Patents

Literature

213 results about "Continuous distributions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

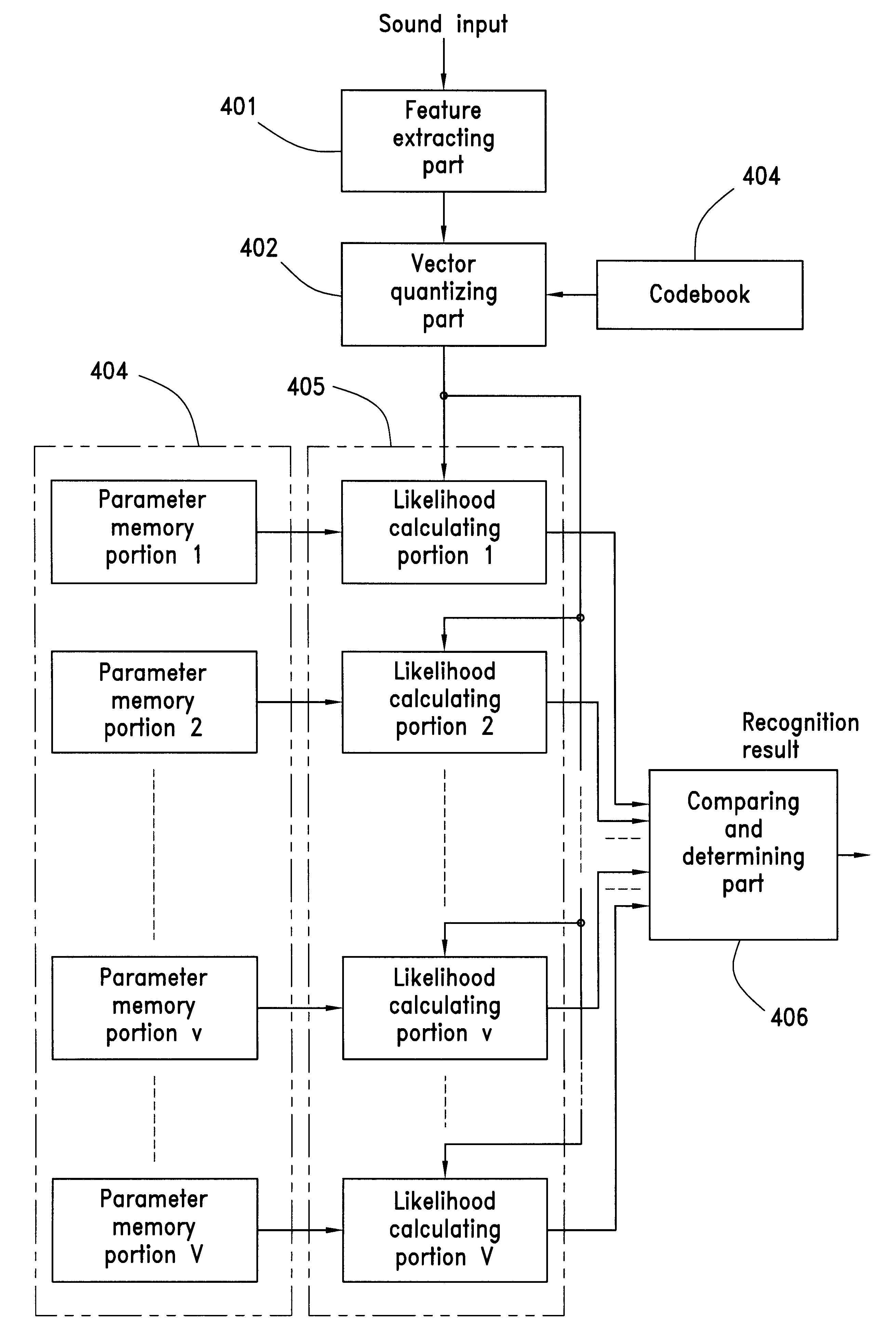

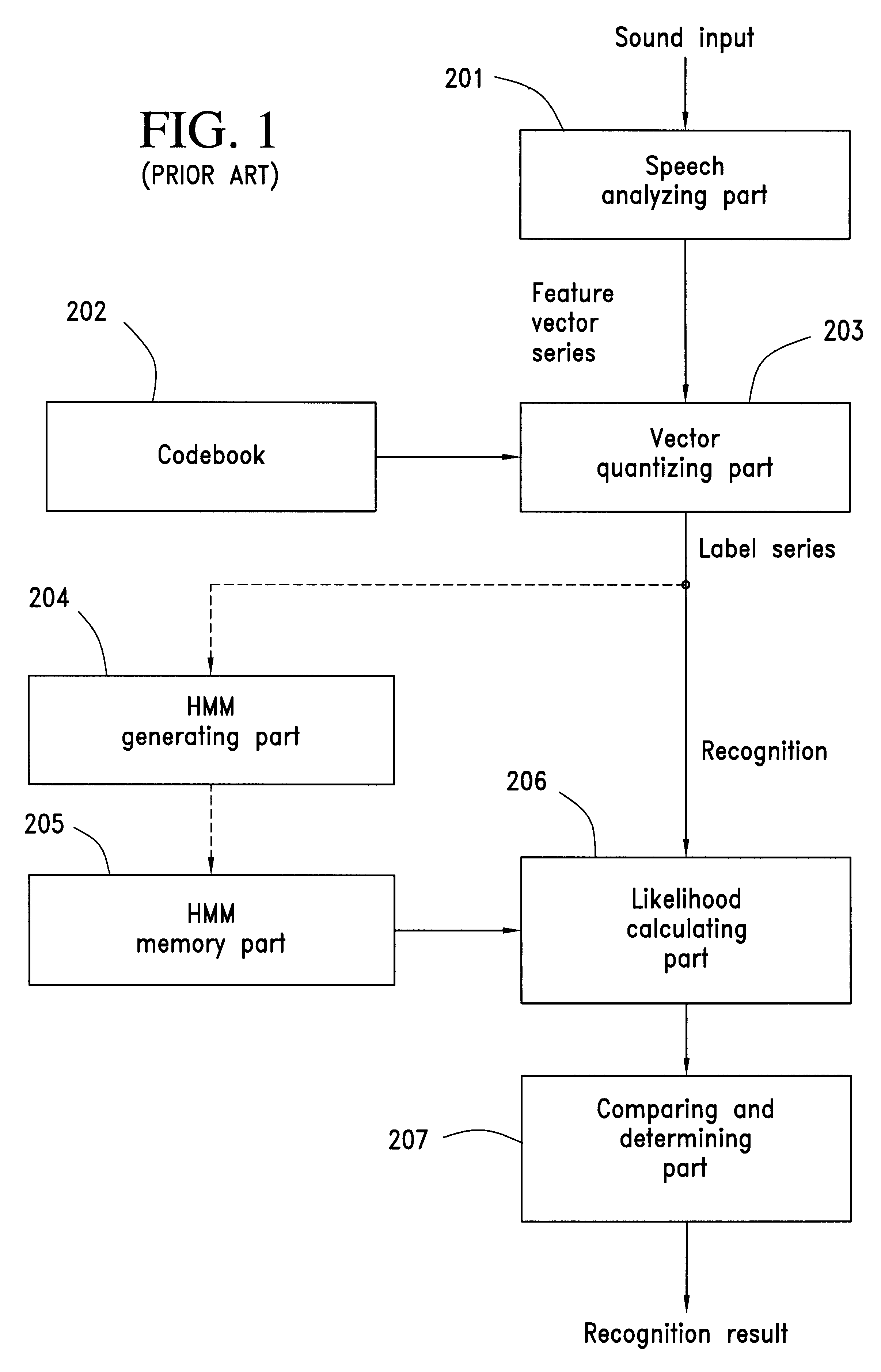

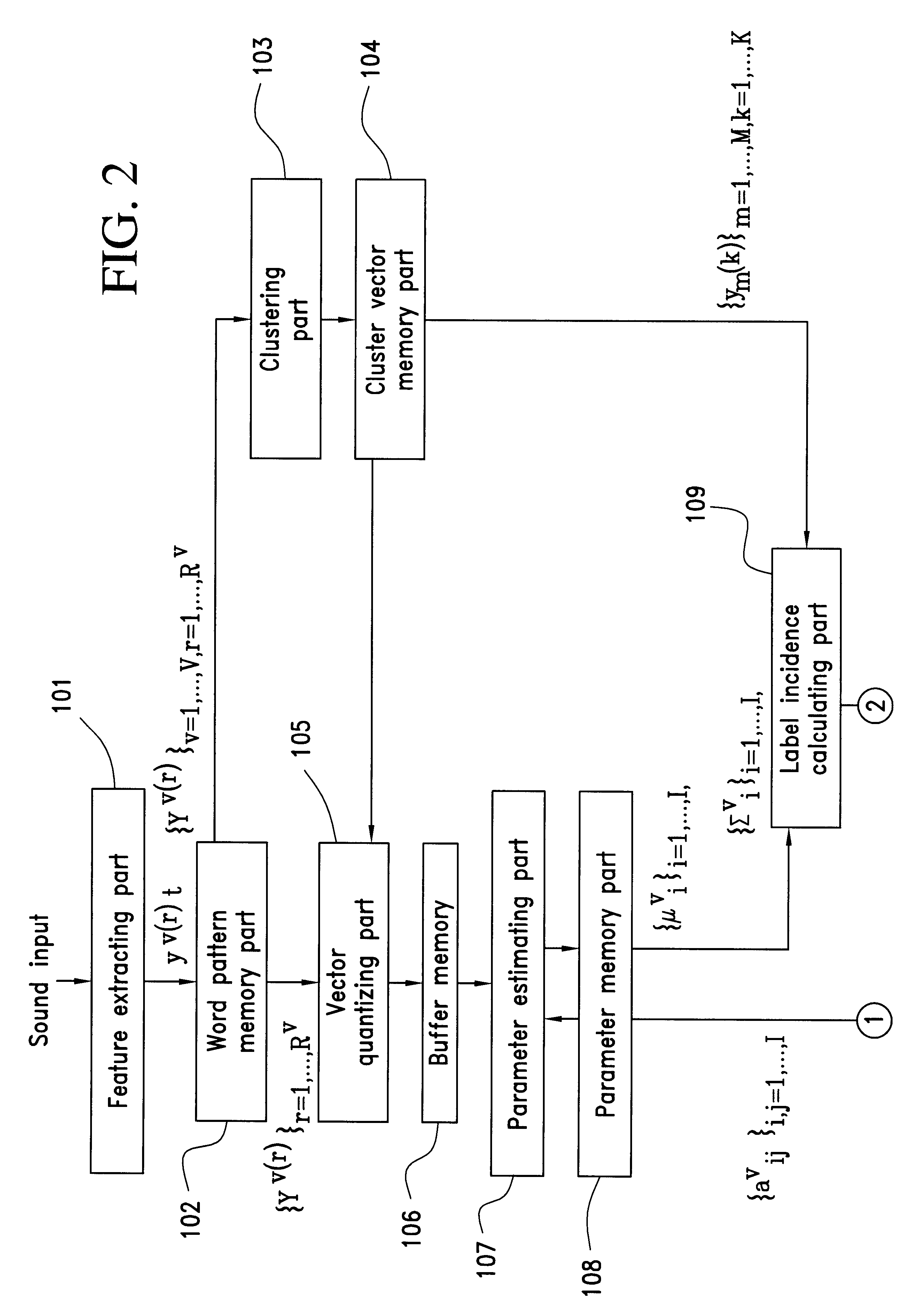

Combined quantized and continuous feature vector HMM approach to speech recognition

A device capable of achieving recognition at a high accuracy and with fewer calculations and which utilizes an HMM. The present device has a vector quantizing circuit generating a model by quantizing vectors of a training pattern having a vector series, and converting the vectors into a label series of clusters to which they belong, a continuous distribution probability density HMM generating circuit for generating a continuous distribution probability density HMM from a quantized vector series corresponding to each label of the label series, and a label incidence calculating circuit for calculating the incidence of the labels in each state from the training vectors classified in the same clusters and the continuous distribution probability density HMM.

Owner:TSUBOKA EIICHI

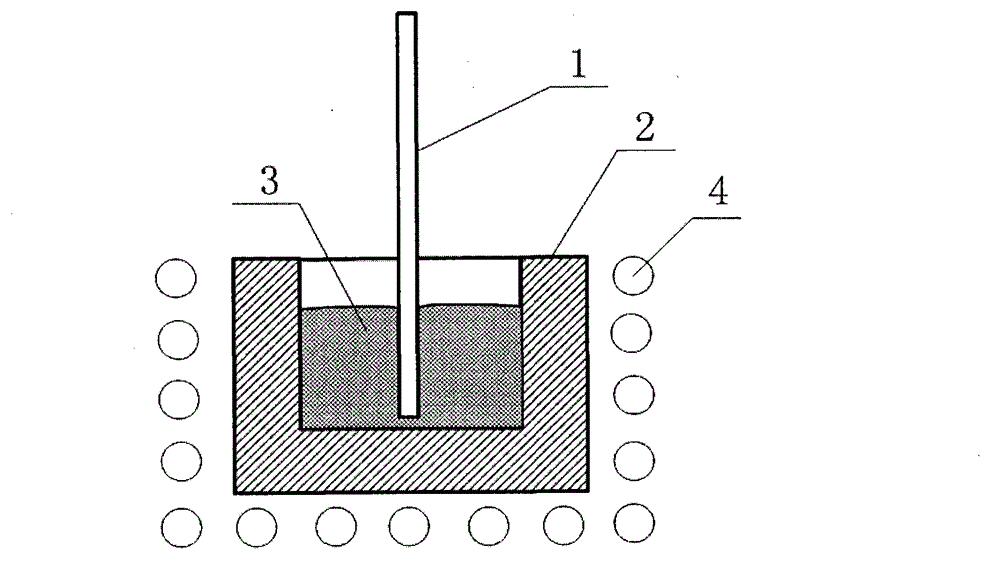

Foam skeleton structure reinforced metal-matrix composite material and preparation method

ActiveCN105779804AImprove thermal conductivityImprove conductivityChemical vapor deposition coatingThree-dimensional spaceCarbon nanotube

The invention discloses a foam skeleton structure reinforced metal-matrix composite material and a preparation method thereof. The composite material comprises a foam skeleton, a surface strengthening material and a matrix, wherein the foam skeleton is made of foam metal, foamed ceramics or foamy carbon; the surface strengthening material is a high heat conduction material adopting a diamond film, a graphene film, a carbon nanotube and the like; the metal matrix material adopts one of copper, aluminum, a copper alloy, an aluminum alloy and the like. A reinforcing phase and a matrix phase of the prepared composite material keep continuous distribution in three-dimensional space, an interpenetrating network structure is formed, the influence of a composite interface on the thermal properties of the material can be weakened effectively, good plasticity and toughness of the metal matrix are not reduced, the reinforcing phase can become a whole, the heat conduction efficiency of a reinforcing body is realized to the greatest extent, the heat conductivity, the electric conductivity and the mechanical strength of the composite material are greatly improved compared with the traditional composite material, and the composite material is a multifunctional composite material with great potential.

Owner:CENT SOUTH UNIV

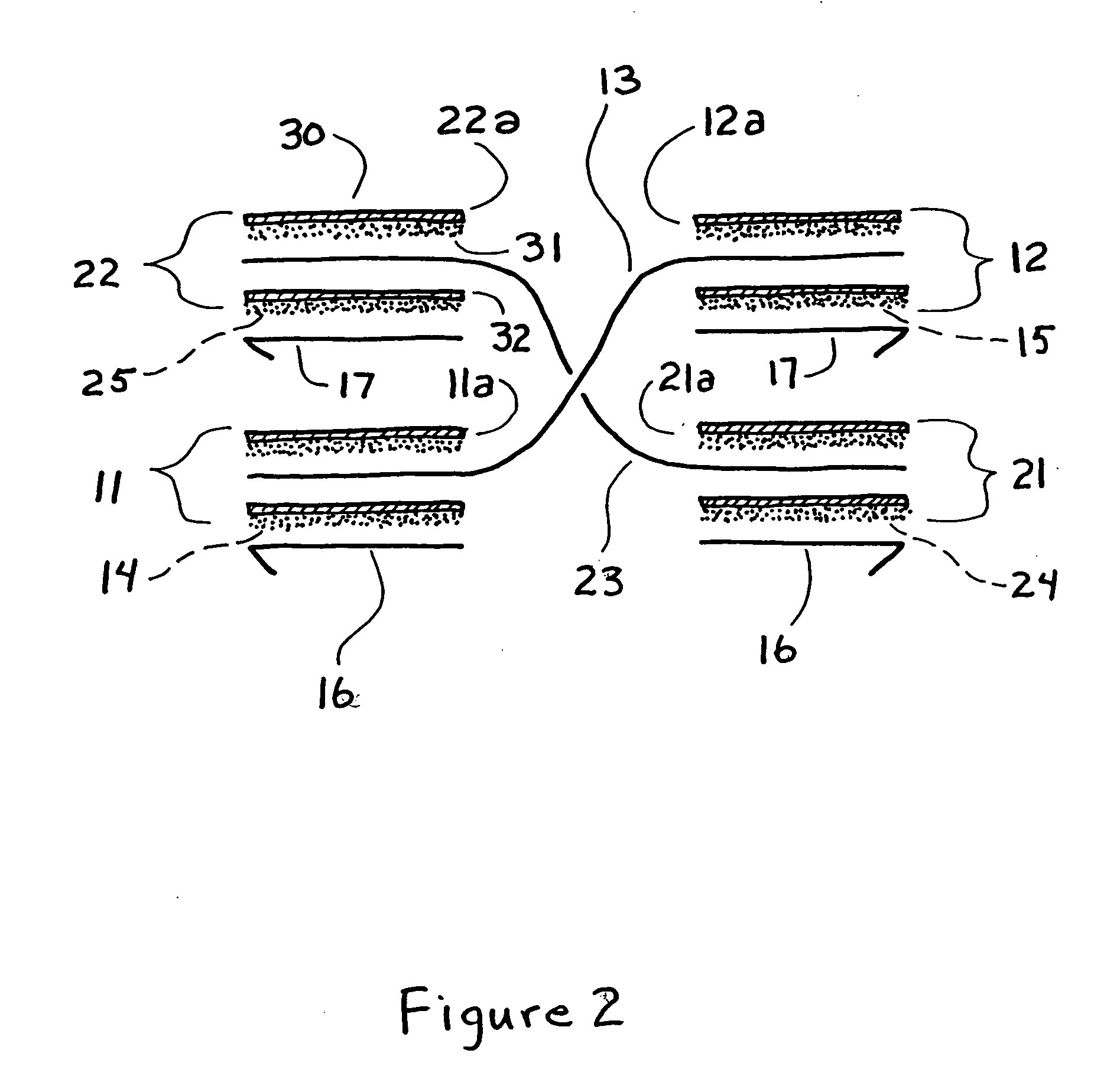

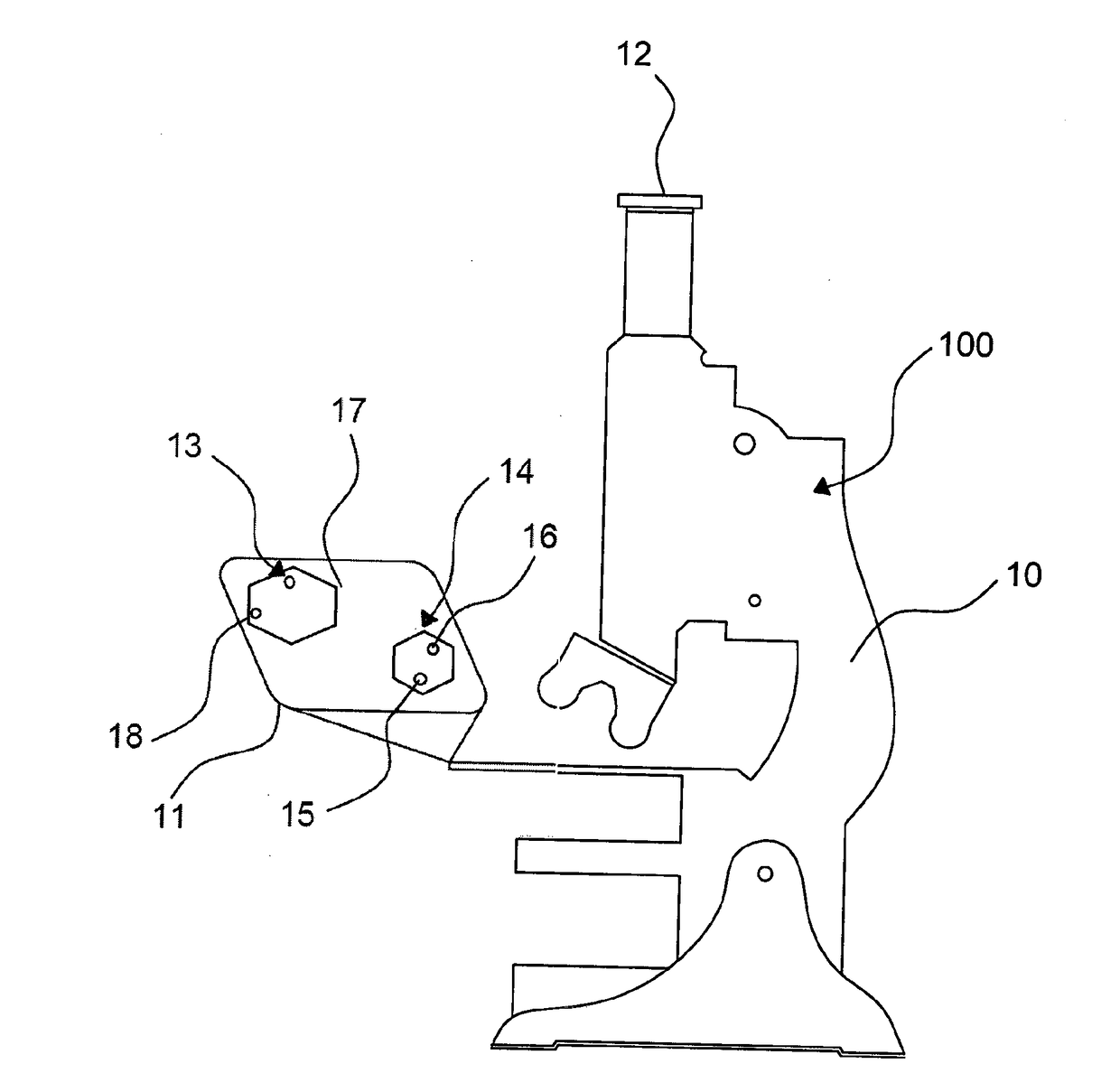

Suture bandage

InactiveUS20050284801A1Easily cut to sizeAvoid difficult choicesThreshersWound clampsVapor bubbleBandage

A method and apparatus are presented for a microscopic valve. The valve is electronically activated. Sensors for detecting objects in the flow may be external or formed in the channels of the valve. Many valves can be formed in parallel and in sequence on a single substrate. Multiple channels may feed each junction. Closure of the valve is accomplished by the formation of a vapor bubble or bubbles. Virtual walls may be formed by a sequence of bubbles. Logic and driver circuitry for producing bubbles may be external or included in the substrate. Such an array is ideally suited for sorting cells. Other materials in a suspension may also be sorted by a variety of criteria. A multi lumen output can produce a continuous distribution of cells or particles thus sorted.

