Patents

Literature

250 results about "Limit pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Upper limit of the pressure or scale range. For example, if a pressure control has a range of. 0 to 100 psig (0 to 689 kPa), the maximum working. pressure is 100 psig (689 kPa). Any pressure. exceeding the 100 psig (689 kPa) maximum working. pressure must be infrequent and short in duration.

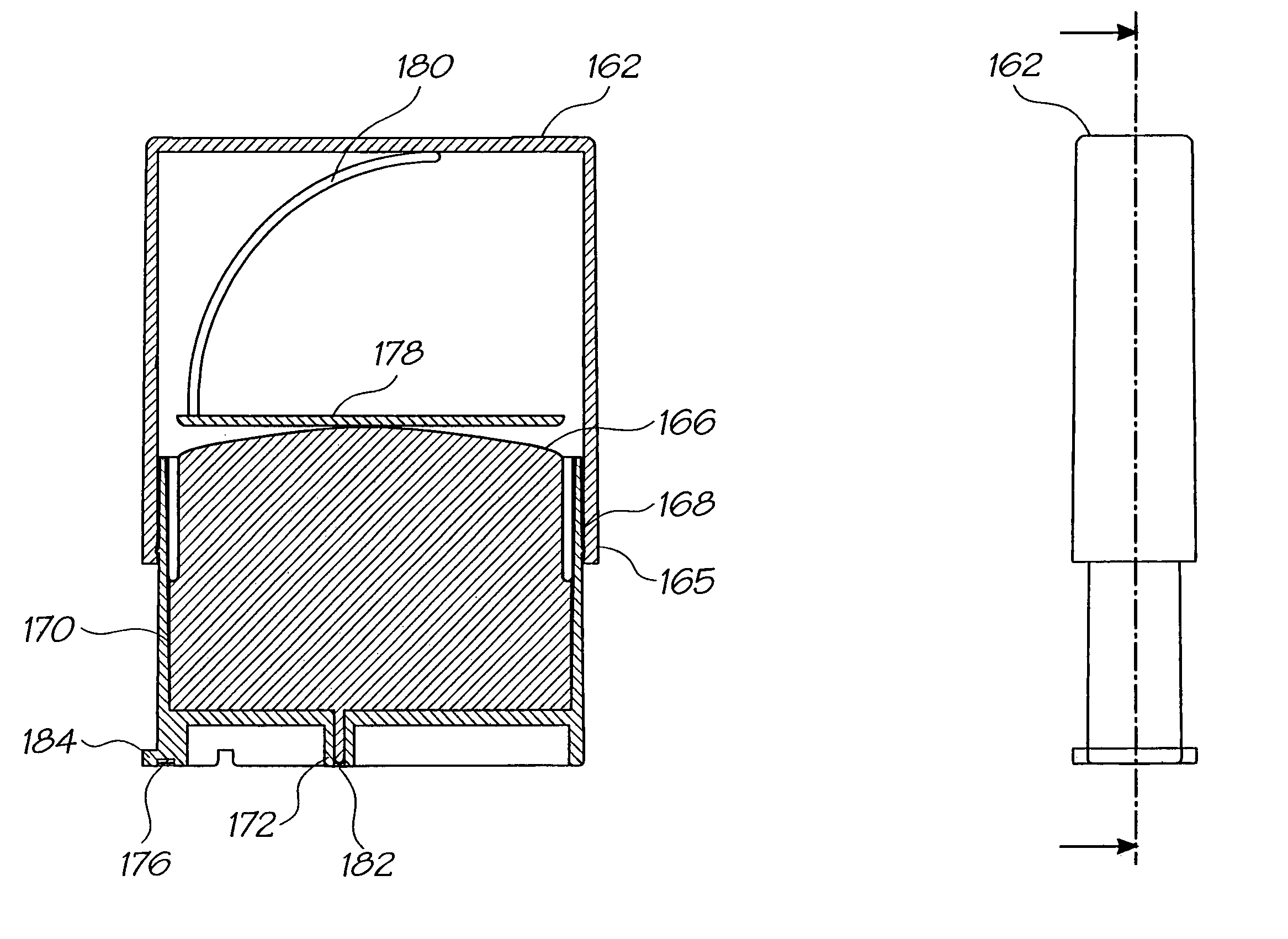

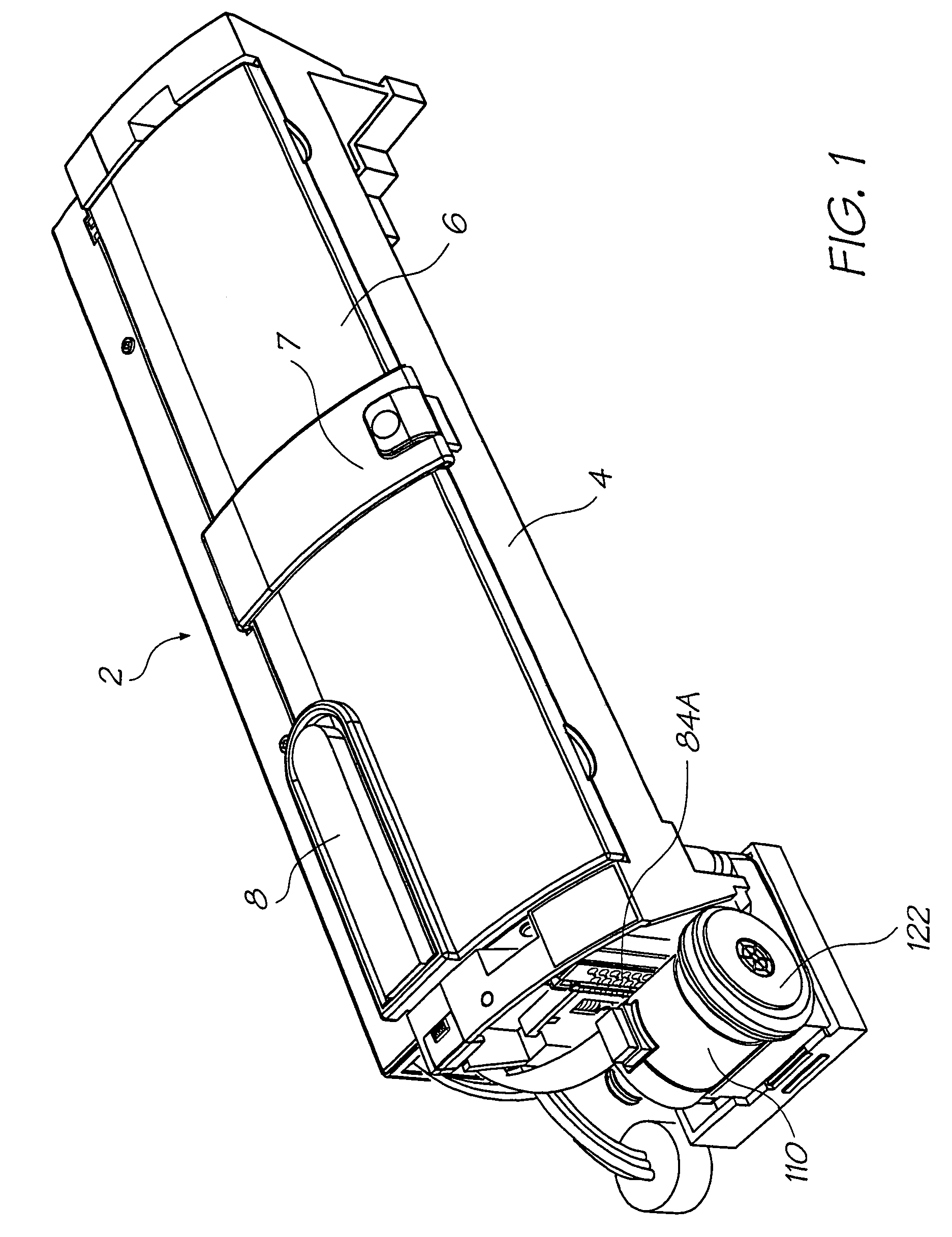

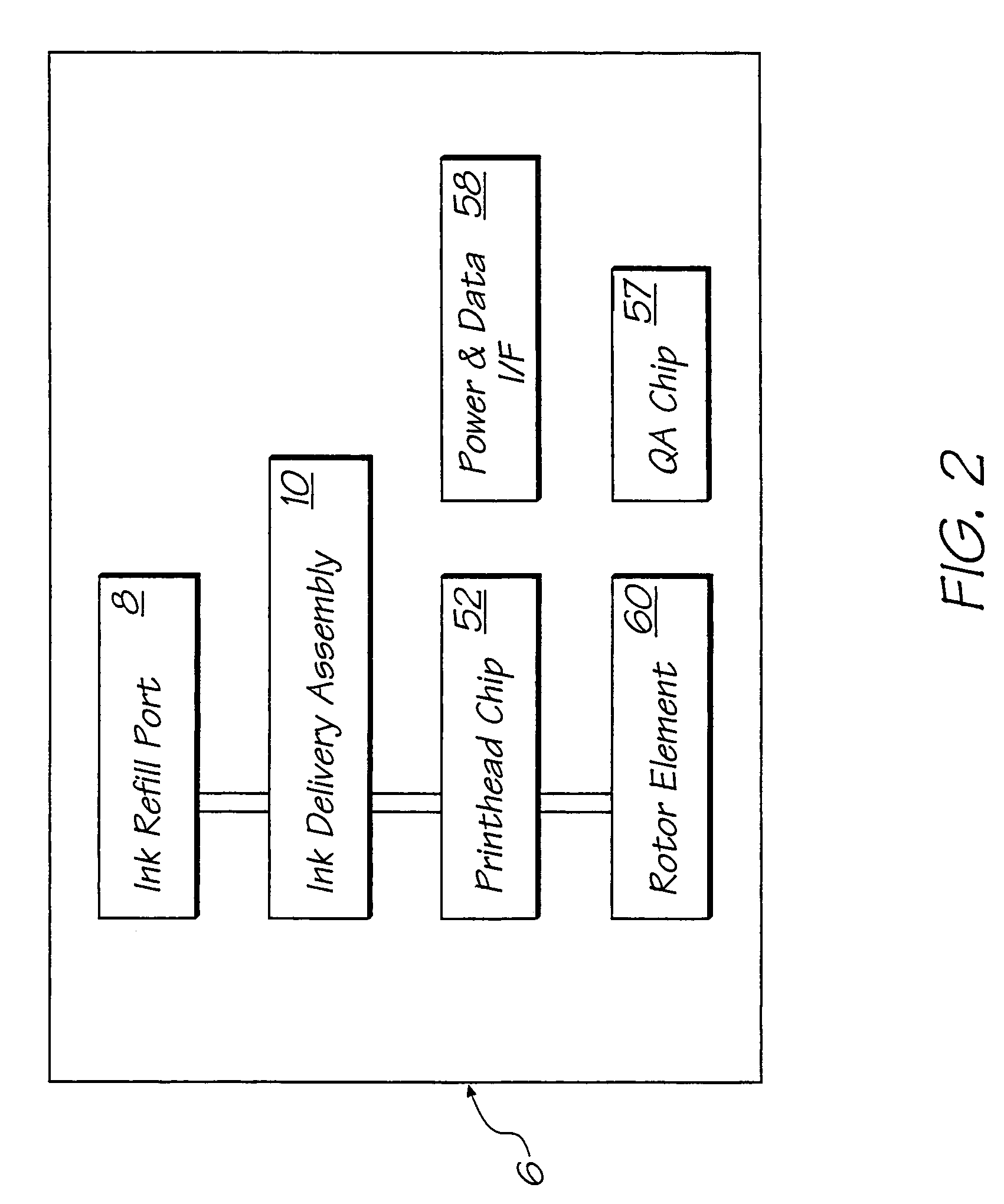

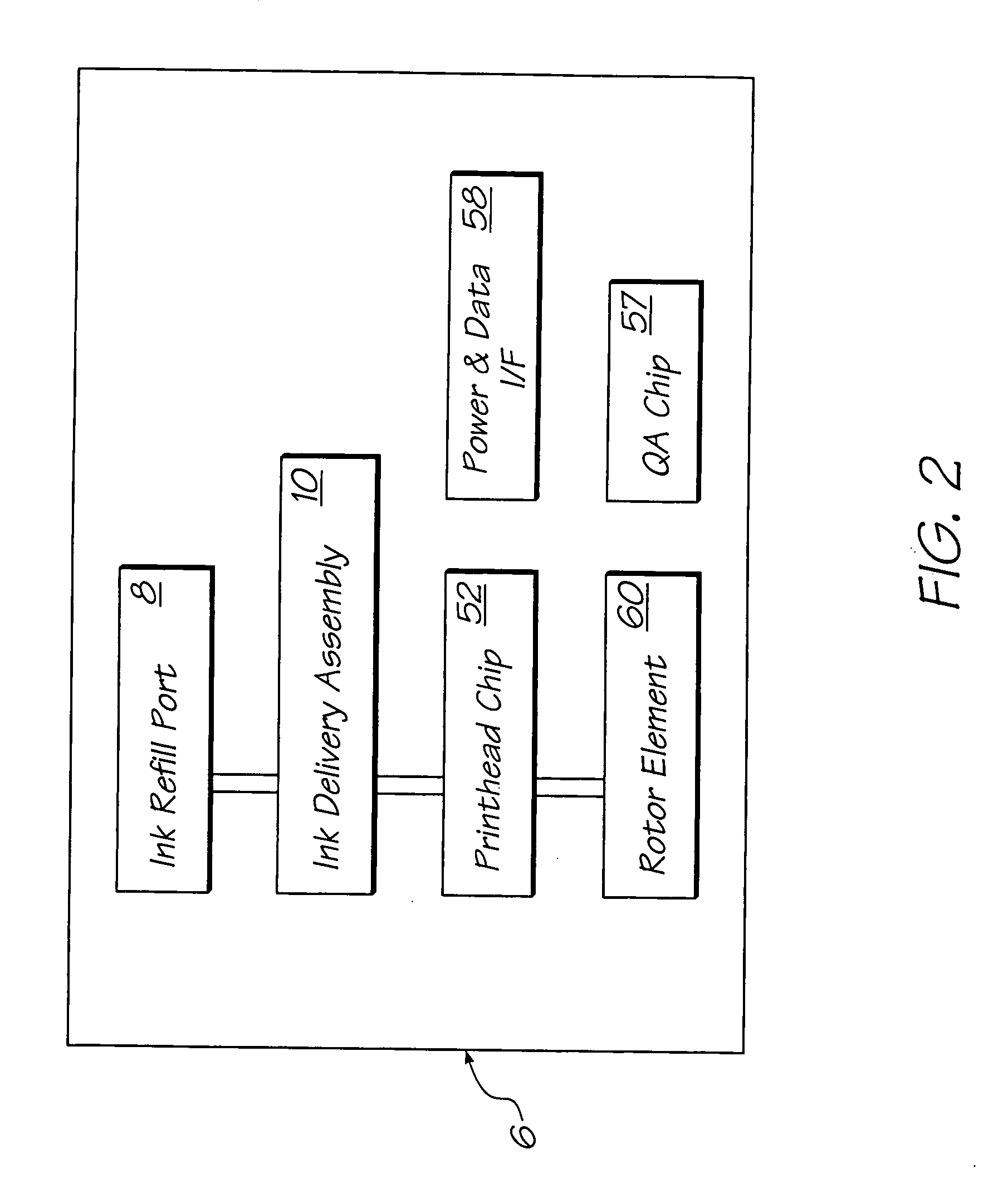

Inkjet printer cartridge refill dispenser with plunge action

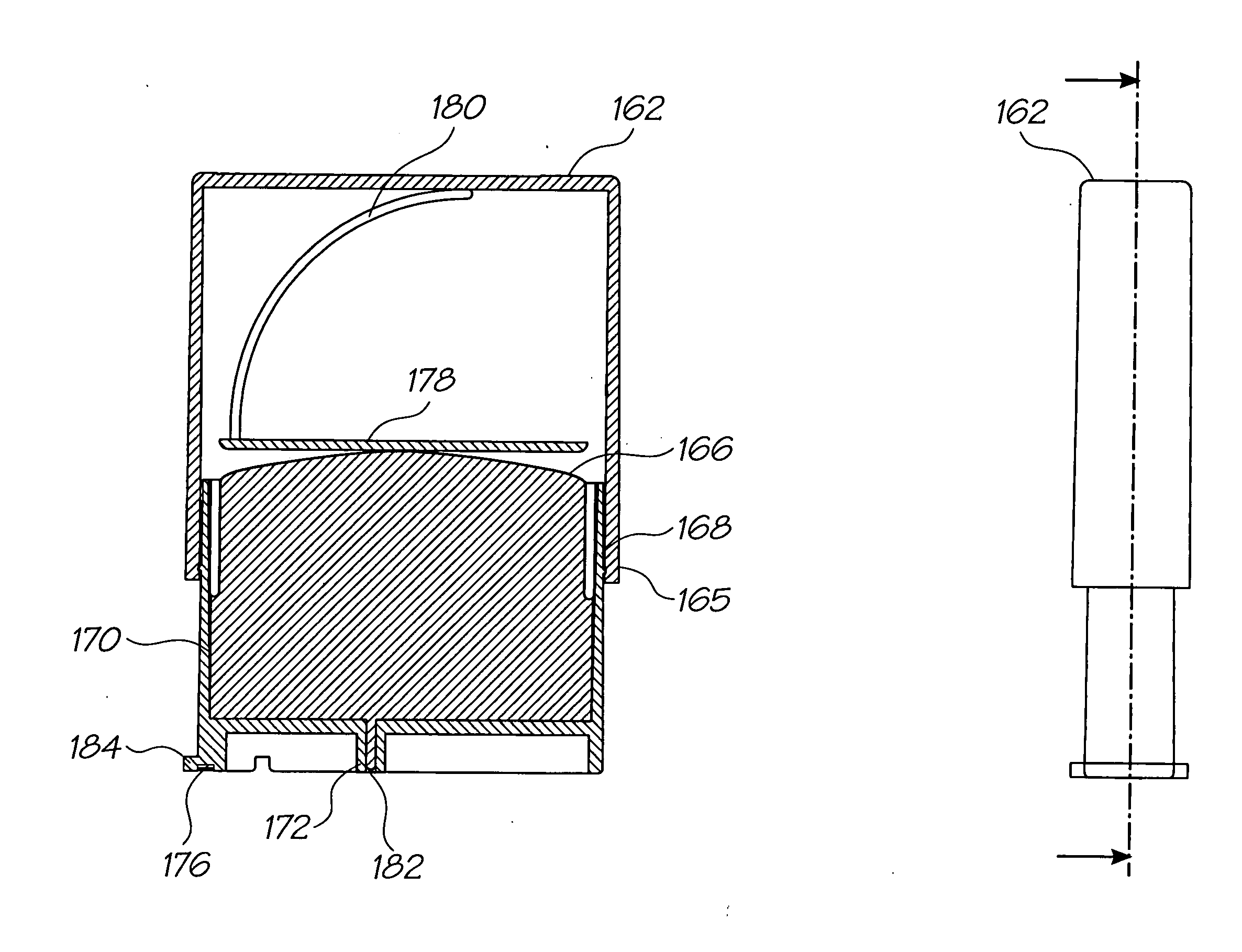

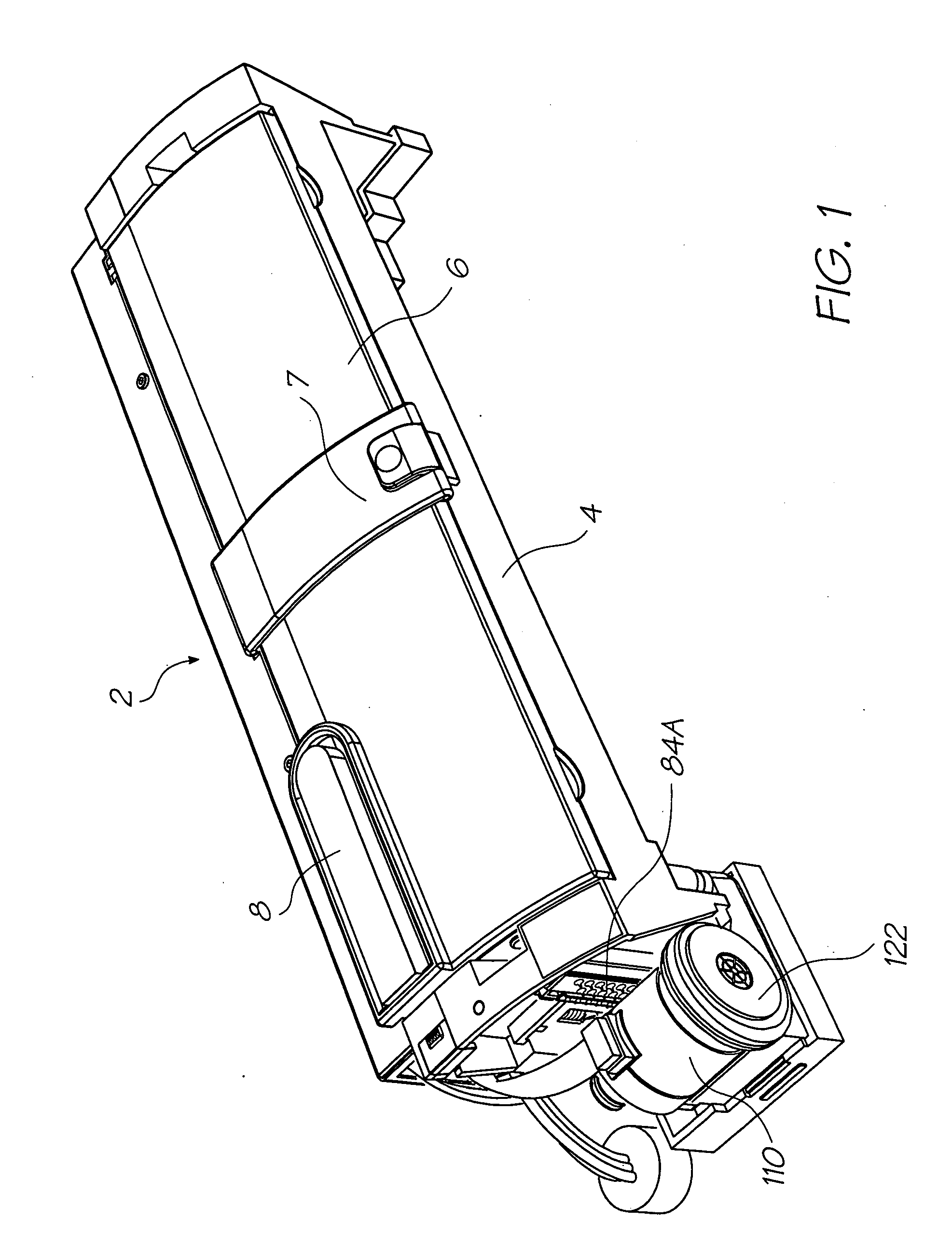

A printing fluid dispenser including: a housing comprising a base and a plunger; a deformable container located within the housing for storing printing fluid; an outlet coupled to the deformable container and arranged to convey the printing fluid to a point external to the housing; and a spring located between the deformable container and the plunger having characteristics selected to limit pressure in the deformable container to a predetermined level in use; wherein in use, bringing the plunger towards the base causes compression of the deformable container between the spring and the base and egress of the printing fluid through the outlet.

Owner:SILVERBROOK RES PTY LTD +1

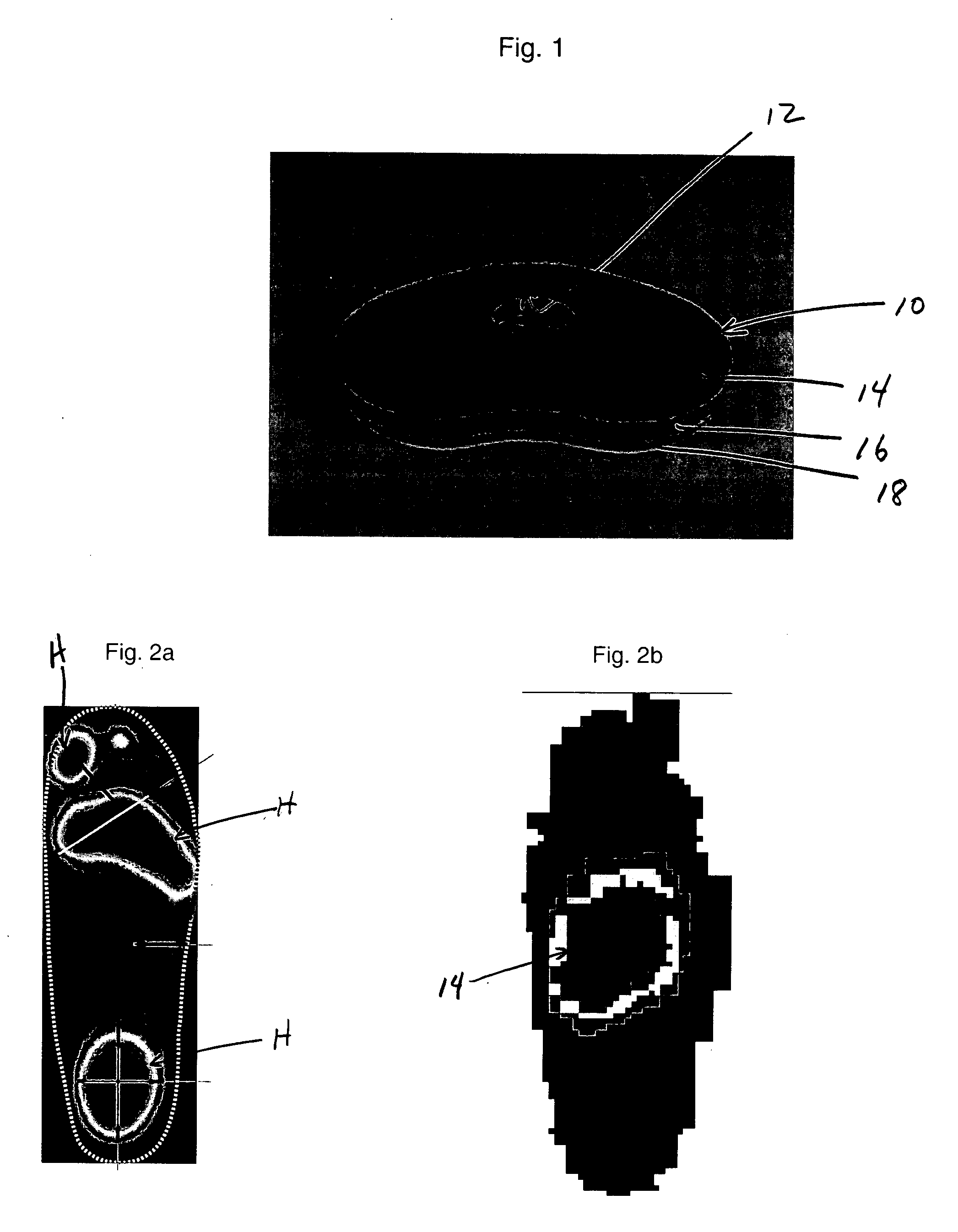

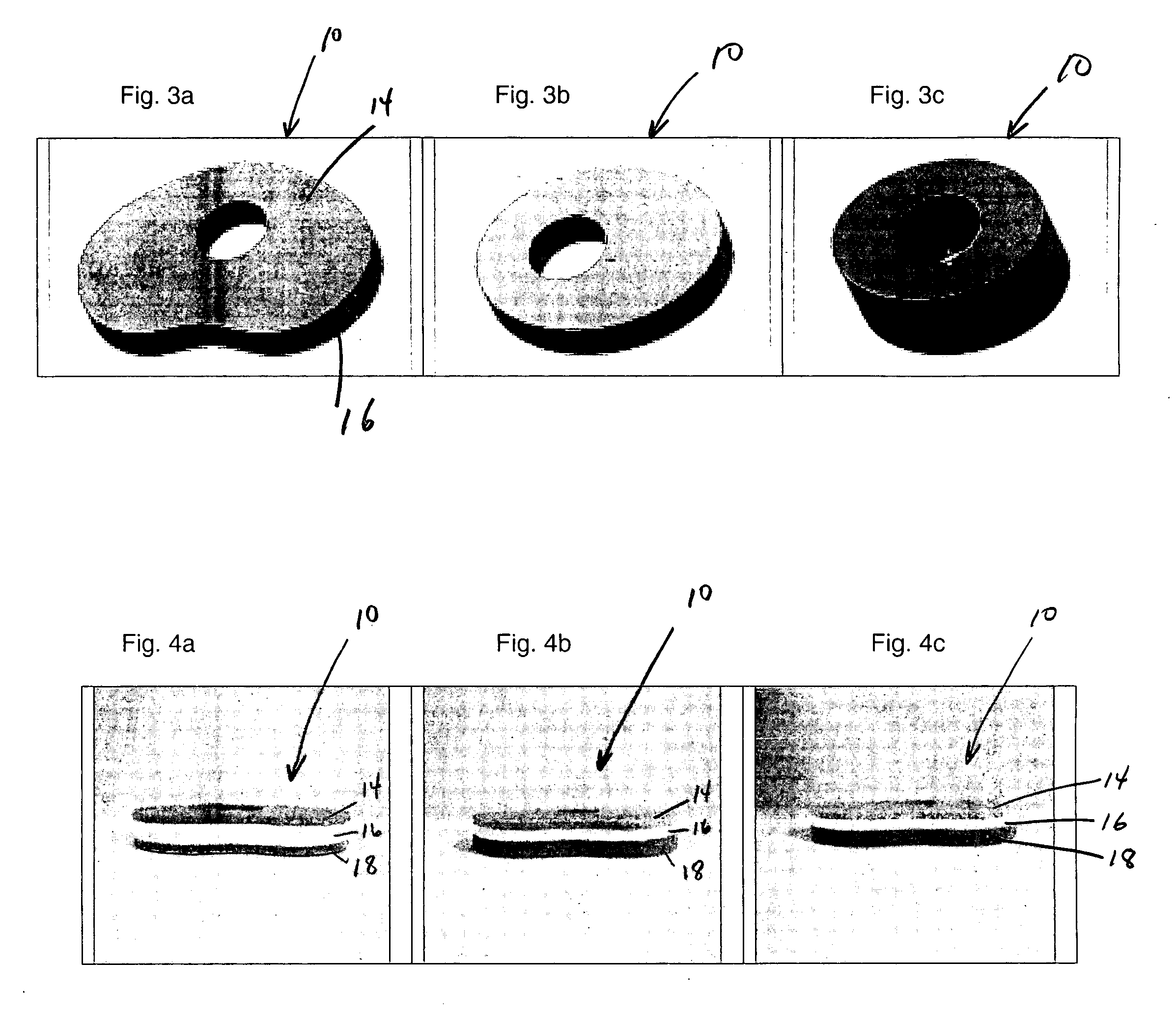

Load relieving wound dressing

An improved load relieving dressing for transferring pressure away from a wound on a foot of a patient. The dressing having a wound opening formed through the dressing for surrounding a wound site. The dressing having an external shape which substantially conforms to the shape of the pressure distribution on the foot during load bearing. A first layer of the dressing interfacing with and cushioning a foot during load bearing. The first layer is of a material sufficient to limit pressure increases at the wound opening and within said dressing adjacent the wound opening. An off-loading layer is engaged with said first layer, and is of a material sufficiently thick and firm to reduce pressure at the wound site.

