Patents

Literature

537results about How to "Increase the outer diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

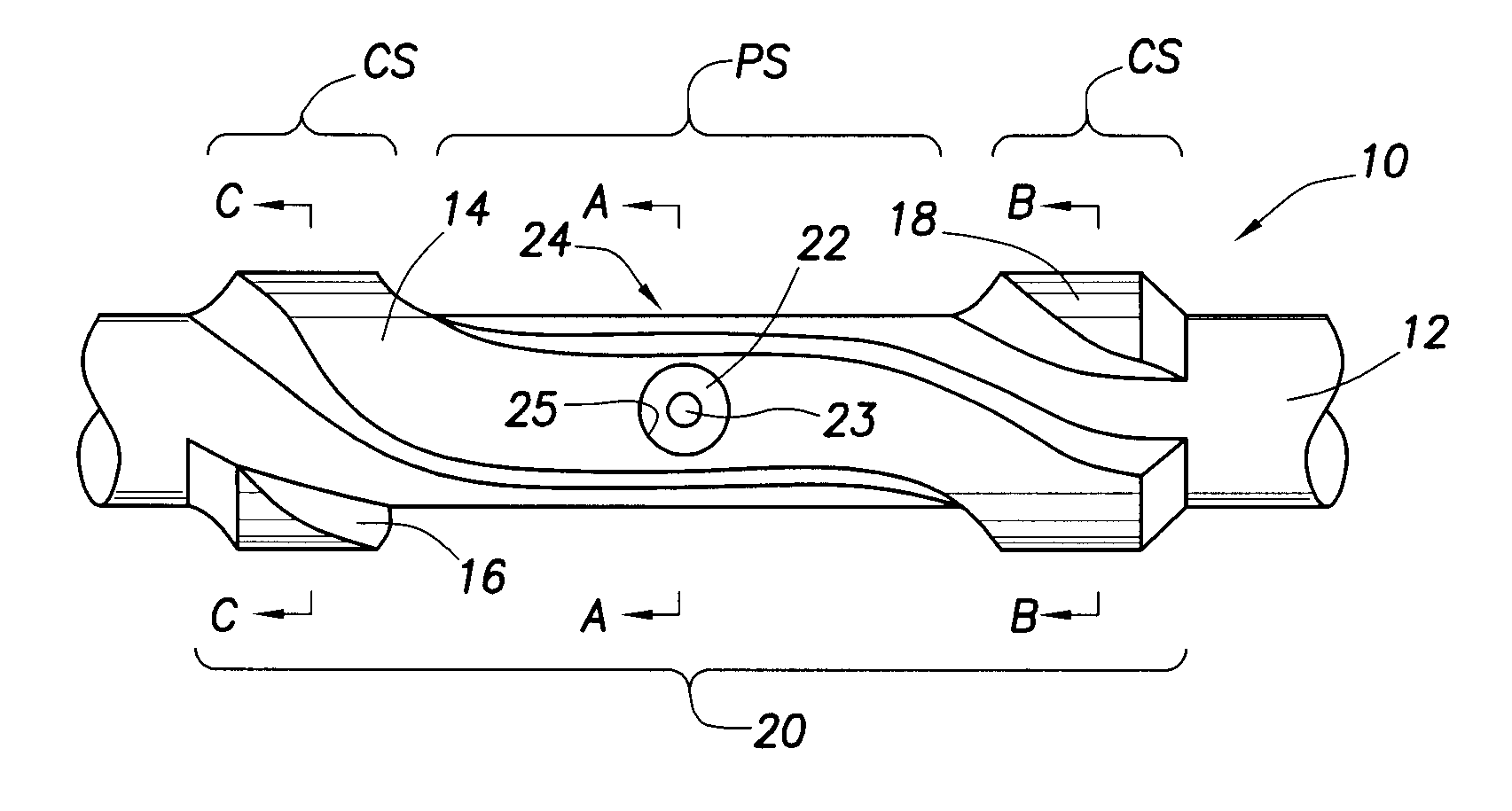

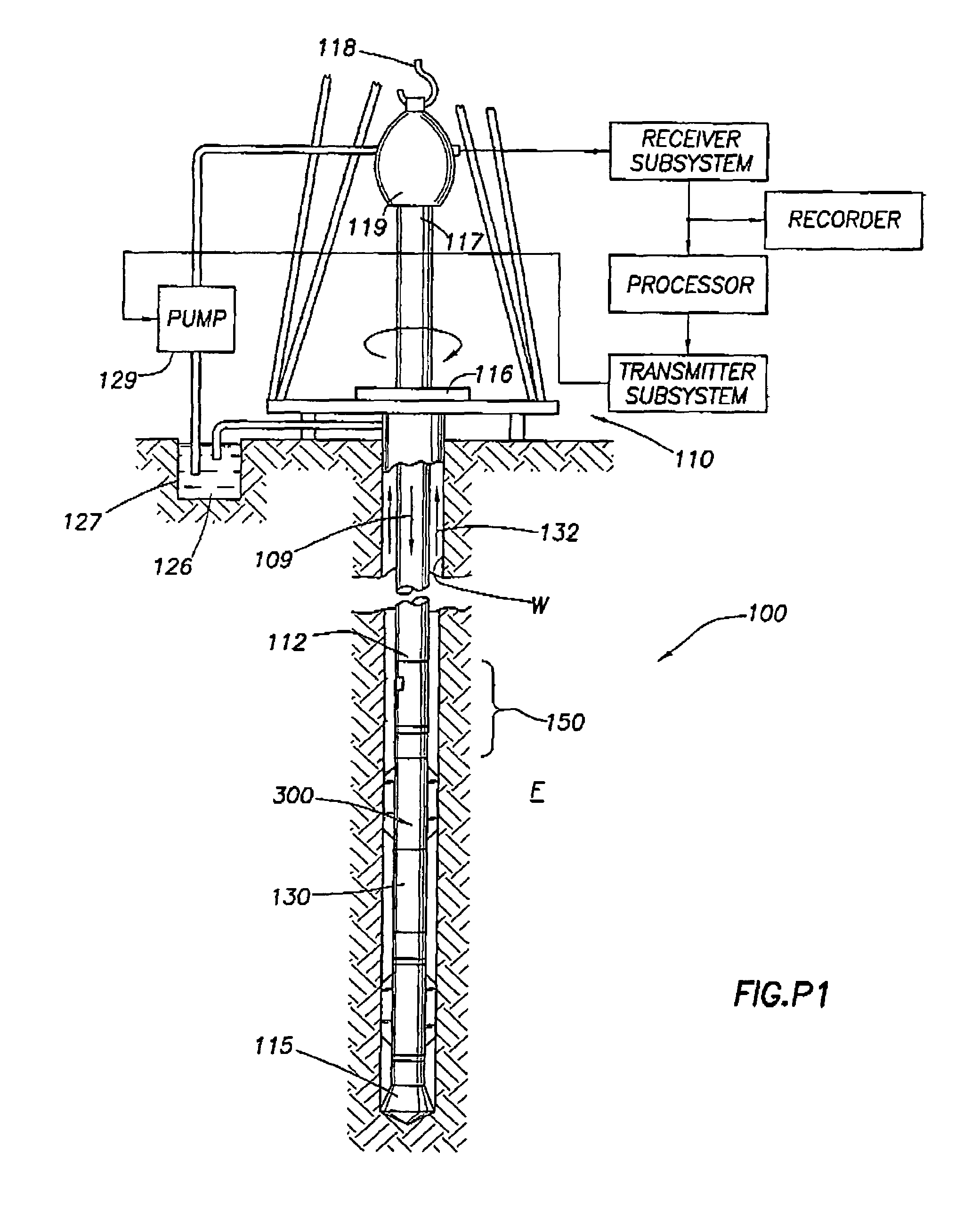

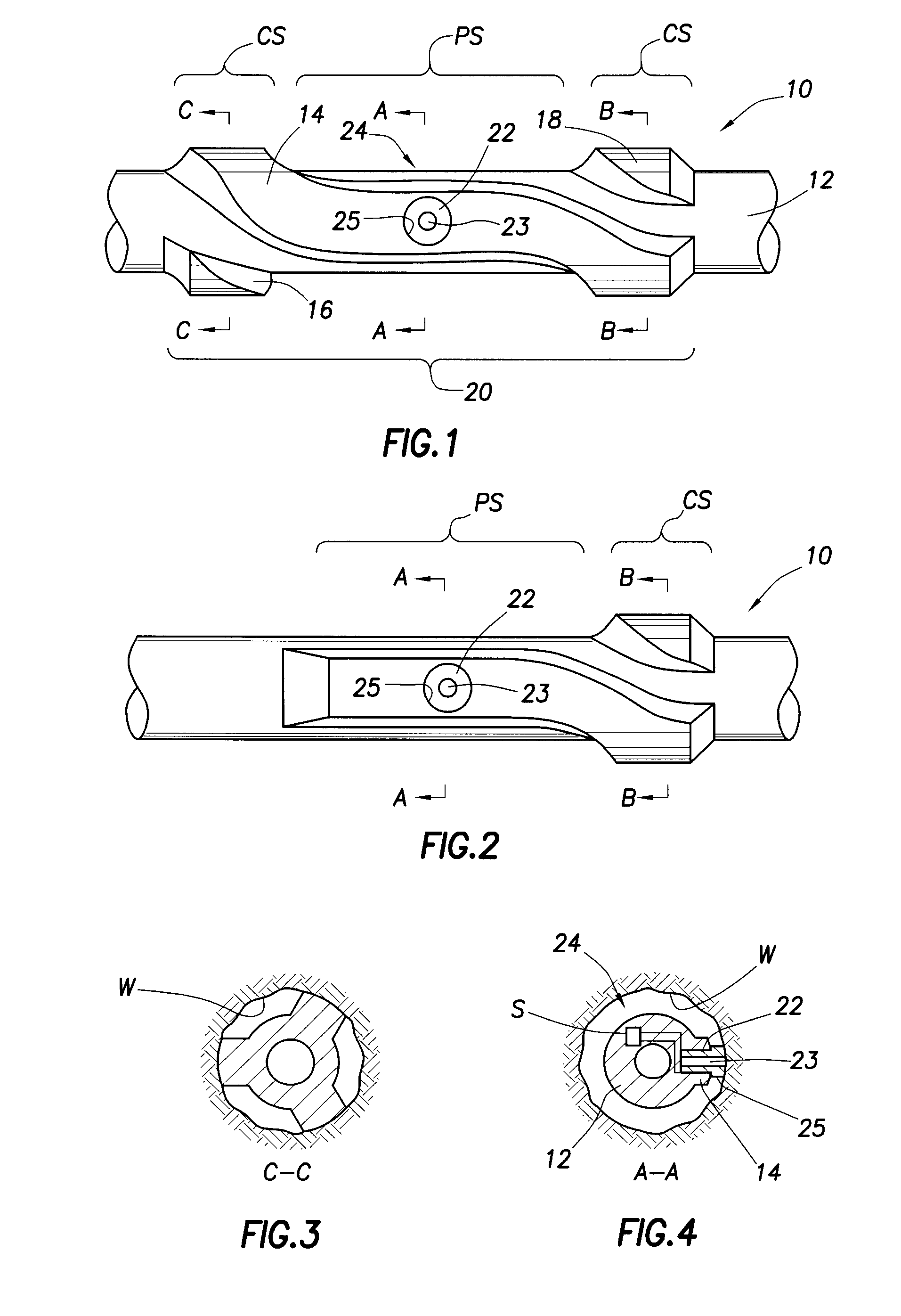

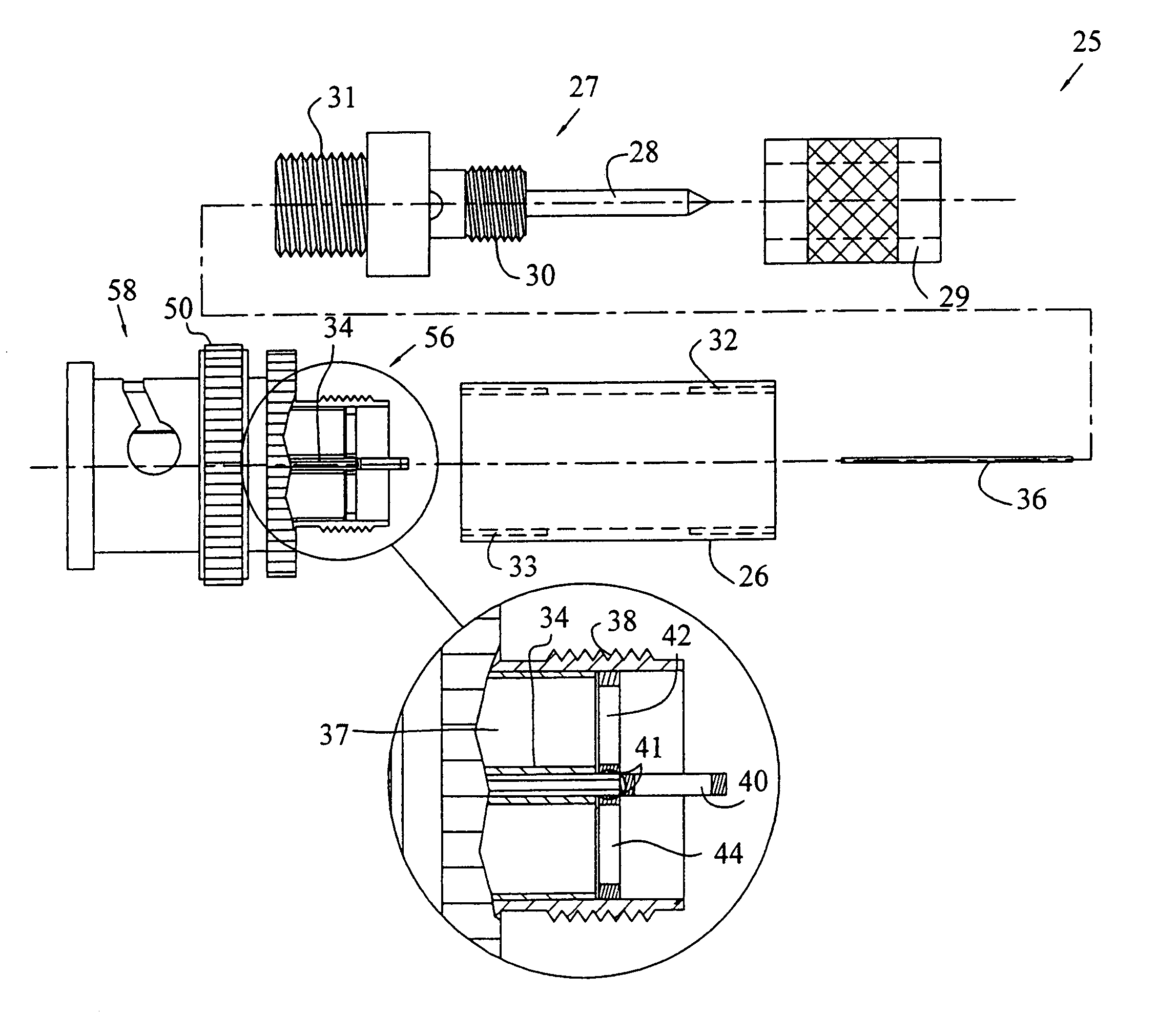

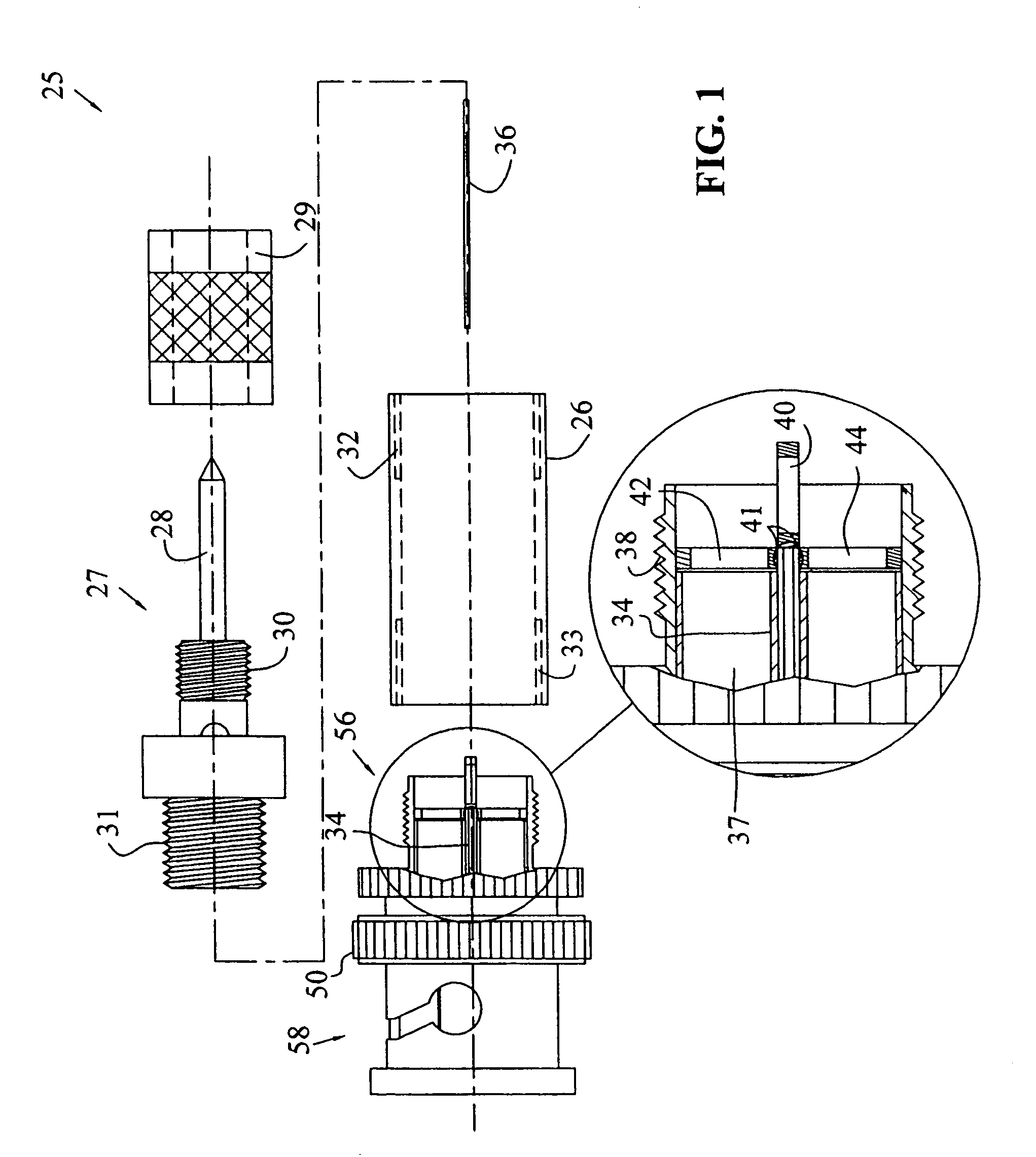

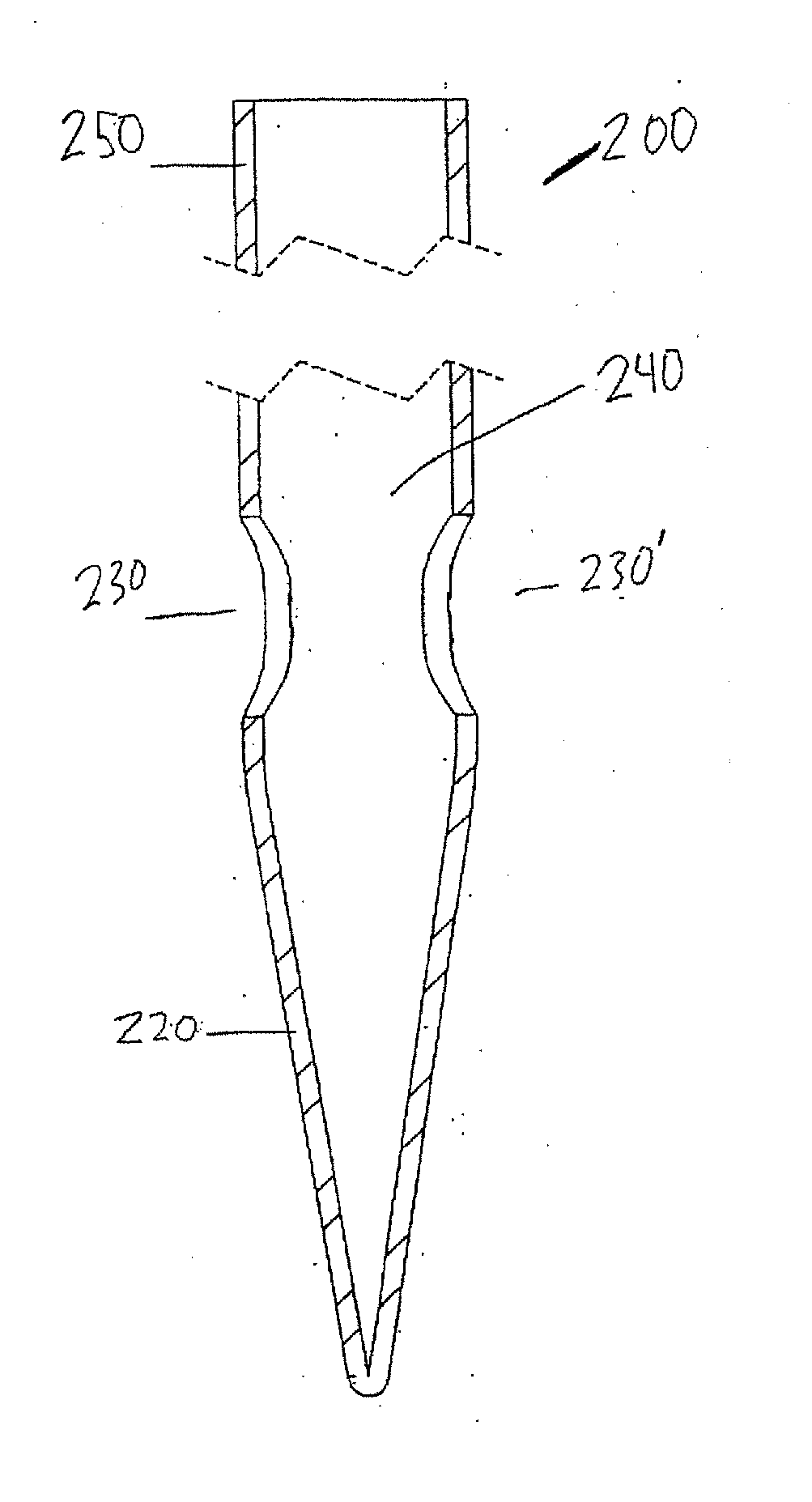

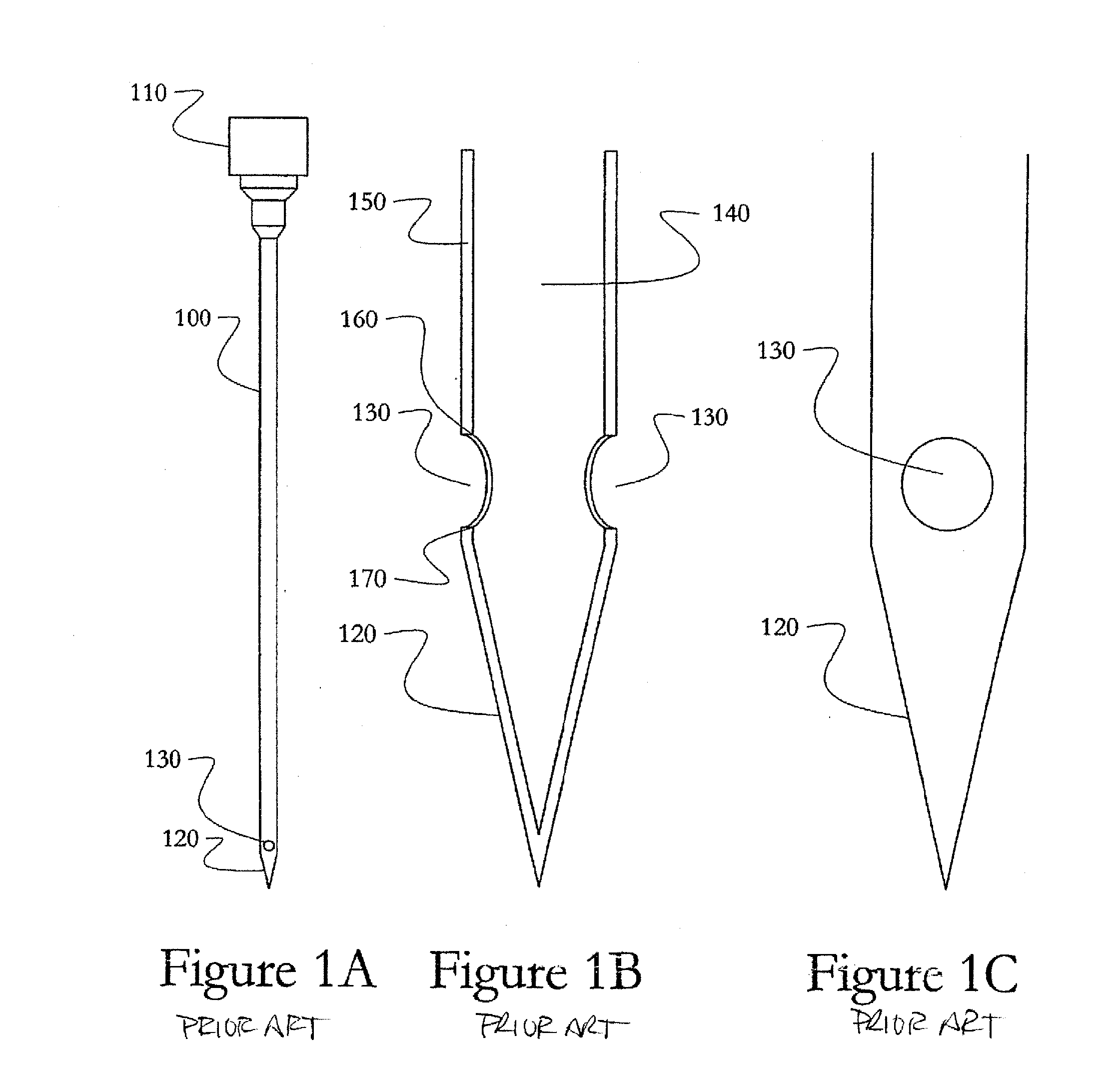

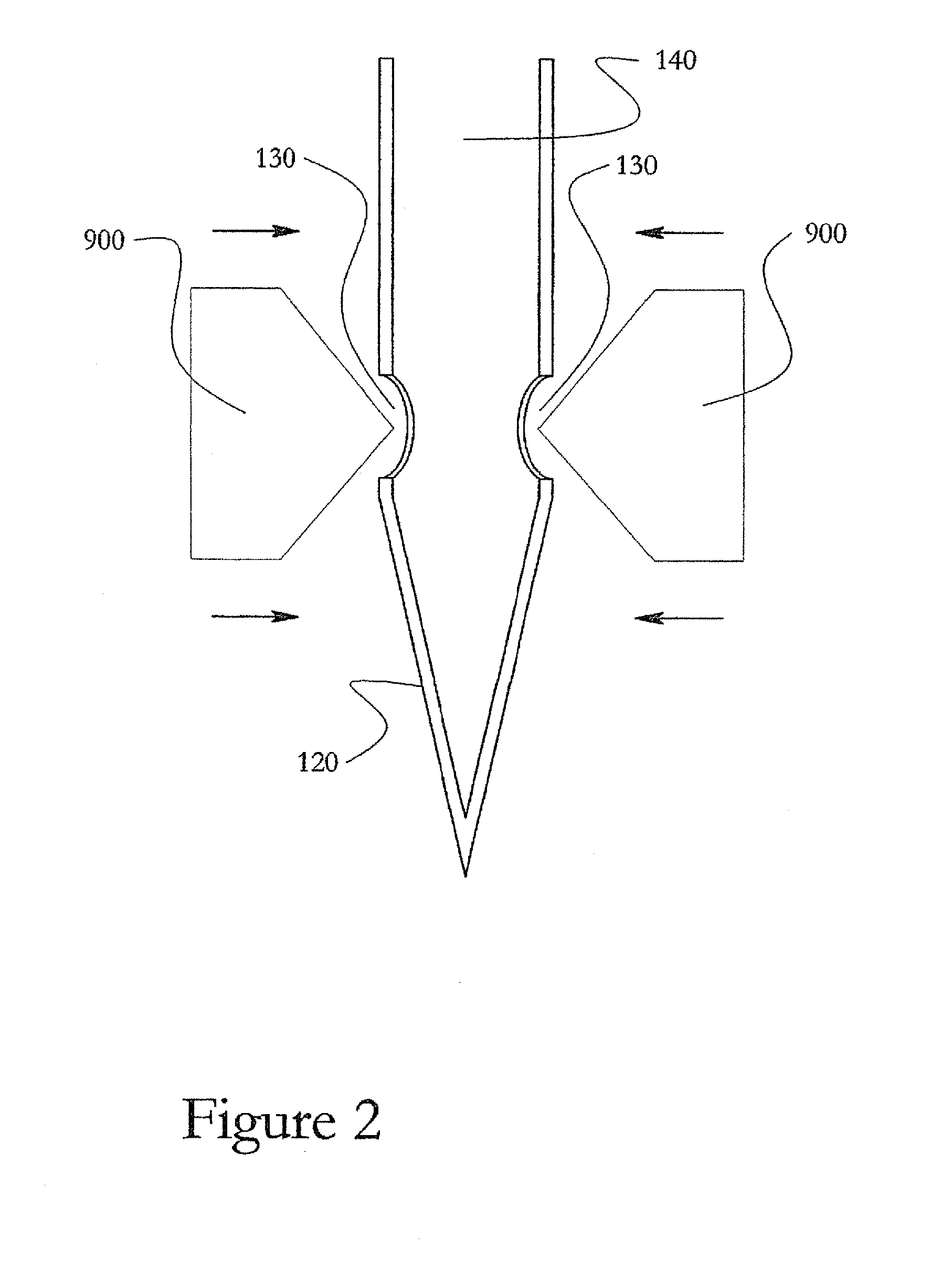

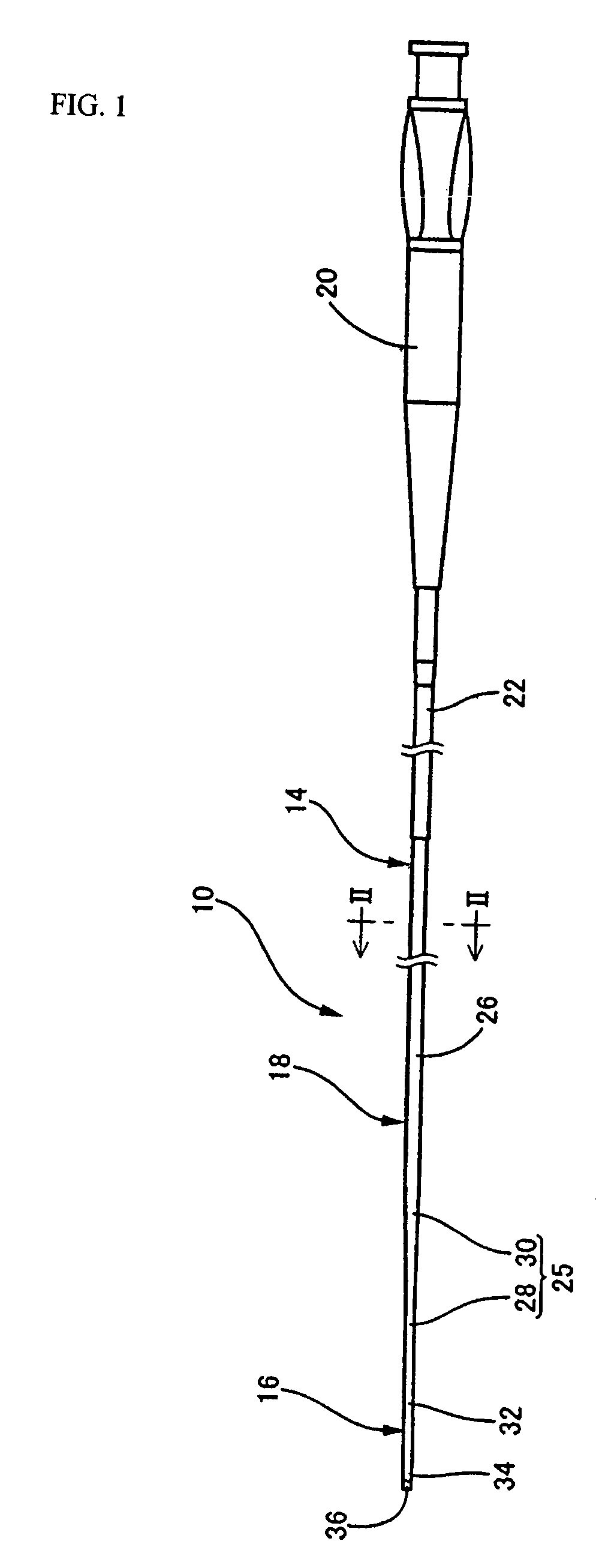

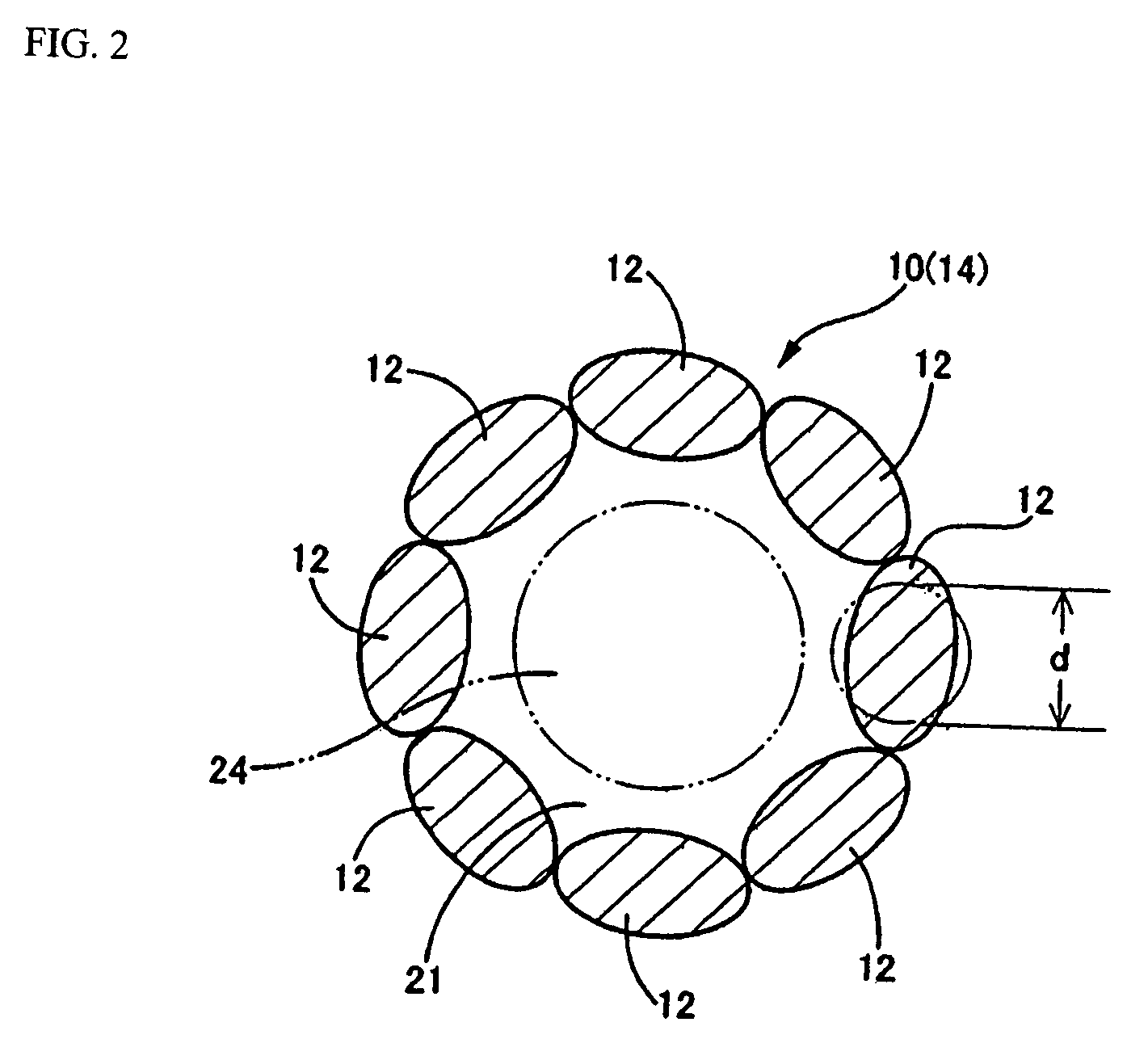

Apparatus and method for acquiring information while drilling

ActiveUS7114562B2Reduce the possibilityIncrease the outer diameterSurveyDrilling rodsWellboreEnvironmental geology

An apparatus and method useful for acquiring information from a subsurface formation penetrated by a wellbore contemplate the use of a tubular body adapted for connection within a drill string disposed in the wellbore. The tubular body is equipped with one or more protuberances (e.g., ribs) defining an expanded axial portion. A probe is carried by the tubular body at or near a first location within the expanded axial portion of the body where the cross-sectional area of the expanded axial portion is a minimum. The probe is movable between retracted and extended positions. In another aspect, the inventive apparatus may further include a cover releasably-secured about the probe for protecting the probe while drilling. In a further aspect, the inventive apparatus may include a shearable backup support carried by the tubular body azimuthally opposite the probe permitting release of the apparatus from the wellbore in the event of a failure. In yet another aspect, the probe is at least partially carried within a debris-clearing channel formed in a protruding portion of the tubular body to promote free movement of the probe within the wellbore.

Owner:SCHLUMBERGER TECH CORP

Ultra-broadband differential voltage probes

ActiveUS7015709B2Reduce parasitic inductanceError minimizationElectrical testingMeasurement leads/probesElectricityElectrical conductor

Passive balanced probes are disclosed for use with a signal analysis device. The probes are very low cost relative to typical commercially available probes and provide an extremely flat response over a frequency range of approximately 0 to at least 1.5 gigahertz. The probes include a probe body constructed primarily from conventional components, a first surface mount resistor electrically connected between a probe tip and a center conductor, and two surface mount resistors electrically connected and parallel between the center conductor and a conductive shield. The probes further include a coaxial cable for connection to an instrument combiner or other instrument connection device.

