Patents

Literature

33results about How to "High position adjustment accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

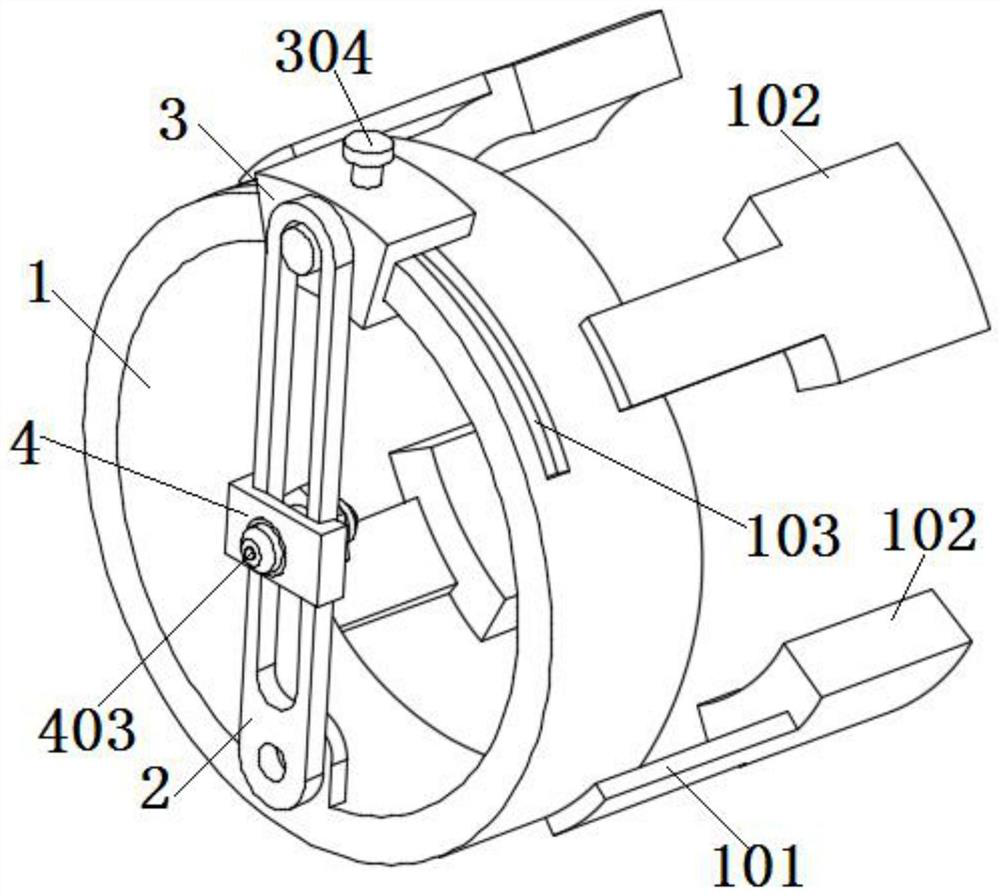

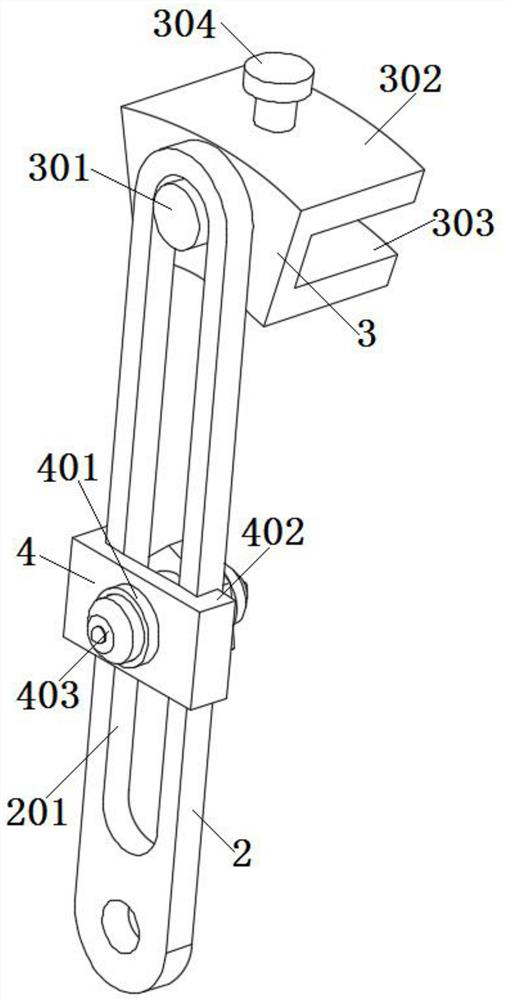

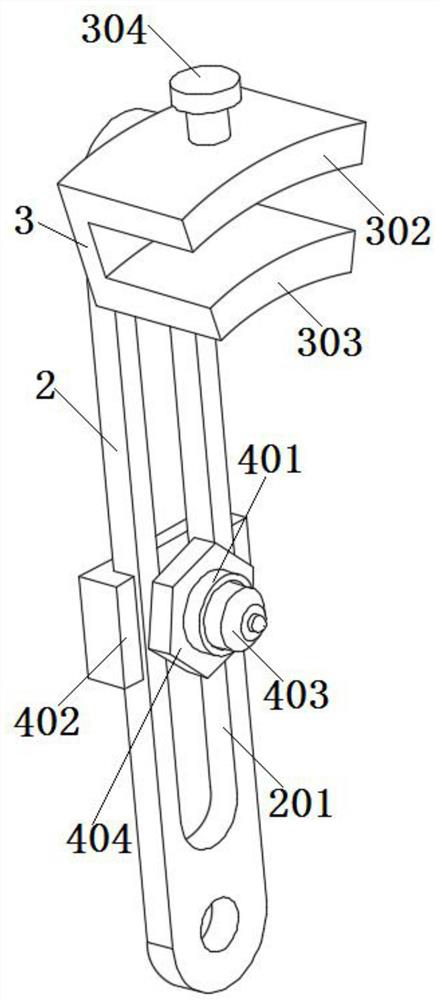

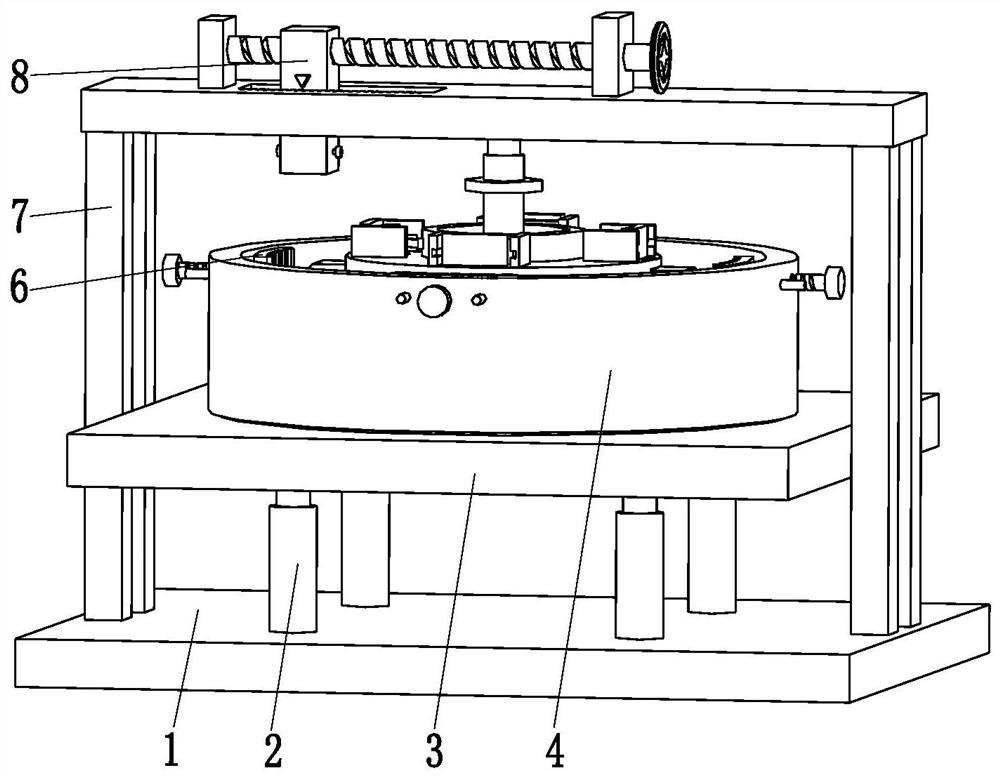

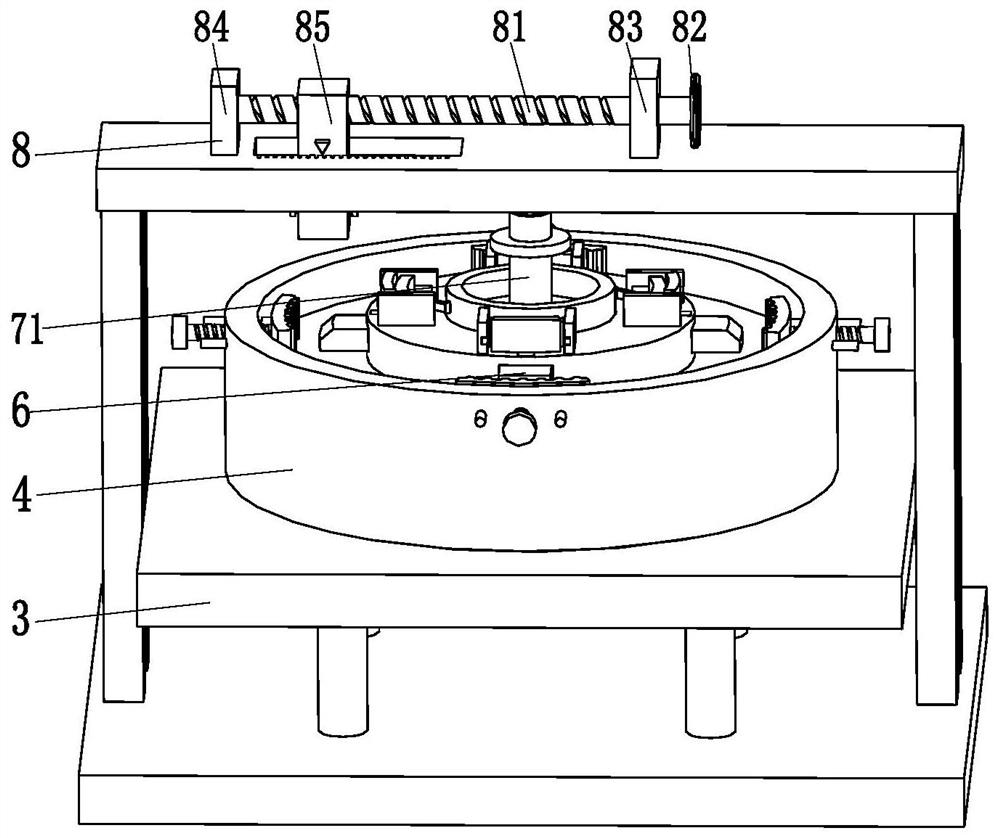

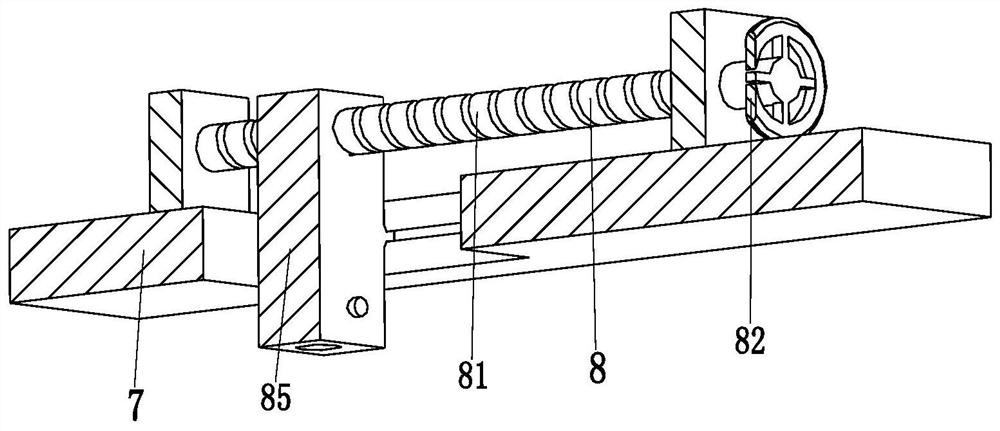

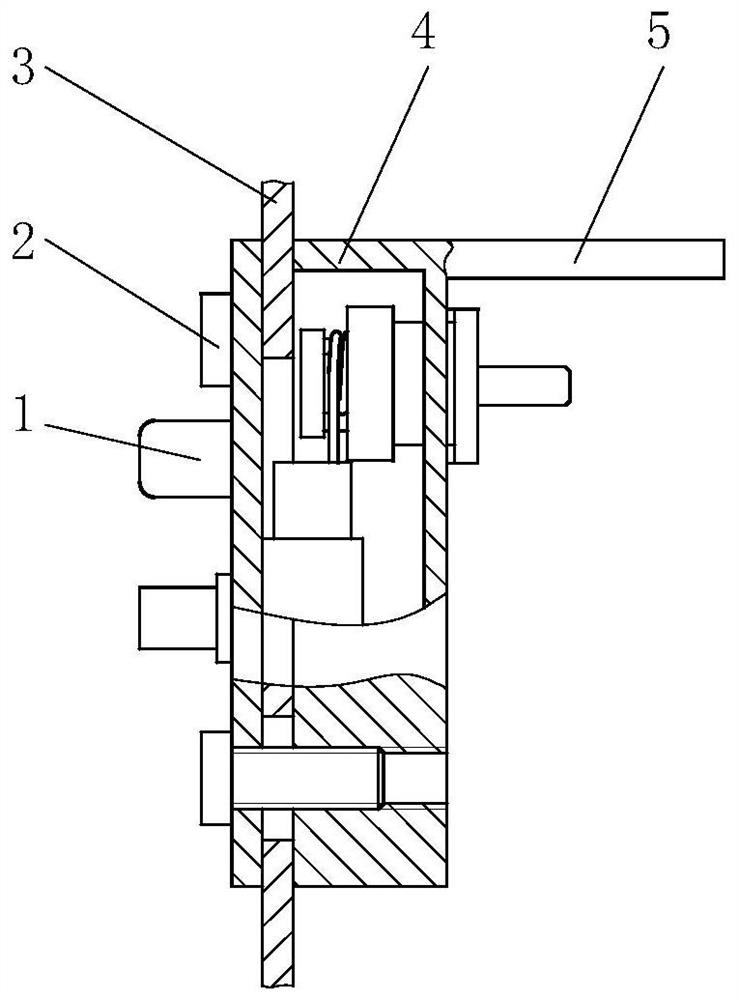

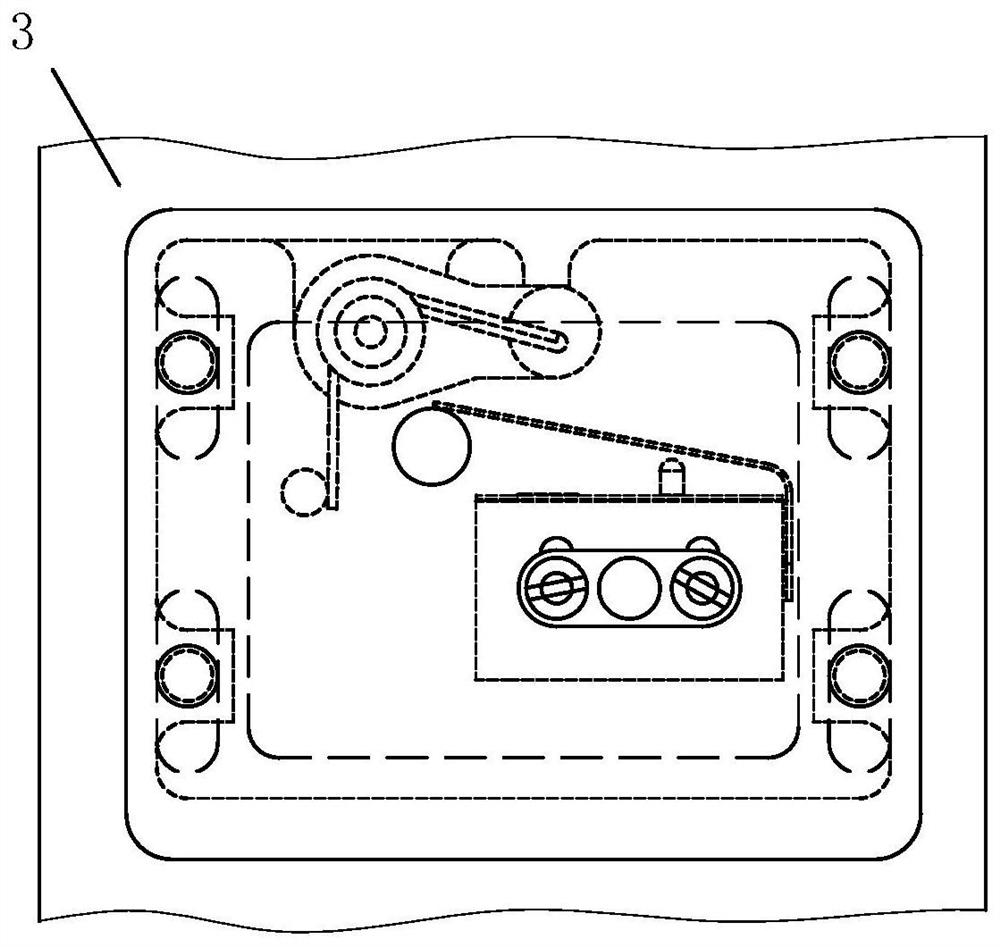

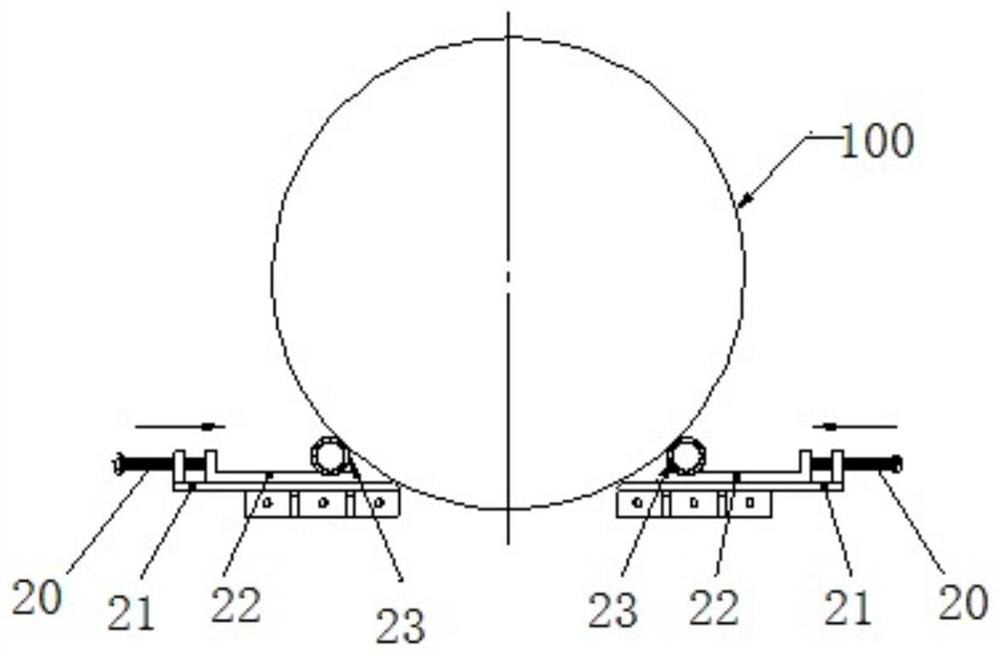

Ultra-low temperature ball valve seat machining device

ActiveCN111545833AImprove stabilityImprove cutting accuracyFeeding apparatusLarge fixed membersElectric machineEngineering

