Patents

Literature

94 results about "Porous sic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous SiC-bodies with micro-channels and process for their fabrication

InactiveUS20060121266A1Large effective internal surface areaImprove filtering effectInternal combustion piston enginesLayered productsParticulatesCellulose

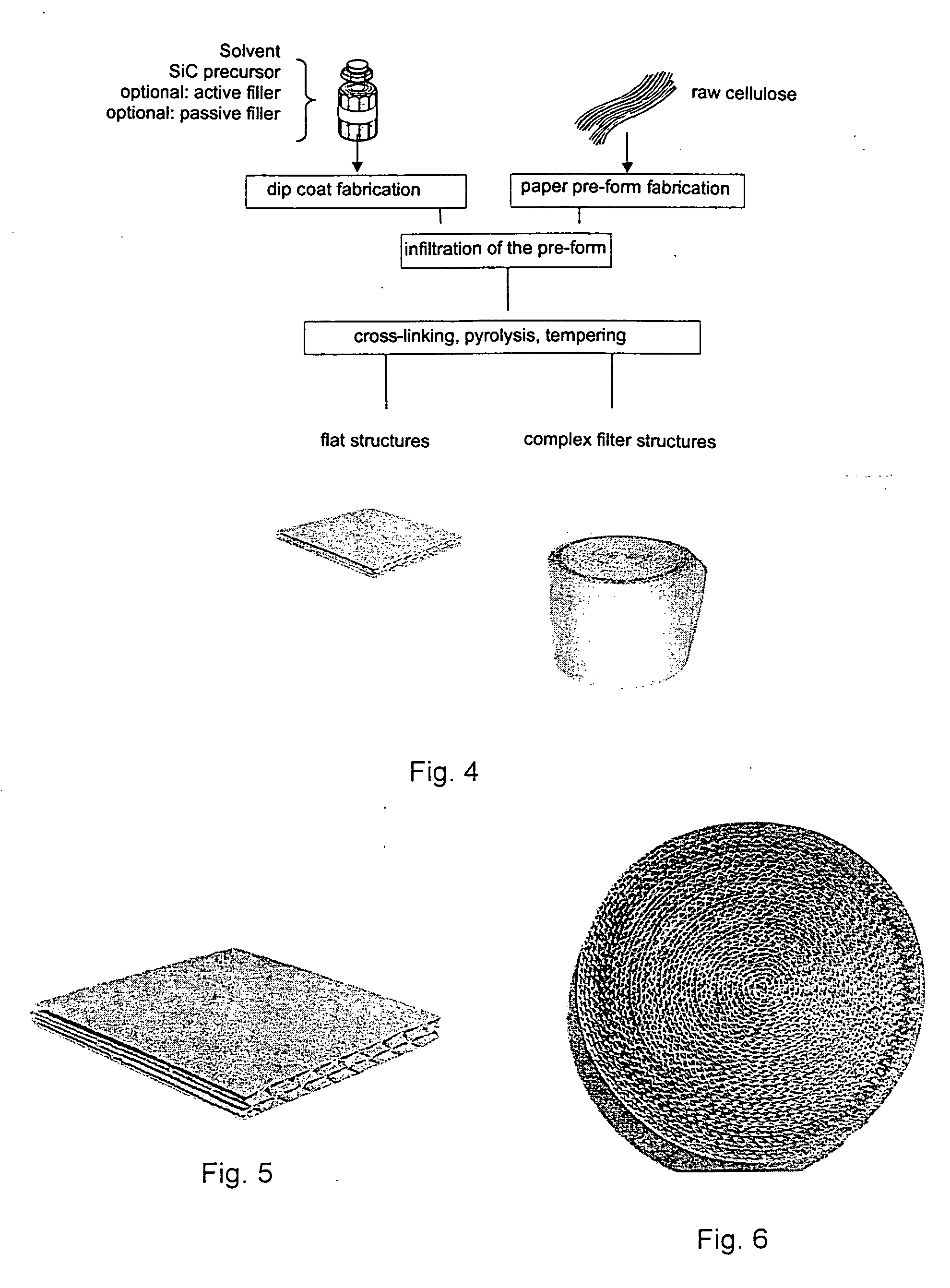

Process for the fabrication of porous bodies mainly constituted by SiC containing ceramic with a microstructure which is interfused with micro-channels which consists of the process steps a) Provision of a pre-body made from cellulose or pulp b) Fabrication of an infiltration solution or a slurry consisting of (A) solvent, polysilazane, polysilane and / or polycarbosilane or (B) solvent, polysilazane and / or polysilane as well as active metallic fillers and / or passive ceramic fillers. c) Infiltrating the body with infiltration solution or slurry d) Cross-linking of the polysilazane, polycarbosilane and / or polysilane while generating a solid green body e) Ceramization through pyrolysis of the green body in an inert-gas atmosphere. f) Removal of residual carbon with an oxidizing thermal process, thereof producible catalyst carriers or carbon particulate filters as well as Porous ceramic which is made from at least 80% SiC in which the porous ceramic features a microstructure with micro-channels consisting mainly of SiC coated micro-channels featuring an average diameter between 1 and 25 μm and webs of SiC located between the micro-channels as well as additional ceramic materials with a content below 20 wt %.

