Patents

Literature

404results about How to "No stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

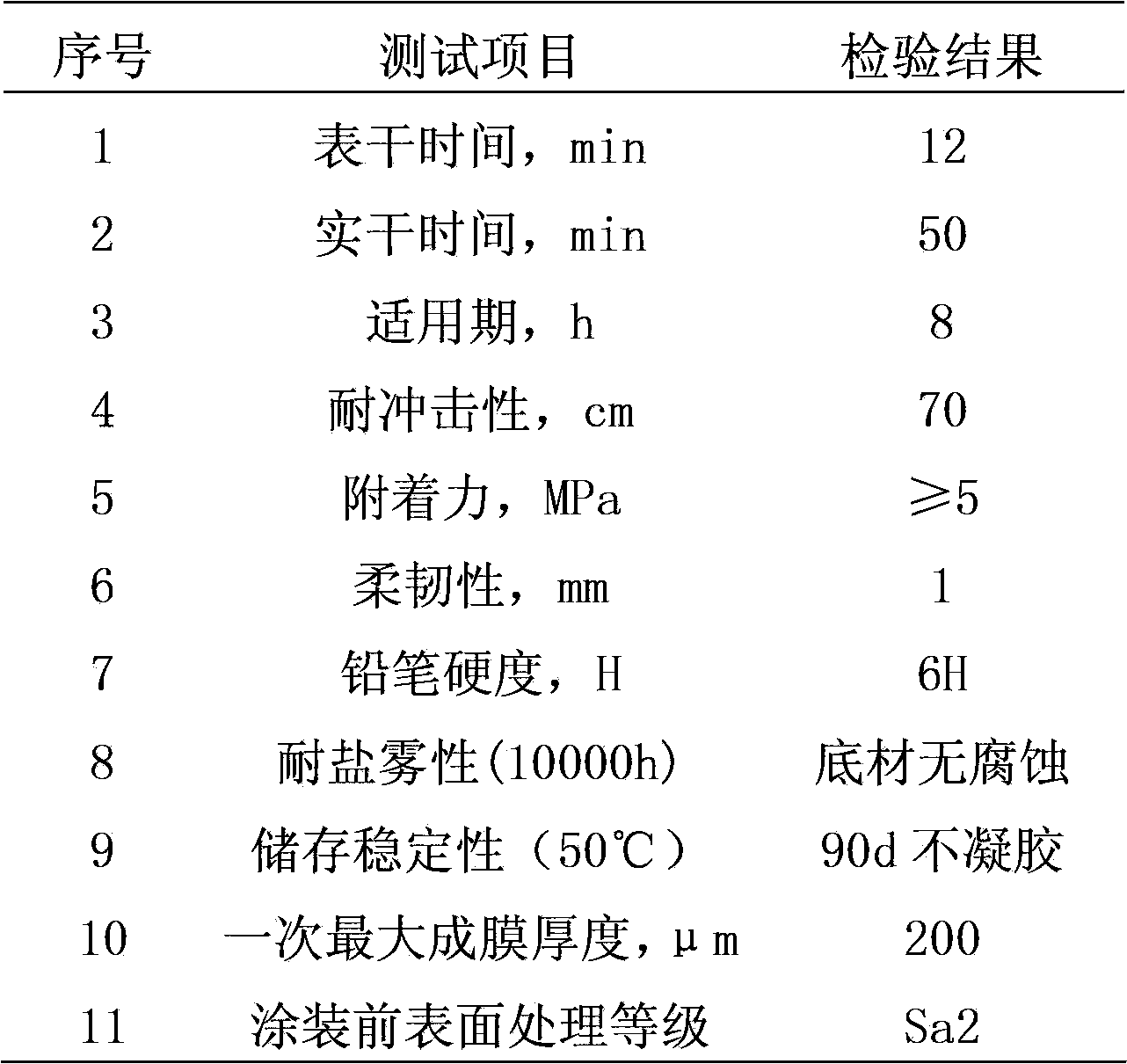

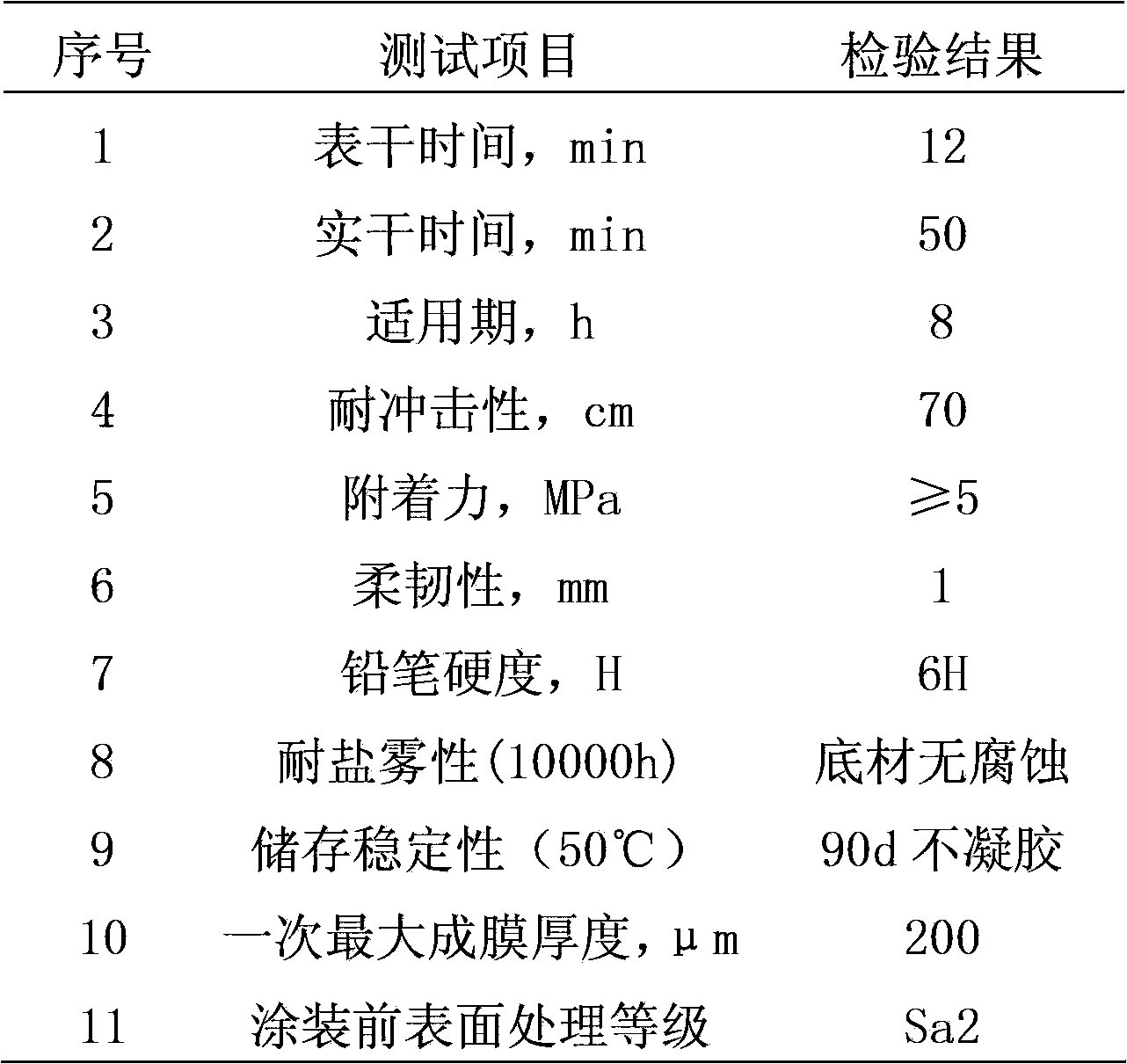

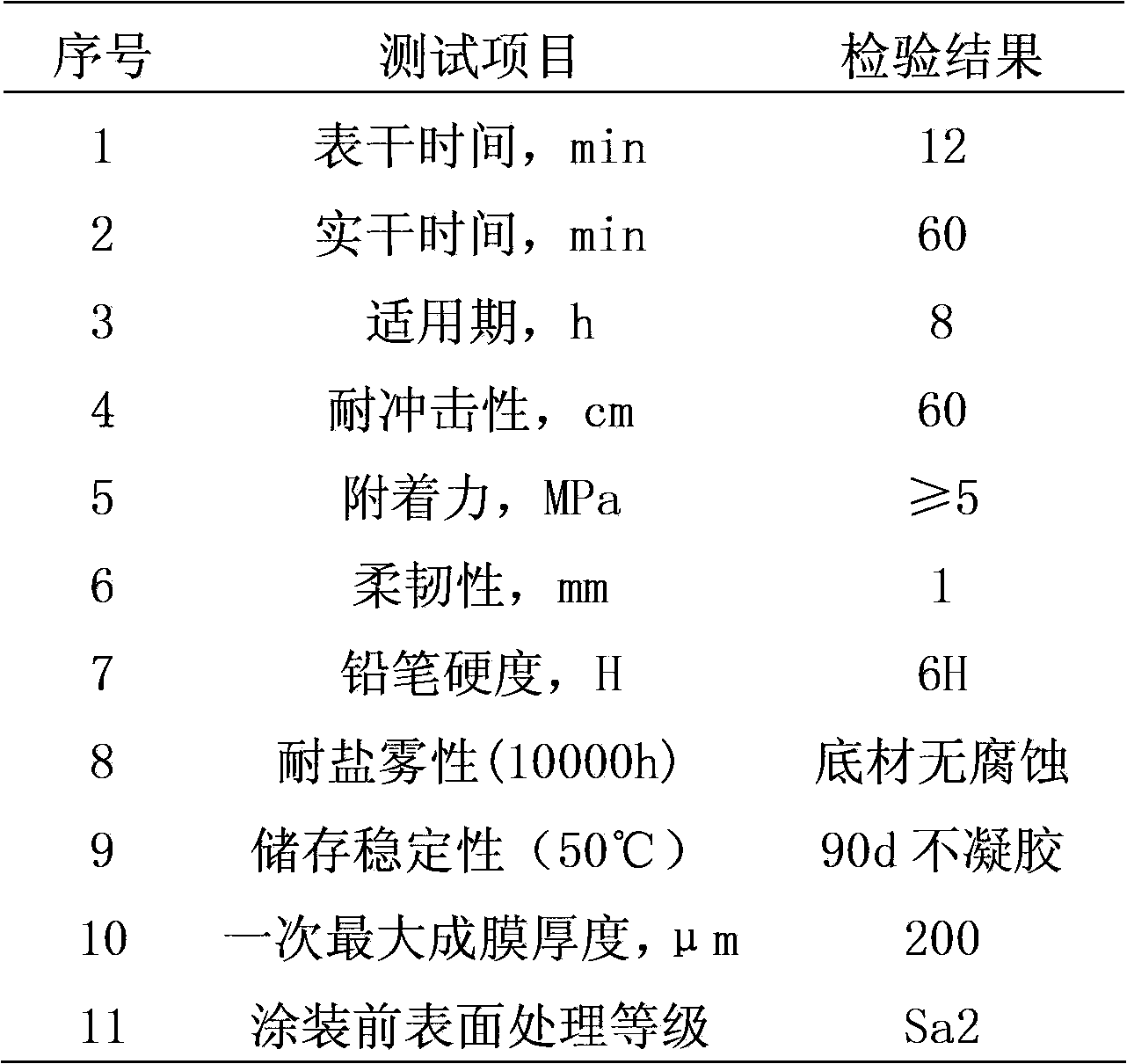

Water-soluble inorganic zinc-rich paint and preparation method thereof

ActiveCN103788734AUniform particle size distributionUniform reaction rateAlkali metal silicate coatingsStress concentrationPowder mixture

The invention provides a water-soluble inorganic zinc-rich paint and a preparation method thereof. The preparation method comprises the following steps: dropwise adding aluminum-modified silica sol into potassium silicate solution with low modulus, so as to obtain a high-modulus potassium silicate solution as a binder; and adding a catalyst, a siloxane oligomer and a modifier to ensure that the high-modulus potassium silicate solution are uniform in size distribution, and does not have gelatinization reaction for a long time, wherein after the high-modulus potassium silicate solution and a zinc powder mixture are stirred uniformly, the zinc-rich paint has the advantages that reaction rates of all parts of a coating are uniform, and no stress concentration phenomenon exist. Proved by experiments, the zinc-rich paint provided by the invention has no gel after being stored for 90 days at 50 DEG C, the thickness of a film formed once can reach 200 mu m, no cracking or bubbling phenomenon exists, construction can be carried out after the treatment level of the steel surface reaches Sa2, and the salt fog resistance of the coating can reach 10000 hours.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

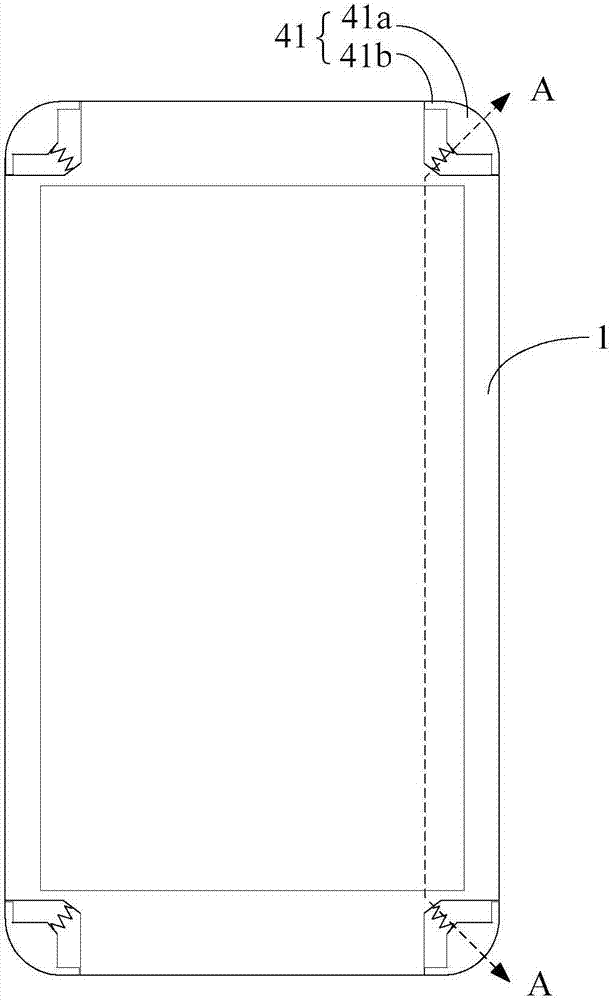

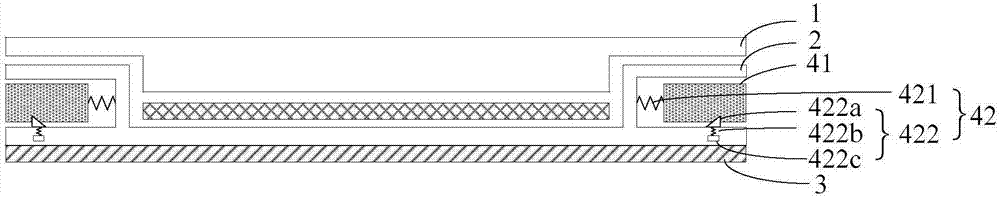

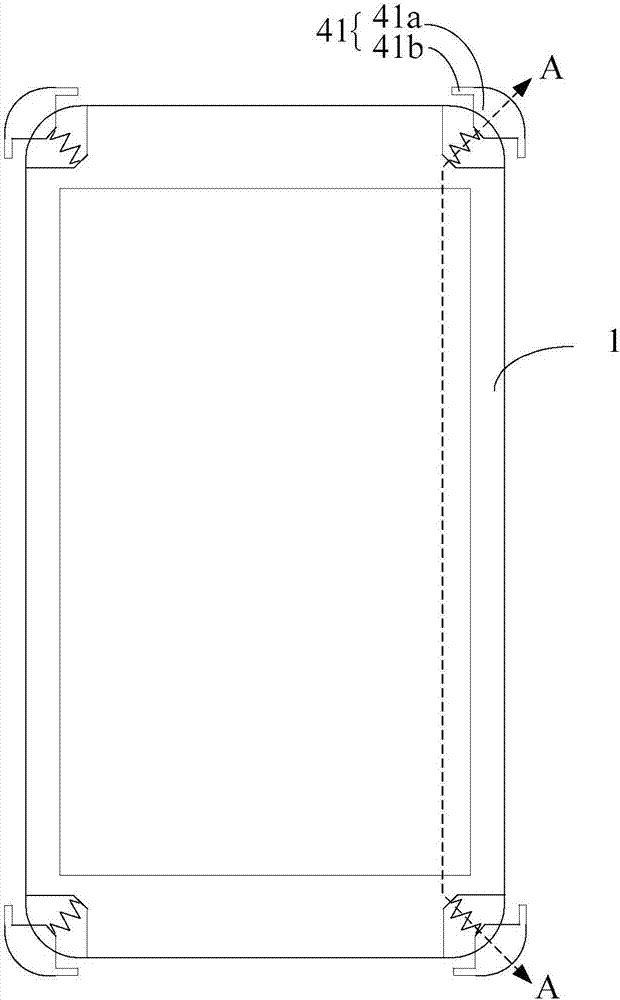

Mobile terminal and falling protection method thereof

ActiveCN107094194AReduce impact stressGood cushioning effectDigital data processing detailsDevices with sensorFall protectionImpact stress

The invention discloses a mobile terminal and a falling protection method thereof and belongs to the technical field of mobile communication. The mobile terminal comprises a display panel, a middle frame, a rear shell, a protection module and a detection module. The middle frame is mounted in the rear shell. The display panel is arranged on the middle frame. The protection module comprises a buffering popup block and a popup block control unit. The buffering popup block is mounted on the middle frame. The popup block control unit is used for controlling the buffering popup block to be popped up when the detection module detects falling of the mobile terminal. At the moment when the mobile terminal falls to the ground, the buffering popup block absorbs the impulse generated in the falling process of the mobile terminal, the instantaneous impact stress of the mobile terminal is reduced, so a module is protected, and a stress concentrated phenomenon is avoided. The buffering popup block is arranged on the middle frame, so the mobile terminal can be protected well, and the problems such as screen breakage and internal module damage resulting from the falling of the mobile terminal can be avoided.

Owner:BOE TECH GRP CO LTD +1

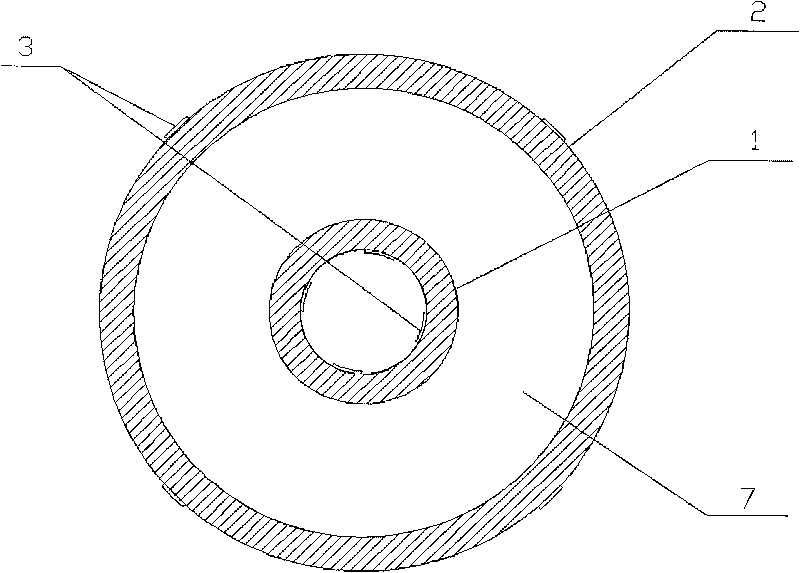

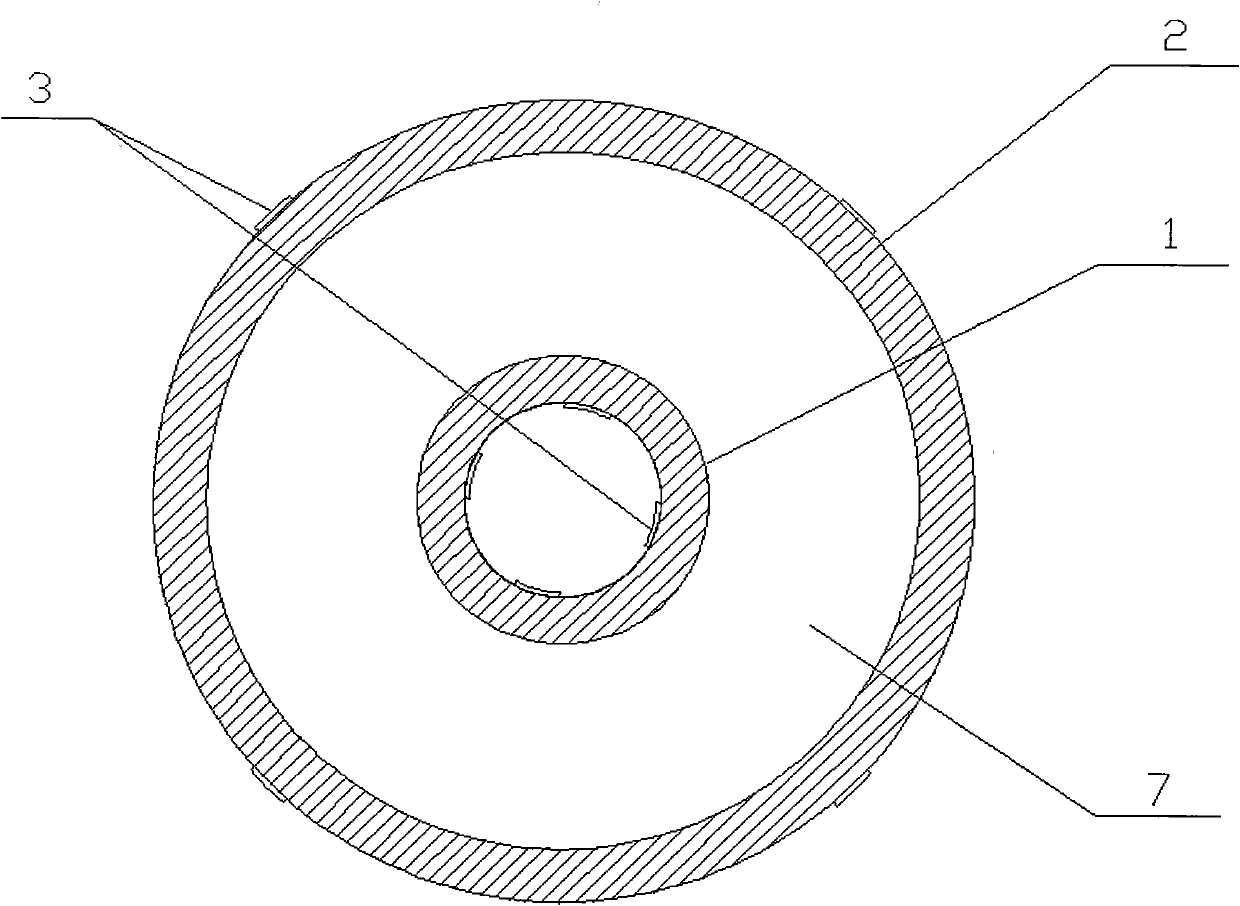

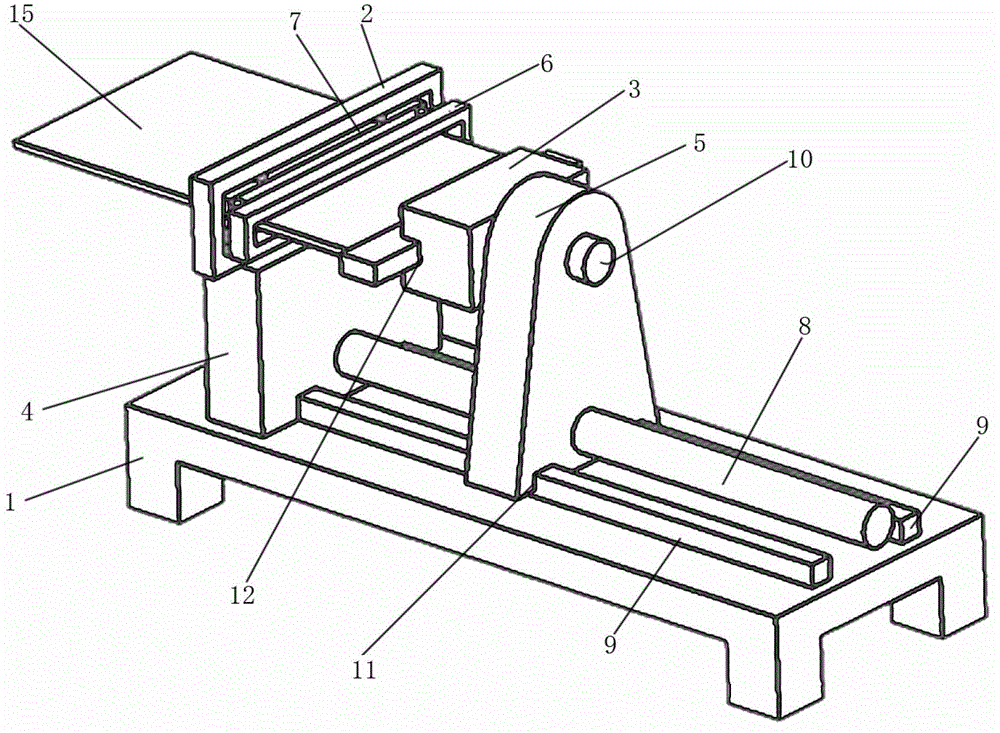

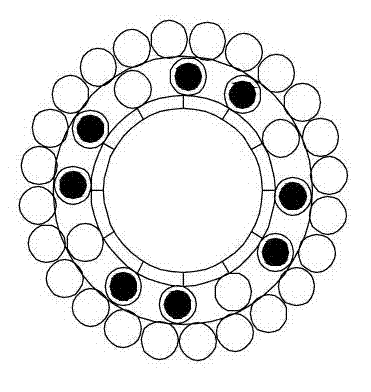

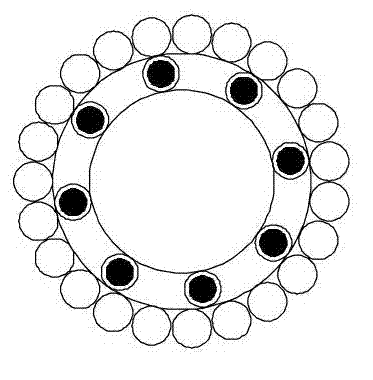

Expansion/shrinkage stress testing device for cement-based material

ActiveCN101738459AEasy to analyzeEasy to compareMaterial testing goodsElectricityStrength of materials

The invention relates to an expansion / shrinkage stress testing device for a cement-based material, which comprises an inner circular ring and an outer circular ring which are coaxial and have the same height, and a stress testing device and a data acquisition device which are electrically interconnected, wherein the inner circular ring and the outer circular ring are made of the same material; and the stress testing device comprises a plurality of test stress plates which are distributed evenly along the circumferential direction on the outer surface of the outer circular ring and the inner surface of the inner circular ring and are electrically connected with the data acquisition device. When the testing device is used, the cement-based material (such as pure slurry, mortar or concrete) is cast between the two rings. The expansion and shrinkage stress can be calculated according to the analysis of material mechanics by measuring the stress. Compared with the prior method, the testing device has the main advantages that: a, the testing device is simple, and simple and convenient to operate; b, the restraint stress is even; and c, the testing of starting self water addition molding can be implemented, the testing process needs no manpower to move the test piece, and continuous and automatic test can be realized.