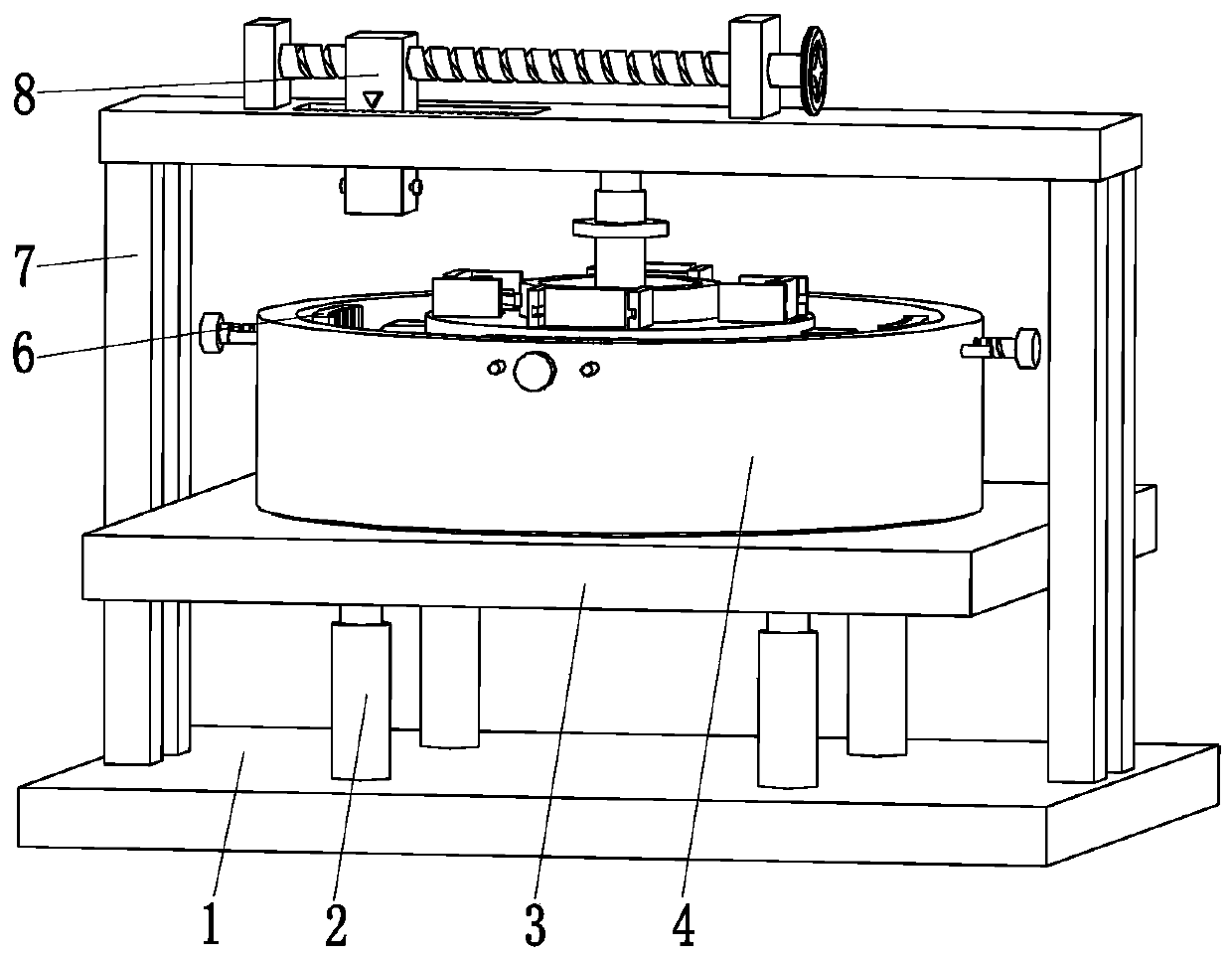

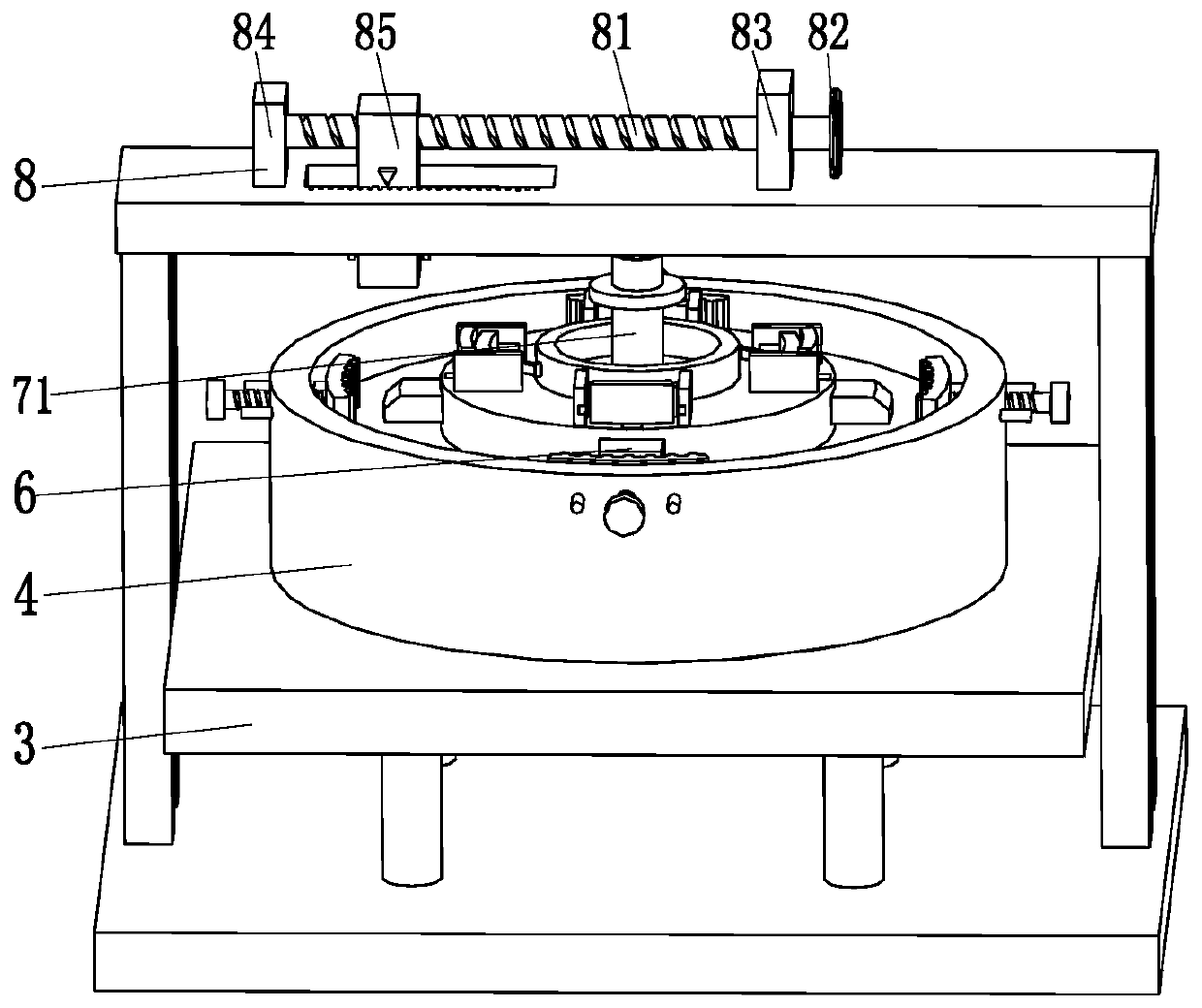

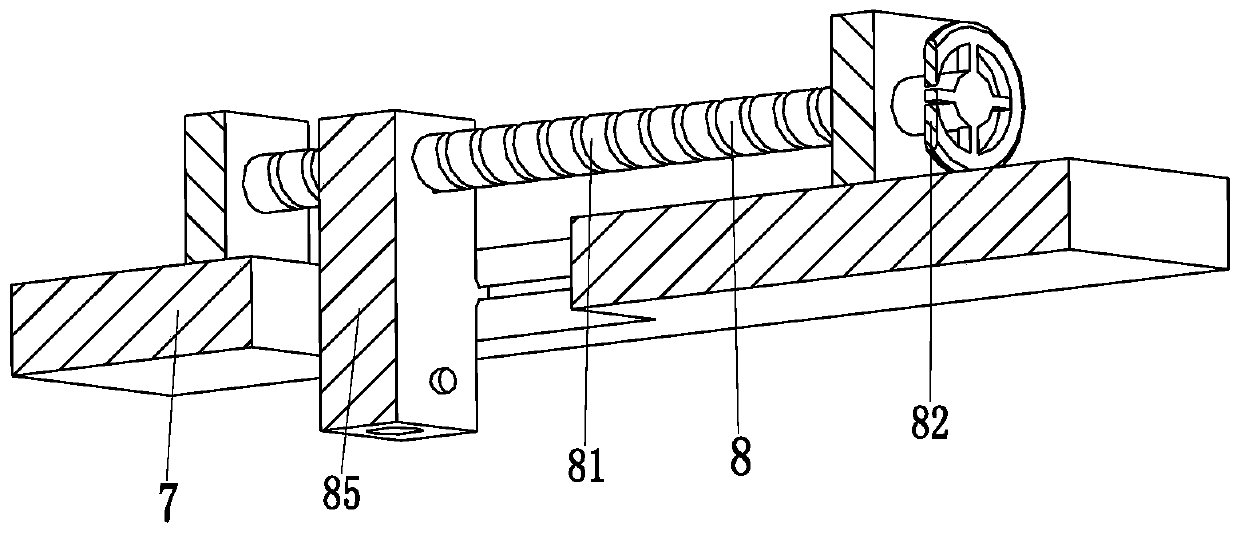

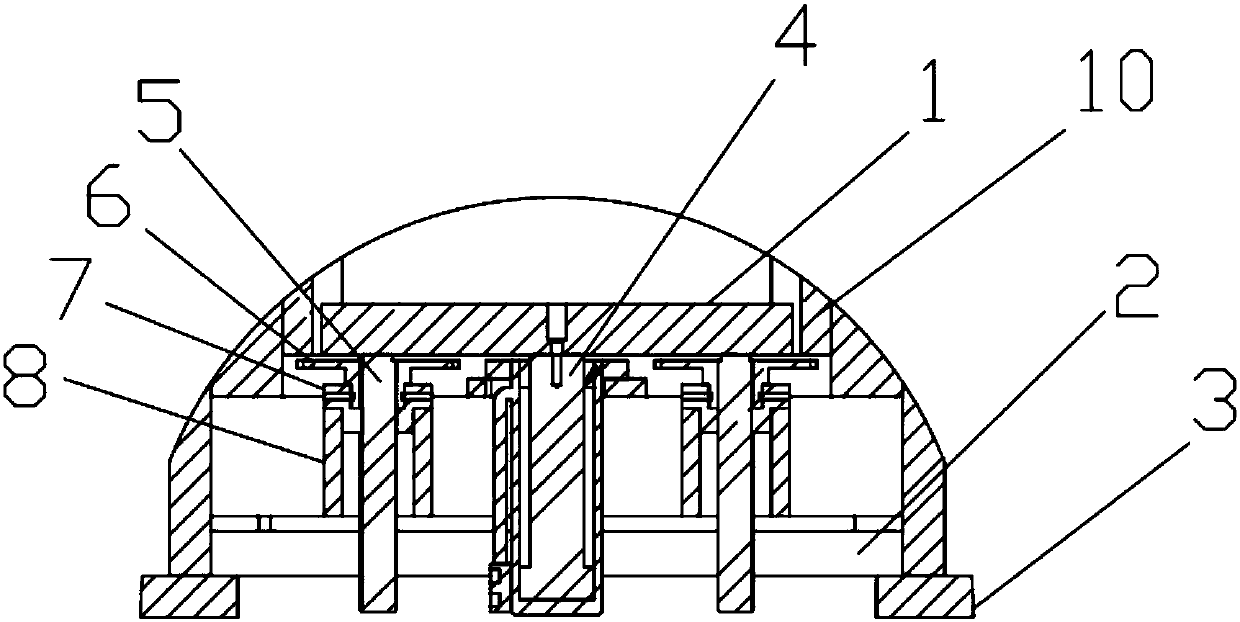

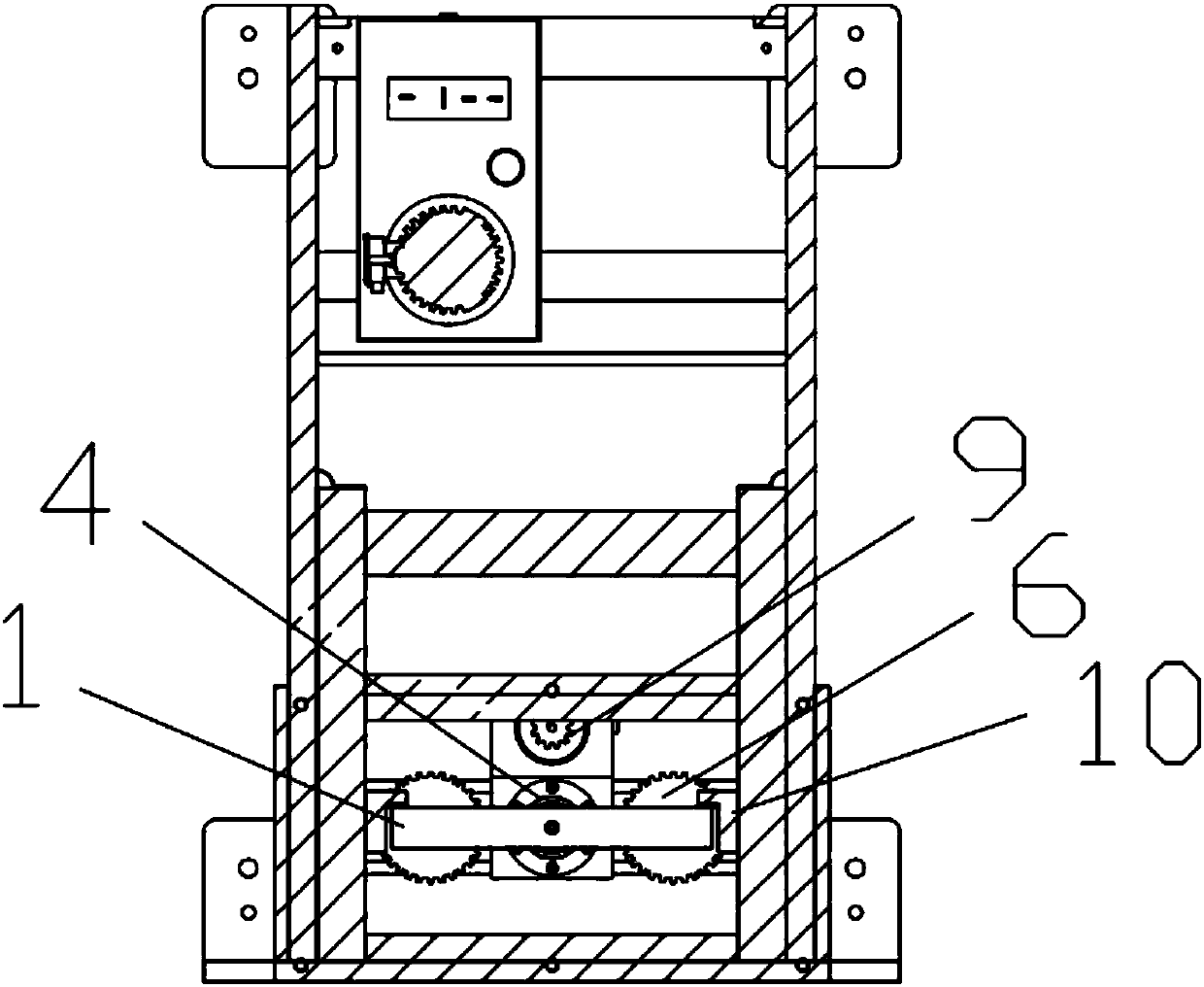

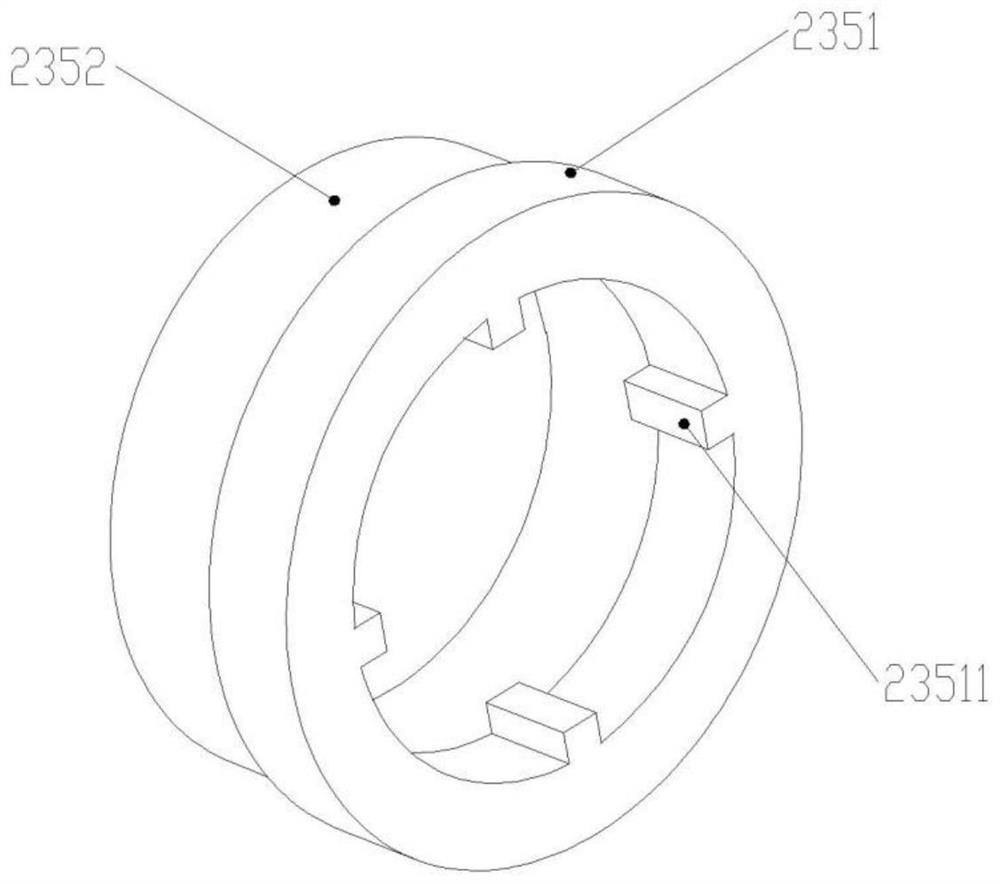

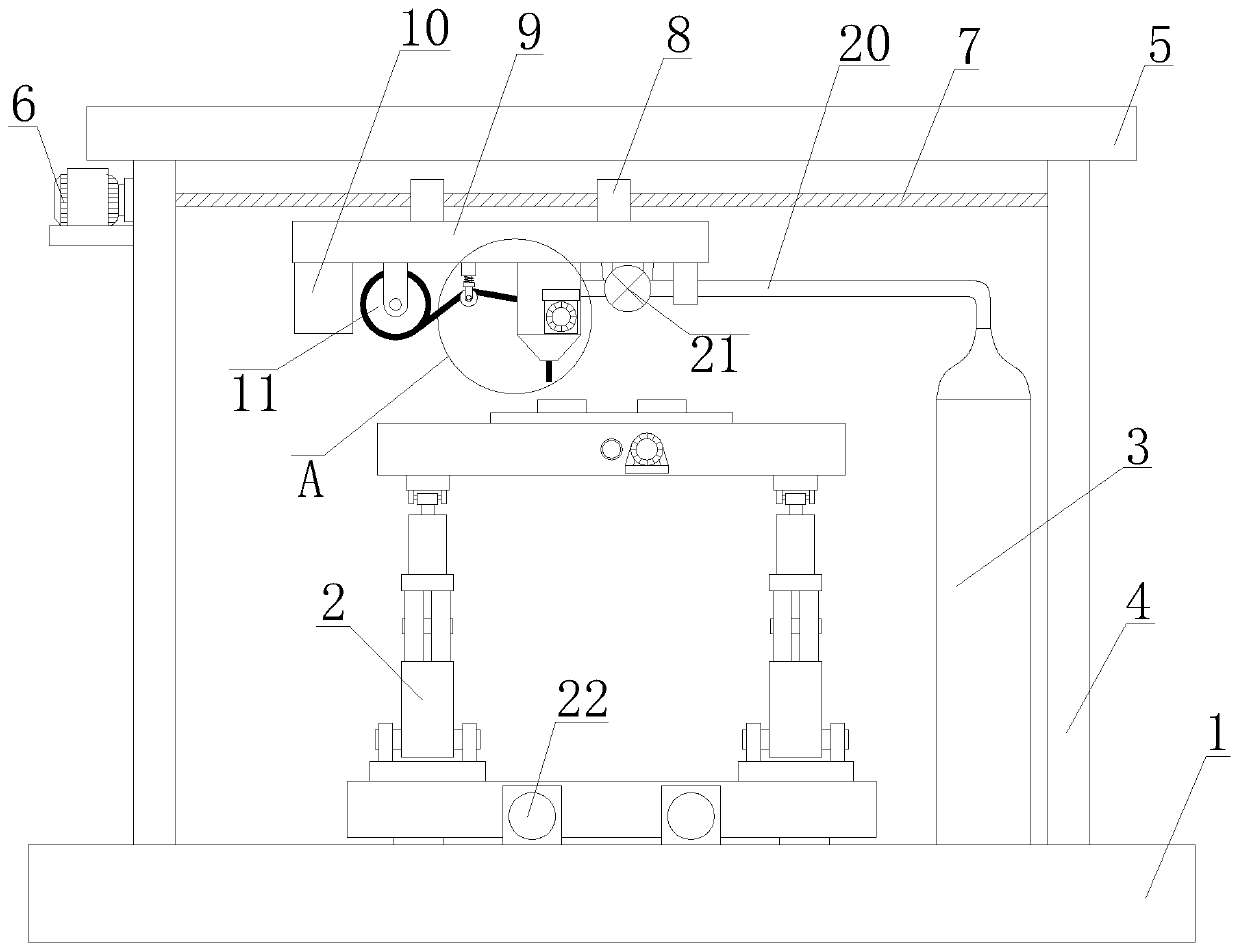

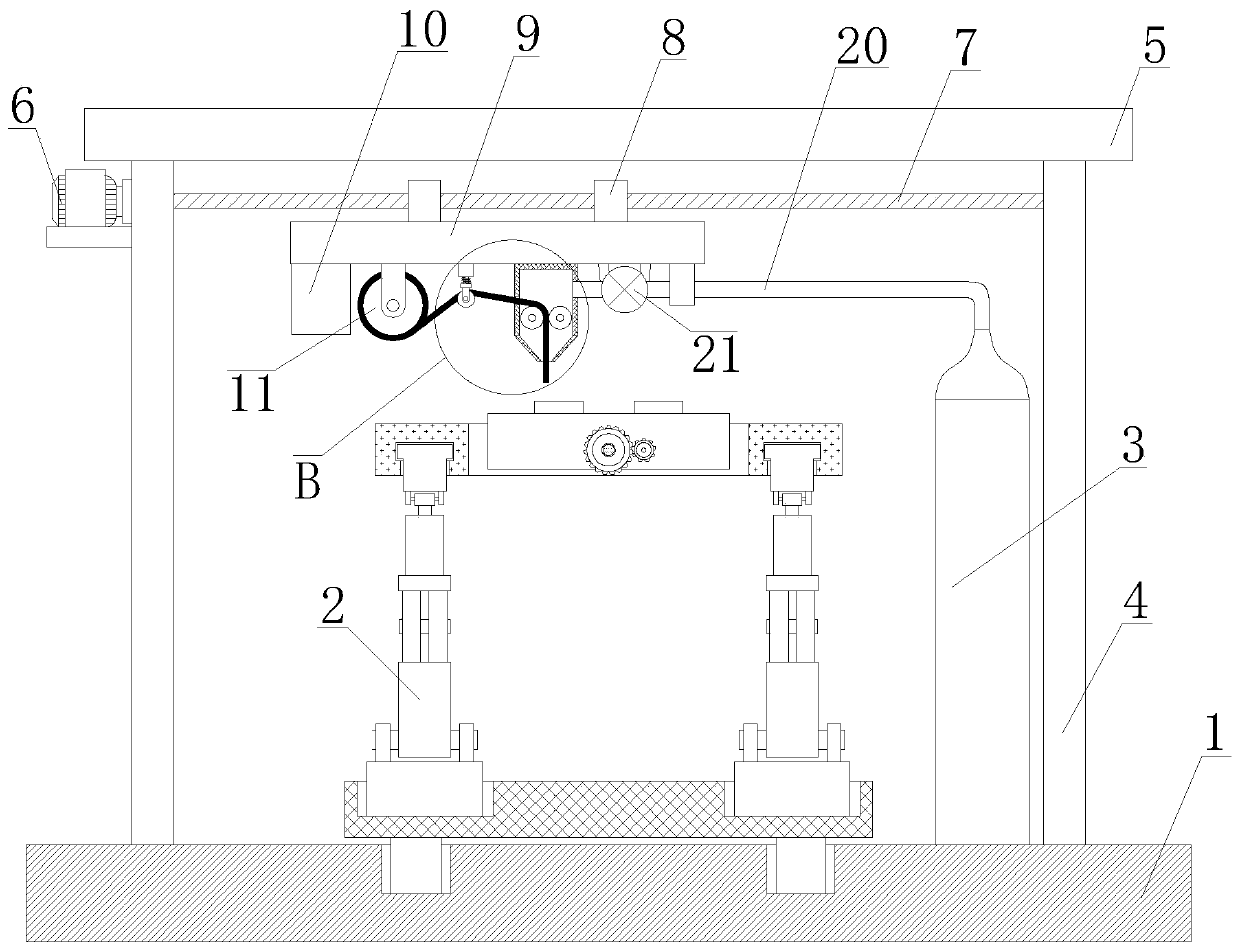

The invention relates to an ultra-low temperature ball valve seat machining device. The ultra-low temperature ball valve seat machining device comprises a bottom plate, a cylinder, a lifting table, aplacing frame, a rotating motor, a locking mechanism, a moving frame and a moving mechanism. The lifting table is installed at the top of the bottom plate through the cylinder, a ring chute is formedin the middle part of the lifting table, and the lower end of the placing frame is connected with the ring chute in a sliding fit mode. The lower end of the placing frame is of a hollow cylinder structure with an opening, an output shaft of the rotating motor is connected with the middle and lower side wall of the placing frame, the locking mechanism is installed on the placing frame, the lower end of the moving frame is connected with the top of the bottom plate, and the moving mechanism is installed on the moving frame. The ultra-low temperature ball valve seat machining device can solve theexisting problems that when an existing ball valve seat is cut and machined, no locking fixture is provided for a valve seat structure during cutting and locking of a ball valve seat, a certain deviation exists between the center position of the ball valve seat after locking and the center position of a rotating shaft, so that the cutting accuracy of the valve seat is poor.

Owner:JIANG SU YAN DIAN FA MEN CO LTD

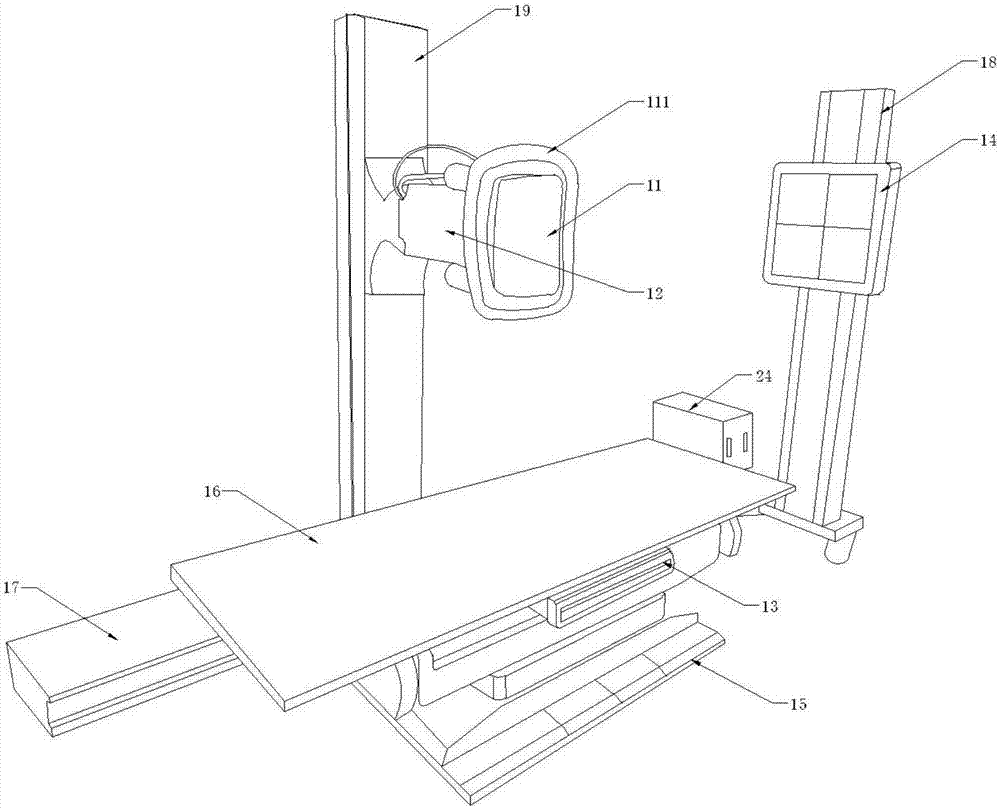

High-automation double-column X-ray photographing system and X-ray photographing method

InactiveCN106859682AReduce work intensityImprove camera efficiencyPatient positioning for diagnosticsX-rayHuman error

The invention provides a high-automation double-column X-ray photographing system and an X-ray photographing method, and belongs to the field of medical equipment. The photographing system comprises a ray emitting device, an emitting device fixing base, a ray receiving device, a receiving device fixing base, a pedestal, a bed, a horizontal track, a first vertical track, a second vertical track, a first driving device, a second driving device, a first infrared measuring device and a controller. The first infrared measuring device can automatically measure the height of a patient and send the height information to the controller; according to the height information, the controller controls the first driving device to drive the receiving device fixing base to move on the first vertical track so that the receiving device fixing base can be flush with the chest of the patient, and meanwhile the controller controls the second driving device so that the ray emitting device can be aligned with the ray receiving device. According to the photographing system, the positions of the ray emitting device and the ray receiving device can be automatically adjusted, so that the work intensity of doctors is relieved, and the photographing efficiency is improved; besides, the position adjusting precision is improved, and human errors are avoided.