Owner:APTIV TECH LTD

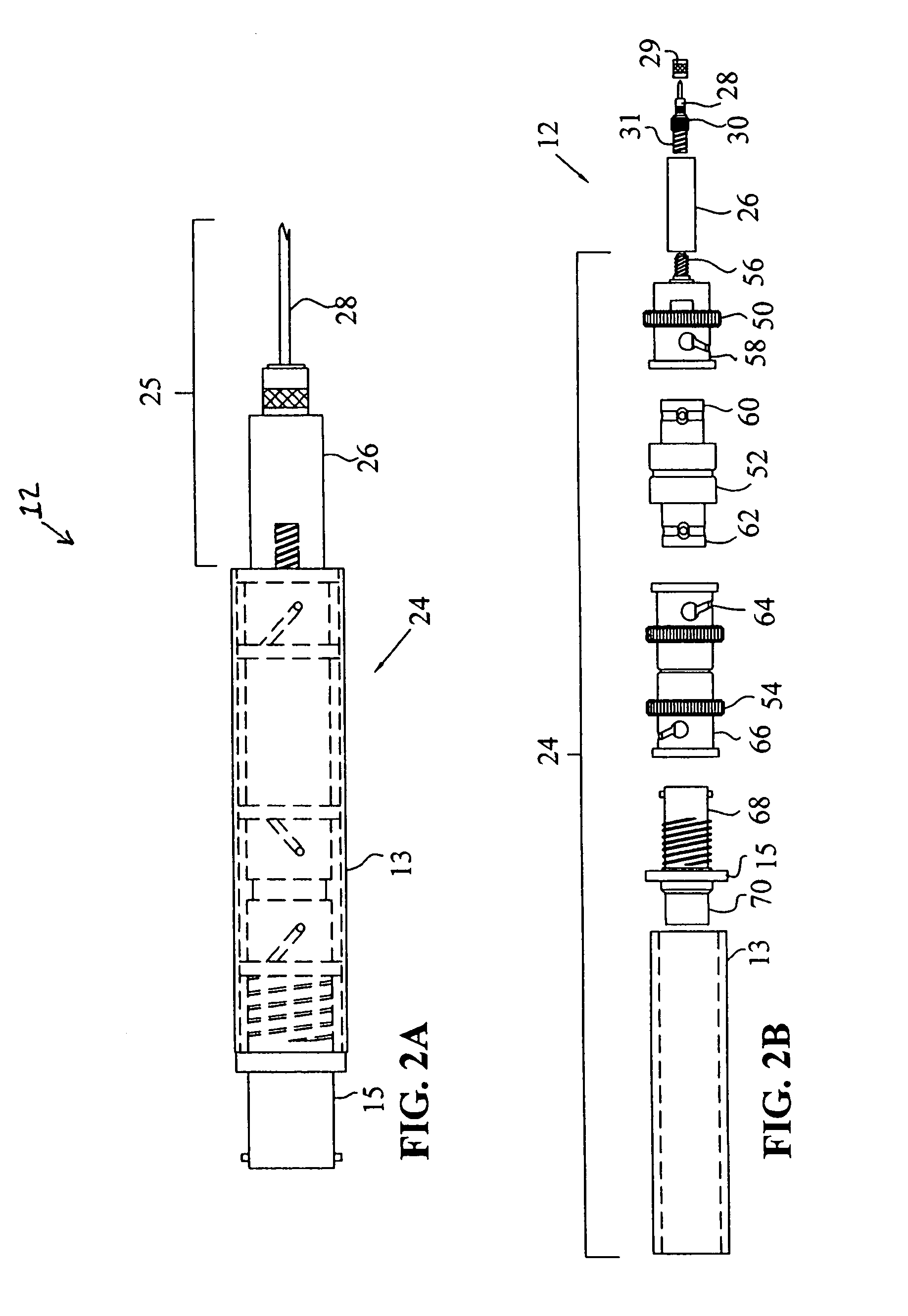

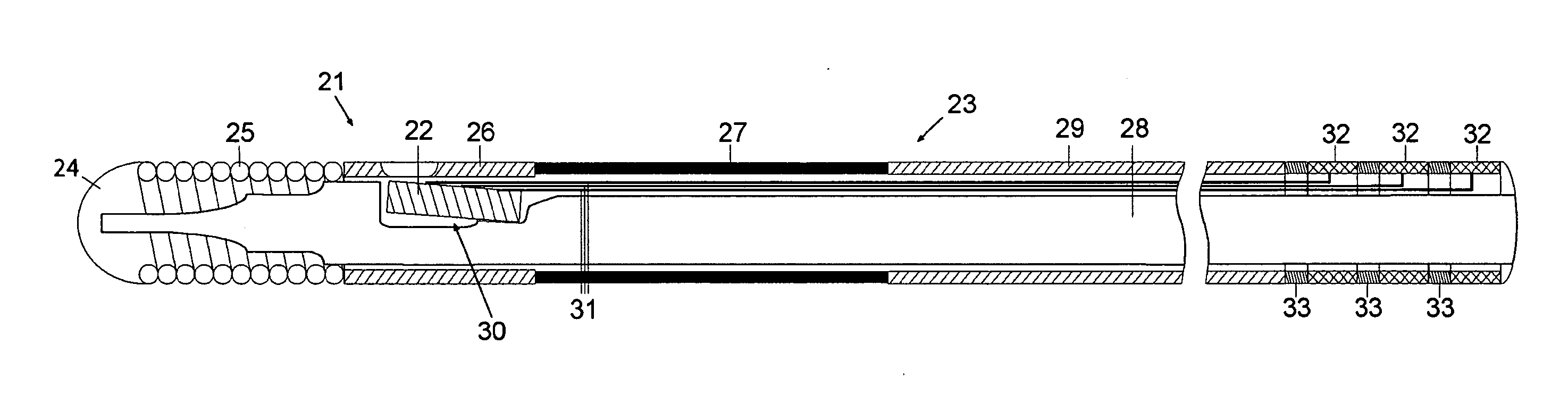

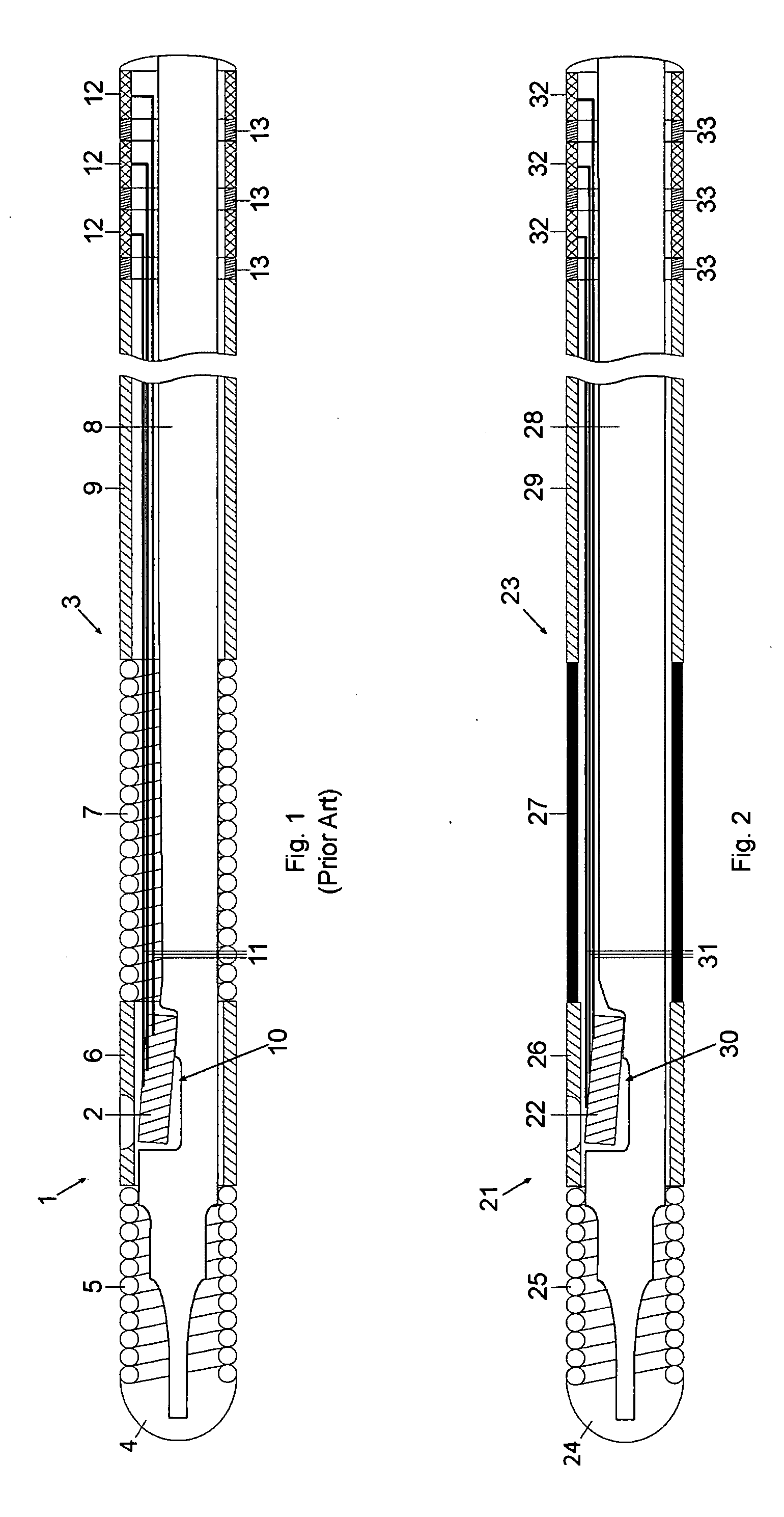

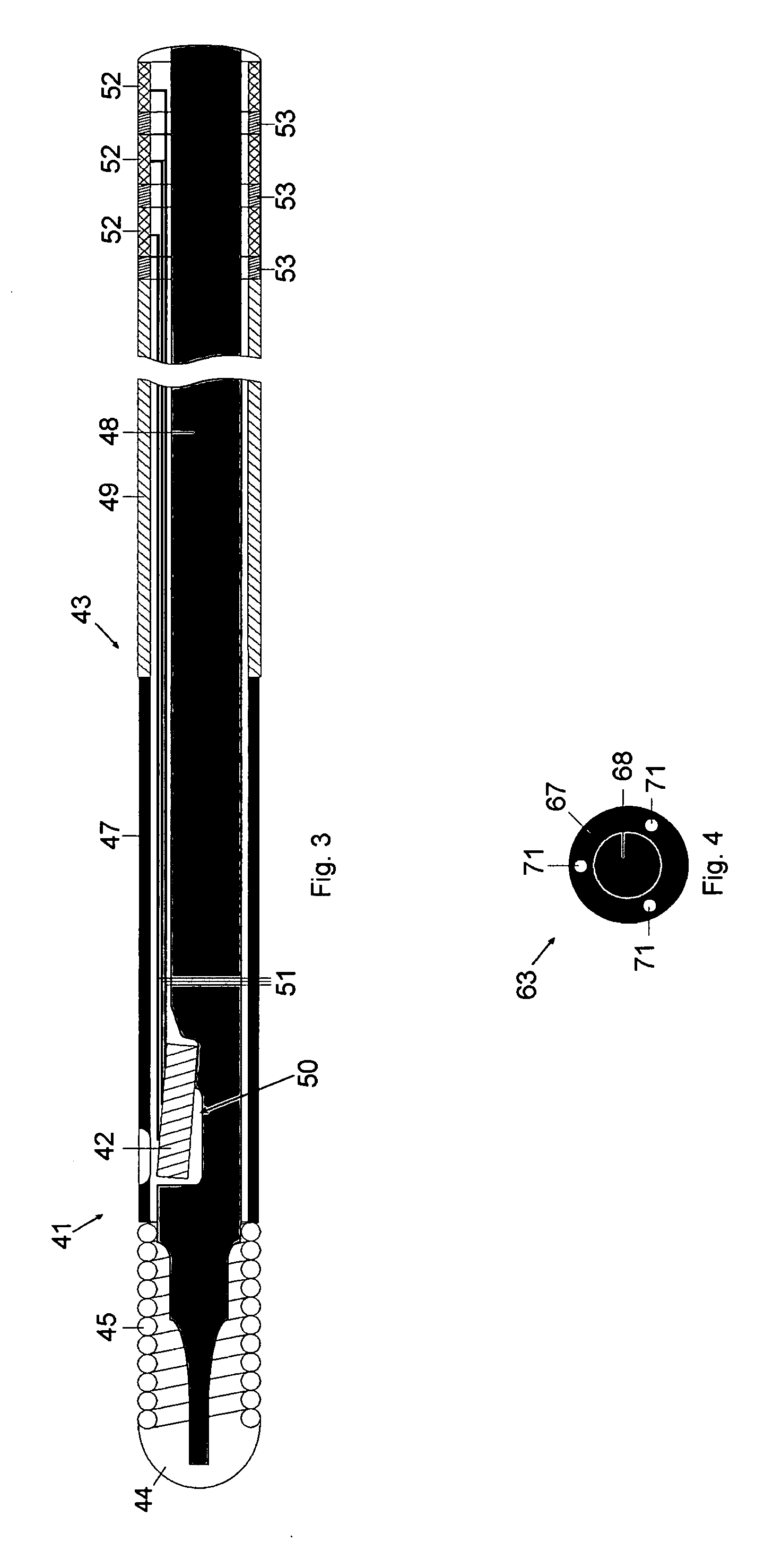

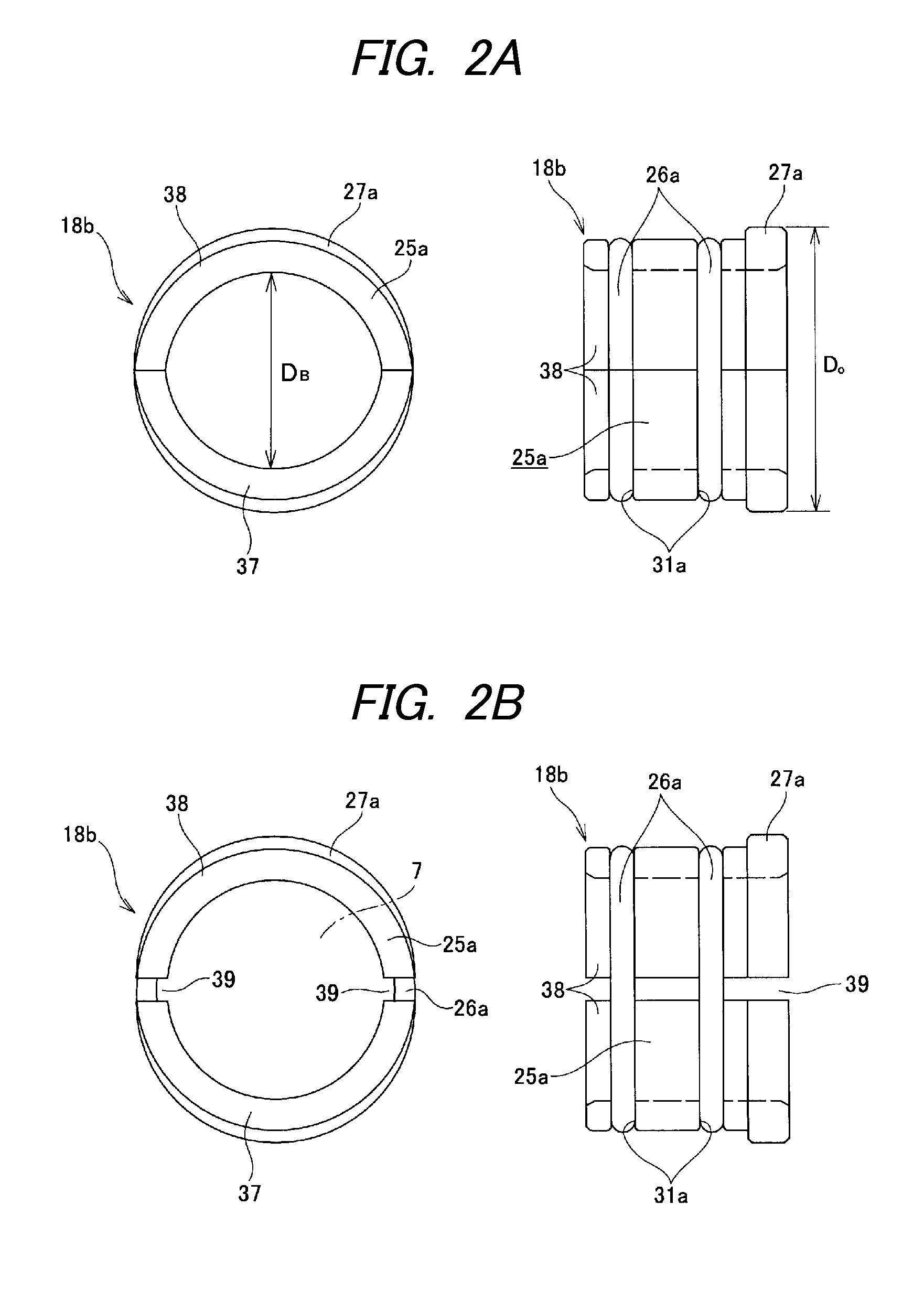

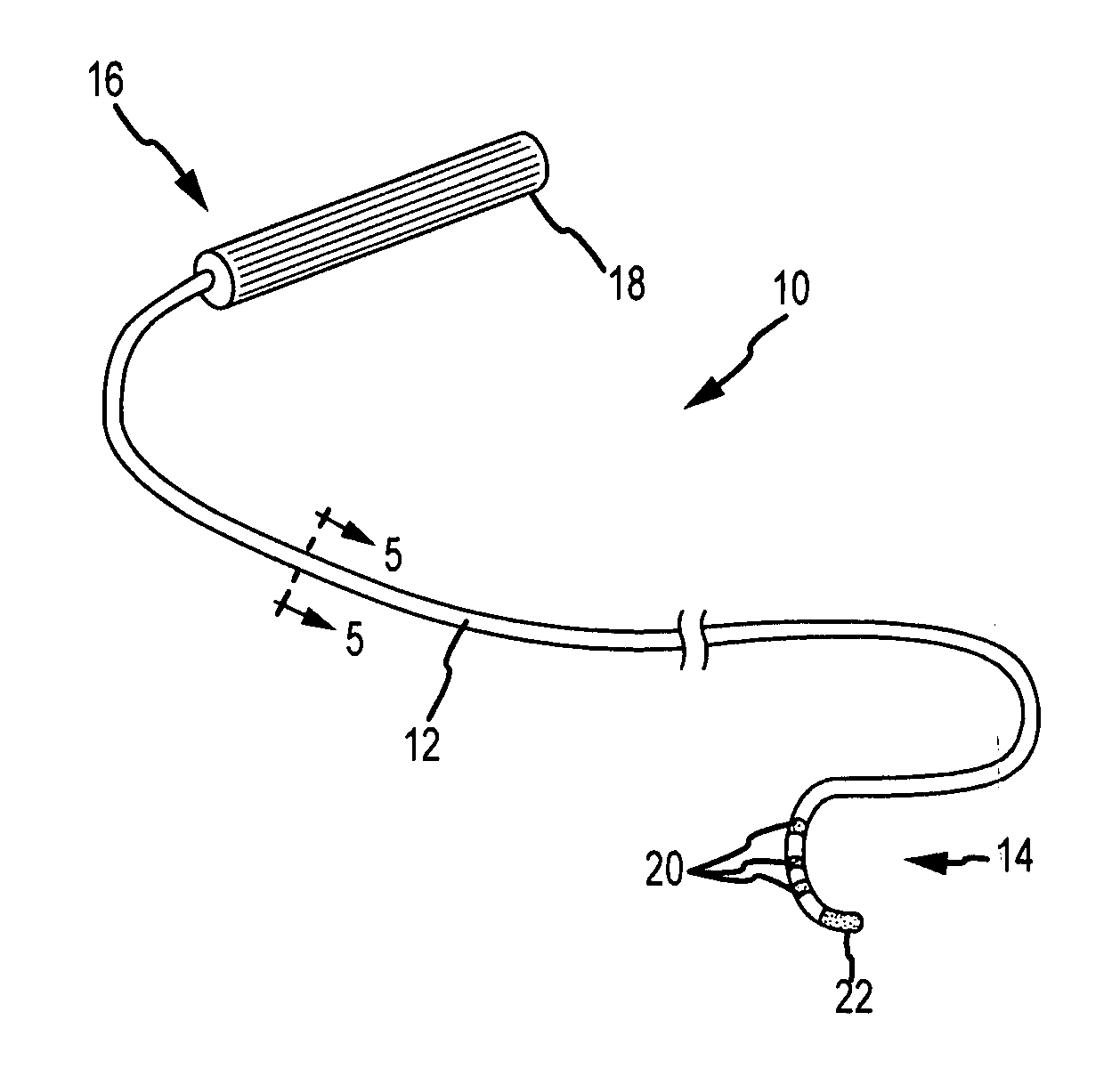

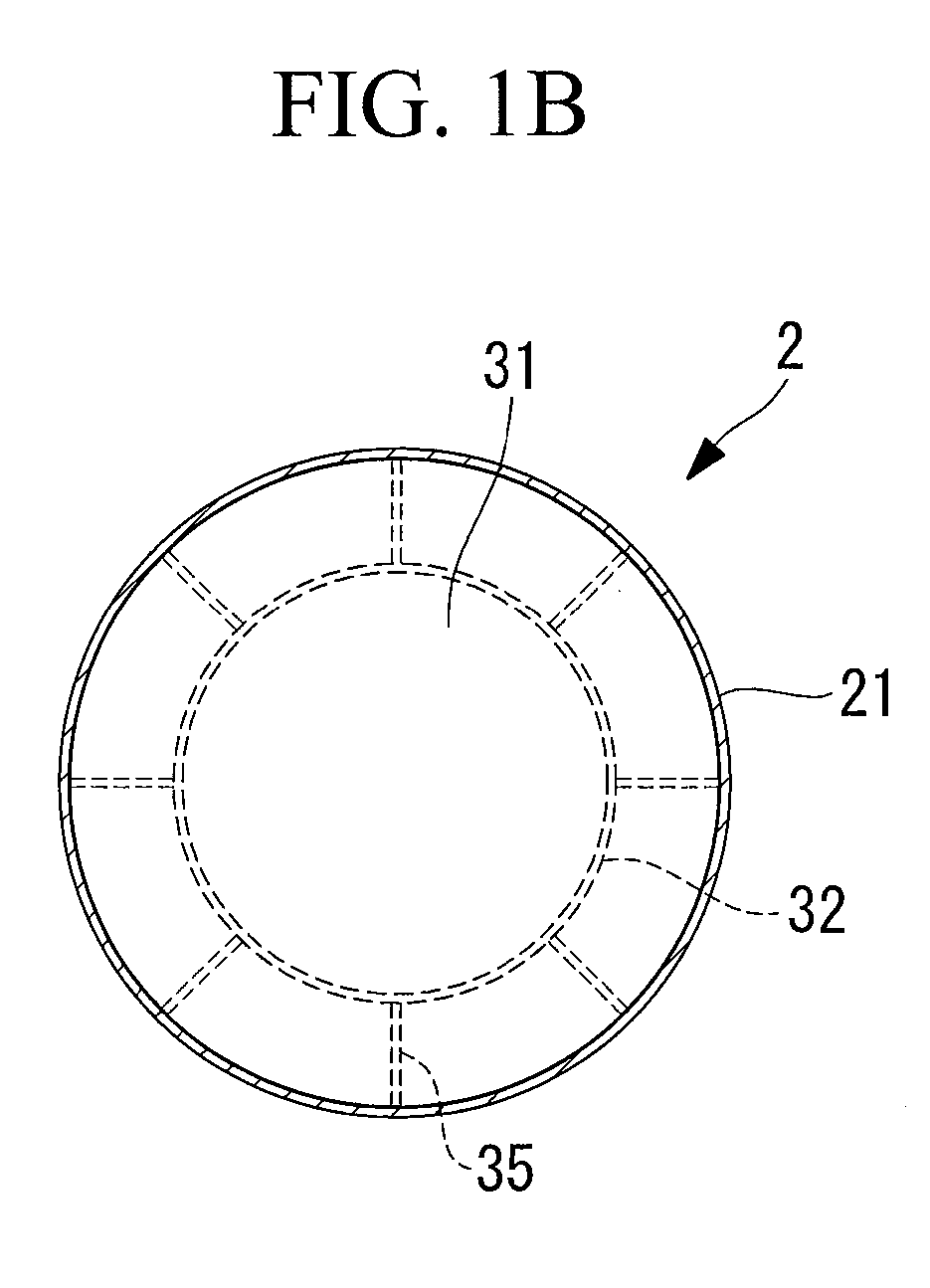

Sensor and guide wire assembly

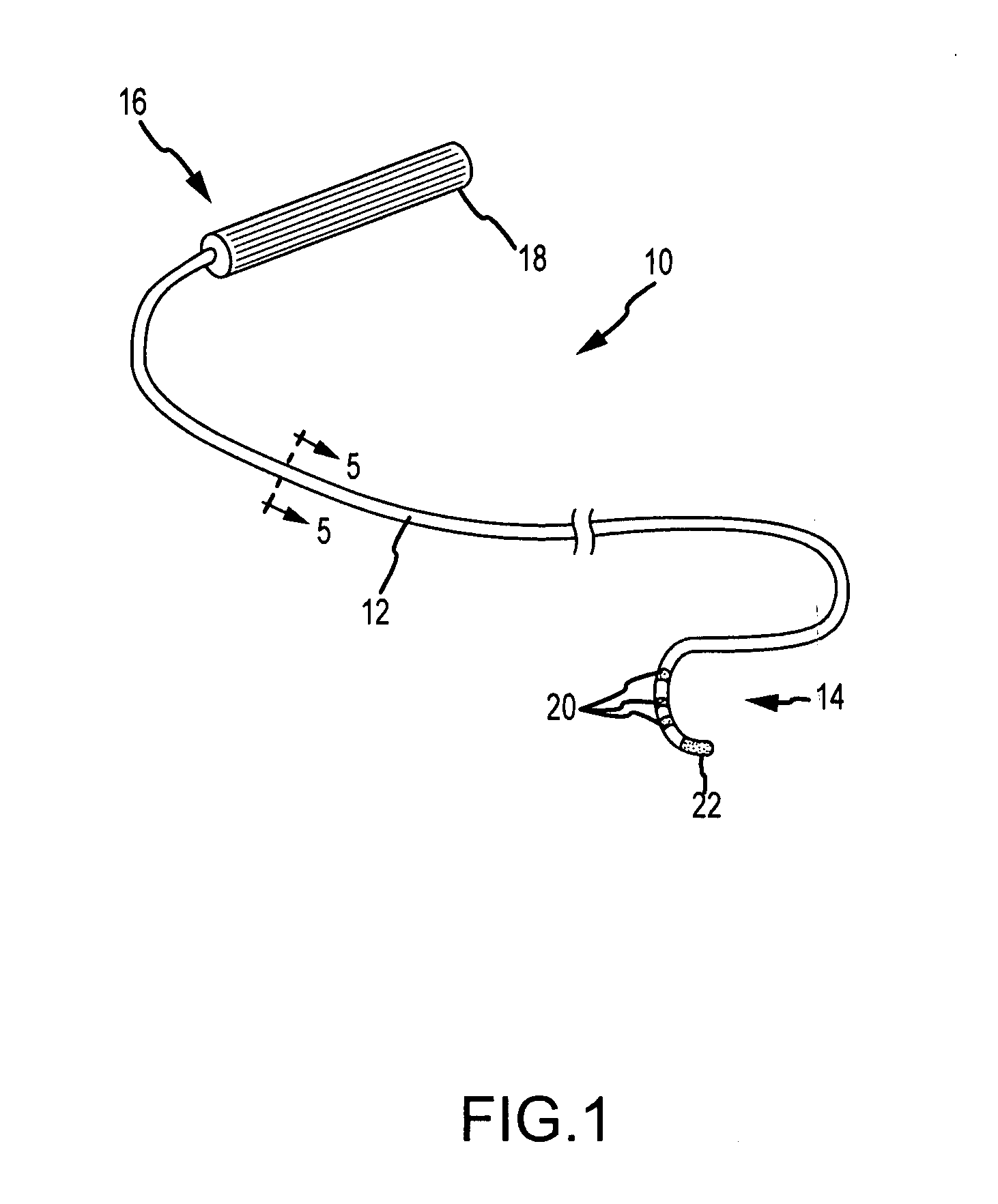

InactiveUS20070255145A1Improve mobilityReduce riskGuide wiresDiagnostic recording/measuringEngineeringLiving body

A sensor and guide wire assembly (21; 41) for intravascular measurements of a physiological variable in a living body, comprises a sensor element (22; 42) and a sensor guide wire (23; 43) comprising a core wire (28; 48) and at least one signal transmitting cable (31; 51) connected to the sensor element, wherein a polymer layer (27; 47) is provided which encloses a portion of the core wire and the at least one signal transmitting cable.

