Patents

Literature

295 results about "Porous silicon carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing porous silicon carbide sintered body

A method for manufacturing a porous silicon carbide sintered body that includes manufacturing a silicon carbide molded body by using a raw material composition containing at least silicon carbide powder, silicon powder, and a binder. The method further includes carrying out a degreasing treatment on the silicon carbide molded body to manufacture a silicon carbide degreased body, and carrying out a firing treatment on the silicon carbide degreased body to manufacture a porous silicon carbide sintered body. The raw material composition has about 1 to about 3% by weight of the total amount of the silicon carbide powder and the silicon powder in a content of the silicon powder. And, the firing treatment is carried out at a temperature allowing silicon carbide powder to mutually form intergranular necks through counter diffusion.

Owner:IBIDEN CO LTD

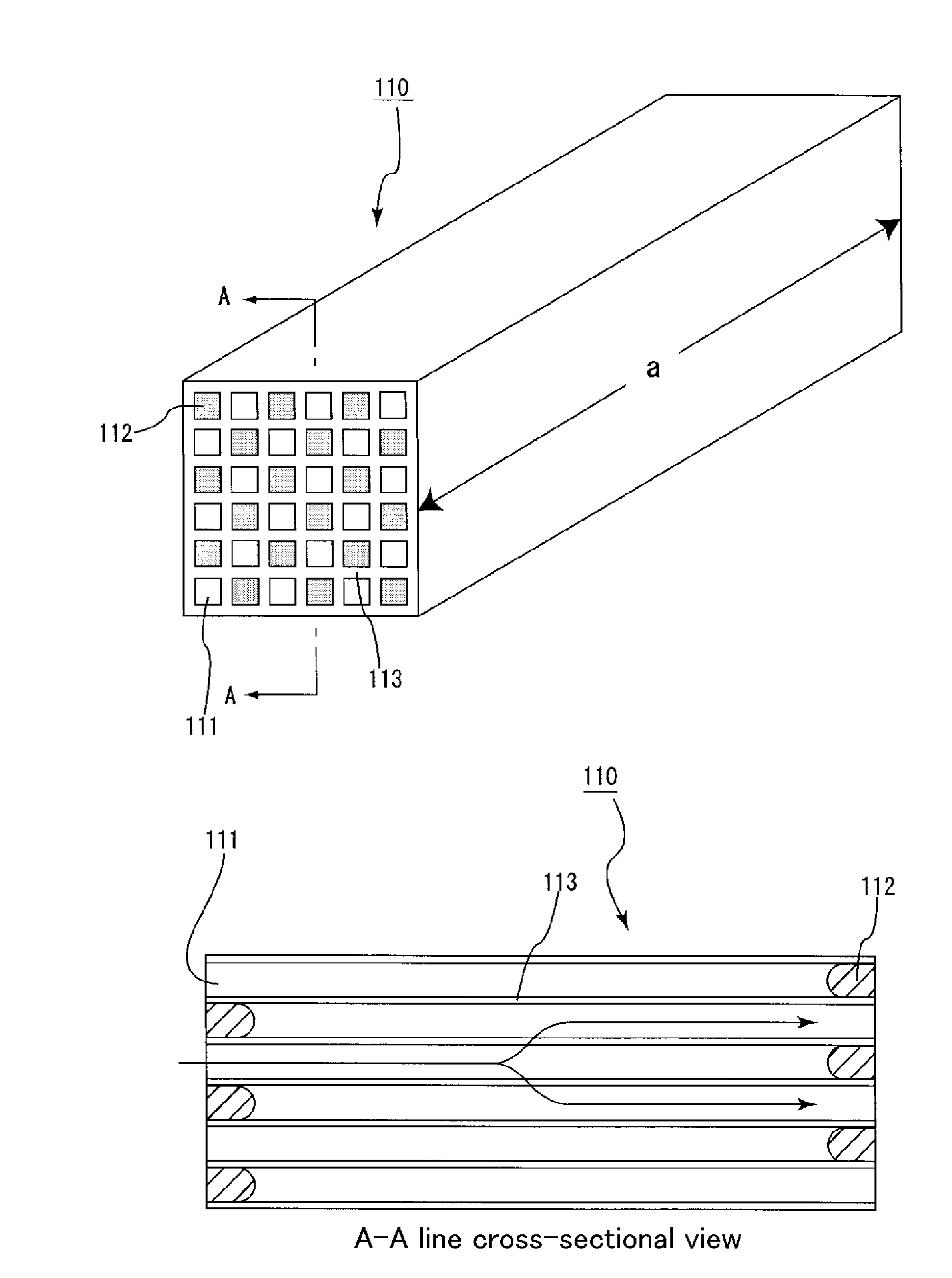

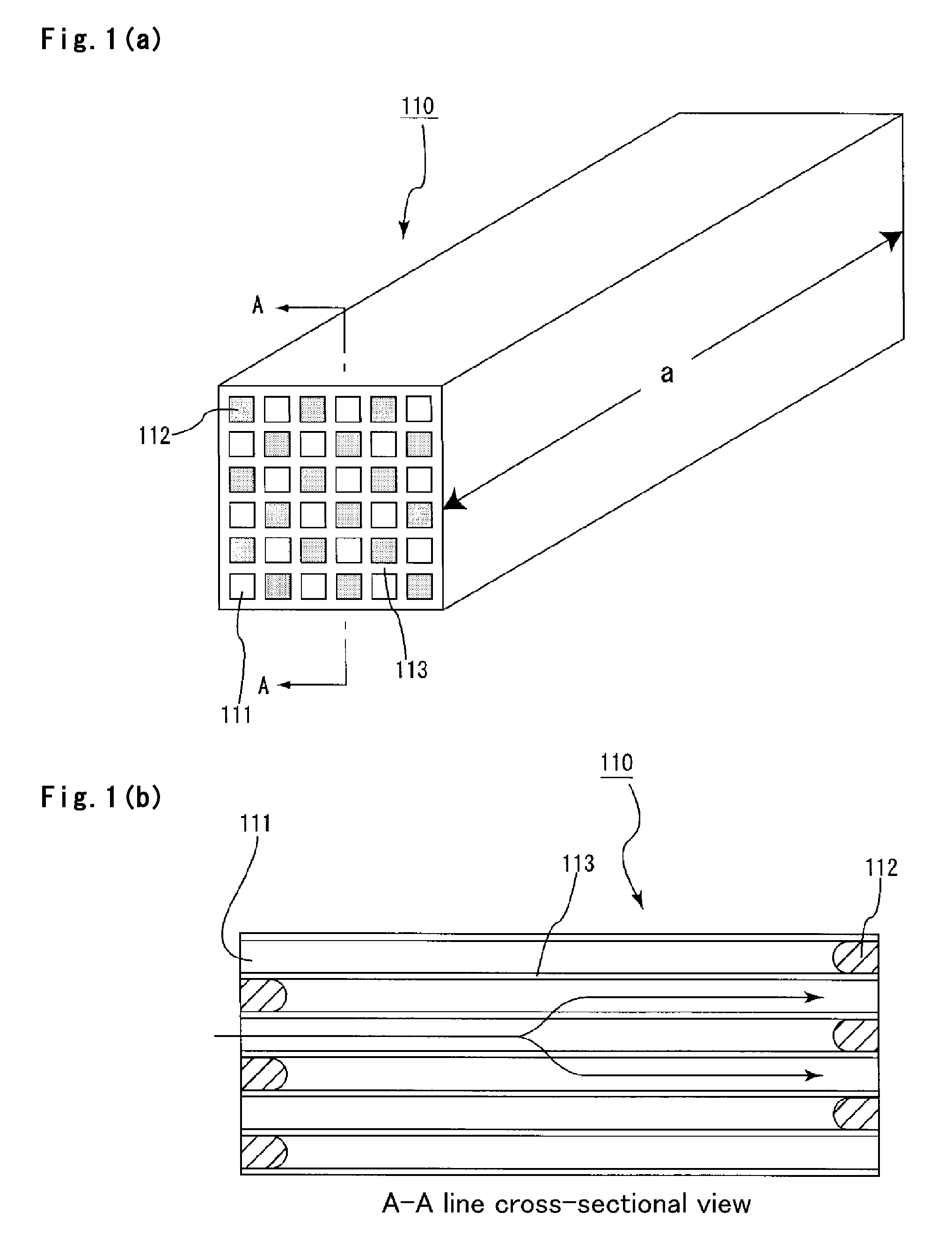

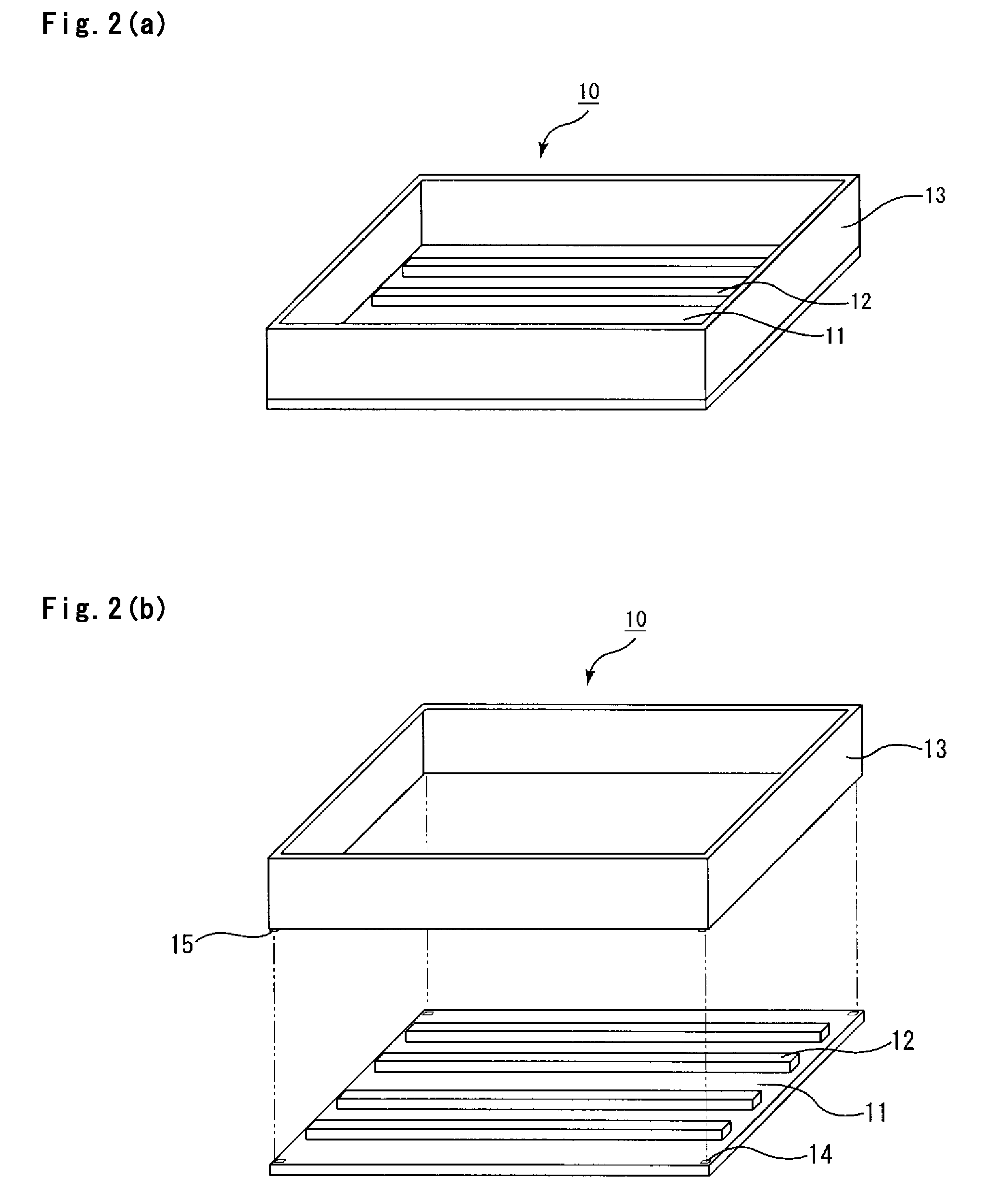

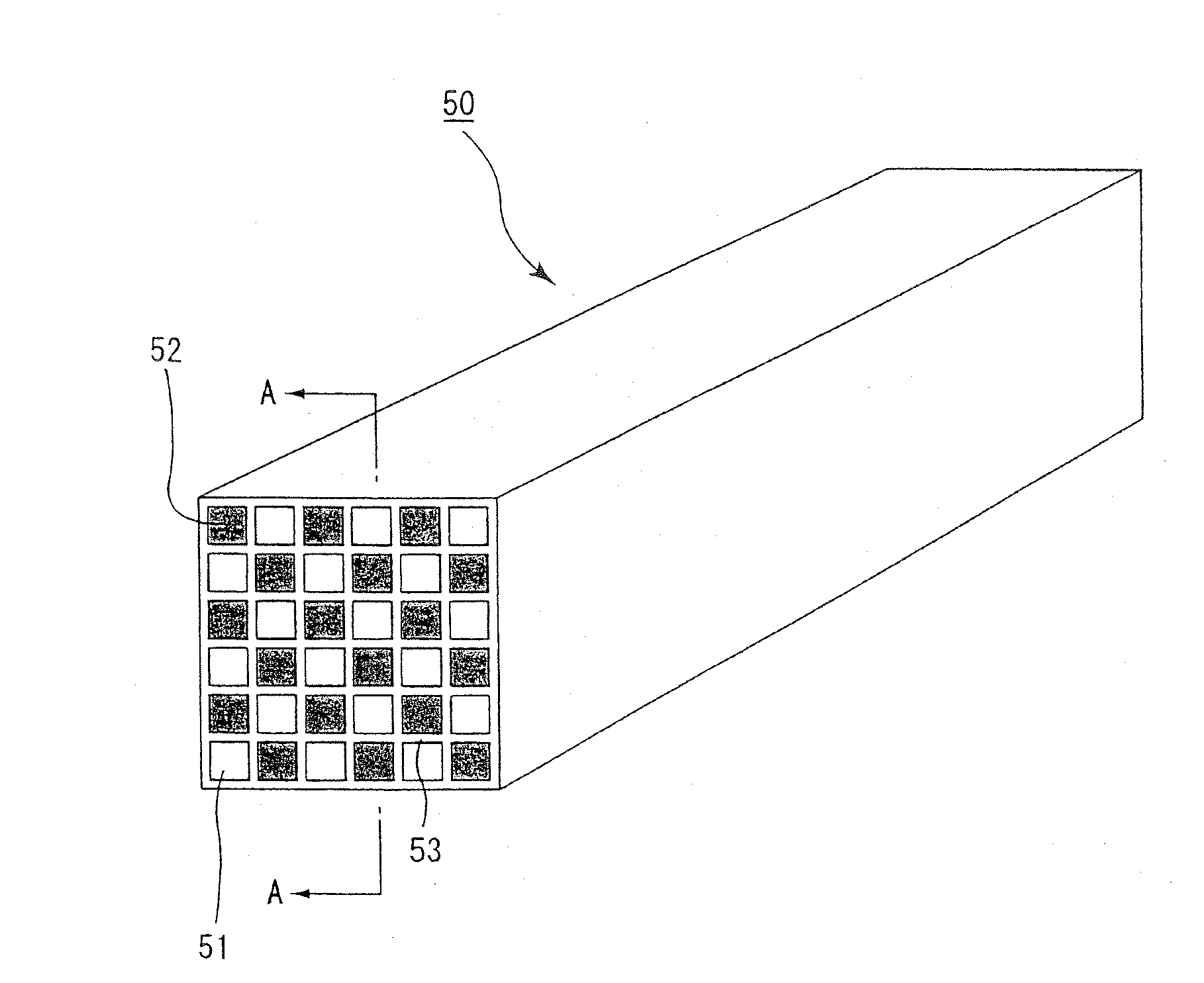

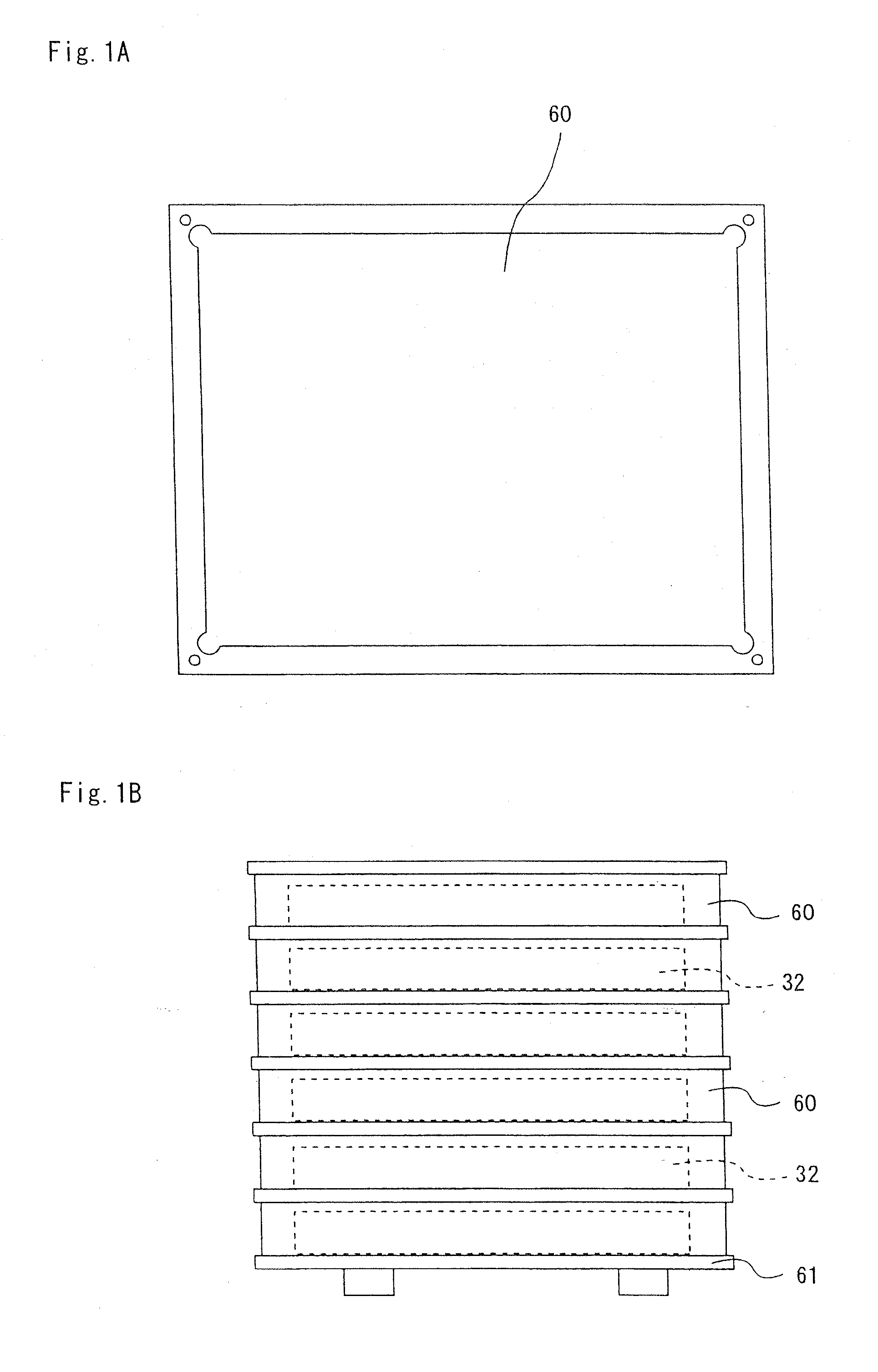

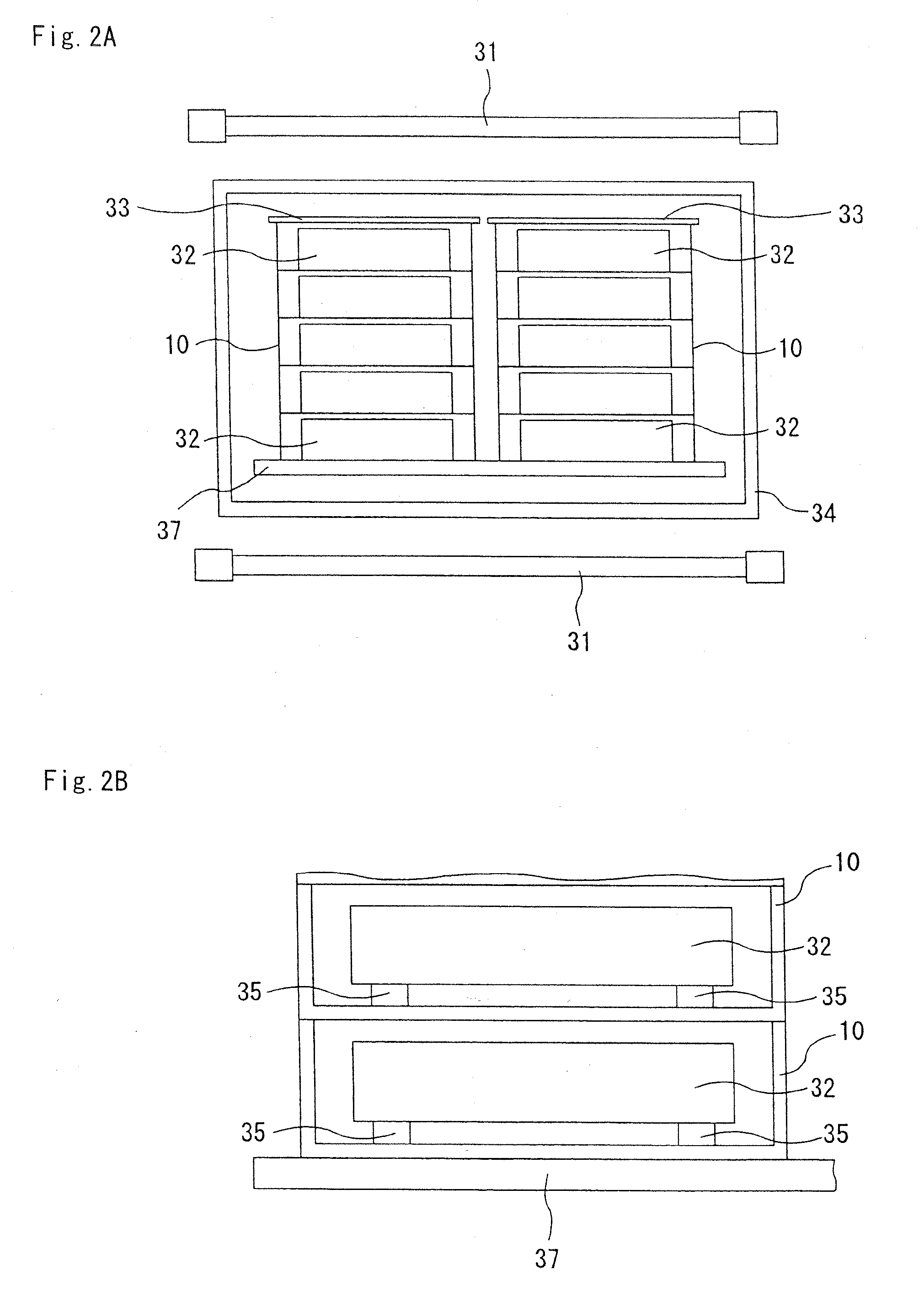

Jig for firing silicon carbide based material and method for manufacturing porous silicon carbide body

InactiveUS20080150200A1Liquid surface applicatorsConfectioneryPorous silicon carbideMaterials science

A jig for firing a silicon carbide based material of the present invention is a jig for firing a silicon carbide based material, which is used for placing a silicon carbide based molded body thereon upon firing of the silicon carbide based molded body, wherein a SiO source layer is formed on at least a part of the surface of the jig for firing a silicon carbide based material.