Owner:JIANGSU SOBUTE NEW MATERIALS

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

Method for testing expansion/contraction stress of cement-based material

ActiveCN101769916AEasy to analyzeEasy to compareElectrical/magnetic solid deformation measurementMaterial testing goodsElectricityRestraint stress

The invention relates to a method for testing expansion / contraction stress of a cement-based material, which adopts a device for testing the expansion / contraction stress of the cement-based material is adopted. The device comprises inner and outer circular rings which are coaxially arranged and have the same height, and a strain testing device and a data acquisition device which are mutually electrically connected, wherein the materials of the inner and the outer circular rings are the same; the strain testing device comprises a plurality of testing strain gauges; the strain gauges are distributed on the external surface of the outer circular ring and the internal surface of the inner circular ring uniformly along a circumferential direction, and each testing strain gauge is electrically connected with the data acquisition device; the cement-based material is poured between the inner and the outer circular rings, and the strain of the inner and the outer circular rings is tested; and the expansion / contraction stress at a position where the internal radius of the cement-based material is r is calculated according to a formula (I). The method has the advantages that a, the test device is simple, and the operation is simple and convenient; b, restraint stress is uniform; and c, the method can test at the initial stage of watering moulding without moving test specimens, and continuous and automatic test.

Owner:JIANGSU SOBUTE NEW MATERIALS

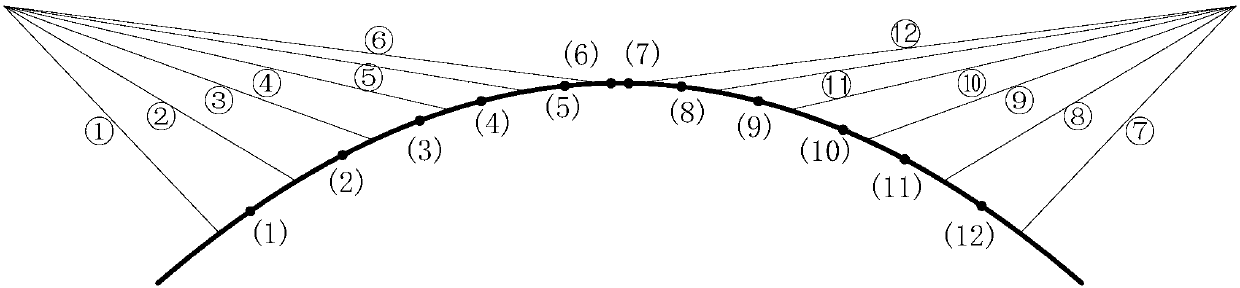

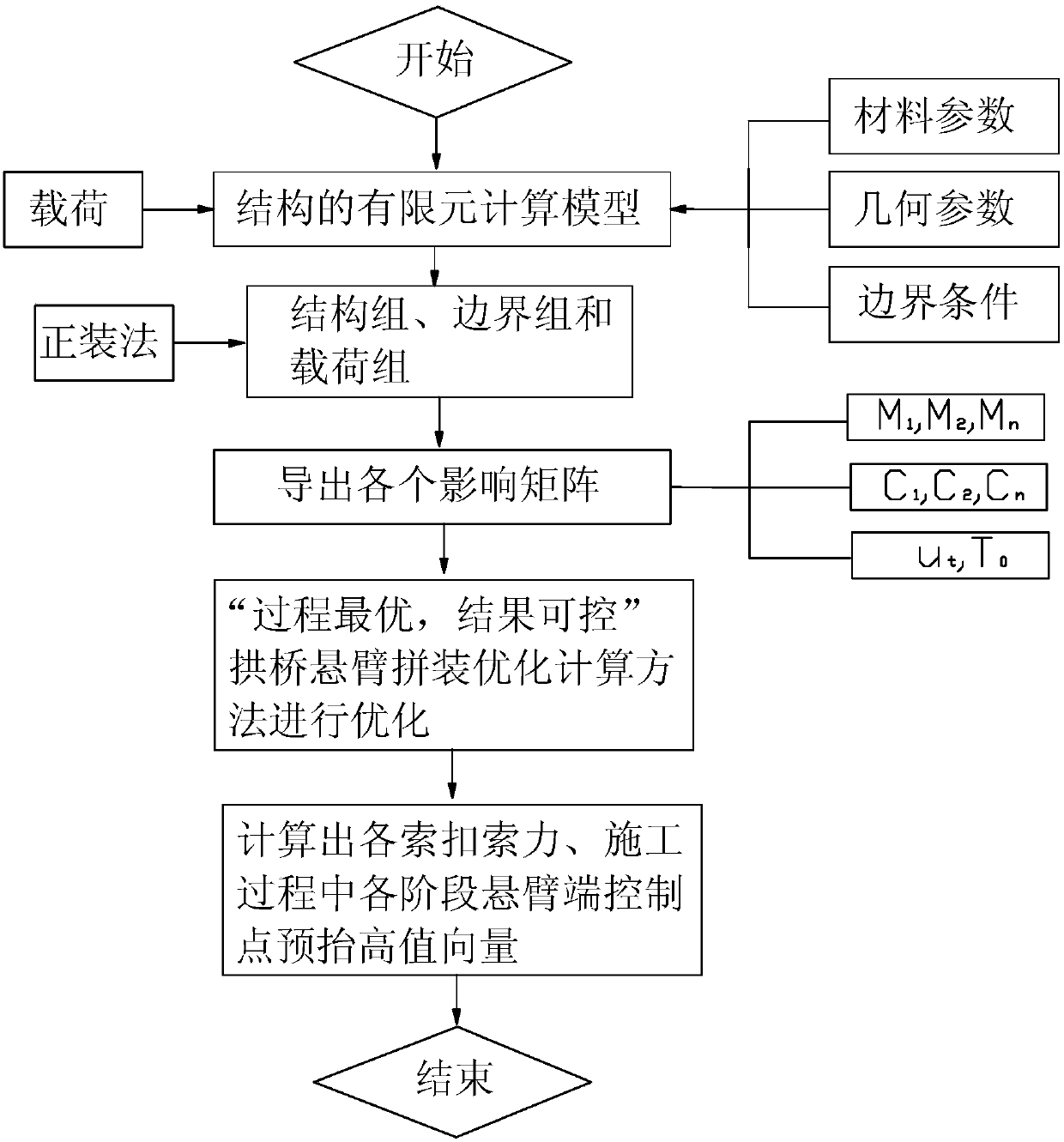

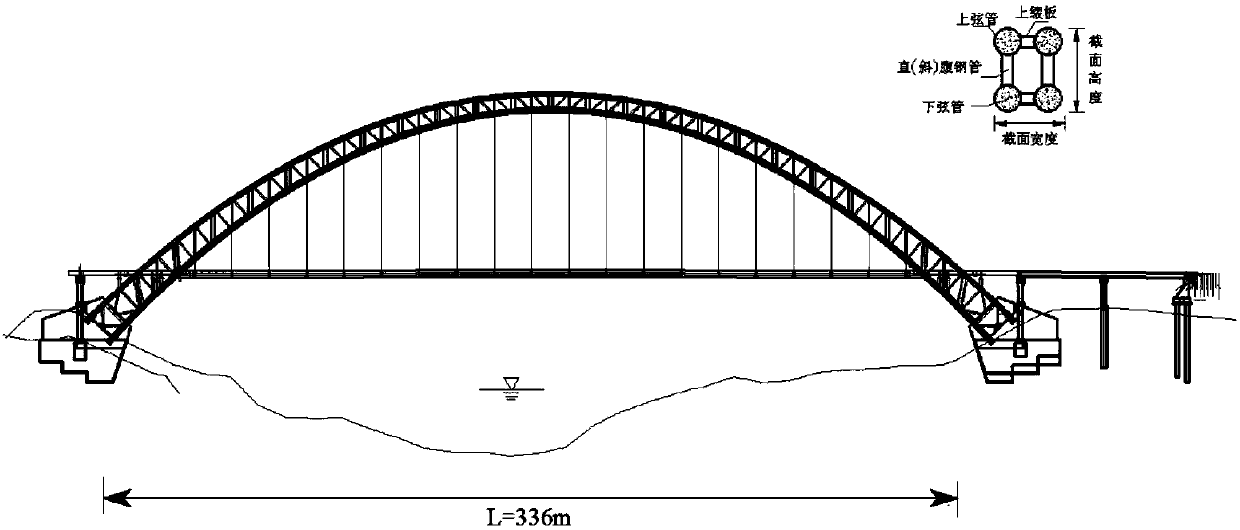

Arch bridge cantilever assembling construction optimization model and optimization calculation method

ActiveCN108038326ASmooth changeNo stress concentrationGeometric CADDesign optimisation/simulationStress concentrationConstraint control

The invention provides an arch bridge cantilever assembling construction optimization calculation method. An actual line shape and a target line shape in each construction lifting stage are strictly controlled, so that the preraised height value of each control node is changed mildly, the cable force uniformity is good, and the stress concentration phenomenon of a material in a construction process does not occur. An arch bridge cantilever assembling construction optimization model has the advantage of relatively few constraint conditions; the constraint condition that a deviation between theline shape after cable tightening and release, and the target line shape is in an allowed range mainly achieves a constraint control effect; and the problems of large buckling cable force gradient, poor uniformity and the like during adoption of a conventional method for performing construction optimization calculation are solved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

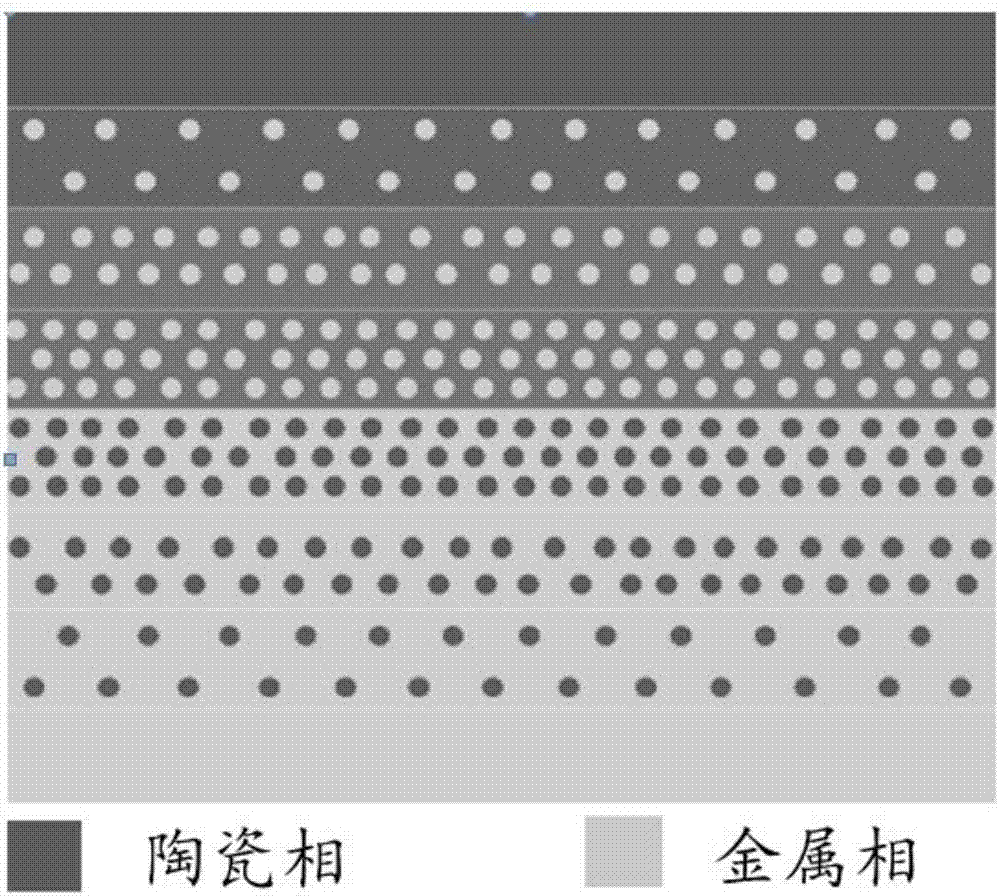

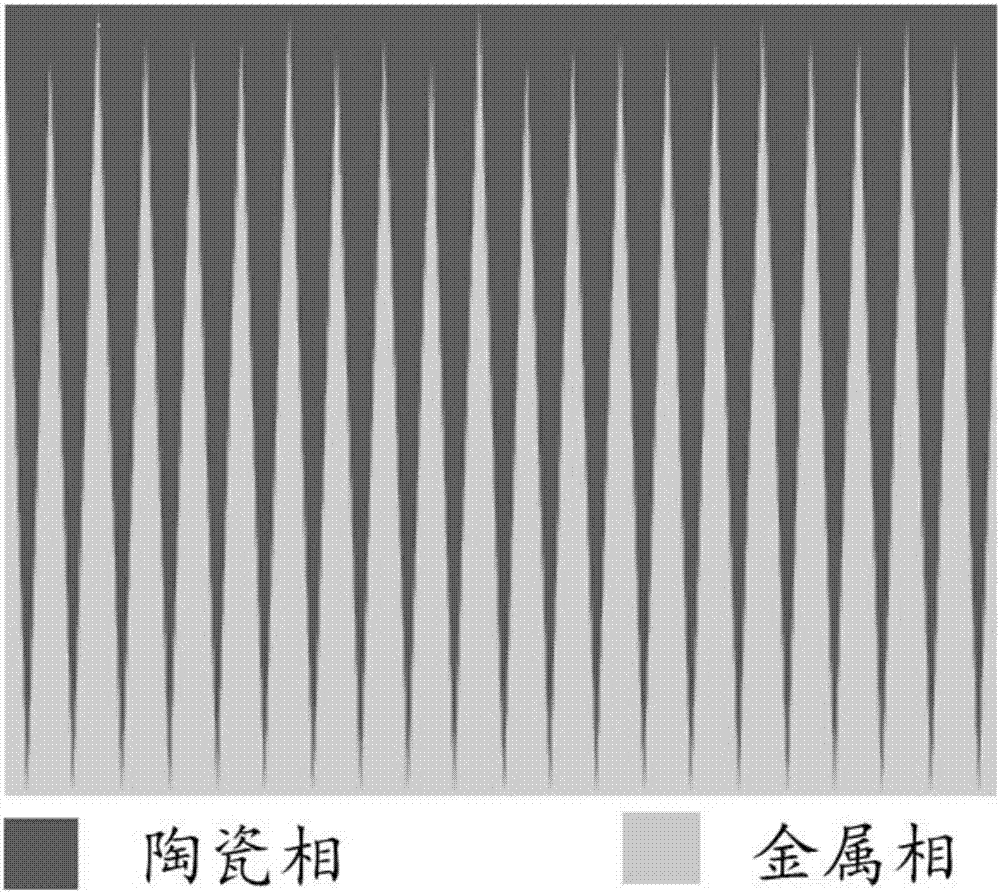

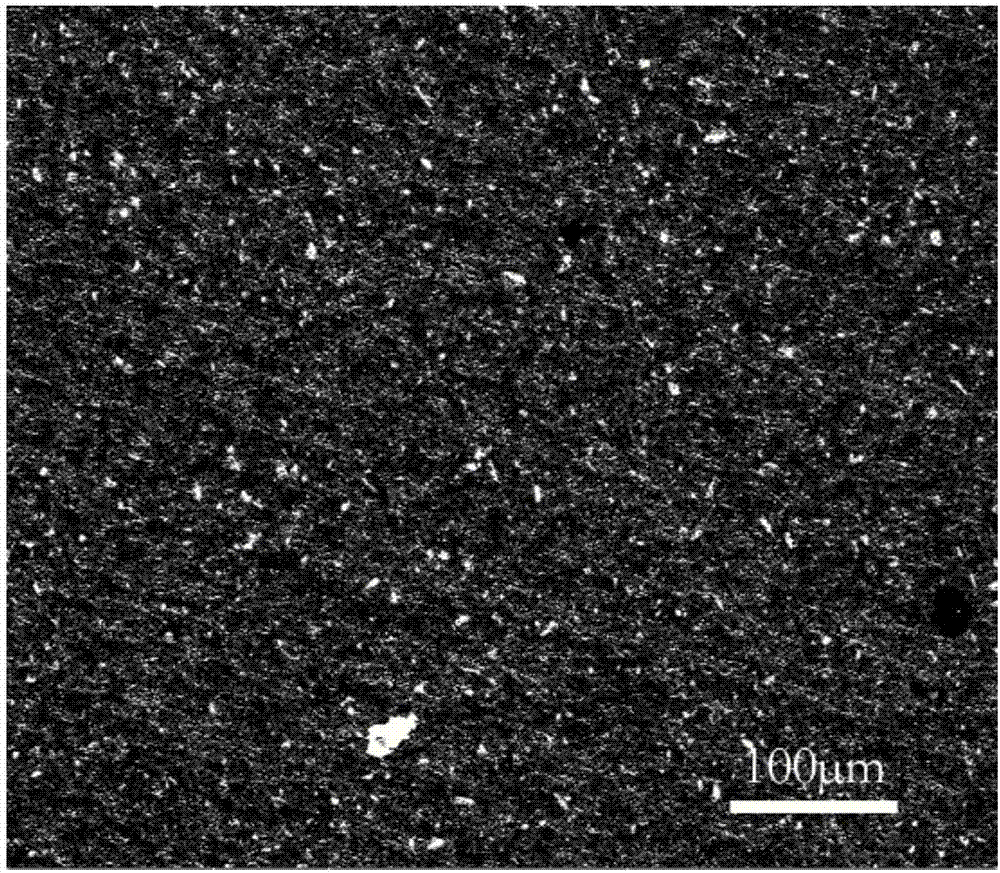

Ceramic/metal composite of gradient double-continuous structure and preparation method and application of ceramic/metal composite

The invention provides a ceramic / metal composite of a gradient double-continuous structure. The ceramic / metal composite is formed by compounding a porous ceramic material with the porosity continuous gradient and a metal material arranged in holes of the porous ceramic material in a filling manner. Any one of Al2O3, SiC, Si3N4, B4C and TiB2 is used as the ceramic material. Any one of an aluminum alloy, a magnesium alloy and an iron alloy is used as the metal material. The ceramic / metal composite has the beneficial effects that in the ceramic / metal composite of the gradient double-continuous structure, ceramic phases and metal phases form the double-continuous structure; and in the structure, due to the continuous distribution of the metal phases, when stressed, the composite is evenly stressed due to the transmission function of the metal phases, no stress concentration is generated, and the composite has the higher bearing capacity and the impact resistance.

Owner:HARBIN INST OF TECH

Composite fabrication process for tooth blank of automobile gear shifting box combining tooth

The invention is a compound making technique of automobile gear-box combined gear blanks, adopting finely forge-molding processing method. It heats the blank material to 1000-1200 deg.C, premolding the blank material on a hot mold forging press, after constant-temperature normalizing, eliminating oxide debris by impeller cleaning, and surface bonderizing and phosphatization, making cold-refining on tooth form, and finally making cone molding on the tooth by radial extruding method. It instantaneously completes hot mold forging premolding, refining, and cone molding on the press without cutting, saving material, saving labor, low-cost, high-efficiency, long-service life. The combined tooth root has no escrape, it has no stress concentration phenomenon and the tooth has high strength; the extrusion molding of the gear blank does not destroy metallic streamlines, it heightens the synthetic performance, the product quality is stable and can meet use and industrialized production requirements of top-grade autocars.

