Patents

Literature

2499results about How to "Increase the cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

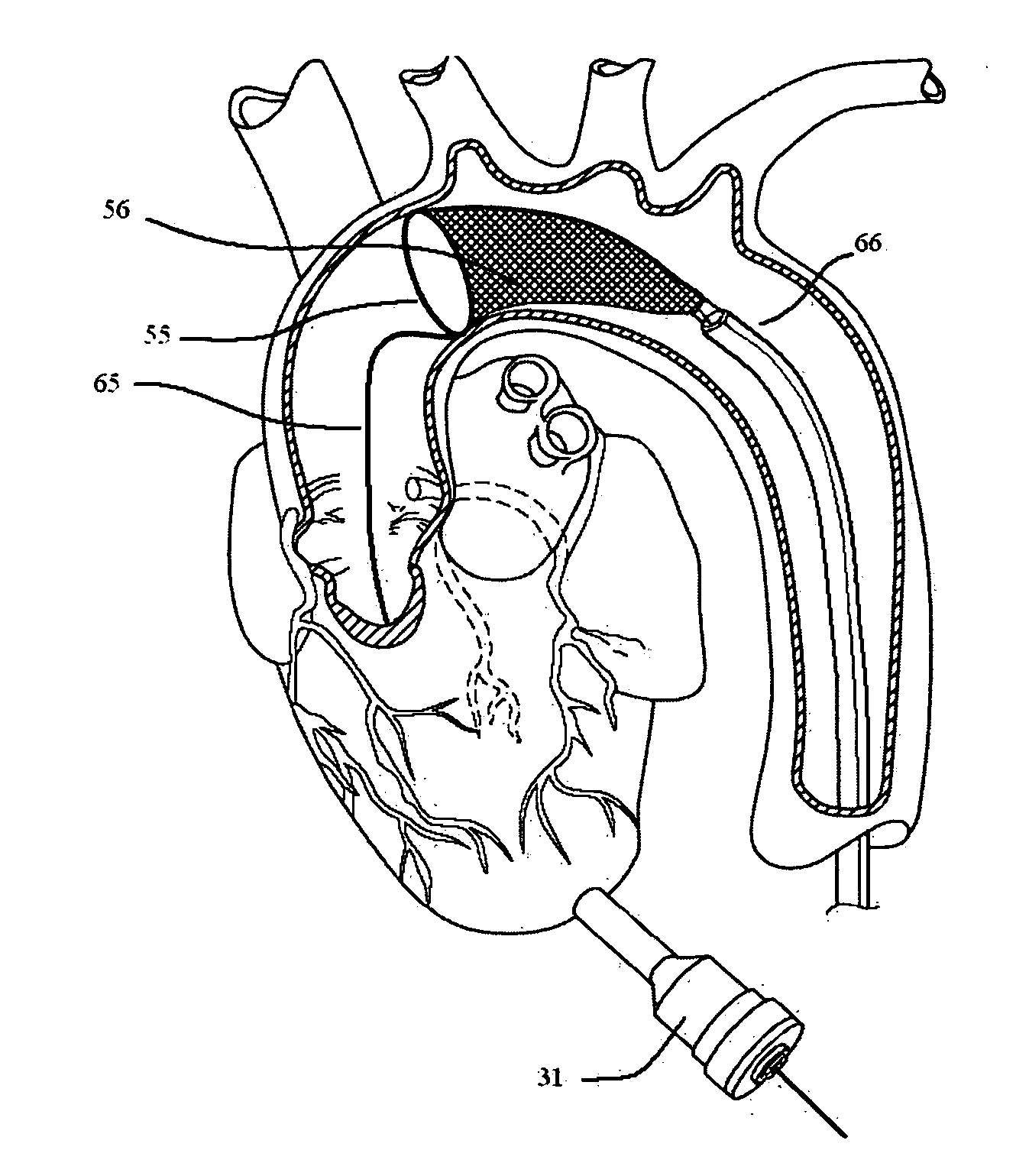

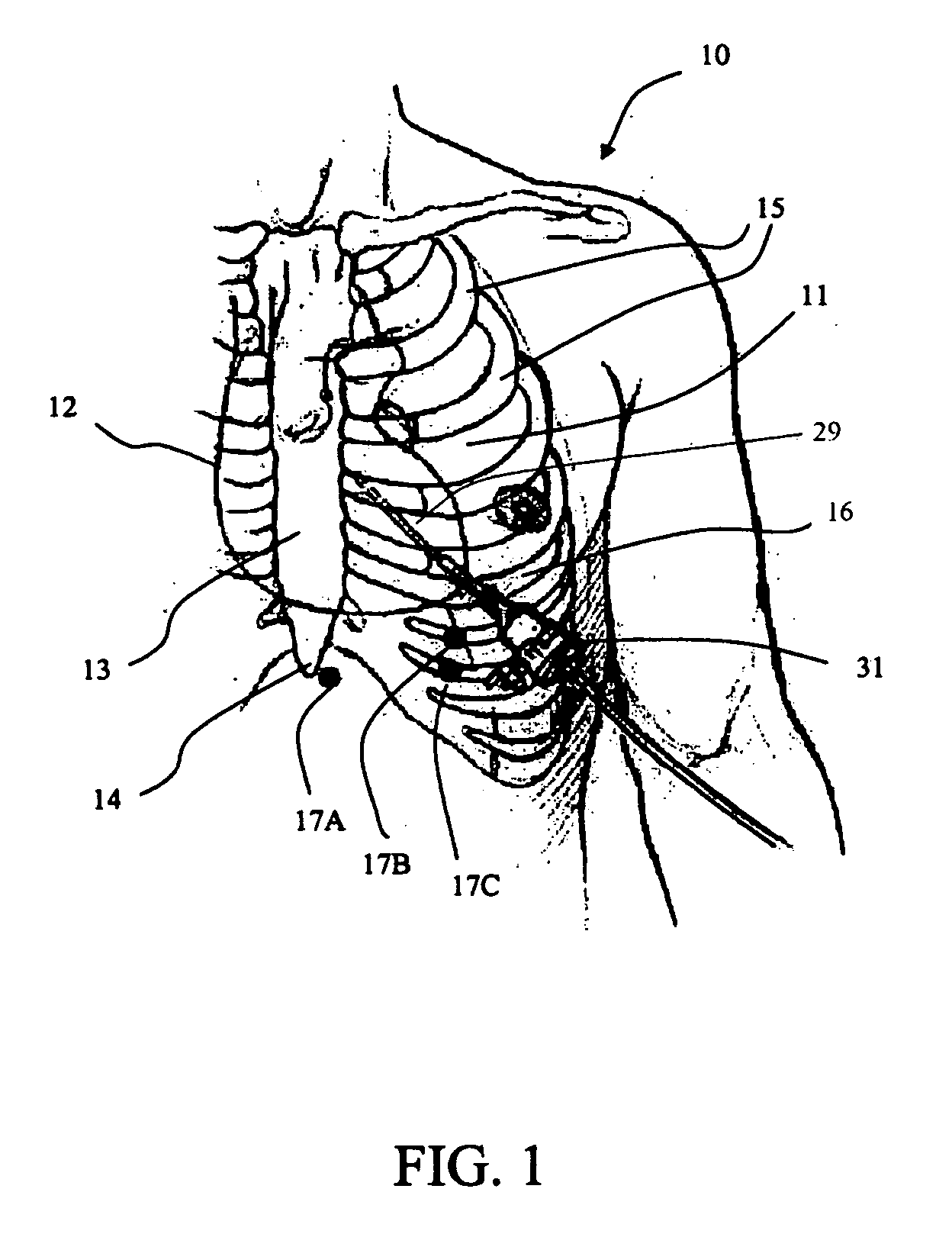

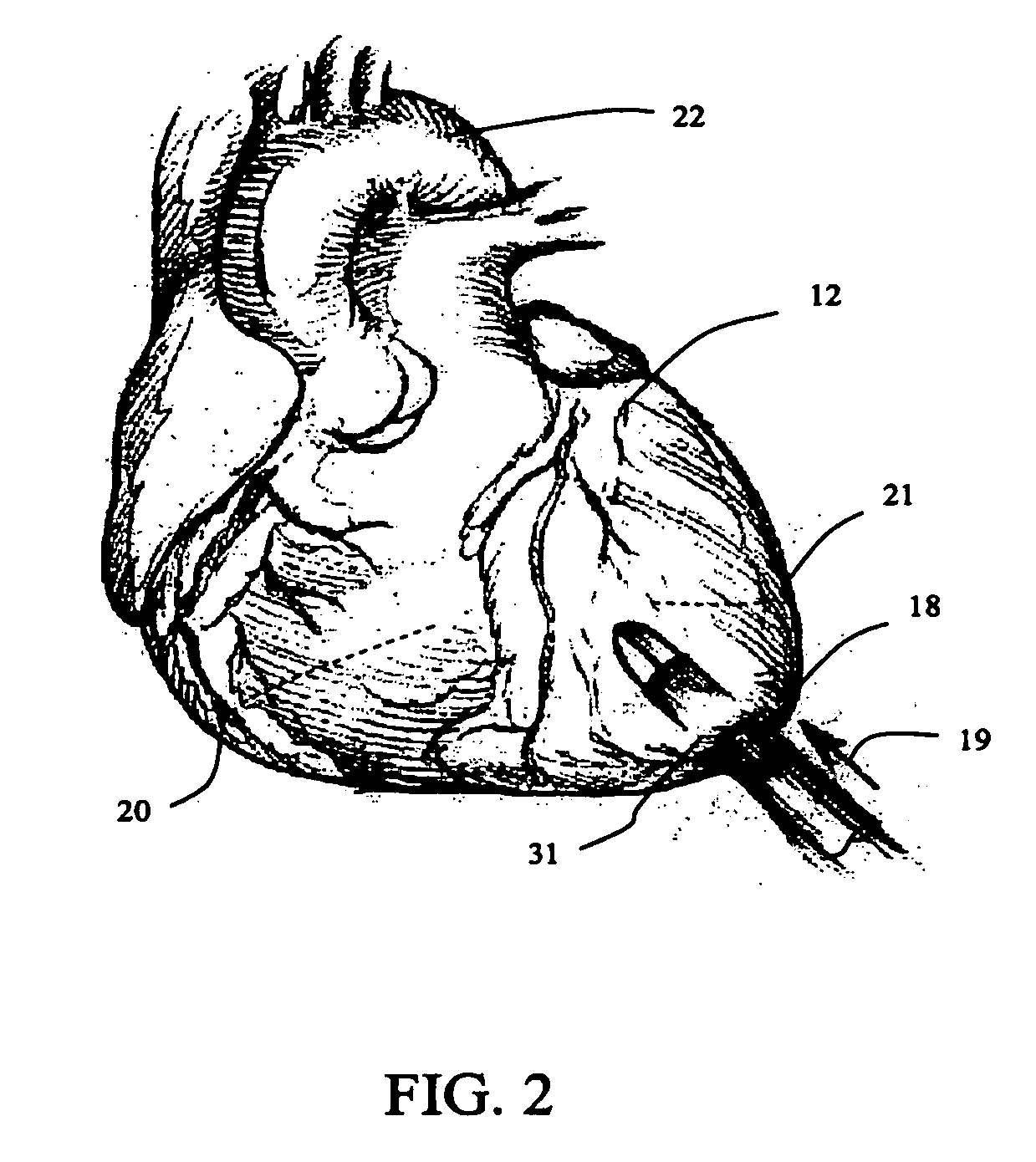

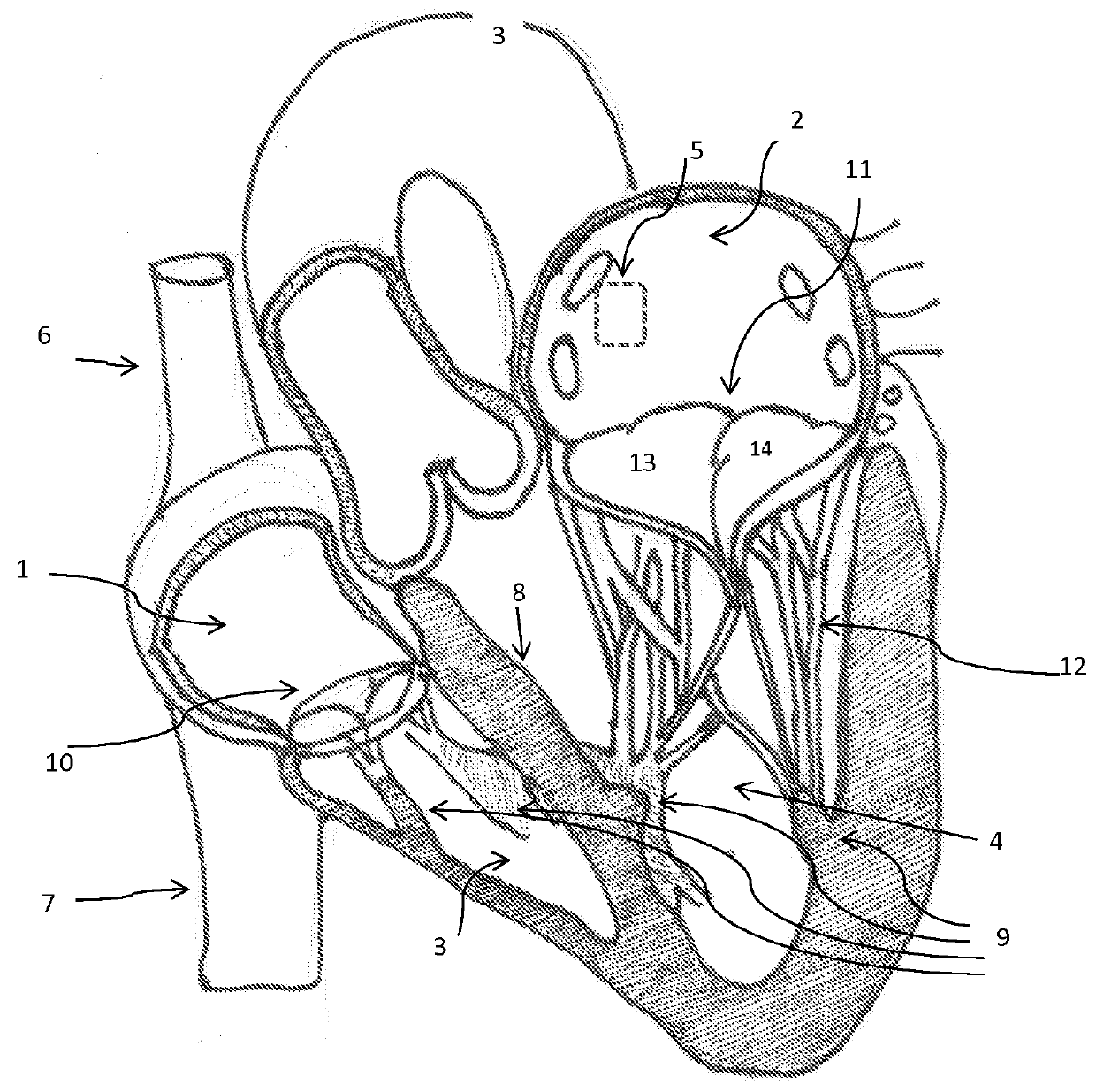

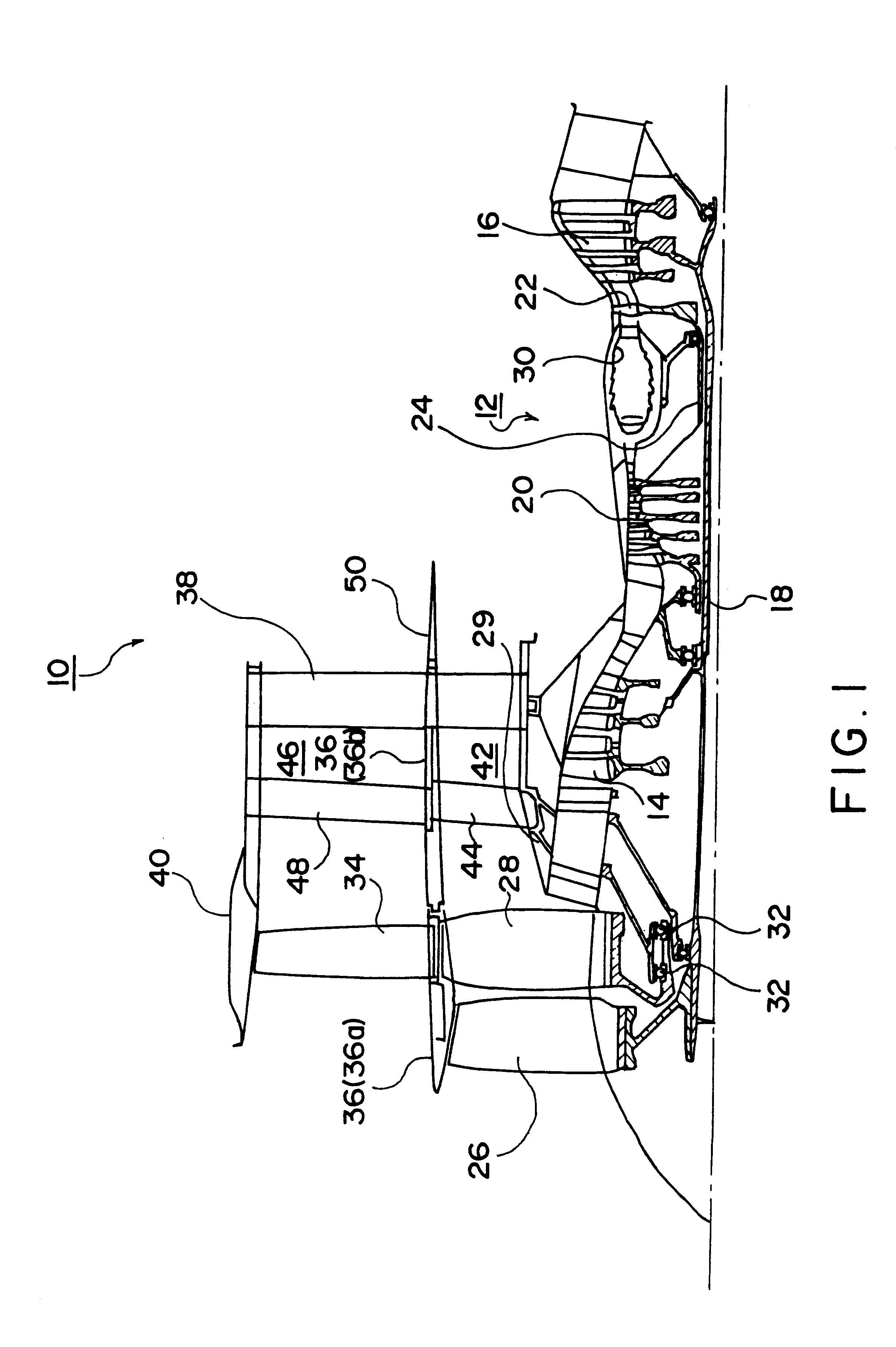

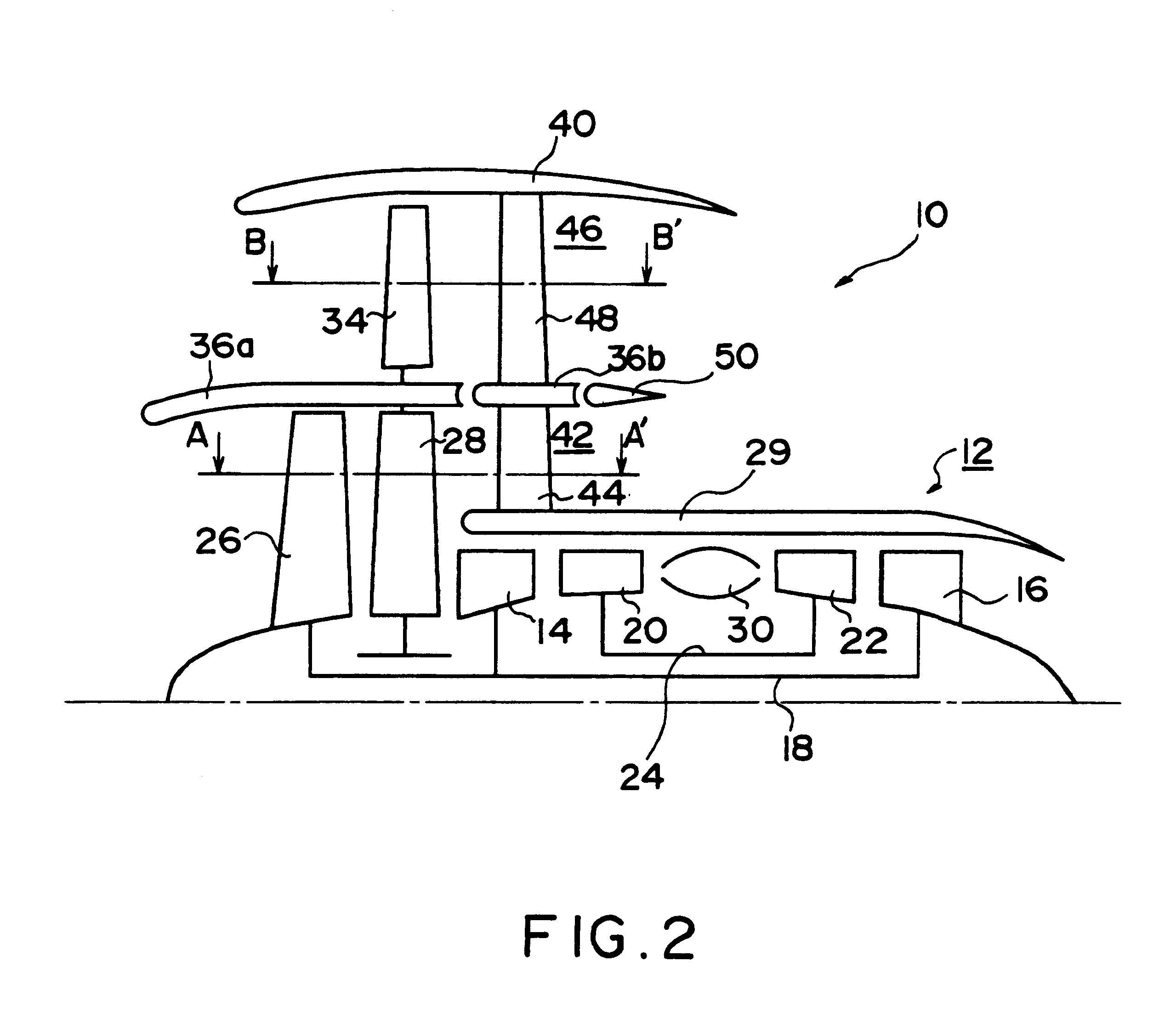

Methods and systems for cardiac valve delivery

The present invention provides systems and methods for the repair, removal, and / or replacement of heart valves. The methods comprise introducing a delivery system into the heart, wherein a prosthesis is disposed on the delivery member attached to the delivery system, advancing the prosthesis to the target site, and disengaging the prosthesis from the delivery member at the target site for implantation. The present invention also provides implant systems for delivering a prosthesis to a target site in or near the heart. In one embodiment of the present invention, the implant system comprises a delivery system, an access system, and a prosthesis.

Owner:MEDTRONIC 3F THERAPEUTICS

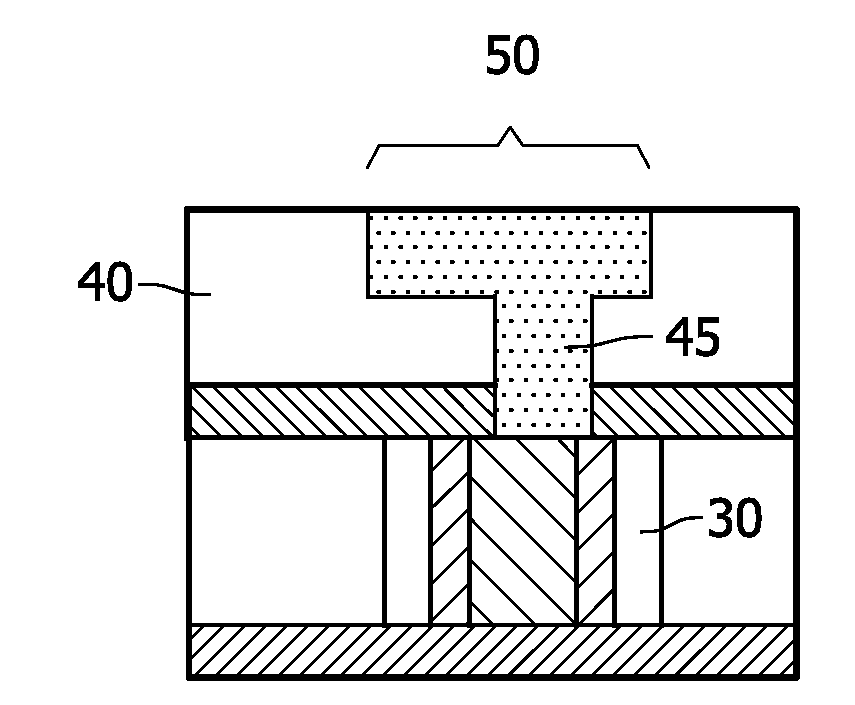

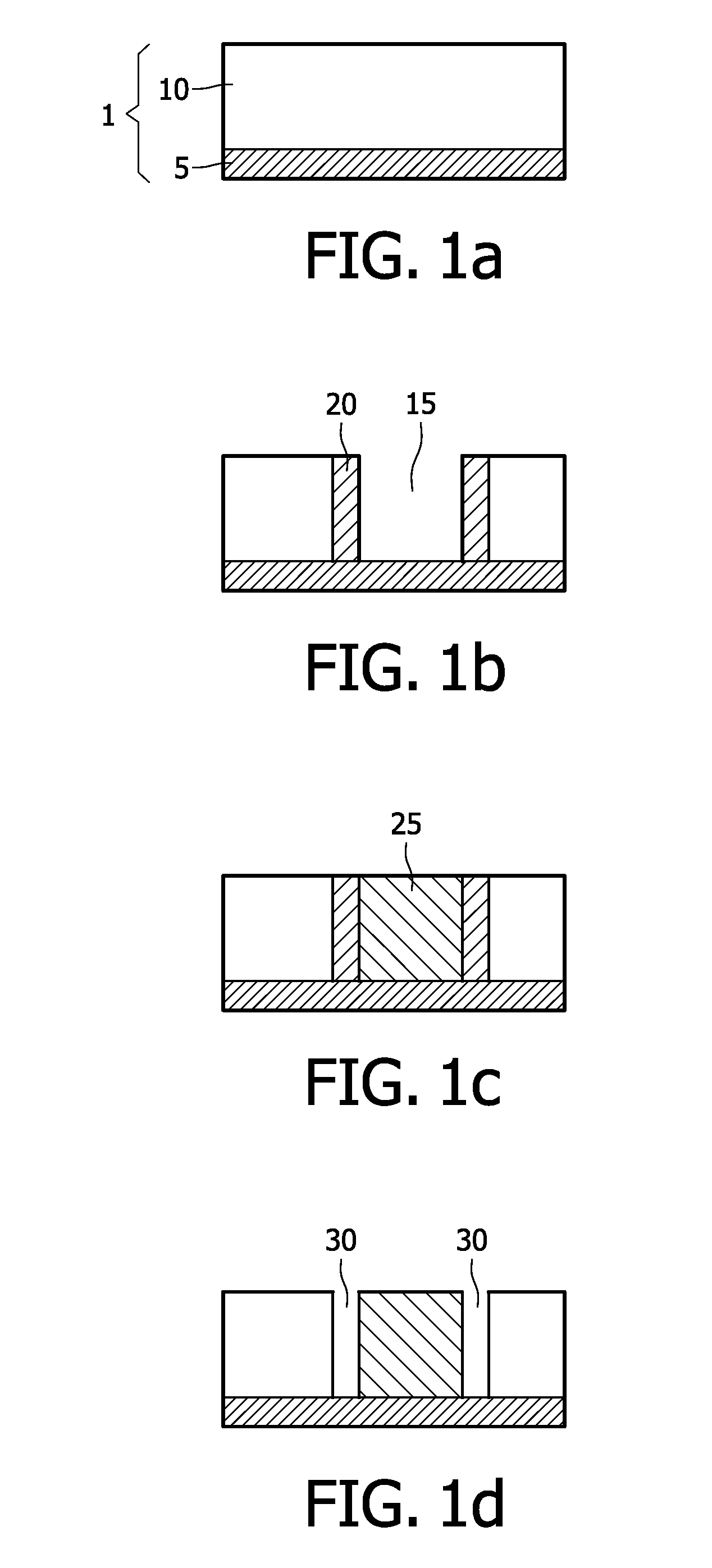

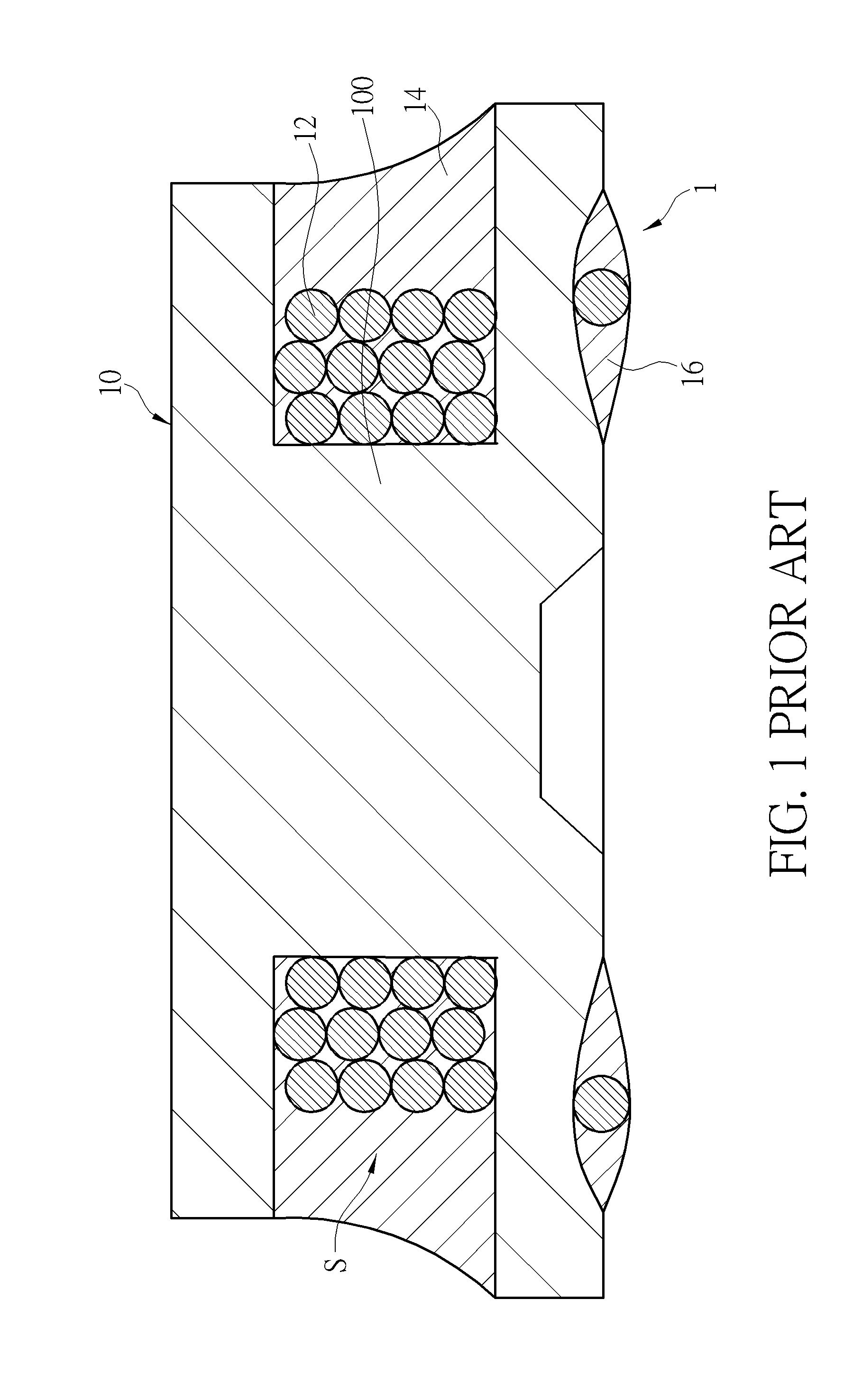

Semiconductor device and method of manufacturing thereof

InactiveUS20100001409A1Increase the cross-sectional areaLower interconnect resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

The invention relates to a semiconductor device comprising: a substrate (1), the substrate (1) comprising a body (5), the body (5) having a surface, the substrate (1) being provided with an insulating layer (10) on the surface of the body (1);—a conductor (25) with insulating sidewall spacers (22) located in the insulating layer (10), the conductor (25) having a current-flow direction during operation, the conductor (25) having a first width, the insulating sidewall spacers (22) each having a second width being smaller than the first width of the conductor (25), the first width and the second width being measured in a direction perpendicular to the current-flow direction of the conductor (25) and parallel to said surface, the conductor (25) having a first top surface extending parallel to said surface, the insulating sidewall spacers (22) having a second top surface, and airgaps (30) located in the insulating layer (10) adjacent to the insulating sidewall spacers (22), characterized in that the first top surface coincides with the second top surface, and in that the airgaps (30) extend from the surface of the body (5) to said first and second top surface. The invention further relates to a method of manufacturing such a semiconductor device. The semiconductor device according to the invention enables a lower resistance of the conductor while still providing a tolerance for unlanded vias.

Owner:NXP BV

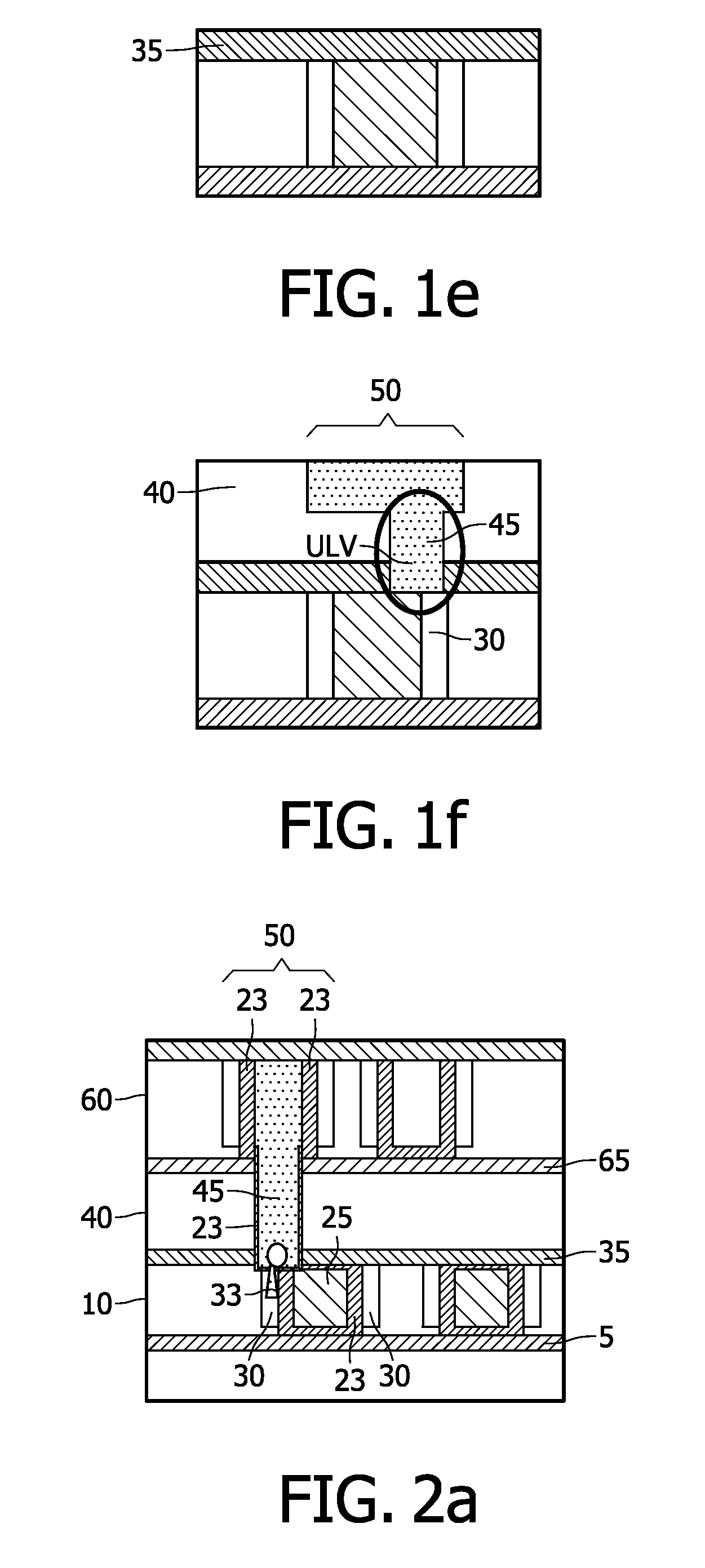

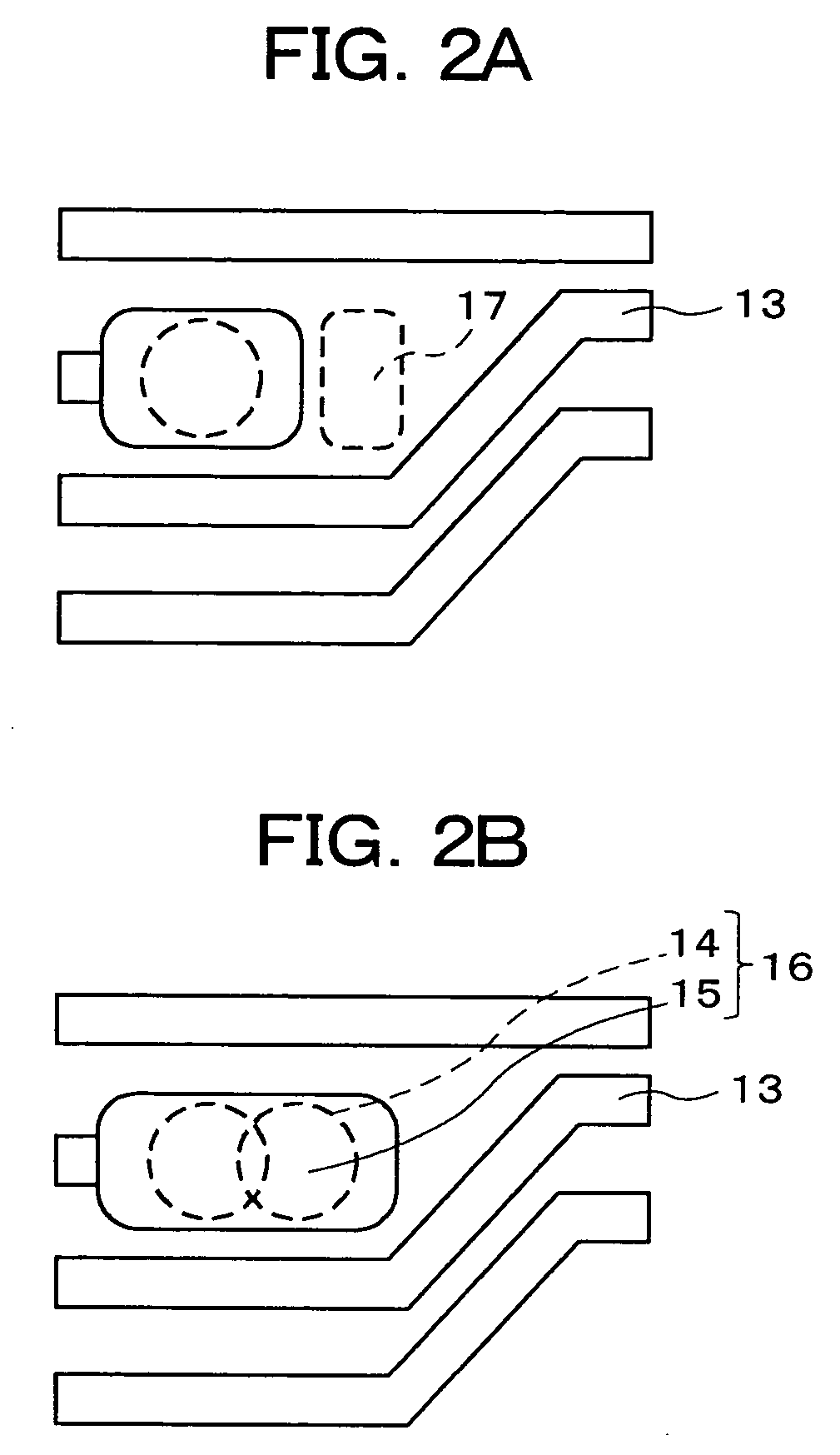

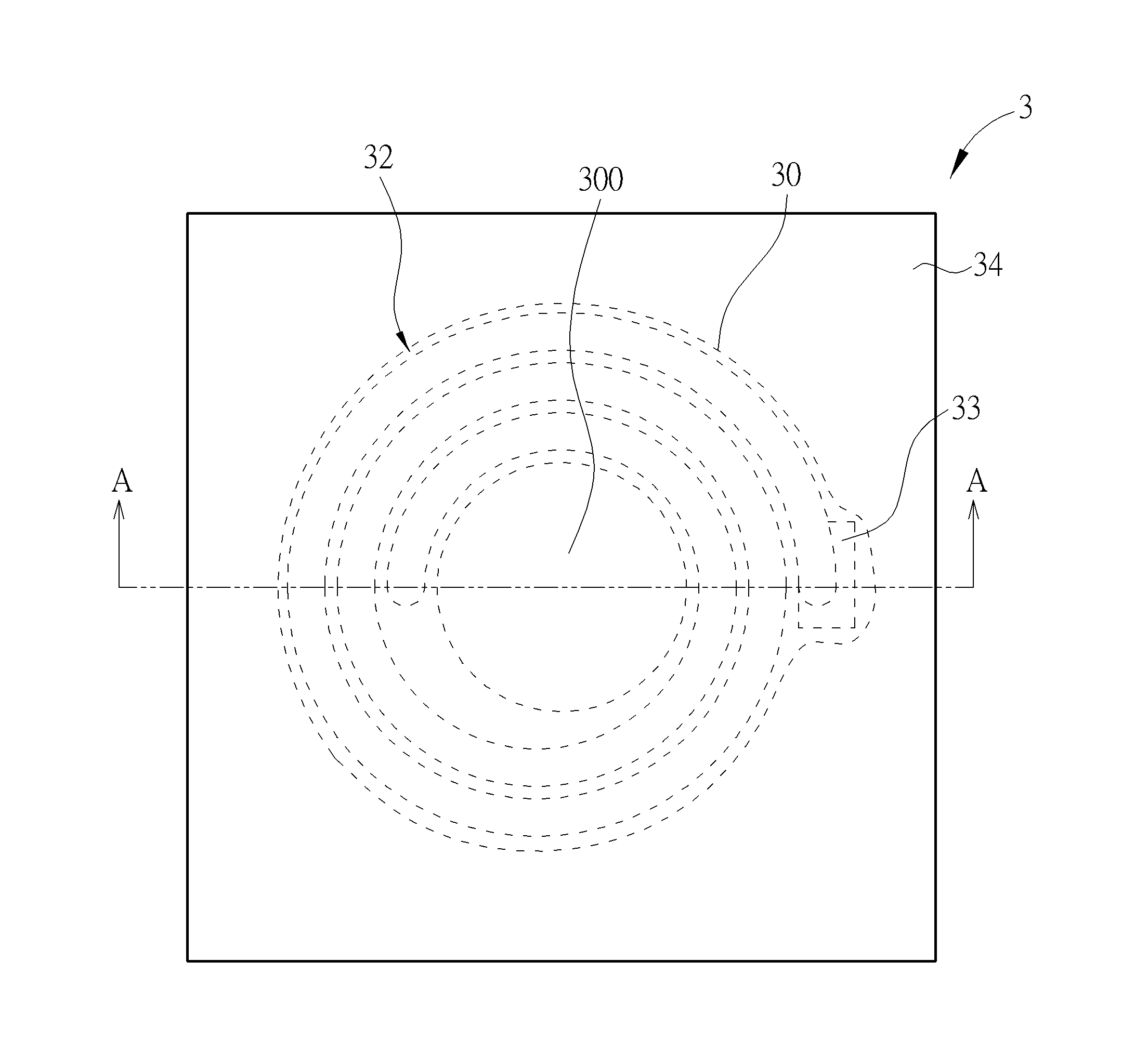

Wiring board and method for manufacturing the same

ActiveUS20060283629A1Easy to performIncrease cross-sectional areaPrinted electric component incorporationPrinted circuit aspectsEngineeringSemiconductor components

