Titanium dioxide nano paper and preparation method thereof

A technology of titanium dioxide and nano paper, which is applied in the field of preparation of inorganic nano materials, can solve the problems of cumbersome, expensive, low success rate, etc., and achieve the effect of simple production method, good filtration performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

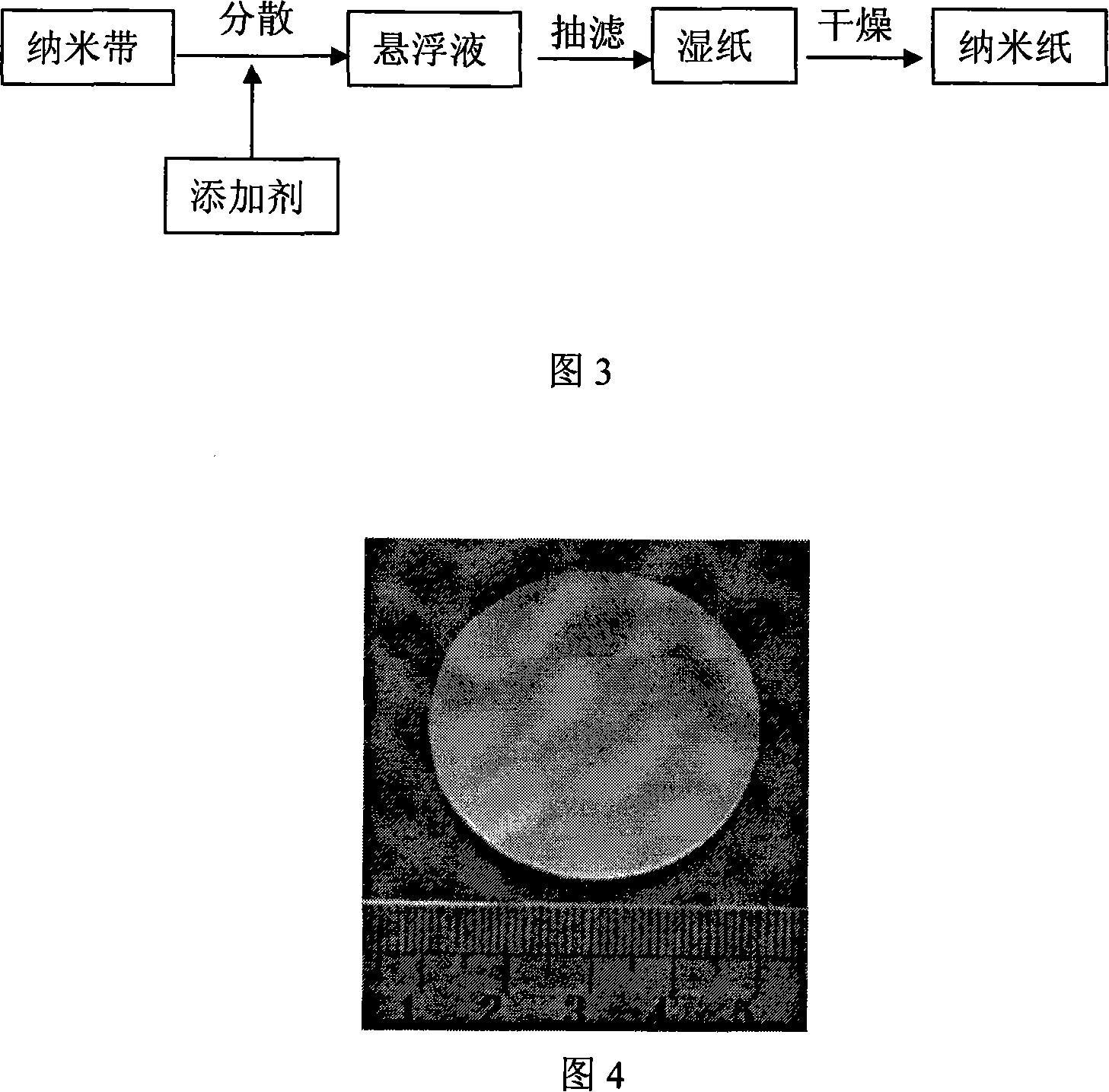

[0031] A titanium dioxide nano paper is mainly composed of titanium dioxide nanobelts or titanium dioxide nanobelts and additives.

