Patents

Literature

178 results about "In situ calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

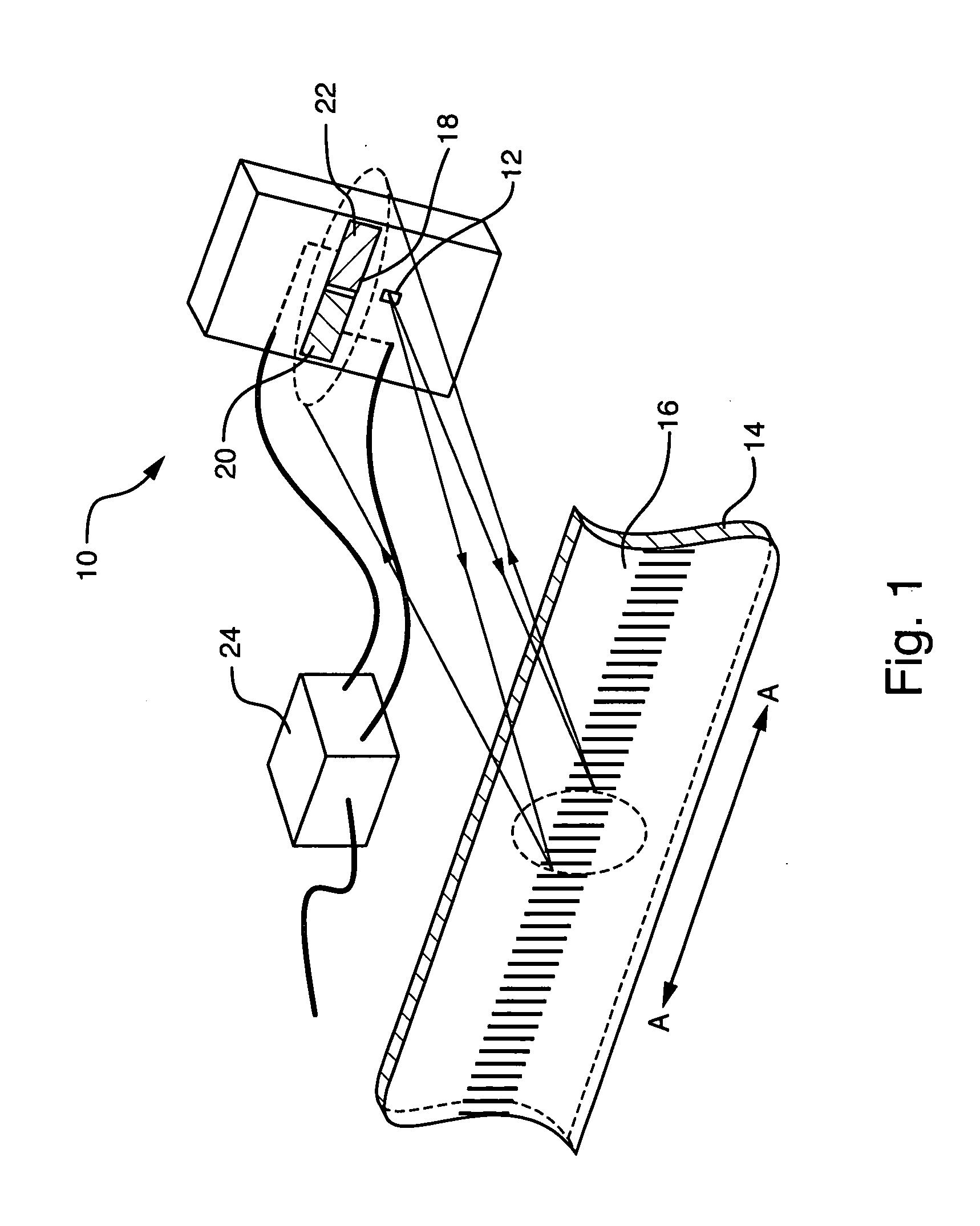

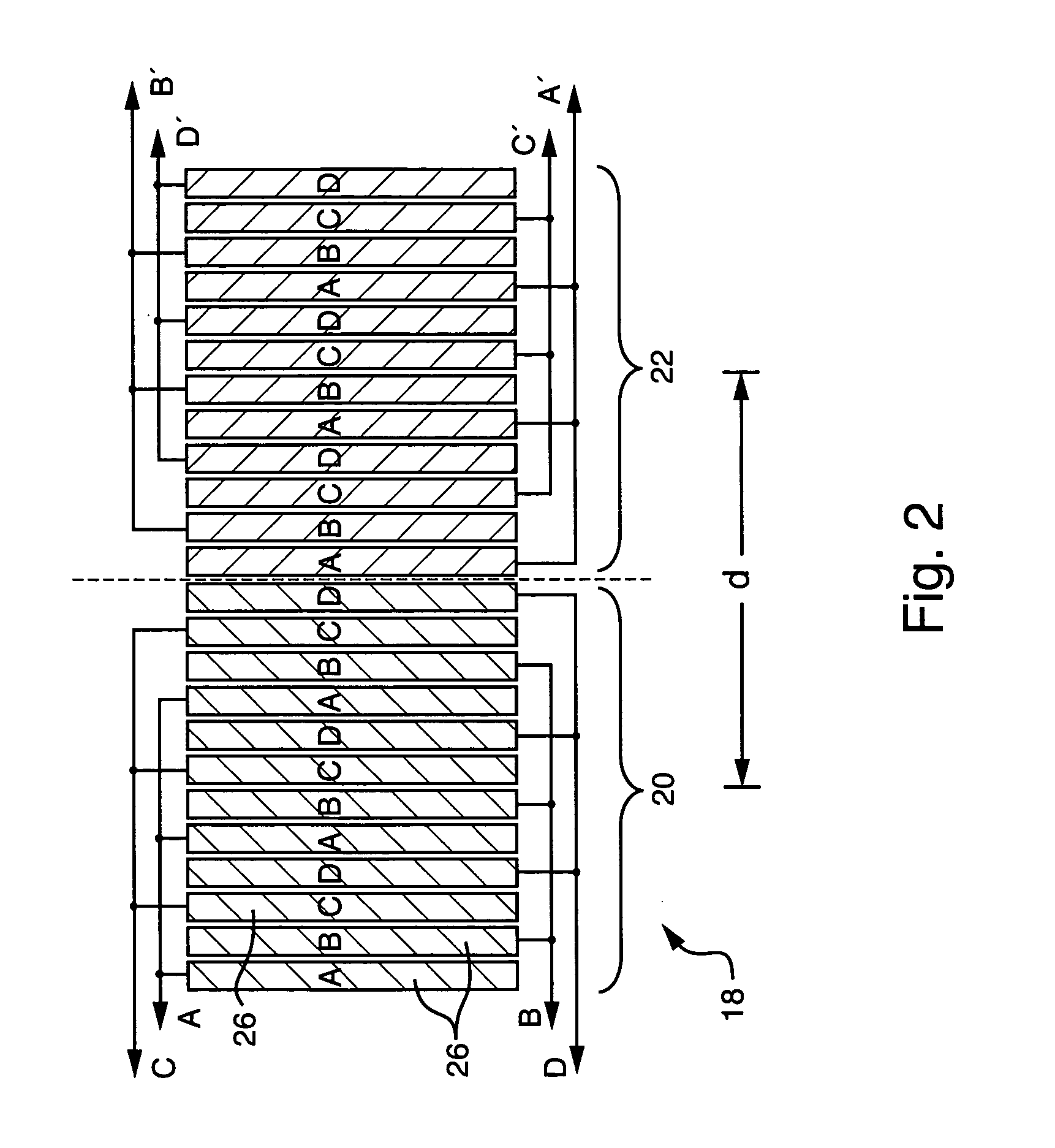

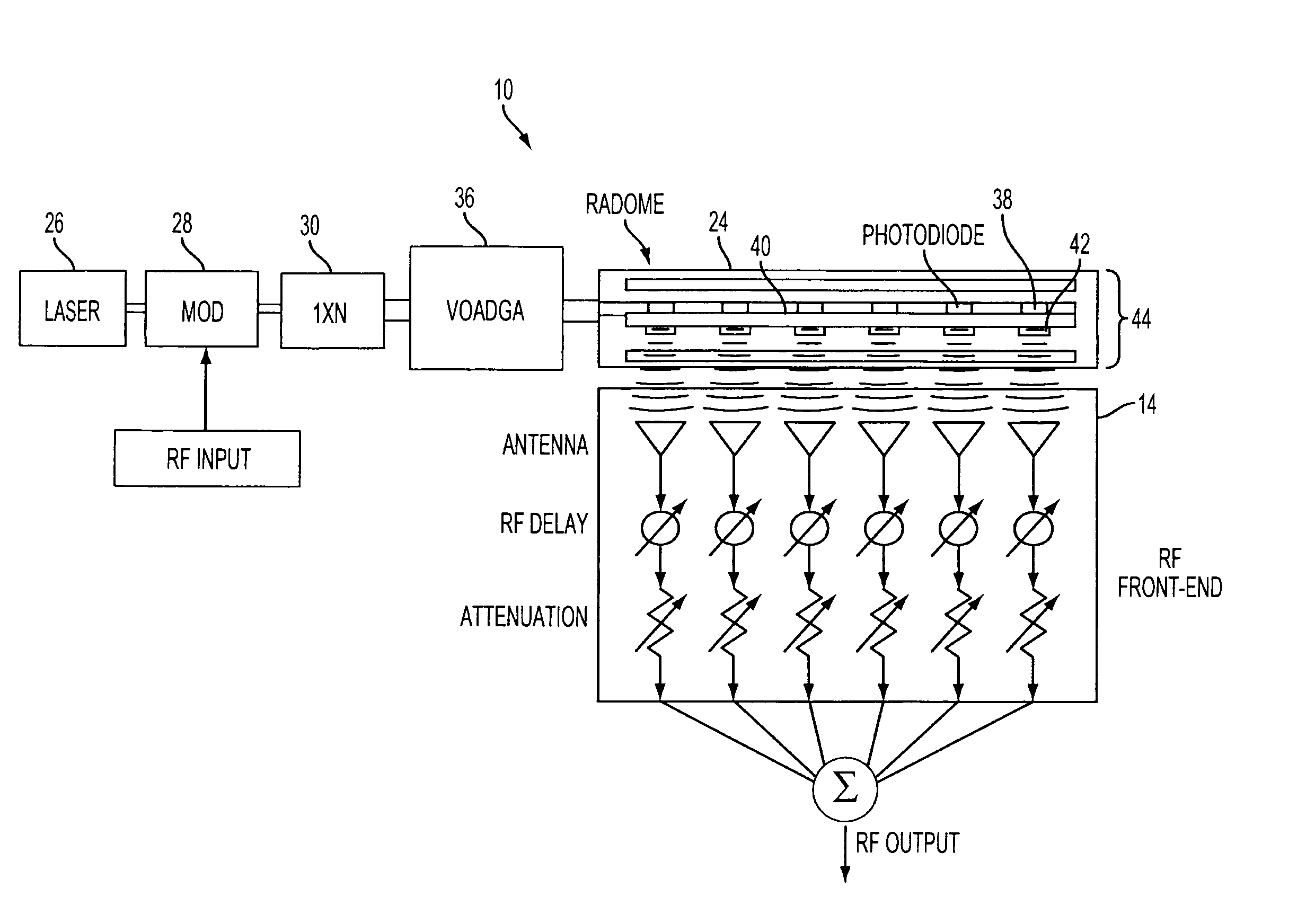

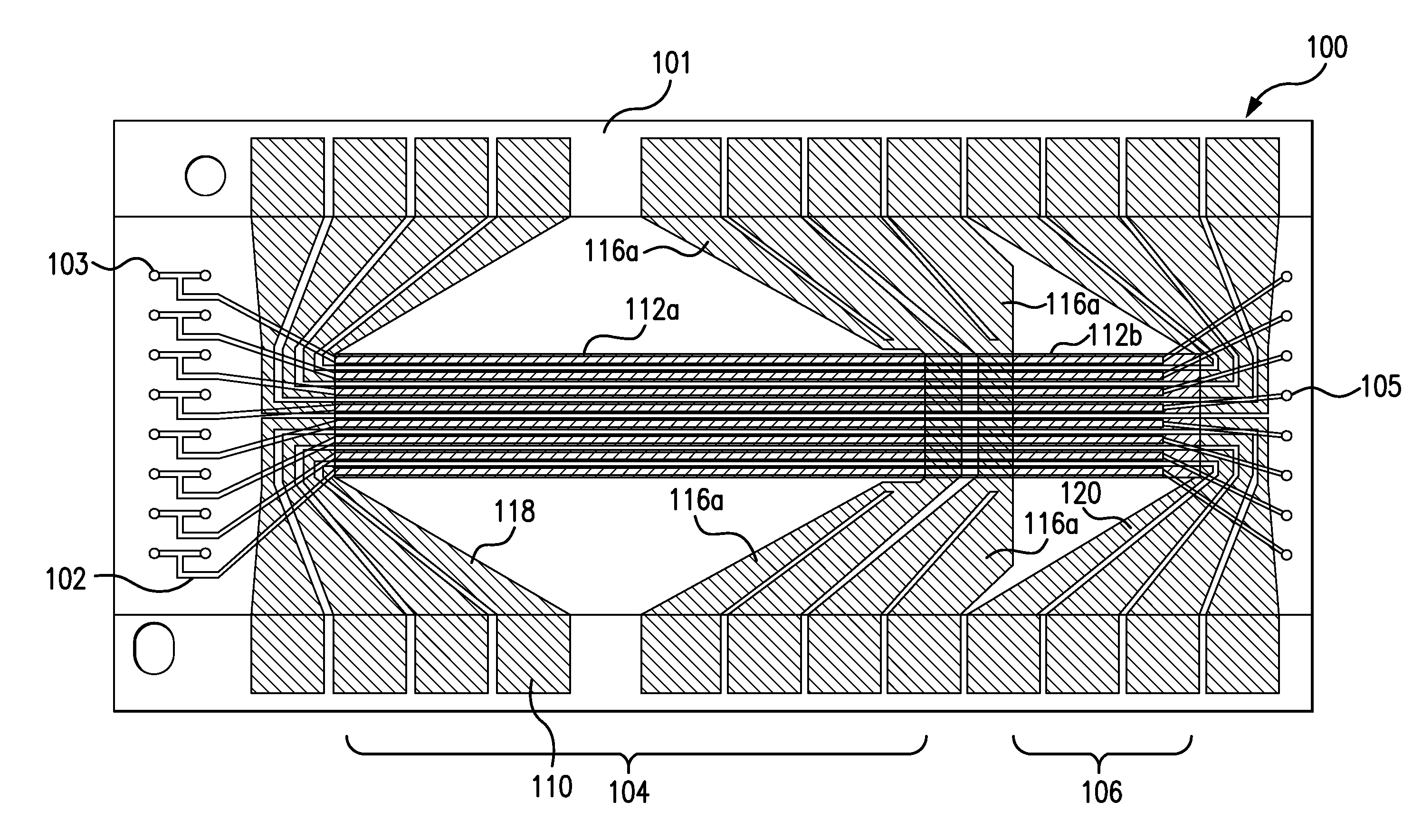

Antenna calibration method and system

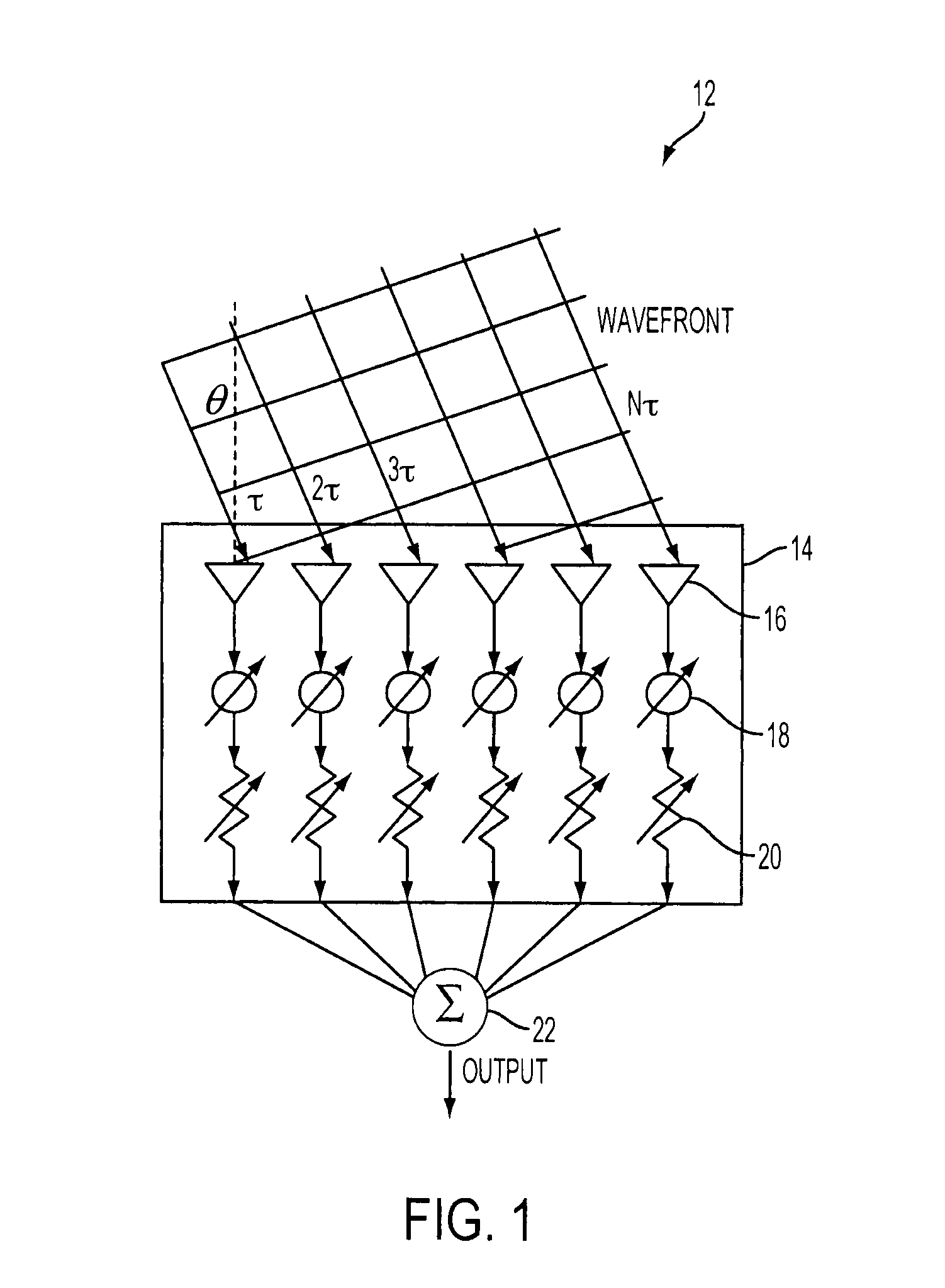

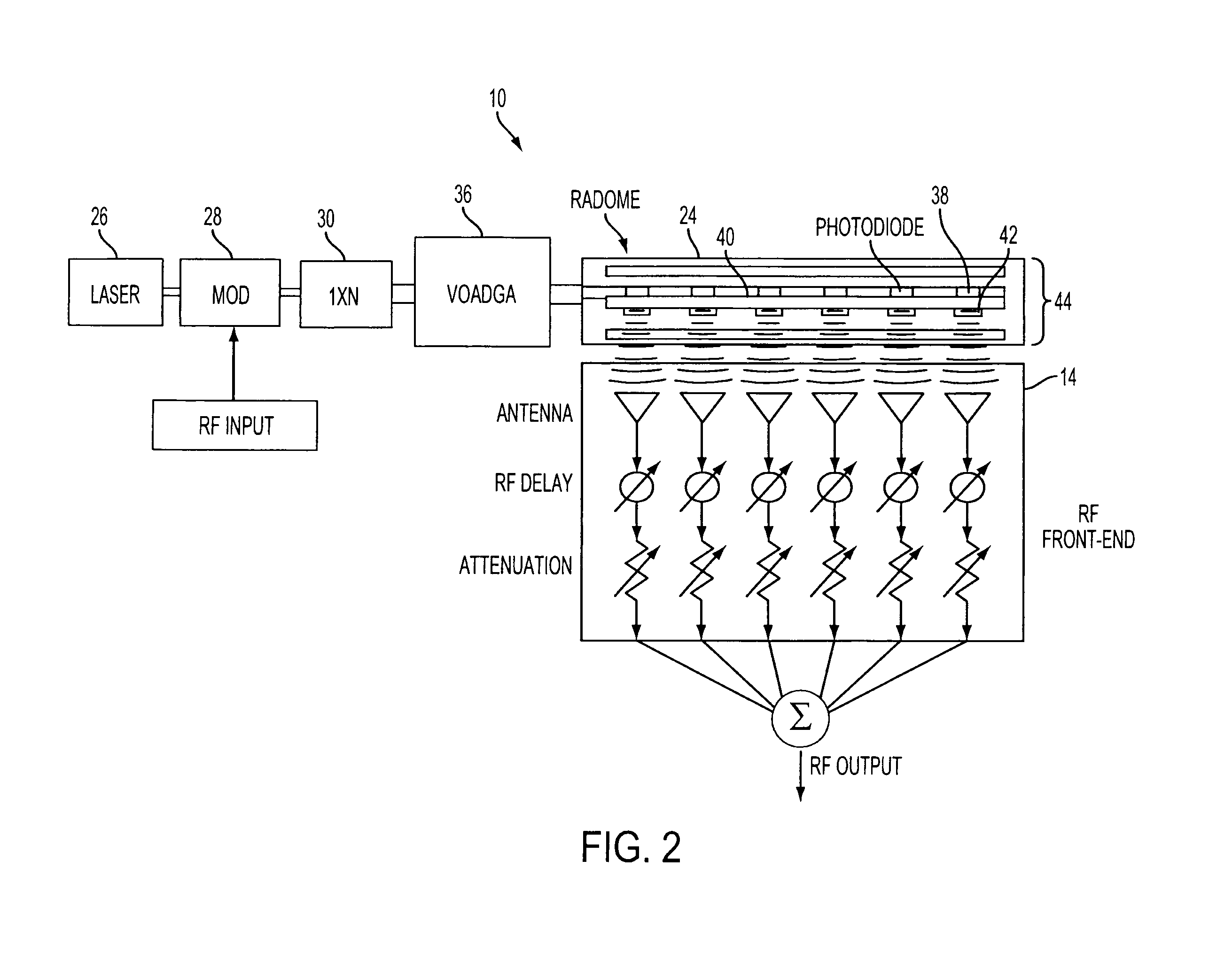

InactiveUS7408507B1Enabling in-situ calibrationReduce calibration timeAntenna arraysBeacon systemsRF front endEngineering

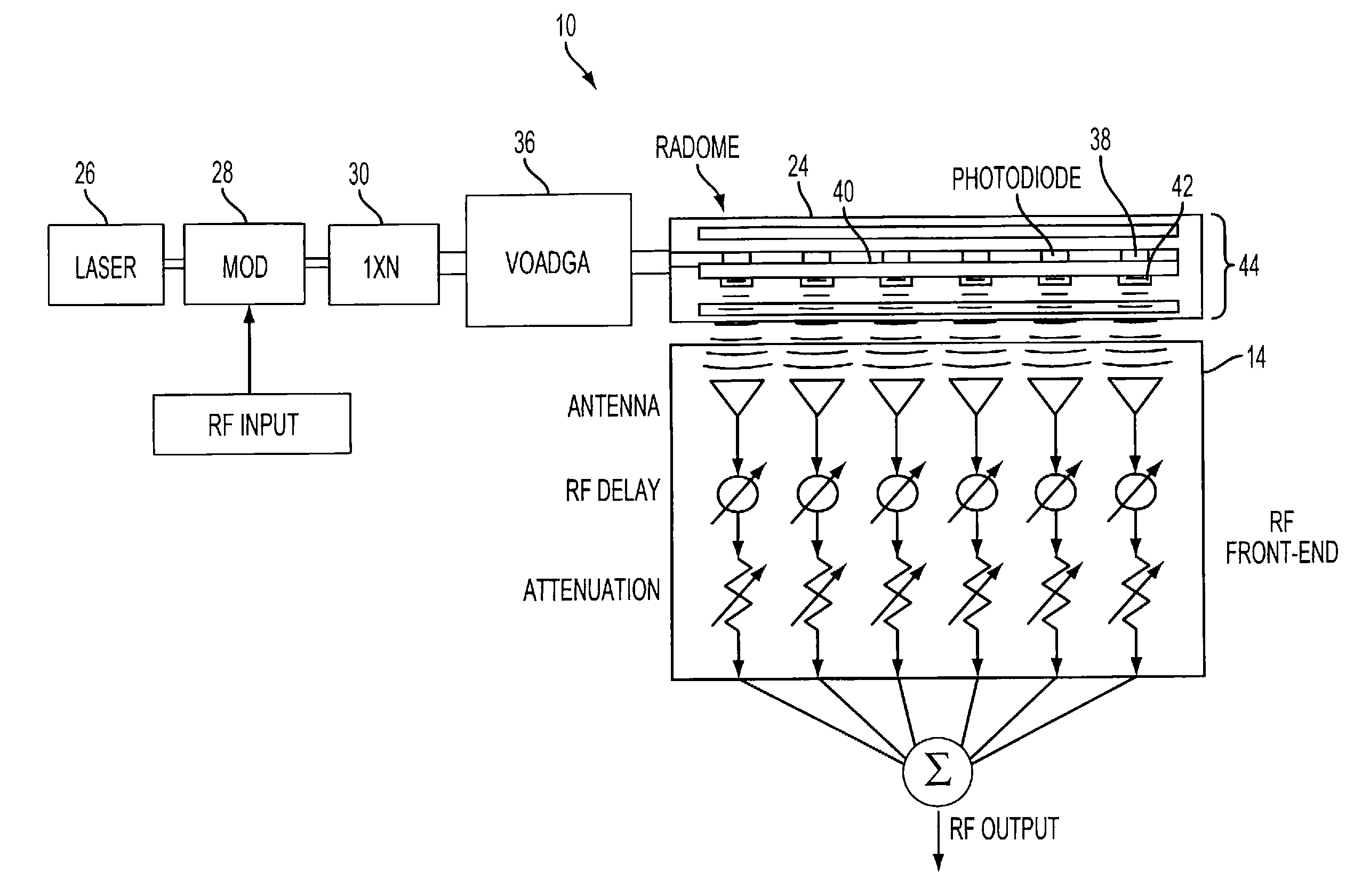

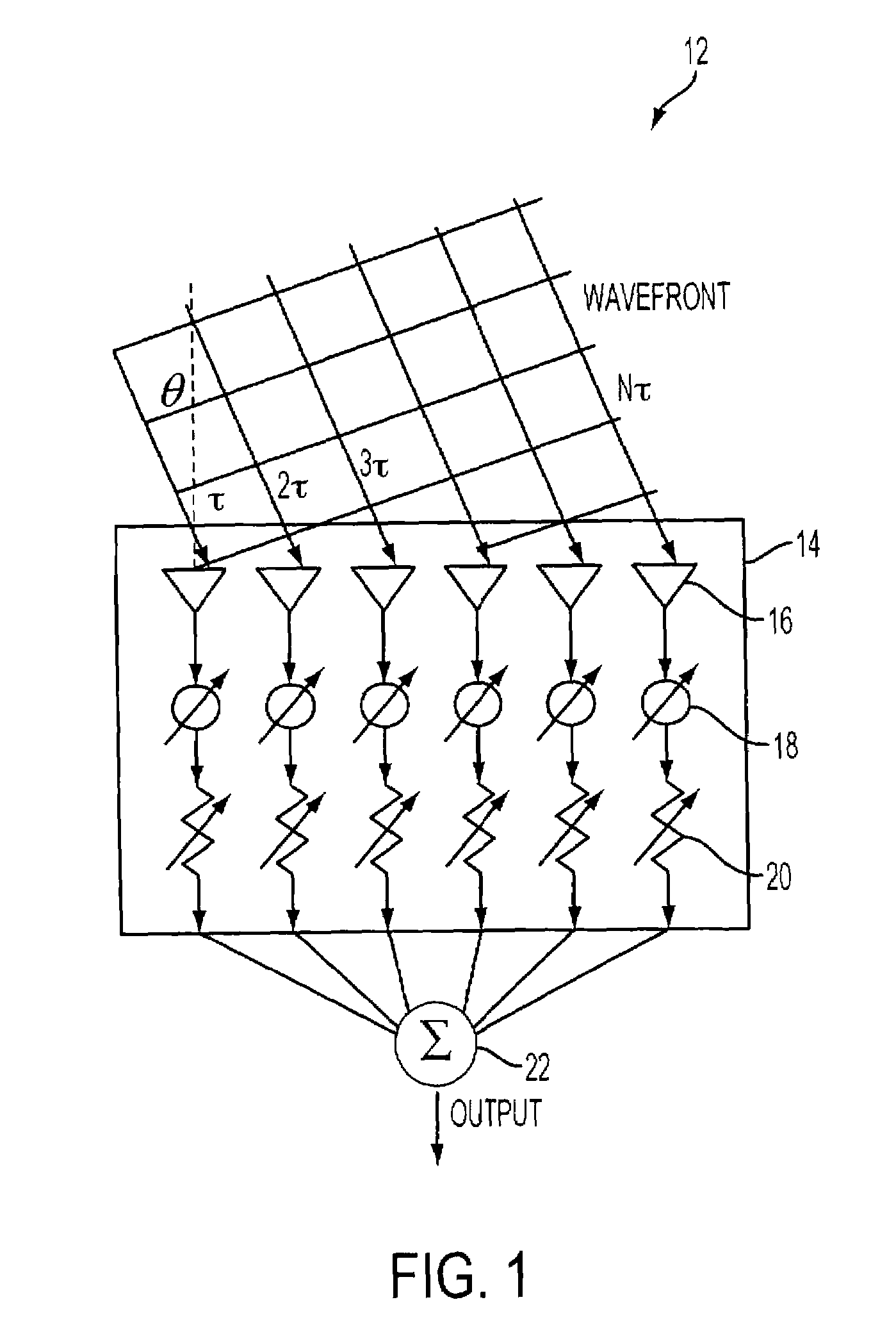

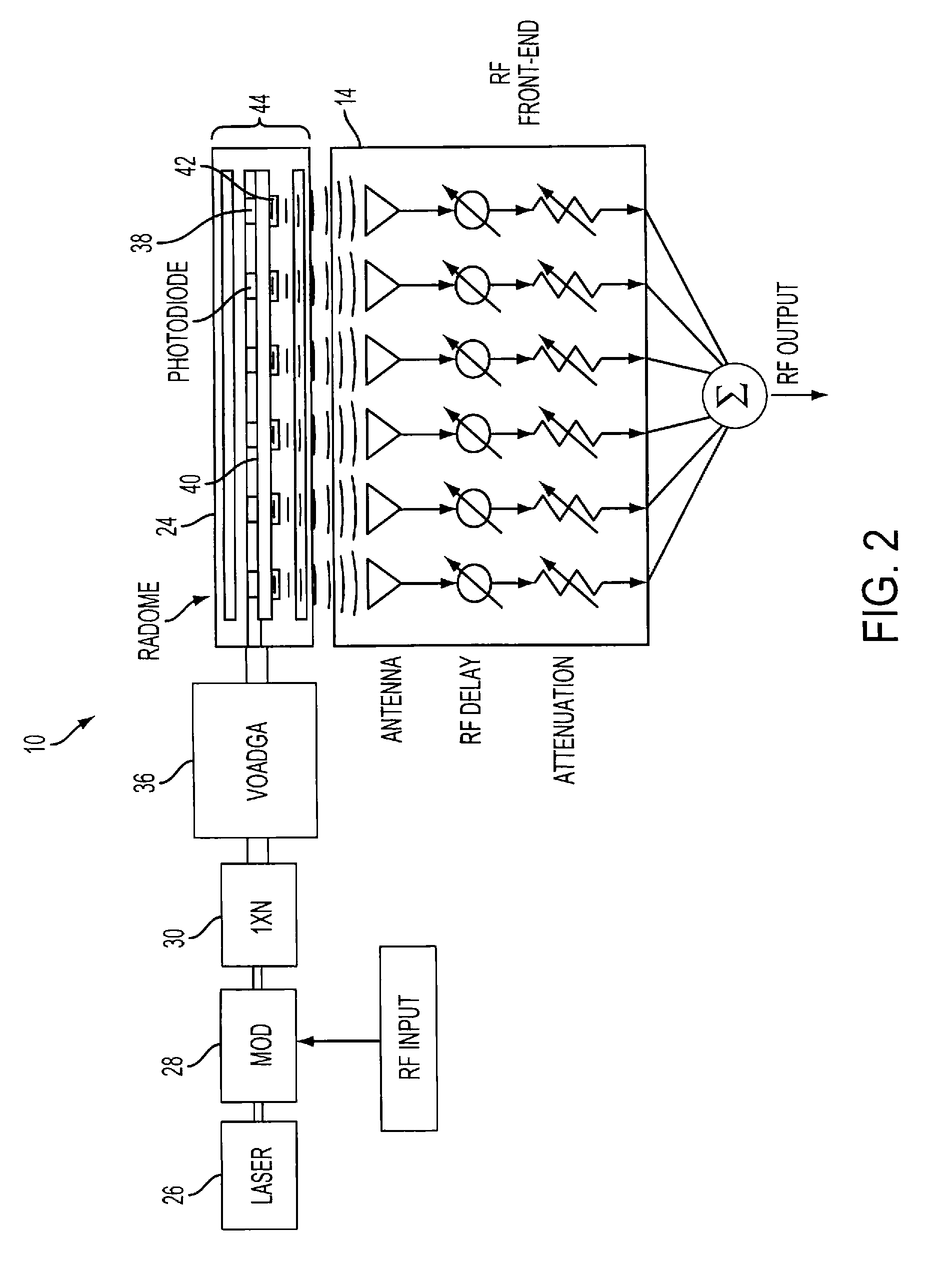

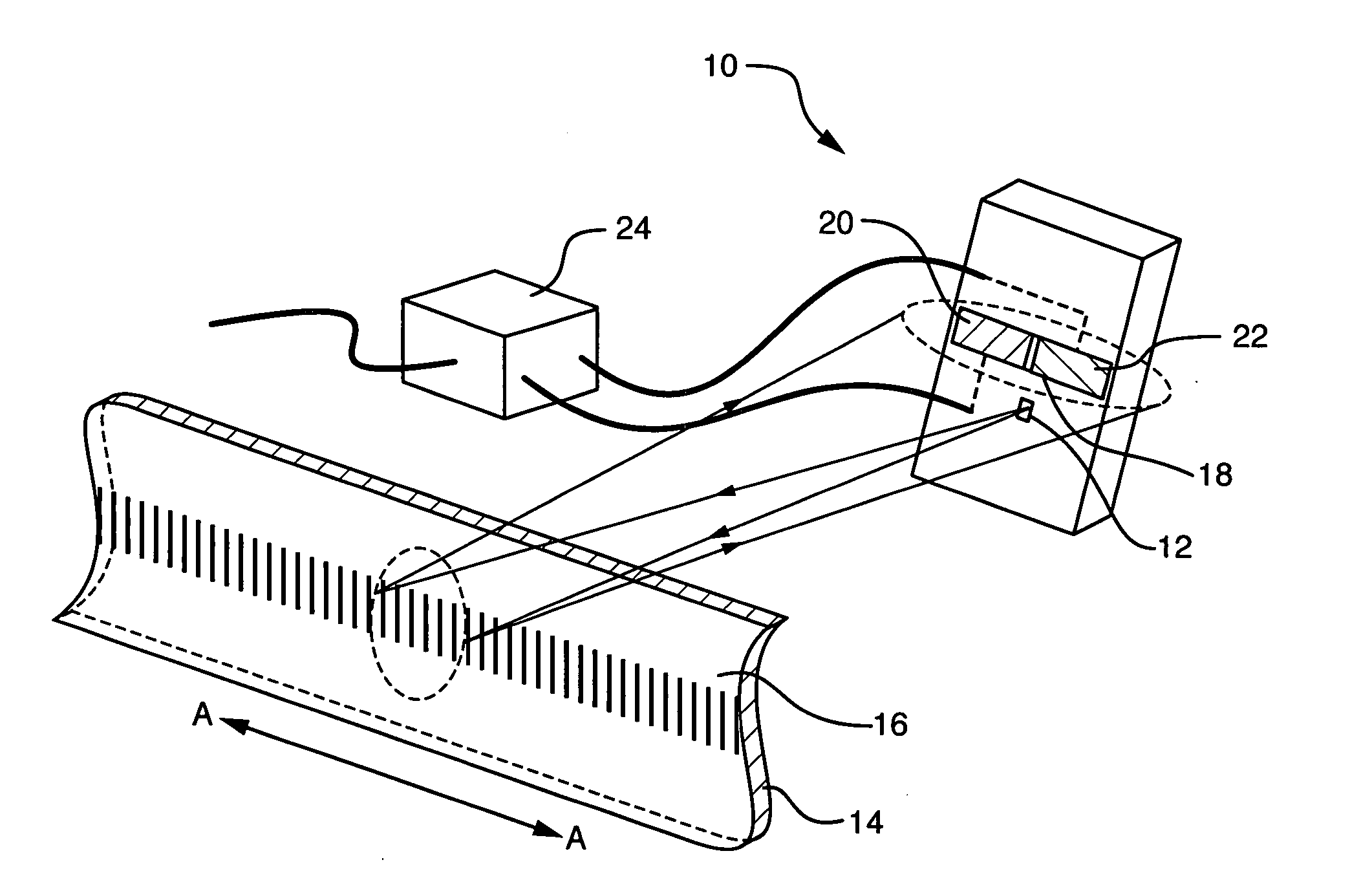

A phased array antenna system includes an RF front end, a radome, and an optical calibrator embedded in the radome for enabling in-situ calibration of the RF front end. The optical calibrator employs an optical timing signal generator (OTSG), a Variable Optical Amplitude and Delay Generator array (VOADGA) for receiving the modulated optical output signal and generating a plurality of VOADGA timing signals, and an optical timing signal distributor (OTSD). The in-situ optical calibrator allows for reduced calibration time and makes it feasible to perform calibration whenever necessary.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