Owner:ST JUDE MEDICAL COORDINATION CENT

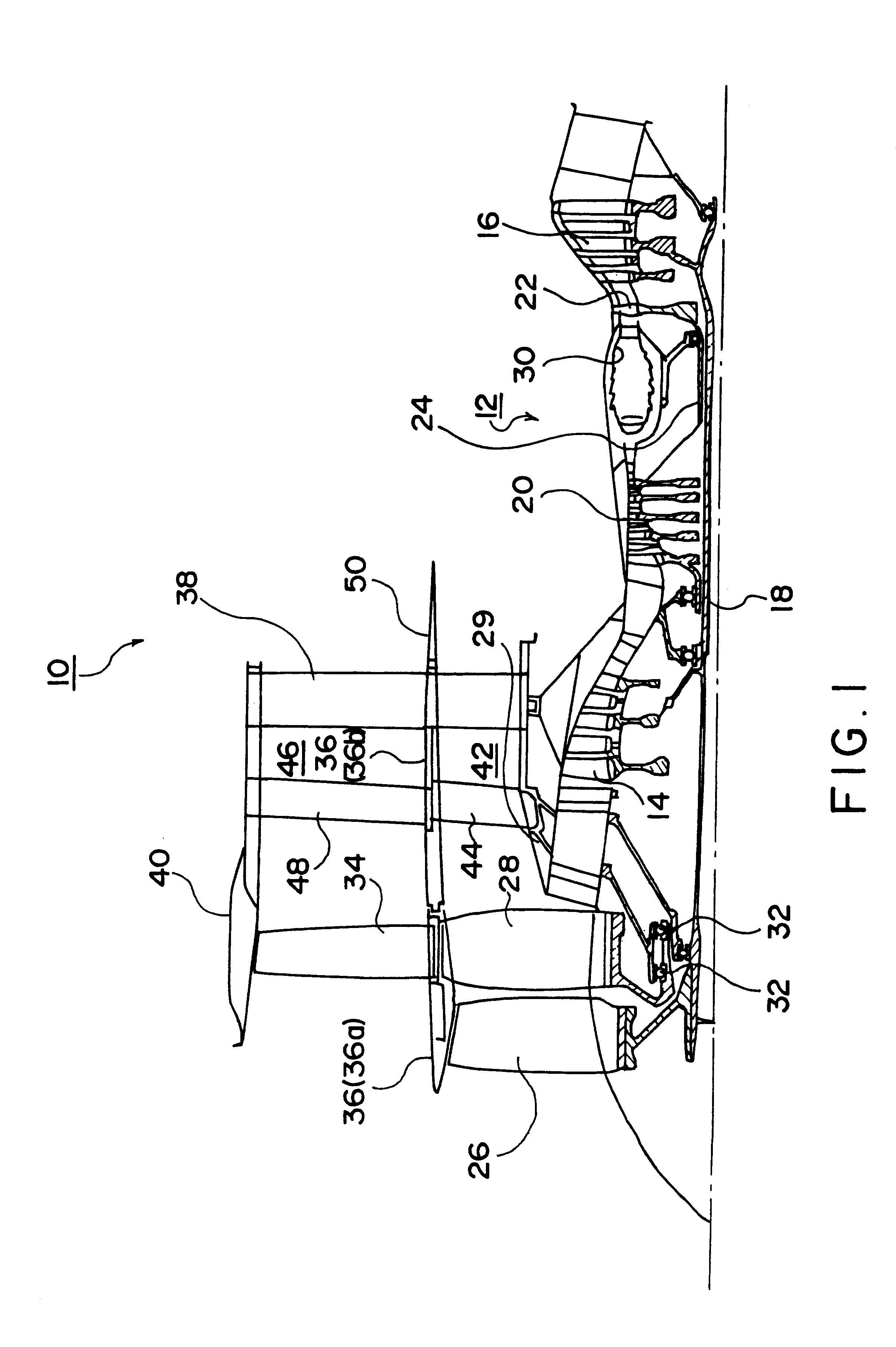

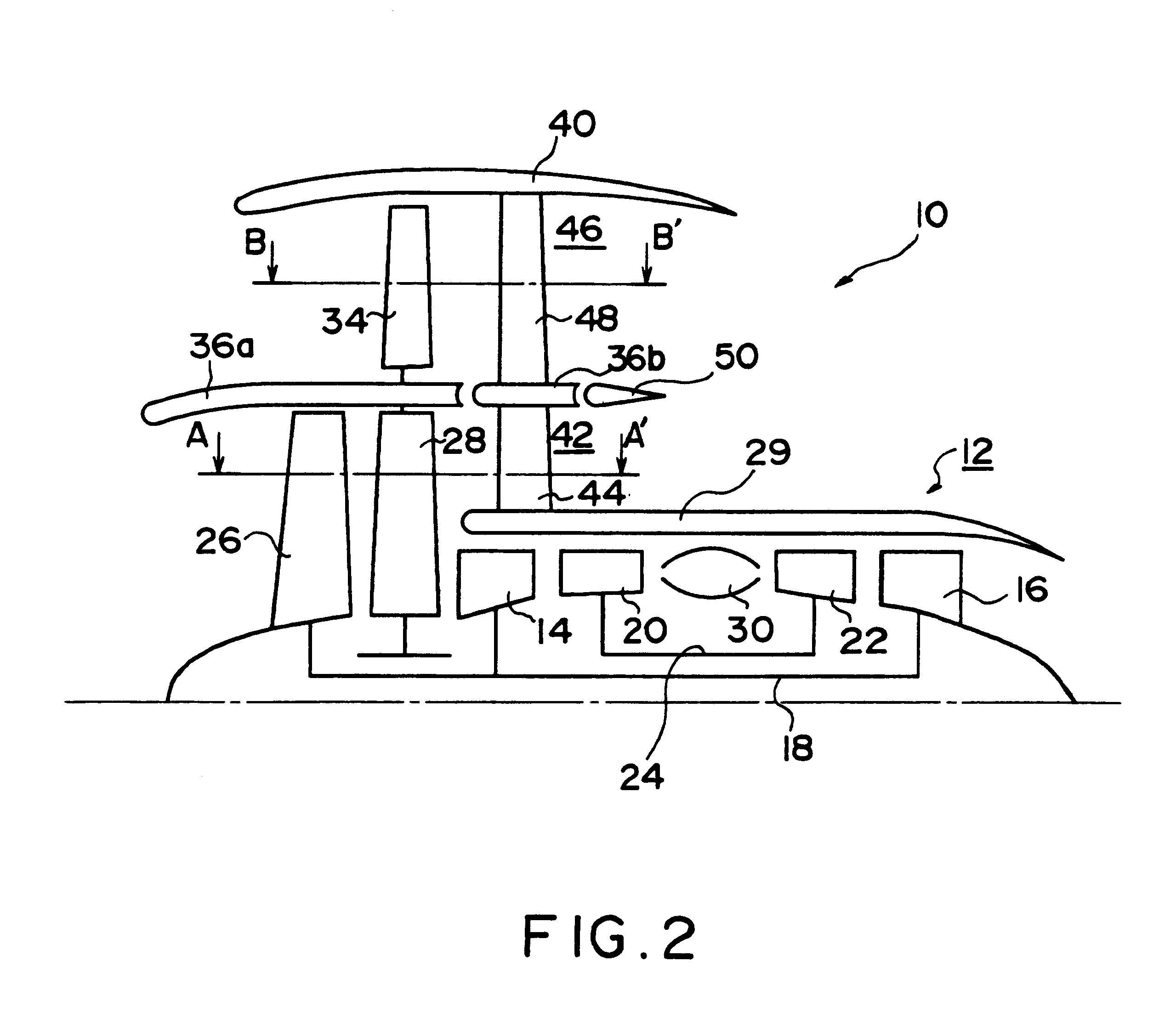

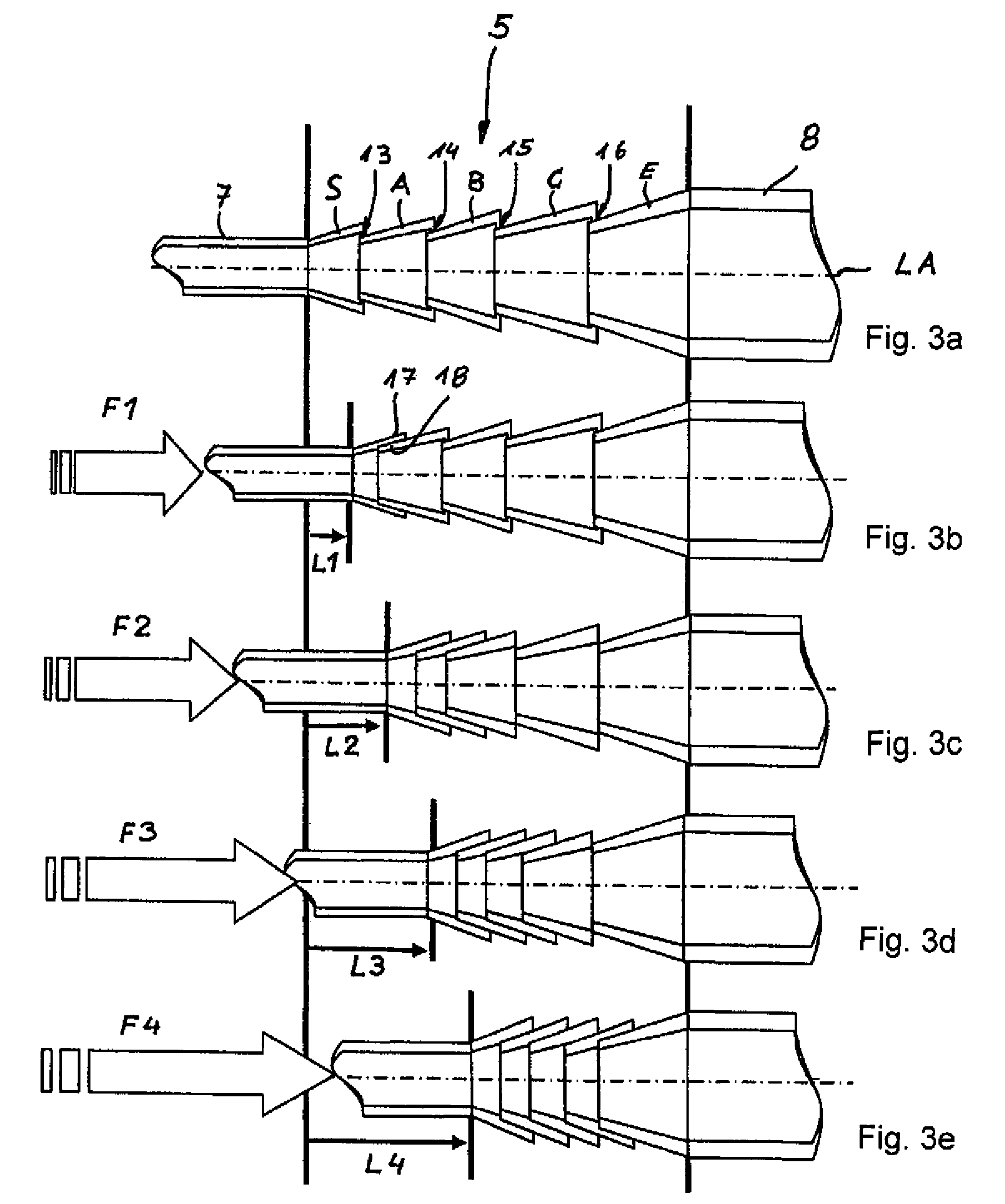

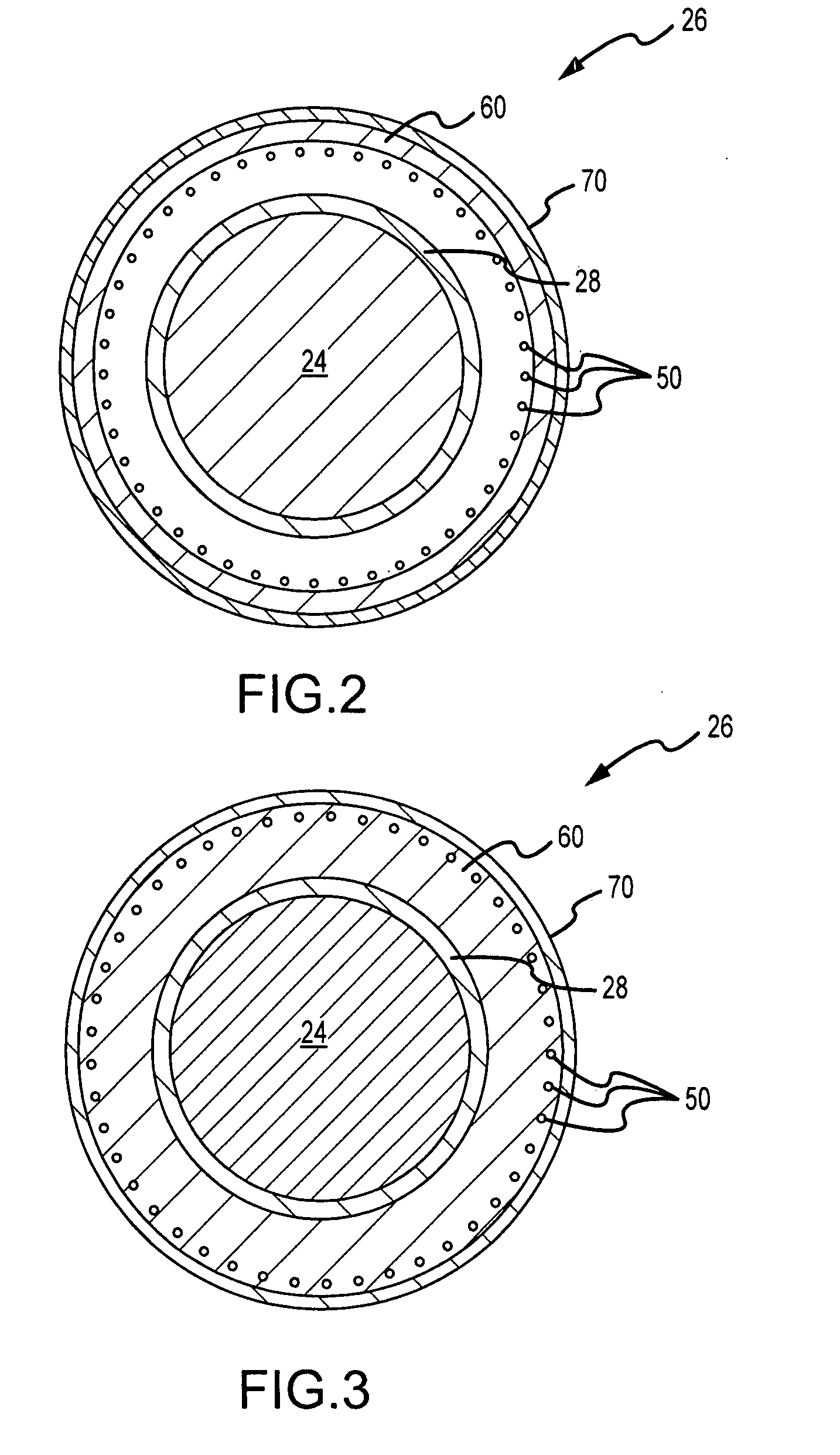

Turbofan engine including fans with reduced speed

InactiveUS6209311B1Shorten speedIncrease the outer diameterGas turbine plantsEfficient propulsion technologiesImpellerFluid coupling

An impeller is directly driven by an output shaft of a core engine. The airflow produced by the impeller rotates an air turbine and a fan disposed integrally with the air turbine. The impeller and the air turbine form a fluid coupling which serves also as a speed reducing mechanism. The rotational speed of the fan can be reduced to be lower than that of the output shaft while retaining efficiency of the core engine. The outer diameter of the fan can be increased, raising a bypass ratio.

Owner:NIKKISO COMPANY

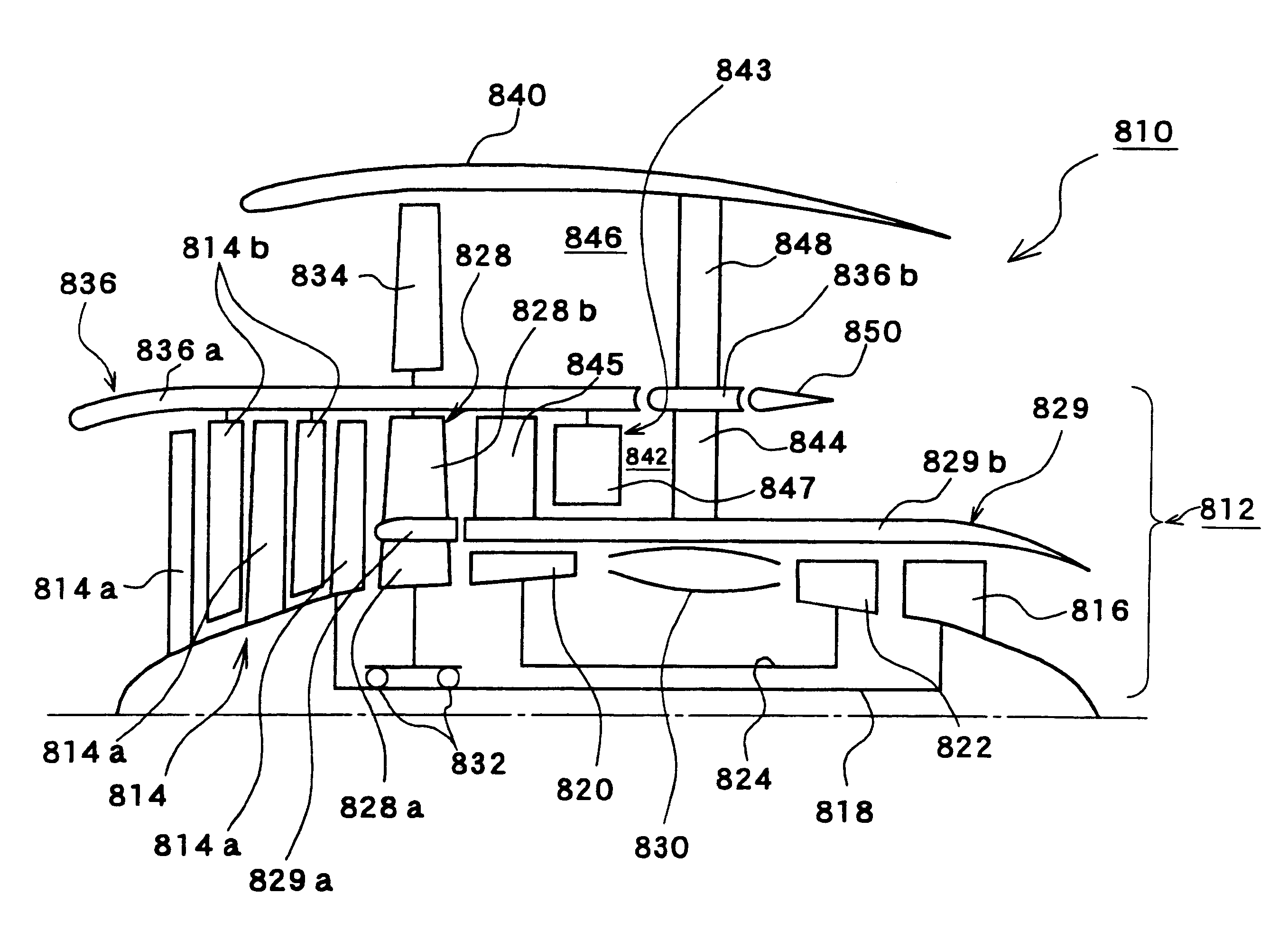

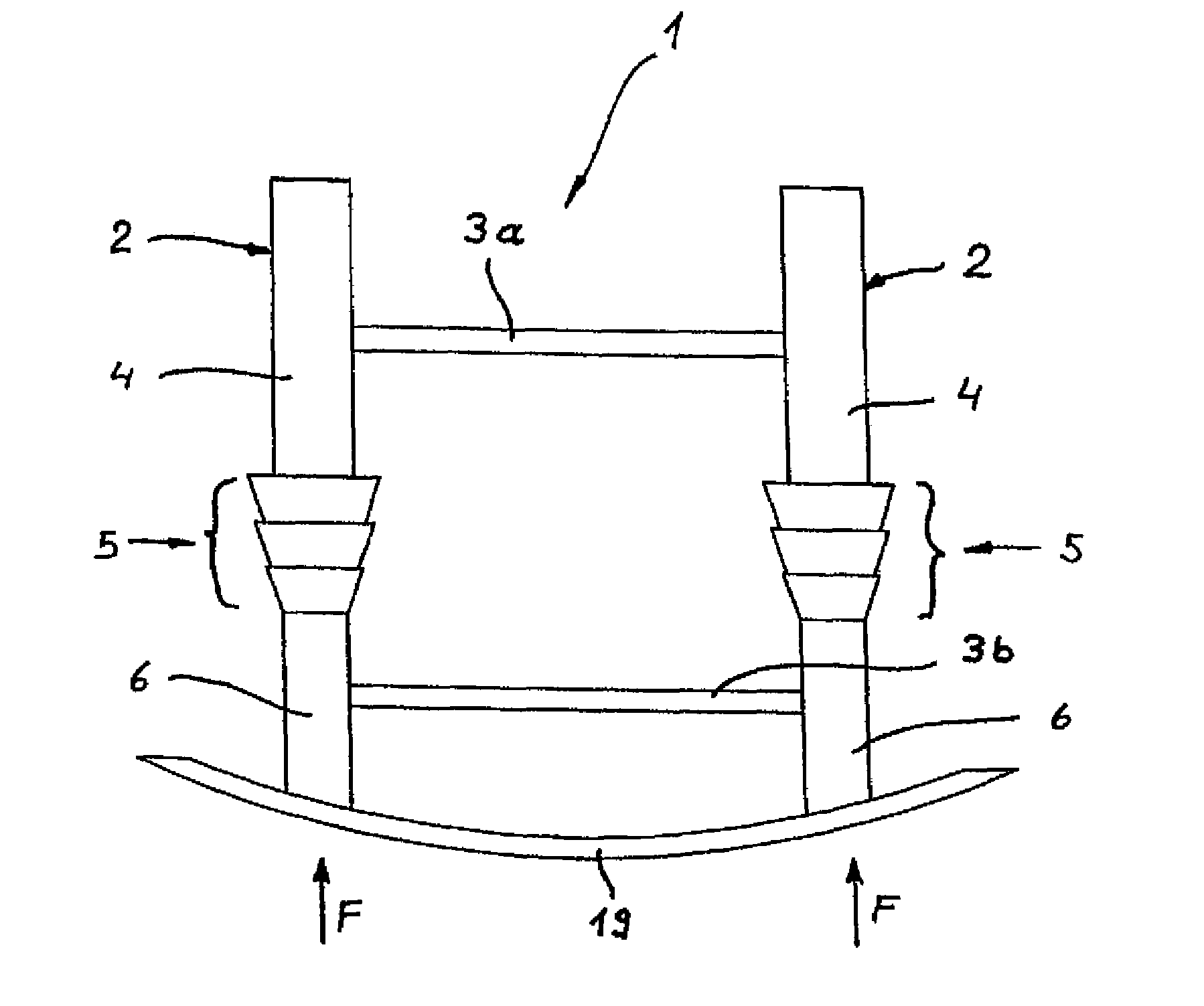

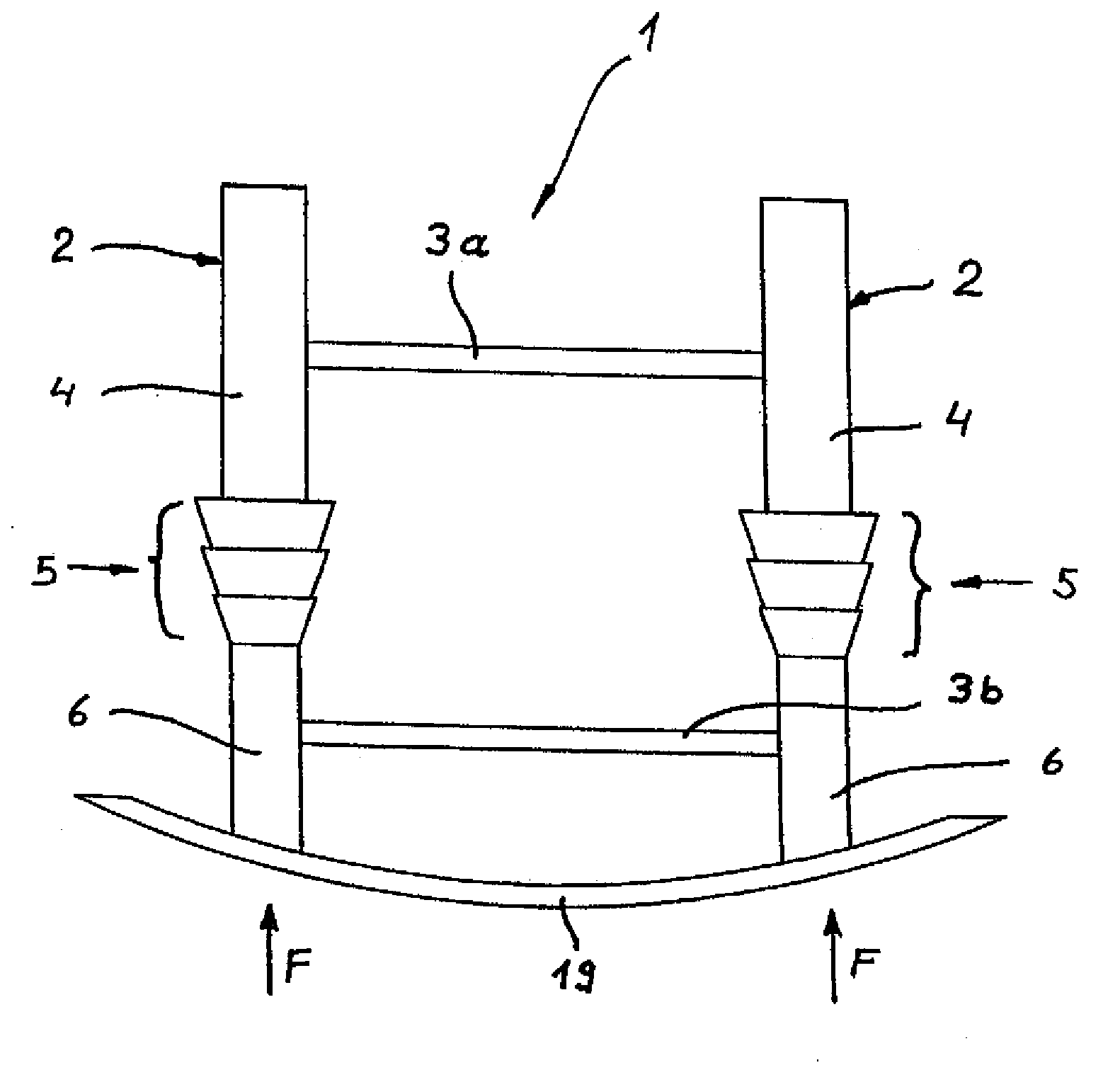

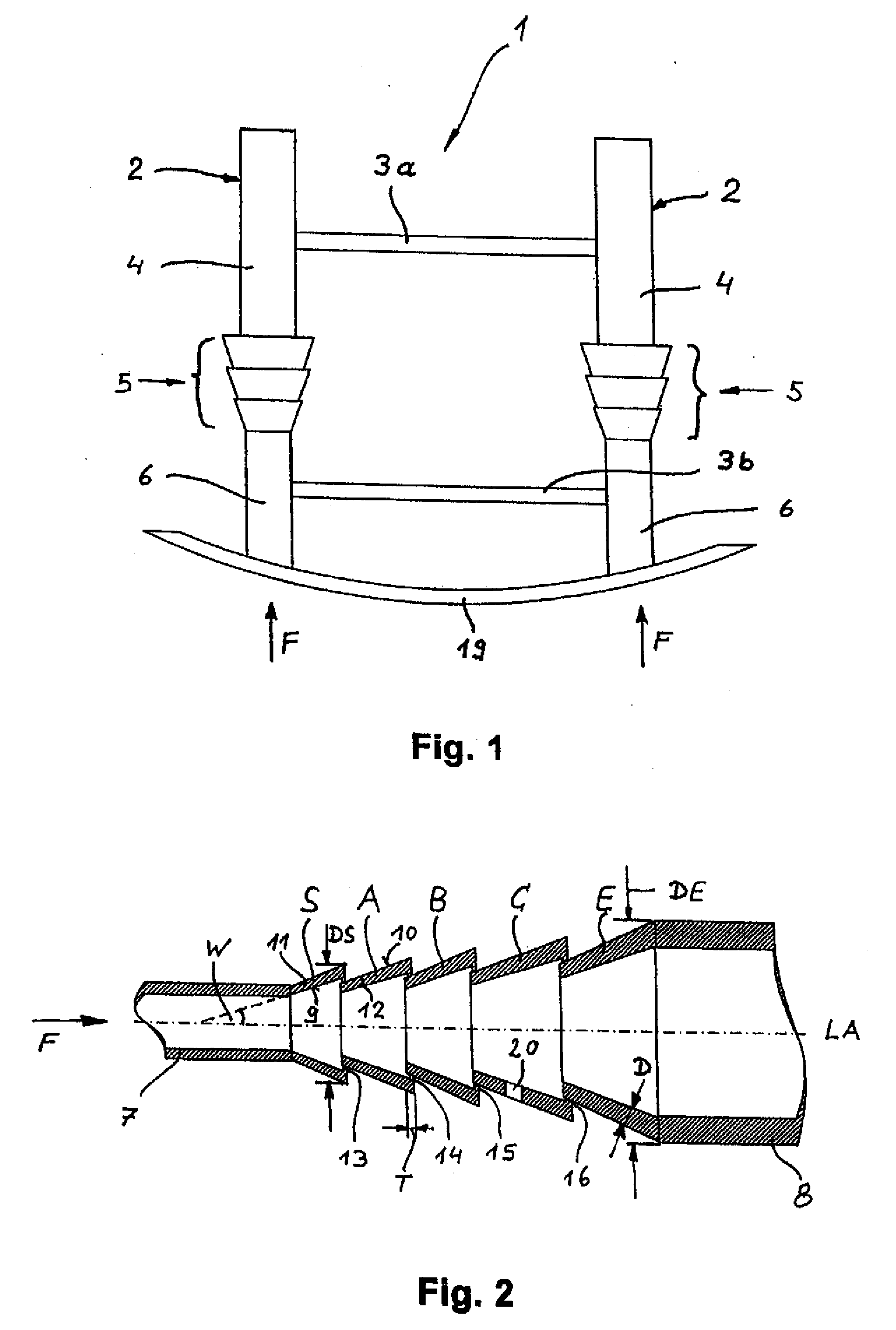

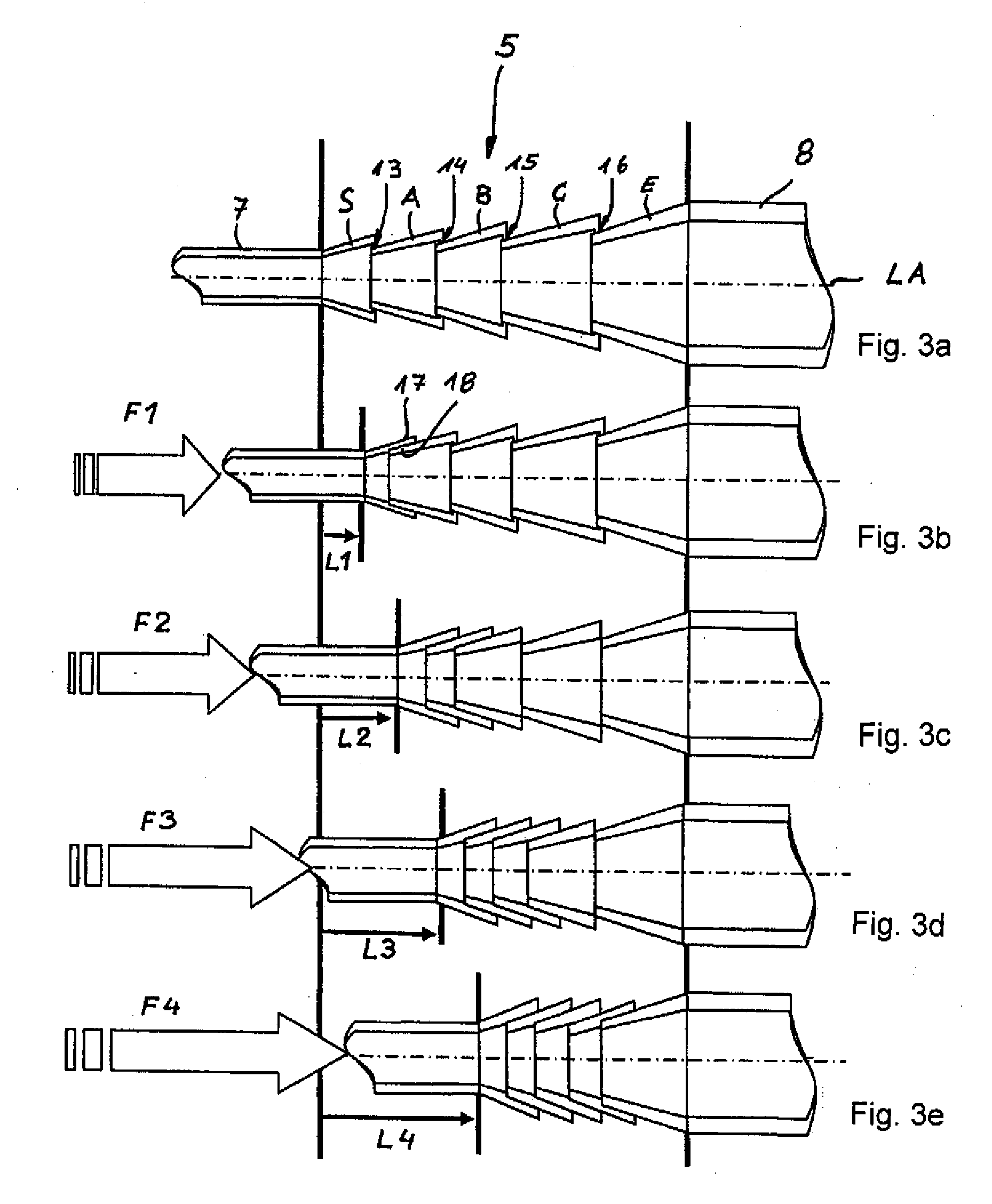

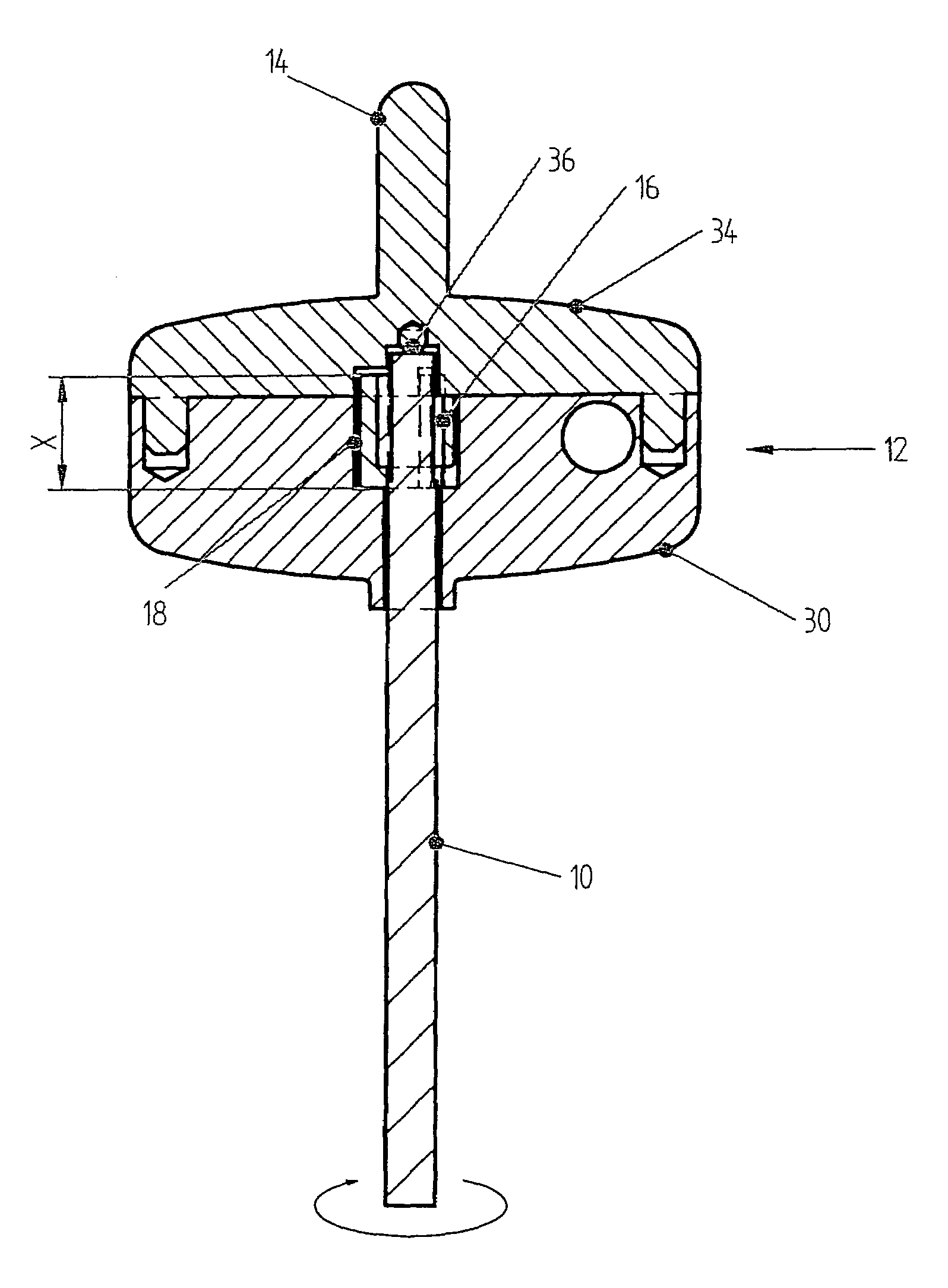

Adaptive crash structure for a vehicle body or chassis of a motor vehicle

InactiveUS7357445B2Reduce warpingAvoid accidental separationVehicle seatsUnderstructuresMobile vehicleMotor vehicle part

An adaptive crash structure of a vehicle body or chassis of a motor vehicle includes a first metal casting and a second metal casting. A deformation element in the form of a metal casting for absorbing energy interconnects and forms with the first and second metal castings a single piece construction through a casting process. The deformation element is comprised of a plurality of funnel-shaped wedge bodies which are disposed in succession, with neighboring wedge bodies being connected through intervention of a predetermined breaking web. Each wedge body is defined by a diameter, wherein the diameters of the wedge bodies are sized to allow the wedge bodies to move telescopically into one another when a limit stress is reached and the predetermined breaking webs rupture so as to effect a tight intergrip of the telescoping wedge bodies in a self-locking manner.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

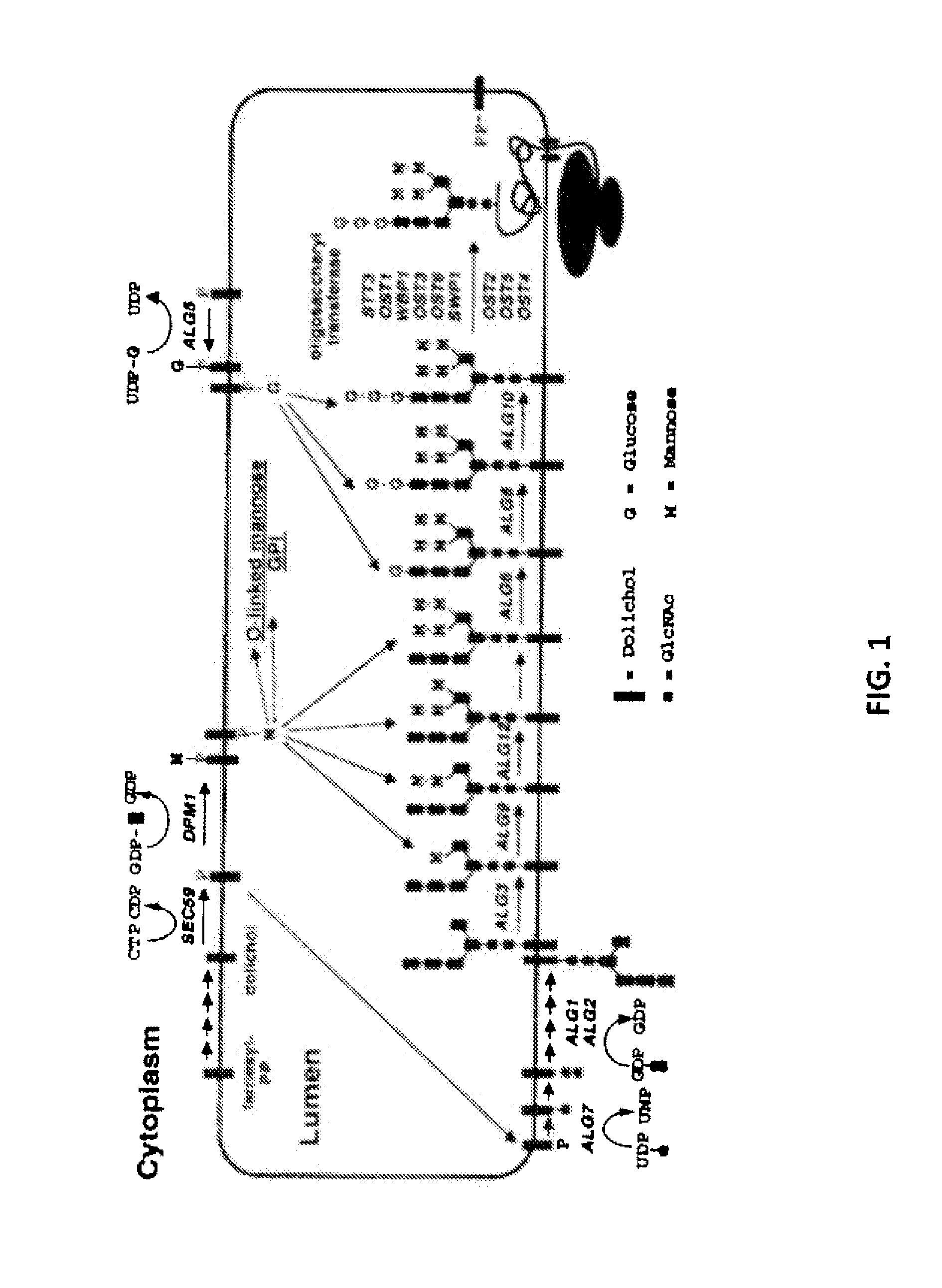

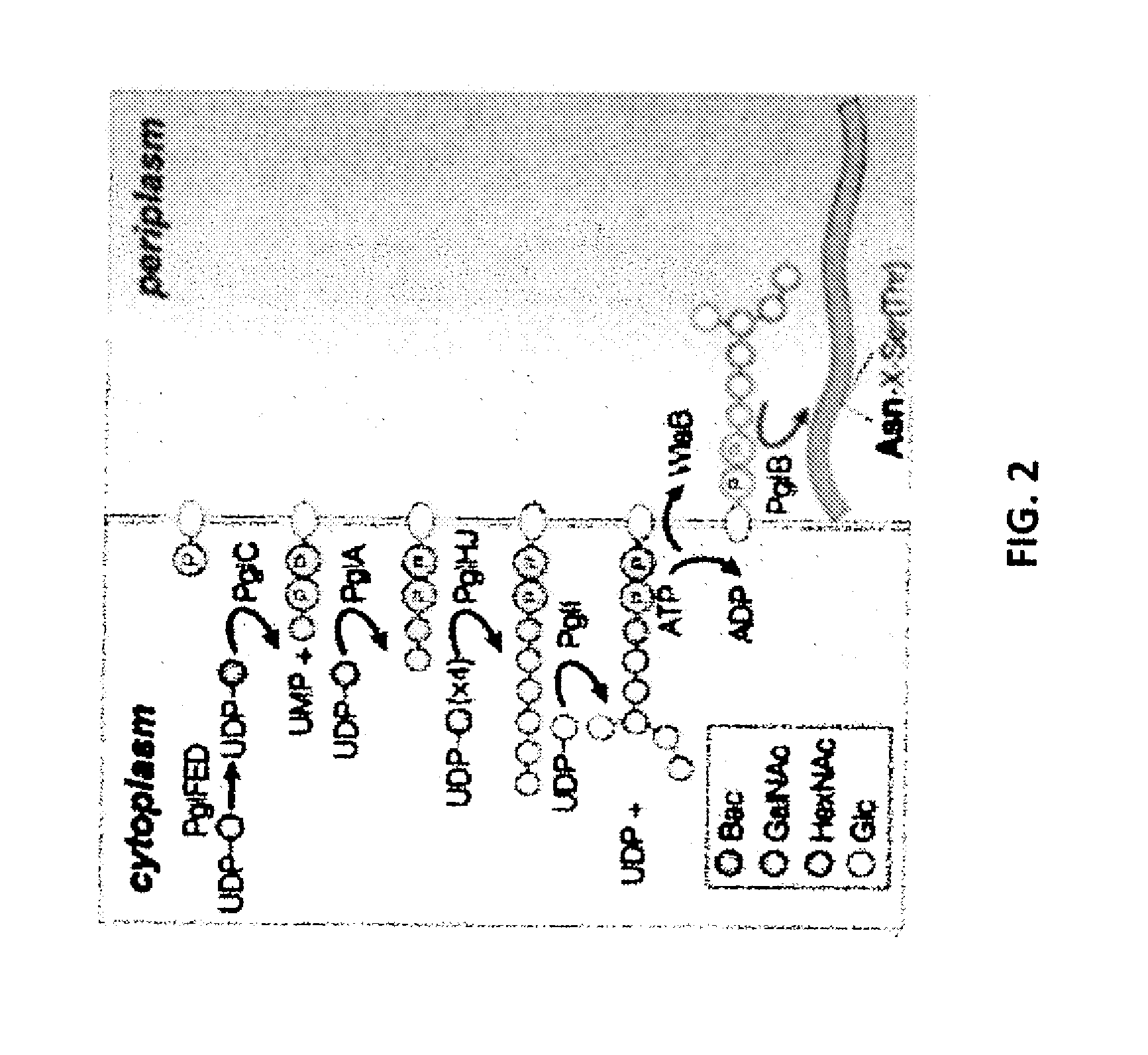

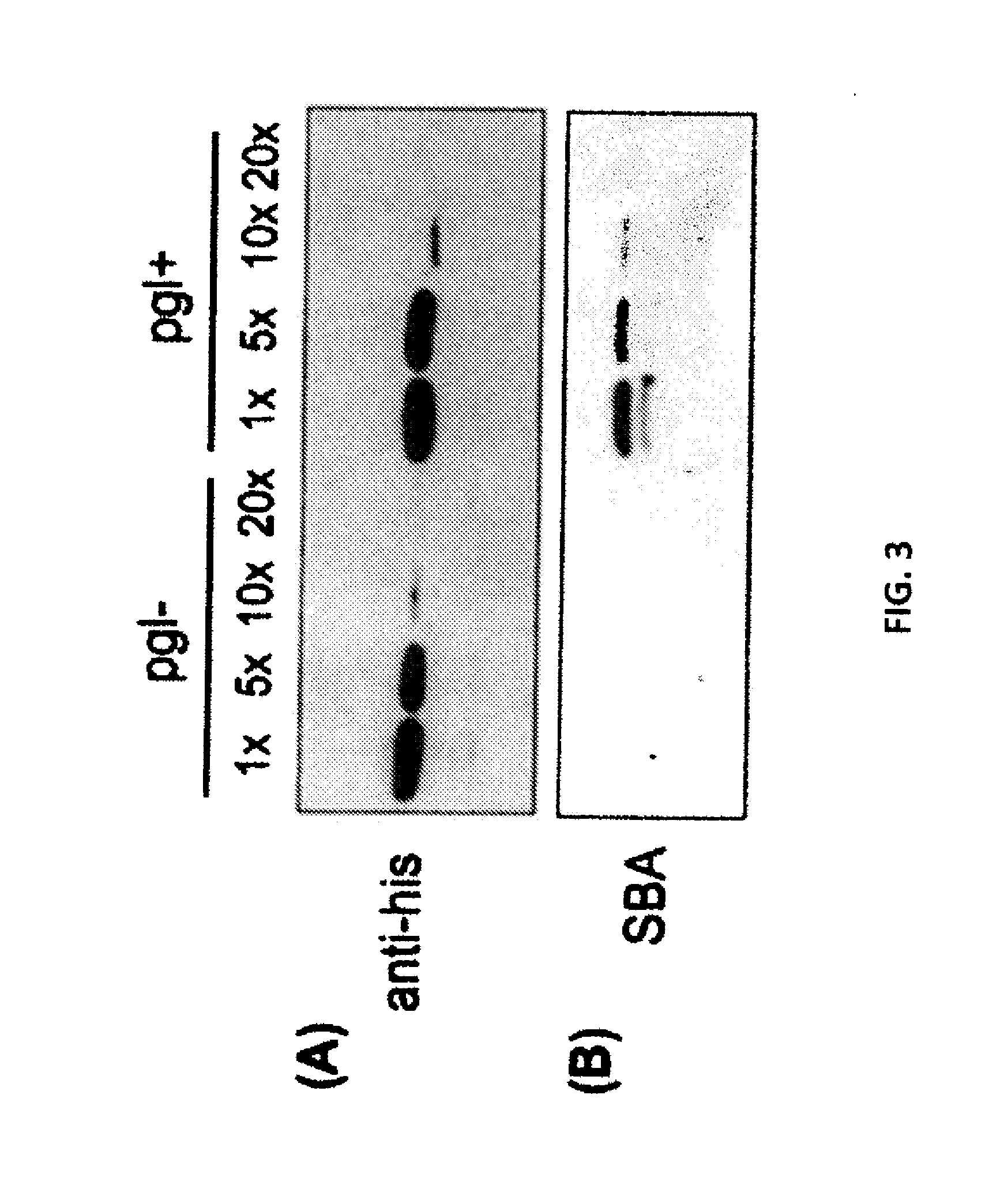

Glycosylated protein expression in prokaryotes

The present invention relates to a prokaryotic host cell comprising eukaryotic glycosyltransferase activity, where the eukaryotic glycosyltransferase activity is eukaryotic dolichyl-linked UDP-GlcNAc transferase activity and eukaryotic mannosyl-transferase activity. Also disclosed is a method of producing a glycosylated protein by providing a prokaryotic host cell comprising the eukaryotic glycosyltransferase activity and culturing the prokaryotic host cell under conditions effective to produce a glycosylated protein. Another aspect of the present invention pertains to a method for screening bacteria or bacteriophages by expressing one or more glycans on the surface of a bacteria, attaching a label on the one or more glycans on the surface of the bacteria or on the surface of a bacteriophage derived from the bacteria, and analyzing the label in a high-throughput format. A glycosylated antibody comprising an Fv portion which recognizes and binds to a native antigen and an Fc portion which is glycosylated at a conserved asparagine residue is also disclosed.