Owner:IBIDEN CO LTD

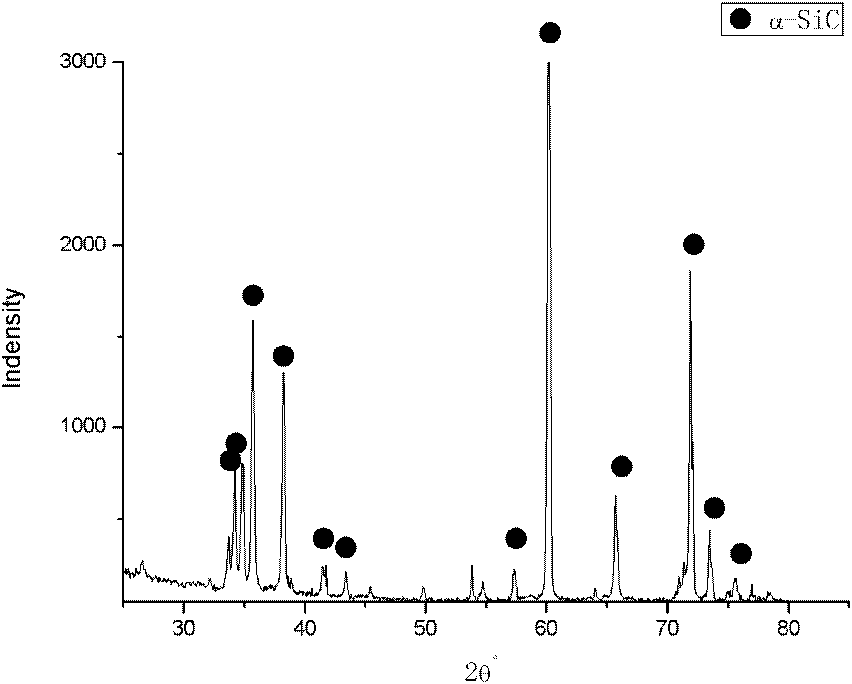

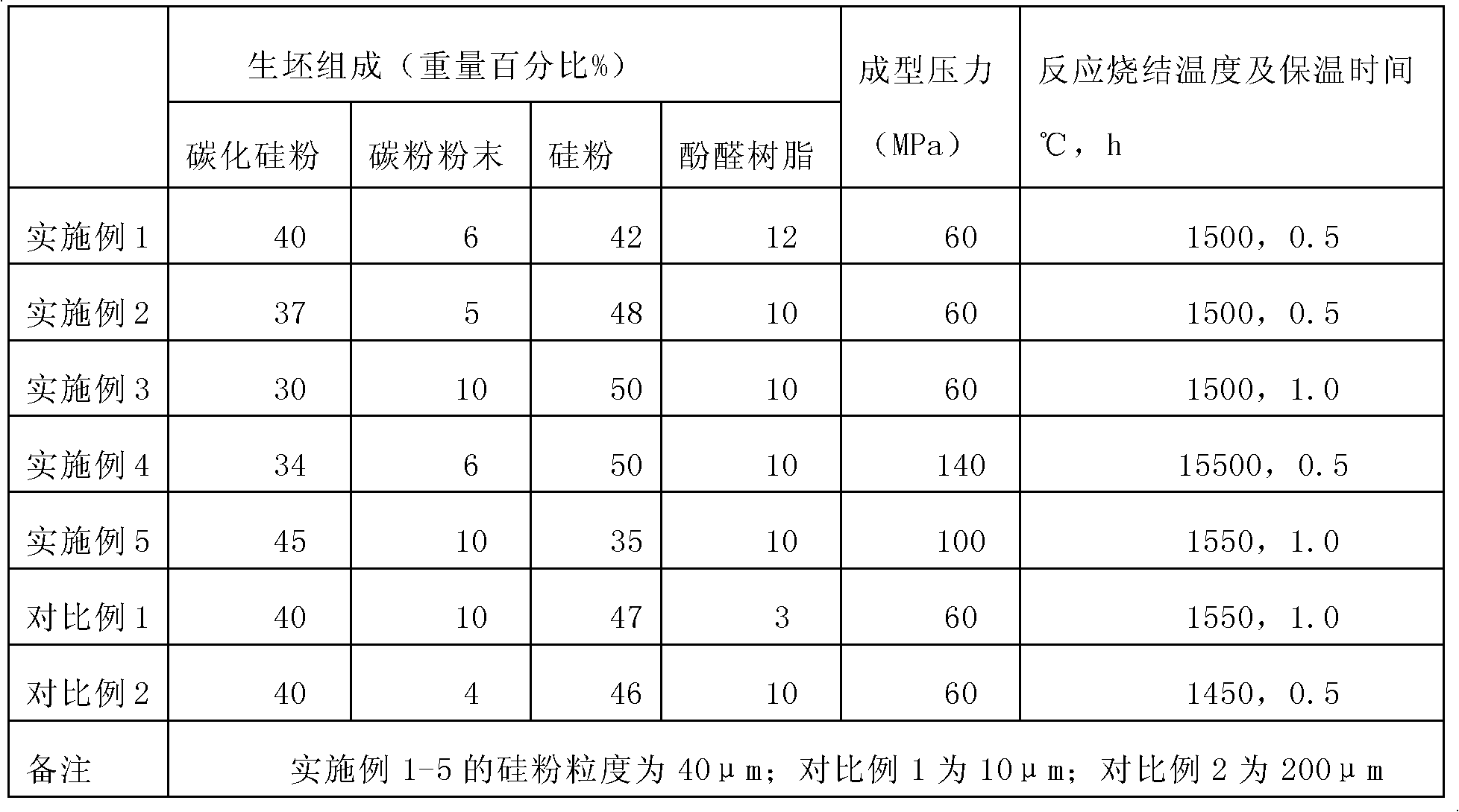

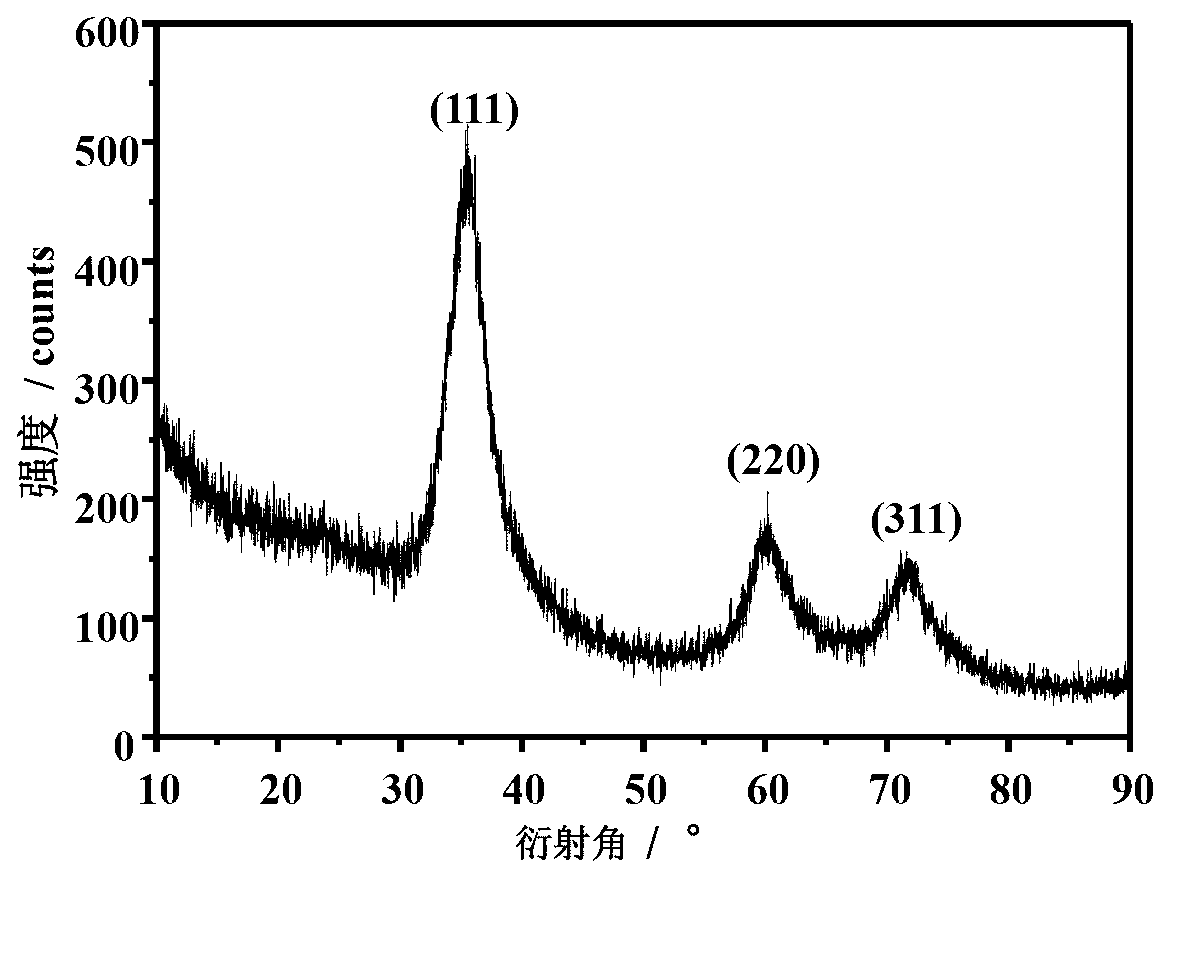

Silicon carbide porous ceramic and preparation method thereof

The invention discloses silicon carbide porous ceramic and a preparation method thereof. The silicon carbide porous ceramic is characterized by comprising the following components in percentage by weight: 30 to 45 percent of silicon carbide powder, 5 to 10 percent of carbon powder, 35 to 50 percent of silicon powder and 3 to 12 percent of adhesive phenol resin. The method comprises the following steps of: ball-milling the silicon carbide powder, the carbon powder and the silicon powder and wet-mixing to obtain mixed powder; adding the adhesive phenol resin for granulation; performing compression molding; drying a molded green body and then placing into an air furnace to remove adhesives; sintering the green body according to a reaction sintering process after the adhesives are removed; and recrystallizing a product obtained by the reaction sintering at the high temperature of over 2,000 DEG C and removing silicon to obtain a single-phase porous silicon carbide material. The porous silicon carbide material prepared by the invention has the characteristics of controllable porosity, high strength, high corrosion resistance and high thermal stability, can be widely used as a filteringmaterial in high temperature atmospheres and corrosive atmospheres and a carrier material for a chemical reaction and can be used for high-temperature heat insulation.

Owner:XI AN JIAOTONG UNIV

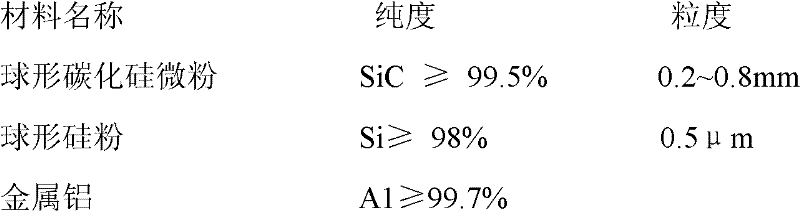

Method for preparing aluminum silicon carbide composite material

The invention discloses a method for preparing an aluminum silicon carbide composite material. Liquid metal aluminum is filled in a porous silicon carbide substrate which is prepared from spherical silicon carbide powder and spherical silicon powder which serve as raw materials and has a three-dimensional through hole structure through an injection molding process so as to form a bicontinuous phase, the density of the aluminum silicon carbide composite material and the product uniformity are improved, and a high-strength AlSiC substrate is obtained by changing molding pressure, adjusting ingredients of the spherical powder with different particle sizes, adding a pore-forming agent, and sintering at the temperature of between 1,400 and 2,400 DEG C. The porous substrate is fixed in a cavityof an injection machine, and the liquid metal aluminum enters the cavity from an injection port and is filled in through holes of the AlSiC substrate through a gas-liquid mixed injection process so as to form the aluminum silicon carbide composite material with a silicon carbide and metal aluminum bicontinuous phase structure. The aluminum silicon carbide composite material prepared by the process has the heat conductivity of 190 to 280 W / mK and the thermal expansion coefficient of 5.5 to 11.5*10(-6)K at room temperature of 200 DEG C, and has high rigidity, low density, high weldability and low machining amount.

