Bacteria-enzyme synergistically fermented feed containing stevia rebaudiana residues and application of feed

A technology of synergistic fermentation and stevia dregs, applied in applications, animal feed, animal feed, etc., can solve the problems of low added value of feed product sales, rough texture of stevia dregs, low acid-soluble protein content, etc., to improve feed Use value, reduce morbidity, and reduce the effect of somatic cell count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Stevia rebaudiana slag self-attached screening of lactic acid bacteria

[0023] The stevia slag (DM=60%) stacked naturally in the factory area of Shandong Zhucheng Haotian Pharmaceutical Co., Ltd. was used as the strain source to carry out the enrichment culture of lactic acid bacteria. Take 1.0g stevia residue and add 9mL MRS culture medium (sucrose 20g / L, peptone 10g / L, beef extract 10g / L, yeast extract powder 5g / L, sodium acetate 5g / L, ammonium citrate 2g / L, K 2 HPO 4 2g / L, MgSO 4 ·7H 2 O0.58g / L, MnSO 4 4H 2 (0.25g / L, Tween 80 1.0mL / L, pH adjusted to 6.3, sterilized at 115°C for 20min) for enrichment culture: after static cultivation at 30°C for 24h, the inoculum size was 1% (volume fraction ratio) The transfer culture was continuously subcultured for 20 generations to obtain a lactic acid bacteria group with stable properties and strains.

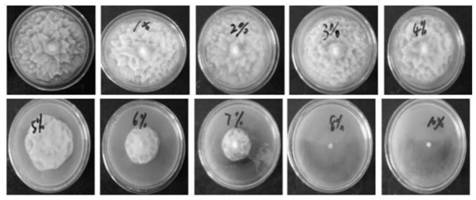

[0024] The enriched culture solution was diluted and spread on the MRS agar medium for 36 hours at 30°C, ...

Embodiment 2

[0032] Inoculate the preserved Lactobacillus casei BFC190201 in the MRS liquid medium, and culture it statically at 25-37°C for 18-24h to obtain the primary seed liquid; ) into the new MRS medium again for secondary activation, after standing for 18-24h, the secondary seed liquid was obtained; the secondary seed liquid was separately inserted into the In the culture medium of the fermenter, the temperature is 25-37° C., and the static culture is carried out for 18-24 hours to obtain the fermentation broth of Lactobacillus casei BFC190201. Centrifuge the fermentation broth of Lactobacillus casei BFC190201 at 4°C at 8,000r / min for 10 minutes to obtain the sludge, add skim milk to the sludge at a ratio of 1:2~4 (m / v), shake and mix on a vortex shaker homogeneously, carry out vacuum freeze-drying, obtain Lactobacillus casei BFC190201 freeze-dried powder, the number of effective viable bacteria ≥ 1 × 10 12 CFU / g.

[0033] Lactobacillus plantarum P-8 was deposited in the General M...

