Patents

Literature

105results about How to "Reduce the difficulty of docking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for welding narrow-gap butt-joint connector of pipeline with large pipe diameter and thick wall

ActiveCN102653022ASolve the costReduce the difficulty of dockingArc welding apparatusShielded metal arc weldingButt joint

The invention relates to a welding method of a butt-joint connector of a pipeline. The invention provides a method for welding a narrow-gap butt-joint connector of a pipeline with a large pipe diameter and a thick wall to solve the problems of a TIG+SMAW (Tungsten Inert Gas+Shielded Metal Arc Welding) welding method in the prior art that the working amount is great, a welding effect is poor and the welding period is long; and a TOCE welding method cannot weld the butt-joint connector with the assembling gap which is more than 1.0 mm so that the working period is prolonged and the cost is high. The diameter of the pipeline is more than 700 mm and the wall thickness is more than 30 mm; test pieces are assembled and are protected by back argon; TIG bottoming welding is carried out on the inner wall of the pipeline to be welded; bottoming original filling welding is carried out and a partial welding path is adjusted according to requirements; and TOCE filling welding and capping covering are carried out, so that the welding is finished. With the adoption of the welding method, the butt-joint connector with the assembling gap which is more than 1.0 mm can be welded and the pipeline butt-joint difficulty is reduced; a TIG manual welding method is used for welding when tack welding and bottoming welding are carried out; other welding work adopts a TOCE automatic welding method to weld; and the welding speed and the welding effect are improved, the working period is shortened and the cost is reduced.

Owner:CHINA NUCLEAR IND 23 CONSTR +2

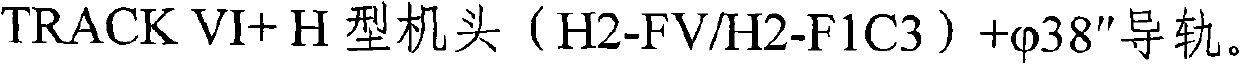

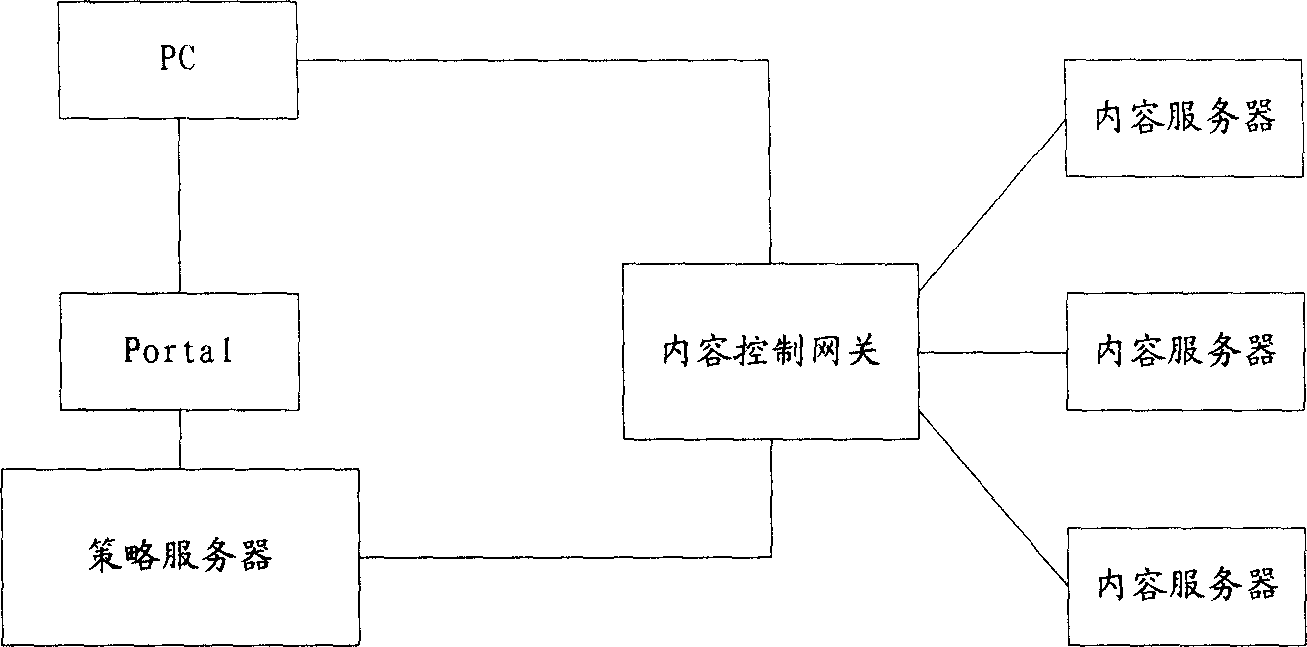

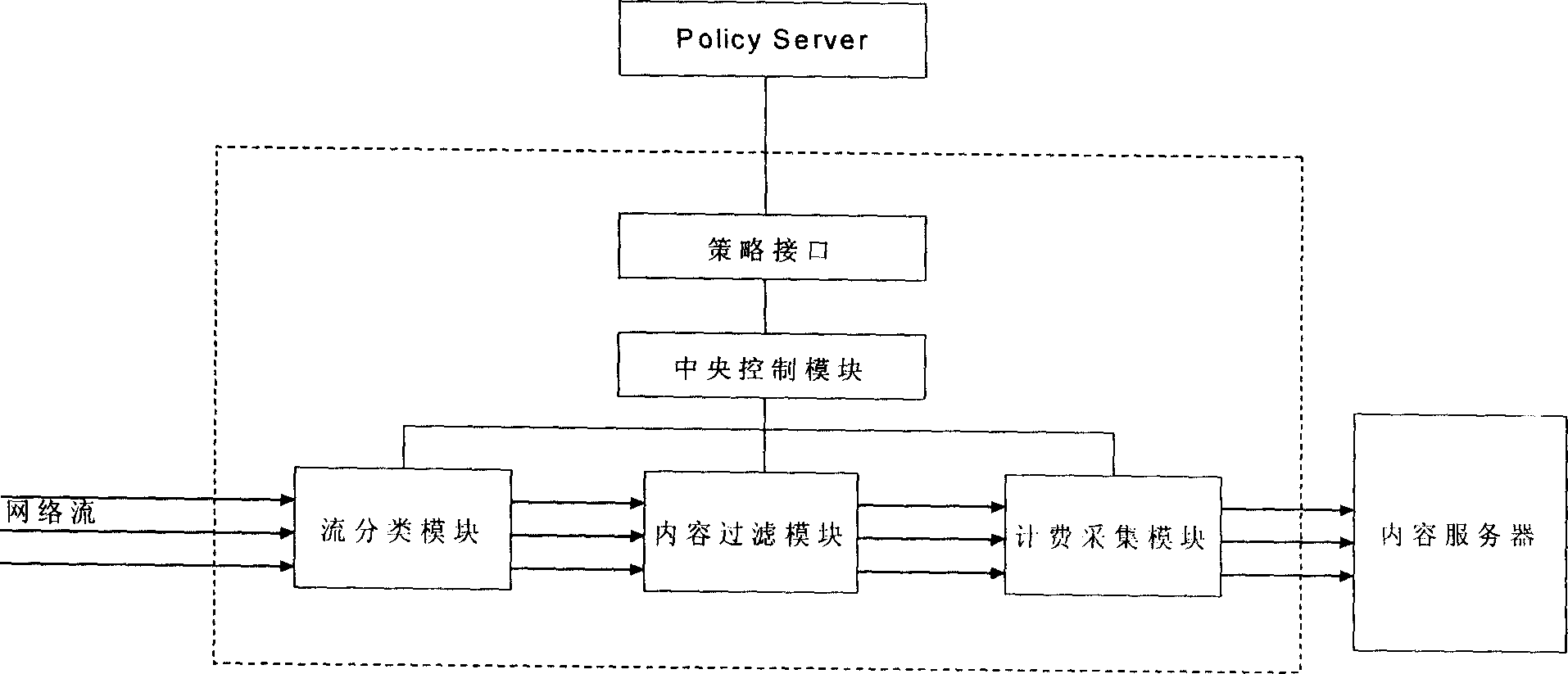

Method and system for realization of content charging

ActiveCN1874239AReduce the difficulty of dockingLow costMetering/charging/biilling arrangementsPayment architectureComputer networkService user

The method for implementing content charging includes steps: receiving request for using service from user, portal server sends request for activating service to strategy server; after receiving the request for activating service, the strategy server determines strategy of service corresponding to information of the service, and sends down message of the strategy of service to content control gateway; executing the strategy of service, the content control gateway allows user to use the service; carrying out content charging according to consumption information of service user uses reported from the content control gateway. The disclosed technical scheme implements content charging precisely as well as satisfies need of dynamic adjusting QoS of content service.

Owner:HUAWEI TECH CO LTD

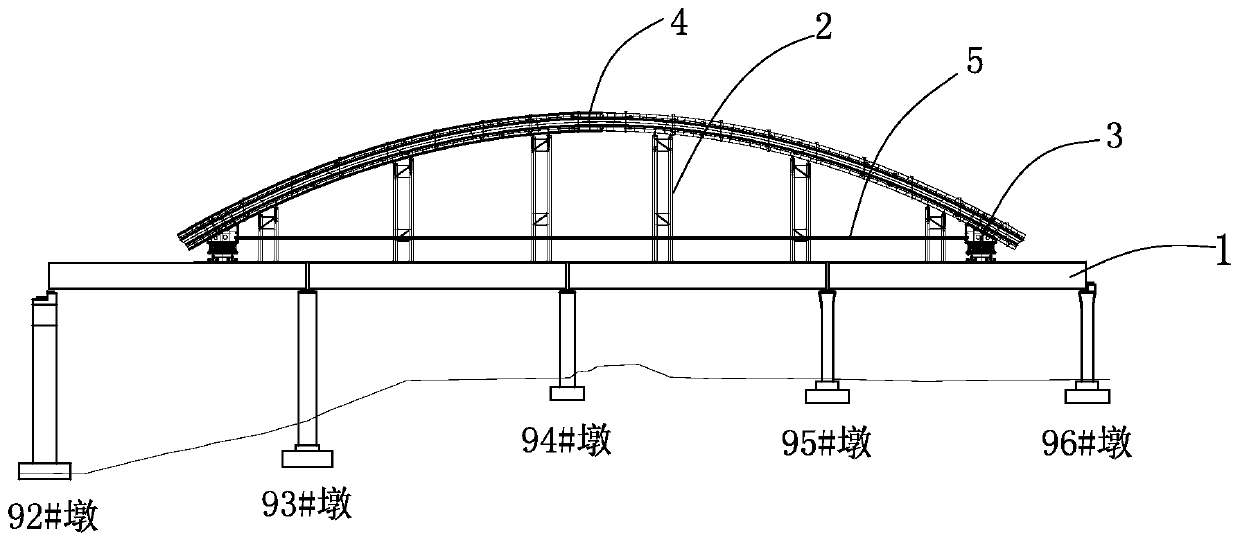

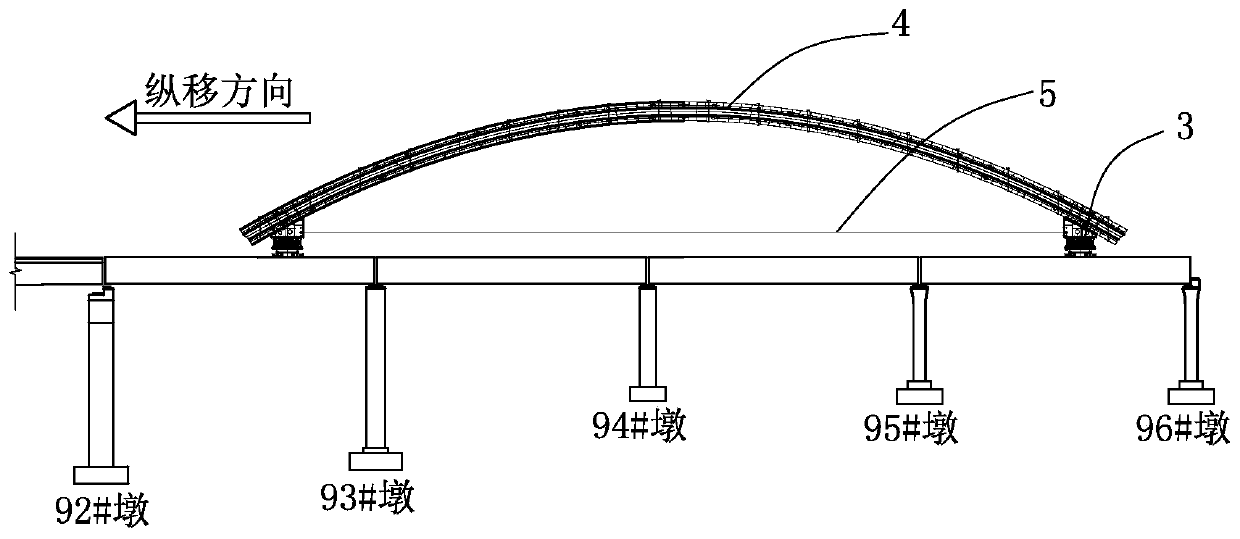

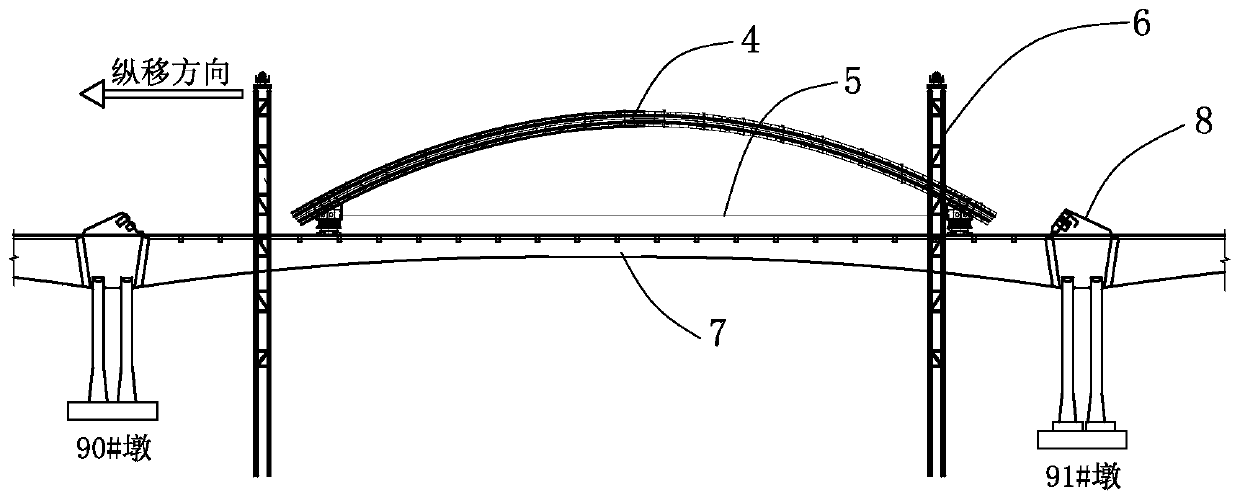

Longitudinal movement and lifting installation construction method for large steel pipe arch

ActiveCN109914266AReduce the difficulty of dockingReduce construction difficultyBridge erection/assemblyCarrying capacityContinuous beam

The invention provides an overall longitudinal movement and lifting construction method for a large steel pipe arch, which comprises the steps: dividing the whole steel pipe arch into a central main arch section and abutment sections at both ends, wherein the weight of the main arch section is limited to not exceeding the maximum carrying capacity of a main bridge steel beam during division; assembling the main arch section on a main bridge approach bridge, wherein when a main bridge continuous beam is constructed, lifting towers for lifting the main arch section are respectively arranged at both ends of a main bridge, and after closure of the main bridge continuous beam is completed, the main arch section is smoothly, continuously and longitudinally moved to a designed lifting position ofa main span; installing the two abutment sections at both ends of designed abutment positions of the steel pipe arch, then lifting the main arch section to a designed installation position by using the lifting towers, and connecting with the two abutment sections, thereby completing the installation of the steel pipe arch. The invention is not limited by the bearing capacity of the main bridge steel beam and the height of a longitudinal movement section, and the applicable range of a traditional longitudinal movement method is greatly expanded.

Owner:ROAD & BRIDGE INT +1

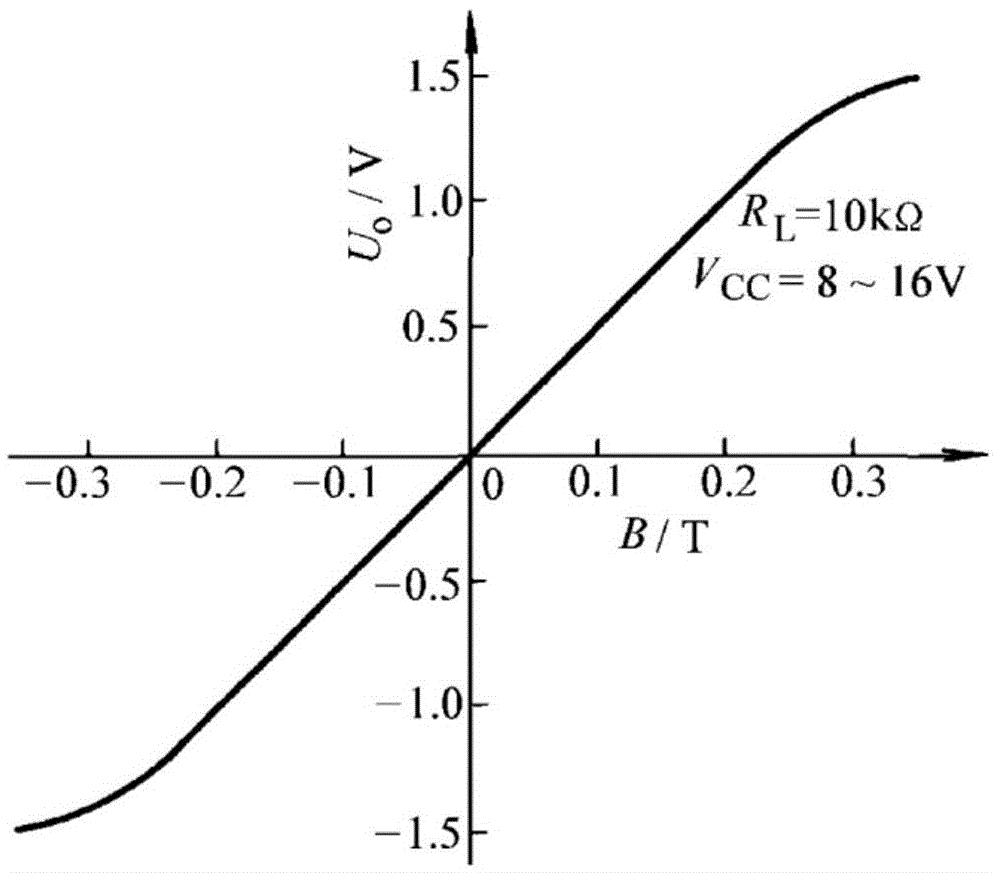

Three-freedom electric automobile charging interface scanning positioning method

InactiveCN105607666AFlexible moving processMove preciselyBatteries circuit arrangementsElectric powerElectricityElectric machine

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

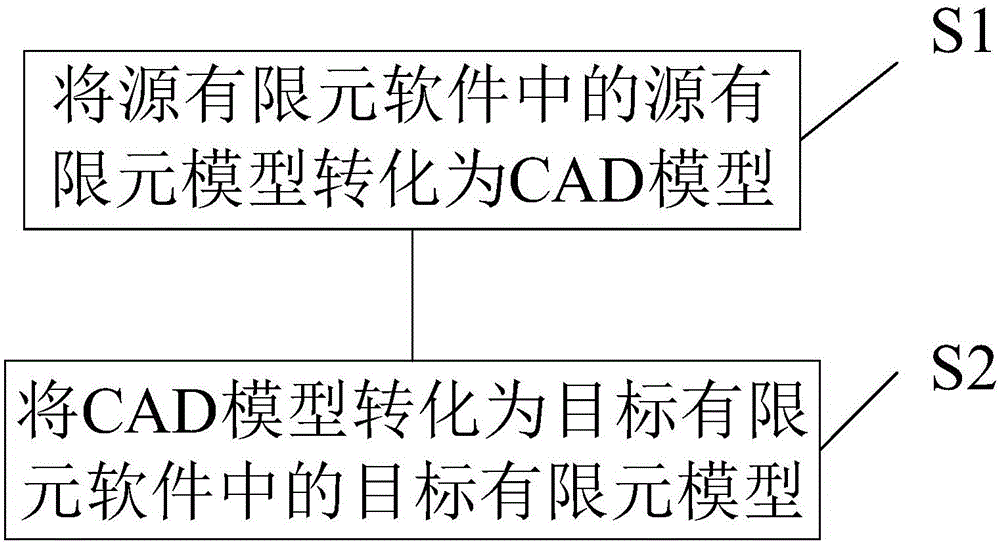

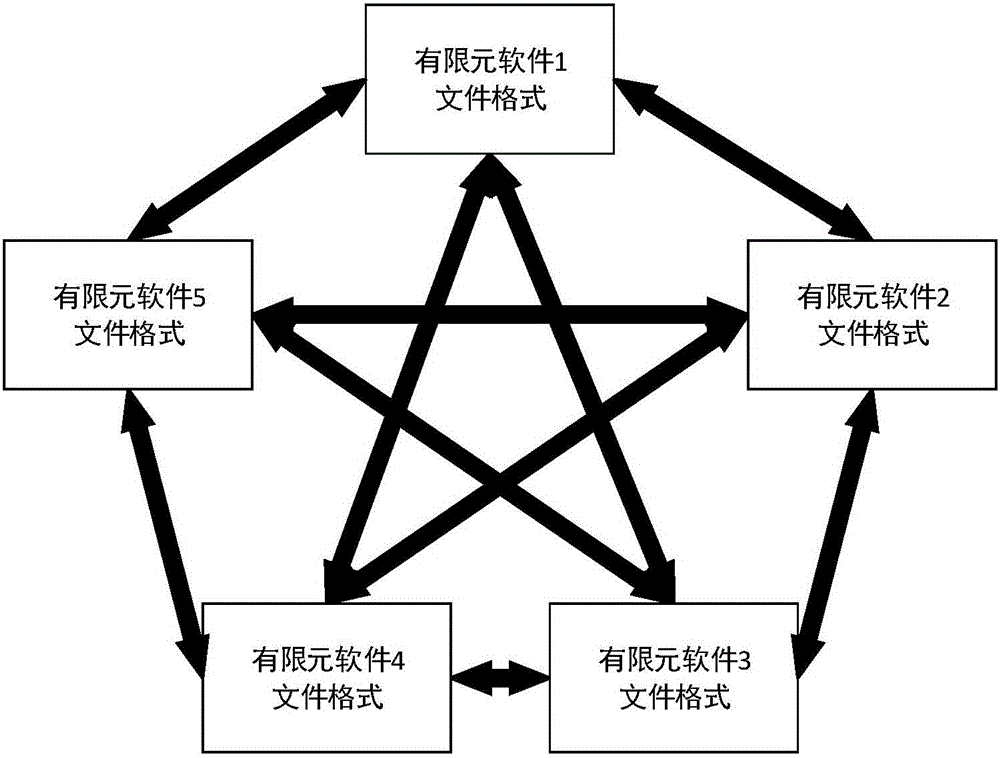

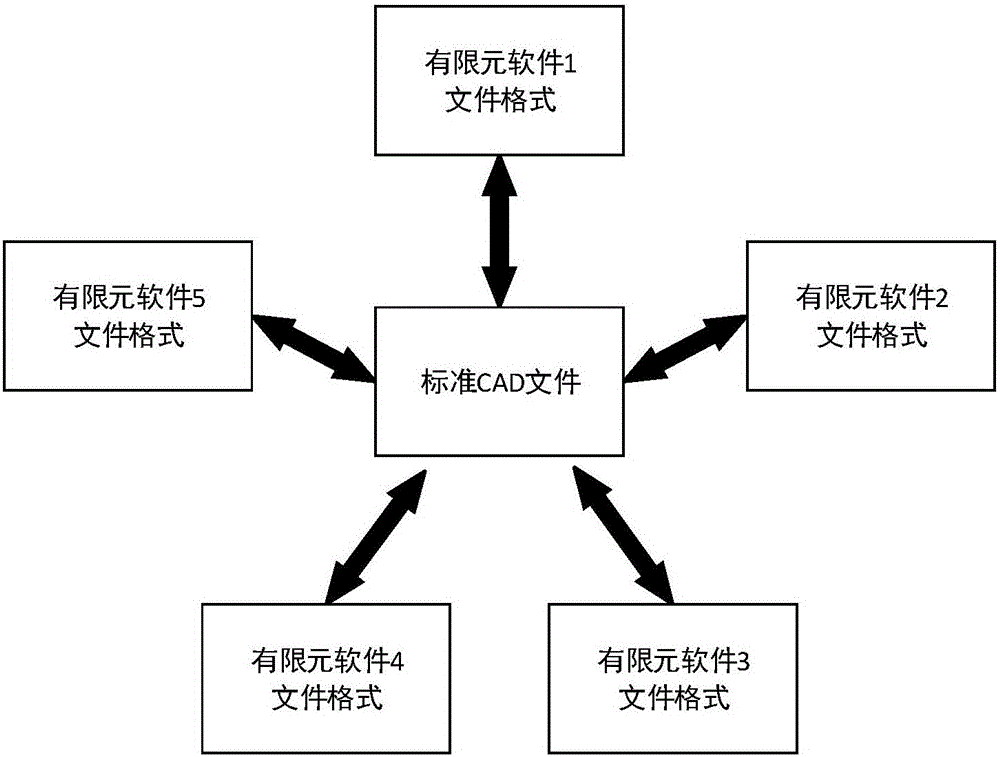

Conversion method of architectural structure model

ActiveCN105005666AReduce conversion mixReduce development difficultySpecial data processing applicationsElement modelFinite element analysis software

The invention relates to a conversion method of an architectural structure model, and is used for carrying out mutual conversion among different pieces of finite element software for the architectural structure model. The conversion method comprises the following steps: S1: converting a finite element model in the finite element software into a CAD (Computer-Aided Design) model; and S2: converting the CAD model into a target finite element model in target finite element software. Compared with the prior art, the conversion method causes a CAD file to become a transfer station used for the conversion of various pieces of finite element software. Since traditional finite element analysis software has multifarious data formats and a CAD file format has a relatively uniform standard, a pairwise-conversion combination has a huge amount among finite element software, a software interface is difficult in development, the CAD file stores unit key information, required conversion combinations can be greatly reduced through CAD conversion, and a development difficulty is lowered.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