Owner:TACKLIND CHRISTOPHER A

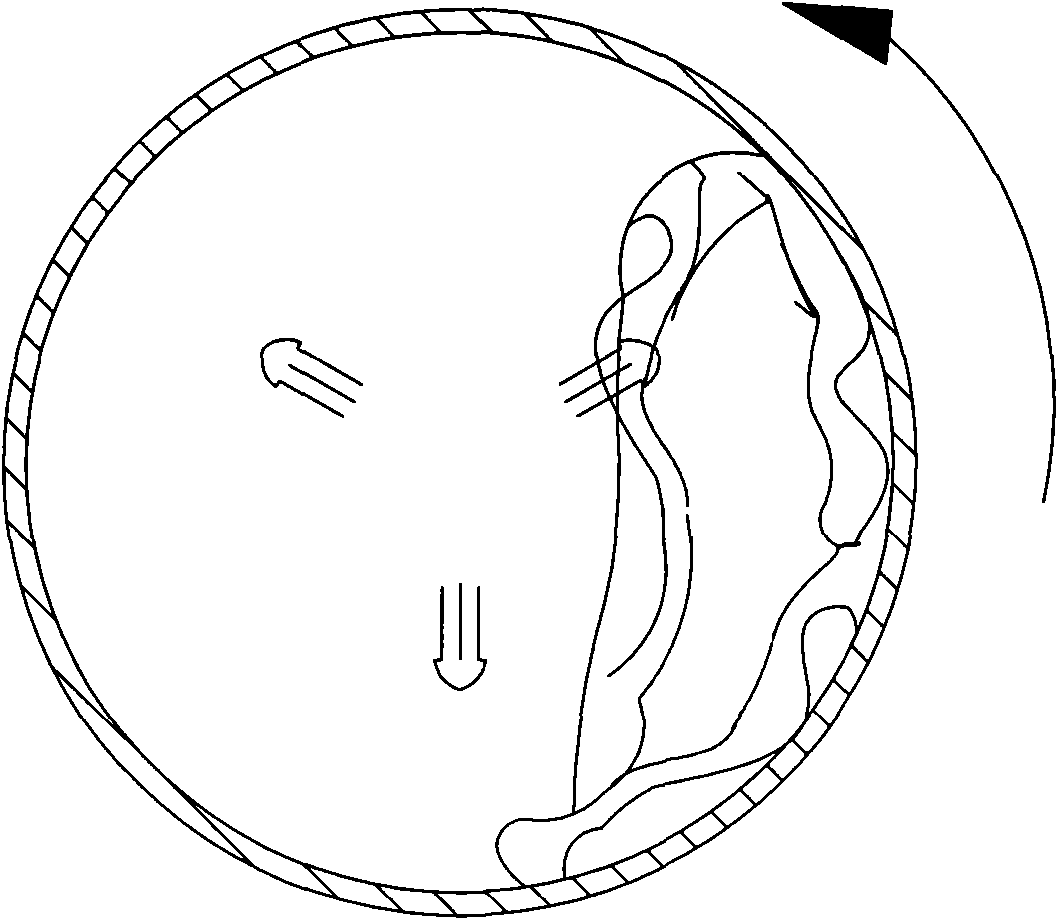

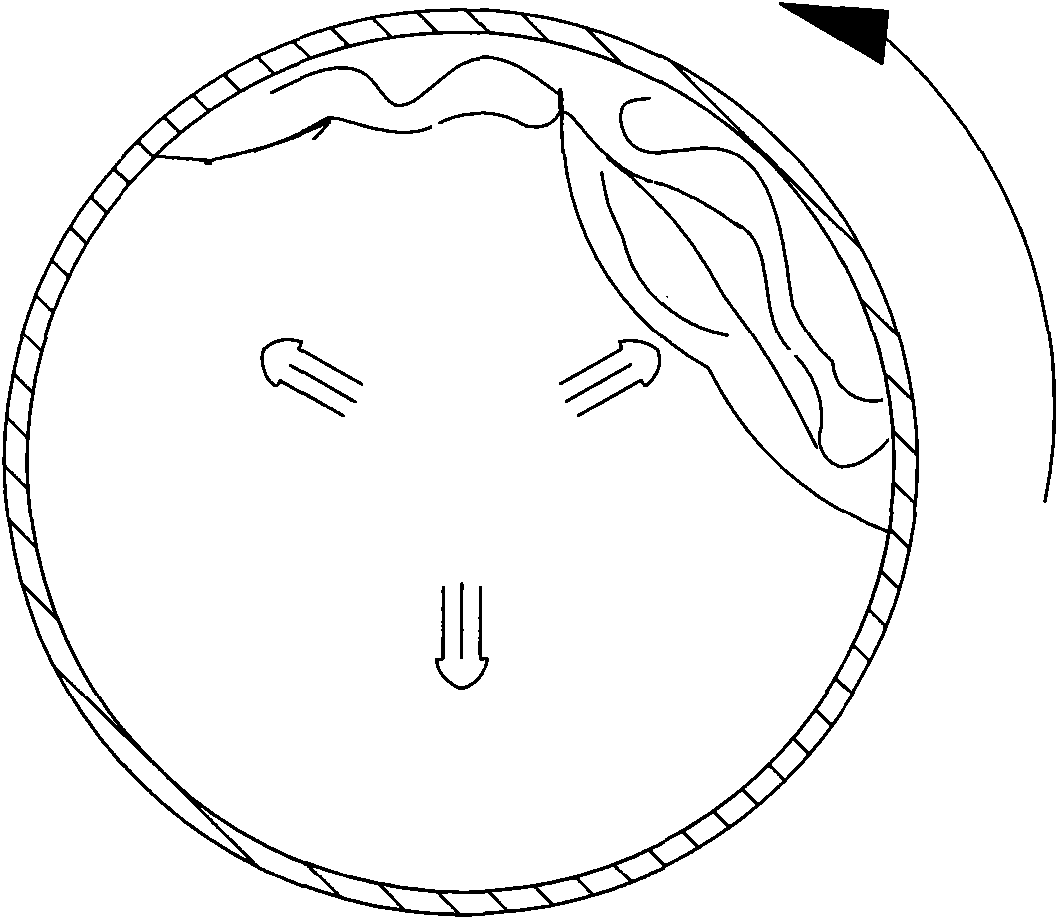

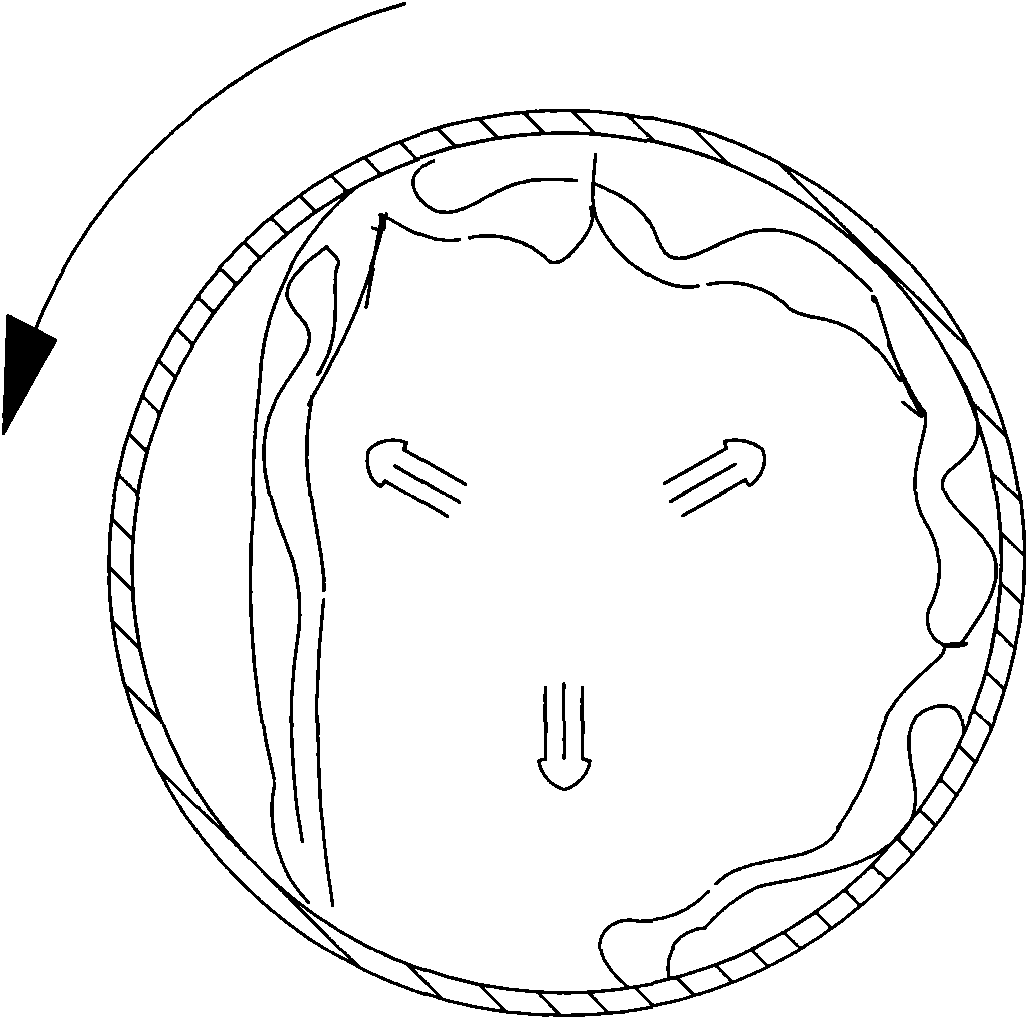

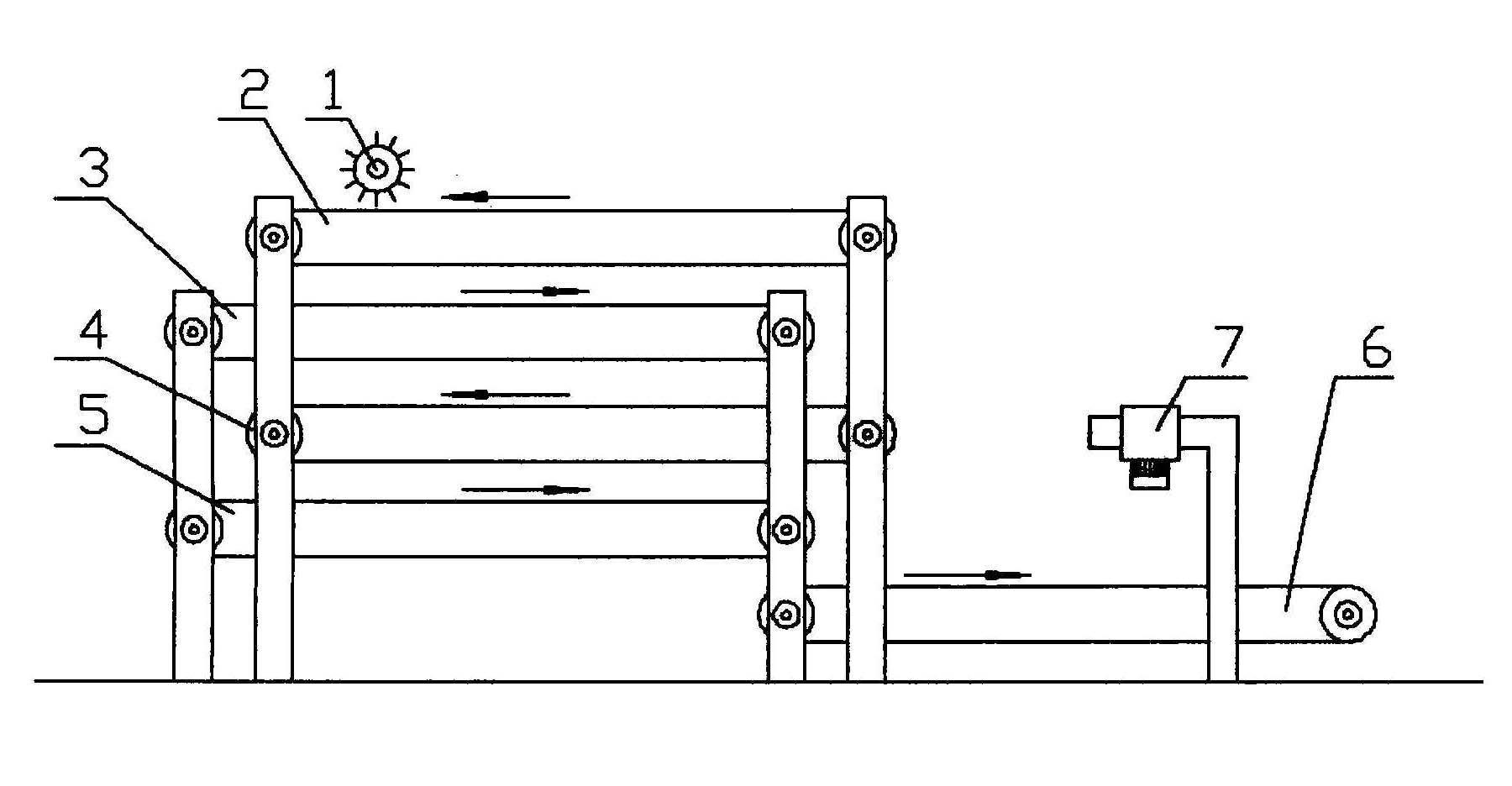

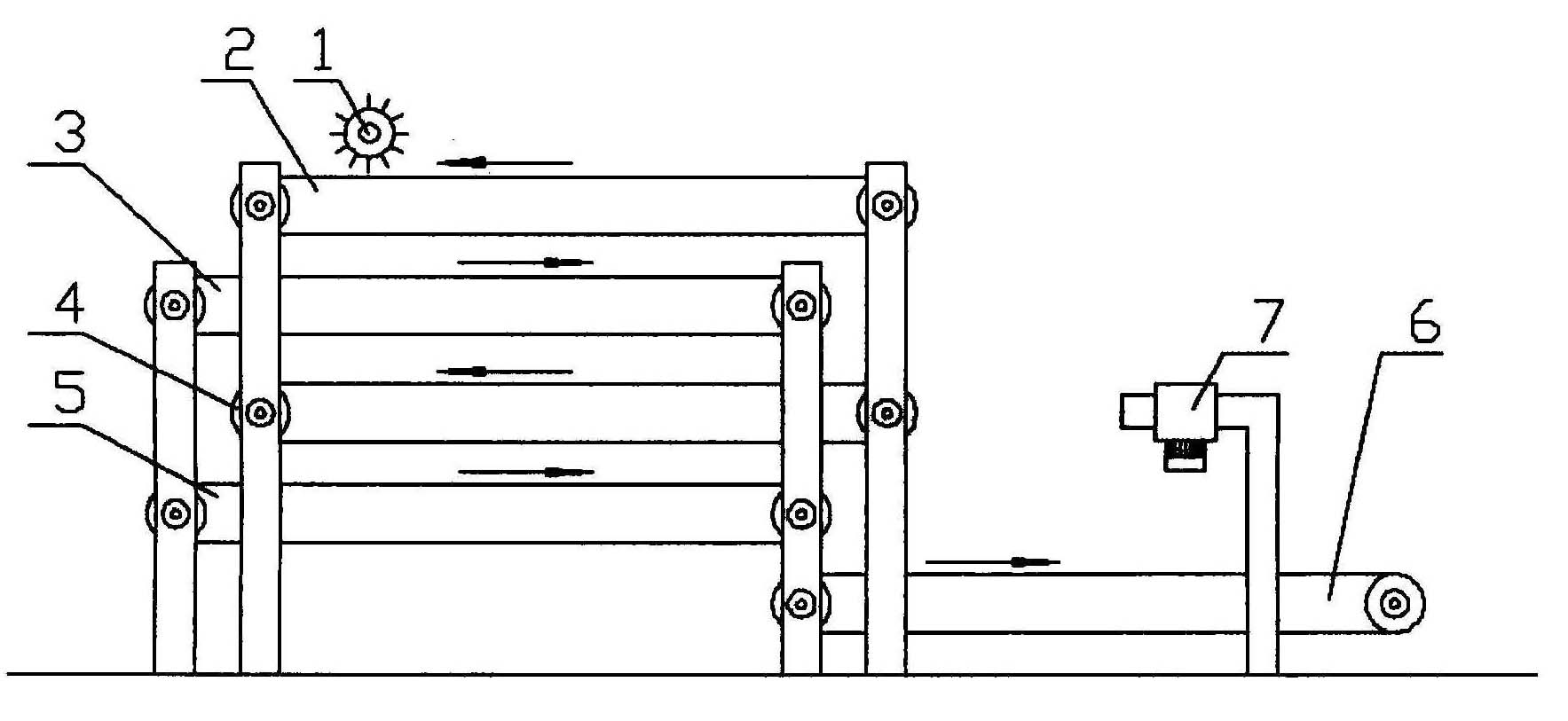

Method for distribution control of drum type washing machine before drying clothes

ActiveCN101768848AControl devices for washing apparatusTextiles and paperDistribution controlProcess engineering

The invention discloses a method for distribution control of a drum type washing machine before drying clothes, which comprises a speed at the beginning of water drainage stage, a low rotating speed of clockwise and anticlockwise rotation in the water drainage stage, a medium rotating speed after a rapid rising state through high-speed rotation in one direction and a high rotating speed after a slow rising stage in the direction identical to the direction of the previous stage. The amount of unbalance is judged after the high rotating speed is stable. When the amount of unbalance is larger than or equal to the amount of weight unbalance set in a program, the rotating speed is reduced to the low rotating speed in the water drainage stage, and the distribution is performed again from the second stage 5-6 seconds later, and if the pulse conditions can not satisfied after continuous distribution for three times, the distribution is performed again from the first stage. If the amount of unbalance is smaller than the amount of weight unbalance, the pre-hydrating and drying can be directly performed. The control method of the invention not only can achieve the best clothes distribution effect, thereby reducing the damage to the drum caused by displacement and centrifugal force resulting from uneven distribution, but also can greatly reduce the time before main drying and simultaneously save the electric energy.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

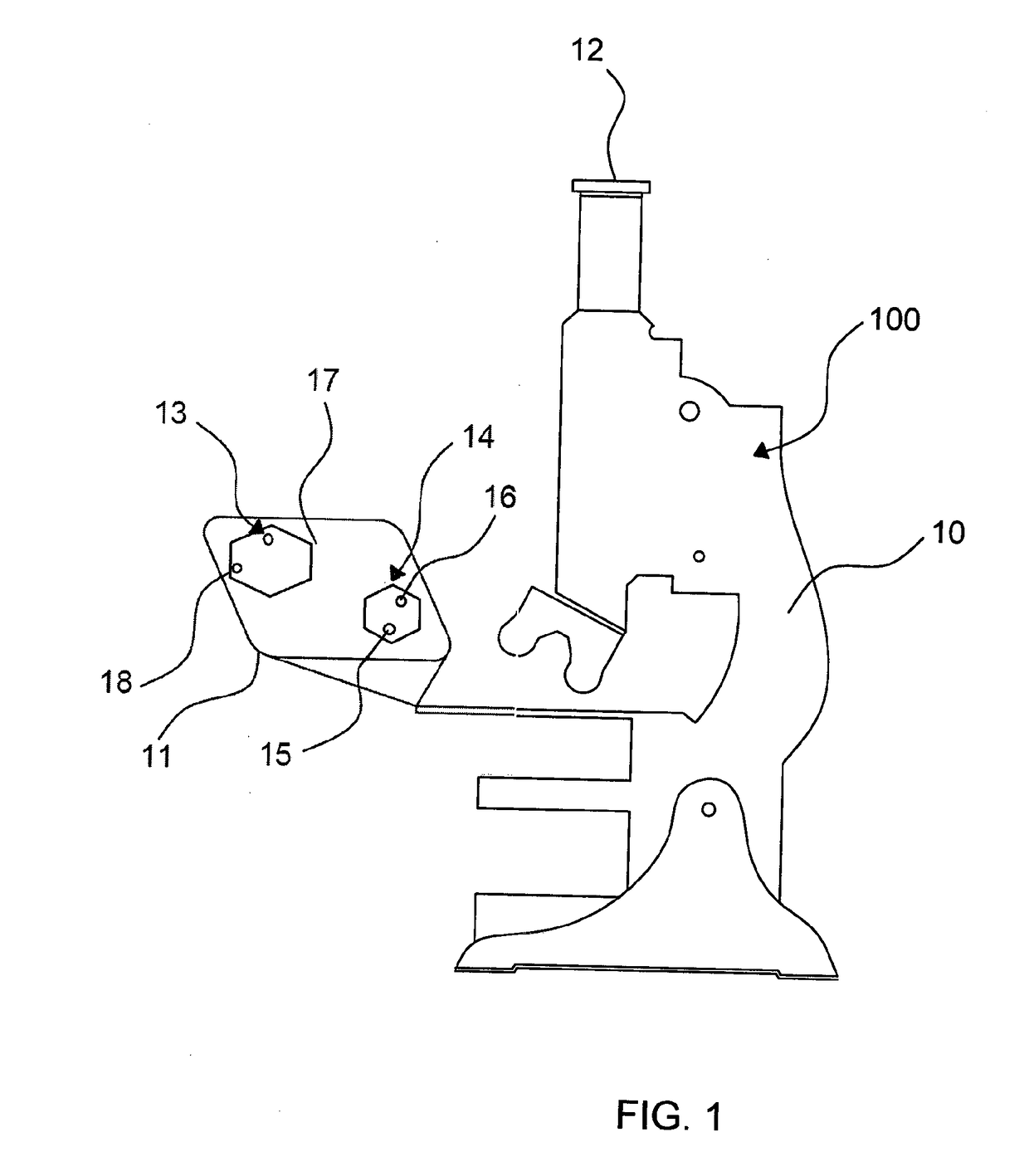

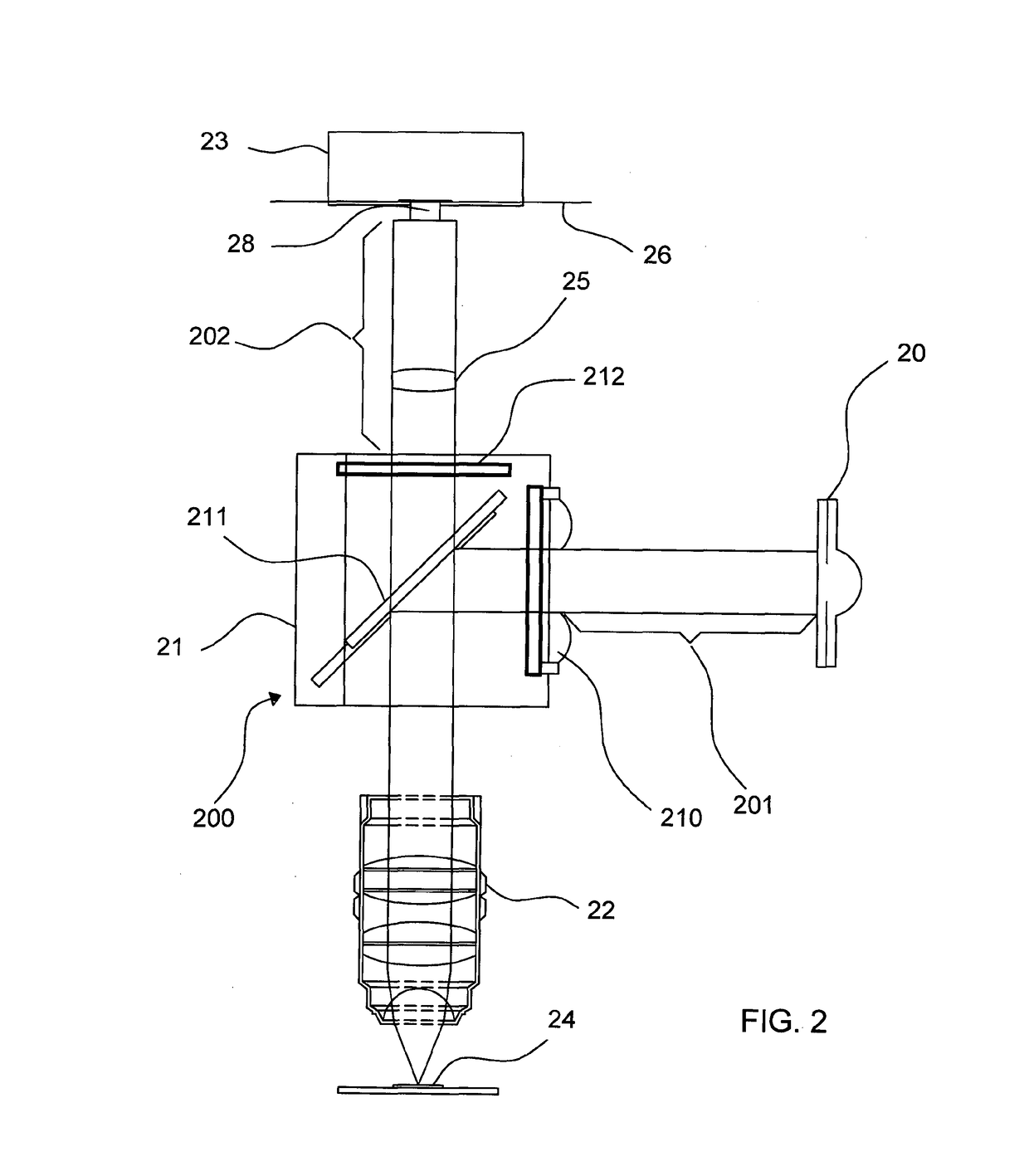

Optical Measuring Device and Process

ActiveUS20170336326A1Quick scanReduced functionalityMicroscopesFluorescence/phosphorescenceDiffraction effectOptical measurements

An achromatic 3D STED measuring optical process and optical method, based on a conical diffraction effect or an effect of propagation of light in uniaxial crystals, including a cascade of at least two uniaxial or conical diffraction crystals creating, from a laser source, all of the light propagating along substantially the same optical path, from the output of an optical bank to the objective of a microscope. A spatial position of at least one luminous nano-emitter, structured object or a continuous distribution in a sample is determined.Reconstruction of the sample and its spatial and / or temporal and / or spectral properties is treated as an inverse Bayesian problem leading to the definition of an a posteriori distribution, and a posteriori relationship combining, by virtue of the Bayes law, the probabilistic formulation of a noise model, and possible priors on a distribution of light created in the sample by projection.