Owner:CORNELL RES FOUNDATION INC

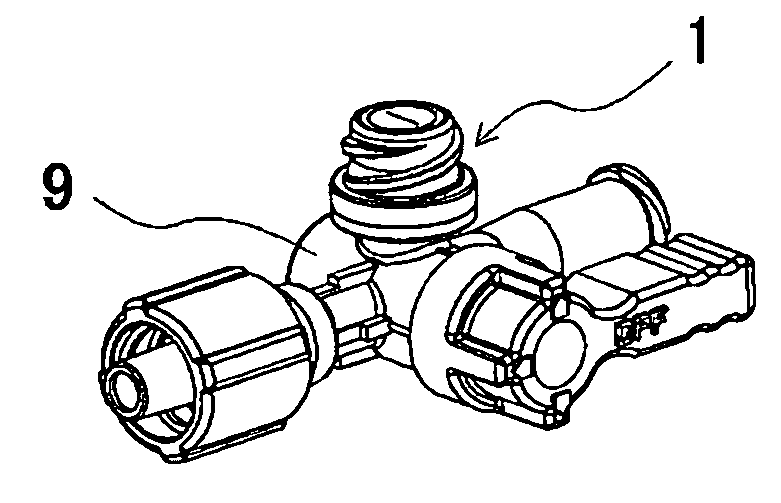

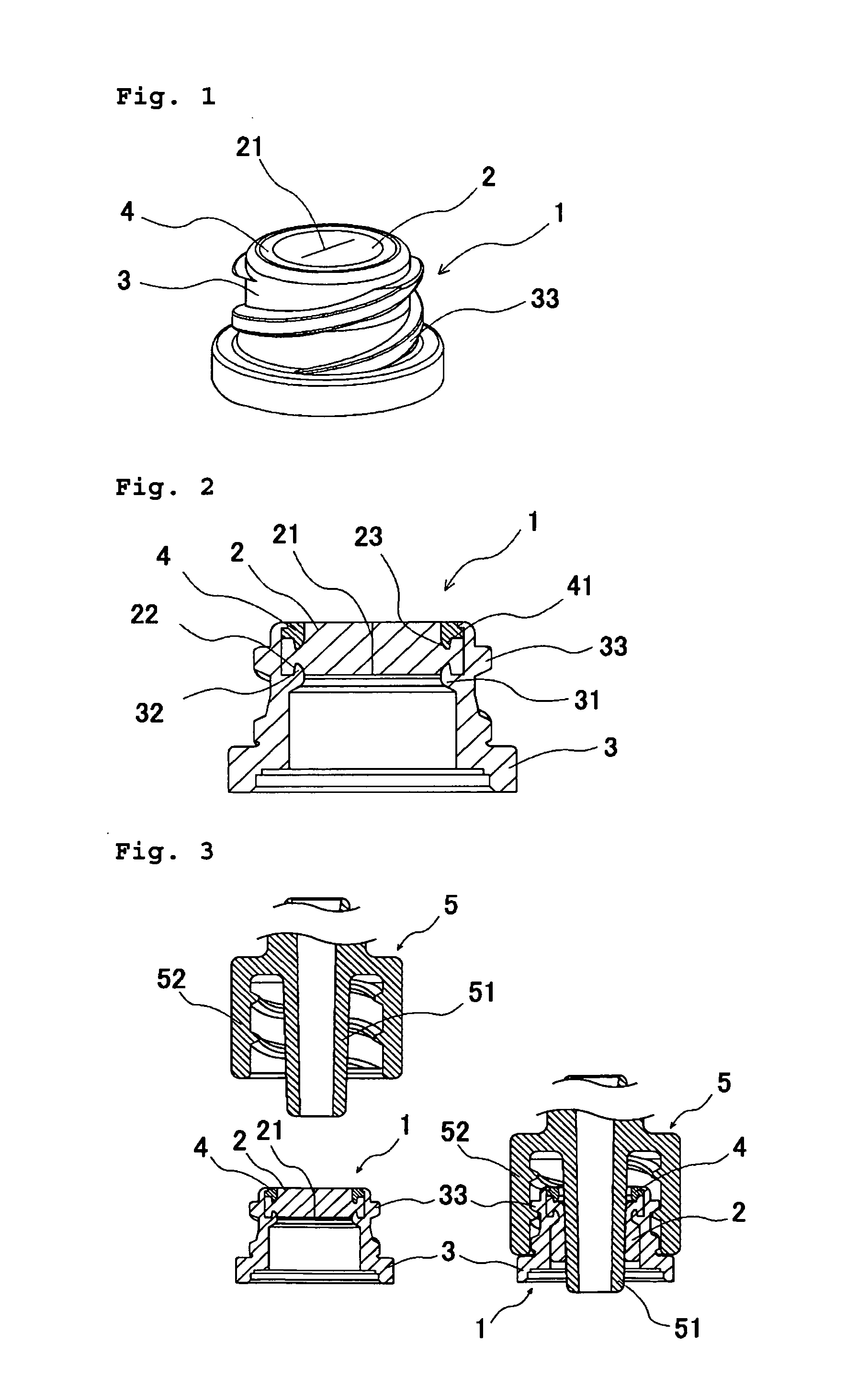

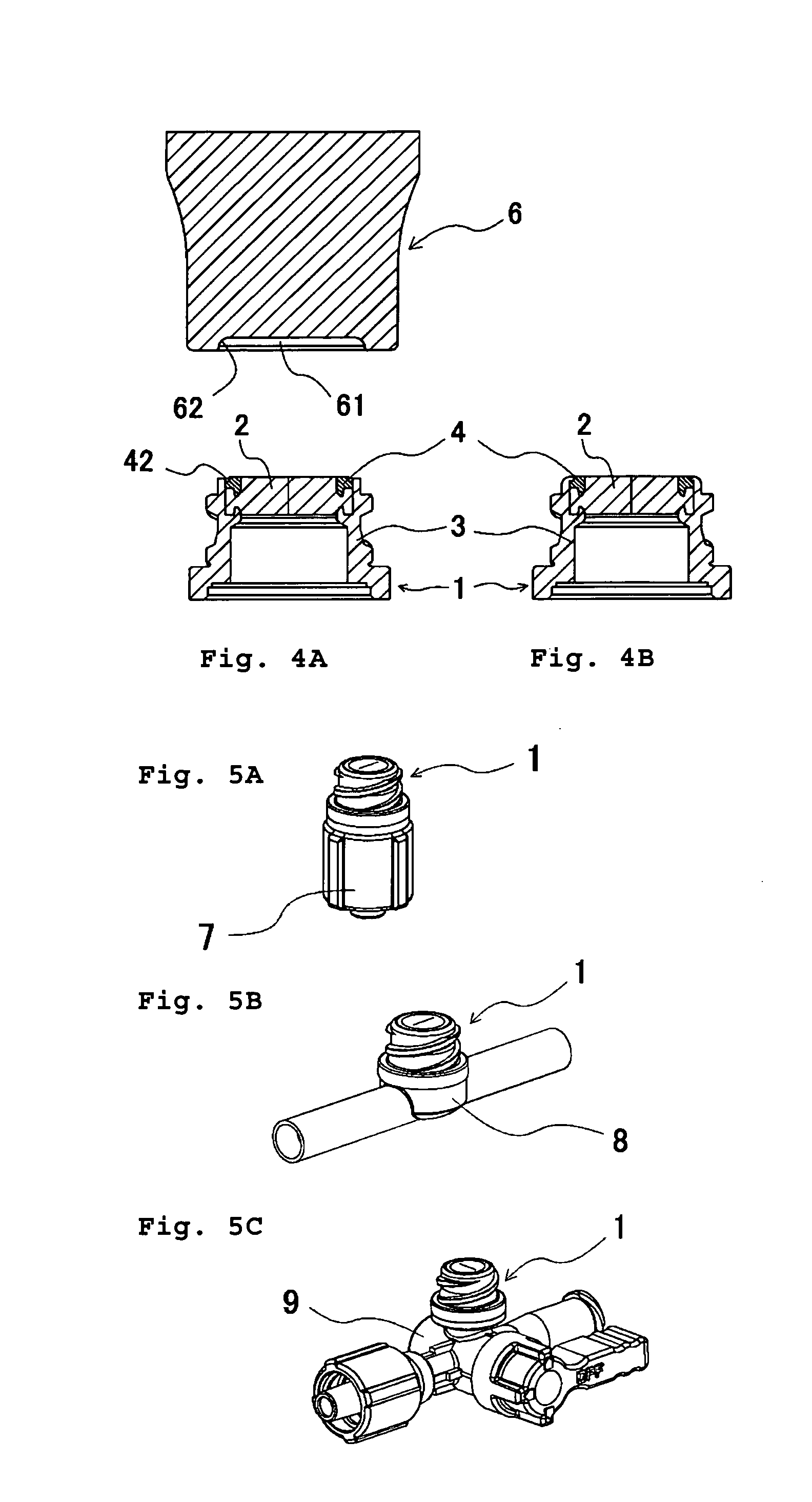

Medical connector

InactiveUS20080306469A1Increase the outer diameterEasy to carryCatheterTube connectorsEngineeringMedical treatment

A medical connector capable of allowing, in which a stepped portion is not formed between upper surfaces of a valve and a housing, includes a disc shaped valve member which has a slit formed at a center portion thereof; a housing with a substantially cylindrical shape which sandwiches a circumferential edge portion of the valve member; and an annular ring member which is disposed on an upper circumferential edge of the valve member other than the center portion thereof, wherein the housing has a pedestal which is formed on an inner circumferential surface thereof so as to protrude inward, the valve member being placed on the pedestal, and wherein the valve member is fixed to the inside of the housing by allowing the ring member and the housing to be joined to each other by a swaging process after the valve member is placed on the pedestal in the housing.

Owner:NIPRO CORP

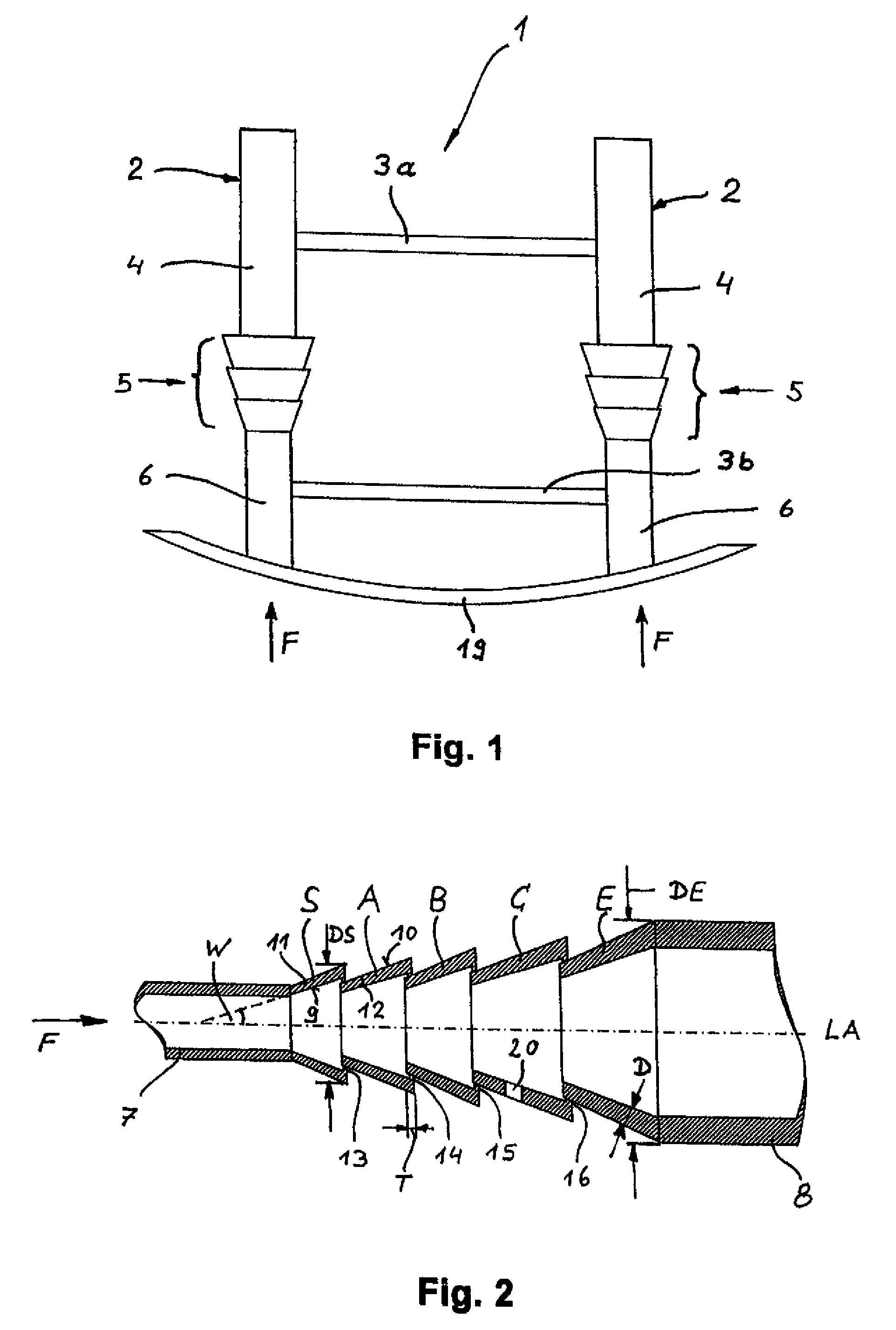

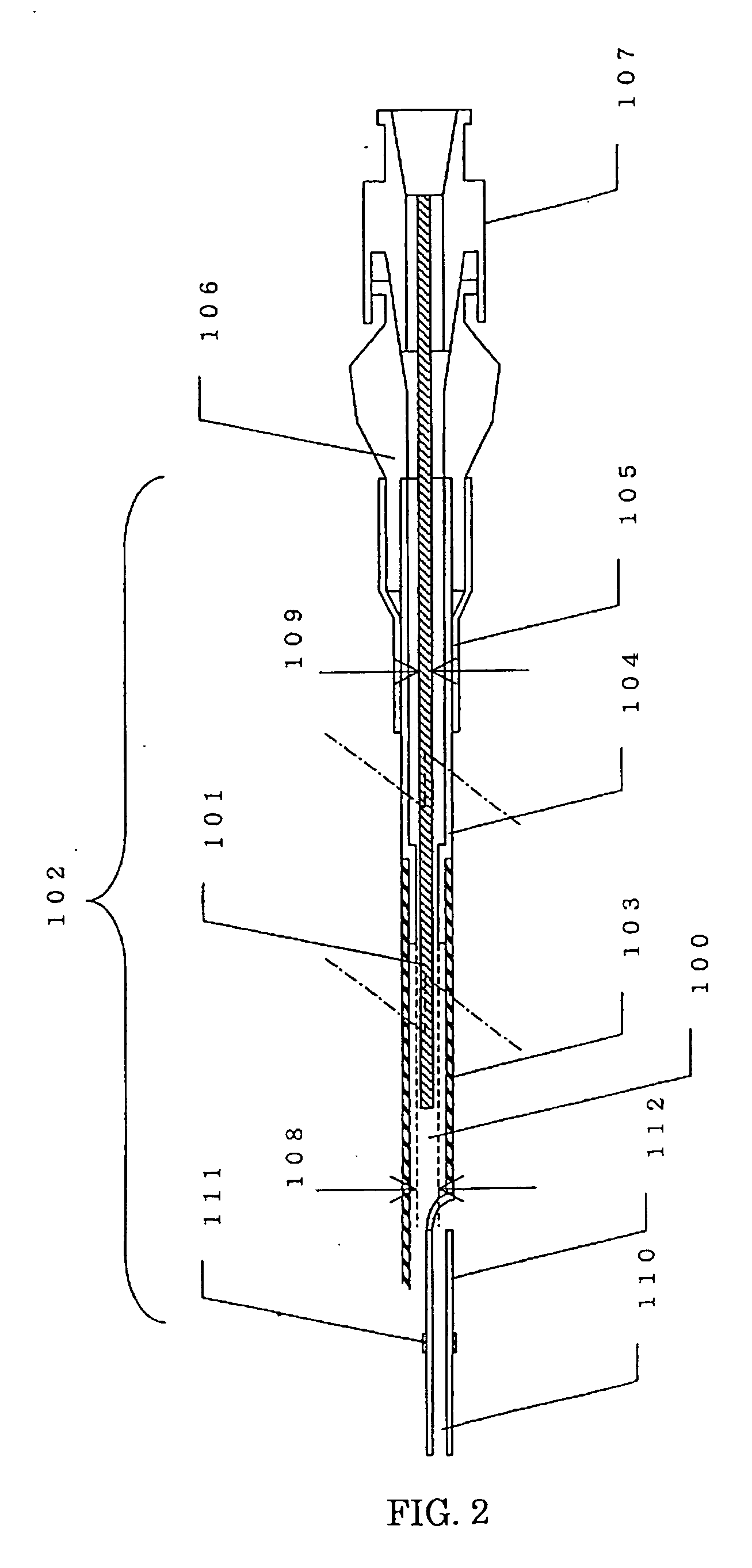

Catheter tube for medical treatment and method of manufacturing the same

InactiveCN101001658AGood follow-upEasy to adjust the positionCatheterCoatingsLeading edgeAccess route

A catheter tube for medical treatment having a high degree of freedom in having its rigidity and flexibility changed stepwise and enabling the setting of a bending rigidity changing position according to a variety of access routes and a method of manufacturing the catheter tube. The catheter tube comprises an inner layer tube, a reinforcement material layer, a marker, and an outer layer tube which are formed integrally with each other. The catheter tube is so formed that a line body forming the reinforcement material layer is densely wound at its tip part, the marker formed of an X-ray impermeable metal wire adjacent to the tip thereof is also densely wound, and comprises a leading-edge part where the reinforcement material layer and the marker are not present. Accordingly, the bending rigidity of the catheter tube from the base part to ward the tip part is stepwise or continuously decreased by the presence of the reinforcement material layer and the outer layer tube. The winding of the line body is terminated at the base part after its interval and tilt angle are changed at positions between the densely wound portion of the tip part and a portion near the base part, and the outer layer tube has a stepwise-changing hardness arrangement. As a result, the catheter tube can be set to a variety of bending rigidity changing positions.

Owner:KANEKA CORP

Adaptive crash structure for a vehicle body or chassis of a motor vehicle

InactiveUS20070114804A1Reduce warpingAvoid accidental separationUnderstructuresElastic dampersAbsorbed energySelf locking

An adaptive crash structure of a vehicle body or chassis of a motor vehicle includes a first metal casting and a second metal casting. A deformation element in the form of a metal casting for absorbing energy interconnects and forms with the first and second metal castings a single piece construction through a casting process. The deformation element is comprised of a plurality of funnel-shaped wedge bodies which are disposed in succession, with neighboring wedge bodies being connected through intervention of a predetermined breaking web. Each wedge body is defined by a diameter, wherein the diameters of the wedge bodies are sized to allow the wedge bodies to move telescopically into one another when a limit stress is reached and the predetermined breaking webs rupture so as to effect a tight intergrip of the telescoping wedge bodies in a self-locking manner.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Screwdriver tool

InactiveUS7080582B2Increase the outer diameterClosely arrangedSlip couplingSpannersTorque transmissionSpring force

Owner:WIHA WERKZEUGE

Brushless motor

ActiveUS7453175B2Improve the efficiency of position adjustmentImprove efficiencySynchronous generatorsAsynchronous induction motorsBrushless motorsEngineering

A second bracket part for holding a resolver stator of a resolver as position detecting means is inserted in an opening hole in a first bracket part. An expanded part formed in the second bracket part and the opening hole in the first bracket hole are connected to each other with a fixing member. A through hole in which the fixing member for the expanded part is inserted has a circular arc shape. By reducing the fixing strength of the fixing member, the second bracket part can be made movable in the circumferential direction.

Owner:NIDEC CORP

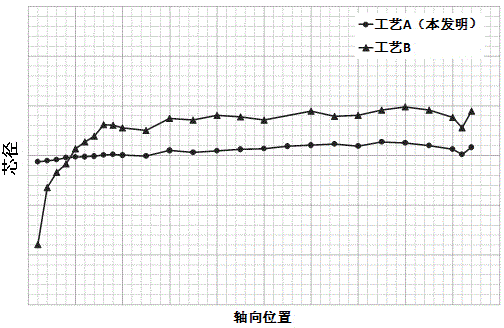

Super austenitic stainless steel pipe manufacturing process

InactiveCN102274854AIncrease the outer diameterReduce manufacturing costMetal rolling arrangementsSolution treatmentMetallurgy

The invention discloses a manufacturing process of a super austenitic stainless steel pipe, which comprises the following steps: A, billet preparation: the steel ingot is forged and formed after electroslag remelting and punched; B, the pipe billet is heated to 1190-1250°C; C. The tube billet is cross-rolled and pierced by a cross-rolling piercer; D. Tube rolling by a periodic tube mill; E. Solution treatment; F. Deep processing of waste tubes; G. Finishing and grinding to finished products. The beneficial effect of the invention is that the outer diameter of the product is greatly increased to 406mm by adopting the manufacturing process of piercing and periodic rolling, and the manufacturing cost and the manufacturing cycle are reduced at the same time.

Owner:SICHUAN SANZHOU SPECIAL STEEL PIPE

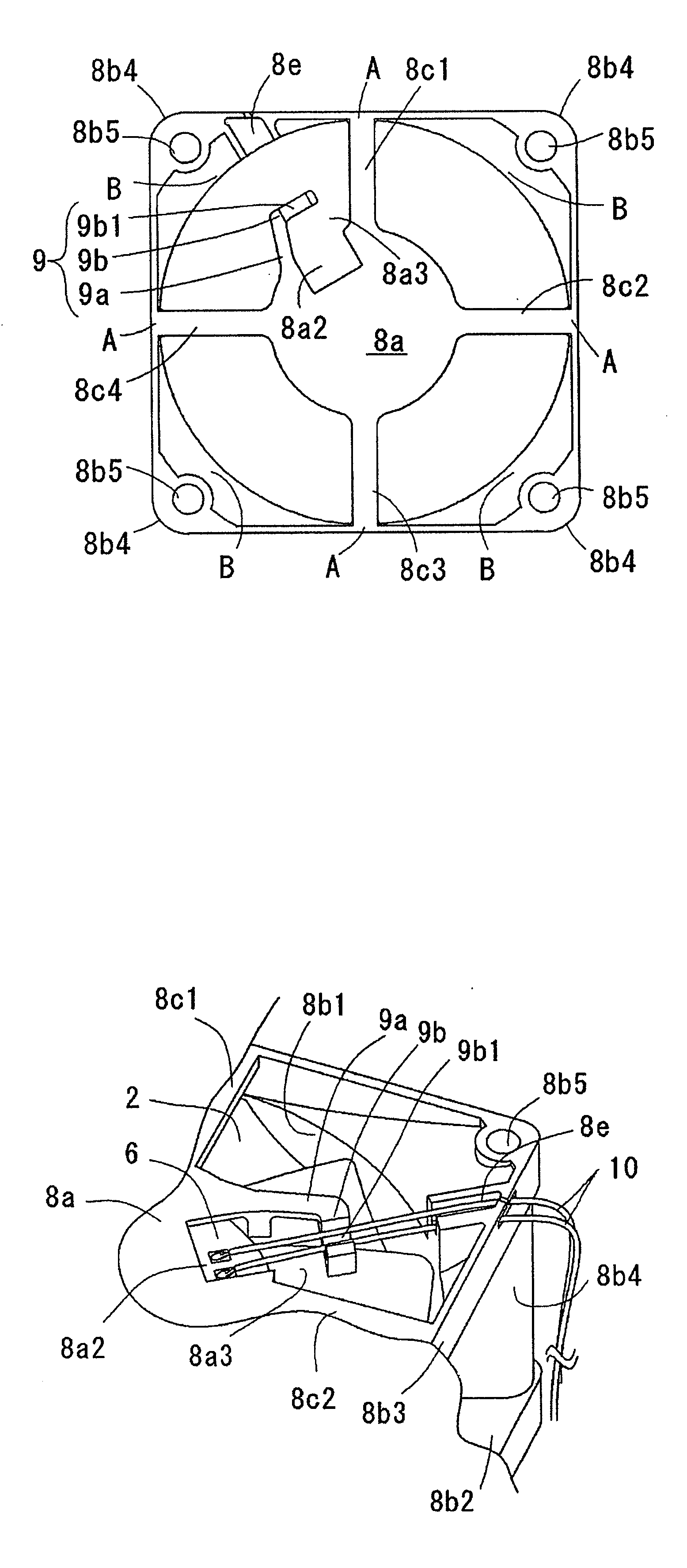

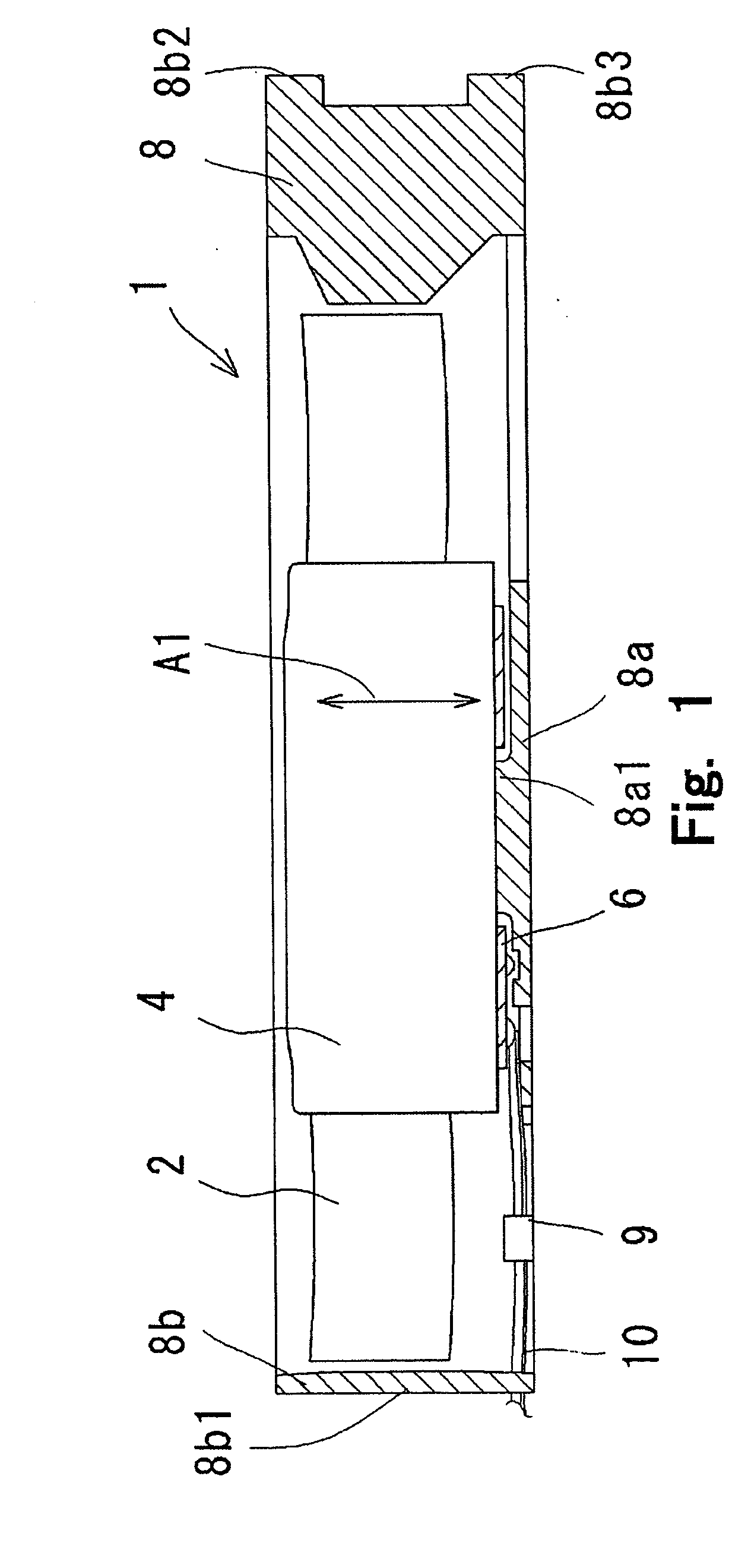

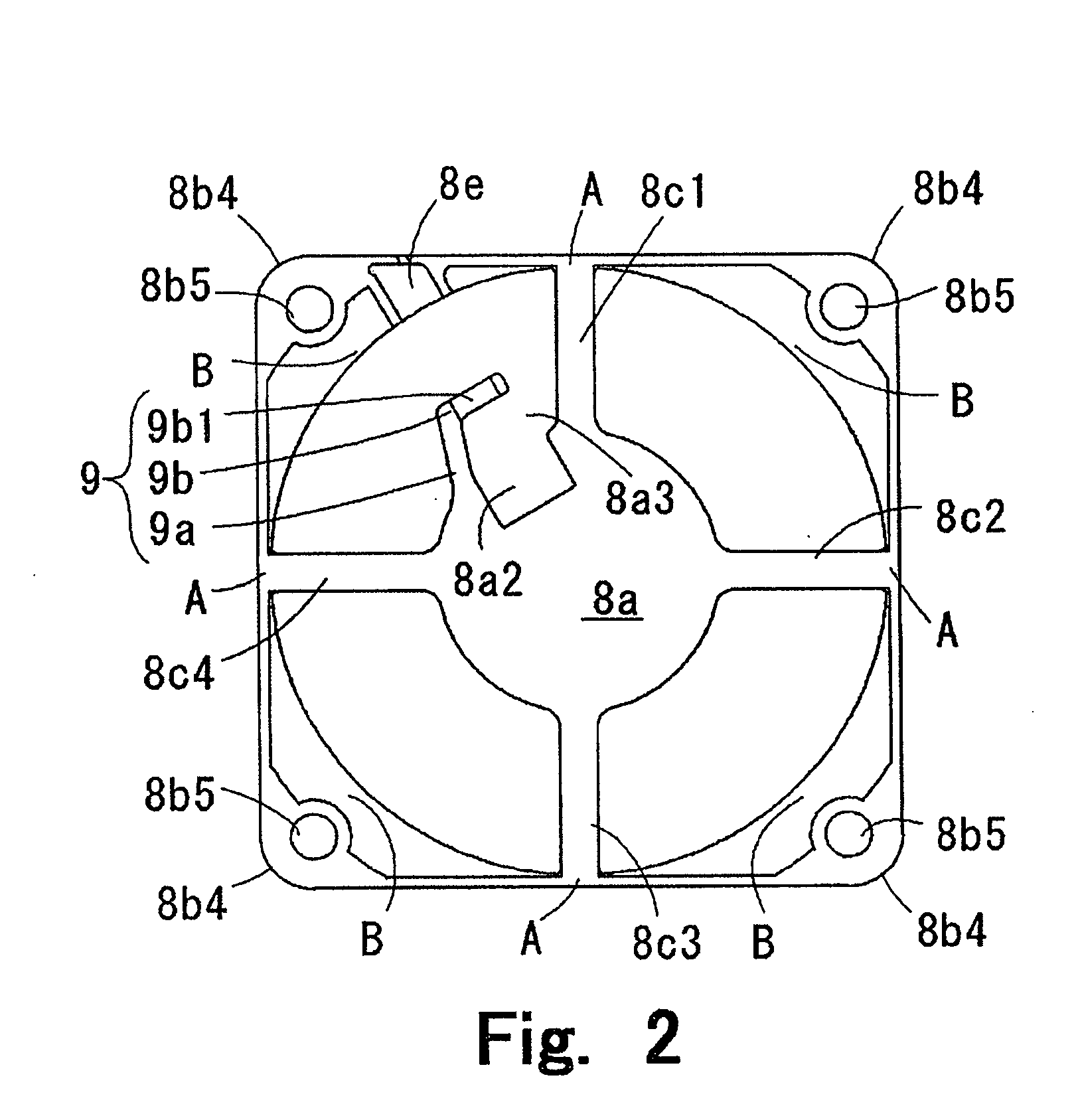

Structure of fan devices for leading out wires

InactiveUS20050180867A1Small wind resistance lossMinimize windage lossPump componentsDigital data processing detailsEngineeringMechanical engineering