Owner:DAIMLER AG

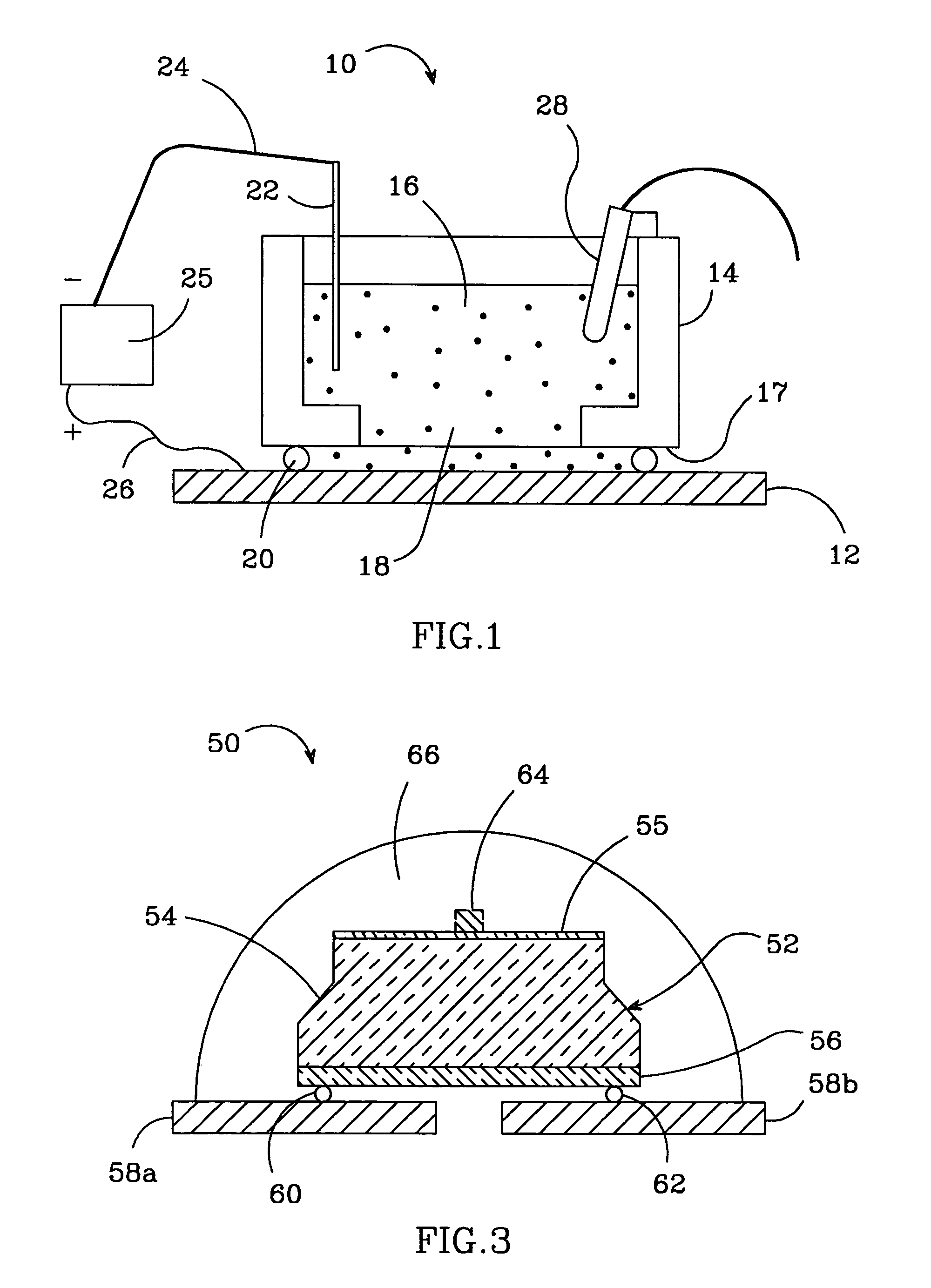

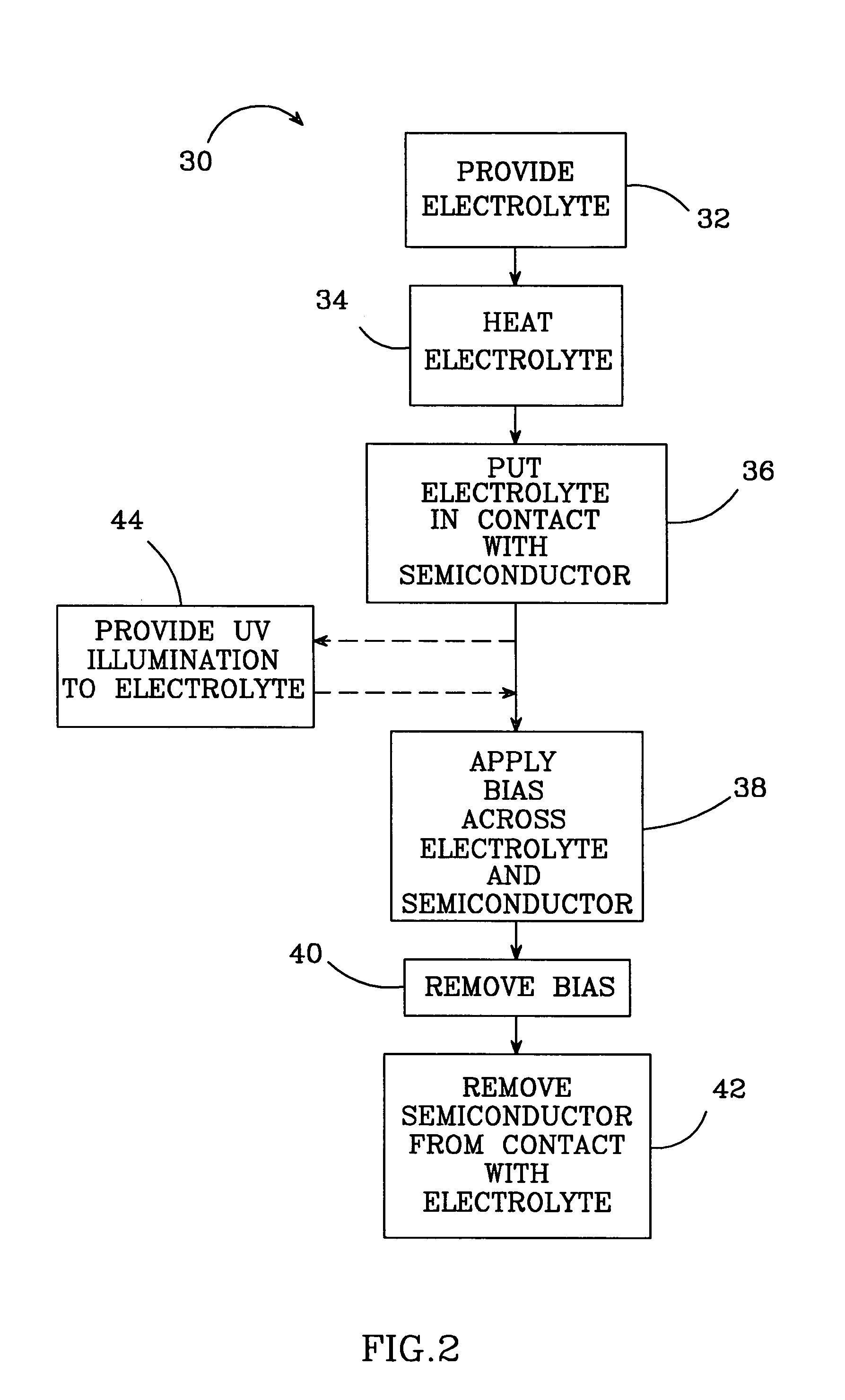

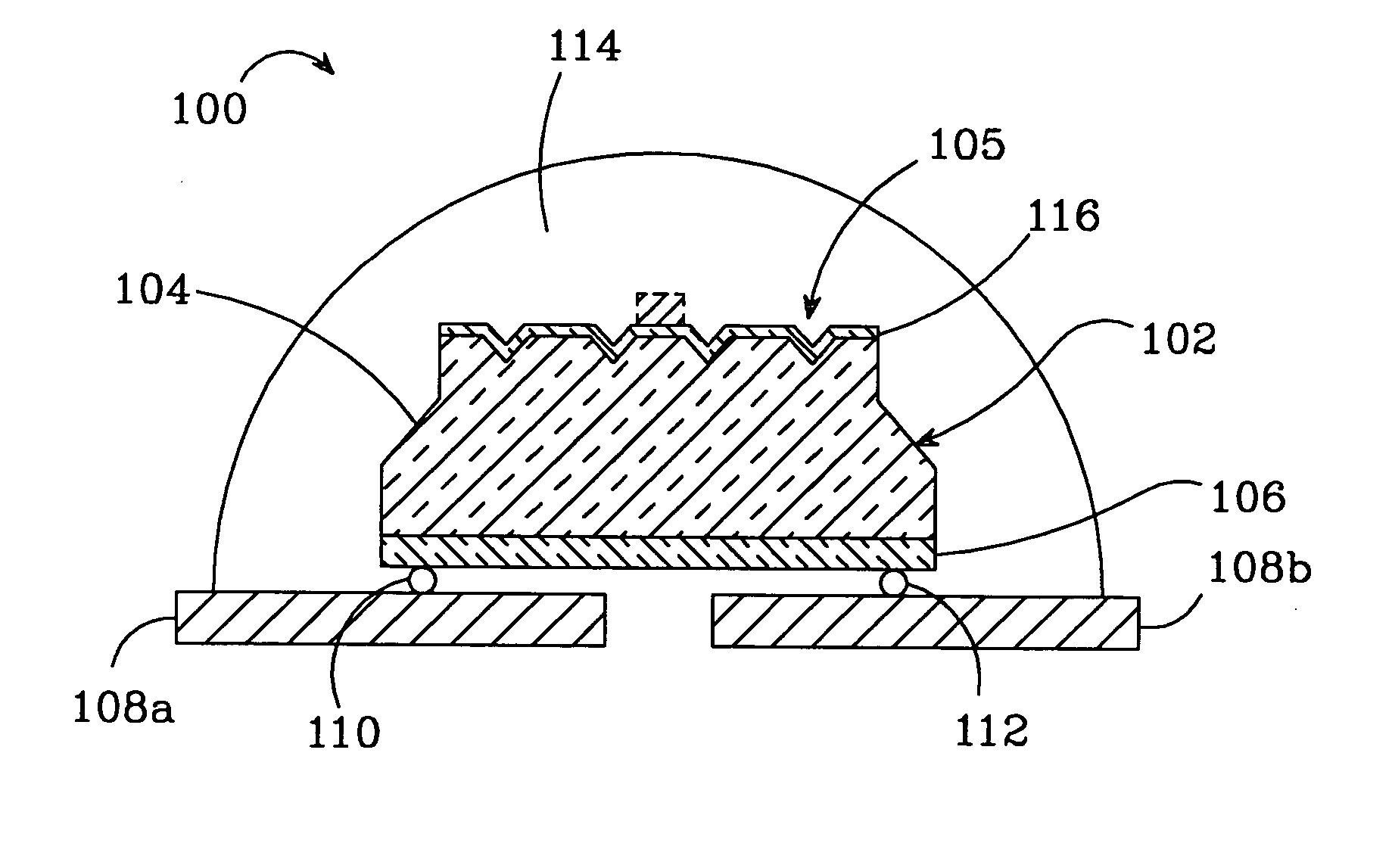

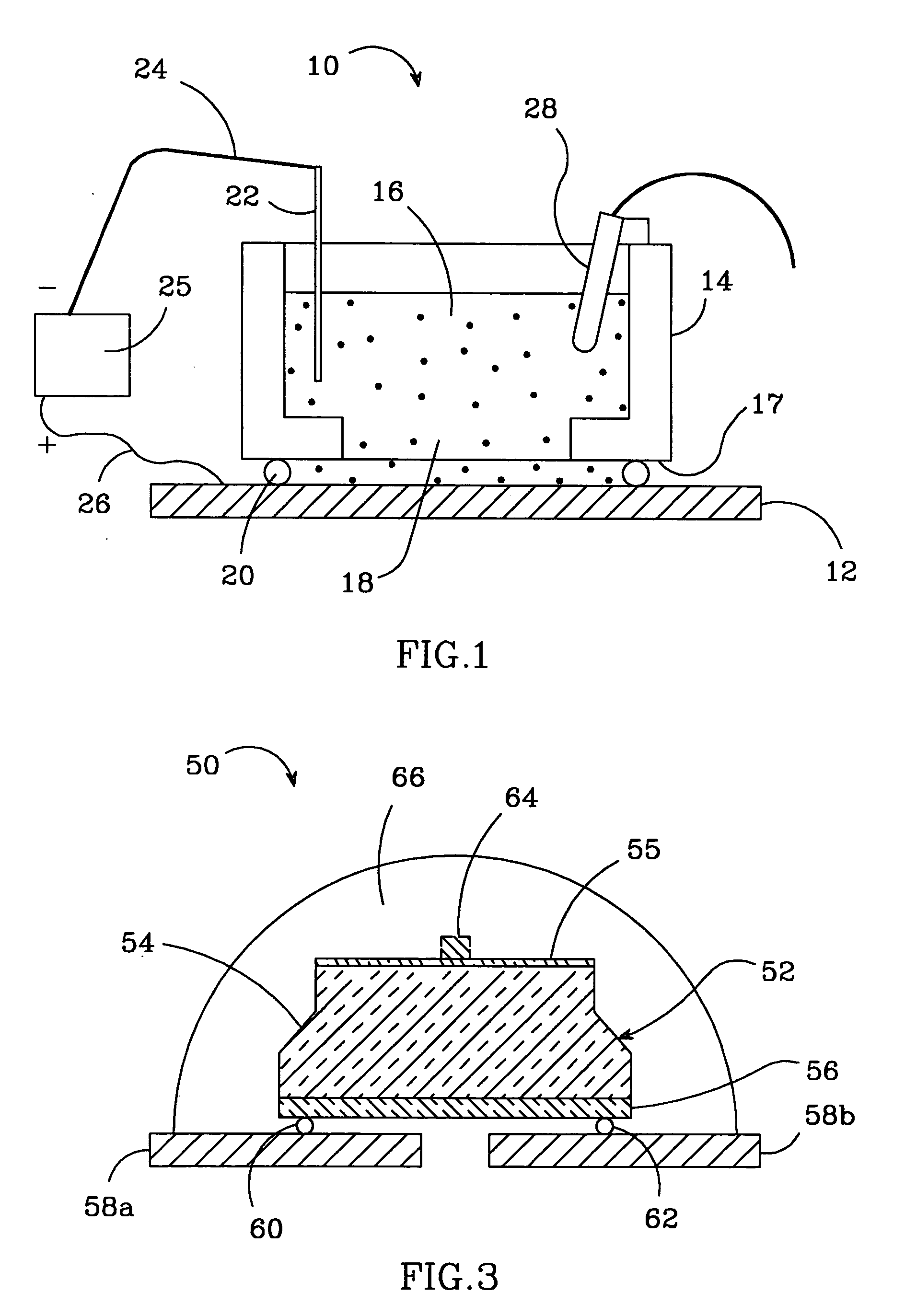

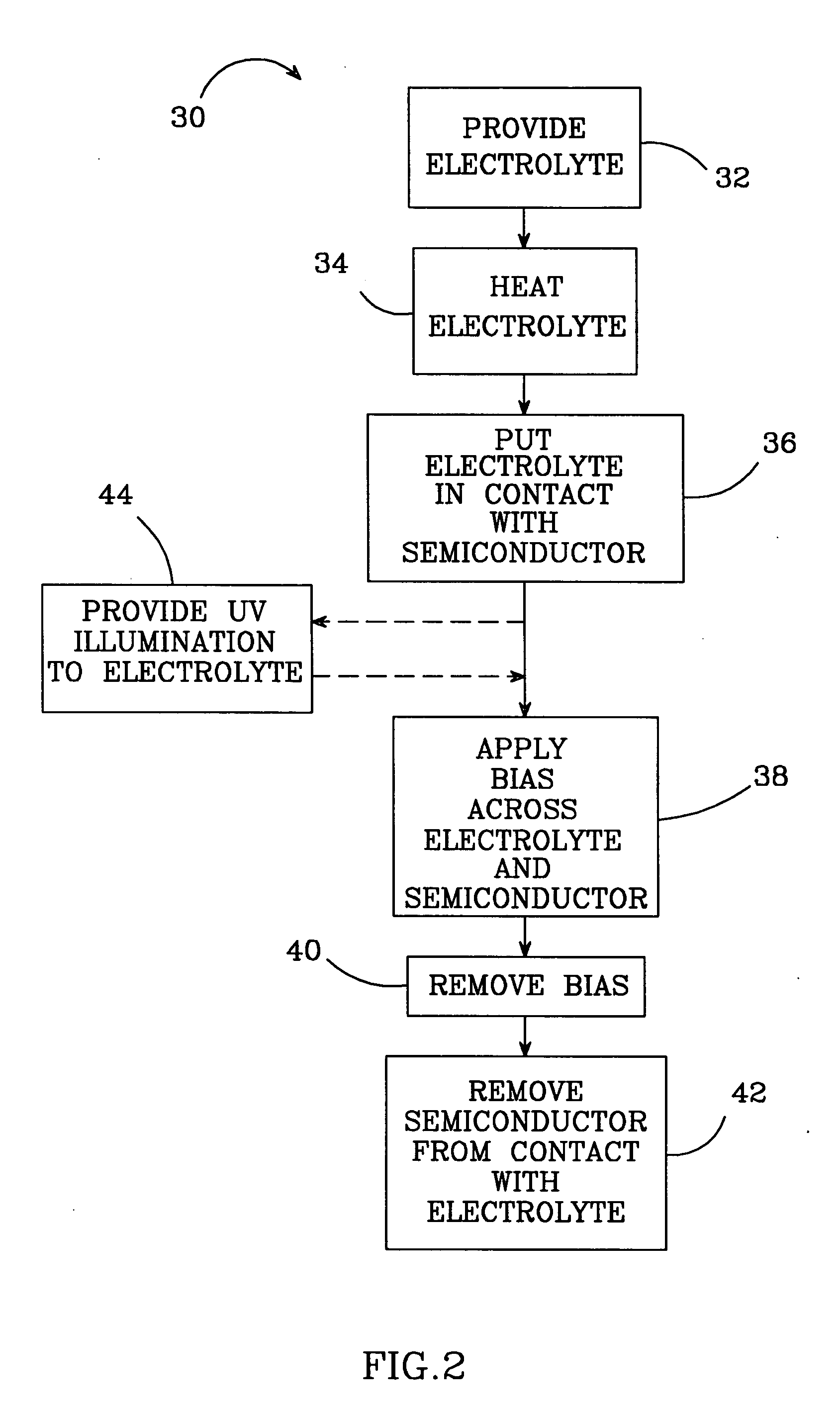

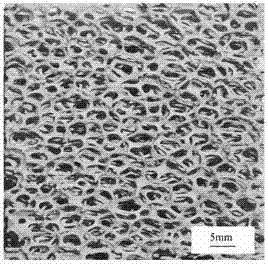

Light emitting diode with porous SiC substrate and method for fabricating

InactiveUS6972438B2Speed up the extraction processImprove light extractionSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsPorous layer

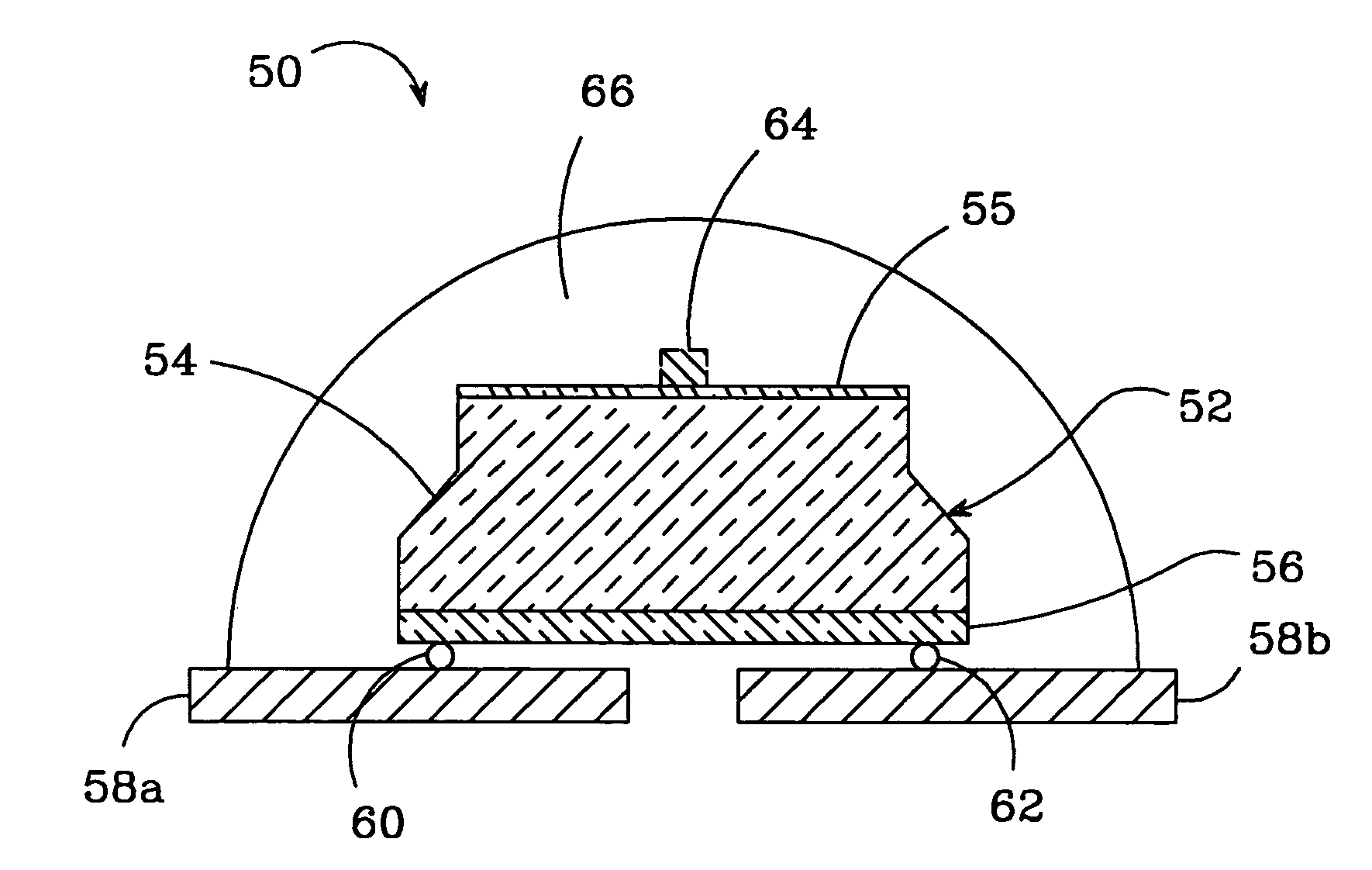

A method and apparatus for forming a porous layer on the surface of a semiconductor material wherein an electrolyte is provided and is placed in contact with one or more surfaces of a layer of semiconductor material. The electrolyte is heated and a bias is introduced across said electrolyte and the semiconductor material causing a current to flow between the electrolyte and the semiconductor material. The current forms a porous layer on the one or more surfaces of the semiconductor material in contact with the electrolyte. The semiconductor material with its porous layer can serve as a substrate for a light emitter. A semiconductor emission region can be formed on the substrate. The emission region is capable of emitting light omnidirectionally in response to a bias, with the porous layer enhancing extraction of the emitting region light passing through the substrate.

Owner:CREELED INC

Method for manufacturing SiC ceramic-based turbine blade based on photocurable 3D printing

The invention discloses a method for manufacturing a SiC ceramic-based turbine blade based on photocurable 3D printing. The method comprises the following steps of firstly manufacturing a turbine blade resin mold based on the photocurable 3D printing technology, casting the blade resin mold by using a non-water-based gel-casting ceramic slurry, curing and carrying out pyrolysis carbonization process to obtain a porous carbon preform; by an in-situ reaction sintering technology, at 1420-1700 DEG C, carrying out siliconizing and silicon discharge processes on the carbon perform to obtain the porous SiC ceramic-based composites material turbine blade; and finally obtaining the dense SiC ceramic-based composites material turbine blade by a chemical vapor deposition / infiltration method. The method has the characteristics of near-net molding, free molding and complex molding and the purpose that ceramic parts are densified can be achieved at a lower temperature.

Owner:XI AN JIAOTONG UNIV

Integral porous carbon-silicon carbide composite material, and preparation method and application thereof

The invention discloses an integral porous carbon-silicon carbide composite material, and a preparation method and an application thereof. The preparation method comprises the following steps: fully stirring and dispersing silicon carbide powder, silicon powder, carbon-containing powder and a sintering aid in water, preparing a green body by using an ice crystal pore formation technology or an organic polymer foam template pore formation technology, and carrying out high temperature sintering to prepare an integral silicon carbide core; and generating a stable carbon-containing shell with high mechanical strength in the pore channels of the porous SiC core through an in-situ generation technology or a carbon-containing precursor polymerization carborization technology. The composite material has the characteristics of high specific surface area, easy activation surface, acid and alkali corrosion resistance, good heat and electricity conduction property, high and stable mechanical strength, low gas passing pressure drop and low preparation cost, can be used as a metal catalyst loading carrier, or can be directly used as a nonmetal catalyst, so the defects of easiness in pulverization, easiness in obstruction, difficulty in molding and high price of present industrial active carbon catalysis carriers are avoided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

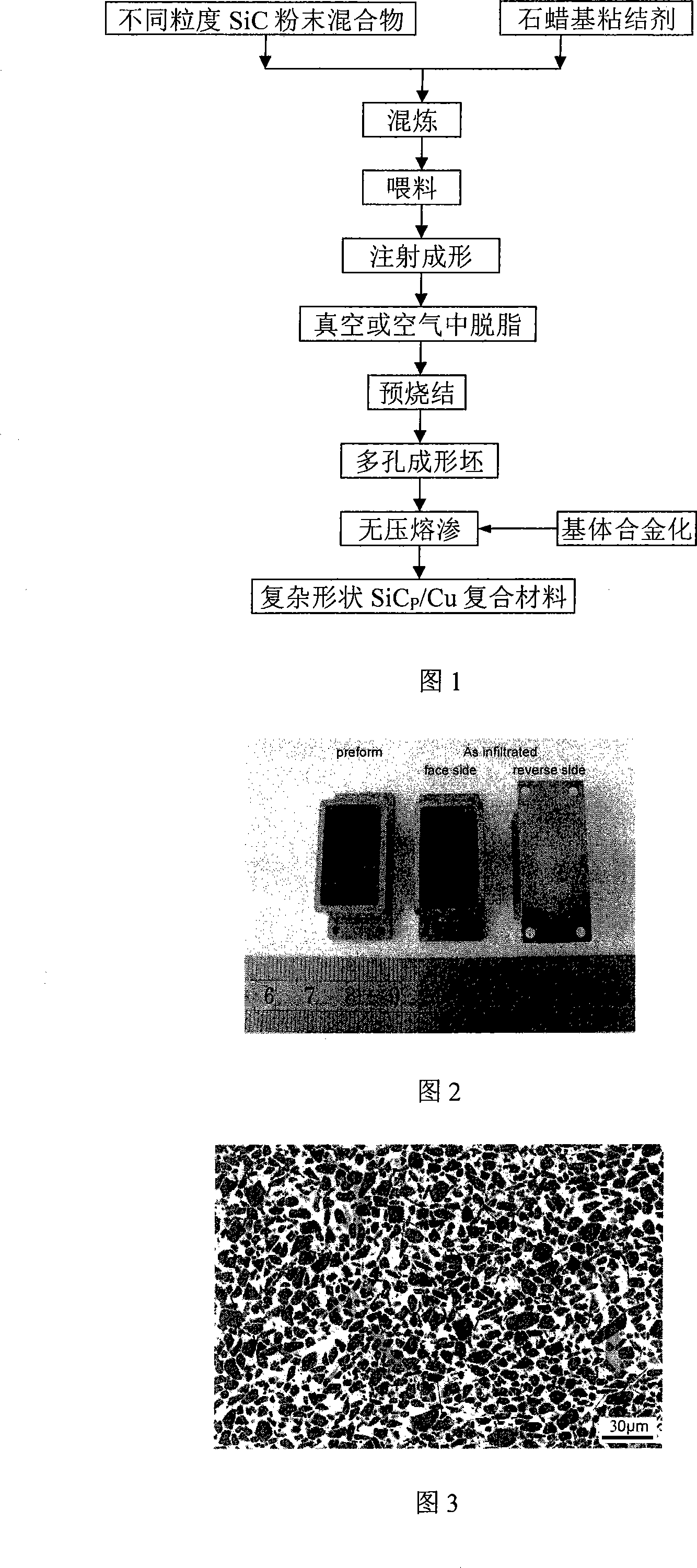

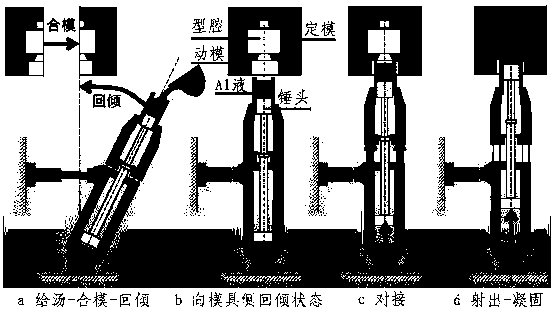

Method for preparing high volume-fraction carborundum granule-reinforced copper-based composite material

ActiveCN101157993AHigh densityThermophysical property adjustmentVolumetric Mass DensityParticle-size distribution

The invention relates to a method to prepare high volume fraction silicon carbide particle to enhance copper matrix composite, belonging to the field of metal matrix composites. The technique is that: proper blended particle size distributed SiC powder is mixed with polymer component paraffin base binder in a volume proportion of 57-68% load in sudarpress, fine blended feedstock is obtained; injection mold in powder injection molding machine in the injection temperature of 150-175 DEG C and the injection pressure of 75-125MPa to obtain a required billet, the billet is degreased in a solution-doff + thermal-doff process, and is first sintered in 600-1120 DEG C to obtain pre-molded billet of porous SiC. Infiltrate copper alloy to the porous SiC pre-molded billet in the temperature of 1400-1450 DEG C in vacuum via non-pressure infiltration. So the high volume fraction SiCp / Cu composite is obtained. The invention can prepare intricate shaped thin wall SiCp / Cu composite parts, enhance the content of phase as high as 57-67% volume fraction, the density of the composite is high, the microstructure is evenly distributed, and the invention has the advantages of high utilization rate of material, high productivity, and low production cost.

Owner:UNIV OF SCI & TECH BEIJING

Light emitting diode with porous sic substrate and method for fabricating

ActiveUS20050184307A1Speed up the extraction processImprove light extractionSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsPorous layer

A method and apparatus for forming a porous layer on the surface of a semiconductor material wherein an electrolyte is provided and is placed in contact with one or more surfaces of a layer of semiconductor material. The electrolyte is heated and a bias is introduced across said electrolyte and the semiconductor material causing a current to flow between the electrolyte and the semiconductor material. The current forms a porous layer on the one or more surfaces of the semiconductor material in contact with the electrolyte. The semiconductor material with its porous layer can serve as a substrate for a light emitter. A semiconductor emission region can be formed on the substrate. The emission region is capable of emitting light omnidirectionally in response to a bias, with the porous layer enhancing extraction of the emitting region light passing through the substrate.

