Patents

Literature

269 results about "Standard distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

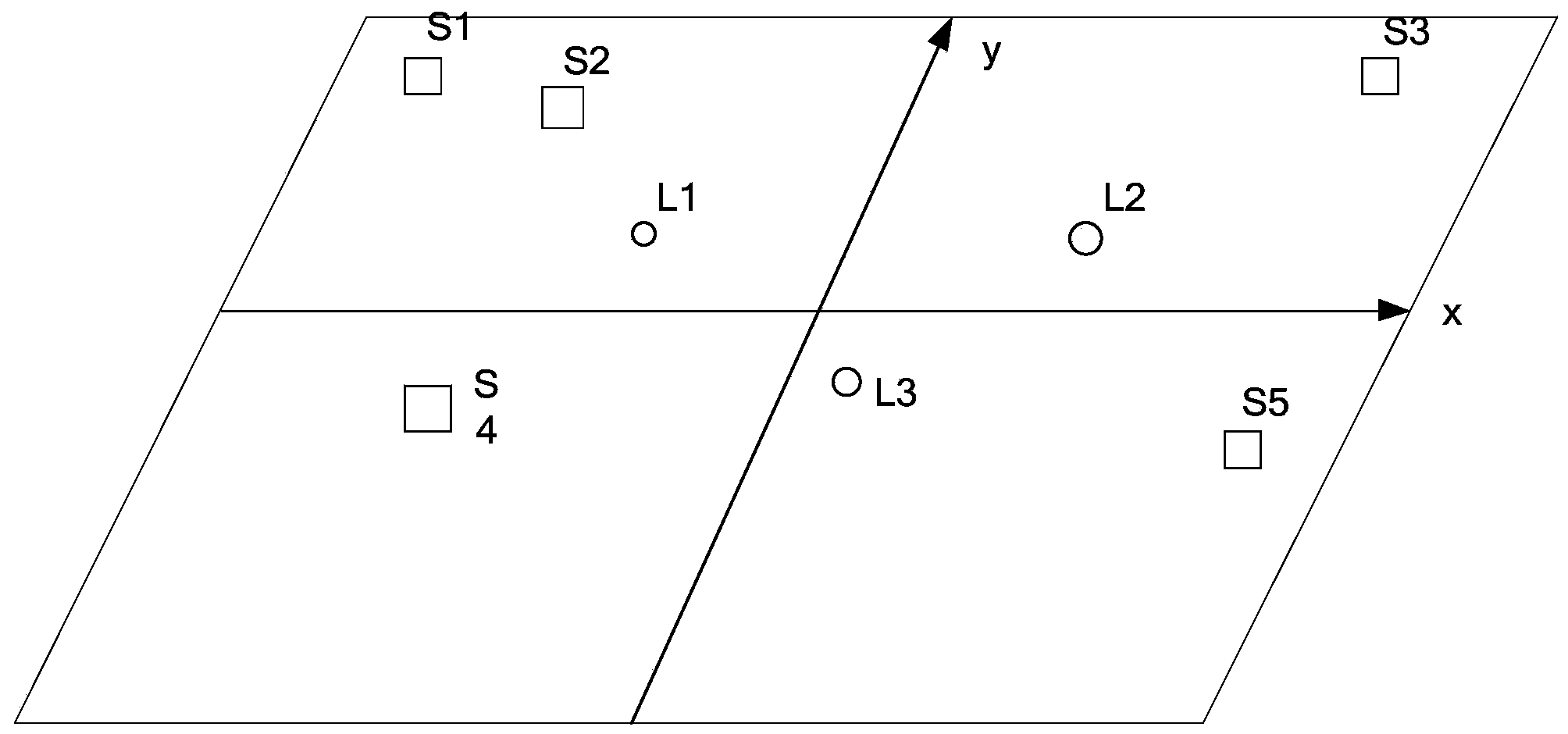

The standard distance is a useful statistic as it provides a single summary measure of feature distribution around their center (similar to the way a standard deviation measures the distribution of data values around the statistical mean). The Standard Distance tool creates a new feature class containing a circle polygon or sphere multipatch centered on the mean for each case.

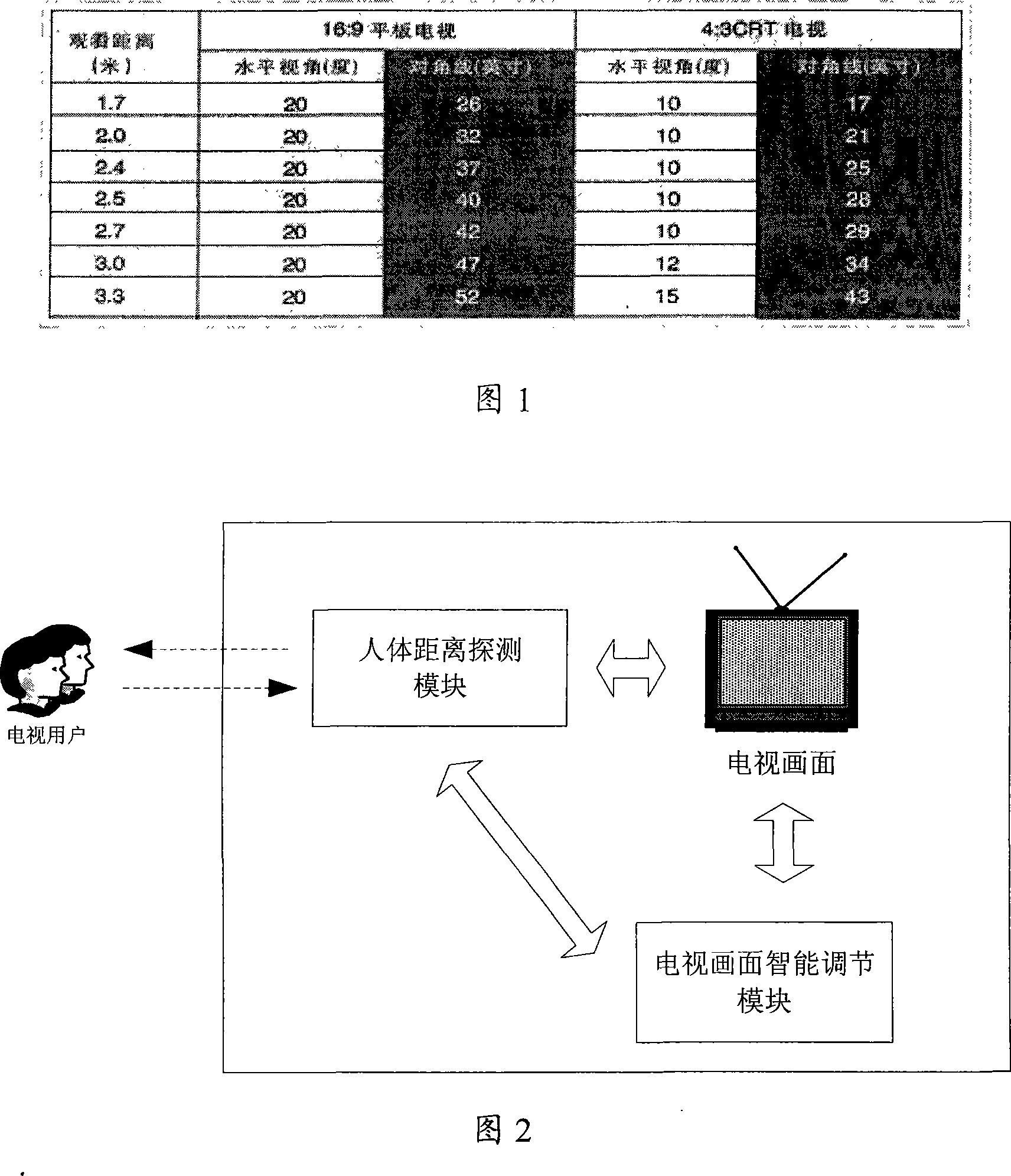

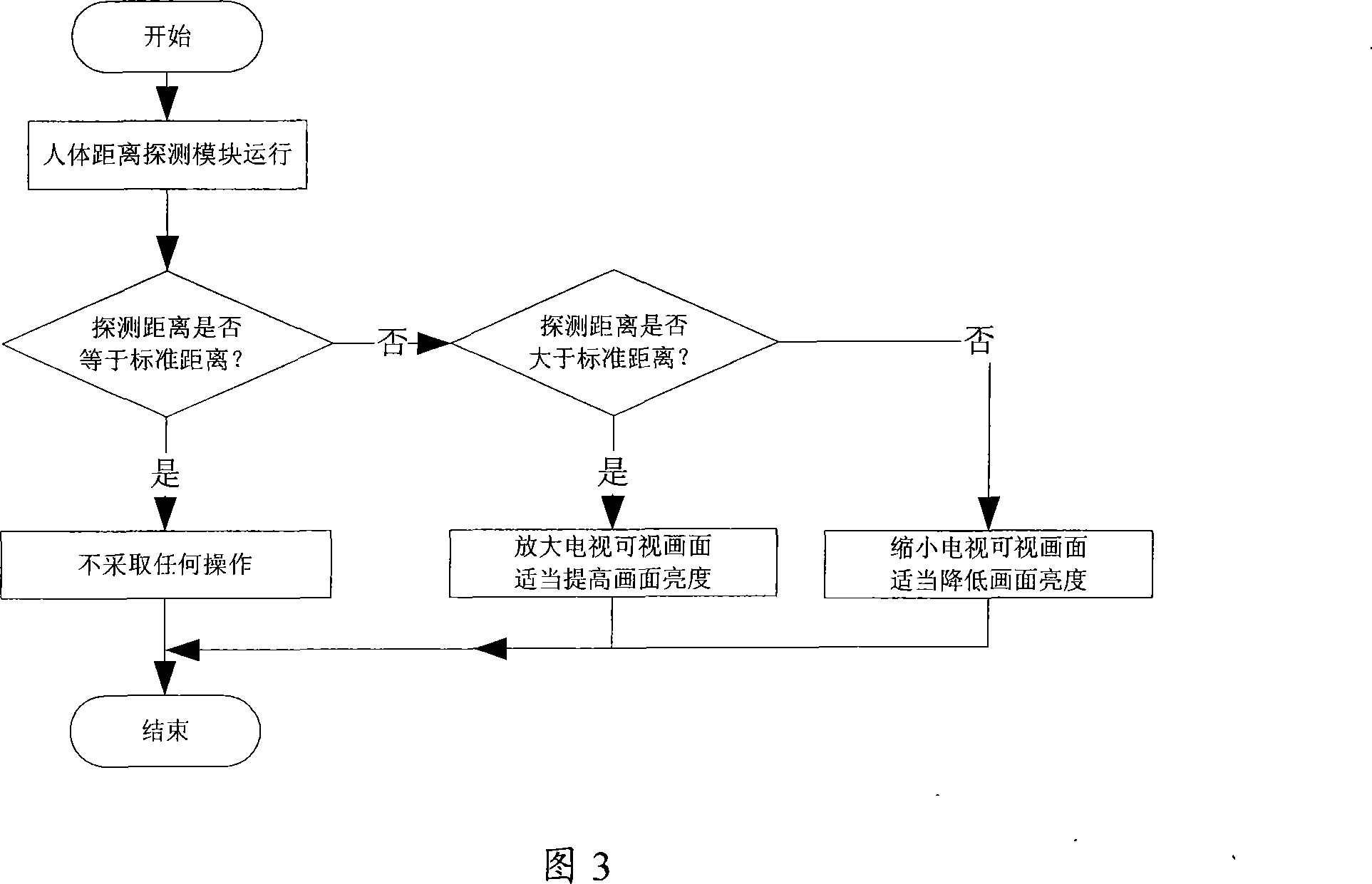

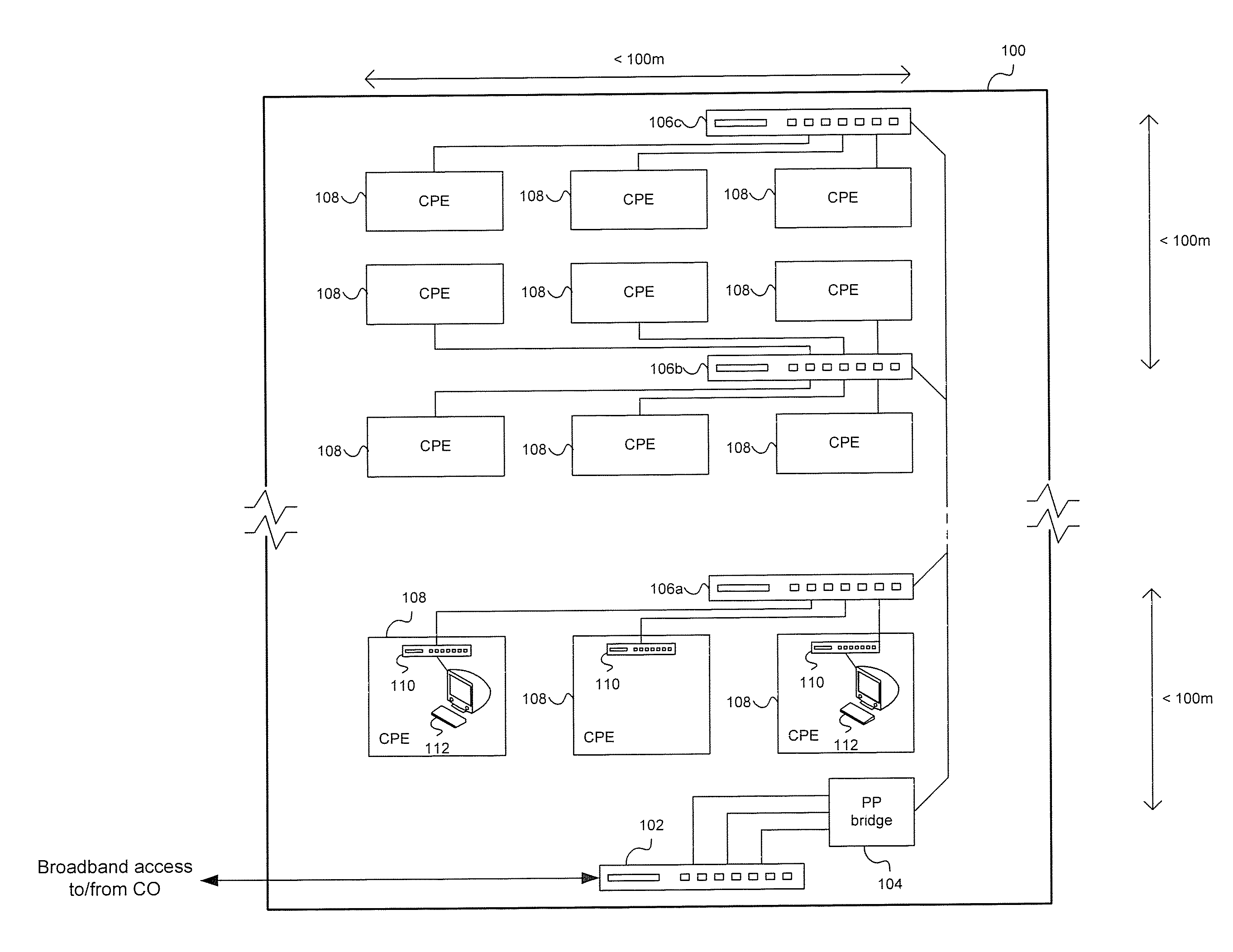

An intelligent adjusting method and device for TV set image

InactiveCN101188665AImprove Adaptive FeaturesProtect eyesTelevision system detailsColor television detailsDistance detectionSelf adaptive

The invention discloses a television picture intelligent adjusting device, which is arranged in a main circuit of a television. The device comprises a human body distance detecting module, used for detecting the distance of a viewer to the television; a television picture intelligent adjusting module, connected with the human body distance detecting module and used for outputting after correspondingly adjusting the size and the brightness of the television picture when the distance value is detected to be smaller than the preset standard distance. Because adopting the human body distance detecting module arranged in the television circuit for viewer distance detection and correspondingly adjusting the television picture, the television picture intelligent adjusting method and the device thereof protect the eyes of the viewer, and enhances the self adaptability of the television.

Owner:KONKA GROUP

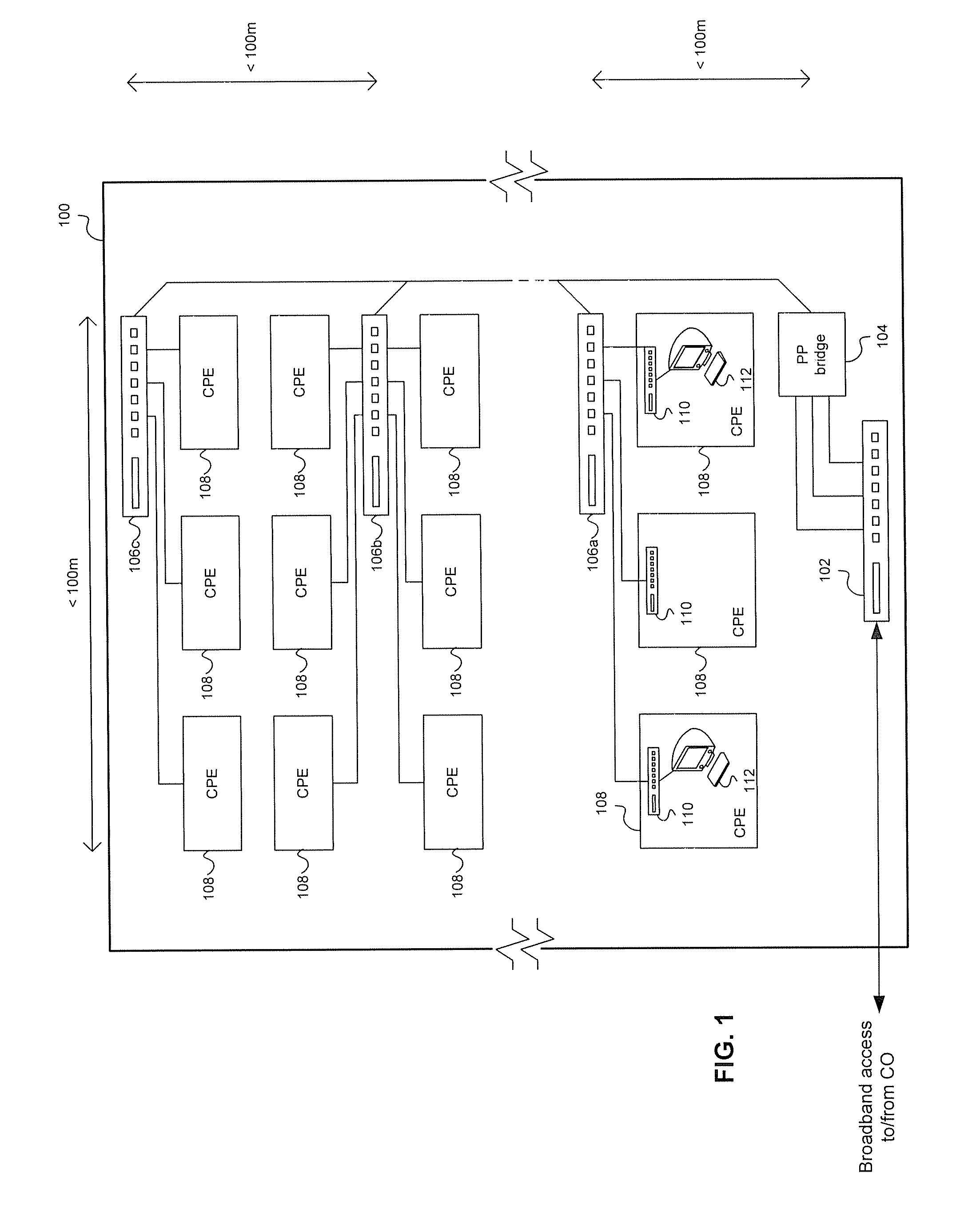

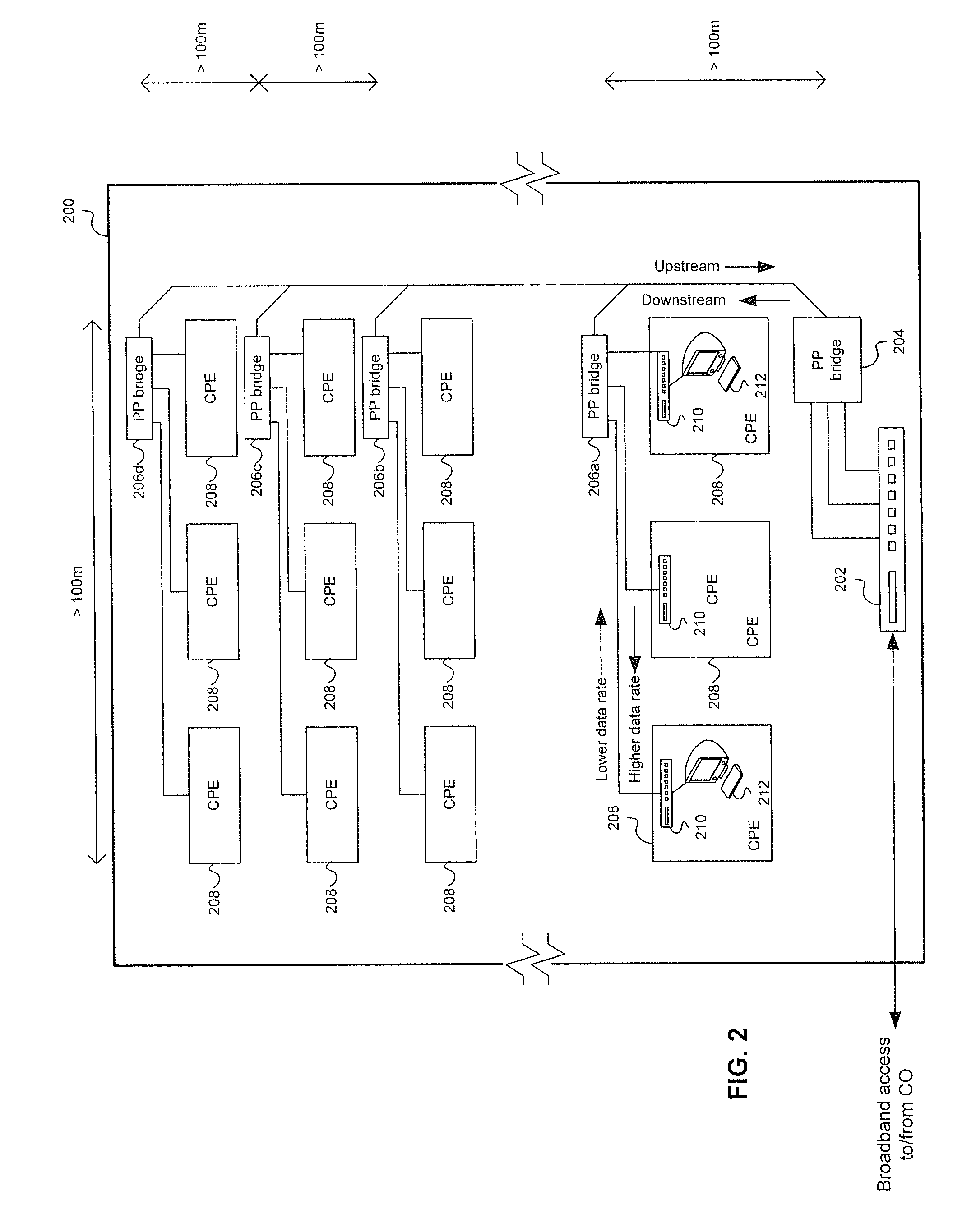

Method and system for an asymmetric phy in extended range ethernet lans

ActiveUS20080056284A1Increase rangeSpecial service provision for substationTime-division multiplexEthernet lanEngineering

Aspects of a method and system for an asymmetric physical (PHY) layer in extended reach Ethernet local area networks (LANs) are provided. Reducing the communication rate provided by an asymmetric Ethernet multi-rate PHY may extend the standard distance over twisted-pair cabling where customer premises equipment (CPE) may be located in the MTU. Downstream and upstream rates may be aggregated evenly or unevenly over each twisted-pair wire in the copper cabling. The asymmetric Ethernet multi-rate PHY may support signal-processing operations, such as echo cancellation and / or equalization, which may be applied to the reduced communication rate to enable range extension. The reduced communication rate may be achieved by reducing the symbol rate provided by the asymmetric Ethernet multi-rate PHY. Reducing the communication rate may also enable utilizing cabling with greater insertion loss than those used for a standard connection distance.