Owner:夏汉关 +1

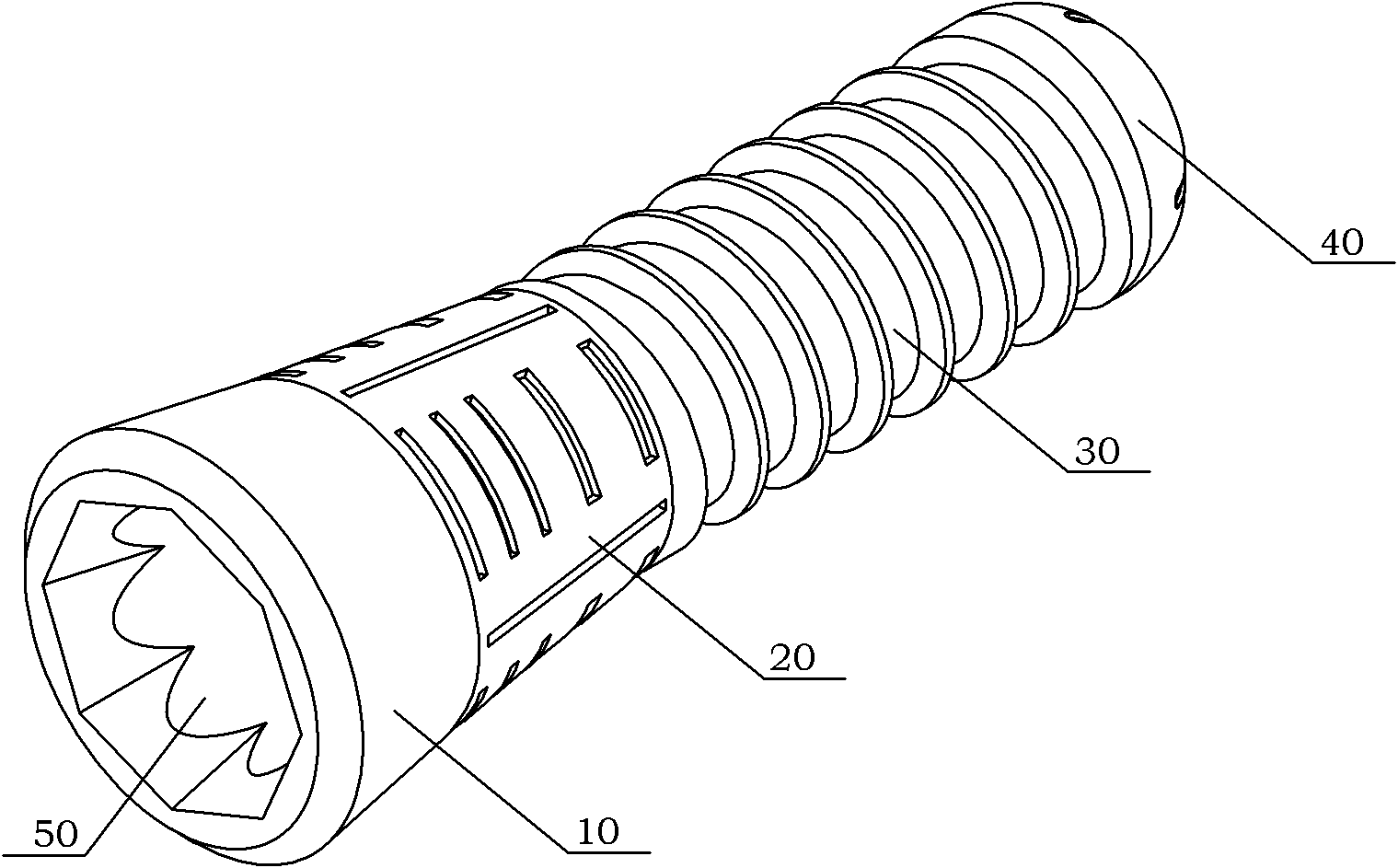

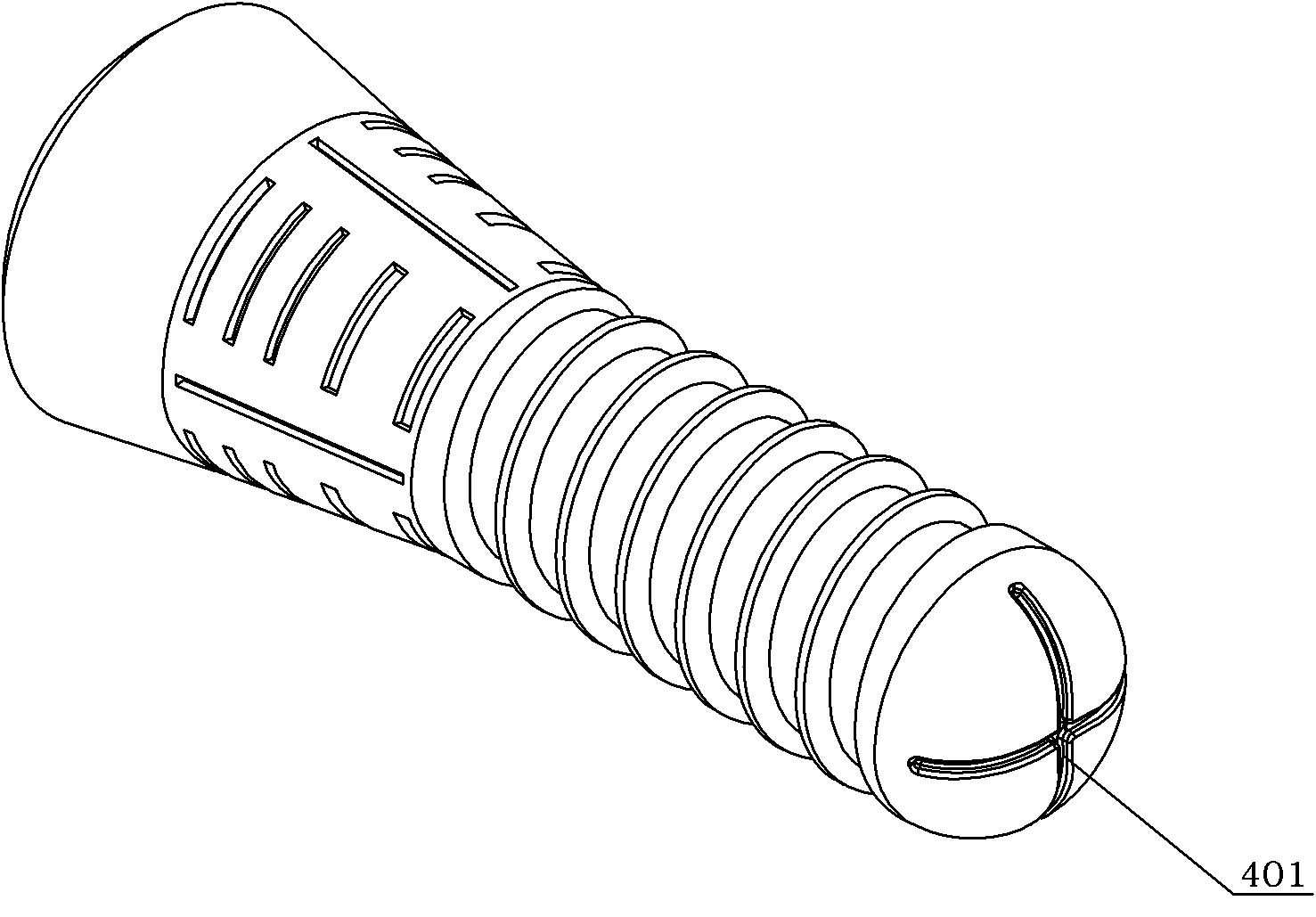

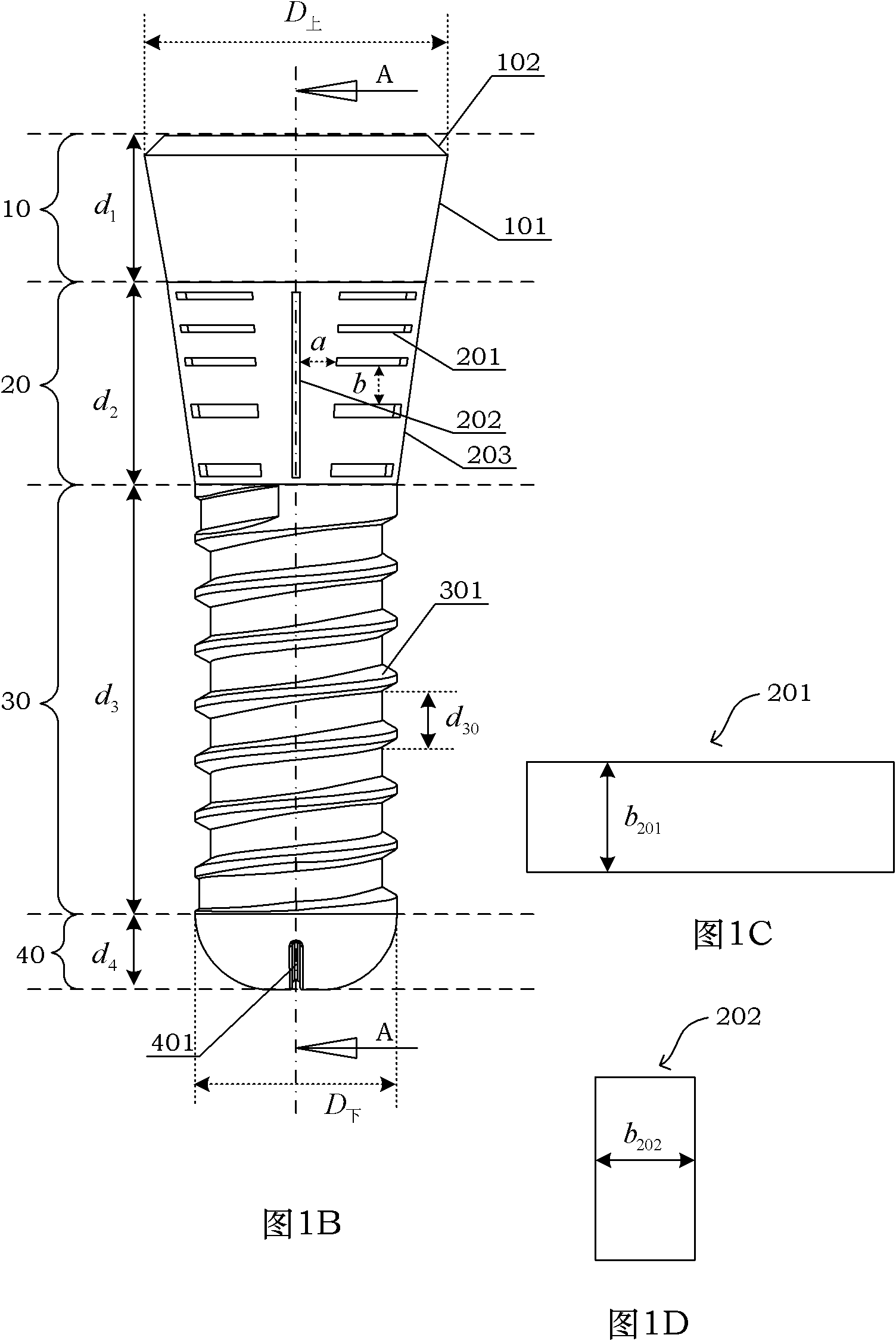

Oral implant with appropriate initial-stage load stimulation

InactiveCN102160821AAvoid stress concentrationAvoid bone resorptionDental implantsSpongy boneBone Cortex

The invention discloses an oral implant with appropriate initial-stage load stimulation. The oral implant is designed into an integrated structure and is divided into a gingival penetration section, a cortical bone fixing section, a spongy bone fixing section and a lead-in fixing section from top to bottom, wherein the center of the oral implant is a composite cavity; the outer surface of the cortical bone fixing section is provided with growing grooves which are staggered longitudinally and transversely; and the lead-in fixing section is 1 / 3 of a segment, and a cross groove is formed at the bottom of the lead-in fixing section. After the implant disclosed by the invention is implanted, an appropriate stress environment is generated in an alveolar ridge crest region, thereby effectively avoiding bone injury and bone absorption, and being favorable for exciting bone remodeling and promoting bone integration. In addition, the growing grooves which are staggered longitudinally and transversely can induce the growth of new bones to form a stable mechanical mosaic structure, thereby being suitable for complex oral occlusion mechanical environments.

Owner:BEIHANG UNIV

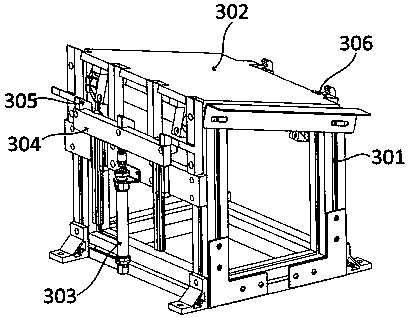

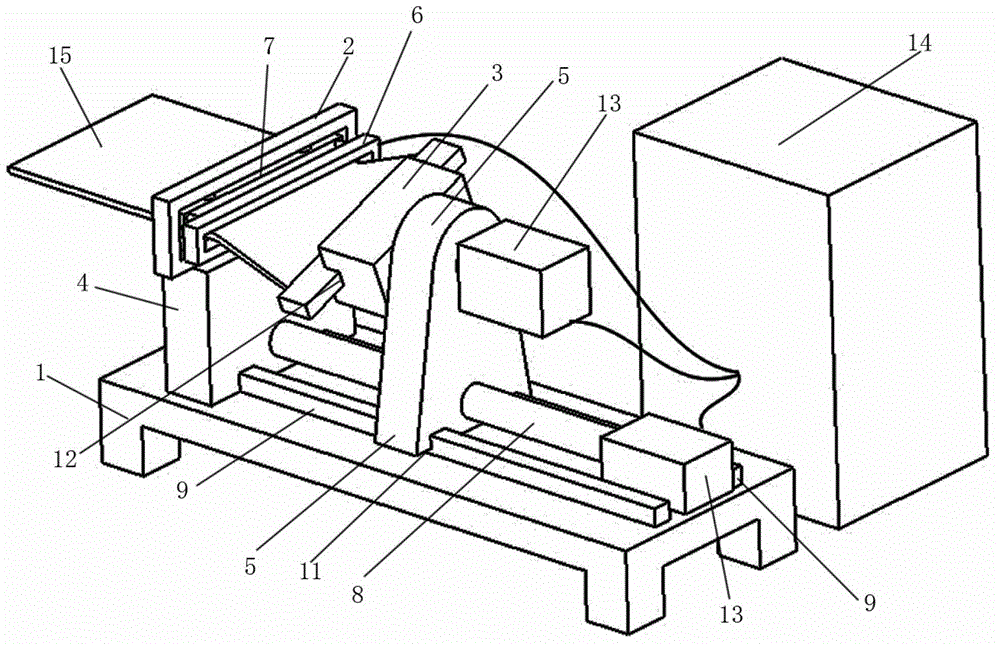

Pipe polishing machine and polishing method thereof

ActiveCN110253412AReduce work intensityHigh automation efficiencyPolishing machinesFlexible-parts wheelsEngineeringUltimate tensile strength

The invention discloses a pipe polishing machine and a polishing method thereof, and belongs to the field of surface polishing. The polishing machine comprises a base mechanism, a feeding mechanism, a polishing mechanism and a discharging mechanism, wherein the base mechanism comprises a machine frame and a machining table top arranged above the machine frame; the feeding mechanism comprises a disc feeding device arranged on the machining platform top, a pipe sliding platform and two linear propelling mechanisms arranged at the starting end and the tail end of the pipe sliding platform; the polishing mechanism comprises an outer surface polishing device and an inner surface polishing device; the outer surface polishing device and the inner surface polishing device are respectively aligned with the two propelling mechanisms. According to the polishing machine, a conveying belt, the disc feeding device and the pipe sliding platform are matched to replace manual feeding and discharging, the working intensity of workers is reduced, and the automation efficiency is improved; and a polishing head of the inner surface polishing device is made of sand cloth and is designed in a cross shape, so that the polishing acting force is more uniform, and the quality of polished products is improved.

Owner:黄冈艾格尔五金制造有限公司

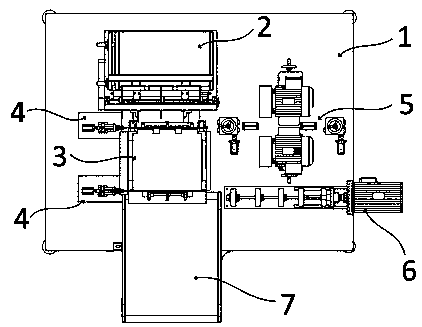

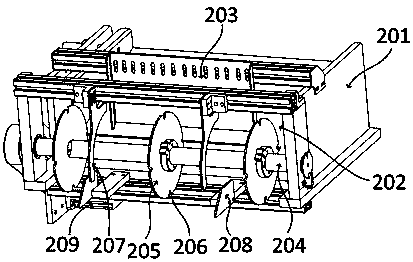

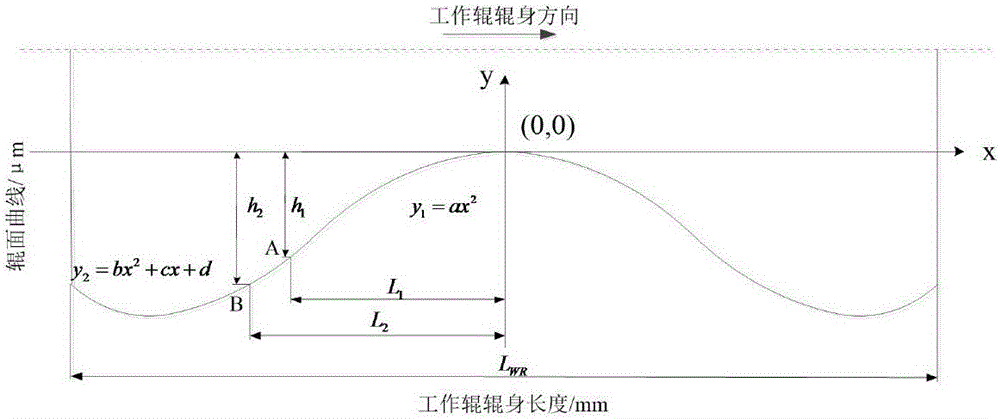

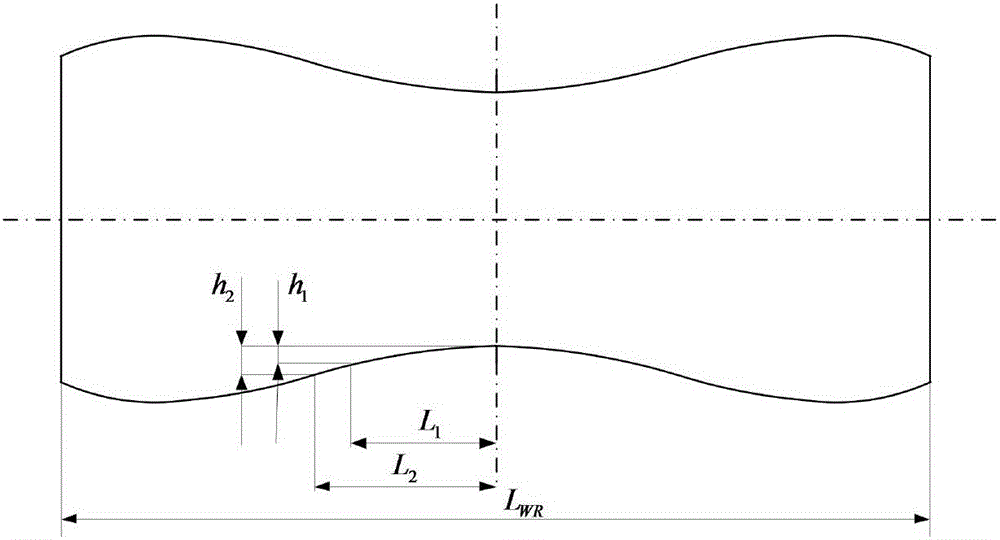

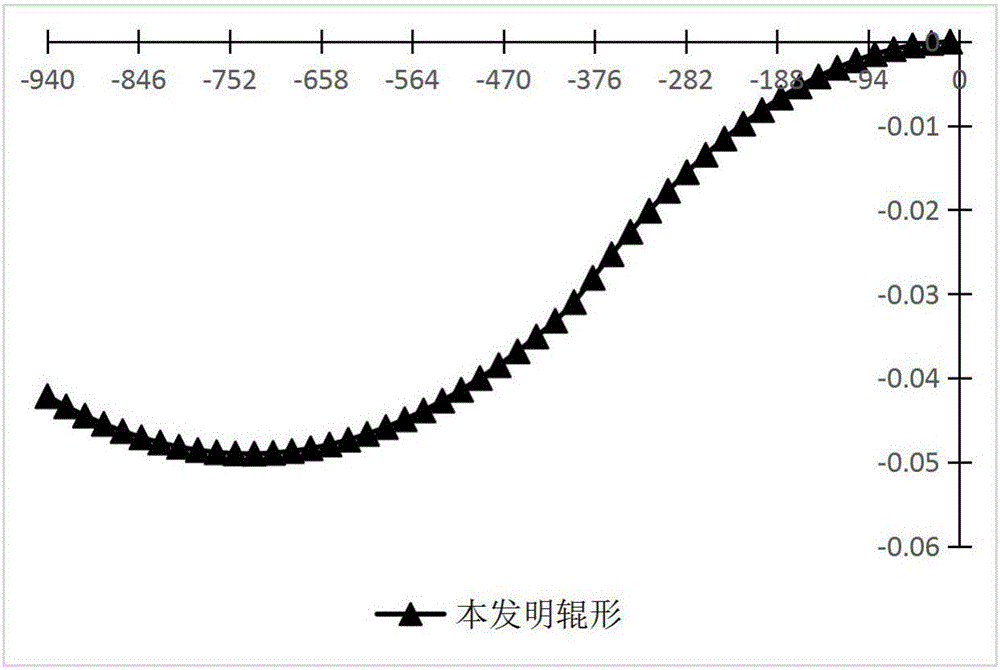

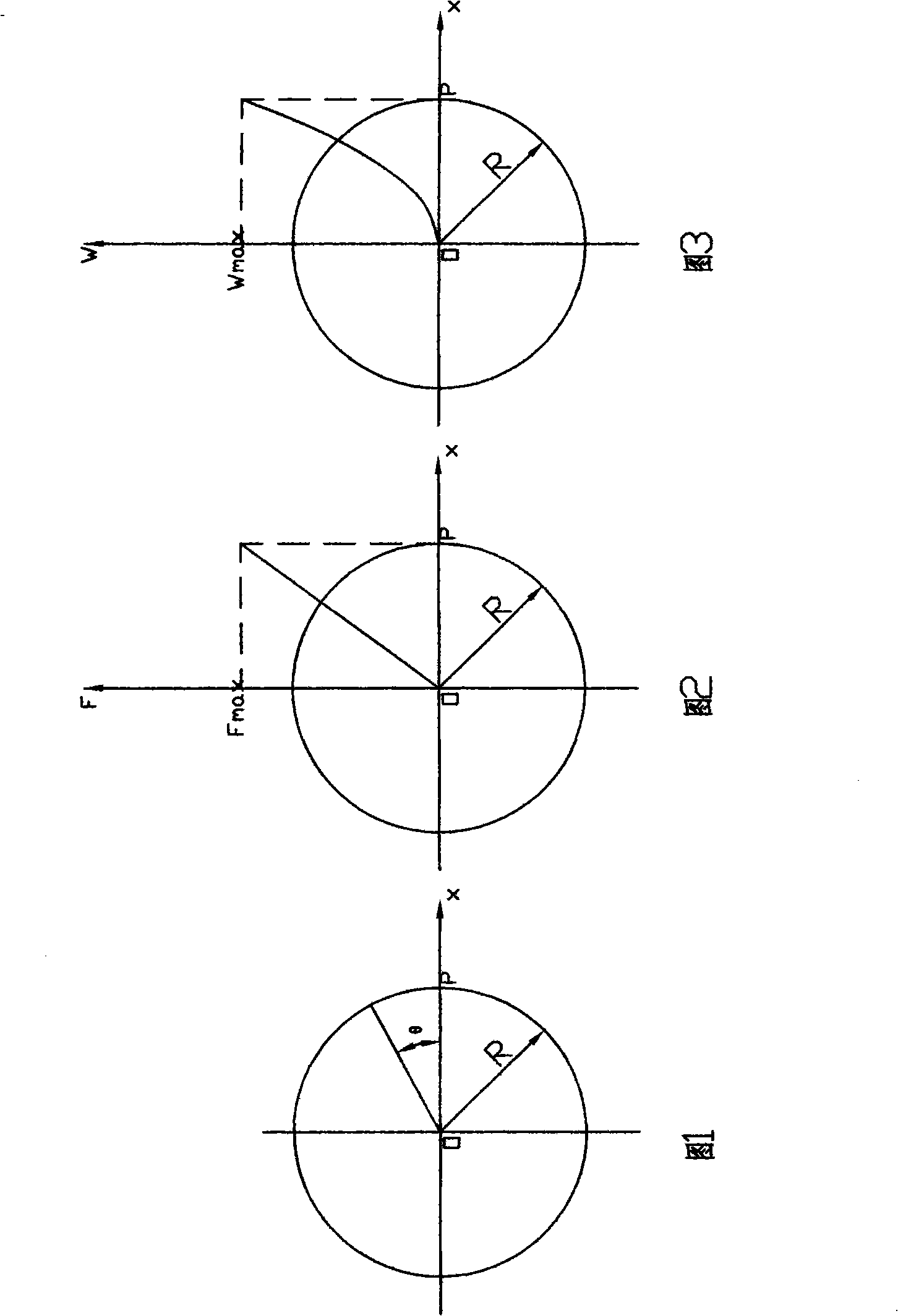

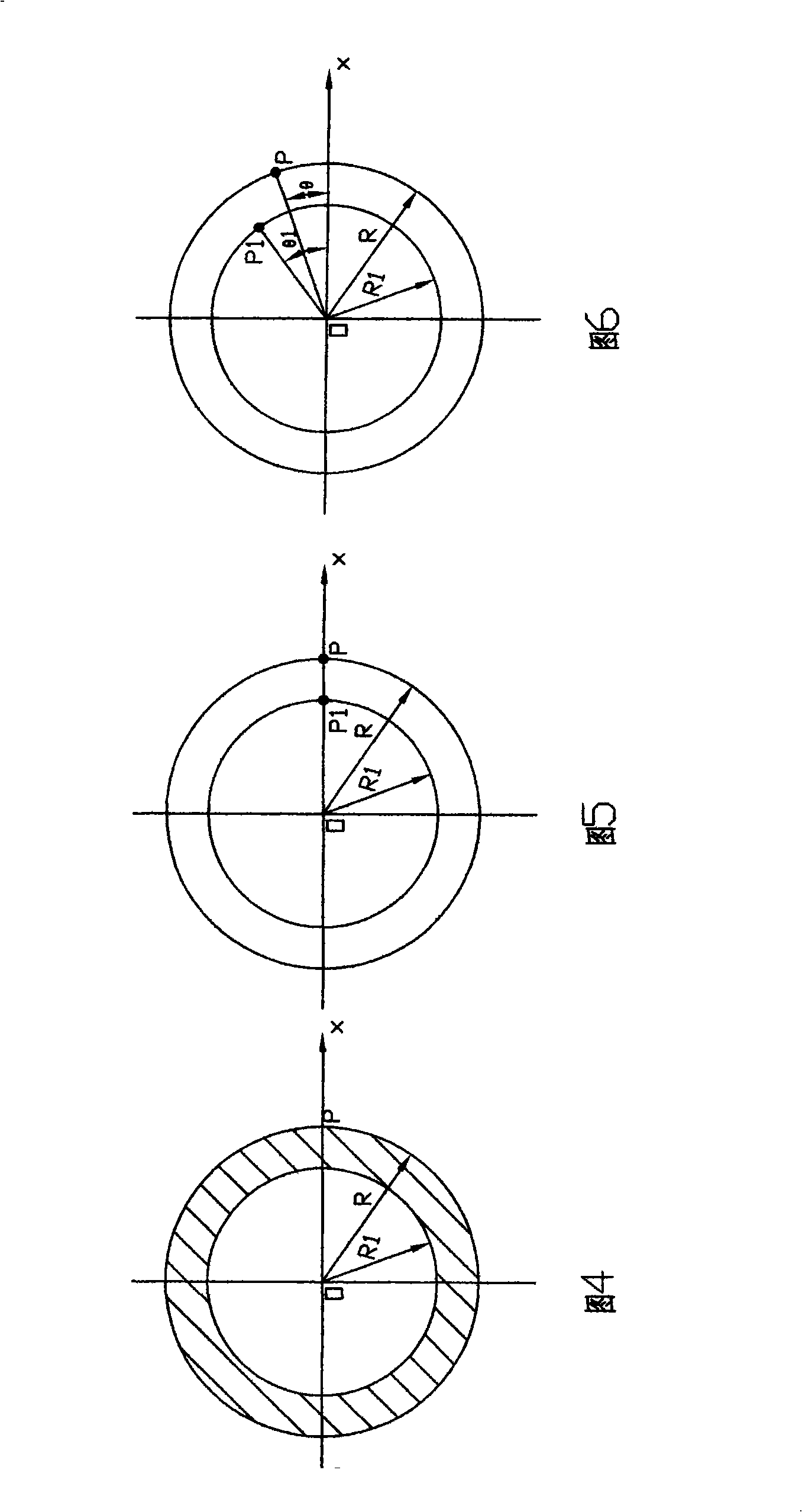

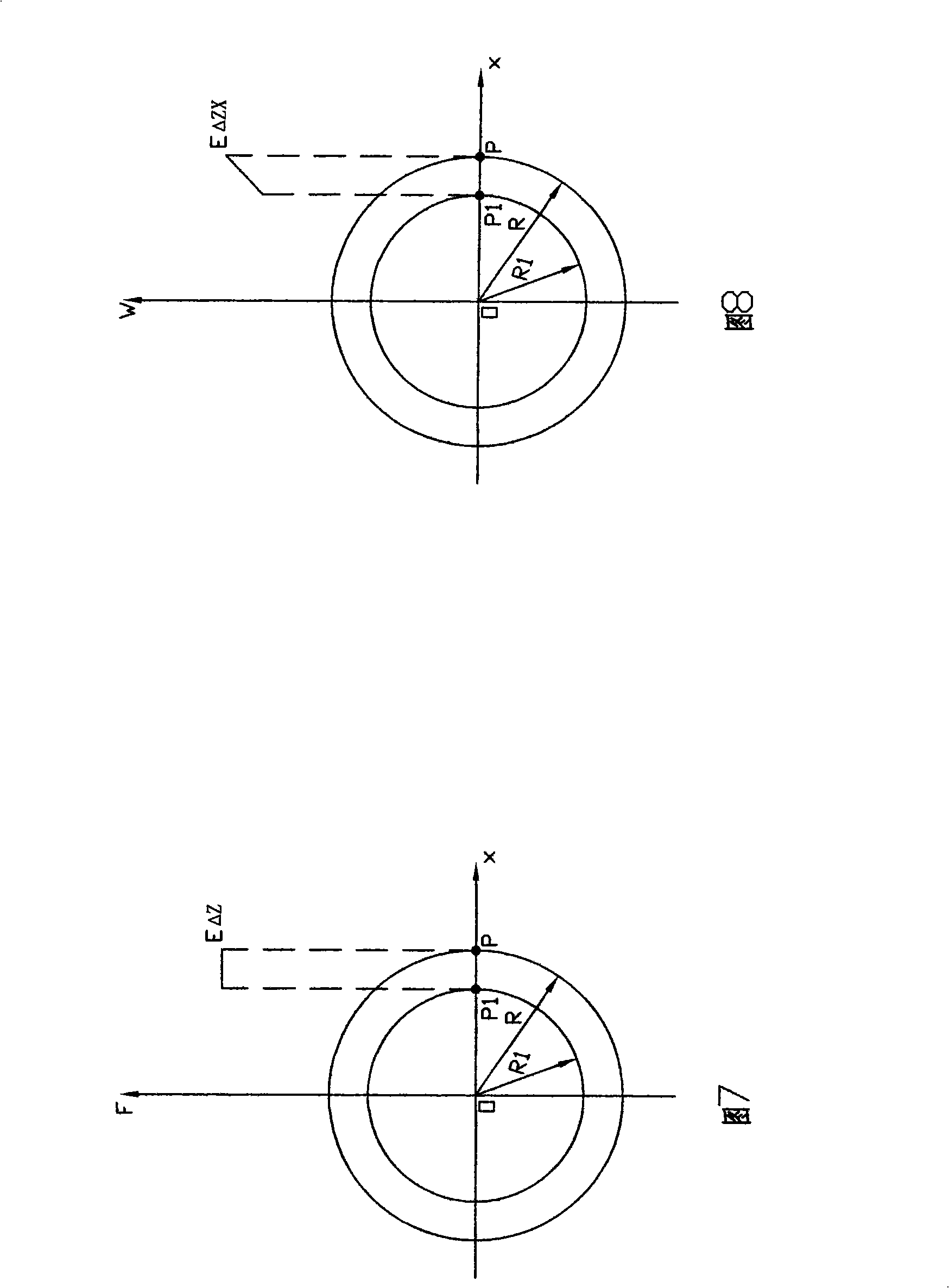

Dual-conicity working roll and roll shape design method thereof

ActiveCN106077098AControl the lateral thickness differenceImprove side landing control abilityGeometric CADRoll mill control devicesWork rollStrip steel

The invention provides a dual-conicity working roll and a roll shape design method thereof, and belongs to the technical field of plate-strip rolling roll shape design. The working roll mainly comprises three curves, a middle convexity control segment and edge drop control segments on the two sides. The two ends of the middle convexity control segment are tangent to the edge drop control segments correspondingly, and smooth transition of the curves is achieved. The special roll shape curves are adopted in the edge drop control segments, and the edge drop is effectively controlled. A quadratic parabola form is adopted in the middle convexity control segment, and the control requirement for the convexity of strip steel can be met. By means of the roll shape parameter correspondence relation provided by the method, the dual-conicity roll shape with the edge drop control capacity can be flexibly designed according to the production requirement of a hot rolling field.