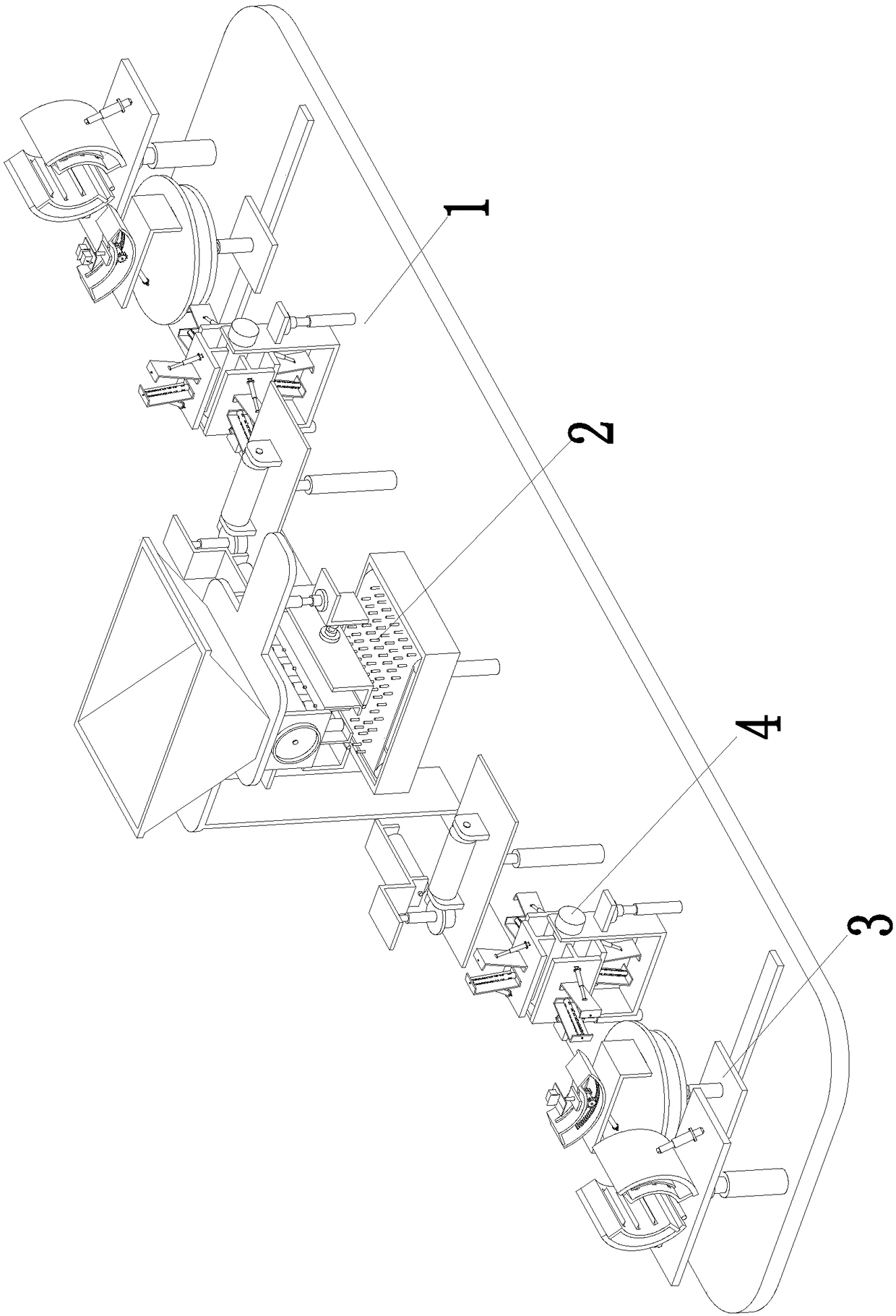

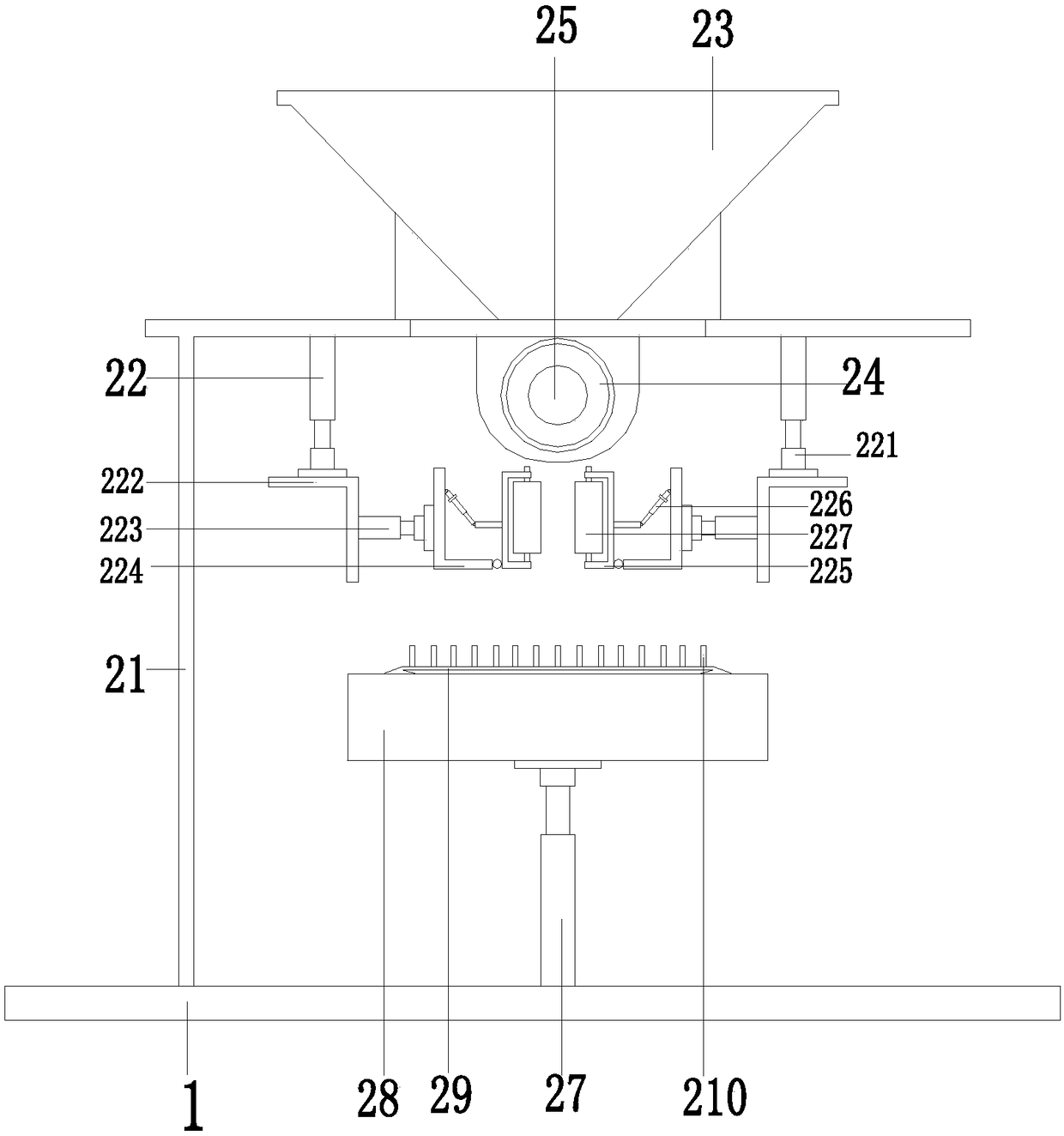

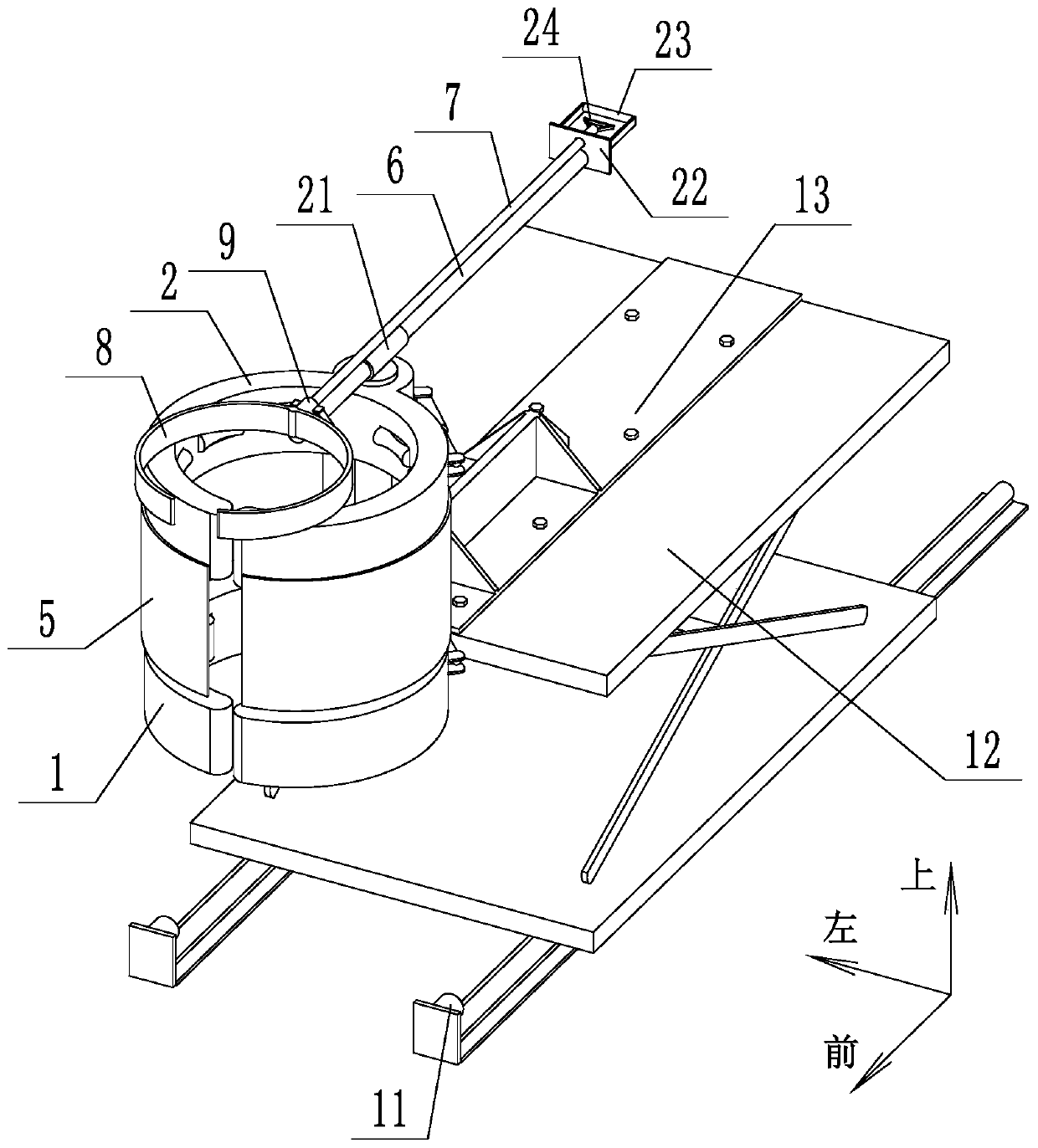

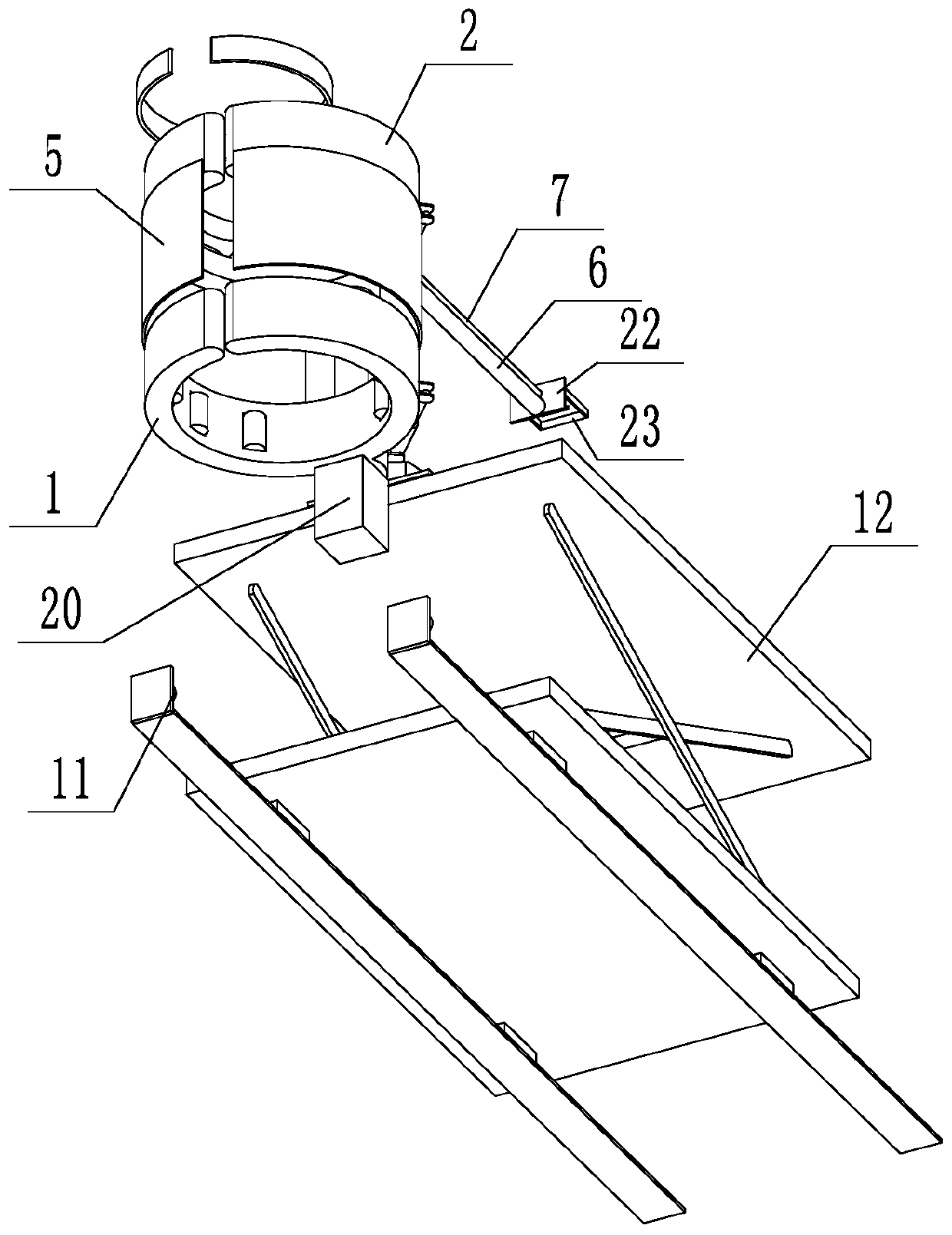

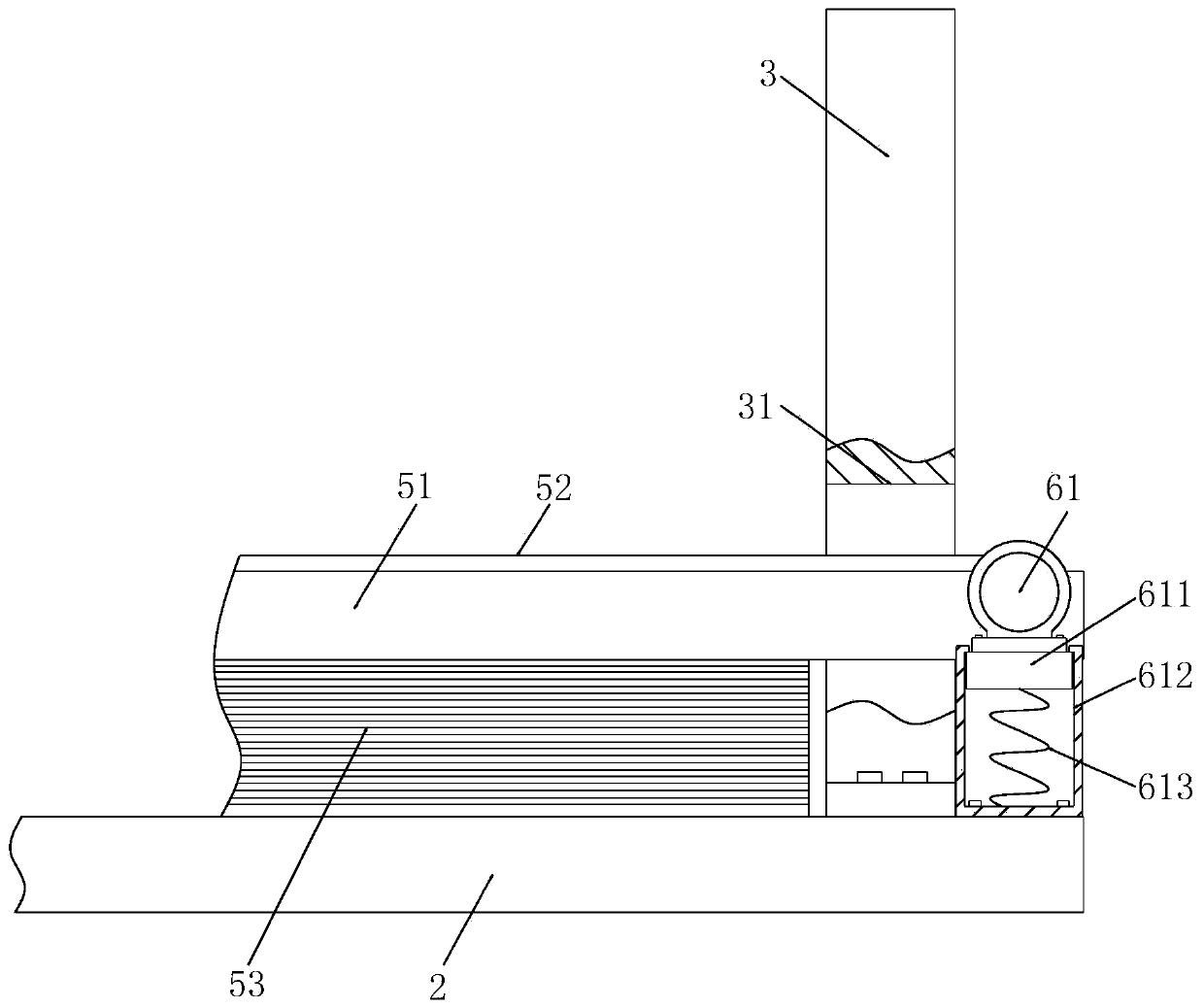

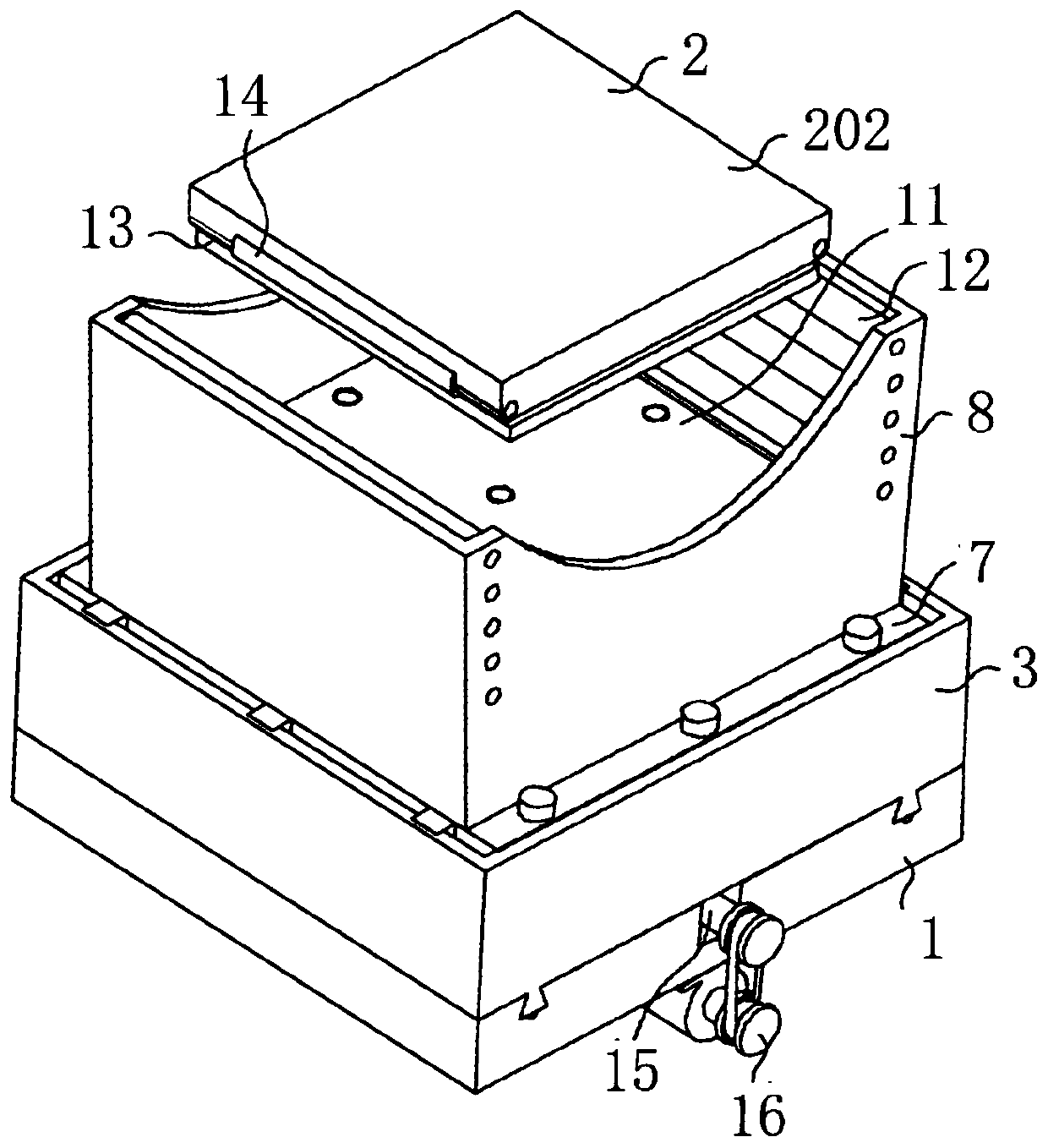

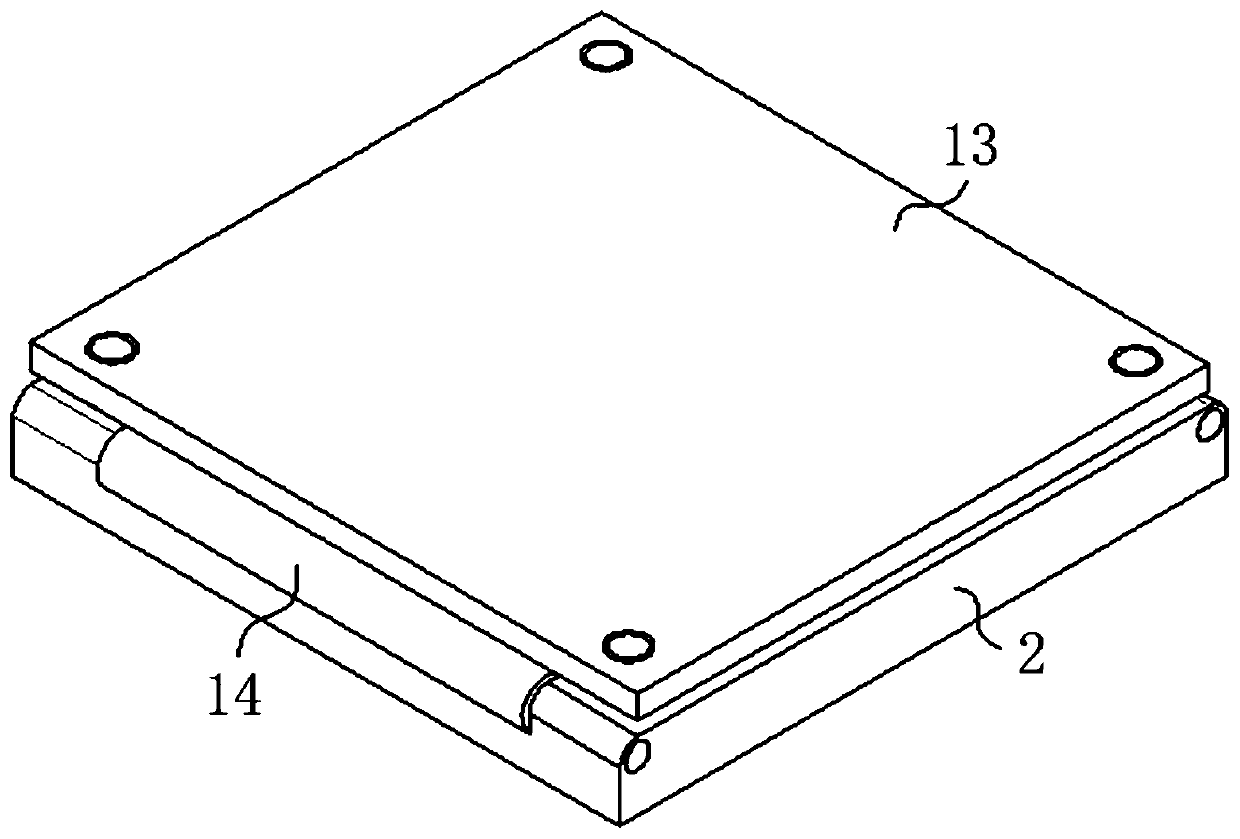

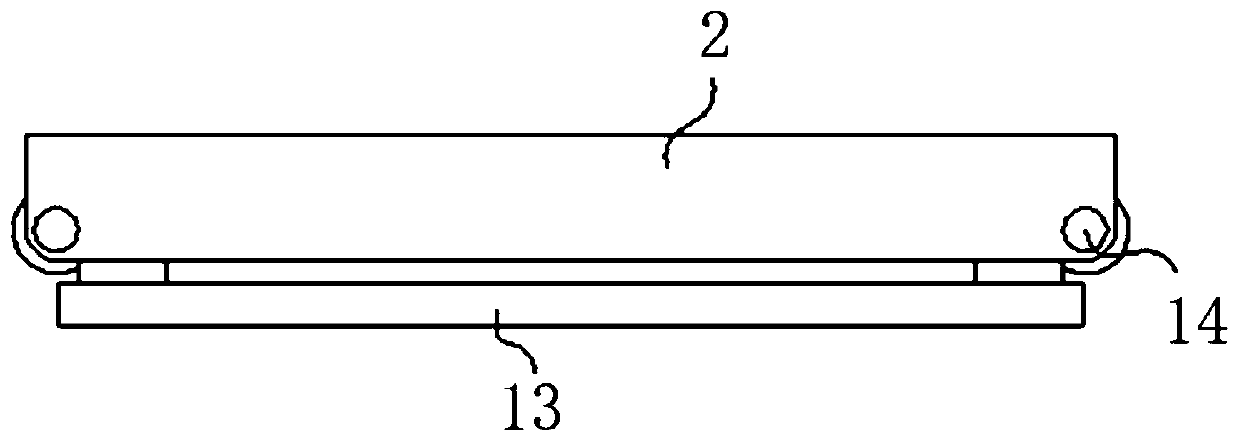

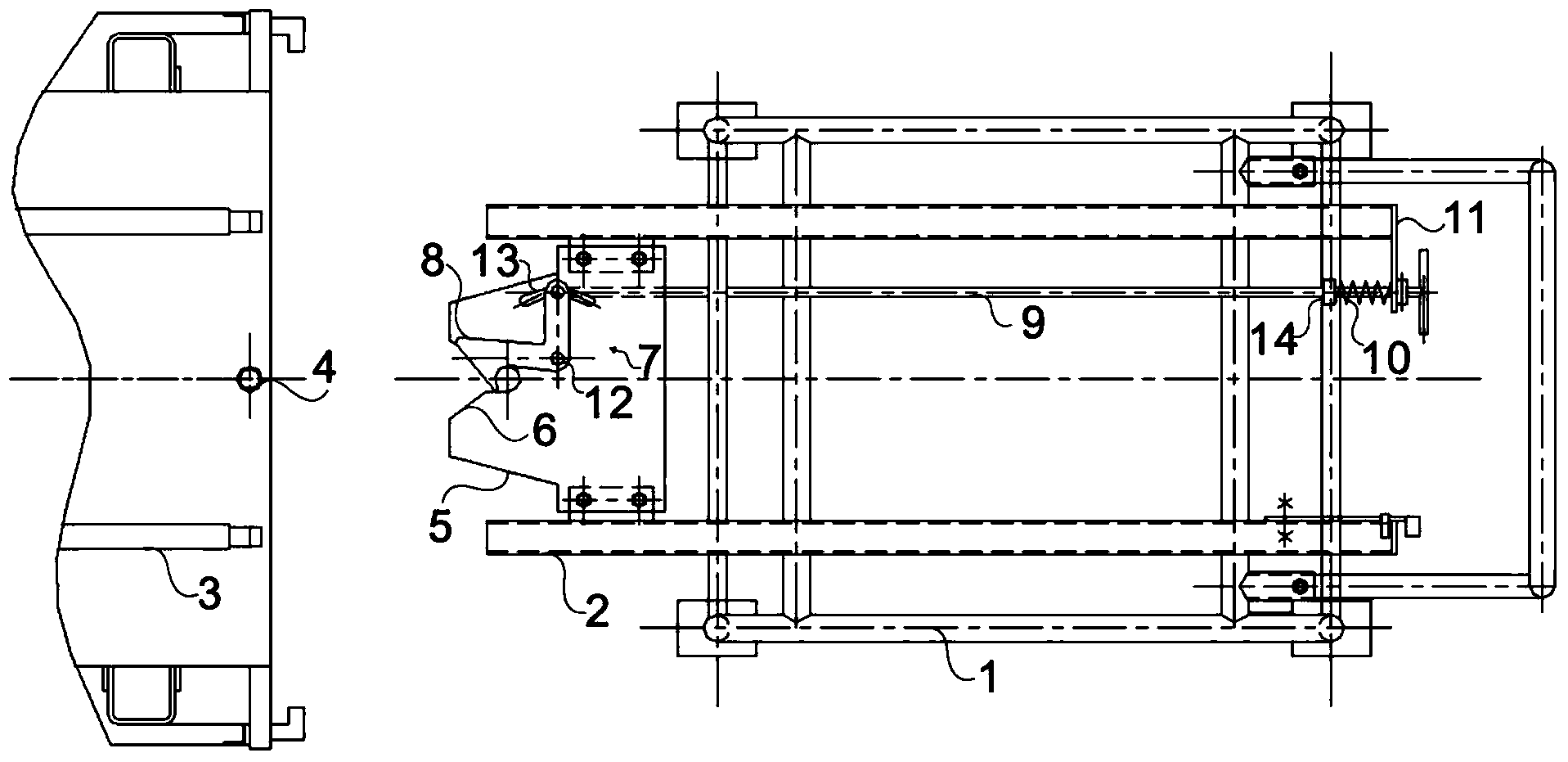

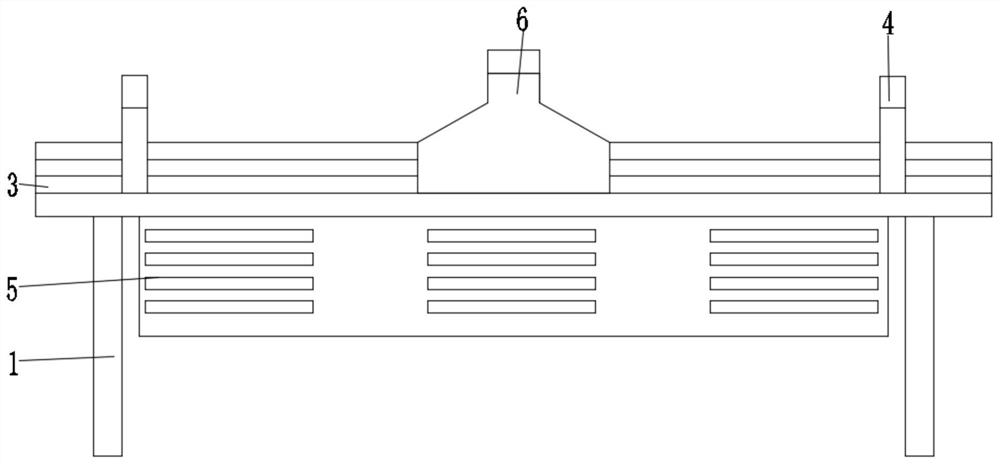

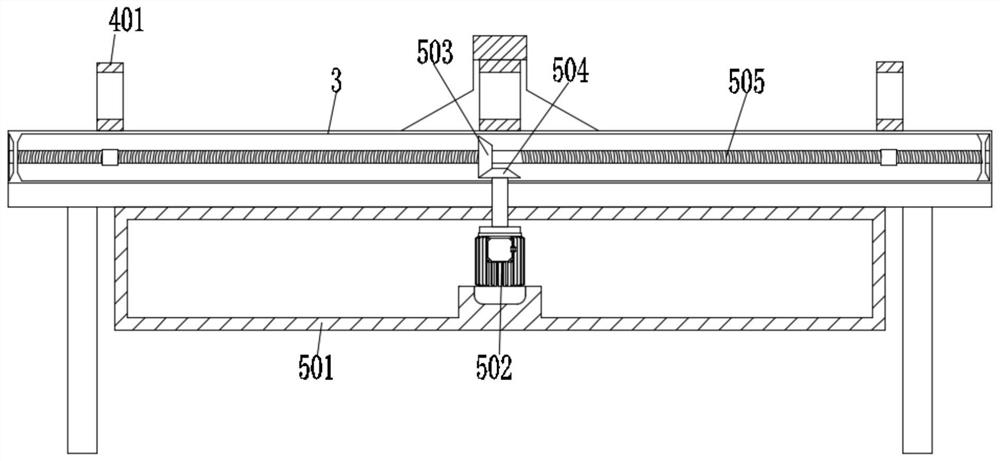

Automatic construction equipment of power cable

InactiveCN108306227AReduce labor intensityReduce the difficulty of dockingApparatus for repairing insulation/armouring cablesApparatus for removing/armouring cablesCable transmissionPower cable

