Porous silicon carbide fibers and preparation method thereof

A technology of porous silicon carbide and polycarbosilane fibers, which can be used in fiber processing, spinning solution preparation, fiber chemical characteristics, etc., can solve the problem of not being able to obtain porous SiC fibers, and achieve good application prospects and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

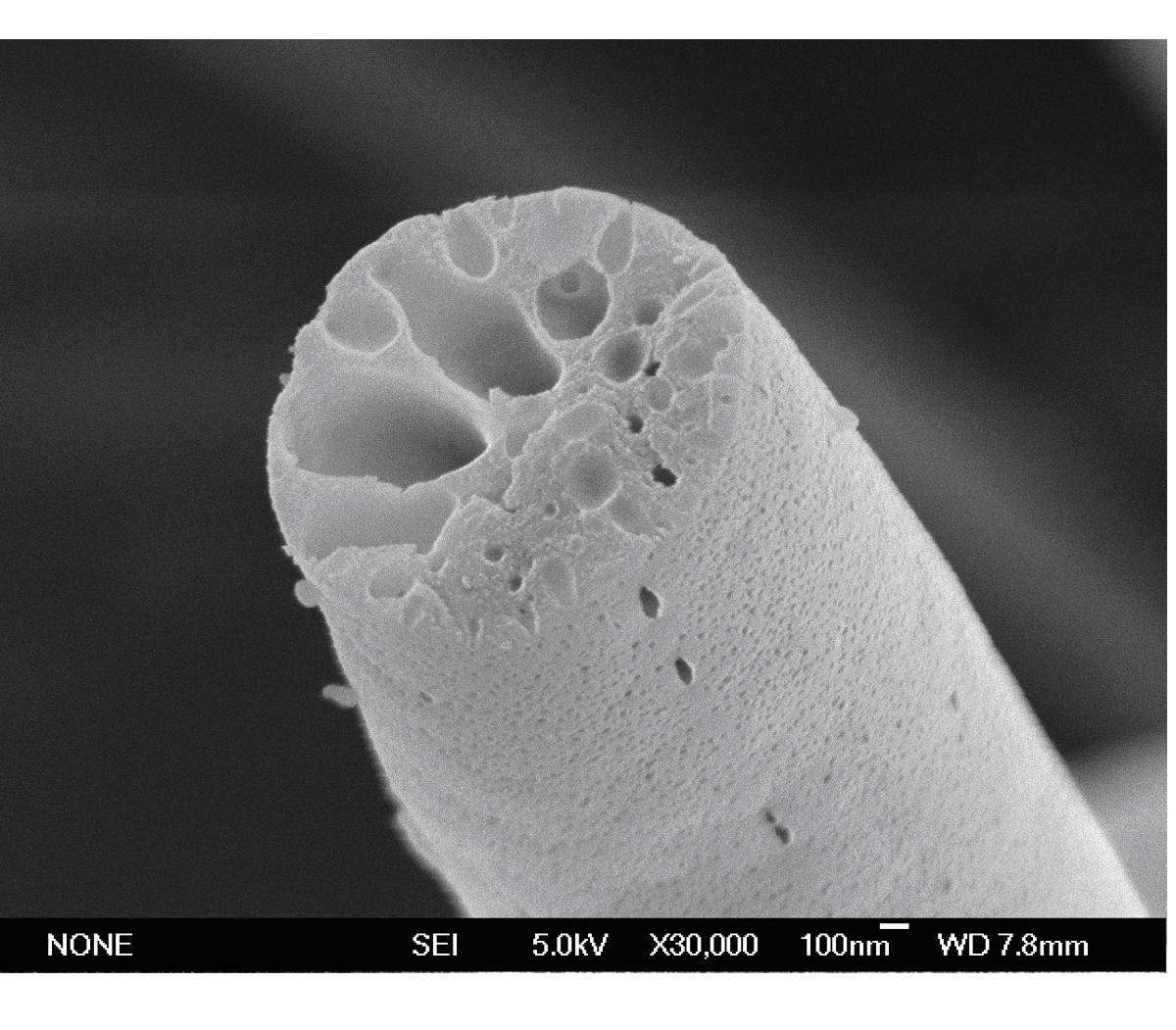

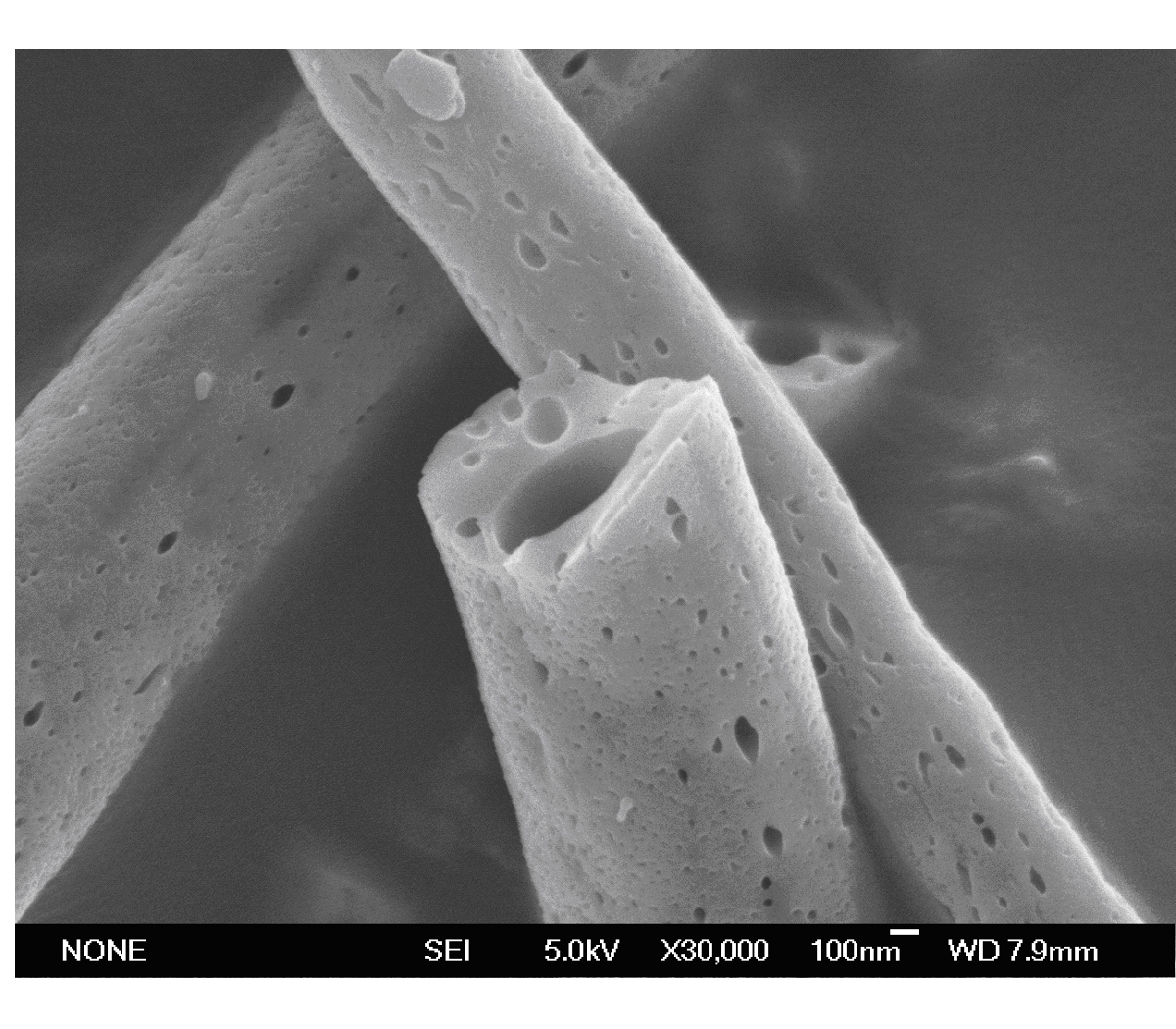

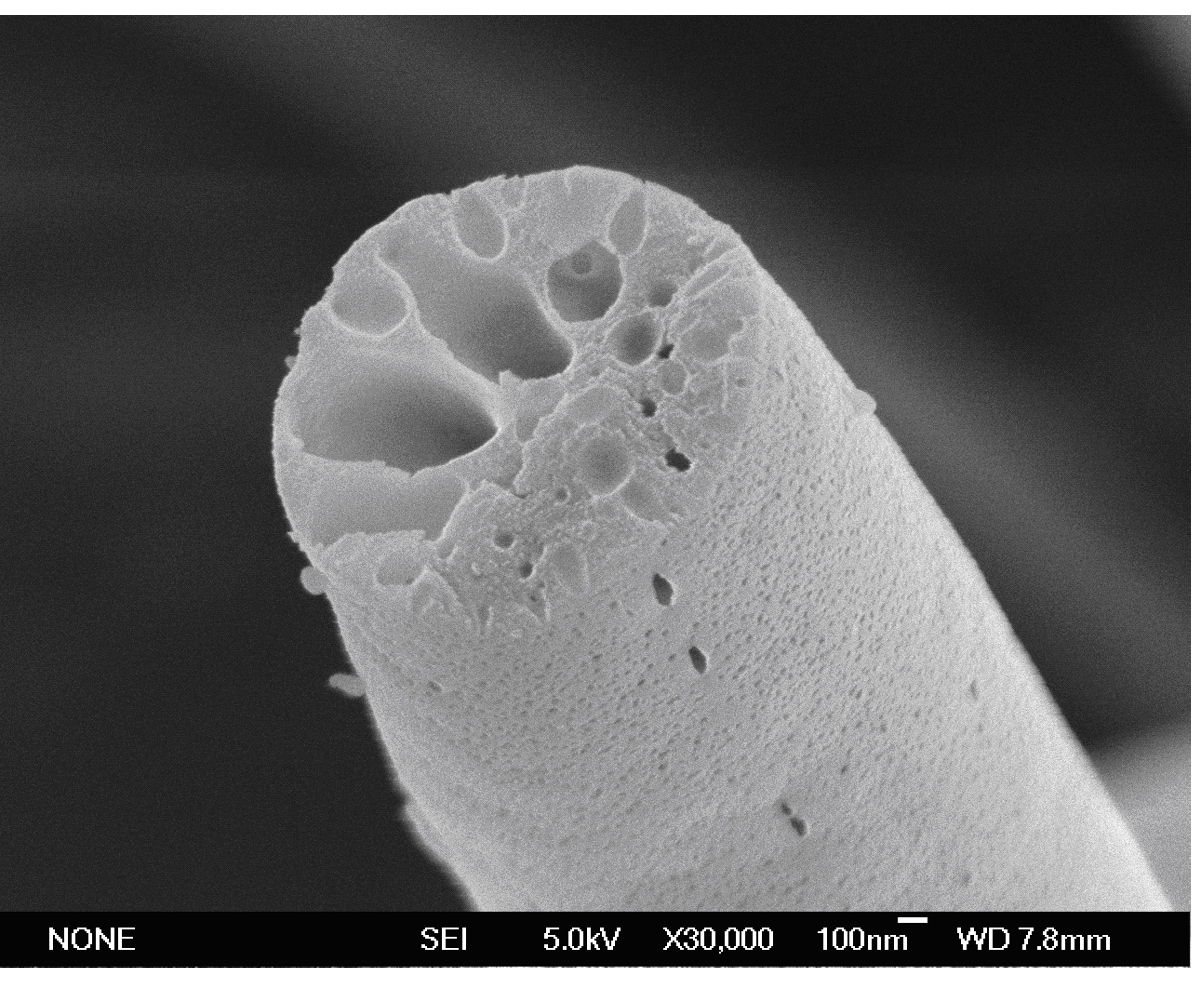

[0024] The Si content of the porous silicon carbide fiber of this embodiment is 55wt%, the C content is 31wt%, and the O content is 14wt%. The specific surface area is 700m 2 / g.

