Patents

Literature

40results about How to "Improve the efficiency of position adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

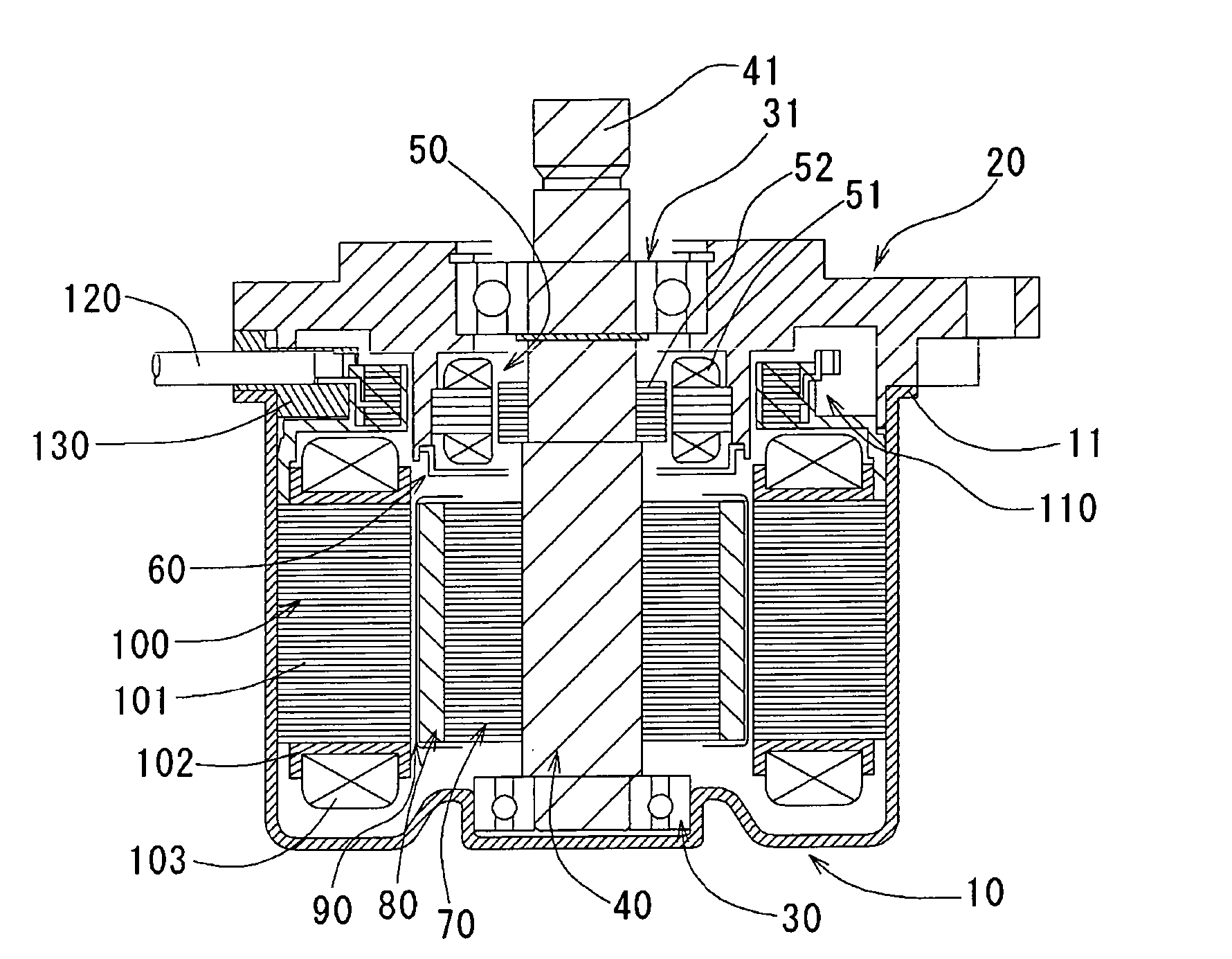

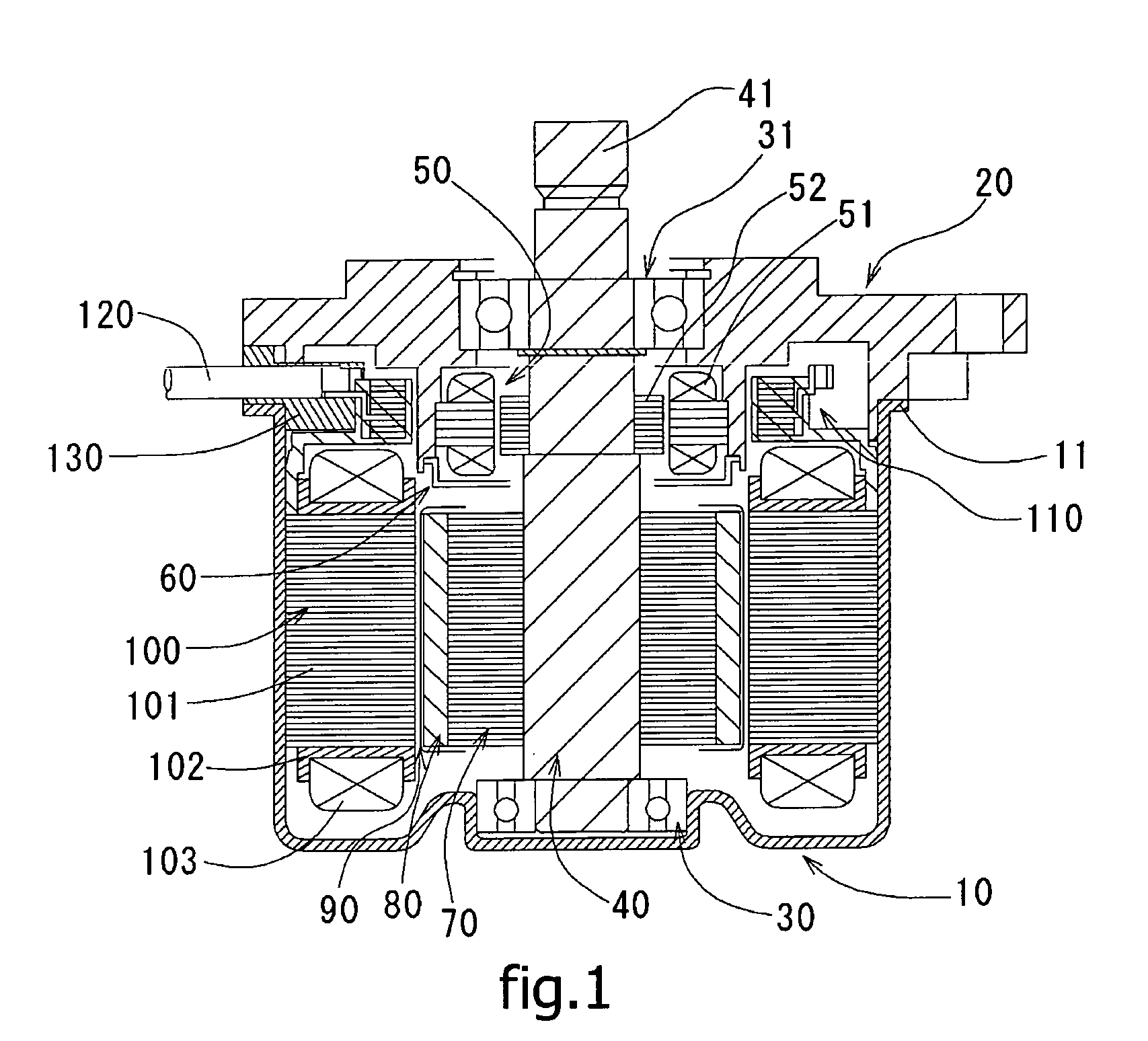

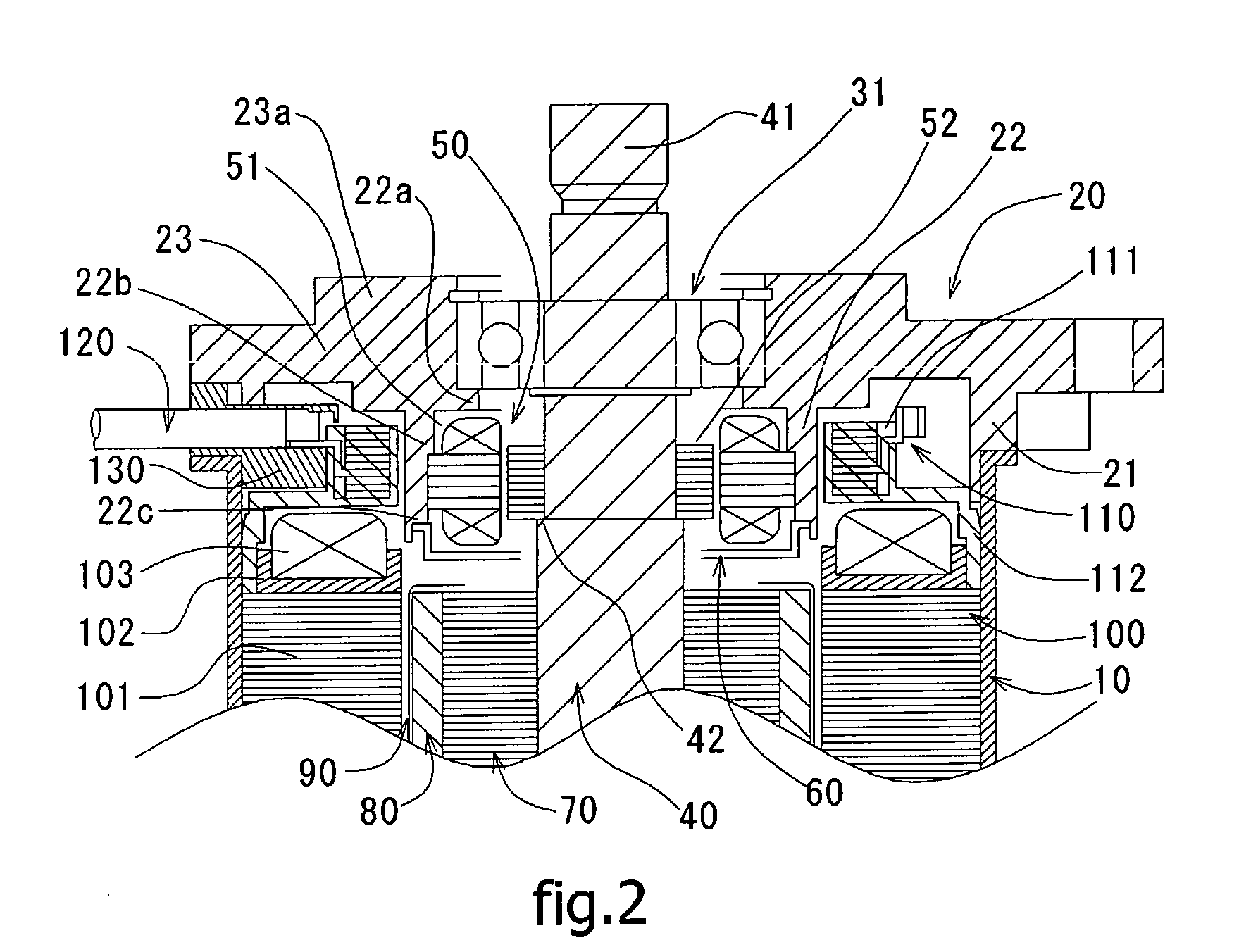

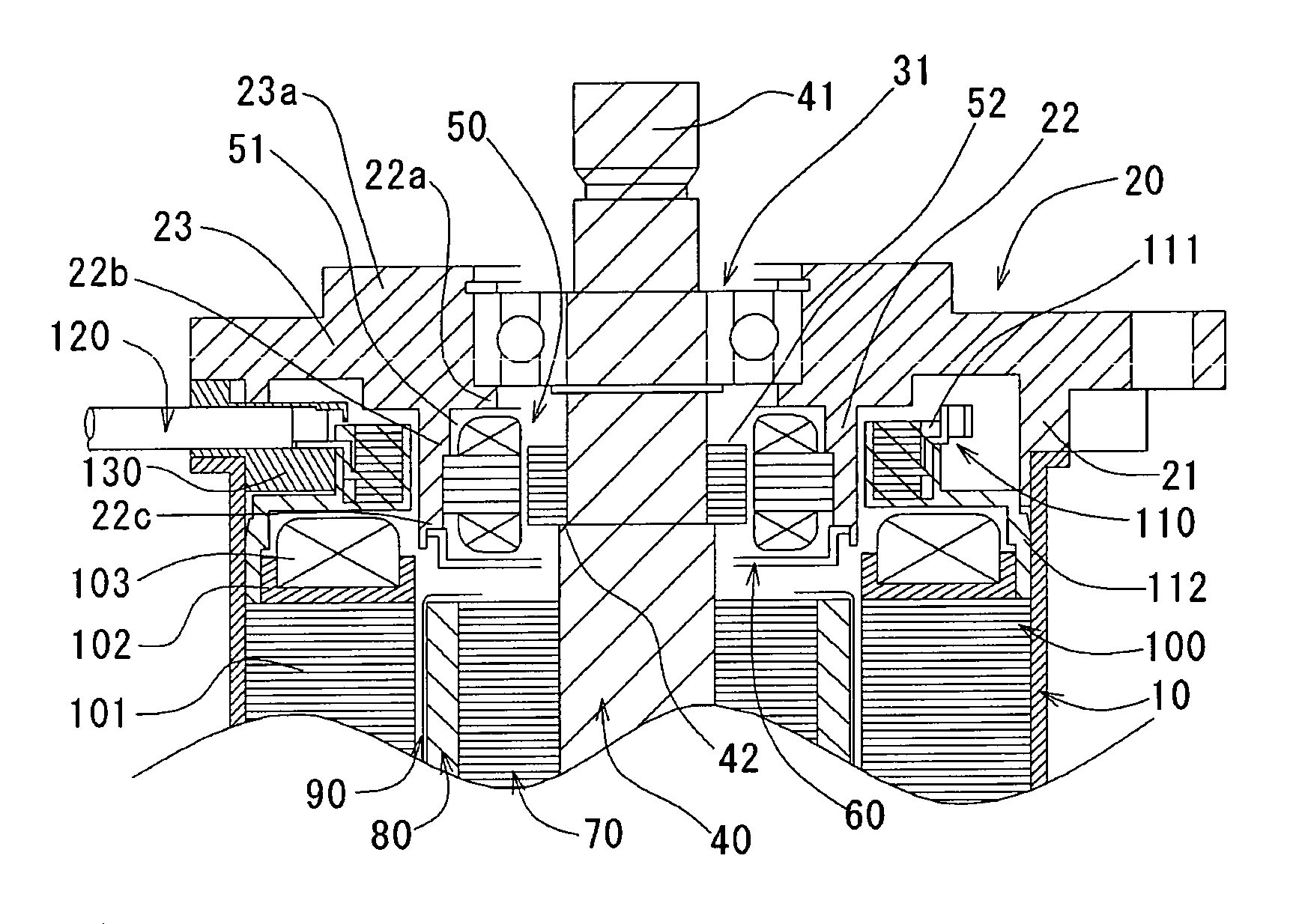

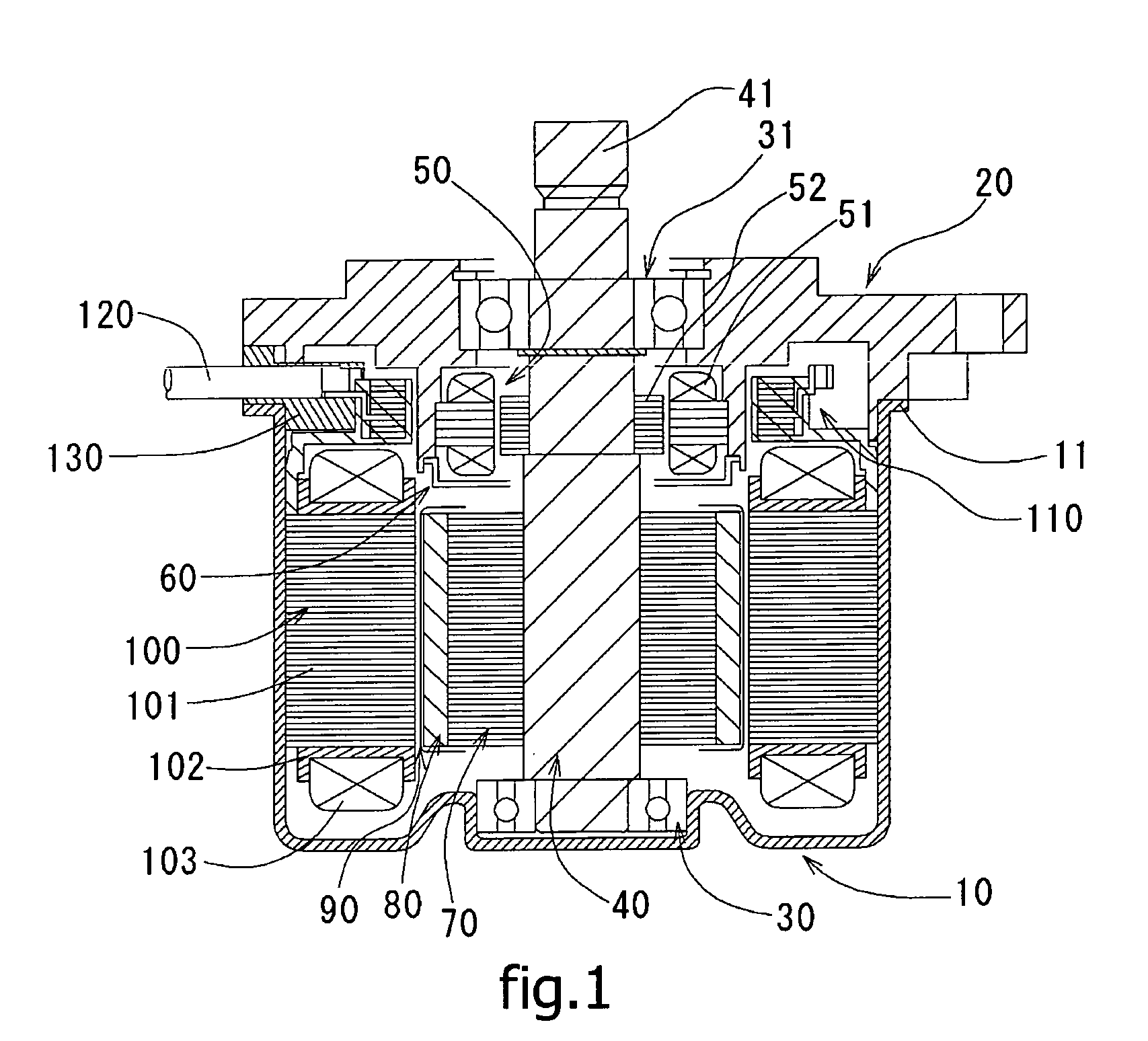

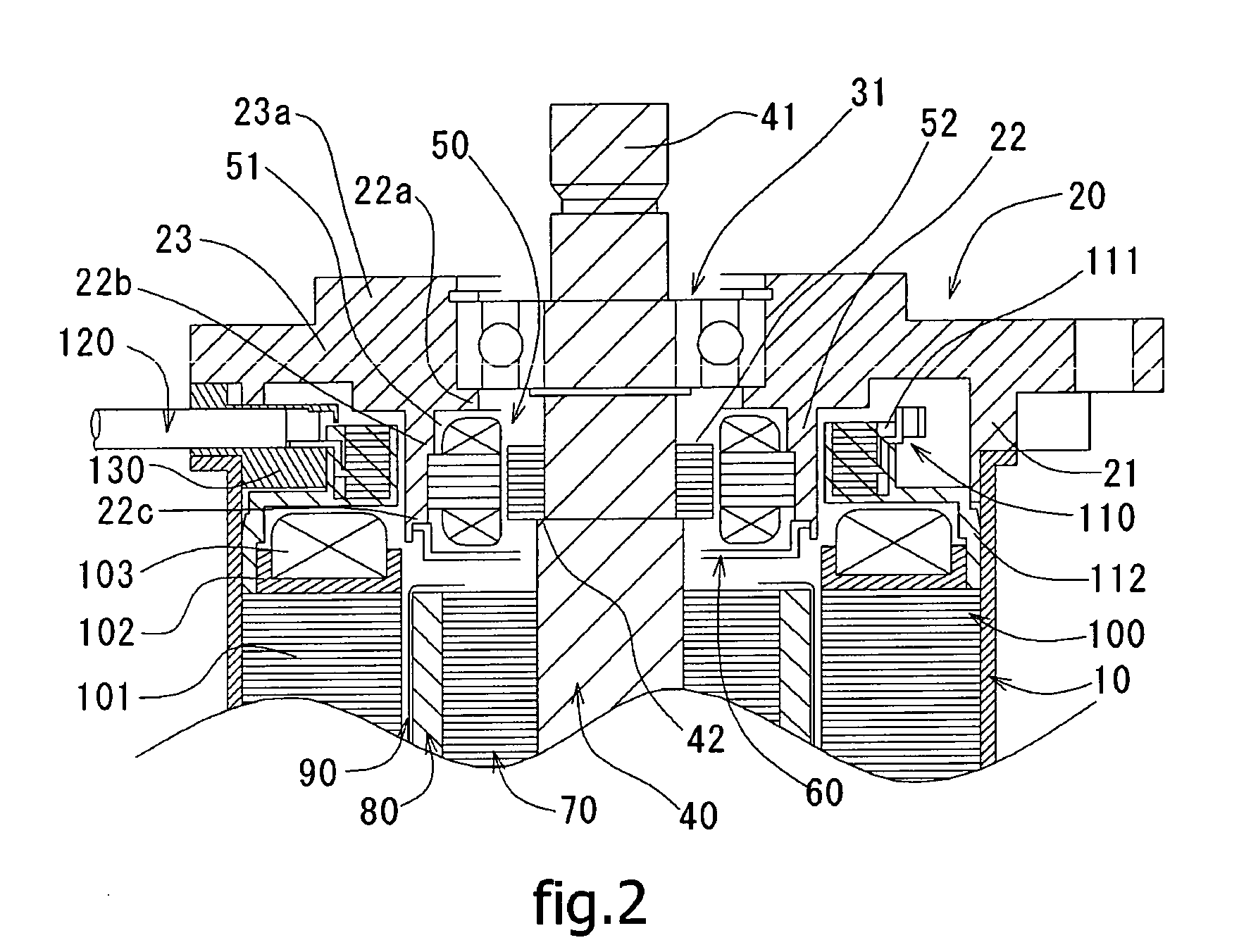

Brushless motor

ActiveUS20060226719A1Increase the outer diameterIncrease the number of polesSynchronous generatorsAsynchronous induction motorsBrushless motorsLocation detection

A second bracket part for holding a resolver stator of a resolver as position detecting means is inserted in an opening hole in a first bracket part. An expanded part formed in the second bracket part and the opening hole in the first bracket hole are connected to each other with a fixing member. A through hole in which the fixing member for the expanded part is inserted has a circular arc shape. By reducing the fixing strength of the fixing member, the second bracket part can be made movable in the circumferential direction.

Owner:NIPPON DENSAN CORP

Brushless motor

ActiveUS7453175B2Improve the efficiency of position adjustmentImprove efficiencySynchronous generatorsAsynchronous induction motorsBrushless motorsEngineering

A second bracket part for holding a resolver stator of a resolver as position detecting means is inserted in an opening hole in a first bracket part. An expanded part formed in the second bracket part and the opening hole in the first bracket hole are connected to each other with a fixing member. A through hole in which the fixing member for the expanded part is inserted has a circular arc shape. By reducing the fixing strength of the fixing member, the second bracket part can be made movable in the circumferential direction.