Owner:YISHITONG SHANGHAI MEDICAL DEVICES

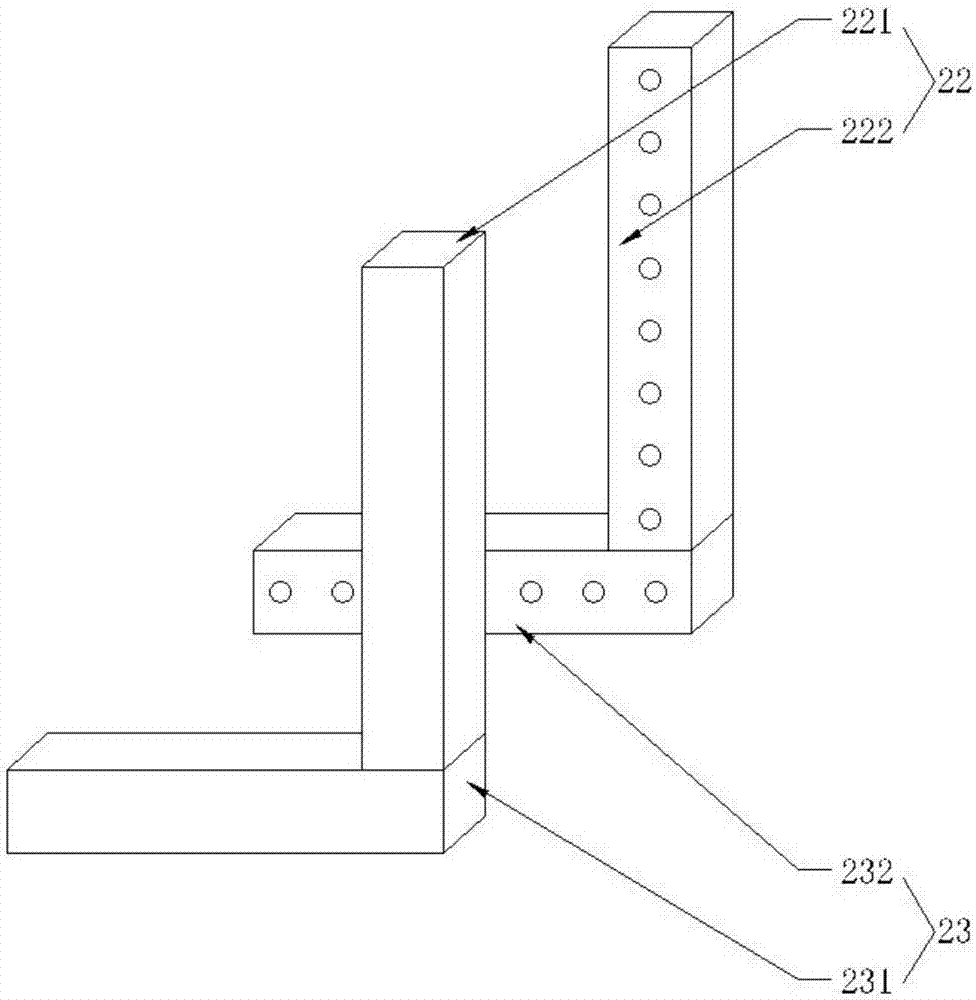

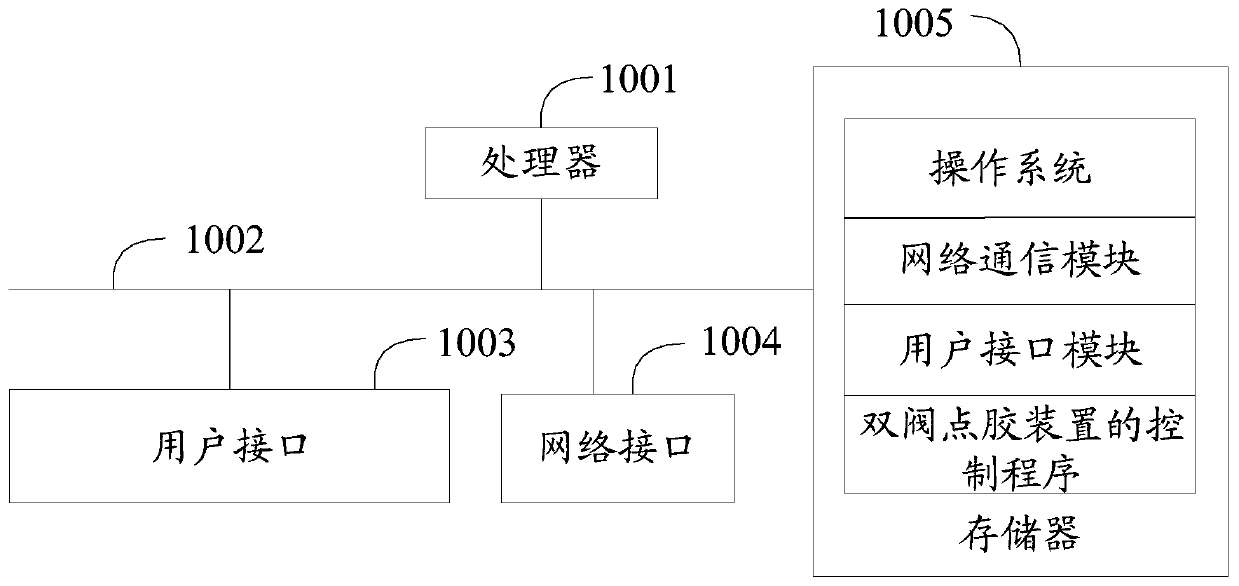

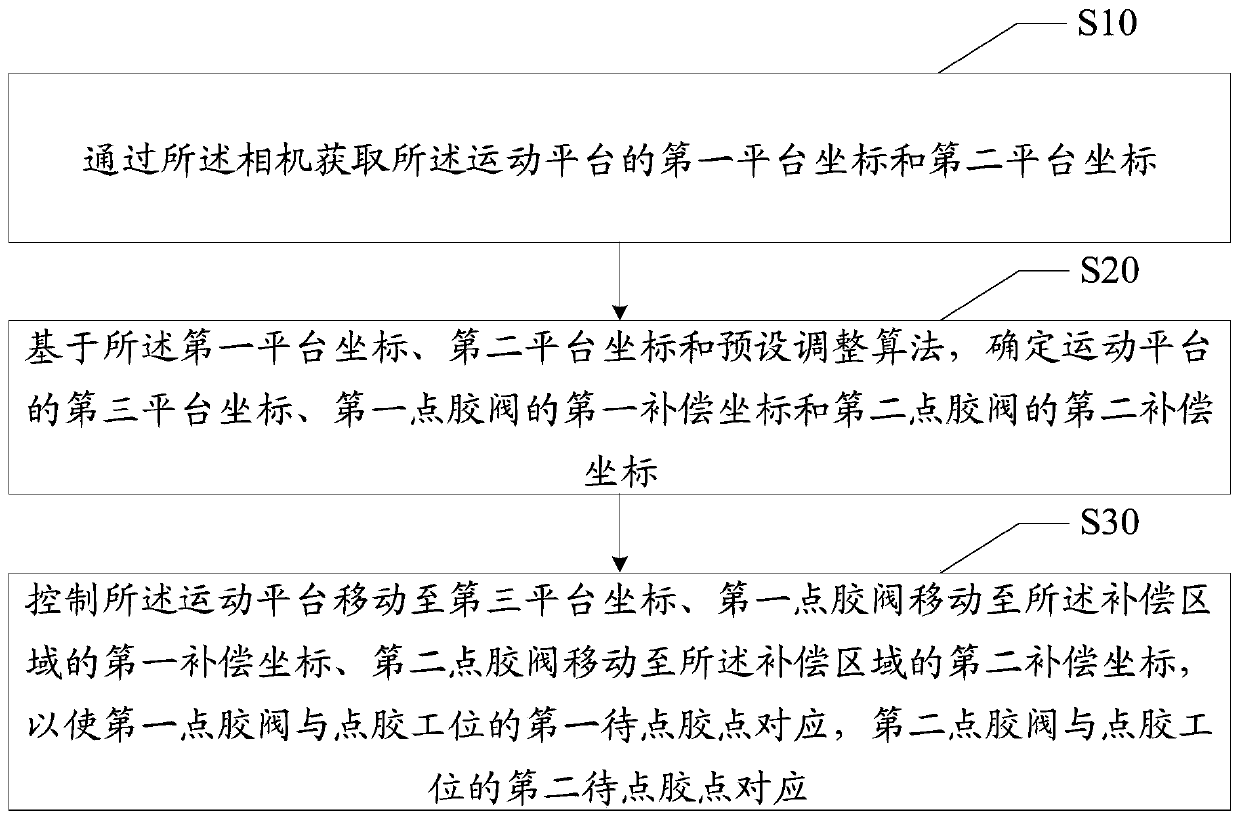

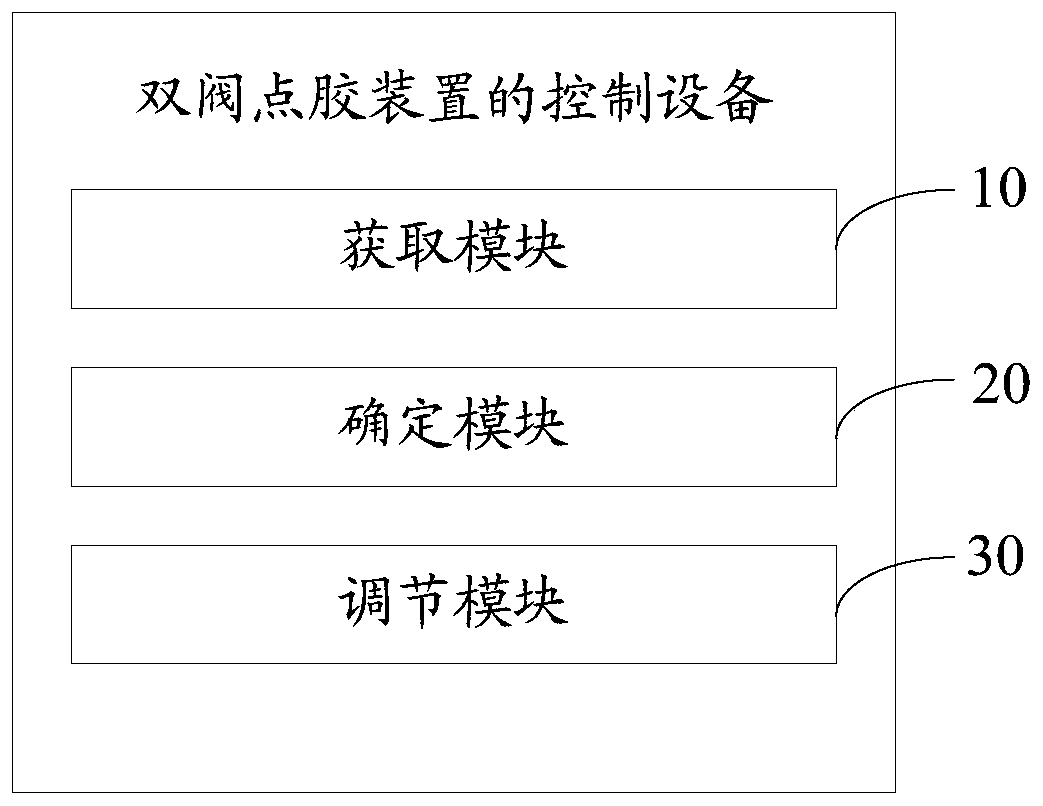

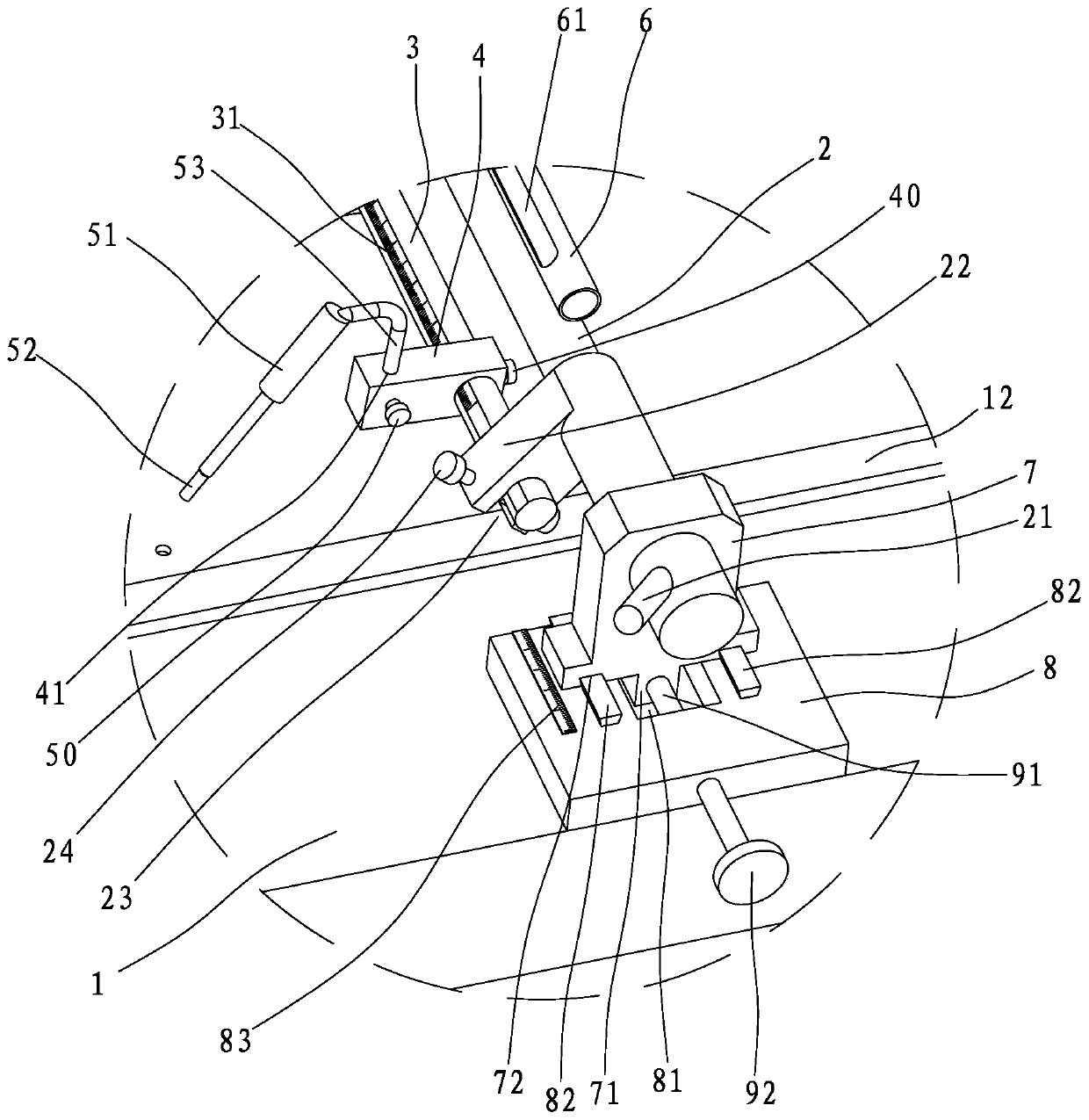

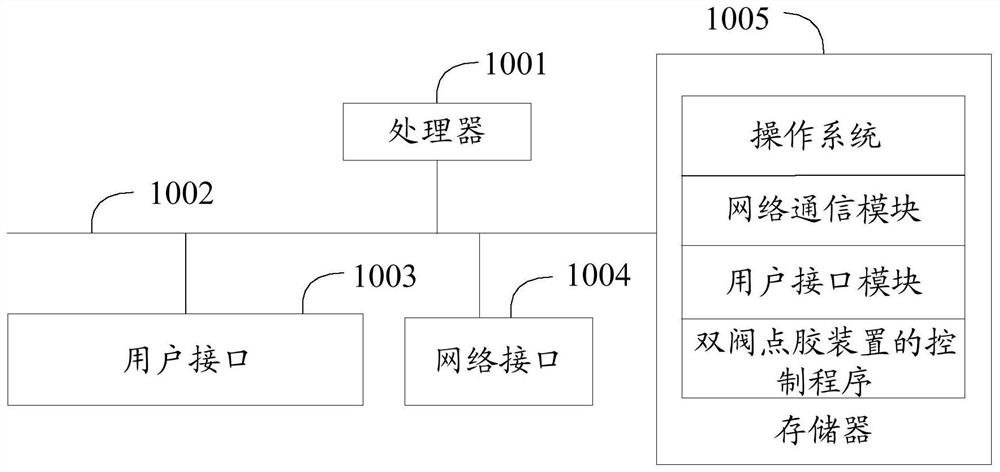

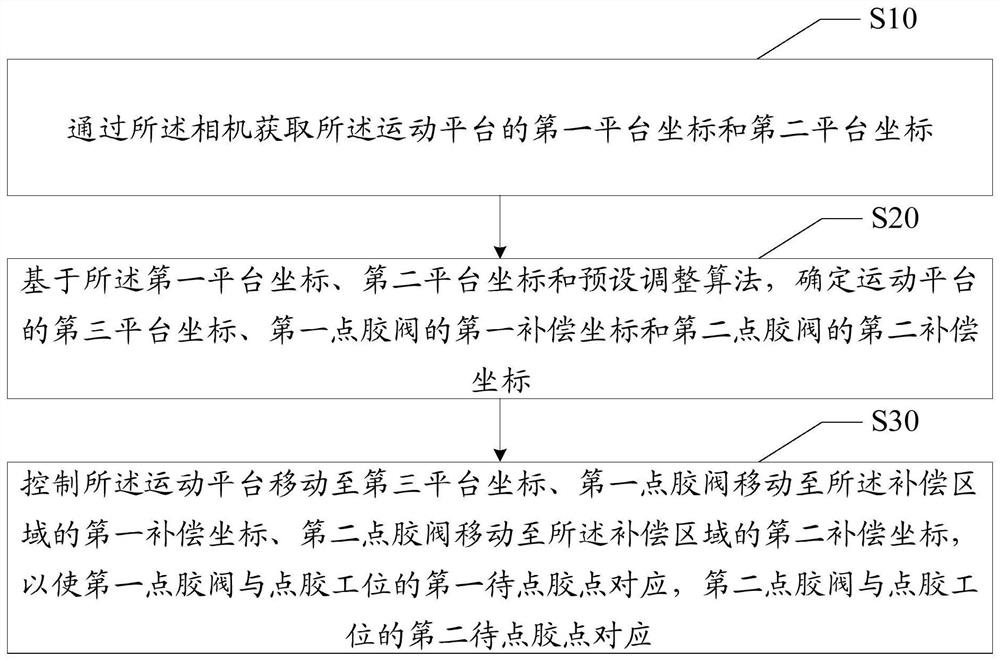

Method and equipment for controlling double-valve adhesive dispensing device and storage medium

ActiveCN110813649AHigh position adjustment accuracySolve the technical problem of low position adjustment accuracyLiquid surface applicatorsCoatingsAdhesiveEngineering

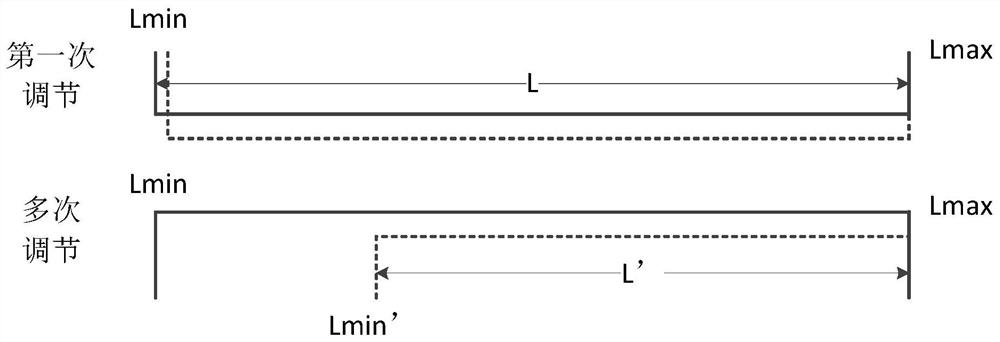

The invention discloses a method and equipment for controlling a double-valve adhesive dispensing device and a storage medium. The method comprises the following steps that when adhesive dispensing valves are located at respective initial positions, first platform coordinates and second platform coordinates enabling the adhesive dispensing valves to correspond to positions to be subjected to adhesive dispensing are determined through a camera; and then third platform coordinates of a motion platform, first compensation coordinates of the first adhesive dispensing valve and second compensationcoordinates of the second adhesive dispensing valve are calculated according to a preset adjusting algorithm, the first platform coordinates and the second platform coordinates; and therefore the motion platform and the adhesive dispensing valves are controlled to move to corresponding positions to guarantee that the positions of the two adhesive dispensing valves correspond to the positions to besubjected to adhesive dispensing. The position adjusting precision of the double-valve adhesive dispensing device is improved, and therefore the technical problem that the position adjusting precision of a double-valve adhesive dispensing device in the prior art is low is solved.