[0025] Preparation: (1) Dissolve 4.0g polycarbosilane in 5mL xylene to make a dilute solution with a concentration of 0.8g / mL, slowly add 3.0mL dimethyl sulfoxide dropwise while stirring to precipitate macromolecular polycarbosilane , forming an electrospinnable suspension. (2) Use a syringe pump to inject the suspension into a metal nozzle with an inner diameter of 1.0mm at the extrusion speed of 0.010mL / min for electrospinning, wherein the positive voltage applied to the metal nozzle is 30kV, and the metal nozzle and The distance between the grounded receiving aluminum plates is 25 cm, and porous polycarbosilane fibers with a diameter of about 2.0 μm are collected on the receiving plates; (3) the precursor fibers are placed in an oxidation furnace, and heated in air at 15 ° C / h heating rate to...

Embodiment 2

[0027] The Si content of the porous silicon carbide fiber of this embodiment is 55wt%, the C content is 31wt%, and the O content is 14wt%. The specific surface area is 600m 2 / g.

[0028] Preparation: The only difference from Example 1 is that in step (1), 4.0 g of polycarbosilane was dissolved in 8 mL of tetrahydrofuran to prepare a dilute solution with a concentration of 0.5 g / mL.

Embodiment 3

[0030] The Si content of the porous silicon carbide fiber of this embodiment is 55wt%, the C content is 31wt%, the O content is 14wt%, it is felt-like, the fiber average diameter is 0.5 μm, the porosity is 72vol%, and the mesopore volume is 59vol%. Surface area is 720m 2 / g.

[0031] Preparation: The only difference from Example 1 is that in step (1), 4.0 g of polycarbosilane was dissolved in 4 mL of benzene to prepare a dilute solution with a concentration of 1.0 g / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com