Owner:北京科技大学设计研究院有限公司

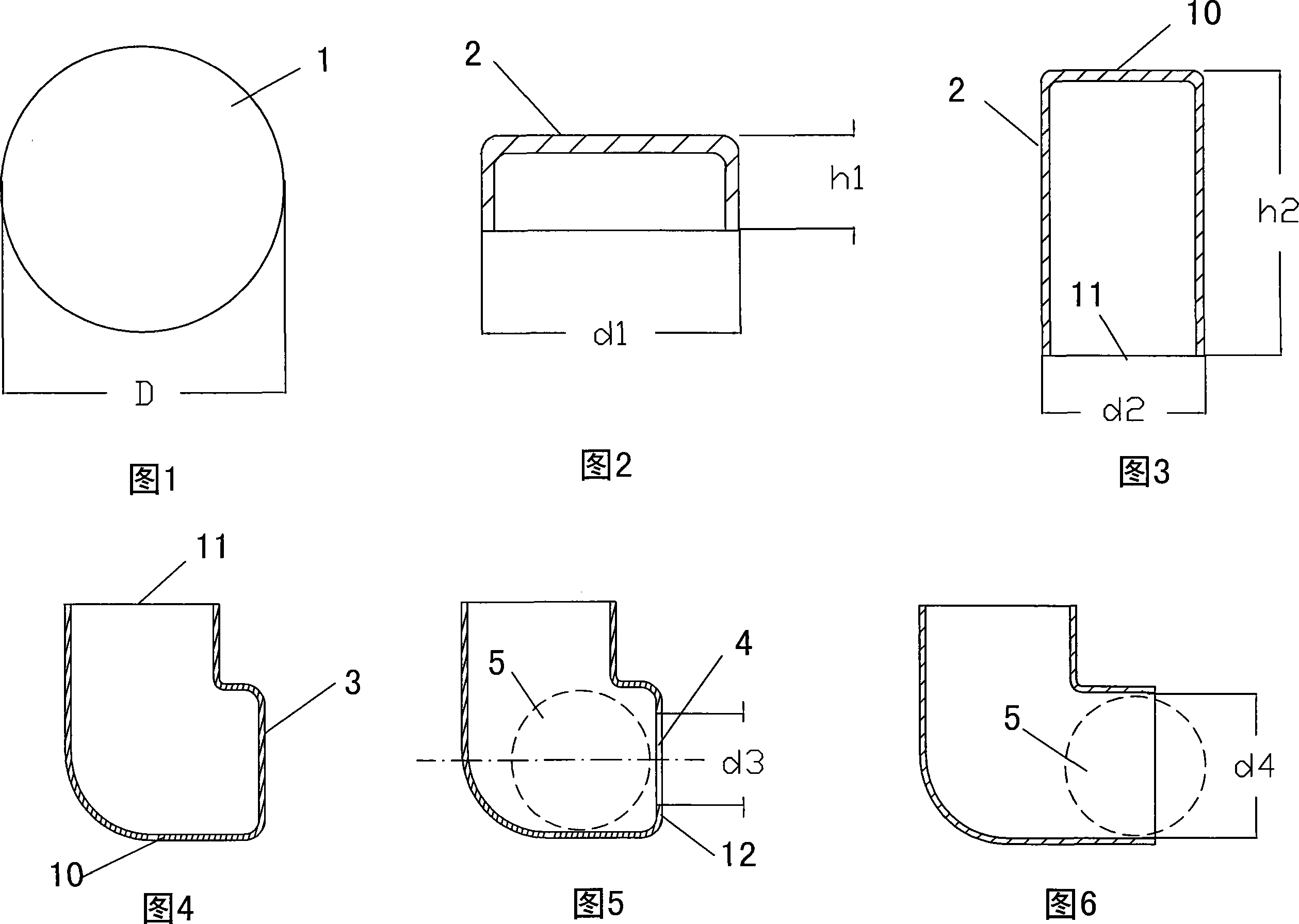

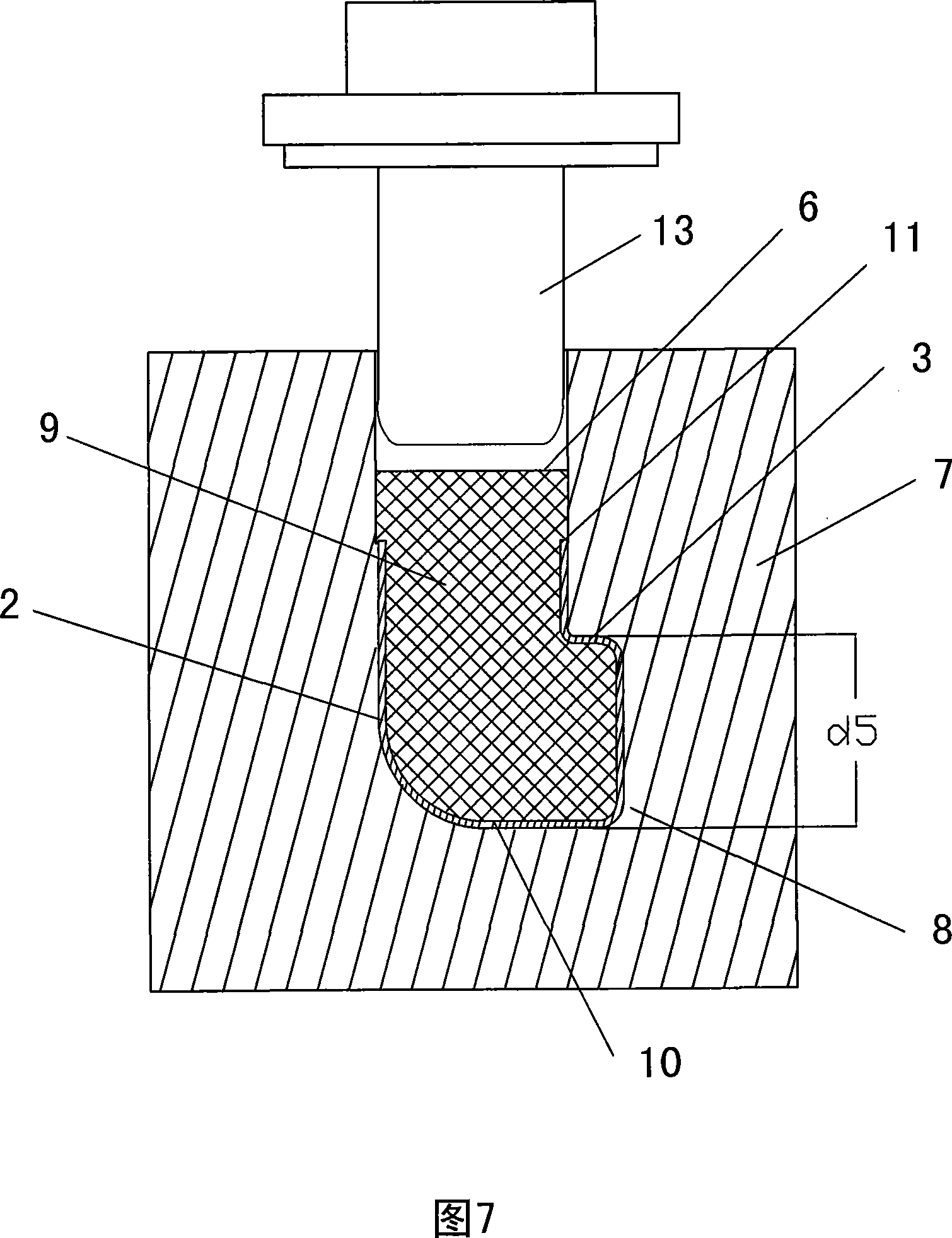

Method for processing thin wall metal elbow

The thin wall stainless bender machining features in the blanking, stretch, flattening, annealing, bulge, boring, hole reversing, dual flattening, trimming and so on. It can machine stainless steel bender with wall thickness of 0.8-2.0mm, saving in material, free from stress accumulation, without welding seam and leakage, small in size, material economical, being able to machine the thin wall stainless steel bender for the connection with the equal radius and abnormal tube path.

Owner:洪信章

Compressional deformation strengthened flexible hollow half axle and fabrication process thereof

InactiveCN101348055AReduce driving noiseReduce vibrationAxle unitsManufacturing technologyMetallic materials

The invention belongs to the field of automobile manufacturing, relating to a jackshaft part in an automobile power transmission system and the manufacturing technology thereof. The process adopts hyposteel bars of normalized condition as the raw stock, and heats the bar raw stock to 900 DEG C for extrusion molding. The entire extrusion molding process comprises the following extrusion technology: forward extrusion molding technology, overall backward extrusion molding technology, long-hole extrusion molding technology, drawing-down extrusion molding technology and diameter extension extrusion technology; wherein, the number of the working steps of the extrusion technique required in the extrusion molding procedures of the jackshaft parts with different structures and dimensions is different; the temperature of the metal material reduces from 900 DEG C to 100 DEG C; the extrusion workpiece, the shape and dimension of which is similar to that of jackshaft part finished product, is obtained, and the part is manufactured after mechanical cutting processing procedure, alignment and inspection procedures. After the entire extrusion molding is finished, the bending strength, shear strength and impact ductility of the extrusion workpiece are superior to the mechanical performance index of a test bar of the same material which is subject to hardening and tempering as well as heat treatment, and the tensile strength is similar to the test bar of the same material which is subject to hardening and tempering as well as heat treatment; the elastic torsion angle of the hollow jackshaft is larger than 120 degrees.

Owner:邓晓光

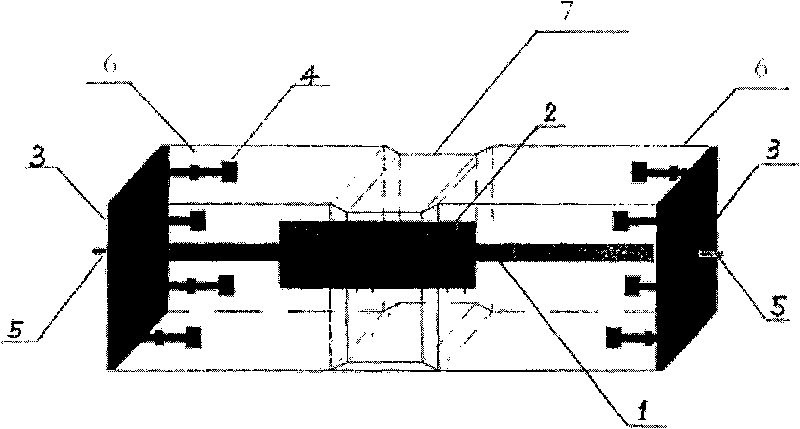

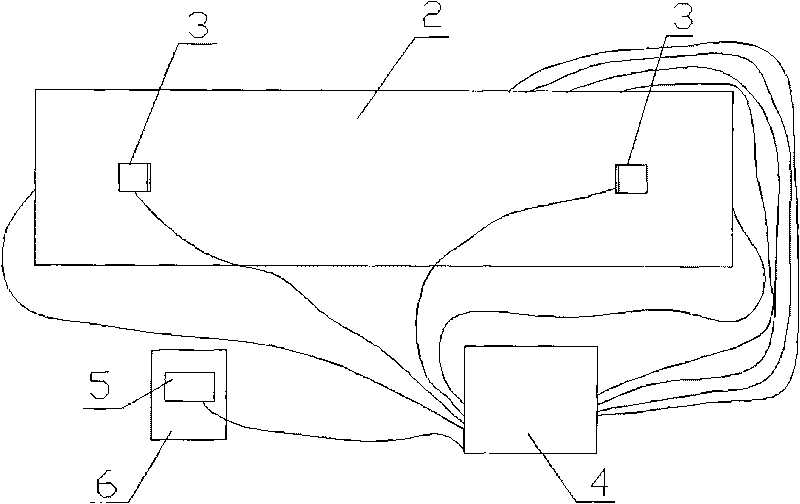

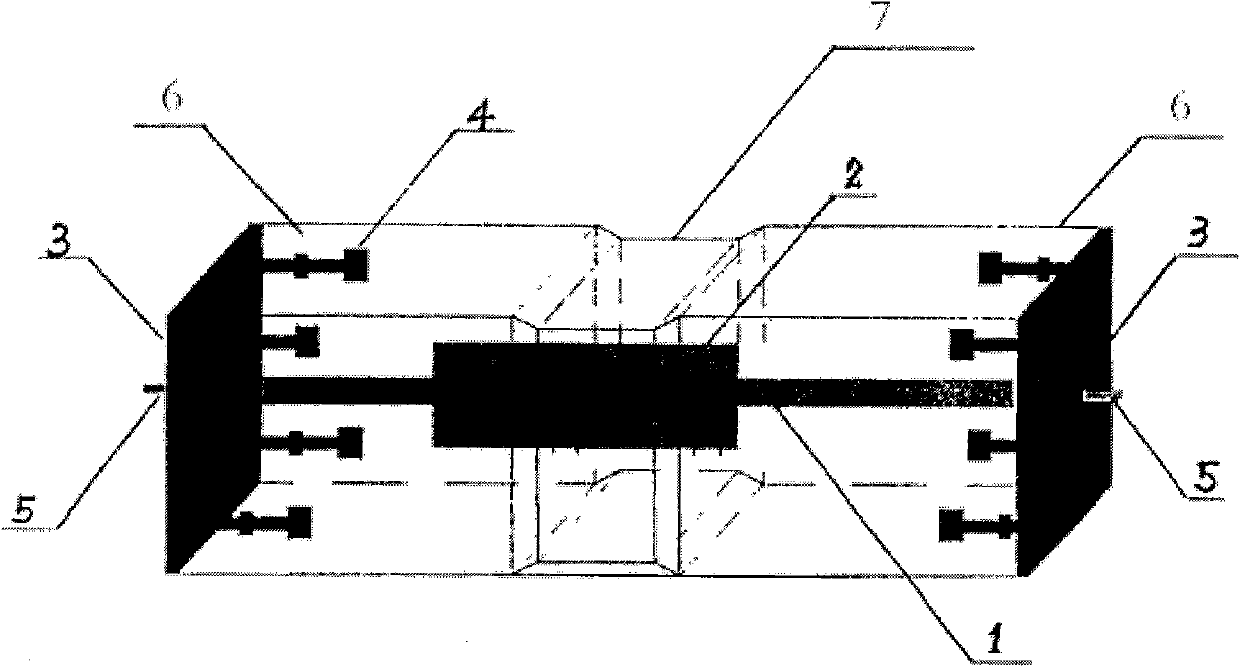

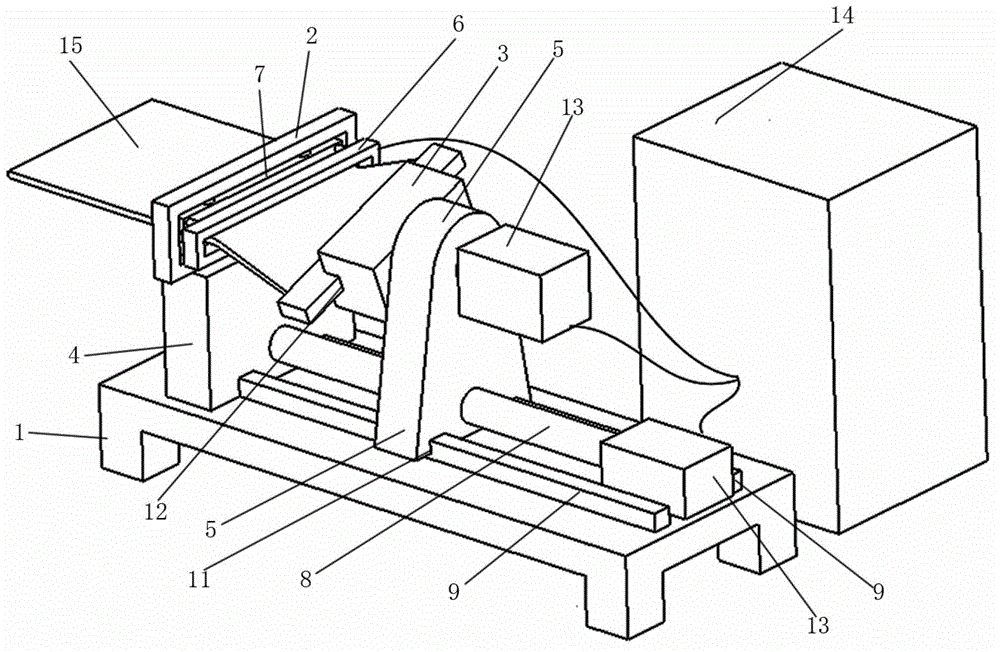

Induction heating torsion system and method using induction heating torsion system for torsion heating

The invention discloses an induction heating torsion system and a method using the induction heating torsion system for torsion heating. The induction heating torsion system comprises a base, a clamping device, an induction coil, a sliding device, a driving device and a torsion device, wherein the clamping device comprises an induction clamping head and a torsion clamping head, the torsion device comprises a rotary shaft, the induction clamping head is fixedly arranged on the base, the rotary shaft is rotatably arranged on the base, the torsion clamping head and the end part of the rotary shaft are fixed, the torsion clamping head is slidingly connected with the base, the center of the induction clamping head is provided with a clamping port, a part penetrates through the induction coil, the head end of the part is detachably and fixedly arranged on the torsion clamping head, the induction coil is connected with a central controller, and the driving device is respectively connected with the central controller, the torsion device and the sliding device. The induction heating torsion system has the advantages that the structure is simple, the size is small, the cost is low, the weight is light, the torsion is more uniform, the local deformation of the part is precisely controlled, the processing efficiency is high, the finished rate of the part is high, and the maintenance and the replacement are convenient.

Owner:北京智创联合科技股份有限公司

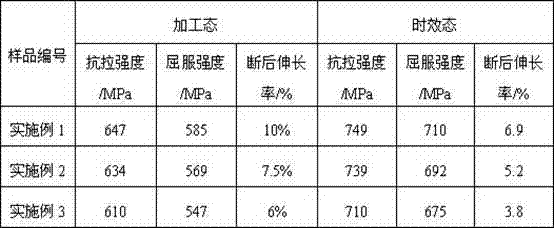

Method for preparing ultrahigh strength high toughness magnesium alloy

The invention relates to a preparation method for ultrahigh strength high toughness magnesium alloy. The ultrahigh strength high toughness magnesium alloy comprises the following components in percentage by mass: 6-13% of gadolinium, 2-6% of yttrium, 0.3-0.8% of zirconium, and the balance of magnesium and inevitable impurities. The magnesium alloy billets are subjected to powerful thermal deformation, and then the magnesium alloy subjected to thermal deformation is subjected to rapid warm deformation at 110-150 DEG C, wherein the deformation force is 1-4KN, the deformation speed is 15-24mm / s, and the total deformation is 10-40%. The magnesium alloy is subjected to aging heat treatment after rapid warm deformation at 140-250 DEG C for 23-38 hours. The alloy subjected to warm deformation at room temperature has a strength of extension of 610-647 MPa, the yield strength of 547-585 MPa, the percentage elongation after fracture of 6-10%. The aging state alloy at room temperature has the strength of extension of 710-749 MPa, the yield strength of 675-710 MPa, and percentage elongation after fracture of 3.8-6.9 %.

Owner:CENT SOUTH UNIV +1

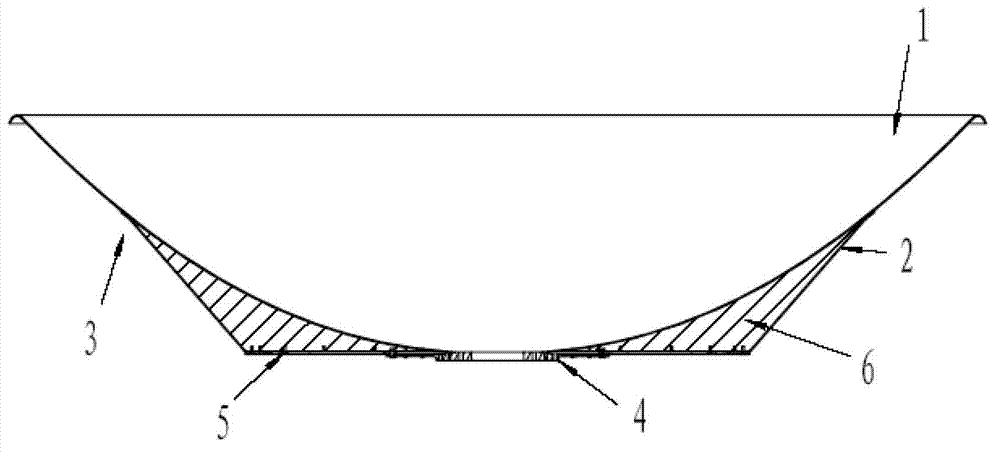

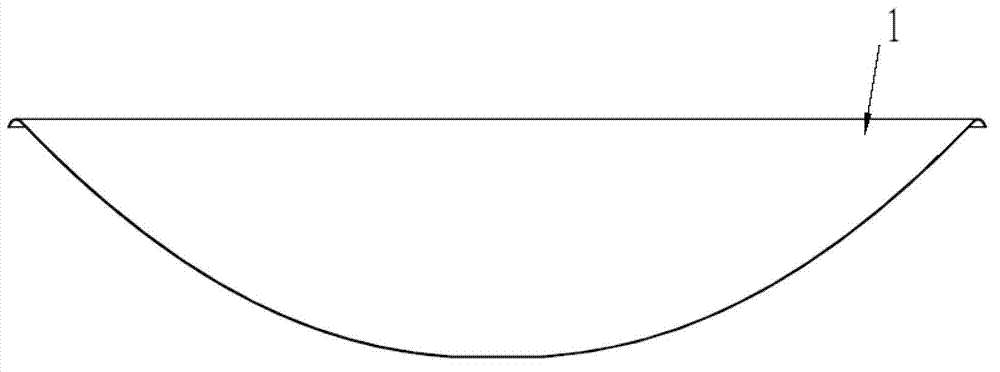

High-precision spinning antenna reflecting surface and manufacturing method thereof

ActiveCN103247864ASimple processLow costAntenna adaptation in movable bodiesManufacturing technologyAdhesion process

The invention discloses a high-precision spinning antenna reflecting surface and a manufacturing method thereof, and relates to radar antenna manufacturing engineering field, in particular to manufacturing technique of main antenna reflecting surface spin forming and support body adhesive foam stabilization precision. The high-precision spinning antenna reflecting surface comprises a spinning formed main reflecting surface, a support body which is designed to be coaxial with the main reflecting surface, a foam materiel used for improving the strength and rigidity of the antenna reflecting surface, and a plurality of parts used for assembling. According to the invention, an adhesion process is adopted to change a traditional spinning antenna reflecting surface from a point-supported mode to a curve-supported mode, and a foam sandwich structure is skillfully adopted, so that the high-precision (the surface precision is 0.3 mm RMS ) spinning antenna reflecting surface can be manufactured without using a high-precision parabolic mold; and the high-precision spinning antenna reflecting surface has the advantages of strong rigidity, high strength, small deformation, good shock resistance and simple processing technique, and is particularly suitable for radar antenna devices on mobile carriers, such as vehicles and ships.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

