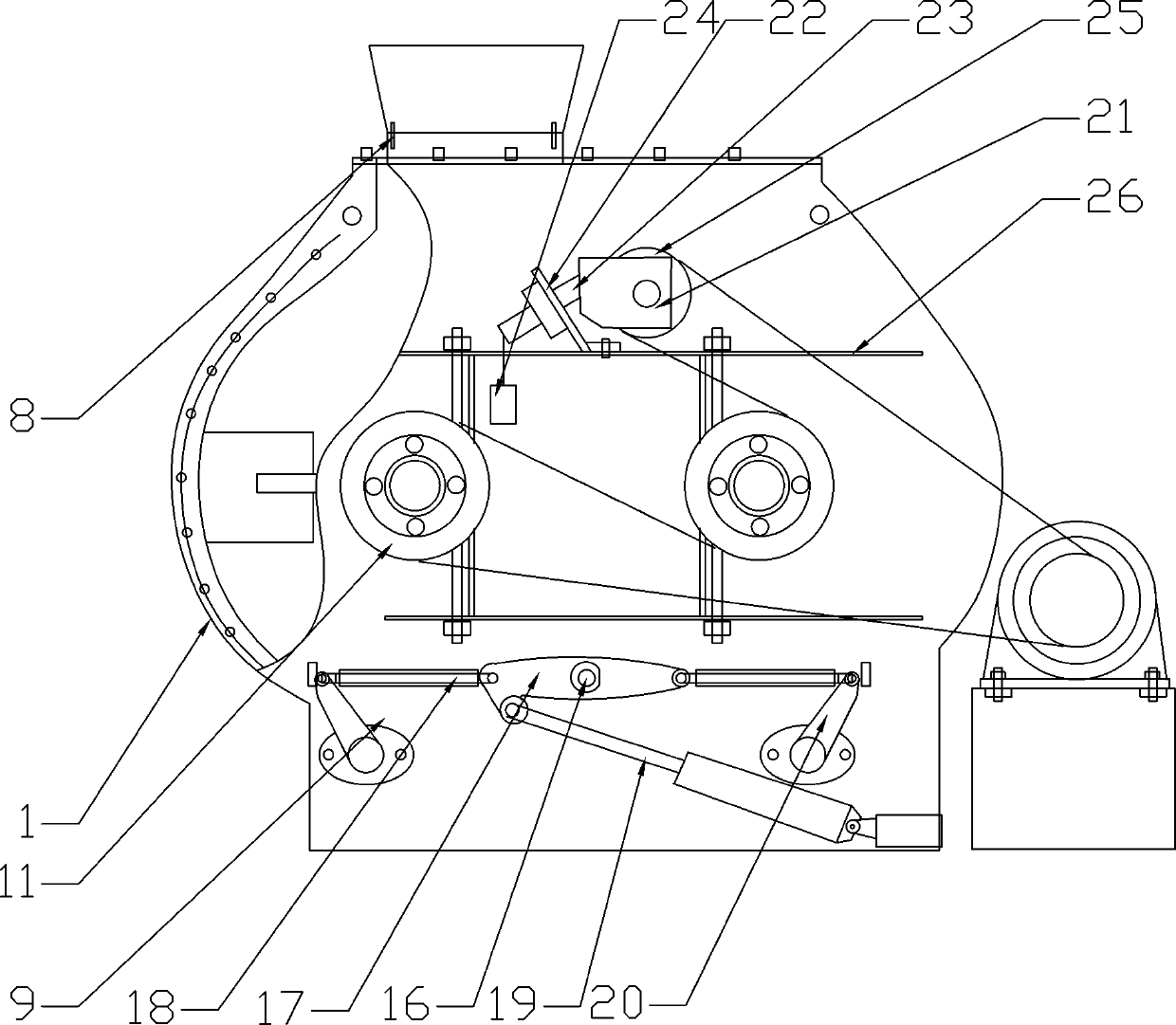

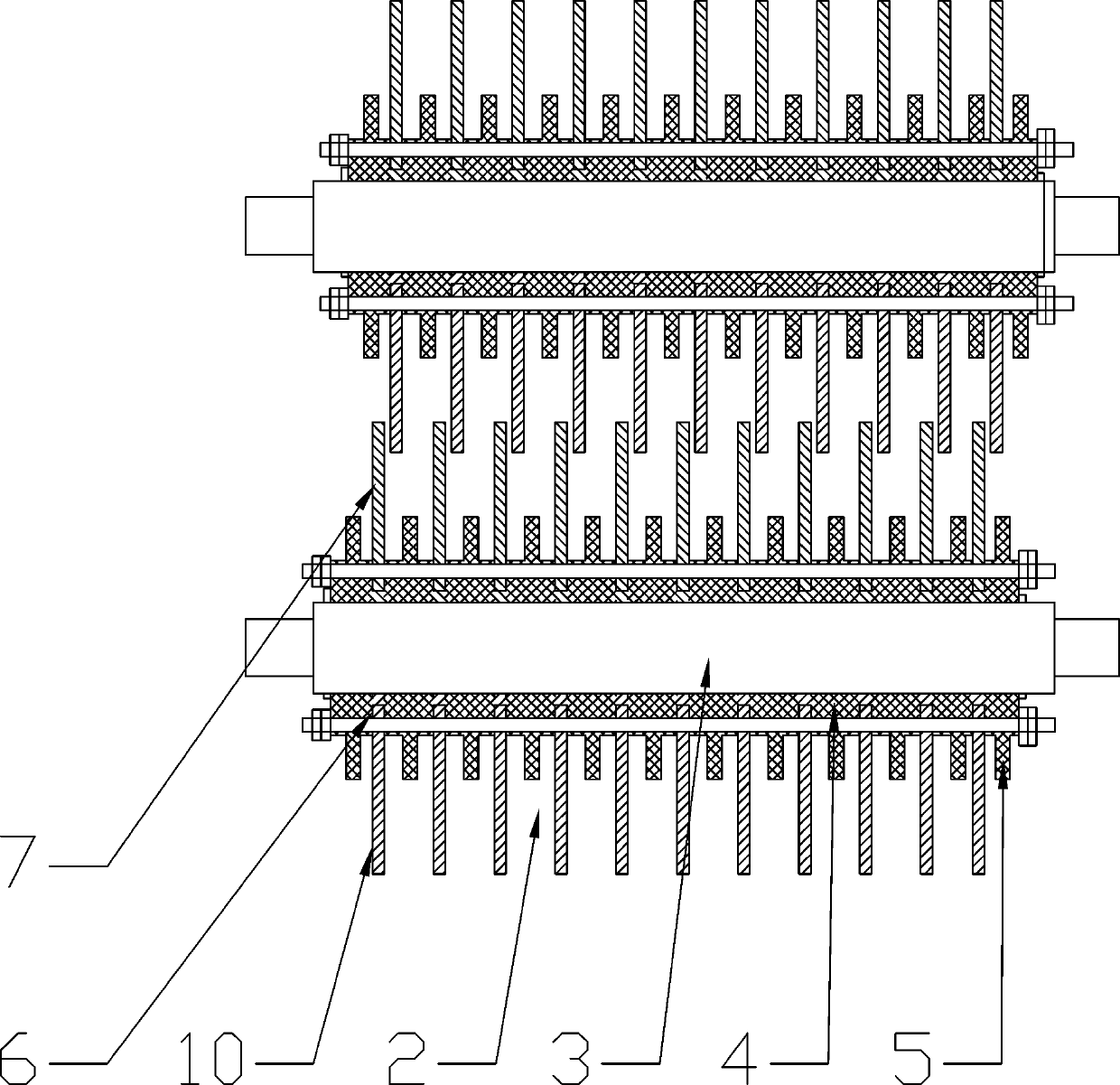

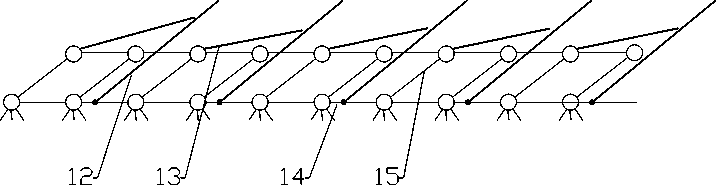

Shear type feed mixing device

InactiveCN107752095AGuaranteed to mix quicklyImprove uniformityFeeding-stuffHorizontal projectionEngineering

A shearing type feed mixing device, comprising a body, a feeding mechanism and a discharging mechanism are respectively arranged on the top and bottom of the body, a stirring mechanism is arranged in the body, and the stirring mechanism is driven by a driving mechanism; the stirring mechanism includes two rotation directions On the opposite rotor, each rotor includes a shaft, on which a mounting base is installed, and the mounting base is alternately provided with levers and grooves along the length direction, and a shearing disc is installed in the groove, and the shearing discs on the two rotors intersect. set, and the edge part overlaps on the horizontal projection plane. The shearing type feed mixing device provided by the invention can improve the uniformity of feed mixing by setting a feeding mechanism, a discharging mechanism and a stirring mechanism.

Owner:宜昌阳光饲料有限责任公司

Chlorination device

ActiveUS9102557B2Avoid accumulationEasy to adjustWater treatment parameter controlOther chemical processesWater chlorinationWater flow

An un-pressurized chlorination device comprises a container having an open top closed by a removable lid. The container defines an inner chamber for a plurality of chlorination tablets. The container has a lower inlet spigot for receiving a water supply inlet pipe. The container also has a lower water outlet through which chlorinated water is delivered. There is a water flow path between the inlet and the outlet. The tablet chamber is not pressurized and the outlet discharges to atmosphere pressure. The device of the invention is useful for dissolving, dispersing and dispensing soluble material in tablet form into a liquid. There is a substantially horizontal fluid path with just enough fall to the outlet to allow the device to drain down out of the outlet when there is no inlet flow.

