Longitudinal movement and lifting installation construction method for large steel pipe arch

A construction method and steel pipe arch technology, which is applied in erecting/assembling bridges, bridges, buildings, etc., can solve the problems of low construction control difficulty, height and weight restrictions, short construction period, etc., achieve good construction period and economic benefits, and improve safety Sex and stability, and the effect of reducing lateral wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

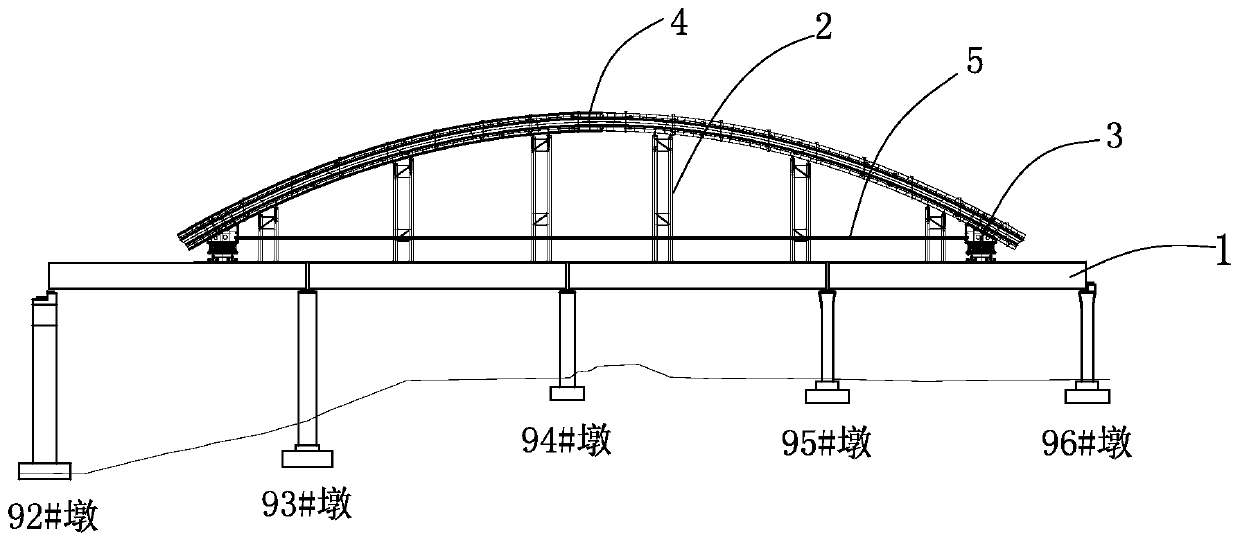

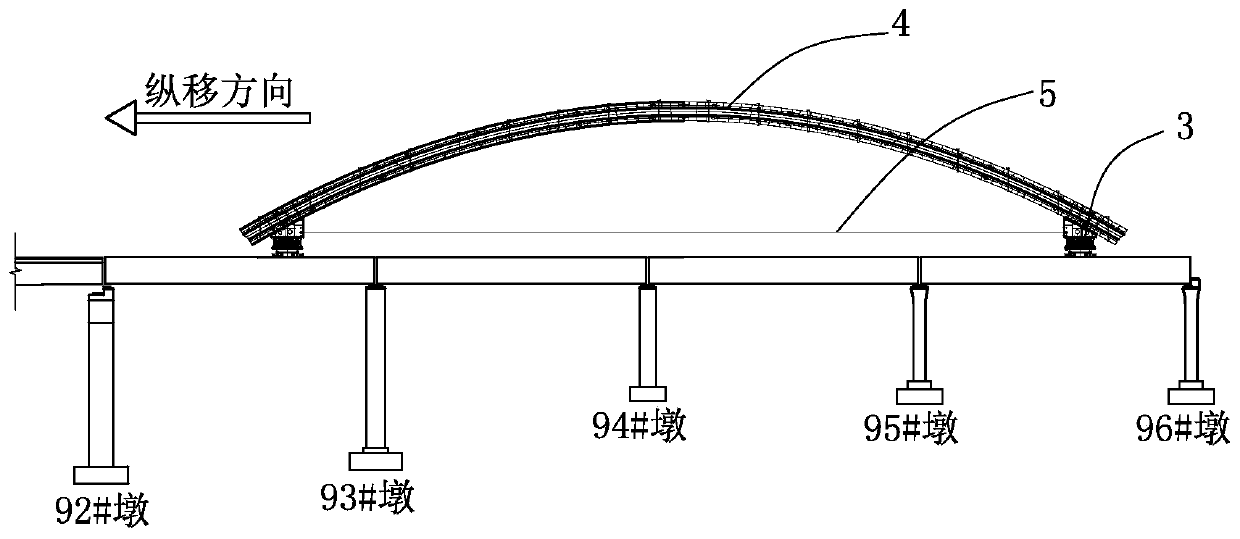

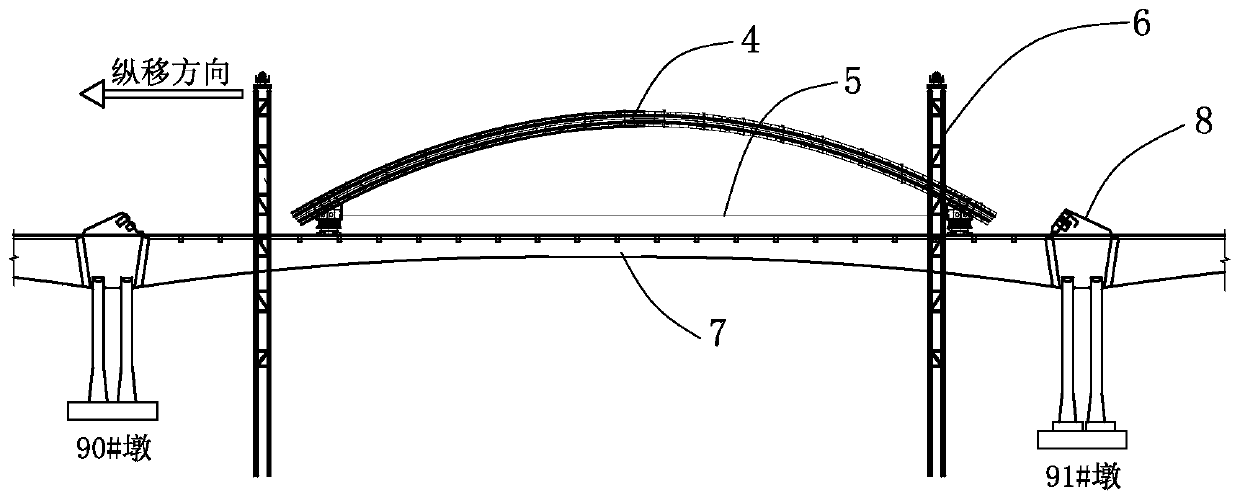

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0025] (1) Before the present invention starts construction, the design of the entire steel pipe arch is divided into the main arch section in the middle and the abutment sections at both ends, and the main arch section adopts the construction method of assembling the bridge head and moving longitudinally in place. When dividing the steel pipe arch, the weight of the main arch section is limited to not exceed the maximum bearing capacity of the main bridge steel girder; considering the influence of wind resistance on the steel pipe supply section during longitudinal movement, in addition to determining the main arch section according to the maximum bearing capacity of the main bridge body, The height of the main arch section can also be determined according to the transverse wind load. Avoid too high a height to cause structural instability during longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com