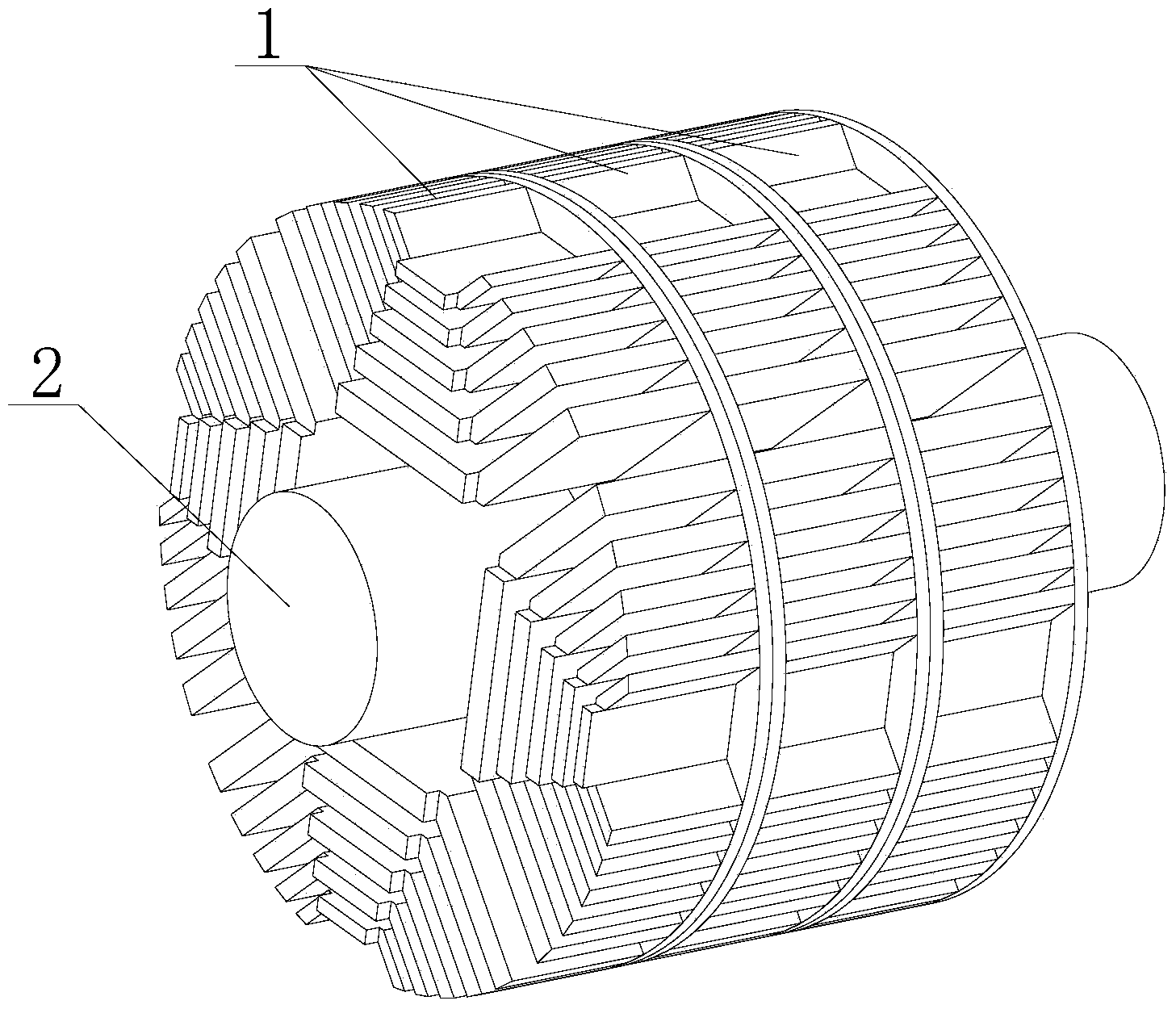

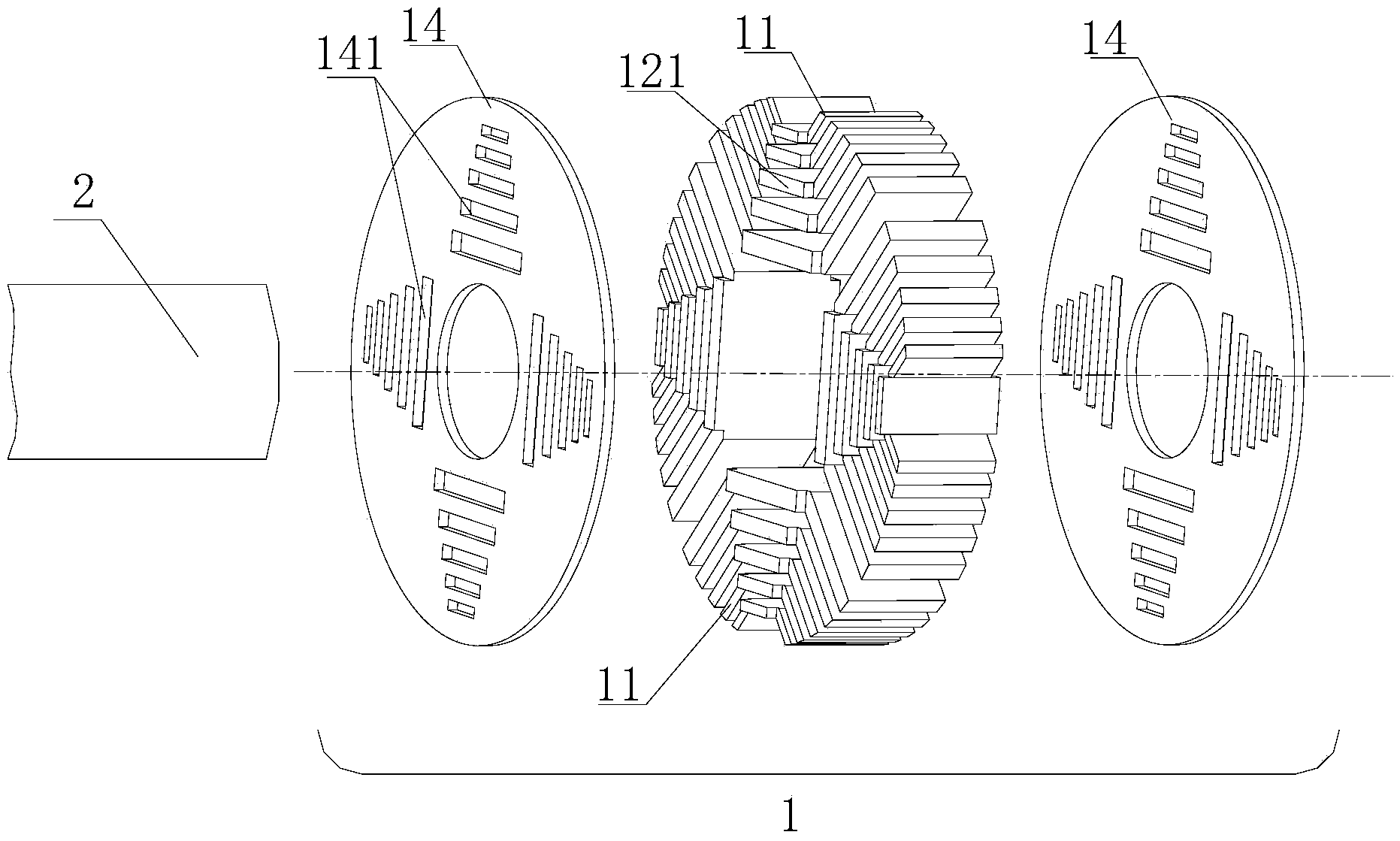

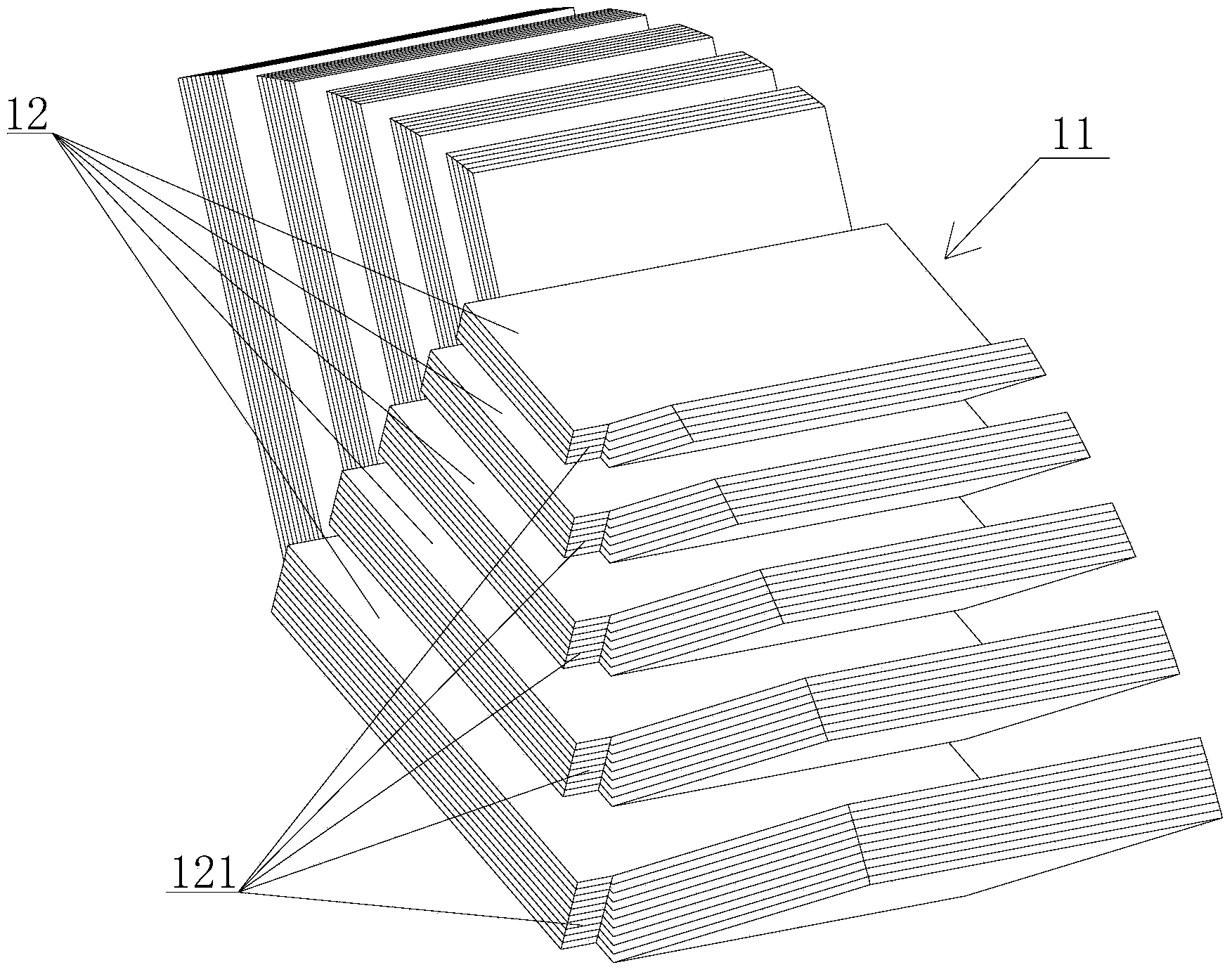

Rotor of synchronous reluctance motor

InactiveCN104242504AReduce in quantityStable structureMagnetic circuit rotating partsSynchronous reluctance motorPower factor

The invention provides a rotor of a synchronous reluctance motor. The rotor of the synchronous reluctance motor comprises multiple rotor modules which are arranged coaxially and staggered sequentially in the axial direction. Each rotor module comprises multiple magnetic poles, and the magnetic poles are arranged in adjacent sections around a common axis. Each magnetic pole comprises multiple magnetic ribs which are distributed in the radial direction at intervals. Each magnetic rib is composed of multiple punched sheets. Locating plates are connected to the two axial side faces of the magnetic poles. The locating plates are mounted on a rotating shaft in a sleeved mode. Bosses are arranged at the two axial ends of each magnetic rib respectively. Grooves are formed in the positions, corresponding to the bosses, of the locating plates. The axial end face of each magnetic pole is tightly attached to the axial end face of the corresponding locating plate in the mode that the bosses are inserted into the grooves. The magnetic poles and the locating plates of the rotor modules of the rotor are assembled through the matching between the bosses and the grooves, assembly is convenient to carry out, the magnetic poles are easy to locate, and position accuracy is high; the rotational inertia of the rotor is lower, manufacturing is easy and convenient to carry out, and the efficiency and the power factors of the motor are improved.

Owner:HANGZHOU EASITECH

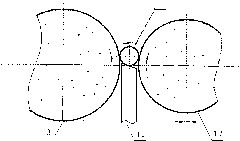

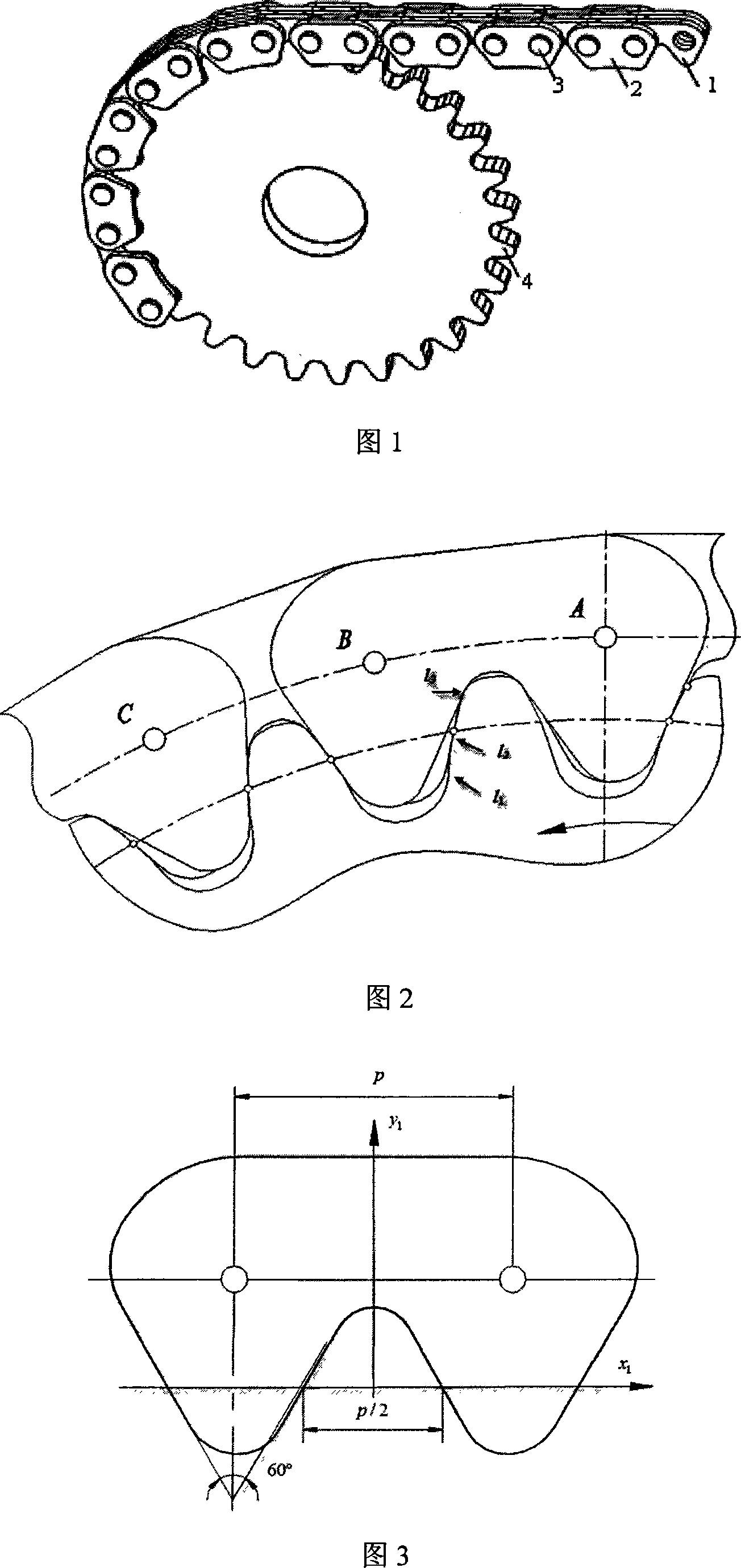

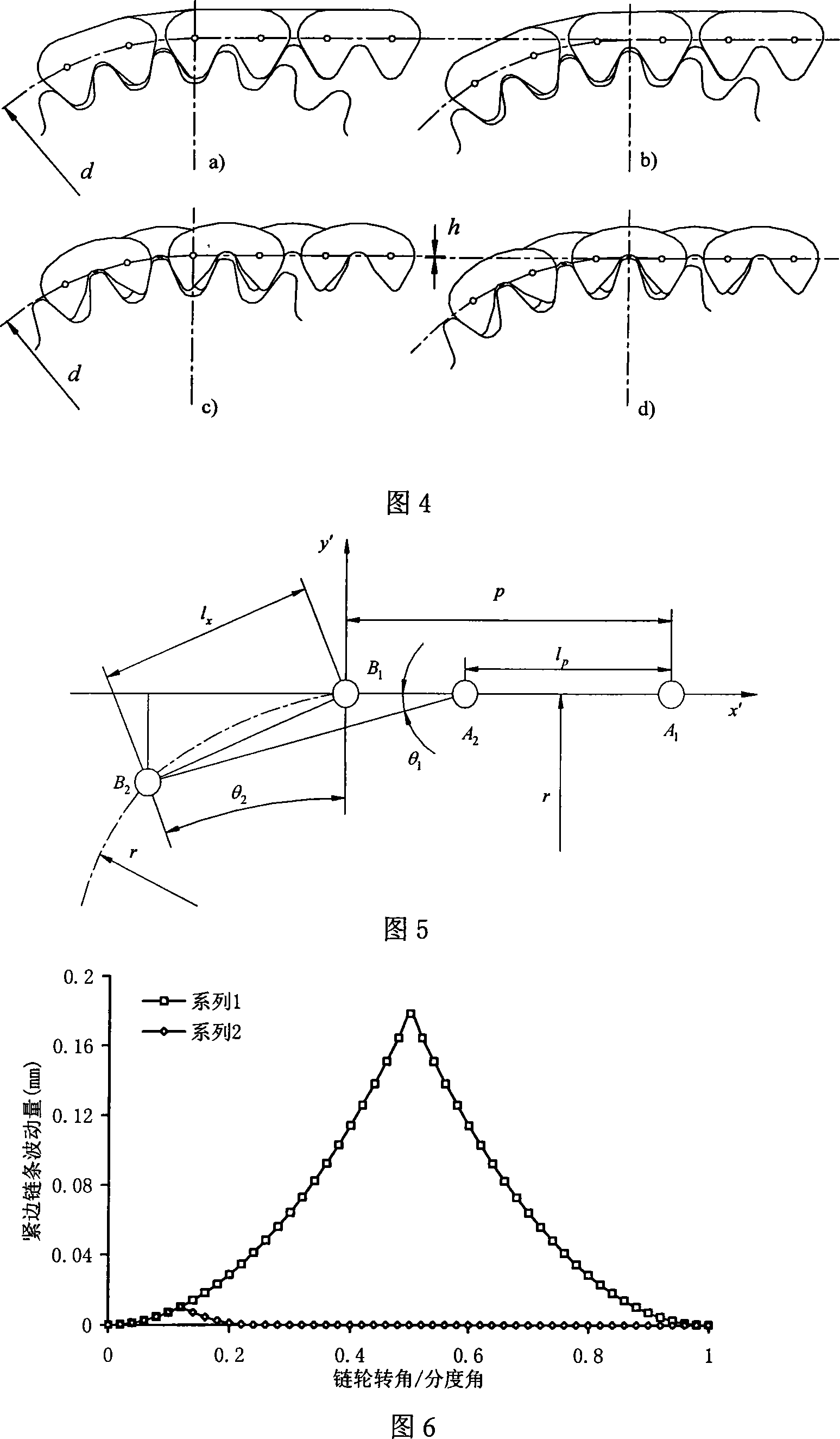

High speed transmission toothed chain and chain wheel

InactiveCN101101049AEliminate position changesEliminate lateral movementGearingPortable liftingLow noiseSprocket

This invention discloses high speed driving toothed chain and chain wheel. The inner and outer tooth profile of tooth link joint can be joggled with gear tooth of chain wheel. The link joint inner tooth profile is first joggled with chain wheel gear tooth. With chain wheel rotating, the link joint inner and outer tooth profile are joggled with chain wheel at the same time. At last, outer tooth profile is located on the gear tooth of chain wheel. The chain wheel single tooth single side tooth profile line is composed of transition curve, involute and correcting involute. The inner profile of inverted tooth chain link joint is convex in respect to outer profile. This invention has low shock and low noise.

Owner:SHANDONG UNIV

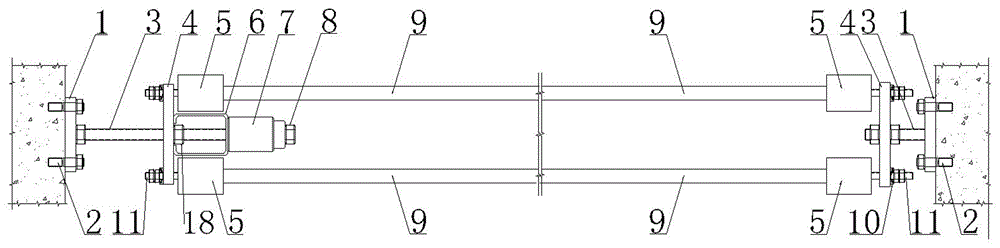

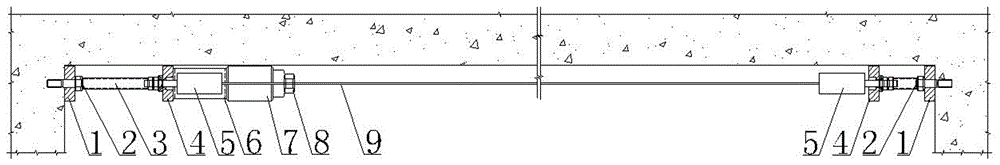

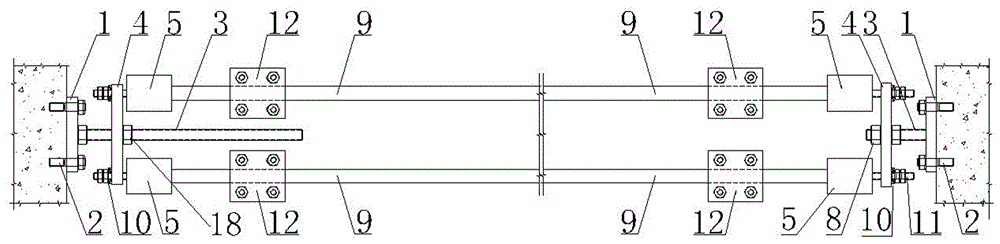

Decomposition-type prestressed carbon fiber tensioning device and construction method thereof

The invention discloses a decomposition-type prestressed carbon fiber tensioning device which comprises a pair of prestressed tensioning components symmetrically fixed on a to-be-reinforced component, at least one carbon fiber board arranged between the prestressed tensioning component, a tensioning anchor connecting the end of each carbon fiber board onto the adjacent prestressed tensioning component, and at least two anchoring boards compressing the carbon fiber boards on the surface of a to-be-reinforced structure. The invention further discloses a construction method applied on the prestressed carbon fiber tensioning device. The decomposition-type prestressed carbon fiber tensioning device is simple in structural design, a prestressed carbon fiber anchor is decomposed into the reusable tensioning anchor and a flat plate anchor which is permanently fixed by means of bonding through epoxy structure glue and compressing through bolts, and the decomposition-type prestressed carbon fiber tensioning device is simple in structure and low in cost.