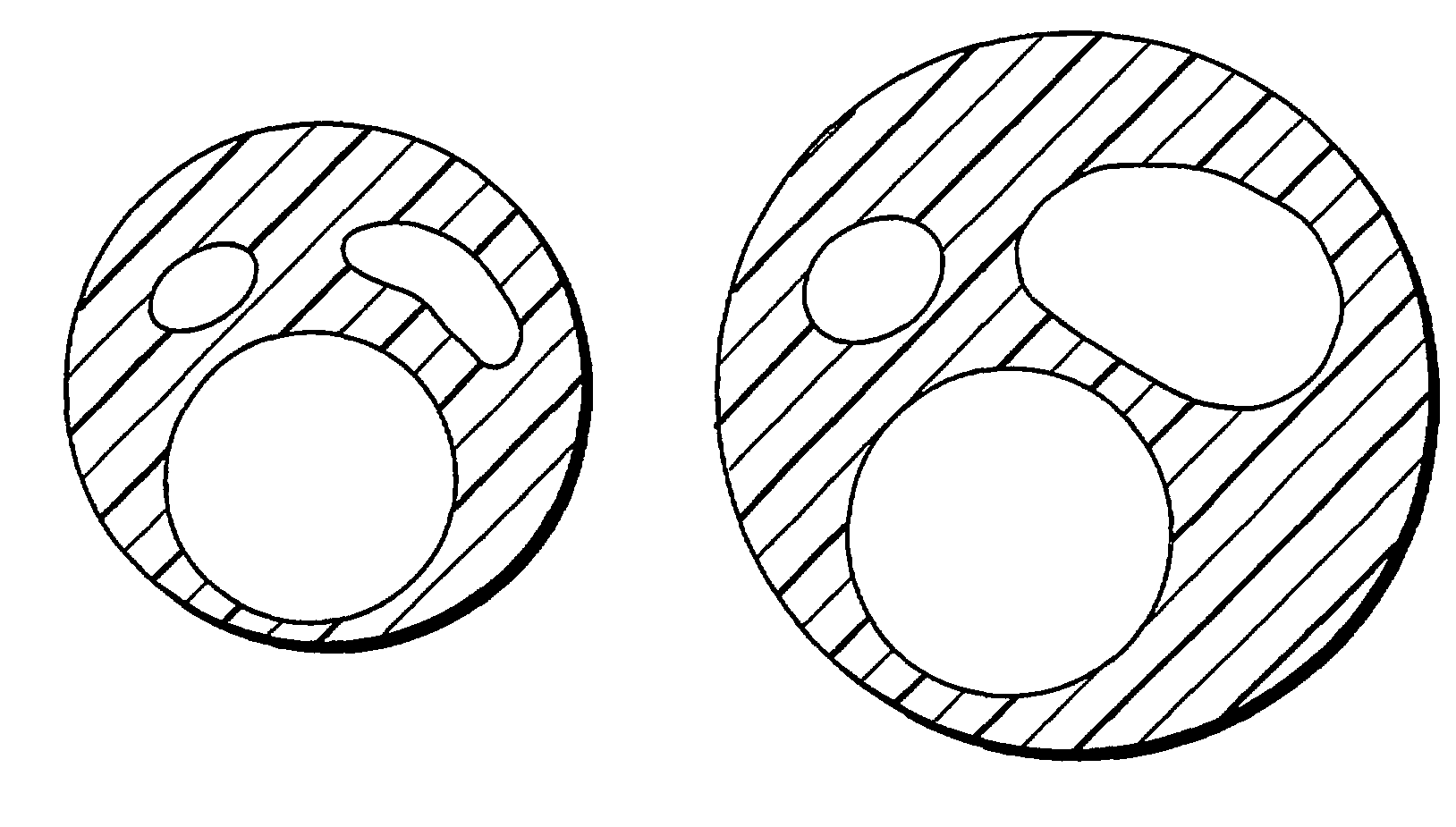

A wiring board for mounting a semiconductor element or electronic component having a plurality of wiring layers, an insulating layer provided between these wiring layers, and a via which is provided to the insulating layer and which electrically connects the wiring layers. In this wiring board, the cross-sectional shape of the via in the plane parallel to the wiring layers is obtained by the partial overlapping of a plurality of similar shapes (circles). Stable operation can be obtained in a semiconductor element by minimizing obstacles to increased density, effectively increasing the cross-sectional area of the via, and preventing the wiring resistance from increasing by making the cross-sectional shape of the via into a shape obtained by the partial overlapping of a plurality of similar shapes.

Owner:RENESAS ELECTRONICS CORP

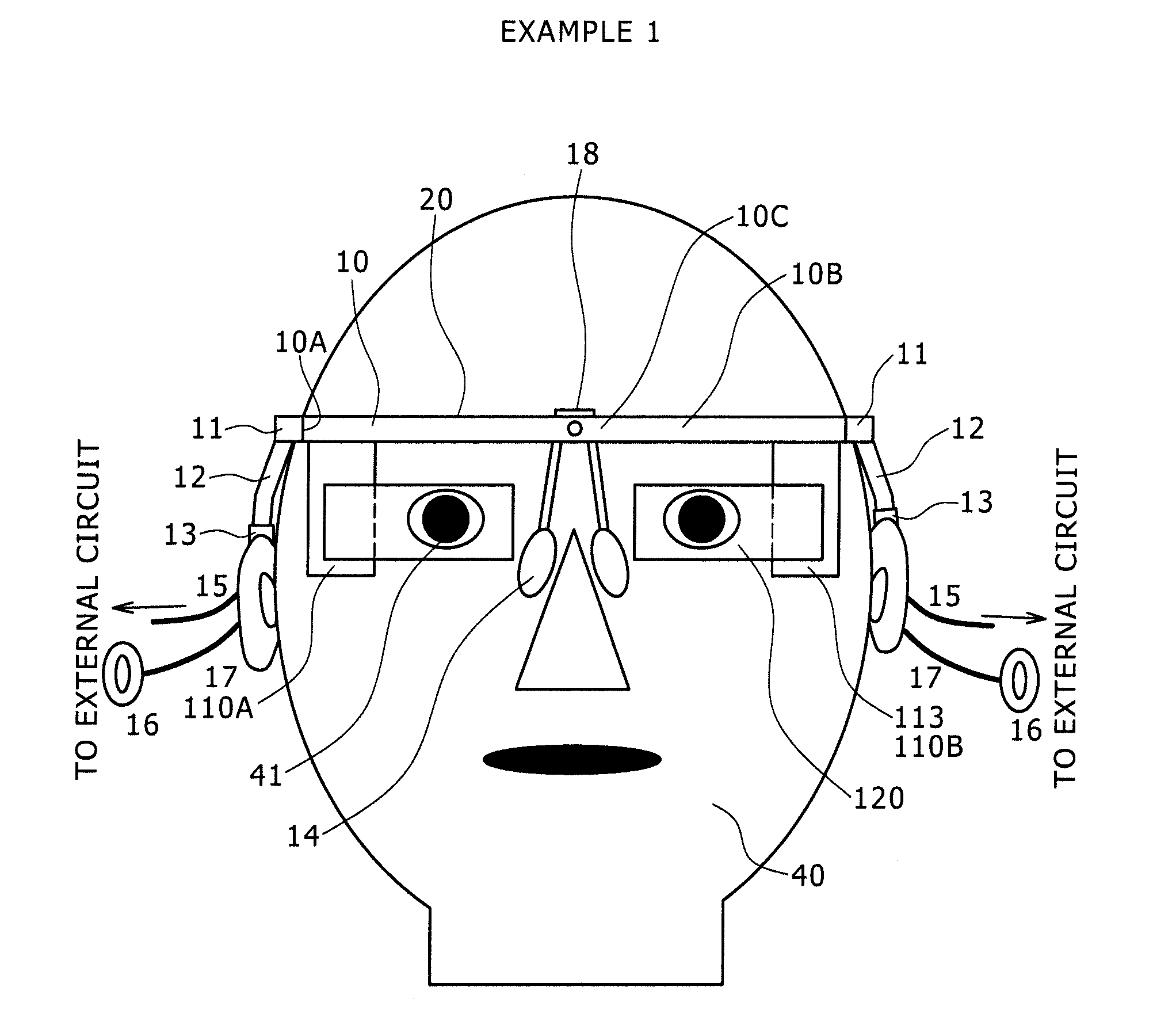

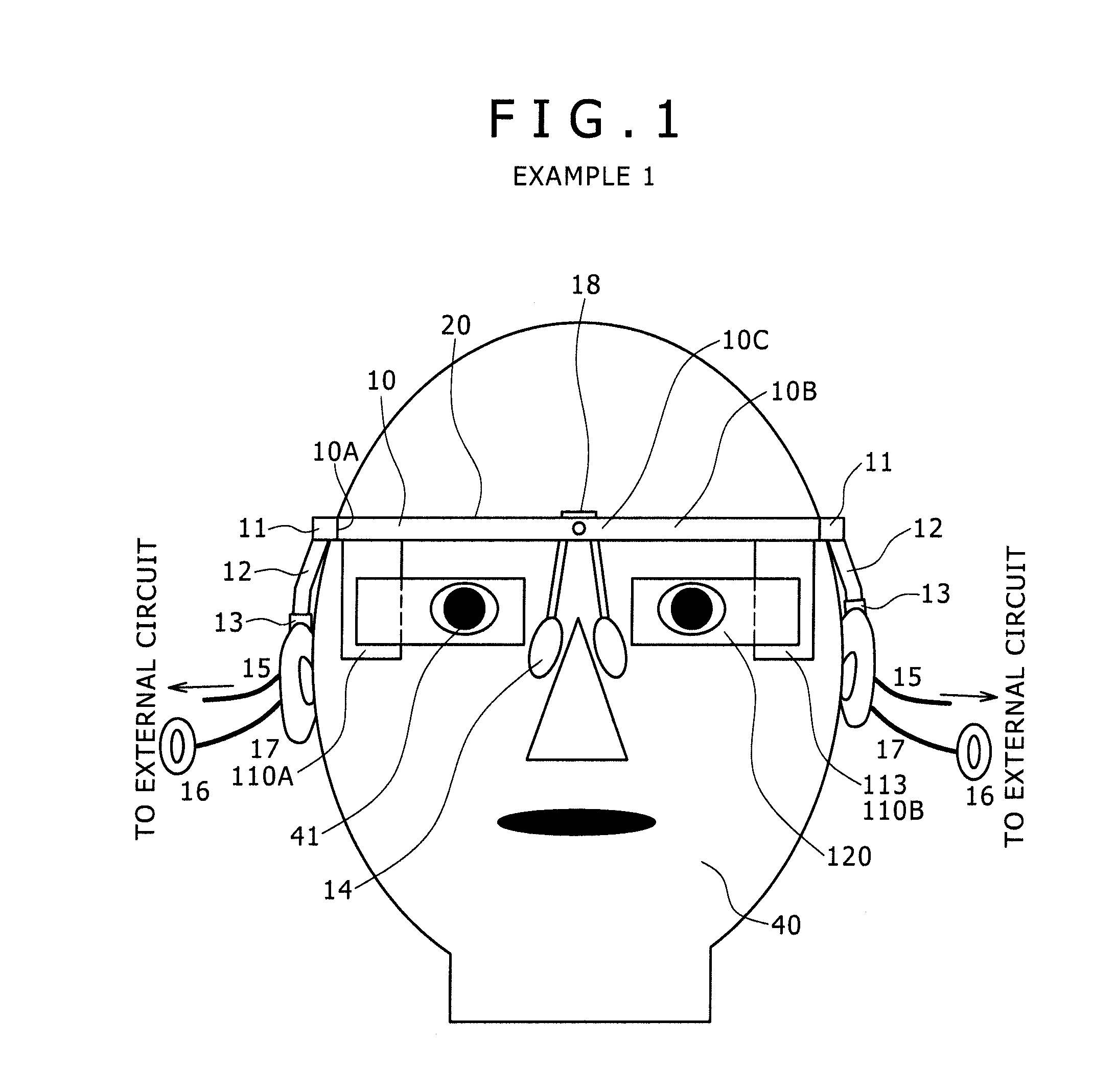

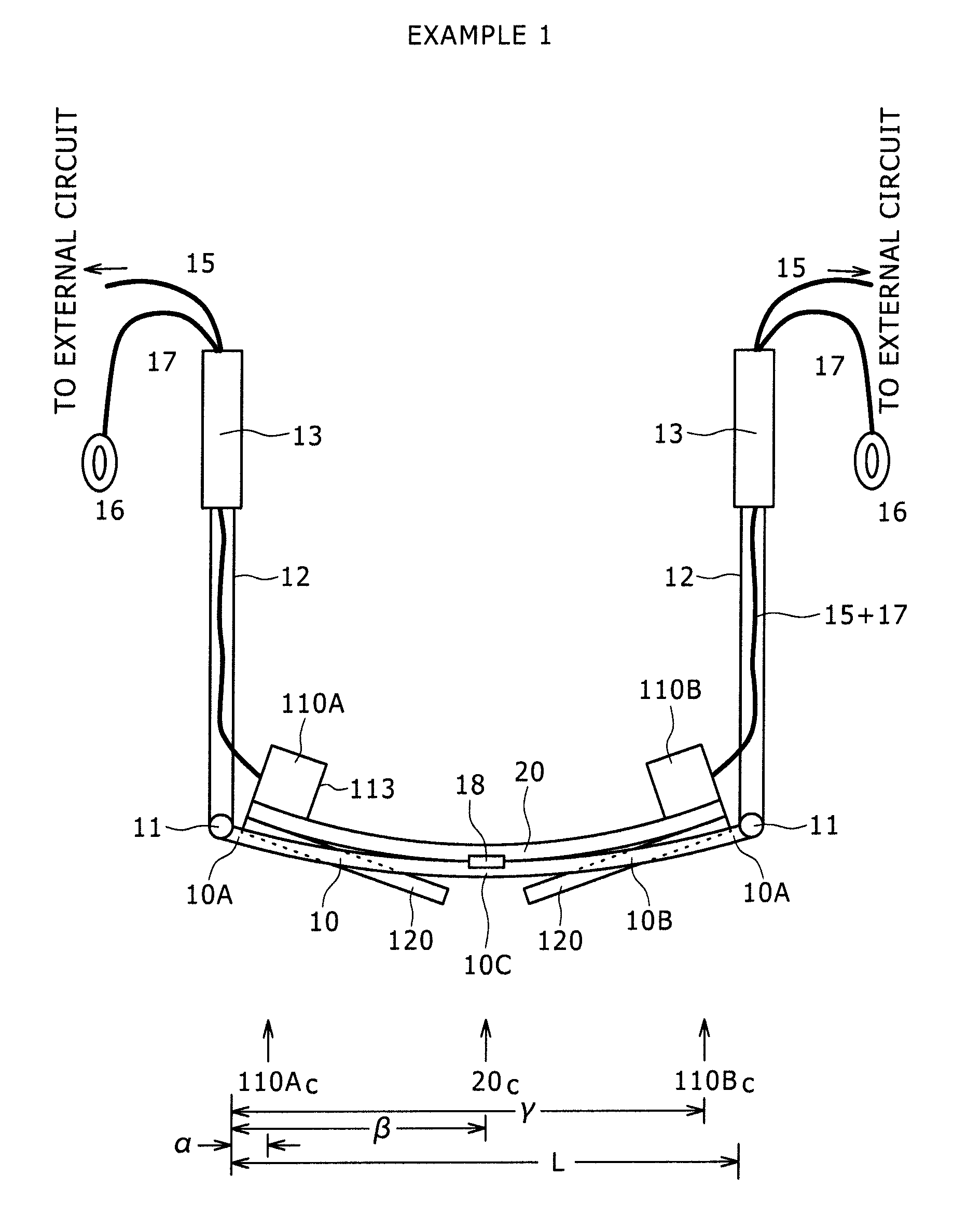

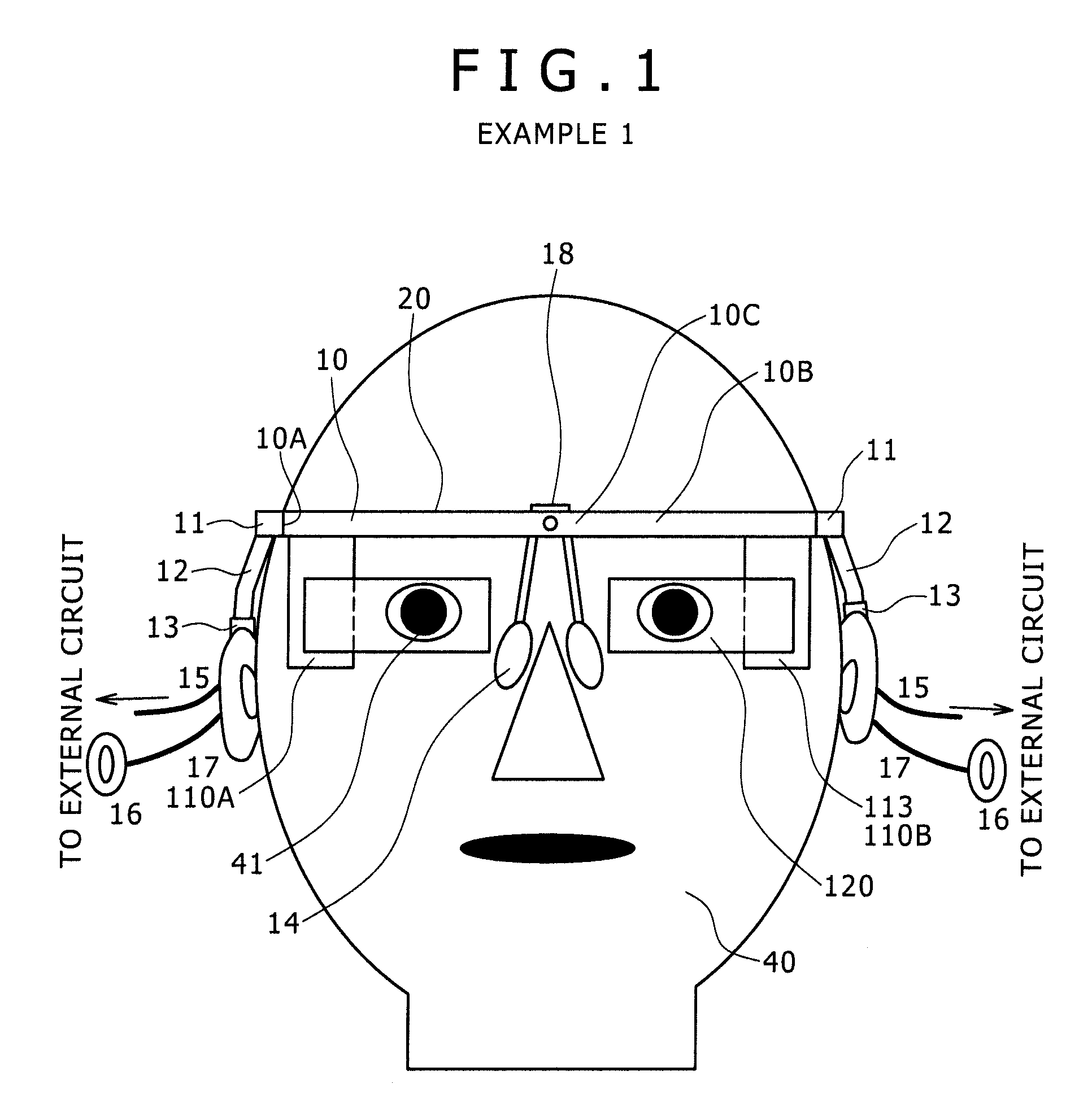

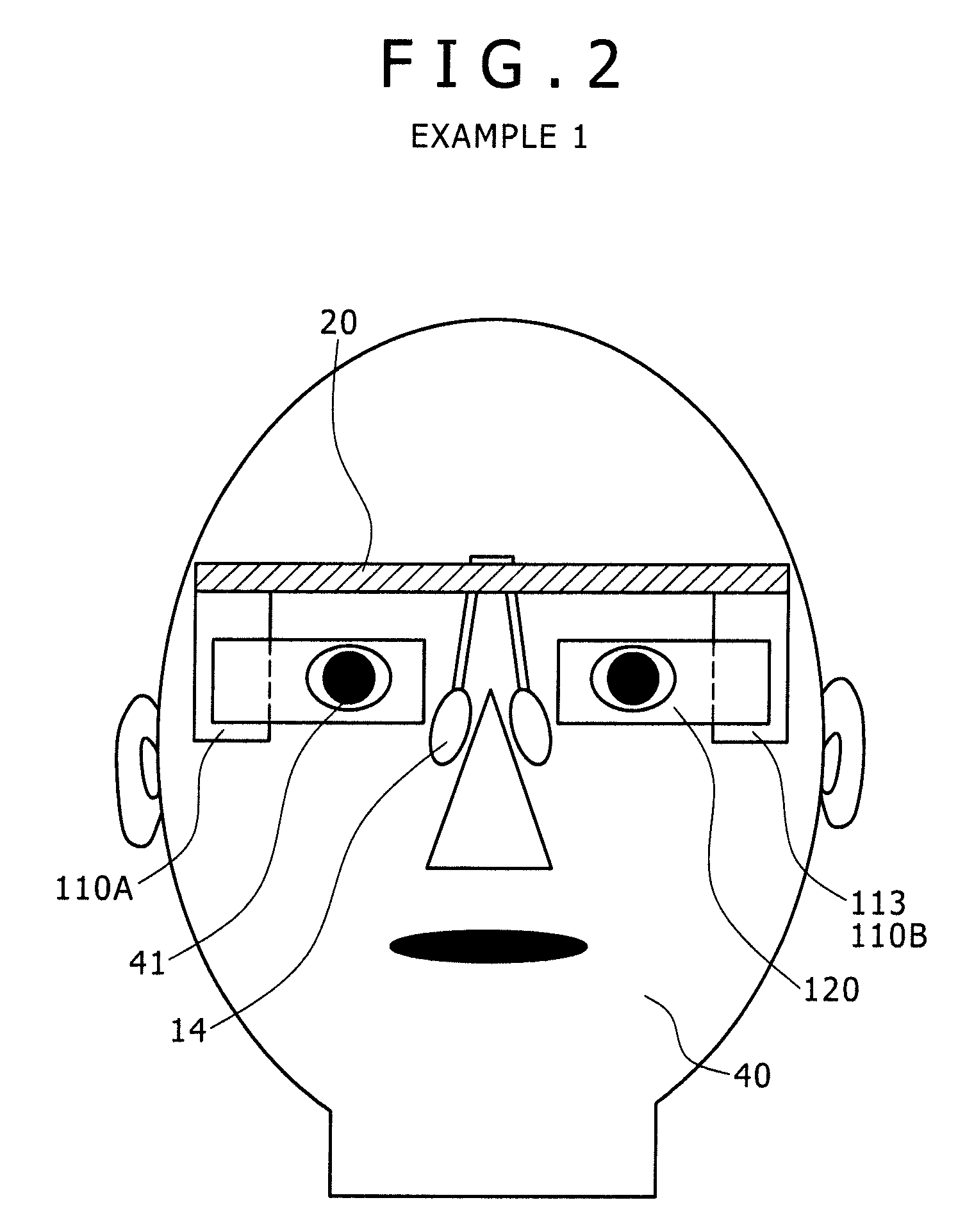

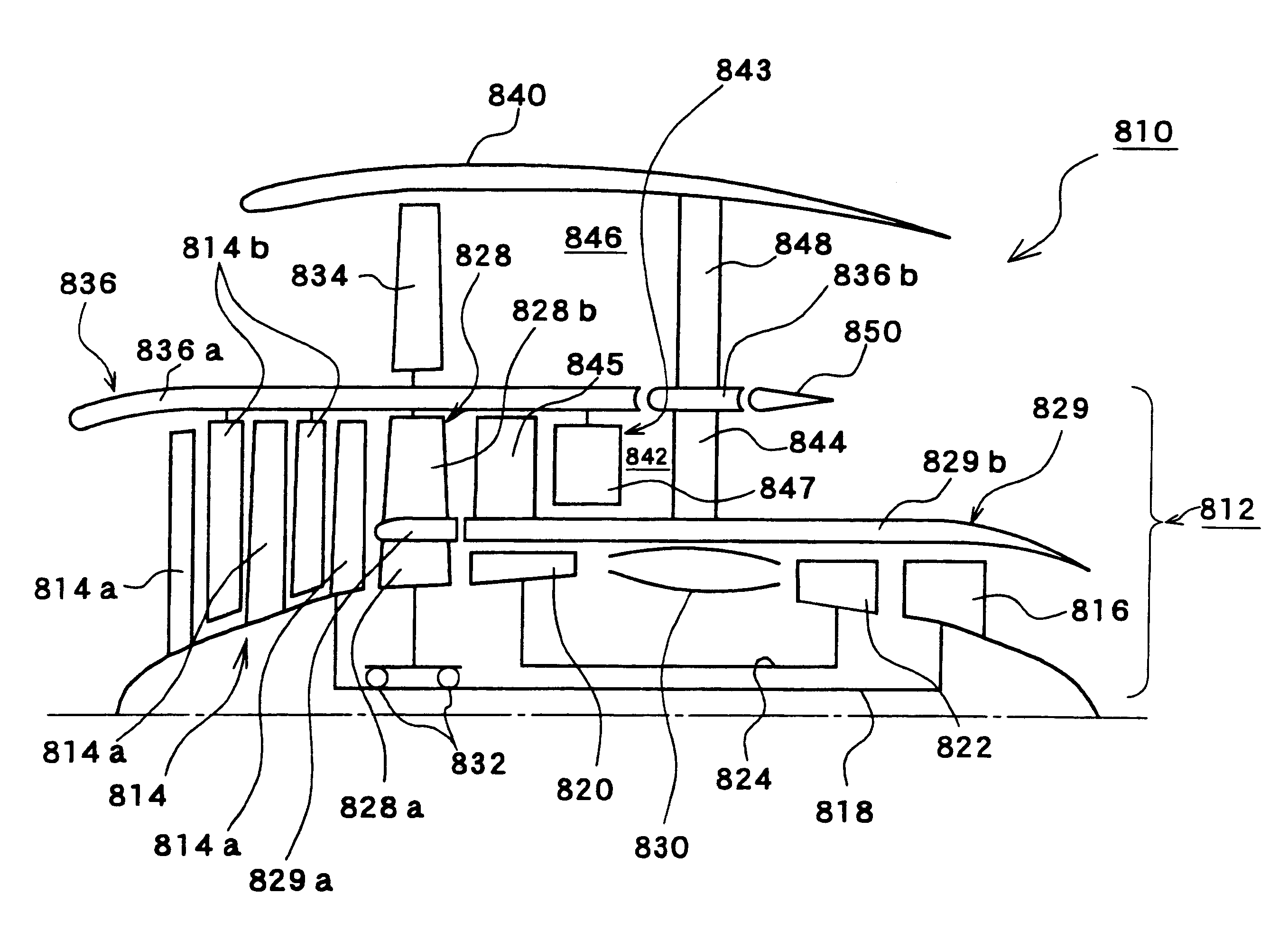

Head mounted display

ActiveUS20100157433A1Increased frame weightIncrease freedomNon-optical adjunctsProjectorsHead worn displayLight guide

Disclosed herein is a head mounted display including: an eyeglasses frame-like frame to be mounted onto an observer's head; and two image display devices, each of the image display devices including an image generating device, and light guide means which is mounted to the image generating device, which as a whole is located on the side of the center of an observer's face relative to the image generating device, on which beams emitted from the image generating device are incident, through which the beams are guided, and from which the beams are emitted toward an observer's pupil.