Owner:CREELED INC

Composite catalyst for preparing sec-butyl acetate with direct esterification of ethyl ester and butylene

InactiveCN101293210ASolve the problem of reduced catalytic efficiencyCatalyst carriersOrganic compound preparationHeteropoly acidCordierite

The present invention relates to a composite catalyst for preparing sec-butyl acetate by direct esterification of ethyl ester and butylene, which takes heteropoly acid as the catalyst active component and porous carrier as the dispersant; the weight proportion of the heteropoly acid and the porous carrier is 0.01:1 to 10:1. The heteropoly acid is one with Keggin structure, which consists of phosphotungstic acid, silicotungstic acid, germanium tungstic acid, arsenowolframic acid, phosphomolybdate, germanomolybdate or arsenicomolybdate. The porous carrier comprises porous SiO2, Al2O3, SBA-15, MCM-41, white carbon black, porous SiC, corallite, andalusite, cordierite, meerschaum, Attapulgite or kaolin. The composite catalyst of the present invention solves the problem that the catalysis efficiency is low if the heteropoly acid is separated out from the reaction system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

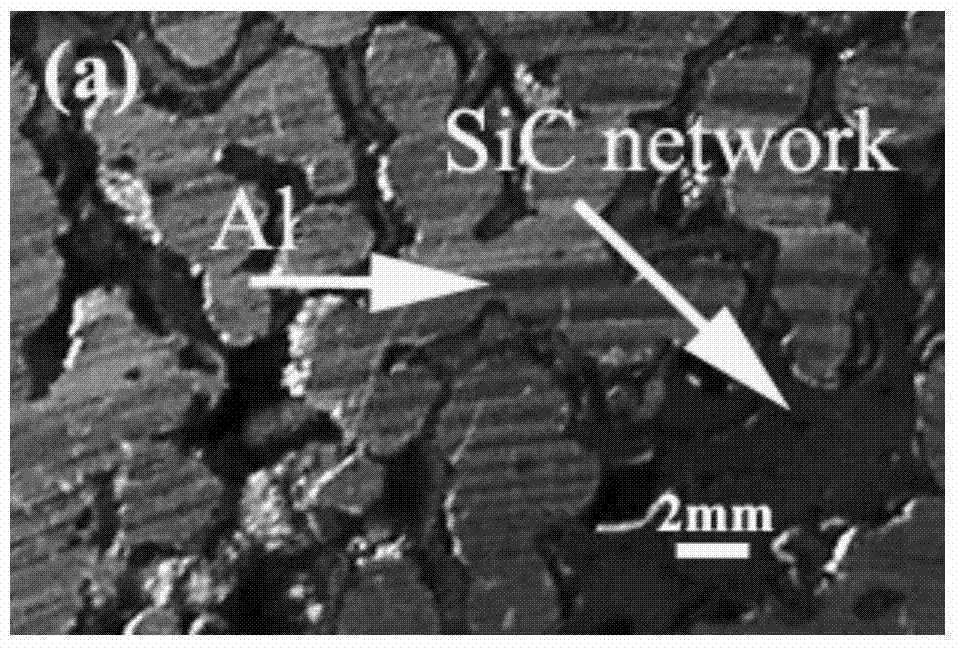

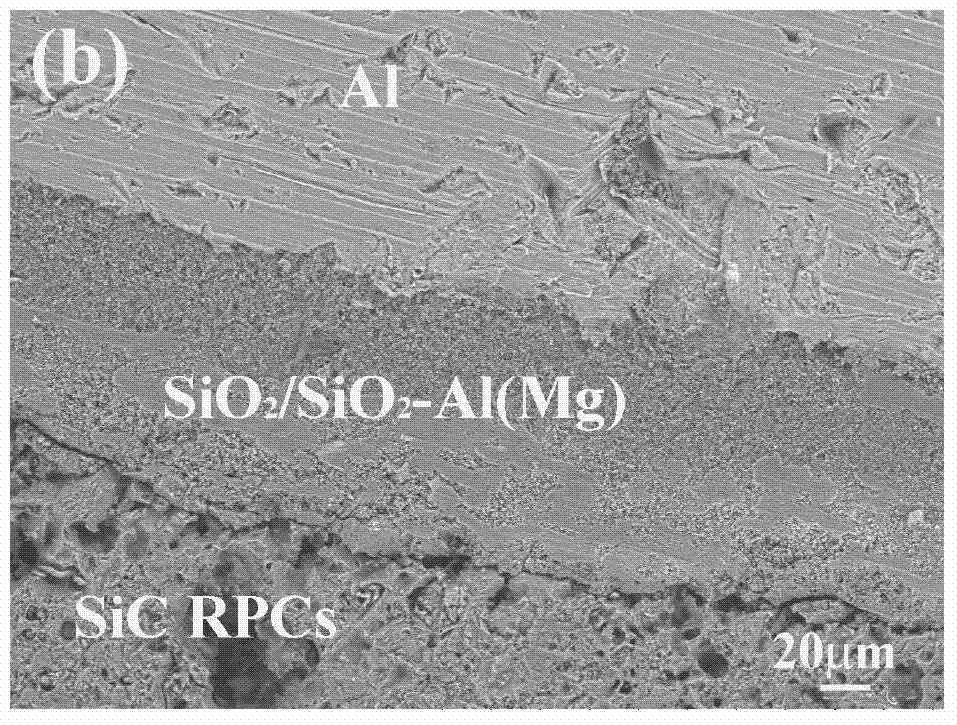

Preparation method of silicon carbide reinforced aluminum base composite material

The invention discloses a preparation method of a SiC / Al composite material. The method comprises the following steps: carrying out ball milling on alumina and / or silicon oxide powder and a dispersant by using a ball milling medium, adding a binder, and continuously carrying out ball milling to obtain a coating slurry, wherein a mass ratio of the powder to the dispersant to water to the ball milling medium to the binder is 1:0.005-0.01:0.1-0.4:2:0.01-0.03; immersing reticulated porous SiC ceramic in the coating slurry for full absorption, centrifuging, and drying; and embedding secondary-coated reticulated porous SiC ceramic into aluminum or aluminum alloy powder, carrying out vacuum pumping heating to fuse the aluminum or aluminum alloy, introducing argon, and carrying out heat insulation and pressure maintenance to obtain the SiC / Al composite material. The SiC / Al composite material obtained through the method is a bicontinuous phase, and the control of an interface structure and an interface reaction is realized through controlling the composition and performances of the coating slurry to realize strong combination between a silicon carbide matrix and the metal Al and uniform continuous distribution in a three dimensional space, so the segregation and the discontinuousness of the silicon carbide reinforcement are avoided, and the performances of the composite material are improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

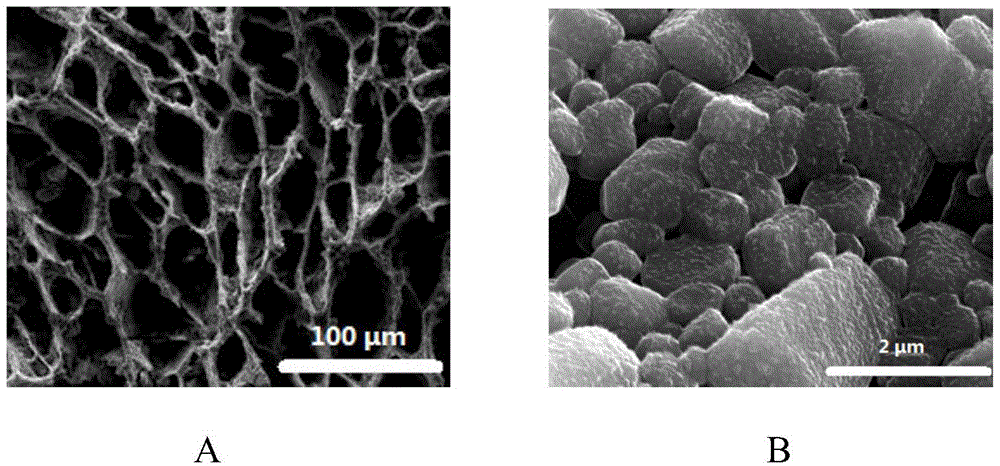

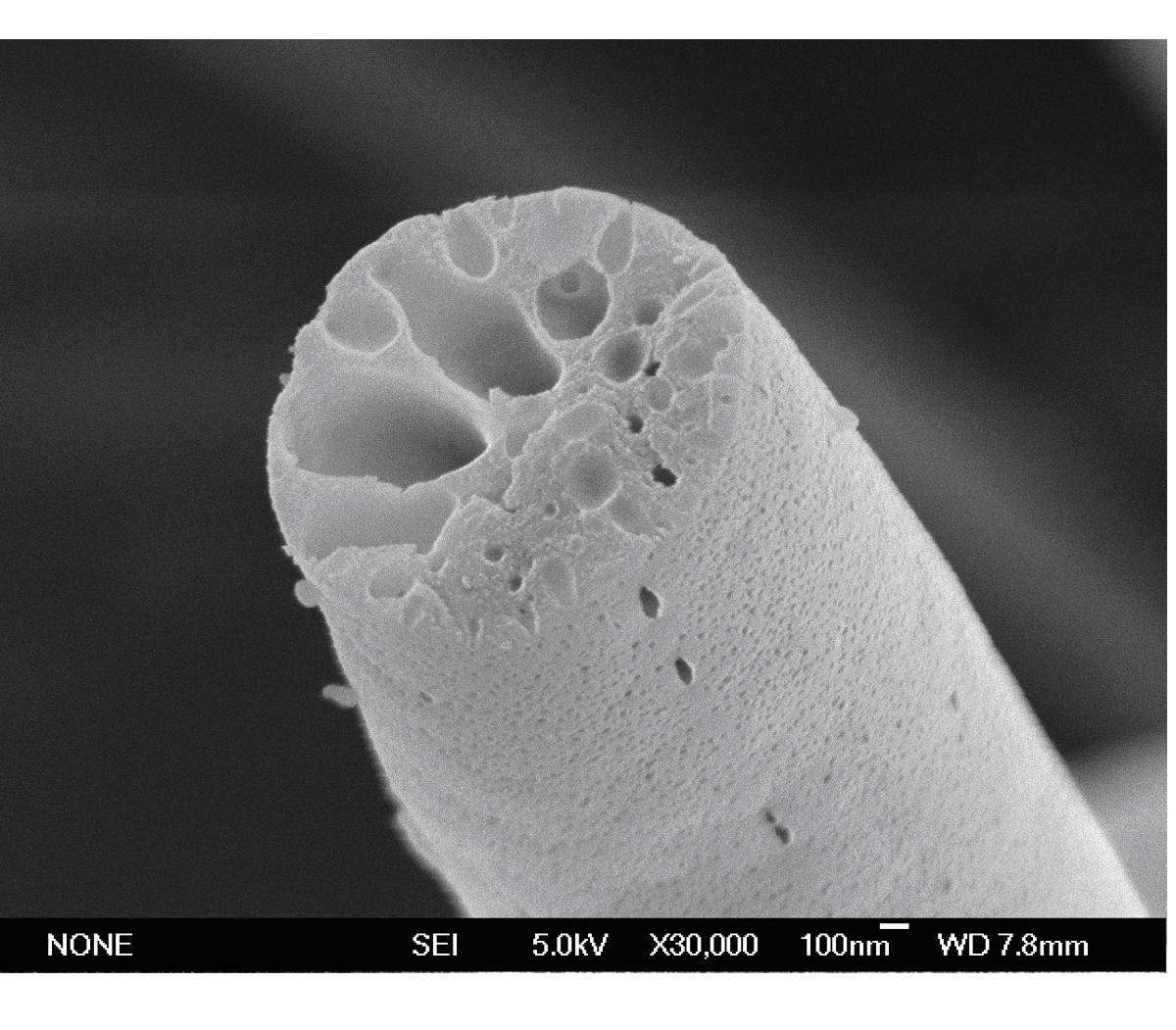

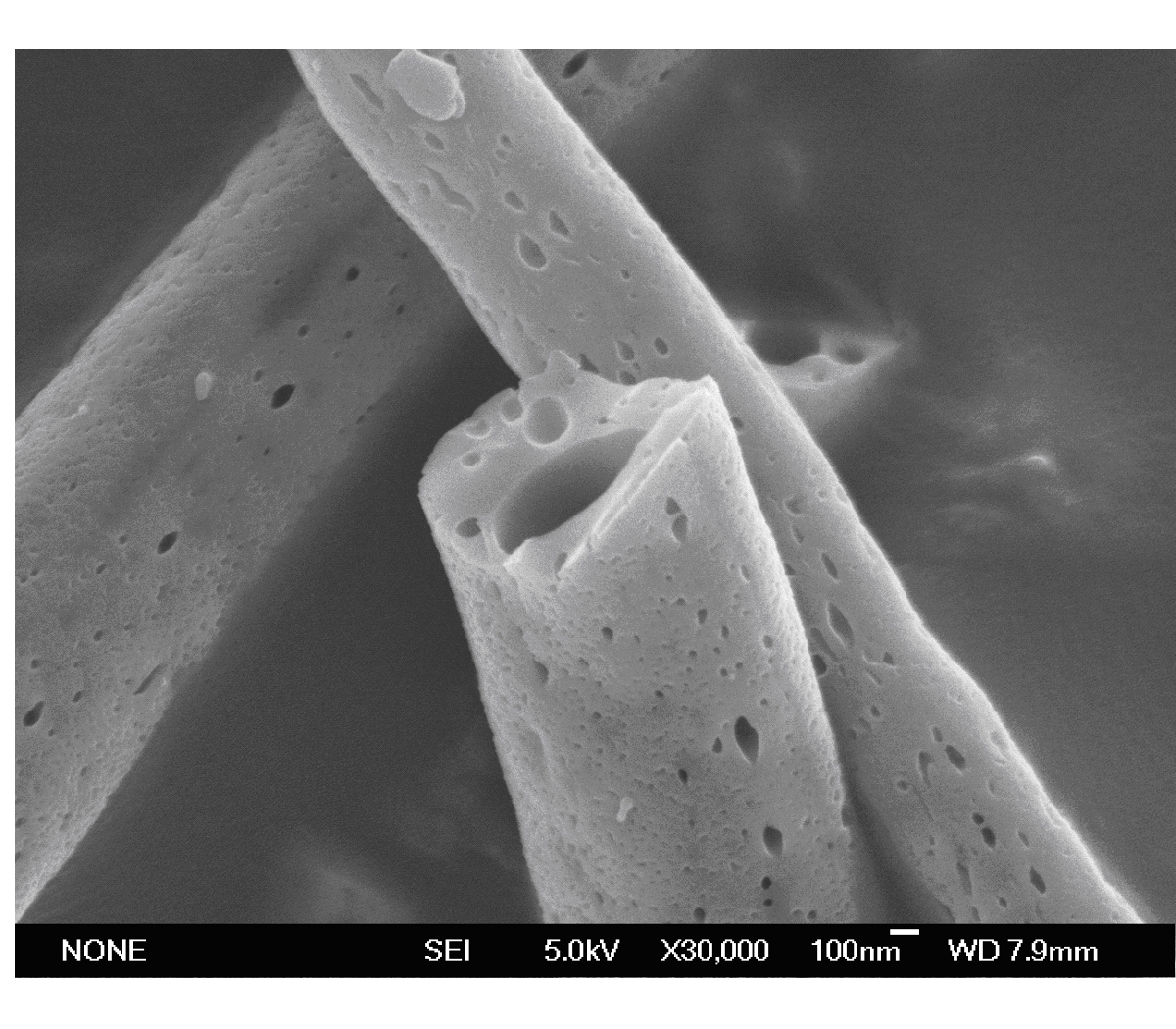

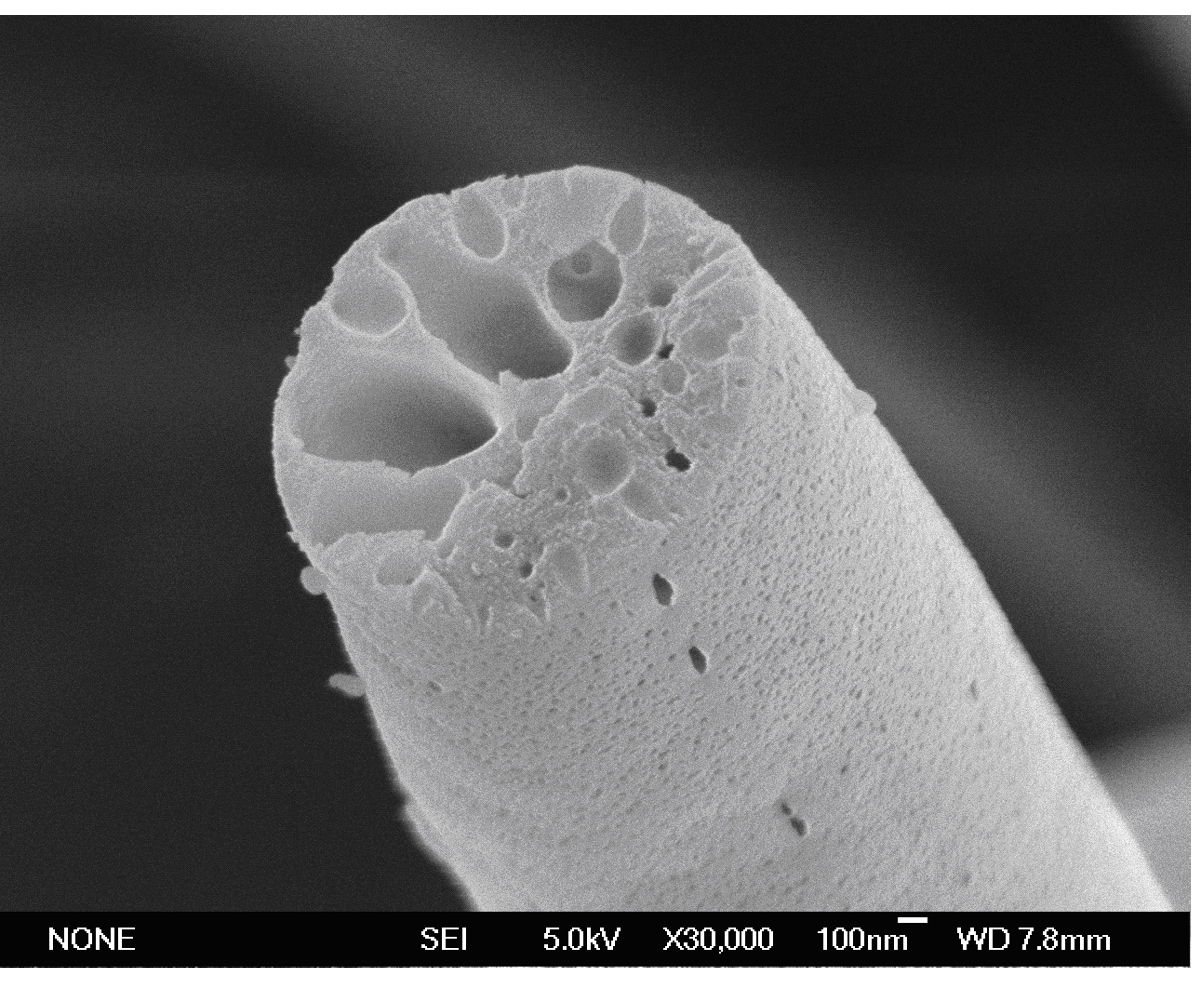

Porous silicon carbide fibers and preparation method thereof

InactiveCN101876095ALarge specific surface areaRealize electrospinningSpinning head liquid feederFilament/thread formingElectrospinningFractionation

The invention discloses porous SiC fibers and a preparation method thereof. The porous SiC fibers are characterized in that the content of Si accounts for 50-60wt%, the content of C accounts for 30-40wt%, and the balance is O, the fibers are felty, the diameter of the fibers is 0.5-2.0 mu m, the porosity is greater than 60vol%, wherein the mesopore volume is greater than 50vol%, and the specific surface area is 400-800 m<2> / g. The preparation method is characterized in that poly carbon silicon alky suspension solution which can spin electrically is prepared by utilizing a precipitation fractionation principle, electrostatic spinning of the extremely dilute carbon silicon alky solution is realized, a large number of mesopore structures are introduced, thus firstly preparing poly carbon silicon alky porous fibers, and then after non-melting and sintering, the porous SiC fibers are prepared. The porous SiC fibers have good application prospects in fields such as high-temperature catalysis, heat insulation, heat preservation, sound insulation and the like. The method has universality and can be used for realizing electrostatic spinning of extremely dilute solution of other precursor polymers and for preparing corresponding porous ceramic fibers.

