Patents

Literature

1897 results about "Arch bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An arch bridge is a bridge with abutments at each end shaped as a curved arch.Arch bridges work by transferring the weight of the bridge and its loads partially into a horizontal thrust restrained by the abutments at either side. A viaduct (a long bridge) may be made from a series of arches, although other more economical structures are typically used today.

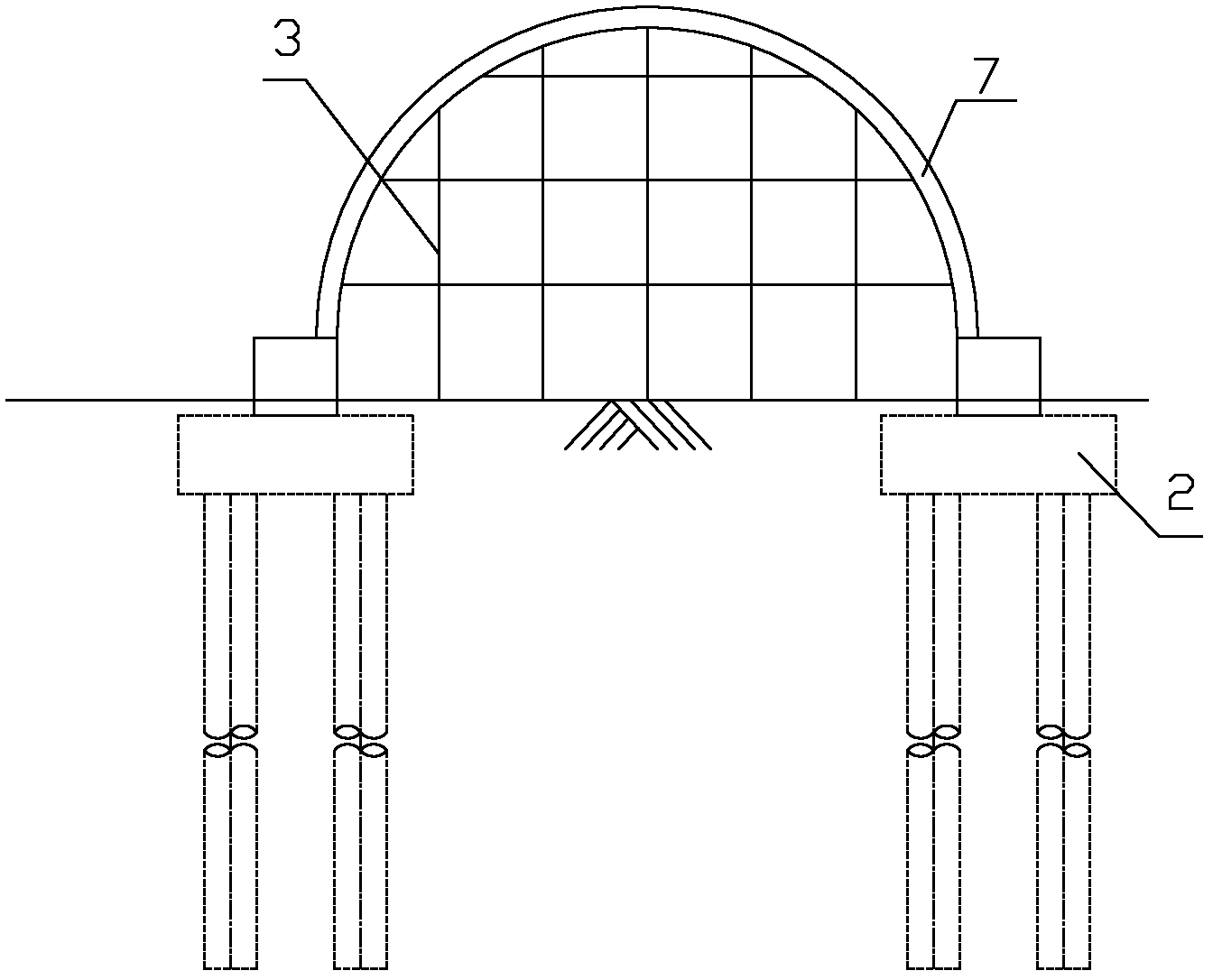

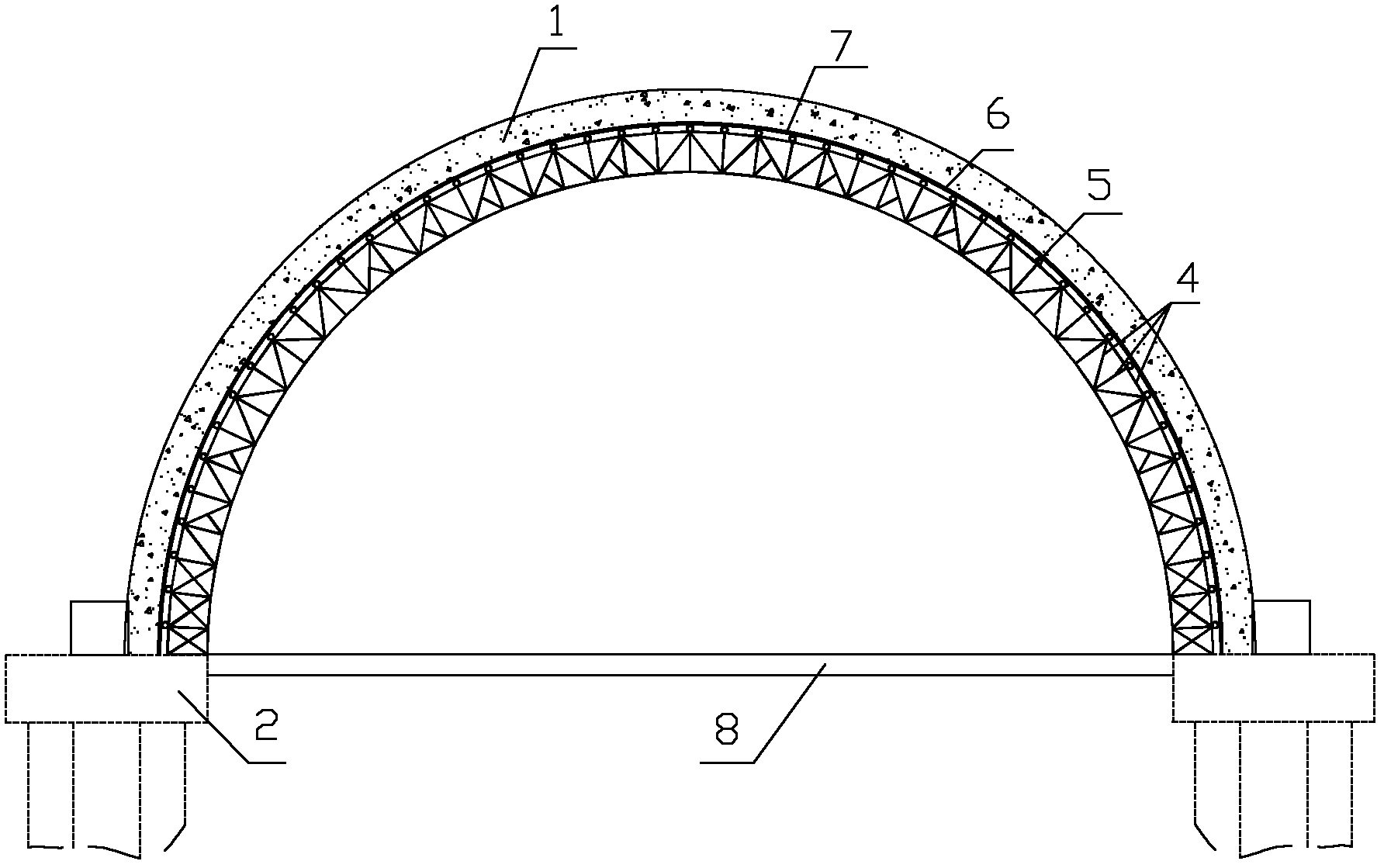

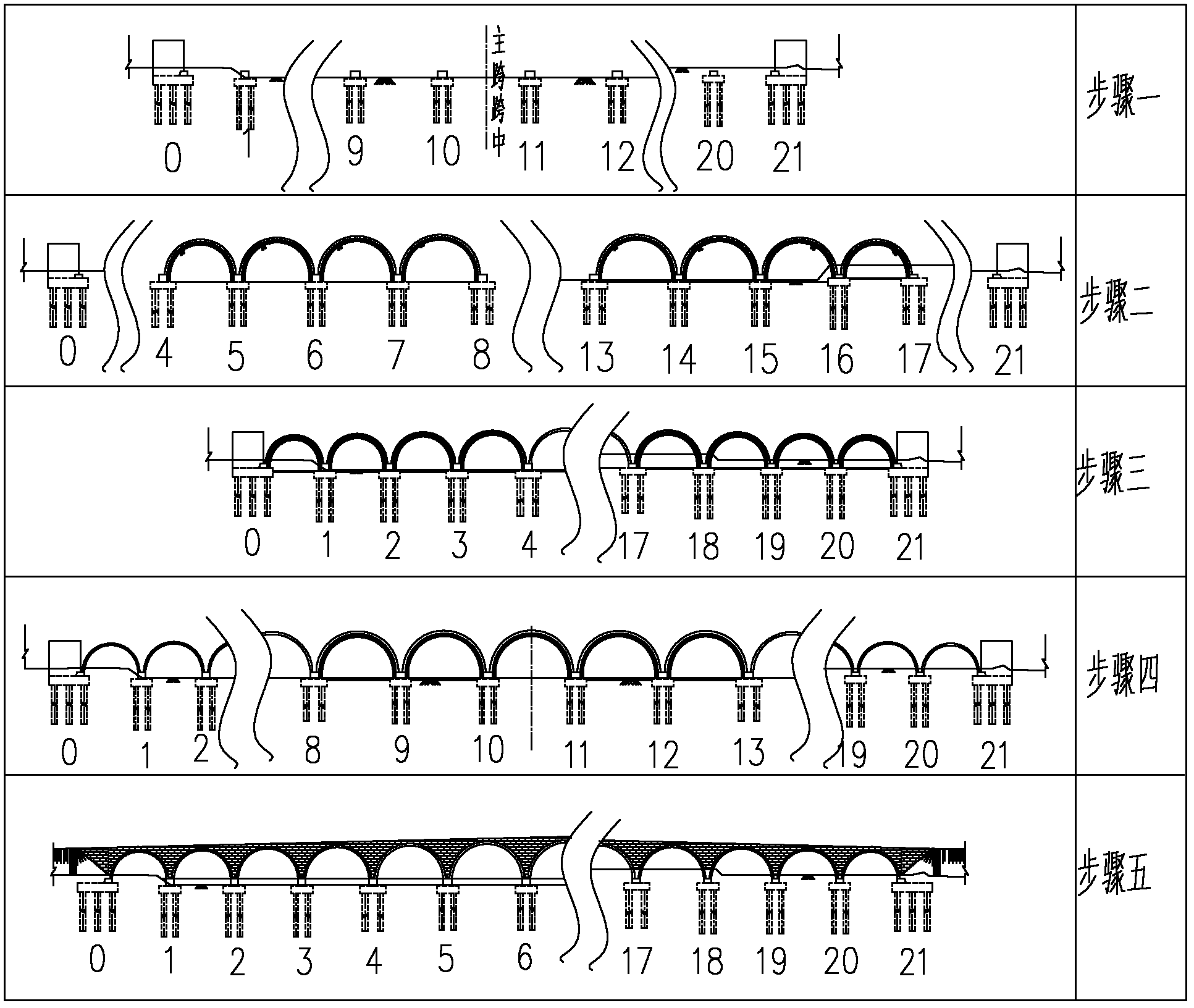

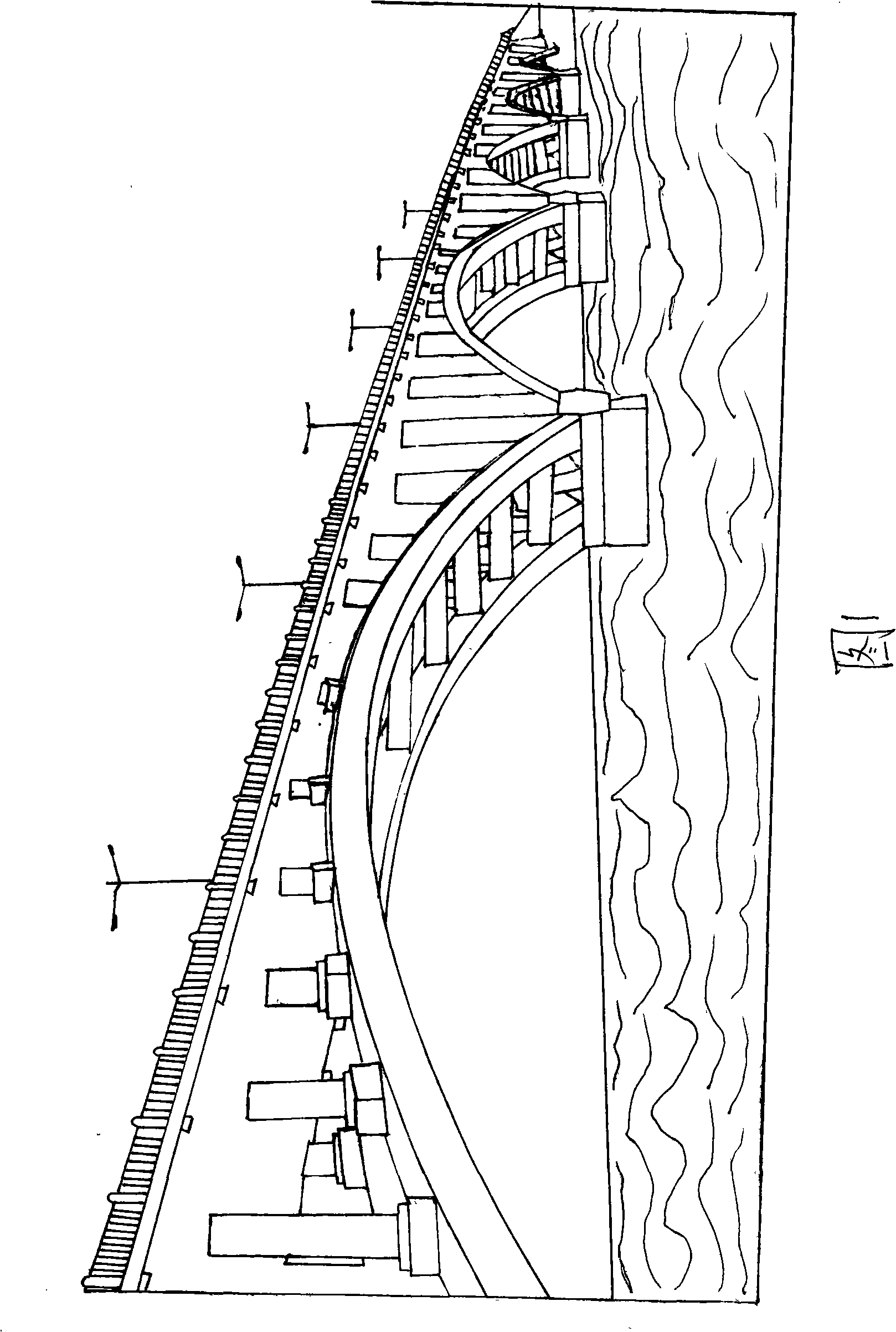

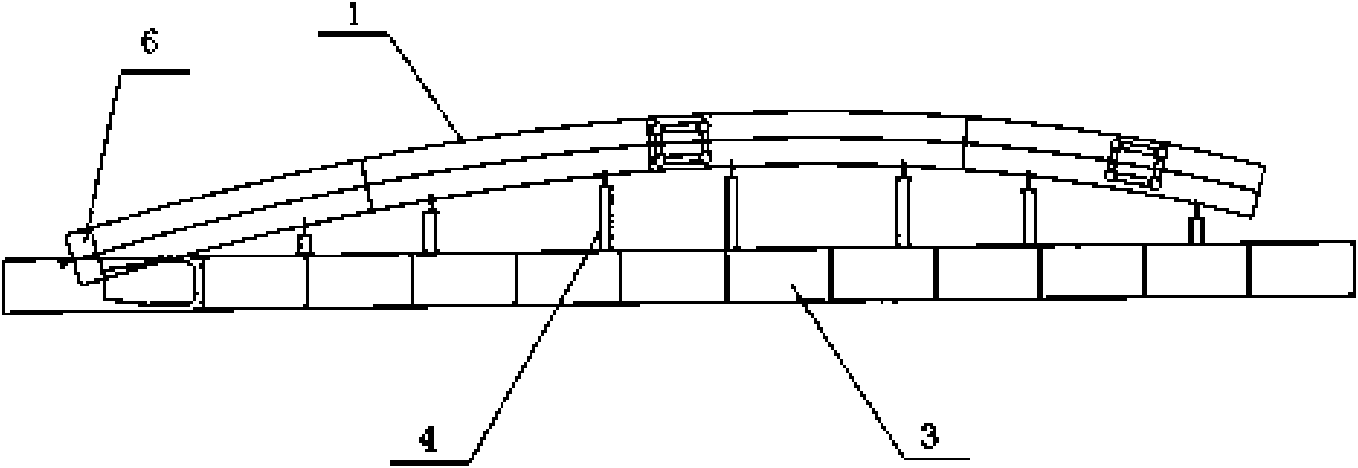

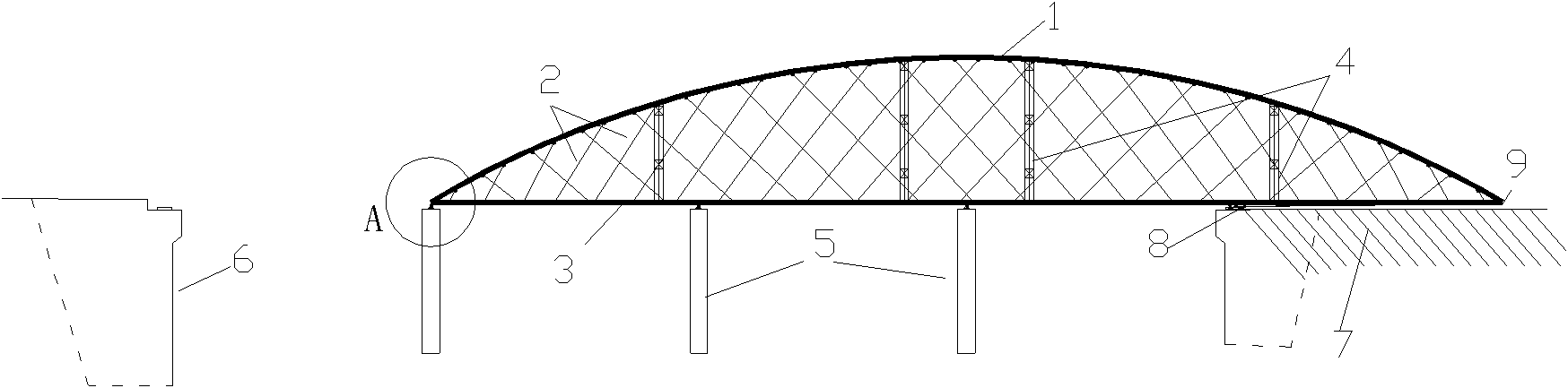

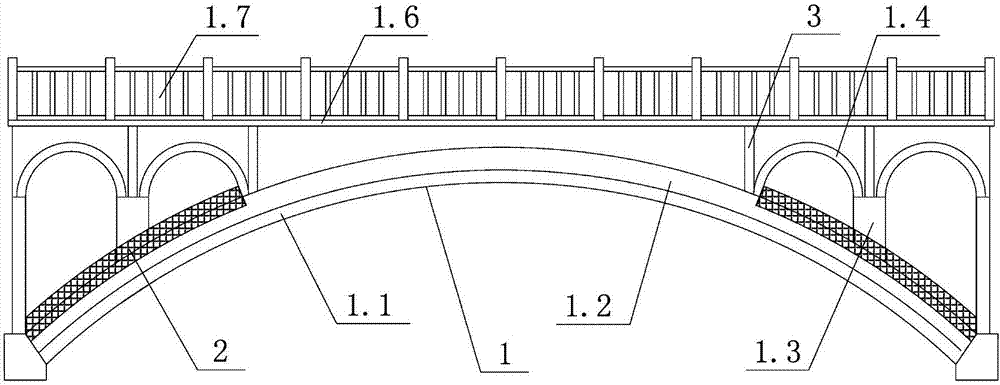

Reinforced concrete arch bridge construction method

ActiveCN102493360AAvoid deformationStable structureBridge erection/assemblyArch-type bridgeReinforced concreteAbutment

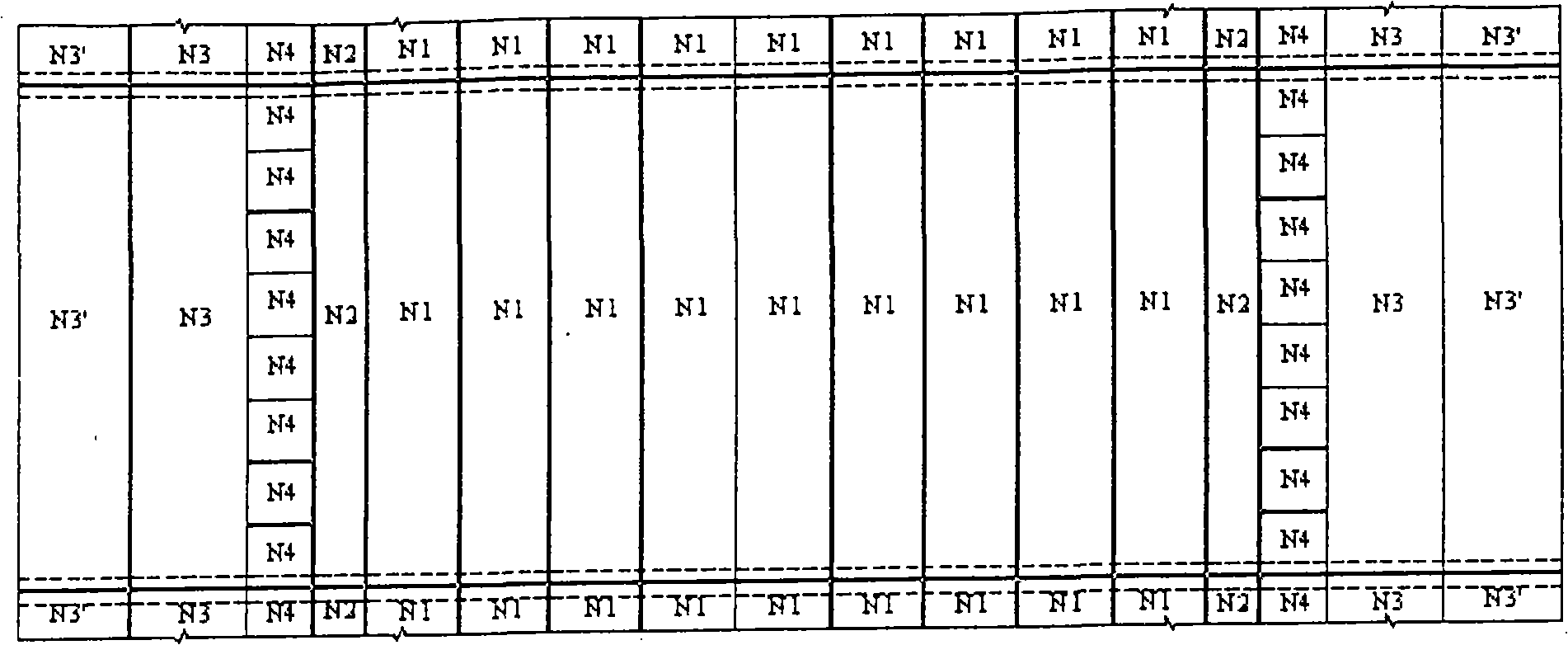

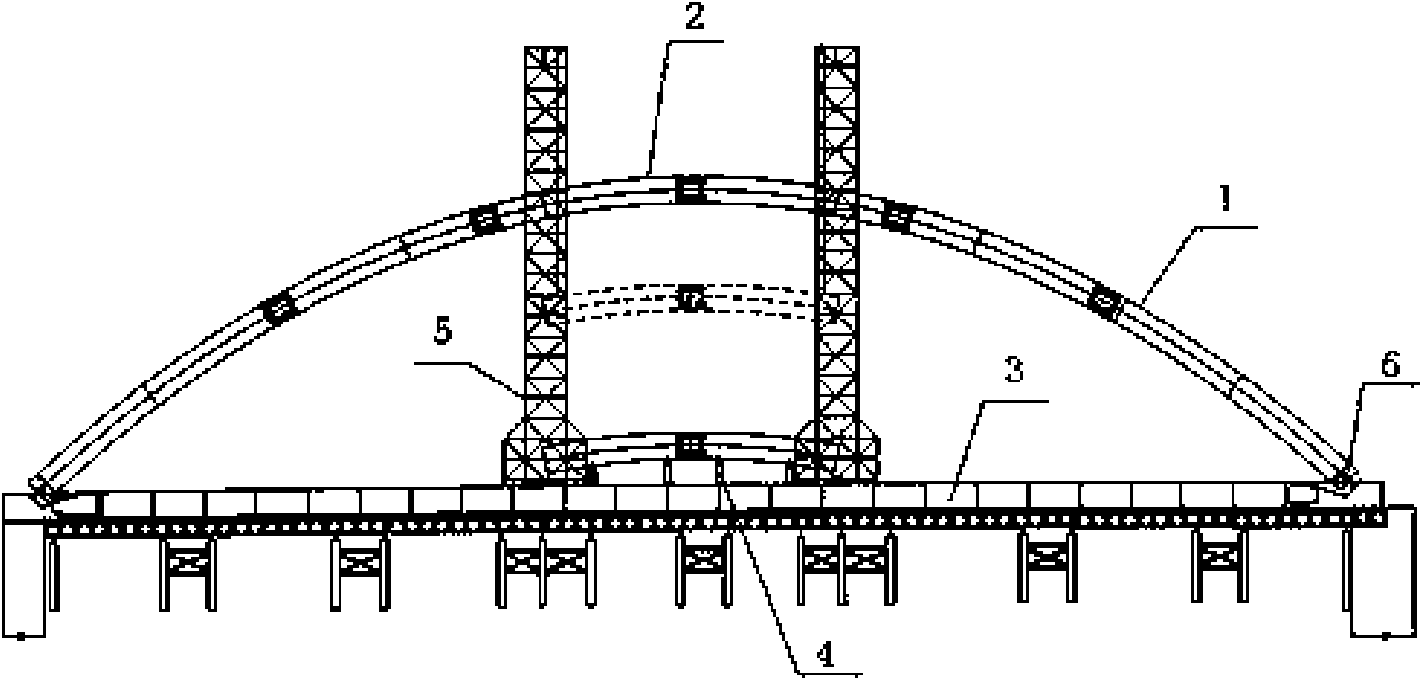

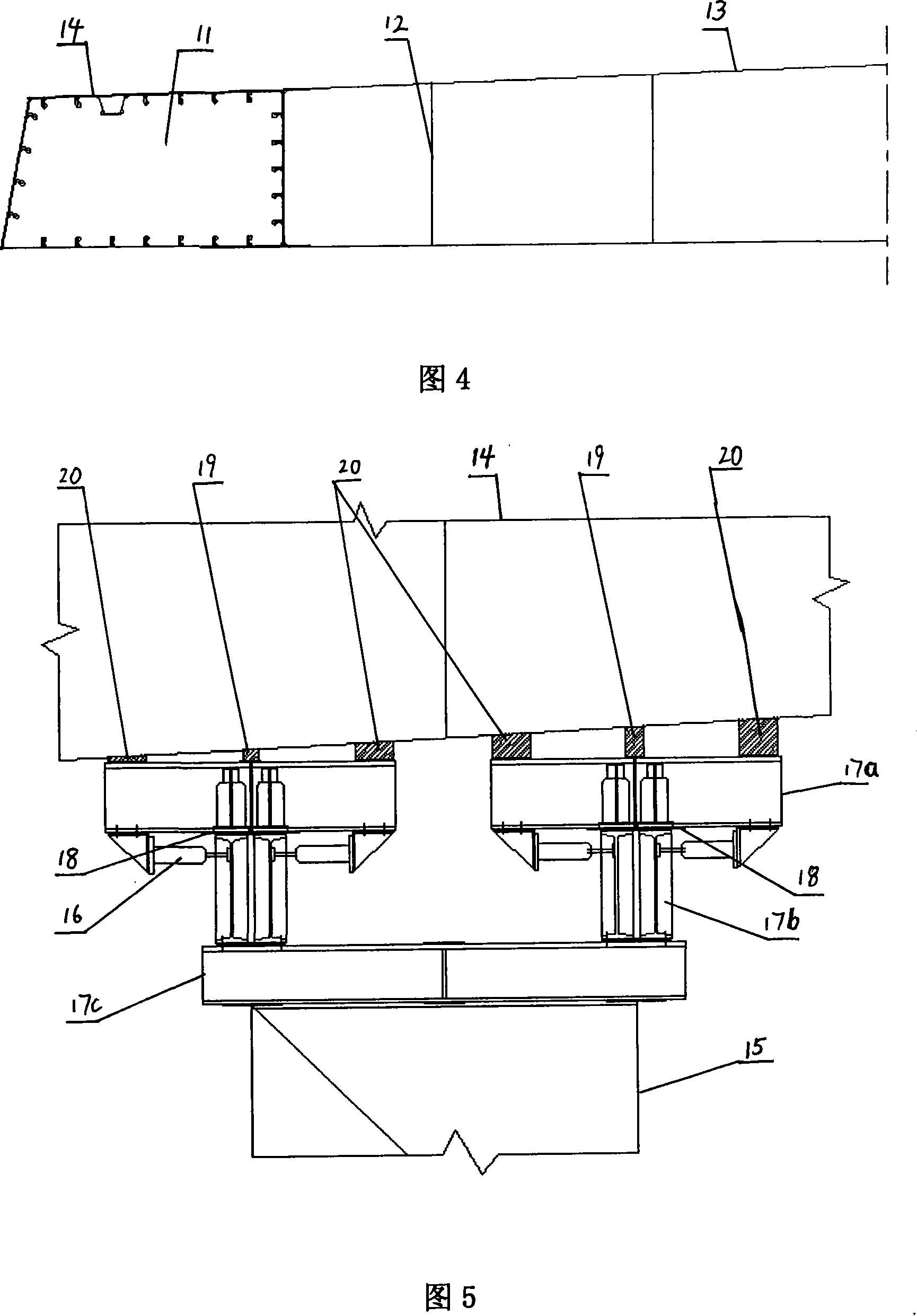

The invention discloses a reinforced concrete arch bridge construction method, which comprises the following steps of: 1, constructing a pile foundation, a pile cap, a bridge abutment body side wall and a bridge pier body; 2, erecting arch ring supports from the fourth hole to the eighth hole and from the thirteenth hole to the seventeenth hole on two sides of an arch bridge, arranging a locking system, and finally pouring concrete to arch rings of the eight holes; 3, detaching the arch ring supports in the step 2, erecting arch ring supports from the zero hole to the fourth hole and from theseventeenth hole to the twenty-first hole on the bridge abutment side, arranging a locking system and finally pouring concrete to arch rings of the eight holes; and 4, detaching the arch ring supports erected in the step 3, erecting arch ring supports from the eighth hole to the thirteenth hole in the span, arranging a locking system, pouring concrete to arch rings of the five holes, and folding the whole bridge. Main bodies of the arch ring supports have arch truss structures, a characteristic that steel bars are tensioned is utilized, the structures are firm, the middles of the structures are not required to be supported, materials are saved, the arch ring supports are convenient to detach, and constriction time is saved.