Owner:MEDENTECH

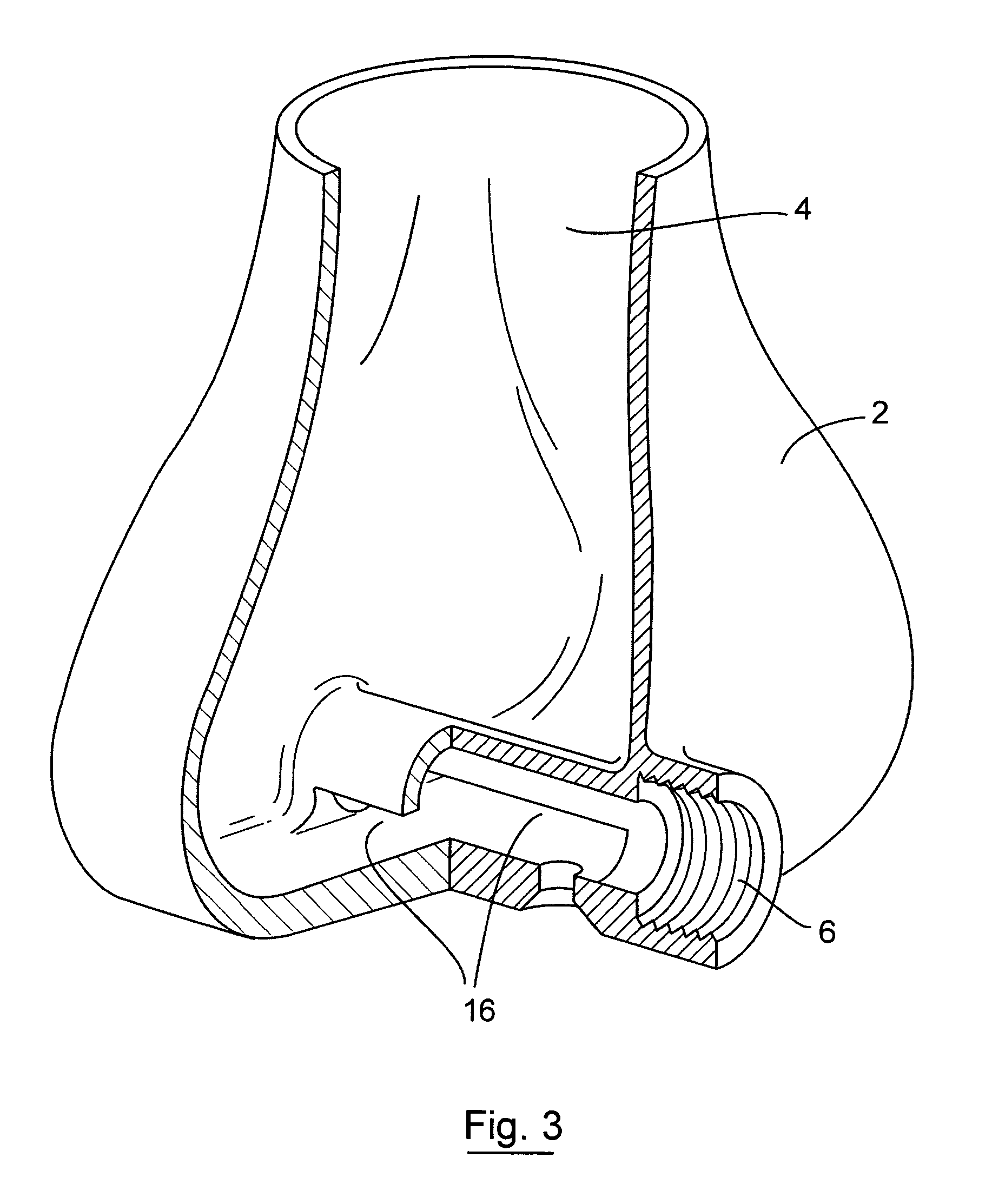

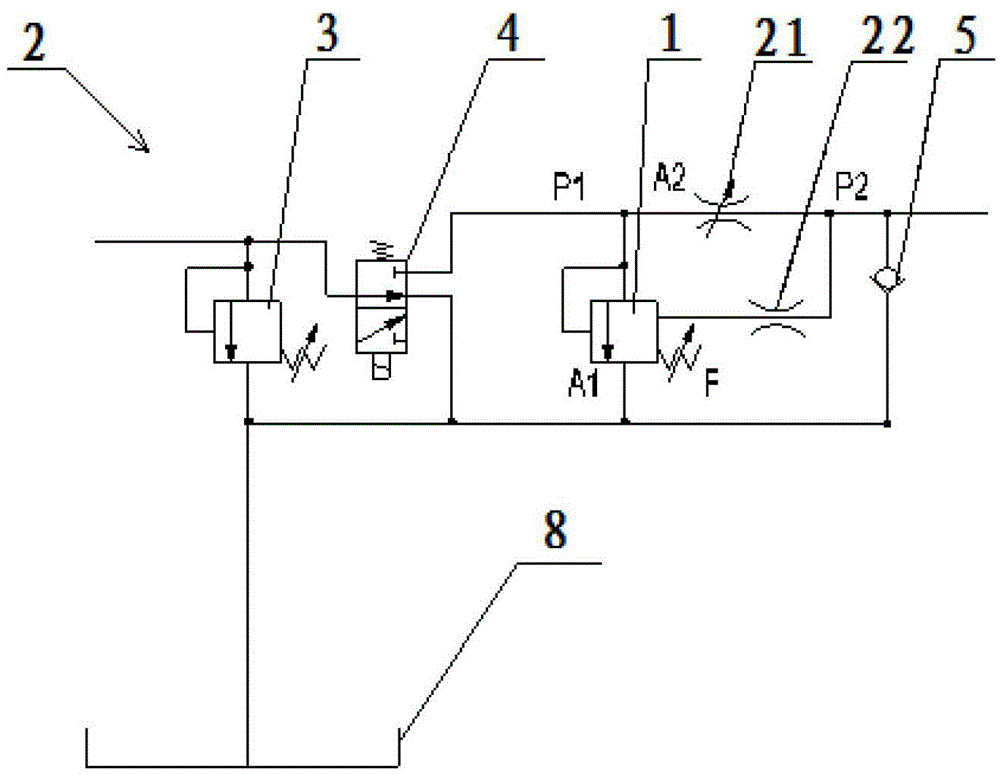

Constant rotating speed automatic control valve assembly of hydraulic motor

InactiveCN105041749AConstant operationConstant speed runningServomotor componentsHydraulic motorAutomatic control