Owner:NIDEC CORP

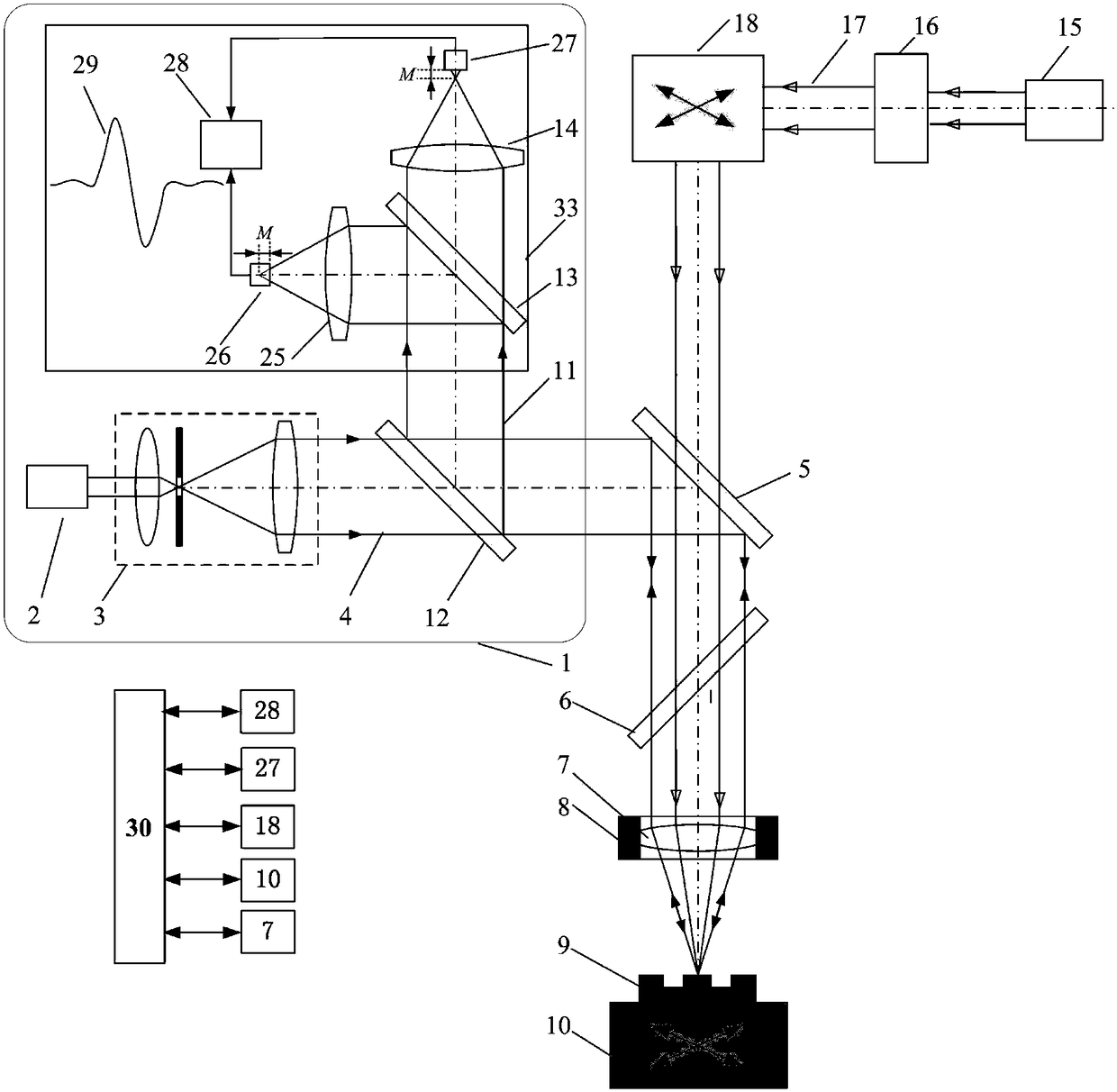

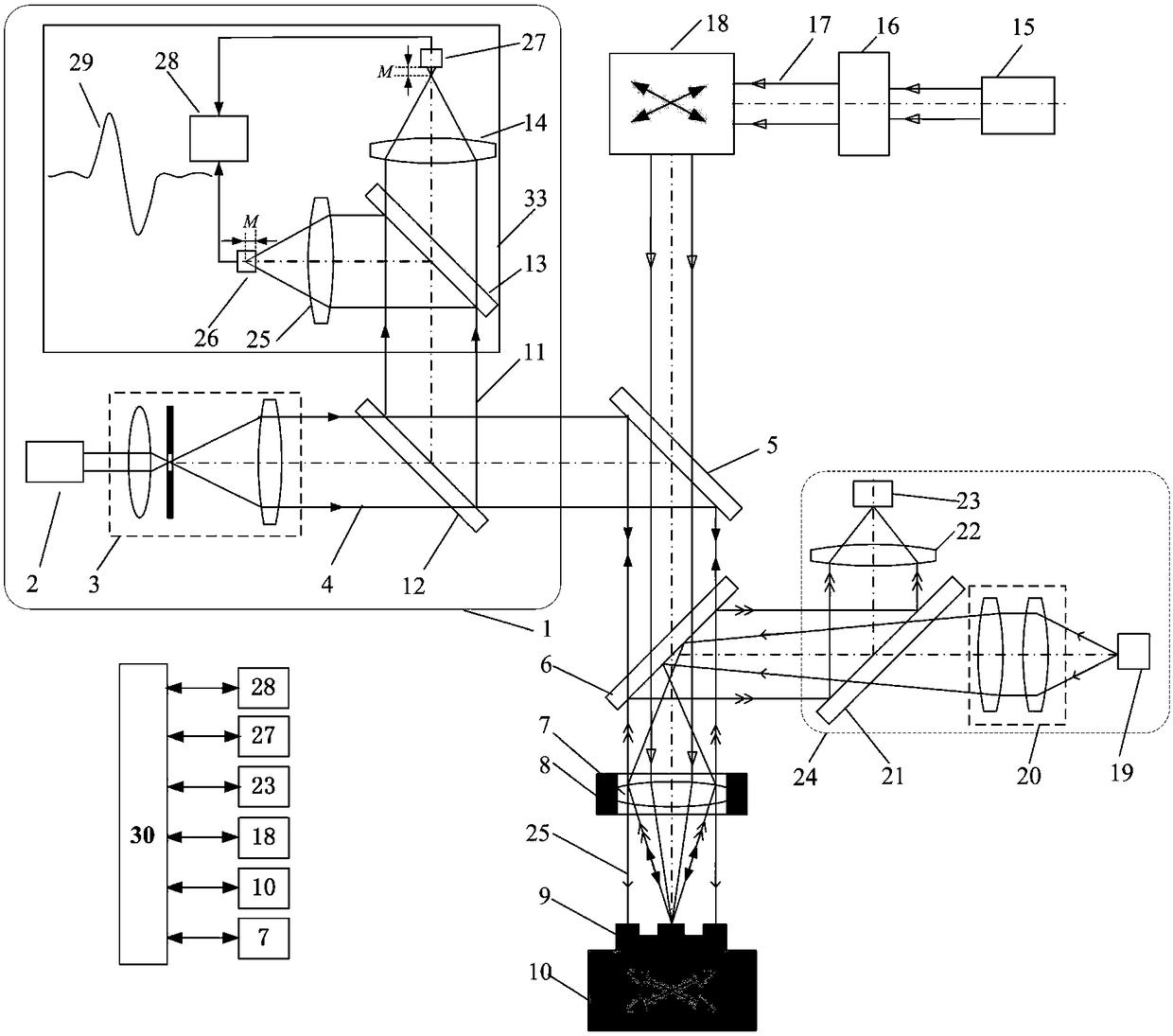

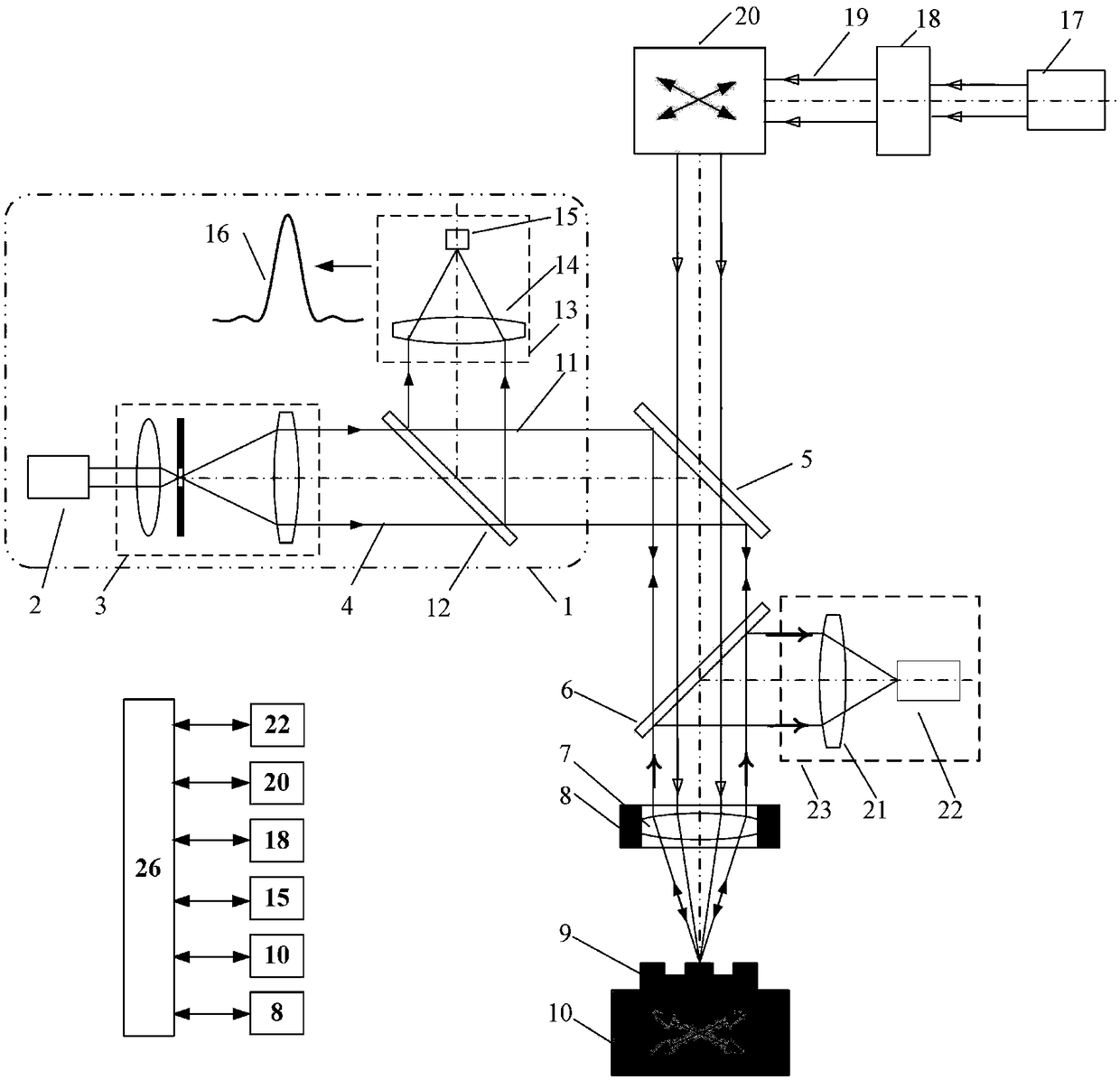

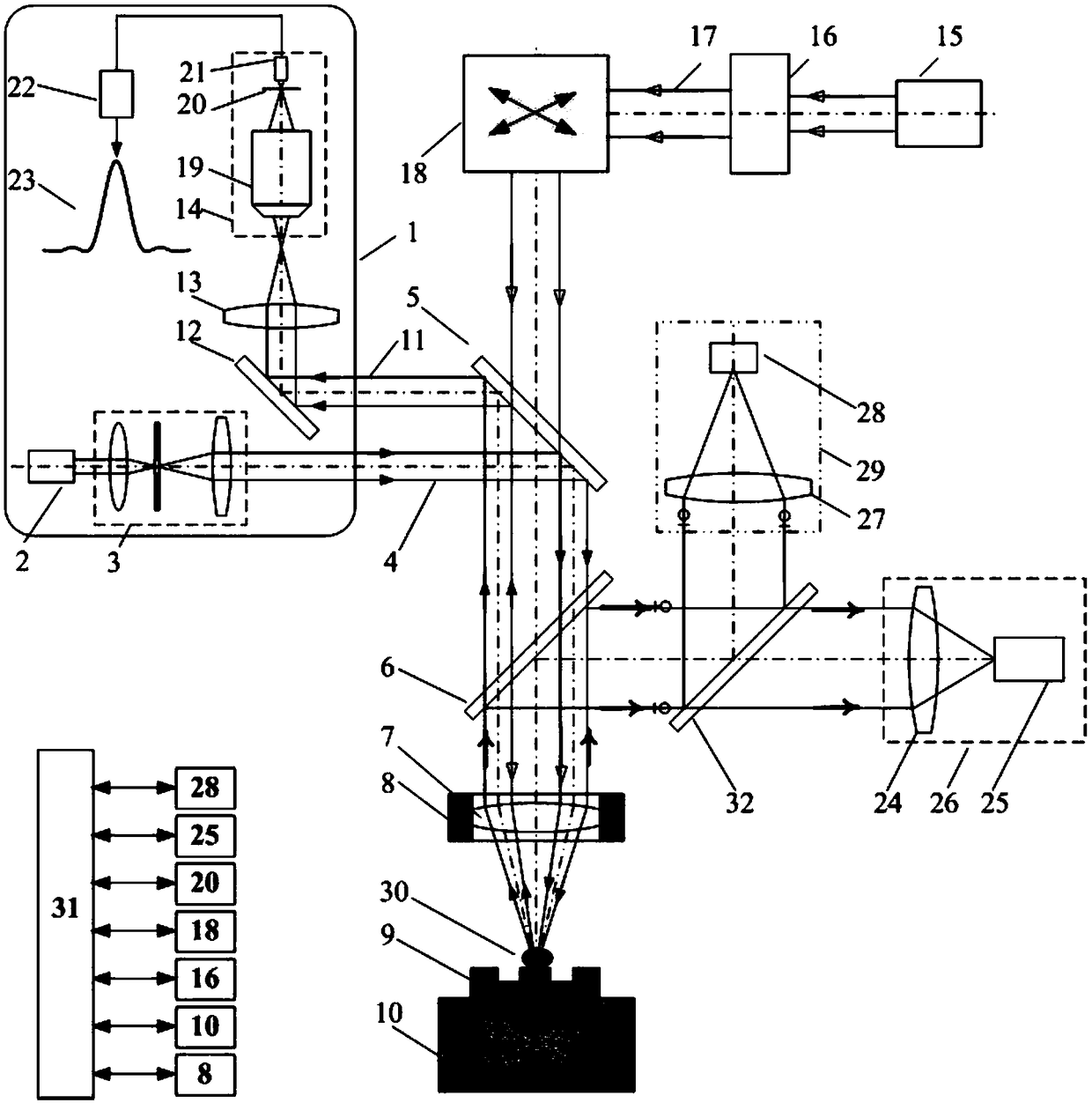

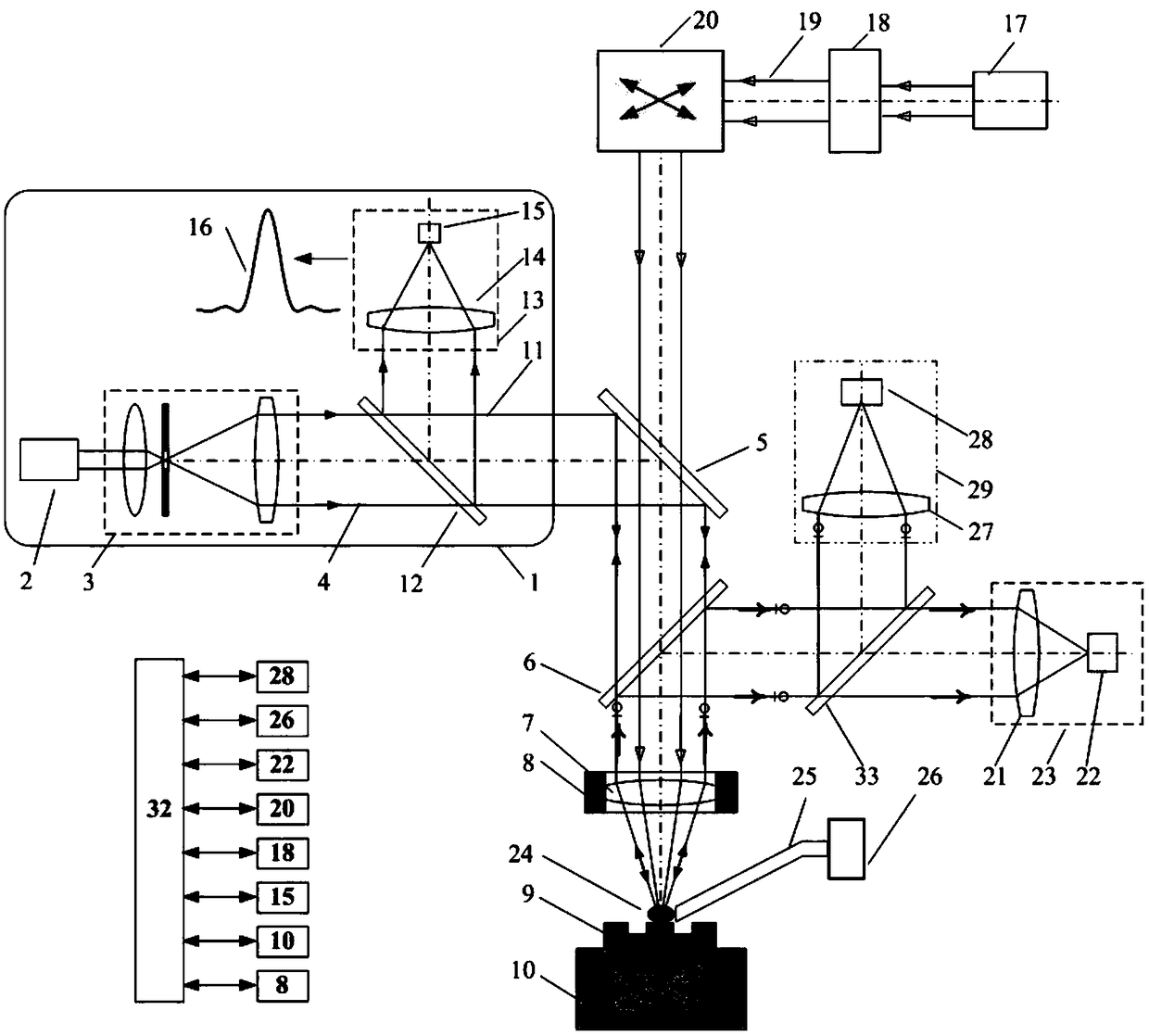

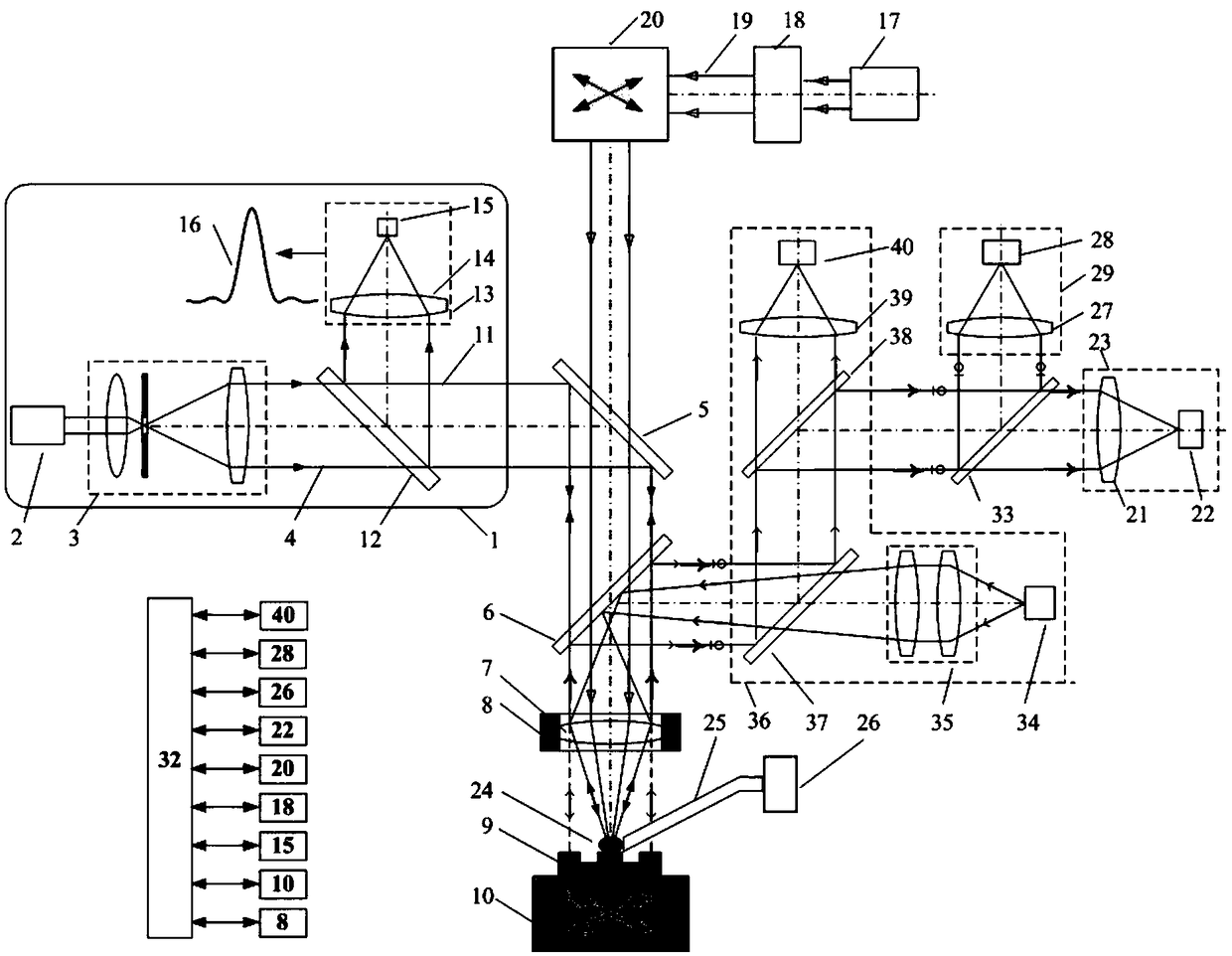

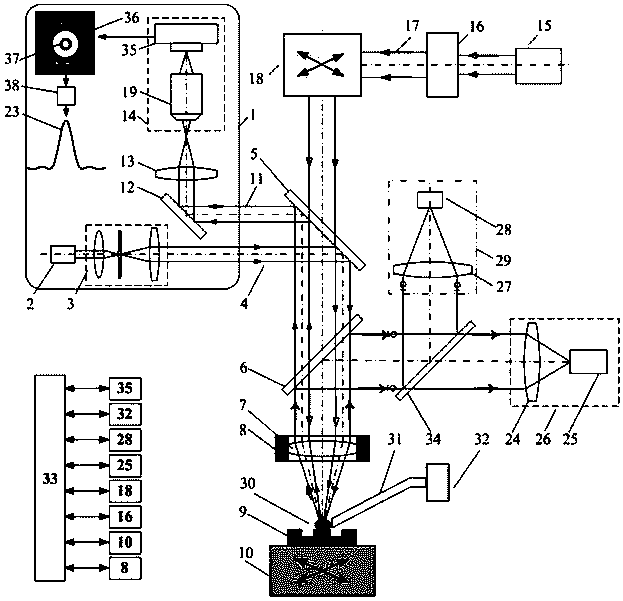

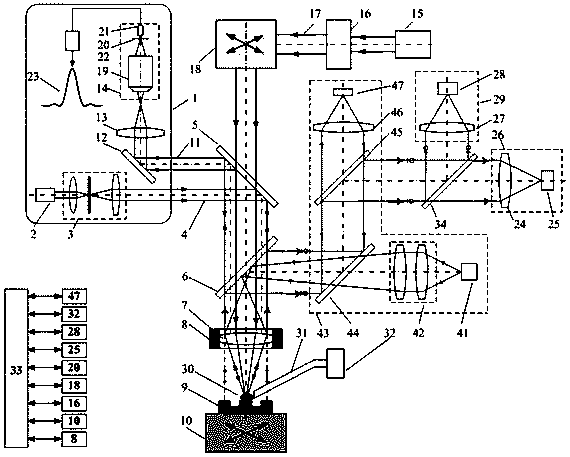

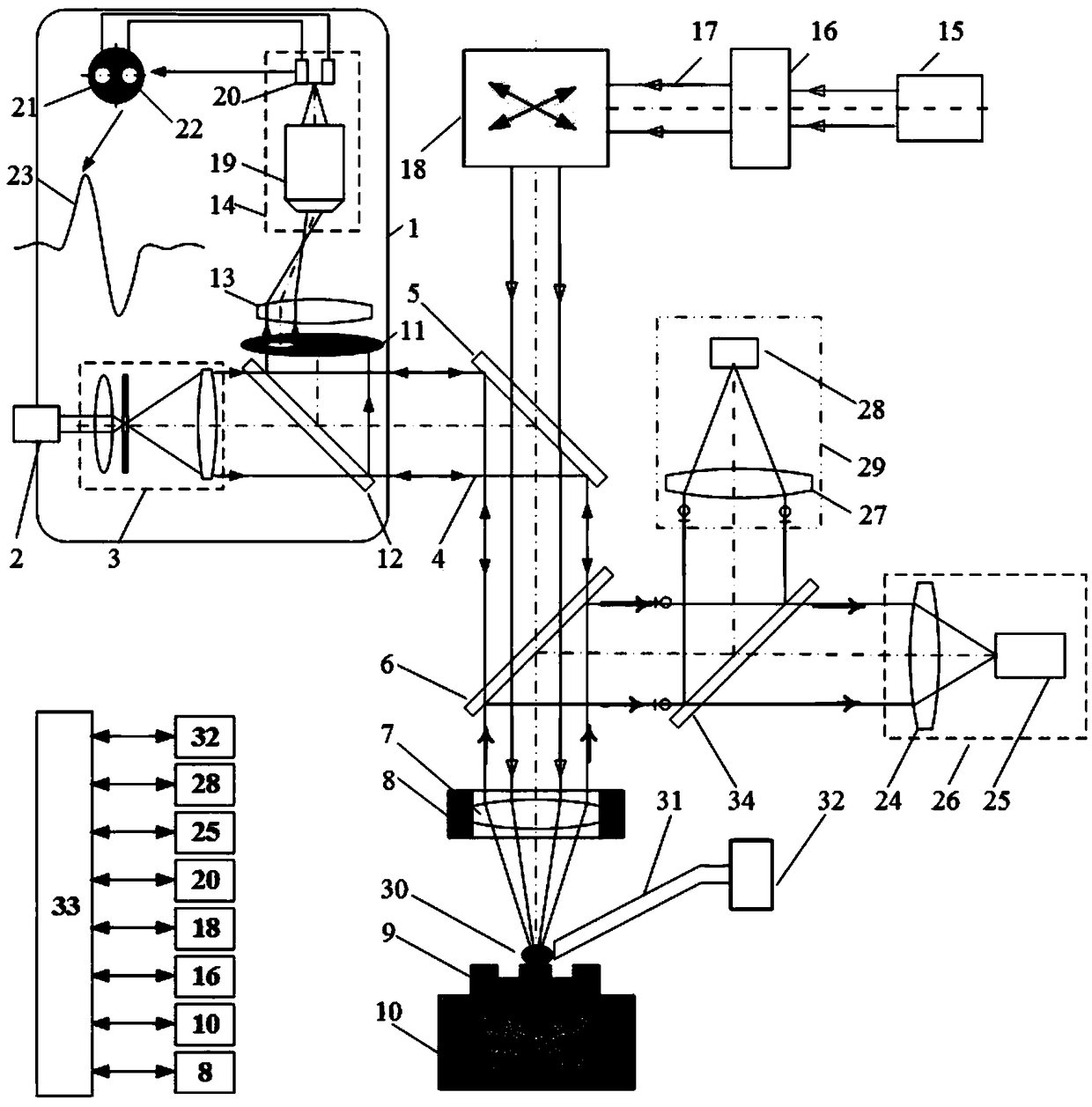

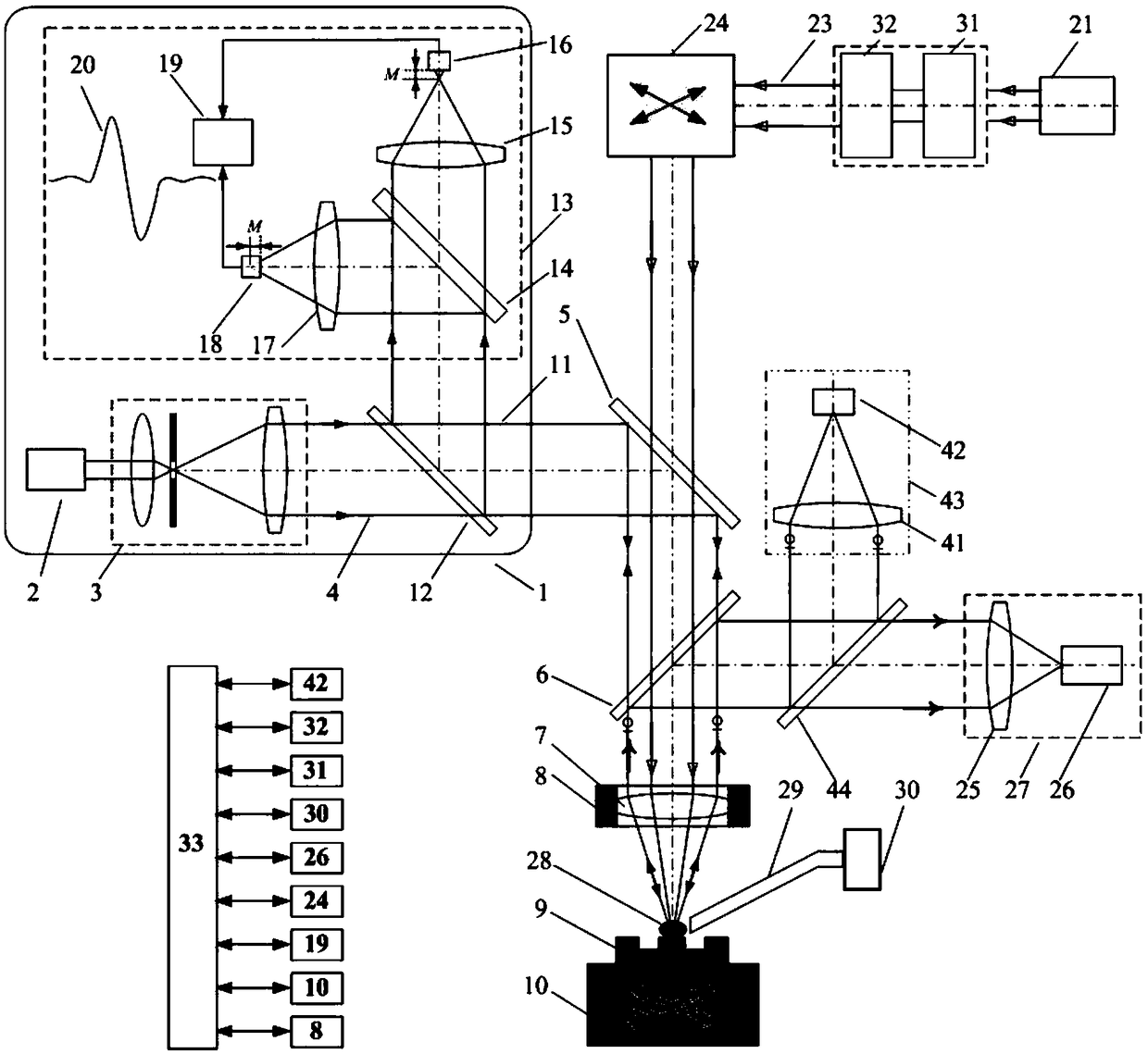

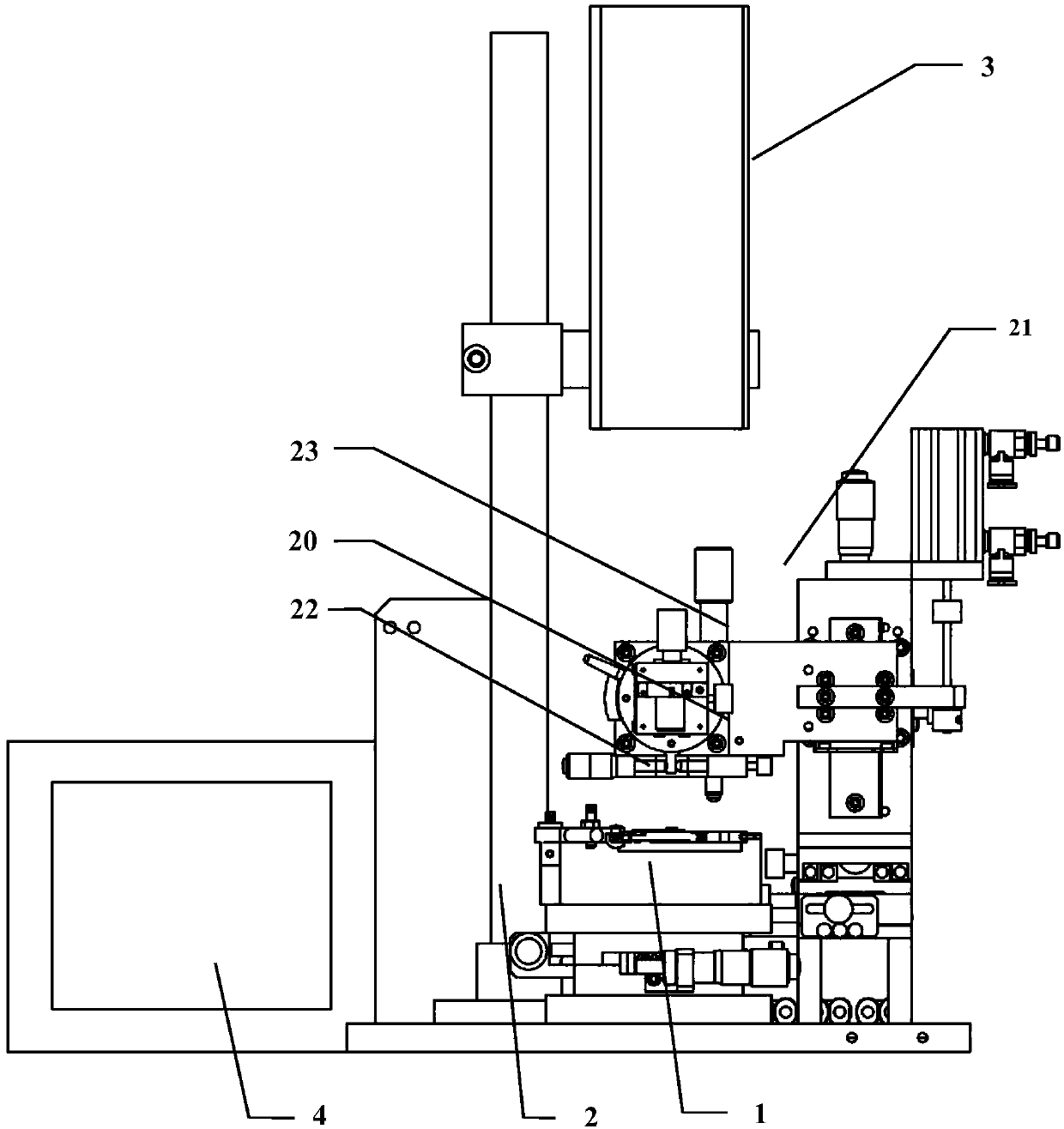

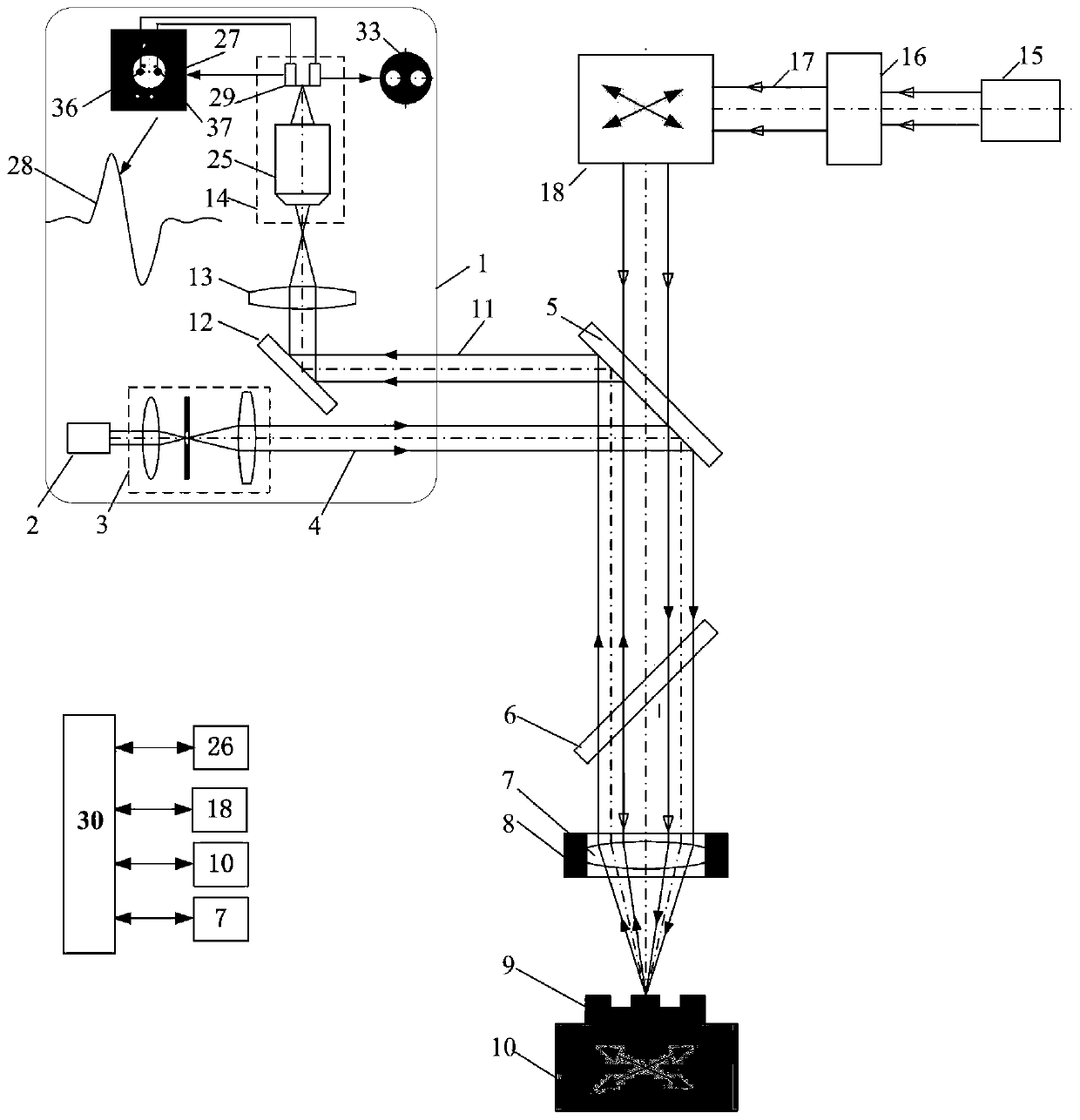

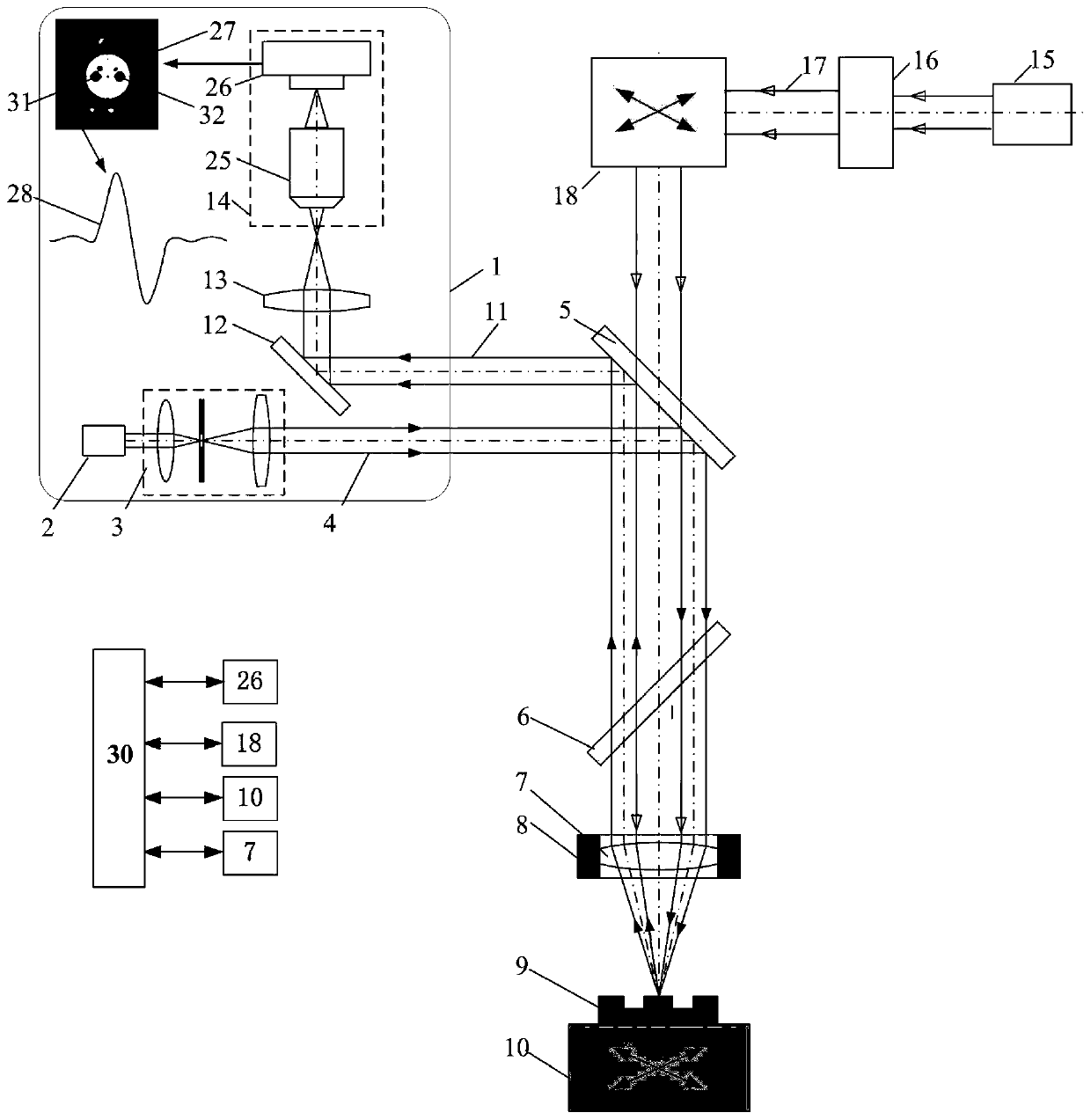

Laser micro-nano machining differential confocal online monitoring integration method and device

PendingCN108286936ASolve driftSolve real-timeNanotechnologyUsing optical meansMicro nanoDimension measurement

The present invention belongs to the field of laser precision detection technologies and laser micro-nano machining monitoring technologies, and relates to a laser micro-nano machining differential confocal online monitoring integration method and device which can be used for laser micro-nano machining and online detection of a complex micro-nano structure. A laser differential confocal axial monitoring module with high axial resolution and a femtosecond laser machining system are organically integrated, a differential confocal system curve zero point is employed to perform nanoscale monitoring of a sample axial position and measurement of a sample axial machining size to achieve real-time fixed focus of the sample axial position and high-precision measurement of the micro-nano structure size after machining, solve the drift problem and the high-precision online detection problem in the measurement process, improve the controllability of micro-nano femtosecond laser machining precisionand sample machining quality. Prior to machining, a microimaging module is utilized to perform rough alignment and horizontal position identification of the sample.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