Owner:深圳市特瑞吉科技有限公司

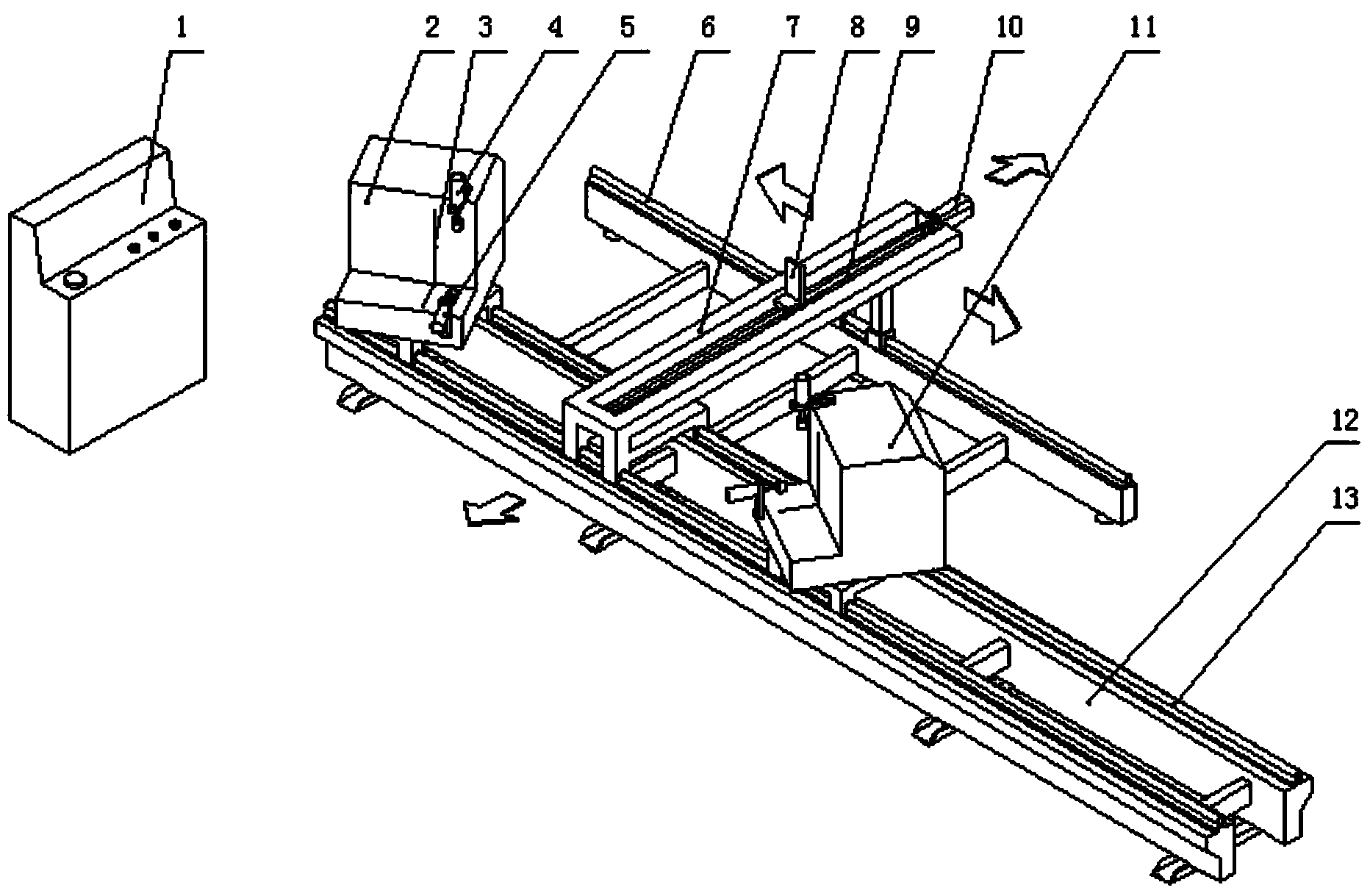

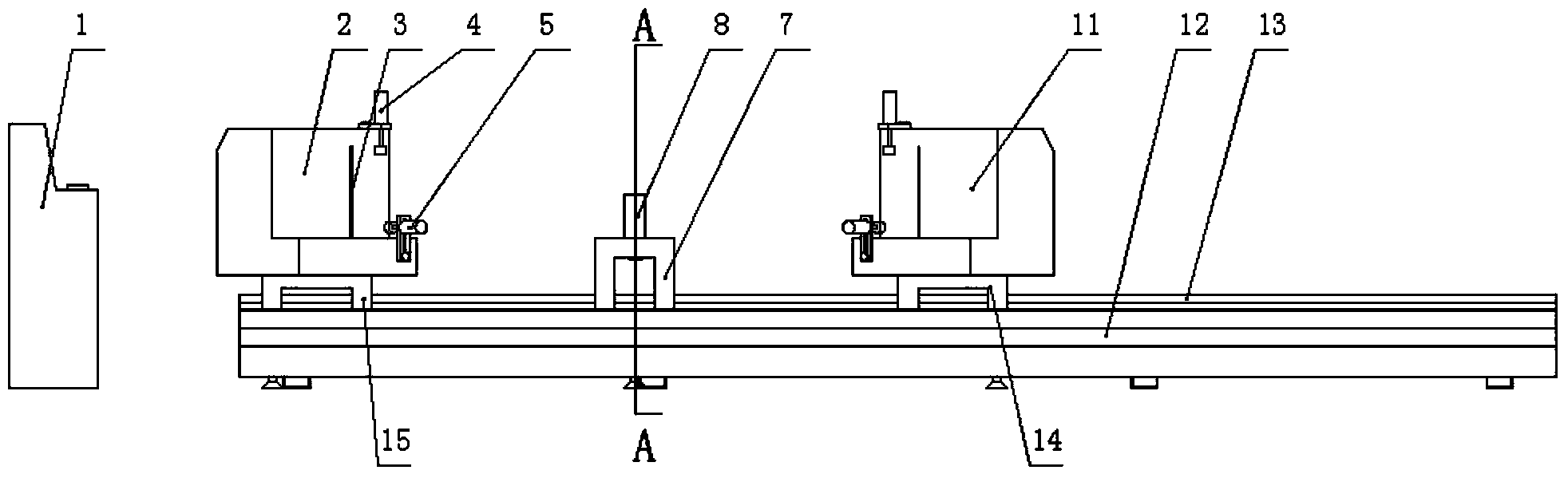

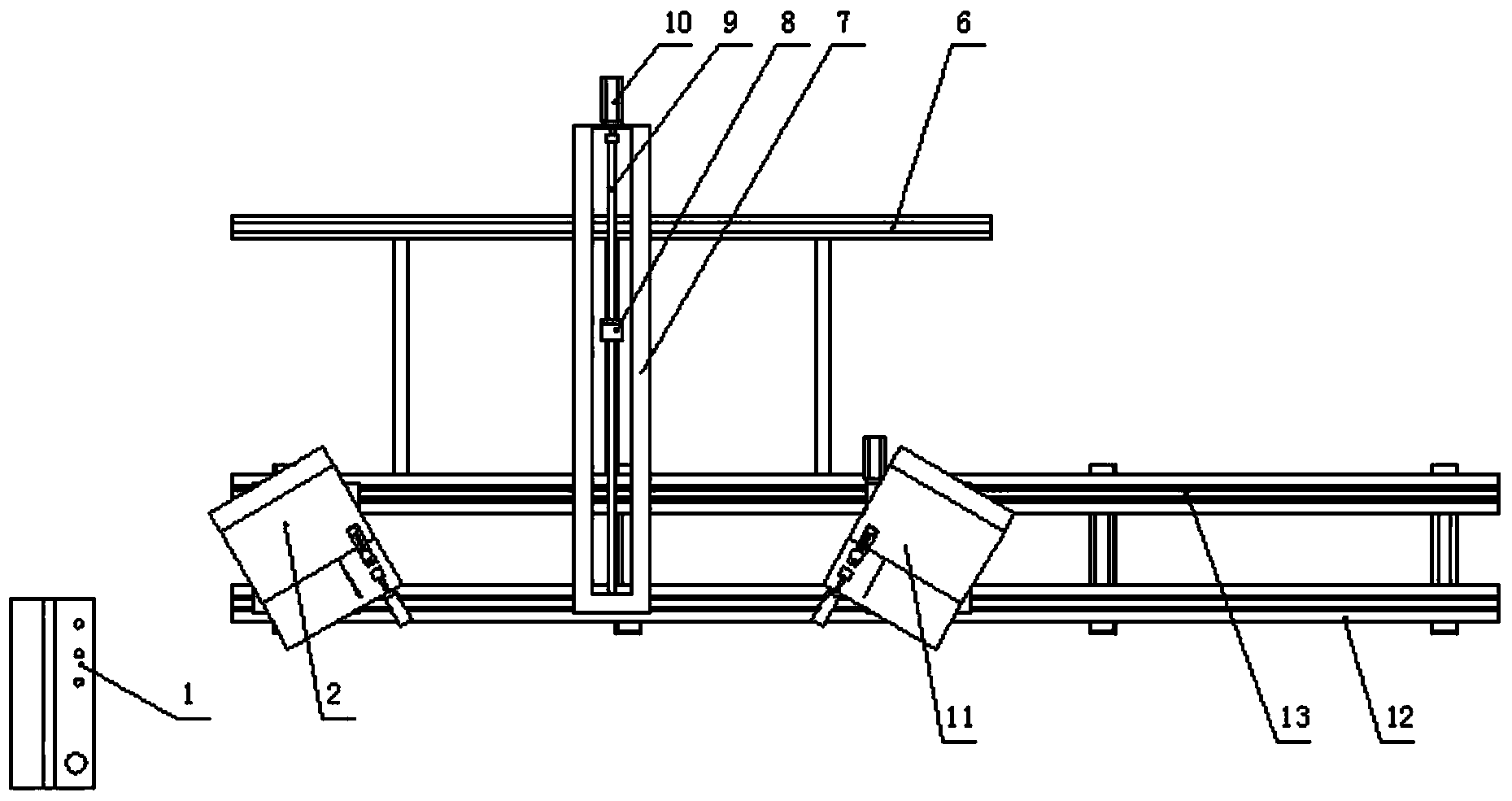

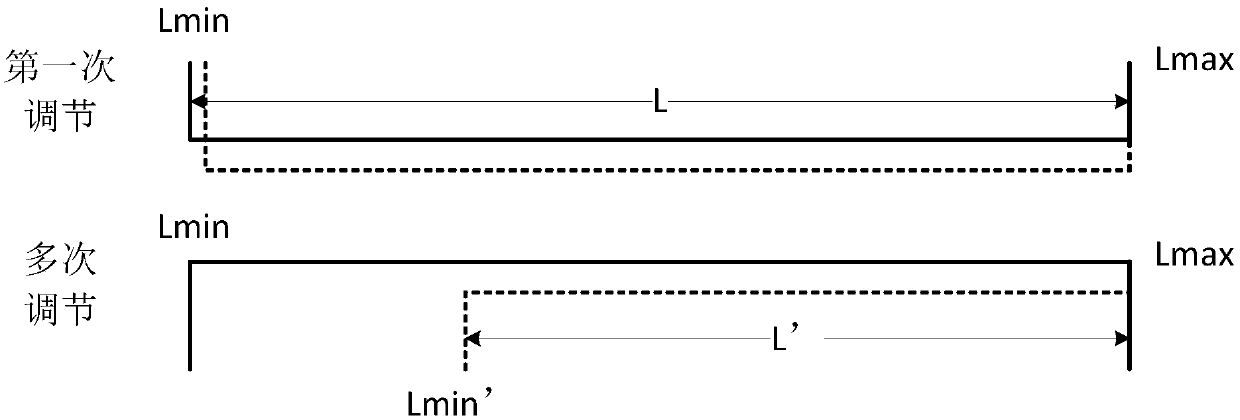

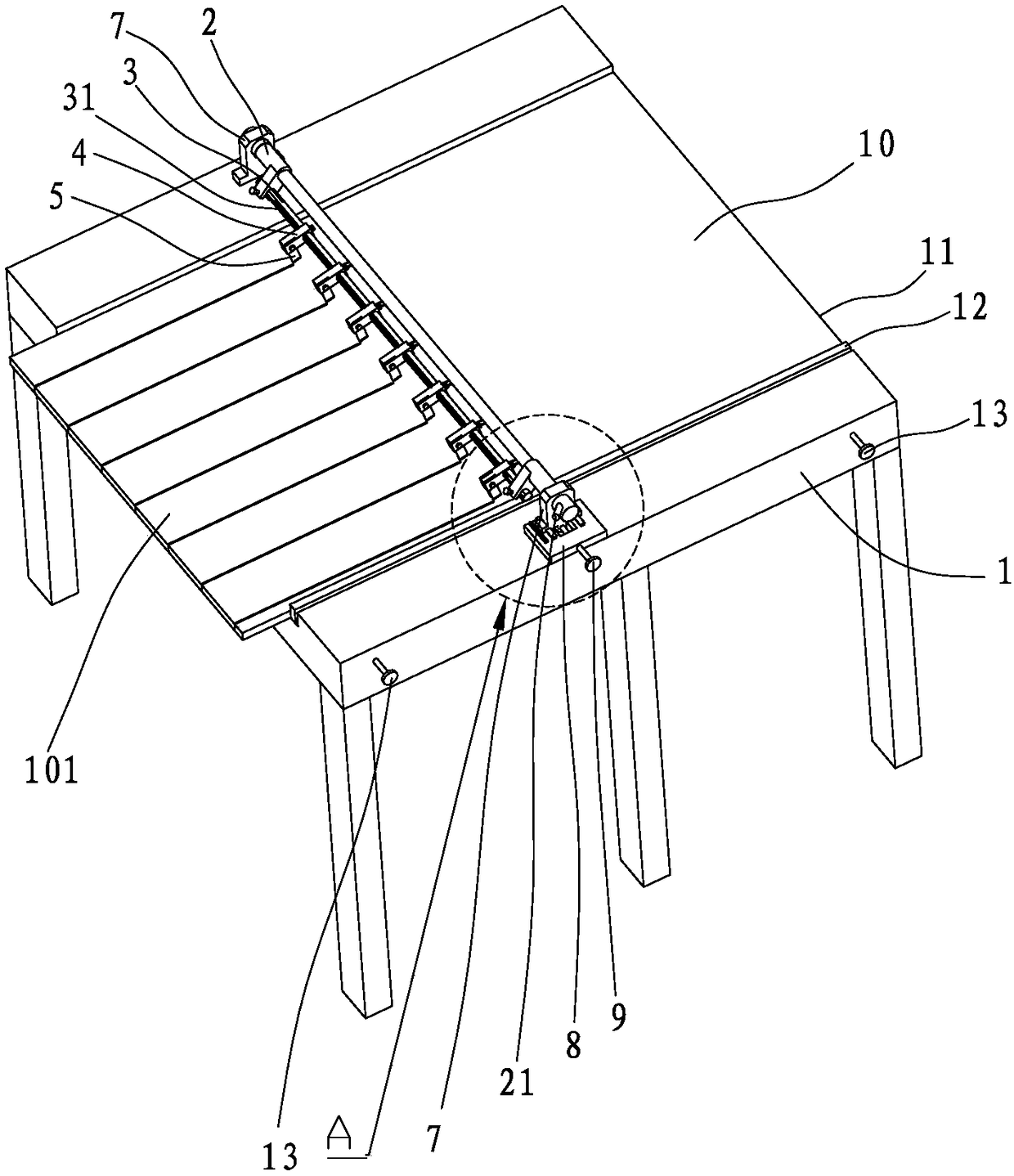

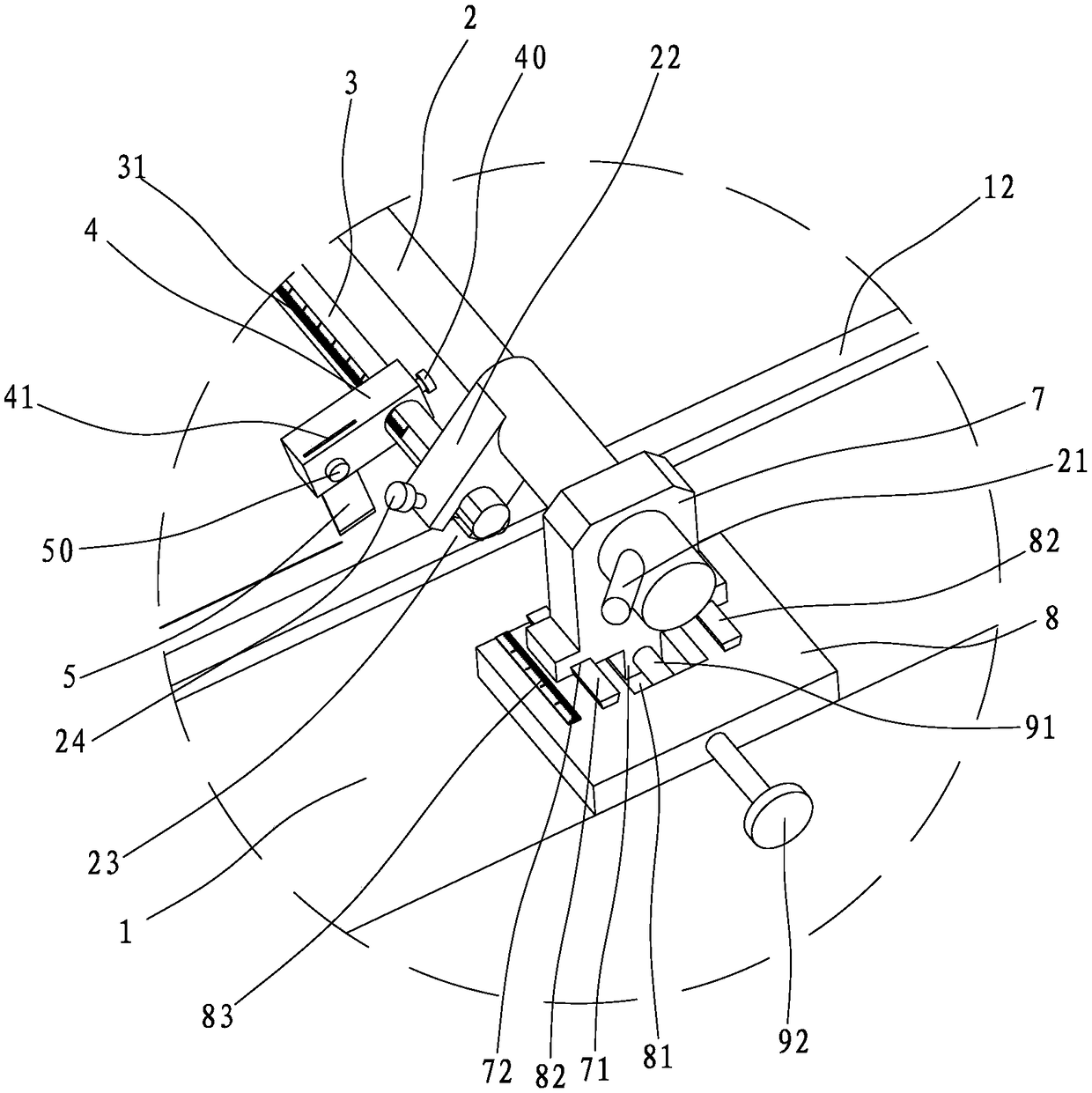

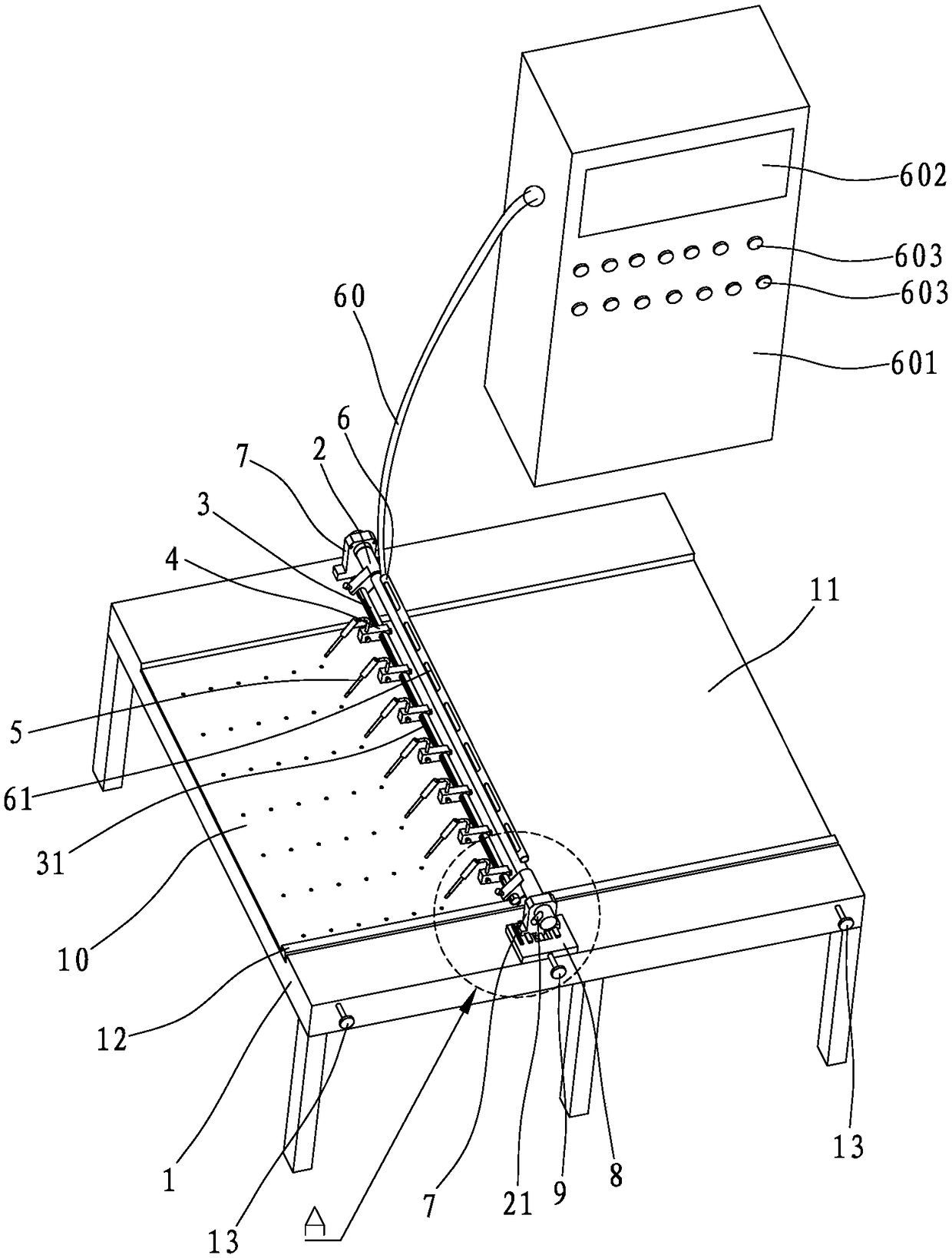

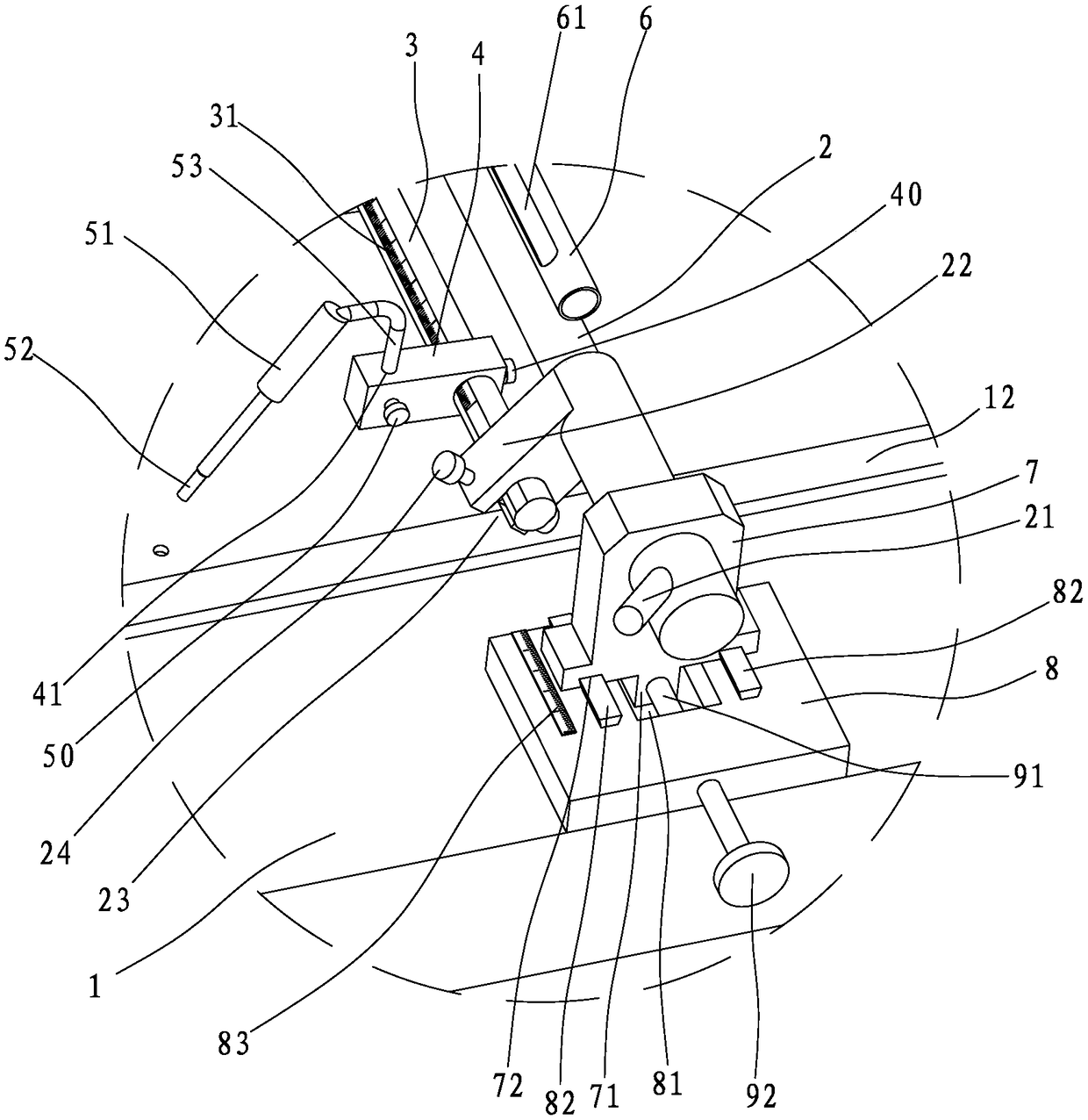

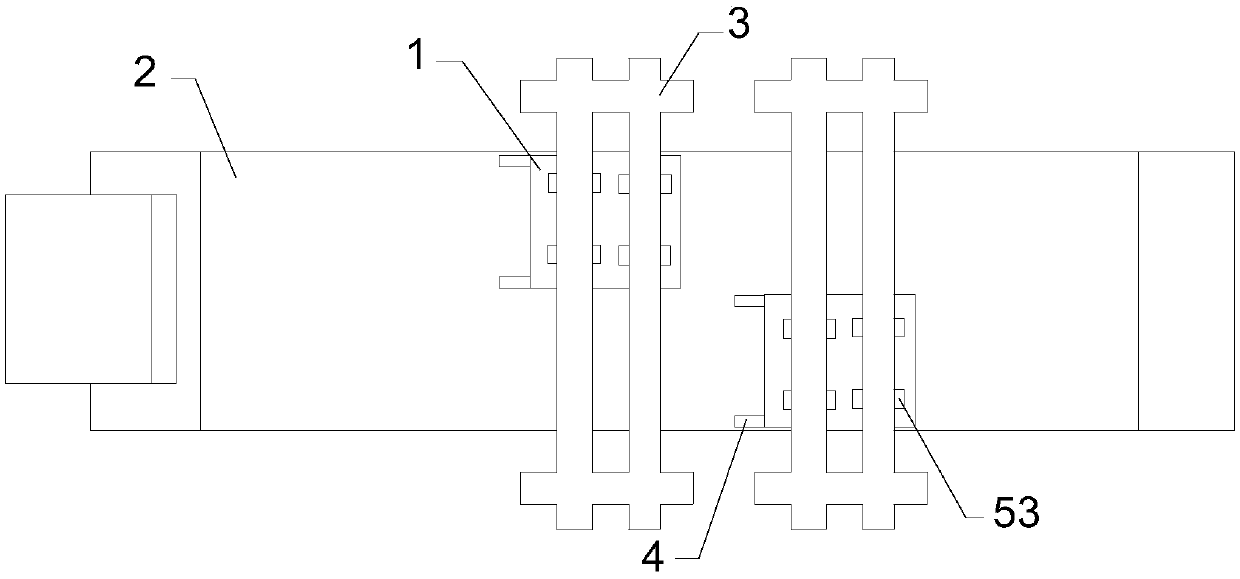

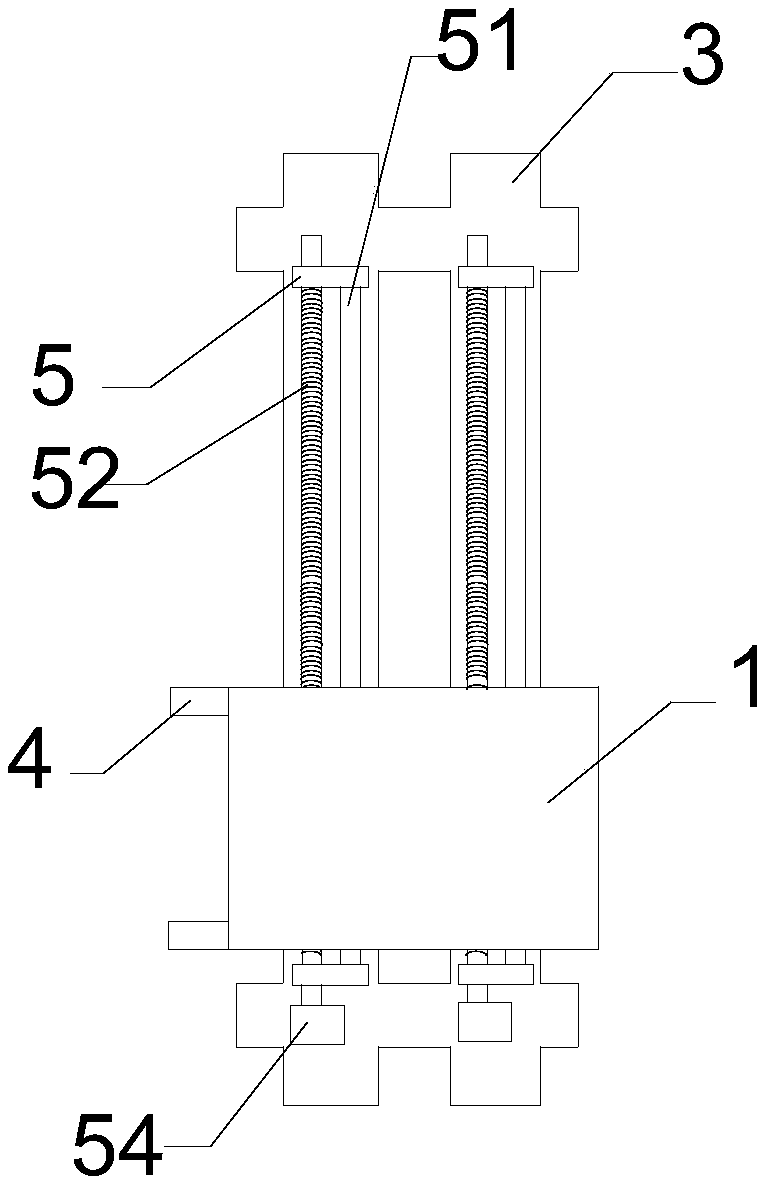

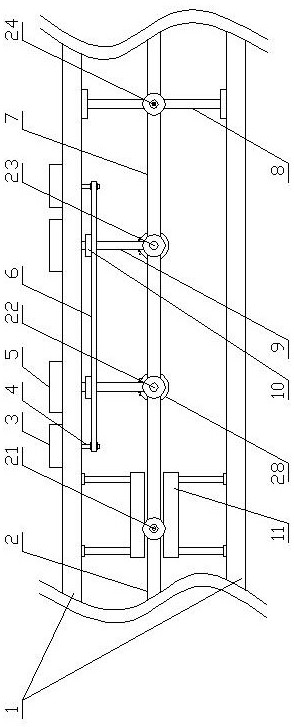

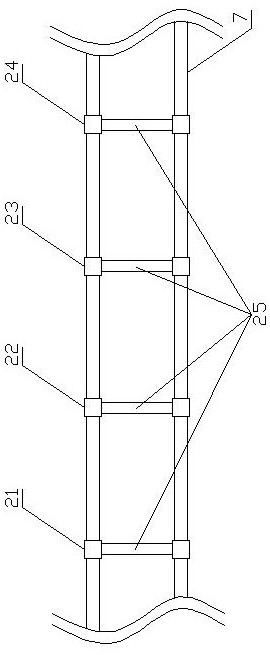

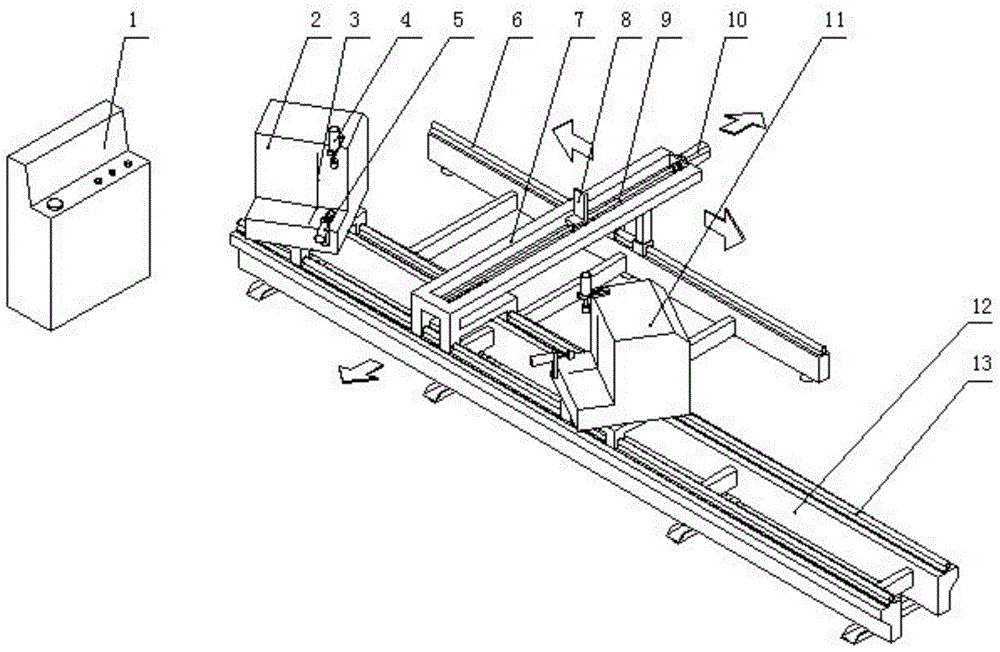

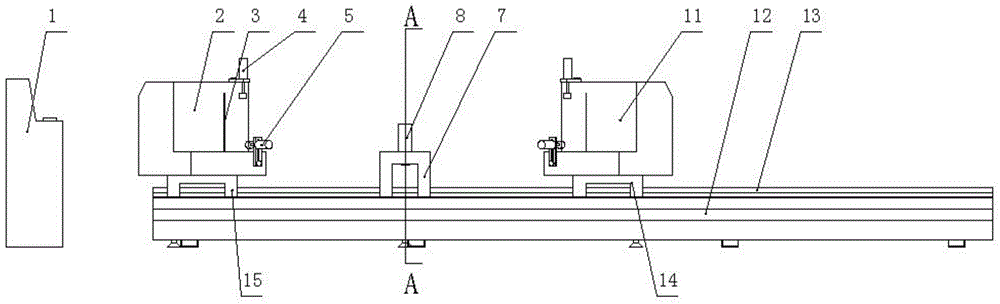

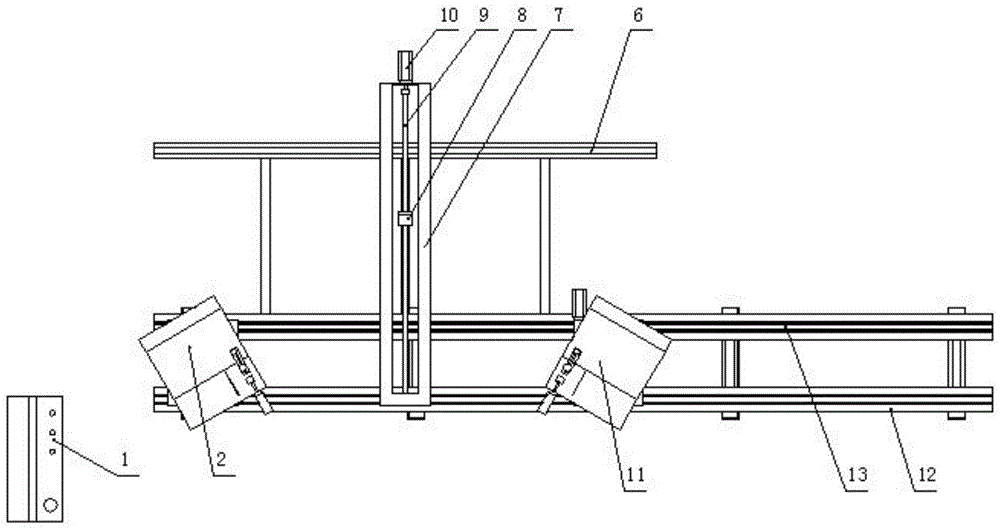

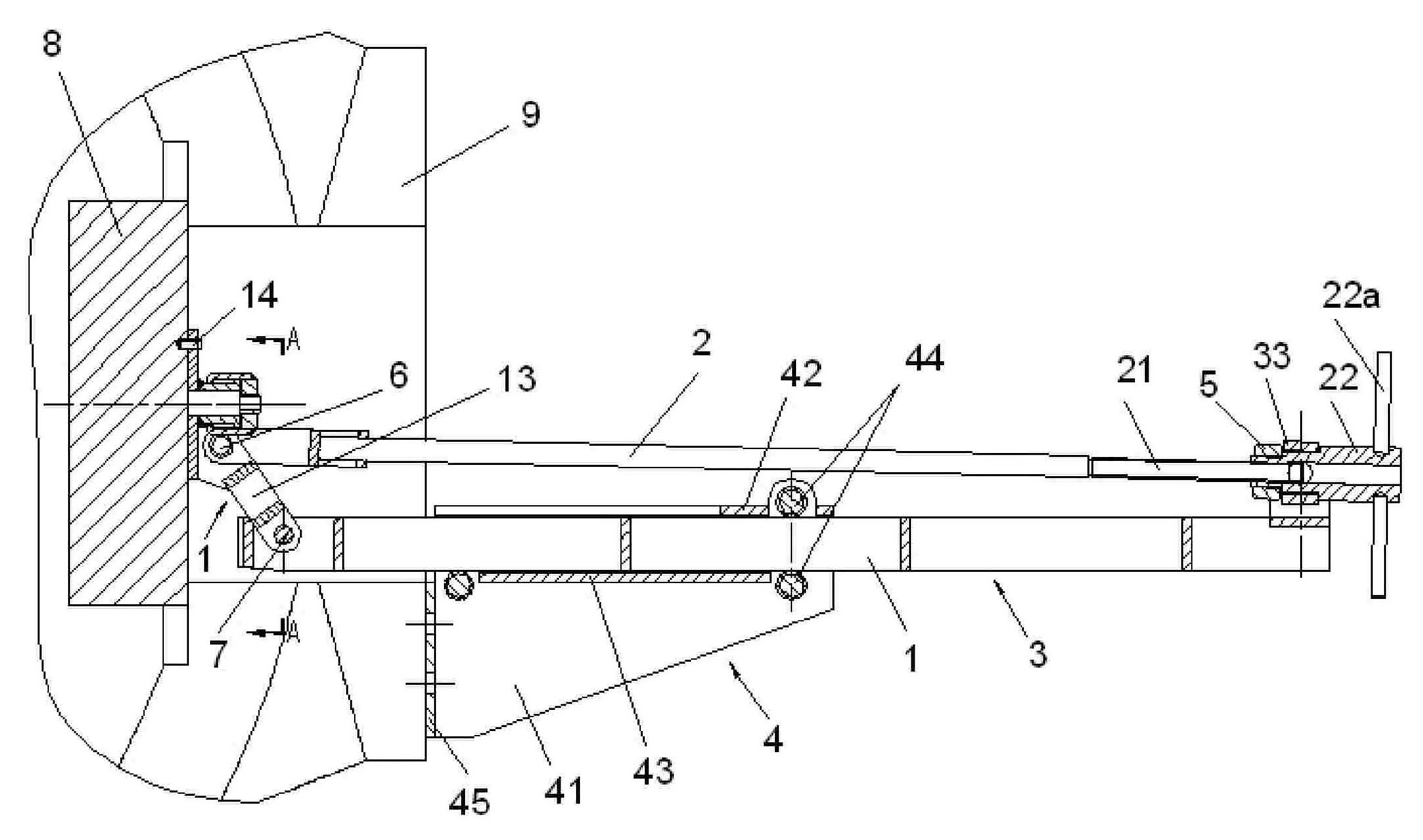

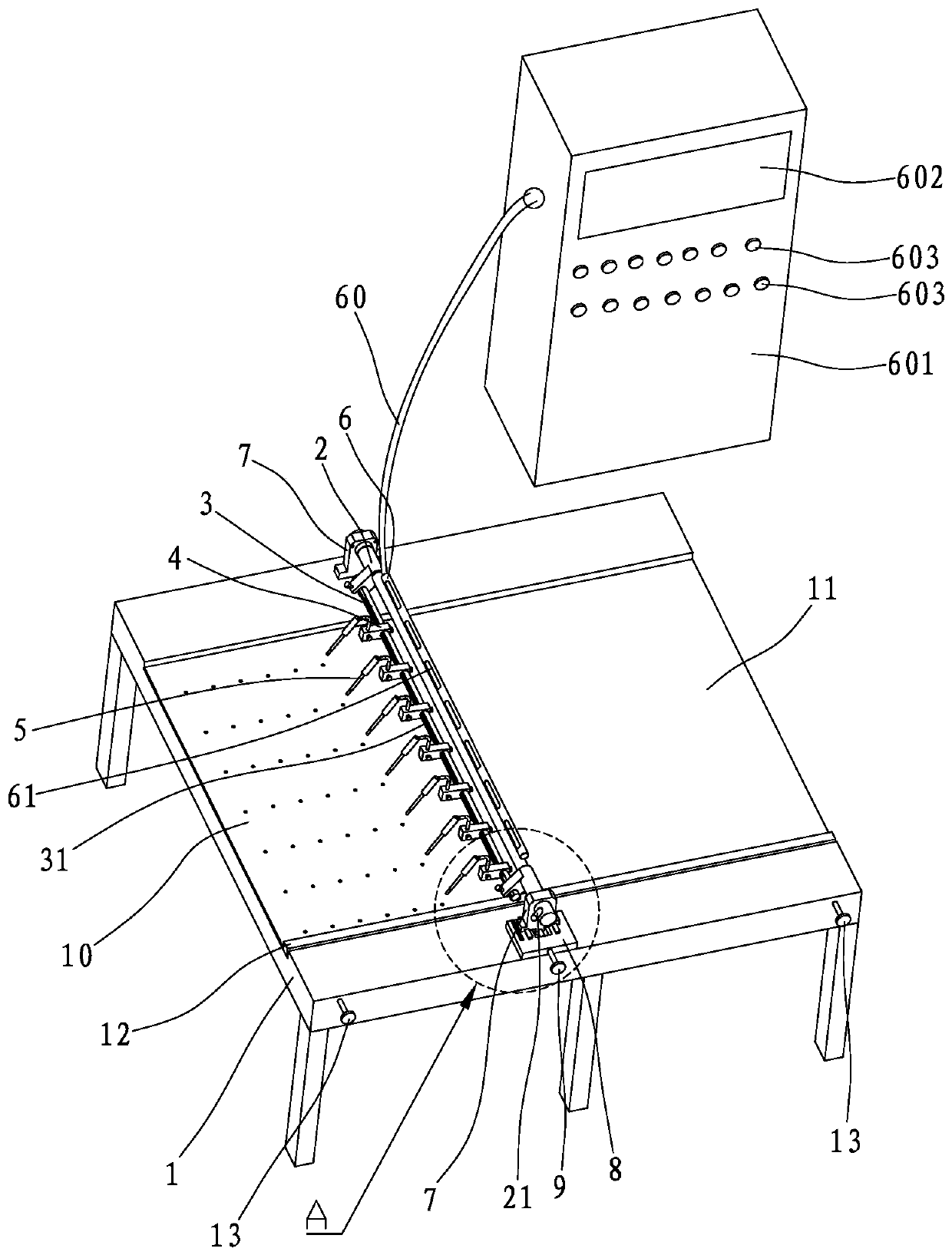

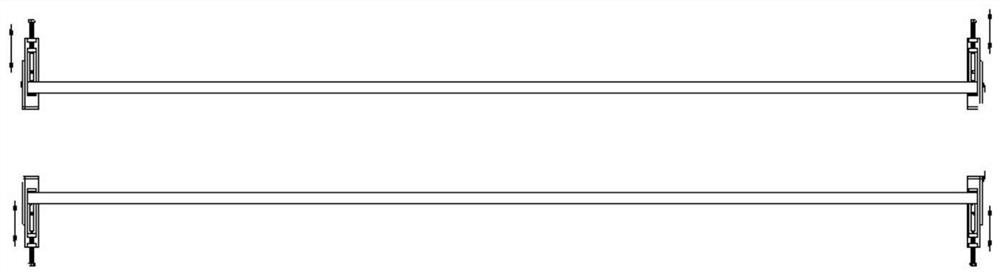

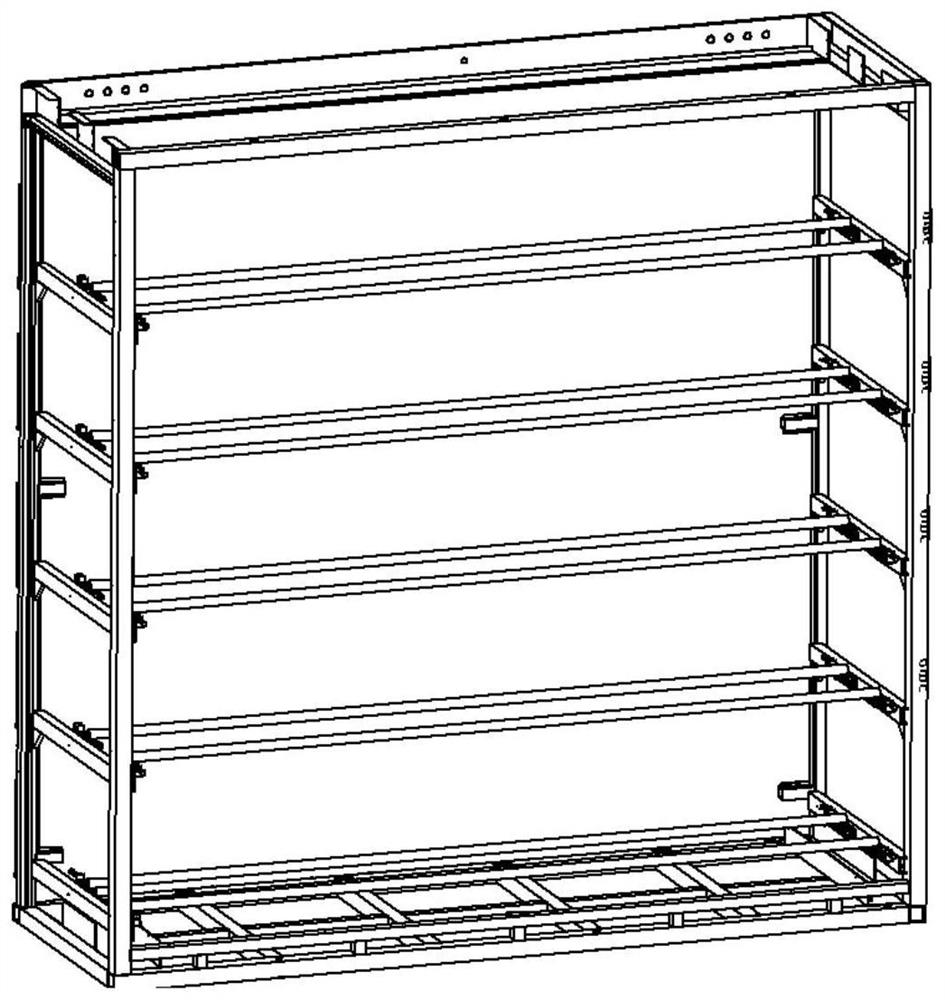

Cutting system of sliding cover of rotating door and processing method of cutting system

ActiveCN104139216AGuaranteed stabilityPrecise positioningMetal sawing devicesPositioning apparatusEngineeringElectric control

The invention relates to a cutting system of a sliding cover of a rotating door and a processing method of the cutting system. The cutting system comprises a rack, an electric control cabinet, parallel guide rails, a fixed cap head cutting saw, a movable cap head cutting saw and a center frame, wherein one side in front of the rack is provided with the electric control cabinet which is convenient for a worker to operate, the upper end of the rack is transversely, horizontally and fixedly provided with the parallel guide rails, the fixed cap head cutting saw is fixedly arranged in the end portions of the parallel guide rails, the movable cap head cutting saw is arranged in the other end portions of the parallel guide rails in a sliding and guiding way, and the center frame is arranged on the parallel guide rails which are arranged between the movable cap head cutting saw and the fixed cap head cutting saw in the sliding and guiding way. According to the cutting system of the sliding cover of the rotating door and the processing method of the cutting system, disclosed by the invention, the structure is simple, intelligence and reliability are realized, the operation is convenient, the processing efficiency is high, the size of a workpiece is set, an accurate position which is located by three points is automatically adjusted, cutting processing can be carried out on the workpiece by clamping the workpiece, the clamping is stable, the cutting accuracy is high, and high quality and high efficiency are realized.