Owner:NAT UNIV OF DEFENSE TECH

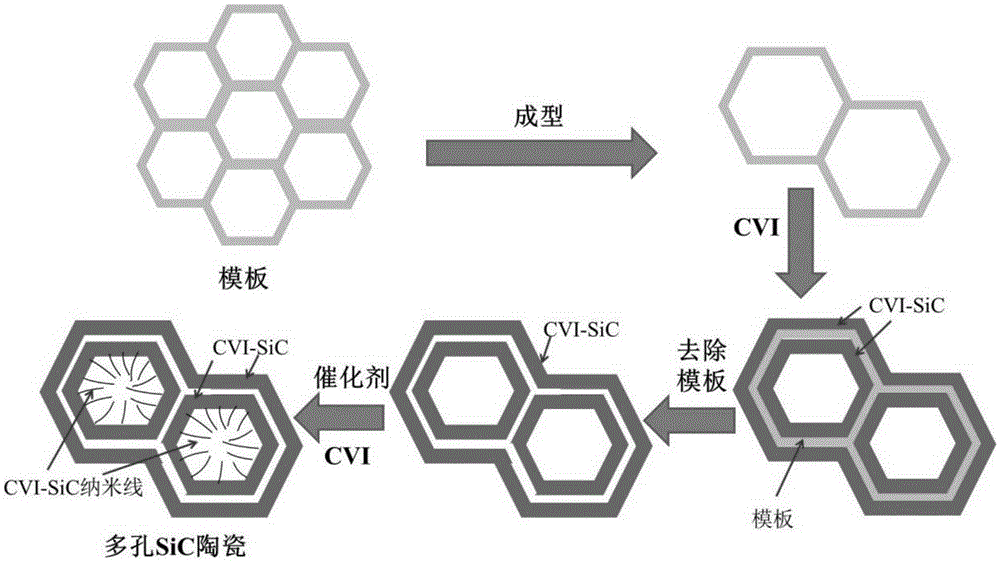

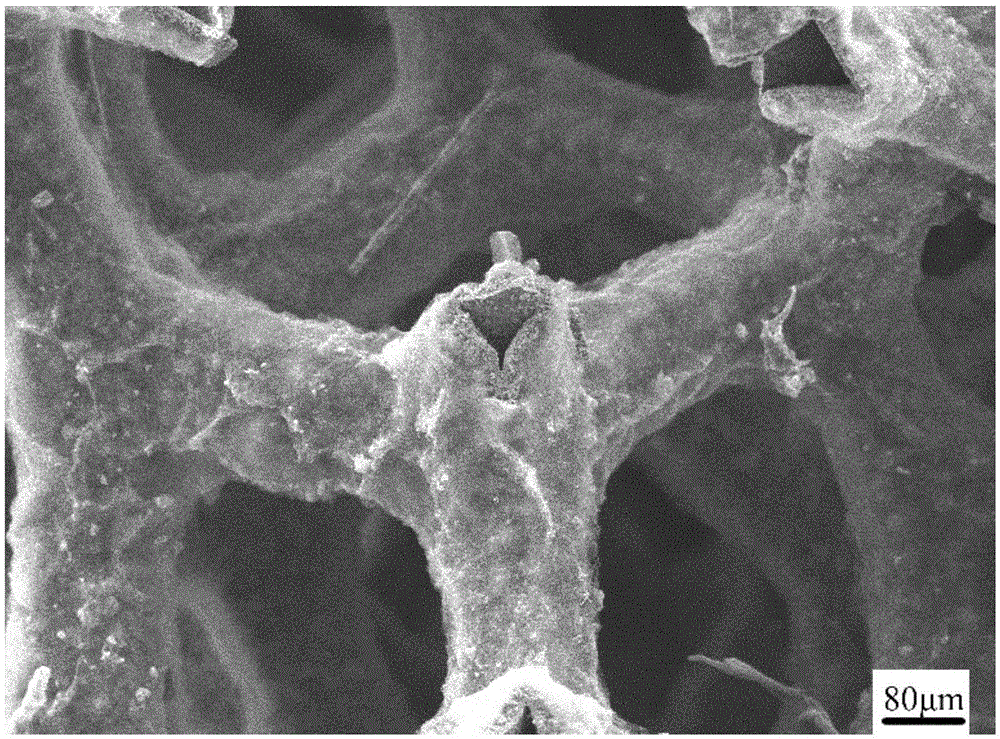

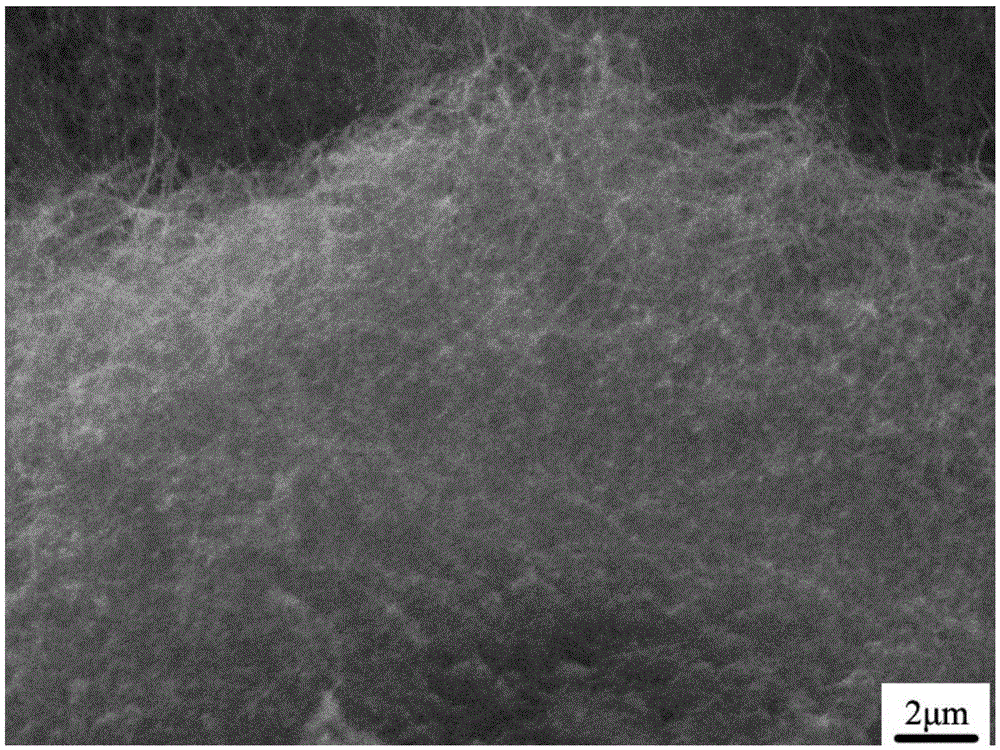

Method for preparing porous silicon carbide ceramic based on template

InactiveCN105237034AUniform pore sizePorosity is easy to controlCeramicwarePorous silicon carbideMaterials science

The present invention relates to a method for preparing a porous silicon carbide ceramic based on a template. According to the present invention, the template method thinking and the characteristics of the CVI process are creatively combined, the CVI method is used to prepare the porous SiC ceramic, and the porous SiC ceramic obtained through the method has characteristics of uniform pore size, controlled porosity and large specific surface area; with the method, the technical problems of complex preparation process, high sintering temperature and the like of other template methods can be solved; and the complex member is easily prepared through the process, and the use range of the porous SiC ceramic prepared through the method is substantially expanded.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of preparation method of porous silicon carbide ceramic material

InactiveCN102260092AMeet application requirements in different fieldsEasy to prepareCeramicwareWater basedSlurry

The invention discloses a method for preparing a porous silicon carbide ceramic material, which comprises: a) adding SiC powder, a sintering aid and a dispersant to water to prepare a ceramic water-based slurry with a solid content of 10-60 wt %; b) pour the slurry into a mold, and freeze at -200-0°C to form a green body; c) dry the frozen green body at -60-80°C and 5-600Pa for 4-48 hours to obtain a porous element d) subjecting the obtained porous green body to high-temperature solid phase sintering. The present invention uses the combination of freeze-drying and high-temperature solid-phase sintering technology to prepare a porous silicon carbide ceramic material that can be used in a high-temperature environment higher than 1500 ° C, and by adjusting the solid content of the slurry, the slurry The content of the added organic polymer and the solid-state sintering temperature can obtain porous SiC ceramic materials with different porosity and strength, which can meet the application requirements of SiC ceramics in different fields.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