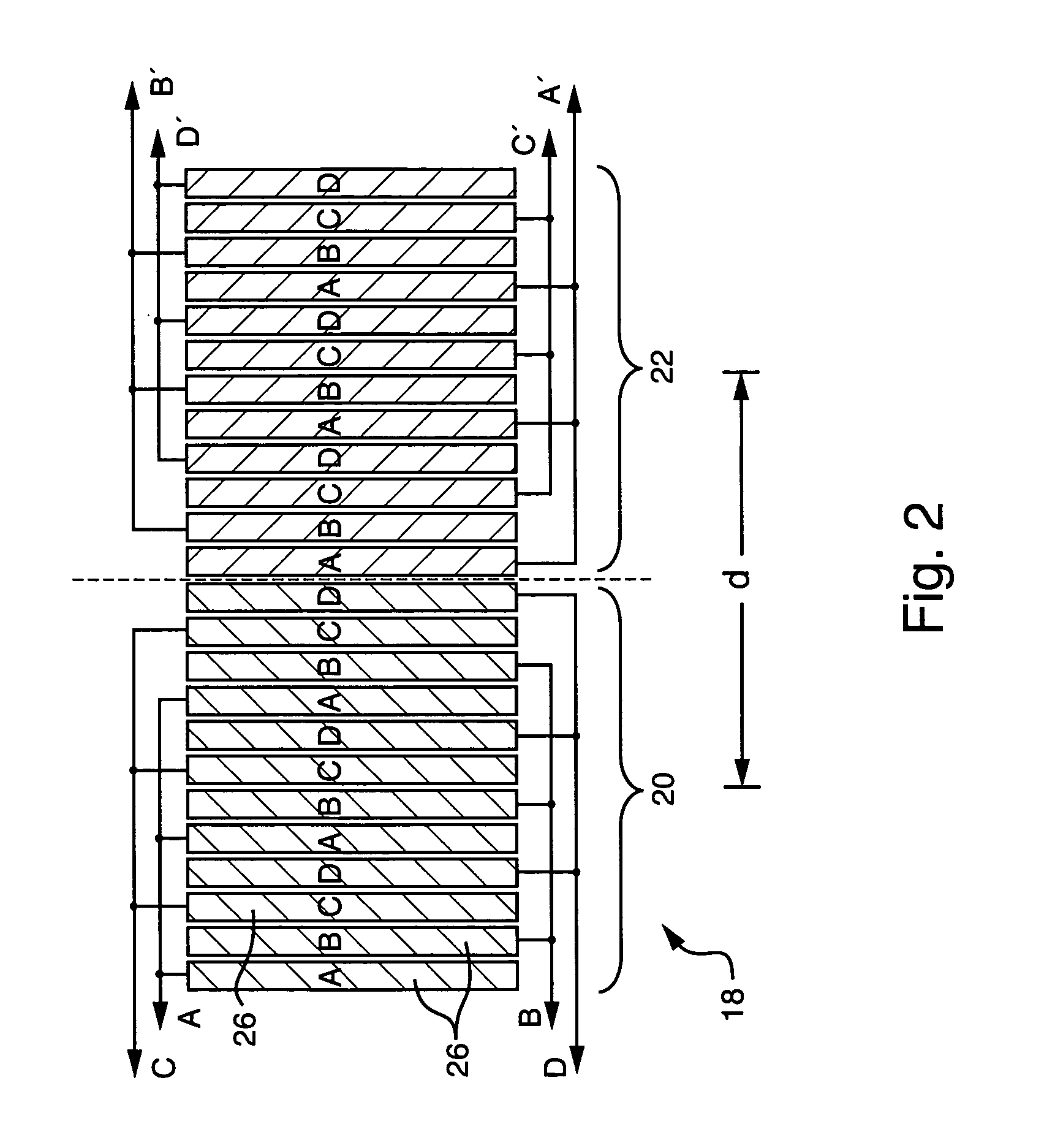

Encoder scale error compensation employing comparison among multiple detectors

InactiveUS20050274878A1High resolutionLow costMaterial analysis by optical meansUsing optical meansPhase differenceIn situ calibration

An encoder calculates position error values and applies compensation values to encoder position measurements in-situ. The encoder includes a scale and a multi-section detector for detecting a spatially periodic pattern, such as an optical interference pattern, produced by the scale. The detector includes spatially separated first and second sections. A signal processor estimates respective phase values from detector sections and calculates a phase difference reflecting a spatial position error in the scale. A compensation value is calculated from the phase difference and included in the estimate of the scale position to compensate for this spatial position error. The compensation values may be calculated and used on the fly, or calculated and saved during an in-situ calibration operation and then utilized during normal operation to compensate uncorrected measurements.

Owner:THE GSI GRP LLC

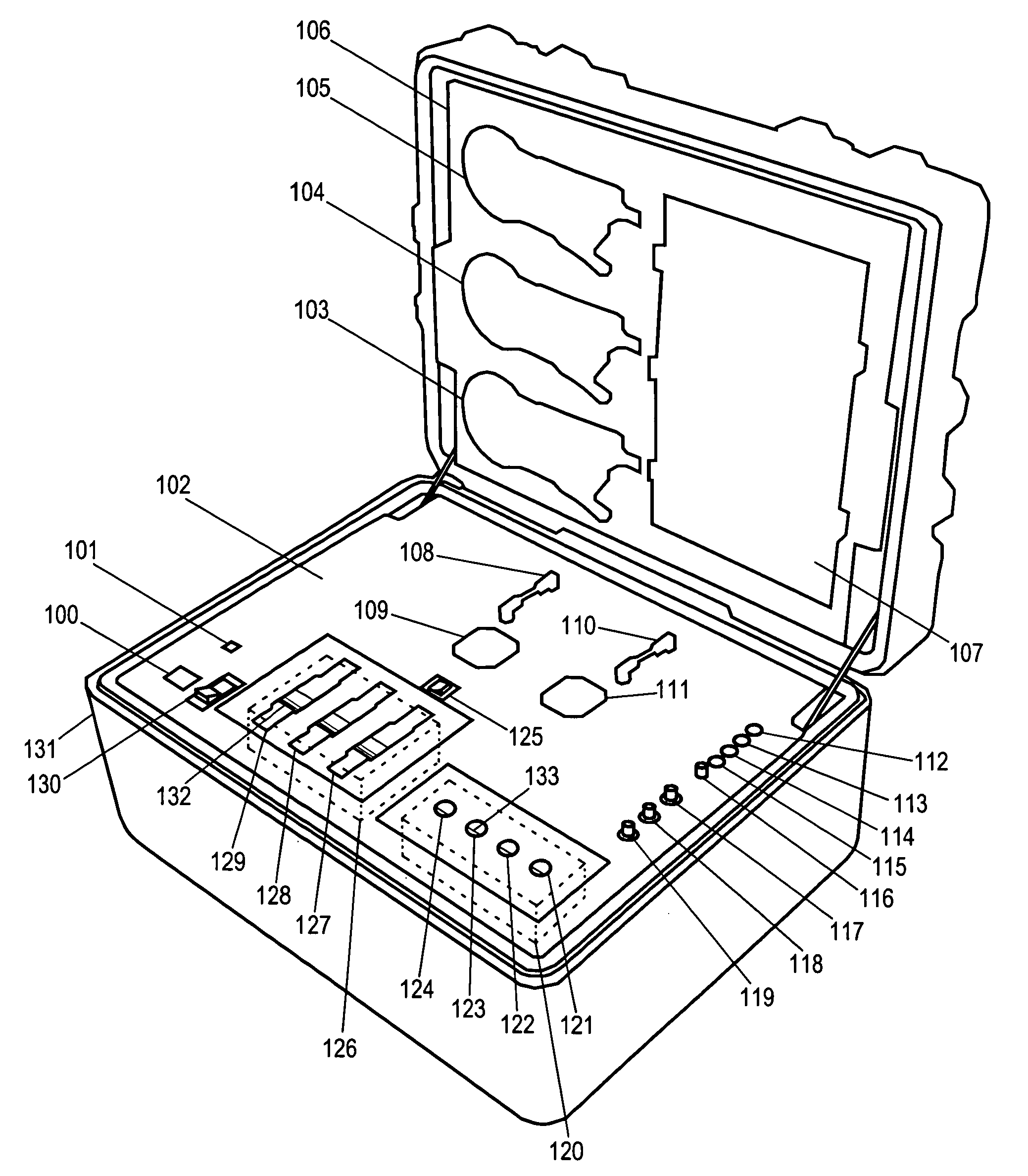

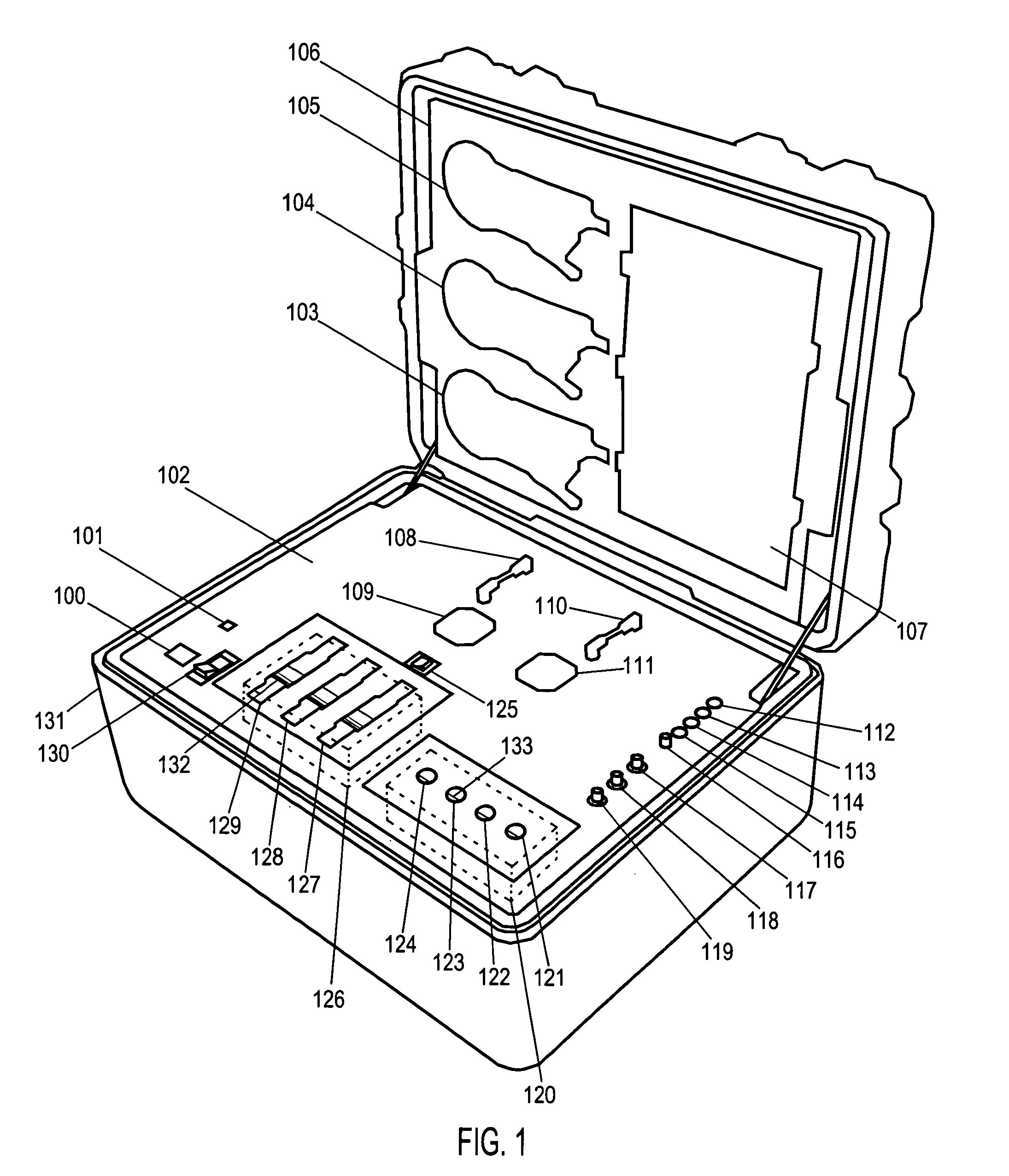

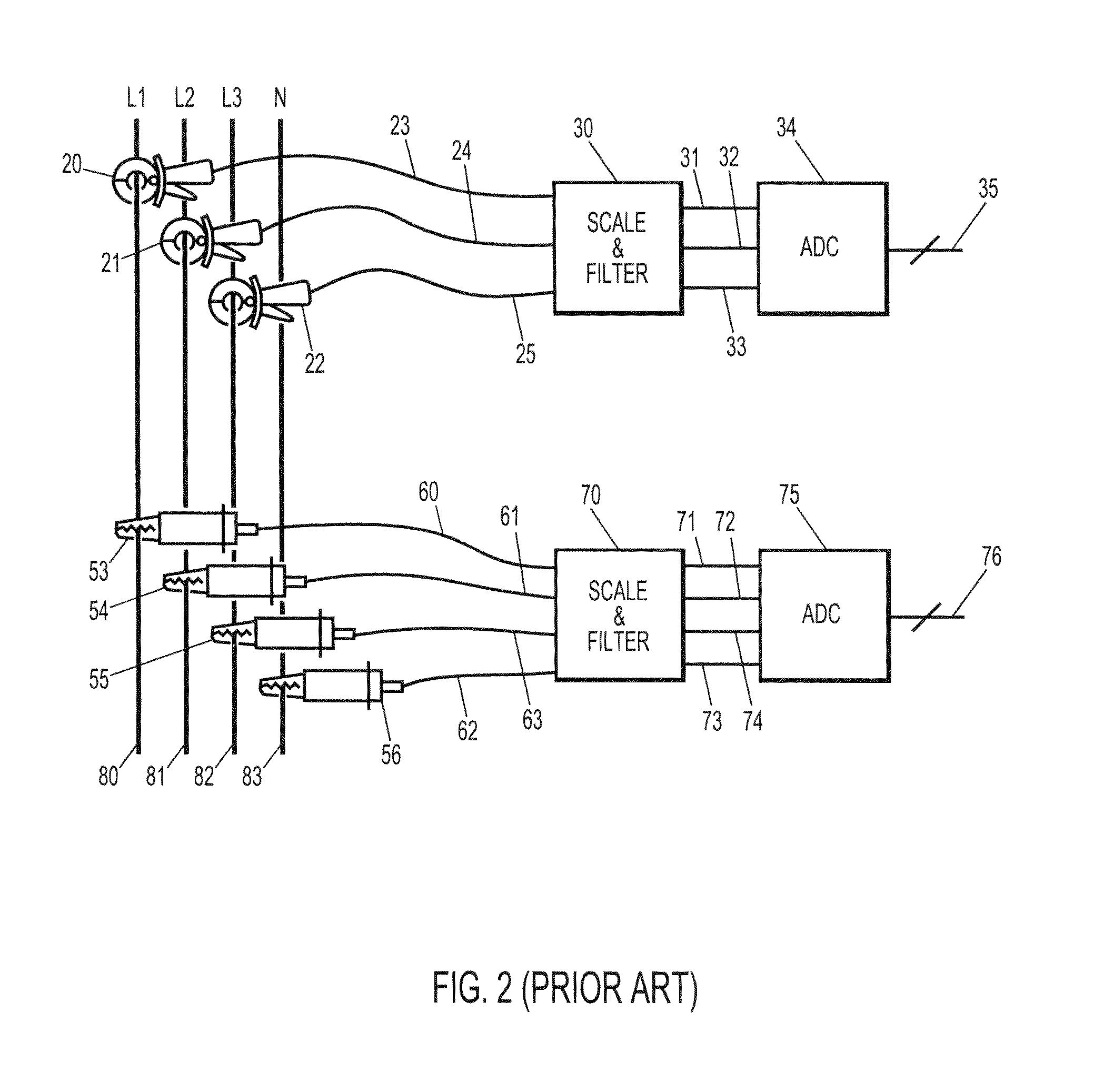

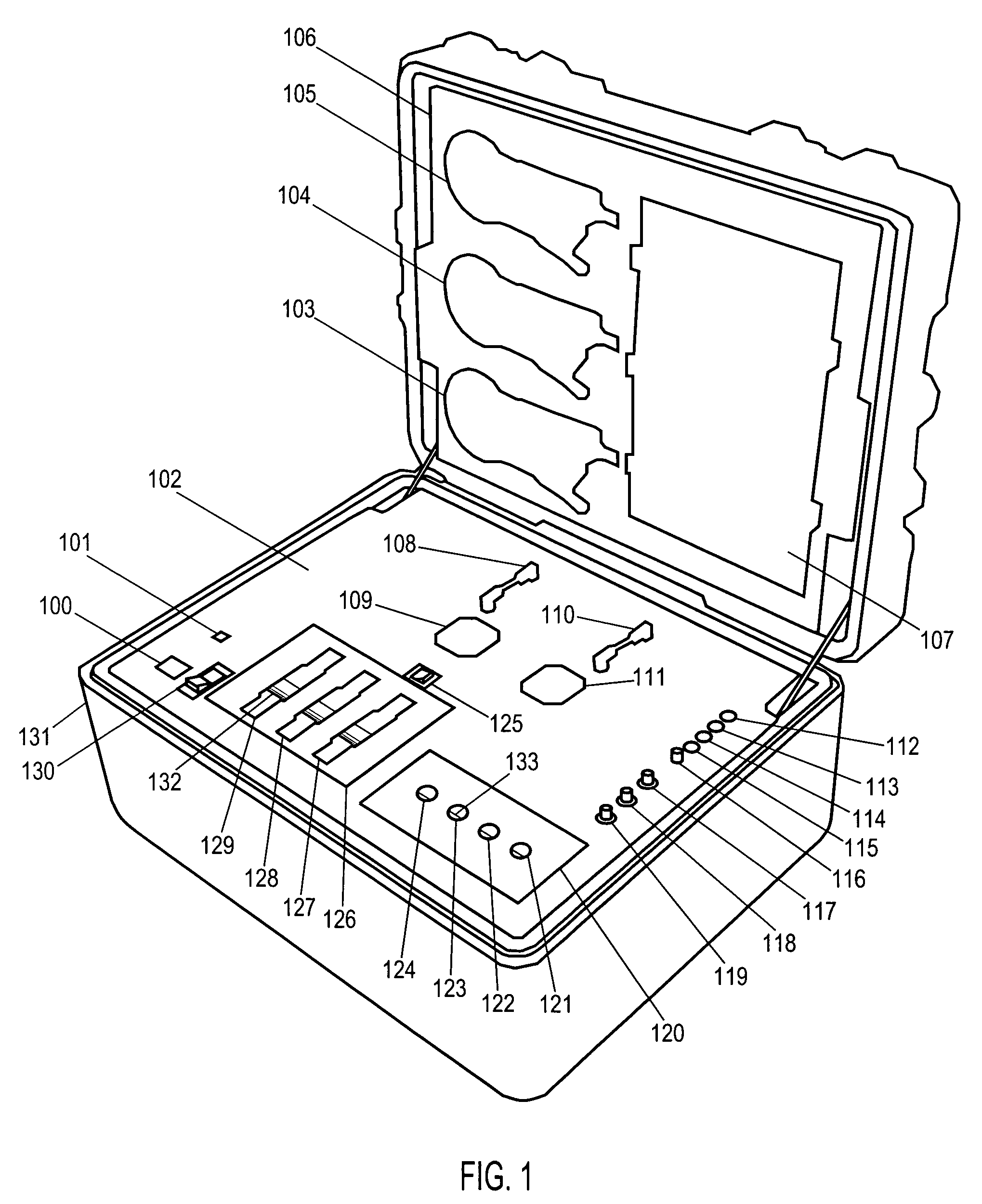

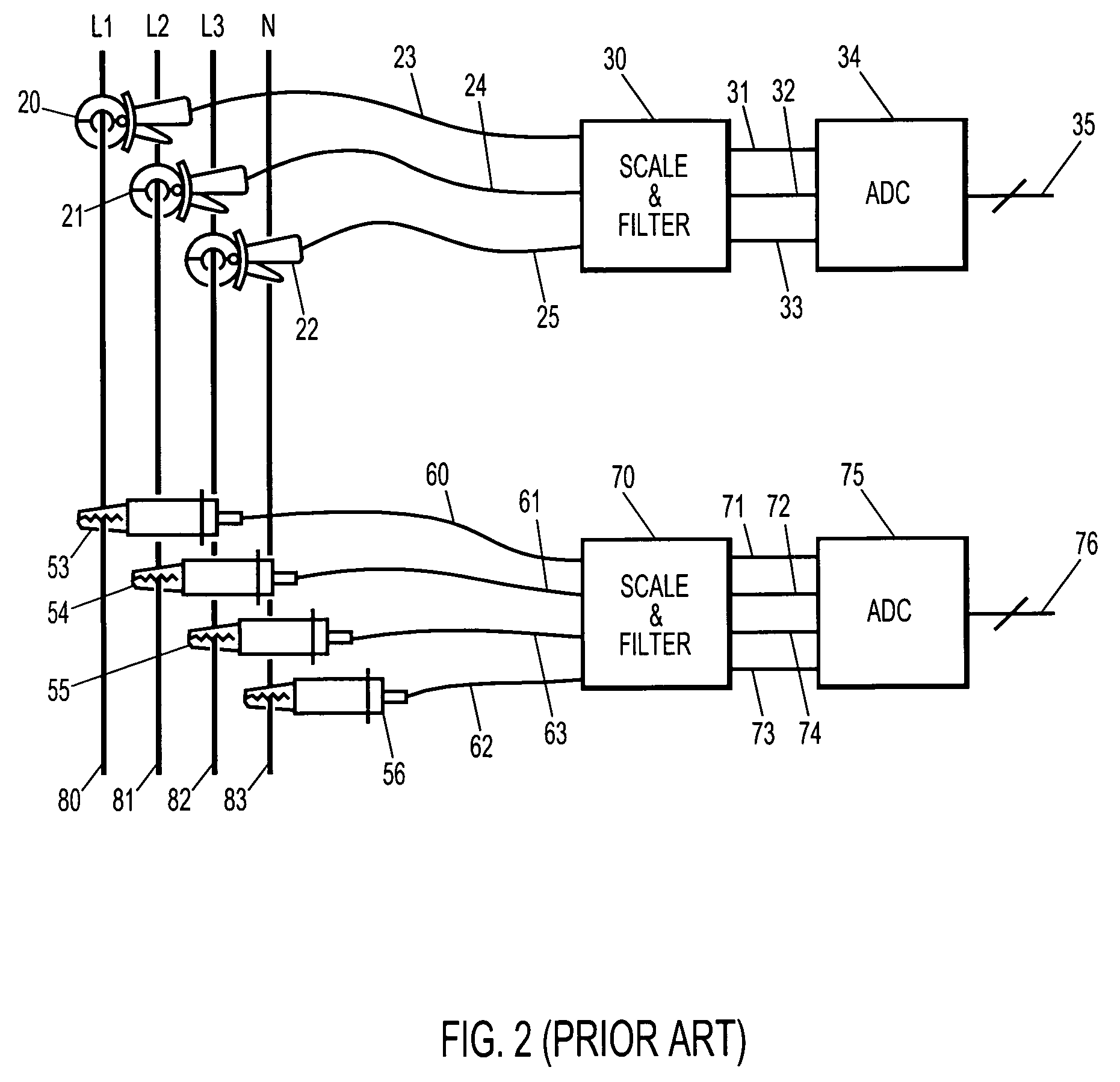

Harmonics measurement instrument with in-situ calibration

InactiveUS7511468B2Current/voltage measurementElectrical measurement instrument detailsHarmonicCurrent sensor

Owner:MCEACHERN ALEXANDER +1

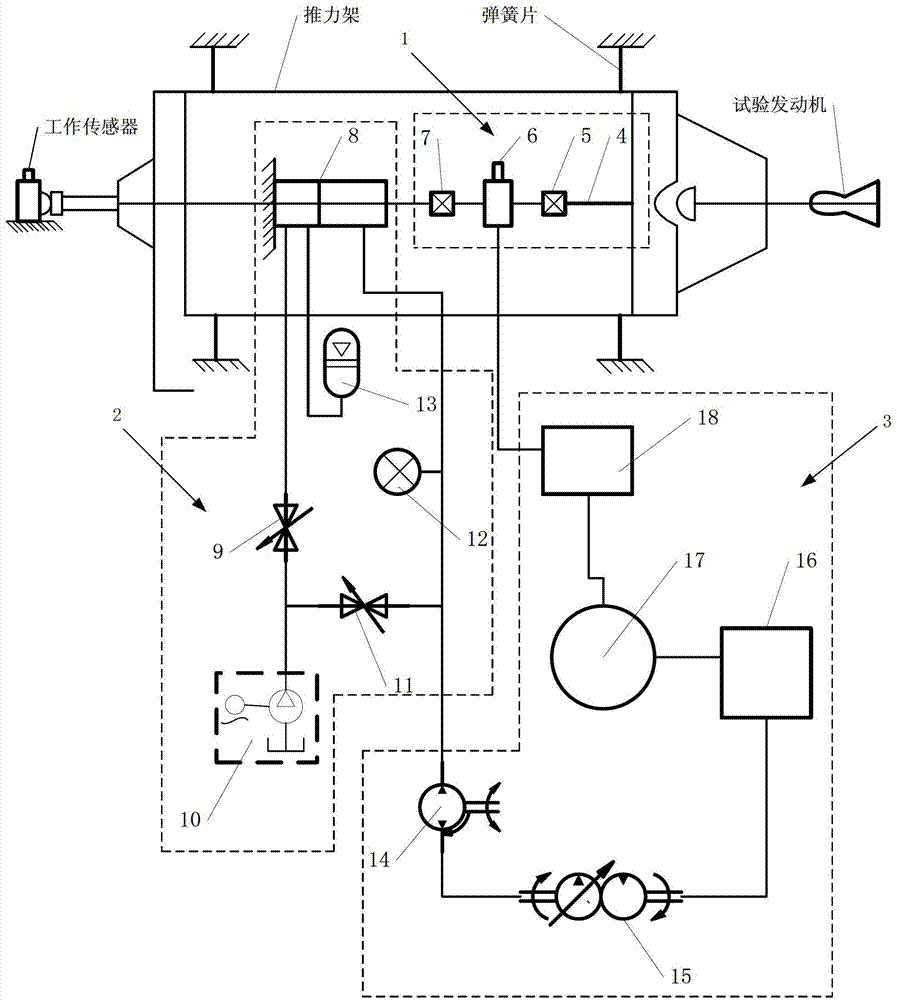

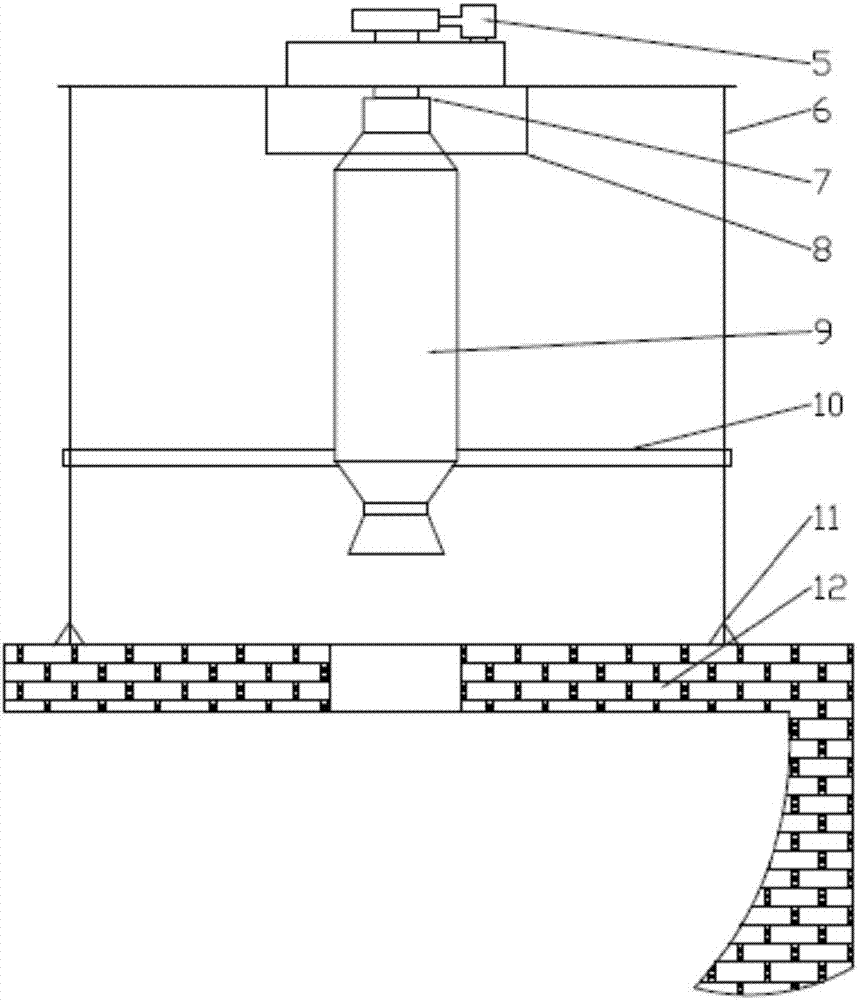

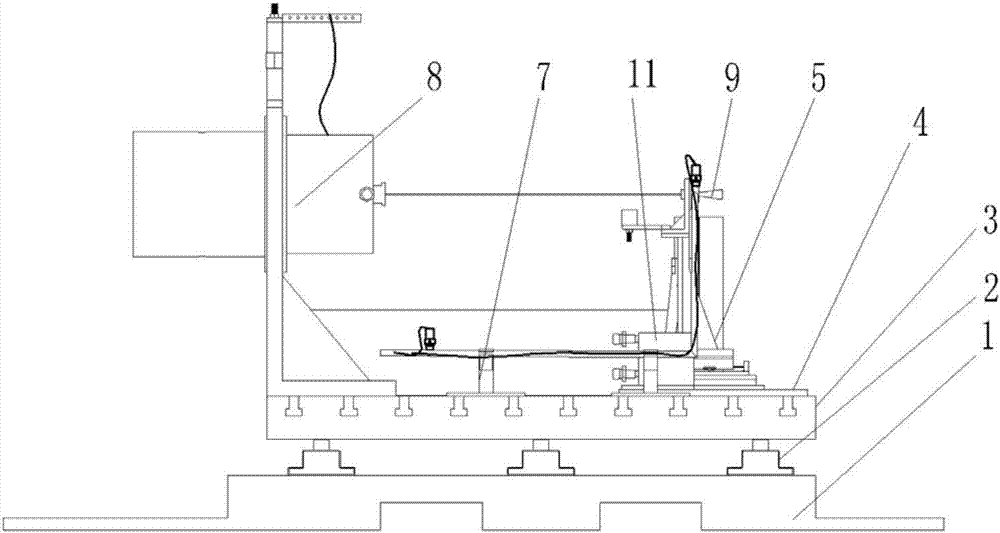

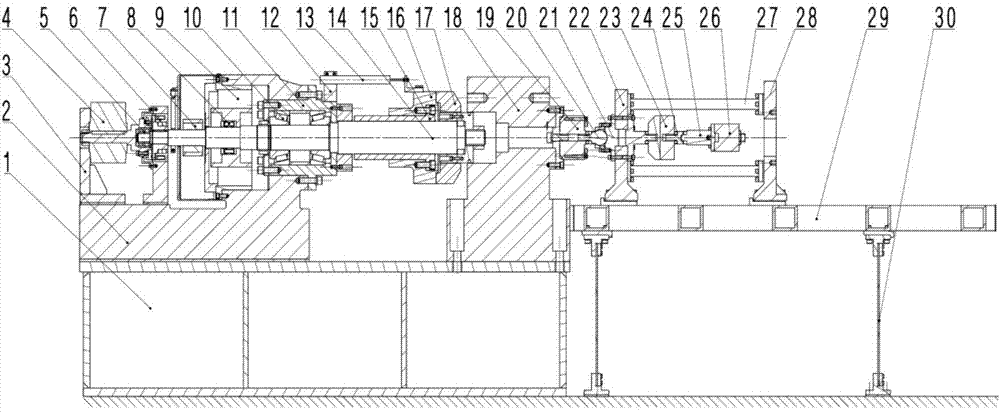

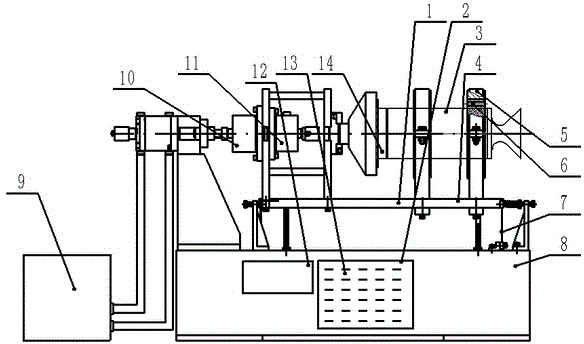

Thrust rack in-situ calibration system

InactiveCN102818676AImprove calibration accuracyHigh calibration stabilityEngine testingForce/torque/work measurement apparatus calibration/testingElectricityHydraulic cylinder

The invention discloses a thrust rack in-situ calibration system, which comprises a standard sensor assembly, a hydraulic system and a loading and unloading control system, wherein the standard sensor assembly comprises a sensor pull rod, a front universal flexible element, a standard sensor and a back universal flexible element, the hydraulic system comprises a hydraulic cylinder, a press cavity oil filling valve, a hand lifting pump, a pulling cavity oil filling valve, an electric joint pressure meter and a pressure cavity energy accumulator, the loading and unloading control system comprises a self control pump, a wide frequency servo motor, a pulse automatic tracking system, a computer and a collecting card, the in-situ thrust calibration system controls the work of the self control pump through the pulse automatic tracking system and the wide frequency servo motor, in addition, measurement signals of the standard sensor are fed back to the computer, the computer transmits the pulse signals to the pulse automatic tracking system through software operation, the automatic loading and unloading on the standard sensor by the hydraulic cylinder is realized, in addition, the necessary time can be stabilized, the loading stability can reach 0.004 percent F.S per 30 minutes (or longer time).