Owner:TIANJIN SENJIAN METAL PROD

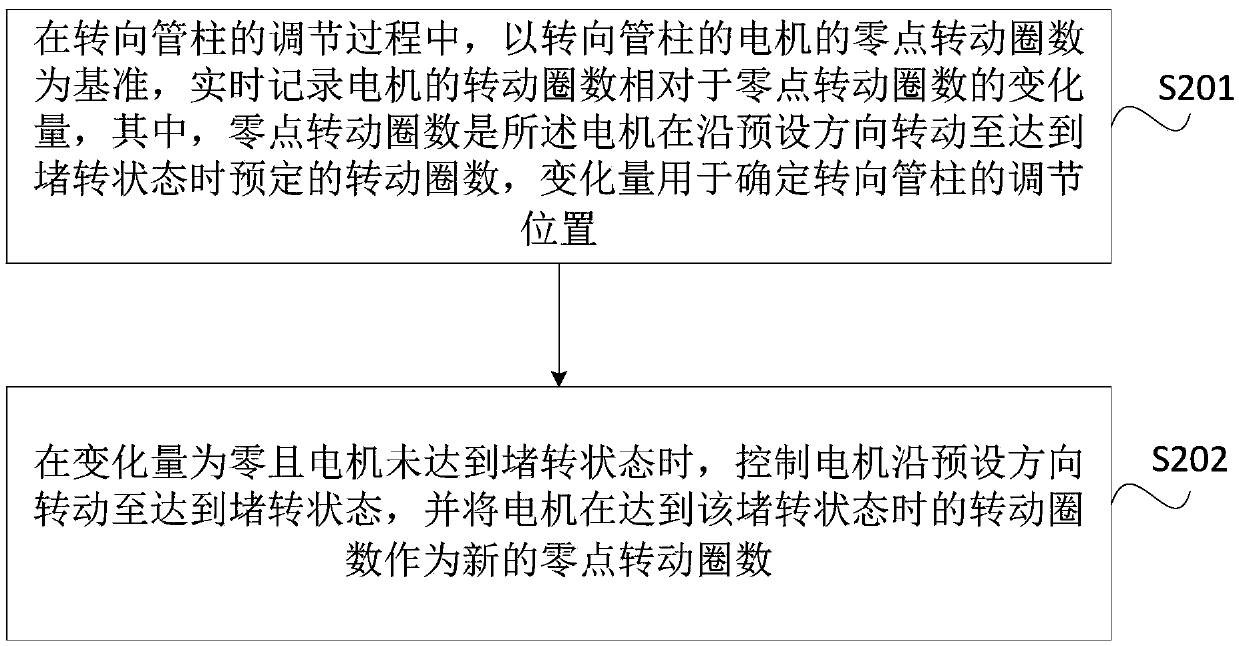

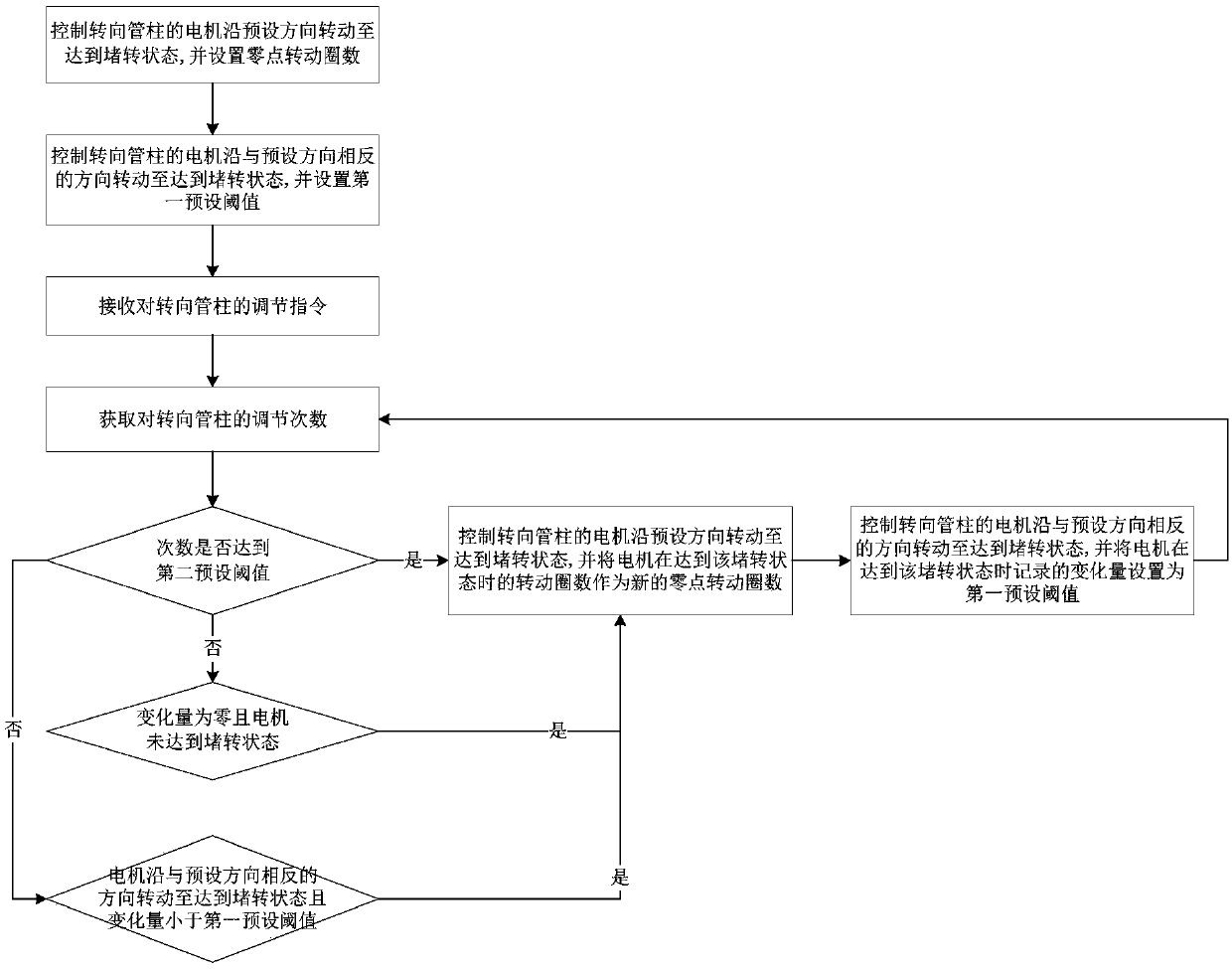

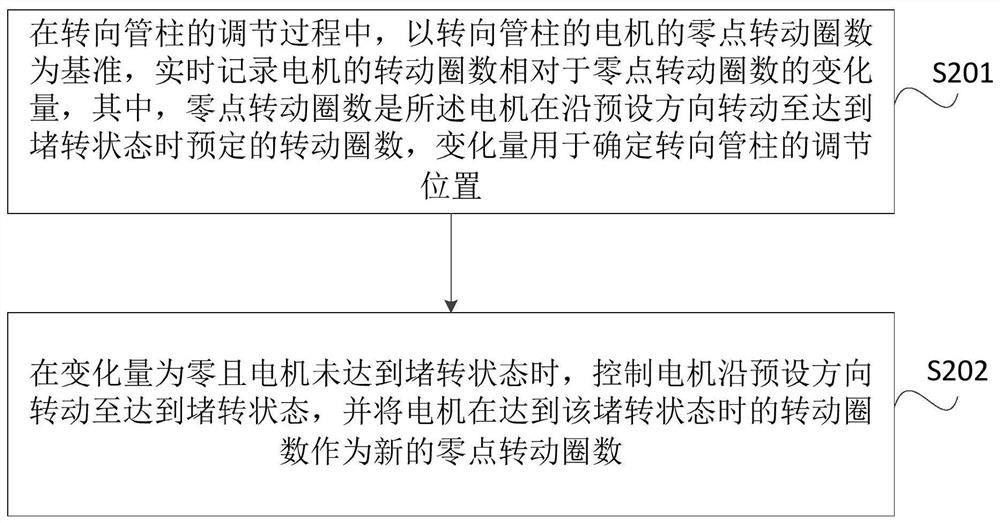

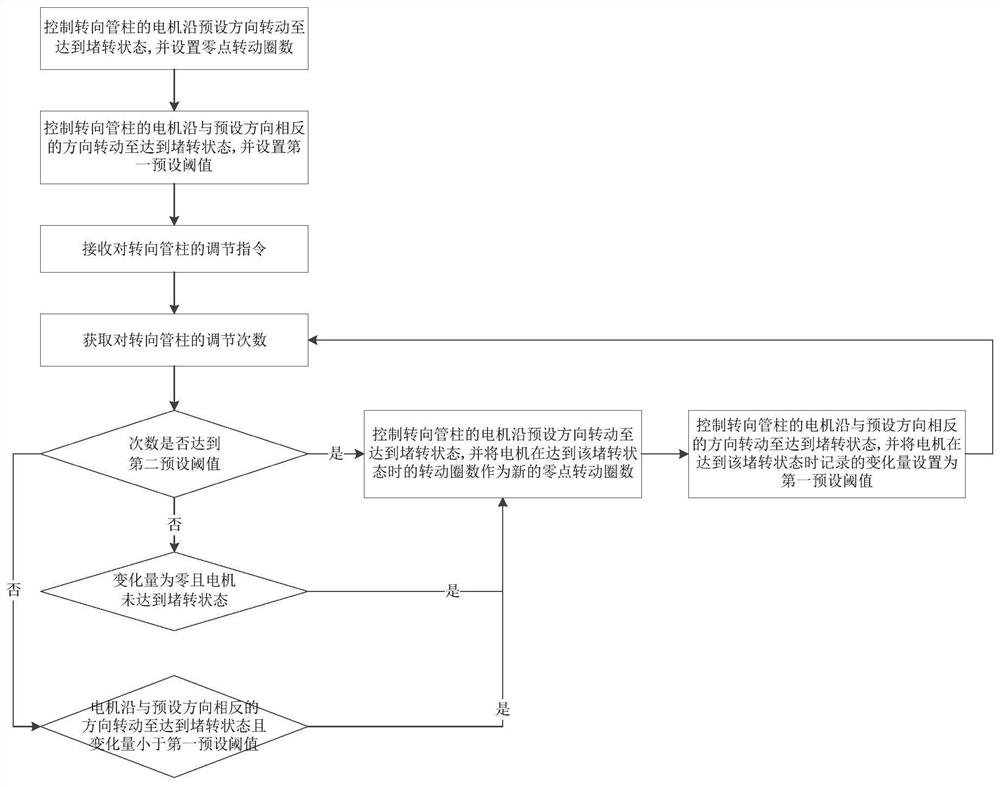

Method and device for correcting position deviation of steering column, storage medium and vehicle

ActiveCN110758544ARegulation stabilityThe adjustment process is stable and reliableSteering controlsSteering columnElectric machinery

The invention relates to a method and device for correcting a position deviation of a steering column, a storage medium and a vehicle. The method includes the steps that in the adjustment process of the steering column, based on the number of turns of rotation at zero of the steering column, the change amount of the number of turns of rotation of a motor relative to the number of turns of rotationat zero is recorded in real time, the number of turns of rotation at zero is the predetermined number of turns of rotation when the motor rotates in a preset direction until the motor reaches a locked-rotor state, the change amount is used for determining the adjustment position of the steering column; and when the change amount is zero and the motor does not reach the locked-rotor state, the motor is controlled to rotate in a preset direction until the motor reaches the locked-rotor state, and the number of turns of rotation when the motor reaches the locked-rotor state is used as new numberof turns of rotation at zero. According to the technical scheme, the deviation between the actually detected steering column position and the actual position of the steering column can be corrected,the position adjustment accuracy of the steering column is improved, the adjustment failure caused by the position deviation is avoided, so that the adjustment process of the steering column is more stable and reliable.

Owner:BYD CO LTD

Cutting structure for cutting slab rubber into rubber strips

The invention discloses a cutting structure for cutting slab rubber into rubber strips. The cutting structure for cutting the slab rubber into the rubber strips comprises a worktable, the worktable isprovided with a recessed flow channel in which the slab rubber can move longitudinally, and the worktable is also provided with a beam stretching over the flow channel; the beam is detachably connected with a mounting rod parallel to the beam, the mounting rod is provided in a sleeve mode with a plurality of mounting blocks which can slide and rotate on the mounting rod, the mounting rod is alsoprovided with first scale marks serving as the axial sliding reference of the mounting blocks, every mounting block is threadedly connected with a first fastening screw capable of fixing the mountingblock onto the mounting rod and detachably connected with a blade for cutting the slab rubber into the rubber strips; both sides of the worktable are provided with a left support and a right support for supporting the beam, the beam is provided with a wrench for wrenching the beam to rotate on the supports and to turn down the blades for cutting. The cutting structure for cutting the slab rubber into the rubber strips can pull the slab rubber to flow relative to the blades and accordingly cut the slab rubber to be cut into the rubber strips.

Owner:广东邦达实业有限公司

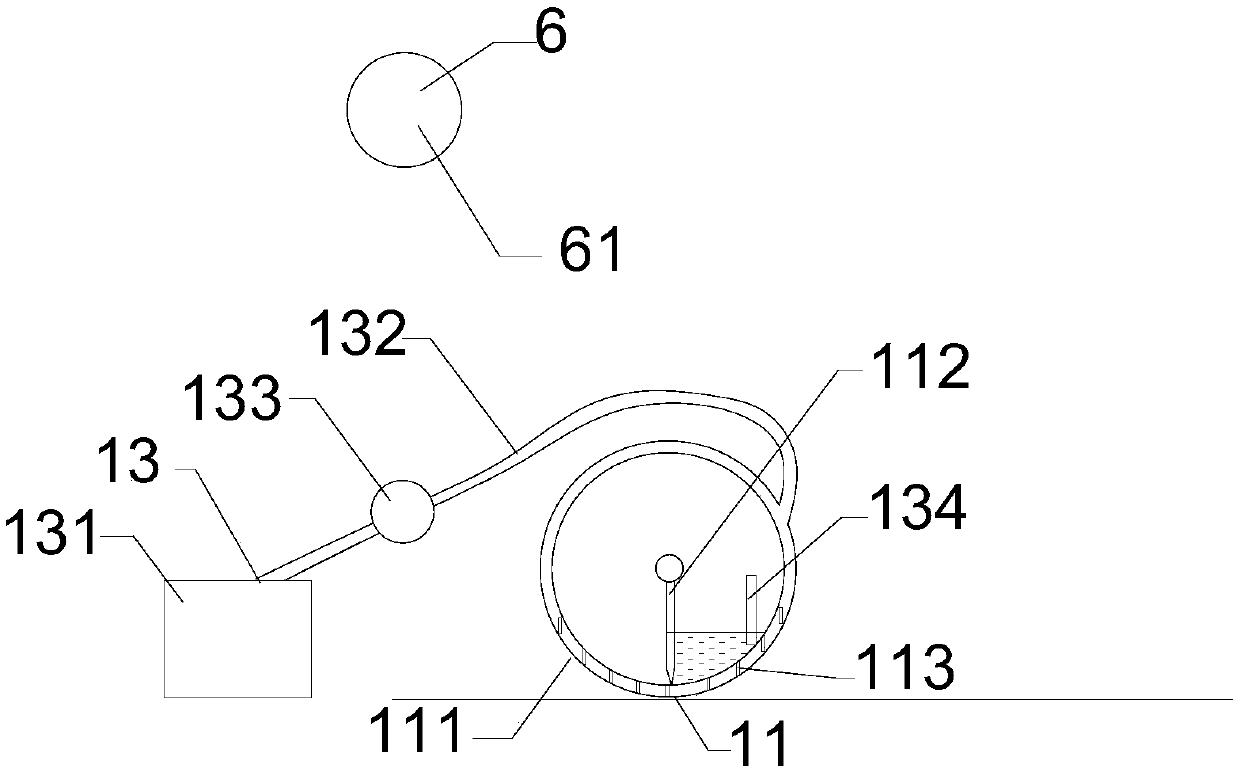

Spiral pot blanking mechanism

PendingCN113716356AImprove convenienceQuality improvementDe-stacking articlesSpiral bladeStructural engineering

The invention discloses a spiral pot blanking mechanism which comprises a rack. Two spiral separating mechanisms used for separating flowerpots are symmetrically arranged on the front face of the rack; an adjusting mechanism used for adjusting the distance between the two spiral separating mechanisms is arranged on the front face of the rack; each spiral separating mechanism comprises a bearing plate and two spiral blades; the two spiral blades are rotatably arranged at the bottom ends of the bearing plates; the two spiral blades are symmetrically arranged front and back; a flowerpot body is movably clamped among the four spiral blades; and driving mechanisms used for rotating the spiral blades are arranged at the top ends of the two bearing plates. According to the spiral pot blanking mechanism provided by the invention, the two spiral separating mechanisms are symmetrically arranged and are matched with the multiple spiral blades in the spiral separating mechanisms, so that stacked flowerpots can be clamped one by one, meanwhile, the multiple stacked flowerpots can be automatically separated in sequence, an operator can operate simply and conveniently, the convenience of separating and blanking the flowerpots is improved, meanwhile, the separating and blanking precision is high, and the flowerpot blanking quality is improved.

