Preparation method for molecular sieve coating material on porous silicon carbide ceramic surface

A technology of porous silicon carbide and silicon carbide ceramics, applied in the direction of molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as large differences in thermal expansion coefficient, molecular sieve coating peeling off, increased side reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

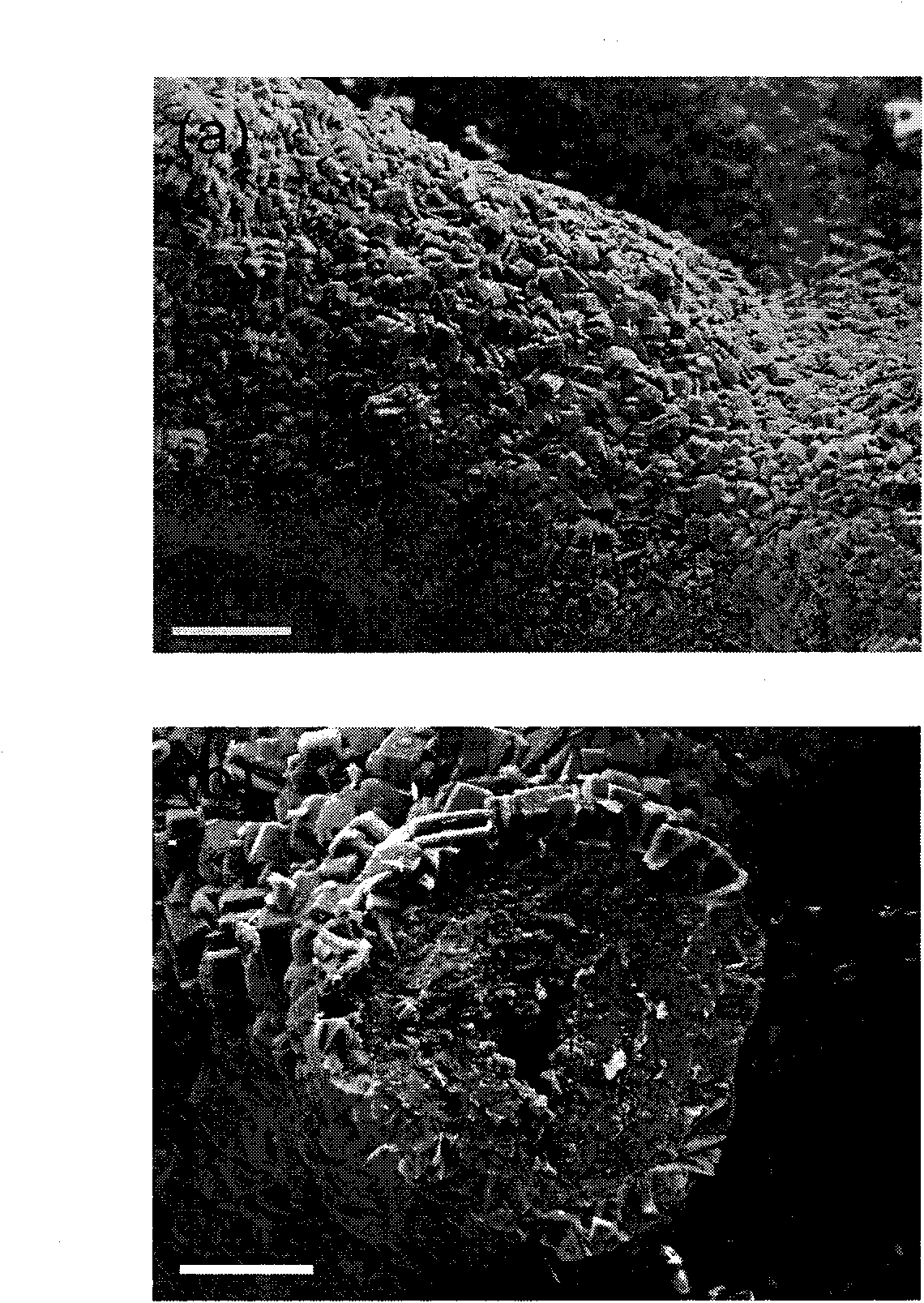

[0051] Preparation method of silicalite-I type molecular sieve coating material on the surface of foamed silicon carbide ceramics (in this embodiment, the micropore size on the surface of silicon carbide is 0.1-2 microns, and the solid raw material used is silicon block):

[0052] First, a hydrothermal synthesis solution was prepared, and tetrapropylammonium bromide, sodium hydroxide, and deionized water were mixed in a molar ratio of 0.1:0.6:100. Introduce foamed silicon carbide ceramics and silicon blocks (average particle diameter 800 to 1500 microns) into the reaction solution, the weight ratio of foamed silicon carbide ceramics to the reaction solution is 1:20, and the weight ratio of foamed silicon carbide ceramics to solid silicon source is 1: 0.5; Foamed silicon carbide ceramics are fixed at 1 cm away from the bottom of the reactor with a polytetrafluoroethylene support frame, and the silicon block is placed at the bottom of the reactor; the volume of the solution is 50...