The invention discloses a constant rotating speed automatic control valve assembly of a hydraulic motor. The constant rotating speed automatic control valve assembly comprises a constant valve block, a constant piston, a constant oil outlet, a constant spring, a constant lock nut, a setting lock nut, a setting adjustment device, a feedback oil opening, a setting oil opening, an adjustment throttling device, an oil inlet, a buffer cavity and other components. After emulsified liquid passes through the oil inlet to enter the buffer cavity to be buffered, the emulsified liquid passes through the setting adjustment device to enter the setting oil opening. The emulsified liquid enters the adjustment throttling device after being set to achieve needed flow. The emulsified liquid passes through the constant piston through the oil inlet. After the flow of the emulsified liquid is constant through the constant piston, the emulsified liquid is supplied to the emulsified liquid motor through the constant outlet. The emulsified liquid motor runs at constant speed after obtaining the emulsified liquid of the constant flow. The constant rotating speed automatic control valve assembly is not influenced by fluid supply flow or pressure; the flow is kept constant automatically; the emulsified liquid motor can obtain constant pressure and flow; and the function that the assembly runs at constant speed and constant torque and runs precisely and stably is achieved.

Owner:天津艾浮瑞特科技有限公司

Flow control device and hydraulic oil cooling system

ActiveCN103573731BConstant cooling powerSolve the technical problem of poor cooling efficiencyServomotor componentsFluid-pressure actuator componentsControl valvesOil cooling

An embodiment of the invention discloses a flow control valve, a flow control device and a hydraulic oil heat dissipation system and relates to the technical field of engineering machinery. The flow control valve comprises a three-way pressure compensated valve, a first throttling valve and a second throttling valve; an oil inlet of the first throttling valve is in parallel connection with an oil inlet of the three-way pressure compensated valve; an oil outlet of the first throttling valve is in parallel connection with an oil inlet of the second throttling valve; an oil outlet of the second throttling valve is communicated with a flow feedback oil opening of the three-way pressure compensated valve. The flow control device and the hydraulic oil heat dissipation system comprise the flow control valve. The hydraulic oil heat dissipation system can improve heat dissipation efficiency of a hydraulic oil radiator.

Owner:XCMG CONSTR MACHINERY

Static random access memory (SRAM) arrays having substantially constant operational yields across multiple modes of operation

ActiveUS9373387B1Constant operational yieldLow costDigital storageCAD circuit designStatic random-access memoryRandom access memory

Aspects disclosed include static random access memory (SRAM) arrays having substantially constant operational yields across multiple modes of operation. In one aspect, a method of designing SRAM arrays with multiple modes operation is provided. The method includes determining performance characteristics associated with each mode of operation. SRAM bit cells configured to operate in each mode of operation are provided to the SRAM array. SRAM bit cells are biased to operate in a mode of operation using dynamic adaptive assist techniques, wherein the SRAM bit cells achieve a substantially constant operational yield across the modes. The SRAM bit cells have a corresponding type, wherein the number of SRAM bit cell types in the method is less than the number of modes of operation. Thus, each SRAM array may achieve a particular mode of operation without requiring a separate SRAM bit cell type for each mode, thereby reducing costs.