Owner:SONY CORP

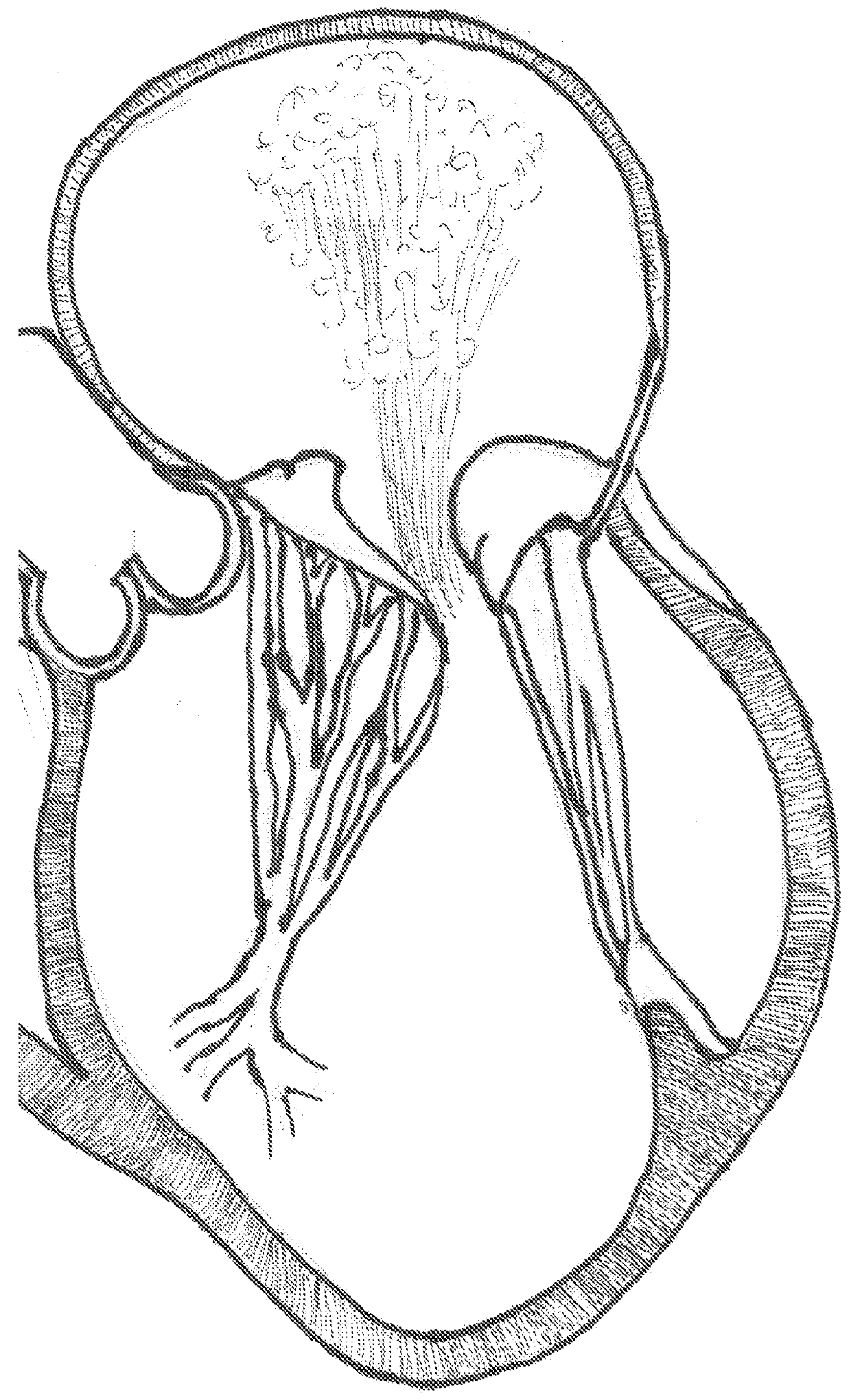

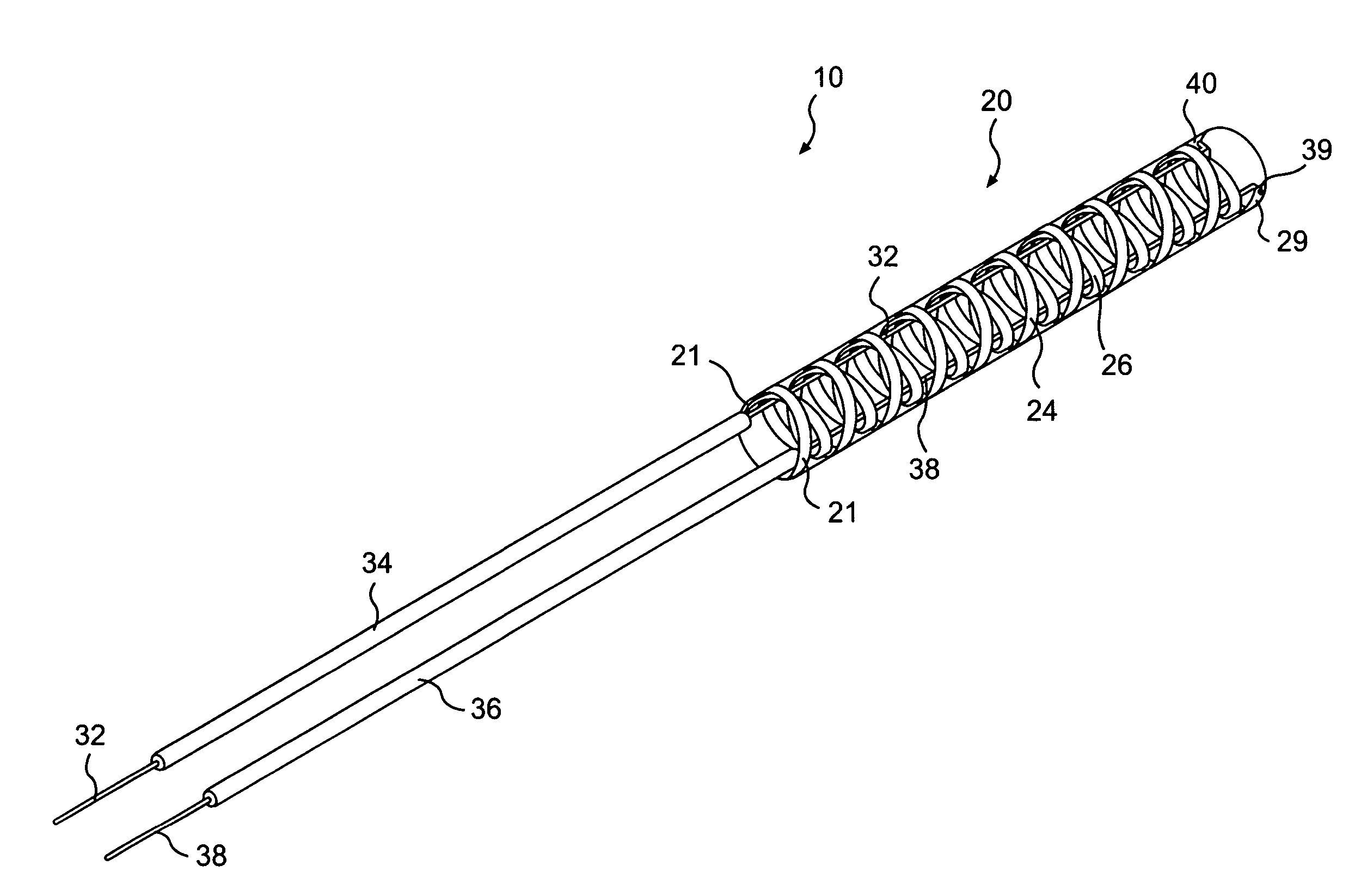

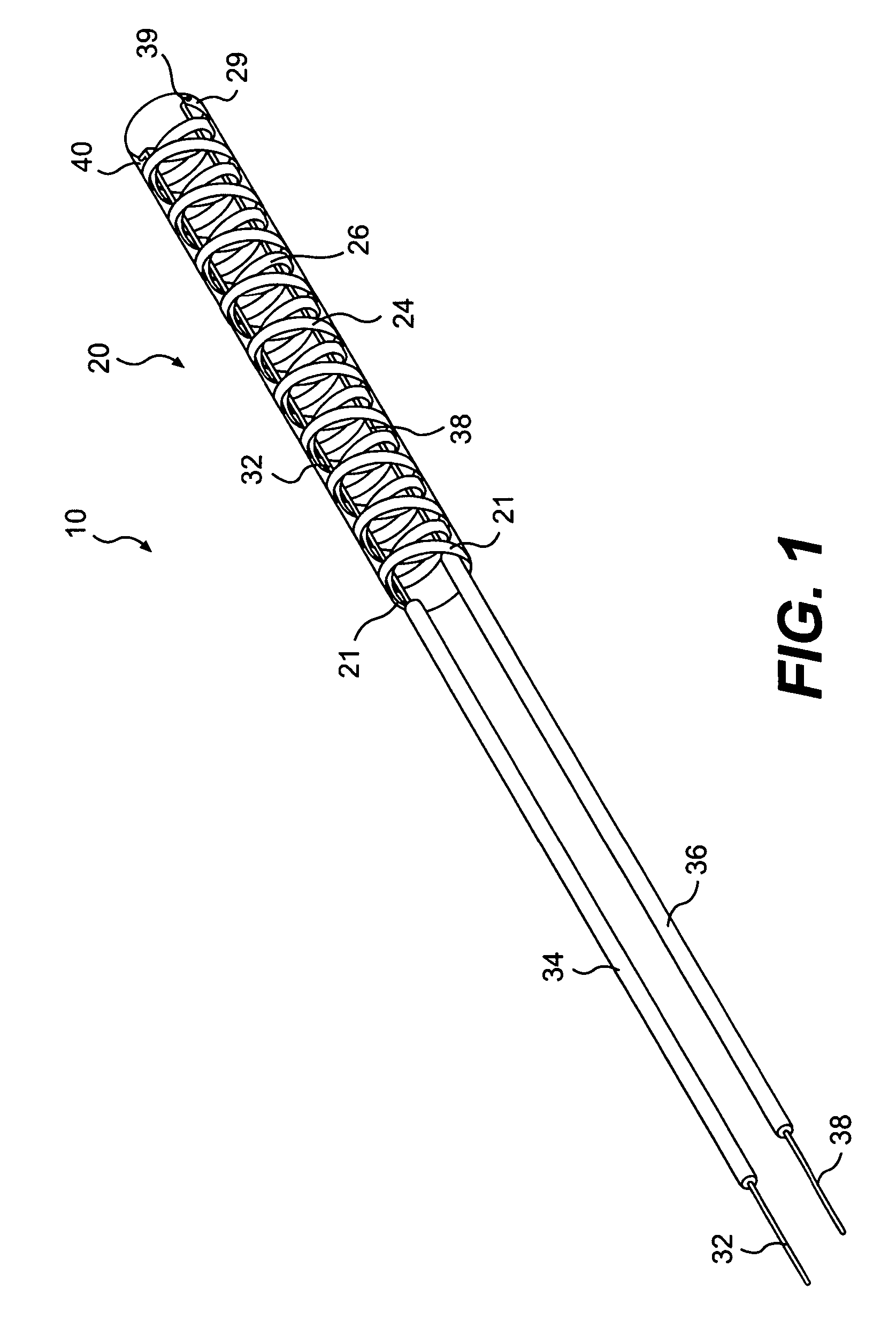

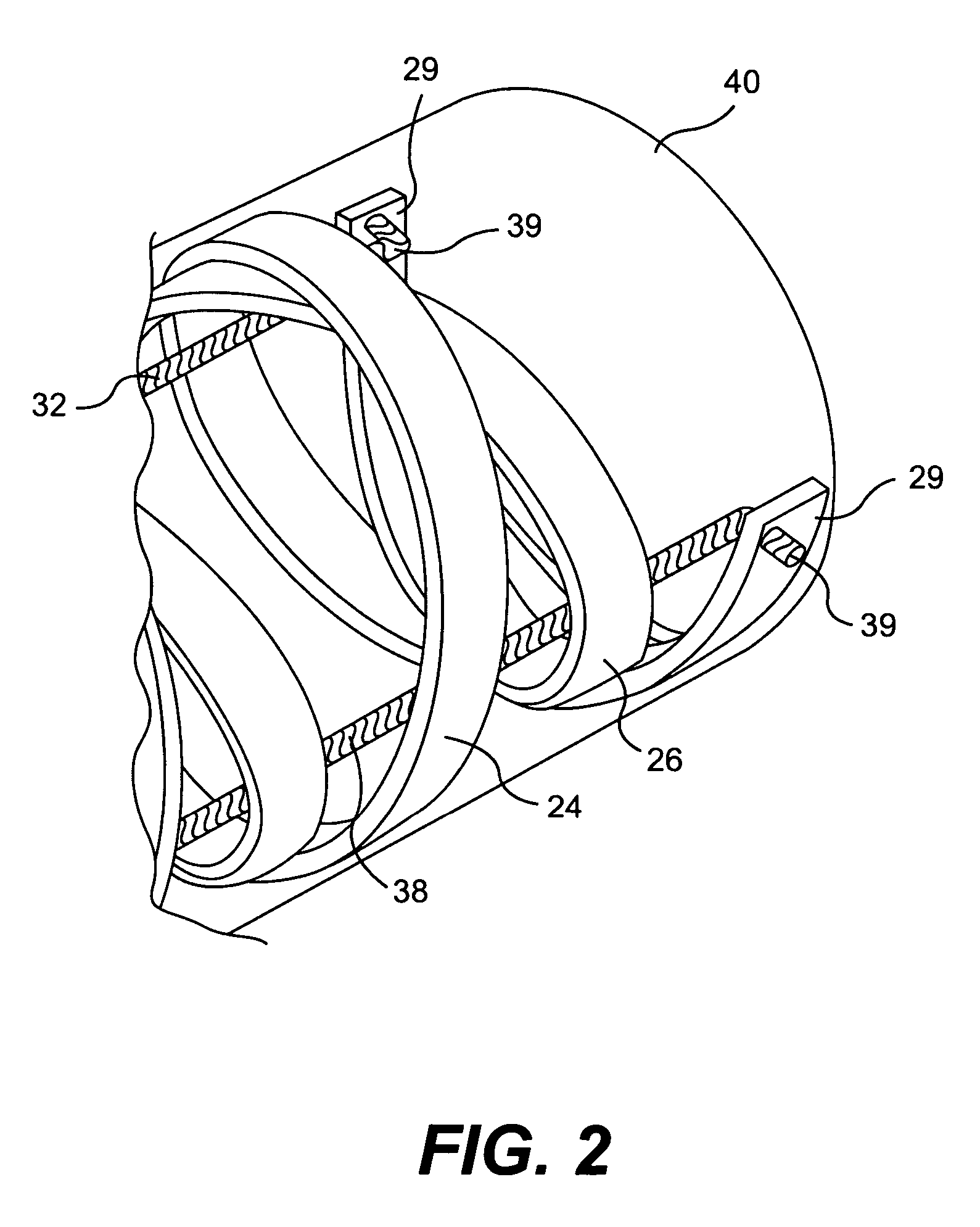

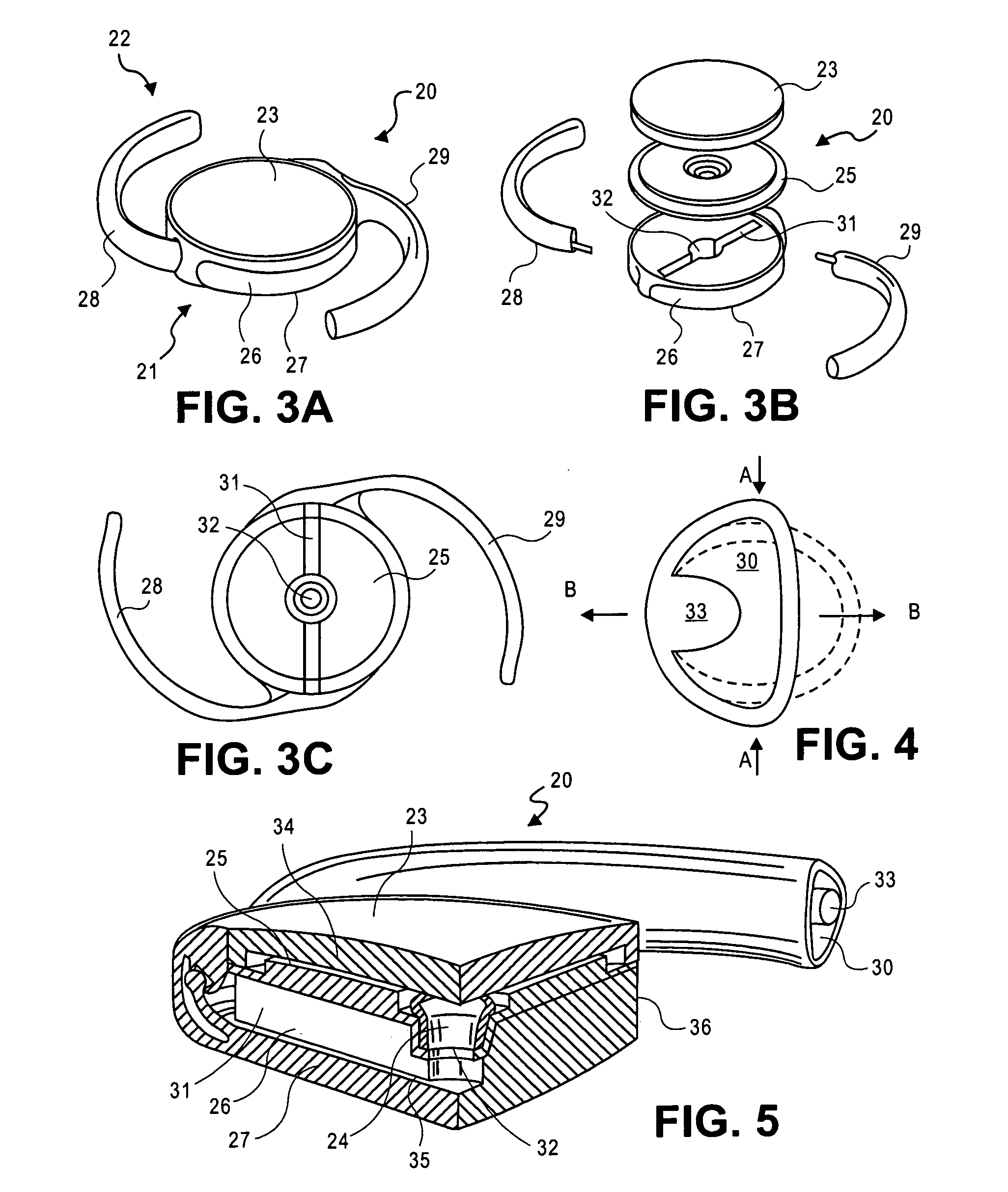

Catheter-guided replacement valves apparatus and methods

ActiveUS20160030171A1Reduced overall height dimensionMinimize intrusionStentsHeart valvesStructure and functionCatheter

The present invention is a replacement mitral valve suitable for catheter-based deployment. The replacement mitral valve has structure and dimensions that are uniquely suited to engage the annulus surrounding the native mitral valve and to restore normal function to a diseased valve. The invention describes the structures and functions of a replacement mitral valve and methods that are adapted for minimally invasive, catheter-based deployment of the valve.

Owner:NAVIGATE CARDIAC STRUCTURES

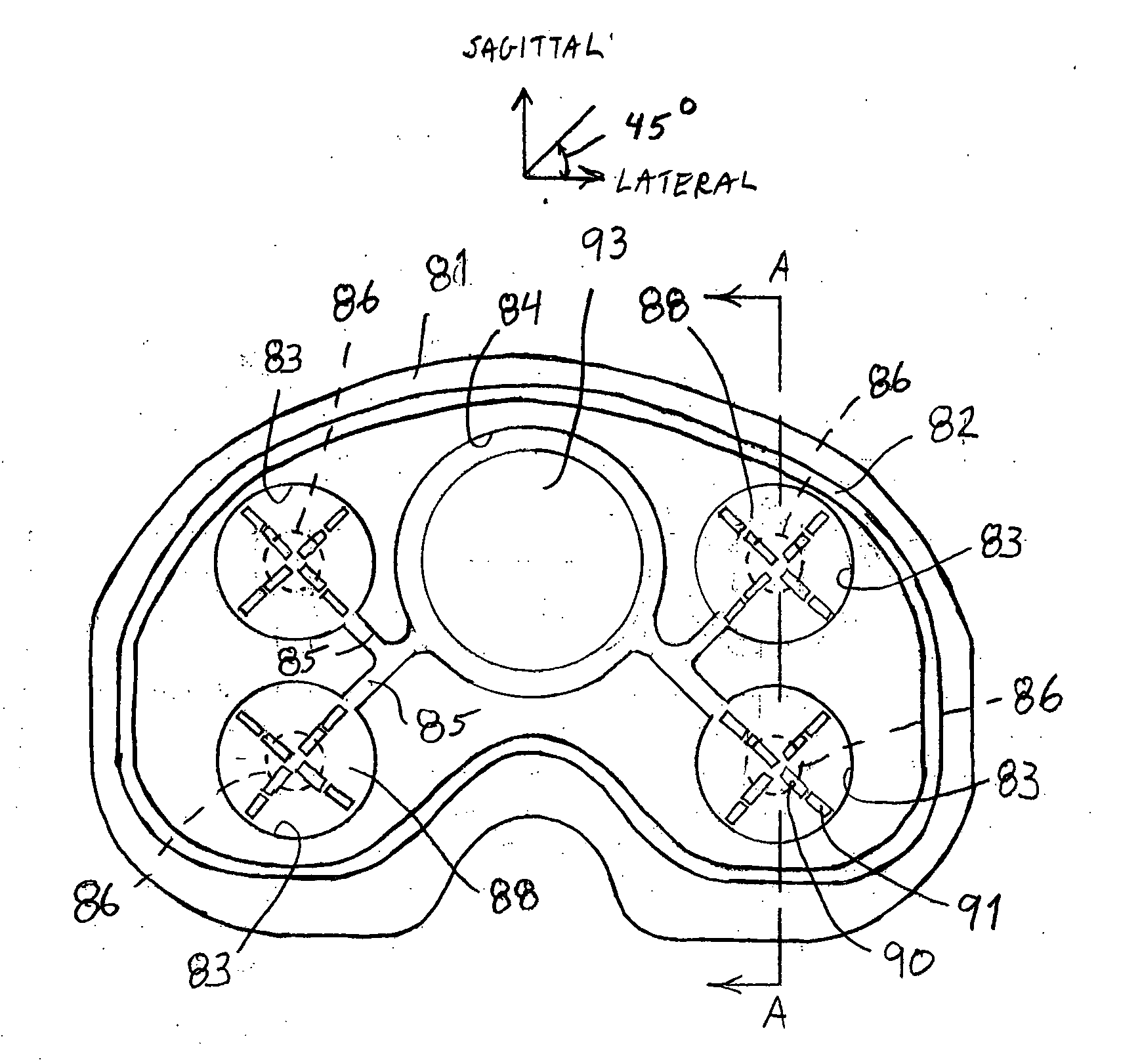

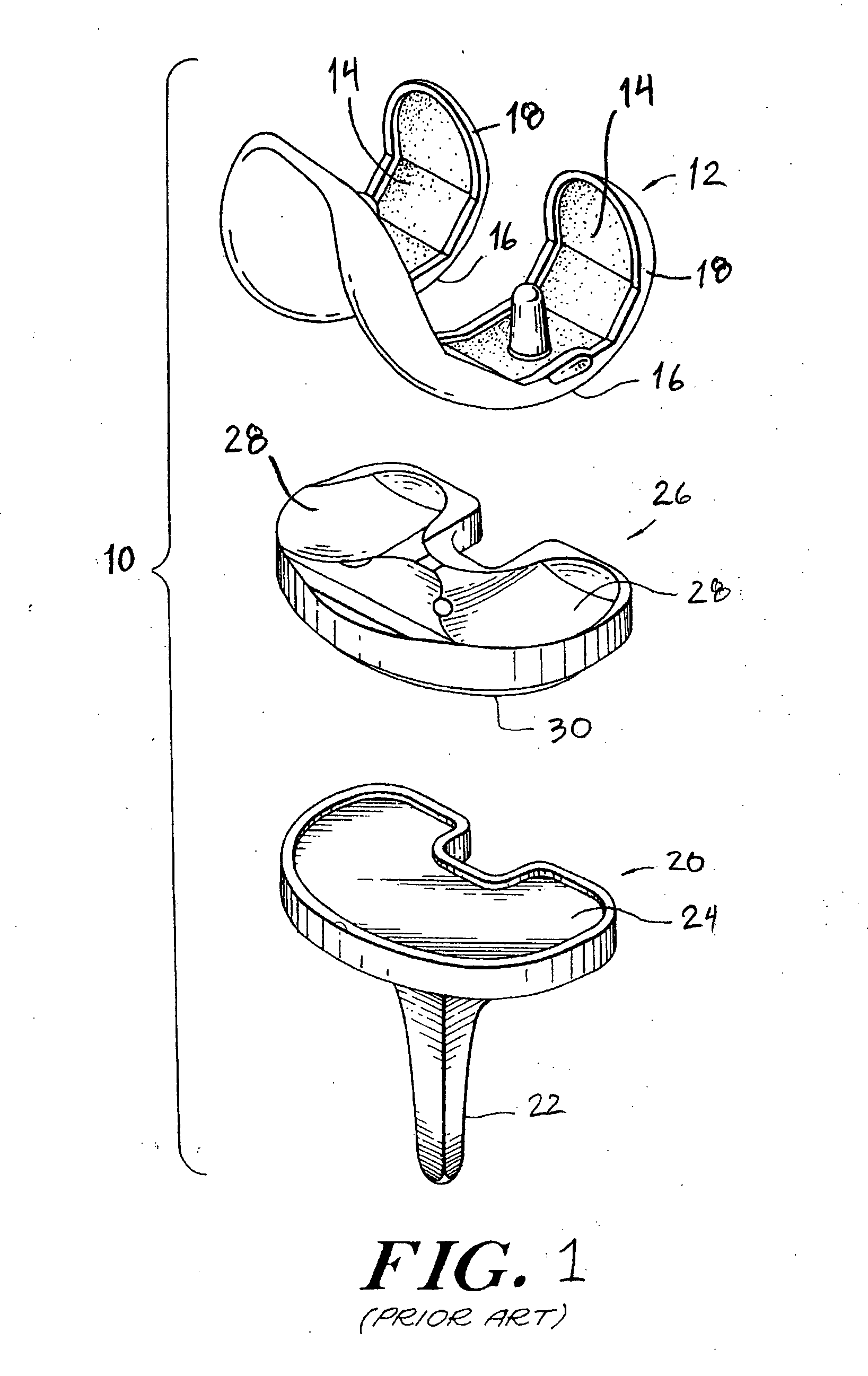

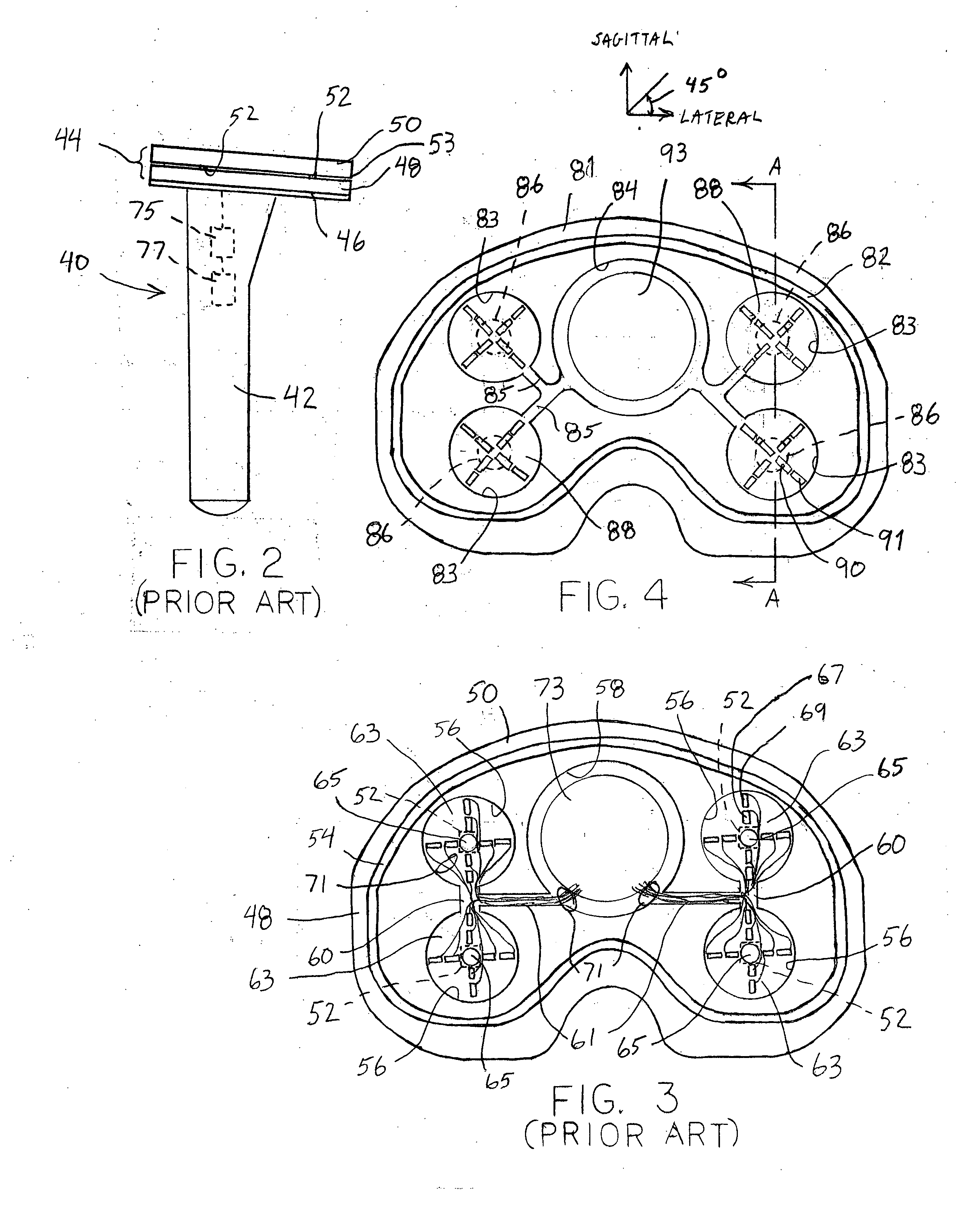

Telemetric tibial tray

ActiveUS20050010302A1Reduce riskEliminates stress riserSurgeryPerson identificationStrain rateKnee Joint

A telemetric tibial tray includes a lower plate that defines a plurality of cylindrical transducer cavities having circular load diaphragms. An upper plate is attached to the lower plate through support posts projecting from the load diaphragms. The support posts have a circular cross-section and a diameter of about 5.0 mm. The lower plate further defines wiring channels communicating between the transducer cavities and a central cavity housing the circuit board for the telemetric tray. The wiring channels are arranged at a 45 degree angle relative to the sagittal plane of the knee joint in order to reduce the effects of the wiring channel intersection on the strain sensitivity of the tray. Each transducer cavity includes a radial strain gage array with four pairs of radially aligned strain gages, each pair aligned at a 45 degree angle relative to the sagittal plane of the knee joint. Each pair of strain gages includes an inner gage positioned at the point of maximum positive micro-strain across the diaphragm when loaded, and an outer gage positioned at the point of maximum negative micro-strain, to thereby increase the differential strain measured by the gages and increase the strain sensitivity of the tibial tray.

Owner:DEPUY PROD INC

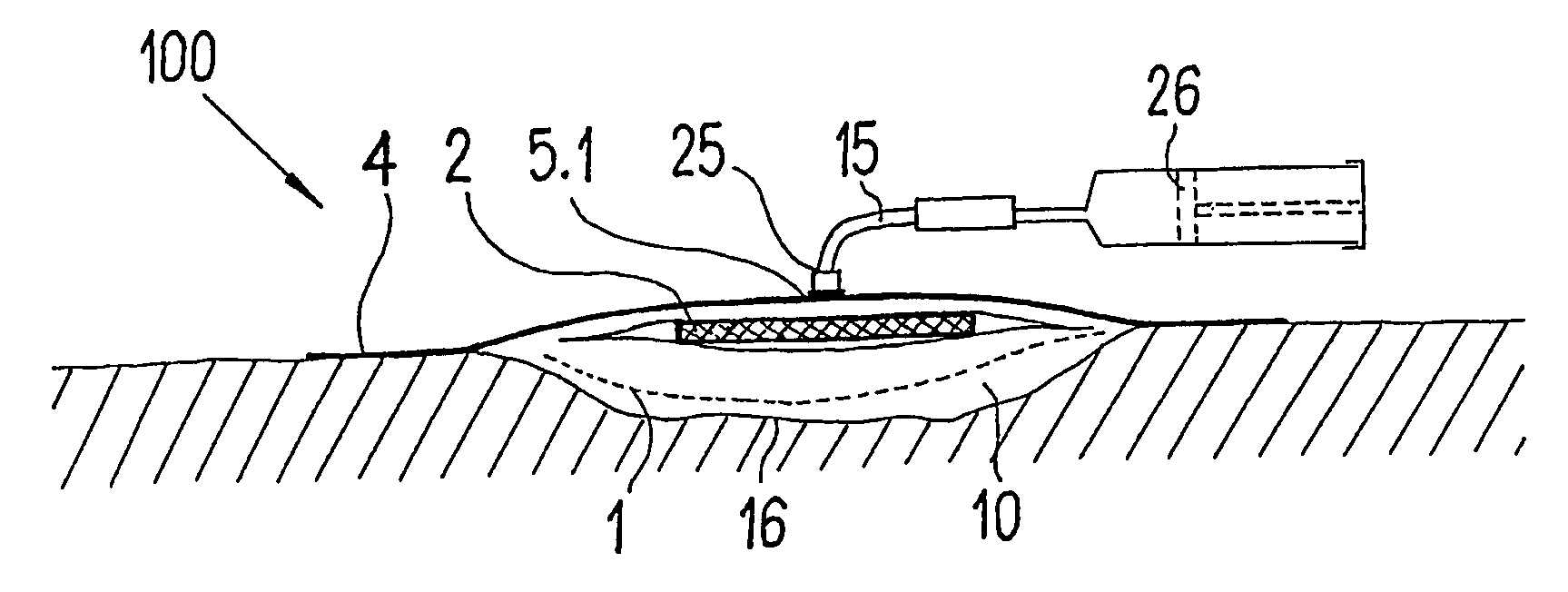

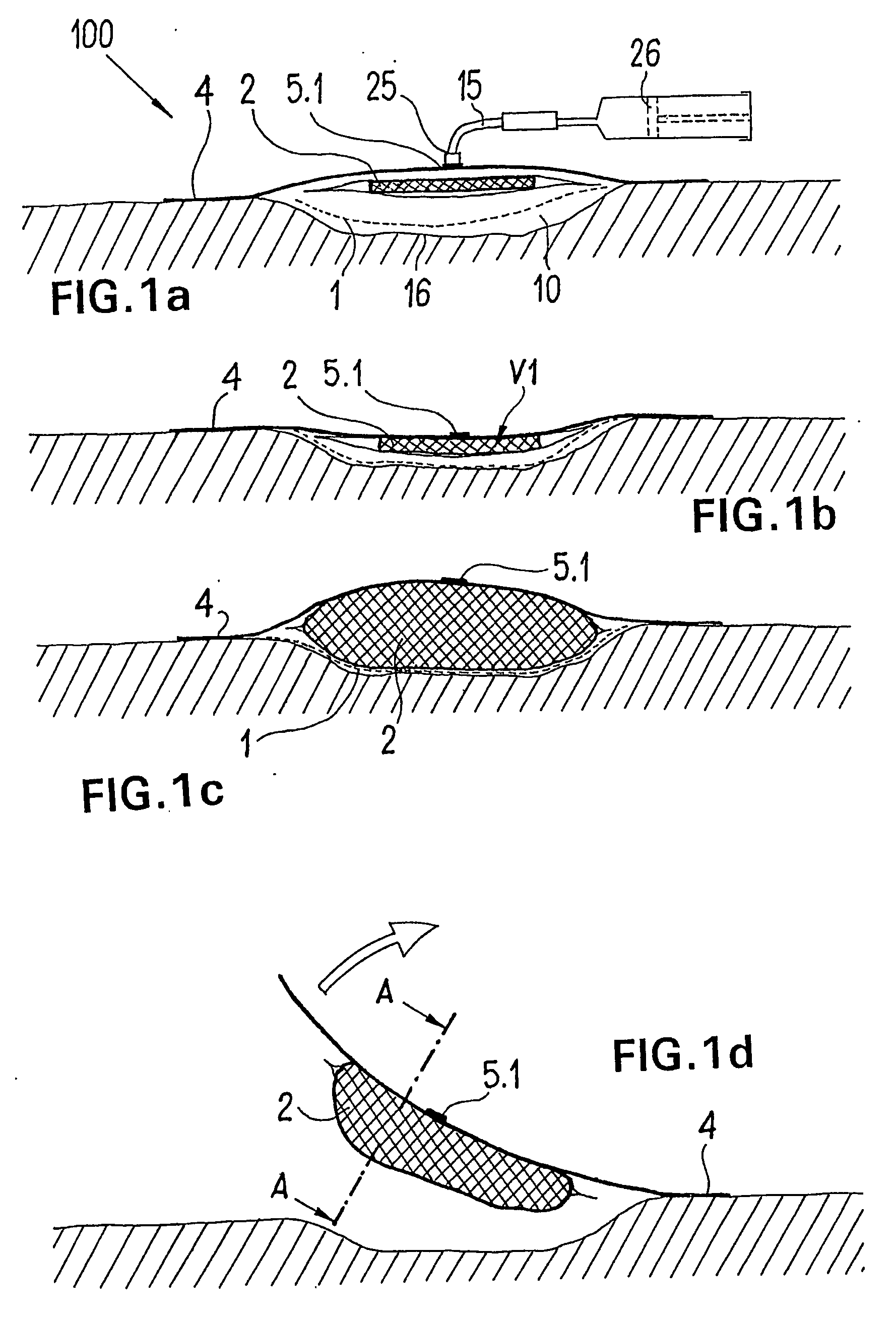

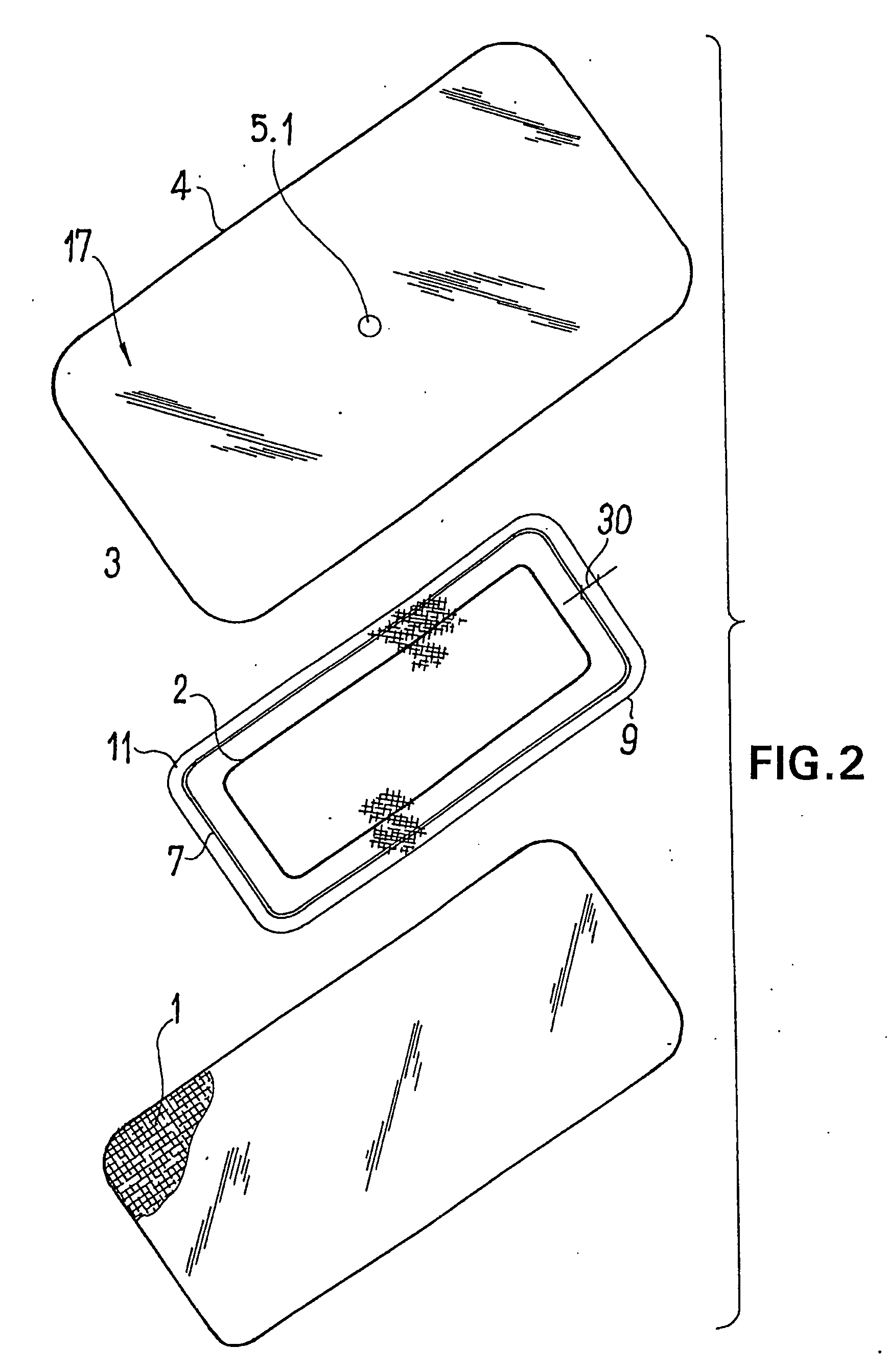

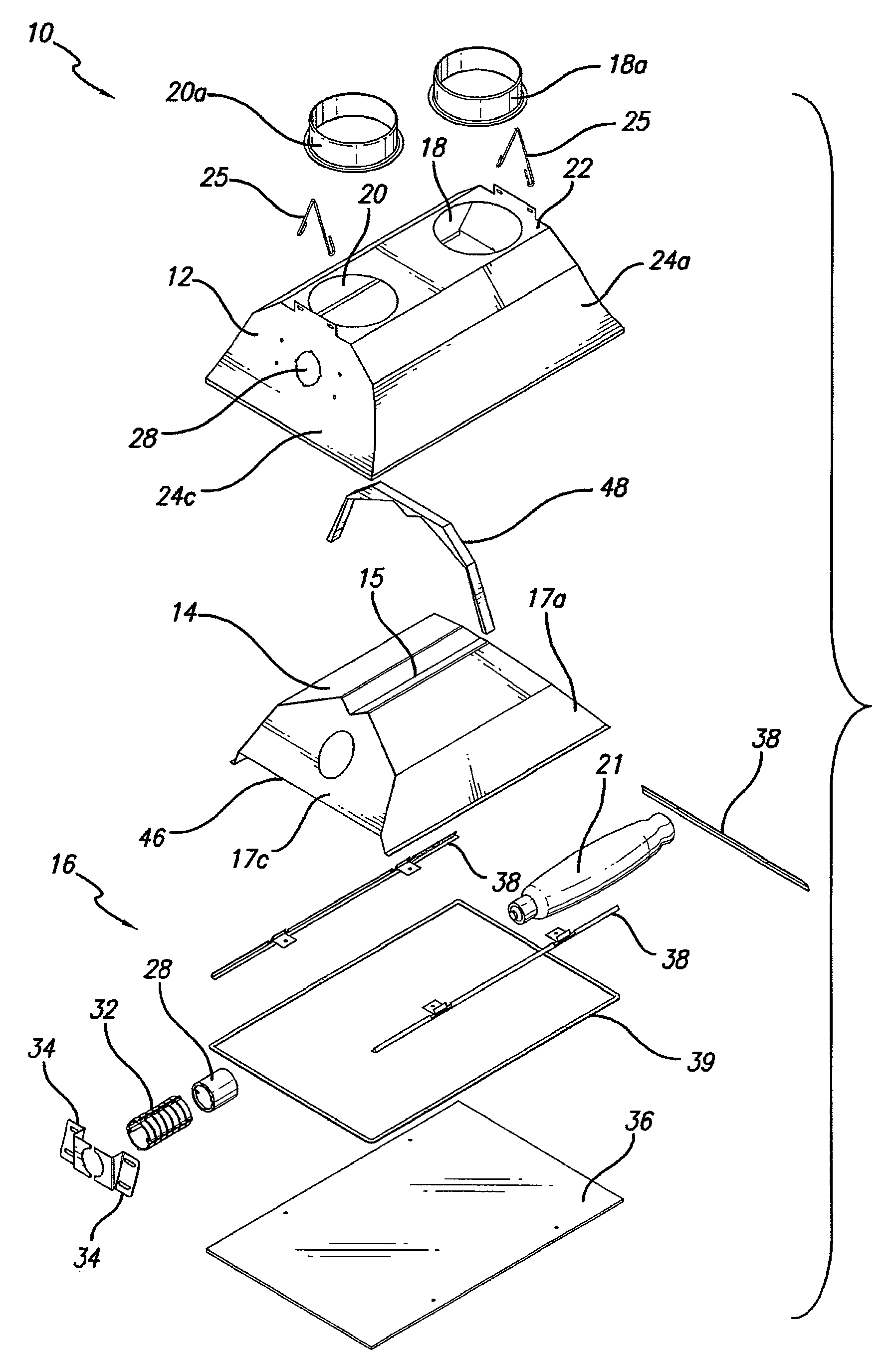

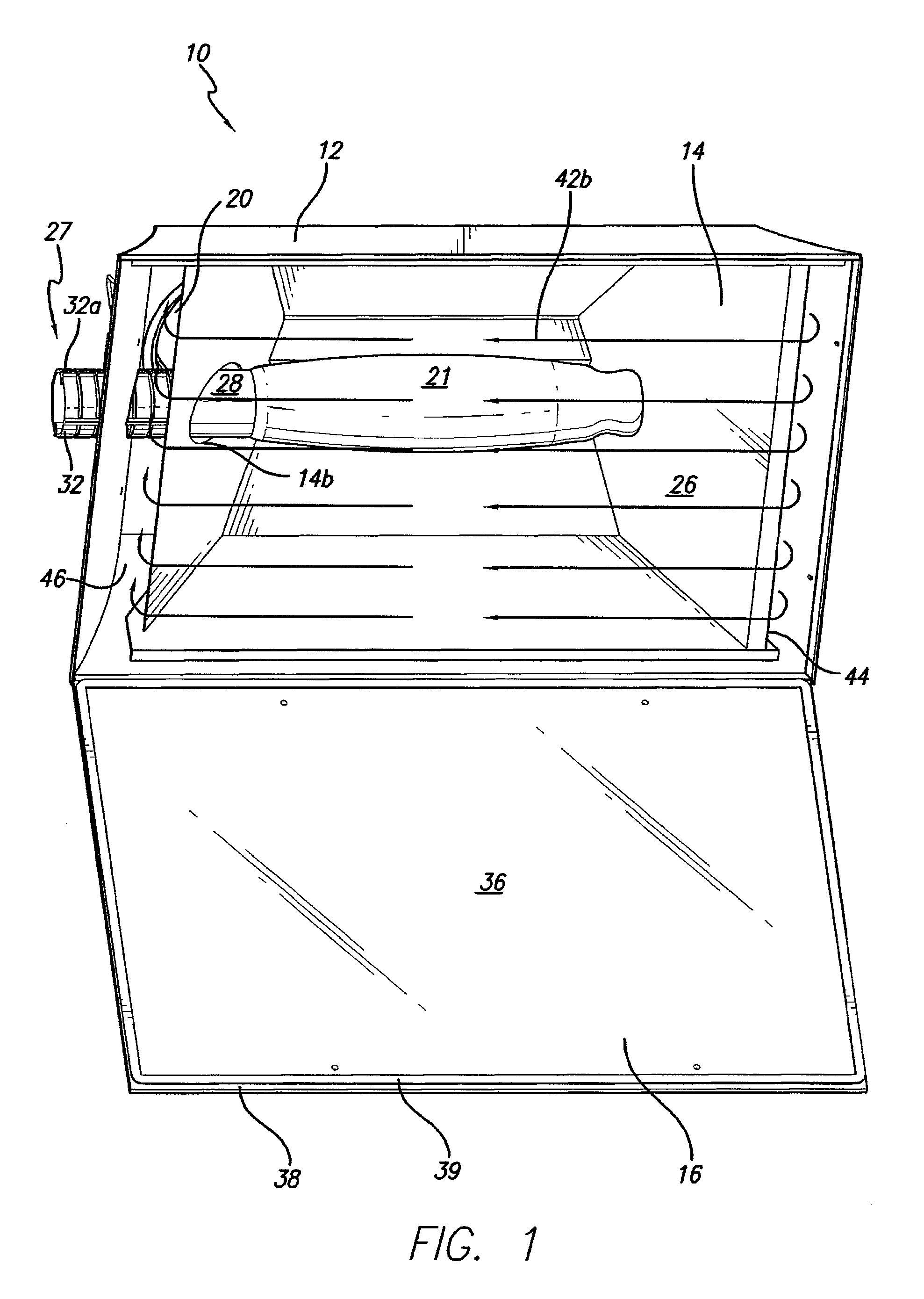

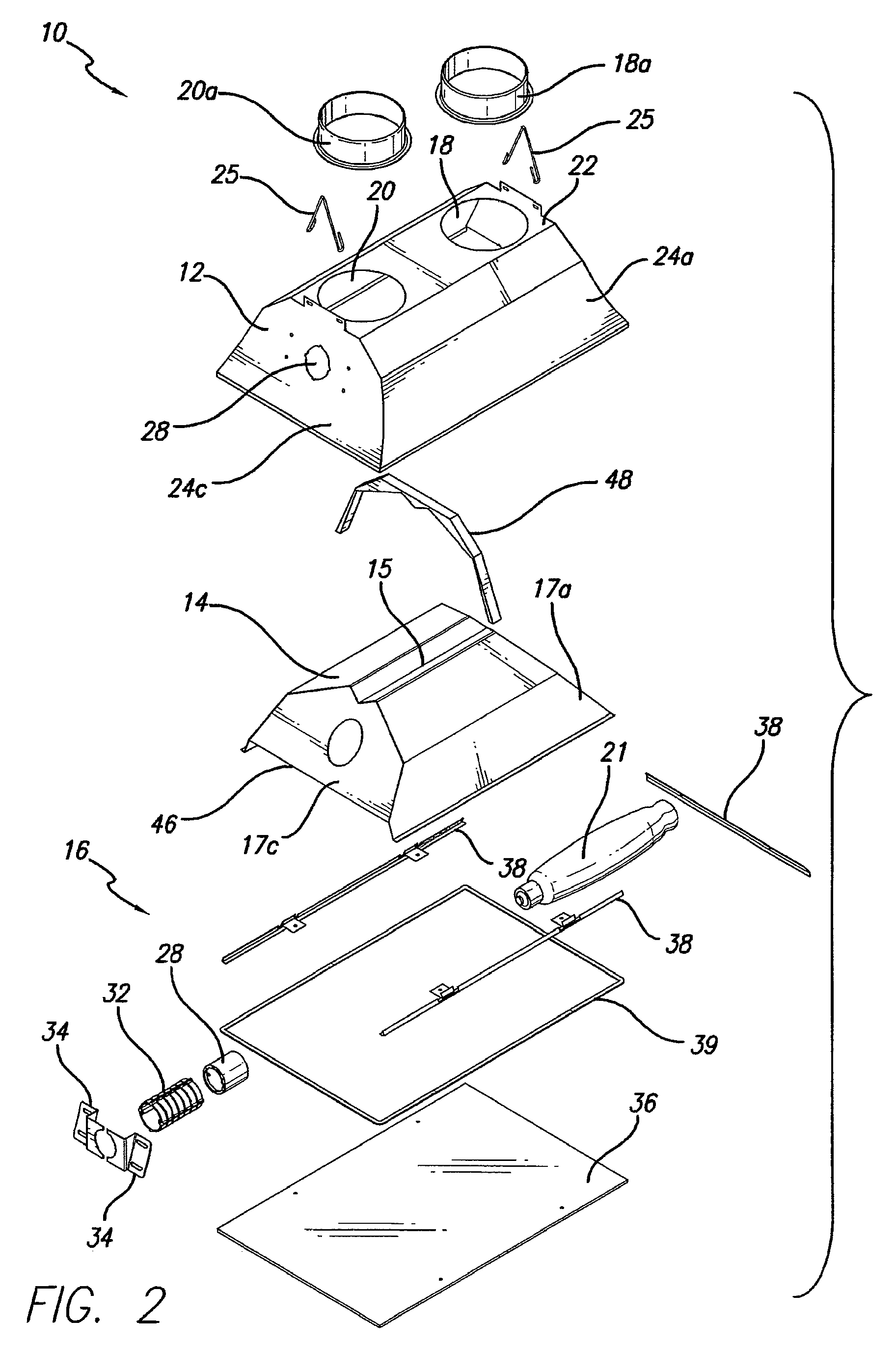

Device for the Treatment of Wounds Using a Vacuum

ActiveUS20080009812A1Cost effectiveSimple designNon-adhesive dressingsPlastersSecretionSecreted substance

The invention relates to a device (100) for treating wounds of the human or animal body using a vacuum and having a gas-tight wound-covering element (4), which, when placed in contact with the body of the patient, forms a wound space (10) between the respective wound and the wound-covering element, at least one connecting site (5.1; 5.2), which is in contact with the wound space (10), an absorption body (2), which is a layer, enclosed in an envelope, of a textile section, interspersed with super-absorbing particles, the envelope being permeable to liquids and having pores, the size of which does not exceed that of the super-absorbing particles. The absorption body (2), which is to be inserted in the wound space (10), has an initial volume, which enlarges in the course of the absorption process, and a final volume, so that, due to the size of the pores of the envelope, the absorbed wound secretions remain within the absorption body (2) and, with that, below the wound-covering element, until the absorption body is removed from the wound space.