Owner:DIAPEDIA

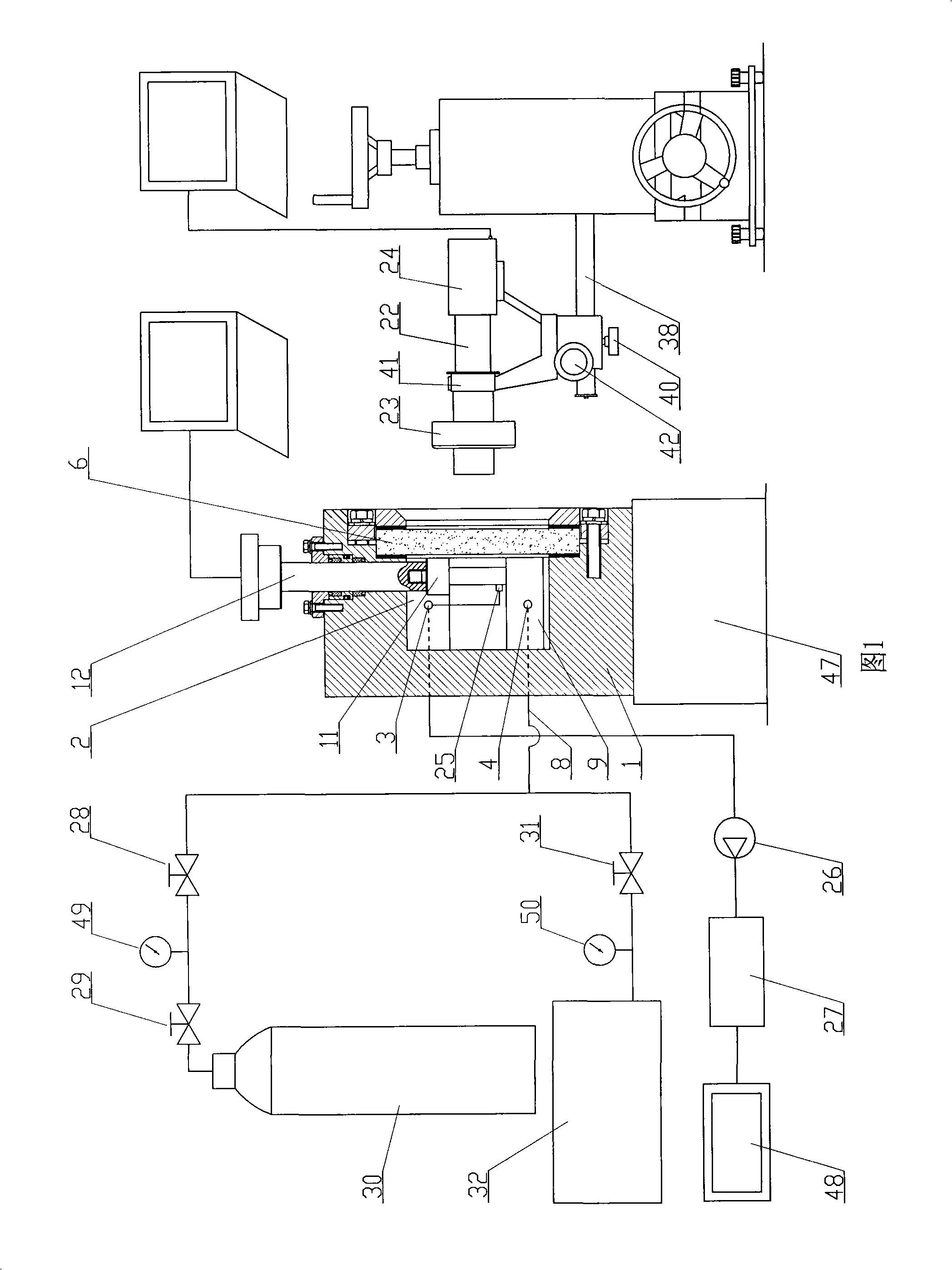

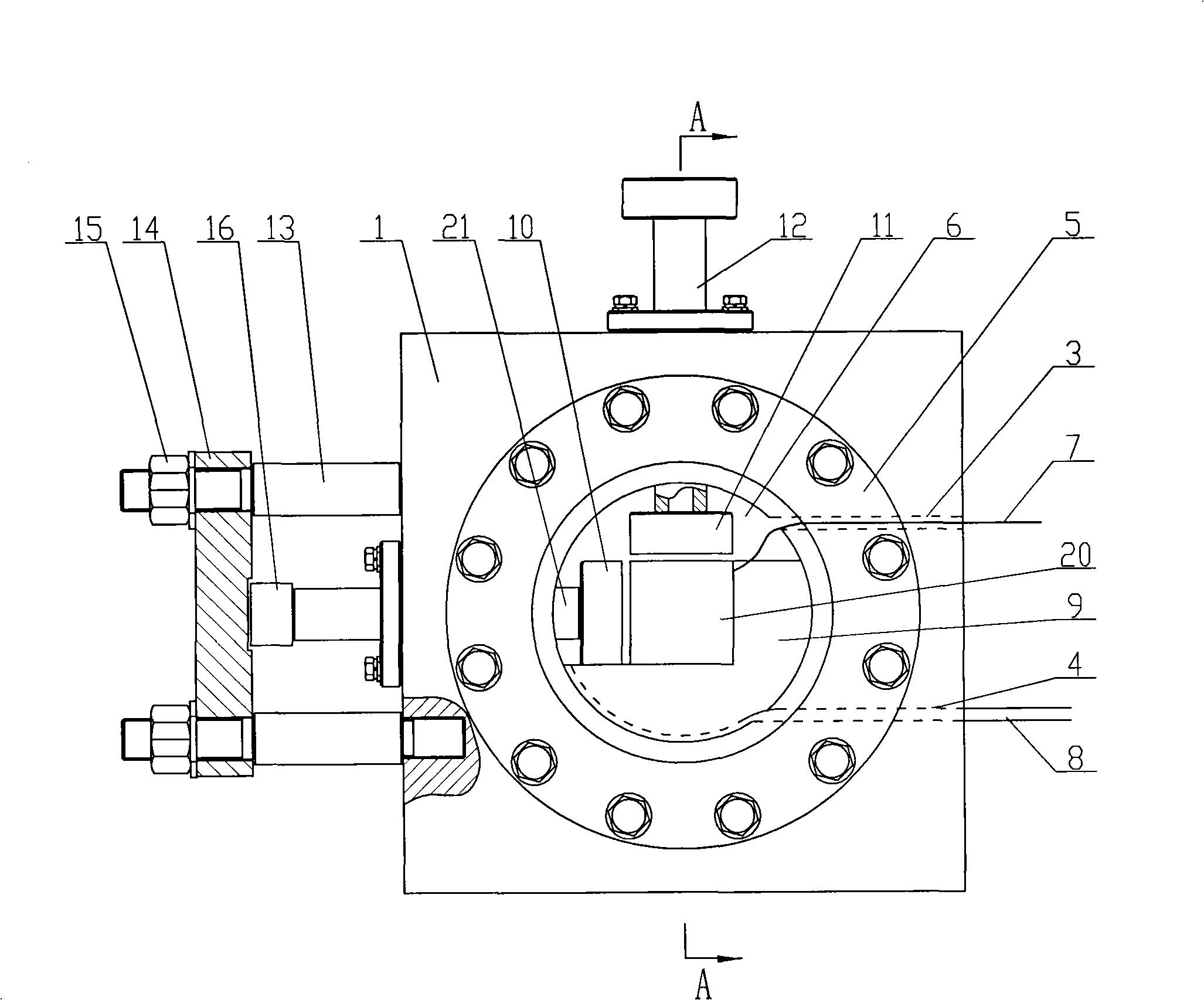

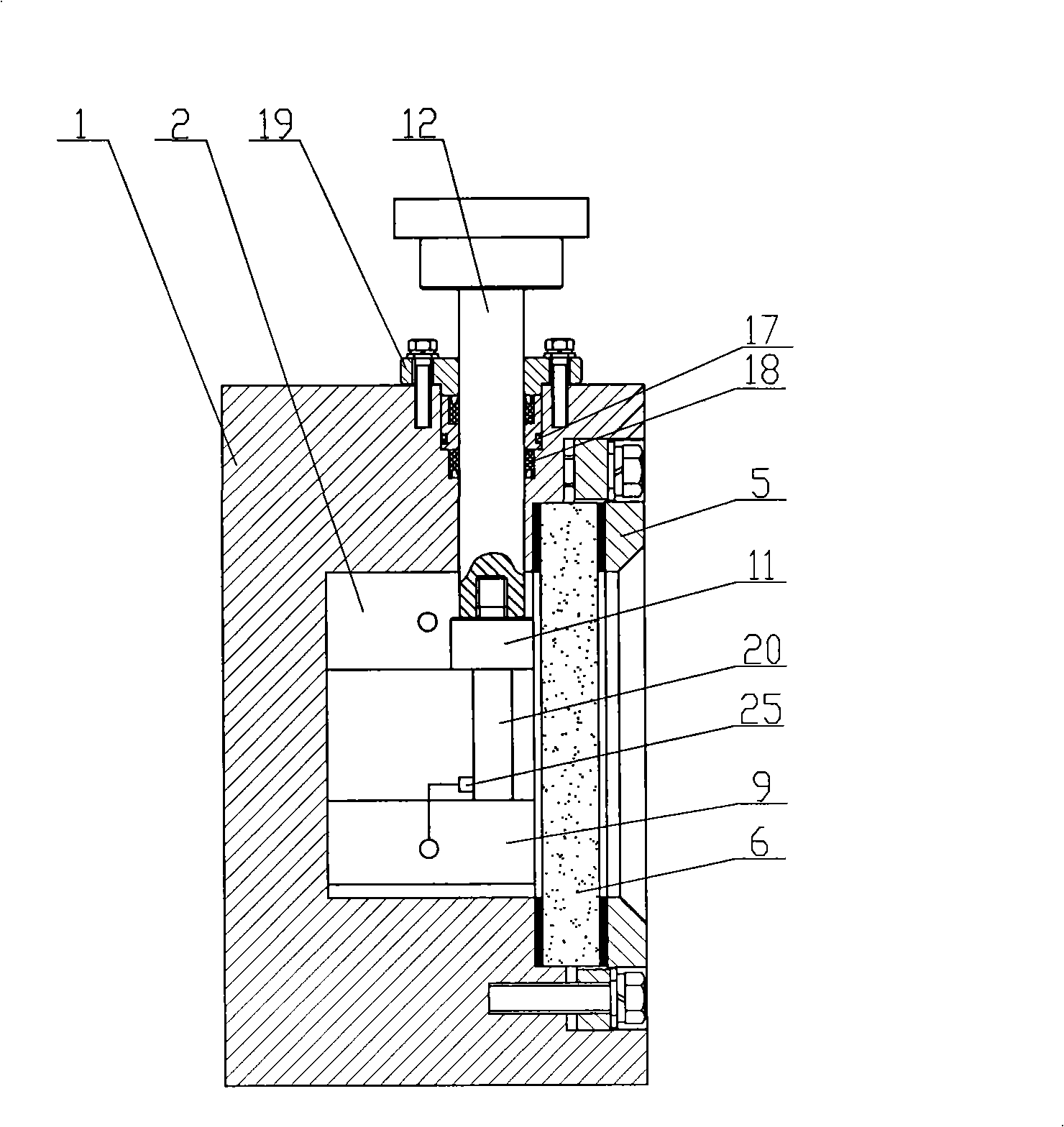

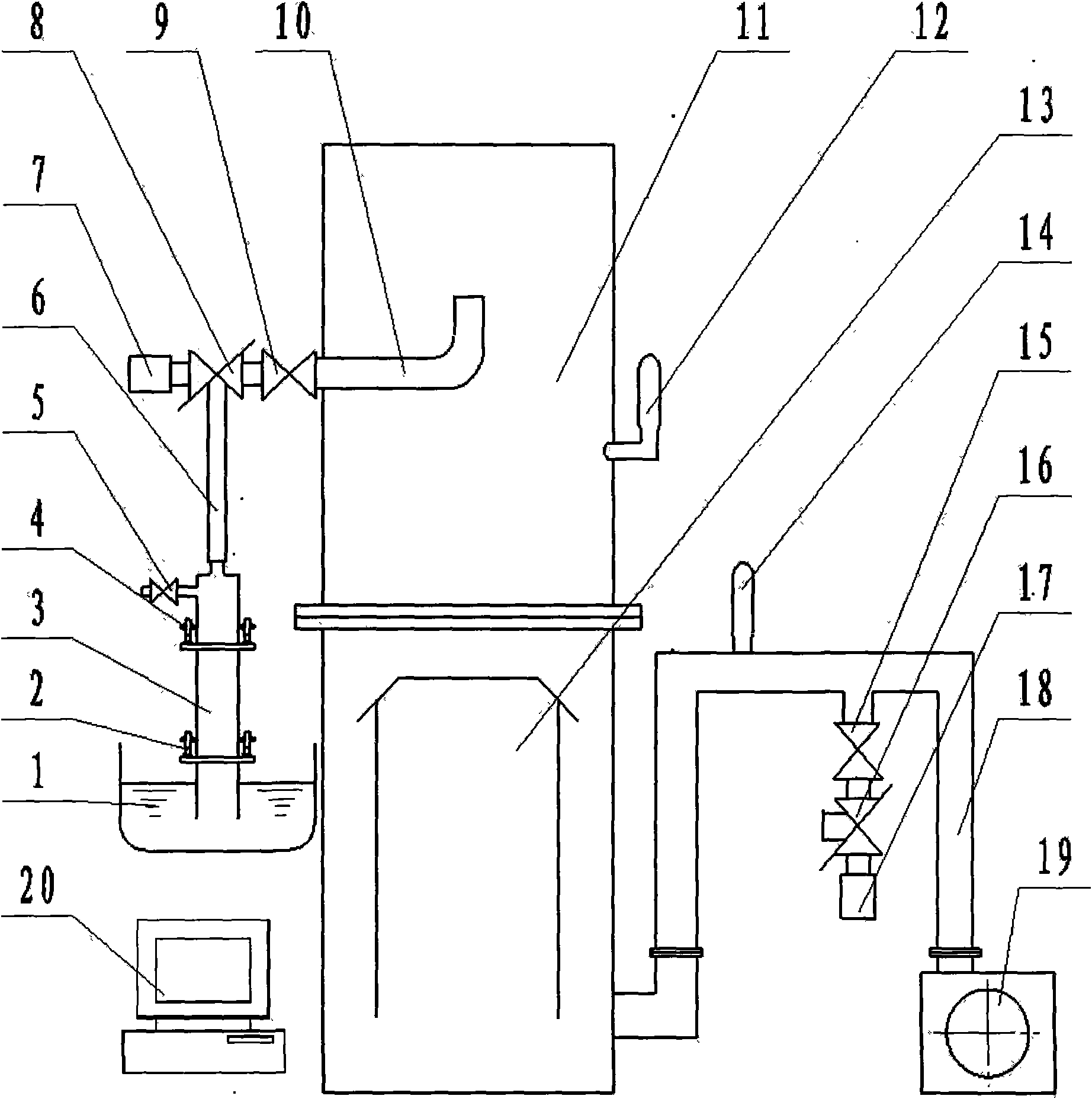

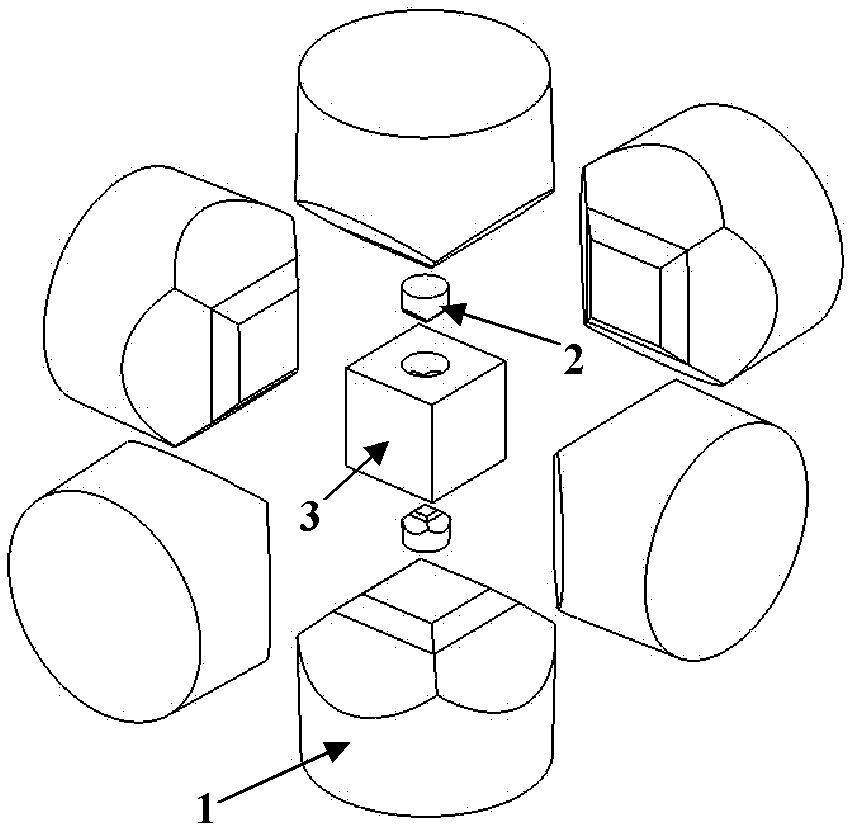

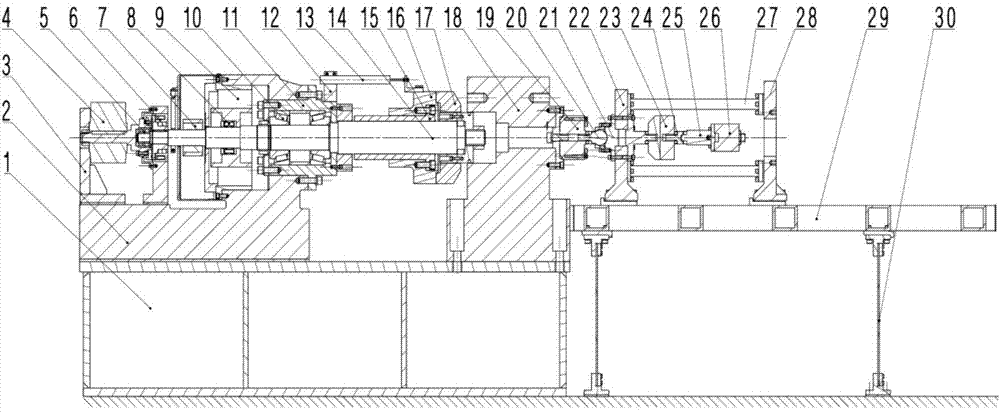

Fine observation mechanical test system containing gas coal rock

InactiveCN101354355AEasy to installEasy to debugMaterial analysis using acoustic emission techniquesMaterial analysis by optical meansGas cylinderCcd camera

The invention discloses a mesomechanics testing system of gas-containing coal rocks, which comprises a transparent sight glass that is fixed at an opening position of a testing cavity, a three-dimensional moving microscopic observing frame that is arranged outside the transparent sight glass, and a stereoscopic microscope and a CCD camera that are arranged on the three-dimensional moving microscopic observing frame; an inner end of a measuring conducting wire is connected with an acoustic emission sensor, and an outer end of the measuring conducting wire is connected with an acoustic emission magnifier and an acoustic emission card; the testing cavity is communicated with a gas pipe through a multi-purpose air vent, and the gas pipe is divided into two paths with one path connected with a high-pressure gas bottle and the other path connected with a vacuum pump; a cushion block, a limit pressure head and a loading head are arranged inside the testing cavity, a vertical surface of an L-shaped nick of the cushion block is over against the limit pressure head, and a transverse surface of the L-shaped nick of the cushion block is over against the loading head. The mesomechanics testing system of the gas-containing coal rocks provides more complete and reliable test methods for revealing the micro-structural damage law of the coal rocks under the gas action, further and deeper finding out the physical and mechanical properties of the gas-containing coal rocks, scientifically revealing the occurrence mechanism of the dynamic phenomenon of the coal rocks, and developing corresponding disaster prevention techniques.

Owner:CHONGQING UNIV

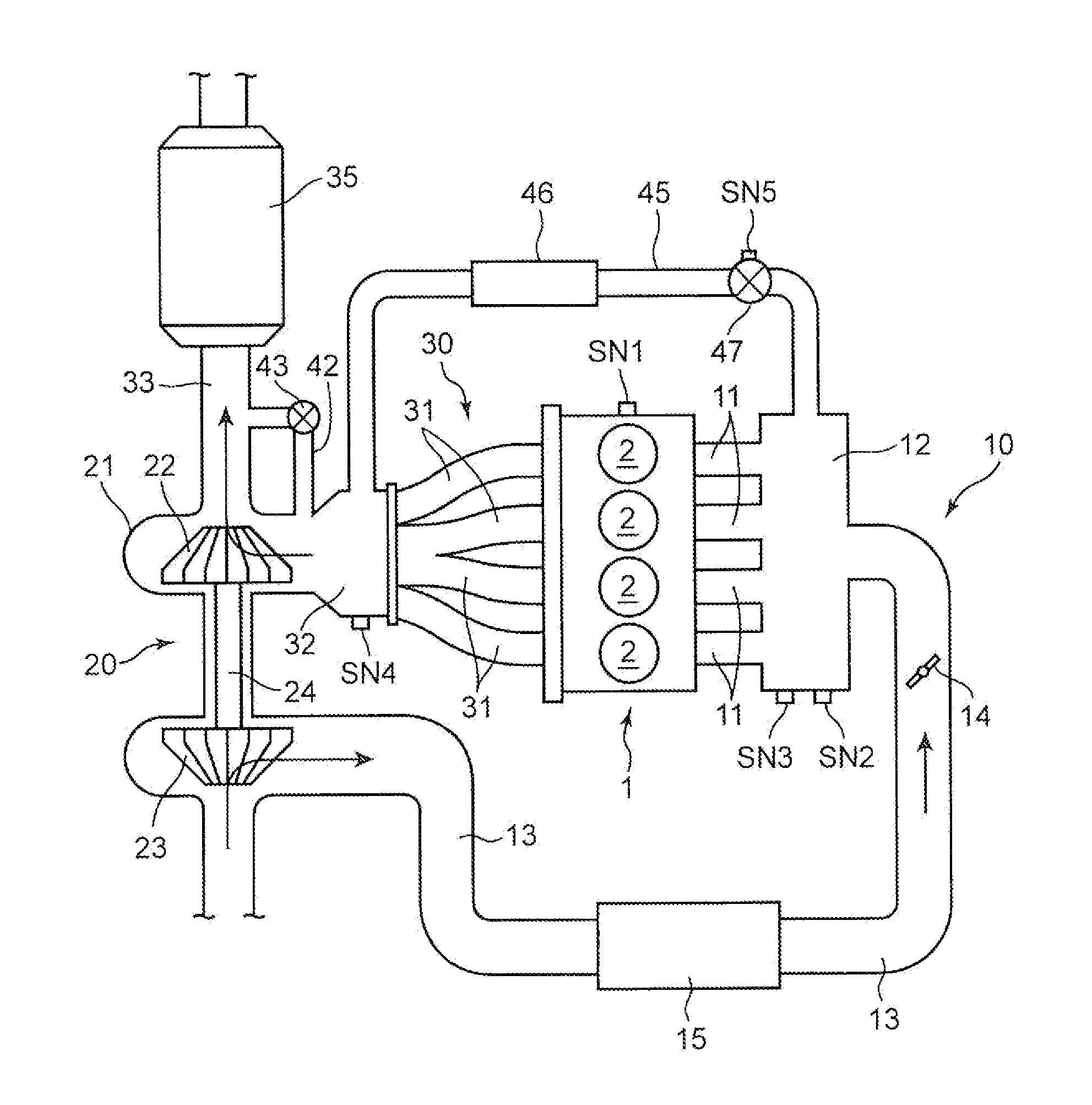

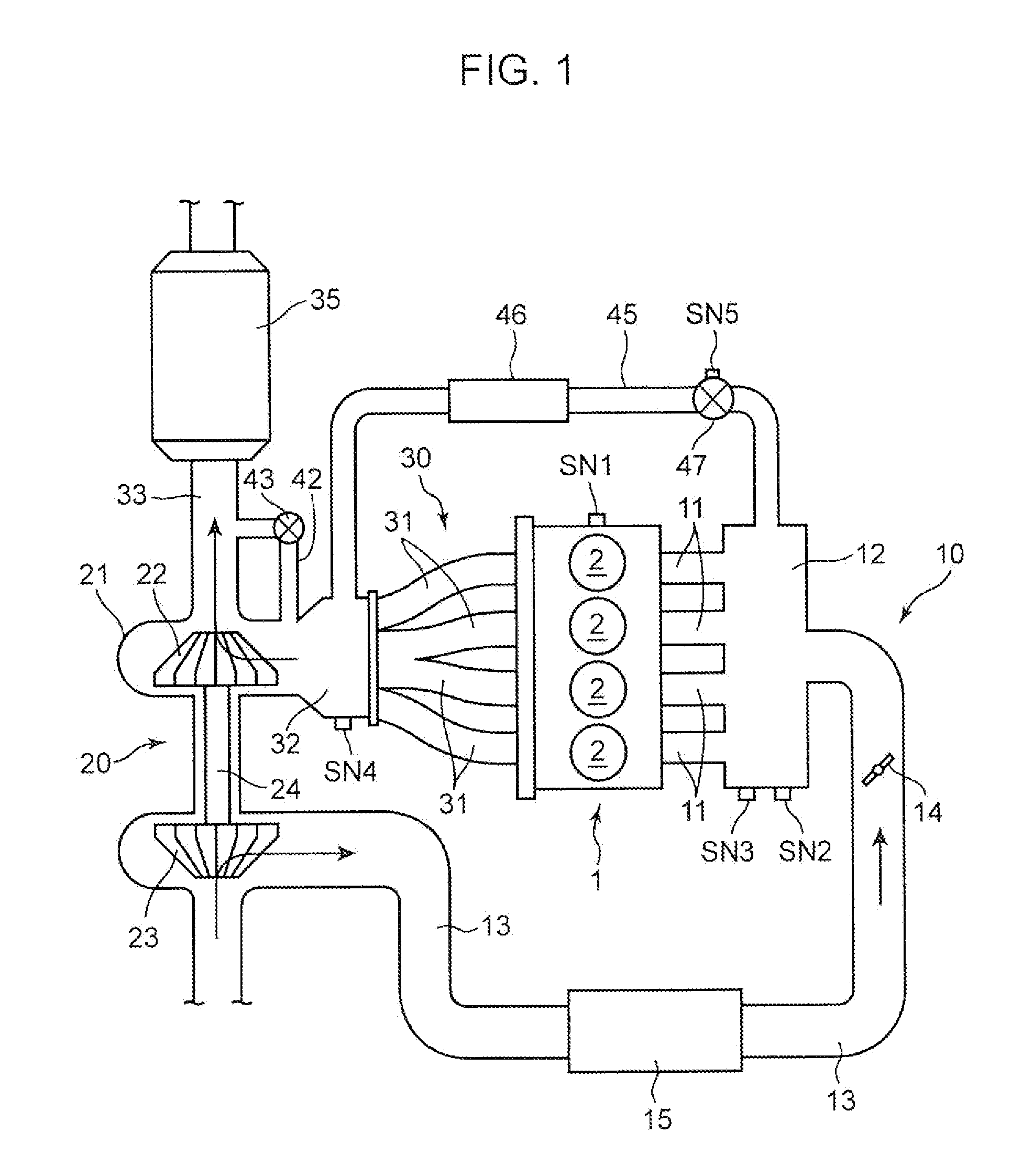

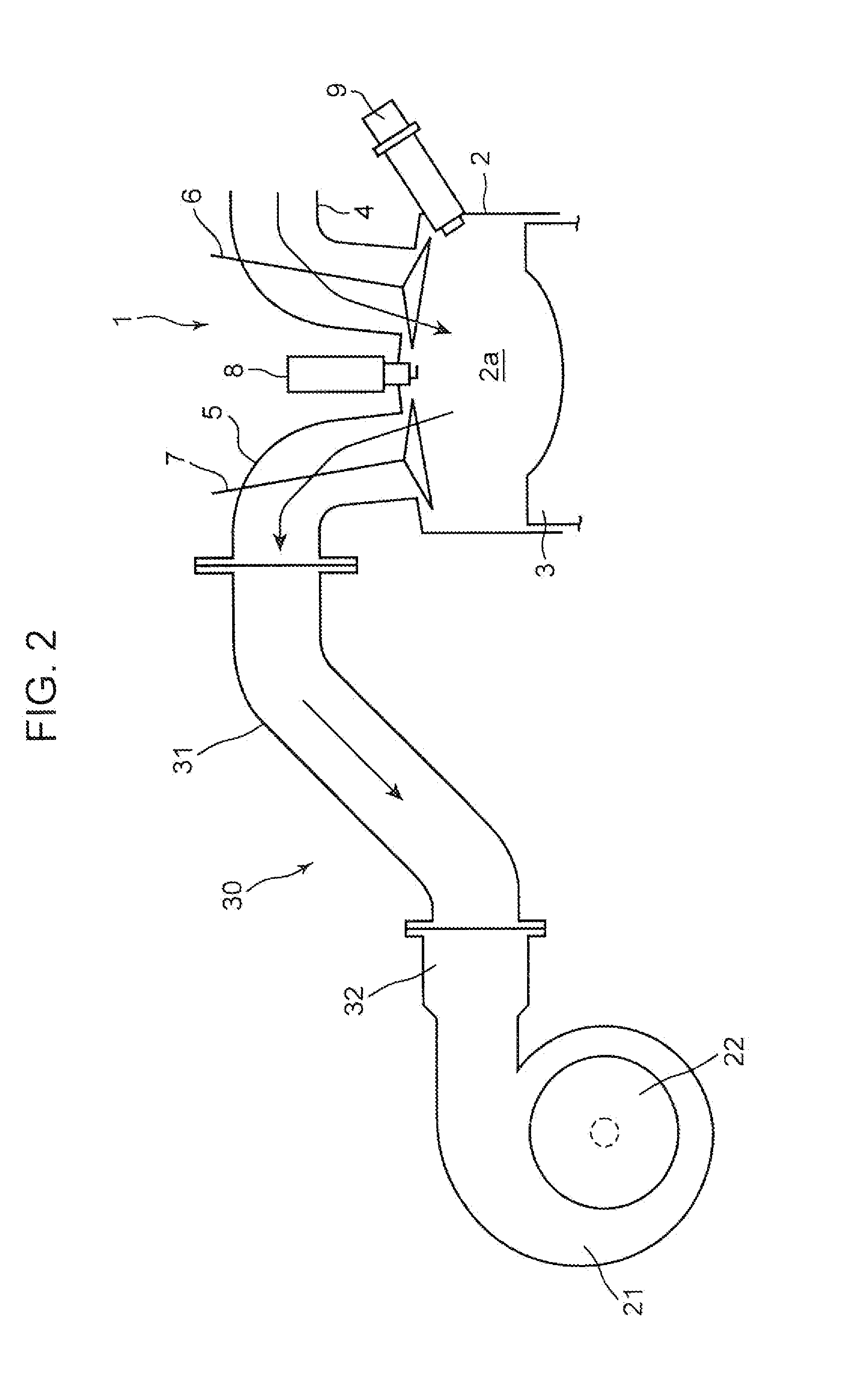

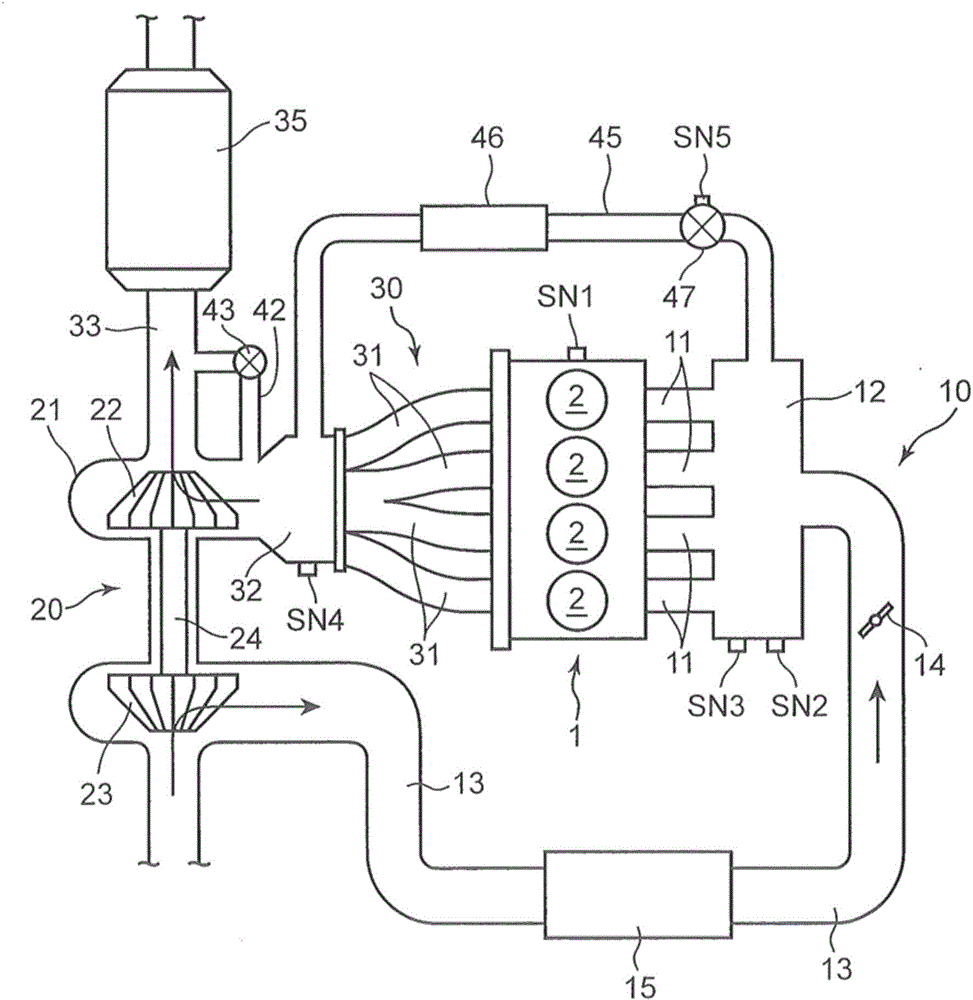

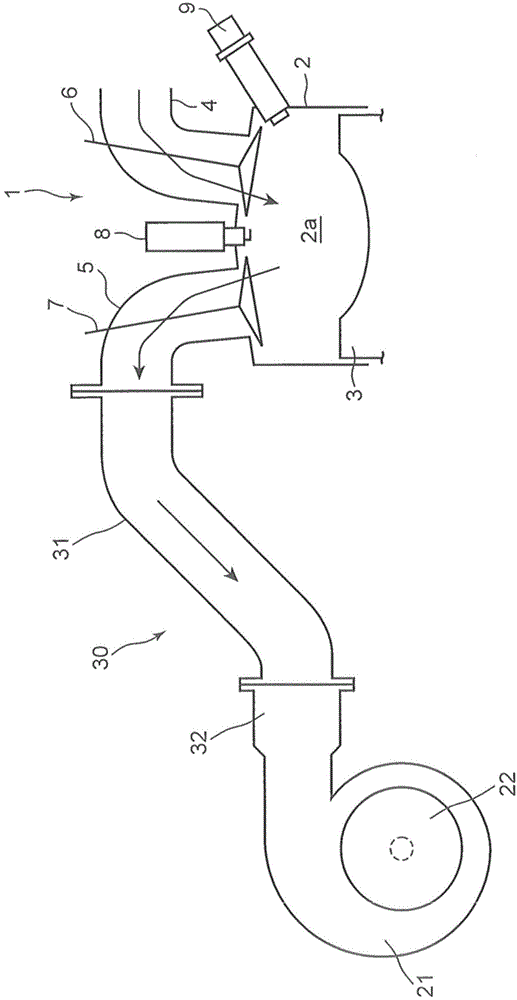

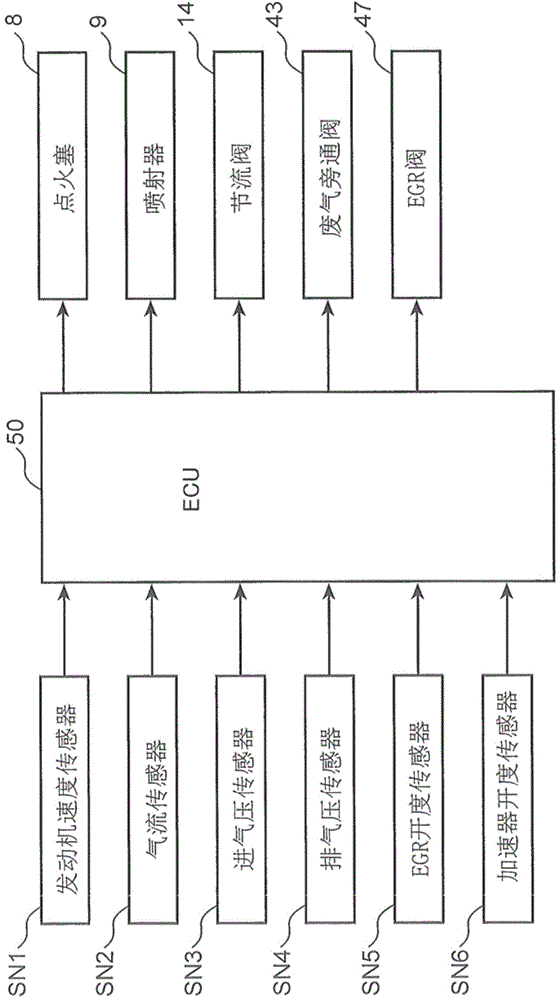

Turbocharged engine

ActiveUS20150240706A1Improve fuel economyElectrical controlInternal combustion piston enginesTurbochargerEngineering

An engine includes: a turbocharger including a turbine and a compressor; an EGR passage connecting an exhaust passage on an upstream side of the turbine and an air intake passage on a downstream side of the compressor; an EGR valve provided in the EGR passage; a bypass passage that bypasses the turbine; and a waste gate valve provided in the bypass passage. In the engine, when a boost pressure is increased to a limit pressure, a first boost pressure control is executed, in which the EGR valve is opened and the waste gate valve is closed. After the first boost pressure control starts, when an engine speed is increased to a prescribed value, a second boost pressure control is executed, in which the waste gate valve is opened in addition to the EGR valve.

Owner:MAZDA MOTOR CORP

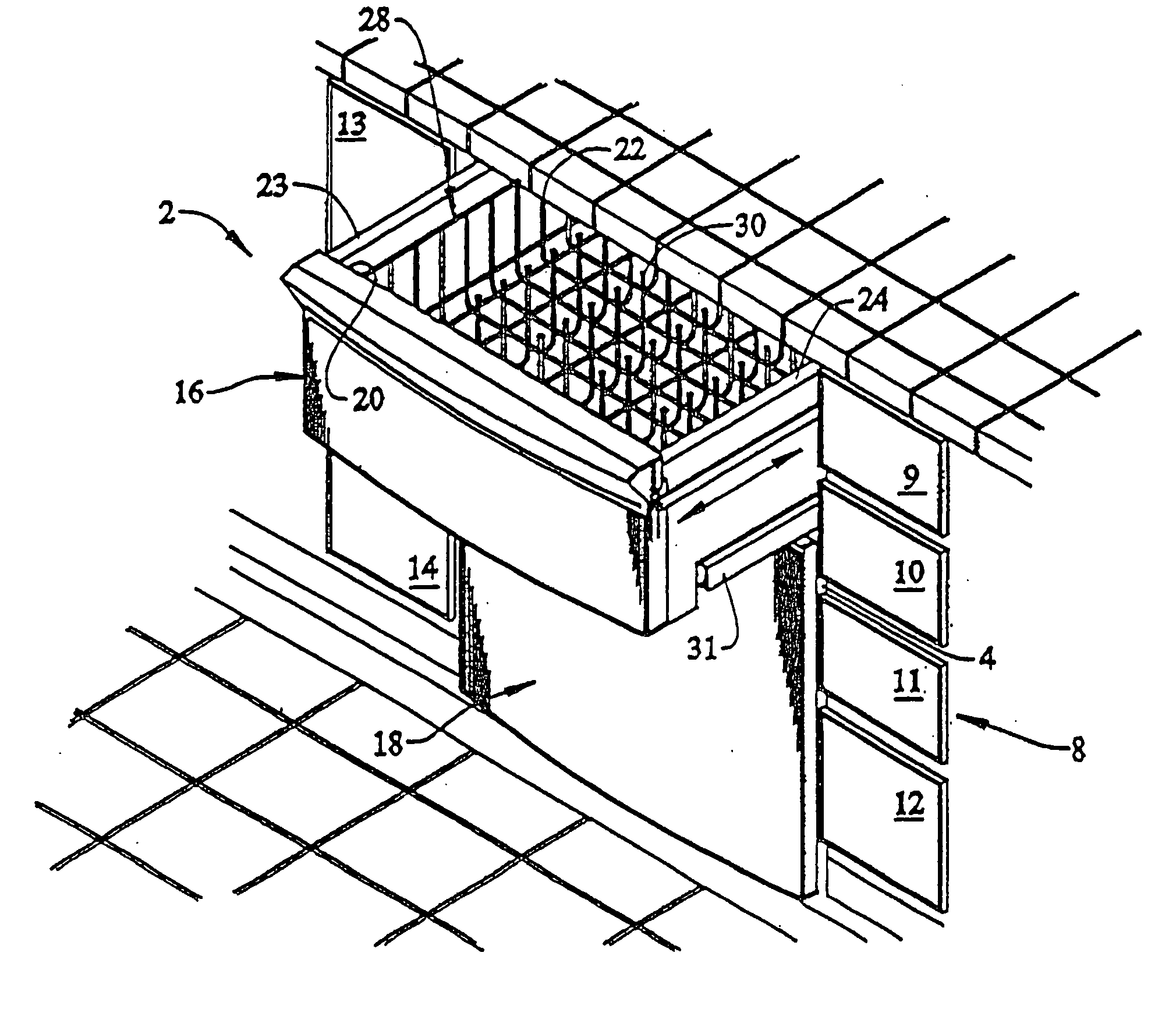

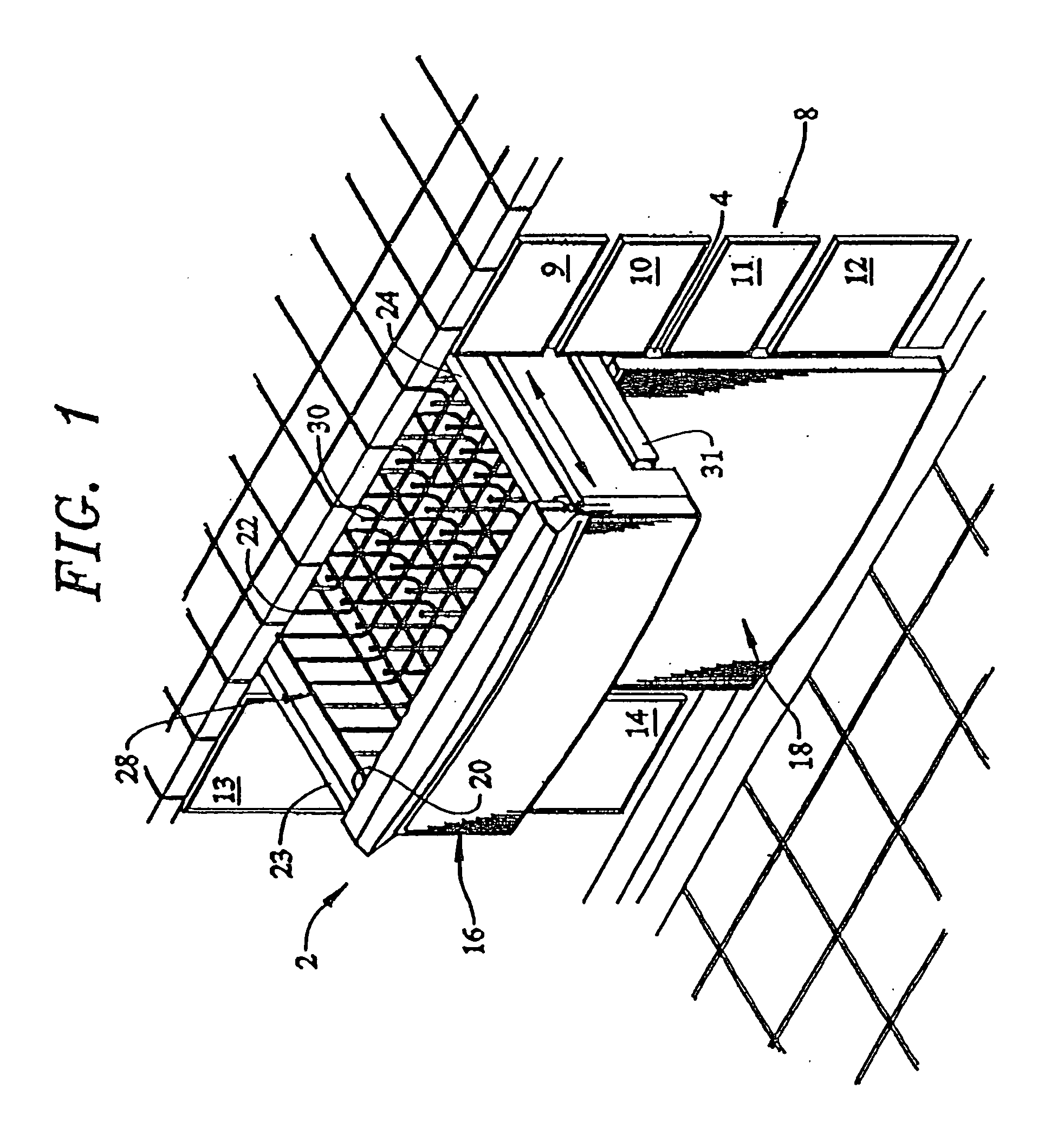

System for limiting pressure in a fine filter chamber for a dishwasher

InactiveUS20060174916A1Reduce pressureEfficient Filtration OperationHollow article cleaningMechanical energy handlingHigh velocityIngested food

A dishwasher includes wash chamber, a wash system for supplying washing fluid to wash arms to clean articles arranged in the wash chamber, and a washing fluid manifold having an inlet portion, an outlet portion and a passage interconnecting the inlet and outlet portions. A filter chamber is fluidly connected to the washing fluid manifold for removing food soil from the washing fluid. A venturi is provided in the passage for establishing a low pressure region. A sampling port for feeding the filter chamber is located in the low pressure region. In addition, a bleed port is provide near an inlet of the filter chamber. In this manner, washing fluid enters the filter chamber at low pressure to increase the efficiency of a filtering process, while washing fluid enters the wash arms at a high velocity to efficiently perform a washing operation.

