Method for preparing porous silicon carbide ceramic based on template

A porous silicon carbide and template technology, which is applied in the field of preparing porous silicon carbide ceramics using templates, can solve the problems of complex preparation process and high sintering temperature, and achieve the effect of complex preparation process, controllable porosity and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

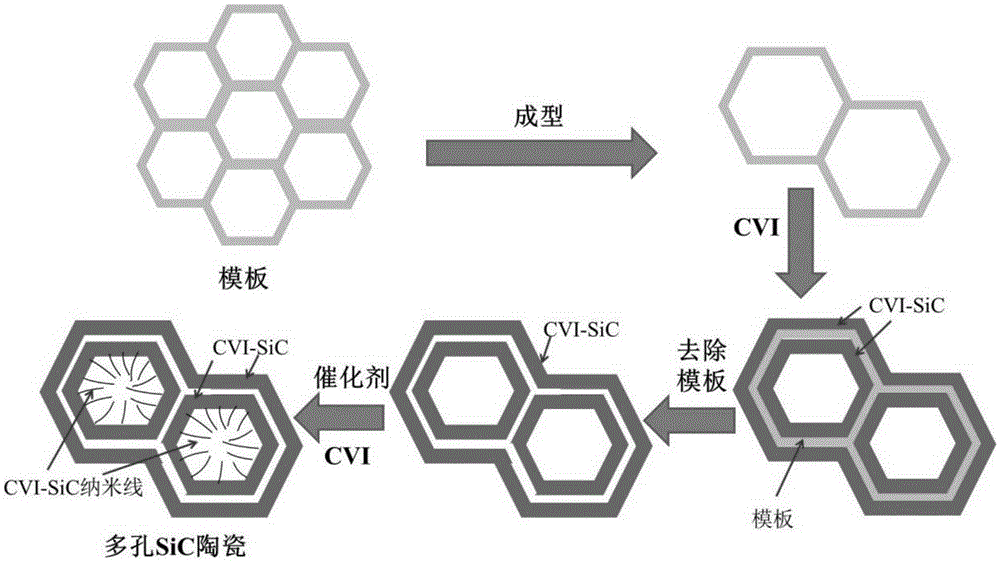

[0025] Step 1: Raw material preparation: The template is made of nickel foam with a porosity of 40%.

[0026] Step 2: Process the template into a specified shape.

[0027] Step 3: Put the templates of different shapes obtained in step 2 into a chemical vapor infiltration furnace (CVI furnace) for chemical vapor infiltration. During the CVI process, the generated SiC ceramic phase gradually covers the template. When the generated SiC ceramic phase When reaching a certain level, porous SiC ceramics with certain strength and controllable porosity can be formed. The process conditions for CVI method to generate SiC ceramic phase are: using MTS(CH 3 SiCl 3 ) as a precursor, hydrogen as a carrier and dilution gas, and argon as a protective gas. MTS:H 2 The ratio of :Ar is 1:12:10, the total gas pressure is 5kPa, the deposition temperature is 1000°C, and the deposition time is 20h.

[0028] Step 4: Remove the template. The obtained porous SiC ceramics are acidified.

[0029] S...

Embodiment 2

[0031] Step 1: Preparation of raw materials: The template is made of nickel foam with a porosity of 60%.

[0032] Step 2: Process the template into a specified shape.

[0033] Step 3: Put the templates of different shapes obtained in step 2 into a chemical vapor infiltration furnace (CVI furnace) for chemical vapor infiltration. During the CVI process, the generated SiC ceramic phase gradually covers the template. When the generated SiC ceramic phase When reaching a certain level, porous SiC ceramics with certain strength and controllable porosity can be formed. The process conditions for CVI method to generate SiC ceramic phase are: using MTS(CH 3 SiCl 3 ) as a precursor, hydrogen as a carrier and dilution gas, and argon as a protective gas. MTS:H 2 The ratio of :Ar is 1:12:10, the total gas pressure is 5kPa, the deposition temperature is 1000°C, and the deposition time is 50h.

[0034] Step 4: Remove the template. The obtained porous SiC ceramics are acidified.

[0035]...

Embodiment 3

[0037] Step 1: Preparation of raw materials: The template is made of nickel foam with a porosity of 70%.

[0038] Step 2: Process the template into a specified shape.

[0039] Step 3: Put the templates of different shapes obtained in step 2 into a chemical vapor infiltration furnace (CVI furnace) for chemical vapor infiltration. During the CVI process, the generated SiC ceramic phase gradually covers the template. When the generated SiC ceramic phase When reaching a certain level, porous SiC ceramics with certain strength and controllable porosity can be formed. The process conditions for CVI method to generate SiC ceramic phase are: using MTS(CH 3 SiCl 3 ) as a precursor, hydrogen as a carrier and dilution gas, and argon as a protective gas. MTS:H 2 The ratio of :Ar is 1:12:10, the total gas pressure is 5kPa, the deposition temperature is 1100°C, and the deposition time is 20h.

[0040] Step 4: Remove the template. The obtained porous SiC ceramics are acidified.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com