Owner:BEIHANG UNIV

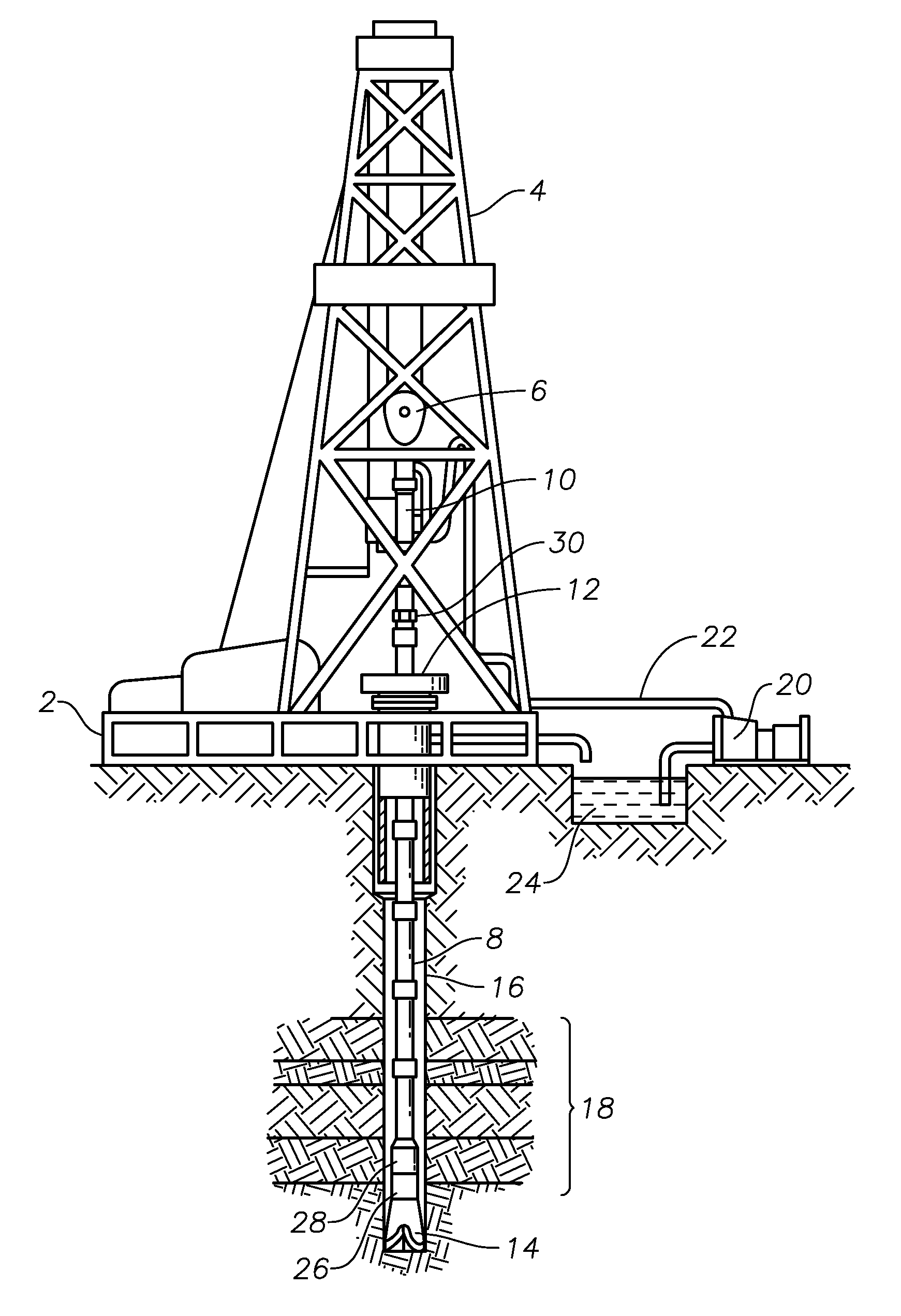

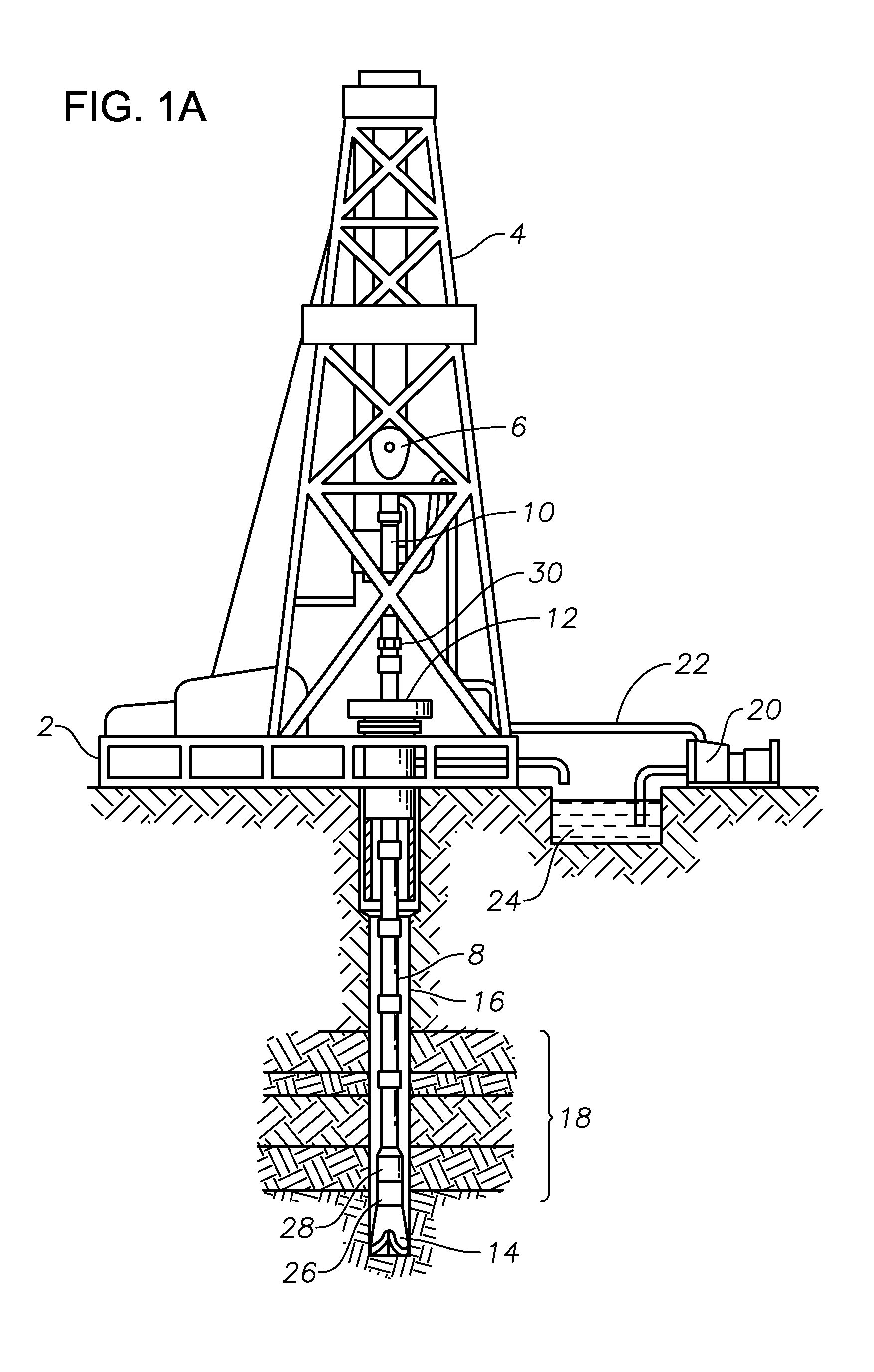

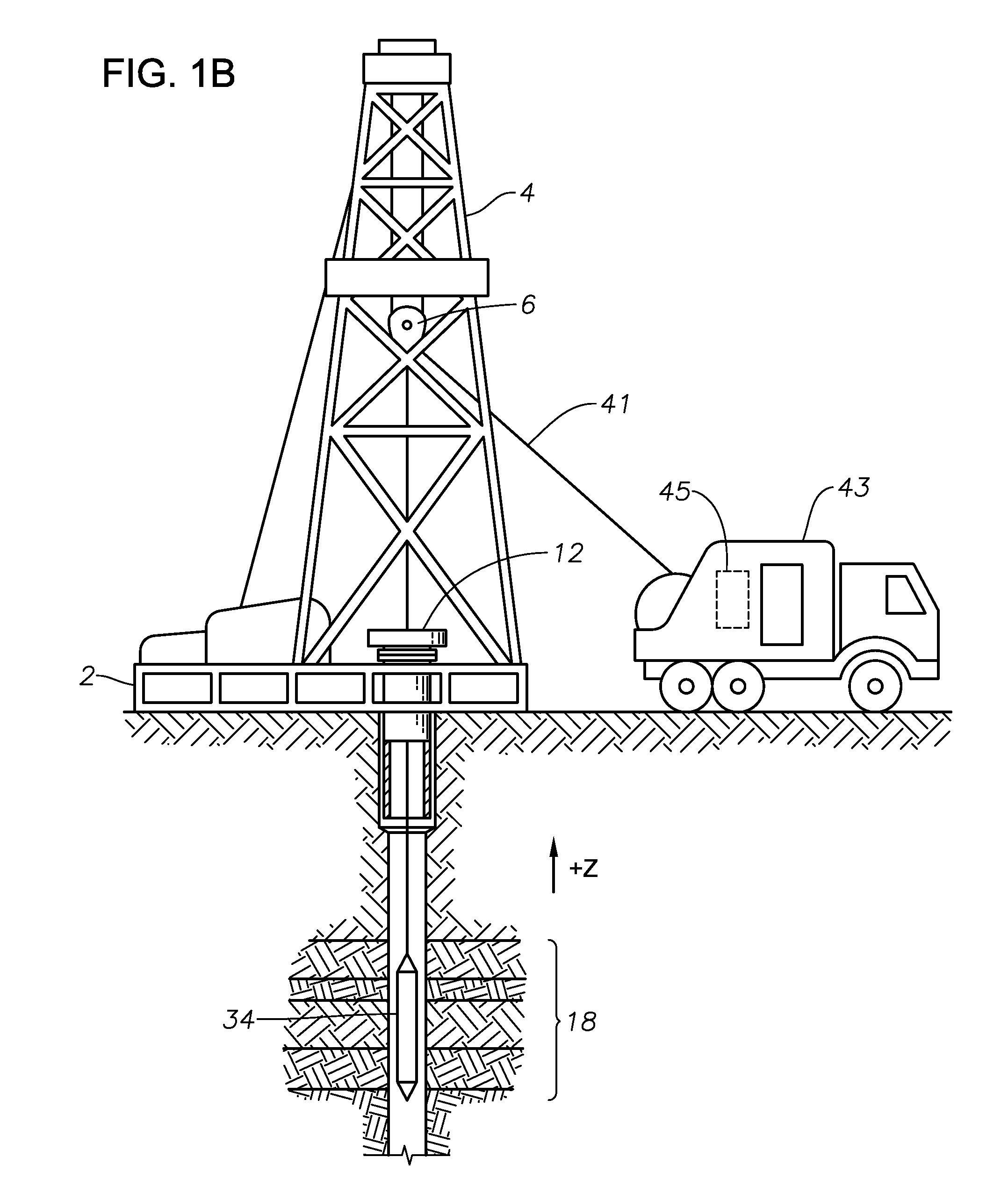

System, Method and Computer-Program Product for In-Situ Calibration of a Wellbore Resistivity Logging Tool

ActiveUS20150241596A1Electric/magnetic detection for well-loggingDirectional drillingIn situ calibrationResistivity logging

In-situ calibration of a resistivity logging tool is accomplished using a variety of methods in which deep measurement signals are calibrated using acquired and simulated measurement signals.

Owner:HALLIBURTON ENERGY SERVICES INC

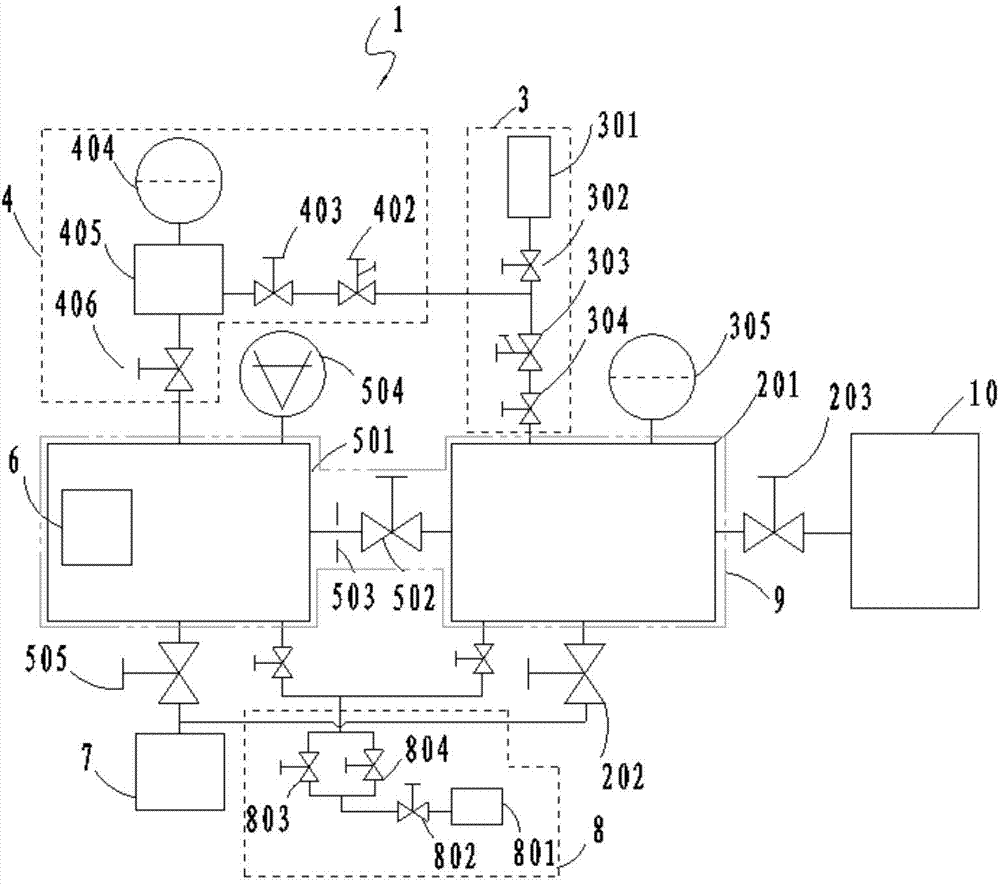

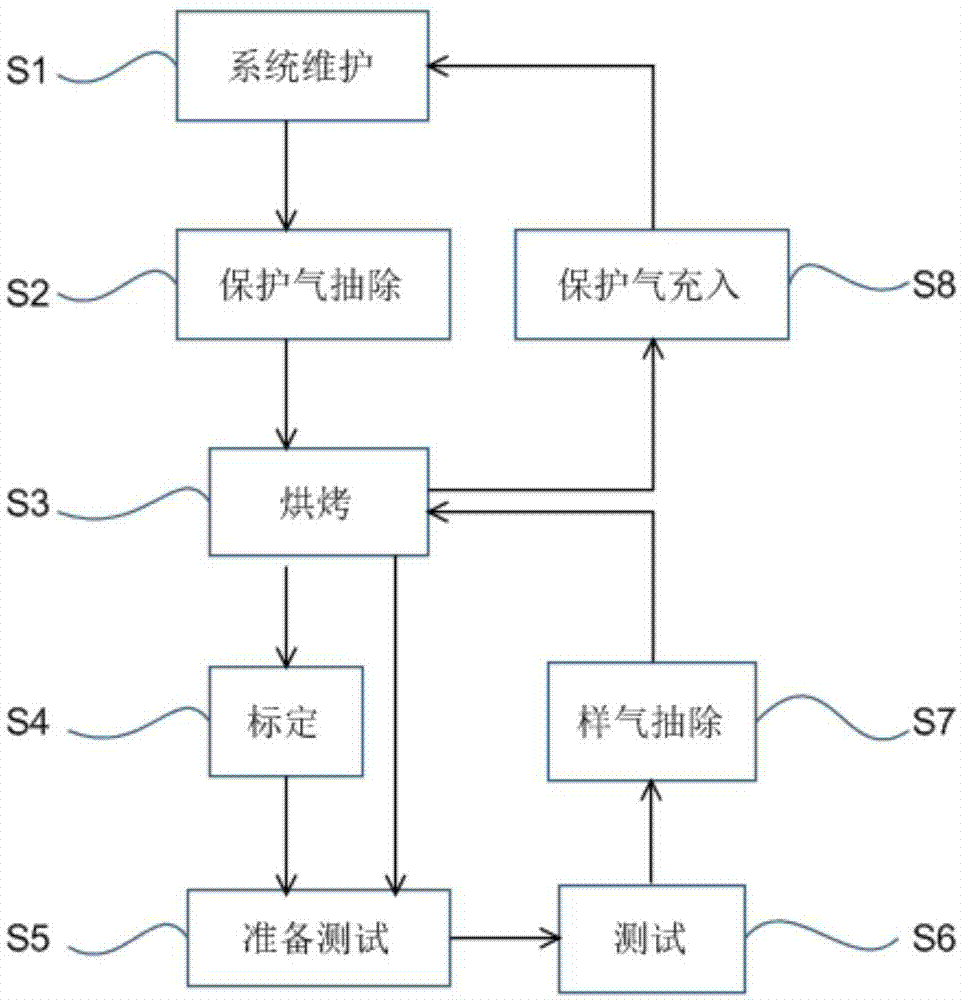

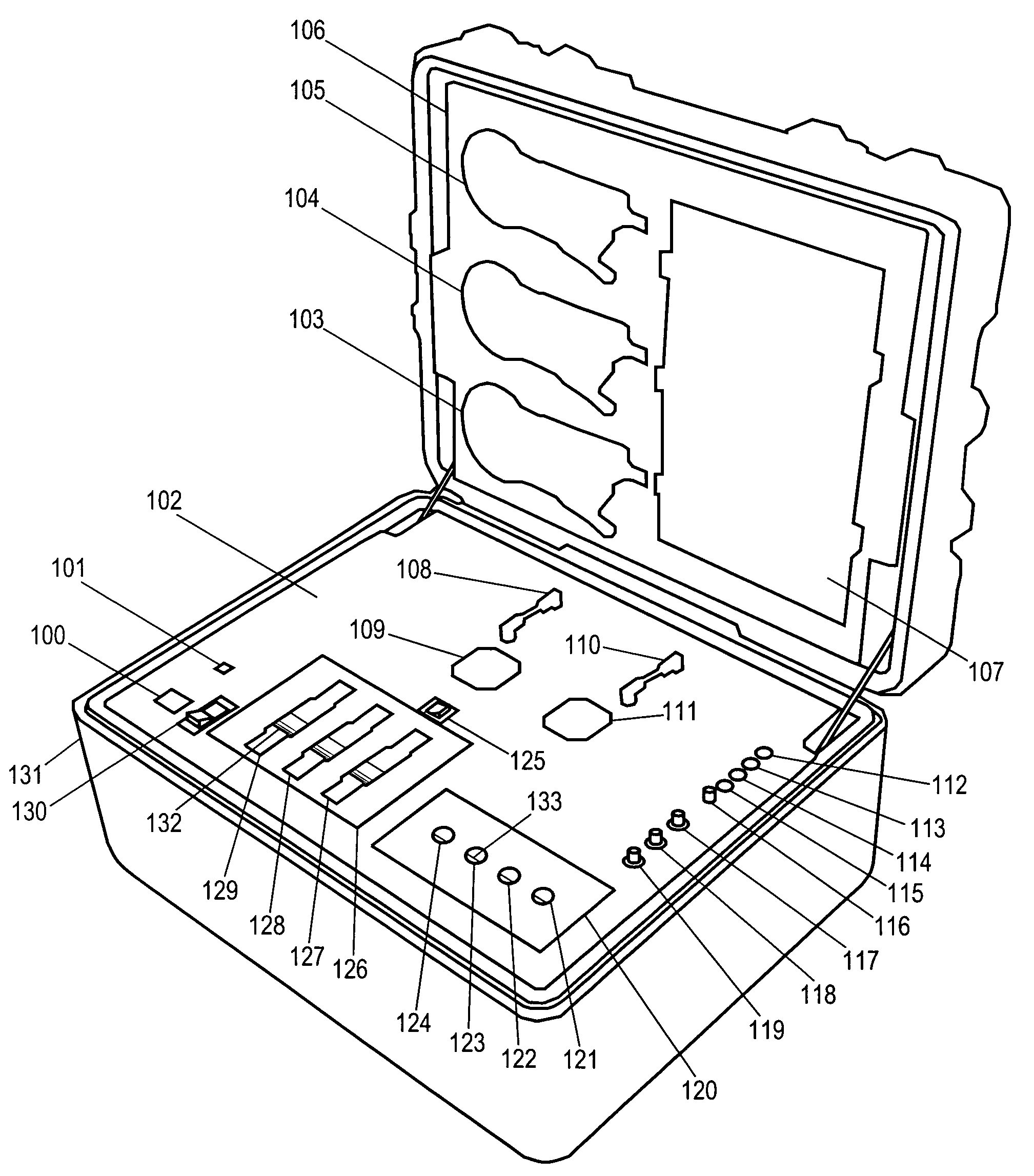

Gas analysis device and method

ActiveCN103487593AGood test backgroundGuaranteed test accuracySemiconductor/solid-state device testing/measurementWithdrawing sample devicesGas analysisComputer module

Owner:RAINBOW SOURCE LASER RSLASER

Harmonics measurement instrument with in-situ calibration

InactiveUS20080116880A1Current/voltage measurementElectrical measurement instrument detailsHarmonicCurrent sensor

A portable harmonics measurement instrument performs in-situ self-calibration of its current transducers and their associated measurement channels and of its voltage probes and their associated measurement channels. In-situ self-calibration is performed immediately before making a measurement on the alternating current power distribution grid. In-situ self-calibration is performed by means of a built-in voltage reference source and a built-in current reference source, which generate highly-accurate voltage and current calibration waveforms with harmonic components.

Owner:MCEACHERN ALEXANDER +1

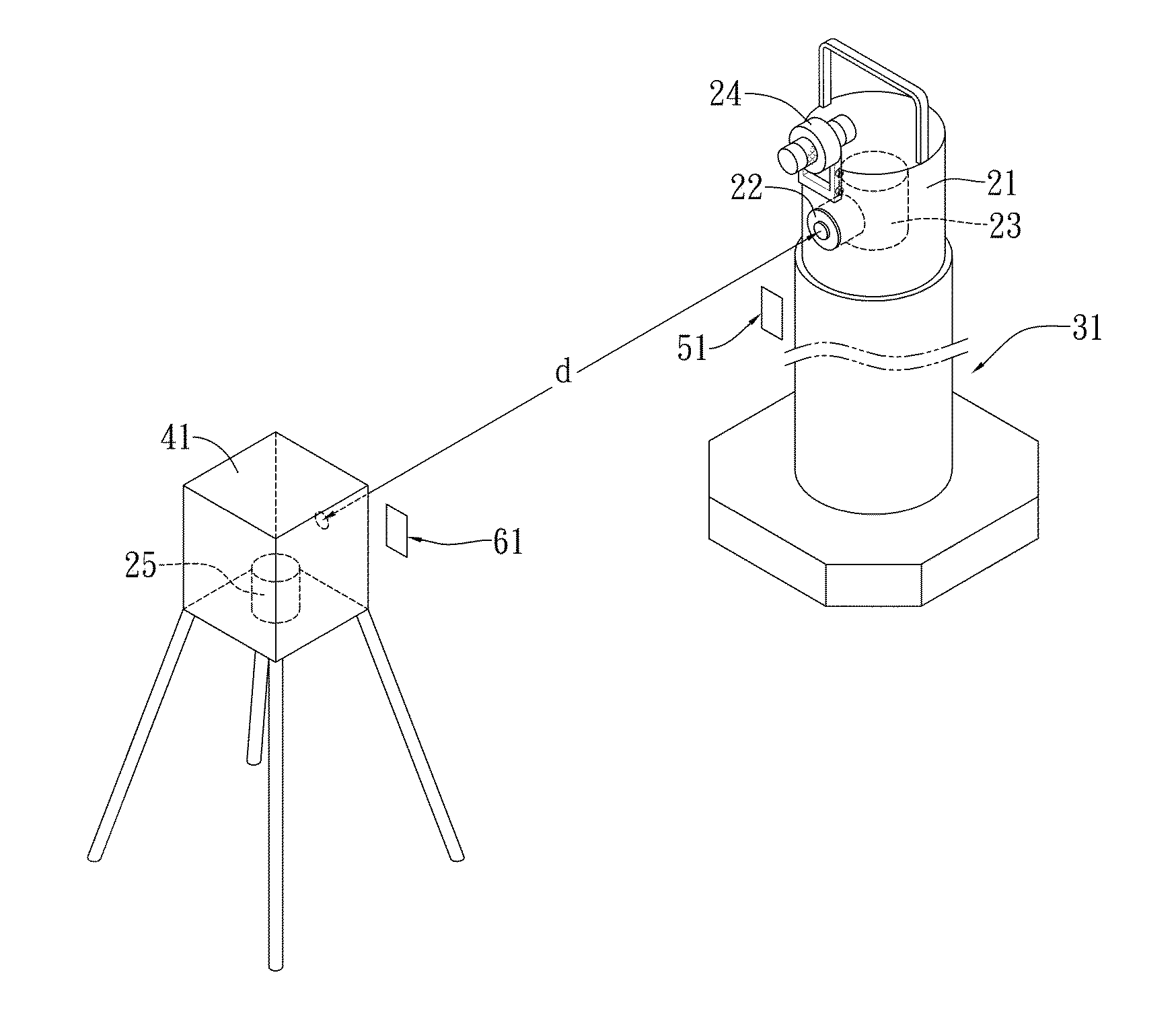

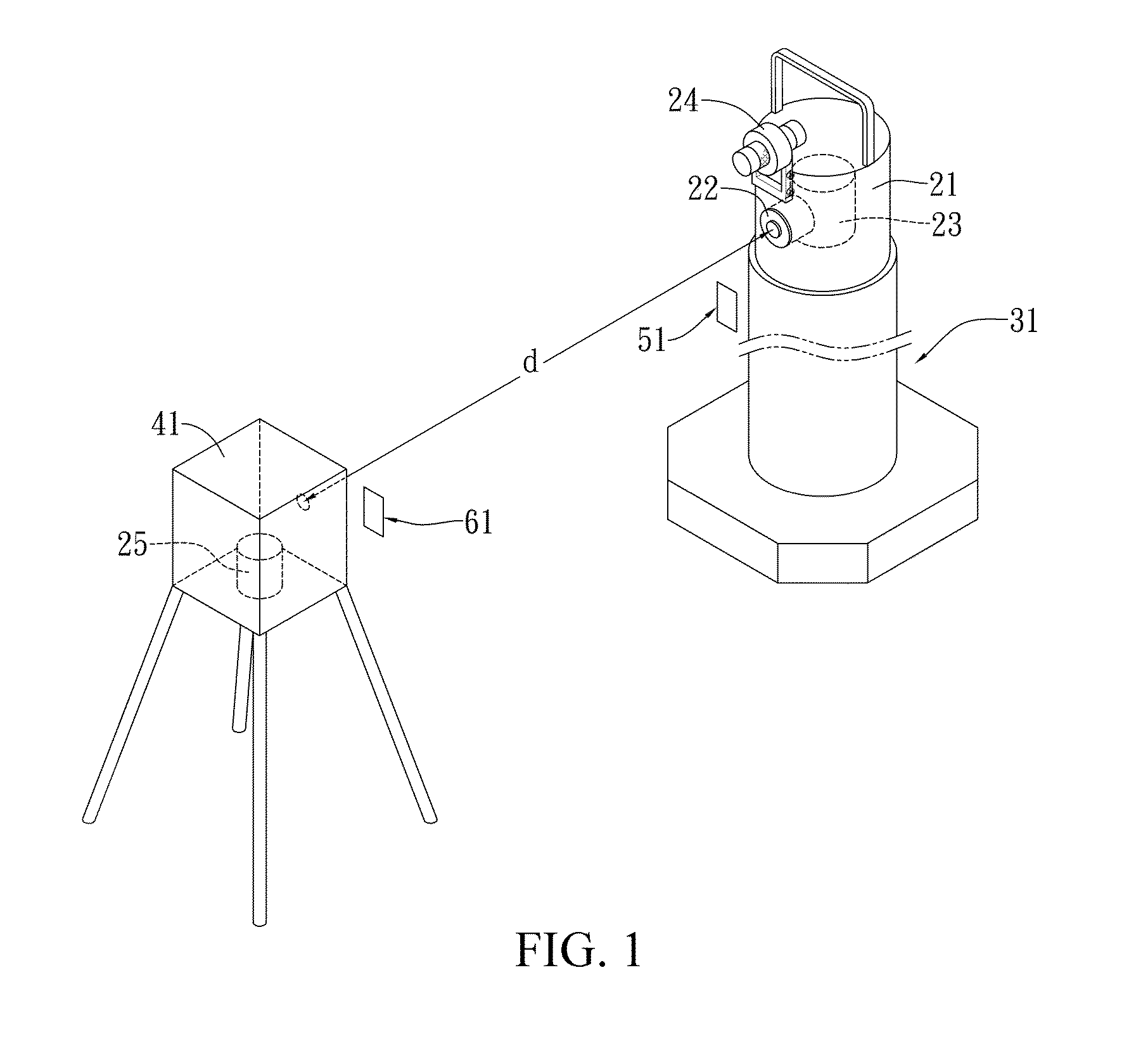

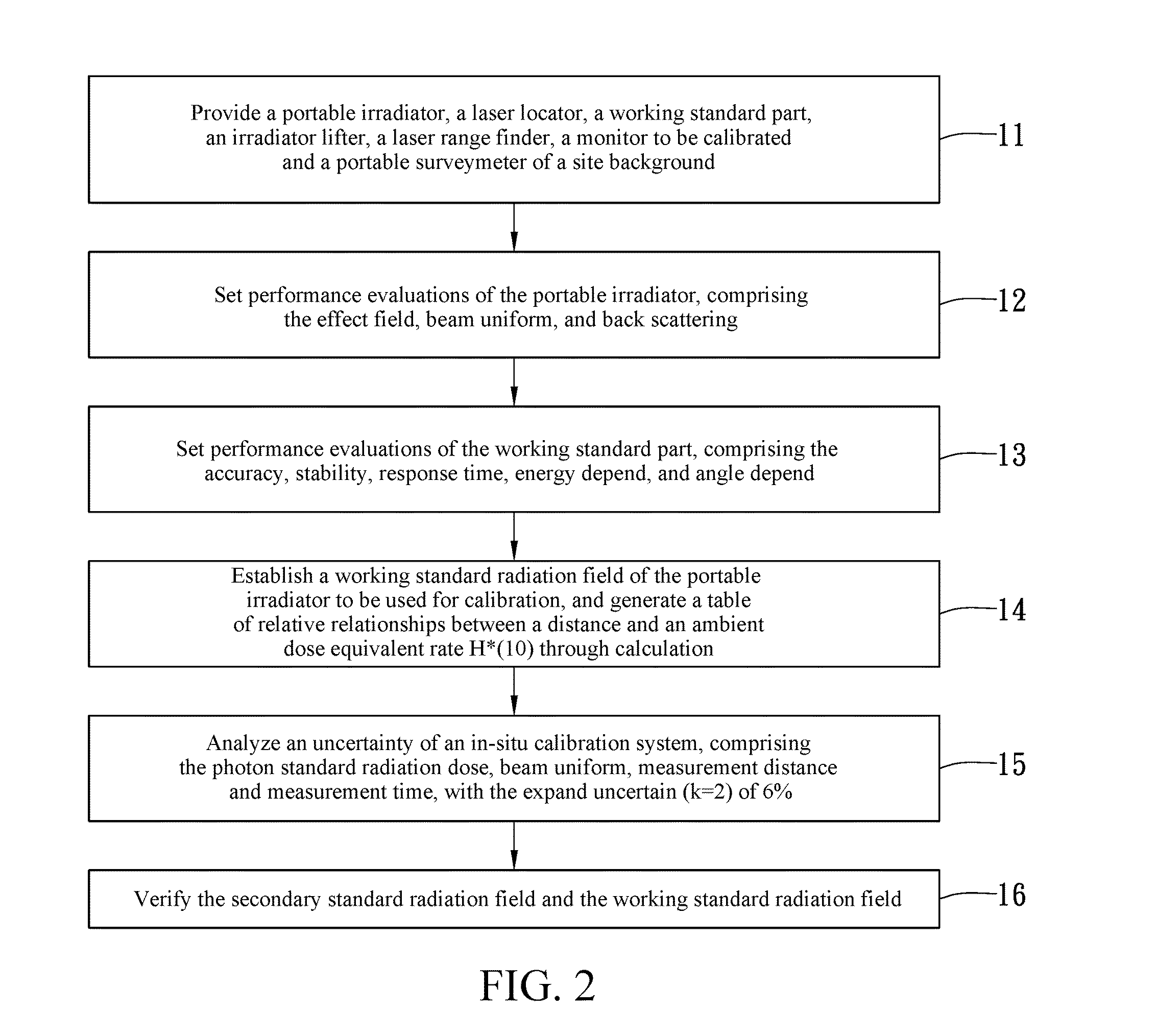

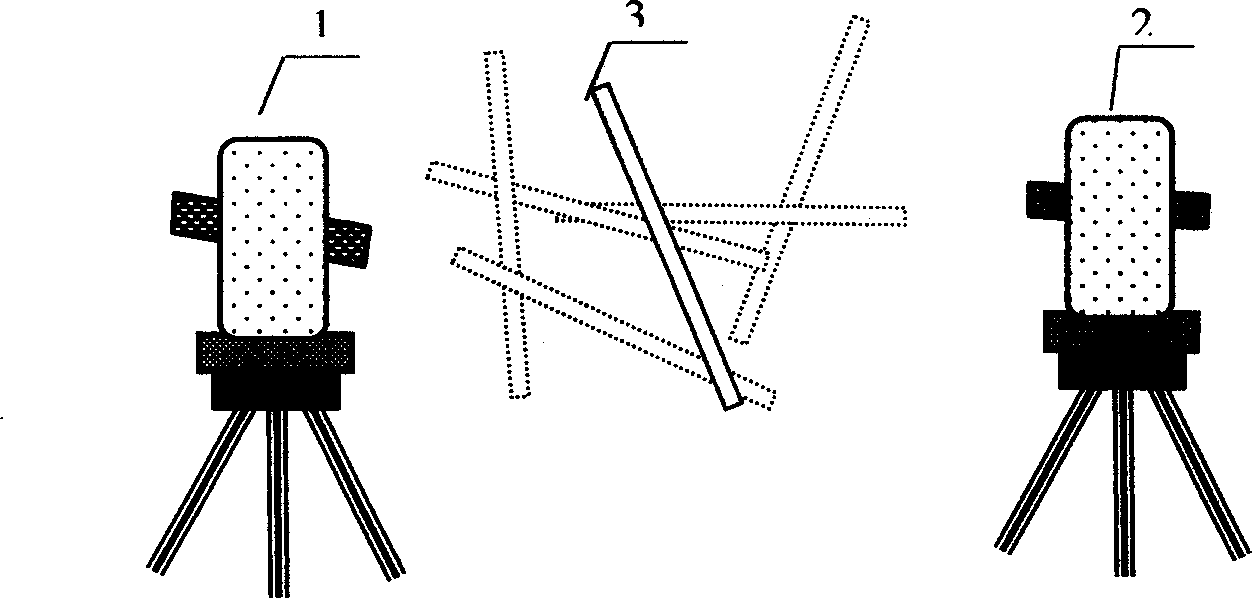

In-situ calibration system and method for radiation monitors

InactiveUS20140042309A1High measurement accuracyMaintain accuracy and reliabilityDosimetersMaterial analysis by optical meansNuclear powerIn situ calibration

By using a scintillation surveymeter with good calibration performance evaluation for a secondary standard radiation field, and a working standard part obtaining an ambient dose equivalent rate, in cooperation with a portable irradiator, and an irradiator lifter, a laser range finder and a laser locator of a relevant radiation source, in-situ calibration is capable of being performed on fixed, or large-scale, or continuous monitoring type radiation monitors to be calibrated stationed in nuclear power plants, nuclear medical departments, and other nuclear facility operating institutions. Moreover, a time-efficient and effective in-situ calibration method is further provided, which can be performed based upon a standard calibration field that is achieved using a portable 137Cs radiation source. The in-situ calibration method is capable of saving the trouble of delivering large-scale monitors, or monitors difficult to move, or monitors requiring continuous monitoring to calibration laboratories for scheduled calibration.