Owner:MAYTAG

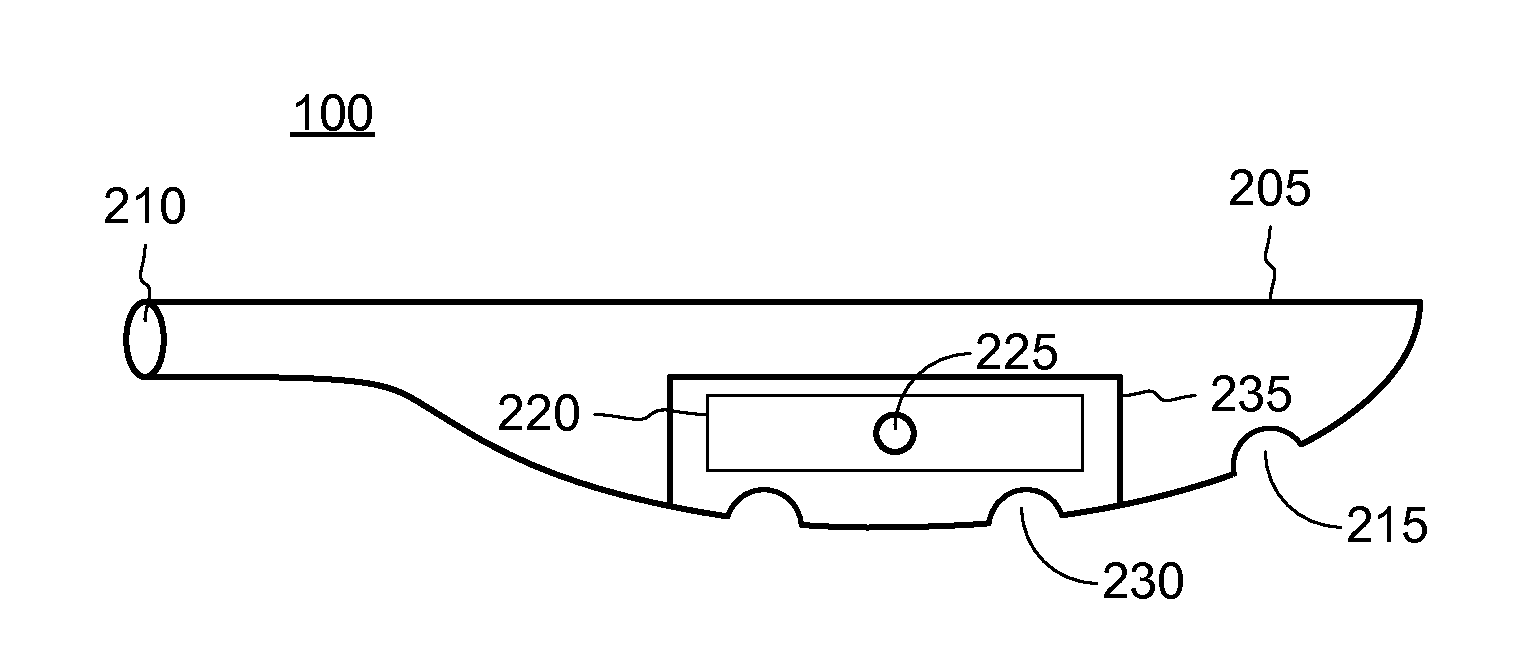

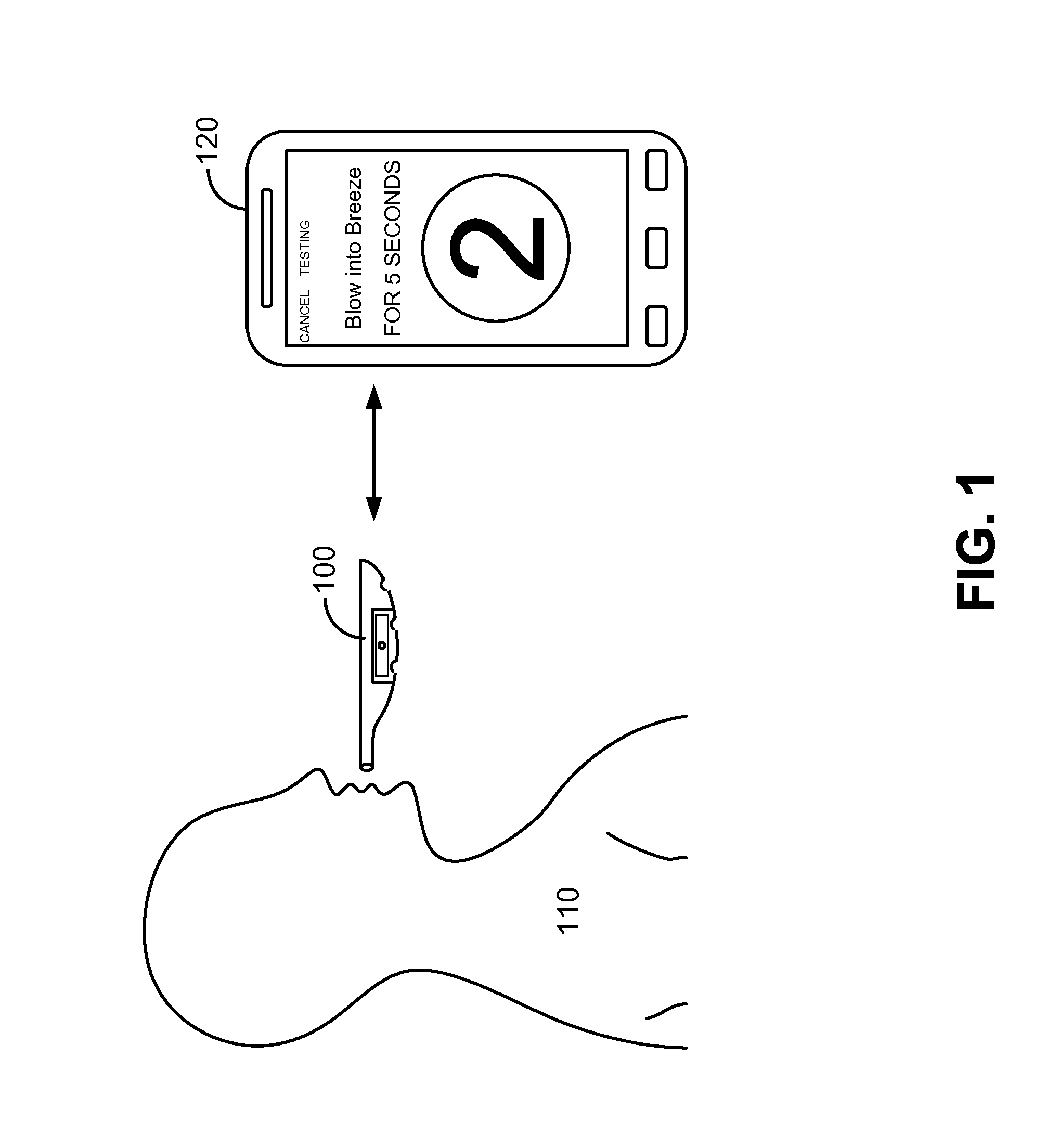

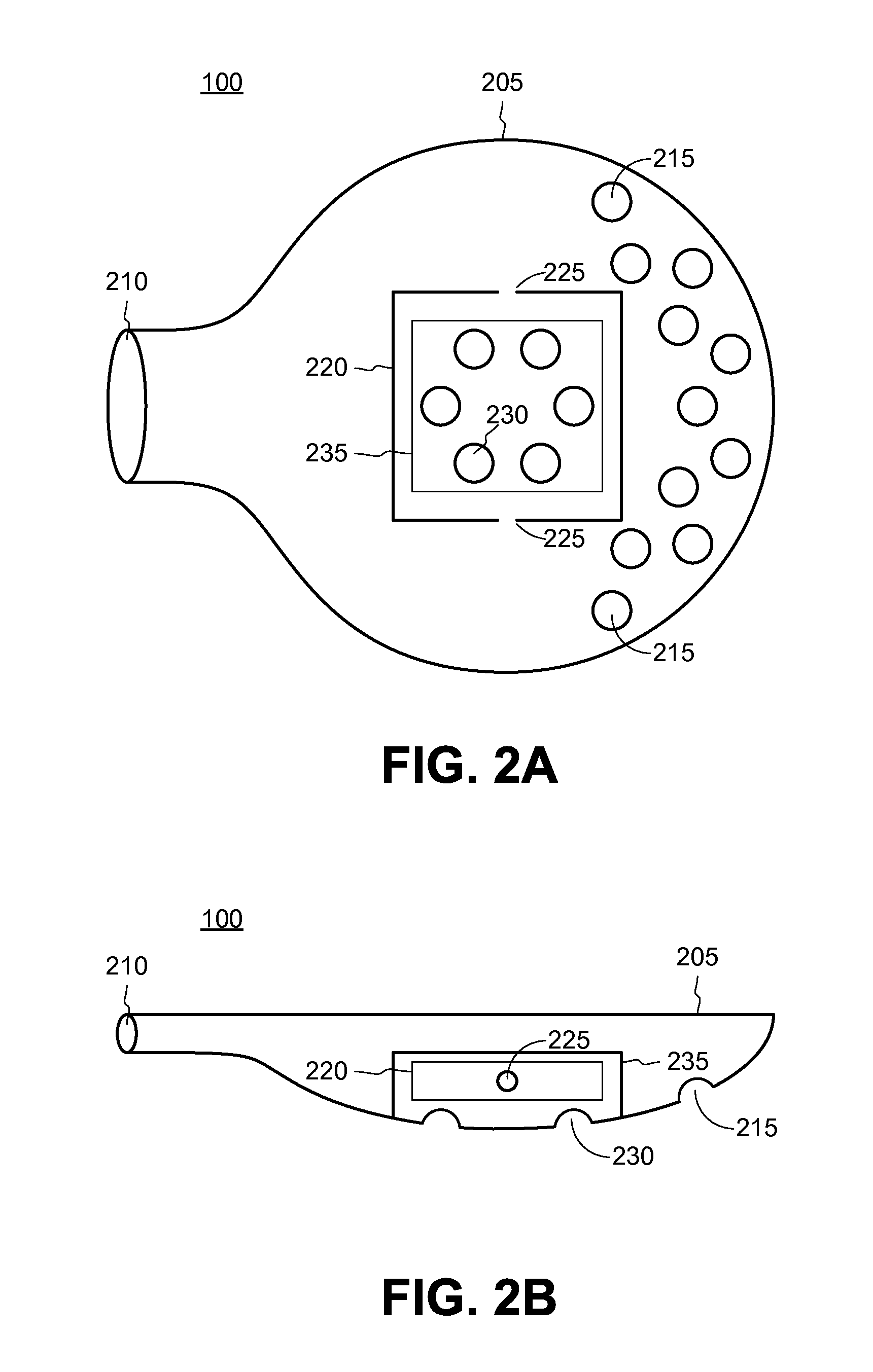

Pumpless breath analysis system

InactiveUS20160146779A1Increase resistanceWithdrawing sample devicesChemical methods analysisHigh resistanceEngineering

A breath analysis device has a housing that limits pressure from a user's breath that passes over a sensor, improving sensor readings of the sensor. The housing includes an inlet opening, one or more outlet openings, and an inner cavity. The inner cavity defines a path between the inlet opening and the one or more outlet openings. The inner cavity includes a sensor housing, a high resistance path between the inlet opening and the sensor housing, a first low resistance path between the housing and a first subset of outlet openings of the one or more outlet openings, and a second low resistance path between the inlet opening and a second subset of outlet openings of the one or more outlet openings. Breath that passes into the sensor housing is analyzed by sensors in the sensor housing.

Owner:BREATHOMETER

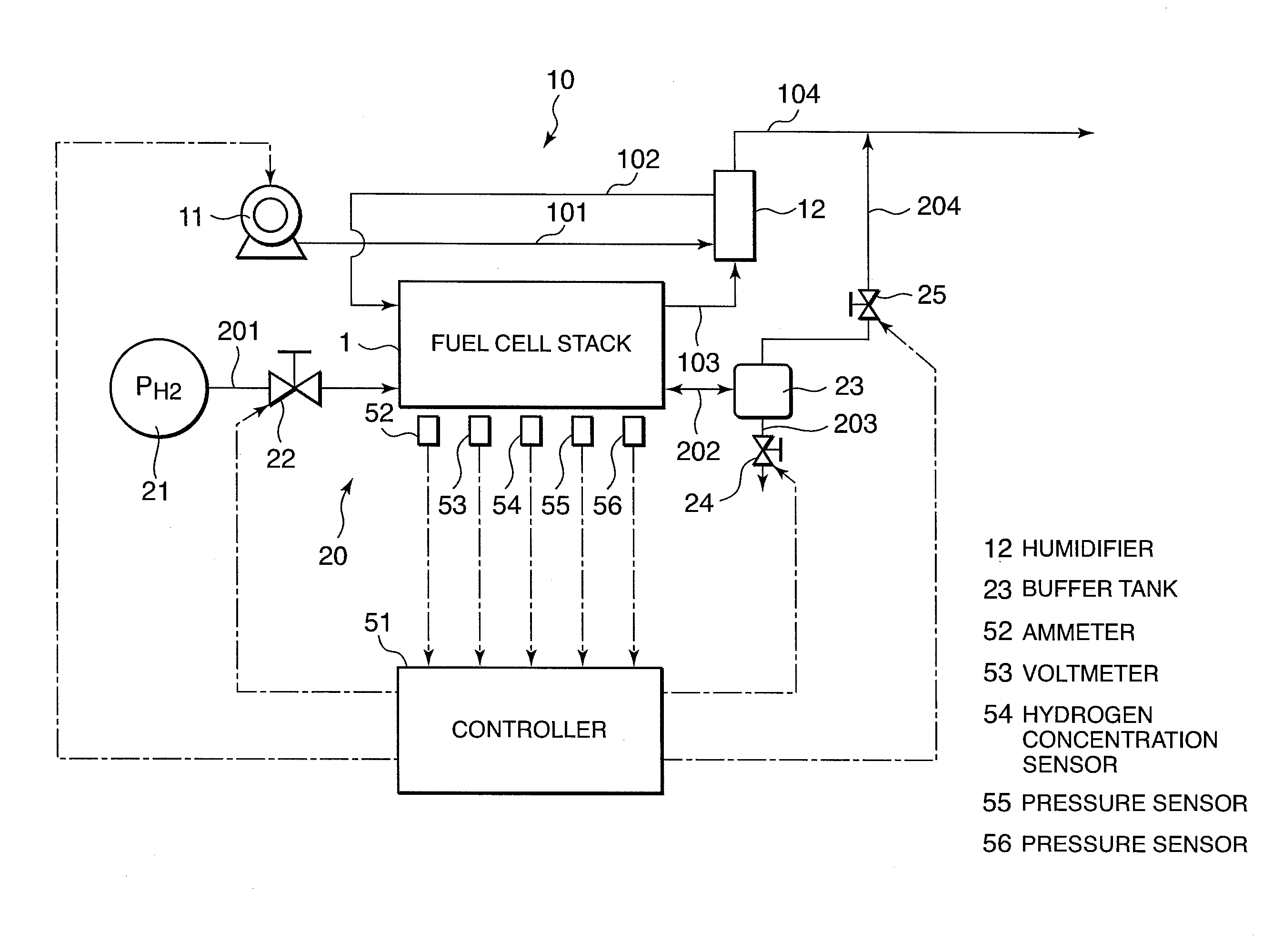

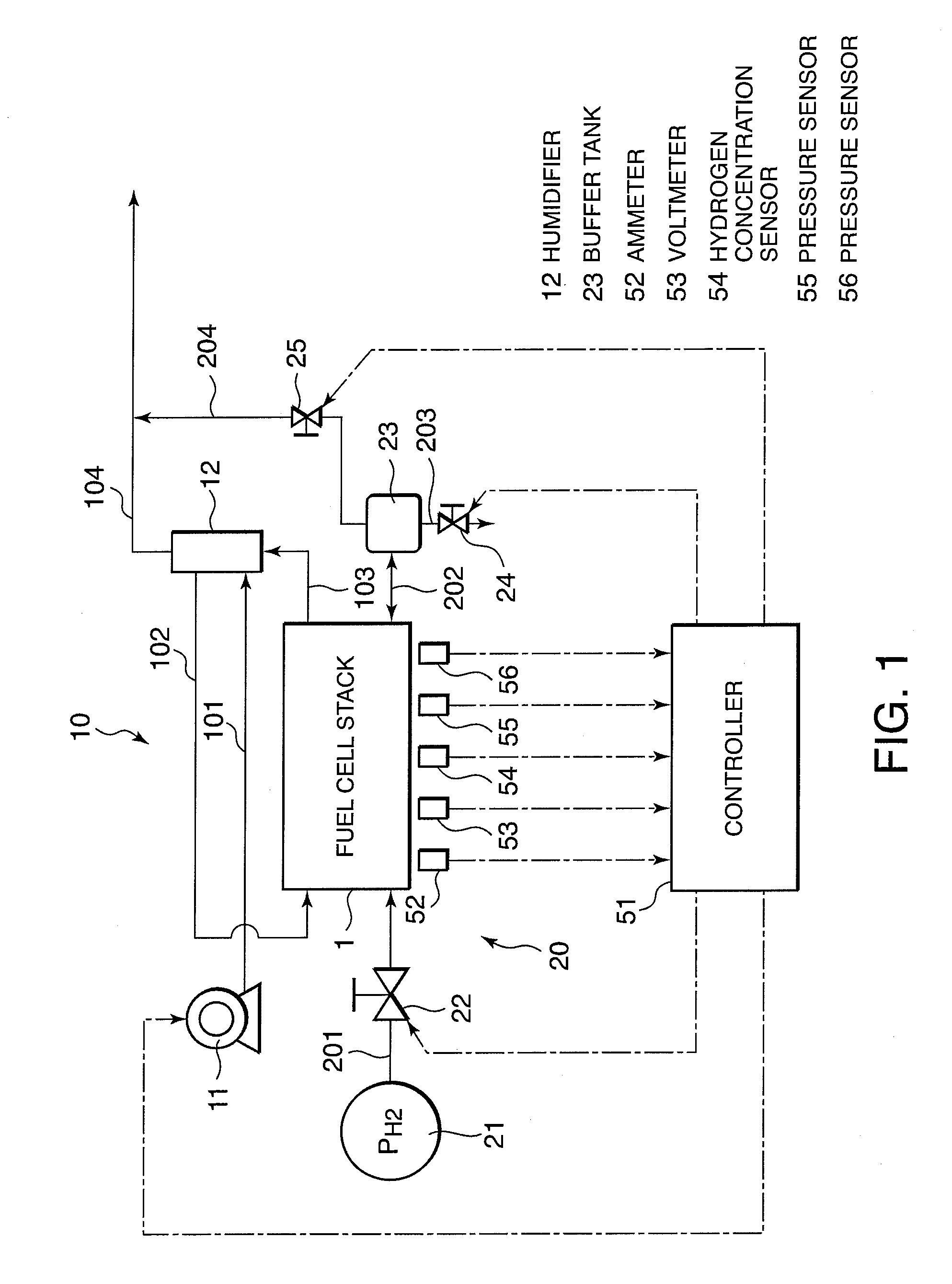

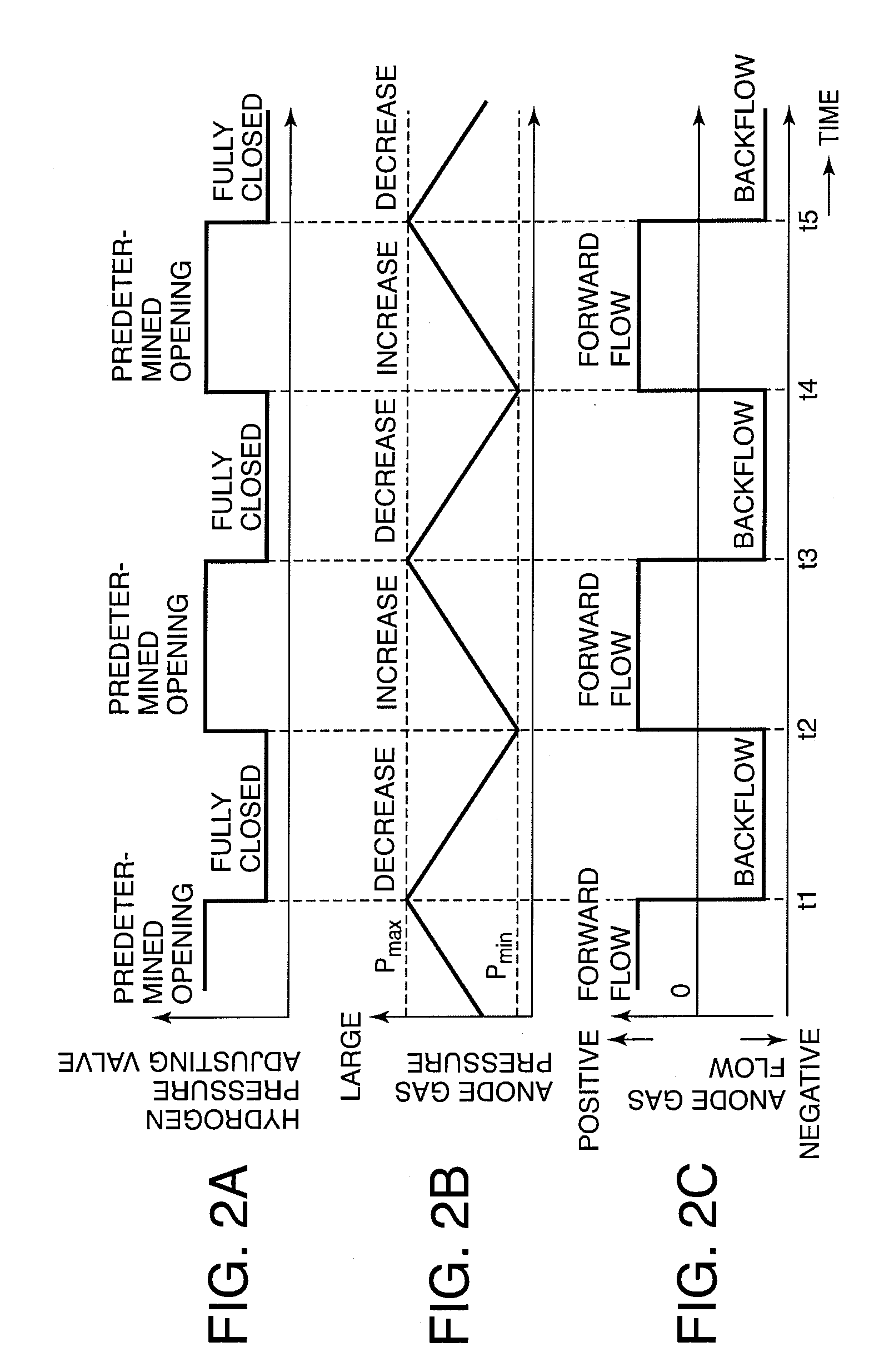

Operation control device and operation control method for fuel cell power plant

A fuel cell power plant stops anode gas supply to a fuel cell stack 1 by an anode gas supply mechanism 20 when an anode gas pressure in the fuel cell stack 1 reaches an upper limit pressure, and resumes supplying the anode gas by the anode gas supply mechanism 20 when the anode gas pressure in the fuel cell stack 1 lowers to a lower limit pressure. A sensor 52-54 detects if a hydrogen supply amount supplied to the fuel cell stack 1 satisfies a required amount to generate a target generated power, and a controller 51 corrects the lower limit pressure in an increasing direction when the hydrogen supply amount does not satisfy the required amount, thereby suppressing a generated power of the fuel cell stack 1 from reducing even when a flooding takes place in the fuel cell stack 1.

Owner:NISSAN MOTOR CO LTD

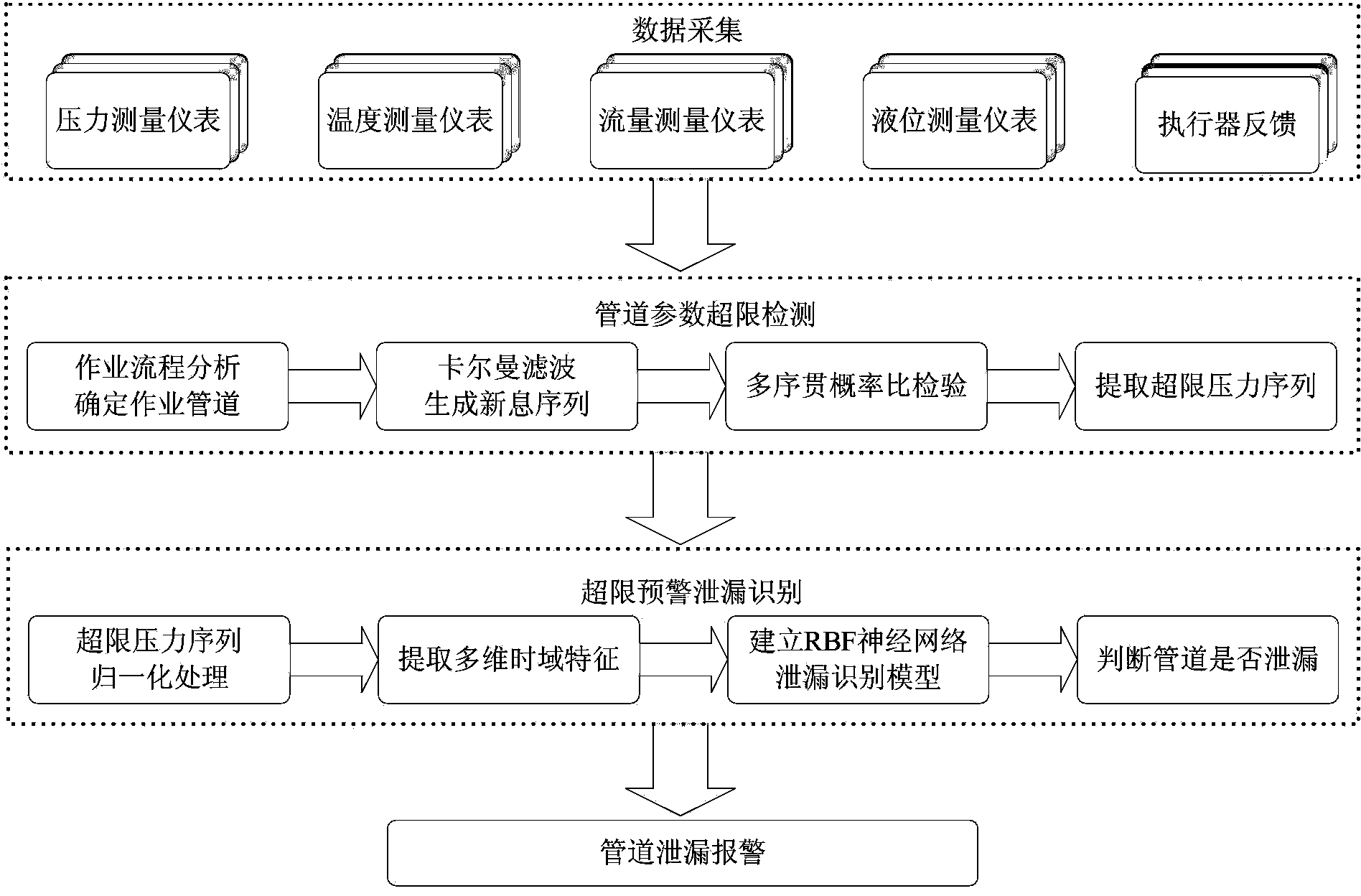

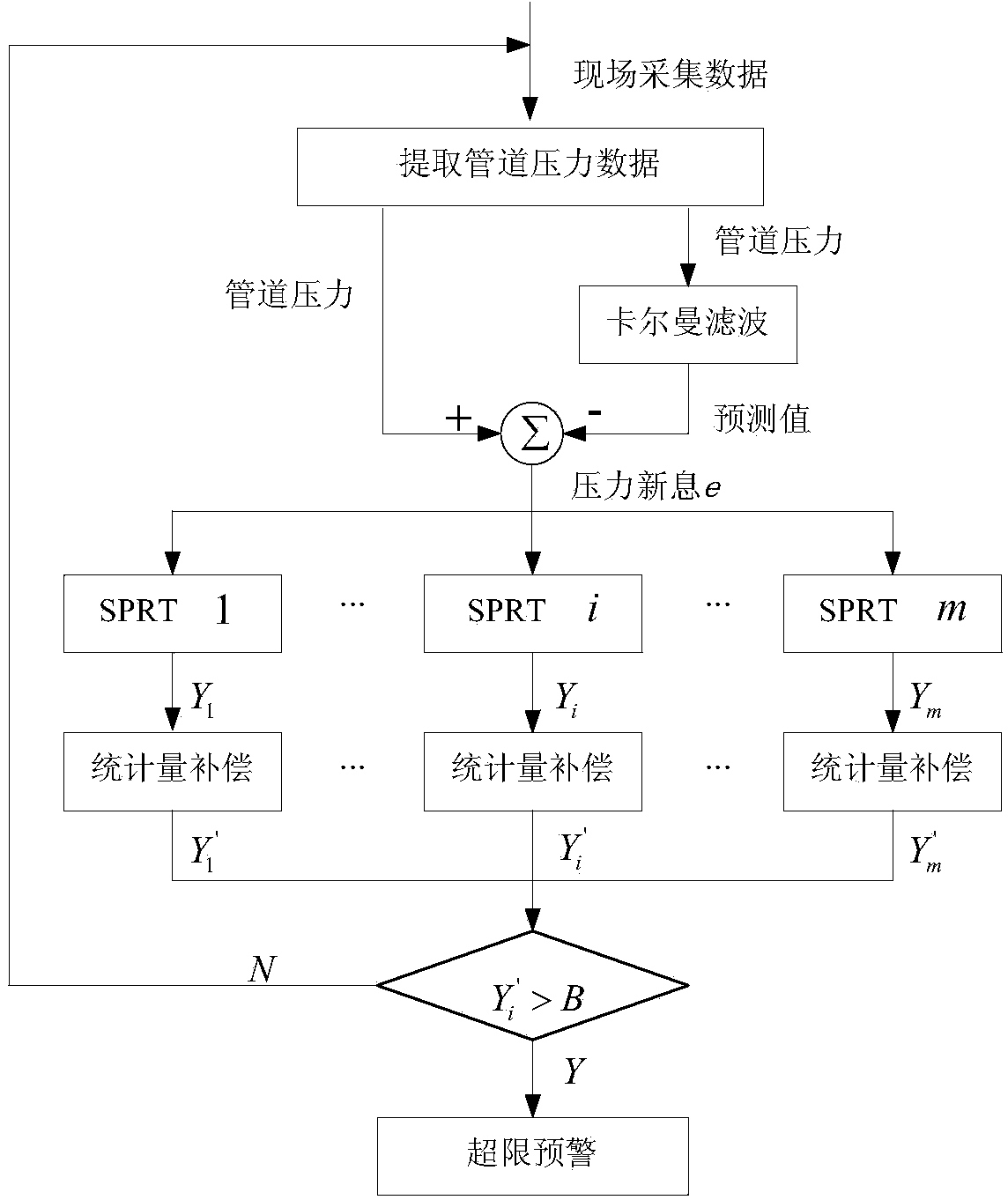

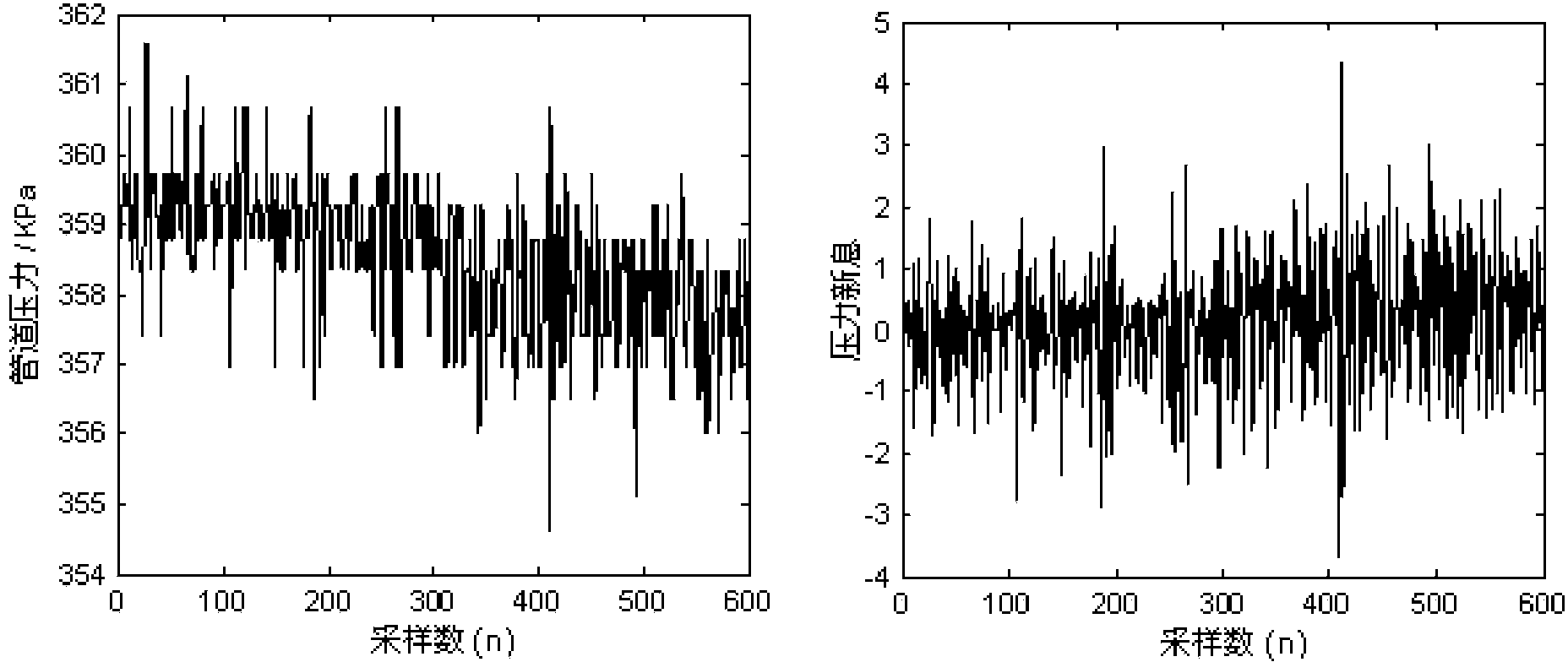

Method for detecting leakage of pipeline of tank farm

InactiveCN103968256AImprove the ability to adapt to changing working conditionsReduce false alarm ratePipeline systemsTime domainMonitoring system