Owner:BIOAXIAL

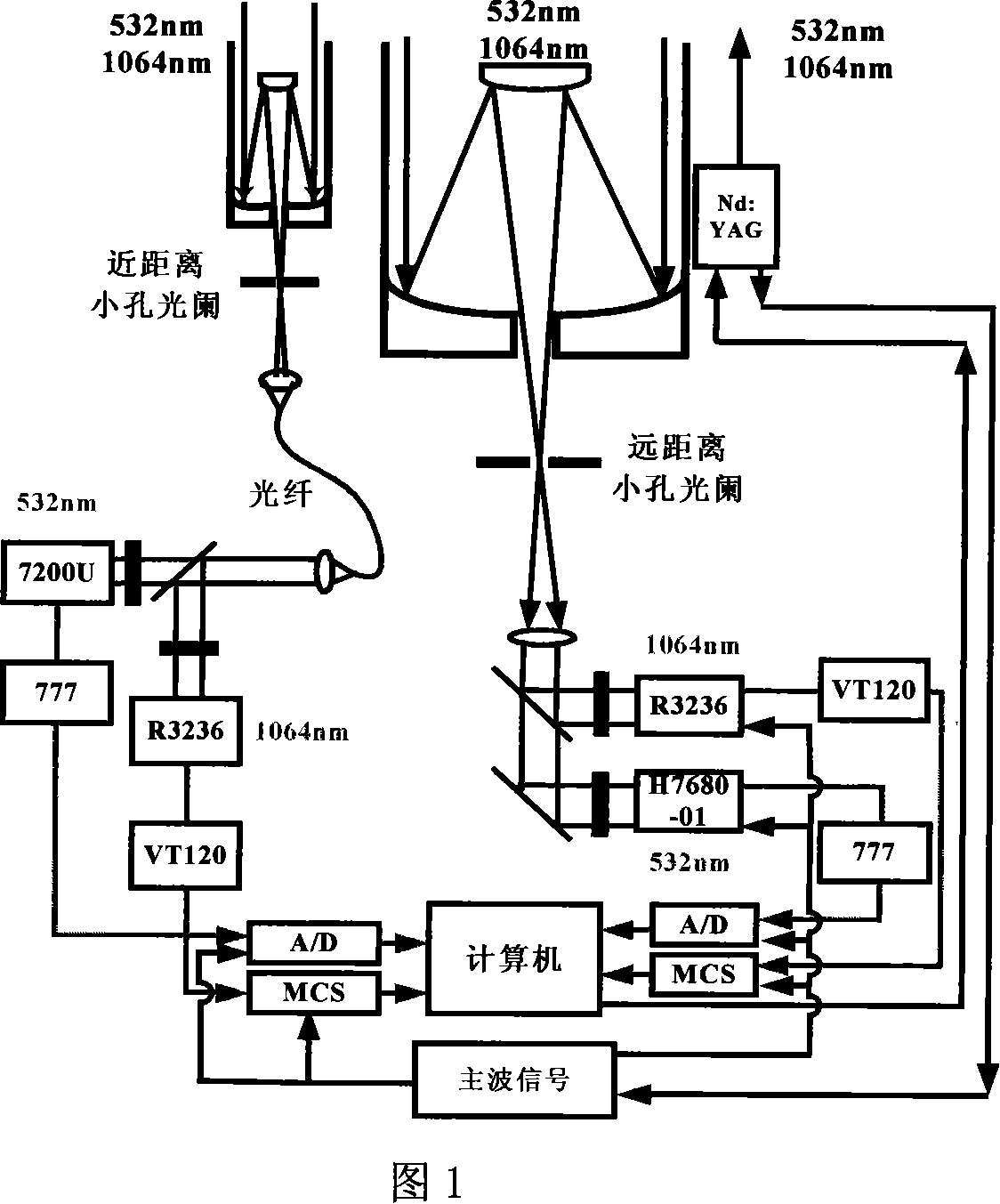

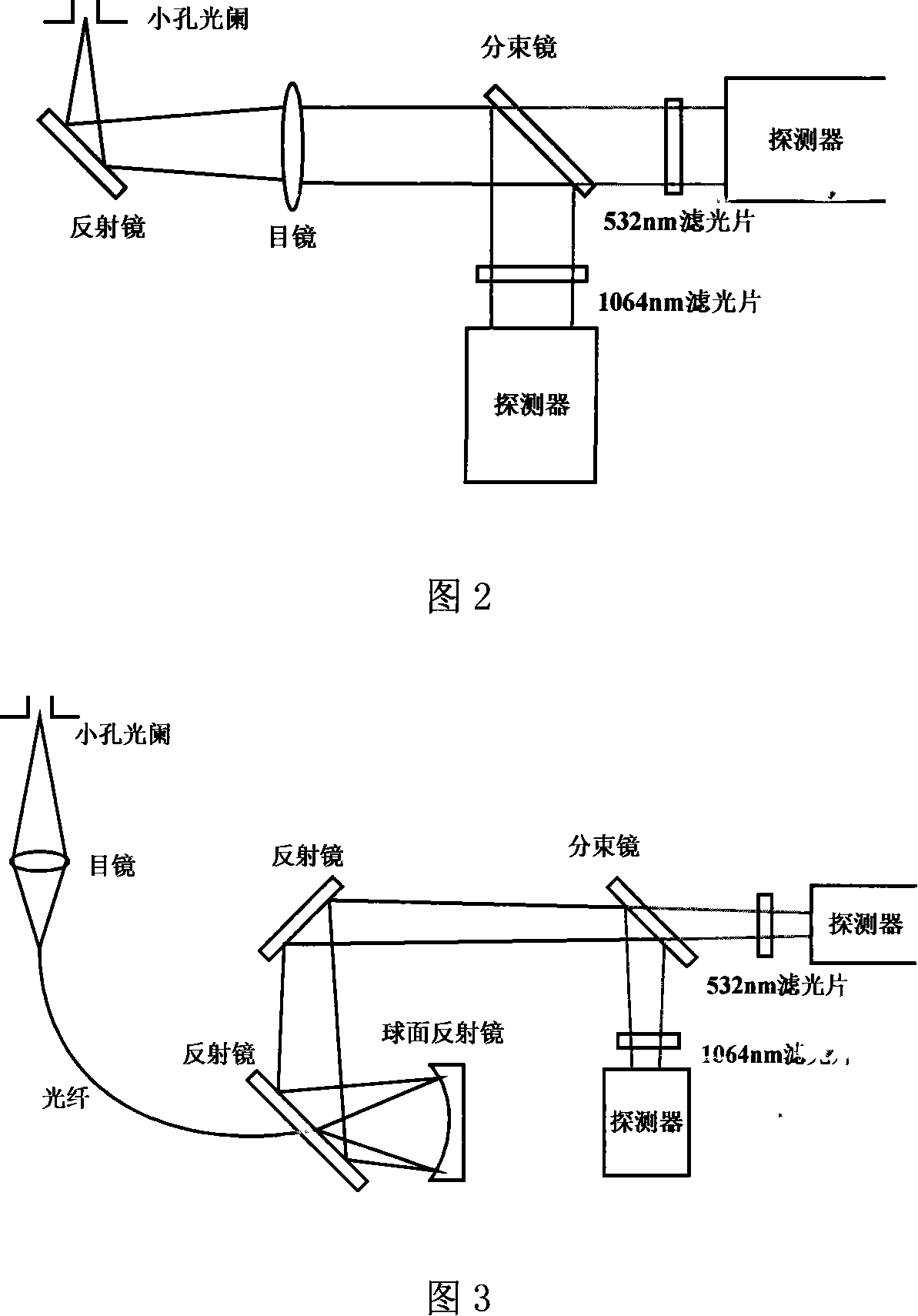

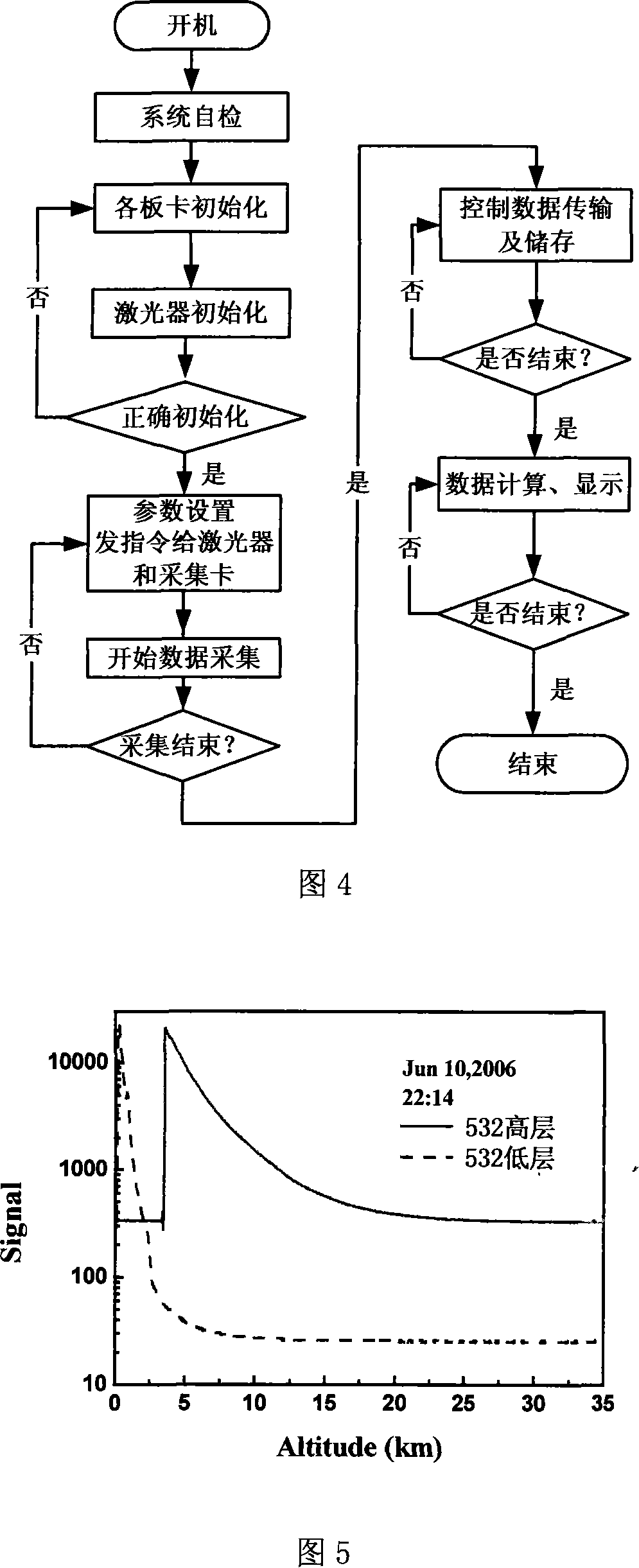

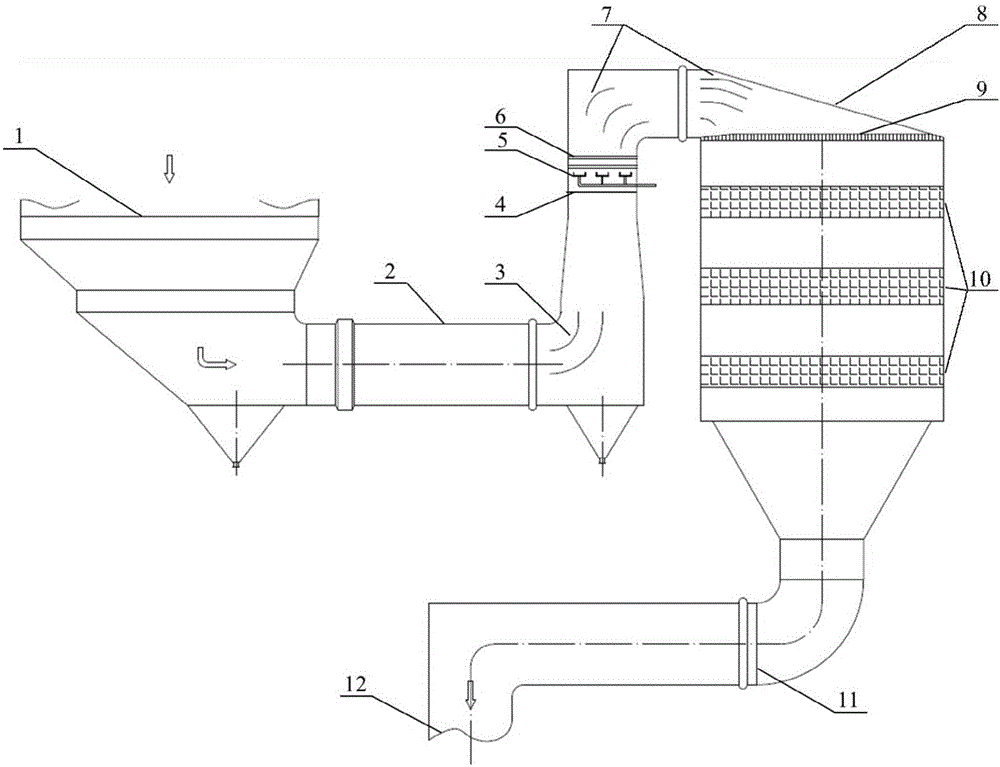

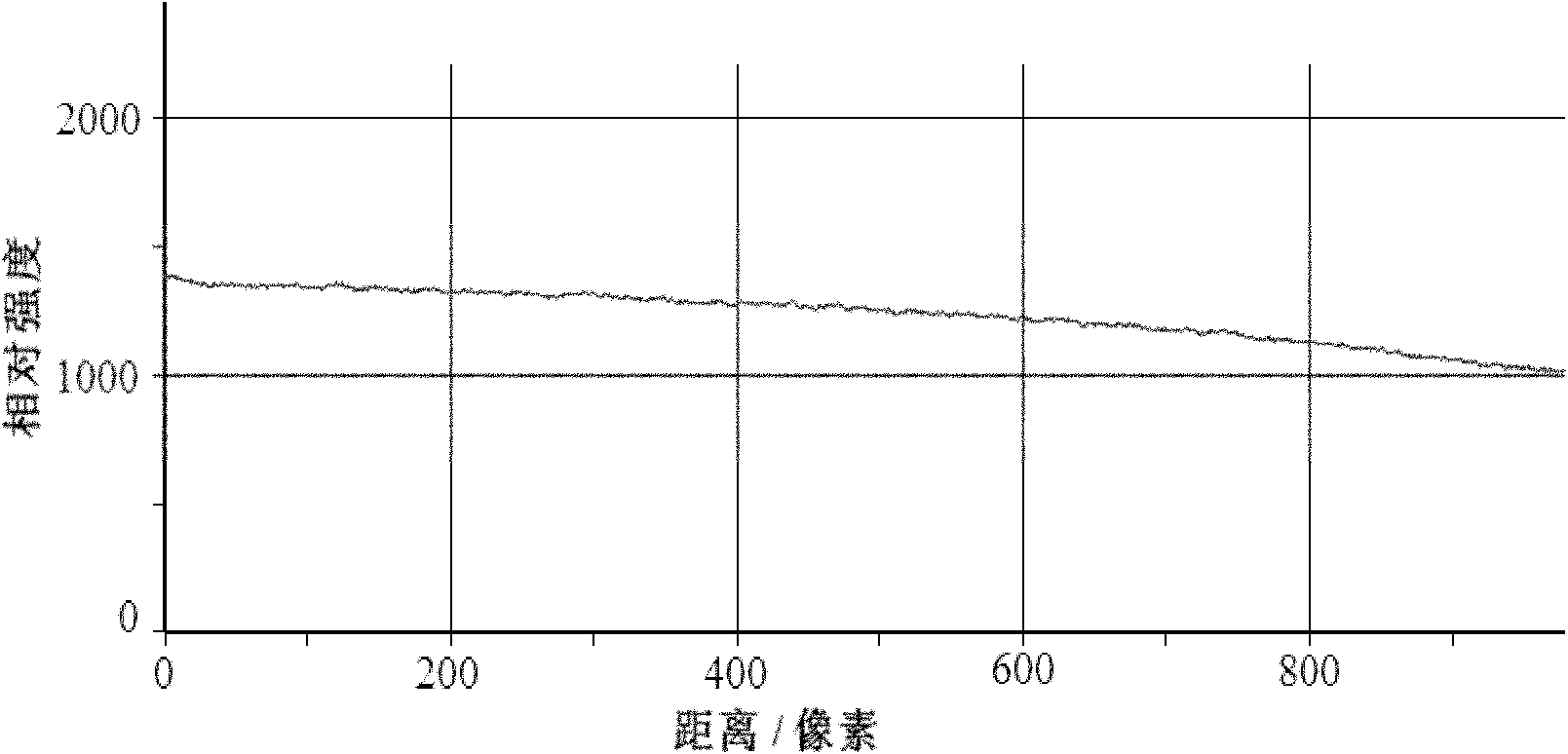

Dualwavelength dual-field Mie scattering laser radar structure and its detecting method

InactiveCN101071171AShorten the timeCorrected overlap factorElectromagnetic wave reradiationNd:YAG laserWavelength

This invention discloses dual field view dual-wavelength laser radar scattering meters structure and detection methods, including laser launch unit echo signal receiver modules, the follow-up optical modules, signal detection and acquisition module and control unit; The laser launch unit using Nd: YAG laser, launching 532 nm and 1064 nm wavelength of the laser pulse at the same time and received by the diameters of 400 mm and 200 mm telescope. Two receiving optical telescope module are follow-up optical module. Optical signal from the follow-up optical module are received by the detection and acquisition module and control unit. atmospheric aerosol extinction coefficient of the vertical profile and continuous distribution, and extinction coefficient level of continuous distribution, can be analyzed through the various atmospheric aerosol optical parameters.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

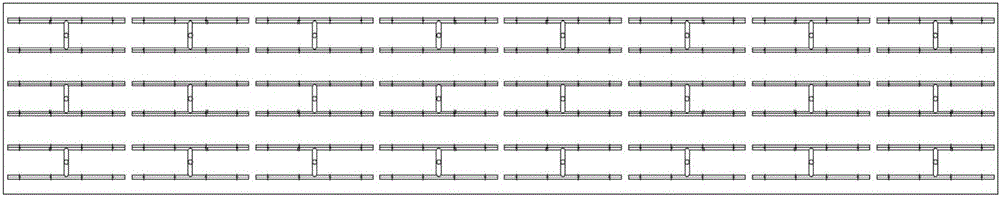

SCR denitration system ammonia spraying optimization method based on weight valve regulation and control

InactiveCN105126616AMake targeted adjustmentsReduce escapeDispersed particle separationConstant loadFlue gas

The invention discloses an SCR denitration system ammonia spraying optimization method based on weight valve regulation and control. The method is divided into four steps: measurement of flue gas flow field characteristics, analysis of flue gas flow field regional flow characteristics, determination of ammonia spraying weight valves and pertinence adjustment of opening degrees of the ammonia spraying valves. The method comprises the particular steps: firstly, measuring the flue gas flow field characteristics of a flue transverse section in front of an ammonia spraying grille of an SCR denitration system under a condition of constant load; then combining with a distribution condition of spray nozzles of the ammonia spraying grille, and analyzing flue gas flow field regional flow continuous distribution characteristics matched with the ammonia spraying spay nozzle distribution; according to the flue gas flow field regional flow characteristics under various load conditions, obtaining the weights of the ammonia spraying valves; and finally, adjusting the opening degrees of all the valves according to the valve weight difference, simultaneously, with the help of a flue gas analyzer, measuring the NOx outlet concentration on an outlet section of the SCR denitration system, and timely feeding back the adjustment effect of the opening degrees of the ammonia spraying valves. The method can ensure good ammonia nitrogen mixing equivalent ratio, effectively improves the denitration efficiency, decreases the ammonia escape and reduces the ammonia amount.

Owner:南京奥麦科仪器自动化有限公司

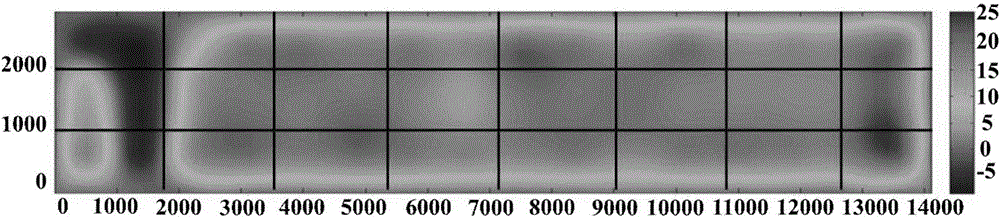

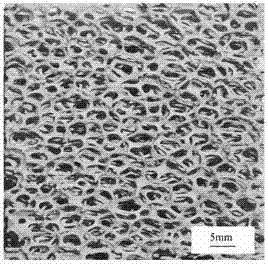

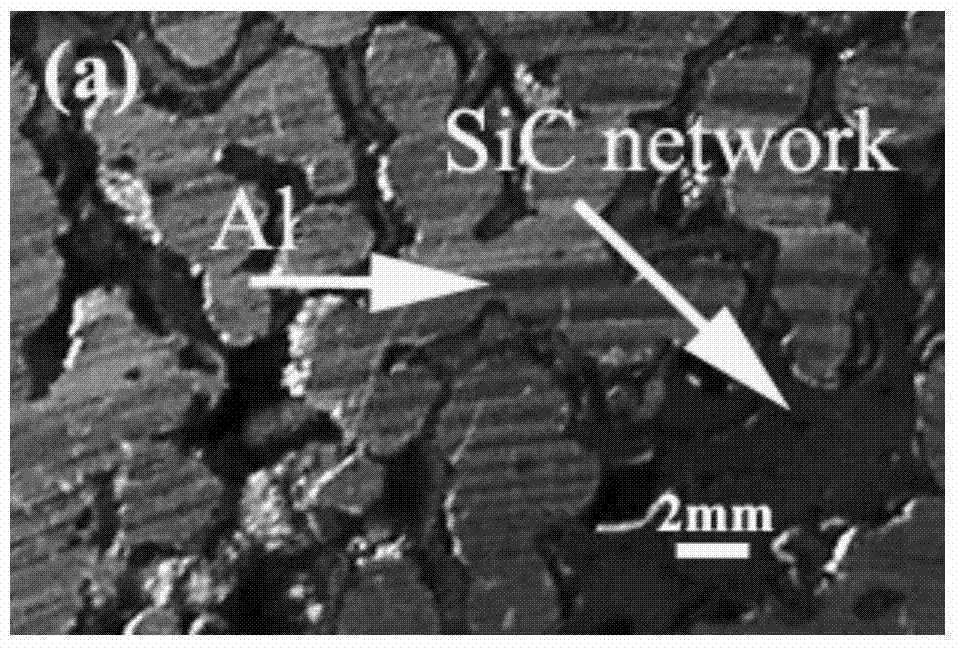

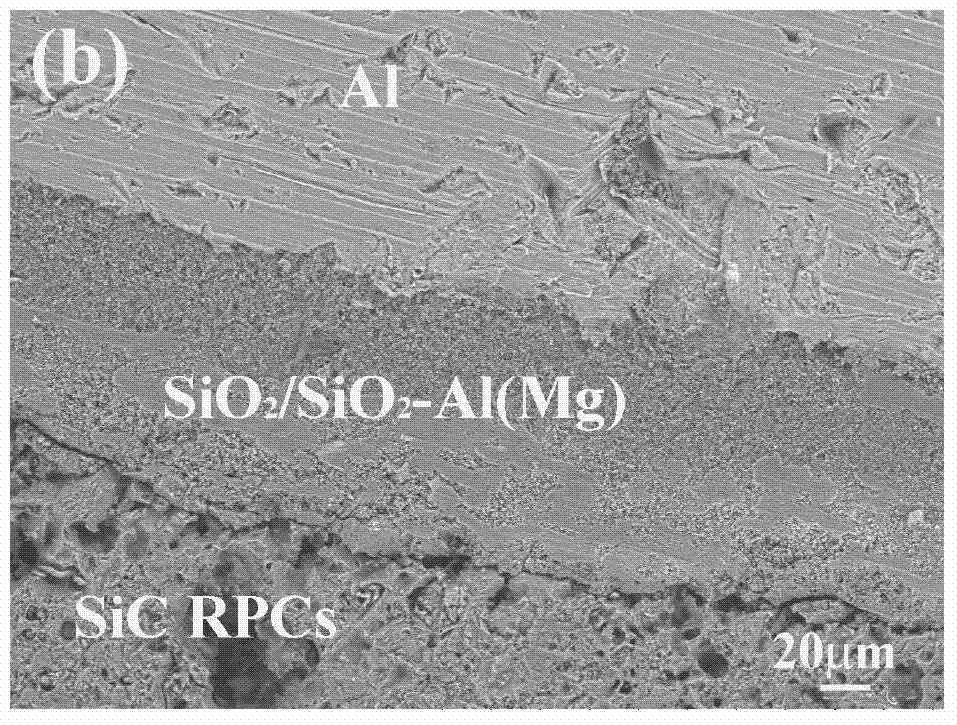

Preparation method of silicon carbide reinforced aluminum base composite material

The invention discloses a preparation method of a SiC / Al composite material. The method comprises the following steps: carrying out ball milling on alumina and / or silicon oxide powder and a dispersant by using a ball milling medium, adding a binder, and continuously carrying out ball milling to obtain a coating slurry, wherein a mass ratio of the powder to the dispersant to water to the ball milling medium to the binder is 1:0.005-0.01:0.1-0.4:2:0.01-0.03; immersing reticulated porous SiC ceramic in the coating slurry for full absorption, centrifuging, and drying; and embedding secondary-coated reticulated porous SiC ceramic into aluminum or aluminum alloy powder, carrying out vacuum pumping heating to fuse the aluminum or aluminum alloy, introducing argon, and carrying out heat insulation and pressure maintenance to obtain the SiC / Al composite material. The SiC / Al composite material obtained through the method is a bicontinuous phase, and the control of an interface structure and an interface reaction is realized through controlling the composition and performances of the coating slurry to realize strong combination between a silicon carbide matrix and the metal Al and uniform continuous distribution in a three dimensional space, so the segregation and the discontinuousness of the silicon carbide reinforcement are avoided, and the performances of the composite material are improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

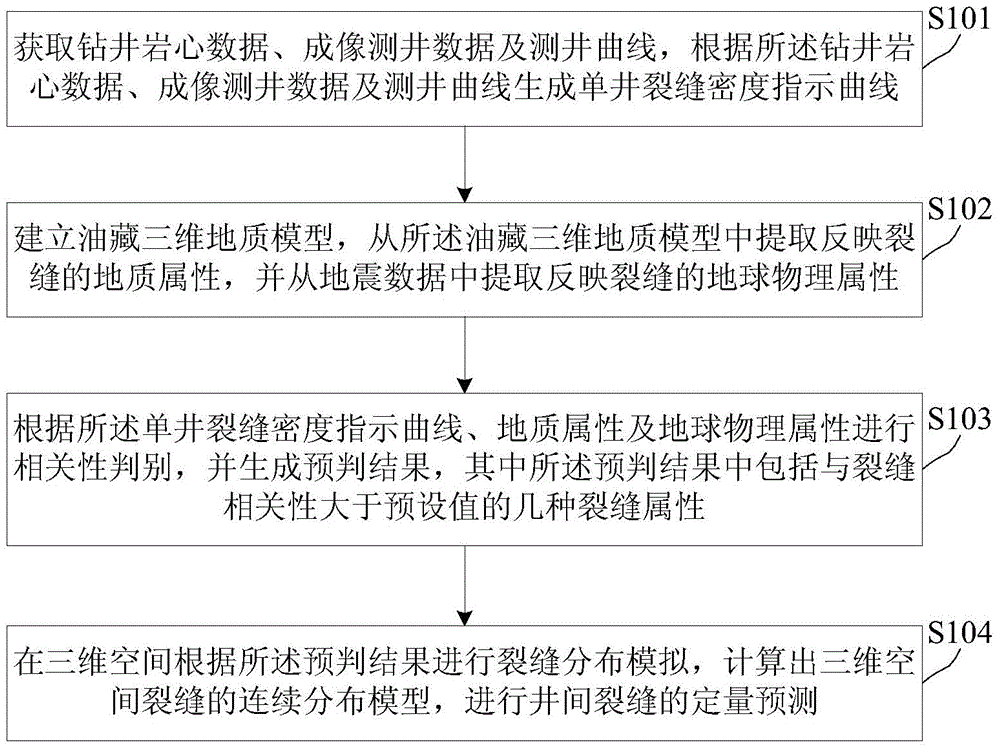

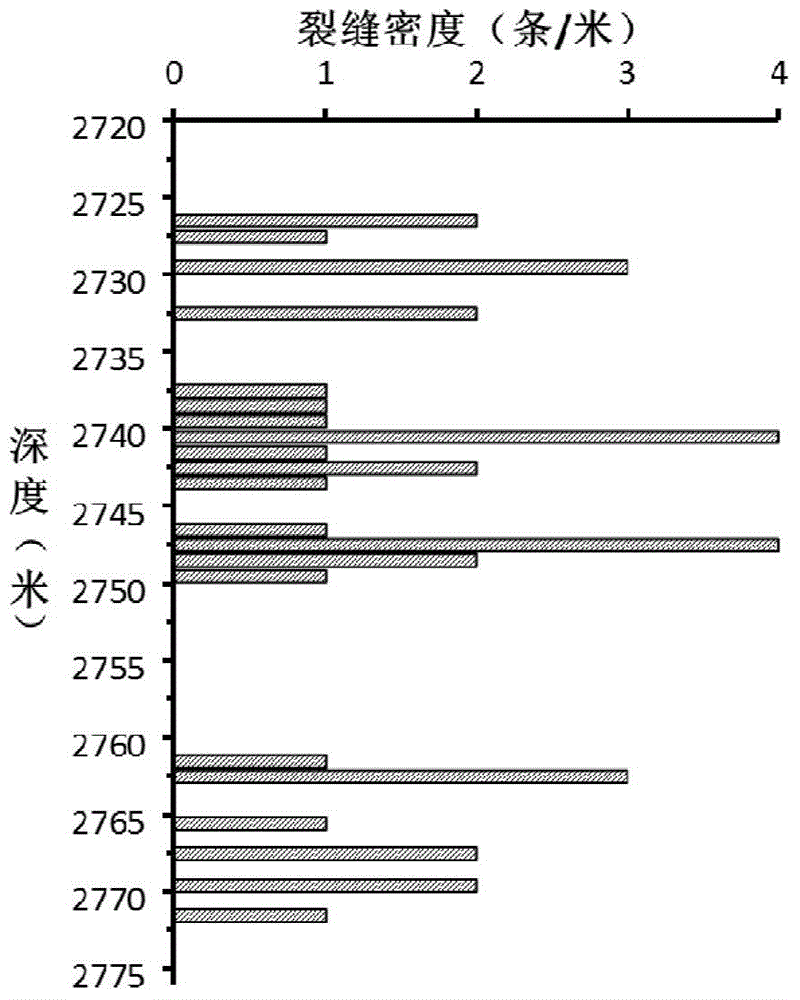

Method and device for volcanic rock crack quantitative prediction

ActiveCN104914465ARealize Quantitative PredictionAccurately determineSeismic signal processingRock coreWell drilling

The invention discloses a method and a device for volcanic rock crack quantitative prediction. The method for volcanic rock crack quantitative prediction comprises steps of obtaining drilling well rock core data, imaging well logging data and logging curves, generating single well crack density indication curves according to the drilling well rock core data, imaging logging data and logging curves, establishing an oil reservoir three dimensional geology model, extracting geology attribute reflecting cracks from the oil reservoir three dimensional geology model and extracting earth physics attribute reflecting cracks from earthquake data, performing correlation discrimination and generating a pre-judging result according to the single well crack density indication curve, the geology attribute and earth physics attribute, wherein the pre-judging result comprises some kinds of crack attributes, the crack correlation of which is greater than a preset vale, performing crack distribution simulation in a three dimensional space according to the pre-judging result, calculating the continuous distribution model of the three dimensional space and performing quantitative prediction on the crack between wells. The method and device for volcanic rock crack quantification prediction disclosed by the invention can realize the quantitative prediction of the crack between wells and can quickly and accurately determine the favorable task during the volcanic rock oil reservoir exploration and development.