Owner:BSN MEDICAL GMBH & CO KG

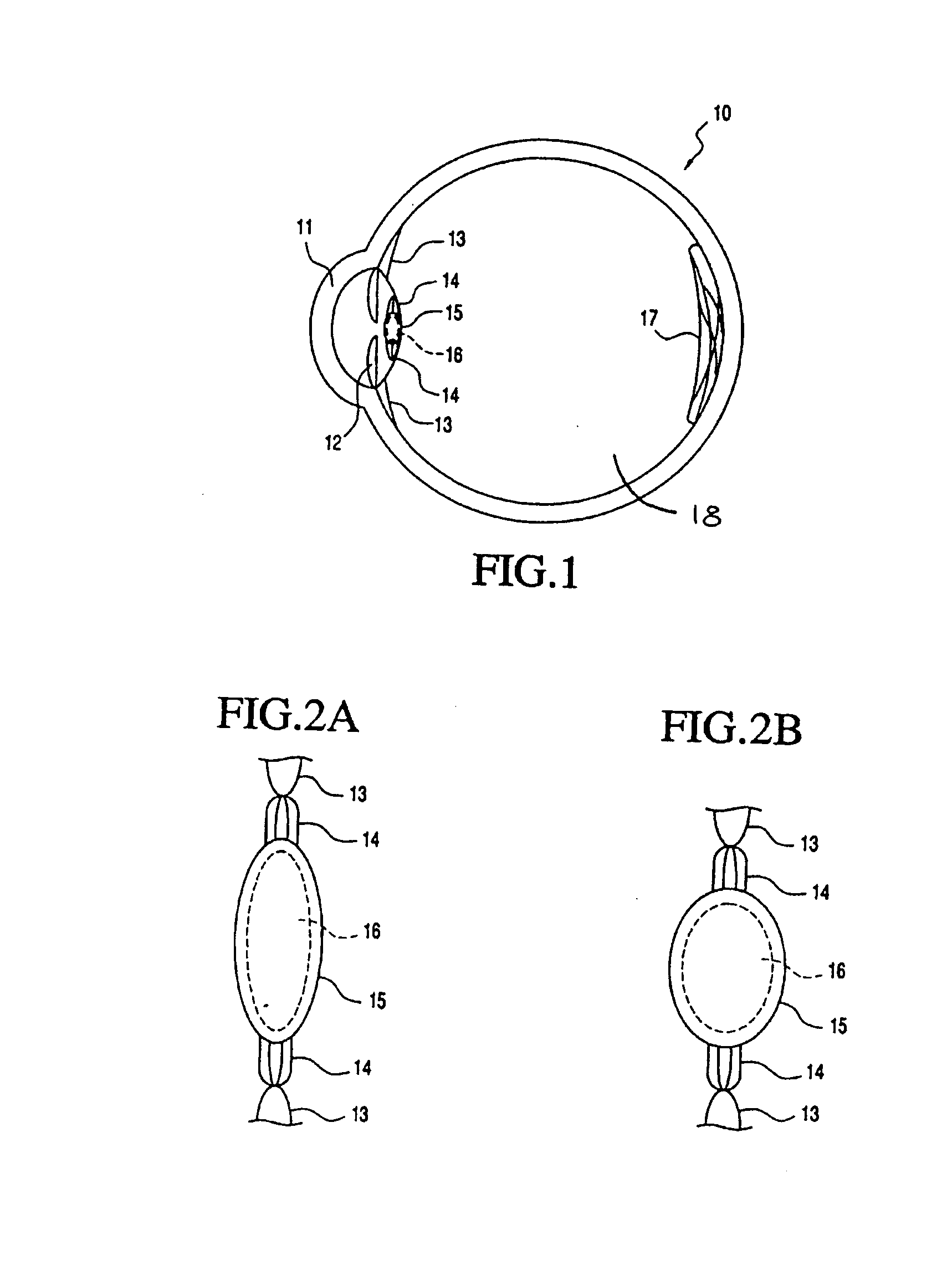

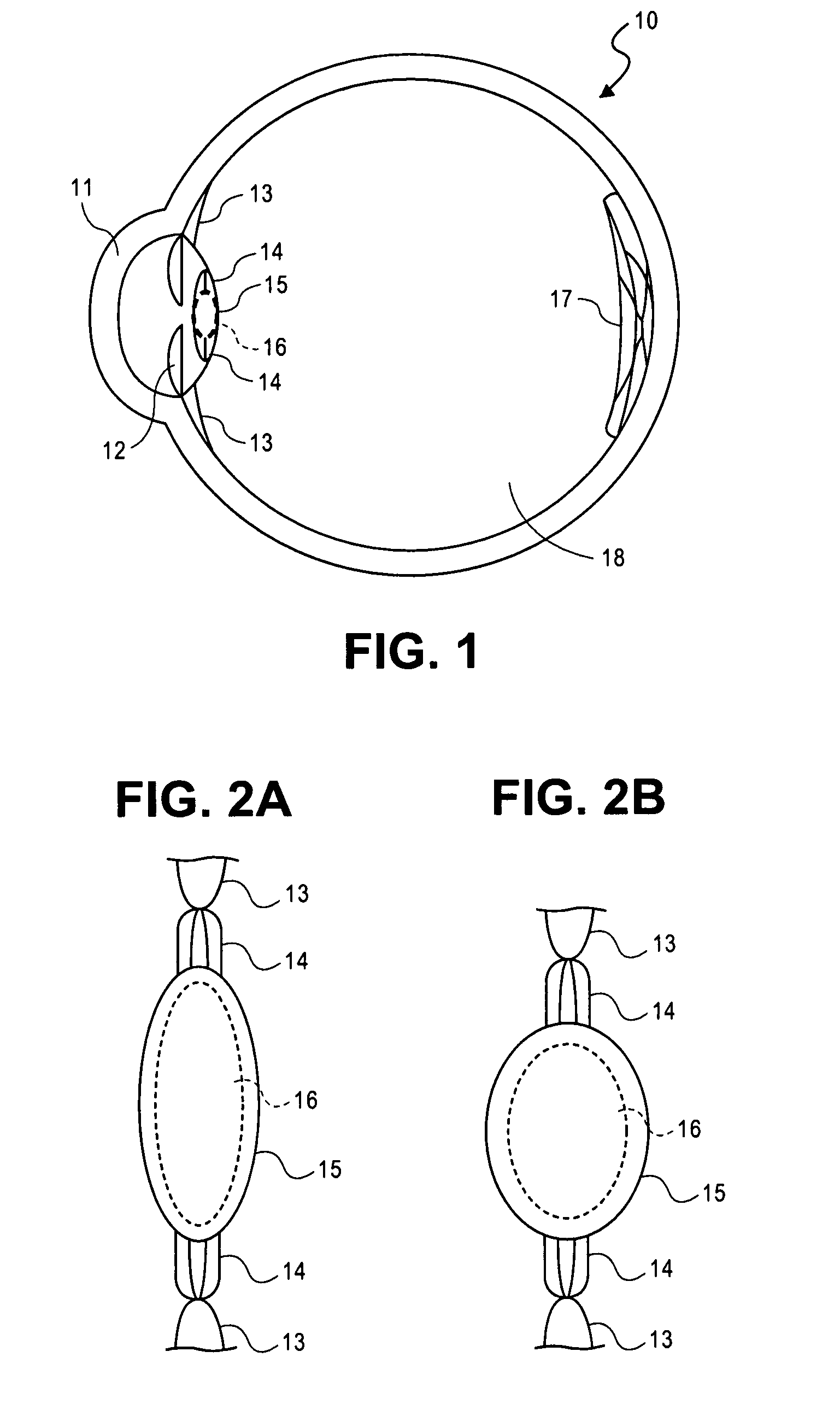

Accommodating intraocular lens system having spherical aberration compensation and method

ActiveUS20070106377A1Small internal volumeIncrease the internal volumeIntraocular lensIntraocular lensOptical power

An accommodating intraocular lens includes an optic portion, a haptic portion. The optic portion of the lens includes an actuator that deflects a lens element to alter the optical power of the lens responsive to forces applied to the haptic portion of the lens by contraction of the ciliary muscles and a secondary deflection mechanism. Movement of the lens element by the actuator causes the lens element to deform and the secondary deflection mechanism causes the lens to further deform.

Owner:ALCON INC

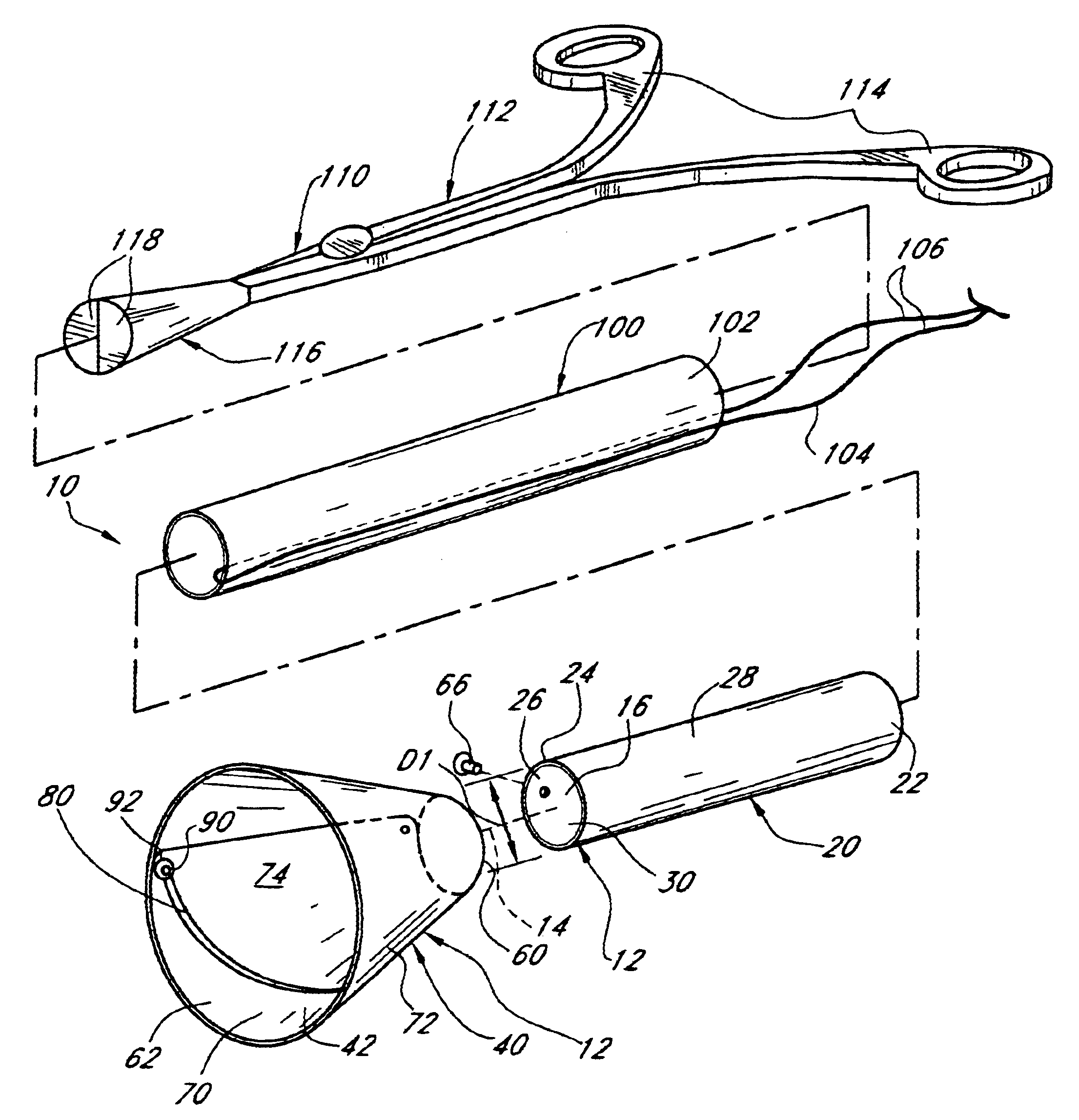

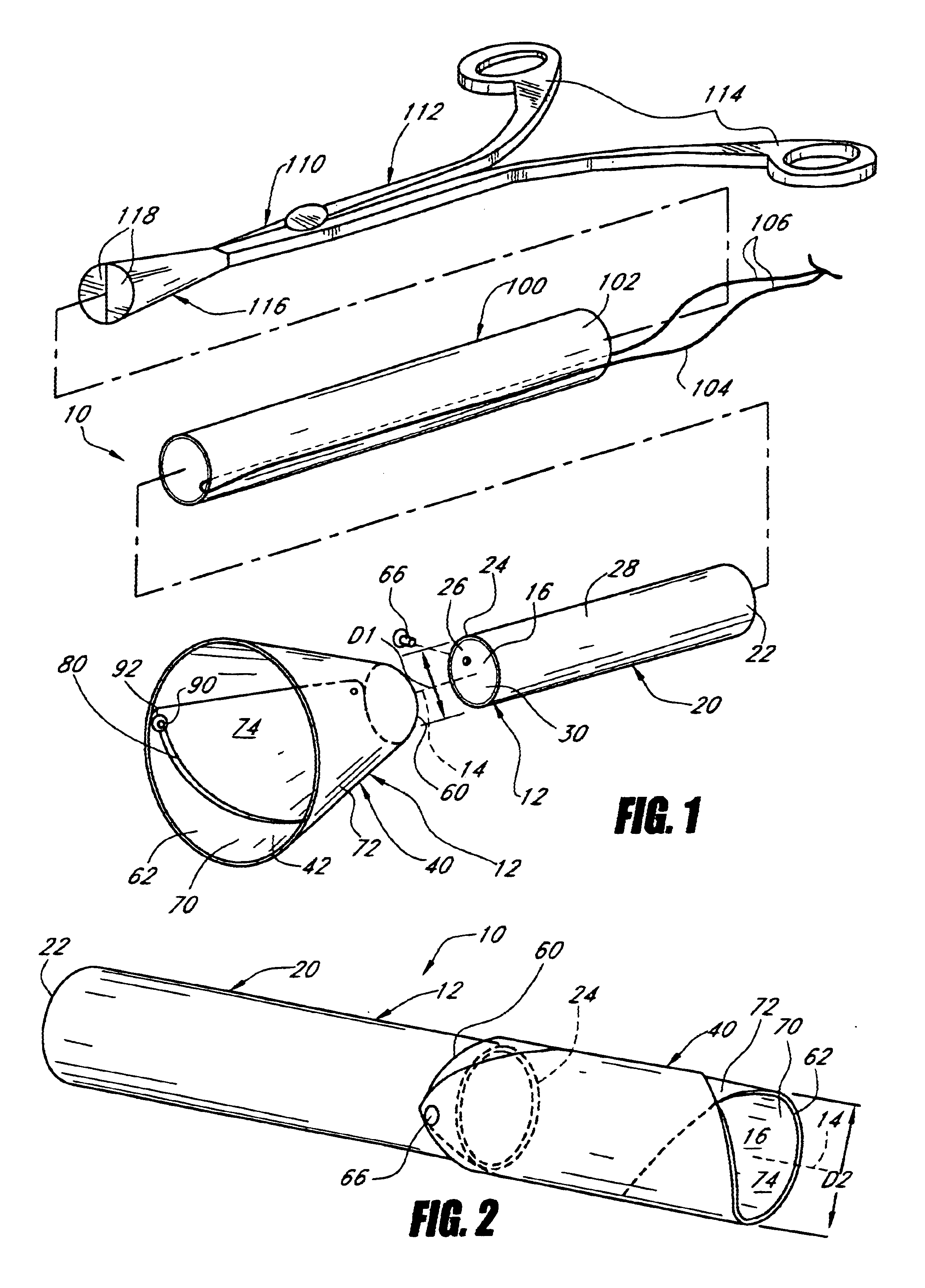

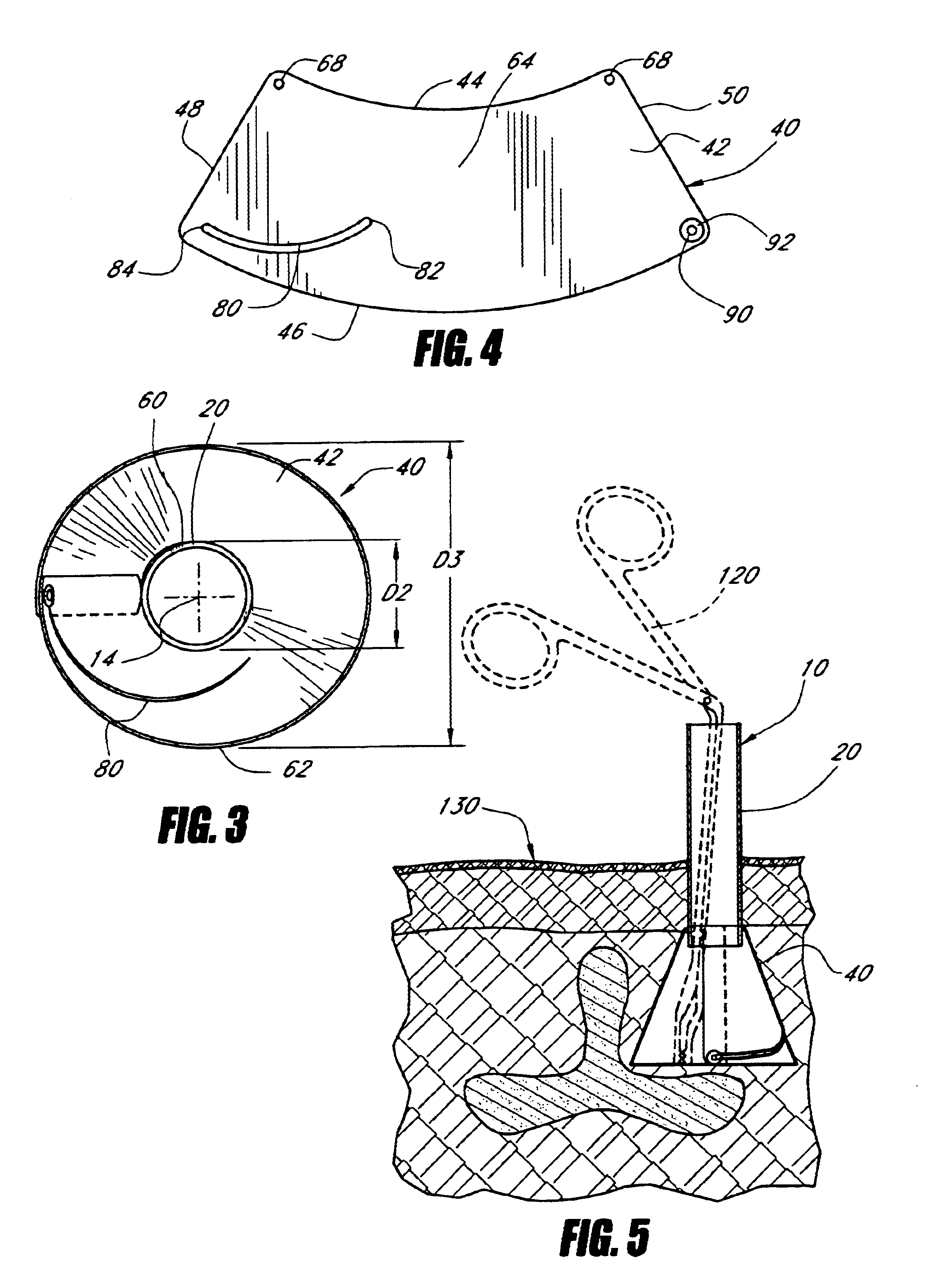

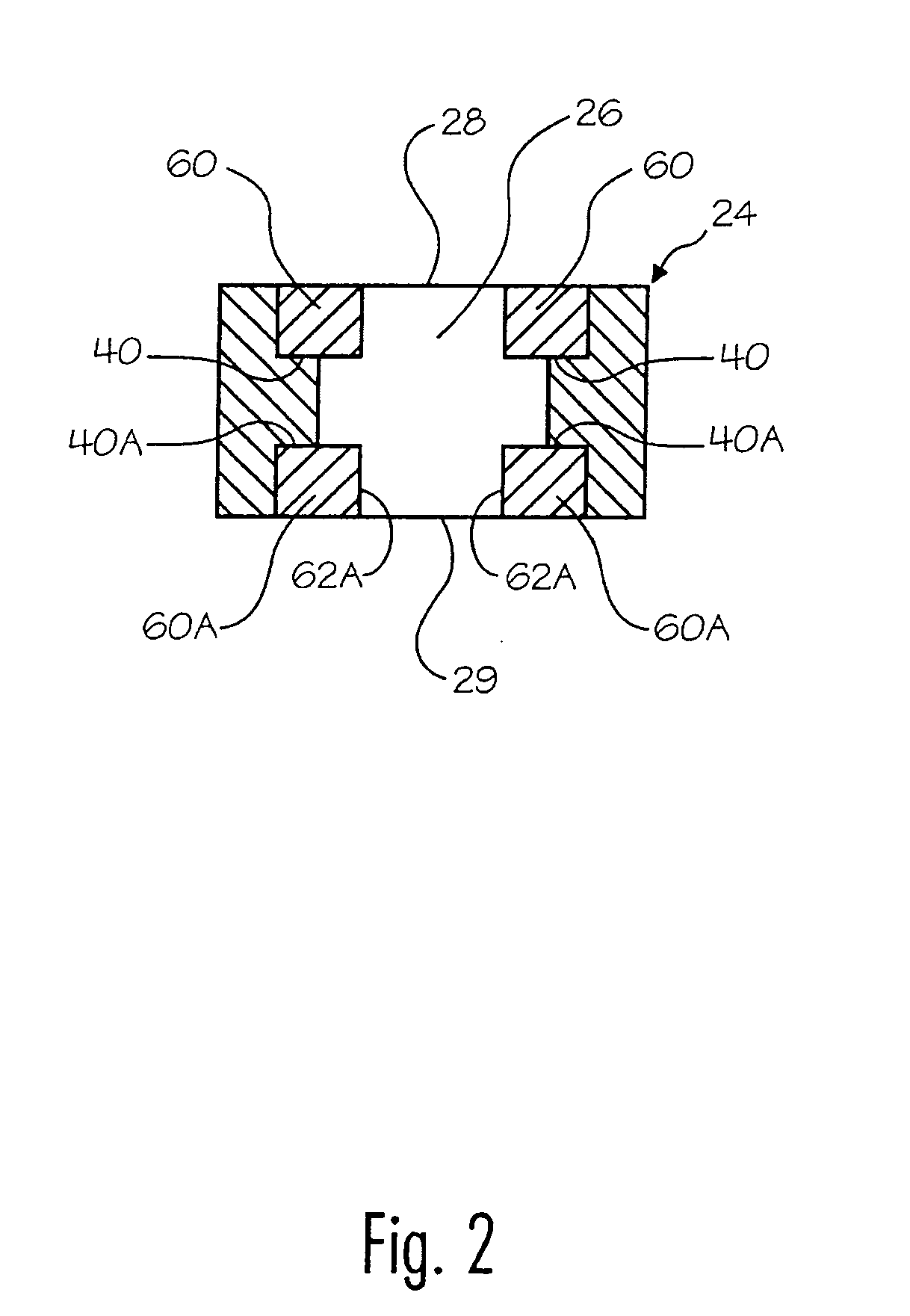

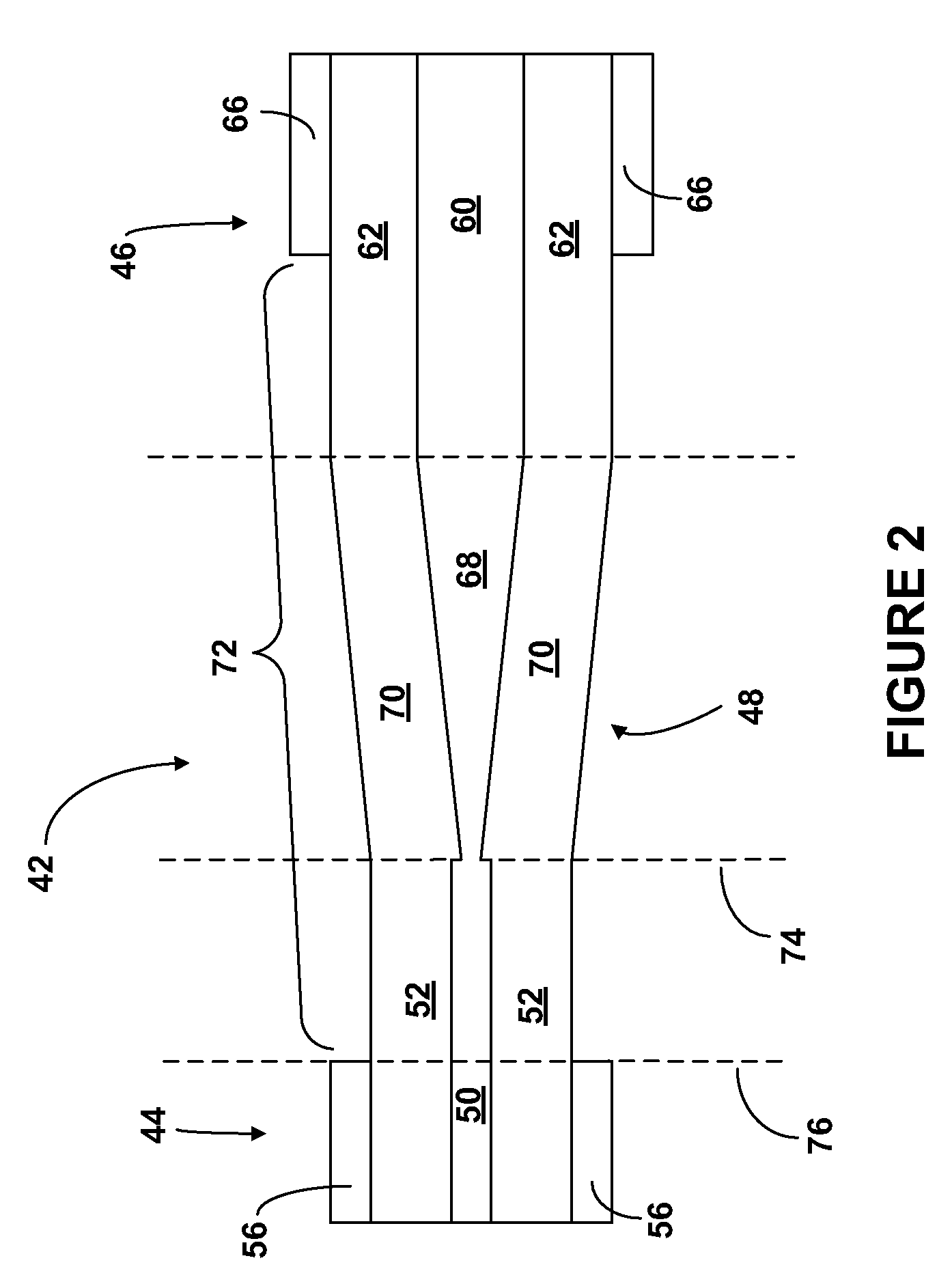

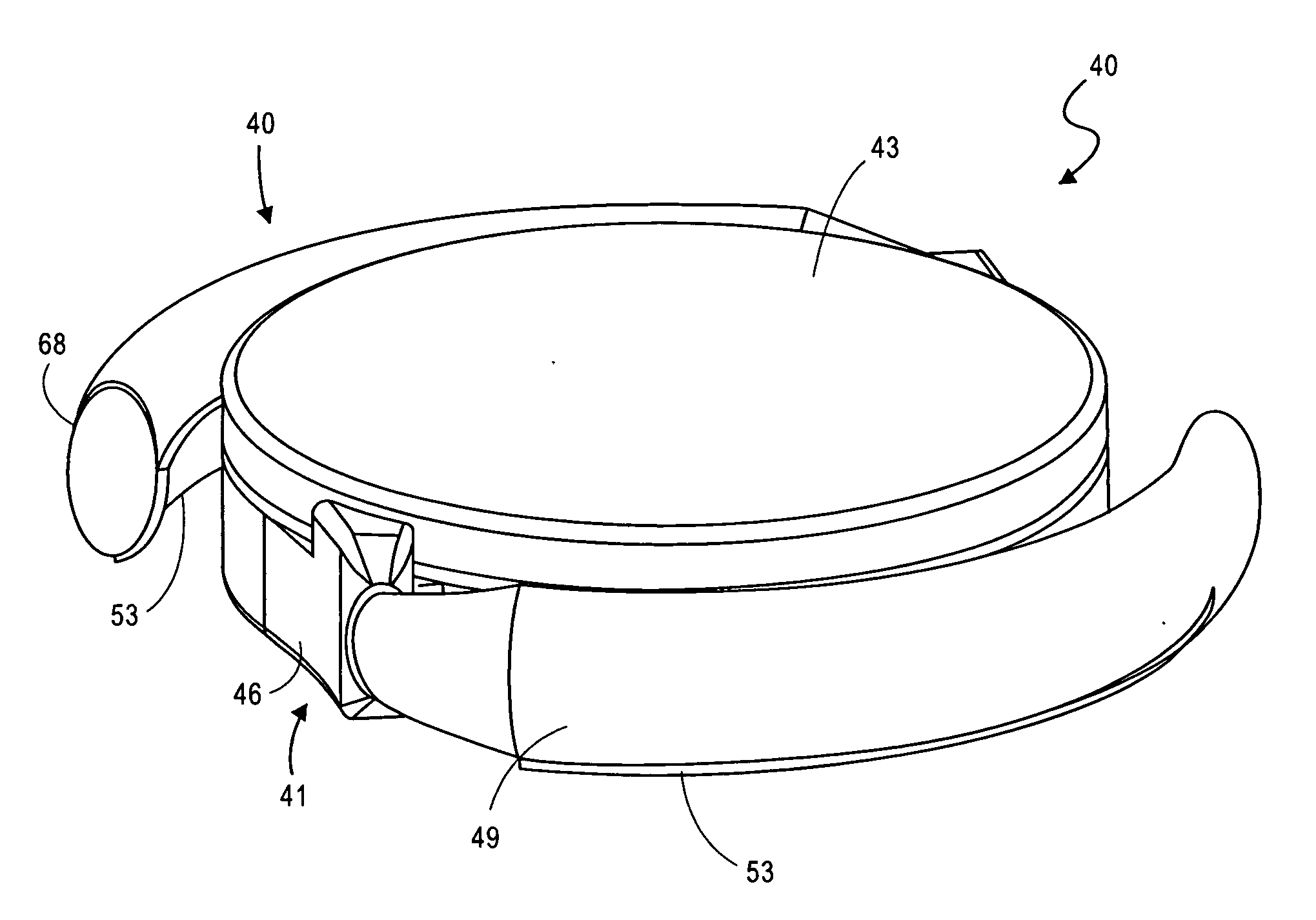

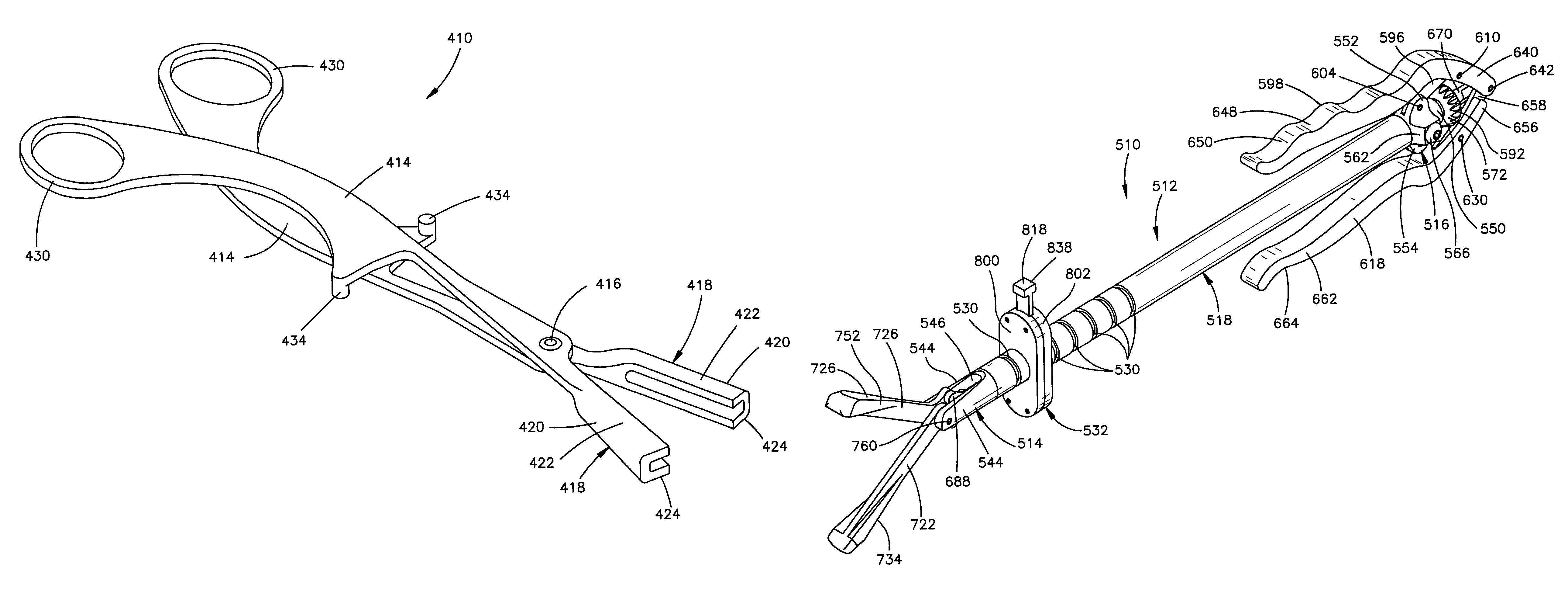

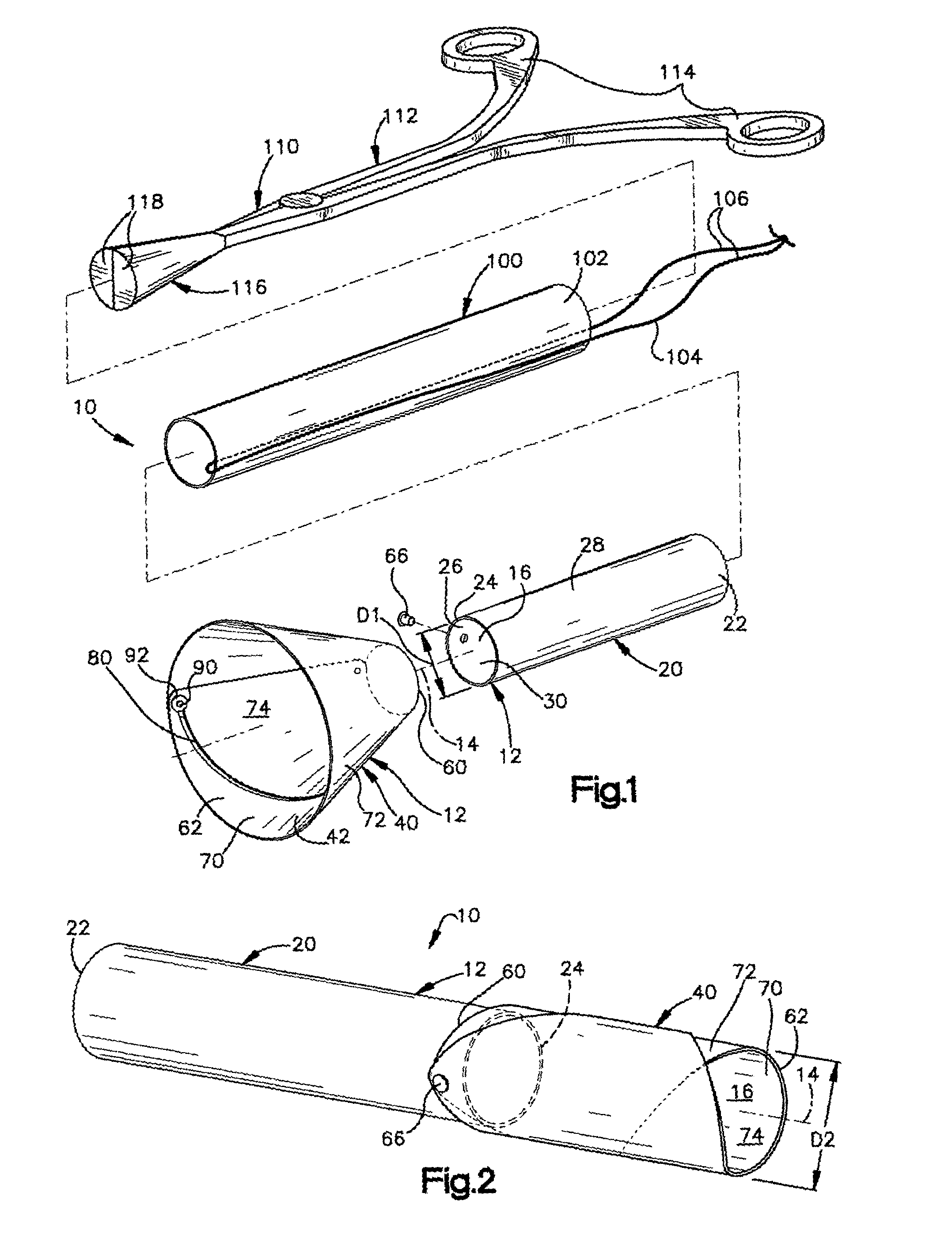

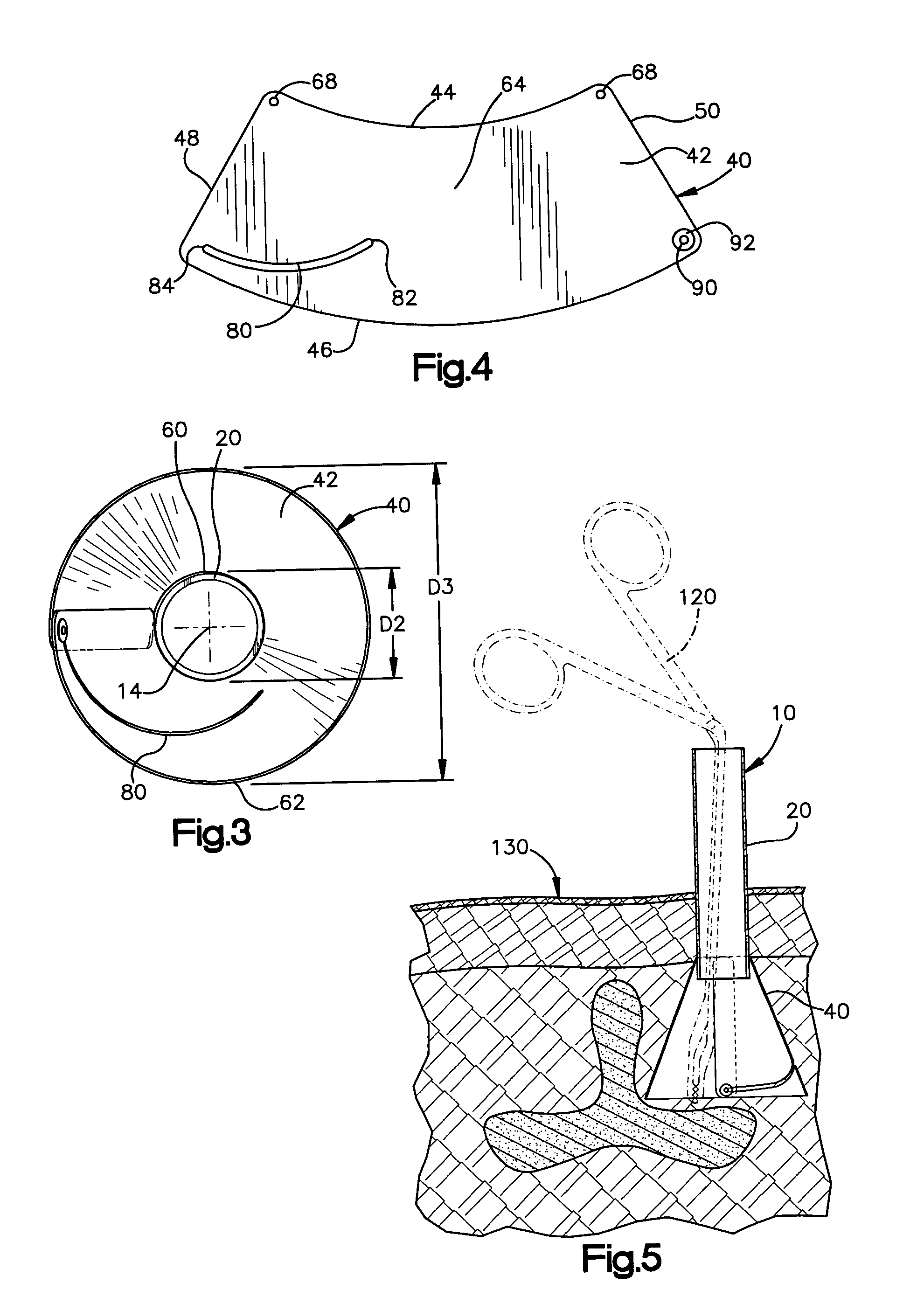

Cannula for receiving surgical instruments

InactiveUS6837891B2Increase the cross-sectional areaInternal osteosythesisEar treatmentSurgical proceduresGeneral surgery

A cannula (10) receives surgical instruments (120) for performing a surgical procedure on a body (130). The cannula (10) comprises a tube structure (12) defining a passage (16) through which the surgical instruments (120) are inserted into the body (130). The tube structure (12) has a proximal end (20) and a distal end (62). The tube structure (12) includes an expandable portion (40) for enabling an increase in the cross-sectional area of the passage (16) at the distal end (62). The expandable portion (40) of the tube structure (12), when expanded, has a conical configuration.

