Patents

Literature

245results about How to "Avoid drastic changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

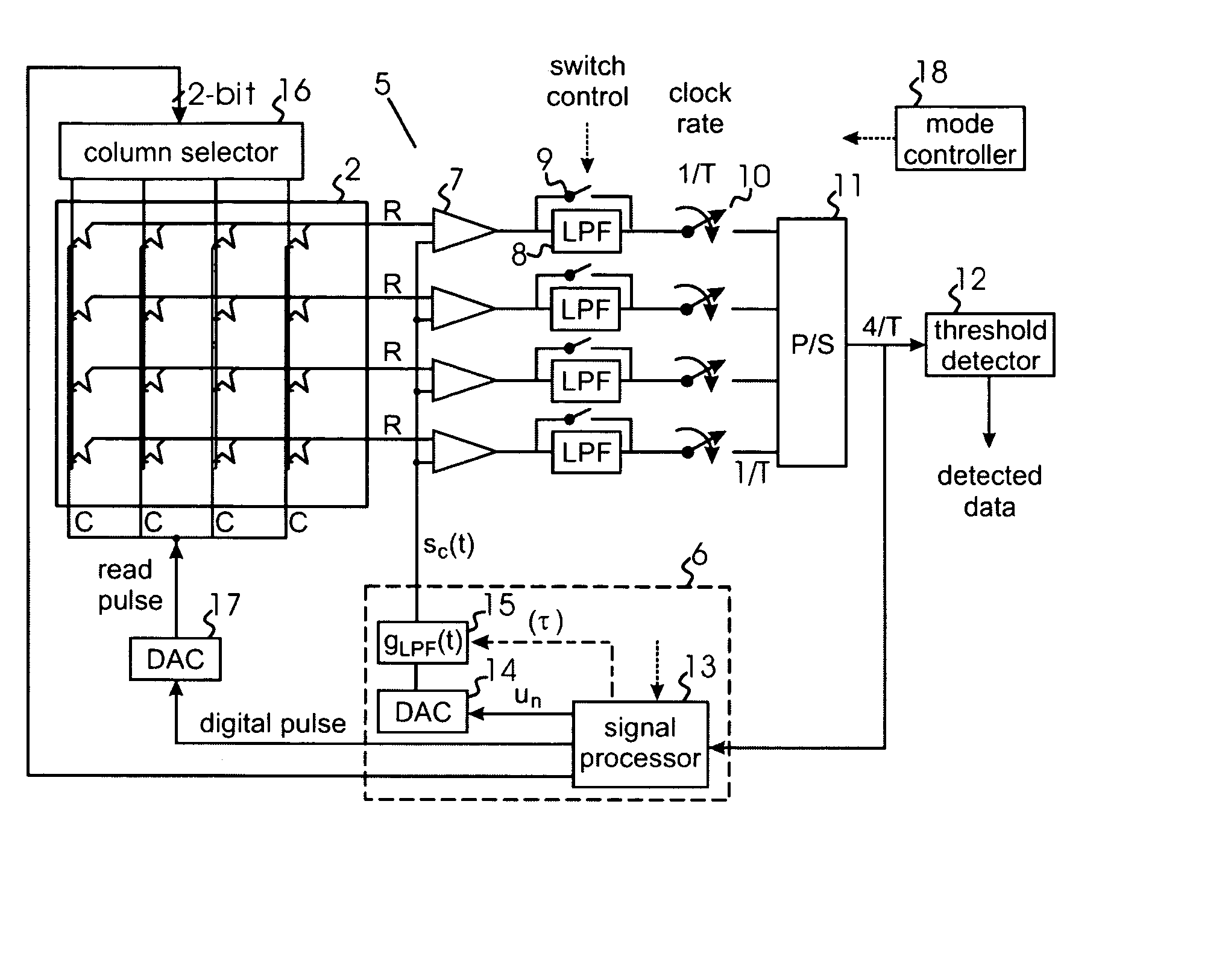

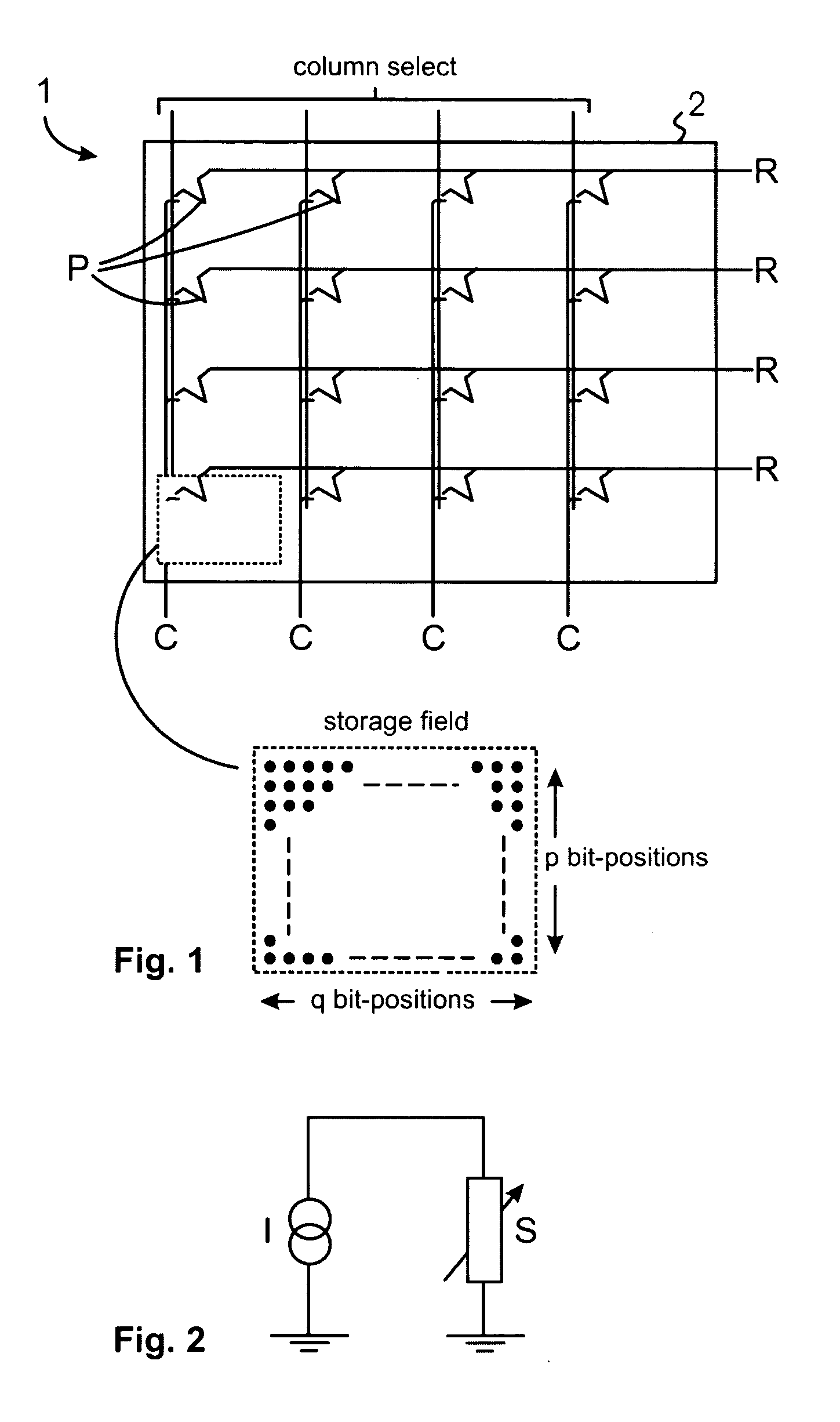

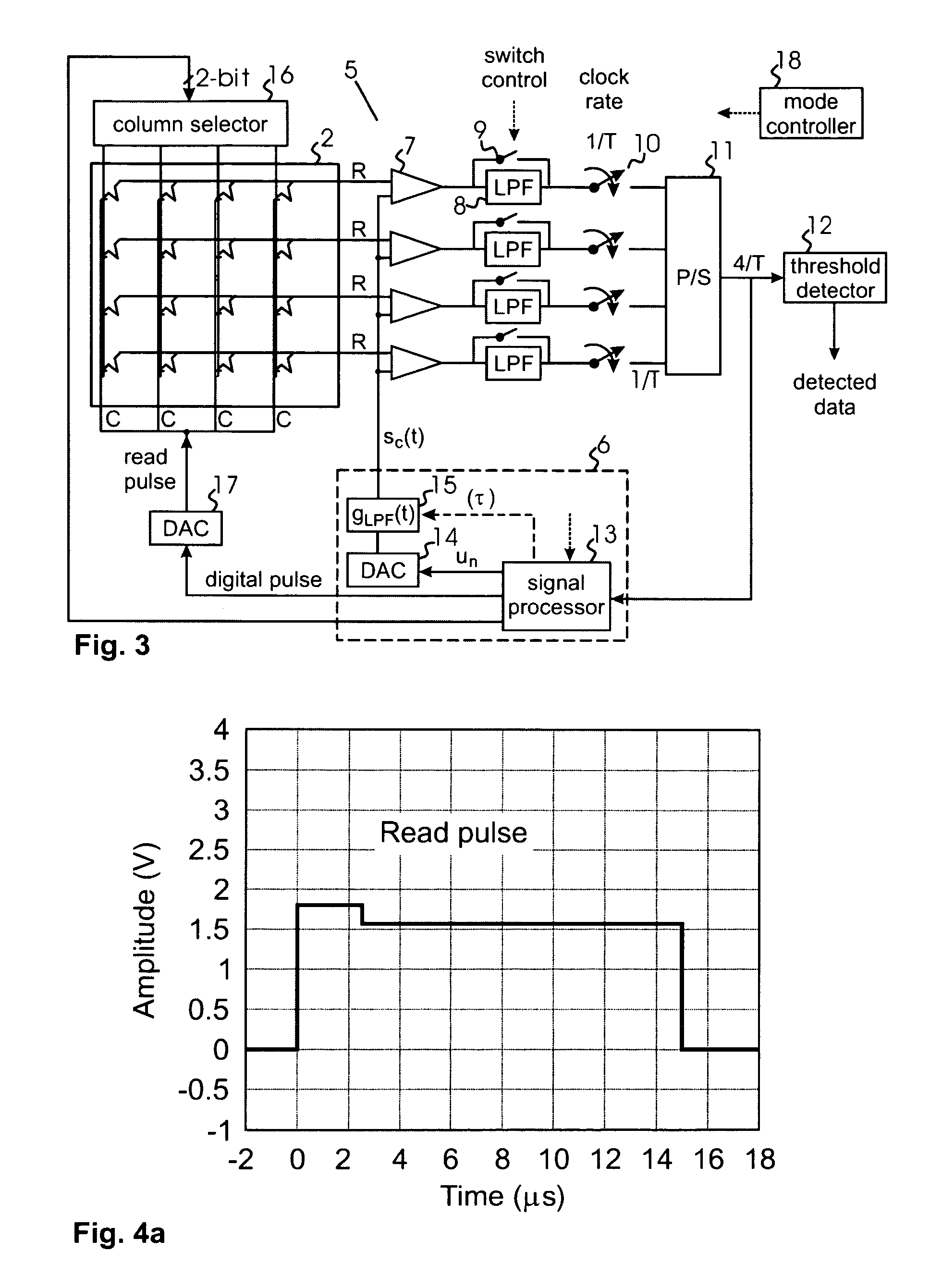

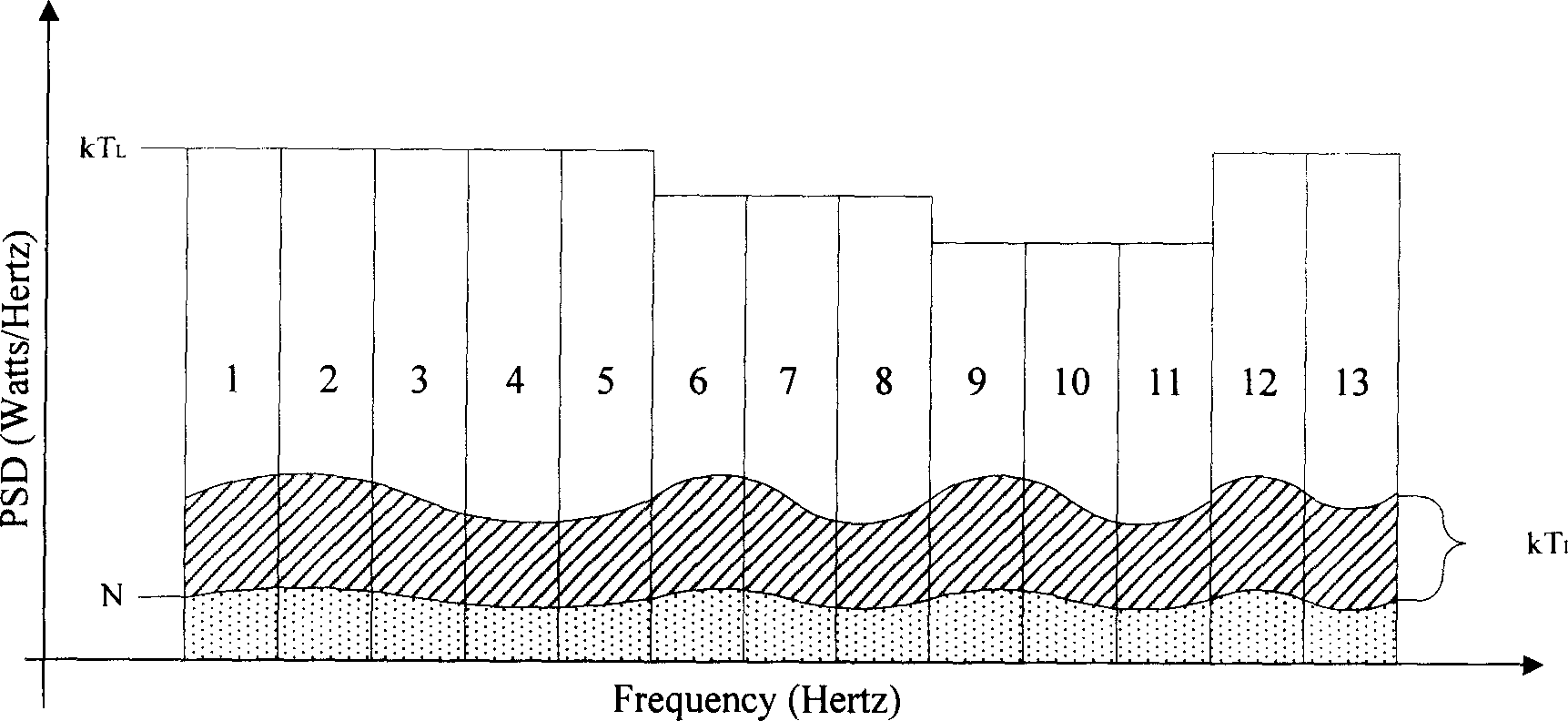

Offset compensation in local-probe data storage devices

InactiveUS20050207234A1Simple and convenient mechanismAvoid drastic changesElectric signal transmission systemsDigital storageSignal generatorLow pass filtering

Methods and apparatus for compensating offsets in a read signal generated by a sensor associated with a probe of a local-probe data storage device during read-scanning by the probe of bit-positions on a storage surface. An apparatus comprises a generator for generating an offset compensation signal, and a subtraction stage for producing an output signal dependent on the difference between the offset compensation signal and the sensor read signal at each bit-position. In some embodiments, an offset signal generator generates an offset compensation signal dependent upon a predetermined measurement of the sensor read signal. In another aspect the offset signal generator low-pass filters the sensor read signal during read scanning to generate the offset compensation signal. Particular embodiments also include a secondary offset compensation stage for applying additional offset compensation techniques to the output signal from the subtraction stage.

Owner:IBM CORP

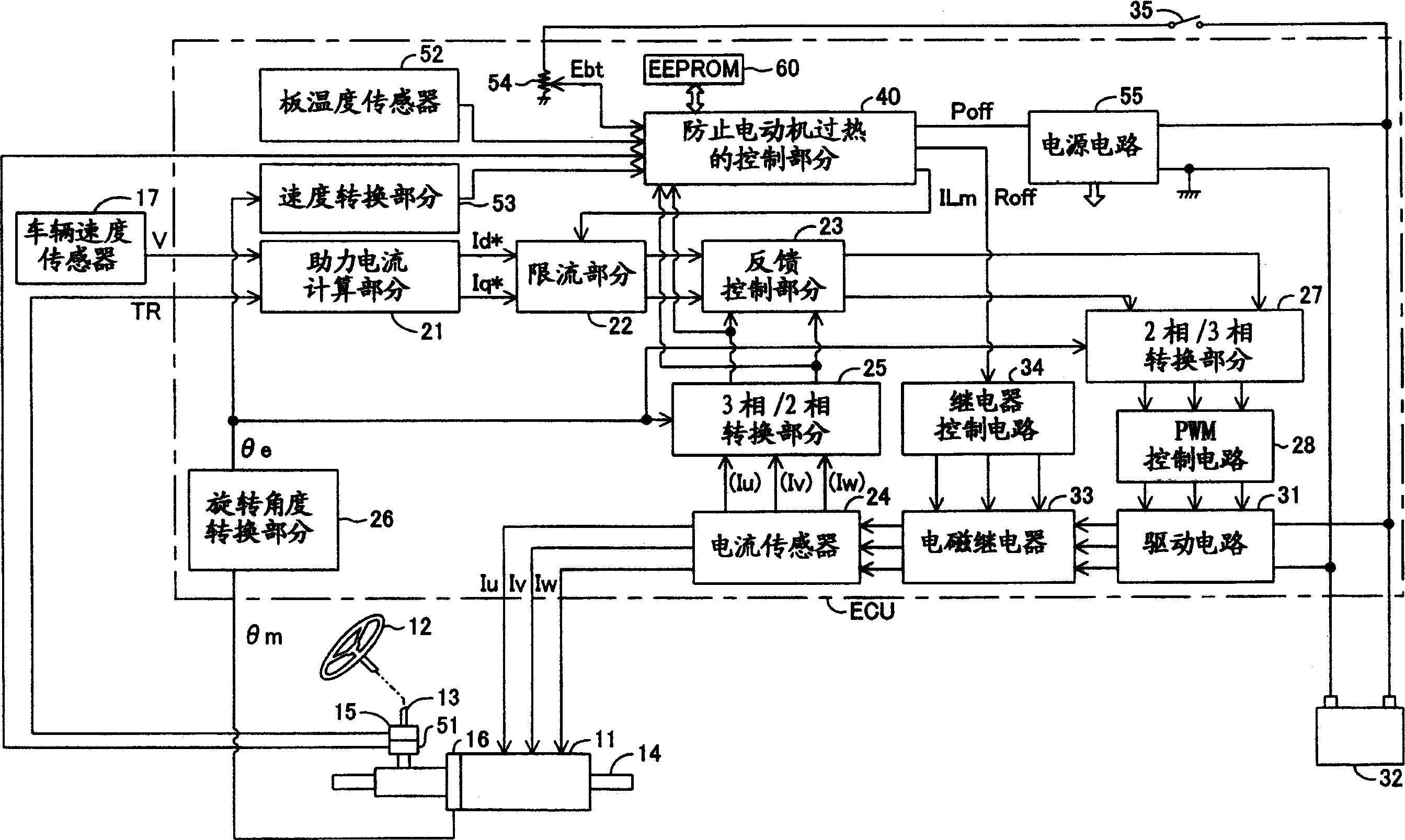

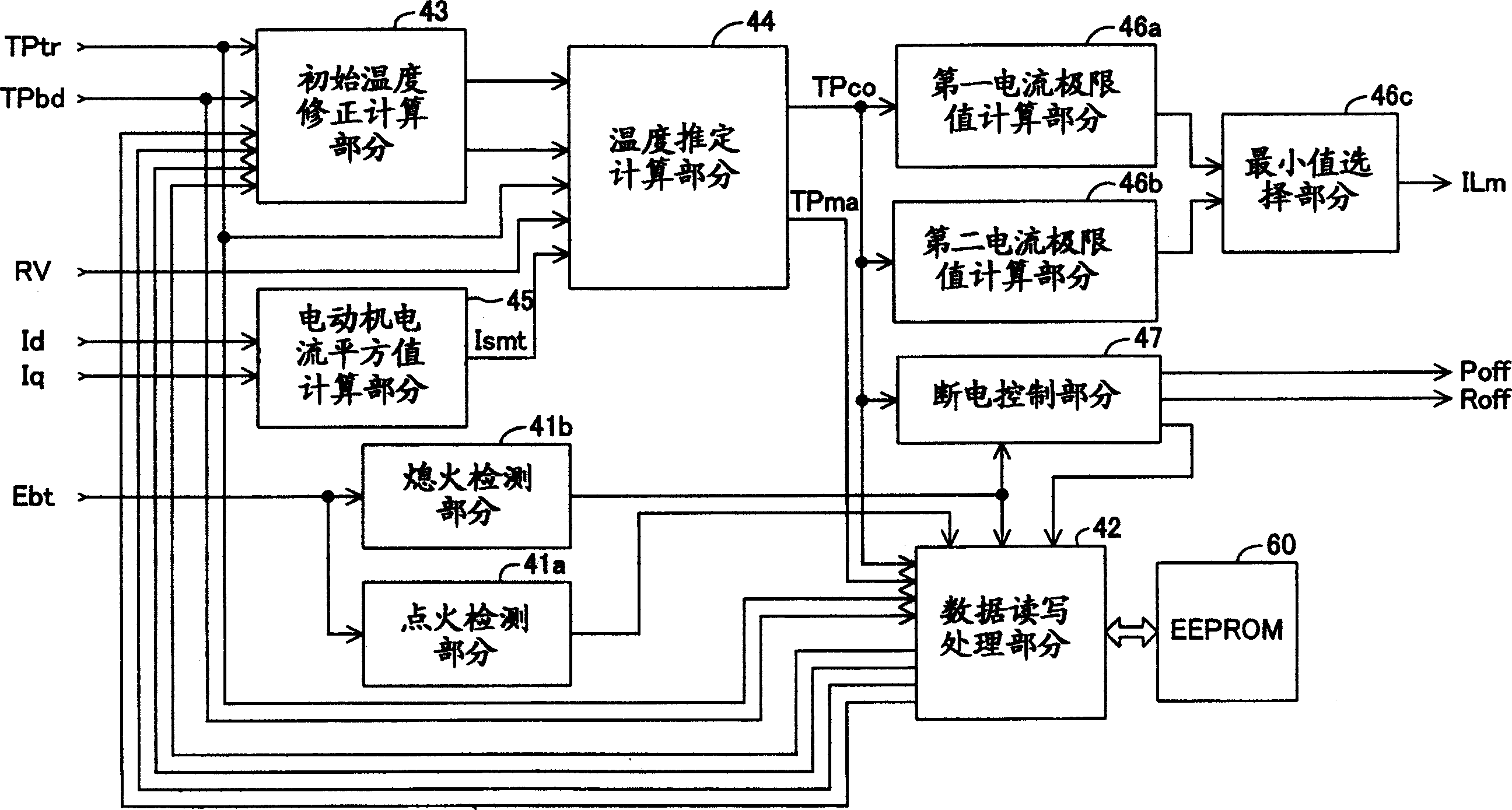

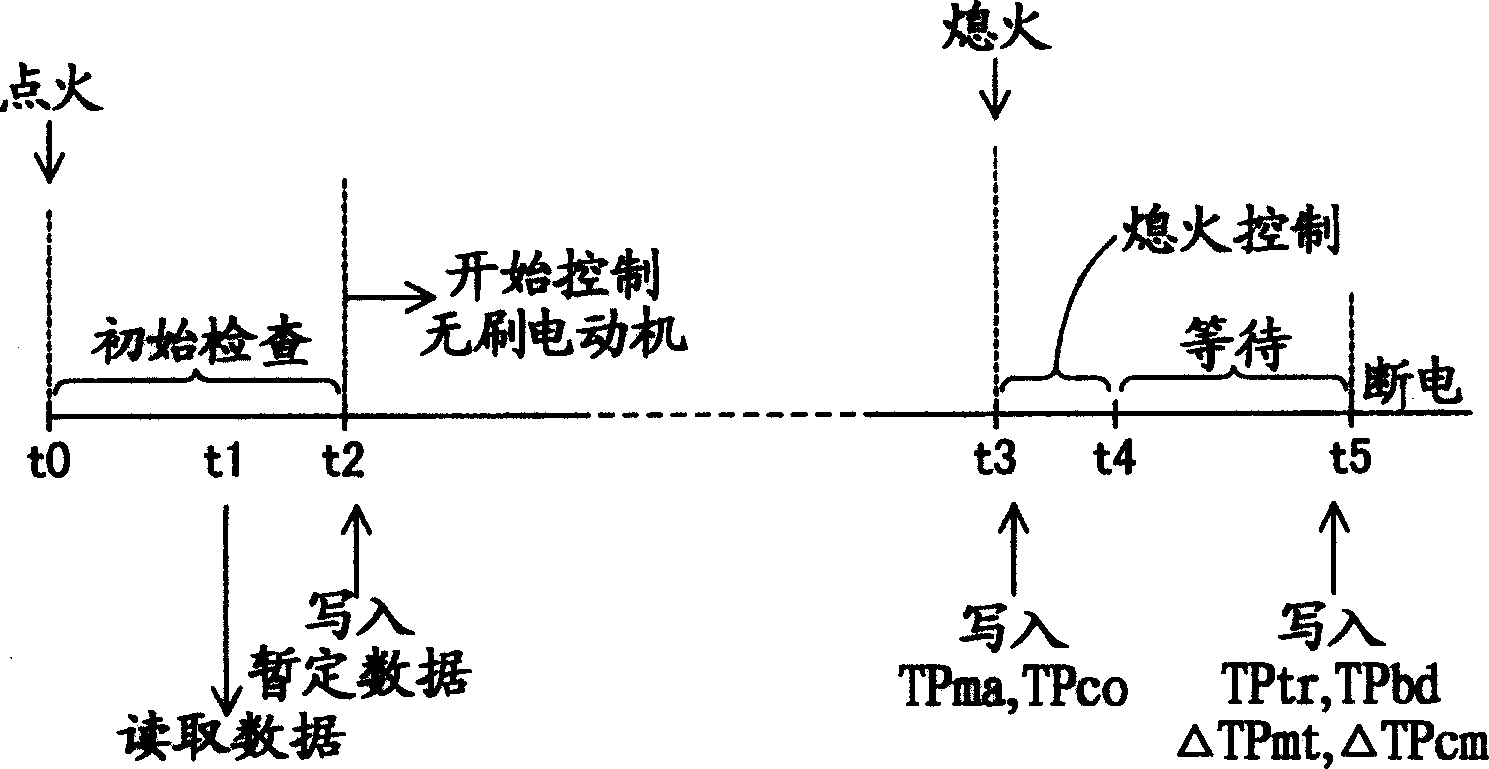

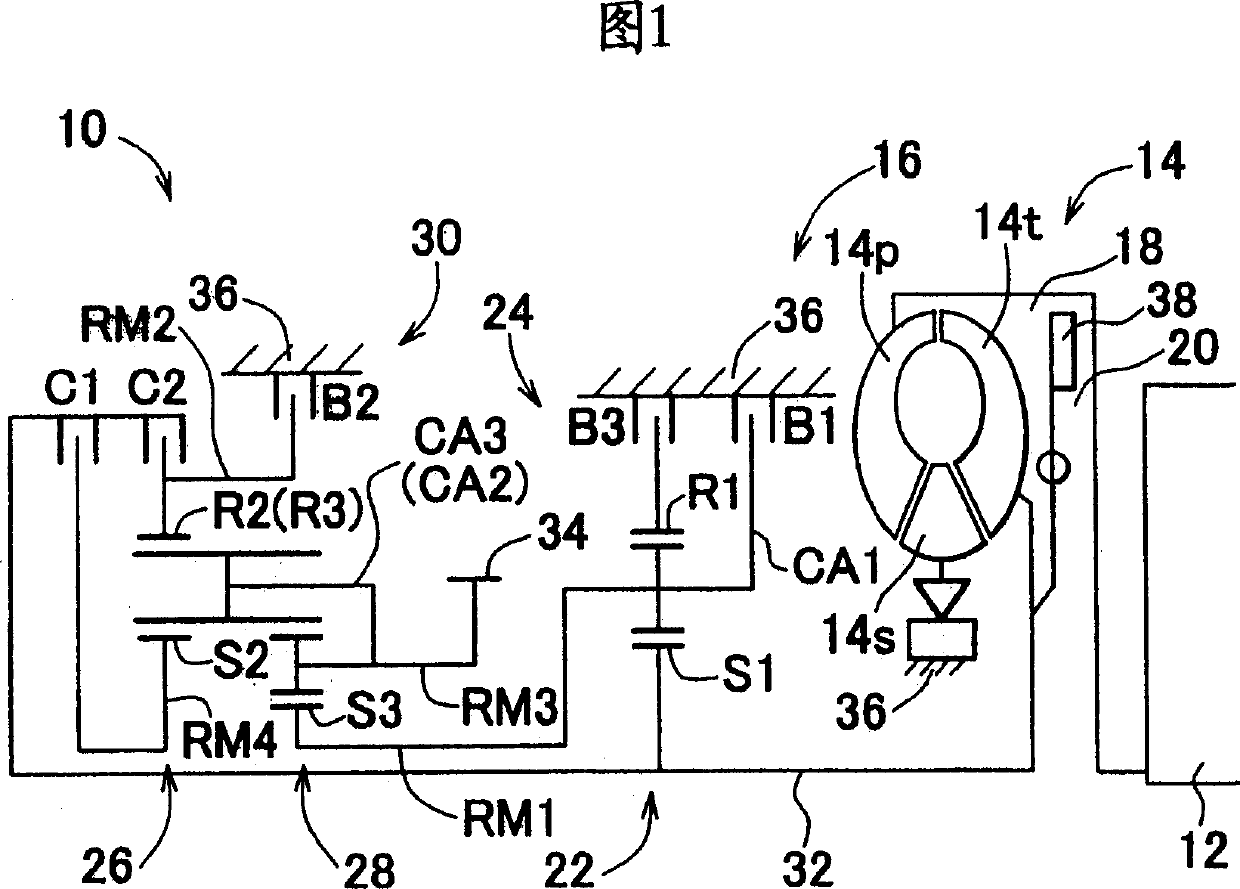

Motor temperature estimator and motor controller

InactiveCN1647361AAvoid drastic changesCommutation monitoringVector control systemsPhase currentsThree-phase

A motor-current square value calculation section 45 calculates, as a motor-current square value, the sum of respective square values of two phase currents converted from three phase currents flowing through an electric motor. A temperature estimation calculation section 44 performs low-pass filtering for the motor-current square value, and calculates temperature increases of the mass portion and coils on the basis of the filtered motor-current square value. In the low-pass filtering, filtering calculation is performed in a manner which changes depending on rotational speed RV of the electric motor; i.e., whether the electric motor is in a rotating state or in a stopped state. The temperature increase of the mass portion is added to ambient temperature of the electric motor to thereby estimate temperature of the mass portion, and the temperature increase of the coils is added to the estimated temperature of the mass portion to thereby estimate temperature of the coils. Accordingly, the coil temperature of the electric motor can be accurately detected, and current flowing through the electric motor is properly controlled in accordance with the detected temperature.