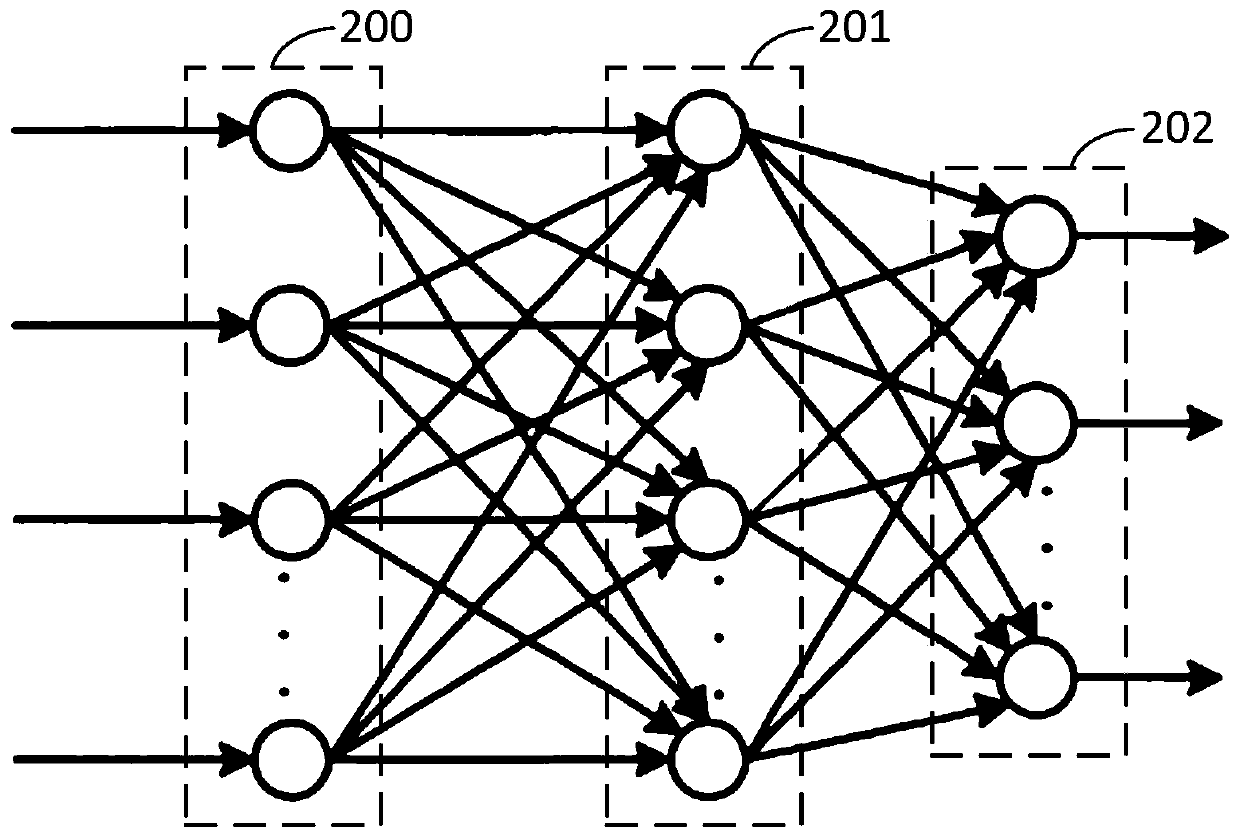

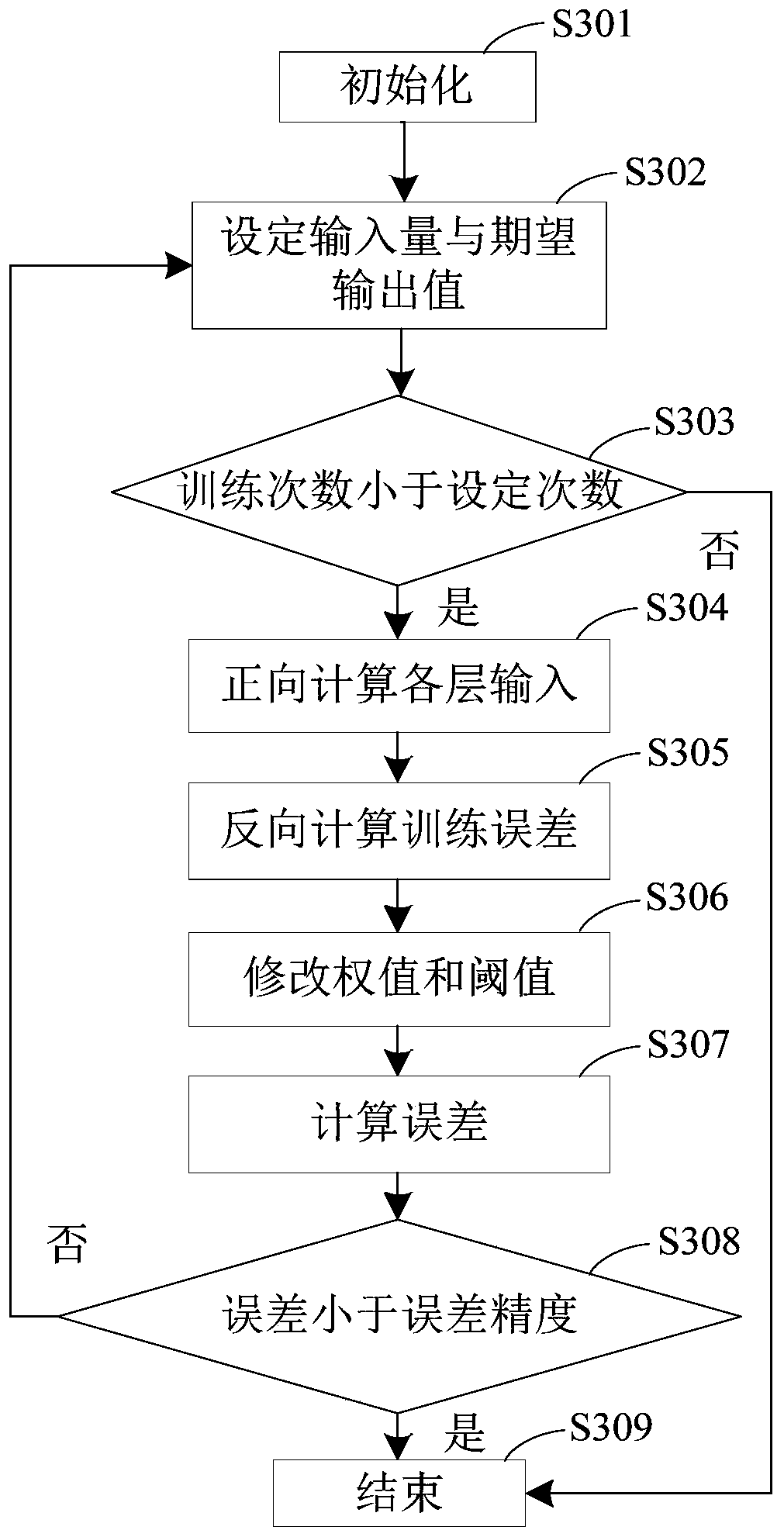

The invention discloses a method for detecting leakage of a pipeline of a tank farm by combining the statistical hypothesis testing technology and the pattern recognition technology. The method comprises the steps that measuring meter data and actuator state feedback information of a working site are acquired through a tank farm monitoring system, an oil transportation path is determined, and Kalman filtering is carried out on pressure measuring meter data to generate pressure information; whether the pressure of the pipeline exceeds a limit is detected according to the multi-sequential probability ratio test, and if yes, an over-limit pressure sequence and the multidimensional time domain features of the over-limit pressure sequence are extracted; recognition of leakage of the pipeline and adjustment of working conditions are carried out based on an established neural network leakage recognition model. By means of the method, a small change of the pressure of the pipeline can be detected in the least time within a regulated false alarm rate and a regulated alarm failure rate, and then whether leakage of the pipeline occurs can be determined.

Owner:税爱社

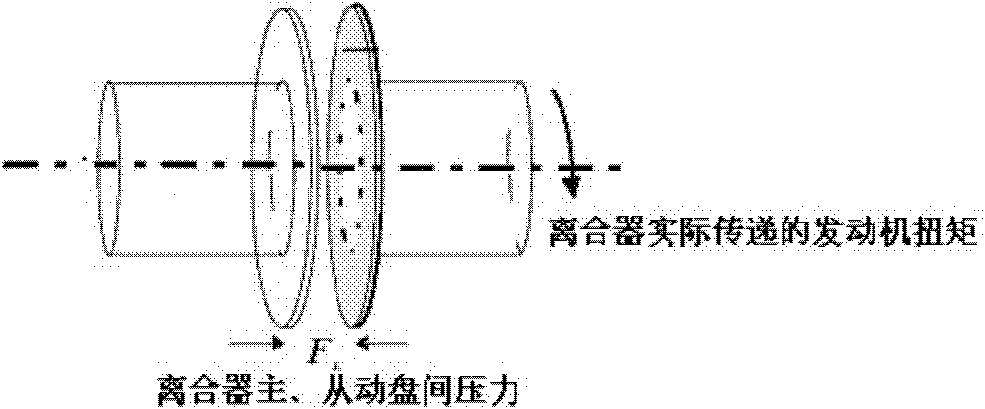

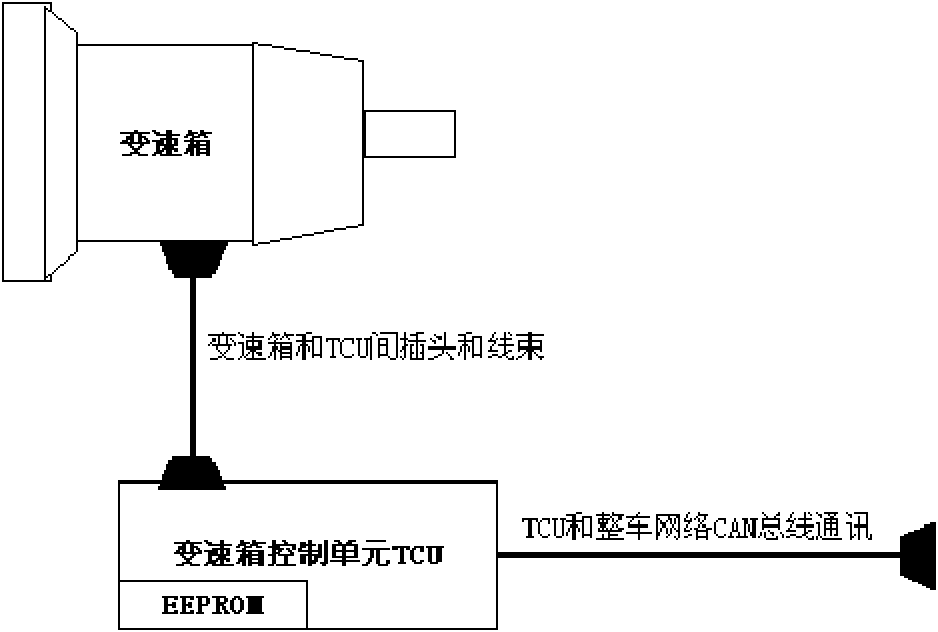

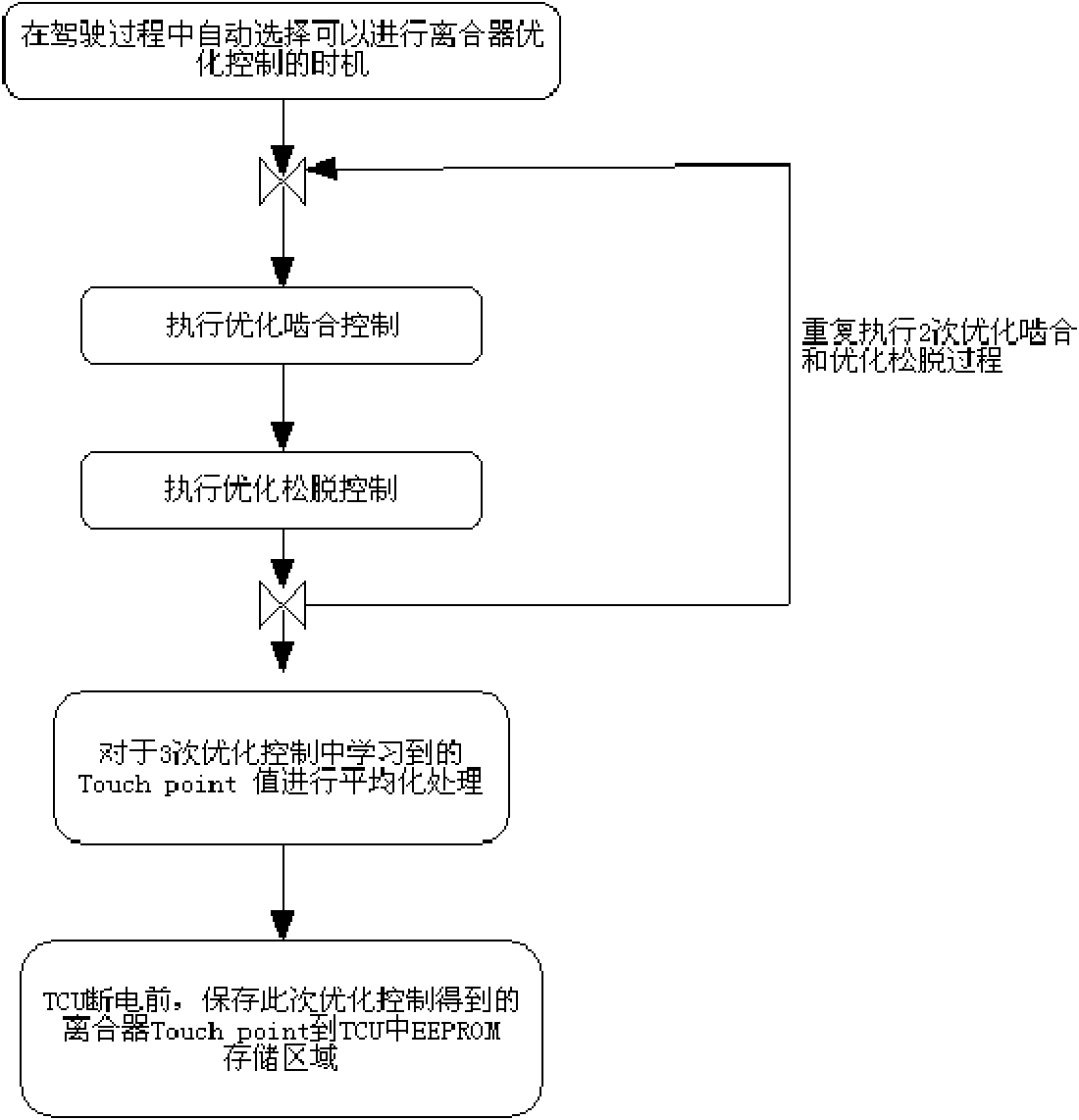

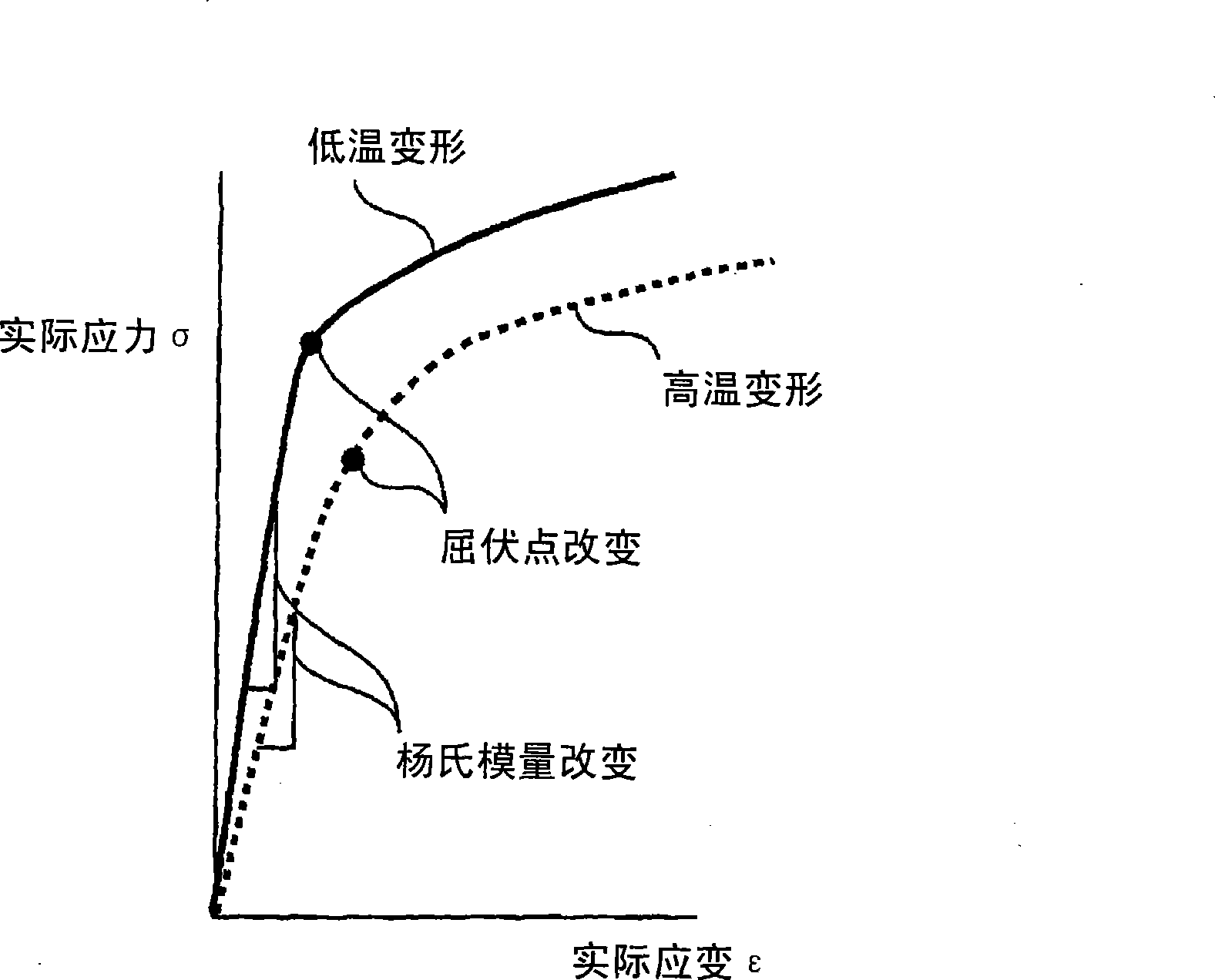

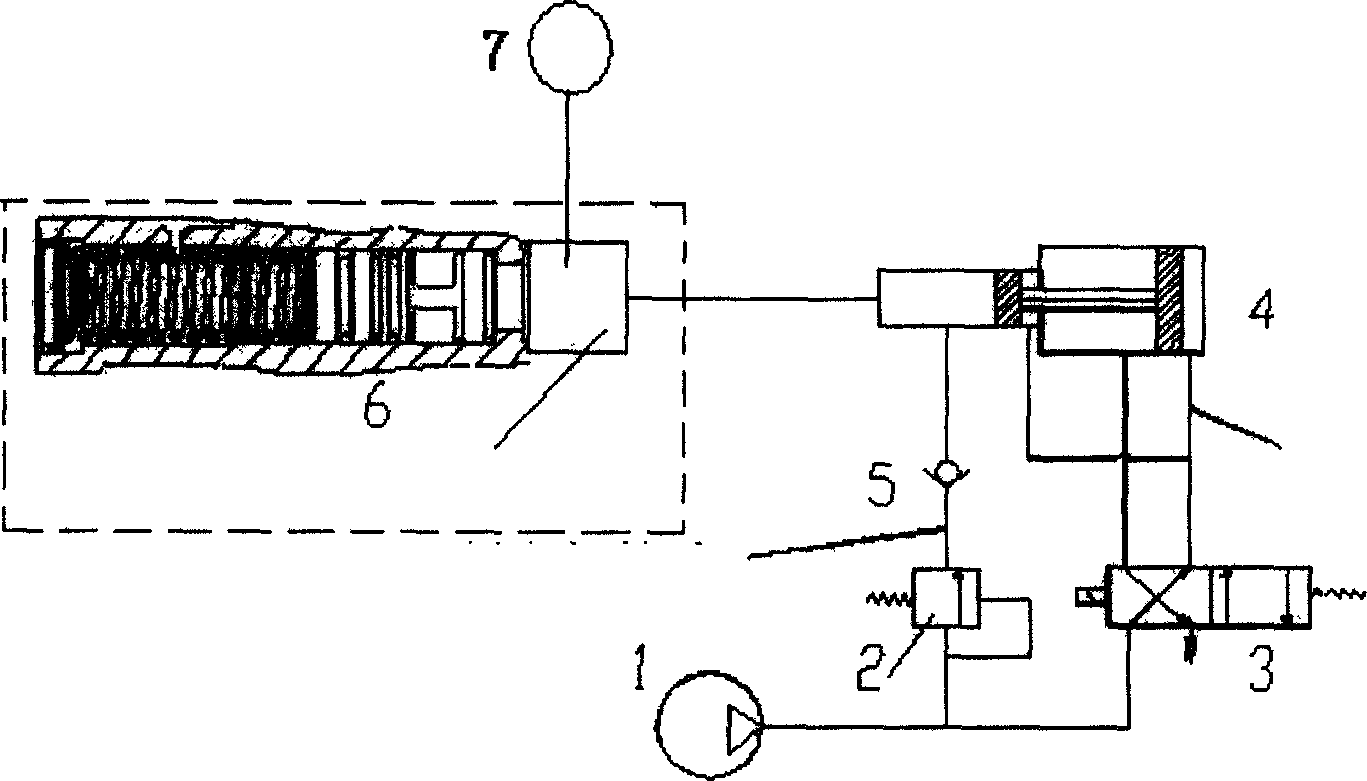

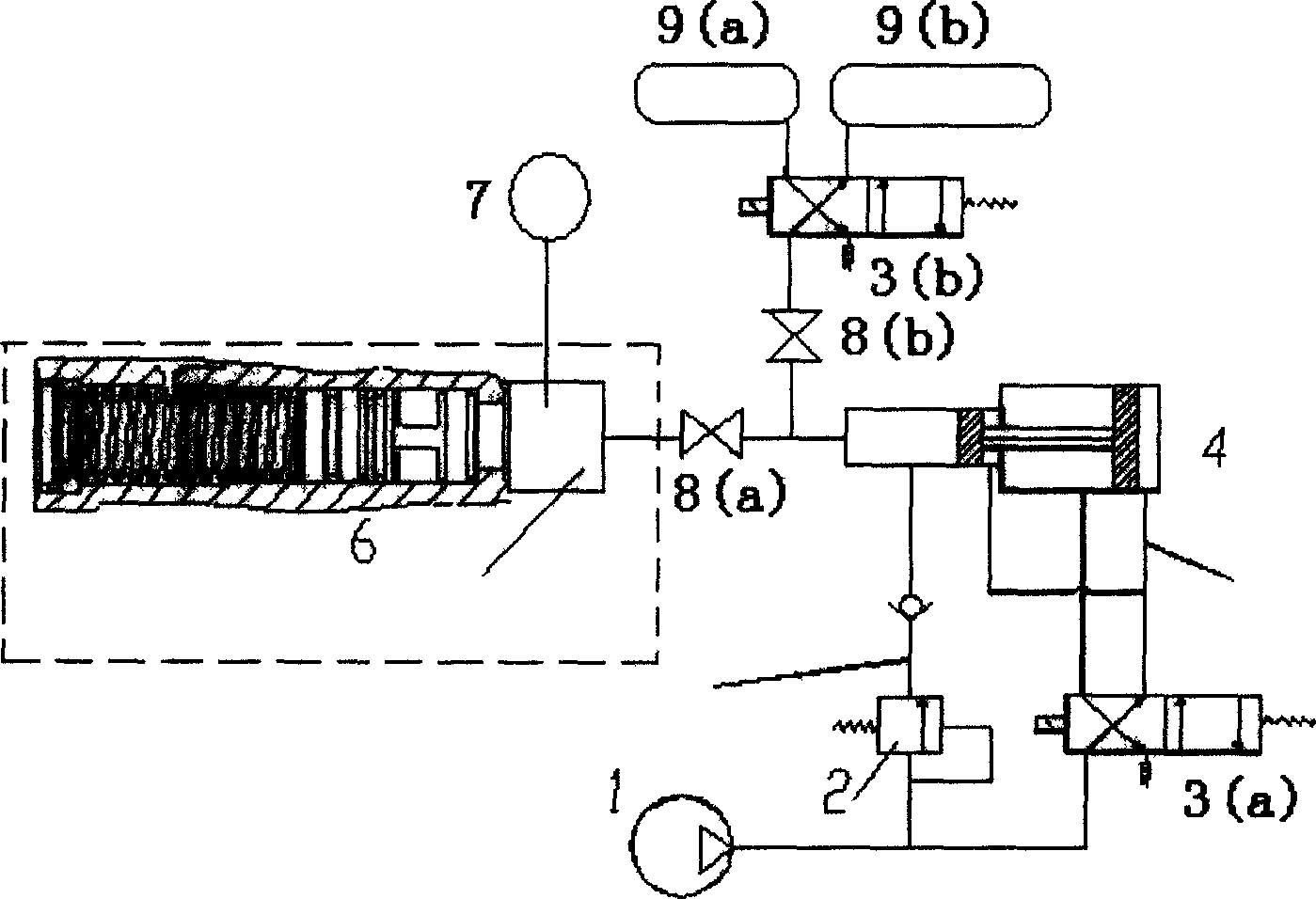

Optimized clutch control method based on wet clutch

The invention discloses an optimized clutch control method based on a wet clutch, belonging to the technical field of automobile transmissions. The optimized clutch control method comprises the steps of: carrying out meshing control optimization and release control optimization for a plurality times to obtain upper limit pressure values to be optimized and lower limit pressure values to be optimized, carrying out summation respectively, averaging to obtain a final optimized upper limit pressure value and a final optimized lower limit pressure value, and storing in an EEPROM (Electrically Erasable Programmable Read-Only Memory) space of a transmission control unit (TCU) to realize optimized clutch control. In the invention, dynamic factors such as clutch abrasion, temperature influences and the like are comprehensively considered so as to ensure that the control of the critical point of the clutch on beginning to transmit the torque of an engine is always maintained in an optimal state.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

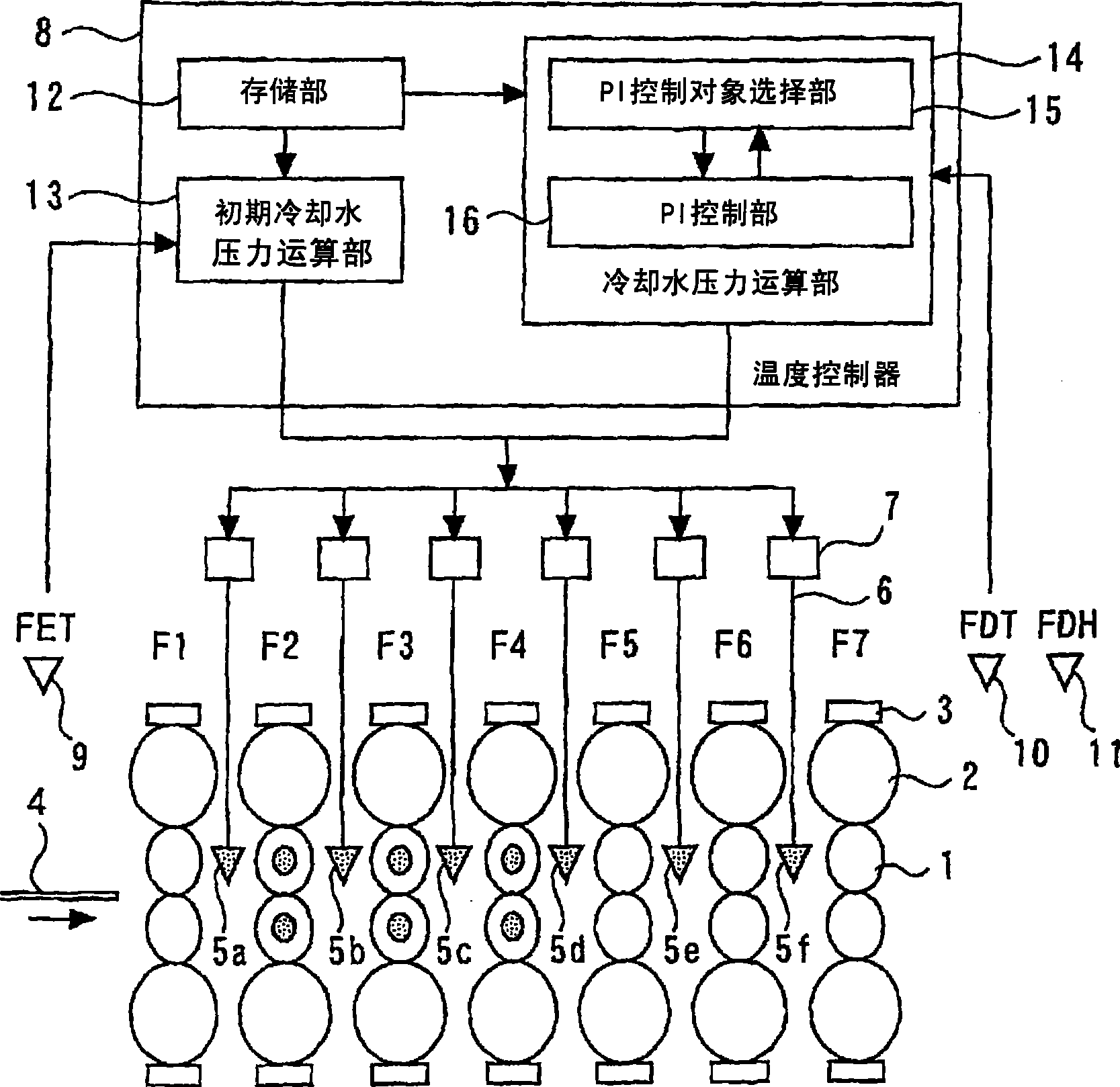

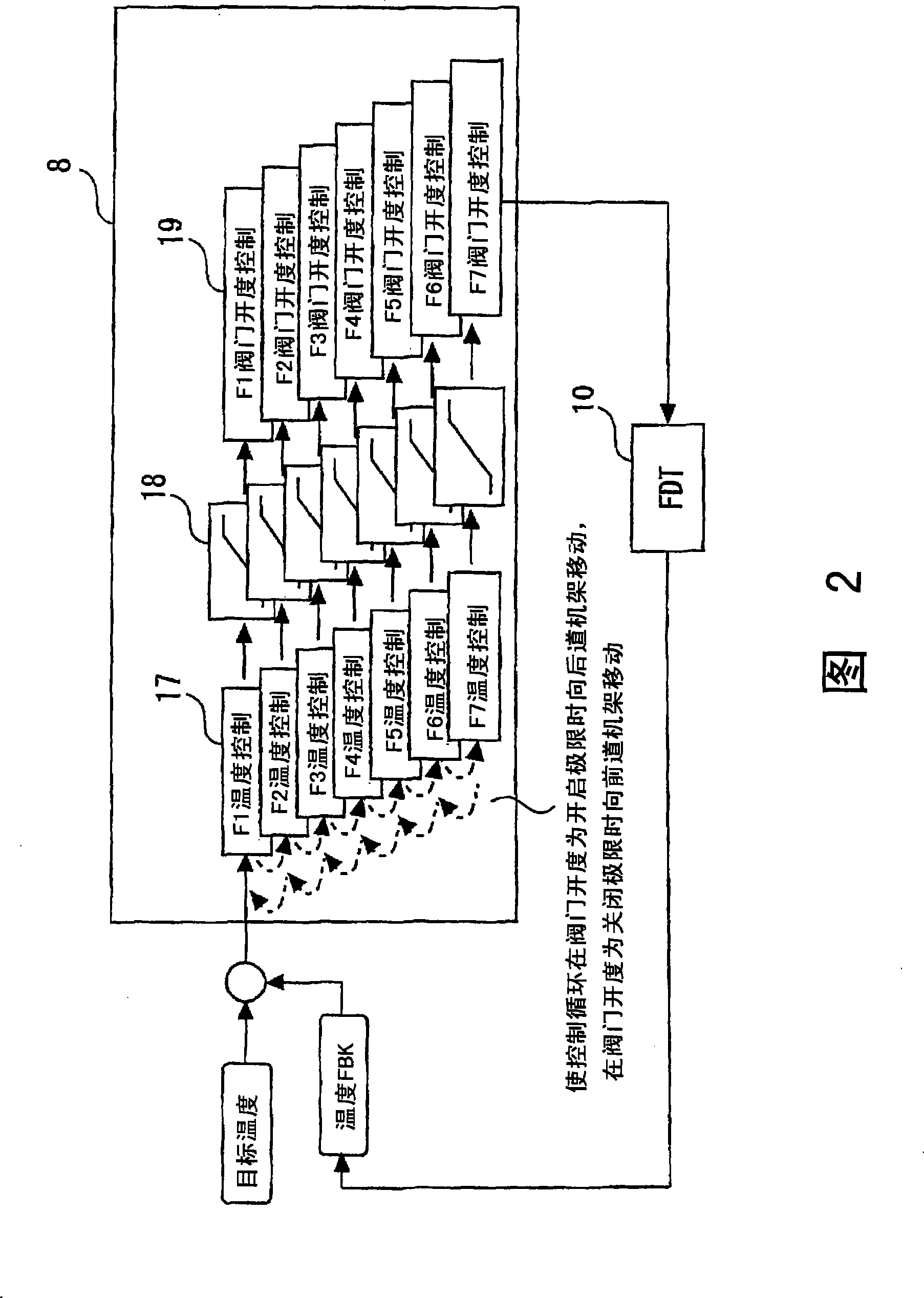

Temperature control device for hot rolling mill

ActiveCN101394945AReduce biasAvoid drastic changesTemperature control deviceWork cooling devicesLower limitTemperature control

A temperature control unit of hot rolling machine that avoids any sharp temperature change of rolling material at a place near the outlet of the rolling machine to thereby realize a high-precision control of sheet thickness. Accordingly, in a hot rolling machine equipped with multiple rolling stands continually disposed and further with multiple cooling units for cooling of rolling material, first, the cooling water pressure of each of the cooling units is computed using up to the upper limit pressure preferentially from one of the multiple cooling units disposed on the inlet side of the rolling machine on the basis of the target temperature and inlet actual temperature of the rolling material. Subsequently, on the basis of the target temperature and outlet actual temperature of the rolling material, so as to reduce any deviation between the target temperature and the outlet actual temperature, there is computed the cooling water pressure of one of the cooling units in operation disposed nearest the outlet of the rolling machine. At that stage, when the cooling water pressure of the cooling unit under control reaches the upper limit pressure, the control object is changed to the cooling unit disposed adjacent to the outlet of the rolling machine. On the other hand, when the cooling water pressure reaches the lower limit pressure, the control object is changed to the cooling unit disposed adjacent to the inlet of the rolling machine.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Compressor sound suppression

ActiveUS20060127235A1Reduce the effective volumeReduce volumePump testingPositive displacement pump componentsDischarge locationElectrical and Electronics engineering

A compressor has a housing. One or more working elements cooperate with the housing to define a compression path between suction and discharge locations. An intermediate port is located along the compression path. A branch path extends to the intermediate port. The compressor includes means for limiting pressure pulsations along the branch path.