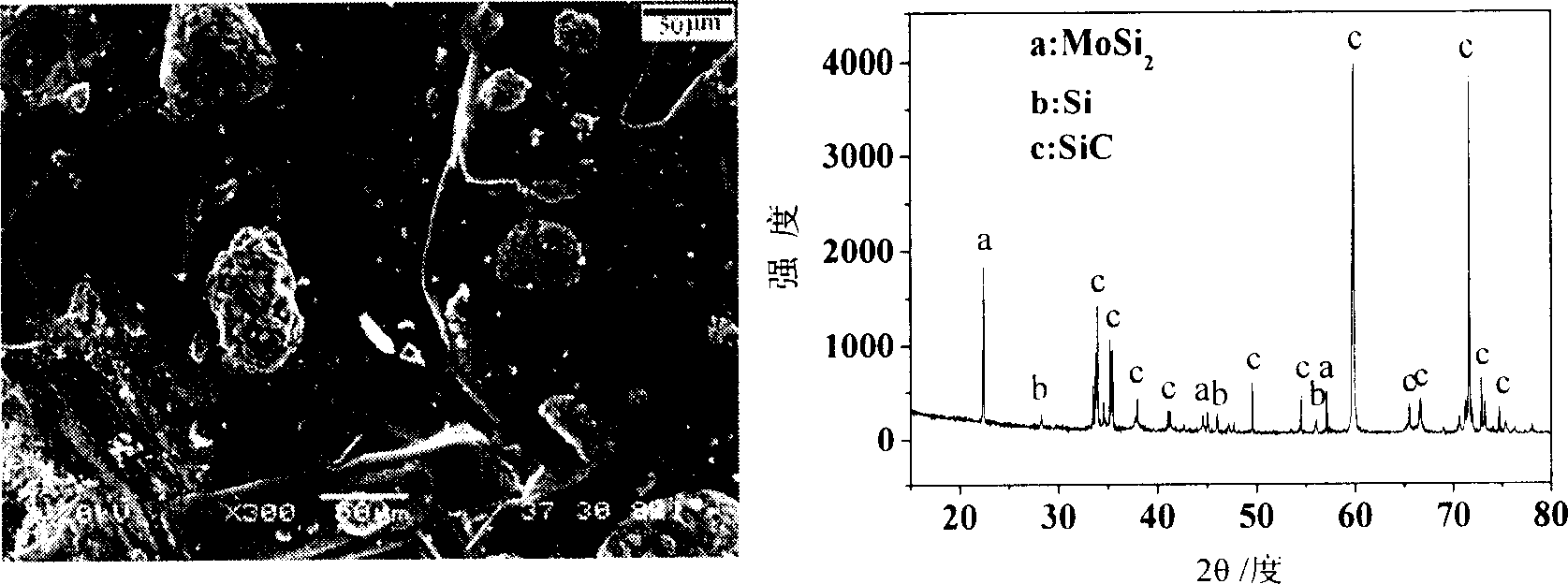

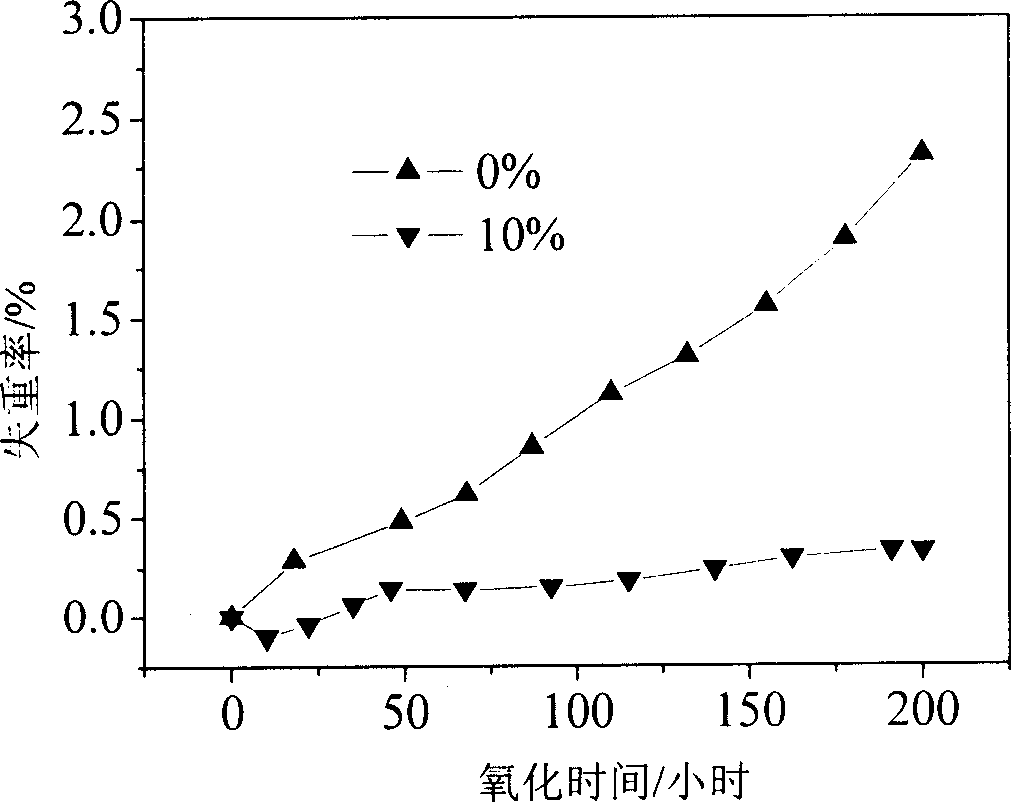

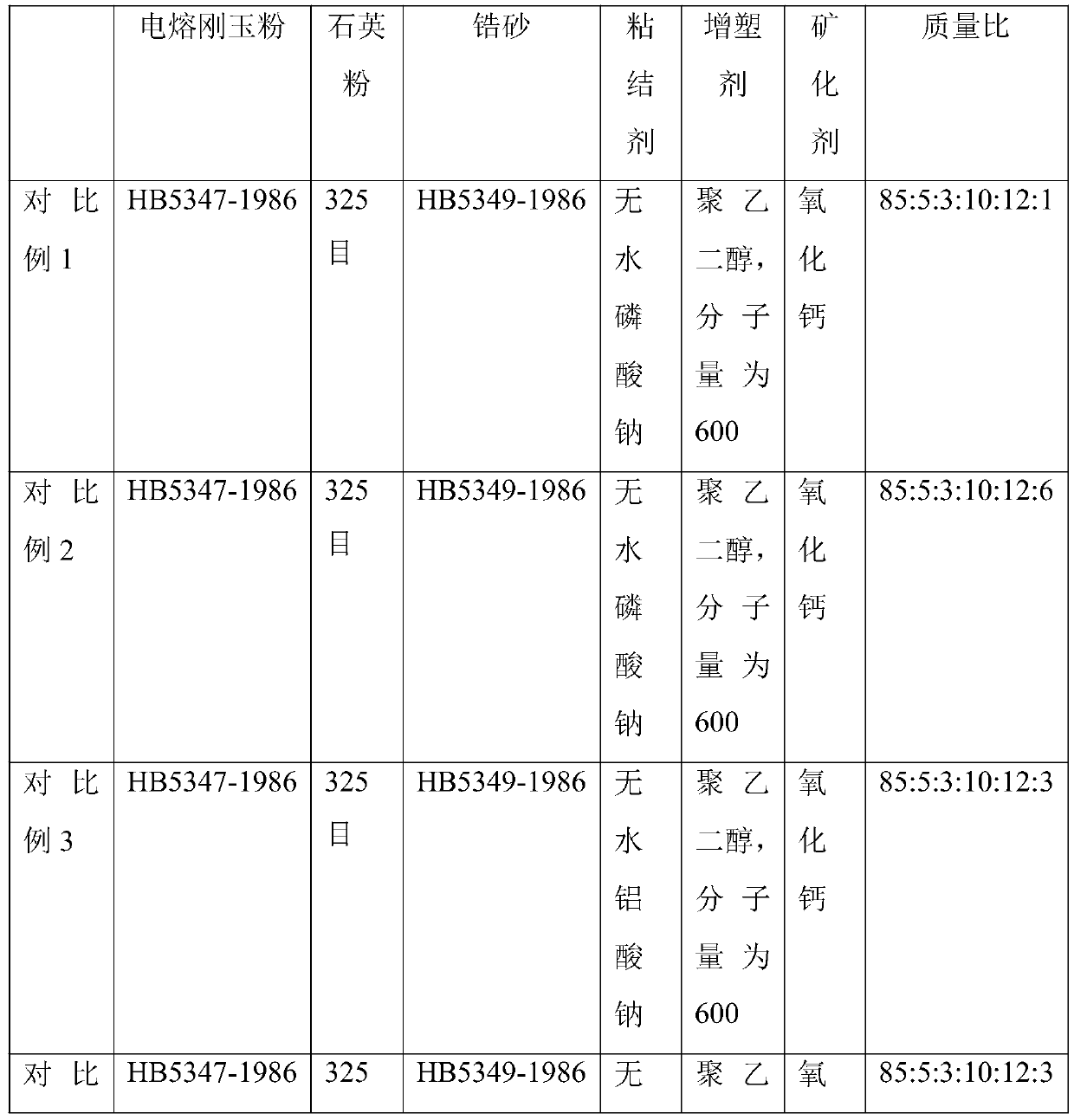

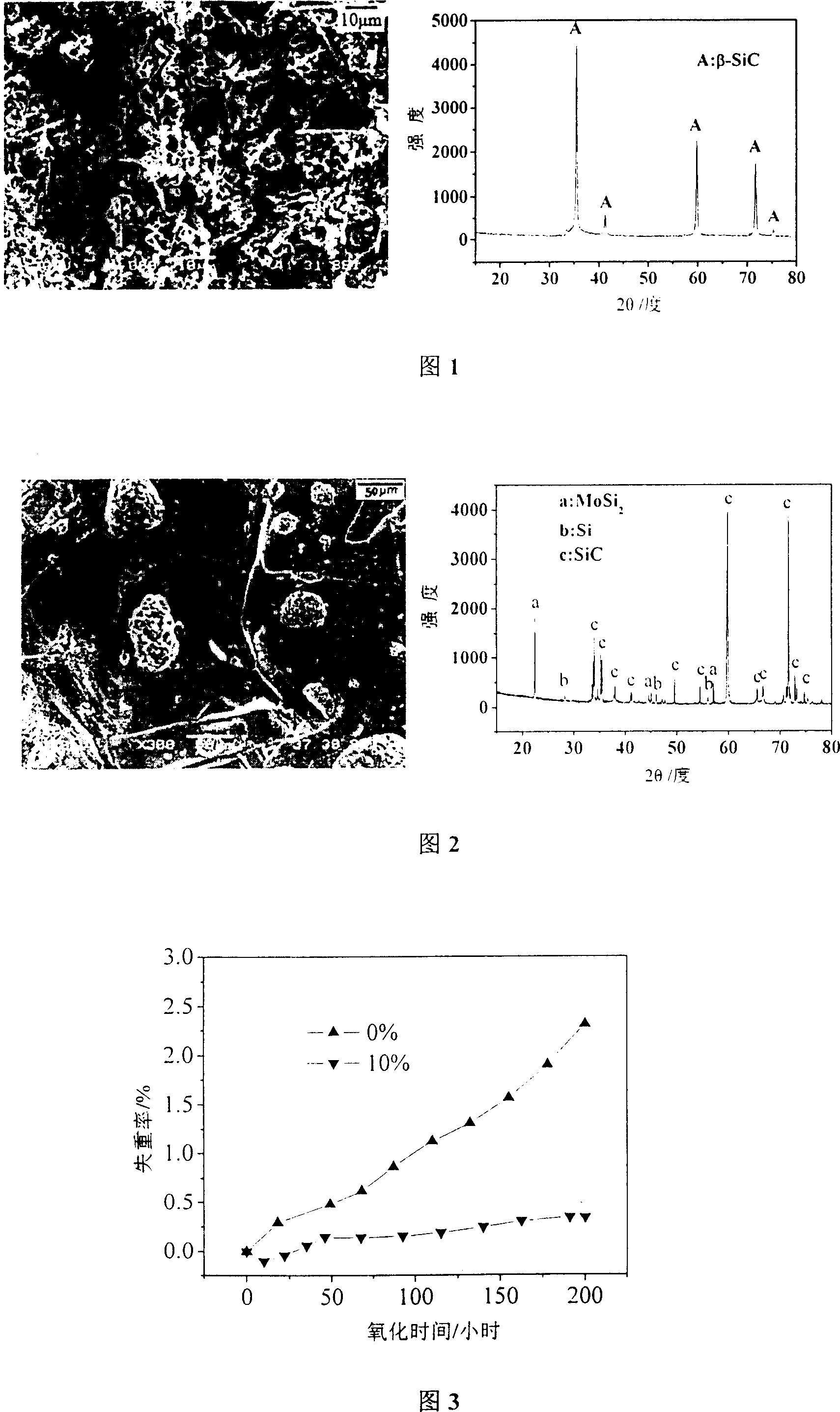

Method for preparing anti-oxidation multiple phase coating of carbon/carbon composite material surface

InactiveCN1821183AHigh temperature anti-oxidation temperature increaseImprove thermal shock resistanceCarbon compositesAlcohol

The present invention discloses the preparation process of antioxidant multiple phase coating on the surface of carbon / carbon composite material. On the surface of carbon / carbon composite material, one porous SiC whisker toughened SiC coating is first prepared with Si powder, C powder, Al2O3 powder and beta-SiC whiskcer as material and alcohol as dispersant, and through a slurry process. The carbon / carbon composite material with SiC whisker toughened SiC coating is coated in mixed powder of high purity Si powder, C powder and MoSi2 powder in certain weight proportion, and sintered in protecting atmosphere; and through serial diffusion reactions, the required coating is obtained. The present invention has the advantages of certain amount of free Si in the coating to result in high compactness, effective inhibition of crack expansion in the multiple phase MoSi2-SiC-Si coating, and raised antioxidant, heat shock resisting and eroslion resisting property.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process for the manufacturing of dense silicon carbide

InactiveUS7799375B2Reduce porosityImprove propertiesChemical vapor deposition coatingCeramicwarePorous carbonNet shape

A method of producing a densified SiC article is provided. Near-net shape porous silicon carbide articles are produced and densified using the developed method. A substantial number of pores within the porous near-net shape silicon carbide article are filled (impregnated) with a carbon precursor, a silicon carbide precursor, or a mixture of both. The carbon precursor can be liquid or gas. The filled SiC preform is heated to convert the carbon or silicon carbide precursor to porous carbon or SiC preform inside the pores of the net-shape silicon carbide article. The impregnation / pyrolysis cycle is repeated until the desired amount of carbon and / or silicon carbide is achieved. In case of a carbon or a mixture of silicon carbide / carbon precursor is used, the pyrolyzed near-net shape silicon carbide article is then contacted with silicon in an inert atmosphere. The silicon diffuses through the pyrolyzed near-net shape silicon carbide article and reacts with the carbon contained within the pores of the porous SiC preform producing a new phase of silicon carbide within the pores of the near-net shape silicon carbide article. The produced silicon carbide is a near-net dense silicon carbide article.

Owner:POCO GRAPHITE

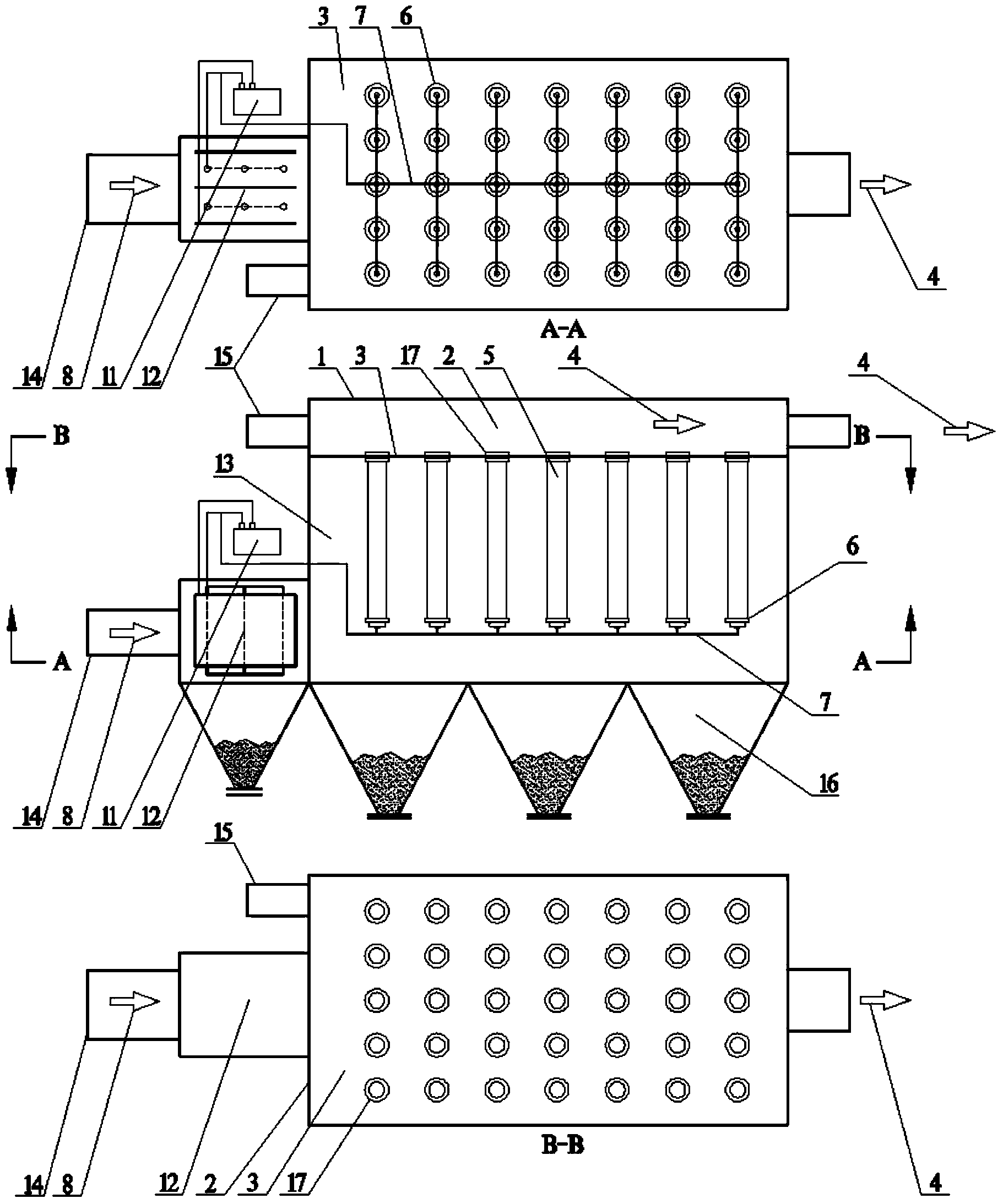

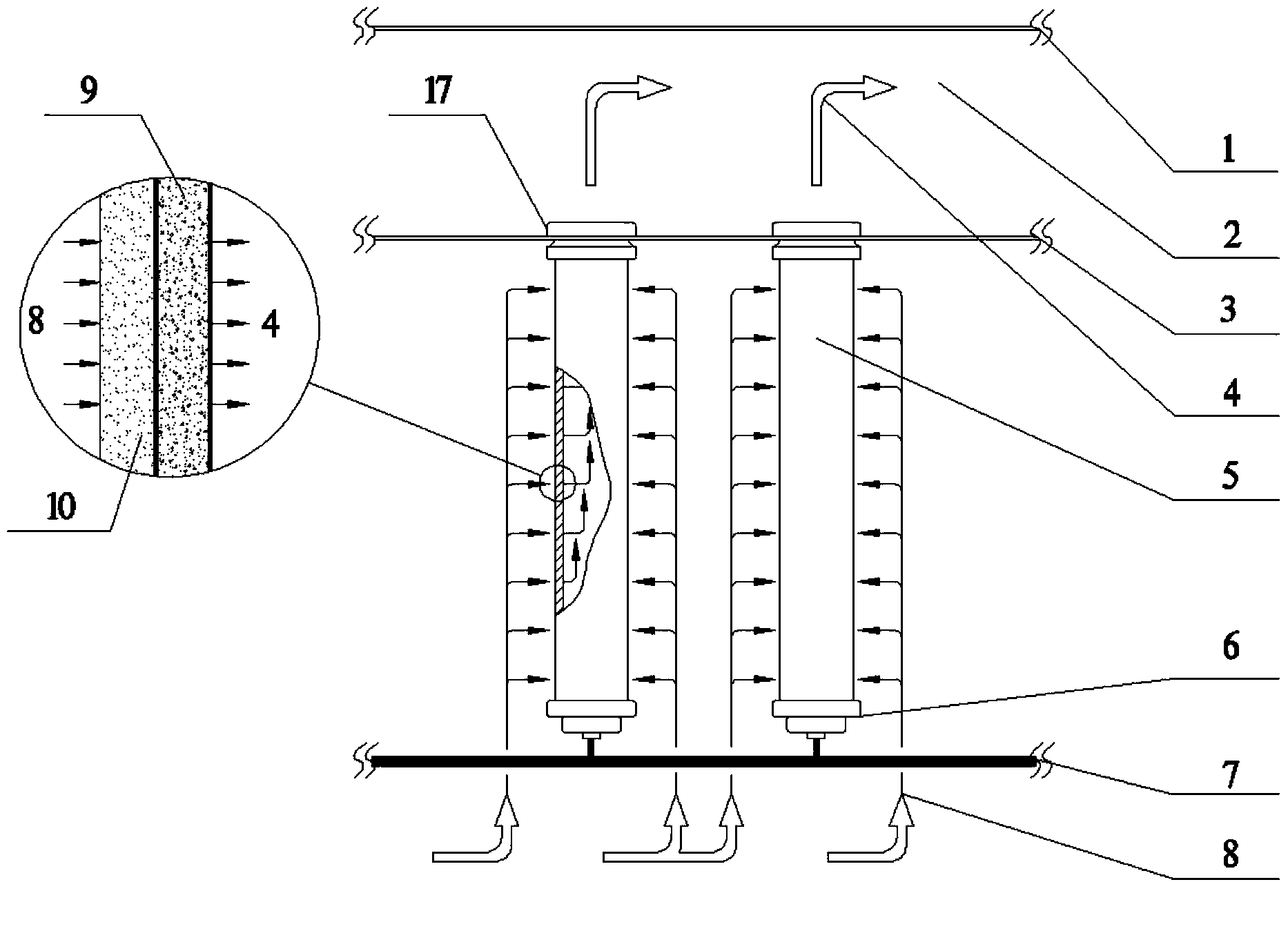

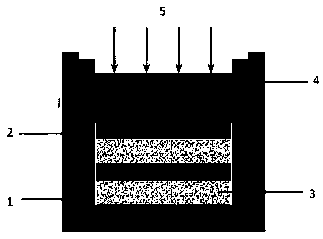

Static electricity and inorganic porous ceramics combined dusty gas purification device

The invention relates to a static electricity and inorganic porous ceramics combined dusty gas purification device and belongs to the technical fields of dust removal, waste gas treatment and environmental protection. The device adopts a high-voltage electrostatic charge module to charge dust in airflow and enable a self corona electrode to be connected with a downstream porous SiC ceramic filtering pipe through an electrode guide frame, so that the surface of the porous SiC ceramic filtering pipe is charged with the electric charge the same with the corona electrode; gas passes through tiny pore passages in the wall surface of the porous SiC ceramic filtering pipe, and dust particles charged by the corona electrode are held back by the porous SiC ceramic filtering pipe so as to complete dust removal. As the porous SiC ceramic filtering pipe and the dust are electrically charged with the same electric charge, strong electrostatic repulsion between the porous SiC ceramic filtering pipe and the dust ensures that the dust particles cannot enter the tiny pore passages in the wall surface of the porous SiC ceramic filtering pipe, are accumulated on the surface of the ceramic pipe only and form loose pressed powder, and the dust can be removed easily; in addition, the pressed powder has small air resistance and is not subjected to excessive airflow voltage drop along with the lengthening of the dust removal time.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

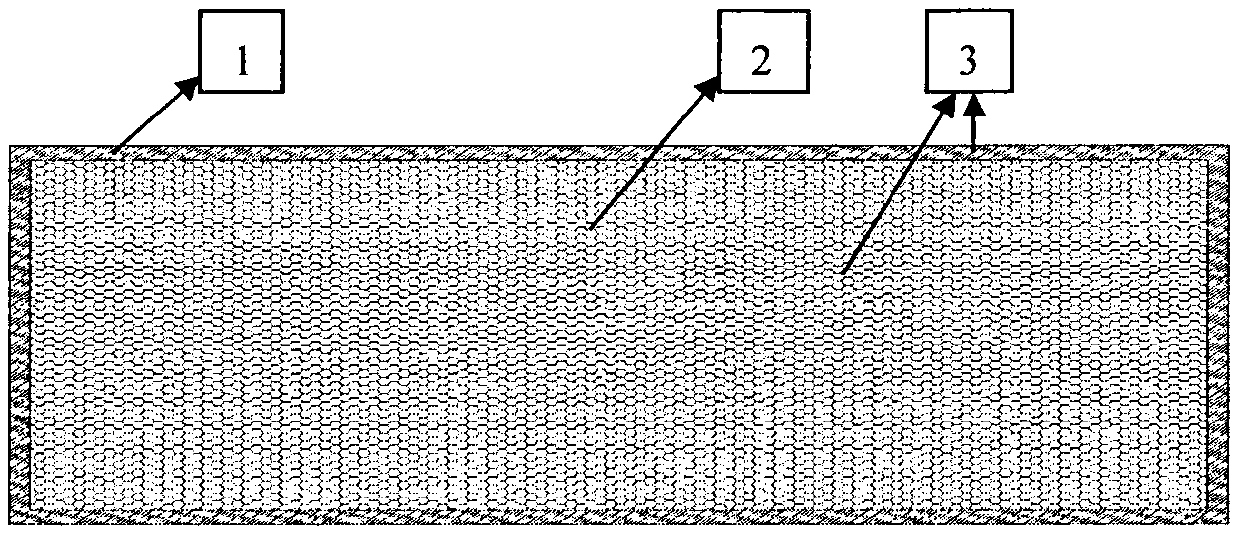

Directional porous SiC and diamond reinforced Al base composite material and preparation method thereof

The invention discloses a directional porous SiC and diamond reinforced Al base composite material and a preparation method thereof. The composite material is composed of a SiC ceramic phase, a diamond particle phase and a Al metal phase. The preparation method of the composite material comprises the following steps: 1, preparing directional porous SiC ceramic; 2, coating a WC coating layer on the surface of diamond particles; 3, filling directional porous apertures of the porous SiC ceramic with the diamond particles; and 4, allowing Al to spontaneously infiltrate into the directional apertures filled with the diamond particles. The directional porous SiC and diamond reinforced Al base composite material prepared through adopting the method has very high heat conductivity in a directional aperture direction, and can timely transmit heat generated by a semiconductor to heat sink in order to dissipate the heat; and the composite material has a heat expansion coefficient matched with a packaging substrate in a direction vertical to the directional aperture direction (the plane of a semiconductor device), so the heat stress between a packaging material and the semiconductor is reduced, the working efficiency of the semiconductor is improved, and the service life of the semiconductor is prolonged.

Owner:咸阳瞪羚谷新材料科技有限公司

High-performance SiC ceramic-based composite material aero-engine blade manufacturing method

The invention discloses a high-performance SiC ceramic-based composite material aero-engine blade manufacturing method. According to the invention, an aero-engine blade mold is prepared with a 3D printing technology; with a gel injection molding method, a SiC ceramic blank part with added carbon fiber is prepared; through processes such as freeze-drying and degreasing, a porous SiC ceramic preform is obtained; the preform is subjected to organic matter precursor impregnation cracking several times, and the pores of the preform are filled with a cracking product, such that preliminary compactness is achieved; and for ensuring the strength and compactness of the part, with a thermal isostatic pressing method, the high-performance SiC ceramic-based composite material aero-engine blade is manufactured. According to the method, various near-net-shape forming methods are combined, such that defects of difficult processing of the SiC material are overcome. Compared with traditional alloy blades, the SiC ceramic-based composite material aero-engine blade has the advantages of light mass and high-temperature resistance. The blade is a development trend of future aero-engine blades.