Owner:TOYOTA JIDOSHA KK +1

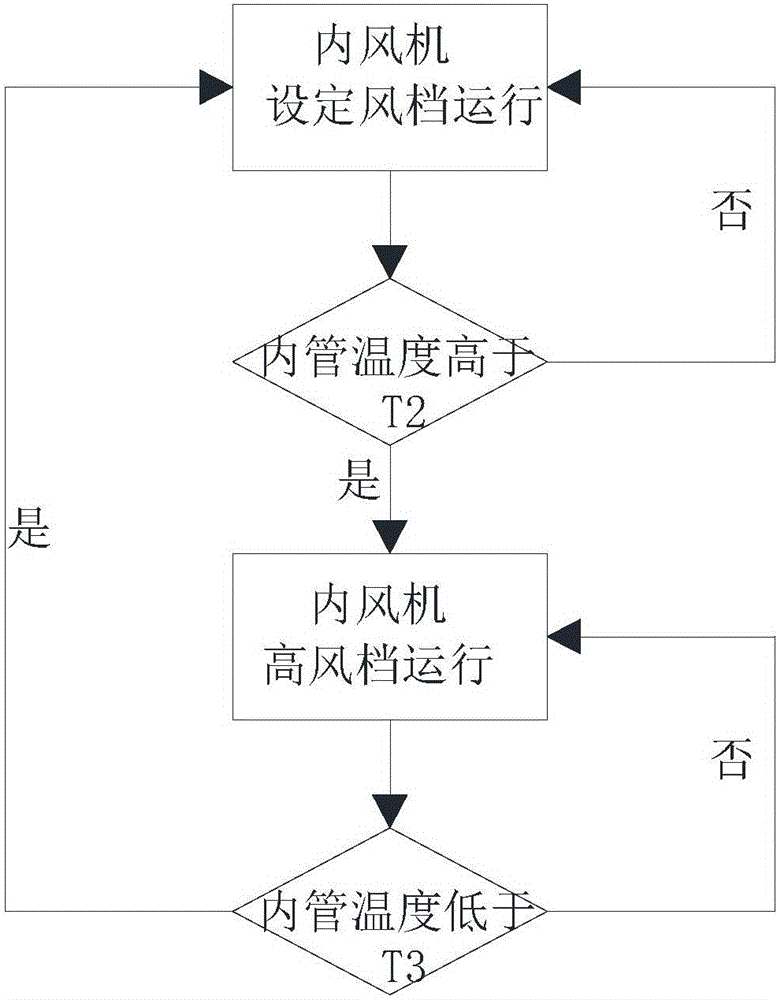

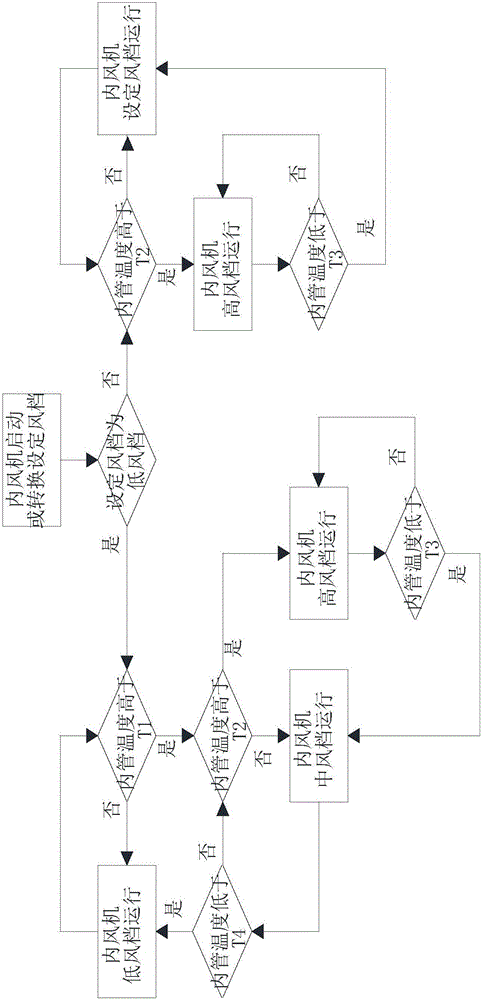

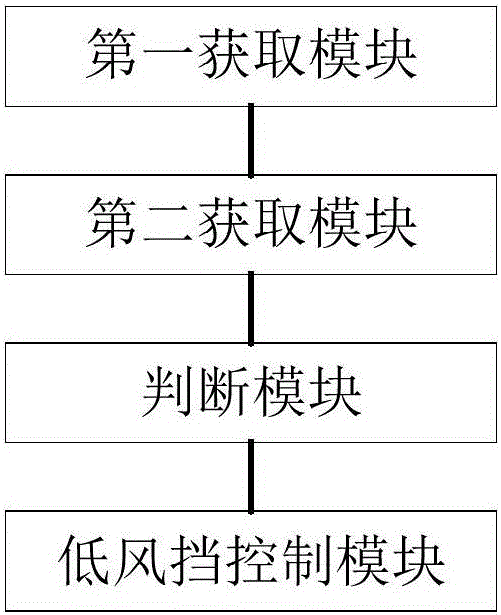

Method and device for controlling heating and high temperature prevention of air conditioner system and air conditioner

ActiveCN105091238AAvoid frequent switchingAvoid drastic changesMechanical apparatusSpace heating and ventilation safety systemsAir volumeEngineering

The invention discloses a method and device for controlling heating and high temperature prevention of an air conditioner system and an air conditioner. The method comprises the steps that a set wind gear of the air conditioner under a heating mode is obtained; the inner tube temperature of the air conditioner is obtained; whether the set wind gear is a low wind gear is judged; under the condition that the set wind gear is the low wind gear, if the inner tube temperature is lower than a first preset temperature, an inner draught fan of the air conditioner is controlled to operate at the lower wind gear; if the inner tube temperature is higher than or equal to a second preset temperature, the inner draught fan is controlled to operate at a high wind gear, and the first preset temperature is lower than the second preset temperature; if the inner tube temperature is higher than or equal to the first preset temperature and lower than the second preset temperature, the inner draught fan is controlled to operate at a middle wind gear. By means of the method and device, the wind gears can be prevented from being shifted frequently, the wind capacity can be prevented from acute change, the detection temperature of a thermal bulb can be prevented from deviating from practical inner tube temperature substantially on account of acute change of the practical inner tube temperature, the high temperature prevention can be prevented from losing efficacy, and therefore the problems of high discharge pressure and compressor overload of a machine set are avoided.

Owner:GREE ELECTRIC APPLIANCES INC

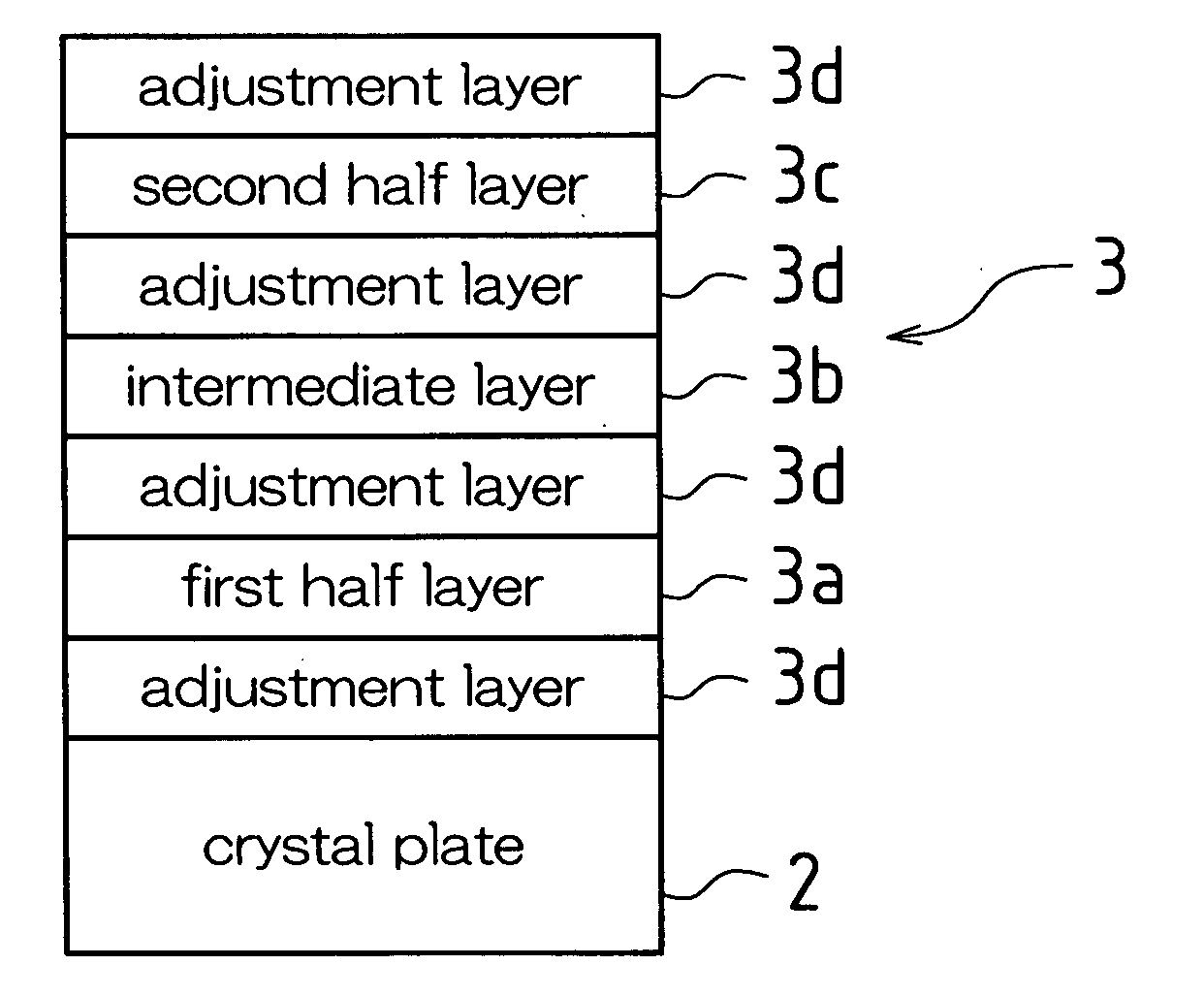

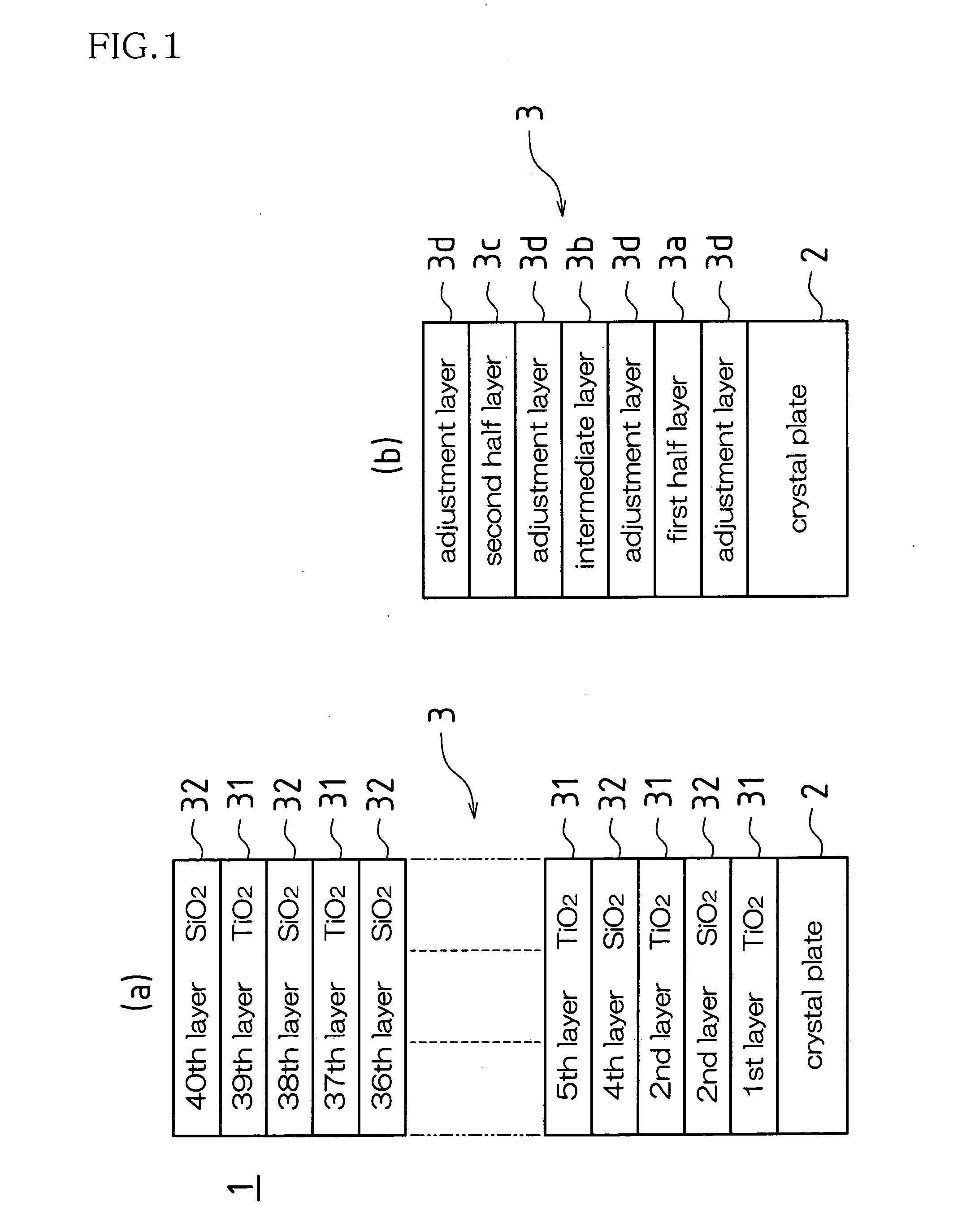

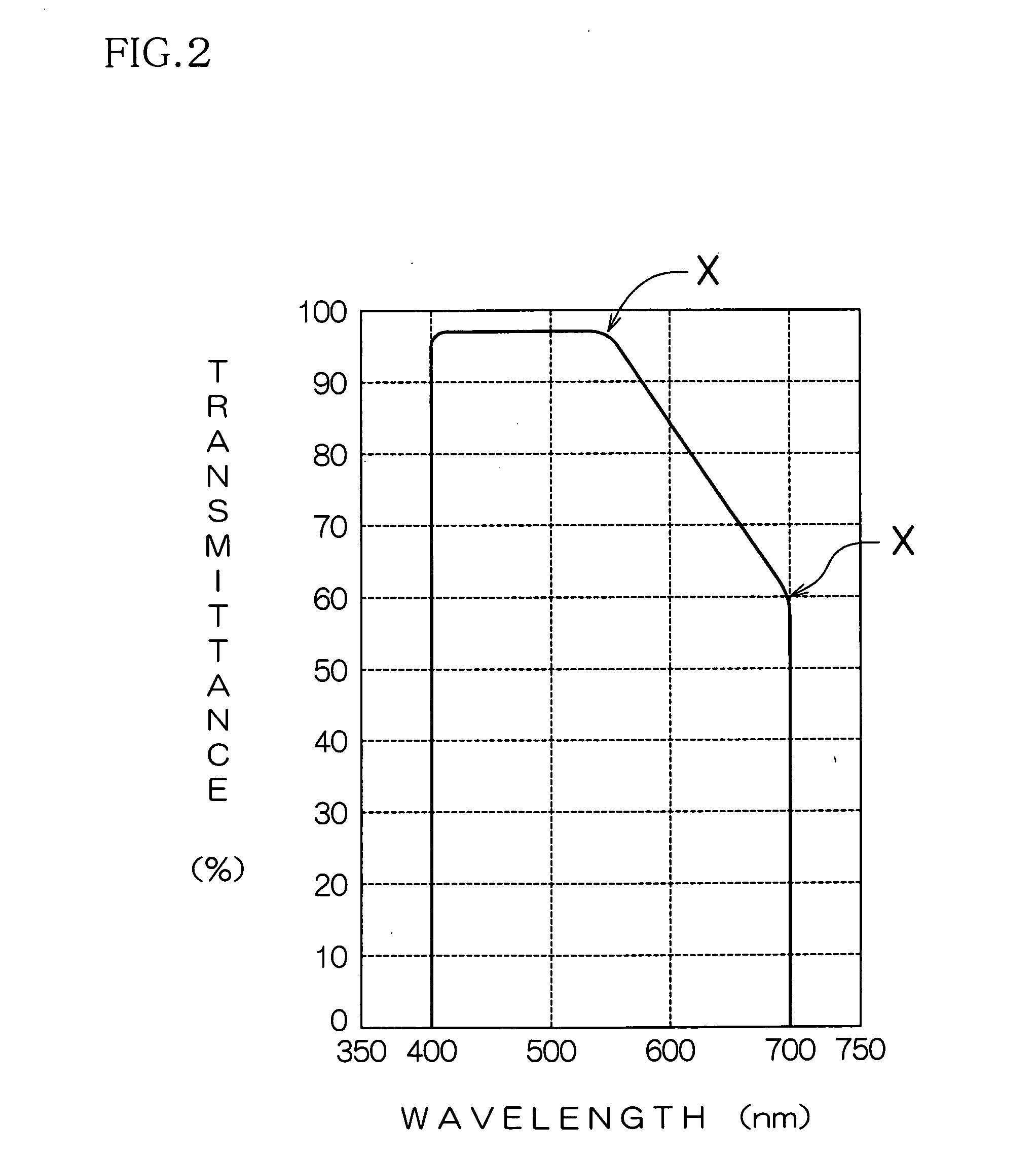

Light ray cut filter

InactiveUS20050253048A1Inhibition of variationPrevents change amountRadiation pyrometryMaterial analysis by optical meansTransmittanceRefractive index

An IR-cut filter comprises a crystal plate and a multilayer film formed on one side of the crystal plate. The multilayer film is composed of first thin films made of a high refractive index material and second thin films made of a low refractive index material, which are alternately layered. The multilayer film is composed of a first layer, a second layer and a third layer sequentially from one side of the crystal plate. Film thicknesses of the layered first and second thin films differ from layer to layer so that the layers have different thicknesses. The layers have thicknesses which are sequentially increased. The multilayer film is provided with a sharpness prevention means for preventing a sharp change in transmittance within a visible region. The sharpness prevention means provides an inflection point at a wavelength band in which transmittance changes sharply.

Owner:DAISHINKU CORP

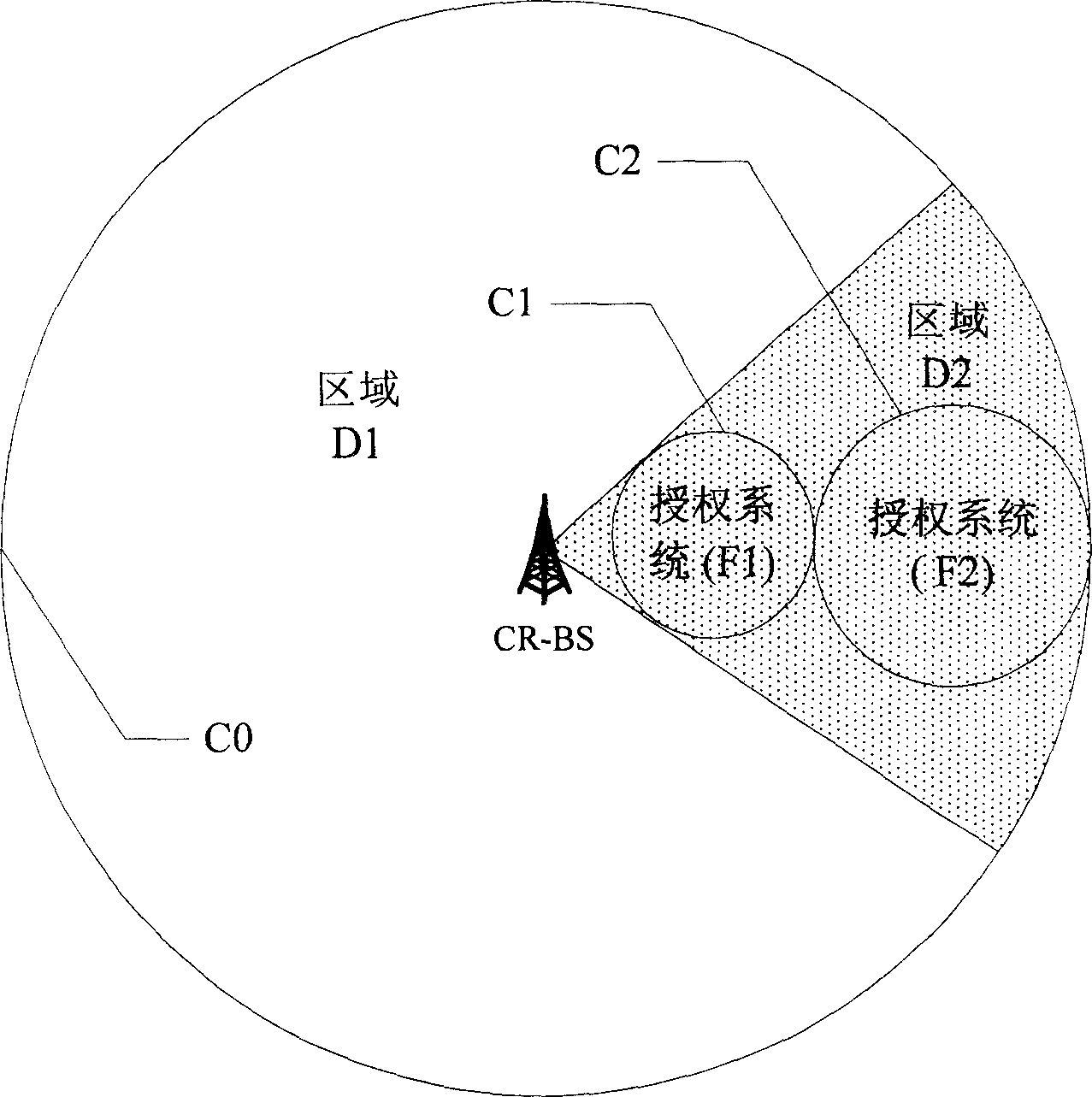

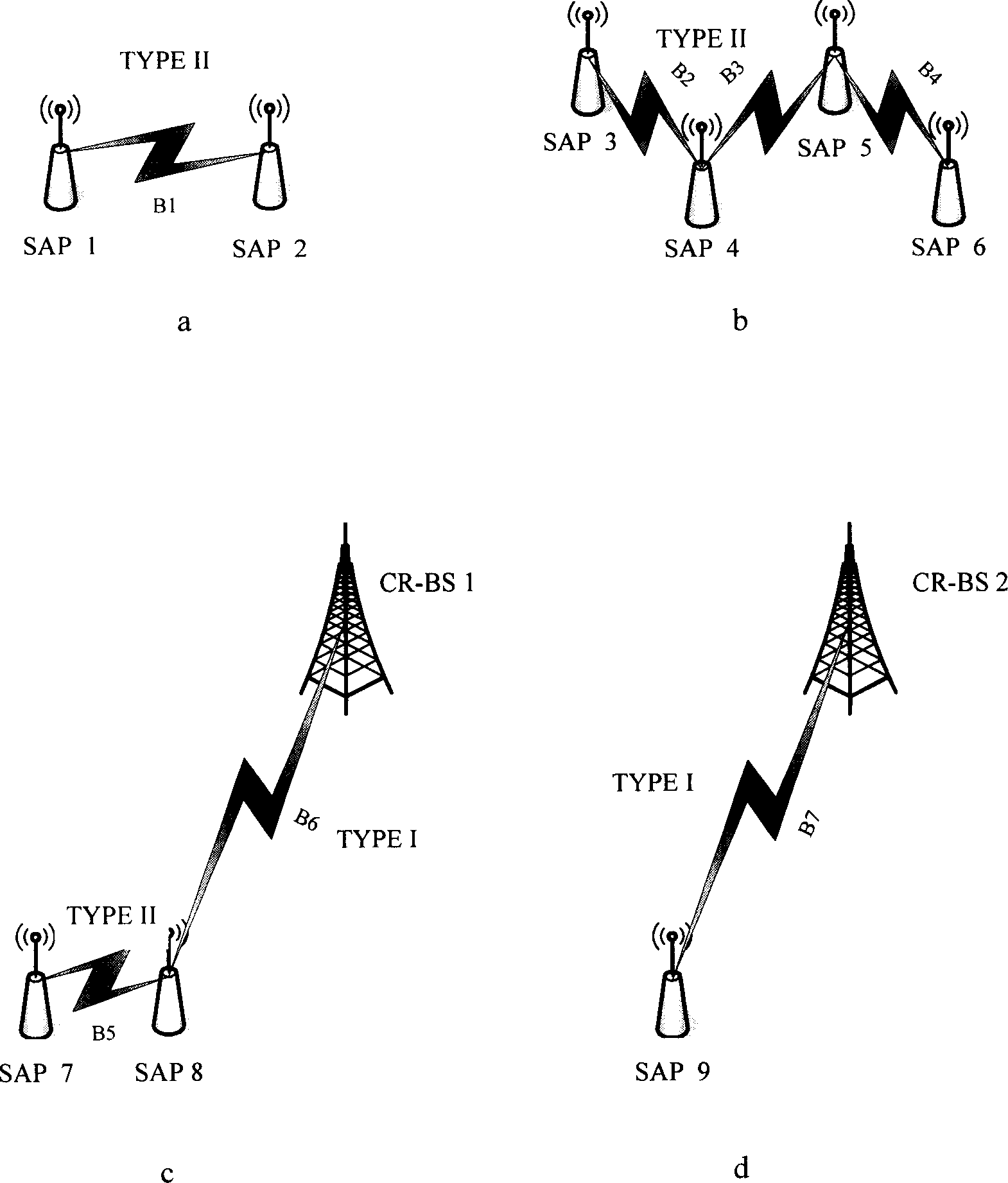

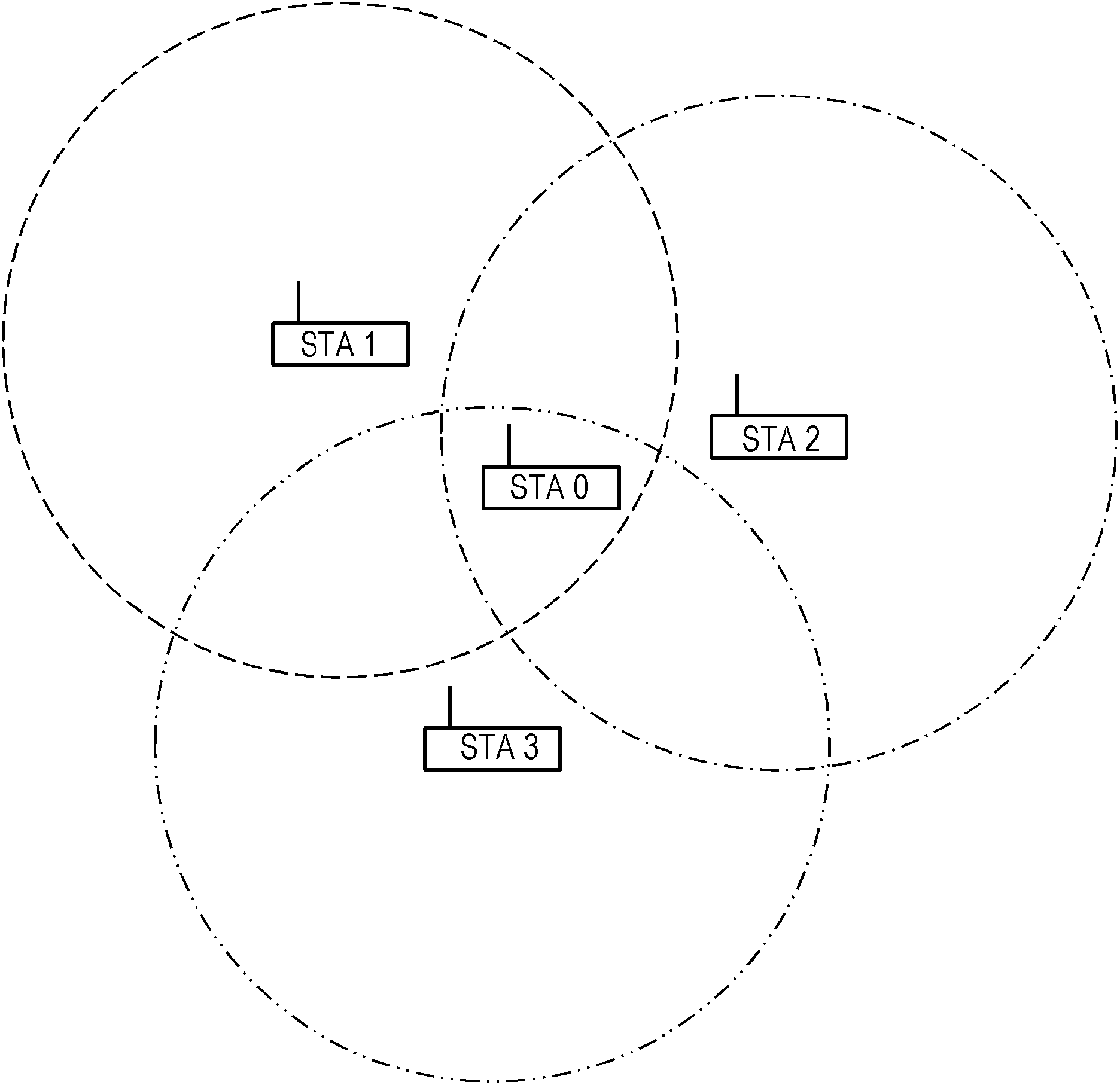

Realization method for mixed network structure in cognitive radio

InactiveCN1882158AIncrease the number ofLarge capacityNetwork topologiesRadio/inductive link selection arrangementsMix networkSystem capacity

The invention relates to a method for realizing mixed network structure, belonging to the wireless communication technique, especially the frequency spectrum application of cognitive radio system and the realization of physical transmission medium of cognitive radio mixed network structure, wherein it comprises: based on the interfere temperature model, calculating the allowed maximum receiving power of receiver at said time, calculating the real emission power of sending terminal, calculating the combination of two effective frequency spectrums, and realizing the point-to-multipoint (PMP) and mesh topology in mixed structure. The inventive classified spectrum share method can realize the mixed structure that supporting the point-to-multipoint (PMP) and mesh topology, to increase the system capacity and expand the area cover range.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

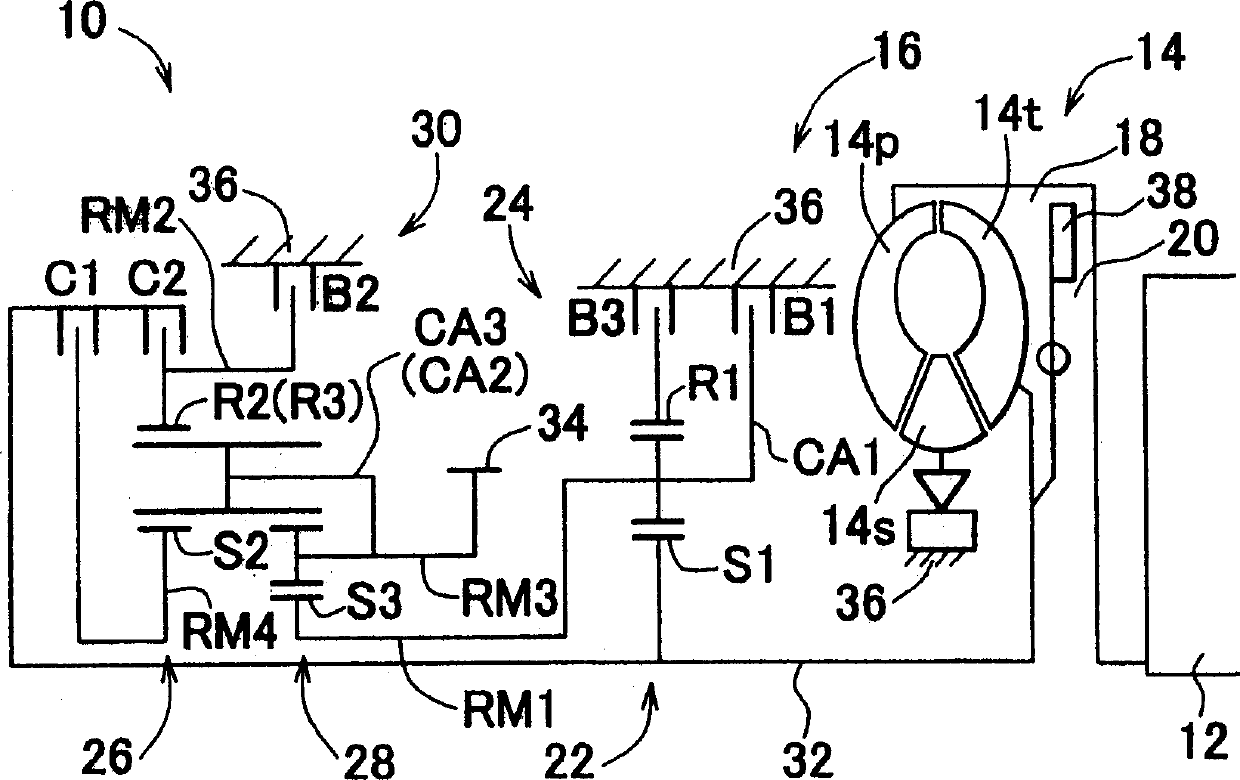

Control apparatus and method for lock-up clutch of vehicle

InactiveCN1550697AImprove fuel economyImprove fuel efficiencyClutchesGearing controlClutch controlEngineering

In a vehicle having a hydraulic power transmitting device equipped with a lock-up clutch on an output side of the engine, a control apparatus for controlling the lock-up clutch is provided which includes a lock-up clutch control unit that places the lock-up clutch in a slipping state when the vehicle is started so that torque received from the engine is transmitted to a later-stage transmission via the lock-up clutch as well as the hydraulic power transmitting device.