Owner:CARRIER CORP

Dry testing method for pressure limiting valve opening pressure

ActiveCN1908609AHigh-precision detectionHigh repeatabilityFluid-tightness measurement using fluid/vacuumInternal pressureEngineering

Owner:FAWER AUTOMOTIVE PARTS

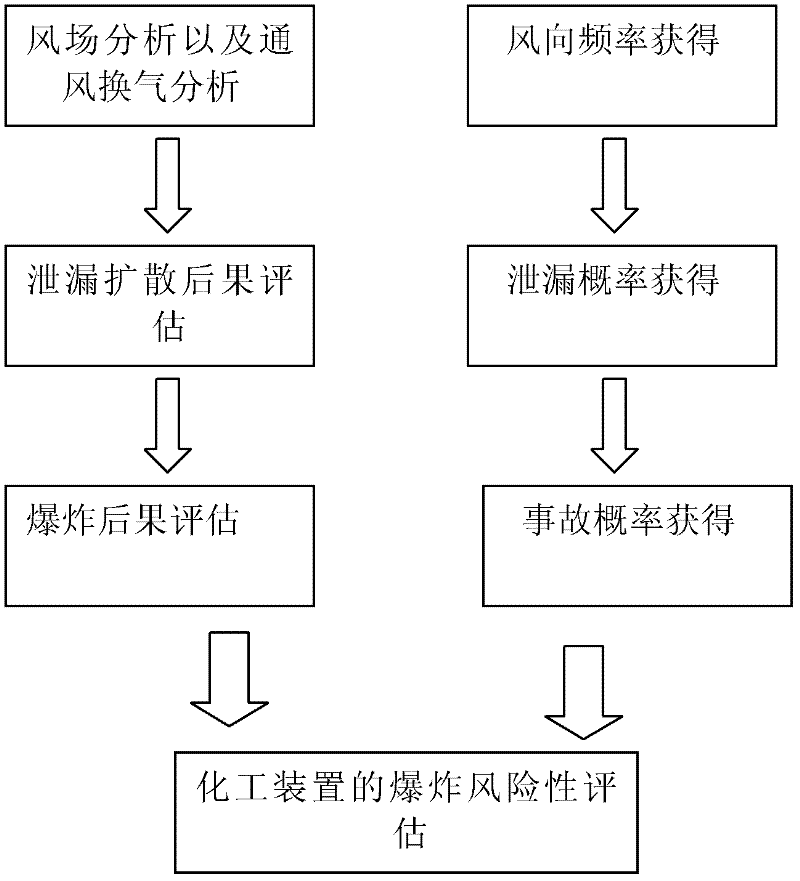

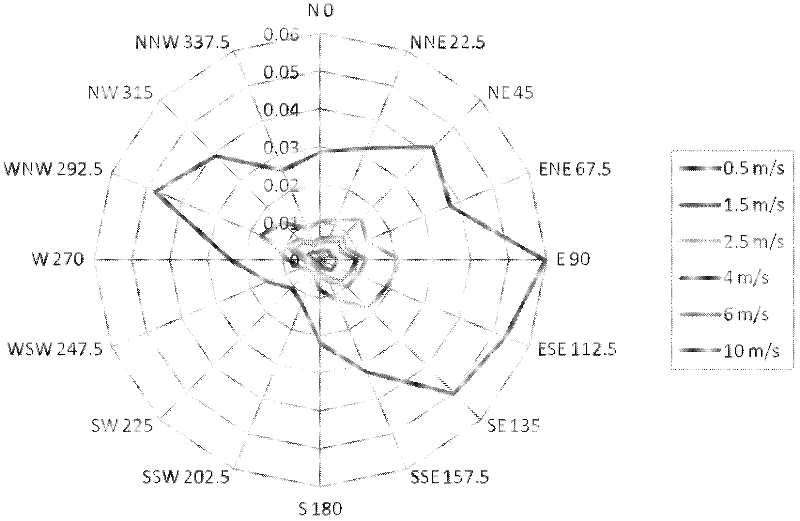

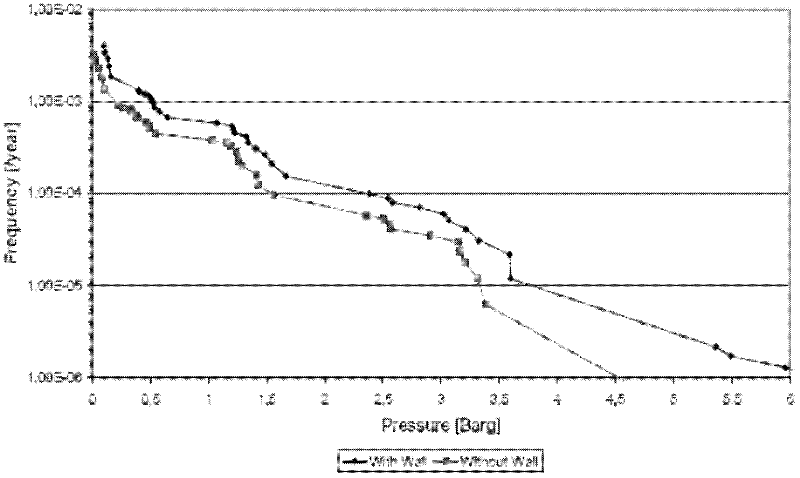

Method and system for evaluating explosion risk of chemical device by utilizing computer

InactiveCN102509003AComprehensive consideration of explosion riskThe results are reasonably accurateSpecial data processing applicationsSystem of systemsRisk evaluation

The invention relates to a method for evaluating explosion risk of a chemical device by utilizing a computer, comprising the following steps of: firstly, calculating limiting pressure when the chemical device explodes under different scenes by utilizing field meteorological data and data obtained by ambient environment of the chemical device; secondly, calculating by utilizing the actual data in production to obtain the explosion probability that the chemical device has an explosion accident; and thirdly, forming an accumulated probability-explosion effect evaluation curve by utilizing the limiting pressure when the chemical device explodes in the first step and the explosion probability that the chemical device has the explosion accident, and finally evaluating the explosion risk of the chemical device. The method and system for evaluating the explosion risk of the chemical device provided by the invention systematacially consider an accident occurrence and development process, and the explosion risk of the chemical device can be comprehensively considered by combining with influence of factors such as an accident probability and the like, thus a result is more reasonable and accurate.

Owner:CHINA PETROLEUM & CHEM CORP +1

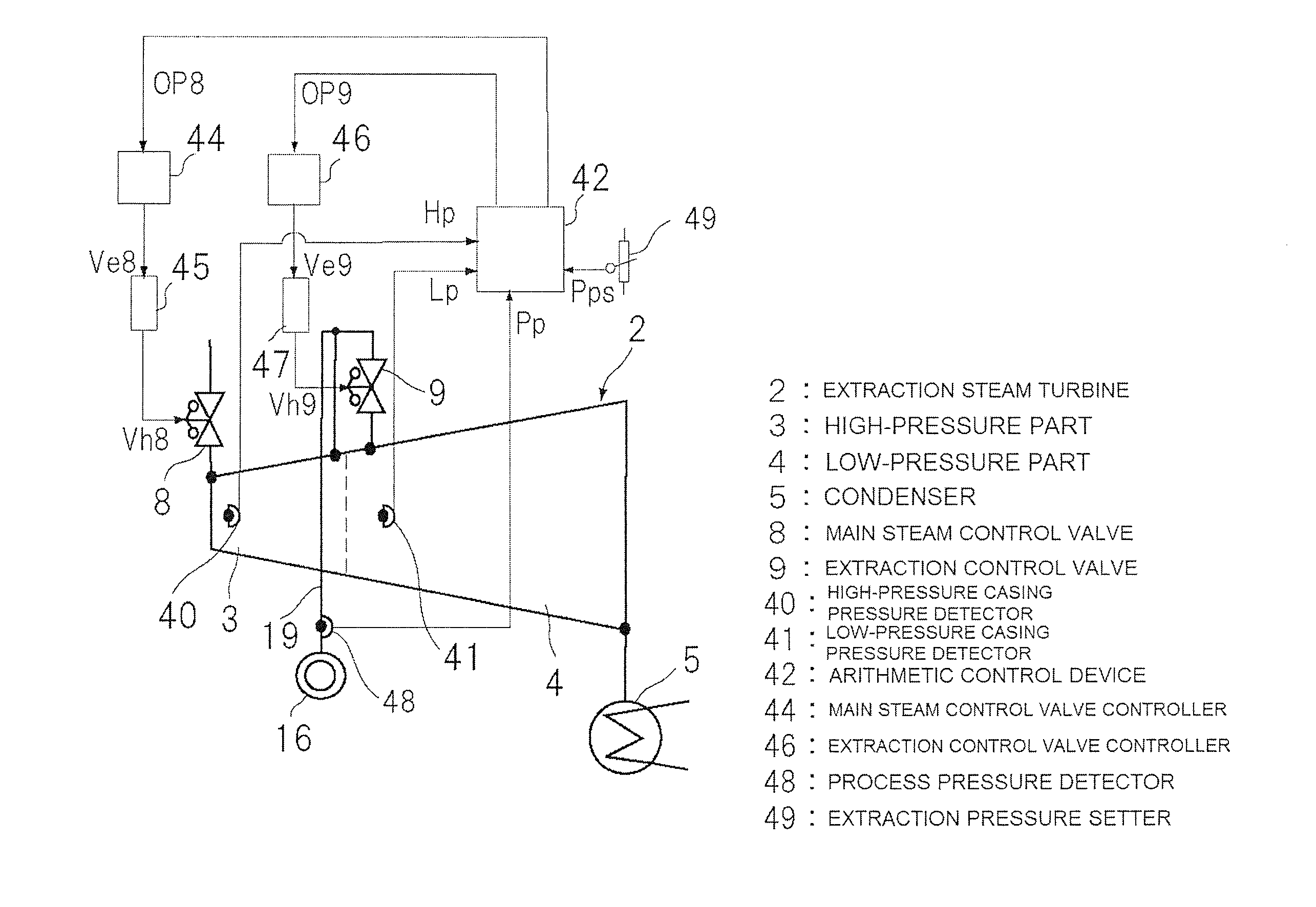

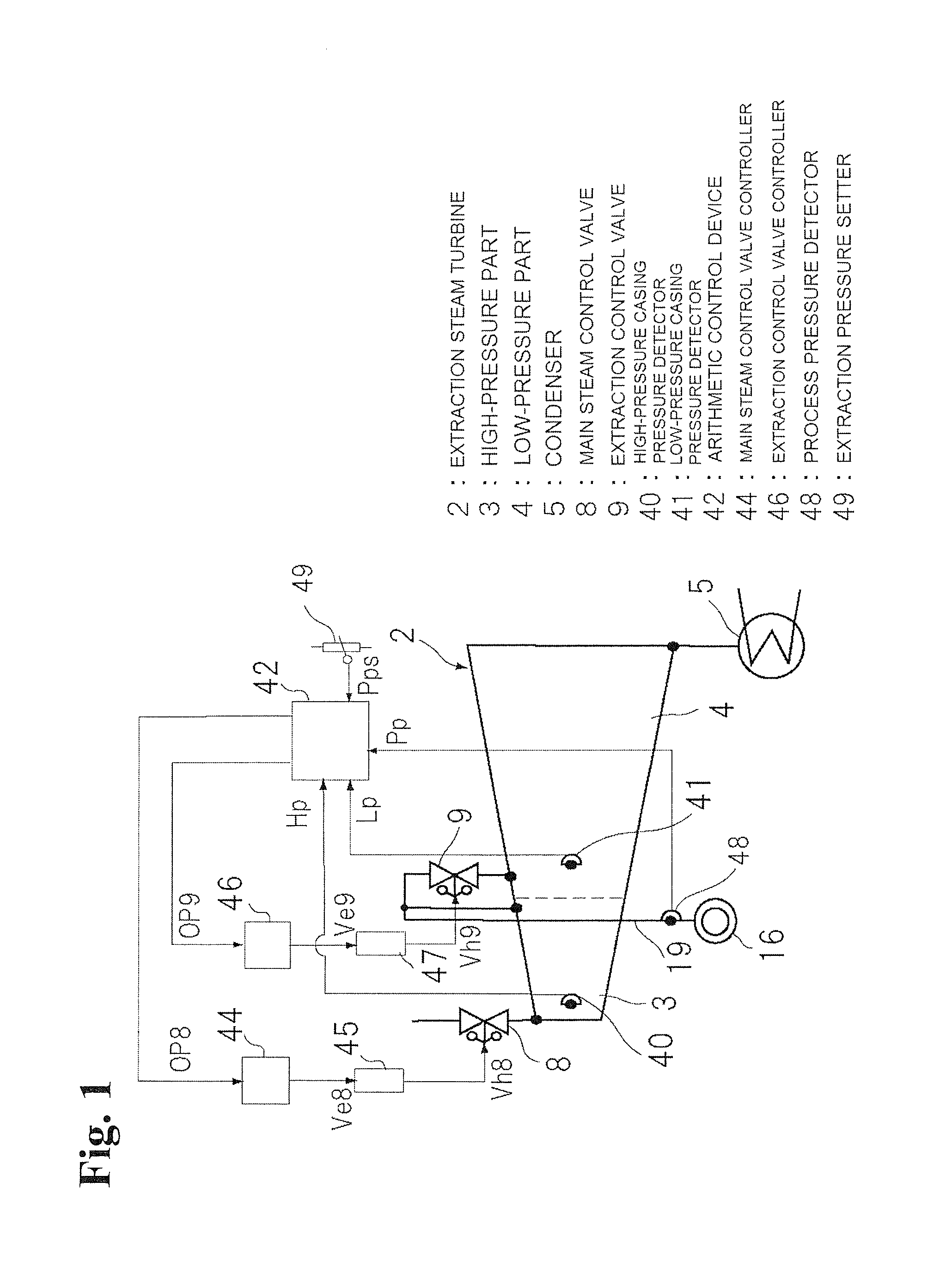

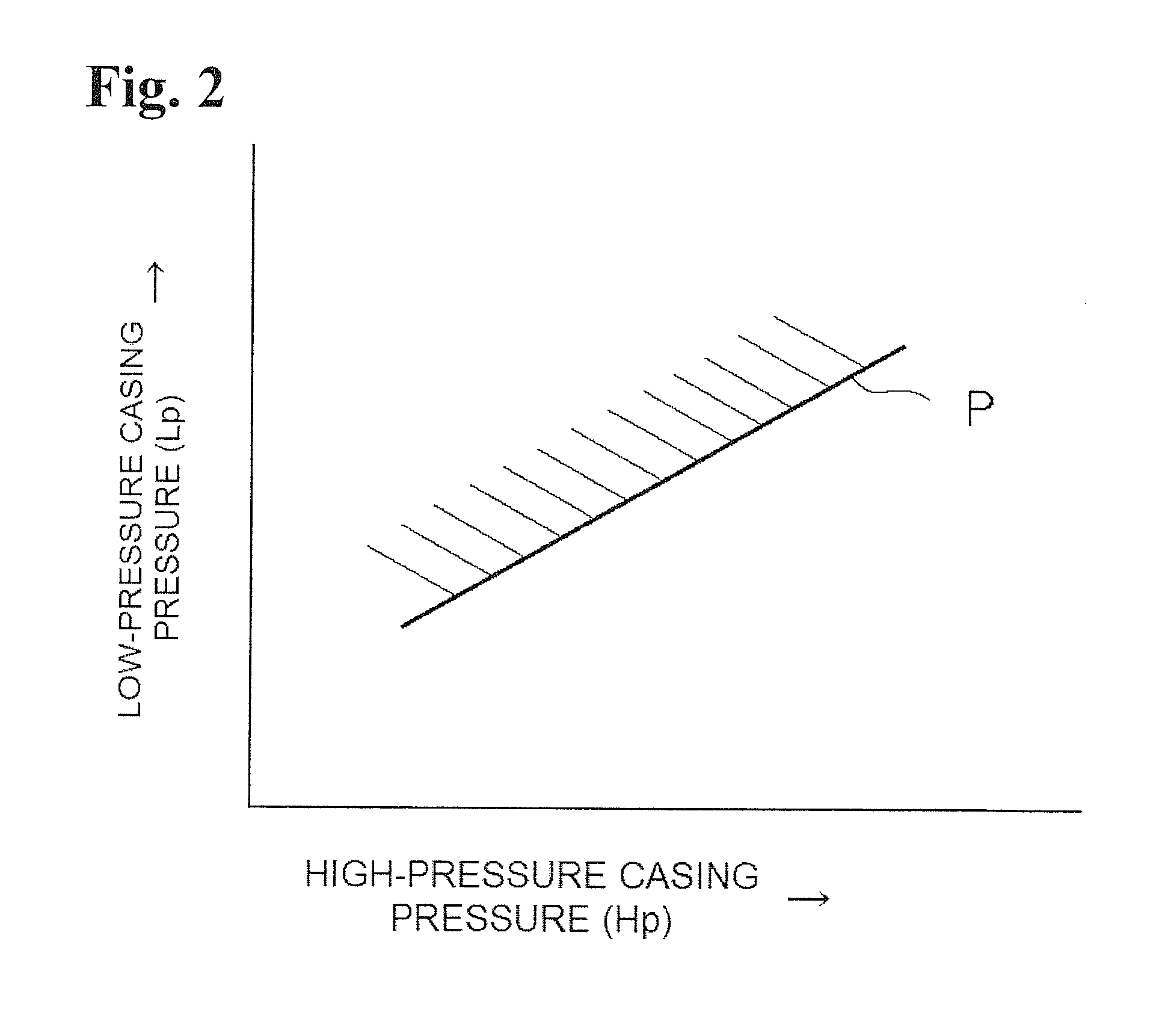

Method and apparatus for safety operation of extraction steam turbine utilized for power generation plant

ActiveUS20140373541A1Minimize impactSafe and stable operationEngine controlSteam engine plantsPower stationSteam pressure

A safety operation method includes detecting a steam pressure inside a high-pressure casing of the high-pressure part and a steam pressure inside a low-pressure casing of the low-pressure part; obtaining a low-pressure casing limit pressure as a reference corresponding to a pressure of the high-pressure casing in each detection, on a basis of a pressure correlation line expressing a prescribed special relation between preset high-pressure casing pressure and low-pressure casing pressure of the extraction steam turbine; comparing the low-pressure casing limit pressure with the detected pressure of the low-pressure casing; and forcibly throttling an opening of the main steam control valve to reduce the flow rate of steam flowing into the high-pressure part, in a state in which the extraction control valves continue controlling an operation of the extraction steam pressure, when the detected pressure of the low-pressure casing is judged to be higher than the low-pressure casing limit pressure.

Owner:FUJI ELECTRIC CO LTD

System and method for automatically measuring property of vapor stream vacuum pump

InactiveCN101608615AAccurate measurementEasy to controlPump testingPositive-displacement liquid enginesInternational standardMagnetic valve

The invention relates to a system and a method for automatically measuring the property of a vapor stream vacuum pump, which belong to the technical field of vacuum test. The invention can be in strict accordance with the test principle and the method specified in national and international standards to automatically complete the test of parameters of the vapor stream vacuum pump. The system comprises a test cover, a gas flow testing unit, a fore pipe gas flow adjusting unit, and the like, wherein the gas flow testing unit comprises a dropper, a dropper magnetic valve is arranged at a gas inlet of the upper part of the dropper, and the outer side of the dropper is provided with an upper liquid level switch and a lower liquid level switch; a test cover gas flow adjusting unit and the fore pipe gas flow adjusting unit both comprise stepping motors, needle type micrometering valves and high-vacuum magnetic valves, drive buttons of the needle type micrometering valves are connected with the stepping motors, and gas outlets of the needle type micrometering valves are connected with the high-vacuum magnetic valves; and the liquid level switches, the dropper magnetic valve, and the like are connected with a computer control unit. The measuring method comprises the following steps of measurement of limit pressure of the vapor stream vacuum pump, measurement of volume flow rate, and measurement of critical fore pressure.

Owner:辽阳南雪水泥管厂

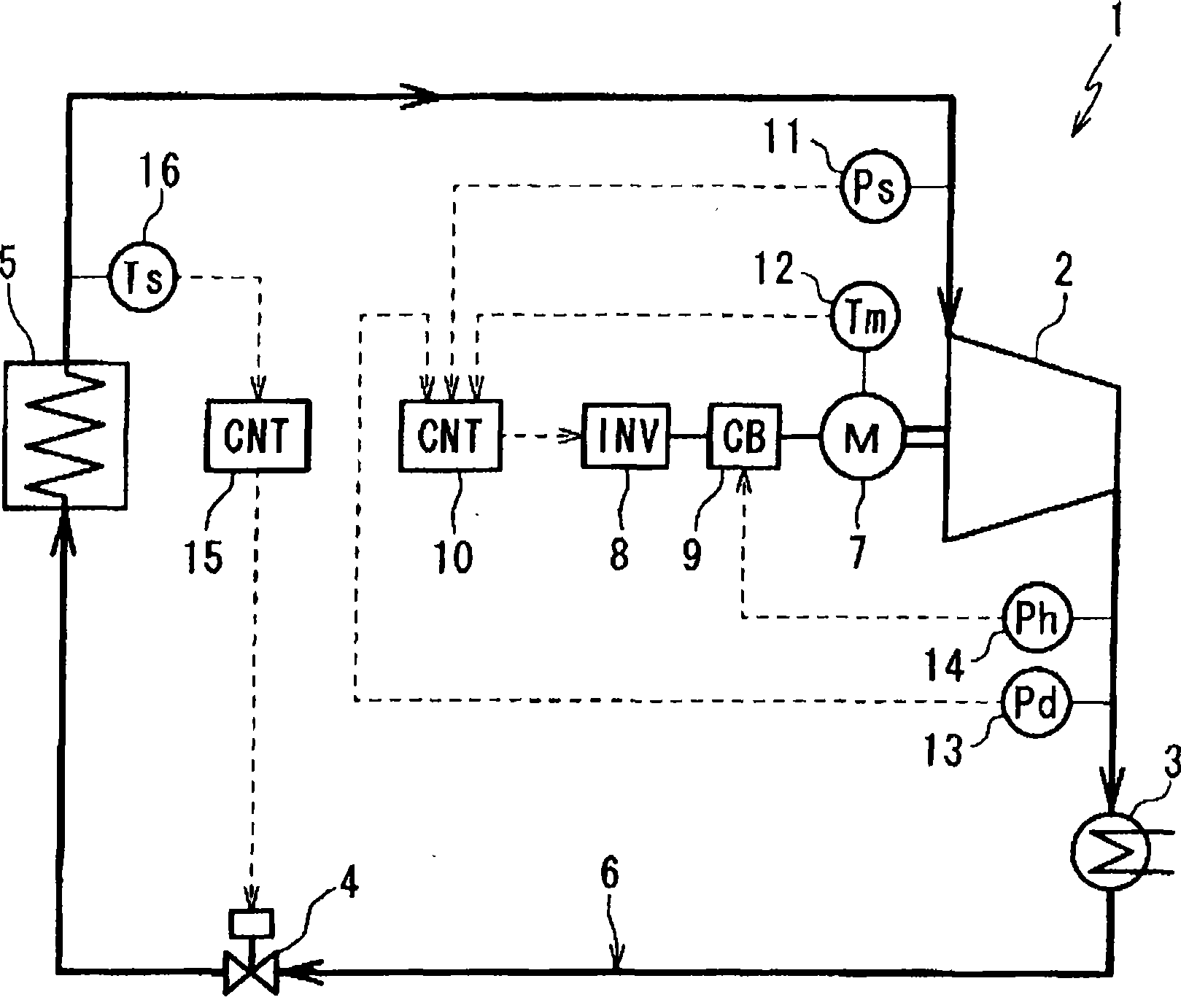

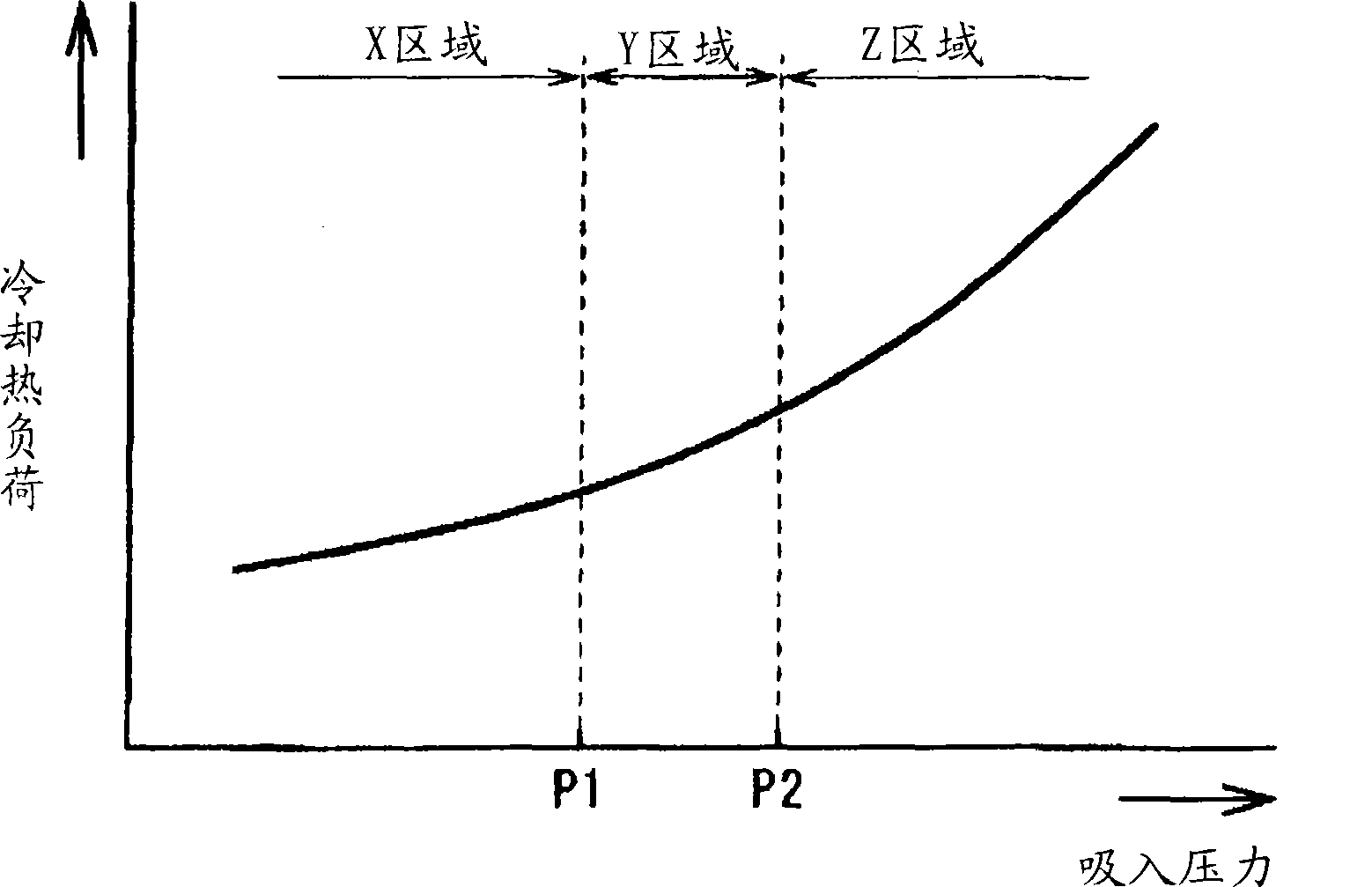

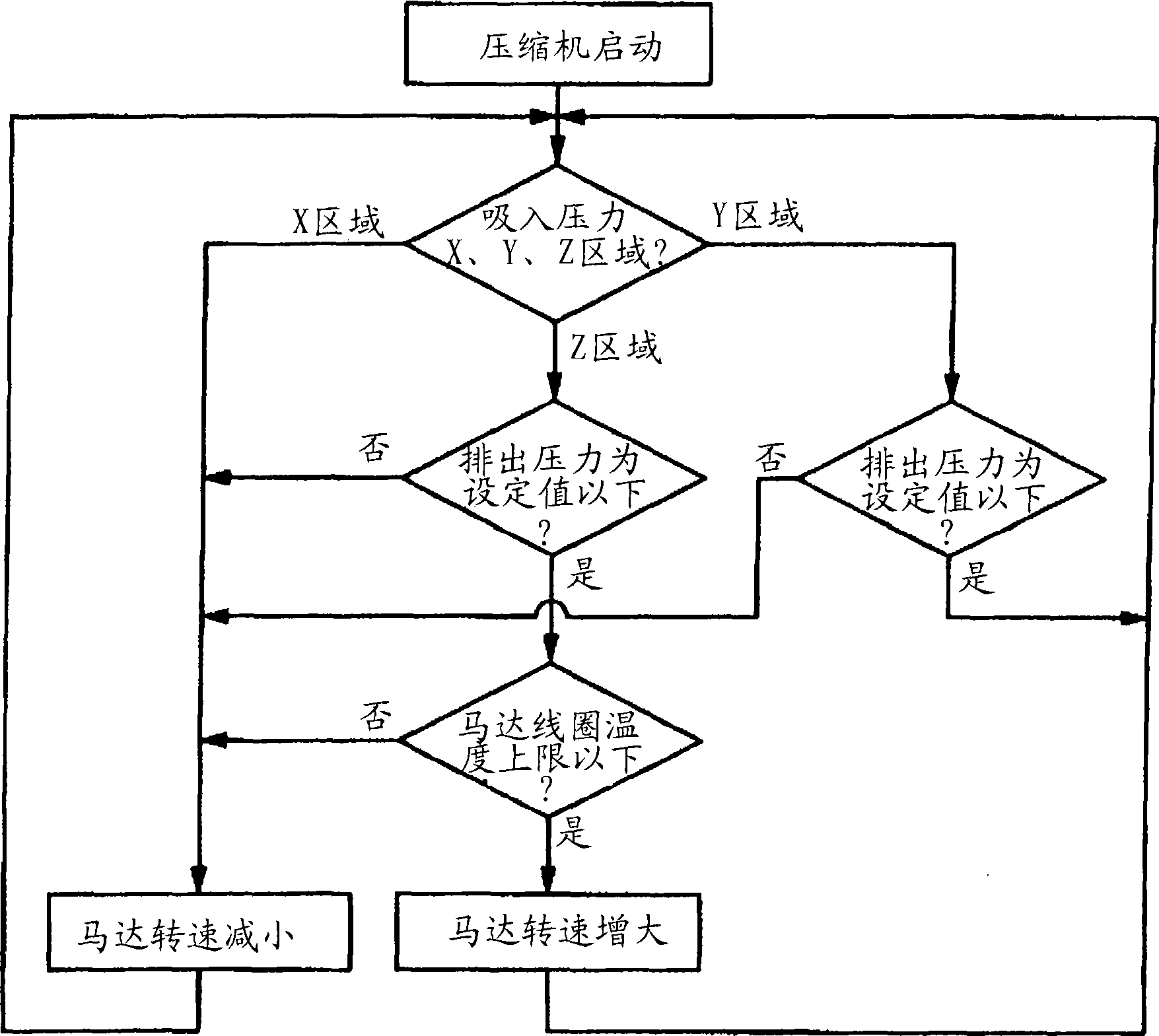

Cooling device

ActiveCN101451774AReduce discharge pressureReduce speedDomestic cooling apparatusCompression machines with non-reversible cycleLower limitEngineering

The present invention provides a refrigeration device having a screw compressor driven by a motor controlled with rotation speed and compressing refrigerant, the rotation speed of the motor is reduced in condition that lower limit pressure is not reached by sucked in pressure. The rotation speed of the motor is held in condition that the sucked in pressure is higher than the lower limit pressure and less than an upper limit pressure and a discharge pressure is less than preset value, and if the discharge pressure is higher than the preset value, the rotation speed is reduced. In condition that the sucked in pressure is higher than the upper limit pressure, the rotation speed of the motor is increased if the discharge pressure is less than the preset value and the screw compressor is in overload, and the rotation speed of the motor is reduced if the discharge pressure is not less than the preset value or the screw compressor is in overload. Thereby over load of the motor and excessive rise of the discharge pressure may be prevented, and the screw compressor may be driven respectively to refrigerating the heat load.

Owner:코벨코컴프레서가부시키가이샤

Flow.pressure combined control valve and pressure-limited, flow-limited hydraulic pump

InactiveCN1936335AReduce manufacturing costLow failure rateRotary piston pumpsRotary piston liquid enginesMobile vehicleGear pump

This invention relates to a combined control valve of flux and pressure and a hydraulic pressure pump for limiting pressure and flux, in which, an inner cavity of a post valve core with a conic node and bottom is assembled with a ball valve or a cone valve and a spring to make up of a pressure control structure, said valve core is assembled in the inner cavity of the valve to be matched with the conic node and conic face to intervals between conic faces, that is the damp channel to make up of a flux control structure for limiting the flux of the working solution, said pump takes a gear pump, a vane pump or a slipper pump as the main structure to assemble said valve in the bottom hole set on the shell to constitute said pressure and flux limit hydraulic pump.