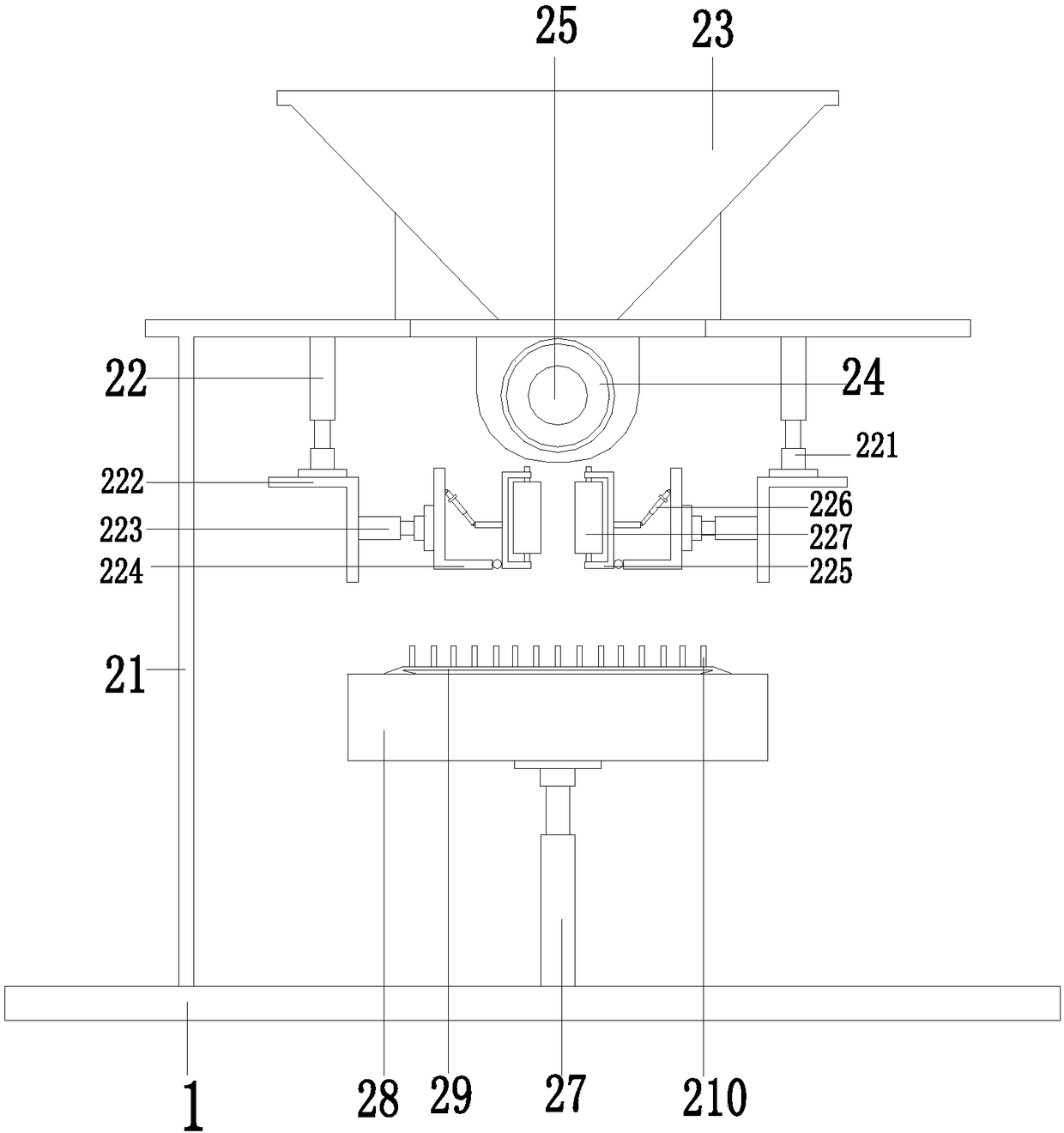

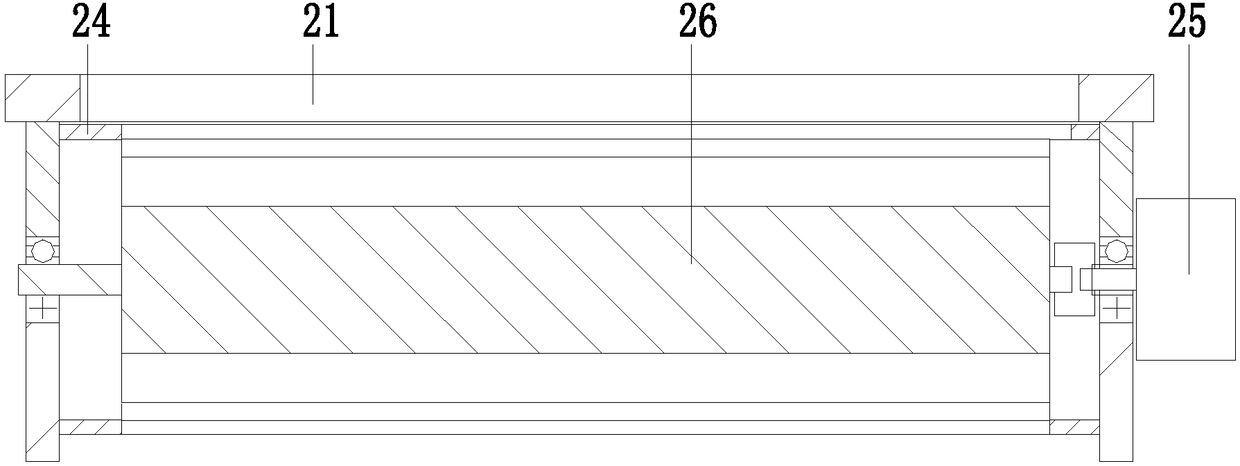

The invention relates to automatic construction equipment of a power cable. The automatic construction equipment comprises a bottom plate, wherein a sleeve device is arranged at a middle part of an upper end of the bottom plate, two cable surface processing devices are arranged on the bottom plate, the two cable surface processing devices are symmetrically arranged at outer sides of a front end and a rear end of the bottom plate, and two cable transmission devices are arranged on the bottom plate and are symmetrically arranged at inner sides of the front end and the rear end of the bottom plate. By the automatic construction equipment, the problems that an insulator on a surface of the cable is needed to be processed by manual during the existing cable recovery process by manual, the cableis needed to be pulled and transmitted by manual, a copper pipe is needed to be taken and placed for abutting, a corresponding processing tool is needed to be selected according to the size of the cable during manual processing insulator on the surface of the cable, the corresponding processing tool is needed to be selected with regard to cables with different sizes, the operation is complicated,manual cable control and copper pipe abutting are not stable and a gap between the cable and the internal size of the copper pipe during the abutting process is relatively small are solved.

Owner:丁佐琳

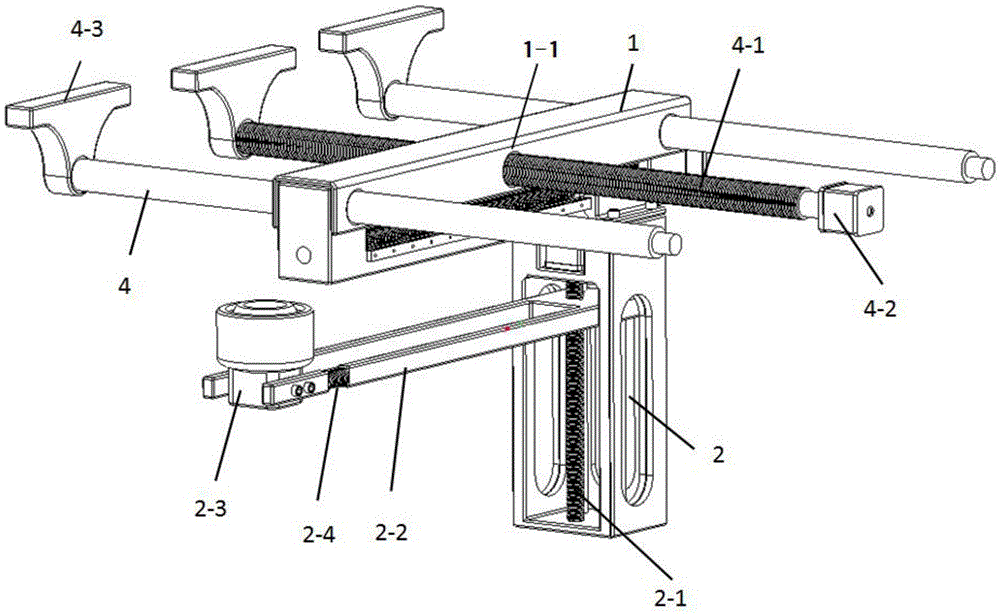

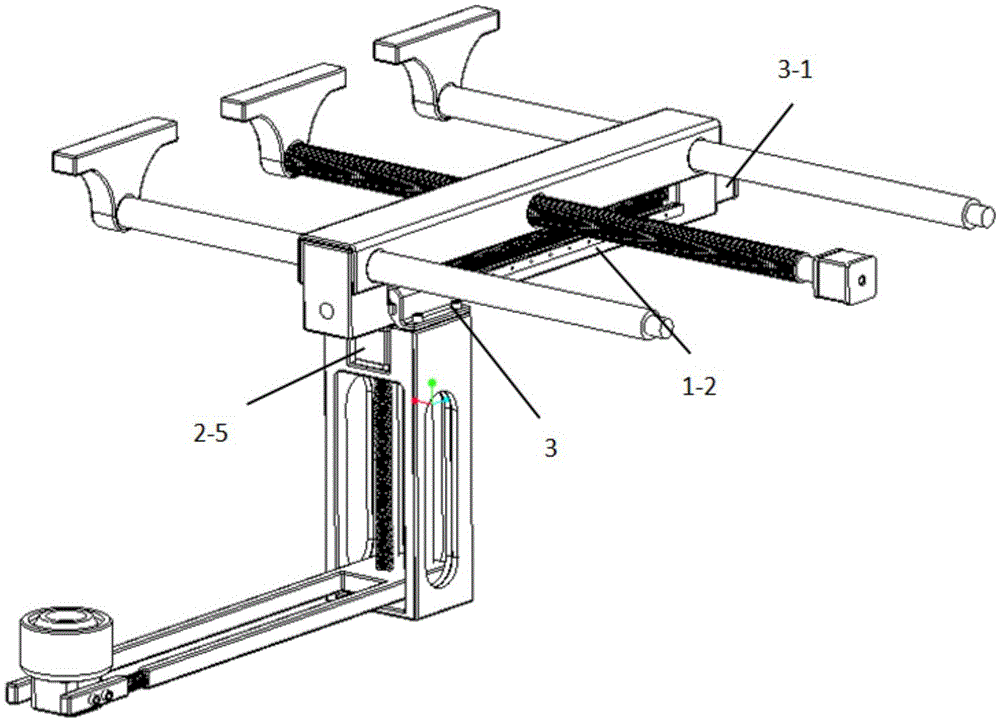

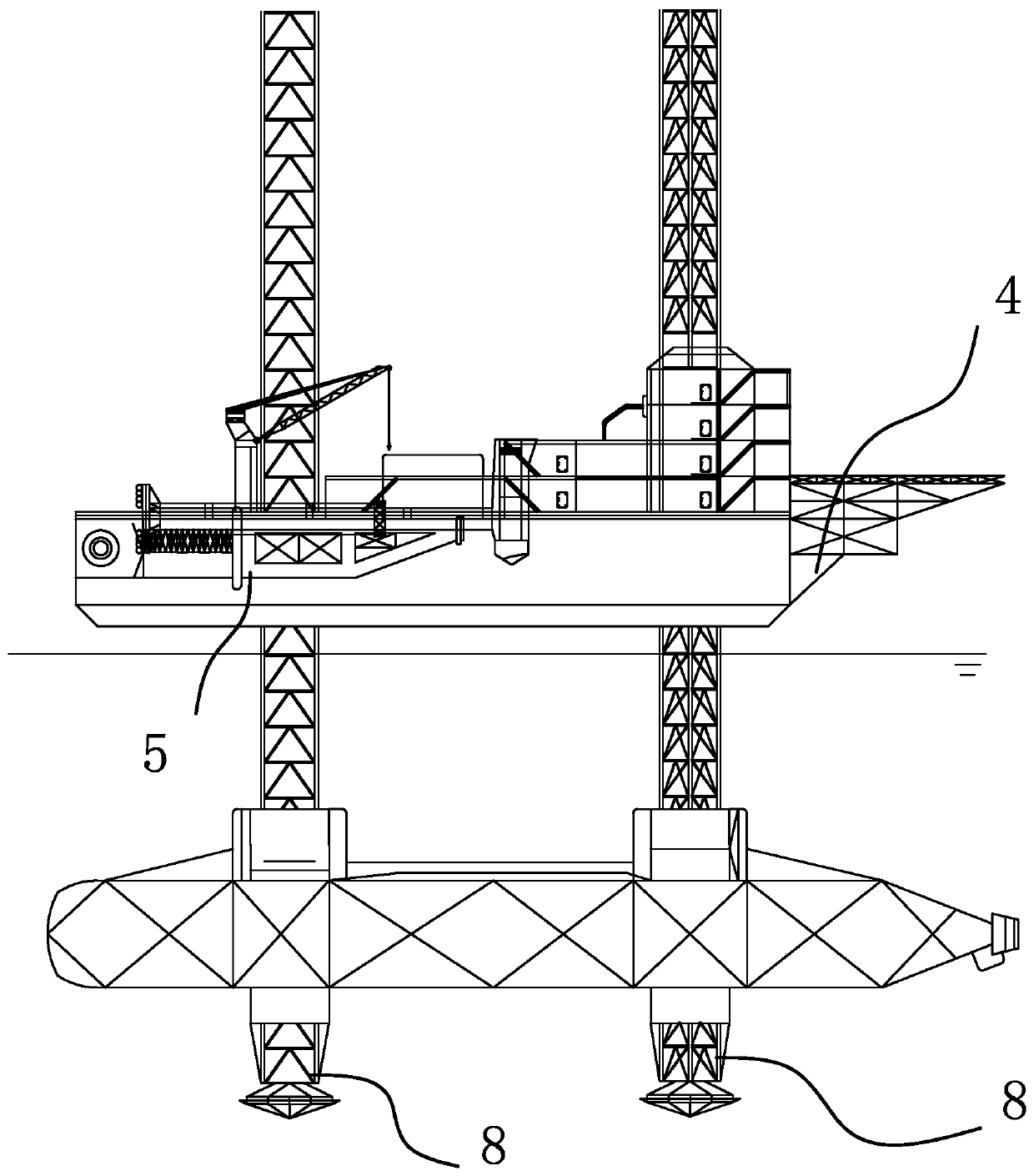

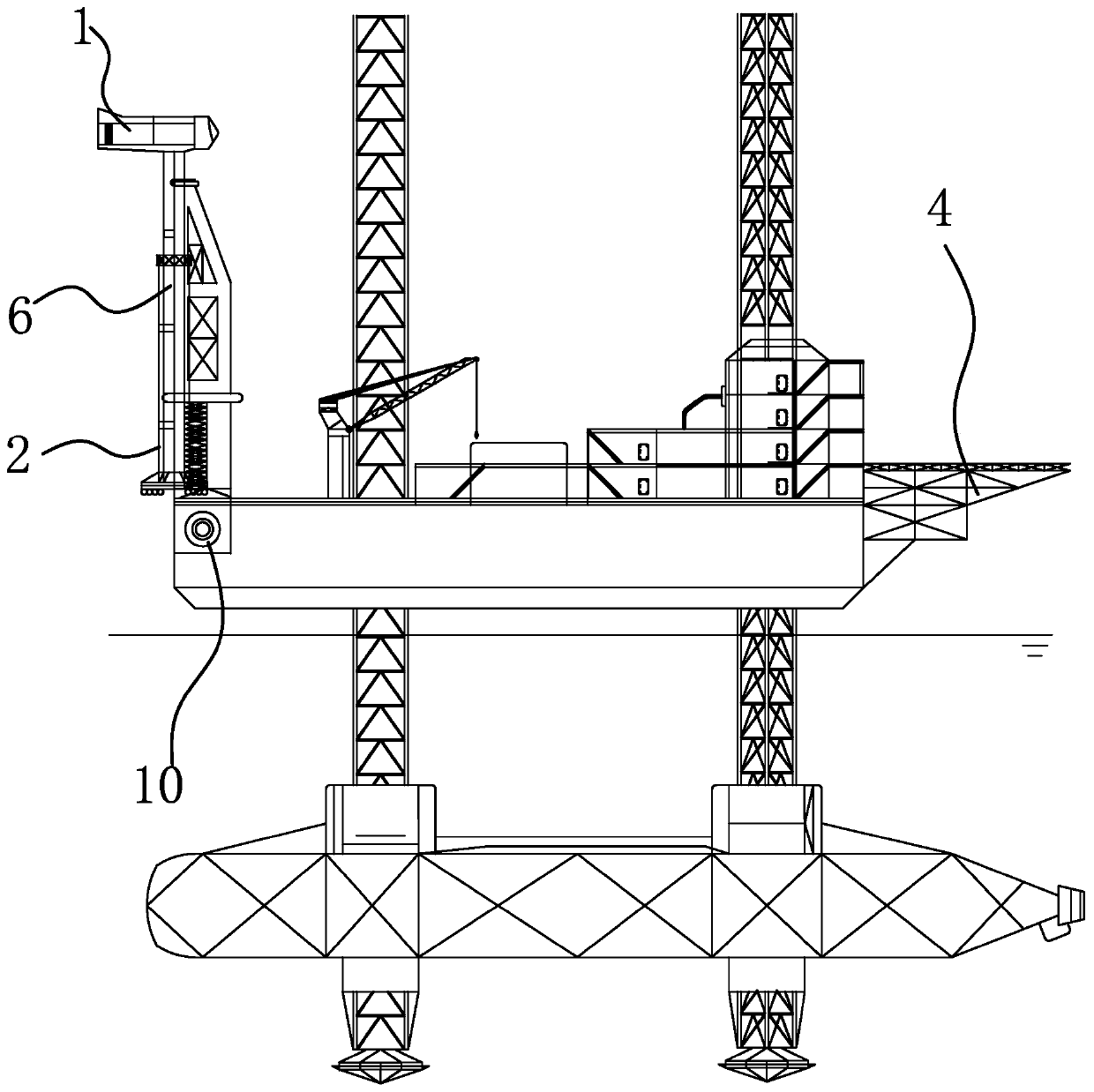

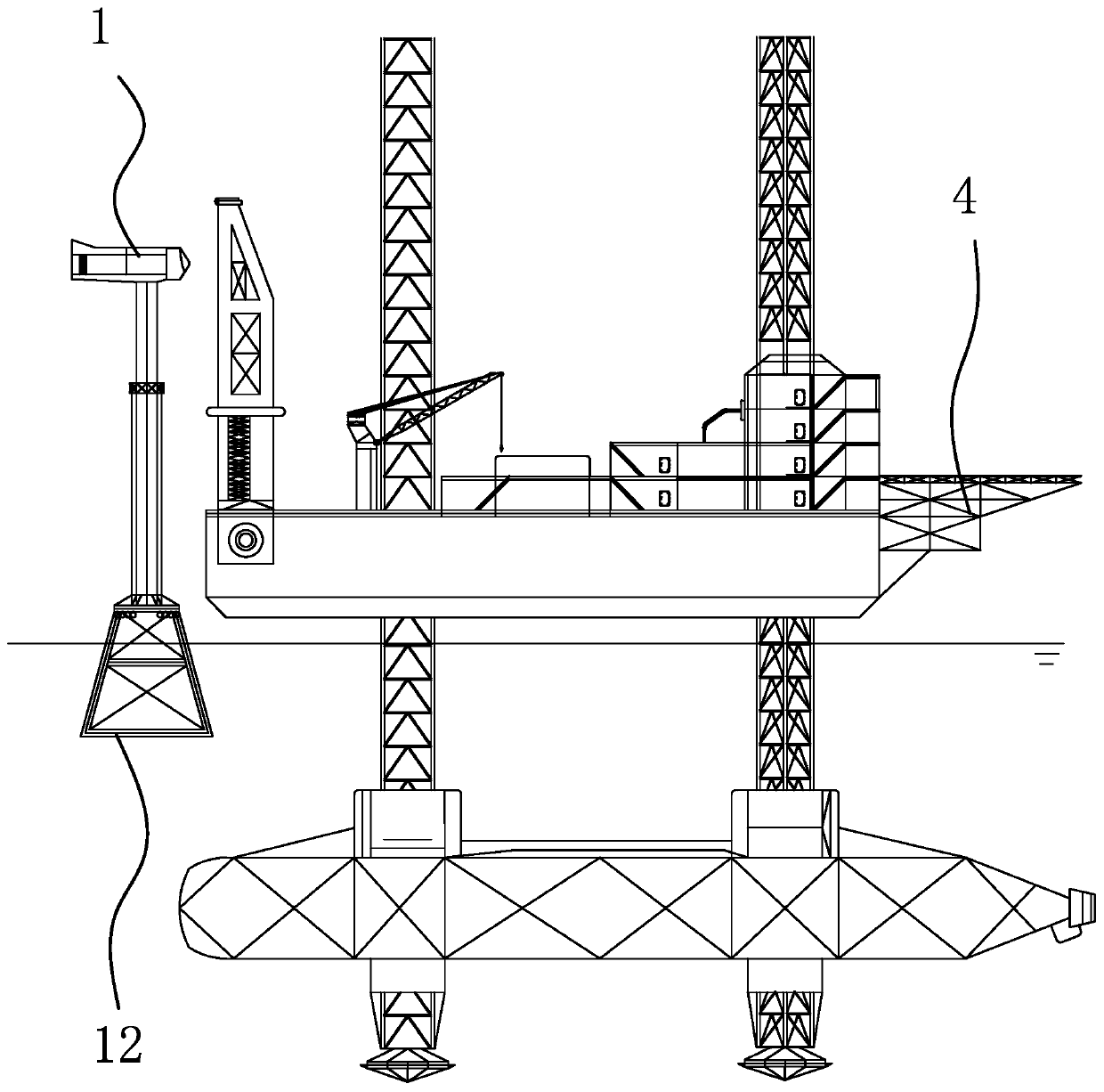

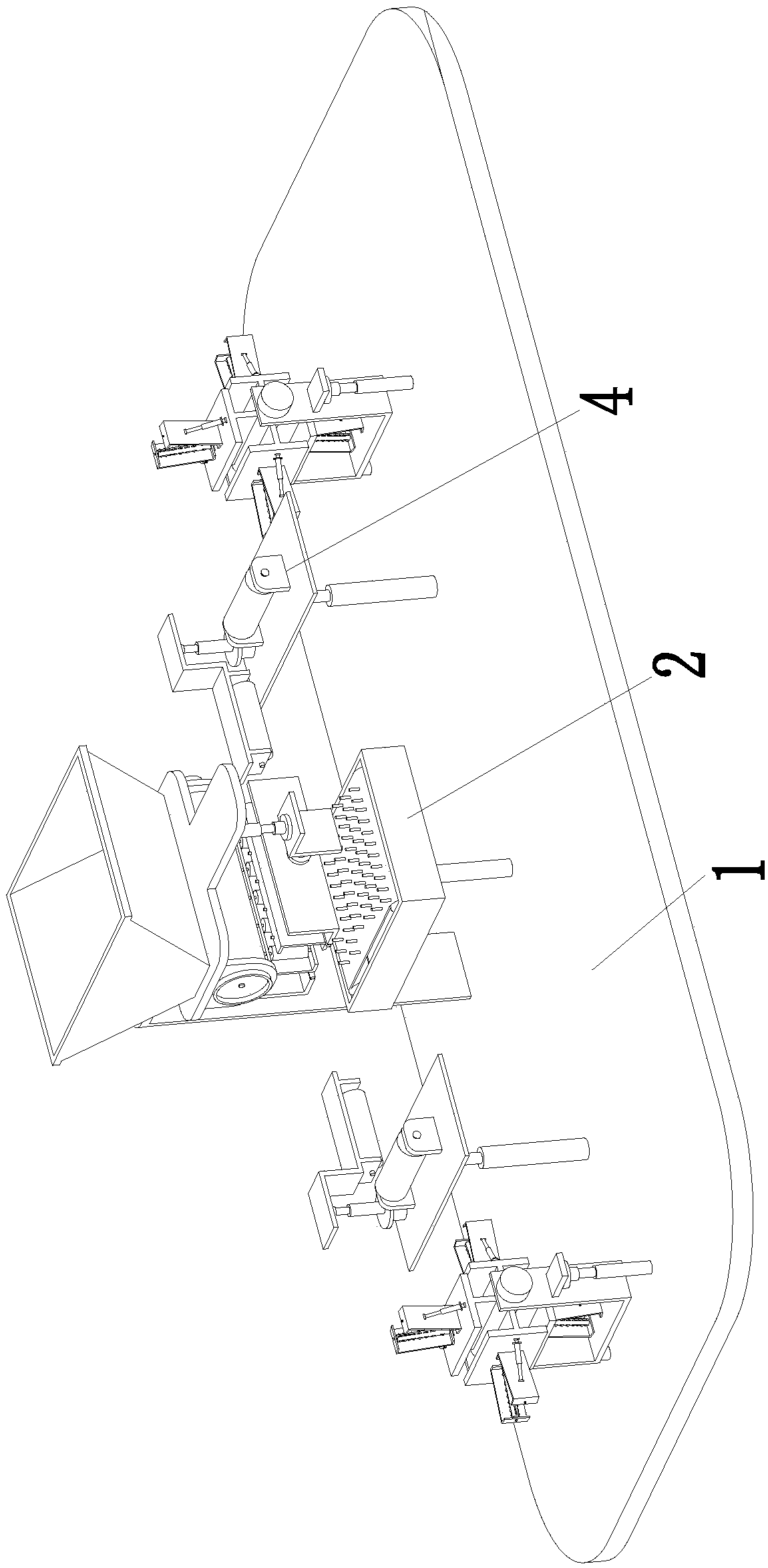

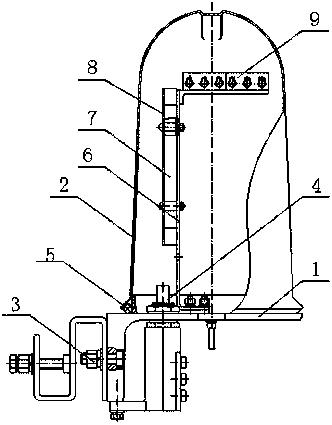

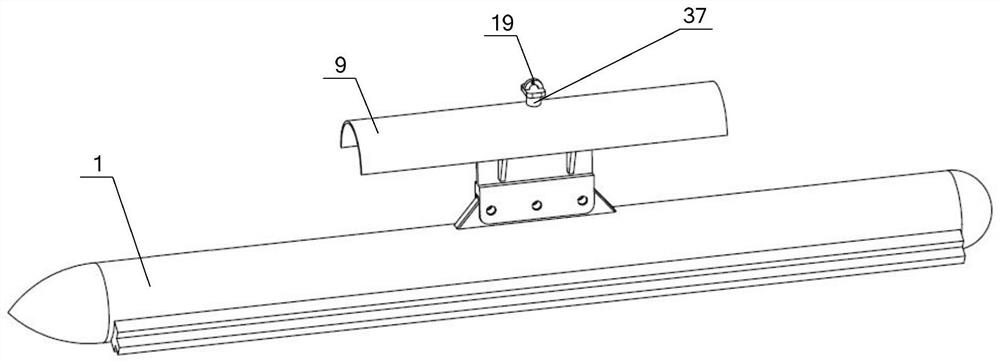

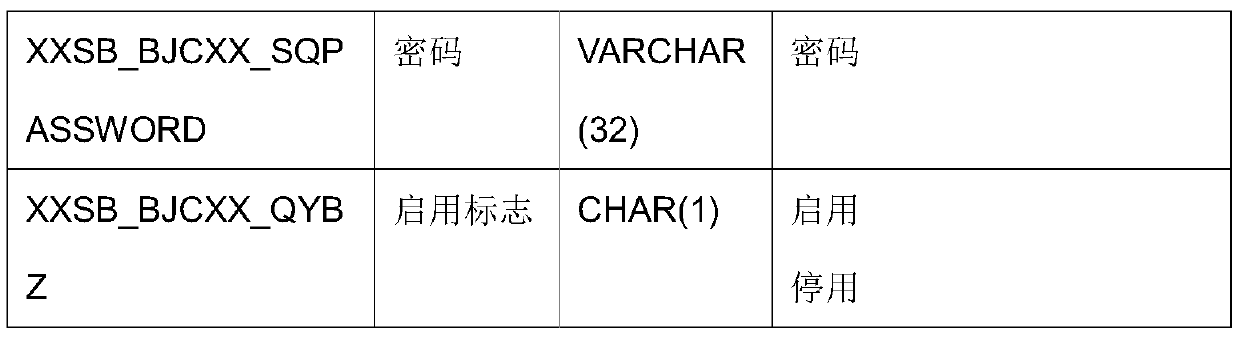

AUV underwater docking device

InactiveCN111268068AReduce the difficulty of dockingLow attitude control requirementsUnderwater equipmentHydraulic ramEnvironmental geology