Owner:ZIMMER SPINE INC

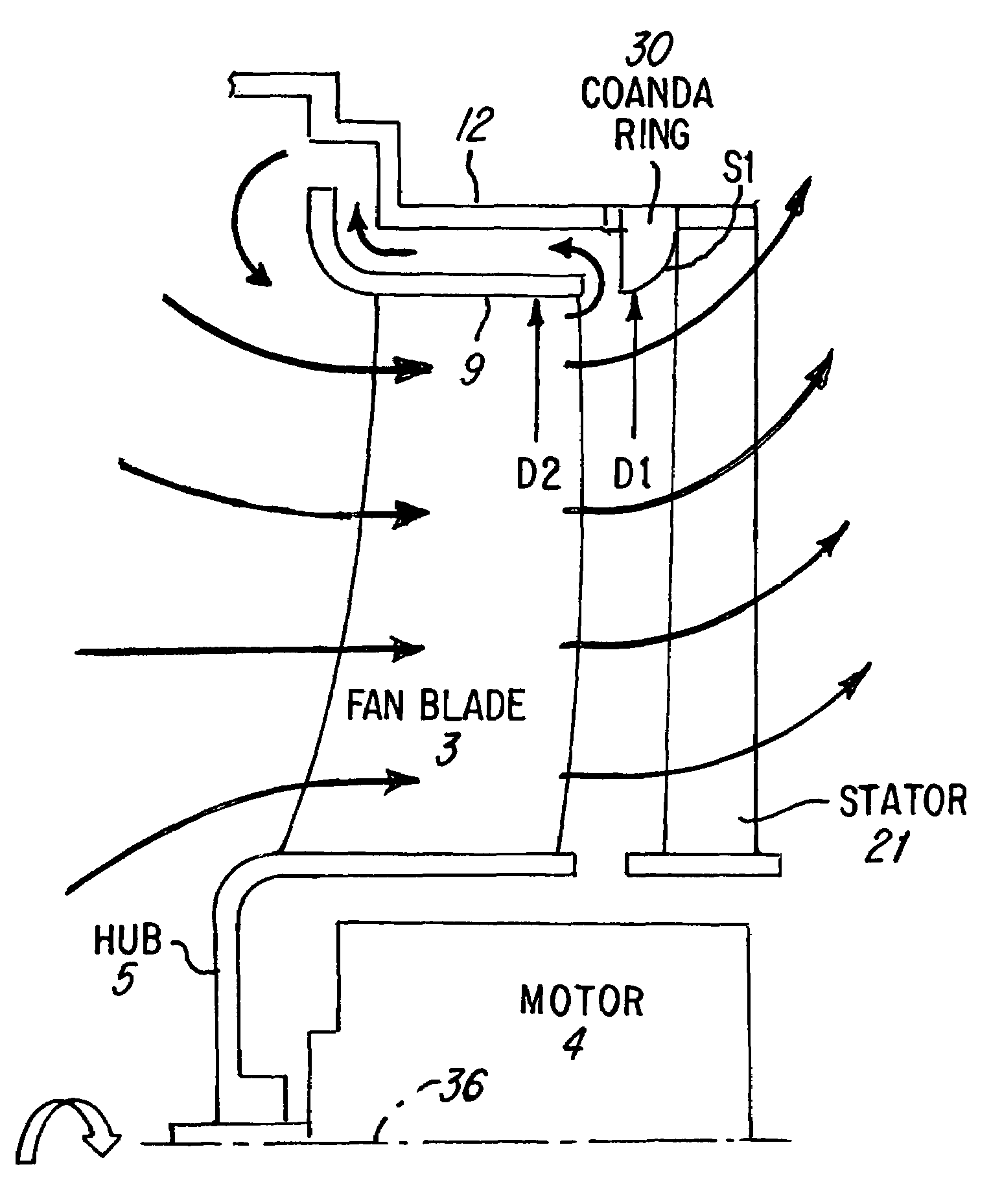

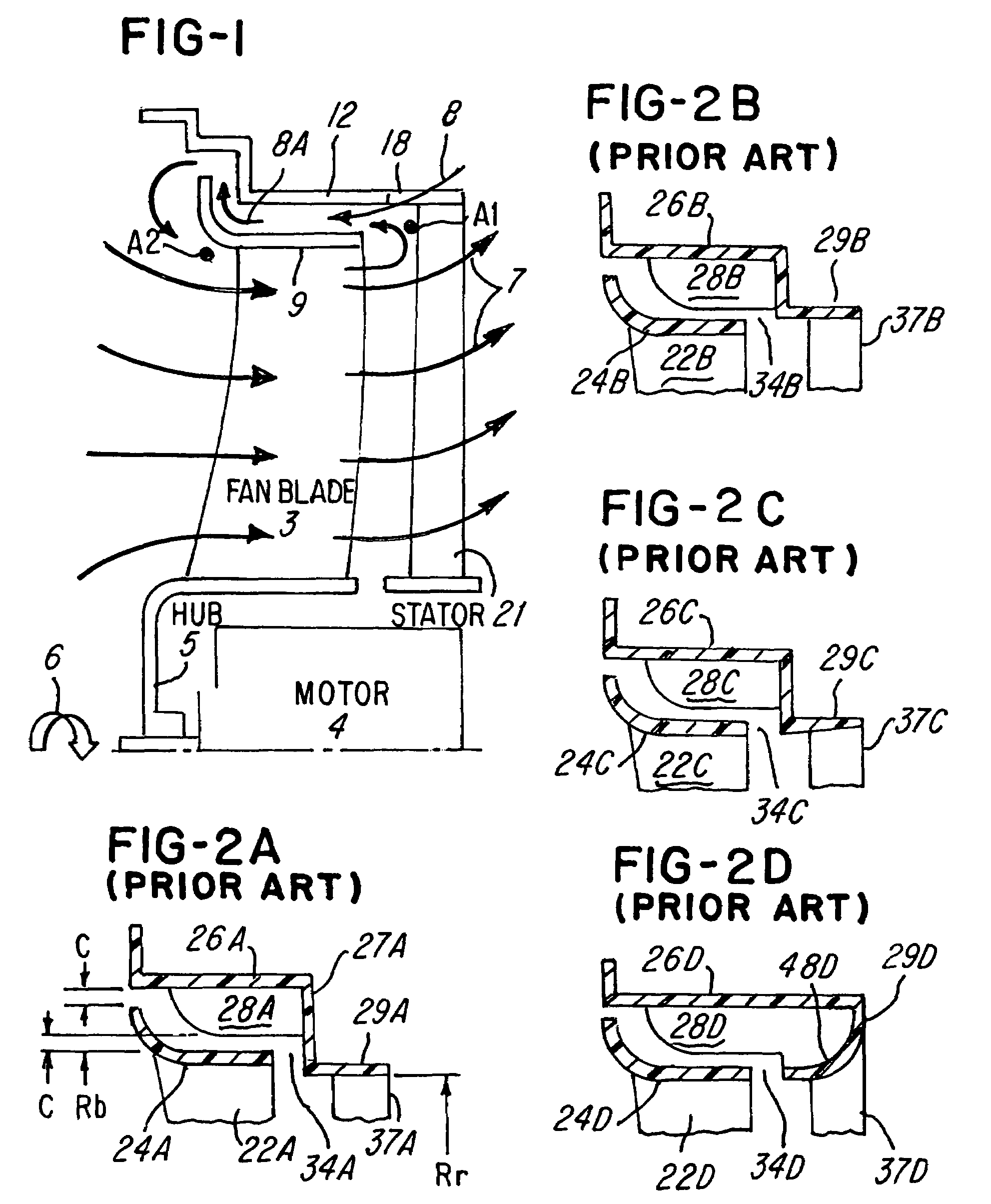

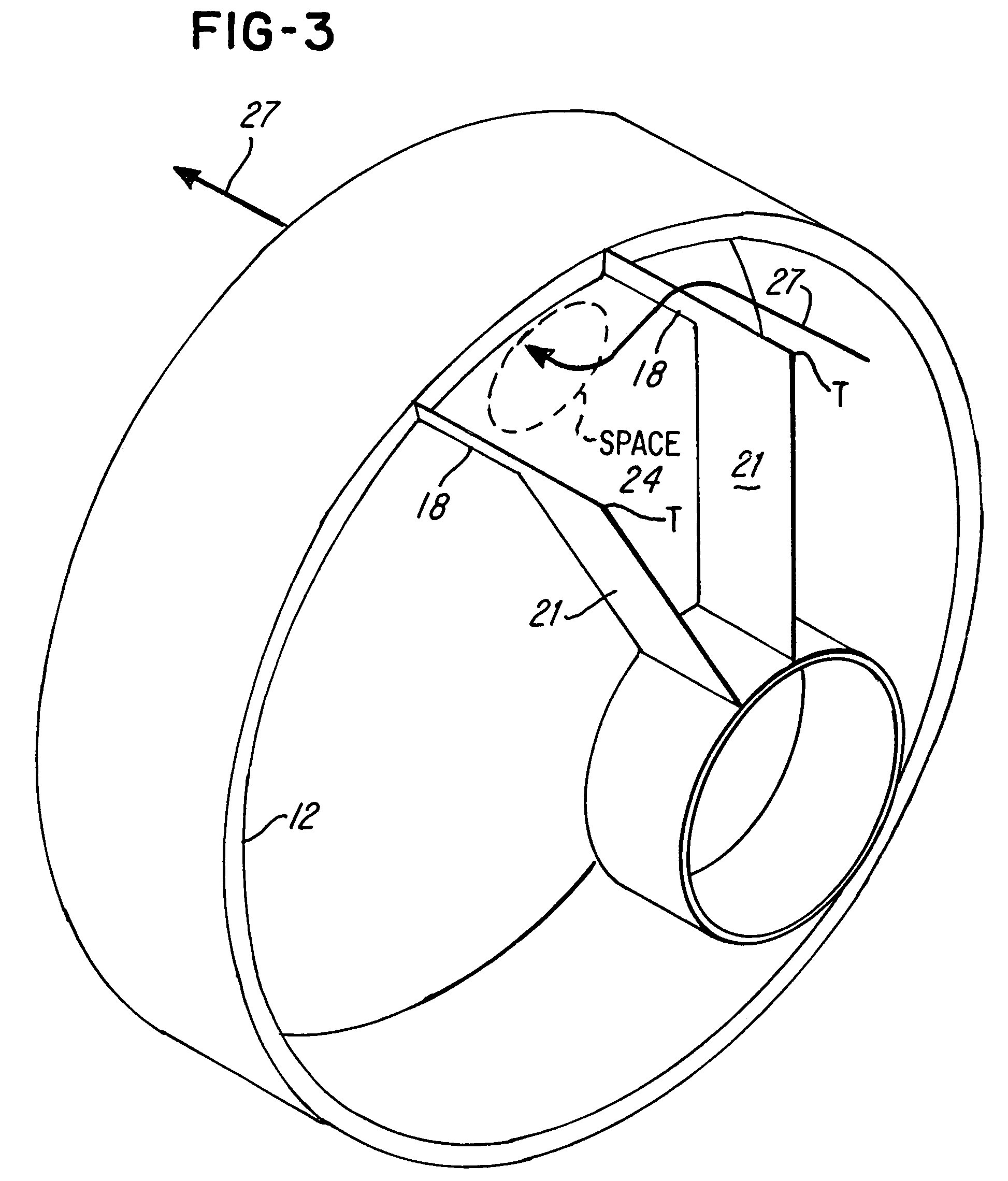

Cooling fan using Coanda effect to reduce recirculation

ActiveUS7478993B2Trend downIncrease the cross-sectional areaPump componentsReaction enginesEngineeringFan blade

Owner:VALEO INC

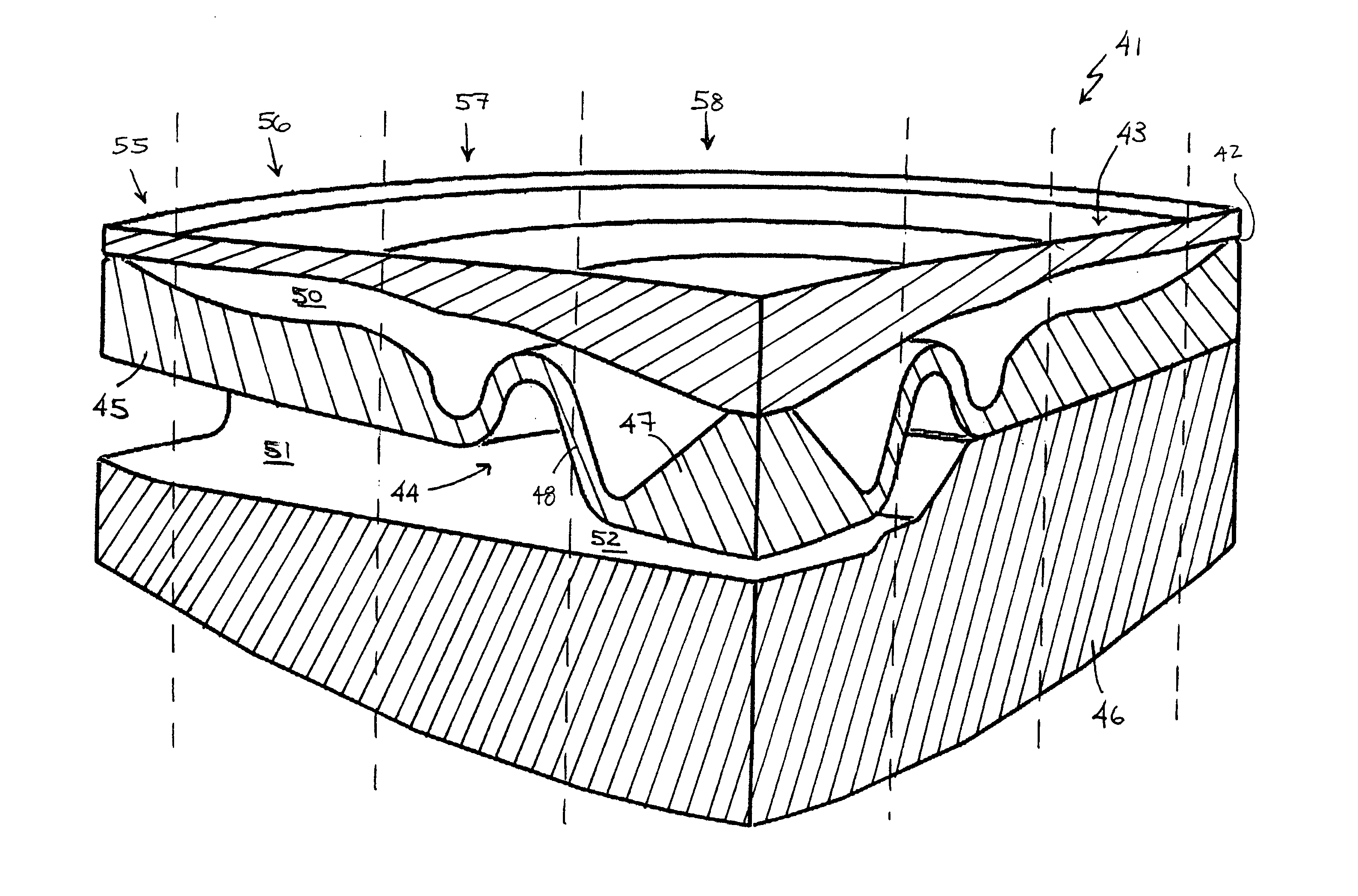

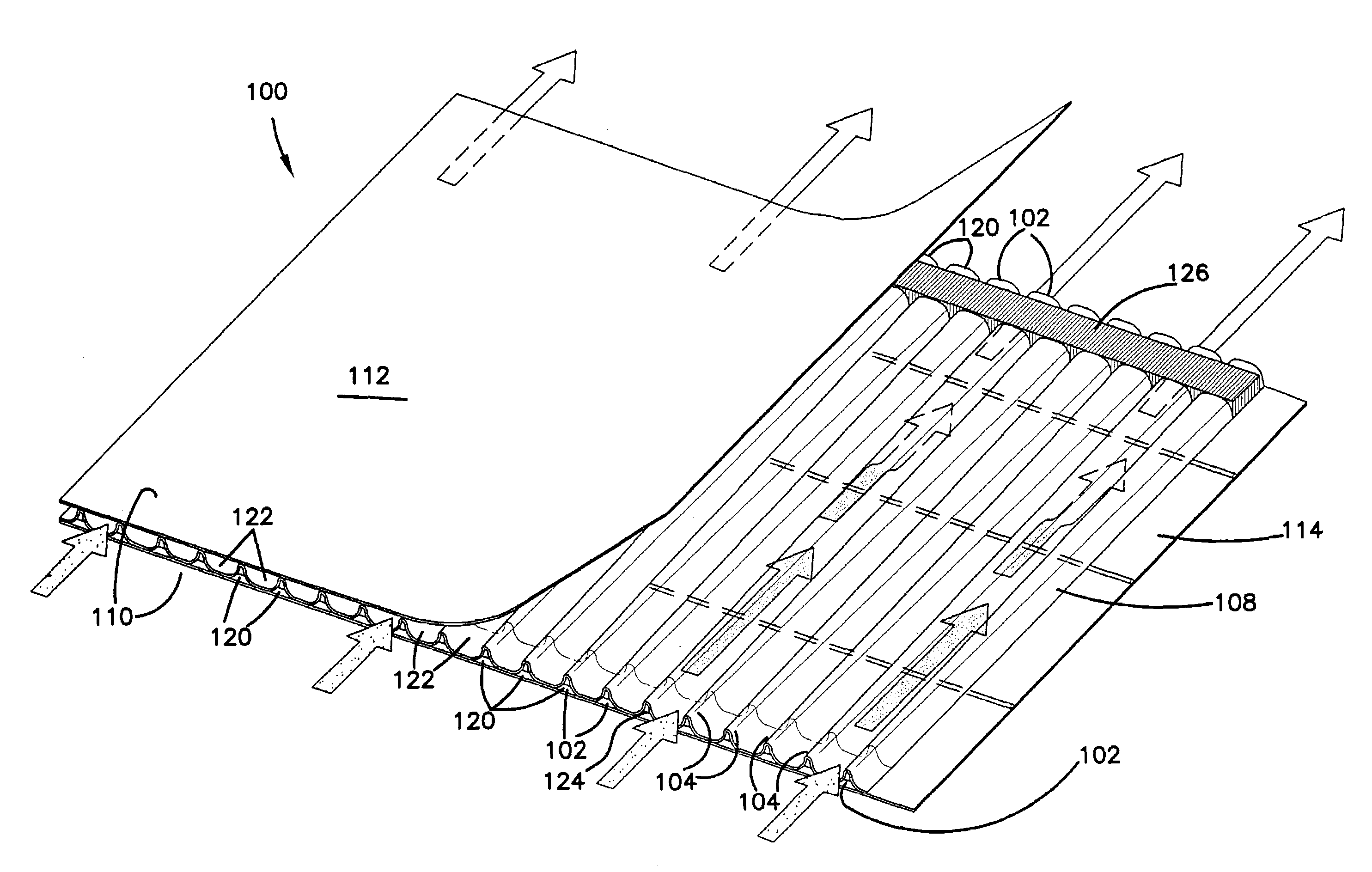

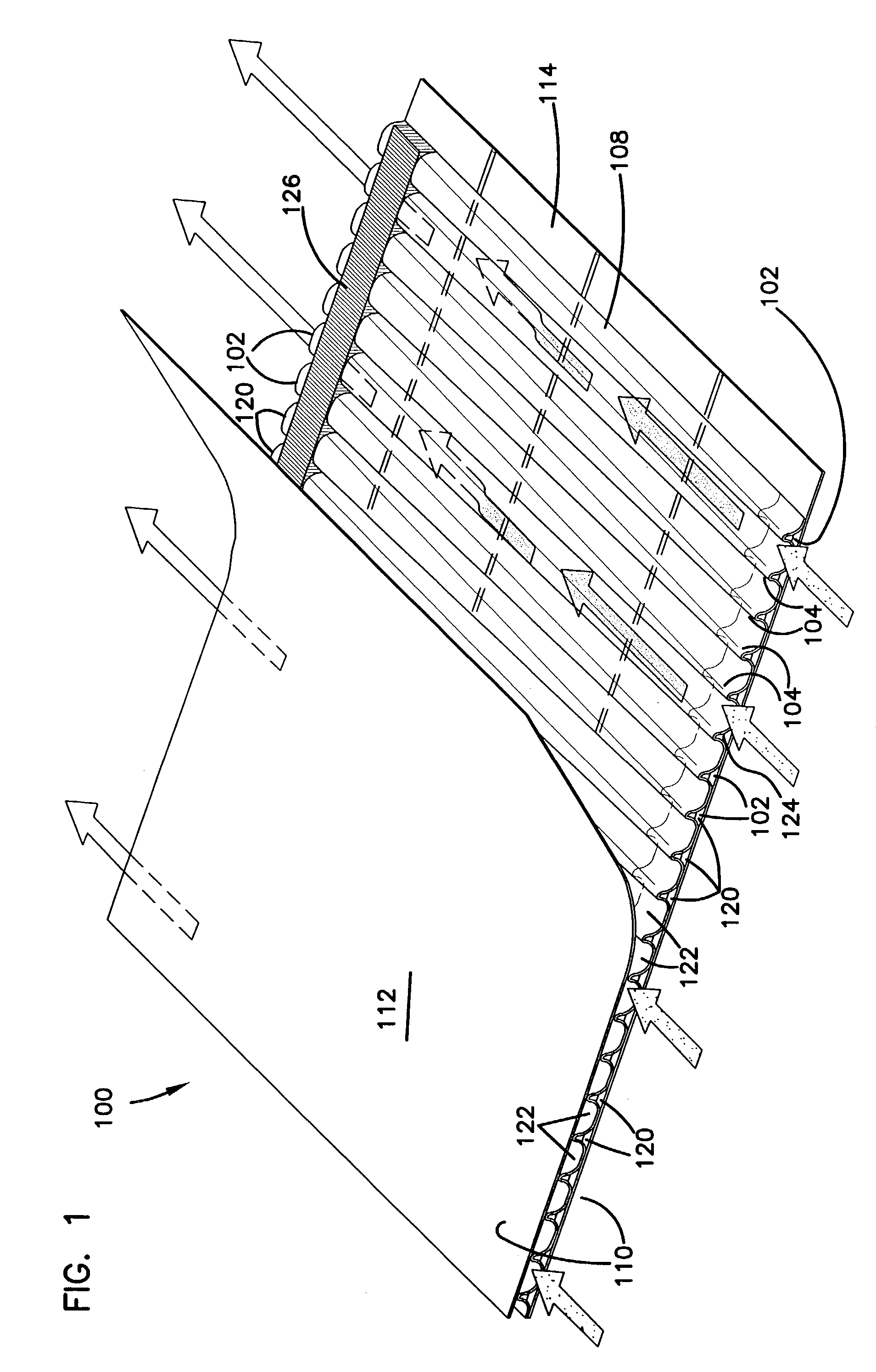

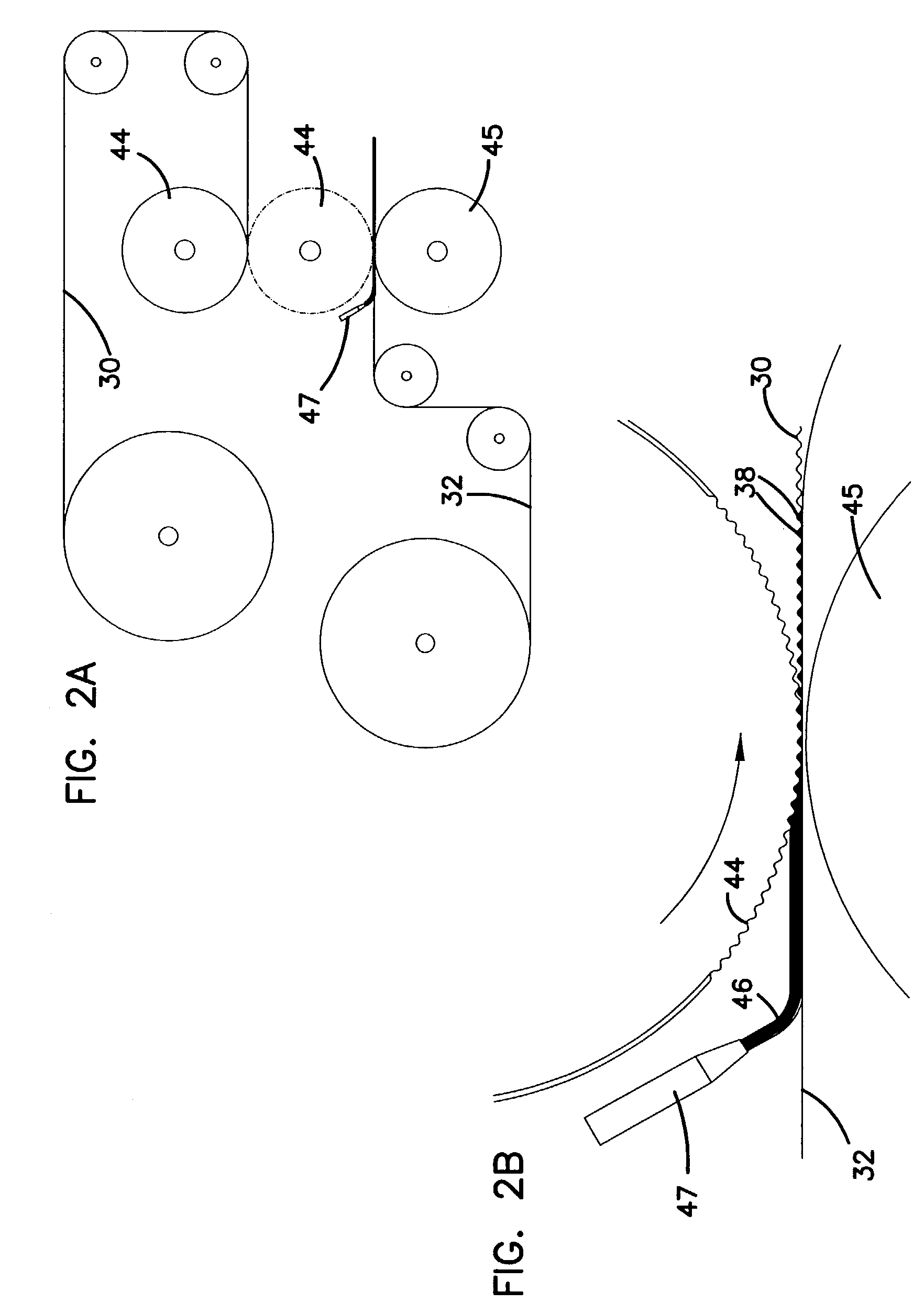

Method of making a fluted filter media for air filter

InactiveUS7329326B2Improve flow characteristicsReduce restrictionsMechanical working/deformationLamination ancillary operationsFluteAir filter

Fluted filter media includes filter material having a plurality of flutes formed therein having alternating ends of adjacent flutes closed to force fluid through filter material. A first embodiment of the filter media includes tapered flutes which have the open ends of the flutes larger in cross-section than the closed flutes, wherein the upstream open flutes converge toward the downstream end and the upstream closed end flutes diverge toward the downstream end. A second embodiment includes filter media which is asymmetric formed with dissimilar upstream and downstream flute cross-sections with larger flute openings to the upstream side of the filter. A third embodiment includes filter media with an upstream edge crushed to improve flow at the upstream edge. A fourth embodiment includes filter media with the upstream sealing material recessed from the upstream edge for reducing effects from blockages at the upstream edge of the filter.