Owner:AVAGO TECH INT SALES PTE LTD

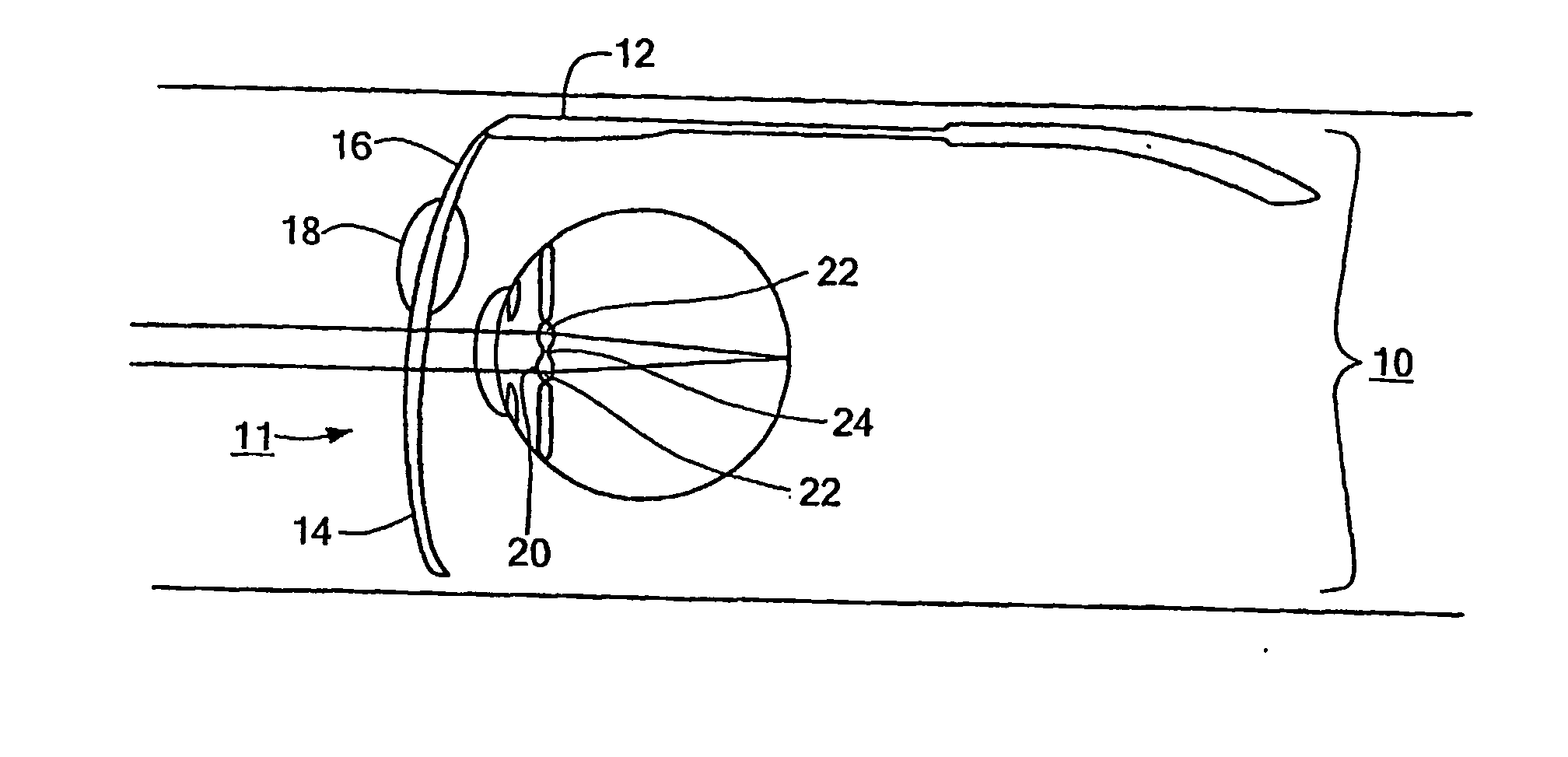

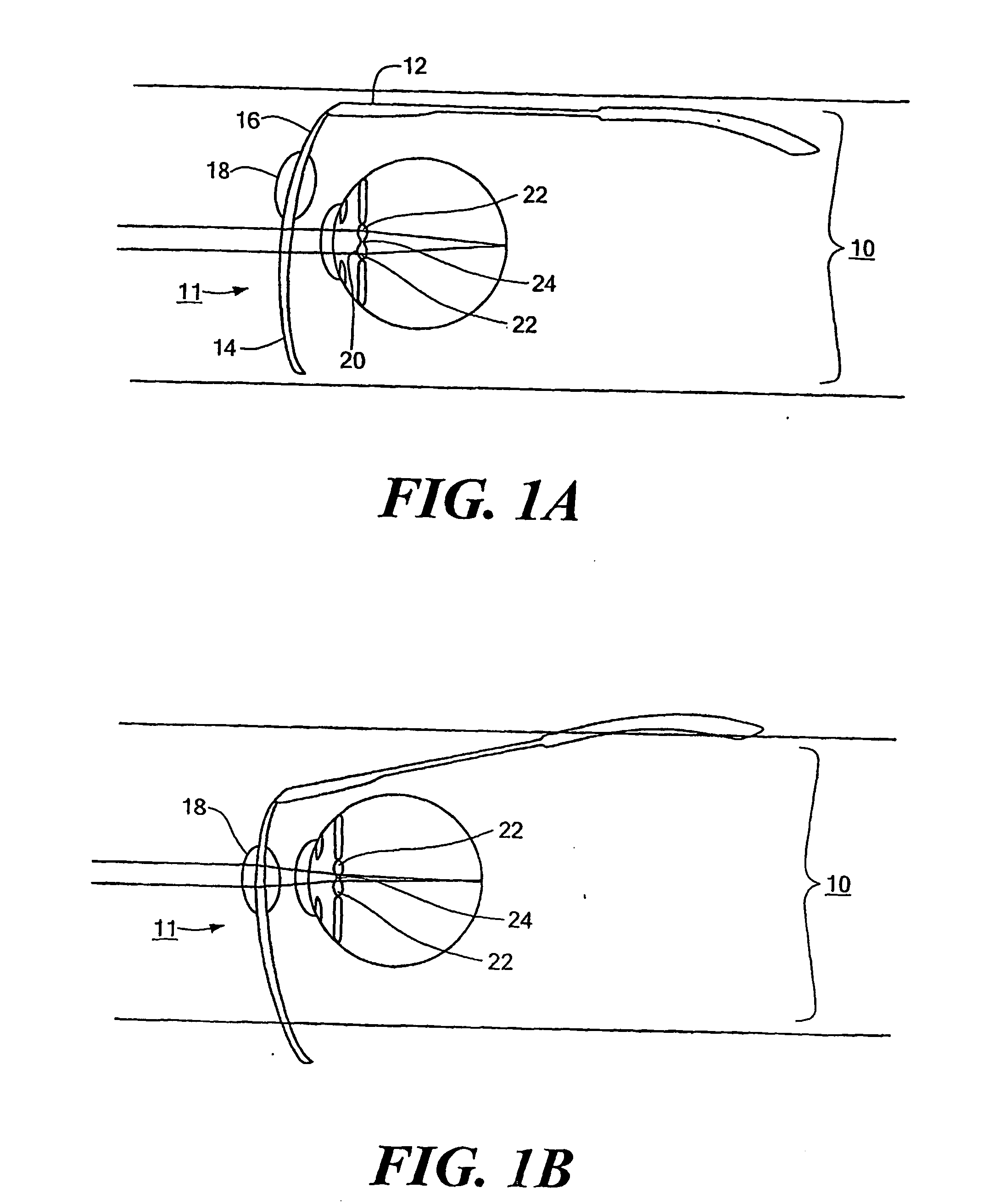

Double bifocal intraocular lens-spectacle telescopic device for low vision use

InactiveUS20060058874A1Improve eyesightHigh magnificationIntraocular lensOptical partsIntraocular lensOptical power

A double bifocal intra-ocular lens and spectacle system that can be used to enhance the vision of persons suffering from low-vision includes a first optical element placed in or on the eye, and a second optical element placed external to the eye. In particular, the first optical element is designed to be placed in or on the eye. This element includes an inner region and an outer annular region with first and second optical powers respectively. A second optical element that has two regions is disposed external to the eye and aligned so that a first region having a third optical power is optically coupled to the outer annular region for normal vision and the respective optical powers are selected to provide for the standard distance correction of the eye. The second region is arranged so that when aligned with the eye, the second region and the inner region of the first optical element form a Galilean telescope that provides for a magnified image to be provided therefrom.

Owner:THE SCHEPENS EYE RES INST

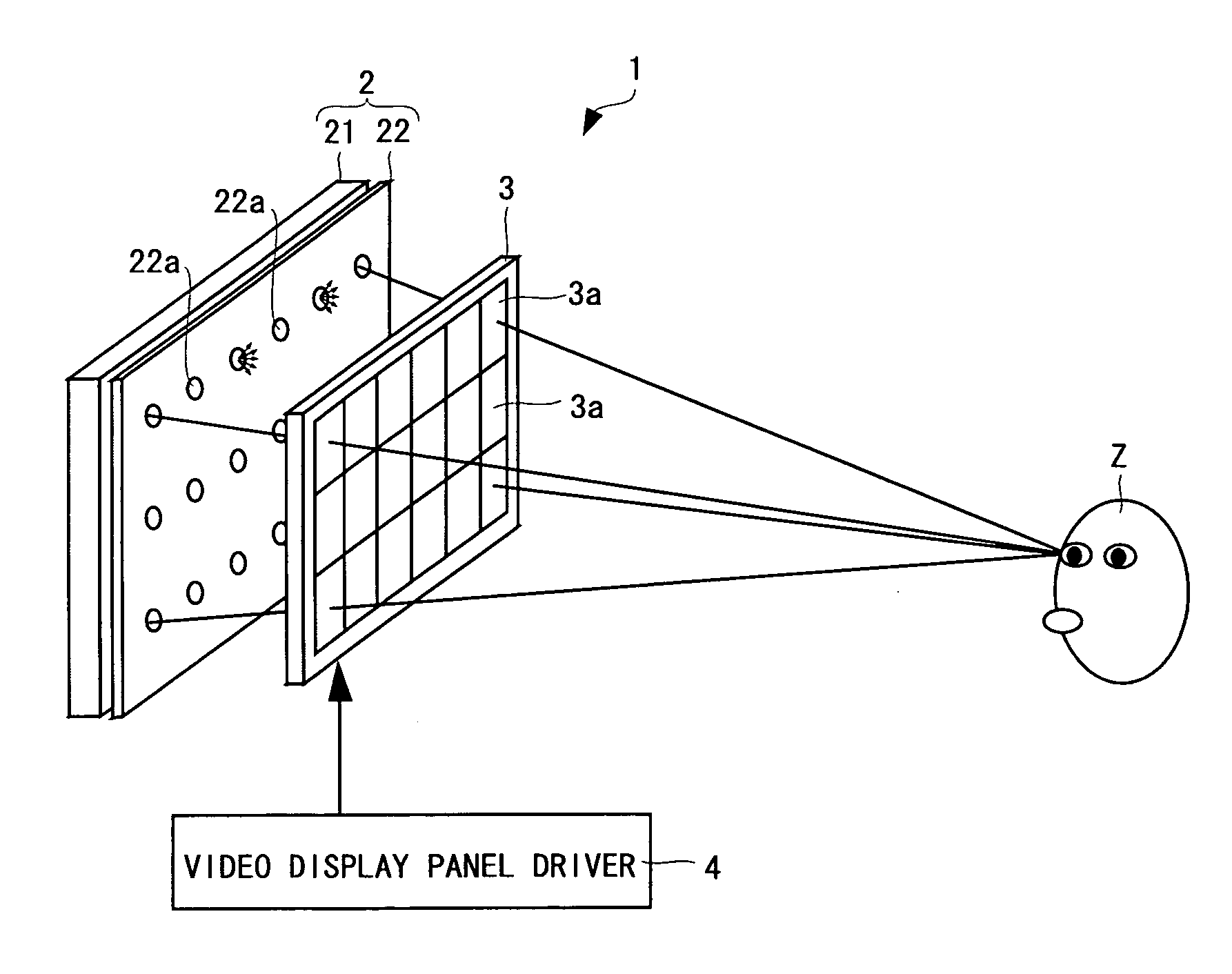

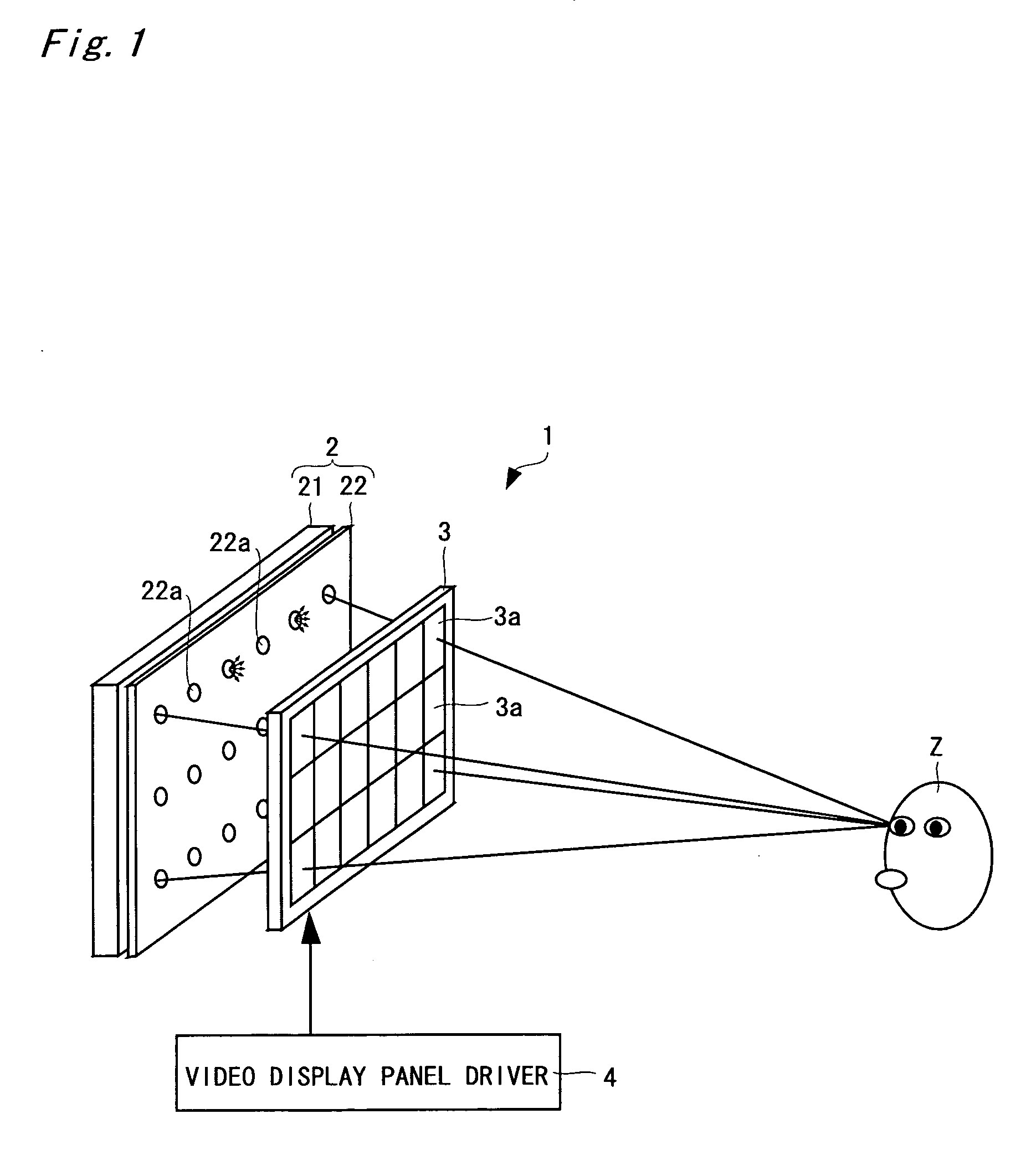

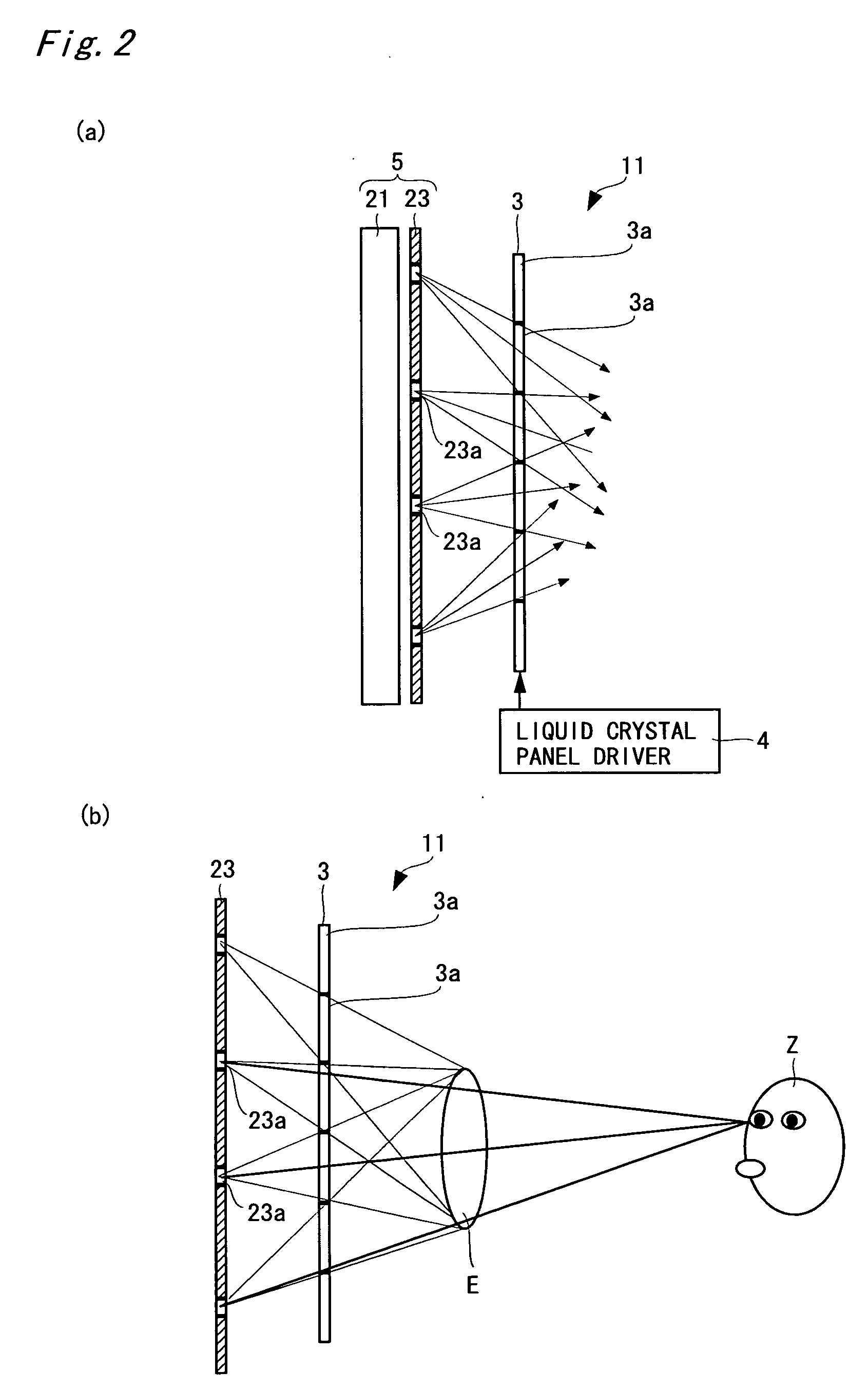

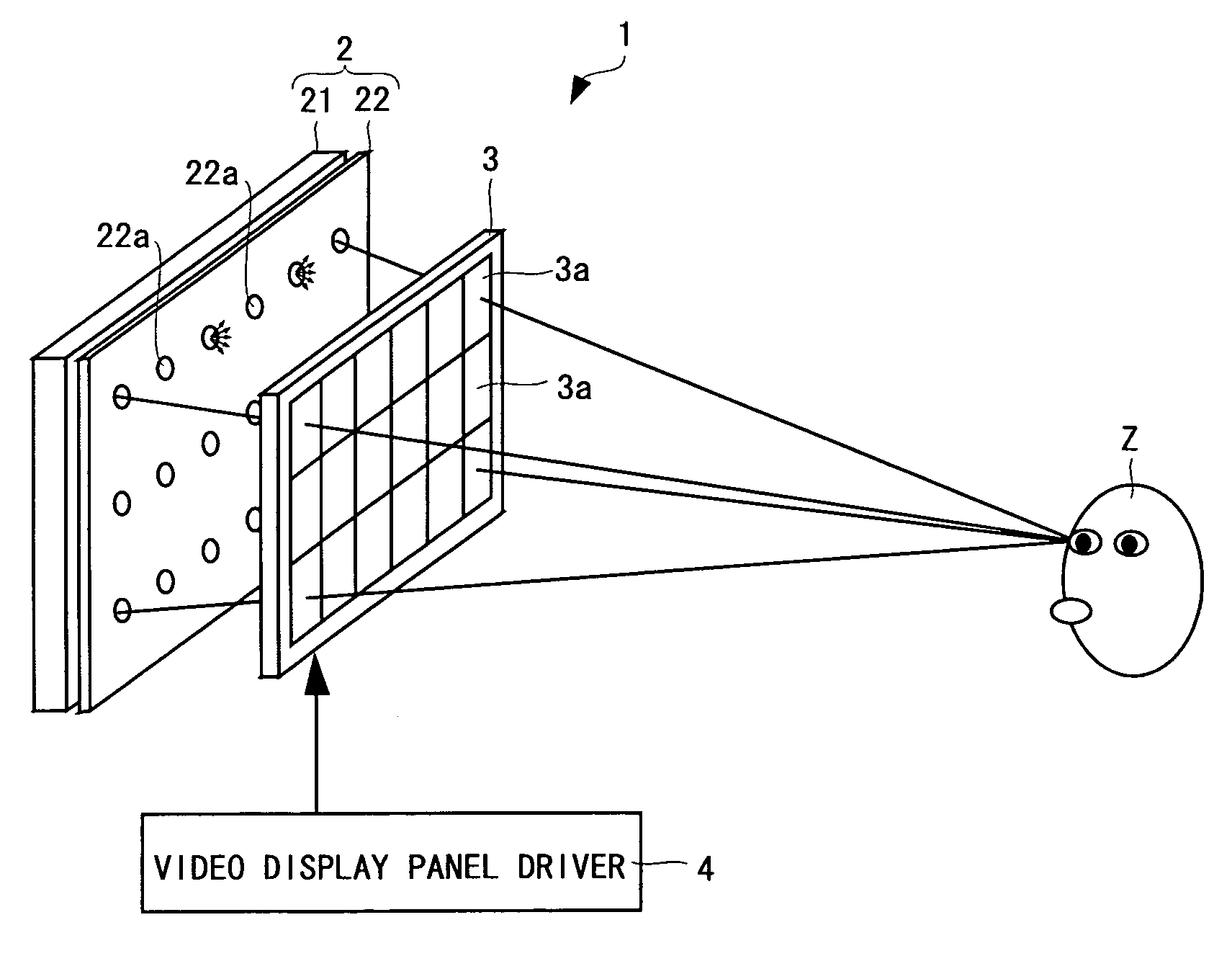

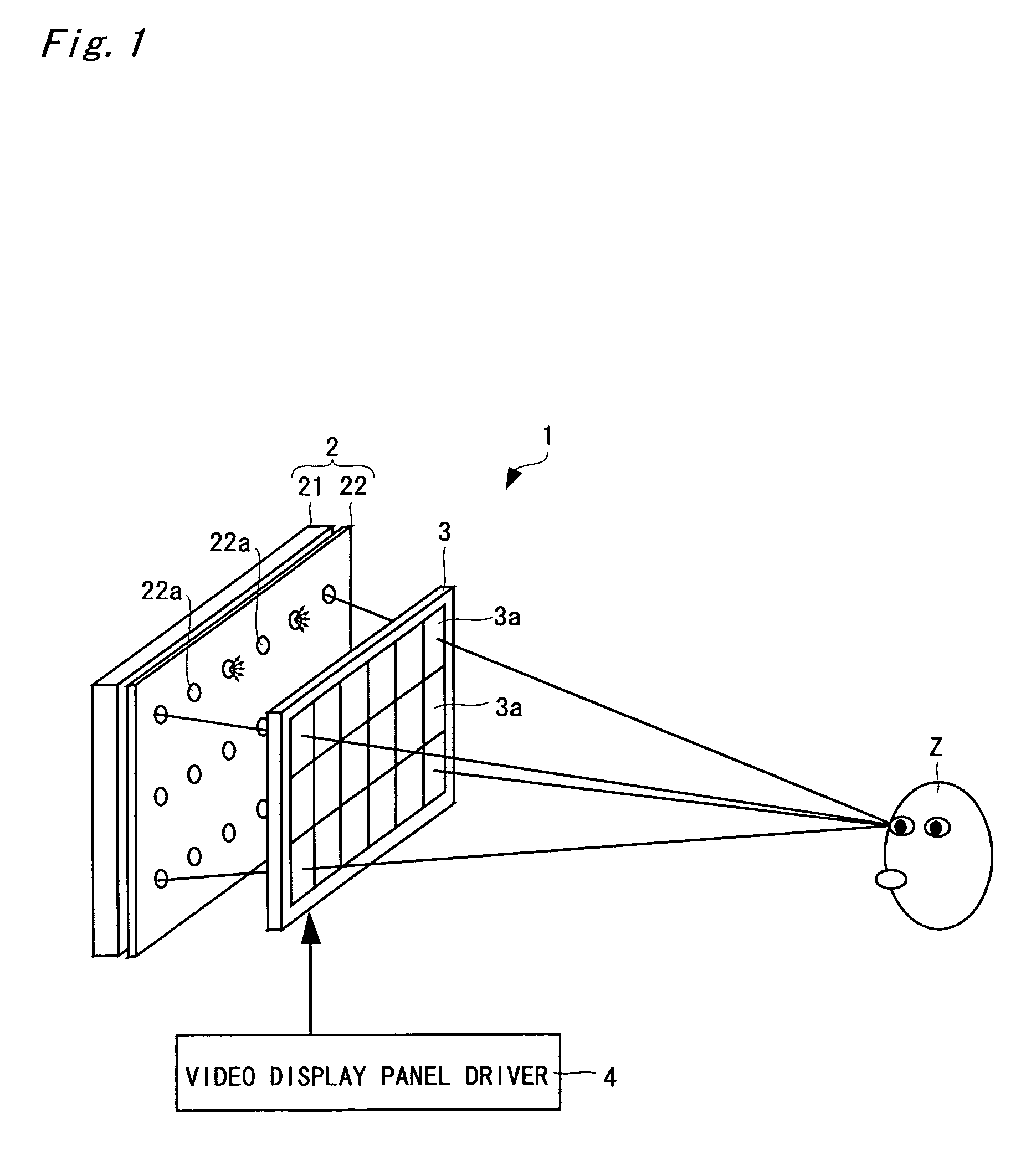

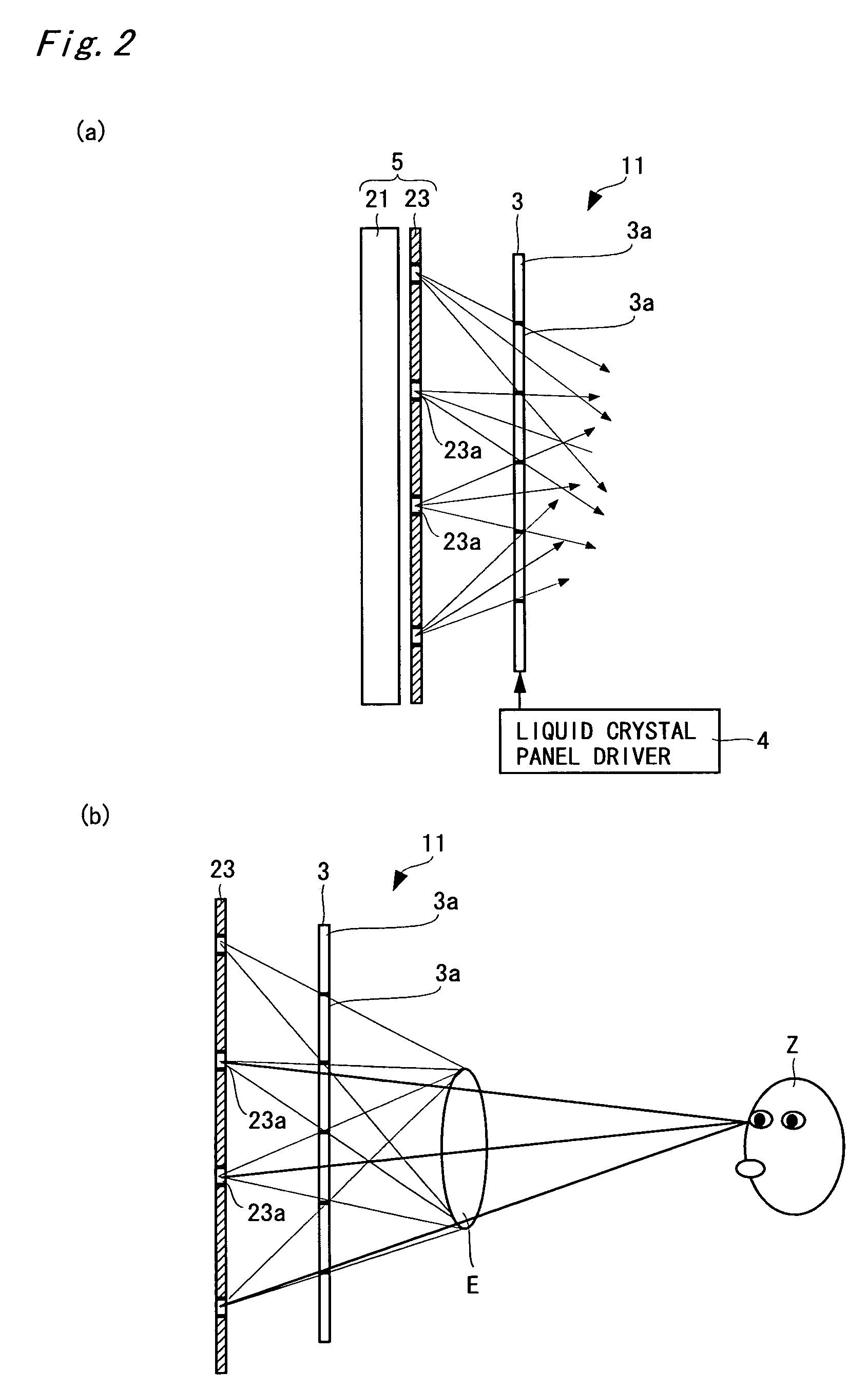

Three-dimensional video display and method for creating supply video supplied to three-demensional video display

InactiveUS20040130503A1Reduce the row spacingEfficient identificationCathode-ray tube indicatorsOptical light guidesStereoscopic videoLiquid-crystal display

There is provided a stereoscopic video display that enables a viewer to recognize a more real stereoscopic video. A light source device 2 comprises a backlight 21 and a pinhole array plate 22. A liquid crystal display panel driver 5 feeds a pixel driving signal to a liquid crystal display panel 3, to form a pixel region 3a composed of a plurality of pixels respectively corresponding to pinholes 22a. Each of the pixels composing the pixel region 3a controls an amount of light transmission with respect to a light beam in each direction from the corresponding pinhole 22a. Consequently, the intensity of the light beam in each direction is reproduced. Lines respectively connecting the centers of the pinholes 22a and the centers of the pixel regions 3a are not parallel to one another, and are so set as to cross at one point of a position corresponding to the standard distance between the video display panel 3 and a viewer Z. Therefore, the light beams are efficiently concentrated at a standard viewing position, thereby making it possible to make the viewer Z recognize a more real stereoscopic video.