Owner:XI AN JIAOTONG UNIV

Method for preparing porous SiC ceramic based on 3D (three dimensional) molding technology

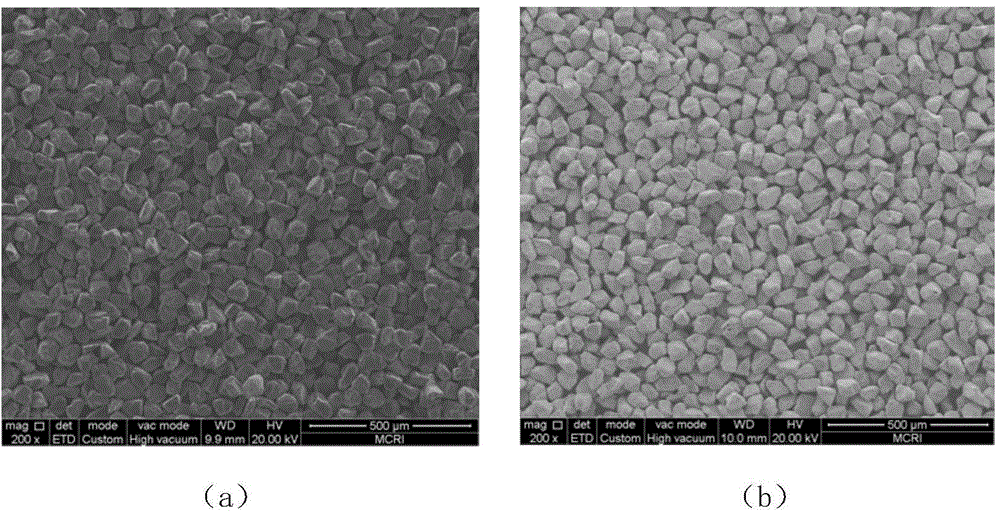

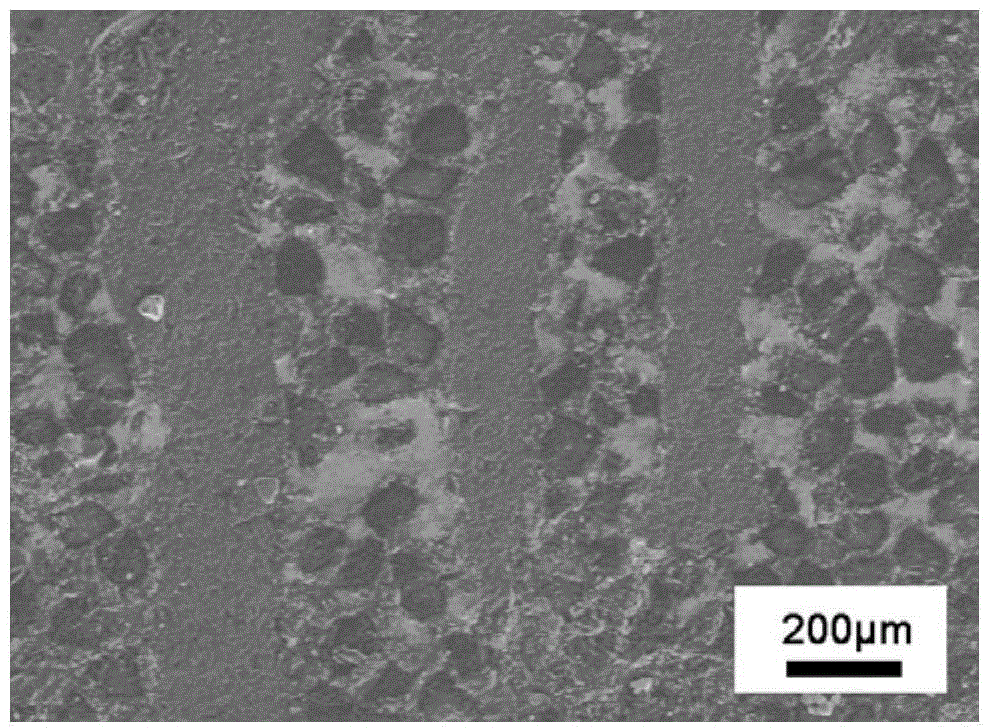

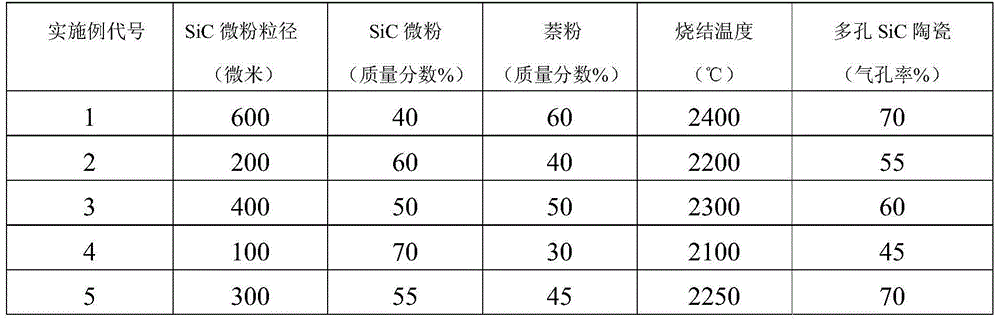

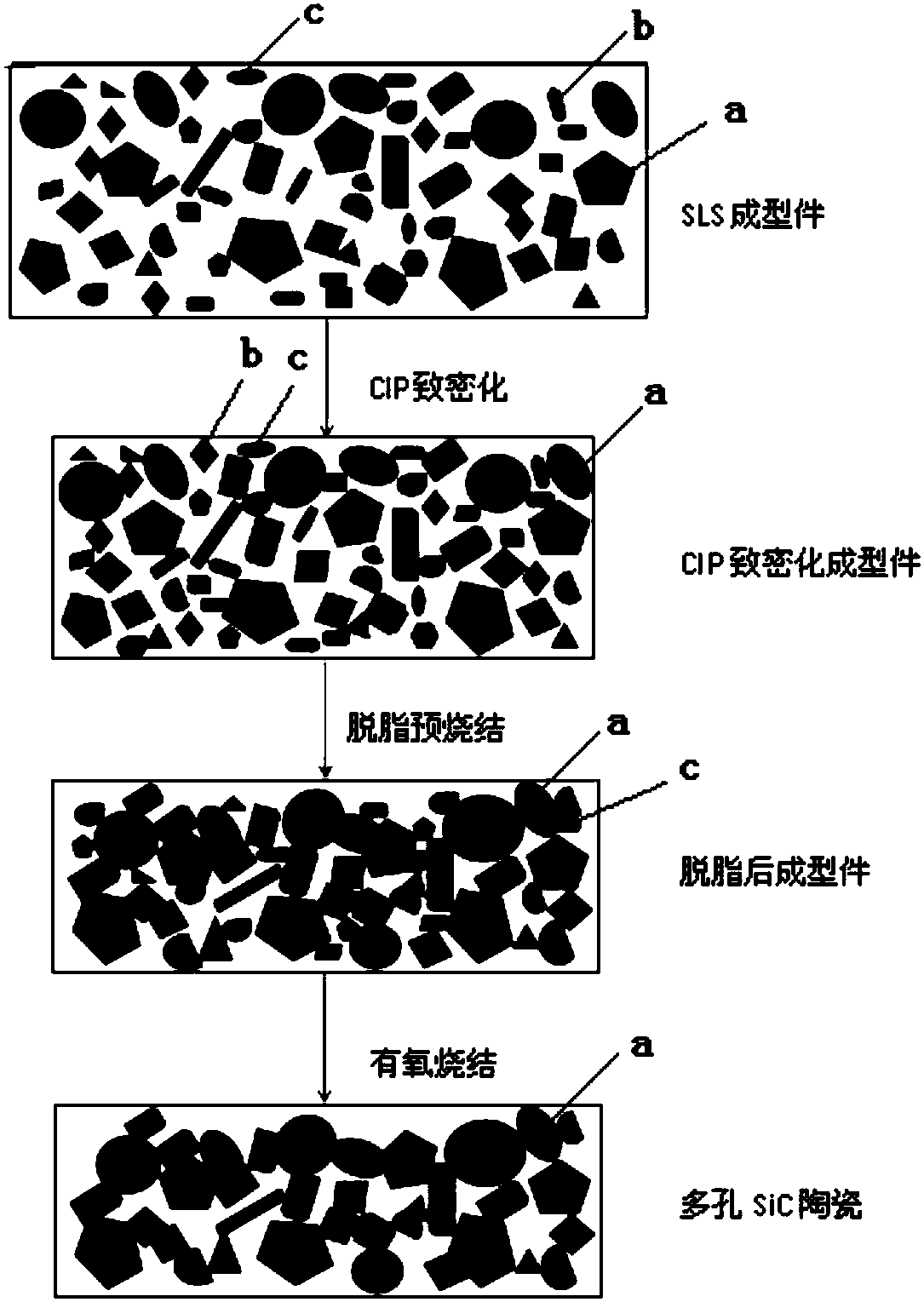

InactiveCN107602130AHigh porosityIncrease profitCeramic shaping apparatusCeramicwareSelective laser sinteringMolding machine

The invention relates to a method for preparing porous SiC ceramic based on a 3D (three dimensional) molding technology, and aims at solving the problem that a molding part is low in porosity when theporous SiC ceramic is prepared by a selective laser sintering (SLS) technology currently. The method provided by the invention comprises the steps of drawing a three-dimensional model of the porous SiC ceramic, setting parameters of an SLS molding machine, mixing SiC powder, binder powder and a pore-forming agent, preparing a ceramic body, performing CIP sheathing, and then performing cold isostatic pressing compacting treatment, performing degreasing presintering, and then sintering in an aerobic environment. The method has the advantages that the operation is simple, the molding speed is high, the raw material utilization ratio is high, the porosity of the porous SiC ceramic is effectively improved, a final molding part has the porosity of 70 to 80%, and certain strength is realized. The method is applied to the field of porous SiC ceramic preparation.

Owner:HARBIN UNIV OF SCI & TECH

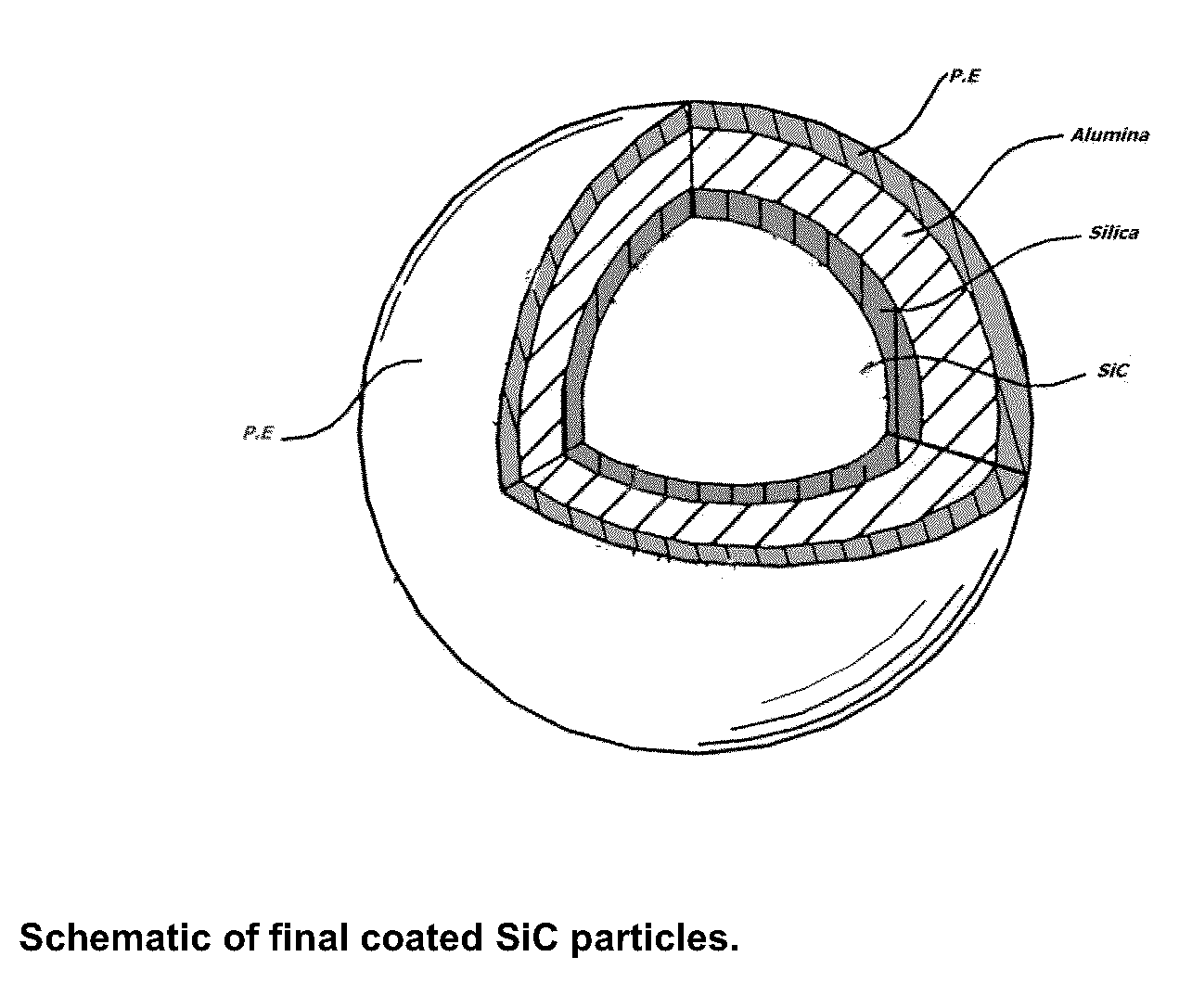

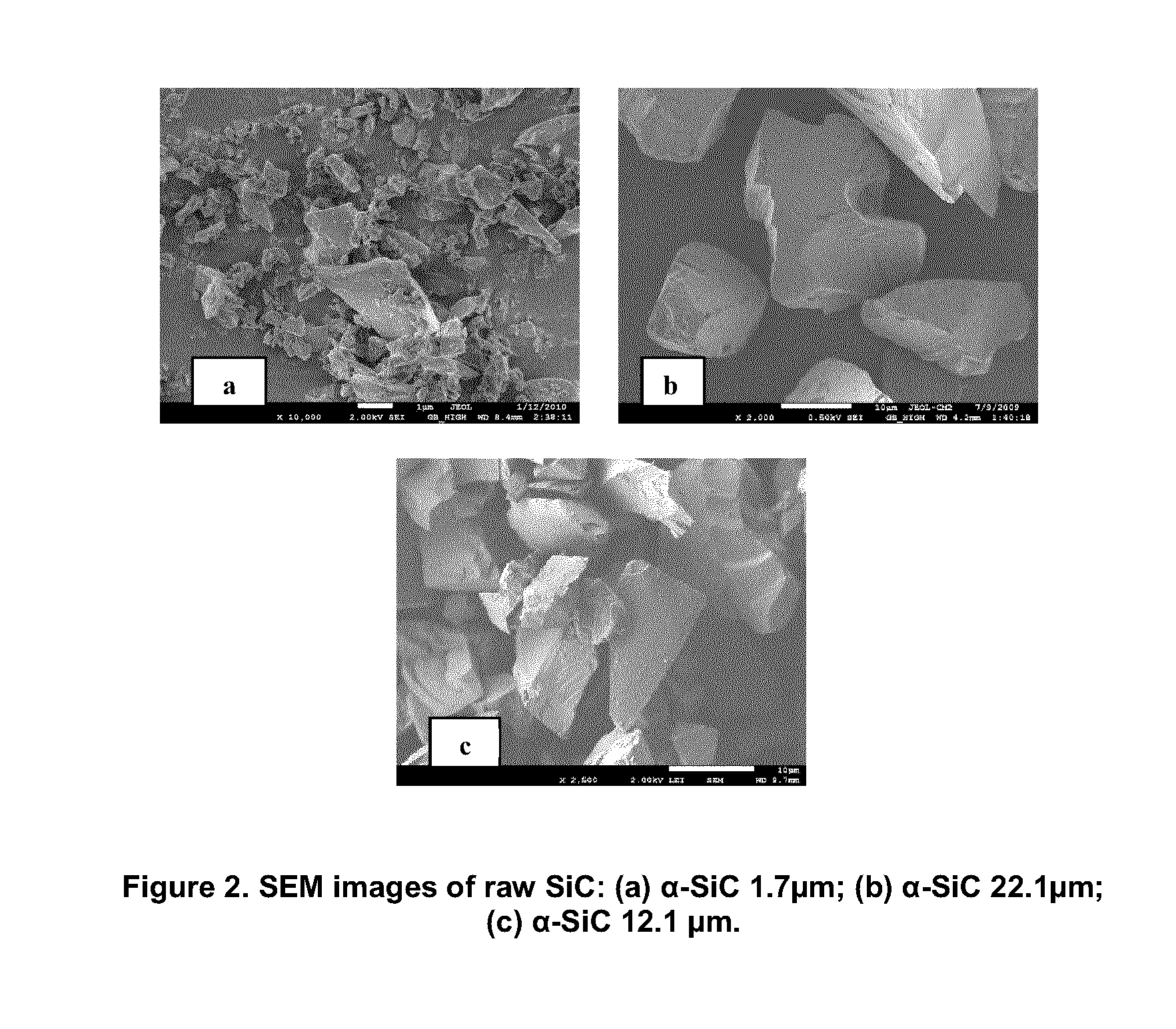

POROUS SiC CERAMIC AND METHOD FOR THE FABRICATION THEREOF

ActiveUS20140206525A1Improve featuresLower sintering temperatureCeramicwareCarbide siliconIn situ polymerization

There is provided a method for the fabrication of porous SiC ceramic. The method comprises oxidizing particles of SiC ceramic thereby forming amorphous silica on the surface of the particles. The oxidized SiC particles are then mixed with an additive. Alternatively, layer(s) of the additive is (are) deposited on their surface by sol-gel technique. The oxidized SiC particles mixed or coated with the additive are then mixed with at least one pore-former. Alternatively, the oxidized SiC particles mixed or coated with the additive are coated with layer(s) of a polymer or pore-former by in-situ polymerization. In embodiments where the oxidized SiC particles are mixed with an additive and a pore-former or polymer, a further additive may be used. In each of these embodiments, the resulting product is then compacted into a green body which is heated and sintered to yield the porous SiC ceramic material. There is also provided a porous SiC ceramic fabricated by the method according to the invention.