The invention belongs to the field of underwater robots, and particularly relates to an AUV underwater docking device. One end of a hydraulic oil cylinder A is hinged to a base, the other end of the hydraulic oil cylinder A is hinged to one end of a self-adaptive adjusting platform, and the other end of the self-adaptive adjusting platform is hinged to the base; and one end of a butt joint frame is installed on the self-adaptive adjusting platform, a guide cover is arranged at the other end of the butt joint frame, and the guide cover and the butt joint frame provide a guide channel for AUV butt joint. Wireless charging equipment, wireless communication equipment and a locking mechanism are installed on the butt joint frame, the AUV and the butt joint frame are locked and positioned through the locking mechanism after being in butt joint, and energy supply and information exchange are achieved through the wireless charging equipment and the wireless communication equipment; and a hydraulic station for providing power is mounted on the base. The pitching mechanism is driven by the hydraulic oil cylinder to adapt to seabed planes with different gradients, and AUV energy supply and information exchange in the marine environment are achieved through passive adjustment of the self-adaptive adjusting platform in cooperation with AUV butt joint.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

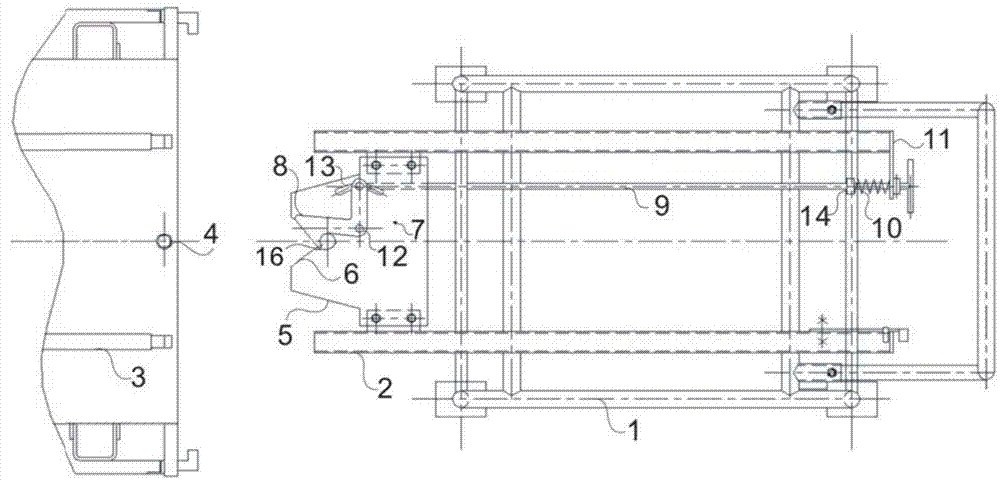

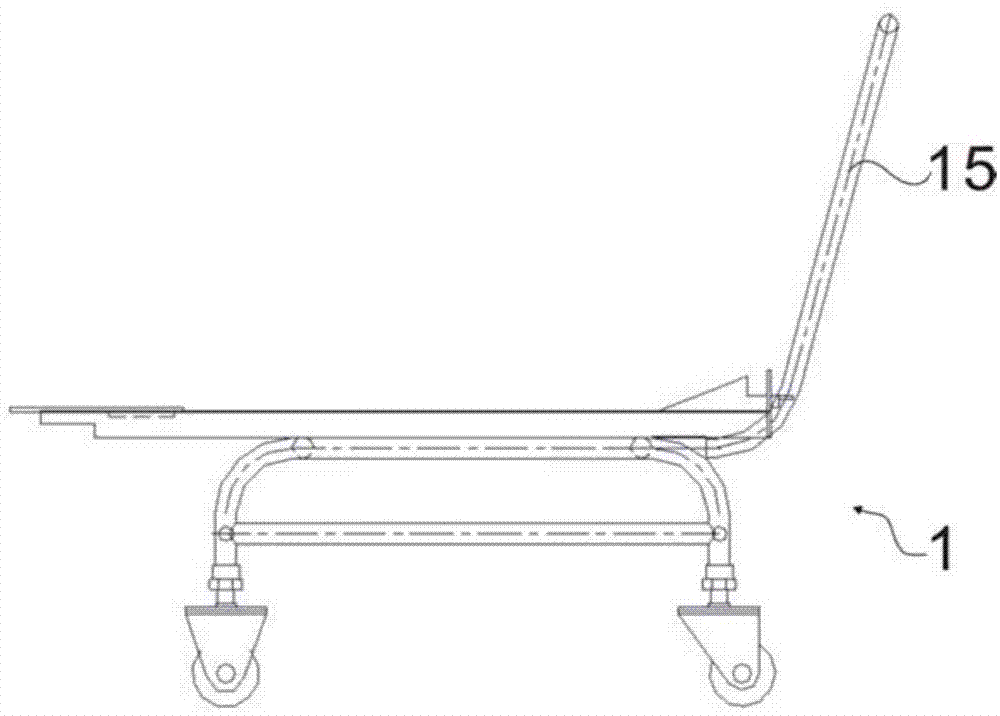

Magnet locking device of carrier

InactiveCN104118456AAvoid displacementEasy to pushLavatory sanitoryDisinfectionButt jointEngineering

The invention provides a magnet locking device of a carrier, and belongs to the technical field of the sterilization cabinet technology. The magnet locking device comprises the carrier, two carrier tracks and two sterilization cabinet tracks, the carrier tracks and the sterilization cabinet tracks are in butt joint, and a first magnet is arranged in the center of the position between the two tracks of a sterilization cabinet and is a cylinder. The front end of the carrier is provided with a guiding plate, the guiding plate is provided with a V-shaped groove corresponding to the first magnet in position, the V-shaped groove is formed in the center of the position between the tracks of the carrier, the bottom of the V-shaped groove is provided with a second magnet, the first magnet and the second magnet are attracted to each other, and the guiding plate is provided with a locking assembly hooking the first magnet to prevent the carrier from moving backwards. An operator can conveniently and smoothly push the carrier into or pull the carrier out of the sterilization cabinet, the butt joint difficulty of the carrier and the tracks in the sterilization cabinet is lowered, the carrier is prevented from moving backwards, and working efficiency is improved.

Owner:ZHANGJIAGANG JIARUI PHARMA MACHINERY

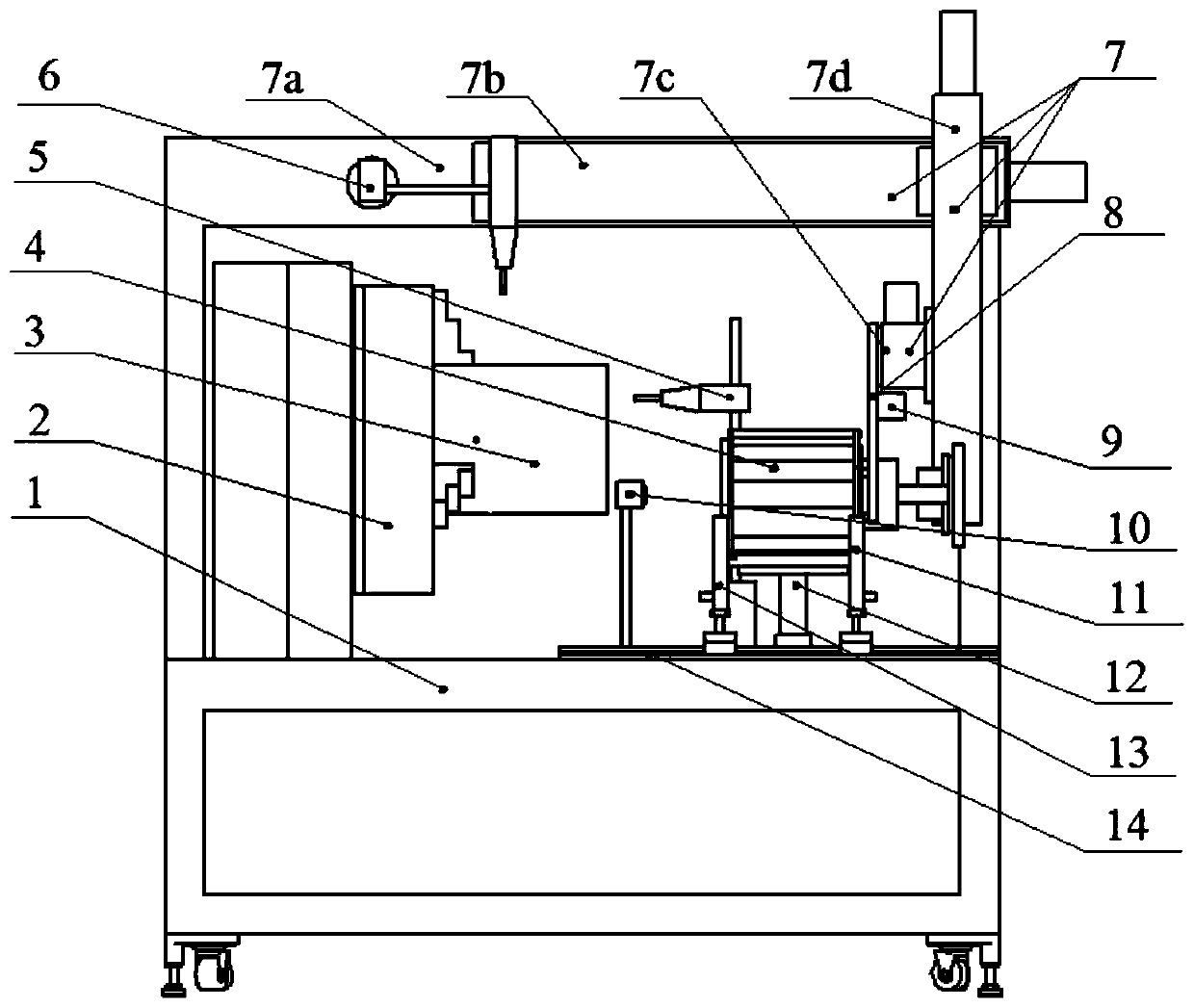

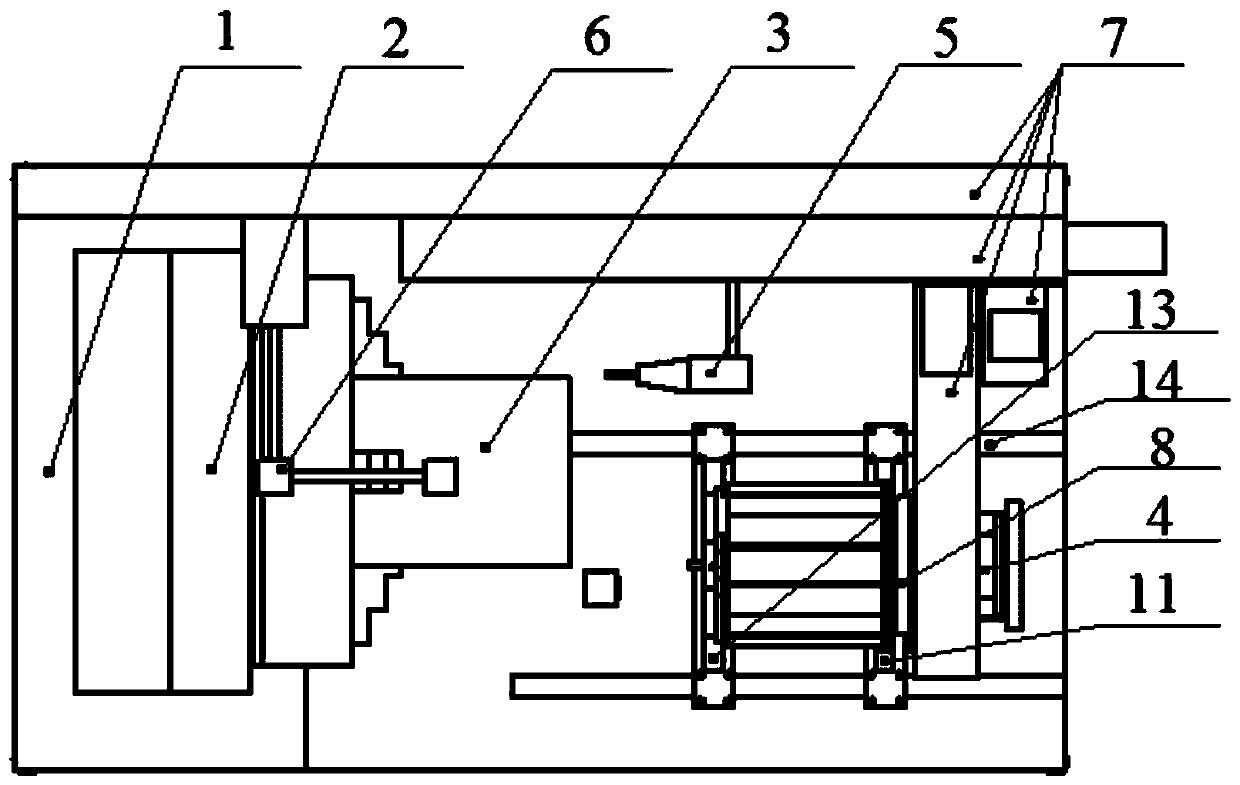

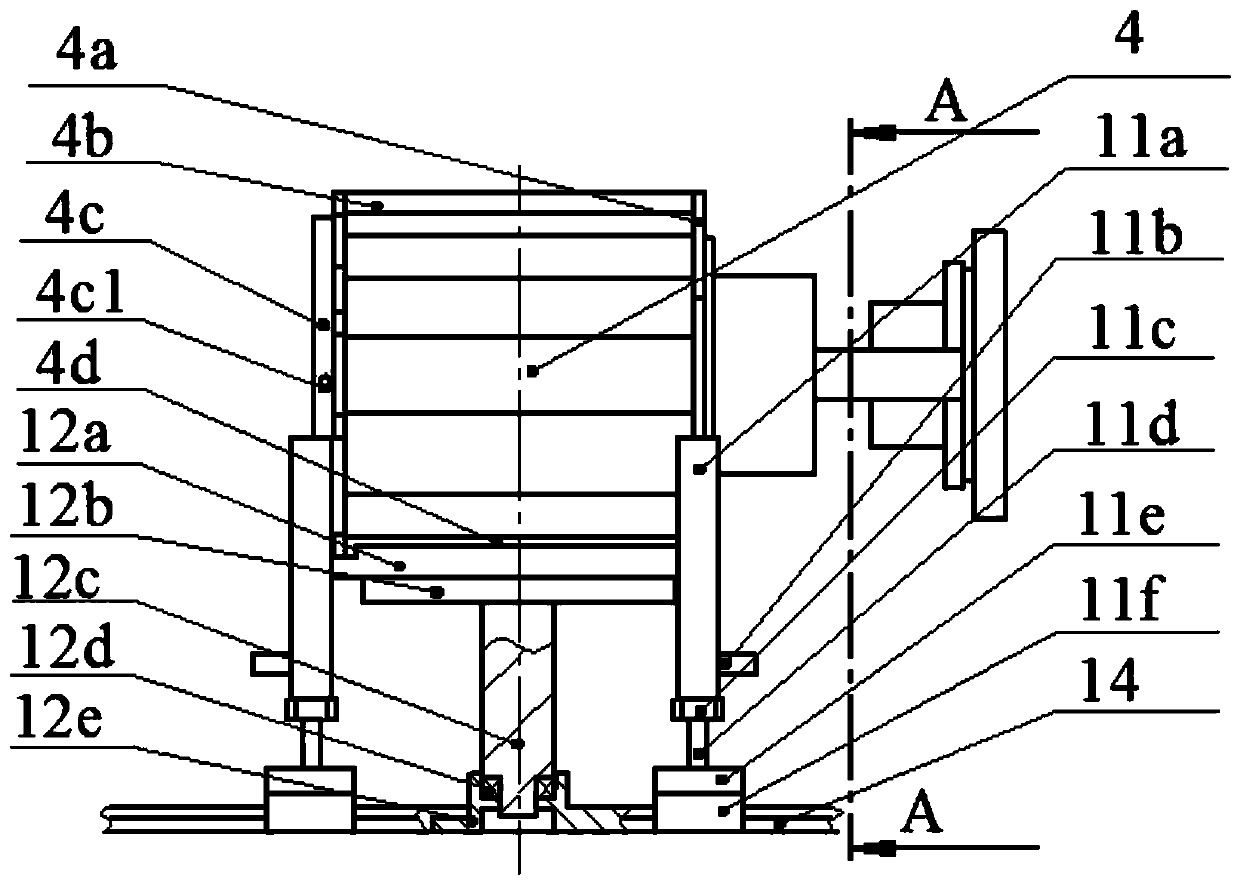

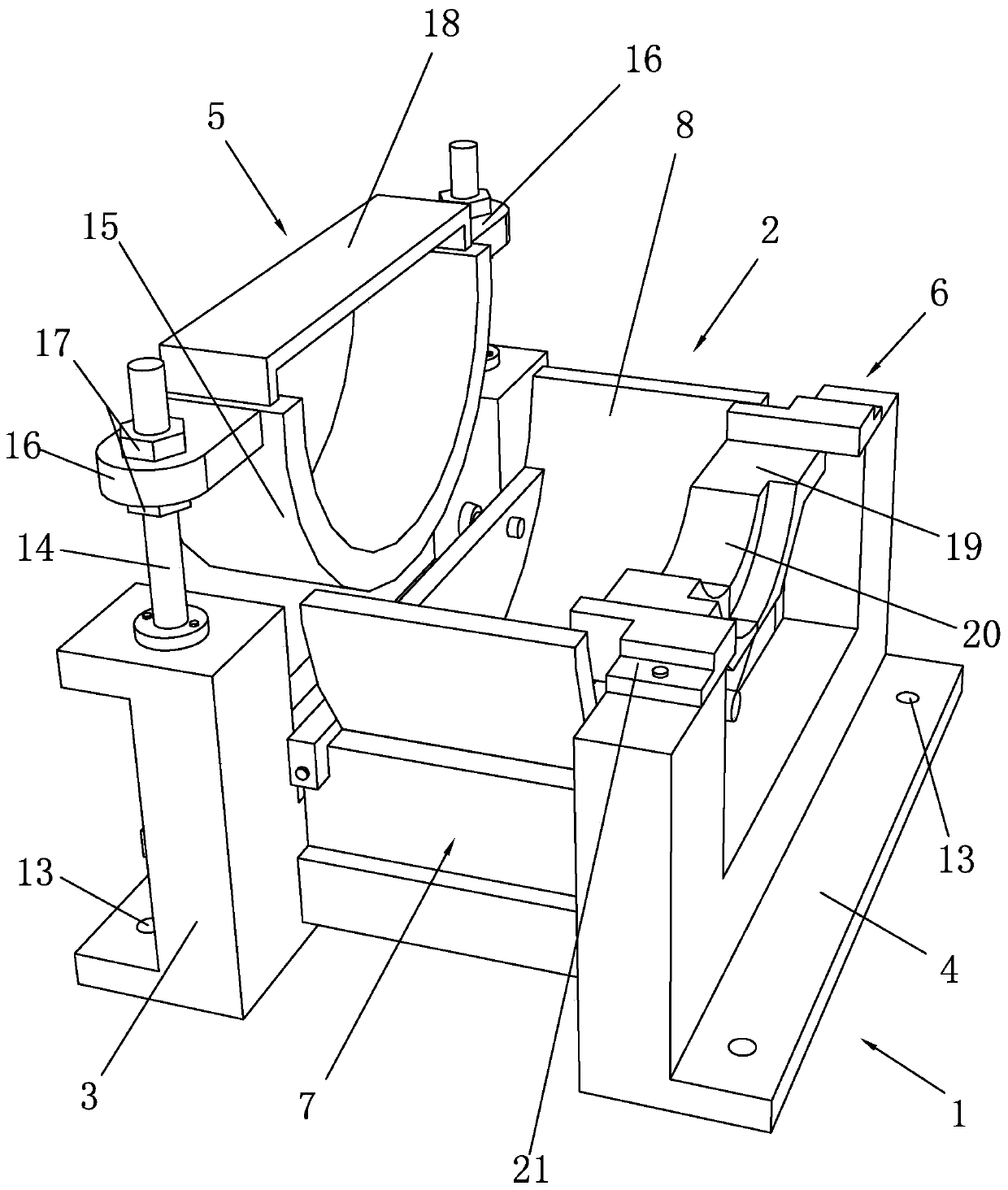

Precise docking device and method for frame type detection mechanism and cabin body

ActiveCN111283405AReduce the difficulty of dockingSolve the adjustmentMetal working apparatusControl engineeringVisual inspection

The invention discloses a precise docking device and method for a frame type detection mechanism and a cabin body. The device comprises a docking movement system, an automatic screwing system, a visual inspection system and a posture adjustment system; the docking movement system comprises a worktable, a rotary main shaft, a transferring mechanism and a transferring clamp; the rotary main shaft isused for clamping the cabin body and can drive the cabin body to rotate; the transferring mechanism drives the frame type detection mechanism to move through the transferring clamp; the automatic screwing system is used for docking, screwing and fixing the frame type detection mechanism and the cabin body; the visual inspection system is used for inspecting a mounting surface so as to determine the rotating angle of the rotary main shaft and the moving amount of the transferring mechanism; and the posture adjustment system is used for performing posture adjustment on the frame type detectionmechanism. According to the precise docking device and method for the frame type detection mechanism and the cabin body, precise docking of the frame type detection mechanism with a complicated special shape, a small clamping surface and a high requirement on reliability can be realized; the operation is flexible, simple and convenient; the docking process is safe and reliable; and the docking device is good in flexibility.