Owner:浙江大东吴集团建设有限公司

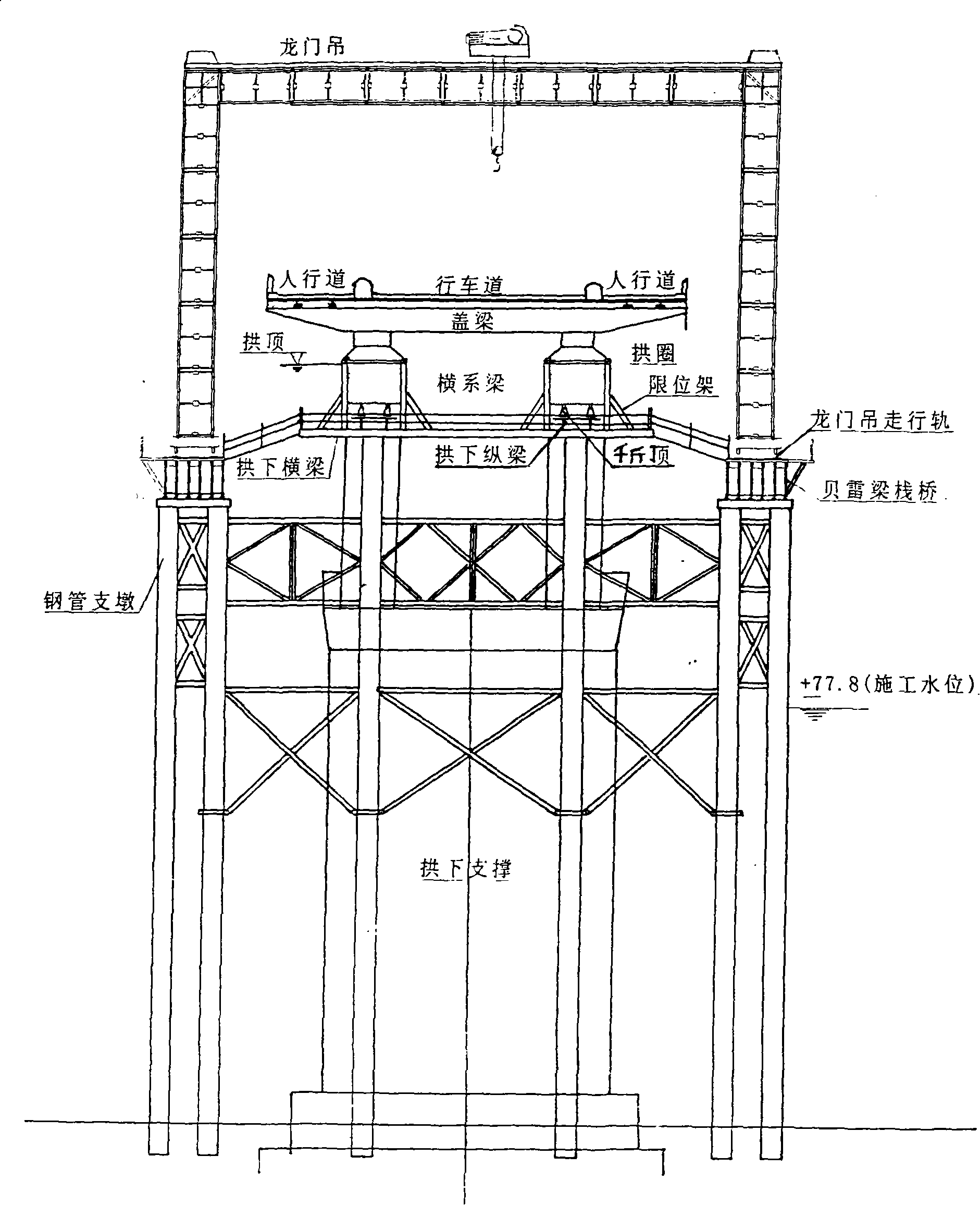

Method for dismantling arch bridge for protection

InactiveCN101265690AShort construction periodEnsure construction safetyBuilding repairsSocial benefitsReverse order

The invention provides a protective method for removing an arch bridge, which belongs to the technology field of bridge removal. The method aims to provide a protective bridge removal method with safety, high efficiency and no pollution. The technical points include: building up a new trestle, erecting a gantry crane, carrying out the bridge removal in a reverse order of the bridge building including bridge decking, coping, column, beam, arch rib and arch support in sequence. The removal stage of the arch rib especially includes removing by adopting methods of top-supporting under the arch, arch box transverse stop and horizontal restraining rope, which better solves the difficult problem of the protective bridge removal with safety, high efficiency and no pollution in a complex construction environment of guaranteeing under-arch navigation, high security level, short construction period and various unpredictable elements, manages to meet the design requirements of the removal safety factor in the protective bridge removal process and the limit control under various removal working conditions and guarantees the removal quality and the construction safety. The removal method has low cost and remarkable social benefit reflected in the direct economic analysis, which is a protective removal method of large-span bridges with safety, high efficiency and practicability.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

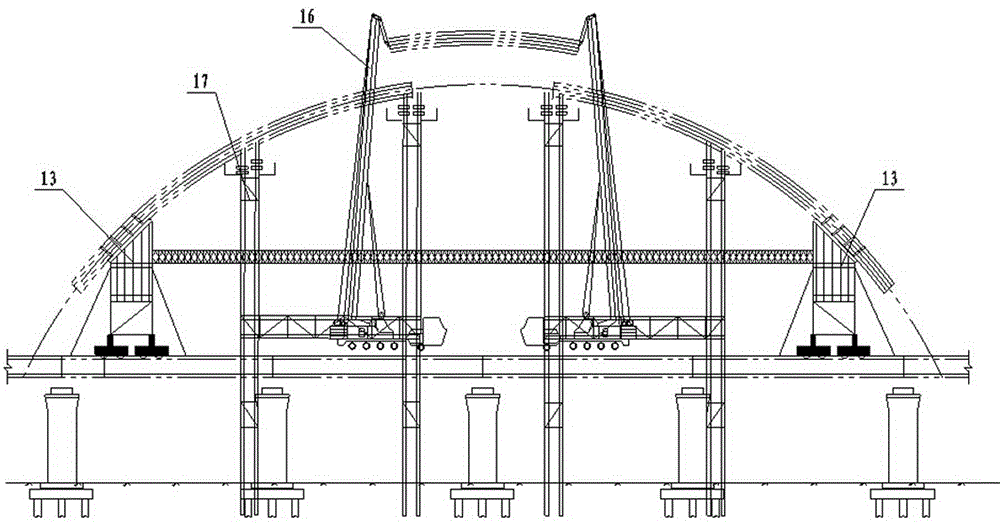

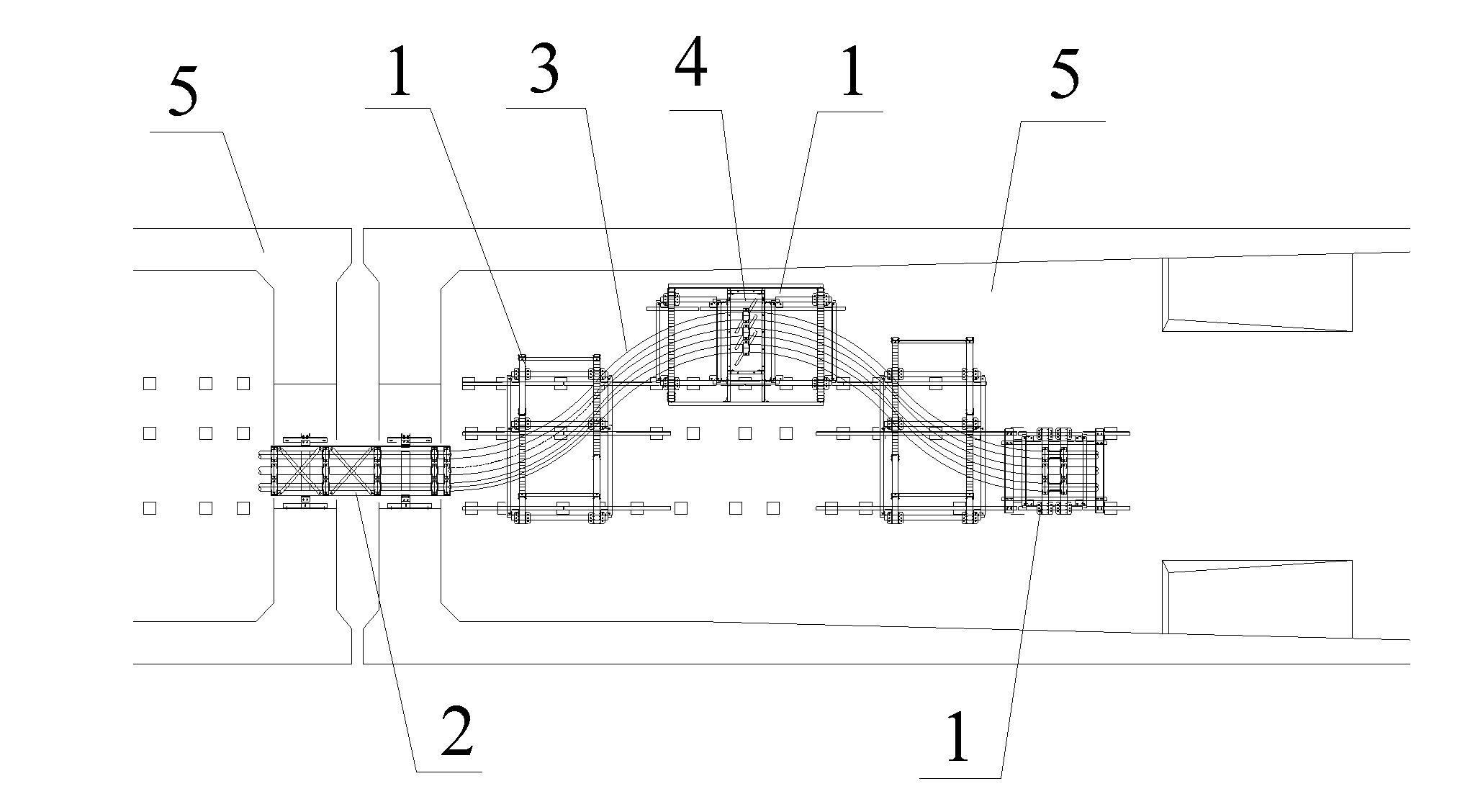

Construction method for continuous tie bar steel tube arch bridge

ActiveCN104562936AStress state is the sameSolving the Linear Control ChallengeBridge erection/assemblyArch-type bridgeEngineeringAbutment

The invention relates to a bridge construction method, in particular to a construction method for a continuous tie bar steel tube arch bridge; the construction method aims at solving the problems that the construction cycle is long, the potential safety hazard is big, the construction difficulty is big, and the like by adopting the existing support method. The construction method comprises the following steps of performing construction on assembling supports for a steel tube arch; processing the steel tube arch by stages, and hoisting the steel tube arch onto the assembling supports; installing temporary abutment supports and opposite-pull steel stranded wires to enable the steel tube arch to form a bowstring whole bearing structure; supporting the steel tube arch by the temporary abutment supports instead of the assembling supports, and removing the whole assembling supports; installing a longitudinal movement pushing system for the steel tube arch to enable the steel tube arch to move forward; welding the steel tube arch after the steel tube arch are pushed in place. Firstly, The difficult problem that the safety risk is big due to the fact that the pushing distance is far and the steel tube arch needs to cross the existing railways and highways after the steel tube arch is assembled is solved; secondly, the problem that arch feet are low in installation accuracy is solved, so that the linearity and design linearity of the whole steel tube arch are enabled to be consistent, and the stress state and the design state of the steel tube arch are finally enabled to be consistent; thirdly, the stress state and the design state of a beam body are consistent, so the construction quality is finally guaranteed.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

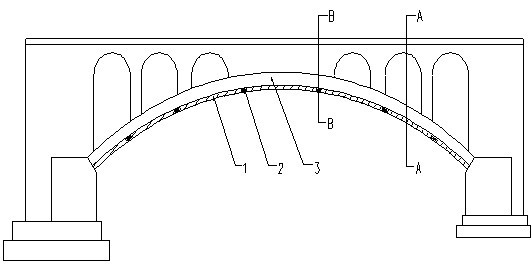

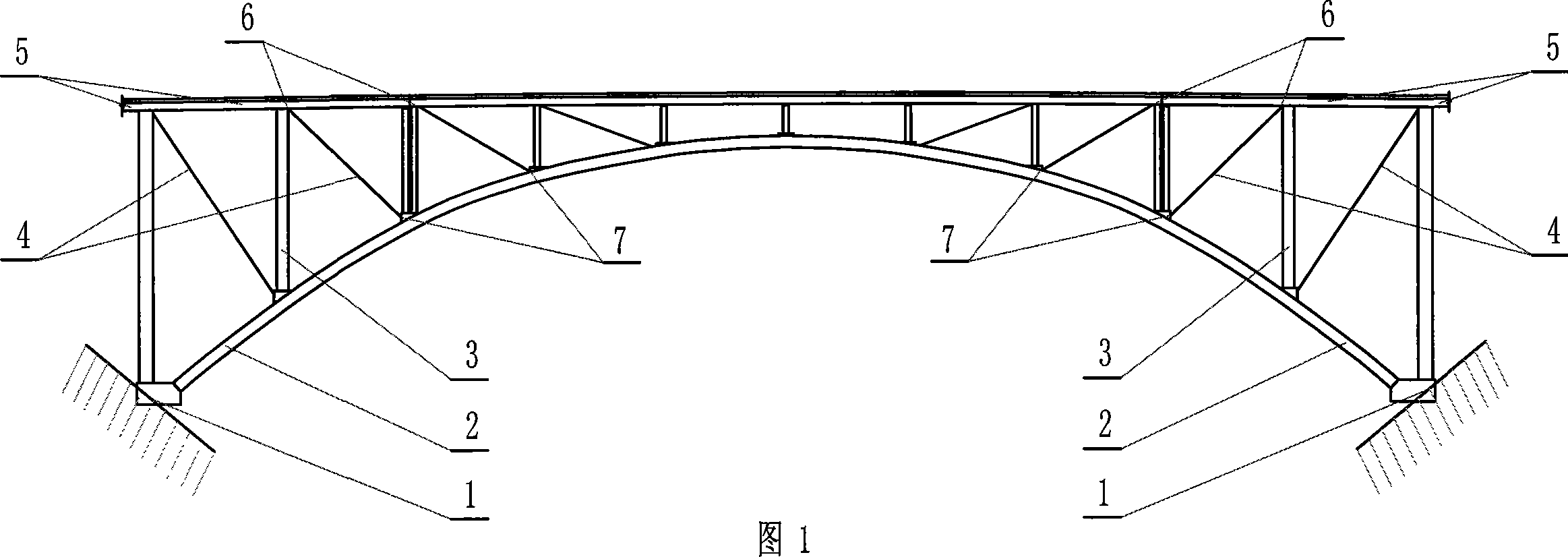

Large-span steel truss arch construction method

InactiveCN101581074AGood effectImprove structural stabilityBridge erection/assemblyArch-type bridgeTerrainReinforced concrete

The invention relates to a large-span steel truss arch construction method. The invention is characterized in that the method comprises the following steps: 1) based on the alignment design of an main arch ring of a reinforced concrete arch bridge, if a main arch span of the reinforced concrete arch bridge is not more than 100m, an arc line is adopted as the line shape of a arch axis line of the steel truss arch; if the main arch span of the reinforced concrete arch bridge is more than 100m, a catenary line or a parabola curve is adopted as the line shape of the arch axis line of the steel truss arch; big samples of a first unit truss segment and a second unit truss segment are produced for steel truss arch ribs on a sample platform according to the scale of 1:1; 2) the inner side of a first main arch support is widened to form a first base of the steel truss arch, the inner side of a second main arch support is widened to form a second base of the steel truss arch; 3) the erection sequence of the unit truss segments is that: first arranging steel truss arch ribs on the upper course of a river, then arranging steel truss arch ribs in sequence to the lower course of the river; 4) the back arch elevation of the steel truss arch is adjusted to the level of the arch soffit elevation of the main arc ring. The construction method is not limited by the terrain condition and site condition of bridge location and is simple and easy to install and remove.

Owner:CHINA FIRST METALLURGICAL GROUP

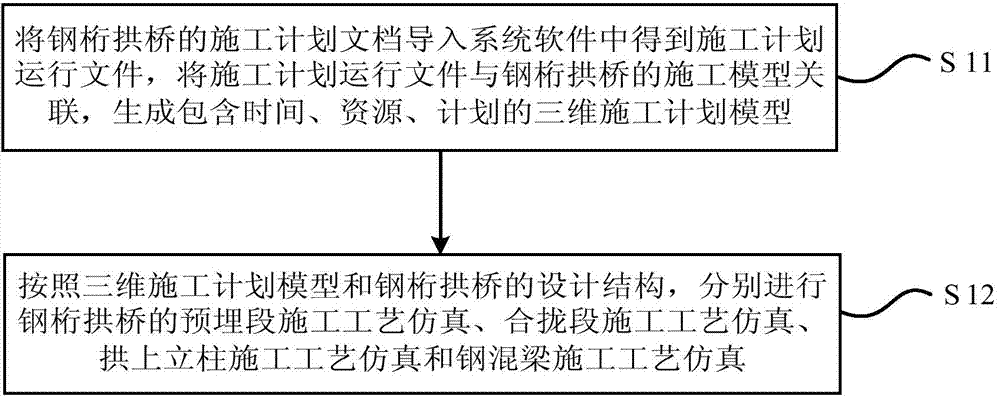

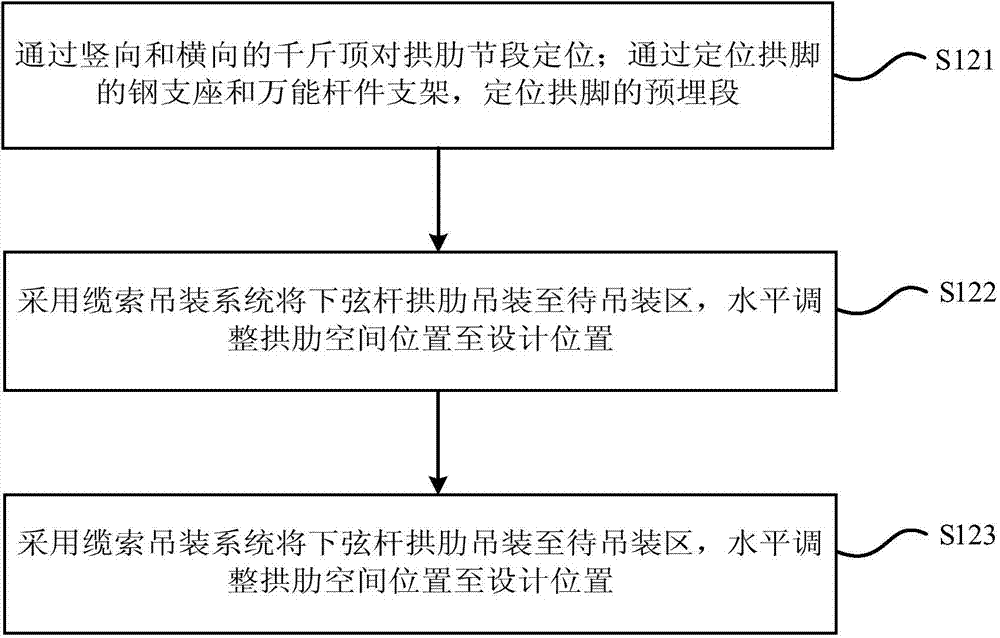

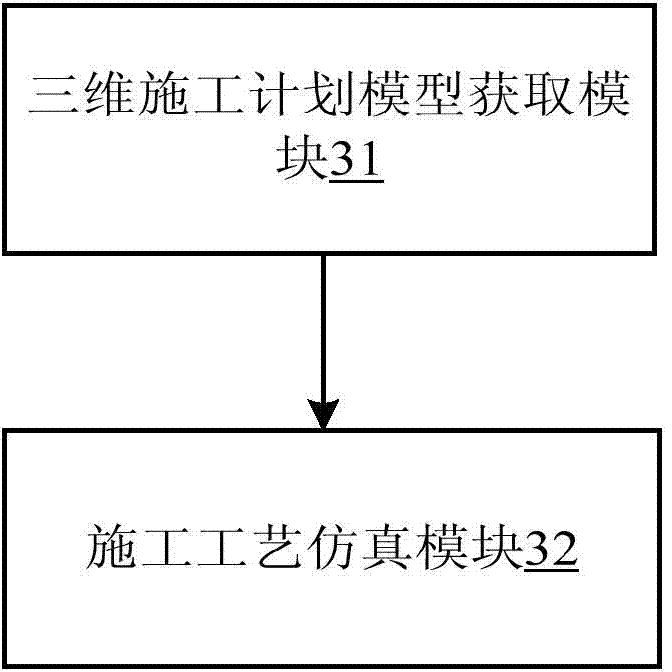

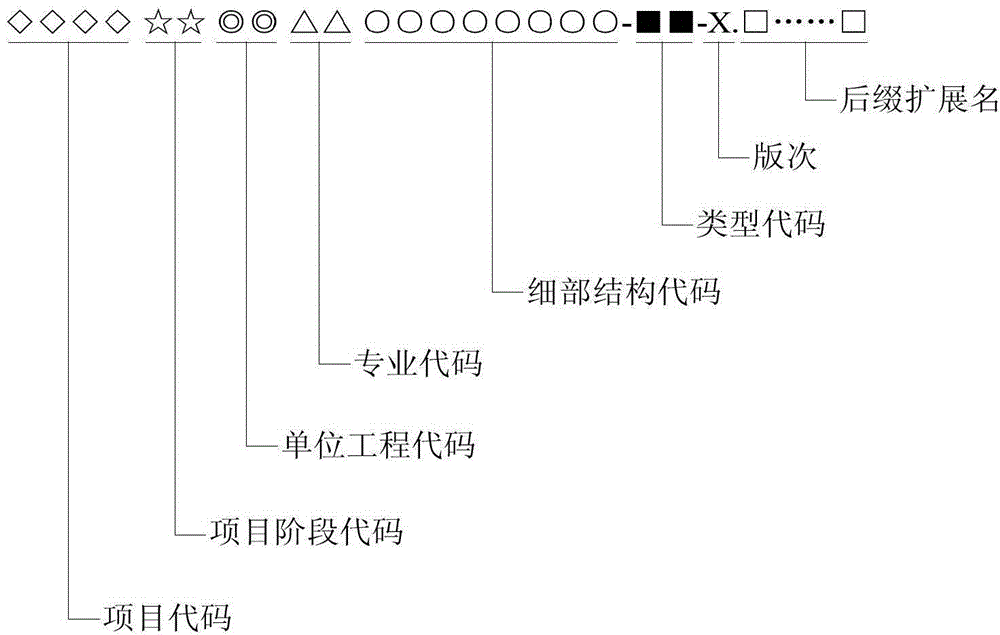

Method and device for conducting construction simulation on steel truss arch bridge through BIM

ActiveCN104715113ARealize simulationBridge erection/assemblySpecial data processing applicationsReinforced concreteDatum reference

The invention relates to the technical field of bridge construction simulation, in particular to a method and device for conducting construction simulation on a steel truss arch bridge through a BIM. The simulation method includes the steps that a construction plan document of the steel truss arch bridge is input into system software, so that a construction plan operation file is acquired, the construction plan operation file is related to a construction model of the steel truss arch bridge, and a three-dimensional construction plan model including time, resources and plans is generated; according to the three-dimensional construction plan model and the design structure of the steel truss arch bridge, embedded section construction process simulation, closure section construction process simulation, on-arch upright construction process simulation and reinforced concrete beam construction process simulation are conducted on the steel truss arch bridge. By the adoption of the method and device for conducting construction simulation on the steel truss arch bridge through the BIM, the construction process of the steel truss arch bridge to be built can be simulated so that problems existing in the bridge construction process can be found in time, and data reference is provided for actual construction of the steel truss arch bridge.

Owner:CHINA RAILWAY ERJU 5TH ENG

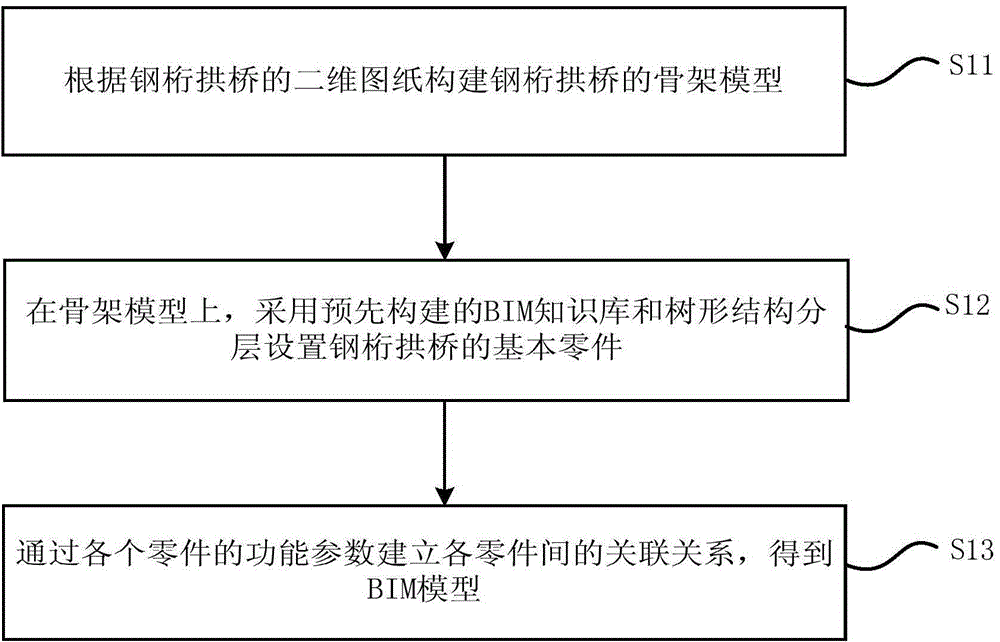

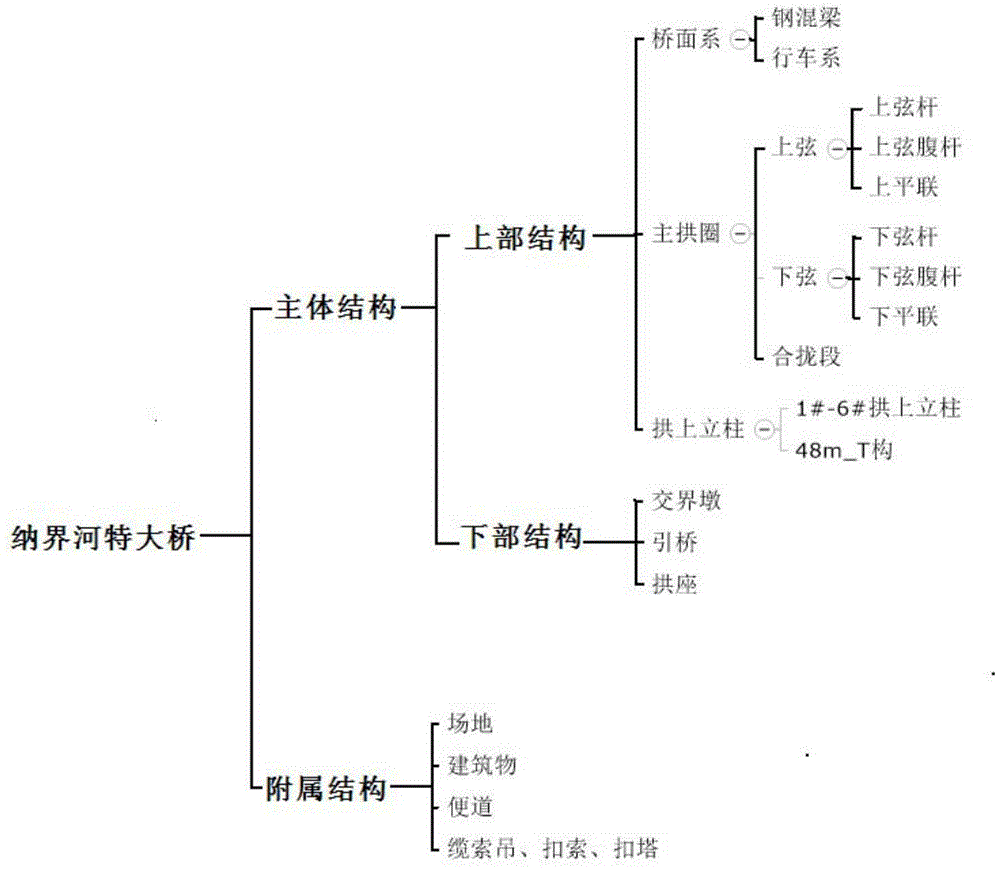

Method and device for realizing rapid steel truss arch bridge modeling by utilizing BIM

ActiveCN104657510AGuaranteed accuracyReflect checkResourcesSpecial data processing applicationsEngineeringArch bridge

The invention relates to the field of bridge construction and in particular relates to a method and a device for realizing rapid steel truss arch bridge modeling by utilizing BIM. The method comprises the following steps: constructing a framework model of a steel truss arch bridge according to two-dimensional drawing of the steel truss arch bridge; setting basic parts of the steel truss arch bridge in a layered mode by adopting a pre-constructed BIM knowledge base and tree structures, wherein the basic parts comprise parts used by a main arch ring of the steel truss arch bridge, parts used for an upright post on the arch of the steel truss arch bridge, and parts used by juncture piers, approach bridges and arch seats of the steel truss arch bridge; and constructing association between the parts by virtue of functional parameters of the various parts, thereby obtaining a BIM model. According to the method and the device for realizing rapid steel truss arch bridge modeling by utilizing BIM disclosed by the invention, the accuracy of data provided for bridge construction can be improved.