Owner:POLYVALOR LP

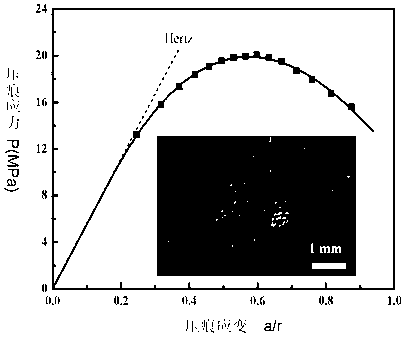

Preparation method of high-strength anti-contact-damage porous SiC

ActiveCN103319194AThe porous structure is not damagedUndamaged shapeCeramicwareMetallurgyHydrogen atmosphere

The invention relates to a preparation method of high-strength anti-contact-damage porous SiC, which comprises the following steps: (1) carbonizing wood at 600-1100 DEG C in an inert gas or hydrogen atmosphere for 1-6 hours; (2) carrying out dipping treatment on the carbonized wood in liquid polycarbosilane in a vacuum environment to obtain a carbon template; (3) curing the carbon template subjected to dipping treatment at 180-250 DEG C for 1-5 hours; and (4) carrying out high-temperature treatment on the cured carbon template in an inert gas or hydrogen atmosphere or in a vacuum environment to obtain the porous SiC ceramic. The method provided by the invention can reserve the porous structure in the wood template, so that the porous SiC can still have high compression strength under the condition of high porosity and also have excellent anti-contact-damage capacity.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Manufacturing method of gradient porous silicon carbide ceramic tube

ActiveCN106045571ASolving Gradient Pore PreparationSolve the control puzzleCeramicwarePipe fittingGas phase

The invention belongs to the field of manufacturing porous silicon carbide ceramic and provides a manufacturing method of a gradient porous silicon carbide ceramic tube. The manufacturing method includes: using a sintered porous SiC ceramic tube as a base material, and coating the inner side or the outer side of the sintered porous SiC ceramic tube with graphite paper; placing the sintered porous SiC ceramic tube in a chemical gas-phase permeation furnace for gas-phase growing; adopting MTS as a precursor in the chemical gas-phase permeation furnace, enabling MTS to be in chemical gas-phase permeation reaction in a gas phase of the chemical gas-phase permeation furnace to generate a SiC phase, and enabling the SiC phase to gradually permeate into the sintered porous SiC ceramic tube from one side without being coated with the graphite paper to form the gradient porous silicon carbide ceramic tube with porosity and pore size gradiently decreasing from one side without being coated with the graphite paper to one side coated with the graphite paper. The gradient porous silicon carbide ceramic tube has the advantages of low preparation temperature, simple preparation process and easiness in manufacturing large pipe fittings.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

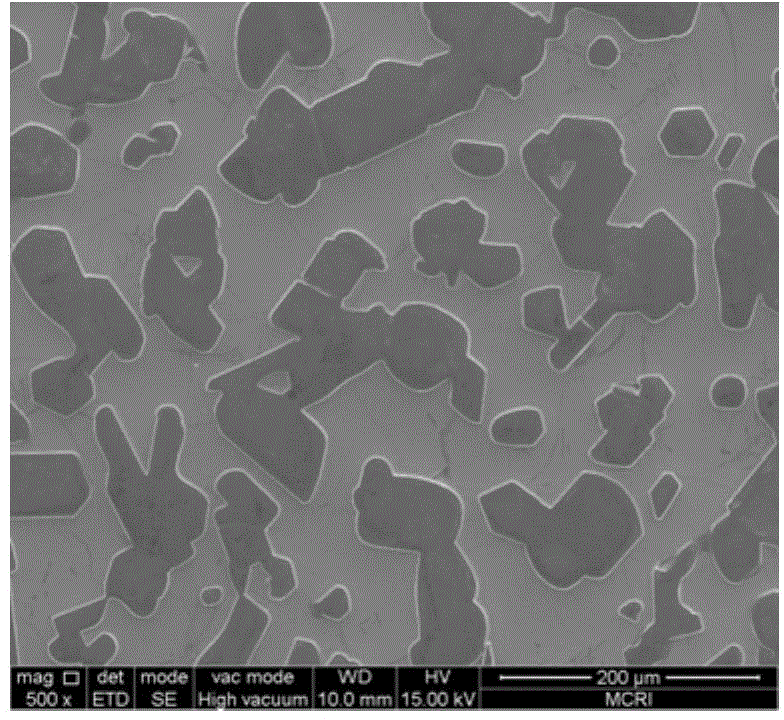

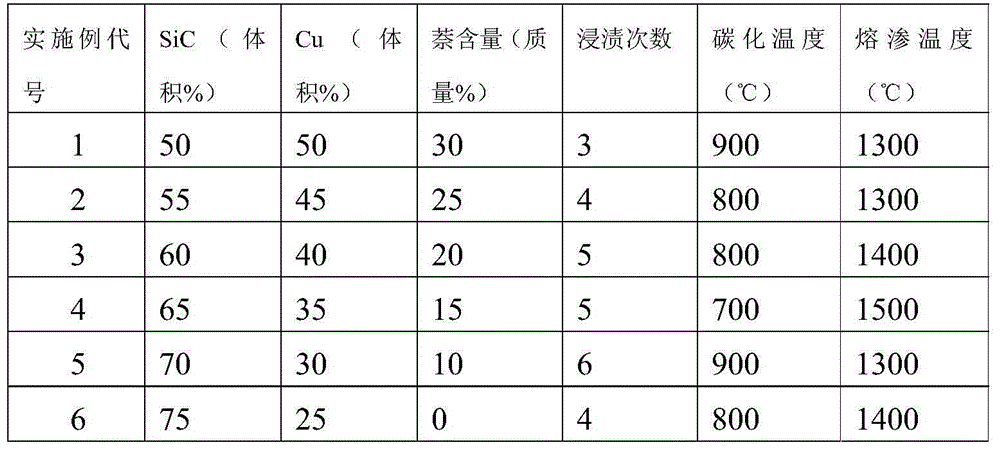

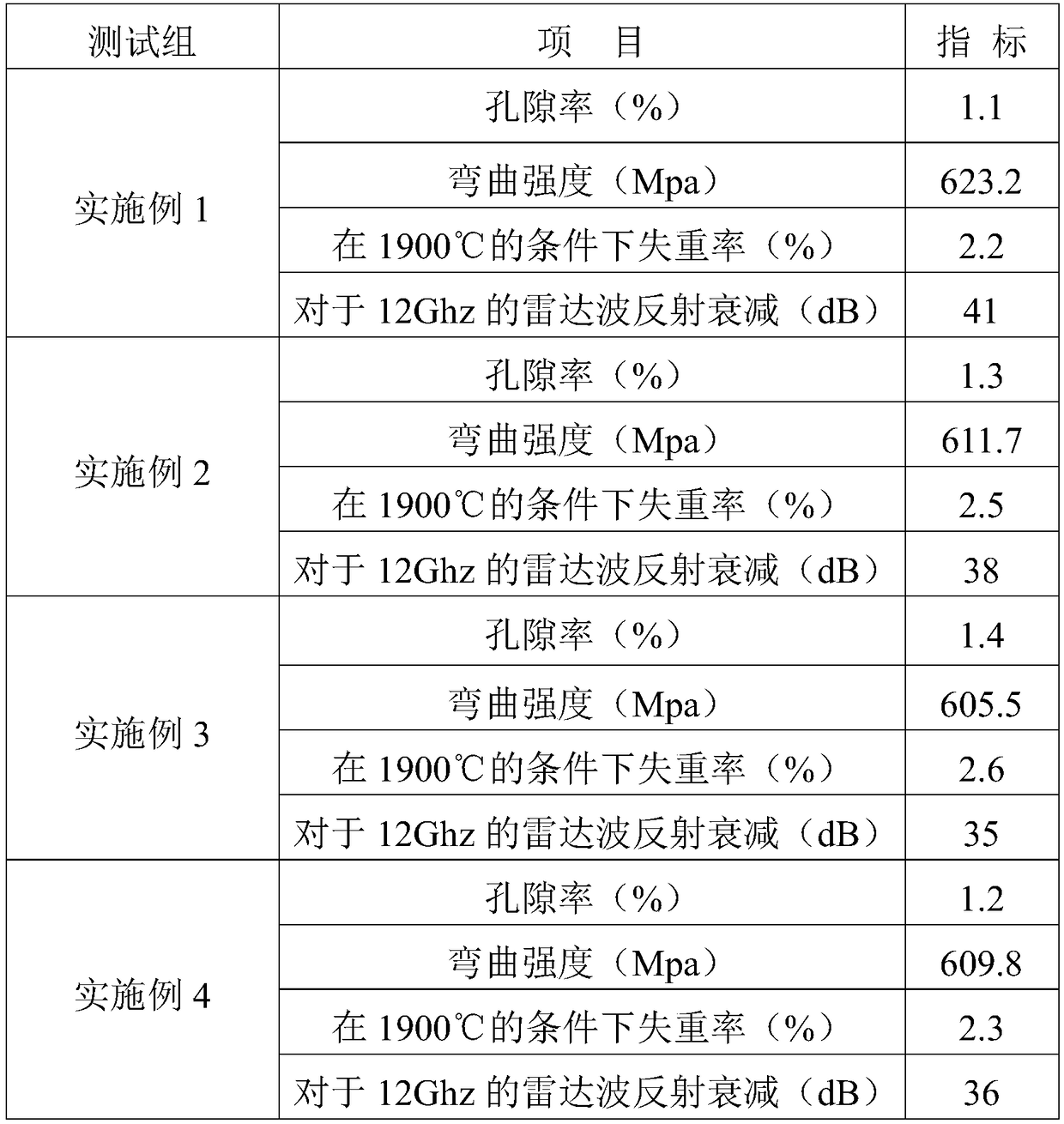

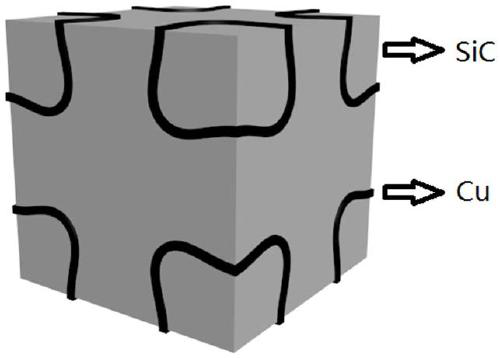

SiC-Cu complex phase sweating cooling material used for thermal protection, and preparation method thereof

The invention discloses a SiC-Cu complex phase sweating cooling material used for thermal protection, and a preparation method thereof. The complex material comprises, by volume, 50-75% of a SiC ceramic phase and 25-50% of Cu metal phase, wherein the SiC ceramic phase is in a porous structure; the pores are communicated in three-dimensional space; and the Cu metal phase adheres on the surface of the pores. The preparation method comprises three key processing steps of preparing recrystallized SiC ceramic; coating tungsten carbide on the inner surface of the porous SiC ceramic and infiltrating Cu into the porous SiC ceramic coated by the tungsten carbide spontaneously. A uniform and continuous tungsten carbide layer coats the inner surface of the crecrystallized porous SiC ceramic by adopting a vacuum sol-gel impregnation technology in combination of a carbonization method; and then the SiC-Cu complex phase sweating cooling material is prepared by a spontaneously infiltration process. The method is simple in process and low in cost, can prepare various components with complex shapes, obviously increase high-temperature ablative resistant property of the SiC-Cu complex phase sweating cooling material.

Owner:XI AN JIAOTONG UNIV

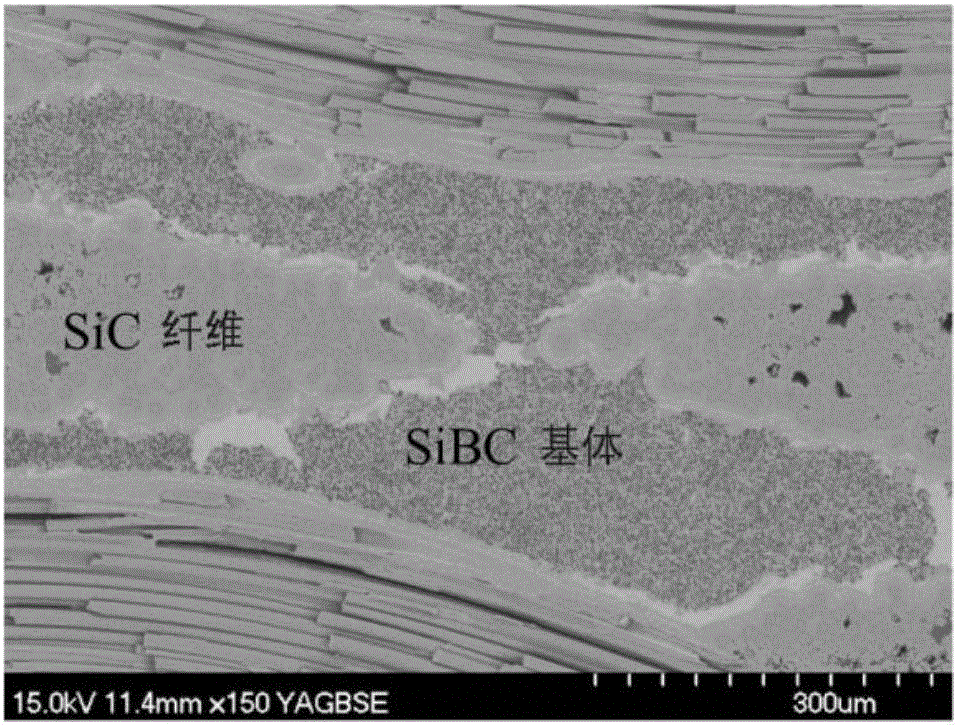

Preparation method of SiC fiber enhanced ceramic-based composite material

The invention belongs to the technical field of composite materials and discloses a preparation method of a SiC fiber enhanced ceramic-based composite material. The preparation method comprises the following steps: 1) preparing SiBCN-Ti precursor powder containing ZrB2; 2) preparing SiC fibers into a pre-formed part; then placing the precursor powder and the SiC fiber pre-formed part into a mold and carrying out hot pressing treatment; after cooling, de-molding to obtain a SiC fiber enhanced composite material; then transferring the SiC fiber enhanced composite material into a cracking furnaceand carrying out cracking treatment to obtain a porous SiC fiber enhanced ceramic-based composite material; and 3) infiltrating SiNBC through a chemical vapor infiltration technology and densifying the composite material. The SiC fiber enhanced ceramic-based composite material prepared by the invention has high purity, has excellent high-temperature stability, bending strength and cracking toughness and has excellent wave absorption performance.

Owner:成都成维精密机械制造有限公司

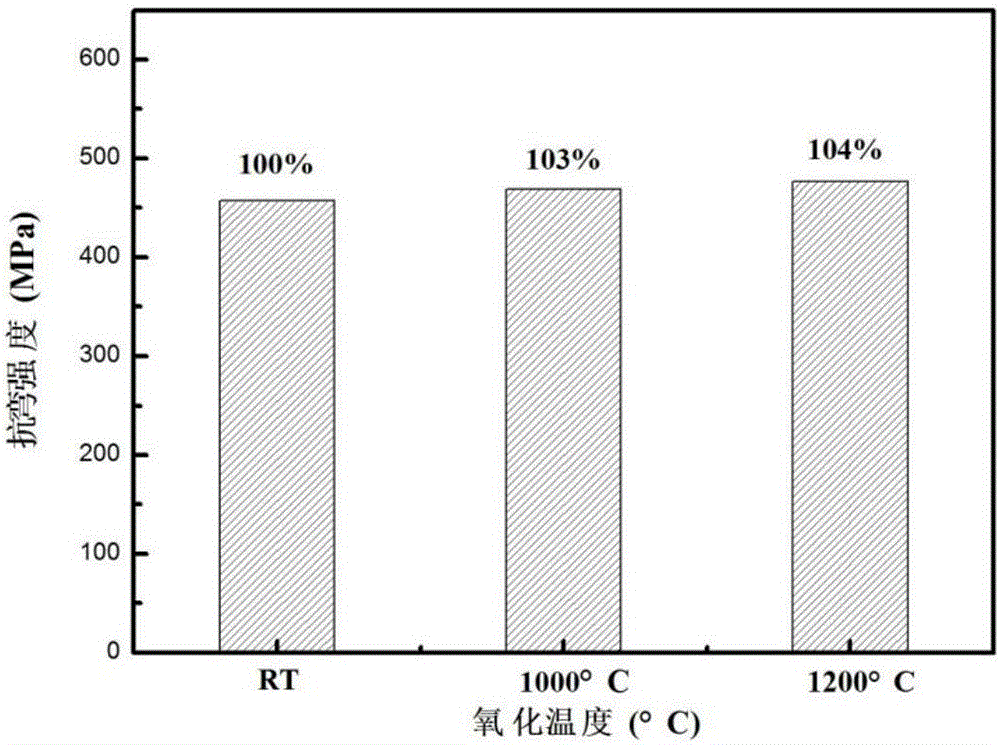

Preparation method for dispersively distributed self-healing phase B12(C,Si,B)3 modified SiC/SiC compound material

The invention discloses a preparation method for a dispersively distributed self-healing phase B12(C,Si,B)3 modified SiC / SiC compound material. The preparation method is adopted for solving the technical problem of poor fracture toughness caused by continuous distribution in the process of introducing a compact self-healing modifying phase according to a present method. According to the technical scheme, the method comprises the following steps: introducing phenolic resin mixed with B4C powder into a porous SiC / SiC compound material by adopting vacuum-pressure dipping; curing, splitting and thermally treating; and performing short-term liquid silicon permeation under a vacuum condition. Fused Si reacts with split C and B4C, thereby generating a ternary phase B12(C,Si,B)3 and SiC which are dispersively distributed in the unreacted Si. According to the invention, a CVI-SiC substrate is capable of effectively protecting SiC fiber and BN interface in the liquid silicon permeation process, the damage to SiC fiber is reduced as far as possible, and the fracture toughness of the compound material is increased to 15-26MPa*ml / 2 from 8MPa*ml / 2 of the background art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