Owner:INST NUCLEAR ENERGY RES ROCAEC

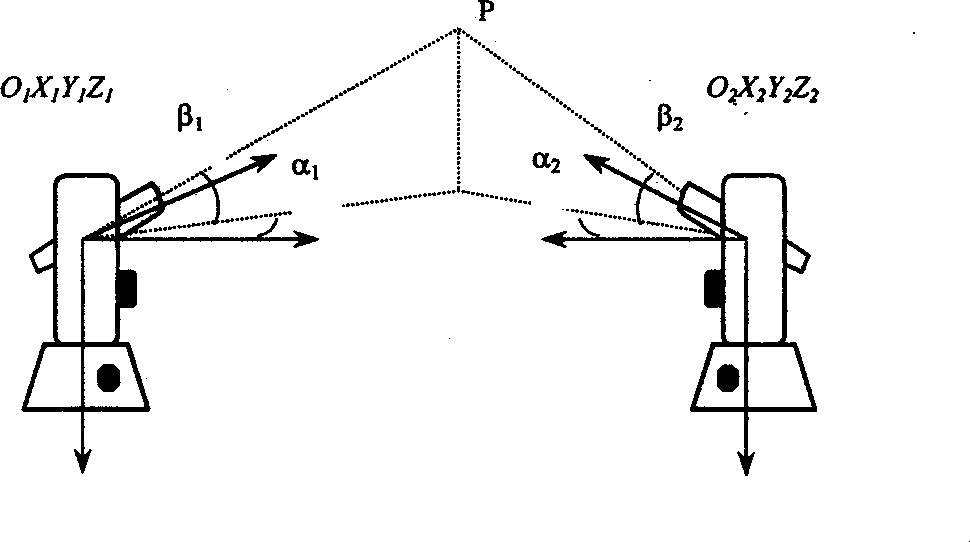

In-situ calibration device for large-size 3D space measurement and its measuring method

An in-situ calibrater for lage-size 3D space measurement and its measuring method is disclosed. A standard object with known reference distance is used, and more than 2 theodolites are used to observe the known standard point on said standard object at same time. A constraint equation is created on the basis of said standard distance and theodolite parameters, and then solved by optimizing method to obtain the model parameters of the odolite. Its advantages include no error caused by human factor, and high measuring precision.

Owner:TIANJIN UNIV

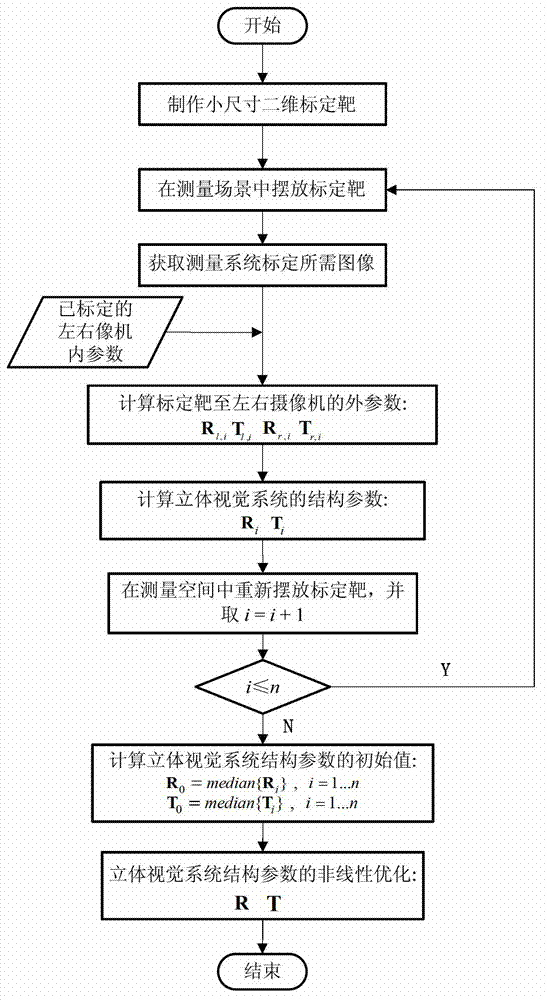

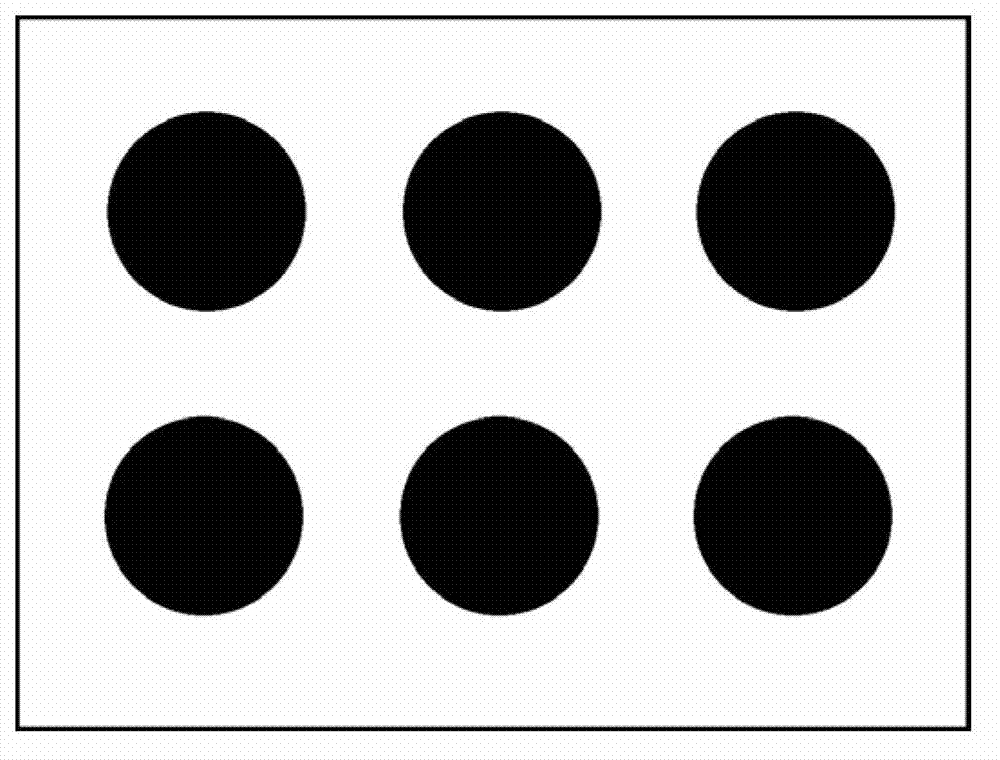

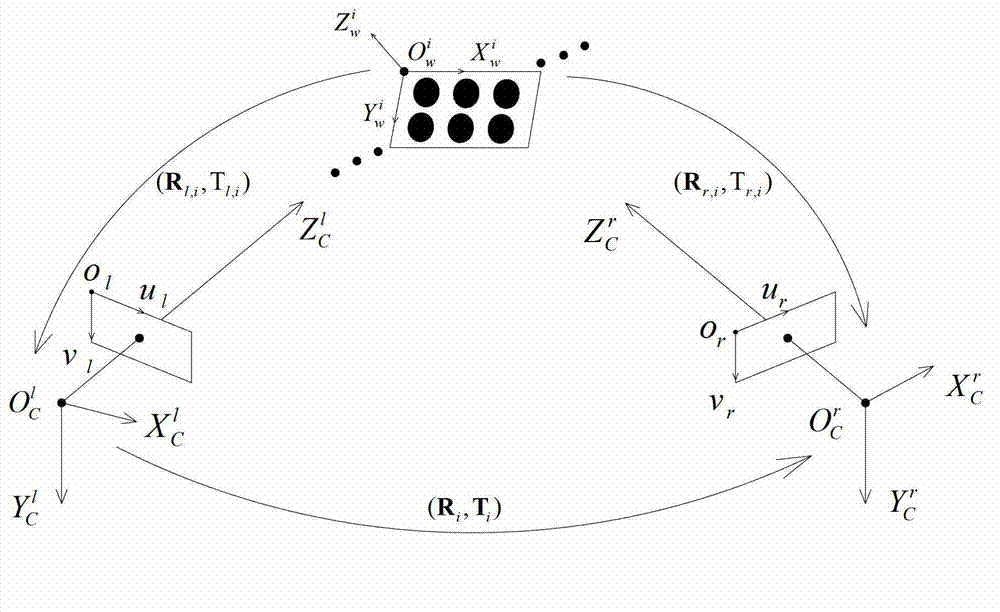

In-situ calibration method for structure parameters of large-visual-field binocular stereo vision system by small two-dimensional targets

ActiveCN102968794AImprove the shortcomings of low calibration efficiencyImprove machining accuracyImage analysisVisual field lossMechanical engineering technology

The invention discloses an in-situ calibration method for structure parameters of a large-visual-field binocular stereo vision system by small two-dimensional targets, which belongs to the technical fields of optical measurement and mechanical engineering. The calibration method comprises the following steps of: acquiring images of the small two-dimensional calibration targets which are placed in different positions in a measurement scene; respectively computing external parameters, which correspond to the calibration targets placed in the different positions and are opposite to left and right cameras, according to internal parameters, which are calibrated in an off-line manner, of the left and right cameras, and further computing the structure parameters of the stereo vision system; and finally, establishing an objective function to perform nonlinear optimization on the structure parameters of the stereo vision system. The small two-dimensional calibration targets effectively solve the problems of high cost, difficulty in transportation and storage and inconvenience in application and maintenance of large high-precision calibration targets, and can be applicable to the in-situ calibration of the structure parameters of the stereo vision system in a complicated environment.

Owner:SHANGHAI JIAO TONG UNIV

Antenna calibration method and system

InactiveUS7671799B1Enabling in-situ calibrationReduce calibration timeLaser detailsAntenna arraysRF front endIn situ calibration

A phased array antenna system includes an RF front end, a radome, and an optical calibrator embedded in the radome for enabling in-situ calibration of the RF front end. The optical calibrator employs an optical timing signal generator (OTSG), a Variable Optical Amplitude and Delay Generator array (VOADGA) for receiving the modulated optical output signal and generating a plurality of VOADGA timing signals, and an optical timing signal distributor (OTSD). The in-situ optical calibrator allows for reduced calibration time and makes it feasible to perform calibration whenever necessary.

Owner:USA AS REPRESENTED BY THE SEC OF THE NAVY THE

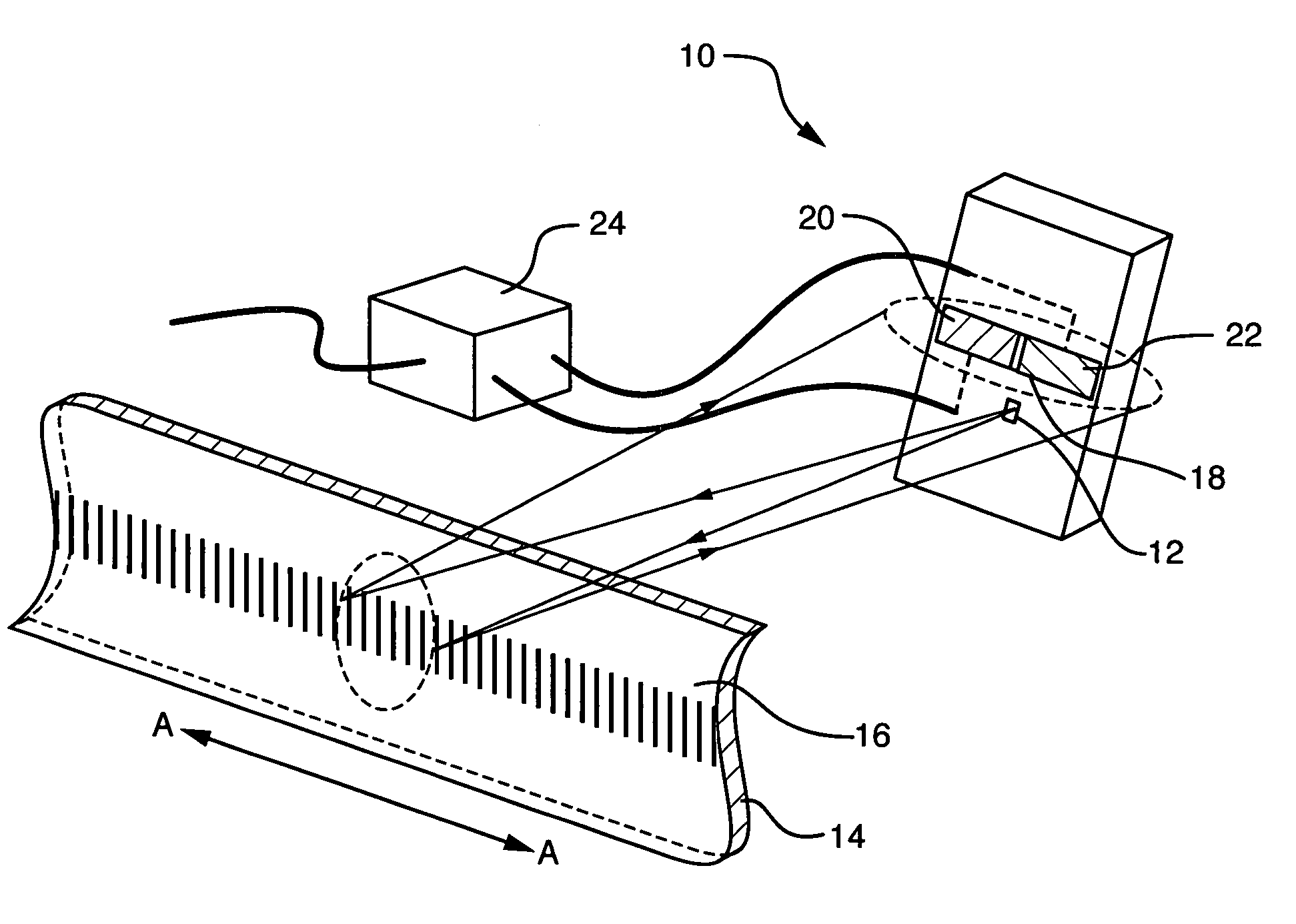

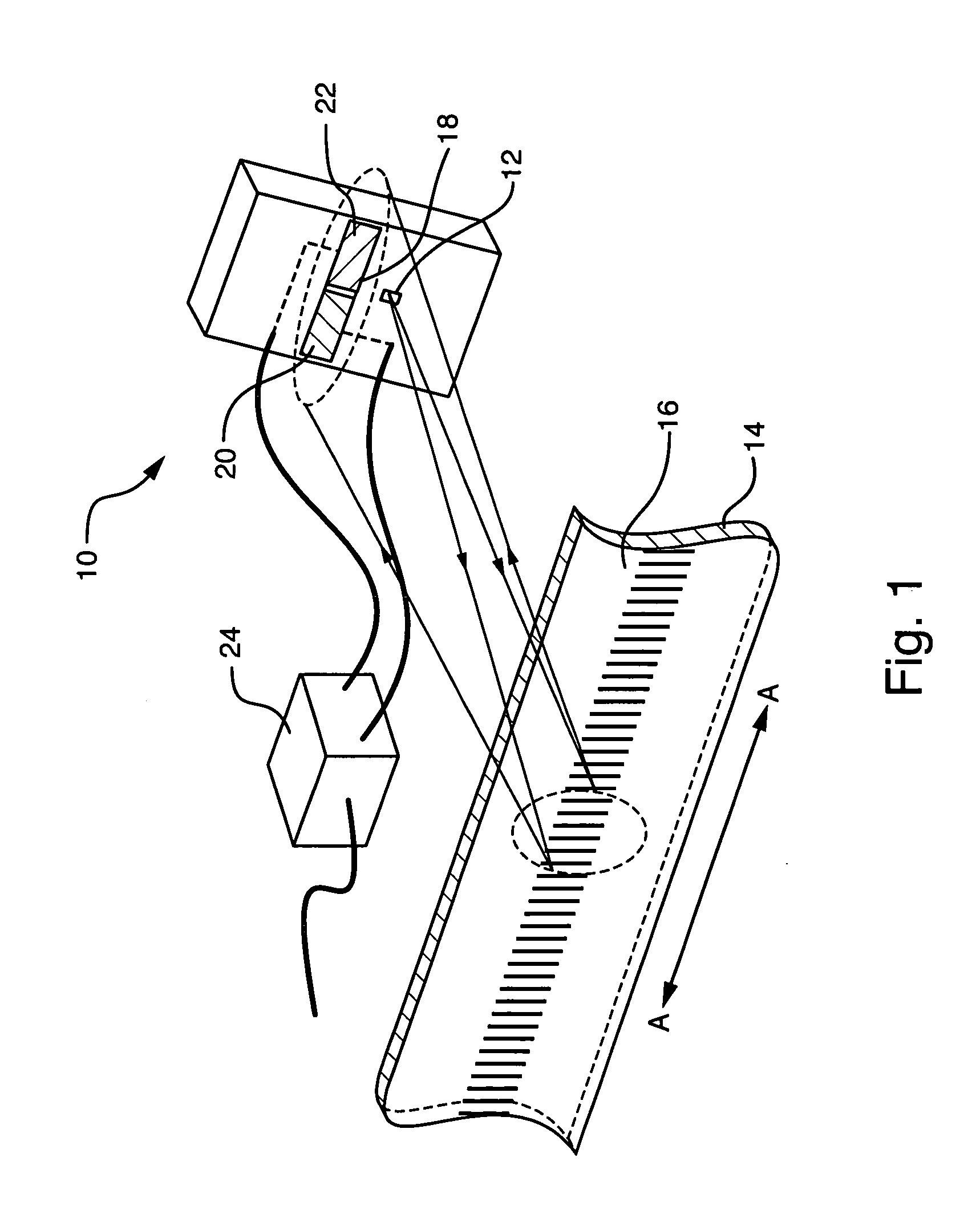

Encoder scale error compensation employing comparison among multiple detectors

InactiveUS7126109B2High resolutionLow costMaterial analysis by optical meansUsing optical meansPhase differenceIn situ calibration

An encoder calculates position error values and applies compensation values to encoder position measurements in-situ. The encoder includes a scale and a multi-section detector for detecting a spatially periodic pattern, such as an optical interference pattern, produced by the scale. The detector includes spatially separated first and second sections. A signal processor estimates respective phase values from detector sections and calculates a phase difference reflecting a spatial position error in the scale. A compensation value is calculated from the phase difference and included in the estimate of the scale position to compensate for this spatial position error. The compensation values may be calculated and used on the fly, or calculated and saved during an in-situ calibration operation and then utilized during normal operation to compensate uncorrected measurements.

Owner:THE GSI GRP LLC

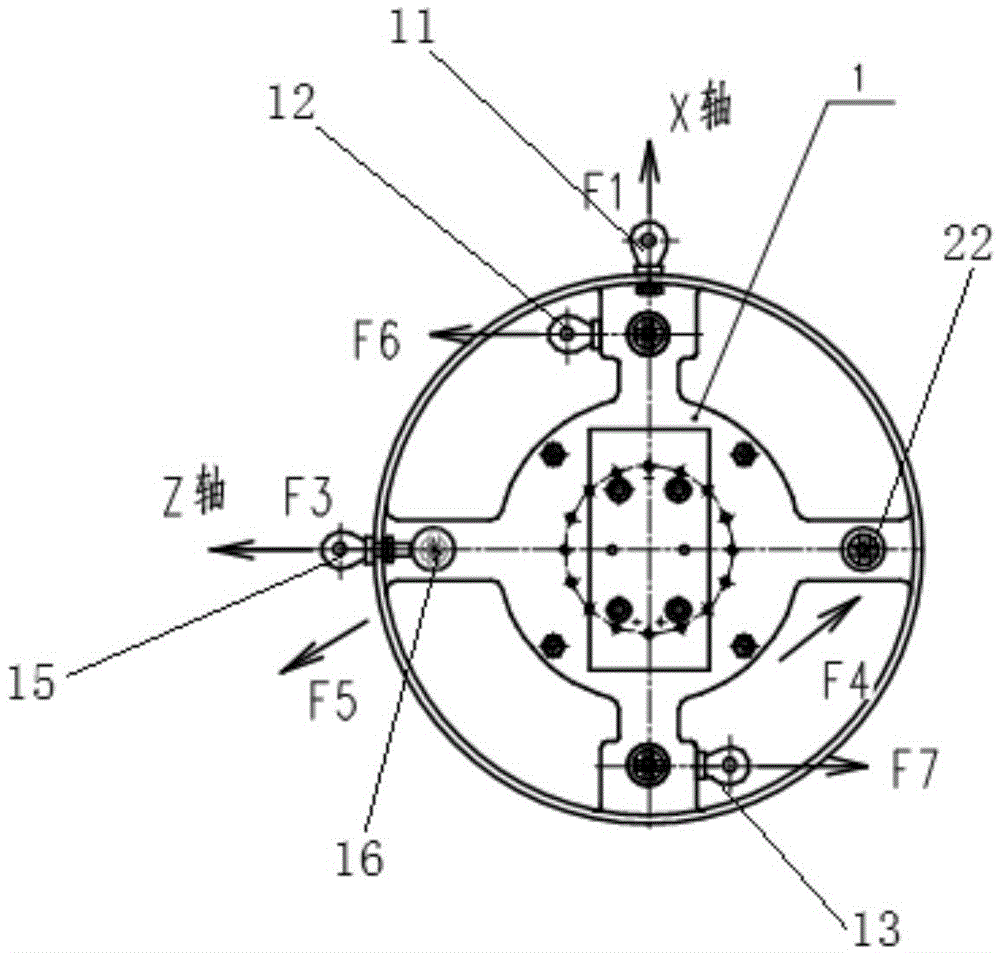

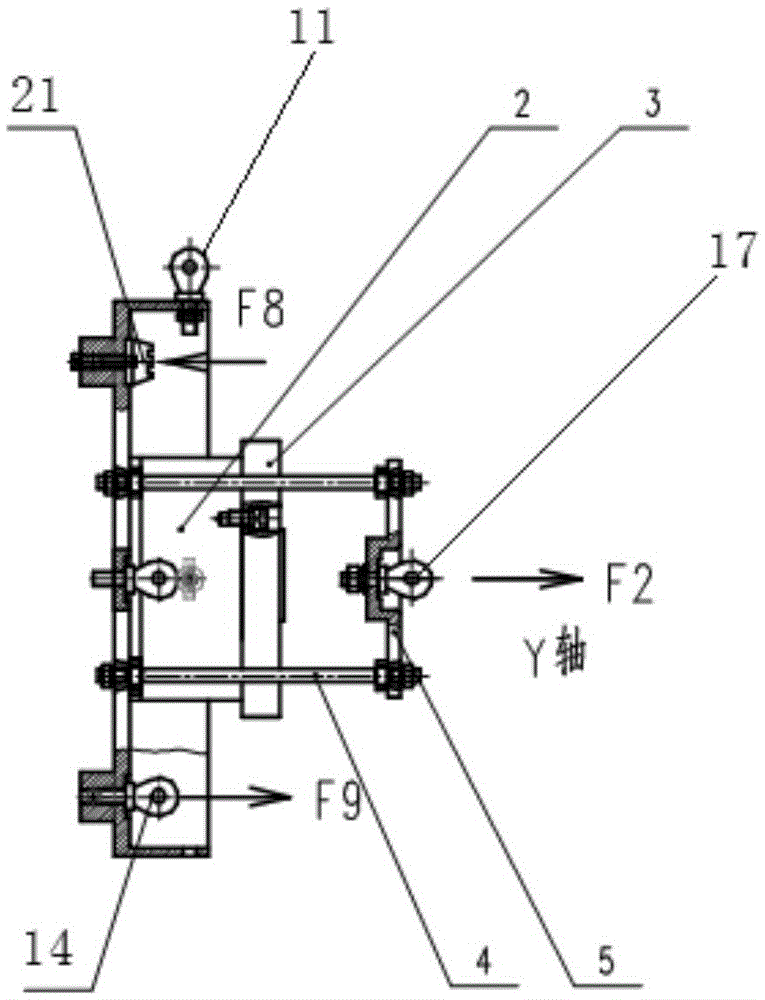

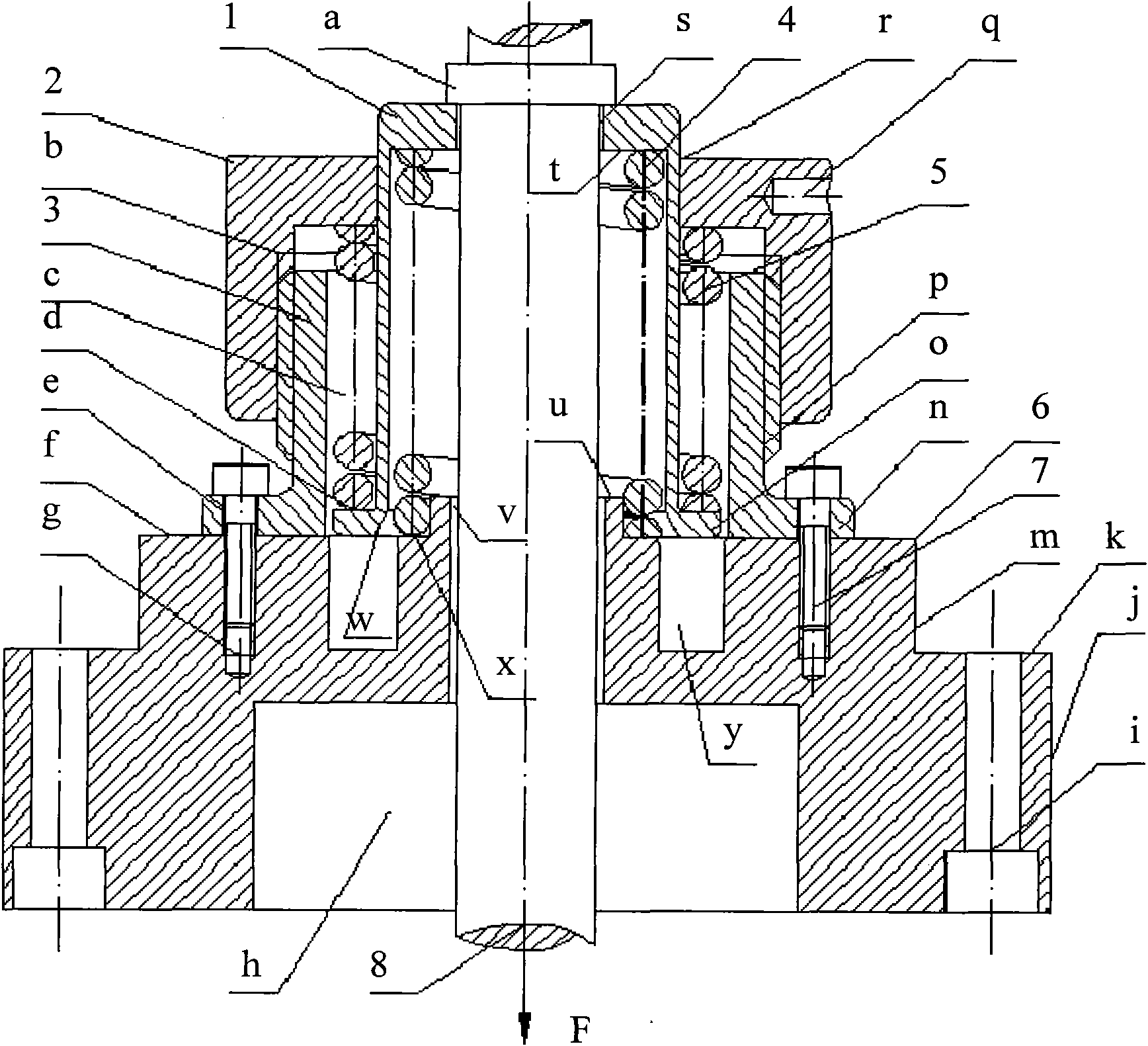

Vector thrust loading device for attitude control engine

ActiveCN105649817AGuaranteed positioning accuracyImprove machining accuracyRocket engine plantsAttitude controlEngineering

The invention relates to a vector thrust loading device for an attitude control engine. The vector thrust loading device comprises a loading head, a connecting rod, a sensor mounting flange and a rear flange, wherein one end of the loading head is connected to the engine; the other end of the loading head is connected to the rear flange through the connecting rod; the sensor mounting flange is arranged between the rear flange and the loading head and is fixed on a stationary foundation; one end of a vector force sensor is fixed on the sensor mounting flange, and the other end of the vector force sensor is fixed on the loading head; the central position of the loading head is set as an original point; six pull rings and two pressing seats are arranged on the loading head; a seventh pull ring is arranged on the rear flange; and the first to sixth pull rings and the two pressing seats realize the application of Fy, Fz, Mx, My and Mz standard forces in a combination manner. According to the invention, the problem of application of standard vector forces under the vector force sensor coordinate system in the in-situ calibration process of the vector force sensor on a testing site is solved.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

