Centrally-mounted drive system of electric bicycle

A technology of electric bicycles and drive systems, which is applied in the directions of rider drives, wheel transmissions, chain/belt drives, etc., and can solve the problems of low difficulty in the design of the central drive system, complex structure of the deceleration system, and large volume of the deceleration body, etc. problem, to avoid substantial changes to the frame and reduce the size of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the drawings and examples.

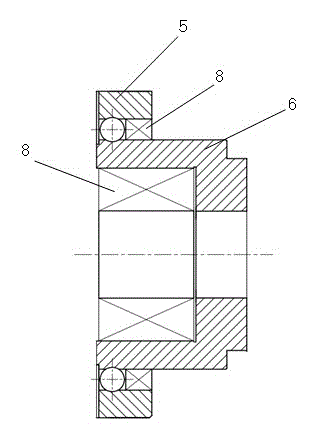

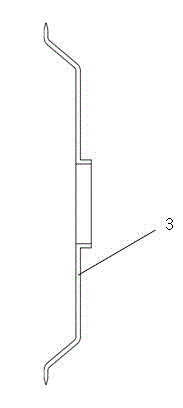

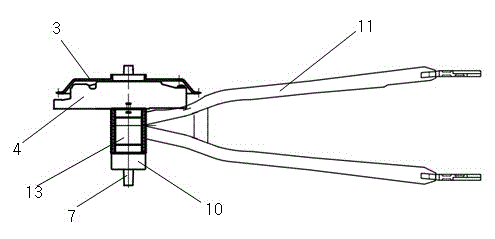

[0027] figure 1 It is a sectional view of the middle drive system of the electric bicycle of the present invention; figure 2 It is a partial cross-sectional view of the composite double overrunning clutch in the middle drive system of the electric bicycle of the present invention; image 3 It is a side view of the sprocket in the middle drive system of the electric bicycle of the present invention; Figure 4 It is a top view when the middle drive system of the electric bicycle of the present invention is fixed to the frame of the electric bicycle.

[0028] Such as Figure 1 to Figure 4As shown, the middle drive system of the electric bicycle of the present invention includes: the sprocket 3, as the power input end of the electric bicycle, transmits the power to the rear wheel of the electric bicycle through the chain matched with the sprocket, and drives the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com