Owner:彭利

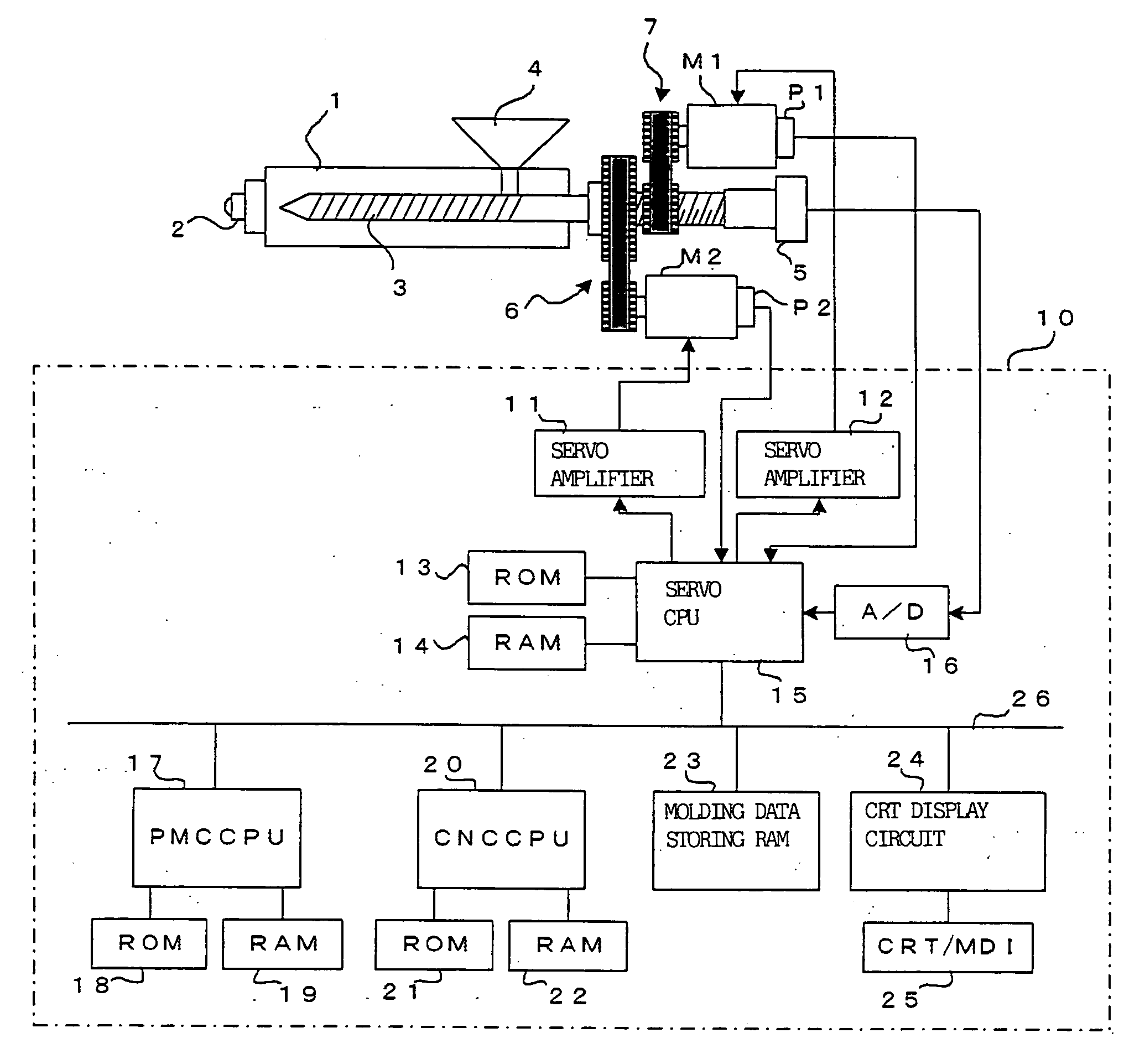

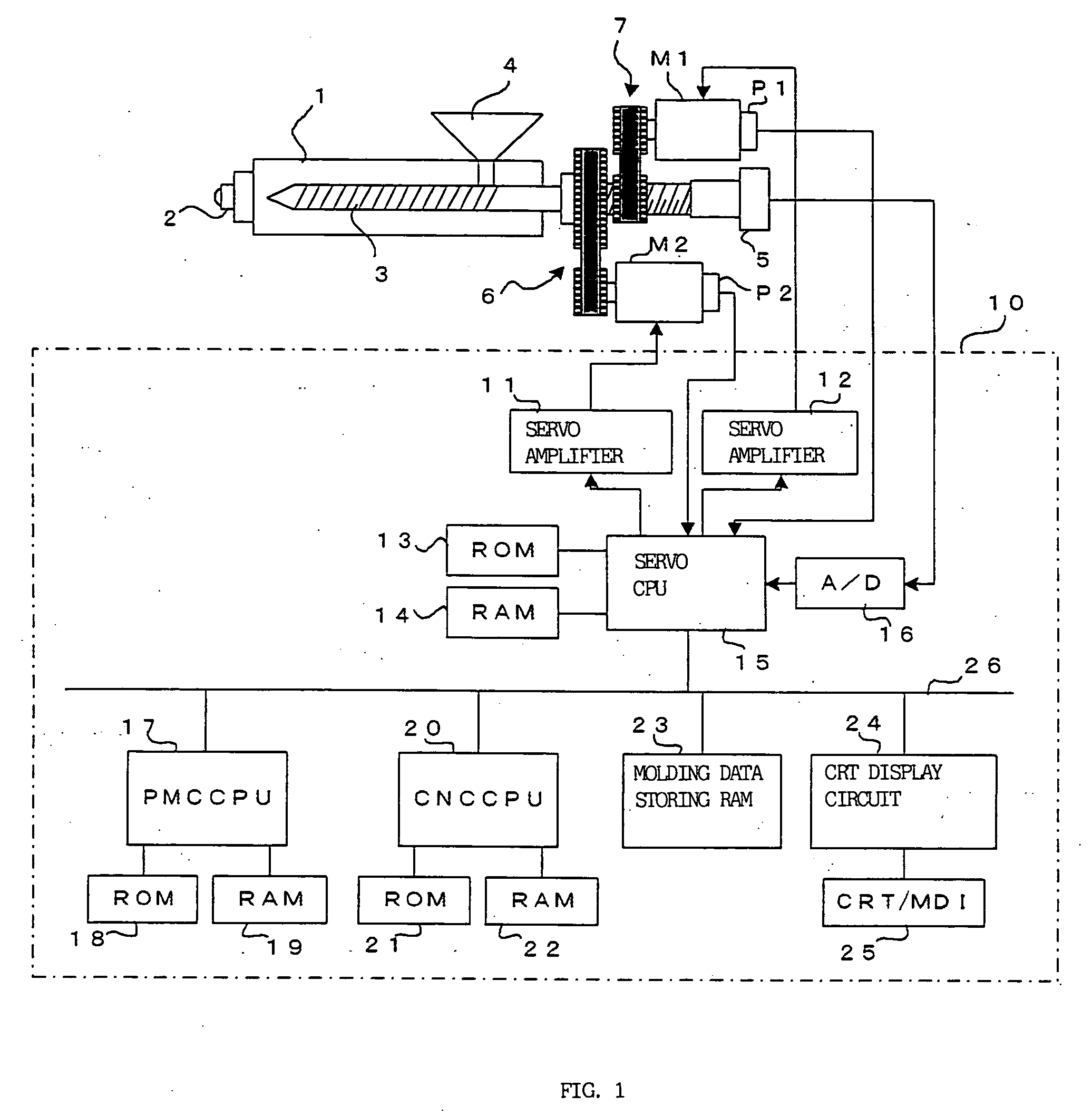

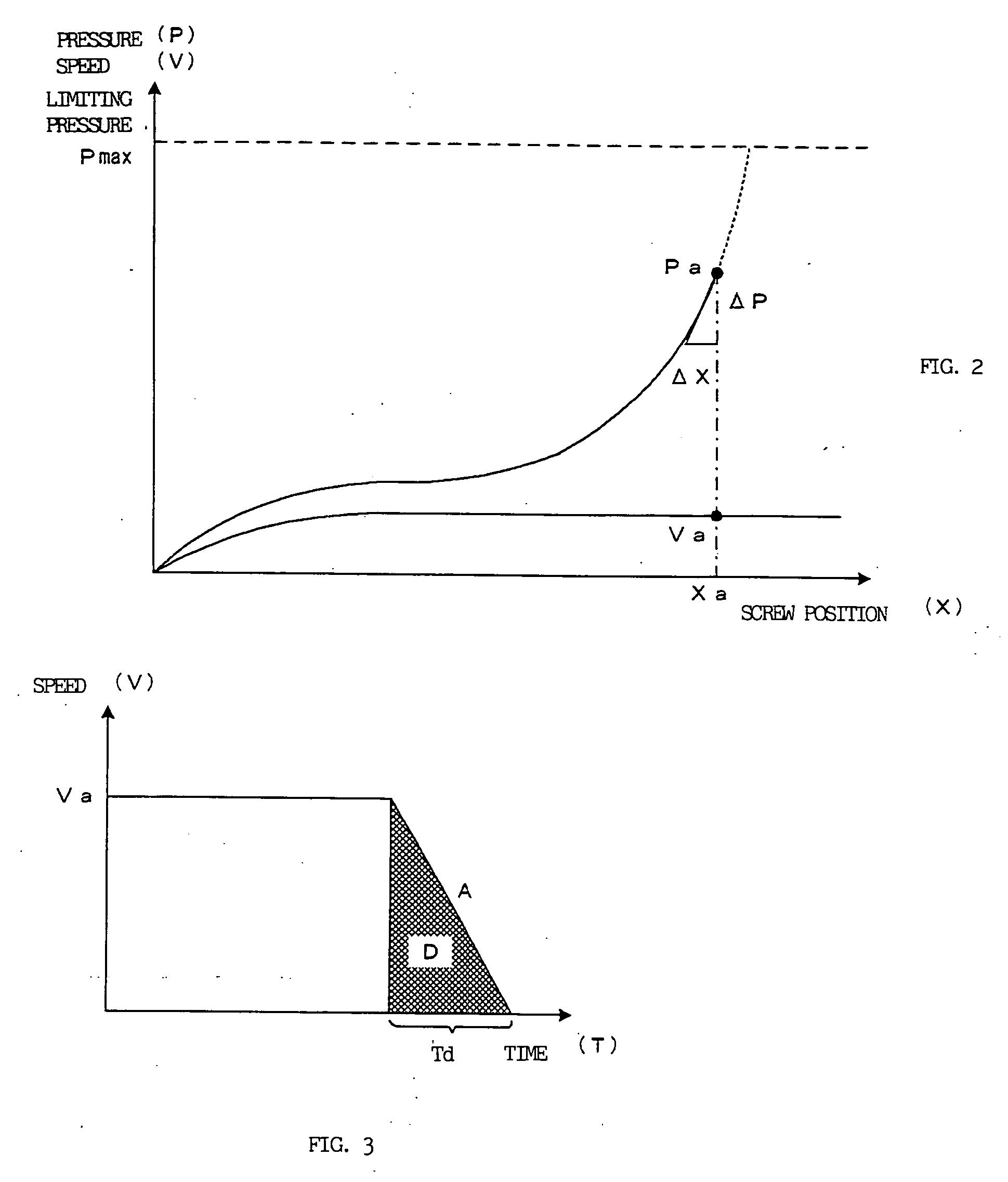

Pressure abnormality detecting device for injection molding machine

ActiveUS20060191347A1Accurate predictionAvoid failureFluid pressure measurement by mechanical elementsInjection pressureScrew position

An injection screw position Xa, injection speed Va, and injection pressure Pa are read. A deceleration distance D the injection screw moves from the point where the injection operation has been stopped at the current moment to be decelerated by maximum deceleration till the point where the injection speed is reduced to zero is determined from a corrected deceleration in which the amount of correction α is added to a predetermined deceleration A inherent in the machine and the read injection speed Va. The determined deceleration distance D is multiplied by the amount of change in injection pressure with respect to the amount of change in the injection screw position to determine a predicted increment in pressure (D·ΔP / ΔX). The predicted increment in pressure is added to the current injection pressure Pa to determine an injection pressure Pa* predicted when the screw is suddenly decelerated at the current moment. If the predicted injection pressure Pa* exceeds the predetermined limit pressure Pmax, the injection operation is stopped to decelerate the screw.

Owner:FANUC LTD

Compressor sound suppression

ActiveUS7156624B2Reduce volumePump testingPositive displacement pump componentsMechanical engineeringDischarge location

Owner:CARRIER CORP

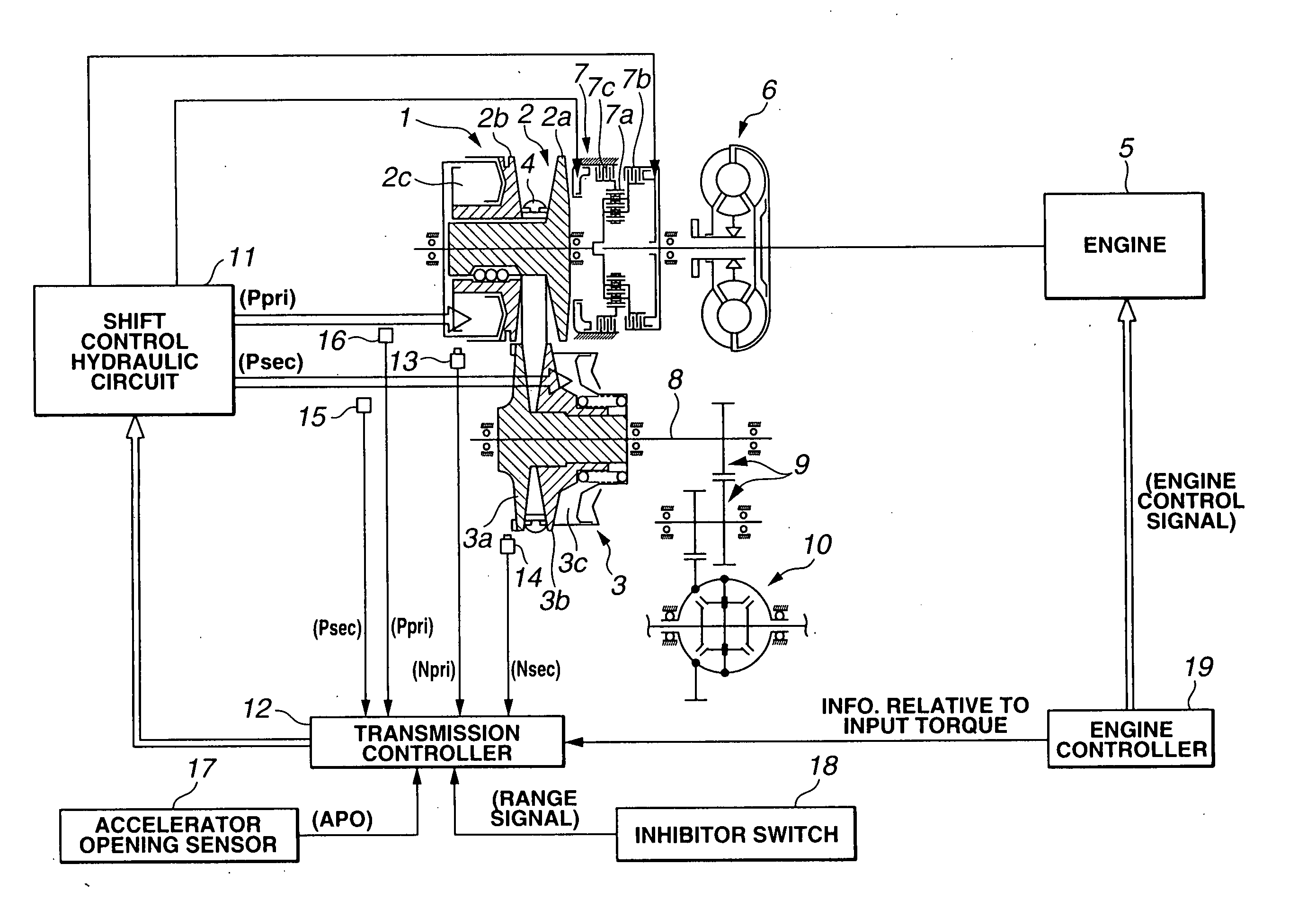

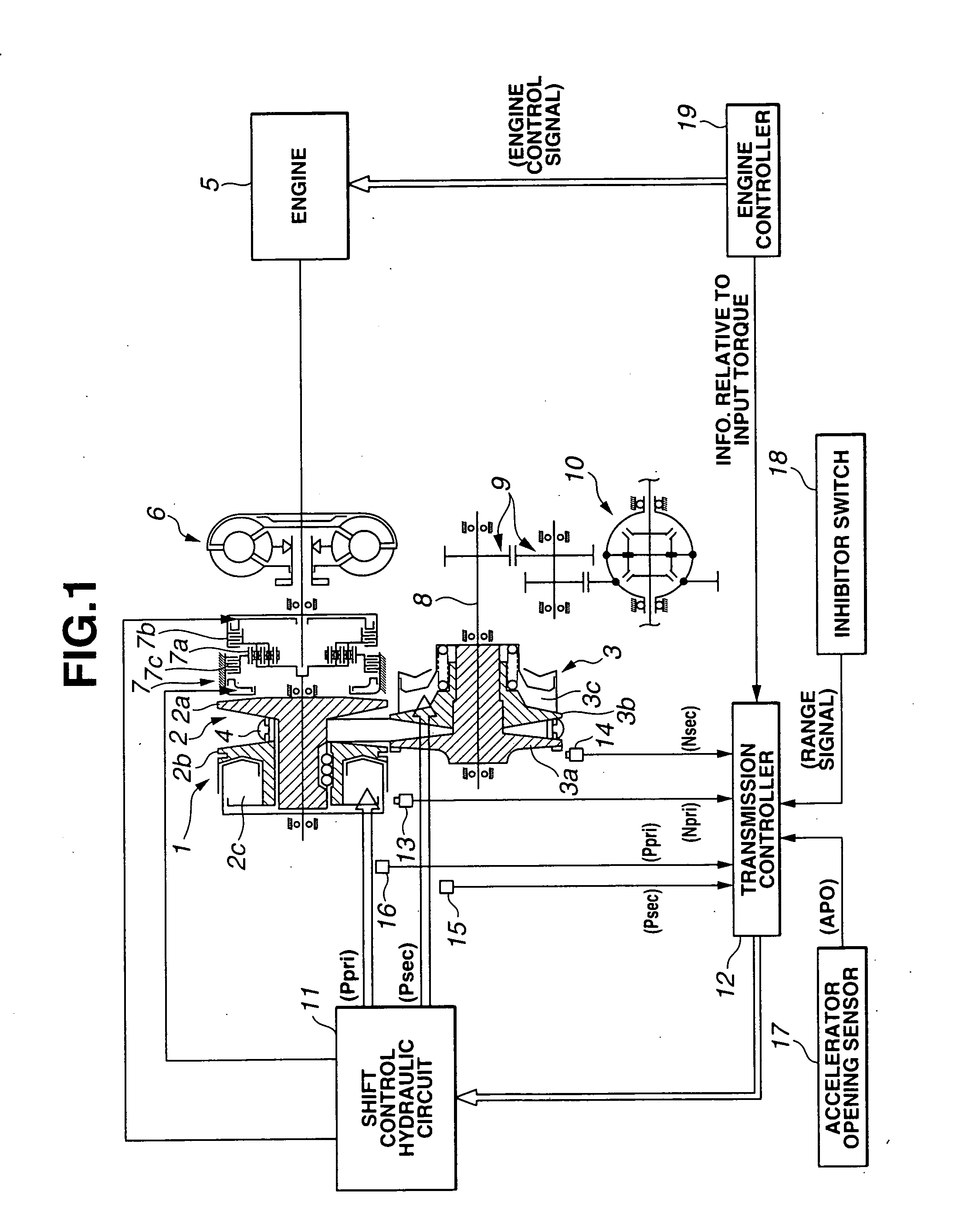

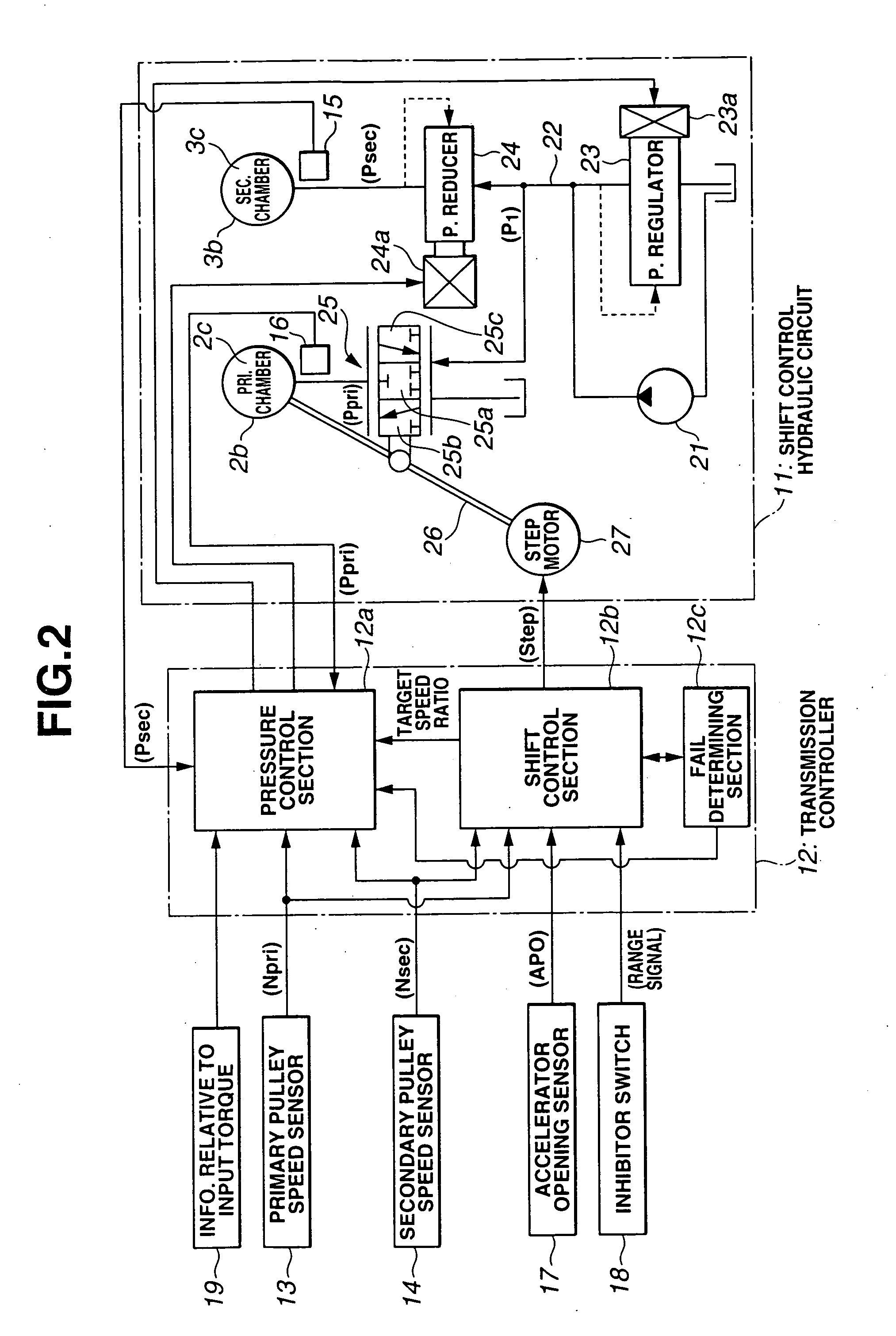

Shift control apparatus and method for continuously variable transmission

ActiveUS20060063641A1Increase the speed ratioStarting performance is deterioratedGearingGearing controlEngineeringActuator

The shift control apparatus for a continuously-variable transmission includes; a primary pulley; a secondary pulley connected with the primary pulley by a belt; a shift actuator adapted to vary a speed ratio; a line pressure adjusting section configured to adjust a line pressure; a secondary-pressure adjusting section configured to adjust a secondary pressure; and a control section configured to control the shift actuator, the line pressure adjusting section, and the secondary-pressure adjusting section. Moreover, the control section includes a fail determining section configured to determine whether the shift actuator is under a failed condition. The control section is configured to carry out a fail-safe shift-actuator fixing control to fix the shift actuator, when the fail determining section determines that the shift actuator is under the failed condition, and is configured to carry out a fail-safe hydraulic control to bring the line pressure to its upper limit pressure and bring the secondary pressure to its maximum pressure, when a control-start criterion predetermined to secure driving performance of the vehicle is satisfied under the failed condition.

Owner:JATCO LTD

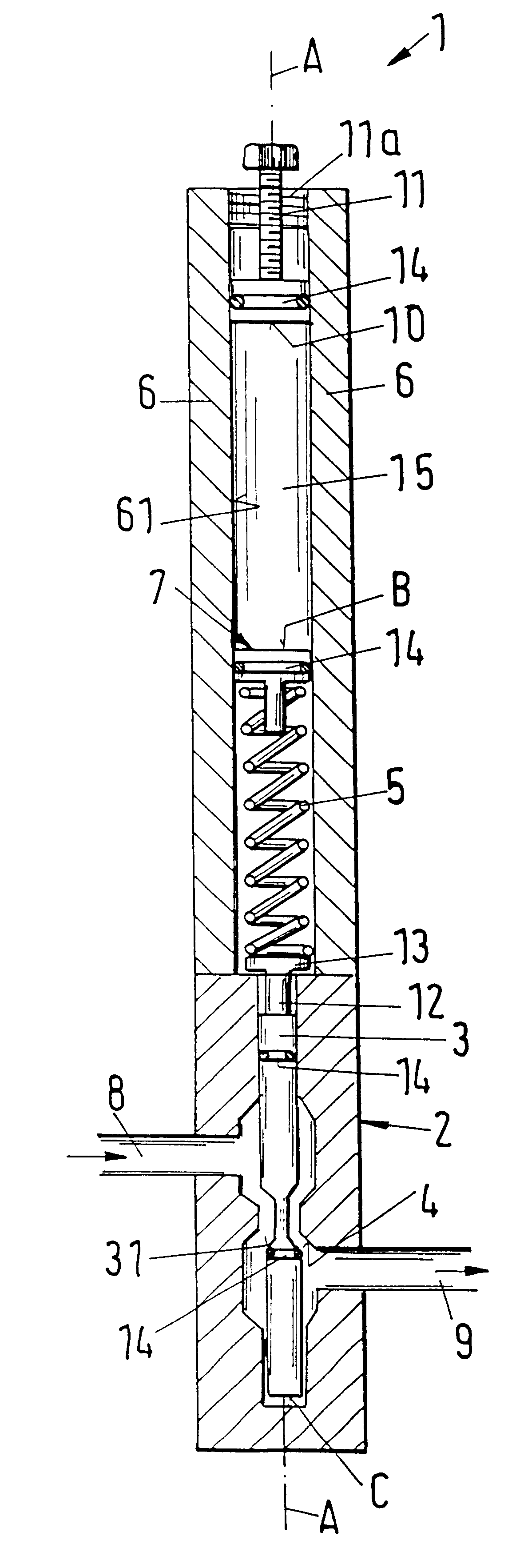

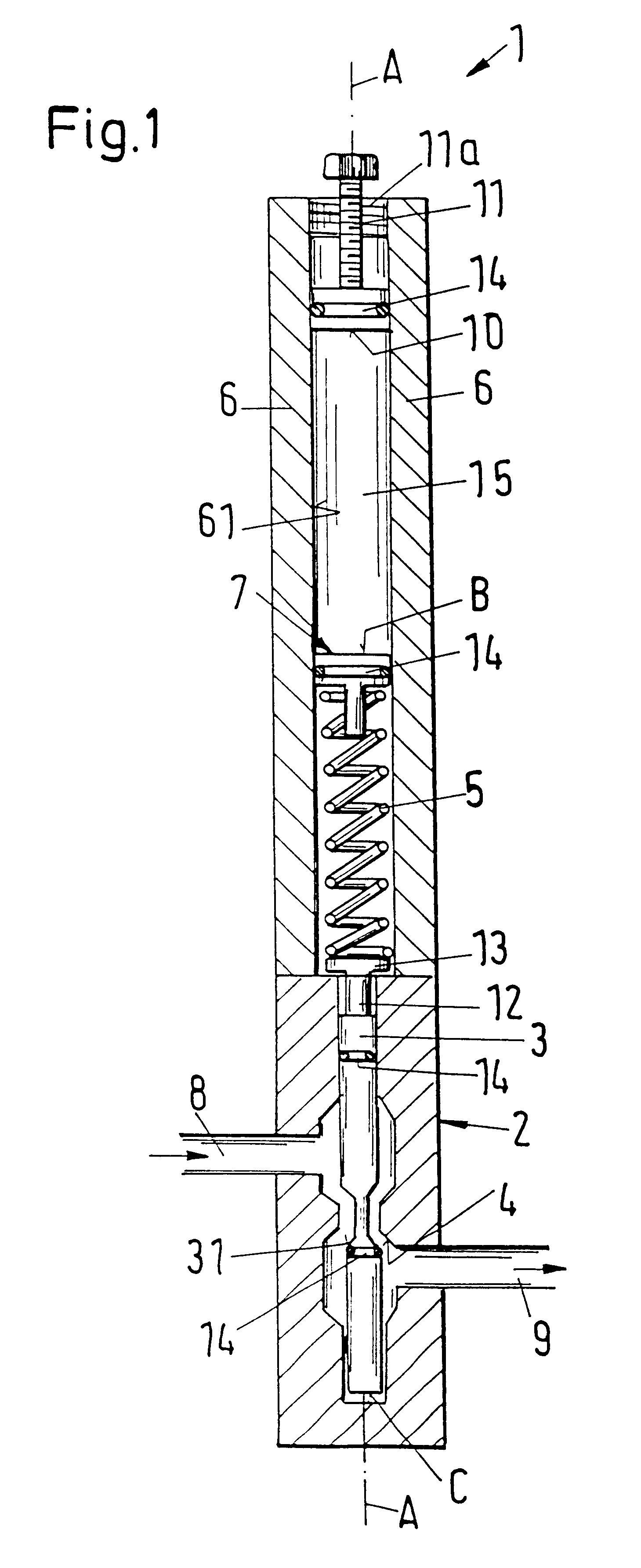

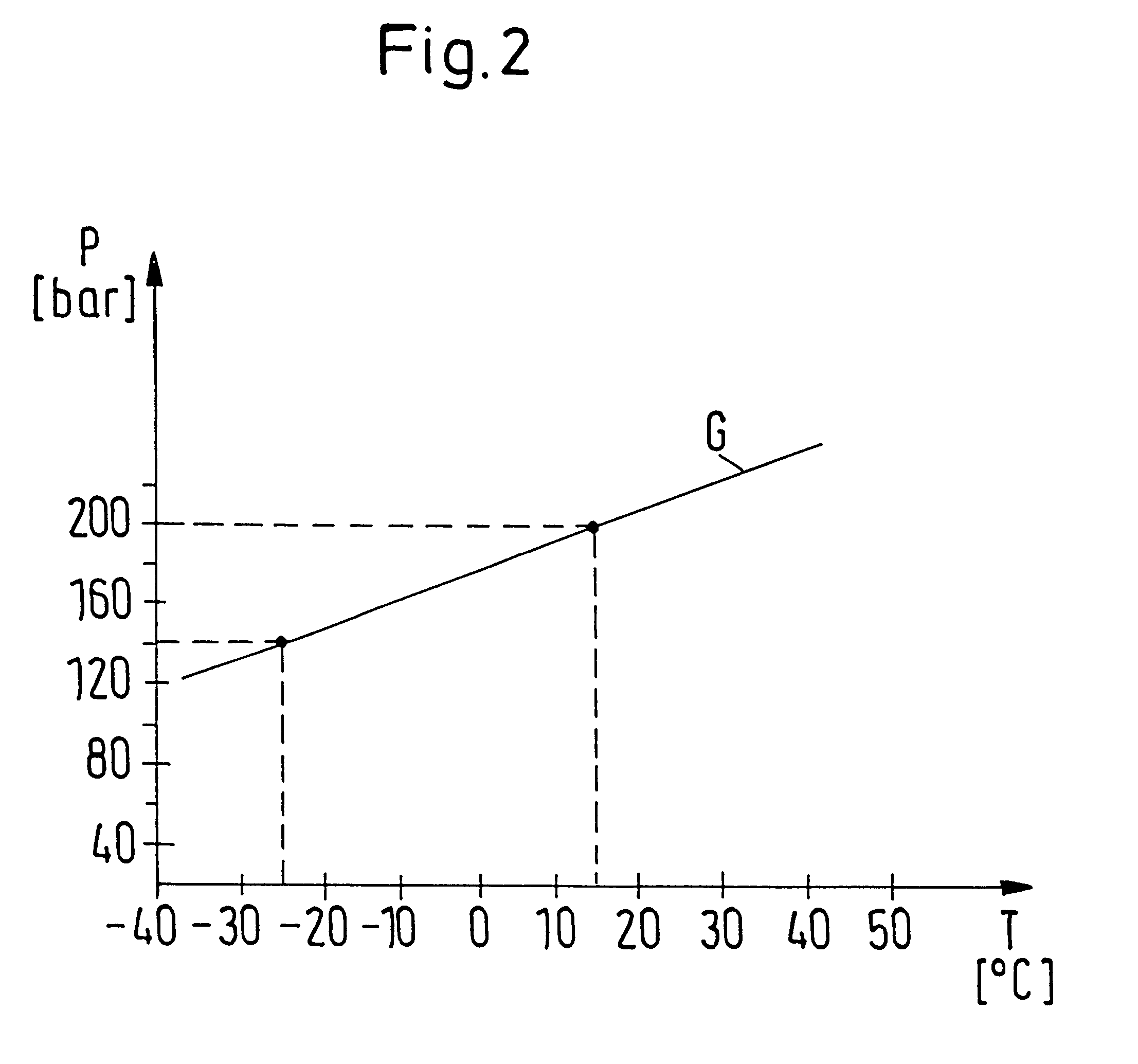

Pressure limiting valve

InactiveUS6341620B1Avoid high pressureVessel mounting detailsOperating means/releasing devices for valvesEngineeringThermal expansion

A pressure limiting valve includes an inlet and an outlet for a fluid, which includes a valve body which cooperates with a valve seat in such a manner that it opens or closes a flow connection for the fluid between the inlet and the outlet when a limiting pressure is reached. The valve also includes a spring element which acts on the valve body and loads the latter. A container for a liquid is provided which is arranged and designed in such a manner that through its thermal expansion, the liquid varies the loading of the valve body which is caused by the spring element, and thus varies the limiting pressure in dependence on the temperature of the liquid.