Owner:SHANGHAI RADIO EQUIP RES INST

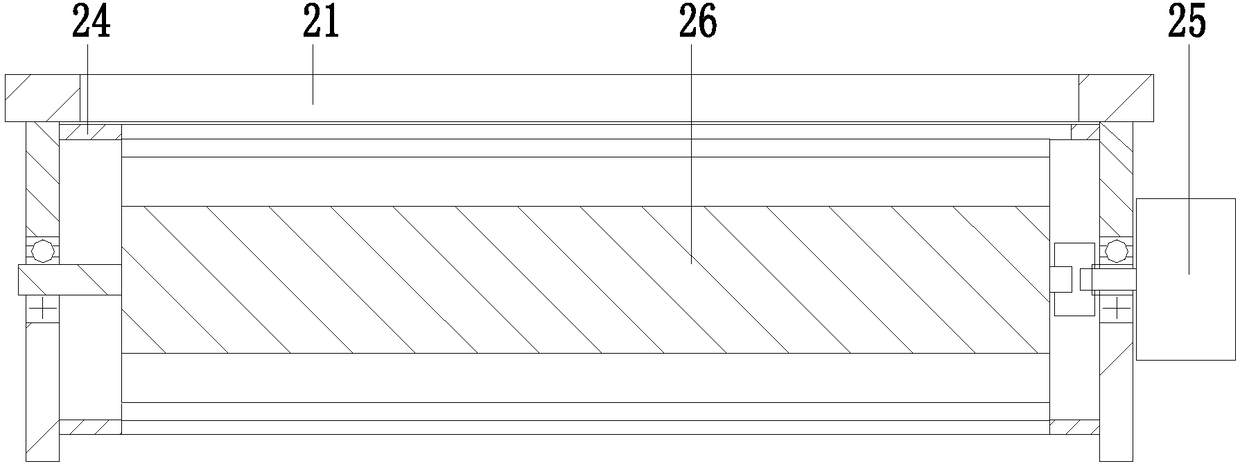

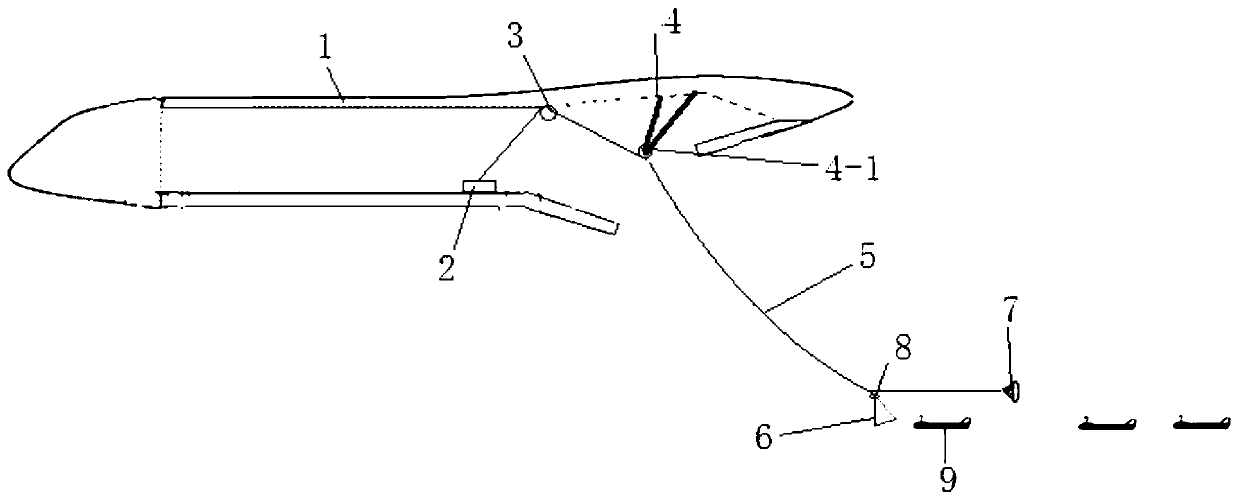

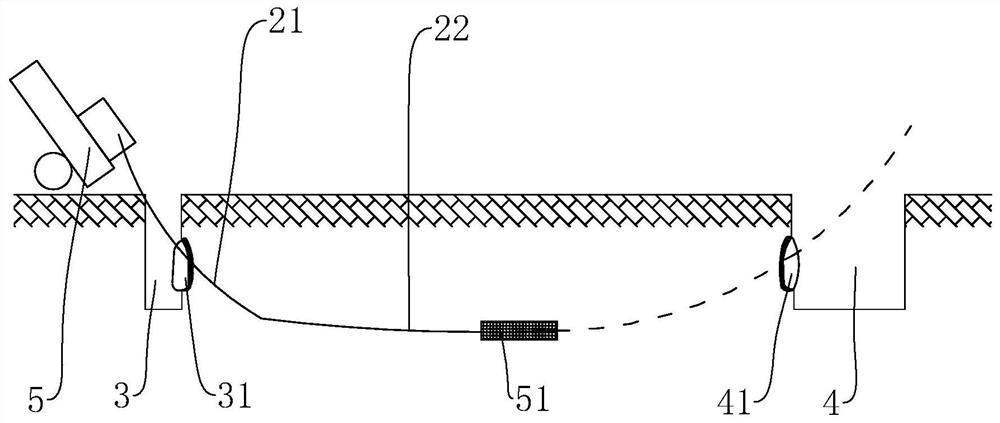

Unmanned aerial vehicle air-based tail cable car type recovery device and method

InactiveCN109747836AImprove recycling efficiencyReduce mutual positioning accuracy requirementsFreight handlingRecovery methodVideo monitoring

The invention discloses an unmanned aerial vehicle air-based tail cable car type recovery device. The recovery device comprises a carrier, a winch, a transferring-connecting pulley, a supporting frame, a guiding pulley, a slip cable, an arresting cable and a pilot parachute; a rear hatch door is formed on the ventral of a rear vehicle body of the carrier, the winch is arranged on floors in a carrier module, the transferring-connecting pulley and the supporting frame are arranged at the inner top of the carrier module, and the guiding pulley is arranged on the supporting frame; one end of the slip cable is fixed to the winch, and the other end of the slip cable penetrates through the transferring-connecting pulley and the guiding pulley and is connected with the pilot parachute; and the arresting cable is arranged on the slip cable and next to the pilot parachute. According to the unmanned aerial vehicle air-based tail cable car type recovery device, recovery of a plurality of unmannedaerial vehicles in sequence can be realized through a set of recovery device, the unmanned aerial vehicles can be directly recycled into the carrier module, and the recovery efficiency is high; the opening of the arresting cable is large, the arresting cable intersects with an arresting hook in a crisscross mode, the abutting difficulty is low, and the mutual positioning precision requirements ofthe unmanned aerial vehicles and the carrier in the recovery process can be reduced; real-time monitoring is carried out through video monitoring equipment in the abutting process, and the abutting successful rate can be improved; and the security of the unmanned aerial vehicles and the carrier in the launching process is improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

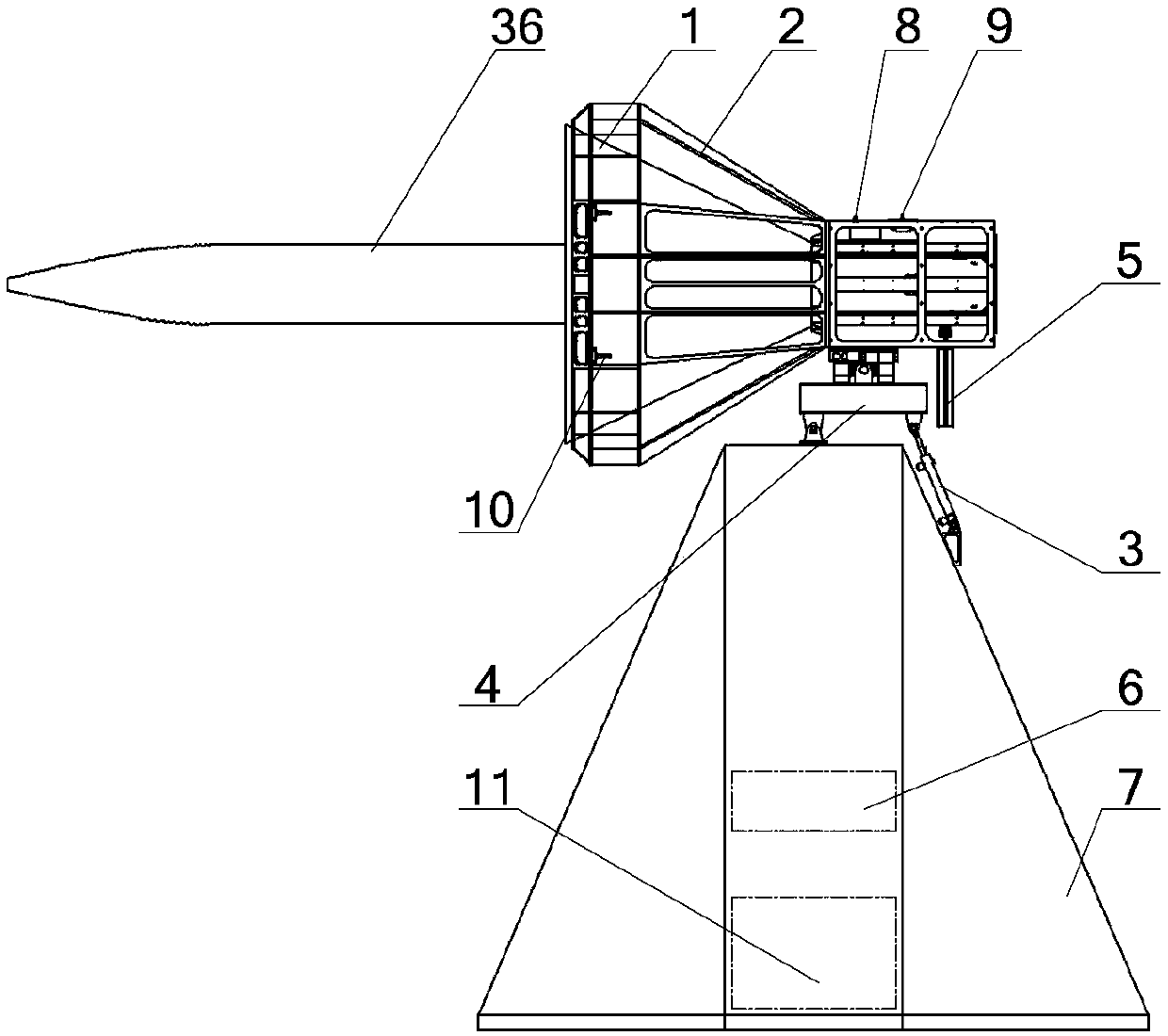

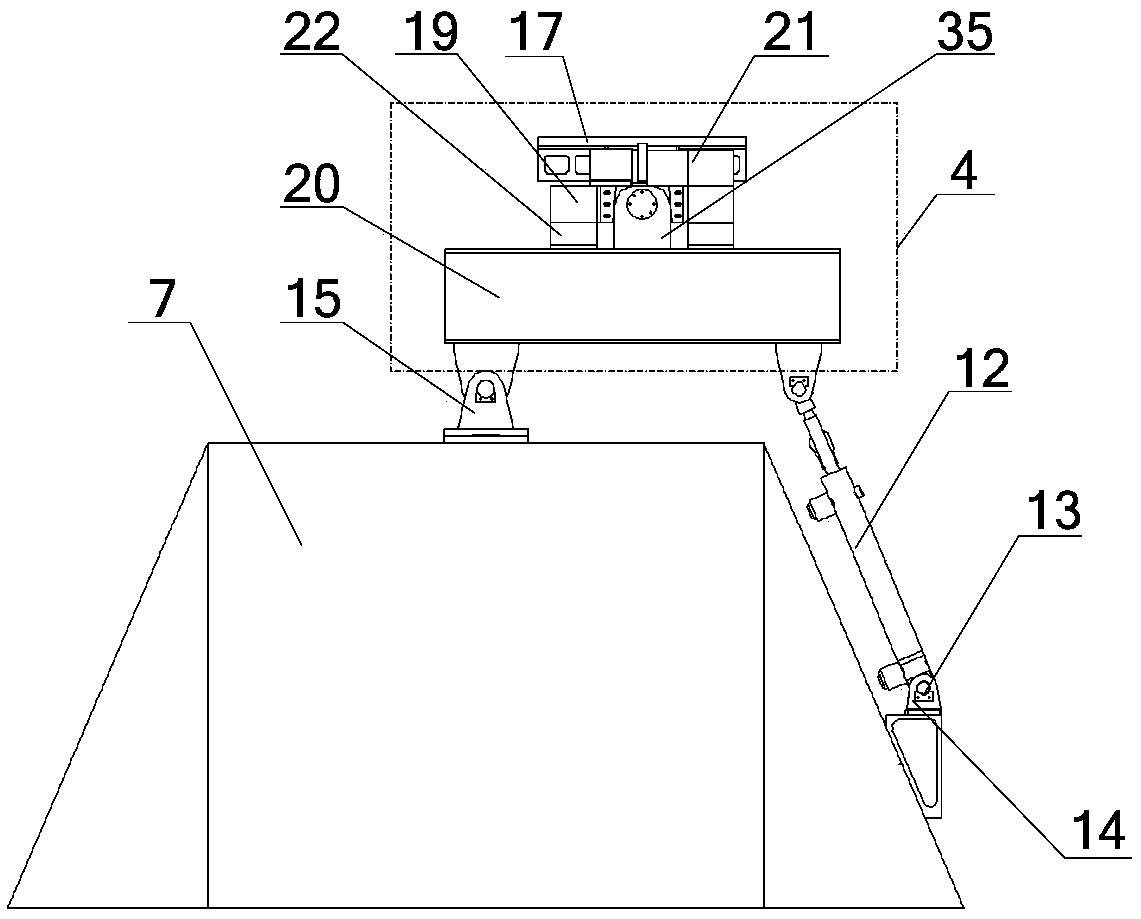

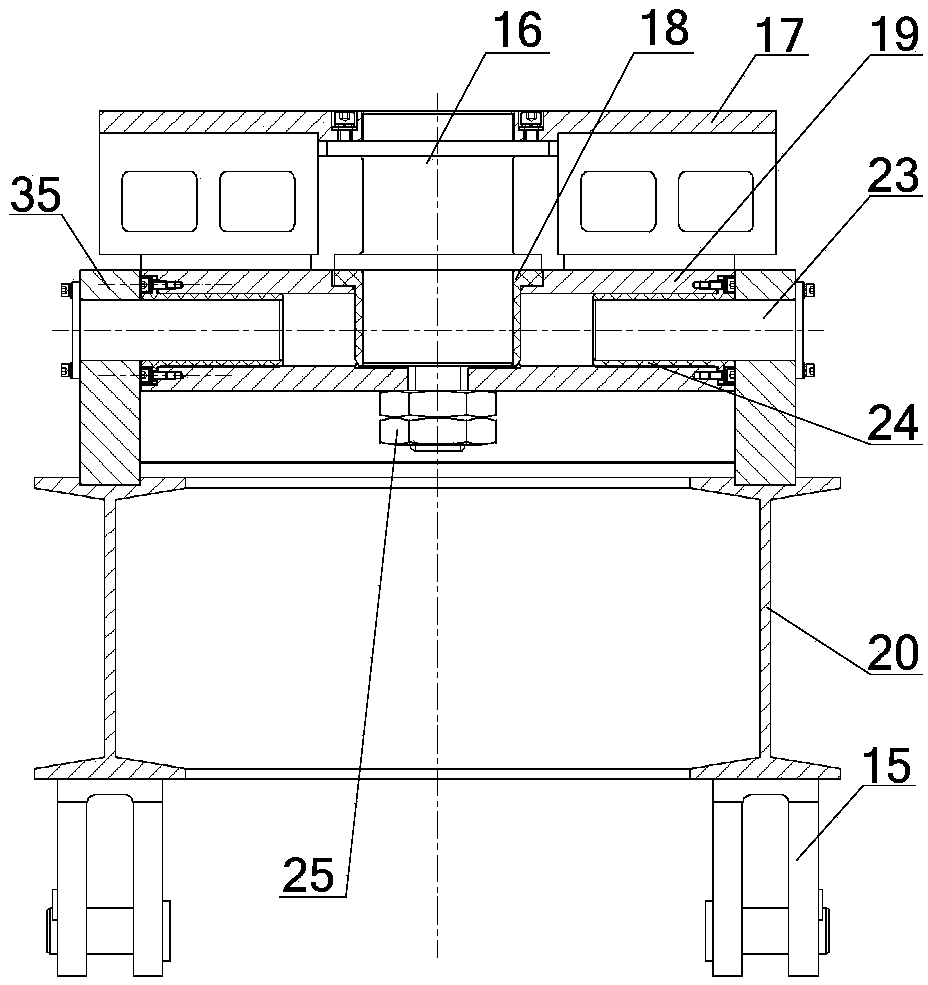

Offshore wind turbine installation method and installation system

ActiveCN109869279AAvoid shakingImprove docking accuracyWind motor assemblyWind energy generationNacelleButt joint

The invention belongs to the technical field of marine machinery, relates to an offshore wind turbine installation method and installation system and aims at solving the problems of large difficulty and the like during butt joint installation of a wind turbine in the prior art. A wind turbine comprises an engine room, a tower barrel and a blade. The installation system comprises a fan mounting ship; the fan mounting ship is provided with a rotating table which can swing between a horizontal position and a vertical position in a reciprocating manner; the rotating table is provided with a translation device capable of moving in the reciprocating manner in a horizontal direction; and the translation device is provided with a fastening device capable of fixing the engine room, the tower barreland the blade and a sliding rail capable of being aligned with a mounting base. For the offshore wind turbine installation method and installation system, when the tower barrel, the engine room and the blade are installed, the sliding rail is designed, so that shaking caused by a wind force during the installation process can be effectively avoided, the butt joint precision during installation iseffectively improved, the butt joint difficulty is lowered, the installation efficiency is improved, and the installation period is shortened.

Owner:ZHEJIANG OCEAN UNIV

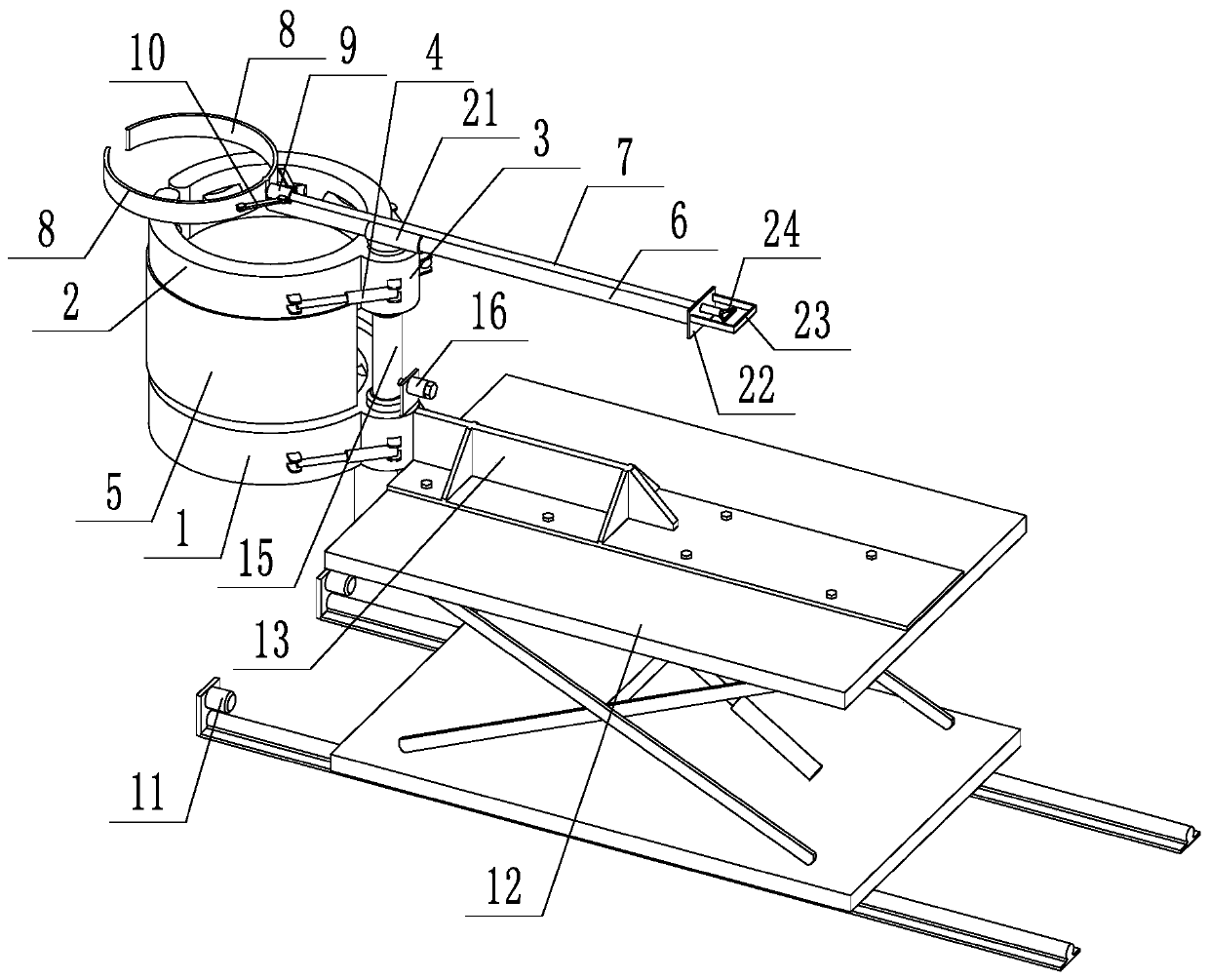

Intelligent repair system of power cable

InactiveCN108598825AReduce labor intensityReduce the difficulty of dockingLine/current collector detailsApparatus for repairing insulation/armouring cablesCable transmissionPower cable

The invention relates to an intelligent repair system of a power cable. The intelligent repair system comprises a bottom plate, wherein a sleeve device is arranged at a middle part of an upper end ofthe bottom plate, two cable transmission devices are arranged on the bottom plate and are symmetrically arranged at a front end and a rear end of the bottom plate, a sleeve placement rack is arrangedon a sleeve fixed rack, the sleeve placement rack and a discharging groove are matched to work, and an inner wall of the sleeve placement rack is of a downward inclined structure from two ends to an inner side. By the intelligent repair system, the problems that an insulator on a surface of the cable needs to be processed by manual work during the traditional manual repair process of the cable, the cable needs to be processed by manual work for transmission, a copper tube is needed to be taken and placed for abutting, the labor intensity of pulling the cable by manual work is large, the cablecontrolled by manual work is unstable to abut with the copper tube, a gap between sizes of the cable and the copper tube during the abutting process is relatively small, the manual abutting difficultyis large, consumed time is long, and the working efficiency is low can be solved.

Owner:仇芳

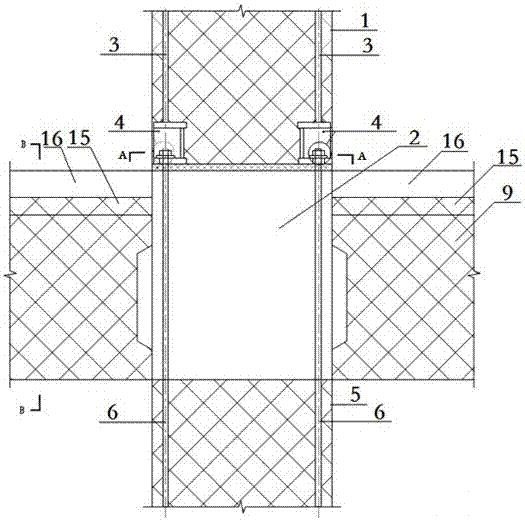

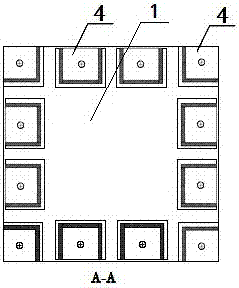

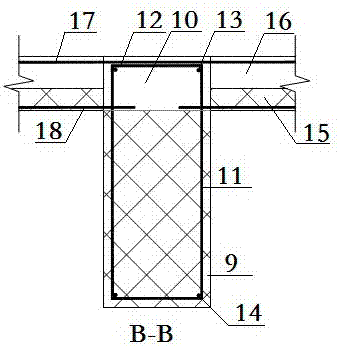

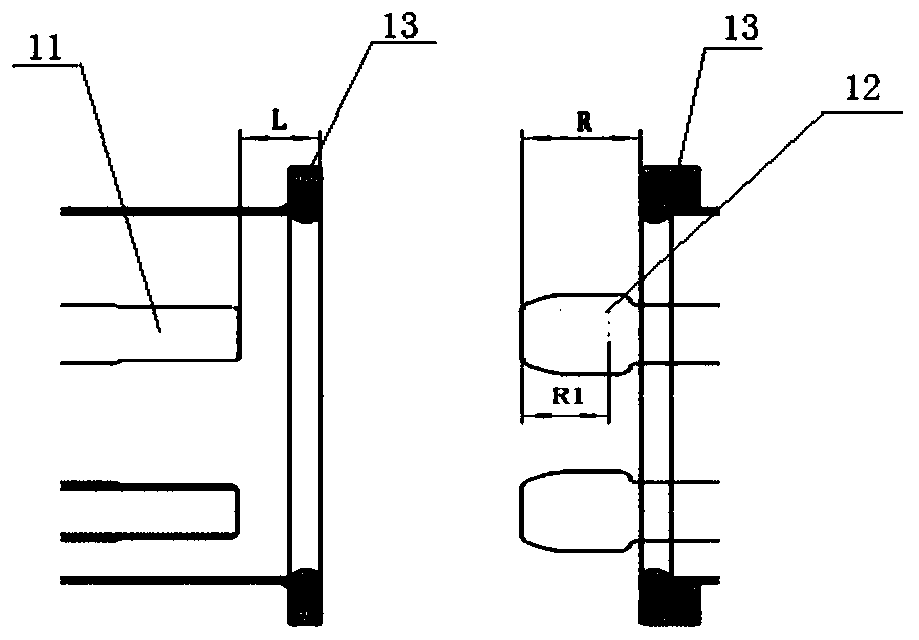

Prefabricated column connecting structure

PendingCN107288217AQuality control High production efficiencyIncrease the tilt angleBuilding constructionsAgricultural engineeringSteel bar

A prefabricated column connecting structure comprises an upper prefabricated column, a lower prefabricated column and a beam-column cast-in-situ connecting joint, wherein the upper end and the lower end of the beam-column cast-in-situ connecting joint are connected with the bottom face of the upper prefabricated column and the top face of the lower prefabricated column correspondingly. An upper prefabricated column connecting steel bar and a steel bar connecting box are pre-embedded in the upper prefabricated column. The bottom end of the upper prefabricated column connecting steel bar is connected and fixed to the steel bar connecting box. A lower prefabricated column connecting steel bar is pre-embedded in the lower prefabricated column. After the upper portion of the lower prefabricated column connecting steel bar stretches out from the top face of the lower prefabricated column to penetrate through the beam-column cast-in-situ connecting joint, the top end of the lower prefabricated column connecting steel bar is fixedly connected with the steel bar connecting box pre-embedded in the upper prefabricated column. The prefabricated columns are prefabricated in a factory, produced in a standardized mode, controllable in quality, free of environment pollution and high in production speed, the upper and lower prefabricated column connecting steel bars are connected easily in a butting mode, the construction efficiency is high, and structural strength is good.

Owner:CHANGSHA HOME BROAD HOMES IND JIANGSU CO LTD

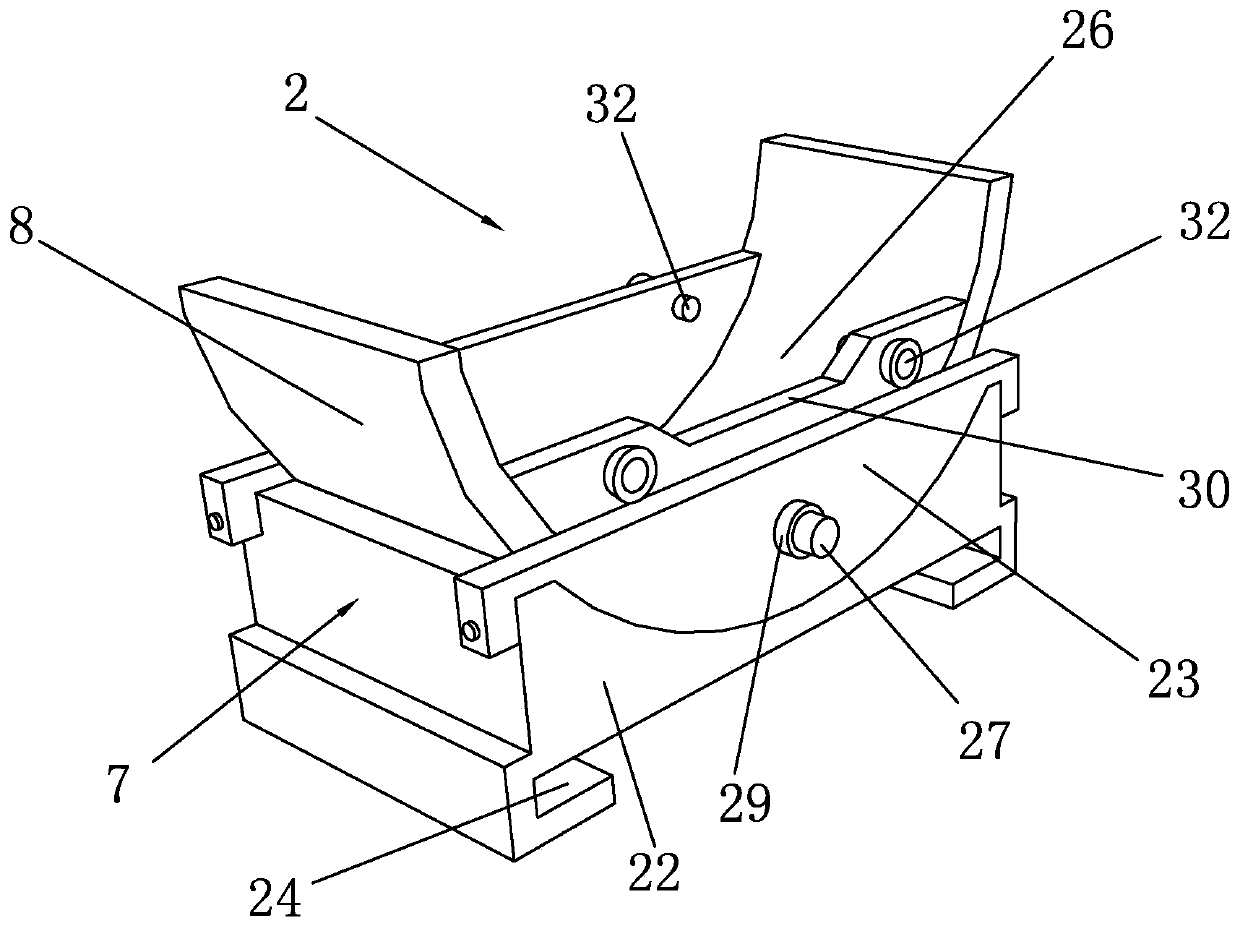

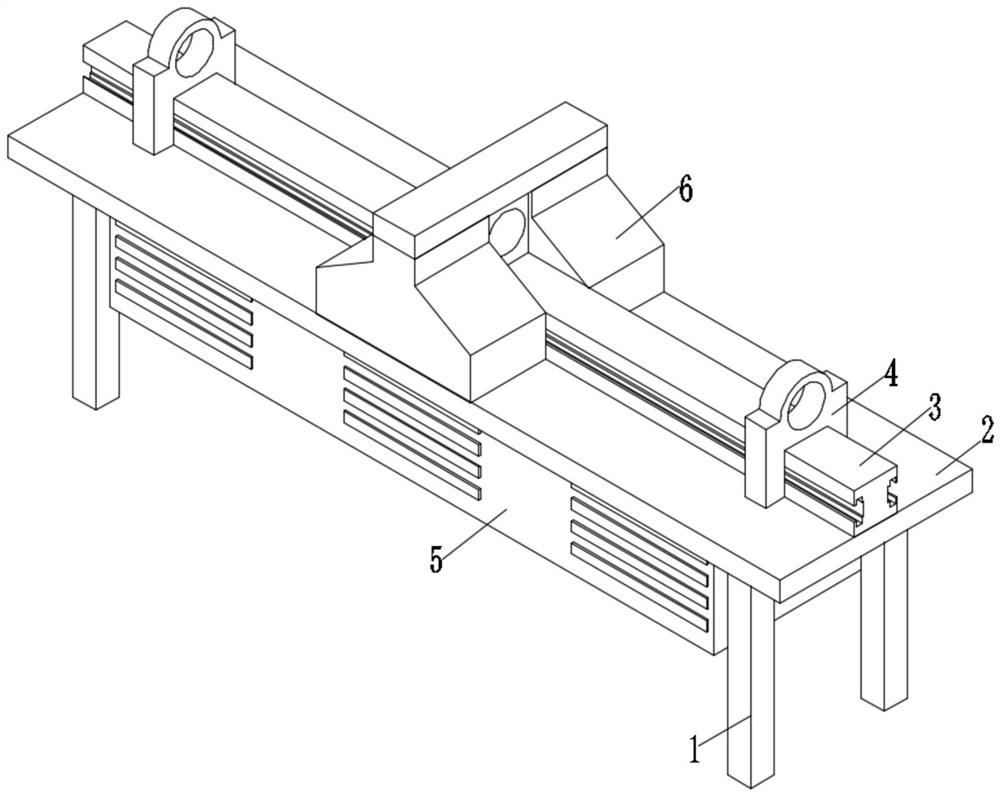

Pipeline butt joint device for hydrogeological exploration drilling

ActiveCN111535759AImprove reliabilityReduce the difficulty of dockingDrilling rodsDrilling casingsHydraulic cylinderButt joint