Owner:CENT SOUTH UNIV

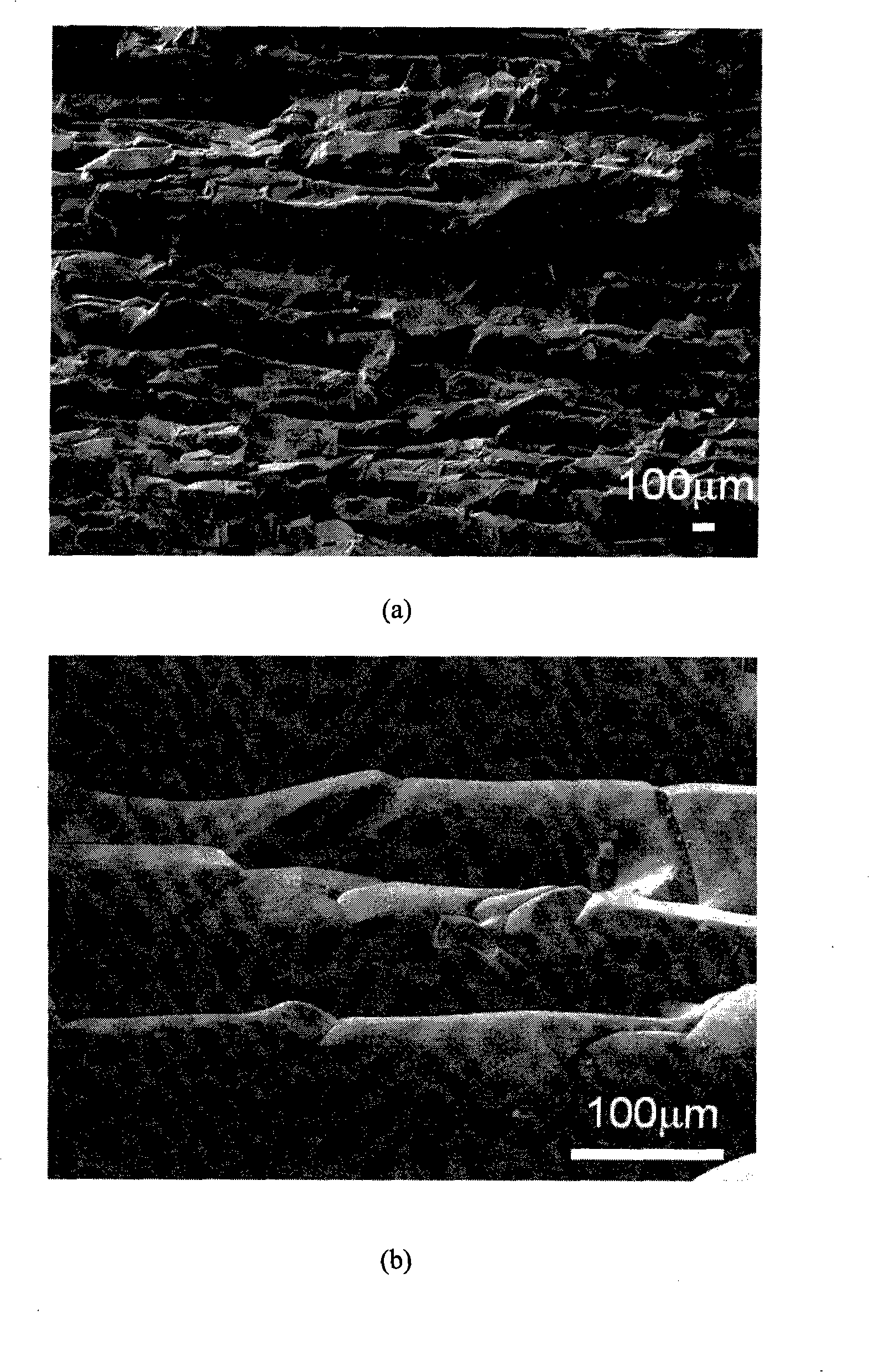

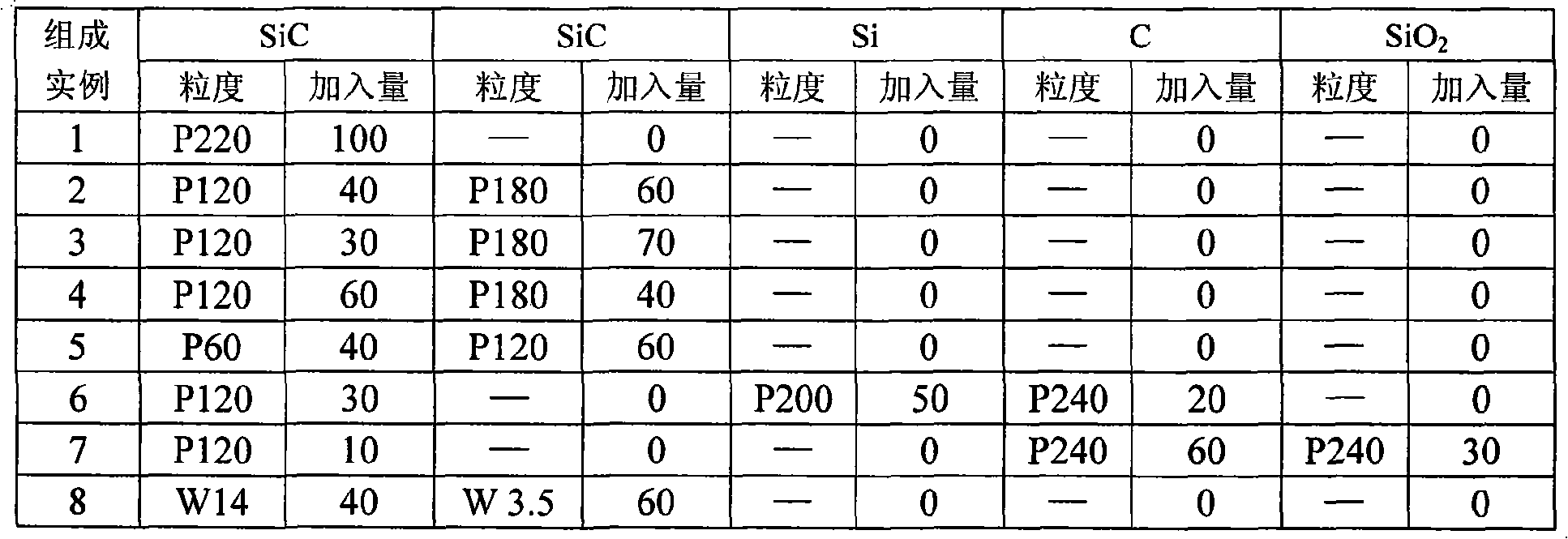

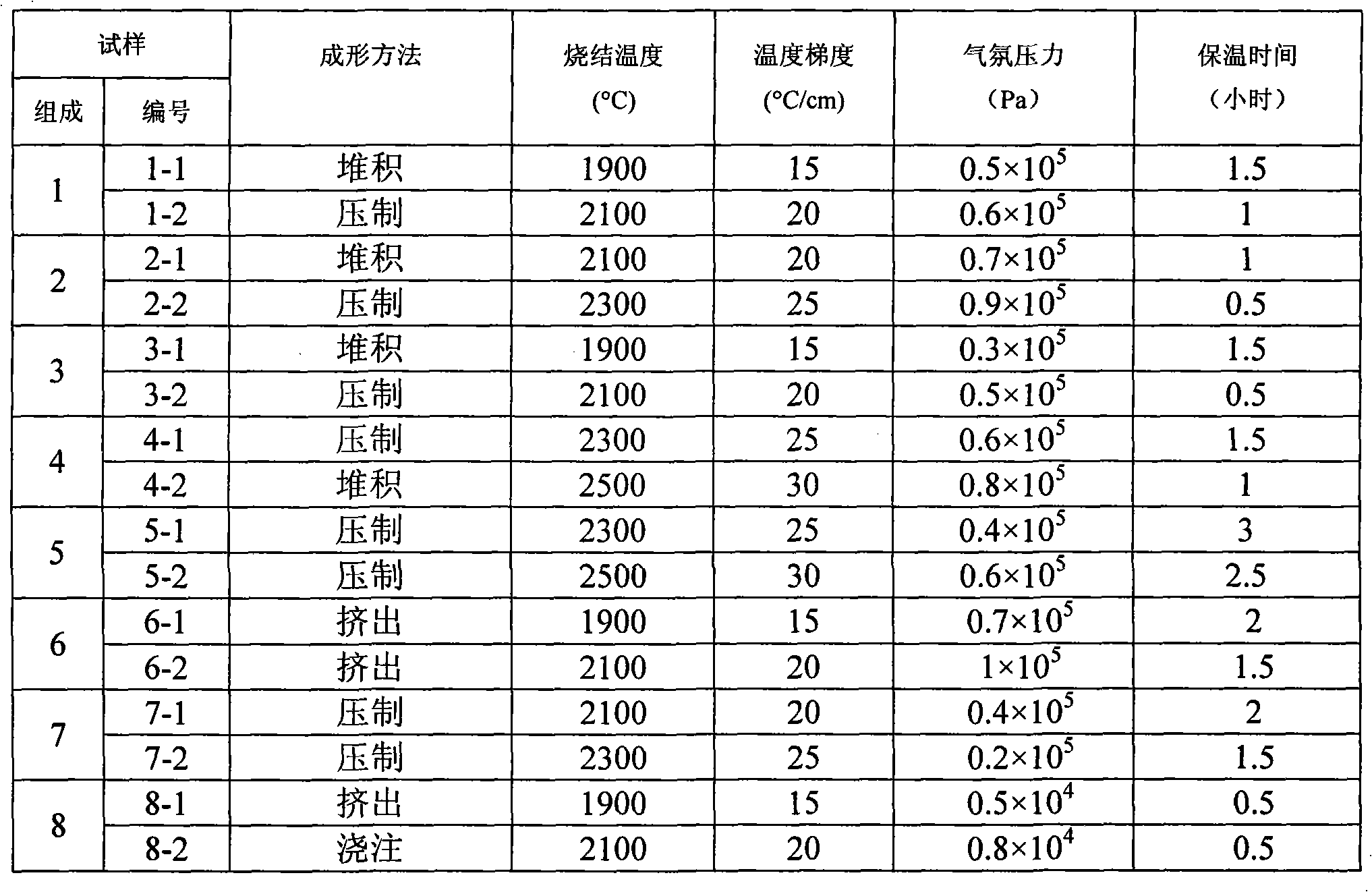

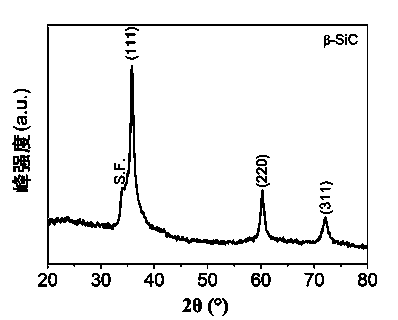

Preparation of oriented hole silicon carbide porous ceramic

InactiveCN101323524AControl evaporation-condensation directionAdjust evaporation-condensation rateCeramicwareGranularitySaggar

The invention discloses a preparation method of a porous silicon-carbide ceramic provided with oriented pores. Firstly, according to weight percentage, 0 to 30 percent of carbon powder, 0 to 50 percent of silicon powder and 0 to 60 percent of silica are added into the 10 to 100 percent of the basic material of silicon-carbide; wherein, the granularity of the silicon-carbide is W3.5 to P220, and one granularity or two granularities are adopted for graduation; then the equally mixed materials are processed through powder accumulation or normal ceramic forming process to obtain a green compact which is put into a graphite crucible or a saggar; the graphite crucible or saggar is placed into a vacuum sintering furnace provided with a temperature field with a temperature grade from 15 to 30 DEG C / cm, and then the temperature is raised to 1900 to 2500 DEG C in an argon environment and with pressure of 0.2 to 1 multipliedby 10 <5>Pa, and the insulation work for the graphite crucible or saggar is preserved for 0.5 to 3 hours; finally the temperature naturally falls down under air protection and the sintered body is taken out, namely, the recrystallization porous silicon-carbide ceramic provided with oriented pores is obtained.