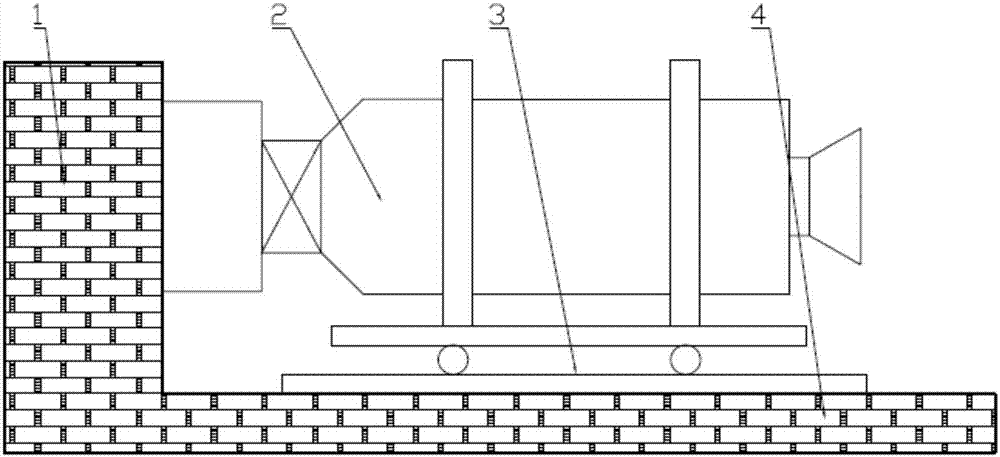

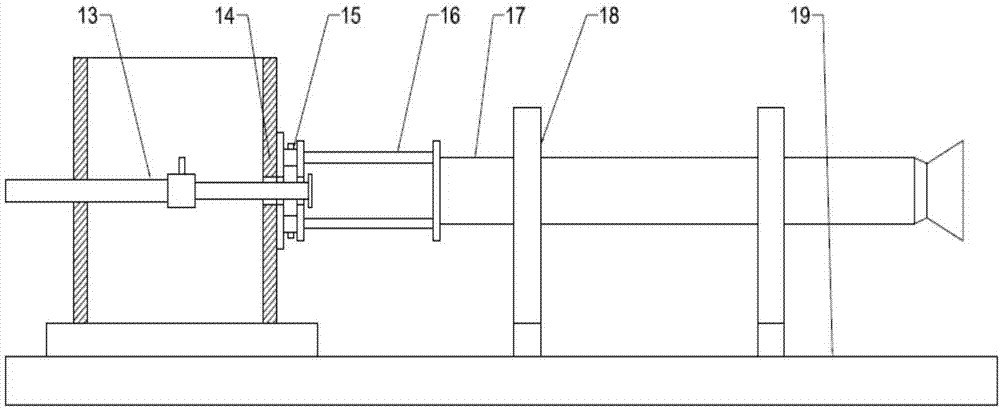

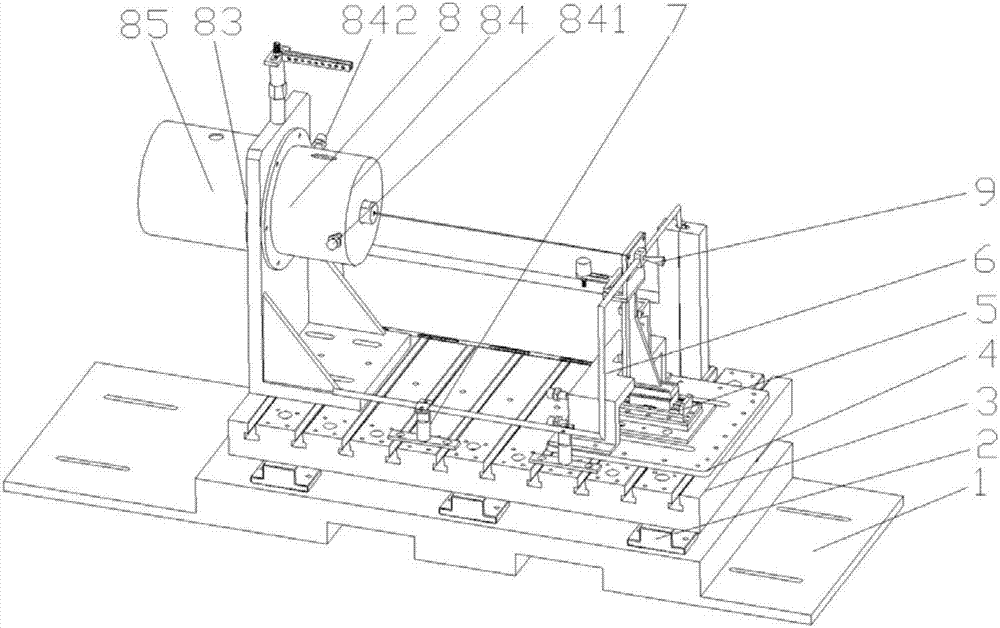

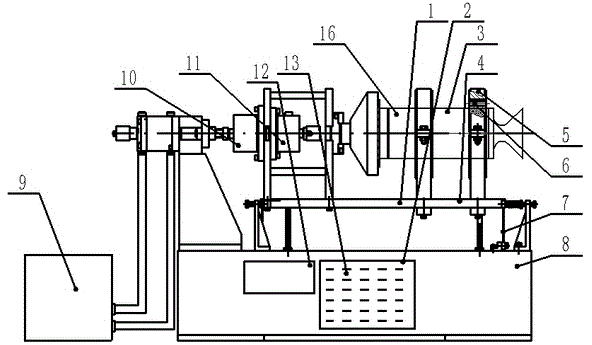

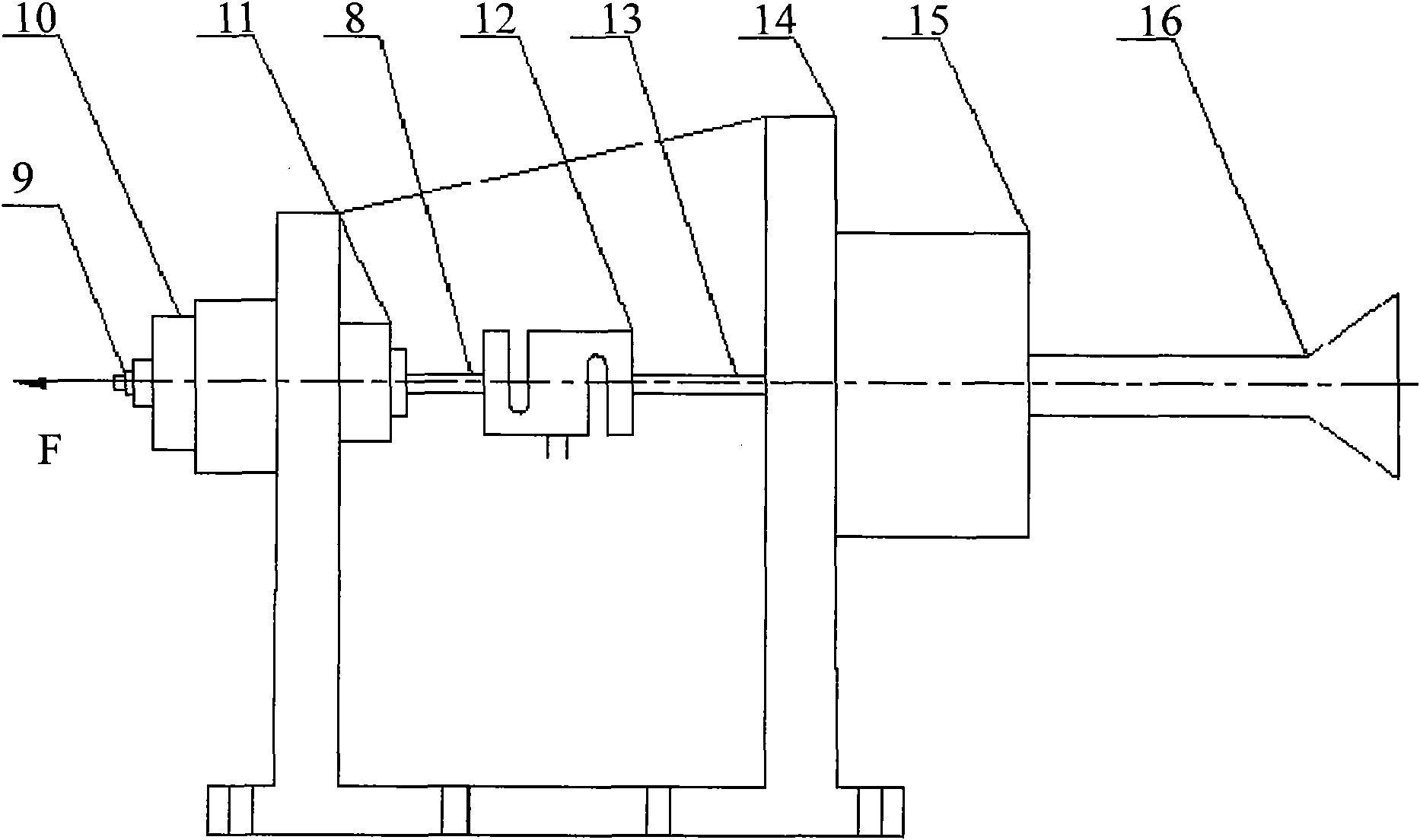

Small thrust measuring device

InactiveCN107238457AReduce in quantityLarge working spaceApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingMeasurement deviceIn situ calibration

The invention discloses a thrust measuring device applicable to a small thrust engine. The thrust measuring device comprises a static frame, a movable frame, an in situ calibration device, a force measuring component and a suspension part, wherein the movable frame, the in situ calibration device and the force measuring component are arranged on the static frame, and the suspension part is used for mounting an engine and can adjust the height of the engine. In the thrust measuring device, the suspension part is composed of a suspension block, a lifting bolt, a lifting thread bushing, an elastic element, a tension part and a rigidity tension and compression part or elastic tension and compression part, the engine is mounted by adopting a suspension way, the quantity of test accessories can be reduced, and mass can be reduced, so that inertia force and frictional force of a test device are reduced, and thrust measurement accuracy is improved; a mechanical loading mode is adopted for implementing static calibration, composition of the in situ calibration device is simplified, time of a test preparatory stage is shortened, and economy of the measuring device is improved; and for a specific engine, appropriate parts are selected for being assembled into the suspension part, and universality of a thrust device can be enhanced.

Owner:BEIHANG UNIV

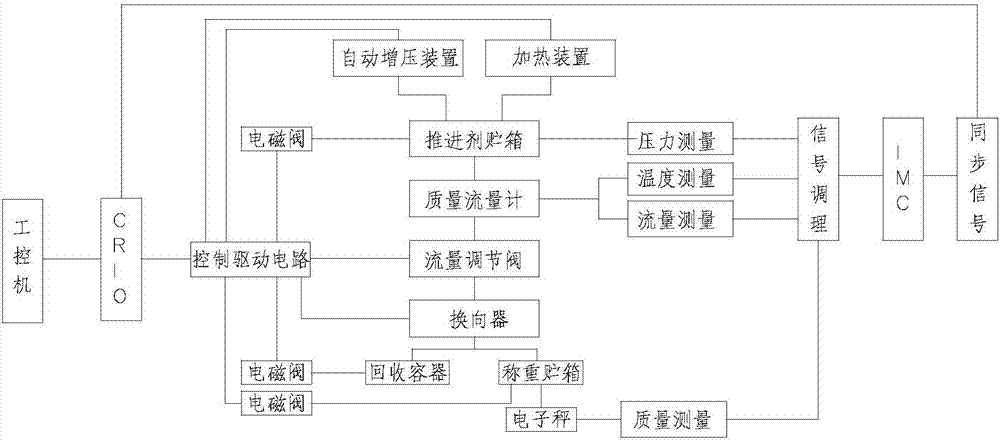

In-situ calibration device for steady state flow rate of high-temperature propellant of attitude control engine and calibration method

ActiveCN107131931AReduce the influence of flow measurementHigh measurement accuracyTesting/calibration apparatusAttitude controlControl system

The invention discloses an in-situ calibration device for the steady state flow rate of a high-temperature propellant of an attitude control engine and a calibration method. The calibration device comprises a propellant supplying device, a high-low temperature box, a weighing and recycling device, a control system and a measuring system; the propellant supplying device is used for supplying flow rate, pressure and propellant at stable temperature for a calibration system according to the flow rate requirement on a mass flow meter to be calibrated; the high-low temperature box is used for heating the propellant supplying device according to the calibration requirement of the mass flow meter to be calibrated; the weighing and recycling device is used for weighing and recycling the propellant which flows through the mass flow meter within the calibration setting time; the control system is used for controlling and regulating the propellant supplying device, the high-low temperature box and the weighing and recycling device; and the measuring system is used for collecting and treating data. By adopting the device, the influence of medium temperature, density and the like on the measuring result of the mass flow meter can be effectively reduced, and the flow rate measuring accuracy is improved.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

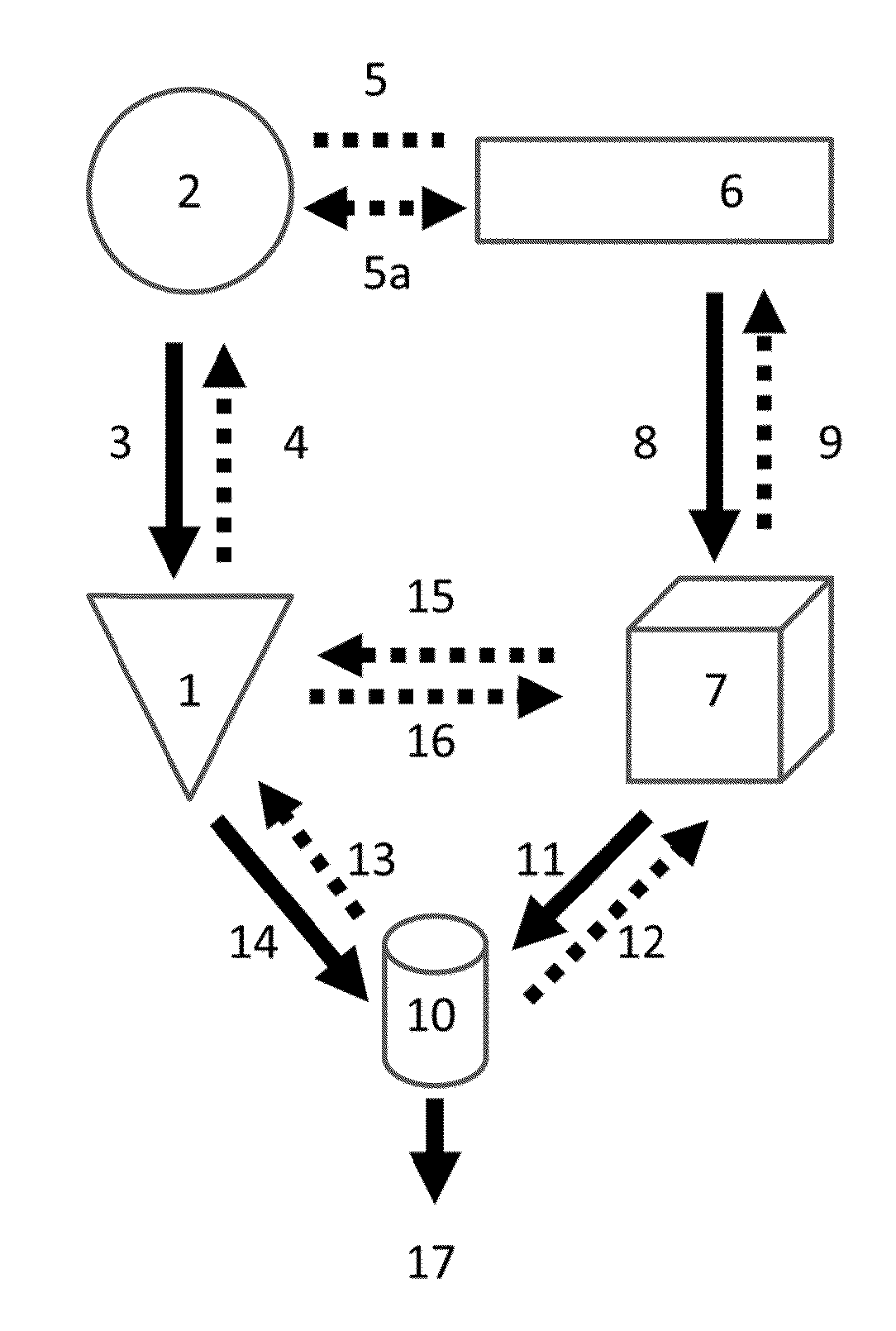

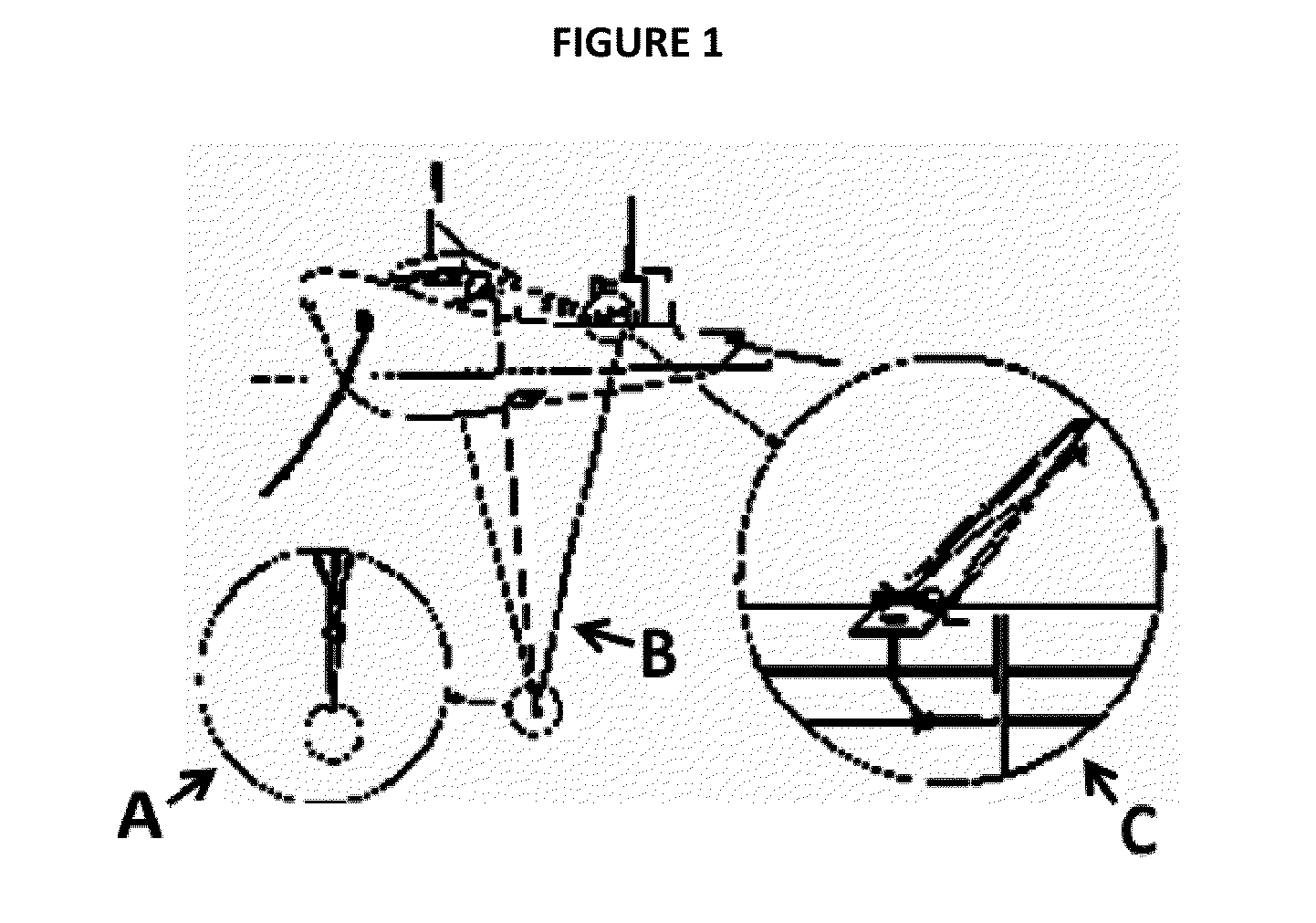

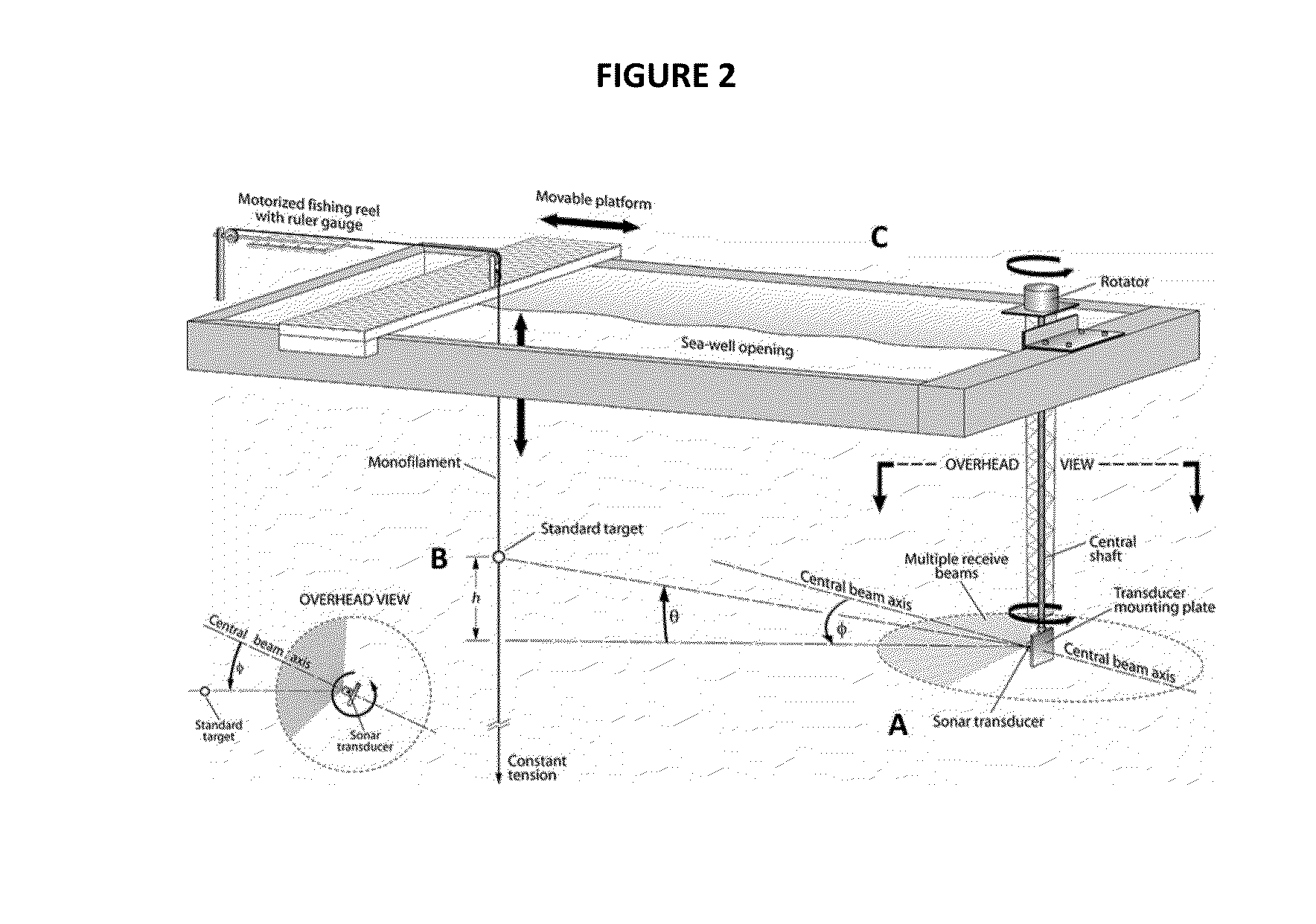

Platform-Independent Sonar Calibration Enabling System

InactiveUS20160069988A1Precise positioningTransmission monitoringAcoustic wave reradiationIn situ calibrationComputer science

The invention enables platform-independent sonar calibration. The associated systems and methods have application to underwater sonar systems and components, enabling an unprecedented flexibility in use. The systems and methods of the invention allow for efficient field calibration of sonars as configured for operational use, with high accuracy at low-cost. The invention provides in situ calibration capability for both stationary and moving sonar platforms and is suitable for calibration during operations.

Owner:WOODS HOLE OCEANOGRAPHIC INSTITUTION

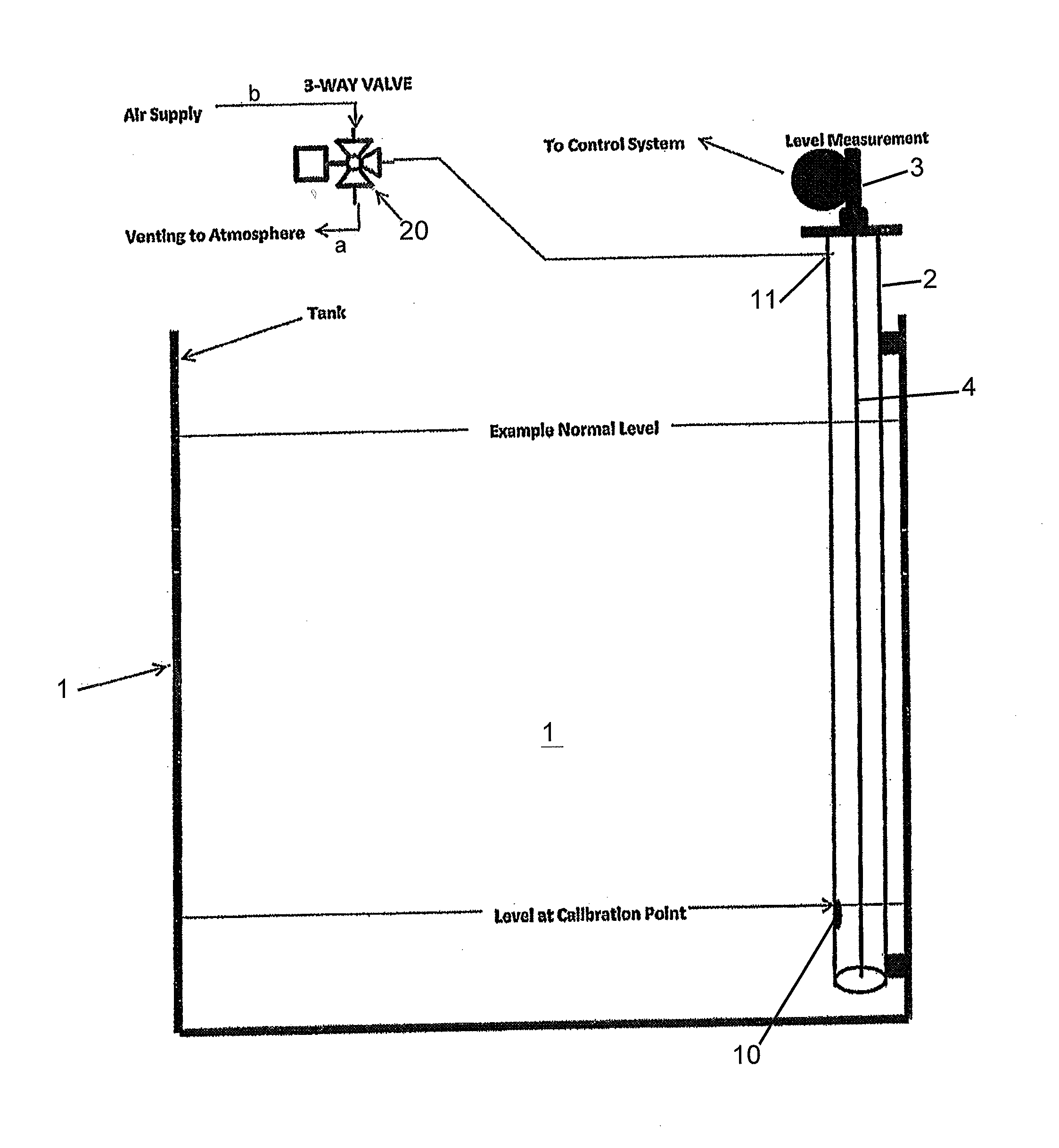

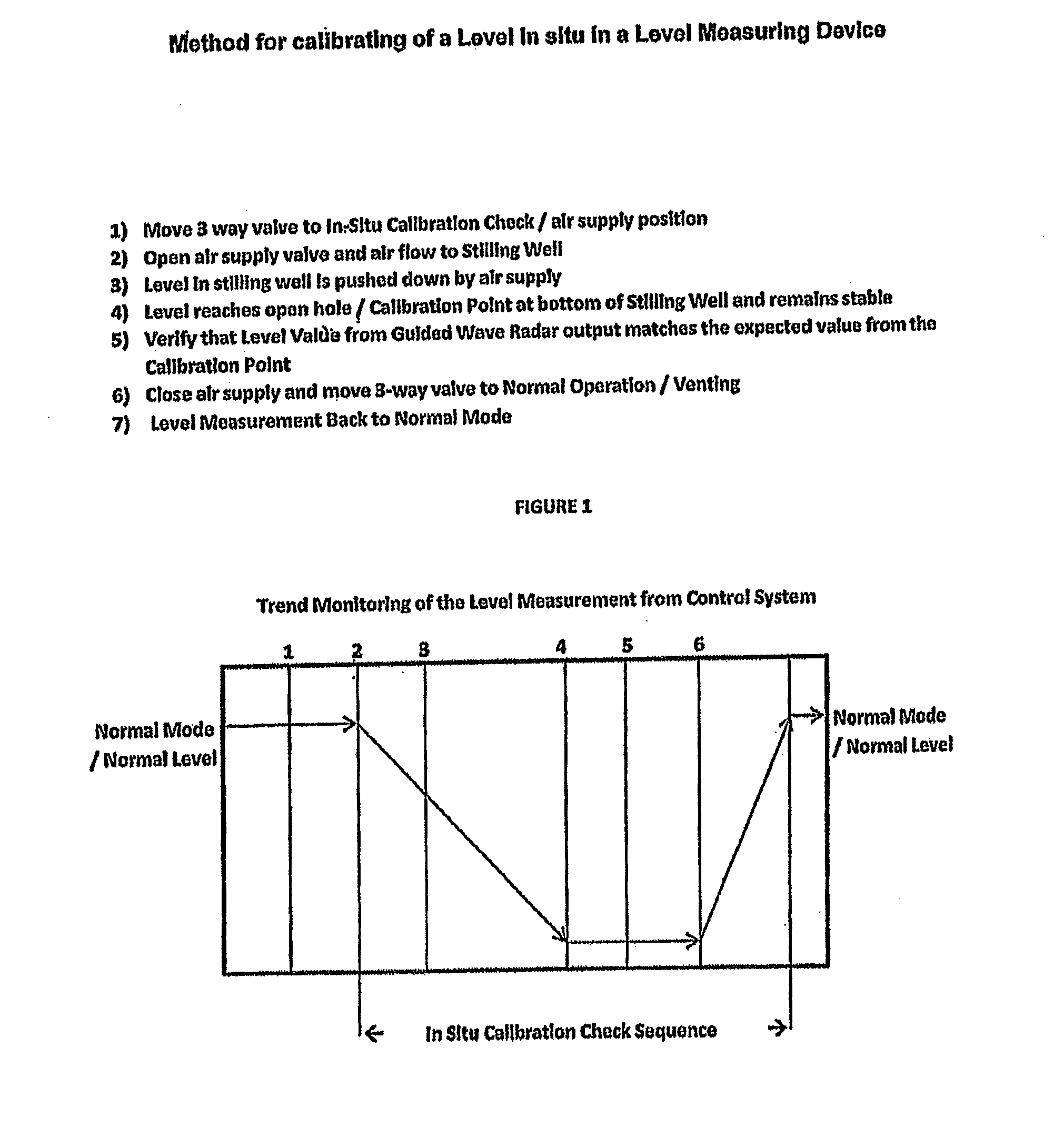

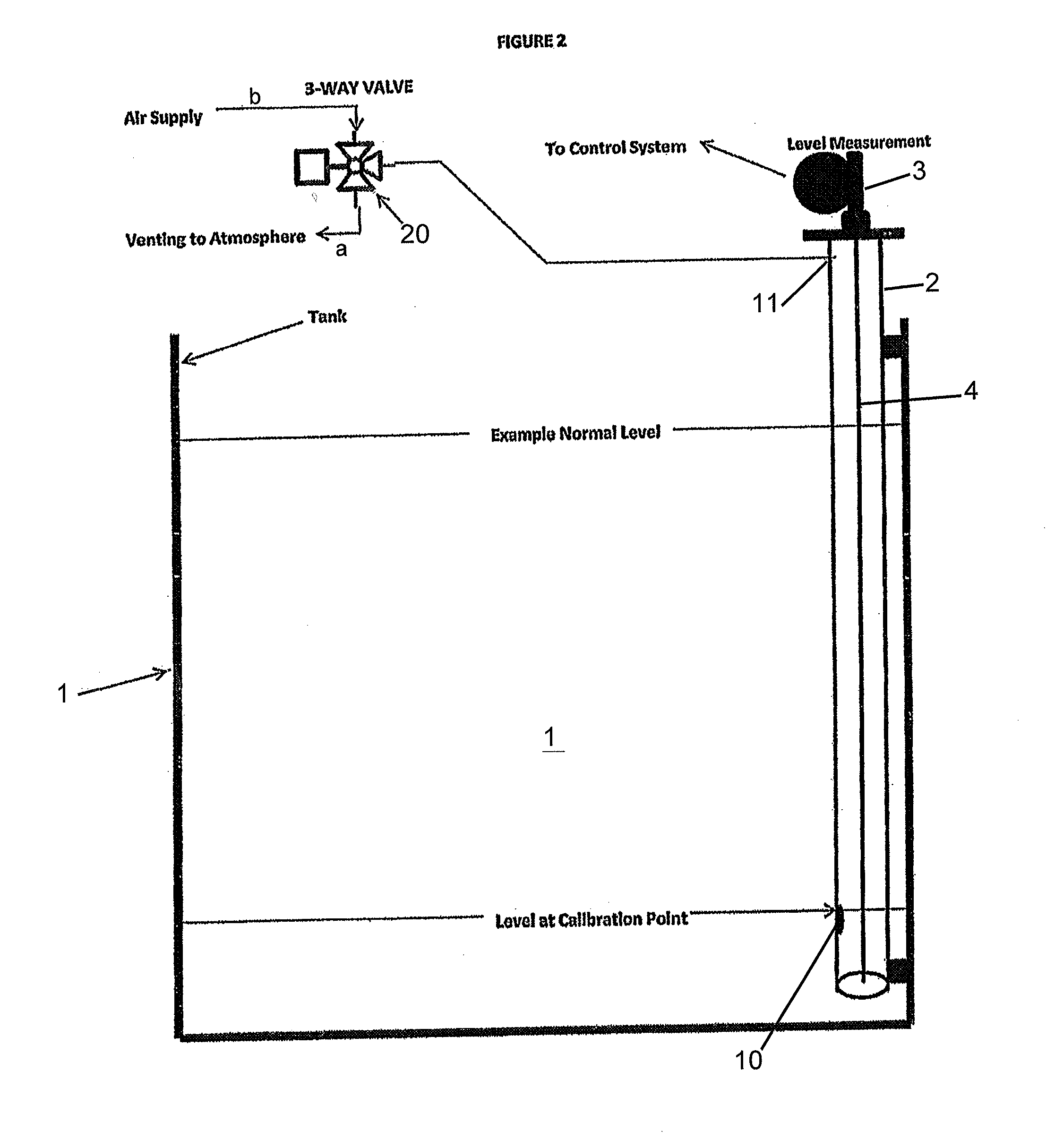

In Situ Calibration of a Level Measuring Device

InactiveUS20140326038A1Testing/calibration apparatusLevel indicatorsIn situ calibrationLevel measurement

A calibration system for a level meter comprising a tank having a sidewall and a bottom defining a tank interior, and a stilling well coupled to said tank, said stilling well having a sidewall, proximal and distal ends and a stilling well interior, and the distal end in fluid communication with the tank interior near the tank bottom, said proximal end of said stilling well being sealingly coupled to said level meter, said stilling well having a calibration fluid path allowing fluids to flow out of said stilling well interior; said stilling well having a vent opening that is sealingly closable near said proximal end; and a source of pressurized gas connectable to said stilling well interior, said stilling well having a measurement configuration where said vent opening is opened allowing said proximal end to vent gases in said stilling well interior, and a calibration configuration, where said pressurized air source is connected to said stilling well and flowing into said stilling well interior, where said pressurized gas may exit said stilling well interior only at said calibration flow path.