Owner:GREENFIELD

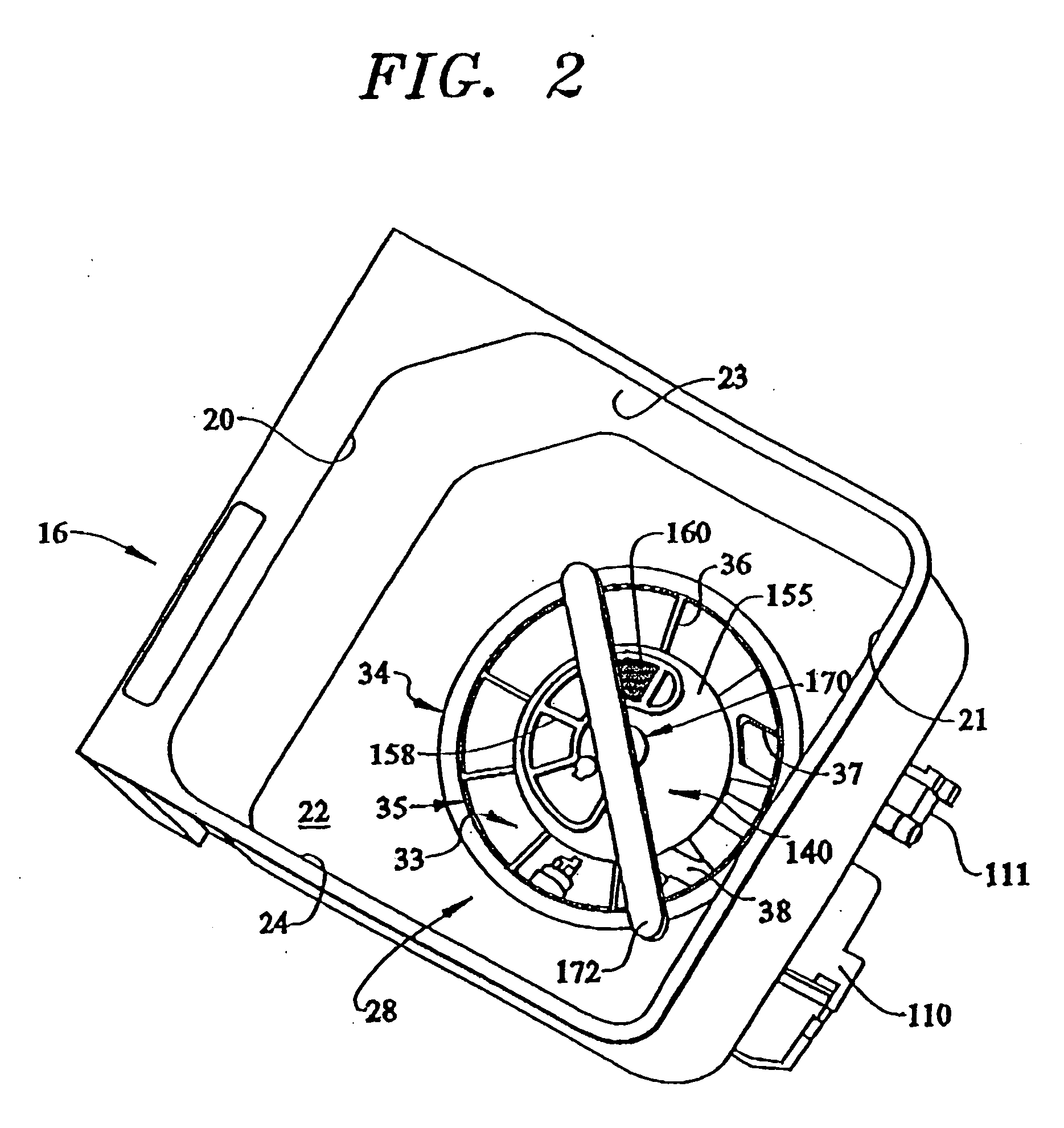

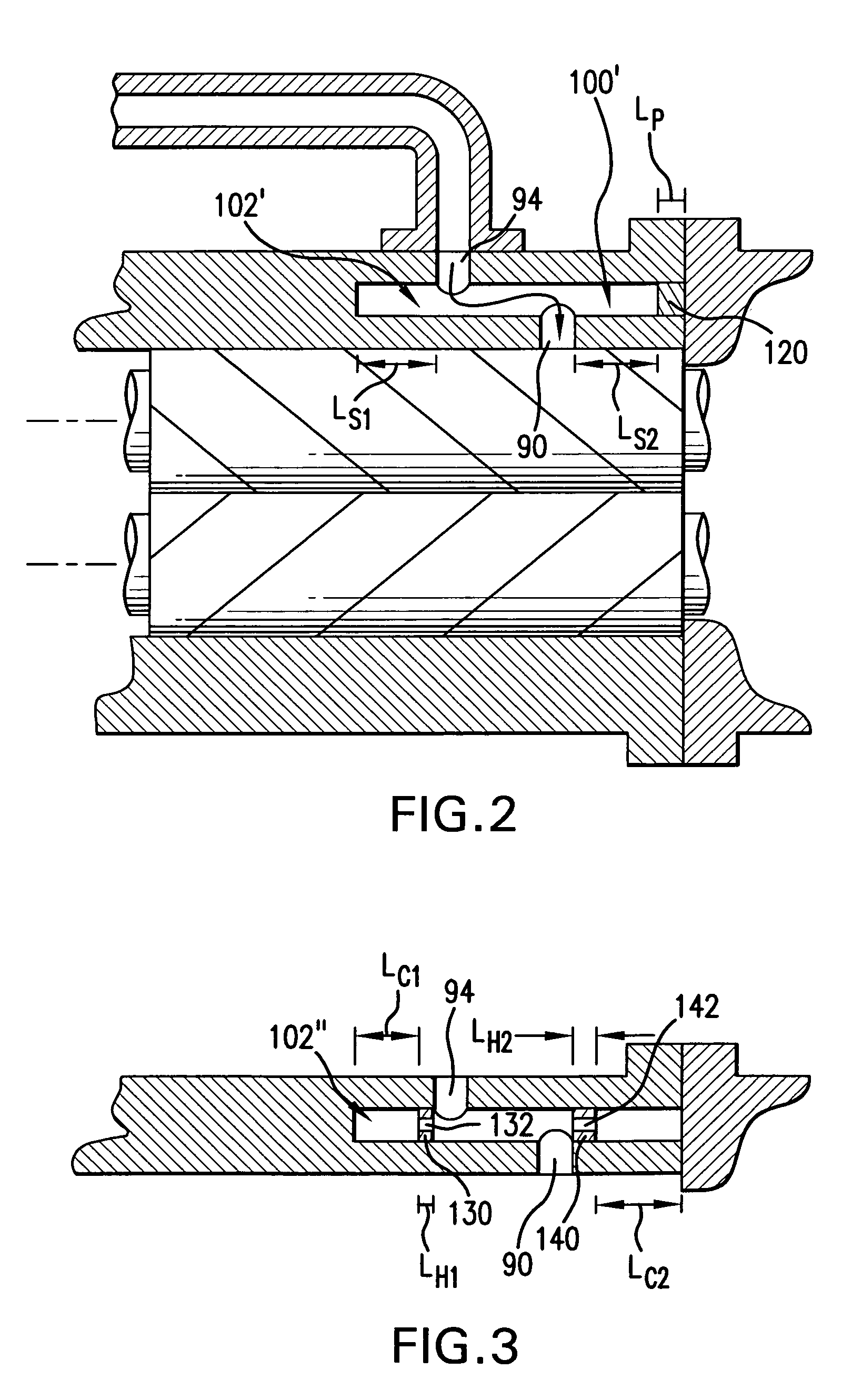

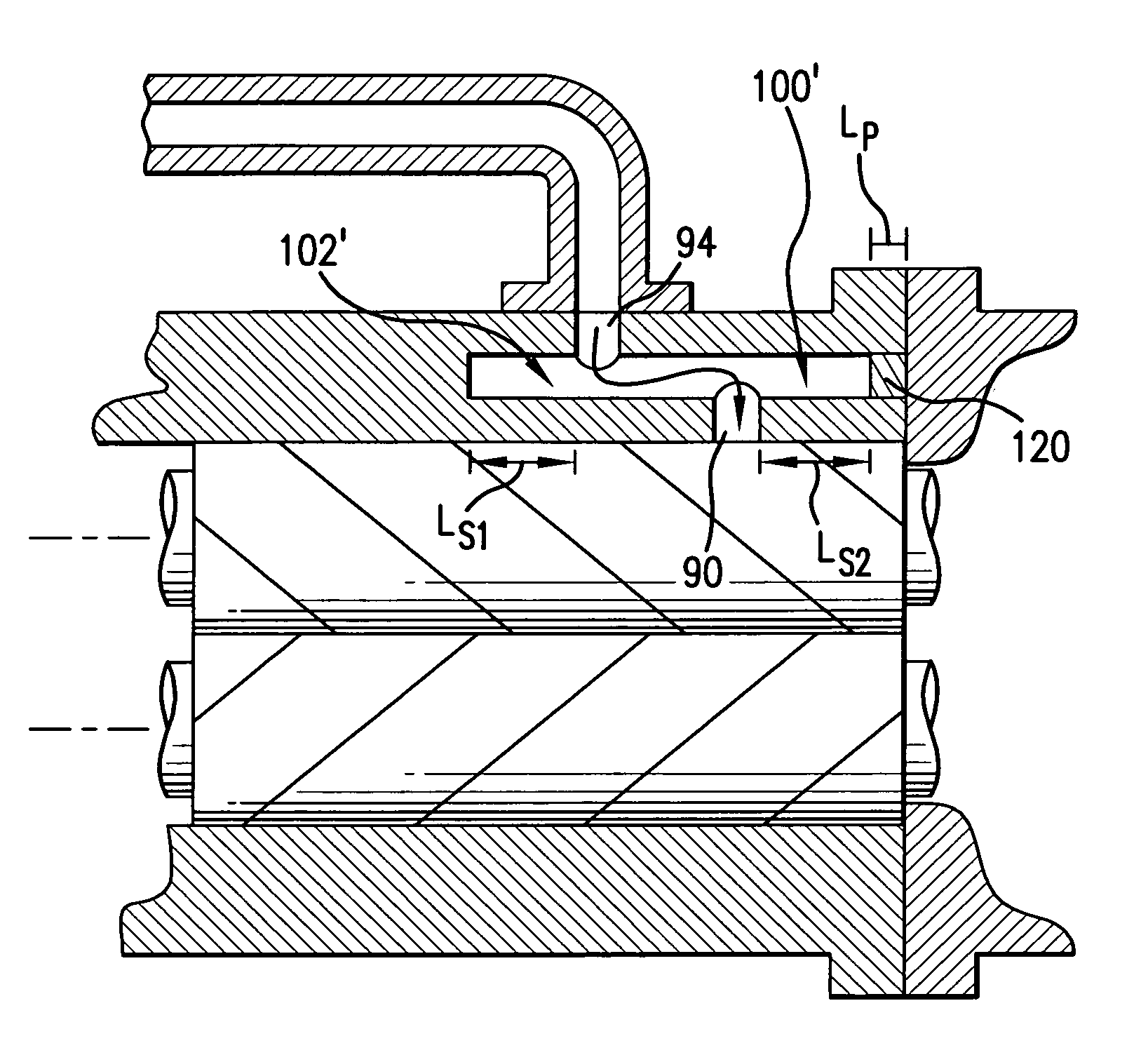

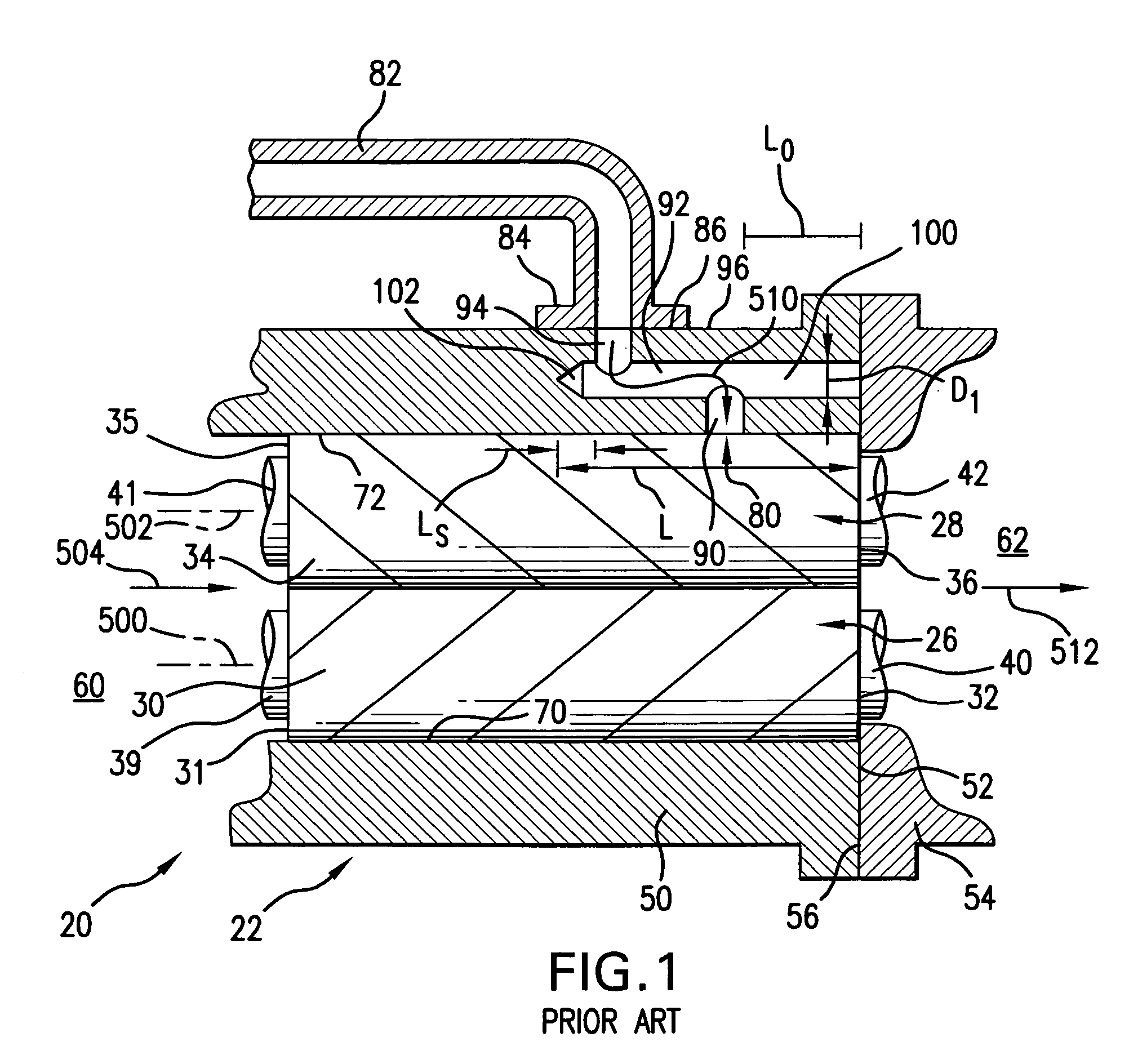

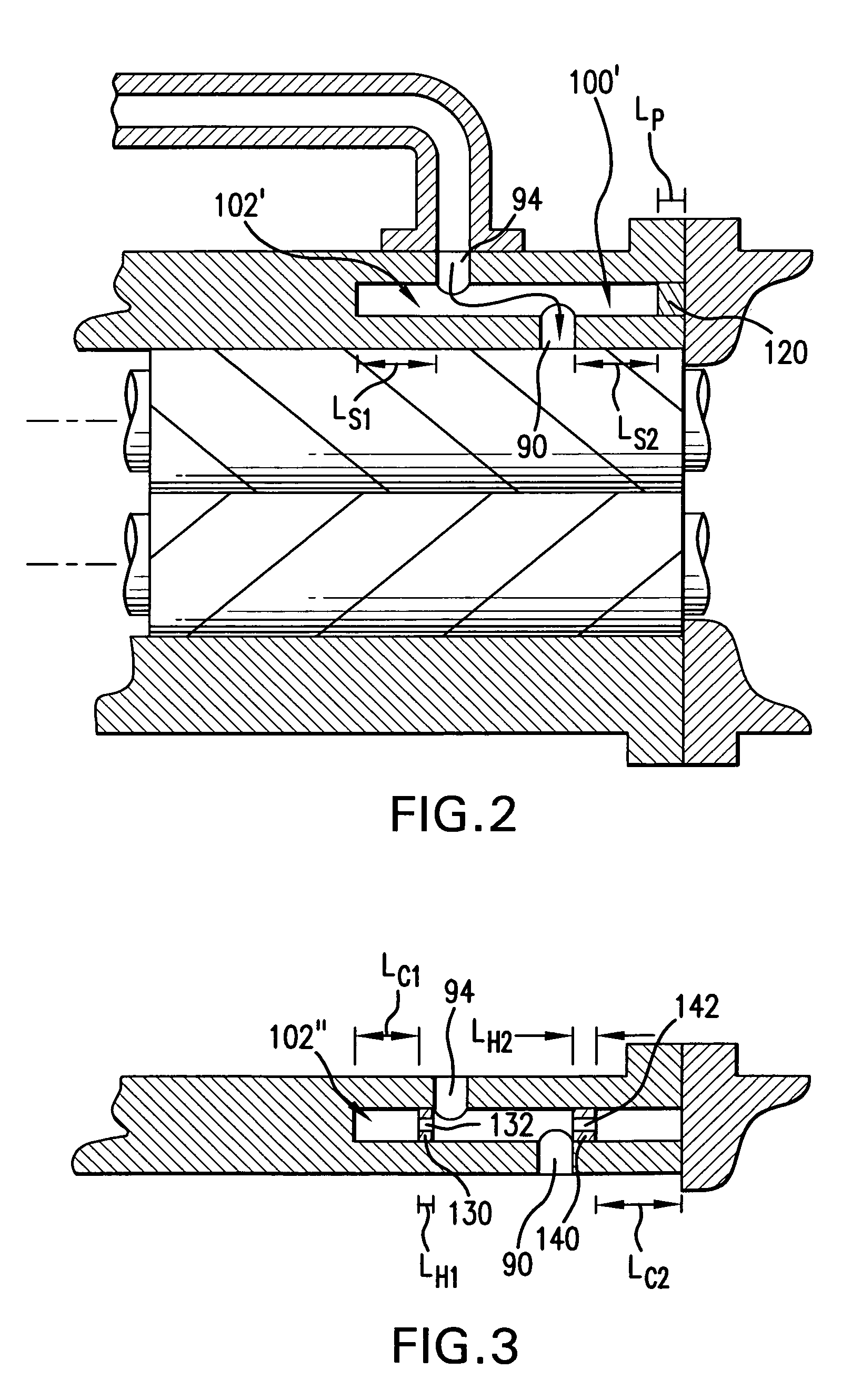

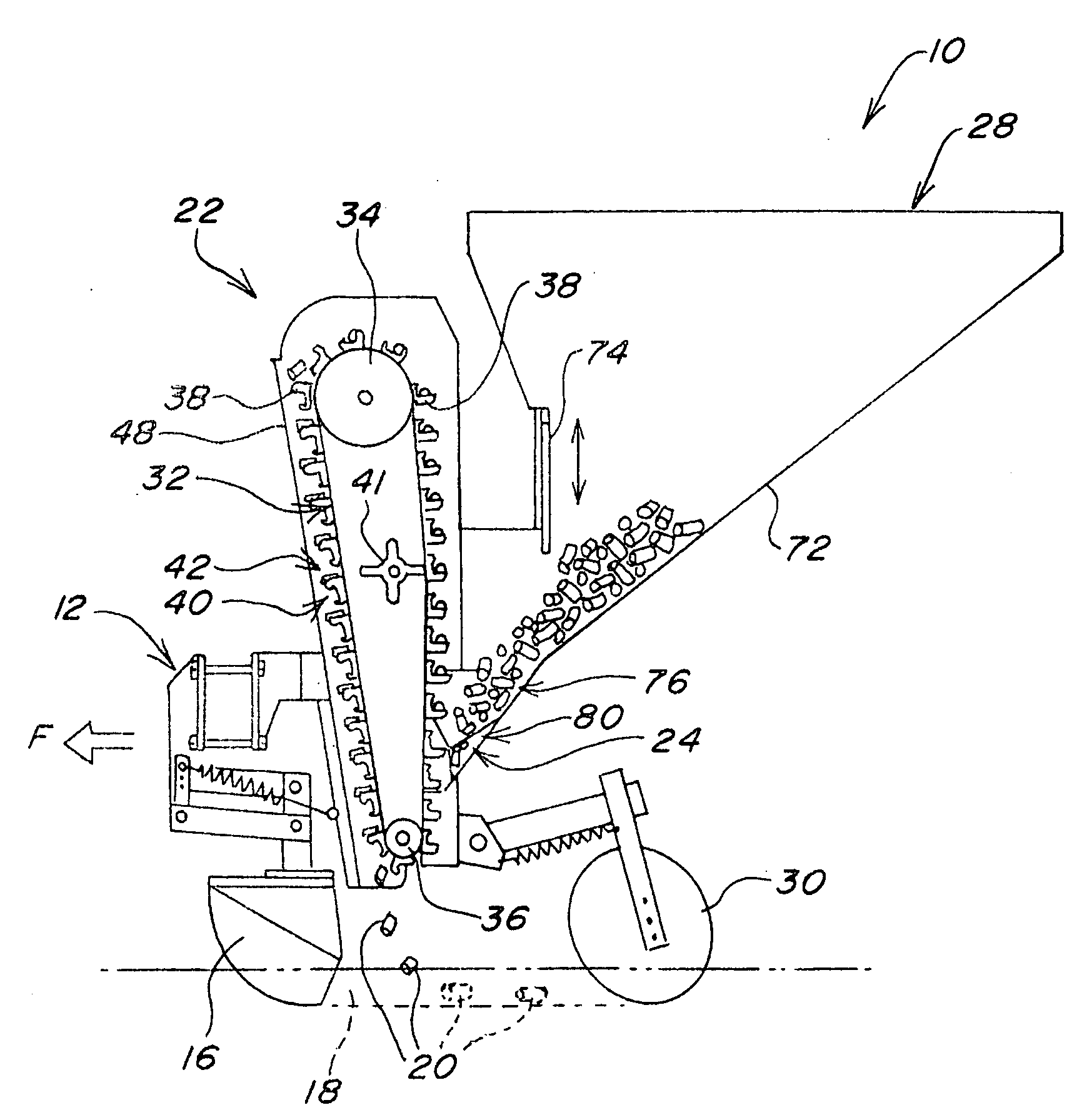

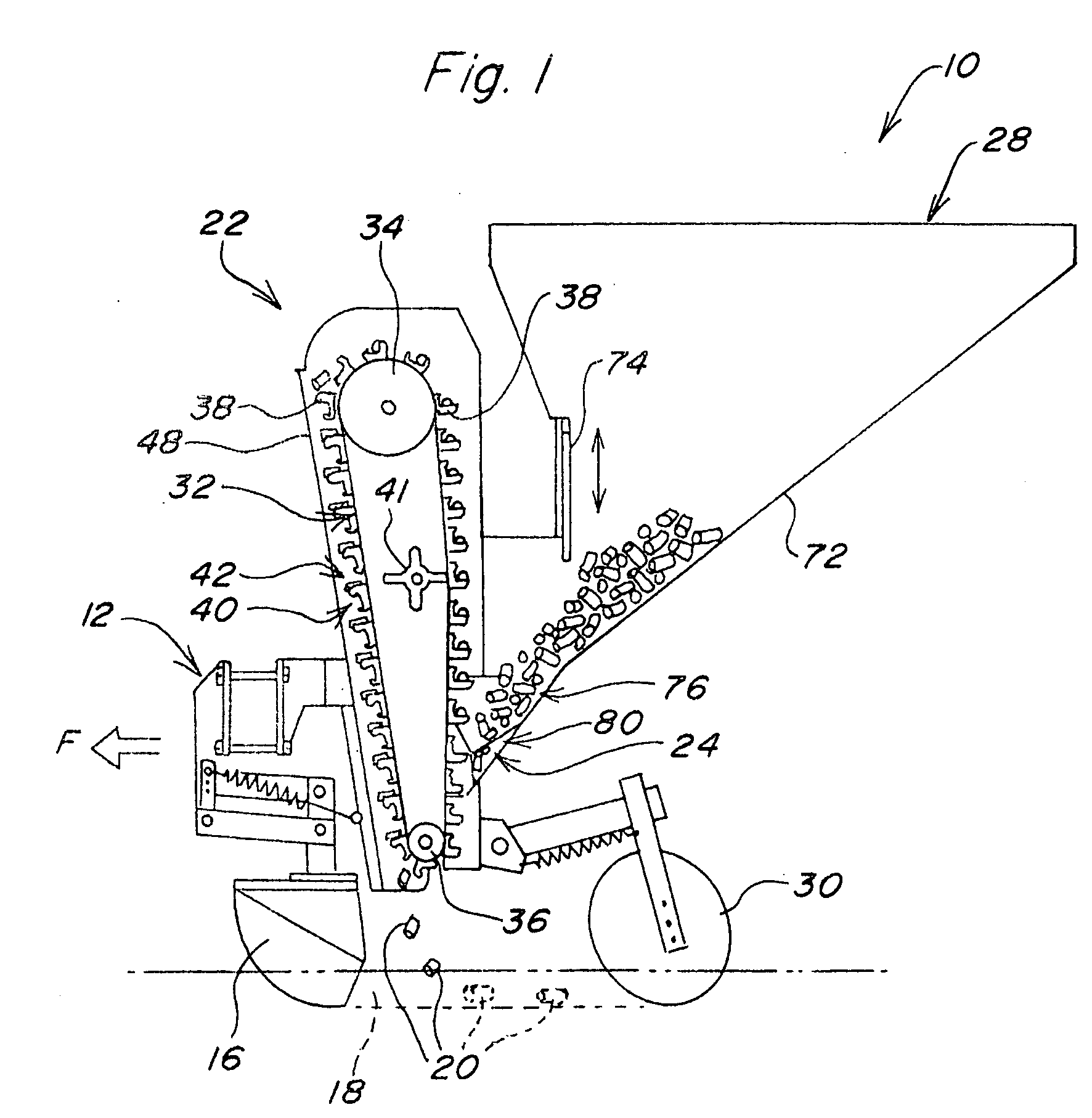

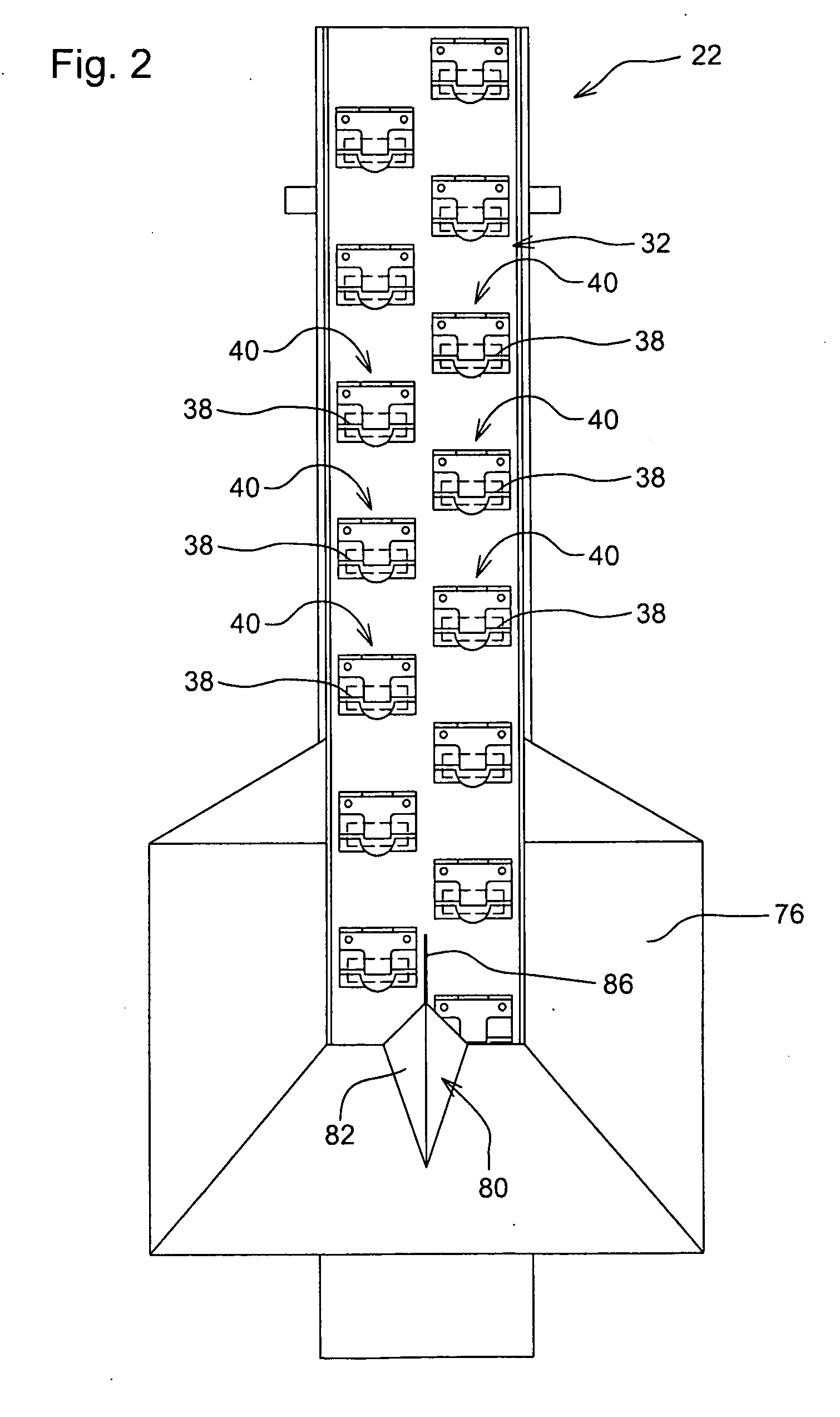

Planter with Cup Belt Meter

ActiveUS20100107944A1Facilitate entrySoften seed impactPotato plantersFurrow making/coveringSeederEngineering

A seed belt cup planter includes seed-intercepting indexing pocket structure facing an adjacent cup on the downward run of the belt towards a furrow for orienting the seed released from the adjacent cup relative to the furrow. In one embodiment, the indexing pocket structure is located on the underside of the cups and receives and orients a cylindrically shaped seed such as a short sugar cane billet. The seed pickup side of the cup is shaped to efficiently receive cylindrical seeds as well as round and oval seeds of differing sizes from a seed puddle. A divider located in the seed hopper between adjacent columns of cups helps channel the seed to the cups and limits pressure on the seed puddle.

Owner:DEERE & CO

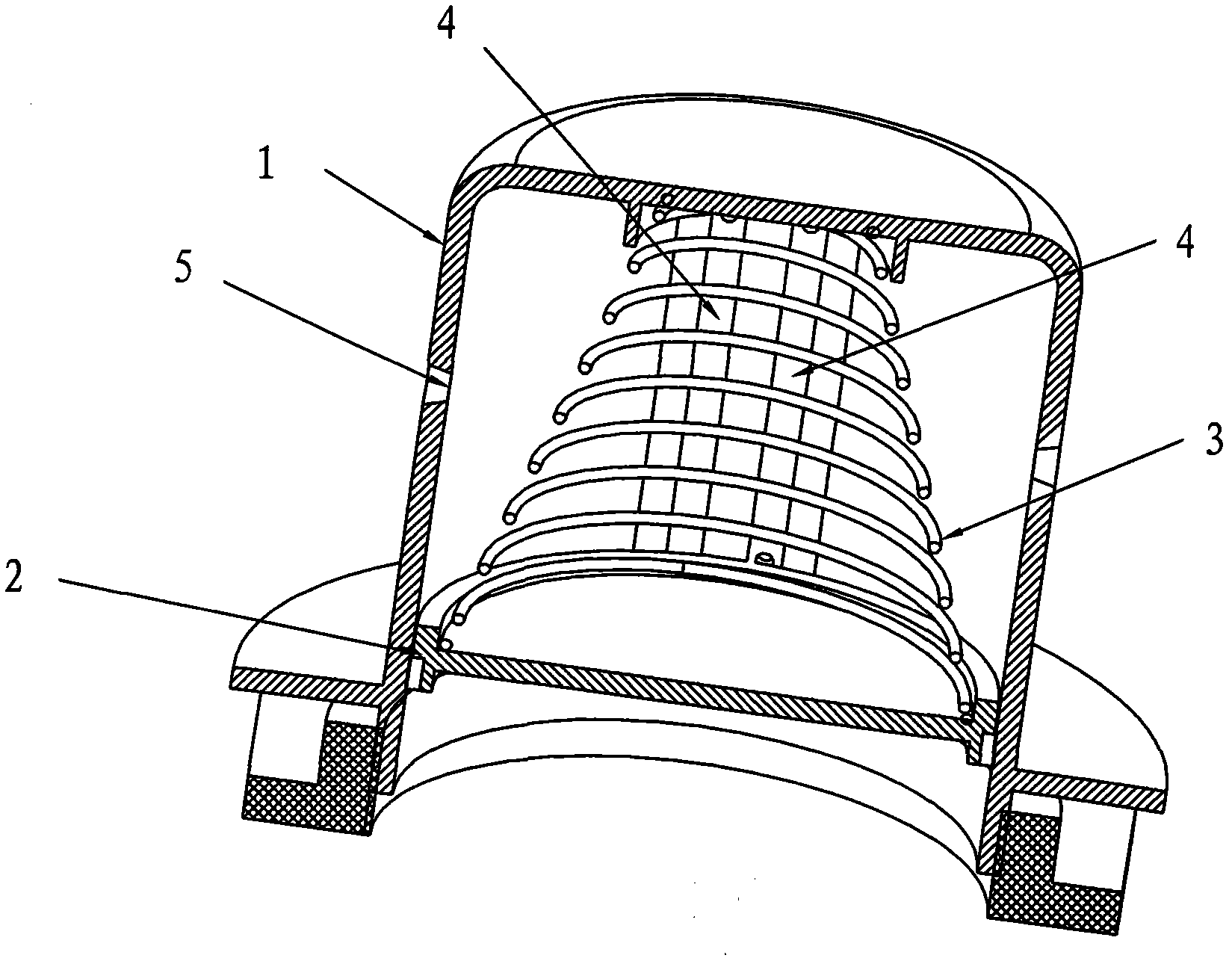

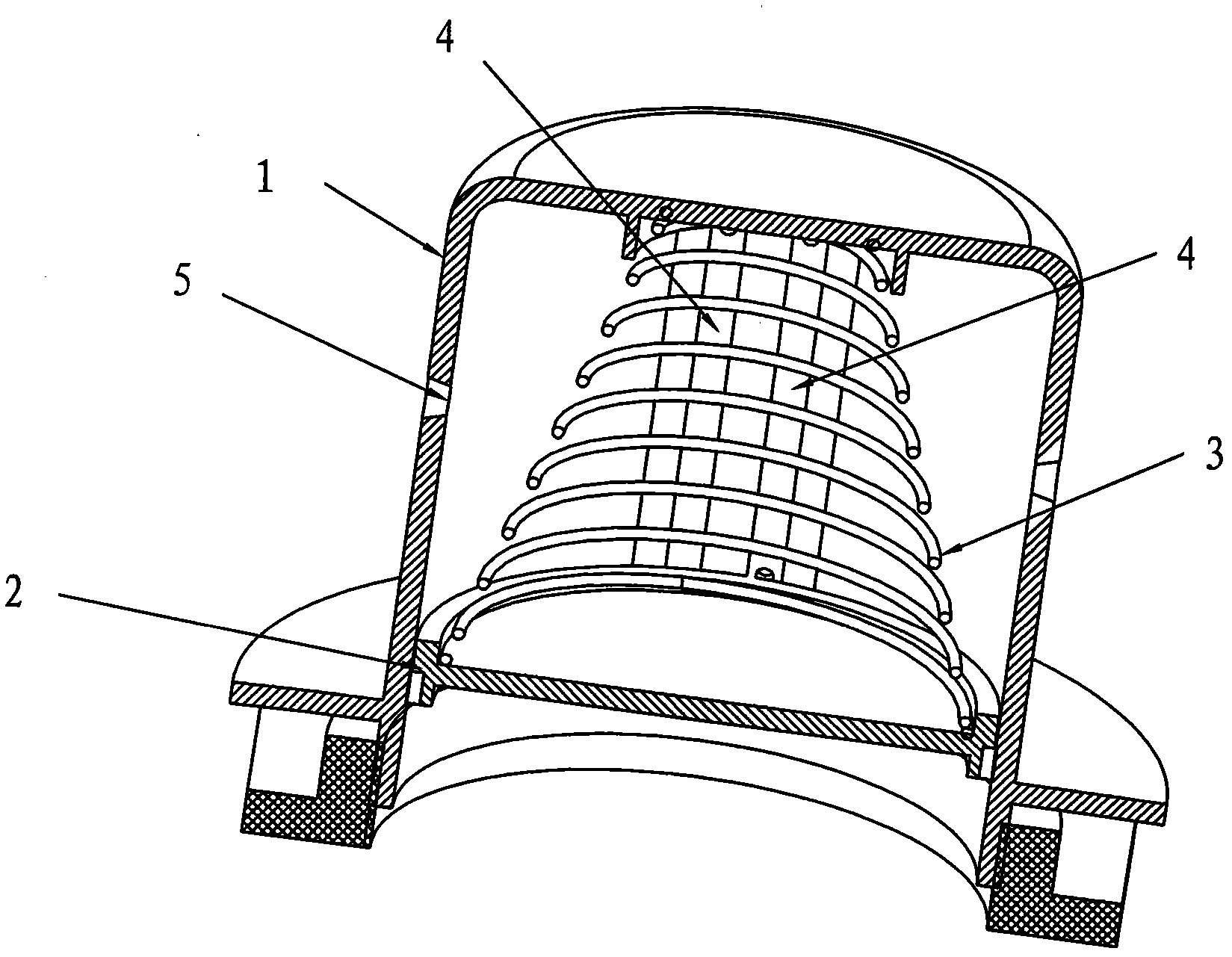

Pressure sensor for electric pressure cooker

InactiveCN101991354ASave energyThere will be no explosion phenomenonPressure-cookersPressure riseEngineering

The invention relates to a pressure sensor for an electric pressure cooker, which comprises a cylinder barrel with a lower opening, a piston, a pressure spring and an a potentiometer, wherein the piston and the cylinder barrel are in sliding fit with each other and subjected to liquid-gas sealing; one end of the pressure spring is matched with the piston, and the other end of the pressure spring is matched with a top plate of the cylinder barrel; and the potentiometer is driven by the piston, and a limit pressure relief hole is formed on the cylinder barrel wall between the piston and the top plate of the cylinder barrel. Due to the adoption of the structure, when the pressure in the cooker ascends, the piston moves upwards, an electrical signal of a resistor is transmitted to a control device of the electric pressure cooker; and when the set pressure requirement is met, the control device is subjected to outage to stop heating and save energy, so even if the potentiometer is damaged and the limit pressure relief hole relieves pressure, the phenomenon of cooker explosion does not occur, and potential safety hazards are eliminated.

Owner:乔林友

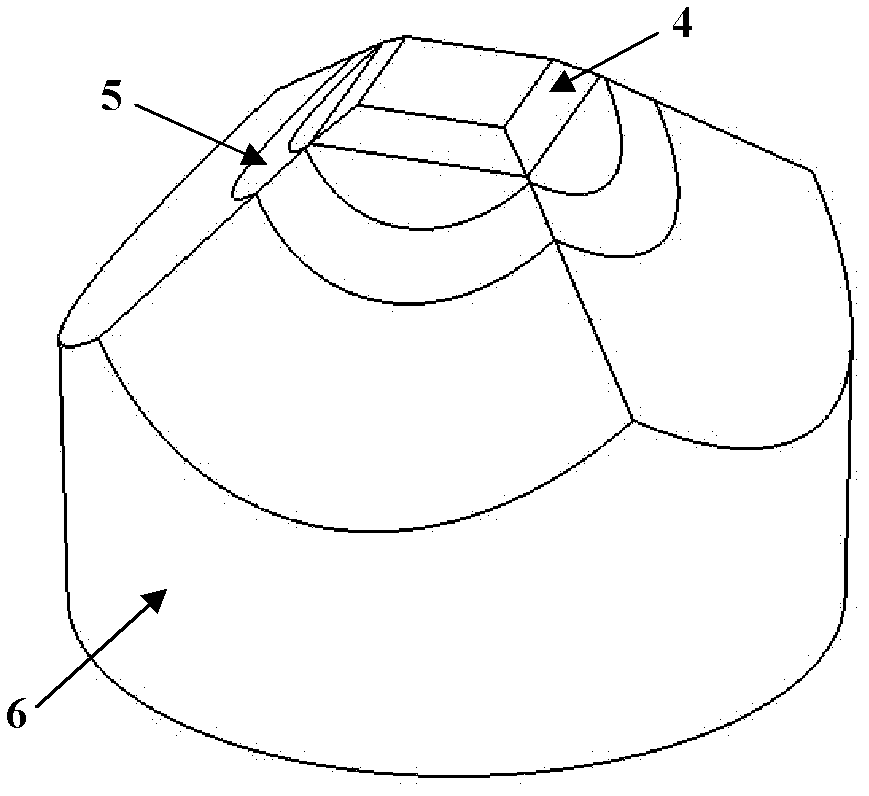

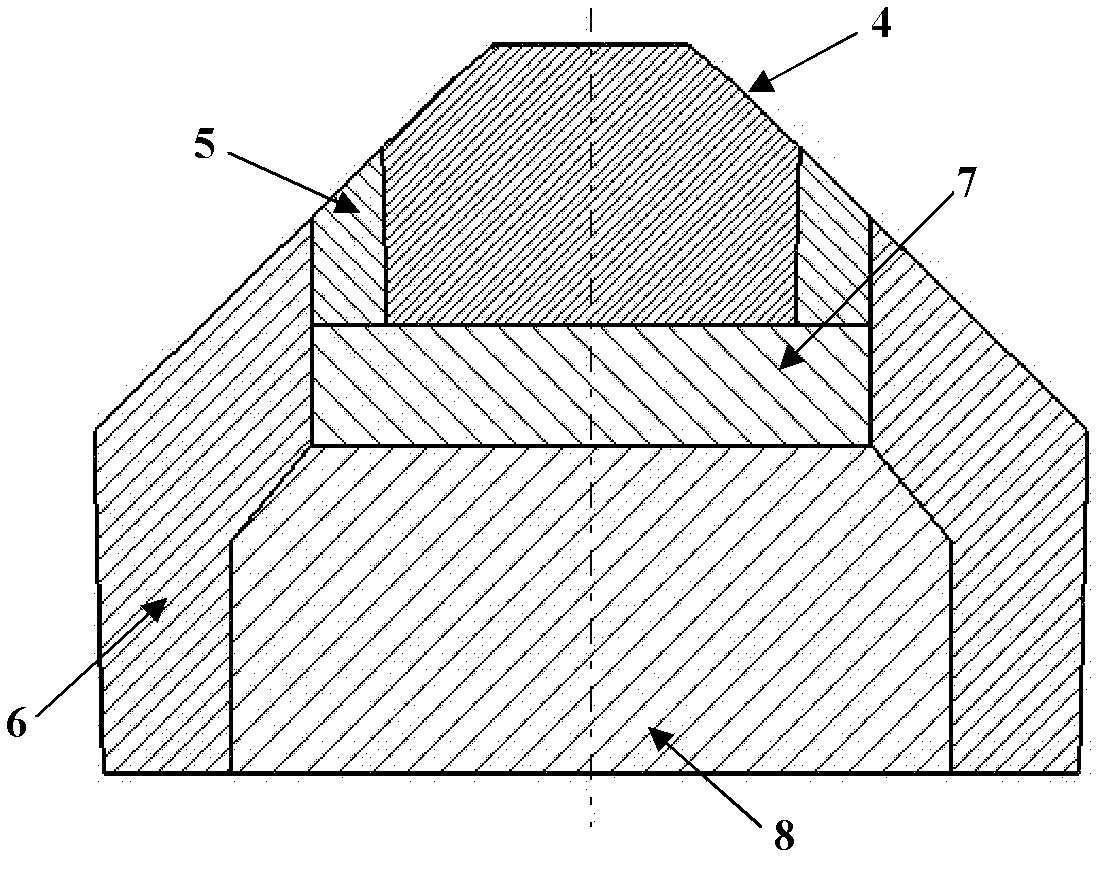

Six-anvil multi-grade supercharging device

InactiveCN102553494AReduce investmentEasy to operateUltra-high pressure processesEngineeringHigh pressure

The invention discloses a six-anvil multi-grade supercharging device, and belongs to the field of high-pressure physics. The device mainly comprises six anvils driven by a six-anvil hydraulic machine, at least two supercharging units and at least one pressure-transferring medium block, wherein every two anvils are symmetrically and coaxially arranged, and three axes are perpendicular to each other and are intersected at one point; each anvil consists of an anvil head, a pre-tightening ring and a cushion block, and the anvil head is assembled with the pre-tightening ring in a matching way; the pressure-transferring medium block is positioned at a point of intersection of the three mutually perpendicular axes, and the supercharging units are externally added or internally embedded, and are provided with high-pressure cavities; and the supercharging units and the pressure-transferring medium block are assembled in a grading way. According to the device, the value of pressure in the high-pressure cavities can be increased to hundreds of thousands of atmospheres, and solves the problem that the limit pressure value obtained by the high-pressure cavity of a six-anvil device is too low, promotes the complementary advantages of the six-anvil high-pressure device and a diamond anvil cell type high-pressure device to certain extent, and meets the development requirement of high-pressure physics and other basic science.