Owner:PETROCHINA CO LTD

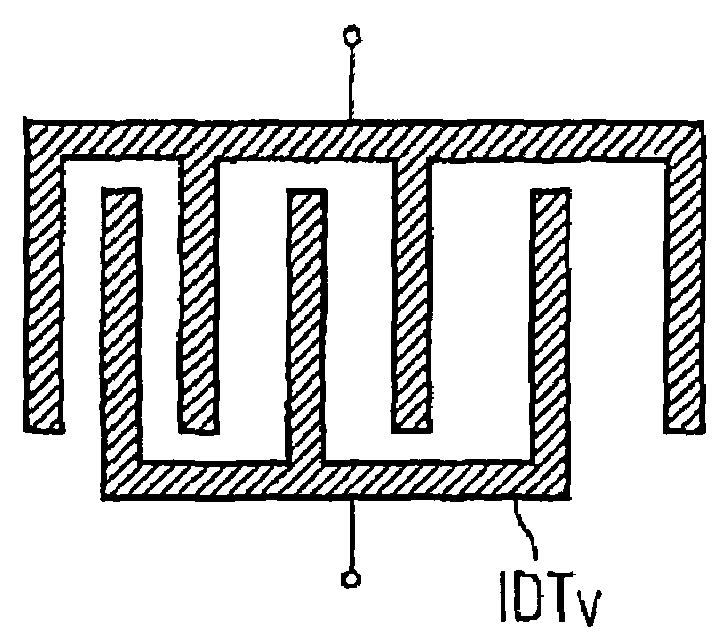

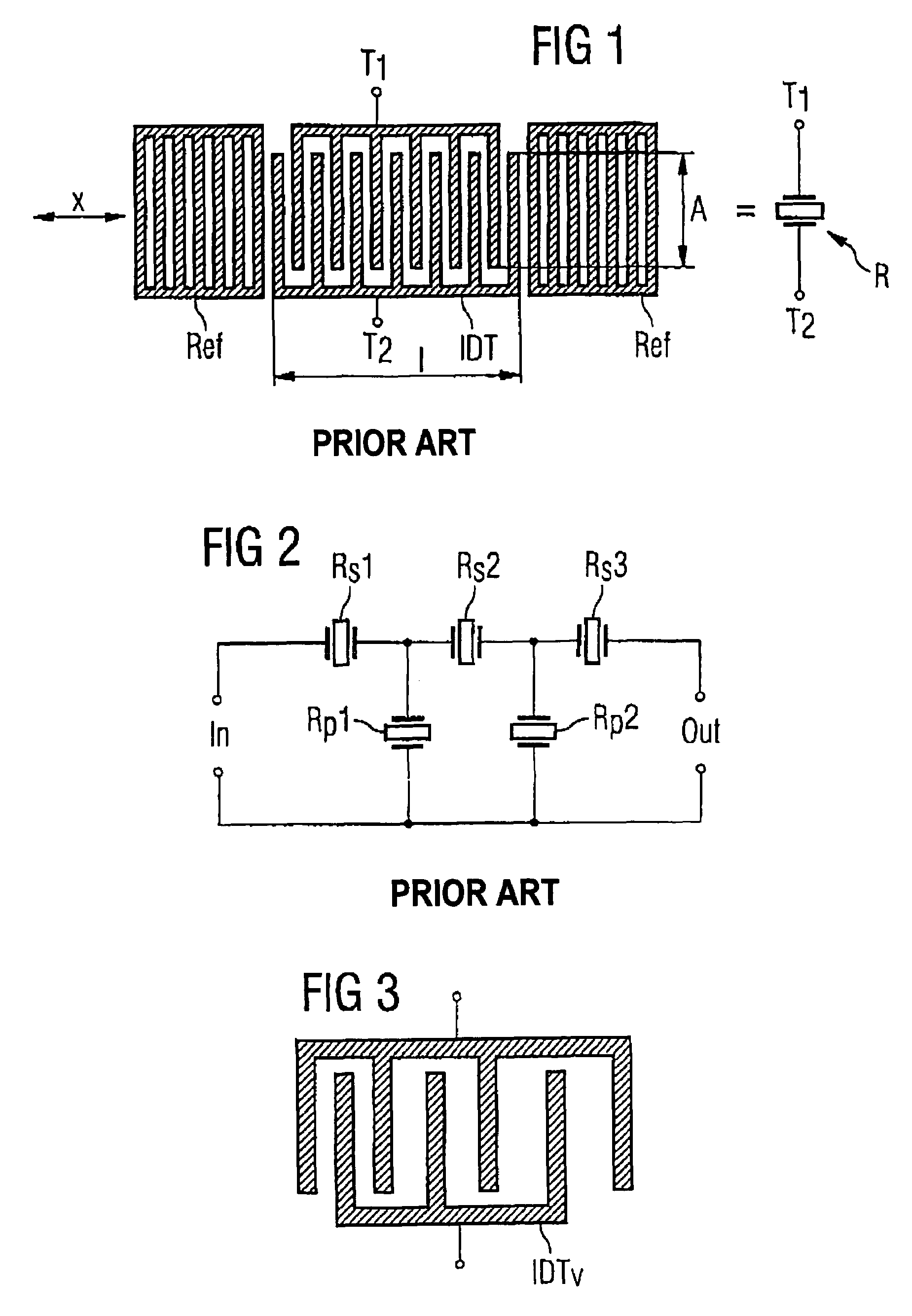

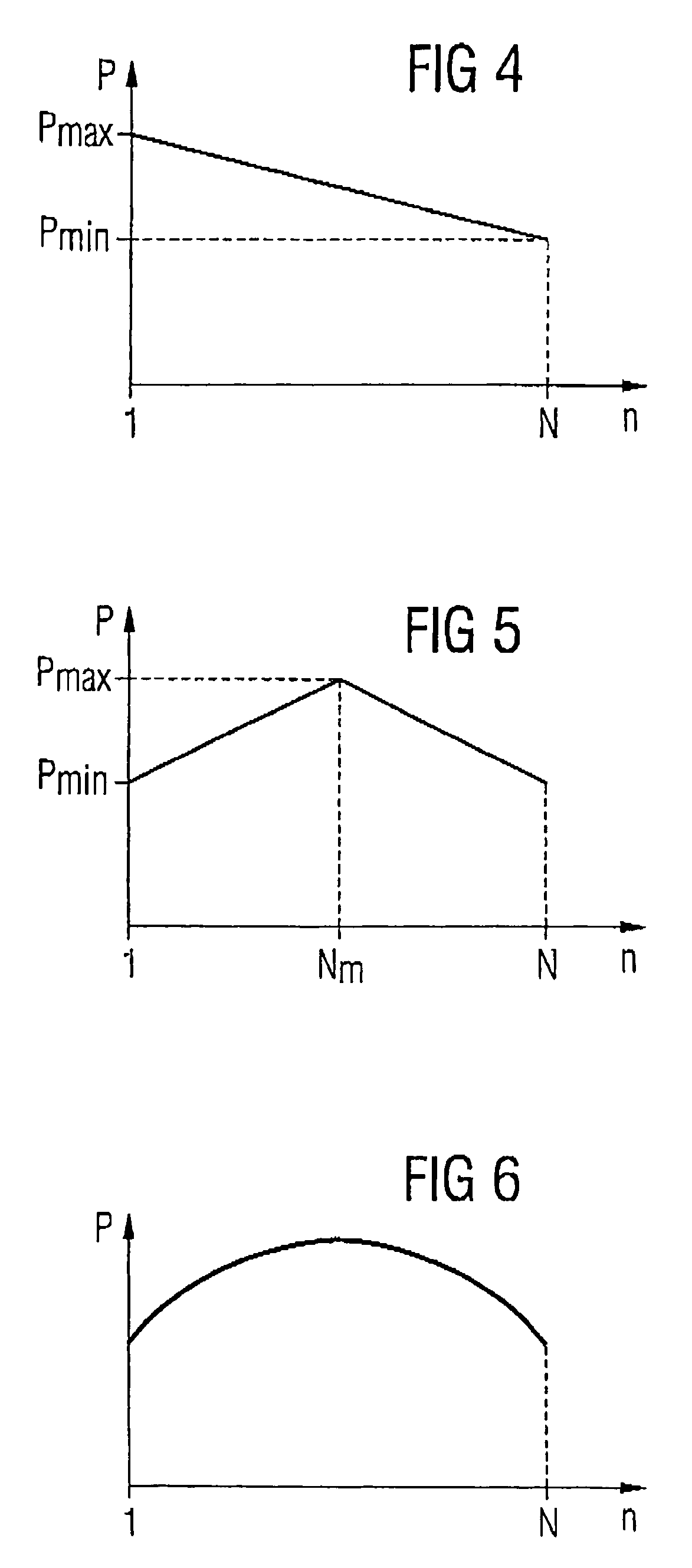

Transducer structure that operates with acoustic waves

InactiveUS7042132B2Improve featuresBetter electric conformancePiezoelectric/electrostriction/magnetostriction machinesImpedence networksTransducerAcoustic wave

For improved conformance of a filter operating with acoustic waves, a transducer structure is provided in which the separations between respectively two adjacent electrode fingers of an inter-digital transducer (IDTv) vary over the length of the transducer. The variation thereby preferably follows a continuous distribution function. Reactance filters that are provided with such filters in the serial branch show an improved electrical conformance in the transmission range.

Owner:SNAPTRACK

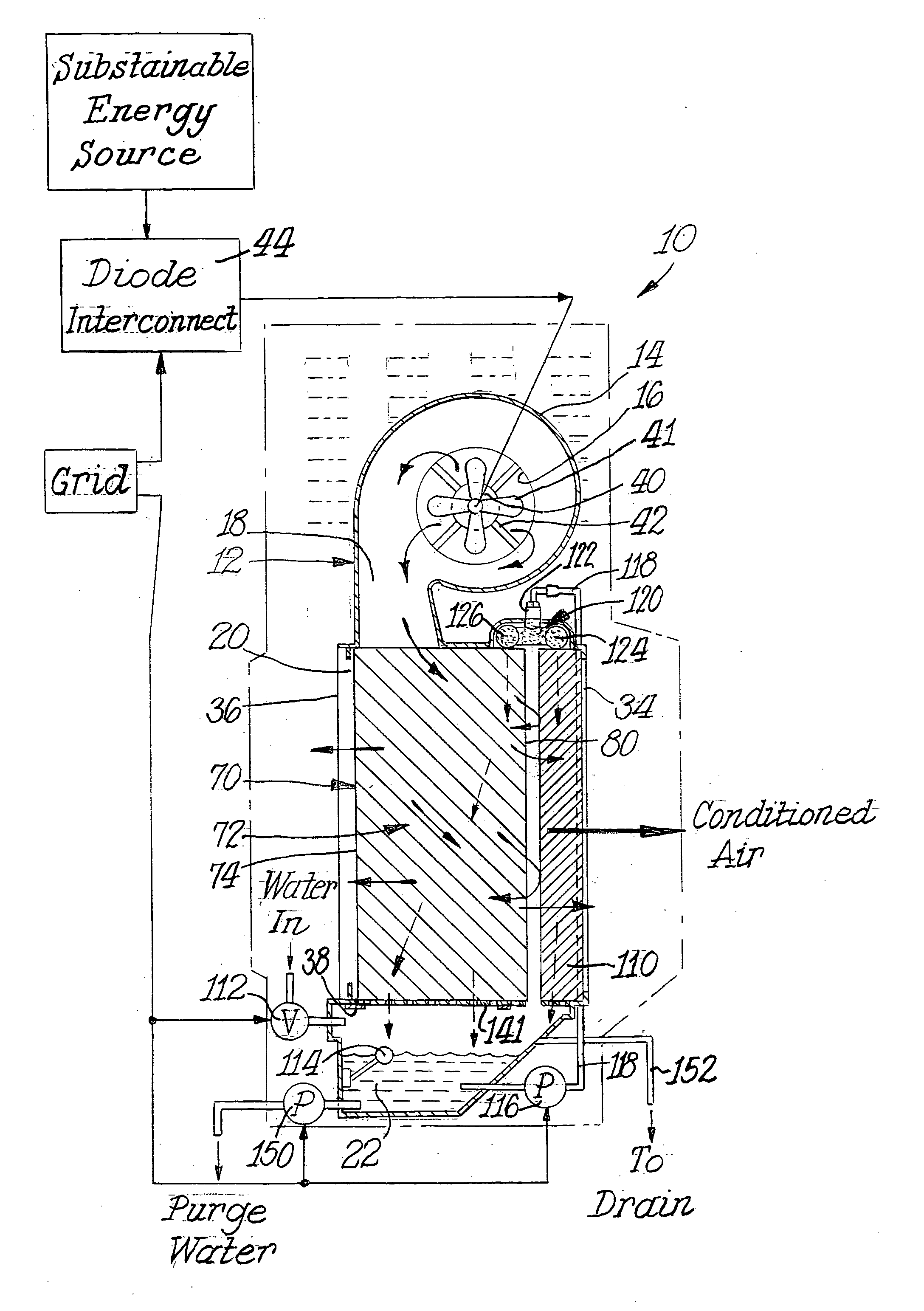

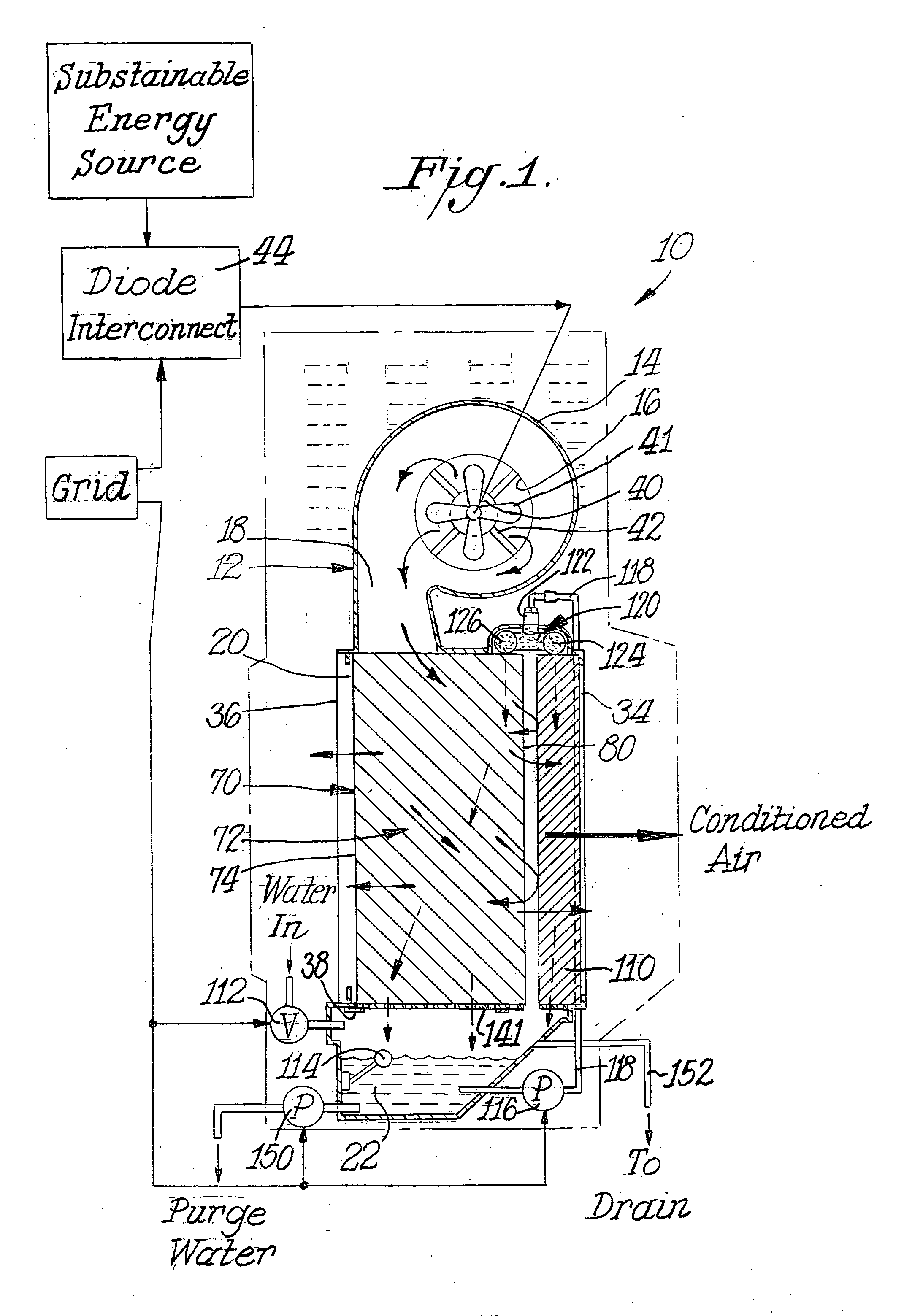

Indirect-direct evaporative cooling system operable from sustainable energy source

InactiveUS20060000227A1Reduce power consumptionReduce the amount requiredFree-cooling systemsStationary conduit assembliesPower gridImproved method

Improved means for powering and increasing evaporative cooling in an indirect-direct evaporative cooling (IDEC) apparatus are disclosed. Sustainable energy from solar energy mixed with grid power, when needed, power the IDEC device. These DC and AC power sources are seamlessly merged in a unique diode interconnect unit. Improved means for evaporative cooling include a rayon-based flocking on the wet side of molded plastic indirect evaporative cooling plates. Separate wet and dry passages through those plates are facilitated by a unique means for clamping the upper ends of the plates. These clamping means also add to the structural integrity of an array of plates so that the array can be inserted in and removed from a housing containing other operational components of the IDEC such as fan, direct cooling plates and water distribution means. Applicants IDEC utilizes improved porous piping that allows uniform and continuous distribution of water to all wet passages within both the indirect and direct stages of the IDEC. Operational controls for the system limit the potential water damage caused by overflow of water from the IDEC housing.

Owner:SPEAKMAN

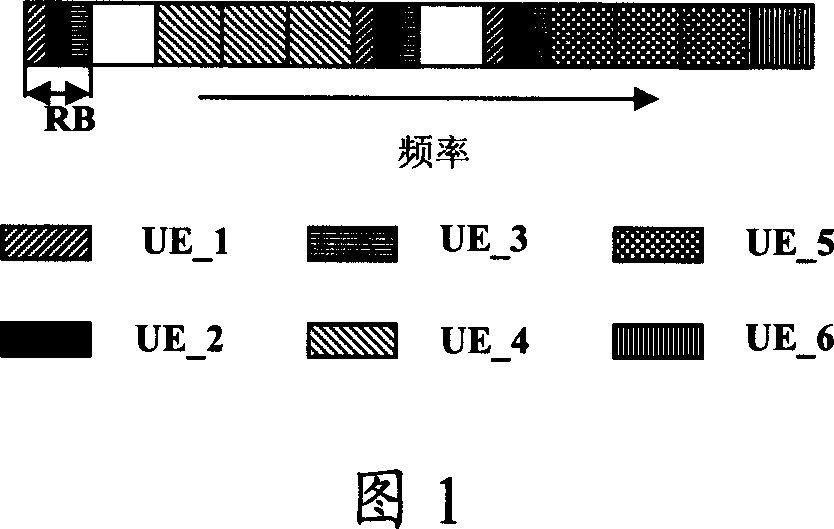

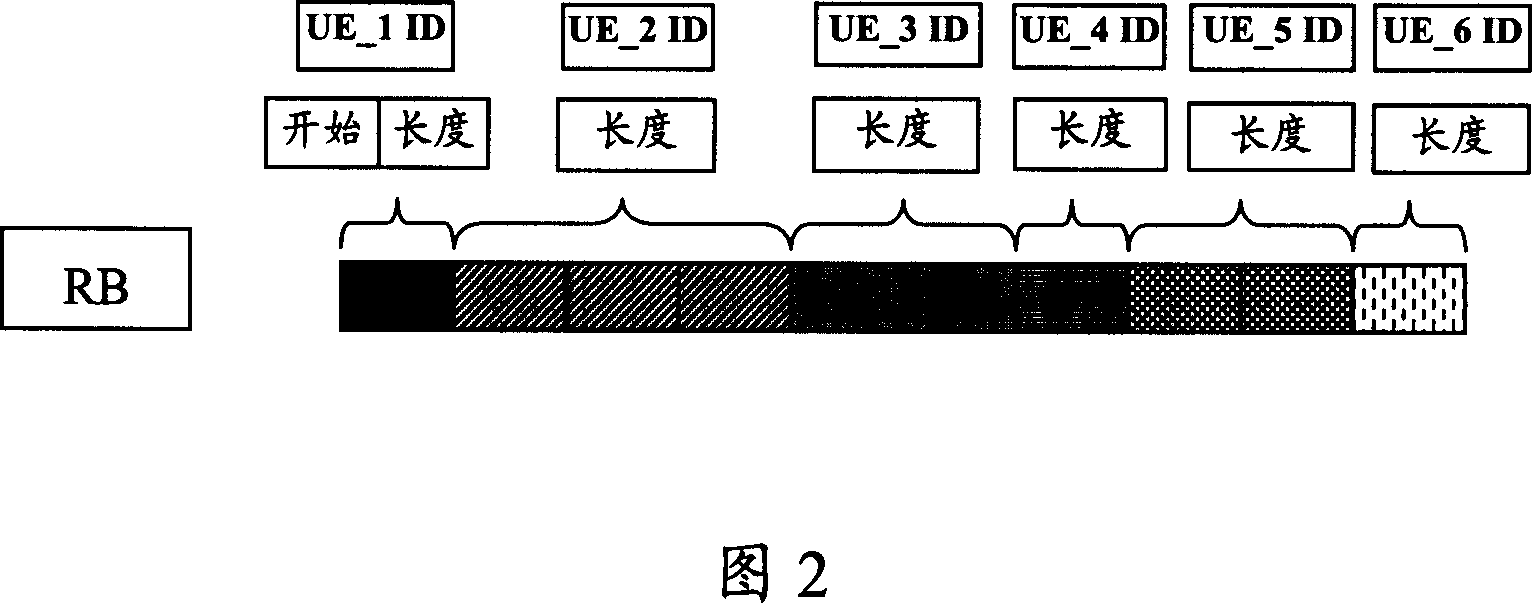

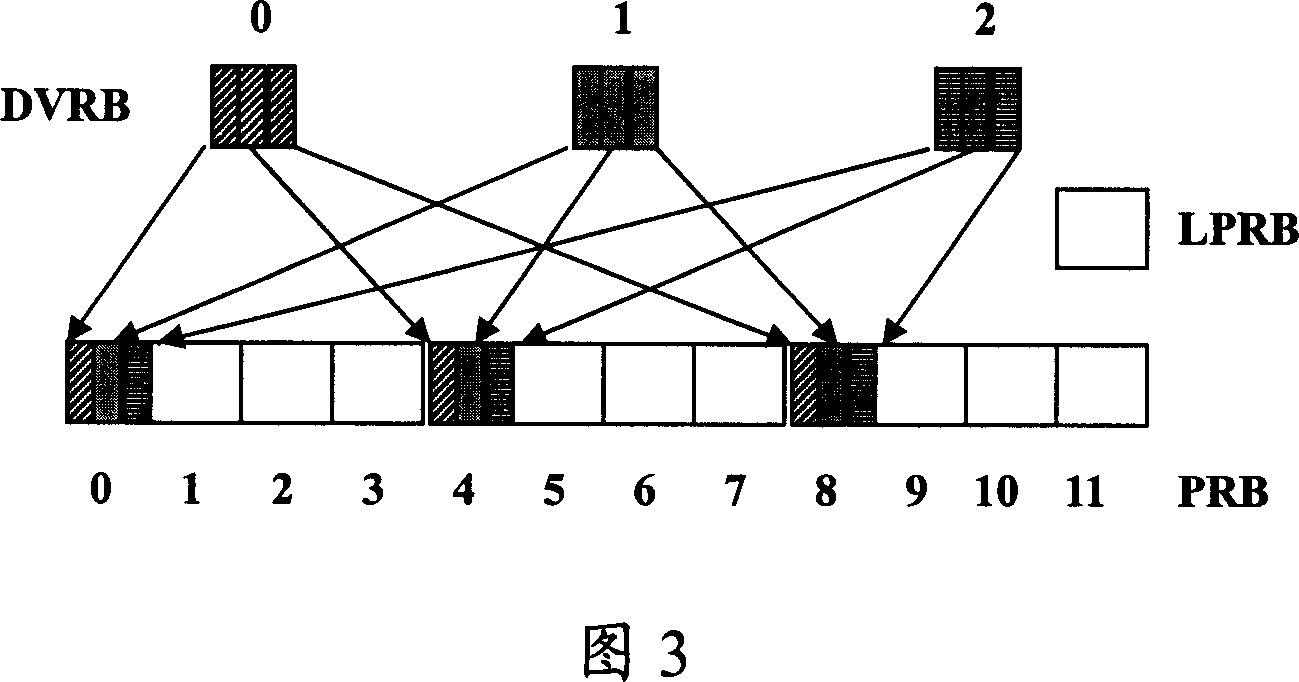

Allocation and indication method of system resource

ActiveCN101080081ANetwork traffic/resource managementRadio/inductive link selection arrangementsTelecommunicationsResource allocation

This invention relates to a distribution and instruction method for system resources including: applying a resource DVRB continuous distribution method for the dispatched scattered UE from the given simple mapping from DVRB to PRB and indicating a first UE to occupy the start position of the DVRB and all UE to occupy the length of the DVRB when instructing each UE to distribute the resource, or distributing the continuous resource from long to short according to the length occupied by UE so as to minimize the spending of the DVRB resource distribution instruction signaling in the way of combined coding of control signaling of scattered users then to determine physical resource occupied by UE according to the mapping relation from DVRB to PRB.