The invention discloses a pipeline butt joint device for hydrogeological exploration drilling. The device comprises a clamping mechanism, a gripping mechanism and a lifting mechanism, wherein the lifting mechanism is mounted on the ground and slidably connected with the ground through a guide rail sliding block pair, the clamping mechanism is supported on the lifting mechanism, the gripping mechanism is supported on the clamping mechanism, the clamping mechanism comprises a lower clamping jaw and an upper clamping jaw, during butt joint, the lifting mechanism is pushed forward, so that the lower clamping jaw corresponds to a drill pipe, a piston rod of a hydraulic cylinder corresponding to the lower clamping jaw extends out, so that the lower clamping jaw clamps the drill pipe, after a sleeve enters the upper clamping jaw, the clamping jaw clamps the sleeve, then the upper clamping jaw is driven to rotate, so that an axis of the sleeve and an axis of the drill pipe are overlapped, thenthe sleeve moves downwards to be inserted into a sleeve, the reliability is good, the butt joint difficulty is low, the efficiency is high, remote control by a worker is realized, security and reliability are achieved. Through cooperative movement of the gripping mechanism and the clamping mechanism, butt joint of the sleeve is completed, people do not directly contact the sleeve, the danger is reduced, and injury caused by the sleeve is prevented.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队 +1

Junction box for through-flow wires

InactiveCN104052013AIncrease the breakdown voltageImprove sealingFibre mechanical structuresCable junctionsButt jointEngineering

The invention discloses a junction box for through-flow wires. The junction box is characterized by comprising a base, a box body, an installation and fixing device and an optical cable inlet adaptor, the box body is arranged on the base, a sealing ring is arranged between the box body and the base, the installation and fixing device is fixedly connected with the base, the optical cable inlet adaptor is arranged at the bottom of the base, a support fixedly connected with the base is arranged in the box body and provided with a cable coiling board, the cable coiling board is provided with a wire coiling clamp, and a ceramic joint is arranged at the top of the support. According to the junction box, jointed cables are wound on the cable coiling board, the wires are in butt joint through the ceramic joint, the butt joint difficulty is reduced, the junction efficiency is improved, breakdown voltage of the junction box is increased, and optical cables and the cables are separated without interference; the structure of the sealing ring is adopted, so that the sealing performance between the box body and the base is improved.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +3

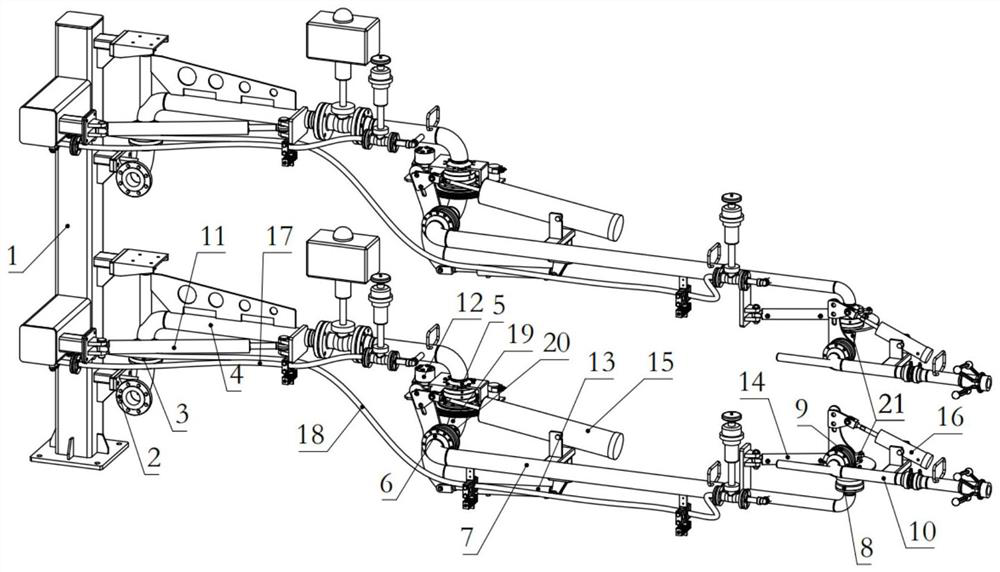

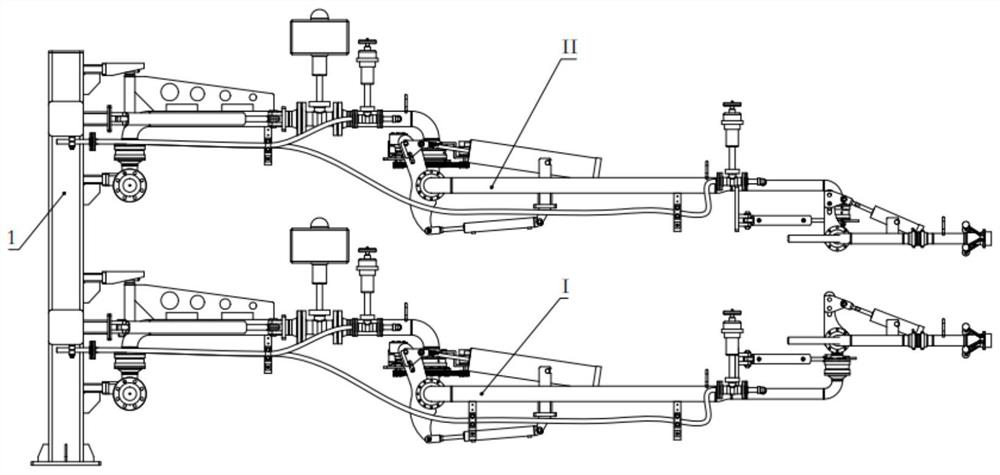

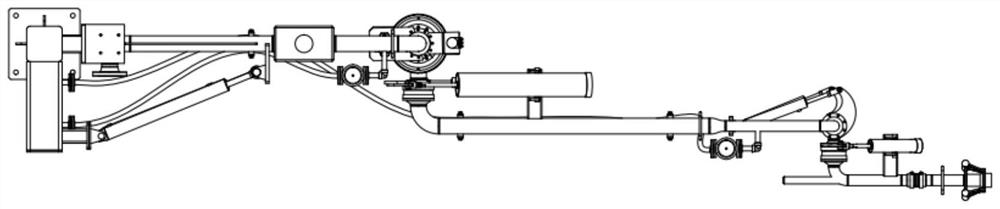

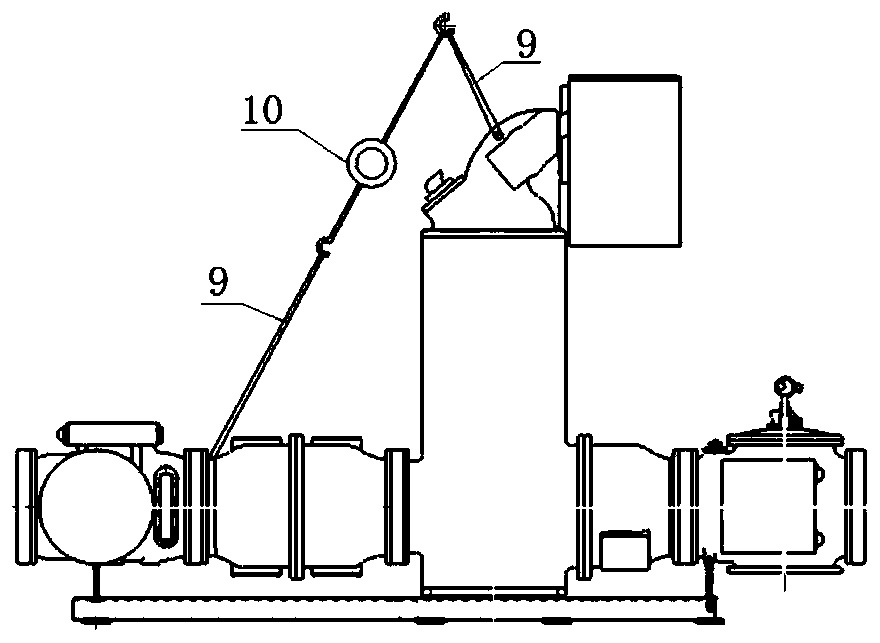

Semi-automatic tank car loading arm and control method thereof

ActiveCN112178451AReduce labor intensityHigh speedContainer filling methodsContainer discharging methodsBalancing machineControl engineering

Owner:JARI AUTOMATION CO LTD CHINA

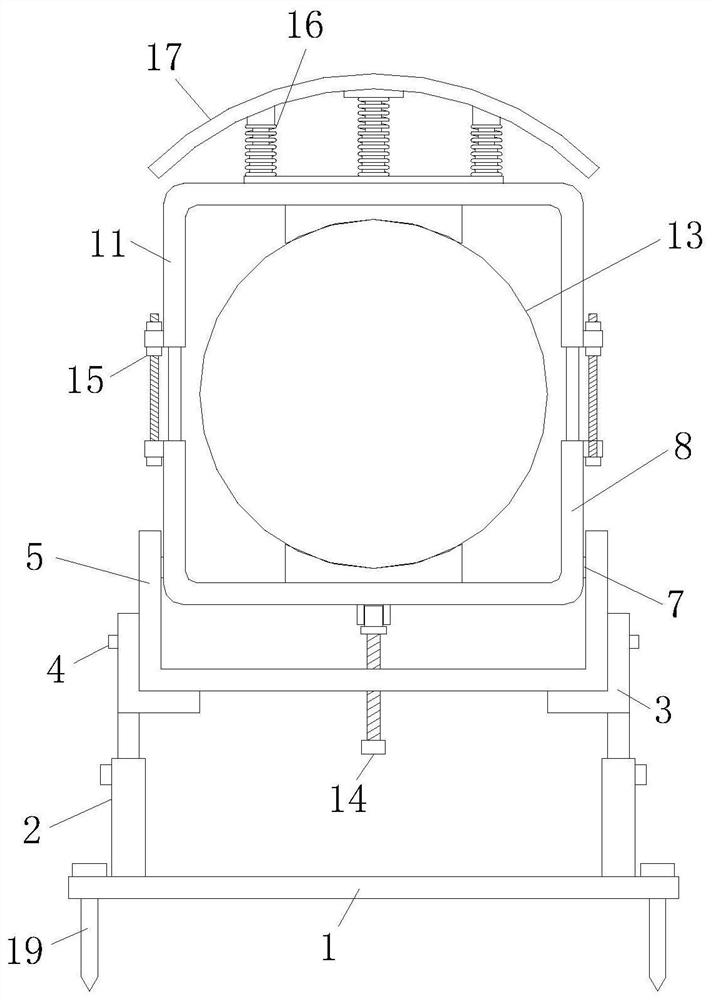

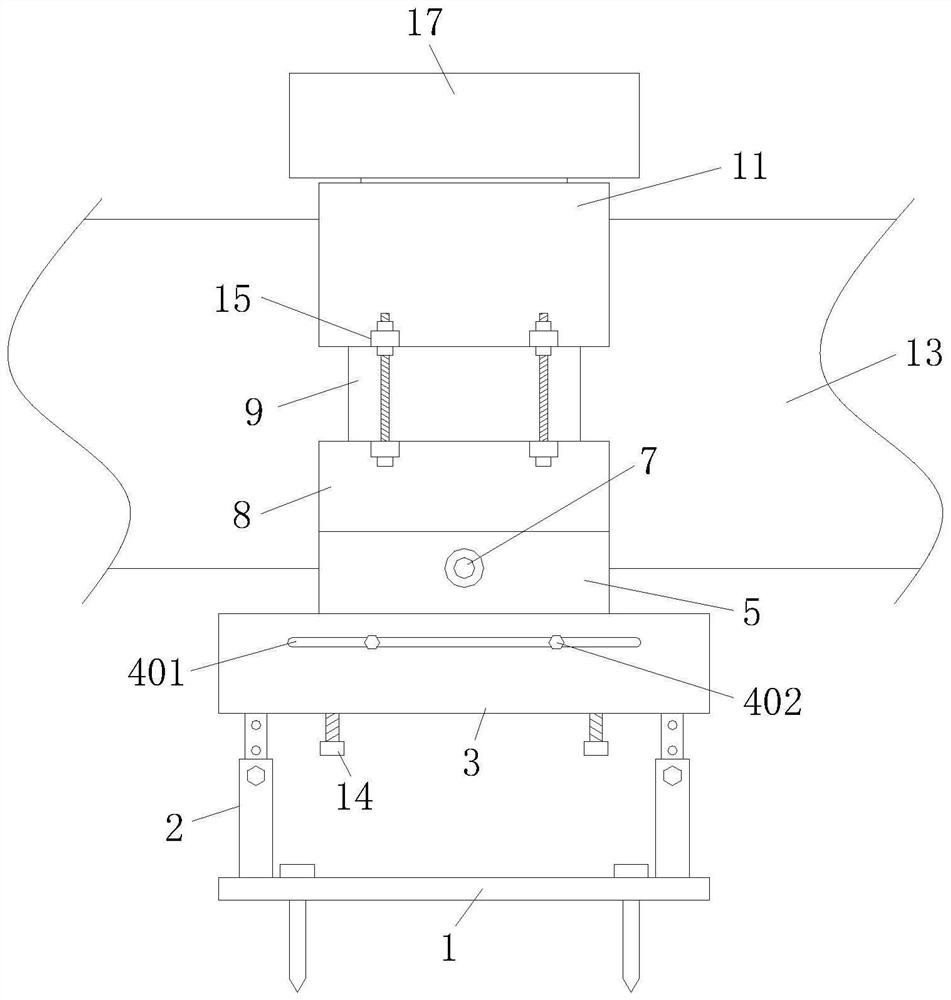

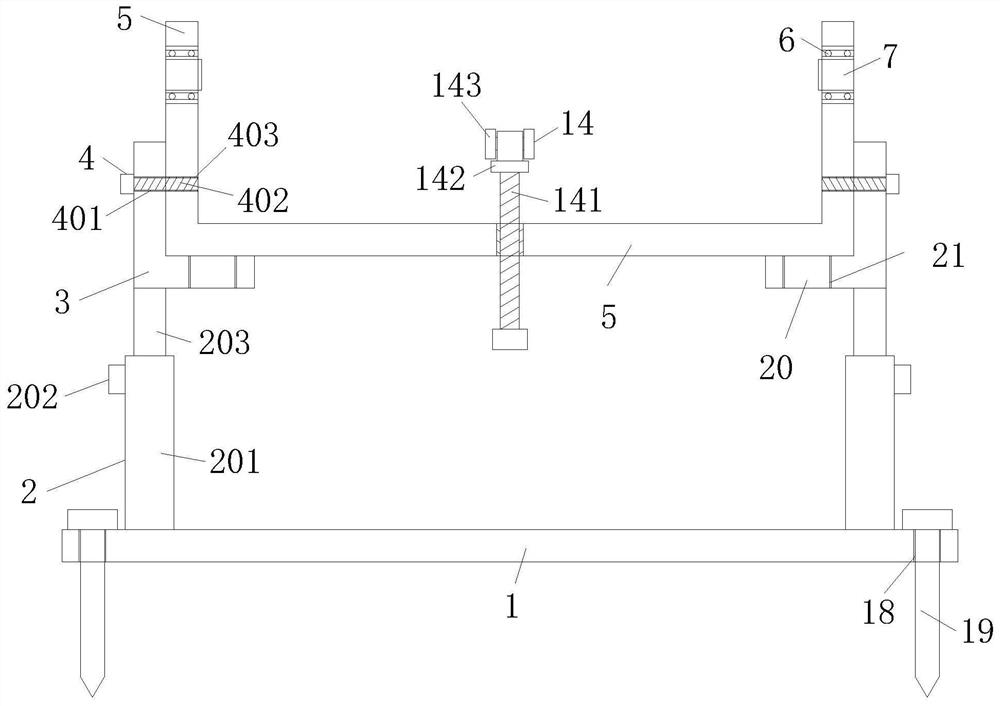

Supporting protective mechanism for pipeline construction

InactiveCN113007446AAdjust the tilt angleReduce the difficulty of dockingPipe supportsPipe elementsBall bearingArchitectural engineering

The invention discloses a supporting protective mechanism for pipeline construction, and relates to the technical field of pipeline construction. The supporting protective mechanism comprises a bottom plate, wherein the four corners of the upper surface of the bottom plate are fixedly equipped with telescopic poles in a rectangular mode; an L-shaped plate is fixedly mounted between upper surfaces of the telescopic poles at left and right sides; the upper surface of the L-shaped plate is equipped with a mounting frame through a fixing mechanism; left and right inner walls of the mounting frame are fixedly equipped with rotary shafts through deep groove ball bearings; and a lower U-shaped frame is fixedly mounted between the rotary shafts. The height, the front-rear position and the inclination angle of the supporting protective mechanism are conveniently adjusted through the telescopic poles, a fixing mechanism and an adjusting mechanism, so that butt-joint difficulty between adjacent pipeline bodies is low, and mounting efficiency is higher, and thus, use of pipeline bodies of different diameters can be met; and through a damping mechanism and a protective plate, the buffering damping effect of the supporting protective mechanism is improved, so that the pipeline body is not easily damaged by pressing, and use is safer.

Owner:YUNNAN SECOND INSTALLATION ENG

Trenchless directional drilling construction method for pipeline burying channel

InactiveCN112252973AAvoid destructionLow costArtificial islandsPipe laying and repairArchitectural engineeringPipe

The invention relates to a trenchless directional drilling construction method for a pipeline burying channel. The trenchless directional drilling construction method comprises the following steps that 1, pipe distribution is conducted, specifically, hot melting connection is conducted on the end faces of two PE solid-wall pipes; 2, directional drilling is conducted, specifically, a working pit and a receiving pit are manufactured, and a directional drilling machine is adopted for hole drilling; 3, back chambering construction is conducted, specifically, chambering is conducted in a step-by-step chambering mode to form a pipeline; 4, the pipe is pulled back, specifically, the pipe is pulled by adopting a pipe puller; and 5, inspection wells are manufactured, specifically, foundation pits are excavated in the two sides of an effective pipe section, the prefabricated inspection wells are installed, the prefabricated inspection wells are in waterproof connection with the PE solid-wall pipes, and then the foundation pits and the peripheries of the prefabricated inspection wells are backfilled. Only the working pit and the receiving pit need to be excavated in the ground, drilling, chambering and pipe pulling operations are carried out at the positions of the working pit and the receiving pit, and environmental influences such as multiple construction technology procedures, a largeamount of road surface damage and traffic obstruction caused by pipeline open excavation construction can be avoided.

Owner:广东省构建工程建设有限公司 +1

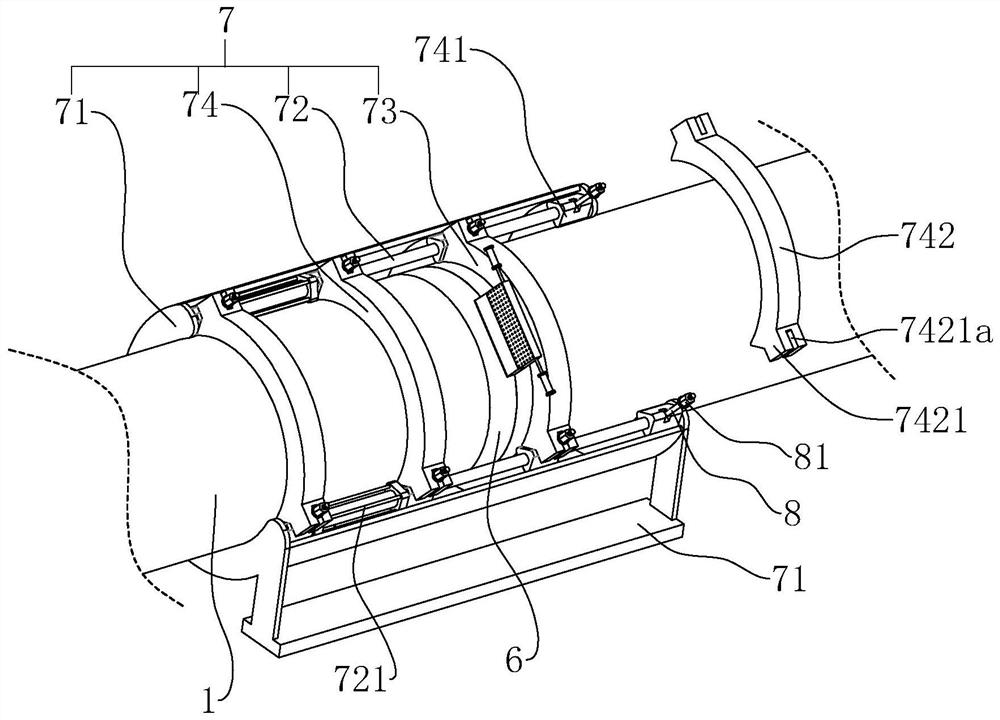

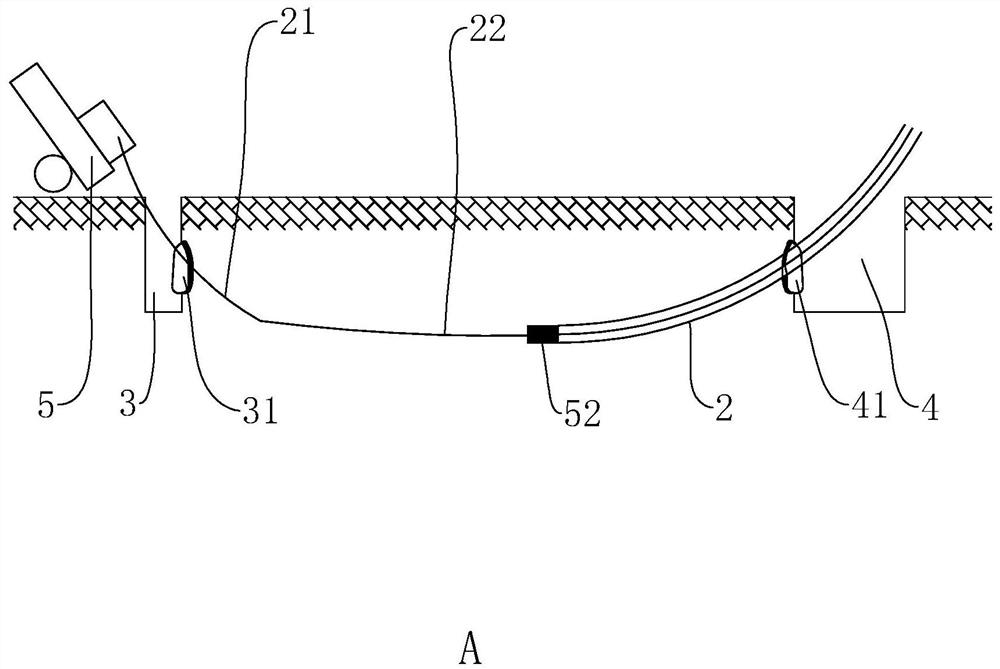

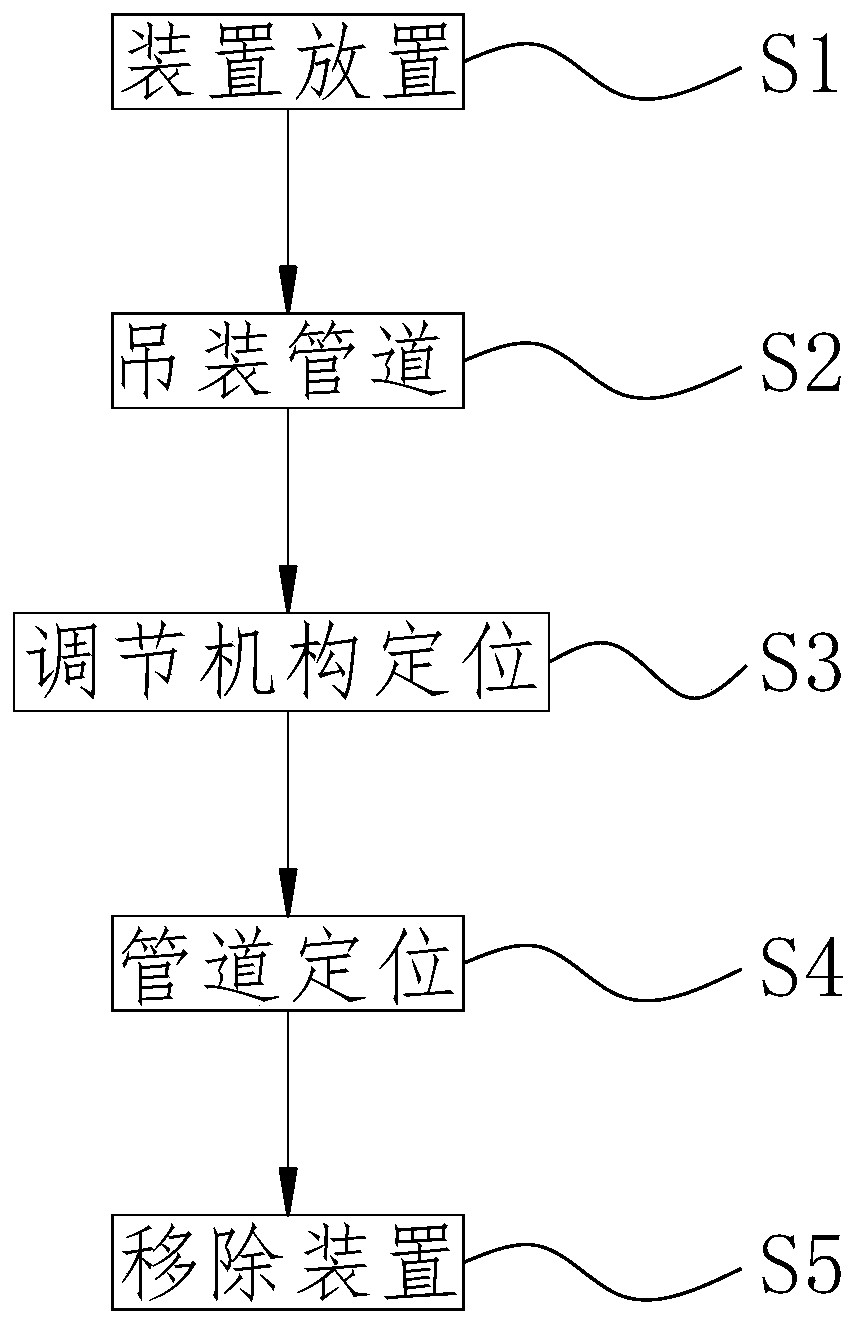

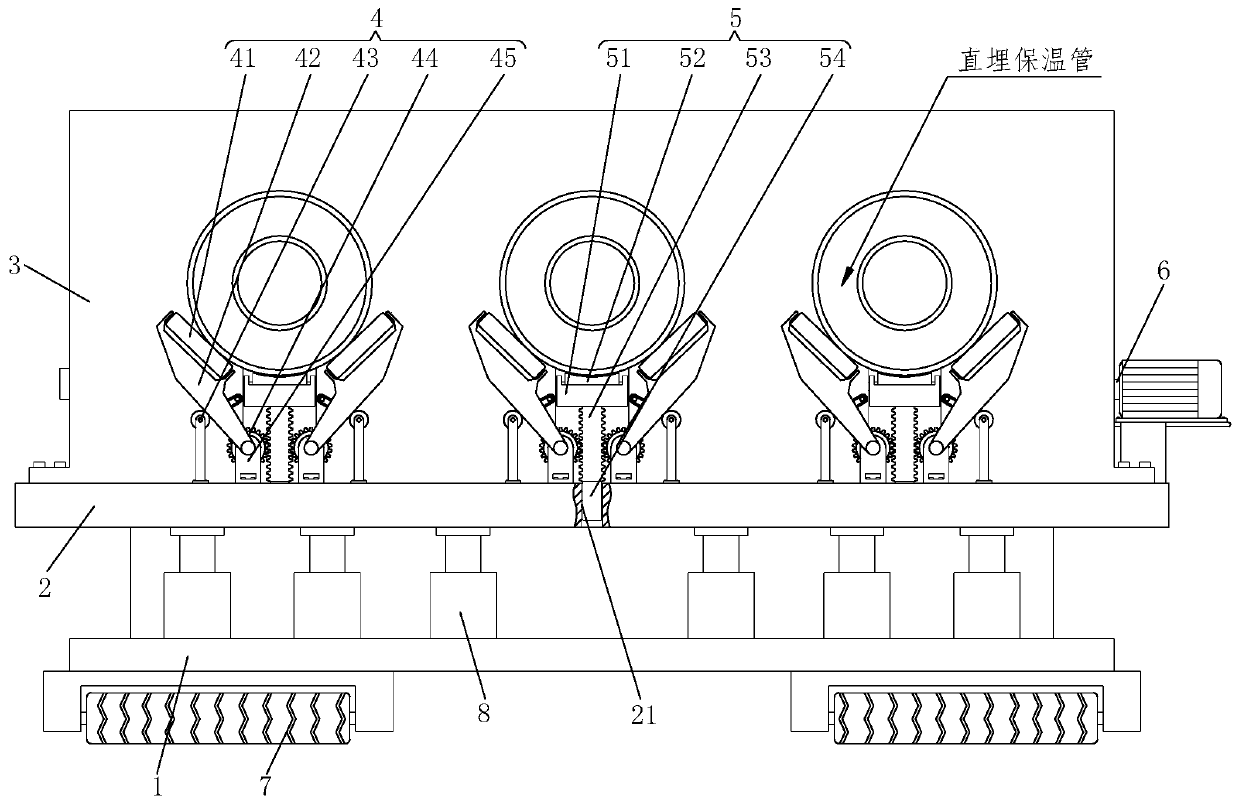

Directly-buried heat preservation pipeline installing construction method

ActiveCN111498743AReduce the difficulty of dockingGuaranteed concentricityConveyorsLifting framesRotational axisGear wheel

Owner:CHINA RAILWAY 22ND BUREAU GROUP +2

Mounting rack for integrated cooker fan and mounting method of mounting rack

ActiveCN110374933ARealize preliminary clamping limitEasy to install and disassembleDomestic stoves or rangesPump componentsPipe supportTurbine

The invention discloses a mounting rack for an integrated cooker fan. The mounting rack comprises a base and an arc-shaped clamping seat, the arc-shaped clamping seat is arranged on the base, the arc-shaped clamping seat comprises a bottom support and an arc-shaped frame, and the arc-shaped frame is located in the bottom support. A mounting method comprises the following steps that 1) the arc-shaped clamping seat is mounted; 2) the arc-shaped clamping seat and the base are mounted; 3) a motor supporting part and an air inlet pipe supporting part are mounted; and 4) the fan and the mounting rack are mounted. According to the mounting rack for the integrated cooker fan, mounting and fixing between the mounting rack and the inner wall of an integrated cooker are realized through the base, thearc-shaped clamping seat can be used for clamping and fixing a turbine casing on the fan, meanwhile, a motor on the fan is supported through the motor supporting part, and then an air inlet pipe on the fan is supported by using the air inlet pipe supporting part, so that the mounting firmness and reliability between the whole fan and the mounting rack are effectively guaranteed, the structural stability of the integrated cooker is improved, moreover, the angle of an air outlet pipe can be adjusted according to the actual position of an air duct pipe in the integrated cooker after the fan is mounted on the arc-shaped clamping seat.

