Automatic alignment device for attaching heat transfer printing film

An automatic alignment and thermal transfer film technology, applied in transfer printing, rotary printing machine, printing and other directions, can solve the problems of automatic adjustment of the transfer position of thermal transfer film, affecting product yield, affecting production efficiency, etc. , to achieve the effect of wide applicability, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

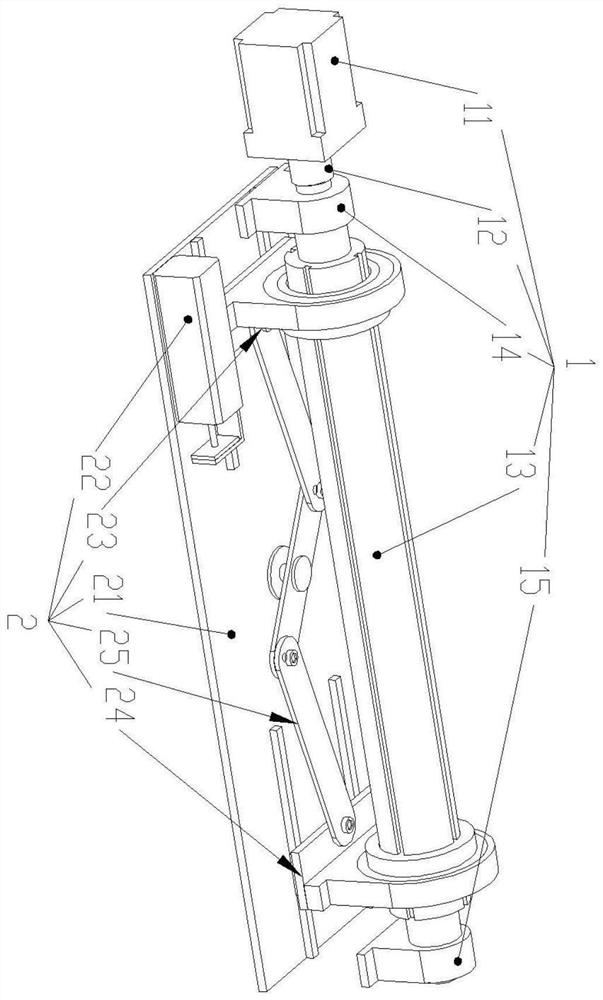

[0024] Such as figure 1 Shown is a perspective view of the present invention, including a roller structure 1, a centering structure 2, and the centering structure 2 is arranged on the roller structure 1; wherein, the centering structure 2 includes a fixed plate 21, a cylinder 22, a first limit Position structure 23, second position-limiting structure 24, connecting rod structure 25, described first position-limiting structure 23, second position-limiting structure 24 are relatively arranged on the fixed plate 21, are connected by connecting rod structure 25, and described cylinder 22 It is arranged on the fixing plate 21 , and its plunger end is connected with the first limiting structure 23 .