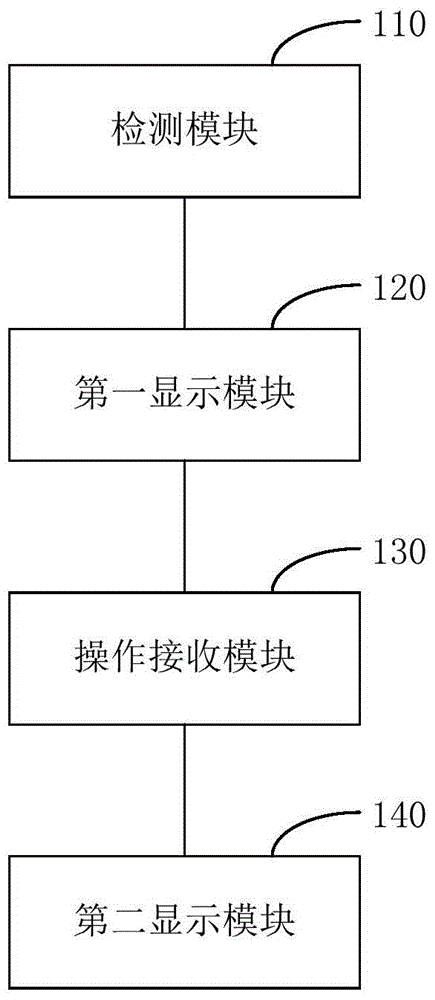

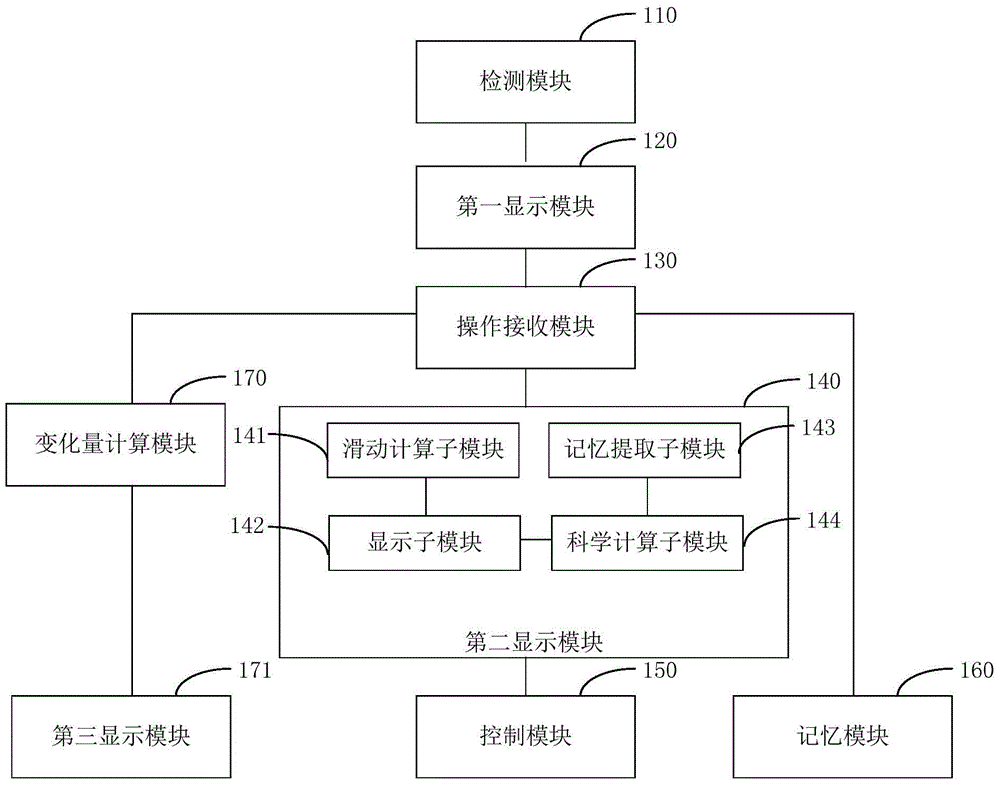

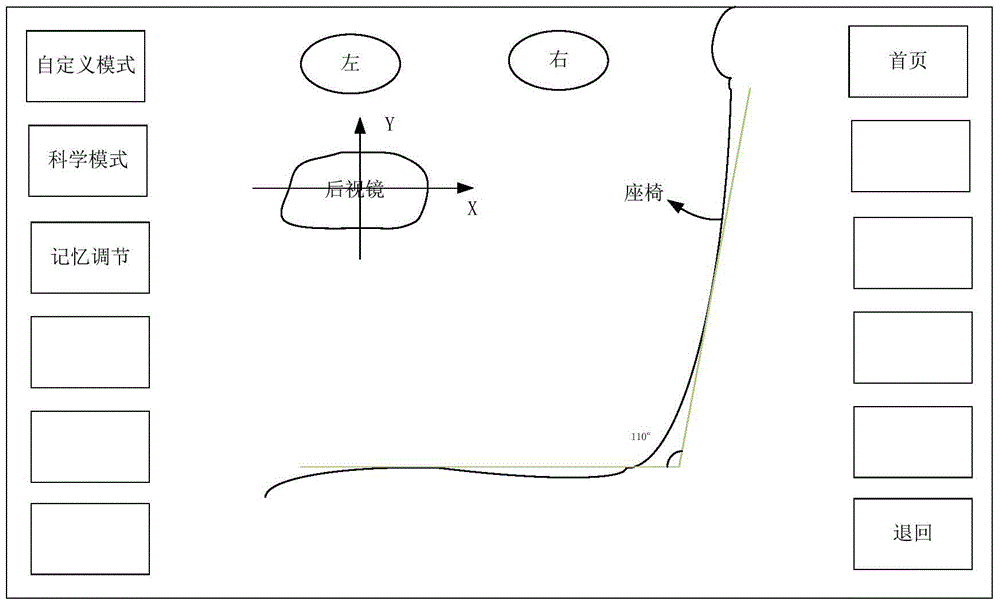

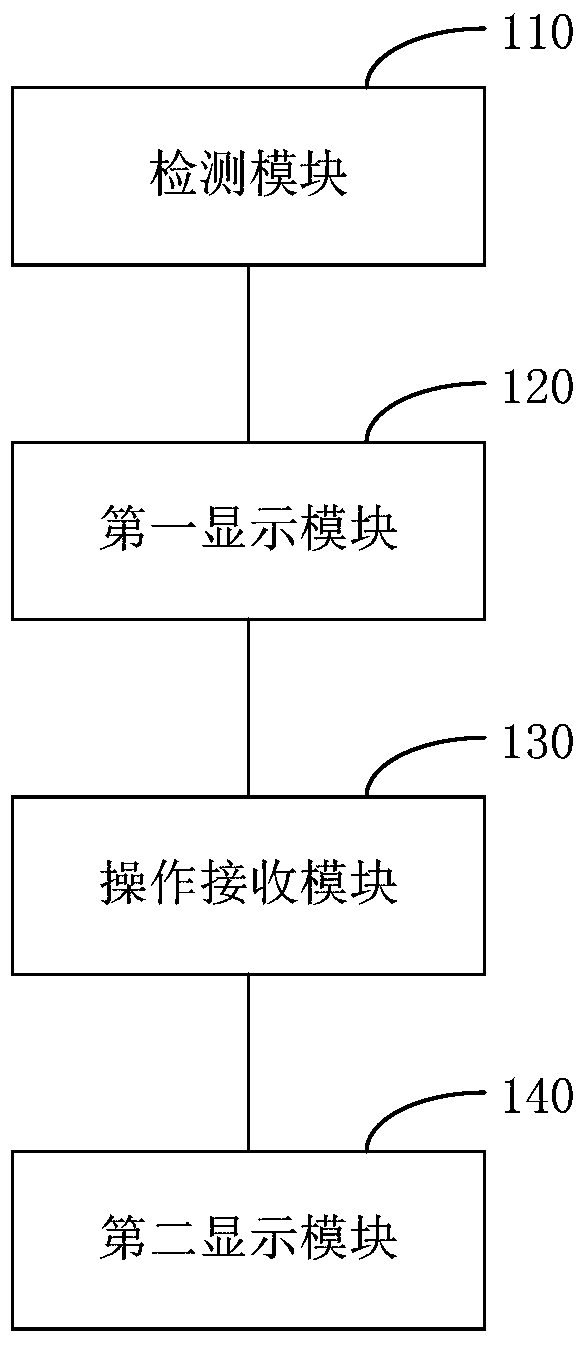

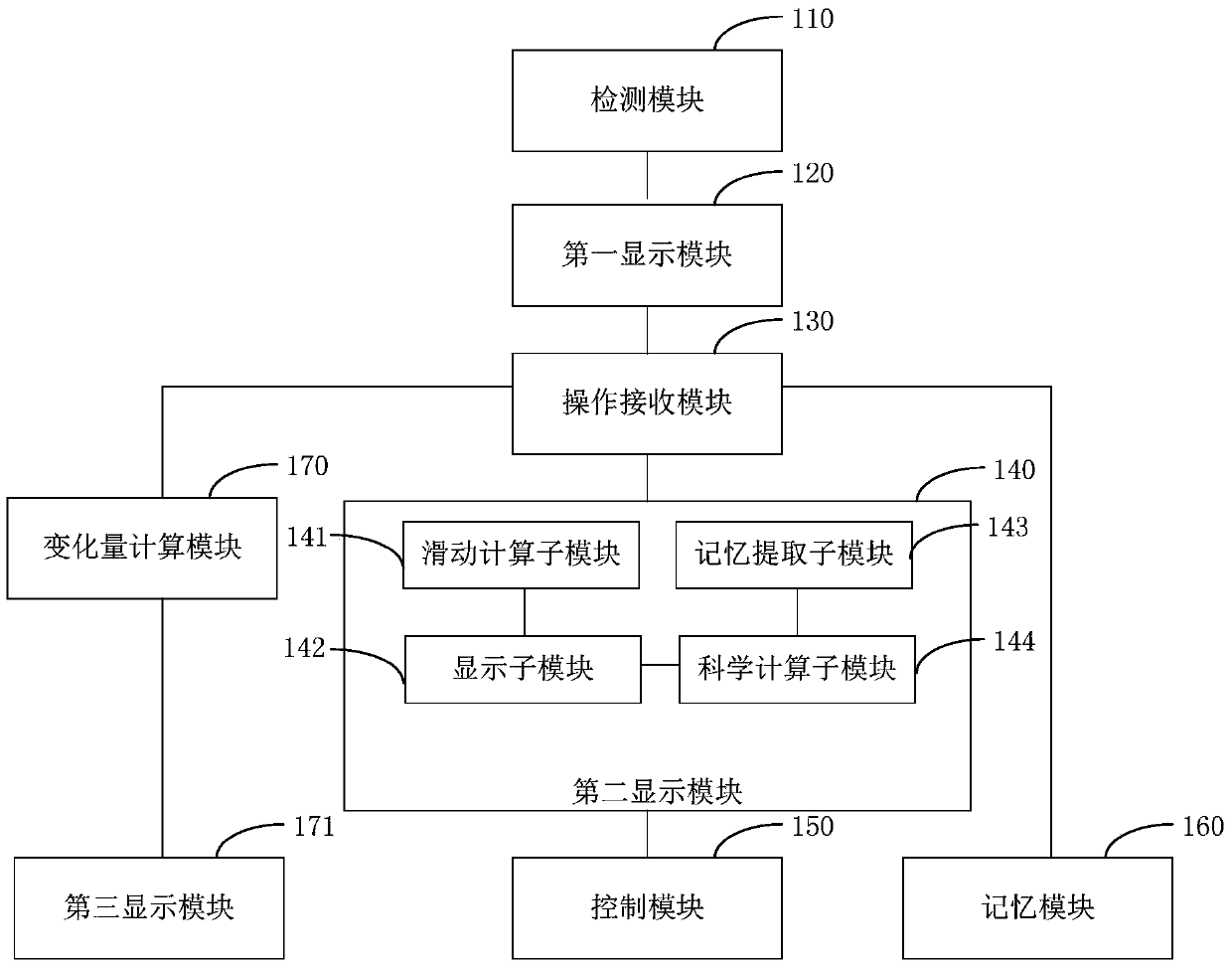

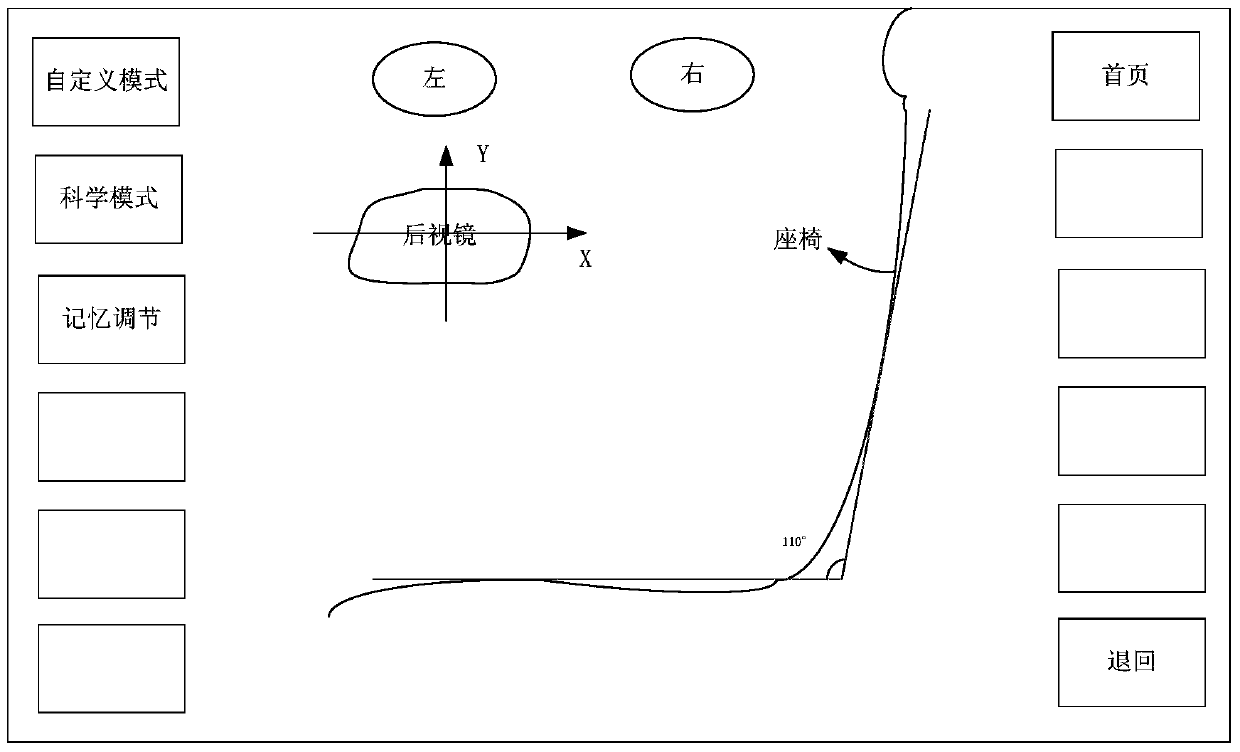

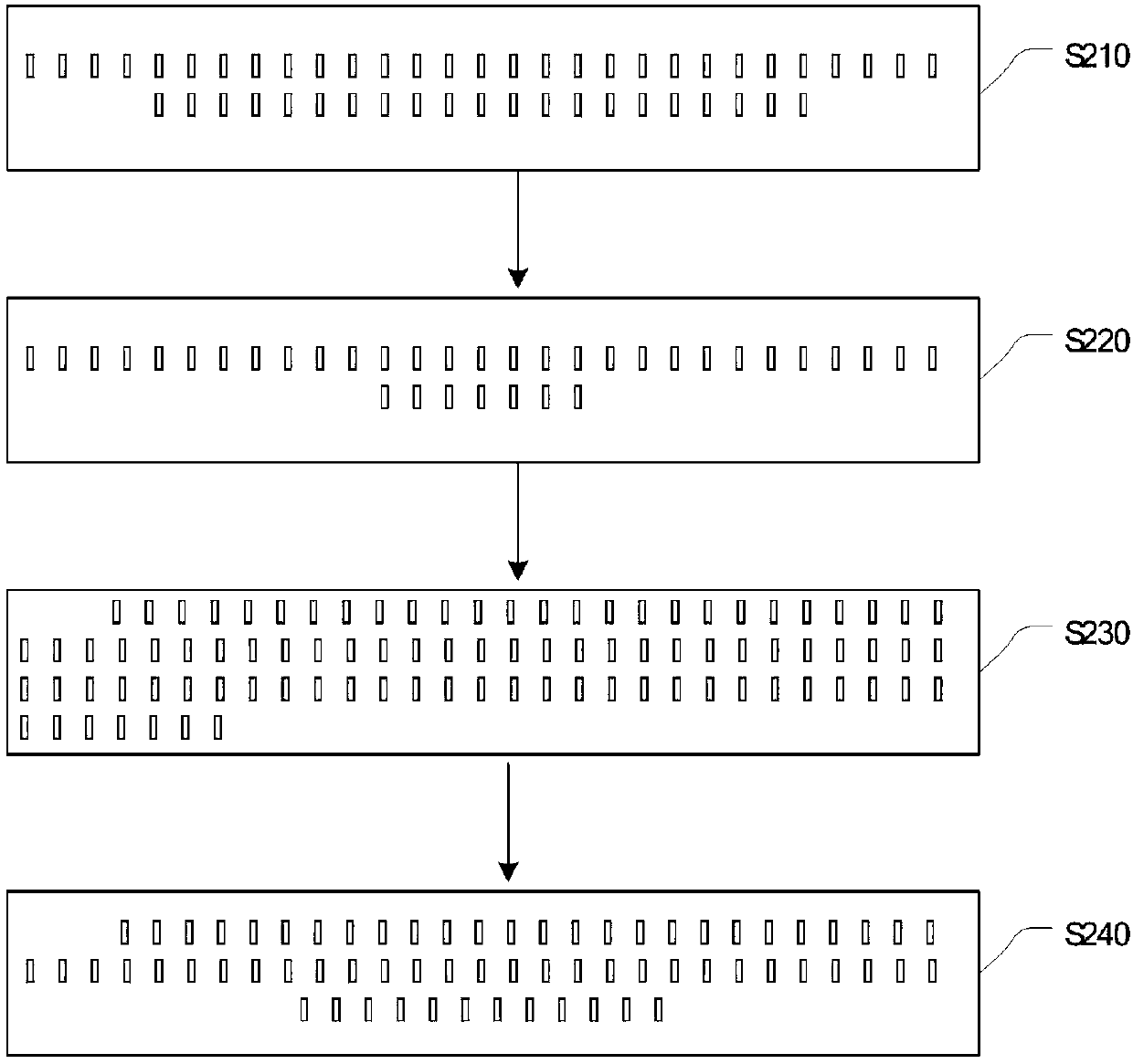

Vehicle controller, control system and using method for vehicle controller

ActiveCN104943632AImprove the efficiency of position adjustmentMovable seatsElectric/fluid circuitControl systemPosition control

The invention discloses a vehicle controller, a control system and a using method for the vehicle controller. The vehicle controller comprises a detecting module, a first displaying module, an operating receiving module and a second displaying module. The detecting module can be used for detecting the first physical position where a vehicle part is located in current, wherein the position of the vehicle part can be adjusted on a vehicle. The first displaying module can be used for controlling a display screen on the vehicle to display a corresponding first form when the vehicle part is placed in the first physical position in real time. The operating receiving module is used for receiving position controlling operation which adjusts the vehicle part form the first physical position to the second physical position. The second displaying module is used for displaying a corresponding second form when the vehicle part is placed in the second physical position in real time. According to the vehicle controller, based on the vehicle part forms which can be watched on the display screen, position adjusting can be carried out by personnel, the visible range is free of limitation, the appropriate position is easier to find, and the efficiency of the position adjusting is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