Owner:SANYO ELECTRIC CO LTD

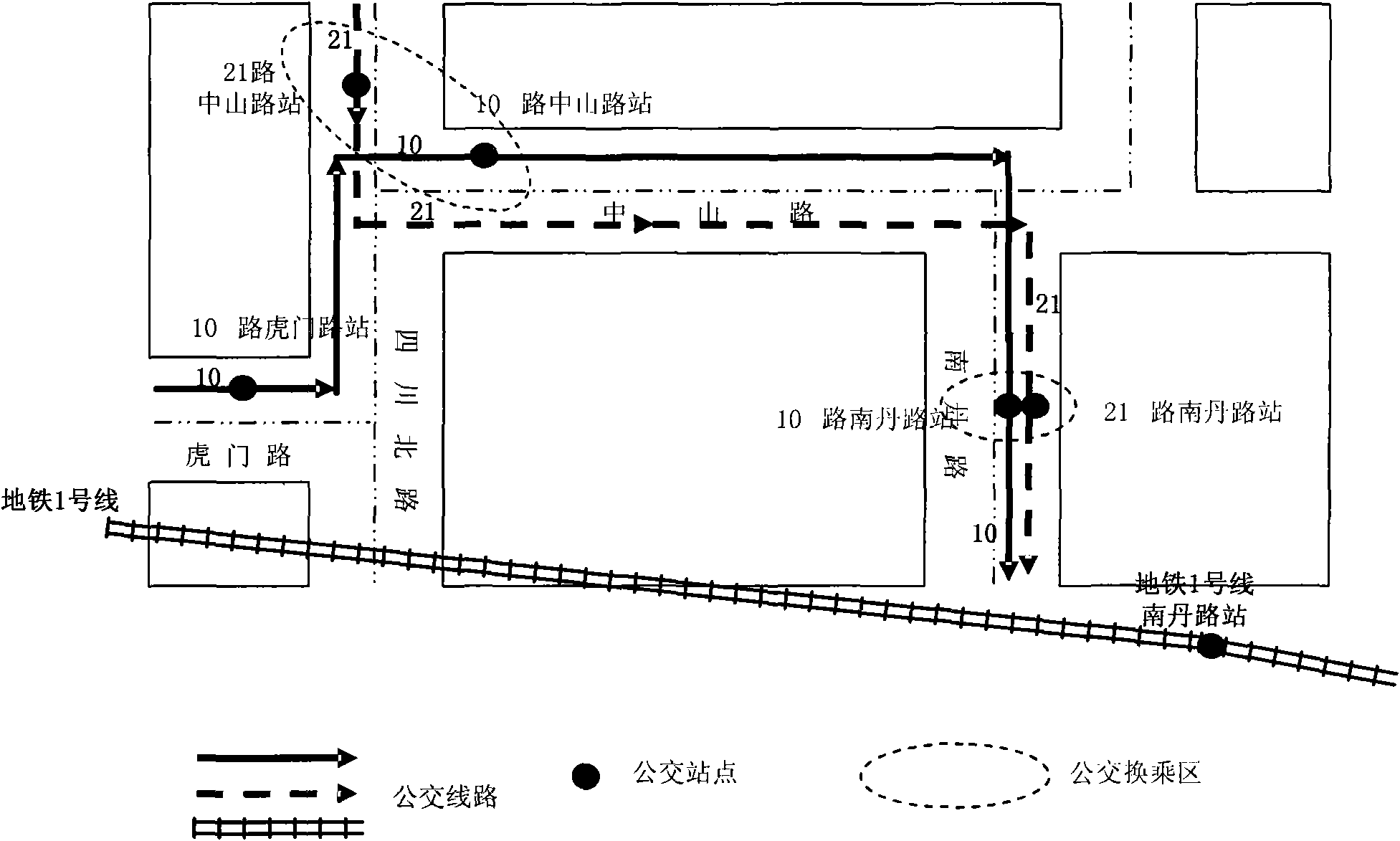

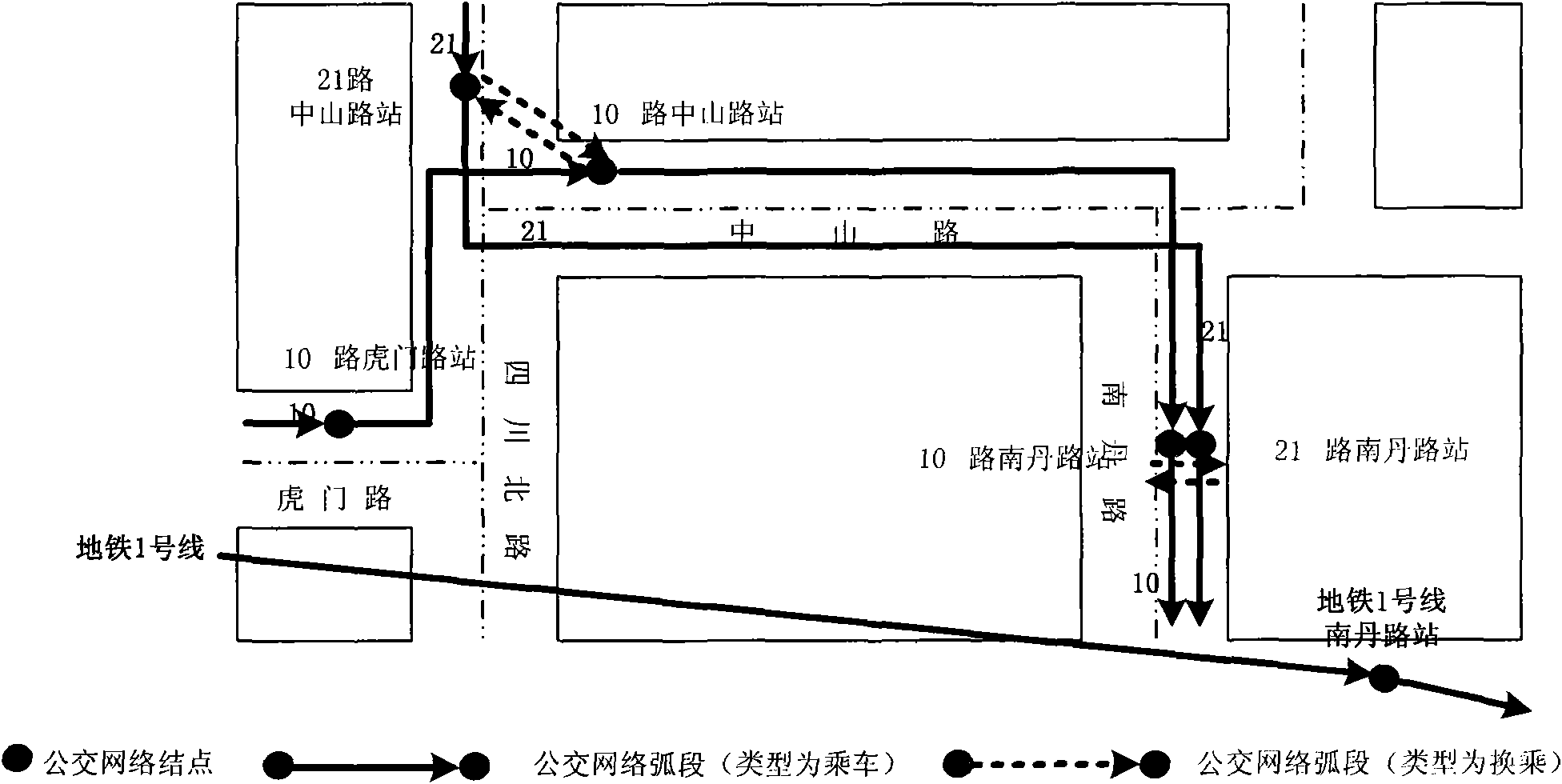

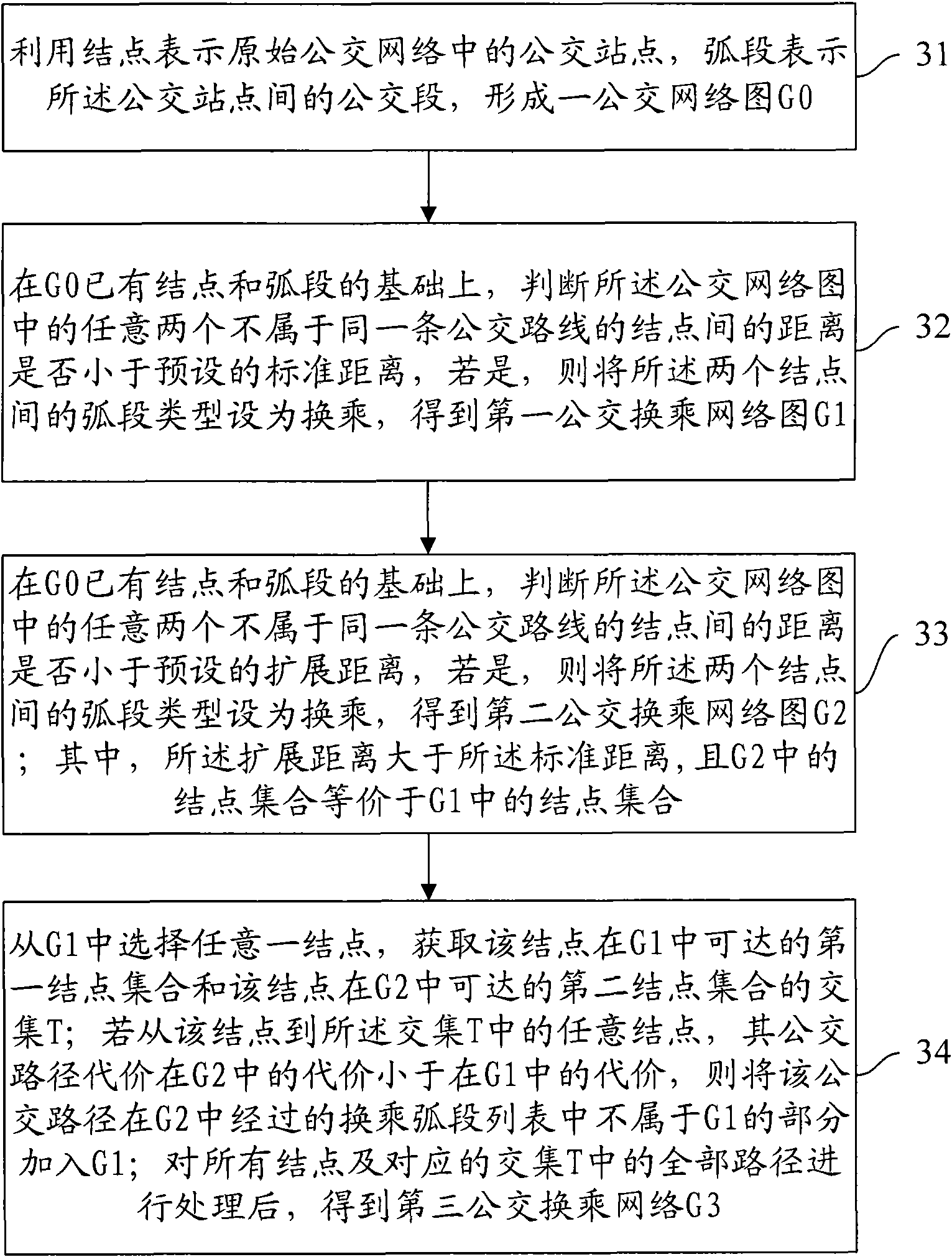

Method and device for constructing bus transfer network

InactiveCN101650705AReduce travel costsBest travel optionSpecial data processing applicationsEmbedded systemStandard distance

The invention provides method and device for constructing bus transfer network. The method comprises the following steps: when the distance between every two junctions belonging to different bus linesis shorter than a preset standard distance, the arc distance between the two junctions is set as transfer to obtain G1; when the distance between every two junctions belonging to different bus linesis shorter than a preset extending distance, the arc distance between the two junctions is set as transfer to obtain G2, wherein the extending distance is larger than the standard distance; a junctionis selected from G1 to obtain an intersection T of a first junction collection that the junction can reach in G1 and a second junction collection that the junction can reach in G2; from the mode to any junction in the intersection T, the cost for taking bus in G2 is less than that in G1, and the parts of the bus line in the list of the interchange arc sections of G2 but out of G1 are added to G1;and all bus lines in all the junctions and corresponding intersection T are processed to obtain G3. The invention is beneficial to providing a better choice for traveling.

Owner:NAVINFO

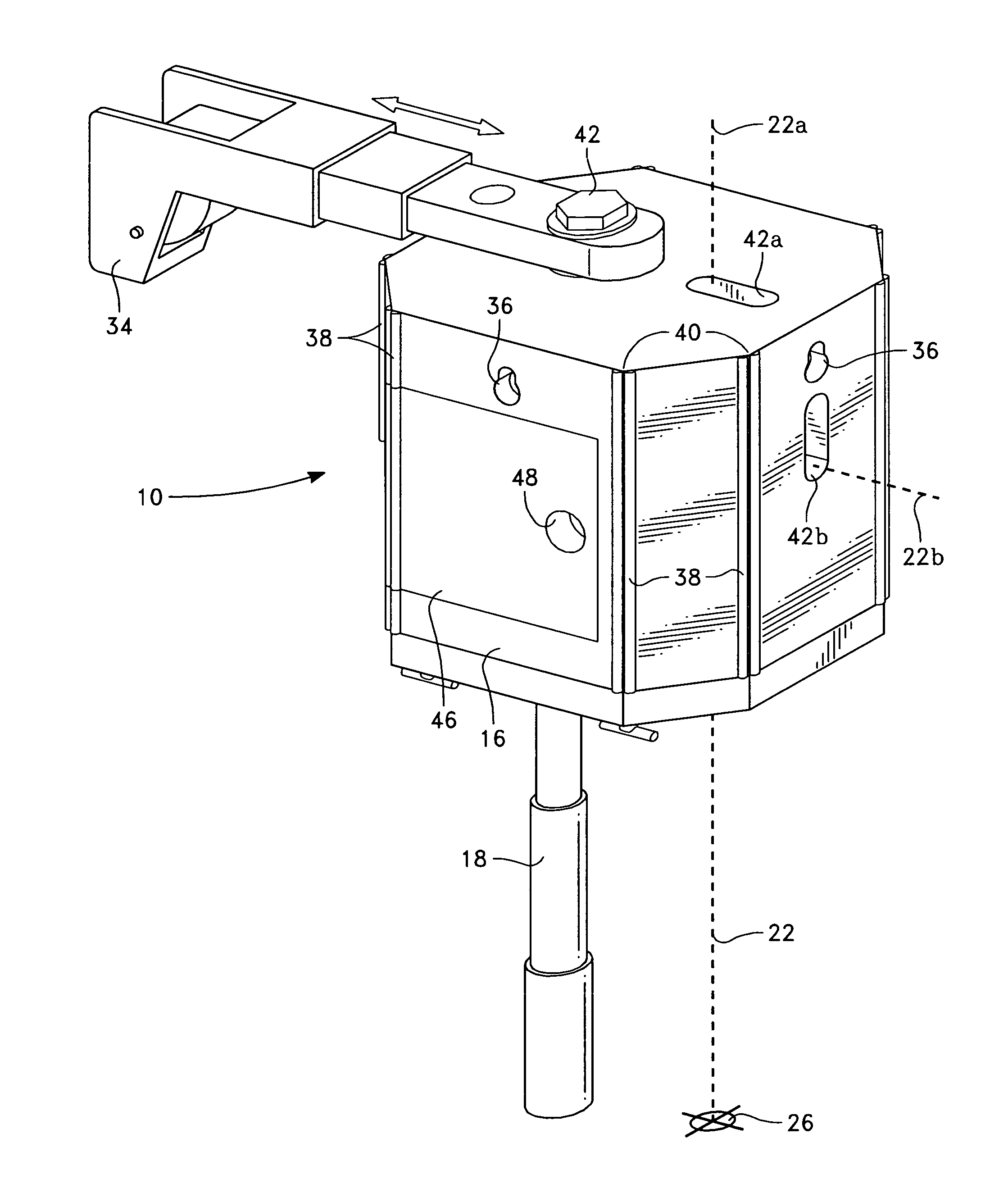

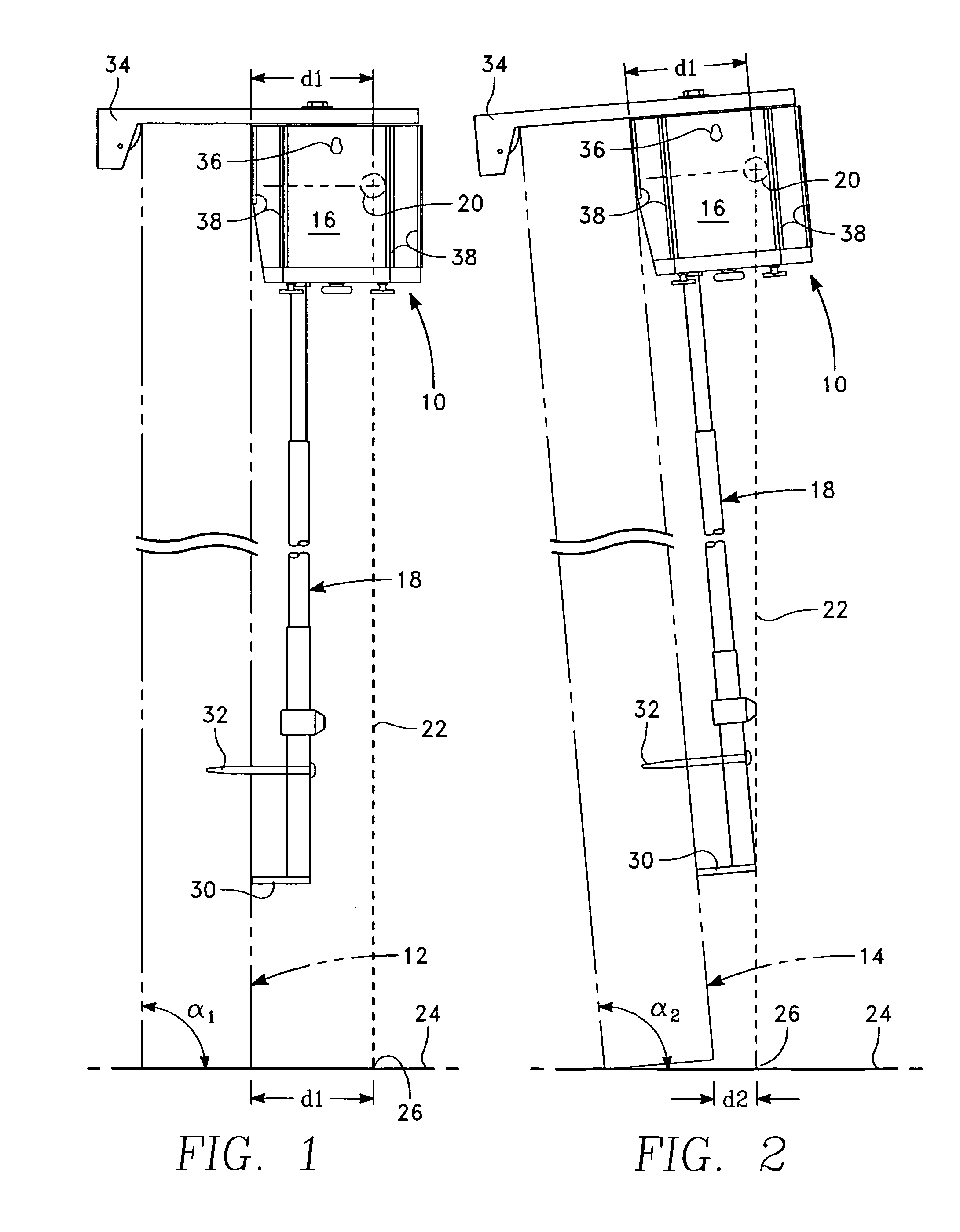

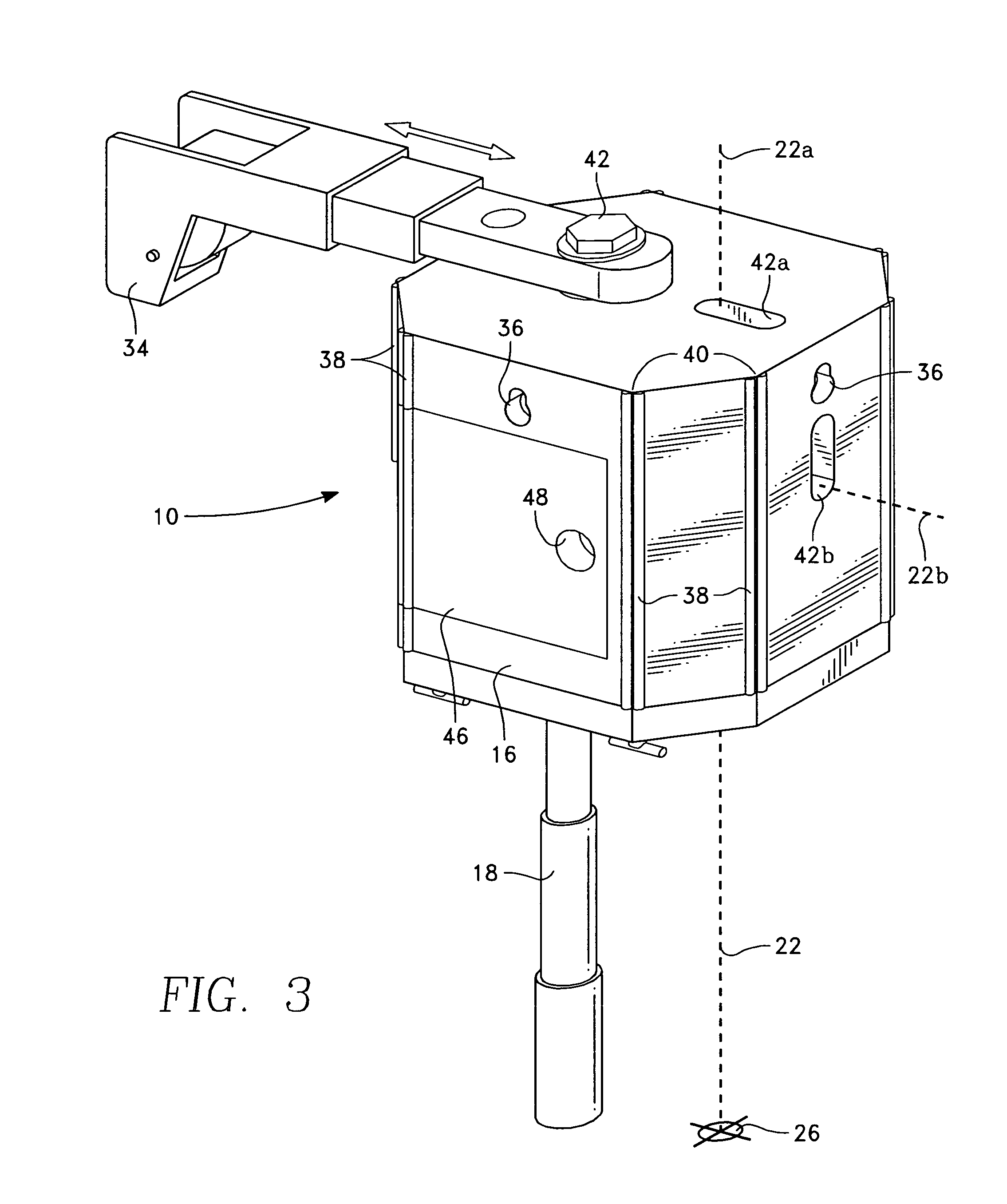

Elevated laser beam positioning device

ActiveUS7886450B1Improve visibilityCorrect placement of deviceMeasuring points markingHeight/levelling measurementStandard distanceMarine engineering

A leveling device that facilitates quick and precise placement of laser beams at a standardized distance from the surfaces against which it bears for the purpose of establishing plumb and level reference lines. It includes a mounting platform that includes various methods of bearing and attachment, including a telescoping pole that includes various features for deployment and stabilization. While the device can be used as a conventional level, it is specifically designed to be temporarily attached to vertical surfaces by a variety of methods, enabling all the advantages of laser use for the operation of plumb alignment, and also eliminating the need for a full time attendant.

Owner:FIANO JOSEPH

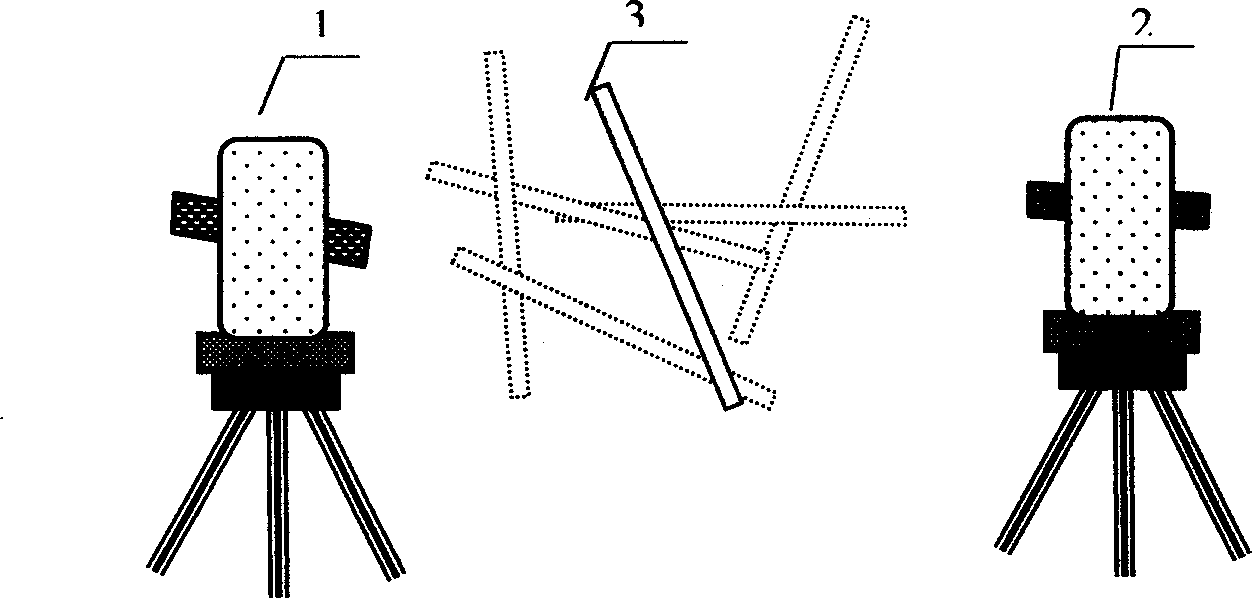

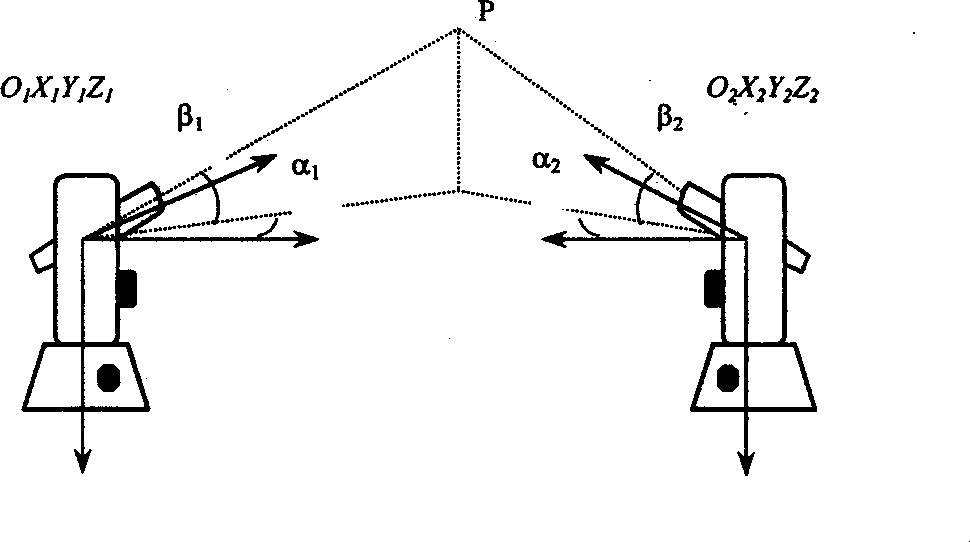

In-situ calibration device for large-size 3D space measurement and its measuring method

An in-situ calibrater for lage-size 3D space measurement and its measuring method is disclosed. A standard object with known reference distance is used, and more than 2 theodolites are used to observe the known standard point on said standard object at same time. A constraint equation is created on the basis of said standard distance and theodolite parameters, and then solved by optimizing method to obtain the model parameters of the odolite. Its advantages include no error caused by human factor, and high measuring precision.