Owner:上海侬盛现代农业科技有限公司

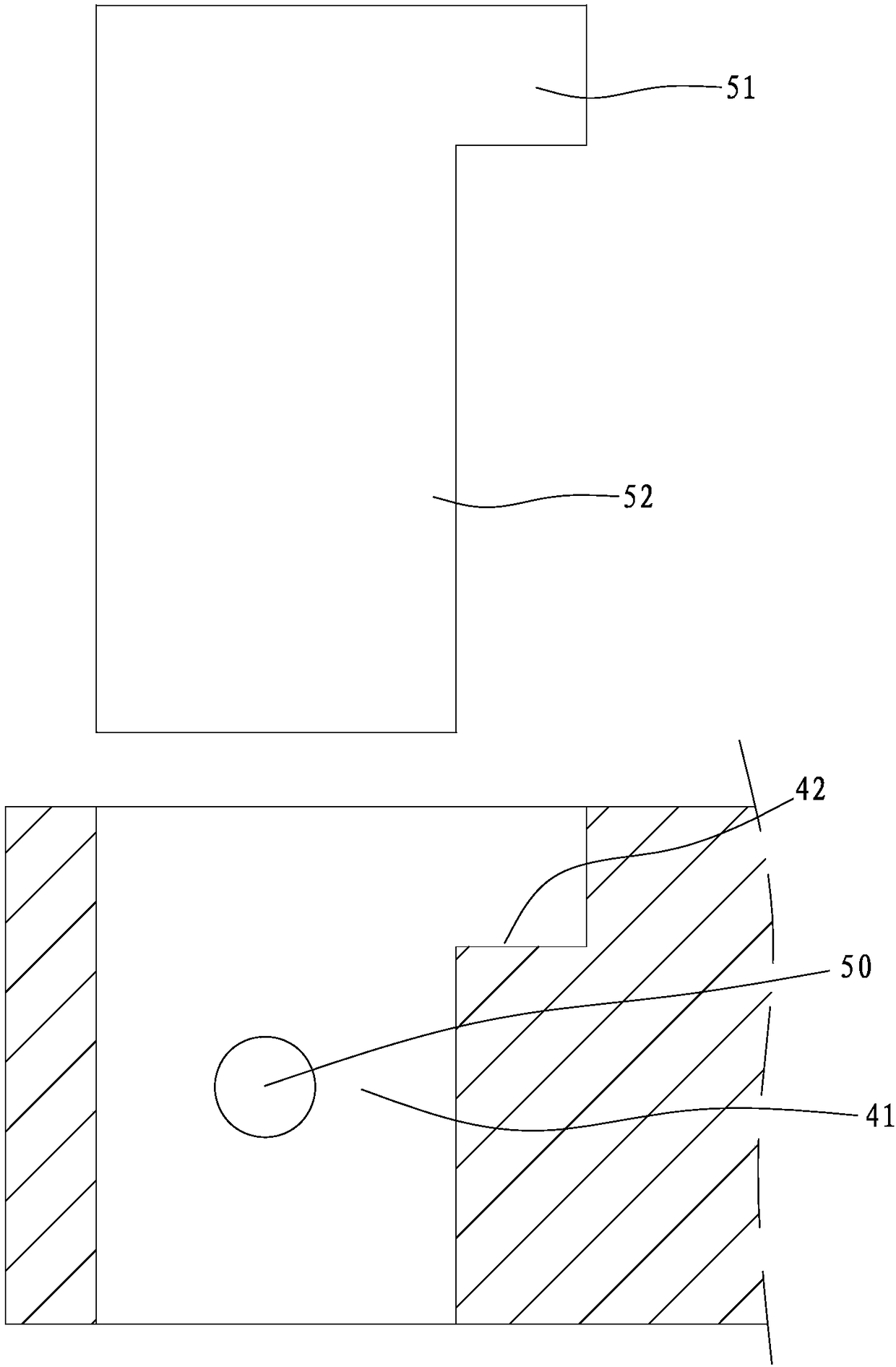

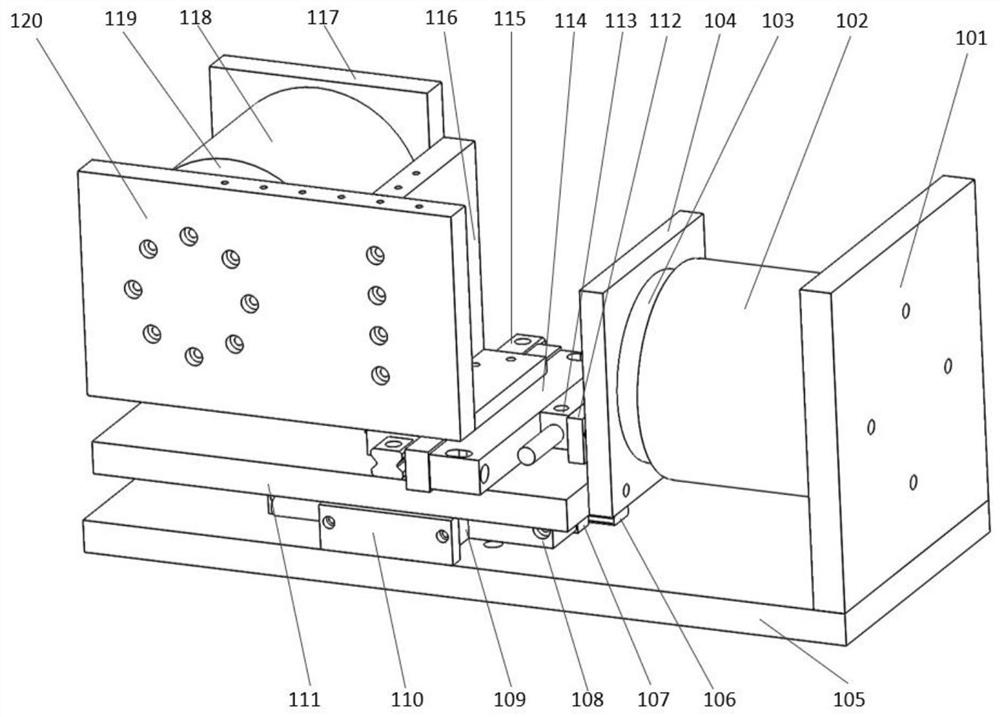

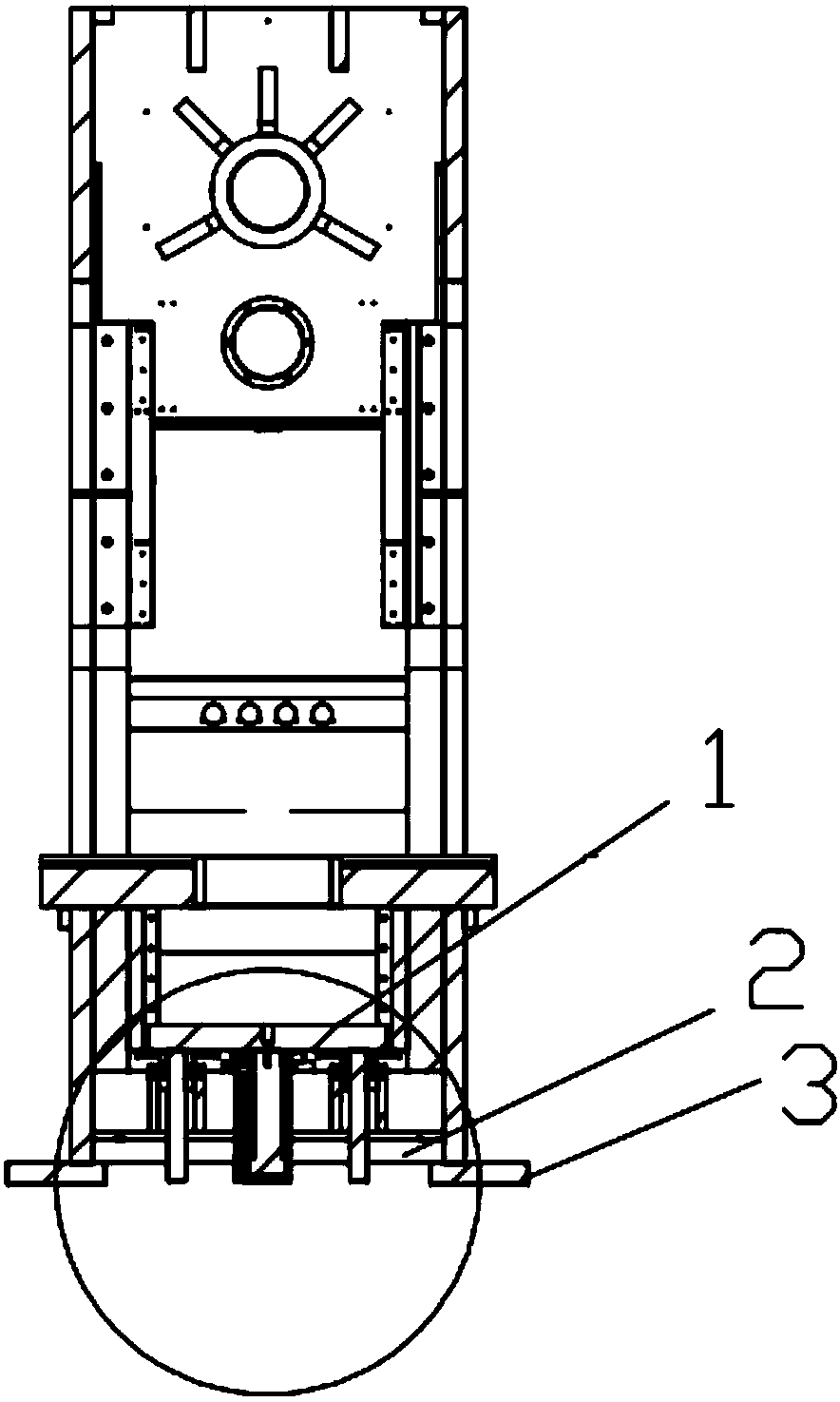

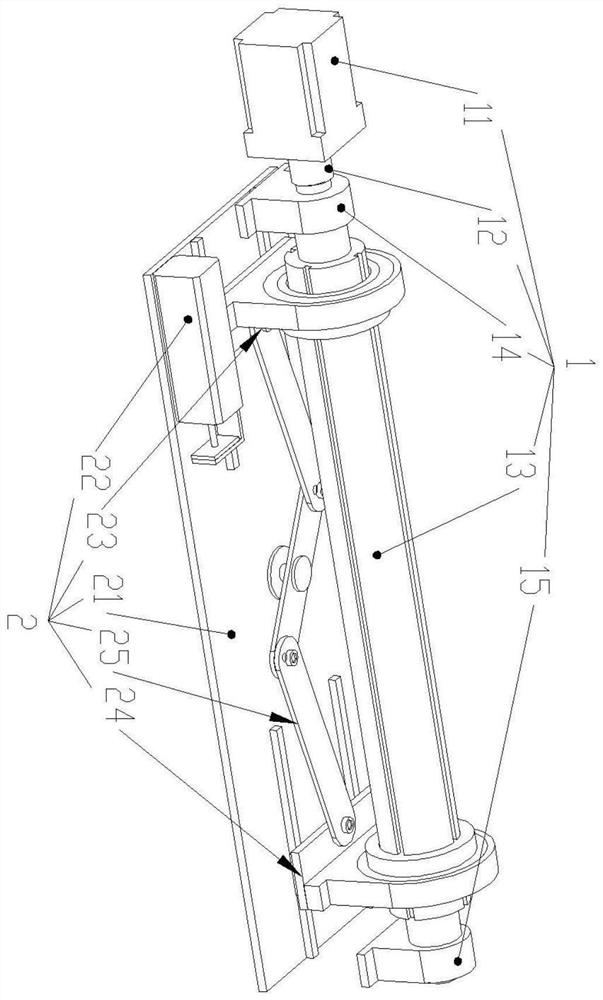

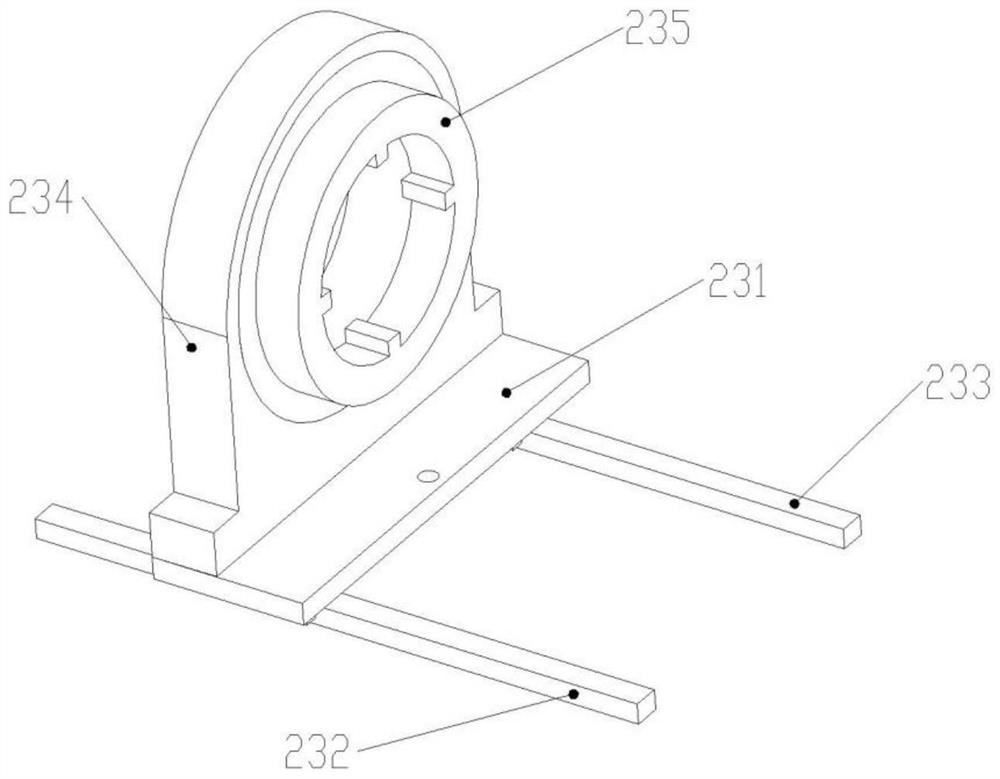

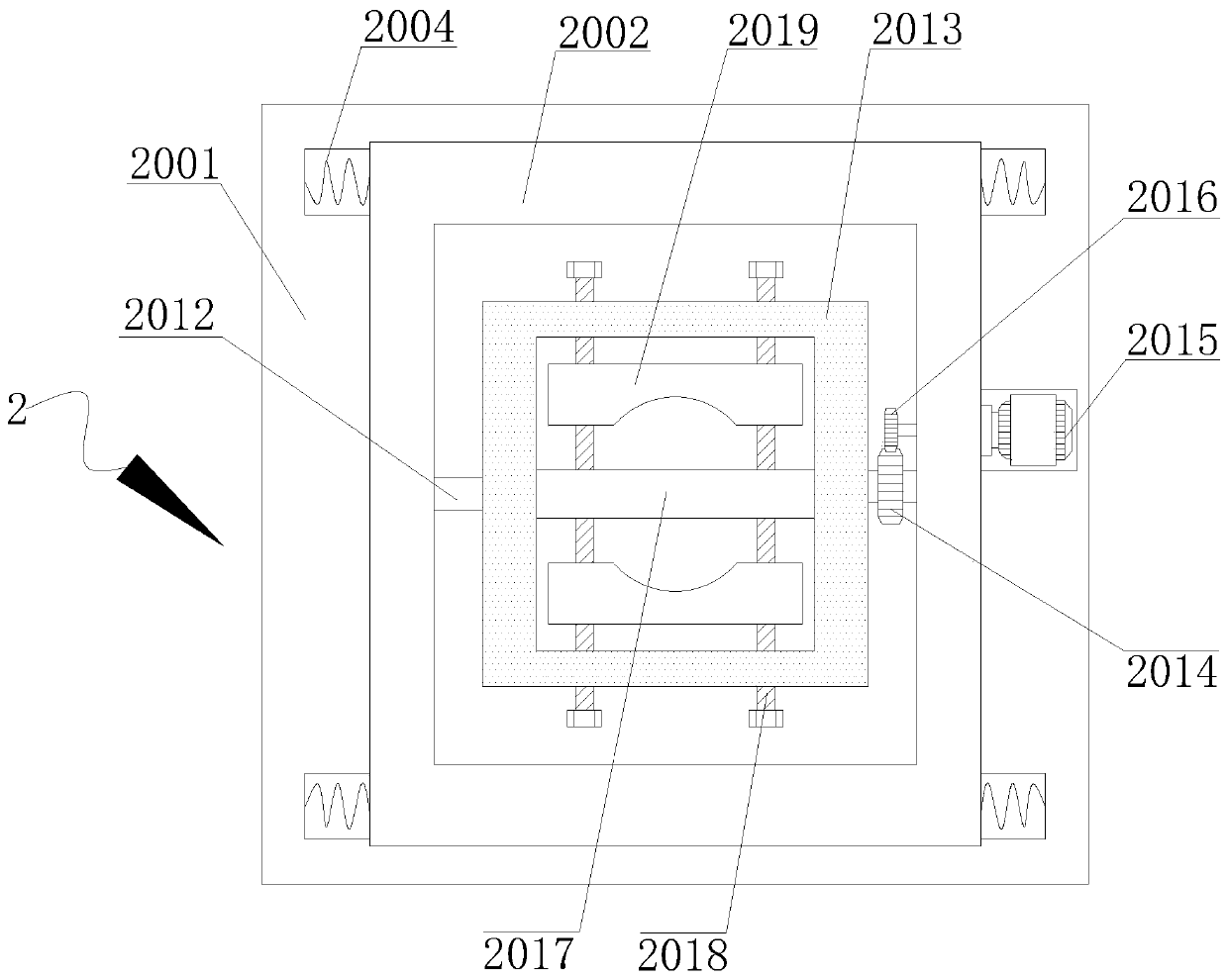

Nuclear power station special-shaped small-diameter tube nondestructive testing device and method

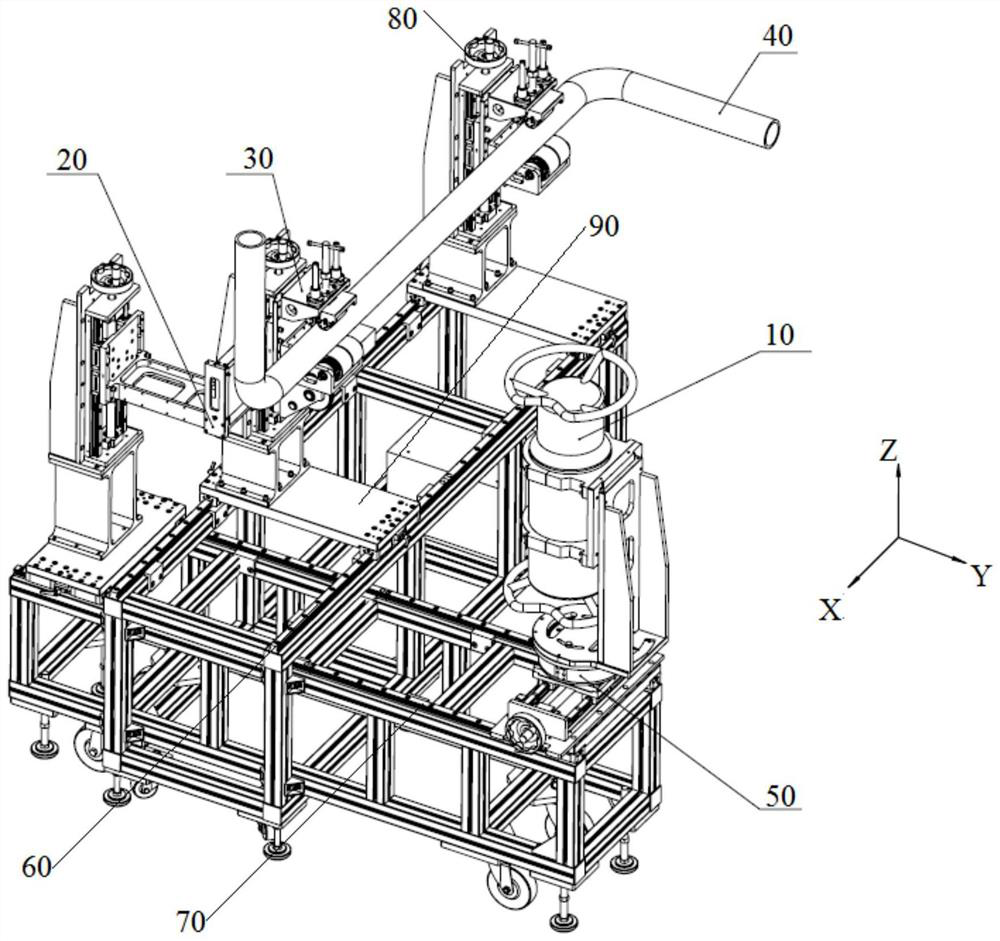

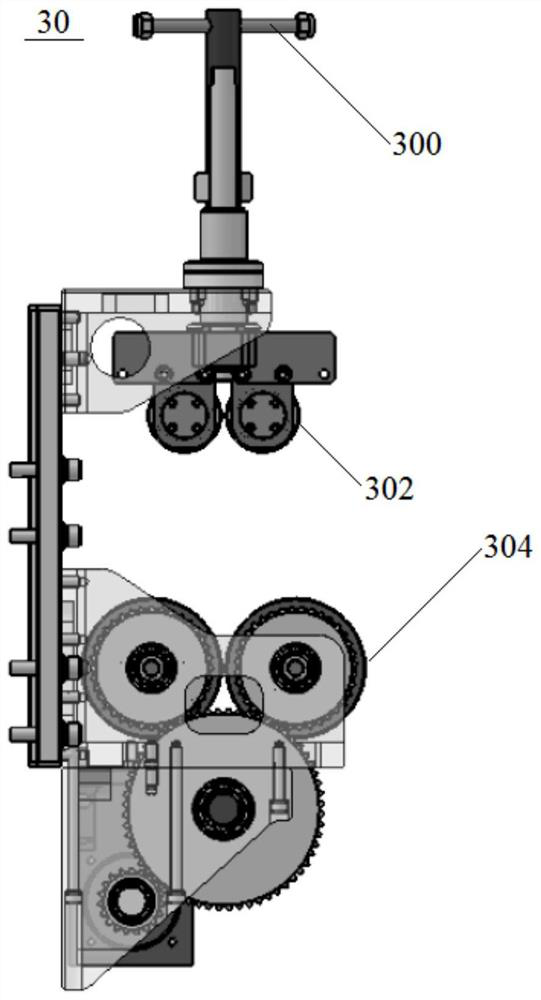

PendingCN112881436ASimple structureHigh position adjustment accuracyMaterial analysis by transmitting radiationNuclear engineeringNuclear power

The invention discloses a nuclear power station special-shaped small-diameter tube nondestructive testing device which comprises a ray machine capable of moving in the Y direction and the Z direction; a detector capable of moving in the Y direction and the Z direction; and a detection clamp which is positioned between the ray machine and the detector, can move along the X direction, and is used for clamping the special-shaped small-diameter tube to be detected and allowing the special-shaped small-diameter tube to rotate around the axis of the special-shaped small-diameter tube. Compared with the prior art, the nuclear power station special-shaped small-diameter tube nondestructive testing device is simple in structure, high in position adjusting precision, accurate in positioning and convenient for field operation to complete ray detection work, and the working efficiency is improved. In addition, the invention also discloses a nuclear power station special-shaped small-diameter tube nondestructive testing method.

Owner:中广核工程有限公司 +1

Dual-suspension DR

PendingCN108852395ASmall footprintExpand the scope of workPatient positioning for diagnosticsRadiation generation arrangementsX-rayEngineering

The invention discloses a dual-suspension DR. The dual-suspension DR includes an X-radiography bed and a dual-suspension device arranged above the X-radiography bed. The dual-suspension device includes a suspended frame, a suspended rack and a suspended X-ray generating device, and the suspended rack and the suspended X-ray generating device are both slidingly connected with the suspended frame. By means of the design above, the disclosed dual-suspension DR solves the problem that digital X-radiography machines in the prior art occupy a large working space. The dual-suspension DR has the advantages of being convenient to operate, wide in application range and the like.

Owner:石家庄华东医疗科技有限公司

Rubber plate cutting structure

The invention discloses a rubber plate cutting structure which comprises a worktable. A recessed flow channel is arranged on the worktable, a rubber plate can longitudinally move in the flow channel,a beam stretching over the flow channel is arranged on the worktable, a mounting rod is arranged on the beam, a plurality of mounting blocks capable of sliding and rotating on the mounting rod sleevethe mounting rod, first scale marks for axial sliding reference of the mounting blocks are arranged on the mounting rod, first locking screws for fixing the mounting blocks onto the mounting rod are arranged on the mounting blocks, electric heating cutting rods capable of cutting the rubber plate to form holes are arranged on the mounting blocks, a storage pipe for storing a cable is arranged on the beam and parallel to the beam, a plurality of leading-out holes for leading out the cable to be in circuit connection with the electric heating cutting rods are formed in the storage pipe, a left support and a right support for supporting the beam are arranged on two sides of the worktable, a wrench is arranged on the beam and pulls the beam to rotate, the electric heating cutting rods are driven to cut the rubber plate, and operation is facilitated.

Owner:广东邦达实业有限公司

Equipment splicing printing method and printing device and production device of graphic and text anti-counterfeiting paper

PendingCN109572180ARealize full format printingIncrease productivityPattern printingRotary pressesGraphicsMethods of production

The invention provides equipment splicing printing method and printing device and a production device of graphic and text anti-counterfeiting paper. The equipment splicing printing device includes atleast two sets of printing equipment, the printing equipment is mounted above the net part of a paper making machine, and each printing equipment includes a printing part and a first driving mechanismfor driving the printing part to move; and the printing path of each printing part is parallel to the moving path of the net part of the paper making machine, the printing path of the printing part of each set of printing equipment is distributed in a staggered mode in the direction of being perpendicular to the moving path of the net part of the paper making machine, and the first driving mechanisms are in synchronized transmission with the driving mechanism of the net part of the paper making machine. The equipment splicing printing method and printing device and the production device of the graphic and text anti-counterfeiting paper do not need to transform the complex structure of existing printing equipment, full print graphic and text anti-counterfeiting pattern can be printed on the paper face manufactured by a wide-width paper making machine, and the production efficiency is high.