Owner:钱松良

Storage transport bracket for SMD (Surface Mounted Devices)

ActiveCN110203513AImprove reliabilityEasy to fixContainers to prevent mechanical damageRigid containersMaterial classificationSurface mounting

The invention discloses a storage transport bracket for SMD. The storage transport bracket comprises an installation platform and an SMD material tray, wherein one surface of the installation platformis movably matched with a shock absorption frame, the bottom of the inner wall of the shock absorption frame is fixedly provided with position-limiting columns and guide rods, the circumference sidefaces of the position-limiting columns and the guide rods are all provided with shock absorption springs in a surrounded manner, one ends of the shock absorption springs are fixedly provided with a supporting plate, one surface of the supporting plate is fixedly provided with a buffer frame, the bottom of the inner wall of the buffer frame is fixedly provided with a buffer mechanism, and the end,away from the bottom of the inner wall of the buffer frame, of the buffer mechanism is fixedly provided with a clapboard. According to the storage transport bracket for the SMD, by means of use of theinstallation platform, the SMD material tray, the shock absorption frame, the position-limiting columns, the shock absorption springs, the supporting plate, the buffer frame, an adsorption iron plateand an electromagnet, improvement is the smoothness in the process of moving and transporting SMD materials by the bracket, furthermore, the bracket can perform size adjustment on the containing material level space corresponding to each category according to the category and quantity of the SMD materials, and the flexibility of SMD material classification storage is improved.

Owner:蒲惠智造科技股份有限公司

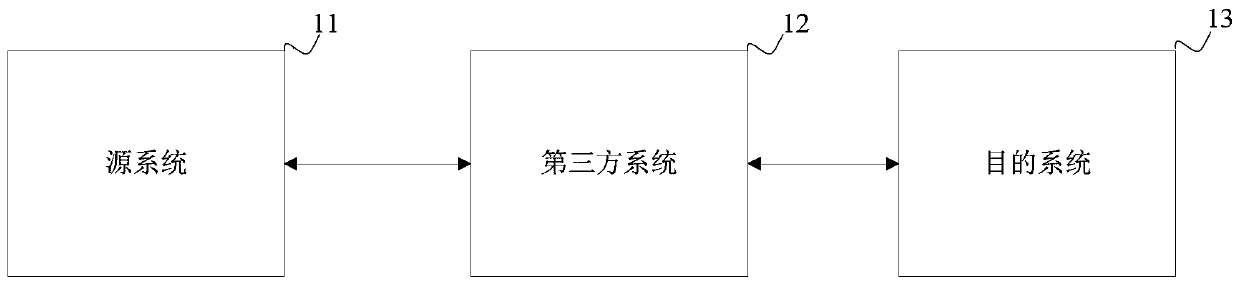

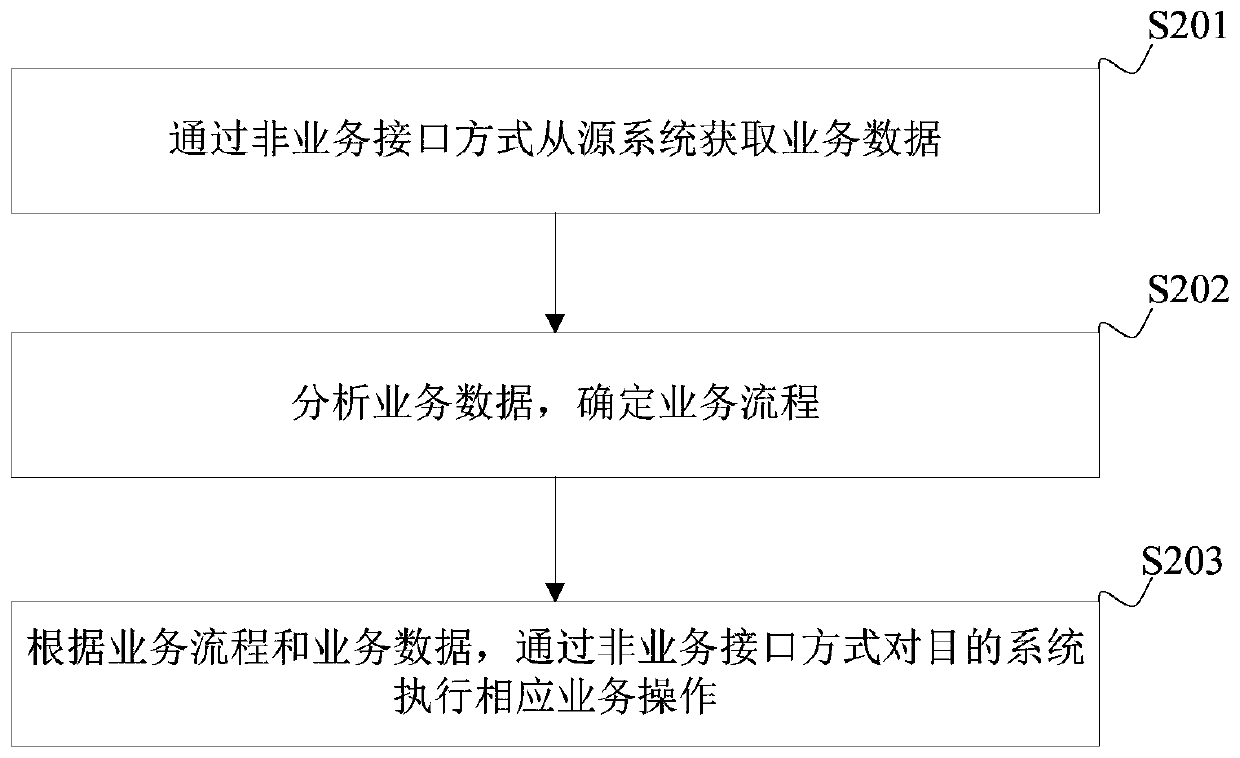

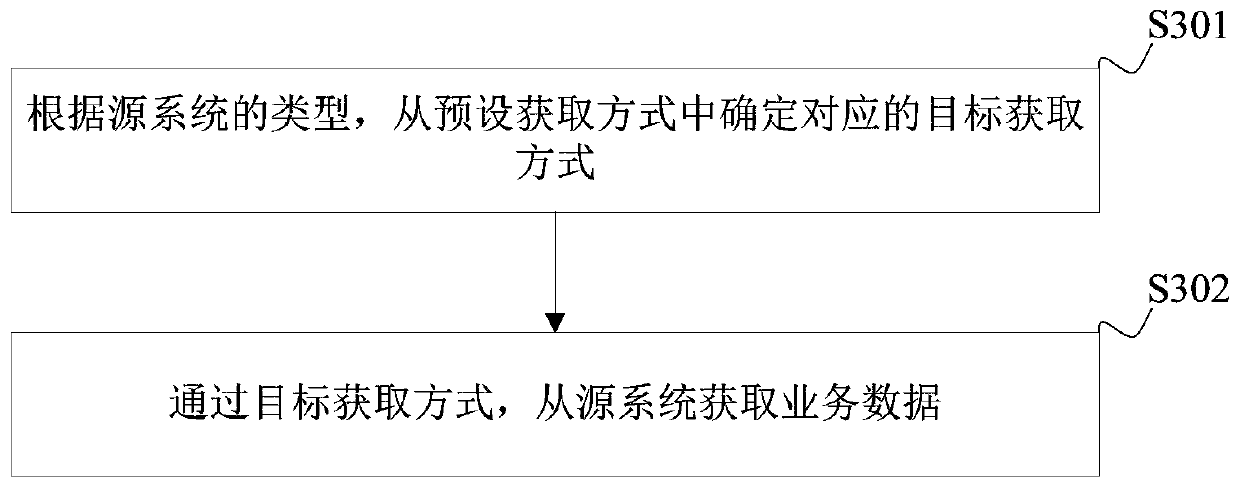

System docking method and device, management system, terminal equipment and storage medium

ActiveCN110147397AReduce the difficulty of dockingImprove docking efficiencyDatabase management systemsSpecial data processing applicationsService flowThird party

The embodiment of the invention is applicable to the technical field of computers, and discloses a system docking method and device, a management system, terminal equipment and a computer readable storage medium. The system docking method comprises the steps that: a third-party system obtains service data from a source system in a non-service interface mode; the third-party system analyzes the service data and determines a service flow; and the third-party system executes corresponding service operation on the target system in a non-service interface mode according to the service process and the service data. According to the embodiment of the invention, by introducing the third-party system, the third-party system obtains service data from the source system in a non-service interface mode, analyzes the service data to determine a service flow, and based on the service data and the service process, executes corresponding service operation on the target system in a non-service interfacemode, so that system development or interface opening is not needed, and system docking between the source system and the target system is achieved without modifying or developing programs, thus reducing the docking difficulty, and improving the docking efficiency and system stability.

Owner:管南风

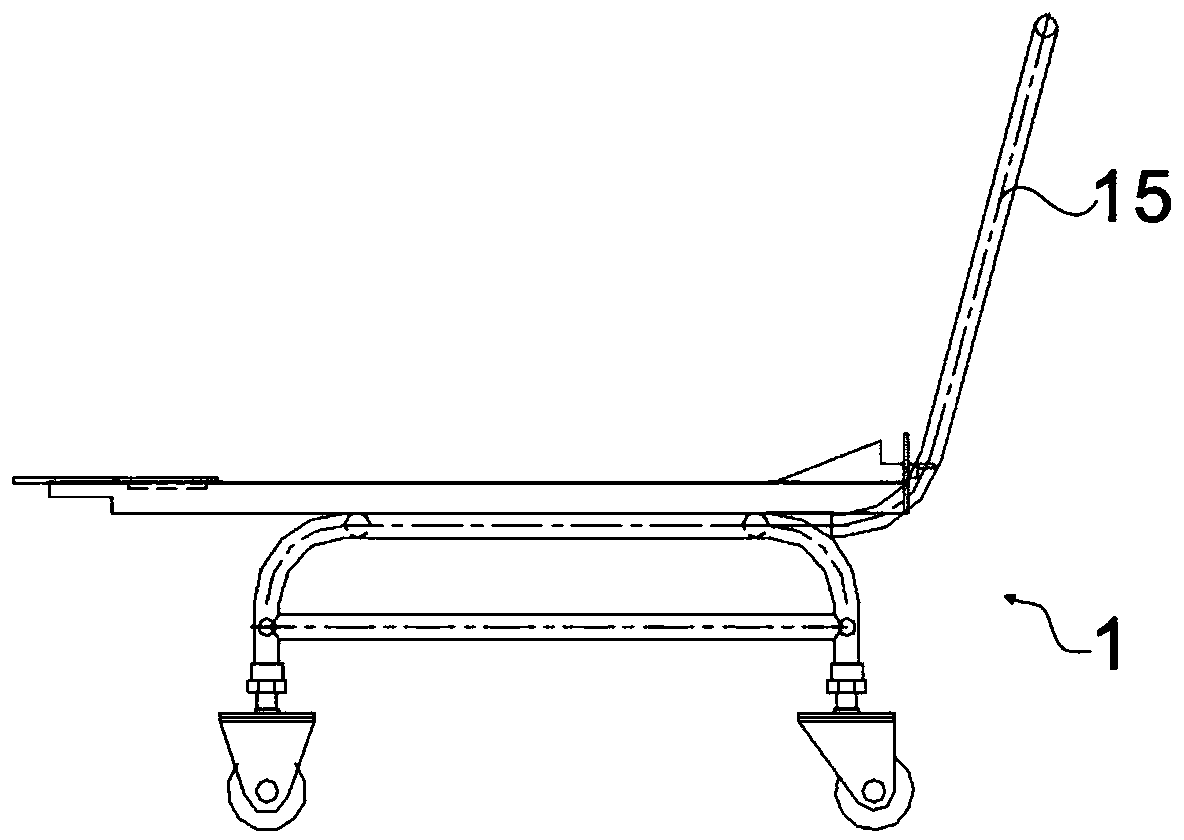

Locking device of sterilization cabinet truck

InactiveCN104015771APrevent backward displacementImprove work efficiencyHand cart accessoriesTruckButt joint

The invention provides a locking device of a sterilization cabinet truck, and belongs to the technical field of sterilization cabinet processes. The locking device comprises the truck, two truck rails and two sterilization cabinet rails. The truck rails are in butt joint with the sterilization cabinet rails, a guide column is arranged at the center of the distance between the two truck rails of a sterilization cabinet, a guide plate is arranged at the front end of the truck, a V-shaped groove or a U-shaped groove corresponding to the position of the guide column is formed in the guide plate, the V-shaped groove or the U-shaped groove is formed in the center of the distance between the truck rails and can accommodate the guide column, and the guide plate is provided with a locking component which prevents the truck from moving backwards. By means of the locking device of the sterilization cabinet truck, an operator can conveniently and smoothly push or pull the truck in or out of the sterilization cabinet, the butt joint difficulty of the truck and inner rails of the sterilization cabinet is lowered, the truck is prevented from moving backwards, and work efficiency is improved.

Owner:ZHANGJIAGANG OUSIRUI TECH

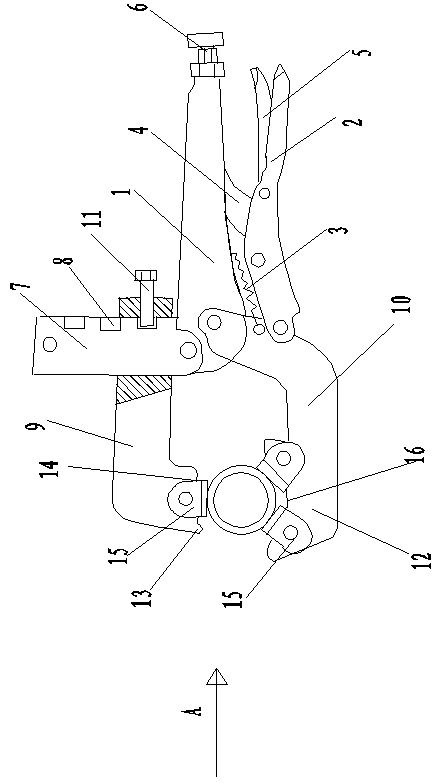

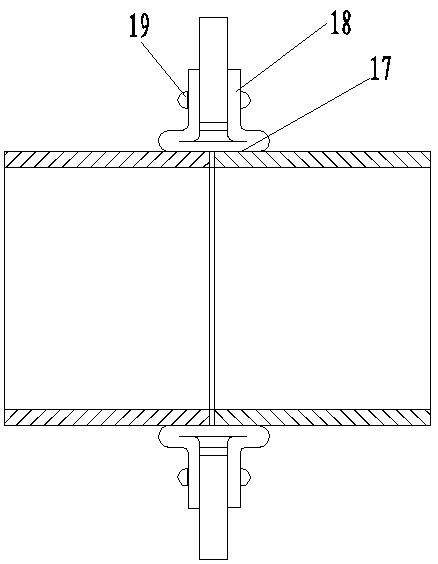

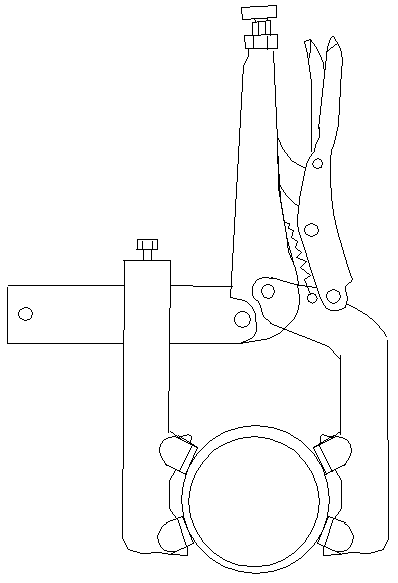

Powerful pliers for pipe butt-joint clamping

The invention discloses a pair of powerful pliers for pipe butt-joint clamping. The powerful pliers comprise a pliers head and a pliers body, wherein the pliers body comprises a large pliers handle, asmall pliers handle, a disengage handle, a tension spring, a supporting rod and a regulating screw; the front end of the large pliers handle is riveted and welded with a slide rod, and is perpendicular to the large pliers handle; the pliers head comprises a movable pliers head and a sliding pliers head; the sliding pliers head is arranged the slide rod in a sleeving mode, and is fixed in up-downposition through a fastening screw at the rear end; the movable pliers head is L-shaped, and the rear end of the movable pliers head is hinged with the large pliers handle and the small pliers handle;the front end of the sliding pliers head and the front end of the movable pliers head are each provided with a widened clamping platform; the two ends of the clamping platform are provided with up-warp limiting parts, so that the clamping surfaces are trapezoidal, and one or two clamping claws are hinged in the clamping surfaces; and a butt-joint tube is placed between upper and lower clamping surfaces, so that fixed splicing is realized through clamping of upper and lower clamping claws; and seam-slicing welding is performed in a seam between the upper and lower clamping claws.

Owner:李昊一

Butt joint device for cable production

ActiveCN113904189AReduce the difficulty of dockingAvoid misalignmentLine/current collector detailsButt jointEngineering

Owner:浙江中兴电缆有限公司

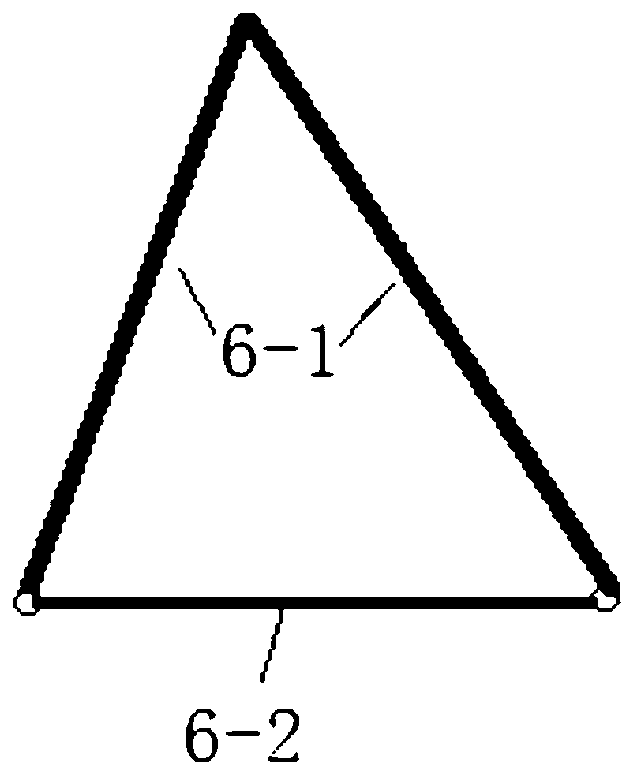

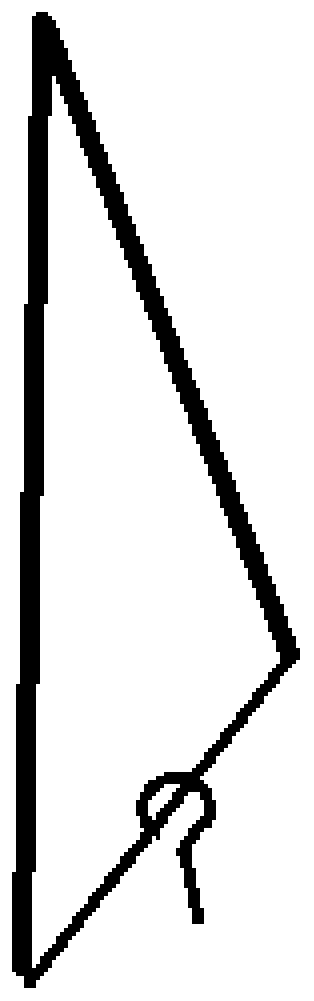

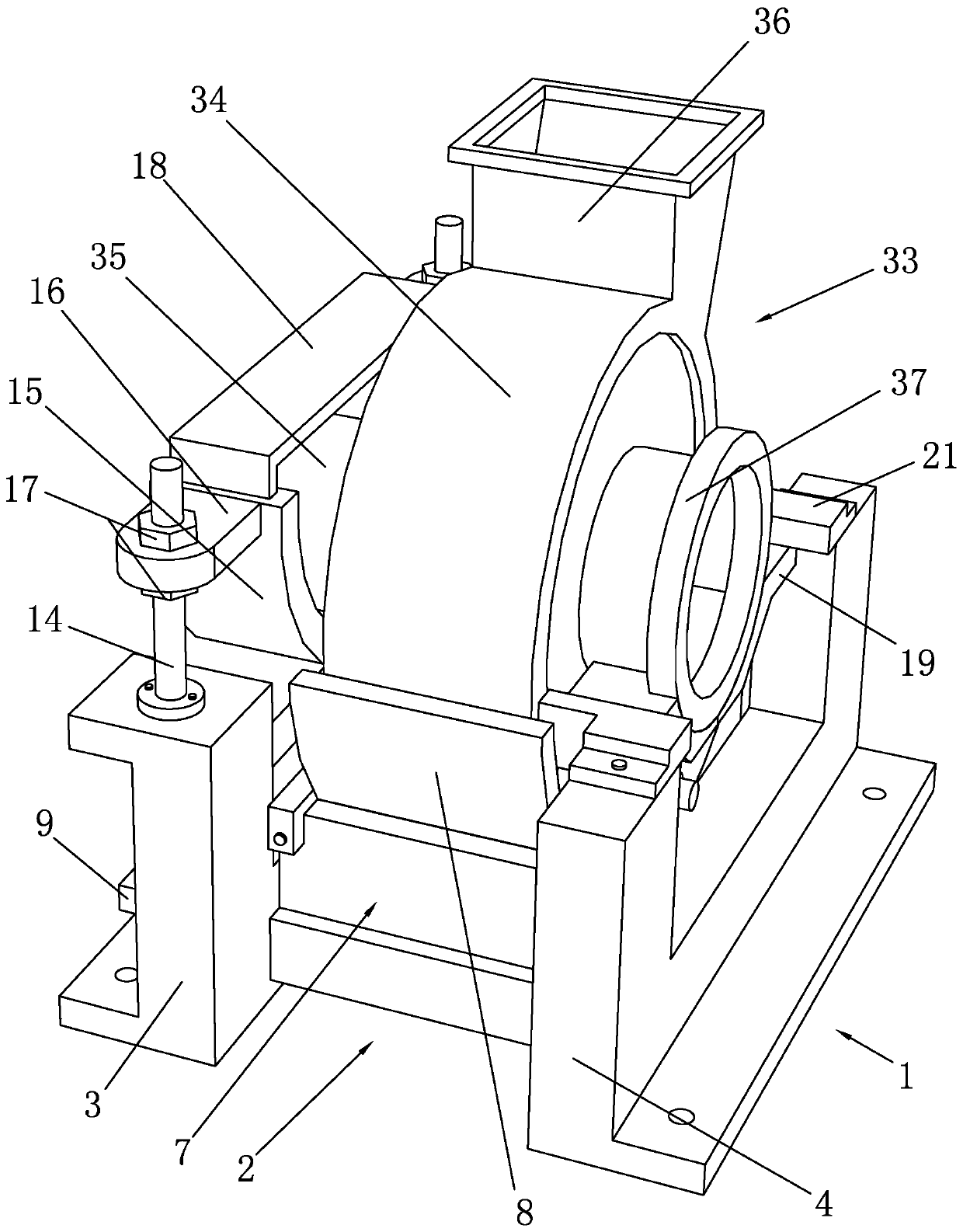

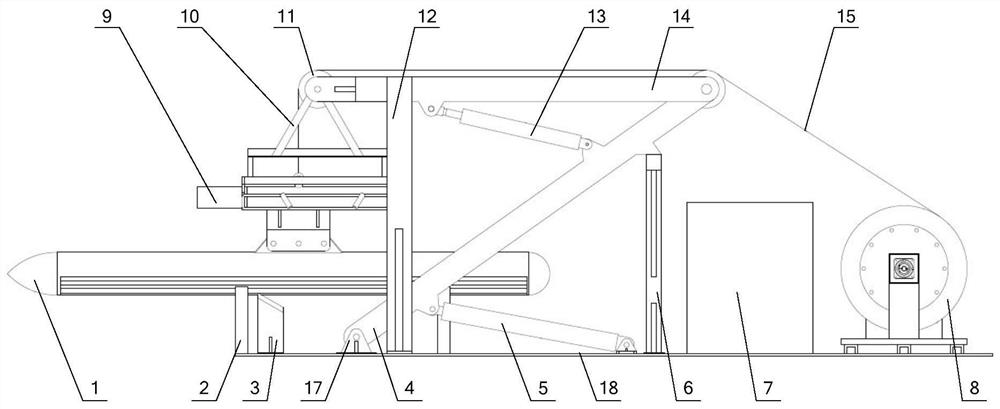

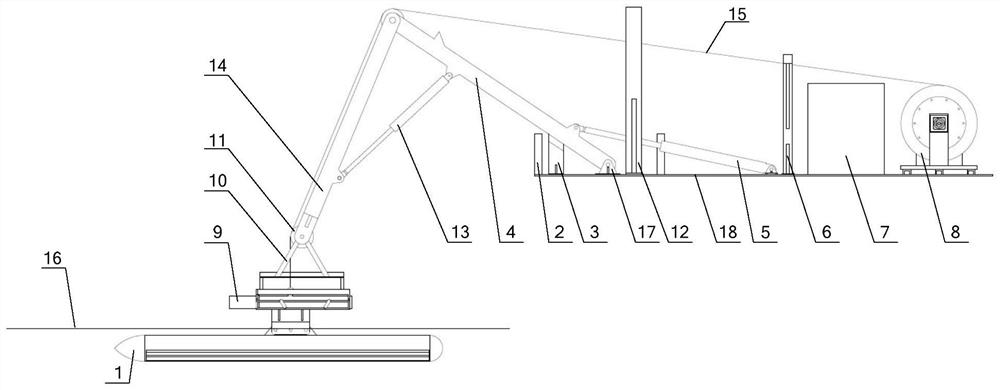

A deployment and recovery device for towed sonar for boats

ActiveCN109866883BReduce the difficulty of dockingReduce riskCargo handling apparatusNon-rotating vibration suppressionSonarHydraulic cylinder