Owner:TOYOTA JIDOSHA KK

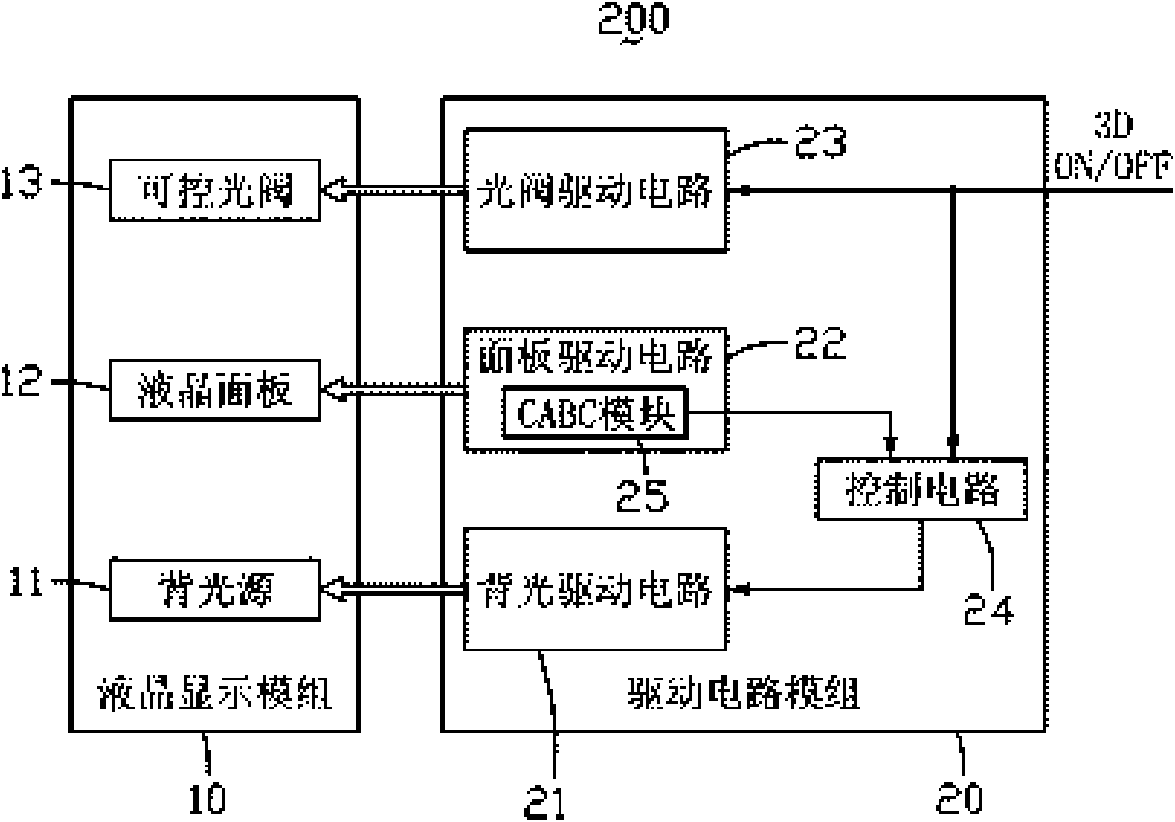

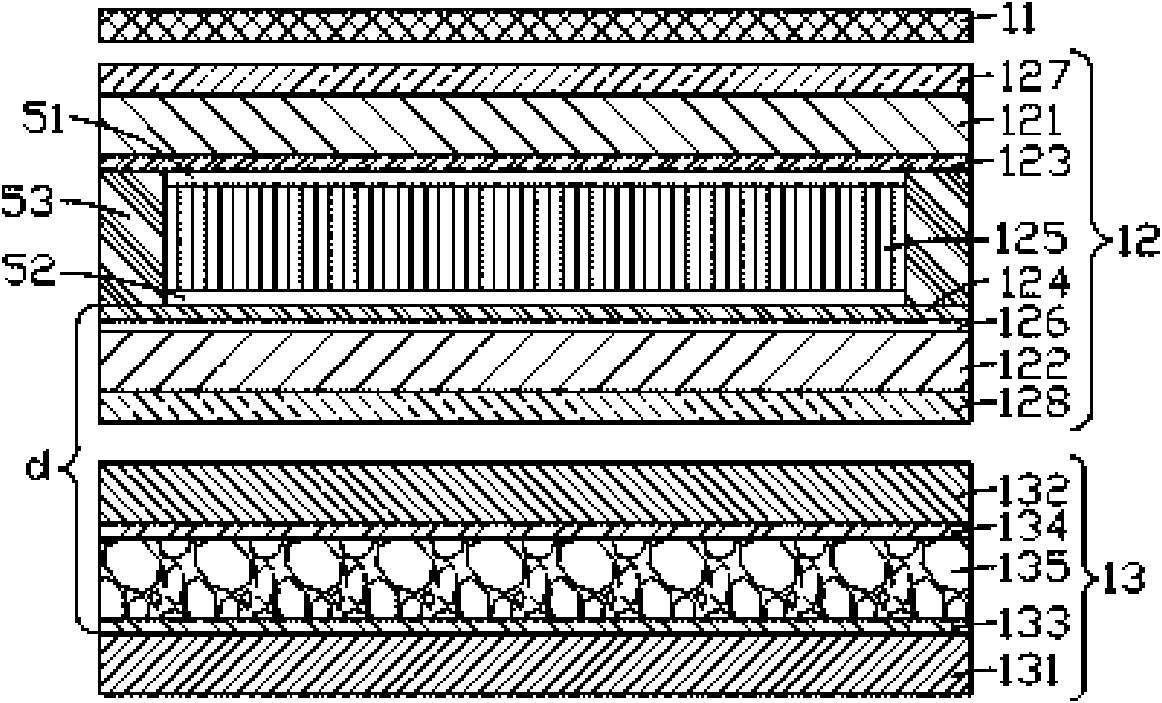

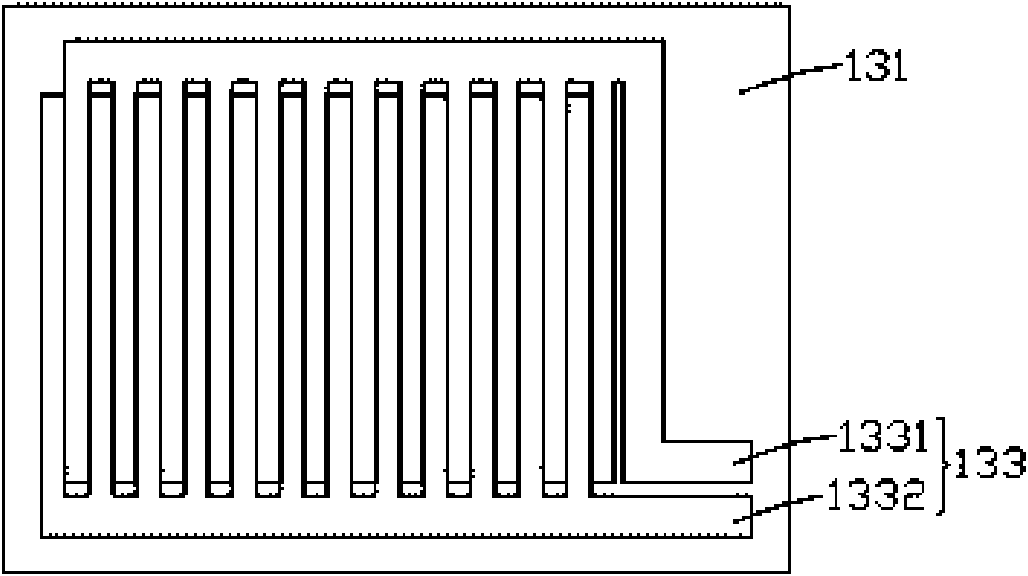

Liquid crystal display device

ActiveCN101630493AImprove stereo display effectIncrease brightnessStatic indicating devicesSteroscopic systemsLiquid-crystal displaySwitching signal

The invention relates to a liquid crystal display device which comprises a display module and a driving circuit module, wherein the display module comprises a backlight source, a liquid crystal panel and a controllable light valve; the driving circuit module comprises a backlight driving circuit, a light valve driving circuit and a control circuit; the backlight driving circuit is used for supplying voltage to the backlight source to drive the backlight source to emit light; the light valve driving circuit is used for controlling the controllable light valve under the action of a display status switching signal, so that the liquid crystal display device can be switched to the corresponding display status; and the control circuit receives the display status switching signal and controls the backlight driving circuit according to the display status switching signal to adjust the brightness of the backlight source.

Owner:TIANMA MICRO ELECTRONICS CO LTD

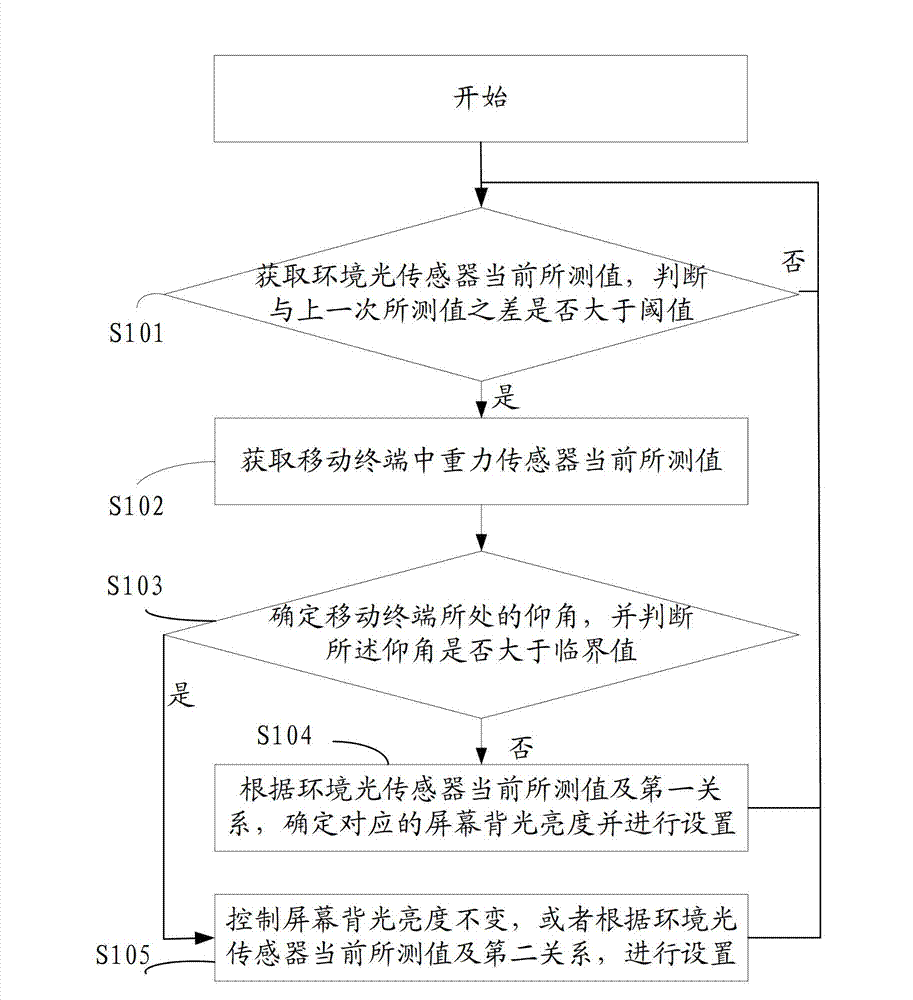

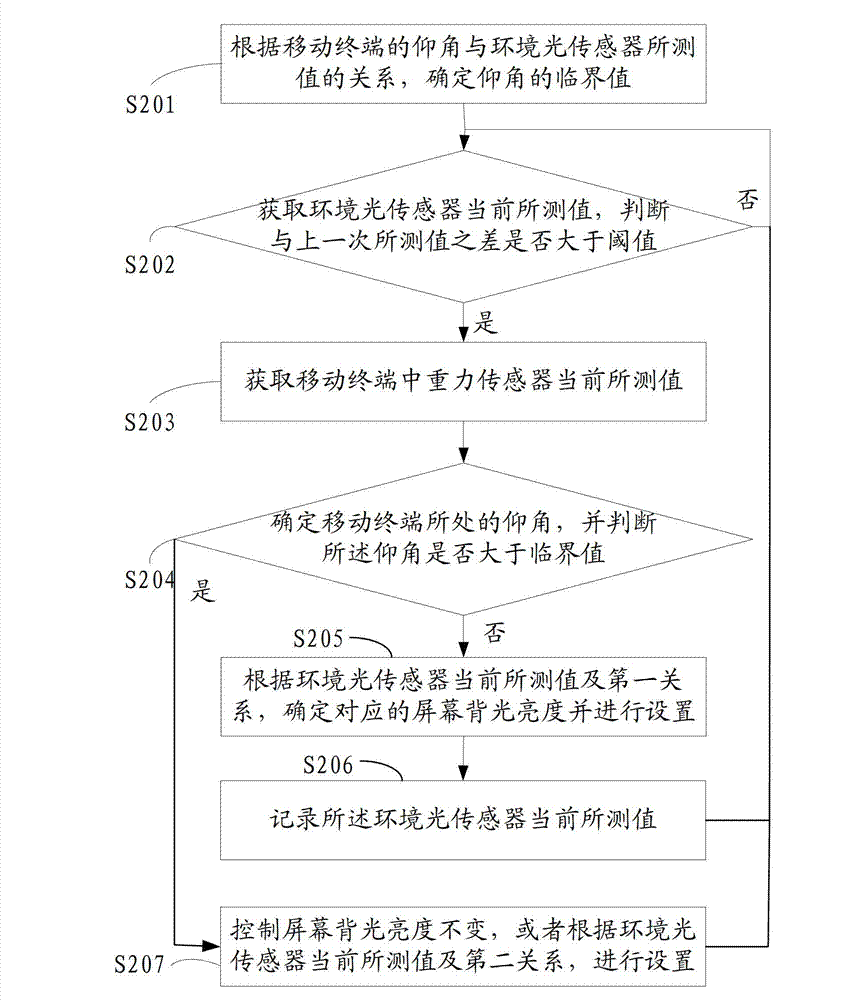

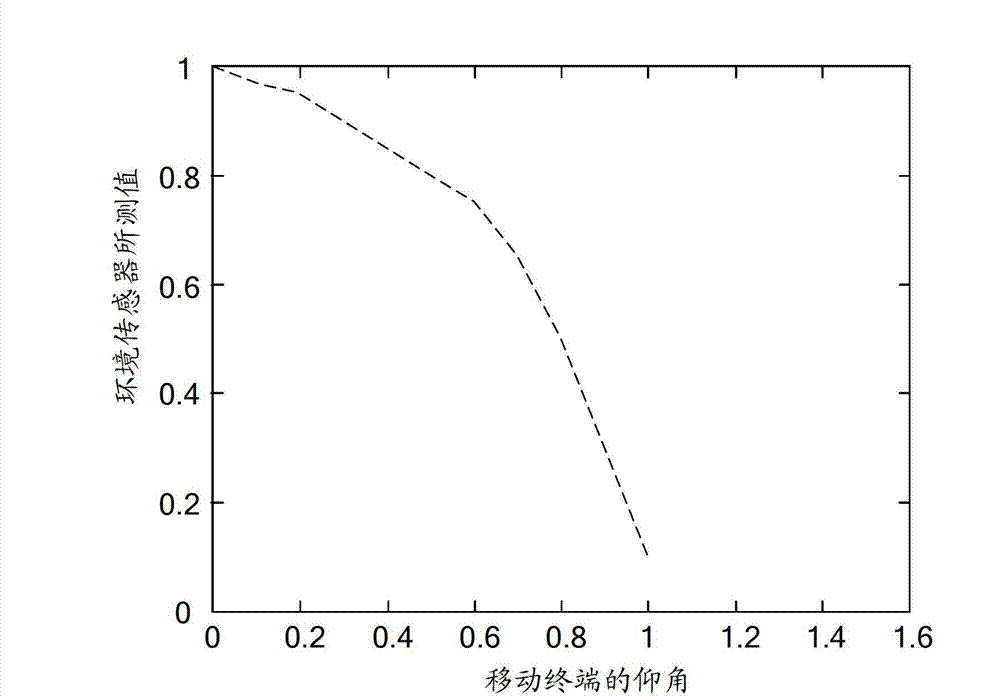

Method and mobile terminal for screen backlight adjusting

ActiveCN103037088AAvoid frequent settingsImprove stabilitySubstation equipmentElevation angleBrightness perception

The invention discloses a method and a mobile terminal for screen backlight adjusting, wherein the method includes: the mobile terminal obtains a present measured value of an ambient light sensor and judges whether the difference between the present measured value of the ambient light sensor and the last measured value is larger than a threshold value, if the difference between the present measured value of the ambient light sensor and the last measured value is larger than the threshold value, a present measured value of a gravity sensor in the mobile terminal is obtained, and an elevation angle of the mobile terminal is determined, whether the elevation angle is larger than a critical value is judged if the elevation angle is smaller than or equal to the critical value, corresponding screen backlight brightness is determined and set according to the present measured value of the ambient light sensor and a first relation, and if the elevation angle is larger than the critical value, the screen backlight brightness is controlled to be constant or be relatively small in variation. Due to the method, in an indoor environment, when the elevation angle of the position which the mobile terminal is located is larger than the critical value, the situation in which drastic change of screen backlight happens can be avoided, and the experience of a user is optimized.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

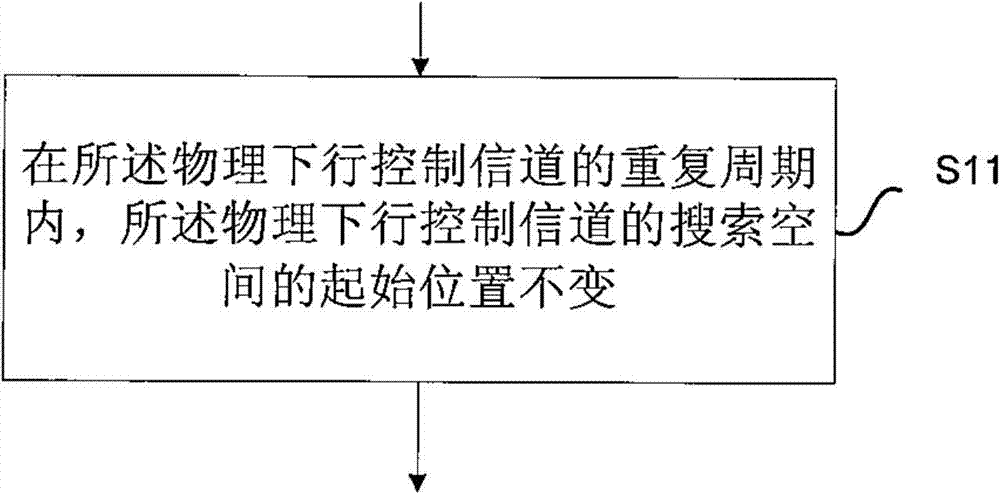

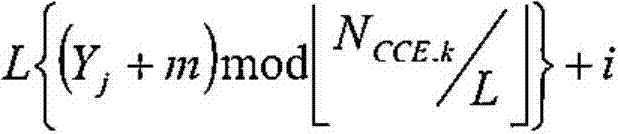

Search space determining method

ActiveCN104754741ASimplified blind decoding operationAvoid drastic changesSignal allocationMachine-to-machine/machine-type communication serviceTime domainCommunications system

A method for determining a search space of a physical downlink control channel in a wireless communication system, wherein the physical downlink control channel is periodically repeated in a time domain, the method characterized in that a starting position of the search space of the physical downlink control channel is unchanged within a repetition period of the physical downlink control channel.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD +1

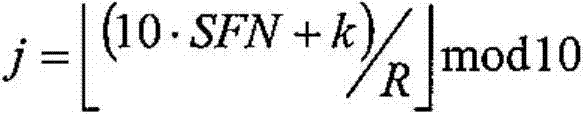

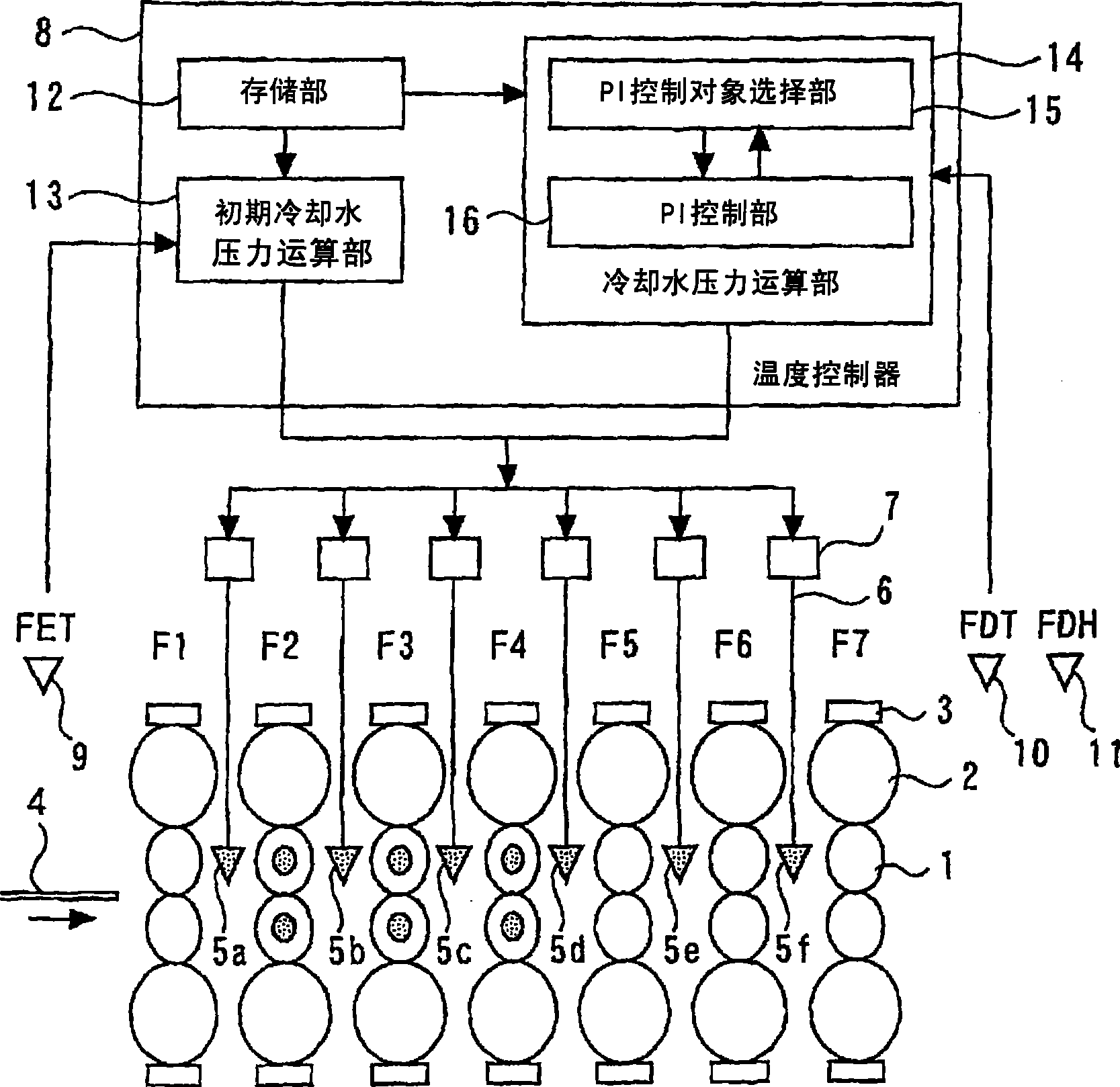

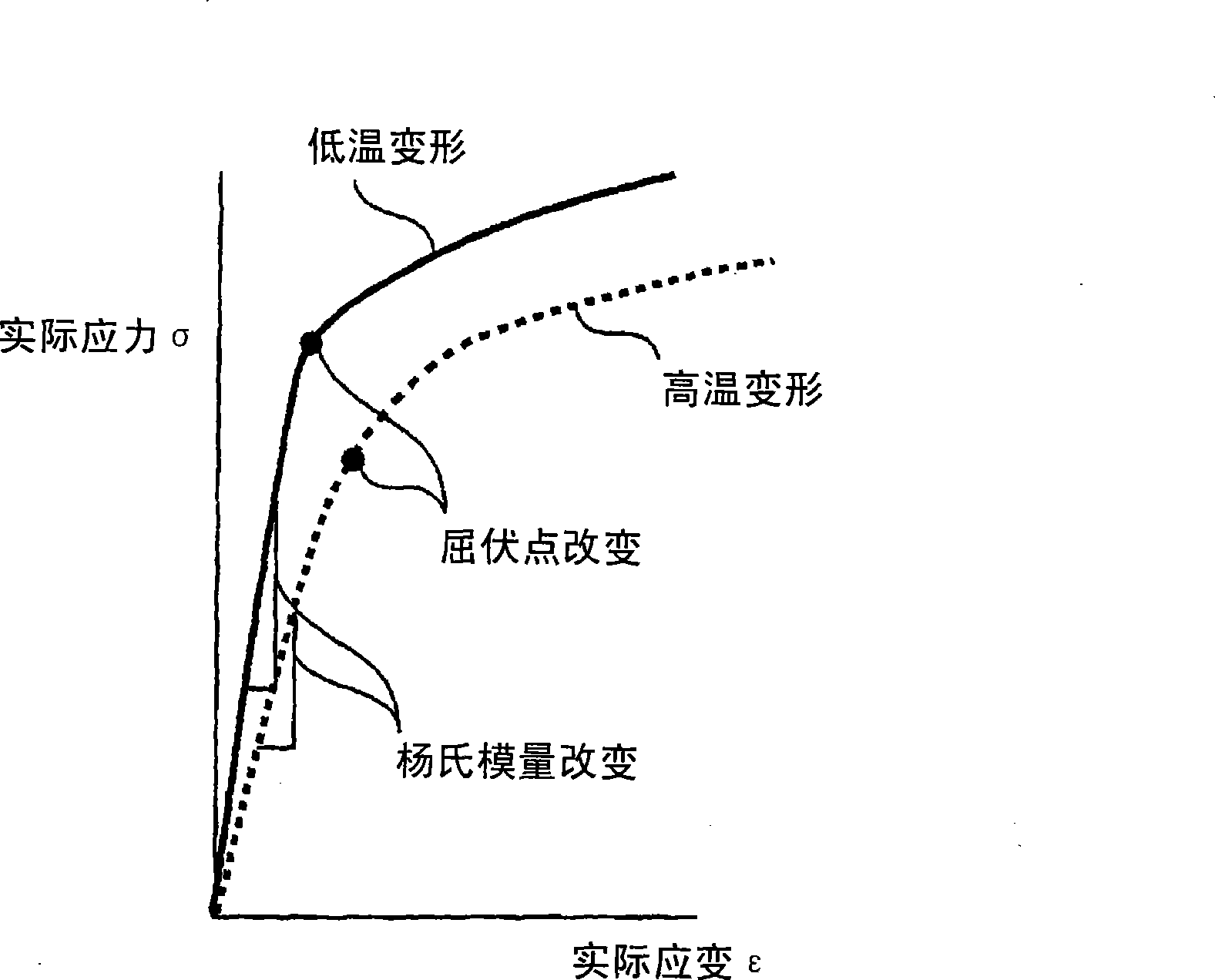

Temperature control device for hot rolling mill

ActiveCN101394945AReduce biasAvoid drastic changesTemperature control deviceWork cooling devicesLower limitTemperature control

A temperature control unit of hot rolling machine that avoids any sharp temperature change of rolling material at a place near the outlet of the rolling machine to thereby realize a high-precision control of sheet thickness. Accordingly, in a hot rolling machine equipped with multiple rolling stands continually disposed and further with multiple cooling units for cooling of rolling material, first, the cooling water pressure of each of the cooling units is computed using up to the upper limit pressure preferentially from one of the multiple cooling units disposed on the inlet side of the rolling machine on the basis of the target temperature and inlet actual temperature of the rolling material. Subsequently, on the basis of the target temperature and outlet actual temperature of the rolling material, so as to reduce any deviation between the target temperature and the outlet actual temperature, there is computed the cooling water pressure of one of the cooling units in operation disposed nearest the outlet of the rolling machine. At that stage, when the cooling water pressure of the cooling unit under control reaches the upper limit pressure, the control object is changed to the cooling unit disposed adjacent to the outlet of the rolling machine. On the other hand, when the cooling water pressure reaches the lower limit pressure, the control object is changed to the cooling unit disposed adjacent to the inlet of the rolling machine.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