Owner:DONALDSON CO INC

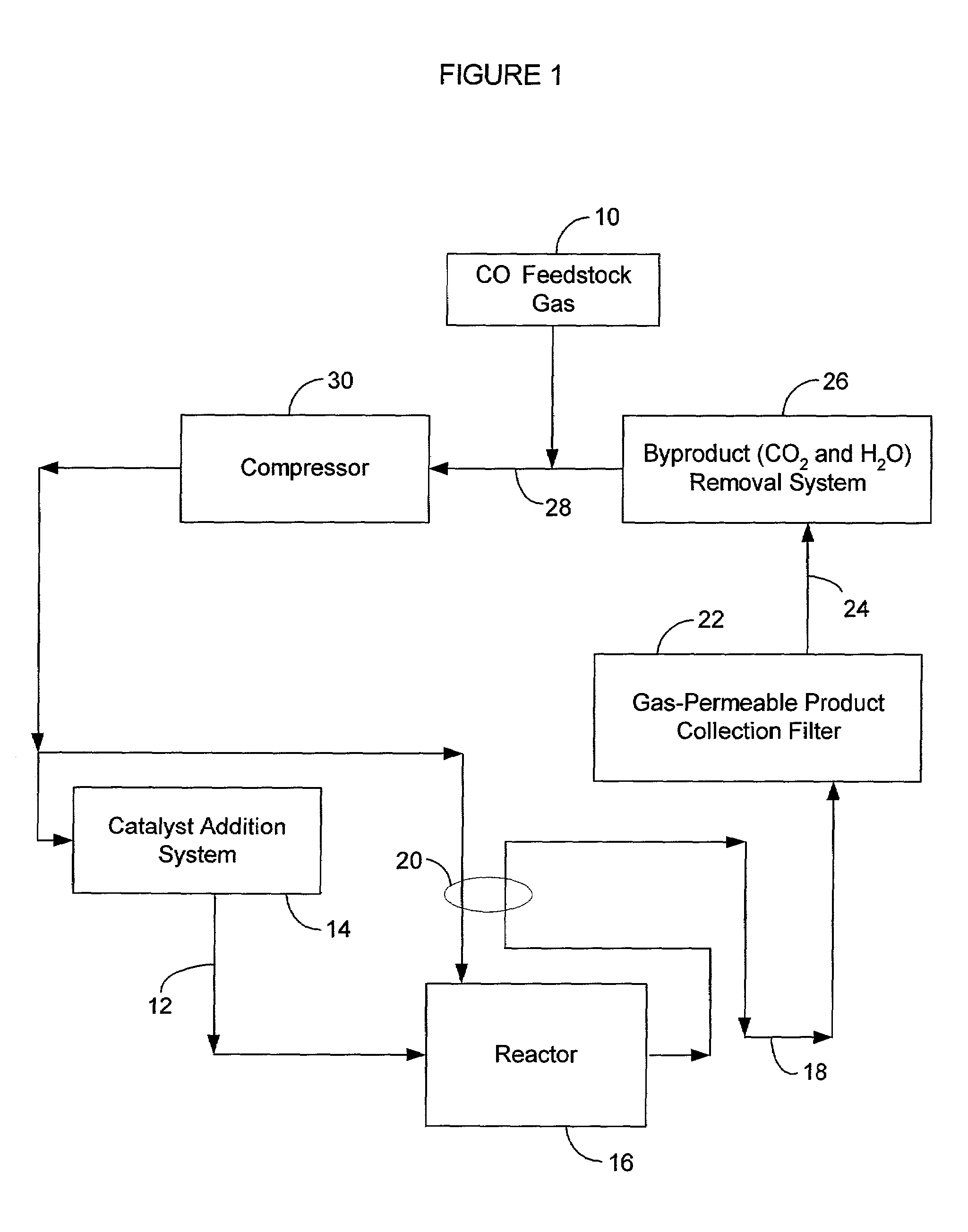

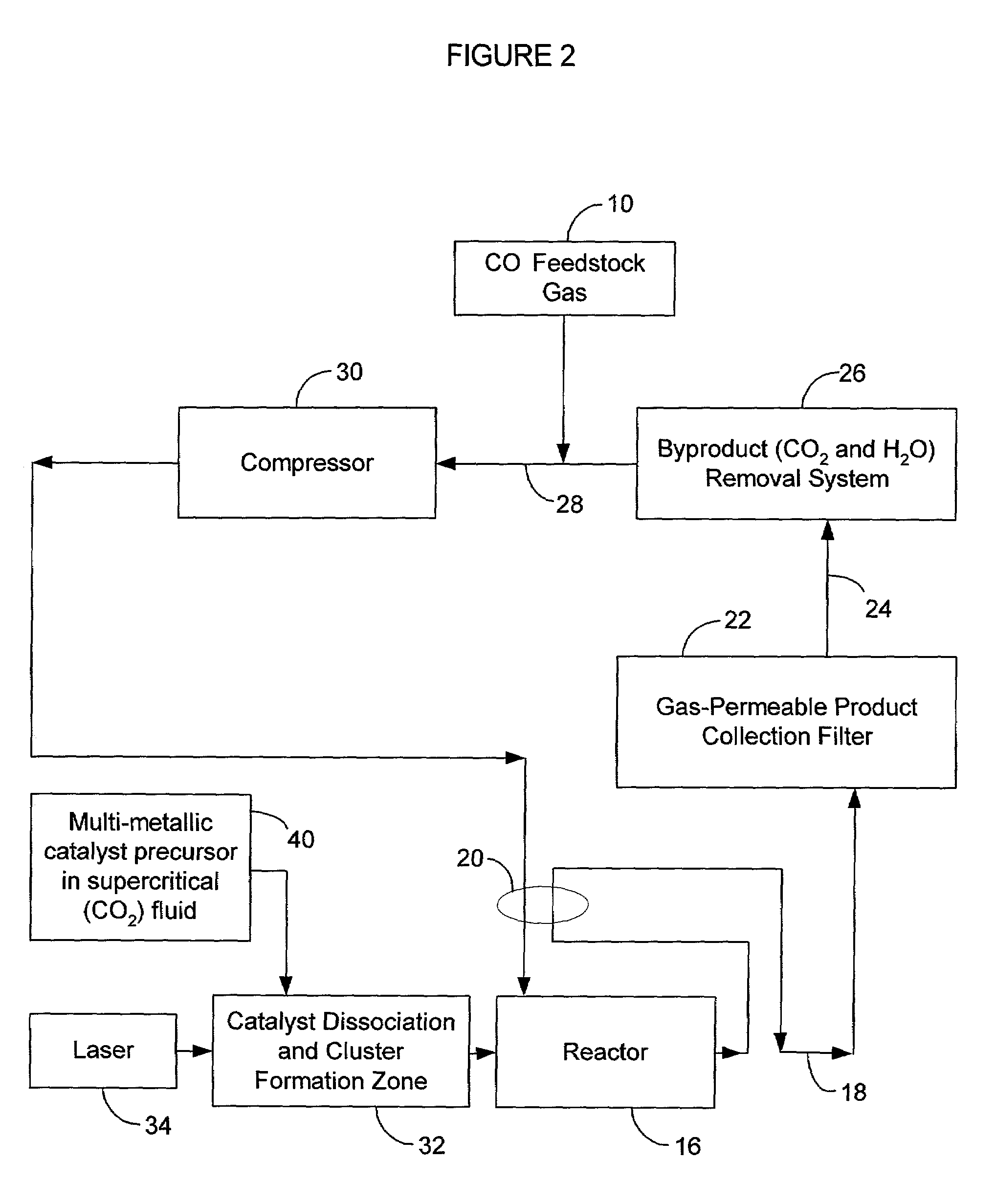

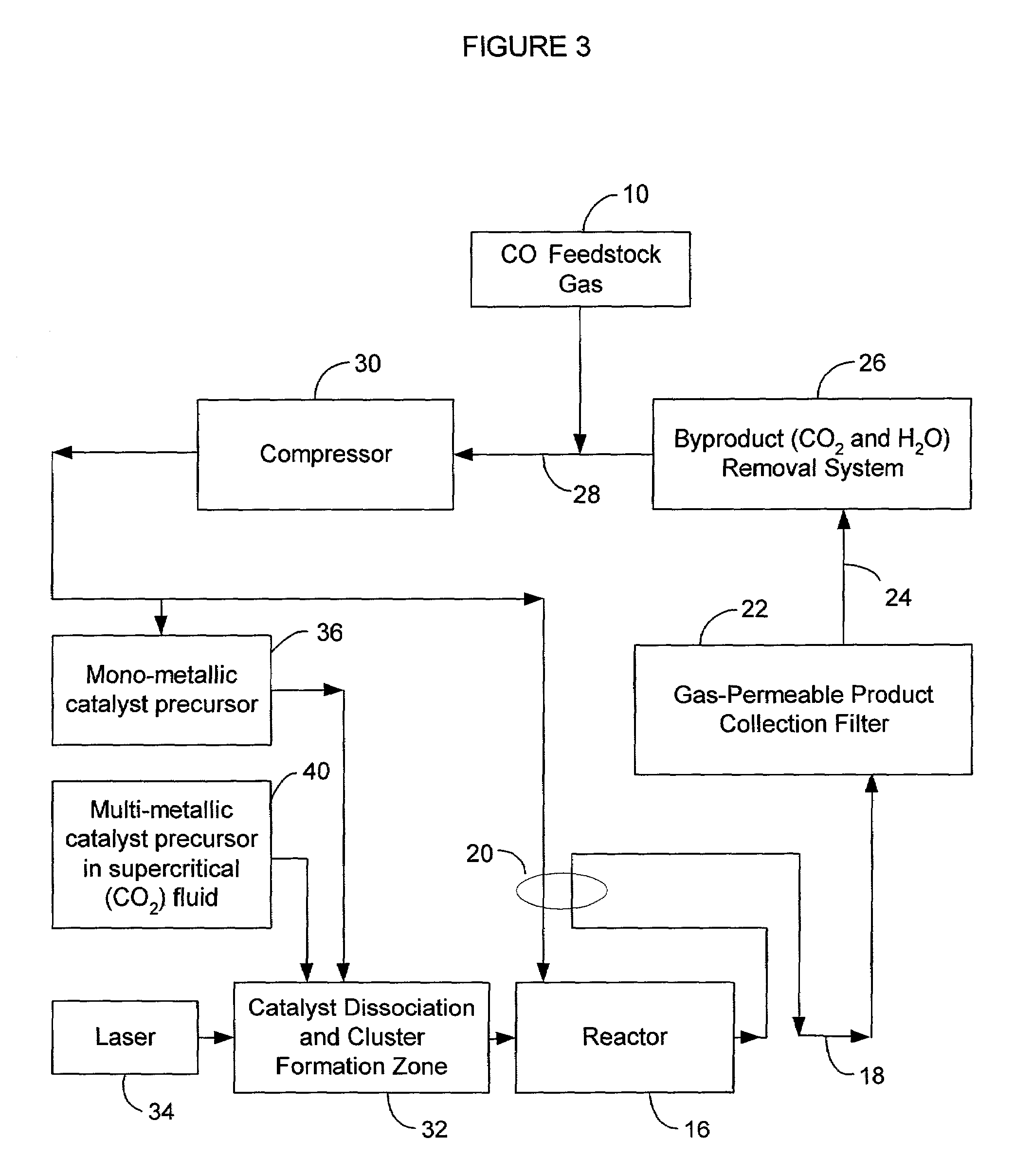

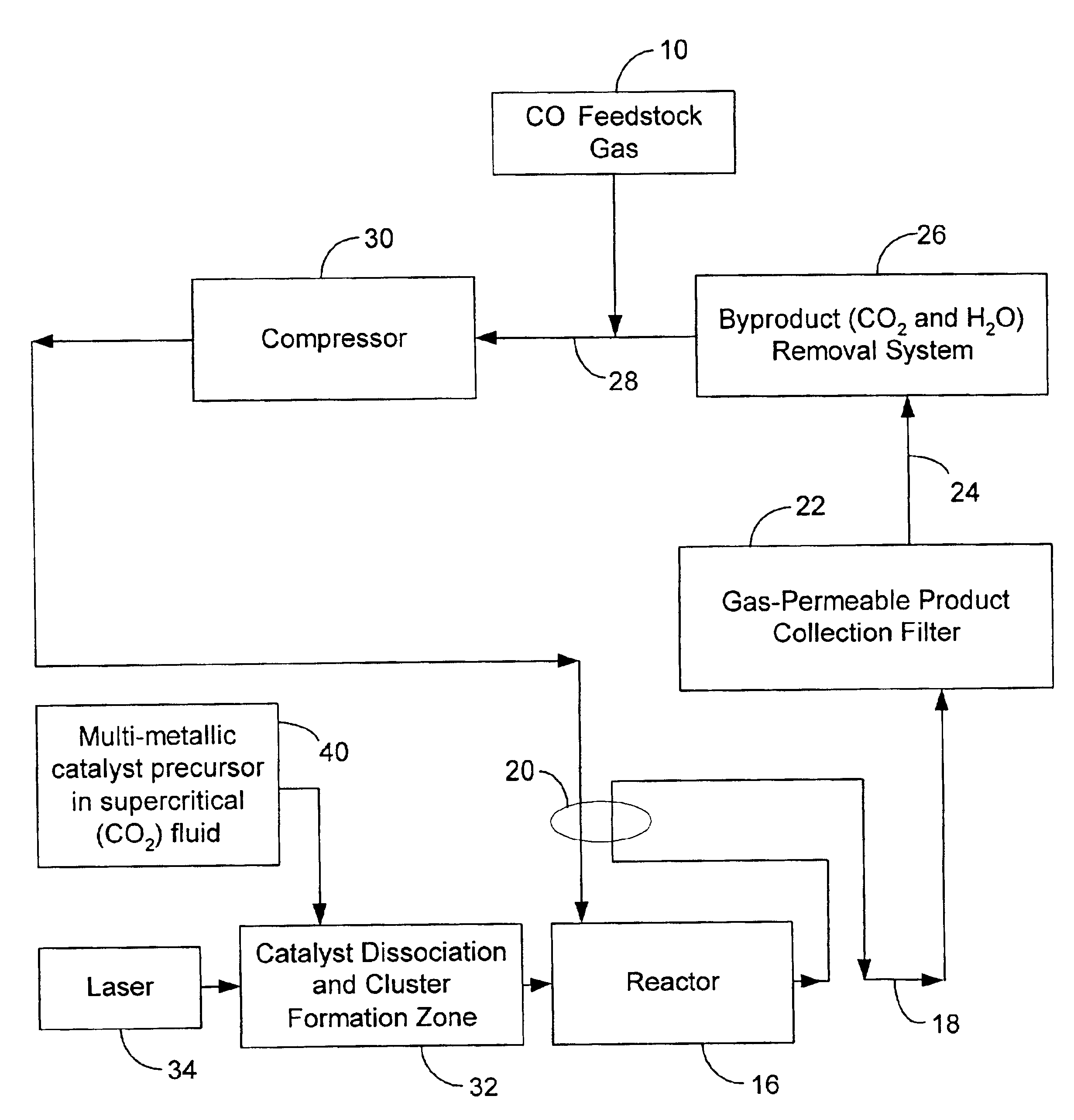

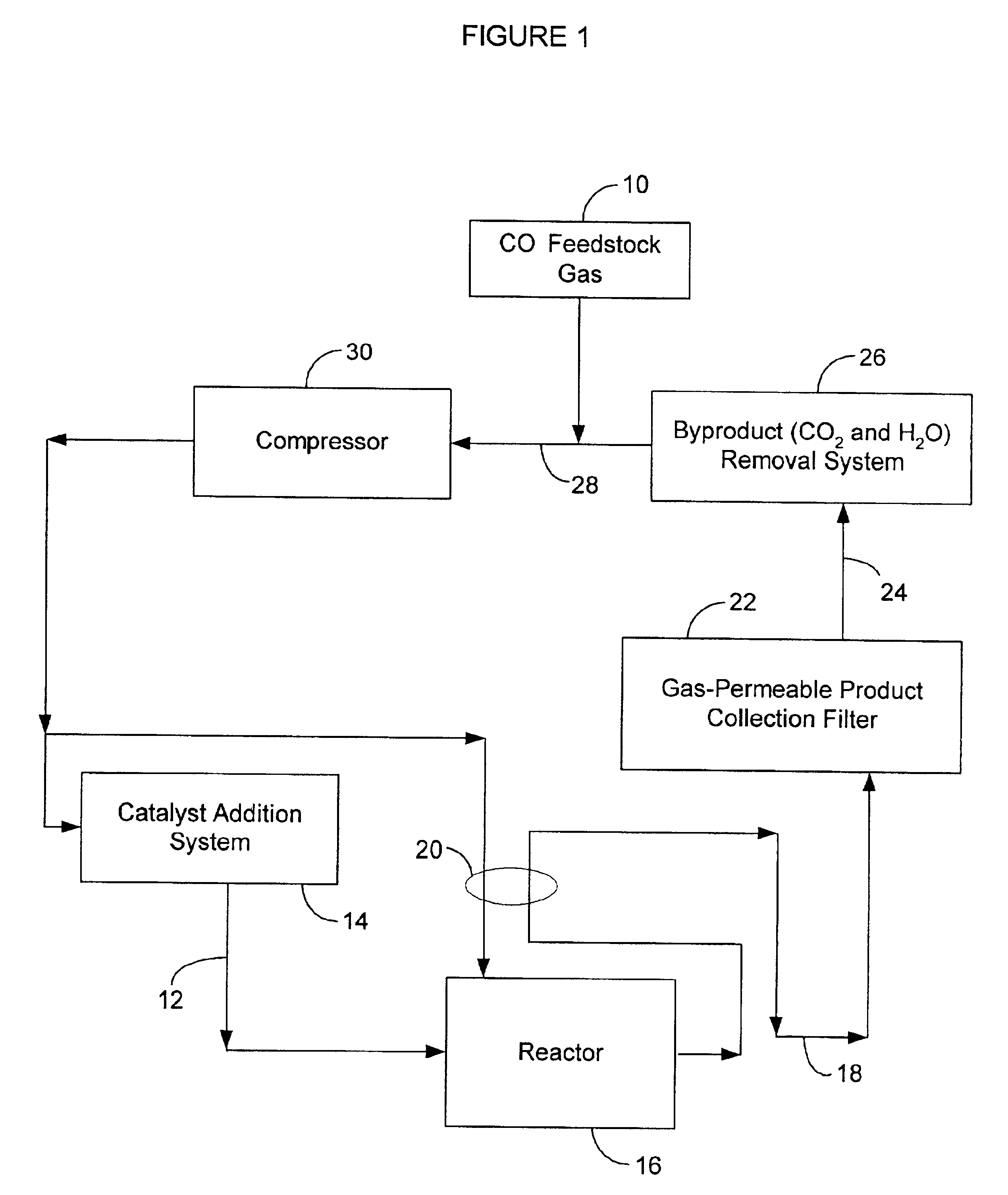

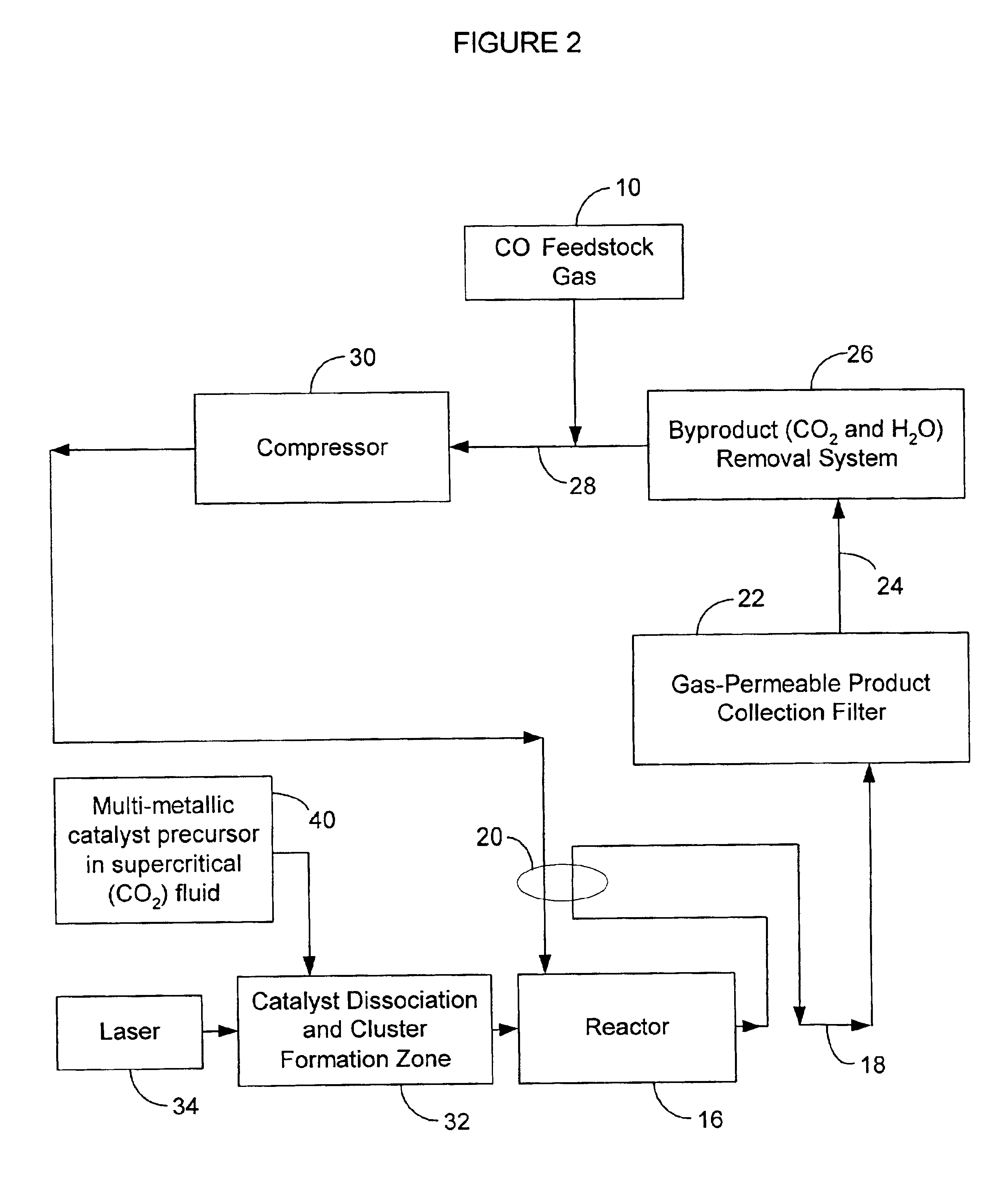

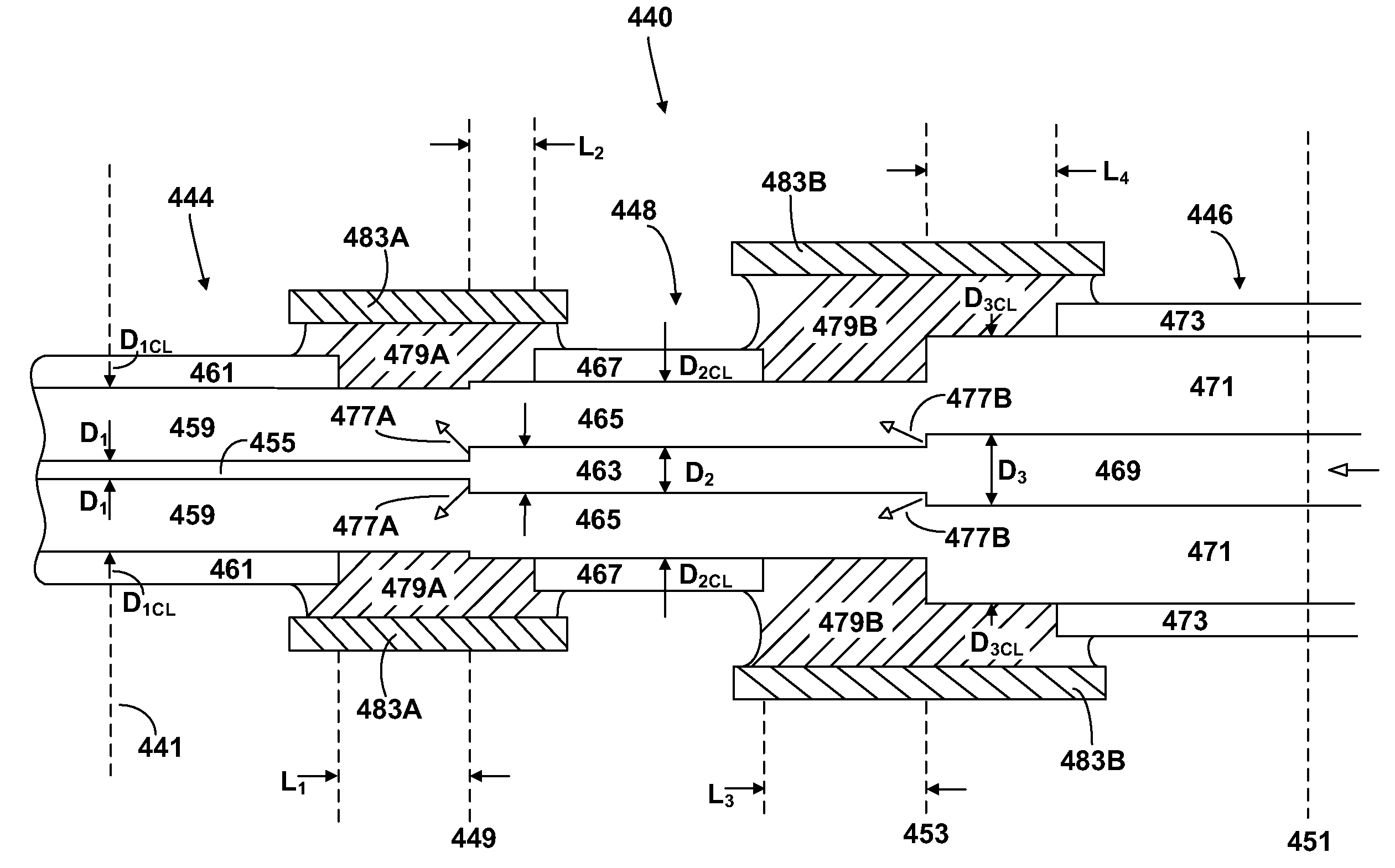

Process utilizing seeds for making single-wall carbon nanotubes

InactiveUS7052668B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFullerenesMetal catalystGas phase

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

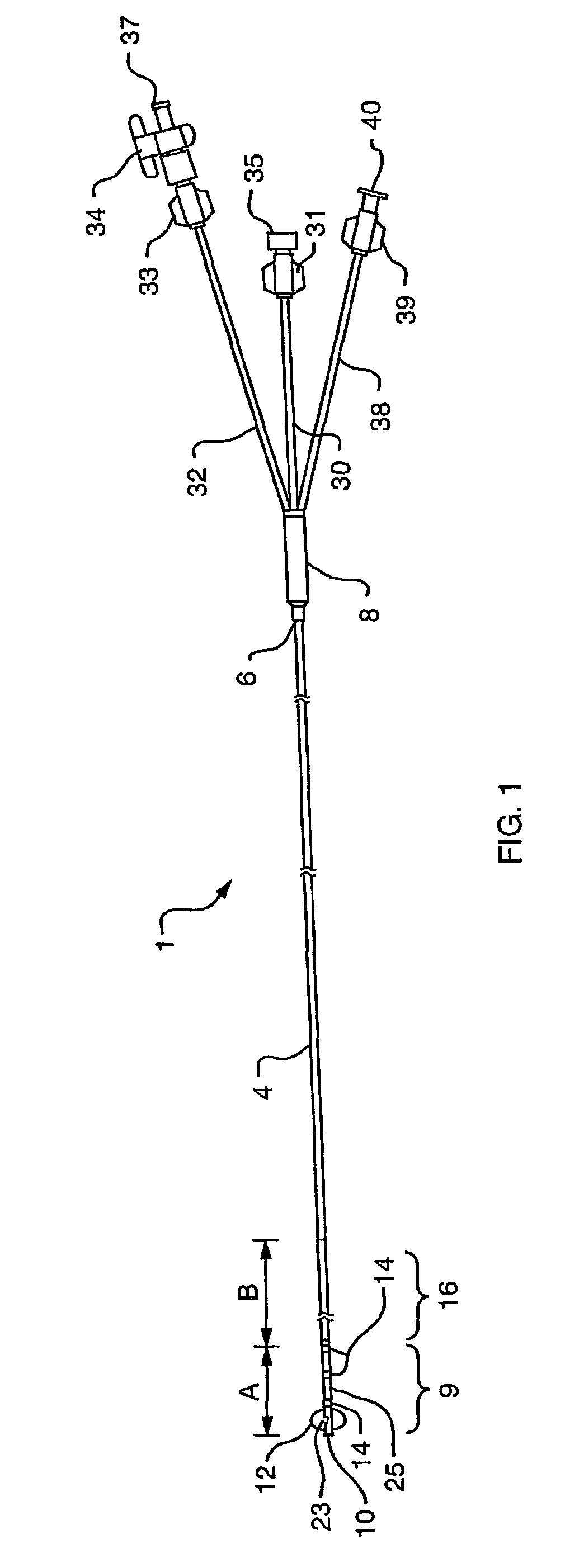

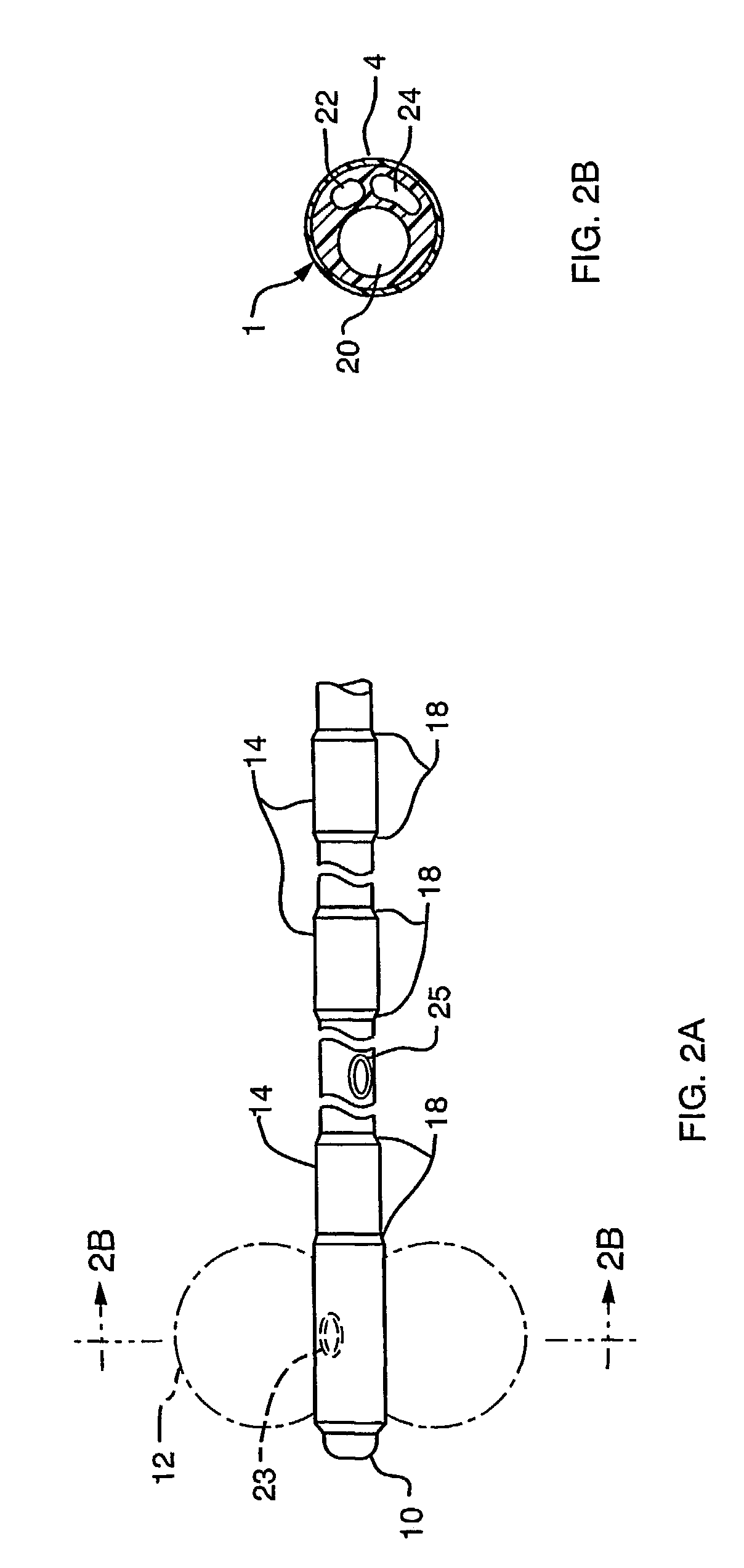

Triple lumen stone balloon catheter and method

InactiveUS7481800B2Acceptable inflationAcceptable deflation rateStentsBalloon catheterBalloon catheterKidney

A triple lumen stone balloon catheter (1) having a tapered distal end (9). A lumen (24) dedicated to transmitting contrast media is dimensioned and adapted to conform to the shape of a kidney in a main shaft of the catheter and conform to the shape of a crescent in a distal end of the catheter. The geometric shaping of the contrast media lumen (24) enables wall thickness to be maintained within acceptable ranges to sustain desirable mechanical characteristics while allowing for enhanced contrast media flow. A method for employing the balloon catheter (1) is also disclosed.

Owner:COMMAND ENDOSCOPIC TECH

Artificial skin and elastic strain sensor

ActiveUS20140238153A1Sufficient cross-sectional areaHigh sensitivitySkin implantsSolesElectrical resistance and conductanceElastic substrate

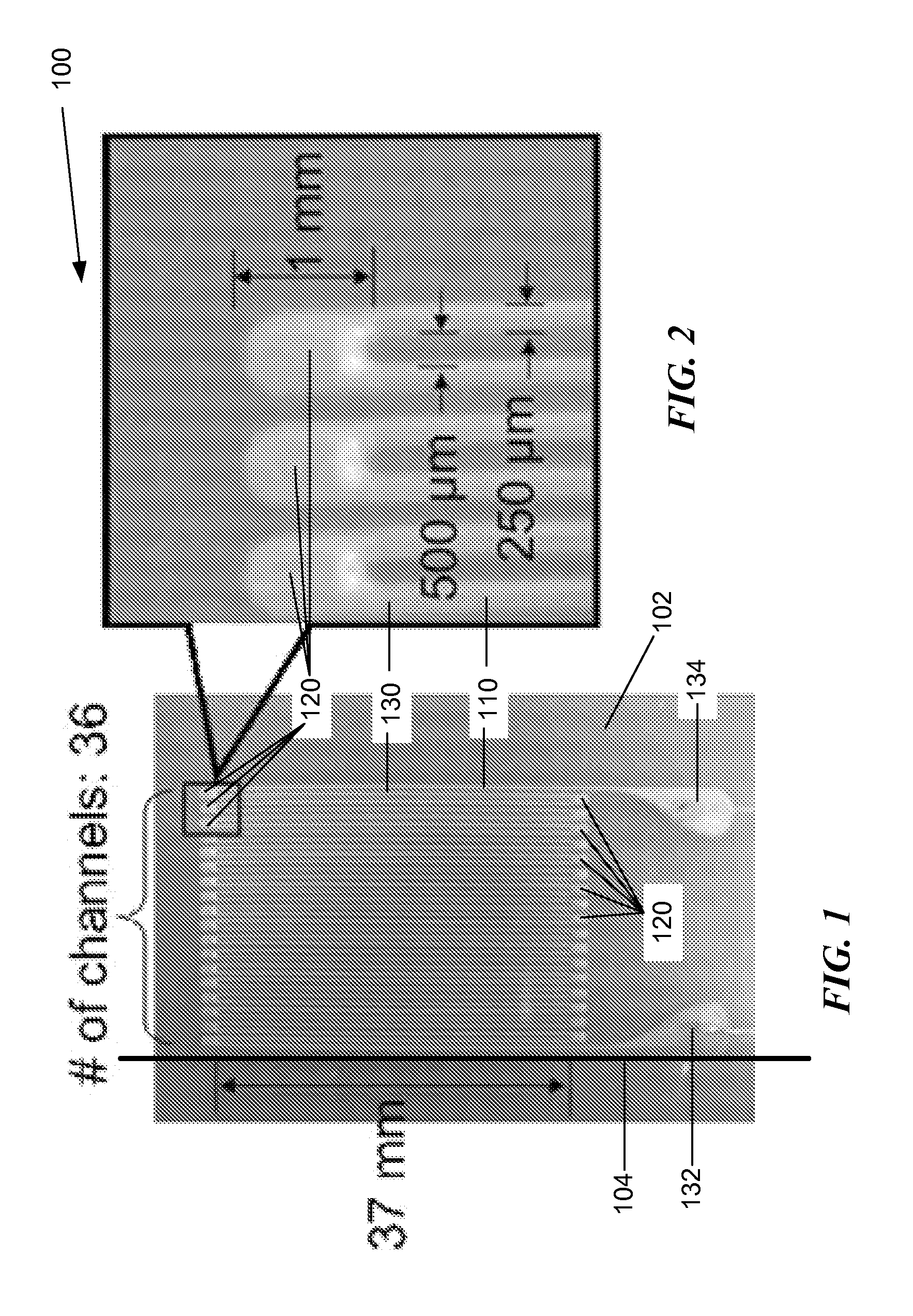

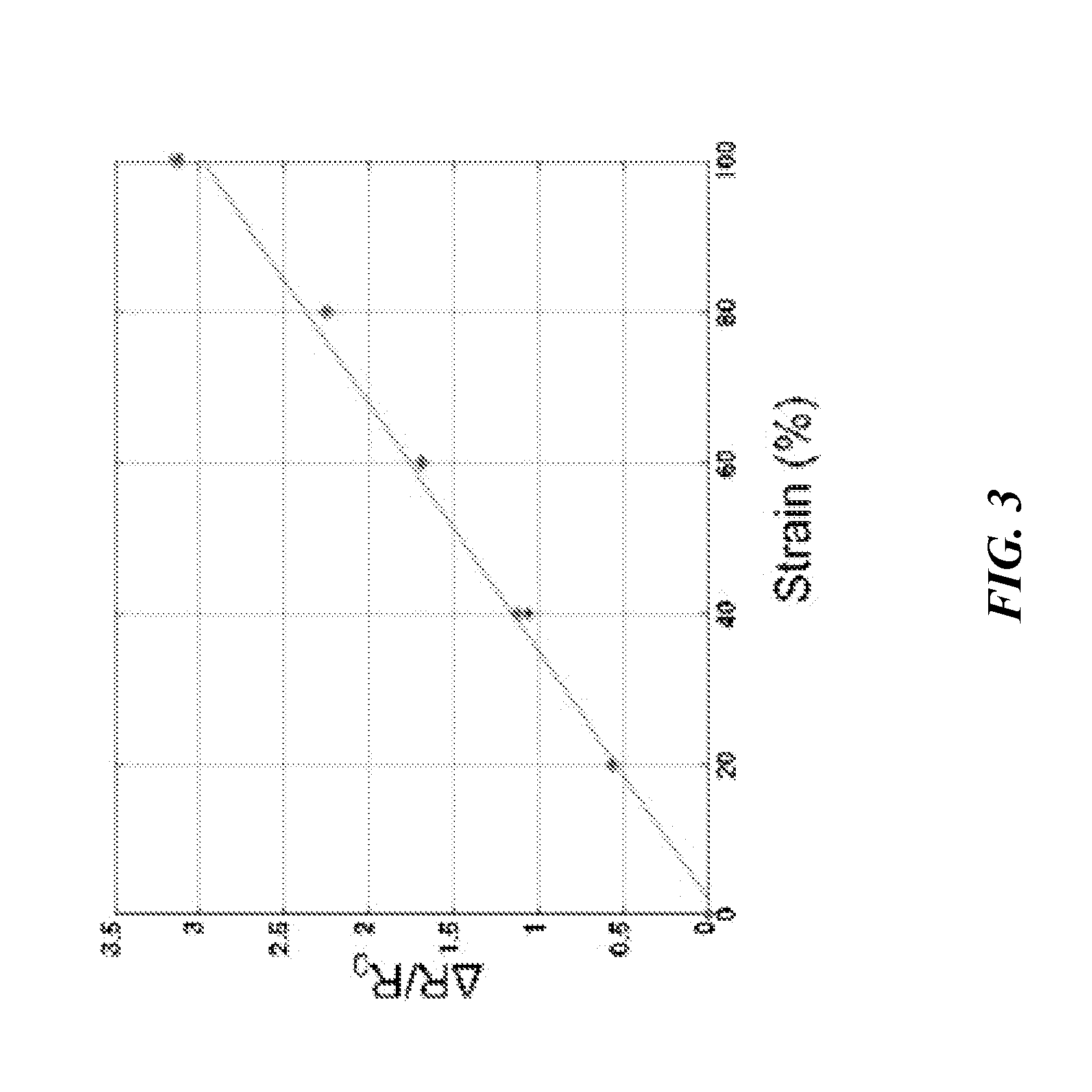

An elastic strain sensor can be incorporated into an artificial skin that can sense flexing by the underlying support structure of the skin to detect and track motion of the support structure. The unidirectional elastic strain sensor can be formed by filling two or more channels in an elastic substrate material with a conductive liquid. At the ends of the channels, a loop port connects the channels to form a serpentine channel. The channels extend along the direction of strain and the loop portions have sufficiently large cross-sectional area in the direction transverse to the direction of strain that the sensor is unidirectional. The resistance is measured at the ends of the serpentine channel and can be used to determine the strain on the sensor. Additional channels can be added to increase the sensitivity of the sensor. The sensors can be stacked on top of each other to increase the sensitivity of the sensor. In other embodiments, two sensors oriented in different directions can be stacked on top of each other and bonded together to form a bidirectional sensor. A third sensor formed by in the shape of a spiral or concentric rings can be stacked on top and used to sense contact or pressure, forming a three dimensional sensor. The three dimensional sensor can be incorporated into an artificial skin to provide advanced sensing.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

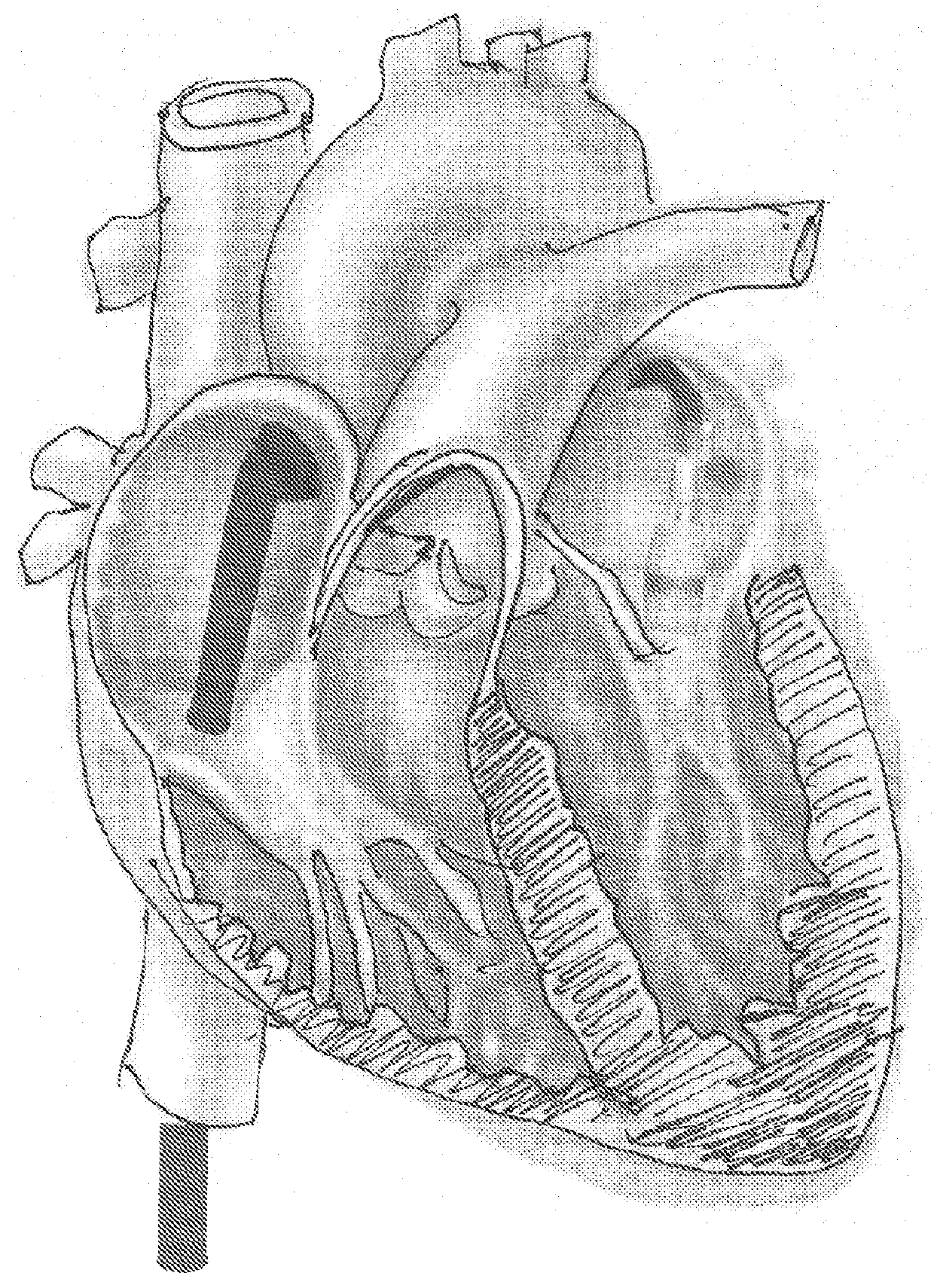

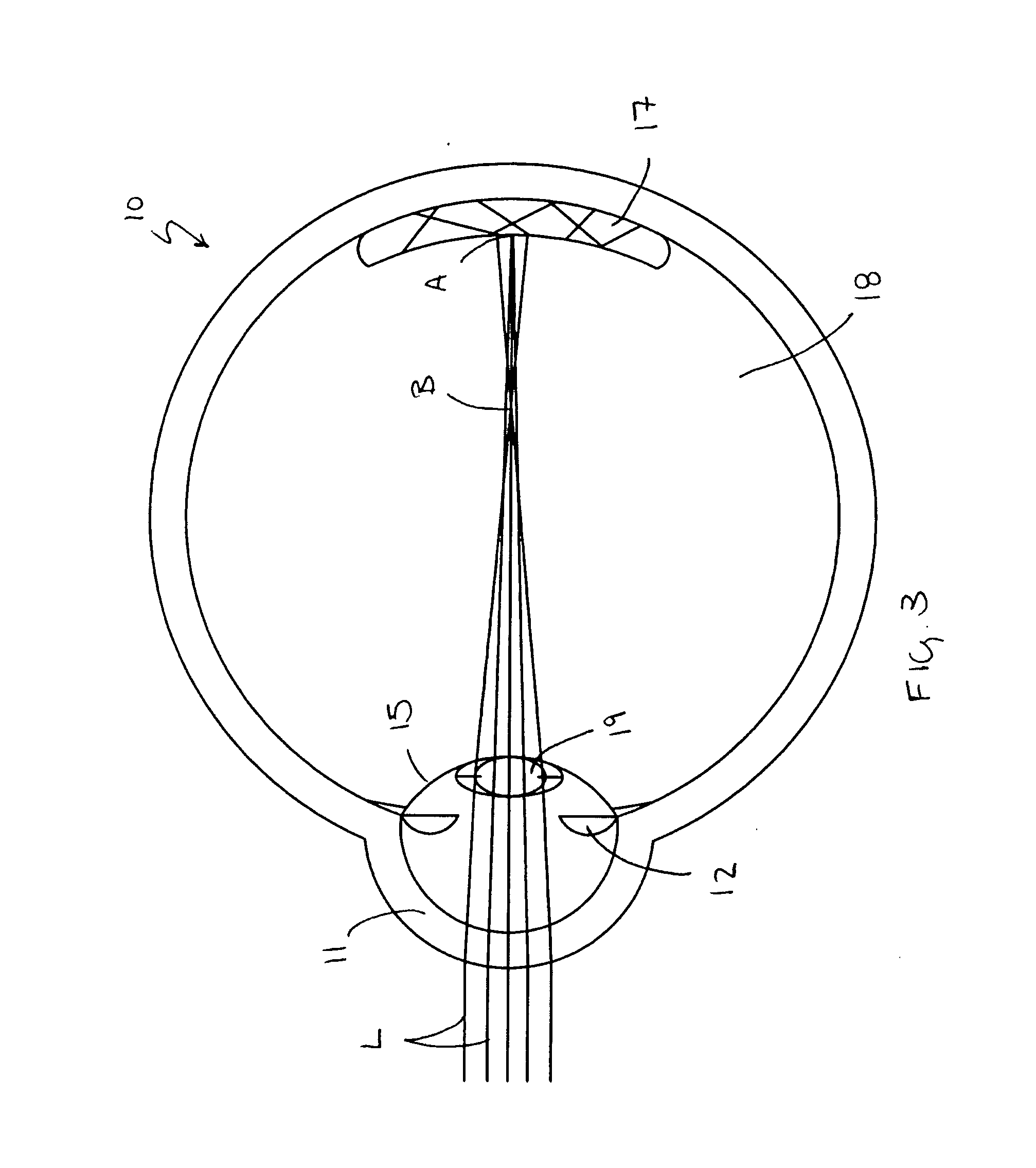

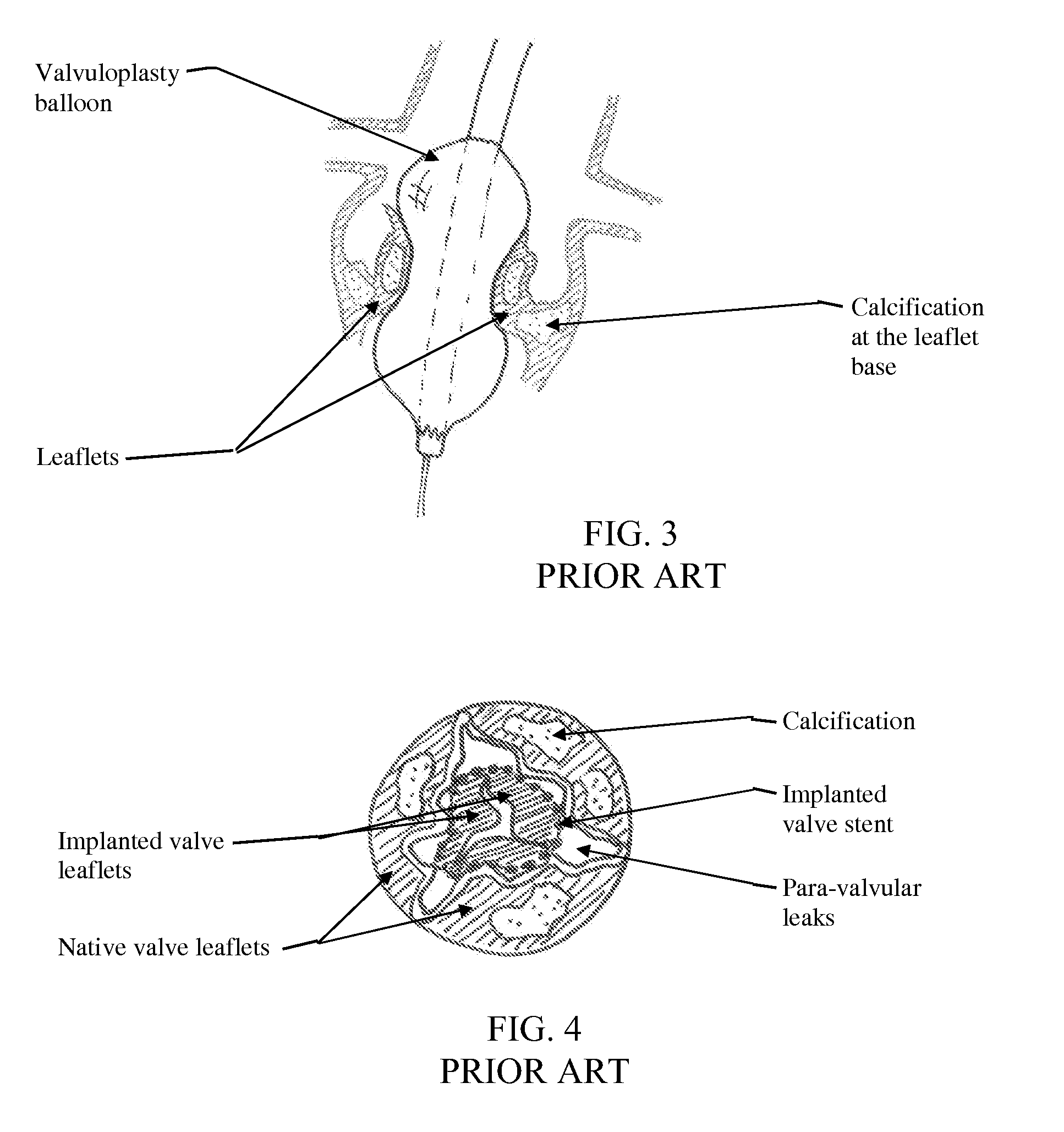

Fracturing calcifications in heart valves

ActiveUS20110118634A1Increase leaflet pliabilityImprove mobilityHeart valvesChiropractic devicesDistal portionCalcification

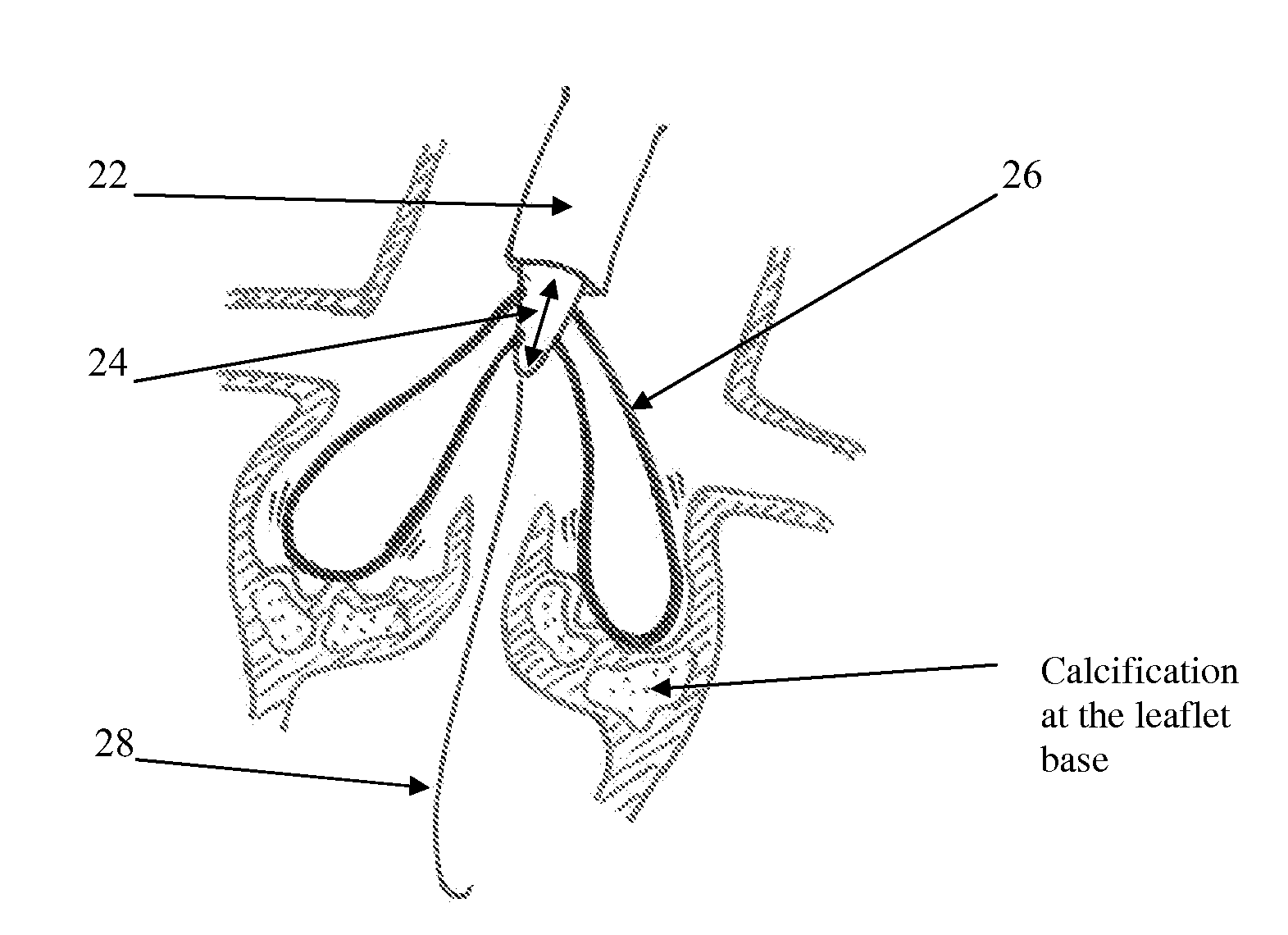

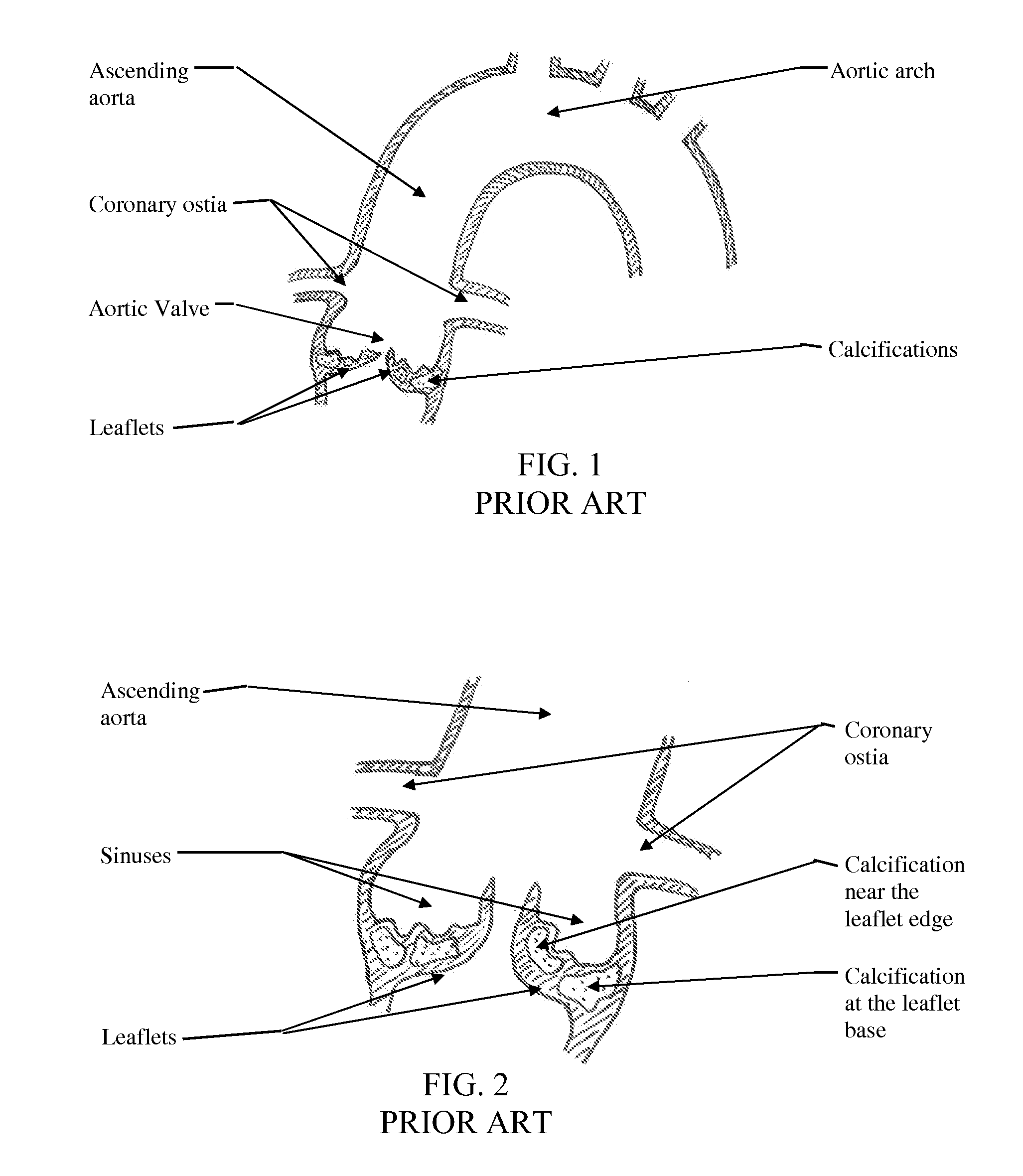

A device for fracturing calcifications in heart valves including a catheter (12, 22, 42) configured for percutaneous delivery to a heart valve, an fracture-producing element (14, 26, 46, 64, 66,82, 124, 152) disposed at a distal portion of the catheter and operative to vibrate and mechanically fracture calcifications when brought into contact with a calcification at a leaflet of the heart valve, and an energy source (34, 47, 79, 98, 152) operative to vibrate the fracture-producing element so that the fracture-producing element fractures the calcification without necessarily removing the calcification from the leaflet. The device may further comprise a valvuloplasty balloon (30), an embolic protection net (56) and a protective sleeve (110, 130).