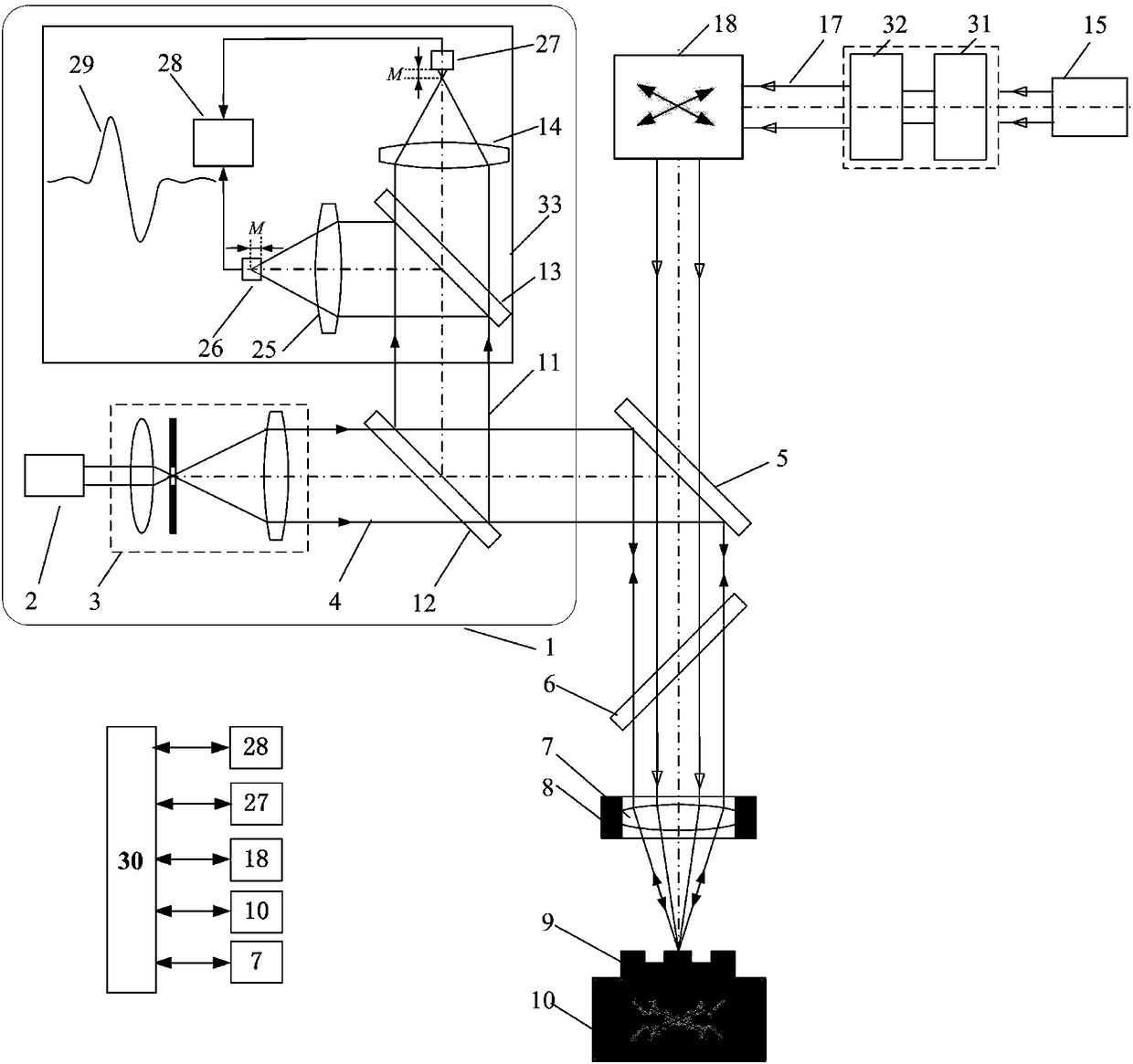

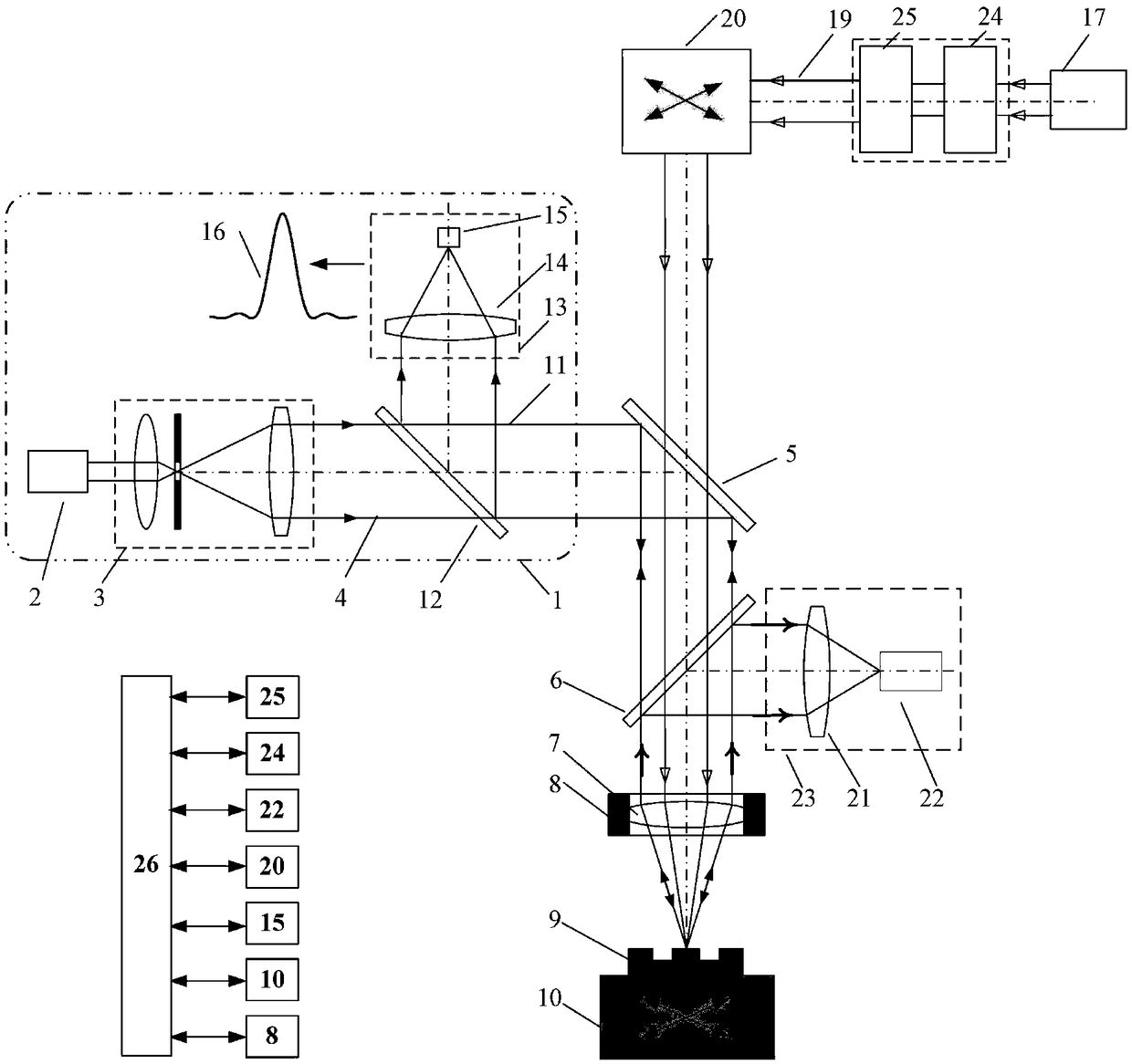

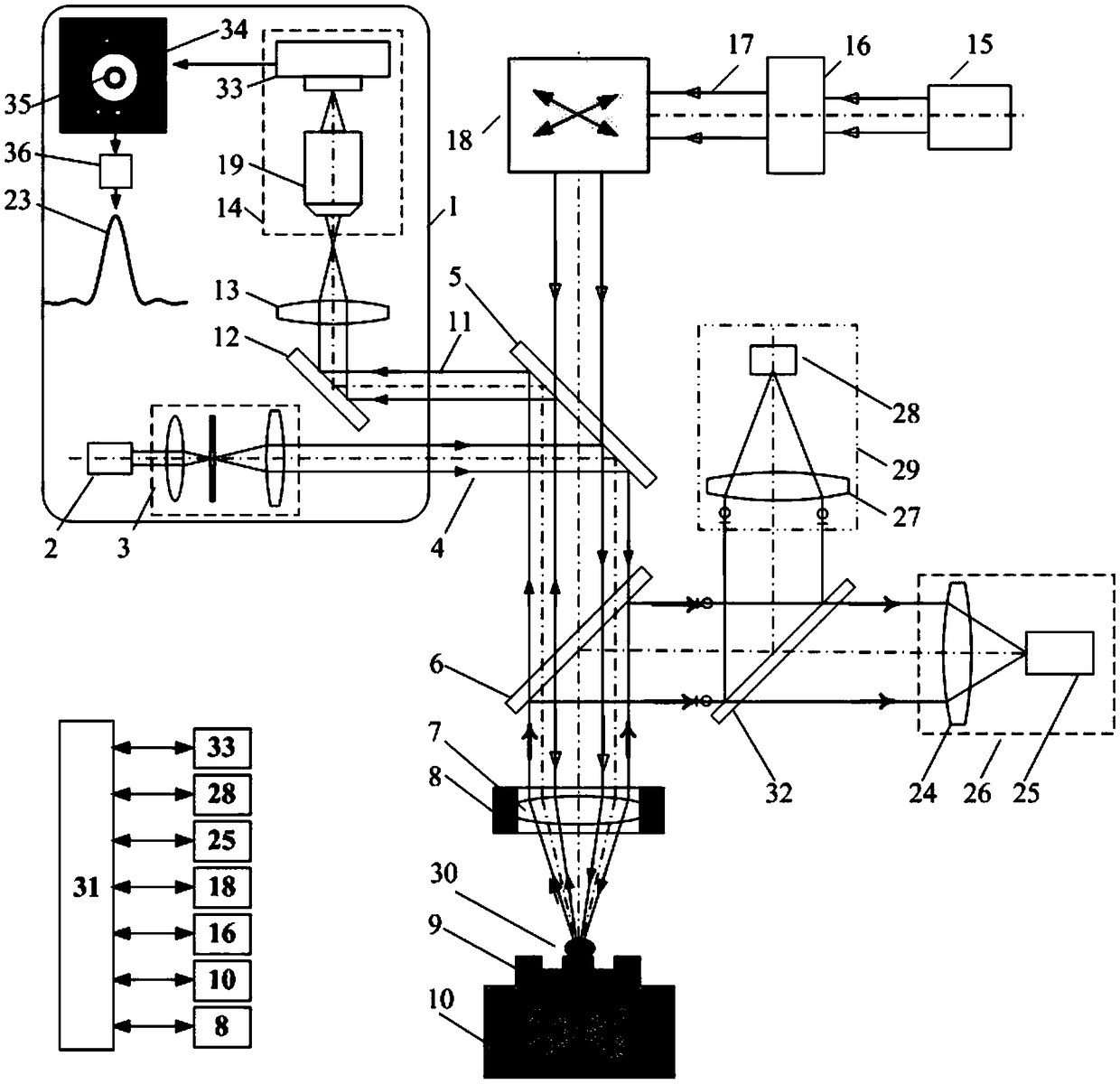

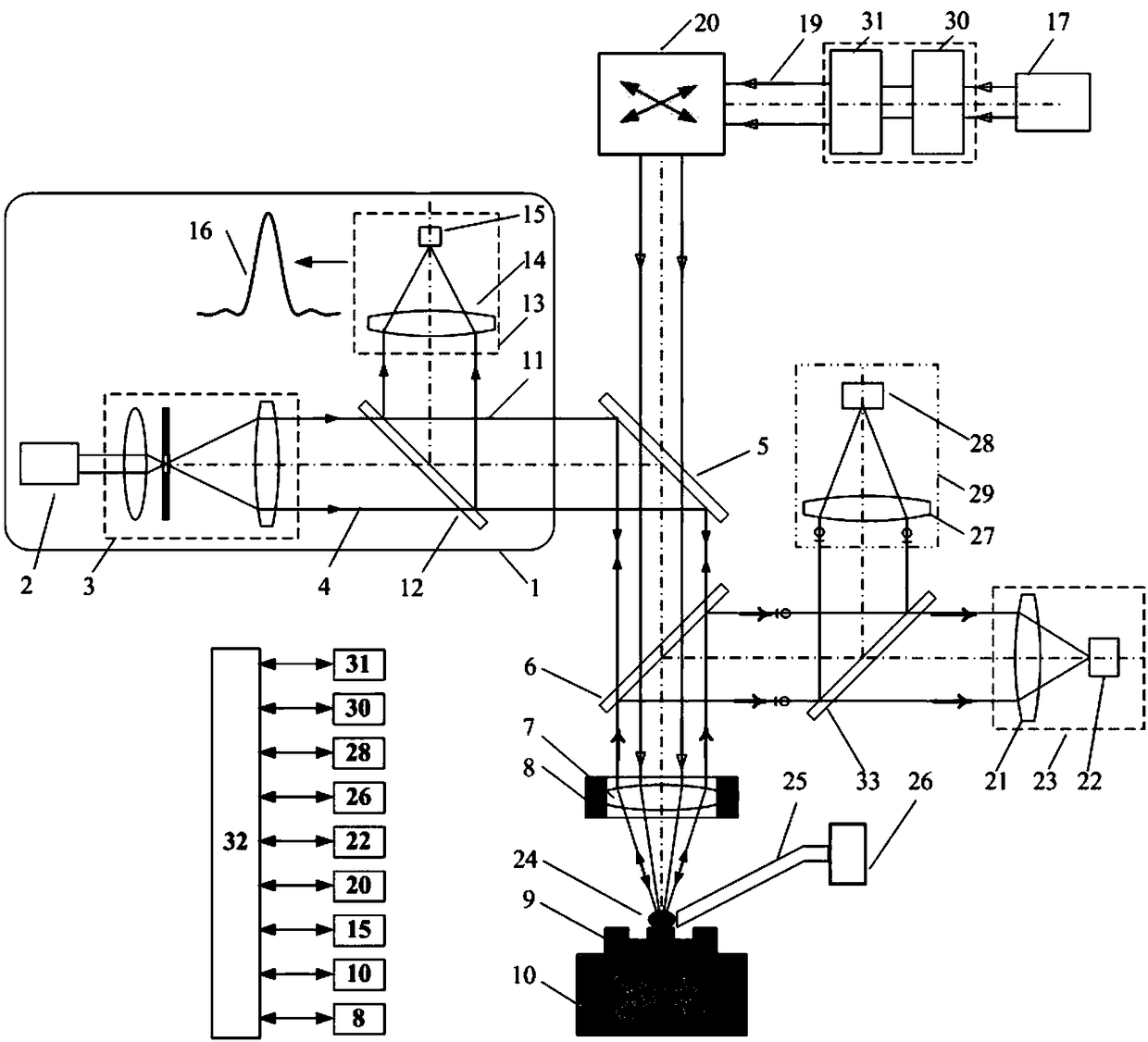

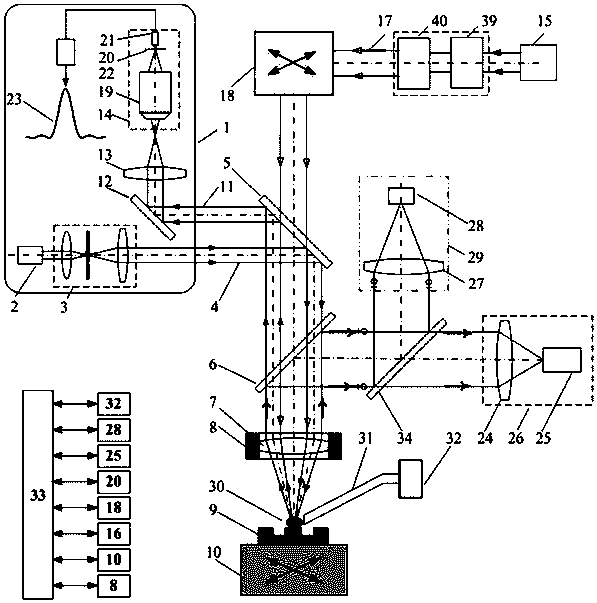

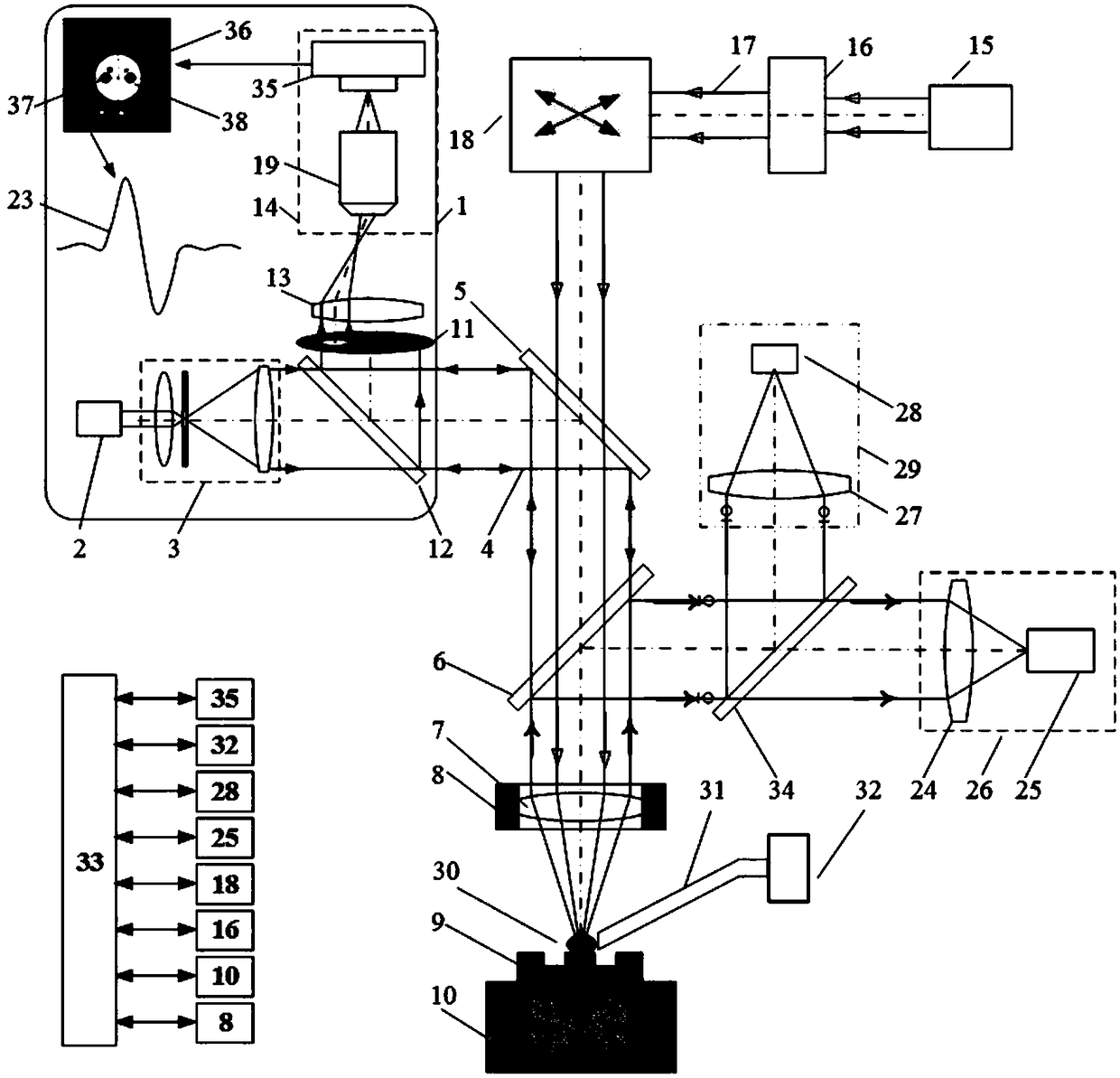

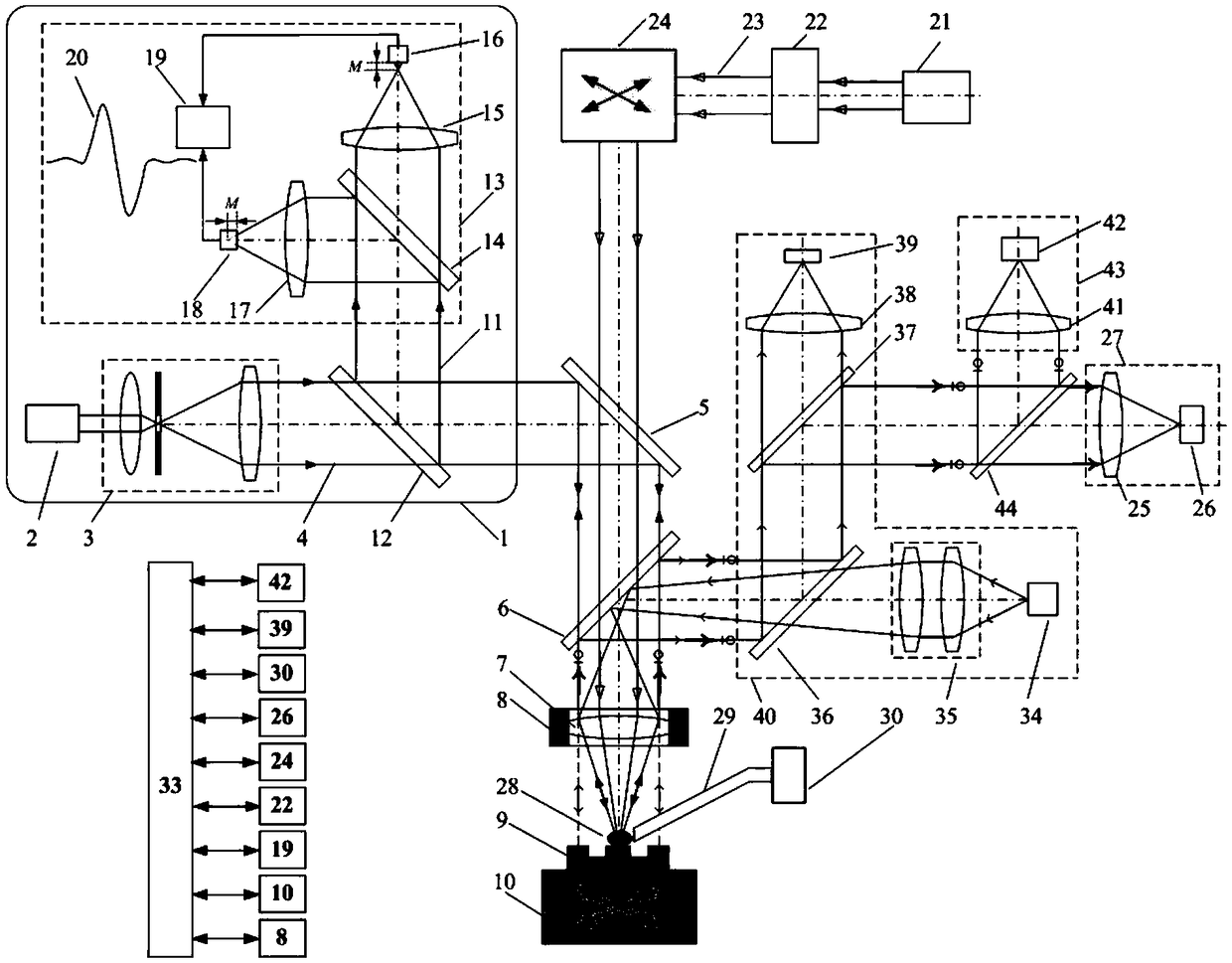

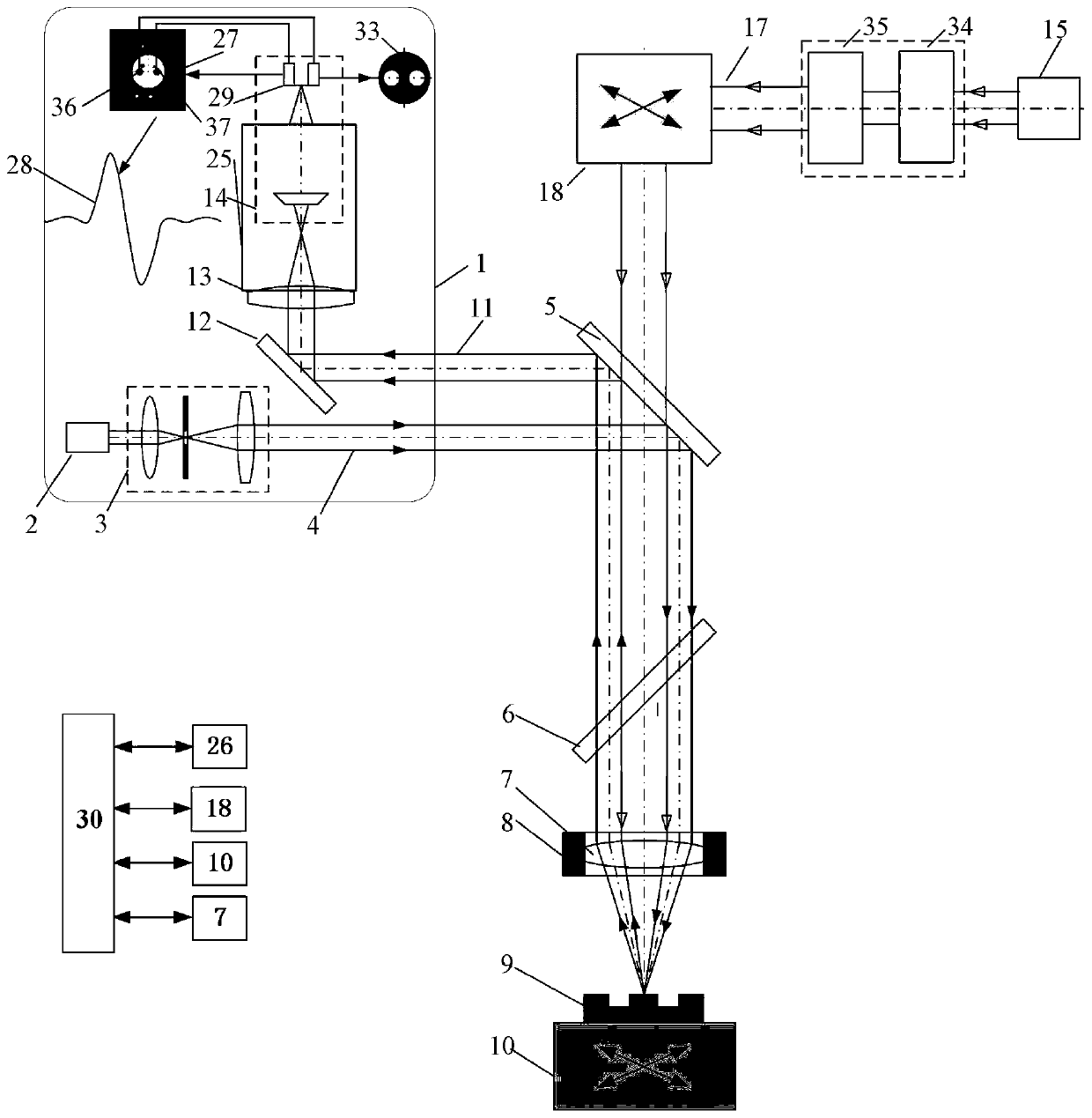

Femtosecond laser processing parameter confocal Raman microspectroscopy in-situ monitoring method and device

InactiveCN109270047AImprove processing qualityRealize integrationRaman scatteringMicro nanoManufacturing technology

The invention relates to a femtosecond laser processing parameter confocal Raman microspectroscopy in-situ monitoring method and device, and belongs to the technical field of laser precision detectionand femtosecond laser processing and manufacturing. A laser confocal axial monitoring module with a high axial resolution is organically integrated with a femtosecond laser processing system, a confocal system curve maximal point is utilized for conducting nanoscale monitoring and sample axial processing size measurement on the sample axial position, real-time focus fixing of the sample axial position and high-precision measurement of the size of a processed micro-nano structure are achieved, and the drifting problem and the high-precision online detection problem in the measurement process are solved; a confocal Raman microspectroscopy detection module is utilized for monitoring and analyzing information such as molecular structures of sample materials subjected to femtosecond laser processing, the information is integrated through a computer, microstructure femtosecond laser high-precision processing and micro-domain form performance in-situ monitoring analysis are integrated, and the controllability of microstructure femtosecond laser high-precision processing and the processing quality of the samples are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

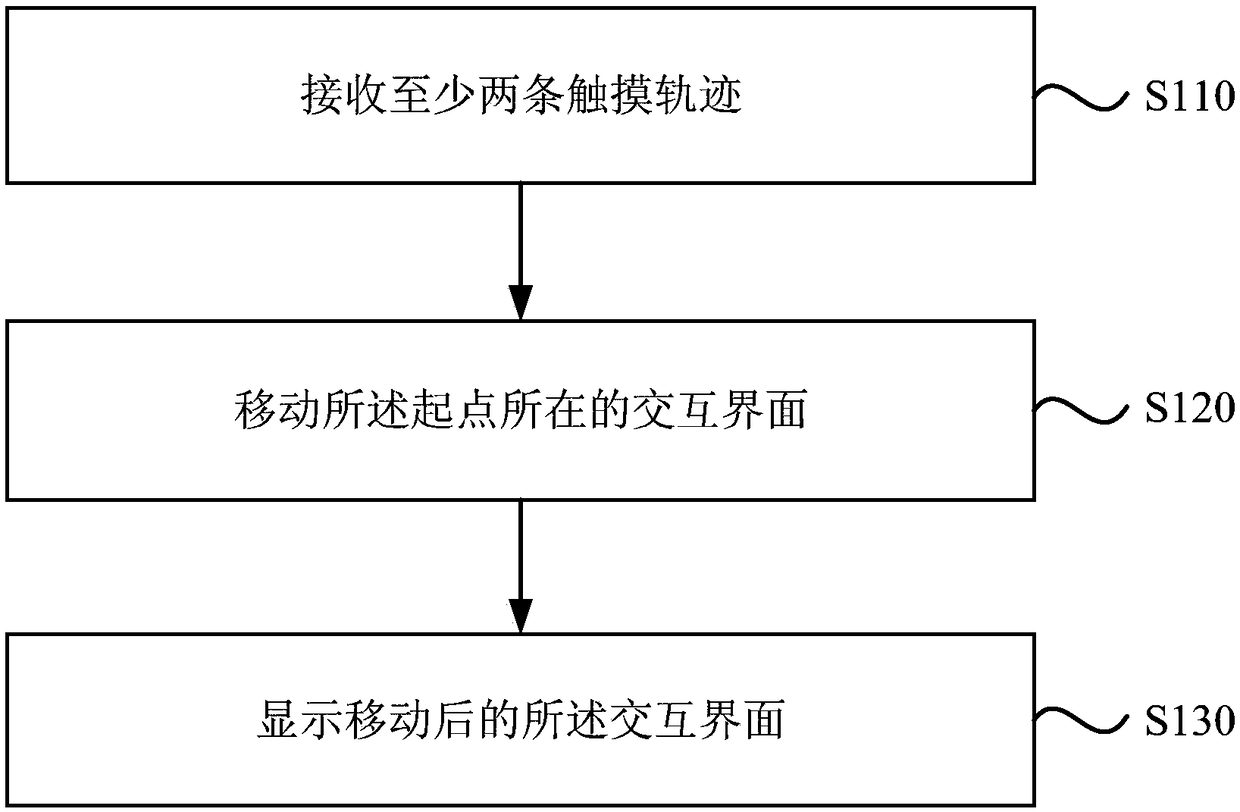

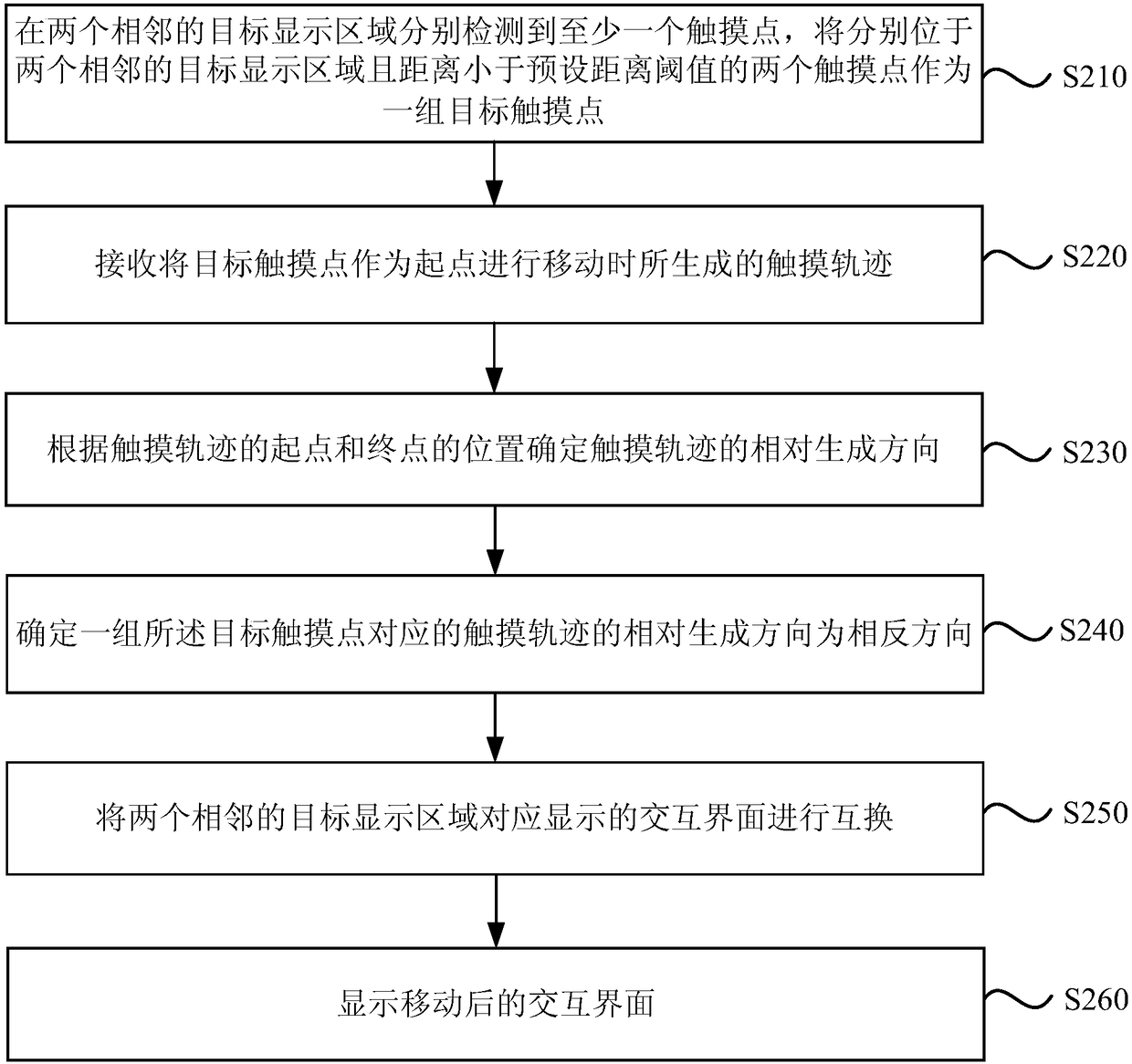

Method and device for adjusting interface position of interactive intelligent device

InactiveCN108519902AImprove experienceResolution timeExecution for user interfacesInput/output processes for data processingInteraction interfaceInterface position

The embodiment of the invention discloses a method and a device for adjusting the interface position of an interactive intelligent device. The method comprises the following steps of: receiving at least two touch trajectories, wherein the starting points of the touch trajectories are respectively arranged at different target display areas, and the different target display areas are used for displaying different interactive interfaces; moving the interaction interface where the starting point is arranged, the moving direction of the interaction interface is matched with the relative generationdirections of the touch trajectories; displaying the moved interactive interface which is displayed in a target display area pointed by the corresponding touch trajectory. According to the technical scheme, the position adjustment efficiency can be improved, the operation process of the user is simplified, and the user experience is improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

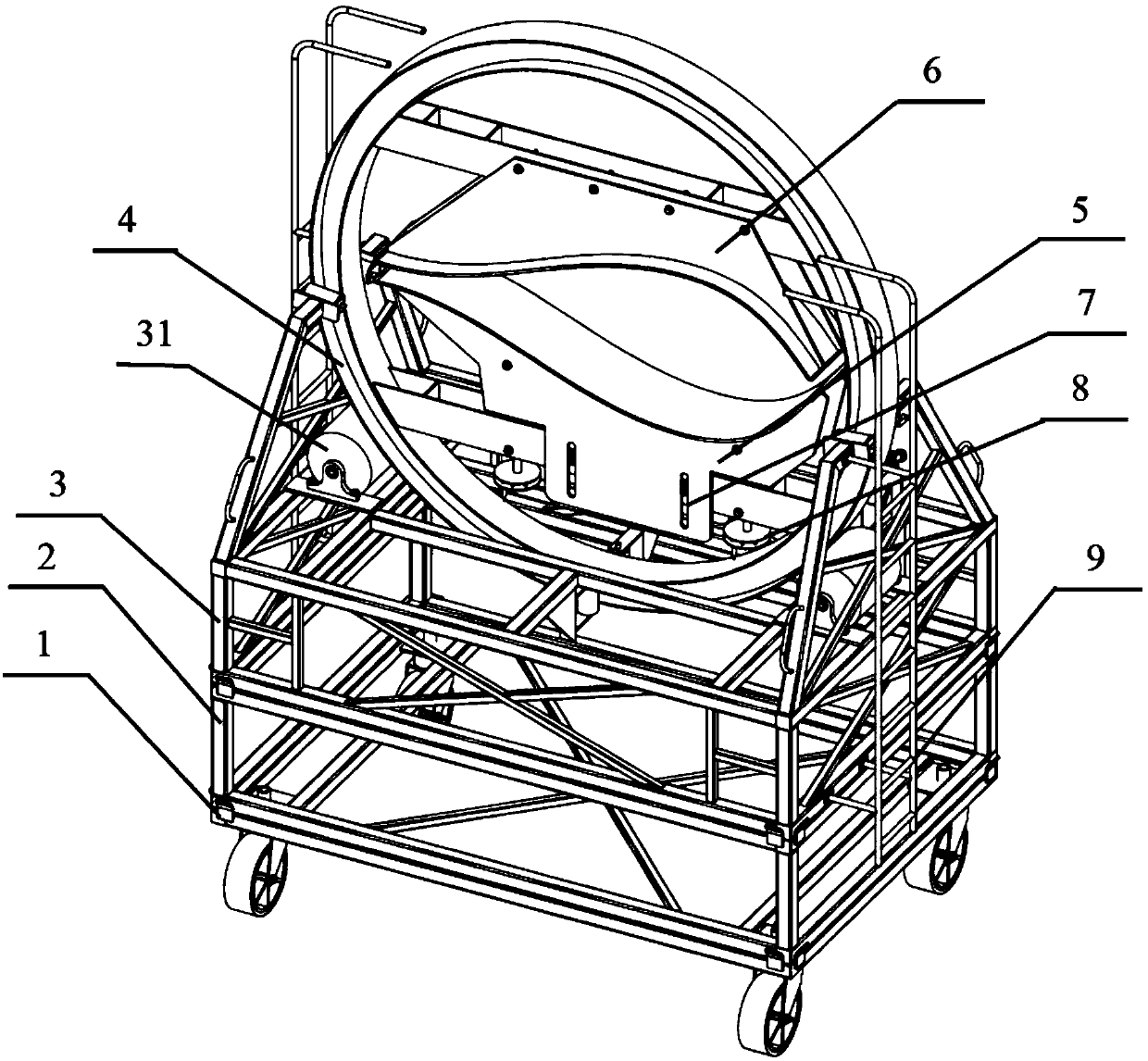

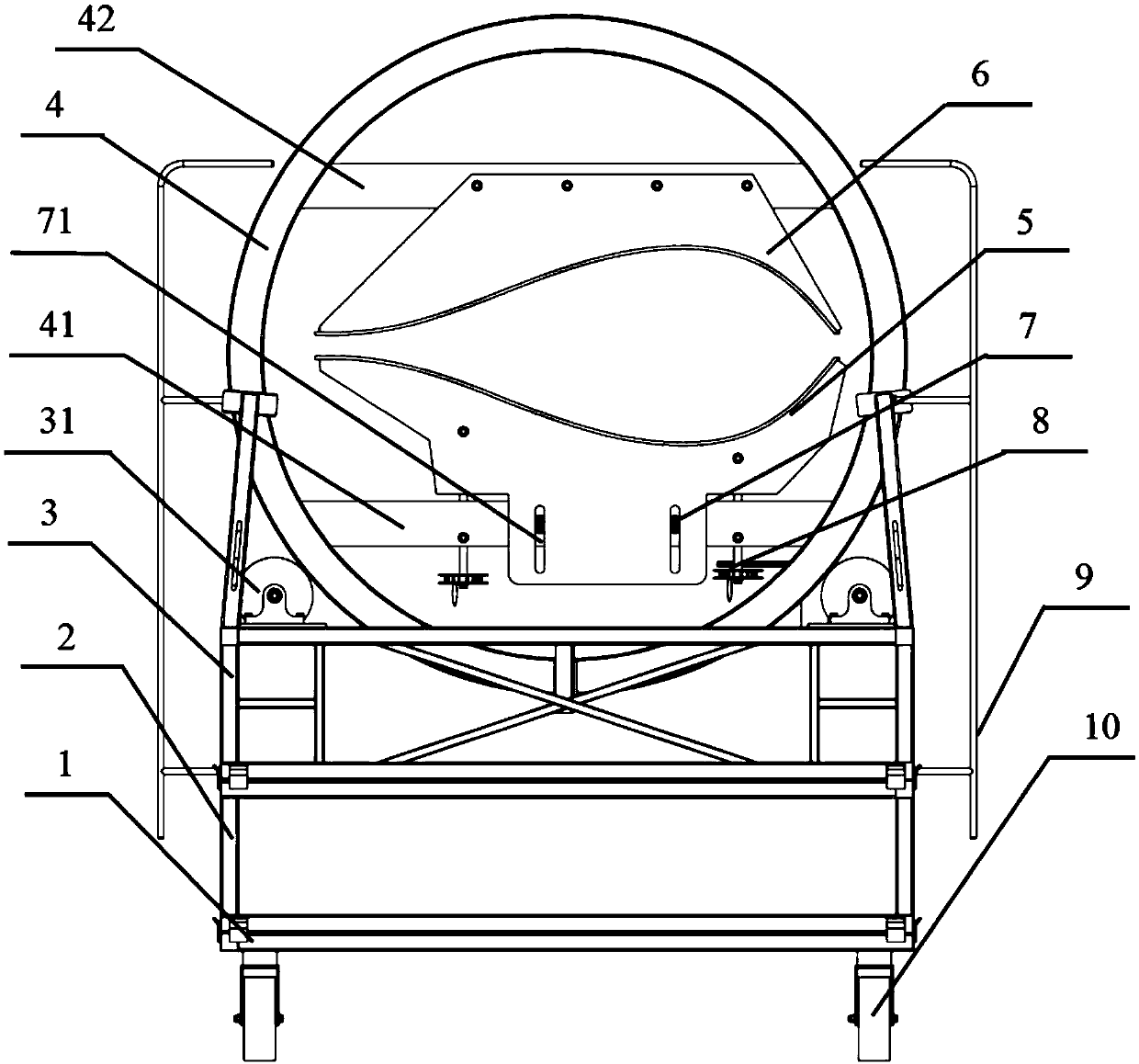

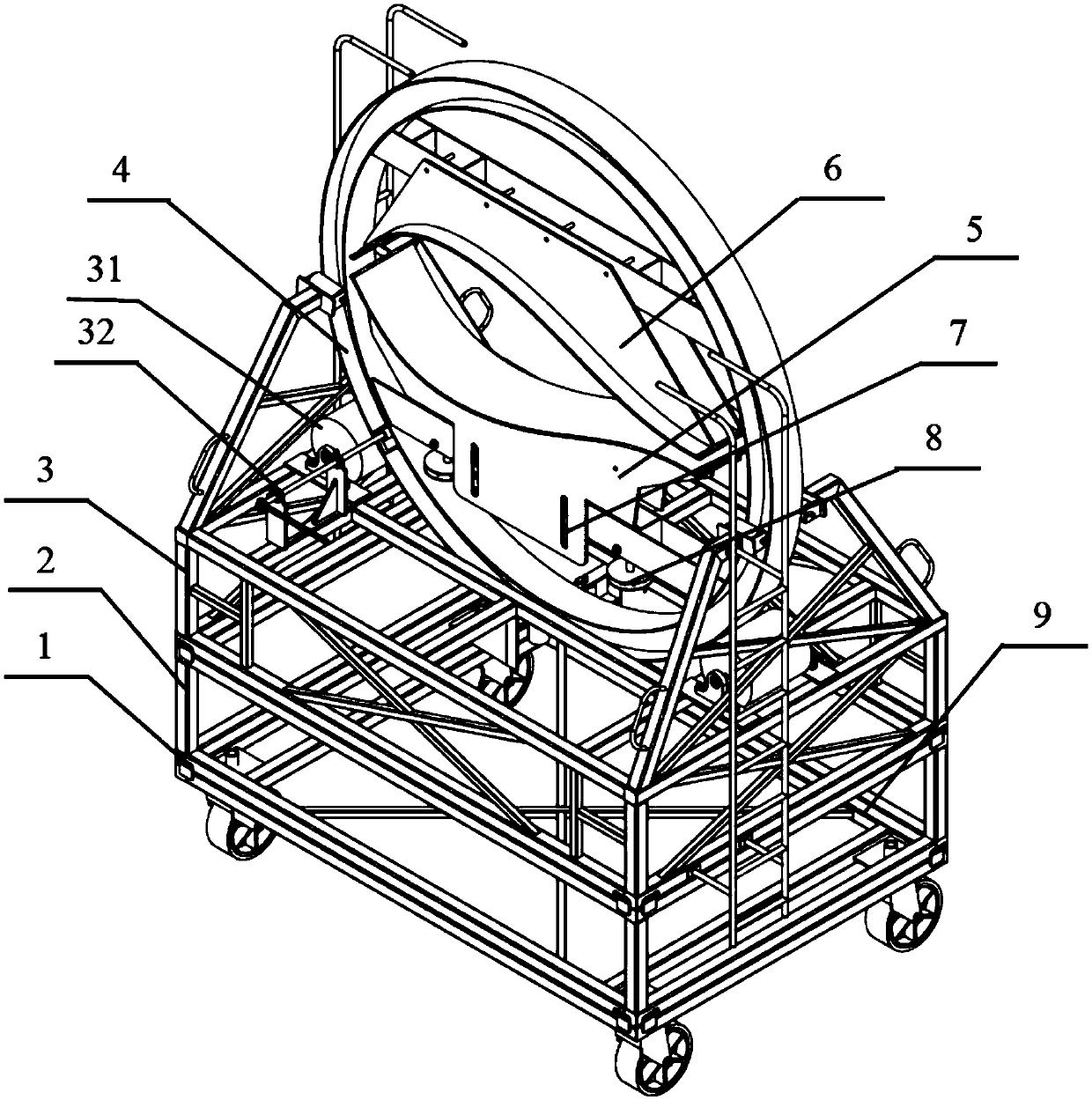

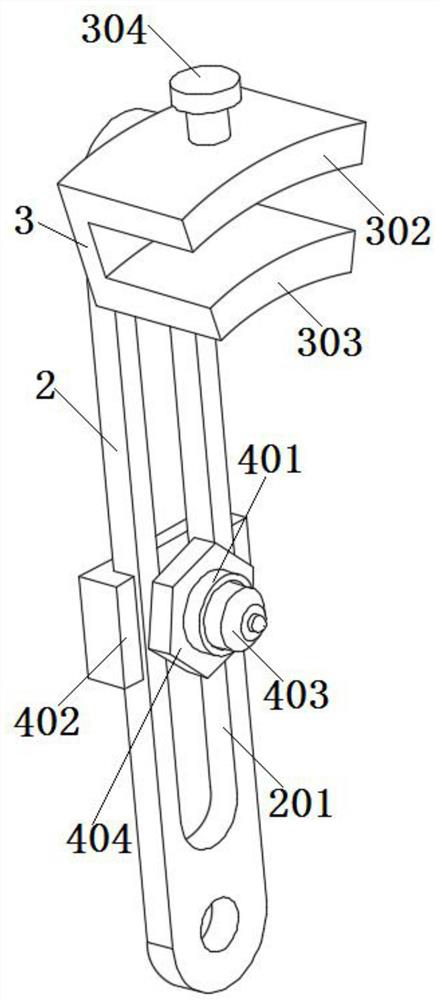

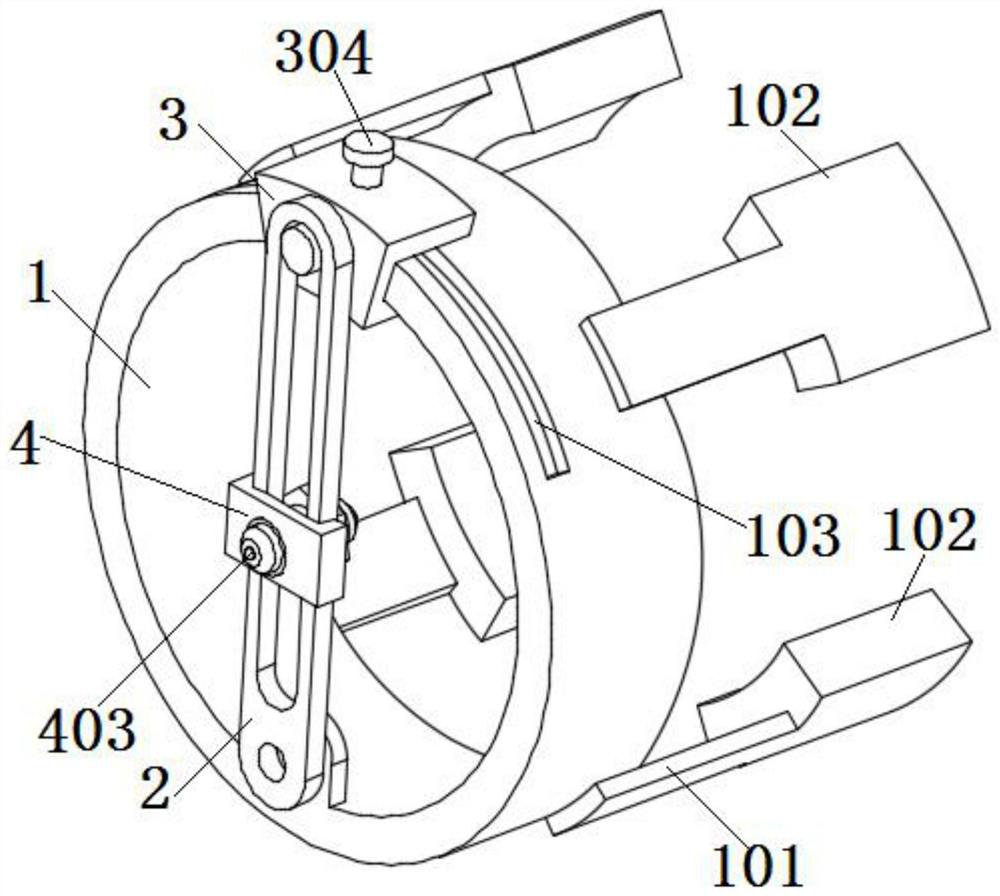

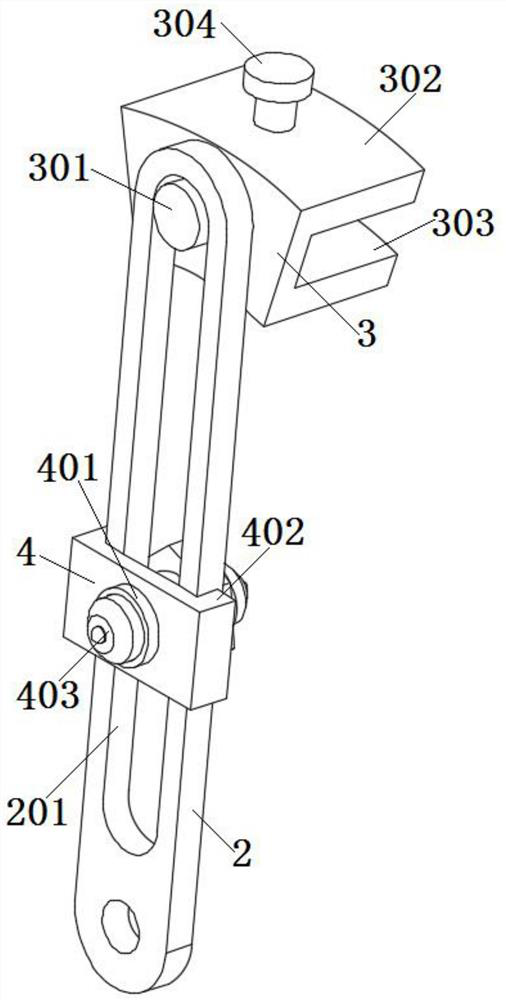

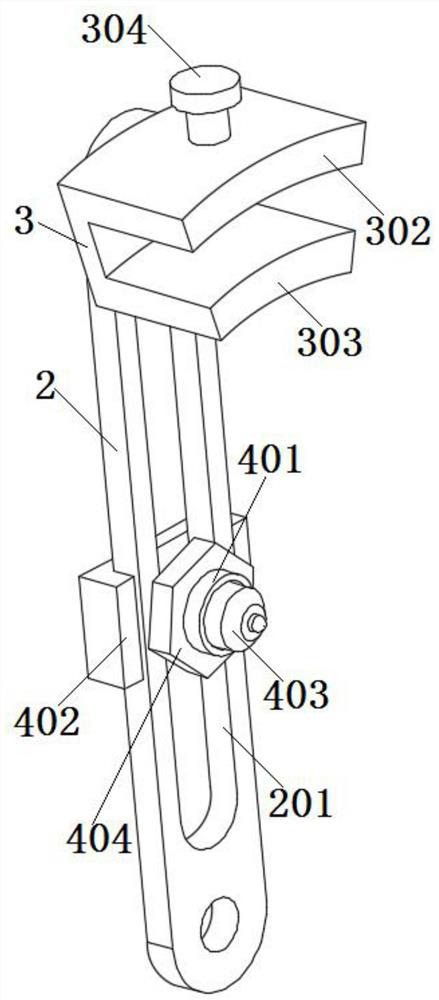

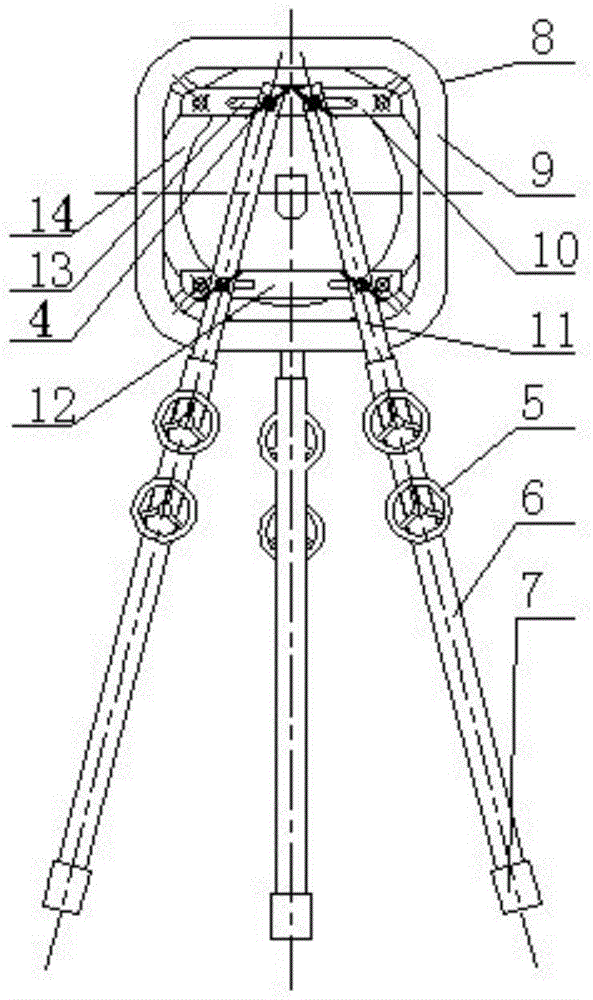

Wind turbine blade overturning vehicle

The invention discloses a wind turbine blade overturning vehicle. The wind turbine blade overturning vehicle comprises a vehicle frame and an overturning device mounted on the vehicle frame; the overturning device comprises a rolling ring, and further comprises a first clamp and a second clamp which are mounted on the rolling ring and face oppositely; a clamping area for wind turbine blades is formed between the first clamp and the second clamp; the first clamp is connected with the rolling ring through two position adjusting mechanisms, and a position adjusting guiding mechanism is arranged between the two position adjusting mechanisms; the position adjusting guiding mechanism comprises a guiding groove formed in the first clamp and an adjusting bearing mounted in the guiding groove; andthe guiding groove and the position adjusting mechanisms are consistent in direction, the outer diameter of the adjusting bearing is consistent with the width of the guiding groove, and the adjustingbearing is fixedly mounted on the rolling ring through bolts. The wind turbine blade overturning vehicle is simple in structure, safe and reliable, it can be ensured that the molded surfaces of the blades are better attached to the clamps and the shape following property is good, and scraping damage of the clamps to the blades in the machining process is reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