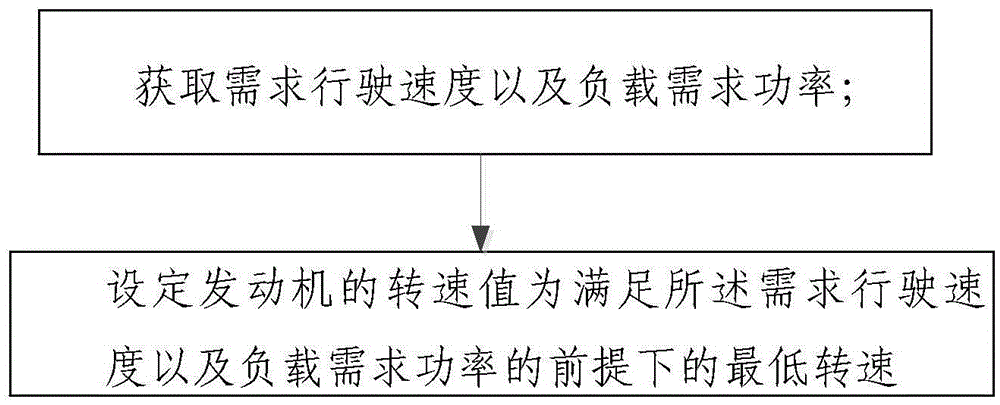

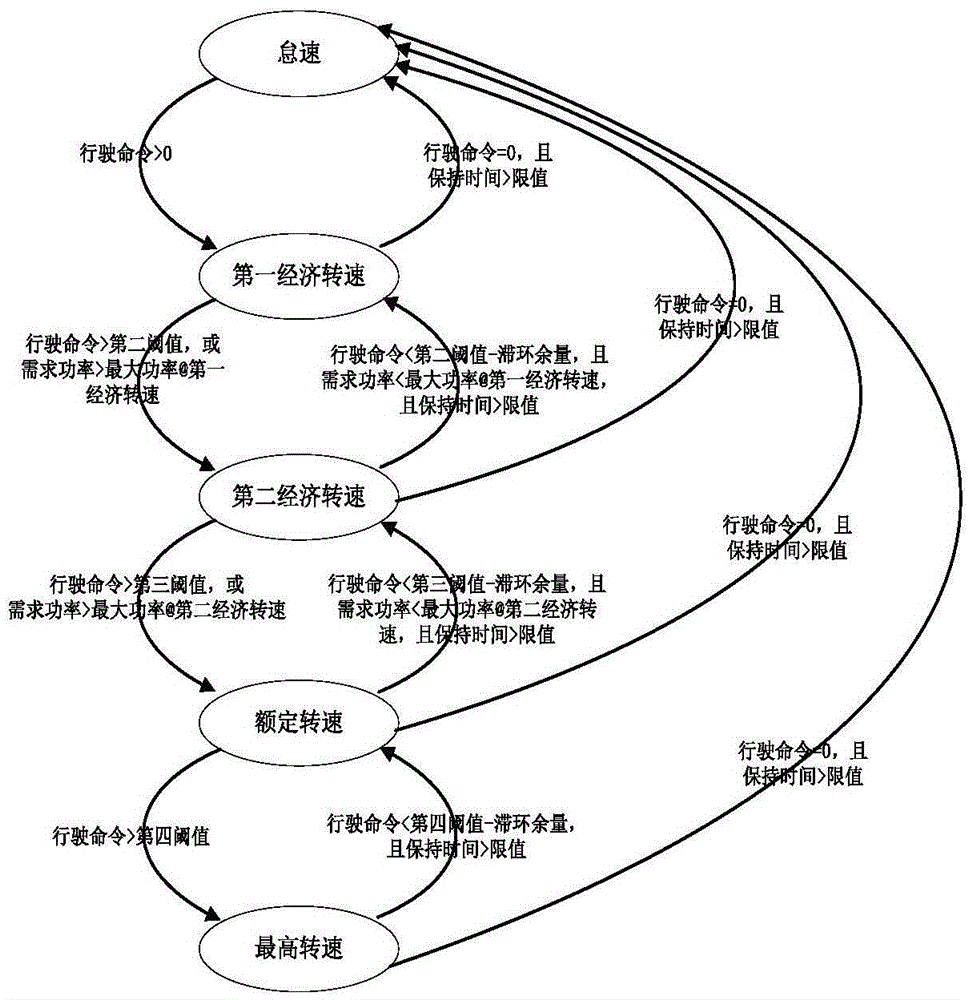

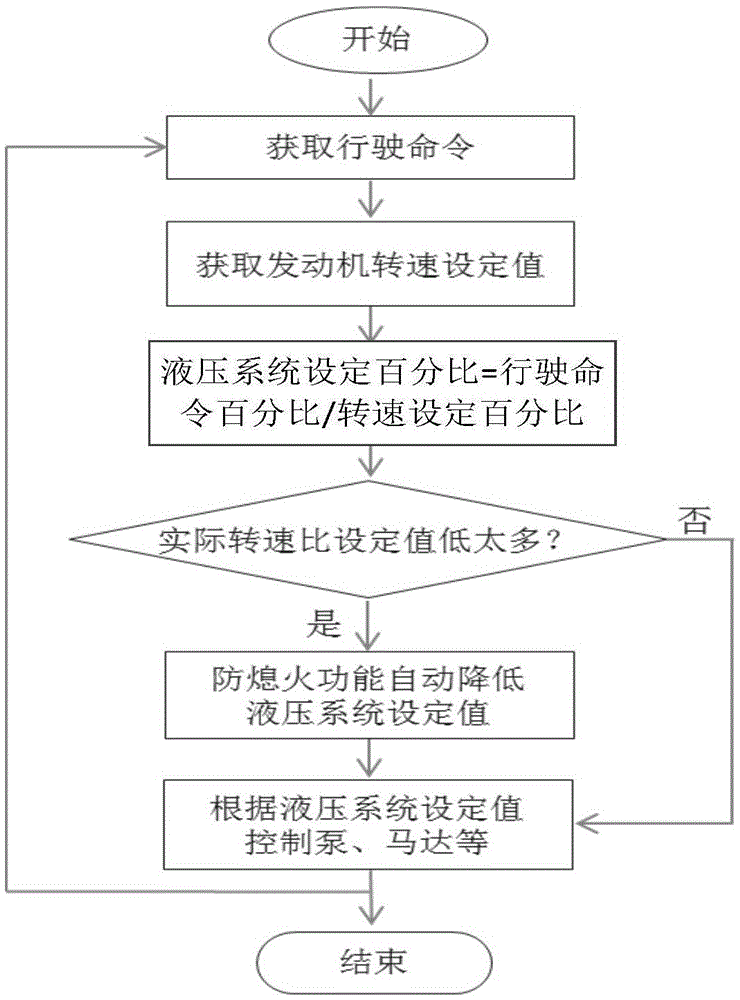

Energy-saving control method and system for revolving speed of engine

ActiveCN105626279AEnsure Stability and ContinuityRealize automatic followSpeed sensing governorsMachines/enginesEngineeringOperating speed

The invention relates to an energy-saving control method and system for revolving speed of an engine. The method comprises the following steps: acquiring required running speed and load required power; and setting a revolving speed value of the engine to be minimum revolving speed on the premise of meeting the required running speed and the load required power. By the energy-saving control method and system for the revolving speed of the engine, the engine runs at economical revolving speed as much as possible on the promise of meeting a vehicle speed requirement and a power requirement, so that the purpose of saving fuel is achieved. Meanwhile, when the revolving speed set value of the engine is changed, a hydraulic system is adjusted in real time so as to guarantee stable running speed and link before and after change of the revolving speed, and stability and driving comfort are good. A power requirement serves as a first priority, and the revolving speed of the engine can be relatively high when high speed or large torque is required. Therefore, a vehicle can meet optional speed requirements. But the required speed of the vehicle is not maximum in most cases, and the advantage of fuel saving can also be played fully.

Owner:WEICHAI POWER CO LTD

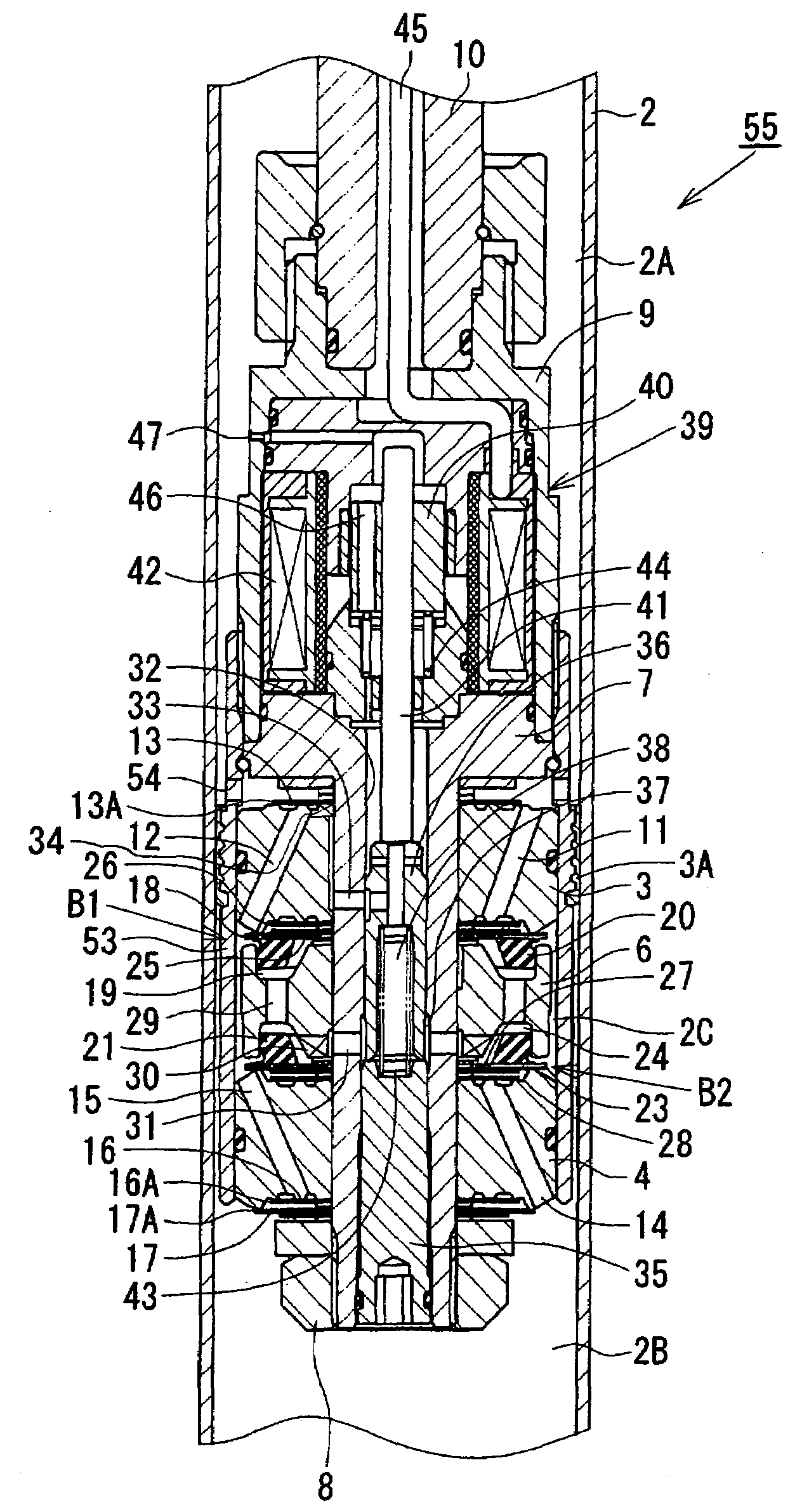

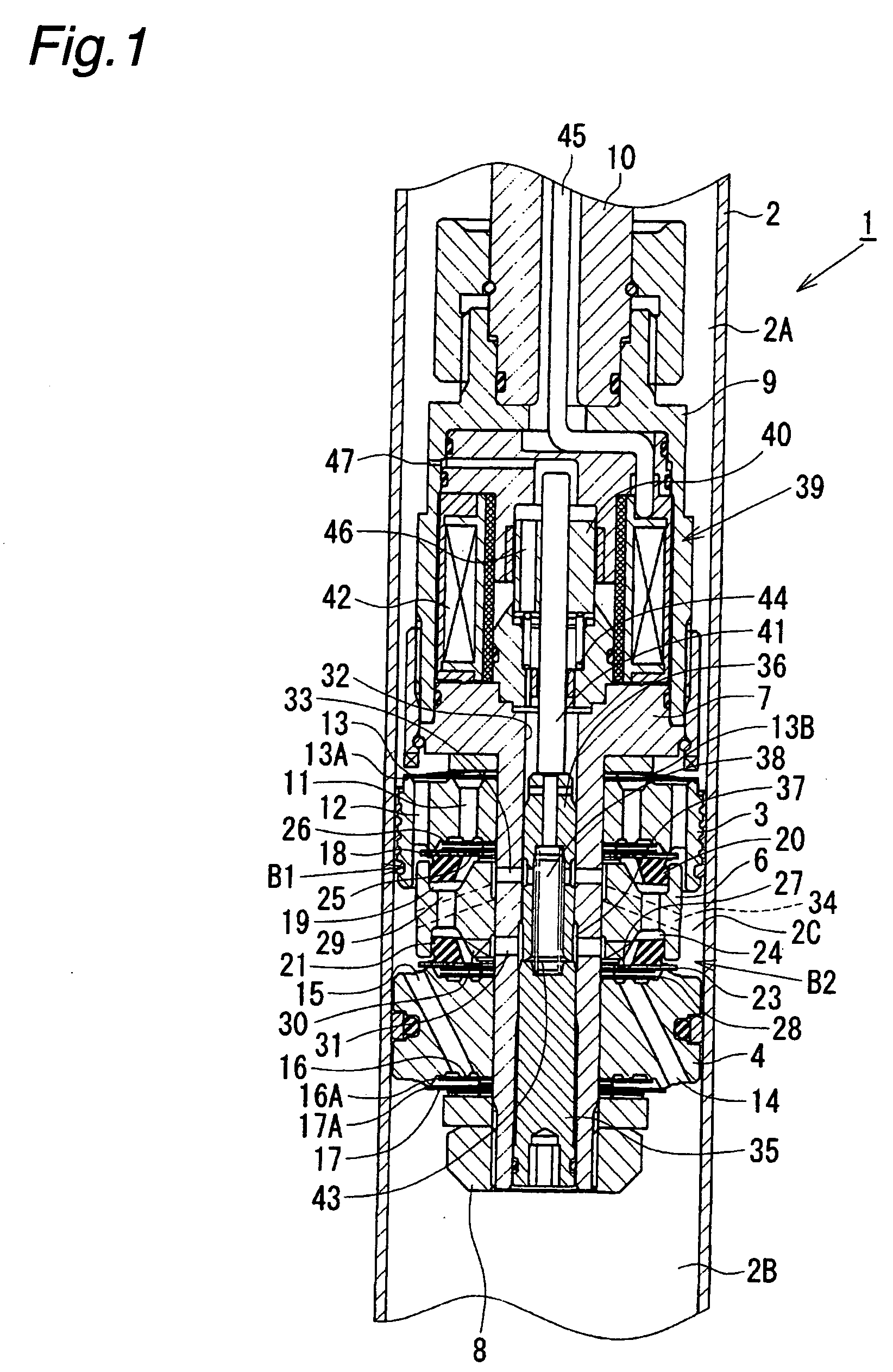

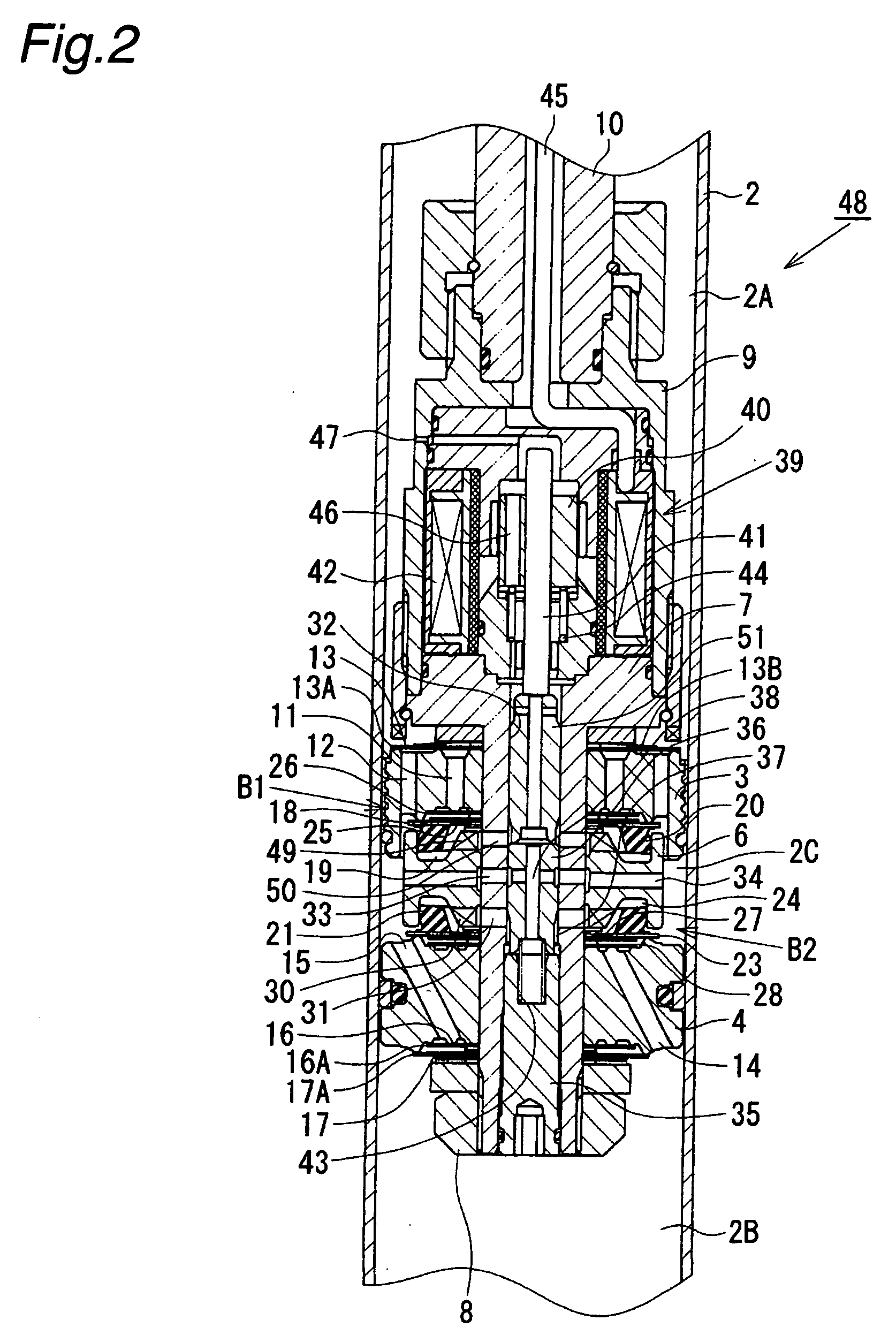

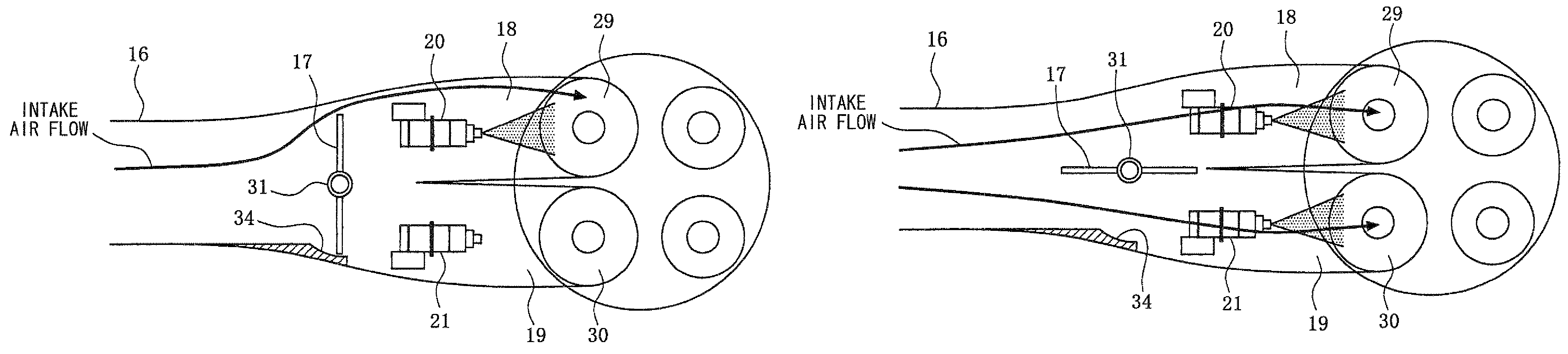

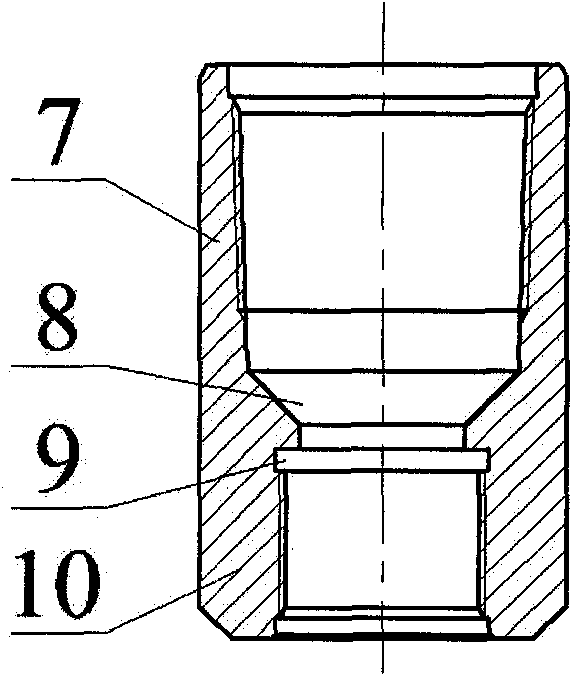

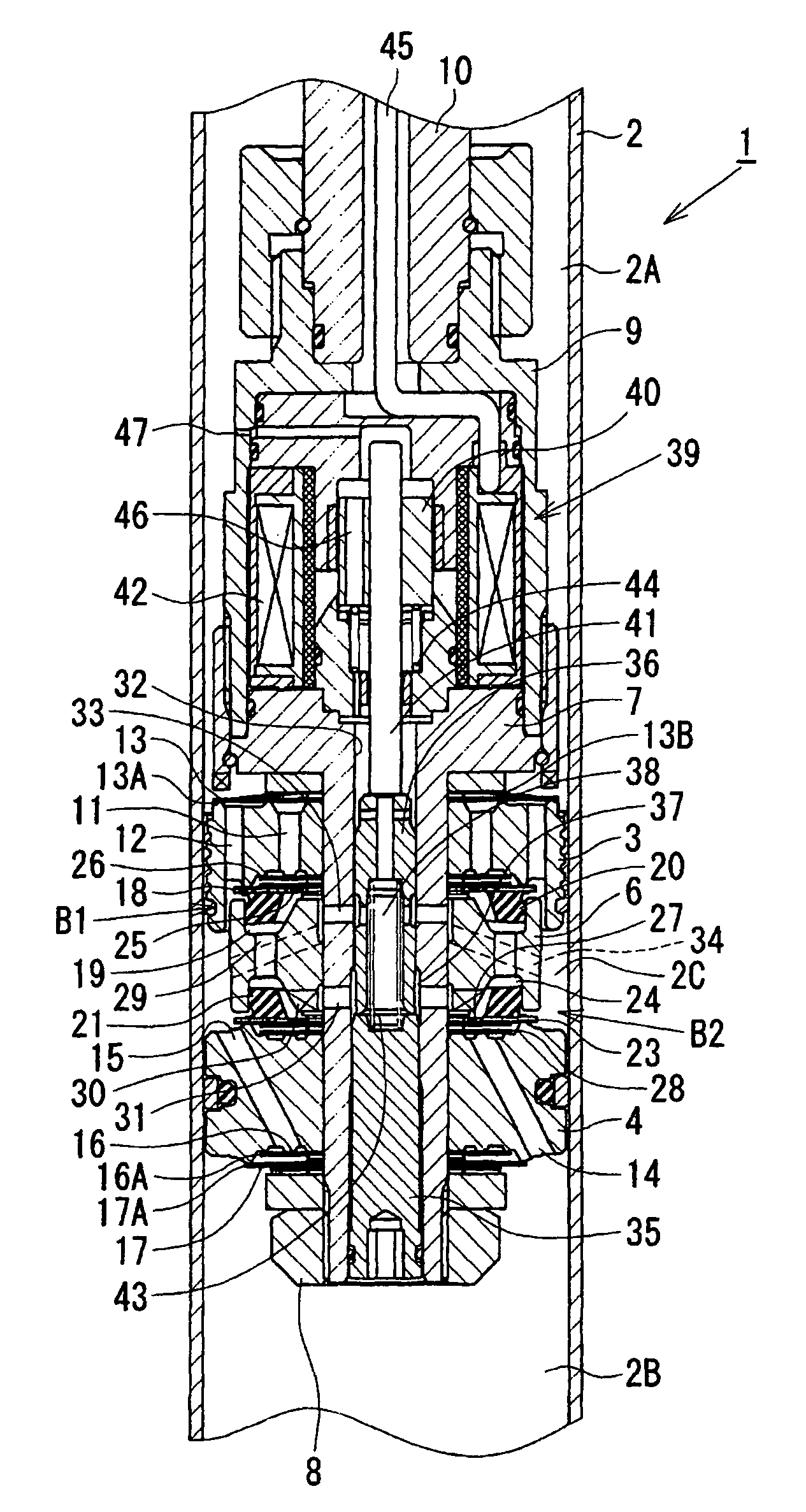

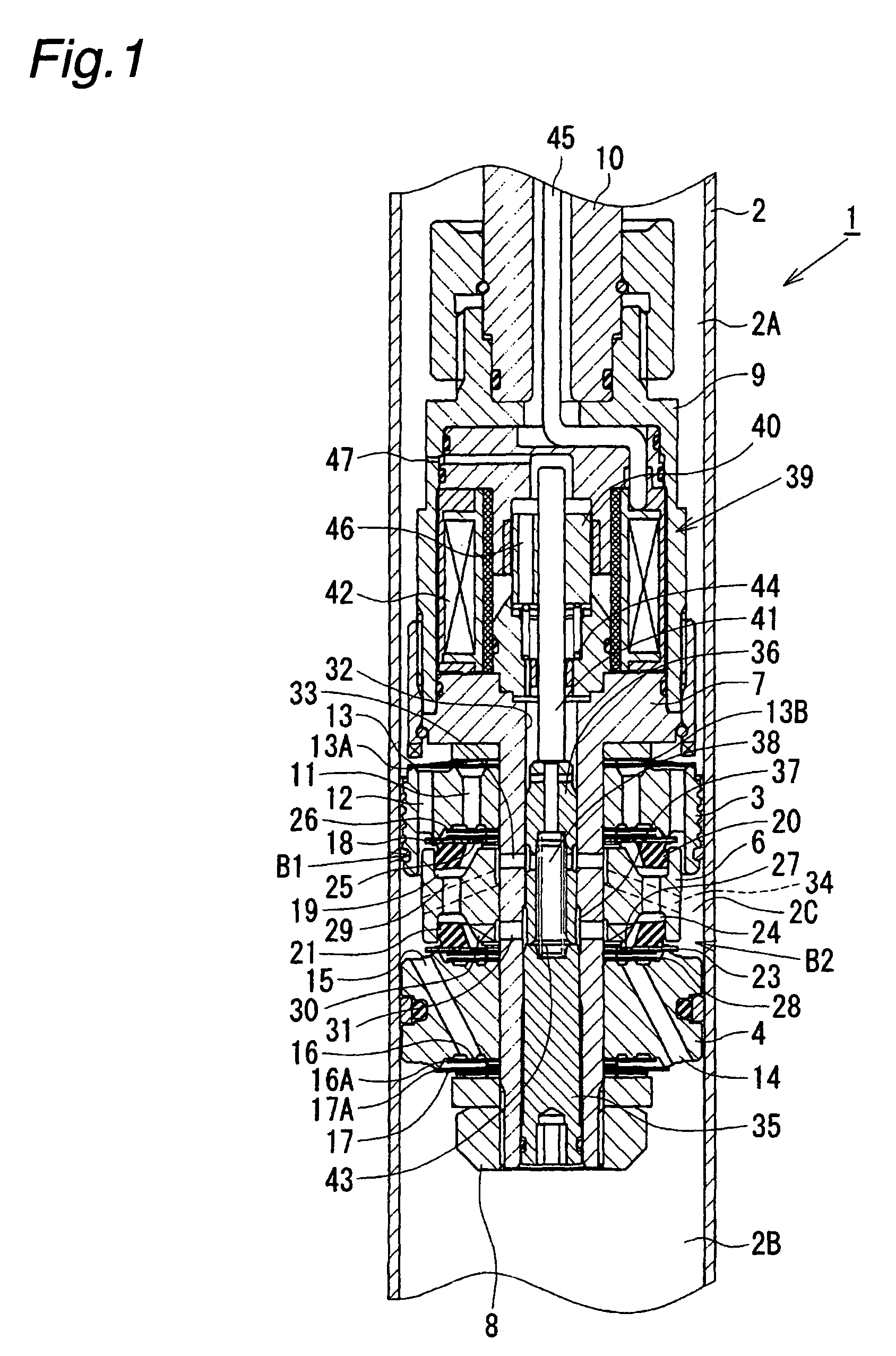

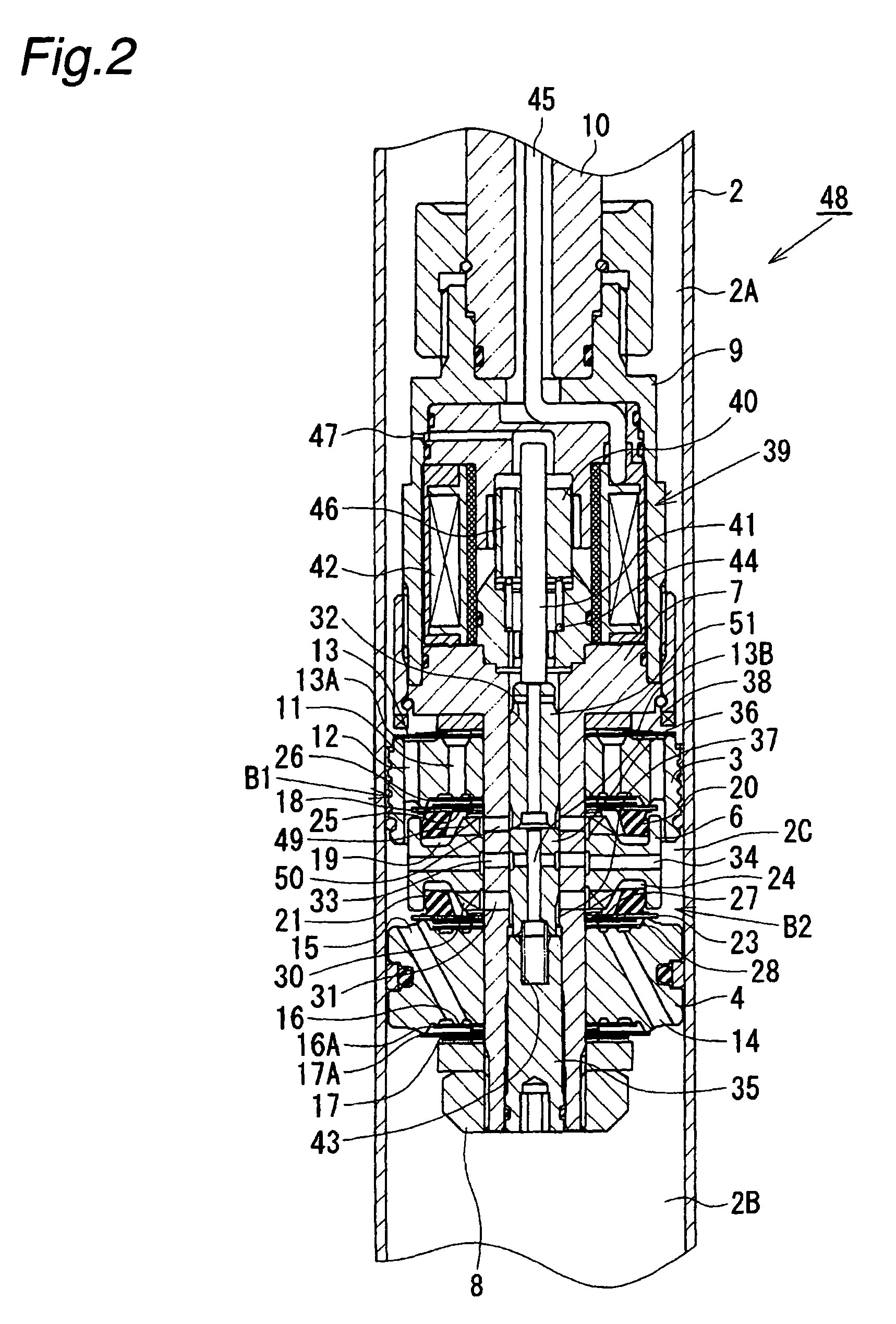

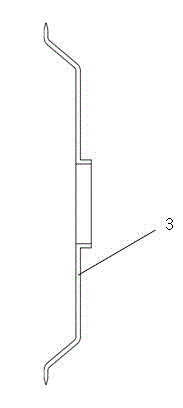

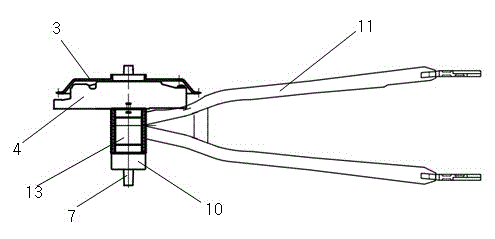

Damping force adjustable fluid pressure shock absorber

InactiveUS20090272611A1Stable damping forceAvoid drastic changesSpringsShock absorbersInternal pressureEngineering

A first piston and a second piston coupled to a piston rod are fitted in a cylinder, and an intermediate chamber is formed between the first and second pistons. A compression-side check valve and an extension-side check valve are provided at the first piston and the second piston. An extension-side main valve and a compression-side main valve are disposed in the intermediate chamber. A downstream side of a damping force adjusting valve is connected to the intermediate chamber. Inner pressures of an extension-side backpressure chamber and a compression-side backpressure chamber are adjusted by the damping force adjusting valve, whereby valve opening of the extension-side and compression-side main valves is controlled. Hydraulic fluid of the downstream side of the damping force adjusting valve is first sent into the intermediate chamber, and then is sent to a cylinder upper chamber or a cylinder lower chamber. Due to this arrangement, it is possible to prevent a sudden drastic change in a hydraulic fluid pressure and thereby to generate a stable damping force.