Owner:深圳市威士邦建筑新材料科技有限公司

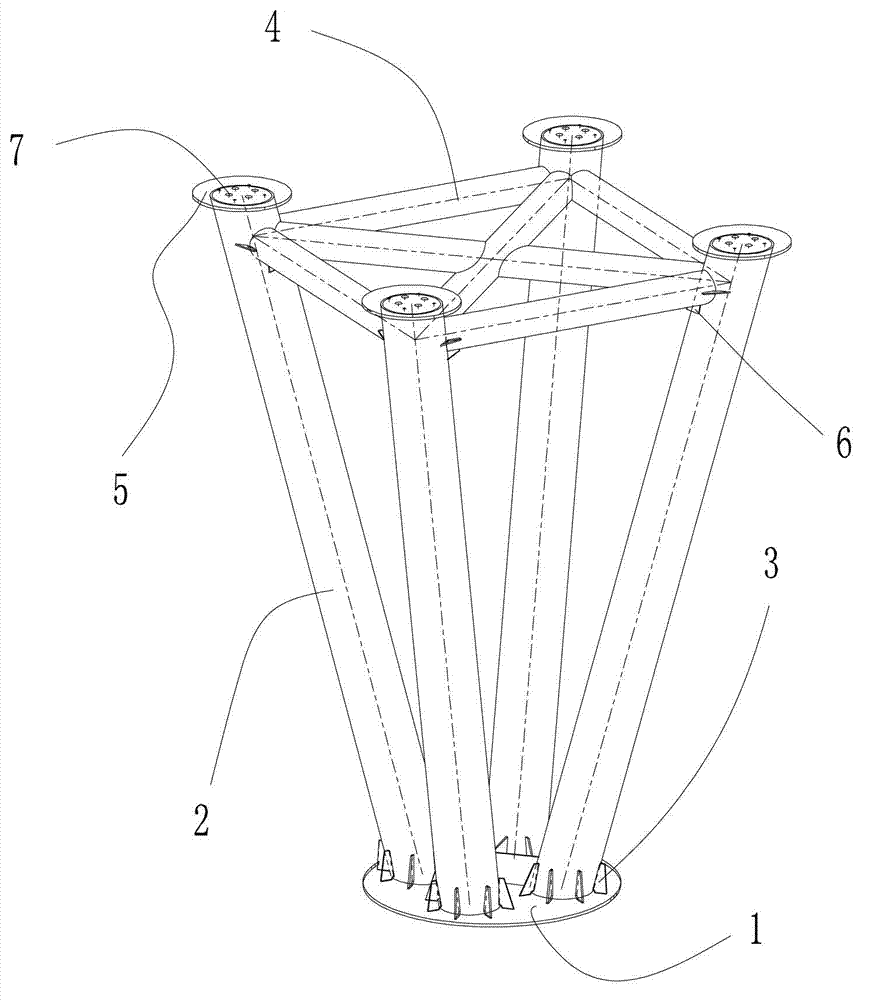

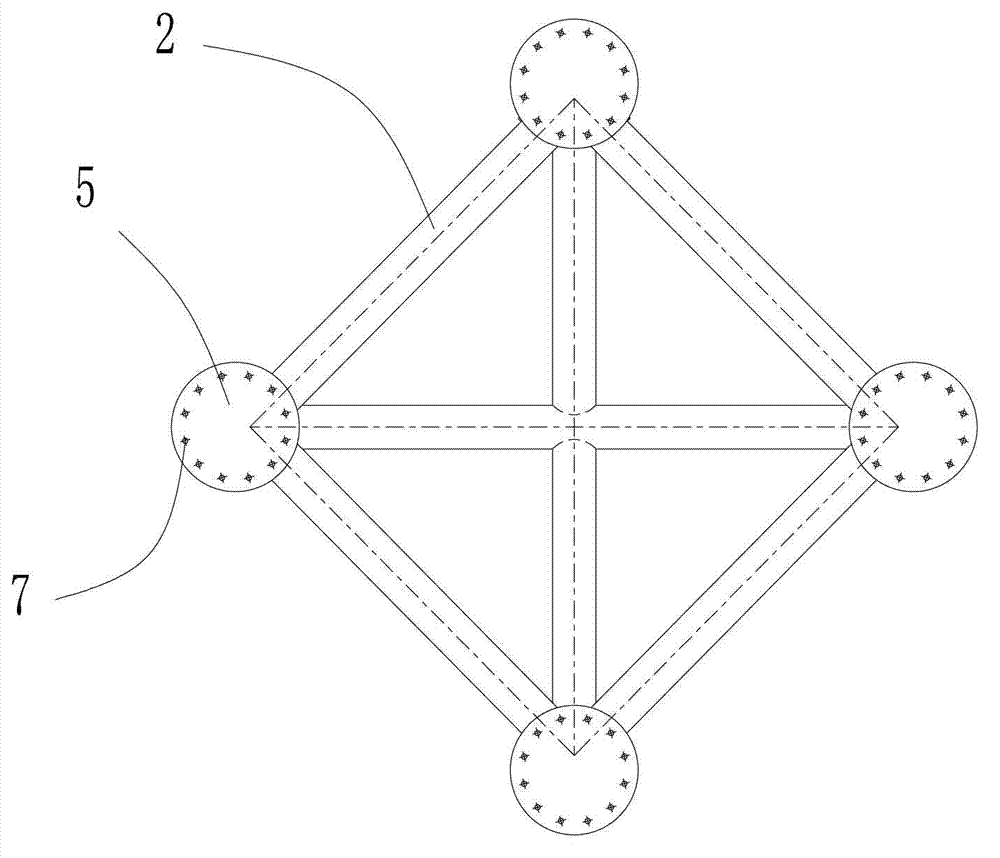

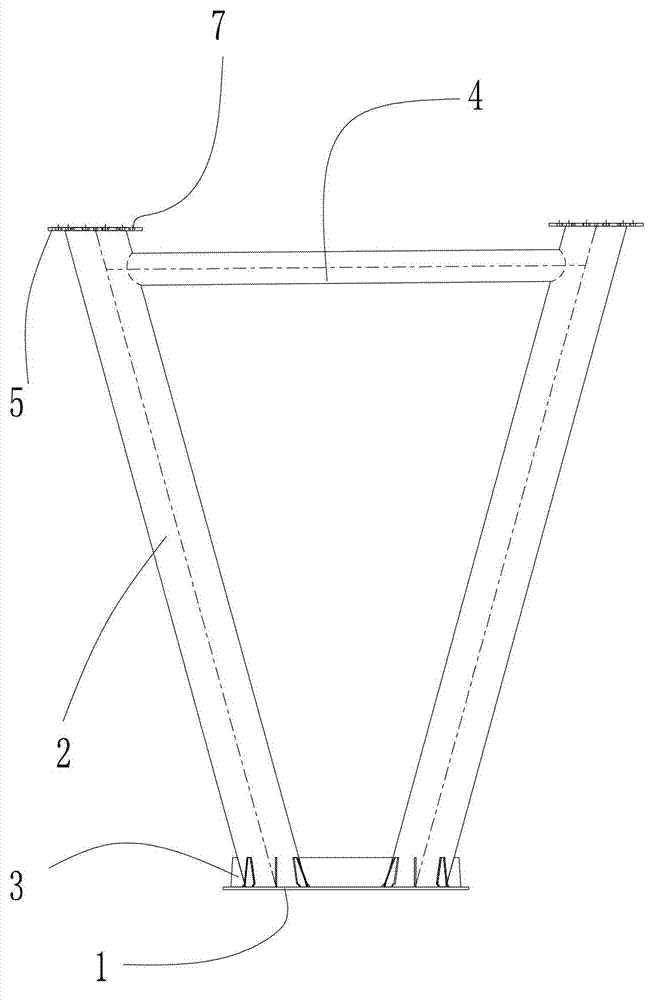

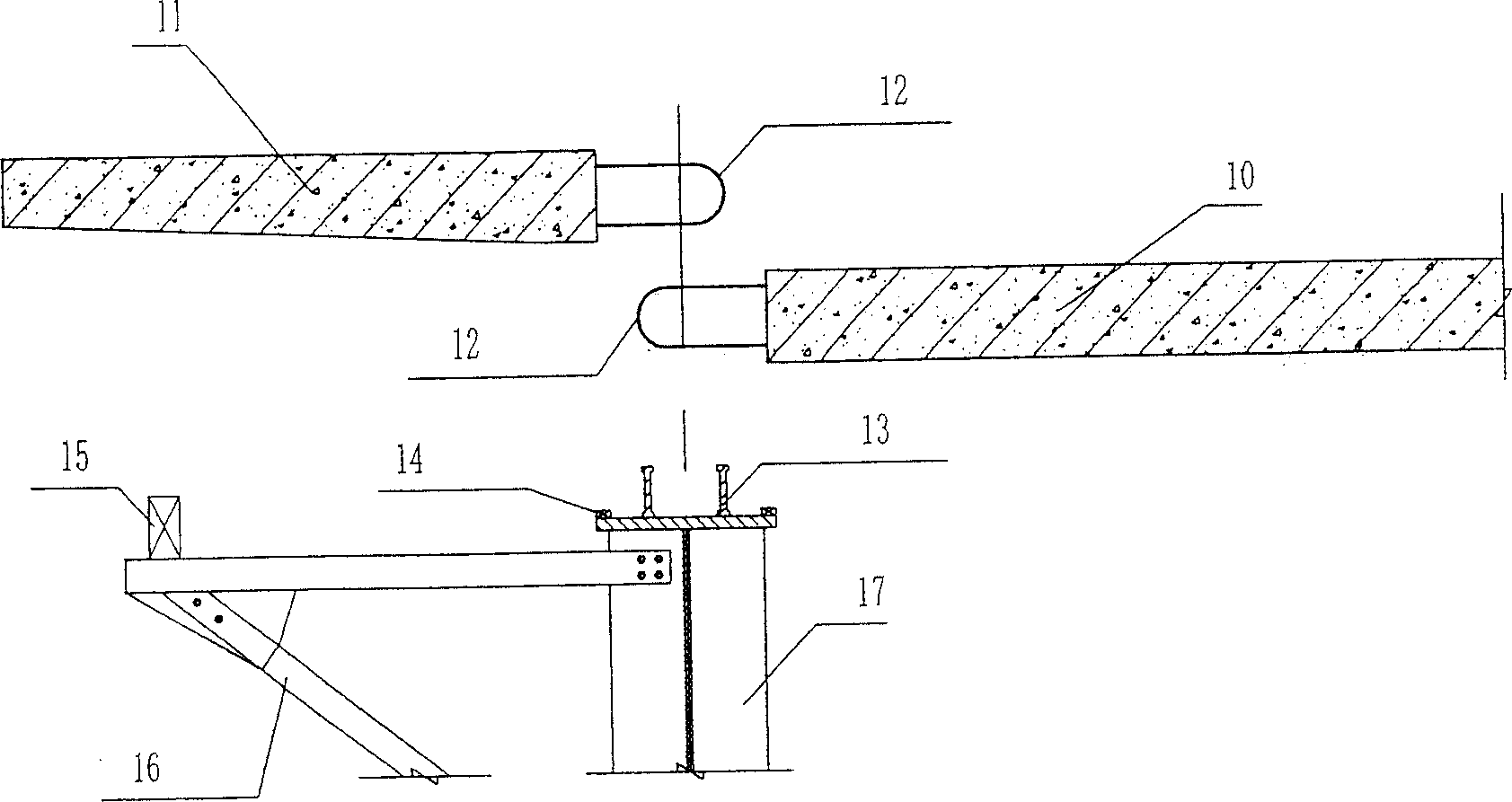

Bridge space radioactive concrete-filled steel tube bridge pier and construction method thereof

ActiveCN103243638ATakes up little space in the citySave urban landBridge structural detailsBridge erection/assemblySteel tubeUrban space

A bridge space radioactive concrete-filled steel tube bridge pier comprises a flange, a plurality of bridge pier bottom stiffening plates, four bridge pier support beams, six tie beam stiffening plates, four pier top anchor plates and a plurality of tie beam stiffening plates. Four mounting positions in even distribution along the circumferential direction are reserved on the top surface of the flange; bottom walls of the four bridge pier support beams are mounted at the four mounting positions on the flange respectively; a tapered space is formed by encircling of the four bridge pier support beams, and the cross section of the tapered space is decreased gradually from top to bottom; one pier top anchor plate is mounted on the top wall of each bridge pier support beam; and a plurality of anchor bolt preformed holes in even distribution are reserved on each pier top anchor plate. A pile foundation of the bridge pier is centralized blow a bearing platform, and occupied urban space is small. Formwork-free pouring of bridge pier concrete pouring is achieved, and the bridge pier is convenient and efficient to construct, safe and rapid, excellent in structural behavior of rod pieces, higher in rigidity of a main beam, good in stability and the like. The invention further relates to a construction method of the bridge space radioactive concrete-filled steel tube bridge pier.

Owner:SHENZHEN BRIDGE DOCTOR DESIGN & RES INSTITUDE CO LTD +1

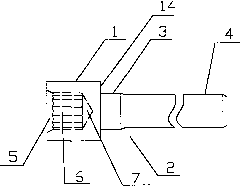

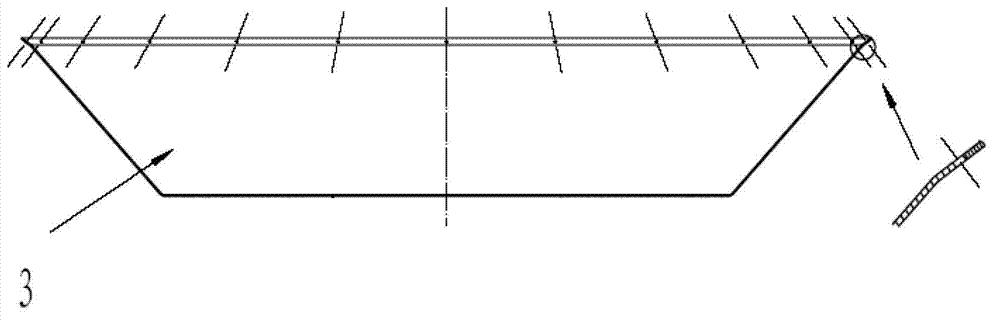

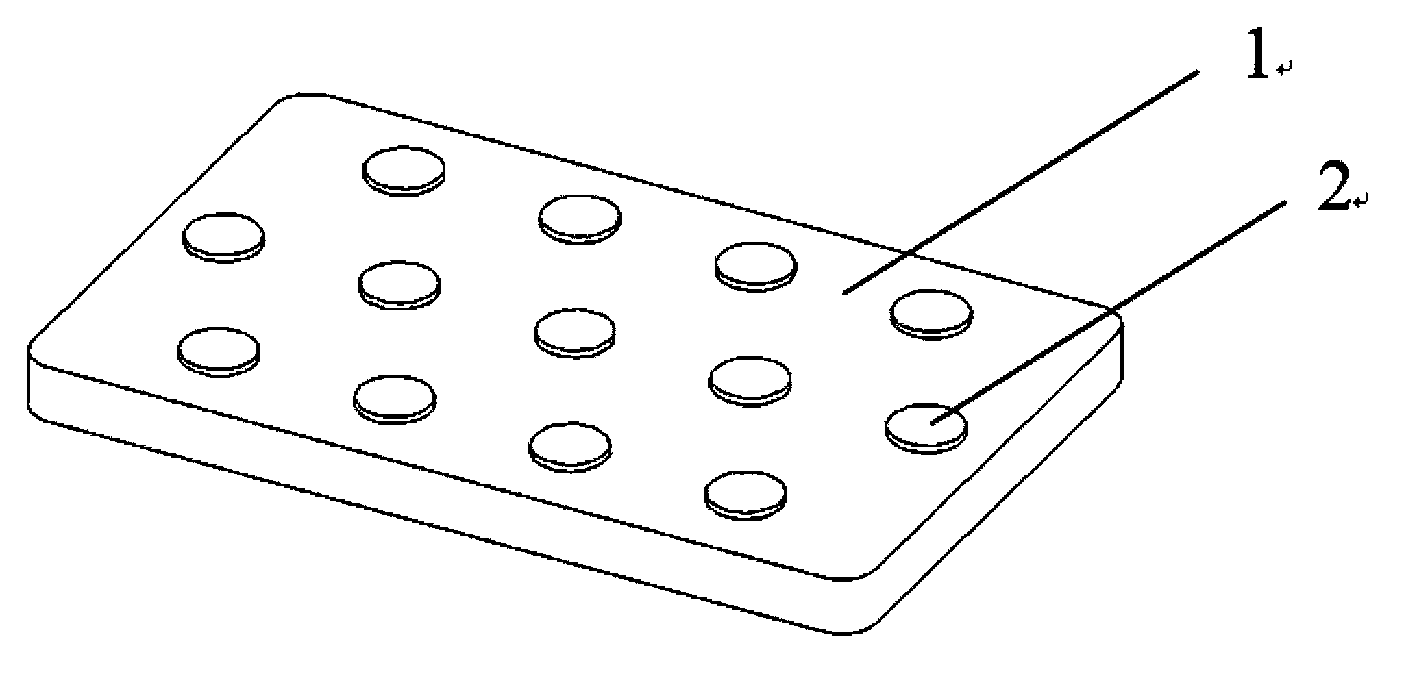

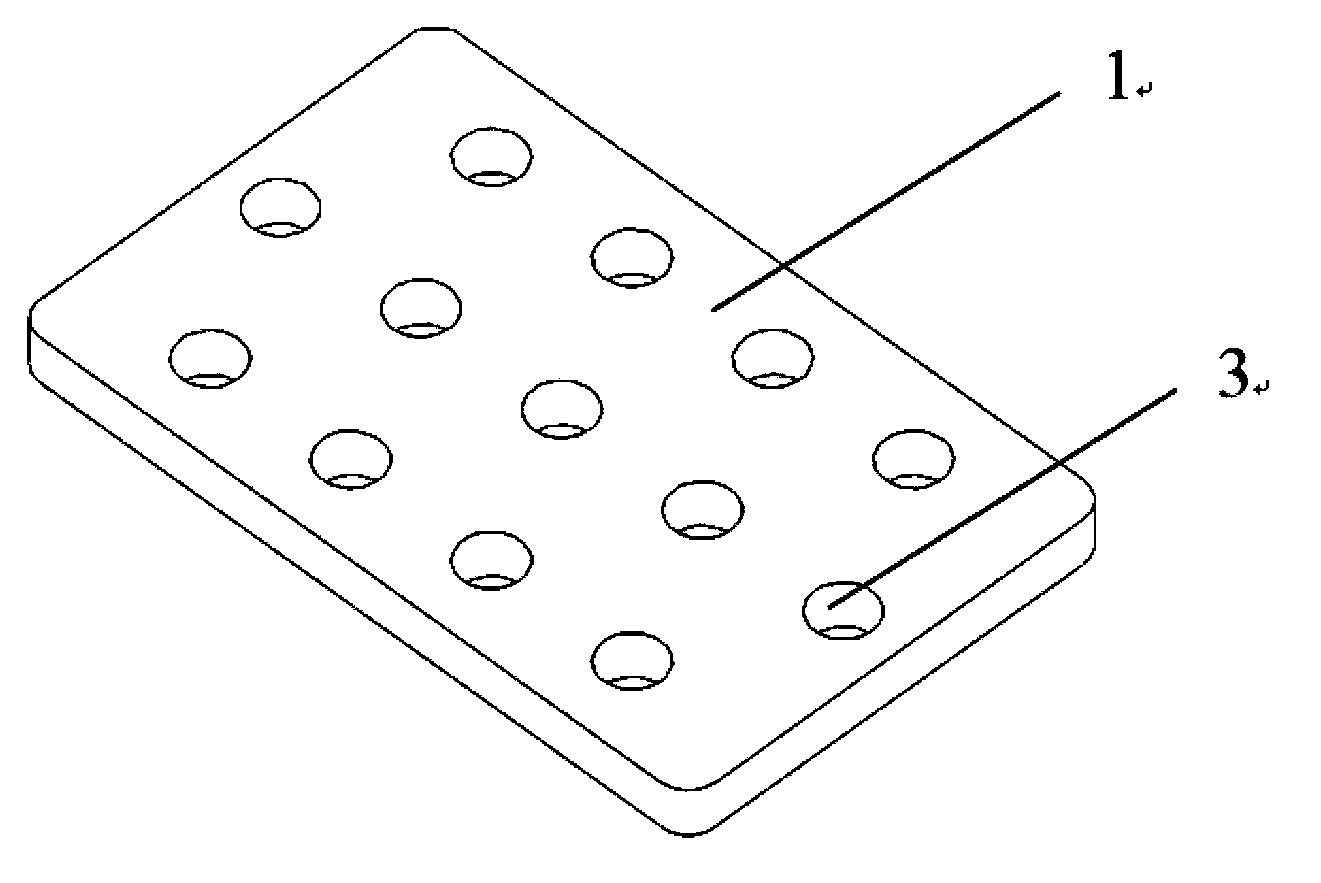

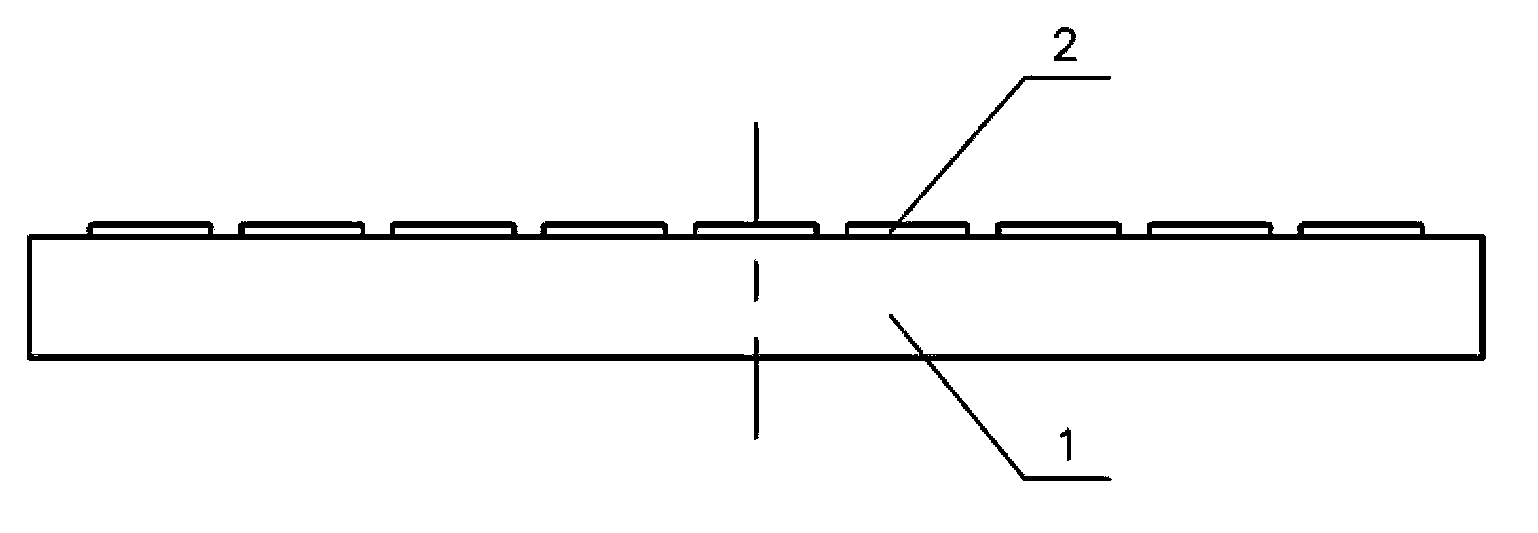

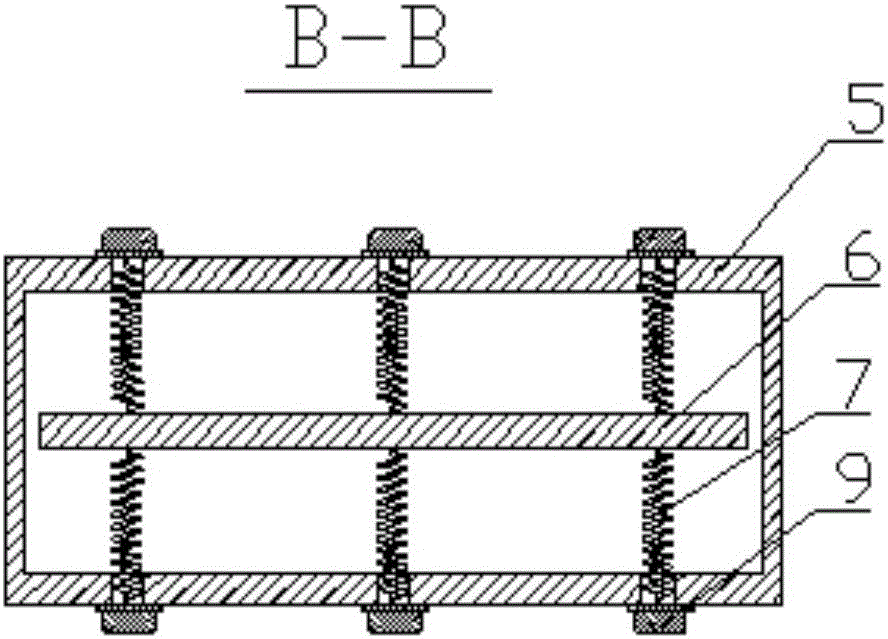

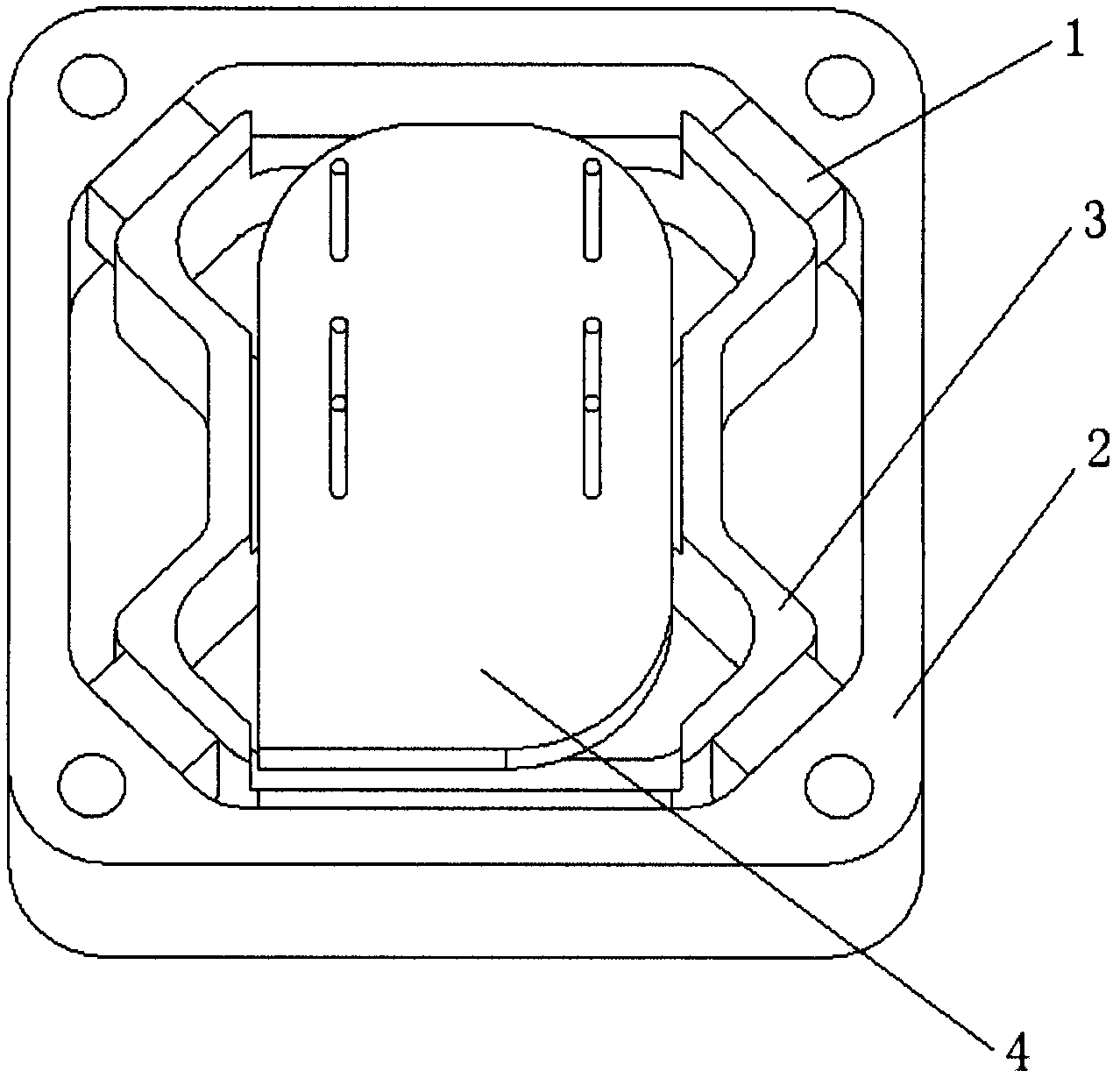

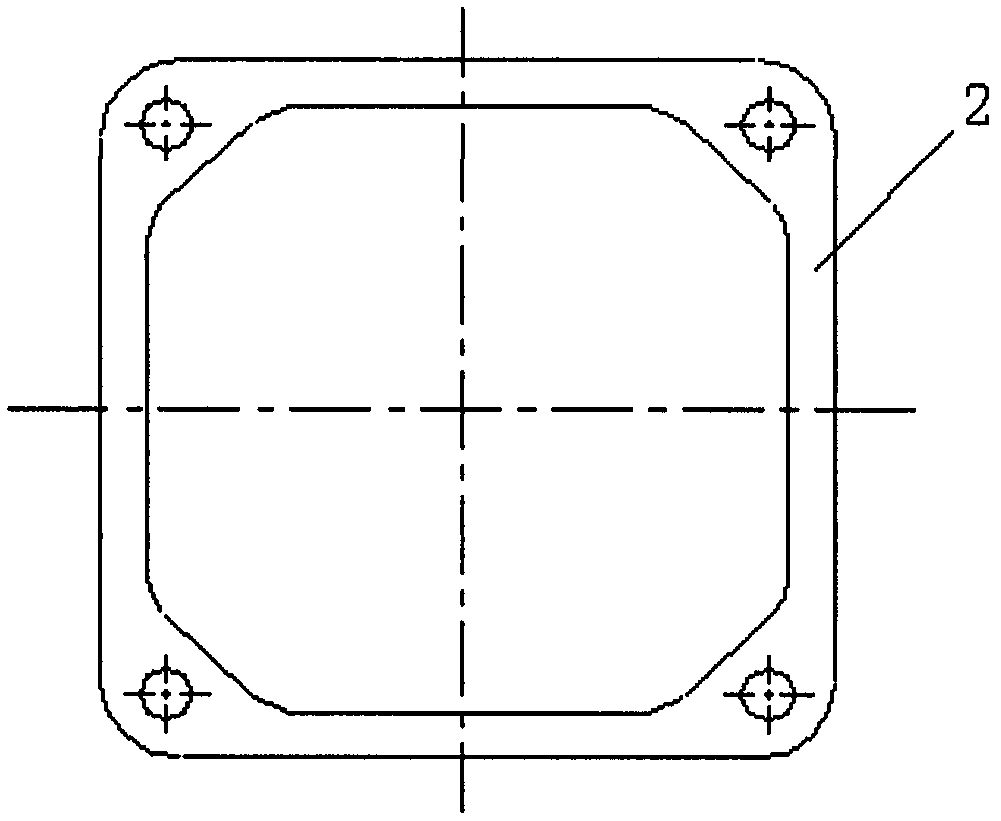

Split-type embedded and combined elastic base plate for rail transit fasteners

ActiveCN103669124AForm the effect of double stiffnessReduce deformation rateRail fastenersEngineeringNoise reduction

The invention relates to a split-type embedded and combined elastic base plate for rail transit fasteners. The elastic base plate is characterized by comprising a basic elastic base plate body (1), through holes (3) are formed in the basic elastic base plate body (1), and elastic columns (2) are arranged in the through holes (3) in a penetrating mode, wherein the thickness of the basic elastic base plate body (1) is different from the height of each elastic column (2). The elastic base plate is simple in structure and convenient to manufacture; the rigidity of the basic elastic base plate body and the rigidity of the elastic columns can be adjusted at will according to different needs, so compatibility of the elastic base plate is improved; the elastic base plate is convenient to maintain and replace, reduces maintenance cost and improves the vibration and noise reduction performance.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +3

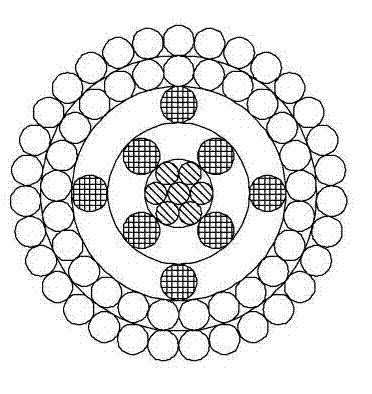

Clamping device for large-section expanded diameter conductors

ActiveCN102832570ATroubleshoot anchor connection issuesNo deformationApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention provides a clamping device for large-section expanded diameter conductors, and relates to the technical field of construction equipment and construction technology of transmission lines. The clamping device is particularly suitable for anchoring connection of large-section supporting-type high-density polyethylene expanded diameter conductors, sparse-coiled concentrically stranded circular aluminum conductors and the like in the tension stringing construction, and simultaneously, can be used for anchoring connection of larger-section four-layer concentrically stranded circular aluminum conductors. When the clamping device disclosed by the invention performs anchoring, the loading capacity is large and no slippage occurs, and the structures of the clamped parts of the conductors do not deform and have no indentation; the weight of the clamping device is lightened, therefore, the clamping device is convenient for working at heights; the good clamping performance provides safe and reliable guarantee for the anchoring connection of the large-section expanded diameter conductors; and the big problem that the clamping device for the expanded diameter conductors is lack in the tension stringing construction is solved.