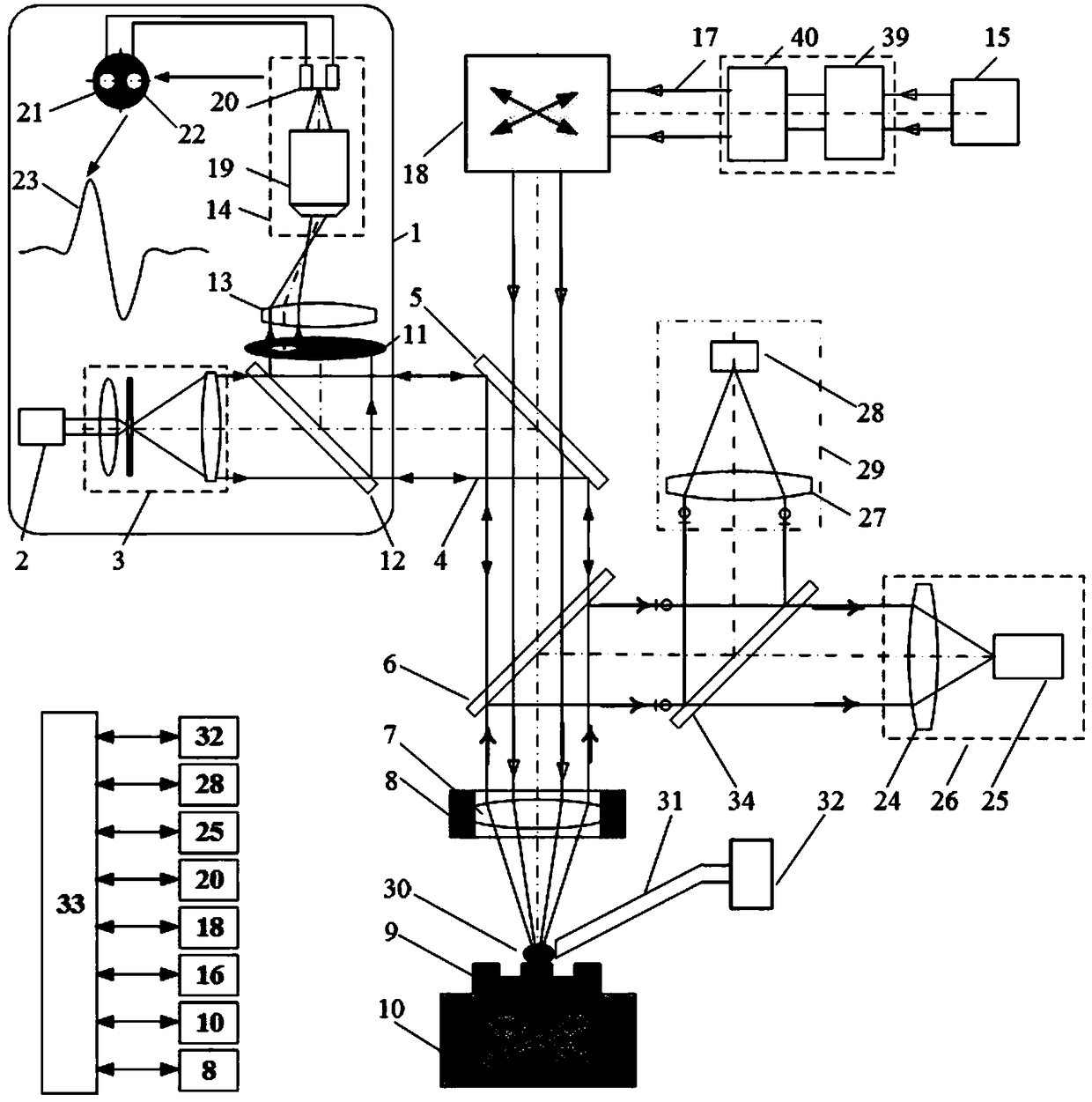

Femtosecond laser processing monitoring method of spectral pupil confocal Raman-LIBS spectrum detection

InactiveCN109187493ASolve driftSolve real-timeRaman scatteringAnalysis by thermal excitationLaser processingSize measurement

The invention relates to a femtosecond laser processing monitoring method of spectral pupil confocal Raman-LIBS (laser-induced breakdown spectroscopy) spectrum detection, and belongs to the technicalfields of the laser precise detection and the femtosecond laser processing monitoring. The femtosecond laser processing monitoring method can be used for femtosecond laser processing and online monitoring and physical comprehensive parameter online detection. A spectral pupil laser confocal coaxial monitoring module and a femtosecond laser processing system are organically integrated, a spectral pupil confocal system is used for performing high-precision in-situ online monitoring and sample axial processing size measurement on a sample axial location; a Raman spectrum detection module and an LIBS spectrum detection module are used for monitoring and analyzing a molecular structure, elements and ion and like information of a sample material after femtosecond laser processing, and integrating the above information through a computer, thereby realizing the microstructure femtosecond laser high-precision processing and microcell morphology performance in-situ monitoring analysis integration, and improving the controllability of the microstructure femtosecond laser processing precision and the processing quality of the sample.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

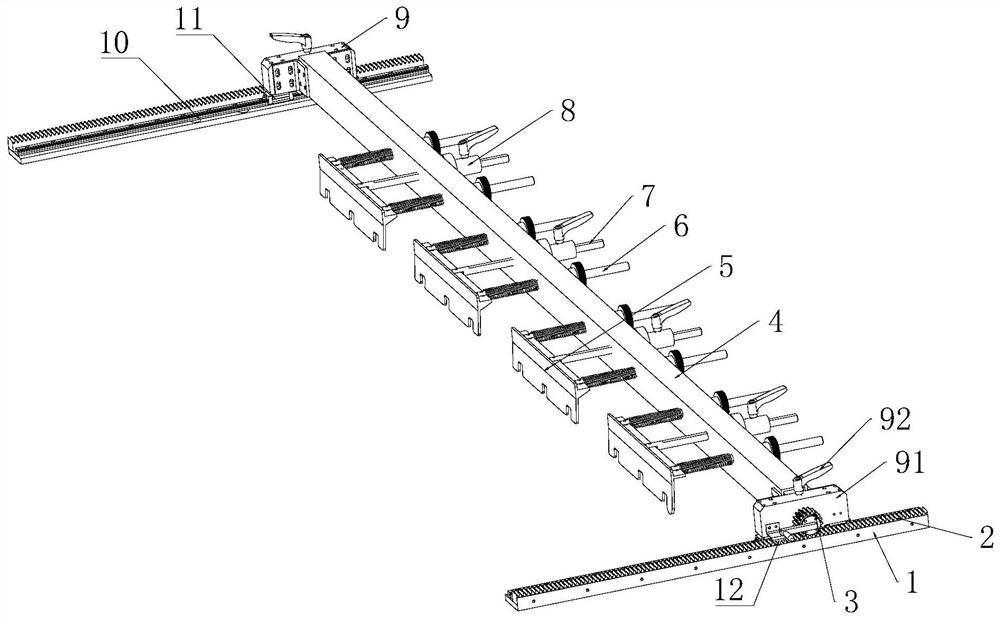

Welding position automatic adjusting device suitable for simulation welding equipment

PendingCN107598470AImprove the efficiency of position adjustmentEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesFlangeWelding

The invention discloses a welding position automatic adjusting device suitable for simulation welding equipment. The welding position automatic adjusting device comprises a horizontal base, a linear sliding table, a horizontal sliding seat, an R-axis rotator, a motion module, a mated driver and a control panel, wherein the linear sliding table is vertically fixed to the rear end part of the horizontal base; the horizontal sliding seat is clamped and embedded in a vertical guide rail of the linear sliding table; the R-axis rotor is horizontally arranged on the horizontal sliding seat; the motion module is connected with the output shaft end of the R-axis rotator; the motion module comprises a gathering frame formed by a flange end plate, a left side plate and a right side plate, an A-axis rotator which is fixed to the upper part of the left side plate in a cantilever mode, a fixer installation shaft which is horizontally arranged at the lower parts of the left side plate and the right side plate in a penetrating way, and a workpiece fixer which is arranged on the fixer installation shaft in a sleeving way; belt wheels are arranged on the output shaft end of the A-axis rotator and the left shaft end of the fixer installation shaft. According to the device, which is capable of realizing all-directional adjusting and automatic adjusting on a welding position, provided by the invention, the device has the advantages of strong expandability, high position adjusting efficiency, simpleness in operation, safety in use, concision and attractiveness.

Owner:ZHENGZHOU J&T HI TECH

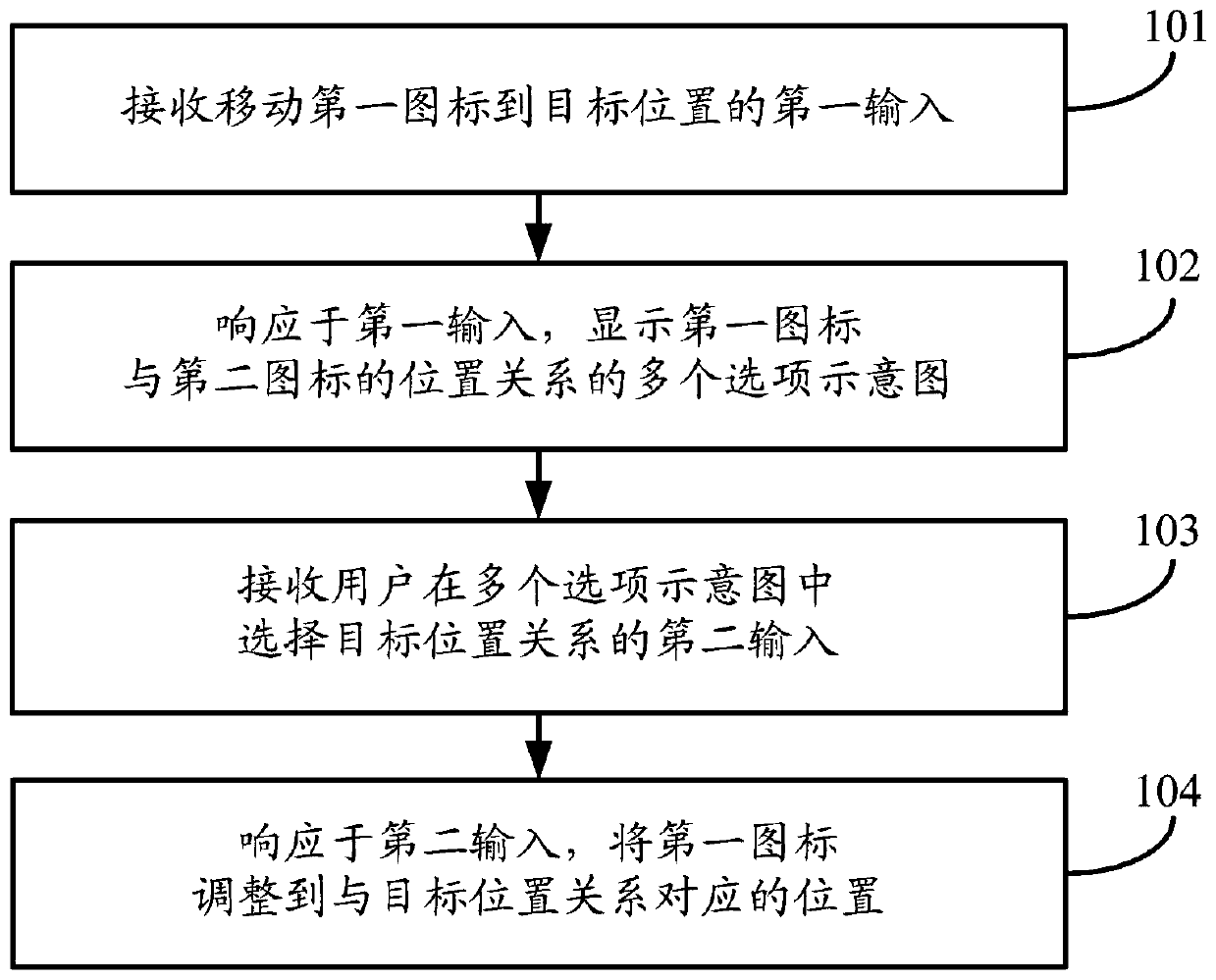

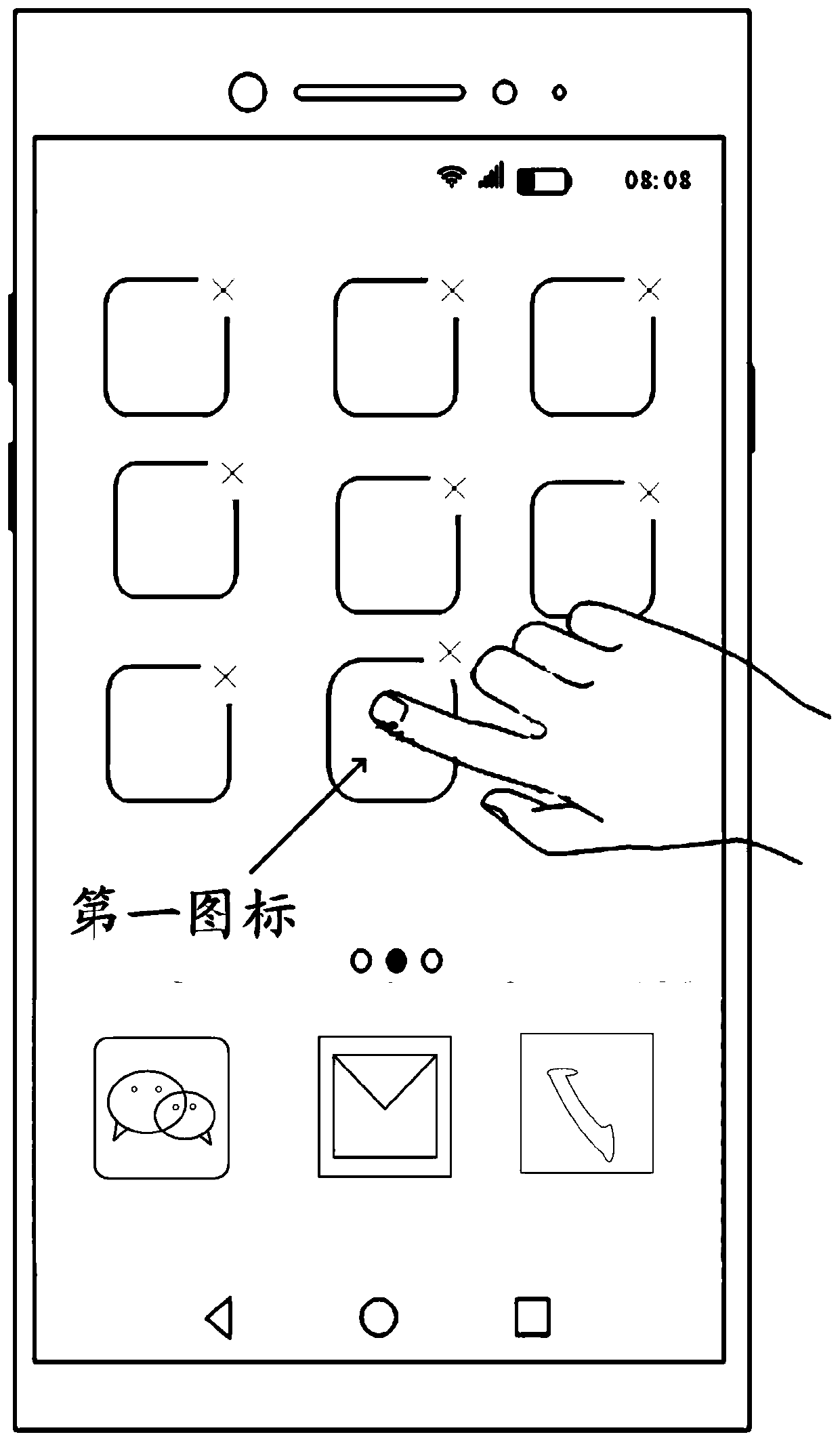

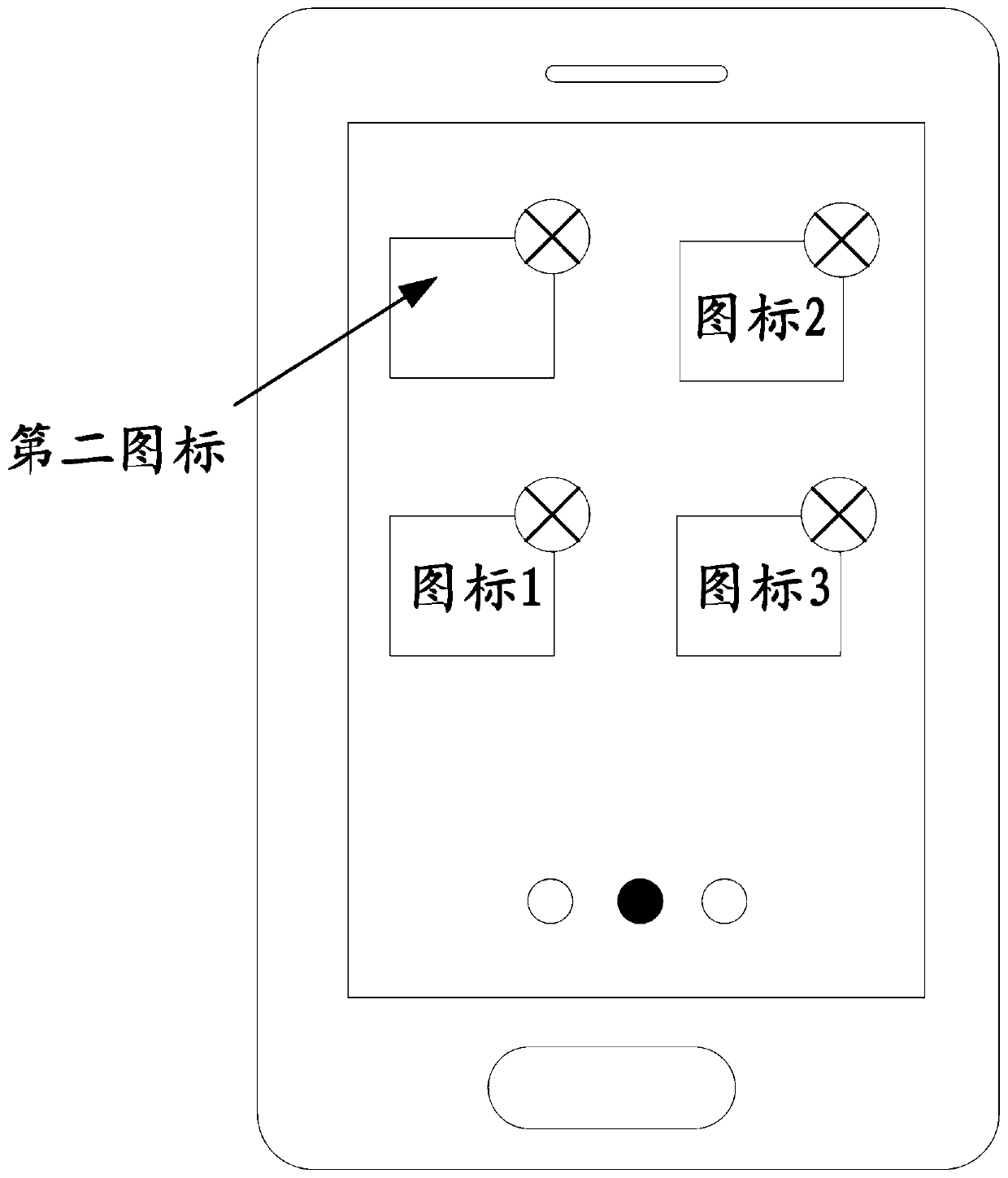

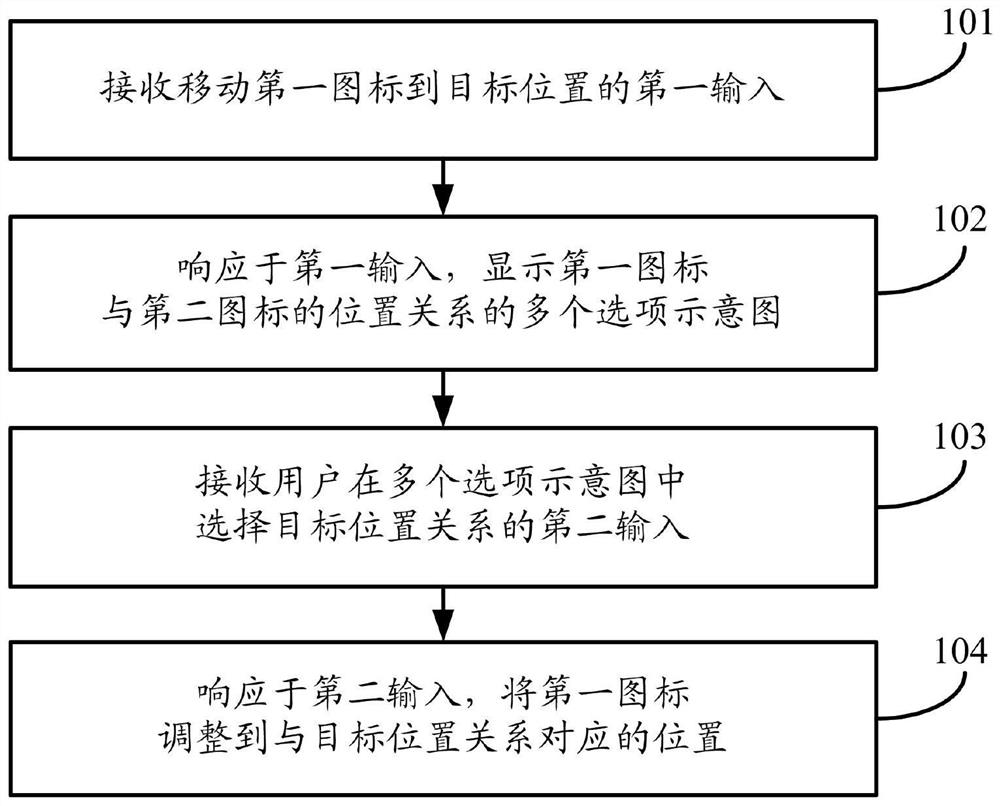

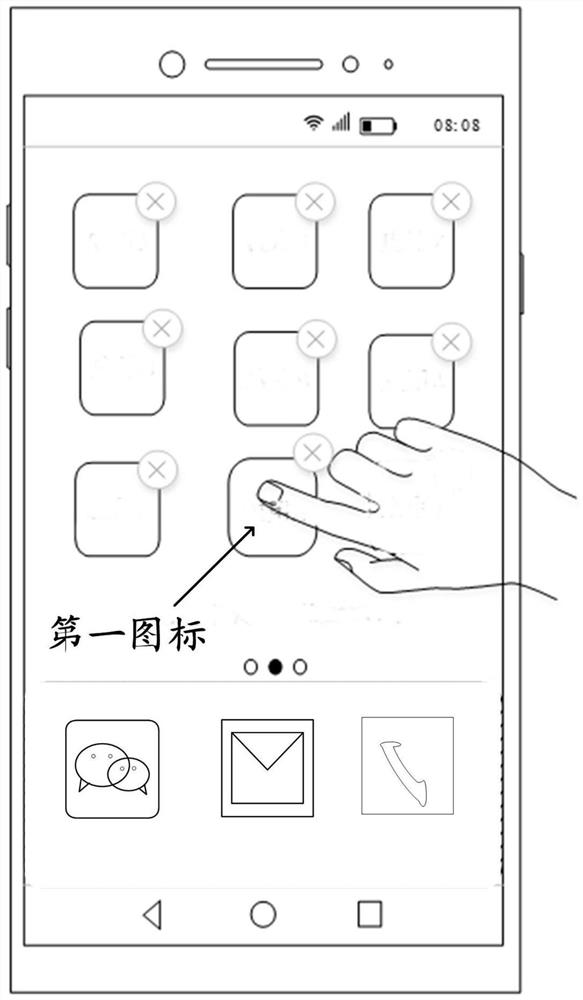

Position adjustment method and electronic equipment

ActiveCN111124206AEasy to adjustEasy to understandSubstation equipmentInput/output processes for data processingSchematic mapsEngineering

The embodiment of the invention discloses a position adjusting method and electronic equipment. The method comprises the following steps of: receiving a first input for moving the first icon to a target position, wherein the target position comprises a second icon; and in response to the first input, displaying a plurality of option schematic diagrams of a position relationship between the first icon and the second icon, receiving a second input of selecting a target position relationship from the plurality of option schematic diagrams by the user, and in response to the second input, adjusting the first icon to a position corresponding to the target position relationship. Through the method, the first icon can be adjusted to the display position meeting the actual requirements of the user, the operation process of position adjustment is reduced, and the position adjustment efficiency is improved.

Owner:VIVO MOBILE COMM CO LTD

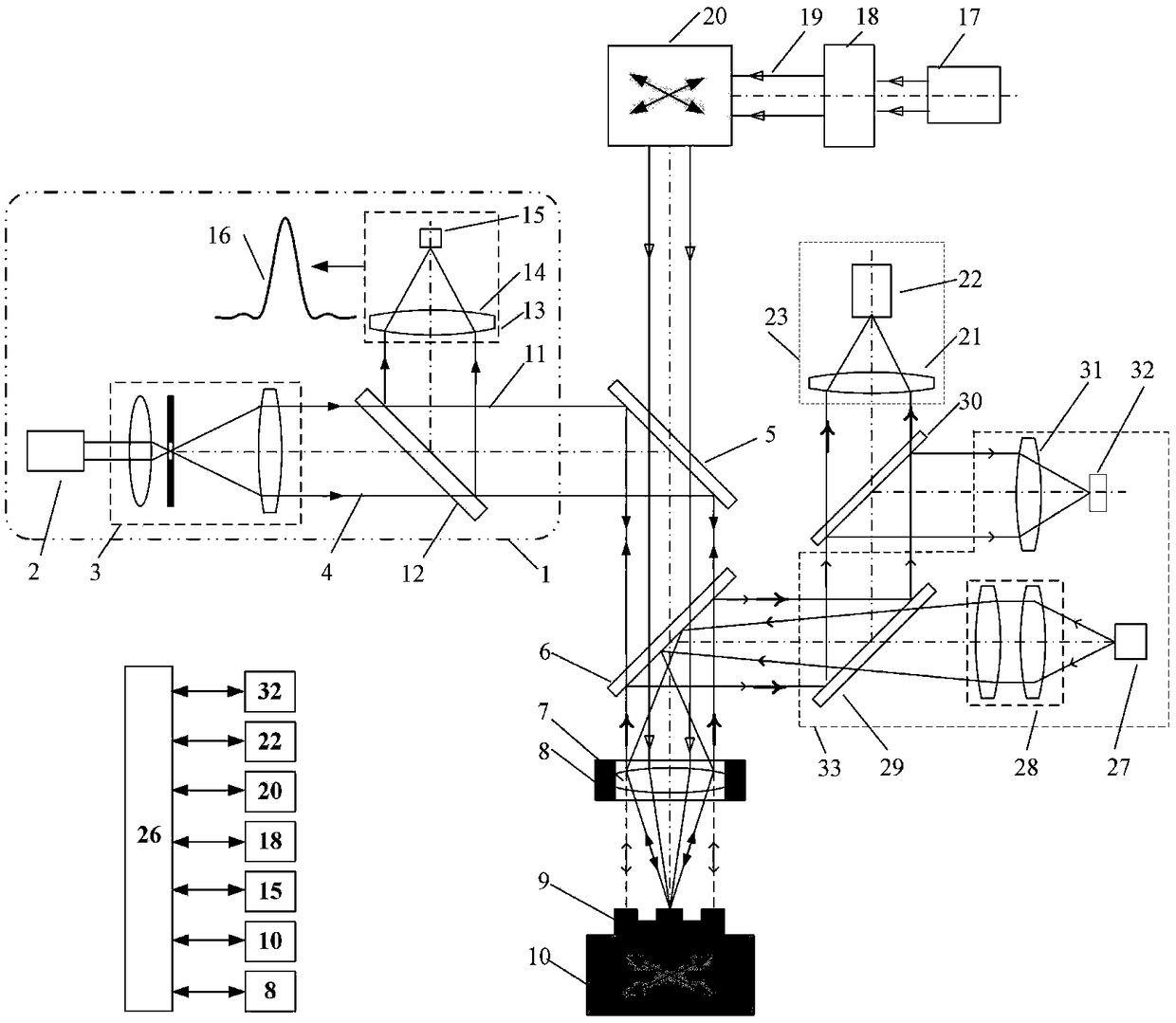

Femtosecond laser machining and monitoring method and device based on confocal Raman-LIBS-mass spectroscopy detection

InactiveCN109187725AImprove processing qualityStrong process controllabilityMaterial analysis by electric/magnetic meansRaman scatteringMicro structureManufacturing technology

The invention relates to a femtosecond laser machining and monitoring method and device based on confocal Raman-LIBS-mass spectroscopy detection, and belongs to the fields of a laser precision detection technology and a femtosecond laser machining and manufacturing technology. A laser confocal axial monitoring module and a femtosecond laser machining system are organically fused, and the axial position of a sample is subjected to high-precision in-situ monitoring and sample axial machining size measurement by utilizing a curve peak point of a differential confocal system, so that the sample drift problem and the high-precision online detection problem in the measurement process are solved; and a Raman spectroscopy detection module, an LIBS spectroscopy detection module and a mass spectrograph are used for carrying out monitoring analysis on information such as molecular structures, elements, ions and the like of a sample material after femtosecond laser machining, and the information is fused through a computer, so that the high-precision femtosecond laser machining of a micro-structure and the in-situ monitoring analysis of the morphology performance of a micro-region are integrated, and the controllability of the femtosecond laser machining precision of the micro-structure, the machining quality of the sample and the like are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