Owner:HITACHI LTD

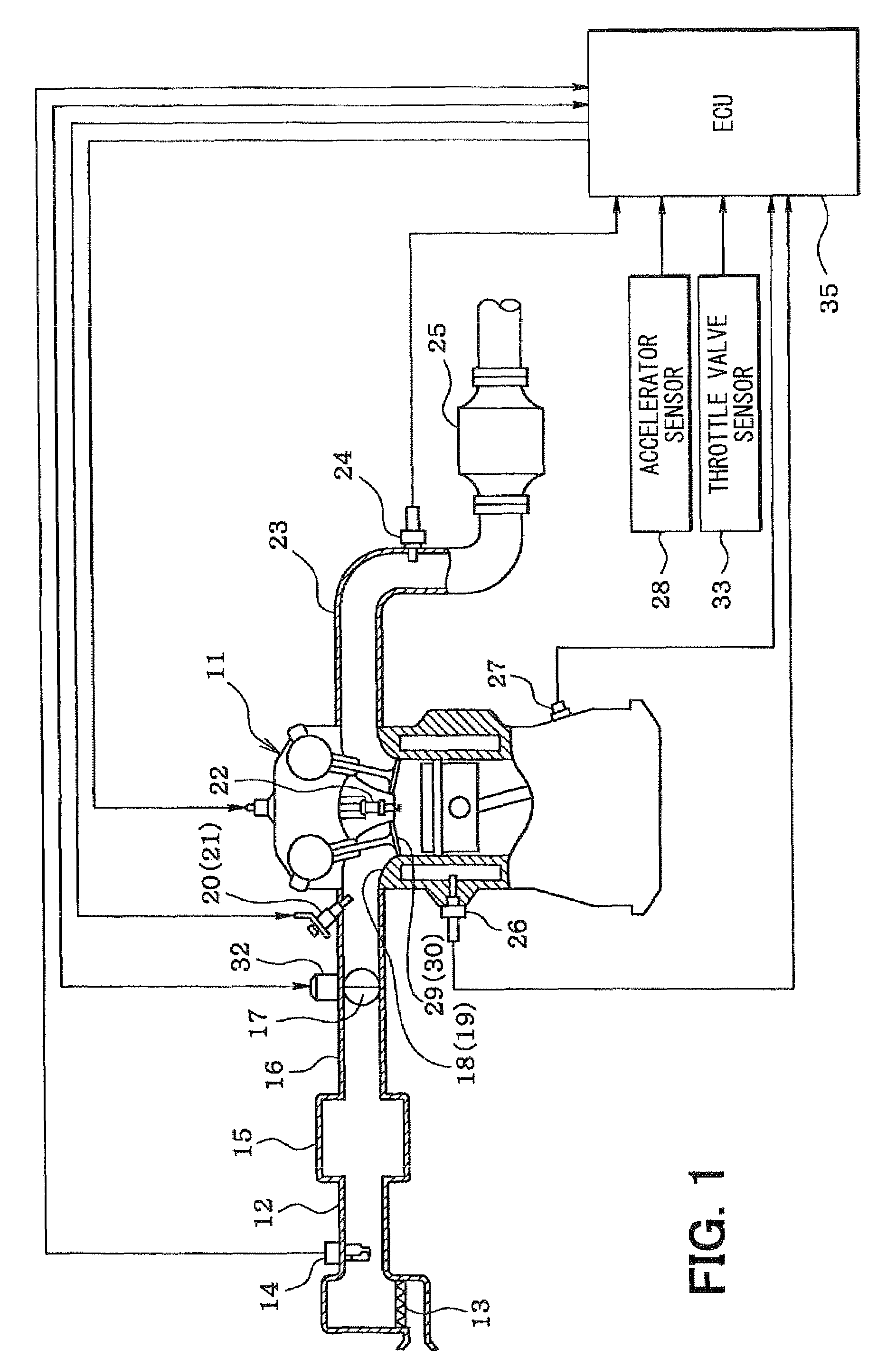

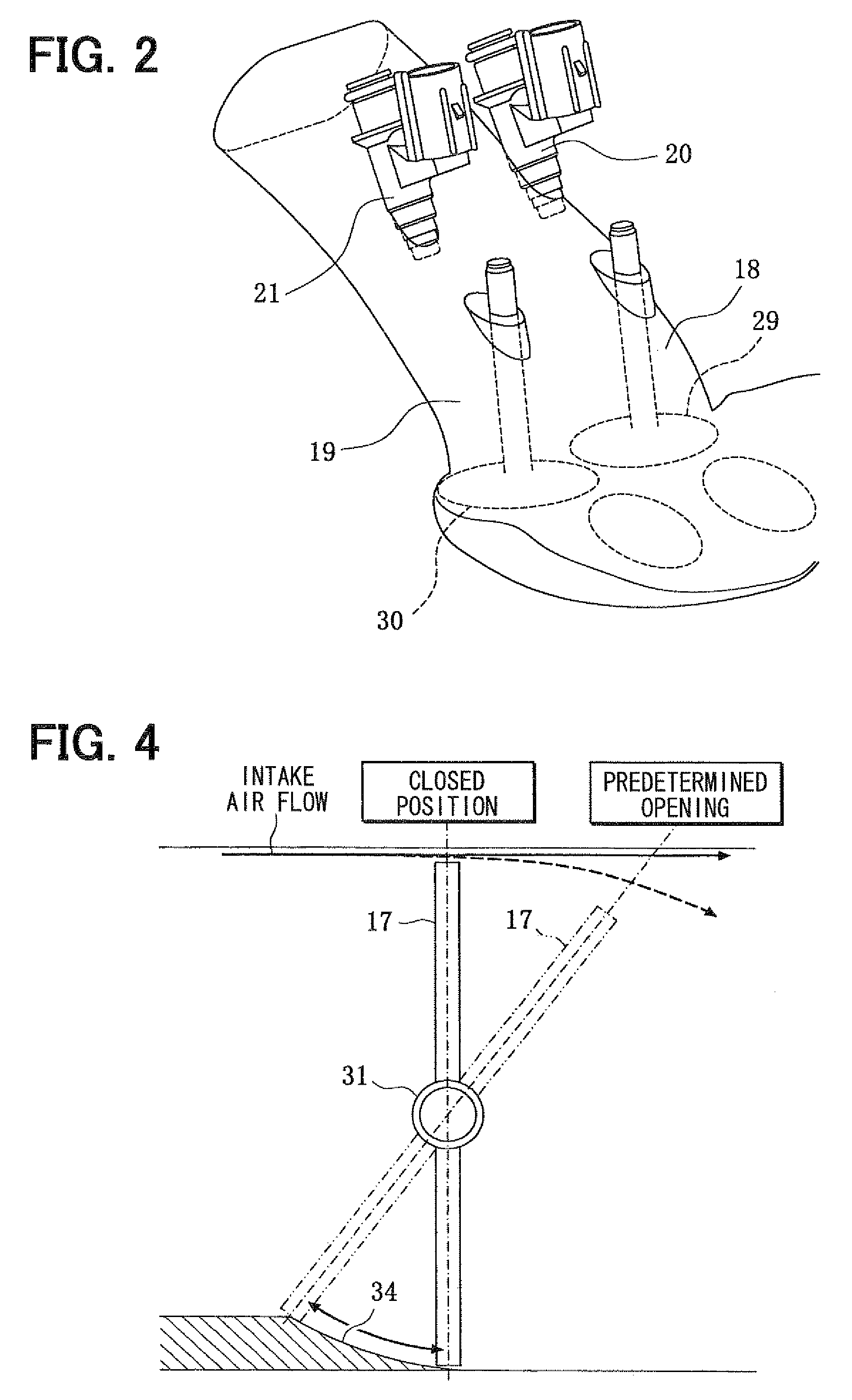

Valve control device and valve control method for internal combustion engine

InactiveUS7472679B2Promote homogenizationEasy to controlElectrical controlInternal combustion piston enginesInternal combustion engineThrottle

Owner:DENSO CORP

Cuttage breeding method for quickly establishing alfalfa clone

InactiveCN104770172AEasy to manageEasy dischargeGrowth substratesCulture mediaAnimal scienceObserved Survival

The invention discloses a cuttage breeding method for quickly establishing an alfalfa clone. The cuttage breeding method comprises the following steps: (1) preparing an alfalfa vegetative propagation seedling bed; (2) preparing and sterilizing soil; (3) performing a specific branch cutting operation method; (4) managing cuttage seedlings; (5) transplanting vegetative propagation seedlings; (6) performing filed management after transplanting. According to the cuttage breeding method disclosed by the invention, the problems of being slow in rooting, low in survival rate and the like of alfalfa cuttage breeding can be solved. The method is suitable for quickly and efficiently establishing the cuttage clone, and has the characteristics of being simple to operate, low in cost, quick and efficient, and capable of remarkably shortening the vegetative propagation breeding time and increasing the cuttage breeding survival rate.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

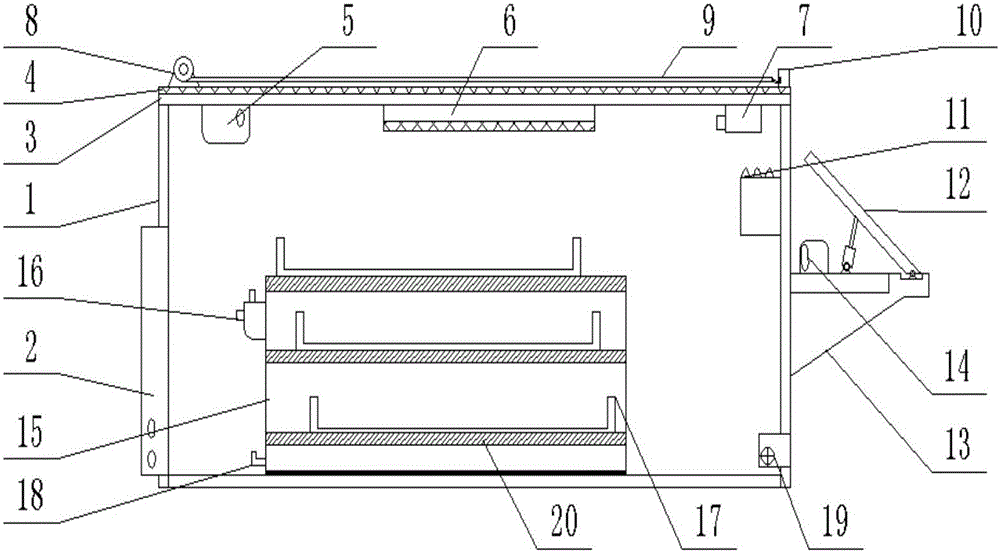

Small-scale edible fungus planting device and planting method

InactiveCN106358752AIncrease humidityAvoid drastic changesHorticultureThermal insulationAgricultural engineering

The invention discloses a small-scale edible fungus planting device and a planting method in the technical field of edible fungus planting. The planting device comprises a box body, wherein a cabinet door is arranged at the bottom of the left side of the box body; a glass plate is arranged at the top of the box body, a transparent thermal insulation coating is arranged on the surface of the glass plate; an electric roller and a hanging seat are arranged on the left side and the right side of the top of the glass plate respectively, a hook is arranged on the bottom of the left side of an edible fungus planting frame and facilitates the edible fungus planting frame to be moved outside the box body manually by workers or by a tractor, so that the working efficiency is increased; horizontal division plates are anti-rust grid plates, so that the plates are prevented from rusting when the humidity is high, and meanwhile light transmission and air circulation are facilitated; meanwhile three sets of cultivation devices are arranged on the left side, the center and the right side of the three sets of horizontal division plates respectively, and the cultivation devices are not on the same vertical straight line, so that the illumination can be fully accepted.

Owner:曲靖市嘉顺农业有限公司

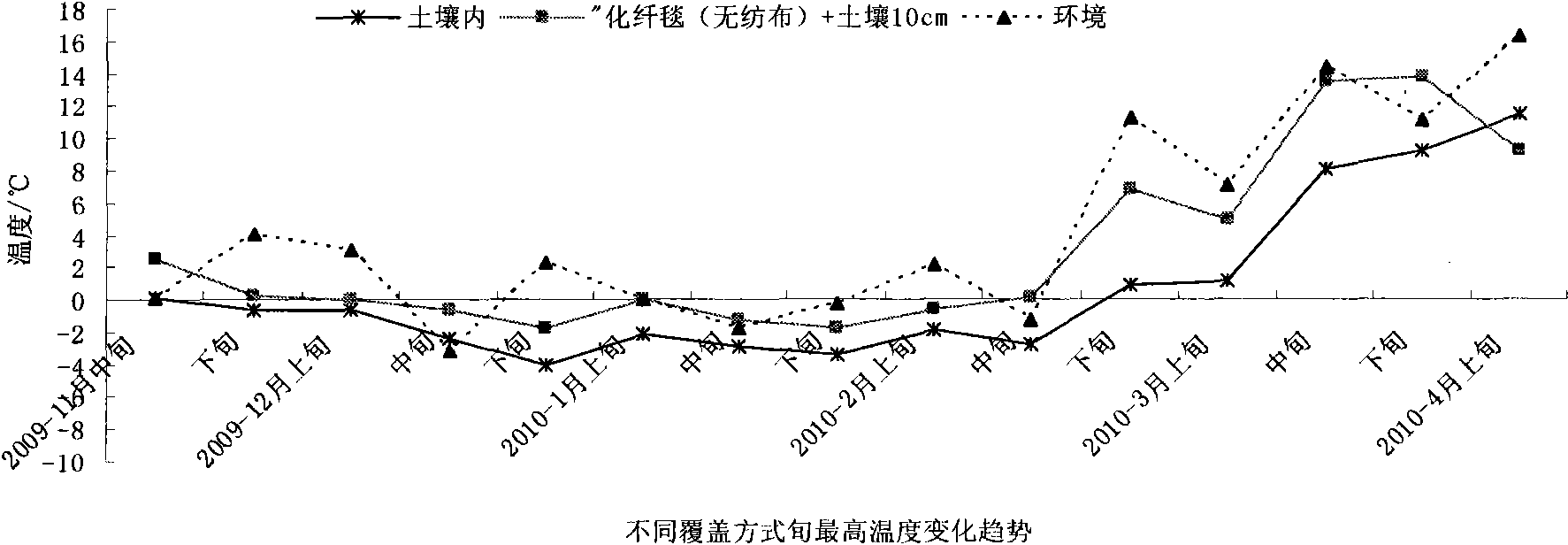

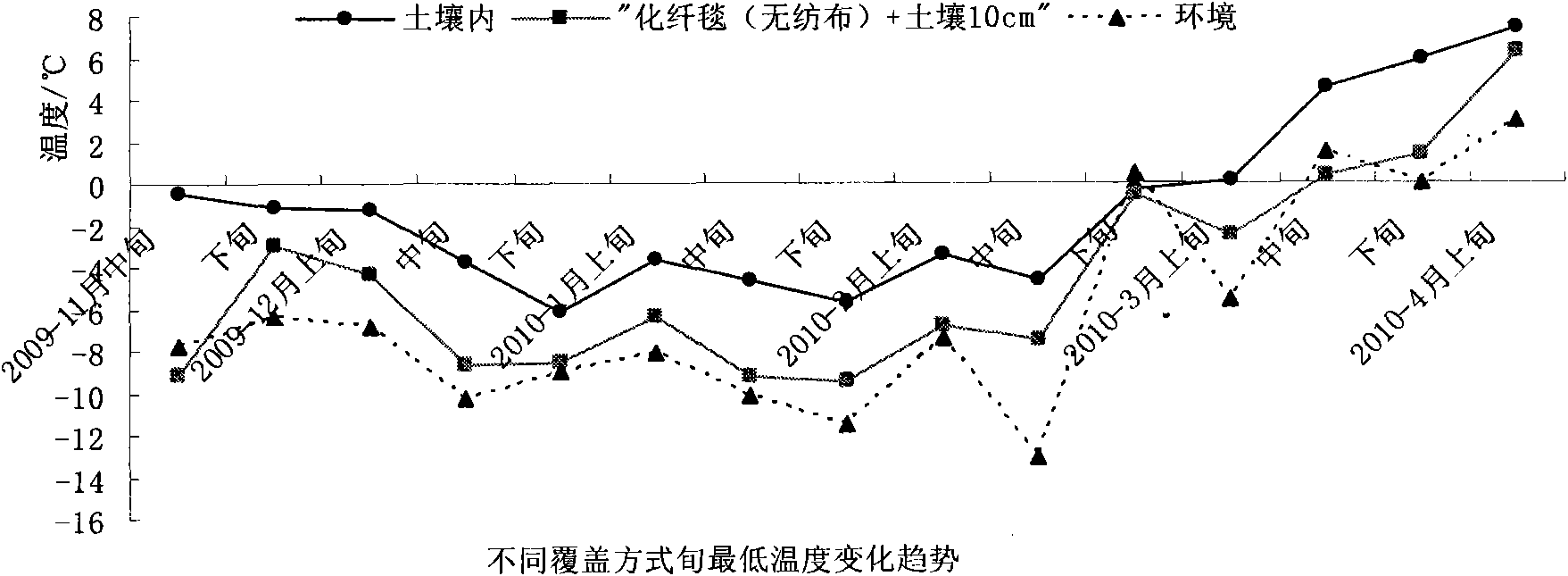

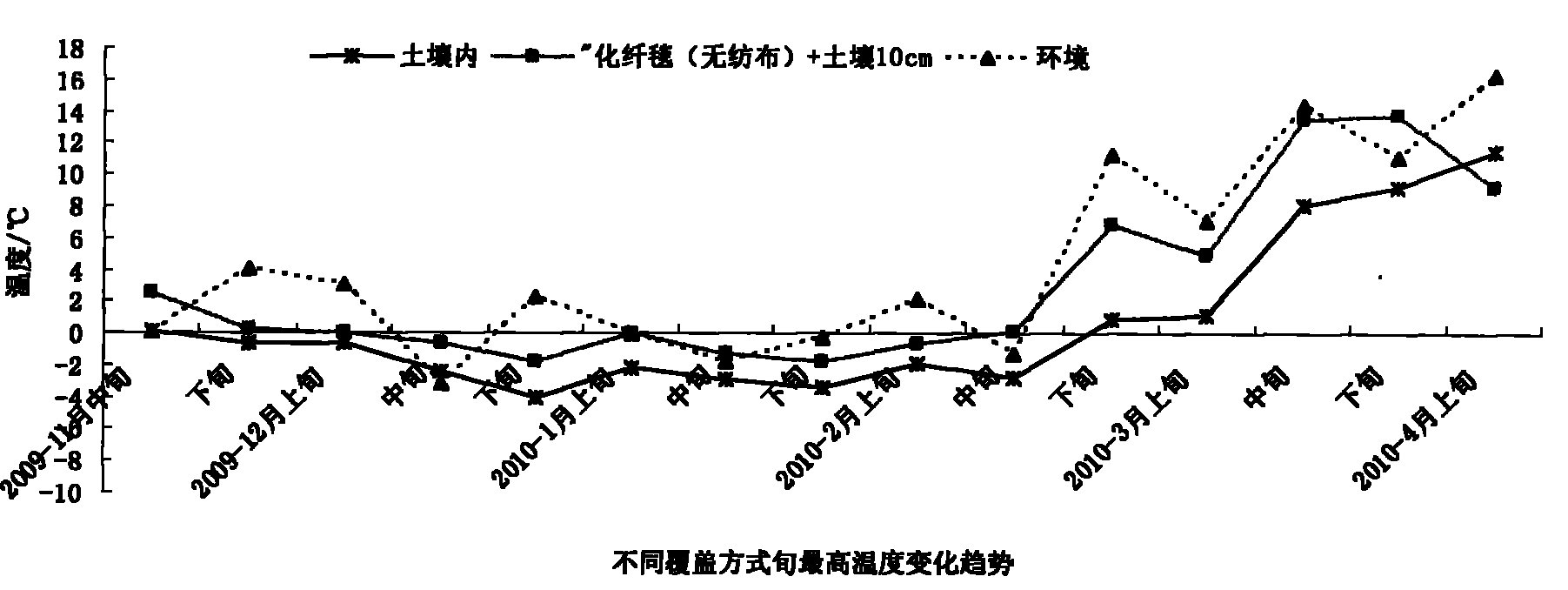

Simple overwintering method for grapes

InactiveCN101869043AImprove efficiencyLow costCultivating equipmentsPlant protective coveringsBrixWoven fabric

The invention relates to a method for adding shallow soil on grape coating materials, in particular to a simple overwintering method for grapes. The method is characterized by comprising the following steps of: selecting a good-durability recovered chemical fiber blanket or a 0.08 to 0.22 kg / m<2> of non-woven fabric with left and right thickness of 1.0mm and the width of 1.0 to 1.3m; at the end of the autumn, trimming the grapes which are cultivated in trellis or shed frames according to the varietal characteristics, and spraying a 3 to 5 degree Brix lime sulfur mixture on grape vines; and filling overwintering water, putting trunks along row trenches of the trellis or shed frames, weaving branches, controlling the climbing height not beyond the cultivation trench for 20cm, covering the grape branches along the rows by using the chemical fiber blanket or the non-woven fabric, and stretching the two sides so as to cover the grape vines tightly. The invention provides a method which is more convenient compared with the traditional soil-burying overwintering method, meets economic development conditions of the region, has low price, is timely, saves the labor, and is easy for mechanically covering and removing the shallow soil on the coating materials.

Owner:NINGXIA UNIVERSITY

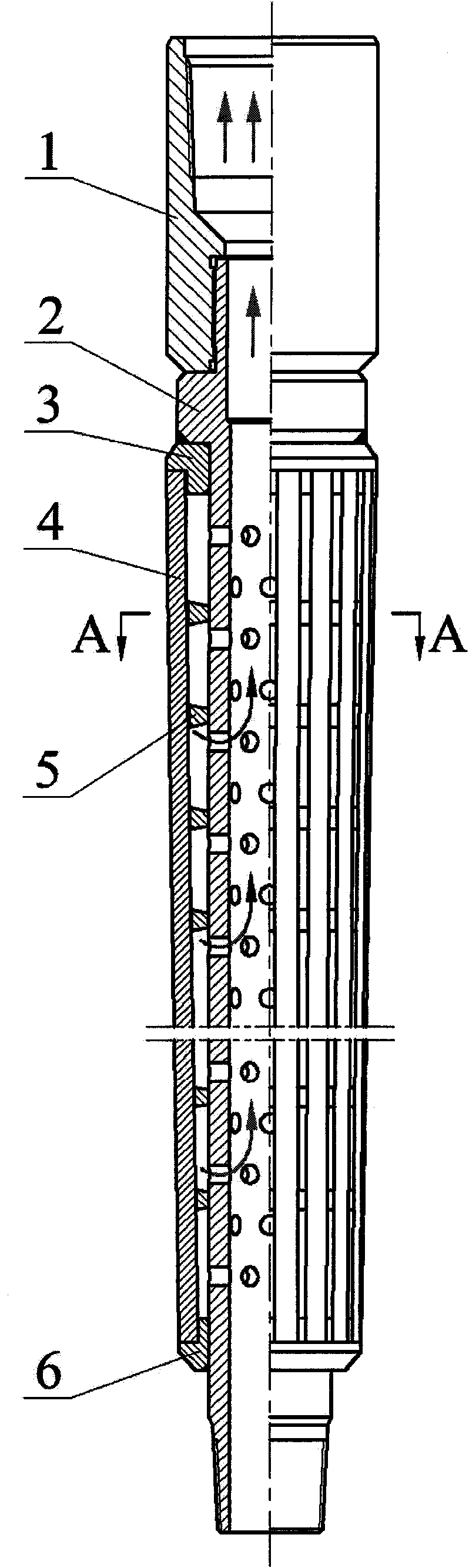

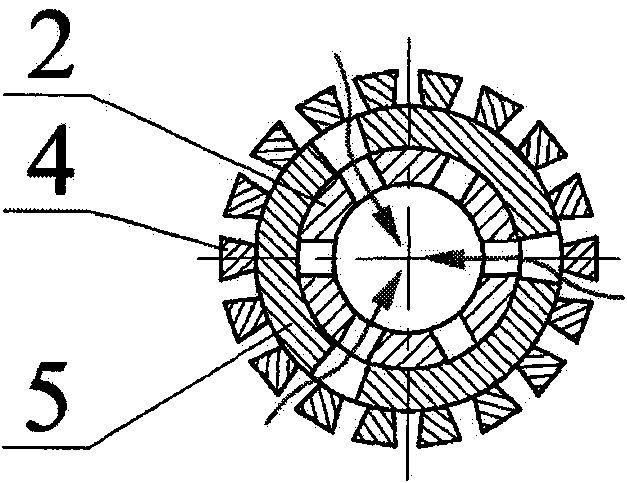

Mouse cage type V-shaped straight wire sieve tube

InactiveCN102146783AAvoid gatheringDeposit in timeDrilling rodsFluid removalStress concentrationCoupling

The invention provides a mouse cage type V-shaped straight wire sieve tube, which is used for sand prevention of oil and gas wells and coal bed gas wells, in particular has functions of adjusting speed of well fluid and self-cleaning. The sieve tube consists of a sieve tube coupling, a matrix, ring ribs, upper and lower hoops and a straight wire sieve tube sleeve; a variable cross-section channelin the middle of the matrix realizes primary adjustment of the flow velocity of the well fluid; a variable cross-section step rotating body channel inside the sieve tube coupling can reduce stress concentration and realize secondary adjustment of the flow velocity of the well fluid; a gap formed between adjacent layers of ring ribs is trapezoidal, particles can be prevented from being gathered inthe gap, and the sieve tube has self-flushing function; screen cut formed between adjacent straight wires is trapezoidal, the particles can be prevented from being blocked in the gap, the sieve tube has the function of self-cleaning the screen cut, and stainless steel straight wires can effectively solve the problems that salvage is difficult to carry out and wound wire is easy to fall off; an outer ring surface of the straight wire sieve tube sleeve is V-shaped, that large particles are timely deposited to the bottom of the well can be guaranteed, and the sieve tube has the function of self-cleaning the straight wires; moreover, the flow area of the well fluid passing through the screen cut can be effectively enlarged, and the probability of collision between the straight wires and the inner wall of the sleeve is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Damping force adjustable fluid pressure shock absorber

InactiveUS7757826B2Stable damping forceAvoid drastic changesSpringsShock absorbersInternal pressureHydraulic fluid

A first piston and a second piston coupled to a piston rod are fitted in a cylinder, and an intermediate chamber is formed between the first and second pistons. A compression-side check valve and an extension-side check valve are provided at the first piston and the second piston. An extension-side main valve and a compression-side main valve are disposed in the intermediate chamber. A downstream side of a damping force adjusting valve is connected to the intermediate chamber. Inner pressures of an extension-side backpressure chamber and a compression-side backpressure chamber are adjusted by the damping force adjusting valve, whereby valve opening of the extension-side and compression-side main valves is controlled. Hydraulic fluid of the downstream side of the damping force adjusting valve is first sent into the intermediate chamber, and then is sent to a cylinder upper chamber or a cylinder lower chamber. Due to this arrangement, it is possible to prevent a sudden drastic change in a hydraulic fluid pressure and thereby to generate a stable damping force.

