Ceramic/metal composite of gradient double-continuous structure and preparation method and application of ceramic/metal composite

A technology of metal composite materials and metal materials, which is applied in the field of ceramic/metal composite materials and its preparation, can solve the problems of restricting the high hardness of ceramic materials, reducing the load-bearing capacity and impact resistance, and achieve high load-bearing capacity and impact resistance. even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

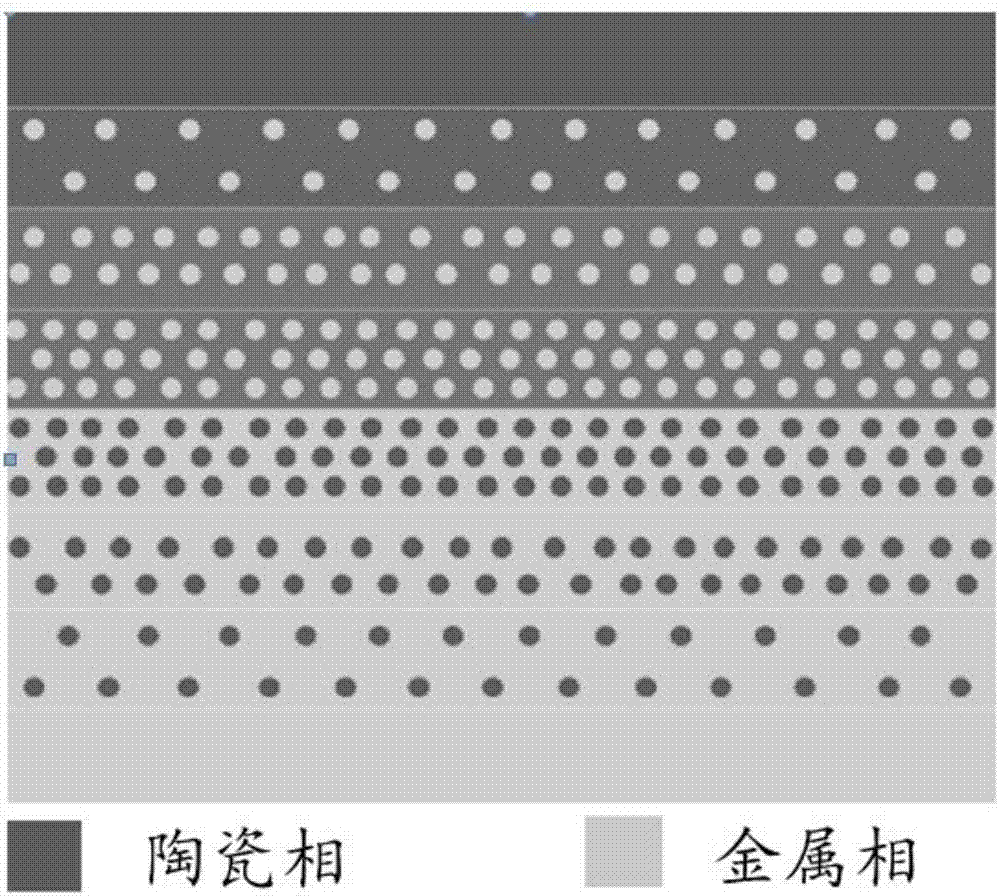

[0033] A ceramic / metal composite material with a gradient bicontinuous structure, which is composed of a porous ceramic material with a continuous gradient of porosity and a metal material filled in the pores of the porous ceramic material, wherein the ceramic material is Al 2 o 3 , SiC, Si 3 N 4 , B 4 C or TiB 2 Any one of them; the metal material is a fusible metal, which is any one of aluminum alloy, magnesium alloy or iron alloy.