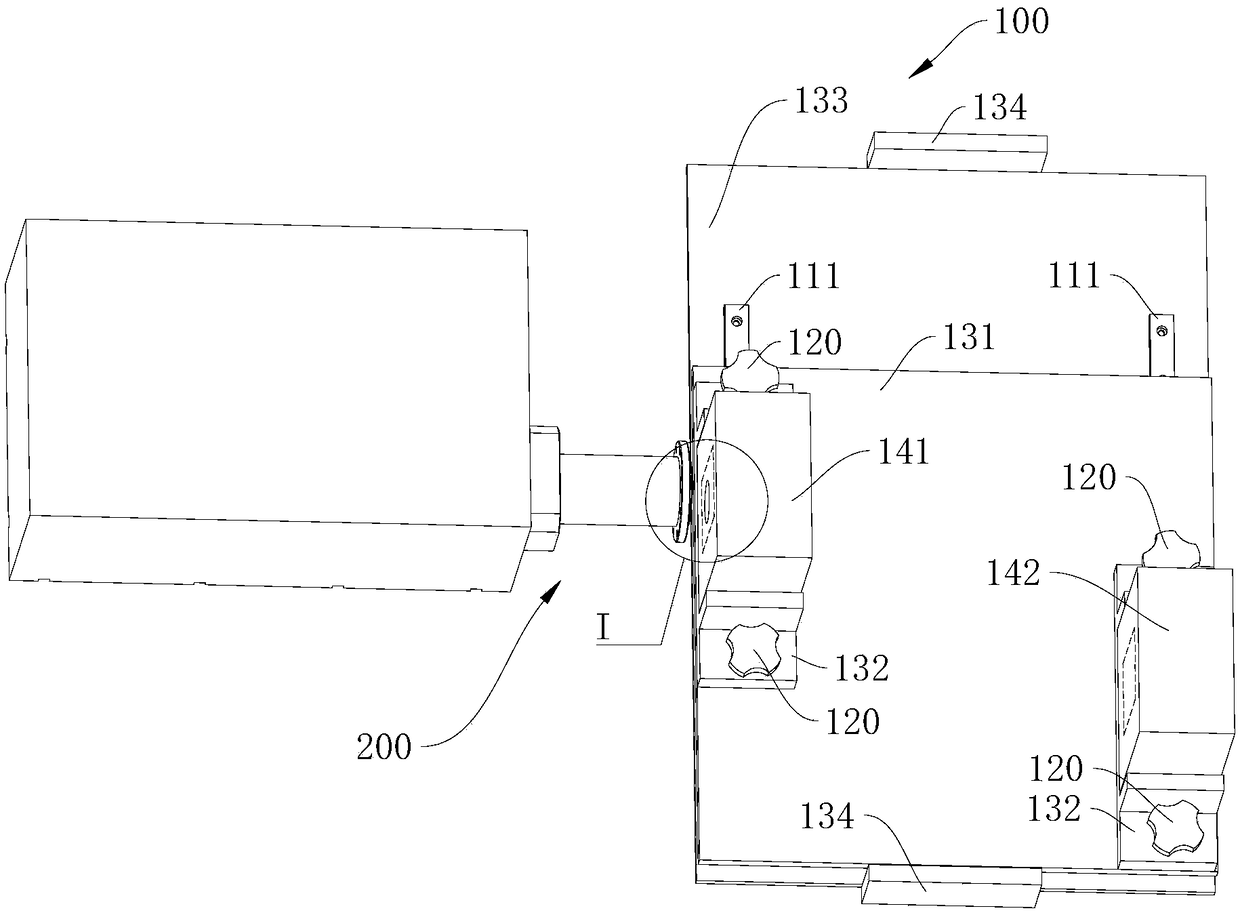

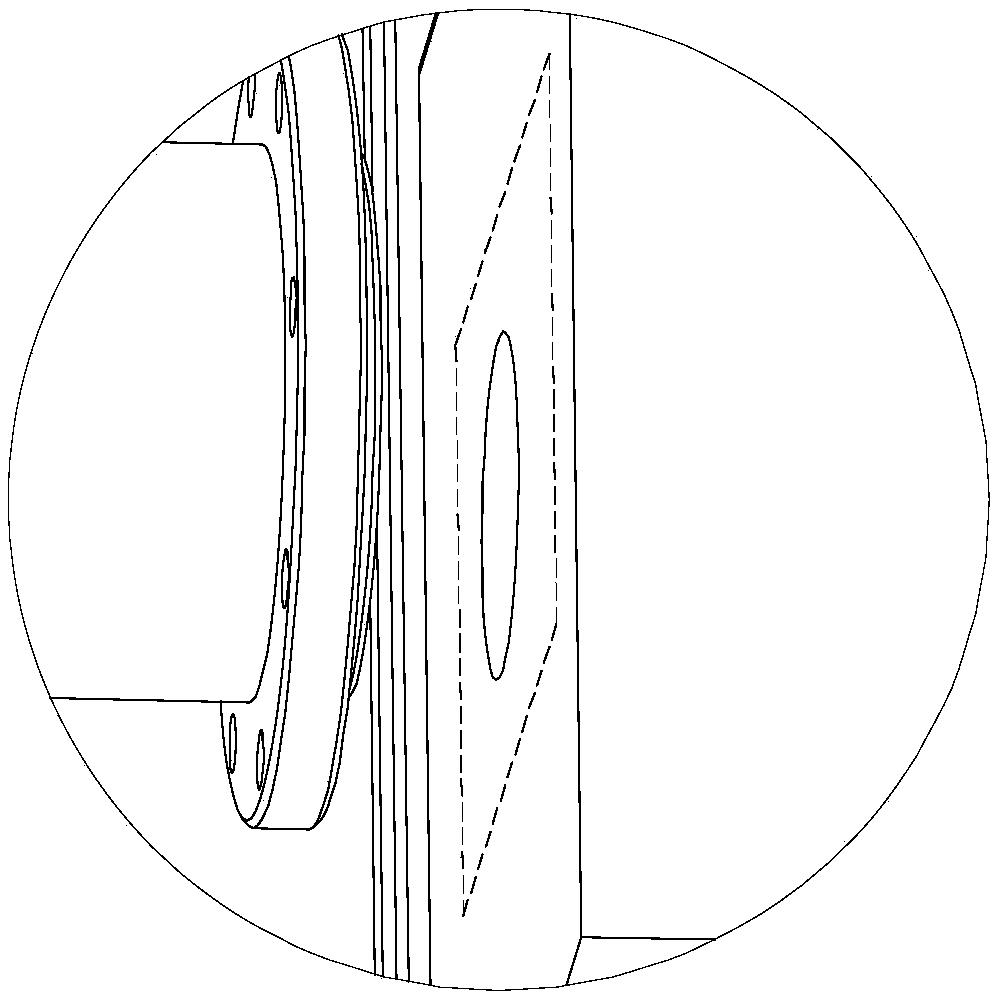

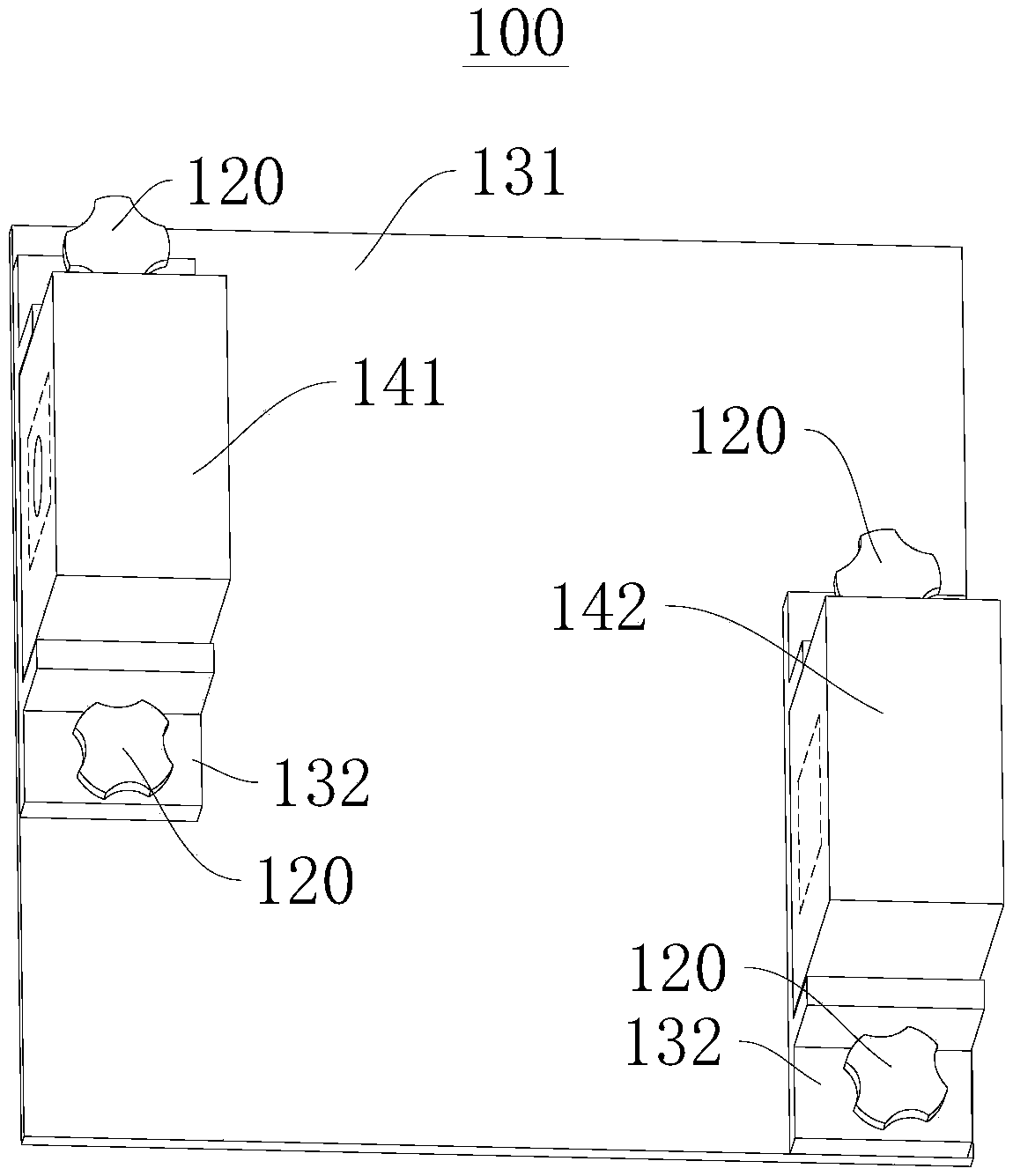

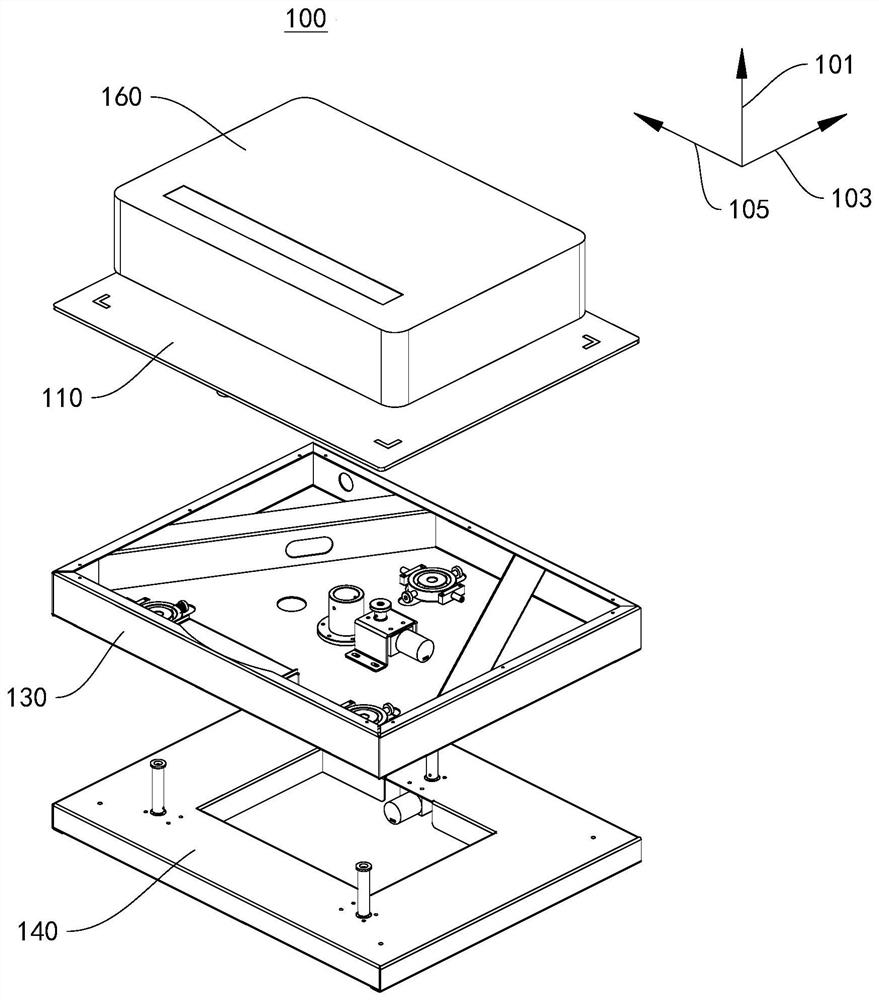

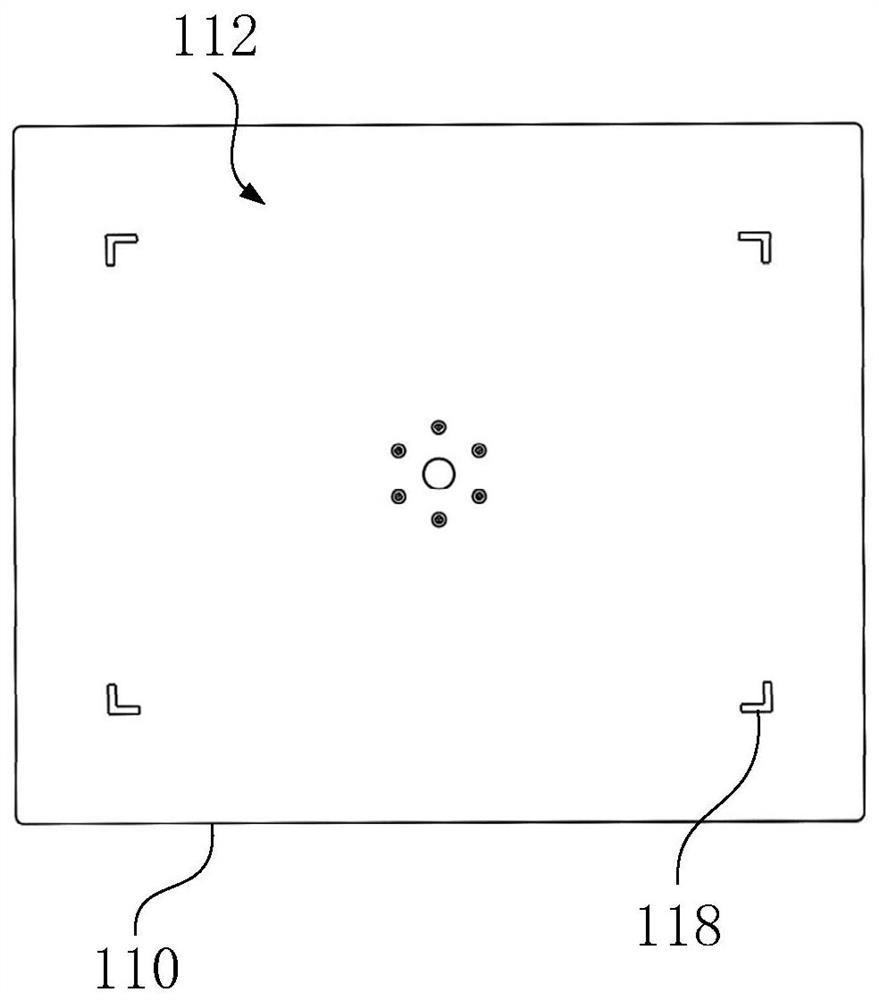

Laser detection device and laser detection control method

InactiveCN109141834AReduce manufacturing costImprove the efficiency of position adjustmentTesting optical propertiesOptoelectronicsLaser detection

The present invention provides a laser detection device and a laser detection control method, and relates to the technical field of laser detection. The laser detection device comprises a position regulation module and a laser detection module, the position regulation module is connected with the laser detection module, and the position regulation module is configured to regulate the space position of the laser detection module to allow a laser emitted by a laser to be measured to be irradiated in a detection area corresponding to the laser detection module. The position regulation module is employed to achieve the regulation of the space position of the laser detection module with no need for increasing processing for the area of the detection area, and to allow the laser to be irradiatedin a corresponding detection area so as to reduce the manufacturing cost of the device. The position regulation module is employed to regulate the space position of the laser detection module with noneed for position regulation of the whole laser detection device so as to improve the efficiency of the position regulation and facilitate improvement of the efficiency of the laser detection.

Owner:SHENZHEN JPT OPTO ELECTRONICS CO LTD

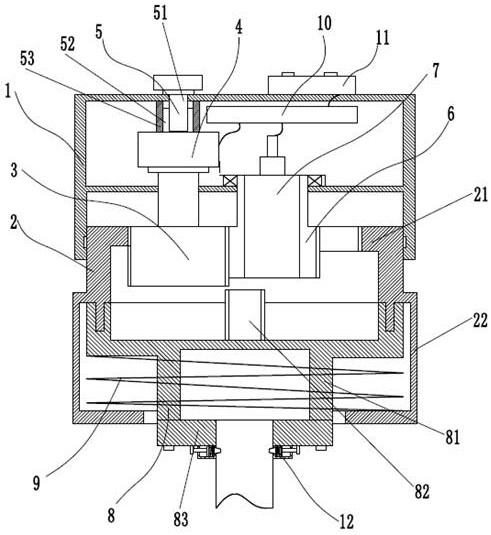

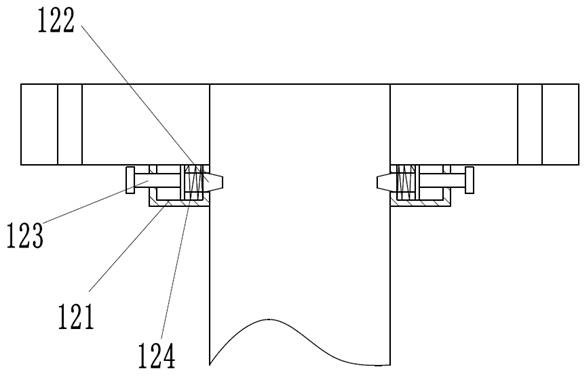

Positioning device of intelligent valve positioner

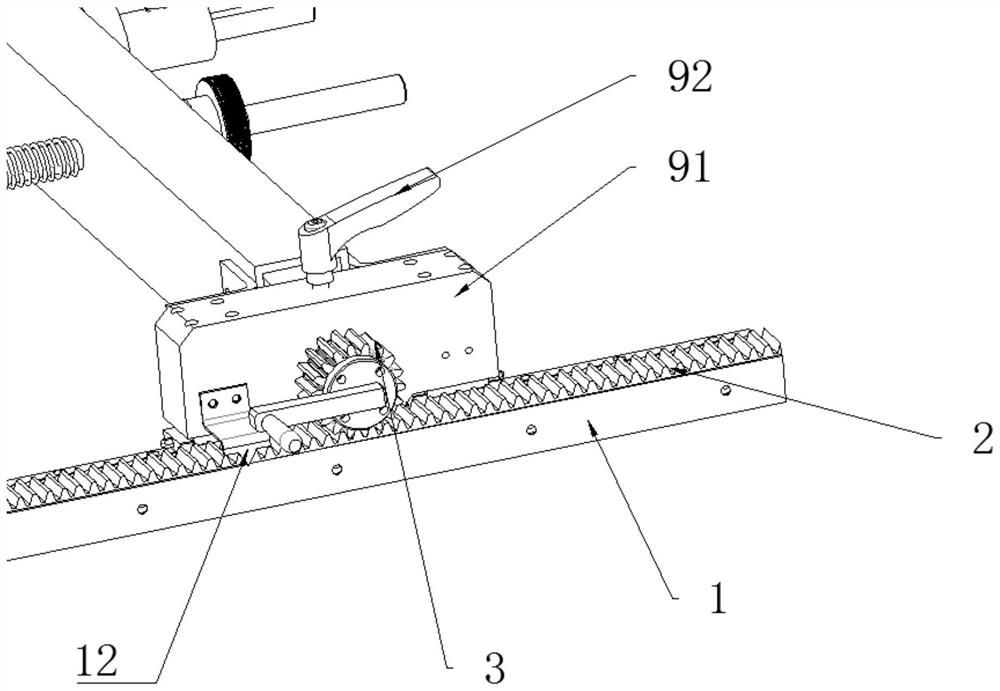

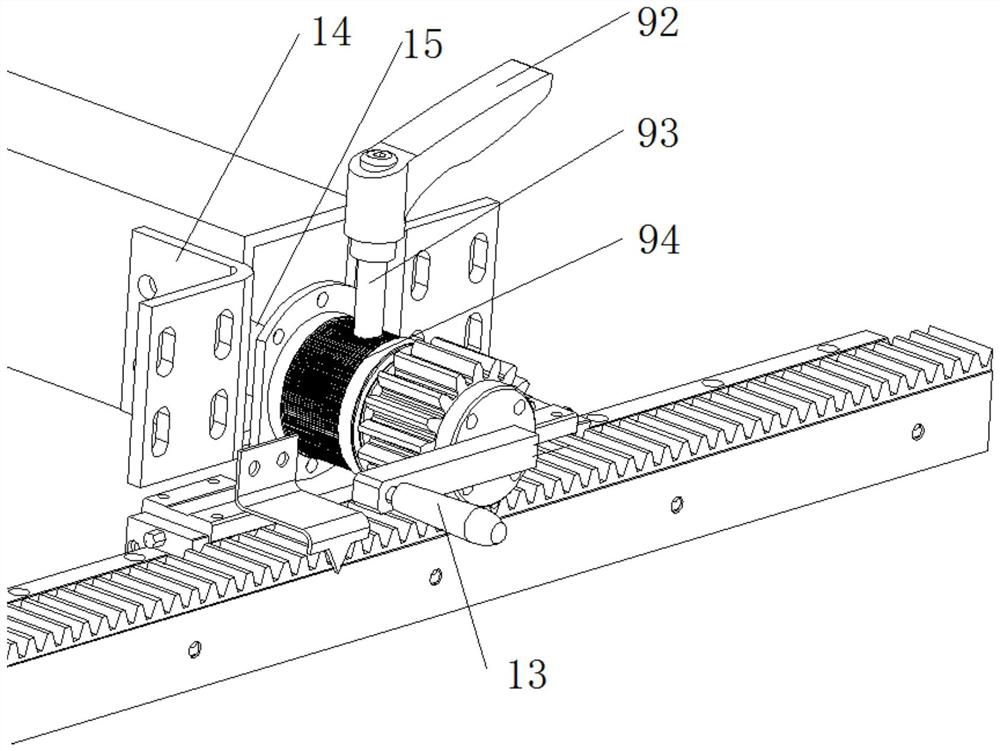

InactiveCN113048286AEasy to useWide applicabilityOperating means/releasing devices for valvesGear wheelDetent

The invention discloses a positioning device of an intelligent valve positioner. The positioning device comprises a fixed shell, an inner gear ring, a driving gear, a motor, a lifting adjusting mechanism, a connecting frame and a locking mechanism, wherein the inner gear ring is pivoted to the inner wall of the fixed shell, a positioning driven gear is pivoted to a partition plate of the fixed shell, the lifting adjusting mechanism is arranged at the top of the fixed shell, the motor is fixedly connected with a lifting block of the lifting adjusting mechanism, the driving gear is fixedly connected with the motor, the driving gear is meshed with the positioning driven gear all the time, a potentiometer fixedly arranged in a cavity of the positioning driven gear is electrically connected with a circuit board arranged in the fixed shell, the connecting frame is slidably arranged at the bottom of the inner gear ring in the axial direction, an adjusting driven gear is arranged on the connecting frame, the driving gear is meshed with a gear ring body of the inner gear ring after ascending and is meshed with the adjusting driven gear after descending, and the locking mechanism is arranged on the connecting frame and used for fixedly connecting a valve rod and the connecting frame into a whole. The positioning device is convenient to use and high in applicability.

Owner:WENZHOU POLYTECHNIC

Light splitting pupil confocal Raman-LIBS-mass spectrum detection-based femtosecond laser machining and monitoring method and device

InactiveCN109187728ASolve driftSolve real-timeMaterial analysis by electric/magnetic meansRaman scatteringMicro structureManufacturing technology

The invention relates to a light splitting pupil confocal Raman-LIBS-mass spectrum detection-based femtosecond laser machining and monitoring method and device, and belongs to the fields of a laser precision detection technology and a femtosecond laser machining and manufacturing technology. The light splitting pupil confocal Raman-LIBS-mass spectrum detection-based femtosecond laser machining andmonitoring method and device is used for online detection of femtosecond laser machining and online monitoring and physical property comprehensive parameters. A light splitting pupil confocal axial monitoring module and a femtosecond laser machining system are organically fused, and the axial position of a sample is subjected to high-precision in-situ online monitoring and sample axial machiningsize measurement by utilizing a light splitting pupil confocal system; and a Raman spectroscopy detection module, an LIBS detection module and a mass spectrometer are used for carrying out monitoringanalysis on information such as molecular structures, elements, ions and the like of a sample material after femtosecond laser machining, and the information is fused through a computer, so that the high-precision femtosecond laser machining of a micro-structure and the in-situ monitoring analysis of the morphology performance of a micro-region are integrated, and the controllability of the femtosecond laser machining precision of the micro-structure and the machining quality of the sample are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

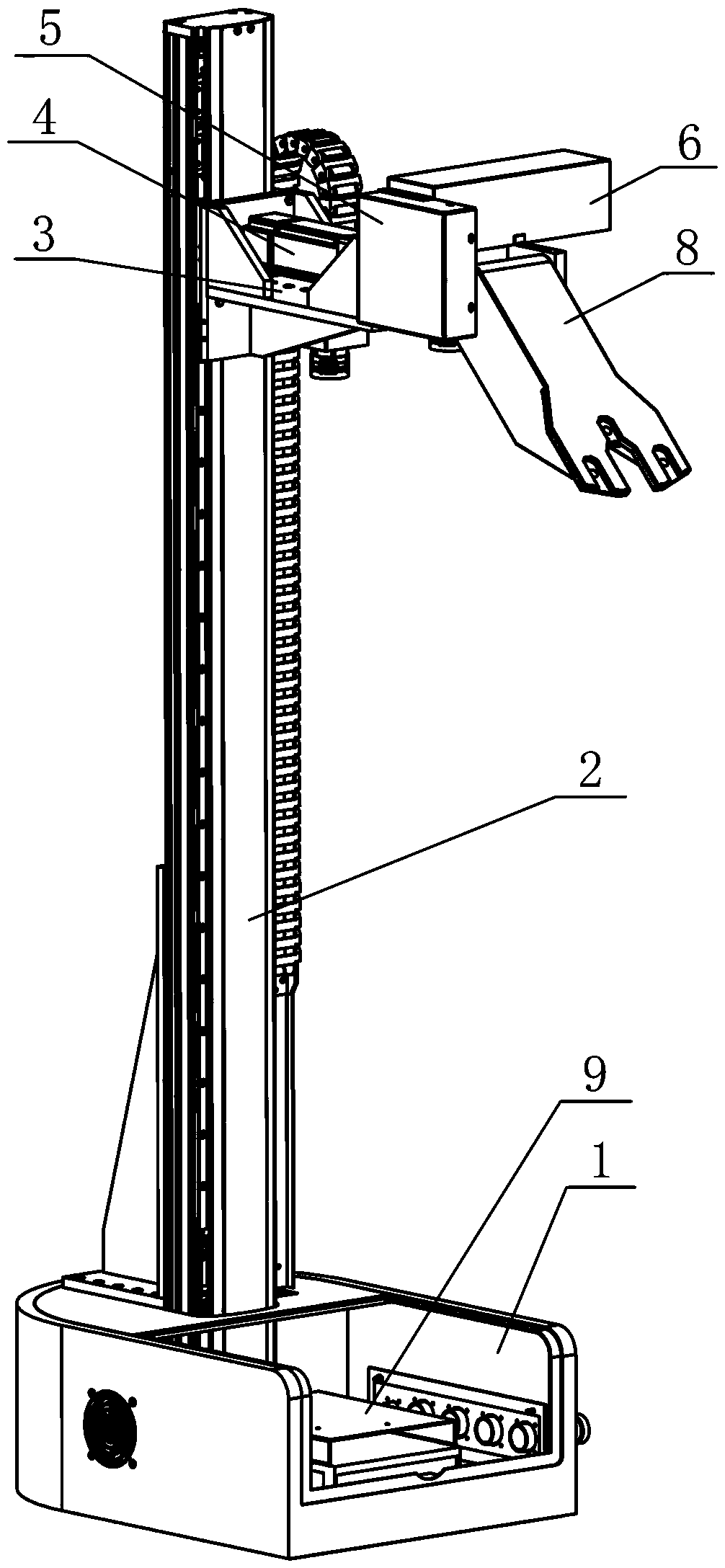

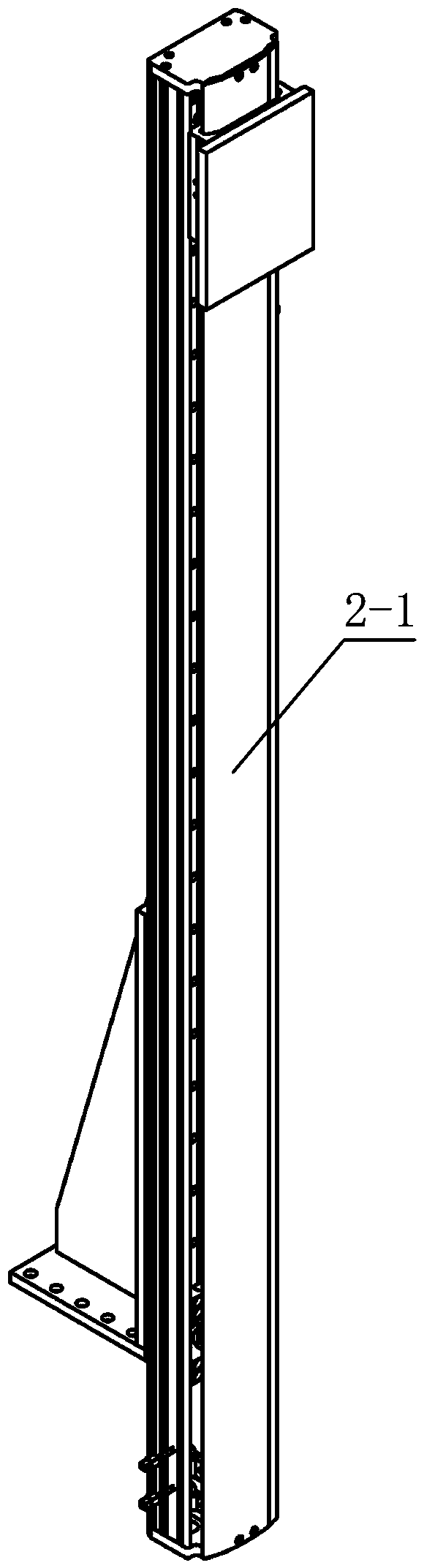

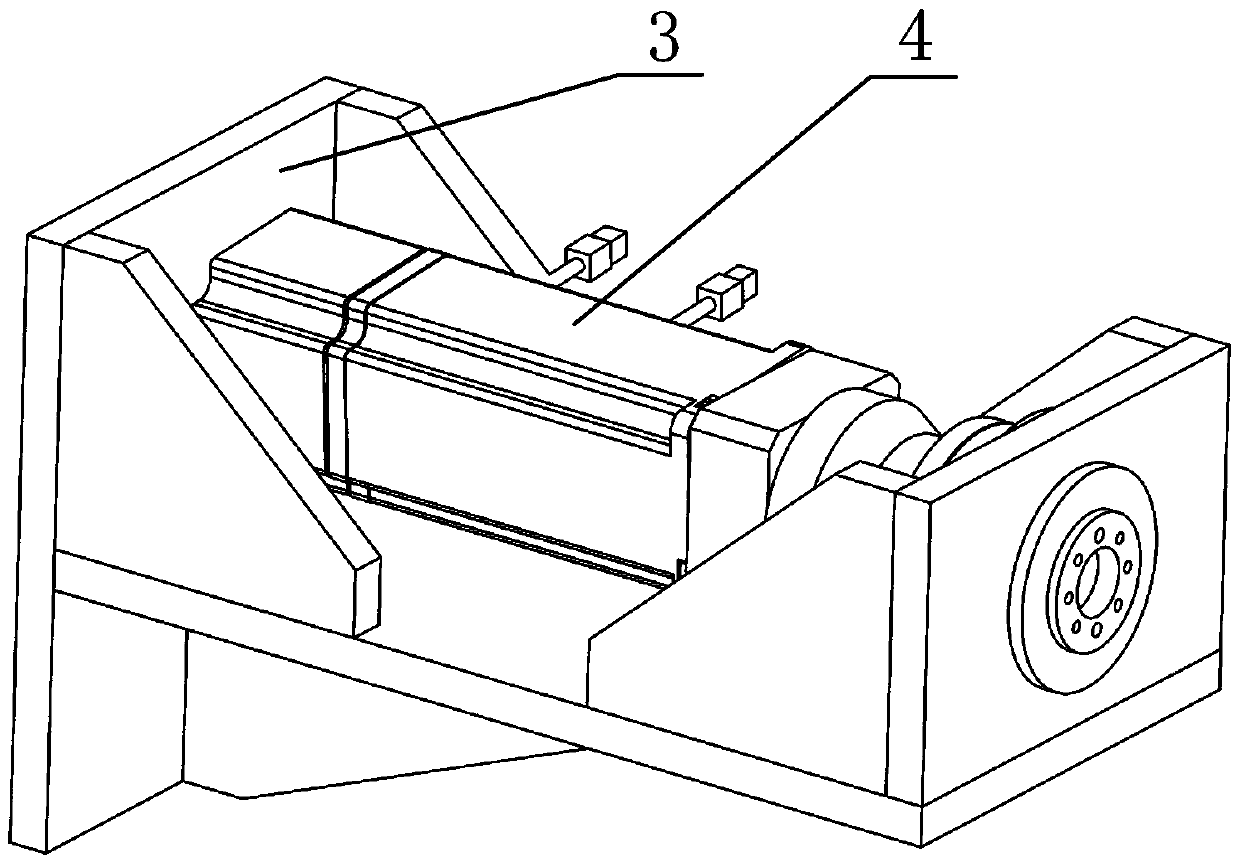

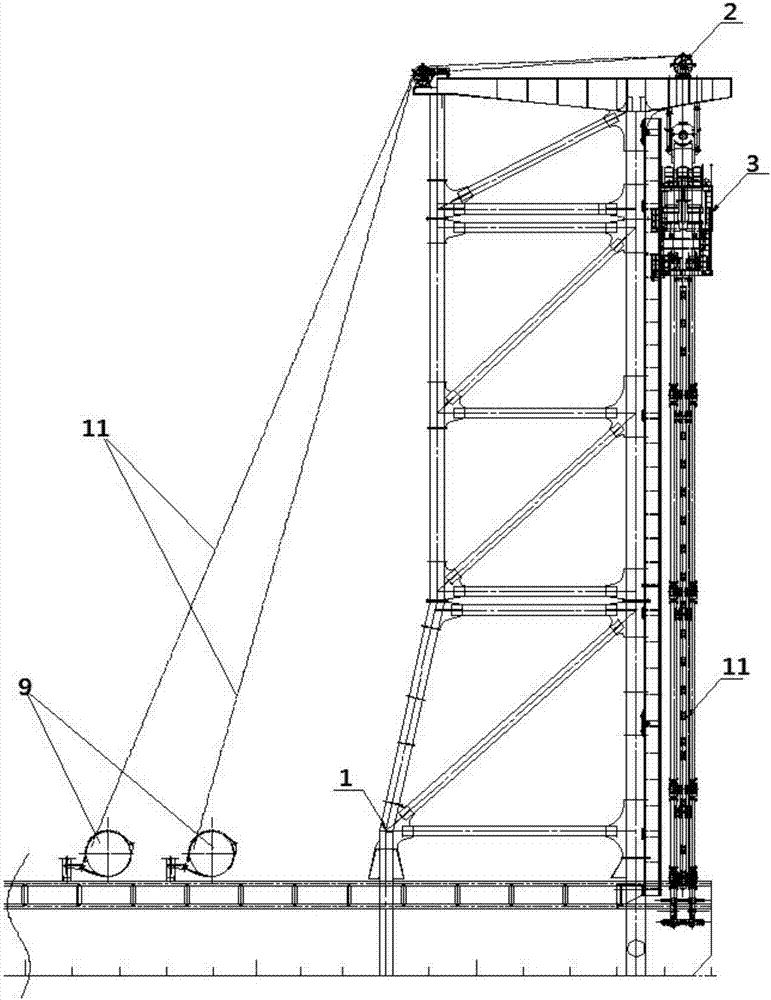

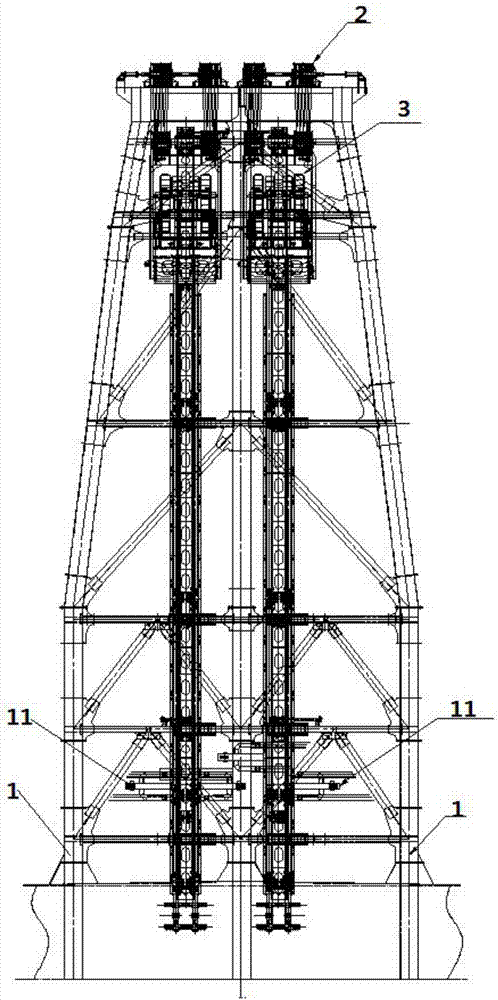

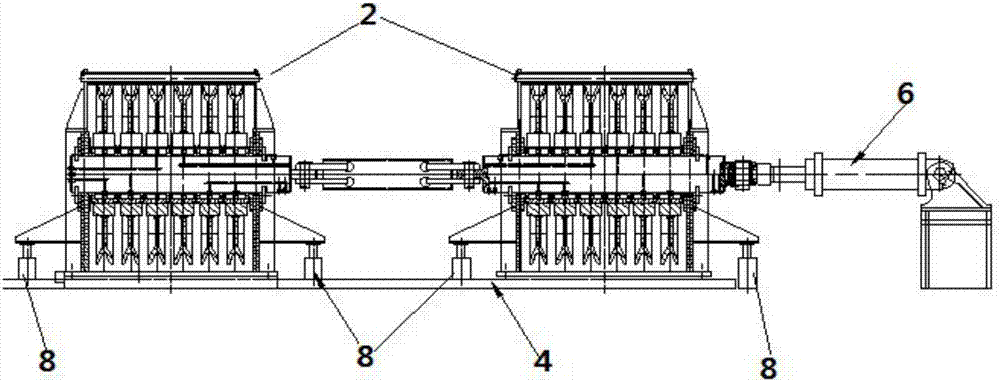

Adjustable pile frame of deep mixing boat for processor

InactiveCN107090827AImprove the efficiency of position adjustmentEasy to adjustBulkheads/pilesBlock and tackleEngineering

The invention discloses an adjustable pile frame of a deep mixing boat for a processor. The pile frame comprises a main pile frame fixed on a boat body, wherein a lifting pulley group, processor guide rails arranged under the lifting pulley group, a first guide rail pair perpendicular to a lifting direction of the lifting pulley group and a second guide rail pair perpendicular to the processor guide rails are arranged on the main pile frame. The lifting pulley group comprises a pulley and a pulley base; the pulley base is connected with the top of the main pile frame by the first guide rail pair; one side of the pulley base is connected with a pulley group moving mechanism; the bottom of the processor guide rail is connected with the side of the main pile frame by the second guide rail pair; one side of the processor guide rail is connected with a manual push rod. The lifting pulley group and the processor guide rail in the invention are respectively connected with the pulley group moving mechanism and the manual push rod, so that the positions of the lifting pulley group and the processor guide rail can be conveniently and quickly adjusted, and the adjustment efficiency of the positions of lifting pulley group and the processor guide rail is improved.