Owner:PI CARDIA

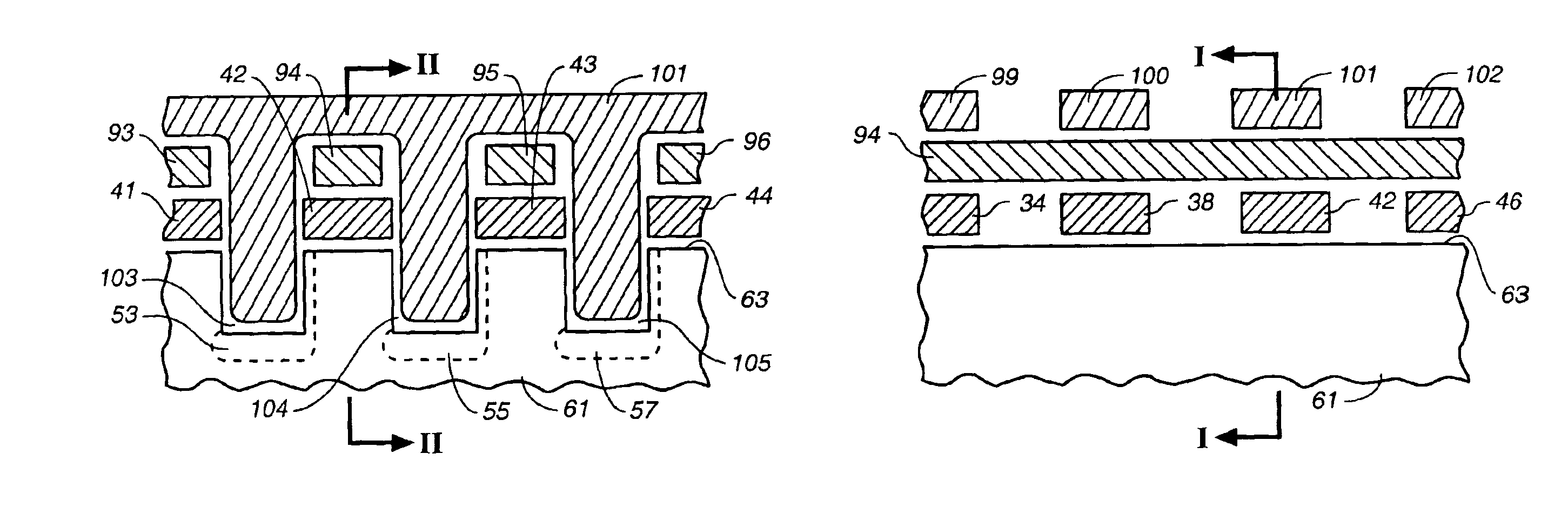

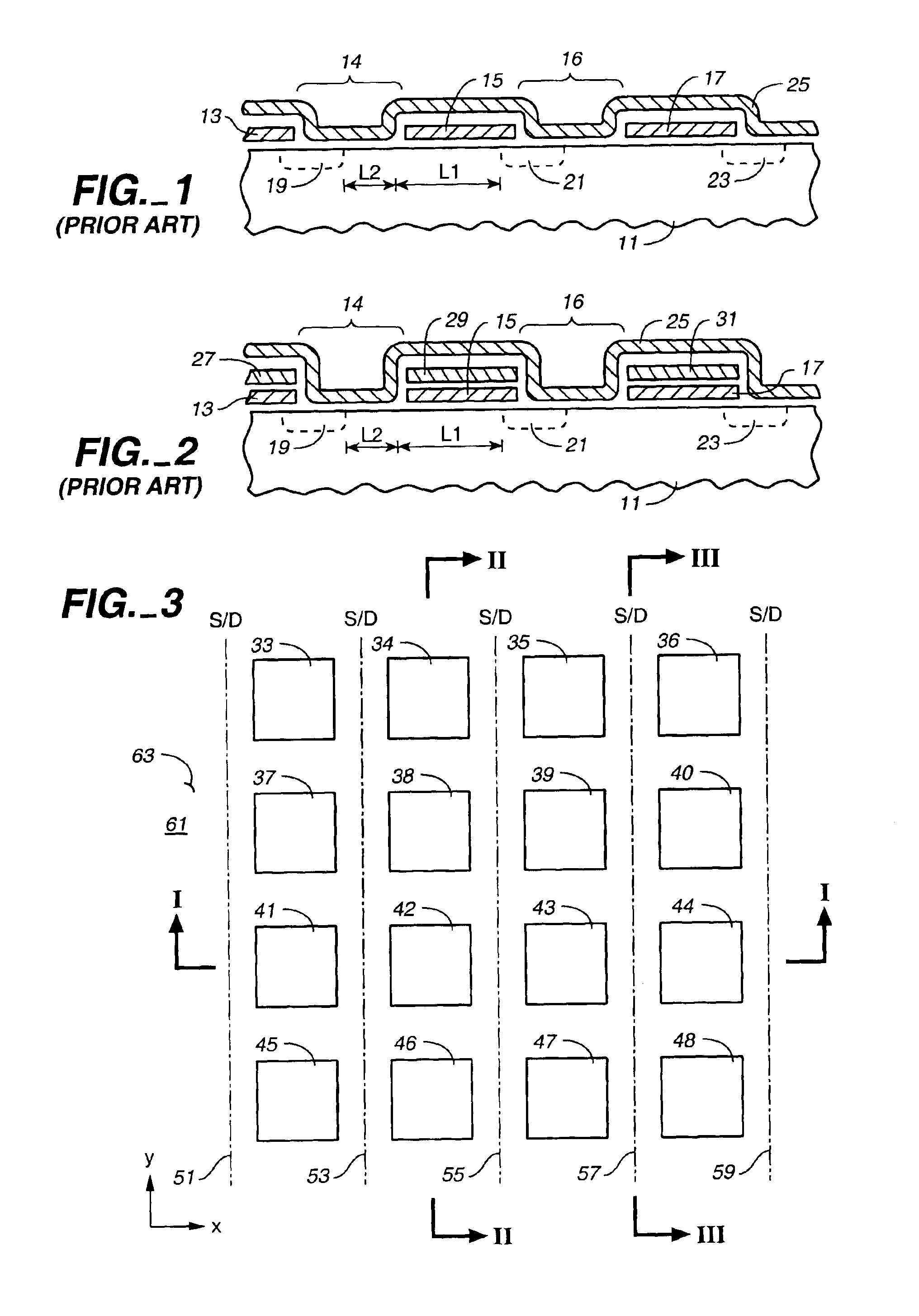

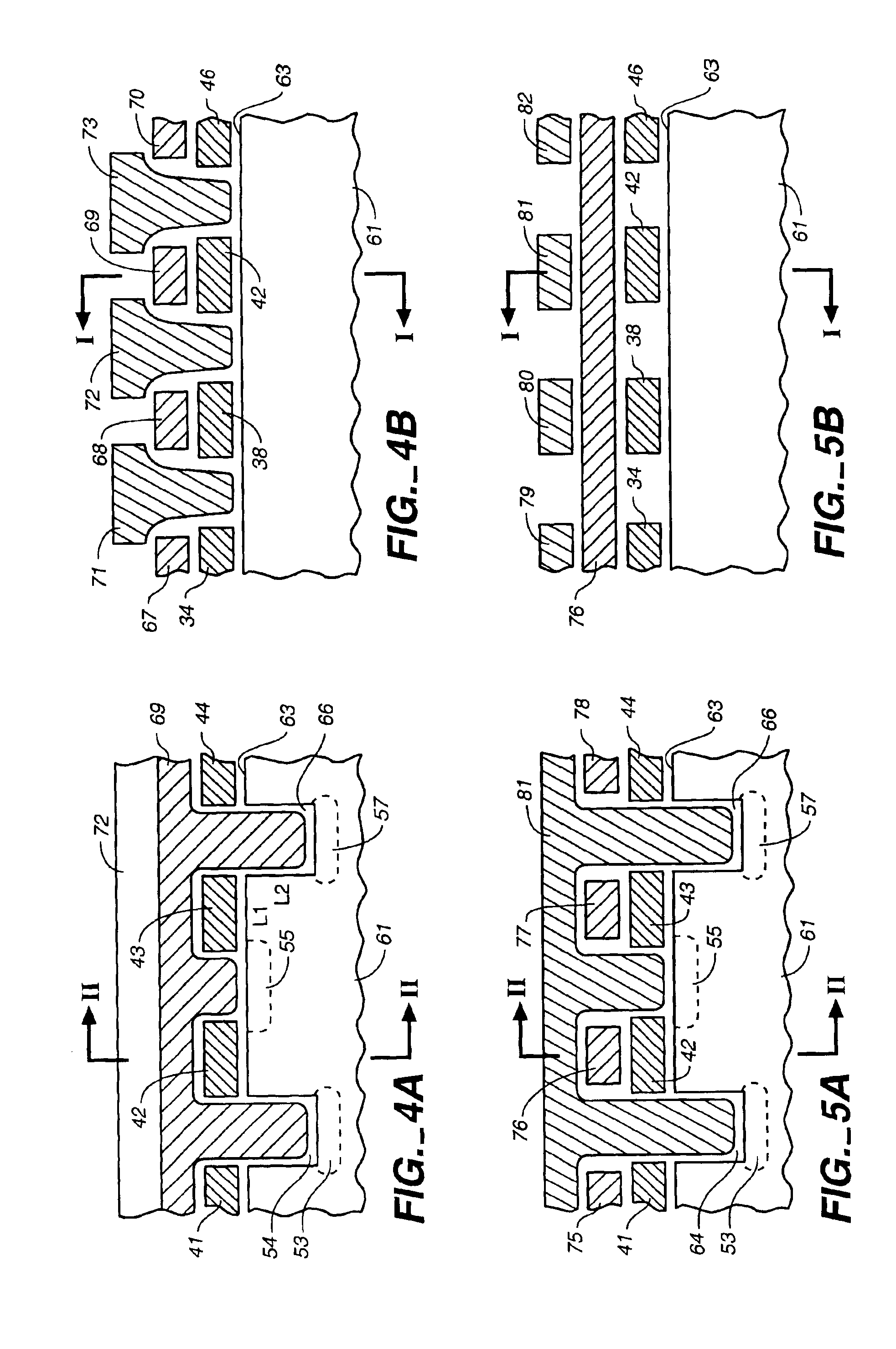

Non-volatile memory cells utilizing substrate trenches

InactiveUS6936887B2Small sizeImprove performanceTransistorSolid-state devicesCapacitanceCapacitive coupling

Several embodiments of flash EEPROM split-channel cell arrays are described that position the channels of cell select transistors along sidewalls of trenches in the substrate, thereby reducing the cell area. Select transistor gates are formed as part of the word lines and extend downward into the trenches with capacitive coupling between the trench sidewall channel portion and the select gate. In one embodiment, trenches are formed between every other floating gate along a row, the two trench sidewalls providing the select transistor channels for adjacent cells, and a common source / drain diffusion is positioned at the bottom of the trench. A third gate provides either erase or steering capabilities. In another embodiment, trenches are formed between every floating gate along a row, a source / drain diffusion extending along the bottom of the trench and upwards along one side with the opposite side of the trench being the select transistor channel for a cell. In another embodiment, select transistor gates of dual floating gate memory cells are extended into trenches or recesses in the substrate in order to lengthen the select transistor channel as the surface dimensions of the cell are being decreased. Techniques for manufacturing such flash EEPROM split-channel cell arrays are also included.

Owner:SANDISK TECH LLC

Head mounted display

InactiveUS7936519B2Improve rigidityIncrease the cross-sectional areaProjectorsOptical light guidesLight guideLight beam

Disclosed herein is a head mounted display including: an eyeglasses frame-like frame to be mounted onto an observer's head; and two image display devices, each of the image display devices including an image generating device, and light guide means which is mounted to the image generating device, which as a whole is located on the side of the center of an observer's face relative to the image generating device, on which beams emitted from the image generating device are incident, through which the beams are guided, and from which the beams are emitted toward an observer's pupil.

Owner:SONY CORP

Turbofan engine including fans with reduced speed

InactiveUS6209311B1Shorten speedIncrease the outer diameterGas turbine plantsEfficient propulsion technologiesImpellerFluid coupling

An impeller is directly driven by an output shaft of a core engine. The airflow produced by the impeller rotates an air turbine and a fan disposed integrally with the air turbine. The impeller and the air turbine form a fluid coupling which serves also as a speed reducing mechanism. The rotational speed of the fan can be reduced to be lower than that of the output shaft while retaining efficiency of the core engine. The outer diameter of the fan can be increased, raising a bypass ratio.

Owner:NIKKISO COMPANY

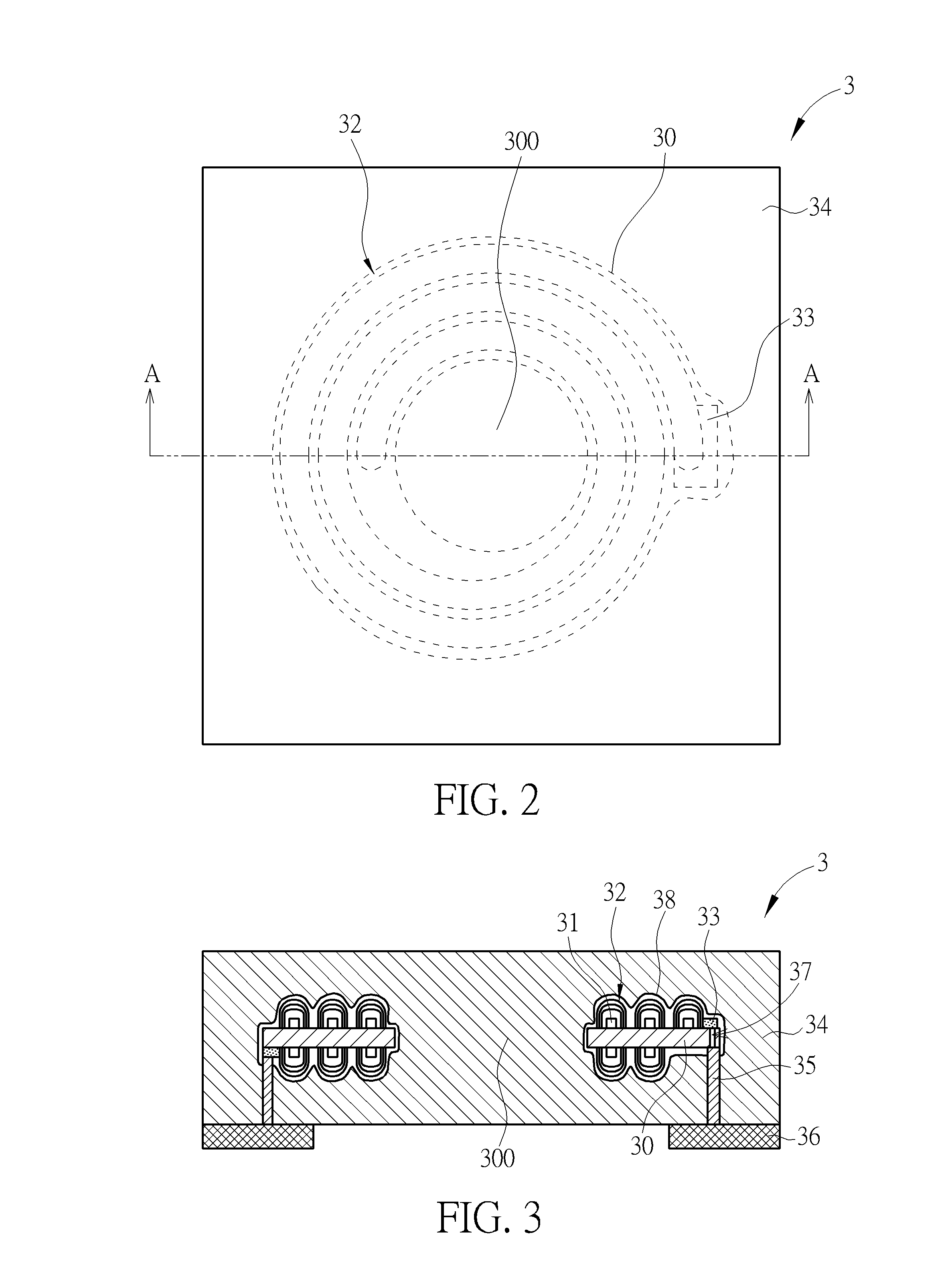

Method of manufacturing multi-layer coil and multi-layer coil device

ActiveUS20150035640A1Less spaceImprove featuresTransformers/inductances coils/windings/connectionsPrinted inductancesEngineeringElectroplating

A method of manufacturing a multi-layer coil includes steps of providing a substrate; forming a seed layer on the substrate; and plating the seed layer with N coil layers by N current densities according to N threshold ranges, so as to form the multi-layer coil on the substrate, wherein an i-th current density of the N current densities is lower than an (i+1)-th current density of the N current densities. A first coil layer of the N coil layers is plated on the seed layer by a first current density of the N current densities. When an aspect ratio of an i-th coil layer of the N coil layers is within an i-th threshold range of the N threshold ranges, an (i+1)-th coil layer of the N coil layers is plated on the i-th coil layer by the (i+1)-th current density.

Owner:CYNTEC

Lighting apparatus

InactiveUS7534011B2Reduce the cross-sectional areaIncrease the cross-sectional areaClimate change adaptationLighting heating/cooling arrangementsEngineeringMechanical engineering

Owner:INT GROWERS SUPPLY

Access catheter having dilation capability and related methods

ActiveUS7476232B2Adequate accessIncrease the cross-sectional areaSurgeryDilatorsMedical deviceGuide tube

Various embodiments of a medical device having a dilation capability and related methods are disclosed. For example, the medical device may include a distal assembly having a radially expandable body defining a passageway therethrough, and a control member extending from the distal assembly to a proximal end of the device. Actuation of the control member may apply a compressive force to the body, causing the body to radially expand and a cross-sectional area of the passageway to increase.

Owner:BOSTON SCI SCIMED INC

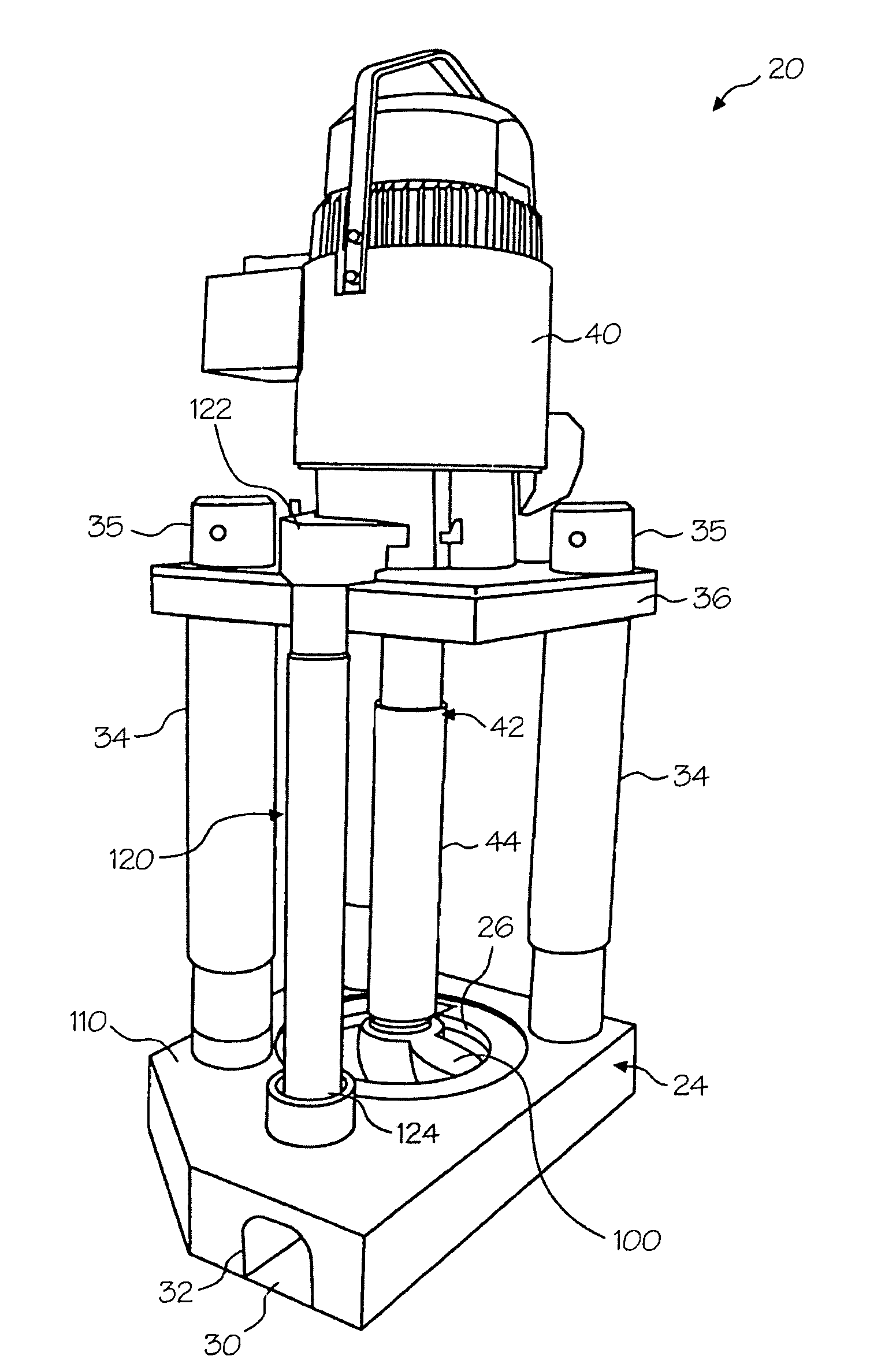

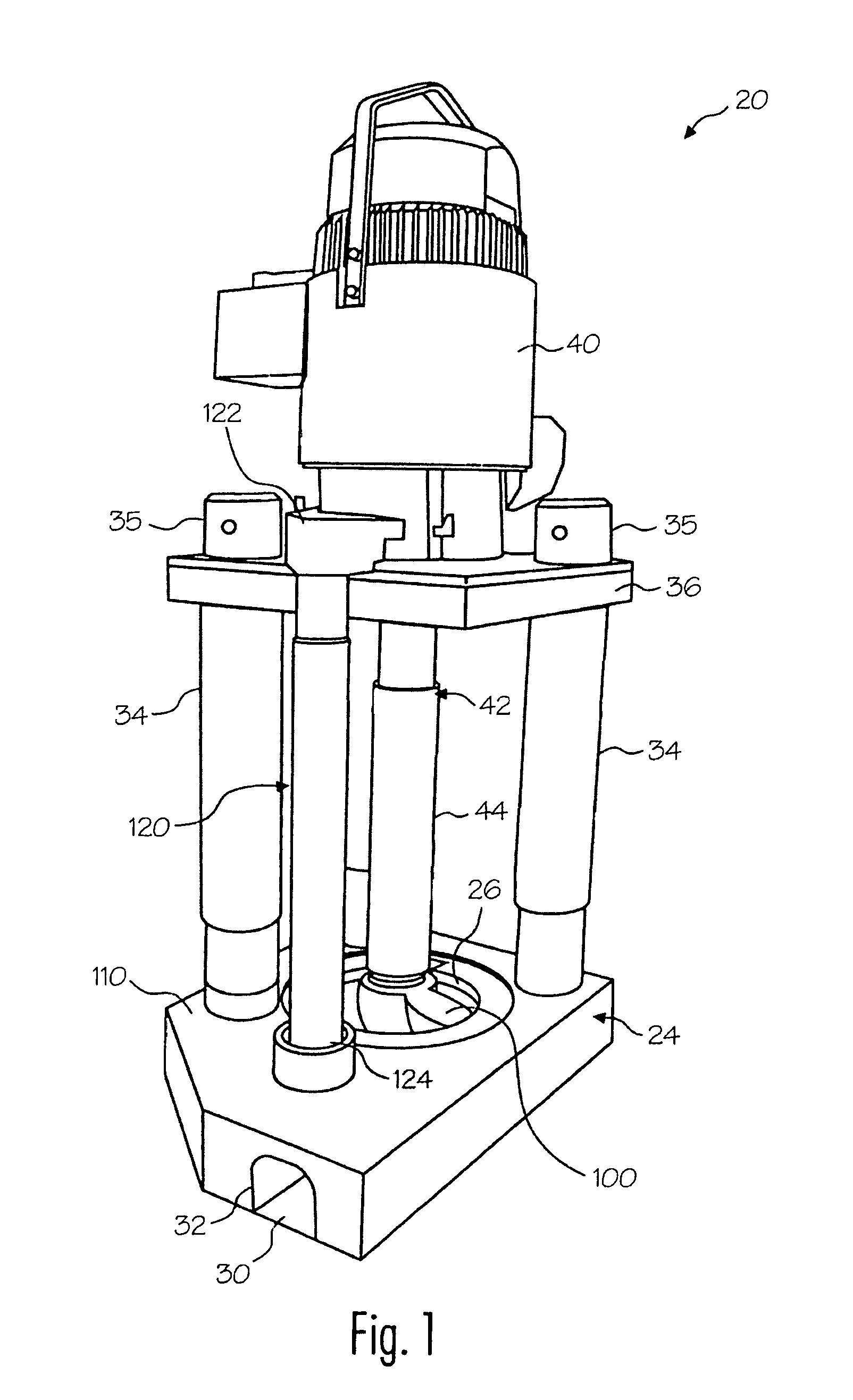

System for releasing gas into molten metal

InactiveUS20080213111A1Reduce amountIncrease the cross-sectional areaSpecific fluid pumpsEngine manufactureMetallurgyGas release

A device for releasing gas into molten metal includes a base having a discharge. The discharge has a first section including a first cross-sectional area and a second section including a second cross-sectional area, wherein the first section is upstream of the second section and the first cross-sectional area is smaller than the second cross-sectional area. A gas-release opening is positioned so that it can release gas into one or more of the first section or the second section. As the molten metal moves from the first cross-sectional area to the second cross-sectional area gas is released into the molten metal and the molten metal flow helps to draw the gas into the flow, thereby lowering the pressure required to release gas into the molten metal. Metal-transfer conduits other than a discharge incorporated in a pump base are also disclosed, as are pumps including either a discharge or other metal-transfer conduit according to the invention.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