Owner:XI AN JIAOTONG UNIV

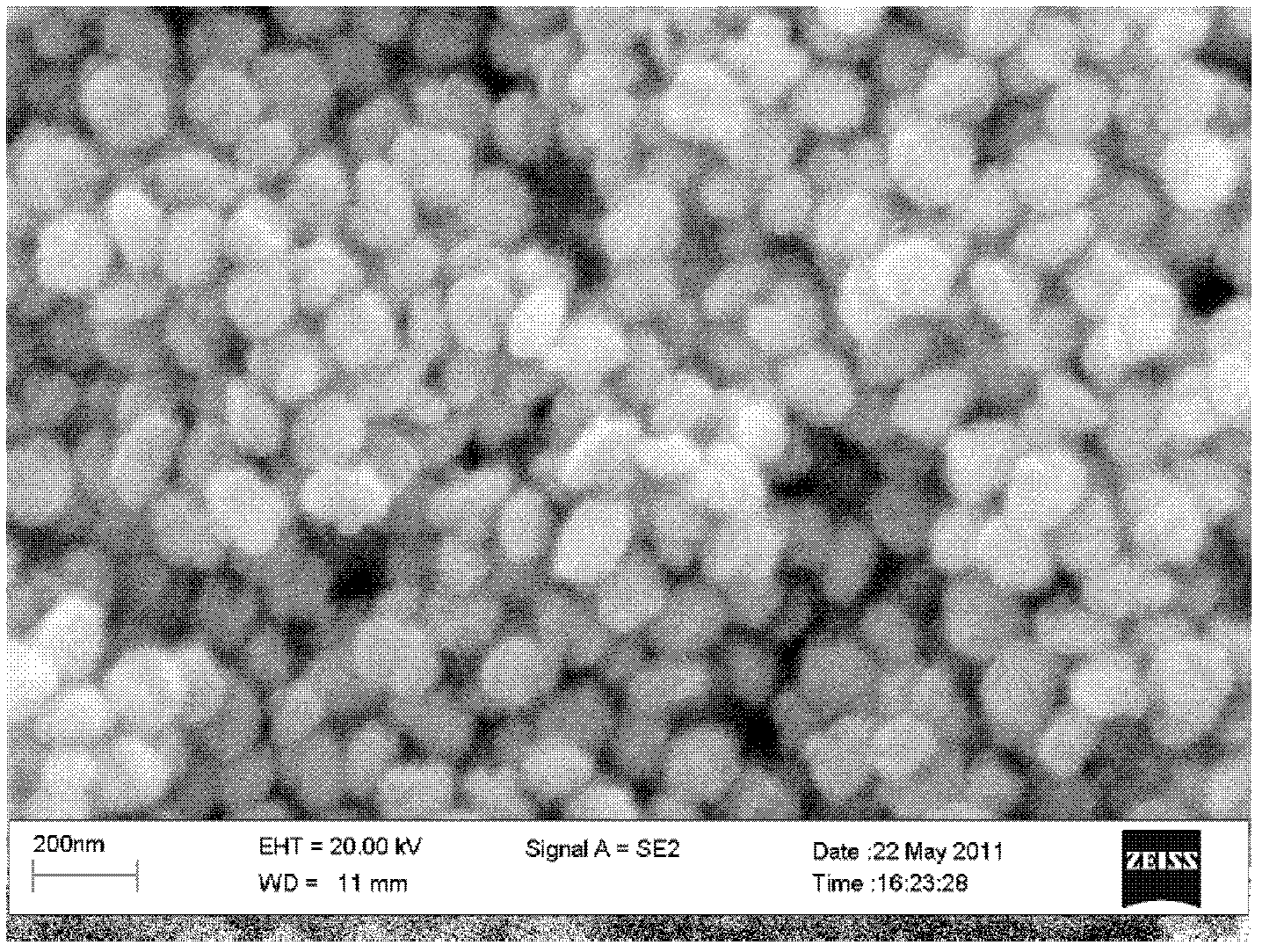

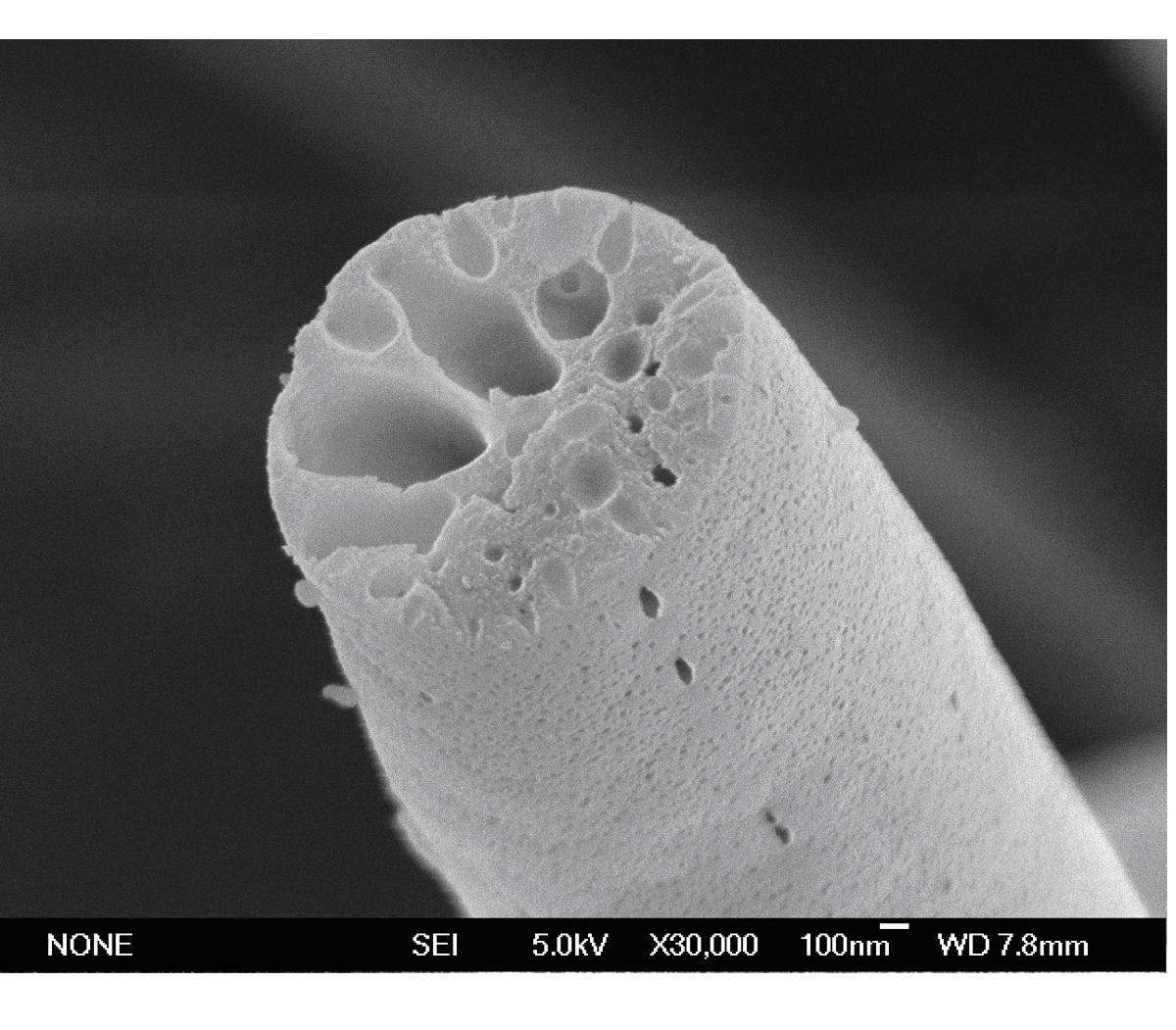

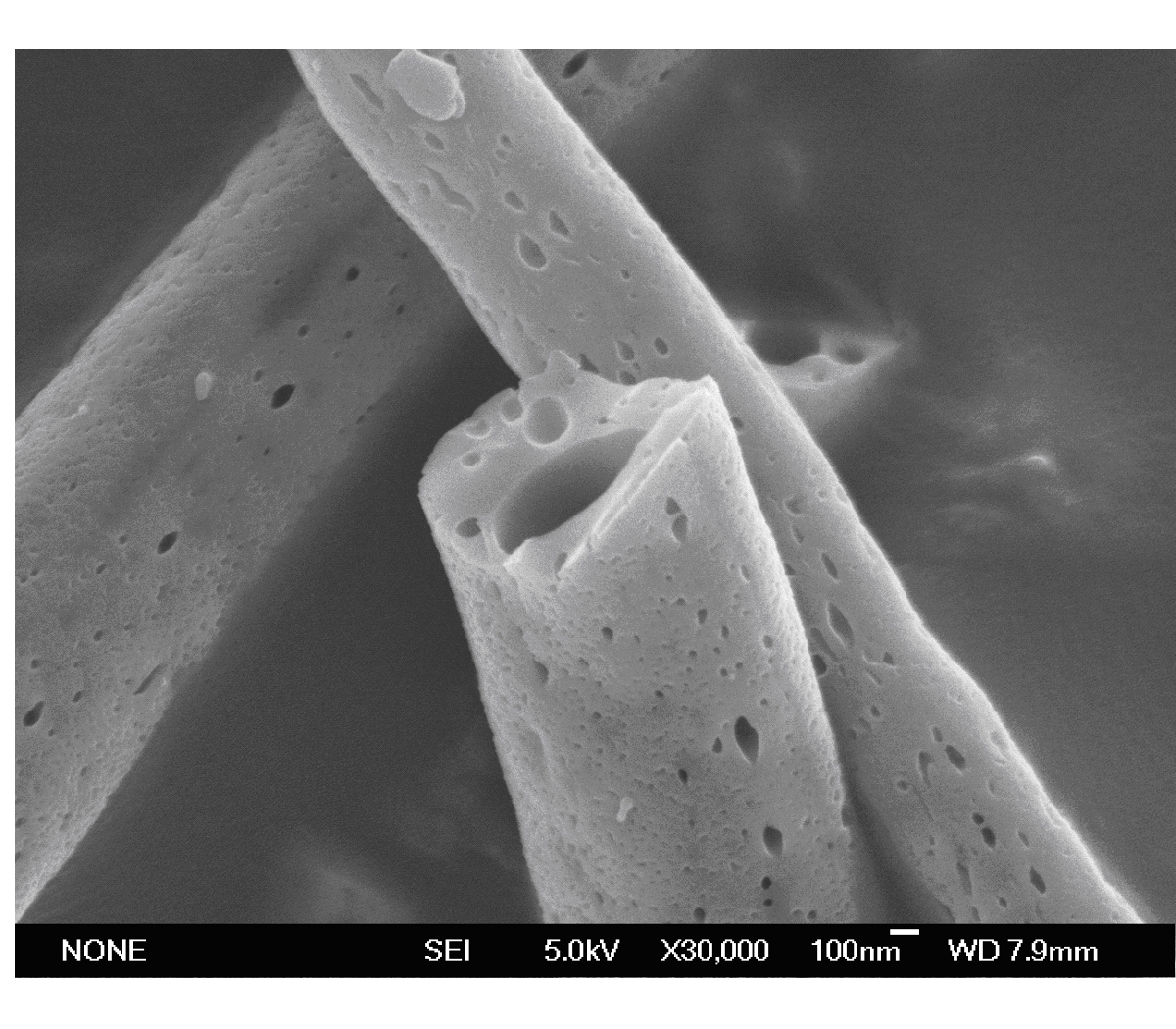

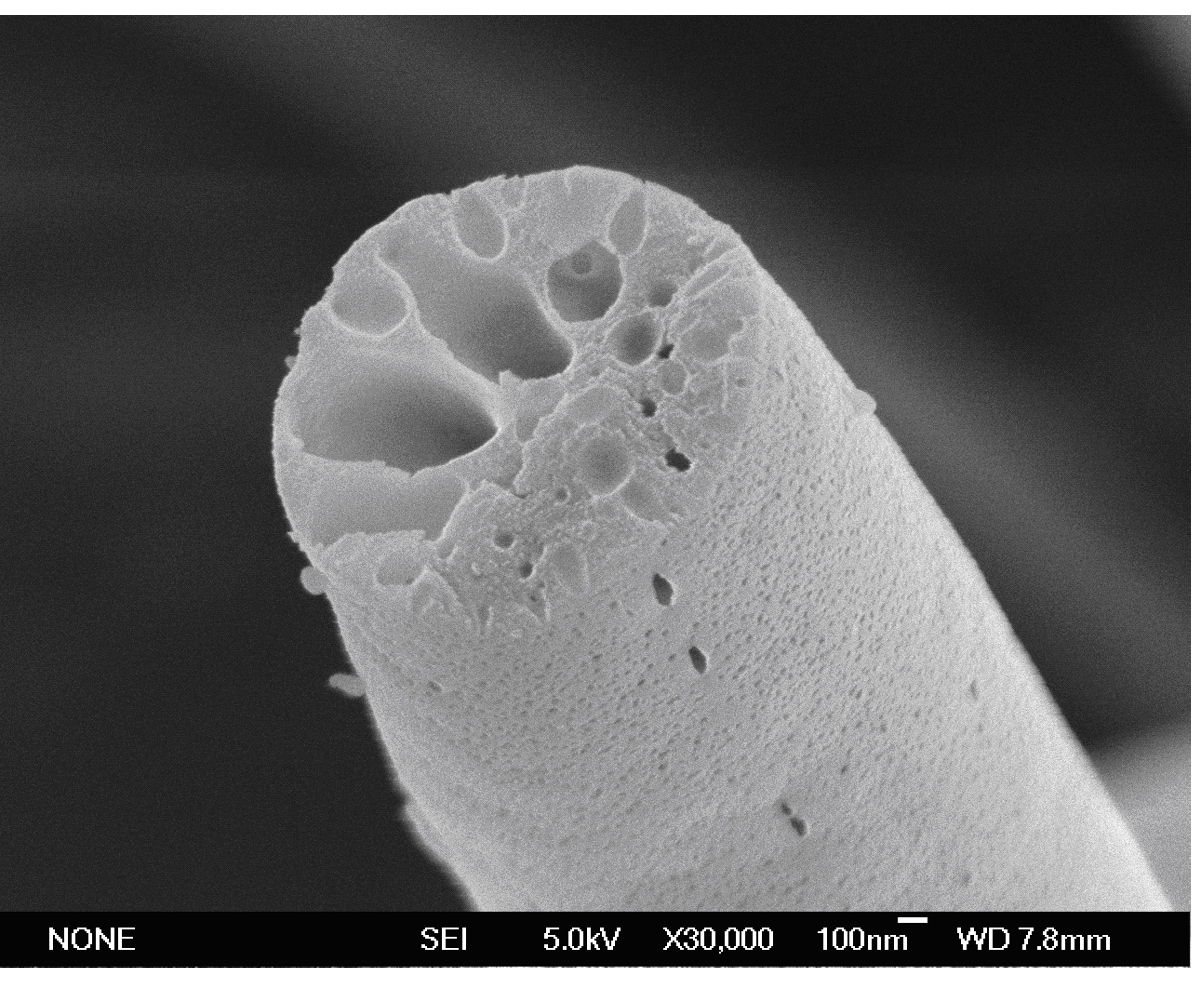

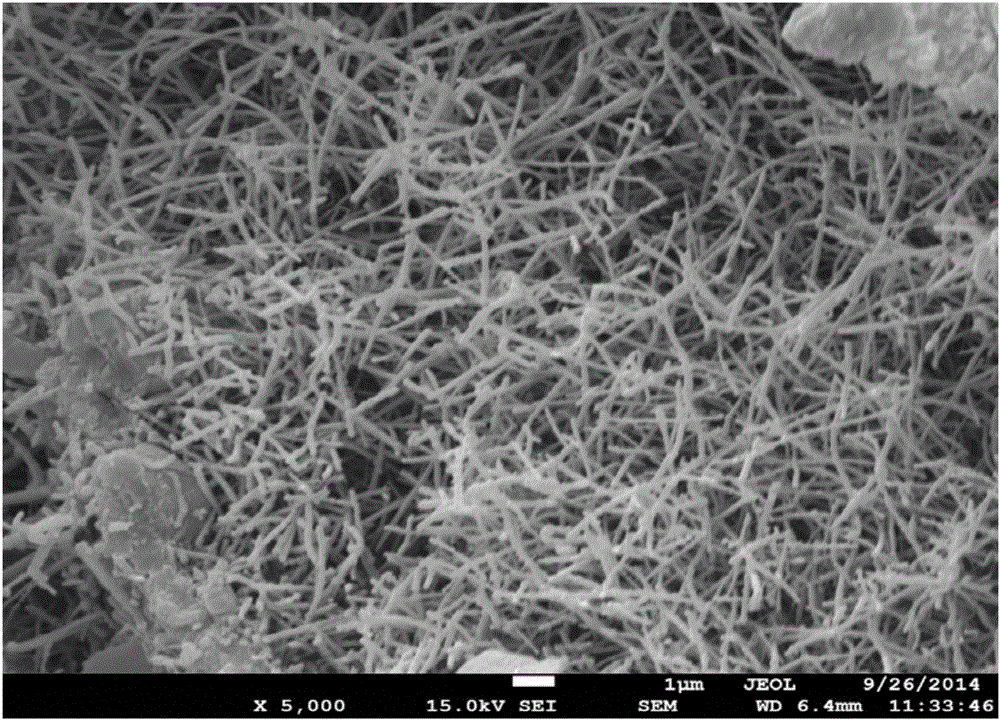

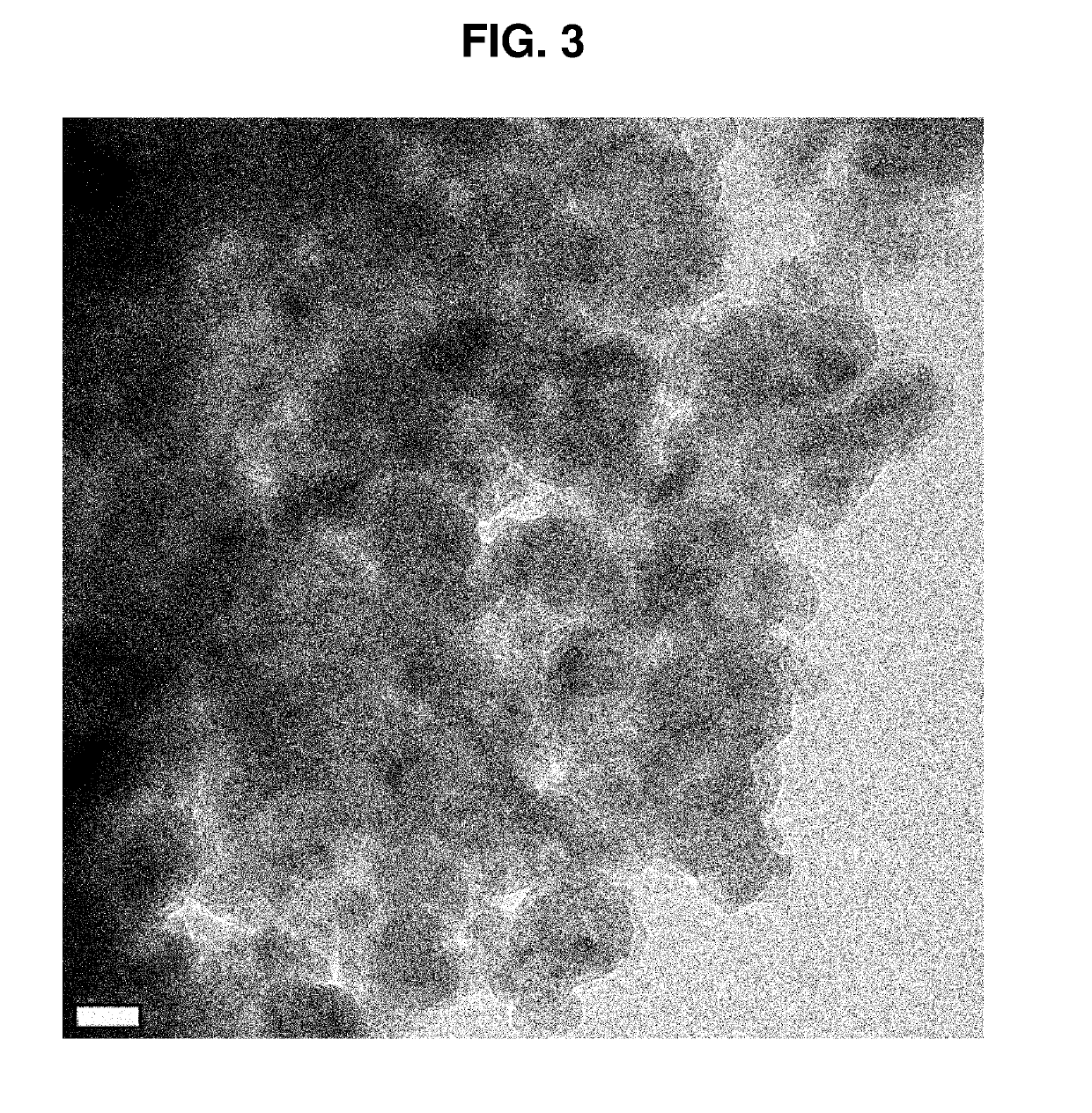

Preparation method of porous silicon carbide nanofiber

ActiveCN103966701AUniform diameterLarge specific surface areaArtificial filament chemical after-treatmentFiltrationElectrospinning

The invention discloses a preparation method of a porous silicon carbide nanofiber. The preparation method comprises the following steps of: (1) preparing a carbon nanofiber precursor polymer spinning solution; (2) performing electrostatic spinning to prepare a polymer nanofiber; (3) carrying out pre-oxidization crosslinking on the polymer nanofiber; (4) carrying out high-temperature firing on the pre-oxidized polymer nanofiber to prepare a carbon nanofiber; and (5) carrying out carbon thermal reduction on the carbon nanofiber and silicon powder to obtain the porous silicon carbide nanofiber. According to the preparation method, the morphology, the diameter and the ordering of the obtained silicon carbide nanofiber can be effectively regulated and controlled through simple means; the production cycle is relatively short so that expanded production can be conveniently realized and the preparation process is simple so that the industrial production can be conveniently realized; the porous silicon carbide nanofiber has wide application prospect in the fields of high-temperature filtration, high-temperature catalysis, catalyst carriers, heat insulation and sound insulation, gas separation, chemical sensors and the like.

Owner:NAT UNIV OF DEFENSE TECH

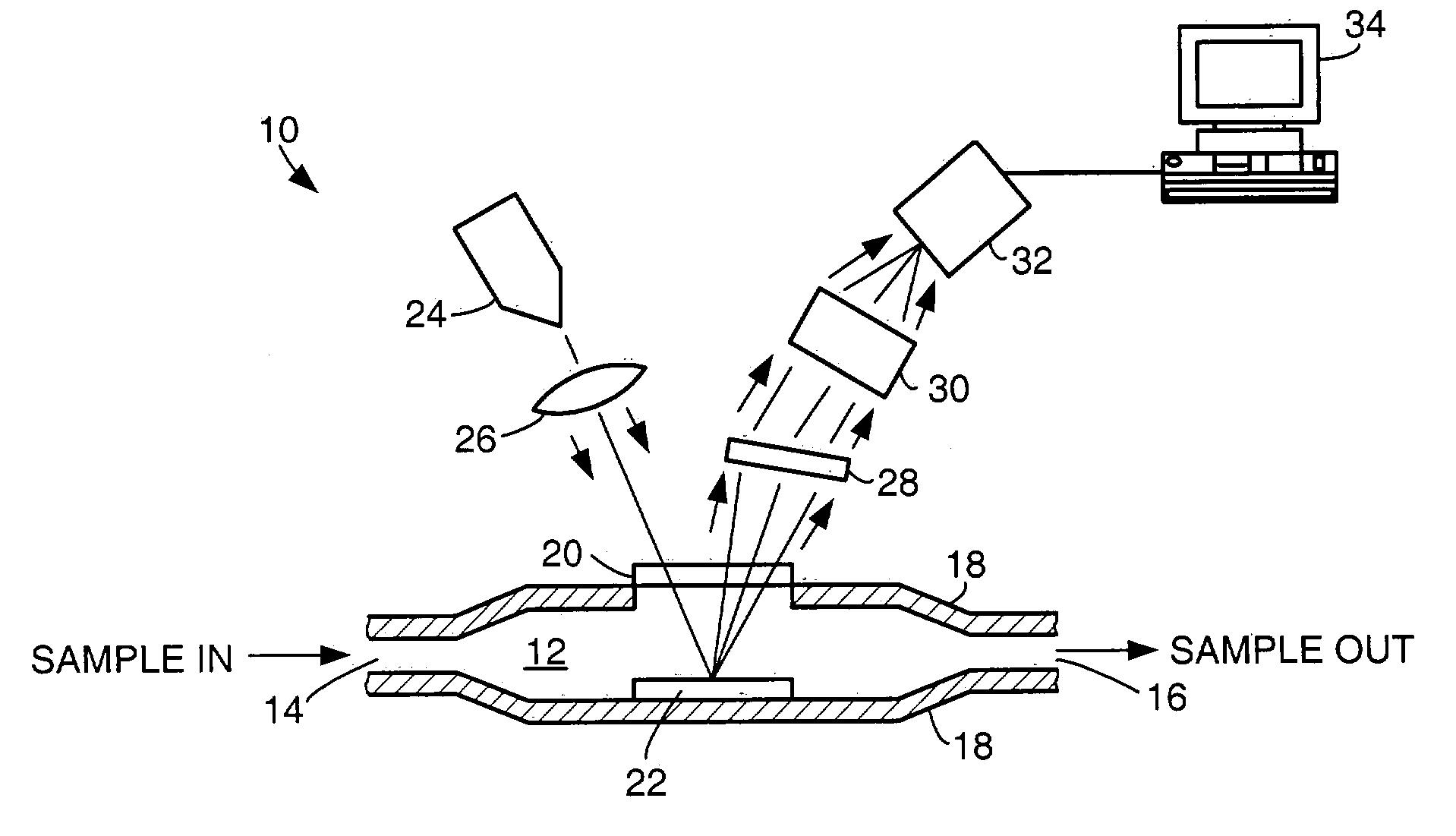

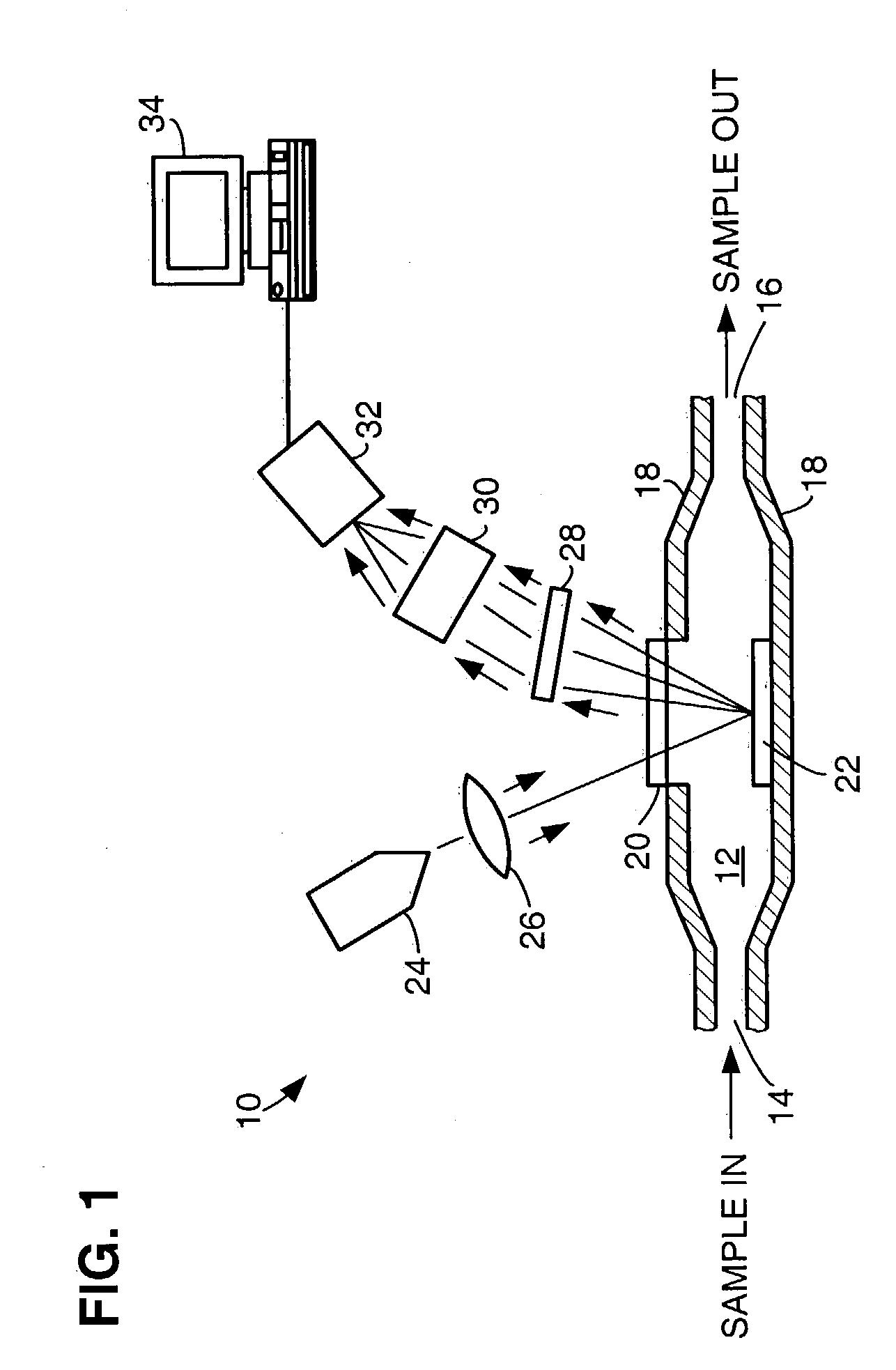

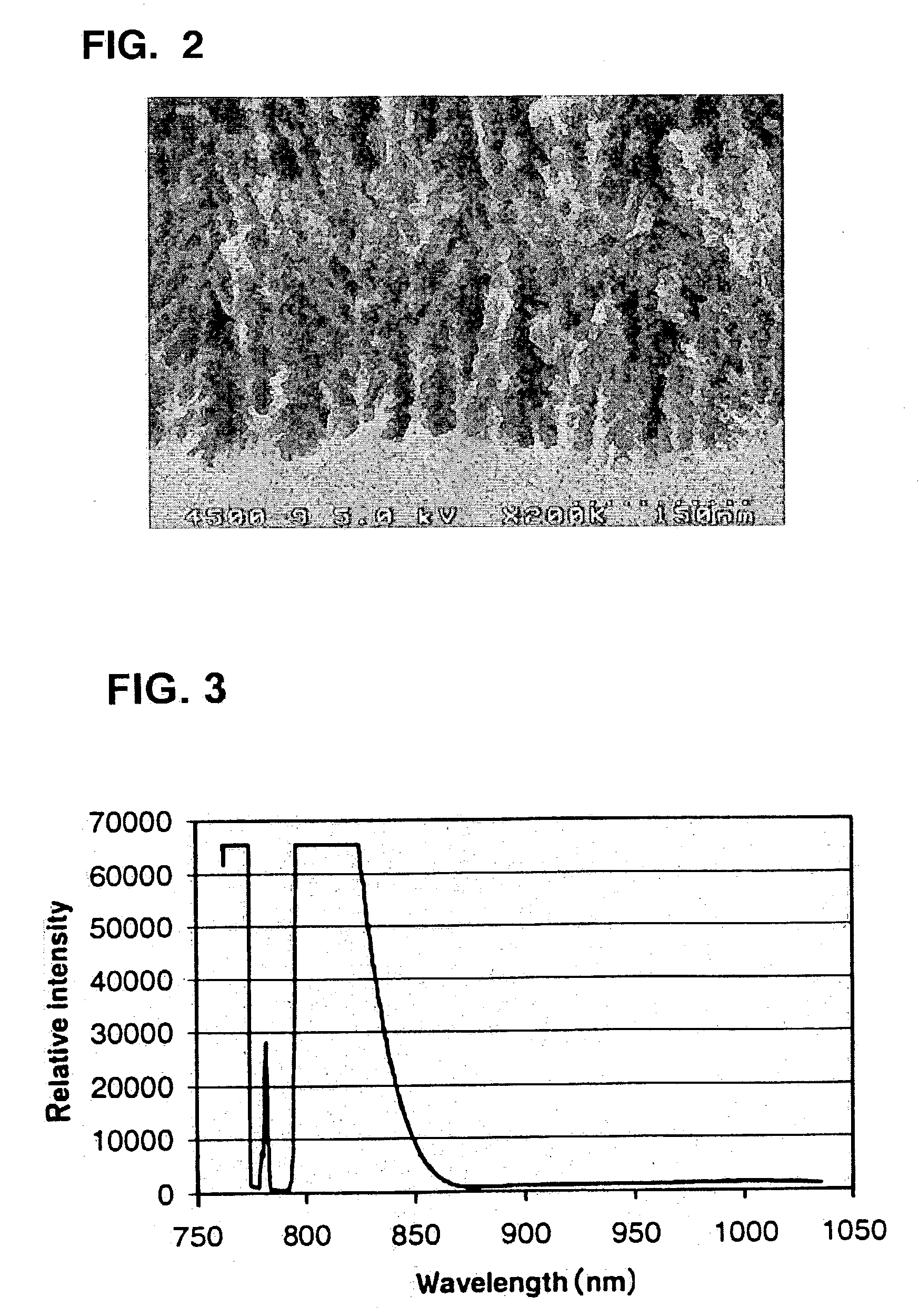

Method, structure, and apparatus for Raman spectroscopy

Disclosed herein are a Raman spectroscopy structure comprising a porous material substrate, and a method of performing Raman spectroscopy of a sample disposed adjacent to the structure comprising the porous material substrate. Generally, the substrate includes one or more layers of a porous material such as porous silicon, porous polysilicon, porous ceramics, porous silica, porous alumina, porous silicon-germanium, porous germanium, porous gallium arsenide, porous gallium phosphide, porous zinc oxide, and porous silicon carbide. It has been discovered that such a substrate material, when excited with near-infrared light, does not exhibit undesired background fluorescence characteristic of other known Raman spectroscopy substrates.

Owner:INTEL CORP

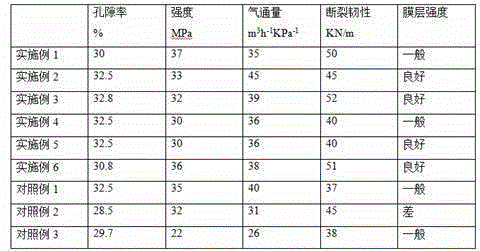

Silicon carbide ceramic membrane and preparation method thereof

ActiveCN105130441ALower sintering temperatureHigh strengthDispersed particle filtrationCarbide siliconCeramic membrane

The invention relates to a silicon carbide ceramic membrane and a preparation method thereof, belonging to the field of preparation of porous ceramic materials. The preparation method comprises the following steps: mixing SiC aggregate, a sintering aid, a toughening aid and a high-molecular binder in proportion; and then successively carrying out stirring and ball milling, molding, high temperature sintering, coating and sintering so as to obtain the porous silicon carbide ceramic membrane. The silicon carbide ceramic membrane prepared in the invention has the advantages of high porosity, great toughness, low sintering temperature, thermal shock resistance, etc., and can be widely applied to the field of high temperature gas-solid separation.

Owner:JIANGSU JIUWU HITECH

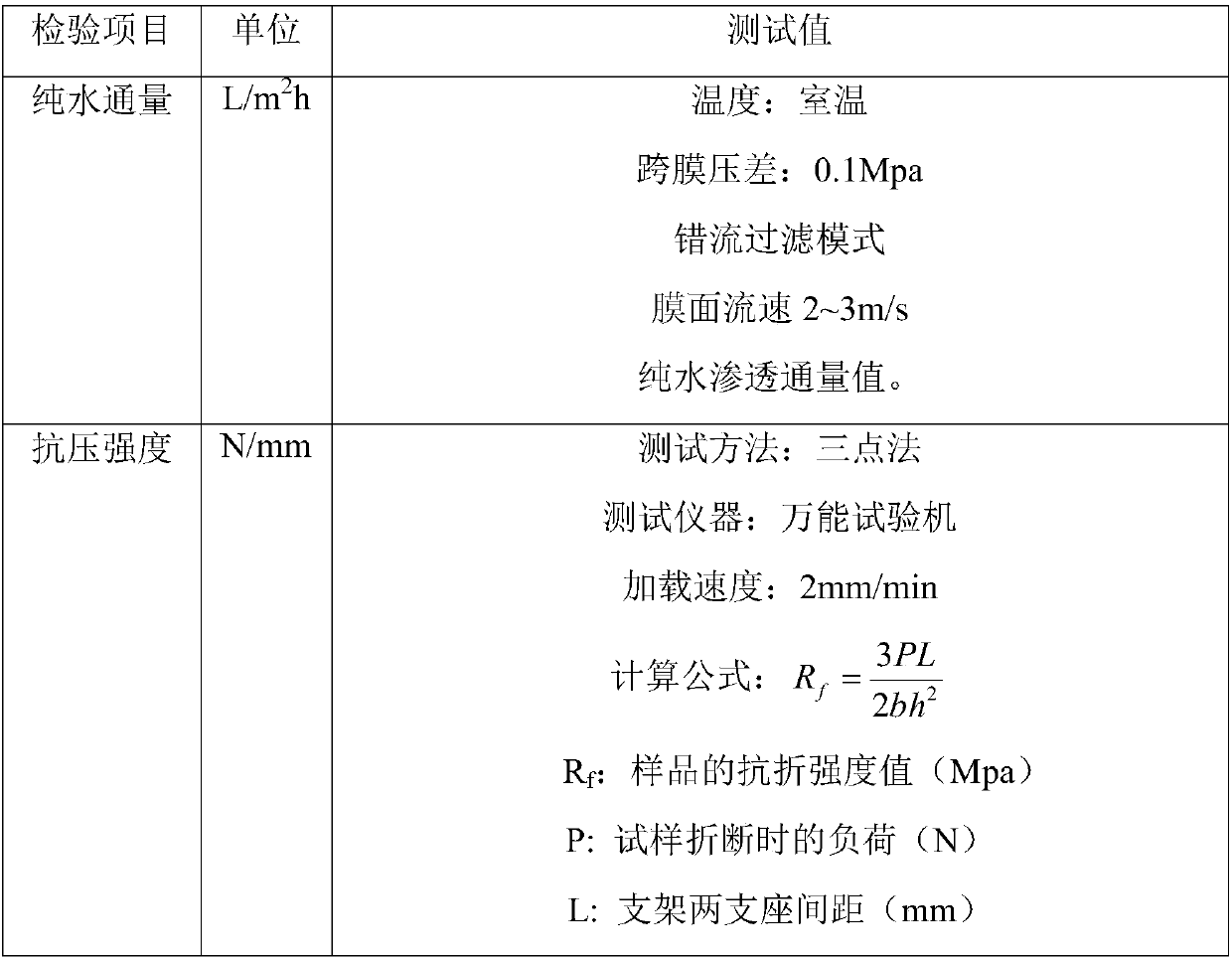

Preparation method of low-temperature sintering acid and alkali resistant porous silicon carbide ceramic film

ActiveCN107663088AImprove hydrophilicityImprove pollutionCeramicwareSeparation technologyPorous ceramics

The invention relates to the technical field of porous ceramic materials and film separation, in particular to a low-temperature sintering acid and alkali resistant porous silicon carbide ceramic filmand a preparation method thereof. The method sequentially comprises the following steps of (1) support body manufacturing; (2) transition layer processing; (3) filtering layer processing; (4) film sintering process. The method provided by the invention has the characteristics that the sintering temperature is low; the production energy consumption is low; the process method is simple; the equipment requirements are low; the production cost and the investment cost are low; the control is flexible; the shaping is easy; the method is suitable for industrial customization and meets the scaled production. The porous silicon carbide ceramic film produced by the method has the characteristics of good hydrophilcity, great filtering flux, high porosity, high filtering precision, high mechanical intensity, good acid and alkali resistant performance and long service life.