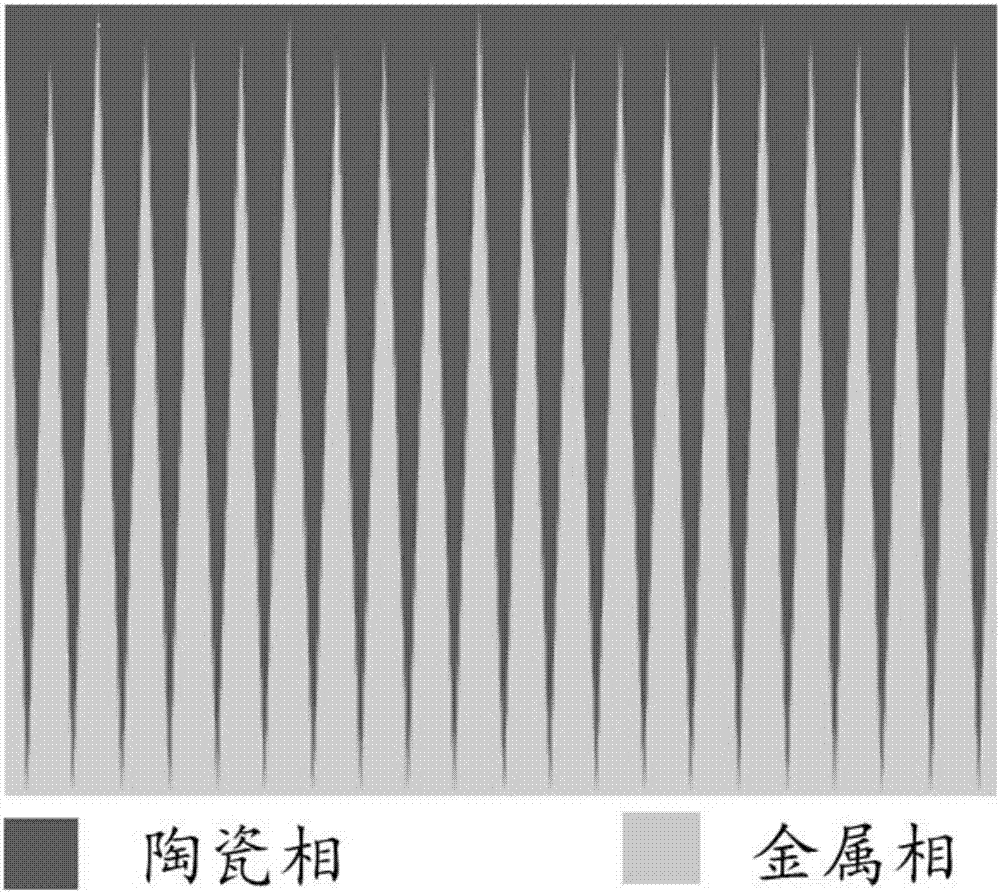

[0034] The schematic diagram of the microstructure of the ceramic / metal composite material with gradient bicontinuous structure is as follows figure 2 As shown, the ceramic phase and the metal phase form a bicontinuous structure. In this structure, due to the continuous distribution of the metal phase, when the force is applied, the composite material is evenly stressed through the transmission of the metal phase, and no stress concentration occurs. The ceramic phase and the metal phase respectively provide high elastic stiffness and failu...

Embodiment 2

[0037] Prepare the ceramic / metal composite material with gradient bicontinuous structure described in Example 1, comprising the following steps: the ceramic material used is B 4 C, the metal material used is aluminum alloy, which is prepared by squeeze casting method, which specifically includes the following steps:

[0038] S1: The porous B with a continuous gradient of porosity 4 C ceramic material is used as a preform, and the preform is put into an infiltration mold and preheated to 400°C;