Owner:HITACHI LTD

Pharmaceutical composition and purpose thereof

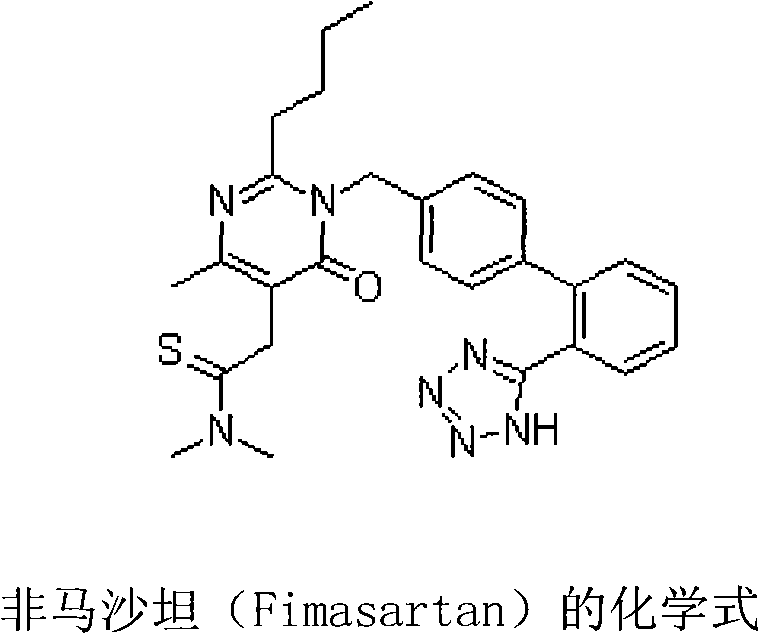

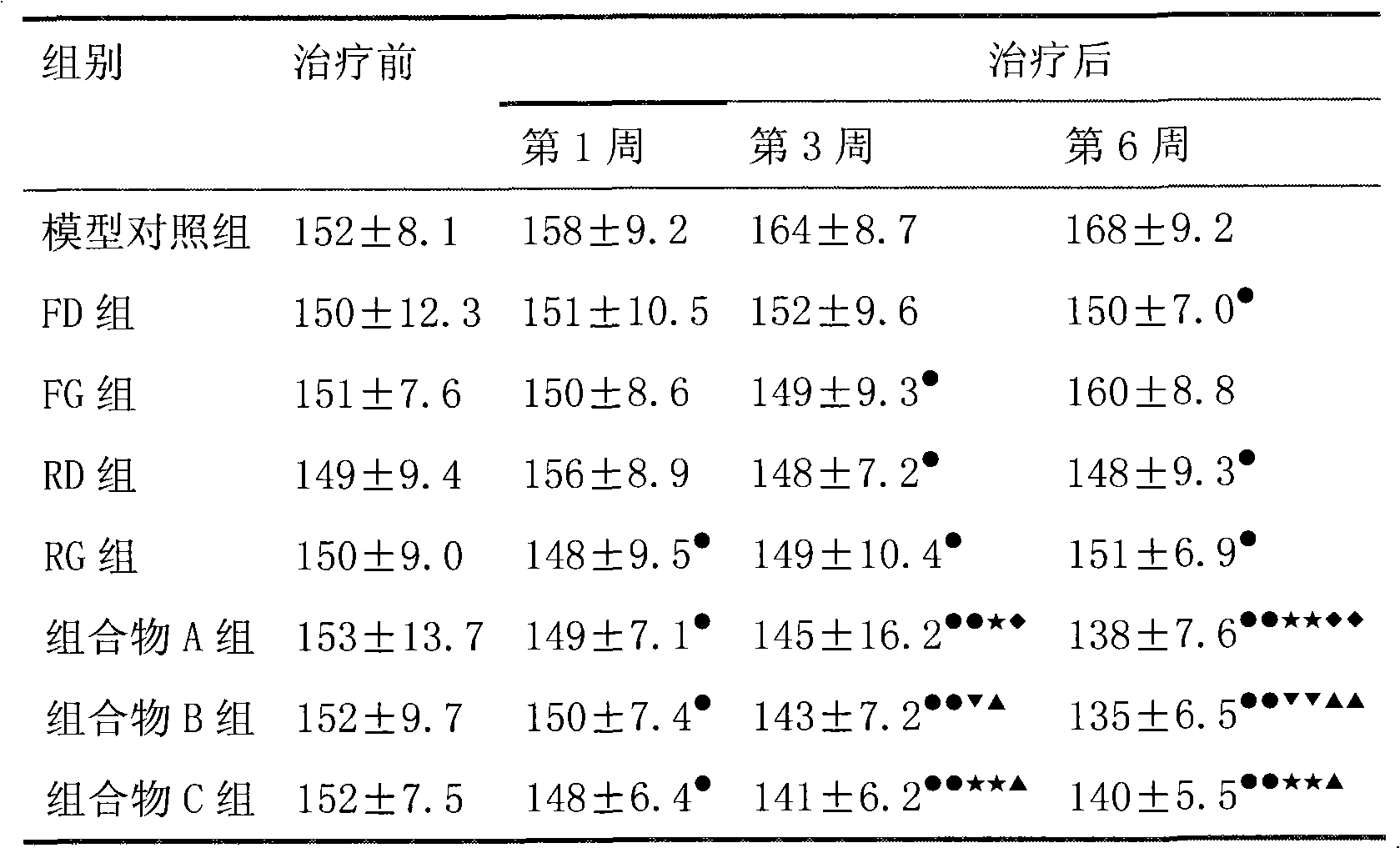

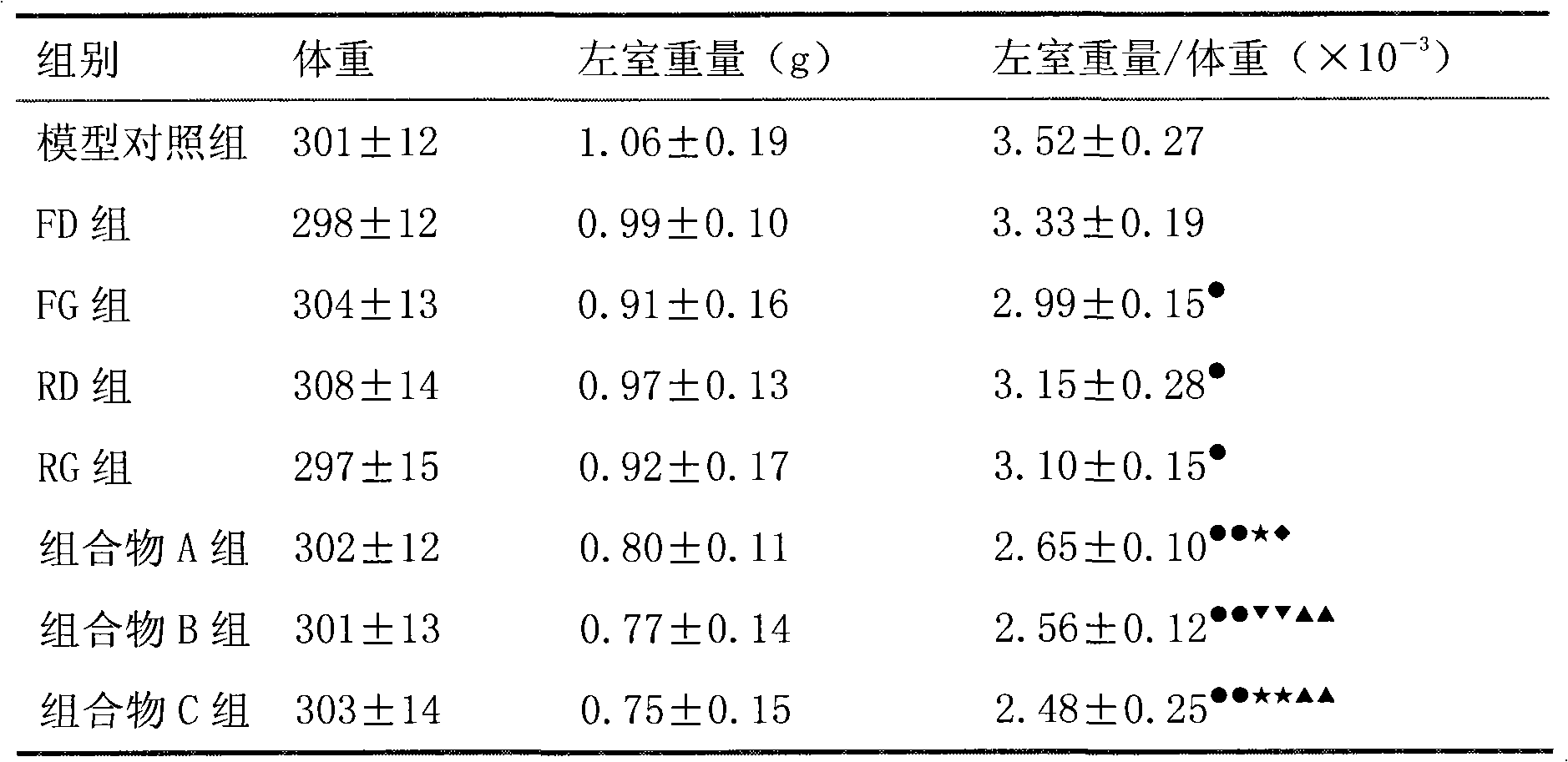

ActiveCN102485228AImprove protectionReduce incidenceOrganic active ingredientsPill deliverySide effectActive component

The invention belongs to the filed of medicine and discloses a pharmaceutical composition using fimasartan and rosuvastatin or medicinal salt thereof as active components, wherein a mass ratio of rosuvastatin or medicinal salt thereof to fimasartan is 1:0.25-250 and preferably 1:10-100. The pharmaceutical composition containing rosuvastatin medicinal salt thereof and fimasartan has obvious synergism on treating hypertension and complications thereof, low treatment cost, little side-effect and good clinic application prospect.

Owner:LUNAN PHARMA GROUP CORPORATION

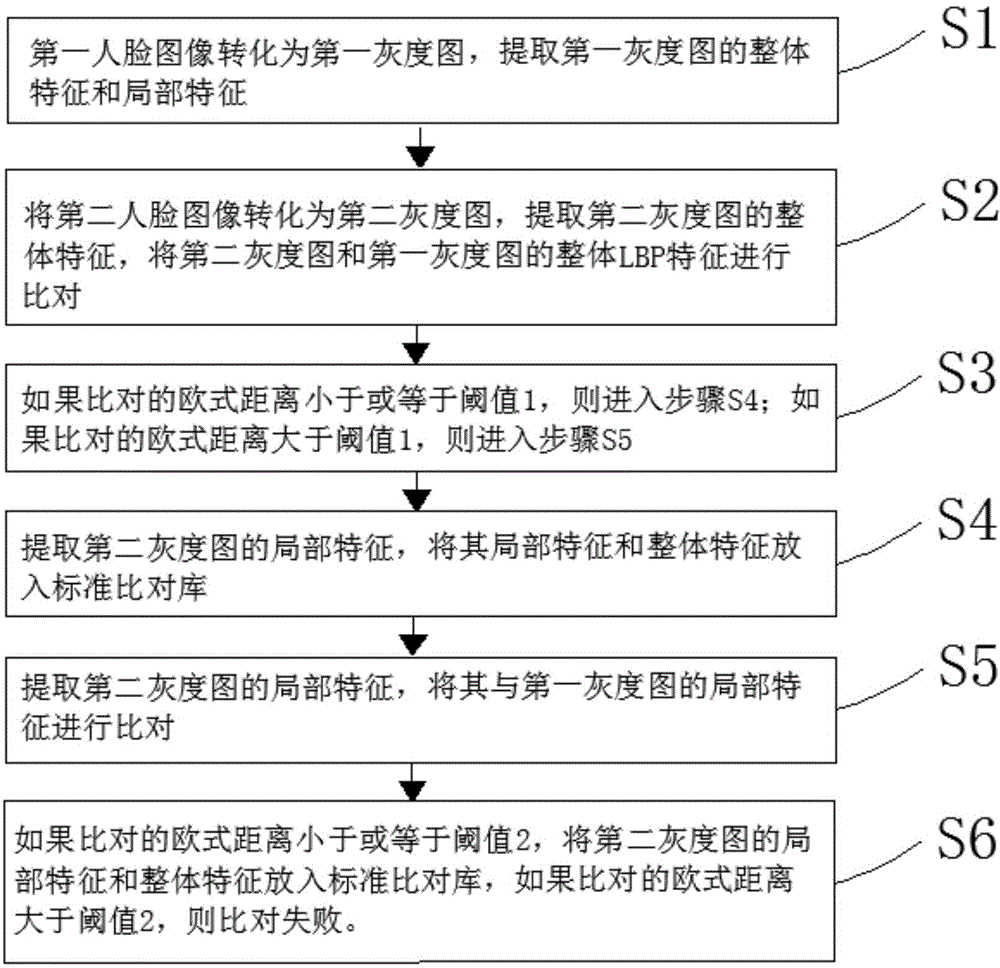

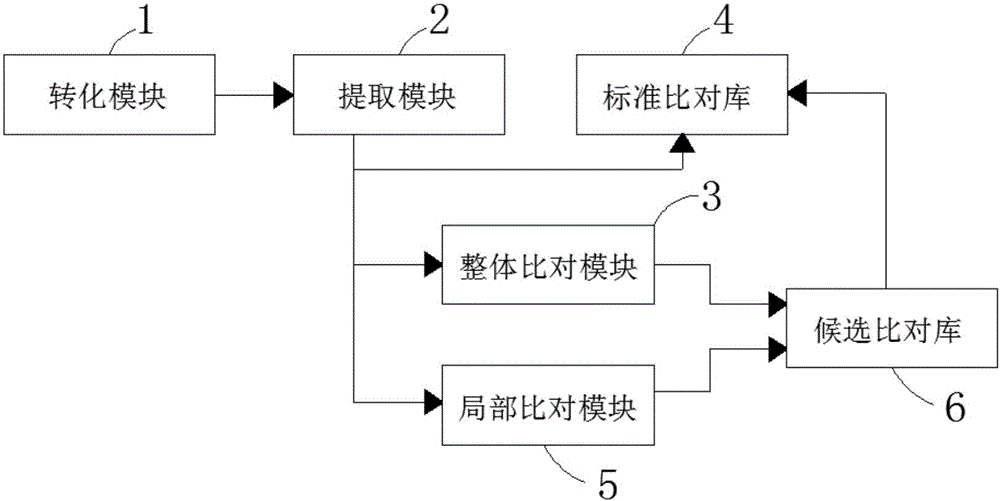

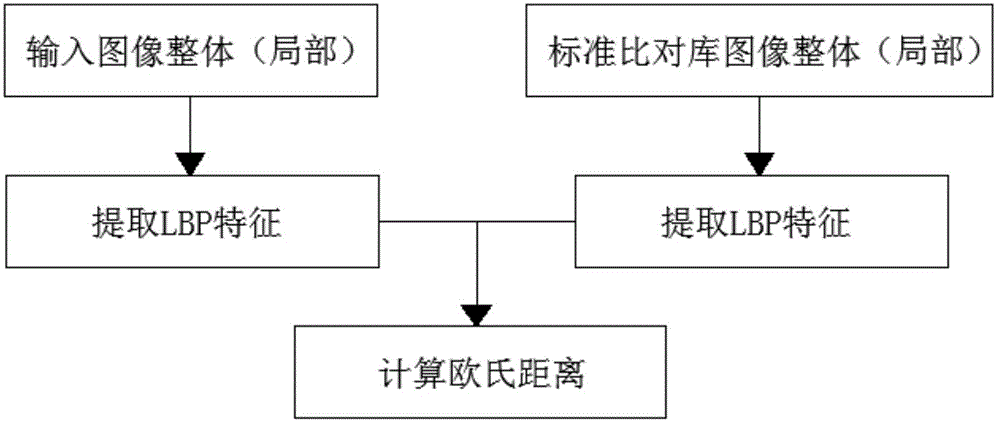

Multi-level human face comparison system and method

InactiveCN104537388AImprove accuracyImprove adaptabilityCharacter and pattern recognitionPattern recognitionComparison standard

The invention relates to a multi-level human face comparison system and method. The method comprises the following steps that a first human face image is transformed into a first grey level image, and the overall feature and the local feature of the first grey level image are extracted and saved; a second human face image is transformed into a second grey level image, the overall feature of the second grey level image is extracted, and the overall feature of the second grey level image is compared with the overall feature of the first grey level image; if comparison succeeds, the local feature of the second grey level image is extracted, and the local feature and the overall feature of the second grey level image are put into a standard comparison library; if comparison fails, the local feature of the second grey level image is extracted and compared with the local feature of the first grey level image; if comparison succeeds, the local feature and the overall feature of the second grey level image are put into the standard comparison library. Compared with the prior art, overall comparison and local comparison are combined, and thus the accuracy of human face comparison is improved; furthermore, the comparison standard can be automatically updated, and the application range is enlarged.

Owner:桂林远望智能通信科技有限公司

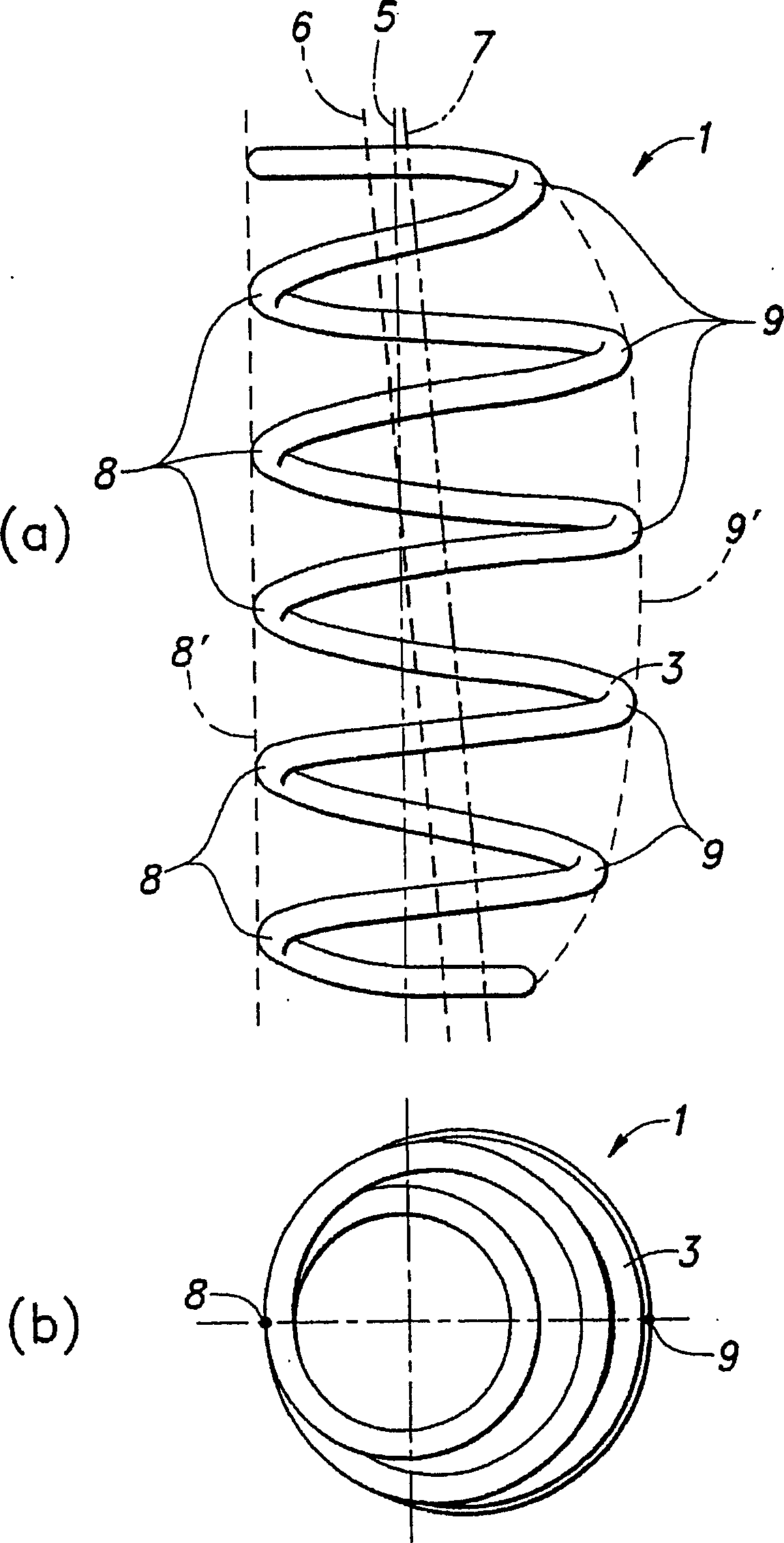

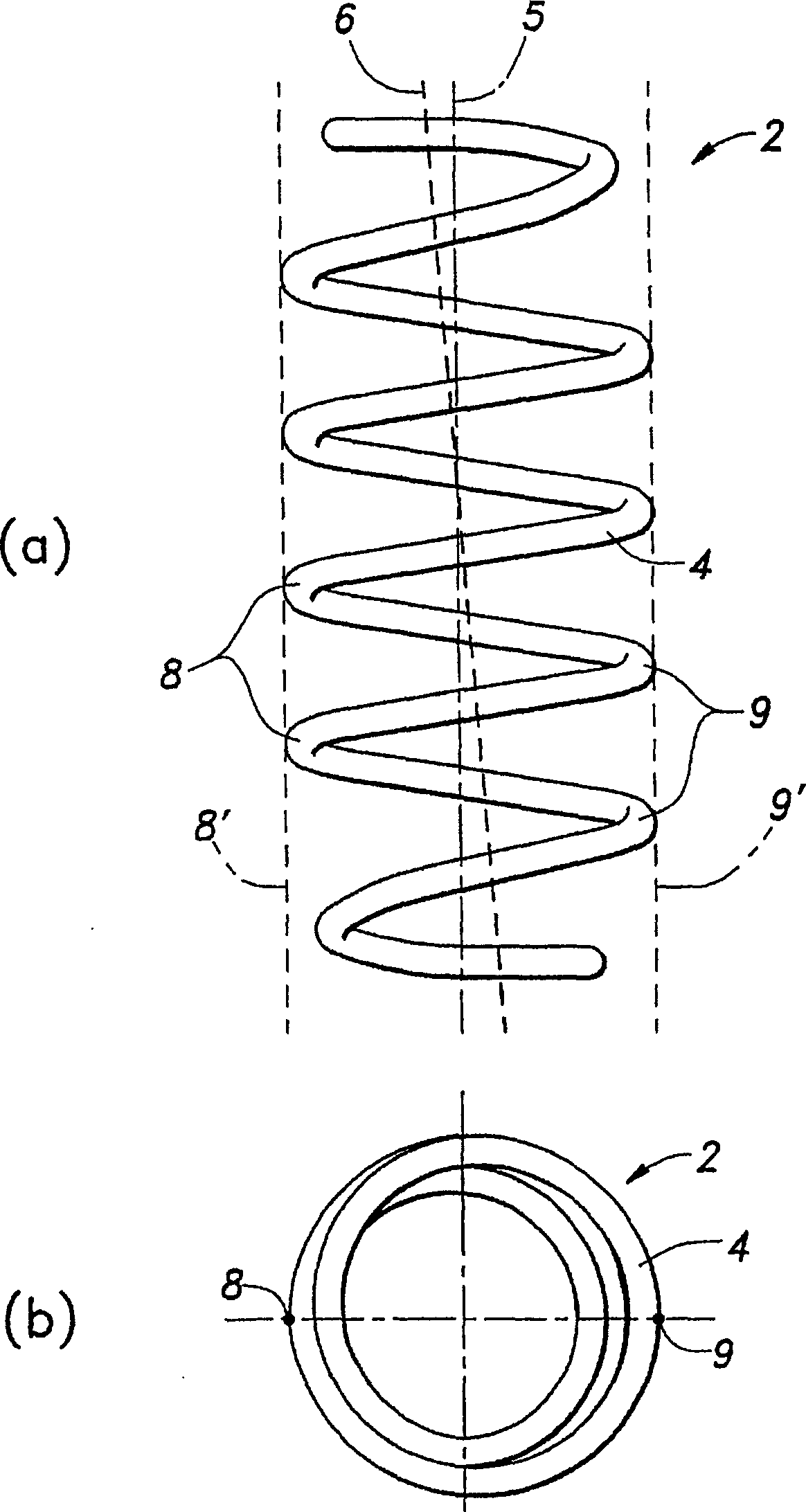

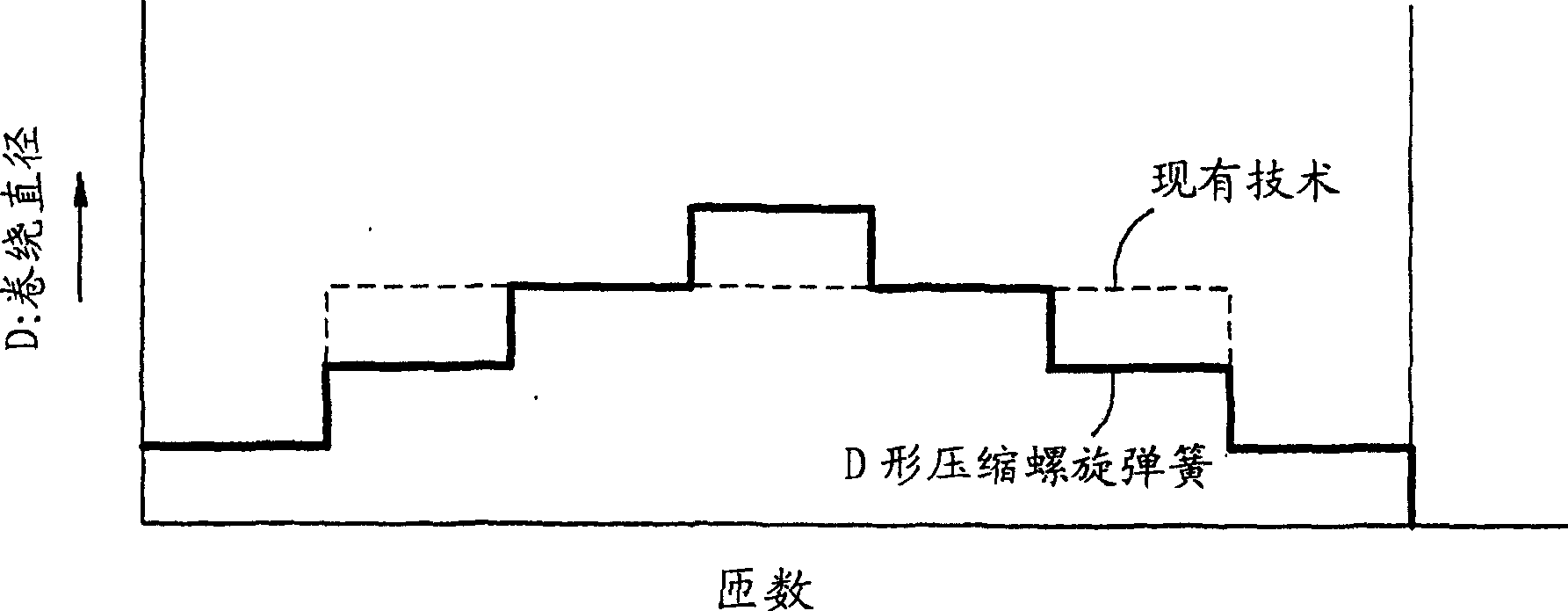

Helical spring and suspension gear

To provide a coil spring with a load axis offset from a geometric axis, and to provide a vehicular suspension system using the same. The coil spring 1 is wound with its winding diameter larger at an intermediate in the axial direction than at the end. At one sidewise position 8, the contour of a coil is aligned almost straight to the axial direction, while at the other sidewise position 9, the contour of the coil is swollen to be protruded outward. Namely, the contour of the coil is in a D-shape in view from a specified sidewise direction. Thus, the coil spring is actualized with the load axis offset in parallel to the axis without being affected by buckling deformation.

Owner:NHK SPRING CO LTD

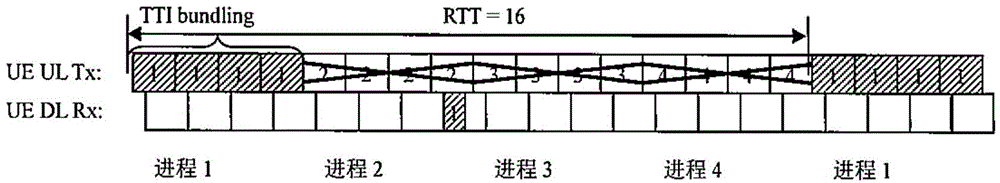

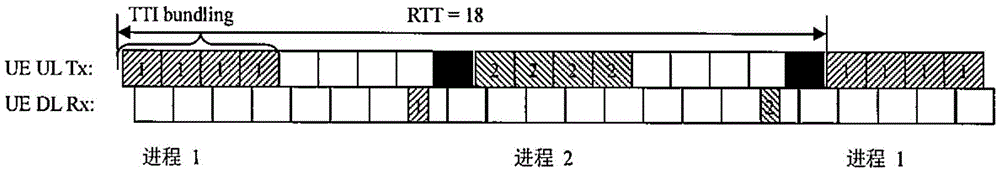

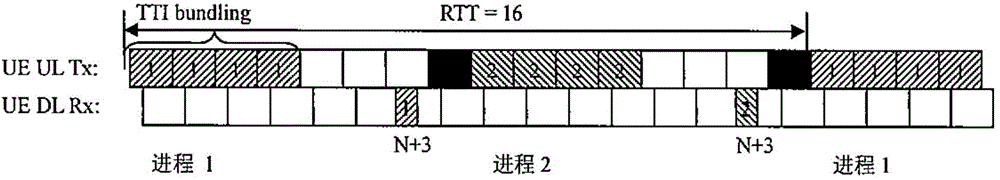

Hybrid automatic repeat request receiving method

ActiveCN105099629AAvoid drastic changesImprove resource efficiencyError prevention/detection by using return channelFrequency division duplexTransmission Time Interval

The invention discloses a method of receiving a hybrid automatic repeat request response on user equipment in an LTE wireless communication system. The user equipment works in a half-duplex frequency division duplex mode. The method is characterized in that the user equipment is configured with transmit time interval bundling and two hybrid automatic repeat request response processing processes.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

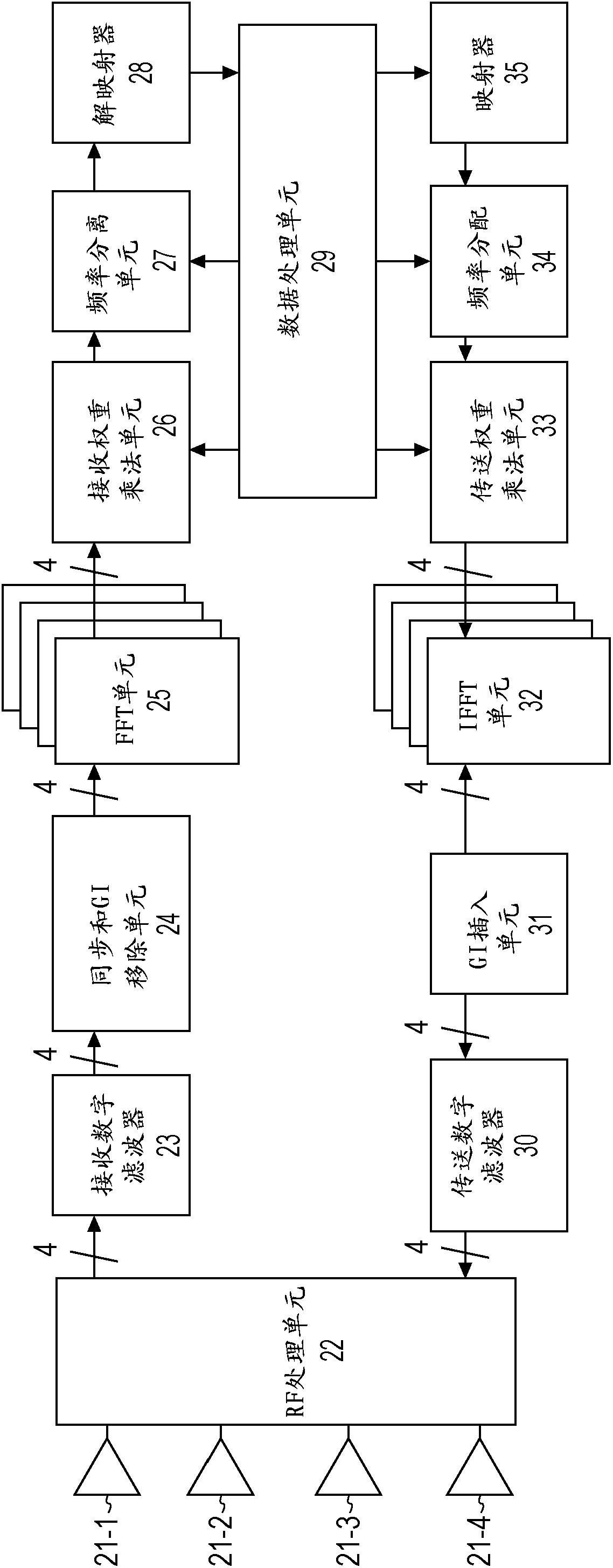

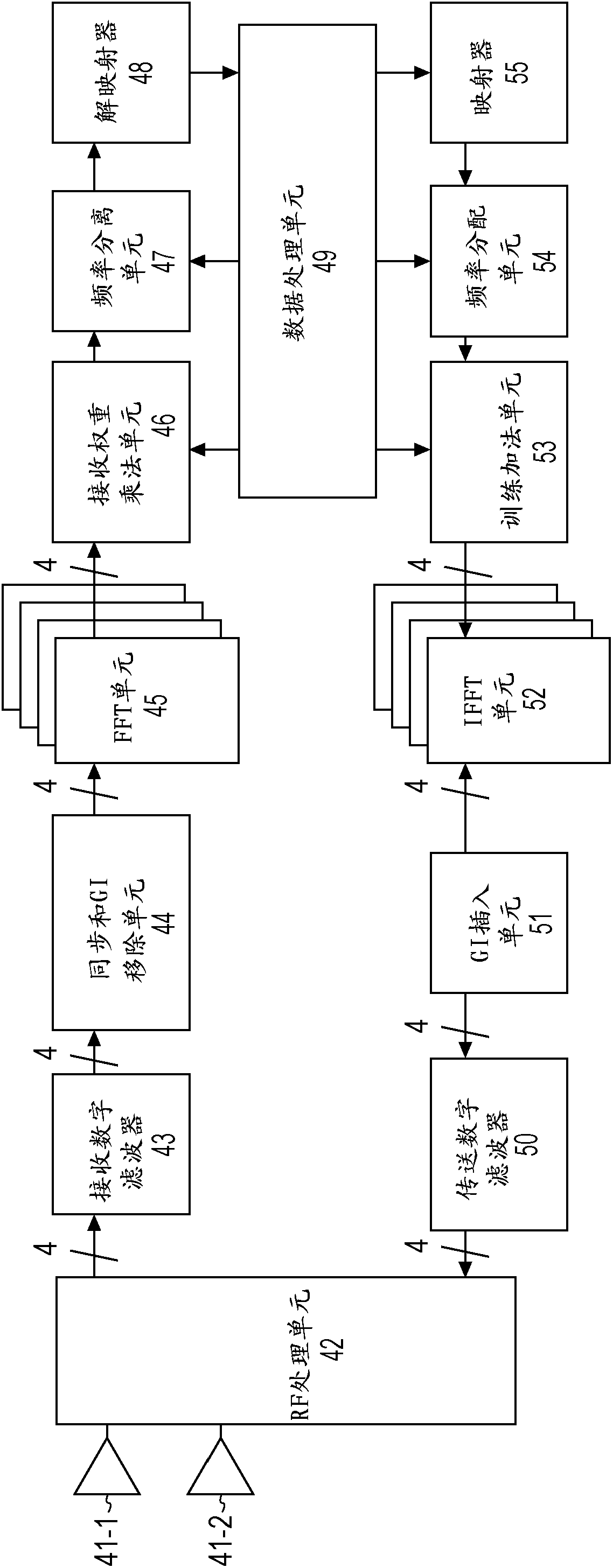

Communication apparatus, communication method, computer program, and communication system

InactiveCN102422674ASatisfactory communication operationAvoid drastic changesNetwork traffic/resource managementModulated-carrier systemsCommunications systemCommunication quality

Space-division multiple access, in which a plurality of users share a radio resource on the spatial axis, is applied to perform suitable communication operations. In a case where the communication quality is high, if the frequency width is narrowed to a band of 20 MHz, then the amount of data that can be transmitted is reduced to about a half, while the frame length can be doubled. If the frame length is too long, the current modulation scheme is changed to another one having a greater number of states, thereby shortening the frame length. Conversely, in a case where the communication quality is low, the current modulation scheme is changed to another one having a smaller number of states, thereby elongating the frame length. If the frame length is still too short, the current frequency width is changed to a narrower frequency width, thereby further elongating the frame length.