Owner:NIPPON DENSAN CORP

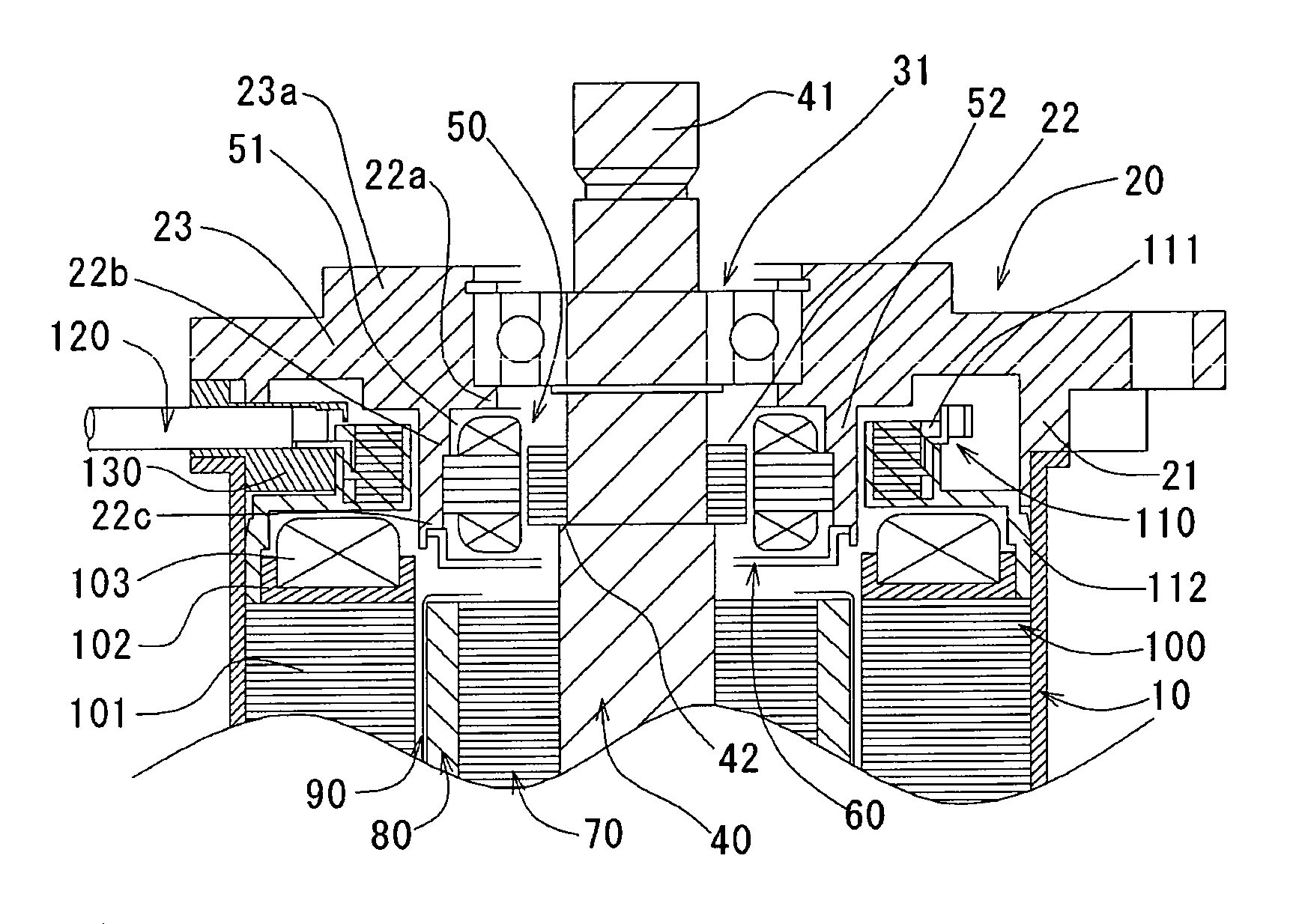

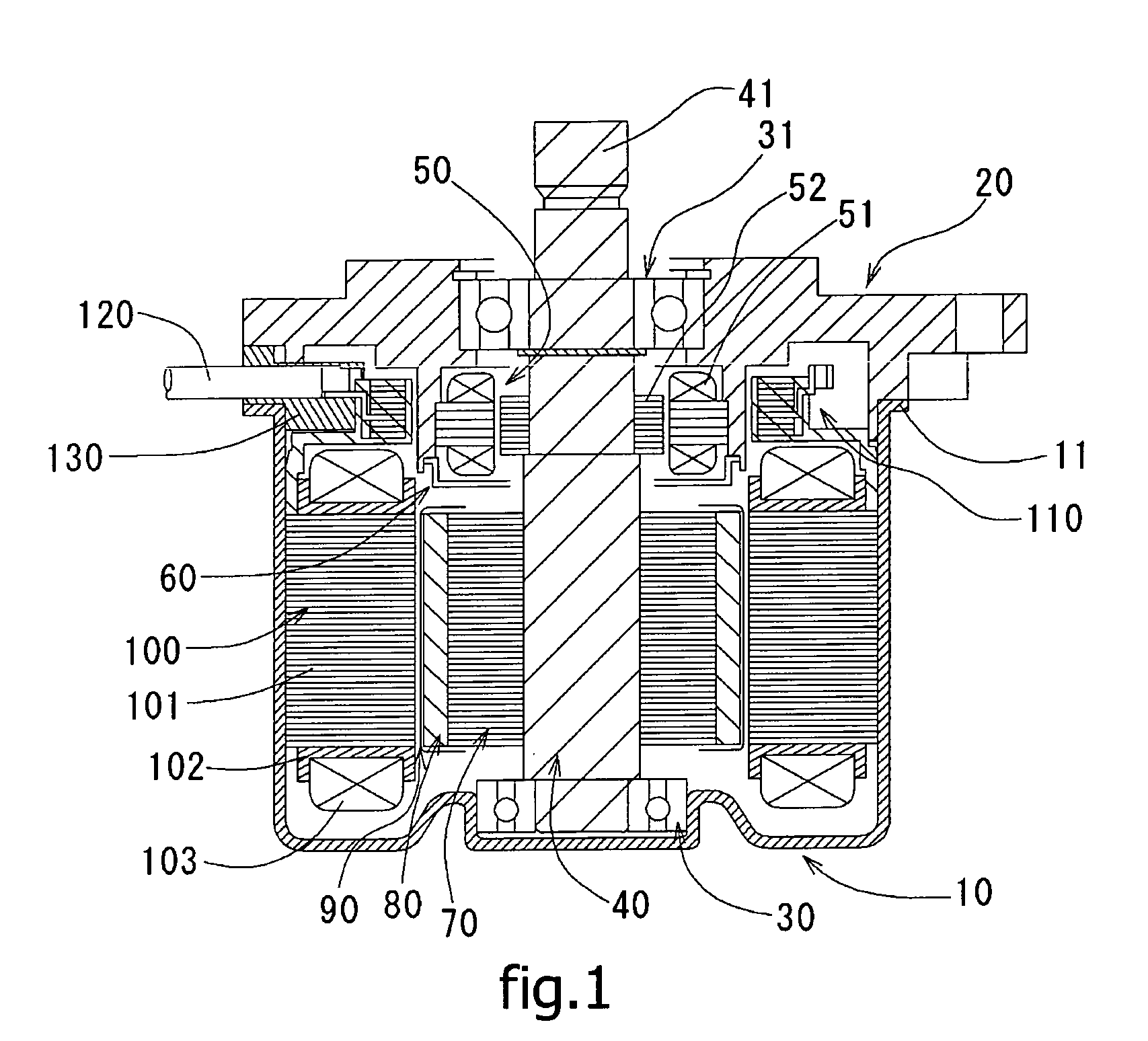

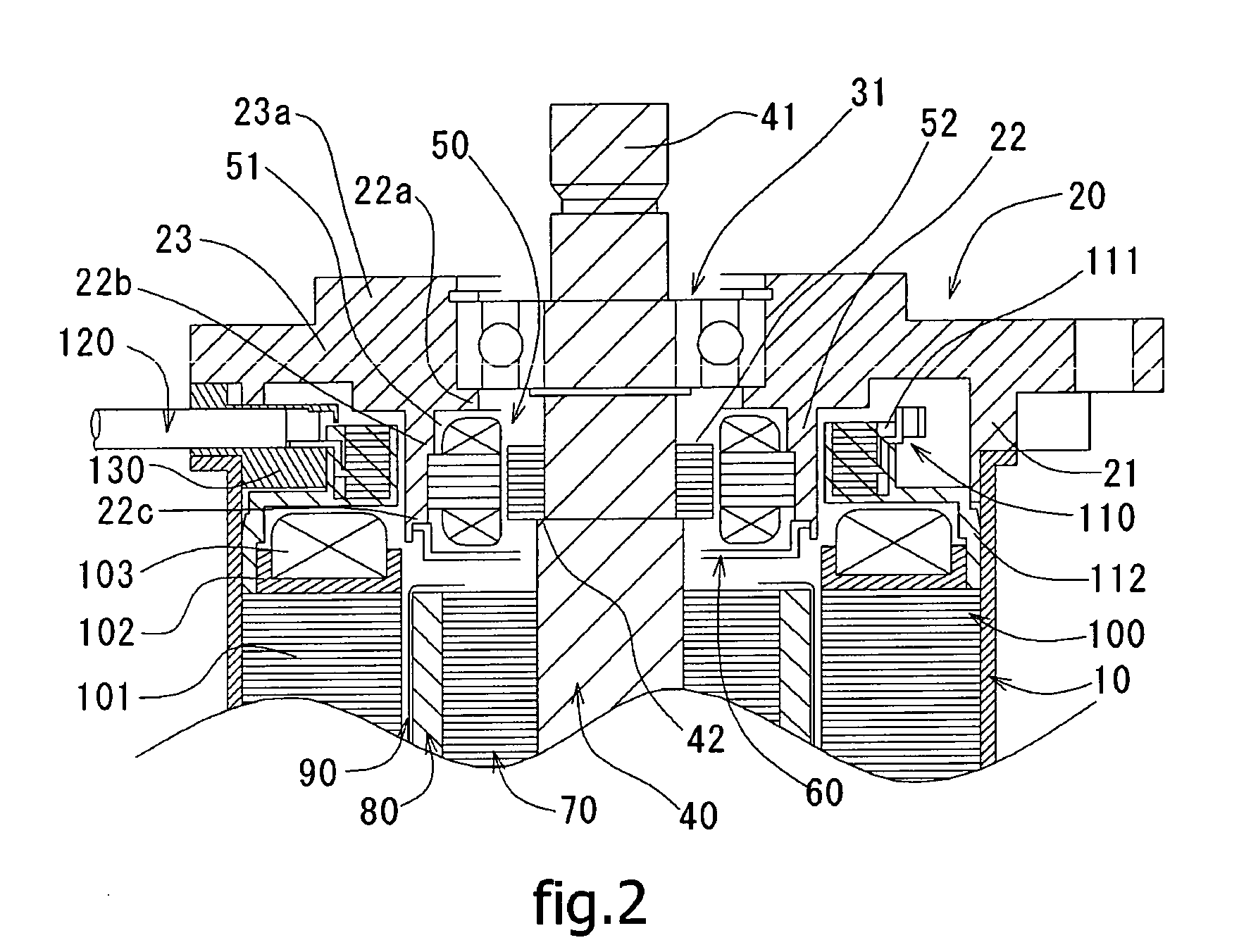

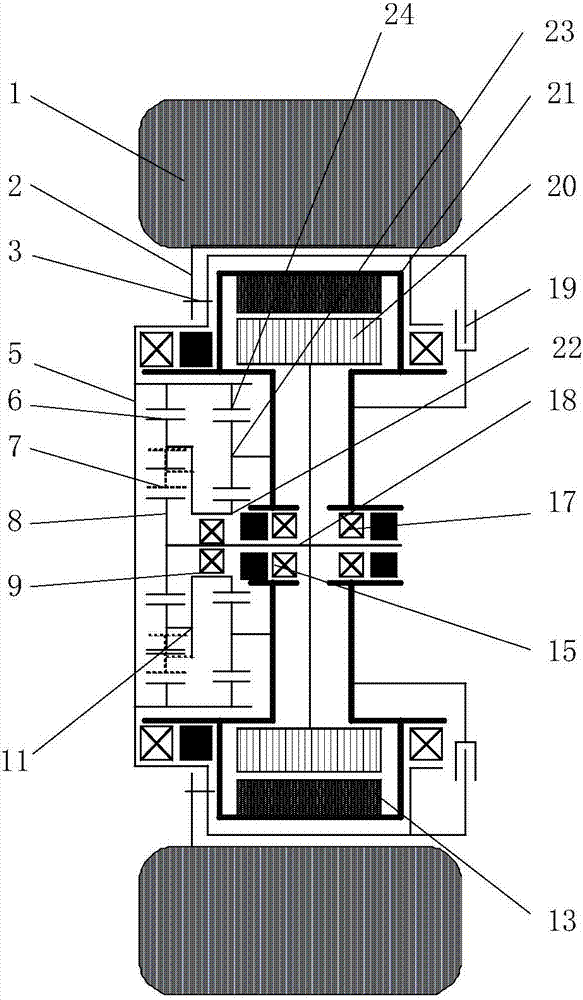

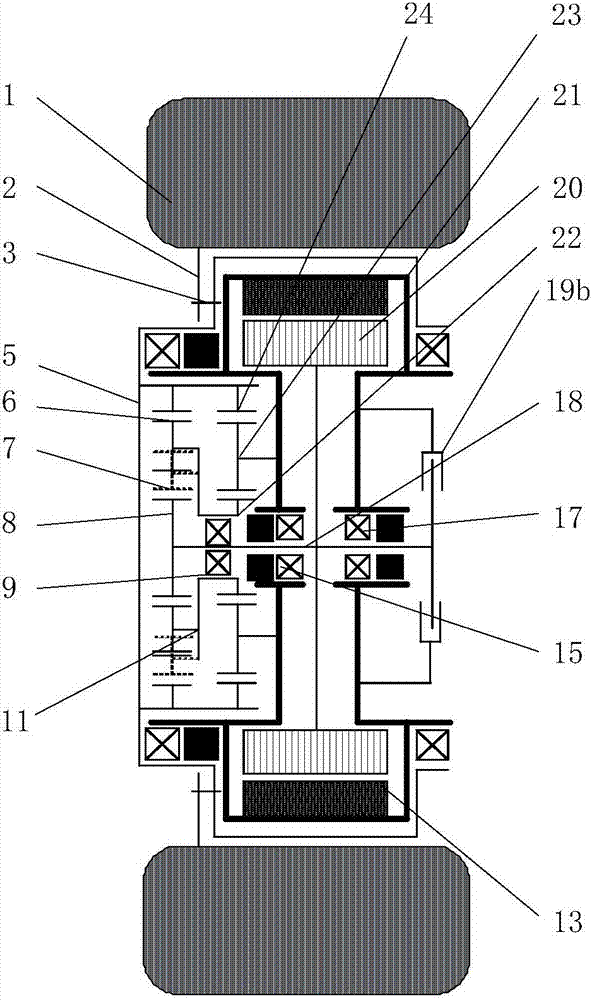

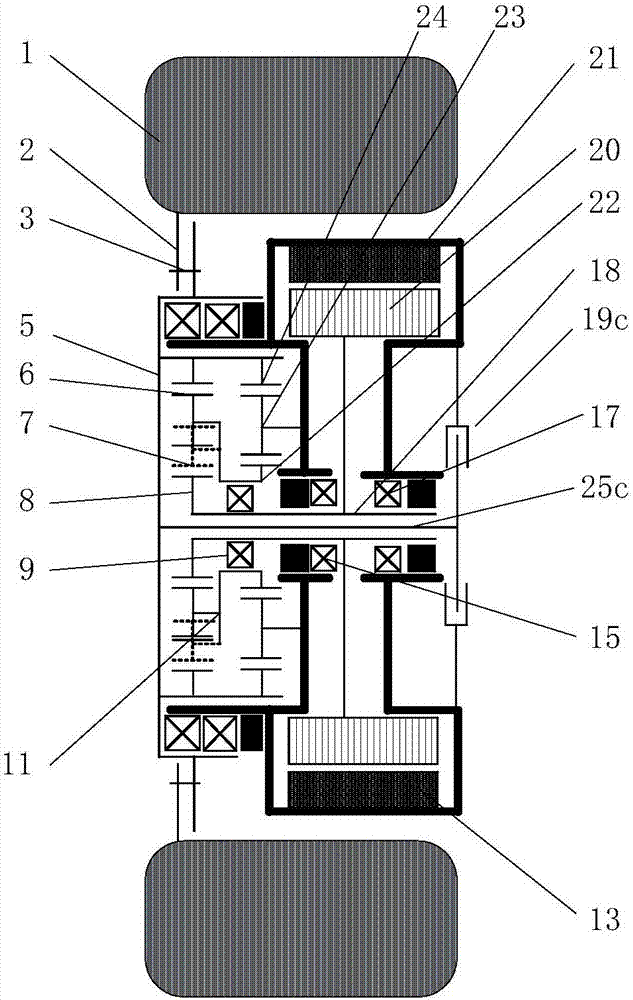

Wheel hub motor driving device

ActiveCN106864251AIncrease speedImprove power densityMotor depositionControl devicesMotor driveElectric machine

The invention belongs to the technical field of electric cars and particularly relates to a power transmission technology. A wheel hub motor driving device comprises a shell (21), a motor, a two-stage planetary reducer, wheel rims (2) and tires (1); and the motor and the two-stage planetary reducer are coaxially arranged, the wheel rims (2) are connected with the output end (5) of the two-stage planetary reducer, and the tires (1) are installed on the wheel rims (2), so that power from the two-stage planetary reducer is transmitted to the tires (1). According to the wheel hub motor driving device, a planetary reducing mechanism is adopted, the manufacturability is good, transmission efficiency is high, the large transmission ratio can be obtained, the rotating speed of the motor can be increased, and thus the power density of the wheel hub motor driving device is improved; output of the reducer serves as a rotating shell and is directly connected with the wheel rims, and wheel detaching and installing are convenient; and brakes are arranged inside the wheels, the outer diameters are large, and thus heat dissipation and thermal capacity guaranteeing are facilitated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

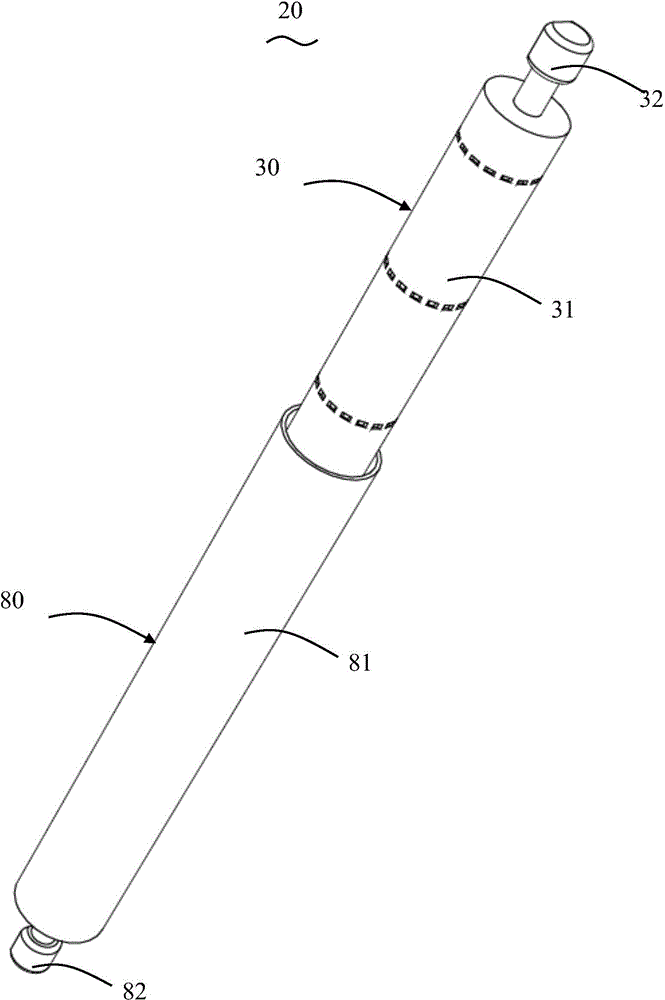

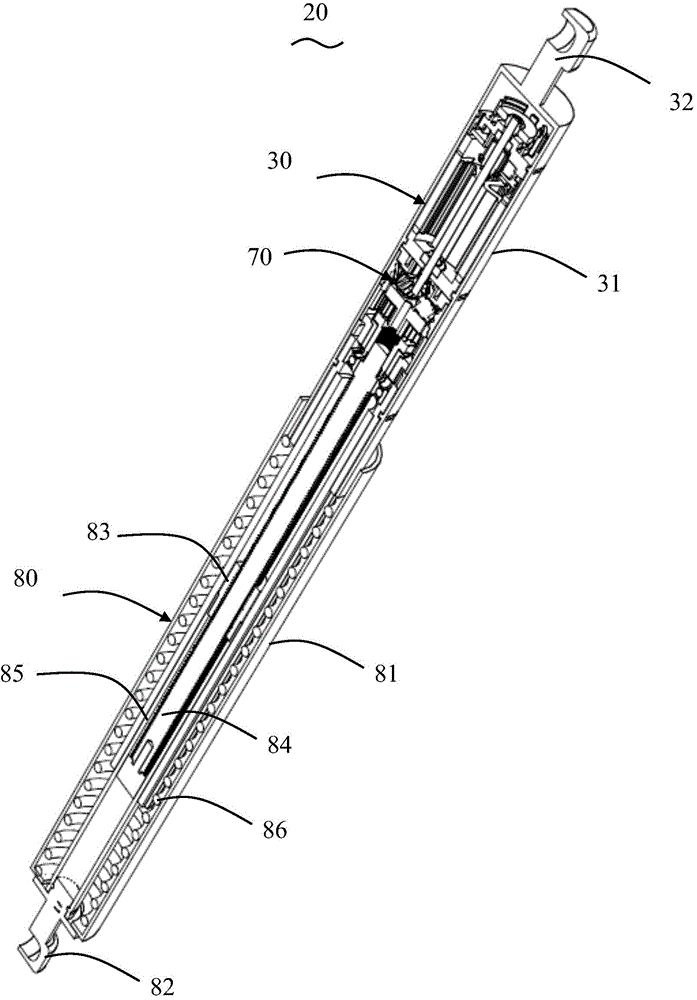

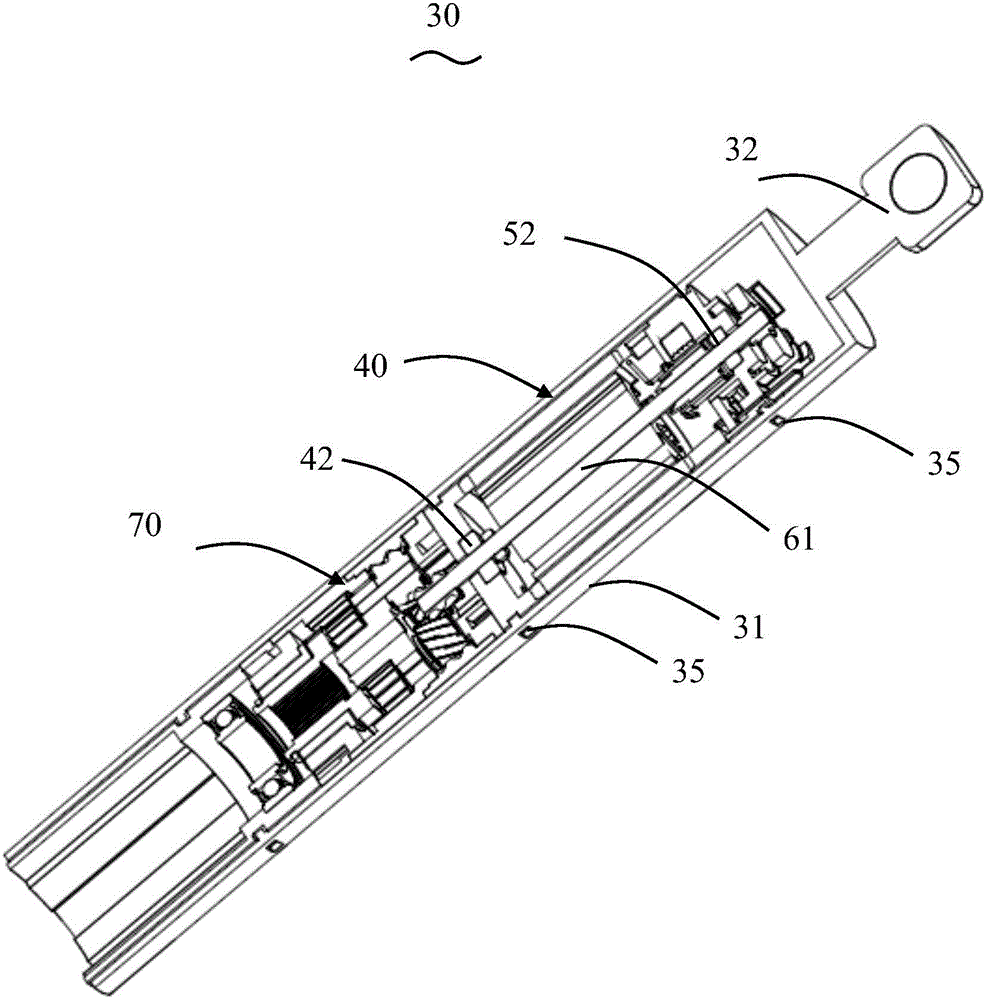

Electric lifting device for automobile stern door

InactiveCN105089408AEliminate the magnetic shellIncrease powerMagnetic circuit rotating partsMagnetic circuit stationary partsMagnet

A power strut for a vehicle lift gate, has a driver sleeve, a lead screw sleeve, a lead screw and a spring mounted in the lead screw sleeve. A gear reduction mechanism and a motor assembly are mounted in the driver sleeve for driving the lead screw. The motor assembly has a magnet mounting bracket fixed to the driver sleeve and a rotor disposed in the magnet mounting bracket. An end cover and multiple permanent magnets are fixed to the magnet mounting bracket. Each of the magnets is positioned between a corresponding pair of adjacent connecting portions and contacts an inner surface of the driver sleeve, thereby the driver sleeve provides a magnetic path between the magnets.

Owner:JOHNSON ELECTRIC SHENZHEN

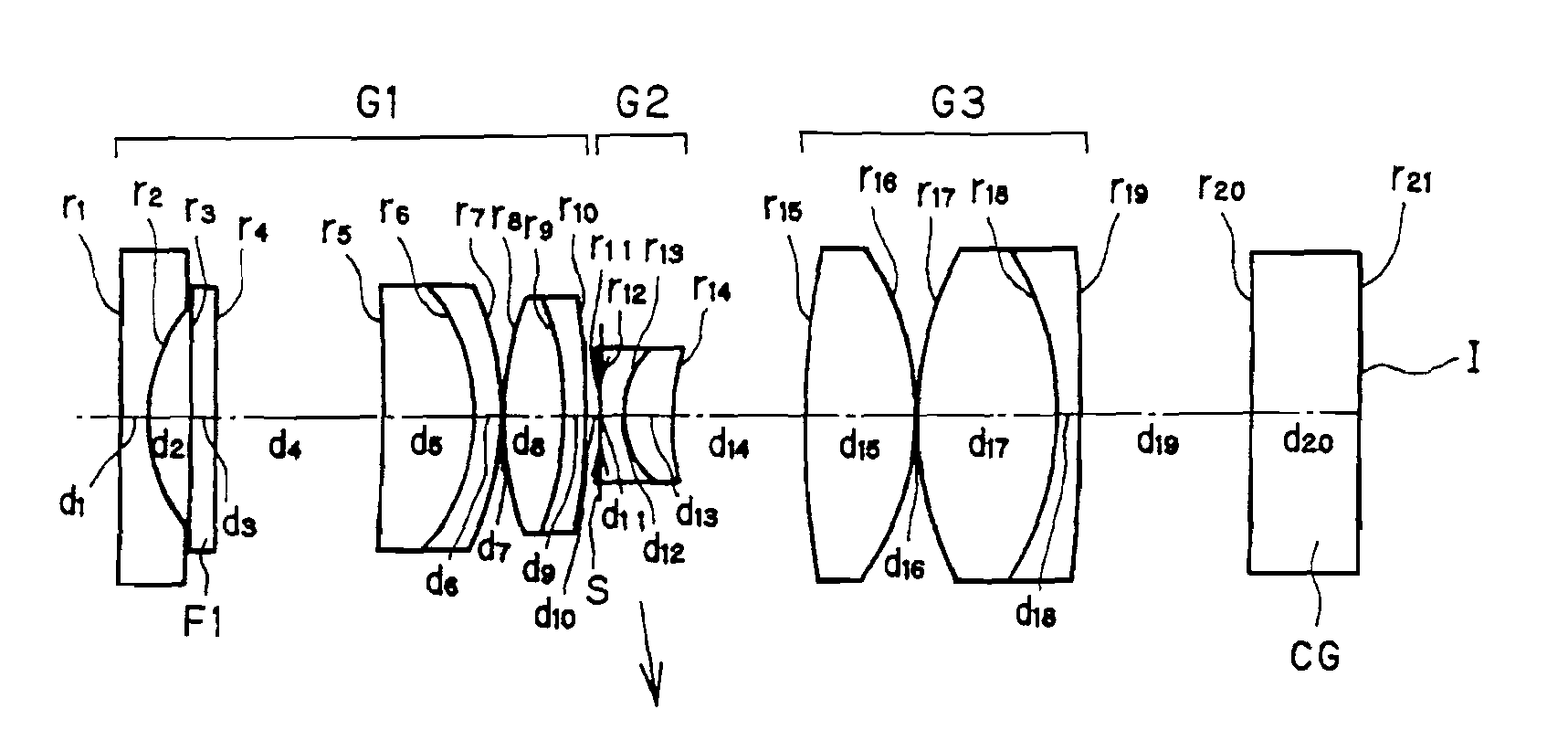

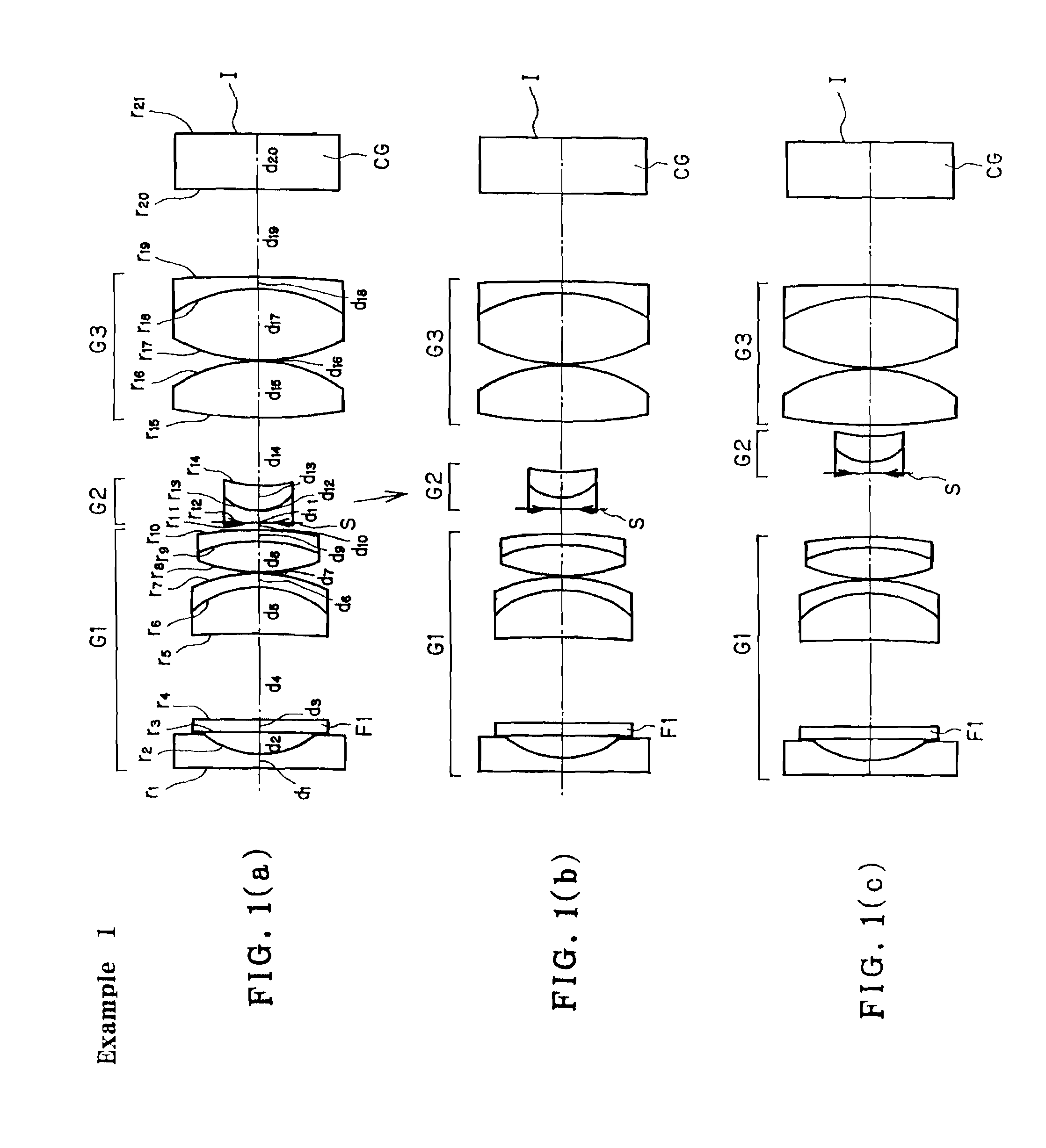

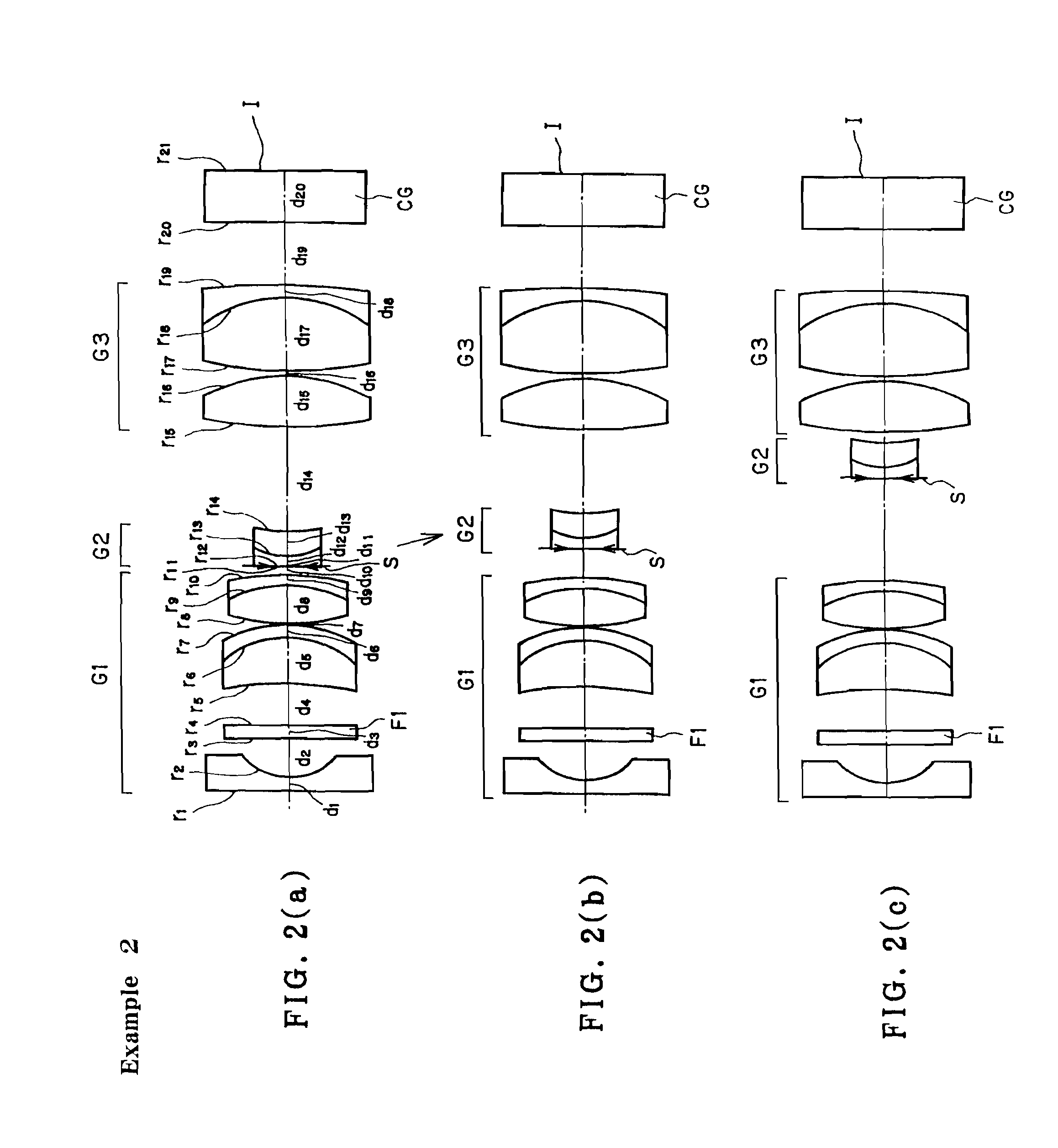

Objective optical system

ActiveUS20100142058A1Better compatibleReduce overall outer diameterMicroscopesTelescopesClose rangeHigh definition

The invention relates to a high-performance imaging optical system that achieves a magnification high enough to be capable of microscopic viewing under an endoscope, and is compatible with high-definition imaging devices. The objective optical system comprises, at least in order from the object side, a positive, first group G1, a second group G2 and a third group G3. In association with an object point change, at least the second group G2 is moved along an optical axis. The objective optical system satisfies a condition with respect to an optical magnification β upon focusing on the closest range.