Owner:ZHEJIANG SCI-TECH UNIV

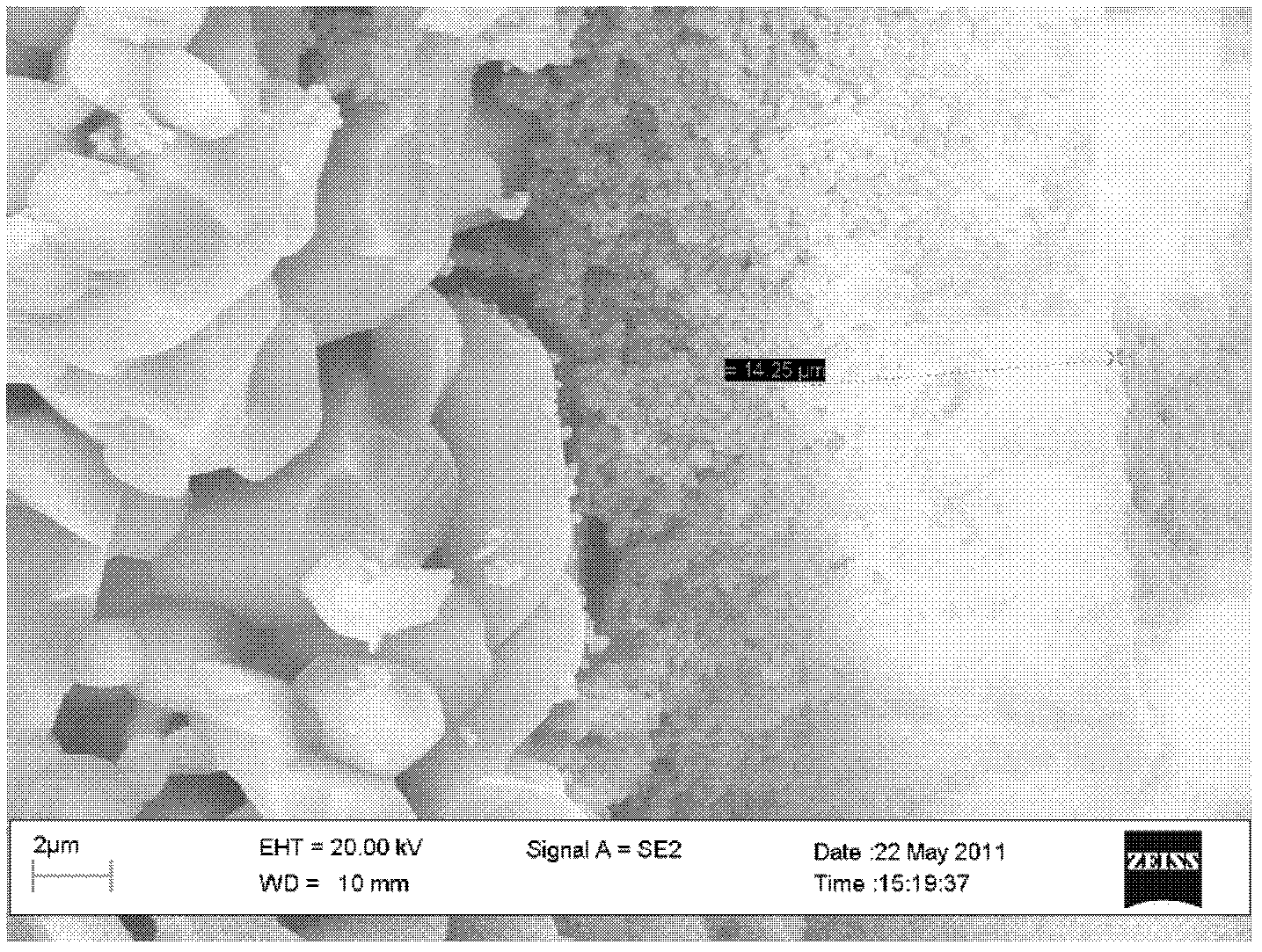

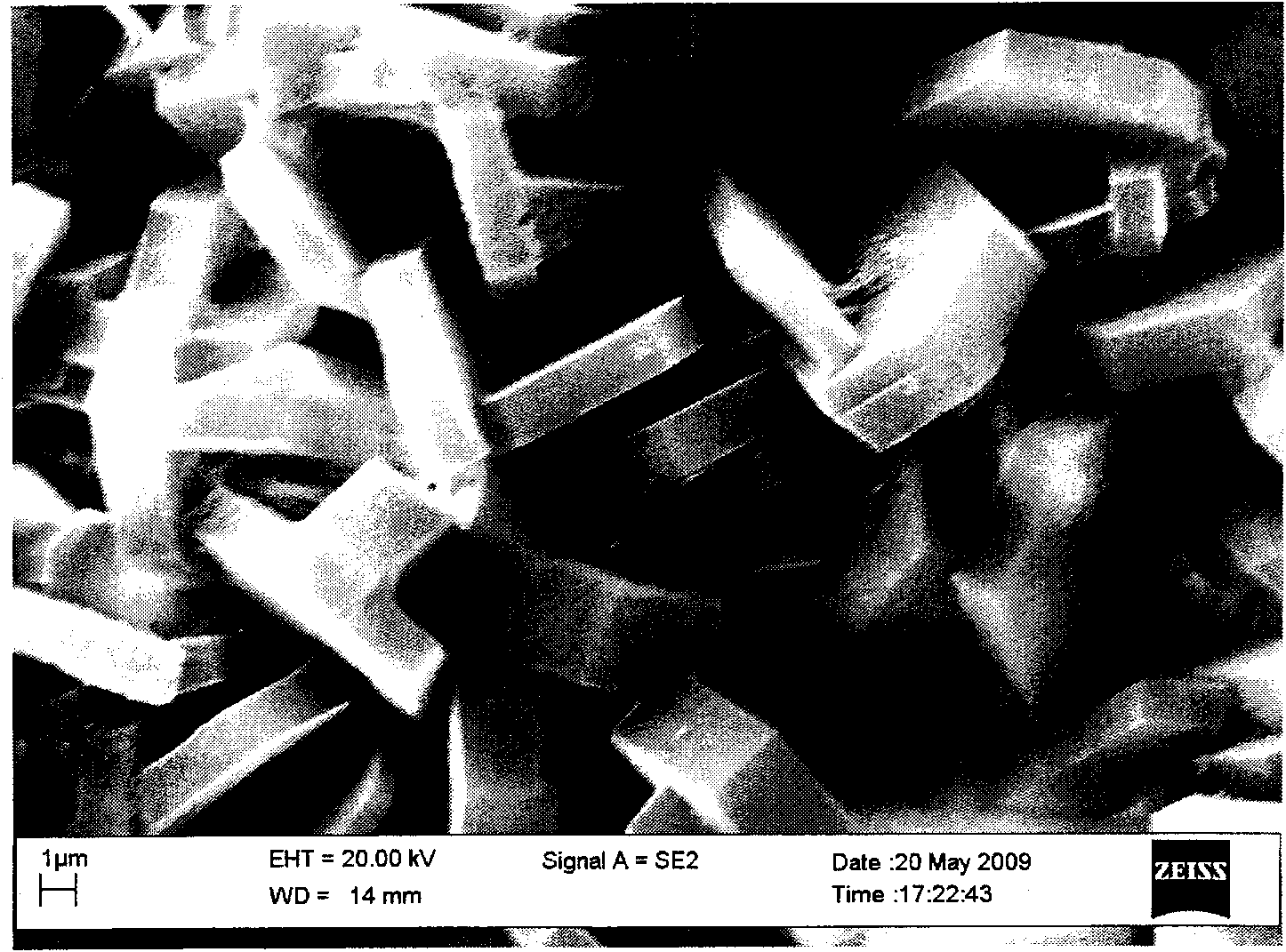

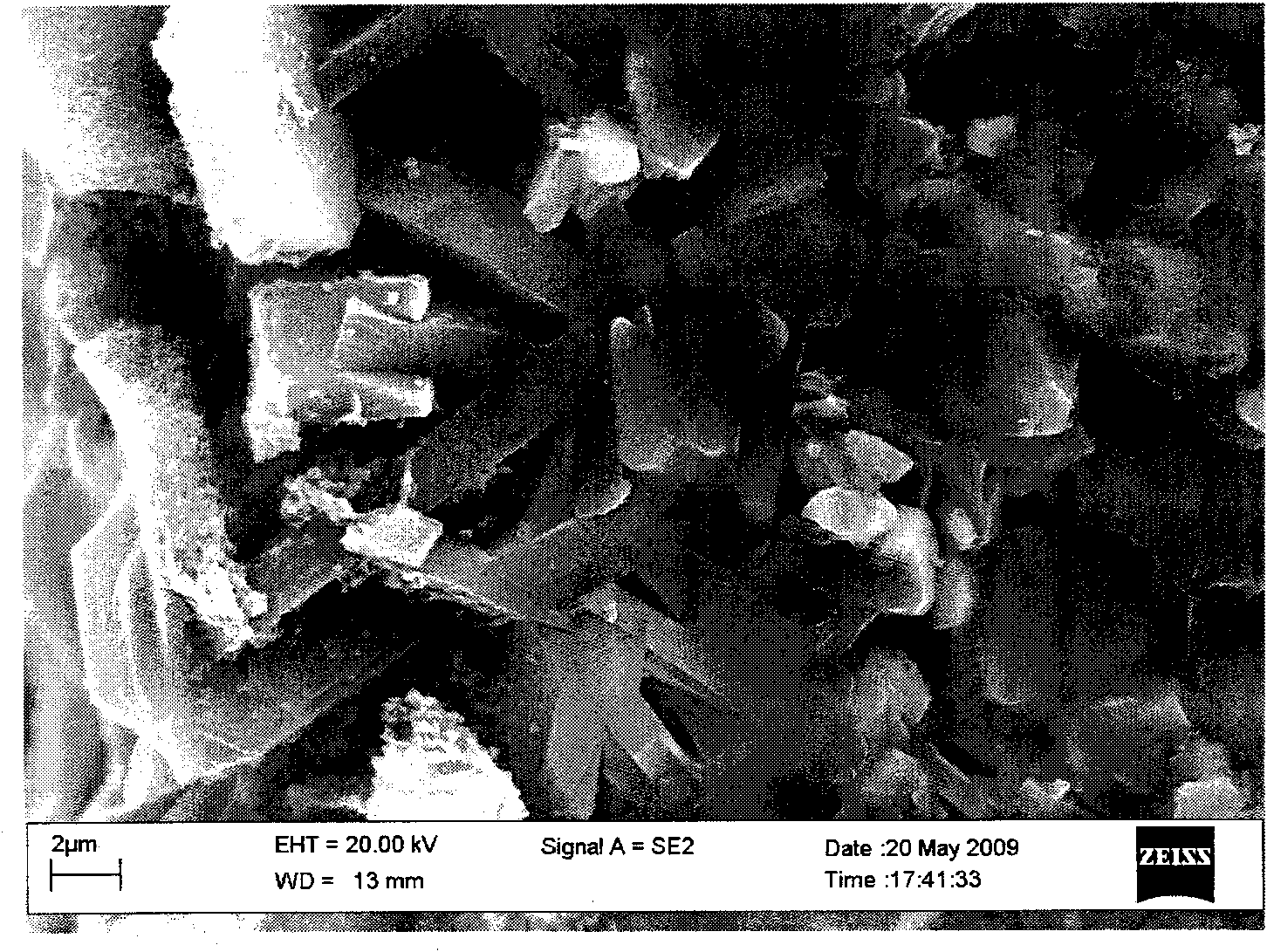

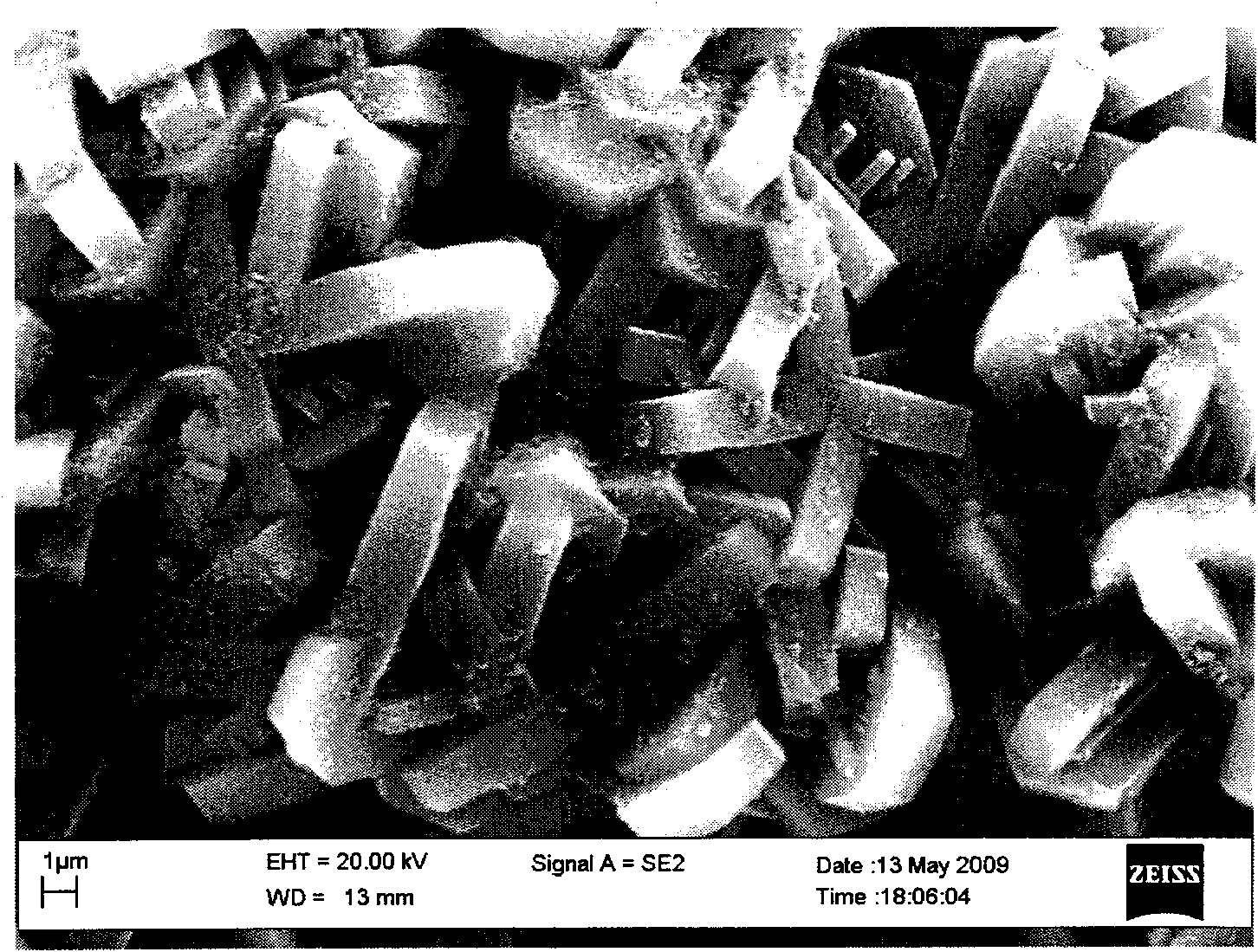

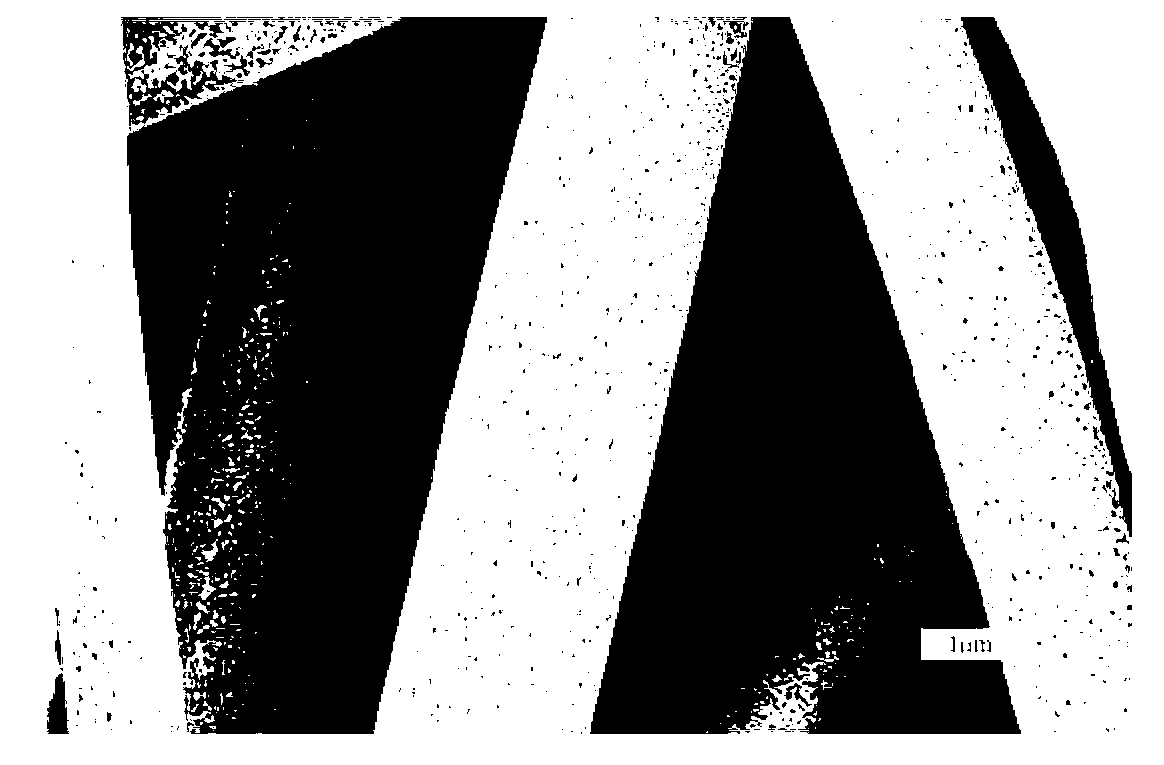

Ultrafine molecular sieve structured catalytic material based on porous silicon carbide carrier and preparation thereof

ActiveCN102716762ACrystal size can be controlledImprove bindingMolecular sieve catalystsMolecular sieveHigh activity

The invention, belonging to the technical field of catalyst and its application, particularly relates to an ultrafine molecular sieve structured catalytic material based on a porous silicon carbide carrier and a preparation method thereof. The material comprises ultrafine molecular sieve crystals as active elements and has a hierarchically porous structure, and the whole ultrafine molecular sieve coating has catalytic activity. The method is characterized by coating a colloidal molecular sieve precursor on the surface of a modified foam silicon carbide carrier, converting the molecular sieve precursor into ultrafine molecular sieve crystals by vapor phase treatment to realize the firm combination between the coating and the carrier. According to the invention, by controlling the synthesis conditions of the colloidal molecular sieve precursor and the method of adding a pore forming agent, the size of the molecular sieve crystals, silica-alumina ratio and intercrystalline porosity can be controlled; a pore structure and the type of the molecular sieve can be designed according to the geometrical structure of a target product; and the capacity of accommodating carbon is raised, the mass transfer capability of the catalyst is reinforced, and the life of catalyst is prolonged while keeping the high activity of the ultrafine molecular sieve and high target product selectivity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing porous silicon carbide ceramic

The invention belongs to the field of inorganic non-metallic materials and relates to a method for preparing porous silicon carbide ceramic. The method comprises that alkaline silica sol and silicon carbide ceramic powder are subjected to ball milling mixing to form silicon carbide ceramic water-based suspension slurry, a surfactant is added into the silicon carbide ceramic water-based suspension slurry, the mixture is stirred and foams at designed multiplying power, the foaming slurry is added with a coagulation accelerator, the mixture is stirred to form uniform slurry, the uniform slurry is poured into a mold without hydroscopicity, the alkaline silica sol is gelation-cured under the action of the coagulation accelerator, the blank is subjected to mold release and drying, then the blank is immersed with a certain amount of a C source-containing solution, and after solvent volatilization, the blank is subjected to reactive sintering at a high temperature in an argon protective atmosphere to produce the porous silicon carbide ceramic. The method has simple processes, low equipment requirements, uniform aperture distribution, controllable porosity and less pollution and can be used for industrial production of the porous silicon carbide ceramic with high porosity.