Embodiment 2

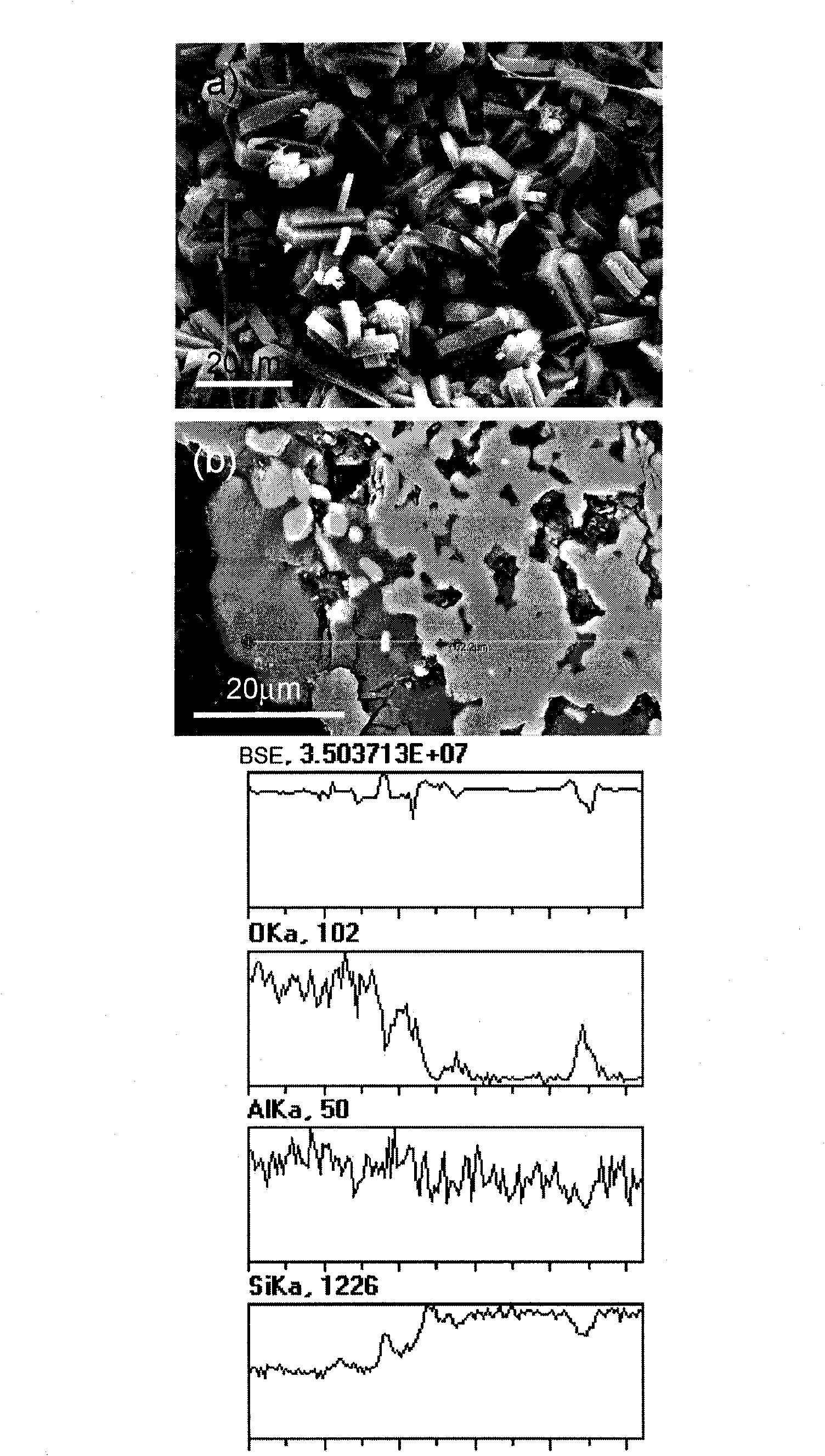

[0054] Foamed silicon carbide ceramics (in this embodiment, the micropore size on the surface of silicon carbide is 0.1 to 2 microns, and the silicon-aluminum composite oxide sintered powder used is a ZSM-5 molecular sieve powder with a silicon-aluminum ratio of 30, which is calcined at 1200 ° C for 1 Obtained in hours.) The preparation method of surface ZSM-5 type molecular sieve coating material:

[0055] First, a hydrothermal synthesis solution was prepared, and tetrapropylammonium bromide, sodium hydroxide, and deionized water were mixed in a molar ratio of 0.1:0.8:100. Introduce foamed silicon carbide ceramics, silicon-aluminum composite oxide sintered powder with a silicon-aluminum atomic ratio of 30:1 (on a 30-mesh sieve) and silicon blocks (average particle size 2 to 3 mm) into the reaction solution, and the foamed silicon carbide ceramics and The weight ratio of the reaction solution is 1:20, and the weight ratio of the foamed silicon carbide ceramics, silicon-aluminu...

Embodiment 3

[0057] Foamed silicon carbide ceramics (the size of micropores on the surface of silicon carbide in this embodiment is 0.1 to 2 microns, and the silicon-aluminum composite oxide sintered powder is a ZSM-11 molecular sieve powder with a silicon-aluminum atomic ratio of 25:1 after granulation and molding. , obtained after sintering at 1200°C for 1 hour) The preparation method of ZSM-11 molecular sieve coating material on the surface:

[0058] First, a hydrothermal synthesis solution was prepared by mixing tetrabutylammonium bromide, sodium hydroxide, and deionized water in a molar ratio of 0.1:0.8:100. Introduce foamed silicon carbide ceramics and silicon-aluminum composite oxide sintered powder (average particle size 800-1500 microns) with a silicon-aluminum atomic ratio of 25:1 into the reaction solution, and the weight ratio of the foamed silicon carbide ceramics to the reaction solution is 1:20 , the weight ratio of foamed silicon carbide ceramics to silicon-aluminum composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com