Owner:TIANJIN UNIV

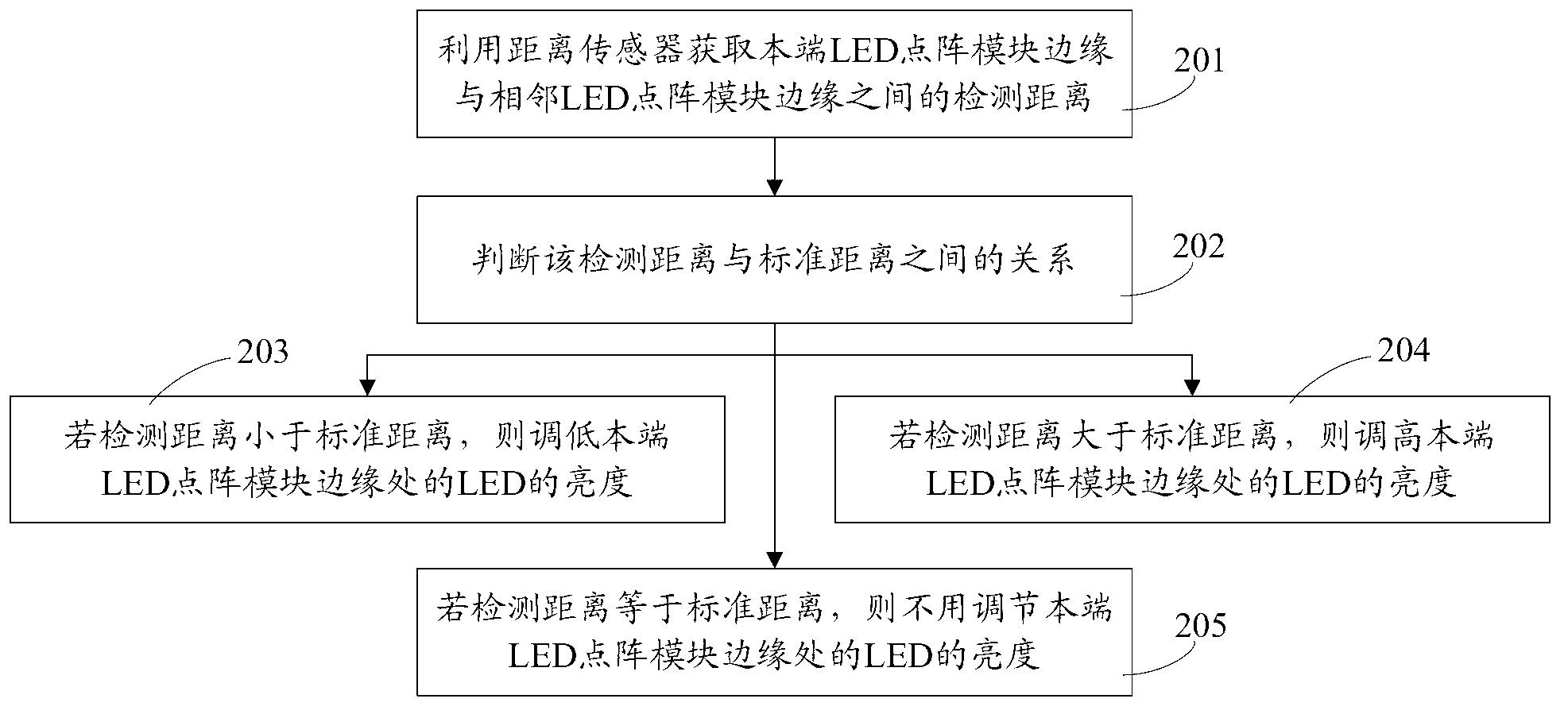

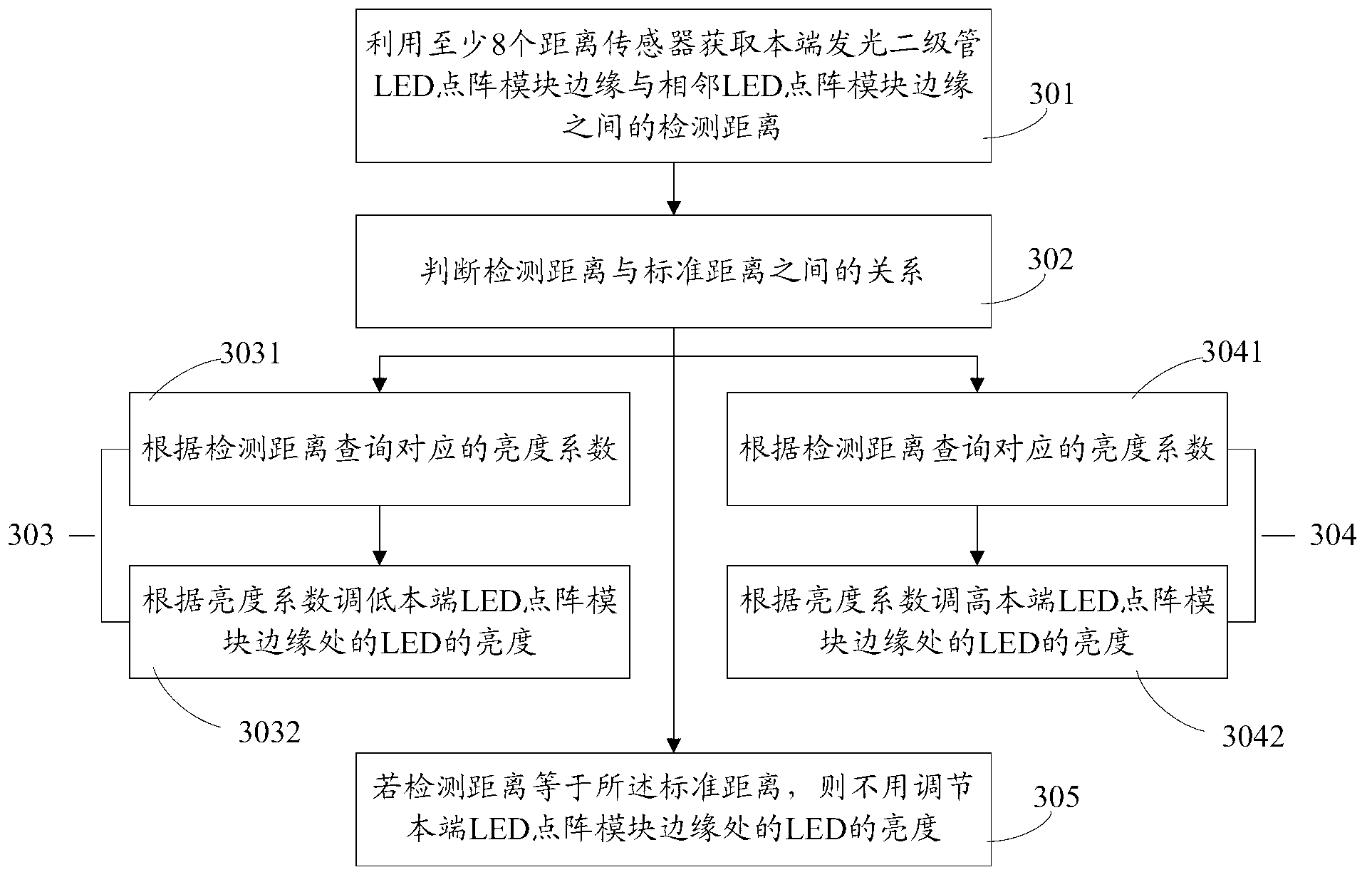

Brightness control method, LED-lattice module and LED-lattice screen

InactiveCN102842285ABrightness upEliminate brightness unevennessStatic indicating devicesIdentification meansComputer moduleDistance sensors

The embodiment of the invention discloses a brightness control method, an LED-lattice module and an LED-lattice screen, and aims to achieve brightness compensation of uneven seams in the LED-lattice screen. The brightness control method provided by the embodiment of the invention comprises the following steps: utilizing a distance sensor to acquire the detection distance between the edge of an LED-lattice module at the end and that of an adjacent LED-lattice module; judging the relationship between the detection distance and the standard distance; turning down the brightness of LEDs at the edge of the LED-lattice module at the end if the detection distance is smaller than the standard distance; and turning up the brightness of LEDs at the edge of the LED-lattice module at the end if the detection distance is larger than the standard distance. By implementing the scheme of the invention, uneven brightness of the LED-lattice screen at the spliced part due to uneven seams between the LED-lattice modules is eliminated, and accordingly, the display effect of the whole screen is improved.

Owner:GUANGDONG VTRON TECH CO LTD

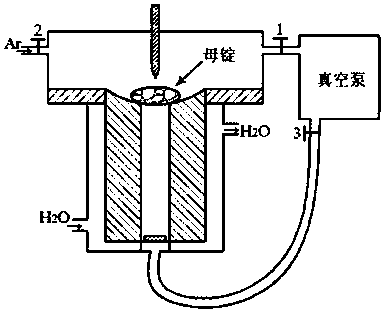

Method for improving Al0.3CoCrFeNi high-entropy alloy intensity

ActiveCN109797303AFine grain boundaryUniform tissueVacuum evaporation coatingSputtering coatingHigh entropy alloysWire cutting

The invention discloses a method for improving Al0.3CoCrFeNi high-entropy alloy intensity. Five kinds of analytical pure metals of Al, Co, Cr, Fe and Ni are blended according to the atomic ratio of 0.3 to 1 to 1 to 1 to 1, smelting is carried out in a vacuum arc melting furnace, the molten alloy is subjected to suction casting to form plate-shaped high-entropy alloy materials with 2mm thickness, 10mm width and 85mm length, and then a high-entropy alloy is subjected to cold rolling and annealing heat treatment to eliminate the residual internal stress, generated in the casting process, of the high-entropy alloy; and then a wire cutting machine is used for cutting bone-shaped standard tensile samples with a standard distance of 5mm, the front faces and back faces and the two side faces of the tensile samples are polished, and the polished samples are subjected to a double-glow chromizing test by using a double-glow metal furnace, and finally, the obtained samples are strengthened high-entropy alloy samples. According to the method for improving the Al0.3CoCrFeNi high-entropy alloy intensity, through a double-glow chromizing technology, the friction coefficient of the high-entropy alloy is reduced, and the amplitude is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

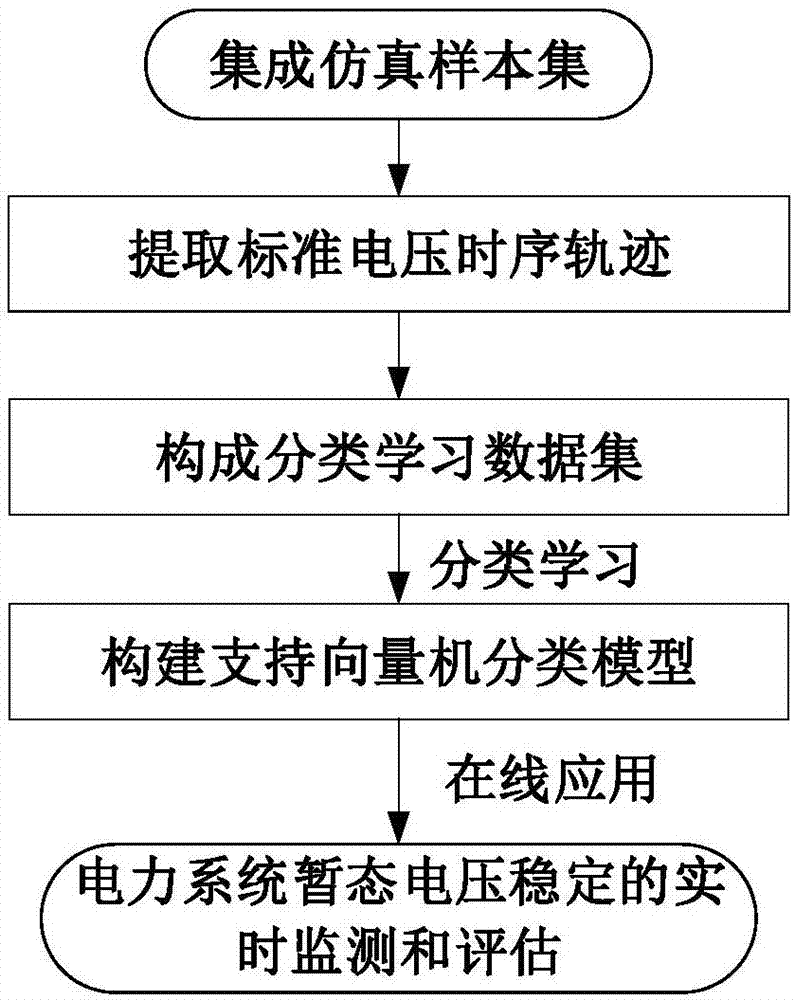

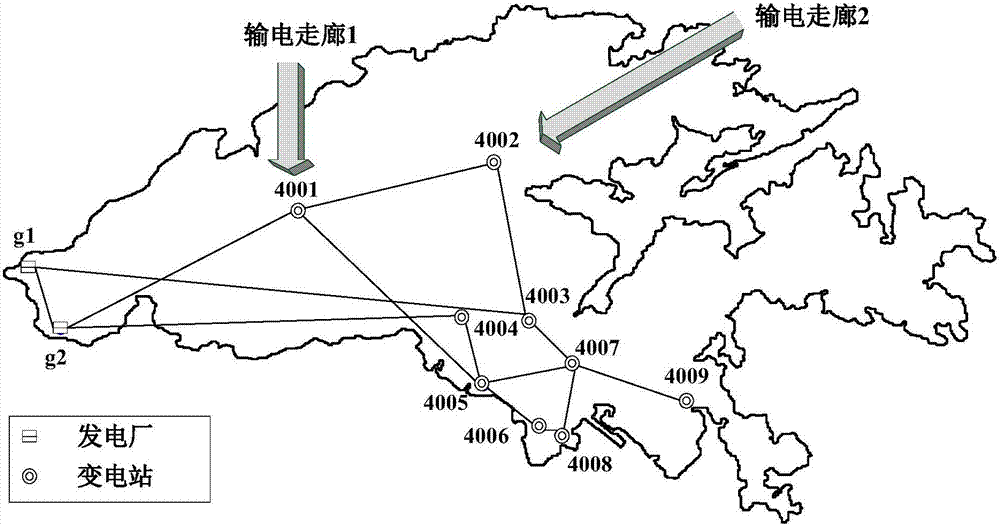

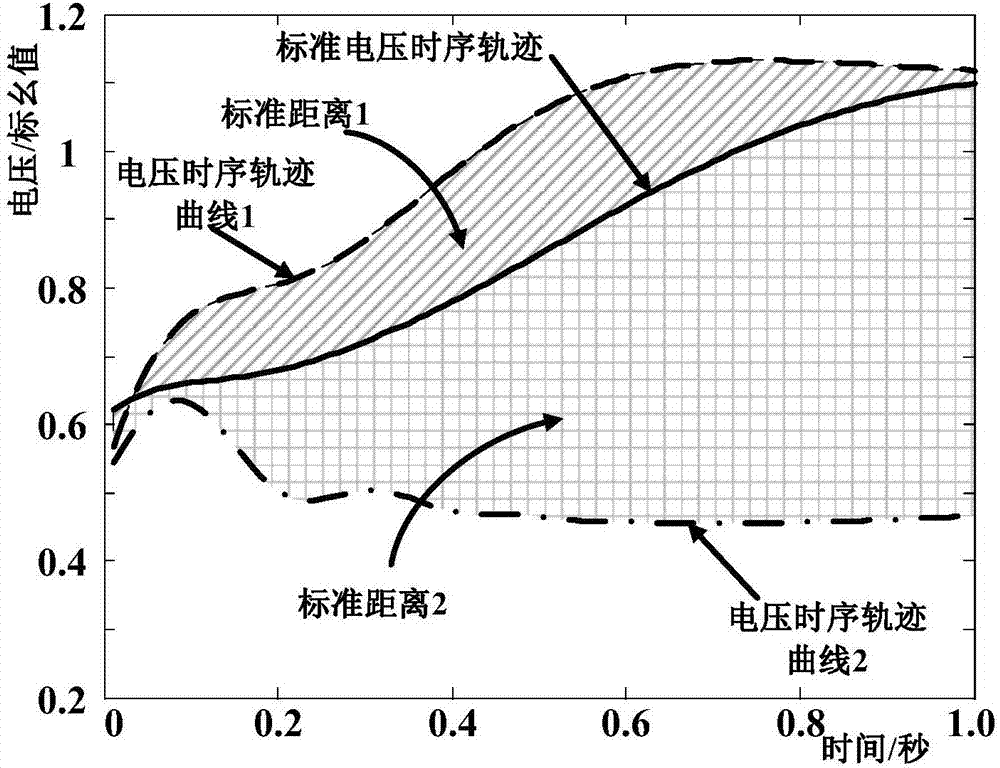

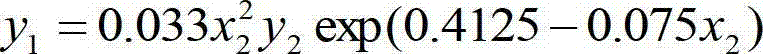

Power system transient voltage stability evaluation method based on voltage time sequence trajectory

ActiveCN107482621AReduce misjudgmentReduce the chance of misjudgmentAc network circuit arrangementsData setElectric power system

The present invention relates to a power system transient voltage stability evaluation method based on voltage time sequence trajectory, belonging to the field of power system stability analysis and evaluation. The method comprises: first simulating various faults of the power system in each operation mode to obtain a simulation sample set; extracting the voltage sub-time-sequence with the highest correlation with the category of the power system state from the voltage sequences of all the simulation samples as the standard voltage time sequence trajectory; calculating the distances from the trajectory to all simulated samples to form a standard distance dataset; using the standard voltage time sequence trajectory and the standard distance data set as input, and the state of the power system as output; training to obtain an SVM classification model; when the power system encounters a temporary state fault, obtaining the voltage time sequence in real time, calculating the distance between the standard voltage time sequence trajectory to the voltage time sequence; and inputting the support vector machine model and outputting the real-time power system state evaluation result by the model. The method of the invention can reliably monitor and evaluate the transient voltage stability of the power system on-line.

Owner:TSINGHUA UNIV +1

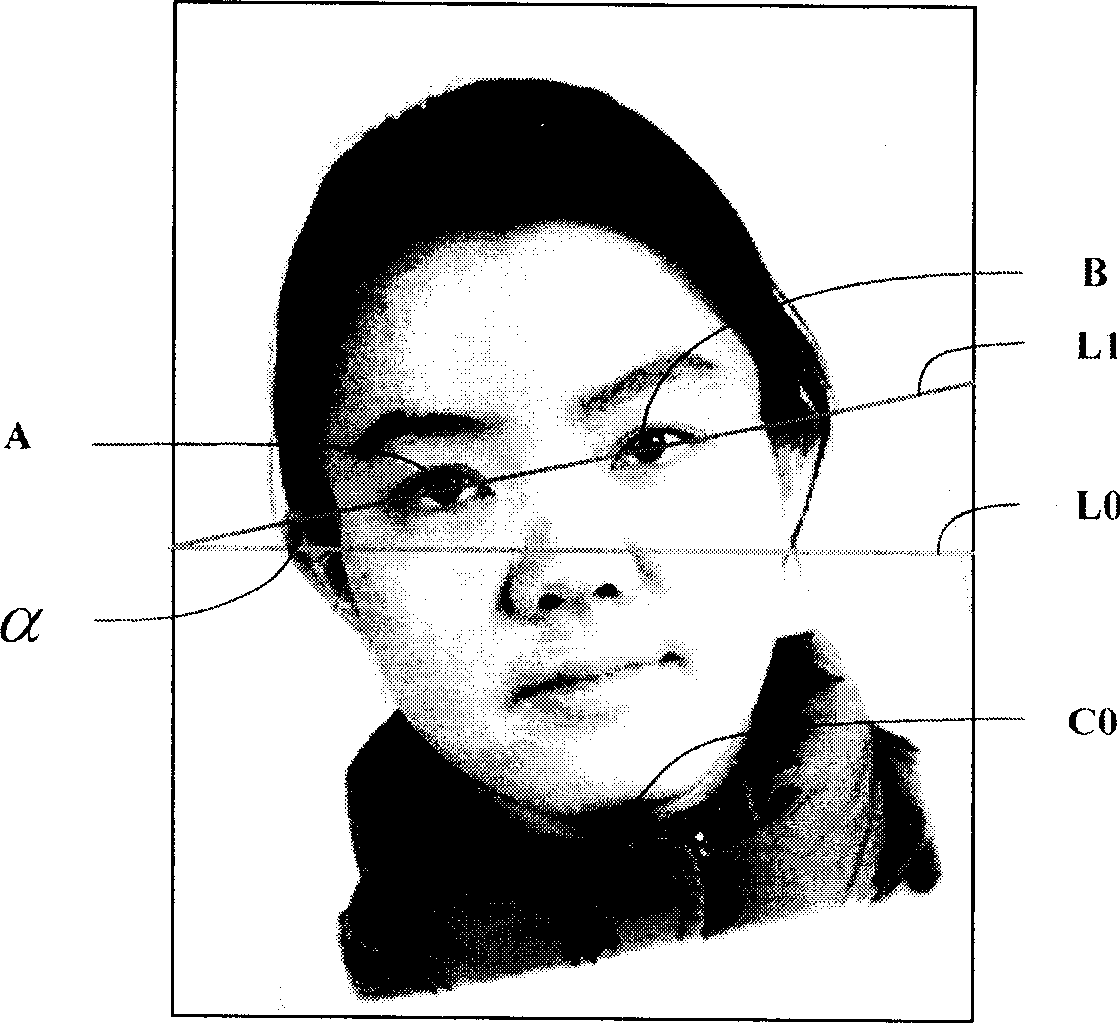

Man face image identifying method based on man face geometric size normalization

InactiveCN1687959AGood normalization effectImprove face visual effectCharacter and pattern recognitionImaging processingImage formation

The invention relates to a human face image recognizing method based on the geometric size normalization of a human face, belonging to image processing technical field, and comprising the steps of: determining the coordinates of the left and right eyeballs on an input human face image, and according to the coordinates, rotating the image to the horizontal position to obtain a new human face image 2, then determining the coordinates of left and right eyeballs and mandible of the new human face image 2, specifying the numeric value of normalized geometric size of a human face, zooming in or out the new human face 2 to obtain another human face image 3 meeting the standard distance; according to the coordinates of left and right eyeballs and mandible of the human face image 3, cutting the human face image 3 to obtaina standard normalized human face image; forming training-set, known and to-be- recognized human face images into human face images of normalized geometric size and extracting human face characteristics, and in a known human face database, adopting the methods of calculating similarity and sequencing according to the similarity to recognize the human face. The invention obviously improves the visual effect of a human face and makes a higher increase in the recognizing ratio.