Owner:CHINA ELECTRIC POWER RES INST +1

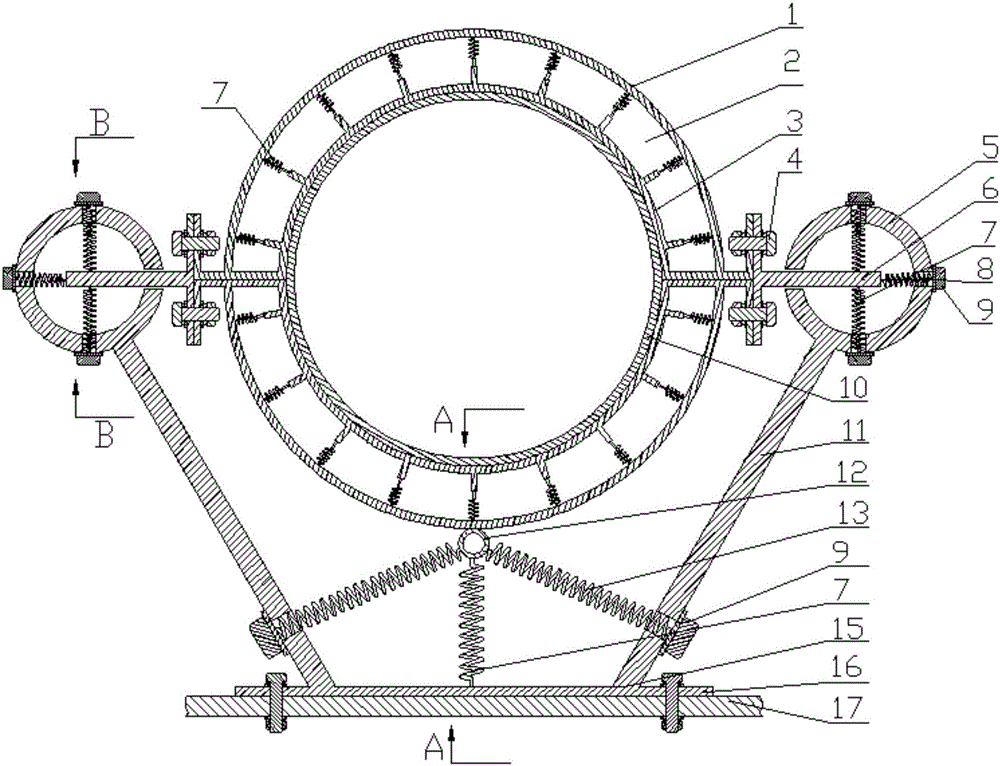

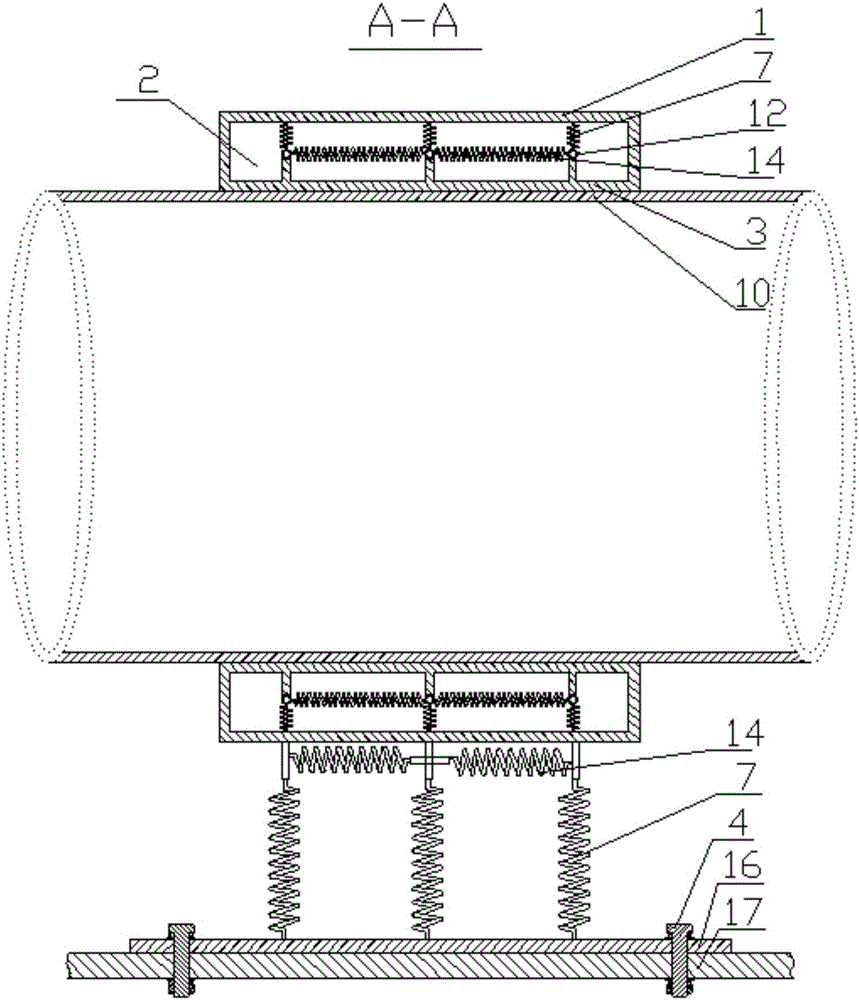

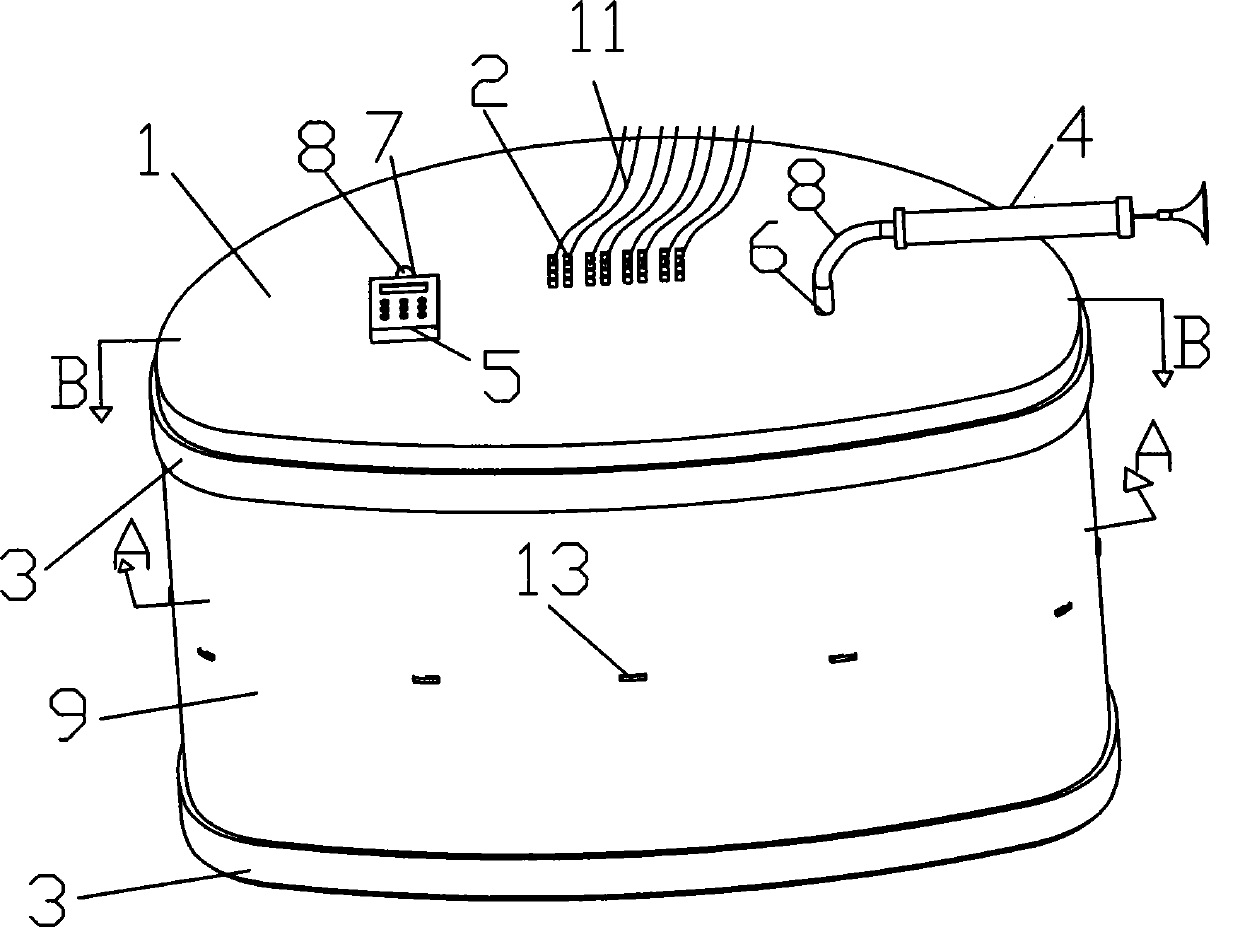

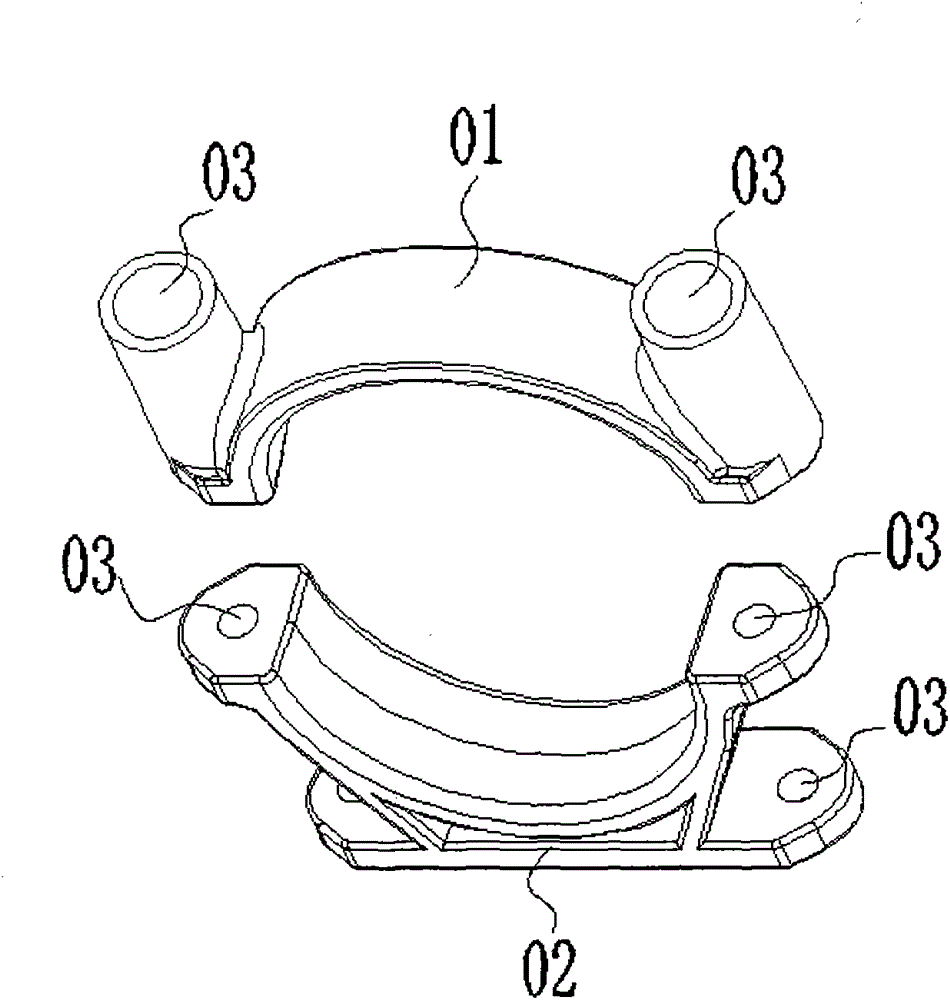

Vibration-damping ship pipe clamp and support frame assembly

ActiveCN106122599AReduce vibration displacementSimple structurePipe supportsManufacturing technologyMarine engineering

The present invention discloses a vibration-damping ship pipe clamp and support frame assembly comprising a pipe, a ship body board and a support frame. A pipe clamp is arranged outside the pipe, and connected to a top cylinder of the support frame by means of a T-shaped connecting piece. A base plate of the support frame is connected to the ship body board. When the pipe vibrates under collision, springs in the pipe clamp, springs in the top cylinder of the support frame and springs in a base of the support frame function in reducing displacements and stresses of the whole assembly in a vertical direction, a lateral direction and a longitudinal direction, thus reducing the vibration displacement of the whole pipe. The vibration-damping ship pipe clamp and support frame assembly is reasonable and simple in structure and low in production cost. Each spring used in the vibration-damping ship pipe clamp and support frame assembly is a cylindrical helical extension spring with centrally curled ring ends, and such a spring is very mature in manufacturing technology and also highly stable in quality.

Owner:连云港苏茂船舶技术服务有限公司

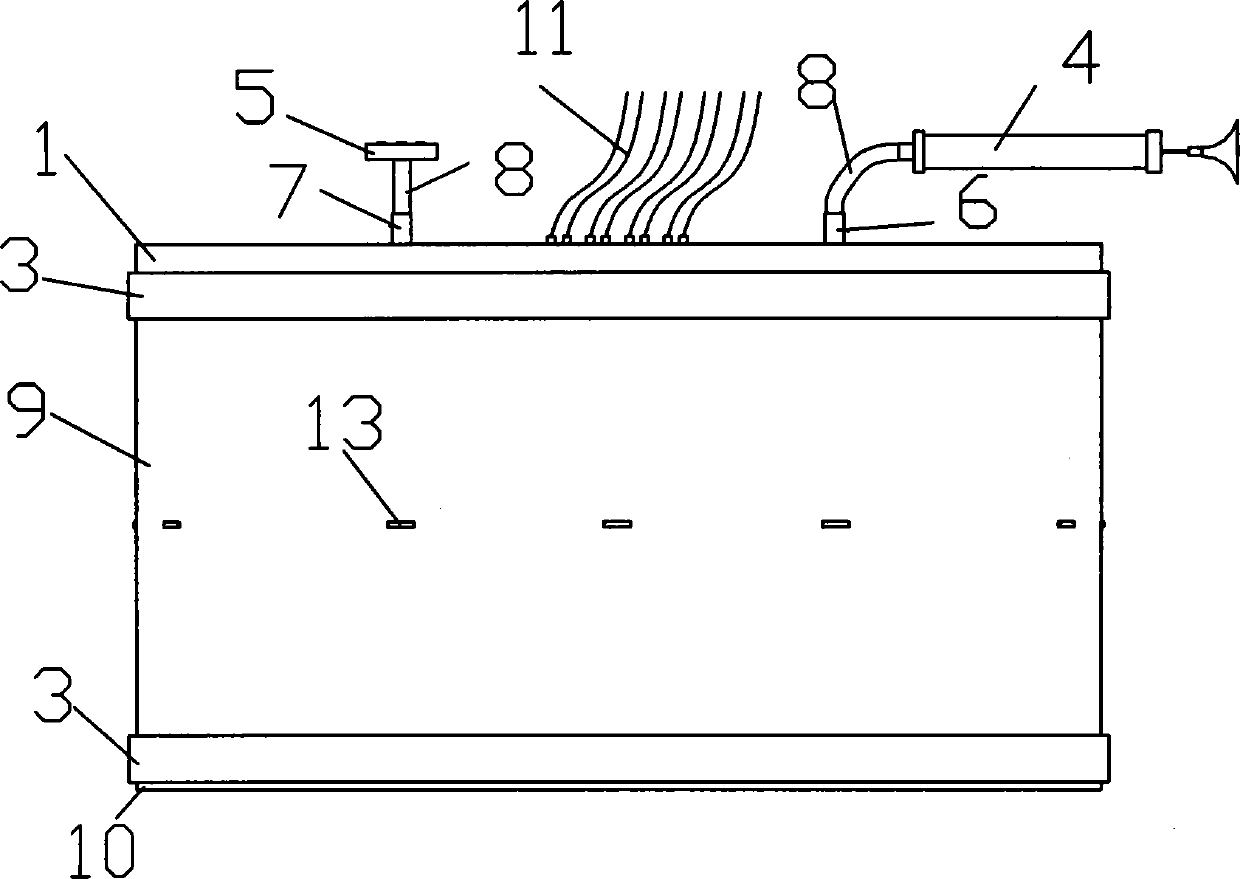

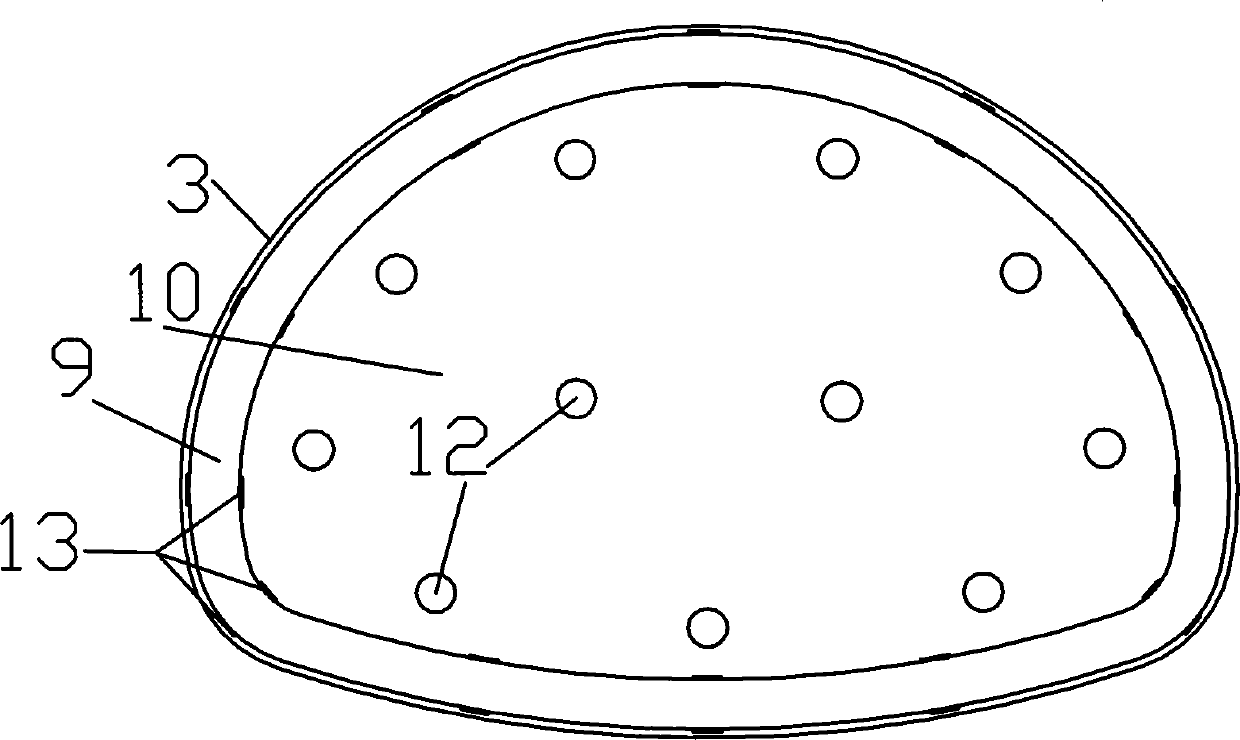

Uniform water pressure simulation loading device and method for tunnel structure model test

InactiveCN104181002ANo stress lossUniform stress loadingStructural/machines measurementElectrical resistance and conductanceThermodynamics

The invention discloses a uniform water pressure simulation loading device and method for a tunnel structure model test. The device comprises a top plate (1), a bottom plate (10), stand columns (12), a flexible sealing strip (3), an air extractor (4), a high-precision absolute barometer (5), a tunnel structure model (9) and an electric resistance strain gauge (13). In the tunnel structure model (9), an air pressure detecting hole (7) is connected with the high-precision absolute barometer (5), and air pressure in the tunnel structure model (9) is controlled through coordination operation of the air extractor (4) and the high-precision absolute barometer (5). By the adoption of the equivalent loading method where air pressure instead of water pressure is used, the characteristic that water cannot resist shearing force can be simulated, additional constraints cannot be generated on deformation of a tunnel structure, and therefore the damage process of the tunnel structure can be reflected actually. The permeation effect of water pressure can be simulated, the expansion process of cracks caused by the water pressure can be simulated, and the unloading effect of the water pressure after the cracks are through can be simulated.