Owner:SONY GRP CORP

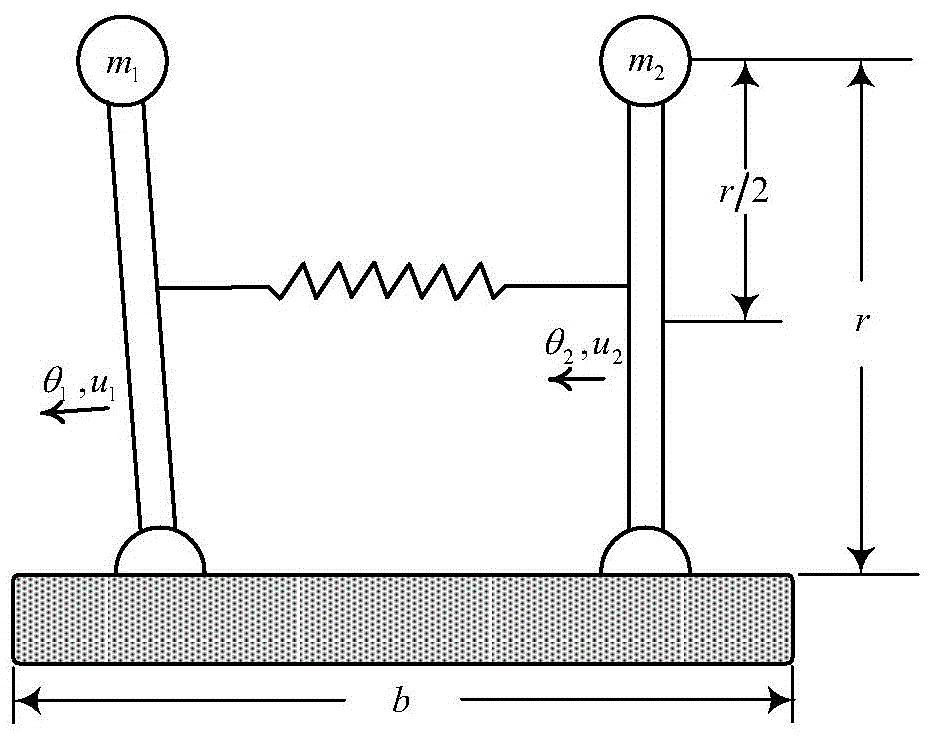

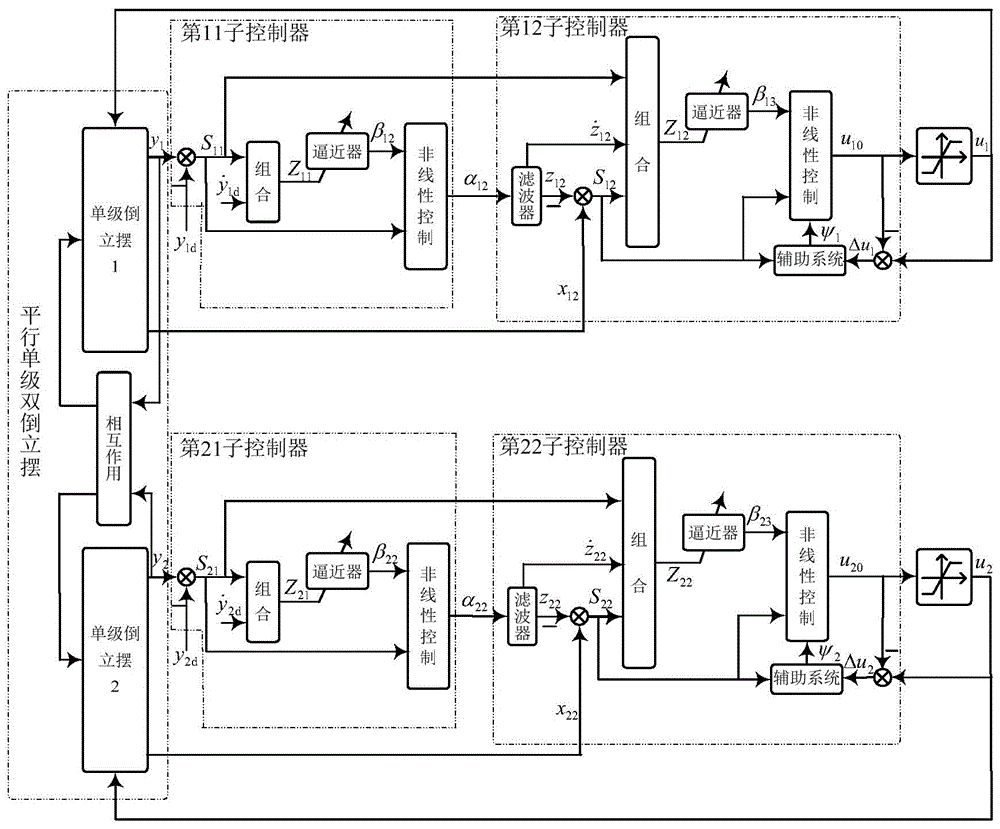

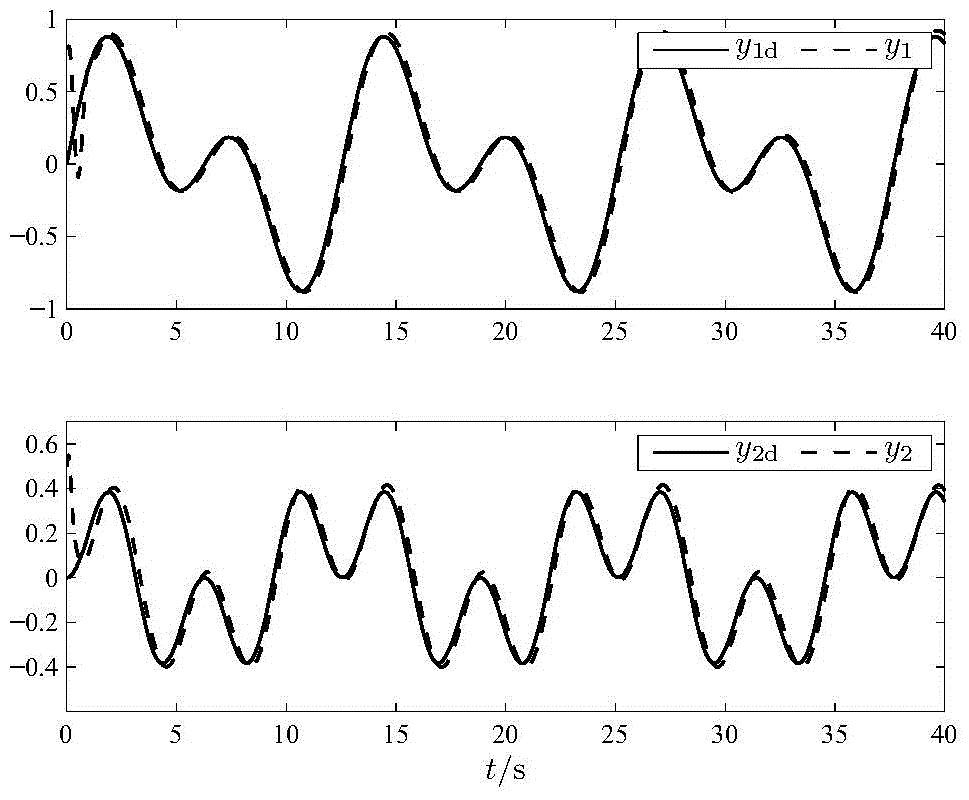

Dynamic surface controller structure and design method of parallel single-stage two-inverted pendulum

ActiveCN104834218AOvercome limitationsAvoid wear and tearAdaptive controlLinear controlNerve network

The invention discloses a dynamic surface controller structure and a design method of a parallel single-stage two-inverted pendulum. The controller structure comprises two controllers. Each controller comprises two stages of sub controllers. The first stage sub controller is composed of a first comparator unit, a combination unit, an approximator unit and a non-linear control unit. The second stage sub controller is composed of a filter unit, a second comparator unit, a combination unit, an approximator unit, a non-linear control unit, an auxiliary system unit and a third comparator unit. According to the invention, the control problem that the parallel single-stage two-inverted pendulum contains a time-lag item; the nerve network approximators are introduced, so that related prior knowledge of a dynamical uncertainty and a time-delay item of a complex system does not need to be known in advance; a dynamic surface control technology is further introduced, so that the complex derivation problem of an intermediate control function of a back-stepping method is solved; in addition, a norm of an adjusting nerve network weight matrix replaces a weight itself, the number of parameters adjusted on-line is reduced, and the calculating loads of the controllers are reduced.

Owner:NANJING UNIV OF POSTS & TELECOMM

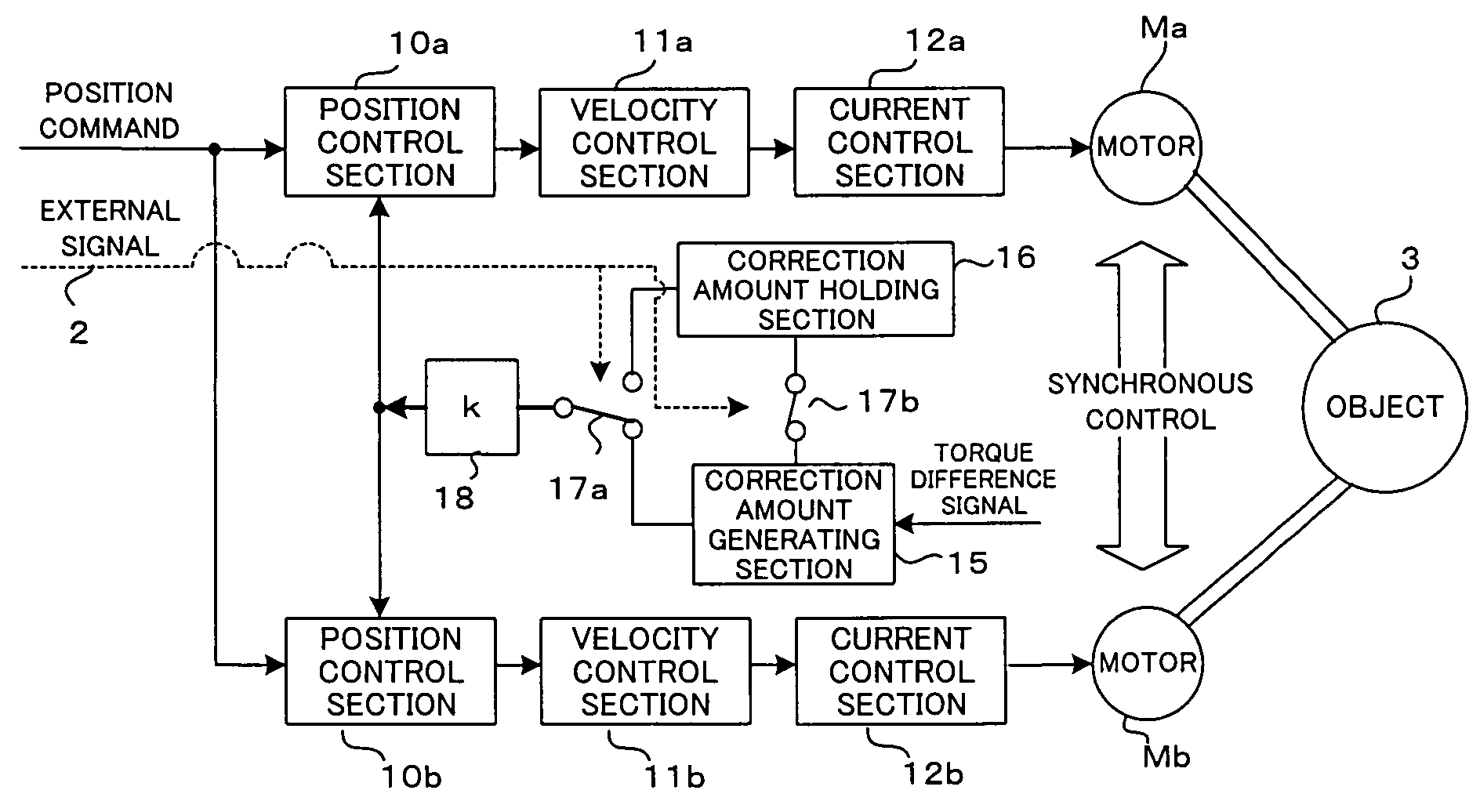

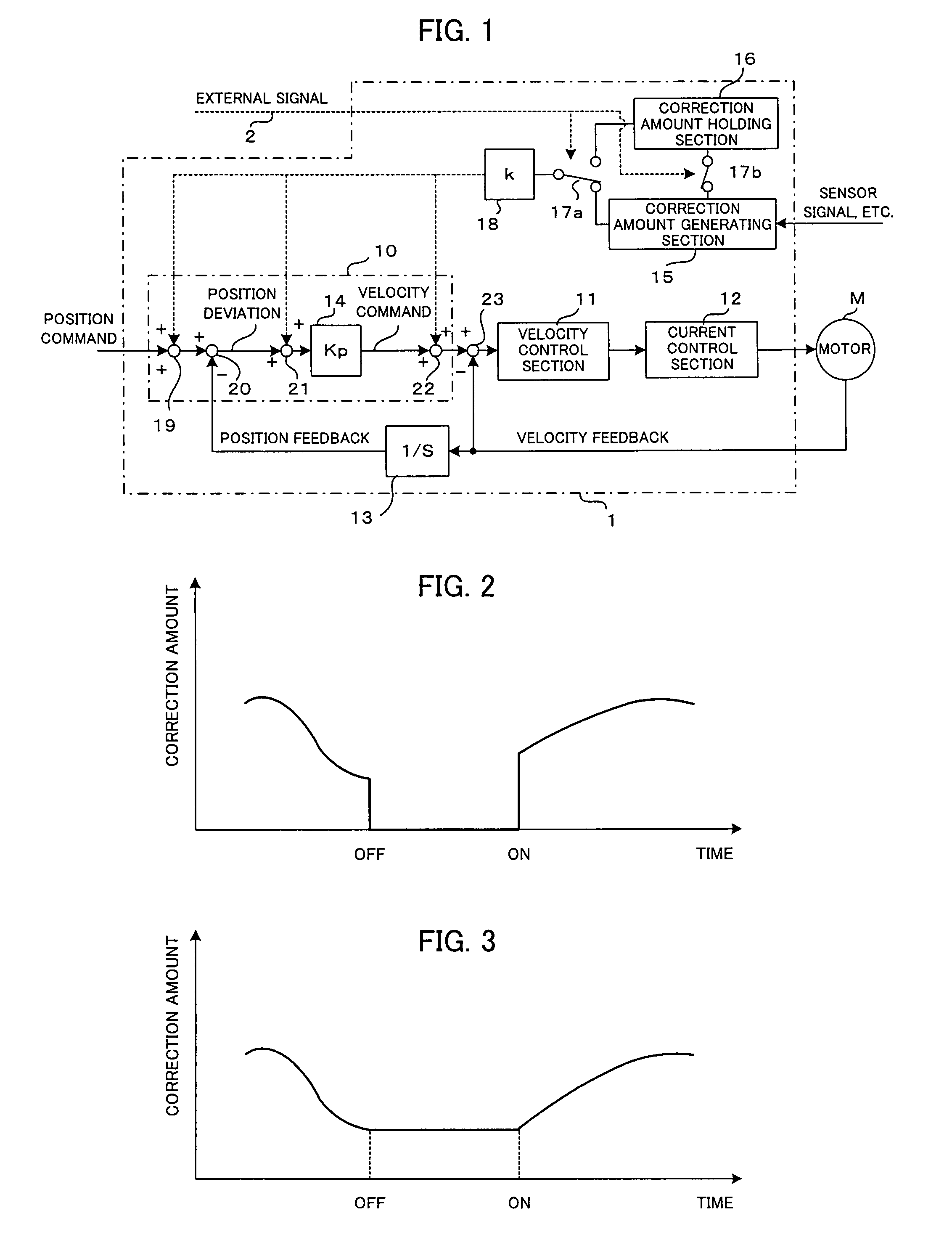

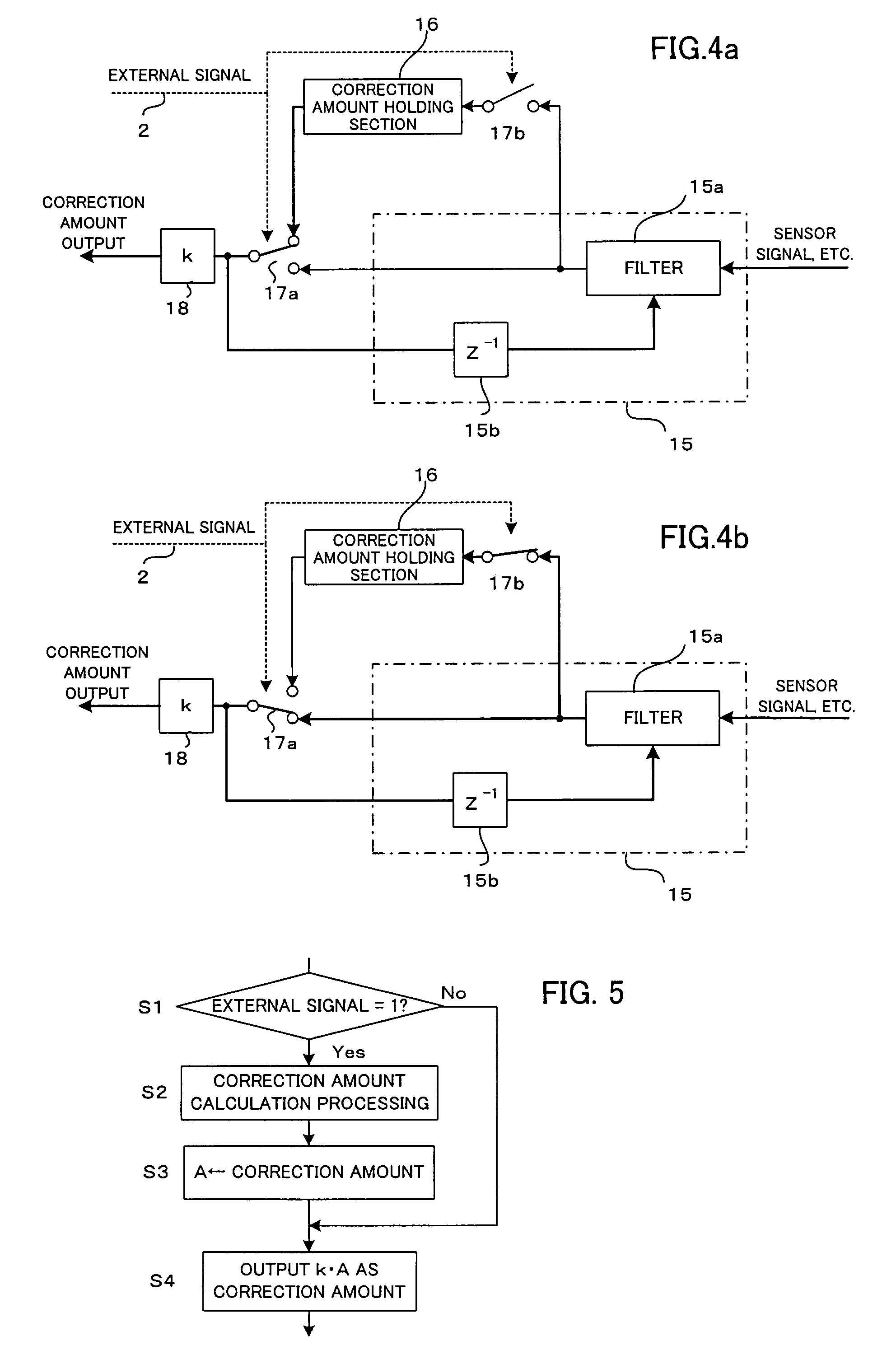

Controller for servomotor

ActiveUS7531981B2Reduce shockSwitch accuratelyElectric motor controlComputer controlMachined surfaceEngineering

A controller for a servomotor capable of improving accuracy of positioning and quality of a machined surface by switching modes of correction of a position command or the like, and reducing a shock at the time of switching. A correction amount generating section obtains a correction amount based on a value of a correction factor such as machine temperature. When the external signal is in ON state, a position command or the like is corrected by the correction amount obtained by the correction amount generating section and sent via switches. A correction amount holding section holds the correction amount obtained by the correction amount generating section. When the external signal turns to OFF state, the connection of the switches is changed so that correction is performed by the correction amount held in the correction amount holding section. When the connection of the switches is changed, the correction amount does not change rapidly, so that the machine does not suffer a shock. In positioning, the external signal is turns to ON state, so that the positioning is carried out accurately by performing correction by the correction amount sent from the correction amount generating section. When a high-quality machined surface is required, the external signal is turned to OFF state so that the correction amount does not change to achieve improvement in the quality of a machined surface.

Owner:FANUC LTD

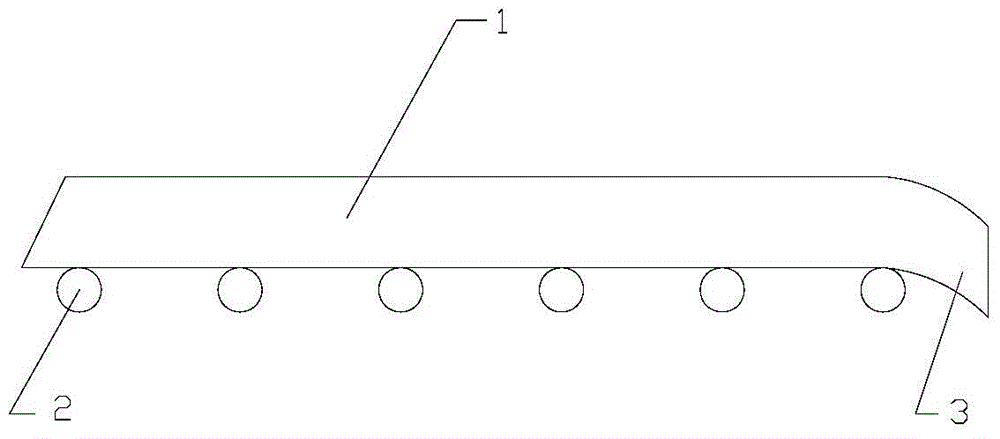

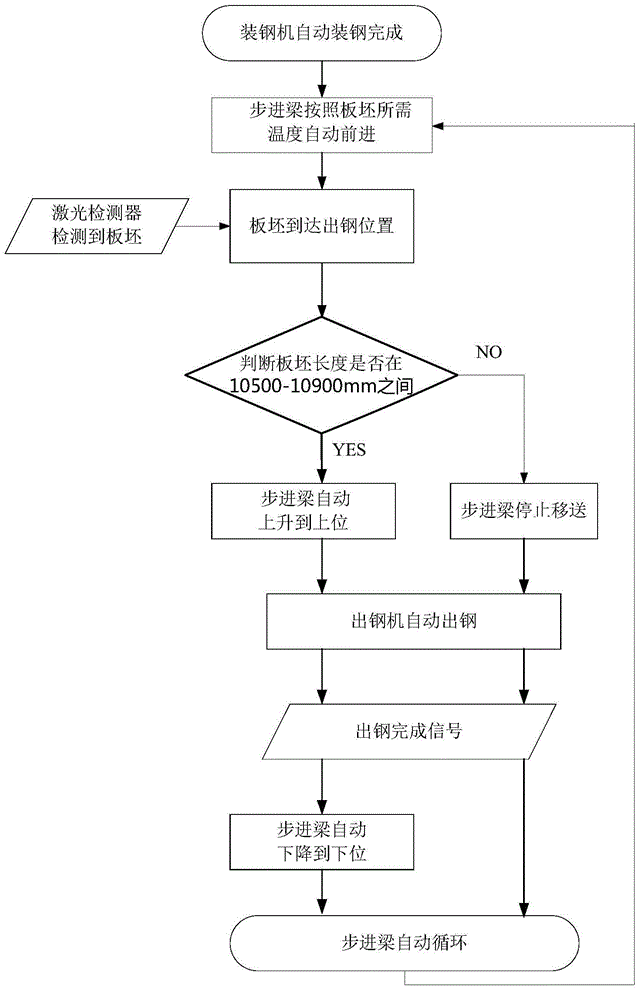

Walking beam furnace high-level tapping automatic control method

ActiveCN106282531AIncrease productivityReduce hands-on timeFurnace typesHeat treatment process controlAutomatic controlEngineering

The invention relates to a walking beam furnace high-level tapping automatic control method. A secondary preset plate blank length is compared with a preset value when a laser detector at a discharging end detects that a plate blank reaches a tapping temperature, and automatic high-level tapping of a walking beam is carried out if the length is in the preset range; and the walking beam furnace high-level tapping automatic control method effectively avoids the accident of blank dropping caused by bumping of the bent part of the plate blank to the wall of the furnace in the tapping process of a tapping machine. The method is enforced to effectively improve the production efficiency, shorten the manual operating time of operators and avoid accidents caused by untimely manual operation. The method has the advantages of effective reduction of the energy consumption, stabilization of the temperature field, reduction of the burning loss, effective improvement of the stability of the furnace pressure, and avoiding of rapid change of the furnace pressure due to furnace door opening and heat exchange.

Owner:ANGANG STEEL CO LTD

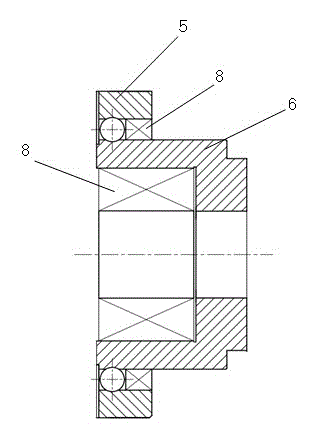

Centrally-mounted drive system of electric bicycle

ActiveCN102745298ALittle impact on appearanceIntensity effectWheel based transmissionChain/belt transmissionSingle stageVehicle frame

A centrally-mounted drive system of an electric bicycle comprises a chain wheel, a motor, a middle shaft and a reduction box, wherein the chain wheel has a disc-shaped structure; a concave circular mounting part is arranged in the middle position of the chain wheel; a housing of the reduction box is arranged in the concave mounting part and matched with the chain wheel; a reducing mechanism in the reduction box is a composite dual-overrun clutch, wherein the inner ring of an outer clutch and the outer ring of an inner clutch share the same component which serves as the output end of a hybrid power source; and the inner ring of the outer clutch is coaxially fixed to the chain wheel. The centrally-mounted drive system of the electric bicycle employs coaxial mounting, coaxial output and single-stage helical gear parallel transmission manners and successfully avoids great change of a frame caused by lift mounting; the single-stage reducing mechanism is employed to realize coaxial output; the volume of the motor is effectively reduced, which has little influence on the appearance of the entire bicycle; and viewed from the angle of the appearance of the entire bicycle, the similarity of the electric bicycle to the bicycle is very high.