Owner:TSINGHUA UNIV

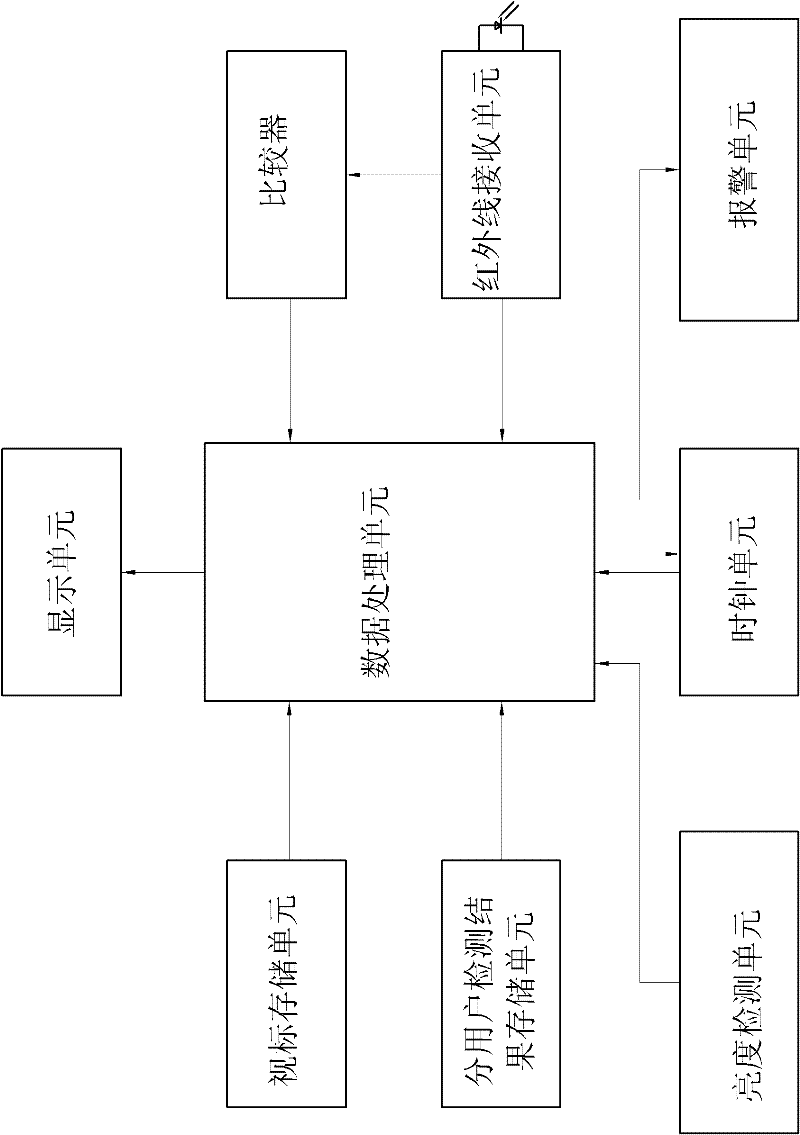

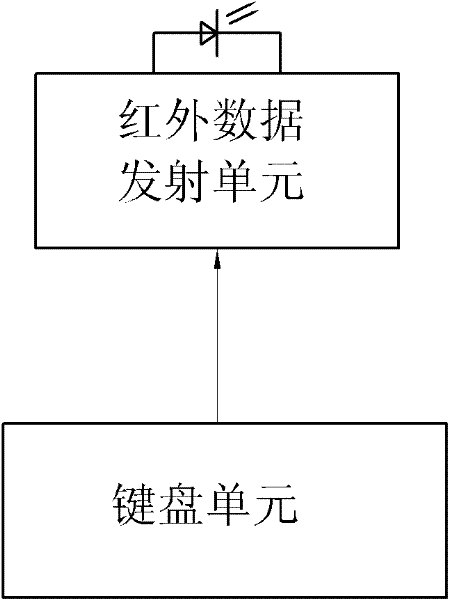

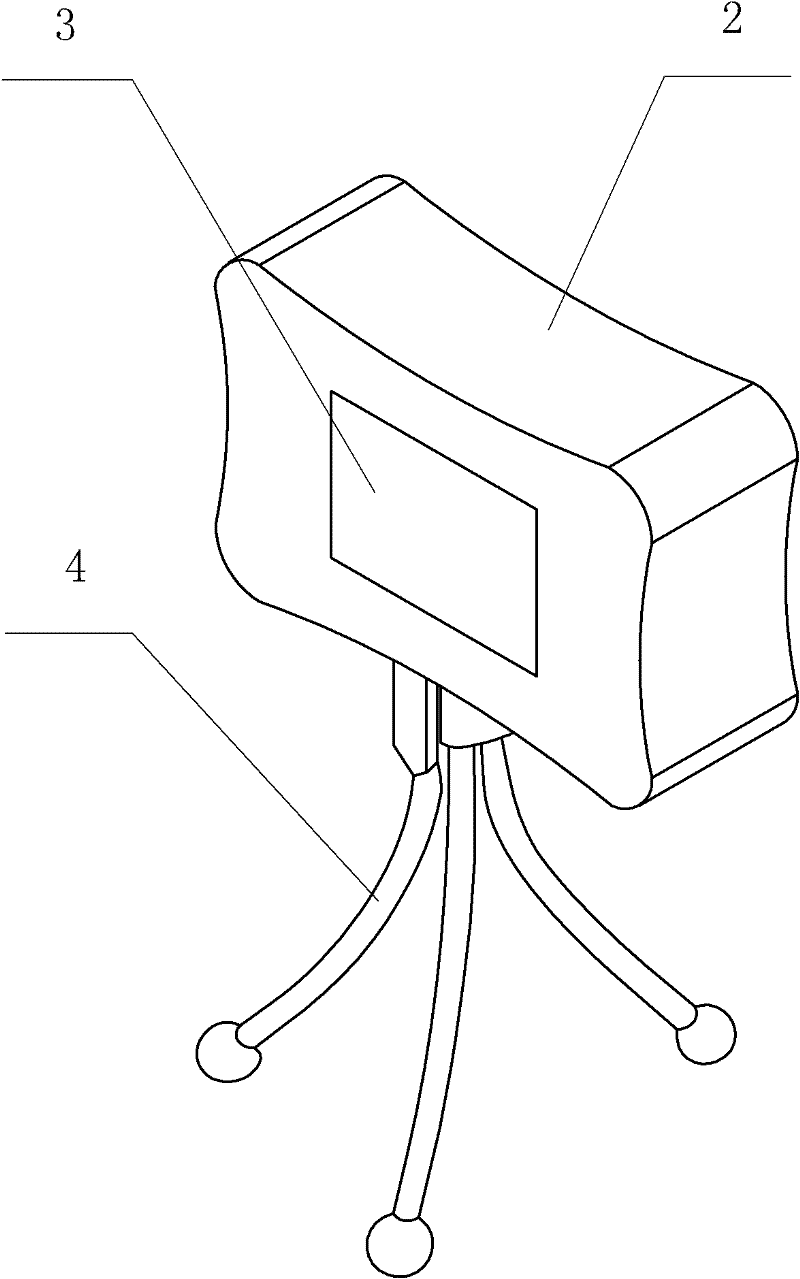

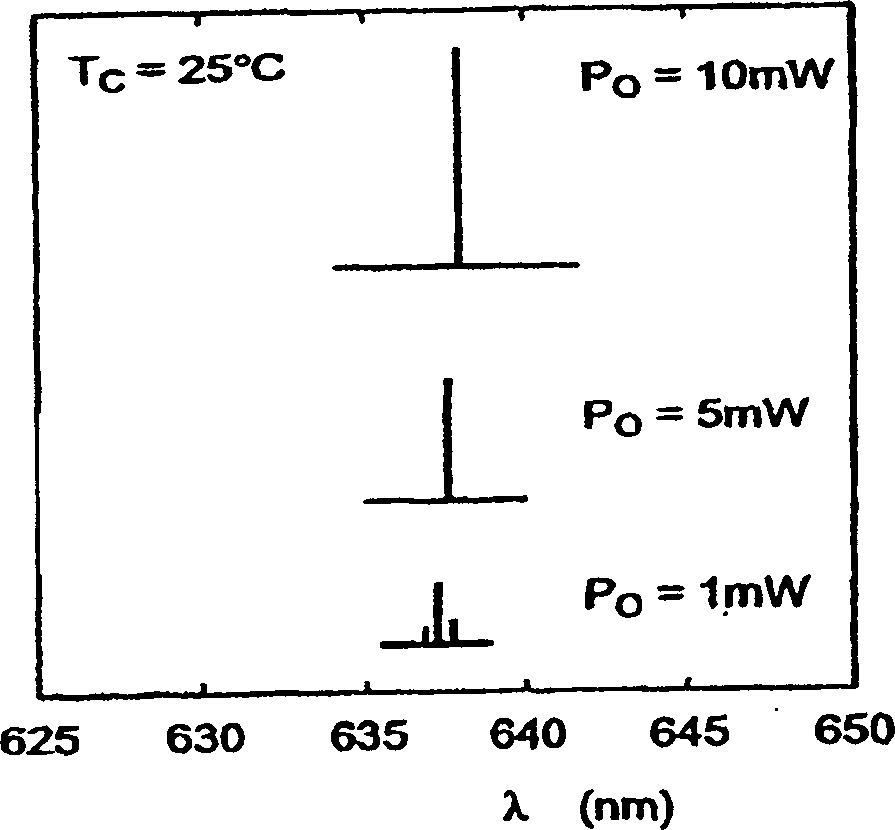

Intelligent vision inspection instrument

InactiveCN102334975ARealize long-term detection and trackingEasy to analyzeEye diagnosticsInfraredVision inspection

The invention discloses an intelligent vision inspection instrument, which is provided with a handheld remote control and a host part, wherein the host part displays a visual target randomly; a tester detects at the standard distance and transmits an infrared signal to the host by pressing a direction key corresponding to a self-considered visual target direction on the handheld remote control; an infrared data receiving unit in the host part receives the infrared signal transmitted from the handheld remote control and sends the infrared signal into a comparator so as to judge whether the judgment of the tester is correct or not; a data processing unit sends a comparison result into a sub-user detection result storage unit and a tester storage unit corresponding to the tester; and after multi-time testing, the tester not only can know the current own vision but also can master the vision change tendency within a certain time, thereby providing a reliable basis for preventing myopia for youngsters and monitoring the vision change of patients with eye diseases. The intelligent vision inspection instrument can be used without help of other people, and therefore the intelligent vision inspection instrument is convenient to use.

Owner:杜学静

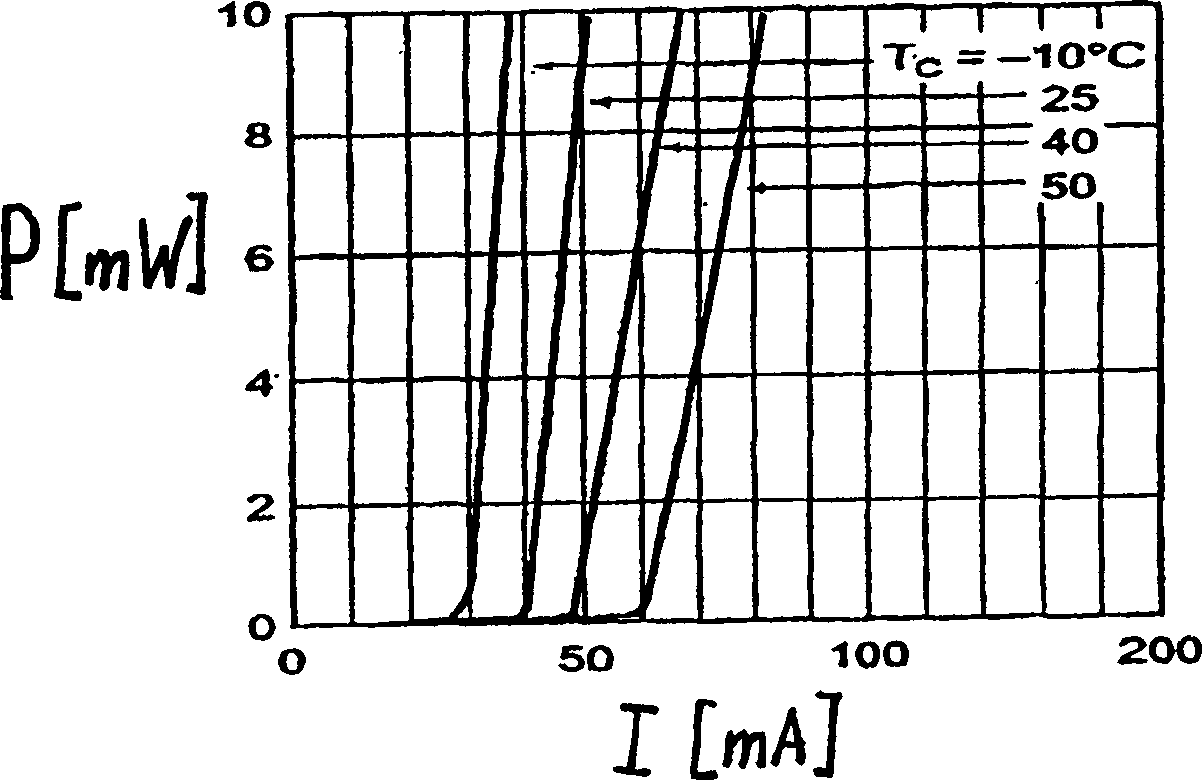

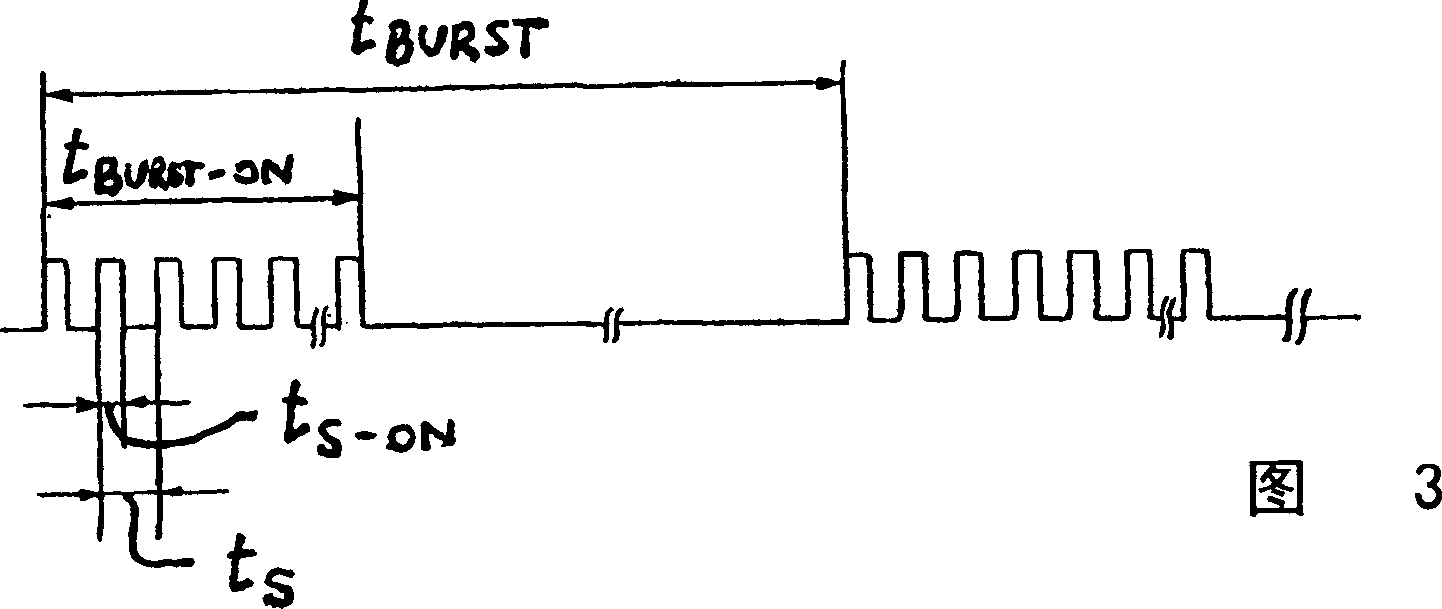

Method and device for measuring distances

InactiveCN1449501AOptical rangefindersElectromagnetic wave reradiationPhase differenceIntensity modulation

The invention relates to a method for measuring distances, based on the phase measurement of an optical measuring beam that is reflected or scattered by an object, on which the beam is sighted. According to said method, the measurement object is exposed to an optical measuring beam of modulated intensity emitted by a measuring device and is converted into electrical measurement signals. The signals are then compared with a reference signal that is generated from the detection and conversion of a portion of measuring light that has been guided on a known reference trajectory, in order to determine the distance between the measuring device and the measurement objet, based on the phase difference that has been determined. The emitted measuring beam is modulated in bursts and the measurement signal of the receiver is only evaluated during the active burst period. The invention also relates to devices for carrying out said method.

Owner:LEICA GEOSYSTEMS AG

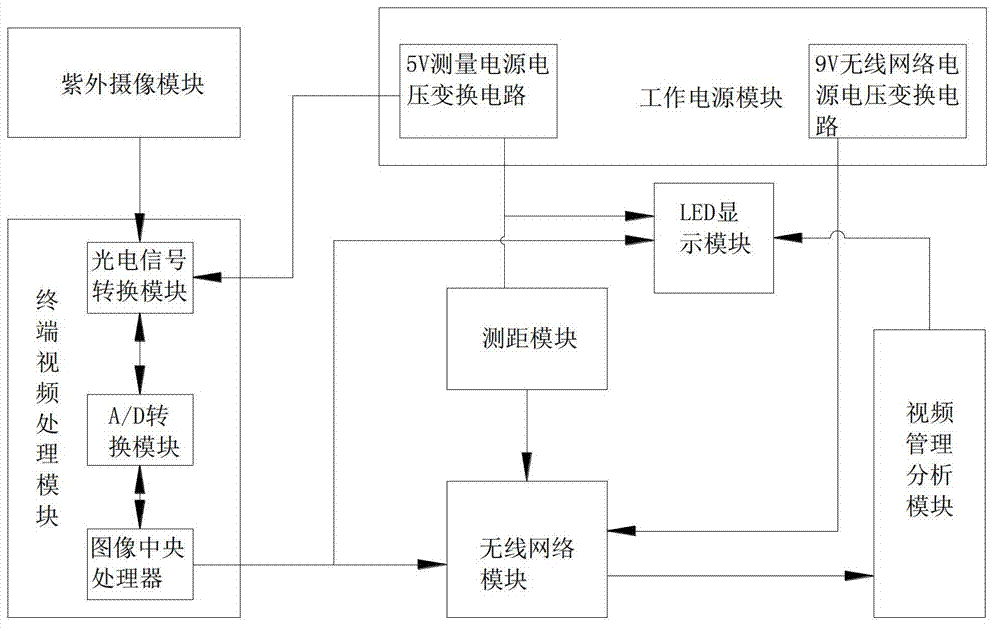

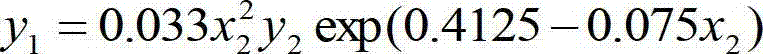

System and method for monitoring and analyzing insulation states of high-voltage device

ActiveCN102928752AEliminate the effects ofAccurate assessment of insulation conditionTesting dielectric strengthCorona dischargeUltraviolet

The invention relates to the field of device detection and specifically relates to an ultraviolet ray detecting based system and a method for monitoring and analyzing insulation states of a high-voltage device. The system comprises an ultraviolet camera shooting module, a terminal video processing module, a distance measurement module, a wireless network module, an ultraviolet video management analysis module and a light emitting diode (LED) display module. By means of an ultraviolet photon number correction method, ultraviolet detection videos are subjected to digital recognition through the ultraviolet video management analysis module to extract information of ultraviolet photon numbers and the like, and the ultraviolet photon numbers are calibrated onto a standard distance scale according to actually measured distances, so that corona discharge intensity can be comprehensively compared and analyzed, influence brought by field detection conditions is eliminated, insulation states of the device is accurately evaluated, and the system and the method have the advantages of being visual, accurate, safe and fast.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

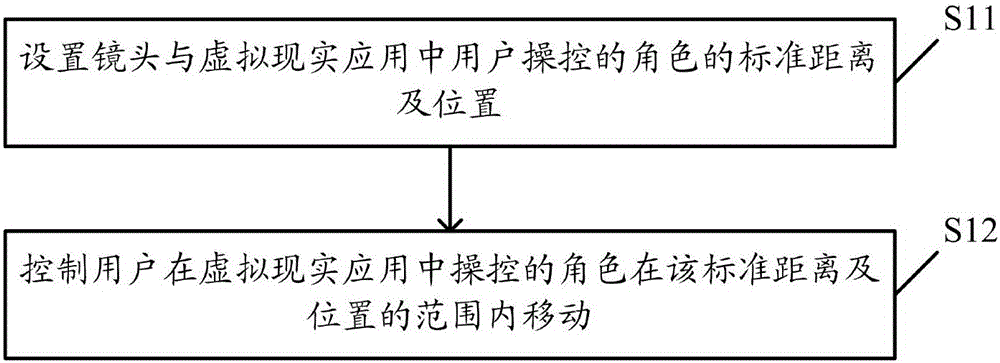

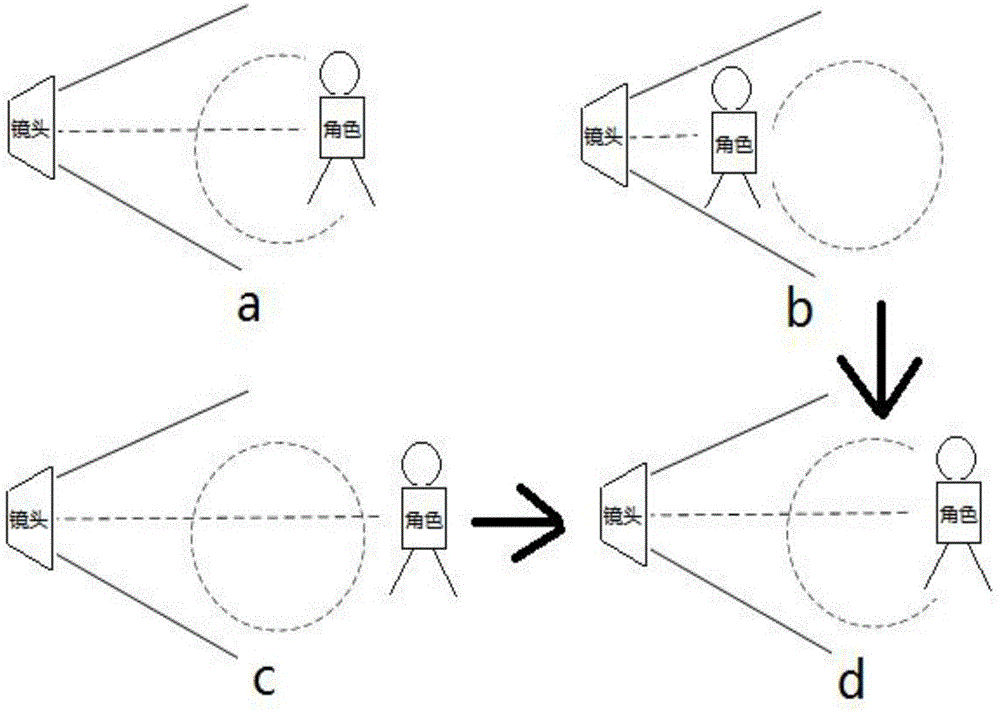

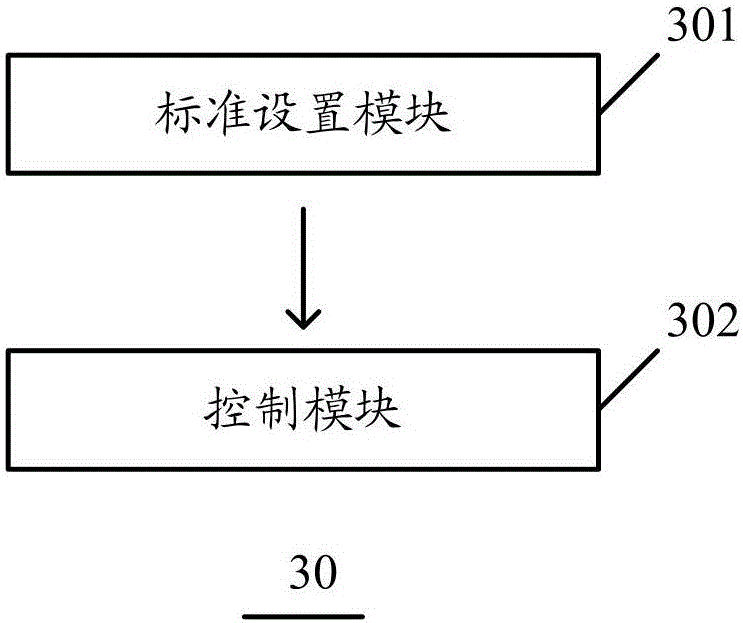

Method and device for preventing dizziness of user in virtual reality application

InactiveCN106502395AAvoid dizzinessAvoid Virtual Reality Motion SicknessInput/output for user-computer interactionGraph readingMotion sicknessCognition

The invention discloses a method and device for preventing the dizziness of a user in virtual reality application. The method comprises the following steps: setting a standard distance from a lens to a role controlled by the user in the virtual reality application as well as the position of the lens; and controlling the role controlled by the user in the virtual reality application to move in the ranges of the standard distance and the position. According to the method, the following movement of the lens occurs instantly, the user cannot sense a displacement feel caused by virtual reality contents, and the cognition and the perception can not conflict at all, so that the virtual reality motion sickness can be completely avoided; the use conditions of the instant movement of the lens include, but not limited to, the distance and the position, are wide in application range, do not need to be supported by any additional hardware equipment and only need to be realized from a software view, so that the realization cost is low; and the user only needs to normally use virtual reality equipment without additional use conditions, such as the space range and specific hardware equipment.