Owner:CHINA RAILWAY ERJU 5TH ENG

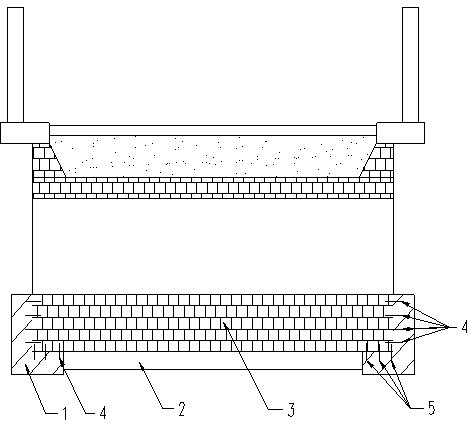

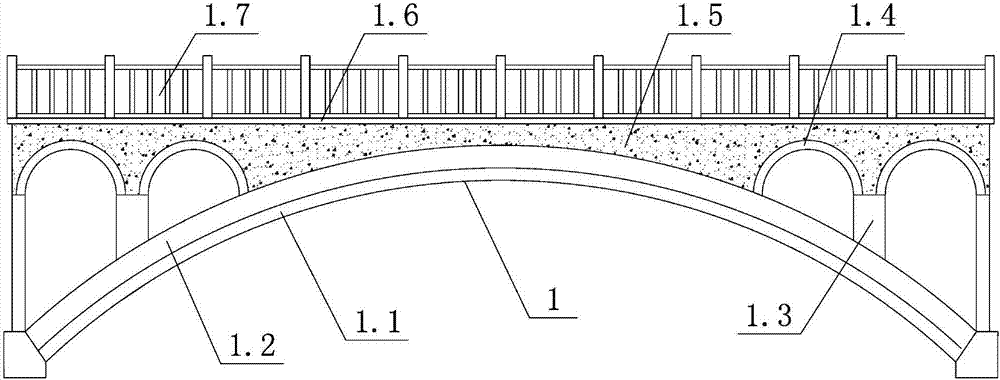

Reinforcing method of masonry arch bridge

InactiveCN102322026AReduce dosageImprove bearing capacityBridge erection/assemblyBridge strengtheningReinforced concreteEngineering

The invention discloses a reinforcing method of a masonry arch bridge, which comprises the following steps of: a, planting ribs on an arch ring of the arch bridge along the cambered surface direction of the arch bridge; b, planting ribs at the position close to the two sides, on the circular arc surface of the arch ring along the cambered surface direction of the arch bridge; and c, forming symmetrically distributed reinforced concrete ribs along the distribution direction of the planted ribs in the step a and the step b in a way of casting molding, wherein the cross section of the reinforcedconcrete ribs is L-shaped. The reinforced concrete ribs which are of integral structures are formed along the two sides of the arch ring in the way of planting the ribs and casting concrete, then load can be directly transferred to an arch base through the symmetrically distributed reinforced concrete ribs of which the cross section is L-shaped, and the stress to the reinforced concrete ribs is equal to that to a ribbed arch bridge. When the method is compared with the method of singly increasing the area of the arch ring, the dependence on the primary arch ring is smaller, even the primary arch ring can be supported, the damage to the primary arch ring is small, the requirement of increasing the loading capacity of the masonry arch bridge is met, and the damage to the primary old arch ring is avoided to the maximal degree.

Owner:CHONGQING JIAOTONG UNIVERSITY

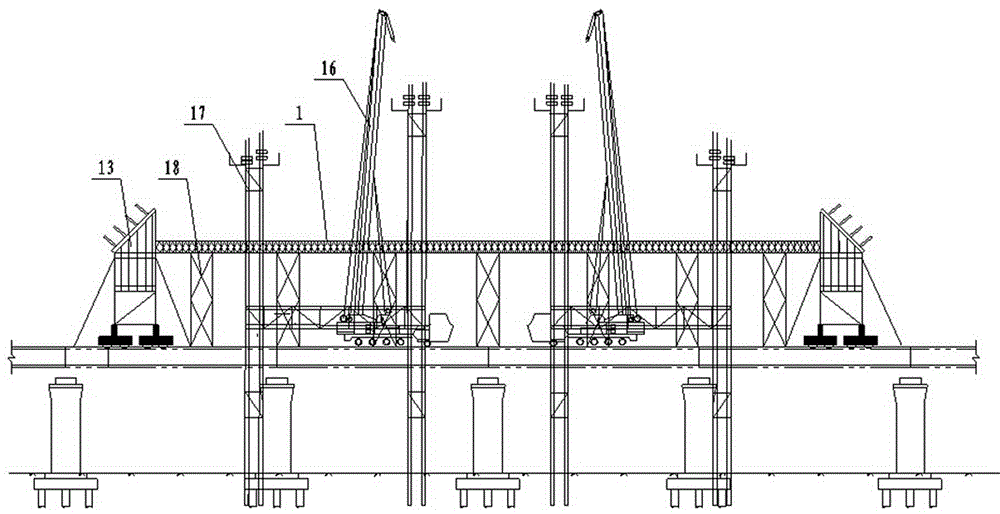

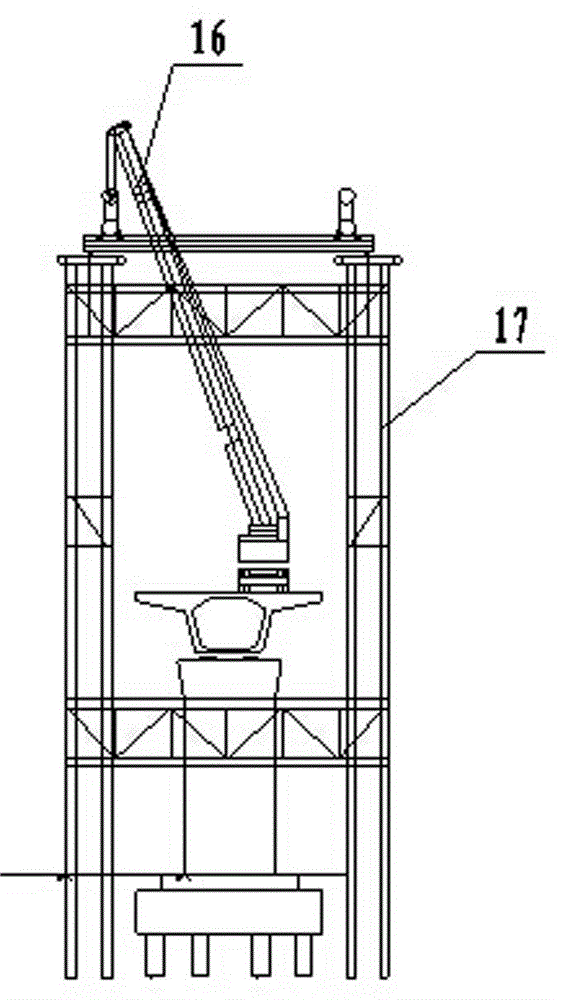

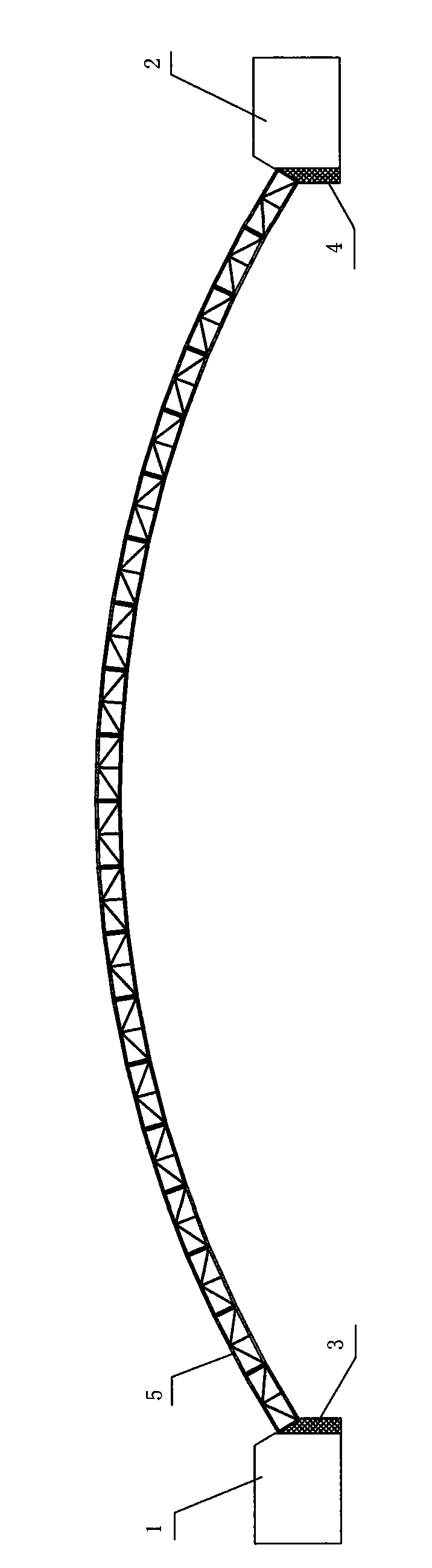

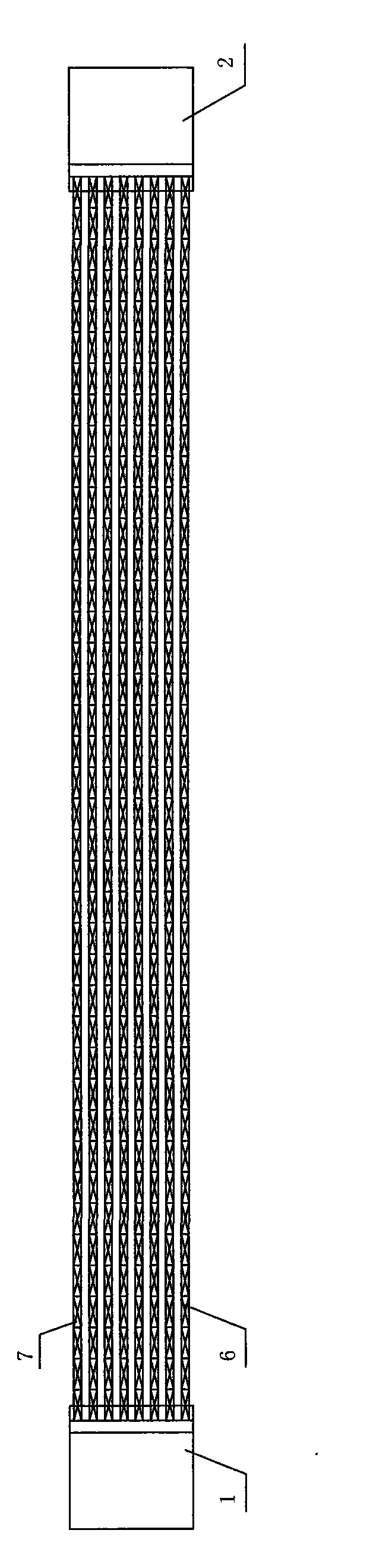

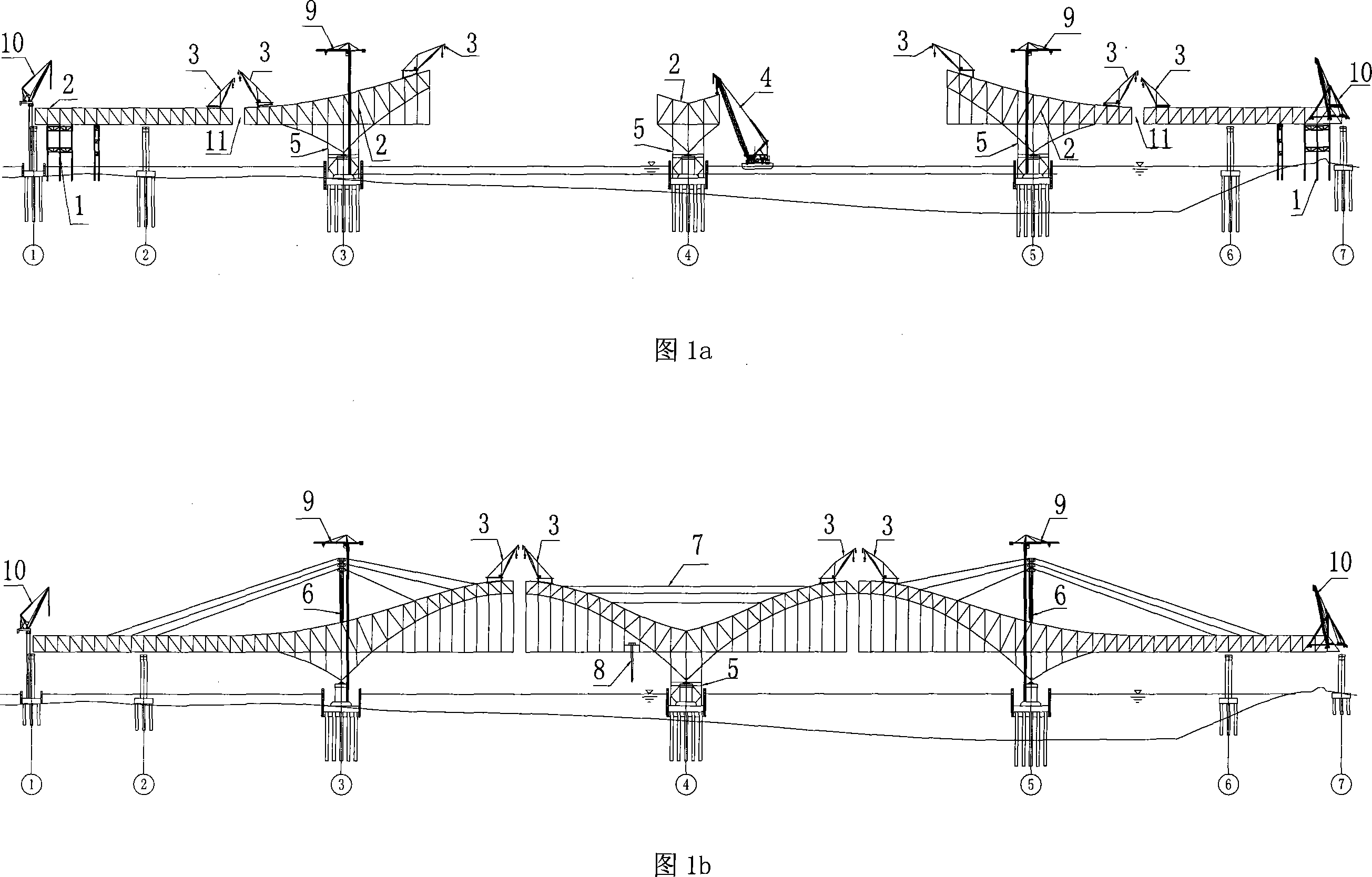

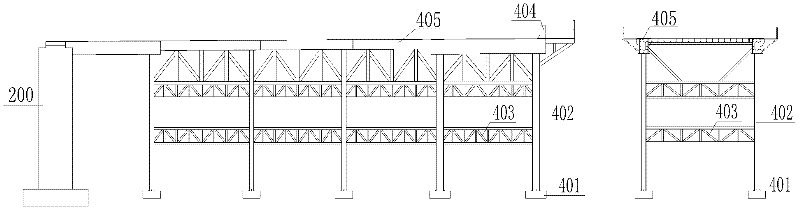

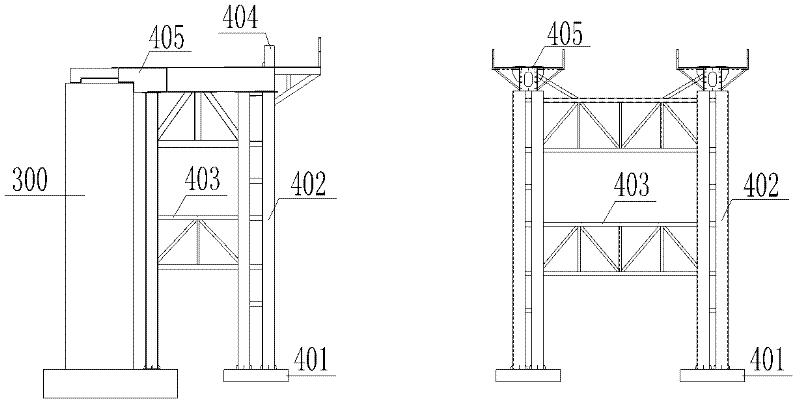

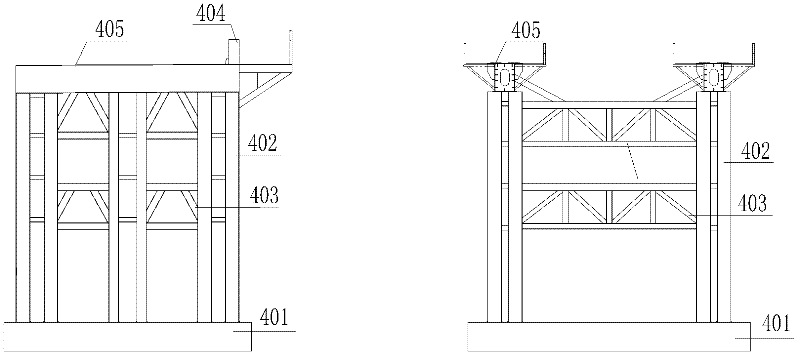

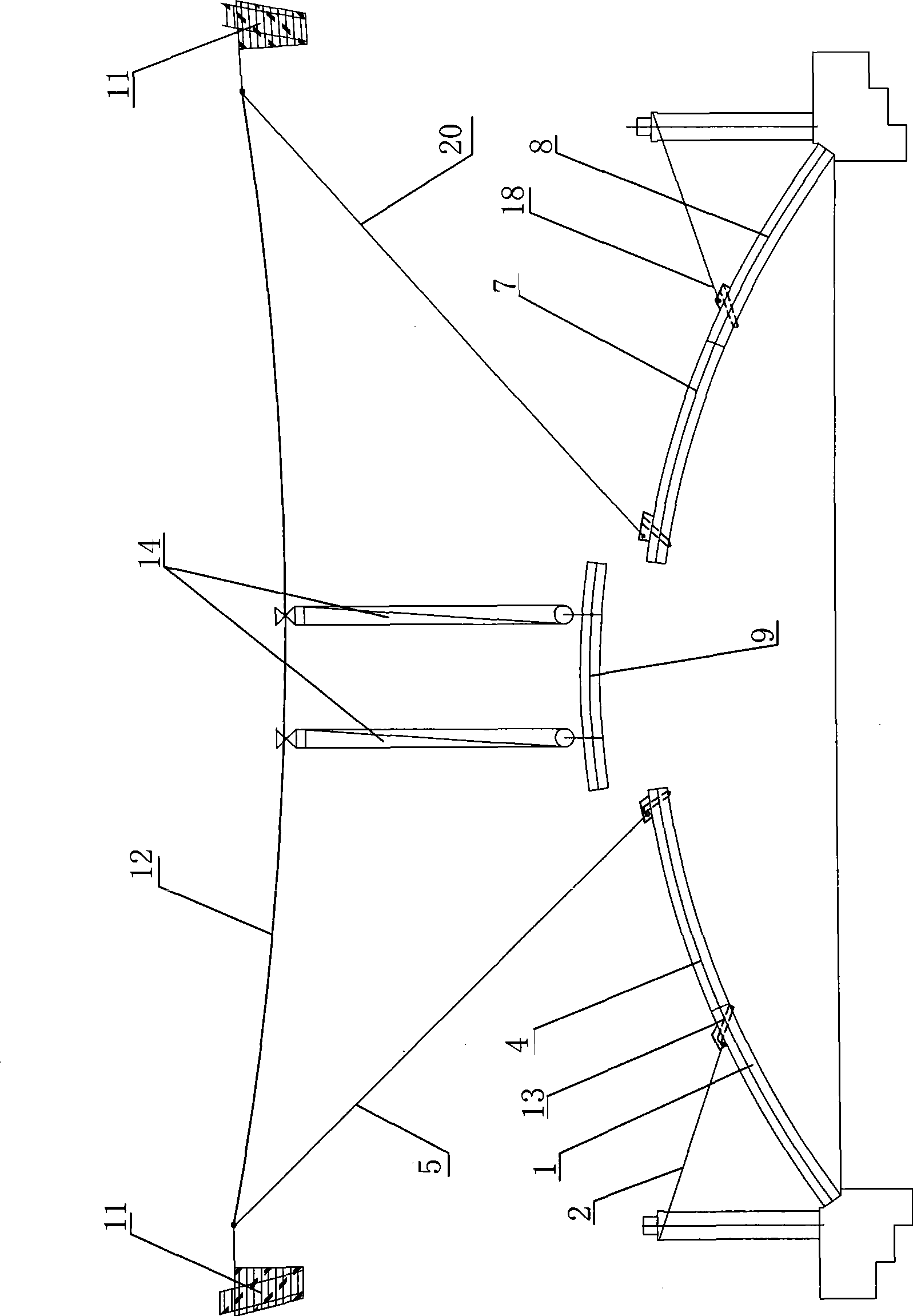

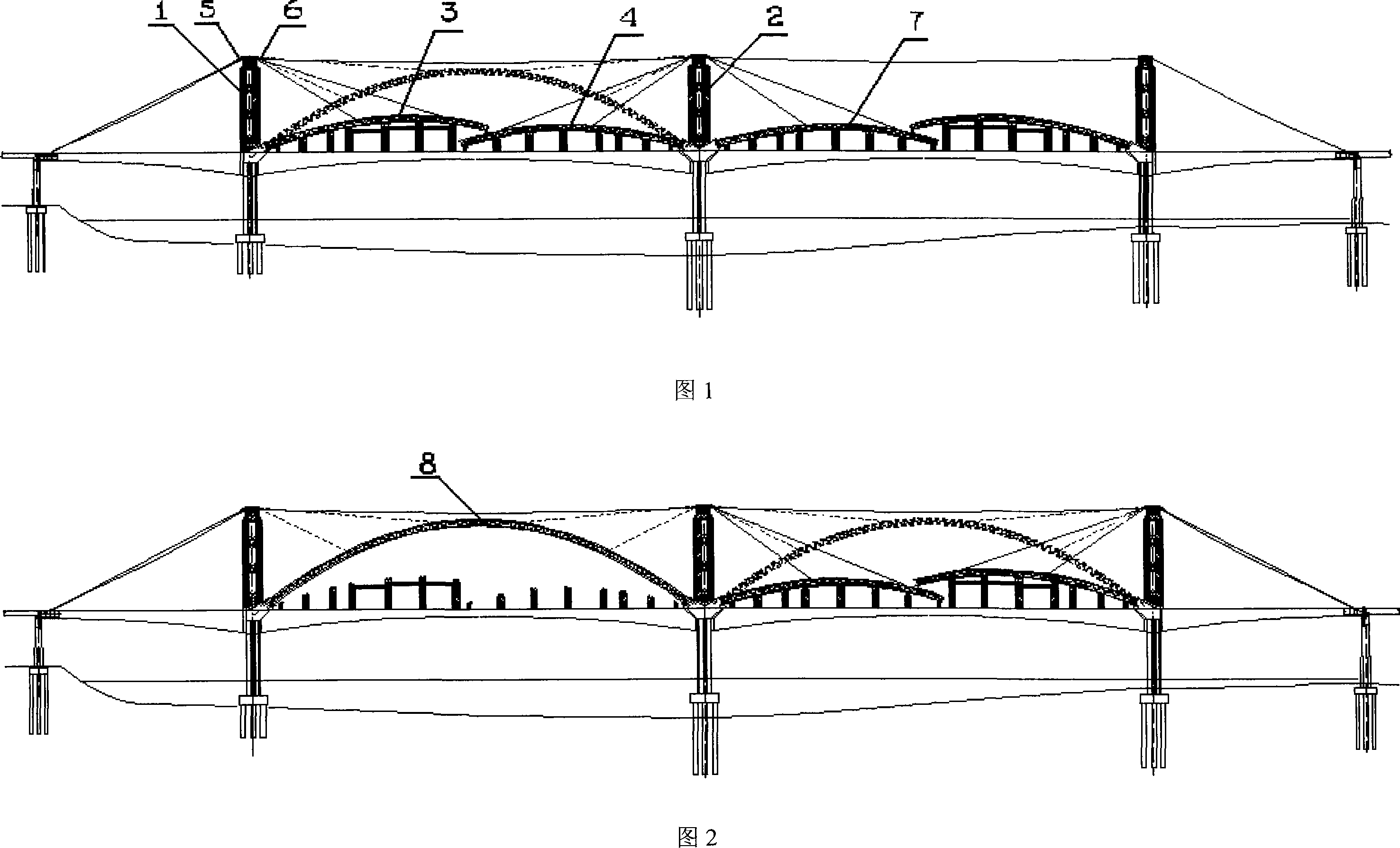

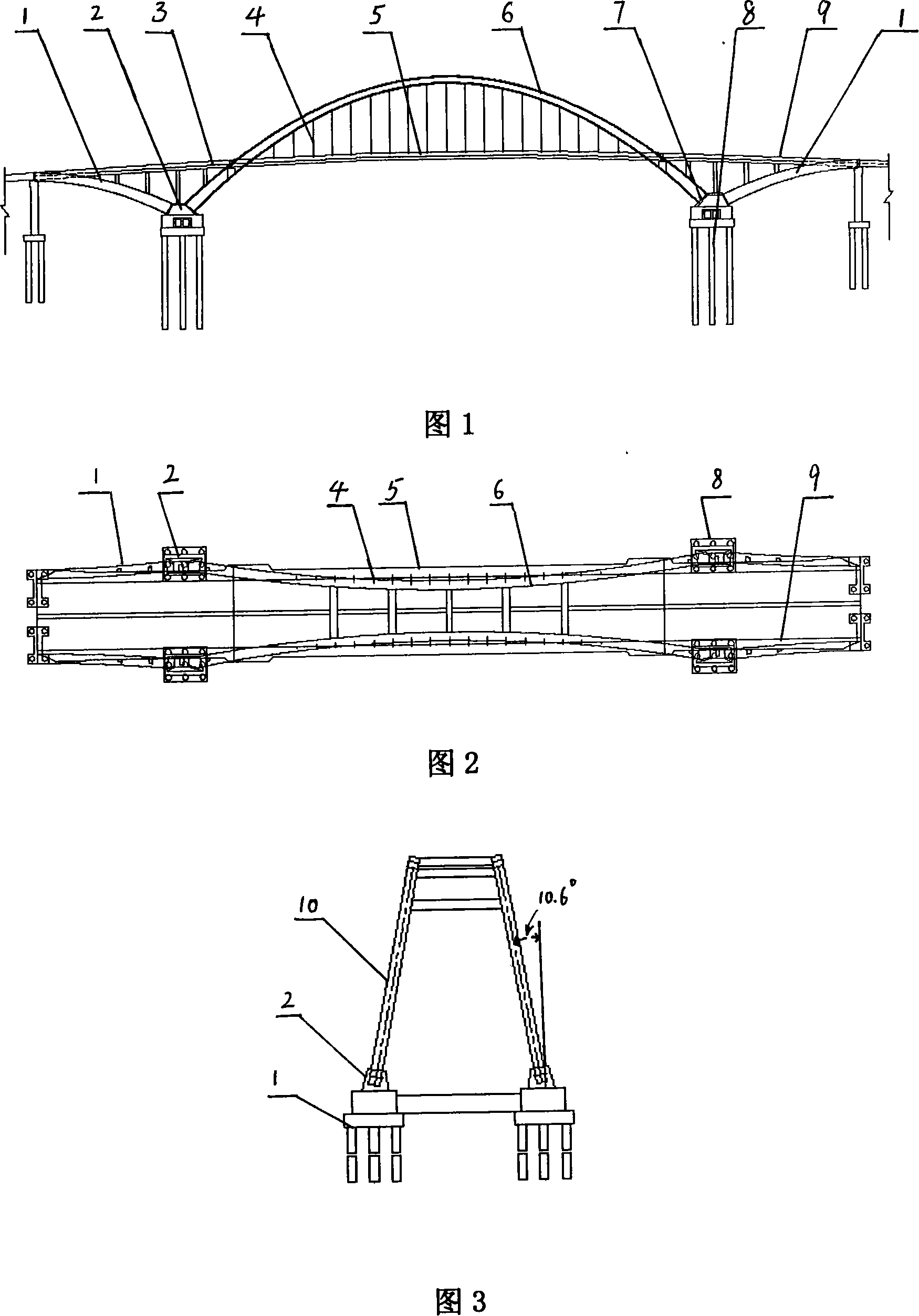

Erection method of large-span continuous steel truss arch

ActiveCN101117792ATimely adjust the space positionImprove scalabilityBridge erection/assemblyTowerCantilever

An erection method of a large-span continuous steel truss arch, in the construction of a large-span continuous truss arch bridge, a bridge pier is taken as the foundation, a bracket beside the pier is arranged, a plurality of steel trusses with an interval on the top pier are arranged on the bracket beside the pier, and a double-suspension erection system is formed. A full-rotation beam erection lifting machine is positioned at the truss of the pier top, and truss bar is arranged one by one. After the suspension arm reaches a certain degree, a horizontal rope or a multi-layer tower with a suspended cable and a stay cable is arranged to maintain the double-suspension arm to extend forwards until closure.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