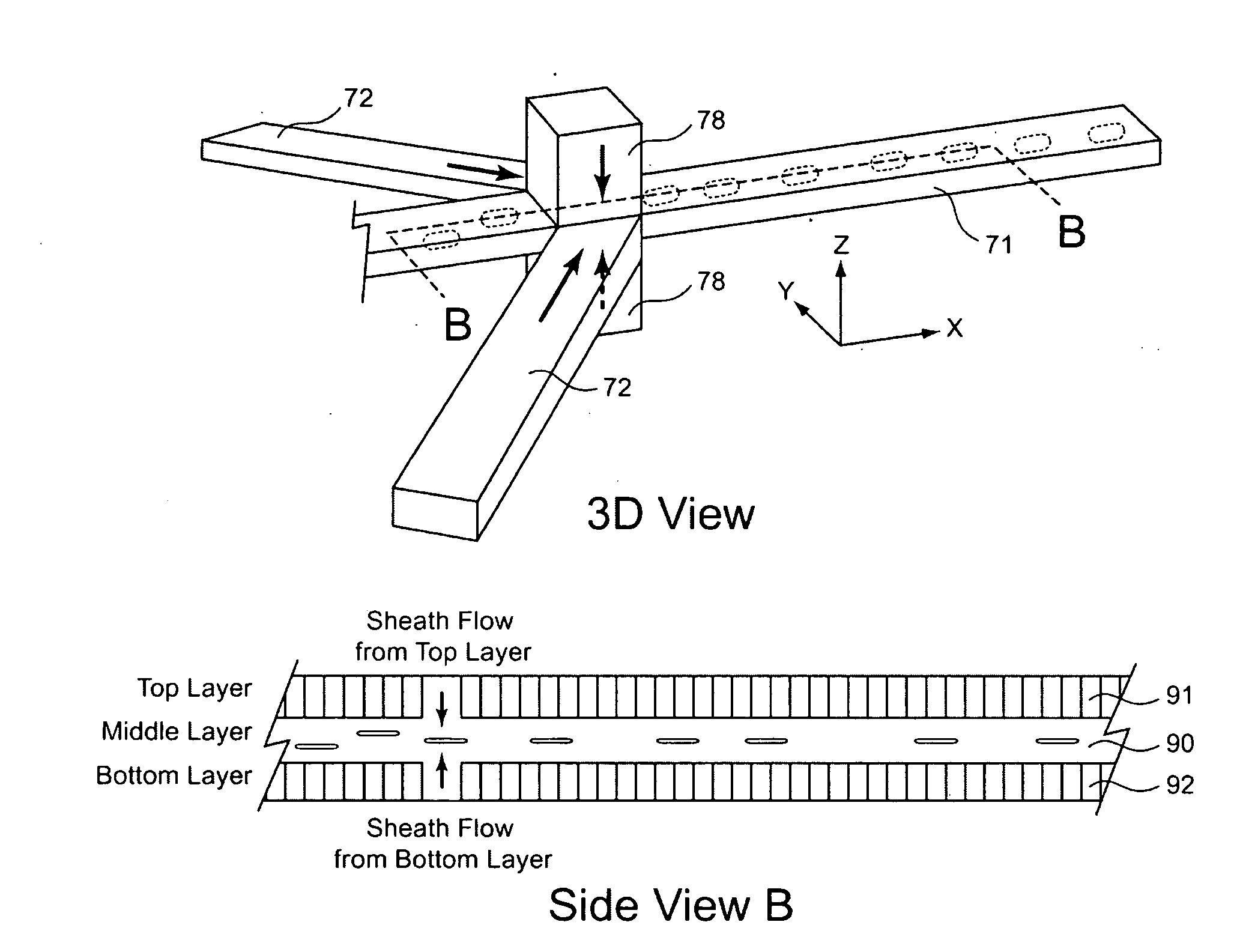

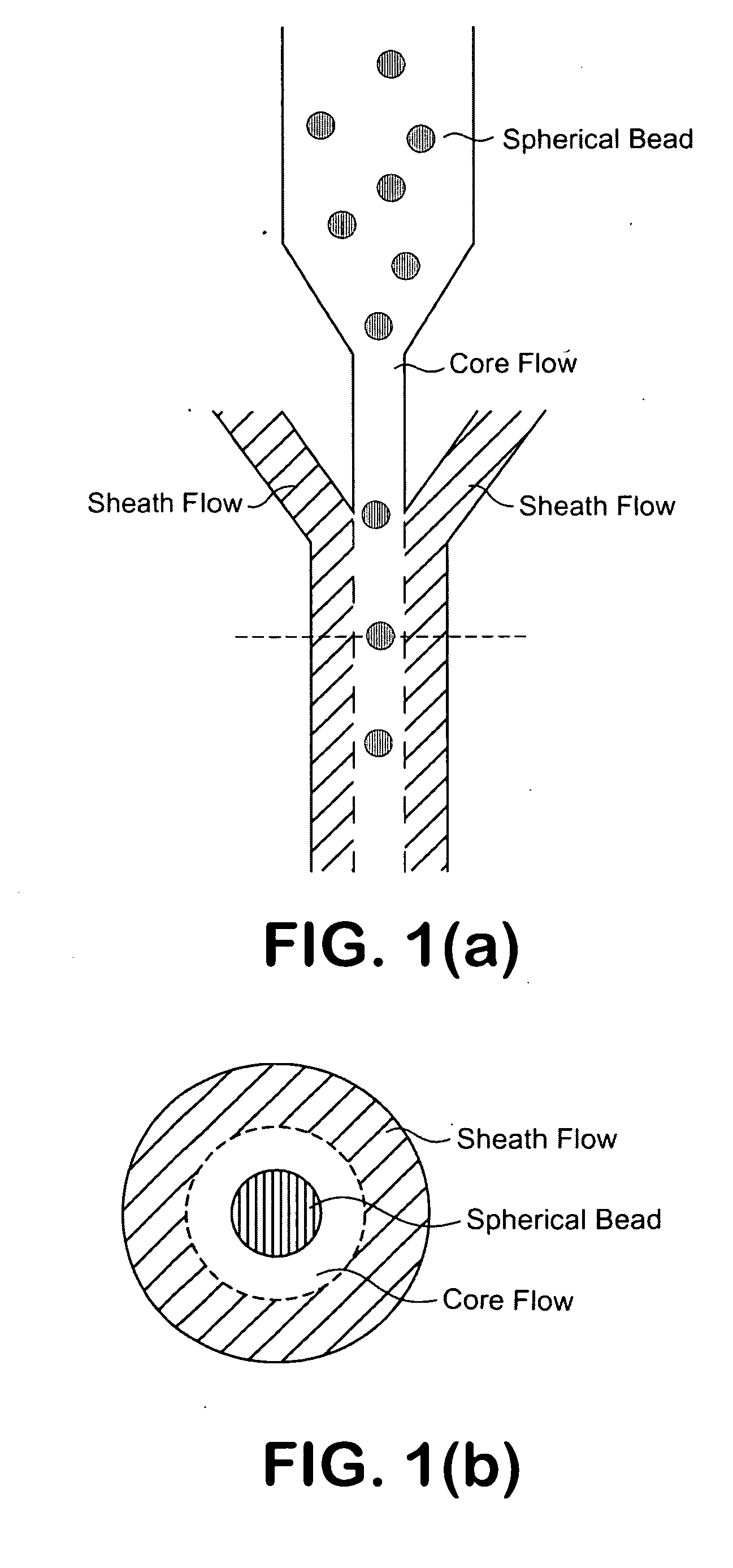

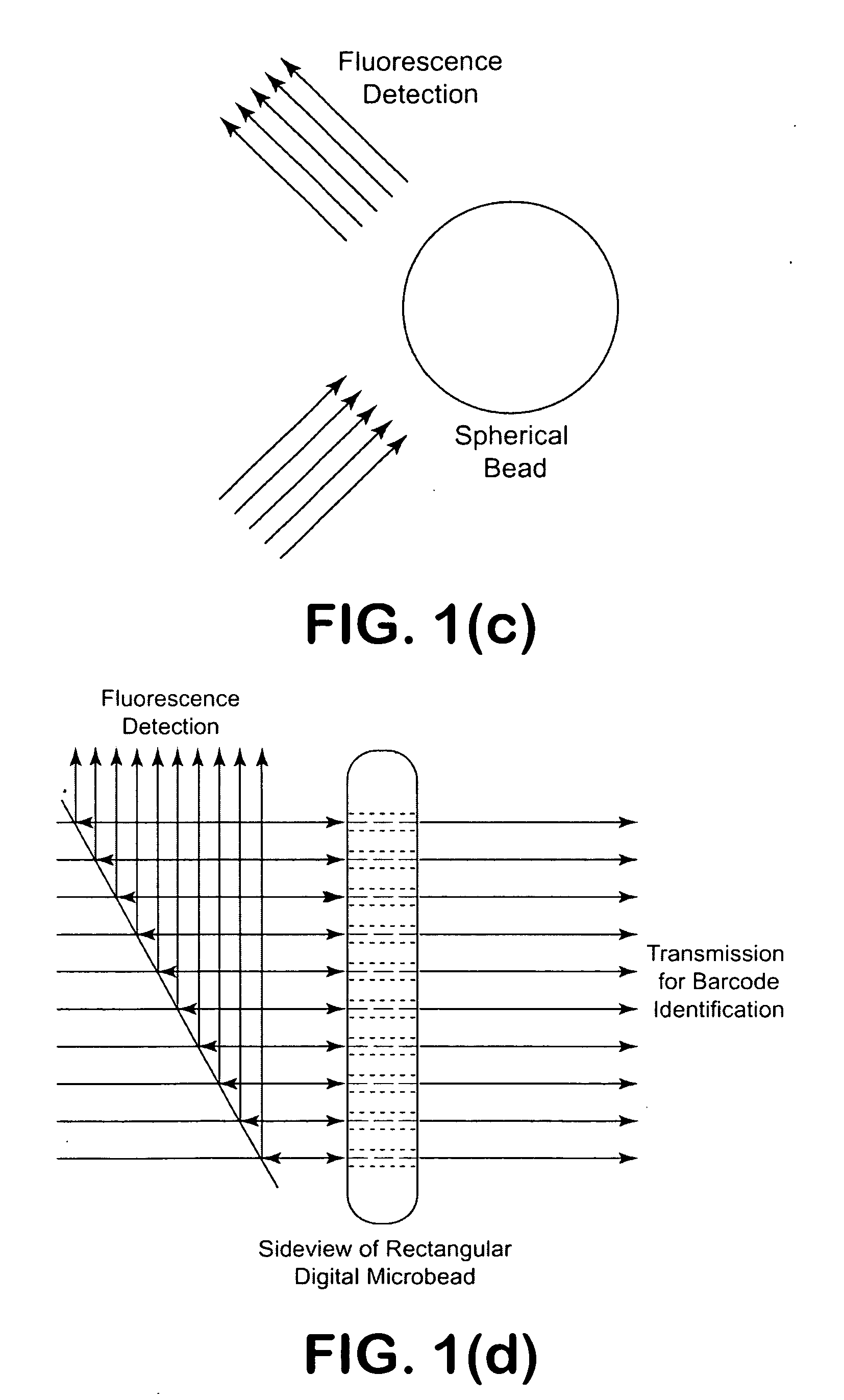

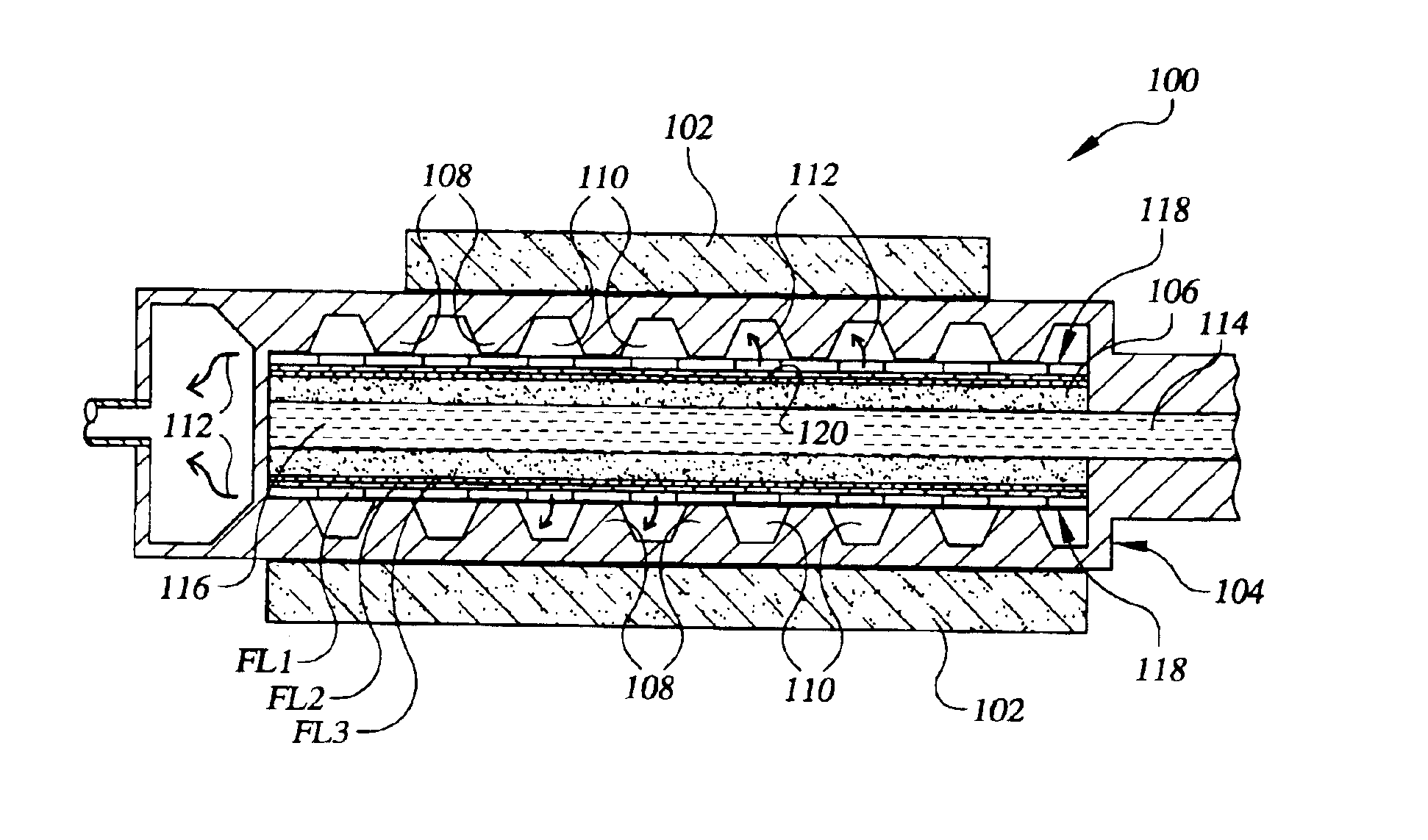

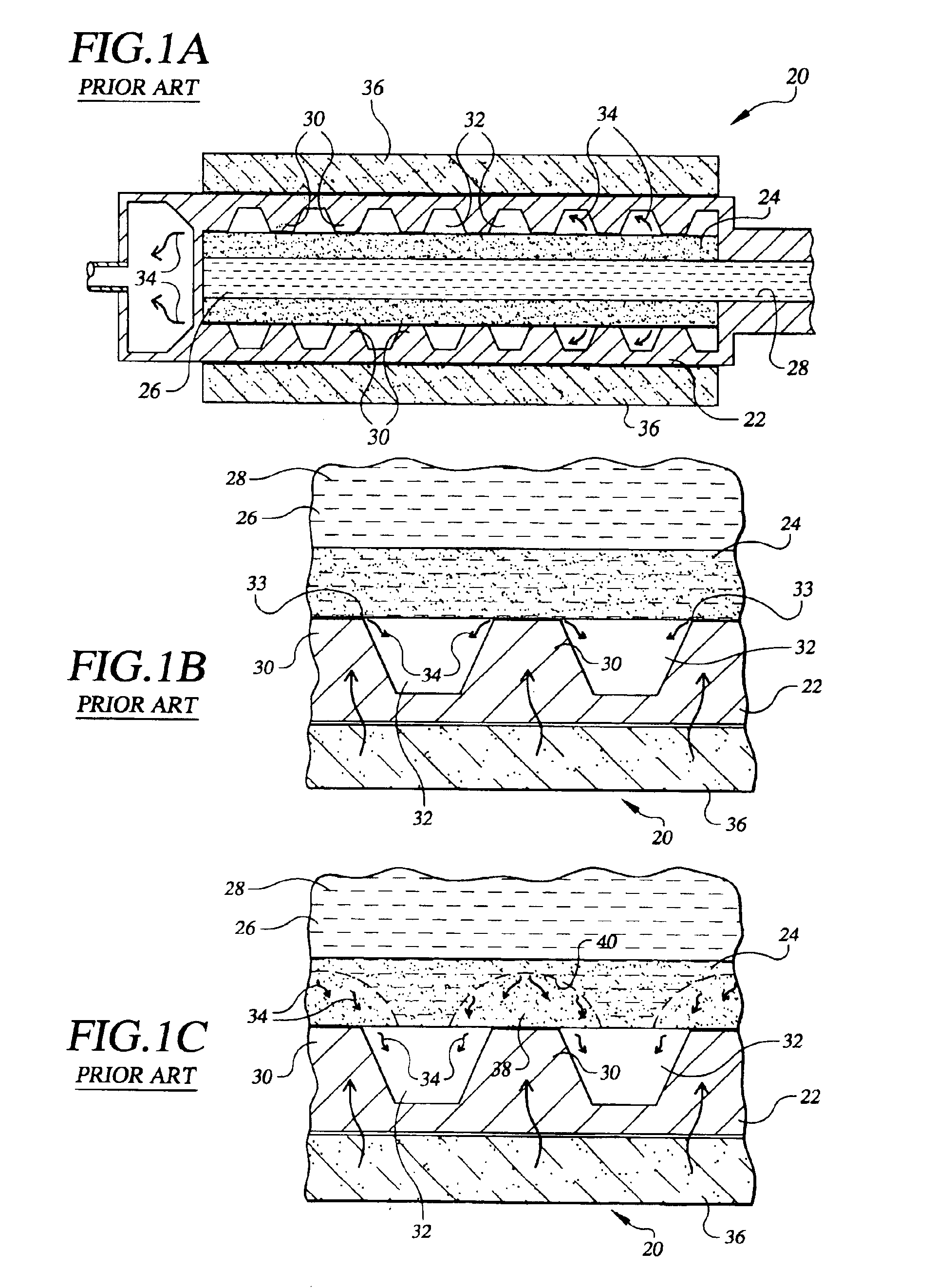

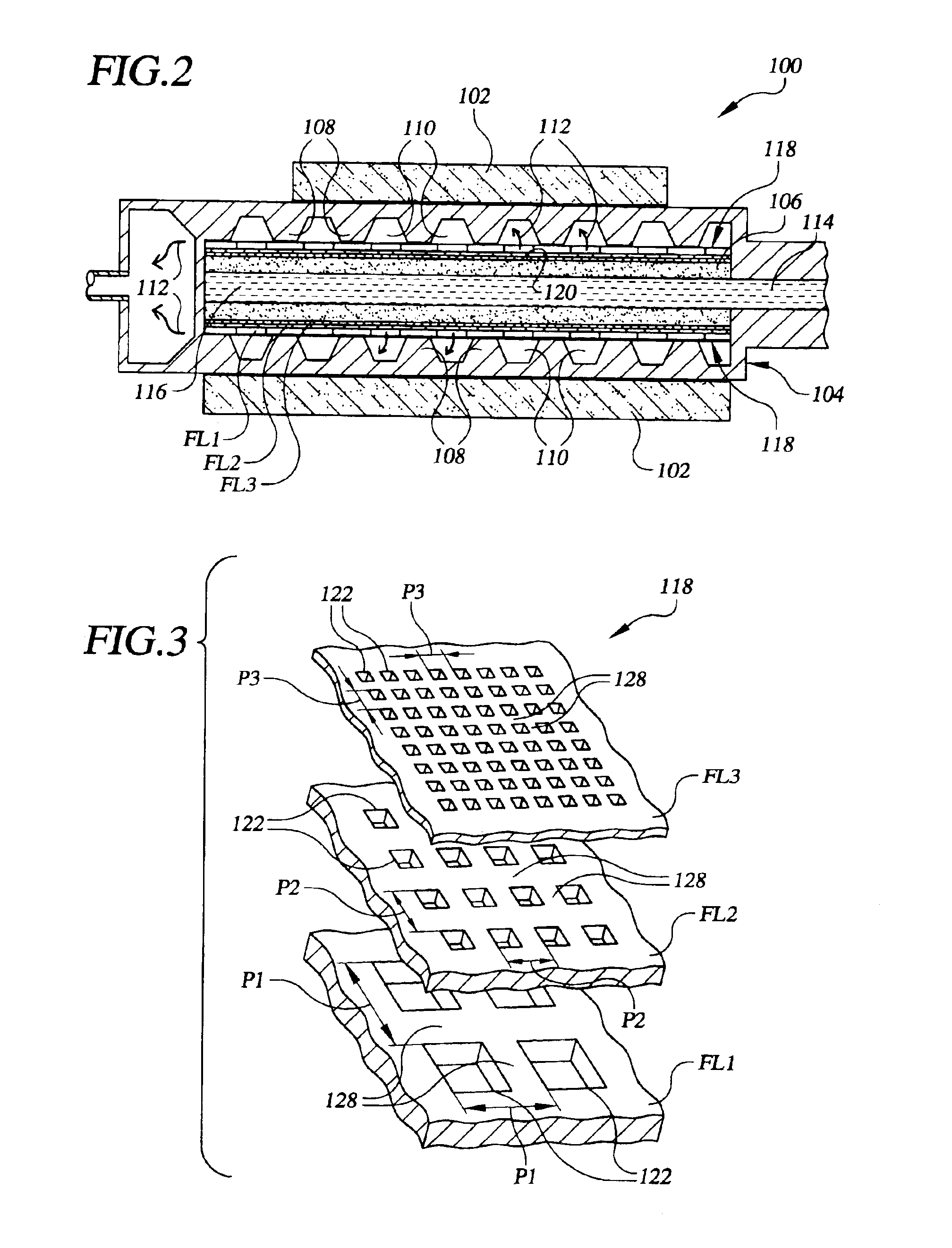

Hydrodynamic focusing for analyzing rectangular microbeads

InactiveUS20090201504A1Improve liquidityNo cloggingVolume/mass flow measurementMaterial analysis by optical meansBarcodeEngineering

A microfluidic apparatus having a one-dimensional or two-dimensional hydrodynamic flow system to control stable and proper digitally coded bead orientation through the optical detection area of a bioanalysis system. The hydrodynamic system include one core flow, which carries the rectangular barcode beads, and sheath flows, on the sides of or about or around the outer periphery of the core flow, pull the core flow into a proper orientation. The sheath flows, at much higher flow speed but lower volume flow rate, can be pushed or pulled by vacuum, gravity, or pressure. By this method, the coded bead will align themselves in line and flow reliably, without wobbling or flipping, in the core flow channel through the detection zone. By adjusting the relative flow rate of core flow and sheath flows, the coded beads flow reliably in the flow system, thus it can be decoded and detected by an optical system accurately.

Owner:MAXWELL SENSORS

Capillary evaporator

Owner:MIKROS MFG

Process utilizing pre-formed cluster catalysts for making single-wall carbon nanotubes

InactiveUS6913789B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFibre chemical featuresGas phaseMetal catalyst

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

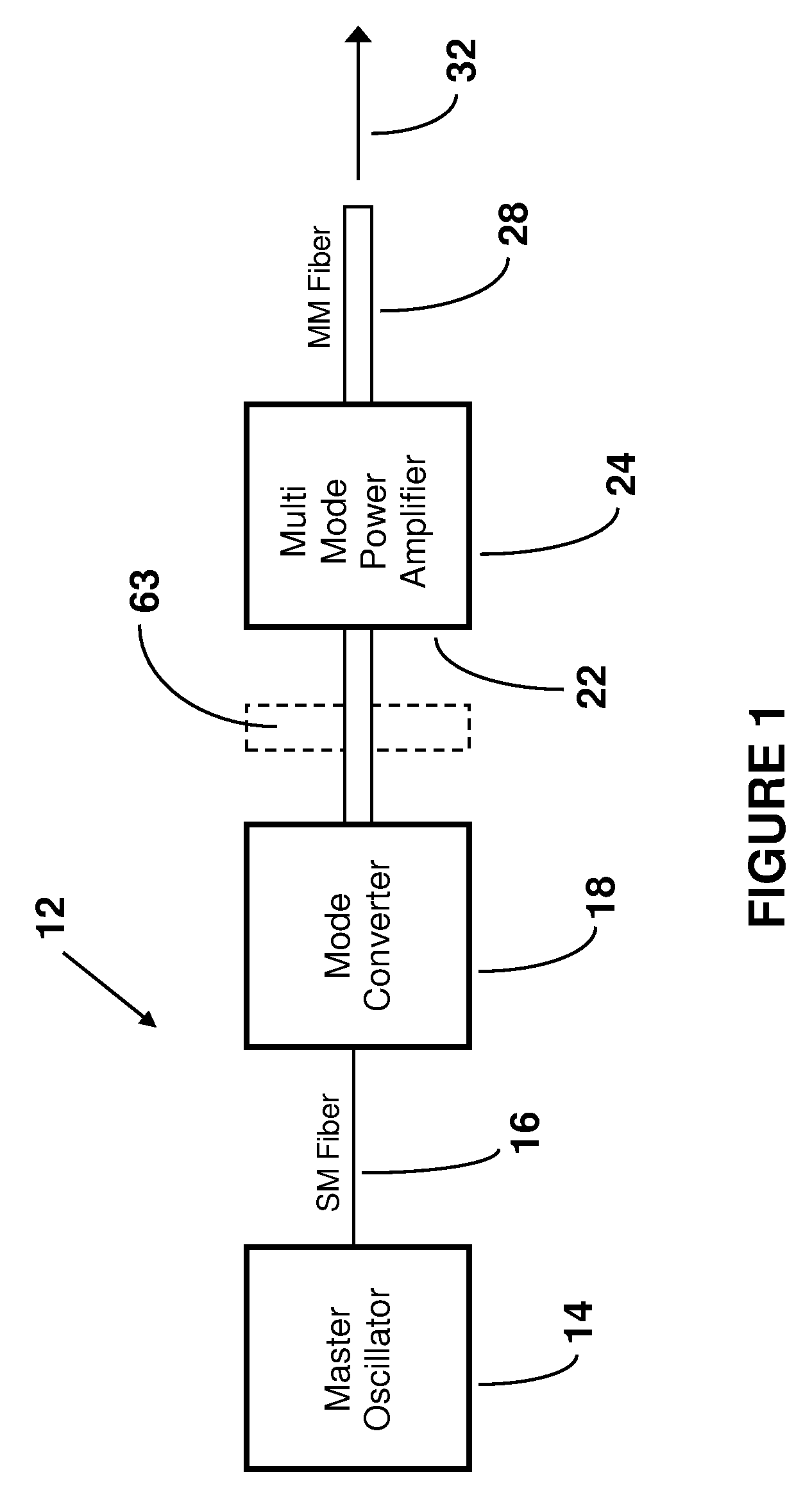

Optical fiber laser, and components for an optical fiber laser, having reduced susceptibility to catastrophic failure under high power operation

ActiveUS20090080835A1Avoid damageReduce susceptibilityLaser using scattering effectsOptical fibre with graded refractive index core/claddingStimulated emissionInterconnection

Optical fiber lasers and components for optical fiber laser. An optical fiber laser can comprise a fiber laser cavity having a wavelength of operation at which the cavity provides output light, the cavity including optical fiber that guides light having the wavelength of operation, the fiber having first and second lengths, the first length having a core having a V-number at the wavelength of operation and a numerical aperture, the second length having a core that is multimode at the wavelength of operation and that has a V-number that is greater than the V-number of the core of the first length optical fiber at the wavelength of operation and a numerical aperture that is less than the numerical aperture of the core of the first length of optical fiber. At least one of the lengths comprises an active material that can provide light having the wavelength of operation via stimulated emission responsive to the optical fiber receiving pump light. Components include a mode field adapter and optical fiber interconnection apparatus, which can be used to couple the first and second lengths of optical fiber, or can couple the fiber laser to an optical fiber power amplifier, which can be a multimode or single mode amplifier.

Owner:NUFERN

Accommodating intraocular lens system having circumferential haptic support and method

ActiveUS20070203578A1Reduce compressionIncrease the internal volumeIntraocular lensIntraocular lensOptical power

An accommodating intraocular lens includes an optic portion a haptic portion and a backstop. The optic portion of the lens includes an actuator that deflects a lens element to alter the optical power of the lens responsive to forces applied to the haptic portion of the lens by contraction of the ciliary muscles. Forces applied to the haptic portion may result in fluid displacements from or to the haptic portion from the actuator. The backstop provides support to the haptic so that bulk translation of the haptic is prevented in response to the forces applied by the capsular sac.

Owner:ALCON INC

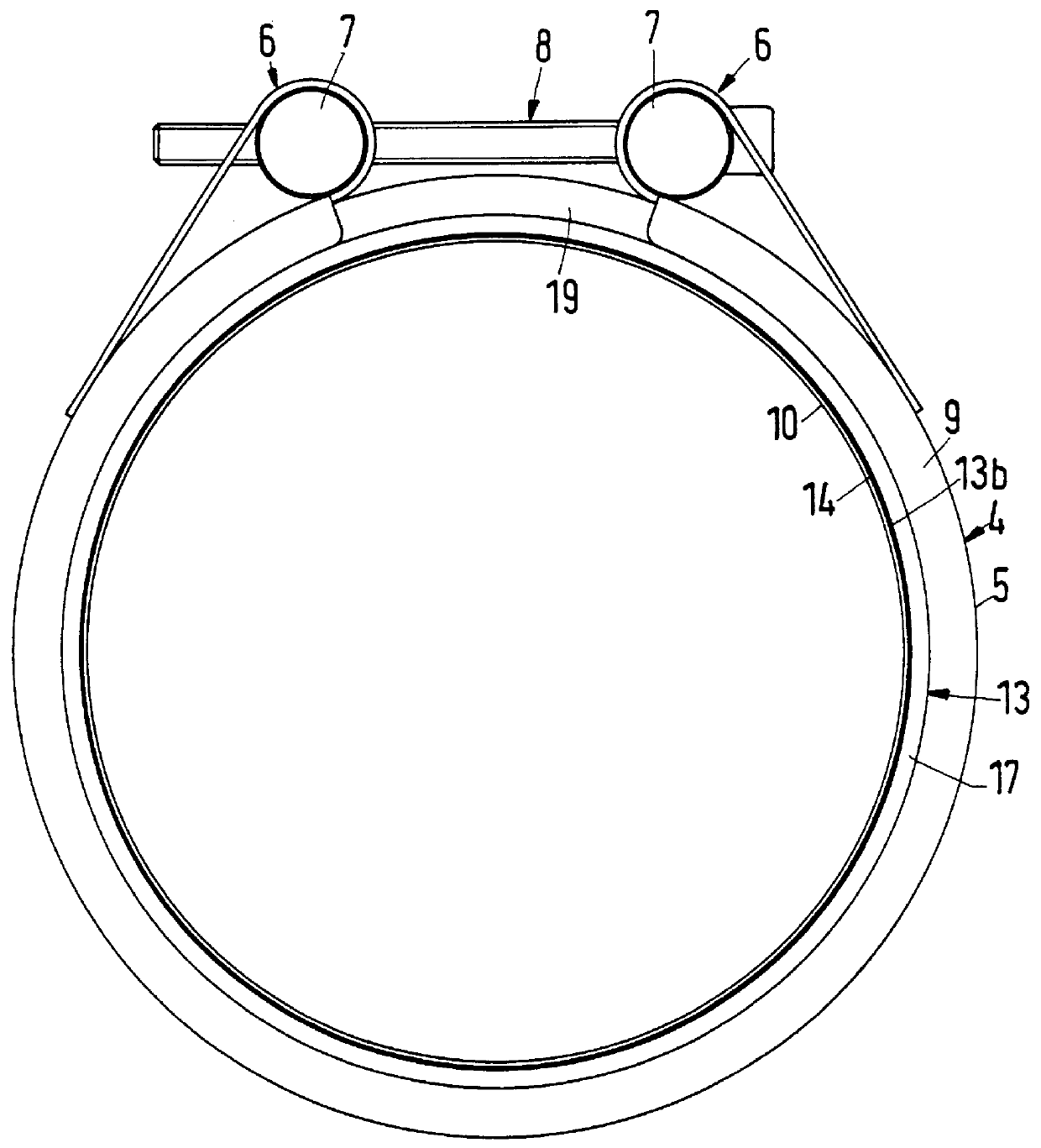

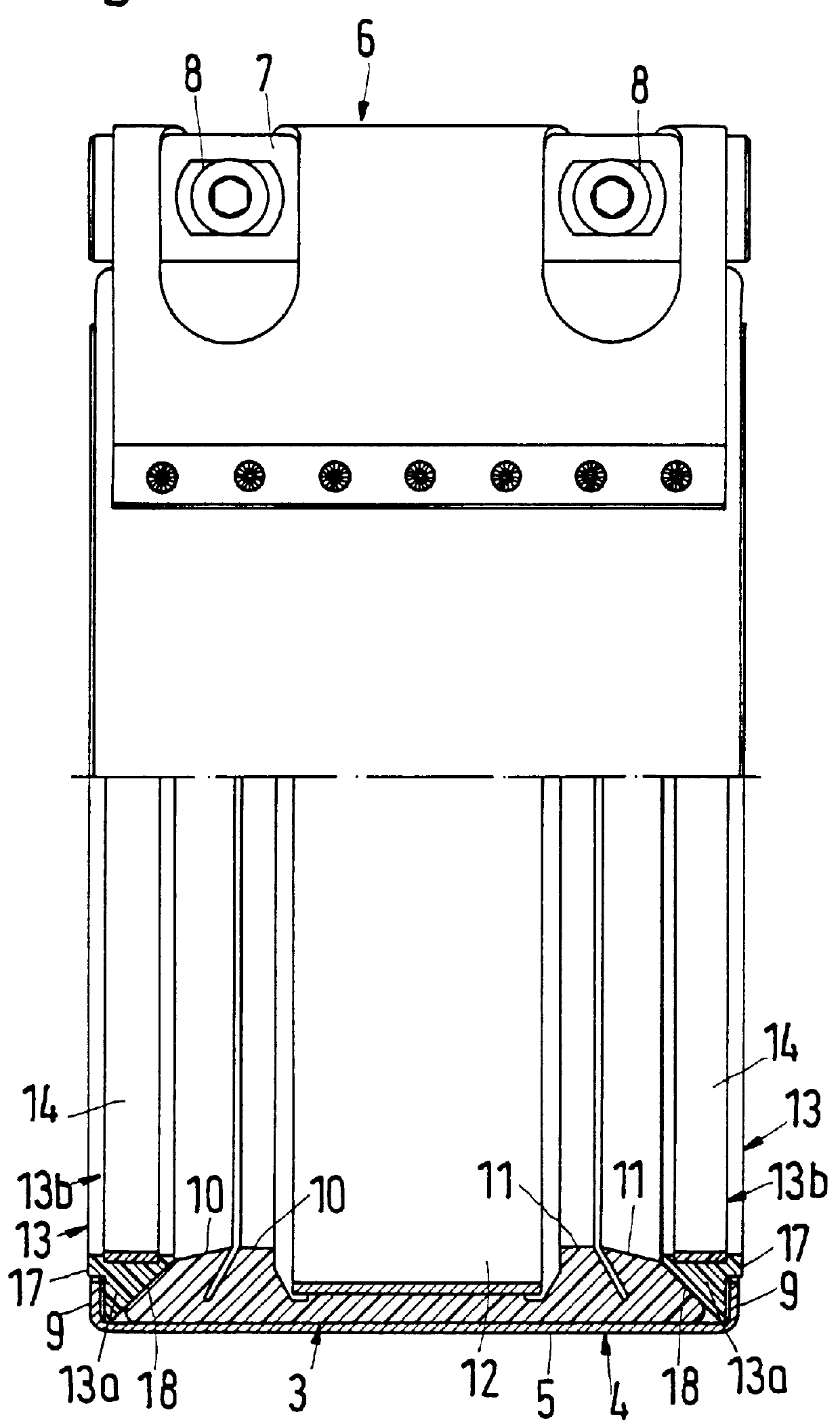

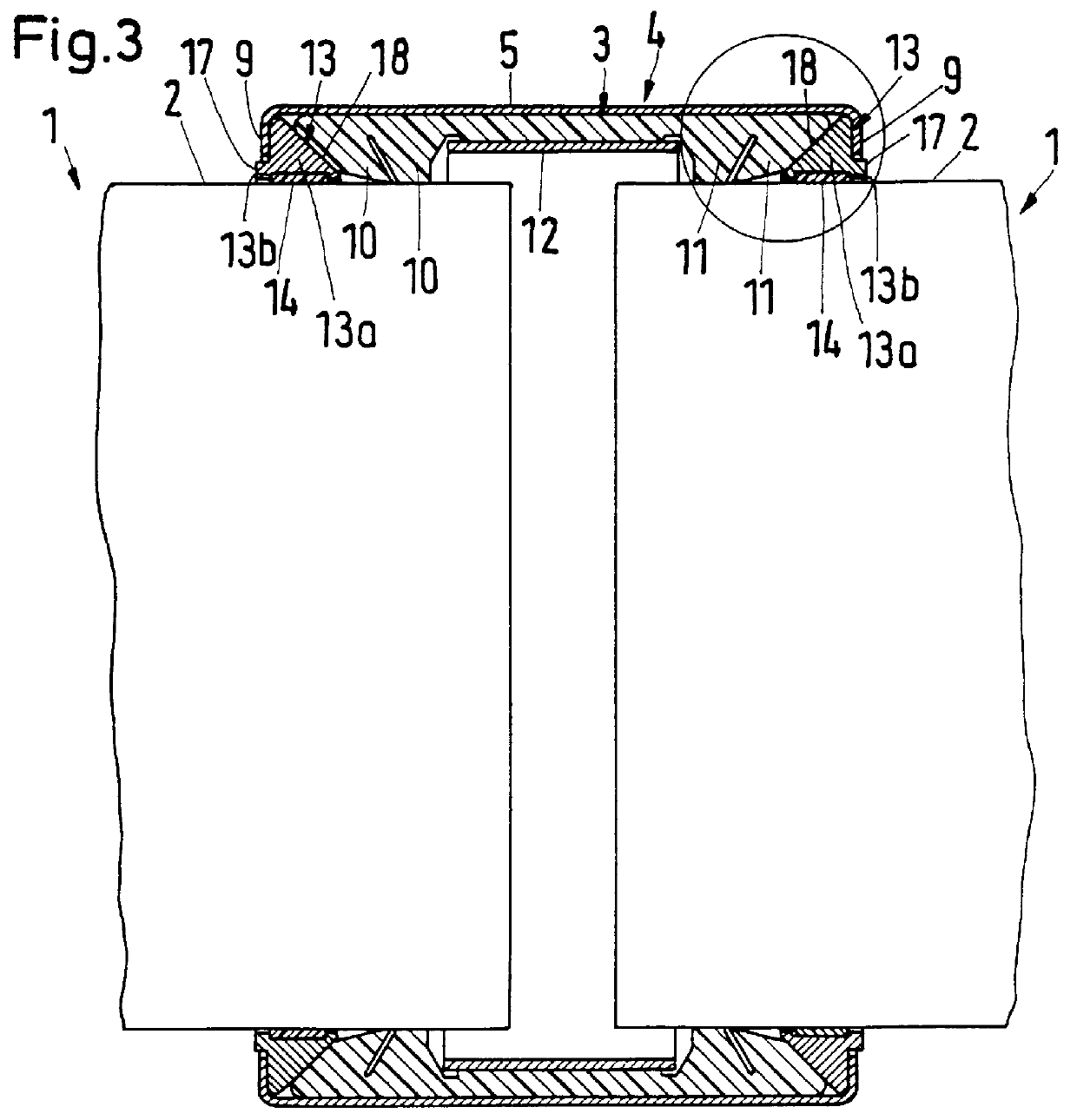

Pipe coupling

InactiveUS6070914AIncrease the cross-sectional areaHigh strengthSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

A pipe coupling for connecting pipes having unprofiled end sections includes an elastomeric sealing gasket for holding the unprofiled pipe end sections in a sealed manner. A clamping clip surrounds the sealing gasket. The clamping clip includes a clip strap having a first end and a second end. A first clamping jaw is formed at the first end. A second clamping jaw is formed at the second end. The clamping jaws are drawn together by a tensioning device. The clip strap has radially inwardly directed projecting flanges on each of its axial ends. A first C-shaped clamping ring and a second C-shaped clamping ring are each disposed between the sealing gasket and one of the flanges. Each of the C-shaped clamping rings are supported on a radially inner side of the clip strap. Each of the C-shaped clamping rings have projections projecting from its radially inner face and, when said clip strap is tensioned, the projections of the C-shaped rings engage in the pipe material. The clamping rings are substantially made of plastic and approximately fill the space between the sealing gasket and one of the flanges. The clamping rings may be formed as a single part or from two ring parts. If formed of two parts, the radially inner part may be made of a brass alloy. The projections may be formed as encircling ribs.

Owner:NORMA GERMANY GMBH

Surgical tool for use in expanding a cannula

InactiveUS7682370B2Increase the cross-sectional areaSimple structureInternal osteosythesisCannulasSurgical instrumentEngineering

Owner:ZIMMER SPINE INC

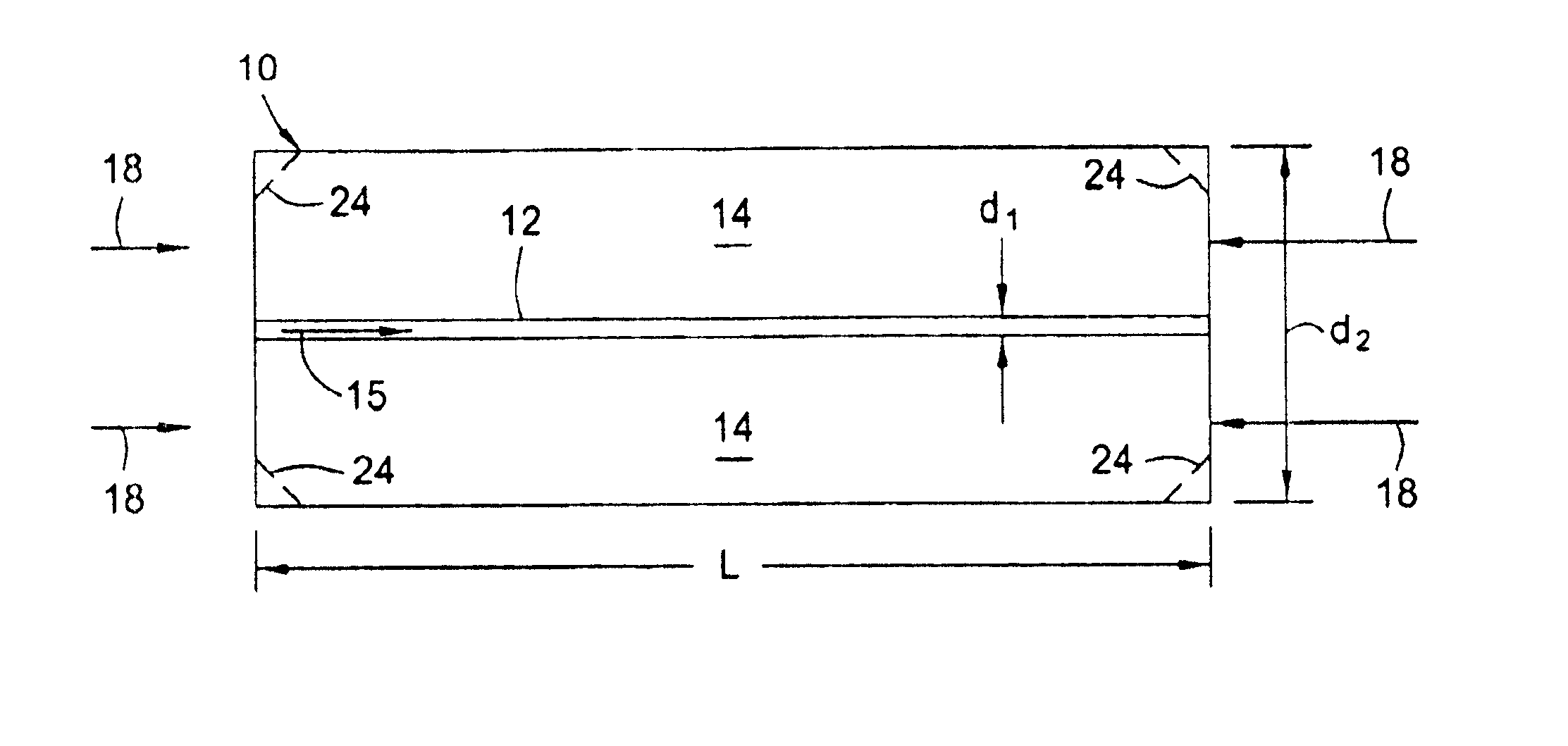

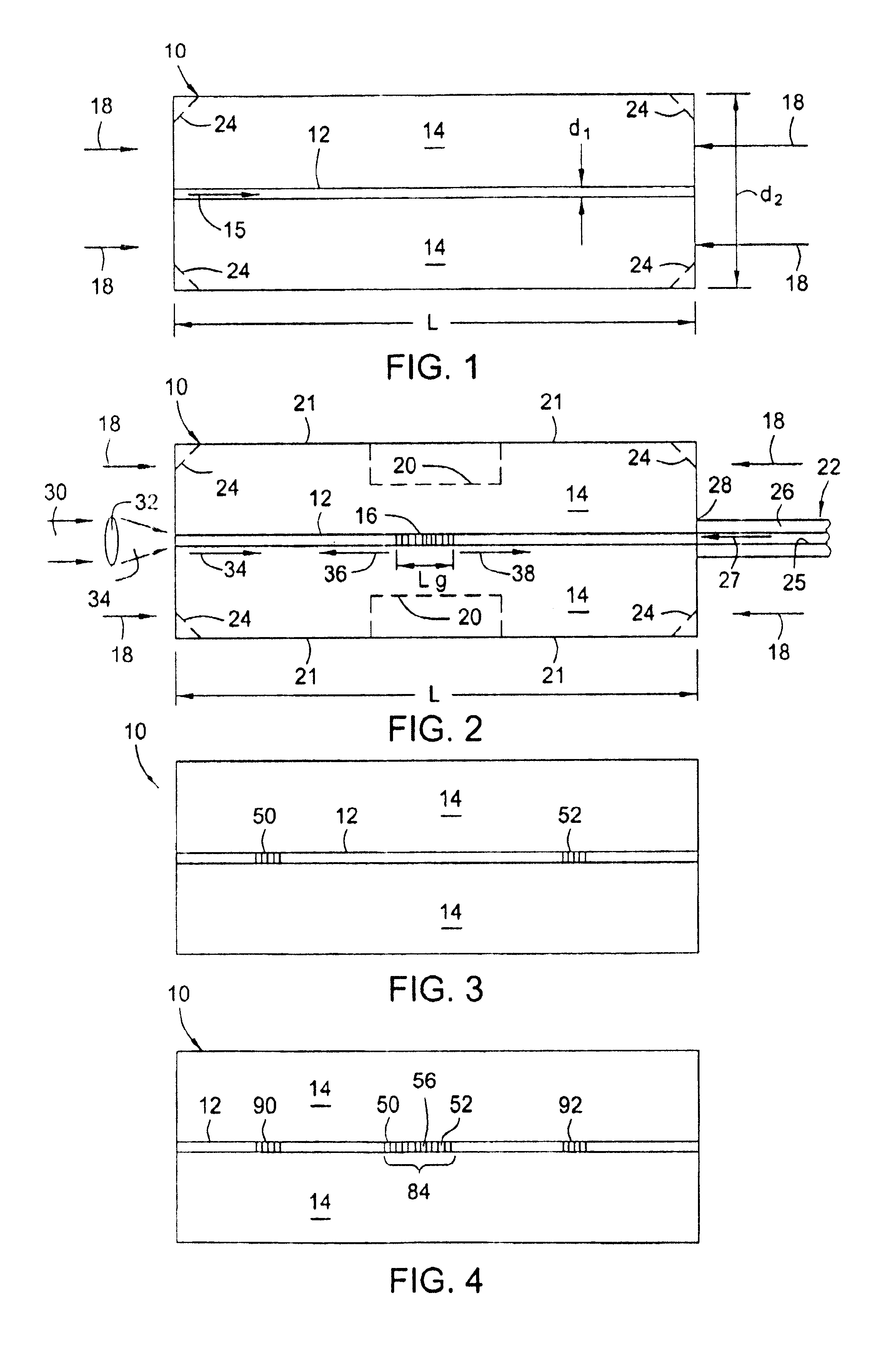

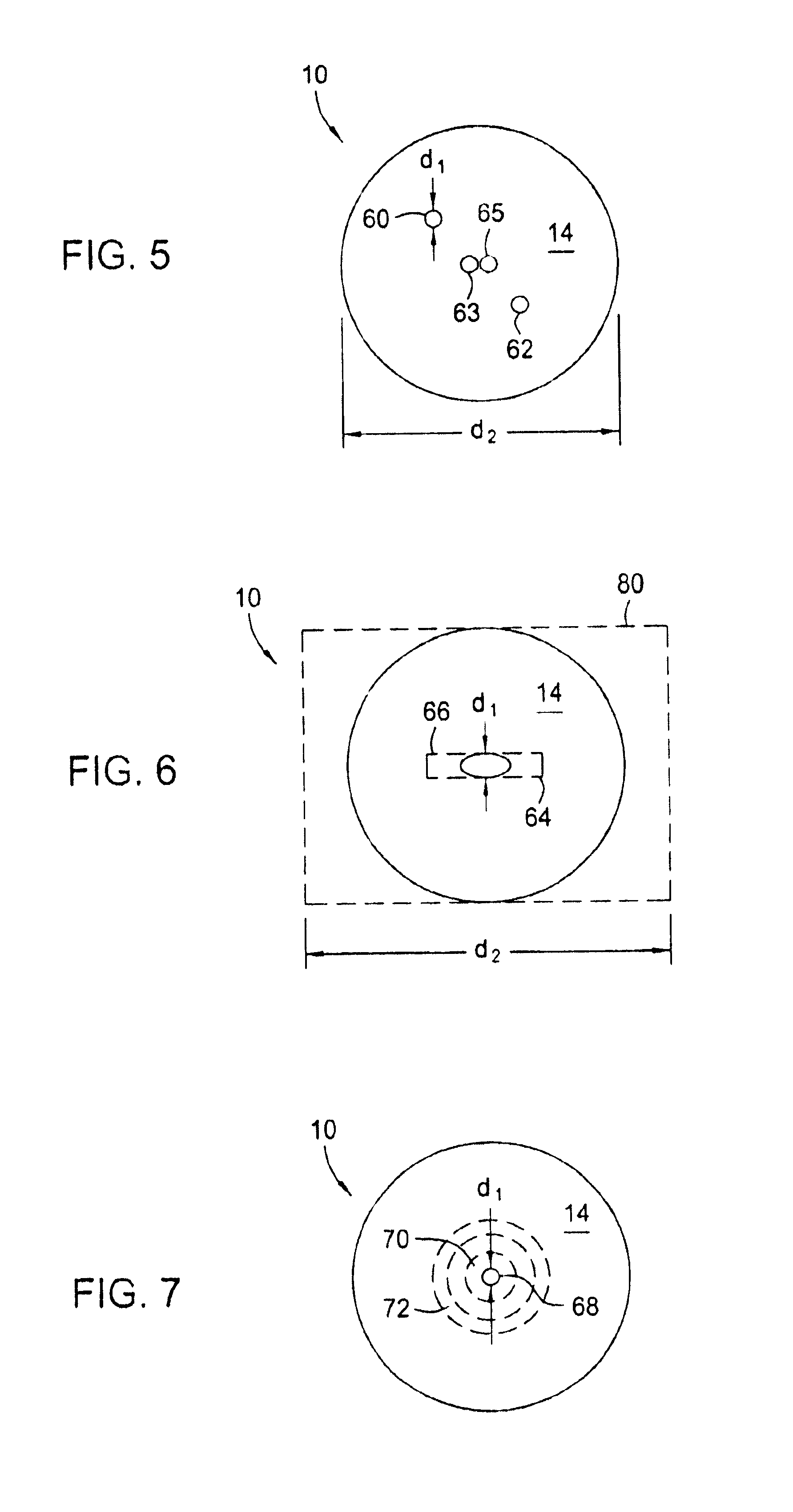

Large diameter optical waveguide, grating, and laser

InactiveUS6982996B1Reducing core to cladding couplingIncrease optical powerLaser using scattering effectsActive medium shape and constructionDopantGrating

A large diameter optical waveguide, grating, and laser includes a waveguide 10 having at least one core 12 surrounded by a cladding 14, the core propagating light in substantially a few transverse spatial modes; and having an outer waveguide dimension d2 of said waveguide being greater than about 0.3 mm. At least one Bragg grating 16 may be impressed in the waveguide 10. The waveguide 10 may be axially compressed which causes the length L of the waveguide 10 to decrease without buckling. The waveguide 10 may be used for any application where a waveguide needs to be compression tuned, e.g., compression-tuned fiber gratings and lasers or other applications. Also, the waveguide 10 exhibits lower mode coupling from the core 12 to the cladding 14 and allows for higher optical power to be used when writing gratings 16 without damaging the waveguide 10. The shape of the waveguide 10 may have other geometries (e.g., a “dogbone” shape) and / or more than one grating or pair of gratings may be used and more than one core may be used. The core and / or cladding 12,14 may be doped with a rare-earth dopant and / or may be photosensitive. At least a portion of the core 12 may be doped between a pair of gratings 50,52 to form a fiber laser or the grating 16 or may be constructed as a tunable DFB fiber laser or an interactive fiber laser within the waveguide 10. The waveguide may resemble a short “block” or a longer “cane” type, depending on the application and dimensions used.

Owner:WEATHERFORD TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com