Owner:CCCC SHANGHAI DREDGING

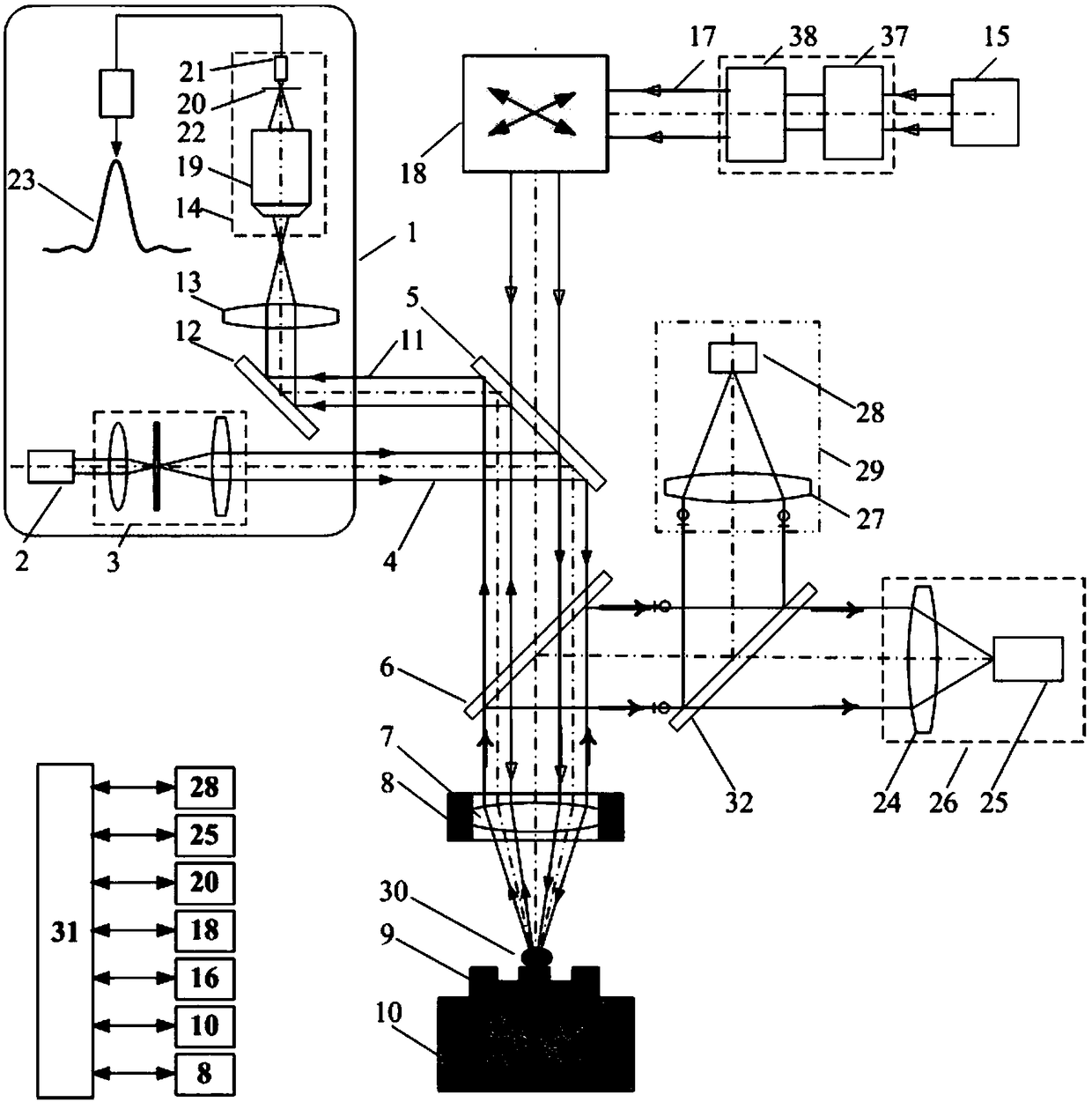

Femtosecond laser machining and monitoring method based on back light splitting pupil differential confocal Raman-LIBS-mass spectroscopy detection

InactiveCN109187726AImprove processing qualityStrong process controllabilityMaterial analysis by electric/magnetic meansRaman scatteringMicro structureSpectrograph

The invention relates to a femtosecond laser machining and monitoring method based on back light splitting pupil differential confocal Raman-LIBS-mass spectroscopy detection, and belongs to the fieldsof a laser precision detection technology and a femtosecond laser machining and monitoring technology. The method can be used for femtosecond laser machining and online monitoring, and online detection of physical property comprehensive parameters. A back light splitting pupil laser differential confocal axial monitoring module and a femtosecond laser machining system are organically fused, and the axial position of a sample is subjected to high-precision in-situ monitoring and sample axial machining size measurement by utilizing a back light splitting pupil differential confocal system; anda Raman spectroscopy detection module, an LIBS spectroscopy detection module and a mass spectrograph are used for carrying out monitoring analysis on information such as molecular structures, elements, ions and the like of a sample material after femtosecond laser machining, and the information is fused through a computer, so that the high-precision femtosecond laser machining of a micro-structureand the in-situ monitoring analysis of the morphology performance of a micro-region are integrated, and the controllability of the femtosecond laser machining precision of the micro-structure, the machining quality of the sample and the like are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

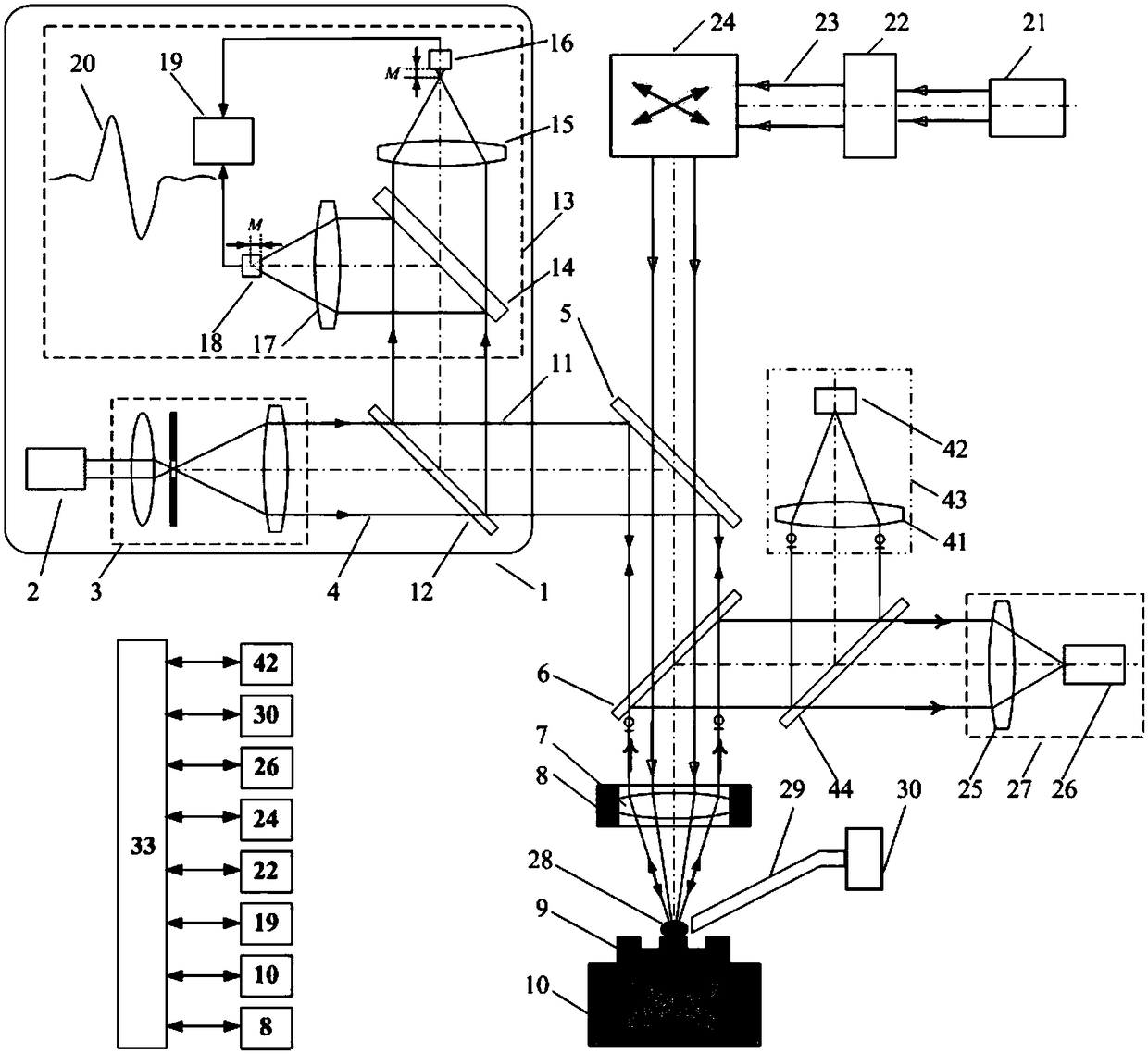

Differential confocal Raman-LIBS-mass spectrum detection-based femtosecond laser machining and monitoring method and device

InactiveCN109187724AImprove controllabilityImprove micro-nano processing capabilitiesMaterial analysis by electric/magnetic meansRaman scatteringPhysicsMass spectrum analysis

The invention relates to a differential confocal Raman-LIBS-mass spectrum detection-based femtosecond laser machining and monitoring method and device, and belongs to the fields of a laser precision detection technology and a femtosecond laser machining and manufacturing technology. A laser differential confocal axial monitoring module with high axial resolution and a femtosecond laser machining system are organically fused, and the axial position of a sample is subjected to nano-scale in-situ online monitoring and sample axial machining size measurement by utilizing a curve zero point of a differential confocal system, so that the drift problem and the high-precision online detection problem in the measurement process are solved; and a differential confocal Raman spectroscopy detection module, an LIBS detection module and a mass spectrometer are used for carrying out monitoring analysis on information such as molecular structures, elements, ions and the like of a sample material afterfemtosecond laser machining, and the information is fused through a computer, so that the high-precision femtosecond laser machining of a micro-structure and the in-situ monitoring analysis of the morphology performance of a micro-region are integrated, and the controllability of the femtosecond laser machining precision of the micro-structure, the machining quality of the sample and the like areimproved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

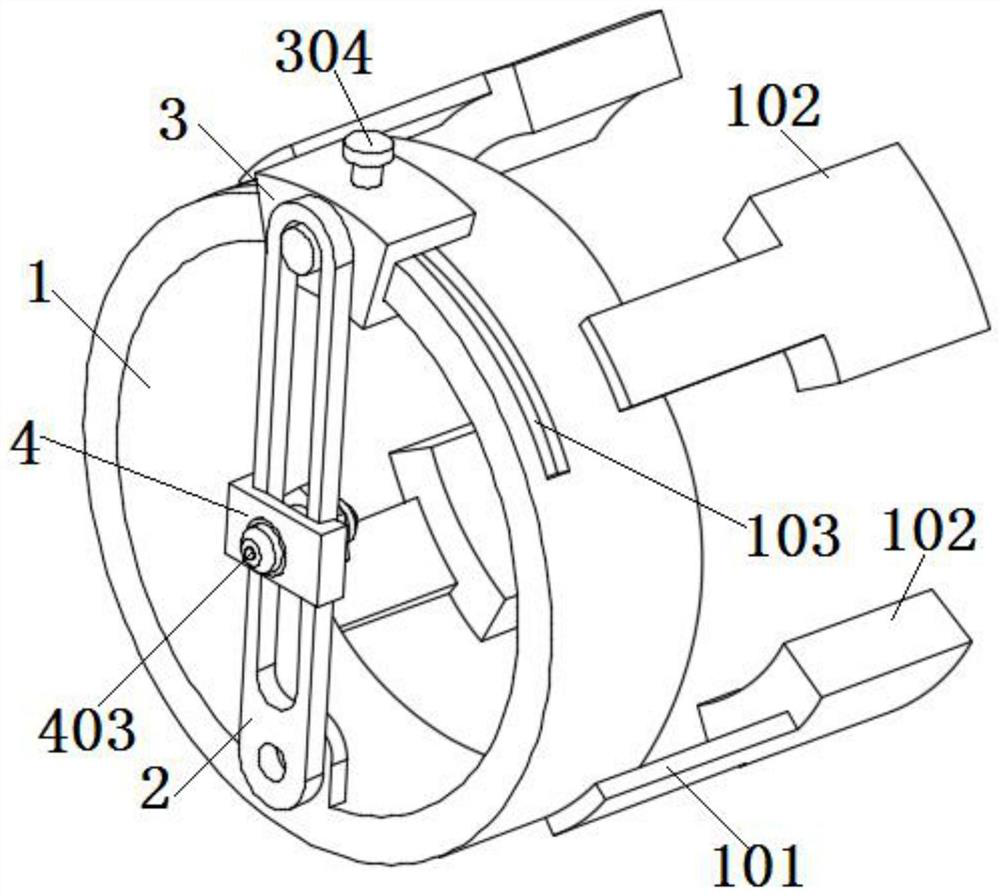

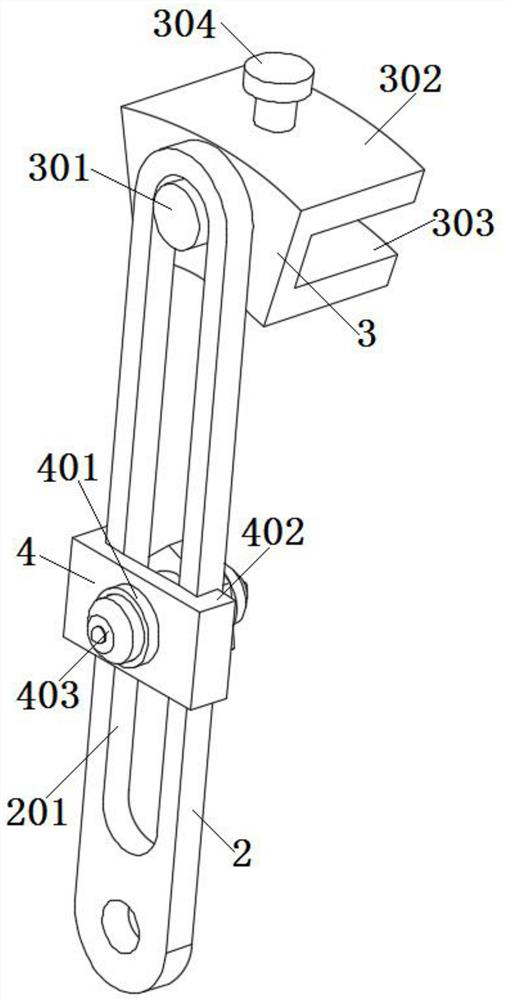

A device and method for adjusting the position of the injection gun head

ActiveCN112123234BImprove the efficiency of position adjustmentHigh position adjustment accuracyWork holdersInjection portIcebox

The invention discloses a device for adjusting the position of a filling gun head, and relates to the technical field of refrigerator foaming. The invention comprises a fixed ring; one side of the fixed ring is hinged with an adjusting rod; the side wall of the fixed ring is slidably connected with an adjusting block; the outer wall of the fixed ring is connected with several spring pieces; the spring piece is connected with a block; The adjusting rod is connected with a mounting block; the mounting block is fixed with a mounting sleeve that fits with the straight slot; both ends of the mounting sleeve are provided with laser positioning lights; the outer wall of the mounting sleeve is threaded with a nut; the adjusting block is fixed with a mounting sleeve that fits with the straight slot The guide column; the side of the adjustment block is fixed with an outer arc plate and an inner arc plate adapted to the fixing ring; the outer arc plate is connected with a thumb nut. The invention fixes the fixed ring on the head of the main material gun through the clamping block, and determines the position through two laser positioning lights, so as to realize the position adjustment of the injection gun head and the injection port, which solves the problem of the existing position adjustment of the injection gun head The efficiency and precision are low, and there are potential safety hazards in manual operation.

Owner:CHANGHONG MEILING CO LTD

Material injection gun head position adjusting device and method

ActiveCN112123234AImprove the efficiency of position adjustmentHigh position adjustment accuracyWork holdersIceboxEngineering

The invention discloses a material injection gun head position adjusting device, and relates to the technical field of refrigerator foaming. The device comprises a fixing ring; an adjusting rod is hinged to one side of the fixing ring; the side wall of the fixing ring is slidably connected with an adjusting block; the outer wall of the fixing ring is connected with a plurality of spring pieces; the spring pieces are connected with clamping blocks; a straight notch is formed in the side face of the adjusting rod; the adjusting rod is connected with a mounting block; a mounting sleeve in clearance fit with the straight notch is fixed on the mounting block; laser positioning lamps are arranged at two ends of the mounting sleeve; a nut is in threaded connection with the outer wall of the mounting sleeve; a guide column matched with the straight notch is fixed on the adjusting block; an outer arc-shaped plate and an inner arc-shaped plate which are matched with the fixing ring are fixed tothe side face of the adjusting block; and the outer arc-shaped plate is connected with a hand-screwed nut. The fixing ring is fixed to a main material gun head through the clamping blocks, the positions are determined through the two laser positioning lamps, position adjustment of the material injection gun head and a material injection opening is achieved, and the problems that an existing material injection gun head is low in position adjustment efficiency and precision, and potential safety hazards exist in manual operation are solved.