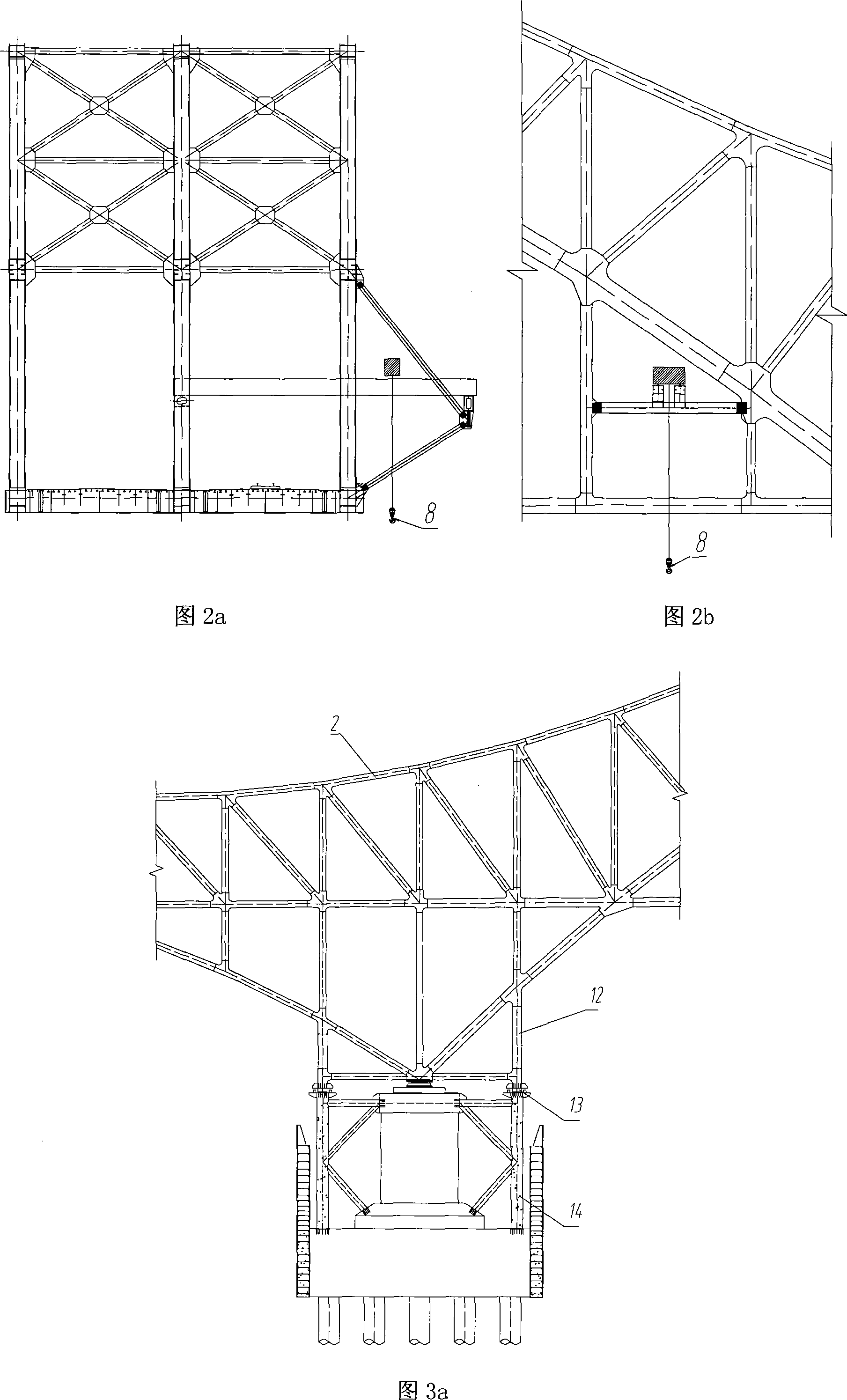

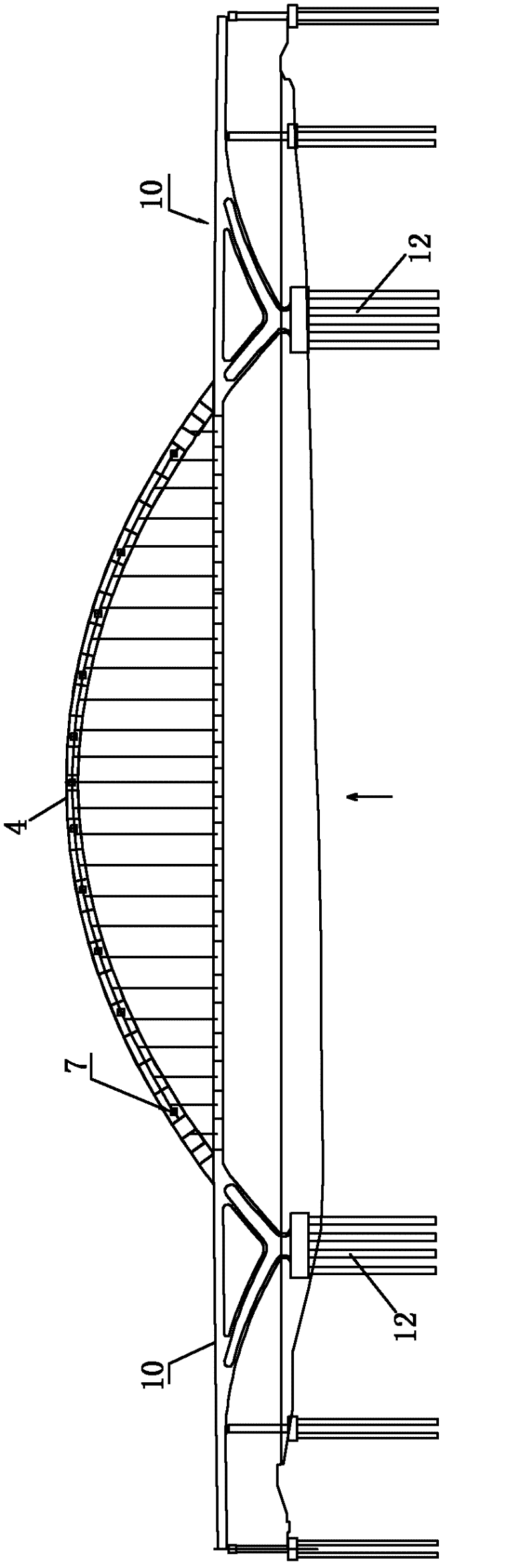

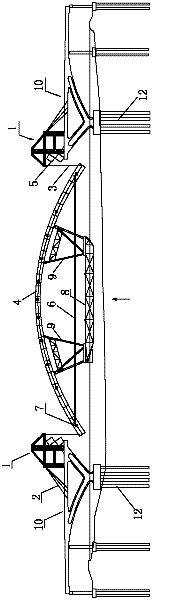

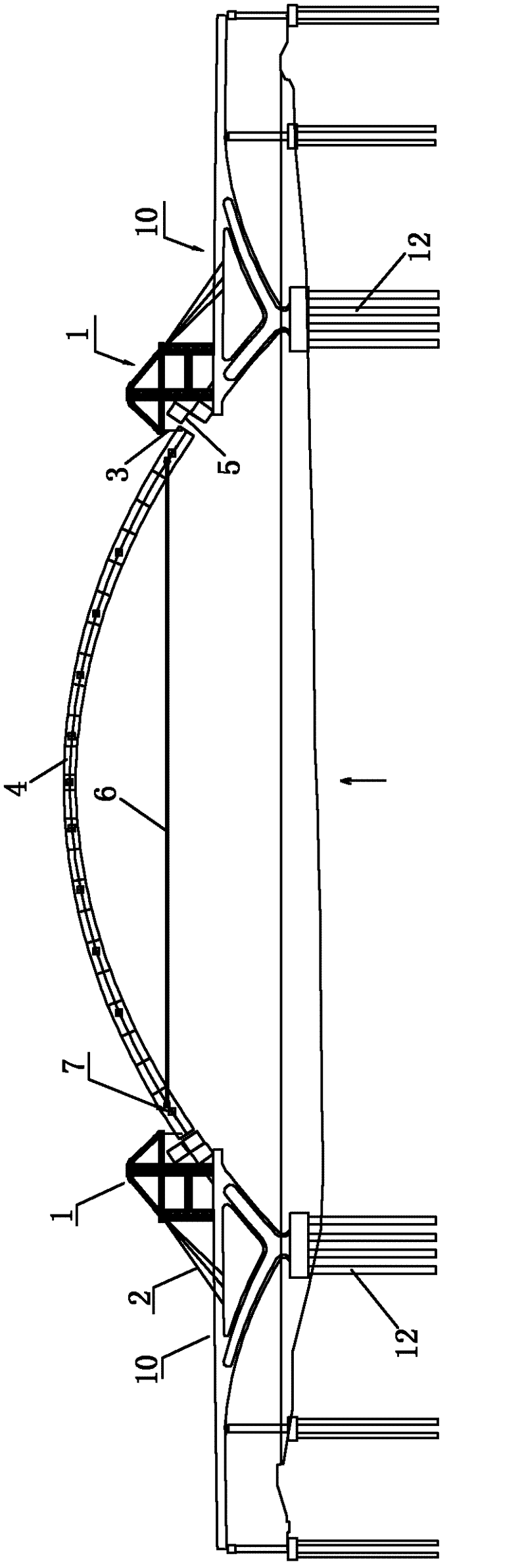

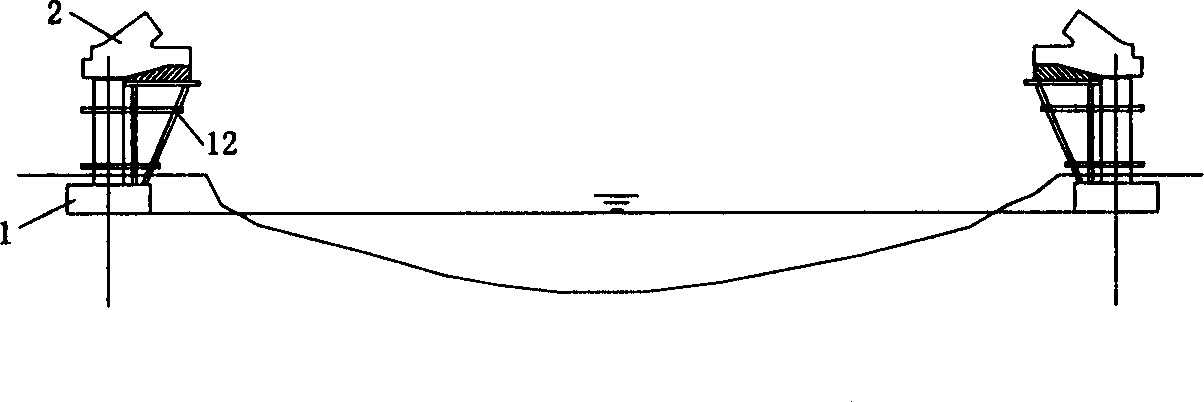

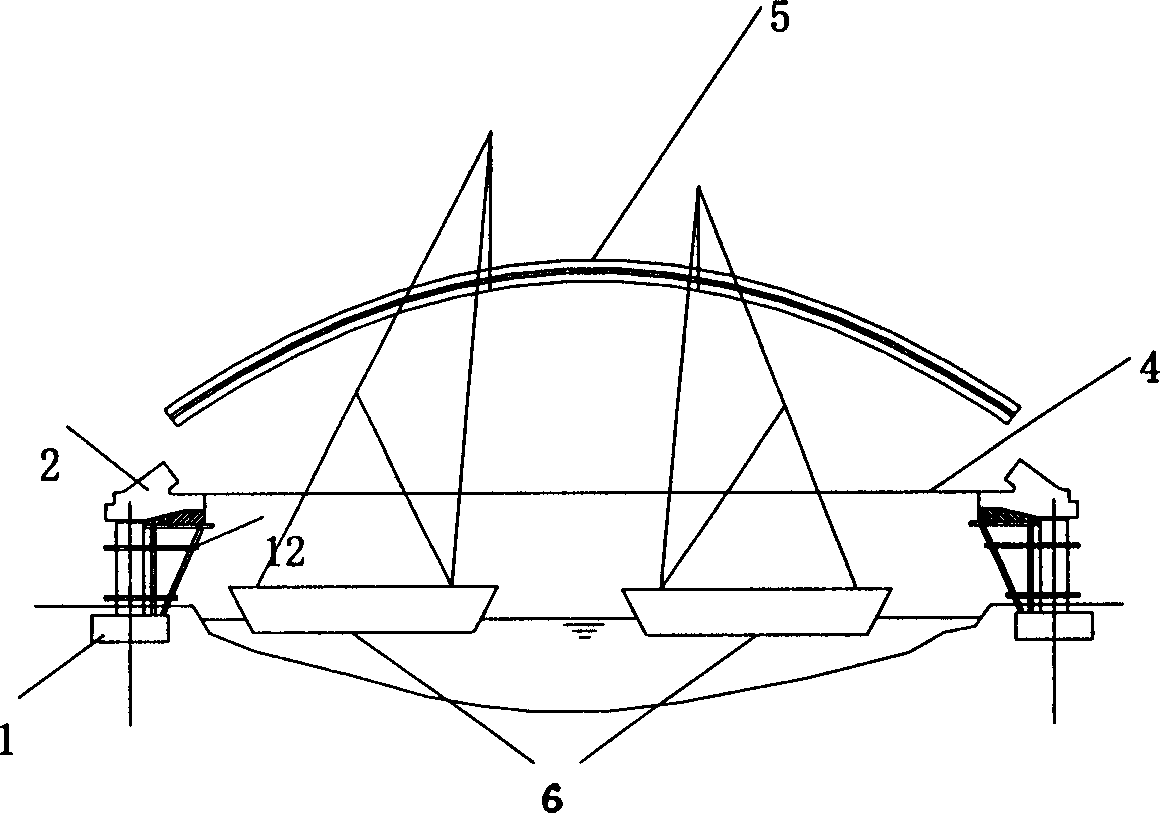

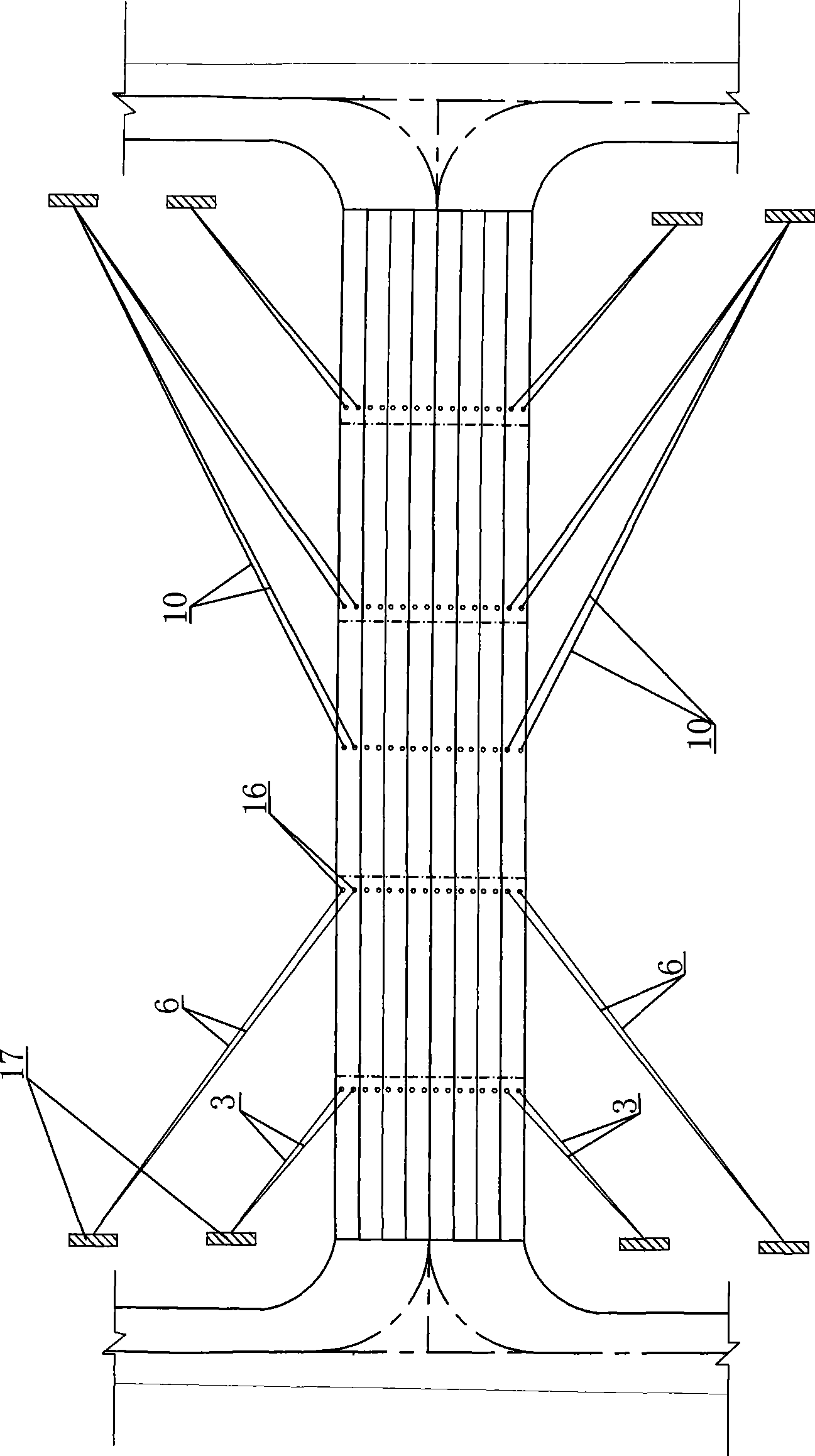

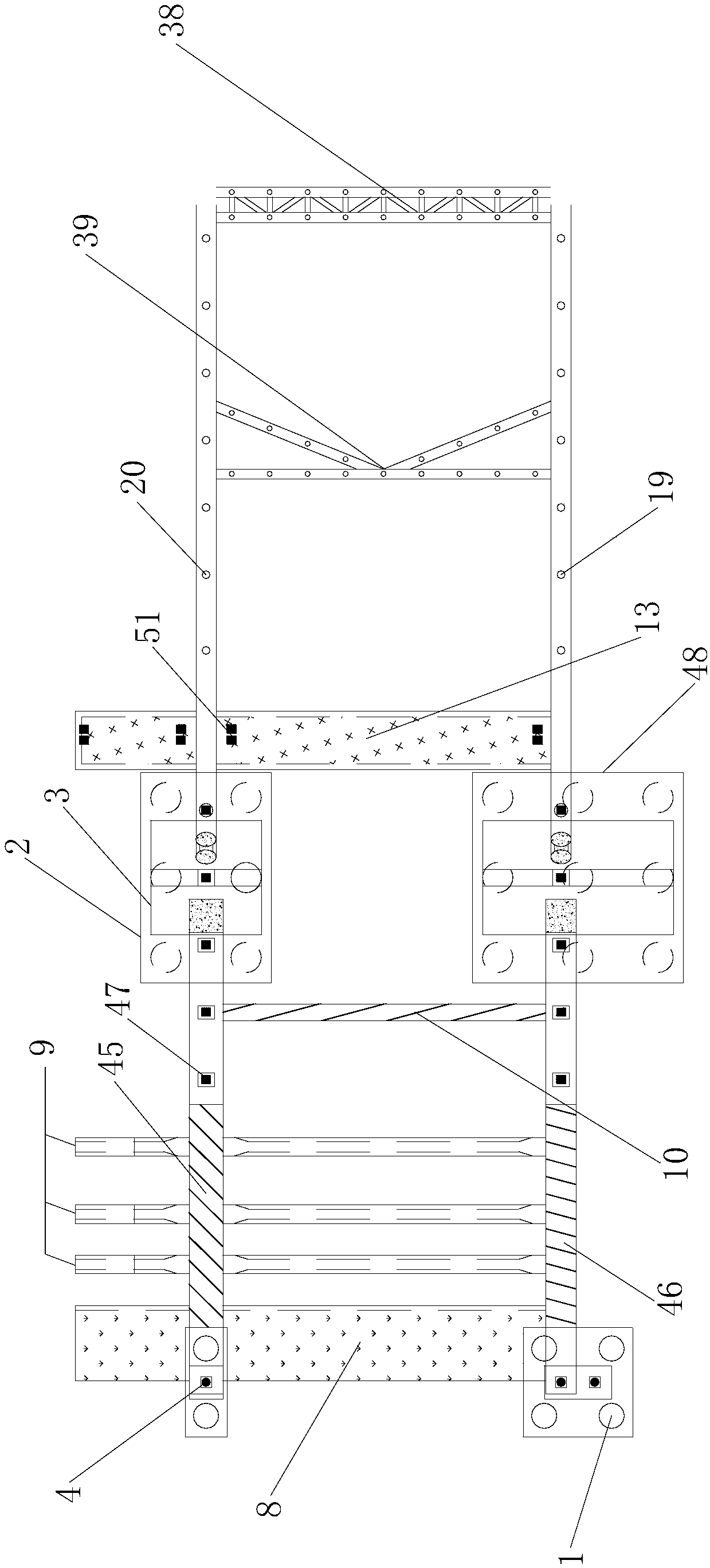

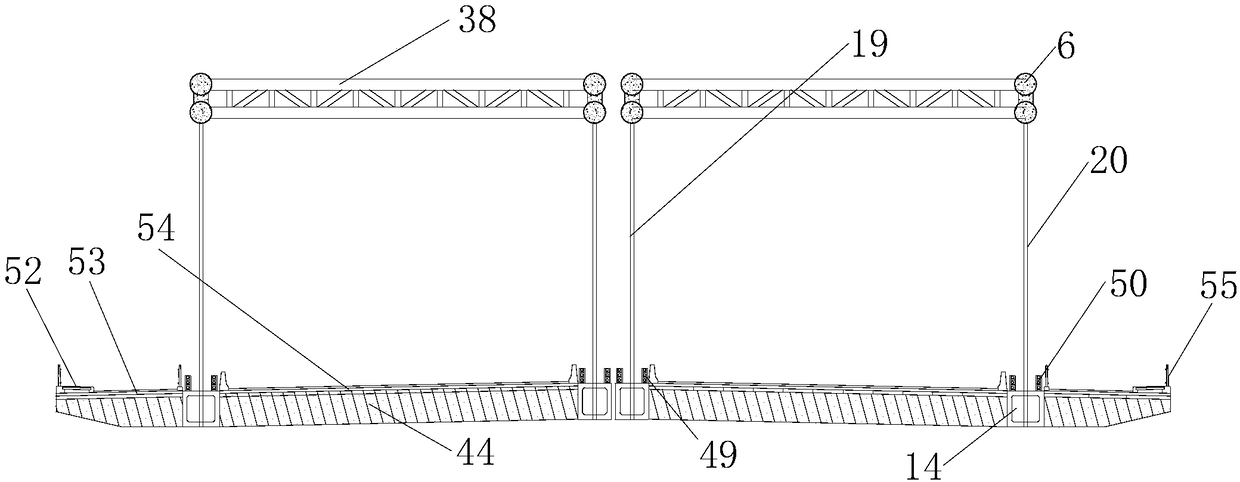

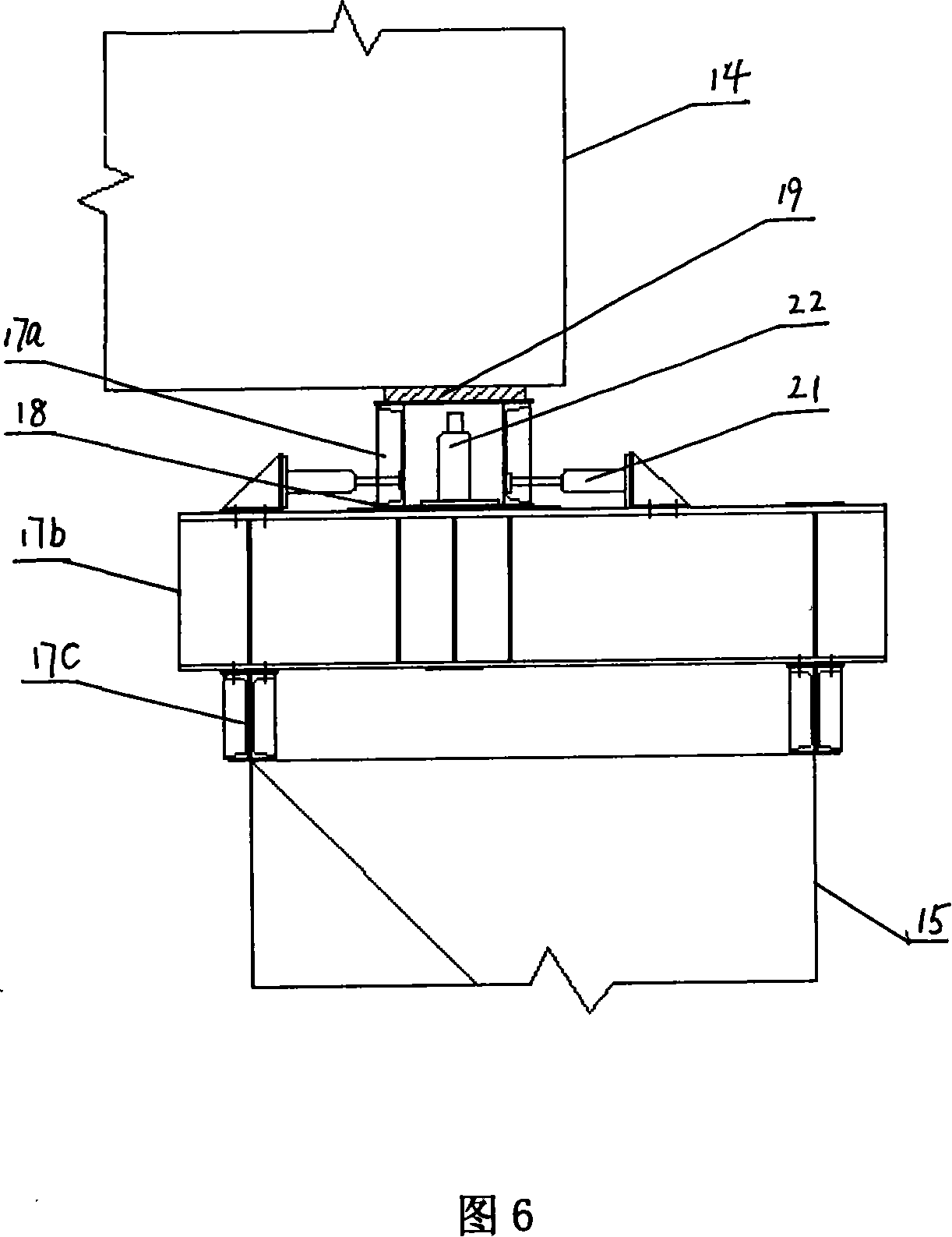

Integral lifting system and construction method for arch bridge ribs

InactiveCN102561191AReduce difficultyReduce working at heightsBridge erection/assemblySteel frameArch bridge

The invention discloses an integral lifting system and a construction method for arch bridge ribs. The integral lifting system comprises a pair of triangular steel frames, two lifting stations, arch rib brackets and an integral arch rib of an arch bridge, and a barge for conveying the integral arch rib. The triangular steel frames are fixedly rested on bridge piers and symmetrically disposed on two sides of main span of the arch bridge, an arch rib closure section in closure with the integral arch rib is disposed on the inner side of the arch bridge main span and close to the corresponding triangular steel frame, the lifting stations are disposed on the triangular frames respectively, the arch rib brackets are rested on the barge and support the integral arch rib, the lifting stations are connected with the integral arch rib through lifting steel stranded wires, the integral arch rib which is lifted up is in fixed closure with the arch rib closure sections, and accordingly the integral arch bridge is formed. The integral lifting system is adaptable to severe construction environments, and accordingly construction progress is quickened. The invention further provides the construction method for integral lifting of the arch bridge rib.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