Owner:OLYMPUS CORP

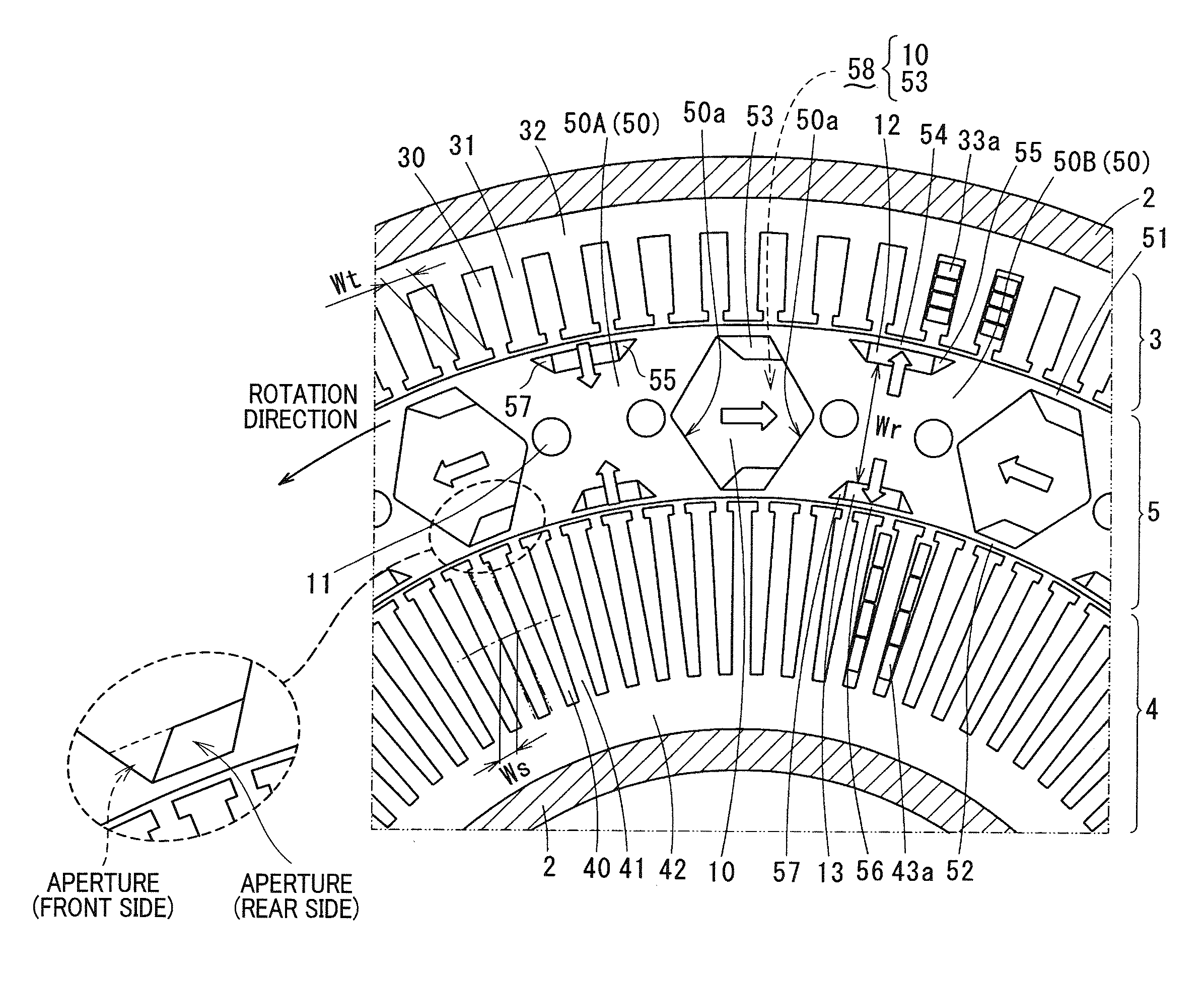

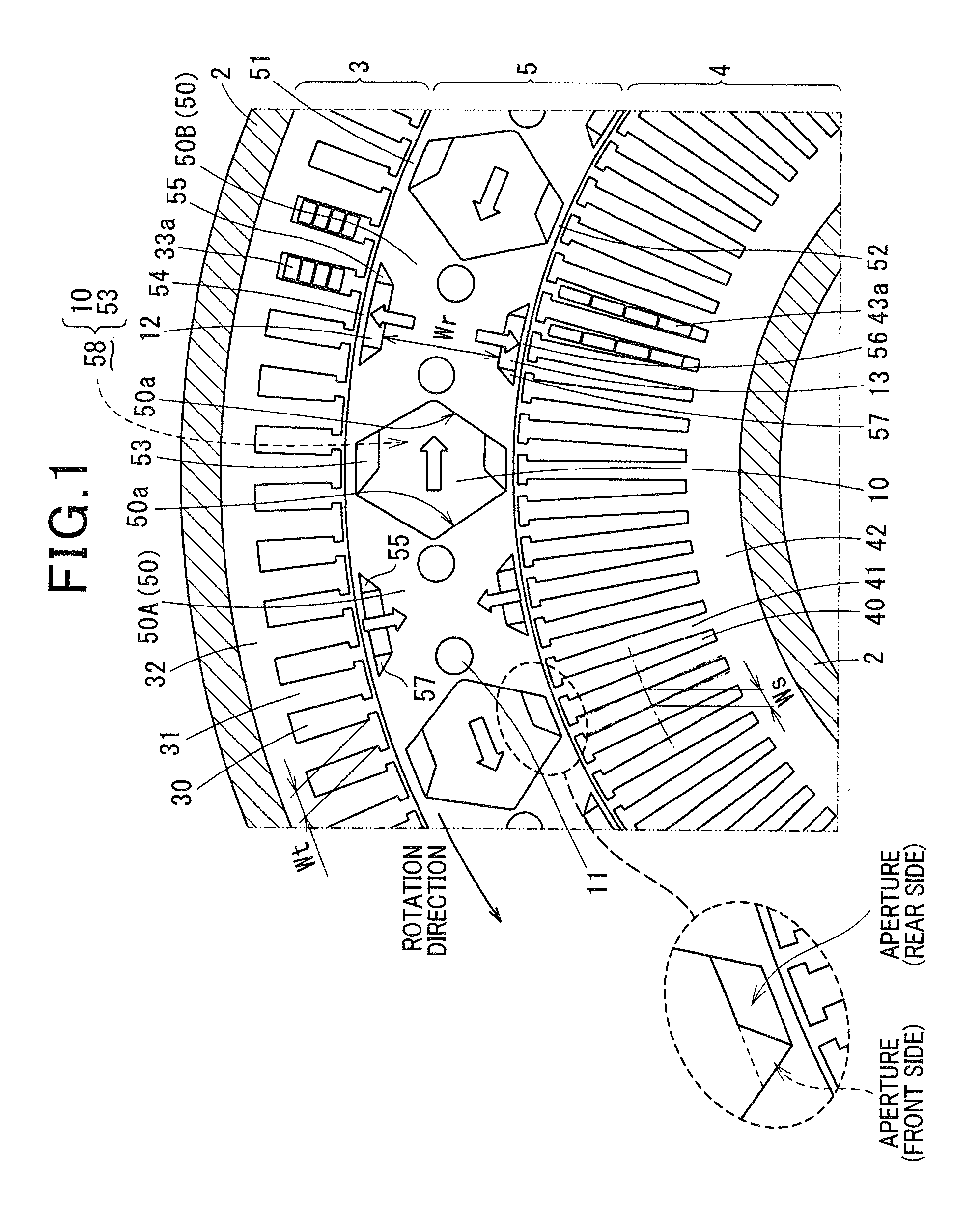

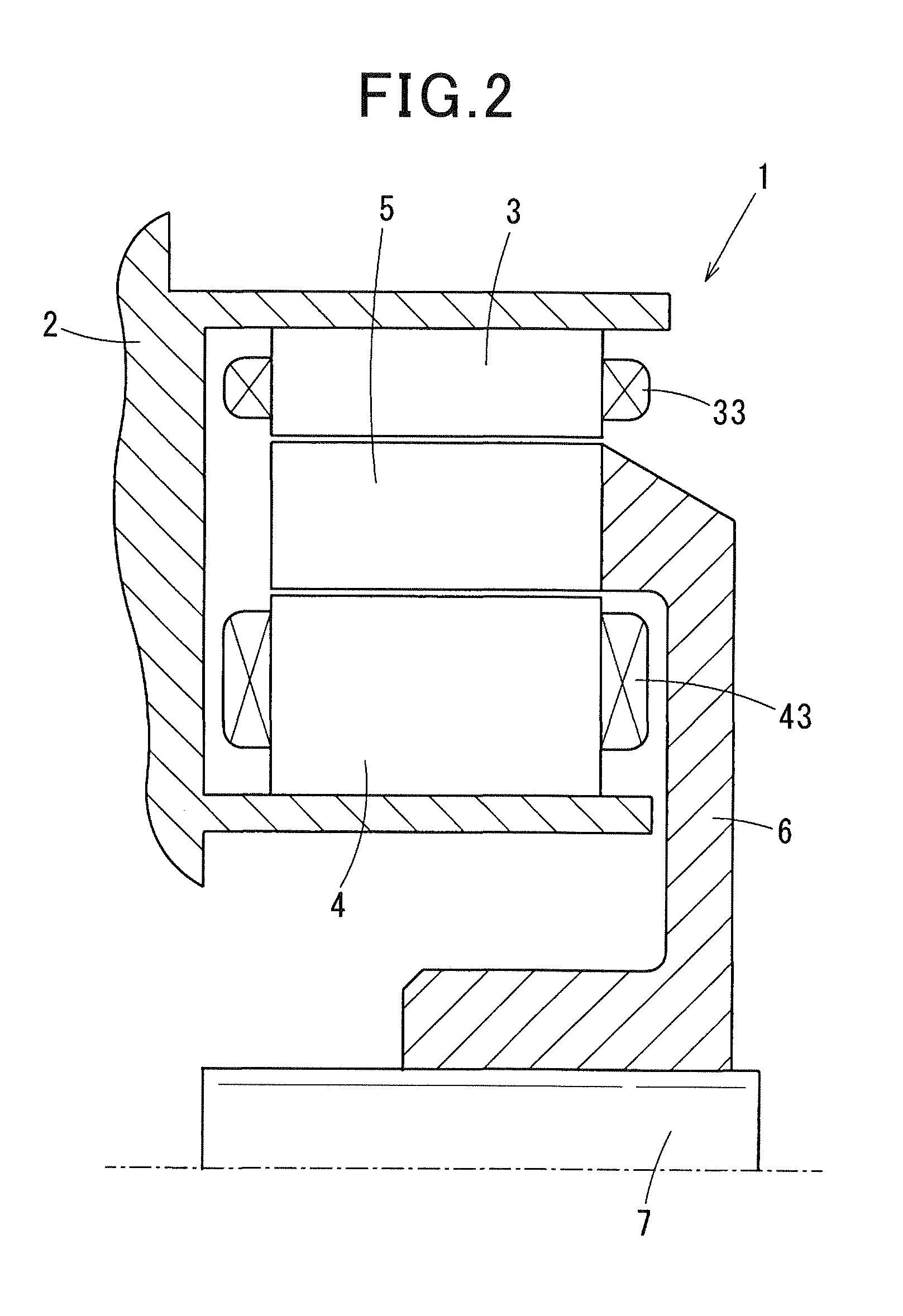

Synchronous motor

InactiveUS20130207498A1Increase output torqueReduce concentrationMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorMagnetomotive force

A double-stator synchronous motor has a rotor, an inner stator and an outer stator. The rotor has segment-magnetic poles arranged in a ring shape. Magnetic poles formed in the inner stator and the outer stator face to each other in a same circumferential position. Each stator has q (q≧2) slots per pole and phase to disperse magnetomodive force. A radially minimum width Wr of each segment magnetic pole is within a range of 1.3q to 2.3q times of a minimum width Wt of outer teeth. A magnetic depth of a magnetic concave section formed in the segment magnetic pole is within a range of not less than an average width Ws of the inner slots. Because this suppresses demagnetization in the permanent magnets caused by stator magnetomotive force, ferrite magnets are used as buried magnets and magnetic-pole central magnets, and suppress the amount of neodymium magnet used in the rotor.

Owner:DENSO CORP

Non-coring reduced shearing needle

InactiveUS20140103065A1Avoiding unwanted blockageImprove flow resistancePinsNailsLeading edgeEngineering

Method and apparatus for beverage extraction needle side holes or apertures. The leading and trailing edges of the apertures may be shaped or otherwise configured to help reduce the possibility of coring or shearing of material as the needle is inserted into and / or withdrawn from material, such as a cork. Convex leading and / or trailing edges may help deflect material away from the aperture, reducing shearing. Concave leading and / or trailing edges may help prevent entry of material into the aperture, again reducing shearing.

Owner:CORAVIN

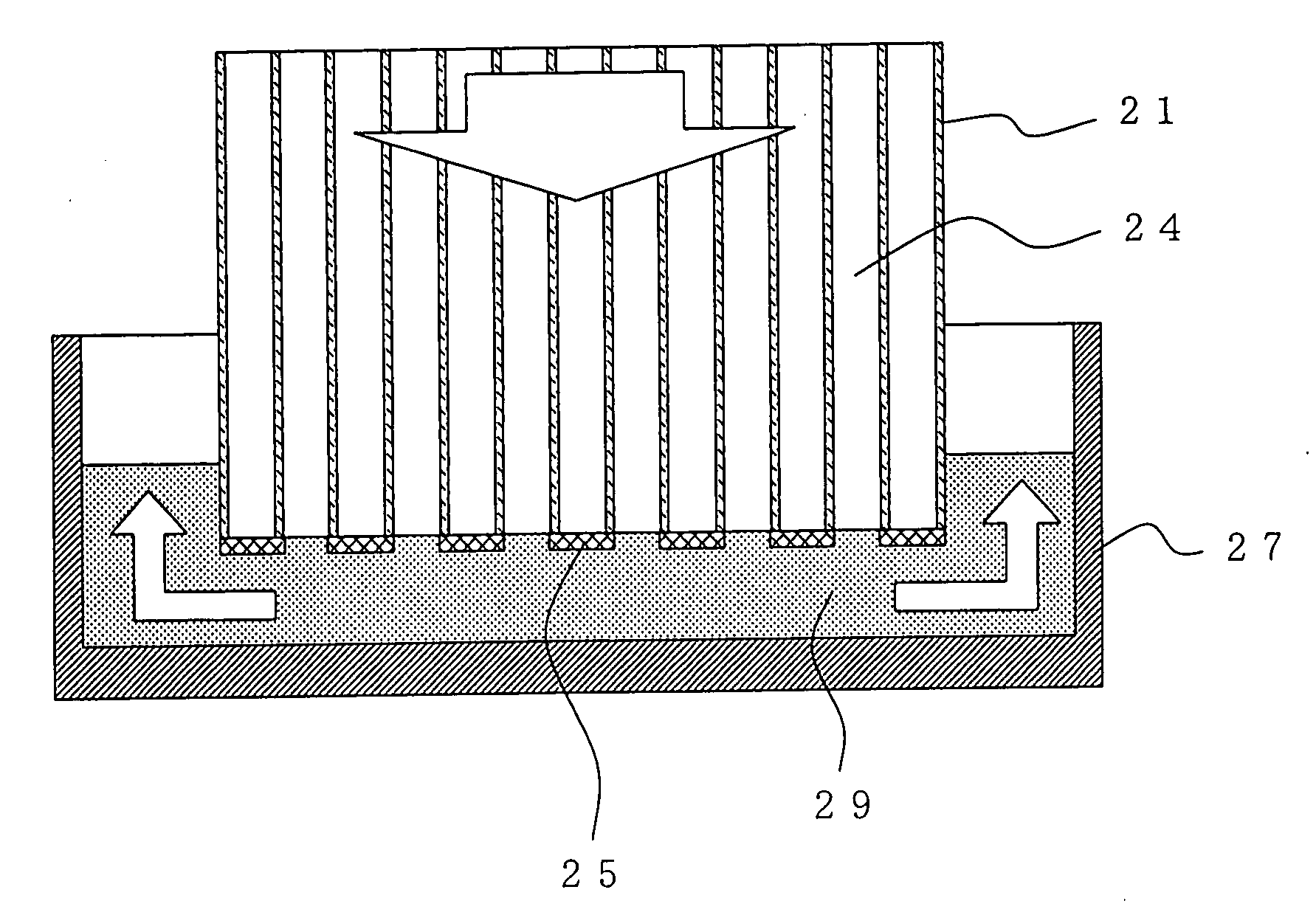

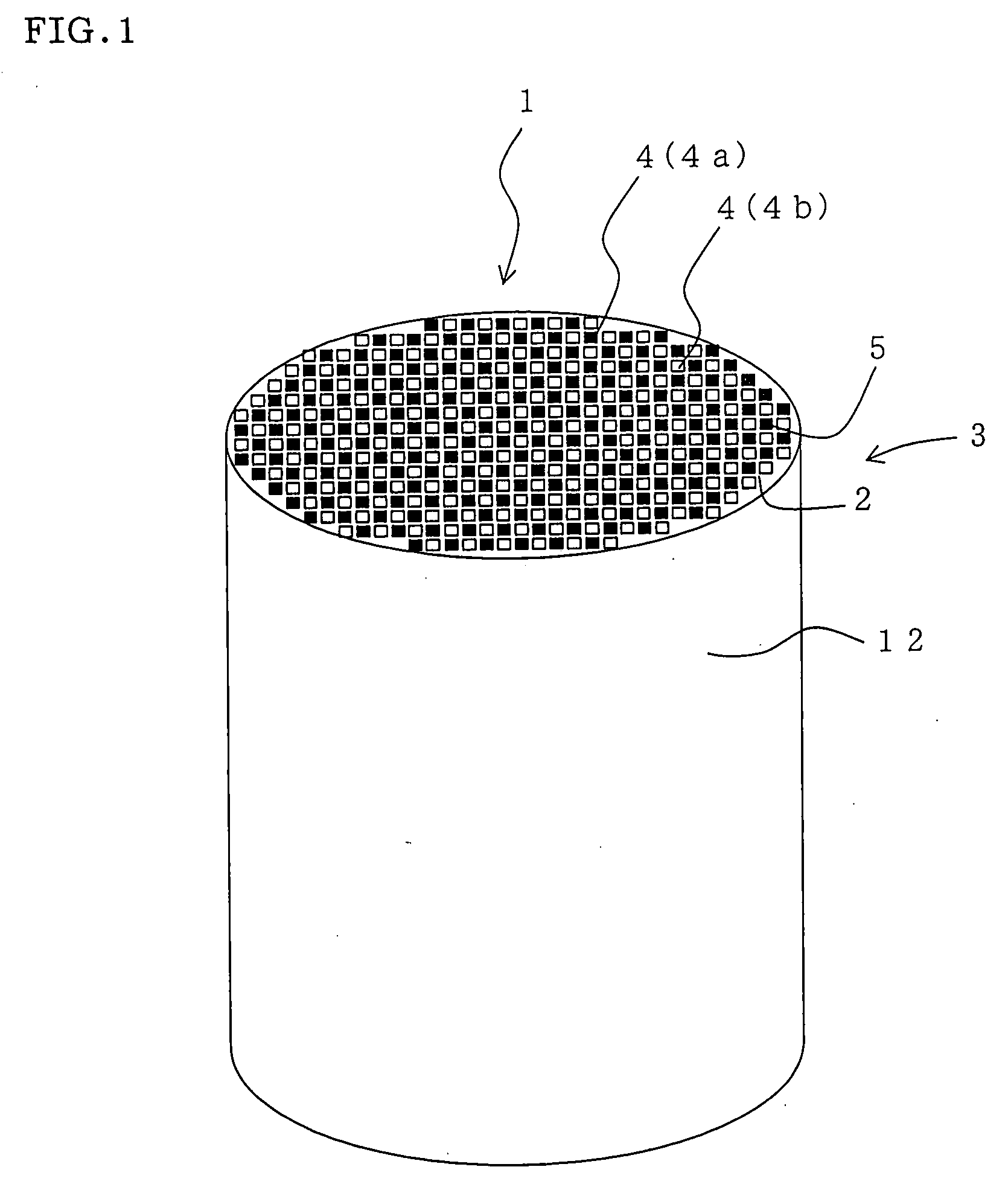

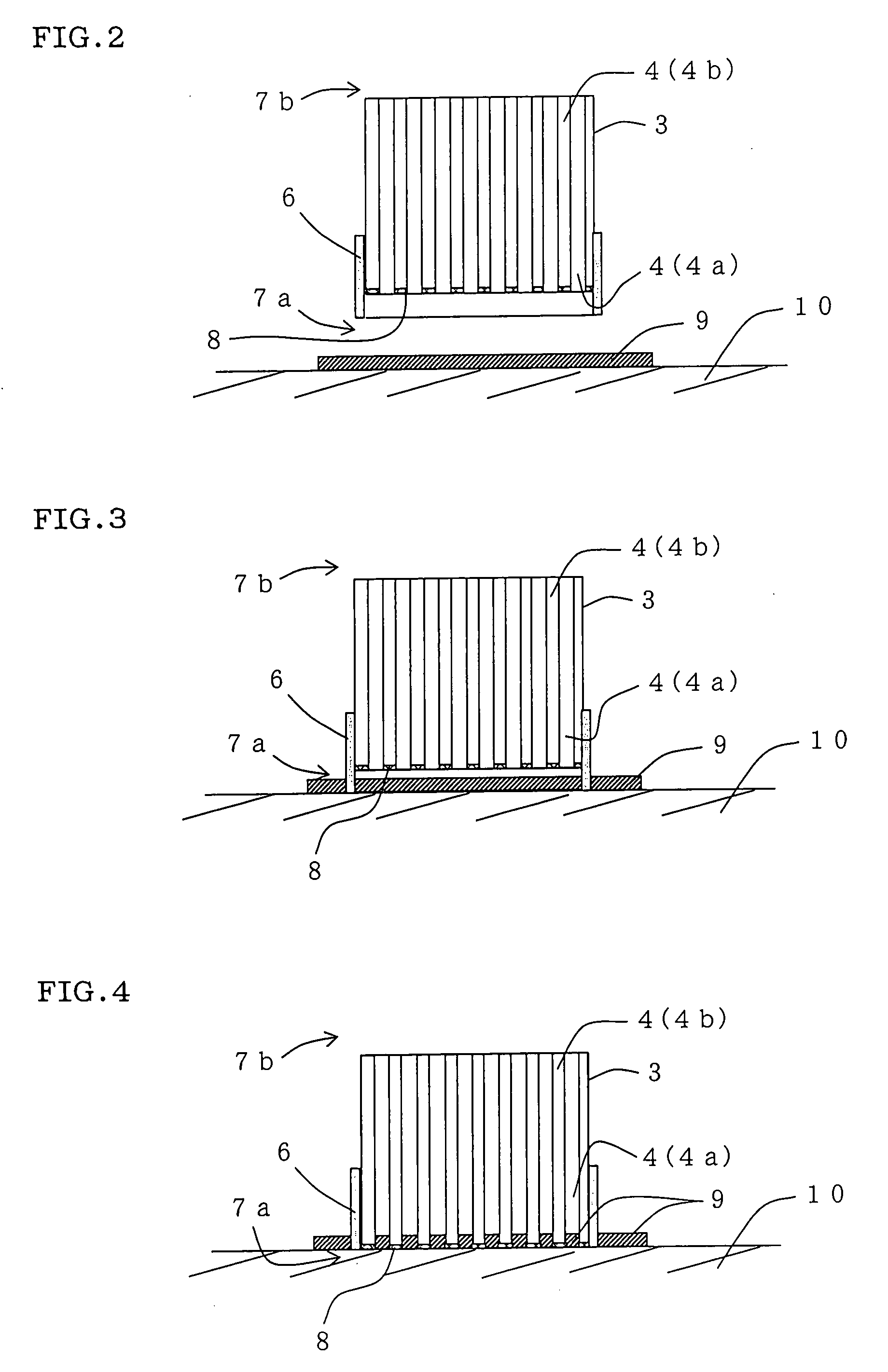

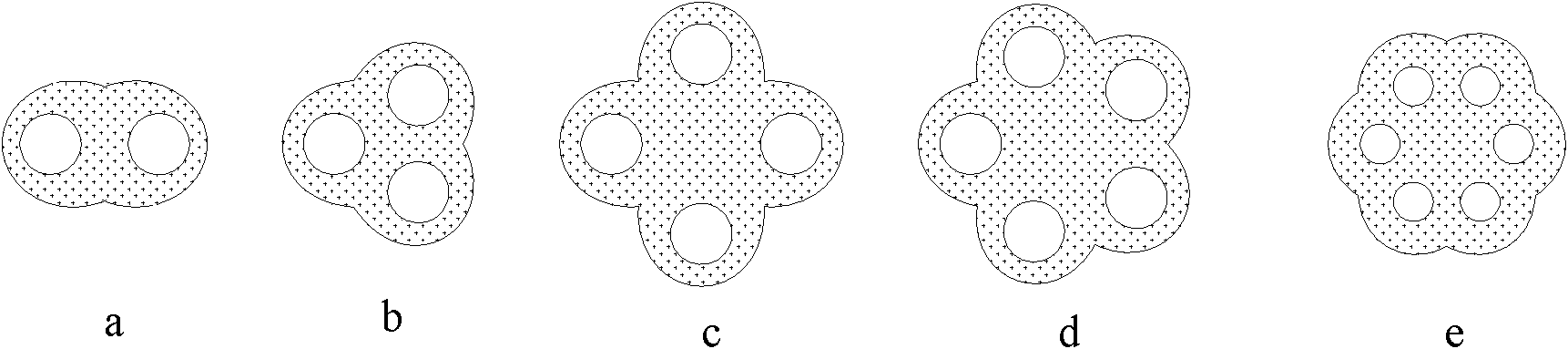

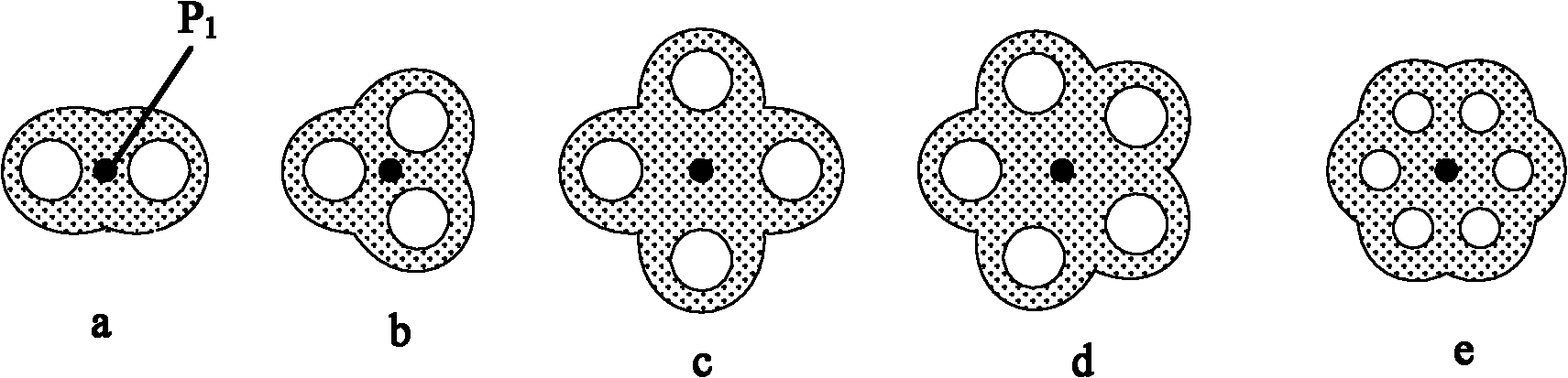

Method for manufacturing plugged honeycomb structure and plug filling jig

There is disclosed a method for manufacturing a plugged honeycomb structure capable of manufacturing a plugged honeycomb structure in which the plugging depth is uniform. A method for manufacturing a plugged honeycomb structure, according to the invention, includes disposing a plug filling jig 6 so that it covers the side of the periphery of one end 7a of the honeycomb structure 3 at the side where plugged cells 4a are open and its tip locates being protruded from the end surface of the one end 7a, the end surface of the side of the one end 7a is separated from the surrounding space and the one end 7a of the honeycomb structure 3 where the plug filling jig 6 is disposed is pressed onto a ceramic slurry to thus introduce the ceramic slurry into the plugged cells 4a to form plugged portions.

Owner:NGK INSULATORS LTD

Aspiration catheter

ActiveUS20070191812A1Easy to separatePrevent thrombosisBalloon catheterMulti-lumen catheterThree vesselsAspiration catheter

There has been a demand for an aspiration catheter which has a sufficient amount of aspiration, which is sufficiently flexible to satisfactorily track tortuous blood vessels, in which the possibility of kinking of a catheter shaft is decreased when the aspiration catheter is inserted into a guiding catheter from outside of the body, and in which good operationality is achieved. An aspiration catheter of the present invention includes an aspiration lumen for removing a substance by aspiration, the aspiration lumen extending to a hub provided at the proximal end of the catheter; and a detachable core wire disposed in the aspiration lumen.

Owner:KANEKA CORP

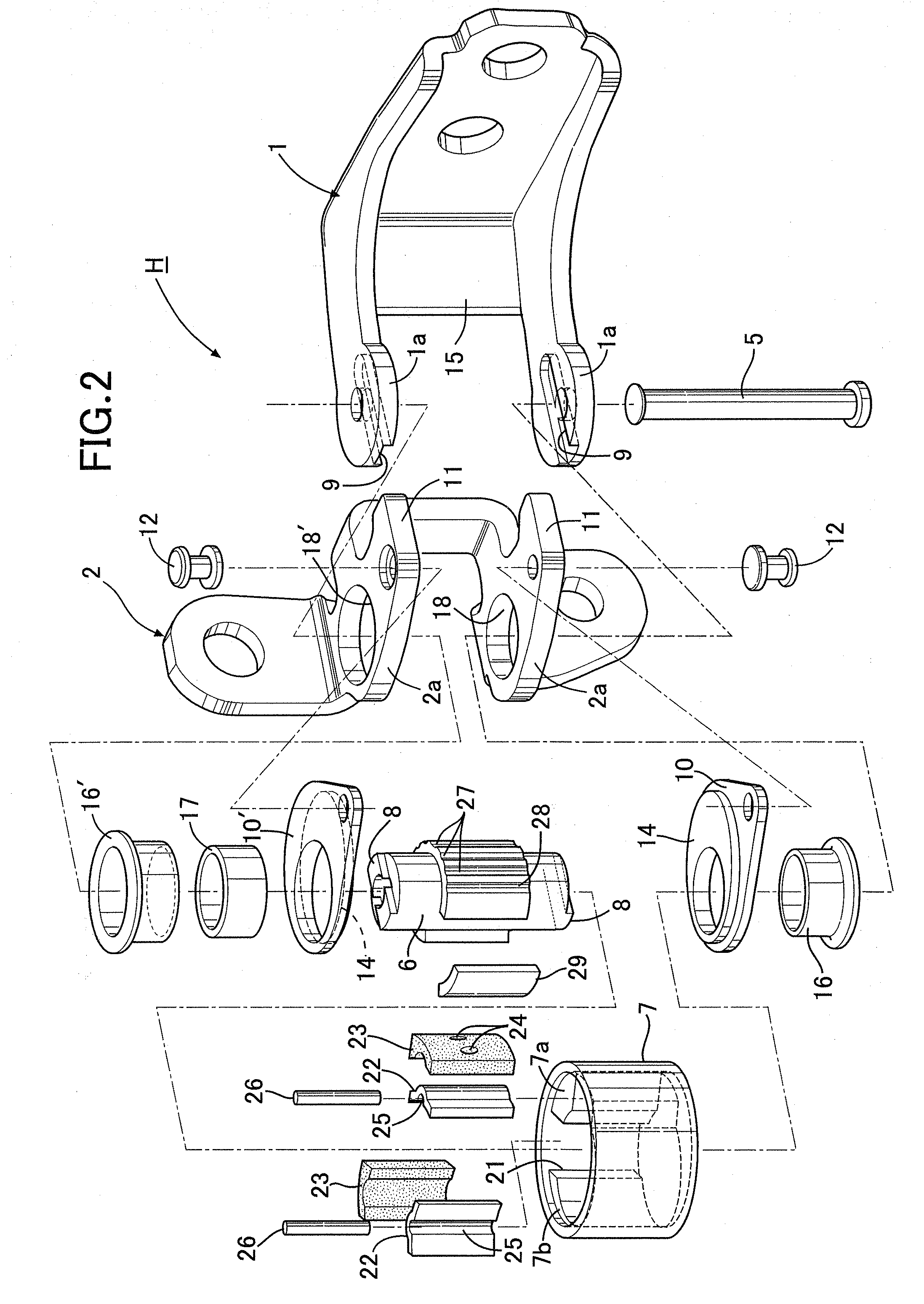

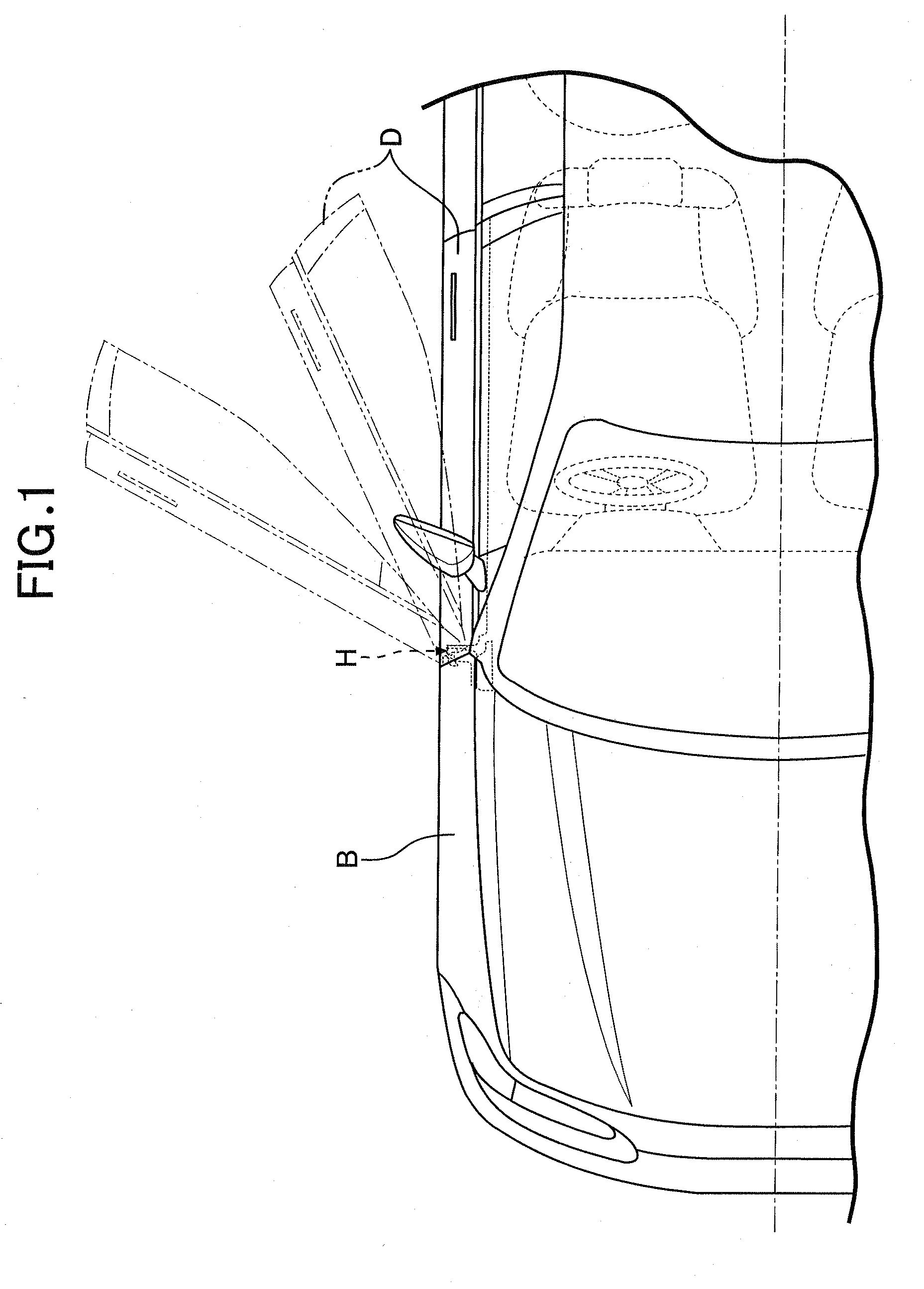

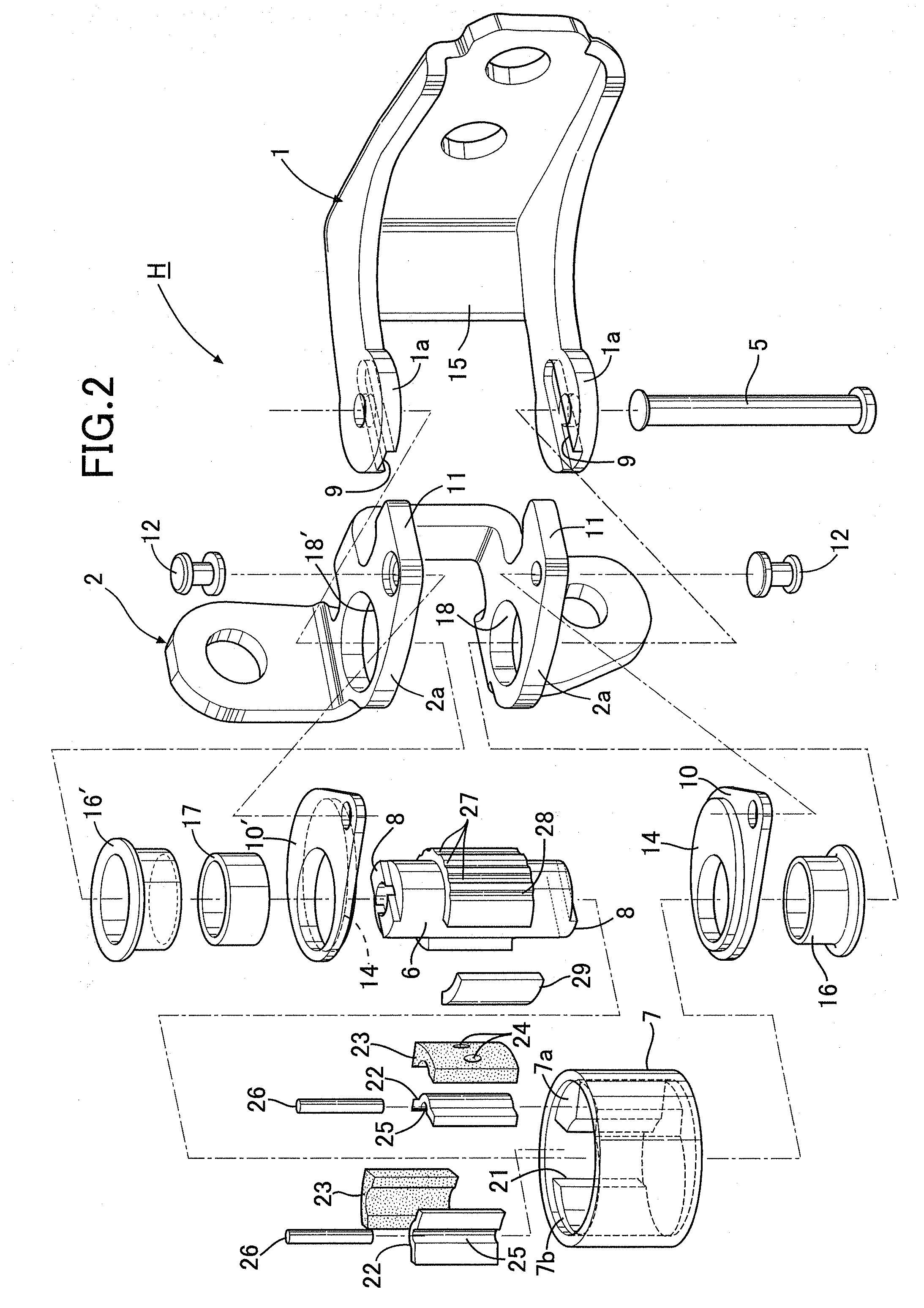

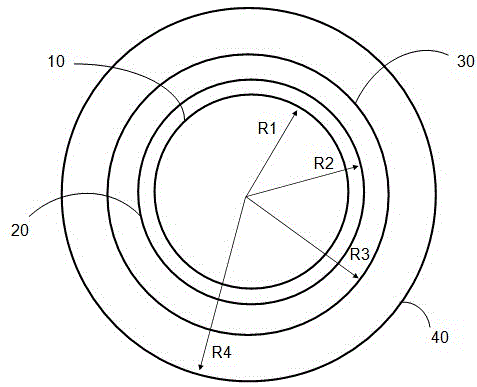

Checker-equipped door hinge device for vehicle

InactiveUS8108969B2Efficiently arrangedConvenient ArrangementBuilding braking devicesWing fastenersThick wallEngineering

A checker-equipped door hinge device for vehicle includes: a first bracket fixed to one of a body and a door; a second bracket fixed to another one of the body and the door; a hinge pin connecting the first and second brackets to each other, and allowing the brackets to be relatively rotatable; an inner cylinder connected integrally to the first bracket and disposed coaxially with the hinge pin; an outer cylinder connected integrally to the second bracket and disposed so as to surround the inner cylinder in a manner of being rotatable relative to the inner cylinder; and a checking-force generating mechanism provided between the inner cylinder and the outer cylinder, the checking-force generating mechanism generating a checking force against the door at a predetermined opening position of the door, wherein an inner peripheral surface and an outer peripheral surface of the outer cylinder are eccentric to each other, so that a thick wall portion having a large distance between the inner peripheral surface and the outer peripheral surface is formed in the outer cylinder, and the checking-force generating mechanism is provided in the thick wall portion. Thereby the door hinge device can be compact, in which the checking-force generating mechanism can be disposed in the outer cylinder without increasing the diameter of the outer cylinder.

