Constant rotating speed automatic control valve assembly of hydraulic motor

A technology for automatic control of valves and motors, applied to servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problem of reducing the flow rate of the emulsion supply motor, increasing the flow rate of the emulsion supply motor, and the inability of the emulsion motor to run constantly, etc. problem, to achieve the effect of stable operation, convenient installation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

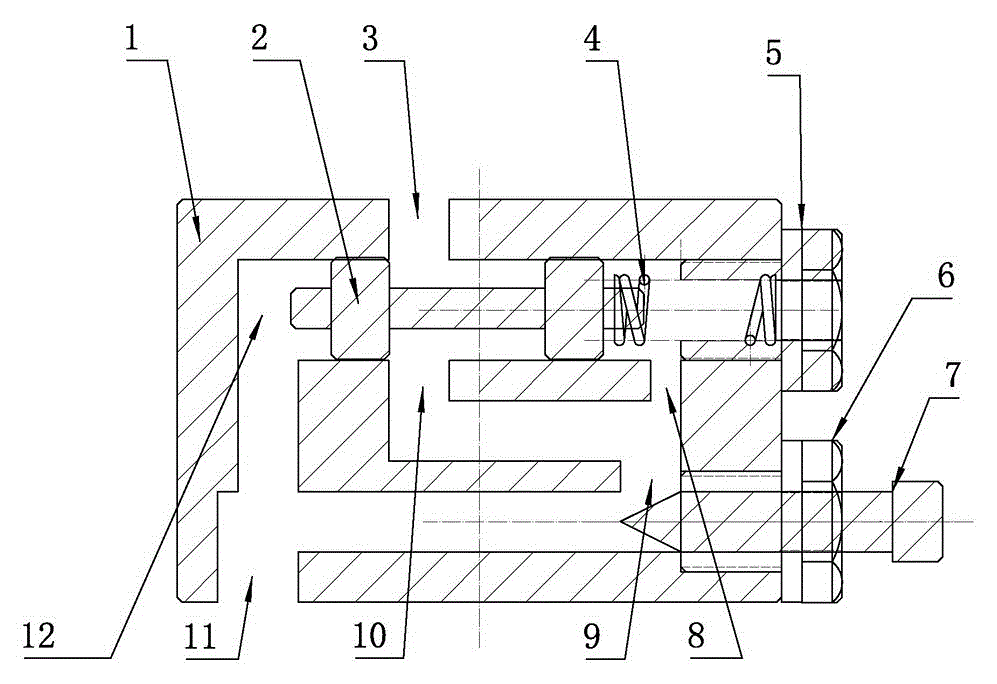

[0016] like figure 1 As shown, the hydraulic motor speed constant automatic control valve assembly described in the embodiment of the present invention includes (1) constant valve block, (2) constant piston, (3) constant oil outlet, (4) constant spring, (5) Spring lock nut, (6) Setting lock nut, (7) Setting adjustment, (8) Feedback oil port, (9) Setting oil port, (10) Adjusting throttling, (11) Oil inlet, (12 ) buffer chamber; characterized in that: the constant valve block (1) is opened to process an oil inlet (11); the oil inlet (11) and the buffer chamber (12) are opened; the setting lock nut ( 6) Connect with the oil inlet (11) and tighten it on the constant valve block (1); the setting adjustment (7) is installed in the setting lock nut (6); the constant piston (2) is installed in parallel on the buffer cavity (12); the constant spring (4) is installed at the end of the constant piston (2); the spring lock nut (5) is screwed on the constant valve block (1); a set of hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com