Owner:SHENZHEN SPARKVR VIRTUAL REALITY TECH CO LTD

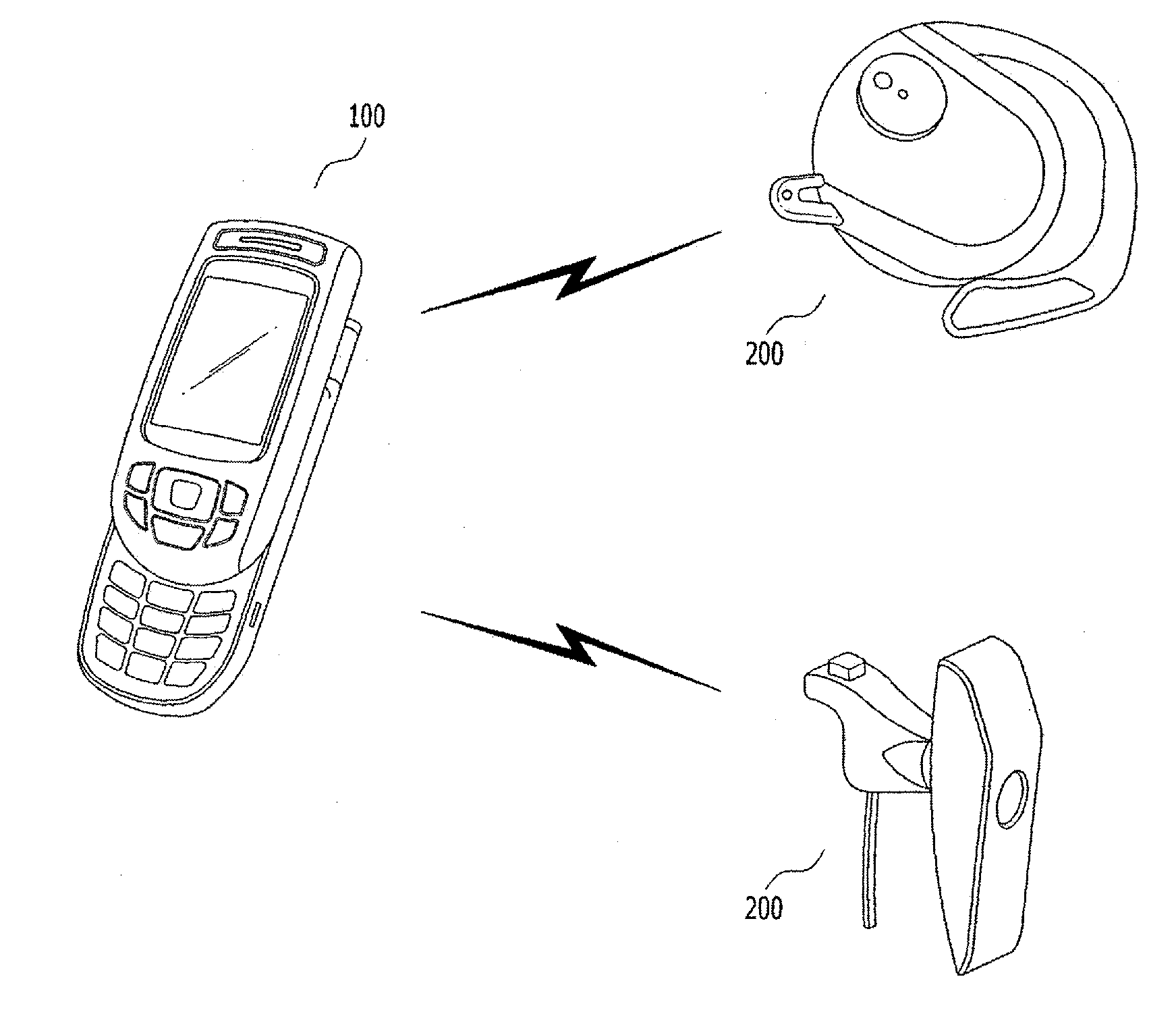

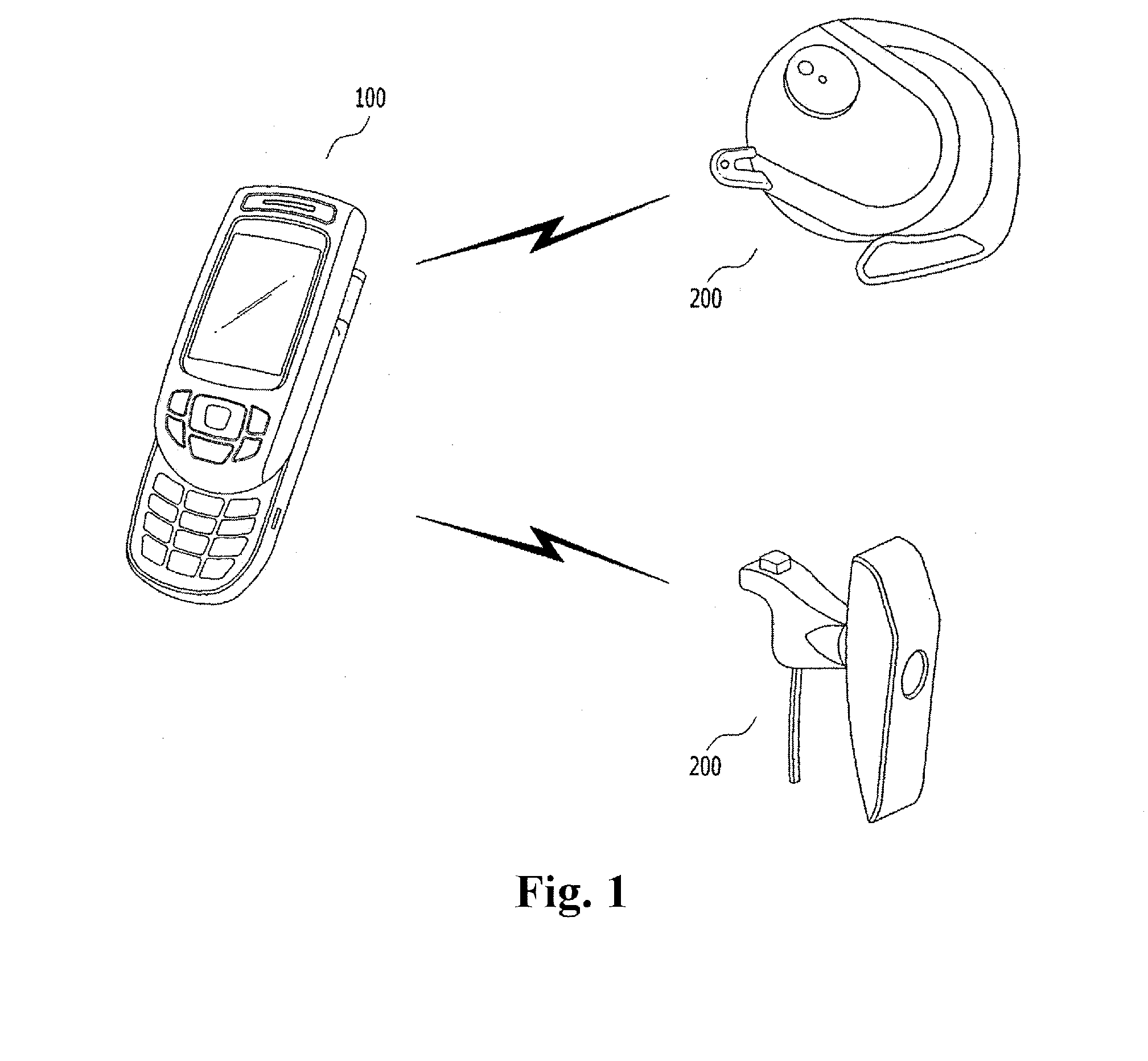

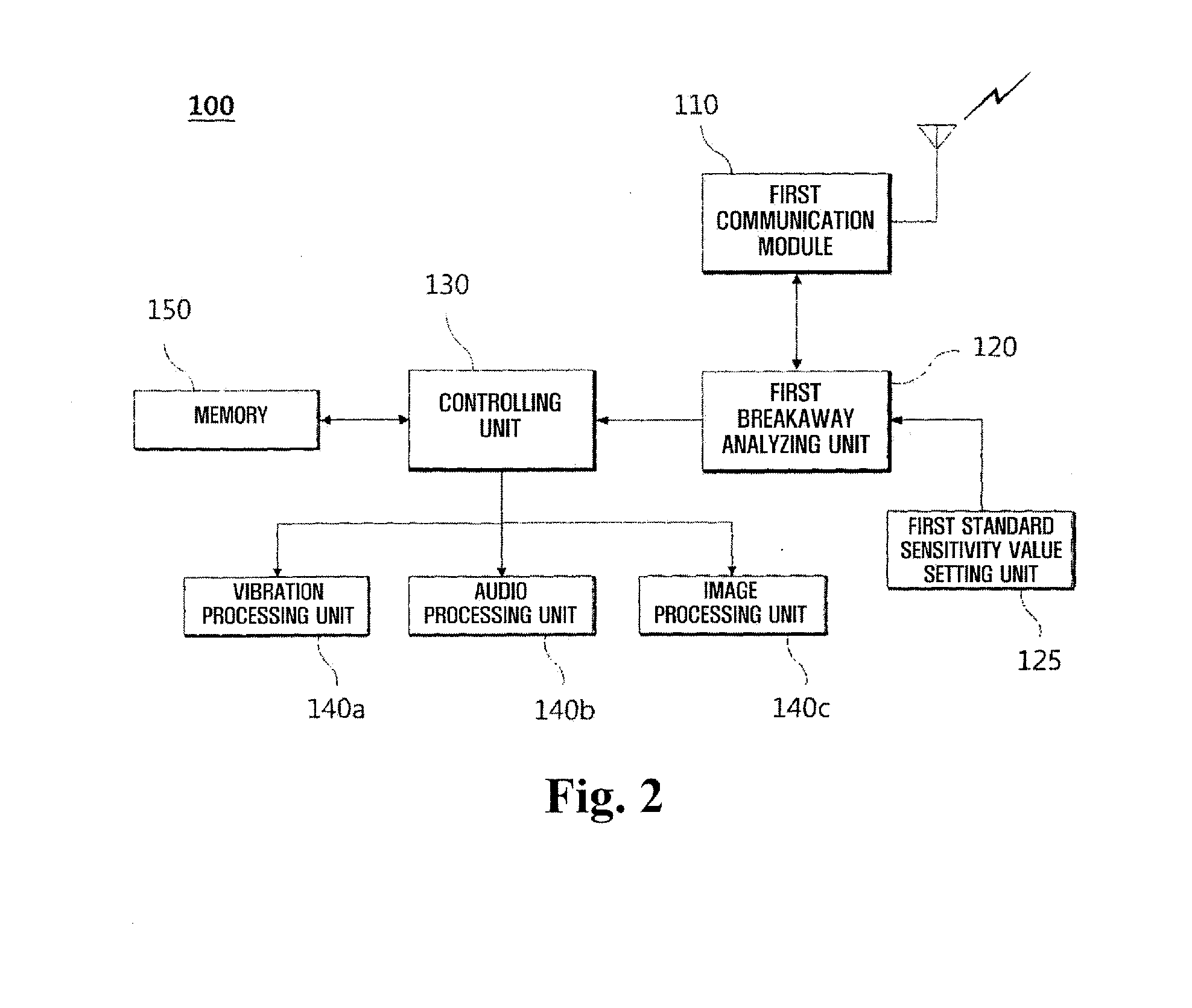

Headset having mobile communication terminal loss prevention function and headset system having loss prevention function

InactiveUS20150078574A1Easily separation distanceLoss preventionSupra/circum aural earpiecesRadio transmission for post communicationComputer terminalEngineering

Each of a mobile communication terminal (100) and a headset (200) in the present invention measures the distance to another wirelessly connected device and determines whether the other device is lost. According to the present invention, the mobile communication terminal (100) in a headset system having a loss prevention function comprises: a first communication module (110) for forming a communication channel with the headset (200); a first breakaway analyzing unit (120) analyzes whether the headset (200) breaks away at a standard distance loss from a location of the mobile communication terminal (100) by analyzing a sensitivity signal delivered via the first communication module (110); and a first breakaway warning unit (140) for warning a user of a breakaway by using at least one of a vibration signal, a sound signal, or an image signal when analysis reveals that the headset (200) has broken away at the standard distance loss from the first breakaway analyzing unit (120). The headset (200) having a mobile communication terminal (100) loss prevention function according to the present invention comprises: a second communication module (210) for forming a communication channel with the mobile communication terminal (100); the second breakaway analyzing unit (220) for analyzing whether the mobile communication terminal (100) breaks away at the standard loss distance from the location of the headset (200) by analyzing a sensitivity signal delivered via the second communication module (210); and a second breakaway warning unit (240) for warning the user of a breakaway when analysis reveals that the mobile communication terminal (100) has broken away from the standard loss distance.

Owner:HAEBORA

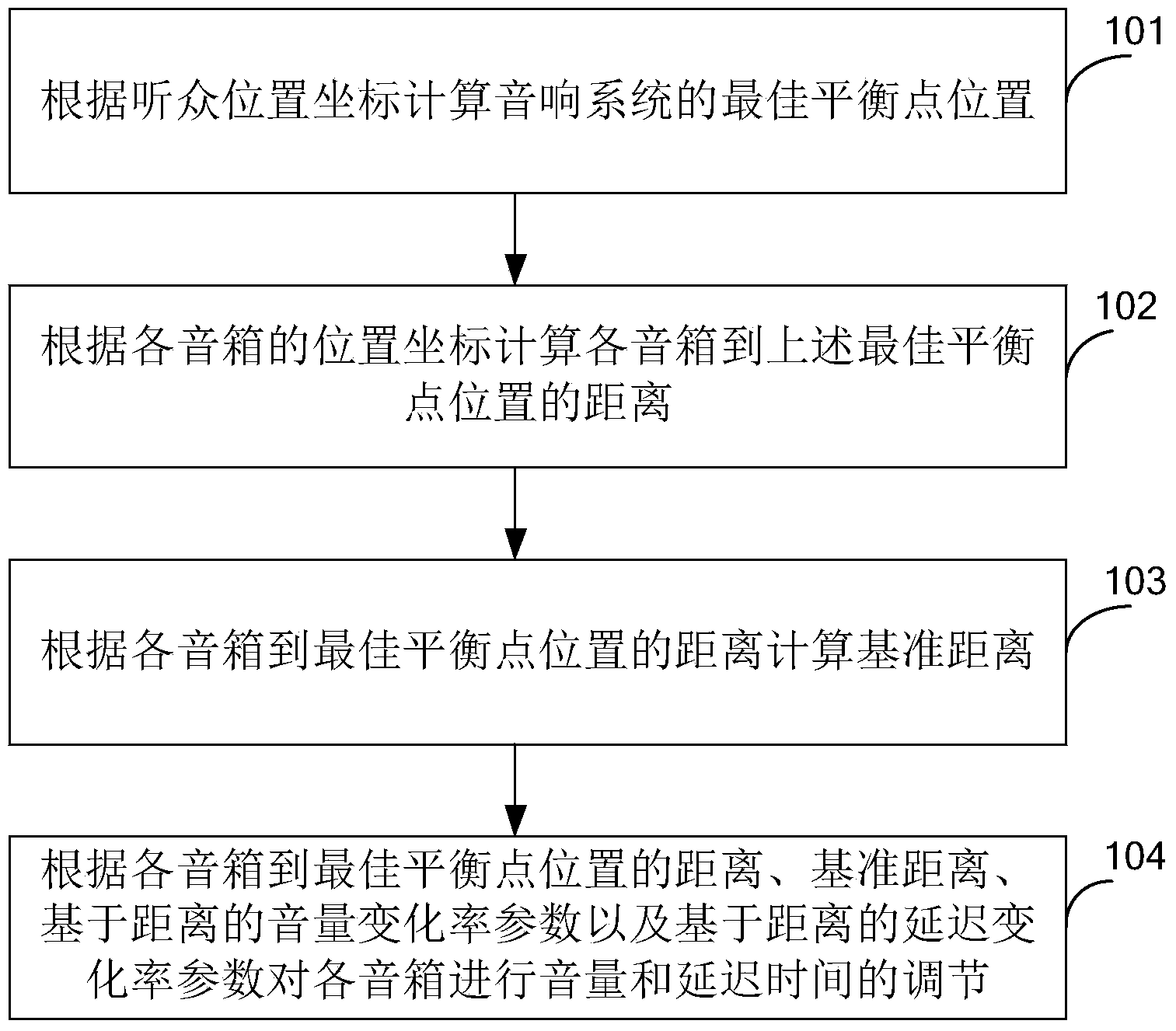

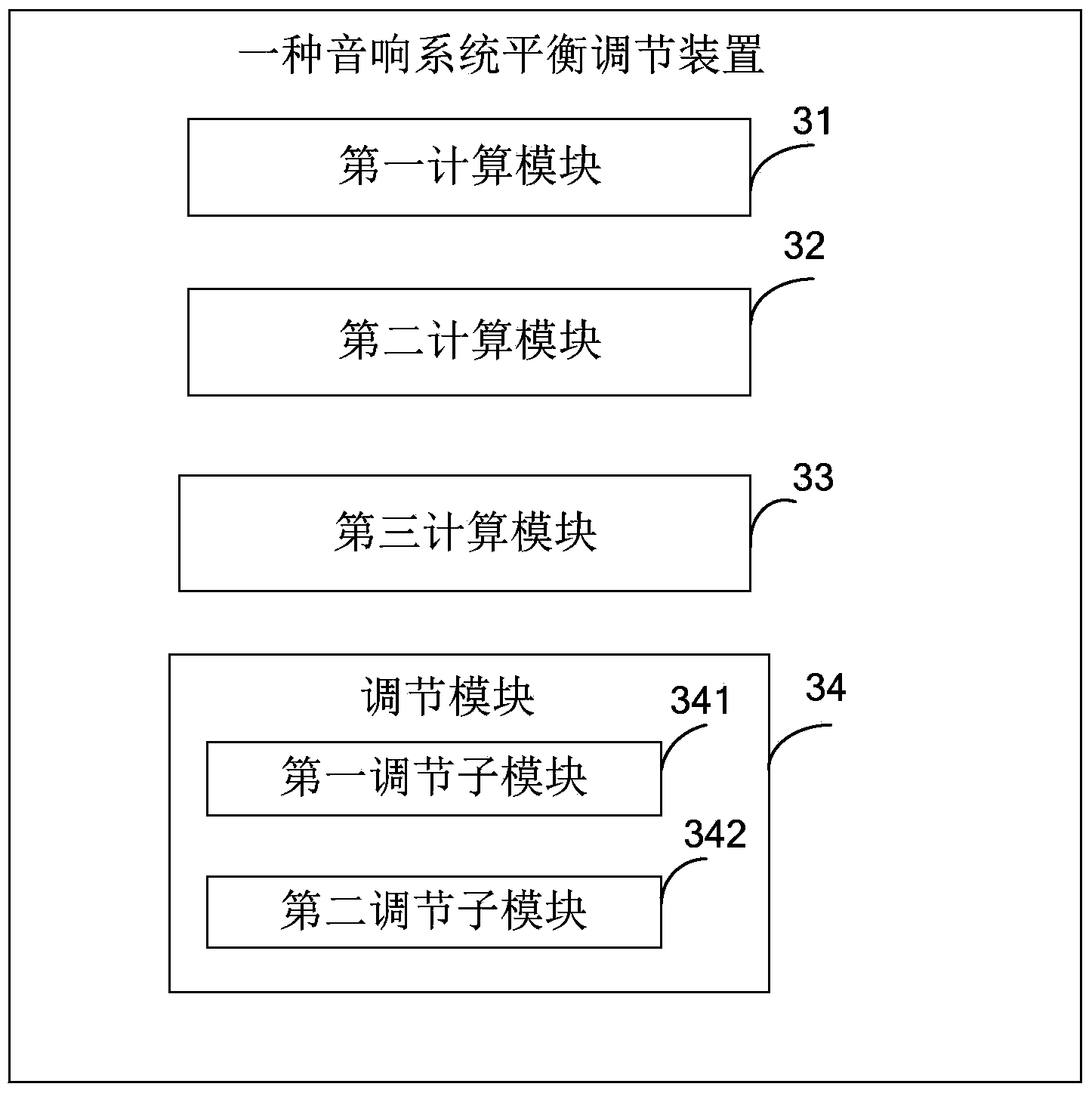

Audio system balance adjustment method and device

ActiveCN103945301AImprove balance adjustment effectSimple and fast operationFrequency/directions obtaining arrangementsRate parameterComputer science

The invention belongs to the technical field of audio systems, and particularly relates to an audio system balance adjustment method and device. The position of the best balance point of an audio system is calculated according to coordinates of audience positions, and the distances between all voice boxes and the best balance point position are calculated according to the positions of all the voice boxes; the standard distance is calculated according to the distances between all the voice boxes and the best balance point position, and finally according to the distances between all the voice boxes and the best balance point position, the standard distance, volume change rate parameters based on the distances and delay change rate parameters based on the distances, the volume and delay time of all the voice boxes are adjusted. Due to the fact that sound channel balance of the audio system is automatically adjusted according to the positions of audiences and positions of all the voice boxes, the balance adjusting effect is effectively improved, manual adjustment is not needed, and operation is simple.

Owner:TCL CORPORATION

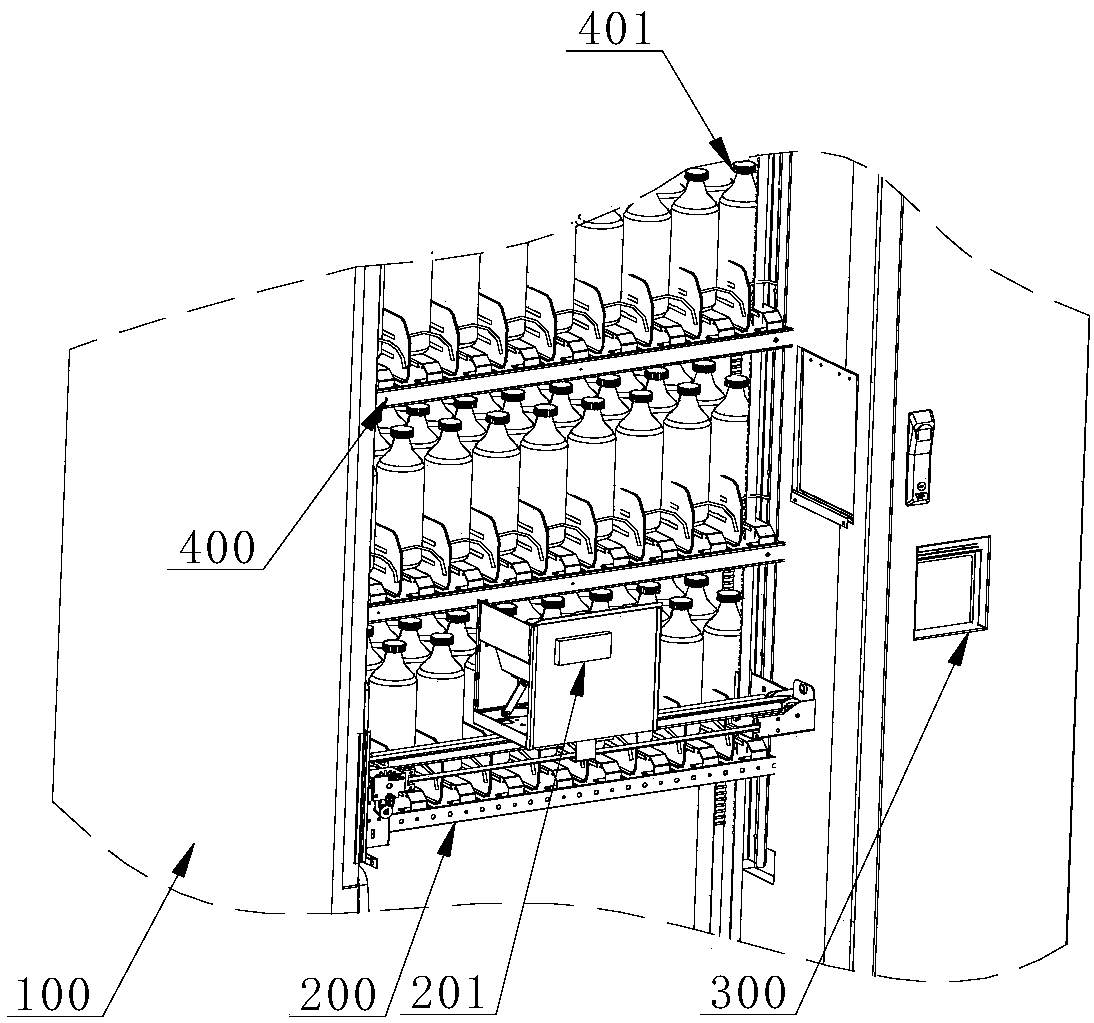

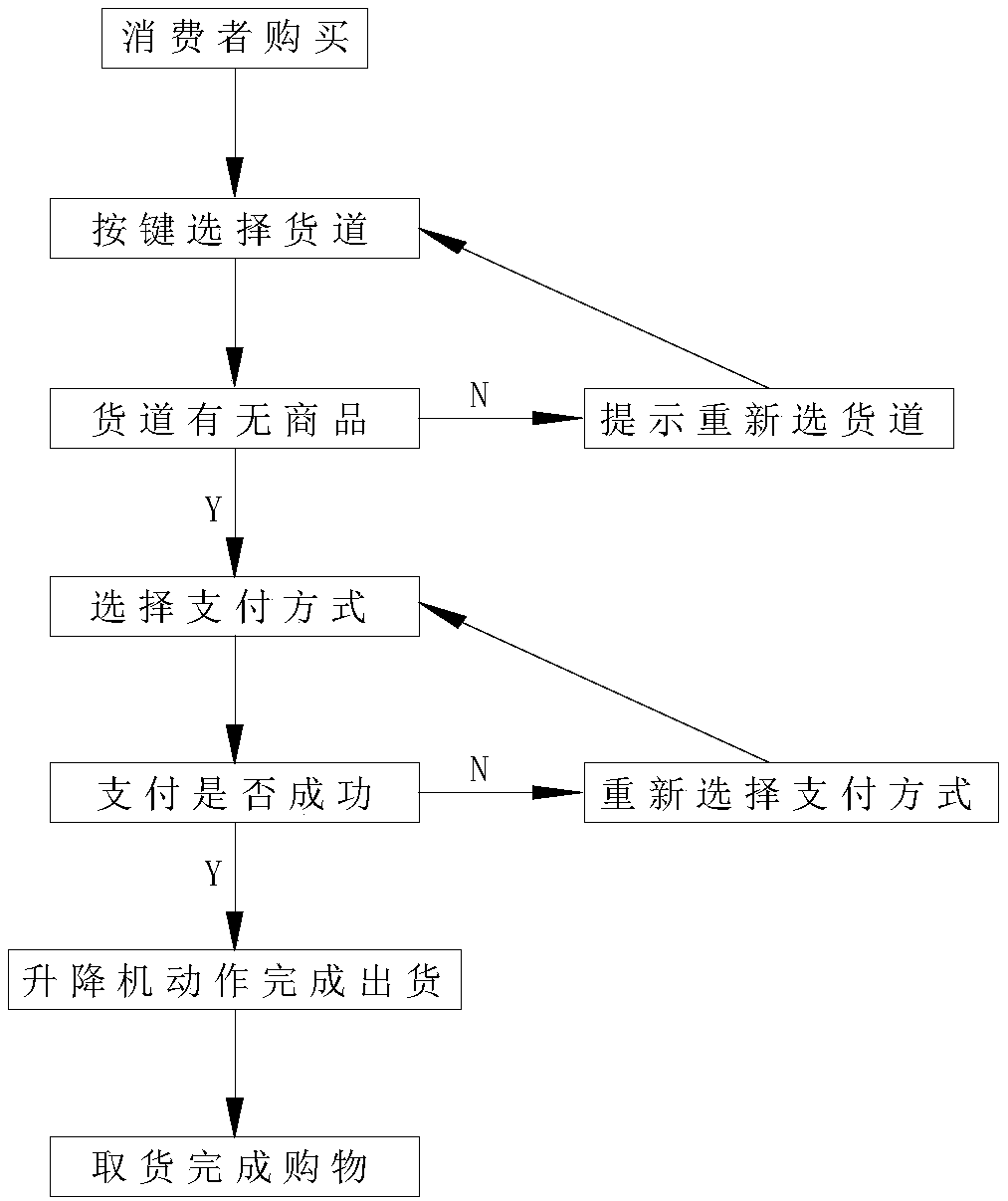

Intelligent inventory management method of vending machine with cargo receiving platform

PendingCN107730732AReal-timeRealize monitoringCoin-freed apparatus detailsApparatus for dispensing discrete articlesControl systemInventory management

The invention discloses an intelligent inventory management method of a vending machine with a cargo receiving platform. The method includes the steps: mounting ultrasonic distance measurement deviceson opposite cargo channels on the cargo receiving platform of the vending machine, and presetting standard distance values of cargo channel outermost commodities and cargo channel inventory state tables in a control system of the vending machine; controlling shelves and cargo channels of the cargo receiving platform to run one by one and the ultrasonic distance measurement devices to detect distances among outermost commodities of the cargo channels and the cargo receiving platform according to the shelves and the cargo channels one by one by the control system after replenishment once, or controlling the cargo receiving platform to move to selling channels and the ultrasonic distance measurement devices to measure the distances among outermost commodities of the selling channels and thecargo receiving platform by the control system after selling once; judging a fact that the cargo channels have cargoes and updating states of the cargo channels in the cargo channel inventory state tables when the detected cargo channel distance values are smaller than or equal to standard distance values; judging a fact that the cargo channels do not have cargoes and updating the cargo channel inventory state tables when the detected cargo channel distance values are larger than the standard distance values.

Owner:HUNAN KIMMA INTELLIGENT EQUIP MFR

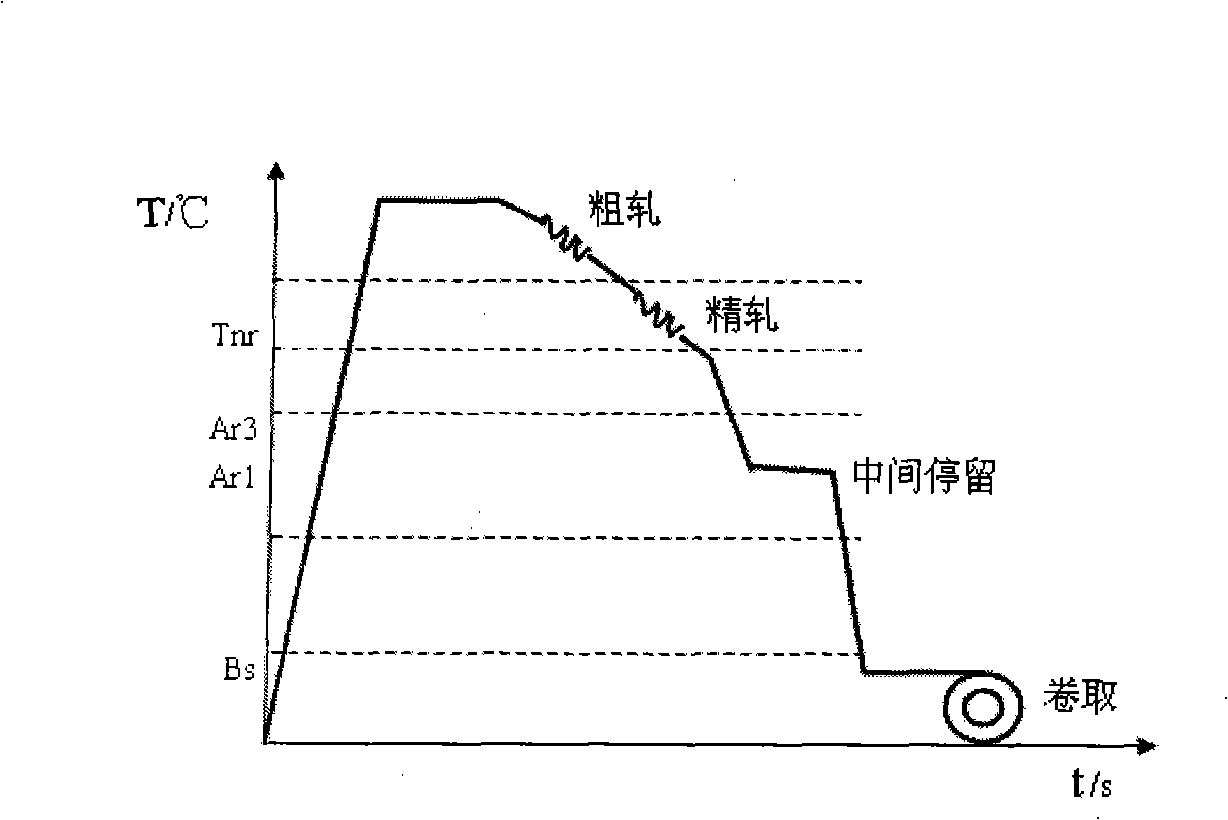

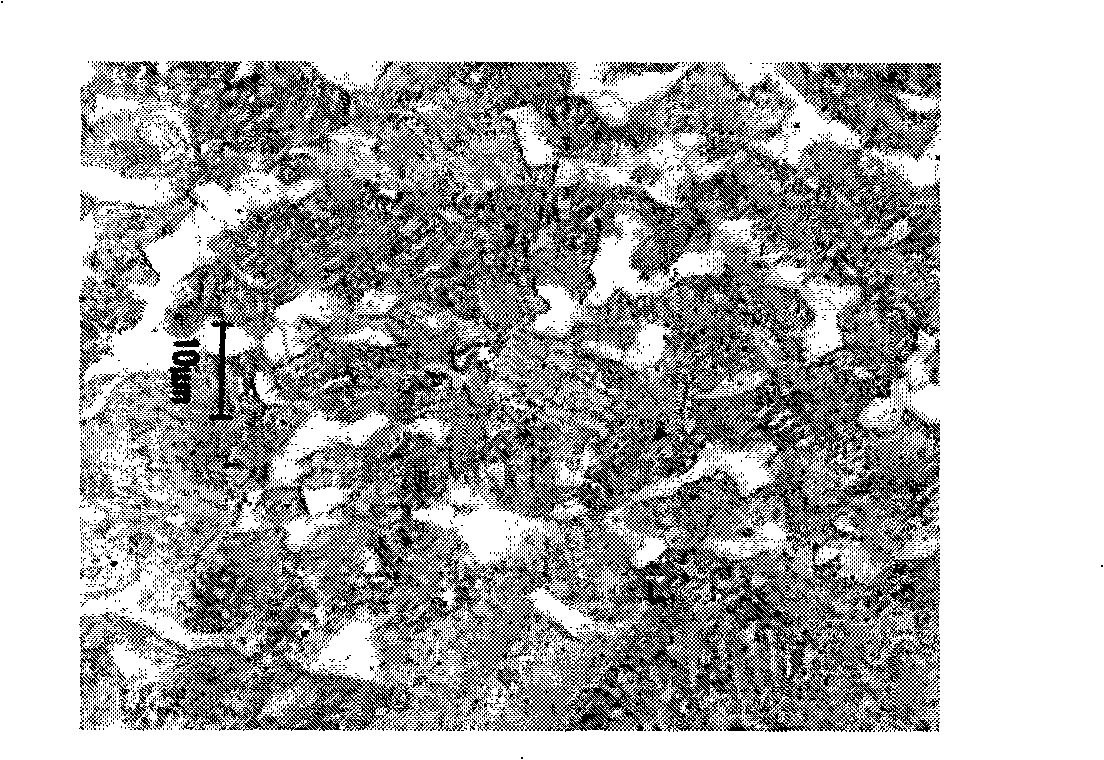

Hot-rolled polyphase steel plate and method for manufacturing same

ActiveCN101270436AGood extensibilityGood formabilityTemperature control deviceSheet steelYield ratio

The invention provides a hot-rolled multiphase steel plate and a preparation method thereof. The invention has the advantages of the economical, reasonable, environmental-friendly design of steel component, being favorable for effective utilization and recycling of resources, being implemented and controlled easily, the simple and convenient process control, the high strength of steel plate and the good performance of cold bending and welding. The thickness of plate is 2.5 to 6 milimeter, the tensile strength of the hot-rolled steel plate is larger than 1000Megapascal, the yield strength is greater than or equal to 500Megapascal, the yield ratio is low, the minimum yield ratio is equal to 0.51 and the maximum is not higher than 0.80, the elongation A80 i.e. the sample of 80 milimeter of JIS13A standard distance is greater than or equal to 11 percent and the highest value reaches 20 percent, and the longitudinal direction and the transverse direction of cold bending meets the requirement of not cracking when d is equal to 4t. The microstructure is mainly Bainite and Martensite of higher than 90 percent and few ferrite of possible residual Austenite.