Owner:HUAWEI TECH CO LTD

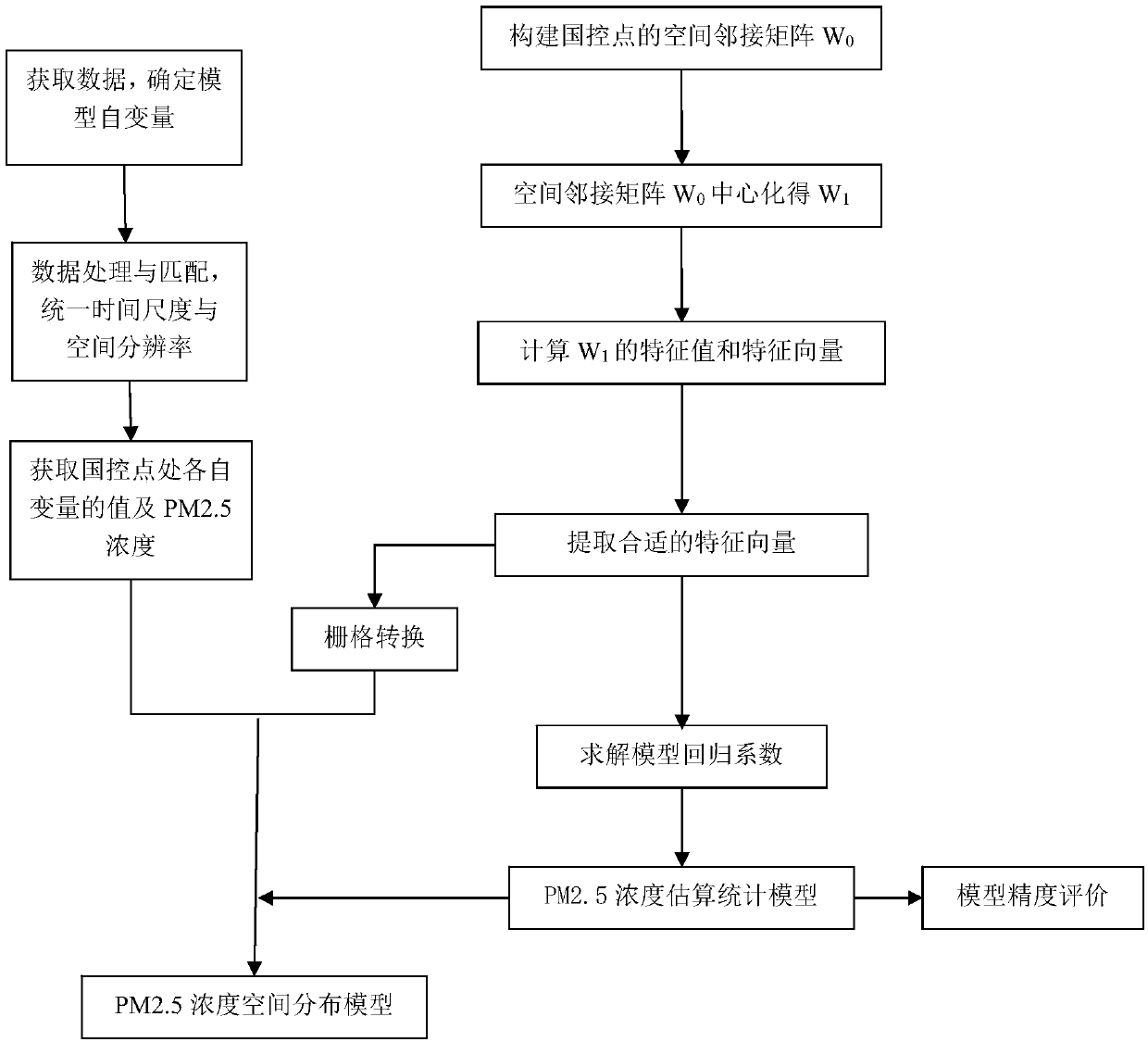

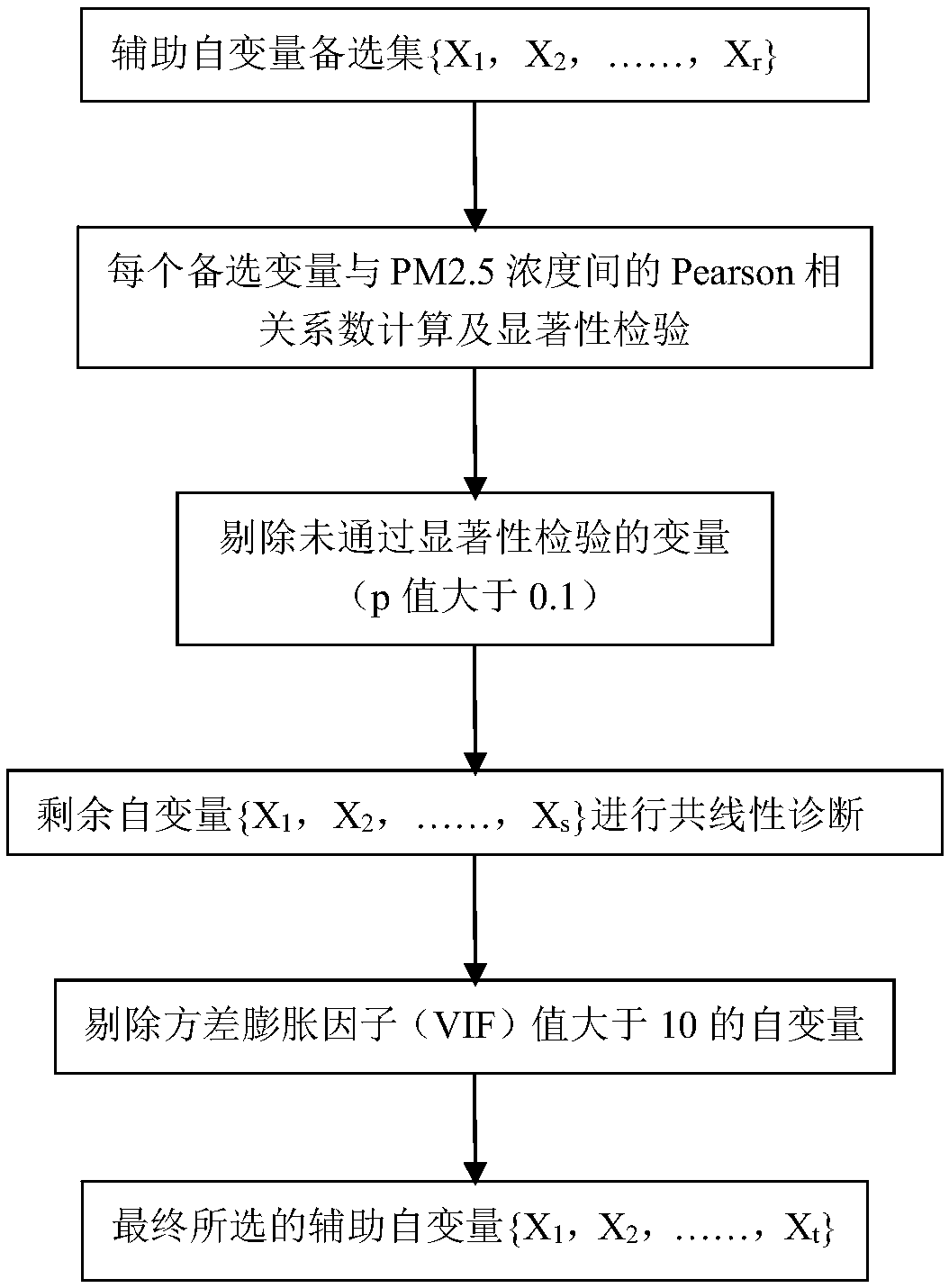

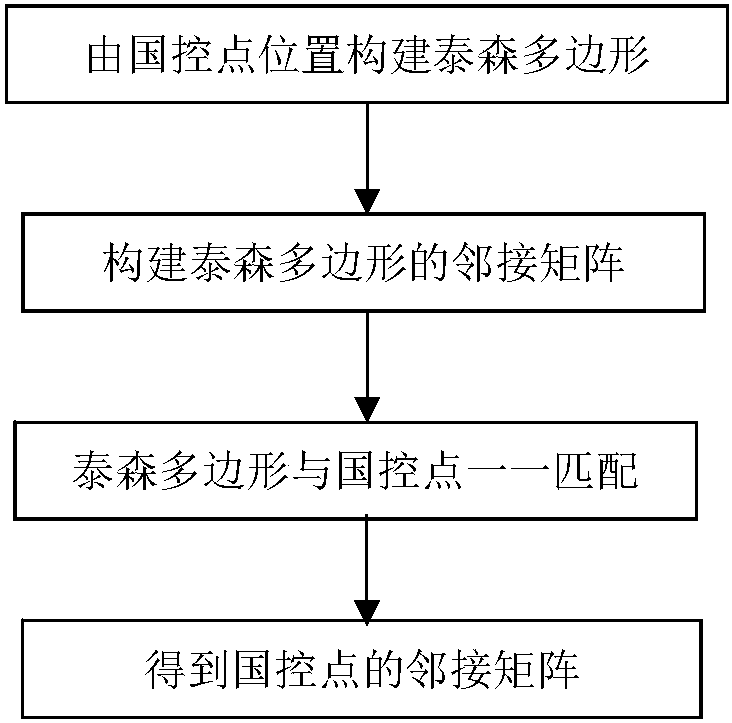

Ground PM2.5 concentration feature vector spatial filter value modeling method based on remote sensing data

ActiveCN108241779AHigh precisionSimple structureDesign optimisation/simulationComplex mathematical operationsEuclidean vectorSpatial distribution

The present invention provides a ground PM2.5 concentration feature vector spatial filter value modeling method based on remote sensing data. The method comprises: obtaining data, selecting a model variable, carrying out data processing and matching, constructing a spatial adjacency matrix from the location of the national control point of a study area, carrying out centralization, calculating thematrix eigenvalues and eigenvectors, and extracting the appropriate eigenvectors from the vector group as the spatial influence factor of the PM2.5 concentration; and obtaining an eigenvector spatialfilter regression model of the PM2.5 concentration, interpolating the extracted eigenvectors raster images with the same spatial resolution as the AOD, and bringing the raster images into the eigenvector spatial filter regression model for raster calculation to obtain the continuous spatial distribution model of the PM2.5 concentration in the study area. According to the method provided by the present invention, for the problem that the number of ground control points is small and the ground control points are unevenly distributed, the remote sensing data with high resolution and continuous distribution is selected to perform the inversion of the ground PM2.5 concentration for study on a wide range of PM2.5 spatiotemporal features.

Owner:WUHAN UNIV

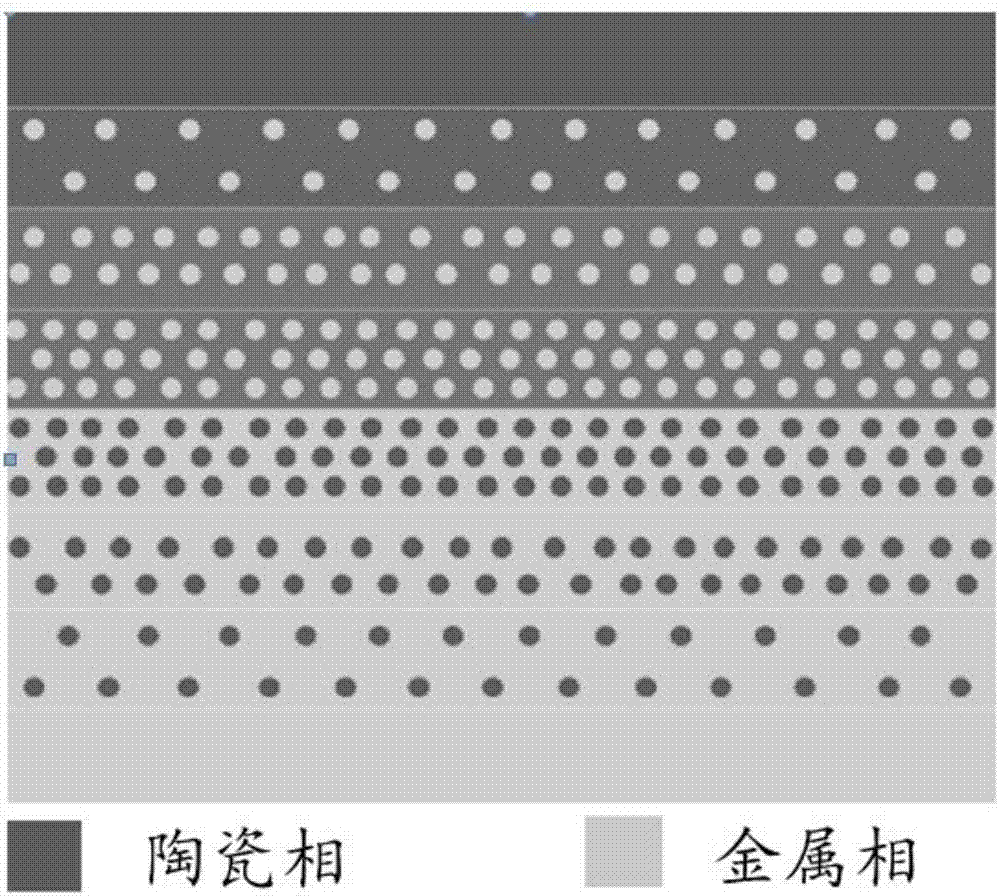

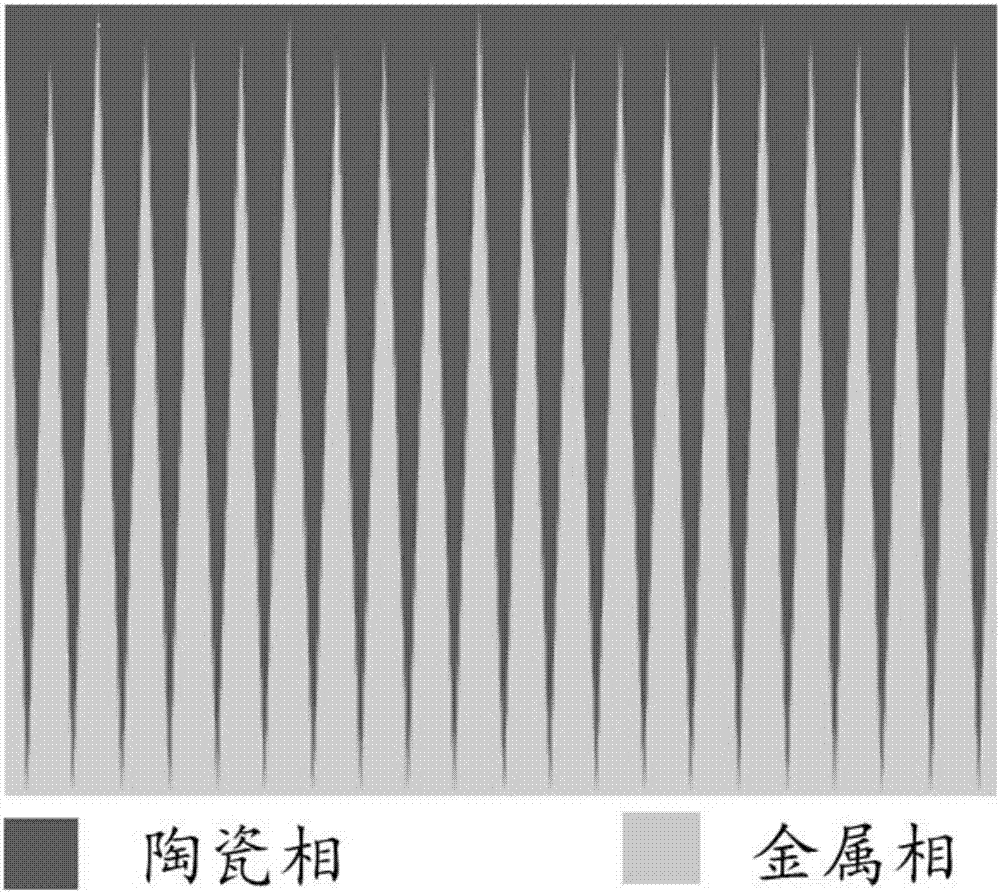

Ceramic/metal composite of gradient double-continuous structure and preparation method and application of ceramic/metal composite

The invention provides a ceramic / metal composite of a gradient double-continuous structure. The ceramic / metal composite is formed by compounding a porous ceramic material with the porosity continuous gradient and a metal material arranged in holes of the porous ceramic material in a filling manner. Any one of Al2O3, SiC, Si3N4, B4C and TiB2 is used as the ceramic material. Any one of an aluminum alloy, a magnesium alloy and an iron alloy is used as the metal material. The ceramic / metal composite has the beneficial effects that in the ceramic / metal composite of the gradient double-continuous structure, ceramic phases and metal phases form the double-continuous structure; and in the structure, due to the continuous distribution of the metal phases, when stressed, the composite is evenly stressed due to the transmission function of the metal phases, no stress concentration is generated, and the composite has the higher bearing capacity and the impact resistance.

Owner:HARBIN INST OF TECH

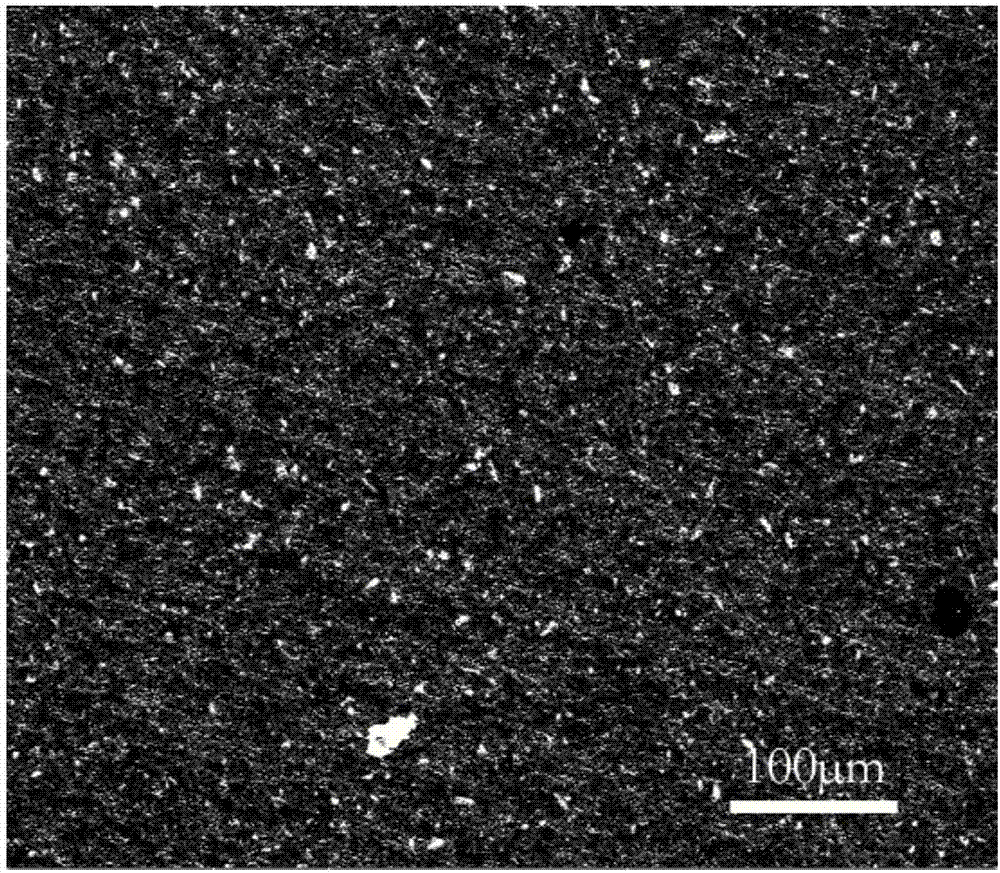

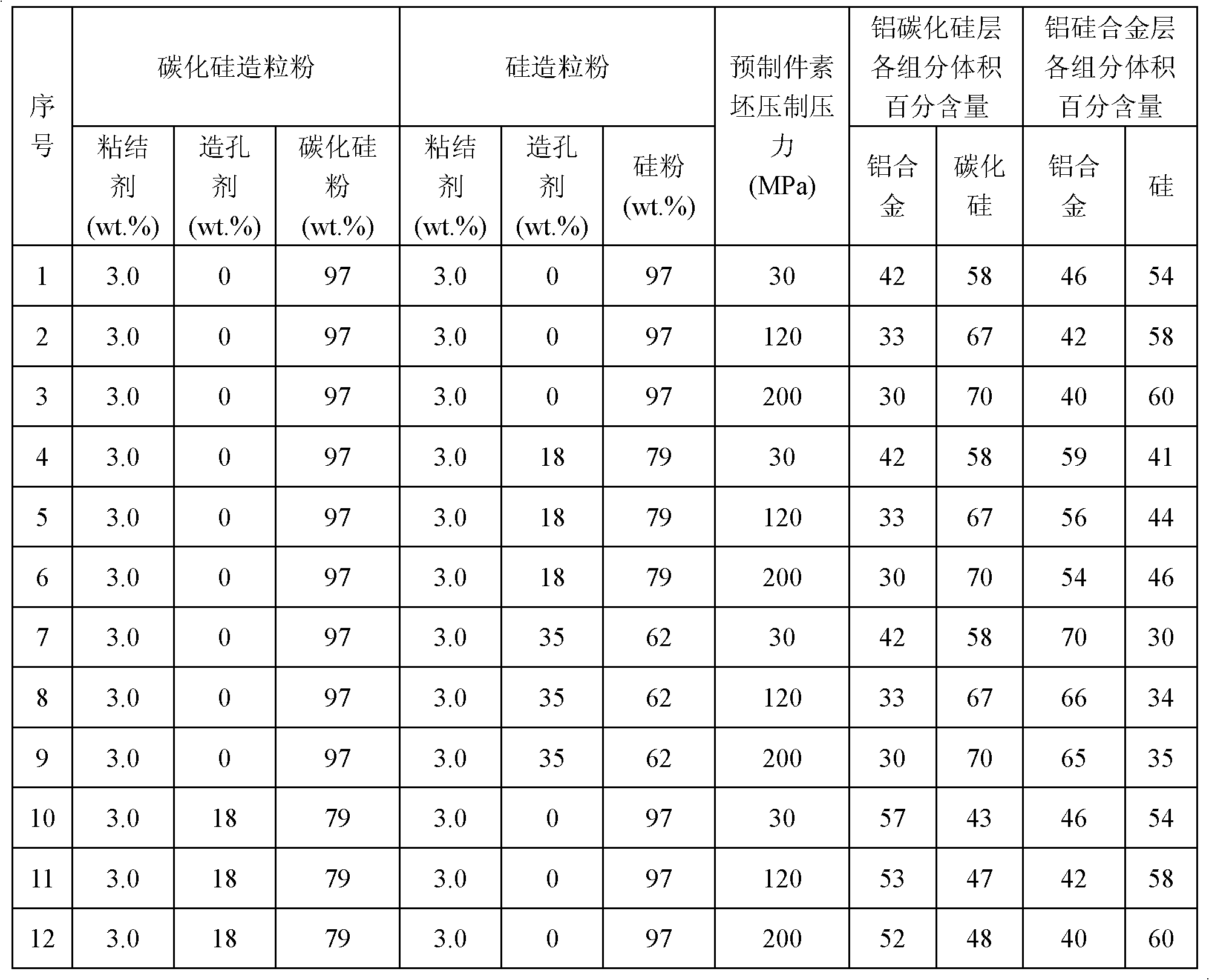

Layered aluminium-silica-alumina-silicon carbide composite material capable of laser welding and preparation method thereof

InactiveCN101973144AIncrease elasticityImprove flexural strengthMetal layered productsSilicon alloyAir tightness

The invention discloses a layered aluminium-silica-alumina-silicon carbide composite material capable of laser welding and a preparation method thereof. The composite material is of a layered structure and composed of an aluminium-silicon alloy layer and an alumina-silicon carbide layer; the volume percentage content of silicon in the aluminium-silicon alloy layer is within 30-60, and the volume percentage content of aluminium in the aluminium-silicon alloy layer is within 40-70; the volume percentage content of silicon carbide in the aluminium-silicon alloy layer is 30-70 and the volume percentage content of aluminum therein is within 30-70%; and aluminum matrixes in the aluminium-silicon alloy layer and the alumina-silicon carbide layer are of a continuous distribution phase. The preparation method comprises the following steps: firstly preparing silicon carbide granulation powder and silicon granulation powder; then preparing layered silicon-silicon carbide prefabricated members; and finally adopting a vacuum liquid-phase pressure infiltration method to prepare the aluminium-silica-alumina-silicon carbide composite material. The composite material of the invention can be subjected to laser welding, has high elastic modulus, high bending strength and high gas tightness, and is suitable for preparing packaging shells which can be subjected to gas tightness welding by the laser.

Owner:NAT UNIV OF DEFENSE TECH

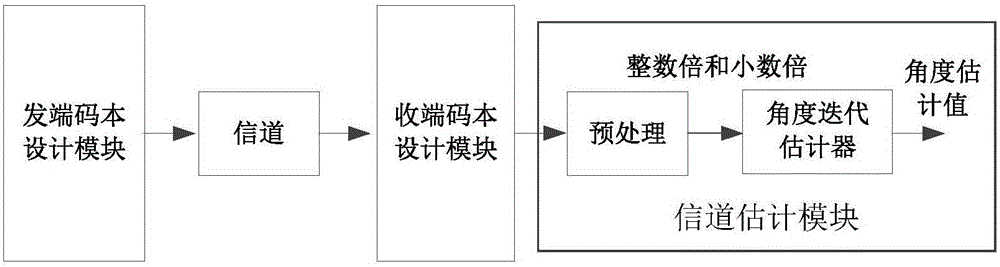

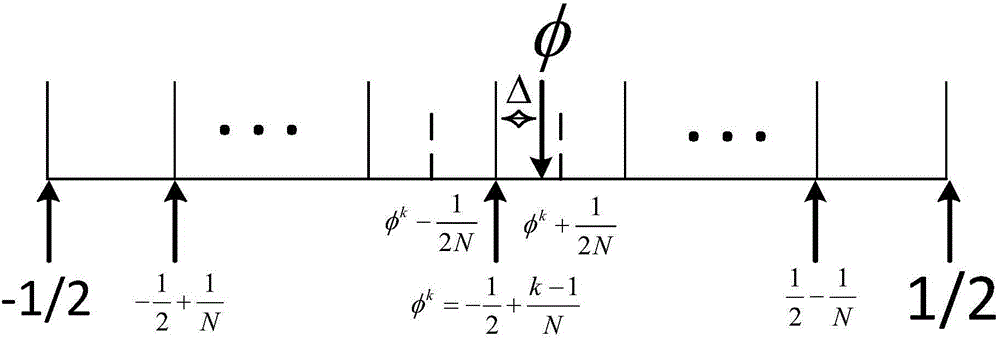

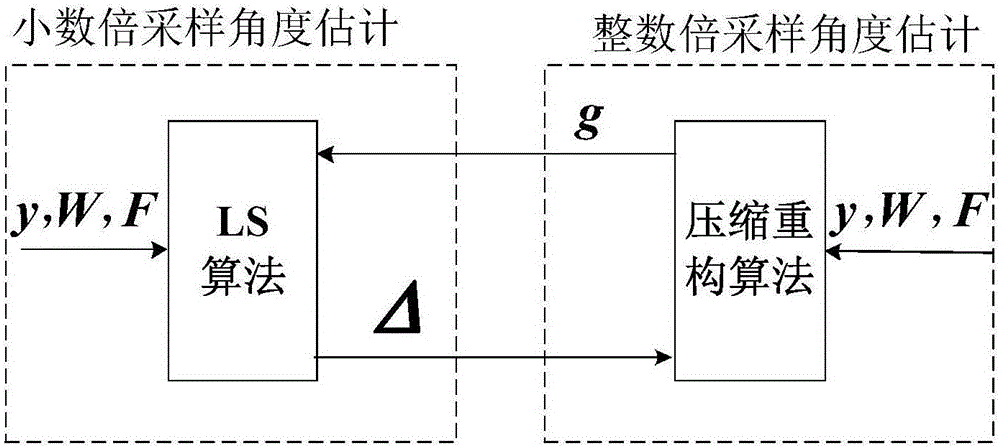

Continuous distribution-based angle estimation method and device for improving estimation precision

ActiveCN105891771ALow costSatisfy the constraint equidistant conditionRadio wave finder detailsRadio wave direction/deviation determination systemsMillimeter wave communication systemsEstimation methods

The present invention provides a continuous distribution-based angle estimation method and device for improving estimation precision, and belongs to the broadband wireless communication technology and multi-antenna technology field. The device comprises a sending terminal codebook design module, a reception terminal codebook design module and a channel estimation module, and the channel estimation module comprises a pre-processing module and an angle iteration estimator. The pre-processing module decomposes the continuously distributed angle information into the integer multiple sampling angles and the decimal multiple sampling angles in an angle domain, and the angle iteration estimator uses the Turbo decoding principle for reference to realize the angle estimation. The angle estimation method comprises the sending terminal codebook design, the reception terminal codebook design and the channel estimation. The continuous distribution-based angle estimation method and device for improving the estimation precision of the present invention can realize the high-precision angle estimation on a smaller antenna number condition, enables the antenna deployment cost to be reduced greatly, and the algorithm complexity of the angle estimation and the processing time of a reception terminal to be reduced, is suitable for a single-diameter millimeter wave communication system under a large-scale antenna array, and has the very good popularization and application prospect.

Owner:BEIJING UNIV OF POSTS & TELECOMM

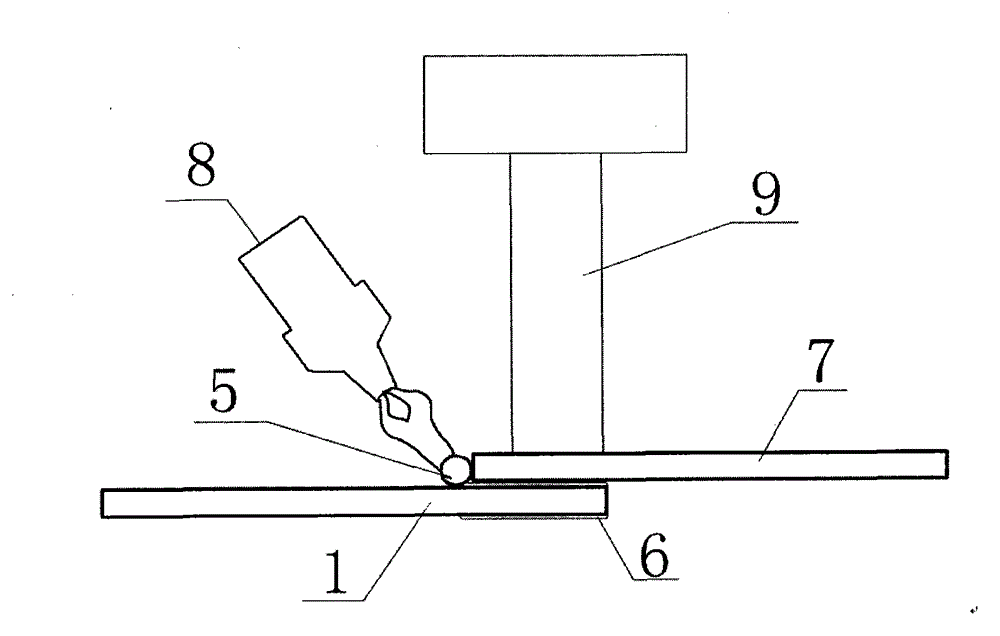

Ultrasonic assisted flame brazing method for titanium and aluminum dissimilar metal

ActiveCN103143804AGood wetting and spreadingReduce the difficulty of brazingWelding/cutting media/materialsWelding/soldering/cutting articlesReaction layerFiller metal

The invention relates to an ultrasonic assisted flame brazing method for titanium and aluminum dissimilar metal, which comprises the steps of conducting hot dip aluminum plating on a titanium plate before brazing to form an aluminizing layer in a certain thickness on the surface of the titanium plate, heating with combustible gas flame to melt an NOCOLOK brazing flux and aluminum silicon brazing filler metal, applying ultrasonic vibration on an overlapping part of a joint till the aluminum silicon brazing filler metal is solidified, and obtaining a titanium and aluminum overlap joint. The method has the main characteristics that the subsequent titanium and aluminum brazing is changed into the brazing of an aluminum plate and the aluminizing layer; the method improves wet spreading ability of the aluminum silicon brazing filler metal on the surface of the aluminized titanium plate and solves the problem that the aluminum silicon brazing filler metal difficultly wets a titanium base during the brazing; layered continuous distribution of an intermetallic compound on a brazing interface reaction layer of the joint is broken; the intermetallic compound is granulated and diffused; and the method facilitates acquirement of the high-quality titanium and aluminum dissimilar metal brazed joint.