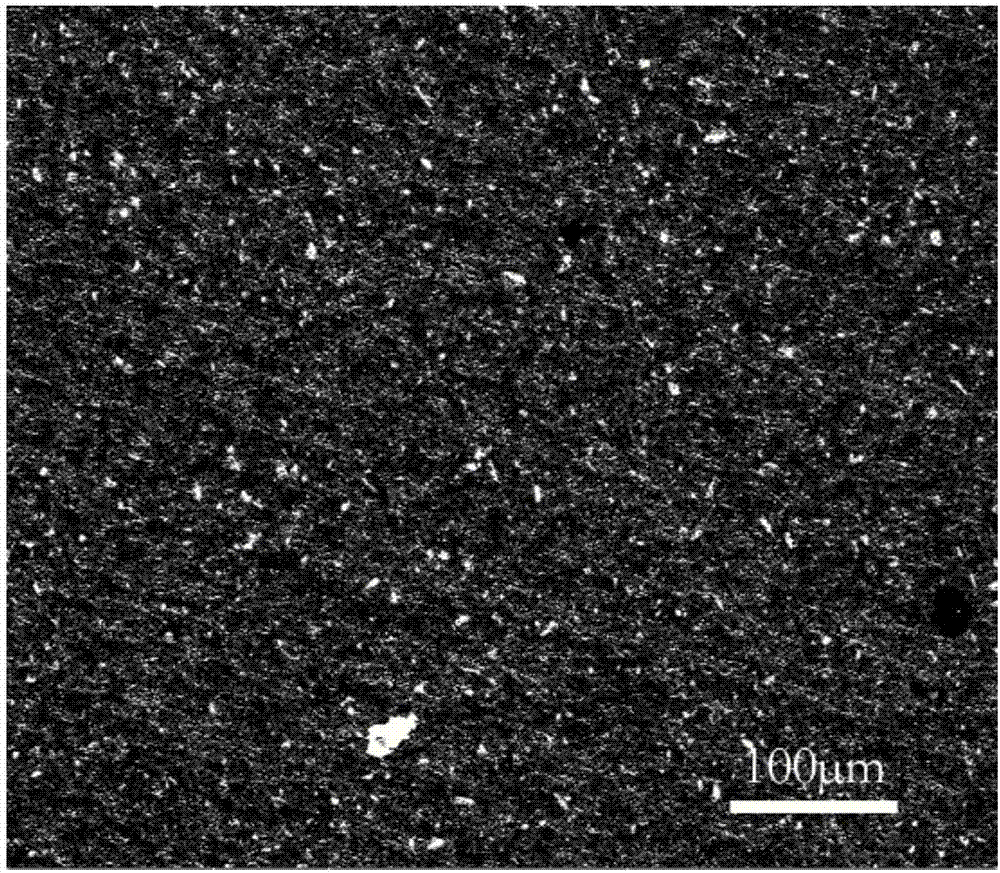

[0039] S2: Heat and melt the aluminum alloy at 800°C, pour the obtained aluminum alloy melt into the impregnation mold, pressurize immediately, the pressure is 80MPa, and infiltrate the aluminum alloy melt from top to bottom Into the prefabricated body; keep the pressure for 20 minutes to ensure that the aluminum alloy melt is completely solidified under this pressure, and then withdraw from the mold. got a B 4 Composite materials with C / Al alloy gradient bicontinuous structure, whi...

Embodiment 3

[0043] The preparation of the ceramic / metal composite material with a gradient bicontinuous structure described in Example 1 comprises the following steps: the ceramic material used is SiC, the metal material used is aluminum alloy, and is prepared by a pressureless infiltration method, specifically including the following steps :

[0044] The porous SiC ceramic material with a continuous gradient of porosity is used as a preform, the preform is placed on the aluminum alloy, and then the whole is placed in a vacuum environment for heating, and the vacuum degree is lower than 10 -2 Pa, the heating rate is 2°C / min; when the temperature rises above the melting point of the aluminum alloy, N 2 Or Ar protective atmosphere, after holding for 0.1-10h, cooling to room temperature and demoulding, a composite material with gradient bicontinuous structure of SiC / Al alloy is obtained, which has a gradient change from high content of ceramic phase to high content of metal phase, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com