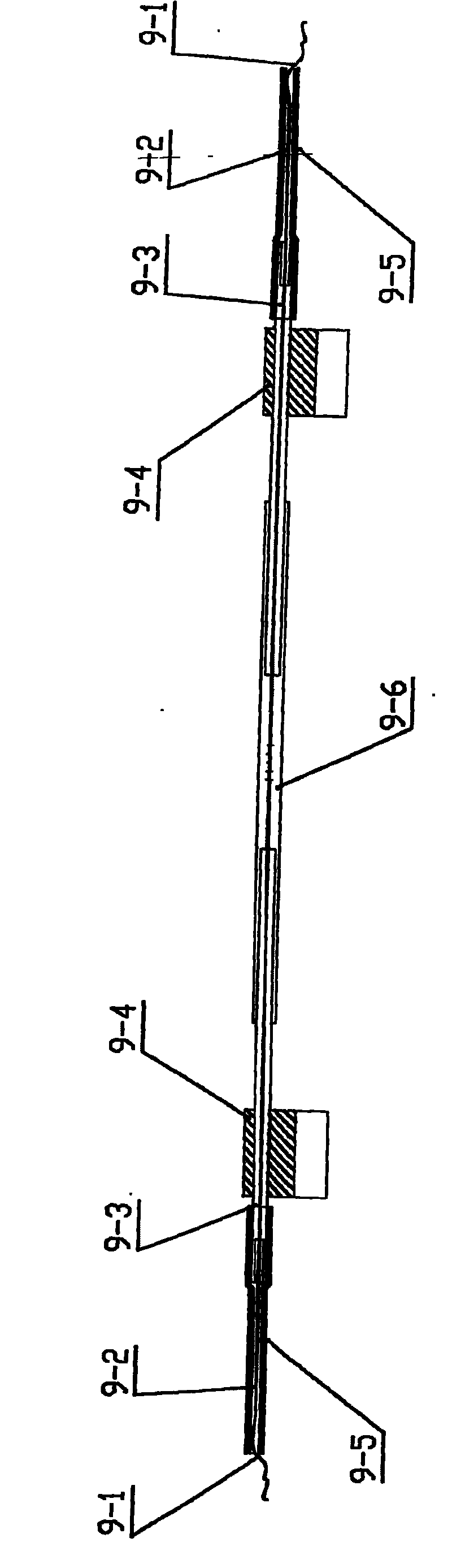

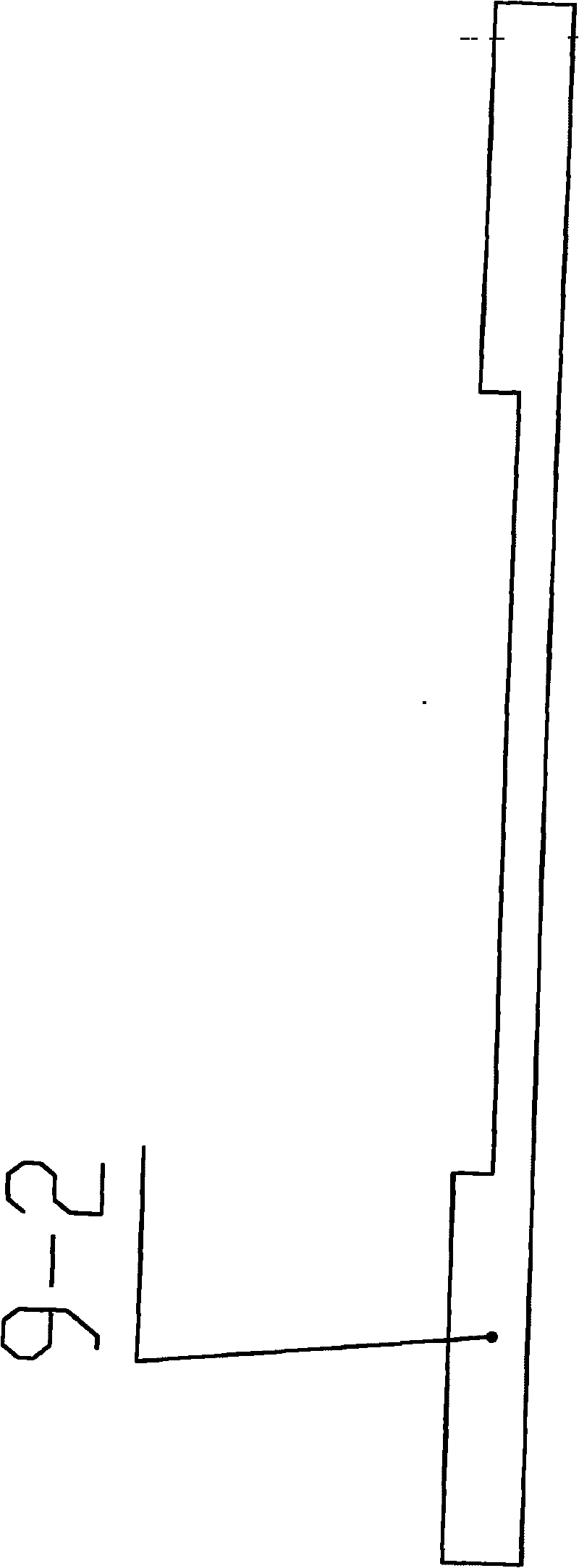

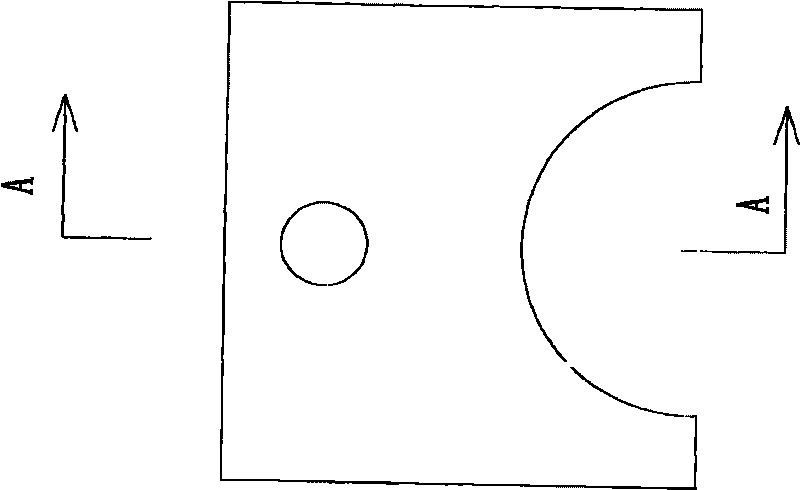

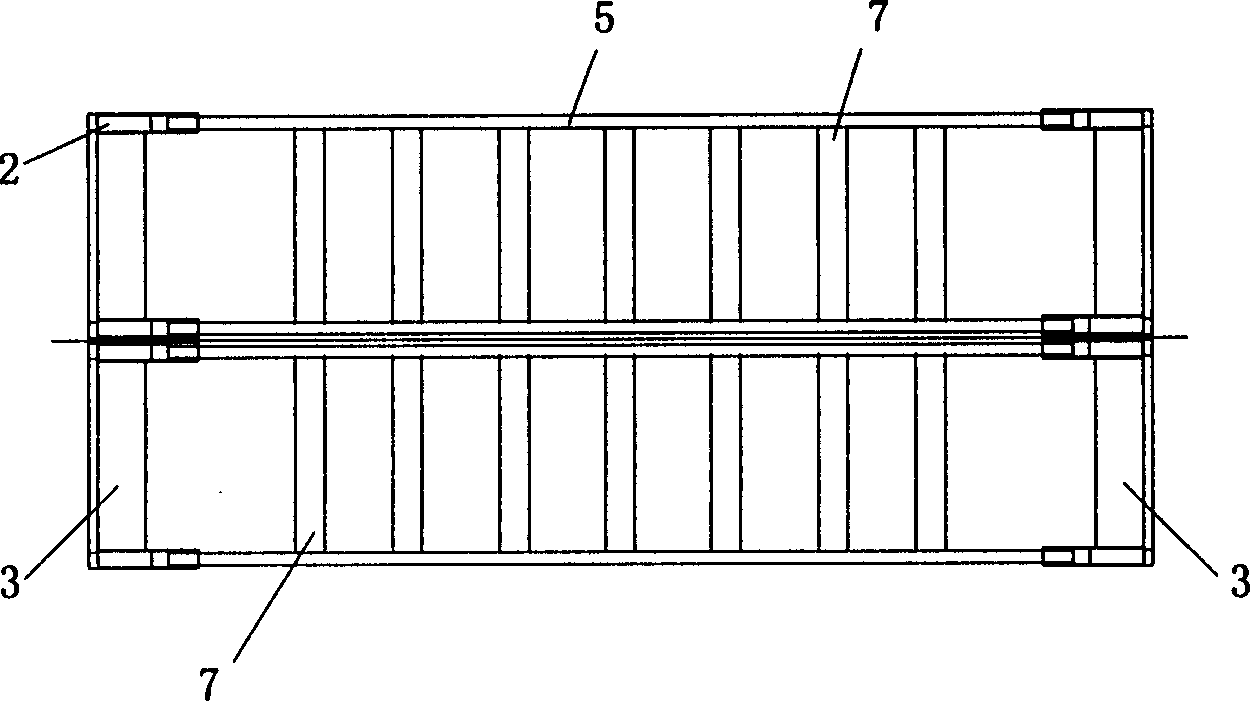

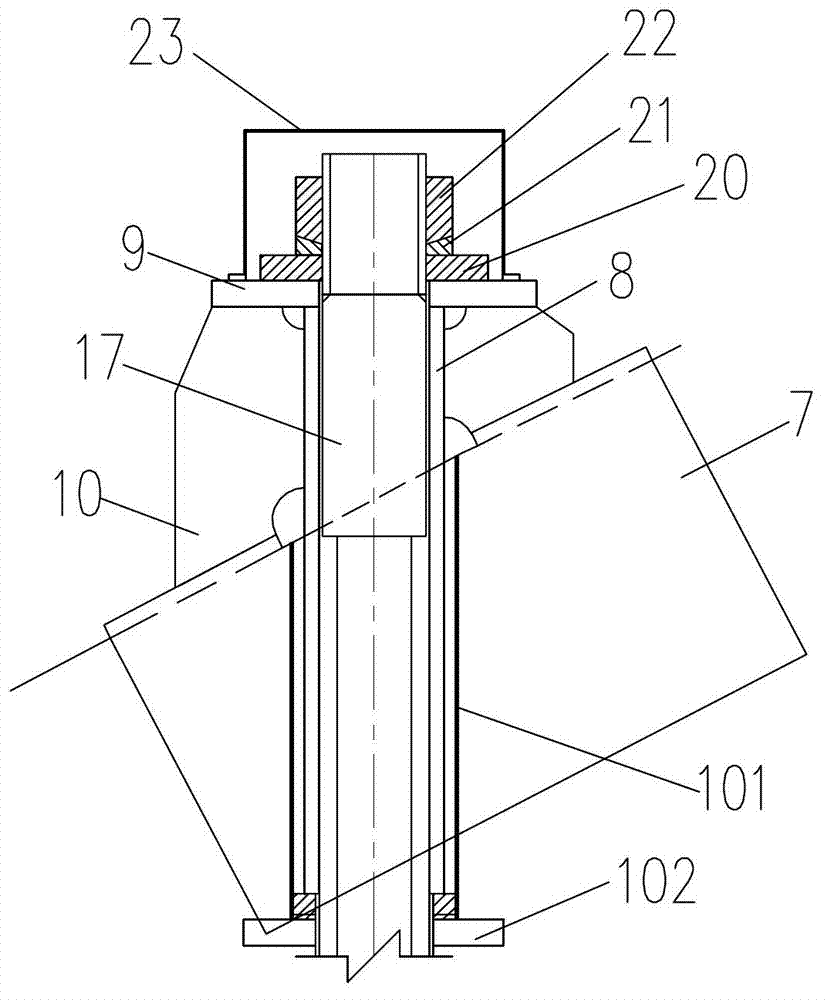

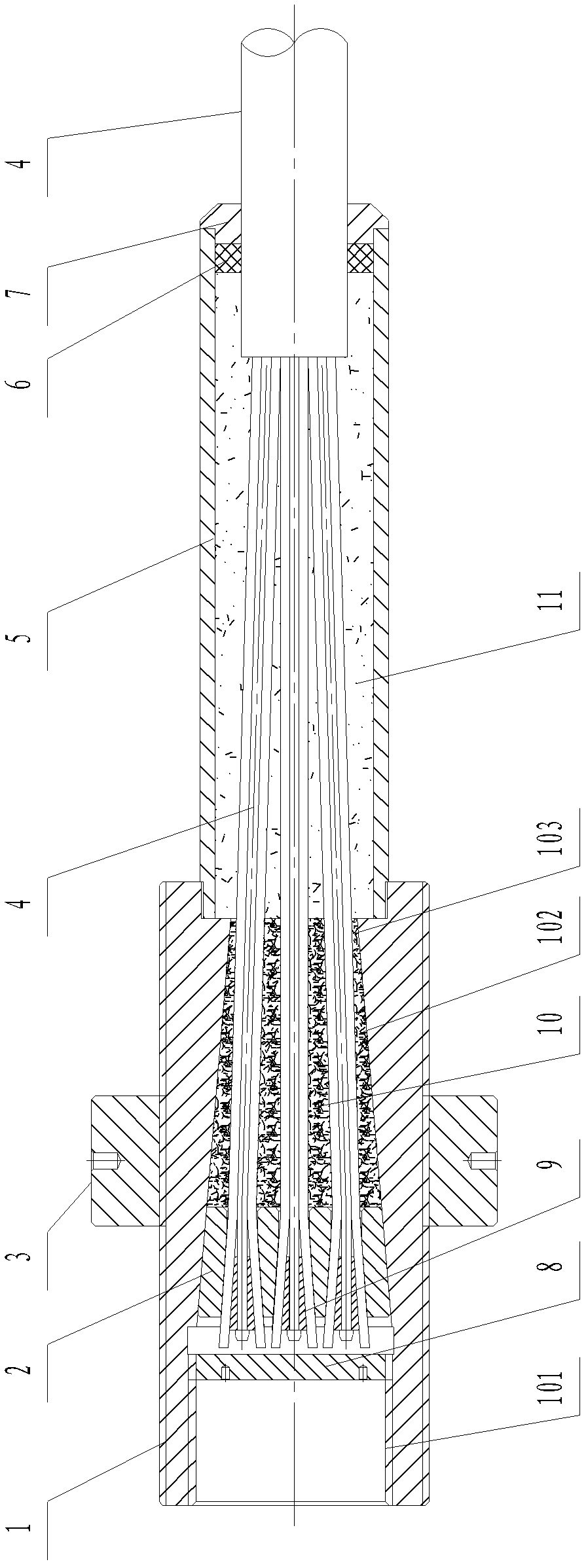

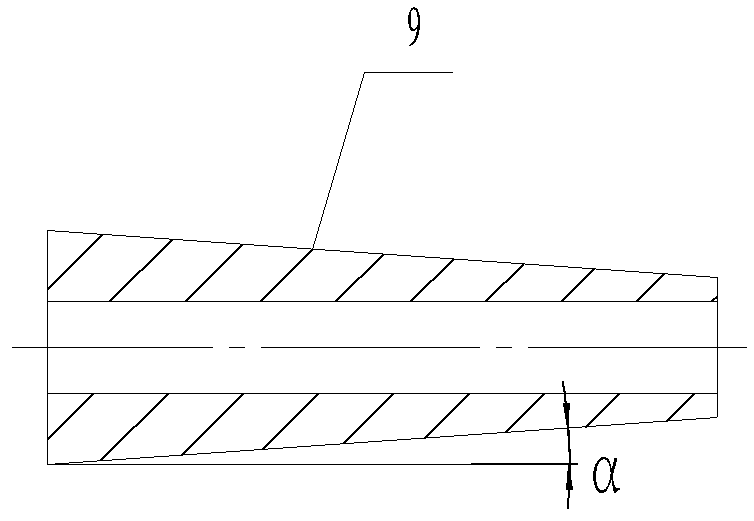

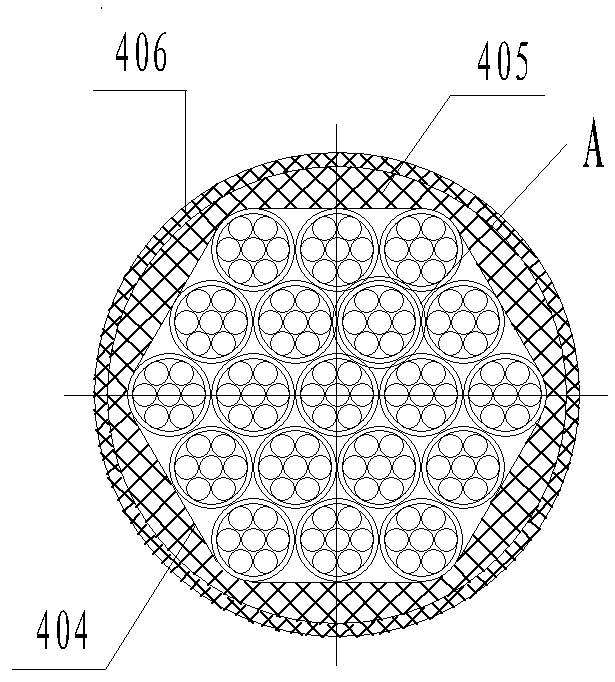

Bridge intelligent cable system with built-in fiber grating sensor

ActiveCN101701450AReal-time monitoring of force statusMeet health monitoring requirementsThermometer detailsControlFiberGrating

The invention relates to a bridge intelligent cable system with a built-in fiber grating sensor, which is used for cable bearing structures of a cable-stayed bridge, a suspension bridge, an arch bridge and the like. The bridge intelligent cable system comprises an anchoring cup (1), a dividing plate (5), a connecting cylinder (4), a fiber grating sensor and a cable body (11), wherein the fiber grating sensor comprises a fiber grating strain sensor (9) and a fiber grating temperature sensor (10), tail fibers of the fiber grating strain sensor (9) and the fiber grating temperature sensor (10) are led out, the packaged fiber grating strain sensor (9) is fixedly connected to an outer steel wire (3) at the position of the connecting cylinder (4), the packaged fiber grating temperature sensor is suspended on the steel wire (3) at position of the connecting cylinder (4), a hole (5-1) is penetrated in the dividing plate (5), and preserved steel pipes (7) are primarily imbedded in the connecting cylinder (4) and the anchoring cup (1) in advance. The invention can improve the survival rate of the fiber grating sensor and the optical fibers during the manufacture and the application of the cable, ensure a reliable embedding process of the fiber grating sensor and effectively lead fiber grating signals out of the cable body in a distortionless way.

Owner:FASTEN GRP CO LTD +1

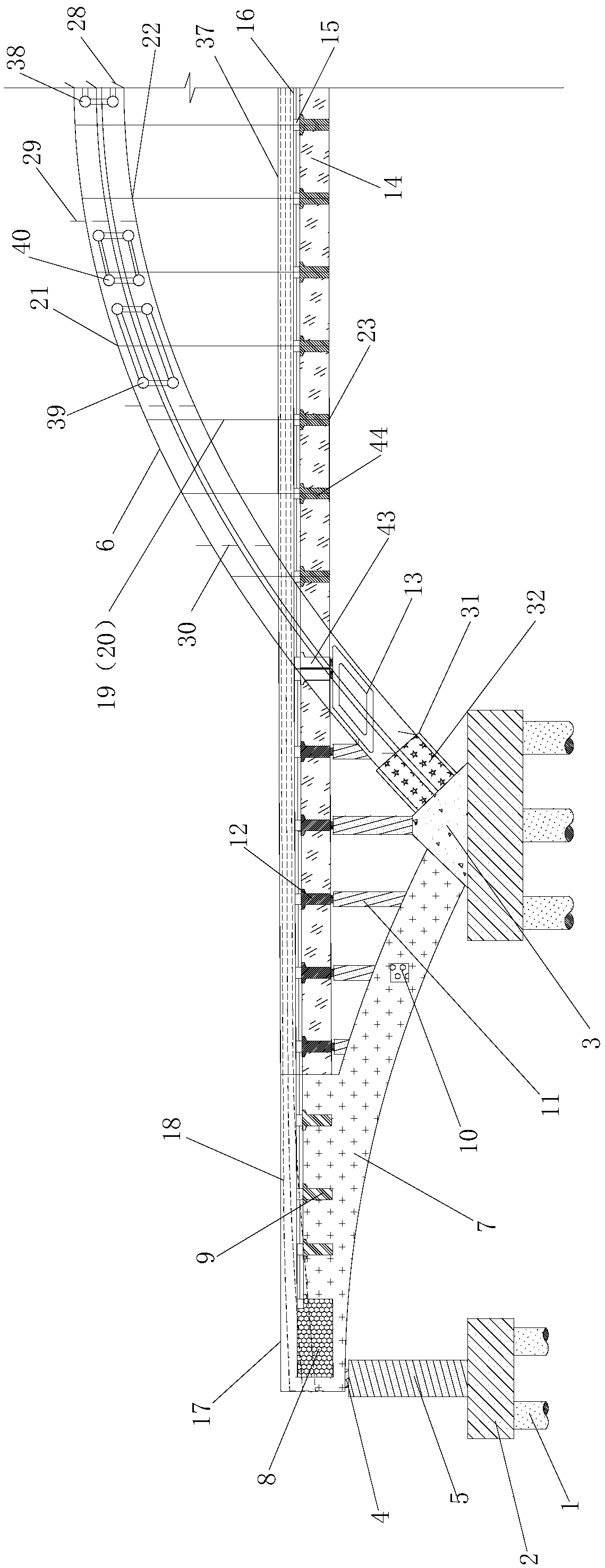

First-arch-then-beam concrete steel skeleton constructing process for through arch bridge with mooring post of steel pipe concrete

InactiveCN1811070AFast constructionLow costBridge erection/assemblyArch-type bridgePre stressPre stressing

The first-arch-then-beam concrete steel skeleton constructing process for through arch bridge with mooring post of steel pipe concrete includes the following steps: A. tensing permanent horizontal pre-stressed steel cable at the end cross beam; B. assembling steel pipe arch rib, floating and conveying the steel pipe arch rib and hoisting with floating crane to the site; C. controlling the displacement of abutment by using the permanent pre-stressed steel cable temporarily as the constructing pulling cable and regulating the tensing stress of the horizontal pre-stressed steel cable to bear the horizontal pushing force of the steel pipe concrete arch bridge; and D. hoisting bridge surface pre-stressed beam to site with the steel pipe concrete arch rib and suspender. Compared with conventional construction process, the present invention has fast construction speed, low cost, reduced overhead welding work load and high construction quality.

Owner:SHANGHAI NO 7 CONSTR

Steel trussed beam and flexible arch bridge construction method with vault pushing

ActiveCN102373671AEnsure driving safetySolve construction problemsBridge erection/assemblyControl systemConstruction engineering

The invention discloses a steel trussed beam and flexible arch construction method with vault pushing, which comprises the following steps of: building an assembly support in the side span of a steel trussed beam, assembling a guide beam and the steel trussed beam into an integral space on the assembly support, arranging a horizontal continuous jack and a mechanical, electrical and hydraulic control system on the assembly support, pushing the steel trussed beam forward by using the horizontal jack, and continuing next round of assembly work on the rear assembly support whenever one round is pushed forward. By using the steel trussed beam and flexible arch construction method with vault pushing provided by the invention, the steel trussed beam and the flexible arch are erected outside the operating limit of a highway, and the construction difficult across the highway is solved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Method for mounting box arch bridge

ActiveCN101519864ASimplified installation procedureReduce engineering costsBridge erection/assemblyArch-type bridgeT-beamAbutment

The invention discloses a method for mounting a box arch bridge. The method comprises the following steps: (1) excavating earth and stone work of a main arch abutment, and mounting a cable system; (2) pouring concrete of the main arch abutment and haunch; (3) hoisting the haunch; (4) mounting a bent on the arch; (5) mounting a T beam; and (6) constructing a bridge floor system. In haunch hoisting, after a first arch rib is mounted, a knotted rope used for stabilizing the haunch is detached, and the knotted rope is used for mounting a second haunch, and the like, so that all haunches can be mounted by the first knotted rope. The method simplifies mounting program of the box arch bridge, and greatly saves construction cost.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

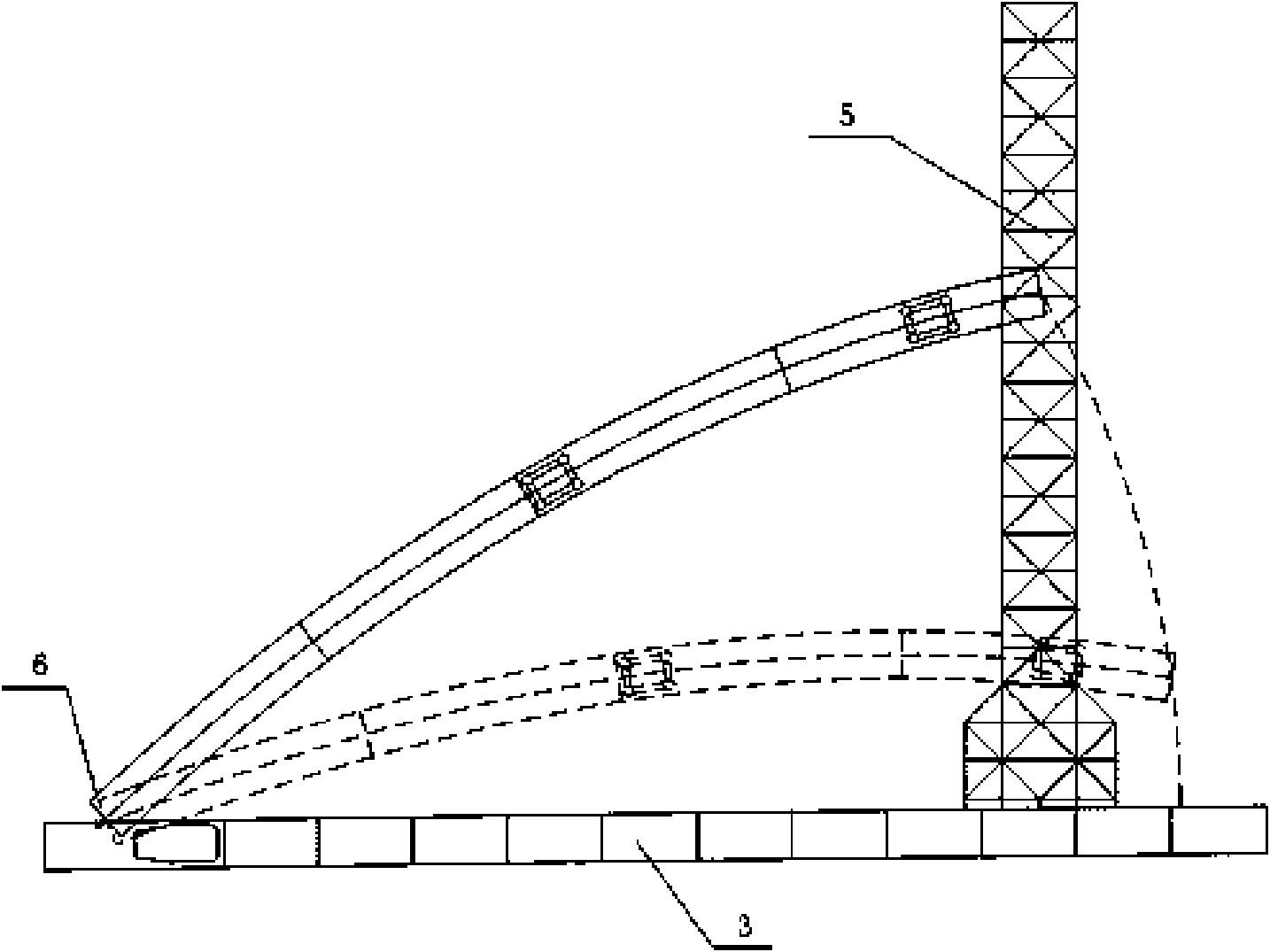

Steel tube arch rib vertical lifting method

ActiveCN101672011AReduce construction investmentThe structural force is clearBridge erection/assemblyArch-type bridgeButt jointTower

The invention discloses a steel tube arch rib vertical lifting method, which comprises the following steps: separating the steel tube arch rib into two side sections and middle-section closure sections, taking an arch hinge of a side section arch springing as a rotating point and vertically lifting the two side sections of the steel tube arch rib, adopting a temporary support for respectively stabilizing the two side sections on two lifting towers after reaching a set position; lifting the middle-section closure sections of the steel tube arch rib which is butt-jointed and closed with the twoside sections; the side sections and the middle-section closure sections can be split into two to four pieces of processing sections; the maximum weight of all sections is less than 20 tons; and all the sections can be assembled and welded on the spot before lifting. The steel tube arch rib vertical lifting method has the beneficial effects that the method has little constructional investment, clear structural force, shortcut and convenient construction process, and effectively solves the technical problem that the steel-tube arch is transferred and assembled into in a hoisting section in theconstruction process of a little span, low height and first-beam and post-arch arch bridge and the section of the steel-tube arch is arranged in place.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