Owner:ABB INC

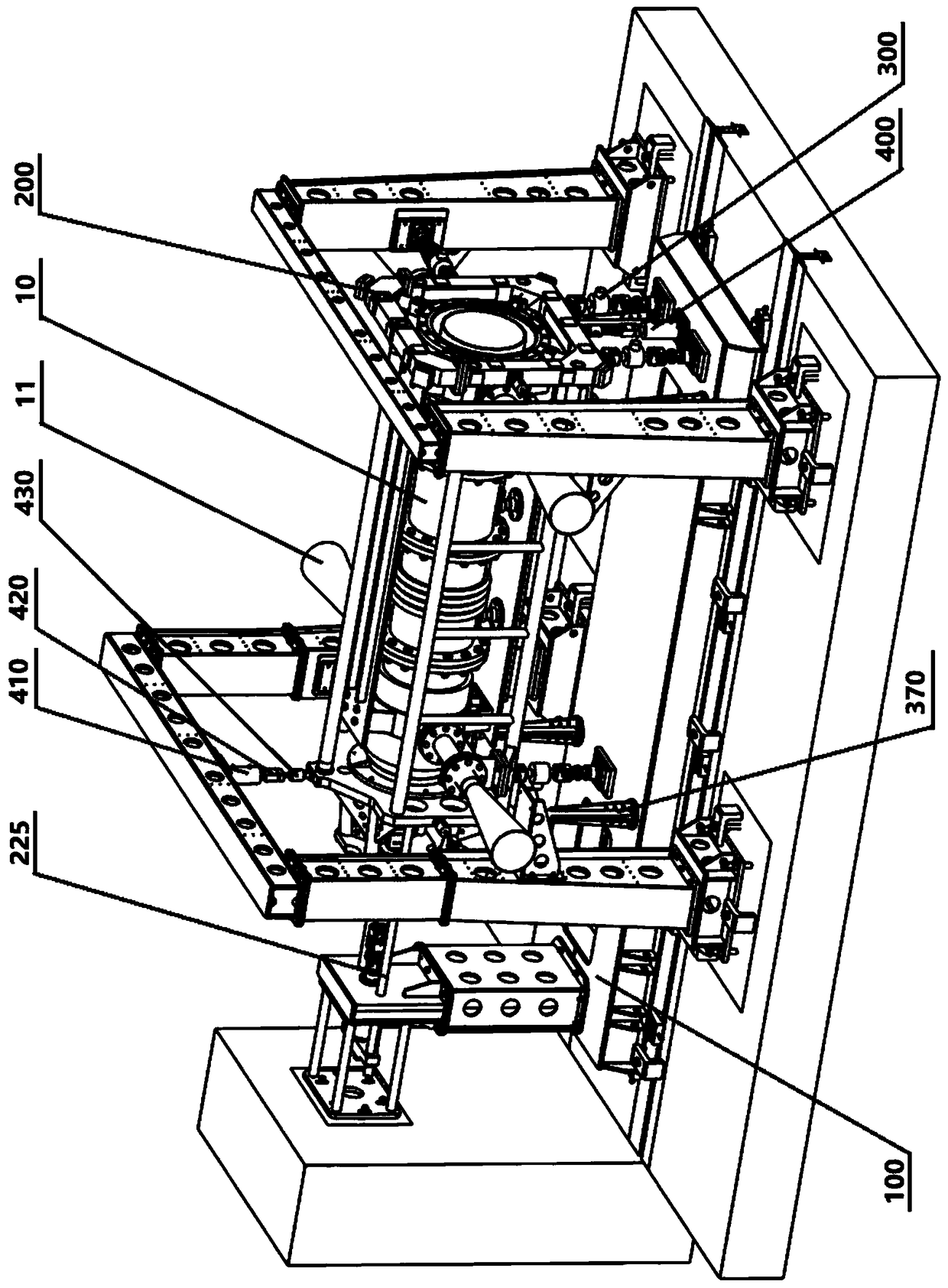

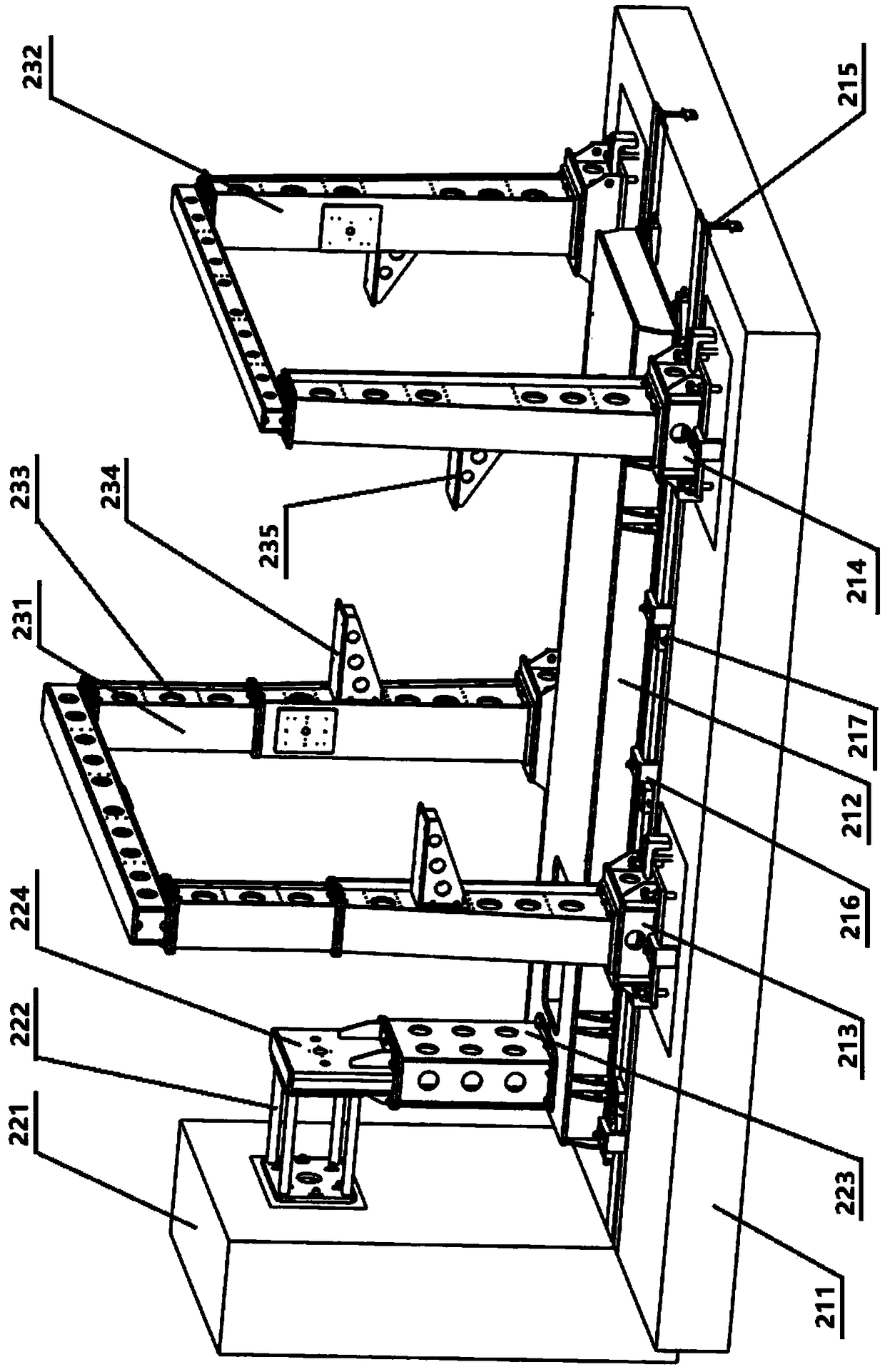

Six-component test stand and method for measuring vector thrust

PendingCN109141905ARealize measurementSimple structureGas-turbine engine testingApparatus for force/torque/work measurementFixed frameIn situ calibration

The invention relates to a six-component test stand, which comprises a movable frame, a fixed frame, force measuring assemblies and in-situ calibration devices, wherein the movable frame includes a transfer frame, a center frame, a reinforcement plate and a truss; the fixed frame includes a horizontal foundation part, a force bearing part and an installation part; the horizontal foundation part includes a horizontal base, a horizontal base plate, a first support base and a second support base; the force bearing part includes a force bearing wall, a force bearing frame, a force bearing seat installation base and a force bearing seat; there are a plurality of force measuring assemblies and a plurality of in-situ calibration devices; and the movable frame is connected with the fixed frame through the plurality of force measuring assemblies and the plurality of in-situ calibration devices. The method for measuring the vector thrust comprises the steps of constructing a six-component model,and calculating the vector thrust, the eccentric angle and the eccentric distance of a test piece through a space force system balance equation set according to the six-component model. The six-component test stand is simple in structure. The method for measuring the vector thrust solves a problem of large occupied space of the existing vertical six-component test system. Meanwhile, the gravity of an engine is taken into consideration, and the measurement accuracy is greatly improved.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

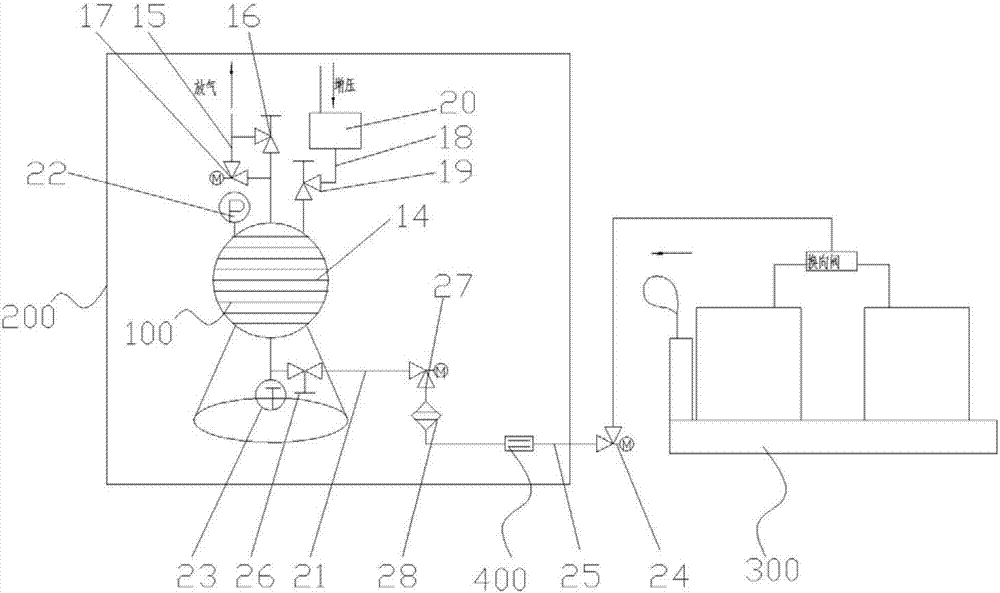

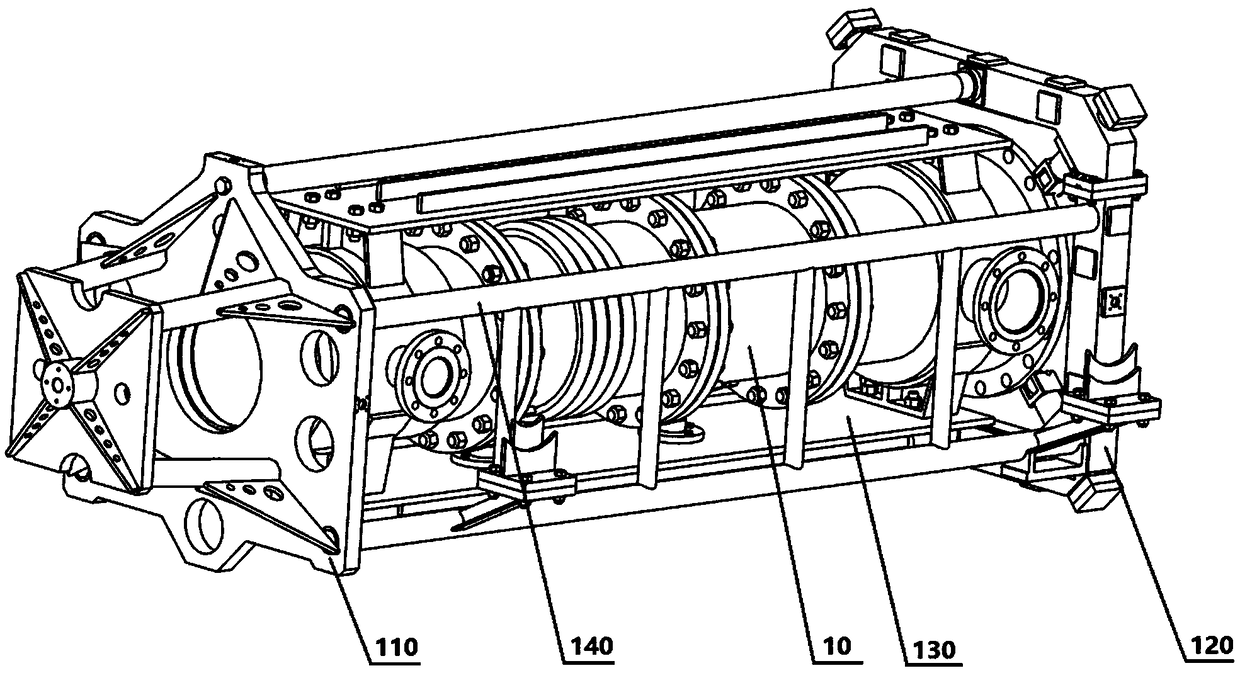

Calibration measurement device for steady-state thrust of 4-25N attitude control engine in thermal vacuum environment

ActiveCN107202660ASolve the problem of many uncertaintiesImprove calibration accuracyApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingMeasurement deviceBalance transfer

The invention relates to a calibration measurement device for steady-state thrust of a 4-25N attitude control engine in a thermal vacuum environment. The calibration measurement device comprises a base transfer frame, shock absorbing blocks, a fixed frame, a balance transfer plate, a single-component balance measurement device, a propellant pipeline, propellant pipeline fixing devices and an in-situ calibration device, wherein the shock absorbing blocks are uniformly mounted between the base transfer frame and the fixed frame; the propellant pipeline fixing devices are fixedly mounted on the periphery of the fixed frame; the propellant pipeline is mounted through the propellant pipeline fixing devices, one end of the propellant pipeline is communicated with an external propellant supply system, and the other end of the propellant pipeline is communicated with a propellant inlet of a to-be-measured attitude control engine; the single-component balance measurement device is mounted at one end of the fixed frame through the balance transfer plate, and the in-situ calibration device is mounted at the other end of the fixed frame. The calibration measurement device meets the requirements of the 4-25N attitude control engine for low thrust calibration measurement and solves the problems that high uncertainty is caused by pipeline constraint, high temperature and vibration in a measurement process, calibration before test run is not proper, the calibration precision is poor and the like.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

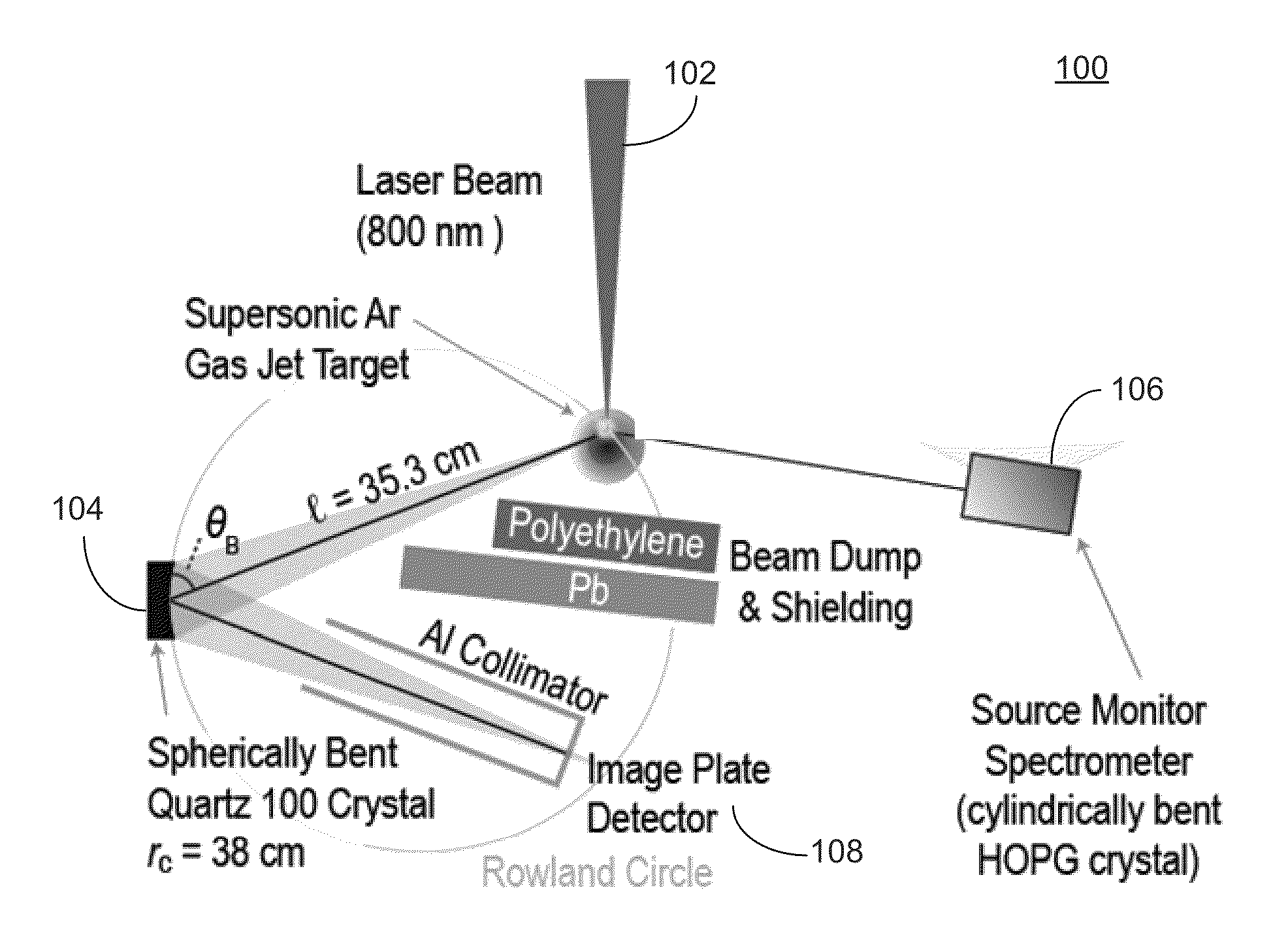

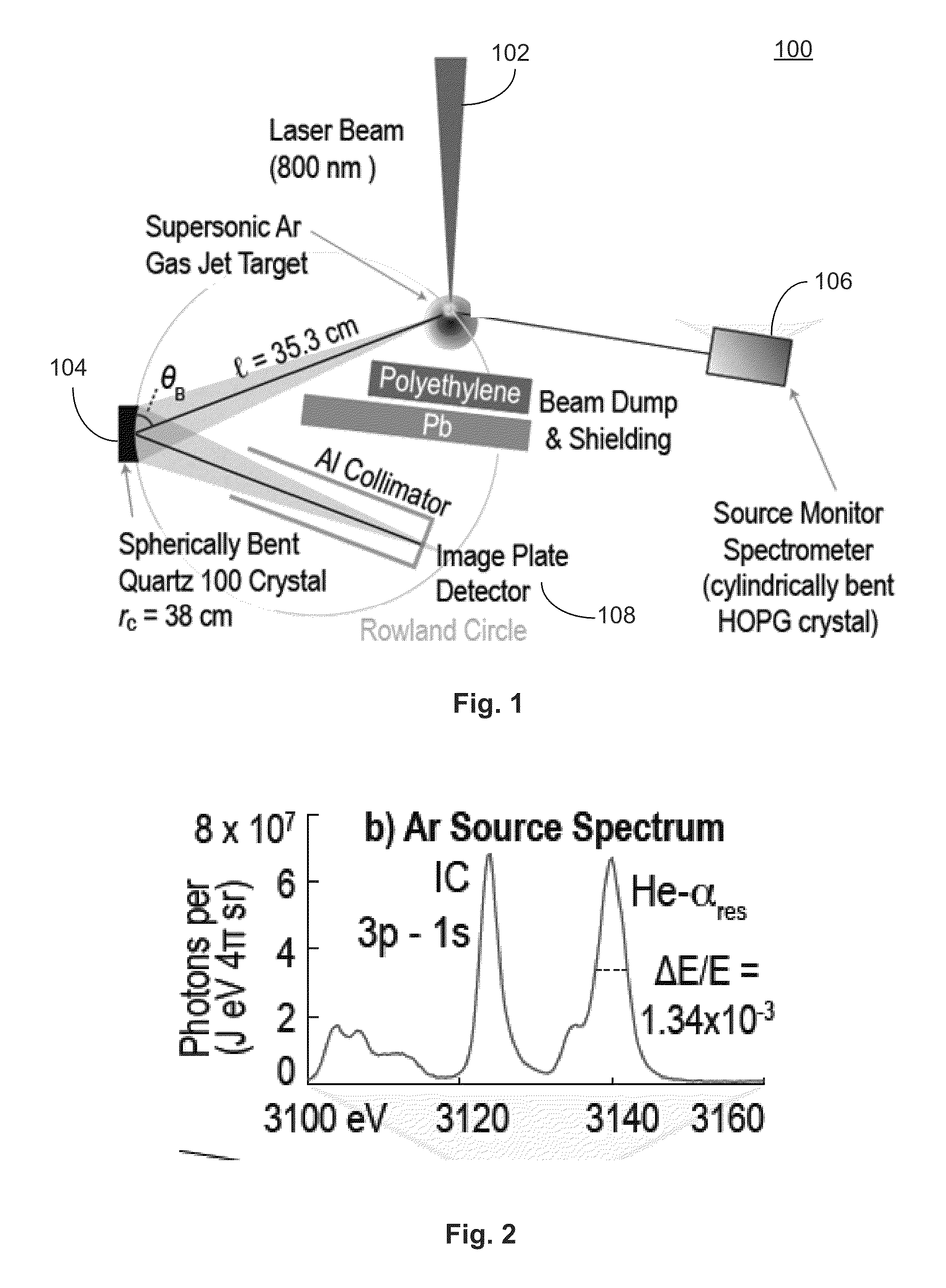

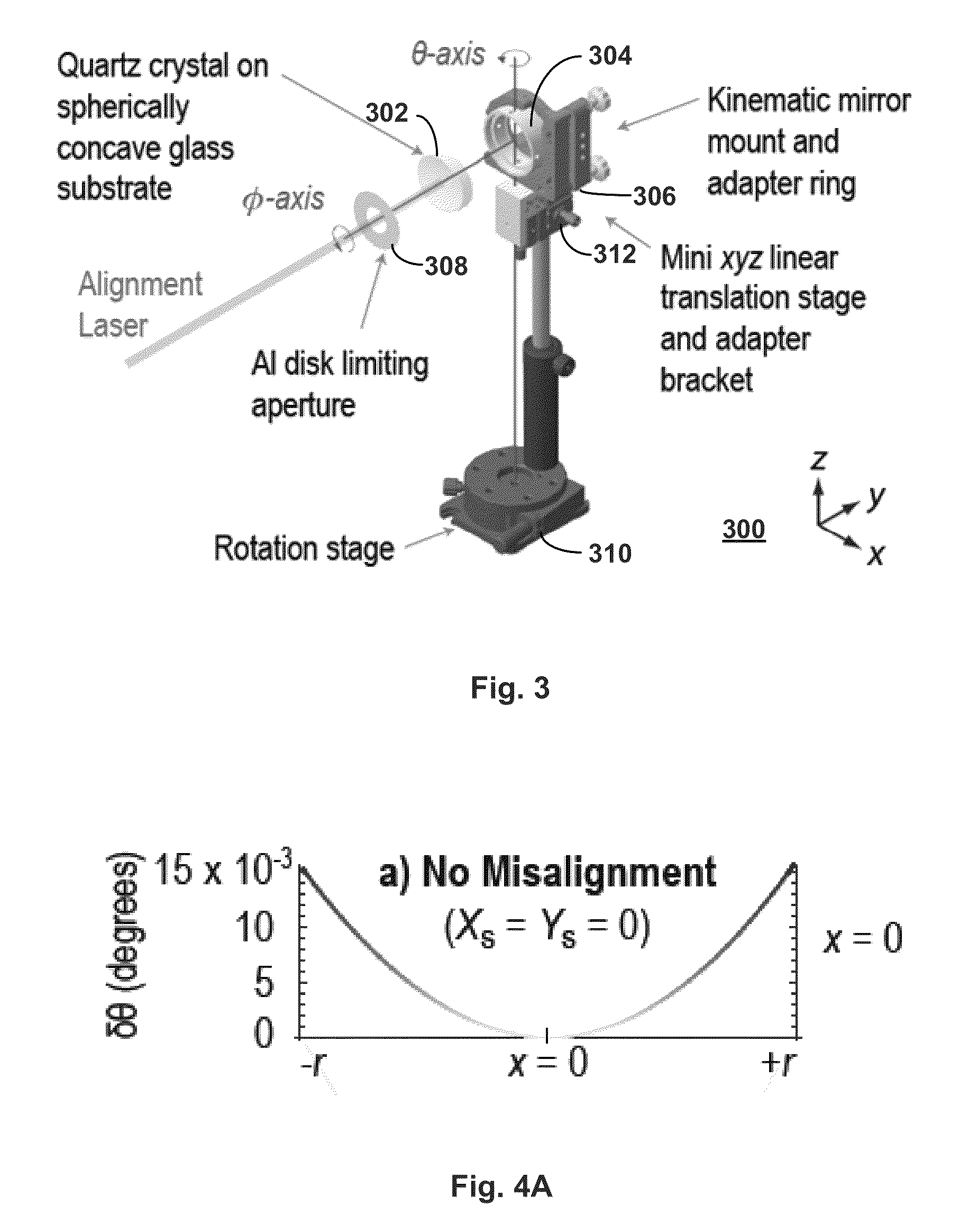

Method for characterization of a spherically bent crystal for Kα X-ray imaging of laser plasmas using a focusing monochromator geometry

InactiveUS9001968B2Accurate imagingEasy alignmentX-ray spectral distribution measurementMaterial analysis using wave/particle radiationGratingX-ray

A method is provided for characterizing spectrometric properties (e.g., peak reflectivity, reflection curve width, and Bragg angle offset) of the Kα emission line reflected narrowly off angle of the direct reflection of a bent crystal and in particular of a spherically bent quartz 200 crystal by analyzing the off-angle x-ray emission from a stronger emission line reflected at angles far from normal incidence. The bent quartz crystal can therefore accurately image argon Kα x-rays at near-normal incidence (Bragg angle of approximately 81 degrees). The method is useful for in-situ calibration of instruments employing the crystal as a grating by first operating the crystal as a high throughput focusing monochromator on the Rowland circle at angles far from normal incidence (Bragg angle approximately 68 degrees) to make a reflection curve with the He-like x-rays such as the He-α emission line observed from a laser-excited plasma.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

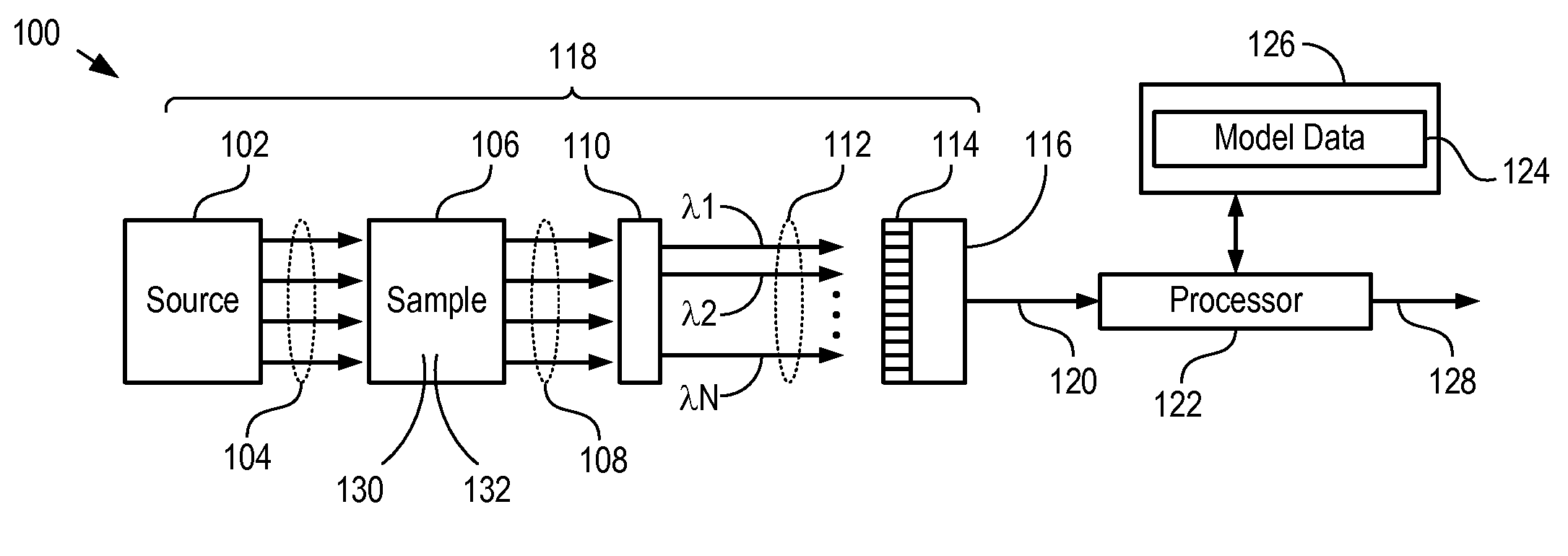

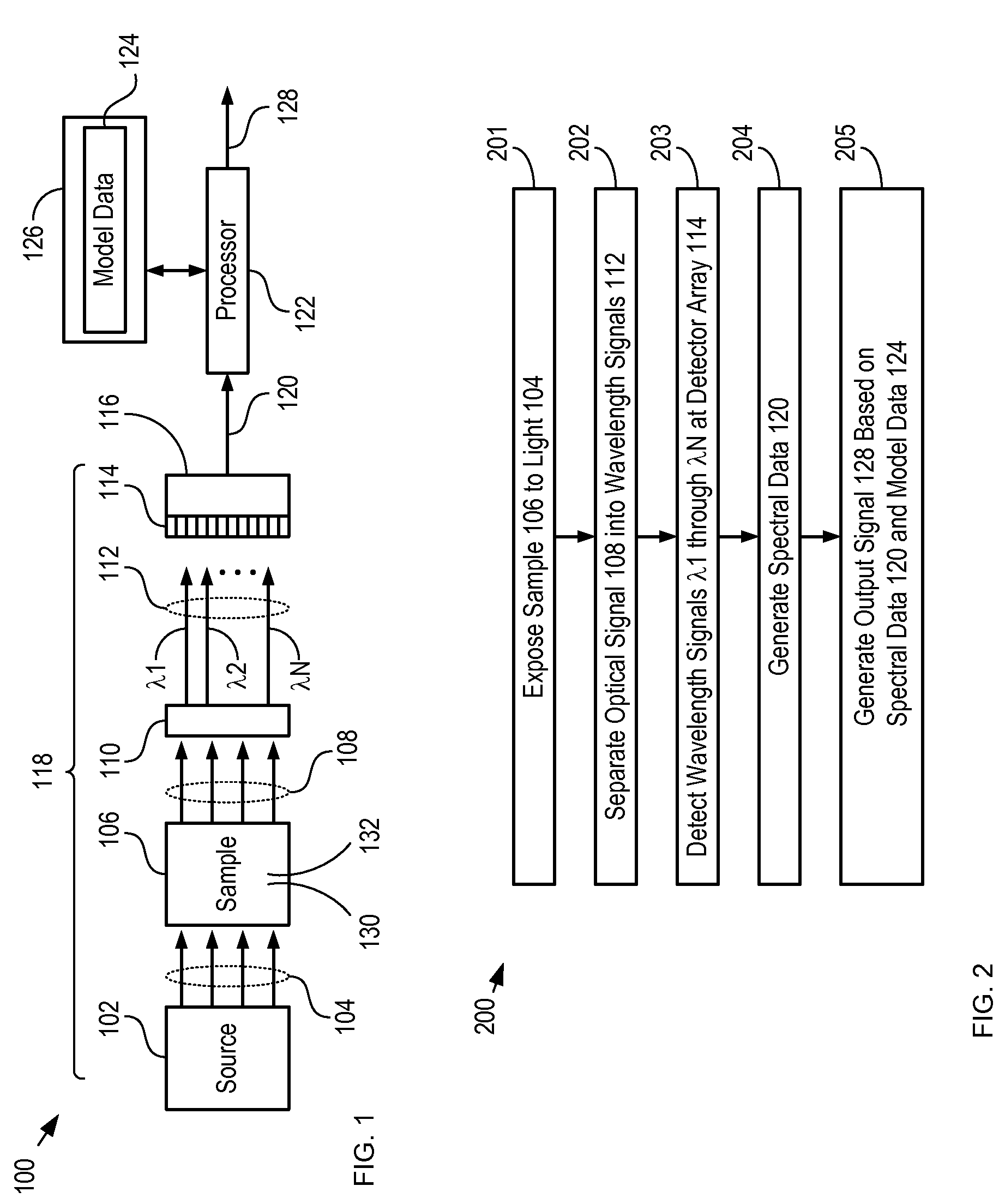

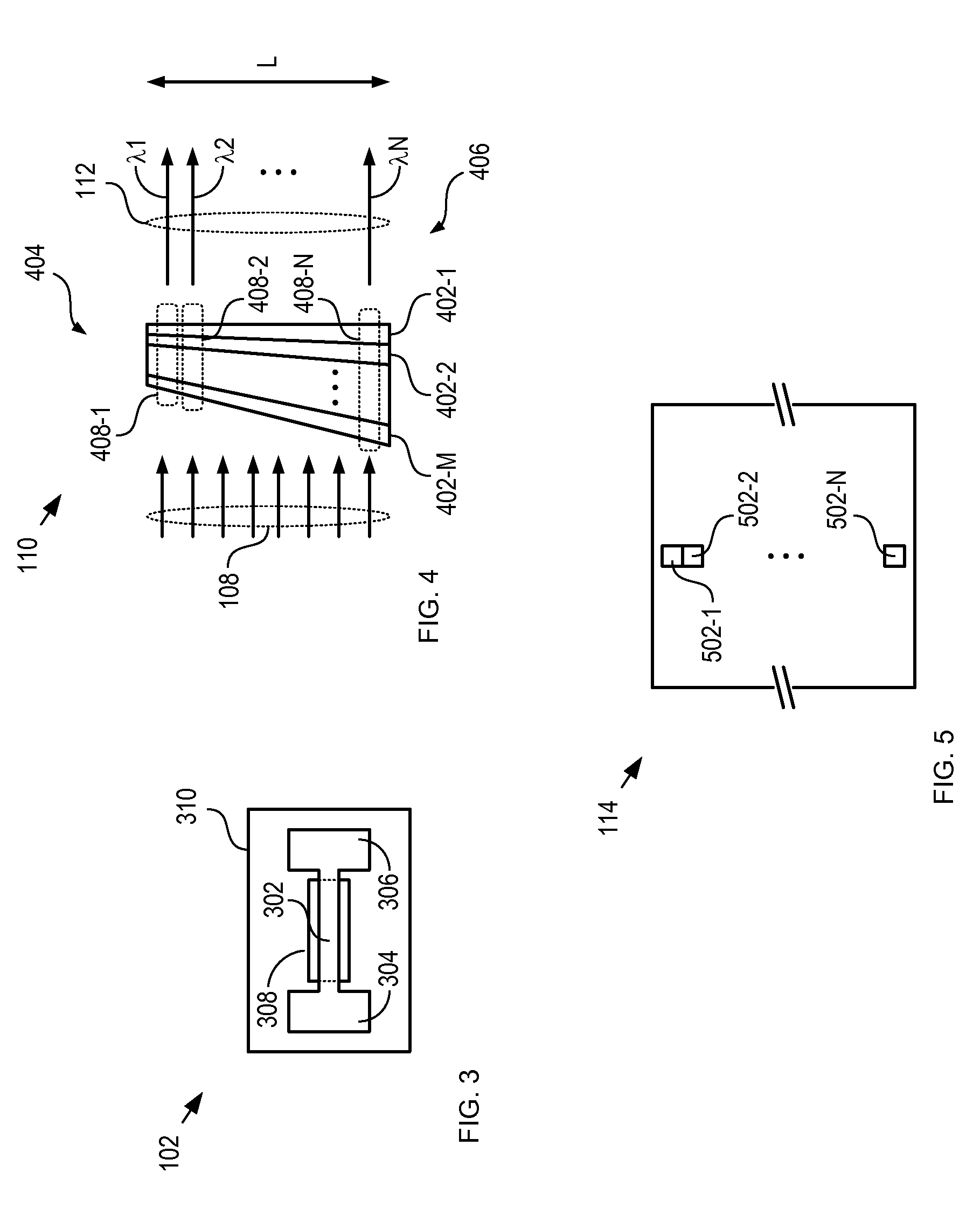

Apparatus and method for detecting and quantifying analytes in solution

ActiveUS8344323B1Easy to identifyEfficient removalAbsorption/flicker/reflection spectroscopySpectrum generation using multiple reflectionPath lengthAnalyte

A method for identifying and quantifying one or more analytes included in a sample comprising a background solvent is disclosed. The present invention enables in-situ calibration and removal of the spectral signature of the background solvent from a composite spectrum so that the spectral features associated with the analyte(s) can be more easily and precisely identified. Further, the method enables estimation of the concentration of the analyte(s) by normalizing the spectrum based on the path length of the infrared radiation through the sample.