Owner:AVIC COMPOSITES

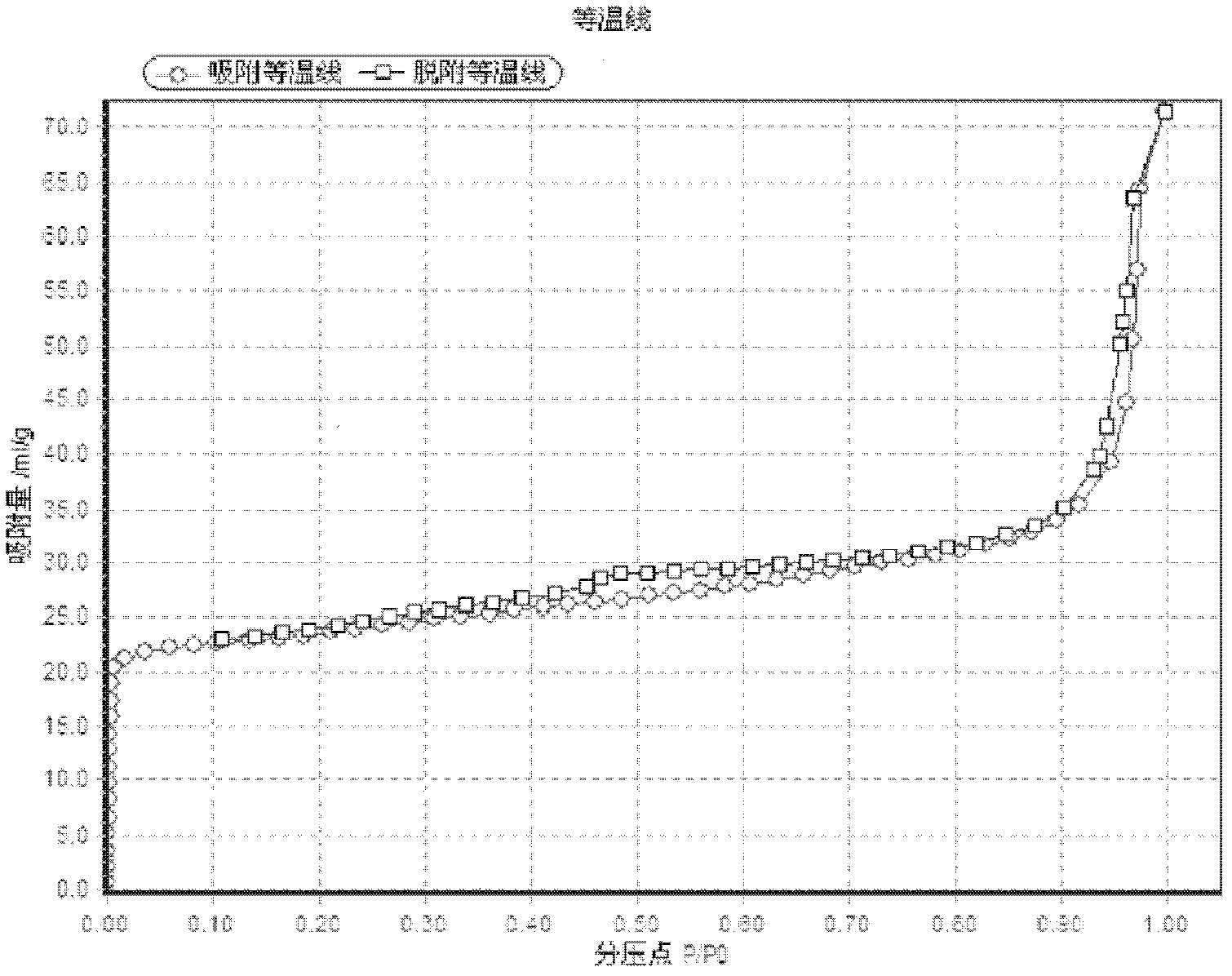

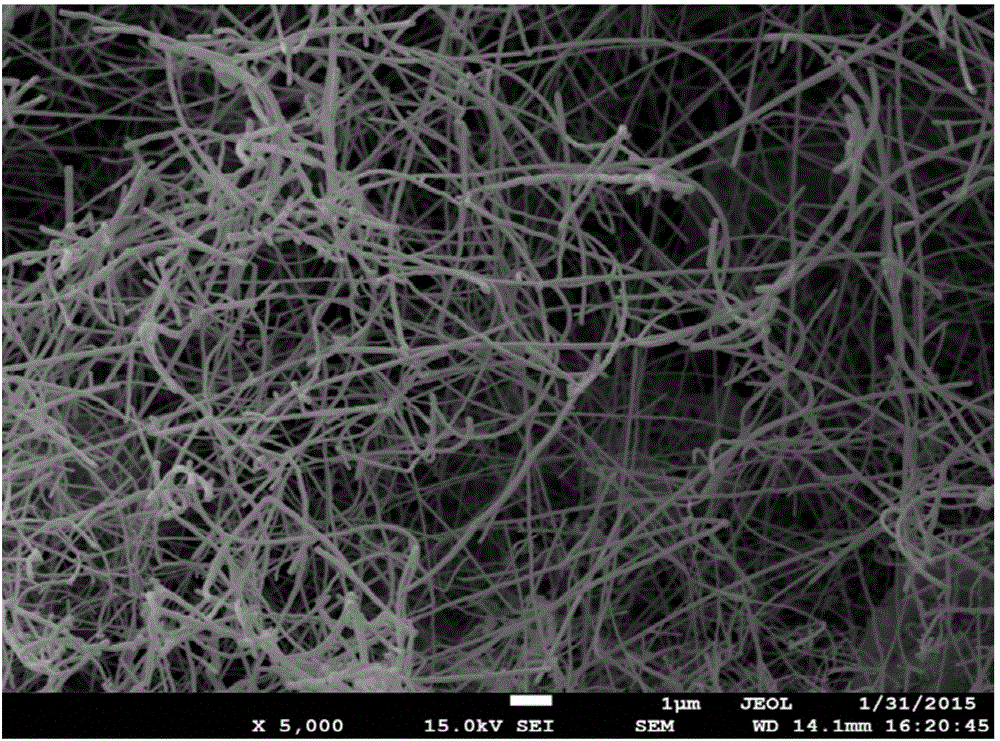

Porous silicon carbide fibers and preparation method thereof

InactiveCN101876095ALarge specific surface areaRealize electrospinningSpinning head liquid feederFilament/thread formingElectrospinningFractionation

The invention discloses porous SiC fibers and a preparation method thereof. The porous SiC fibers are characterized in that the content of Si accounts for 50-60wt%, the content of C accounts for 30-40wt%, and the balance is O, the fibers are felty, the diameter of the fibers is 0.5-2.0 mu m, the porosity is greater than 60vol%, wherein the mesopore volume is greater than 50vol%, and the specific surface area is 400-800 m<2> / g. The preparation method is characterized in that poly carbon silicon alky suspension solution which can spin electrically is prepared by utilizing a precipitation fractionation principle, electrostatic spinning of the extremely dilute carbon silicon alky solution is realized, a large number of mesopore structures are introduced, thus firstly preparing poly carbon silicon alky porous fibers, and then after non-melting and sintering, the porous SiC fibers are prepared. The porous SiC fibers have good application prospects in fields such as high-temperature catalysis, heat insulation, heat preservation, sound insulation and the like. The method has universality and can be used for realizing electrostatic spinning of extremely dilute solution of other precursor polymers and for preparing corresponding porous ceramic fibers.

Owner:NAT UNIV OF DEFENSE TECH

Process for the manufacturing of dense silicon carbide

InactiveUS20060003098A1Reduce porosityImprove propertiesPretreated surfacesChemical vapor deposition coatingPorous carbonNet shape

A method of producing a densified SiC article is provided. Near-net shape porous silicon carbide articles are produced and densified using the developed method. A substantial number of pores within the porous near-net shape silicon carbide article are filled (impregnated) with a carbon precursor, a silicon carbide precursor, or a mixture of both. The carbon precursor can be liquid or gas. The filled SiC preform is heated to convert the carbon or silicon carbide precursor to porous carbon or SiC preform inside the pores of the net-shape silicon carbide article. The impregnation / pyrolysis cycle is repeated until the desired amount of carbon and / or silicon carbide is achieved. In case of a carbon or a mixture of silicon carbide / carbon precursor is used, the pyrolyzed near-net shape silicon carbide article is then contacted with silicon in an inert atmosphere. The silicon diffuses through the pyrolyzed near-net shape silicon carbide article and reacts with the carbon contained within the pores of the porous SiC preform producing a new phase of silicon carbide within the pores of the near-net shape silicon carbide article. The produced silicon carbide is a near-net dense silicon carbide article.

Owner:POCO GRAPHITE

Method for preparing porous silicon carbide ceramic with high porosity

The invention discloses a method for preparing porous silicon carbide ceramic with high porosity which comprises preparing mix-coated powder from silicon powder, phenol resin and ethanol by a predetermined proportion, then carrying out low-temperature low-pressure modeling to produce ceramic blanks, high temperature carbonizing the ceramic blanks, finally sintering at high temperature to obtain the end product whose factor of porosity is greater than 80%.

Owner:TSINGHUA UNIV

Porous zeolite molecular sieve coating material on surface of silicon carbide ceramics and preparation method thereof

ActiveCN101992126AIncrease profitEnhanced mass transferMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAmmonium hydroxide

The invention belongs to the field of catalysis of zeolite crystals, in particular to a porous zeolite molecular sieve coating material on a surface of silicon carbide ceramics and a preparation method thereof. The zeolite molecular sieve coating is uniformly loaded on the surface of a porous silicon carbide ceramics carrier, and the zeolite molecular sieve coating has a double-pore canal structure composed of micropores of zeolite molecular sieves and macropores formed by mutual overlapping of zeolite crystals. The preparation method comprises the following steps: coating a zeolite precursor sol layer on the surface of porous silicon carbide ceramics, wherein the mol ratio of ethyl orthosilicate, tetrapropyl ammonium hydroxide and de-ionized water is 1:0.1-1.0:29; and growing in a secondary growth solution, wherein the mol ratio of ethyl orthosilicate, tetrapropyl ammonium hydroxide and de-ionized water is 1:0.05-1.0:110. Micron-sized pore canals are formed among the zeolite crystals in the coating, thereby improving the utilization efficiency of the zeolite coating. At the same time, the method has the advantages of simple process and low energy consumption, and the prepared zeolite molecular sieve coating is uniformly loaded and stably combined.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Rice-husk-based porous silicon carbide ceramic material and preparing method thereof

The invention discloses a rice-husk-based porous silicon carbide ceramic material and a preparing method thereof. The rice-husk-based porous silicon carbide ceramic material is mainly prepared from rice husks and a mixture, and mass of the mixture is 30%-70% of that of the rice husks; the mixture is prepared from, by mass, 1%-30% silicon powder, 5%-40% carbon source, 1%-15% catalyst and 30%-70% binding agent. Agricultural residue rice husk serves as the main raw material of the rice-husk-based porous silicon carbide ceramic material, and is mixed with silicon powder, carbon source, catalyst and binder to prepare a semi-finished product after formation, drying and calcination; the source of the raw material which are used has wide source and low cost, the prepared product has the advantages of high porosity, big mechanical strength, good filtering effect, excellent thermal shock resistance, micro and fine hole diameter of pore, adjustable micro-morphology and the like, has wide development space and application prospect, and is suitable for industrial popularization and application.

Owner:马琰珂

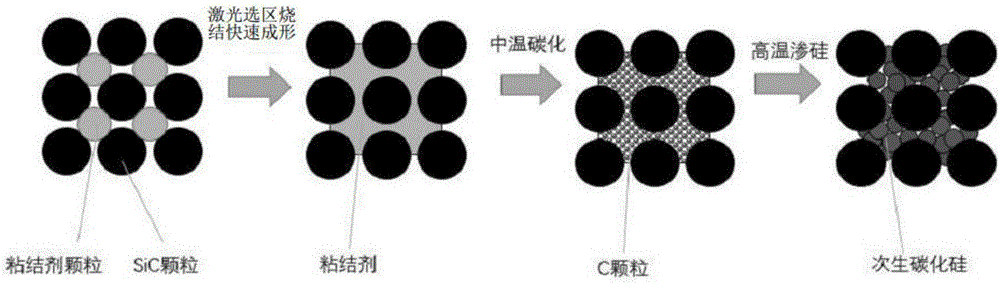

Method using selective laser sintering process to produce silicon carbide ceramic part

The invention discloses a method using selective laser sintering process to produce a silicon carbide ceramic part. The method includes: weighing carbon powder, silicon carbide powder, binder and curing agent according to preset mass ratio, pouring into a ball milling tank, and performing ball milling to obtain binder-silicon carbide mixed powder; using a computer to perform three-dimensional digital modeling on the to-be-produced part, inputting three-dimensional digital model information into a selective laser sintering forming machine, using the binder-silicon carbide mixed powder as the raw material, and using selective laser sintering fast forming process to perform powder sintering forming to obtain the silicon carbide biscuit of the part; heating and curing the silicon carbide biscuit; placing the cured silicon carbide biscuit into a medium-temperature tubular sintering furnace under Ar protection so as to perform carbonization treatment to obtain a porous silicon carbide blank; performing infiltration sintering treatment on the porous silicon carbide blank under a vacuum condition to obtain the compact silicon carbide ceramic part.

Owner:HUAZHONG UNIV OF SCI & TECH +1

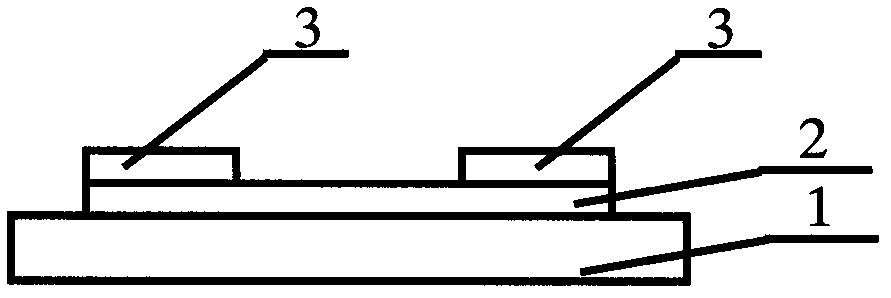

Copper line-clad aluminum silicon carbide ceramic substrate applicable to radiation of high-power LED

InactiveCN102569625AImprove thermal conductivityImprove thermal stabilitySemiconductor devicesCopperPorous silicon carbide

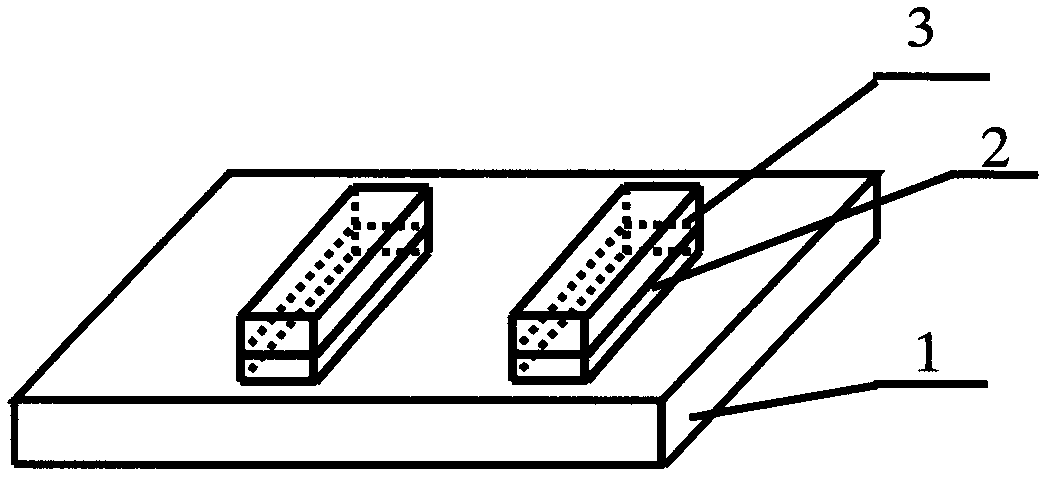

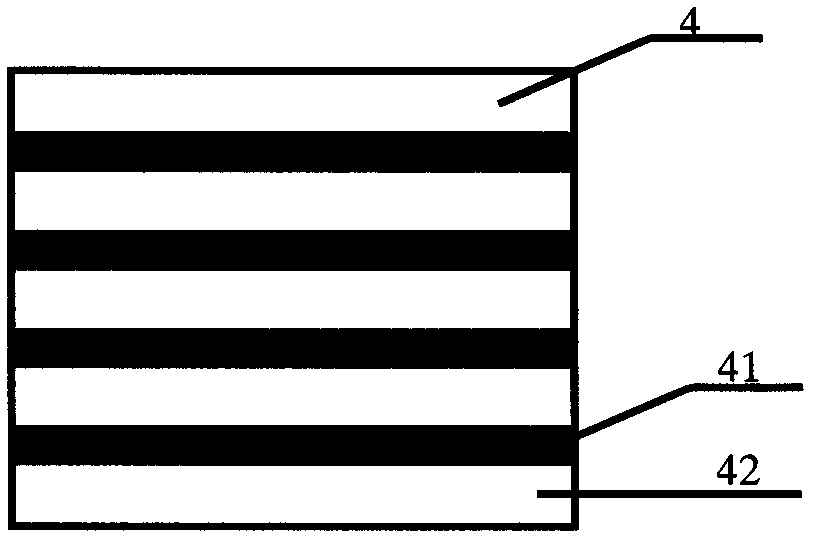

A copper line-clad aluminum silicon carbide ceramic substrate applicable to radiation of a high-power LED is characterized by consisting of an aluminum silicon carbide layer (1), a copper and aluminum oxide layer (2) and copper lines (3), wherein the copper and aluminum oxide layer (2) is arranged on the alumina layer (1); the copper lines (3) are arranged on the copper and aluminum oxide layer (2); the distance between the copper lines (2) is 0.1-1mm; the widths of the copper lines (2) are 200-1000 microns; the heights of the copper lines (2) are 0.01-2mm; the copper line-clad aluminum silicon carbide ceramic substrate is manufactured by the following steps: weighing SiO2, coke and a fluxing agent, and preparing the raw materials into porous silicon carbide; heating an aluminum block and melting the aluminum block into liquid aluminum, mixing the liquid aluminum with the porous silicon carbide in a certain ratio, and preparing the mixture into aluminum silicon carbide powder and a high-thermal conductivity aluminum silicon carbide substrate; cladding copper on the aluminum silicon carbide substrate, heating at a high temperature to form an eutectic melt, and forming an aluminum silicon carbide ceramic substrate layer, the copper and aluminum oxide layer and a copper layer from the bottom up; and etching conductive copper lines. The ceramic substrate has a good application prospect in the aspect of the radiation of the high-power LED.