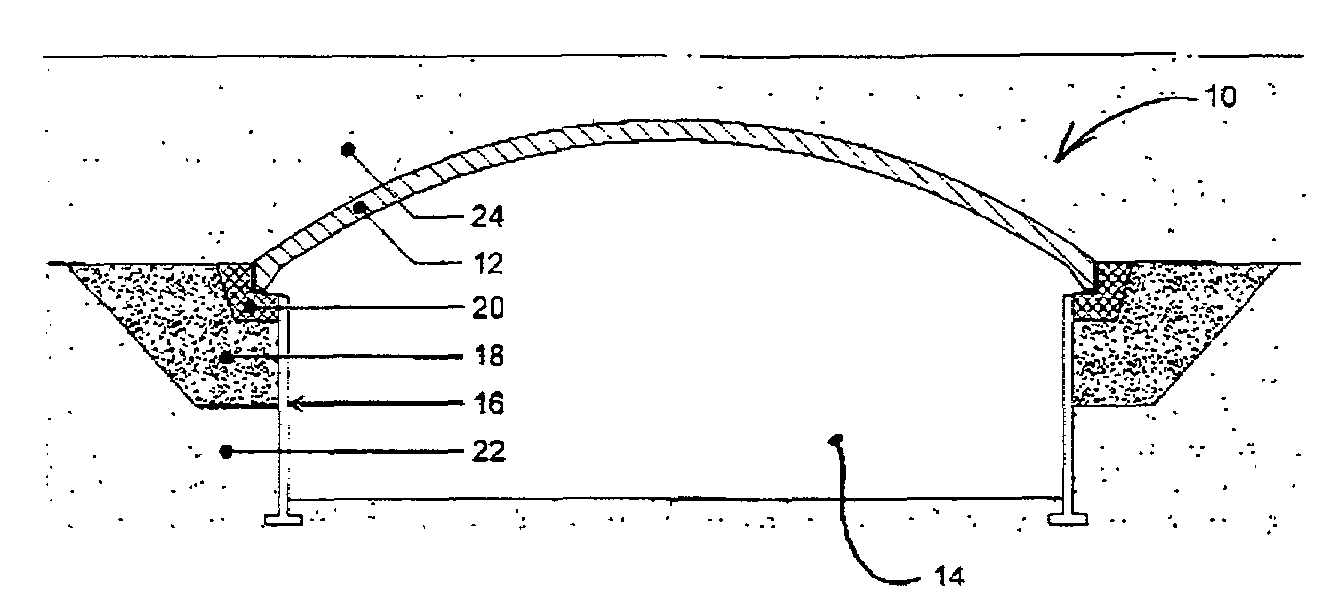

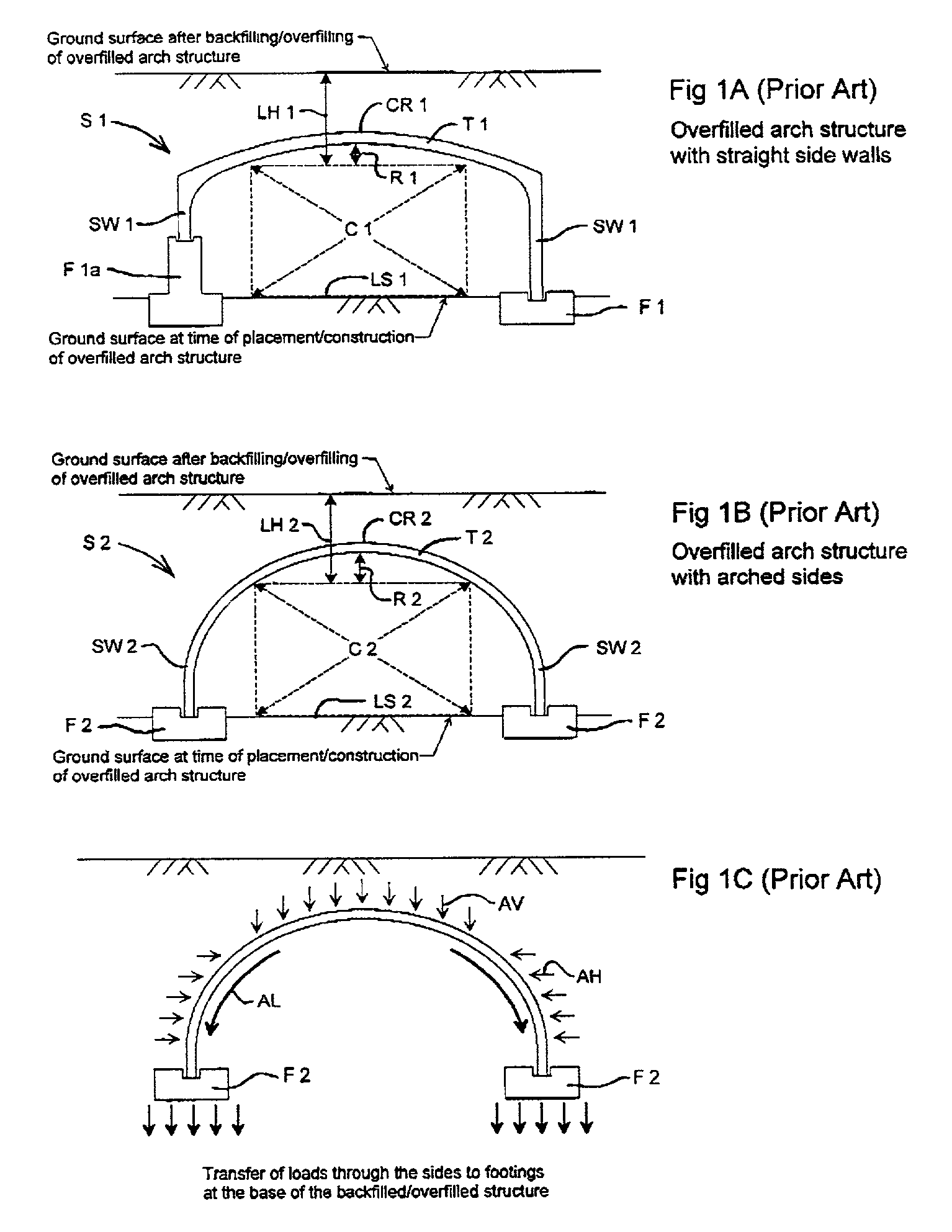

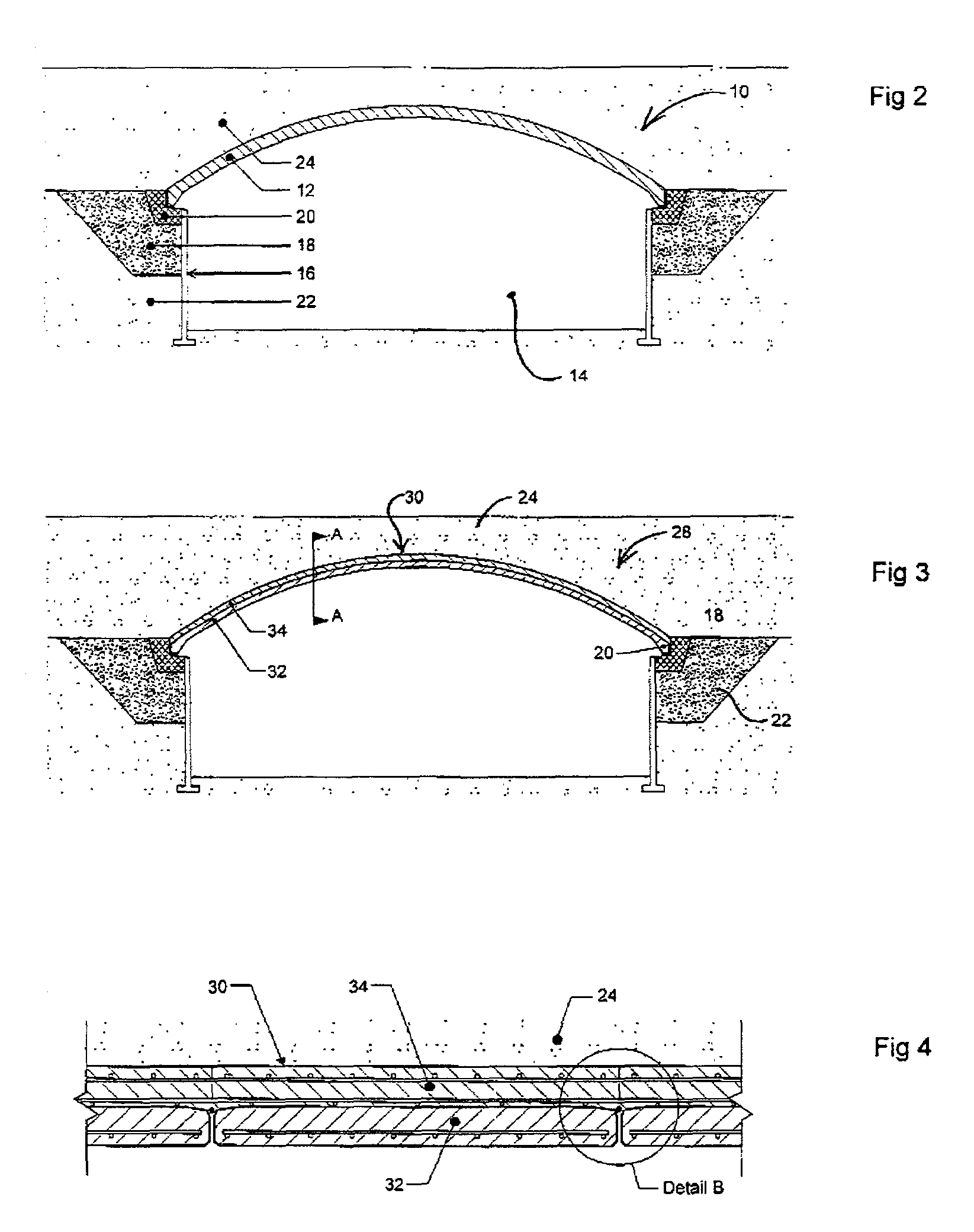

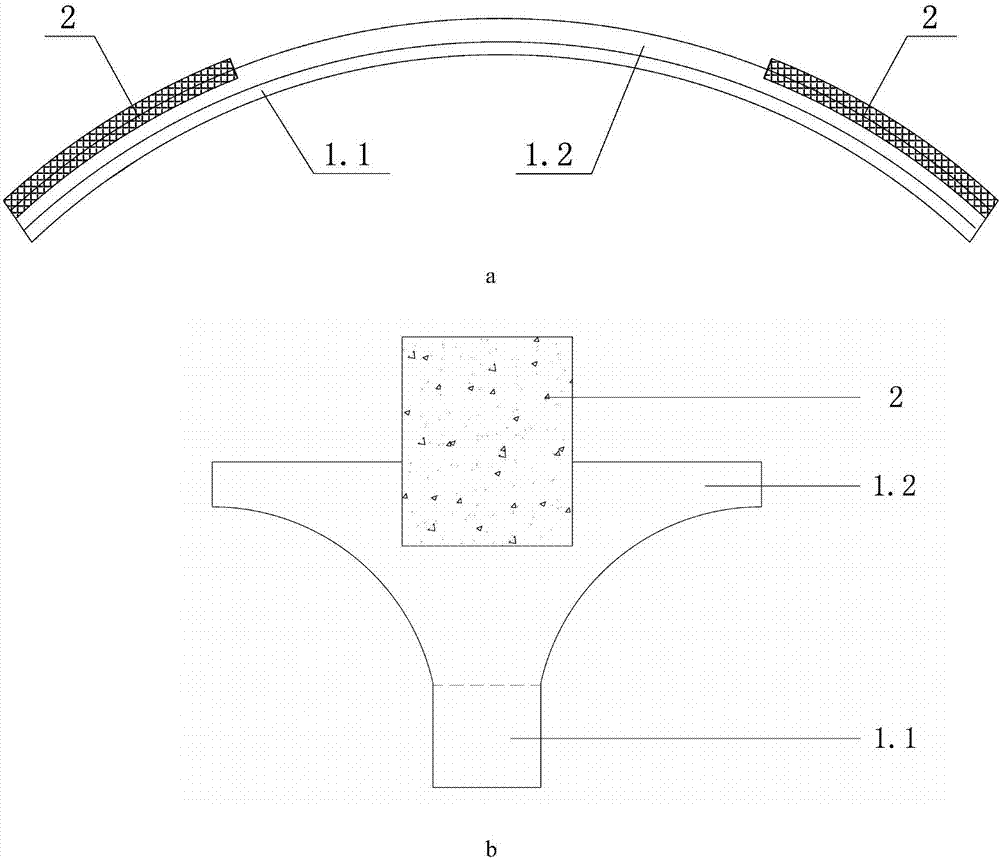

Composite overfilled arch system

InactiveUS7305798B1Enhanced advantageEfficiently and effectively accommodatedGround-workArched structuresPre stressArch bridge

An overfilled arch bridge system includes a composite arch which has a precast layer and a cast-in-place layer. The system further includes means for reducing bending moments within the overfilled arch. The means include customizing the arch end geometry and prestressing the arch prior to or during loading. The system can be used in connection with the overfilled arch system disclosed in co-pending patent application titled “Top Arch Overfilled System” filed by the same inventor on Mar. 22, 2002.

Owner:CONTECH ENGINEERED SOLUTIONS

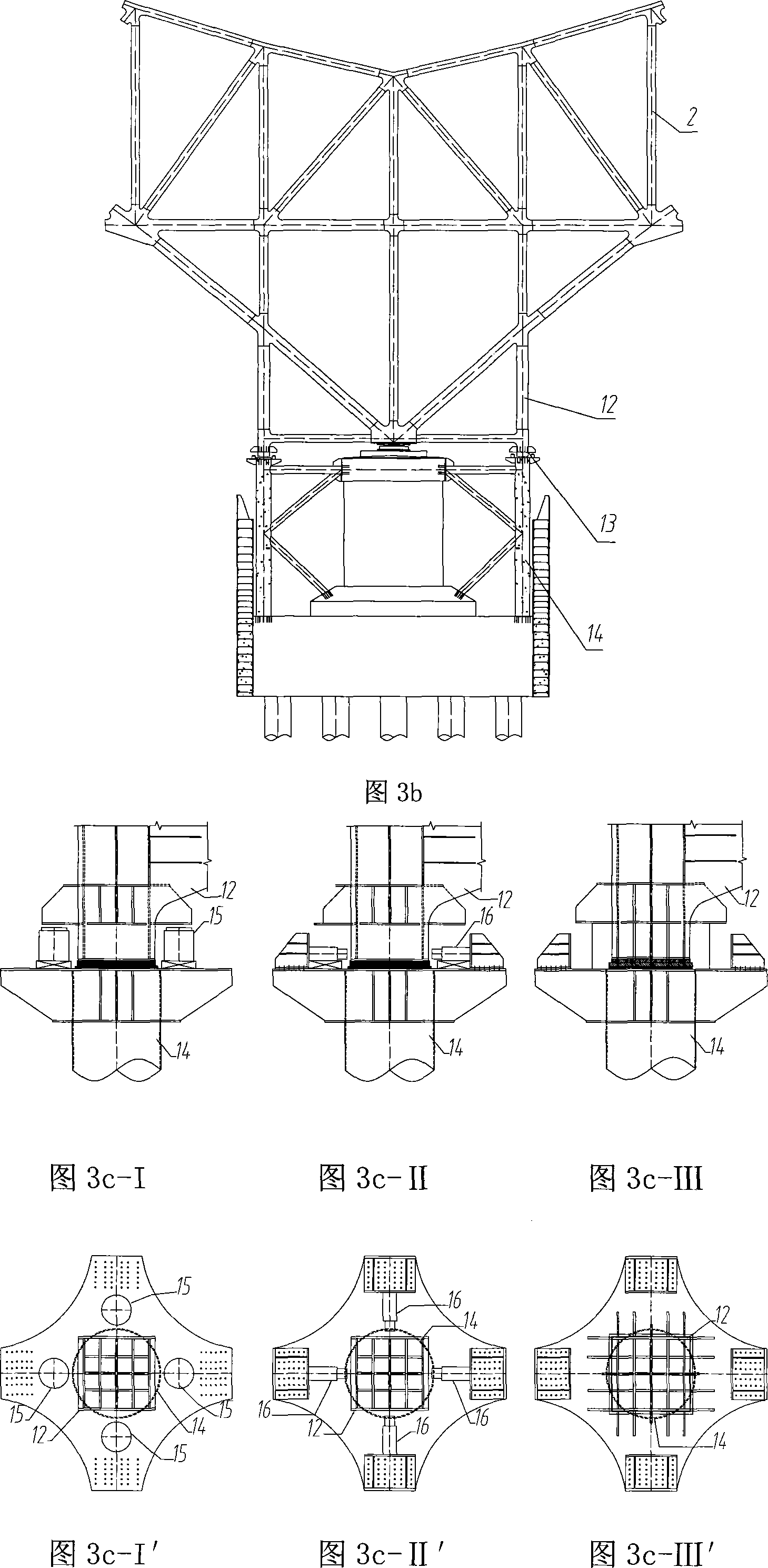

Concrete-filled steel tube arch bridge and construction method

PendingCN108660903AImprove stabilityGuaranteed docking accuracyBridge erection/assemblyArch-type bridgeReinforced concreteButt joint

The invention relates to a concrete-filled steel tube arch bridge. The concrete-filled steel tube arch bridge includes side arch ribs, main arch ribs, suspension bars, tie bars and a bridge pier and abutment structure. Side span structures include side arch supports, side span cast-in-place reinforced concrete arch ribs, cast-in-place side arch end cross beams, side span cast-in-place cross beamsbetween ribs, cast-in-place side arch rib tie beams, cast-in-place side upright posts, flexible prestressed tie bars and cast-in-place bridge deck slabs. Mid-span structures include abutments, mid-span concreted-filled steel tube arch ribs, main arch hollow cross beams between ribs, precast hollow longitudinal beams, flexible prestressed tie beams, tie-bar steel plate boxes, truss-type permanent upper wind braces, K-shaped permanent intermediate wind braces, temporary wind braces, arch foot pre-embedded sections, inner steel strand whole-bundle-squeezed inhaul cable suspension bars and outer steel strand whole-bundle-squeezed inhaul cable suspension bars. The concrete-filled steel tube arch bridge has the beneficial effects that steel tube arch rib fixation brackets involved in the concrete-filled steel tube arch bridge can improve the stability during installation and construction of steel tube arch ribs, and the accuracy of butt joint can be guaranteed effectively.

Owner:ANHUI HIGHWAY ENG CORP

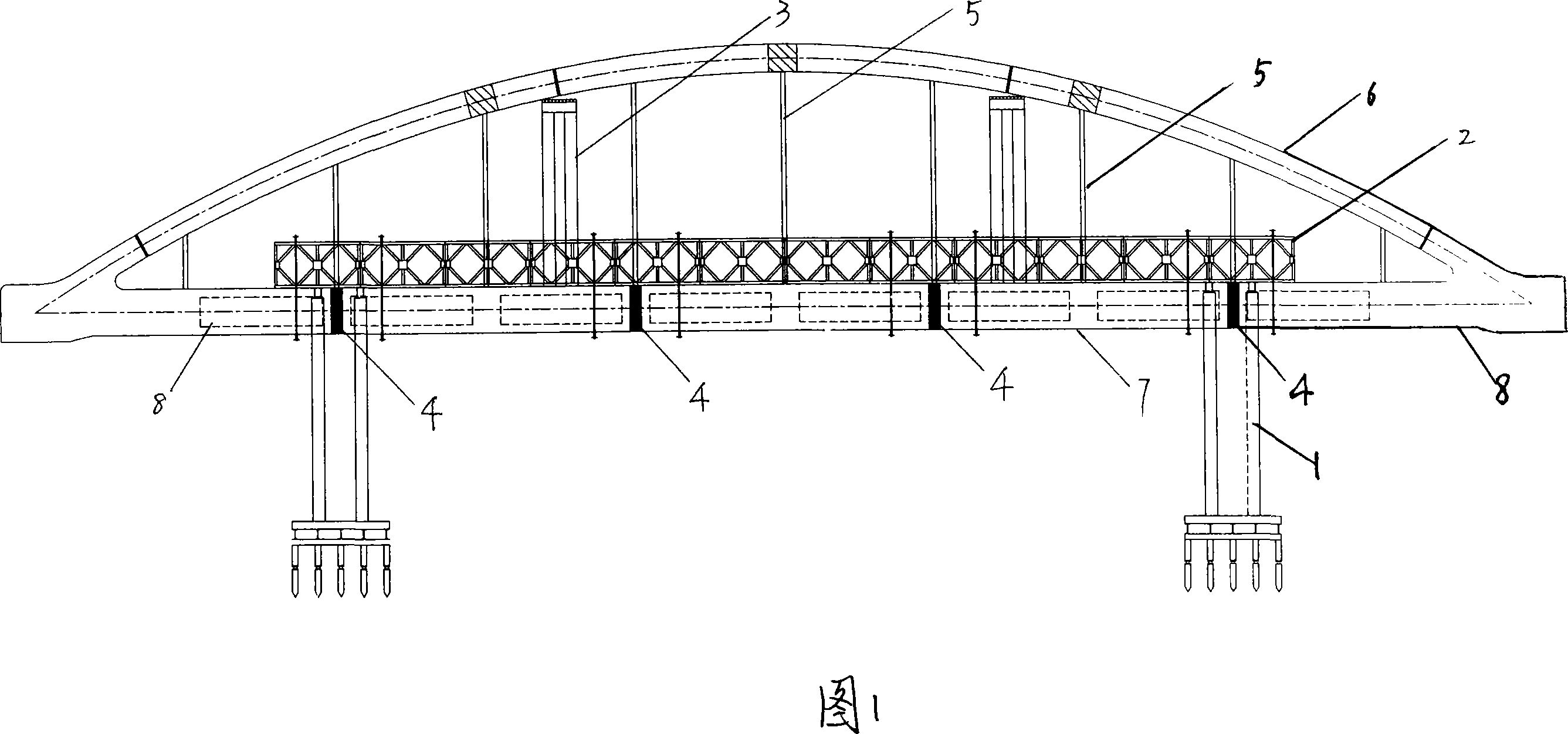

Joist type cable arch bridge structure and its construction method

A truss-type cable arch bridge structure is provided, whose last quarter main arch ring is composed of a plurality of arch steel pipes of the inner injecting concrete or the steel pipe to form the concrete truss-type main arch ring. The steel pipe concrete column is tightly fixed on the lower node of the last quarter main arch ring, while the upper end of the steel pipe concrete column is tightly fixed on the node of the first quarter driveway beam. The two ends of the inclined dragline equipped with an adjustable anchor nip are respectively fixed on the upper node and the lower node of the steel pipe concrete column adjoint the upper node. The construction method is that, the inclined dragline with the adjustable anchor nip is used to hoist the concrete truss-type main arch ring of the first unit, the steel pipe concrete column and the driveway beam from the bridge abutment on the two banks, and combined together; then to hoist the second unit, and the like, till the arch bridge folds, concrete is poured into each arch steel pipe or the steel box spar frame from the lower end; after forming a bridge, the inclined dragline at each node is adjusted for uniform stress on the entire arch. The invention can exert the cooperating combination, complementary advantages of different materials for the high strength steel cable, the steels and concrete etc, which is applicable for large span building the bridge in the V-shape valley of the a mountainous area.

Owner:EAST CHINA JIAOTONG UNIVERSITY

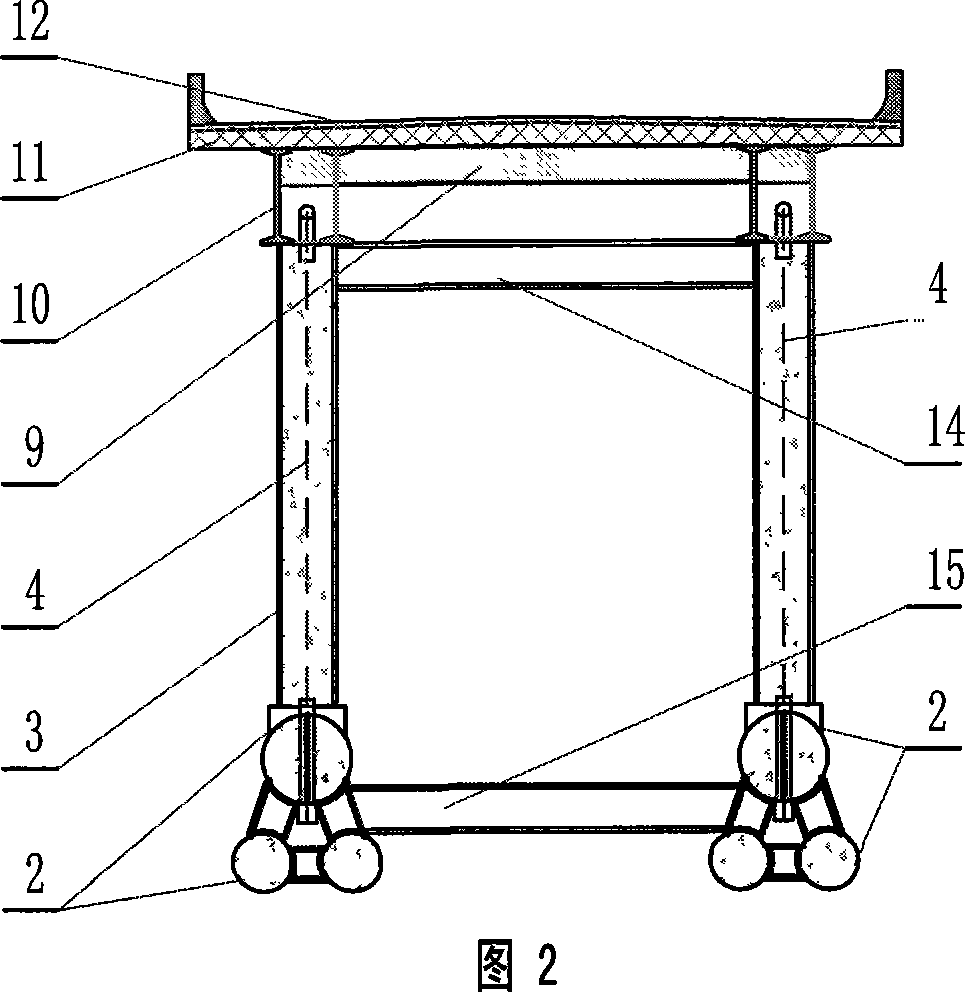

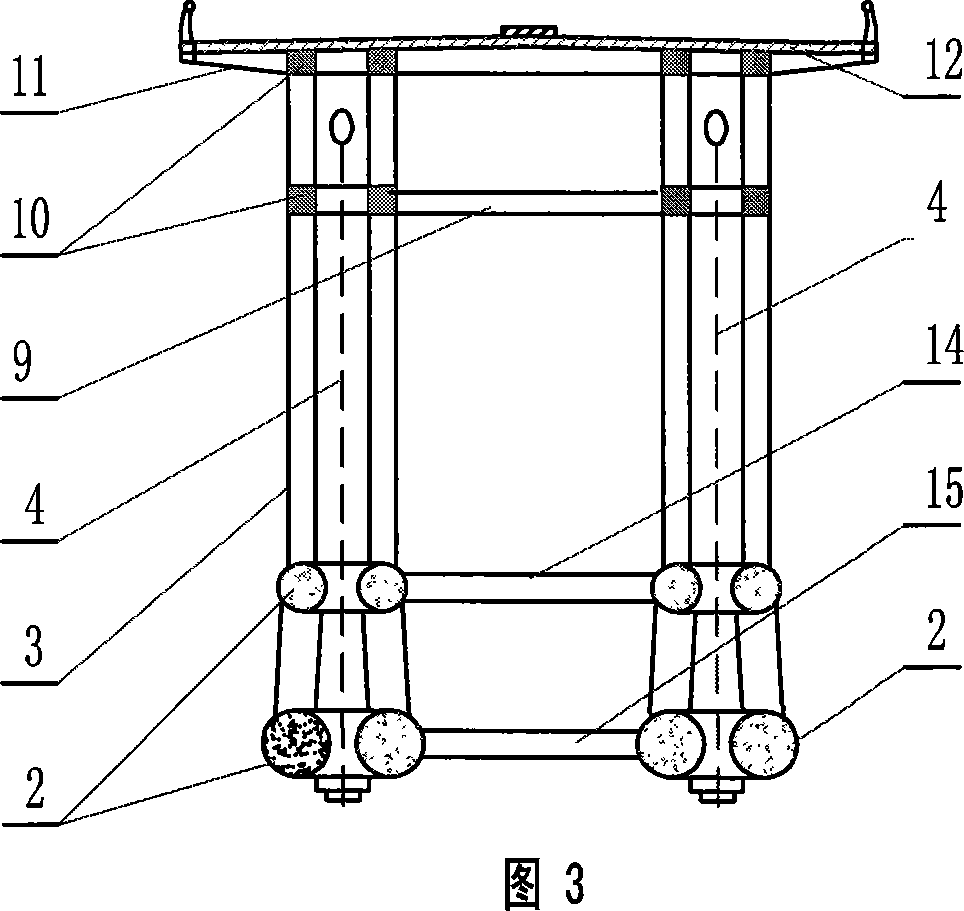

Gate-type crane semiarch integral-hoisting steel-pipe arch process

InactiveCN1851137AQuick investmentImprove securityBridge erection/assemblyArch-type bridgeSpandrelSteel tube

The invention relates to erecting construction of a steel pipe concrete arch bridge, especially a door crane-used half-arch integral steel pipe arch hoisting process, dividing each arch rib into two hoisted units, where each 1 / 2 arch is hoisted by two door cranes, where a fixed door crane serves as an arch span hoister and an active door crane serves as an arch foot hoister. And the invention is applied to bottom, middle and top bearing arch bridges constructed by bracket-free process. And the span of the steel pipe arch installed by the invention can reach above 300 meters, and the weight of the installed steel pipe can reach above 2000 tons. And it does not influence navigation, able to applied to single- or multiple- span construction; the hoisting safety is higher; and the shape of the arch axis is good; it needs no huge anchoring system and applied to various arch bridges.