[0032] The preparation method of the above-mentioned titanium dioxide inorganic nano-paper mainly includes a dispersion-suction filtration-drying process, and the specific preparation process steps are as follows:

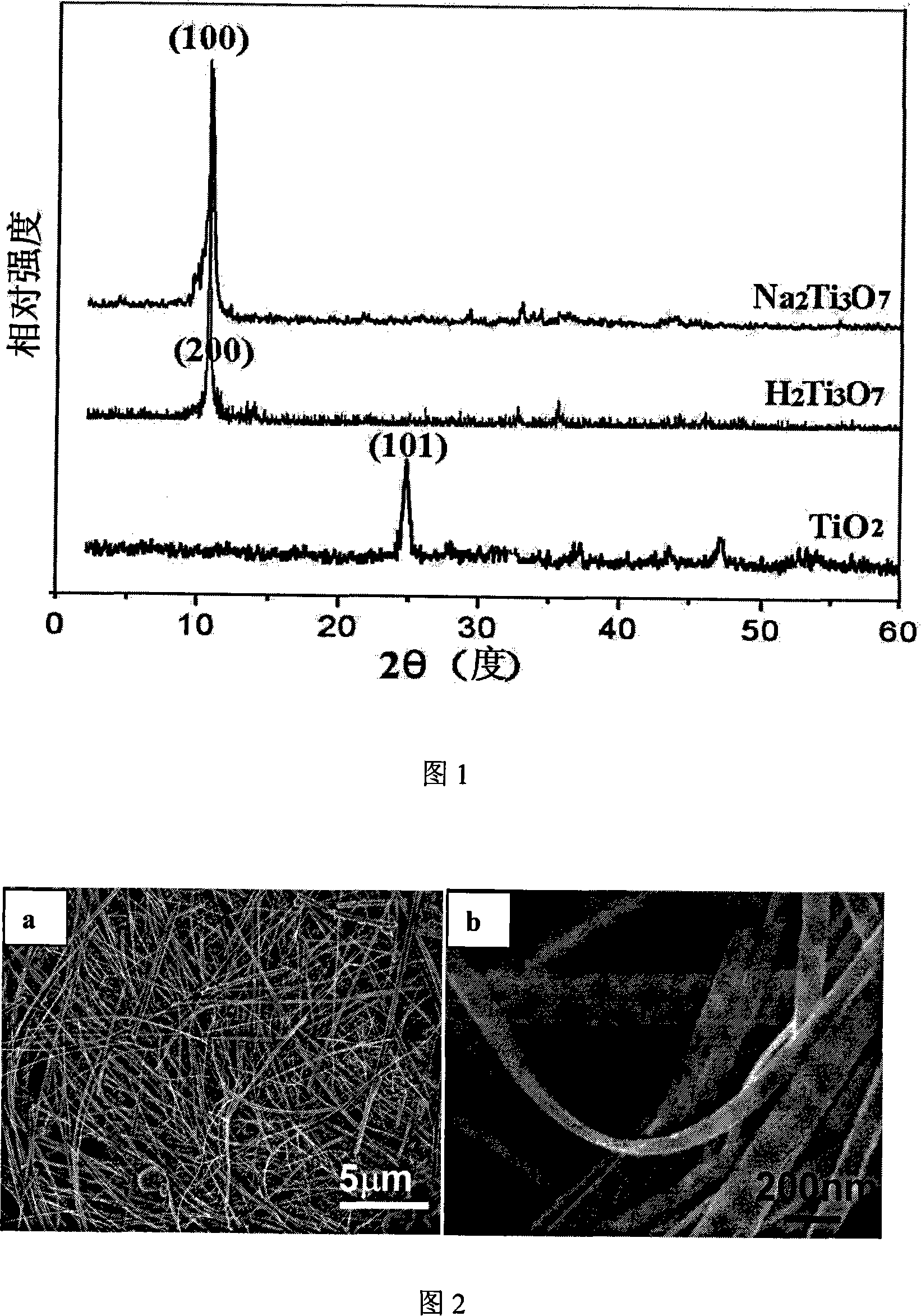

[0033] 1) Preparation of titanium dioxide nanoribbons

[0034] Weigh 0.1~0.5g TiO 2 The powder is placed in a stainless steel reaction kettle with 15-20ml or 5-15mol / L NaOH or KOH solution and lined with polytetrafluoroethylene. After stirring with a glass rod, close and tighten the reaction kettle, and place it in a preheated 180 ℃~230℃ oven reaction for 24~72h, after the reaction is completed, naturally cool to room temperature, pour out the product in the kettle, wash with deionized water to obtain sodium titanate nanobelts; Soak in HCl solution for 24 hours, wash with deionized water to obtain titanate nanobelts; heat-treat the ...

Embodiment 2

[0039] The preparation steps are the same as in Example 1, except that 0.01 g of titanium dioxide nanobelts is weighed, placed in 1000 g of water, and ultrasonically dispersed for 1 hour to form a nanobelt suspension.

Embodiment 3

[0041] The preparation steps are the same as in Example 1, except that 0.1 g of titanium dioxide nanobelts is weighed, placed in 1000 g of water, stirred and dispersed for 1 hour, and a nanobelt suspension is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com