Owner:安徽万宇机械设备科技有限公司

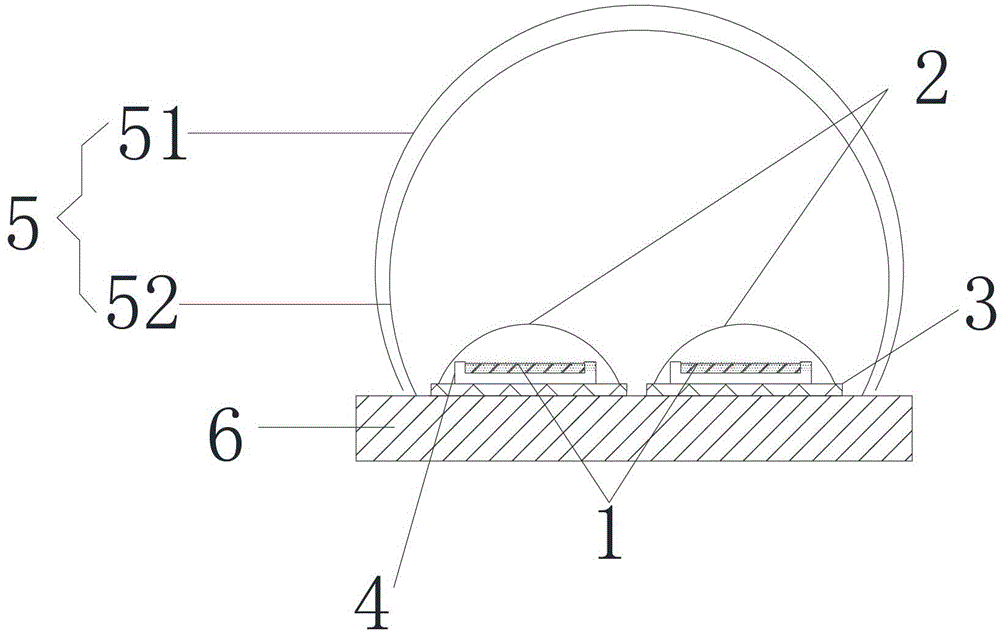

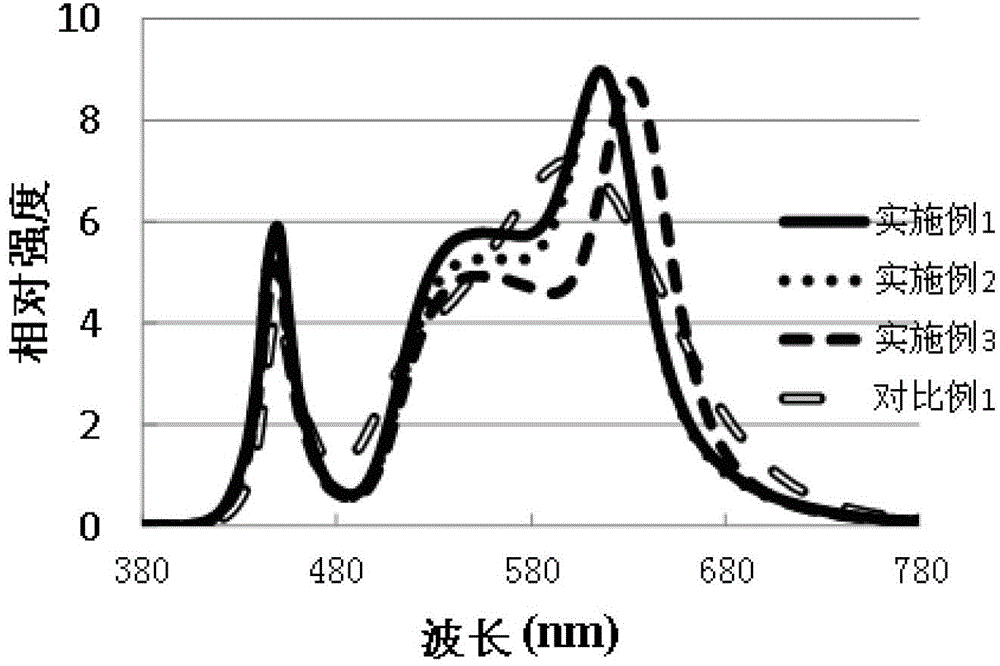

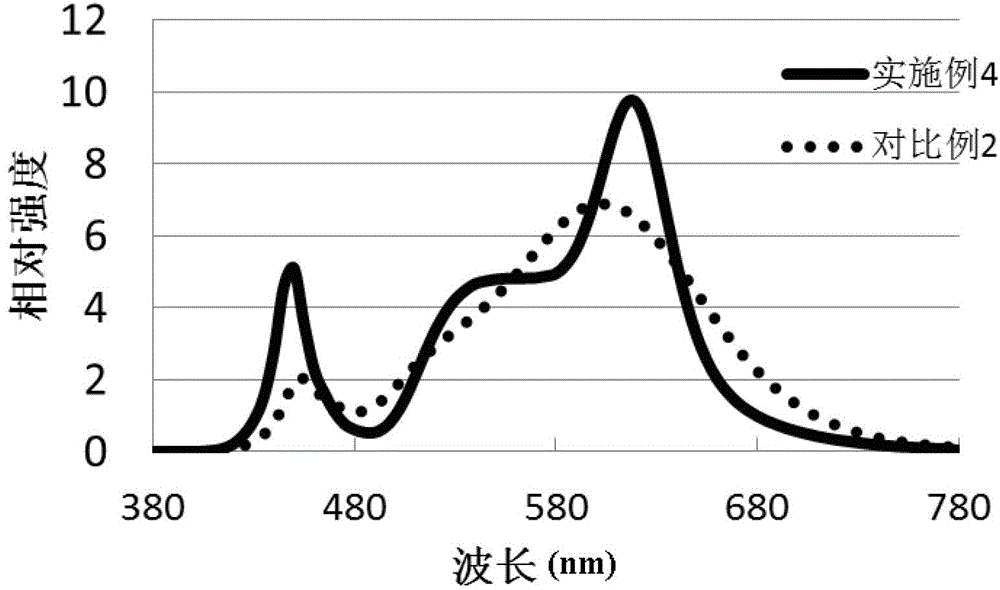

Silica gel lens, fabrication method of silica gel lens and LED light emitting device comprising silica gel lens

ActiveCN102983250ANarrow spectral half widthSelf-absorbingSemiconductor devicesQuantum dotSelf-absorption

The invention provides a silica gel lens, a fabrication method of the silica gel lens and an LED (light-emitting diode) light emitting device comprising the silica gel lens. The silica gel lens comprises a quantum dot macromolecule dispersion, fluorescent powder and silica gel with a mass ratio of 1:(3-7):(40-50), wherein mass content percentage of quantum dot materials in the quantum dot macromolecule dispersion is 0.01-10%. As the quantum dot materials have the characteristics of a wide excitation spectrum and continuous distribution of the spectrum, and light emitting wavelengths of quantum dots can be controlled by adjusting the particle diameter, the quantum dot materials with the different particle diameters can be selected according to design requirements; and as the spectrum half peak widths of the quantum dot materials are smaller, and the quantum dot materials have no self-absorption characteristics or low self-absorption characteristics, the light emitting efficiency and light emitting quality can be better improved, and a light emitting effect of the silica gel lens can be effectively improved.

Owner:NANJING TECH CORP LTD

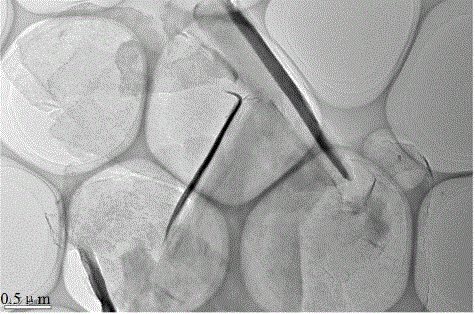

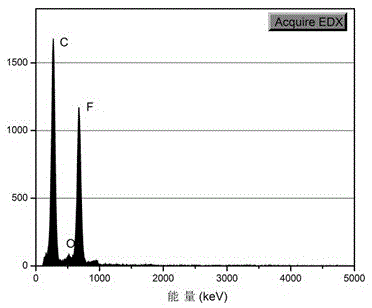

Preparation method of ultrathin fluorinated graphene composite lubrication film

InactiveCN105602298ALower surface energyReduce adhesionNon-macromolecular adhesive additivesFinal product manufacturePolymer scienceWear resistant

The invention discloses a preparation method of an ultrathin fluorinated graphene composite lubrication film. The method comprises (i) preparation of a fluorinated graphene dispersion liquid; (ii) preparation of a poly-dopamine bonding-buffering layer; (iii) preparation of a fluorinated graphene composite lubrication film. The stable fluorinated graphene dispersion liquid is prepared with convenient melting alkali treatment and ultrasonic dispersion methods and is spin-coated to form the film, the film is composited with a saline coupling agent and the poly-dopamine bonding layer, and the anti-friction and wear-resistant lubrication film which has the ultrathin thickness and uniform and continuous distribution is obtained; the lubrication film also has low surface energy and low adhesive force and shows dependence on the fluorine content; the lubrication film has bright application prospect in aspects of anti-friction, wear-resistant, hydrophobic and non-stick surface engineering and the like due to these characteristics.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD +1

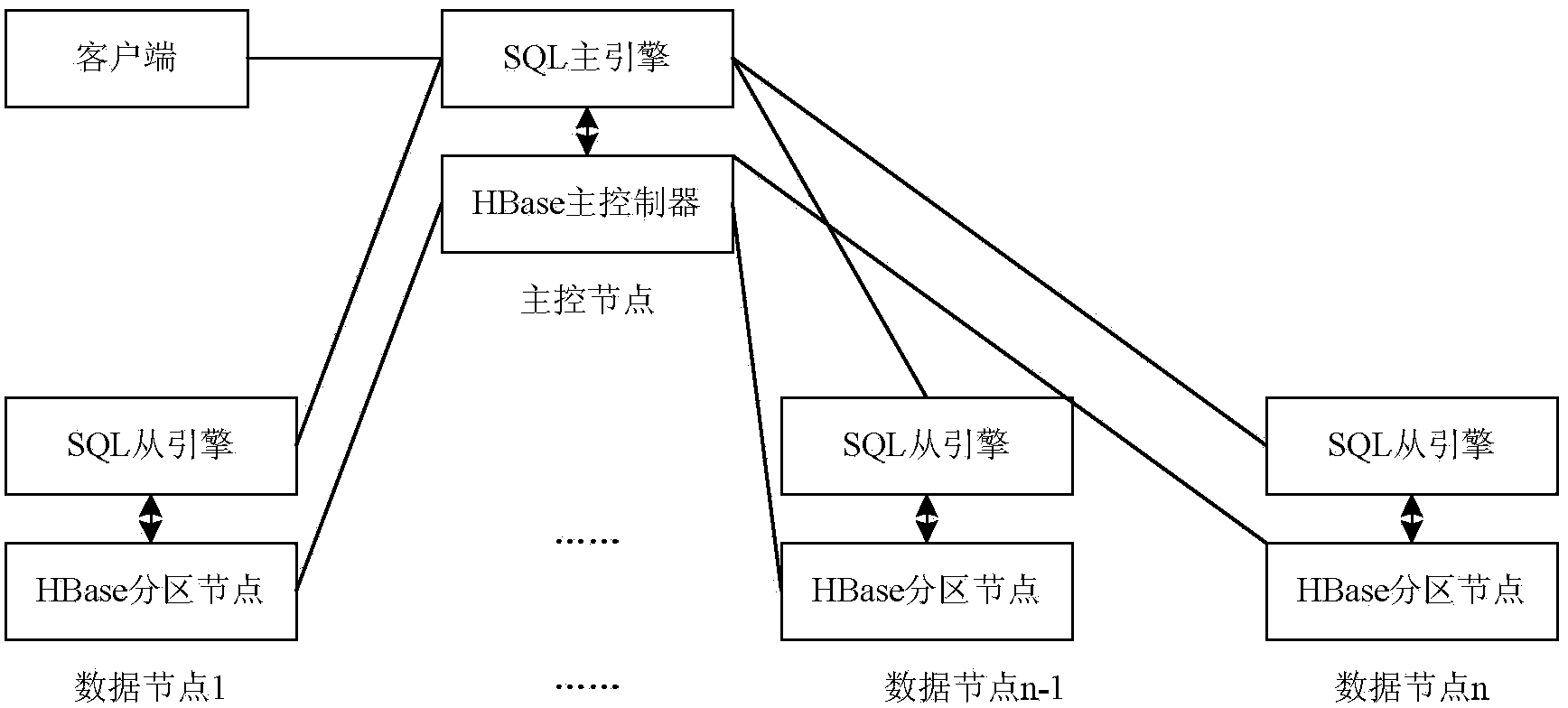

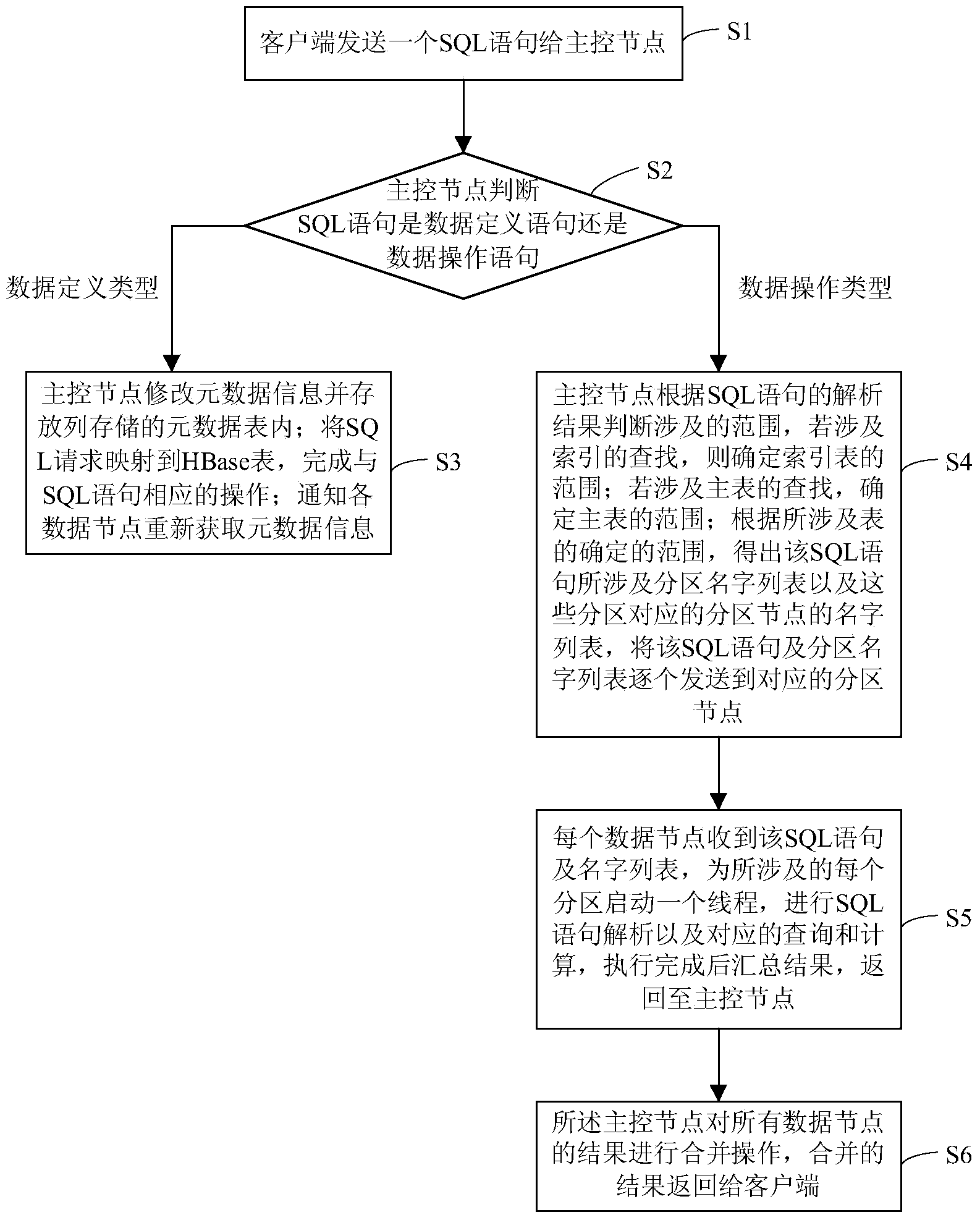

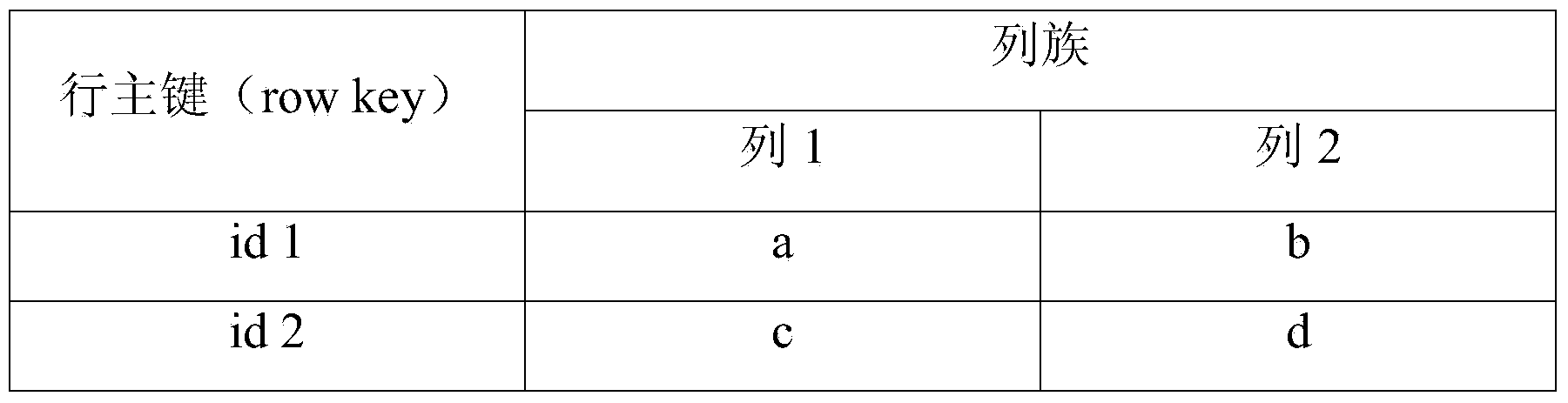

Big-data parallel processing system and method based on column storage

ActiveCN103646051AMeet data processing performanceRelational databasesSpecial data processing applicationsOn columnMaster controller

The invention provides a big-data parallel processing system and method based on column storage and relates to the field of big-data processing. The big-data parallel processing system comprises a client-side, a master control node and multiple data nodes, wherein the master control node comprises an HBase master controller and an SQL main engine. The HBase master controller takes charge of management and maintenance of the data nodes, the SQL main engine takes charge of analysis of SQL statements and continuous distribution of the SQL statements to the data nodes. Each data node comprises an HBase subarea node and an SQL sub engine, wherein the HBase subarea node takes charge of data storage and management on each data node, and the SQL sub engine takes charge of analysis and execution of SQL on the data nodes. The master control node and the data nodes comprise HBase tables and further respectively comprise SQL tables. The big-data parallel processing system and method based on the column storage is suitable for an environment with large-scale data volume and provides an SQL interface of a perfect structuralized relational data model.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

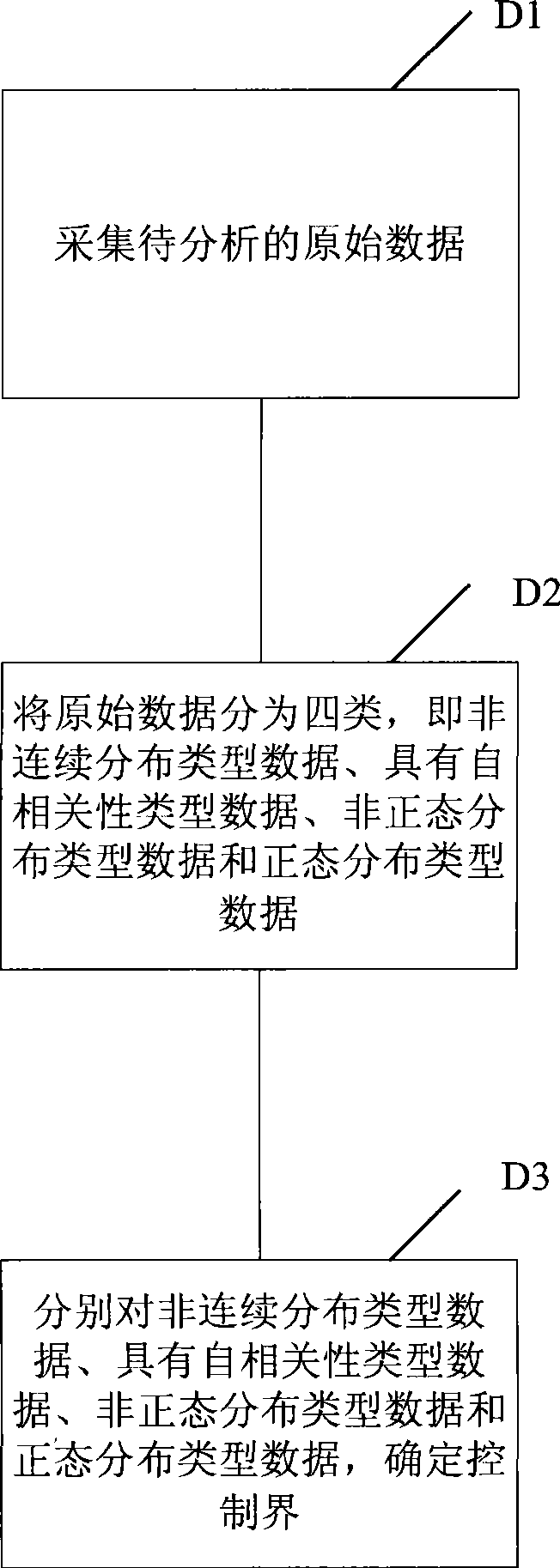

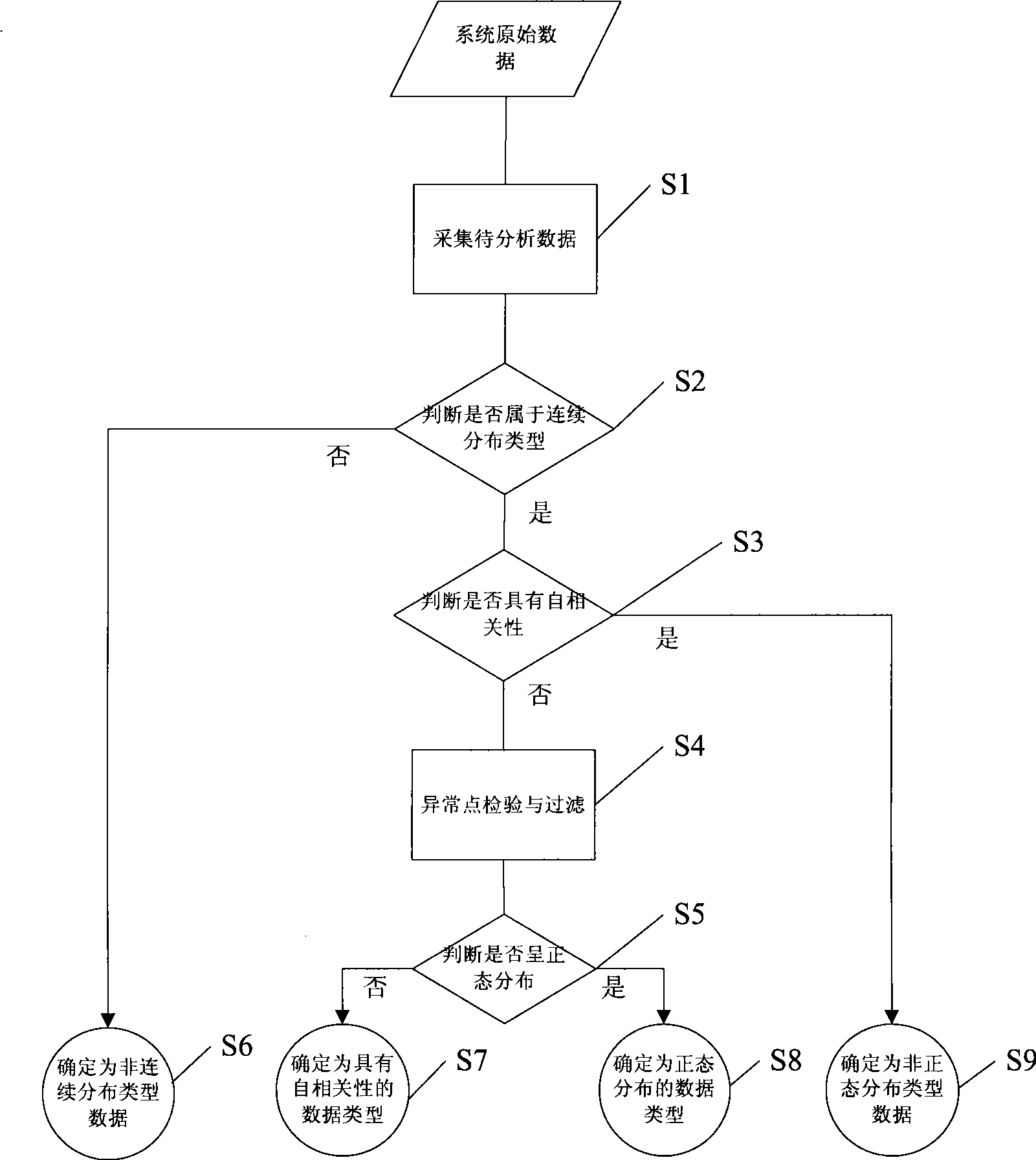

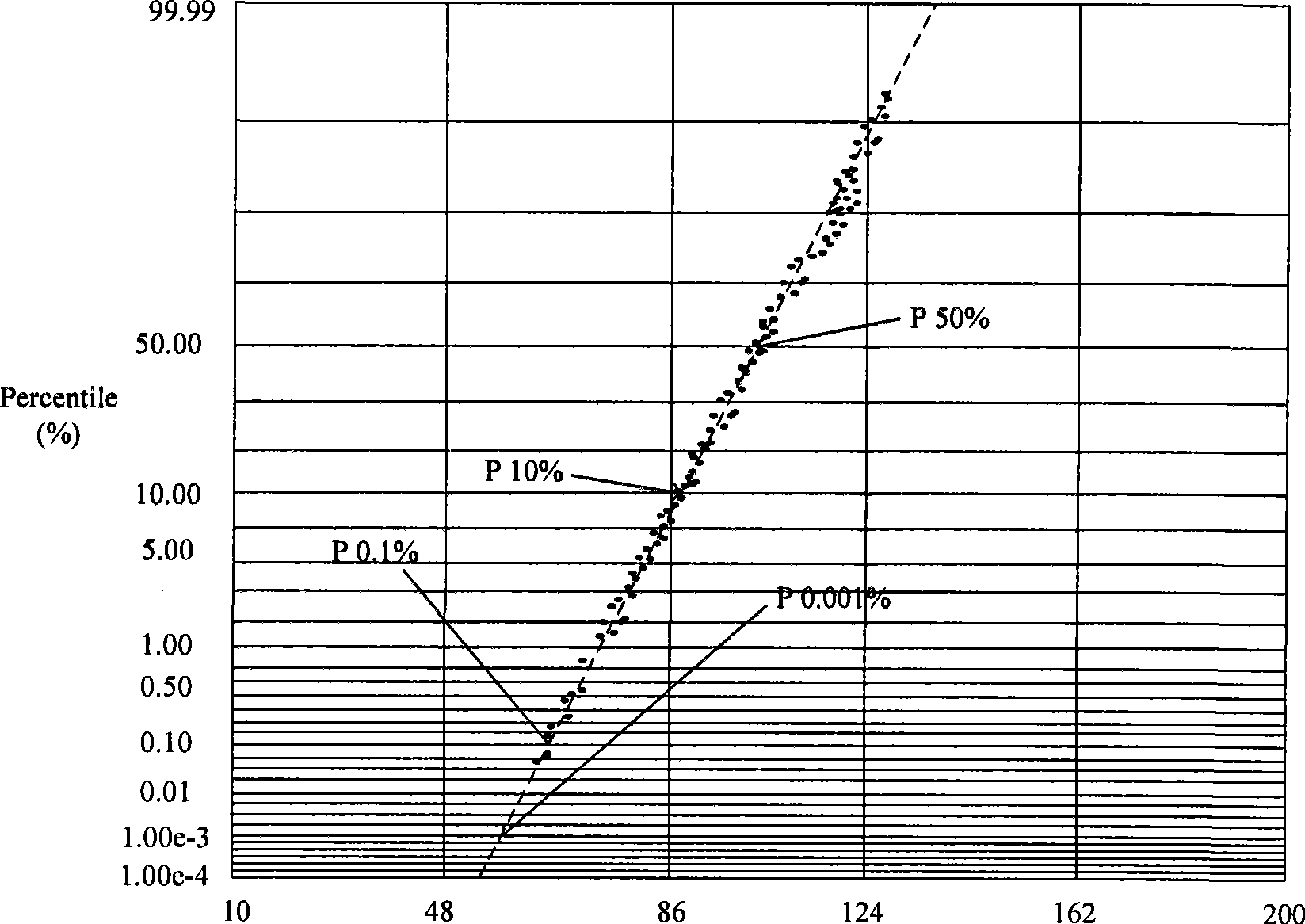

Statistical process control method and apparatus

InactiveCN101477358AEffective classificationSimple classificationTotal factory controlProgramme total factory controlRegular distributionControl limits

The invention relates to a statistical process control method and a statistical process control device applying the method. The method comprises the following steps: acquiring initial data to be analyzed during production, dividing the initial data into non-continuous distribution data, autocorrelation data, nonnormal distribution data and normal distribution data, determining the control limit according to different data types respectively, and monitoring and / or analyzing the production process according to the determined control limit. The statistical process control method simplifies classification of control charts through data classification, solves the problem of calculating the control limit of limited data points subjected to normal distribution and nonnormal distribution, realizes monitoring of a complex system with a large quantity of parameters which can not be realized in the prior art, saves the data processing time, and improves the work efficiency.