Owner:ROC8SCI

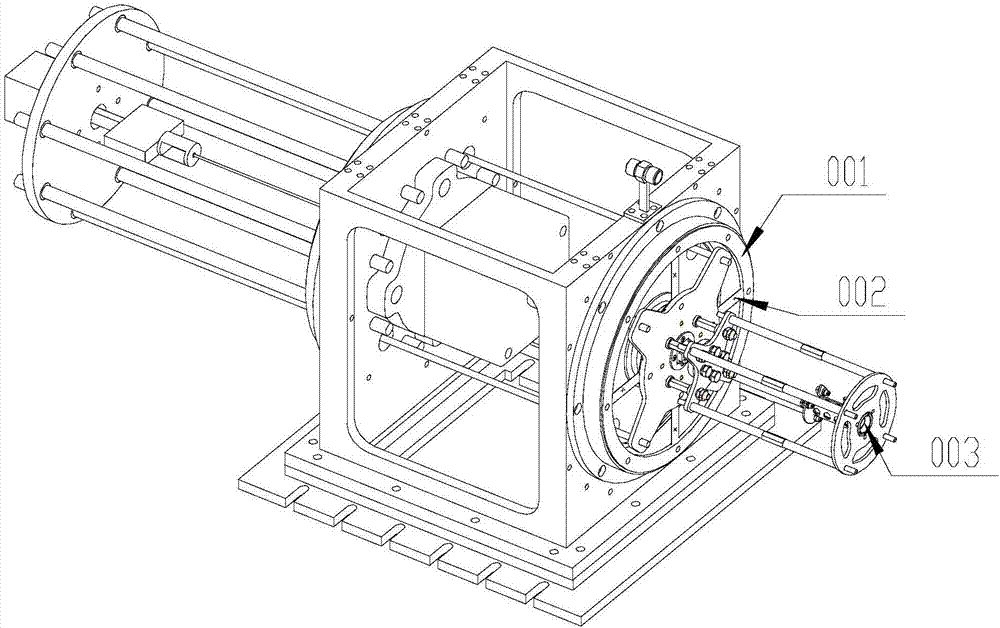

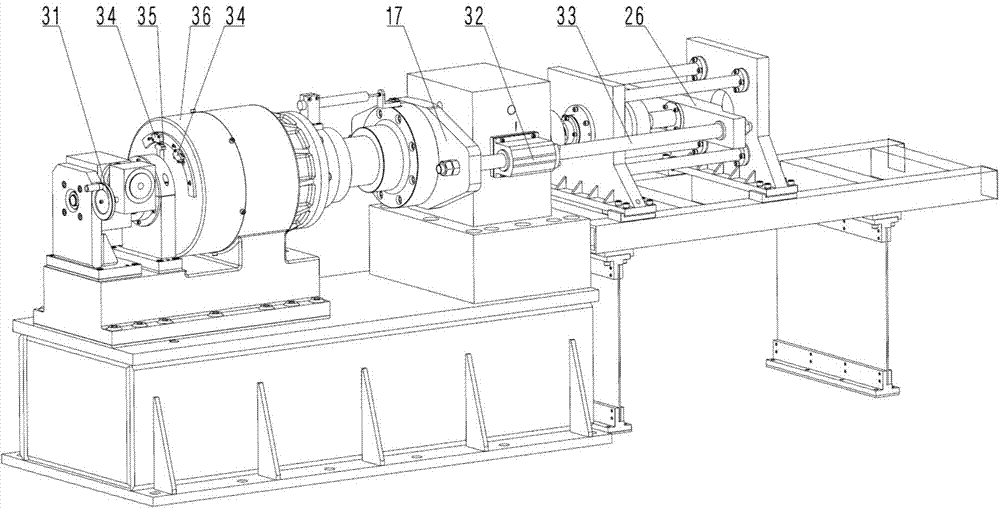

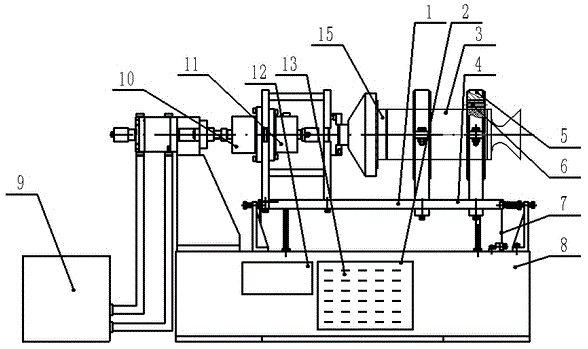

In-situ calibrating device with loaded direct-current torque motor and loaded driving ball screw assembly

ActiveCN104515684AReduce measurement errorImprove accuracyEngine testingForce/torque/work measurement apparatus calibration/testingAutomatic controlTorque motor

The invention belongs to the field of engine tests, discloses mechanical subsystems of in-situ calibrating systems, and relates to an in-situ calibrating device with a loaded direct-current torque motor and a loaded driving ball screw assembly. The in-situ calibrating device comprises the direct-current torque motor, the high-precision ball screw assembly, a high-precision encoder, a linear displacement sensor, a force transfer frame, a standard force sensor, a working force sensor, force transfer balls, force transfer ball sockets, a thrust frame, a force bearing frame, a motor base, a base, tapered roller bearings, a linear bearing, an electromagnetic clutch, double worm gear reducers, a hand wheel, an electric limit switch, a limit pressure plate and the like. The in-situ calibrating device has the advantages that an in-situ calibrating system comprises the in-situ calibrating device, a control subsystem of the in-situ calibrating system and a software subsystem of the in-situ calibrating system, an electric servo automatic control mechanical device loading method is implemented, accordingly, the in-situ calibrating device is high in in-situ calibrating loading force precision, is high in stability, good in safety and applicable to small-tonnage force and has an overload protection function, calibrating procedures can be automated, and manual loading modes are taken into consideration.

Owner:北京瑞赛长城航空测控技术有限公司 +2

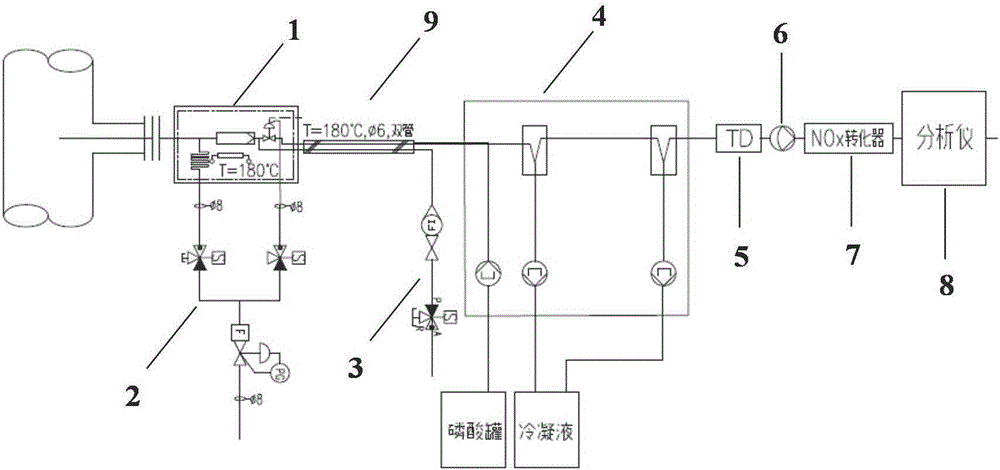

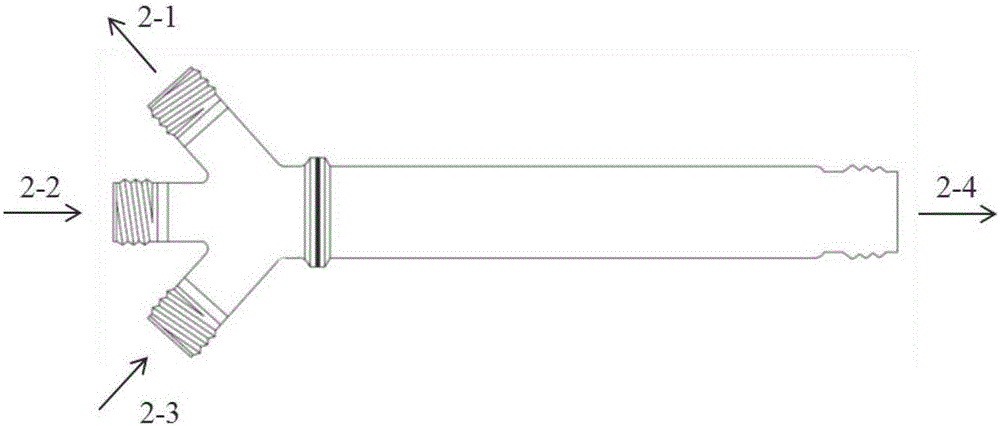

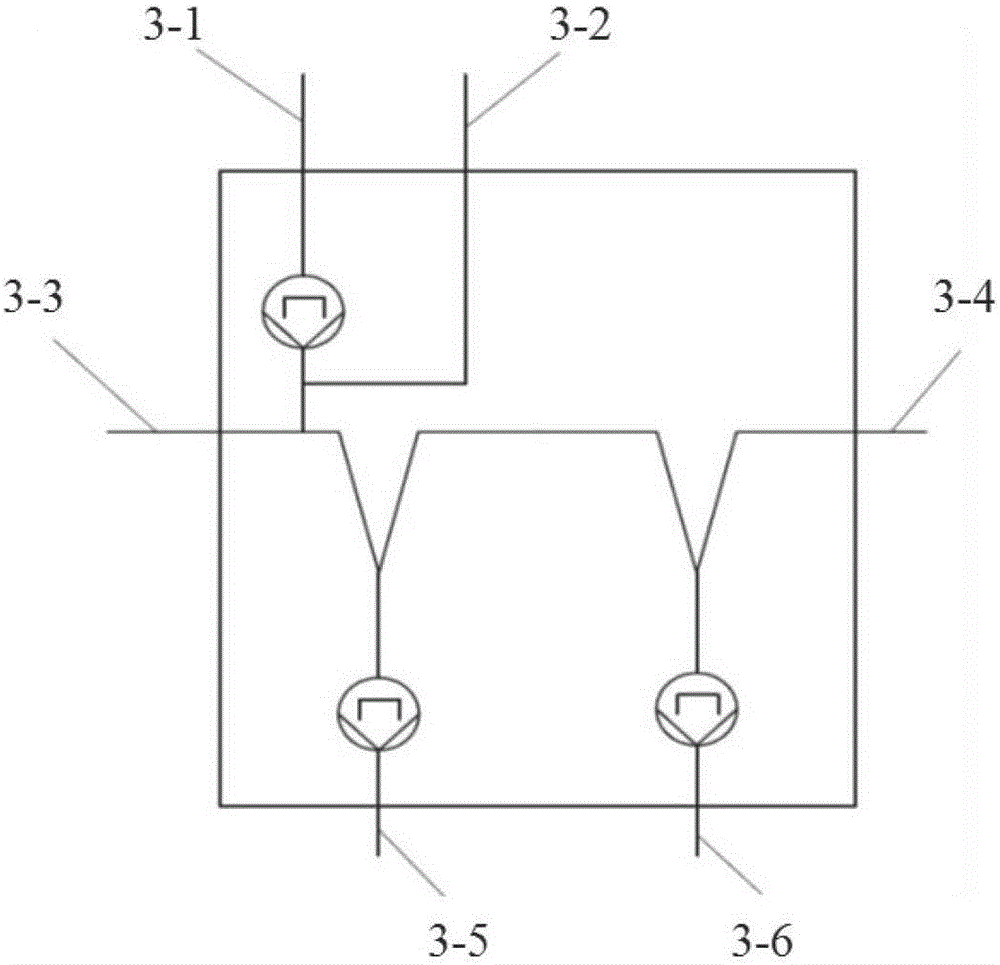

Ultralow emission online monitoring system for flue gas pollutants of coal-fired power plants

ActiveCN106053375AShorten the timeReduce contact areaMaterial analysis by optical meansMonitoring systemIn situ calibration

The invention discloses an ultralow emission online monitoring system for flue gas pollutants of coal-fired power plants. The system comprises a sampling unit, a back blowing unit, a heat tracing pipe, a calibration unit, a dew-point meter, an air pump, an NOX converter, an analyzing device and a data collecting, processing and transmitting unit. The system is characterized in that an acidification dehumidifier is arranged between the calibration unit and the dew-point meter and used for acidification of flue gas entering the acidification dehumidifier to prevent to-be-tested components in flue gas from dissolving in condensate, and the acidification dehumidifier is provided with an in-situ calibration passage used for calibration of a zero point and a measuring range of the analyzing device. By the ultralow emission online monitoring system, the problem of how to realize accurate and reliable online monitor ultralow emission of sulfur dioxide and nitrogen oxides in desulfurized and denitrified flue gas of the coal-fired power plants is solved, parameters are provided for an ultralow emission process of the coal-fired power plants, and national requirements of ultralow emission online monitoring are met.

Owner:NANJING HOPES TECH

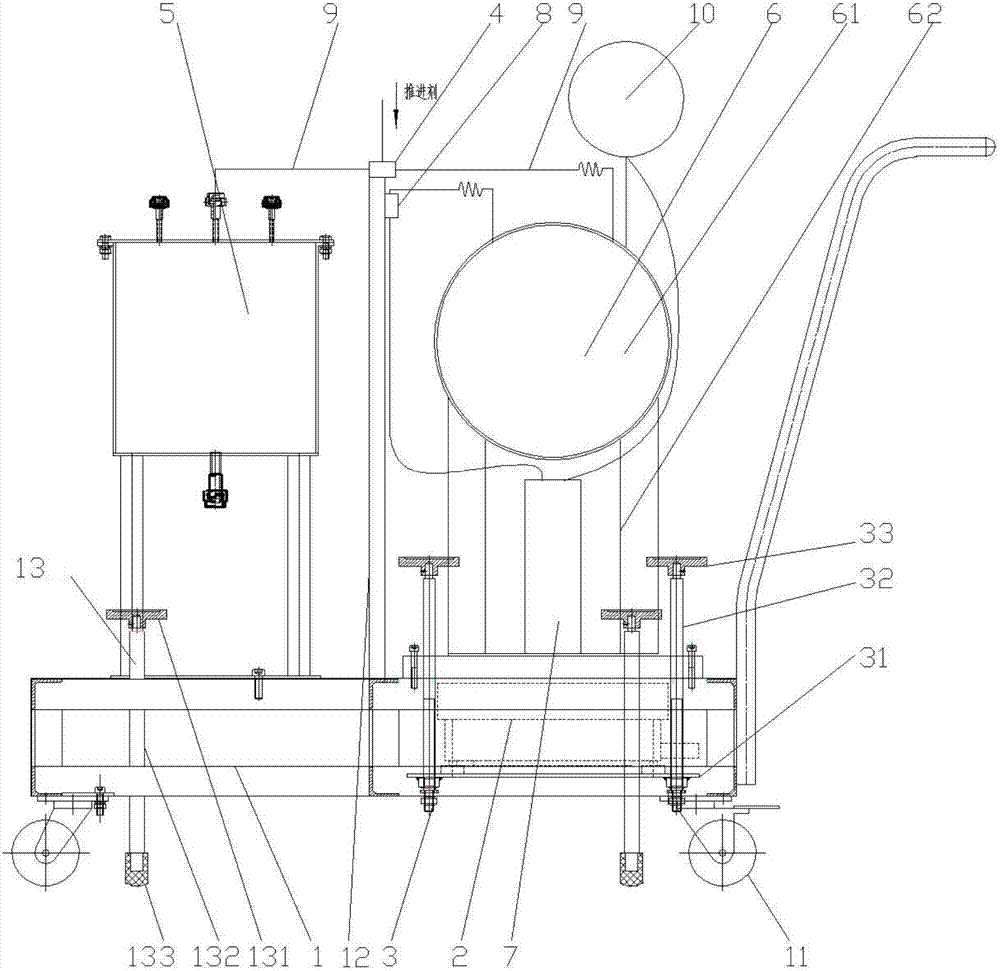

Multi-type compatible high-precision ground static testing stand for rocket engine

ActiveCN105319072AAchieve matchingGuarantee test detection accuracyGas-turbine engine testingJet-propulsion engine testingComputer moduleIn situ calibration

The invention relates to a multi-type compatible high-precision ground static testing stand for a rocket engine. The testing stand is composed of a stand system and an in-situ calibration system thereon; the stand system is provided with a movable rack, a counterweight clasp, a counterweight module and a plate spring, and the counterweight clasp and counterweight module are combined, match a solid rocket engine sample and them mounted on the movable rack; and the in-situ calibration system comprise an oil hydraulic press, a standard thrust sensor, a work thrust sensor, a standard calibration value table and an accurate number table. The counterweight clasps and modules of different specifications can match solid rocket engine samples of different types. The counterweight clasps and modules of different specifications are used to match the solid rocket engine samples of different types, the standard testing stand is used to test the engines of different types, so that the testing stand can be used flexibility for multiple types, the standard testing stand is compatible with and adapted to small solid rocket engine, and the testing stand has the advantages of reasonable structure, convenient adjustment, safe operation and reliable data.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Compound calibrator for thermal sensors

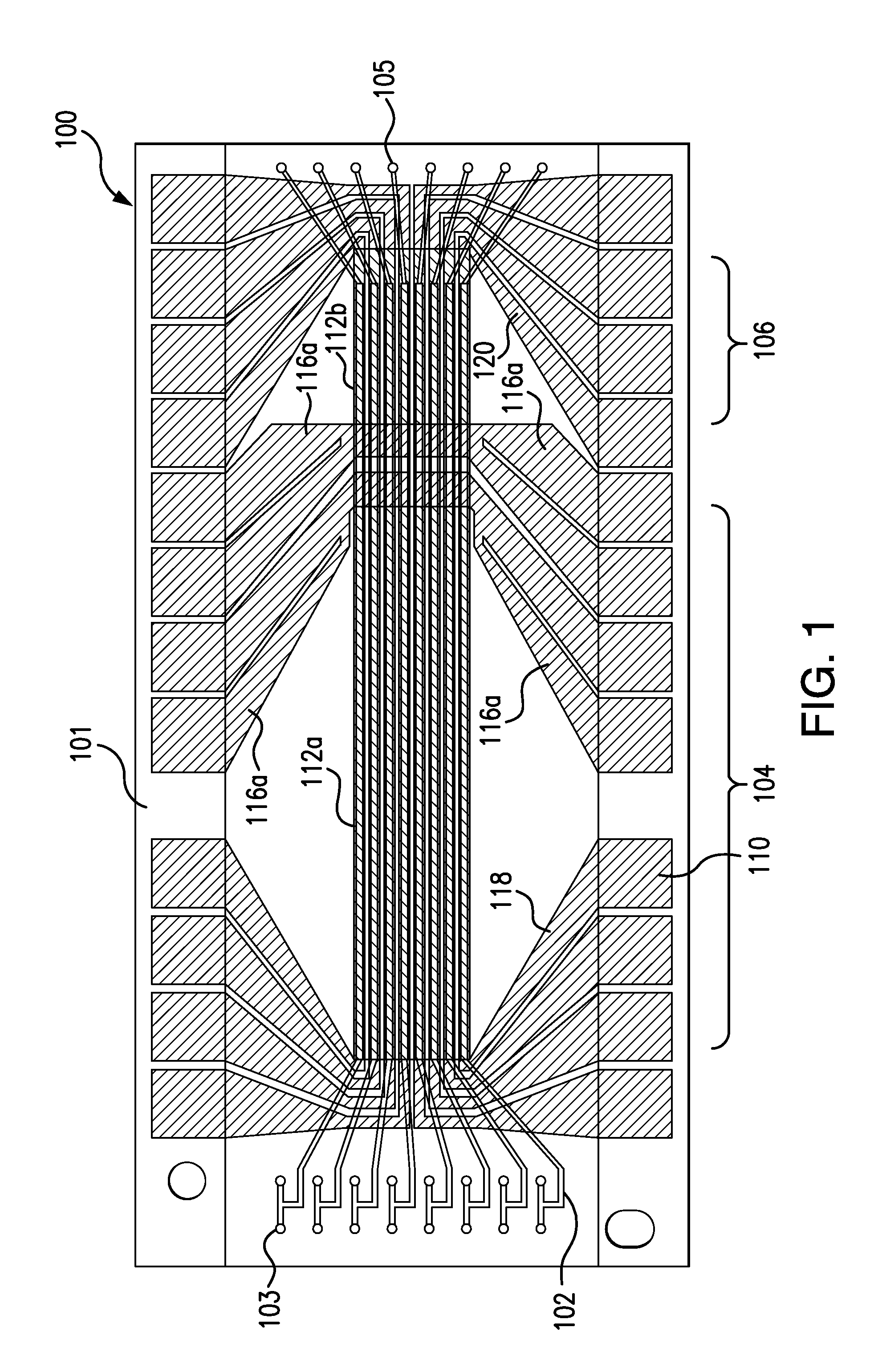

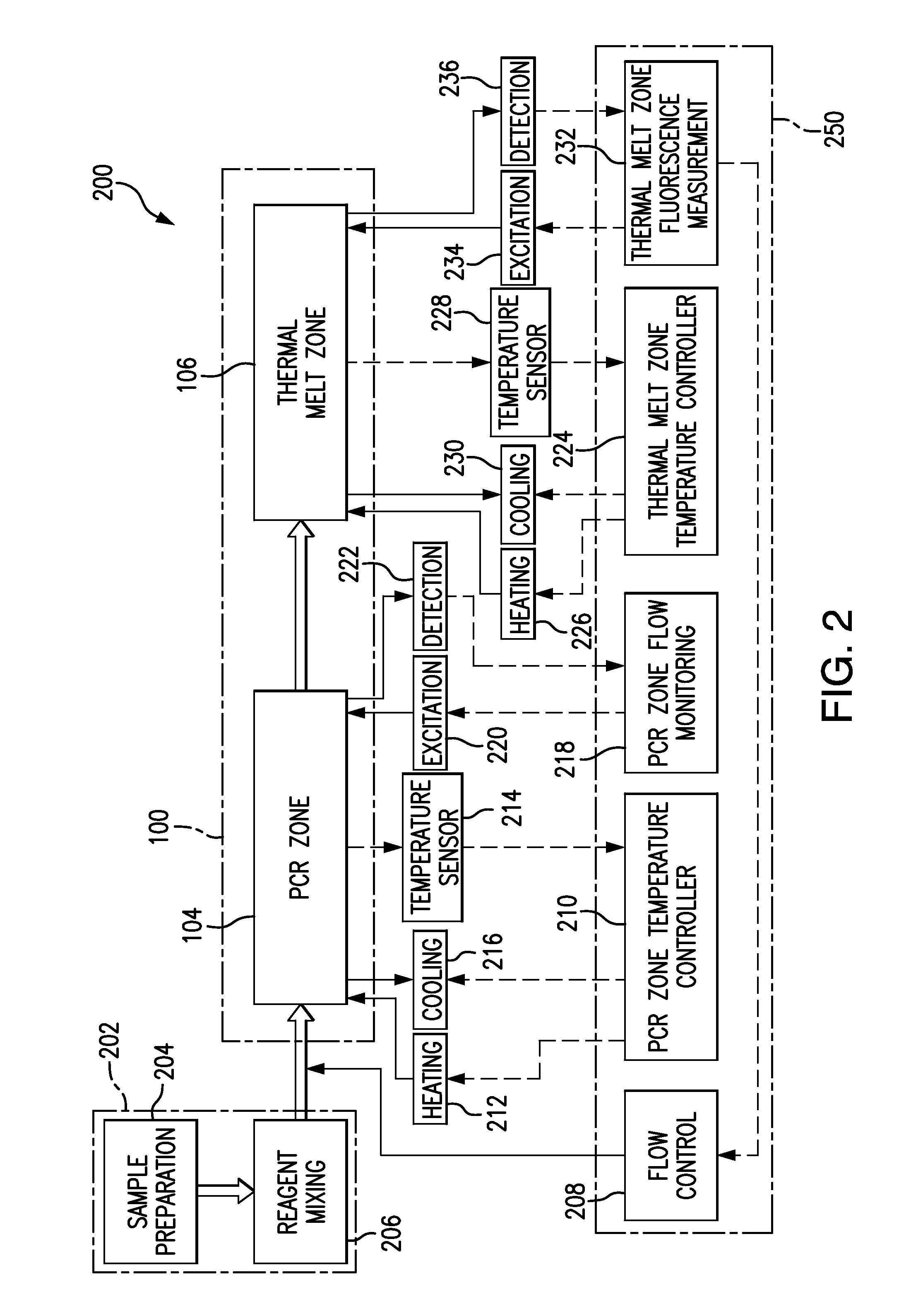

InactiveUS20120051390A1Heating or cooling apparatusPreparing sample for investigationLinear regionContinuous flow

The present invention, in one aspect, provides a method for calibrating thermal control elements in situ using a single compound calibrator. In some embodiments, the present invention uses a compound calibrator to calibrate thermal control elements on a microfluidic device. In non-limiting embodiment, the compound calibrator can be a droplet, plug, slug, segment or continuous flow of any appropriate solution that, when heated, yields a thermal response profile with a plurality of features (e.g., maxima, minima, inflection points, linear regions, etc.).

Owner:CANON US LIFE SCIENCES INC

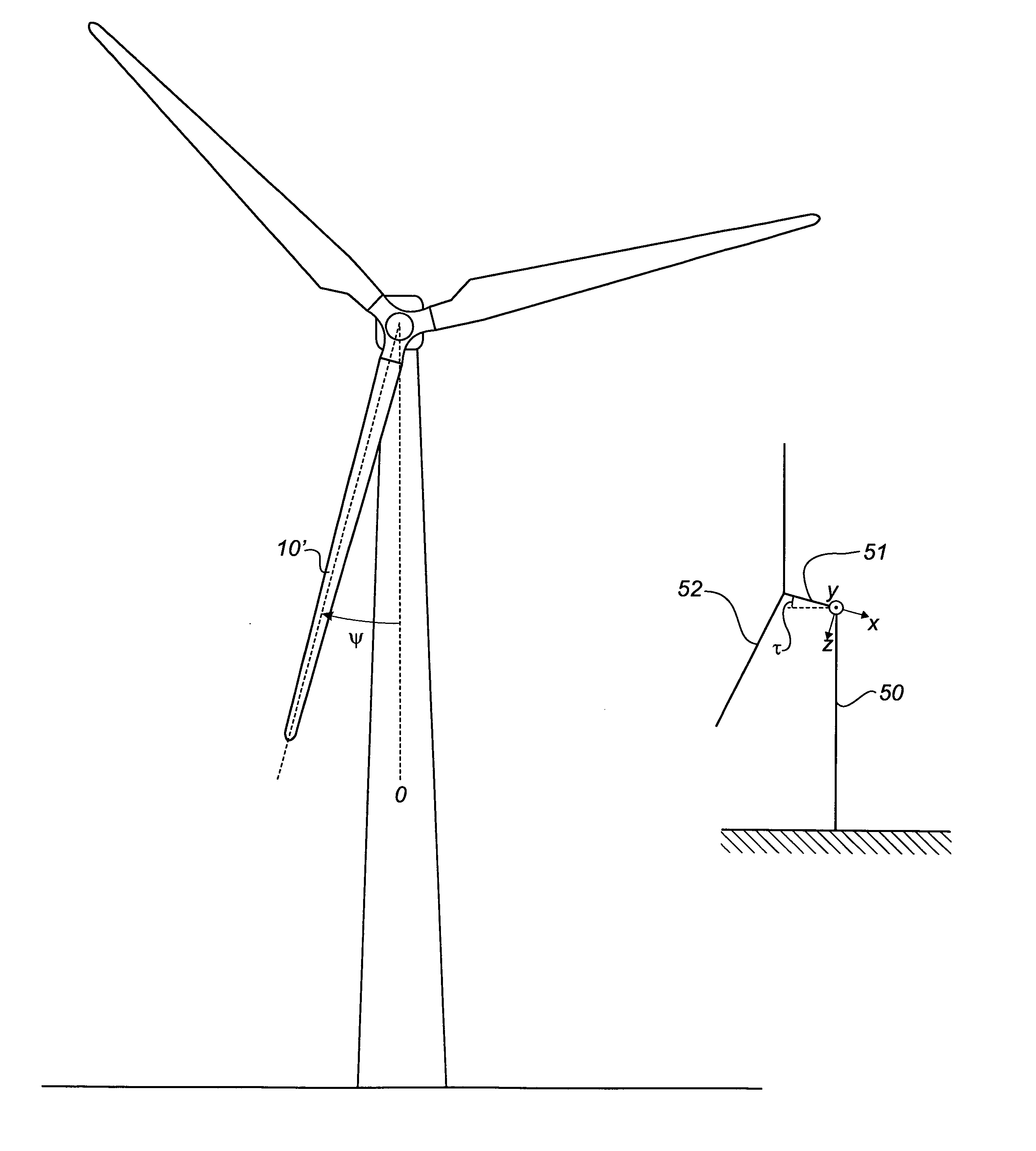

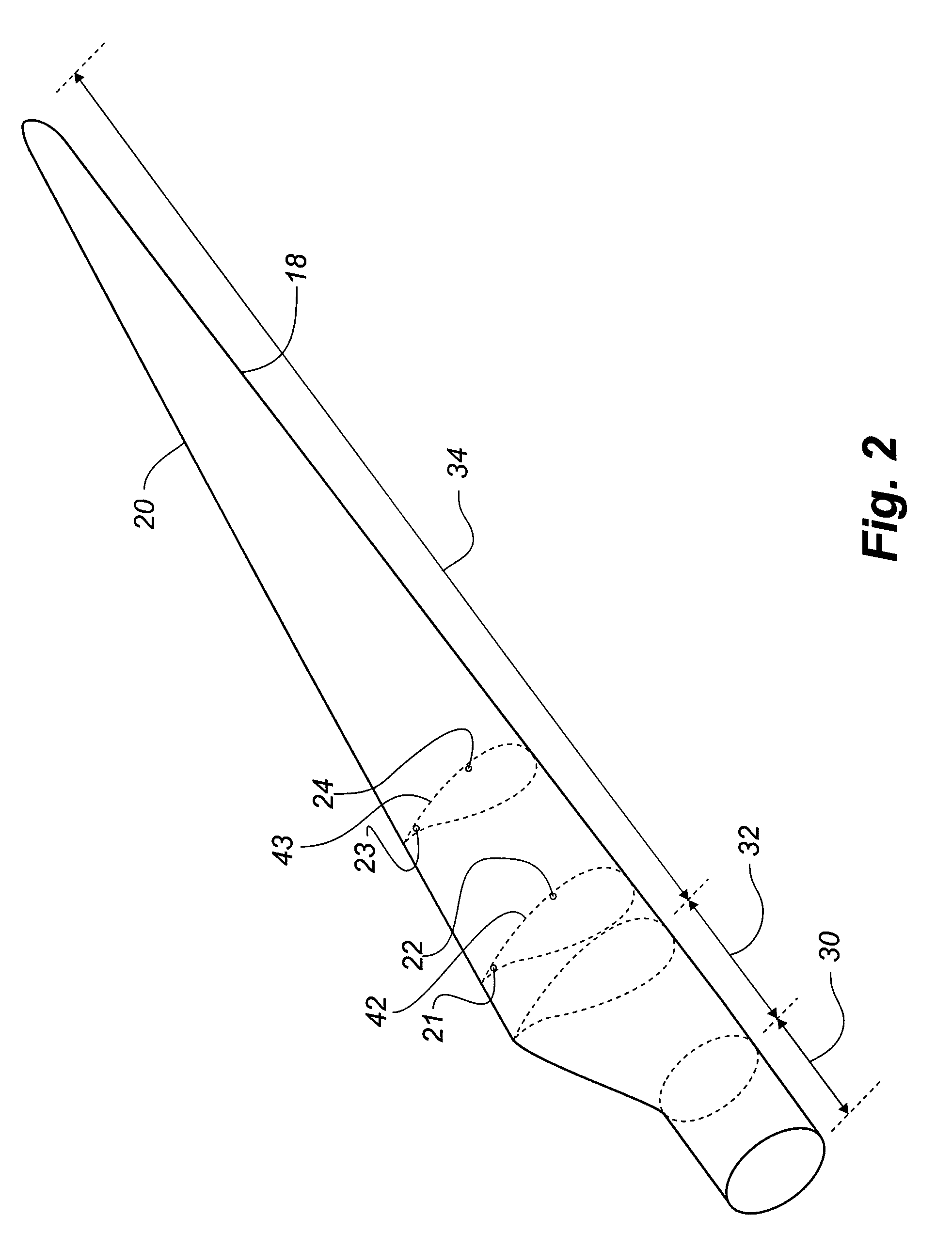

Method of in situ calibrating load sensors of a wind turbine blade

ActiveUS9353727B2Reliable calibrationReduce needMachines/enginesWind motor combinationsTurbine bladeHorizontal axis

A method of in situ calibrating load sensors of a horizontal axis wind turbine is described. The method comprises the steps of: a) determining a rotor azimuth angle of a first wind turbine blade, b) determining a pitch angle of the first wind turbine blade, c) measuring loads in a first cross-section of the first wind turbine blade using the first load sensors, d) calculating theoretical loads based on at least the rotor azimuth angle and the pitch angle of the blade determined in steps a) and b), e) comparing the loads measured in step c) with the theoretical loads calculated in step d), and f) calibrating the first load sensors based on the comparison of step e), wherein the calibration are based only on measurements carried out, when the generator is cut out.