Owner:万国纸业太阳白卡纸有限公司

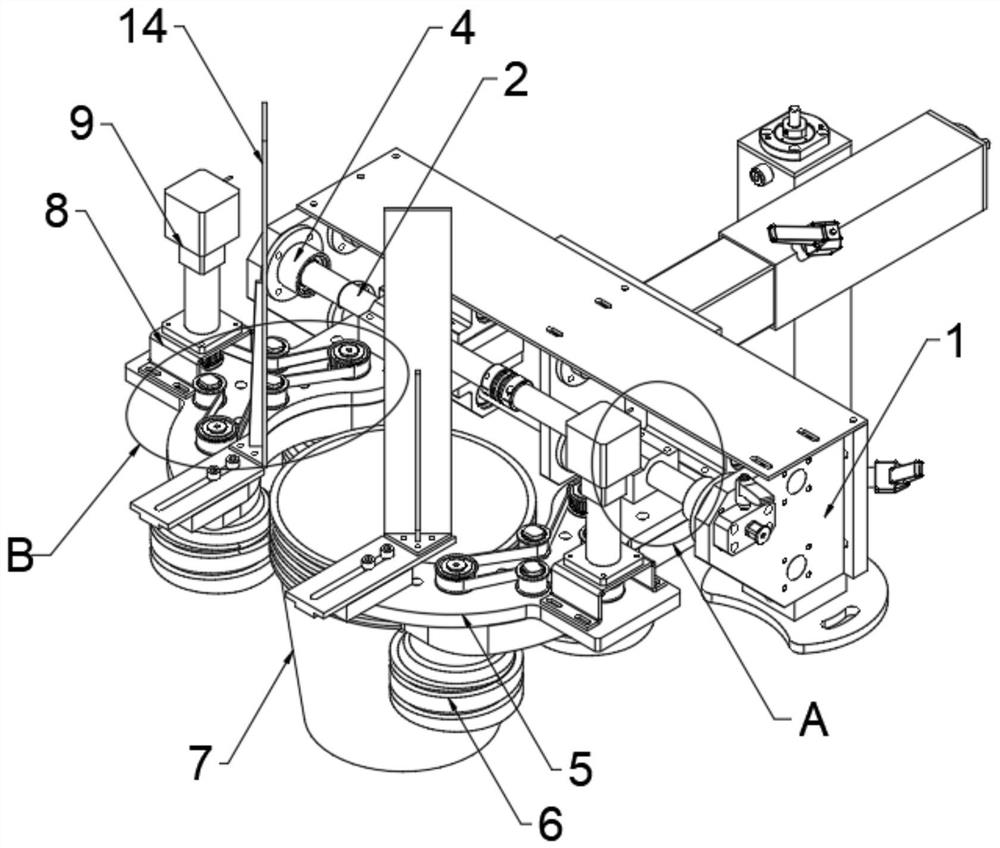

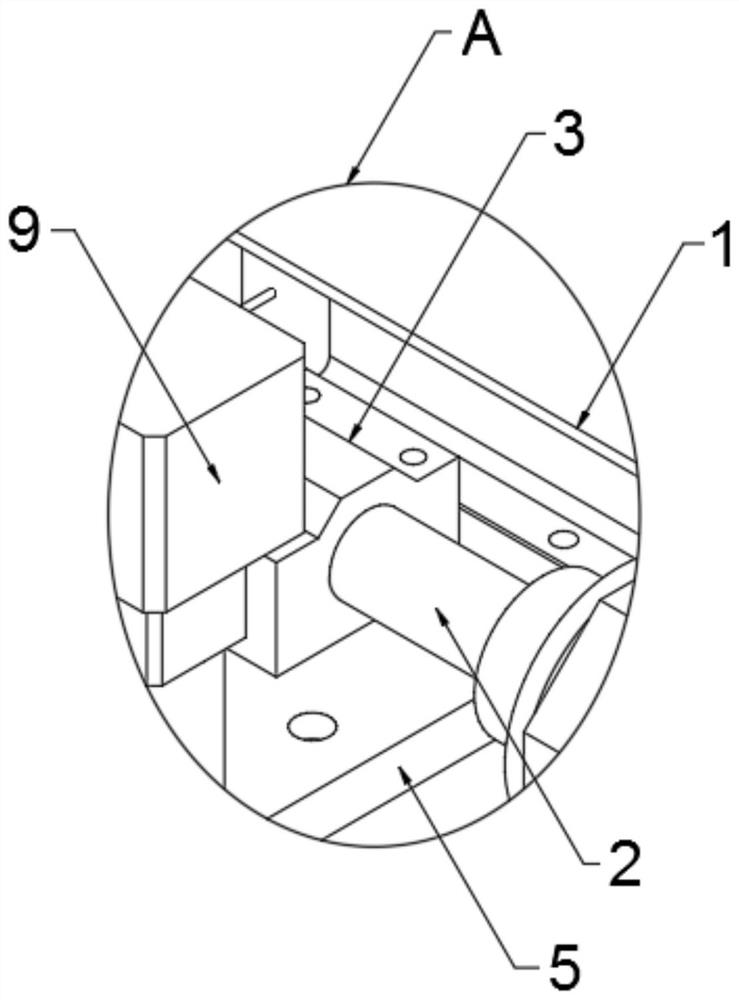

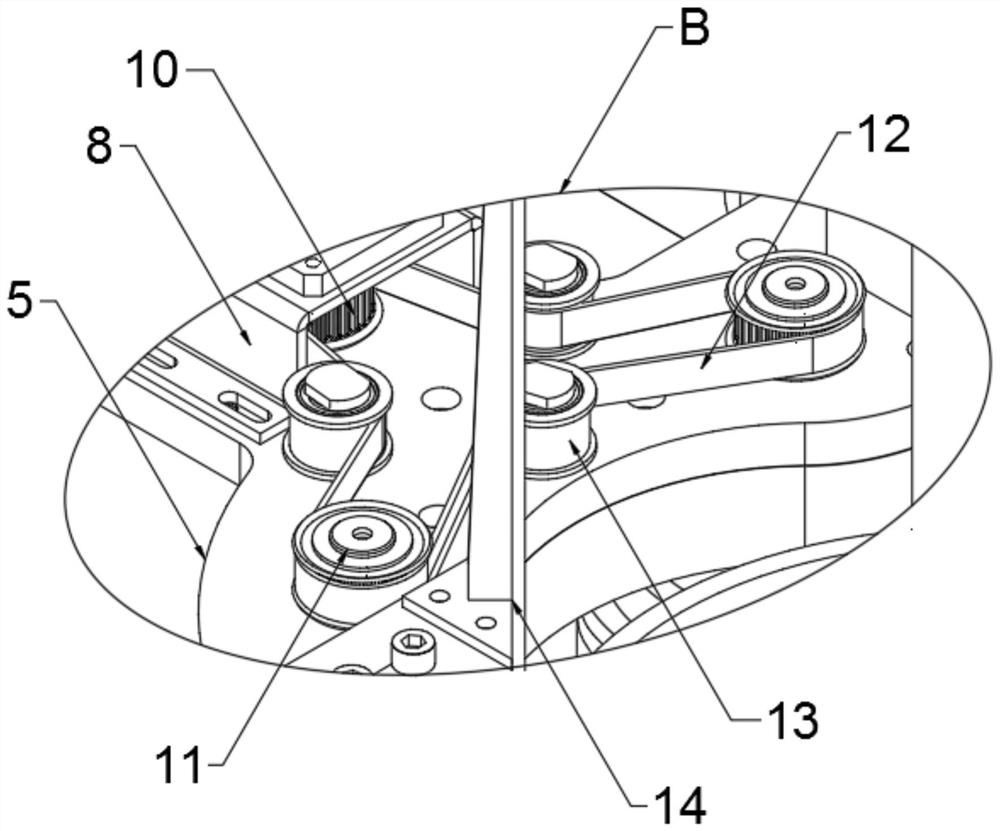

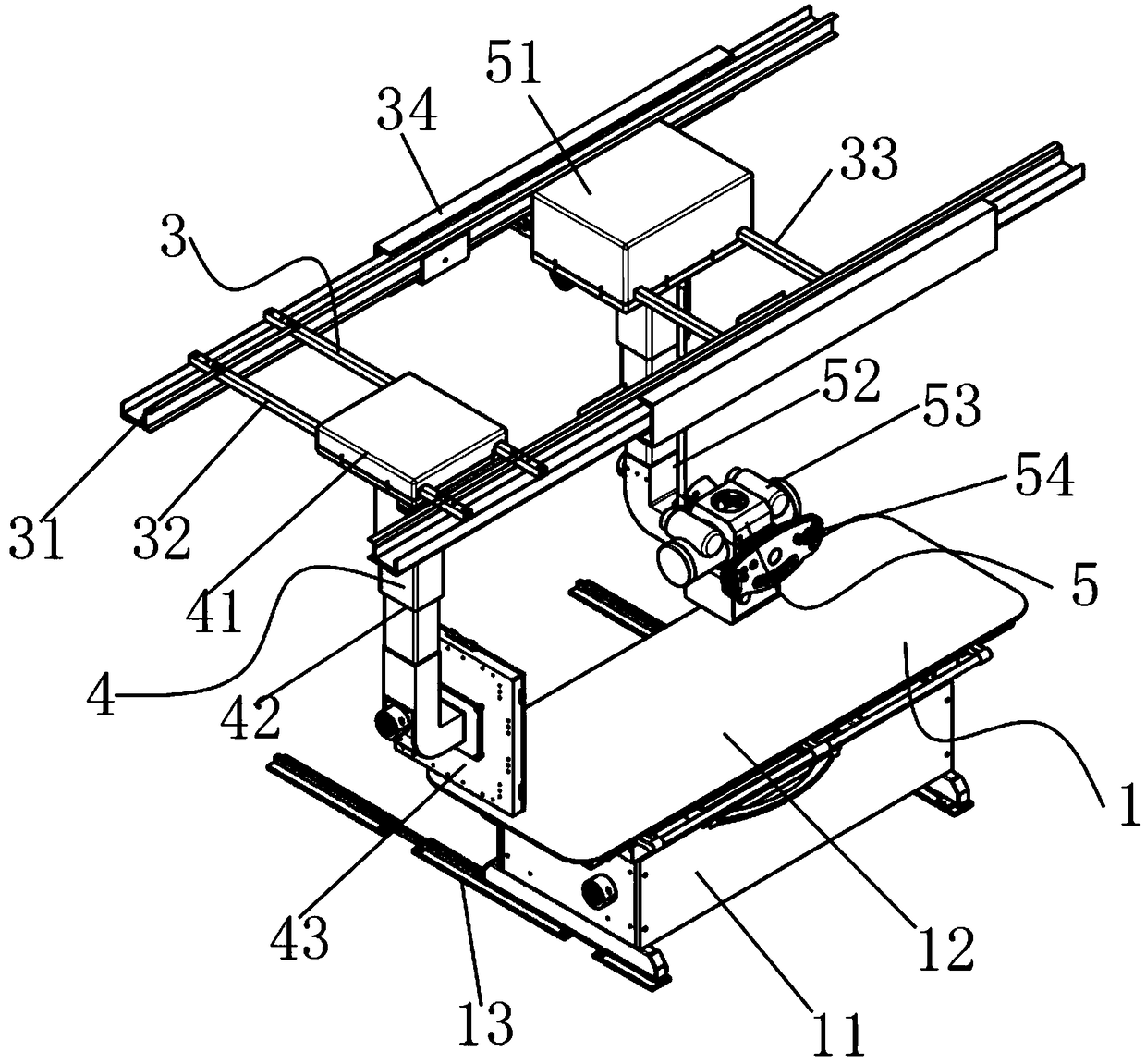

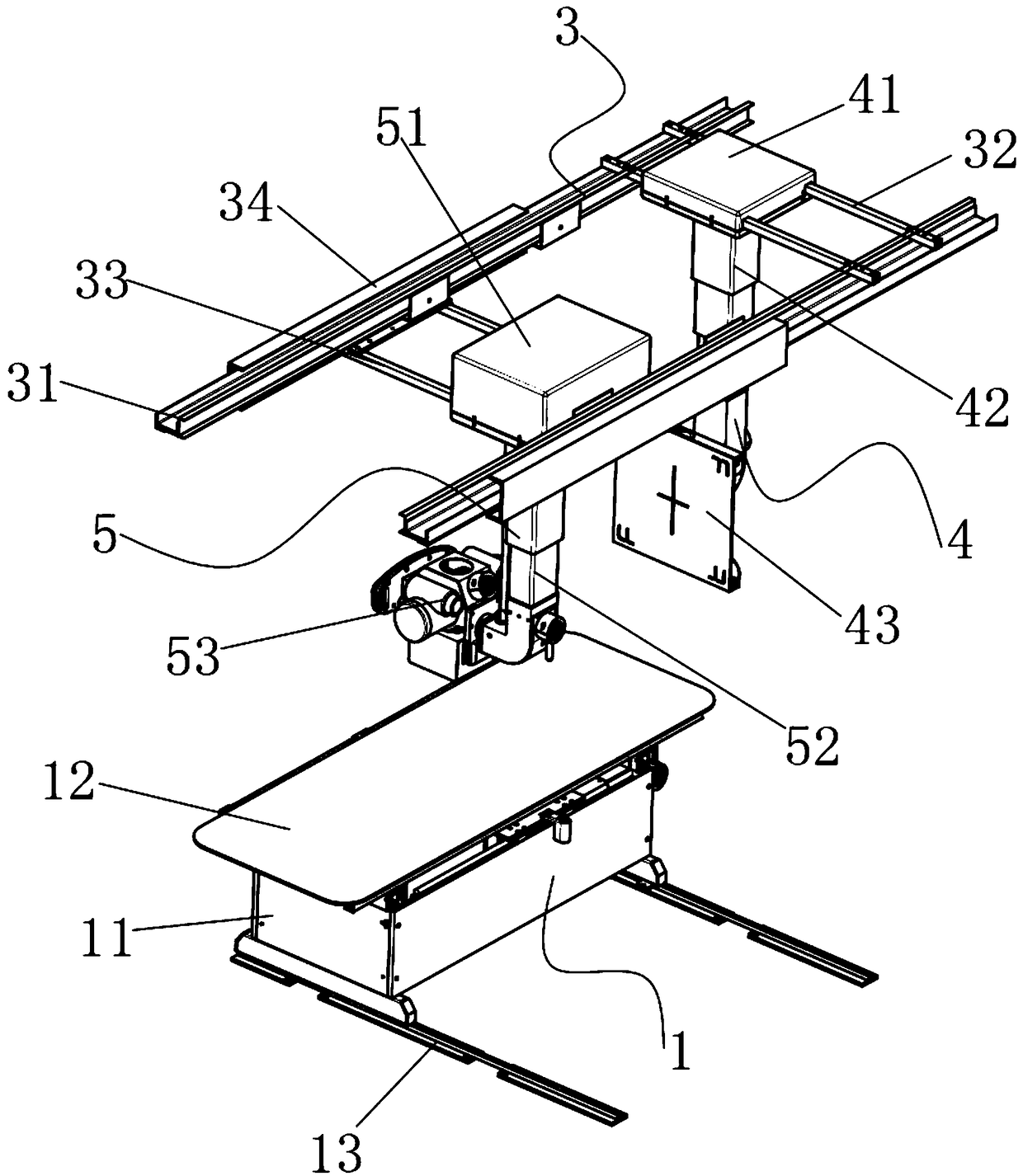

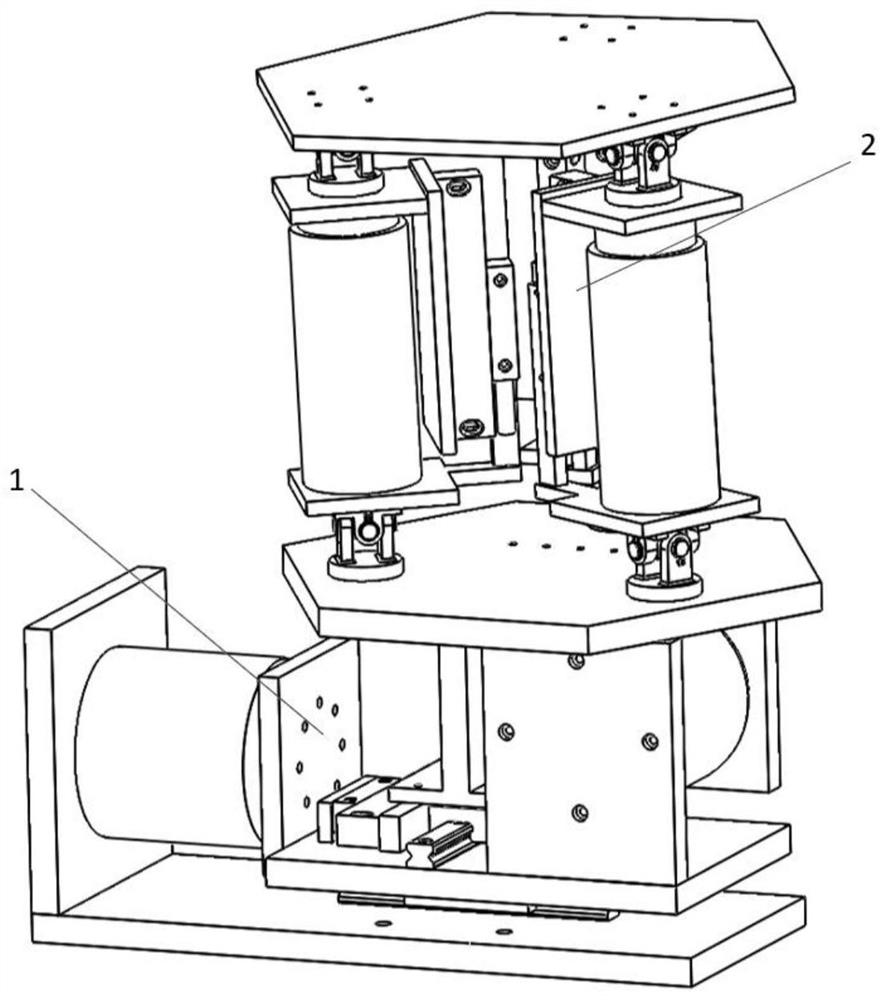

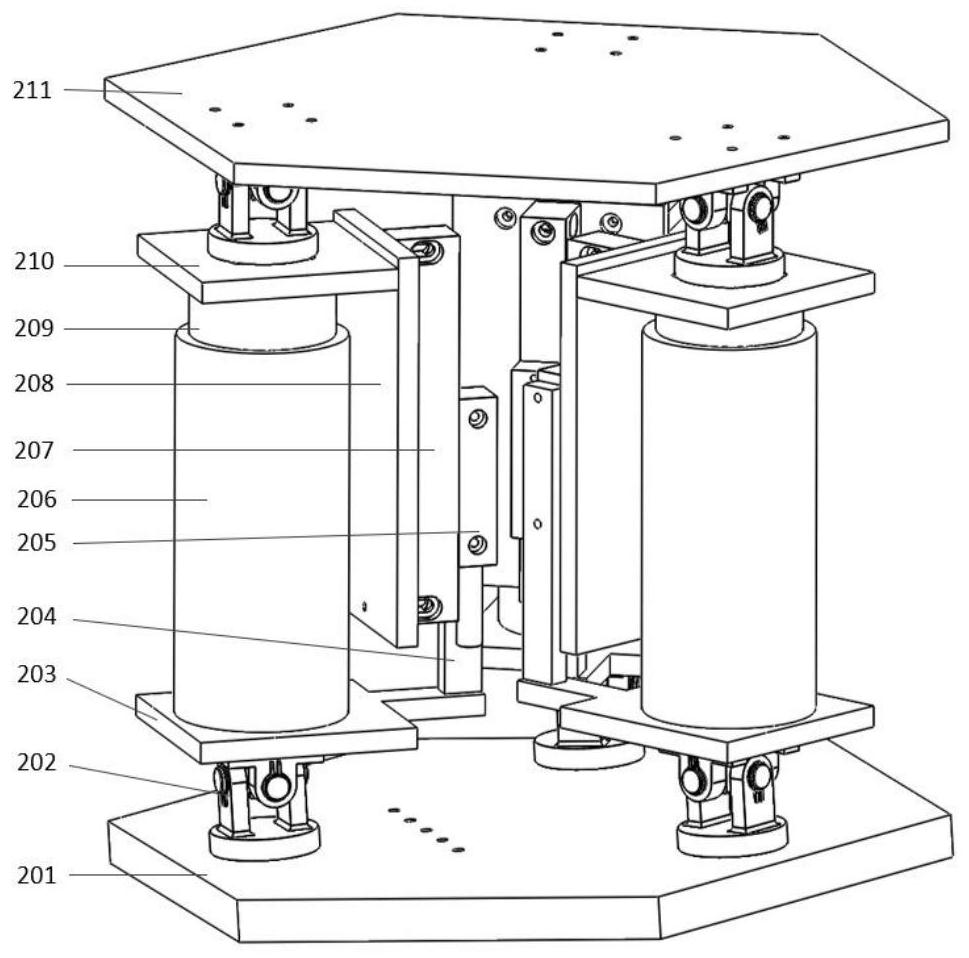

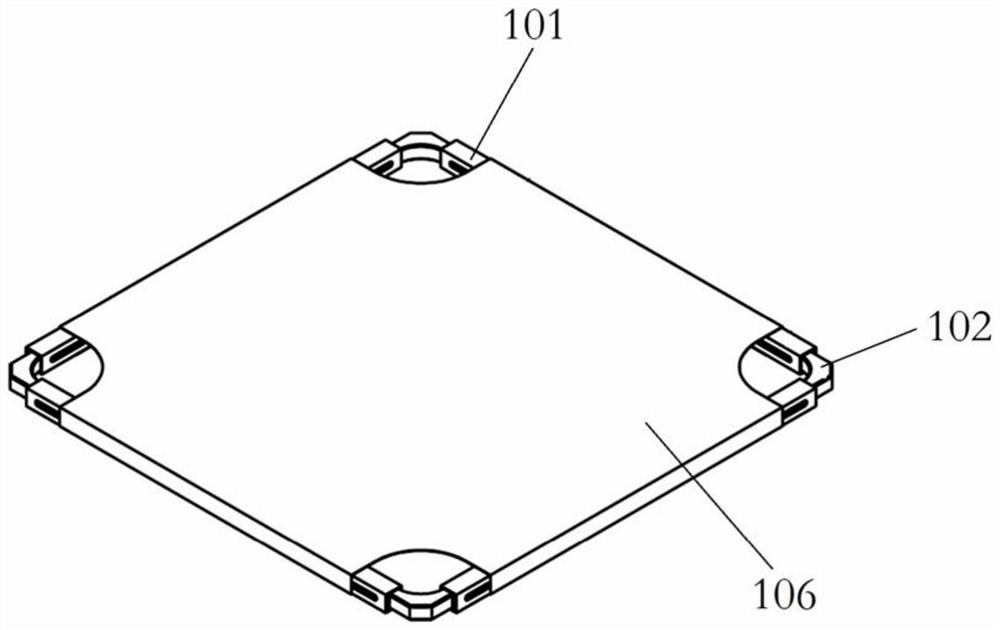

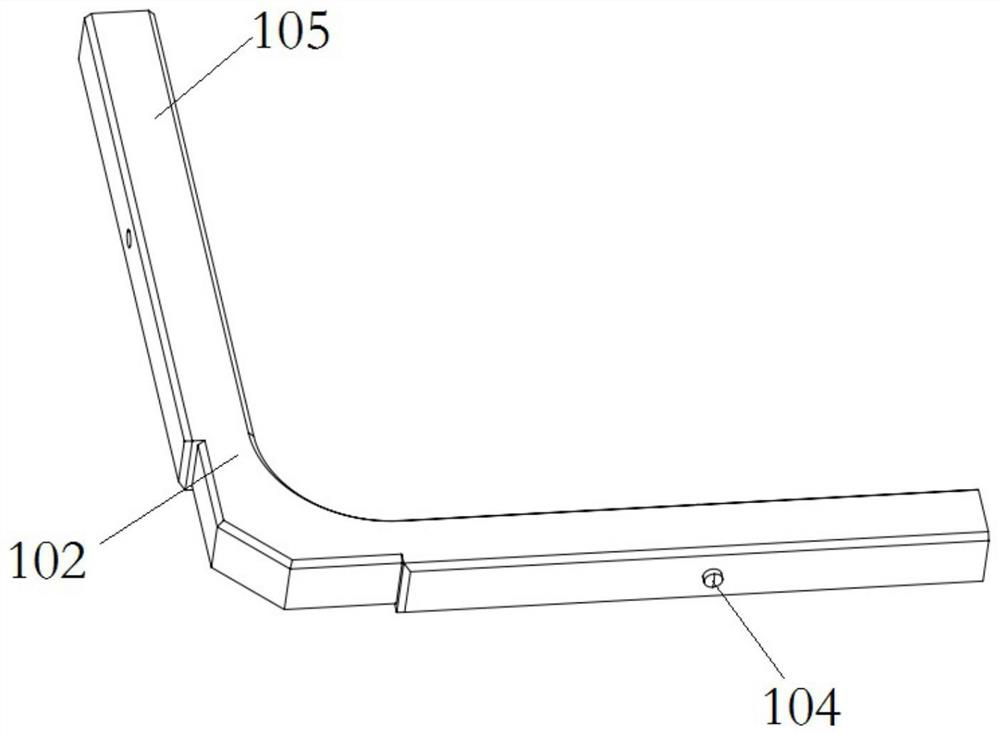

Five-degree-of-freedom adjusting platform for splicing off-axis aspheric sub-mirrors

PendingCN113126239ARealize five-degree-of-freedom pose adjustmentImproved overall motion regulation accuracyMountingsElectric machineComputer science

The invention discloses a five-degree-of-freedom adjusting platform for splicing off-axis aspheric sub-mirrors, a first mobile platform is used for realizing two-degree-of-freedom adjustment of movement in X and Y directions, a second mobile platform is arranged above the first mobile platform, and the second mobile platform is used for realizing three-degree-of-freedom adjustment of movement in Z direction and turnover movement in X and Y directions. The second mobile platform is provided with an off-axis aspheric sub-mirror, and five-degree-of-freedom pose adjustment of the off-axis aspheric sub-mirror is realized through the first mobile platform and the second mobile platform. According to the invention, the motion position information of the linear motor can be collected in real time, the position adjustment precision is high, the adjustment efficiency is high, and the micron-order adjustment precision of the position attitude of the off-axis aspheric sub-mirror is realized.

Owner:XI AN JIAOTONG UNIV +1

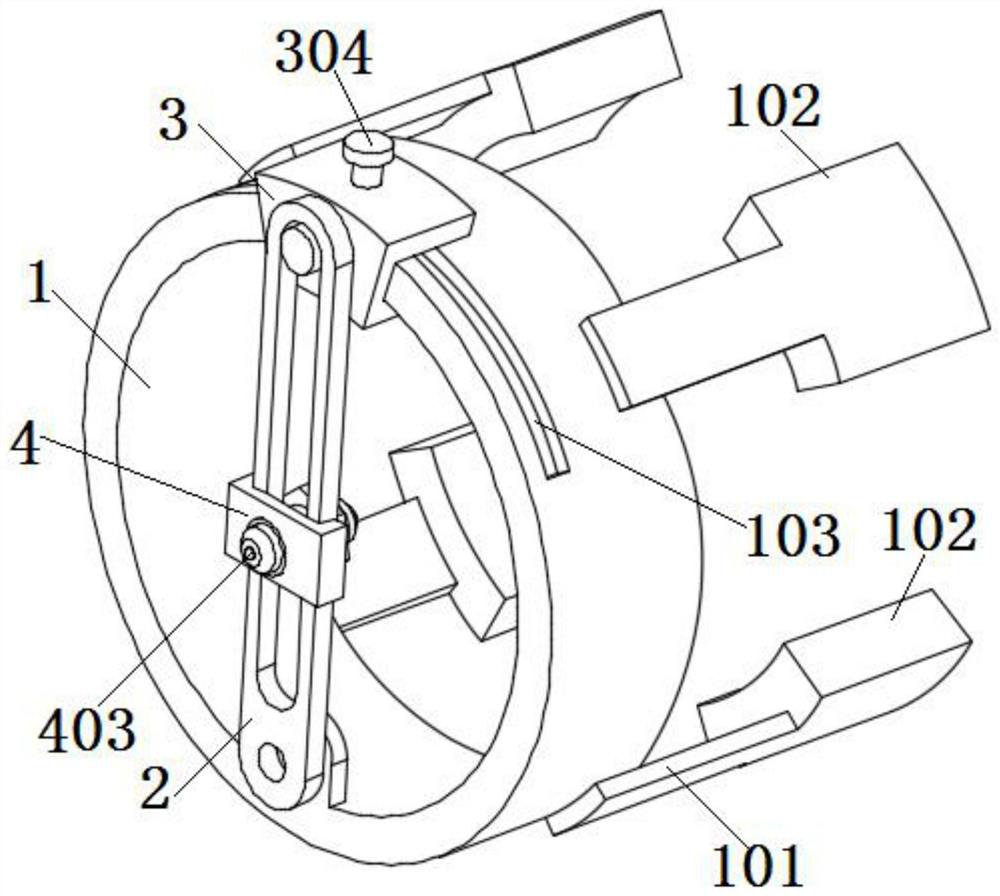

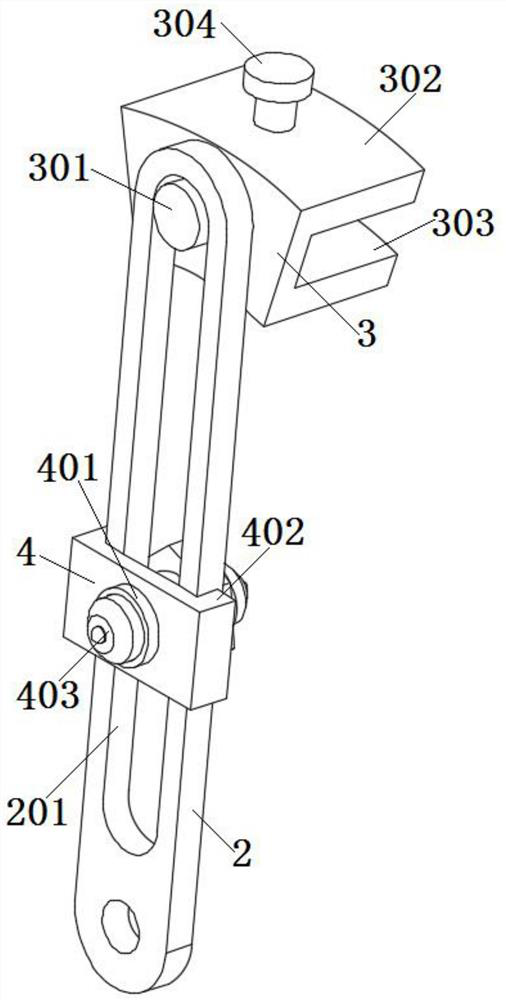

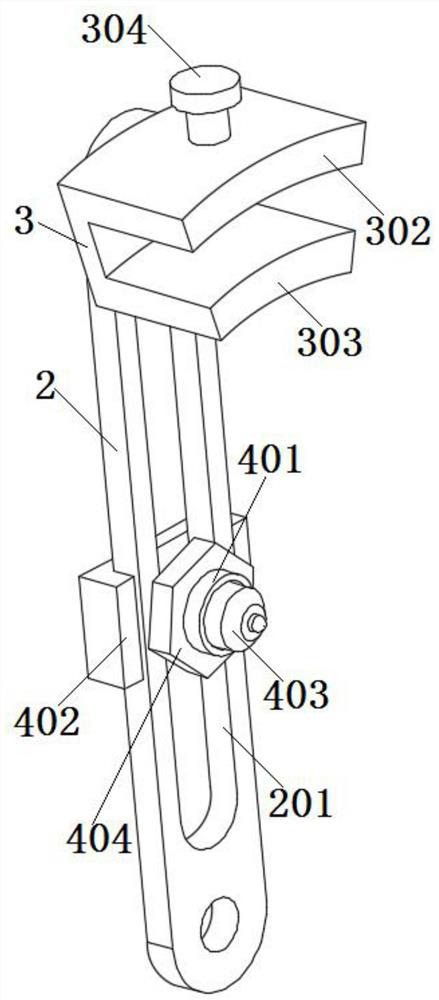

A device and method for adjusting the position of the injection gun head

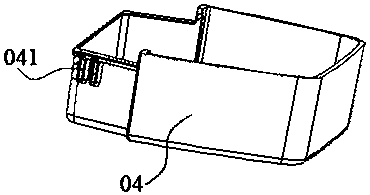

ActiveCN112123234BImprove the efficiency of position adjustmentHigh position adjustment accuracyWork holdersInjection portIcebox

The invention discloses a device for adjusting the position of a filling gun head, and relates to the technical field of refrigerator foaming. The invention comprises a fixed ring; one side of the fixed ring is hinged with an adjusting rod; the side wall of the fixed ring is slidably connected with an adjusting block; the outer wall of the fixed ring is connected with several spring pieces; the spring piece is connected with a block; The adjusting rod is connected with a mounting block; the mounting block is fixed with a mounting sleeve that fits with the straight slot; both ends of the mounting sleeve are provided with laser positioning lights; the outer wall of the mounting sleeve is threaded with a nut; the adjusting block is fixed with a mounting sleeve that fits with the straight slot The guide column; the side of the adjustment block is fixed with an outer arc plate and an inner arc plate adapted to the fixing ring; the outer arc plate is connected with a thumb nut. The invention fixes the fixed ring on the head of the main material gun through the clamping block, and determines the position through two laser positioning lights, so as to realize the position adjustment of the injection gun head and the injection port, which solves the problem of the existing position adjustment of the injection gun head The efficiency and precision are low, and there are potential safety hazards in manual operation.

Owner:CHANGHONG MEILING CO LTD

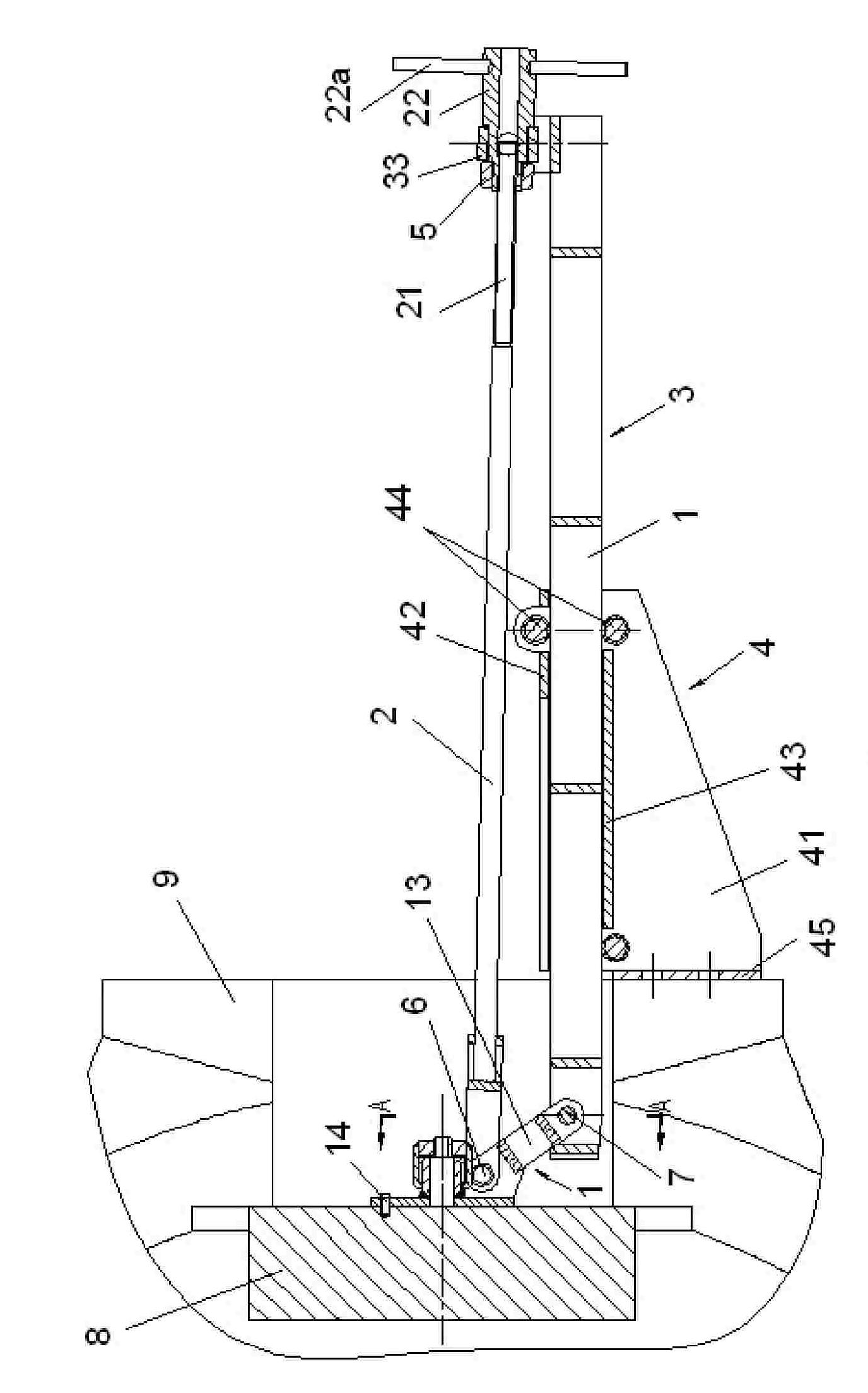

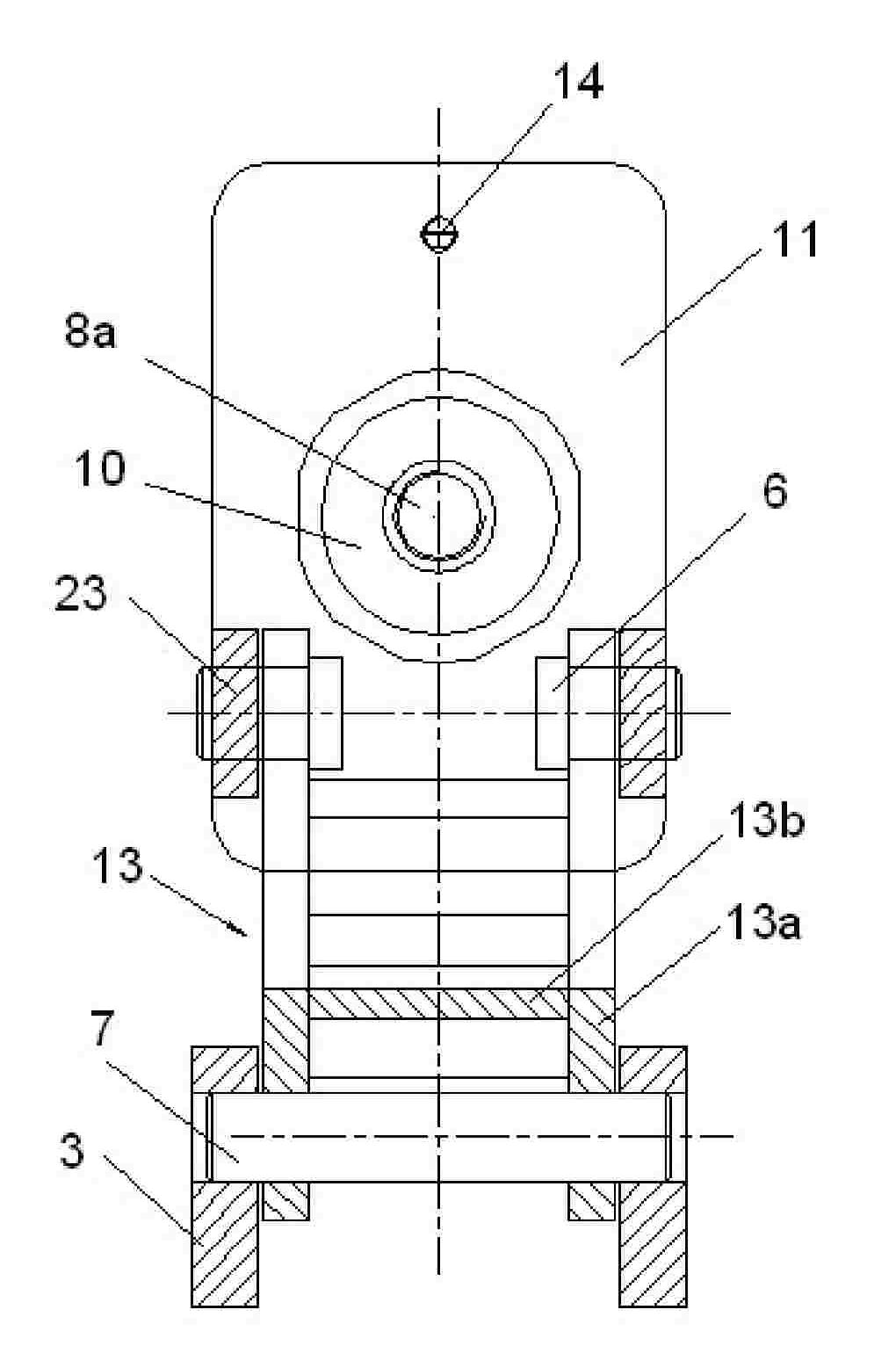

An ultra-low temperature ball valve seat machining device

ActiveCN111545833BImprove stabilityImprove cutting accuracyFeeding apparatusLarge fixed membersElectric machineEngineering

The invention relates to a machining device for an ultra-low temperature ball valve seat, which includes a bottom plate, a cylinder, a lifting platform, a placement frame, a rotating motor, a locking mechanism, a moving frame and a moving mechanism. The middle part of the platform is provided with an annular chute, and the lower end of the placing frame is connected with the annular chute through sliding fit. connected, the locking mechanism is installed on the placement frame, the lower end of the mobile frame is connected with the top of the base plate, and the mobile mechanism is installed on the mobile frame. The present invention can solve the problems existing in the cutting process of the ball valve seat: there is no locking fixture for the seat structure when the ball valve seat is cut and locked, and there is a certain discrepancy between the locked center position of the ball valve seat and the center position of the rotating shaft. Deviation, resulting in poor cutting accuracy of the valve seat and other problems.

Owner:JIANG SU YAN DIAN FA MEN CO LTD

A mechanical arm mechanism for tumor resection

ActiveCN111000635BImprove stabilityEasy to moveSurgical manipulatorsSurgical robotsSurgical robotEngineering

Owner:HENAN CANCER HOSPITAL

Material injection gun head position adjusting device and method

ActiveCN112123234AImprove the efficiency of position adjustmentHigh position adjustment accuracyWork holdersIceboxEngineering

The invention discloses a material injection gun head position adjusting device, and relates to the technical field of refrigerator foaming. The device comprises a fixing ring; an adjusting rod is hinged to one side of the fixing ring; the side wall of the fixing ring is slidably connected with an adjusting block; the outer wall of the fixing ring is connected with a plurality of spring pieces; the spring pieces are connected with clamping blocks; a straight notch is formed in the side face of the adjusting rod; the adjusting rod is connected with a mounting block; a mounting sleeve in clearance fit with the straight notch is fixed on the mounting block; laser positioning lamps are arranged at two ends of the mounting sleeve; a nut is in threaded connection with the outer wall of the mounting sleeve; a guide column matched with the straight notch is fixed on the adjusting block; an outer arc-shaped plate and an inner arc-shaped plate which are matched with the fixing ring are fixed tothe side face of the adjusting block; and the outer arc-shaped plate is connected with a hand-screwed nut. The fixing ring is fixed to a main material gun head through the clamping blocks, the positions are determined through the two laser positioning lamps, position adjustment of the material injection gun head and a material injection opening is achieved, and the problems that an existing material injection gun head is low in position adjustment efficiency and precision, and potential safety hazards exist in manual operation are solved.