Owner:CHANGHONG MEILING CO LTD

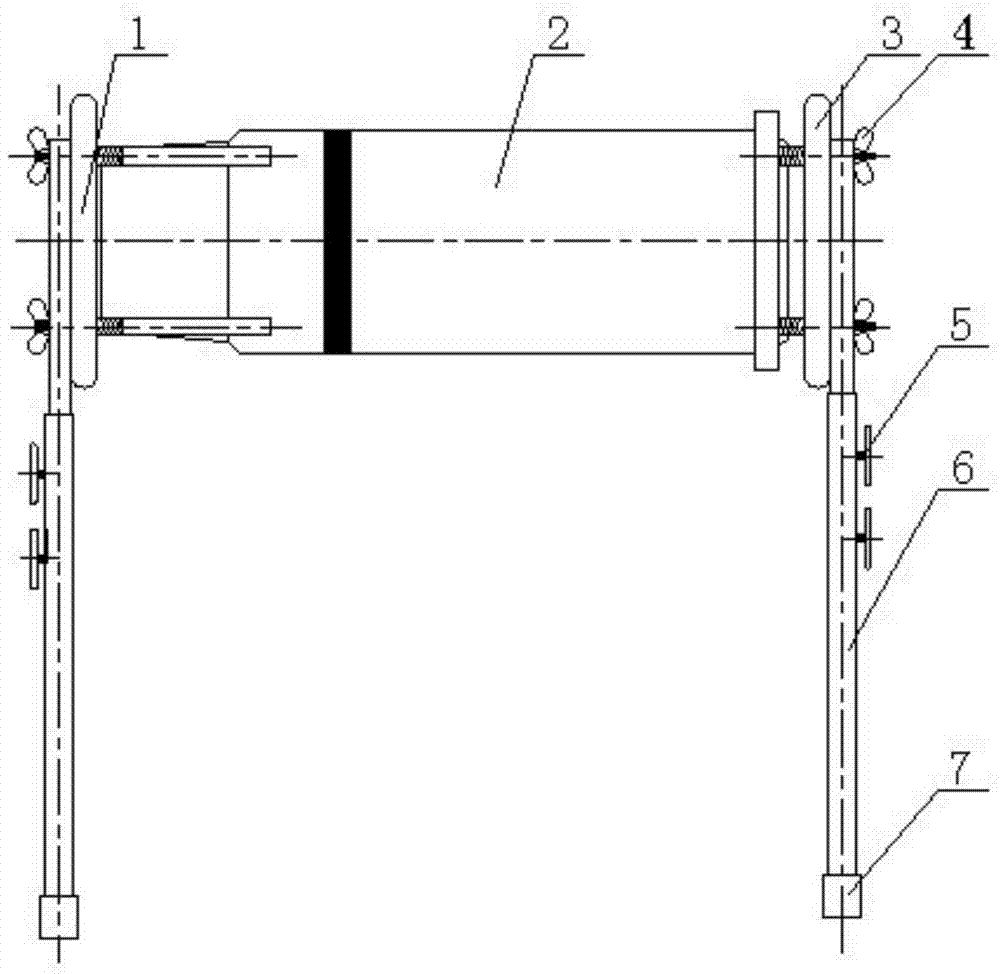

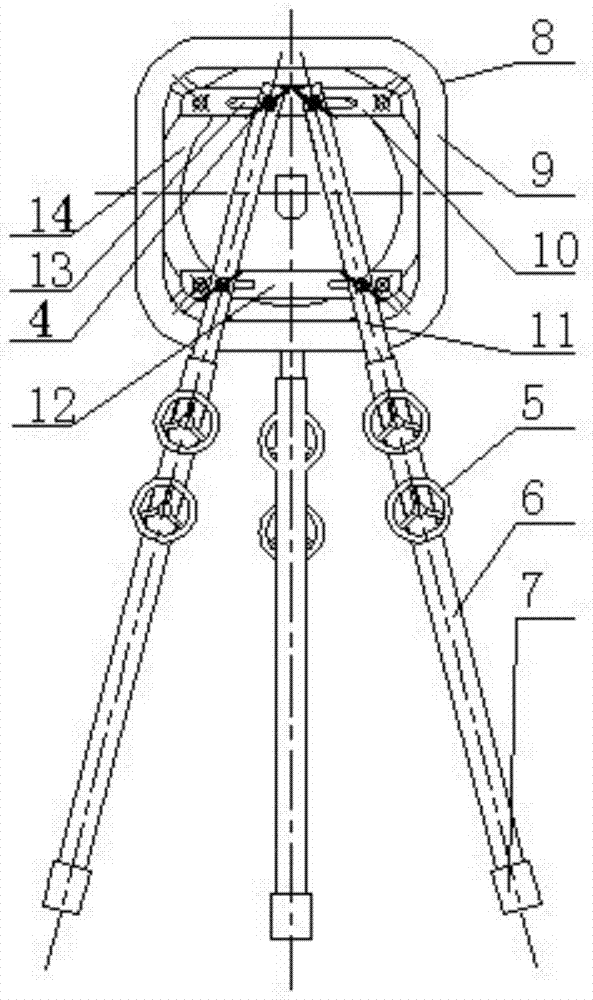

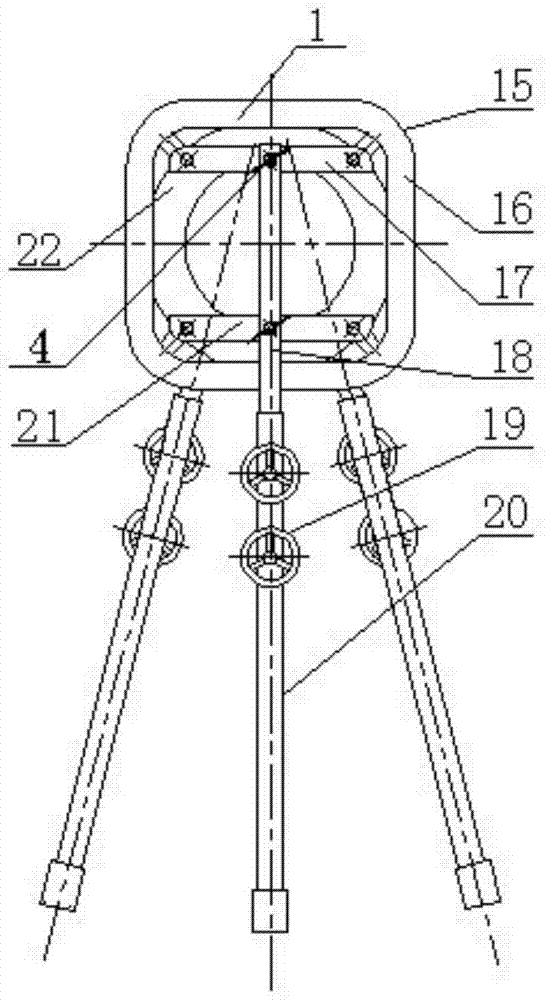

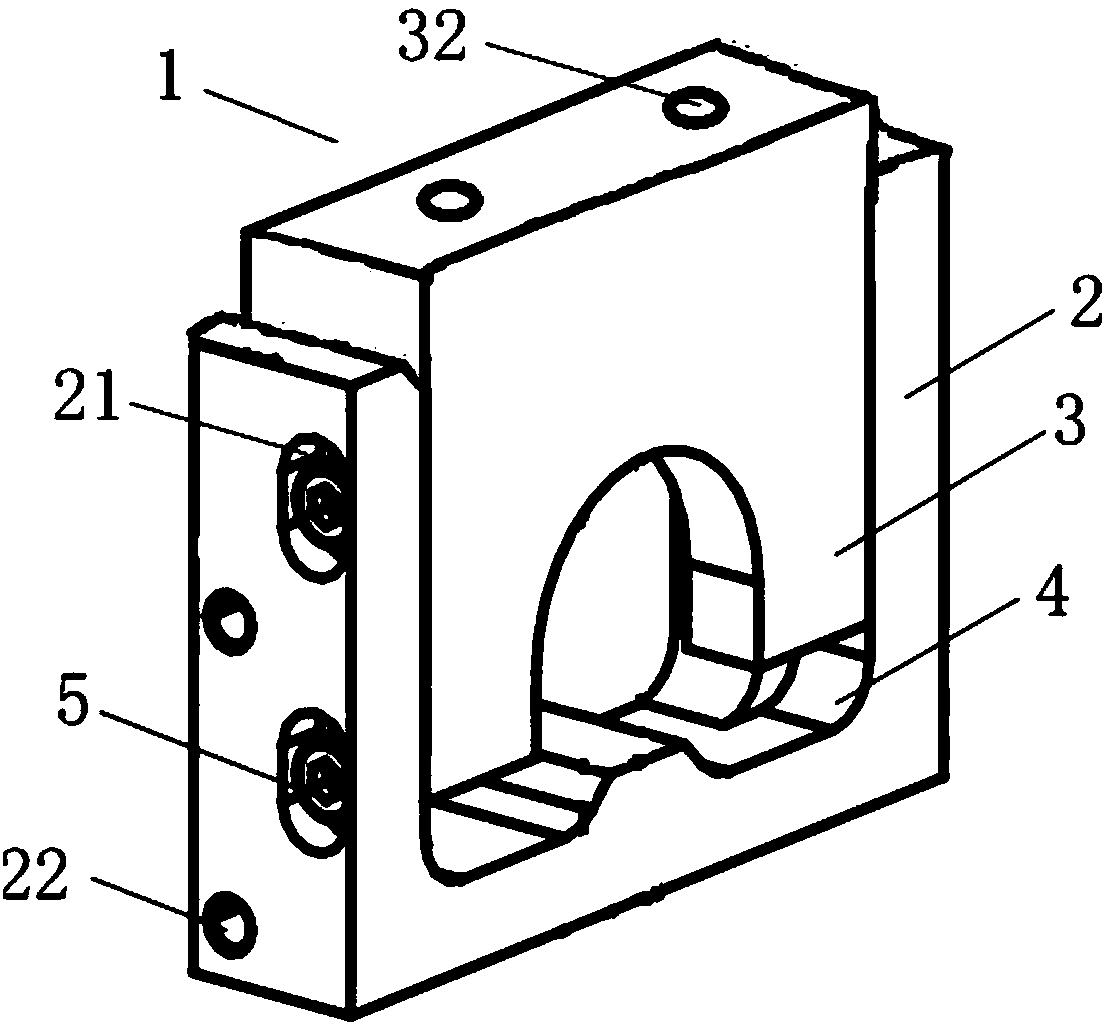

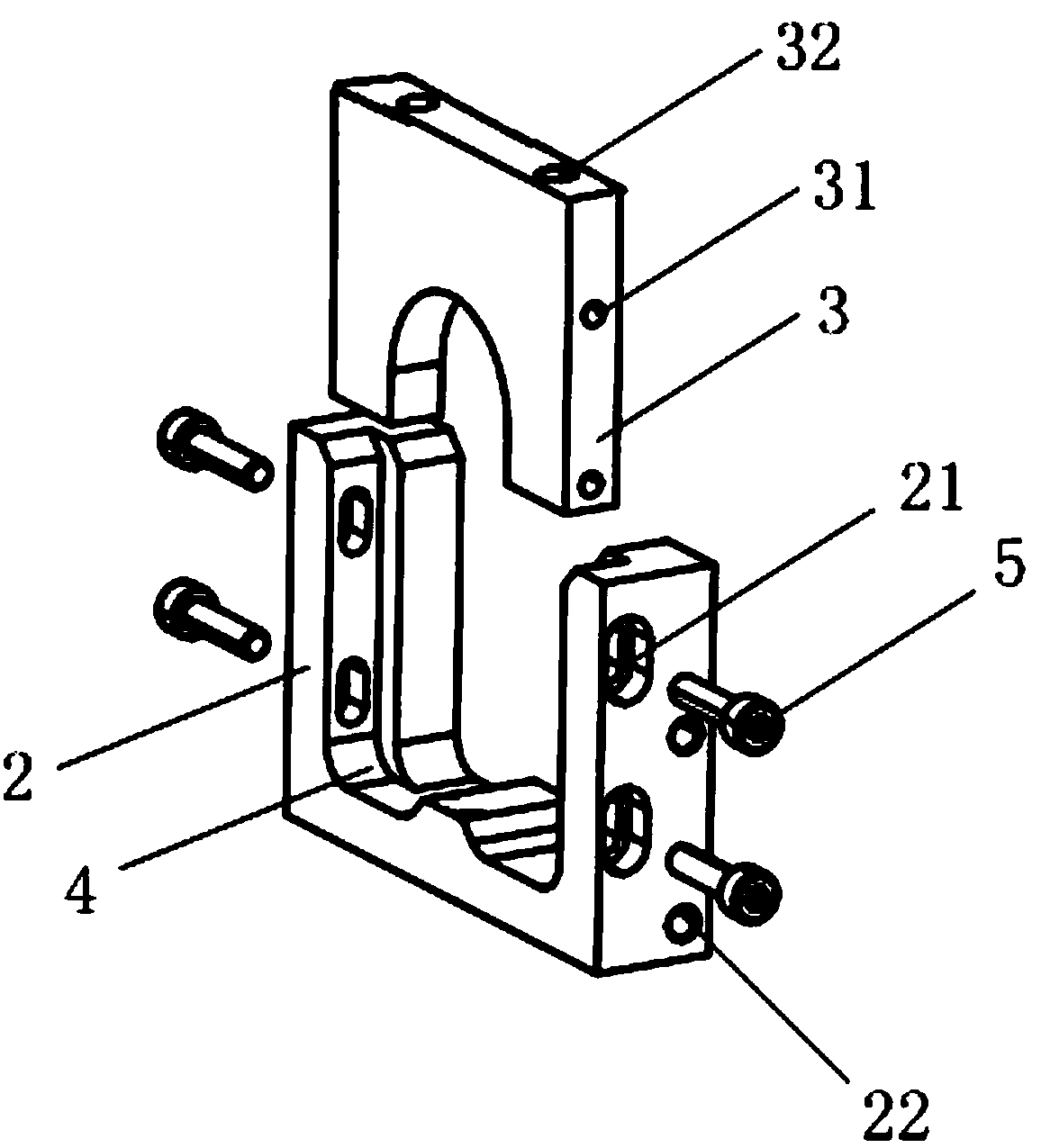

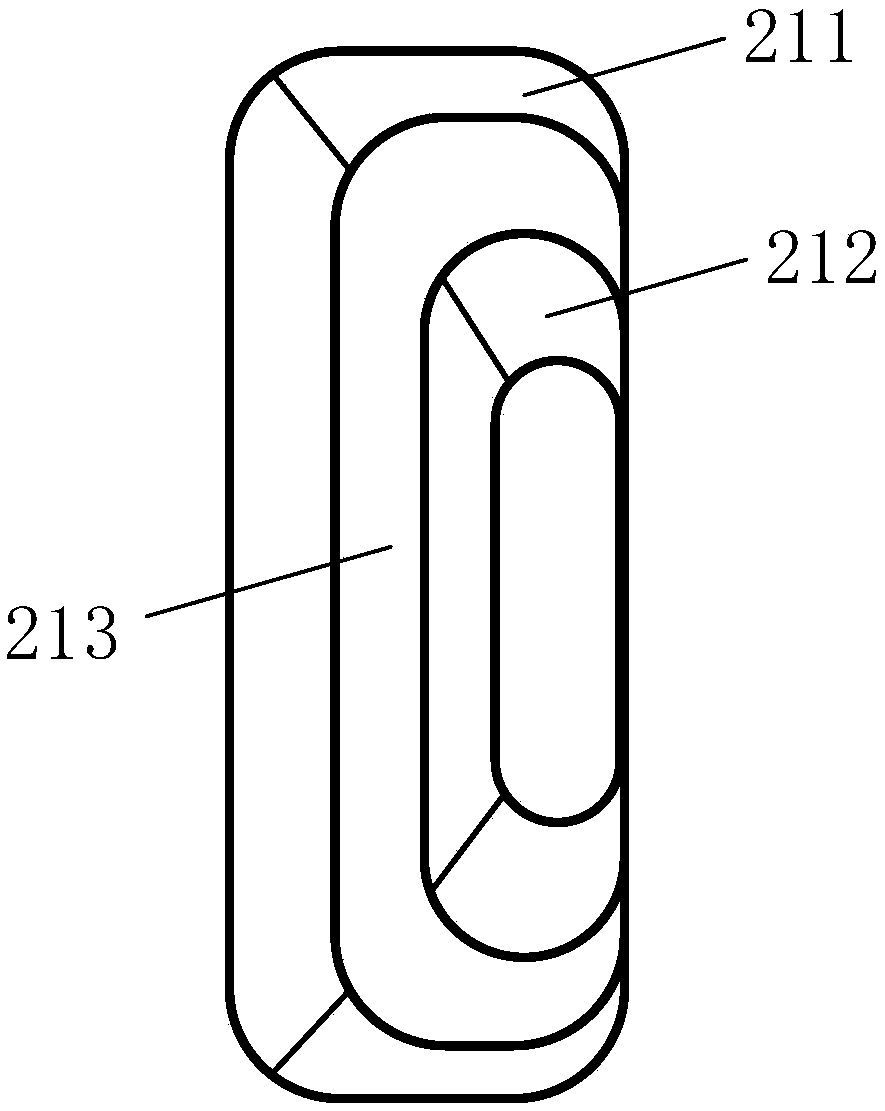

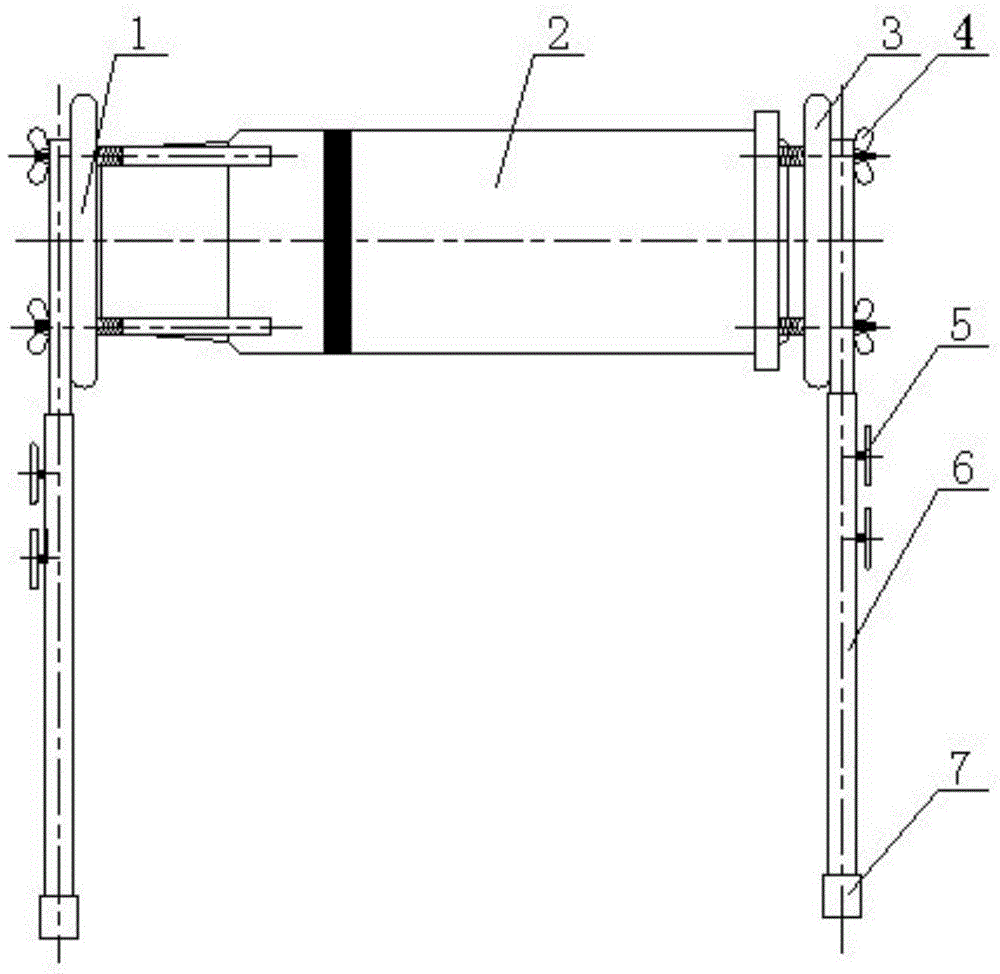

A Method of Focus Positioning of X-ray Machine Based on Adjusting Long Hole

ActiveCN104730093BImprove the efficiency of position adjustmentImprove stabilityX-ray apparatusMaterial analysis by transmitting radiationX-rayBeam direction

The invention relates to a method for positioning the focus of an X-ray machine based on adjusting a long hole, comprising the following steps: installing a double-leg adjustable bracket at the front end of the X-ray machine; installing a single-leg adjustable bracket at the rear end of the X-ray machine; Preliminary adjustment of the height of the X-ray machine and its separation angle; position and place it according to the beam direction and focal length required by the process, and at the same time visually observe the focal length to meet the requirements; measure and adjust the positioning and adjustment of the double leg adjustable bracket and the single leg by the central exposure method and eccentric exposure method The legs can adjust the bracket until the positioning accuracy meets the requirements of the detection process to complete the focus positioning. The invention is easy to operate, scientific and reasonable, has low cost, shortens the adjustment time of the ray machine, facilitates focus positioning, and improves work efficiency.

Owner:MCC TIANGONG GROUP

Accurately-adjustable stopper

PendingCN112077195AImprove efficiencySmall footprintMetal-working feeding devicesHandling discharged materialStructural engineeringMechanical engineering

Owner:东实(武汉)实业有限公司

Position adjustment method and electronic device

ActiveCN111124206BEasy to adjustEasy to understandSubstation equipmentInput/output processes for data processingSchematic mapsEngineering

Owner:VIVO MOBILE COMM CO LTD

Adjustable mounting frame and unmanned aerial vehicle thereof

InactiveCN107792378ANot easy to shiftEasy to operatePower plant constructionLocking mechanismEngineering

The invention provides an adjustable mounting frame and an unmanned aerial vehicle thereof. The adjustable mounting frame comprises a fixed supporting piece, a mounting piece and a longitudinal locking mechanism, wherein an accommodating groove is formed in the fixed supporting piece; the thickness of the mounting piece is smaller than the width of the accommodating groove, so that the mounting piece is fitted with the accommodating groove; and during mounting, the mounting piece is placed in the accommodating groove, is in longitudinal motion relative to the fixed supporting piece along the accommodating groove, and is fixed to a position at any height in the longitudinal direction of the accommodating groove by the longitudinal locking mechanism. Through the adoption of the adjustable mounting frame disclosed by the invention, when an engine of the unmanned aerial vehicle is mounted, the maneuverability and the mounting and maintaining flexibility can be effectively improved, and thepositioning efficiency can be effectively adjusted.

Owner:珠海佰家科技有限公司

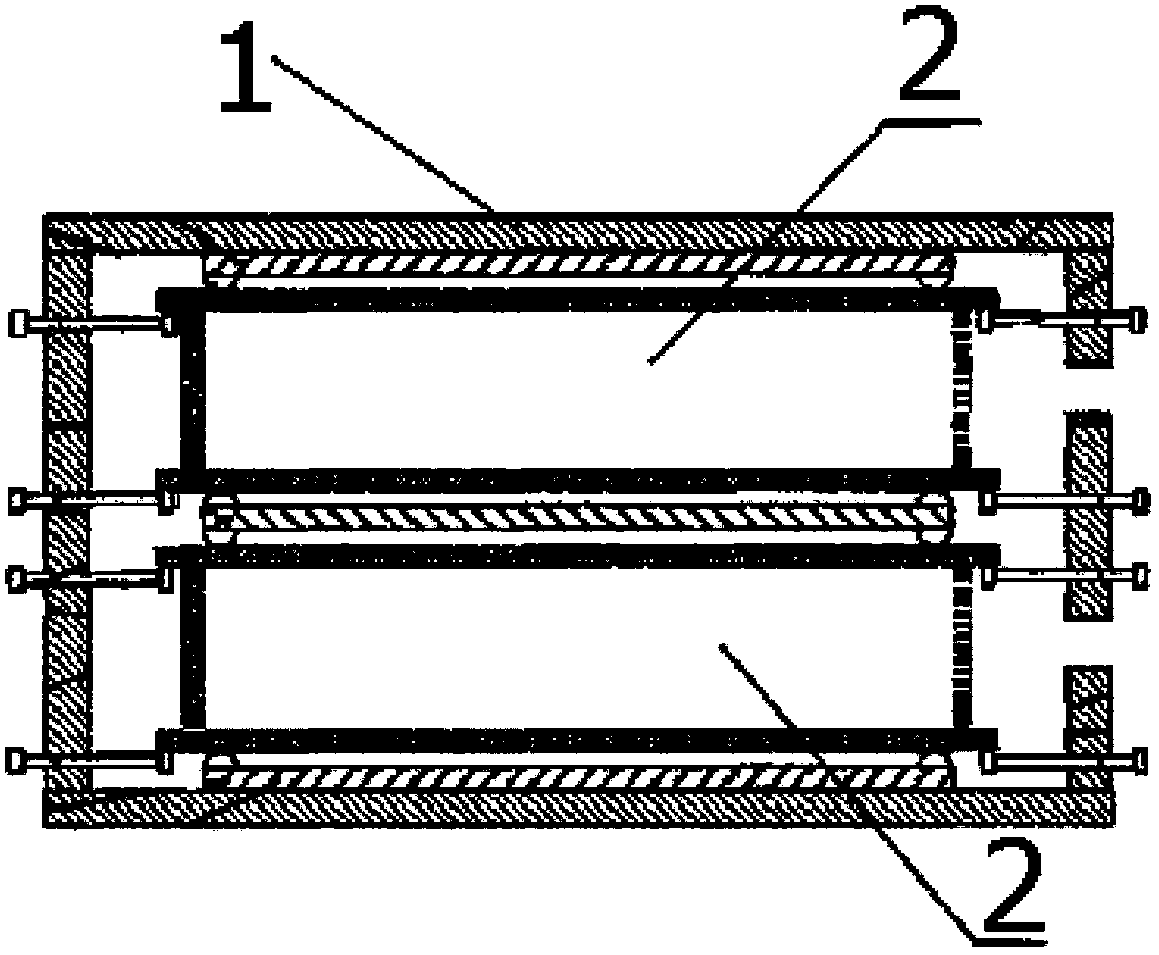

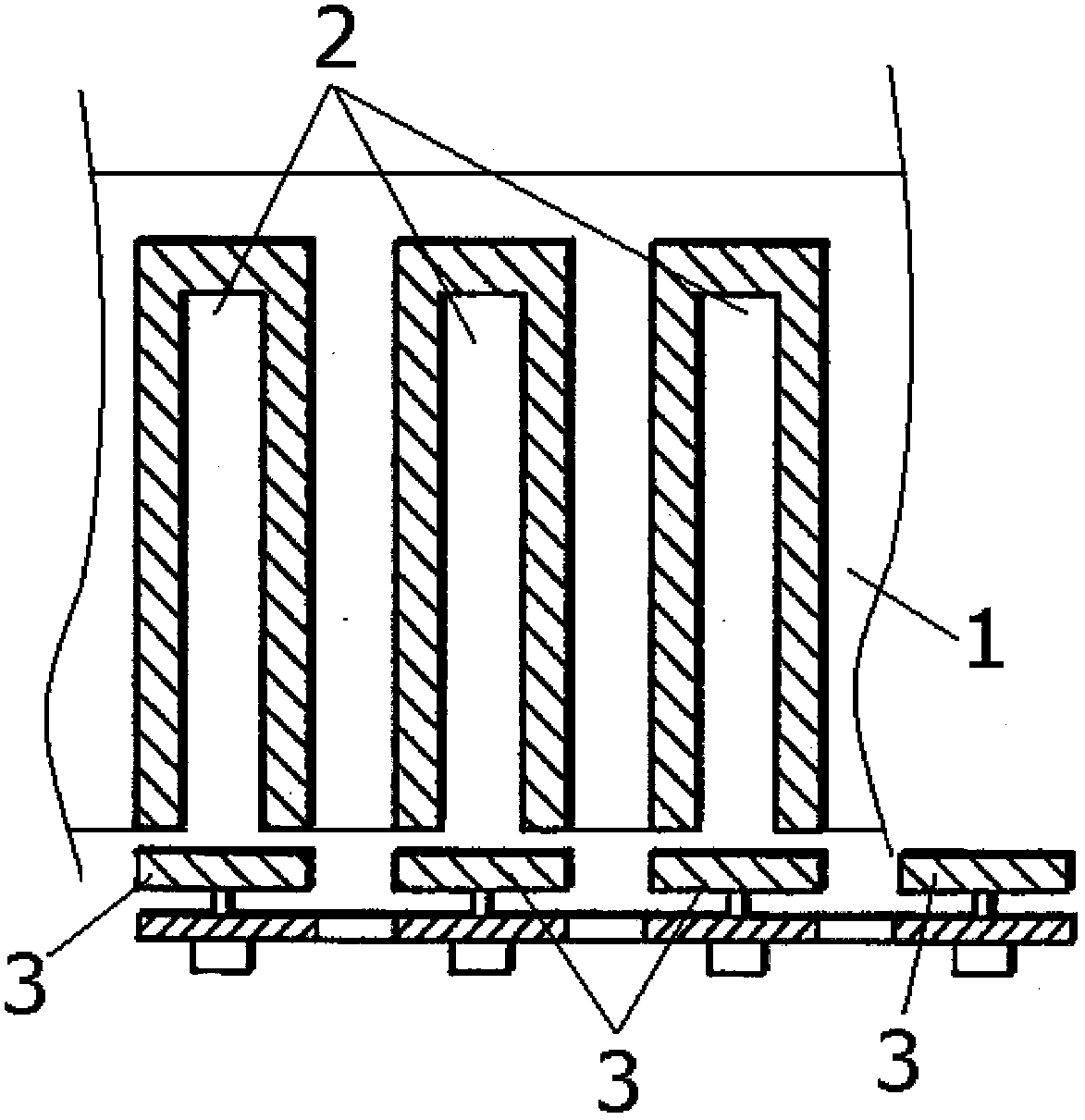

Vacuum treatment system valve assembly and chemical vapor deposition system

ActiveCN103510079AImprove job stabilityGuaranteed tightnessChemical vapor deposition coatingGas phaseAirbag

The invention discloses a vacuum treatment system valve assembly and a chemical vapor deposition system. The vacuum treatment system valve assembly comprises a partition board provided with transmission through holes and sealing valve mechanisms corresponding to the transmission through holes; each sealing valve mechanism comprises a backboard, a sealing board arranged on the backboard, and an airbag which is located between the backboard and the partition board and is used for controlling sealing of the sealing board on each transmission through hole, and the sealing board is matched with a through hole structure; the airbag operating temperature is higher than 100 DEG C. The vacuum treatment system valve assembly controls opening and closing of the transmission through holes on the partition board and the sealing boards by the airbag so as to realize conduction and sealing of two sides of the partition board, and improves the sealing and conduction effects of the two sides of the partition board; and besides, the airbag work temperature is higher than 100 DEG C, so that the working stability of the vacuum treatment system valve assembly is improved, and even under a condition of high temperature, stability of a thin film deposition technological process is not affected.

Owner:理想万里晖真空装备(泰兴)有限公司

Automotive controller, control system, and method used in automotive controller

ActiveCN104943632BImprove the efficiency of position adjustmentElectric/fluid circuitMovable seatsControl systemComputer module

The invention discloses a vehicle controller, a control system and a using method for the vehicle controller. The vehicle controller comprises a detecting module, a first displaying module, an operating receiving module and a second displaying module. The detecting module can be used for detecting the first physical position where a vehicle part is located in current, wherein the position of the vehicle part can be adjusted on a vehicle. The first displaying module can be used for controlling a display screen on the vehicle to display a corresponding first form when the vehicle part is placed in the first physical position in real time. The operating receiving module is used for receiving position controlling operation which adjusts the vehicle part form the first physical position to the second physical position. The second displaying module is used for displaying a corresponding second form when the vehicle part is placed in the second physical position in real time. According to the vehicle controller, based on the vehicle part forms which can be watched on the display screen, position adjusting can be carried out by personnel, the visible range is free of limitation, the appropriate position is easier to find, and the efficiency of the position adjusting is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

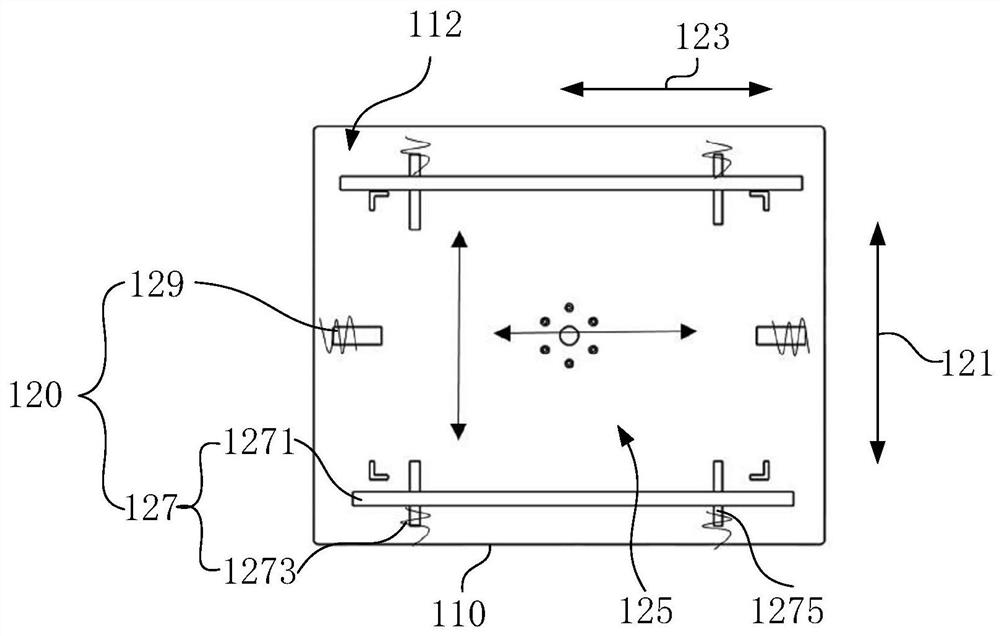

Method and device for position adjustment of objective lens in optical pickup head

InactiveCN104282319BEasy to adjustImprove the efficiency of position adjustmentRecord information storageOptical beam guiding meansOptical pickupRadial position

The embodiment of the invention provides a method and device for adjusting the position of an objective lens in an optical pick-up head. The device mainly comprises a tangential adjusting device, a radial adjusting device and an objective lens guide frame, wherein the tangential adjusting device is used for adjusting the tangential displacement of the objective lens guide frame in the tangential direction of the objective lens, the radial adjusting device is used for adjusting the radial displacement of the objective lens guide frame in the radial direction of the objective lens, the objective lens guide frame is used for making contact with the objective lens when the objective lens in the optical pick-up head moves towards an optical disc, the radial position of the objective lens can be adjusted through displacement of the objective lens guide frame in the radial direction of the objective lens, and the tangential position of the objective lens can be adjusted through displacement of the objective lens guide frame in the tangential direction of the objective lens. According to the method and device for adjusting the position of the objective lens in the optical pick-up head, the objective lens can be fast adjusted to the needed optimal position so that the position adjustment efficiency of the objective lens can be improved, and compared with the scheme of knob screw adjustment in the prior art, the accuracy and the stability of the position adjustment of the objective lens can be guaranteed.

Owner:DONGGUAN HUAQIANG INFORMATION TECH CO LTD

Projection equipment position adjusting support

PendingCN114076246AHigh precisionEasy to adjustStands/trestlesCamera body detailsControl engineeringControl theory

The embodiment of the invention provides a projection equipment position adjusting support, and relates to the technical field of projection equipment. The projection equipment position adjusting support comprises a fixing seat, a first adjusting mechanism and a second adjusting mechanism. The fixing seat is used for fixing projection equipment and is fixedly connected with a first transmission part. The first adjusting mechanism is arranged on the face, close to the first transmission part, of the fixing seat and comprises a first adjusting seat, a first driving assembly and a second transmission part, and the first driving assembly is in transmission connection with the first transmission part so as to drive the fixing seat to rotate around a first shaft. The second adjusting mechanism is located on the face, away from the fixing seat, of the first adjusting mechanism and comprises a second adjusting seat and a second driving assembly, the second driving assembly is in transmission connection with the second transmission part, the second transmission part drives the first adjusting seat, and the first adjusting seat drives the fixing seat to do lifting motion or pitching motion. The projection equipment position adjusting support is simple in structure, convenient to adjust, high in adjusting precision and beneficial to improving the position adjusting efficiency of the projection equipment.

Owner:APPOTRONICS CORP LTD

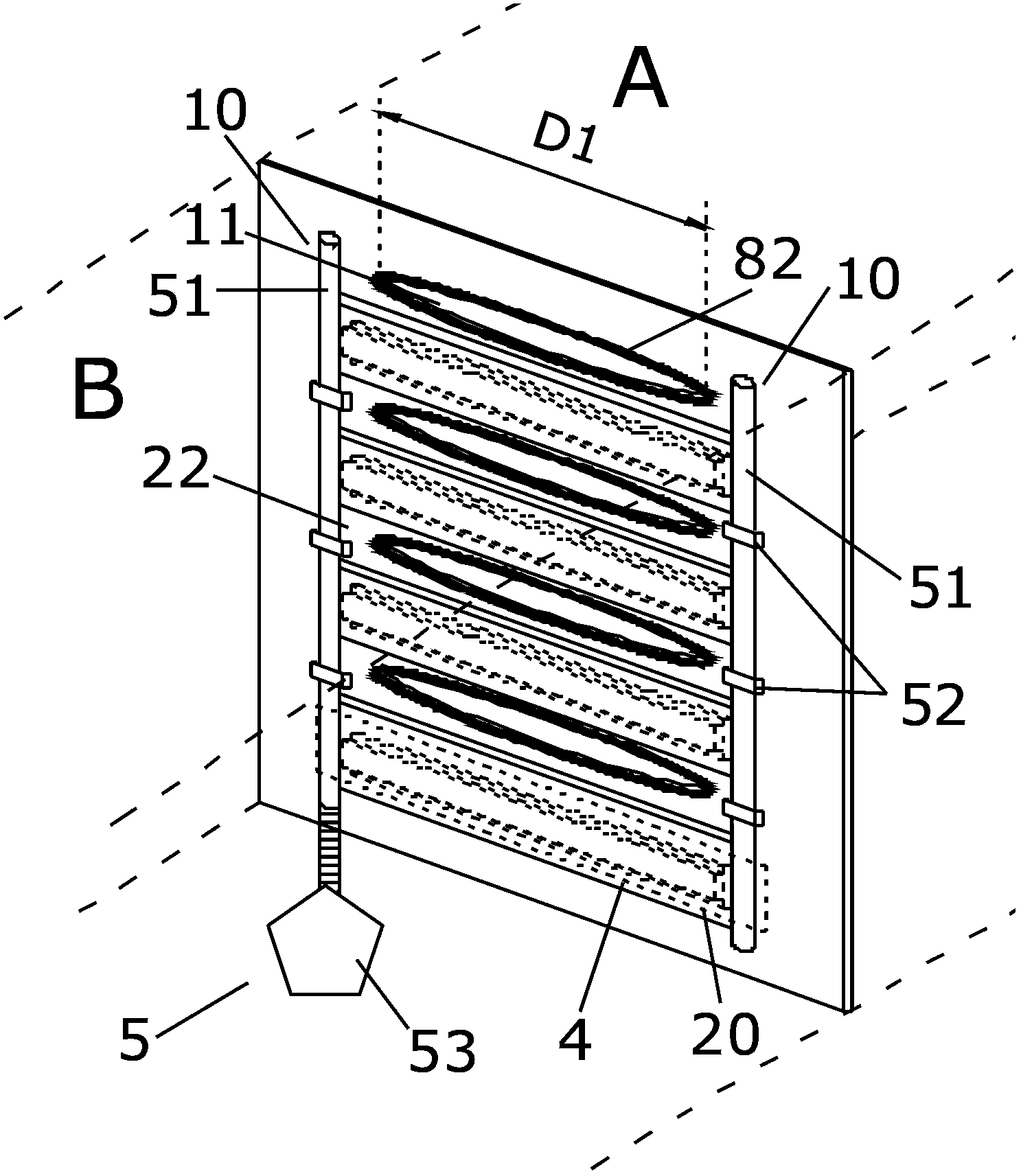

Laser micro-nano processing split-pupil differential confocal online monitoring integrated method and device

ActiveCN108413867BSolve driftSolve real-timeUsing optical meansLaser beam welding apparatusMicroscopic imageMicro imaging

The invention belongs to the laser precision detection technology and laser micro-nano processing monitoring technology field and relates to a laser micro-nano processing light splitting pupil differential confocal online monitoring integration method and device which can be used for the laser micro-nano processing and online detection of a complex fine structure. In the invention, a long workingdistance and high axial resolution light splitting pupil laser differential confocal axial monitoring module is organically integrated with a femtosecond laser processing system. A light splitting pupil differential confocal system curve zero point is used to carry out nanoscale monitoring on the axial position of a sample so as to realize the real-time fixed focus of the axial position of the sample and the high precision measurement of a processed micro-nano structure size. A drift problem and a high-precision online detection problem in a measurement process are solved, and the controllability of micro-nano femtosecond laser processing precision, the processing quality of the sample and the like are improved. Before processing, a microscopic imaging module can be used to carry out coarse alignment and transverse position identification on the sample.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for focus positioning of x-ray machine with locking handwheel

ActiveCN104735892BImprove the efficiency of position adjustmentImprove stabilityX-ray apparatusX-rayVisual inspection

The invention relates to a method for positioning the focus of an X-ray machine with a locking hand wheel. The method for positioning the focus of the X-ray machine with the locking hand wheel comprises the following steps that an adjustable two-leg support is installed at the front end of the X-ray machine; an adjustable single-leg support is installed at the rear end of the X-ray machine; the height and the separation angle of the X-ray machine are adjusted primarily; the X-ray machine is placed in a positioned mode in the ray bundle direction required by the technique according to the focal length required by the technique, and it is judged that the focal length meets the requirements through visual inspection at the same time; the adjustable double-leg support and the adjustable single-leg support are measured, positioned and adjusted according to the central exposure method and the eccentric exposure method till the positioning precision meets the detection technological requirements, and then focus positioning is completed. The method for positioning the focus of the X-ray machine with the locking hand wheel has the advantages that operation is easy, the method is scientific and reasonable, cost is low, time for adjusting the X-ray machine is shortened, focus positioning is convenient and fast, and working efficiency is improved.

Owner:MCC TIANGONG GROUP

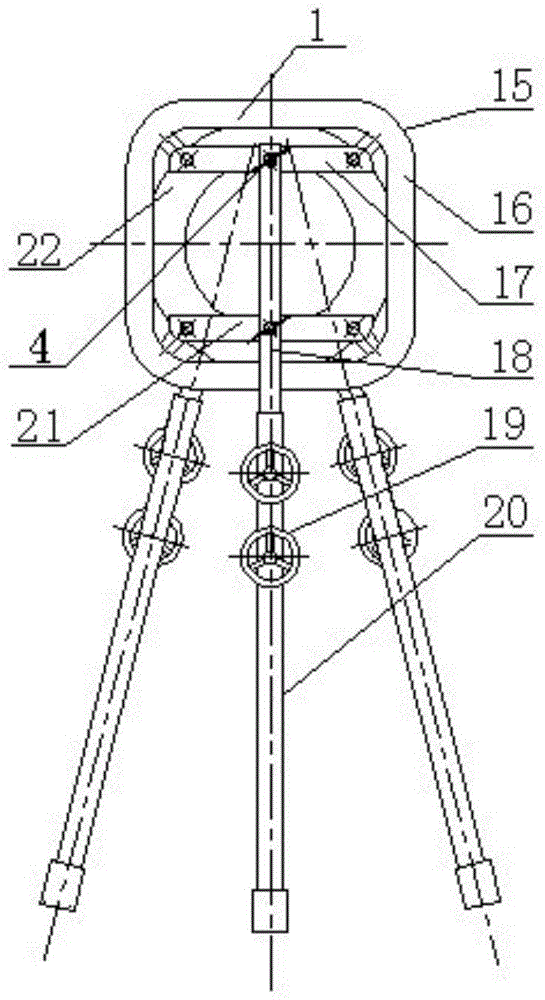

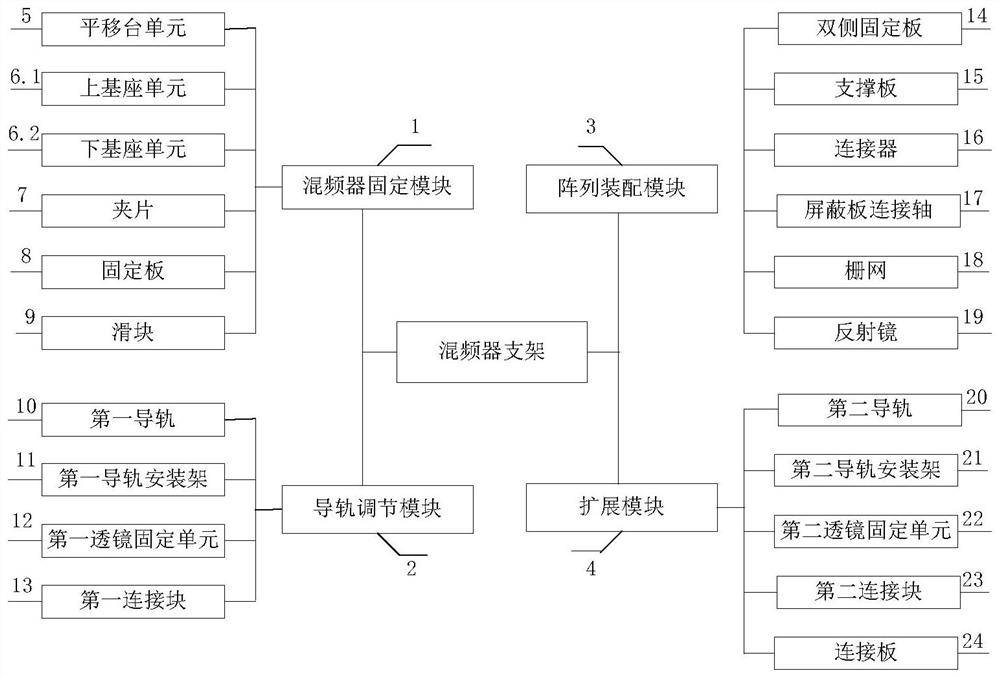

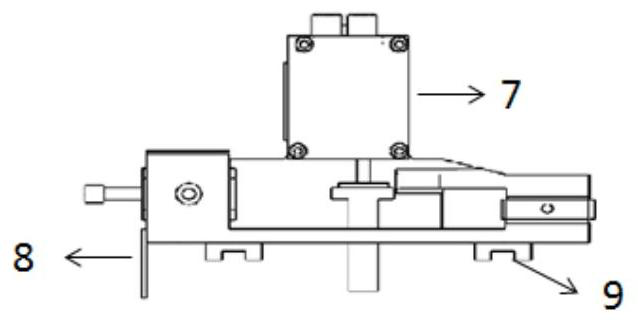

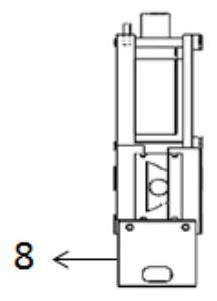

A mixer stand

ActiveCN111219572BAchieve regulationAchieve fixationStands/trestlesMulti-frequency-changing modulation transferenceFrequency mixerLight reflection

The invention discloses a frequency mixer bracket which belongs to the field of precise regulating mixer brackets. The frequency mixer bracket comprises a frequency mixer fixing module, a guide rail regulating module and an array assembly module, wherein the frequency mixer fixing module is positioned above the guide rail regulating module; the array assembly module is connected to the guide railregulating module; the frequency mixer fixing module is used for regulating a frequency mixer to a focused light signal position front, back, left and right, and fixing the frequency mixer; the guiderail regulating module is used for focusing a light signal, and is connected to the frequency mixer fixing module for regulating the position of the frequency mixer left and right; and the array assembly module is used for reflecting incident light and is combined with transmission light to form the light signal which is propagated to the guide rail regulating module. The frequency mixer bracket realizes fixing of the frequency mixer, and realizes precise regulation on the position of the frequency mixer.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com