Owner:CHINA JILIANG UNIV

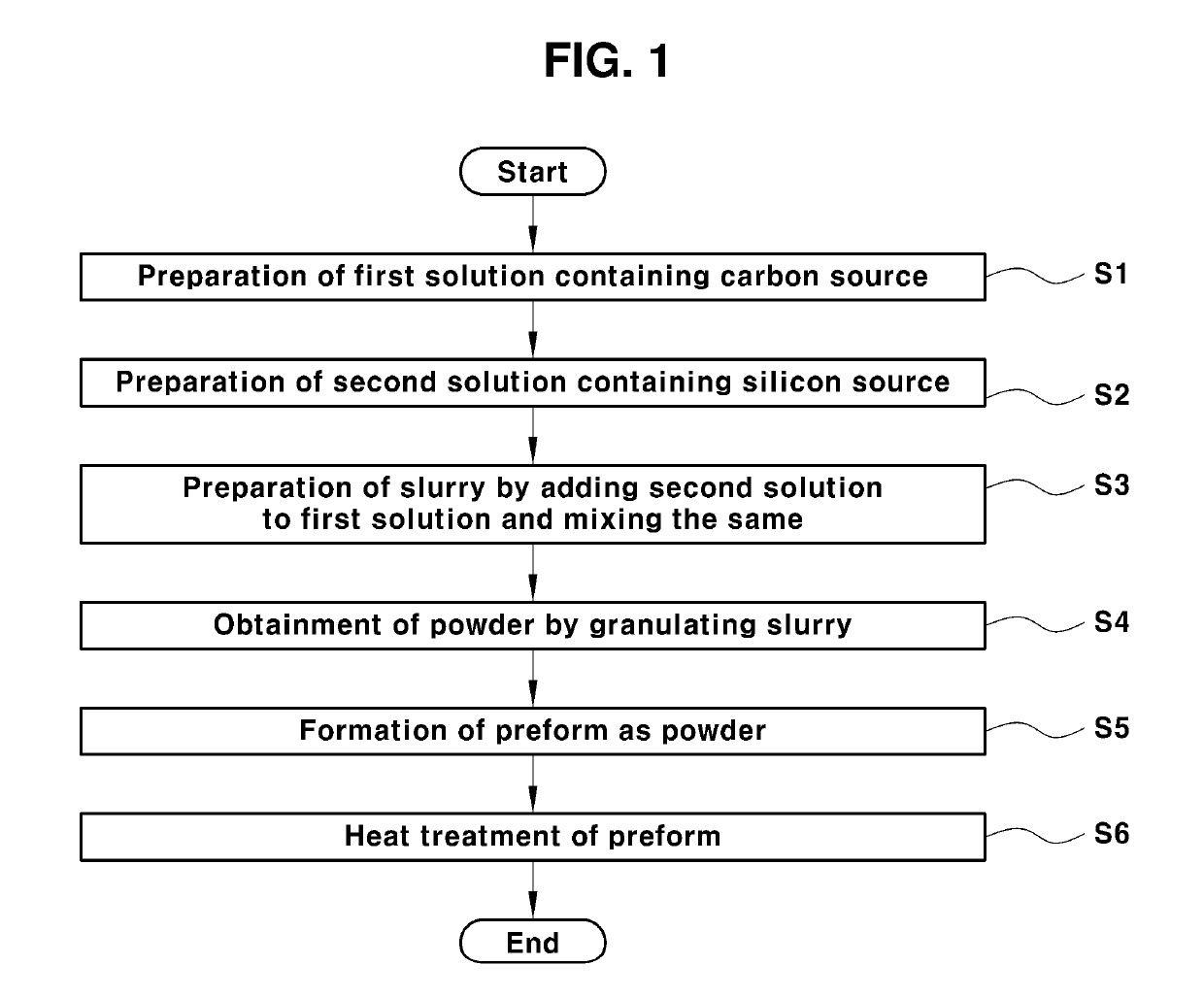

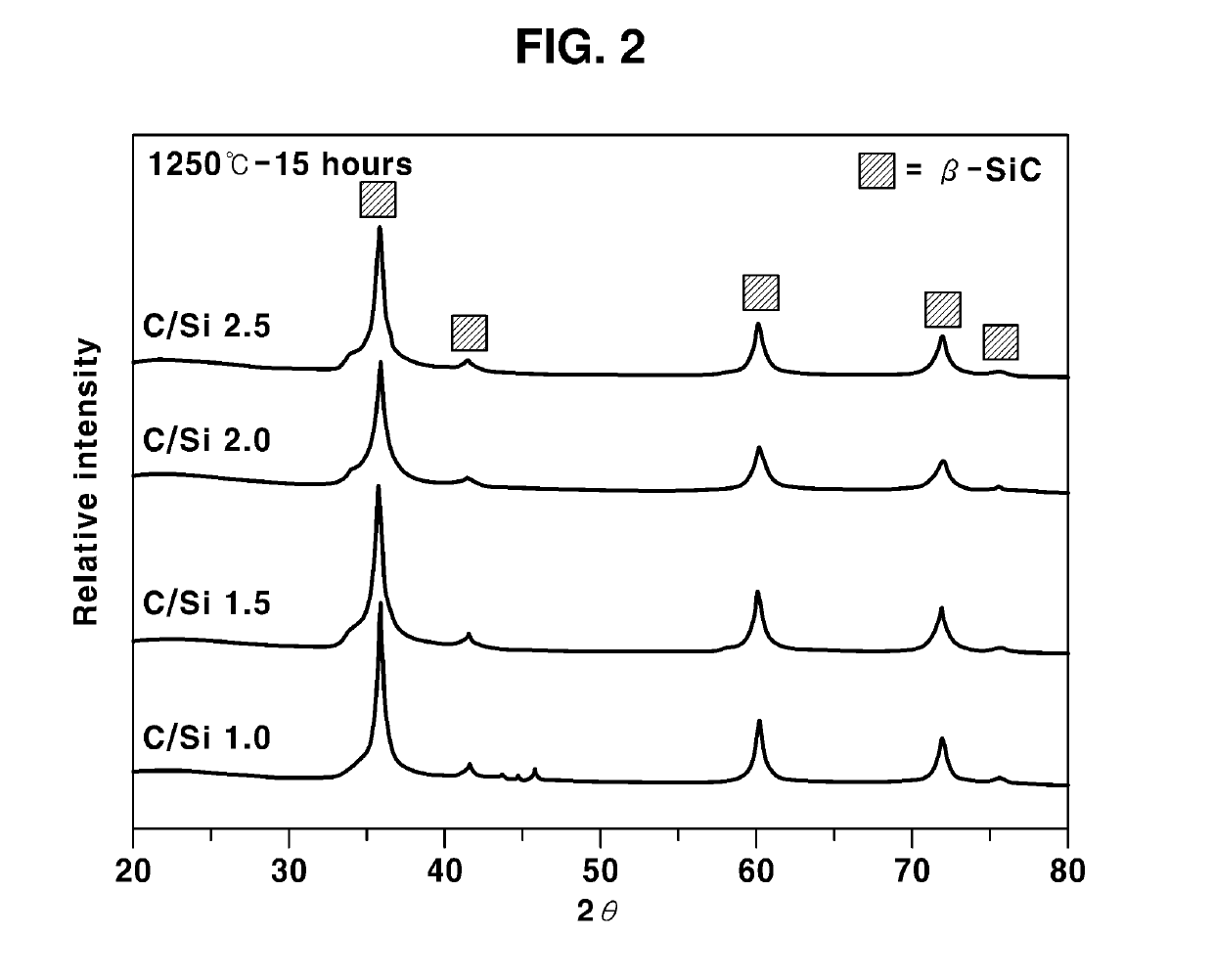

Eco-friendly method for manufacturing of porous silicon carbide structure

ActiveUS20190144287A1Securing price competitivenessExcellent price competitivenessPhysical/chemical process catalystsCarbon compoundsPorous silicon carbideCarbon source

The present invention relates to an eco-friendly method for preparing a porous silicon carbide structure, which is capable of preparing a porous silicon carbide structure having meso- or macro-sized pores without using a harmful phenolic resin as a carbon source.

Owner:KOREA INST OF SCI & TECH

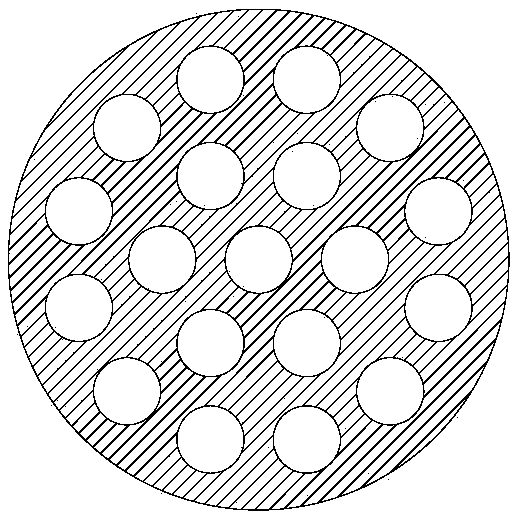

Porous ceramic carrier for high-temperature and high-pressure inorganic filtering membrane and preparation method for porous ceramic carrier

The invention discloses a porous ceramic carrier for a high-temperature and high-pressure inorganic filtering membrane and a preparation method for the porous ceramic carrier. The porous silicon carbide ceramic carrier is prepared by silicon carbide, a binding agent and a pore-forming agent, wherein the mass ratio of the silicon carbide to the binding agent is 80-90:10-20, and the utilization quantity of the pore-forming agent is 35-45% of the sum of the volumes of the silicon carbide, the binding agent and the pore-forming agent. The preparation method includes adding the binding agent and the pore-forming agent in silicon carbide powder; performing ball milling, drying and vacuum heat casting forming; and performing pressureless sintering for a formed blank. Sintering temperature rangesfrom 1250 DEG C to 1350 DEG C, and heat insulation time ranges from 2 hours to 4 hours. As raw materials form main materials by means of fine size grading, the binding agent and the pore-forming agent are added by a special process, technologies such as unique vacuum heat casting forming and the like are adopted, and mechanical strength and porosity of the porous carrier can be improved effectively. The prepared silicon carbide porous ceramic carrier has excellent performances of fine thermal shock resistance, low coefficient of thermal expansion, fine mechanical and chemical stability at high temperature and under high pressure, and the like.

Owner:TSINGHUA UNIV

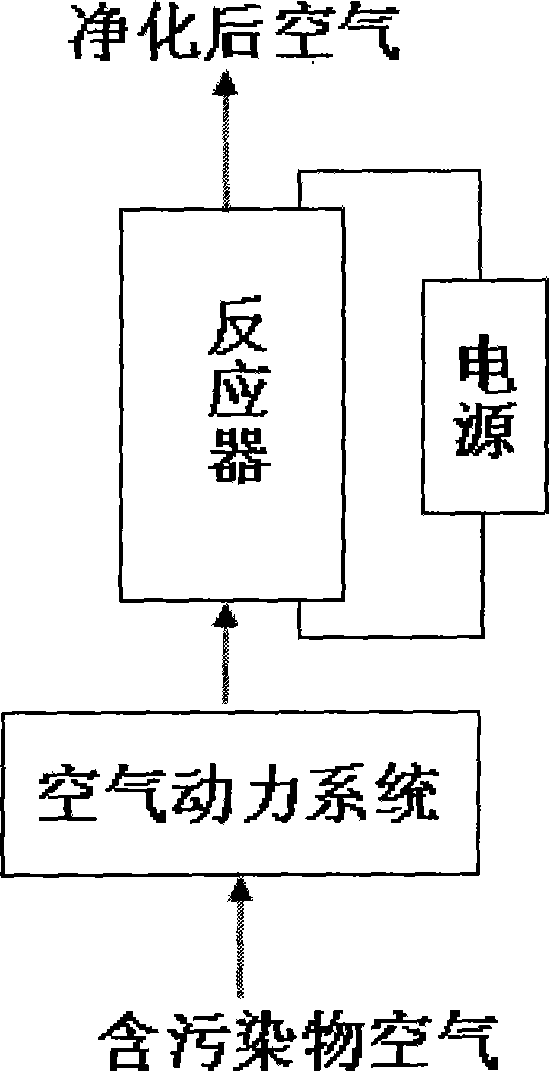

Method for purifying air

ActiveCN101530716AOther chemical processesLighting and heating apparatusSorbentBiological activation

The invention relates to a method for removing carbon monoxide or volatile organic contaminants, which is realized by contacting polluted air with filler contained in a reactor. The filler of the reactor is porous graphitizing carbon or porous silicon carbide or porous graphitizing carbon or porous silicon carbide which is loaded with reactive metal components; the filler is used as adsorbent or oxidation catalyst and is heated up by accessing to electric current to realize regeneration of the adsorbent or activation of the catalyst. The method of the invention is applicable to removal of the carbon monoxide and the volatile organic contaminant discharged by households, cars or industrial polluting sources and has the advantages of safety and energy saving.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method of flexible porous silicon carbide micro-nano fibrofelt

ActiveCN103343425AGood flexibilityHigh porosityFilament/thread formingFibre chemical featuresMicro nanoNon solvent

The invention provides a preparation method of a flexible porous silicon carbide micro-nano fibrofelt, relating to silicon carbide fibers. The invention provides a preparation method of a flexible porous silicon carbide micro-nano fibrofelt which is small in fiber diameter and enriched in nano-pores and can realize a flexible porous characteristic. The preparation method comprises the following steps of: mixing and uniformly stirring a good solvent and a non-solvent in proportion to obtain a mixed solvent; dissolving a silicon carbide ceramic precursor containing a silicon polymer in the mixed solvent, adding an electrolyte, and stirring until the components are fully dissolved to obtain an electrostatic spinning solution; performing electrostatic spinning on the obtained electrostatic spinning solution through an electrostatic spinning device, and continuously spinning to obtain precursor micro-nano fibrofelts with different thicknesses; and heating the obtained precursor micro-nano fibrofelts, performing drying and oxidation crosslinking, then heating again under the protection of an inert atmosphere, and performing high temperature pyrolysis to obtain the flexible porous silicon carbide micro-nano fibrofelt. The process is simple and high in production efficiency; and the fiber diameter of the obtained fibrofelt is 0.5-3 microns, and the nano-pore diameter is 5-100 nanometers.

Owner:LVNA TECH CO LTD

Preparation method for molecular sieve coating material on porous silicon carbide ceramic surface

InactiveCN101857462AIntensity effectImprove the bonding strength of the interfaceMolecular sieve catalystsCrystalline aluminosilicate zeolitesInterfacial bondingRaw material

The invention relates to a preparation technique for a molecular sieve coating material, in particular to a preparation method for a molecular sieve coating material on a porous silicon carbide ceramic surface. Porous silicon carbide ceramic is used as a carrier, solid raw materials such as silicon blocks, quartz, silicon-aluminum composite oxide sintered powder with adjustable silicon-aluminum atomic ratio and the like are used as a silicon source or a silicon-aluminum source, and the raw materials are synthesized through in-situ hydrothermal reaction. The porous silicon carbide ceramic surface is provided with microporous structures. The use of the solid silicon source or silicon-aluminum source can enable the release speed of the silicon source or silicon-aluminum source for the growth of crystal nucleus to be controllable. Thereby, the prepared molecular sieve coating is evenly loaded on the surface of the silicon carbide ceramic carrier, the silicon-to-aluminum ratio can be accurately controlled, and the composite material formed by the molecular sieve and the porous silicon carbide ceramic has unique microporous / macroporous structures; and the chemical bonding between the molecular sieve and the porous silicon carbide ceramic is realized and the interfacial bonding strength is high. The invention has the advantages that the technology of the method is simple, the operation is convenient, the complex equipment is not required, the preparation cost is low and the method is more suitable for industrialized mass production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

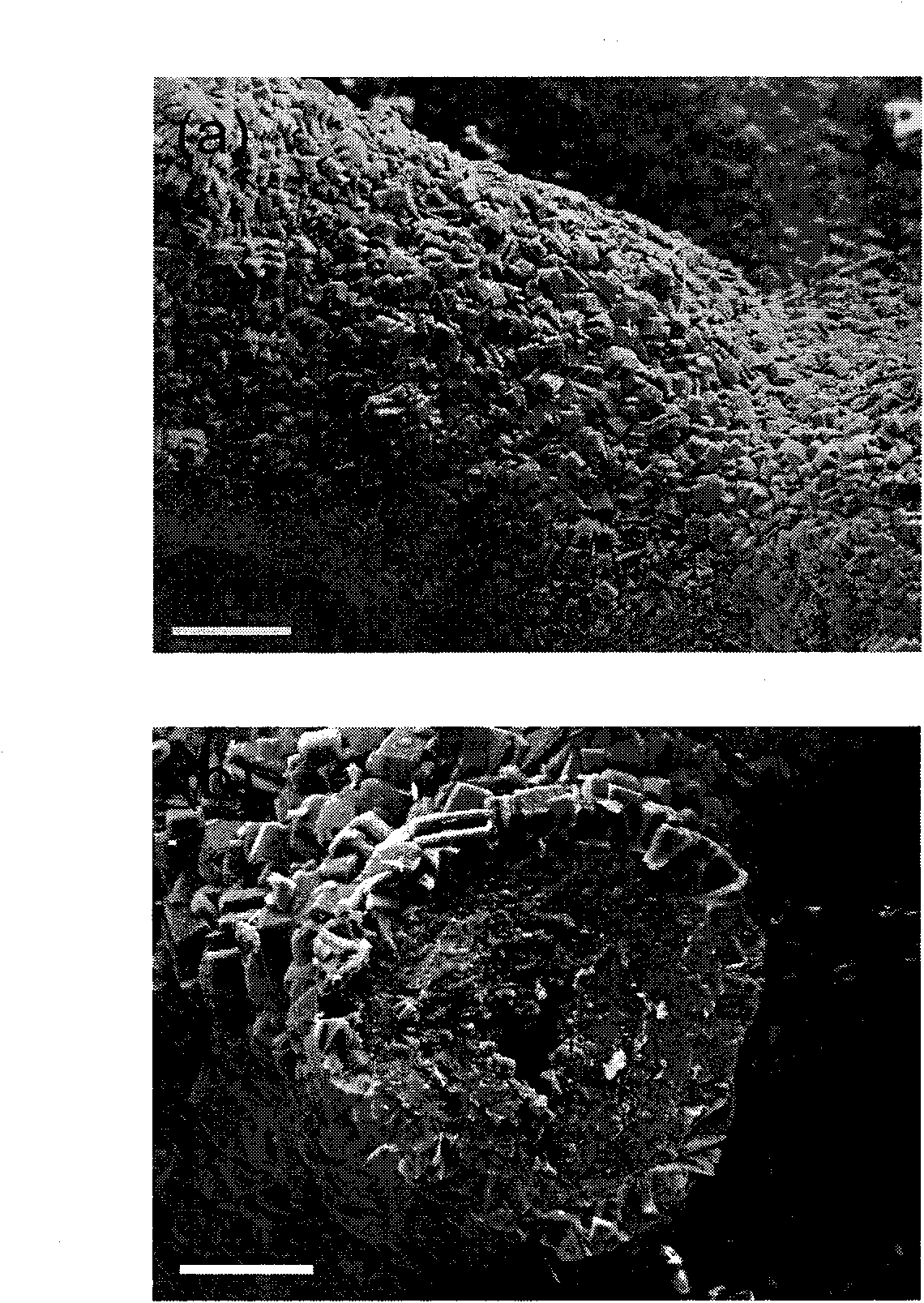

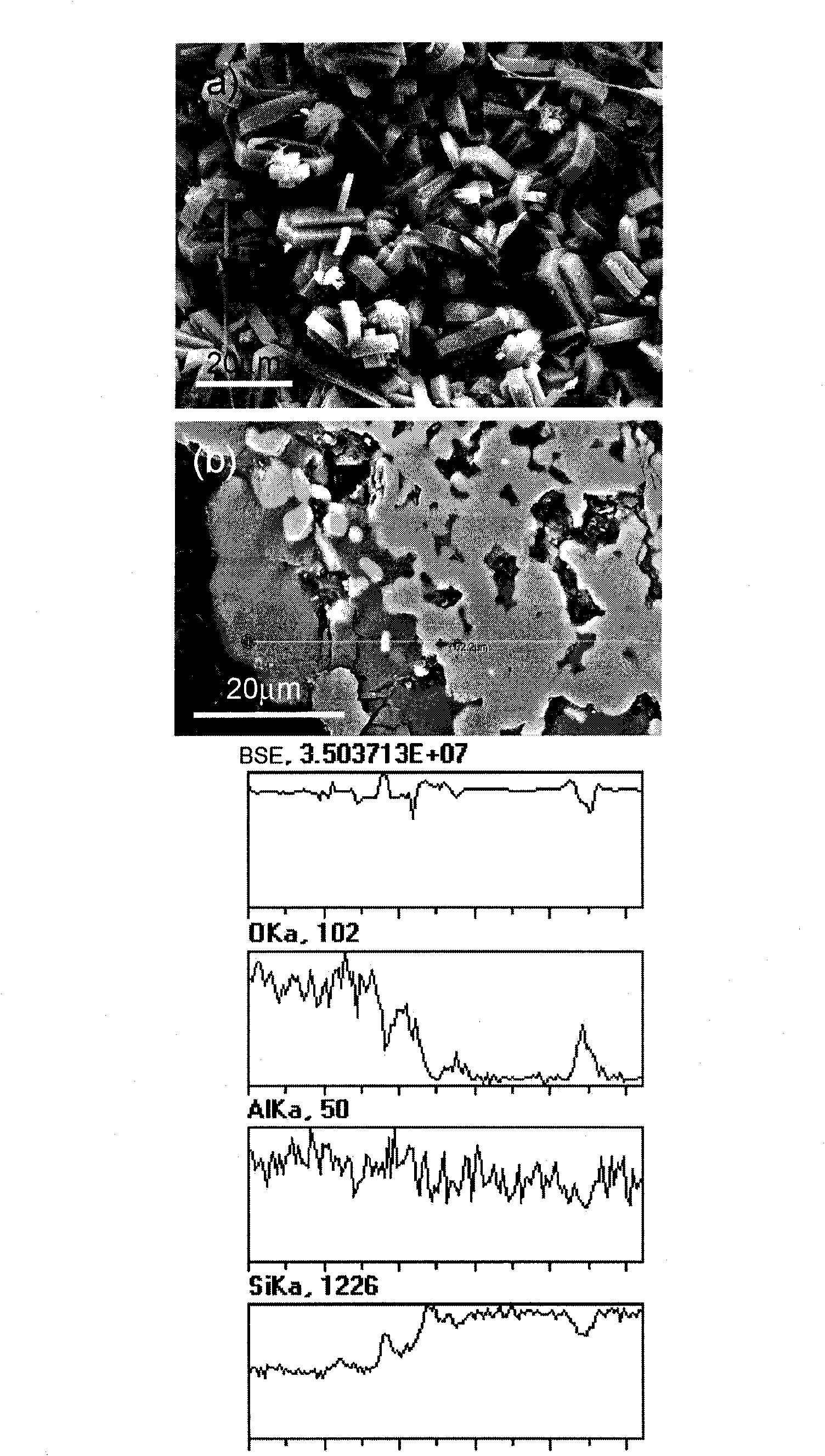

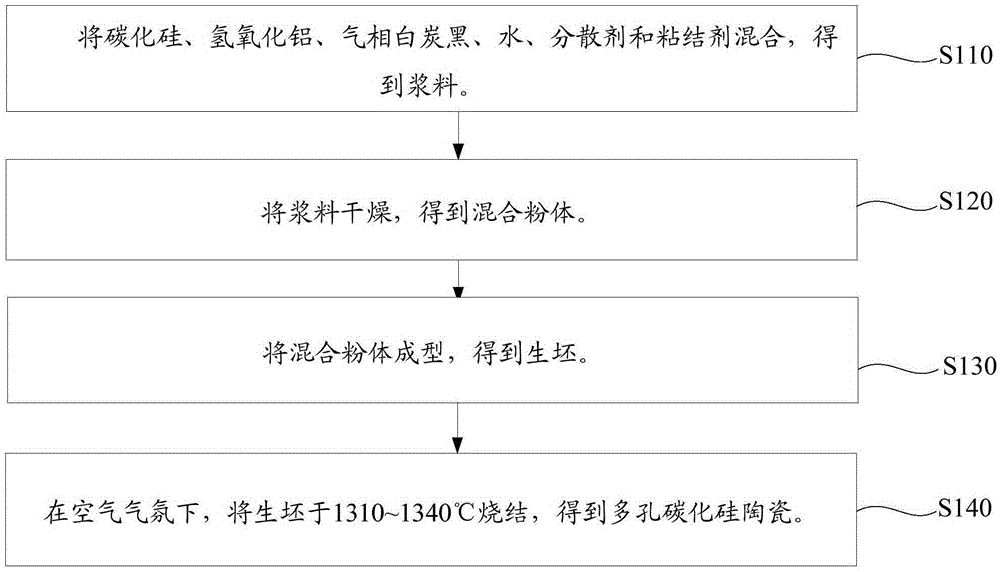

Porous silicon carbide ceramic and preparation method thereof

The invention relates to porous silicon carbide ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing silicon carbide, aluminum hydroxide, fumed silica, water, a dispersant and a binder so as to obtain slurry, wherein the sum of the mass of aluminum hydroxide and fumed silica accounts for 5 to 30% of the sum of the mass of silicon carbide, aluminum hydroxide and fumed silica, and a mol ratio of aluminum hydroxide to fumed silica is 2-5: 1; drying the slurry so as to obtain mixed powder; molding the mixed powder to obtain a green body; and sintering the green body in an air atmosphere at 1310 to 1340 DEG C so as to obtain the porous silicon carbide ceramic. The preparation method can prepare the porous silicon carbide ceramic with good bending resistance at a low sintering temperature.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

