In-situ calibrating device with loaded direct-current torque motor and loaded driving ball screw assembly

A DC torque motor and in-situ calibration technology, applied in the calibration/testing of force/torque/power measuring instruments, measuring devices, engine testing, etc., can solve problems such as easy oil leakage, fire hazards, and loud noise from oil sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

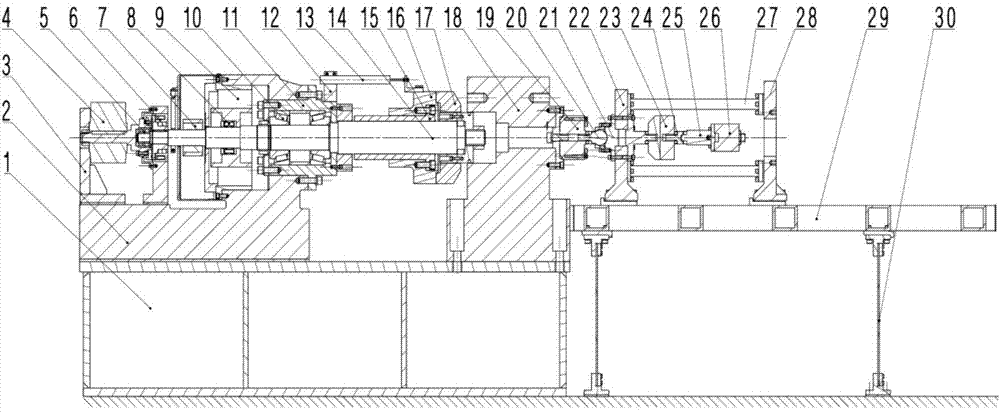

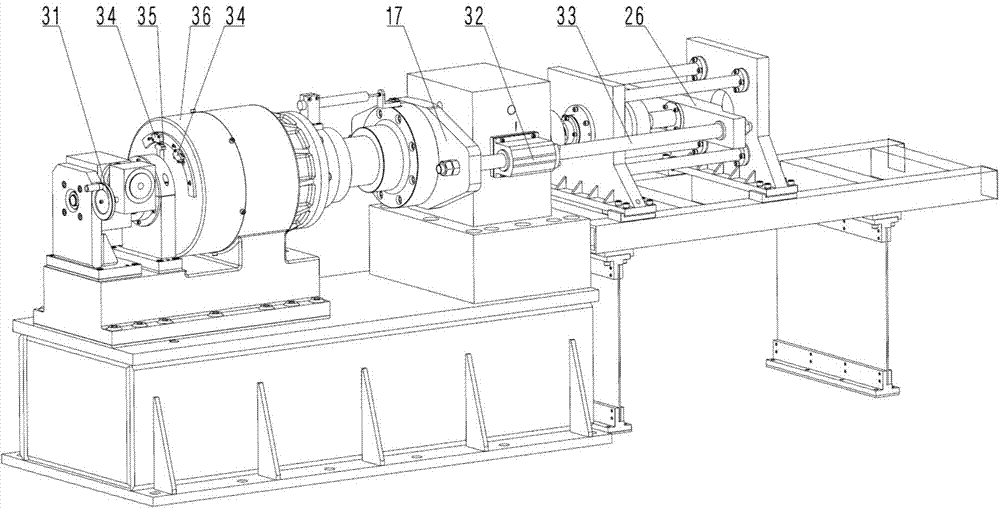

[0018] As shown in the figure, the structure of the present invention mainly includes base 1, motor base 2, reducer bracket 3, double worm gear reducer 4, single row cylindrical roller bearing 5, electromagnetic clutch 6, encoder 7, tensioner sleeve 8 , DC torque motor 9, tapered roller bearing 10, bearing housing 11, displacement sensor mounting base 12, linear displacement sensor 13, ball screw 14, screw nut 15, screw nut seat 16, back beam 17, bearing frame 18, work Force sensor 19, working force sensor force transmission ball head 20, working force sensor force transmission ball socket 21, thrust frame back plate 22, standard force sensor 23, standard force sensor force transmission ball socket 24, standard force sensor force transmission ball head 25 , Force transmission frame front beam 26, thrust frame connecting rod 27, thrust frame front plate 28, moving fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com