Owner:CHINA RAILWAY FIRST GRP CO LTD

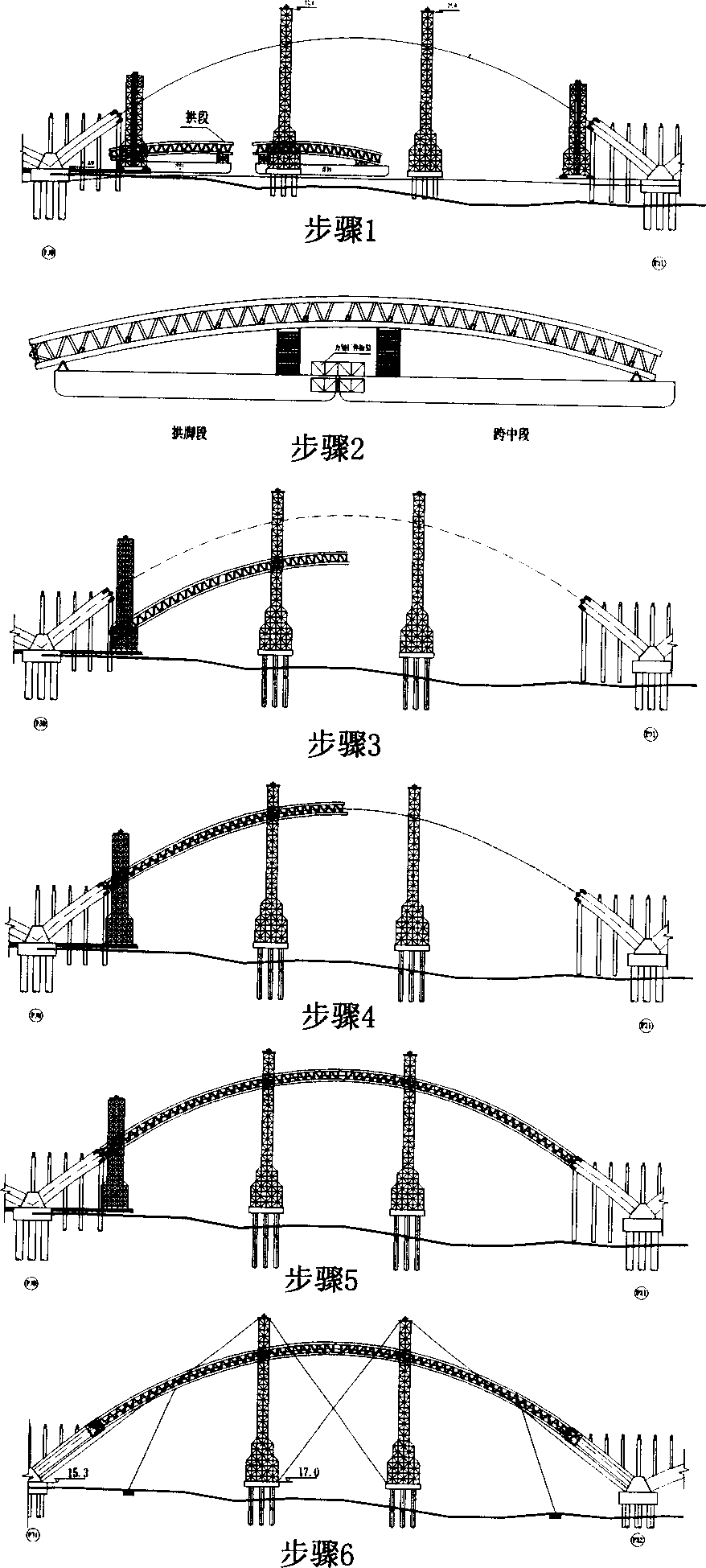

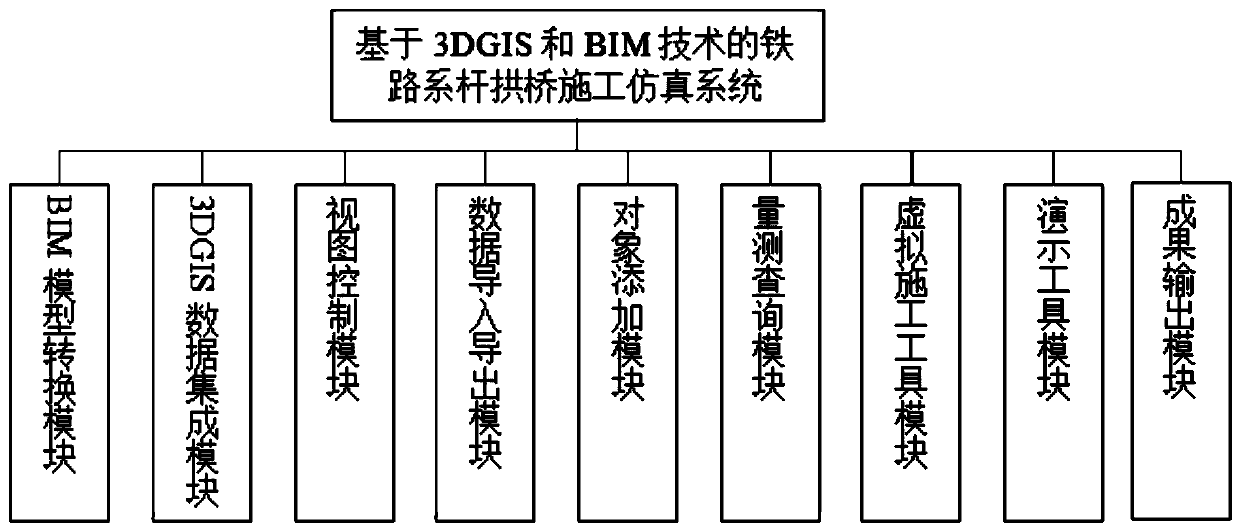

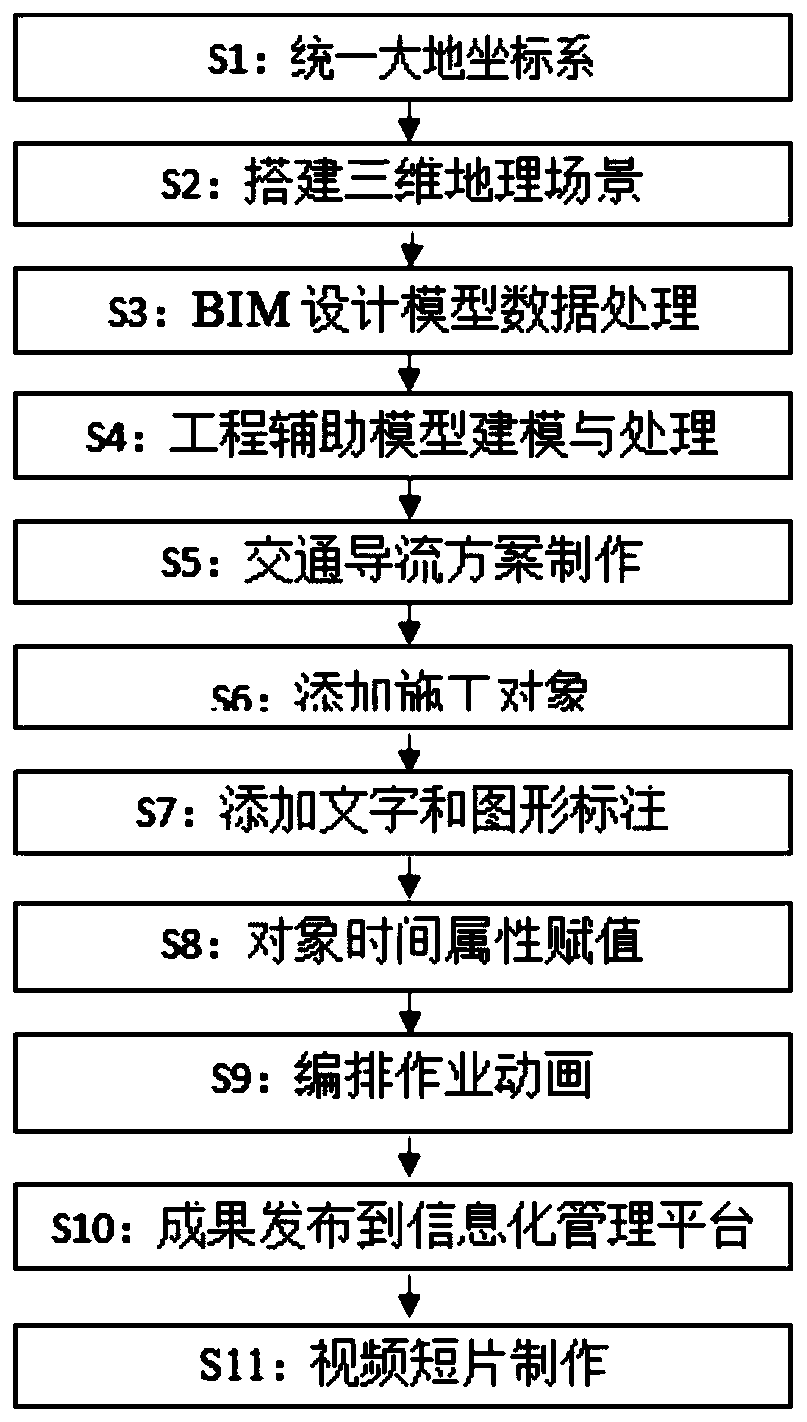

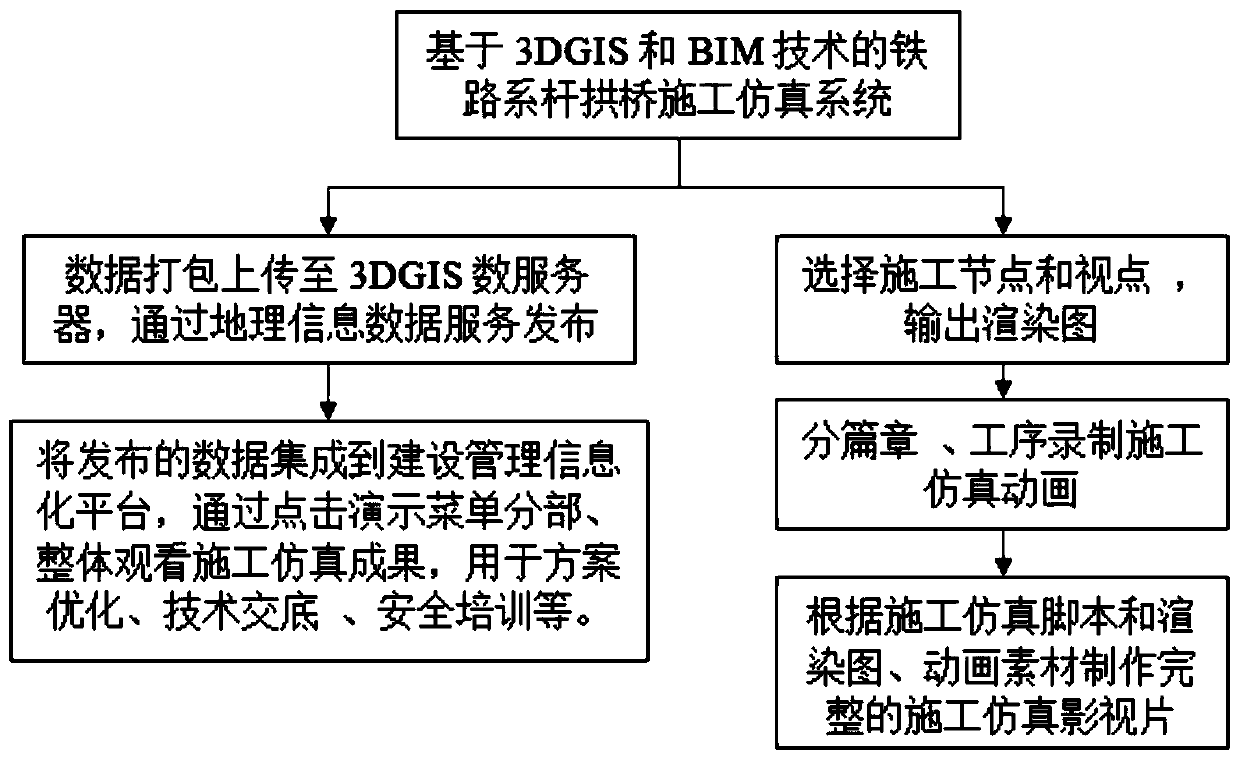

A railway tied-arch bridge construction simulation system and method based on a 3D GIS and a BIM technology

PendingCN109783851AImprove communication efficiencyEfficient use ofAnimationSpecial data processing applicationsInformatizationLandform

The invention discloses a railway tied arch bridge construction simulation system based on a 3D GIS and a BIM technology. The railway tied arch bridge construction simulation system comprises a BIM model conversion module, a 3D GIS data integration module, a view control module, a data import and export module, an object adding module, a measurement query module, a virtual construction tool moduleand a demonstration tool module. The invention further discloses a simulation method using the system. a virtual scene can be constructed in a 3D GIS system, topography and geomorphology and safety risk information of a construction site can be inquired, process technology virtual simulation in the construction process is carried out, existing problems are found in time, the communication efficiency is improved, and the construction organization and safety management quality of the railway tied-arch bridge can be remarkably improved. According to the method, on the premise that railway BIM design and 3D GIS construction management informatization system construction are carried out, survey data and BIM design results can be effectively utilized, integration with an informatization systemis achieved, and the difficulty and cost of construction simulation are greatly reduced.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Cable telescopic arc device

InactiveCN102738760AImprove reliabilityCoping with flexibilityCable arrangements between relatively-moving partsPower cableSlide plate

The present invention relates to a cable telescopic arc device which comprises a clamp, a guide rail, a cable and a sliding plate. The clamp is arranged on the sliding plate. The cable is connected with the clamp at a side by the guide rail. The cable is set as an arch bridge structure. The sliding plate is arranged at a position of the arch bridge structure of the cable. Compared with the prior art, according to the invention, a conventional cable is used to substitute an expensive submarine cable, economical efficiency is high, a power cable is laid through a bridge, a channel is provided for the future repair and maintenance of the cable, the reliability of cable operation is greatly raised, moreover, the cable can cope with expansion and contraction amplitudes of the bridge, and a service life of the cable is long.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

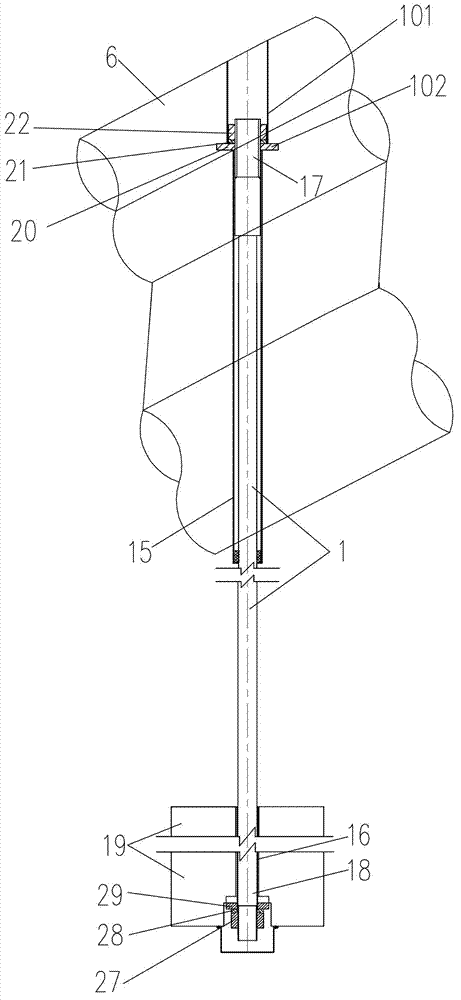

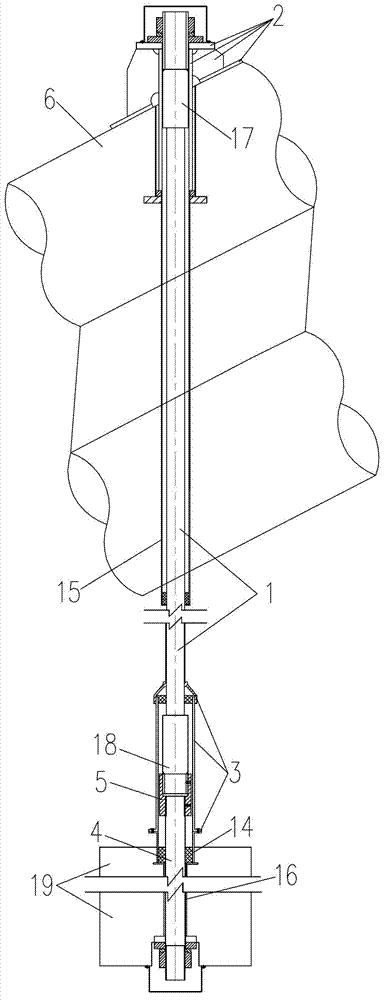

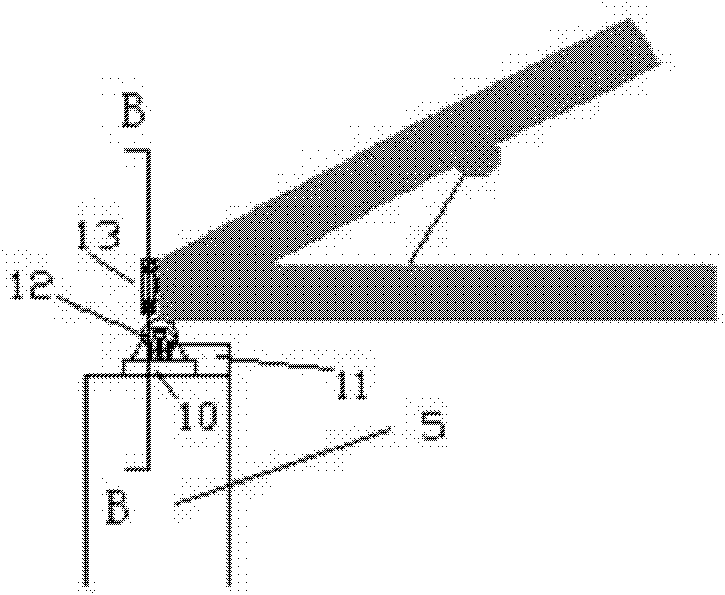

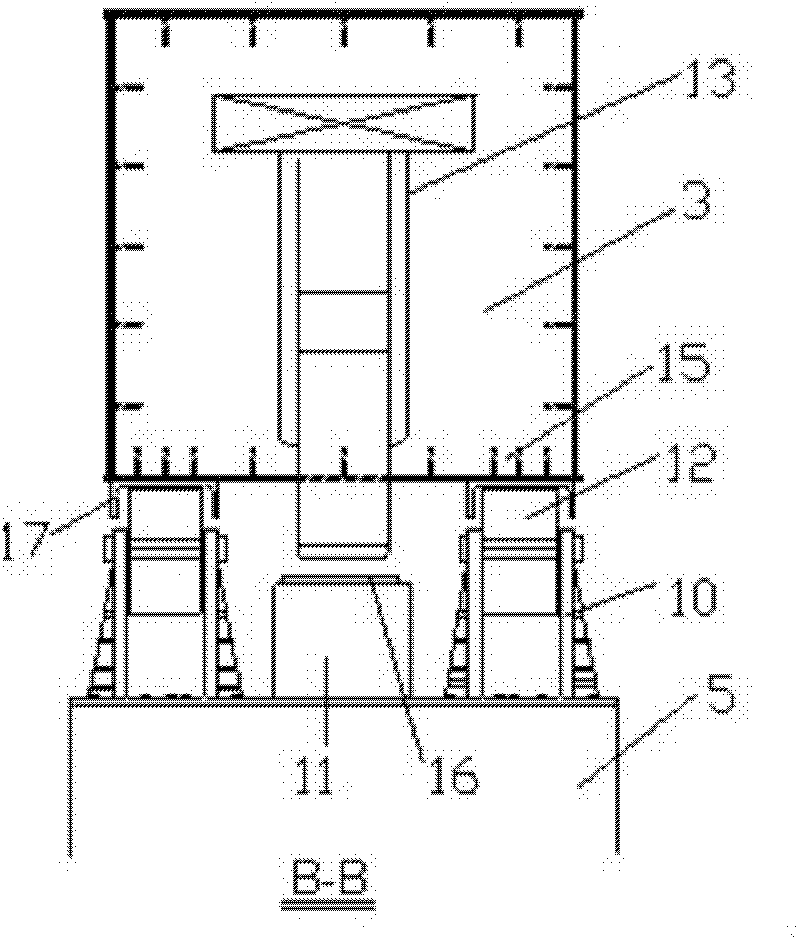

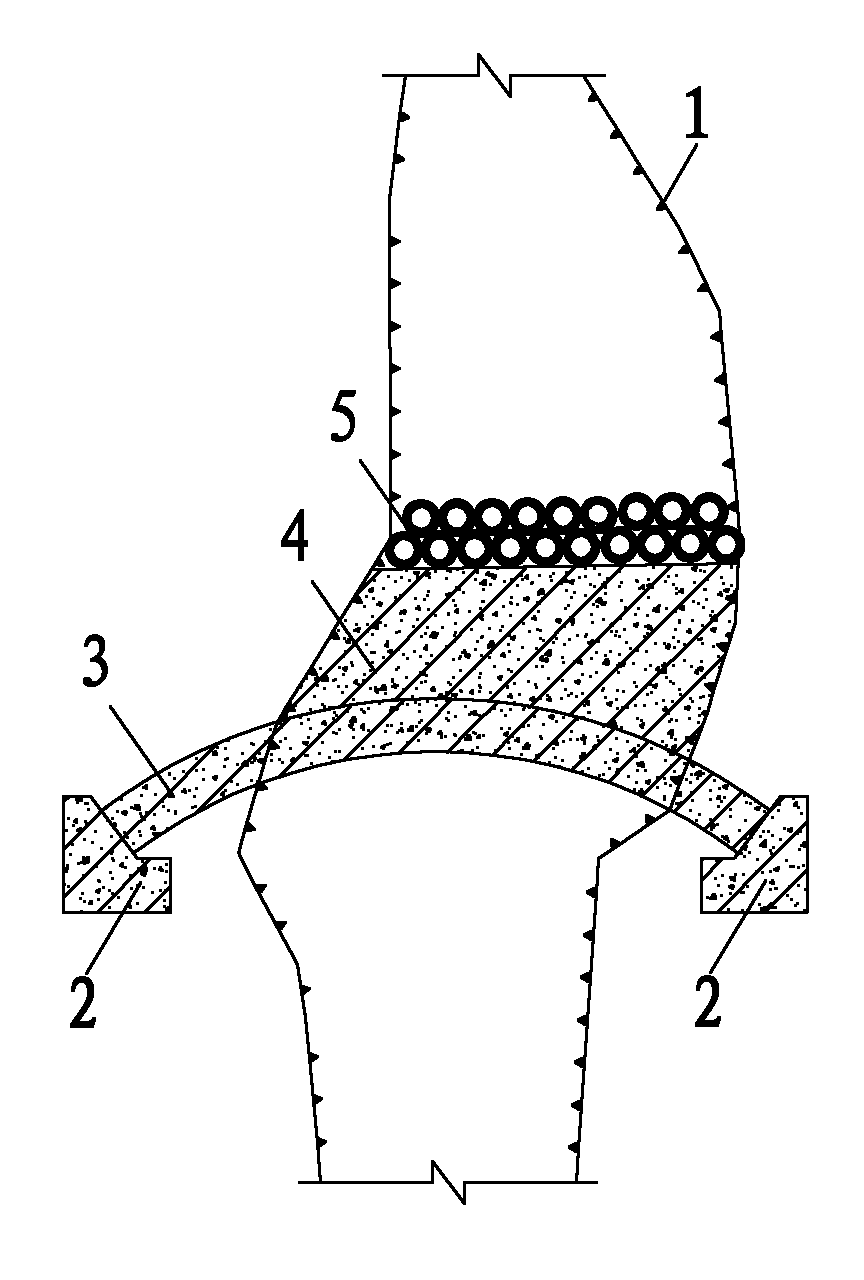

Detectable, replaceable and adjustable arch bridge suspender system and method for constructing same

ActiveCN103046466ASolve inspection difficultiesEasy to adjustBridge structural detailsBridge erection/assemblyEngineeringArch bridge

The invention discloses a detectable, replaceable and adjustable arch bridge suspender system and a method for constructing the same. The arch bridge suspender system comprises a suspender, an upper anchor head steel structure and a rigid connecting screw. The suspender is provided with an upper anchor head, a middle suspender body and a lower anchor head, the upper anchor head steel structure is positioned on an arch rib of an arch bridge and is welded with the arch rib, the upper anchor head of the suspender extends outwards after penetrating through the arch rib and the upper anchor head steel structure, an extending end of the upper anchor head is anchored on the upper anchor head steel structure via an upper anchoring unit, the upper end of the rigid connecting screw is detachably and integrally connected with the lower anchor head of the suspender, and the lower end of the rigid connecting screw is anchored on the bottom surface of a crossbeam via a lower anchoring unit after penetrating through the crossbeam of the arch bridge. The arch bridge suspender system is convenient to check and replace, and force of the suspender can be adjusted conveniently. The invention also discloses the method for constructing the arch bridge suspender system. By the method for constructing the arch bridge suspender system, the detectability, the replaceability, the adjustability and excellent corrosion resistance of the arch bridge suspender system can be guaranteed.

Owner:GUANGDONG HELI CIVIL ENG CO LTD

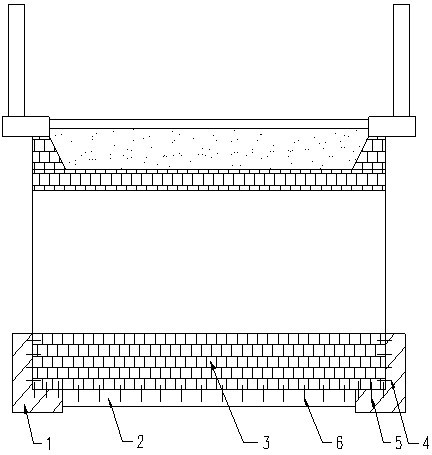

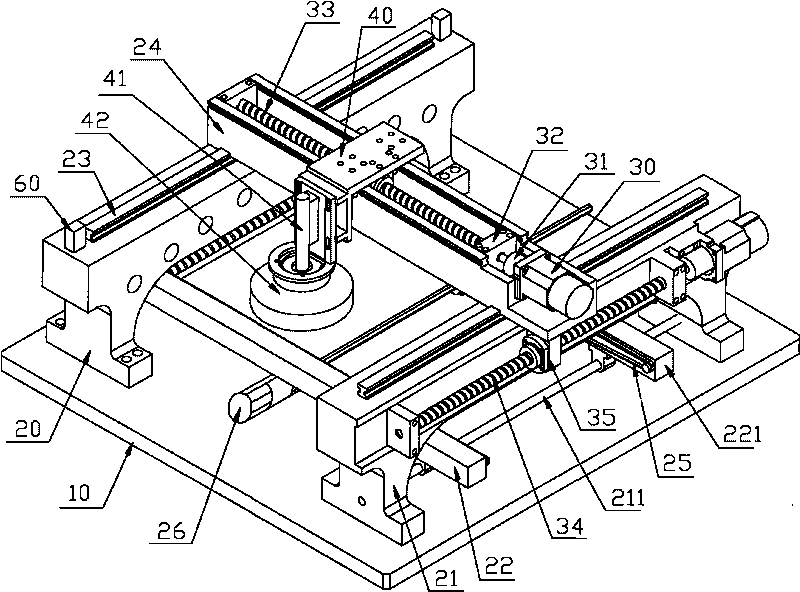

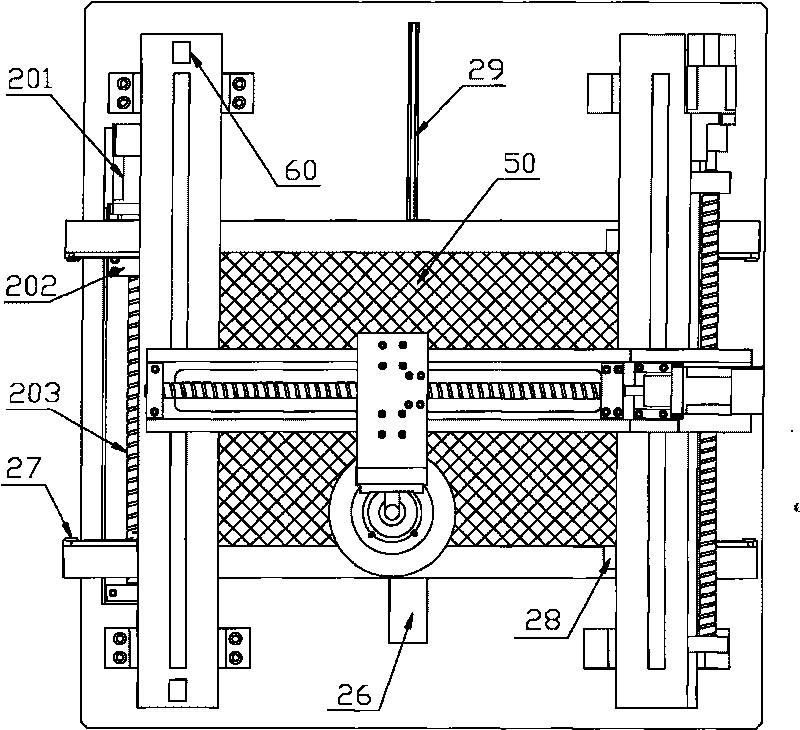

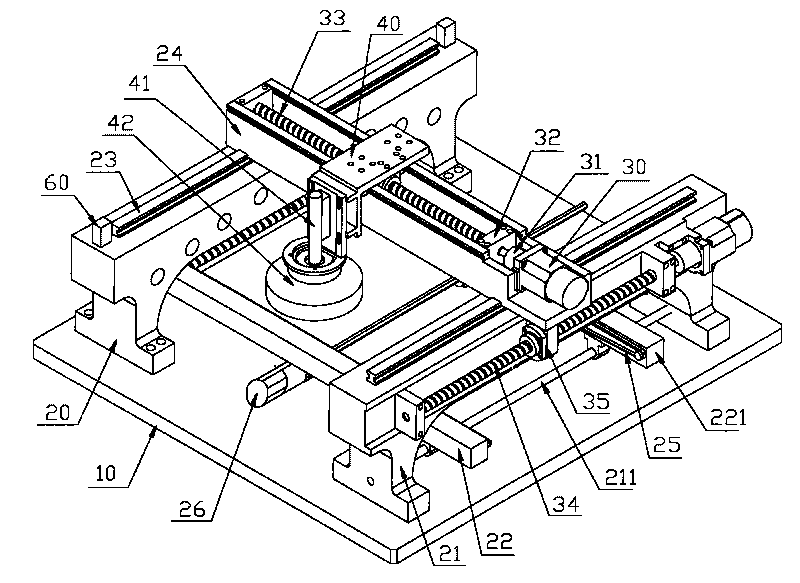

Automatic optical detection device of online PCB board

InactiveCN101762609AAvoid defectsImprove efficiencyMaterial analysis by optical meansProduction lineBiochemical engineering

The invention relates to an automatic optical detection device, in particular to the automatic optical detection device of an online PCB board. The automatic optical detection device comprises a base, an inlet arch bridge seat and an outlet arch bridge seat are respectively arranged in parallel on two sides of the base, a guide rail is respectively arranged on the inlet arch bridge seat and the outlet arch bridge seat, a driving belt is arranged on the inner side of a fixing loading platform, which corresponds to an adjusting loading platform, and is correspondingly connected with a hexagonal threaded rod arranged in the middle of the loading platform, and the other ends of the fixing loading platform and the adjusting loading platform are connected with an adjusting device arranged under the inlet arch bridge seat. The invention can be installed in various positions requiring real-time detection of the product on the production line, and can be operated along with the production line synchronously. Moreover, no special personnel are needed for operation, thereby saving labor resources and greatly improving the efficiency of detection. In addition, all the products requiring detection on the production line can be detected 100 percent, thereby ensuring the product quality.