Owner:SOUTHWEST JIAOTONG UNIV

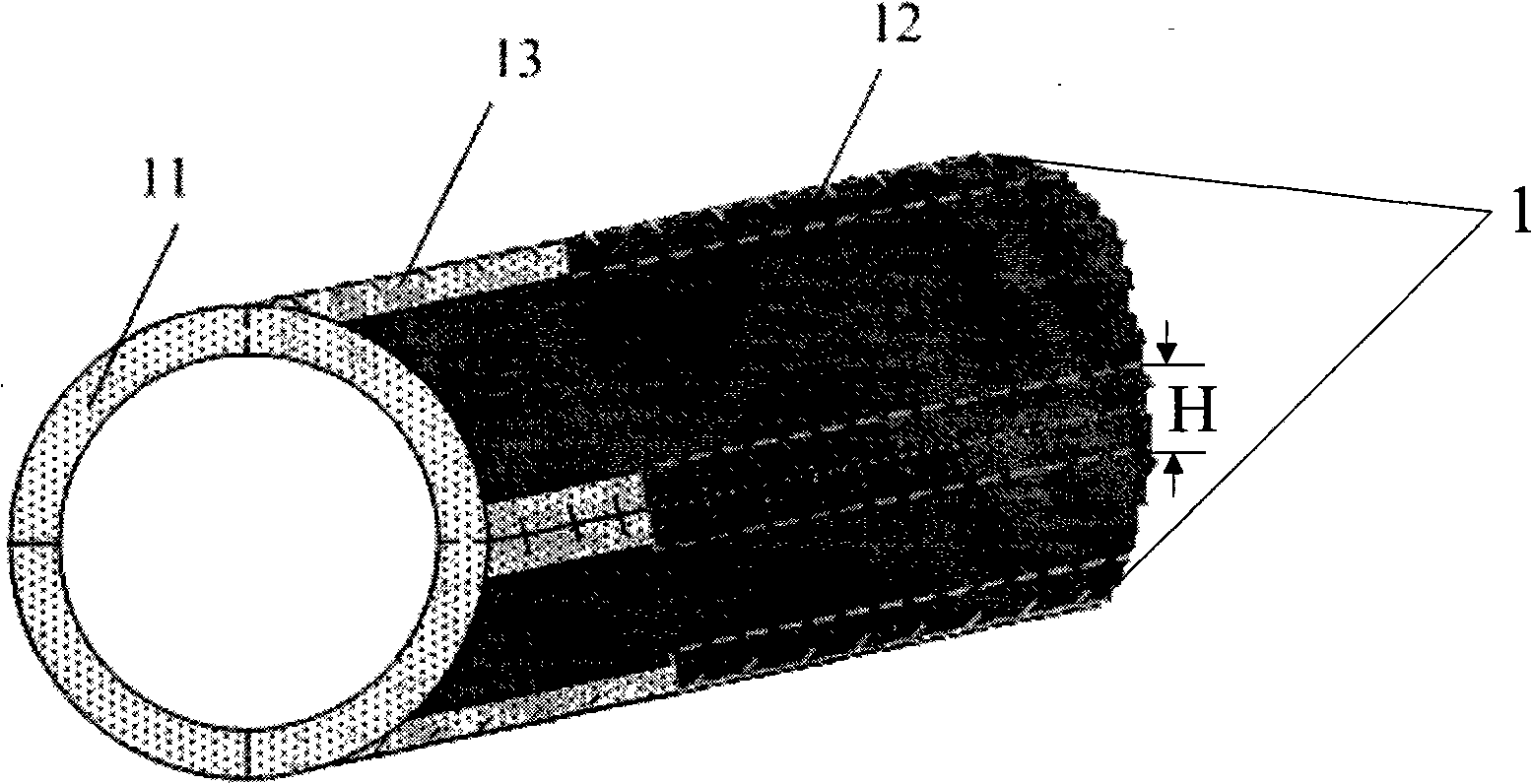

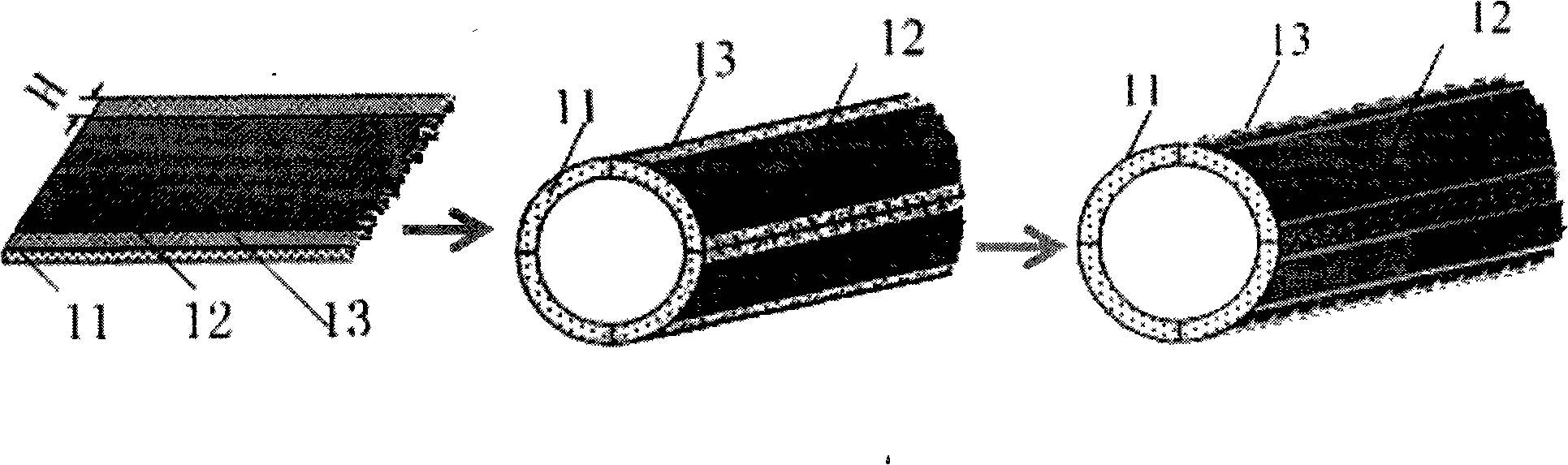

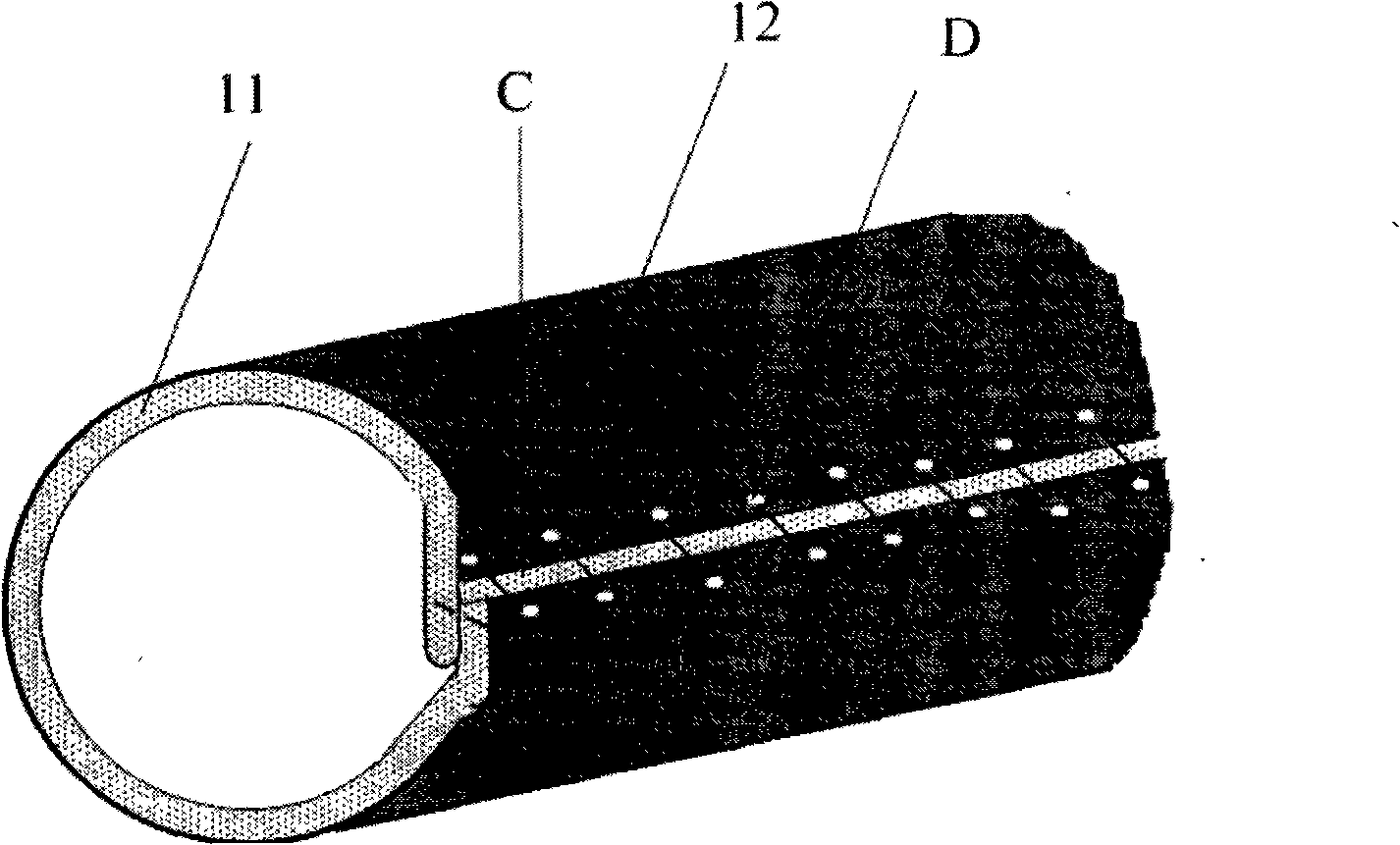

Tubular nonwoven compound material and manufacturing method thereof

InactiveCN101280872ASimple processIncrease productivityPipe elementsWoven fabric compositeEngineering

The invention relates to a tube shaped composite material non-woven fabric and method of producing the same, the composite material is made by tubular opposite joint of non-woven fabric base fabric and coating layer on it in width direction, the composite material is used for non-digging repair of damaged pipeline burred in city, the invention is characterized in that the base fabric of the composite material is made by opposite joint stitch of 2 or more than 2 same no-woven fabric base fabric in width direction, and is stitched into tubular non-woven fabric base fabric, and integral thickness of the coating layer on the same is uniformly consistent. The production method includes techniques: 1 designing split joint block number of the non-woven fabric base fabric; 2 remaining joining edge on both sides of each non-woven fabric base fabric in width direction, and homogeneously coating resin on other place; 3 using joining edge to oppositely joint the non-woven fabric base fabric with designed block number into tubular shape; 4 executing complement resin process at joining place and uniforming the thickness of resin at joining place of plane opposite joint and coated resin at other place, thereby obtaining the tube shaped non-woven fabric composite material.

Owner:TIANJIN POLYTECHNIC UNIV

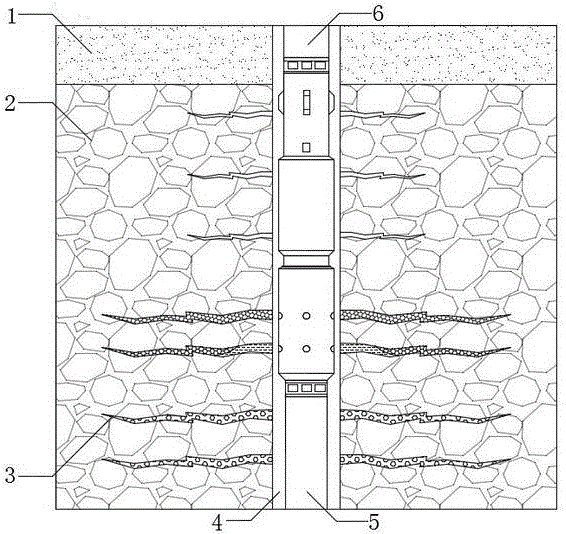

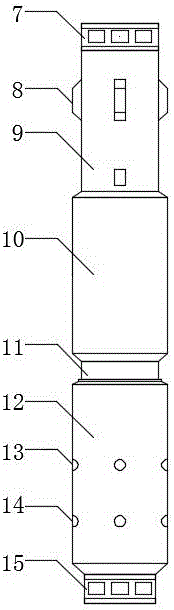

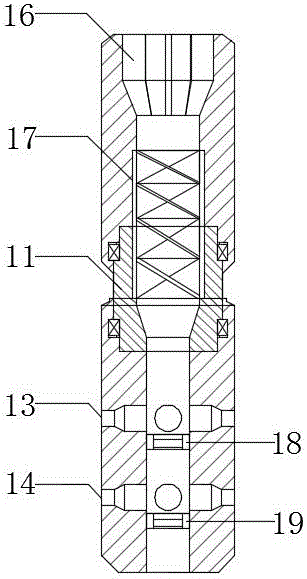

Device and method for supporting yield increase fractures of ocean natural gas hydrate

ActiveCN106545325AImprove mining efficiencyRealize large-scale commercial miningFluid removalDecompositionUpper joint

The invention discloses a device and method for supporting yield increase fractures of ocean natural gas hydrate. The device comprises a fracture monitoring section, a filling material prefabricated section, a filling section, an upper joint and a lower joint, wherein the upper joint, the fracture monitoring section, the filling material fabricated section, the filling section and the lower joint are connected together from top to bottom in sequence; the upper joint is connected to an upper drill column; and a locator is arranged on the periphery of the fracturing monitoring section. The device and method have the advantages that three-dimensional network skeleton structures are constructed in the fractures to extend and support the fractures and improve the seepage capability of the fractures, thereby improving the heat and mass transfer efficiency of an exploitation process, providing seepage channels for decomposing products and solving the problem of sediment blockage on the immediate vicinity of a wellbore; the energy loss of two-phase flowing caused by exploitation and product decomposition is reduced; lots of traditional fracturing fluid is prevented from flowing into a hydrate stratum; the purposes of stabilizing yield increase fracture structures, improving the rate of an exploitation project and prolonging the exploitation time are achieved; and the large-scale commercialized exploitation of the ocean hydrate is realized.

Owner:JILIN UNIV

Novel cable bracket hoop and preparation method thereof

InactiveCN104419157AImprove flame retardant performanceNo eddy currentPipe supportsGlass fiberEngineering

The invention relates to the technical field of cable burying, and particularly provides a novel cable bracket hoop and a preparation method thereof. The novel cable bracket hoop is a molded part of an even SMC composite material; a reserved inserting hole is formed in the novel cable bracket hoop; the novel cable bracket hoop is connected with a cable bracket upright post through a bolt made of the SMC composite material; and the SMC composite material comprises the following components in percentage by mass: 18%-22% of unsaturated polyester resin, 8%-10% of a low-shrinkage additive, 45%-50% of a flame-retardant filler, 18%-20% of glass fiber and 3%-4% of other additives. The preparation method comprises the following steps: firstly preparing resin paste in preparation; and adding the glass fiber, stirring, heating, pressurizing and molding. The novel cable bracket hoop disclosed by the invention is energy-saving, environmentally-friendly, long in service life, good in flame retardant property, free of eddy, good in safety performance.

Owner:重庆杰友电气材料有限公司

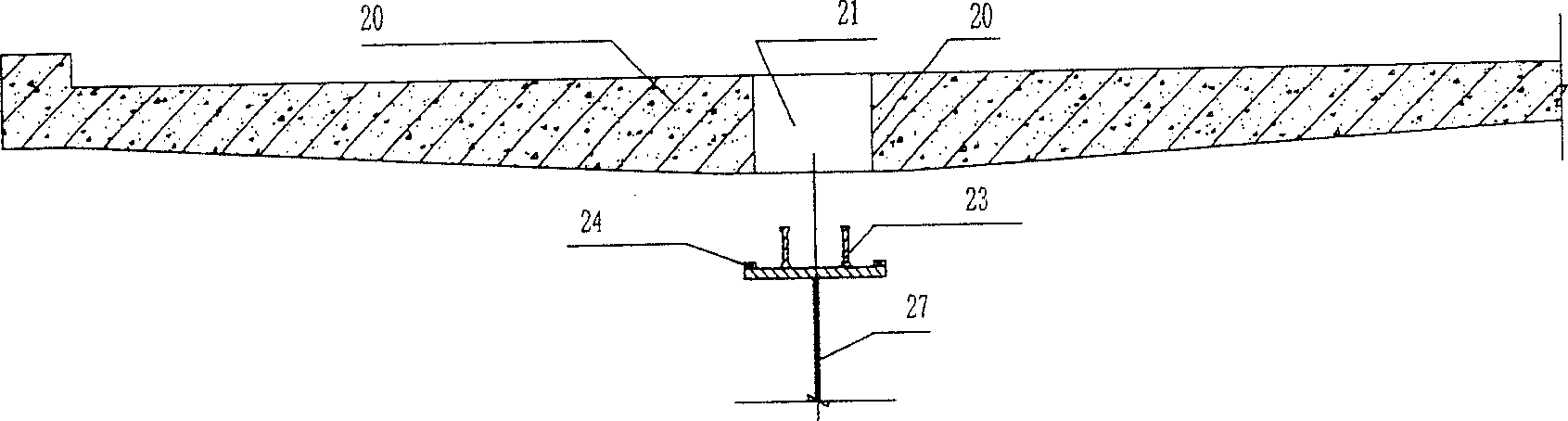

Superposition beam structure for prefabricated bridge surface plate and steel beam close combination

ActiveCN1900422AContinuous and even arrangementNo crevices susceptible to corrosionBridge structural detailsBuilding constructionsBridge deckRebar

A prefabricated bridge deck and steel beam tight coupling composite beam structure includes precast concrete bridge deck assembly and steel beam assembly. Said precast concrete bridge deck assembly has precast concrete bridge deck, end surface loop type steel reinforcement, bottom surface shear resistant slot, and bottom surface shear resistant unit. Said steel beam assembly has upright steel beam, steel beam top flange plate, integrated steel plate side formwork, shear resistant unit, integrated steel mesh end mould, said steel beam top flange plate shear resistant unit intersect polymerizing with said bridge slab bottom surface shear resistant unit..Said invention is suitable for prefabricated bridge deck with overhung tight coupling with steel beam, but also capable of having tightwire hole, wherein capable of setting bridge floor prestressed cable tensile in factory for prefabrication.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

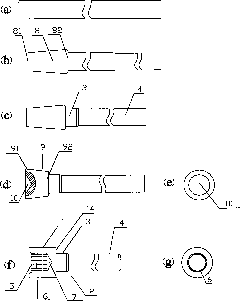

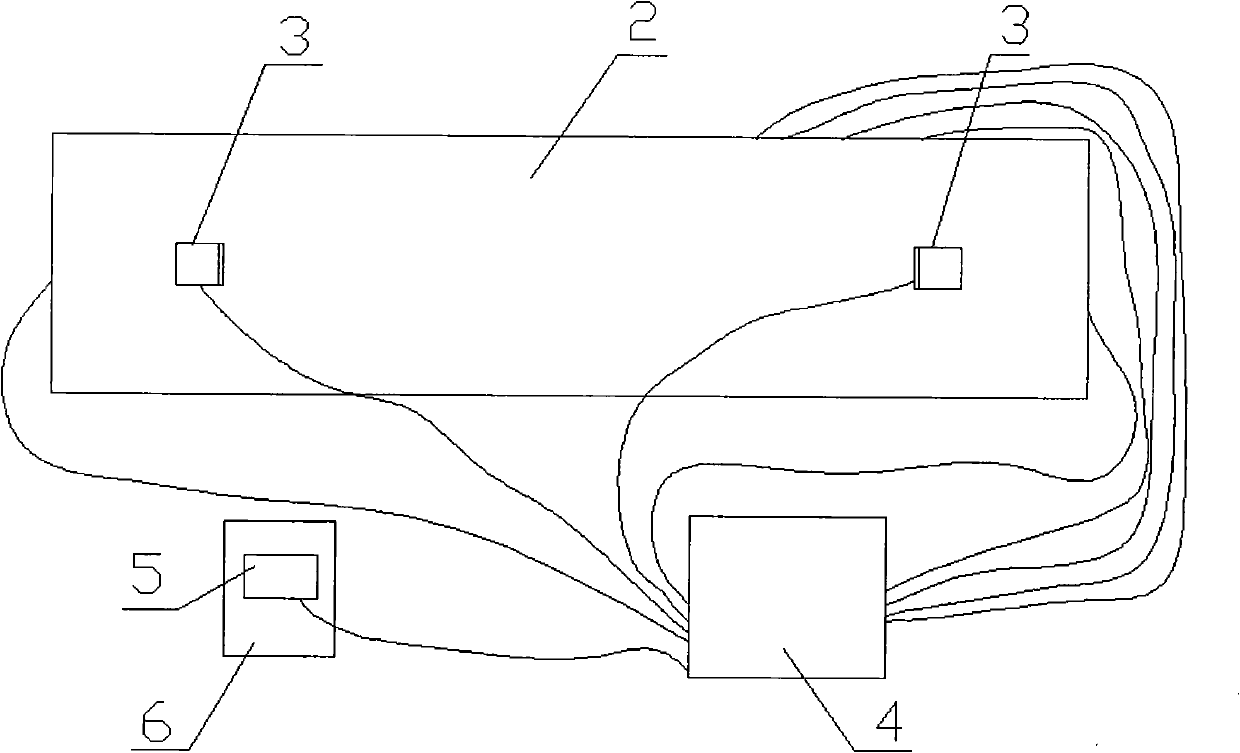

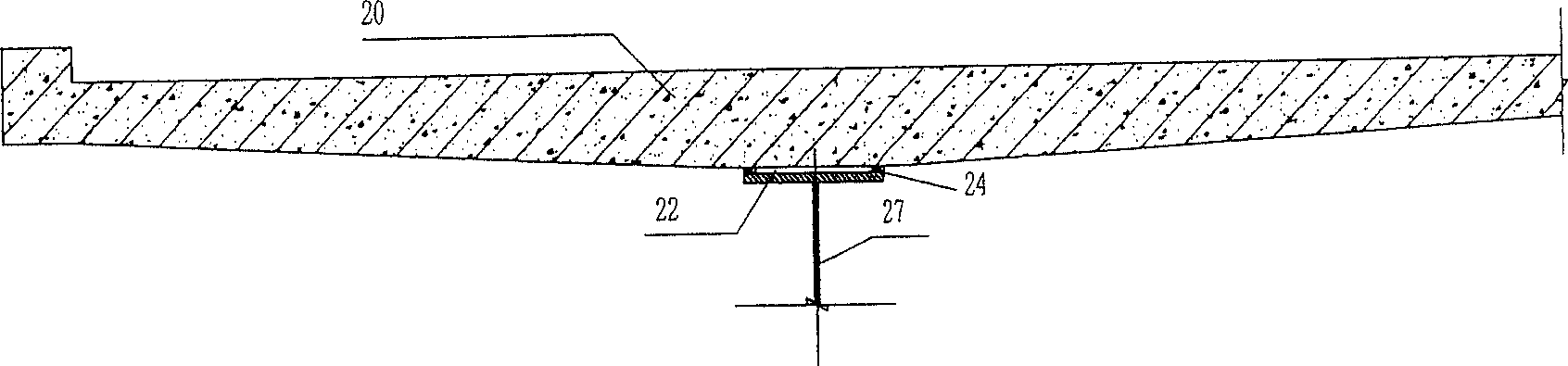

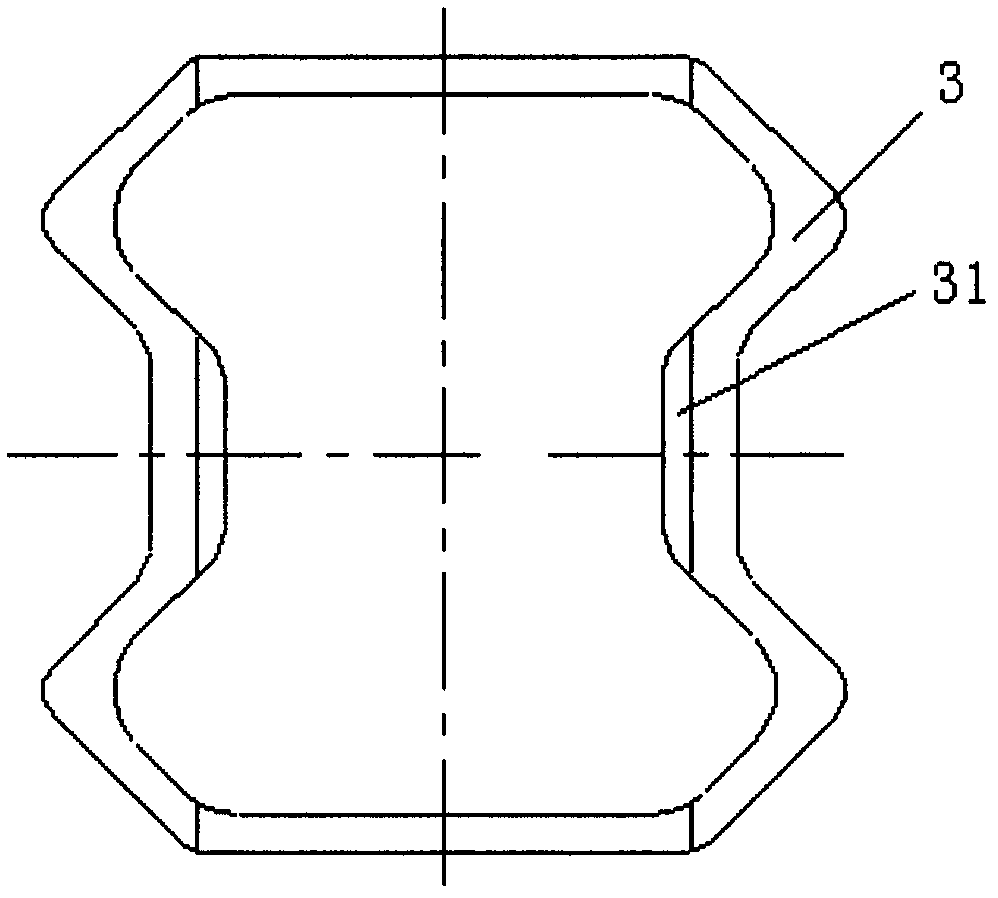

Independent vibration damping structure of gyro sensitive element

InactiveCN102538772AGuaranteed performanceNo stress concentrationSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesStress concentrationEngineering

The invention discloses an independent vibration damping structure of a gyro sensitive element, which includes vibration damping units (1), an outer frame (2) and an inner frame (3), wherein the inner frame (3) is a square frame with upper and lower straight edges and two M-shaped side edges; the gyro sensitive element (4) is positioned in the inner frame (3) and connected with the upper and the lower straight edges of the inner frame (3) and the bosses (31) protruding from the middle parts of the two M-shaped side edges of the inner frame (3); and the vibration damping units (1) are arranged at the contact positions of the outer frame (2) and the two M-shaped side edges of the inner frame (3). In the independent vibration damping structure, by combining the outer frame, the inner frame and the vibration damping units, the gyro sensitive element is suspended on the structural element, so as to enable the gyro to withstand the test of the dynamic environment conditions as impact and vibration on the basis that the performance of the gyro sensitive element is ensured. At the same time, as the inner frame adopts the symmetrical M-shaped structure, the stress externally transmitted to the gyro sensitive element is uniformly distributed, so as to avoid stress concentration.

Owner:BEIJING RES INST OF TELEMETRY +1

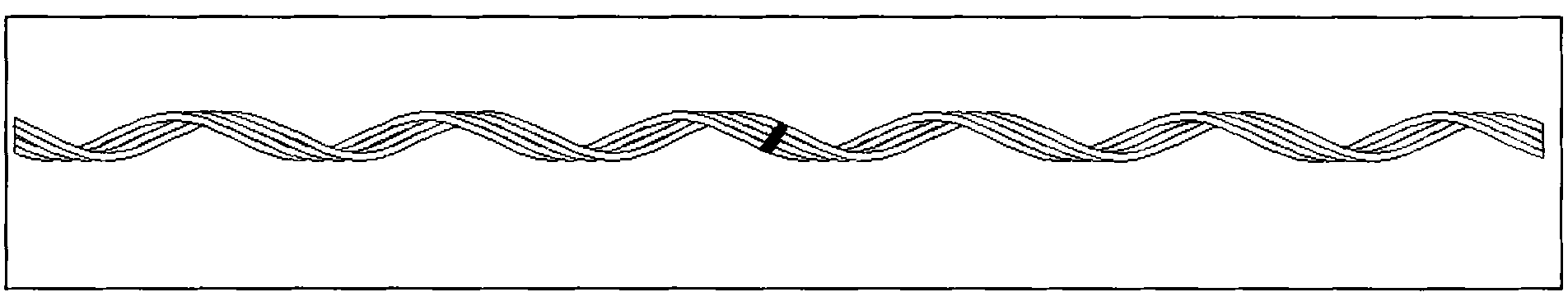

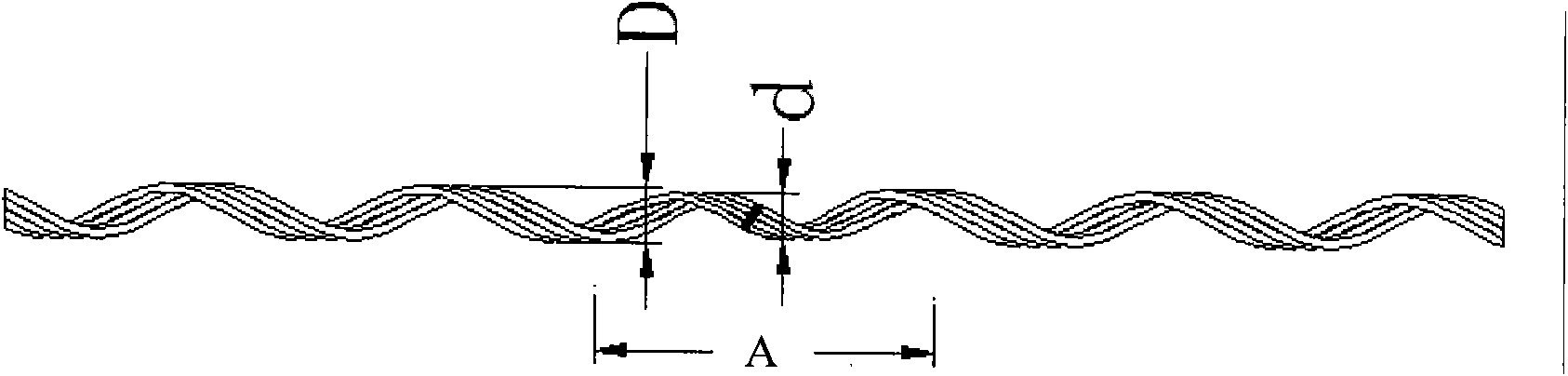

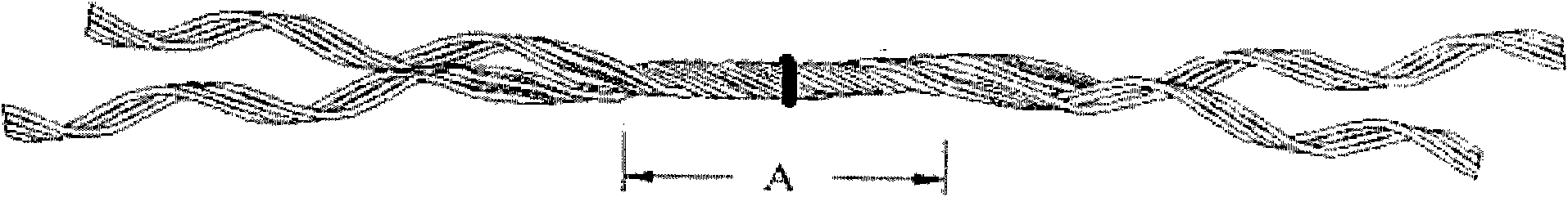

Anti-fatigue pre-twisted protective bar

InactiveCN102398533AIncrease stiffnessReduce stress and strainTrolley linesStress concentrationFatigue damage

The invention discloses an anti-fatigue pre-twisted protective bar. The protective bar comprises two spiral pre-twisted wire sheets; and the centers of the two pre-twisted wire sheets are twisted to form an enclosed circular tube. The anti-fatigue pre-twisted protective bar uniformly disperses pressure borne by a bearing seat to two sides without stress concentration; the stress strain of a lead at the position is reduced, the anti-fatigue property is improved, and the fatigue damage of the lead is effectively avoided; in addition, the invention has the advantages that the anti-fatigue pre-twisted protective bar can be installed manually, and is easy and quick to operate.

Owner:北京盈电电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com