Owner:JILIN UNIV

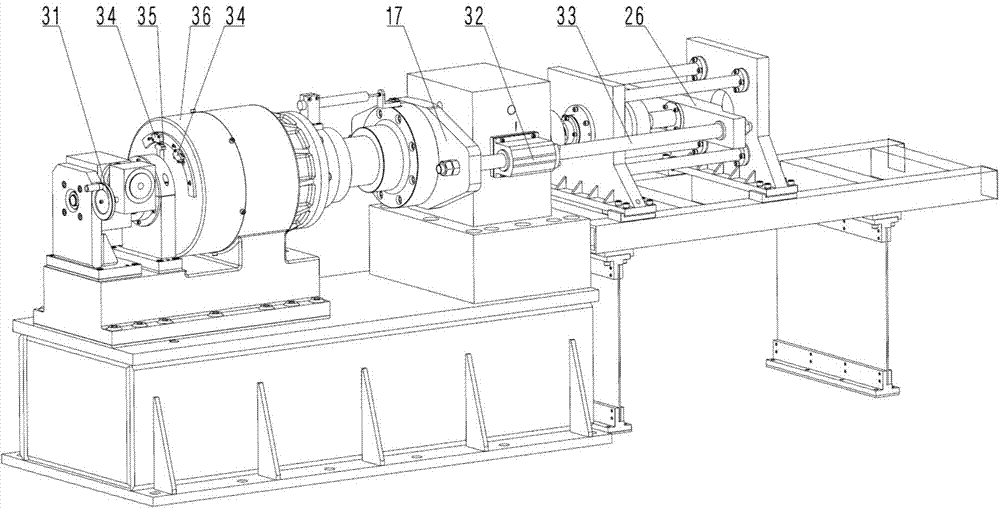

In-situ calibrating device with loaded direct-current torque motor and loaded driving ball screw assembly

ActiveCN104515684AReduce measurement errorImprove accuracyEngine testingForce/torque/work measurement apparatus calibration/testingAutomatic controlTorque motor

The invention belongs to the field of engine tests, discloses mechanical subsystems of in-situ calibrating systems, and relates to an in-situ calibrating device with a loaded direct-current torque motor and a loaded driving ball screw assembly. The in-situ calibrating device comprises the direct-current torque motor, the high-precision ball screw assembly, a high-precision encoder, a linear displacement sensor, a force transfer frame, a standard force sensor, a working force sensor, force transfer balls, force transfer ball sockets, a thrust frame, a force bearing frame, a motor base, a base, tapered roller bearings, a linear bearing, an electromagnetic clutch, double worm gear reducers, a hand wheel, an electric limit switch, a limit pressure plate and the like. The in-situ calibrating device has the advantages that an in-situ calibrating system comprises the in-situ calibrating device, a control subsystem of the in-situ calibrating system and a software subsystem of the in-situ calibrating system, an electric servo automatic control mechanical device loading method is implemented, accordingly, the in-situ calibrating device is high in in-situ calibrating loading force precision, is high in stability, good in safety and applicable to small-tonnage force and has an overload protection function, calibrating procedures can be automated, and manual loading modes are taken into consideration.

Owner:北京瑞赛长城航空测控技术有限公司 +2

Engine equipped with turbocharger

InactiveCN104884772AIncrease fuel consumptionElectrical controlInternal combustion piston enginesTurbochargerPressure control

An engine includes: a turbocharger including a turbine and a compressor; an EGR passage connecting an exhaust passage on an upstream side of the turbine and an air intake passage on a downstream side of the compressor; an EGR valve provided in the EGR passage; a bypass passage that bypasses the turbine; and a waste gate valve provided in the bypass passage. In the engine, when a boost pressure is increased to a limit pressure, a first boost pressure control is executed, in which the EGR valve is opened and the waste gate valve is closed. After the first boost pressure control starts, when an engine speed is increased to a prescribed value, a second boost pressure control is executed, in which the waste gate valve is opened in addition to the EGR valve.

Owner:MAZDA MOTOR CORP

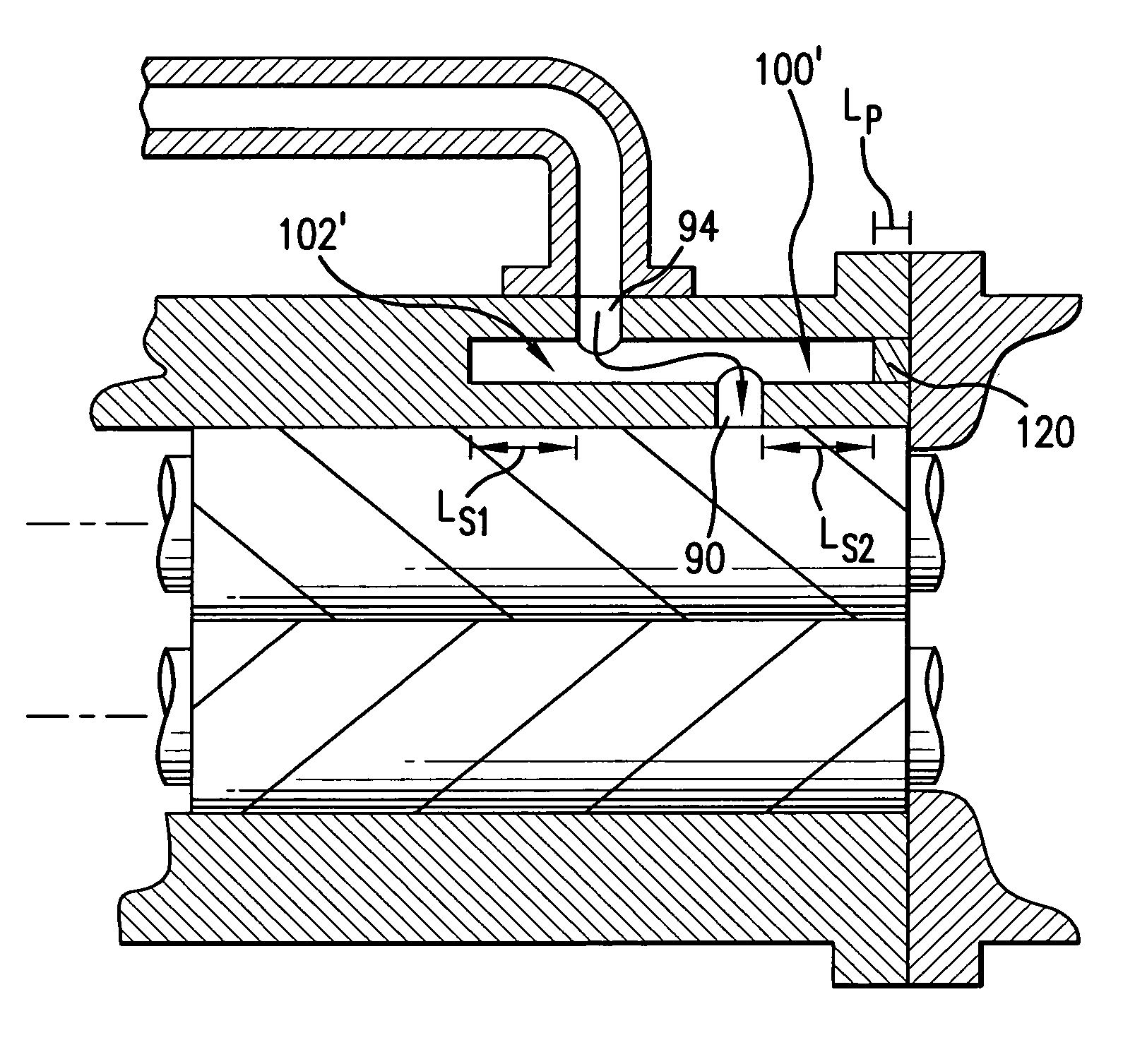

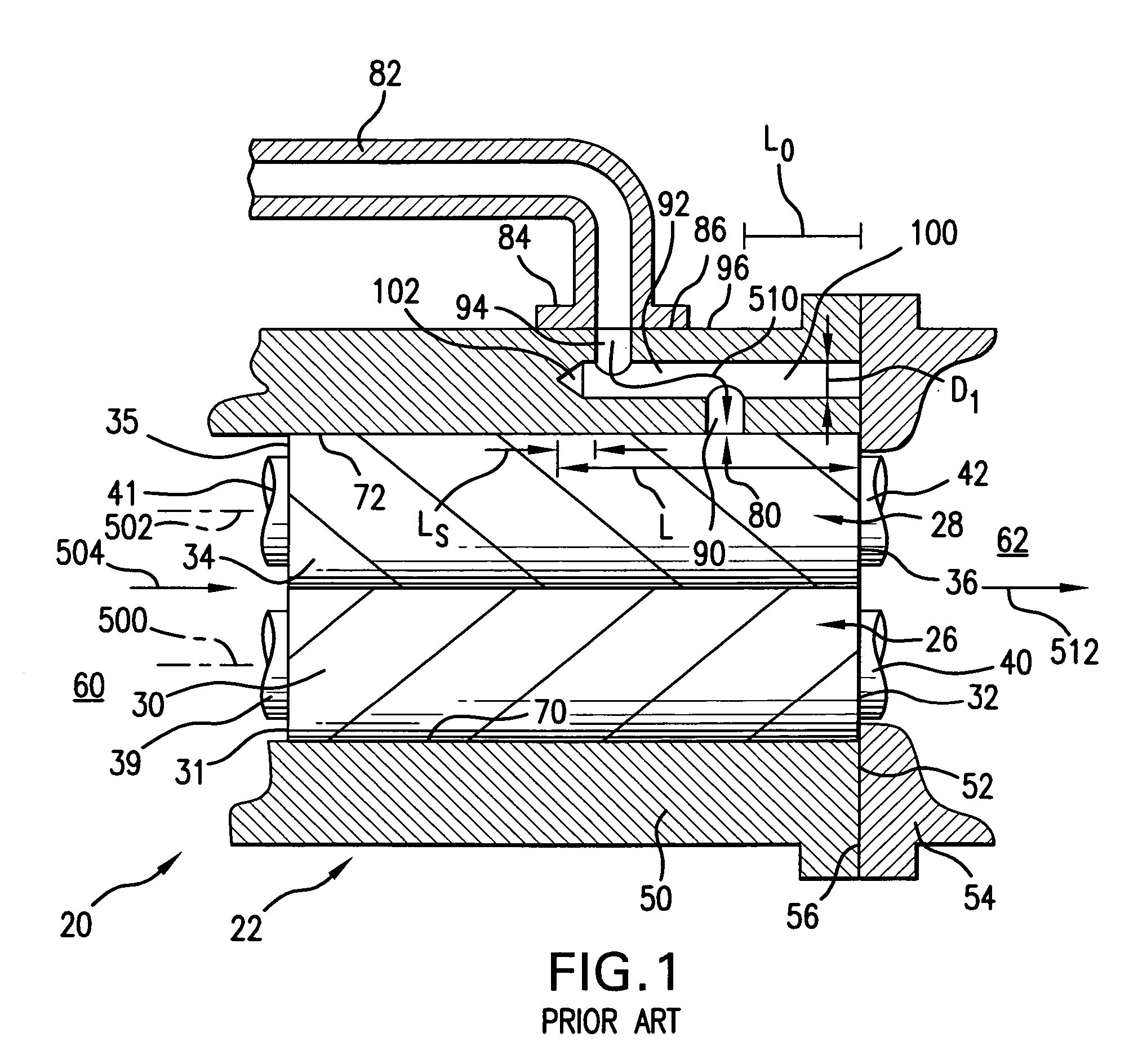

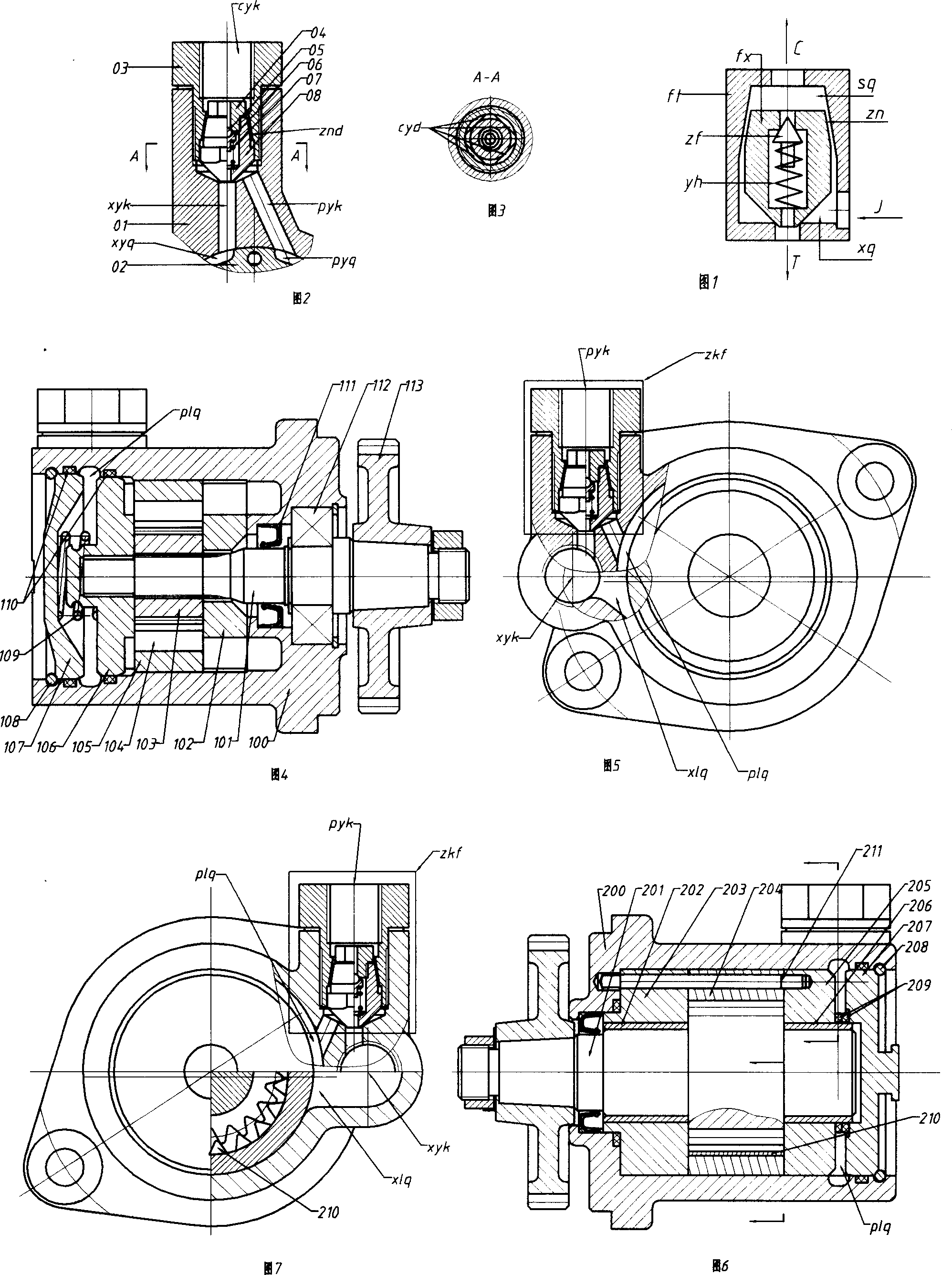

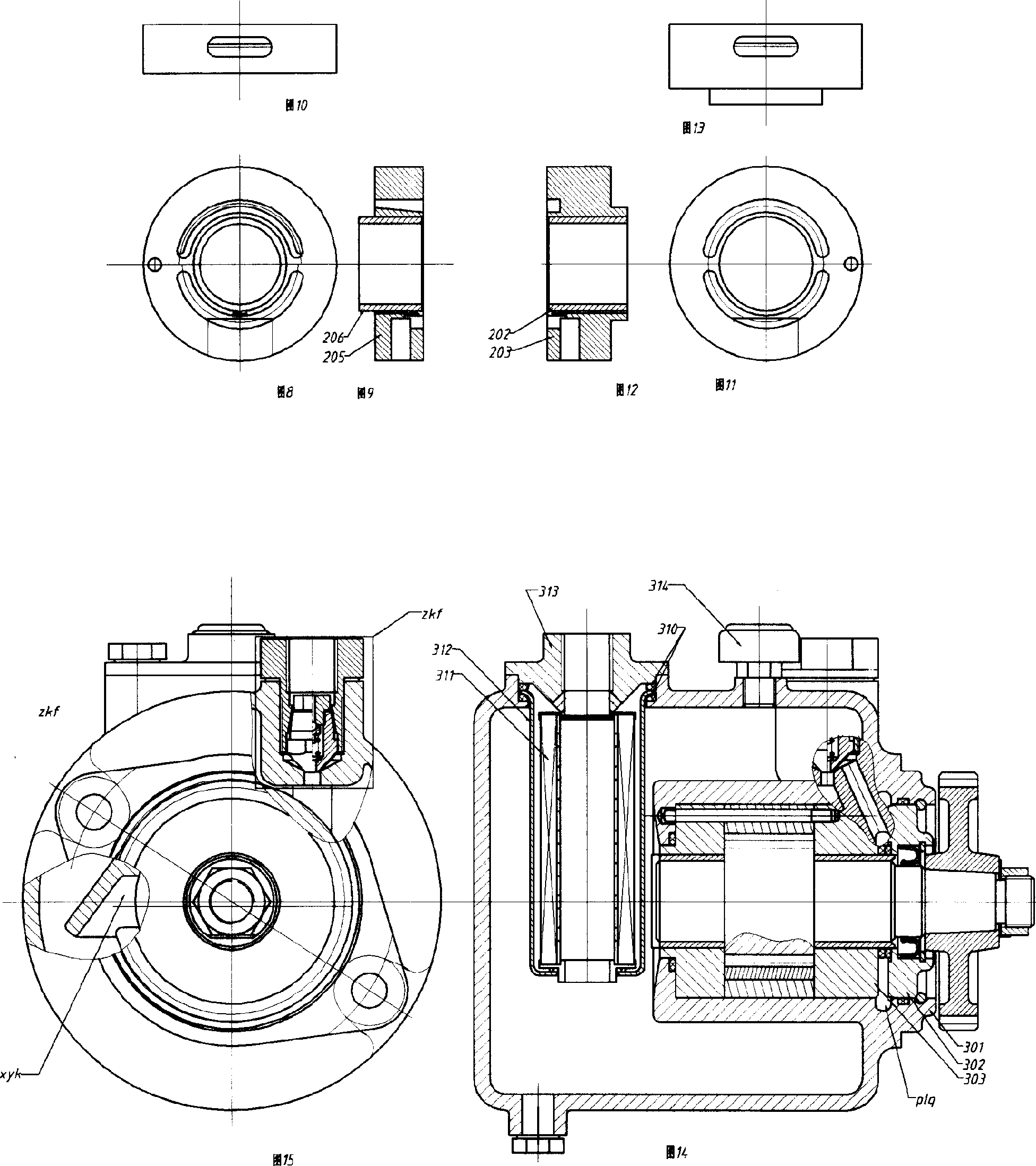

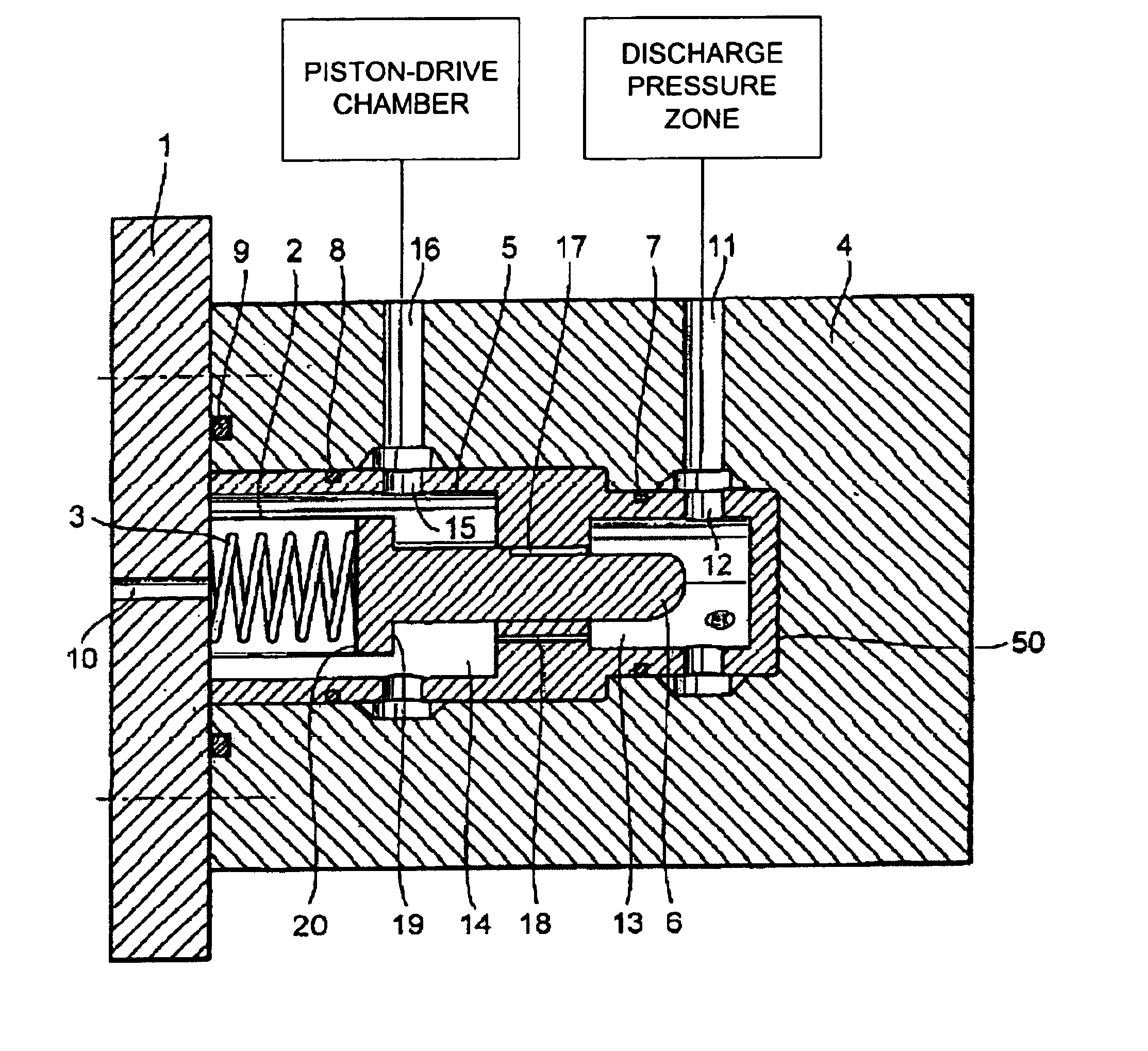

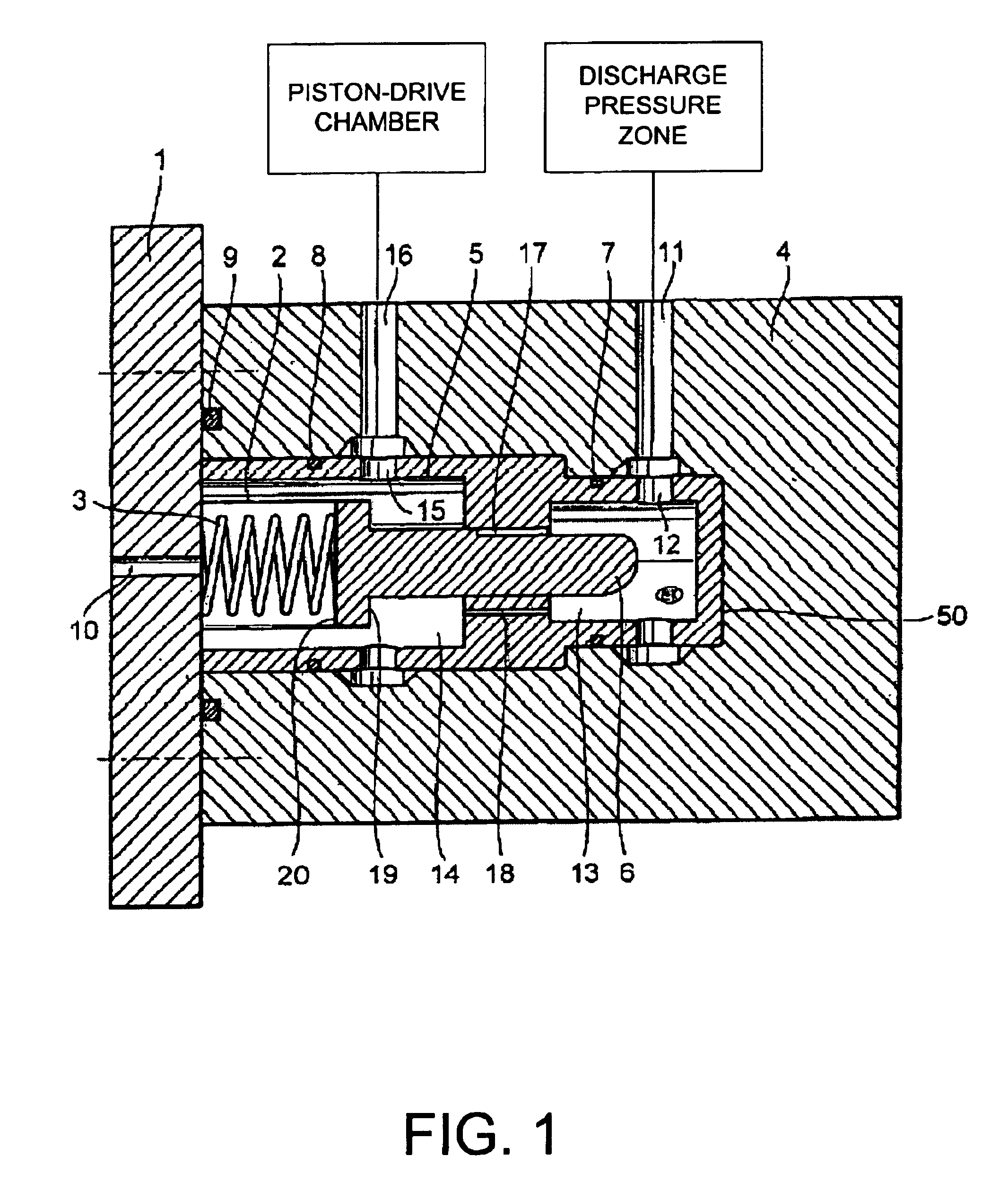

Safety device to limit pressure in an axial-piston compressor housing

InactiveUS6953325B2Air-treating devicesCompression machines with non-reversible cyclePressure differenceHigh pressure

A safety device limits the pressure in an axial-piston compressor with variable piston displacement. The compressor has as wobble plate or swash plate whose tilt angle can be variably controlled by the pressure differential between the high pressure in the discharge pressure zone and the pressure in the piston-drive chamber. The safety device consists of a valve arranged in a connector channel between the discharge pressure zone and the pressure zone of the piston-drive chamber. When the discharge pressure exceeds a given pressure limit, the safety device responds by allowing an increased flow of pressure medium from the discharge pressure zone to the piston-drive chamber. The influx of pressure medium into the piston-drive chamber causes a reduction of the tilt angle of the swash plate or wobble plate.

Owner:LUK FAHRZEUG HYDRAULIK +1

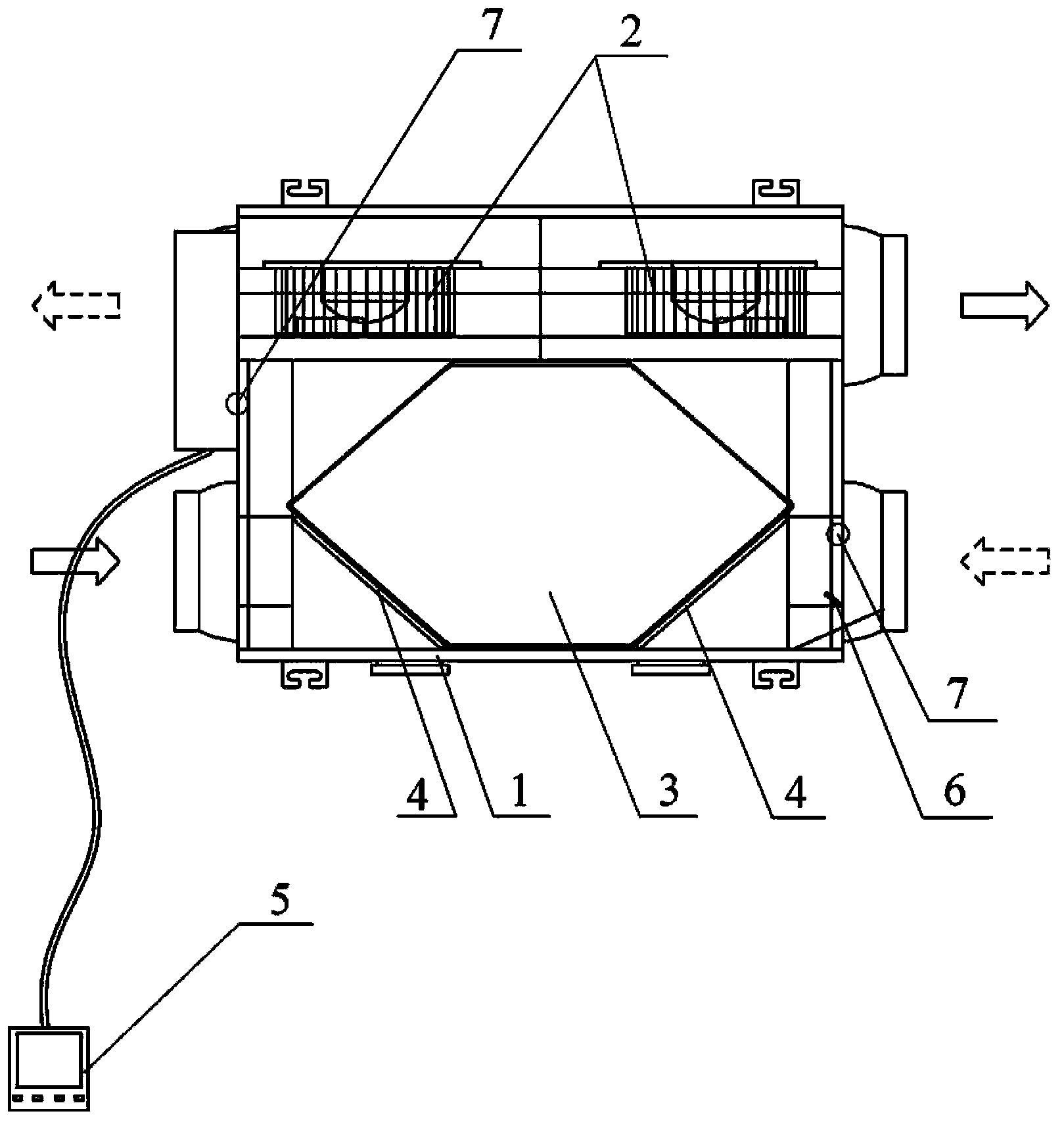

Intelligent total heat exchanger

ActiveCN104236056AAvoid frostTimely replacementSpace heating and ventilation safety systemsLighting and heating apparatusStart timeAutomatic control

The invention discloses an intelligent total heat exchanger, wherein an air quality sensor can control the rotating speed of a fan; a fan speed setting machine can set the rotating speed of the fan at different times throughout the day, and can automatically control the rotating speed according to the time; an operation time accumulator can accumulate the whole machine starting time, can compare the whole machine starting time with the longest use time limiting value of a filter cotton pre-arranged in the controller, and controls the rotating mode of the fan according to the compared result; and the front-back pressure difference value of a pressure sensor is compared with the limit pressure difference value of the filter cotton pre-arranged in the controller, and an alarm is controlled to warn according to the compared result. The intelligent total heat exchanger can automatically control the rotating speed of the fan all day according to the living habits of general crowds, can monitor the indoor temperature and the outdoor temperature in real time, can automatically monitor the use time of the filter cotton and the sudden failure, and starts different rotating modes of the fan through monitoring the outdoor temperature to prevent the frost from forming on an impeller of the fan to cause unsmooth operation.

Owner:恩科(苏州)通风系统有限公司

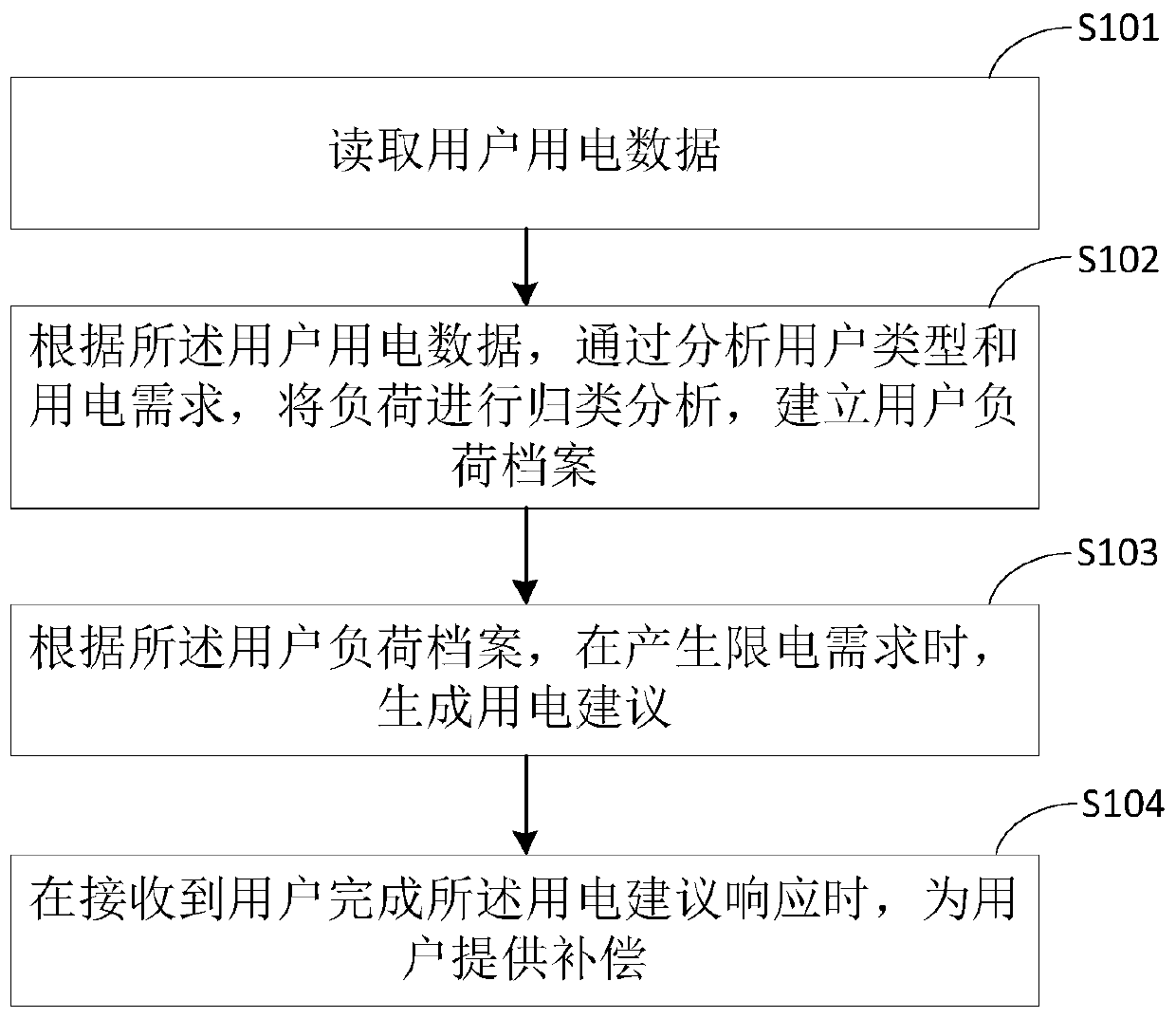

Power supply and consumption demand side response load regulation transaction method and system and terminal equipment

InactiveCN110135761ADiversified ways of using electricityIncrease motivationDiscounts/incentivesForecastingElectricityTerminal equipment

The invention relates to the technical field of data perception, edge calculation and e-commerce transaction modes, in particular to a power supply and consumption demand side response load regulationtransaction method and system and terminal equipment. The method comprises the following steps: reading power consumption data of a user; according to the user electricity consumption data, by analyzing the user type and the electricity consumption requirement, classifying and analyzing loads, and establishing a user load file; generating electricity consumption suggestions when electricity limiting requirements are generated according to the sub-user load archives; and providing compensation for the user when the power consumption suggestion response completed by the user is received. According to the method, the electricity limiting pressure can be reduced, meanwhile, diversified electricity utilization modes are provided for the user, and the enthusiasm of the user for participation isaroused.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

Inkjet printer cartridge refill dispenser with plunge action

A printing fluid dispenser including: a housing comprising a base and a plunger; a deformable container located within the housing for storing printing fluid; an outlet coupled to the deformable container and arranged to convey the printing fluid to a point external to the housing; and a spring located between the deformable container and the plunger having characteristics selected to limit pressure in the deformable container to a predetermined level in use; wherein in use, bringing the plunger towards the base causes compression of the deformable container between the spring and the base and egress of the printing fluid through the outlet.

Owner:SILVERBROOK RES PTY LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com