Owner:BAOSHAN IRON & STEEL CO LTD

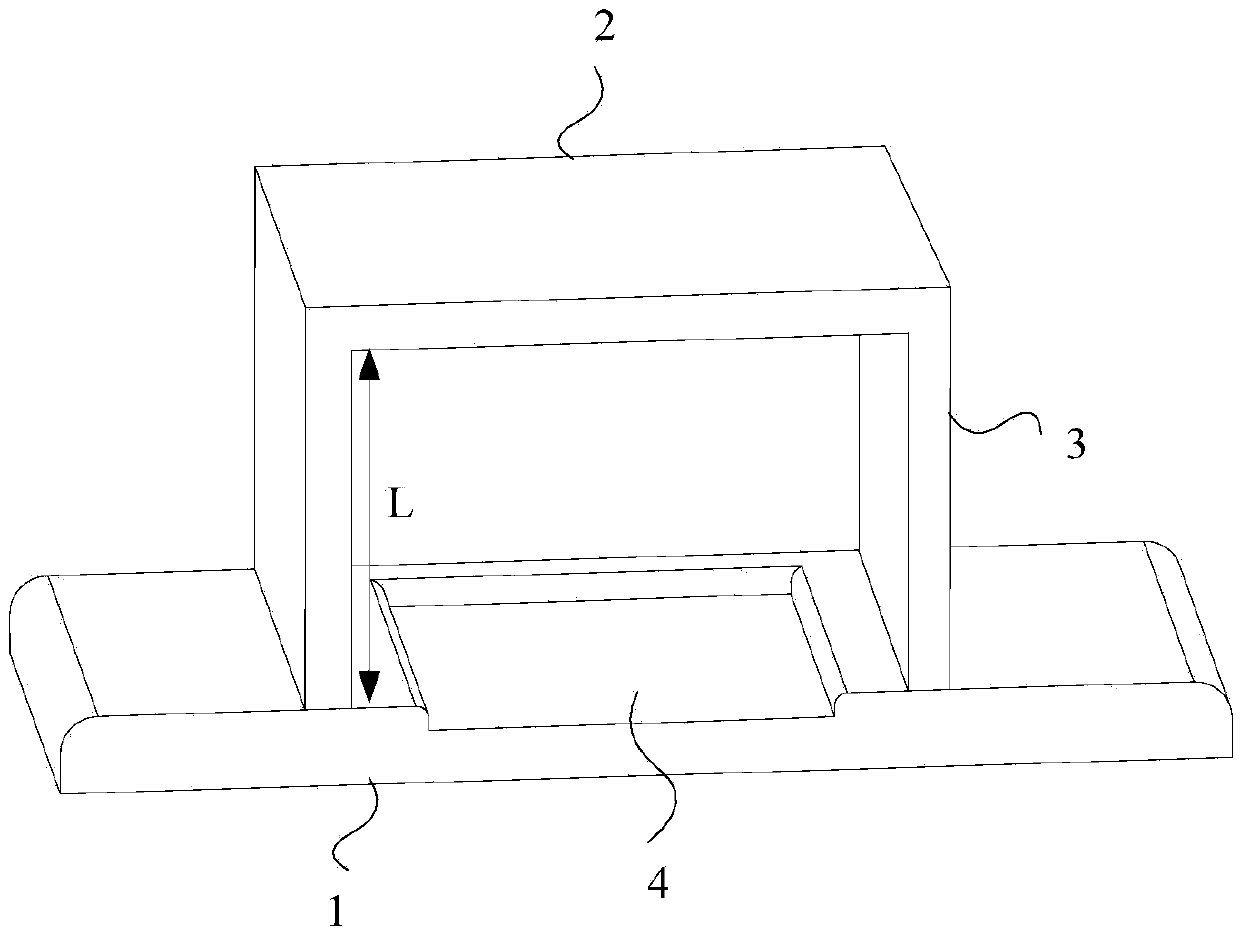

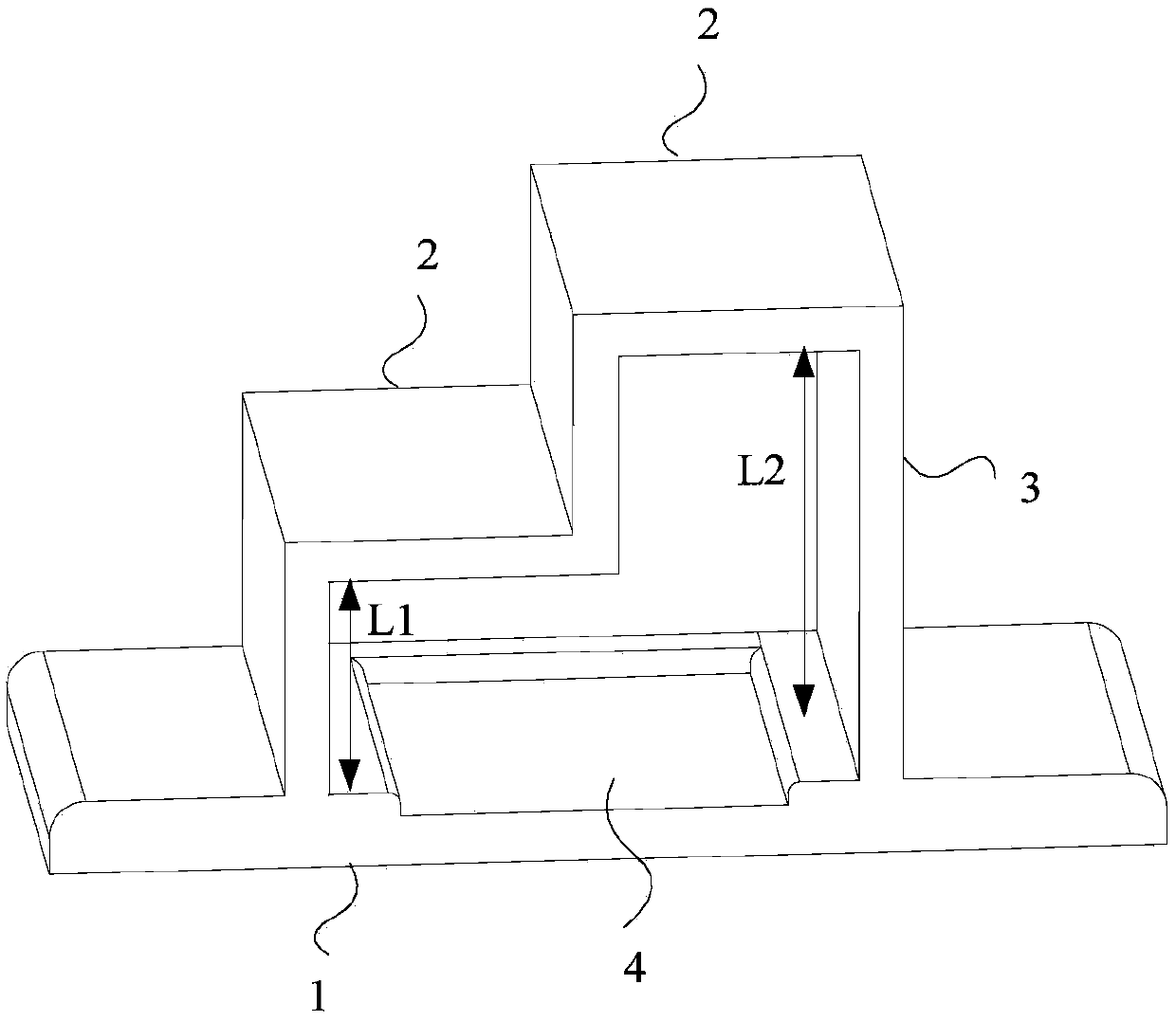

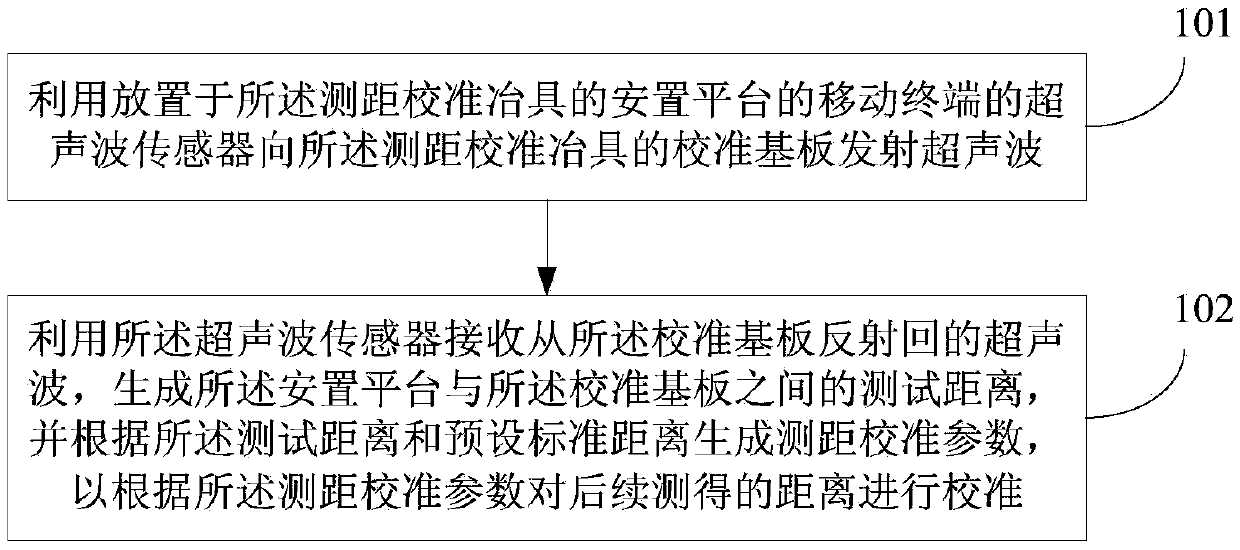

Range-finding calibration tool and range-finding calibration method and device

The invention discloses a range-finding calibration tool and a range-finding calibration method and device. The range-finding calibration tool comprises a placing platform and a calibration substrate over the placing platform. The placing platform and the calibration substrate are in parallel. A mobile terminal is placed on the placing platform in order that an ultrasonic sensor of the mobile terminal emits ultrasonic to the calibration substrate. The calibration substrate is used for reflecting received ultrasonic back to the ultrasonic sensor of the mobile terminal in order that the mobile terminal may generate a test distance between the placing platform and the calibration substrate and generates a range-finding calibration parameter according to the test distance and a preset standard distance. According to the technical scheme provided by the embodiment of the invention, the range-finding calibration tool calibrates the range-finding function of the ultrasonic sensor of the mobile terminal and increases the range-finding accuracy of the ultrasonic sensor of the mobile terminal after the mobile terminal is used.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

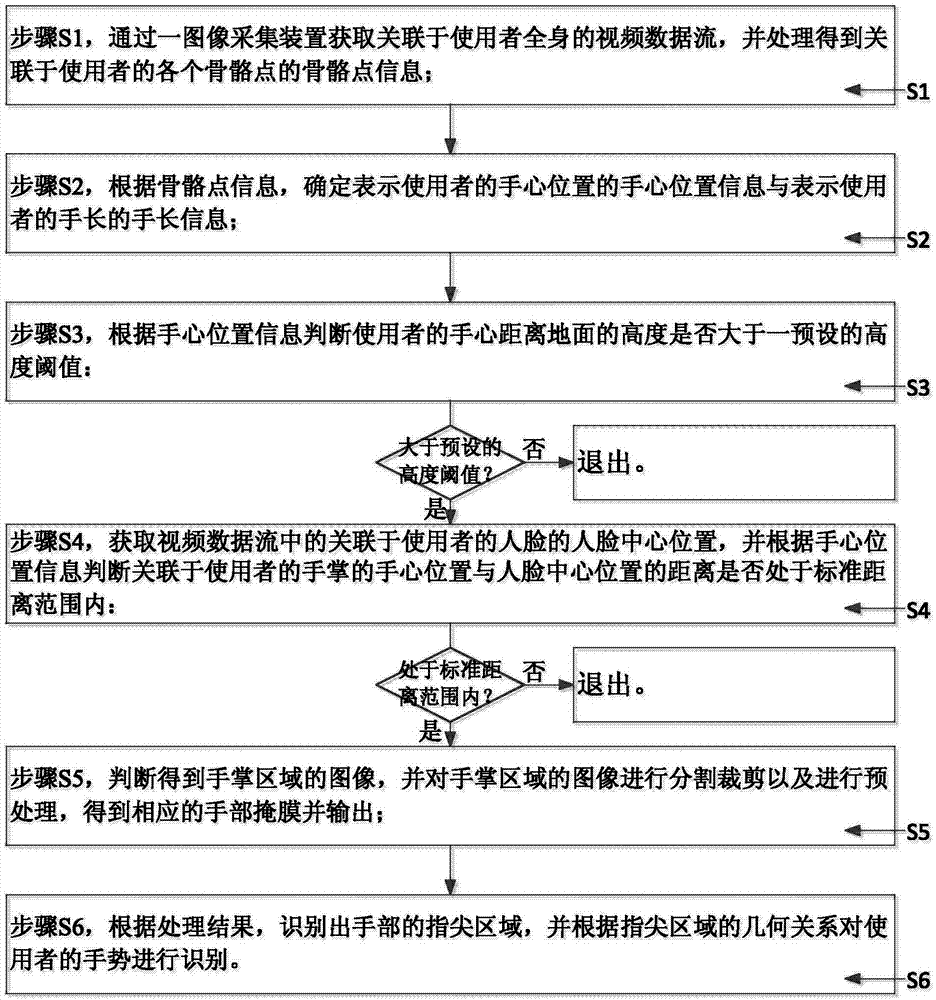

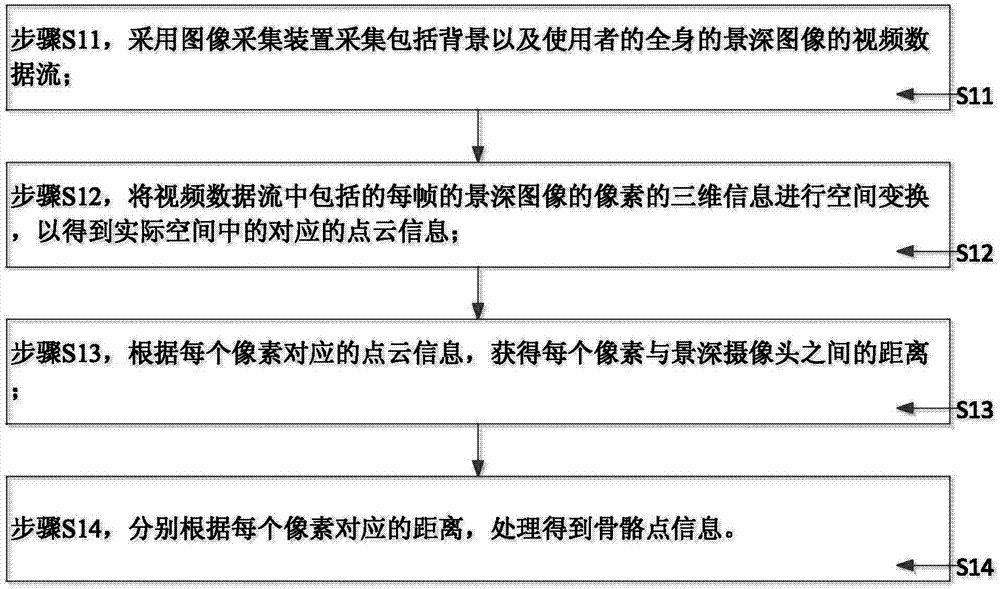

Gesture recognition method taking face as reference

InactiveCN106971130AImprove accuracyAvoid gesture command inputCharacter and pattern recognitionData streamComputer vision

The invention discloses a gesture recognition method taking face as reference, and belongs to the technical field of gesture recognition. The method includes the following steps: obtaining video data flow and obtaining skeleton point information through processing; according to the skeleton point information, determining palm position information and hand length information of hand length of a user; judging whether the height of the palm of the user away from the ground is larger than a preset height threshold value according to the palm position information: if no, exiting; obtaining the face central position in the video data flow, and judging the distance between the palm position and the face central position is in a standard distance range according to the palm position information: if no, exiting; obtaining an image of a palm area through judgment and performing segmentation, cutting and preprocessing, thereby obtaining a hand mask; and recognizing a fingertip area and then recognizing a gesture. The beneficial effects of the abovementioned technical scheme are that back influence is eliminated, and the circumstances that some invalid gestures are mistaken for gesture instruction input of a user are avoided, thereby improving the accuracy of gesture recognition.

Owner:YUTOU TECH HANGZHOU

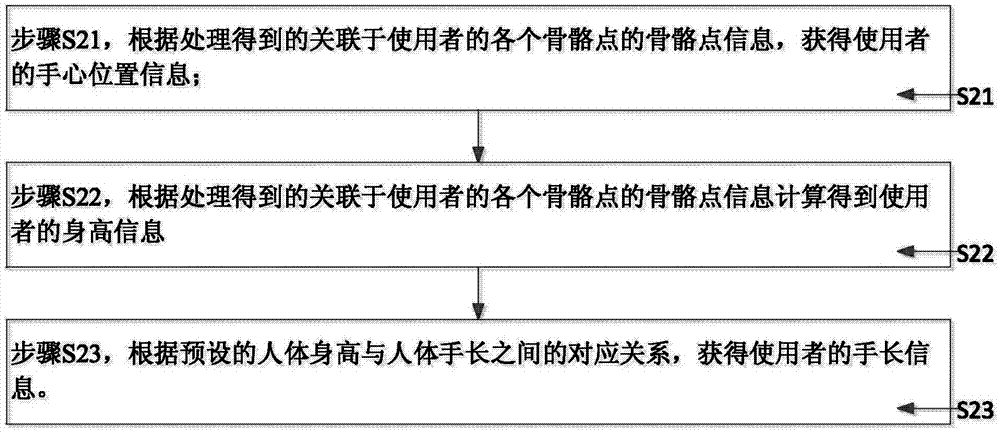

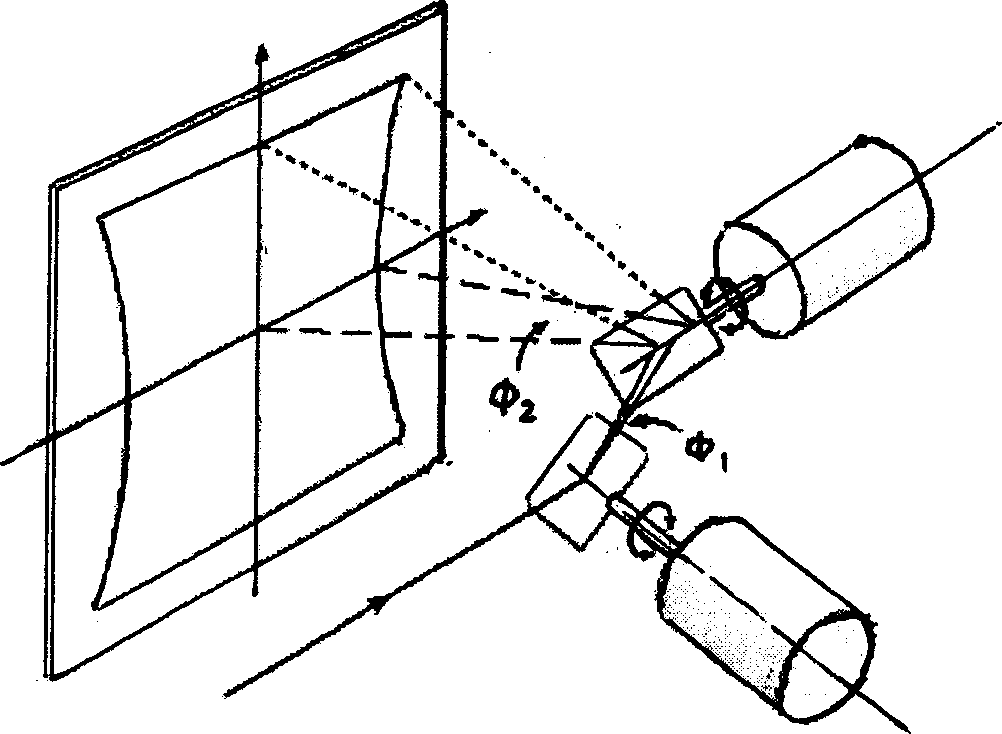

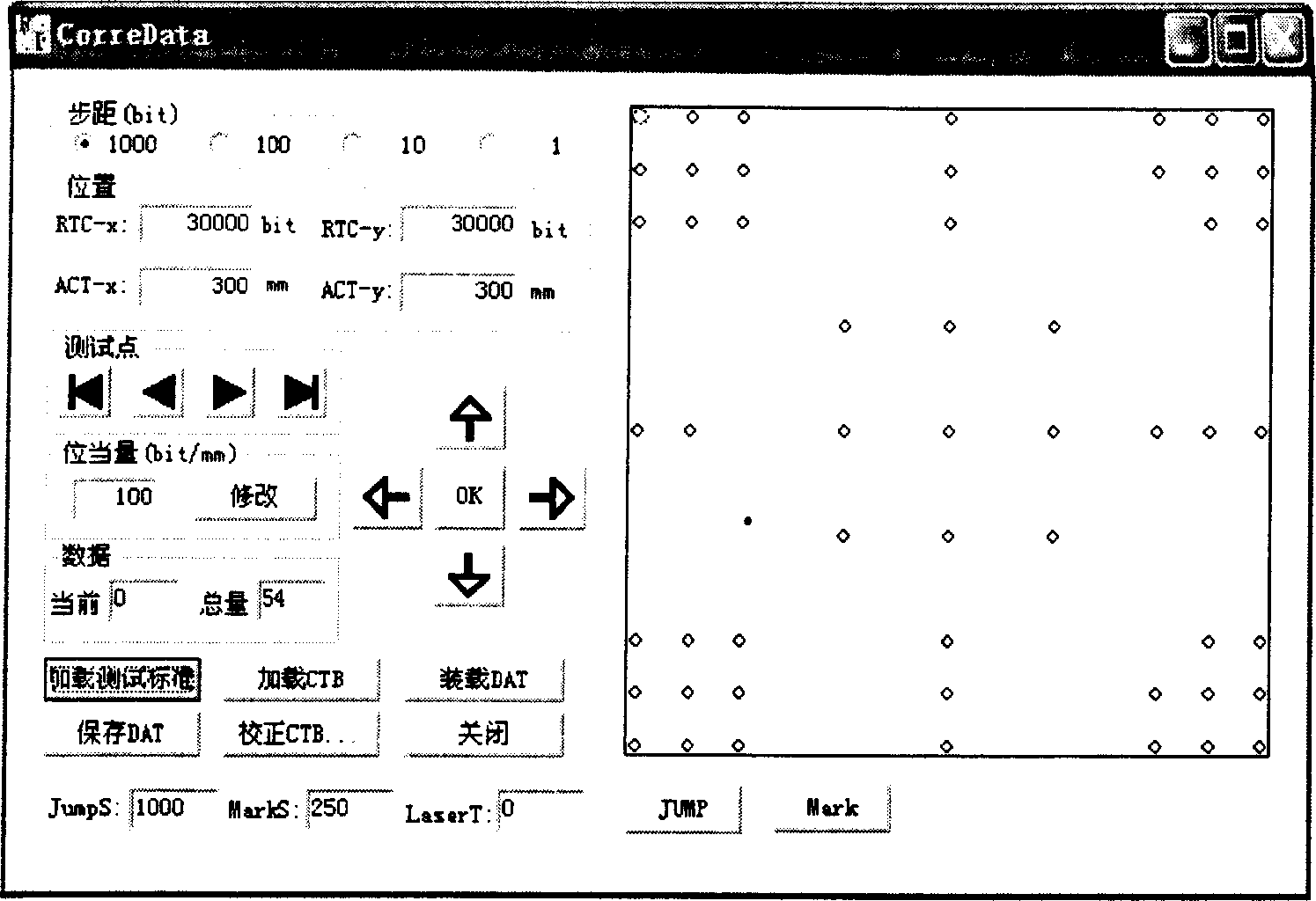

Accuracy correction for light-curing fast formation

A precision correcting method for the fast shaping technology by optical solidifying includes such steps as arranging a calibrating plate on a lattice plate with a standard distance from the edge of resin bath and coinciding with the shaping plane of fast photosolidifying shaping machine, and controlling a scanner by computer to correct each dots one by one. Said computer has a movement control card and a correcting program for creating a correcting file.