Owner:SEMICON MFG INT (SHANGHAI) CORP

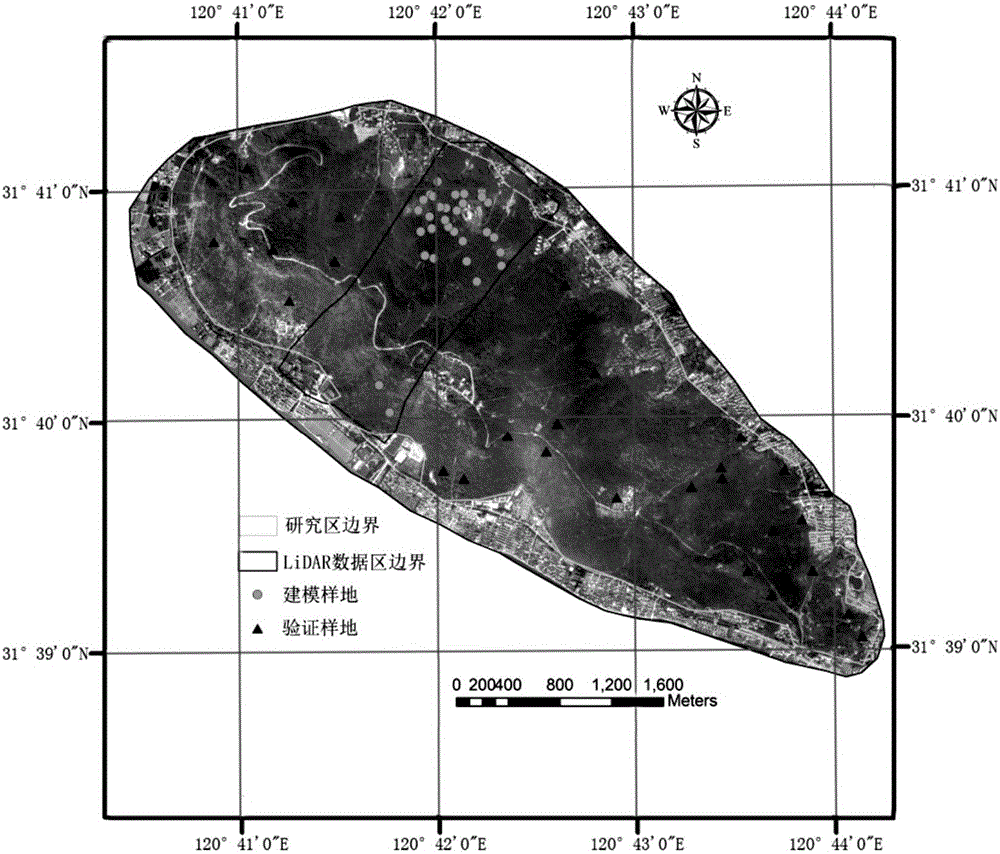

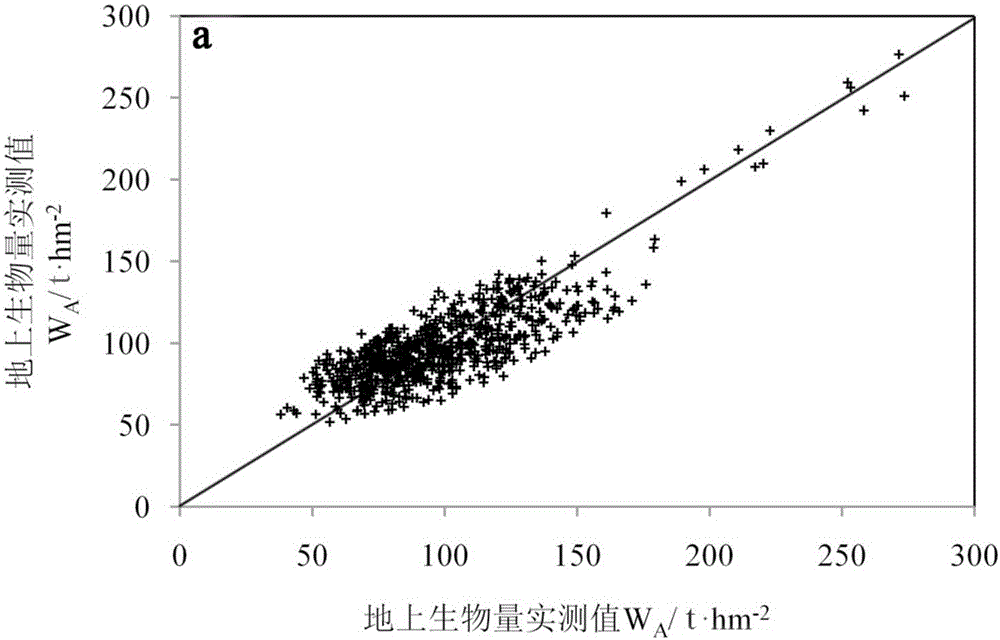

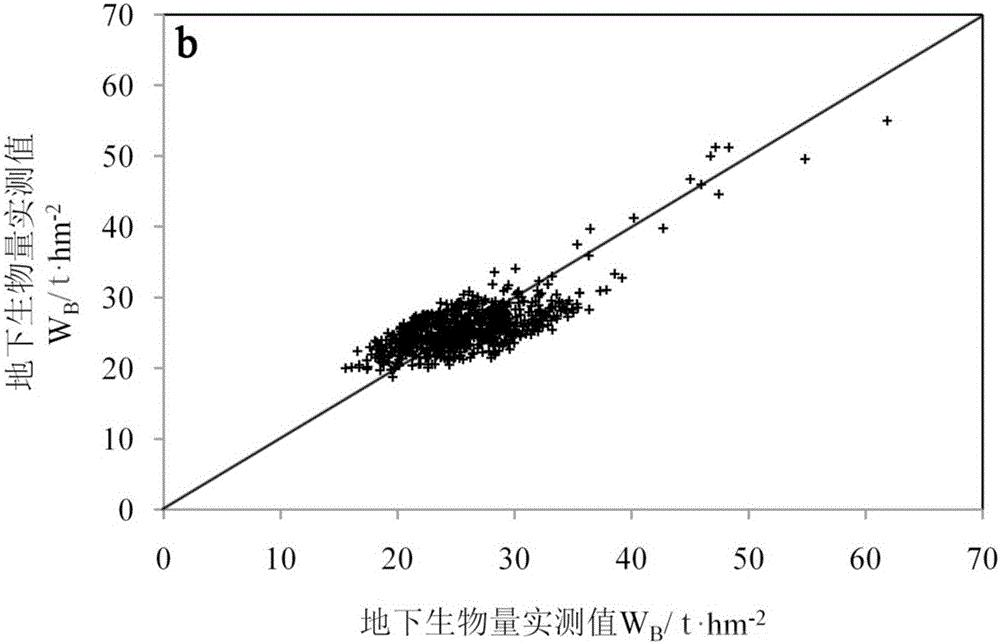

Strip LiDAR data upscaling-based forest biomass estimating method

InactiveCN105913016AReduce estimated costsImprove estimation accuracyCharacter and pattern recognitionSecondary forestSensing data

The invention discloses a strip LiDAR data upscaling-based forest biomass estimating method. A method implementation object is a subtropical natural secondary forest at a hilly area of southern Jiangsu Province; 9 characteristic variables are extracted from LiDAR strip data and are combined with ground estimated biomass to invert biomass continuous distribution information in a strip, sampling operation is conducted in a strip inverting result zone, samples are combined with Landsat OLI image characteristic variables covering a whole research zone, and biomass of the whole research zone can be estimated in an upscaling manner. Based on full acquisition of remote sensing data characteristic information, forest farm level biomass estimation cost is lowered via strip LiDAR data, and biomass estimating precision of a remote sensing method on the scale is improved.

Owner:NANJING FORESTRY UNIV

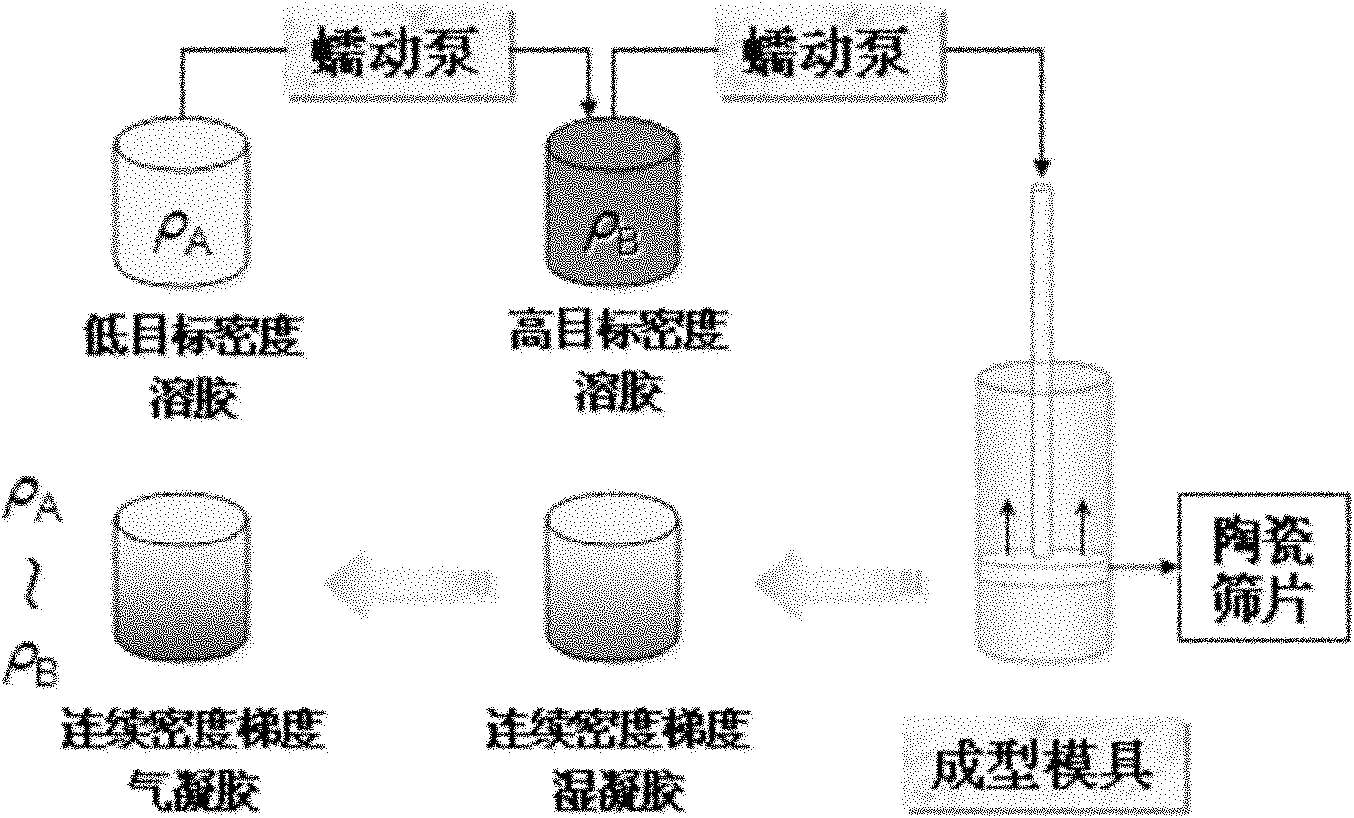

Method for preparing silicon dioxide (SiO2) aerogel with continuous density gradient

InactiveCN102030337ALarge density differenceFormed structure is completeSilicaSupercritical dryingThermal insulation

The invention provides a method for preparing silicon dioxide (SiO2) aerogel with continuous density gradient. The method comprises the following steps of: mixing precursor sol with high target density and precursor sol with low target density continuously by using tetraethoxysilane as an organic silicon source, by adopting a continuous forming process and by automatically designing and constructing a density gradient mixed forming device so as to obtain SiO2 sol with continuous density gradient; standing to gelate; and preparing the SiO2 aerogel with continuous density gradient by an aging replacement process and a supercritical drying process. The physical property of the SiO2 aerogel is in gradient distribution along with the change of density, so the application range is widened. The SiO2 sol with continuous density gradient prepared by the method has the characteristics of large density gradient, complete forming structure, continuous distribution of density, simpleness, convenience and controllability of preparation process and the like, so the SiO2 sol can be applied in the fields of space particle capture for aerospace, research on impact wave characteristics for an inertial confinement fusion test, acoustic resistance anti-gradient matching application, high-resolution Cerenkov detectors, high-vacuum thermal insulation materials and the like.

Owner:TONGJI UNIV

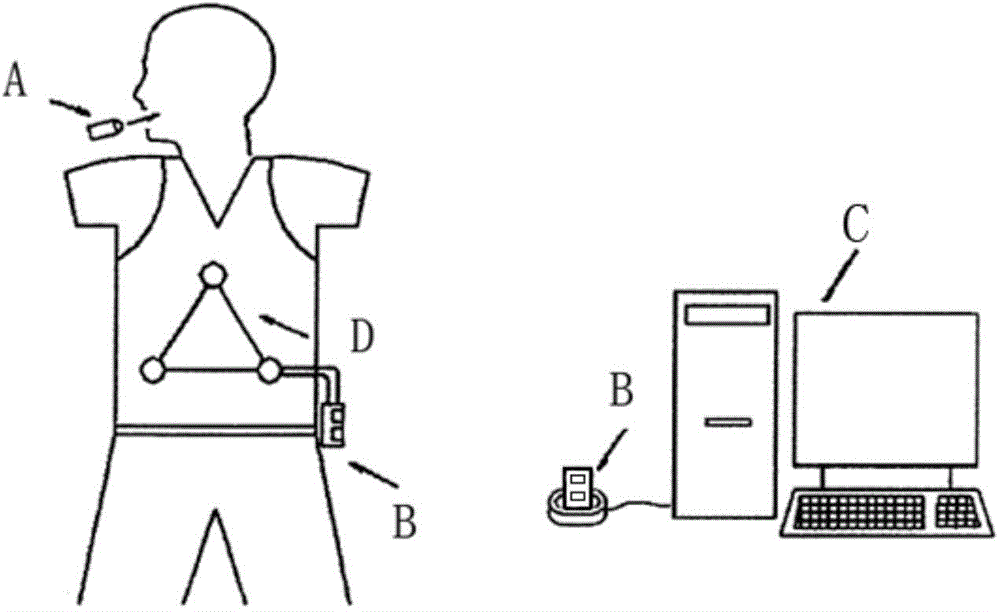

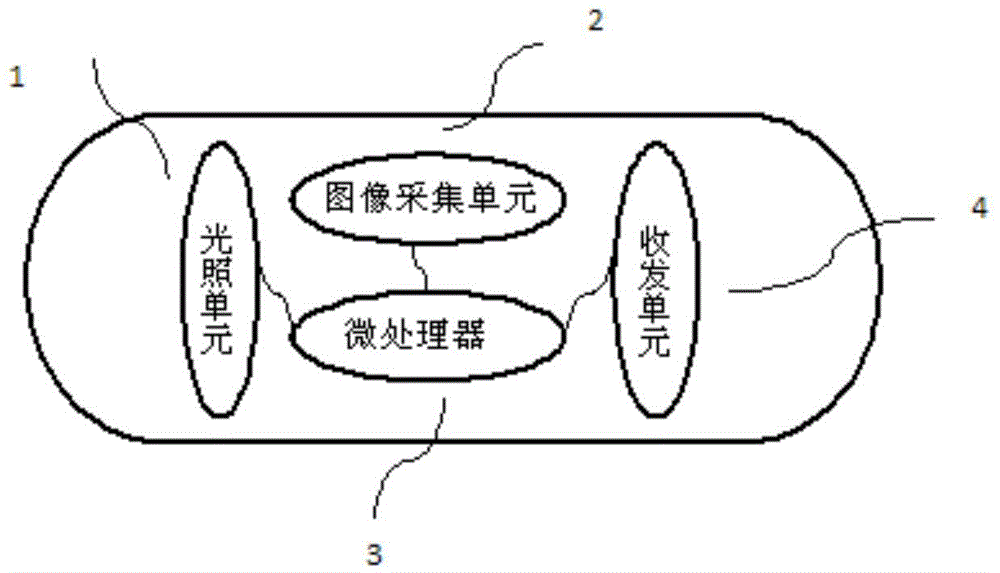

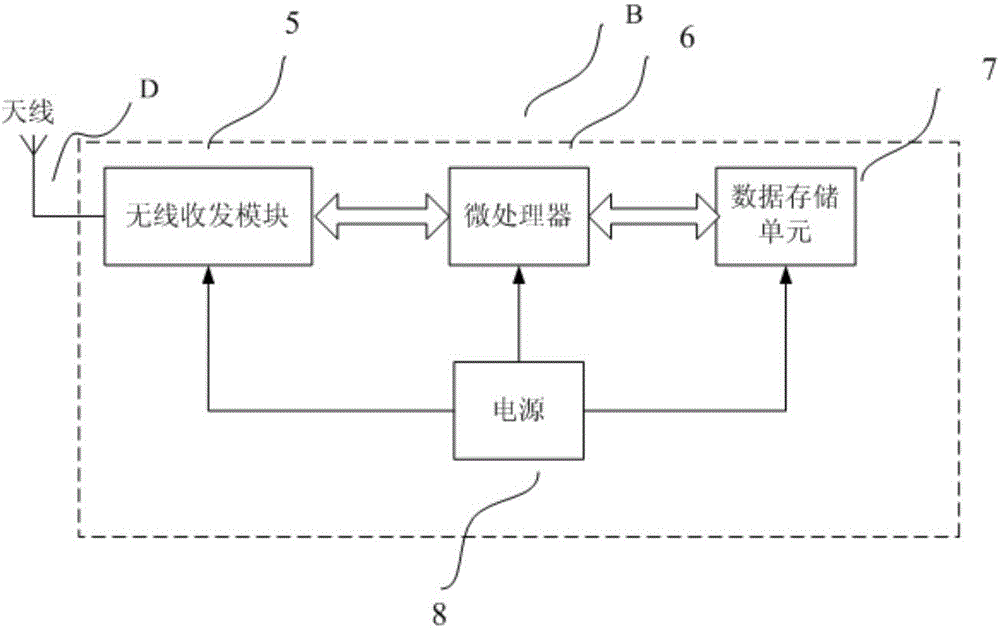

Method for detecting in-vivo chromaticity abnormality

ActiveCN104658014AImprove accuracyAccurate judgmentImage enhancementImage analysisPattern recognitionMathematical model

The invention discloses a method for detecting in-vivo chromaticity abnormality. The method comprises the following steps: 1, converting an image to an HSV color space and an RGB color space, extracting spectral characteristics of the image from the HSV color space and the RGB color space, and screening pixel points of which spectral characteristics meet preset conditions, wherein the pixel points are primarily-screened pixel points; 2, by using a BP neural network mathematical model, secondarily screening the primarily-screened pixel points to obtain pixel points with abnormal chromaticity, wherein the pixel points are abnormal pixel points; 3, forming abnormal blocks by the abnormal pixel points in continuous distribution in the image, acquiring the number of the abnormal pixel points in each abnormal block, defining the abnormal block with the maximum number of the abnormal pixel points as the maximum abnormal block, comparing the maximum abnormal block with a preset threshold of an abnormal-chromaticity image, and according to the preset threshold, judging whether the image is the abnormal-chromaticity image or a normal-chromaticity image. By the method, the abnormal blocks can be accurately and rapidly judged.

Owner:CHONGQING JINSHAN SCI & TECH GRP

Wear-resistant spheroidal graphite cast iron and preparation method thereof

The invention discloses a wear-resistant spheroidal graphite cast iron and a prepration method thereof, and the cast ion contains the following chemical elements by weight percent: 3.5-3.7% of C; 2.8-3.3% of Si; not more than 0.5% of Mn; less than 0.02% of S; 0.15-0.4% of P and the balance of iron. The preparation method comprises the working procedures of material preparation, smelting and interrupted front treatment. Compared with the prior art, rare earth elements are utilized in the method for obtaining the spheroidal graphite cast iron with a binary iron phosphide eutectic structure, and the spheroidal graphite cast iron has uniform and continuous distribution and high hardness, and can not reduce the elongation rate of the cast ion, thereby being particularly applicable to delivering solid powder and granular substances.