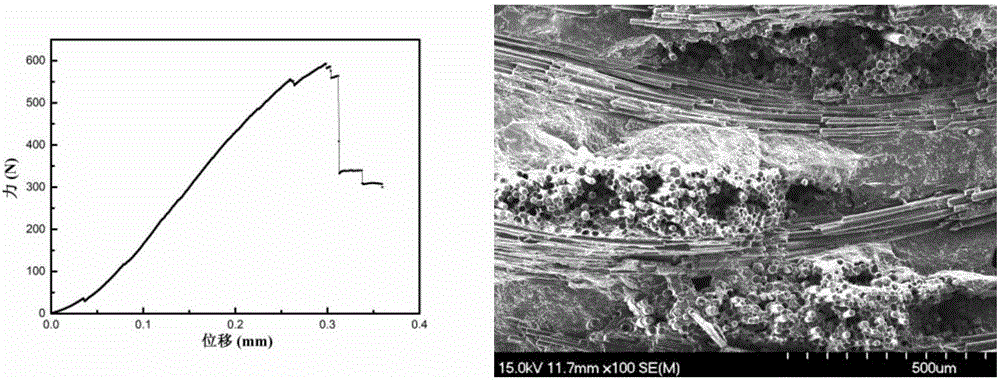

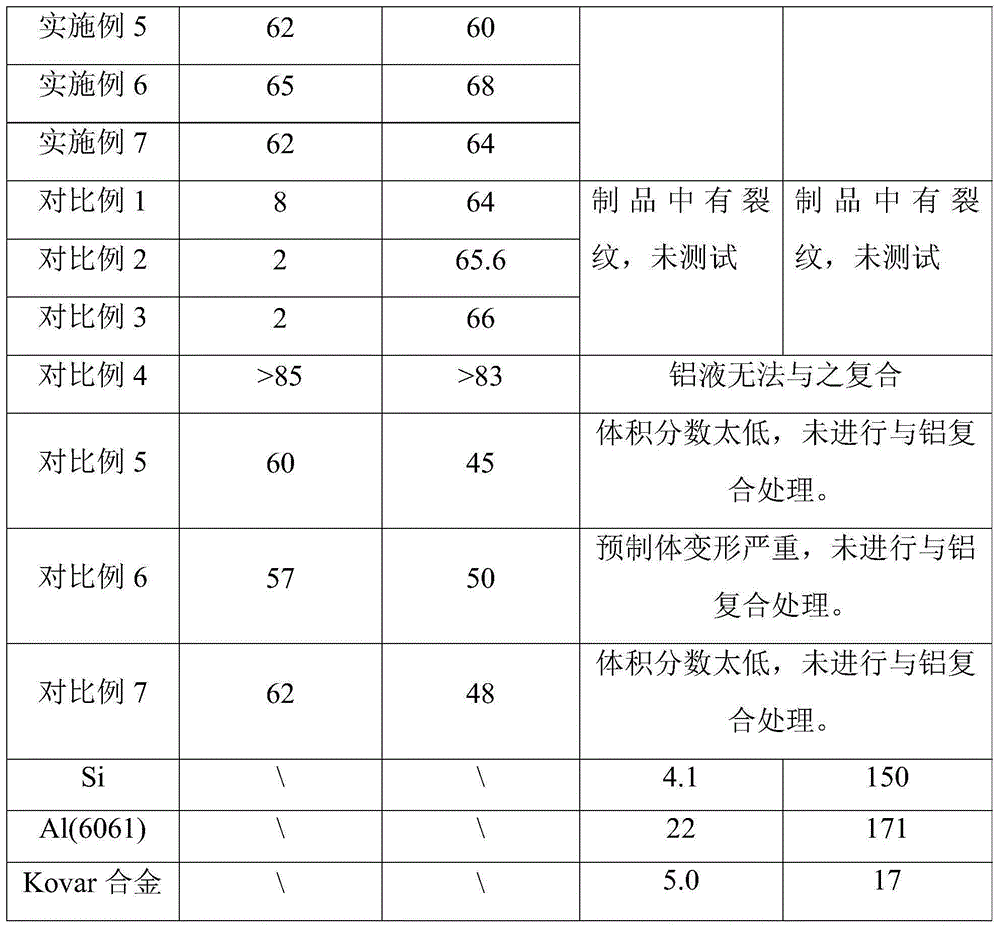

Porous SiC prefabricated product, its preparation method and ceramic-metal composite material

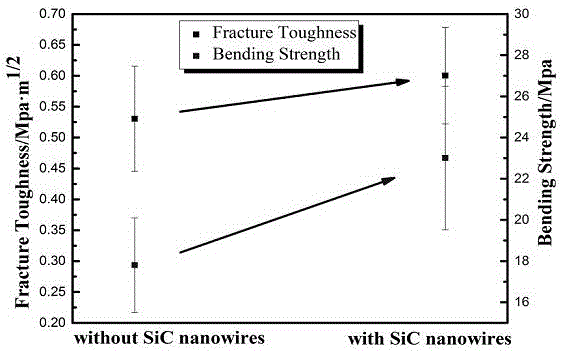

ActiveCN105523765AImprove flexural strengthOvercome limitationsCeramicwareCeramic metalMaterials science

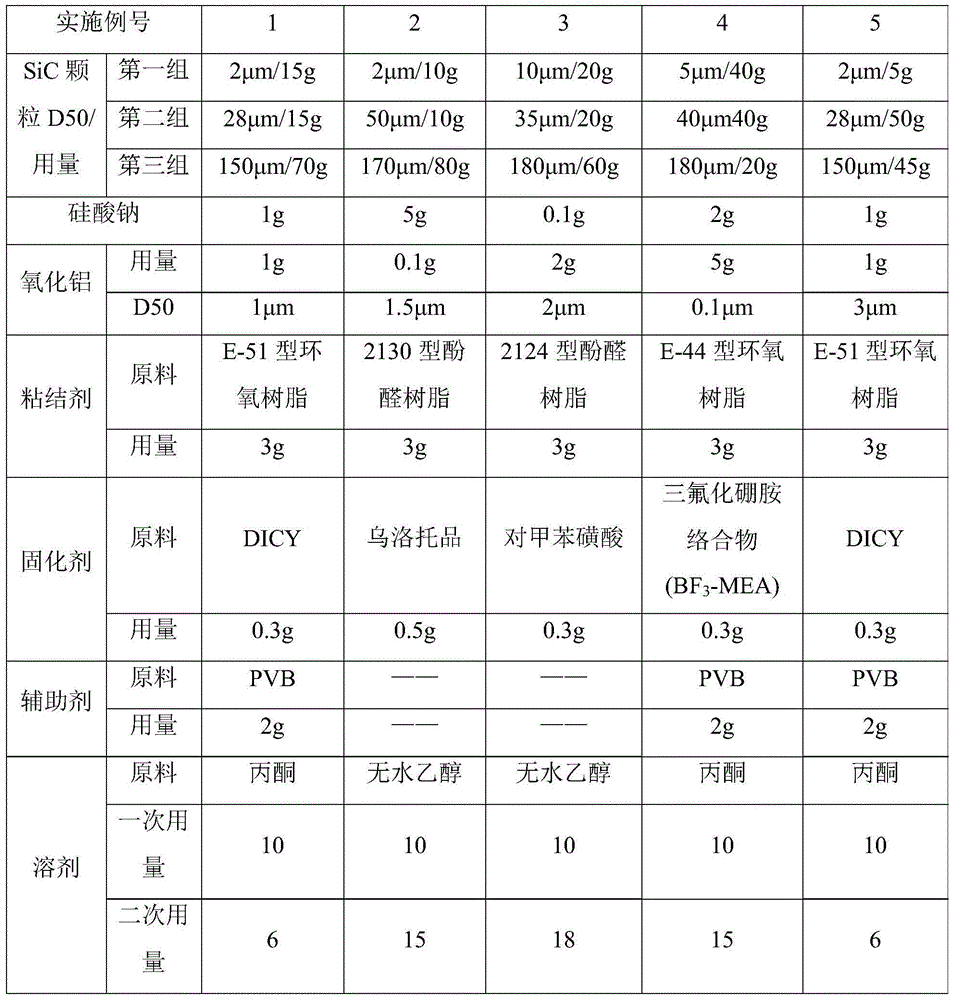

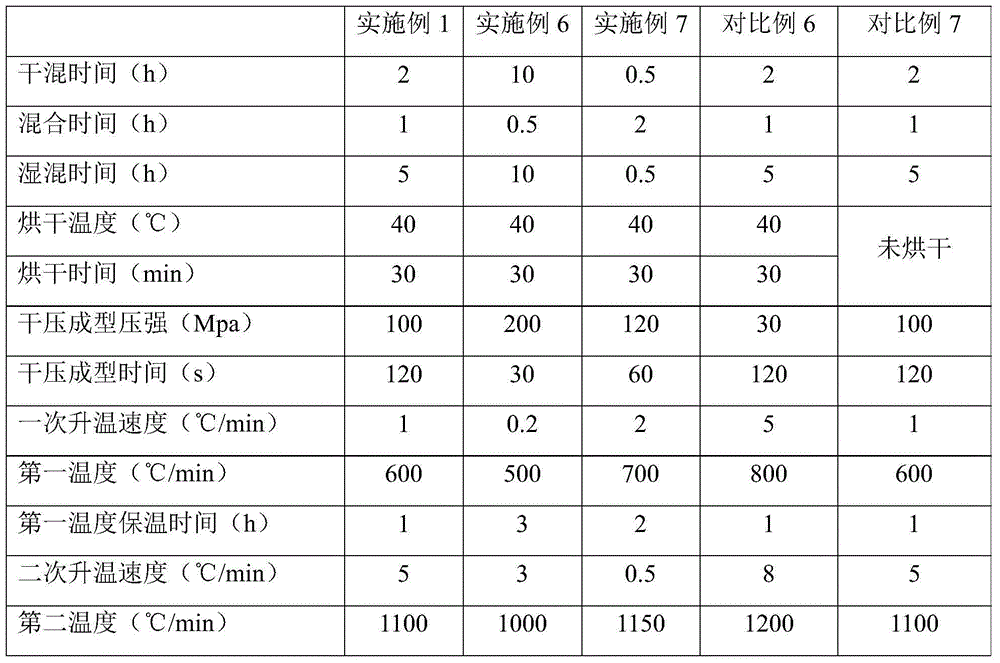

The invention discloses a porous SiC prefabricated product, its preparation method and a ceramic-metal composite material. The porous SiC prefabricated product comprises, by weight, 100 parts of a SiC particle mixture, 0.1-5 parts of Al2O3 particles and 0.1-5 parts of Na2SiO3. The SiC particle mixture contains three groups of SiC particles with different particle sizes D50, wherein the particle size D50 of the SiC particles in the second group is 2-600 times that of the SiC particles in the first group and the particle size D50 of the SiC particles in the third group is 2.5-6 times that of the SiC particles in the second group. Through use of Na2SiO3 and Al2O3 particles in the porous SiC prefabricated product and cooperation of the SiC particle mixture, Al2O3 particles and Na2SiO3 according to a specific ratio, porous SiC prefabricated product bending strength is improved.

Owner:BYD CO LTD

Aquaculture water cleaning agent and preparation method thereof

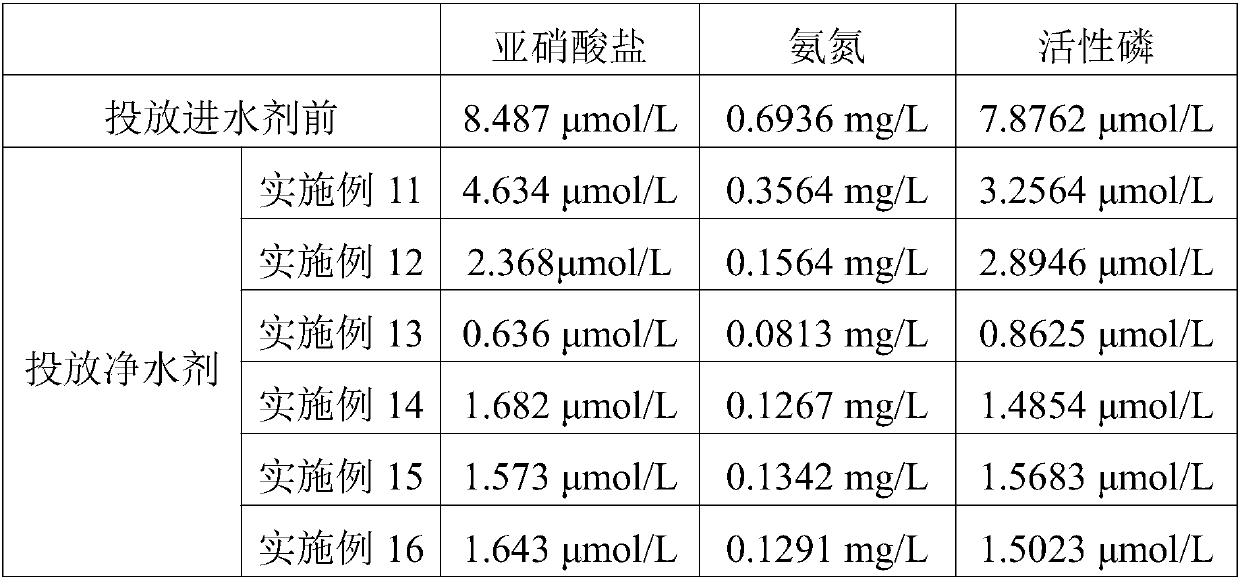

ActiveCN107673481AImprove water qualityAdjust pHBacteriaWaste water treatment from animal husbandryDenitrifying bacteriaWater quality

The invention discloses an aquaculture water cleaning agent and a preparation method thereof. By culturing photosynthetic bacteria, denitrifying bacteria and bacillus in a culture medium containing porous SiC ceramic particles, microorganisms are enriched on the porous SiC ceramic particles to prepare the aquaculture water cleaning agent. Compared with the prior art, the prepared aquaculture watercleaning agent has good effects on water purification and disease prevention for aquaculture water.

Owner:江苏好润生物产业集团股份有限公司

Method for preparing SiC3D/Al composite through vacuum pressure infiltration positive-pressure method

The invention discloses a method for preparing a SiC3D / Al composite through a vacuum pressure infiltration positive-pressure method for the first time. The method comprises the steps that soluble ceramic is adopted as a mold material to prepare a soluble ceramic mold, then, a three-dimensional continuous porous SiC perform is placed in the soluble ceramic mold, the soluble ceramic mold, to-be-infiltrated Al or an to-be-infiltrated alloy are placed in a crucible to be heated, subjected to heat preservation and cooled, in the preparation process, molten liquid Al is infiltrated into pores of theSiC preform under the action of external gas pressure and then subjected to cooling solidification at certain pressure, and finally the corresponding SiC3D / Al composite is formed. According to the method, the problems of difficult stripping of an existing graphite or alloy steel mold and excessively-high machining cost after the SiC3D / Al composite is prepared are solved, and thus the production cost of the SiC3D / Al composite is greatly lowered.

Owner:DONGGUAN UNIV OF TECH

Surface modified SiC reinforced aluminum-based composite material and preparation method thereof

The invention discloses a surface modified SiC reinforced aluminum-based composite material and a preparation method thereof. The surface modified SiC reinforced aluminum-based composite material is characterized by taking a metal aluminum as a matrix and taking a surface modified SiC porous ceramic as a reinforcement; the preparation method includes the steps that firstly SiC is deposited on a carbon foam substrate through a CVI method; a carbon foam framework is removed through an oxidation method to obtain a SiC porous ceramic blank body; the SiC porous ceramic is further obtained through aPIP method; then porous SiC whiskers are prepared on an outer layer of the SiC porous ceramic through laser sintering; and finally the SiC reinforced aluminum-based composite material is prepared through high-pressure infiltration. The surface-modified SiC reinforced aluminum-based composite material is uniform in structure distribution and good in forming property, and due to surface modification, the strength of the composite material is ensured and the wear resistance of the composite material is improved. By means of the surface modified SiC reinforced aluminum-based composite material, the problems that SiC of a traditional silicon carbide reinforced aluminum-based composite material is not uniformly dispersed in an aluminum matrix, the wear resistance is poor are solved, and the surface modified SiC reinforced aluminum-based composite material can be widely applied to bearing structural parts in the aerospace field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

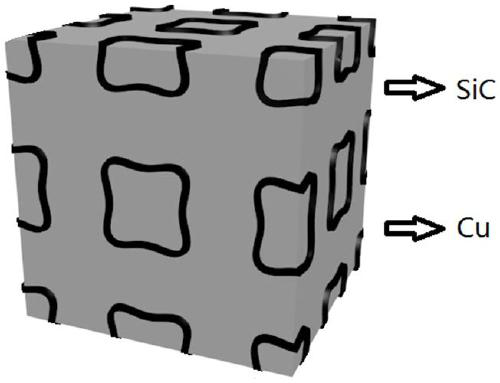

Preparation method of copper/silicon carbide composite material based on I-WP curved surface

InactiveCN109516809AImprove connectivityGood strengthCeramicwareStress concentrationMechanical property

The invention discloses a preparation method of a Cu / SiC composite material based on an I-WP curved surface. The Cu / SiC composite material is a composite material prepared from metal phase Cu and ceramic phase SiC which are continuous in a three-dimensional space network structure and are mutually wound together on the basis of a three-period minimal surface I-WP structure. The I-WP curved surfacestructure can achieve effects of effectively avoiding stress concentration and increasing the mechanical property of the composite material. The Cu / SiC composite material has excellent plasticity andelectrical and thermal conductivity of the metal and also has the characteristics of the ceramic such as high hardness, high wear resistance and chemical stability and the like. The preparation method specifically comprises the following steps: designing and performing 3D printing on the structure of the I-WP curved surface; preparing a porous SiC ceramic preform; and infiltrating the metal Cu. Meanwhile, by changing the printing parameters of the I-WP curved surface structure and controlling the content of the metal and the ceramic, the prepared Cu / SiC composite material is suitable for industrial needs.

Owner:CHINA THREE GORGES UNIV

Method for preparing SiC3D/Al composite material through squeezing impregnation method

ActiveCN109822077AReduce manufacturing costLow priceFoundry mouldsFoundry coresRoom temperatureMaterials science

The invention provides a method for preparing a SiC3D / Al composite material through a squeezing impregnation method. The method comprises the steps that soluble ceramic is taken as an auxiliary mold for preparing the composite material, a squeezing impregnation technology is utilized to rapidly fill pores of a porous SiC preform with molten Al, higher mechanical pressure is exerted, the liquid Alis condensed and cooled to the room temperature before being put into sufficient hot water to be mechanically vibrated, demolding is completed by using the characteristic that the soluble ceramic auxiliary mold easily diffuse in water, and finally an excessive Al material is removed to obtain the SiC3D / Al composite material. The method has the advantages that the production efficiency of the SiC3D / Al composite material can be improved, the problems of difficult auxiliary mold demolding, higher cost and the need of a large amount of machine processing in the composite material taking process are solved by the application of the soluble ceramic auxiliary mold. The invention provides an efficient method for SiC3D / Al composite material industrial production.

Owner:DONGGUAN UNIV OF TECH

Method for preparing anti-oxidation multiple phase coating of carbon/carbon composite material surface

InactiveCN1321092CHigh temperature anti-oxidation temperature increaseImprove thermal shock resistanceCarbon compositesAlcohol

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com