The invention belongs to the field of underwater equipment arranging and recycling, and particularly relates to an arranging and recycling device of a boat towed sonar. A portal system comprises a first-stage portal, a first-stage hydraulic cylinder, a second-stage portal and a second-stage hydraulic cylinder; one end of the first-stage portal is hinged to a boat platform, the other end of the first-stage portal is hinged to one end of the second-stage portal, the other end of the second-stage portal is connected with a sonar bracket, one end of the first-stage hydraulic cylinder is hinged tothe boat platform, the other end of the first-stage hydraulic cylinder is hinged to the first-stage portal, and two ends of the second-stage hydraulic cylinder are hinged to the first-stage portal andthe second-stage portal; a protection cover is arranged on the arranged and recycled towed sonar, the protection cover is connected with a winch pulley system on the boat platform, the sonar bracketis provided with a locking mechanism for locking the protection cover, and the first-stage hydraulic cylinder, the second-stage hydraulic cylinder and a locking power source of the locking mechanism are connected with a hydraulic system mounted on the boat platform through hydraulic pipelines. The towed sonar is arranged and recycled on the water level, the structure is safe and reliable, and operation is easy.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

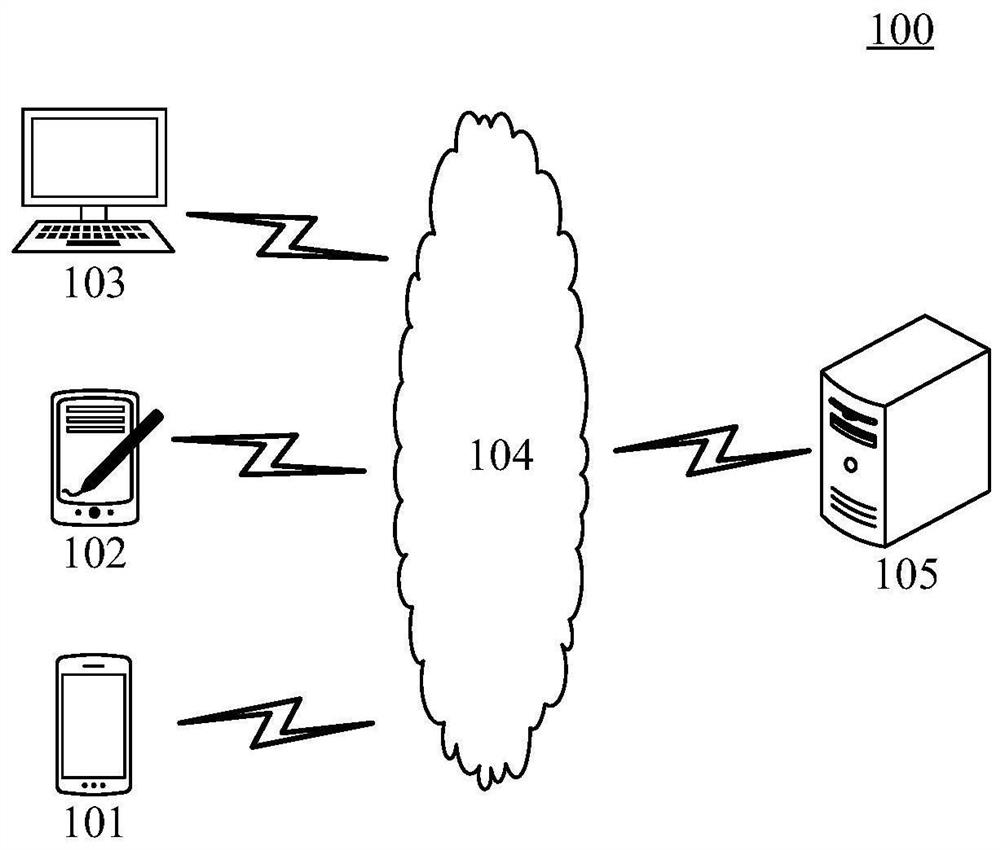

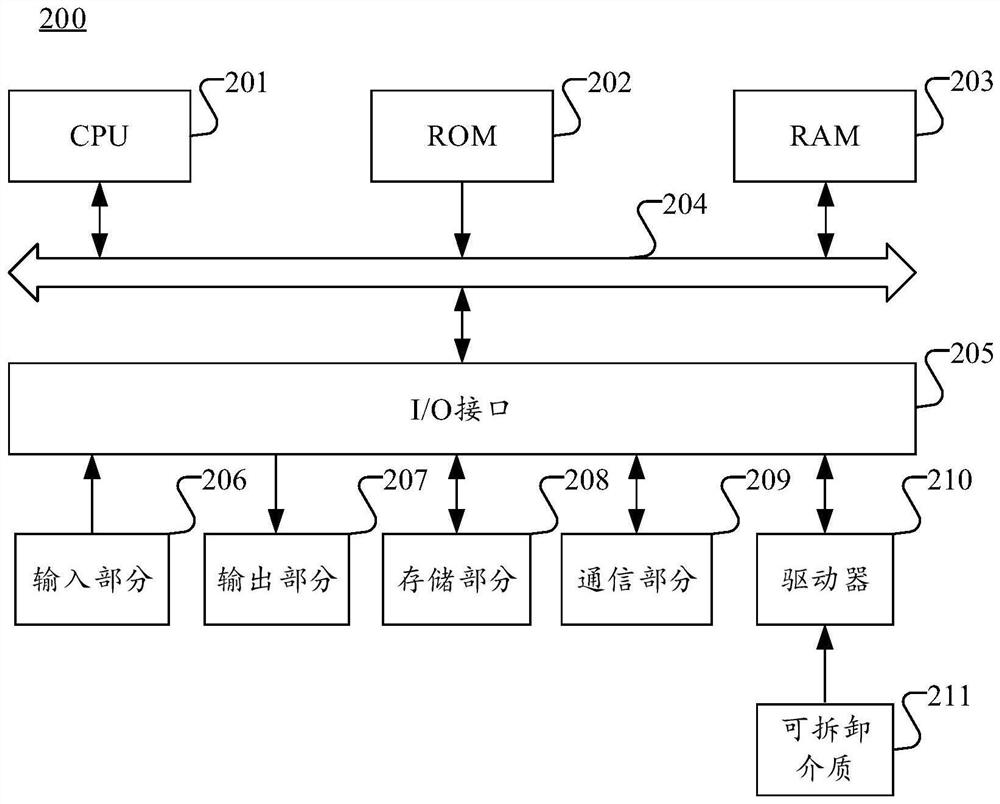

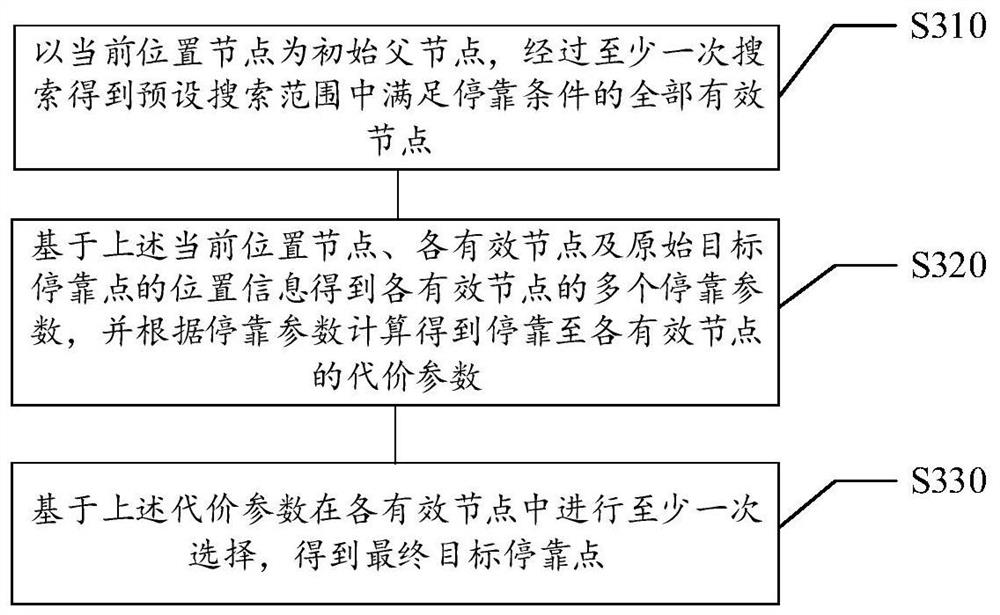

Unmanned vehicle parking point selection method and device, storage medium and electronic equipment

ActiveCN112419779AAvoid occupyingImprove securityIndication of parksing free spacesOffice automationSimulationEquipment computers

The invention provides an unmanned vehicle parking point selection method and device, electronic equipment and a computer readable storage medium, and relates to the technical field of artificial intelligence. The unmanned vehicle parking point selection method comprises the steps of: taking a current position node as an initial father node, and performing at least one search to obtain all effective nodes meeting parking conditions in a preset search range; acquiring a plurality of parking parameters of each effective node based on the current position node, each effective node and an originaltarget parking point, and calculating a cost parameter of parking to each effective node according to the parking parameters; and performing at least one selection in each effective node based on thecost parameter to obtain a final target parking point. According to the method, the suitable parking point can be selected for the unmanned vehicle without human intervention, and the problem that when the original target parking point cannot be reached, the unmanned vehicle occupies an unreasonable area for a long time, and traffic safety is affected is solved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

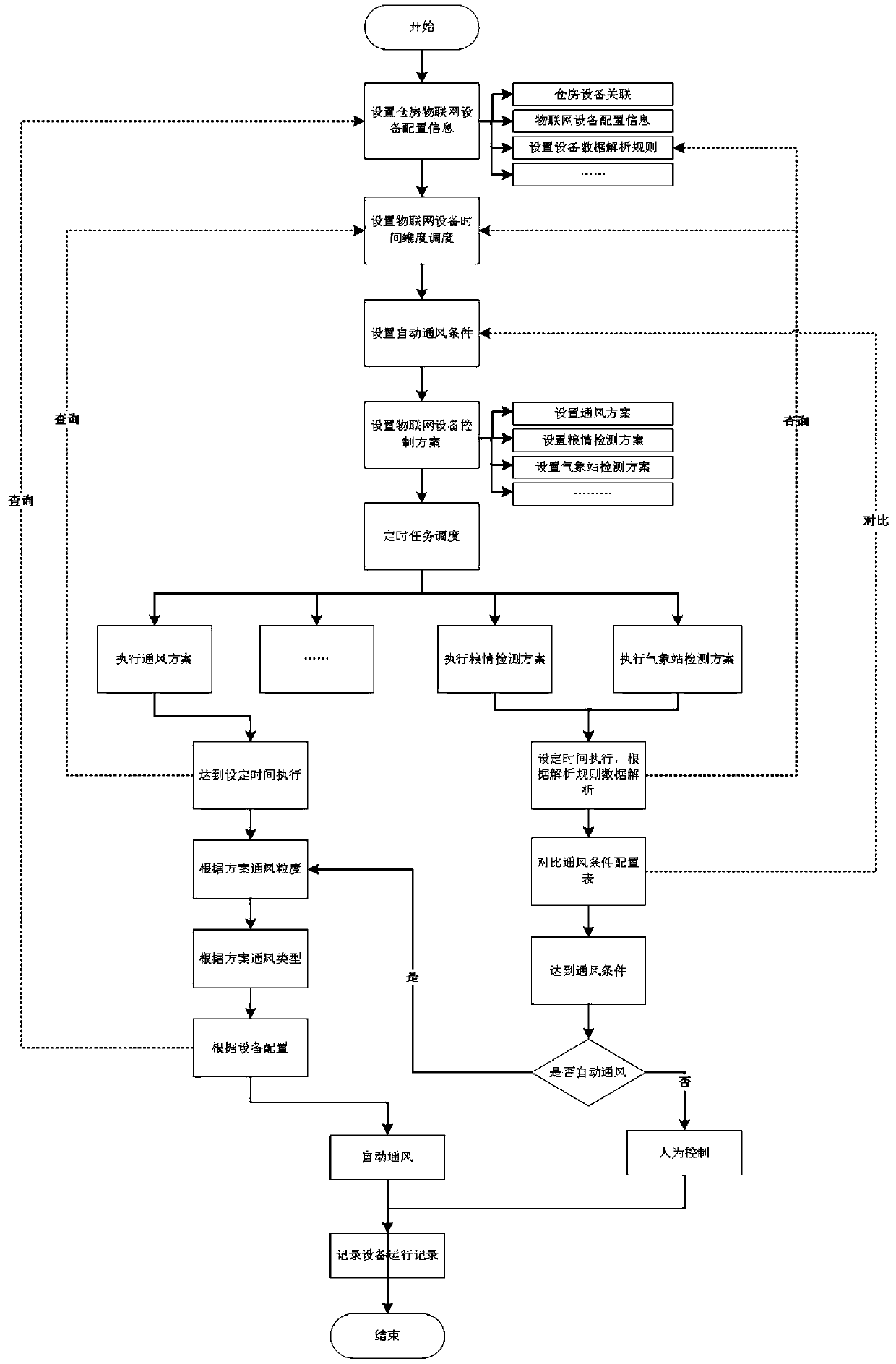

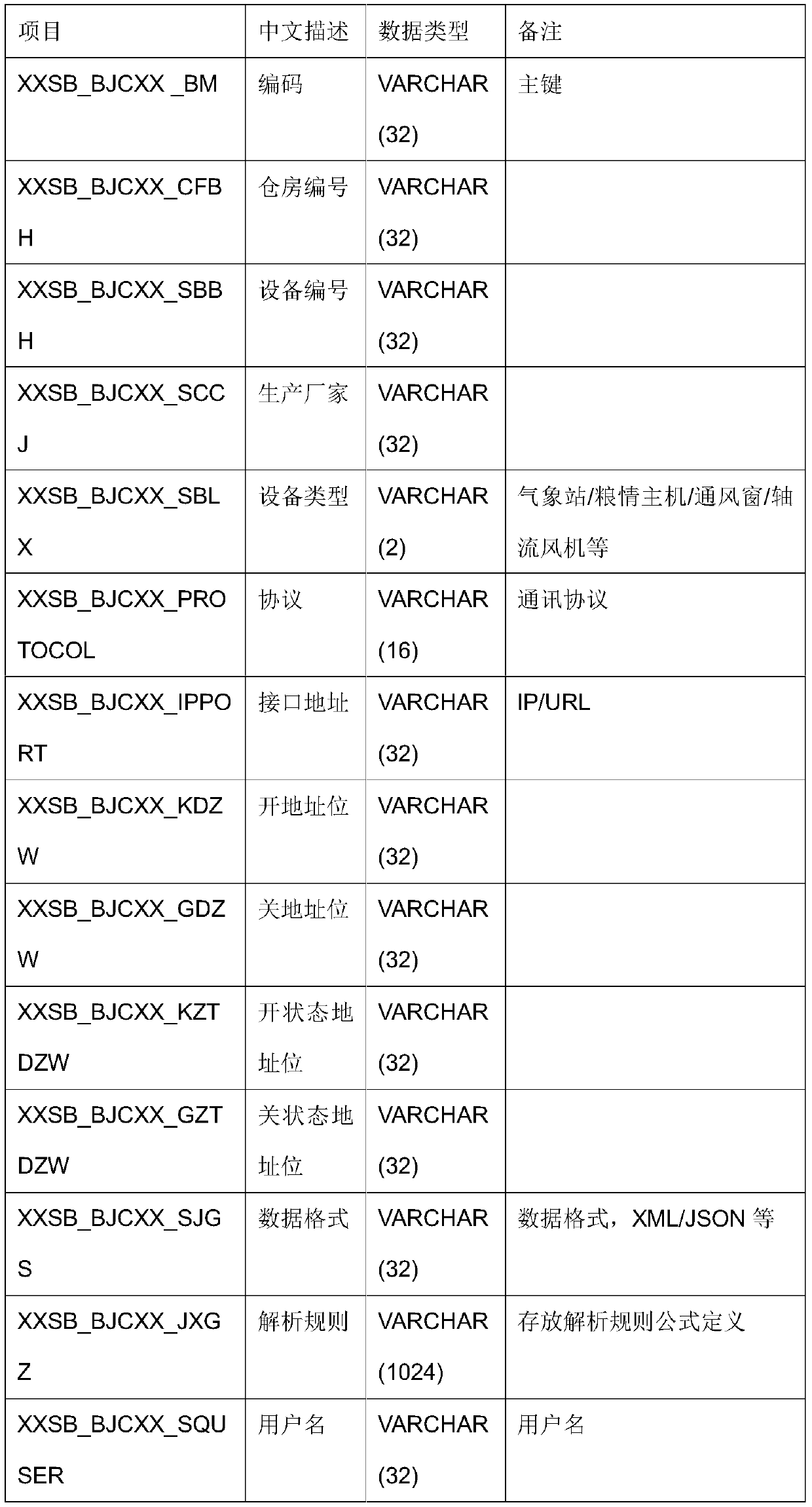

Method and system for realizing intelligent ventilation of grain storage based on Internet of Things equipment

PendingCN111240261AReal-time accurate supervisionReal-time precise controlProgramme control in sequence/logic controllersGrain storageThe Internet

The invention discloses a method and a system for realizing intelligent ventilation of grain storage based on Internet of Things equipment, and belongs to the field of PLC industrial control, networkprogramming and multithreading knowledge. The method flexibly configures different Internet of Things equipment and parameters thereof to realize automatic docking of different Internet of Things equipment, and the parameters comprise device types, communication protocols, data formats and data parsing rules. Multi-granularity and multi-dimensional ventilation strategy configuration is carried outin time and space. Data collected by the Internet of Things equipment is intelligently analyzed, and intelligent ventilation is achieved. The system comprises a warehouse Internet of Things equipmentbasic information configuration module, an Internet of Things equipment time dimension scheduling configuration module, a ventilation condition configuration module, an Internet of Things equipment control module and a timing task scheduling module. The ventilation equipment can be flexibly and intelligently controlled during grain storage, so that the grain storage environment of the granary iscontrolled, and the purpose of safe grain storage is achieved.

Owner:SHANDONG INSPUR GENESOFT INFORMATION TECH CO LTD

Method for installing booster stations for wind power and photovoltaic power generation systems

PendingCN110474248AReduce installation accumulation errorsGuaranteed tightnessMulti-purpose toolsSwitchgearElectricityElectrical conductor

The invention relates to a method for installing the booster stations for wind power and photovoltaic power generation systems. According to the method, a foundation adjustment method and an initial spacer in-place method are adopted; the highest point of metal embedded parts is found out; an initial spacer installation foundation height is adjusted through gaskets; other spacer foundation heightsare pre-adjusted according to the initial spacer installation foundation height; a bus-bar connection spacer is adopted as an initial spacer to be installed; and after the bus-bar connection spacer is installed, other spacer on two sides of the bus-bar connection spacer are installed. With the method adopted, the accumulated error of the installation of a GIS can be reduced, and the sealing degree of the GIS is ensured; after the spacers are in butt joint with one another, the insertion depths of contacts are calculated; the insertion depths of conductors and contact seats are confirmed, andtherefore, requirements for the sealing degree of the GIS and the safety of a plug are satisfied; the rapid pressing and separation of flanges between the spacers can be facilitated through a multifunctional clamp, and therefore, damage to equipment contacts during the separation of the flanges is avoided; and the multifunctional clamp has a cable shearing function and a cable head crimping function, so that the multifunctional clamp can be used in other electrical construction.

Owner:CHINA THIRD METALLURGICAL GRP

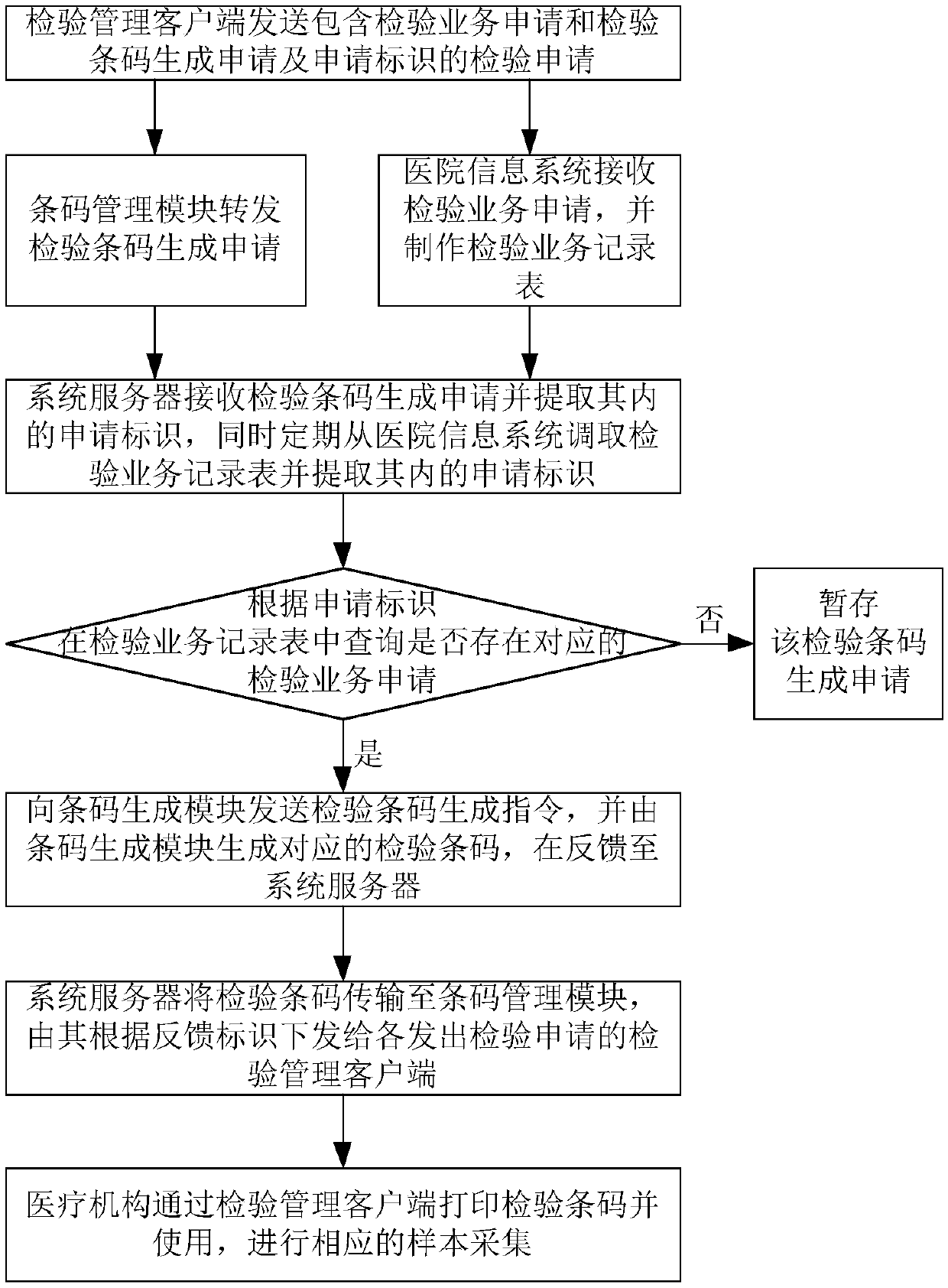

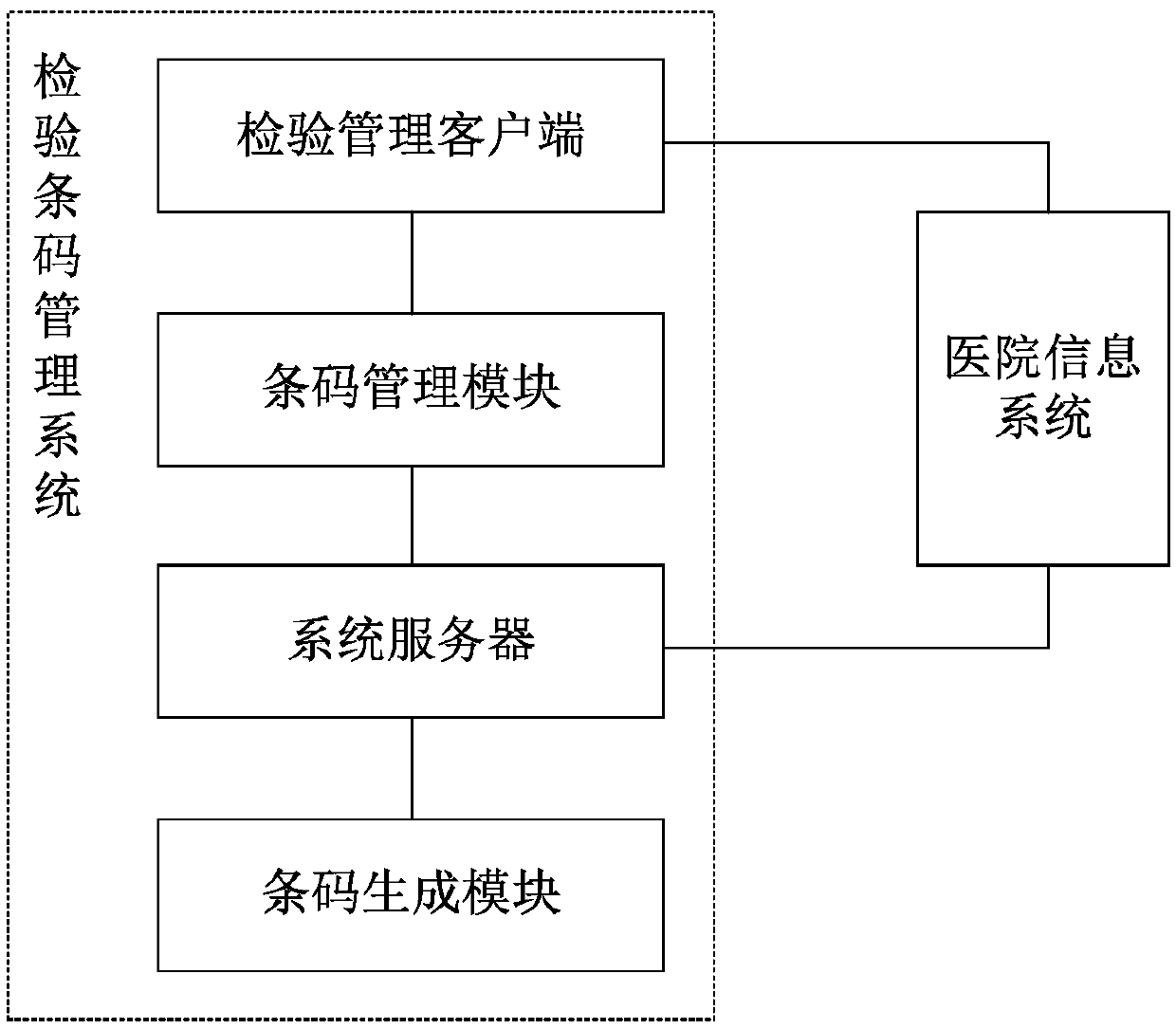

A bar code management method based on medical regional examination

PendingCN109599167ASaves time on sample container retrievalSimple processMedical communicationCo-operative working arrangementsBarcodeClient-side

The invention discloses a bar code management method based on medical regional examination. The method is realized by an inspection bar code management system which is intercommunicated with a hospital information system configured by a central medical institution. The examination barcode management system comprises examination management clients arranged at medical institutions, a barcode management module connected with the examination management clients, a system server connected with the barcode management module and a hospital information system, and a barcode generation module connectedwith the system server. The examination barcode management system is further configured on the basis of an existing hospital information system and is specially used for managing examination barcodes,so that a medical institution applying for examination business can remotely apply for the examination barcodes in real time, and defects and waste caused by the fact that the examination barcodes are distributed in advance in an examination environment of a medical area are avoided.

Owner:THE AFFILIATED HOSPITAL OF SOUTHWEST MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com