Owner:LM GLASSFIBER

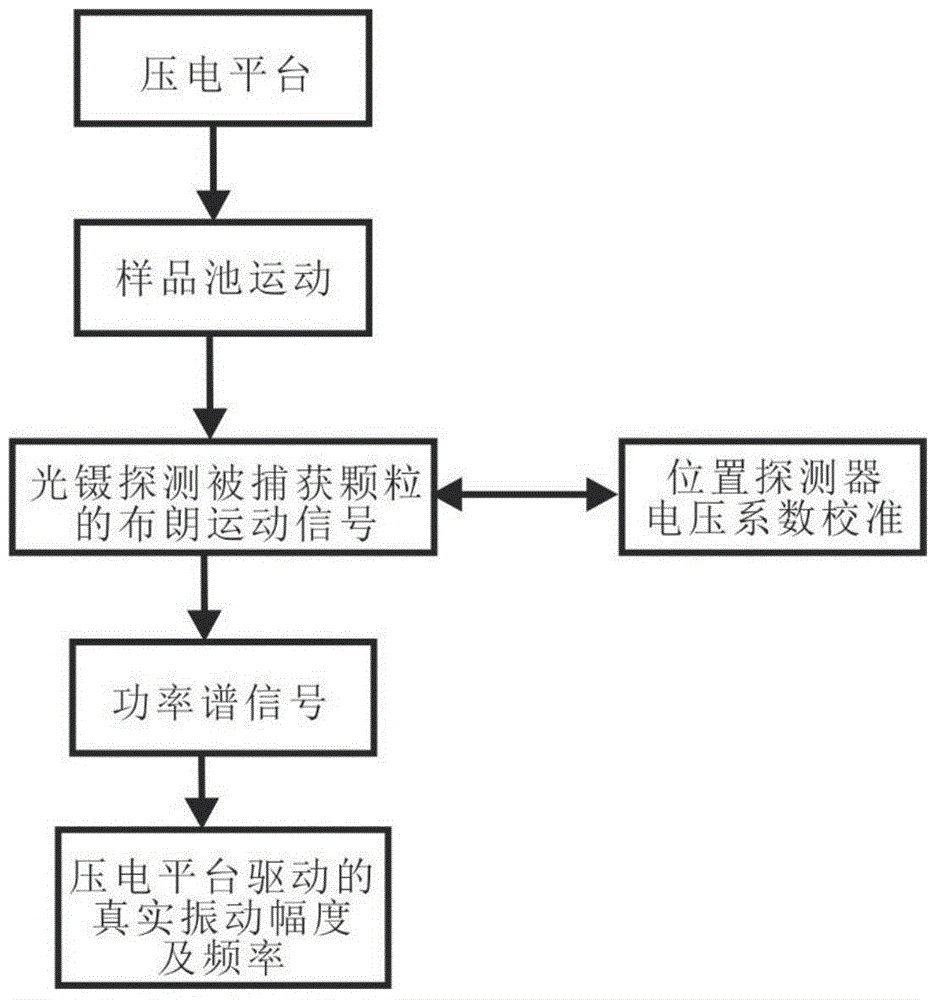

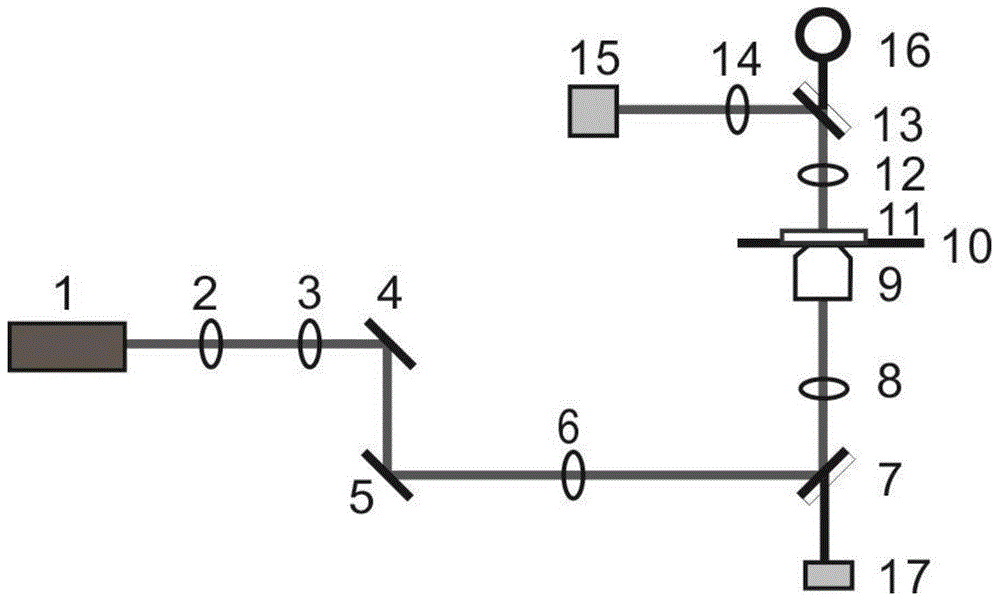

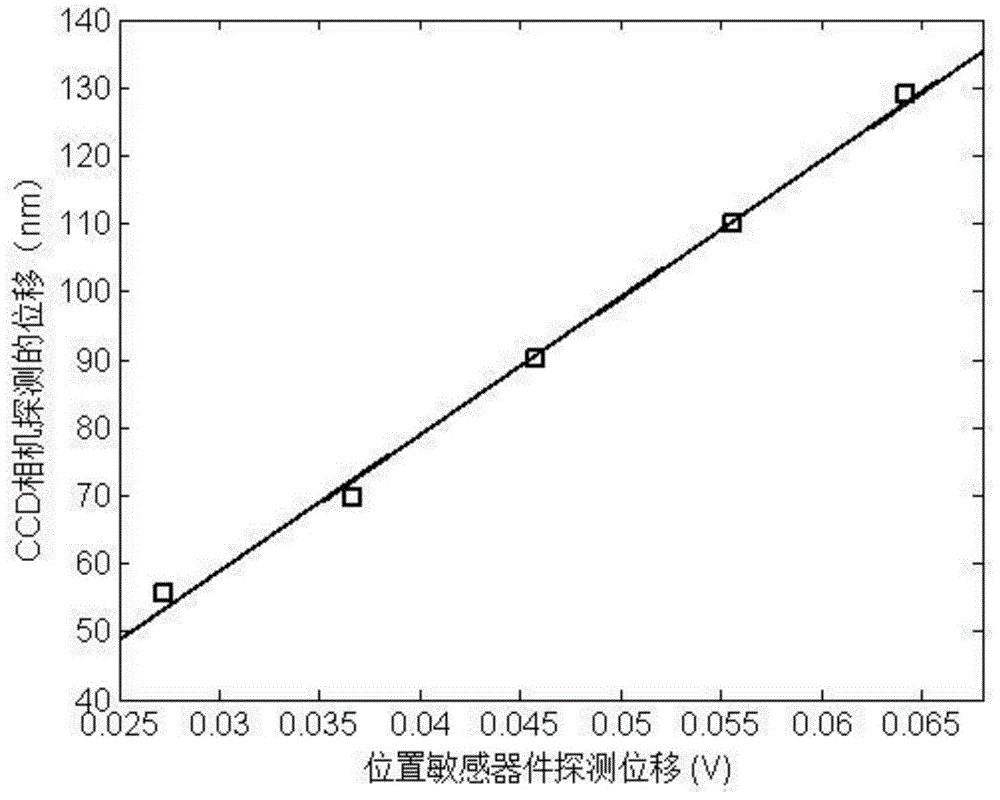

Optical trapping based method for in-situ calibration of displacement of piezoelectric platform

The invention provides an optical trapping based method for in-situ calibration of displacement of a piezoelectric platform. High-precision detection of motion displacement amplitude and frequency of the piezoelectric platform can be realized by analysis of position signals of Brownian motion of standard-size globules trapped in an optical trap system. Besides detection of the piezoelectric platform, standard particles are trapped by laser under microscopic imaging, and position motion signals of the particles are quickly detected by a detector. The piezoelectric platform sends low-frequency fixed-amplitude motion signals to drive a sample chamber to move, the particles trapped in a light trap is subjected to actions of fluid periodic viscous resistance, and voltage proportionality coefficient of a position sensitive detector can be calibrated by detecting the motion signals of the particles. The piezoelectric platform sends signals to drive the sampling chamber to move again, a power spectrum of the trapped particles is analyzed, a peak of the power spectrum is compared with background thermal noise to invert real motion displacement amplitude of the piezoelectric platform, and frequency of the peak stands for motion frequency of the piezoelectric platform.

Owner:UNIV OF SCI & TECH OF CHINA

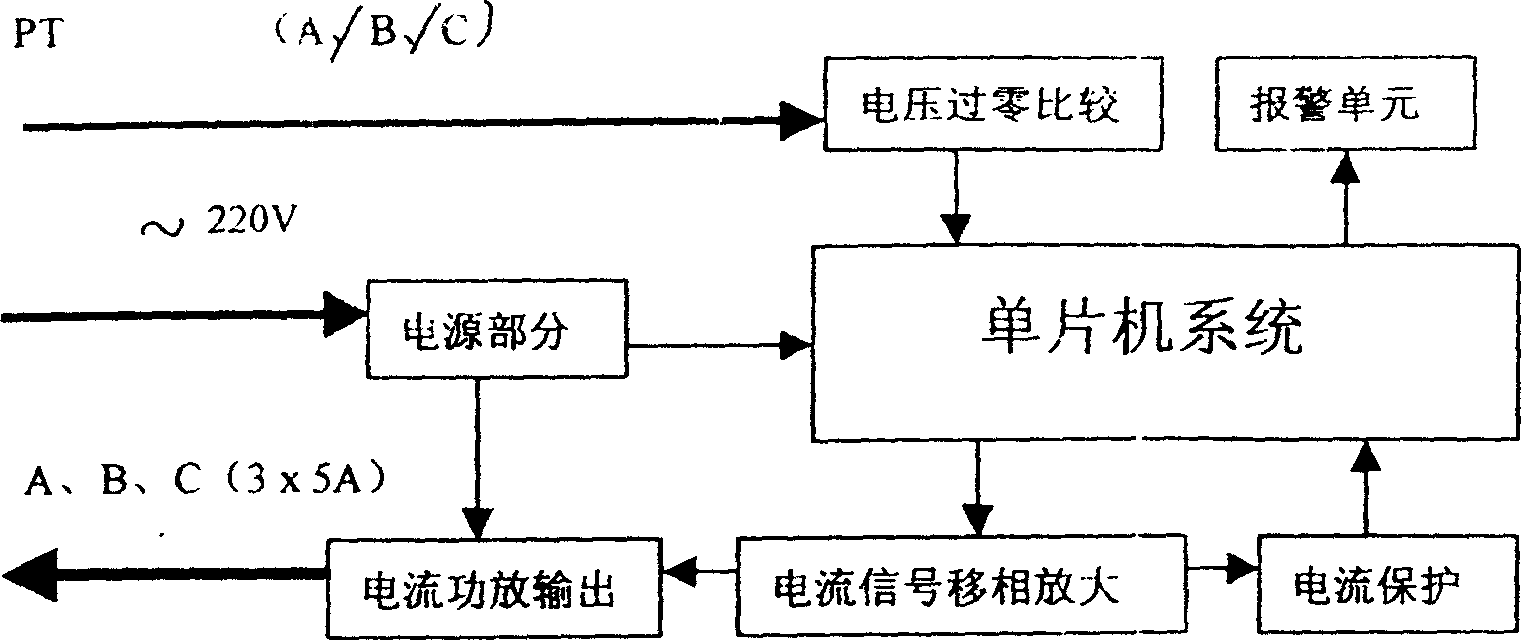

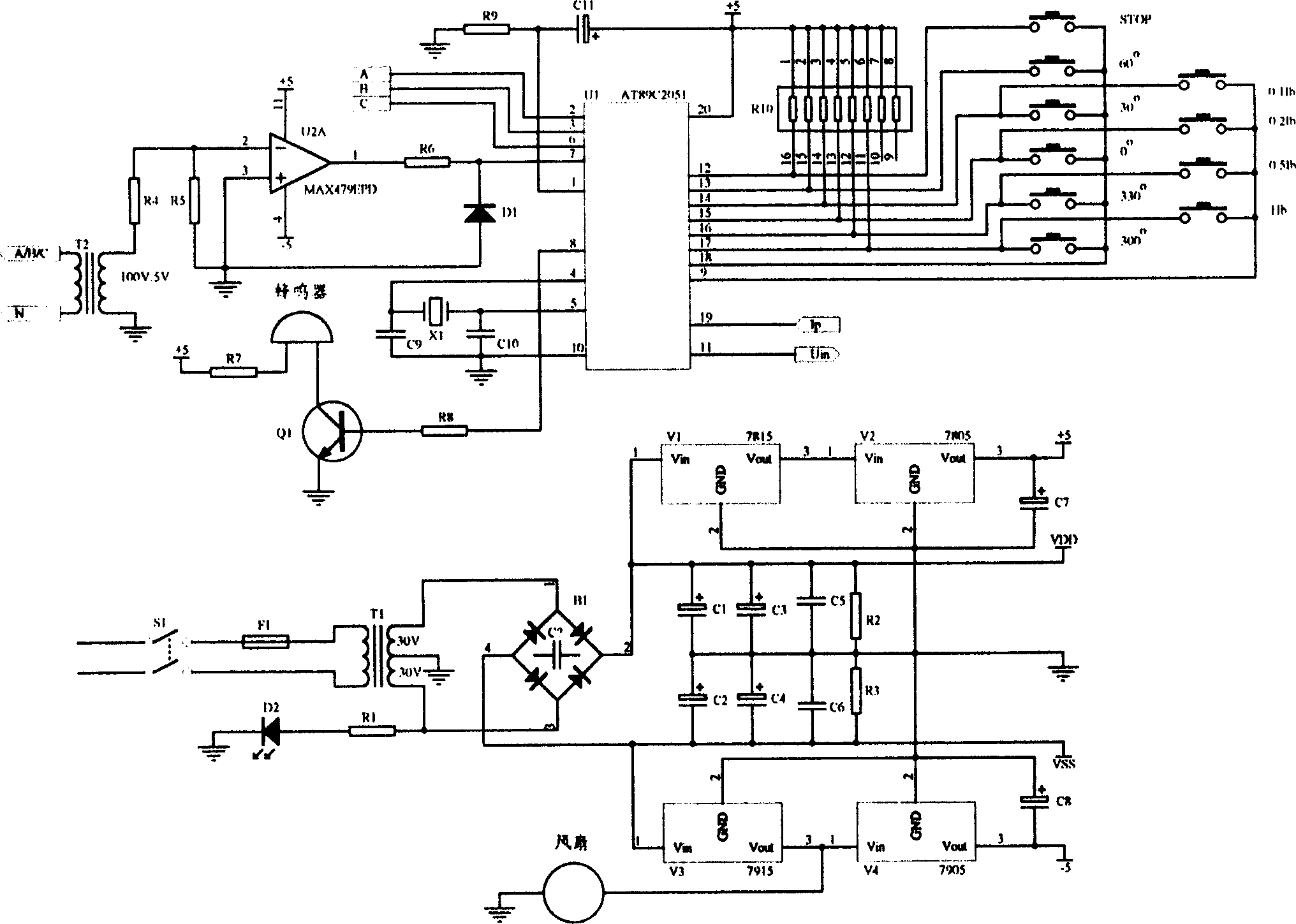

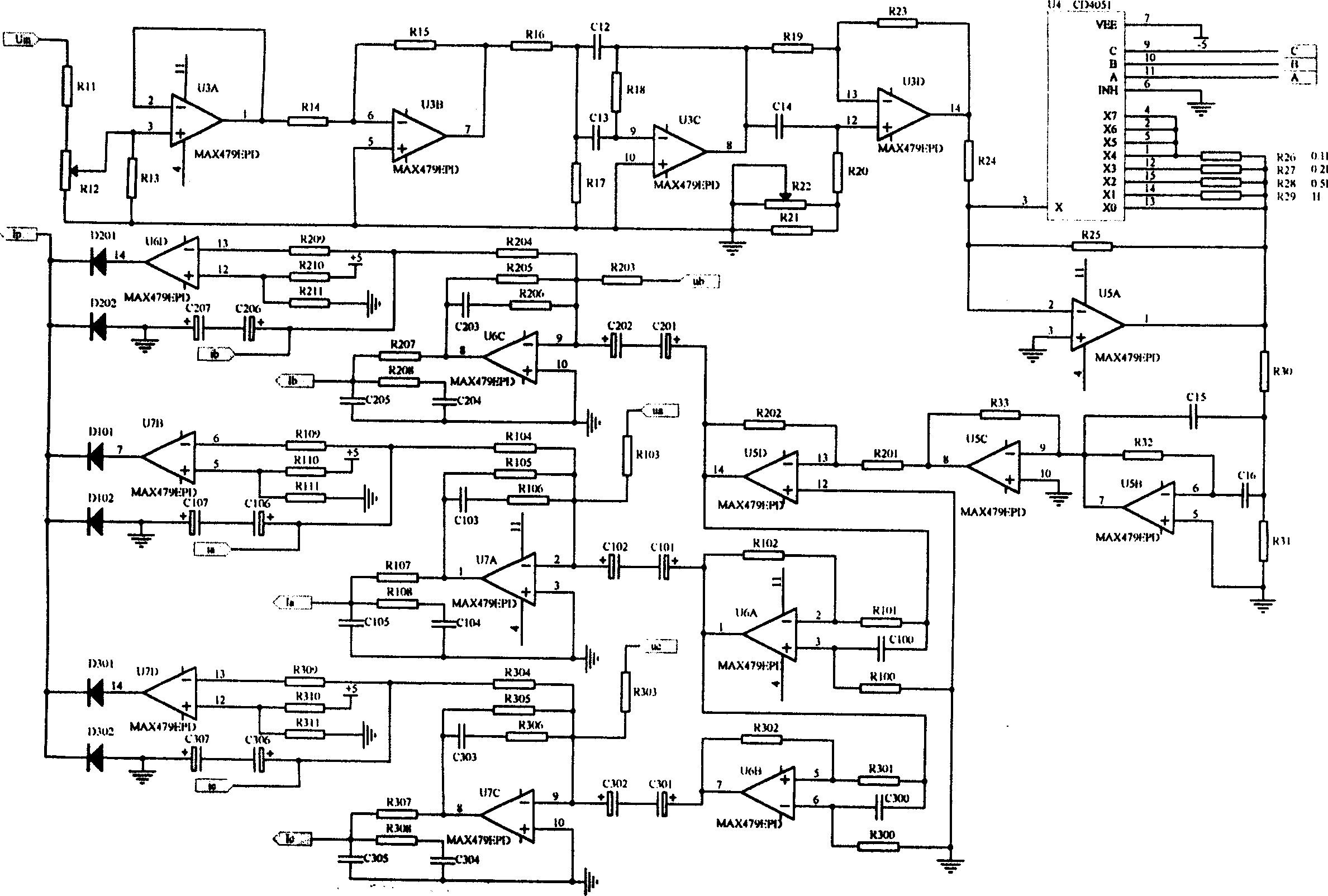

Fictitious load source for in-situ checking electric energy meter

A simulative load source for in-situ calibration of electric energy meter is composed of zero cross voltage comparator, alamr unit, power supply, single-chip microcomputer, phase-shift current amplifier, current power amplifier and its output circuit, and current protecting circuit.

Owner:湖南省电力试验研究所

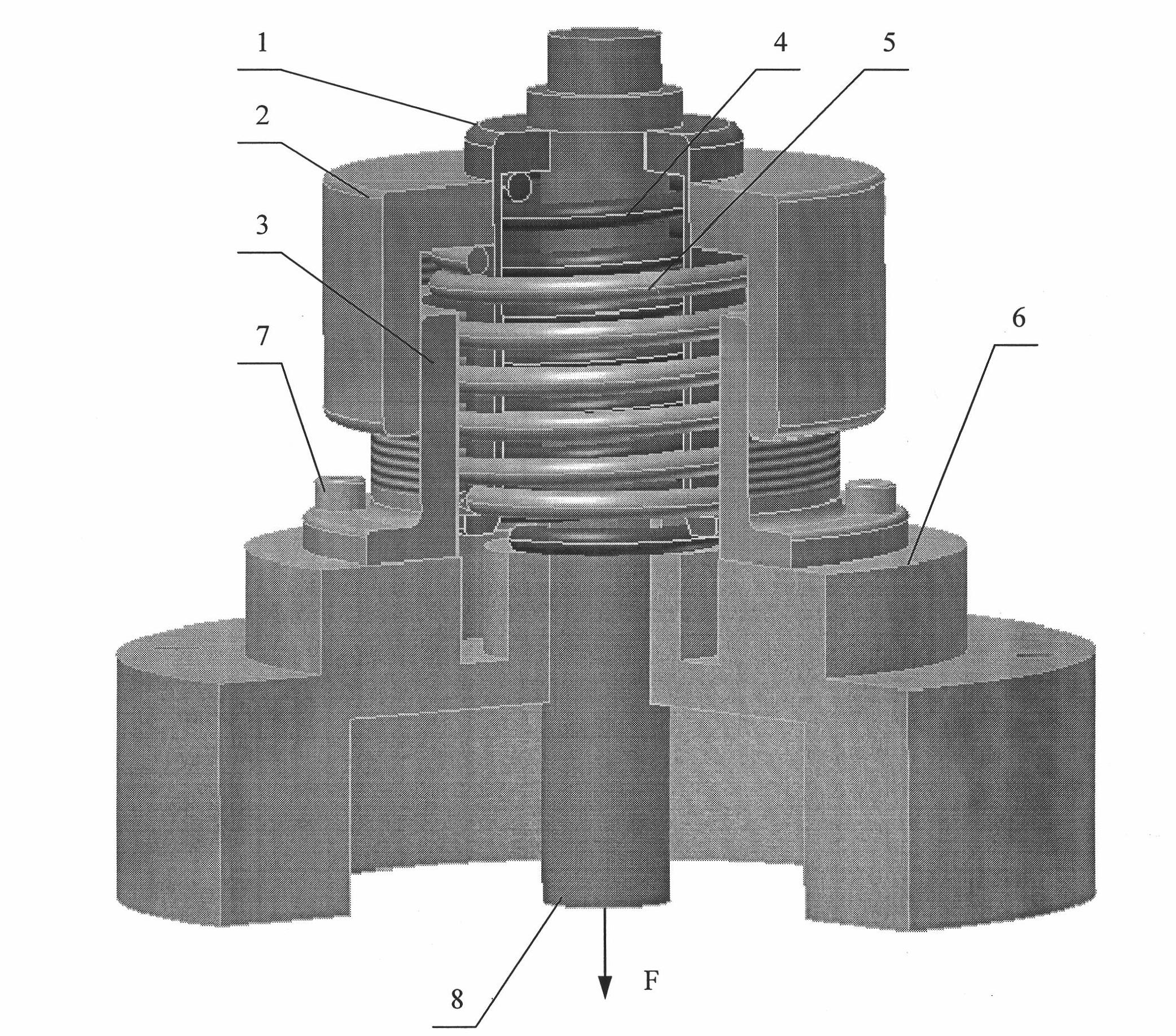

Device for unloading and buffering pull force

The invention relates to a device for unloading and buffering pull force, in particular to a static calibration device of a thrust test system of a rocket engine, belonging to the field of sensing measurement and control devices. The device adopts inner and outer dual pressure springs as unloading and buffering elements and comprises a cylinder, an upper cover, a base, an inner spring, an outer spring, a hydraulic cylinder supporting flange and a connecting bolt, wherein the hydraulic cylinder supporting flange used as a support is of a stepped revolving body structure provided with a central through hole; and the base is of a structure, which is provided with an outer surface tapped with screw threads and is provided with a central through hole of the base. The invention realizes the total unloading of loaded force during the in-situ calibration of a work sensor and effectively buffers the impact of the loaded force on the thrust test system and a hydraulic loading system during an unloading moment, and thus, hydraulic oil is prevented from being leaked, the unloading is also stabilized and return-trip calibration can be carried out accurately; and in addition, the device has the advantages of higher adaptability, wider usage range and certain popularization and use value.

Owner:DALIAN UNIV OF TECH

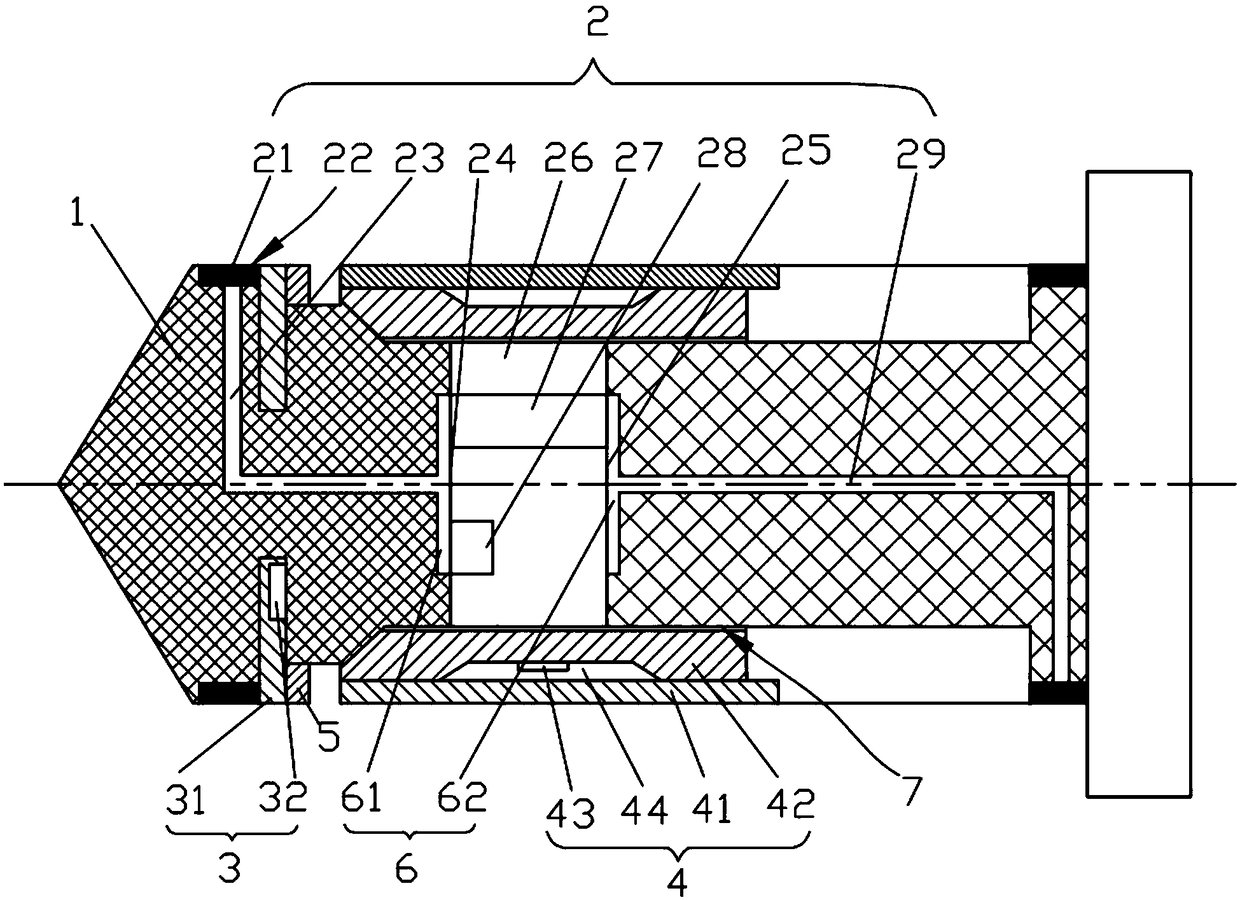

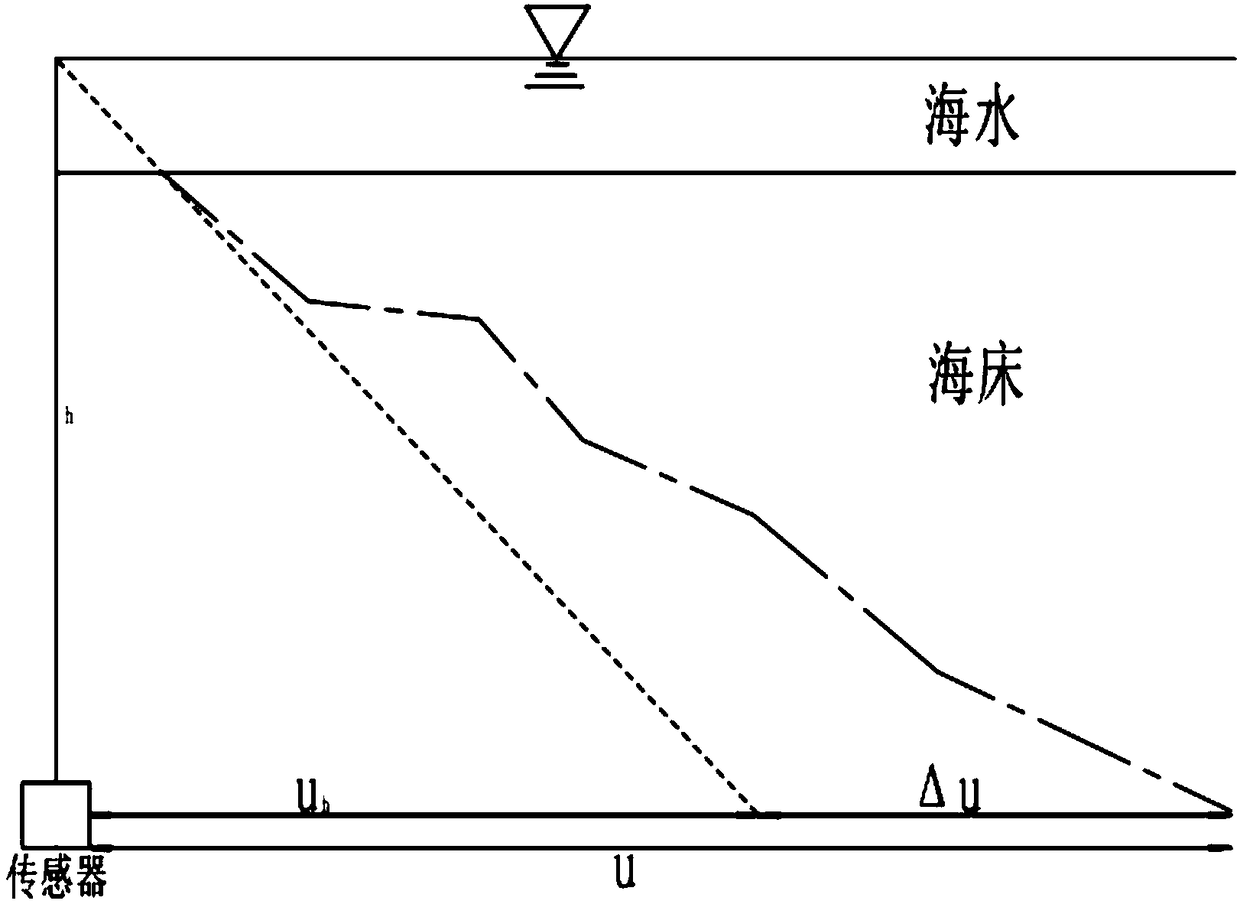

Cone penetration test probe suitable for use in deep sea

PendingCN109252505ASmall rangeReduce resolutionIn situ soil foundationDifferential pressureImage resolution

The invention discloses a cone penetration test probe suitable for use in deep sea, comprising a conical head and a pore pressure detection device. A pressure cavity is arranged in the probe; the conical head is provided with a water hole. The pore pressure detection device divides the pressure cavity into a front pressure cavity and a rear pressure cavity. The front pressure cavity is communicated with the water hole via a first water passage. The rear pressure cavity is communicated with the outside via a second water passage. The pore pressure detection device includes a first diaphragm, asecond diaphragm, a differential pressure measuring element and an absolute pressure measuring element. The cone penetration test probe herein has the advantages that the differential pressure sensorand the absolute pressure sensor complement each other; namely the differential pressure measuring element having small range but high resolution helps measure a difference between pore pressure and static pressure, so that measurement precision is improved; the absolute pressure measuring element having wide range but small resolution is used to measure static pressure of sea water, thereby facilitating in-situ calibration and giving a consideration to both measurement range and measurement precision.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com