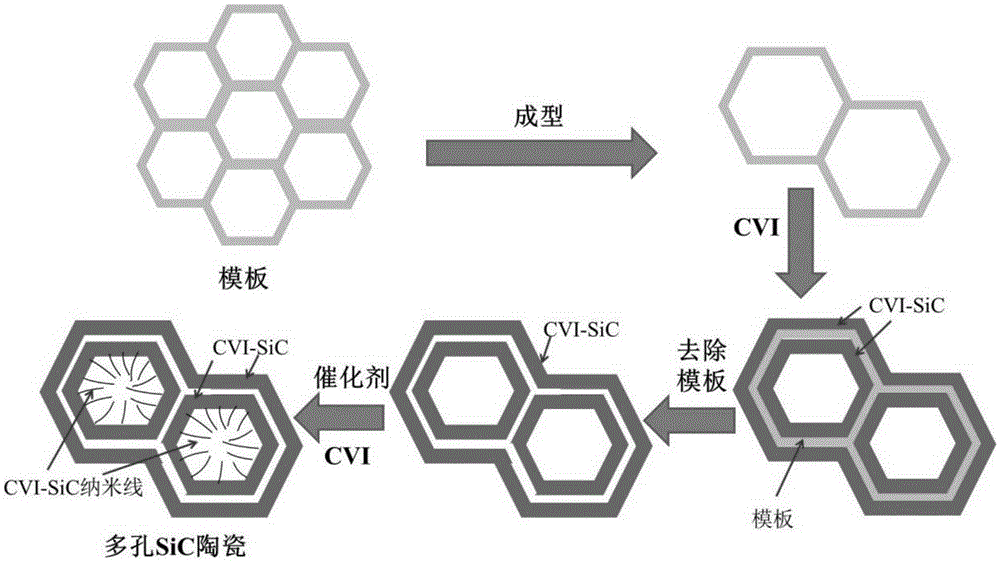

Method for preparing porous silicon carbide ceramic based on template

InactiveCN105237034AUniform pore sizePorosity is easy to controlCeramicwarePorous silicon carbideMaterials science

The present invention relates to a method for preparing a porous silicon carbide ceramic based on a template. According to the present invention, the template method thinking and the characteristics of the CVI process are creatively combined, the CVI method is used to prepare the porous SiC ceramic, and the porous SiC ceramic obtained through the method has characteristics of uniform pore size, controlled porosity and large specific surface area; with the method, the technical problems of complex preparation process, high sintering temperature and the like of other template methods can be solved; and the complex member is easily prepared through the process, and the use range of the porous SiC ceramic prepared through the method is substantially expanded.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Silicon carbide thermostable porous structural material and process for producing the same

InactiveUS20050209088A1Well formedImprove wettabilityPhysical/chemical process catalystsFiltration separationBone structureSlurry

After a slurry containing powdered silicon and a resin used as a carbon source is applied by impregnation to a carbon powder-made porous structural body having a bone structure, which is formed from powdered carbon, and is then carbonized at 900 to 1,300° C. in a vacuum or an inert gas atmosphere, reaction sintering is performed at a temperature of 1,300° C. or more in a vacuum or an inert gas atmosphere. Accordingly, since a carbonized porous structural body can be obtained which has open pores generated by a volume-reduction reaction at the same time when porous silicon carbide having a good wettability to molten silicon is formed, this carbonized porous structural body is impregnated with molten silicon at a temperature of 1,300 to 1,800° C. in a vacuum or an inert gas atmosphere.

Owner:NAT INST OF ADVANCED IND SCI & TECH

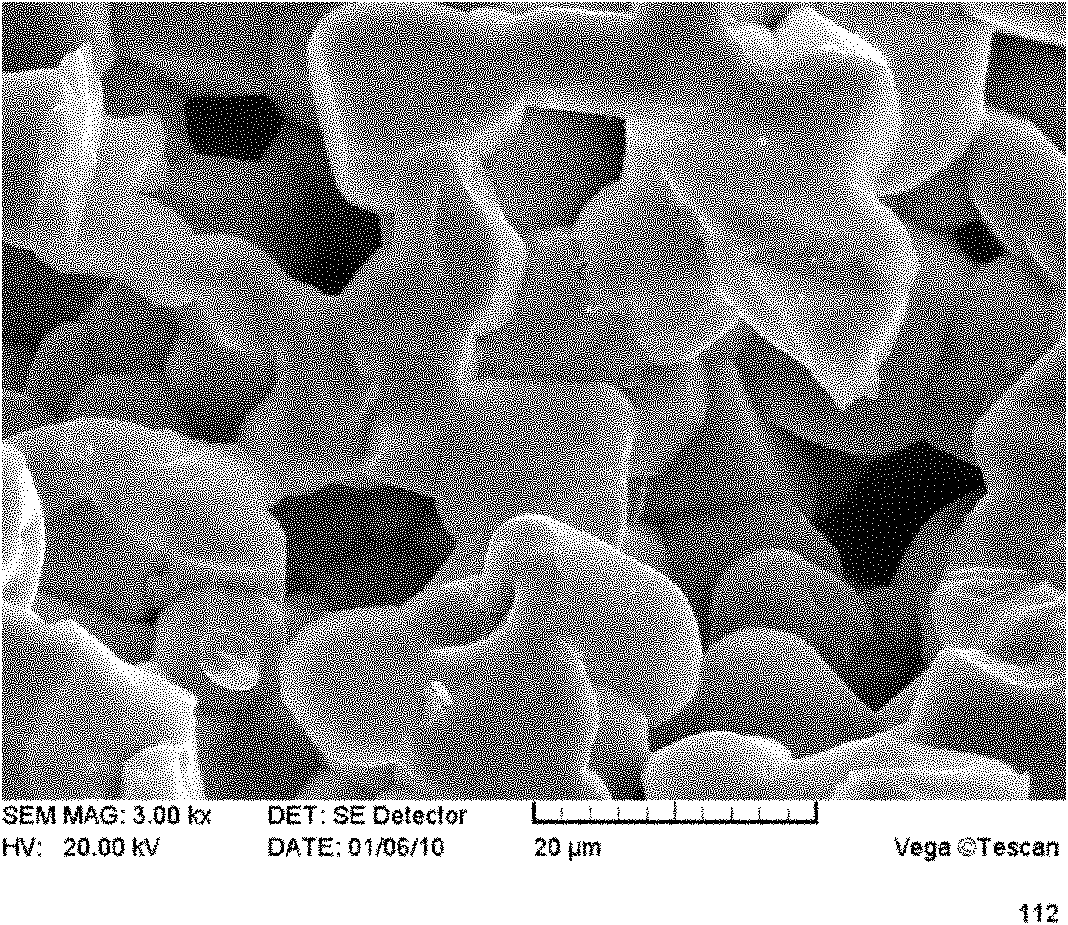

Method for preparing ball shaped, porous ceramic material contg. silicon carbide with biological structure

ActiveCN1830901ARaw materials are cheap and easy to getSimple process conditionsCeramicwareGas phasePorous ceramics

A spherical porous silicon carbide ceramic material with biologic structure is prepared from the seeds of agricultural crops (millet, rice, soybean, etc) through carbonizing in argon gas, the gas-phase osmosis of Si, liquid-phase osmosis of Si, or sol-gel carbothermal reduction for siliconizing, heat treating at 600-800 deg.C, and washing with hydrochloric acid and hydrofluoric acid.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

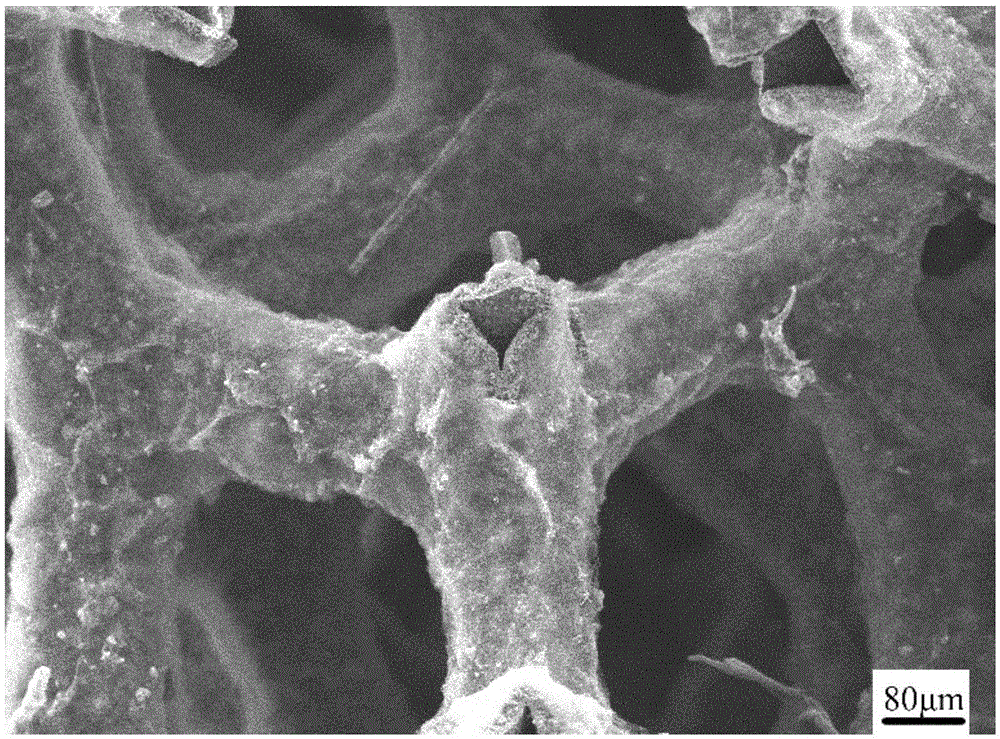

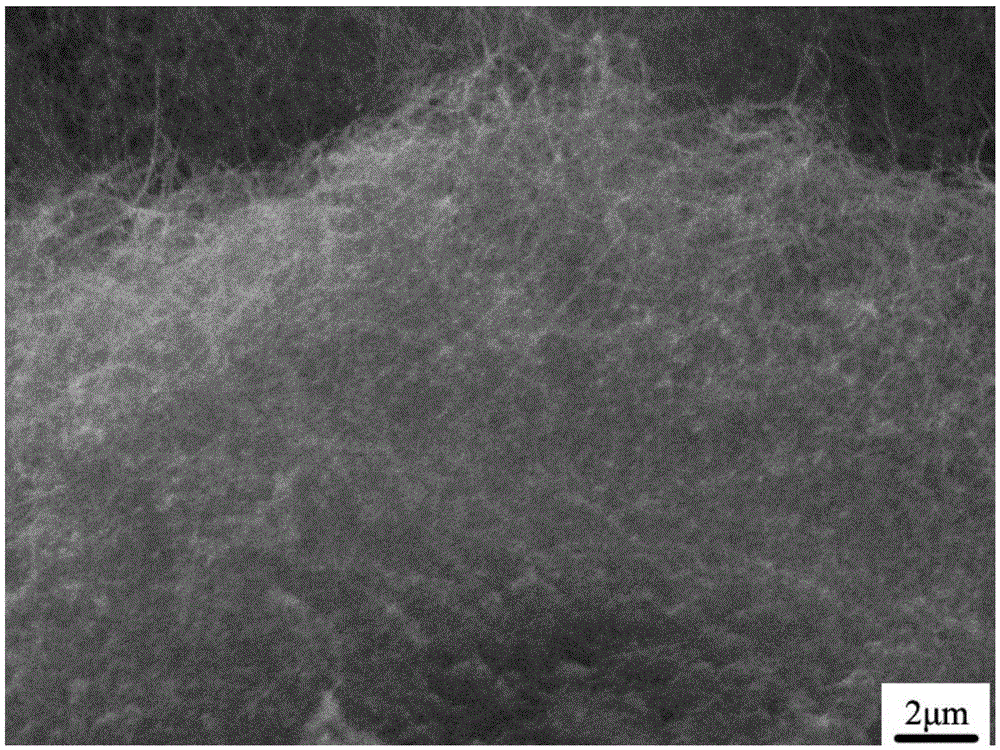

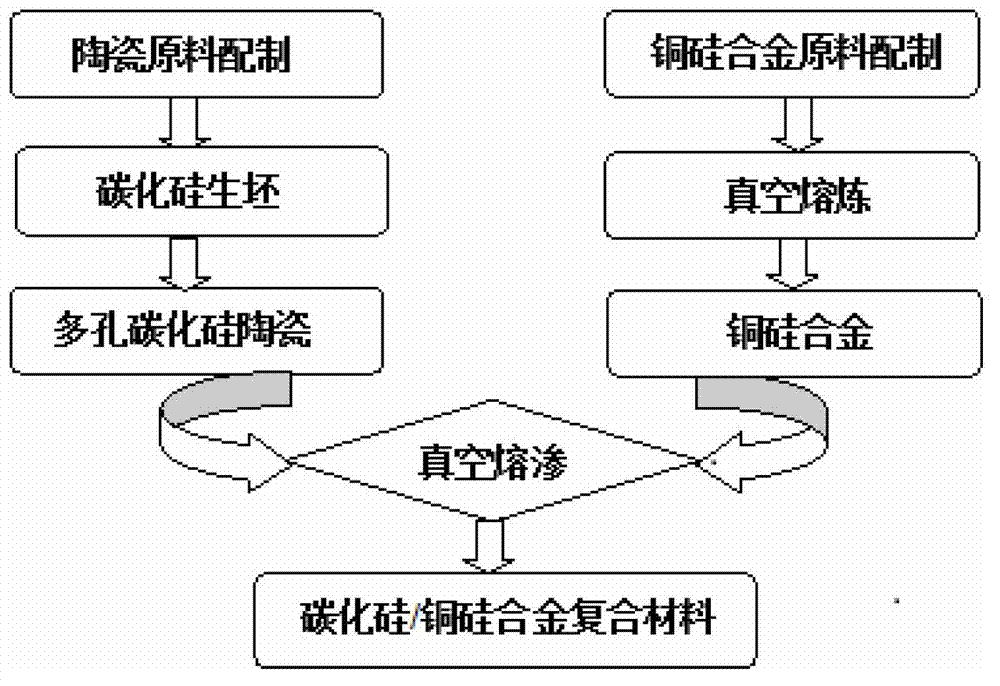

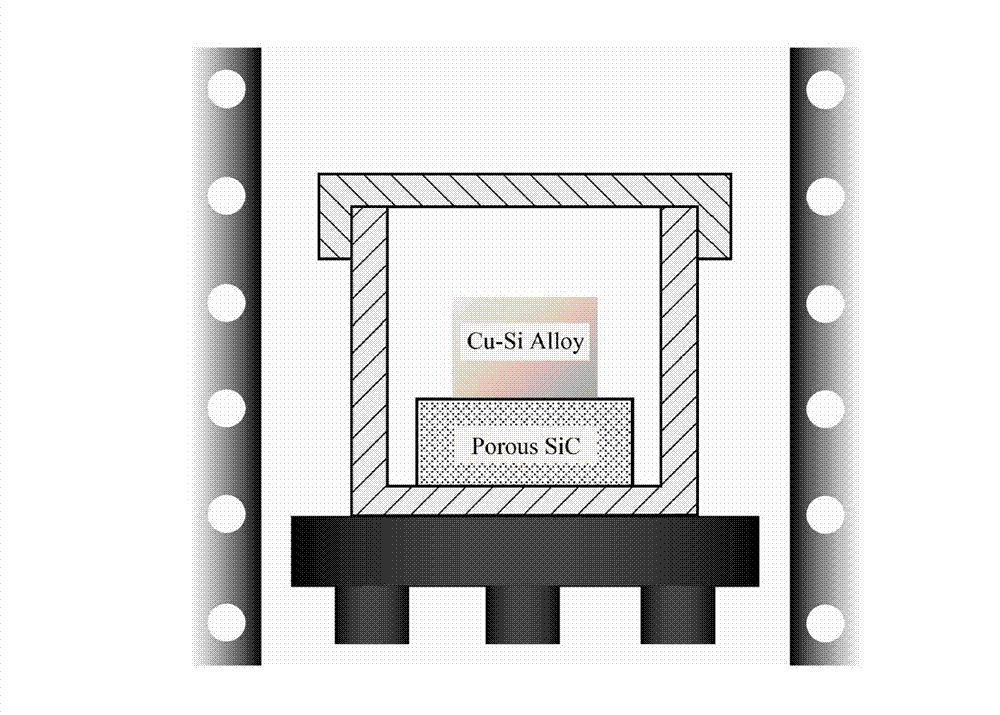

Silicon carbide/copper silicon alloy codual-continuous composite and preparation method thereof

The invention discloses a silicon carbide / copper silicon alloy codual-continuous composite and a preparation method thereof. The composite material comprises the following components in volume fraction: 35-50 percent of porous silicon carbide ceramics and 50-65 percent of copper silicon alloy, wherein the atomic percentage composition of silicon in the copper silicon alloy is 15-40 percent. The preparation method comprises two key processing steps of: preparing the porous silicon carbide ceramics and vacuum infiltrating porous silicon carbide through the copper silicon alloy. Silicon is adopted as an alloying element of copper, so that the problems of wettability and reactivity between copper and silicon carbide are solved simultaneously. In addition, the invention adopts a vacuum infiltrating process as a near net forming preparation process, and specialized die casting equipment and a specific module are not needed, so that the preparation process is simple, has low cost, and can be used for manufacturing various composites with complicated shapes.

Owner:XI AN JIAOTONG UNIV

Zeolite coating material with high intercrystalline porosity on the surface of porous silicon carbide support and its preparation

InactiveCN102274743ASmall external areaIncrease the outer surface areaMolecular sieve catalystsOther chemical processesHoneycomb structureSupport surface

The invention which belongs to the technical field of structured catalysts and application technologies thereof concretely relates to a high intercrystal poriness zeolite coating material on the surface of a porous silicon carbide carrier and a preparation method thereof. The porous silicon carbide carrier involved by the material has a macroscopic porous structure, for example a foamy structure,and a honeycomb structure. The zeolite coating has a high intercrystal poriness. According to the preparation method, the surface of the porous silicon carbide carrier is modified by a colloidal zeolite guiding agent to realize the preferred growth of zeolite crystal on the surface of the porous silicon carbide carrier; and the alkalinity of a secondary growth solution, the concentration of nutrients, and the addition of alkali metal ions are controlled to control the intercrystal poriness of zeolite. The coating material has the advantages of high intercrystal poriness, small zeolite crystaldimension, good molecular diffusion ability, large zeolite load capacity, adjustable silica-alumina ratio of the zeolite crystal and zeolite coating thickness, and good binding ability of the zeolitecrystal with the surface of the porous silicon carbide carrier. The structured catalyst which is in favor of mass and heat transfer reinforcement has wide application prospects in fields of catalysis, adsorption, separation and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Porous silicon-carbide carrier surface gradient pore molecular sieve coating and preparation method thereof

ActiveCN103252253AImprove mass transfer effectExtend your lifeMolecular sieve catalystsMolecular sieveSurface gradient

The invention belongs to the field of catalysts and an application of the catalysts, and in particular relates to a porous silicon-carbide carrier surface gradient pore molecular sieve coating and a preparation method thereof. The porous silicon-carbide carrier surface gradient pore molecular sieve coating has the intercrystal porosity with continuous gradient change, the porosity among molecular sieve crystals in an inner molecular sieve coating is low, and the porosity among molecular sieve crystals in an outer molecular sieve coating is high. The coating is realized through two-step coating combined with steam treatment: a colloidal state molecular sieve precursor is coated on the surface of a foamed silicon-carbide carrier; a mixer of the colloidal state molecular sieve precursor, the molecular sieve crystals and a pore forming agent is coated; and finally, the molecular sieve precursor is converted into the molecular sieve crystals through steam treatment so as to realize the firm bonding between the coating and the carrier. The proportion of the colloidal state molecular sieve precursor to the molecular sieve crystals is controlled, the pore forming agent is added, and the intercrystal porosity of the coating can be regulated. The gradient coating and the carrier are firmly bonded, and the coating is high in mass transfer capacity and suitable for large-scale preparation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com