Owner:QUALCOMM INC

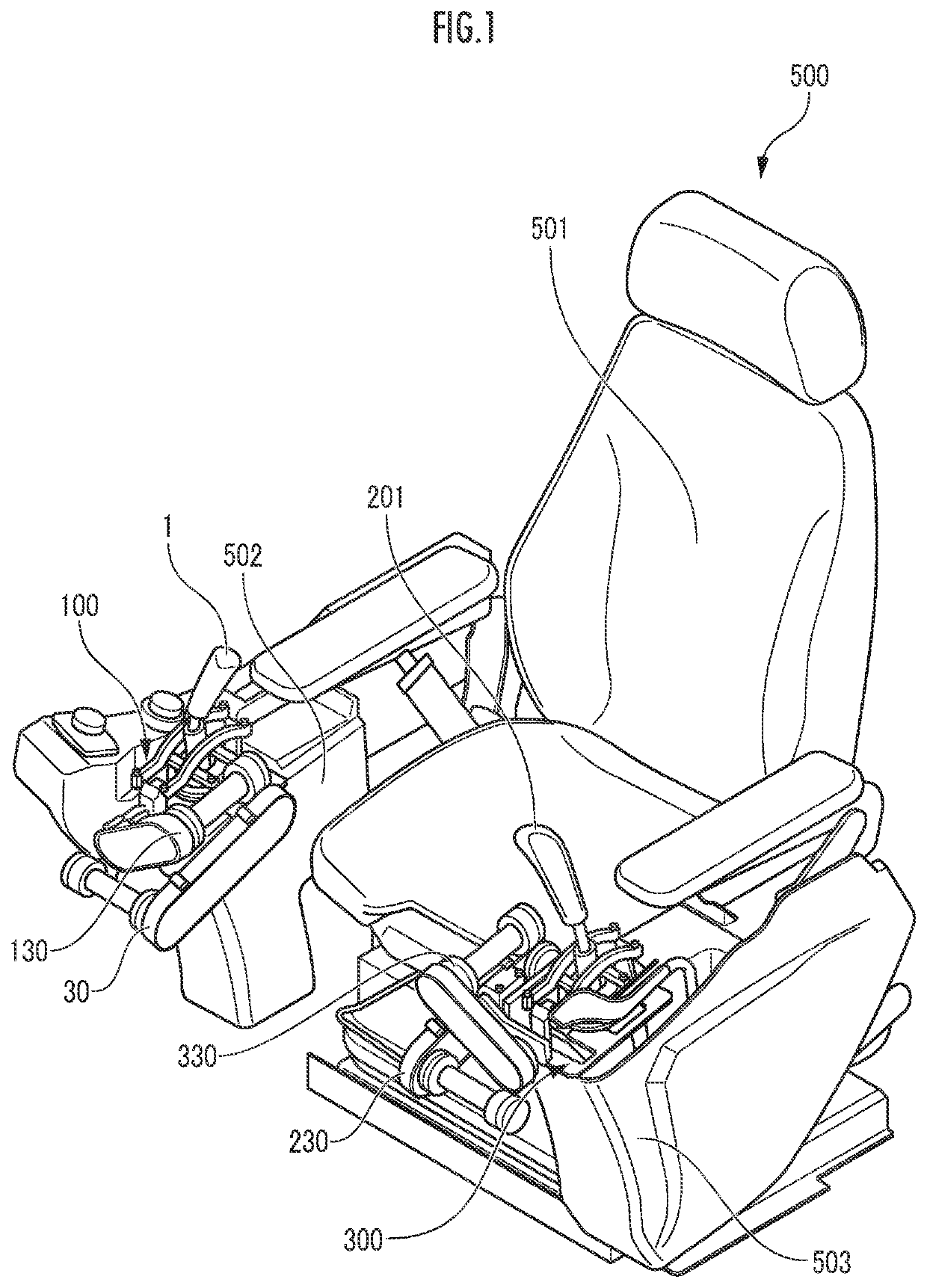

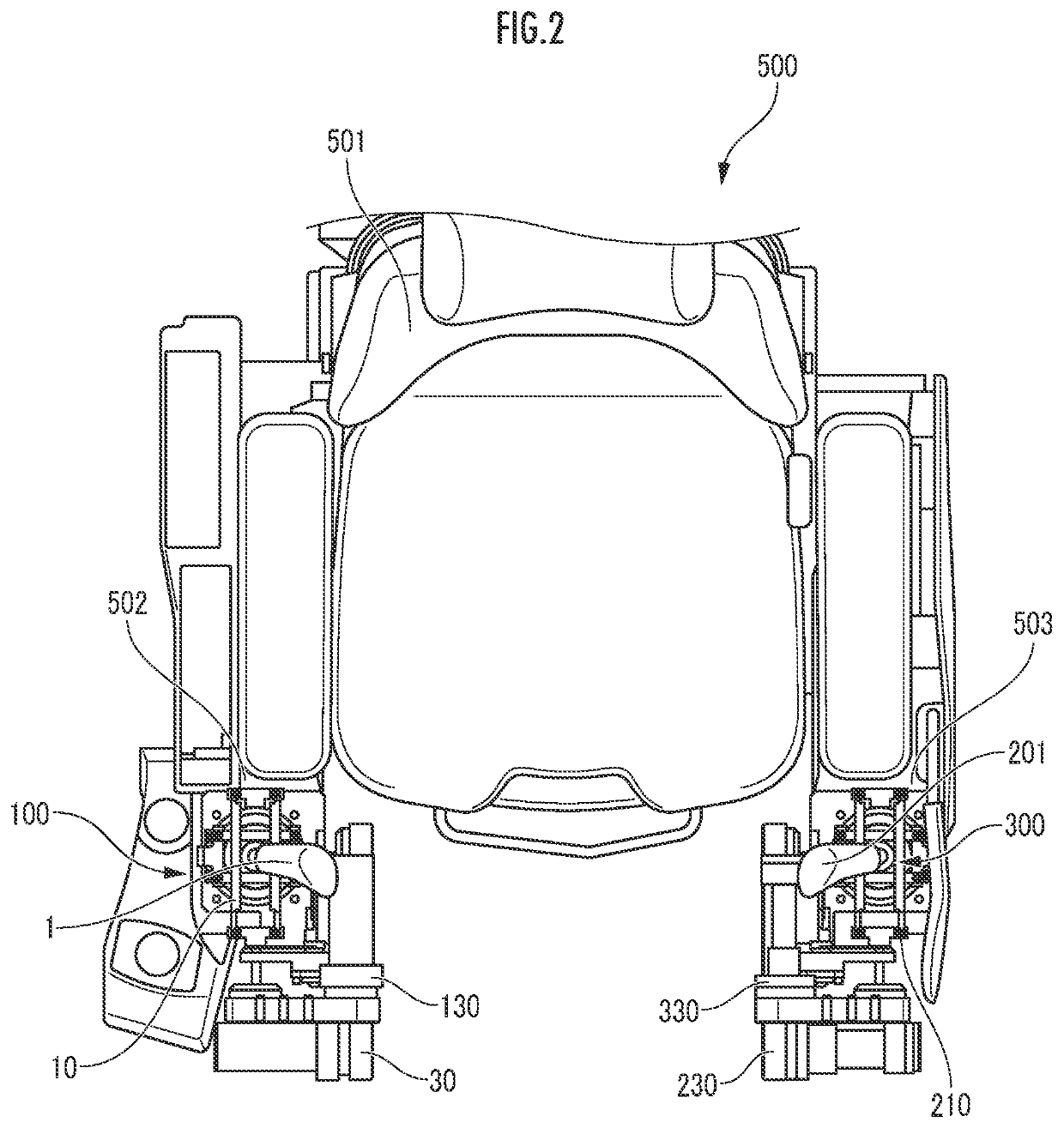

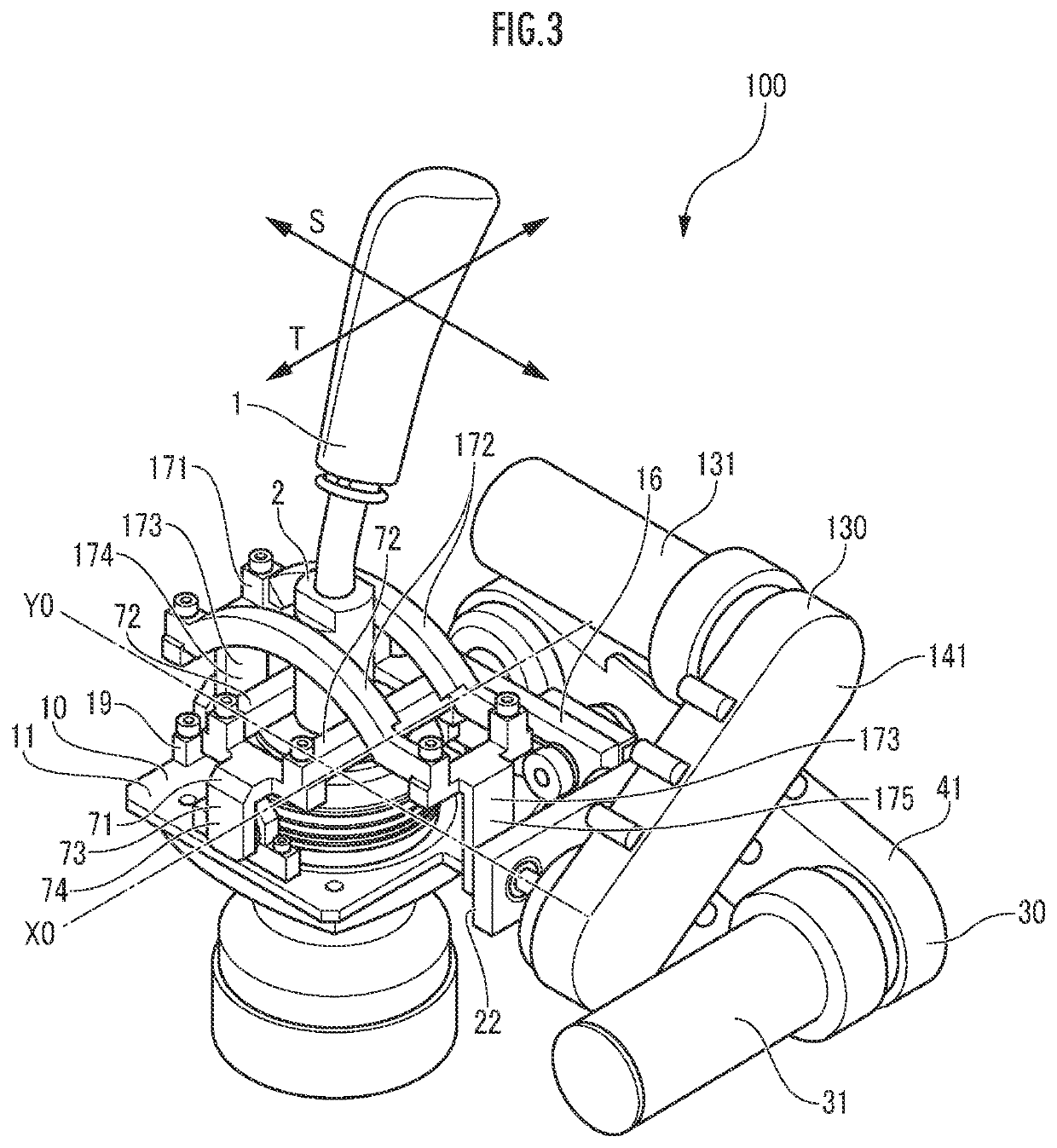

Remote driving device and operation mechanism for work machine

PendingUS20220316180A1Constant operationManual control with multiple controlled membersSoil-shifting machines/dredgersDrive shaftMachine

A remote driving device (100) includes an operation lever (1) to be operated based on an operation command signal, and a first operation mechanism (30) which tilts the operation lever (1). The first operation mechanism (30) includes a first actuator (31) which generates a driving force to tilt the operation lever (1) based on the operation command signal, a first transmission device (41) which transmits the driving force of the first actuator (31), a first detector (61) which detects a tilting amount of the operation lever (1), and a first drive shaft (51). On the first drive shaft (51), a first rotation output part (52) is provided, and the first drive shaft rotates with the tilting of the operation lever (1). The first detector (61) detects the tilting amount of the operation lever (1) via the first rotation output part (52).