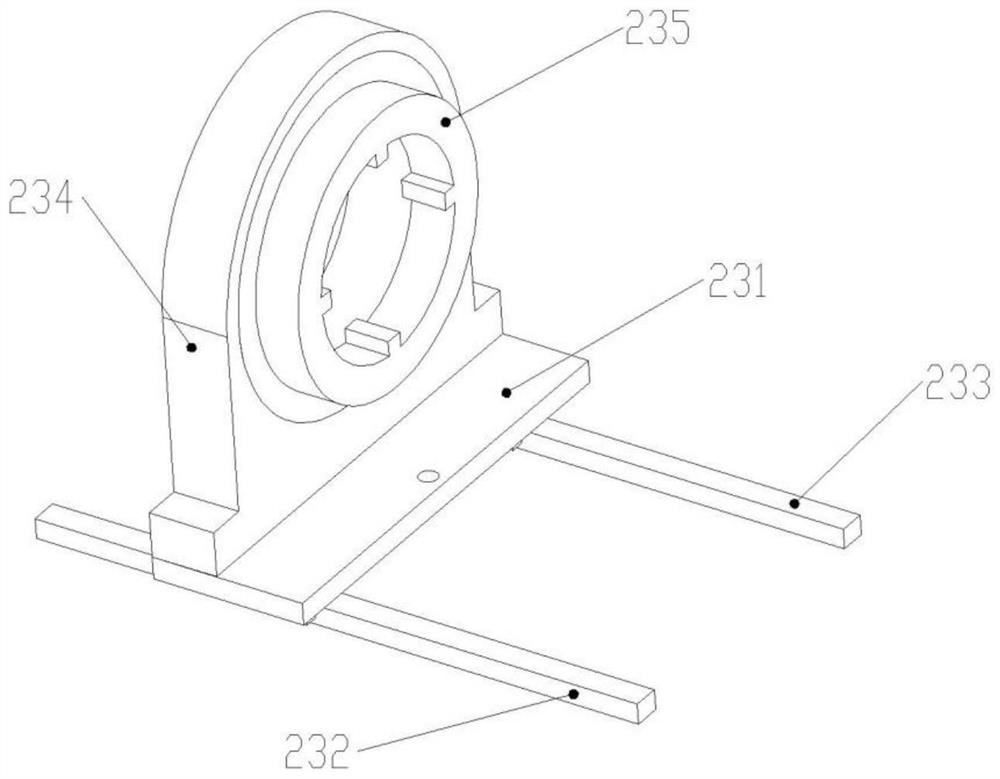

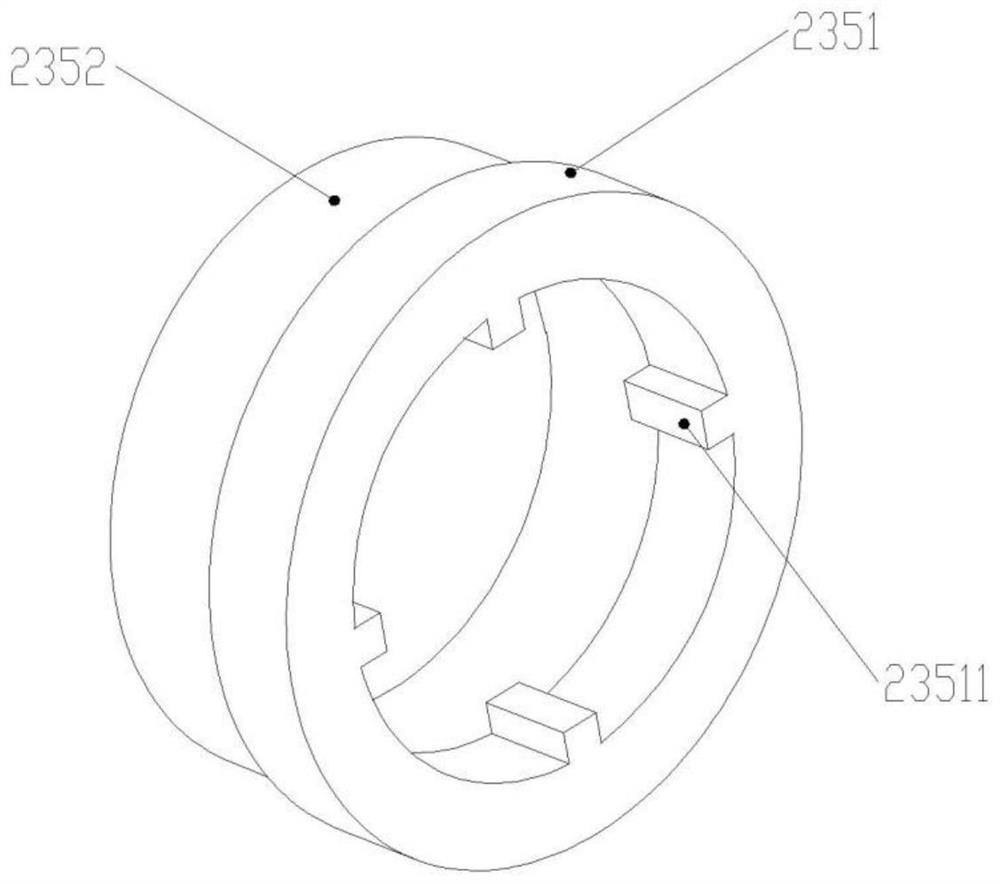

[0025] The first limiting structure 23 and the second limiting structure 24 have the same structure, as figure 2 Shown is a perspective view of the first limit structure 23, including a moving plate 231, a first guide rail 232, a second guide rail 233, a first bearing seat 234, a lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com