Owner:RIKEN KAKI KOGYO CO LTD

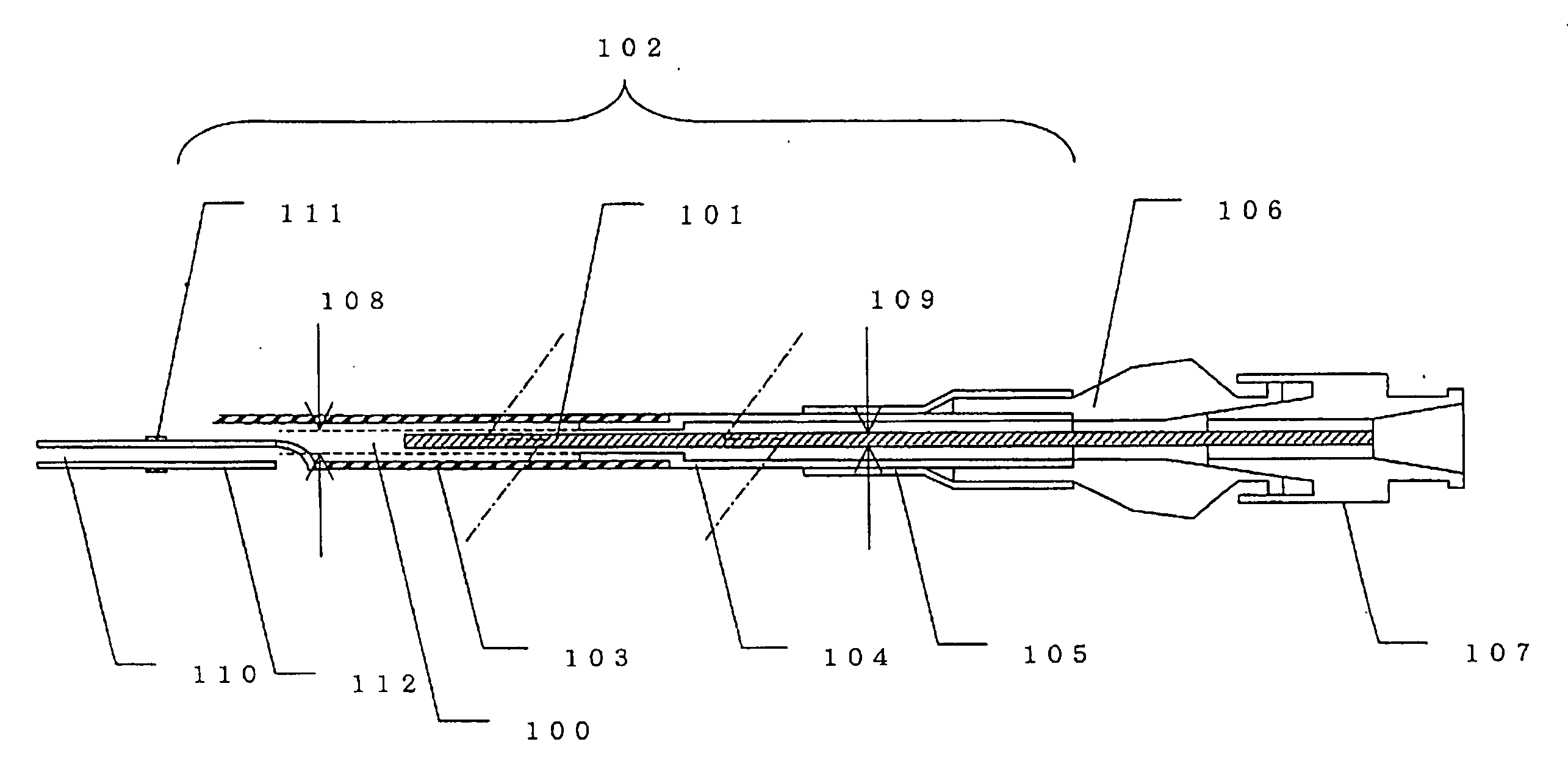

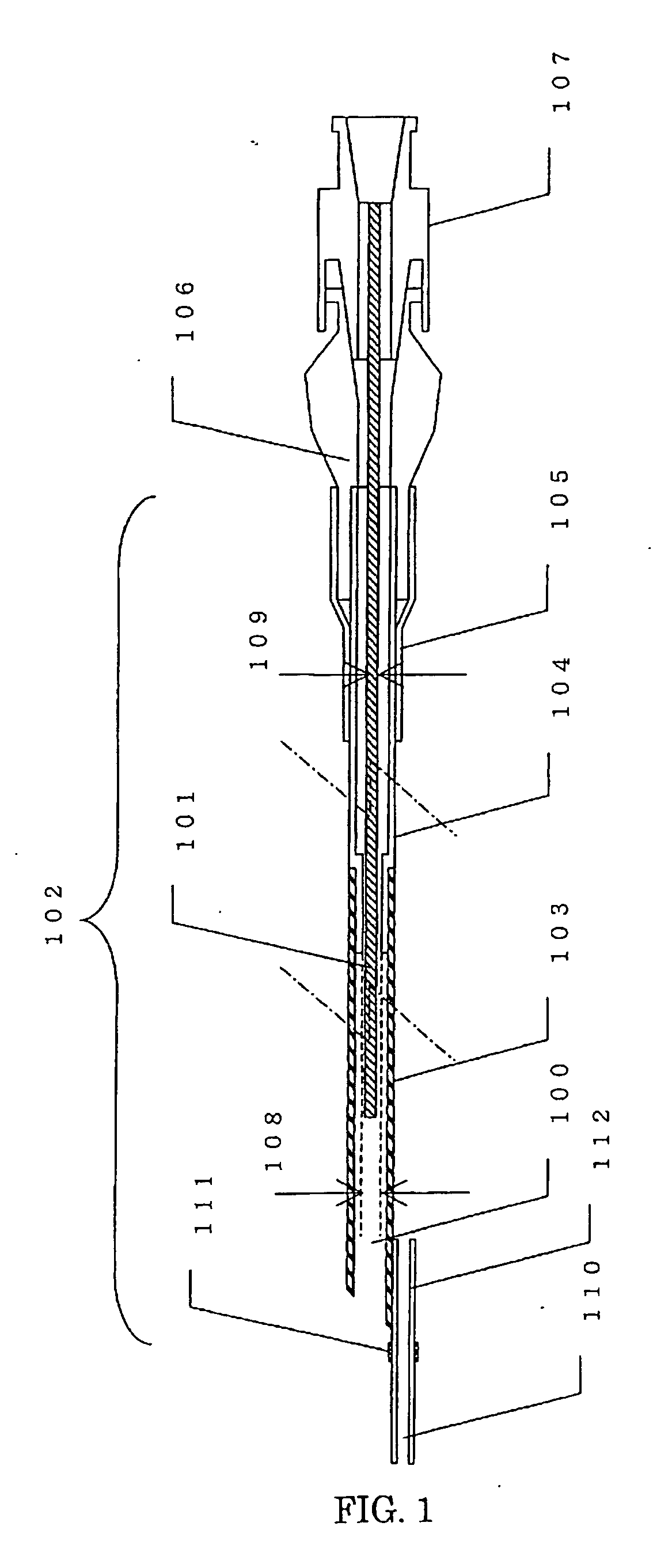

Catheter and method of producing the same

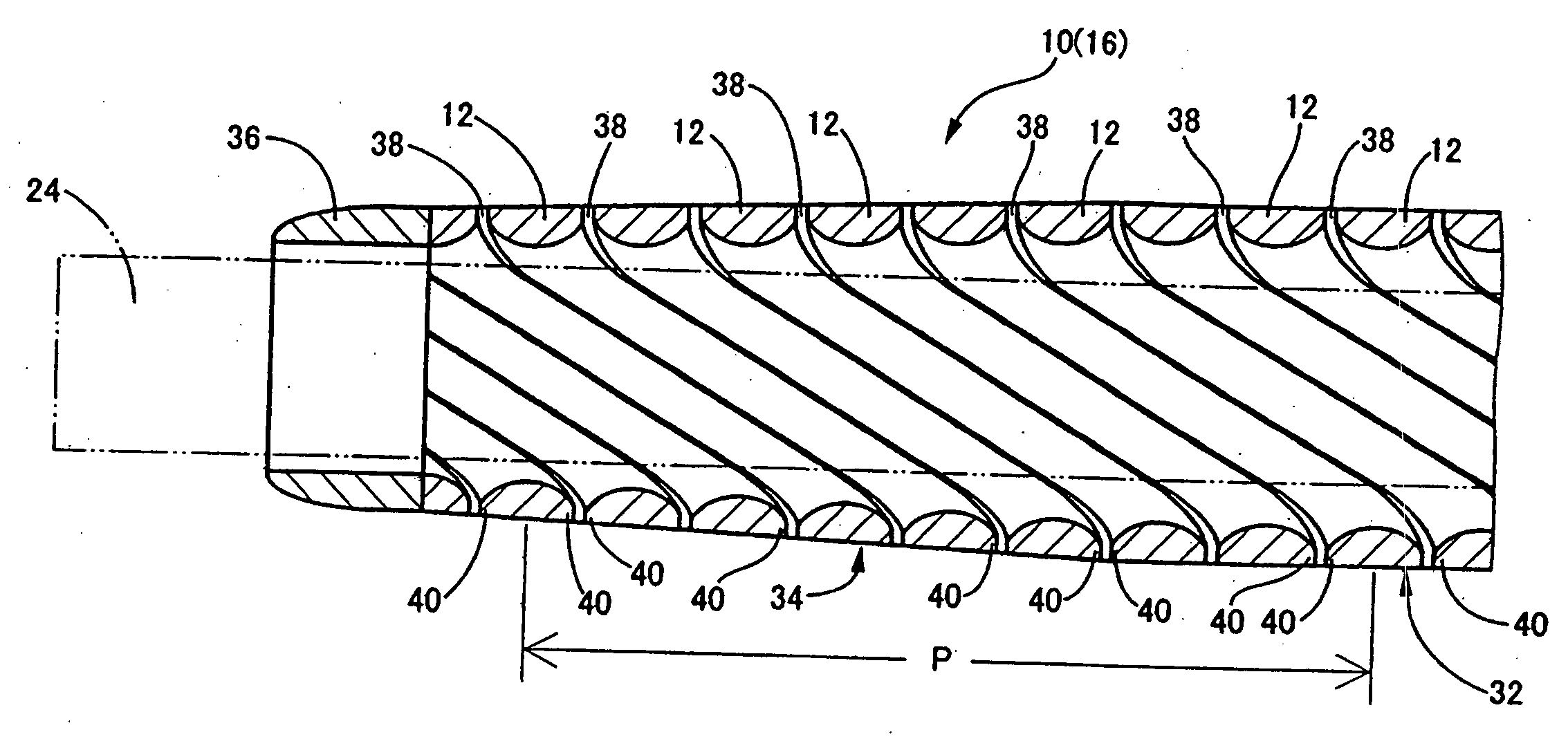

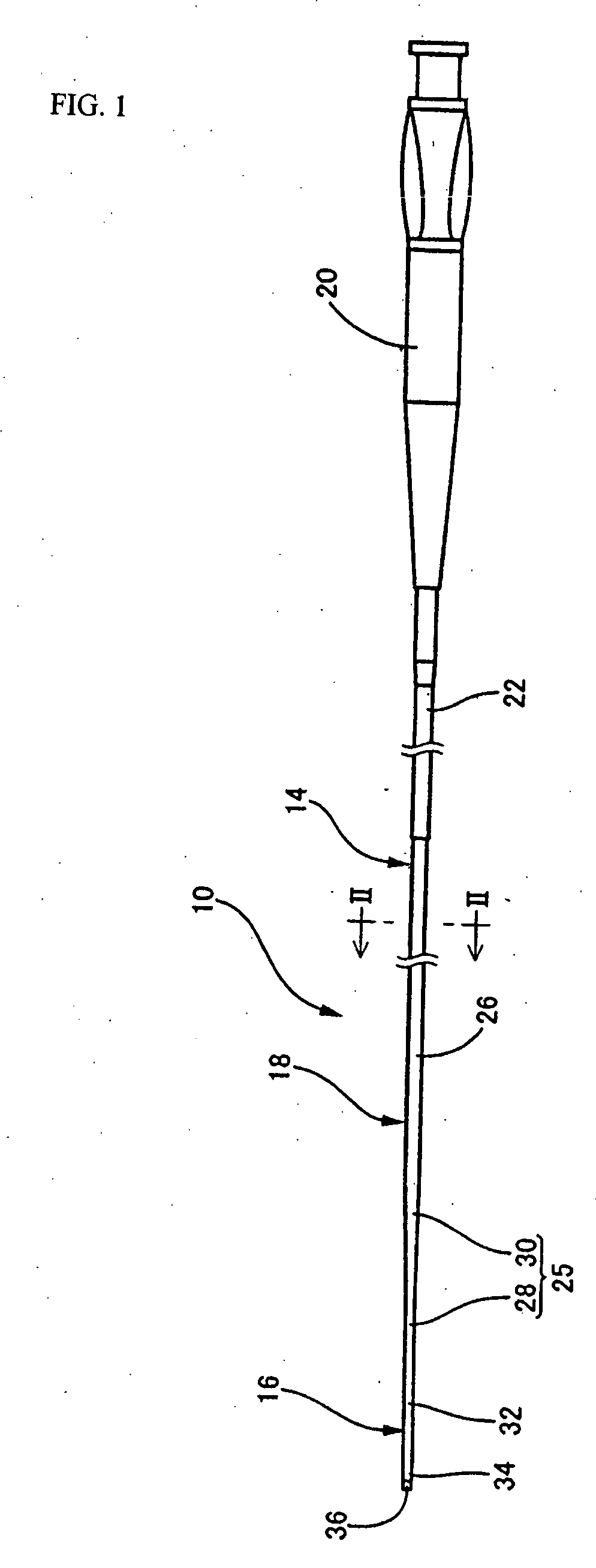

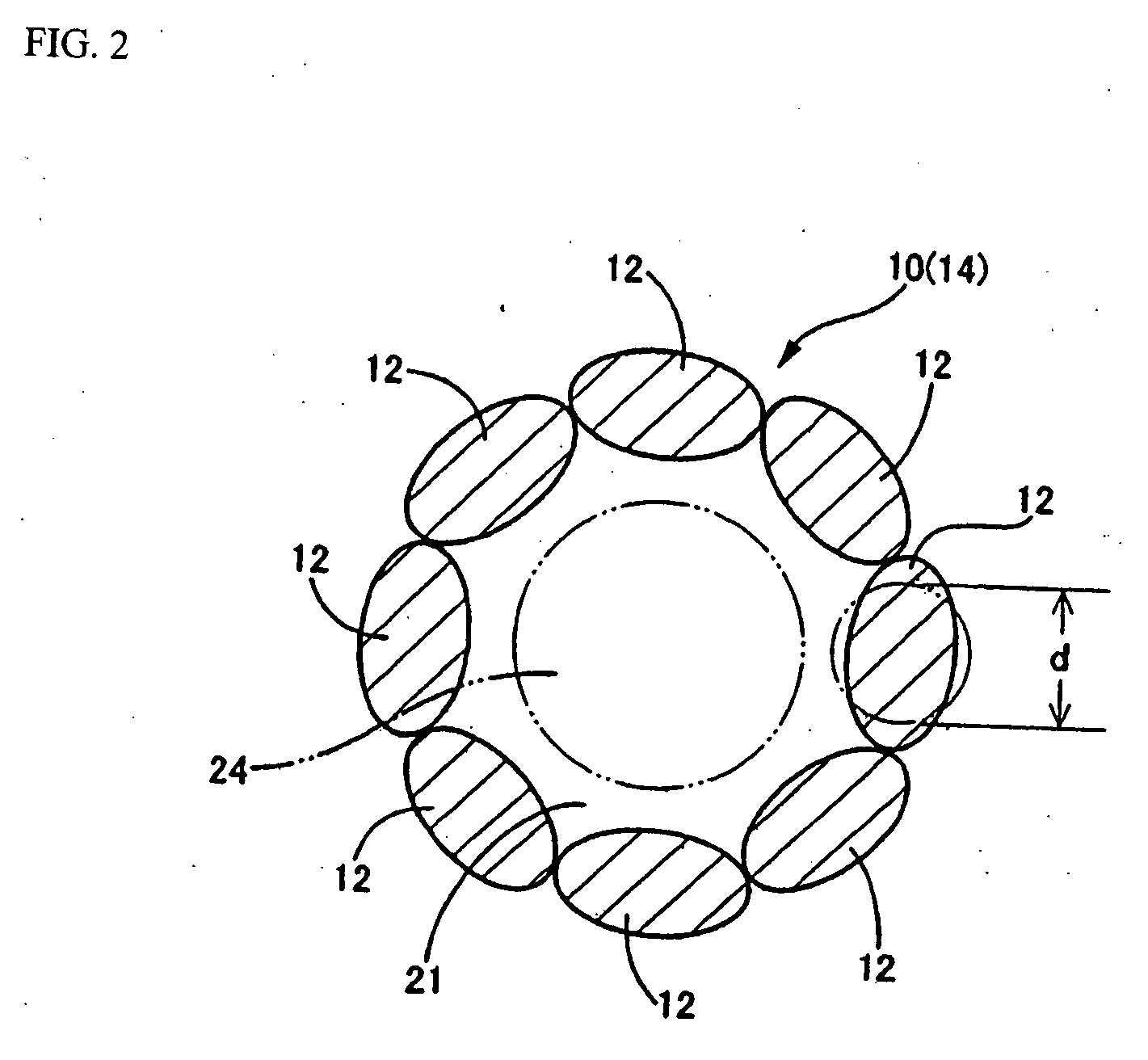

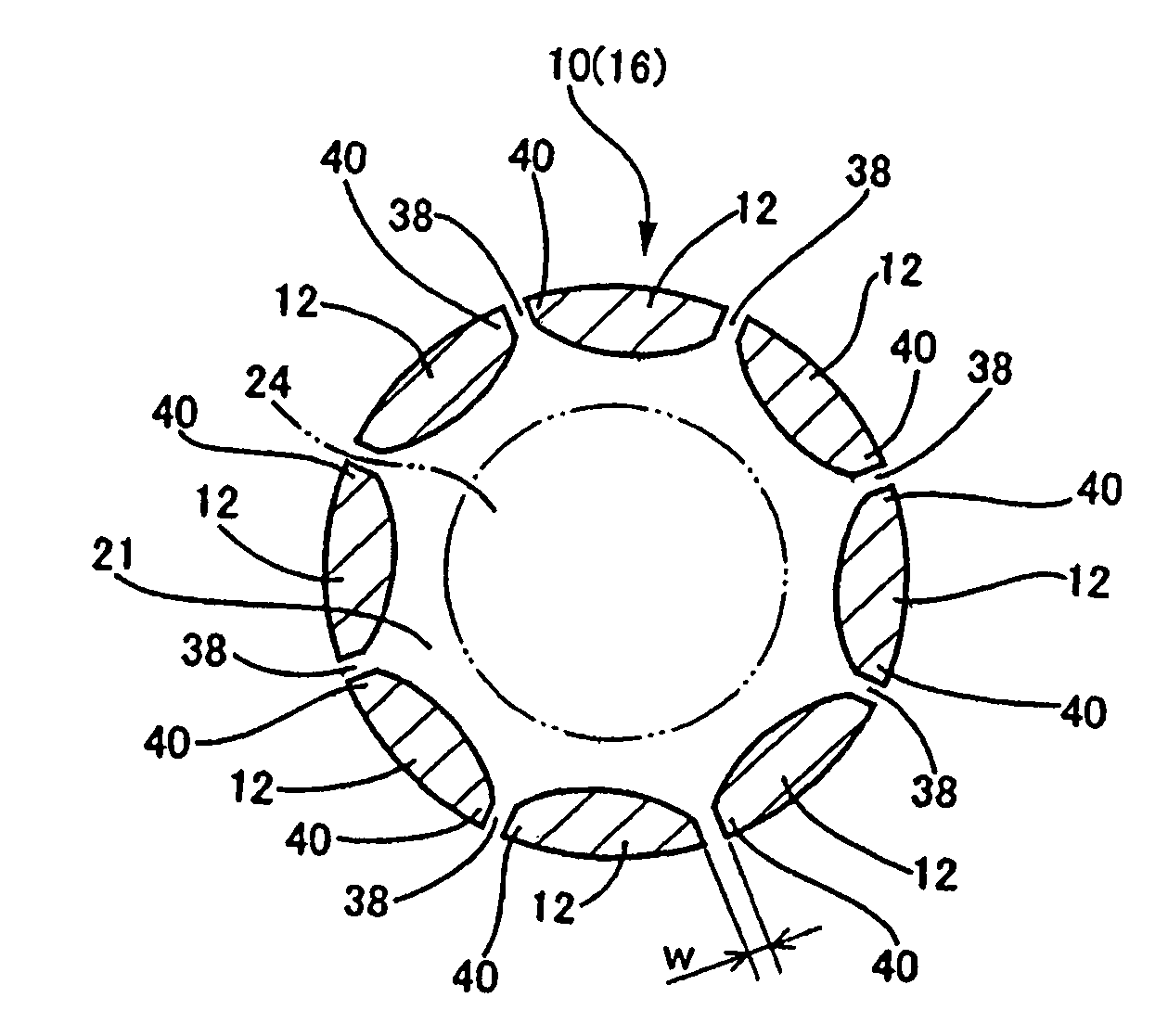

ActiveUS20060178653A1Guaranteed uptimeEasy to operateGuide wiresDiagnostic recording/measuringMedicineDistal portion

A catheter body includes a coil body (10) which is formed by winding or stranding metal wires (12) and having a distal portion (16) and a proximal portion. The distance between coils (12) adjacent to each other in the distal portion (16) is greater than the distance between coils (12) adjacent to each other in the proximal portion (18 or 14). The pitch in the distal portion (16) of the coil body (10) is substantially or nearly the same as the pitch in the proximal portion (18 or 14).

Owner:ASAHI INTECC CO LTD

Catheter and method of producing the same

ActiveUS7909779B2Reduce the burden onEliminate needGuide wiresDiagnostic recording/measuringDistal portionMedicine

A catheter body includes a coil body (10) which is formed by winding or stranding metal wires (12) and having a distal portion (16) and a proximal portion. The distance between coils (12) adjacent to each other in the distal portion (16) is greater than the distance between coils (12) adjacent to each other in the proximal portion (18 or 14). The pitch in the distal portion (16) of the coil body (10) is substantially or nearly the same as the pitch in the proximal portion (18 or 14).

Owner:ASAHI INTECC CO LTD

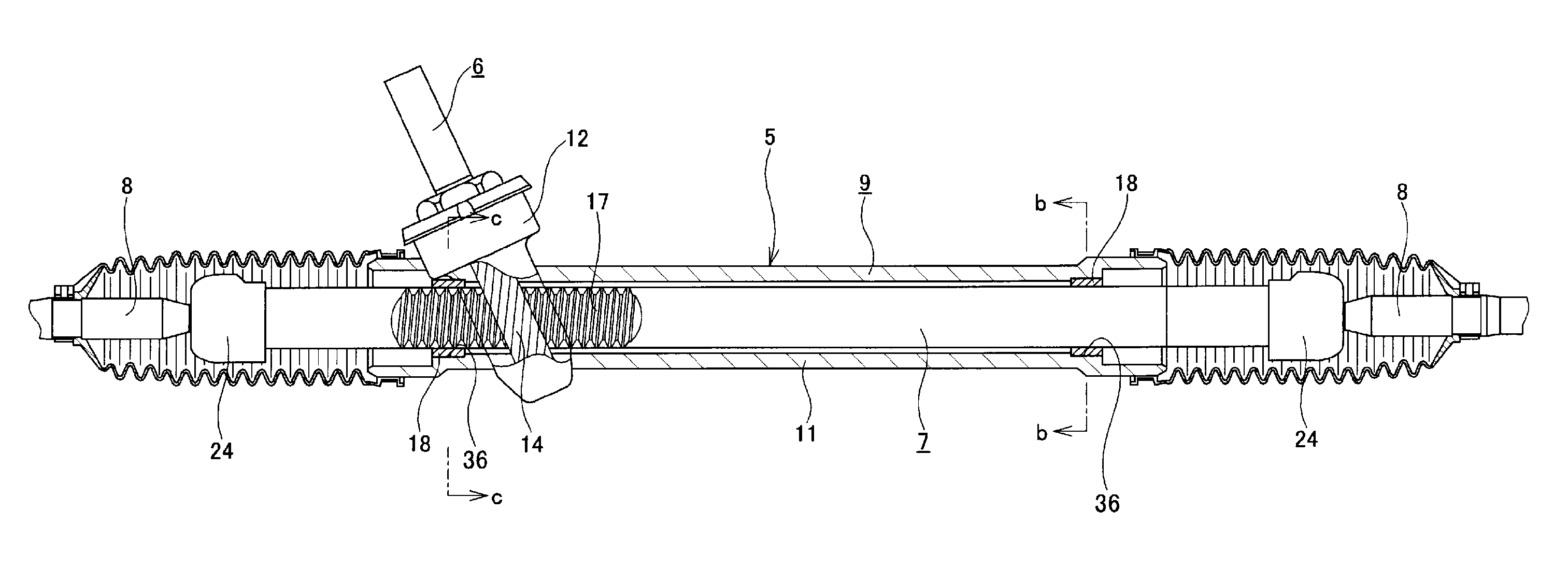

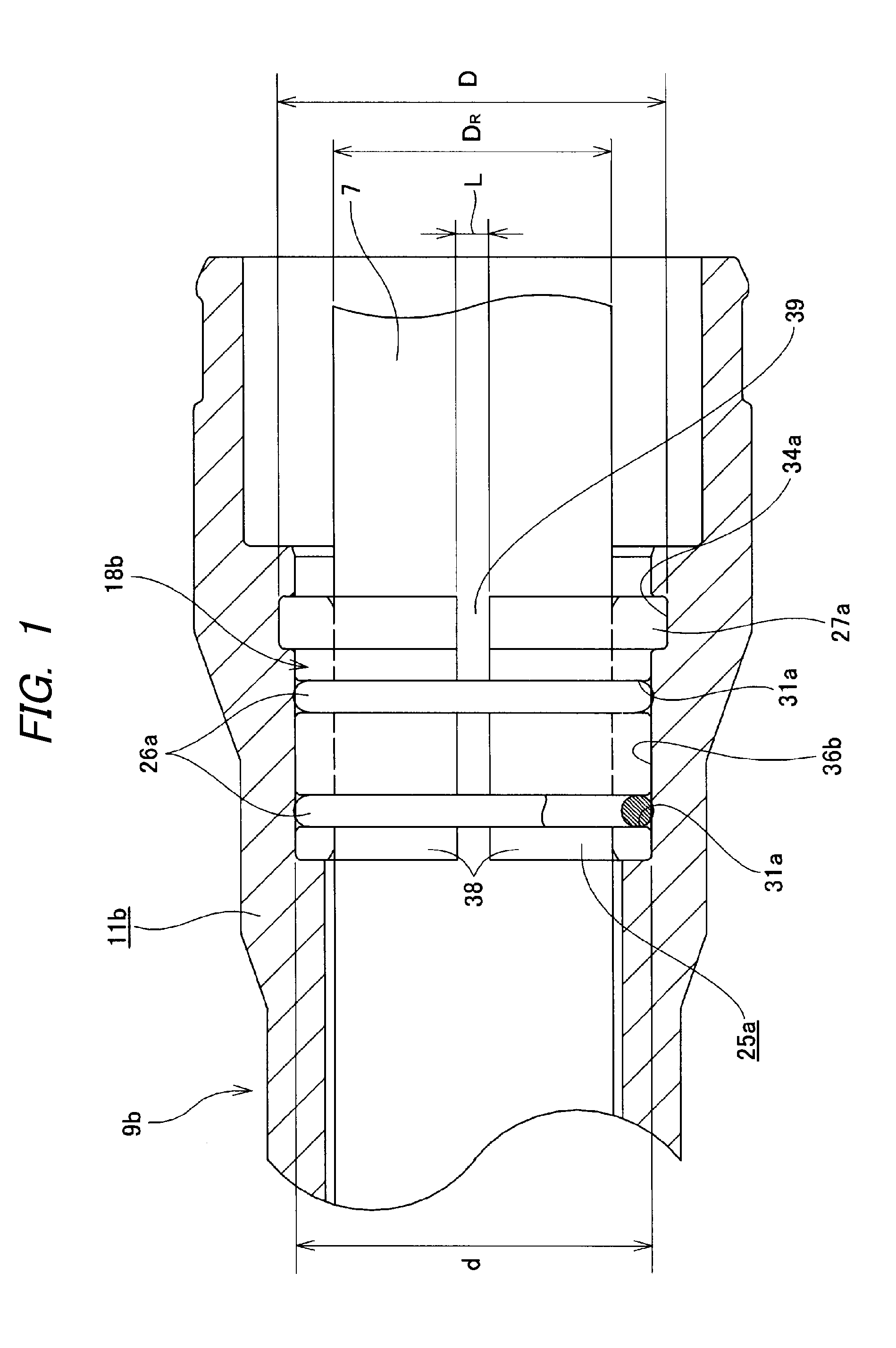

Guide bush and rack-and-pinion steering gear unit

InactiveUS20160059883A1Increase and reduce outside diameterLow costLinear bearingsShaftsRack and pinionGear wheel

A guide bush includes a plurality of bush elements combined to form a cylindrical shape as a whole. The plurality of bush elements includes a cylindrical fitting portion. The cylindrical fitting portion is fitted in a fit-and-hold portion of a housing, and has an inner peripheral surface configured to guide an outer peripheral surface of a displacement shaft that has been inserted in the cylindrical fitting portion in an axially displaceable manner. The diameter of the circumscribed circle of the plurality of bush elements in a state in which the end faces of the plurality of bush elements with respect to a circumferential direction abut each other is not greater than the inside diameter of the fit-and-hold portion.

Owner:NSK LTD

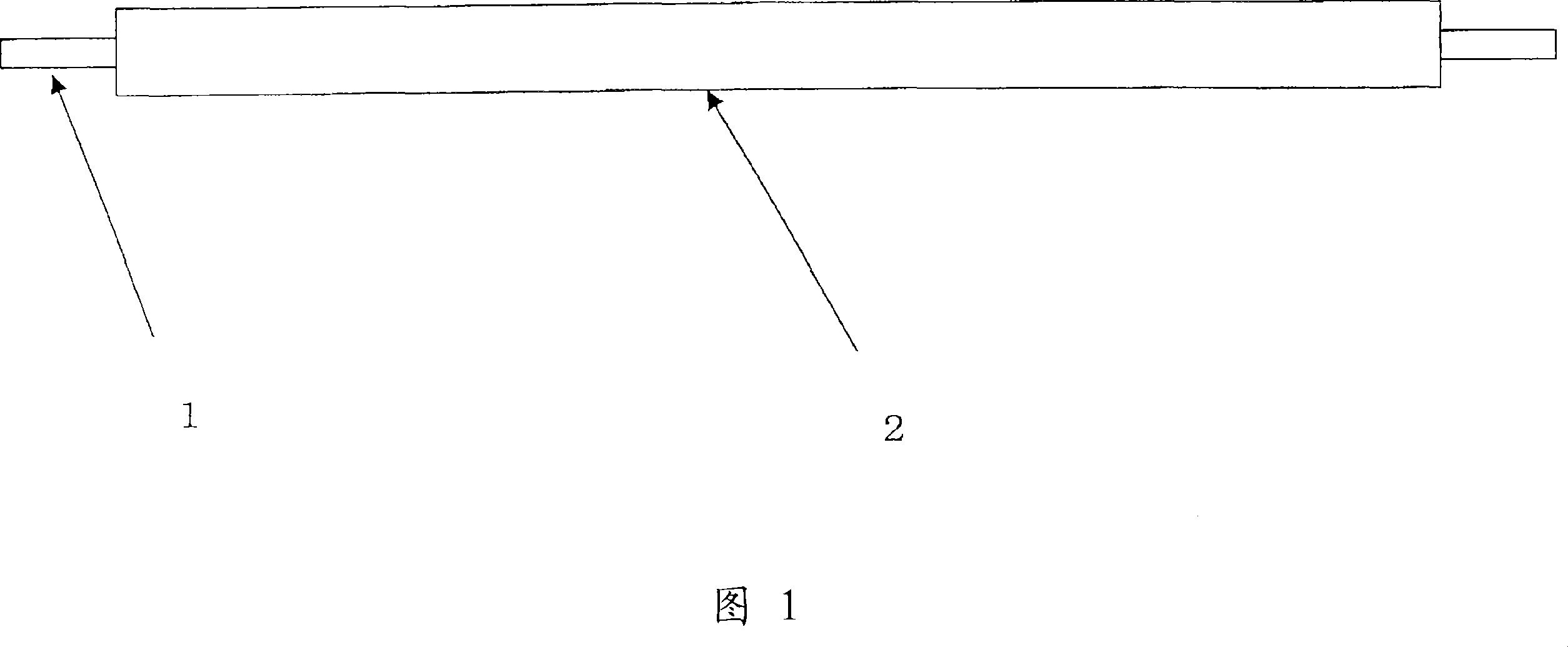

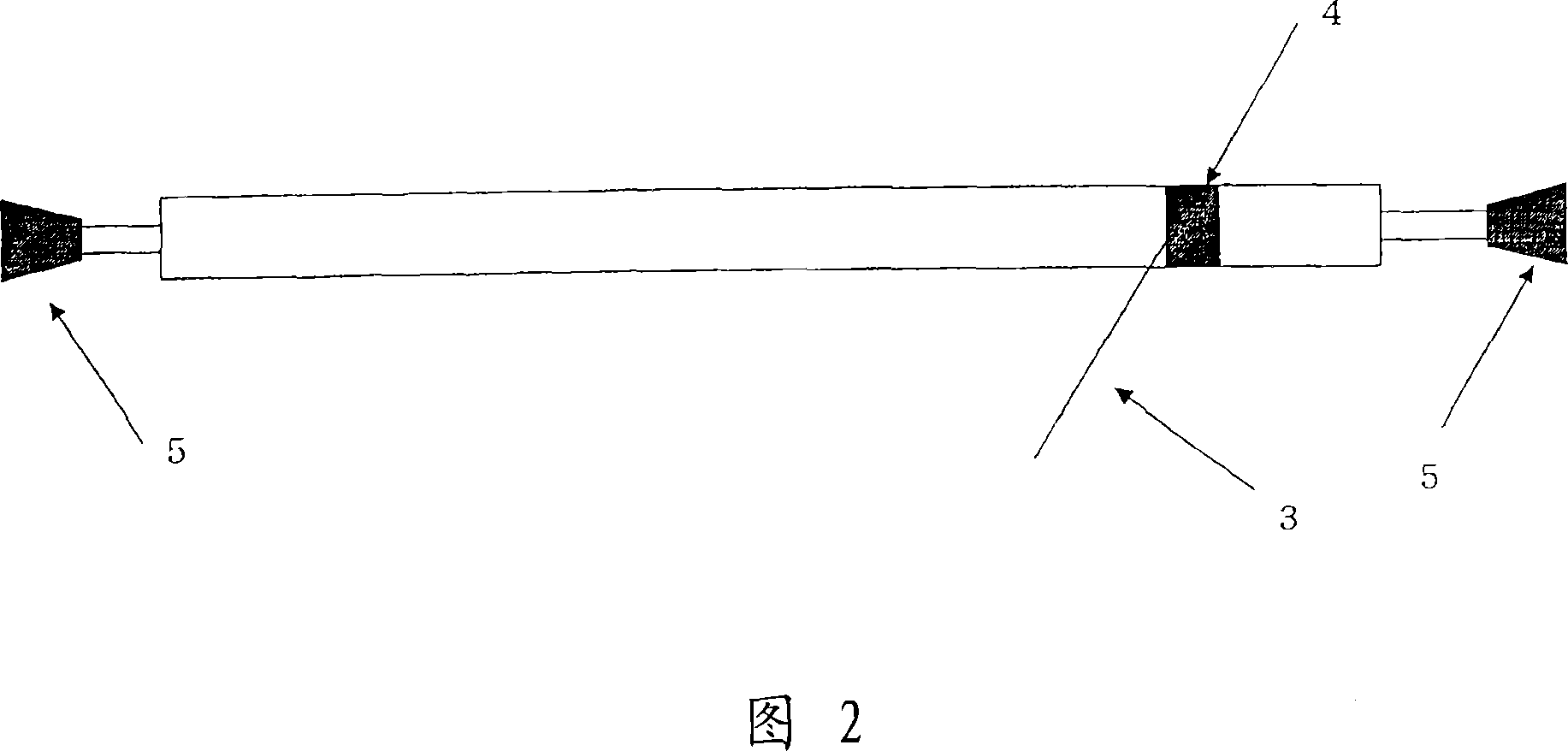

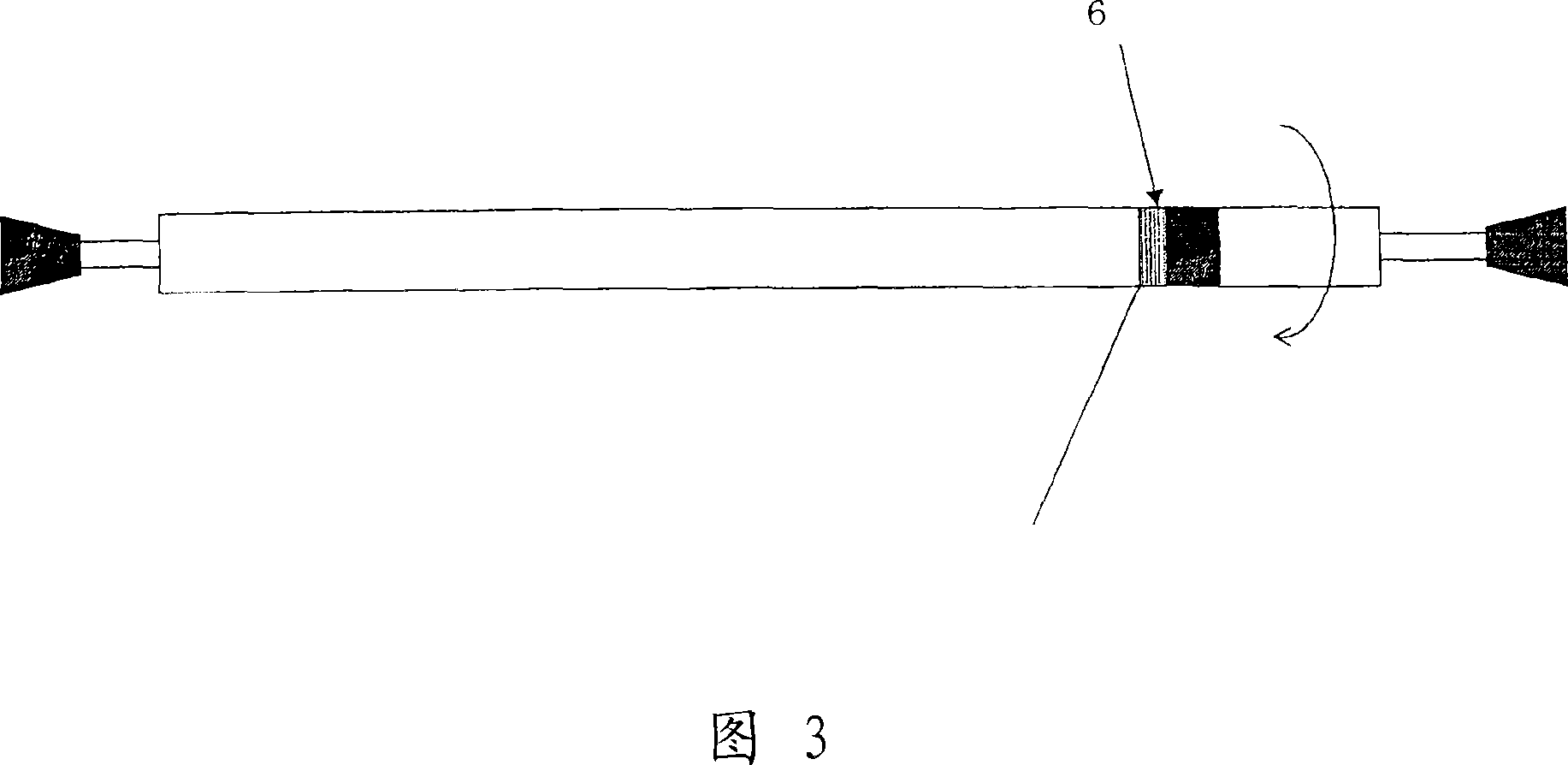

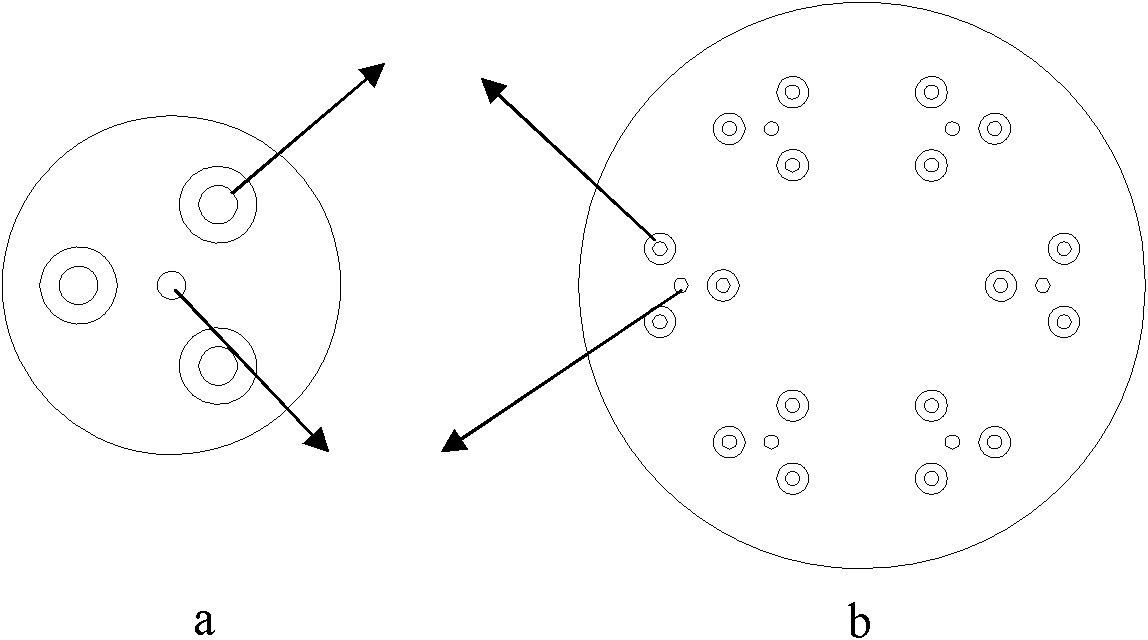

Multi-core hollow fiber porous membrane and preparation method thereof

InactiveCN102151489AAdjusting Cluster Fusion CircularityIncrease swingSemi-permeable membranesFiberNon solvent

The invention discloses a multi-core hollow fiber porous membrane and a preparation method thereof and relates to a polymer. The multi-core hollow fiber porous membrane is provided with at least two hollow fiber membrane bundles, the outer diameter of a single hollow fiber membrane is 0.2-3mm, the wall thickness of the single hollow fiber membrane is 0.05-1mm, the porosity is 50%-90%, the membrane separation pore size is 0.01-1 mu m, the rupture strength is 0.3-2MPa, the tension fracture tension of the hollow fiber membrane bundles is 0.2-10.0kg / bundle, and the pure water flux is 600-10000L / m2.h at 0.1MPa and 25 DEG C. The dry-wet non-solvent induced phase separation (NIPS) spinning process is adopted for enabling polymer casting solution and spinning core solution to simultaneously pass through a spinning spray head for forming nascent hollow fibers, and 2-8 single nascent hollow fibers are gathered into one bundle before entering into a coagulation bath water tank, and further enter into the coagulation bath water tank for forming the bundle-like hollow fiber membrane.