Owner:KOBELCO CONSTR MASCH CO LTD

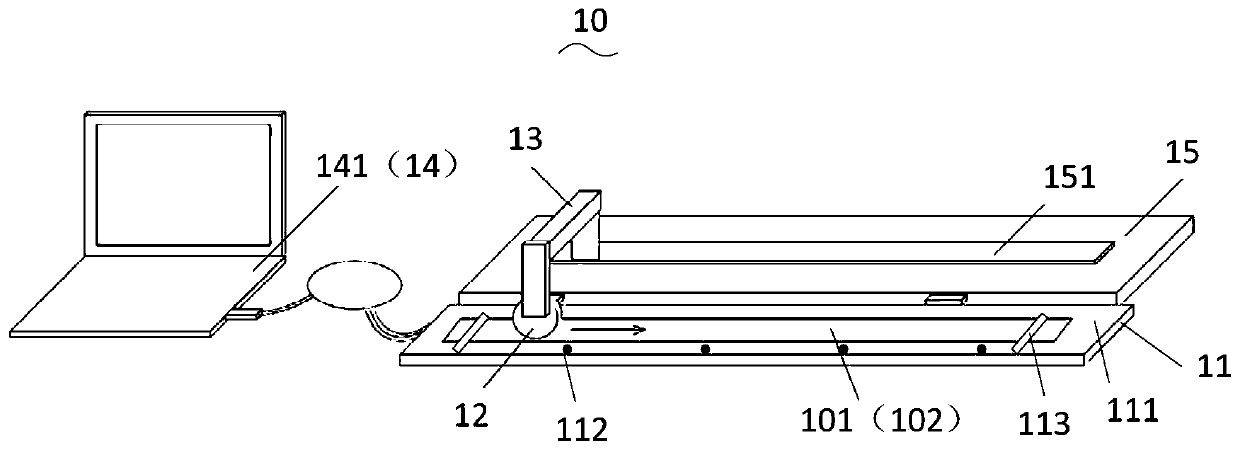

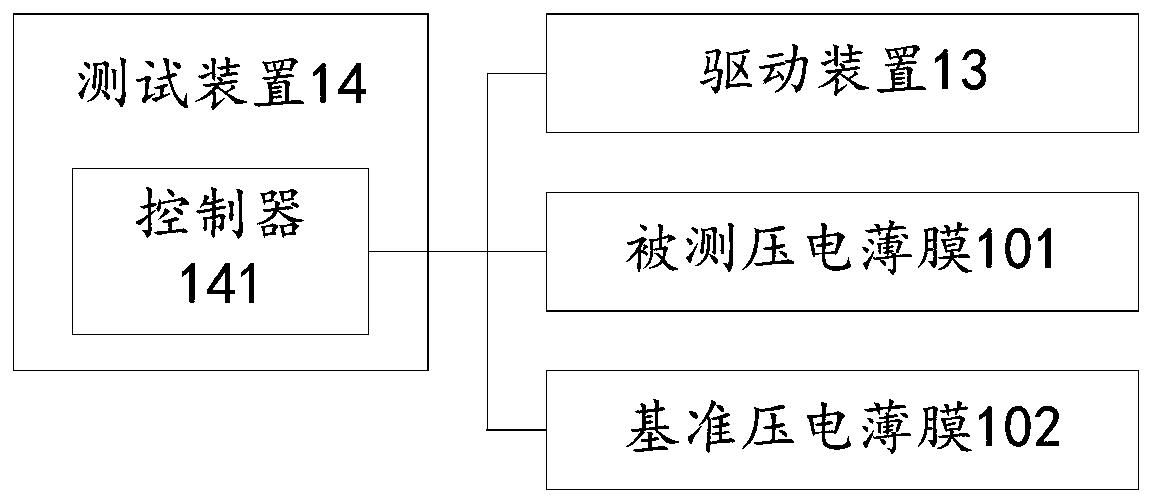

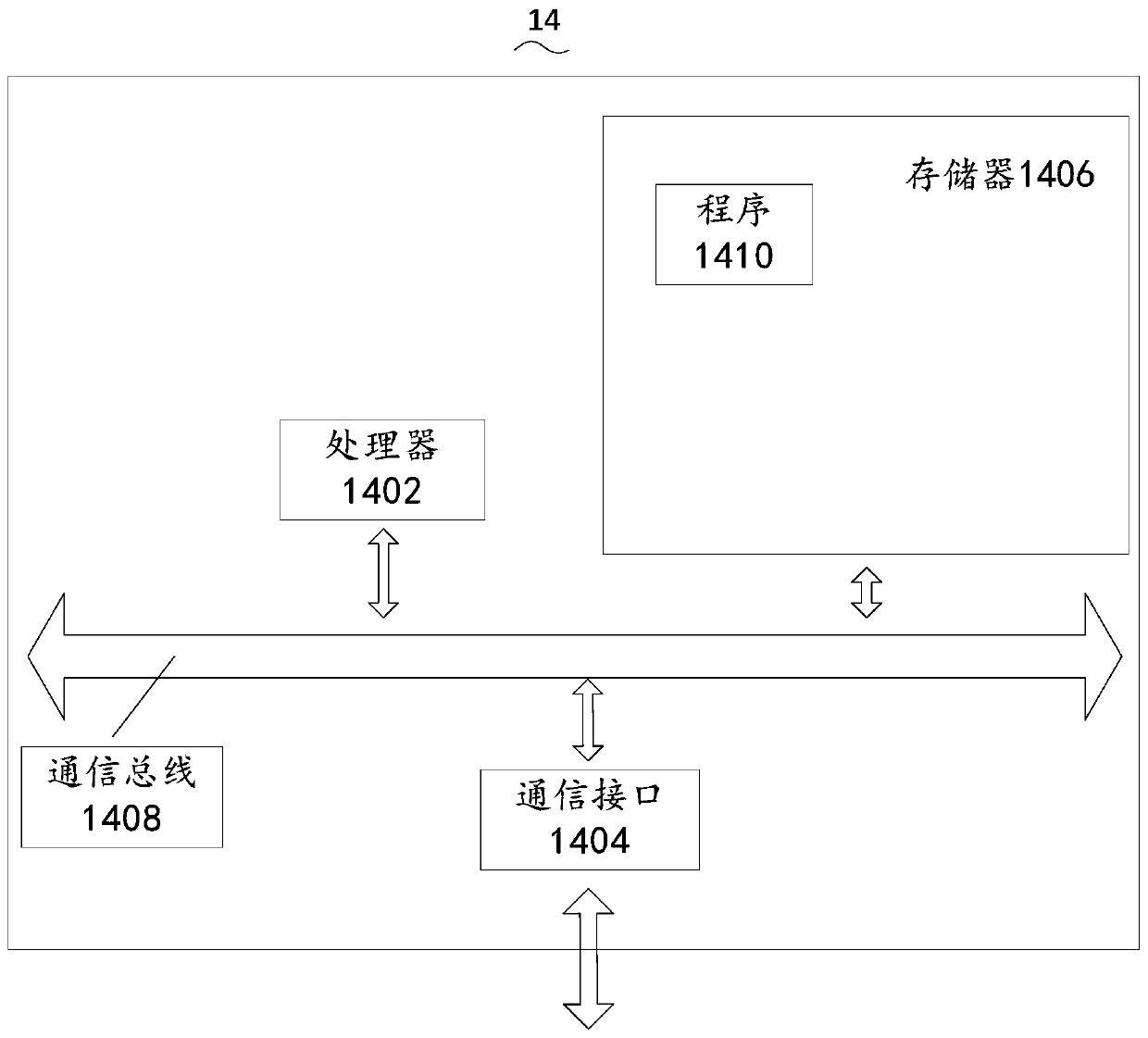

Piezoelectric thin film sensitivity test method and equipment

The invention relates to the technical field of piezoelectric thin film, and discloses piezoelectric thin film sensitivity test method and equipment. The test method is applied to the piezoelectric thin film test equipment. The test equipment comprises a test table, a roller, a driving device and a test device, wherein the test table is provided with a bearing surface, the bearing surface is usedfor bearing a tested piezoelectric thin film and a reference piezoelectric thin film which are laminated, the driving device is used for driving the roller to move on the bearing surface, the test device comprises a controller, and the controller is connected to the tested piezoelectric thin film and the reference piezoelectric thin film. The test method comprises the steps that the controller controls the driving device to drive the roller to roll on the tested piezoelectric thin film and the reference piezoelectric thin film which are laminated; the controller acquires a first electrical signal waveform output from the tested piezoelectric thin film and a second electrical signal waveform output from the reference piezoelectric thin film; and the controller performs sensitivity test on the tested piezoelectric thin film according to the first electrical signal waveform and the second electrical signal waveform. With the test method and the test equipment, disclosed by the embodimentof the invention, the test method and the test equipment can be used for a long time, and an accurate test result is obtained.

Owner:深圳数联天下智能科技有限公司

Hydraulic system and wind-driven power generator set

ActiveCN102454555BConstant operationConstant powerEnergy industryWind motor combinationsWind drivenHydraulic pump

The invention relates to the technical field of wind-driven power generator sets, and particularly discloses a hydraulic transmission system for transmitting the power generated by a wind wheel of a wind-driven power generator set to a power generator, wherein the hydraulic transmission system comprises a first hydraulic pump and a hydraulic motor; the power input end of the first hydraulic pump is connected with a wind wheel main shaft; the oil inlet of the first hydraulic