Owner:CHANGHONG MEILING CO LTD

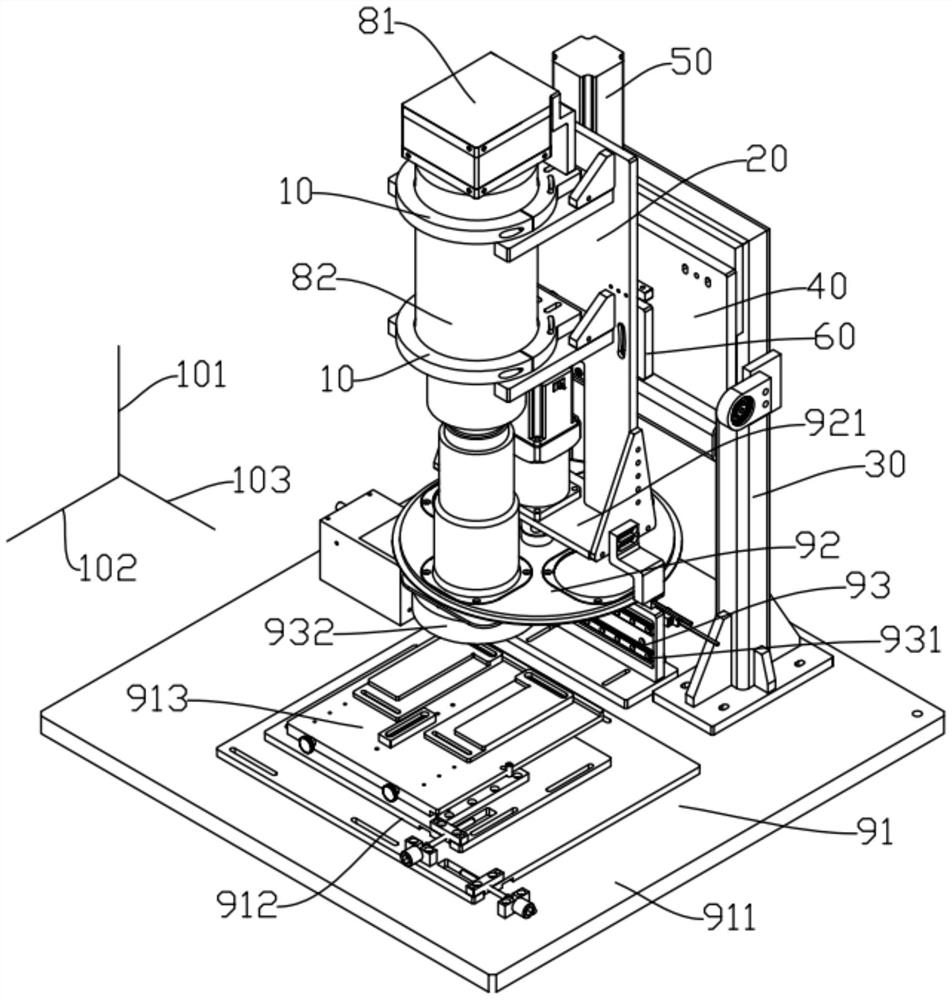

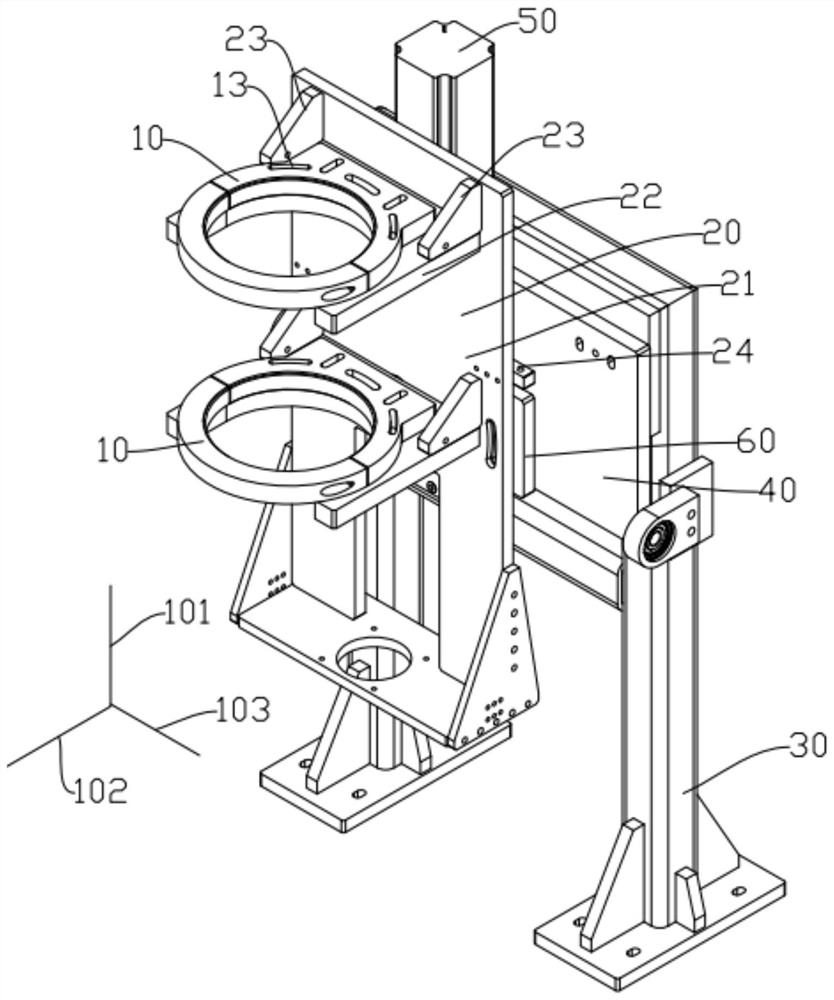

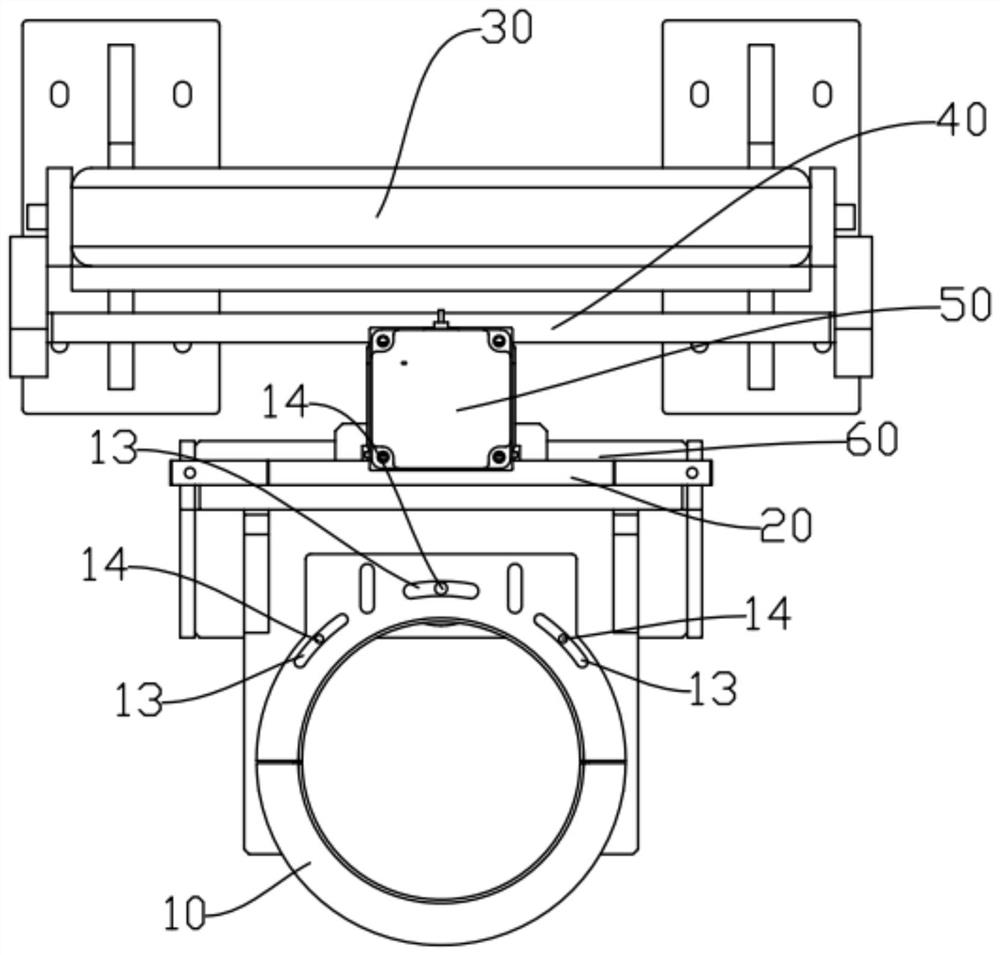

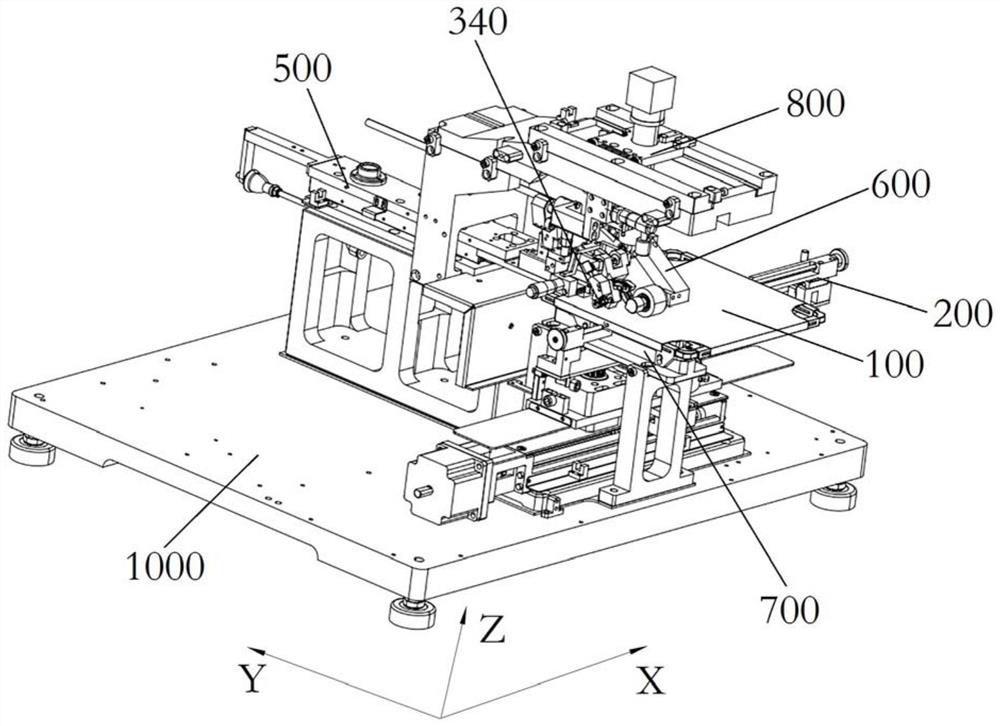

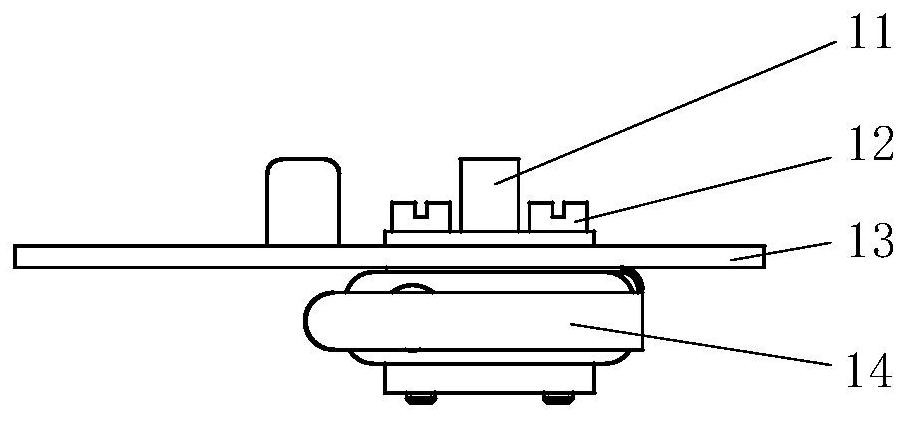

MicroLED detection equipment

PendingCN112881288ASimple structureHigh position adjustment accuracyOptically investigating flaws/contaminationEngineeringMechanical engineering

Owner:苏州凌云光工业智能技术有限公司

Position adjusting mechanism of punch press ejector plate

The invention relates to a position adjusting mechanism of a punch press ejector plate. The position adjusting mechanism comprises a bottom plate arranged at the lower part of a machine frame of a punch press, an oil cylinder is vertically arranged in the middle of the bottom plate, and the ejector plate is fixedly connected to the upper end of a piston rod of the oil cylinder; two supporting blocks are symmetrically arranged between the bottom plate and the ejector plate, a bearing is fixedly arranged at the upper end of each supporting block, a driven chain wheel is arranged on the inner ring of each bearing, a screw rod is mounted on an inner thread of each driven chain wheel, and the upper ends of the screw rods abut against the lower end of the ejector plate; a driving chain wheel connected with the driven chain wheels through a chain is arranged behind the oil cylinder, and a disc type motor for driving the driving chain wheel to rotate is vertically arranged below the driving chain wheel. The position adjusting mechanism has the characteristics of being stable in structure, high in position adjusting precision, high in production efficiency and the like.

Owner:NINGBO BOXIN MACHINERY

A method for cutting and processing revolving door sliding cover

ActiveCN104139216BGuaranteed stabilityPrecise positioningMetal sawing devicesPositioning apparatusEngineeringMechanical engineering

The invention relates to a sliding door sliding cover cutting system and a processing method thereof. The cutting system includes a frame, an electric control cabinet, parallel guide rails, a fixed hat head cutting saw, a moving hat head cutting saw and a center frame. There is an electric control cabinet that is convenient for workers to operate. The upper end of the frame is horizontally fixed with a parallel guide rail. One end of the parallel guide rail is fixed with a fixed hat head cutting saw. A central frame is installed on the sliding guide on the parallel guide rail between the cap cutting saw and the fixed cap cutting saw. The invention is simple in structure, intelligent and reliable, convenient in operation and high in processing efficiency. It sets the precise position of three-point positioning and automatically adjusts the size of the workpiece, and clamps the workpiece for cutting processing. The clamping is stable, the cutting precision is high, and the quality and efficiency are high.

Owner:TIANJIN SENJIAN METAL PROD

Chip cleavage equipment

PendingCN113178407AHigh position adjustment accuracyHigh precisionSemiconductor/solid-state device manufacturingWorking accessoriesPhysicsEngineering

The invention provides chip cleavage equipment, and belongs to the technical field of chip cleavage. The chip cleavage equipment comprises: a film stretching frame which is used for placing a chip and is connected with a film stretching frame driving device; a cutting-up head device provided with a cutting-up knife for cutting up the chip; a chip splitting head device provided with a roller for splitting the chip, wherein the cutting-up head device and the chip splitting head device are connected with the cutting-up driving device; and a chip splitting supporting device provided with a chip splitting beam for supporting a chip and connected with the chip splitting driving device. The chip splitting supporting device is driven by the chip splitting driving device to be adjusted in the X direction and the Z direction. According to the chip cleavage equipment, through cooperative arrangement of all the devices, the chip cleavage process from the cutting-up knife is achieved, the position adjusting precision is high, accurate point fixing can be achieved, and the chip cleavage precision is high.

Owner:精良(北京)电子科技有限公司

An adjustable limit device

ActiveCN109677583BHigh position adjustment accuracySimple structureFuselagesClassical mechanicsEngineering

The invention belongs to the technical field of mechanical structures, and relates to an adjustable limit device for an aircraft unfolding mechanism. The high-precision adjustable limit device of the present invention includes an adjustment cover assembly (1) and an adjustment support assembly (4), wherein the adjustment cover assembly (1) passes through the screw (2) around the fixing frame (3) The waist-shaped hole is connected with the adjustment support assembly (4) on the other side, so that the adjustment support assembly (4) can be adjusted in position along with the cover plate assembly (1) along the waist-shaped hole of the fixing frame (3). The high-precision adjustable limit device of the present invention can realize the independent adjustment of the limit position and the independent adjustment of the switch position after being installed by adjusting the specific structural design of the cover plate assembly and the adjustment support assembly, thereby effectively improving the position adjustment accuracy of the unfolding mechanism. Moreover, the utility model has the advantages of simple structure, light weight, small volume, convenient installation and adjustment, easy popularization and application, and has great practical application value.

Owner:TAIYUAN AERO INSTR

Assembly and disassembly device for elliptical manhole cover plate of pressure vessel

The invention discloses an assembly and disassembly device for an elliptical manhole cover plate of a pressure vessel, which is characterized by comprising a pivoted arm component, a transmission connecting rod, a beam component and a track bracket, wherein the pivoted component comprises a bottom plate and a connecting shaft housing which is vertically fixed on the bottom plate; a pivoted arm isalso fixed on the plane of the bottom plate which is fixedly connected with the shaft housing; a fixing end and a free end of the pivoted arm are respectively articulated with the front end of the transmission connecting rod and the front end of the beam component; the track bracket is sleeved on a beam of the beam component in a sliding mode; and the rear end of the beam component is movably connected with the transmission connecting rod through a shaft housing with a handle and a transmission shaft housing. The invention has the advantages of light weight, material saving, manufacture cost saving, convenient use, time-saving and labor-saving operation, small needed operation space, simple operation process and easy positioning for the installation of the manhole cover plate; and only one person can assembly or disassembly the manhole cover plate and replace a spacer without a dragging system provided by exterior.

Owner:四川川润股份有限公司

Automatic alignment device for attaching heat transfer printing film

PendingCN114161817AHigh position adjustment accuracyImprove teleport position accuracyTransfer printingEngineeringMechanical engineering

The invention discloses an automatic alignment device for laminating a heat transfer film. The automatic alignment device comprises a roller structure and a centering structure, the centering structure comprises a fixing plate, an air cylinder, a first limiting structure, a second limiting structure and a connecting rod structure. The alignment device is mounted in front of the thermal transfer film laminating roller, namely before the thermal transfer film is laminated, the feeding conveying position of the thermal transfer film is adjusted by adjusting the position of the centering structure on the roller structure, so that the position precision during laminating is improved, and the product quality is improved. The air cylinder drives the first limiting structure to conduct limiting action, the second limiting structure is driven by the connecting rod structure to conduct synchronous limiting action, operation is easy and convenient, the device is suitable for position adjusting action when heat transfer printing films with different widths are attached, and the device has wide applicability.

Owner:JIANGSU XUETAI PRINTING

Novel efficient mold repairing device

InactiveCN111570972AChange up and down positionChange front and rear positionsWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention relates to the technical field of mold repairing, and discloses a novel efficient mold repairing device. The novel efficient mold repairing device comprises a base, wherein a position adjusting mechanism is slidably arranged at the top of the base through a sliding groove and a sliding block, a carbon dioxide gas tank is fixedly connected to the top of the base, two vertical plates are symmetrically and fixedly connected to the top of the base, a top plate is fixedly connected between the tops of the two vertical plates, two first motors are symmetrically and fixedly connected tothe left side face of the vertical plate located on the left side through supporting plates, lead screws are fixedly connected to the output ends of the first motors, and the right ends of the lead screws penetrate through the left vertical plate and are rotationally connected with the left side face of the right vertical plate. The problems that when most existing mold repairing devices repair molds, due to the fact that welding wires need to be moved frequently, the stability of the welding wire conveying speed is difficult to guarantee, the mold repairing quality is reduced, and the mold repairing efficiency is seriously reduced are solved.

Owner:CHUZHOU MODERN MOLD MFG

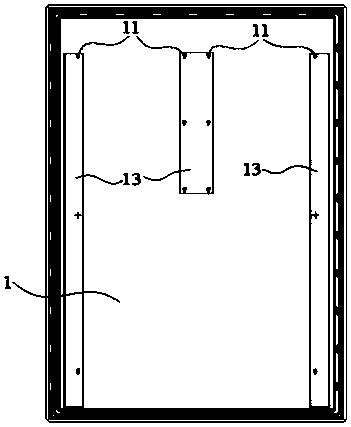

A refrigerator door shelf installation structure and refrigerator

ActiveCN108679915BHigh position adjustment accuracyEasy to operateDomestic cooling apparatusLighting and heating apparatusIceboxStructural engineering

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

A rubber sheet cutting structure

The invention discloses a rubber plate cutting structure which comprises a worktable. A recessed flow channel is arranged on the worktable, a rubber plate can longitudinally move in the flow channel,a beam stretching over the flow channel is arranged on the worktable, a mounting rod is arranged on the beam, a plurality of mounting blocks capable of sliding and rotating on the mounting rod sleevethe mounting rod, first scale marks for axial sliding reference of the mounting blocks are arranged on the mounting rod, first locking screws for fixing the mounting blocks onto the mounting rod are arranged on the mounting blocks, electric heating cutting rods capable of cutting the rubber plate to form holes are arranged on the mounting blocks, a storage pipe for storing a cable is arranged on the beam and parallel to the beam, a plurality of leading-out holes for leading out the cable to be in circuit connection with the electric heating cutting rods are formed in the storage pipe, a left support and a right support for supporting the beam are arranged on two sides of the worktable, a wrench is arranged on the beam and pulls the beam to rotate, the electric heating cutting rods are driven to cut the rubber plate, and operation is facilitated.

Owner:广东邦达实业有限公司

Control method, equipment and storage medium of double-valve dispensing device

ActiveCN110813649BHigh position adjustment accuracySolve the technical problem of low position adjustment accuracyLiquid surface applicatorsCoatingsControl engineeringMechanical engineering

The invention discloses a control method, equipment and storage medium of a double-valve glue dispensing device. The method comprises the following steps: when the glue dispensing valves are in their respective initial positions through a camera, the glue dispensing valves correspond to the positions to be glued. The coordinates of the first platform and the second platform at that time, and then calculate the third platform coordinates of the motion platform, the first compensation coordinates of the first dispensing valve and the second platform coordinates according to the preset adjustment algorithm, the first platform coordinates and the second platform coordinates The second compensation coordinates of the two dispensing valves, so as to control the motion platform and each dispensing valve to move to the corresponding position, so as to ensure that the position of the double dispensing valve corresponds to the position to be dispensed, and improve the position adjustment accuracy of the double valve dispensing device, thereby The technical problem of low position adjustment accuracy of the double-valve dispensing device in the prior art is solved.

Owner:深圳市特瑞吉科技有限公司

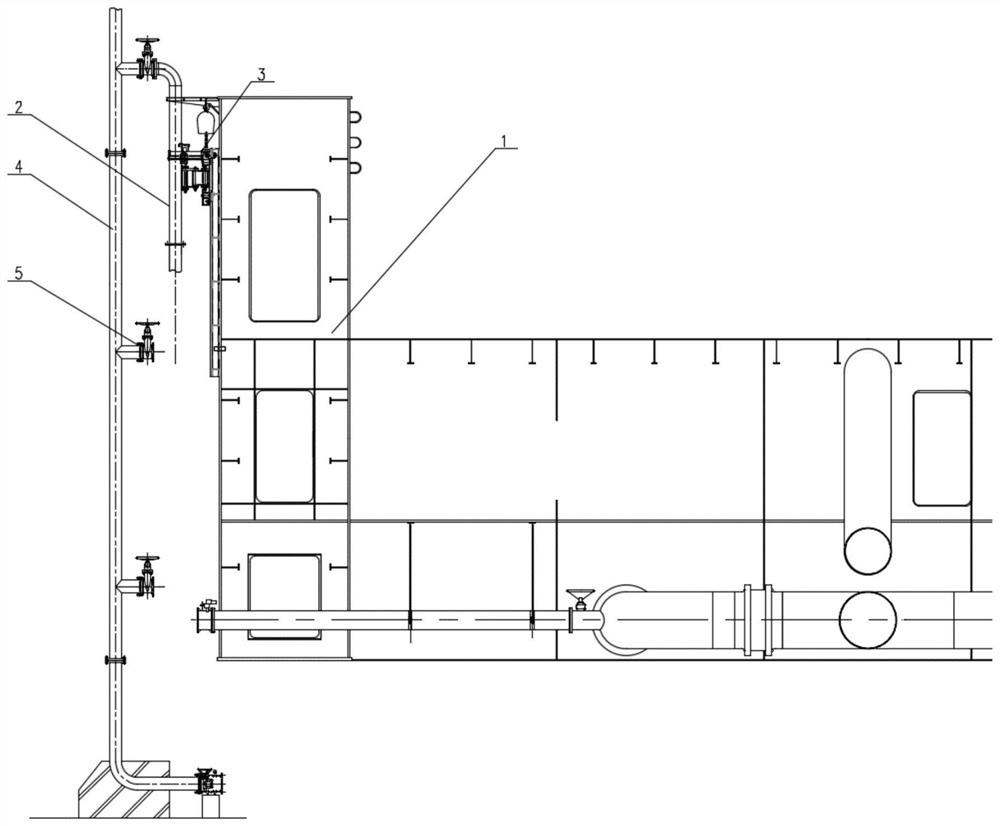

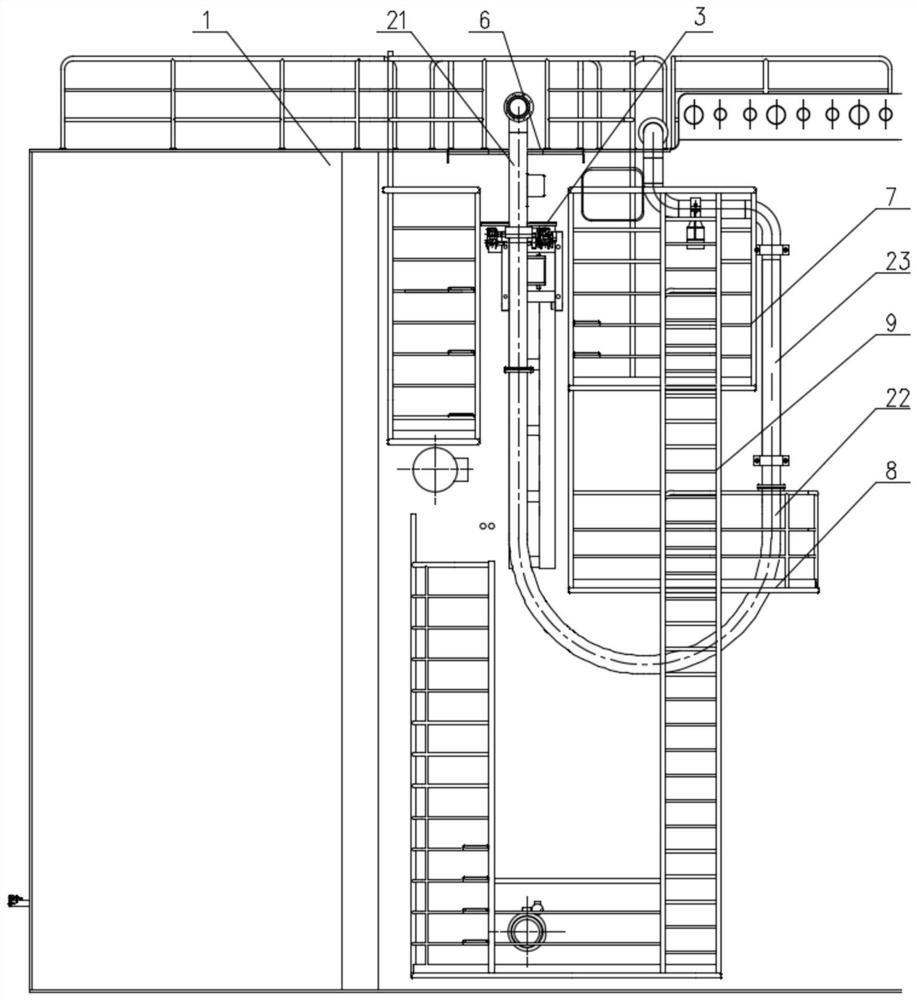

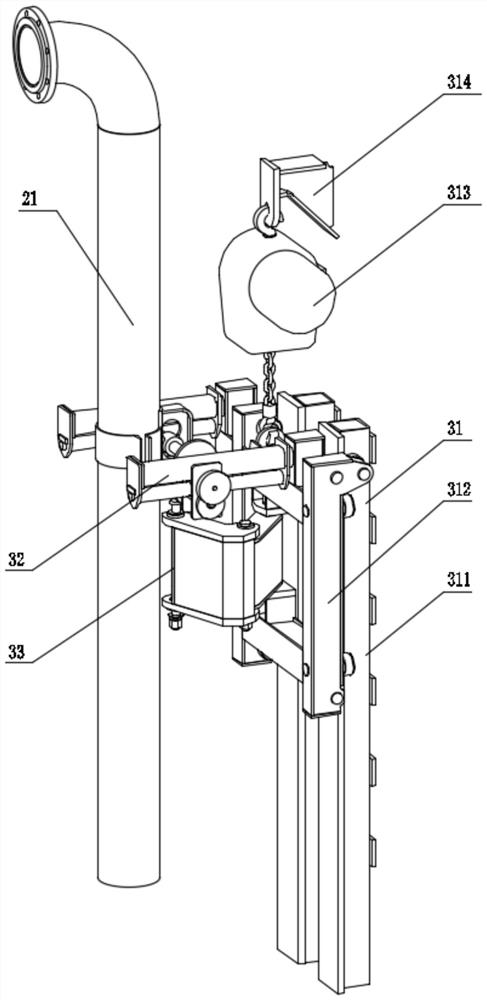

Water replenishing connecting pipe system for ship lift

ActiveCN114182712AHigh position adjustment accuracyReduce the difficulty of dockingClimate change adaptationWater supply tanksWater storageMarine engineering

The invention relates to a water replenishing pipe connecting system for a ship lift, which belongs to the technical field of ship lifters and comprises a ship lift chamber, a water replenishing pipe connecting system and a water replenishing pipe connecting system, the water supplementing pipe unit is arranged on the side wall of the ship reception chamber so as to supplement and drain water to the ship reception chamber, the water supplementing pipe unit comprises a lifting pipe and a fixed pipe, the fixed pipe is fixed to the ship reception chamber and communicates with the water storage pond, and the lifting pipe communicates with the fixed pipe through a hose; the lifting pipe adjusting unit comprises a lifting device for driving the lifting pipe to move up and down and a transverse moving device for driving the lifting pipe to move in the horizontal direction, the transverse moving device is fixed to the lifting device, and the lifting pipe is fixed to the transverse moving device. The spatial position of the lifting pipe is accurately adjusted through the lifting device for driving the lifting pipe to move up and down and the transverse moving device for driving the lifting pipe to move in the horizontal direction. The lifting pipe adjusting unit reduces the butt joint difficulty of the lifting pipe and the water supplementing and draining valve, and the position adjusting precision of the lifting pipe is improved.

Owner:HEAVY EQUIP ENG CO LTD OF WUCHANG SHIPBUILDING IND

Steering column position offset correction method, device, storage medium and vehicle

ActiveCN110758544BRegulation stabilityThe adjustment process is stable and reliableSteering controlsSteering columnSimulation

The present disclosure relates to a method, a device, a storage medium and a vehicle for correcting the position offset of a steering column. Record the amount of change in the number of rotations of the motor relative to the number of rotations at zero point. The number of rotations at zero point is the predetermined number of rotations when the motor rotates in the preset direction until it reaches the locked-rotor state. The amount of change is used to determine the adjustment of the steering column Position; when the variation is zero and the motor has not reached the locked-rotor state, control the motor to rotate in the preset direction until it reaches the locked-rotor state, and use the number of rotations of the motor when it reaches the locked-rotor state as the new zero-point rotation number . Through the technical solution of the present disclosure, the deviation between the actually detected position of the steering column and its actual position can be corrected, thereby improving the position adjustment accuracy of the steering column, and avoiding adjustment failures caused by position deviation, so that the steering column The adjustment process of the column is more stable and reliable.

Owner:BYD CO LTD

Position adjusting device of horizontal heating furnace tube

PendingCN113380668AEasy to assembleEasy to installFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringHeating furnace

The invention discloses a position adjusting device of a horizontal heating furnace tube. The device comprises: a fixing plate fixedly connected with a rack; an up-down adjusting plate comprising a horizontal plate and a vertical plate, wherein the vertical plate is in sliding fit with the side face of the fixing plate through a vertical guide structure in the vertical direction; an up-down adjusting guide plate and a vertical adjusting assembly, wherein the up-down adjusting guide plate is in sliding fit with the side face of the fixing plate, the up-down adjusting guide plate is located below the up-down adjusting plate, and the vertical adjusting assembly is used for adjusting the position of the up-down adjusting guide plate in the vertical direction so as to drive a furnace tube to move in the vertical direction; and a left-right adjusting plate and a horizontal adjusting assembly, wherein the left-right adjusting plate is arranged on the horizontal plate in a sliding mode through a horizontal guide structure, and the horizontal adjusting assembly is used for adjusting the position of the left-right adjusting plate in the horizontal direction.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com