Owner:WUHU JINMAO FLUID TECH CO LTD

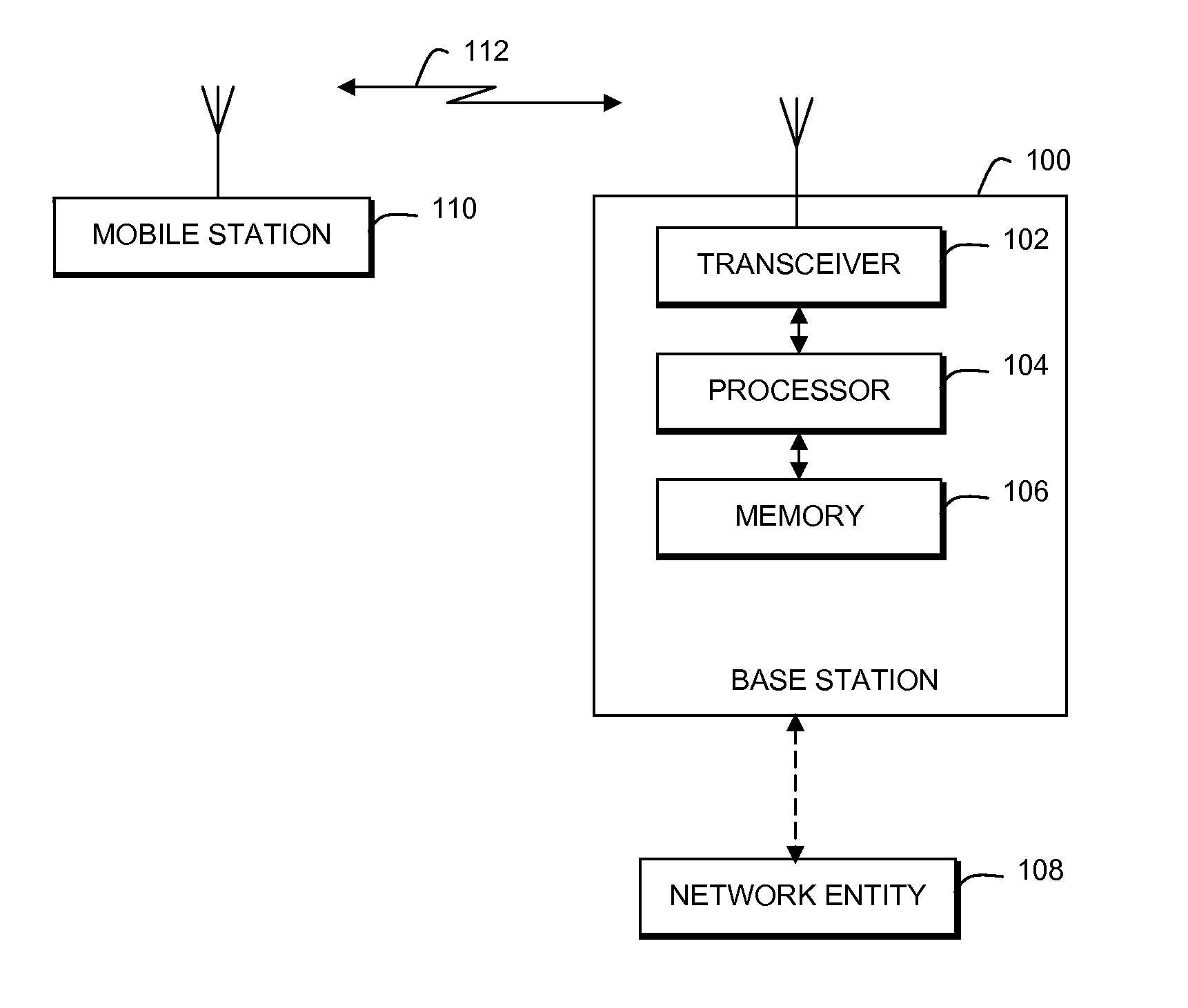

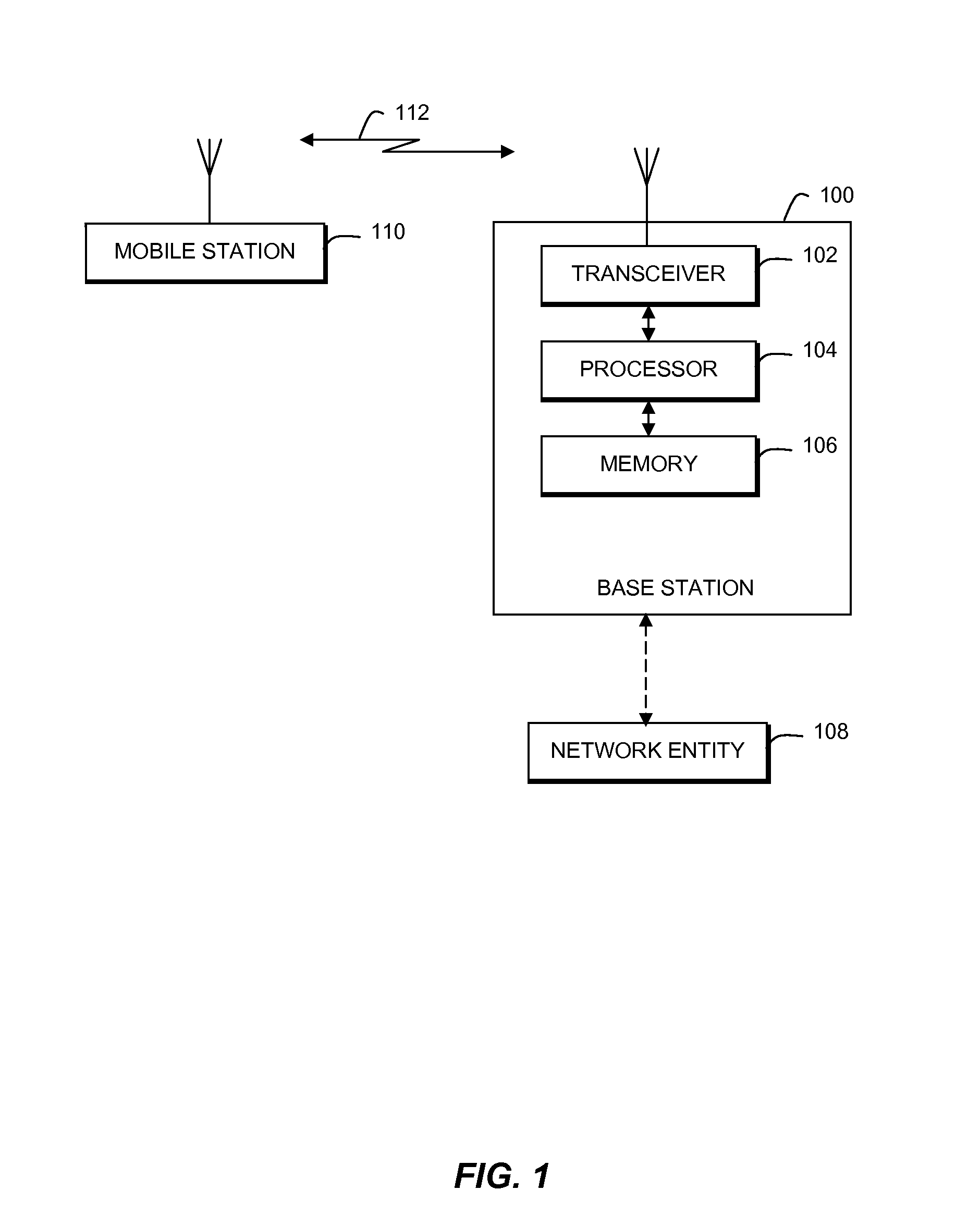

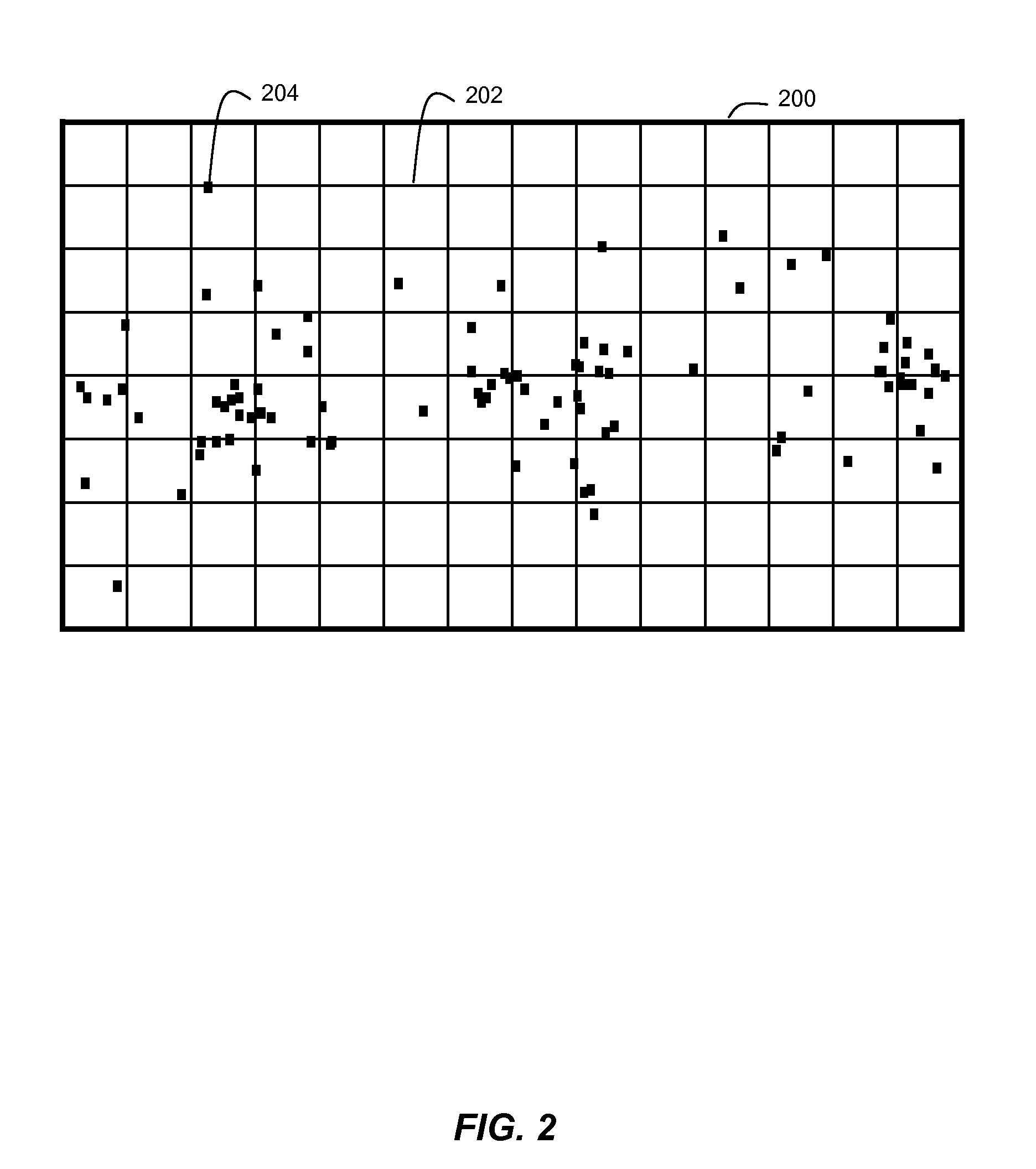

Real-time location estimation of a mobile station in a wireless communication system

An apparatus and method is provided for real-time location estimation of a mobile station (MS) on a map of roads using non-Global Positioning Satellite location data (300) of the MS and includes a step of determining (302) a mobility of the MS. A next step (306) includes identifying a region that covers all location data. A next step (310) includes dividing the region into smaller blocks, where each block constitutes a Hidden Markov Model state. A next step (312) includes determining a distance between blocks, to be used in a varied continuous probability distribution to determining a state transition probability of each block to represent a likelihood of the MS moving to any one block. A next step (314) includes using a univariate continuous distribution as a function of a distance between each block and a raw location data. A next step (316) includes finding a most likely state / block sequence of the MS motion using the HMM state transition probability and the univariate continuous distribution as the location of the MS.

Owner:GOOGLE TECH HLDG LLC

Cheap high-strength heat-resistant deforming magnesium alloy

The invention was involved in the preparation method of high intensity heat resisting magnesium alloy containing Ca. The alloy consist of 3-9%Al, 0.5-2.5% Ca, 0.1-1% Mn,0.05-1.0%Zn, impurity which was composed with <0.005%Fe, <0.015%Cu and <0.002% Ni and the rest was Mg. The invention wasn't involved rare metal, the cost was low and the technology was simple. The strength of extension under room temperature / high temperature(150deg.C), yield strength, extensibility and creep resistance were improved magnesium alloy obviously. Fine texture of magnesium alloy was refined obviously. The shape of Al2Ca was changed into small stick from thick Chinese character. Continuous distribution of magnesium alloy was changed into isolated diffusion distribution.

Owner:江苏锦绣铝业有限公司

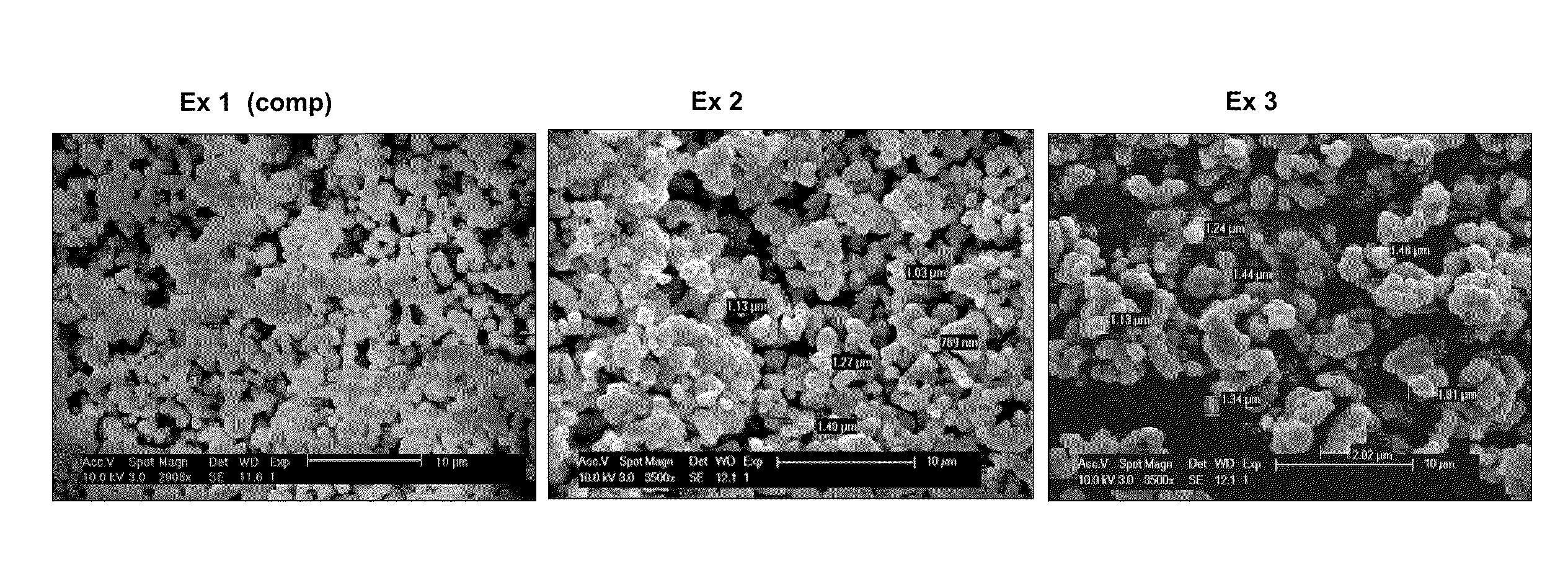

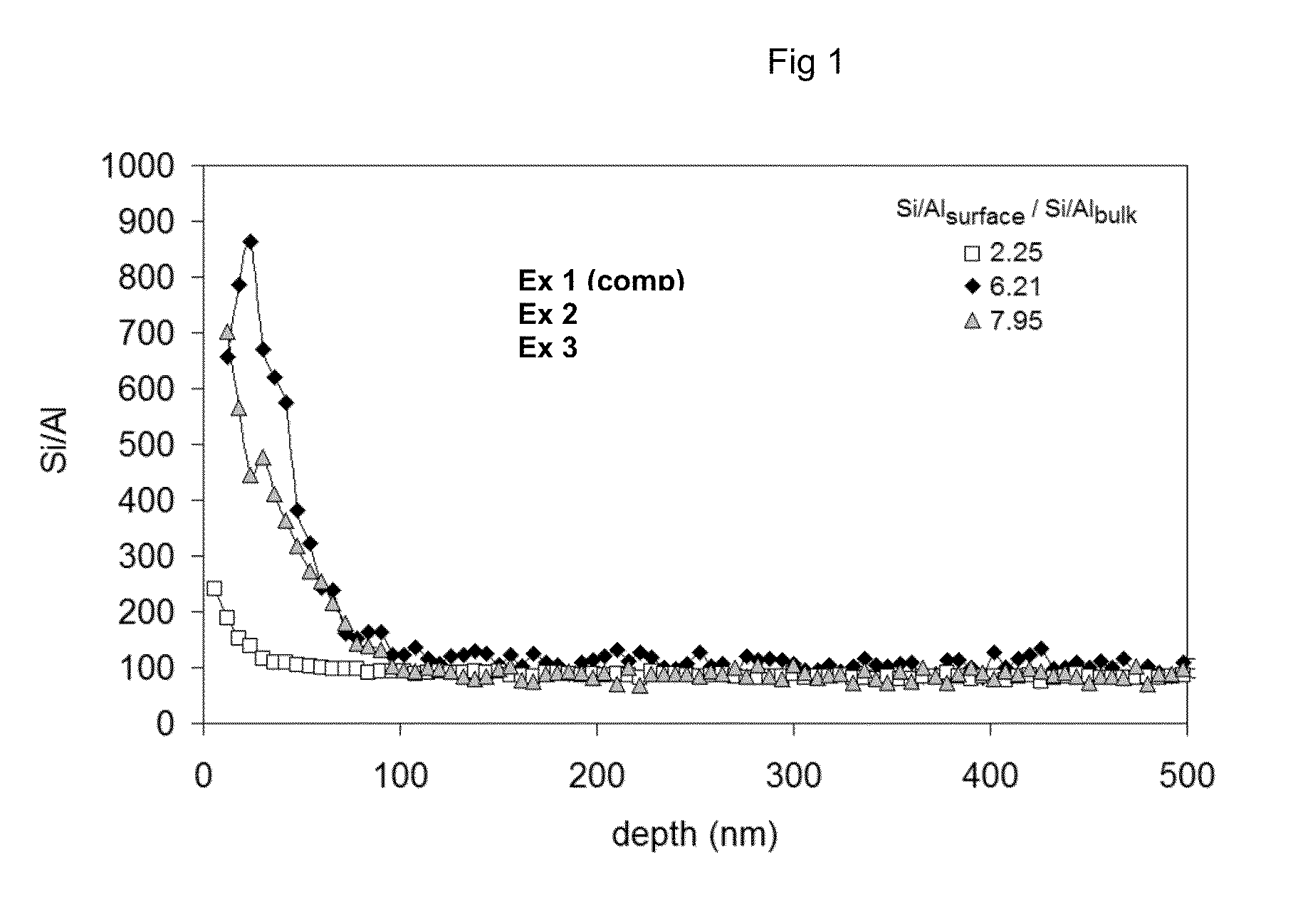

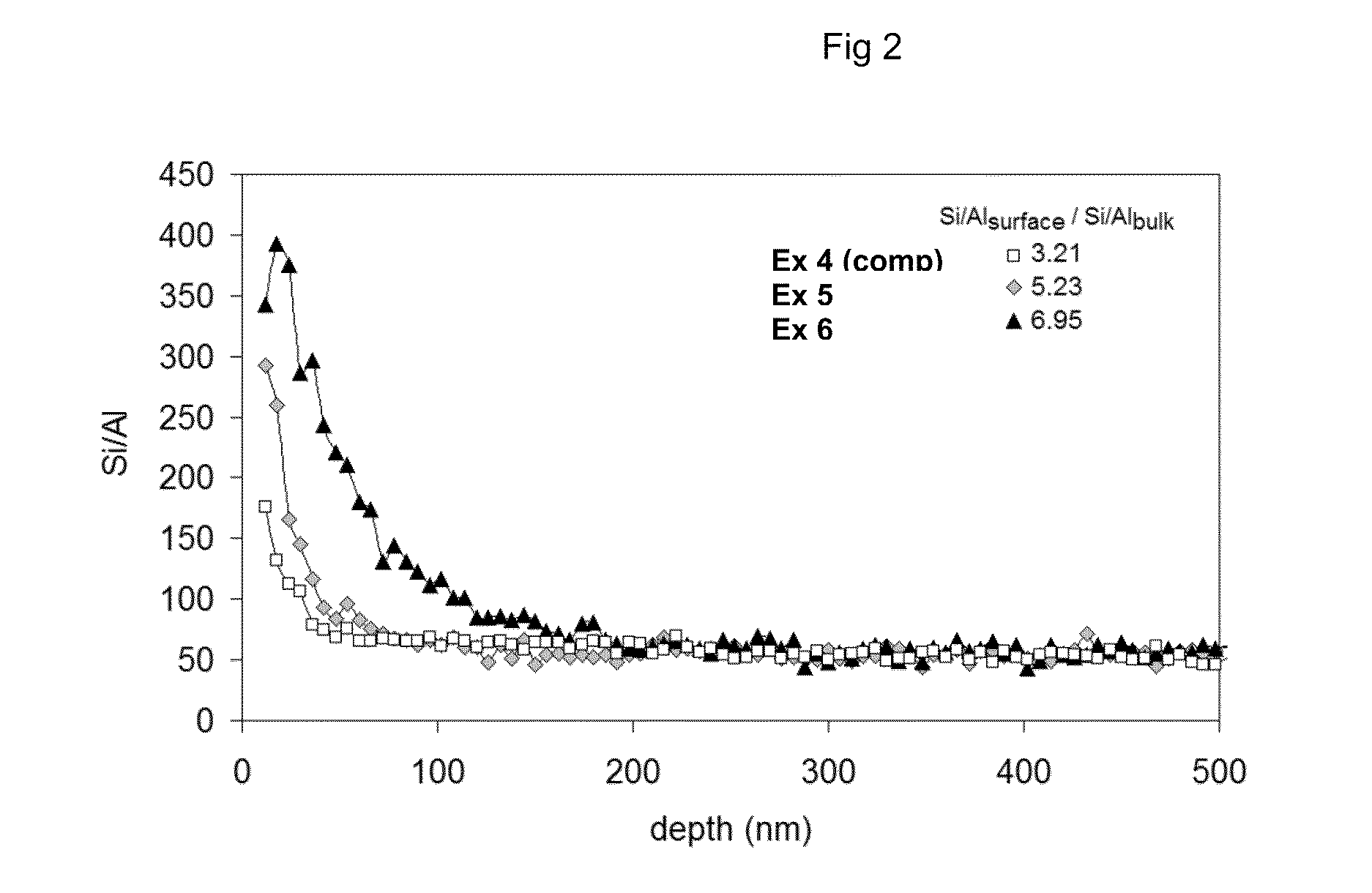

Process for Making Crystalline Metallosilicates

InactiveUS20110201861A1Increase productionReduce surface activityAluminium compoundsMolecular sieve catalystsLiquid mediumRoom temperature

The present invention relates to a process for making a crystalline metallosilicate composition and comprising crystallites having an inner part (the core) and an outer part (the outer layer or shell) such that:the ratio Si / Metal is higher in the outer part than in the inner part,the crystallites have a continuous distribution of metal and silicon over the crystalline cross-section,said process comprising:a) providing an aqueous medium comprising OH− anions and a metal source,b) providing an aqueous medium comprising an inorganic source of silicon and optionally a templating agent,c) optionally providing a non aqueous liquid medium comprising optionally an organic source of silica,d) mixing the medium a), b) and the optional c) at conditions effective to partly crystallize the desired metallosilicate,e) cooling down the reaction mixture a)+b)+c) to about room temperature,f) decreasing the pH of the reaction mixture by at least 0.1 preferably by 0.3 to 4, more preferably by 0.5 to 3,g) subjecting the resulting mixture of step f) at conditions effective to continue the crystallization of the desired metallosilicate,h) recovering the desired metallosilicate,wherein at step d) in the mixture a)+b)+c), before crystallization,the ratio Si org / Si inorganic is <0.3, advantageously <0.2 and preferably 0,the molar ratio OH− / SiO2 is at least 0.3, advantageously from 0.3 to 0.62, preferably from 0.31 to 0.61, more preferably from 0.32 to 0.61, very preferably from 0.33 to 0.6.

Owner:TOTAL RES & TECH FELUY

Method for characterizing lamina structure of tobacco leaf

ActiveCN101968346ACharacterizing structure distributionEasy accessUsing optical meansComputer scienceContinuous distributions

The invention relates to a method for characterizing the lamina structure of a tobacco leaf. The method is characterized by comprising the following steps of: (1) sampling; (2) dispersing and paving materials; (3) collecting a lamia image; (4) measuring a lamina area; (5) calculating the area percentage of intervals; (6) calculating the accumulative area percentage; (7) fitting a distribution equation; (8) calculating a characteristic area; and (9) acquiring the lamina content of the intervals of any areas. The method has the advantages that: the distribution of lamina size is described by using the continuous distribution equation, the uniformity of the distribution of the lamina size and the integral size of the lamina are characterized by utilizing a uniformity coefficient b and the characteristic area x0.5, and simultaneously, the lamina content of the intervals of any areas can be acquired by the distribution equation of the lamina. The method overcomes the defects of the conventional method, and characterizes the structural distribution condition of the lamina comprehensively.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

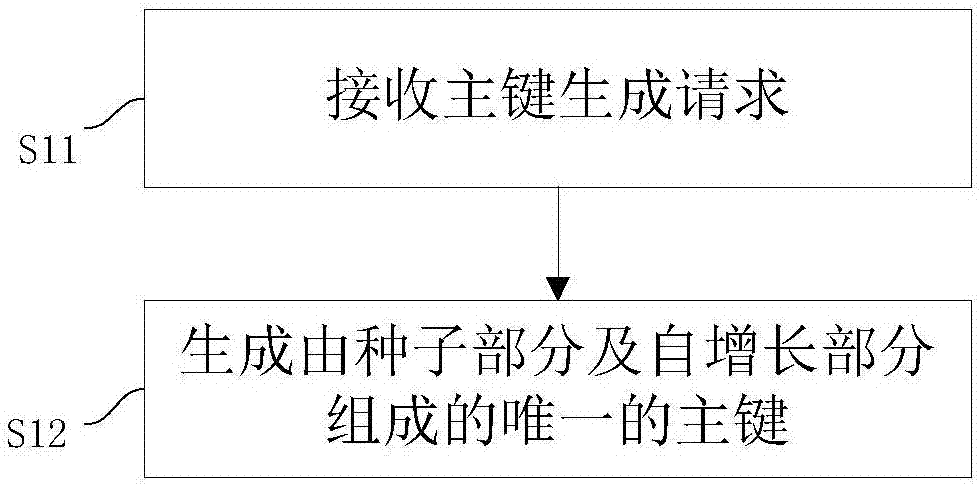

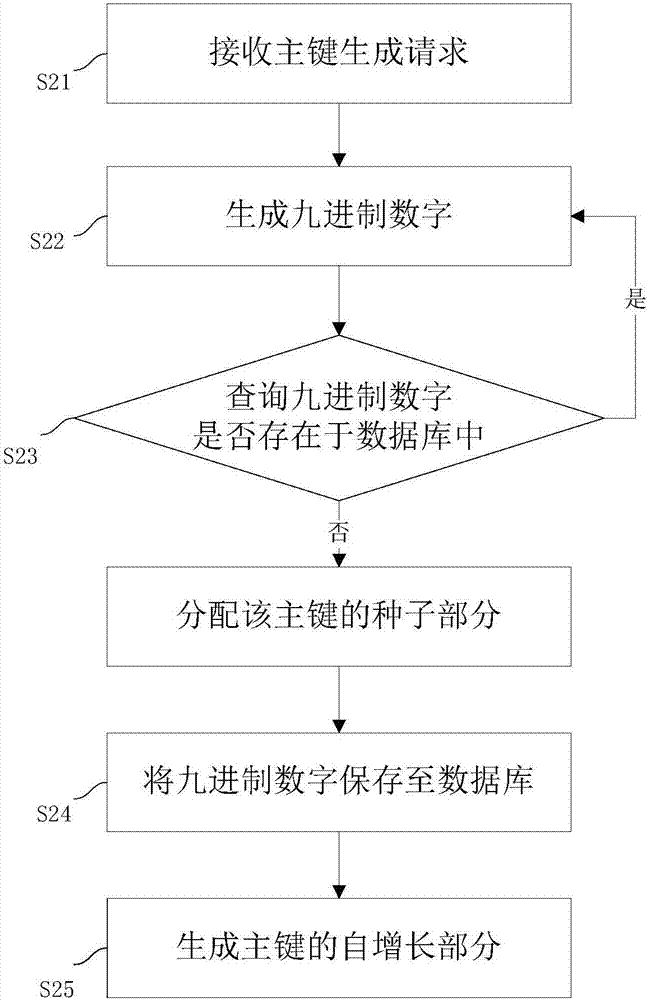

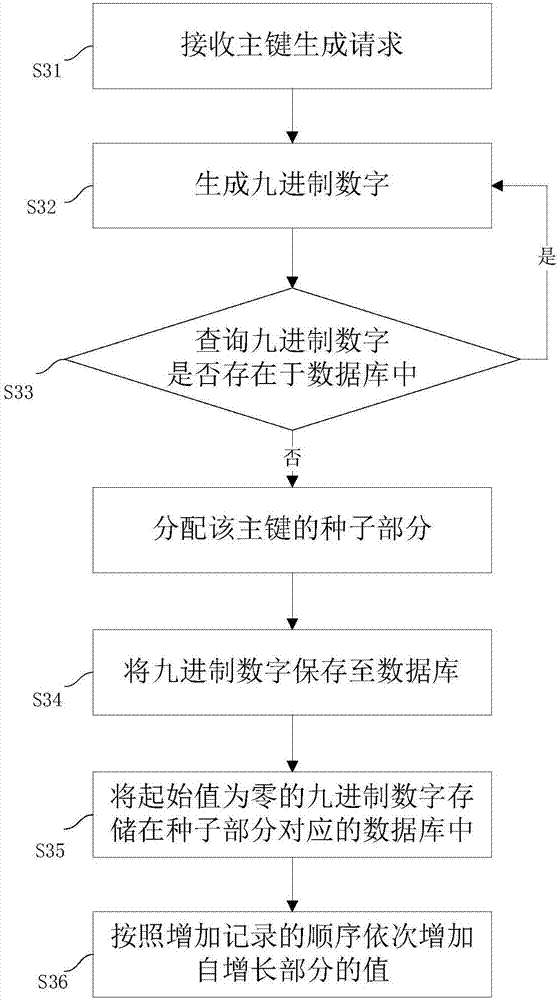

Method and system for generating main key of distributed database

InactiveCN107247734AMeet the continuitySatisfy the problem of efficient concurrent performanceSpecial data processing applicationsKey generationContinuous distributions

The invention provides a method and system for generating a main key of a distributed database and aims to solve the problem that the main key word length generated by an existing distributed database is limited. The method comprises the steps that (S1) a main key generation request is received; and (S2) a unique main key is generated according to the main key generation request, wherein the main key is composed of a seed part and a self-growth part. Through use of the method and system provided by the invention, global uniqueness, single database continuous distribution and efficient concurrence performance of the main key can be satisfied at the same time; and the word length of the generated main key is not limited.

Owner:PHICOMM (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com