Owner:广东广天机电工业研究院有限公司

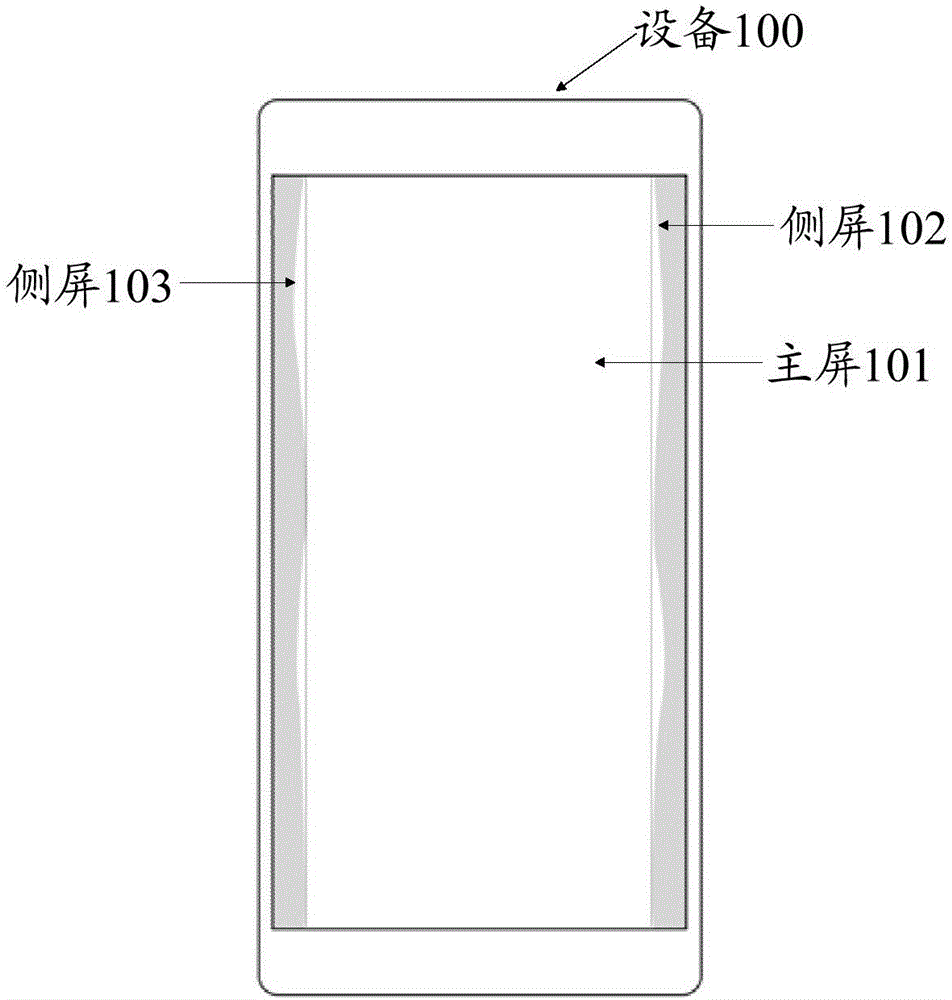

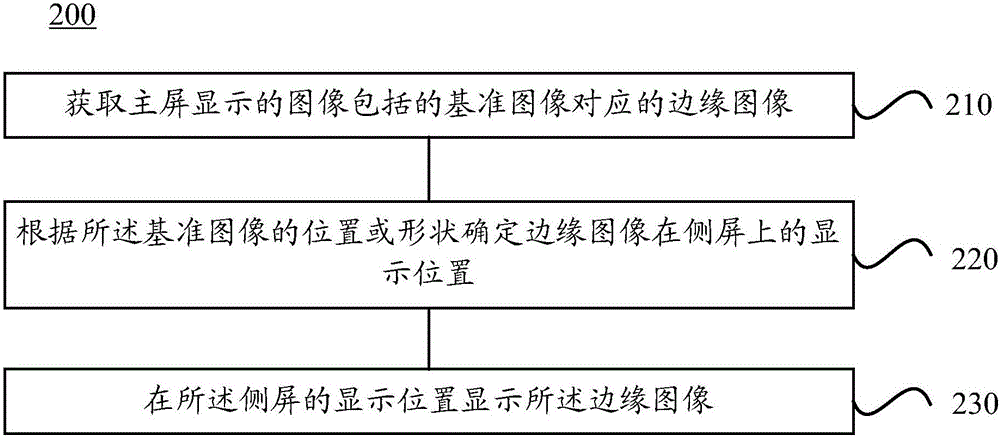

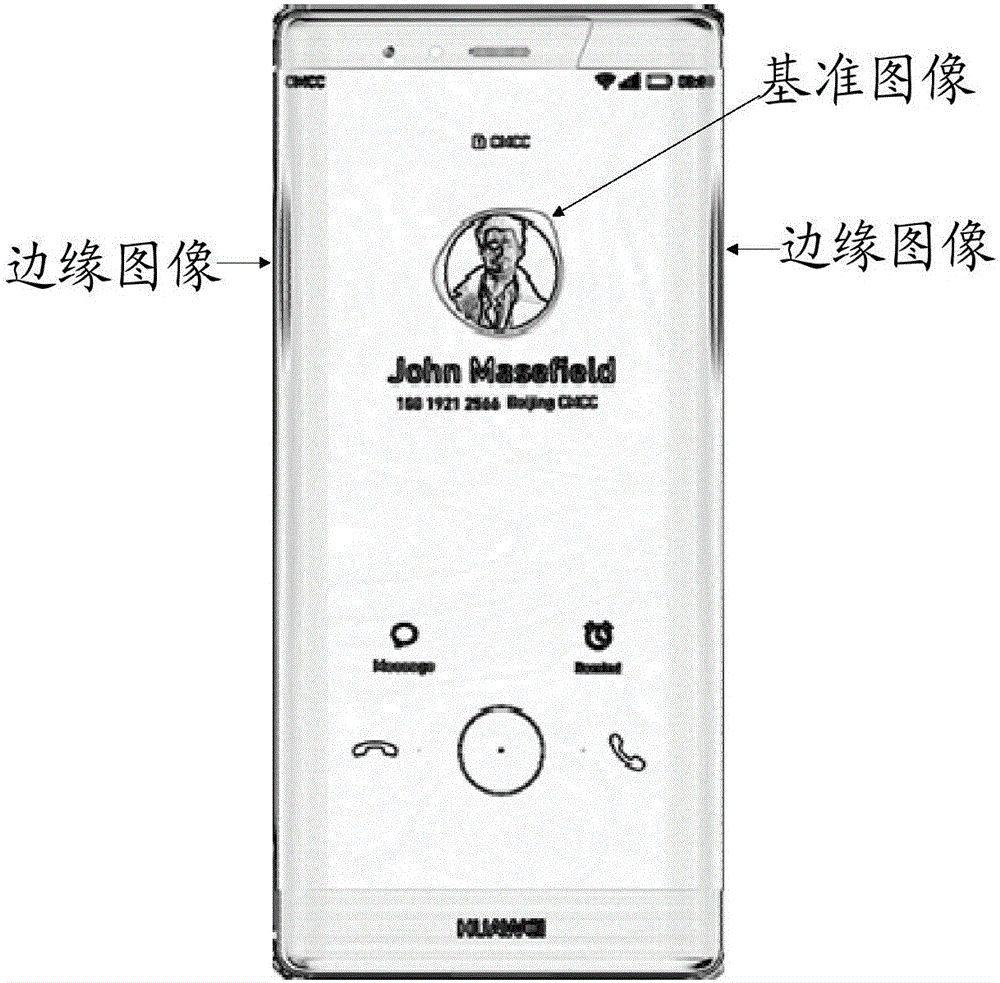

Method for displaying edge image and electronic device

ActiveCN106502606AImprove visual experienceImprove satisfactionDigital output to display deviceReference imageVisual perception

The embodiment of the invention discloses a method for displaying an edge image and an electronic device. The method includes the steps that the edge image corresponding to a reference image included in images displayed by a main screen is obtained; the display position of the edge image on a lateral screen is determined according to the position or shape of the reference image, and the edge image is displayed on the display position of the lateral screen. By means of the method, the reference image displayed on the main screen is determined, and the display position of the edge image on the lateral screen is determined according to the position or shape of the reference image, so that a visual dynamic effect and a three-dimensional sense are added for a user, and the satisfaction degree of user experience is improved.

Owner:HUAWEI MACHINERY

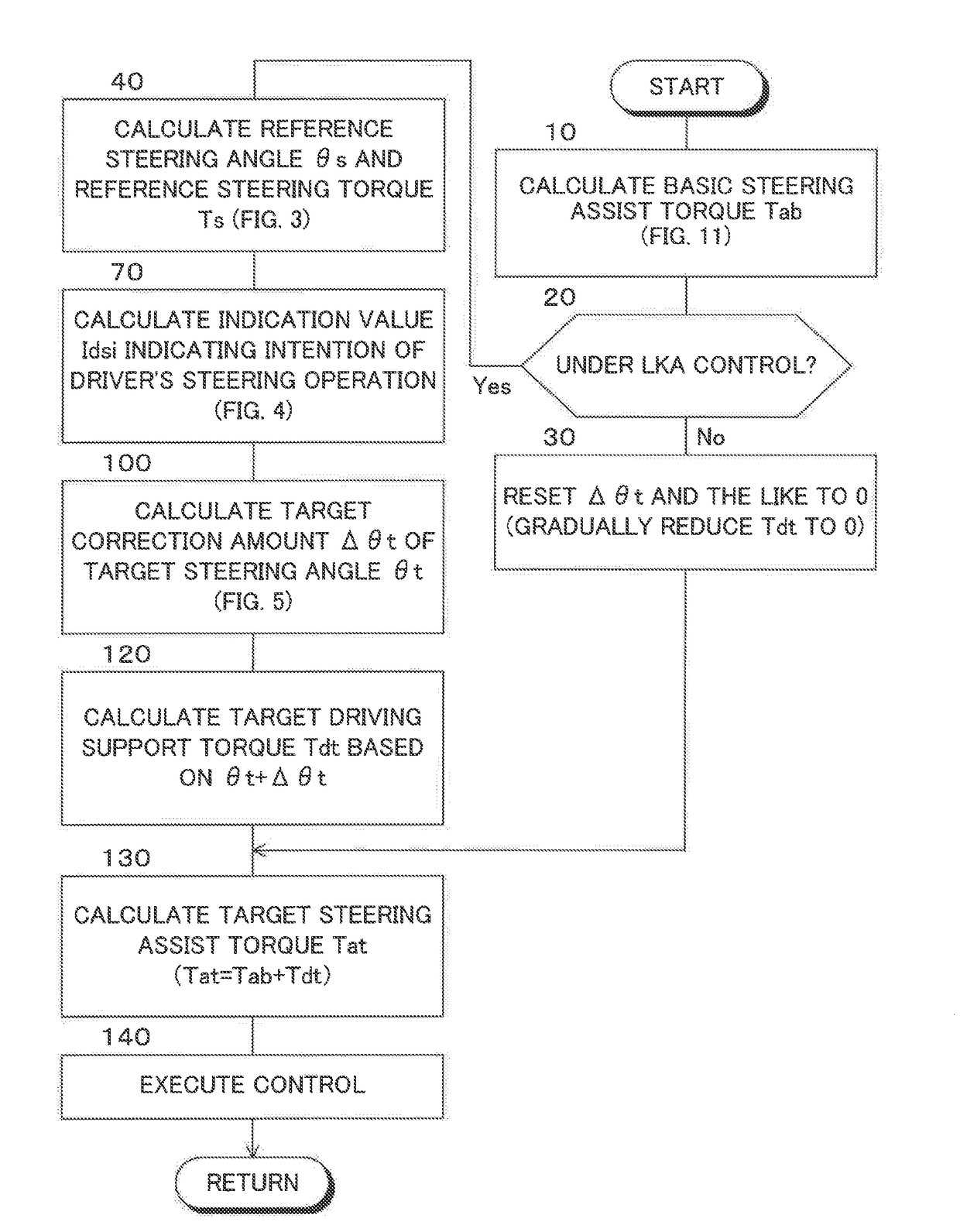

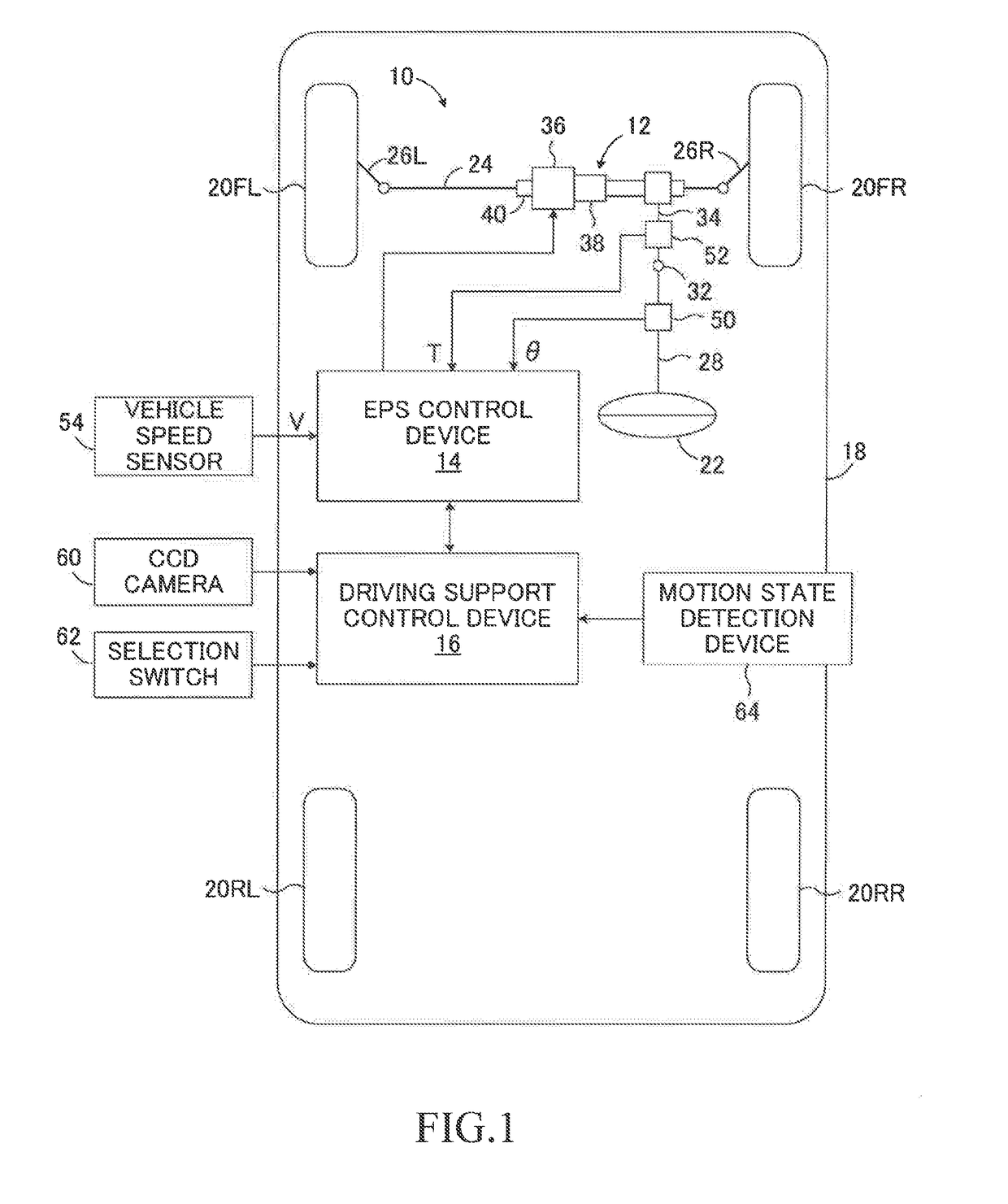

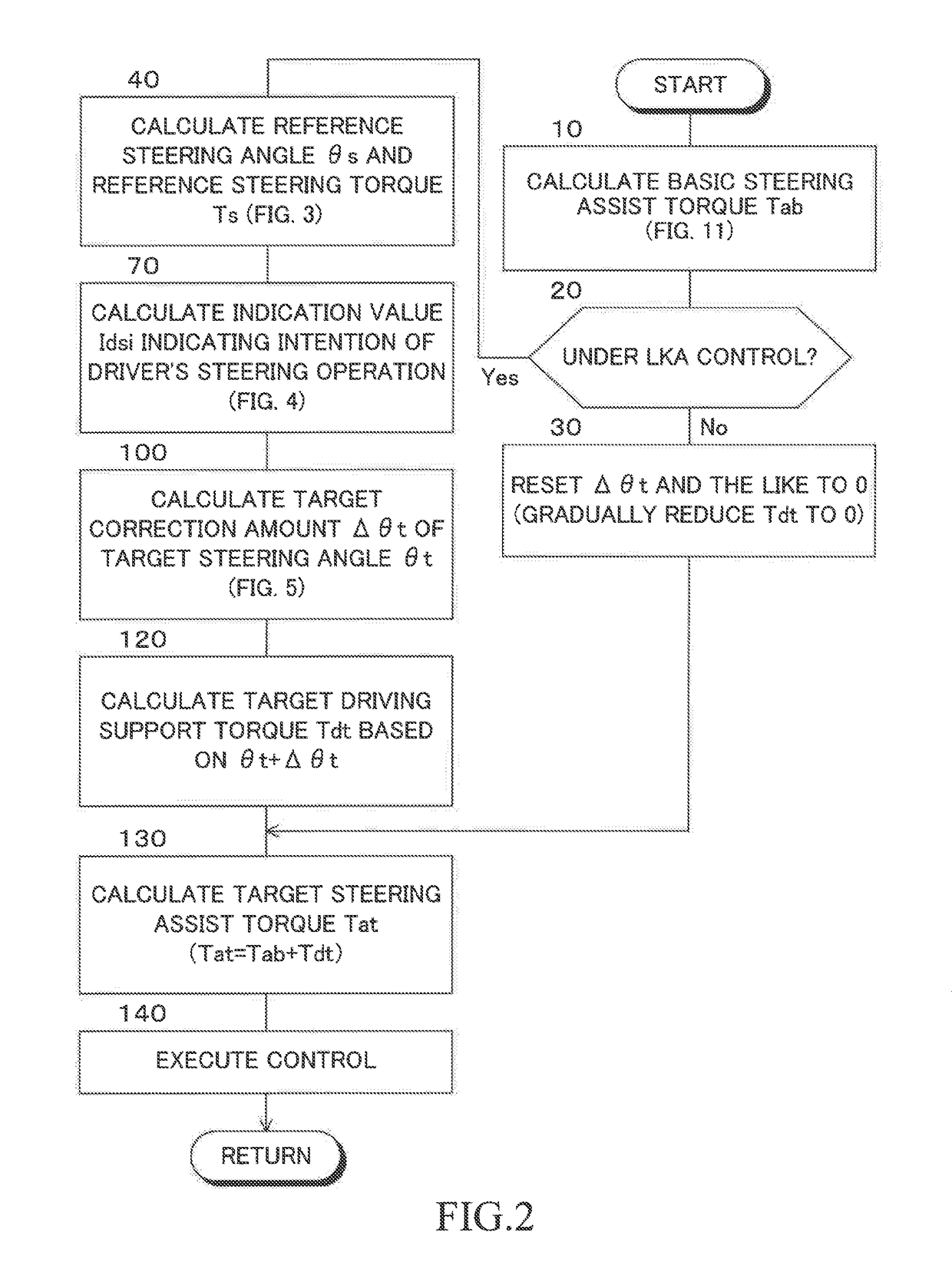

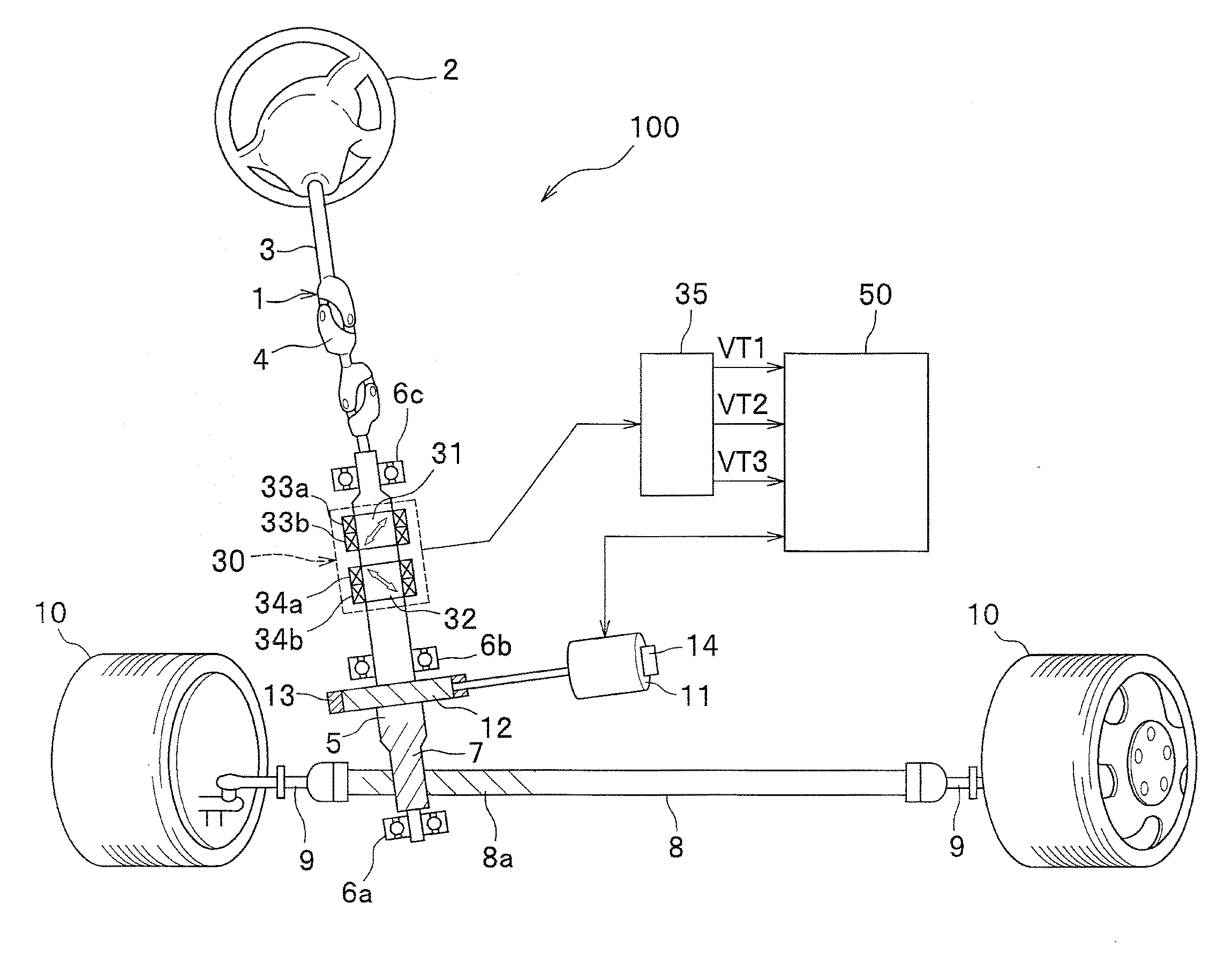

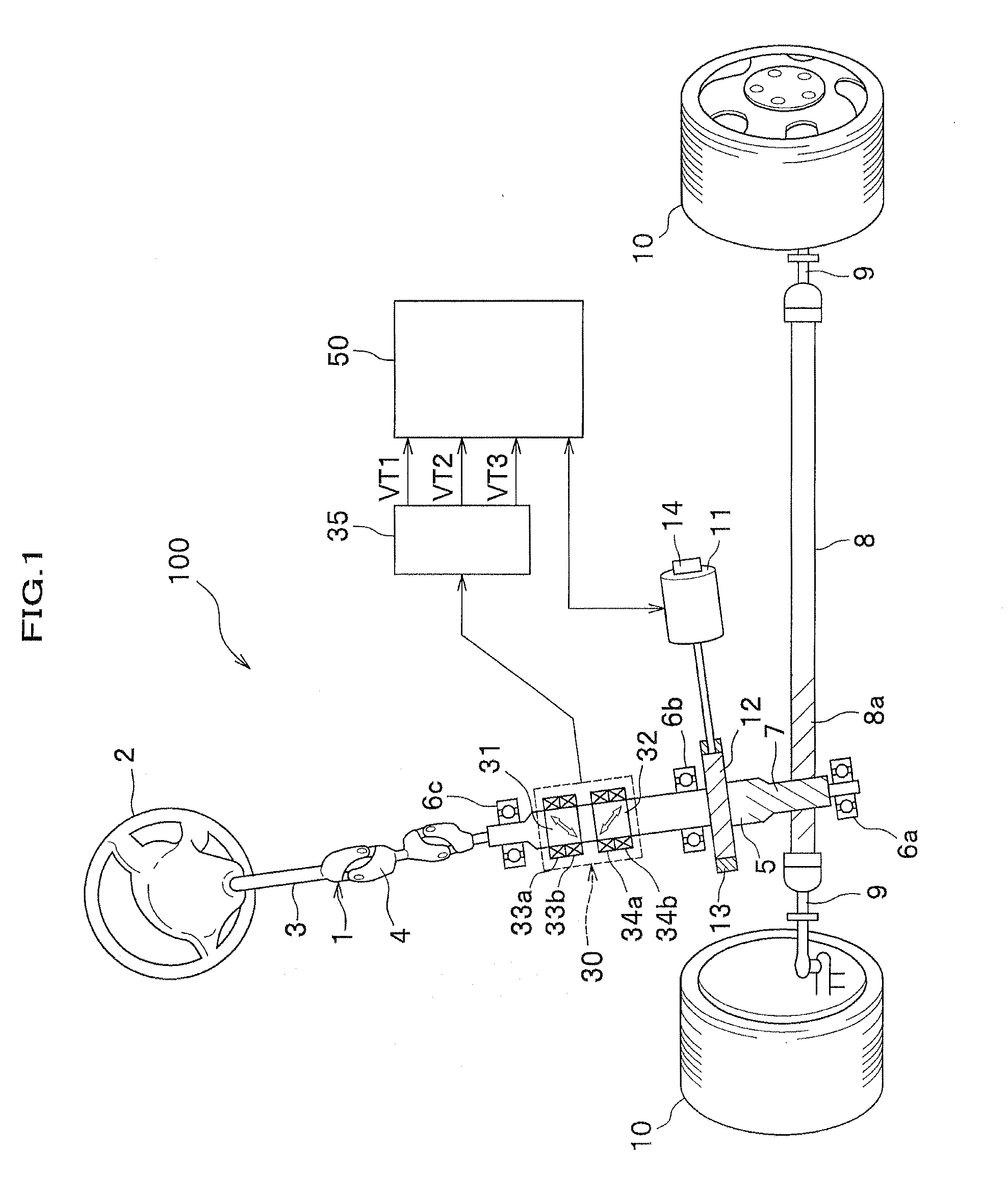

Driving support device for vehicle

ActiveUS20170088166A1Change in supportAvoid drastic changesSteering linkagesAutomatic steering controlSteering angleVehicle driving

A driving support device may be configured to calculate a target steering angle for allowing a vehicle to travel along a target course; set, as a reference steering angle, a steering angle when a difference between the steering angle and the target steering angle is small; calculate an indication value indicating intention of a driver's steering operation as a sum of a first product of a corrected steering angle and a steering torque, a second product of a derivative of the corrected steering angle and the steering torque, and a third product of the corrected steering angle and a derivative of the steering torque; and correct the target steering angle based on the indication value so that a target driving support torque is corrected in accordance with the intention of the driver's steering operation.

Owner:TOYOTA JIDOSHA KK

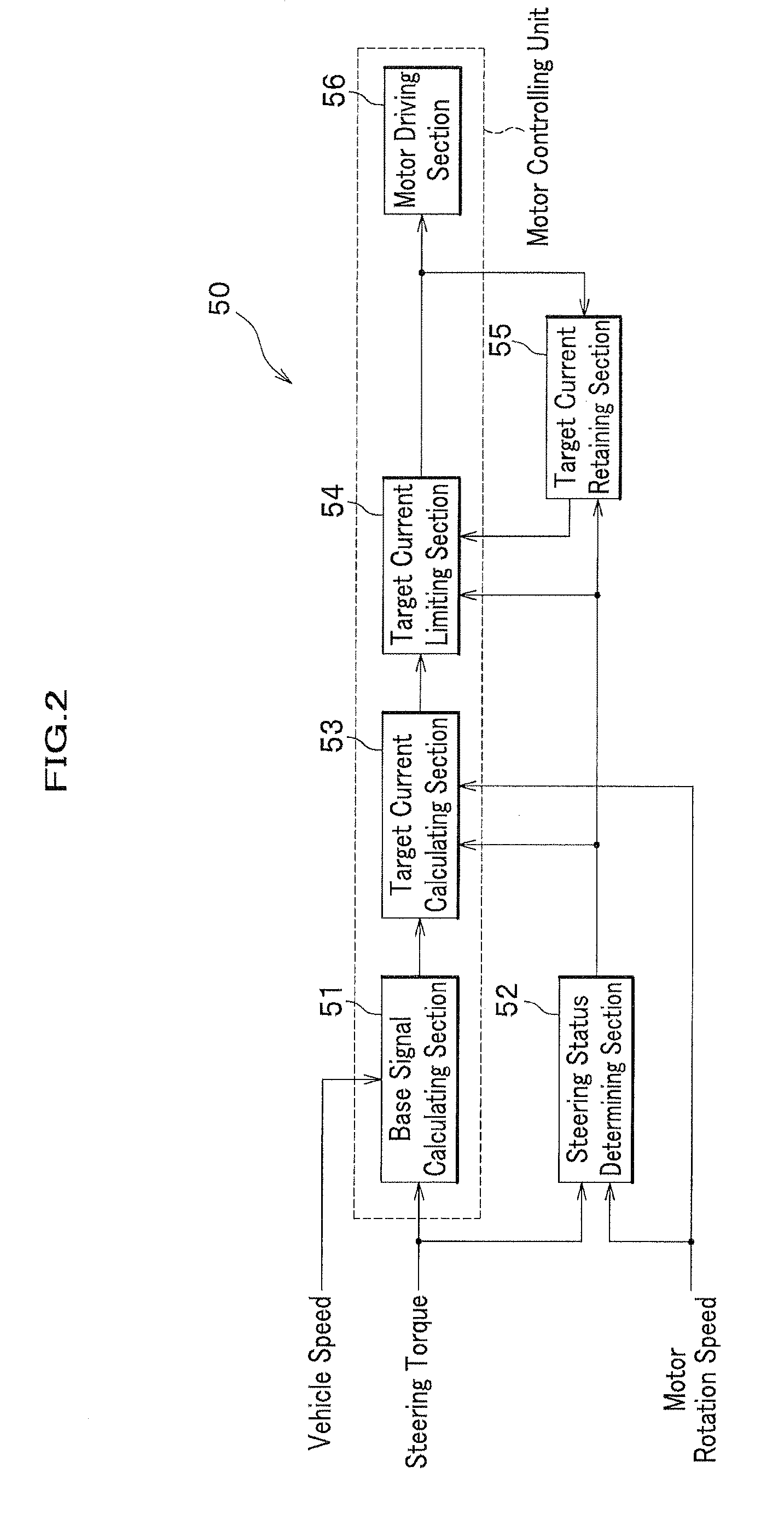

Controller of electric power-assist steering system

ActiveUS20100121531A1Avoid drastic changesSteering feelingSteering initiationsDigital data processing detailsElectric power steeringSteering wheel

The present invention discloses a controller of an electric power-assist steering system including a torque detector for detecting a torque applied with a steering wheel that steers a steering system; a steering status determining section for determining a steering status of either “turn” or “return” of a steering wheel; and a motor controlling unit for driving a motor n accordance with a target current value calculated based on at least a torque value from the torque detector and the steering status of either “turn” or “return” of the steering wheel from the steering status determining section, wherein the motor controlling unit sets a target current value right after a time when the steering status is switched between “turn” and “return” to be substantially equal to an actual current value right before a time when the steering status is switched between “turn” and “return”.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com