Owner:苏州德天光学技术有限公司

Integral Pushing Construction Method of Network Tied Arch Bridge

InactiveCN102261039AFast constructionReduce coefficient of frictionBridge erection/assemblyArch-type bridgeEngineeringPiston

The invention relates to a guiding-beam-free integral thrusting construction method of a network tied arch bridge. The method is characterized in that the following structure and method are adopted for thrusting the network tied arch bridge: a vertical jack is arranged at the front end in the thrusting direction of a steel box tie beam; a sliding mechanism which can ensure a piston of the jack toslide on the top surfaces of temporary piers is arranged on the top surfaces of the temporary piers; during thrusting, when the front end of the arch bridge is close to the temporary piers, the piston of the jack moves downwards to push against the sliding mechanism and the height of the front end of the arch bridge relative to the top surfaces of the temporary piers is adjusted by controlling the extension elongation of the piston to ensure chutes at the bottom of the steel box tie beam to fall on pulleys; and the chutes are supported by the pulleys and slide relative to the pulleys along with thrusting movement of the arch bridge. The method has the following beneficial effects: in the thrusting process, a main arch ring, inclined hangers, the steel box tie beam, the temporary supports and the like are integrally thrust, thus giving play to the function of partial inclined hangers to enhance the structural rigidity in the thrusting process, simultaneously avoiding installation inconvenience and construction difficulty after the members are thrust in place and improving the thrusting construction efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

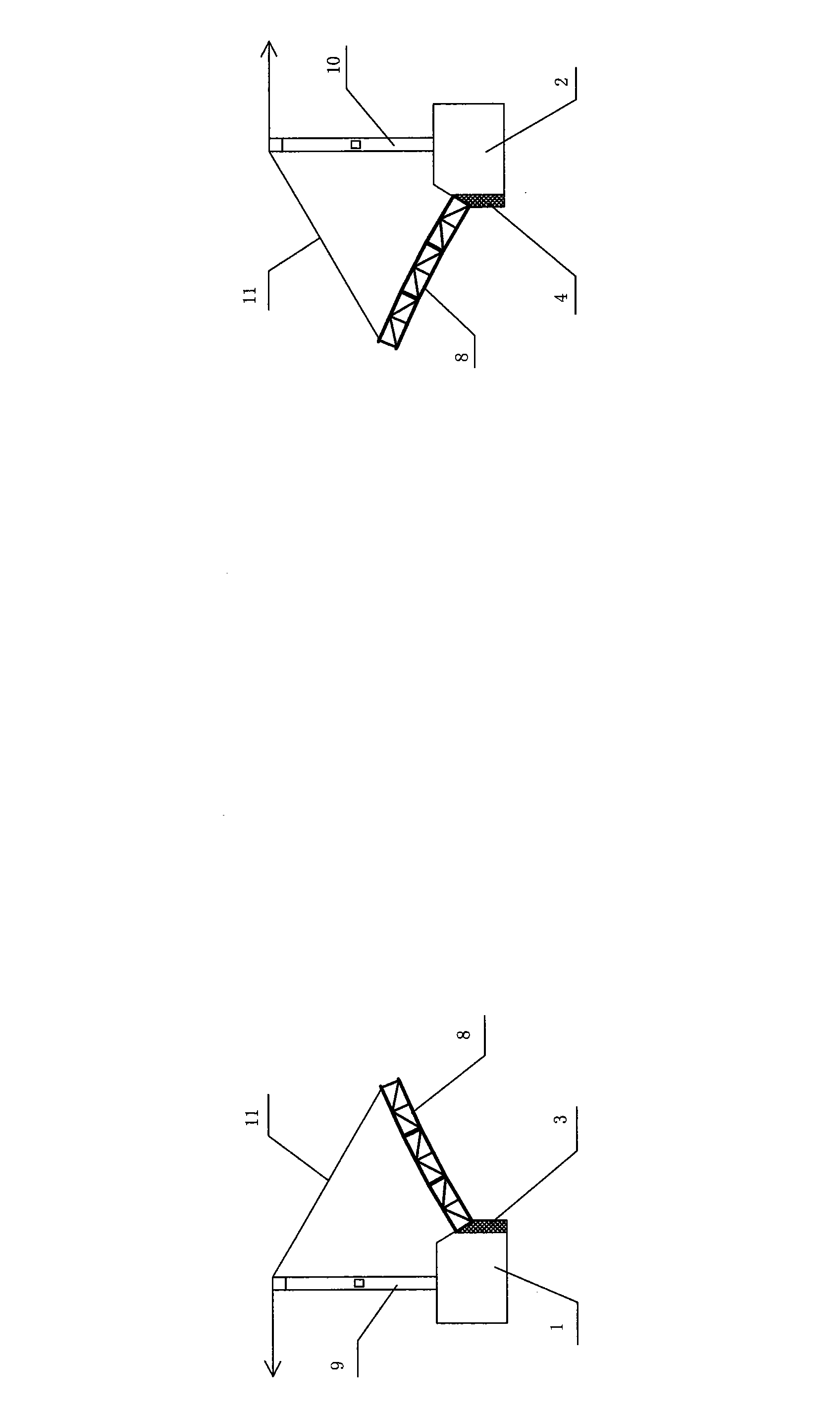

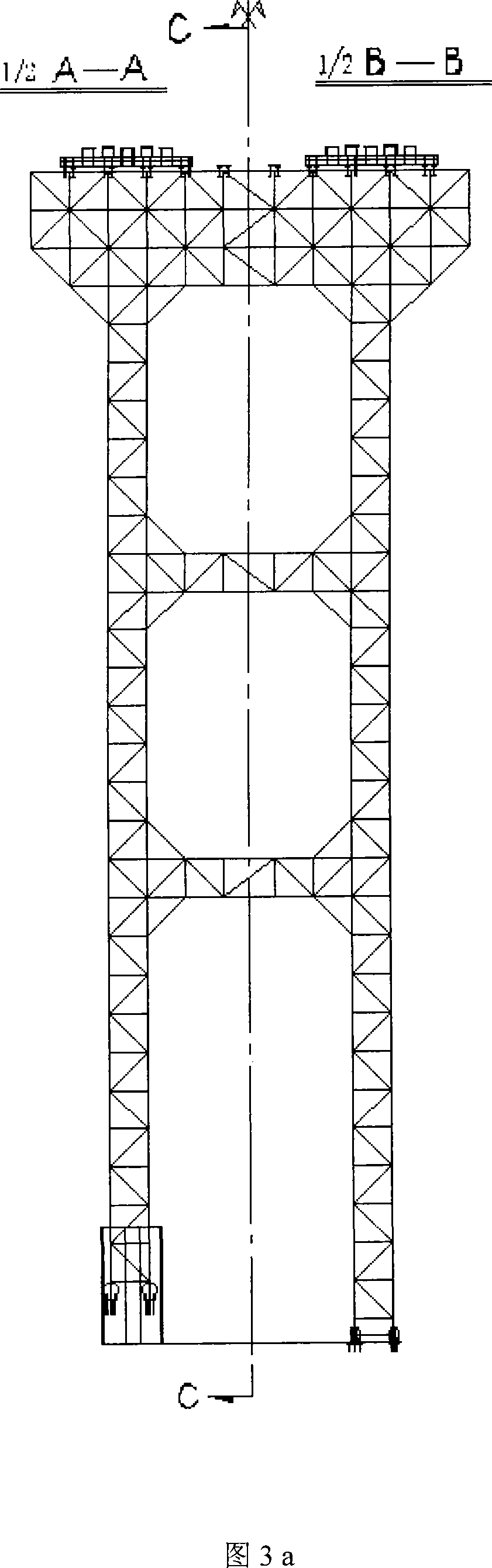

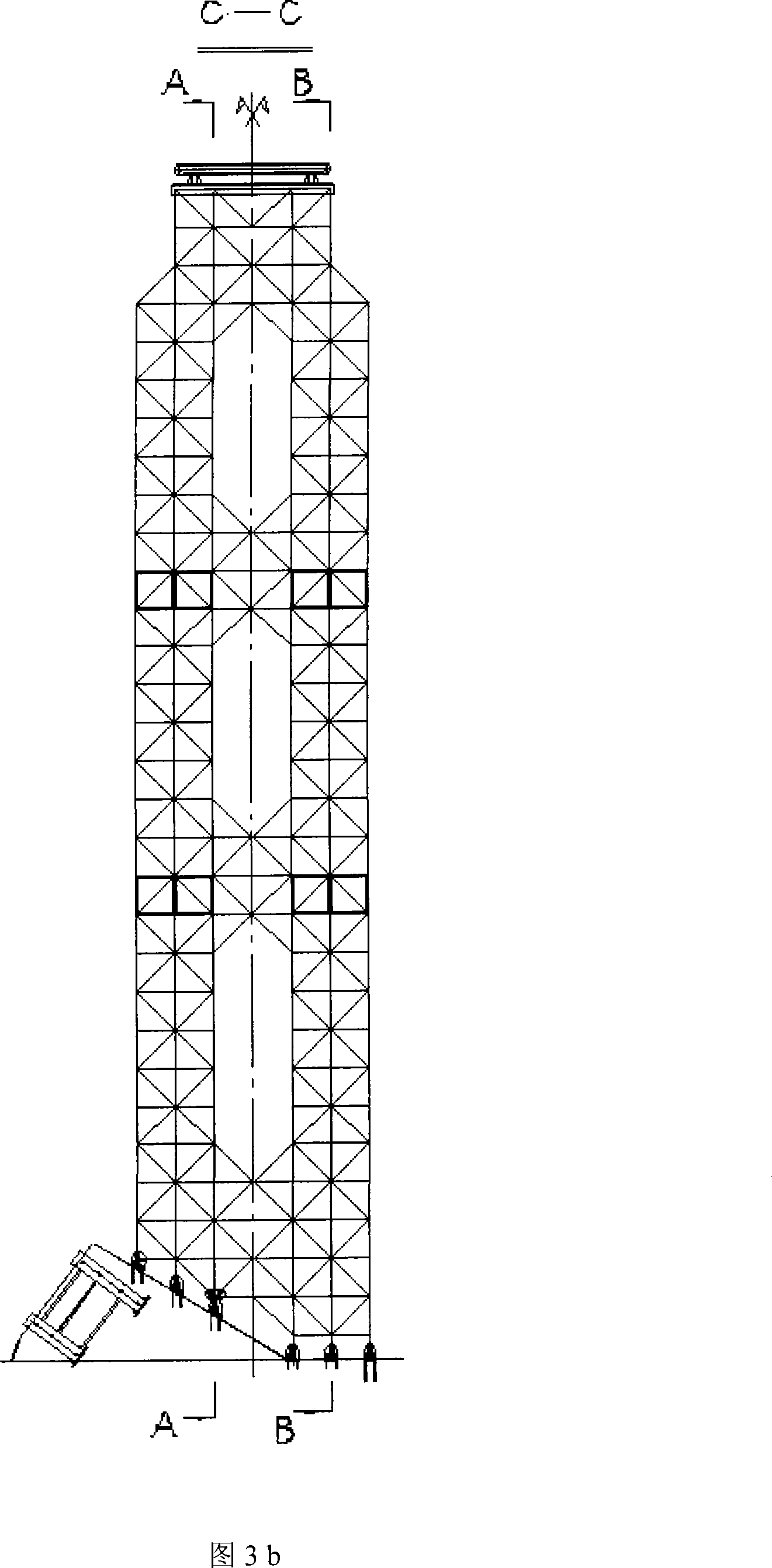

Multi-arch bridge rib vertical turning technical method

ActiveCN101200879AEasy constructionReduce construction costsBridge erection/assemblyRotation methodTower

The present invention relates to a construction method of bridges, in particular to a vertical rotation method of the arch ribs of a multi-span continuous arch bridge. The construction method includes seven steps: (1) the tower frames of a side tower and a middle tower, a hoisting station, a mobile gantry crane and an arch rib trestle are assembled, and a rear archorage system is installed; (2) arch ribs are assembled on the arch rib trestle; (3) the fastening anchorage cables of the steel pipe arch ribs of a first span are hung, and a swivel tensioner is installed; (4) the steel pipe arch ribs of the first span are rotated and closed; (5) the fastening anchorage cables of the steel pipe arch ribs of a second span are hung; (6) the steel pipe arch ribs of the second span are rotated and closed, and the working procedure is repeated until the rotation and the closure of the steel pipe arch ribs of the nth span are finished; (7) arch feet are closed, steeves are adjusted and the construction equipment is disassembled. The present invention has the advantages of convenient construction, safety, reliability and low construction cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

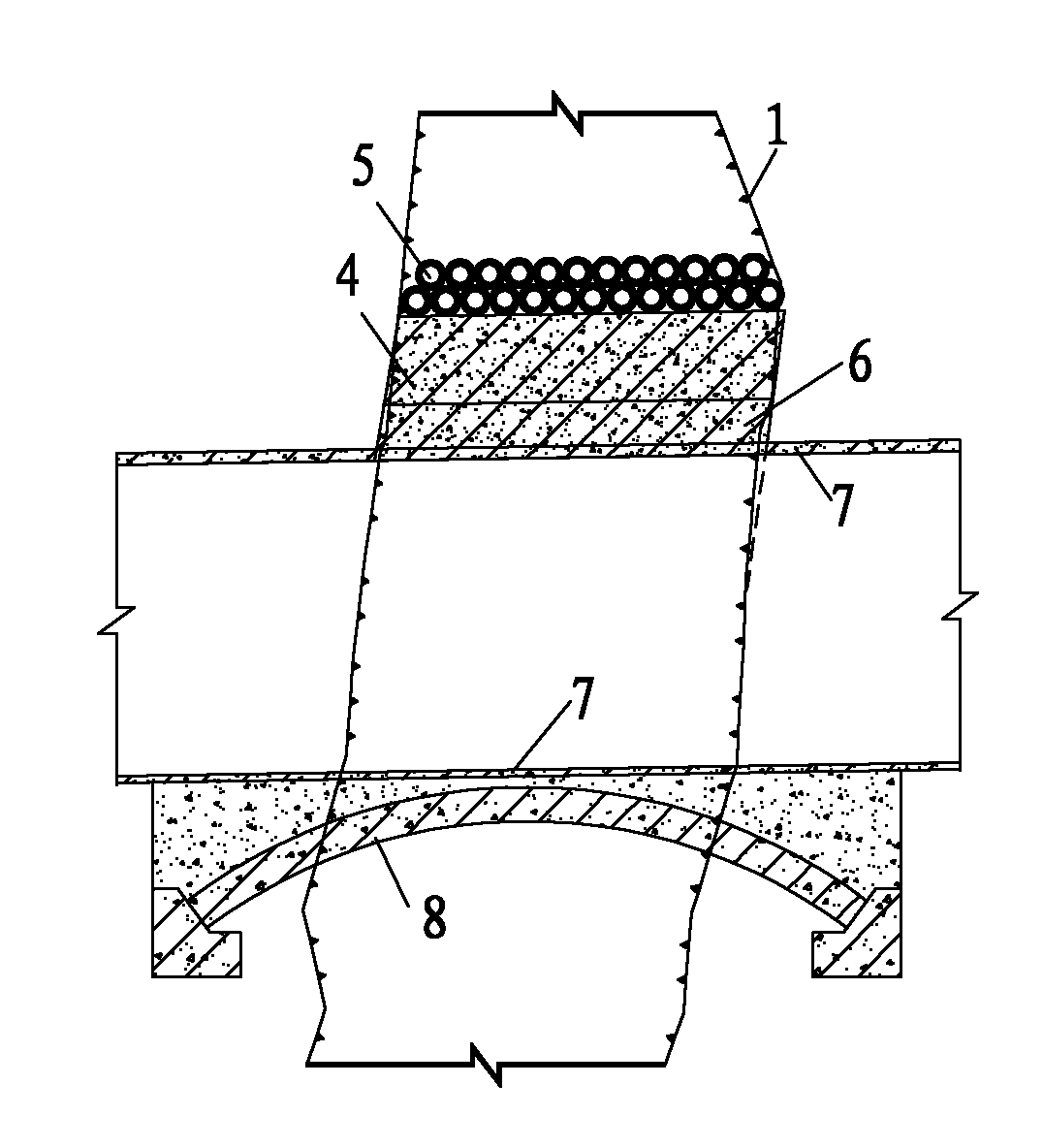

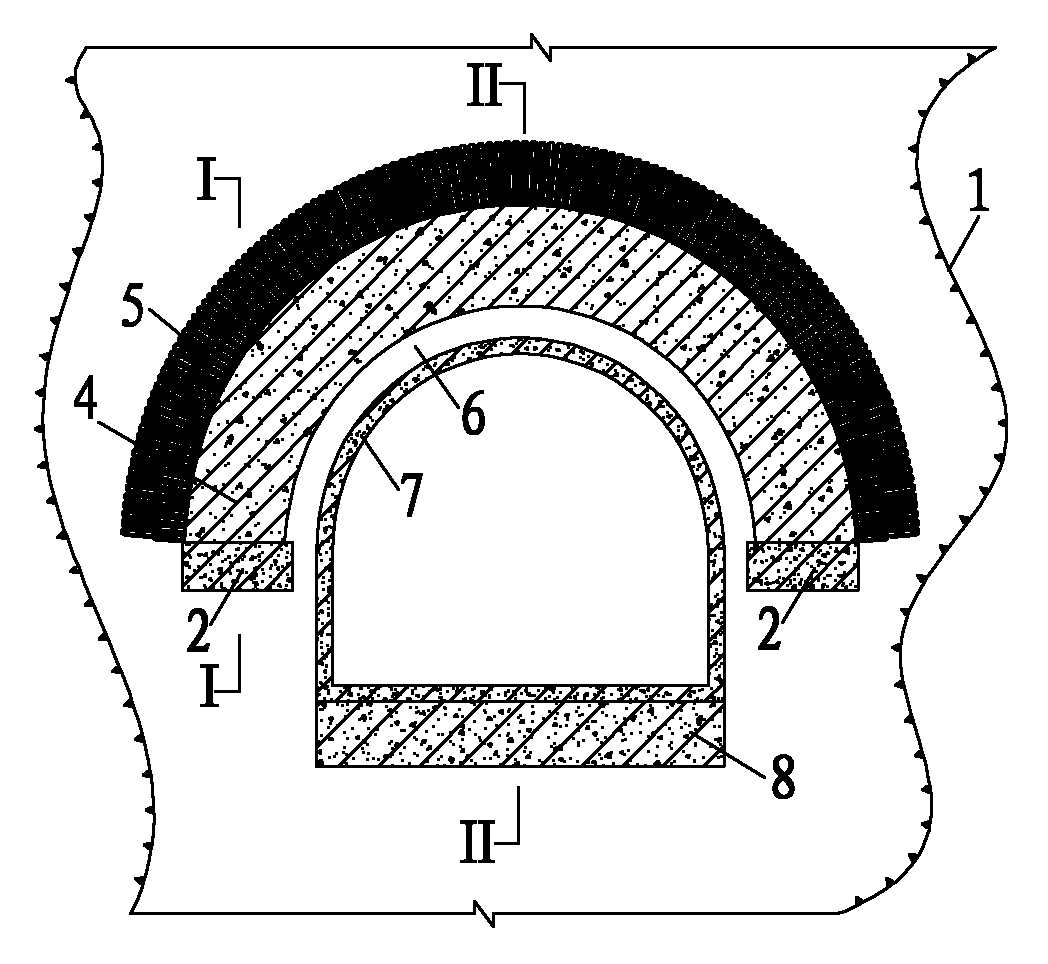

Tunnel protection structure crossing high-top and deep-bottom karst cave

InactiveCN101922301ASerious harm reductionFix security issuesUnderground chambersTunnel liningKarstEngineering

The invention relates to a tunnel protection structure crossing a high-top and deep-bottom karst cave, which is arranged in the high-top and deep-bottom karst cave and comprises a main body structure of a tunnel, a protective cover, a foundation protective cover, a foundation arc structure of the protective cover and a supporting arch bridge of the tunnel. The tunnel protection structure crossing a high-top and deep-bottom karst cave is characterized in that the protective cover is arranged above the main body structure of the tunnel; the foundation arc structure of the protective cover is arranged at the foundation root of the protective cover; and the foundation arc structure of the protective cover spans over the karst cave; a tunnel bottom arc structure spanning over the karst cave is arranged below the main body structure of the tunnel; and the tunnel bottom arc structure supports the main body structure of the tunnel. , by the tunnel protection structure crossing a high-top and deep-bottom karst cave, a high-top and deep-bottom semi-filling karst cave with short longitudinal distance can be protected, the purpose of minimizing serious damage of dangerous falling rocks to projects is realized, and the safety and the reliability of the construction and the long-term operation of the main body structure of the tunnel can be ensured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Prestressing force concrete series rob arch bridge inverted sequence dismounting method

The invention discloses an inverted sequence demolition method of a prestressing concrete tied arc bridge, which comprises adopting demolition of bridge deck tied affiliated projects to reduce self weight; erecting tied girders and arc rib supports, releasing prestressing in the tied girders by steps and phases; demolishing prior suspension rods tension in inverted sequence, cutting and demolishing the support between the arc ribs by steps and phases, removing the arc rib racks, demolishing and hanging off the tied girders and inner beams from the middle to both sides by steps and phases, demolishing end beams and other temporary equipment. The method has strong scientific and safety properties.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Construction method for bridge steel box basket arch

ActiveCN101148860AStructure can be controlledWeld quality can be controlledBridge erection/assemblyEngineeringTotal station

The steel box and basket arch bridge constructing process with 500-ton crane boat and full framing includes the following steps: determining the structural shape, rise-to-span ratio, arch rib toe-in angle and arch rib section form; installing the steel box girder support and midspan steel box girder; hoisting side arch and sidespan steel box girder and finally hoisting arch center. During the process, a total station meter and water level gages are adopted for overall process measurement, and jacks in longitudinal, transverse and vertical directions are utilized to locate the arch ribs and the steel box girder precisely, so as to ensure correct structural form and construction safety. At the same time, ANSYS program for calculating the installation profile and sensors for structure and stress control are also utilized. The constructing process is simple and easy to control, and the steel box and basket arch bridge has high typhoon resistance and high efficiency.

Owner:THE 5TH ENG MBEC +1

Novel reinforcement method for two-way curved arch bridge

InactiveCN106958208AIncrease weightLess weight gainBridge erection/assemblyBridge strengtheningBridge deckOperability

The invention discloses a novel reinforcement method for a two-way curved arch bridge comprising the following steps: (1) closing to traffic on a bridge deck, dismantling the bridge deck and auxiliary facilities of the bridge deck and removing fillings on arches; (2) cutting rectangular grooves along the two-way curved arch bridge on the top of an extrados corresponding to an original arch rib; (3) chipping the bottom of the rectangular grooves, planting anti-shear reinforcement bars, erecting a formwork on the extrados on the top of the rectangular grooves, assembling the anti-shear reinforcement bars and pouring concrete to form new arch ribs, of which the height is same relative to the extrados, protruding from the extrados; (4) repairing transverse walls, chipping the sections, which are at the outer side of the transverse walls along the two-way curved arch bridge, of the extrados and the new arch ribs, planting reinforcement bars on the extrados and the new arch ribs which are chipped, erecting the formwork and pouring the concrete; (5) chipping the top of the transverse walls, planting vertical reinforcement bars and erecting new columns for supporting the bridge deck; (6) newly building the bridge deck. The novel reinforcement method for the two-way curved arch bridge has the advantages of being small in dead weight of a bridge structure, good in unity of an old structure and a new structure, low in reinforcement cost, good in adaptability, not restricted by surroundings under the two-way curved arch bridge, unchanged about the original appearance of the two-way curved arch bridge, good in operability and good in application prospect.

Owner:WUHAN UNIV OF TECH

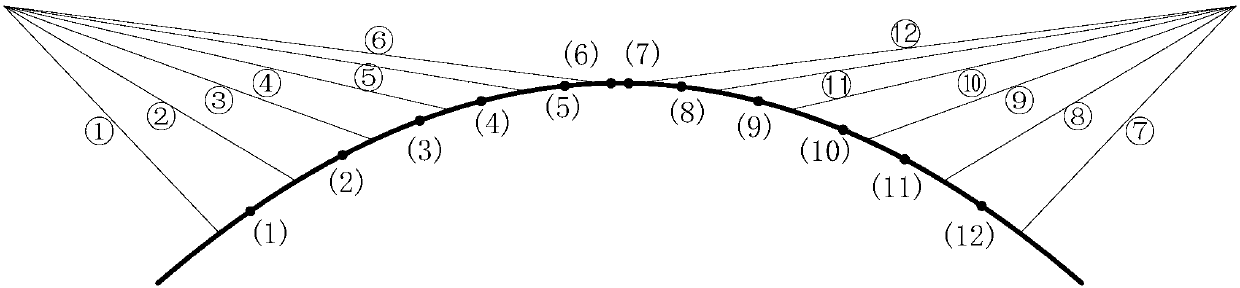

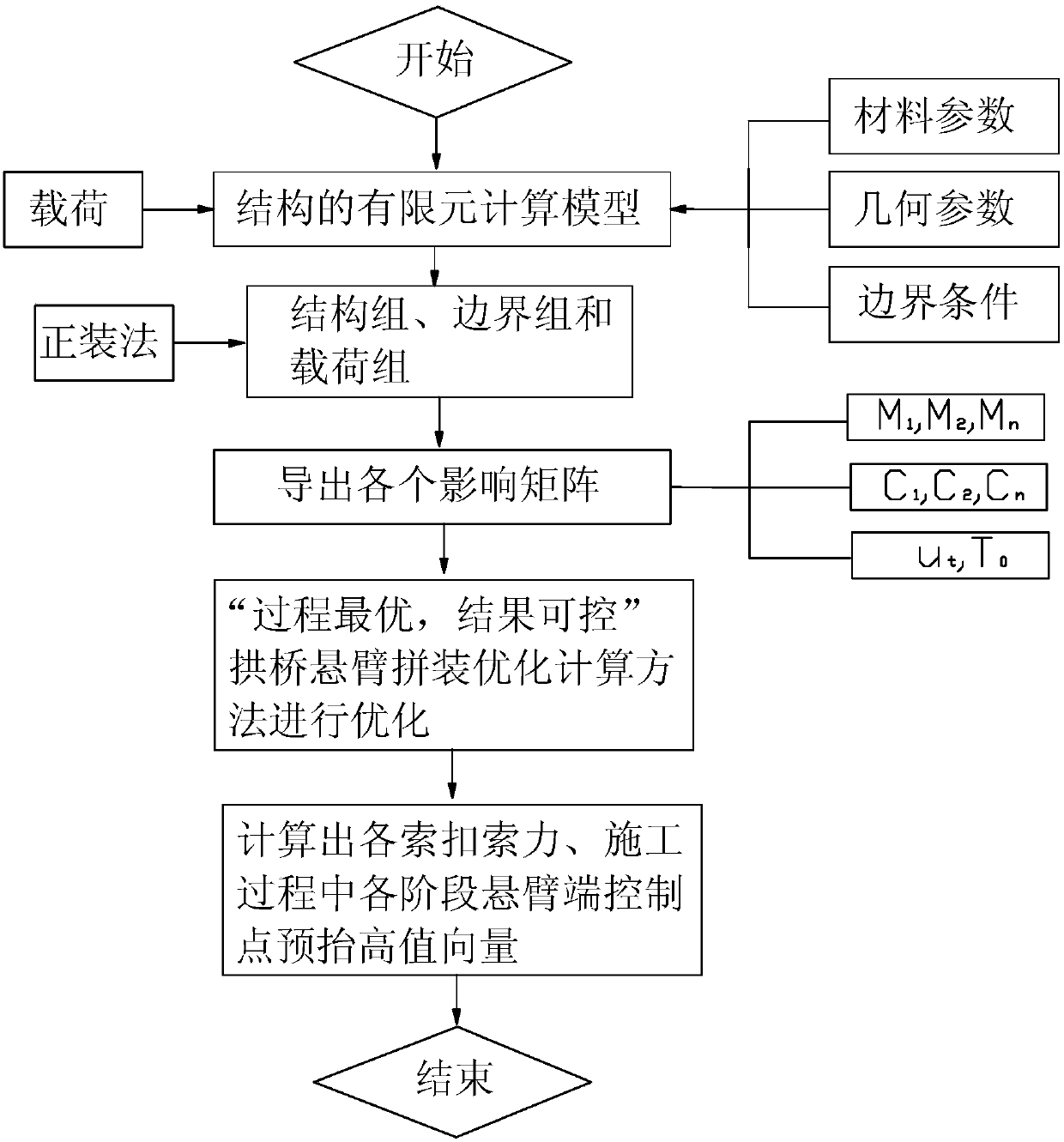

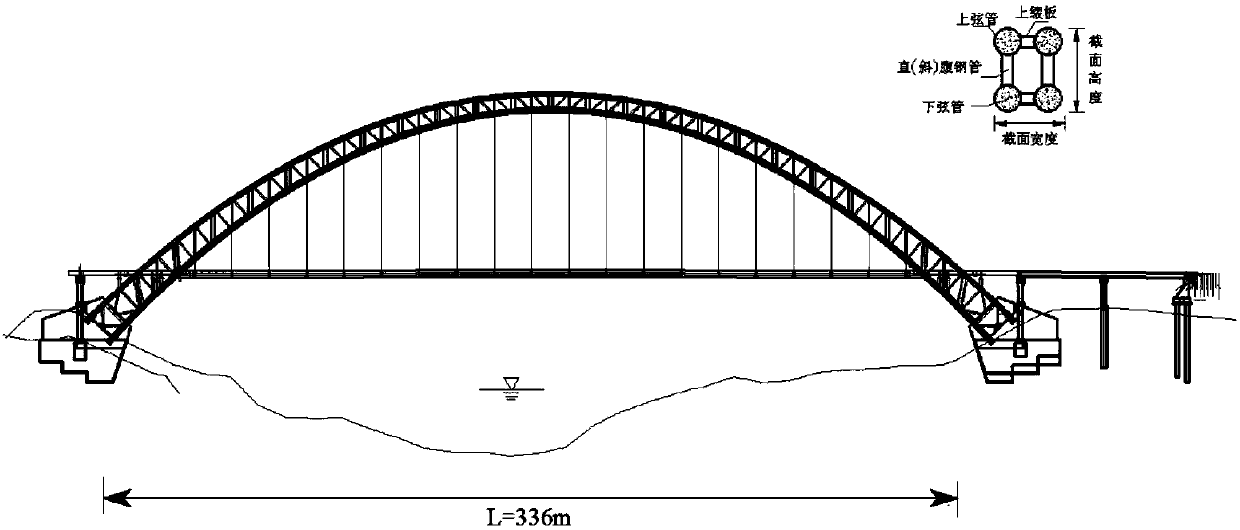

Arch bridge cantilever assembling construction optimization model and optimization calculation method

ActiveCN108038326ASmooth changeNo stress concentrationGeometric CADDesign optimisation/simulationStress concentrationConstraint control

The invention provides an arch bridge cantilever assembling construction optimization calculation method. An actual line shape and a target line shape in each construction lifting stage are strictly controlled, so that the preraised height value of each control node is changed mildly, the cable force uniformity is good, and the stress concentration phenomenon of a material in a construction process does not occur. An arch bridge cantilever assembling construction optimization model has the advantage of relatively few constraint conditions; the constraint condition that a deviation between theline shape after cable tightening and release, and the target line shape is in an allowed range mainly achieves a constraint control effect; and the problems of large buckling cable force gradient, poor uniformity and the like during adoption of a conventional method for performing construction optimization calculation are solved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Chill-cast steel-stranded anchor cable

InactiveCN102587278AEasy to makeEffective surface anti-corrosion treatmentBridge structural detailsCable stayedEngineering

A chill-cast steel-stranded anchor cable relates to a prestressed cable and comprises a finished cable body and a chill-cast anchor. The chill-cast anchor comprises a chill-cast anchor cup, an anchor plate, a seal cylinder and a seal device, wherein the anchor plate is mounted at an opening of the chill-cast anchor cup, the seal cylinder is connected to the bottom of the chill-cast anchor cup, and the seal device is mounted in the seal cylinder. The finished cable body is a steel-stranded finished cable body, steel strands at the bare-wire end of the cable body are positioned in anchor holes of the anchor plate, central wires of the steel strands pass through small tapered plugs in the anchor holes of the anchor plate and headed and fixed to the end faces of the small tapered plugs, and other steel wires are positioned around the small tapered plugs and scattered to form large tapered plugs. Other positions of the bare-wire end of the steel-stranded finished cable body are disposed in the chill-cast anchor cup and the seal cylinder, and chill casting material and anticorrosion material are filled among the other positions, the chill-cast anchor cup and the seal cylinder. The chill-cast steel-stranded anchor cable has the advantages of simplicity in manufacture, reliable anchorage, low manufacturing cost and wide application range, and is especially suitable for cable-stayed bridges, suspender arch bridges and suspension bridges.

Owner:柳州豪姆机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com