Embodiment 3

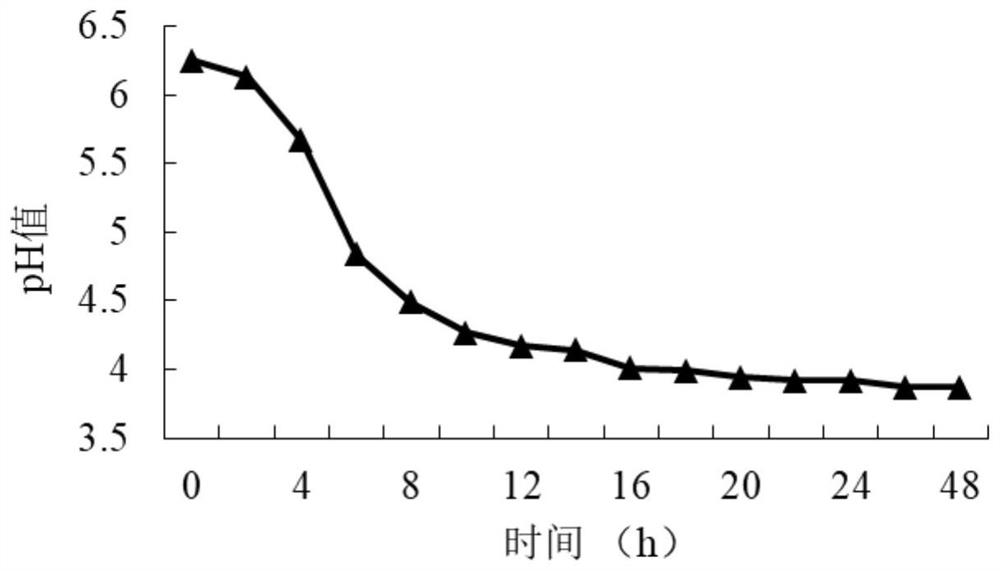

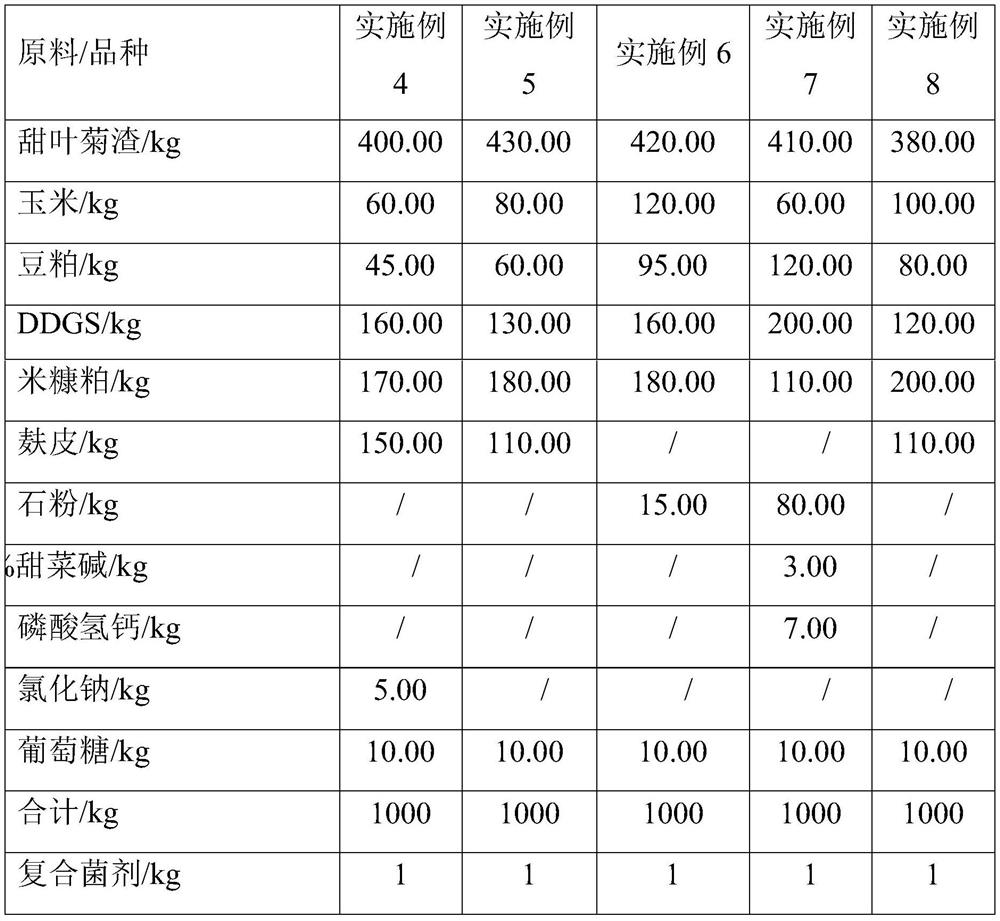

[0037] Embodiment 3 contains the processing of stevia rebaudiana slag fermented feed

[0038] (1) Stevia rebaudiana slag aerobic fermentation pretreatment

[0039] Stevia rebaudiana dregs (DM=30%), molasses and urea are fully mixed according to the mass ratio of 93:6:1, inoculated with Aspergillus niger, put into a cement pool or fermentation tank, aerobic fermentation is fermented for 42h, and the temperature rises to Turn over and throw at 40°C to ensure that the fermentation temperature is lower than 40°C. As the fermentation time prolongs, the true protein content increases and the crude fiber content decreases. The results are shown in Table 2. After 24h, 36h and 48h of fermentation, the true protein content increases by 13.77%, 36.96% and 51.12%, respectively.

[0040] Table 2

[0041] True protein % Crude fiber% Before fermentation 15.61 18.32 Fermentation 24h 17.76 17.54 Fermentation 36h 21.38 15.55 Fermentation 48h 23.59 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com