pump is communicated with an oil tank, and the oil outlet of the first hydraulic pump is communicated with the oil inlet of the hydraulic motor; the oil outlet of the hydraulic motor is communicated with the oil tank; the power output end of the hydraulic motor is communicated with the power input end of the power generator; and an oil channel between the first hydraulic pump and the hydraulic motor is provided with a speed regulating valve. No matter how the wind speed changes, the transmission system can always enable the power generator to operate always at a constant speed, and can enable the power and frequency of electricity to be constant. The invention also discloses a wind-driven power generator set.

Owner:SANY ELECTRIC CO LTD

One-time heating heat pump water heater outlet water temperature control device and temperature control method

The invention discloses a temperature control device for yielding water of a single-heat type heat pump water heater. A pipeline is connected with a heat storage water tank, a tee-joint proportioning valve, a heating water heat exchanger, a water pump and a yielding water constant temperature control module connected with the heat storage water tank, wherein the yielding water constant temperature control module is connected with an ambient temperature probe, and controls the switching on and off of the tee-joint proportioning valve; and an opening in the A-B direction of the tee-joint proportioning valve is communicated with a water inlet end, and an opening in the B-C direction is communicated with the heating water heat exchanger. In addition, the invention also discloses a temperature control method, the temperature of the heat storage water tank, the ambient and the heating water heat exchanger are subjected to sampling detection, and according to different ambient temperatures, different yielding water temperature values can be set, the switching on-off degree of the tee-joint proportioning valve is adjusted, the water feeding amount is adjusted by the temperature control regulating valve, so that the yielding water temperature of the heating water heat exchanger can reach the set value. The temperature control device can run with safety, stability and high efficiency, and meanwhile, the engineering installation is simple, the cost is low, and the supplied hot water is constant.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com