Manufacturing method of gradient porous silicon carbide ceramic tube

A silicon carbide ceramic, gradient porous technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of limited product shape and size, complex preparation process, high sintering temperature, and easy to manufacture large pipe fittings, process Simple, low preparation temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

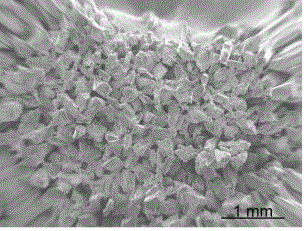

[0024] A method for preparing a gradient porous silicon carbide ceramic tube. The preparation method uses a sintered porous SiC ceramic tube with a single-layer pore structure with a porosity of 20% and a pore diameter of 50 μm as the base material, and the sintering of the single-layer pore structure type porous SiC ceramic tubes such as figure 1 As shown, graphite paper is coated on the inside; the coated base material is placed in a CVI furnace for vapor phase growth to prepare a gradient porous SiC ceramic material; on the outside of the base material, SiC ceramic pellets grown by CVI technology are used to control The pore structure of the base material; the growth process is: using MTS as a precursor, hydrogen as a carrier gas and dilution gas, and argon as a protective gas; MTS:H 2 :Ar ratio is 1:15:10, the total gas pressure is 0.5kPa, the deposition temperature is 800°C, and the deposition time is 100h; the specific surface area of the prepared gradient porous silic...

Embodiment 2

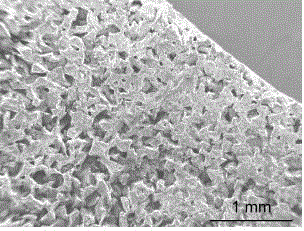

[0026] A method for preparing a gradient porous silicon carbide ceramic tube. The preparation method uses a sintered porous SiC ceramic tube with a single-layer pore structure with a porosity of 40% and a pore diameter of 100 μm as the base material, and graphite paper on the outside Coating: Put the coated base material into a CVI furnace for vapor phase growth to prepare a gradient porous SiC ceramic material. The inner side of the base material is as follows: MTS is used as the precursor, hydrogen is used as the carrier gas and dilution gas, and argon is used as the protective gas. MTS:H 2 :Ar ratio is 1:10:5, the total gas pressure is 3kPa, the deposition temperature is 1200°C, and the deposition time is 10h; the fracture morphology photo of the gradient porous SiC tube is as follows figure 2 As shown, its specific surface area is 12m 2 / g, the strength is 37MPa, and the fracture toughness is 0.36MPa m 1 / 2 , the pressure drop is 45hPa.

Embodiment 3

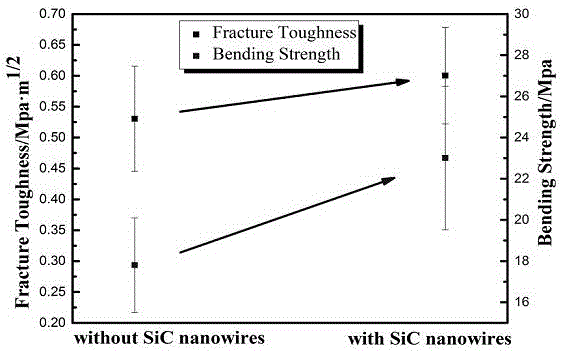

[0028]A method for preparing a gradient porous silicon carbide ceramic tube, the preparation method uses a sintered porous SiC ceramic tube with a porosity of 20% and a double-layer pore structure as a base material, the outer layer has a pore diameter of 20 μm, and the inner layer has a pore size of 100μm; coated with graphite paper on the inside; put the coated substrate material into the CVI furnace for vapor phase growth to prepare gradient porous SiC ceramic material; on the outside of the substrate material, use SiC whiskers grown by CVI technology to control the substrate The pore structure of the material; the growth process is: using MTS as a precursor, hydrogen as a carrier gas and dilution gas, and argon as a protective gas; MTS:H 2 The ratio of :Ar is 1:20:15, the total gas pressure is 0.5kPa, the deposition temperature is 1000°C, and the deposition time is 1h; the catalyst used is FeCl 3 ; The specific surface area of the gradient porous SiC tube is 40m 2 / g, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com