Owner:凌雪萍 +1

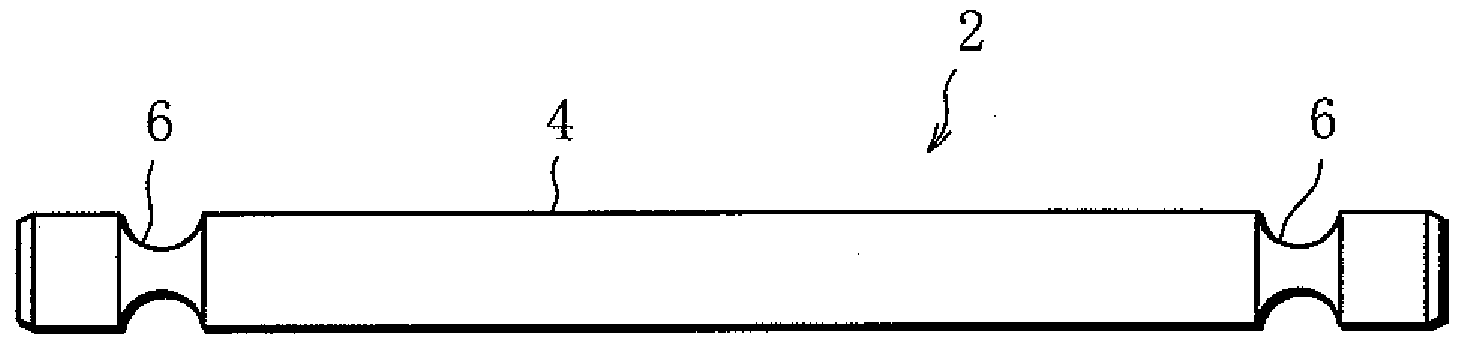

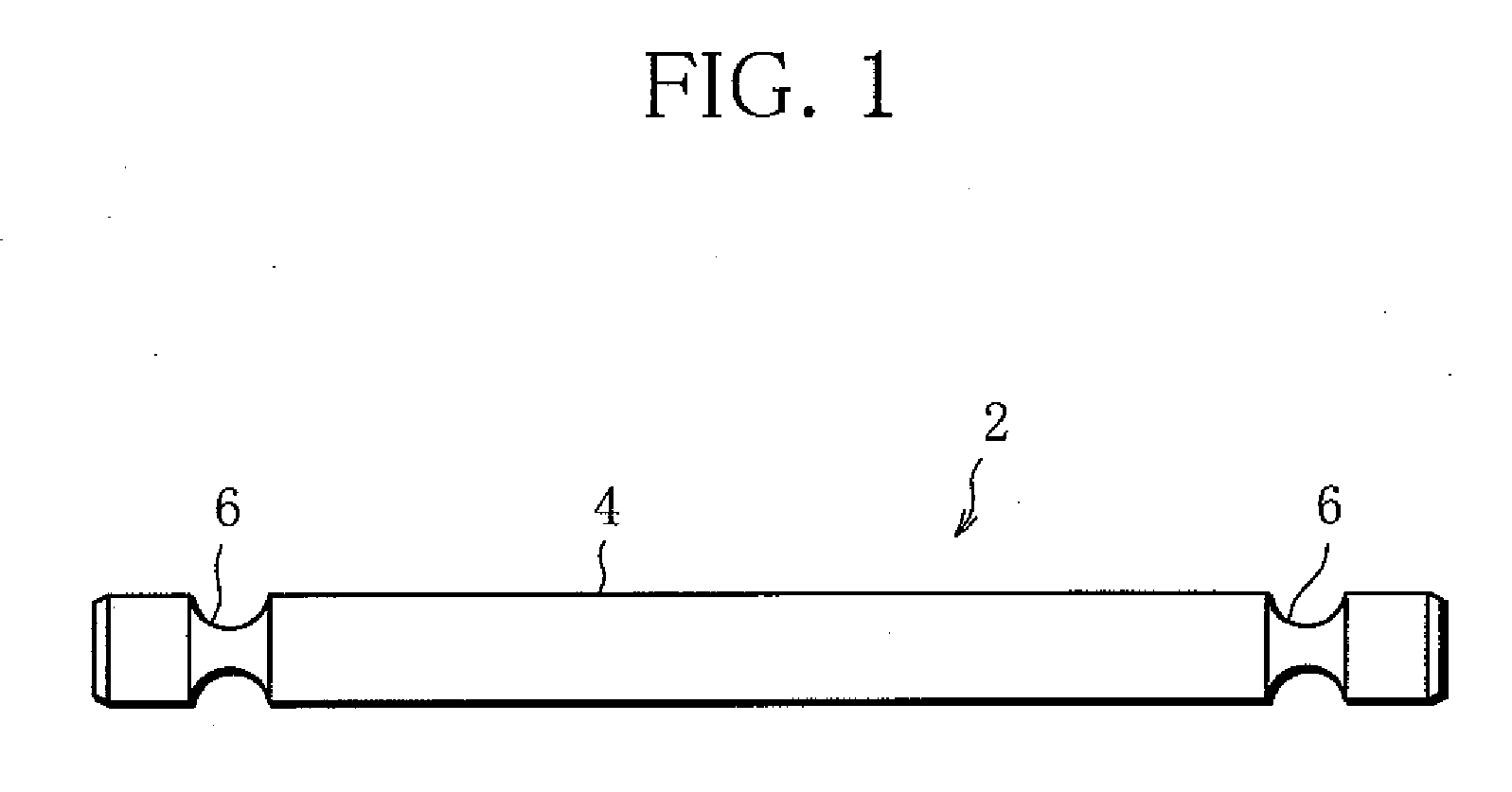

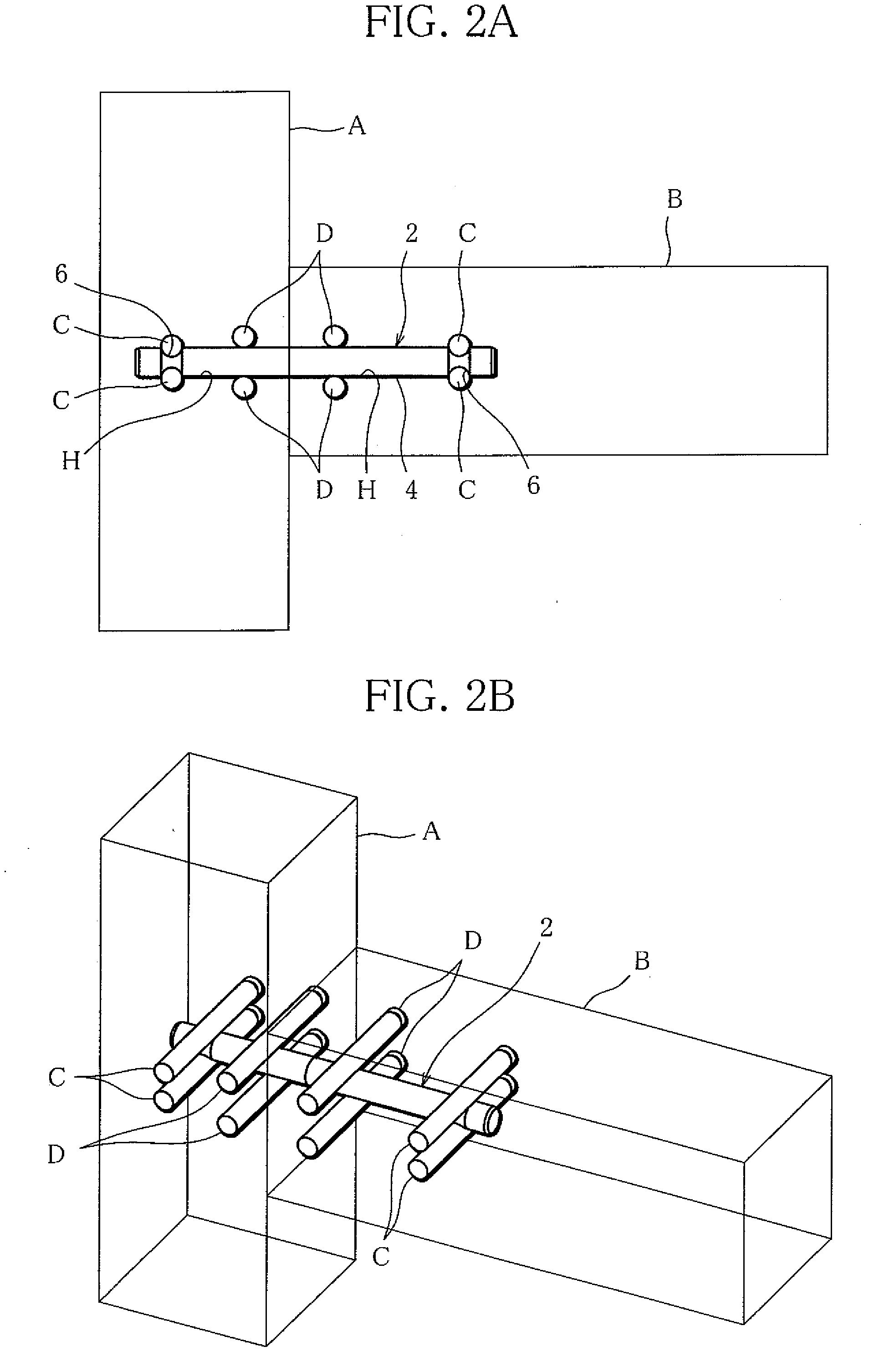

Tenon Rod and Tenon Joint

InactiveUS20100232872A1Easy and quick joiningReduce laborConveyorsRopes and cables for vehicles/pulleyBiomedical engineeringEngineering

A tenon rod for joining two members has a rod body, a helical groove formed on an end portion of the rod body for a drift pin to be fitted therein, and a hexagonal head provided at the other end of the rod body to enable the tenon rod to be turned about its axis.

Owner:KATO TOSHIYUKI

Catheter employing shape memory alloy shaping wire or pull wire and method of its manufacture

InactiveUS20080234661A1Increase the outer diameterIncrease stiffnessTransvascular endocardial electrodesSurgical instrument detailsShape-memory alloyAlloy

An electrophysiology catheter includes an elongate catheter body having a distal end and a proximal end, a catheter tip including at least one metallic catheter component, such as an electrode, thereon, and at least one internal catheter component joined to the at least one metallic catheter component. The at least one internal catheter component includes a shape memory alloy and a metal compound that is capable of both bonding with the shape memory alloy and being metallurgically joined to the at least one metallic catheter component as by brazing. The metal compound may be a coating on or a core within the shape memory alloy. Suitable metal compounds include, without limitation, nickel, copper, brass, and combinations thereof.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

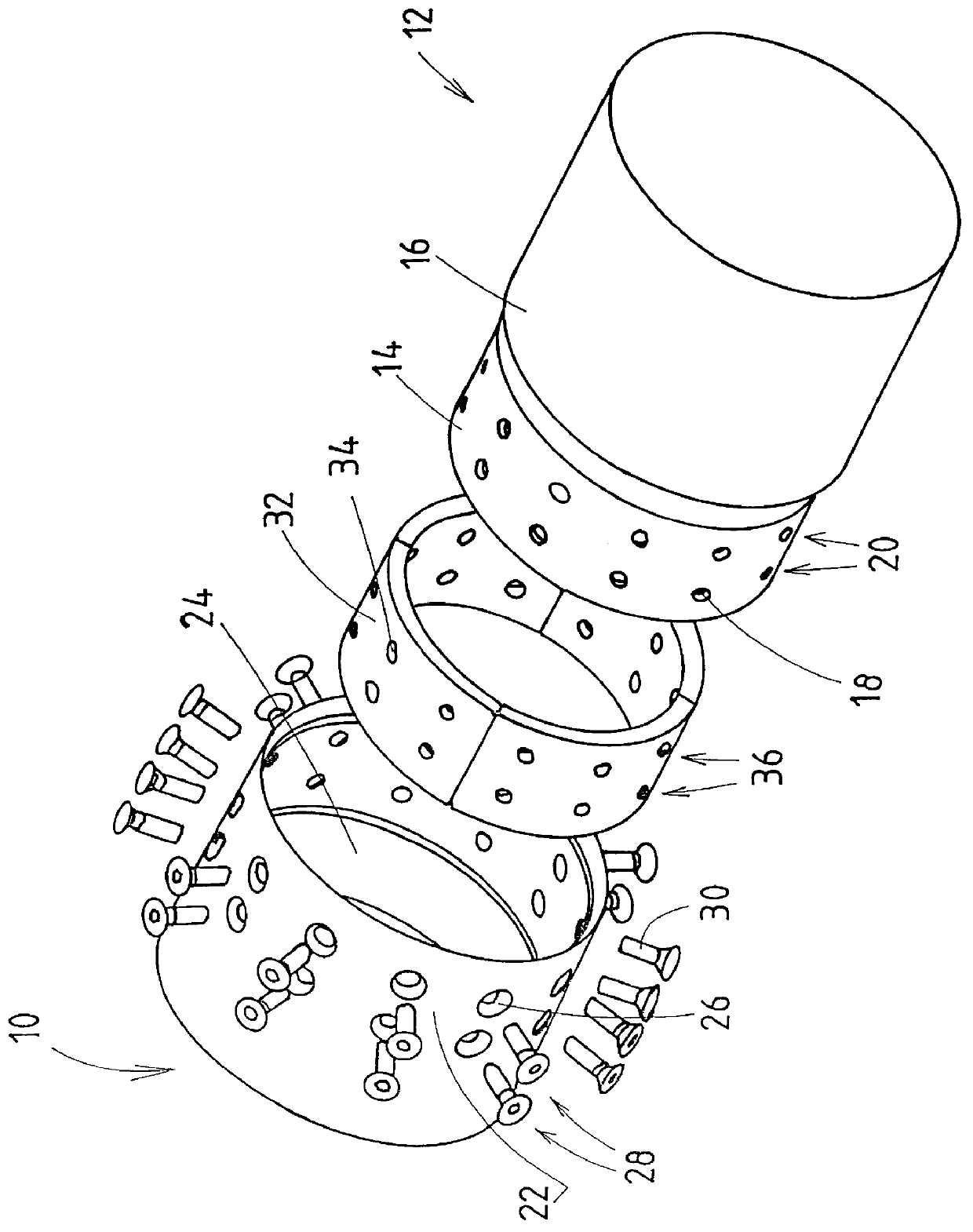

Tube connection, in particular, for connecting two tubular fuselage portions of a missile

InactiveUS6098928AHighly stable and highly stiffHighly stable and highly stiff connectionFuselage framesSelf-propelled projectilesEngineeringFuselage

A connection is described for connecting two tubular fuselage portions of a missile. The inner diameter of the rim of a first tubular fuselage portion to be connected with a second tubular fuselage portion corresponds to the outer diameter of the rim of the second tubular fuselage portion to be connected to the first tubular fuselage portion, deducting a jointing tolerance, The rims of the tubular fuselage portion to be connected are provided with radial bores to accommodate connection screws, Clamp segments are mounted in the second tubular fuselage portion along the inner circumference thereof. The clamp segments define threaded bores, connection screws being screwed into these threaded bores.

Owner:BODENSEEWERK GERATETECHNIK GMBH

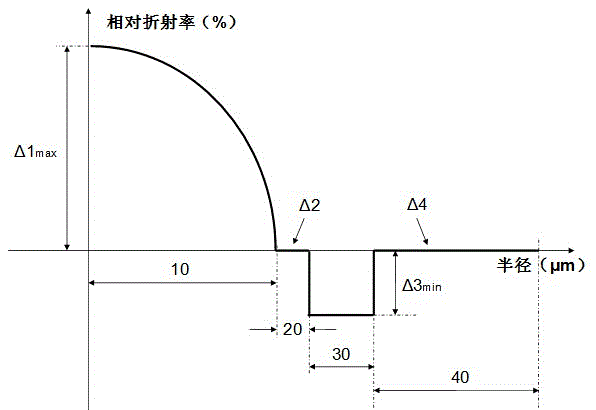

Preparation method for large-sized bended insensitive multimode optical fiber preform

ActiveCN105060701AImprove production efficiencyLow costGlass making apparatusMulti-mode optical fiberFluorine doping

The invention relates to a preparation method for a large-sized bended insensitive multimode optical fiber preform. The preparation method comprises: firstly carrying out doping and deposition through an in-tube method to form a multimode optical fiber core layer, melting a deposition tube through a heating furnace to form a solid mandril after deposition, and carrying out doping and deposition through an out-tube process to deposit a sunken coating and an outer coating separately by taking the mandril as a target rod; or carrying out negative doping by using a pure quartz glass outer lining tube through an in-tube method process to form the sunken coating and the outer coating of the preform; and then combining the prepared mandril with a deposited outer sleeve to form the optical fiber preform for an RIT (rod in tube) process or combining the prepared mandril with fluorine-doped or boron-doped quartz glass sleeve in a packaging manner and melting the two to a solid rod for a SCR (solid core rod) process, and then combining the solid rod with a large-diameter outer sleeve to form the optical fiber preform for the RIT process. The prepared optical fiber preform not only is large in outer diameter and high in core precision, but also is low in manufacturing cost, simple and agile in method and suitable for large-scaled production.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

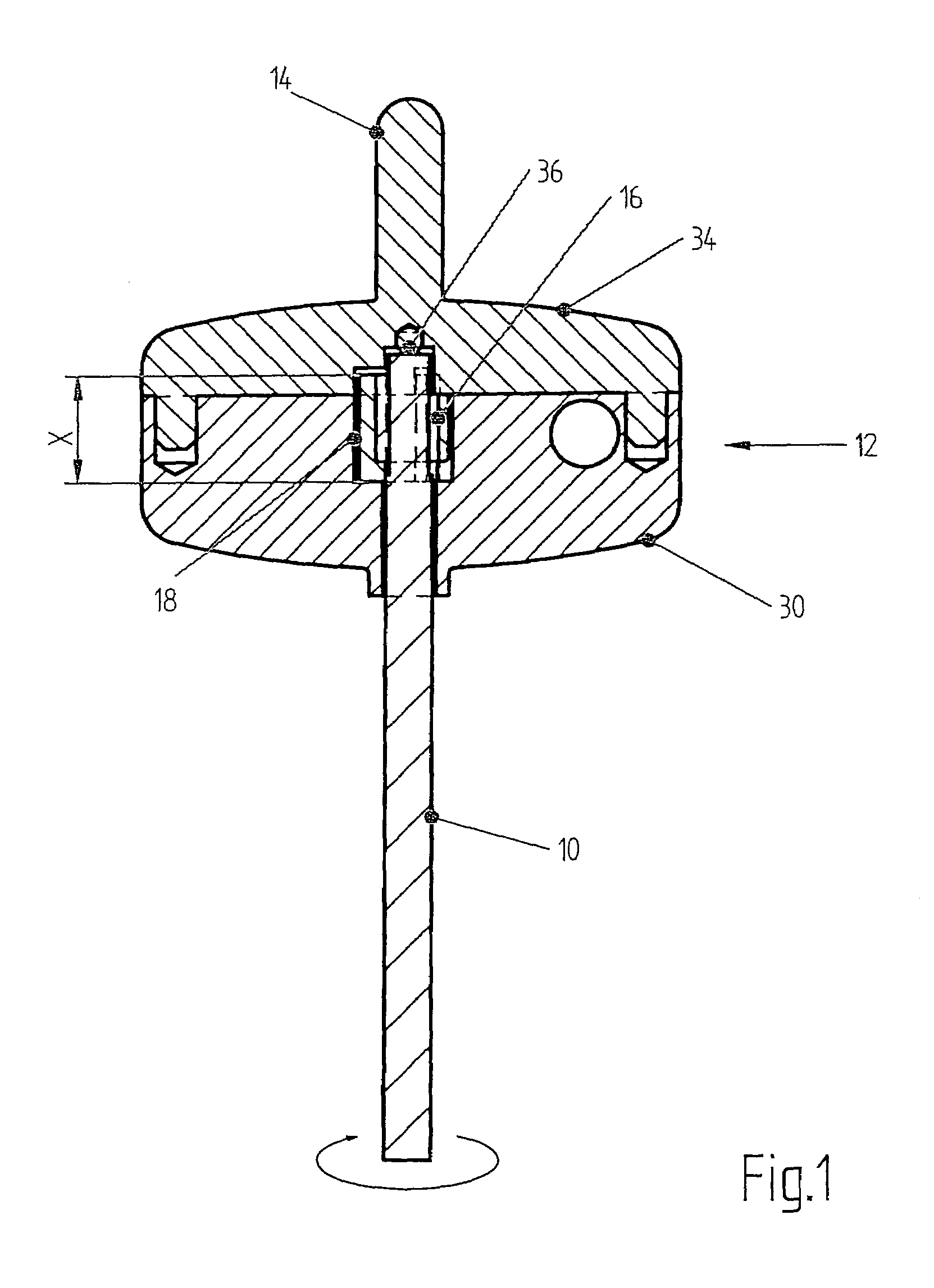

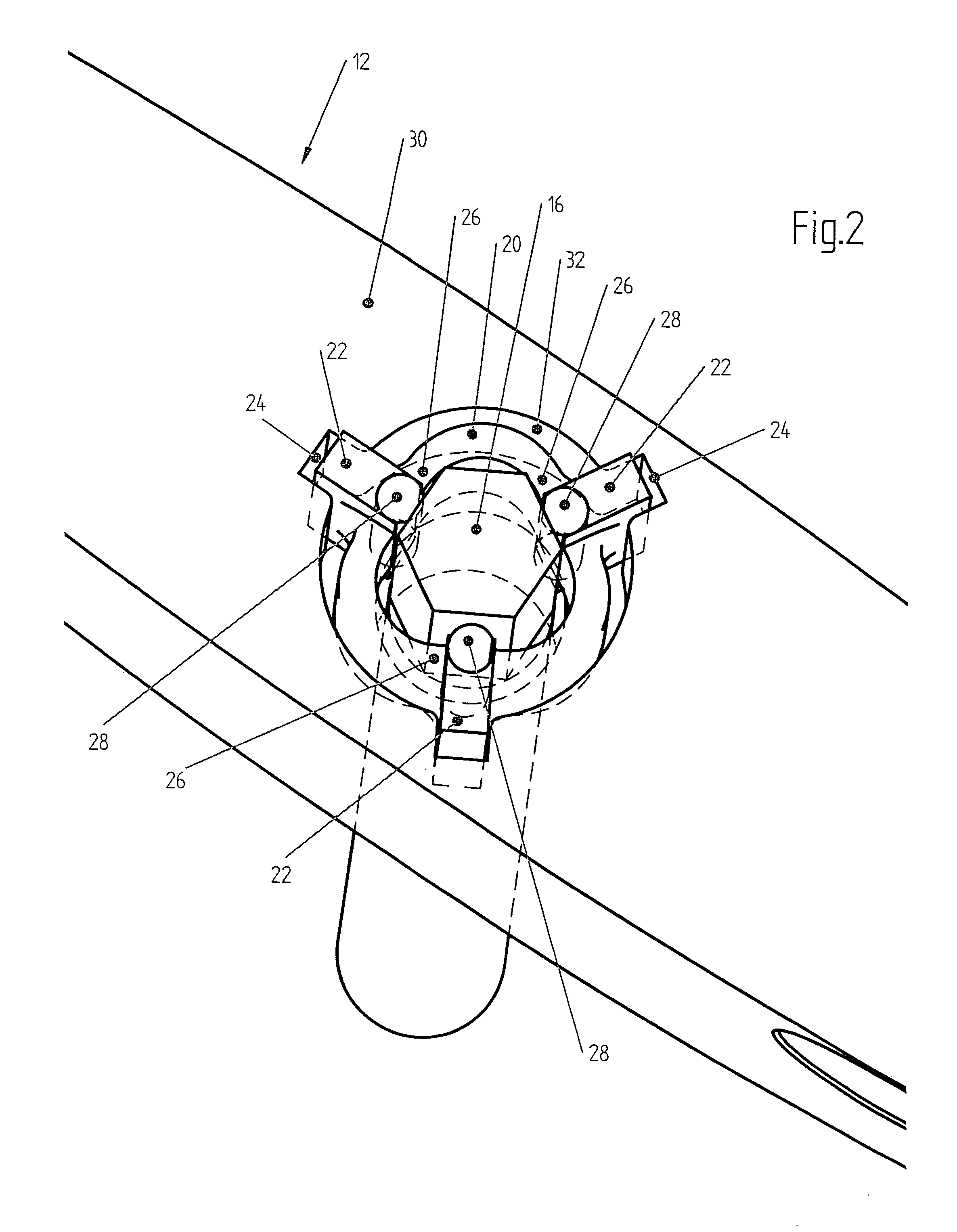

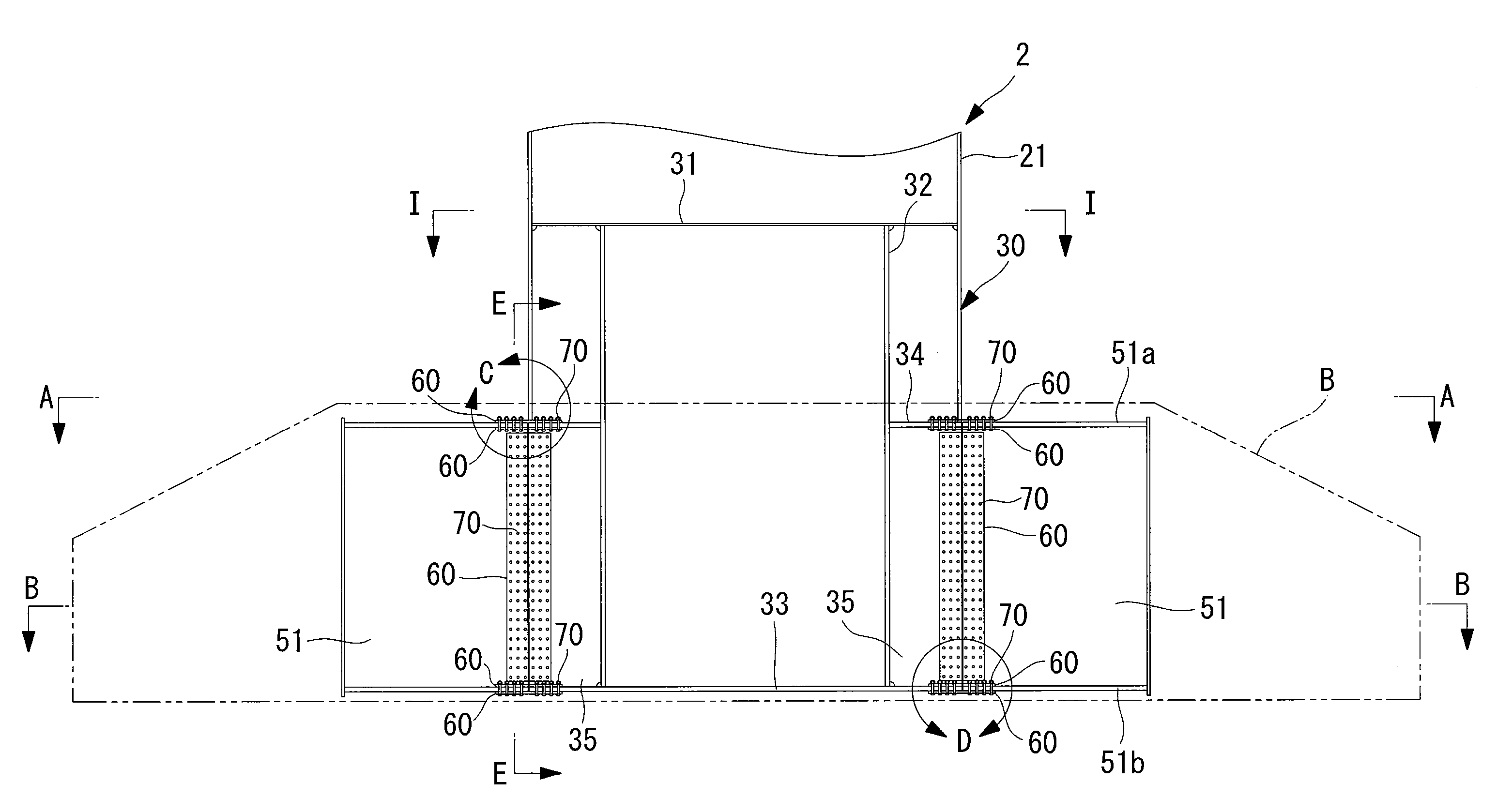

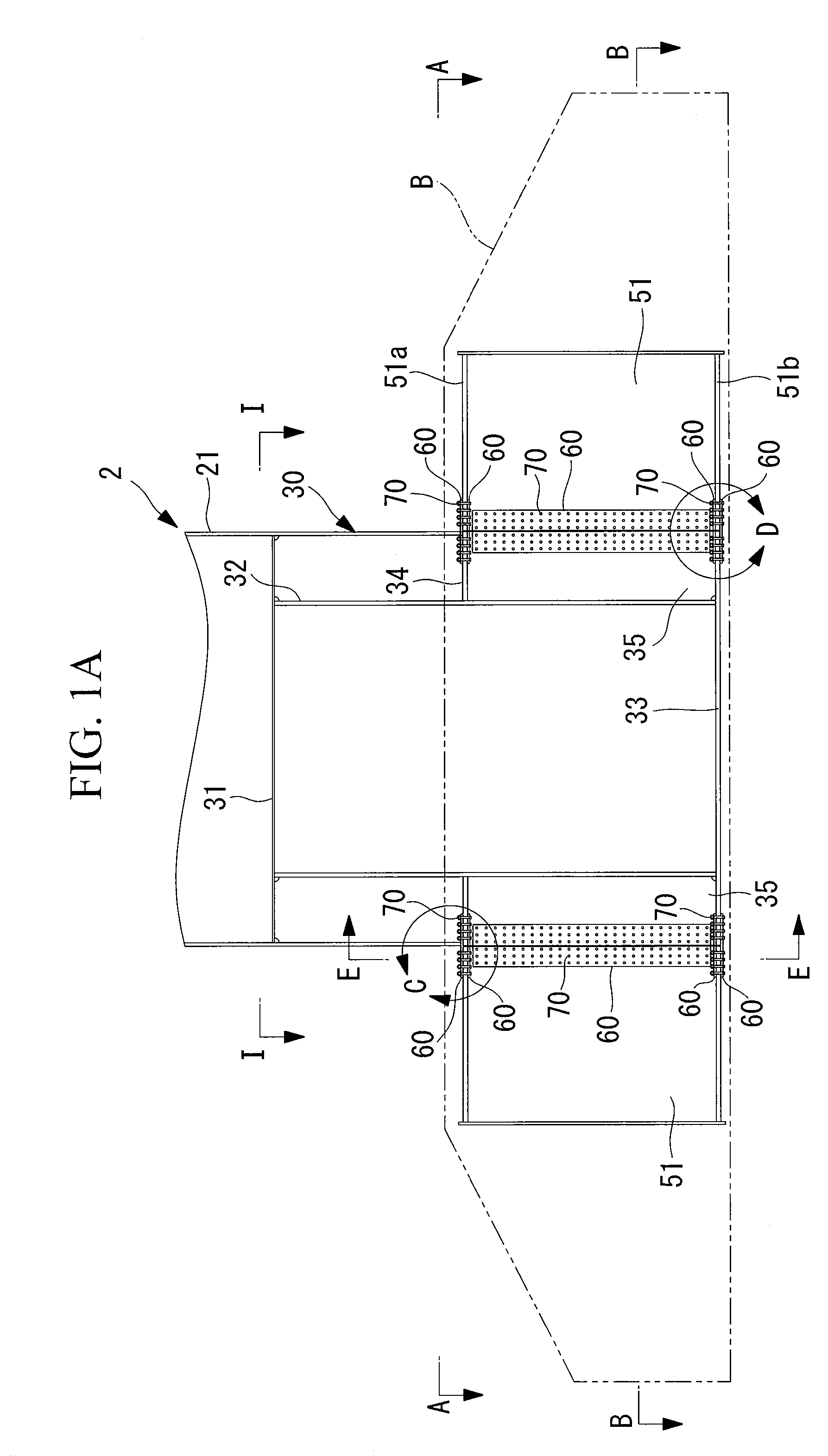

Monopole tower and wind turbine generator having monopole tower

ActiveUS20110278850A1Efficient processIncrease the outer diameterWind motor supports/mountsLoad-supporting elementsMaximum dimensionCoupling

The present invention provides a monopole tower having a tower supporting structure in which the outer dimension of a tower shell is the maximum dimension by eliminating a base plate which extends toward the outside of the tower shell. In a monopole tower provided upright on a foundation B, a lower end side of the tower 2 comprised a tower-side coupling member in a range equal to or less than outside diameter of a tower shell 21. In a space comprising a foundation-side coupling member provided on the foundation B, the foundation-side coupling member and the tower-side coupling member are coupled by welding, a bolt using a splice plate, or a rivet.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com