Owner:NANJING HONNY 3 DIMENSIONAL TECH

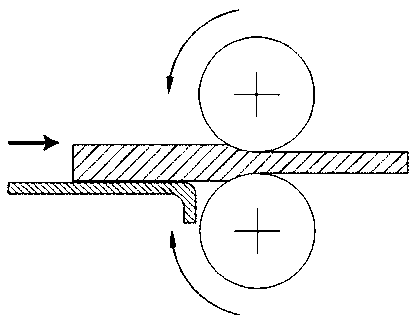

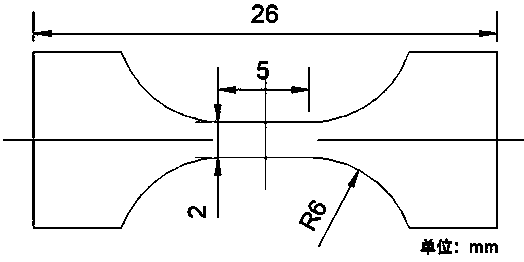

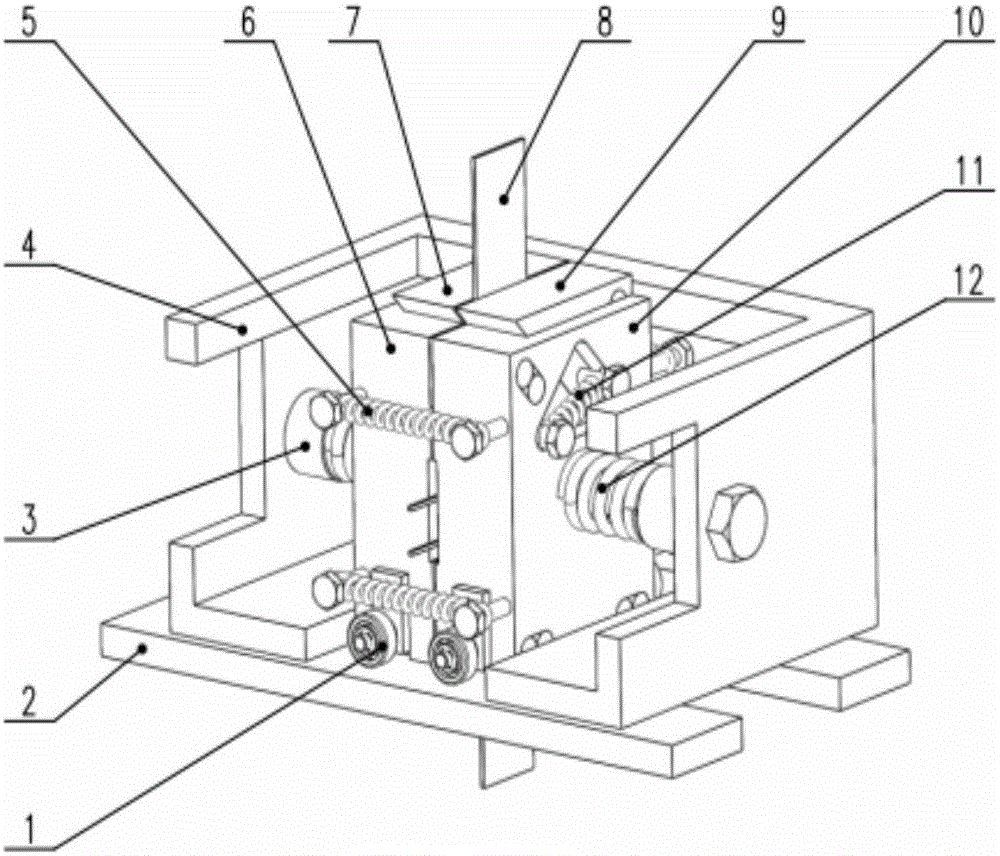

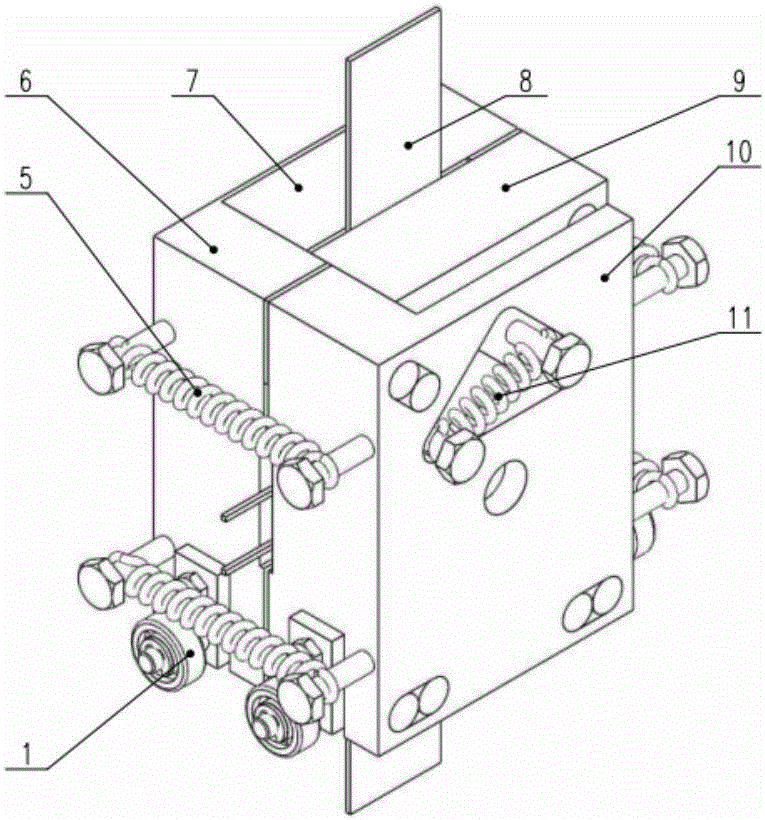

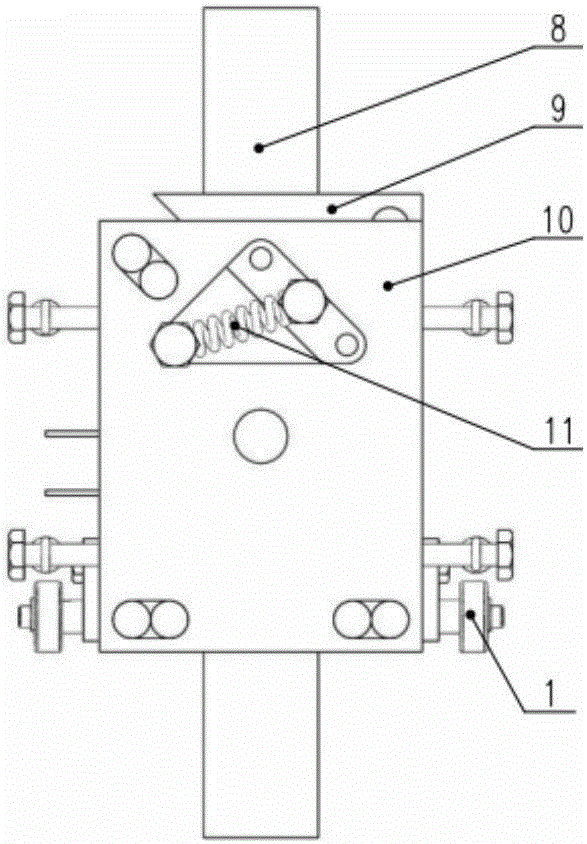

Asymmetric clamping device and experimental method for sheet compressing

ActiveCN106353181AAvoid wrinklesReliable side pressureMaterial strength using tensile/compressive forcesWrinkle skinExperimental methods

An asymmetric clamping device and experimental method for sheet compressing are provided; two clamp plates of the asymmetric clamping device are positioned in retaining grooves in a center spring support baseplate, lateral pressure is applied to a sheet through the clamp plates and sliders such that the sheet wrinkles in the thickness direction and loses stability in the width direction; two return springs are each fixed between the corresponding clamp plate and slider; tension springs are connected to the lateral sides of the two clamp plates to provide uniform symmetric pressure for the clamp plates; lateral pressure is applied through the springs, a sample is given planar clamping force through the clamping device, the sample is kept moving evenly in the thickness direction, it is guaranteed that a clamping gap may automatically adjust with changes in sheet thickness; a slider movement area is positioned in a sample non-standard distance segment, the transverse frictional force on the sample may not affect a standard distance segment, and the impact of slider movement induced width-directional frictional force upon experimental results is eliminated; the invention provides three travel options, and various sheet tensioning and compressing experimental needs can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

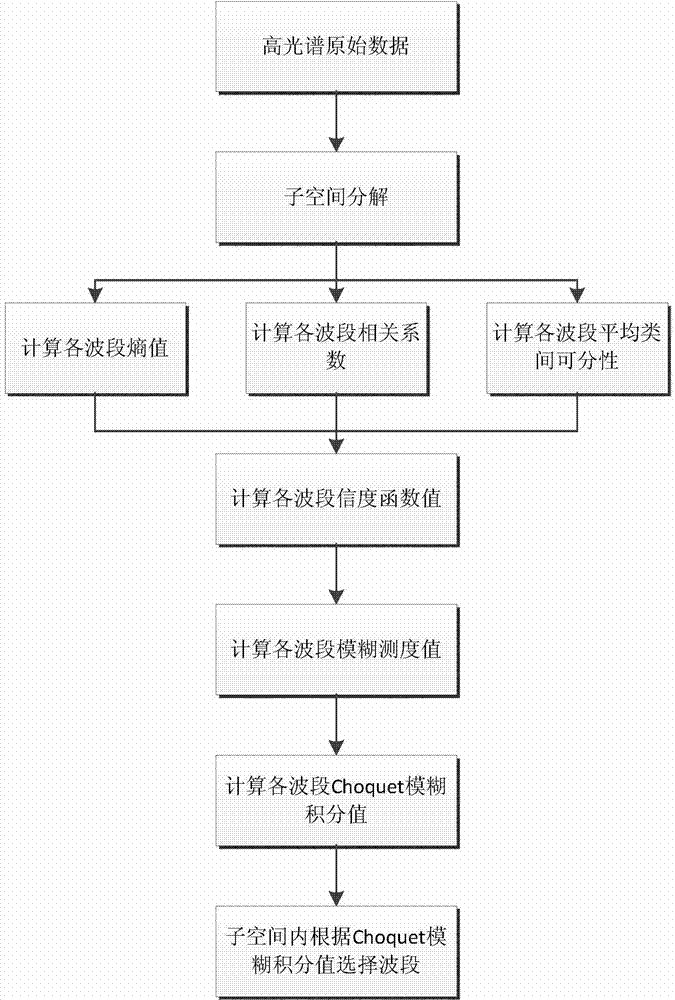

Multi-index fused hyperspectral remote sensing image dimensionality reduction method

InactiveCN103886334AAvoid lossReasonable distributionCharacter and pattern recognitionCorrelation coefficientComputer science

The invention discloses a multi-index fused hyperspectral remote sensing image dimensionality reduction method. Dimensionality reduction can be efficiently and rapidly achieved through a band selection method. At first, subspace decomposition is carried out on obtained hyperspectral remote sensing images, the entropy and the standard distance between mean values of a band and correlation coefficients between bands are fused by means of a method based on Choquet fuzzy integral in each subspace, and then band selection is carried out according to unified indexes to achieve data dimension reduction.

Owner:HOHAI UNIV

Three-dimensional video display and method for creating supply video supplied to three-dimensional video display

InactiveUS7180478B2Efficient workReduce the row spacingCathode-ray tube indicatorsOptical light guidesStereoscopic videoLiquid-crystal display

There is provided a stereoscopic video display that enables a viewer to recognize a more real stereoscopic video.A light source device 2 comprises a backlight 21 and a pinhole array plate 22. A liquid crystal display panel driver 5 feeds a pixel driving signal to a liquid crystal display panel 3, to form a pixel region 3a composed of a plurality of pixels respectively corresponding to pinholes 22a. Each of the pixels composing the pixel region 3a controls an amount of light transmission with respect to a light beam in each direction from the corresponding pinhole 22a. Consequently, the intensity of the light beam in each direction is reproduced. Lines respectively connecting the centers of the pinholes 22a and the centers of the pixel regions 3a are not parallel to one another, and are so set as to cross at one point of a position corresponding to the standard distance between the video display panel 3 and a viewer Z. Therefore, the light beams are efficiently concentrated at a standard viewing position, thereby making it possible to make the viewer Z recognize a more real stereoscopic video.

Owner:SANYO ELECTRIC CO LTD

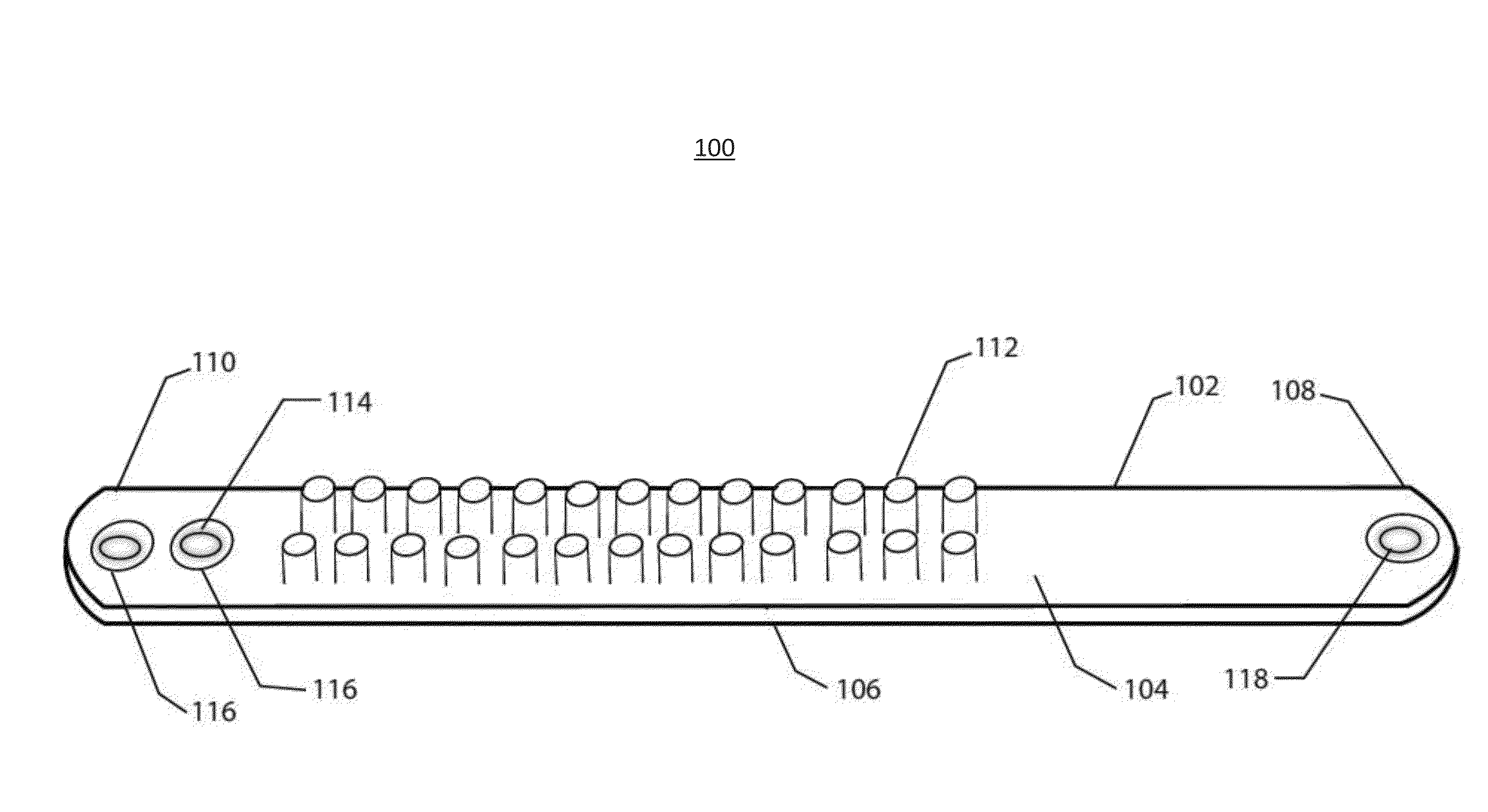

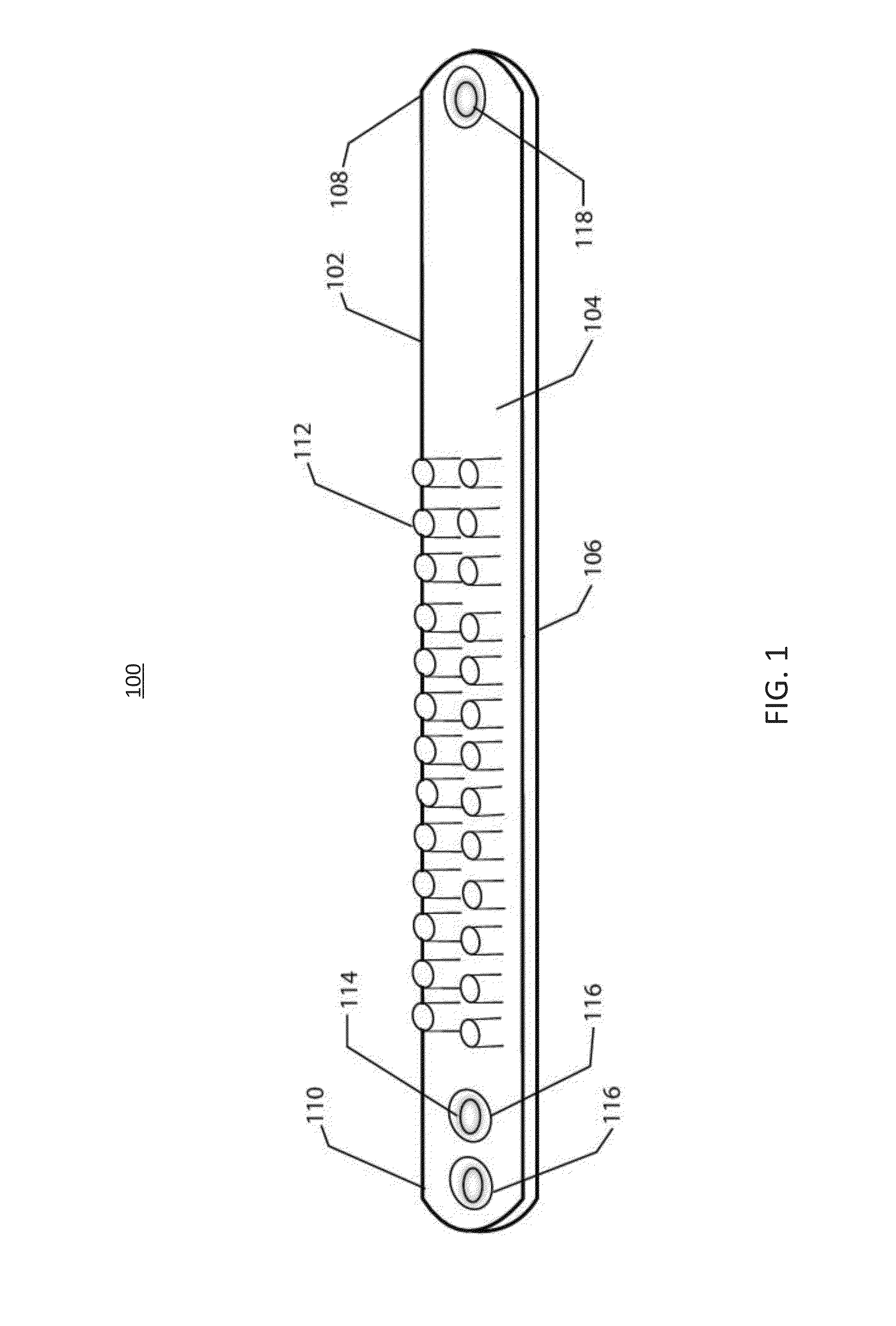

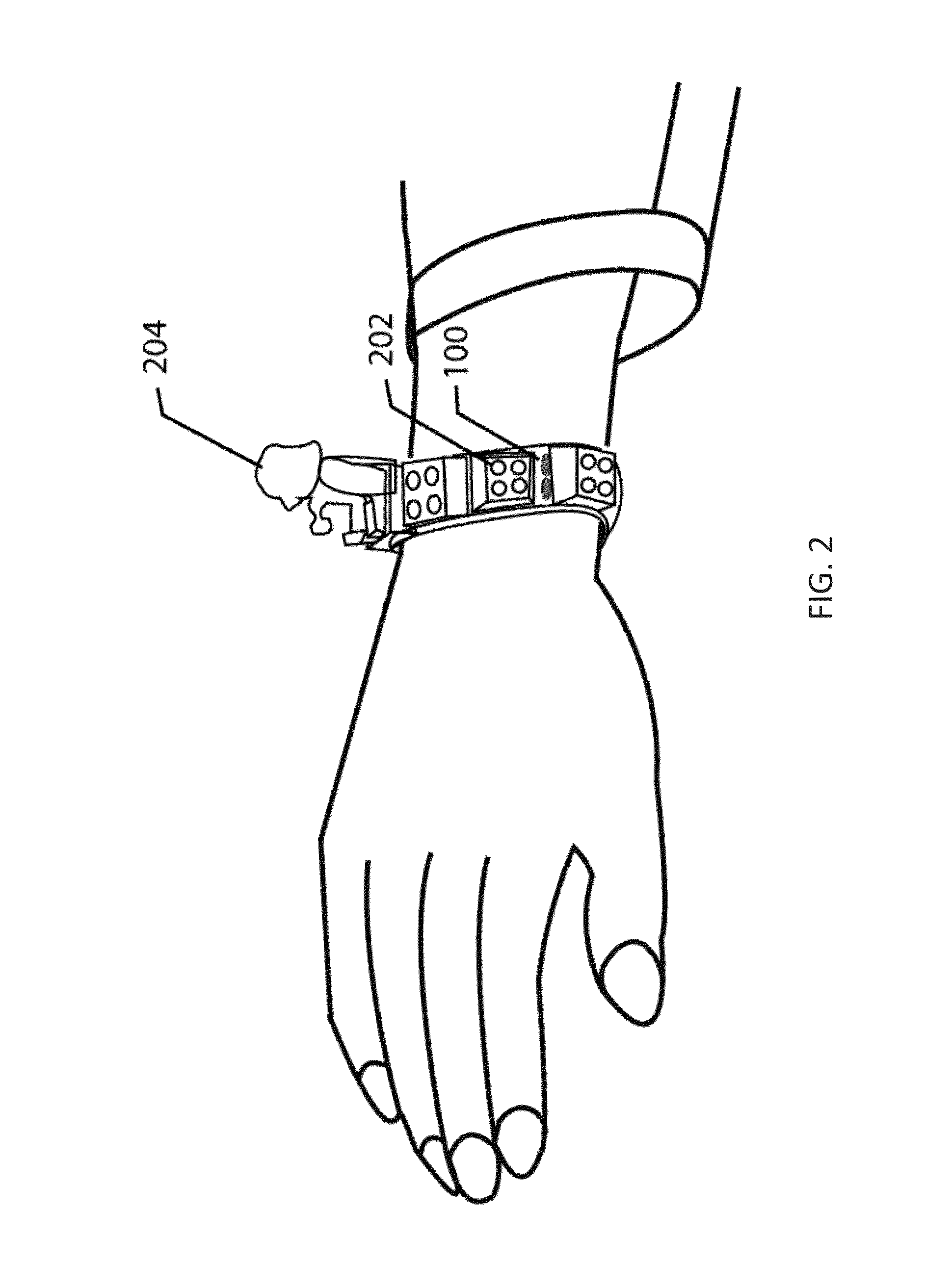

User configurable wearable device

InactiveUS20150296935A1Coupling device connectionsElectric discharge tubesEngineeringStandard distance

Owner:PLEYING

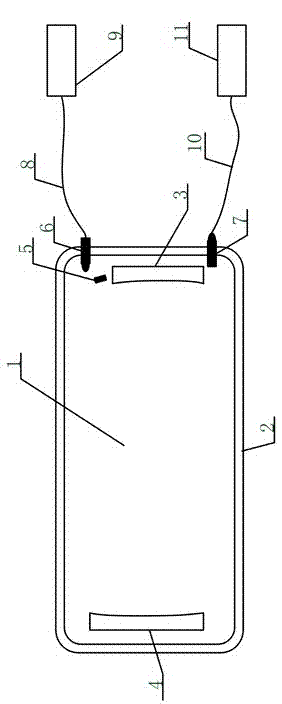

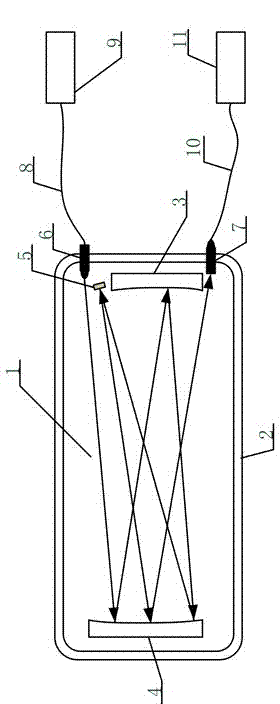

Long-optical-path gas detection device with fine adjustment mechanism

ActiveCN103487401AReduce volumeEasy to detectColor/spectral properties measurementsEngineeringGas chamber

The invention relates to a long-optical-path gas detection device with a fine adjustment mechanism. The long-optical-path gas detection device comprises a container, wherein the container is internally provided with an airtight gas chamber; a first concave mirror and a second concave mirror which are arranged opposite to an emitting surface are arranged in the gas chamber of the container; a fine adjustment reflecting mirror is arranged on one side of the first concave mirror; a parallel light emitter and a photoelectric sensor are arranged on the container and positioned on the two sides of the first concave mirror; the parallel light emitter is close to the fine adjustment reflecting mirror; a light source emitting end of the parallel light emitter and a light ray receiving end of the photoelectric sensor stretch into the gas chamber. The long-optical-path gas detection device adopts a multiple reflection method to reduce the volume of the gas chamber and improve the detection capability of an instrument. The fine adjustment reflecting mirror can change the path of reflected light and reflect back the reflected light again, so the effective optical path can be increased and the standard distance effect can be avoided.

Owner:HENAN RELATIONS

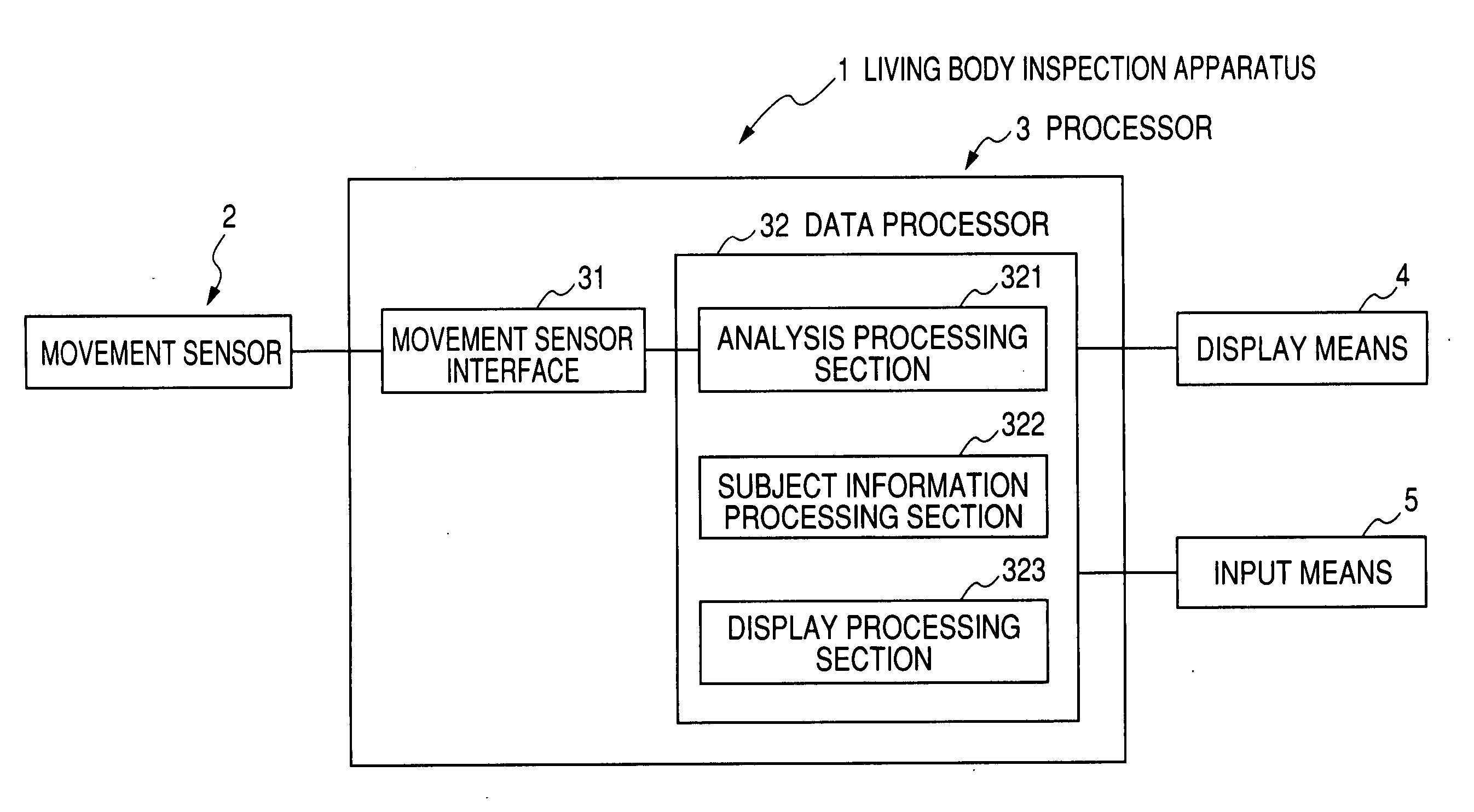

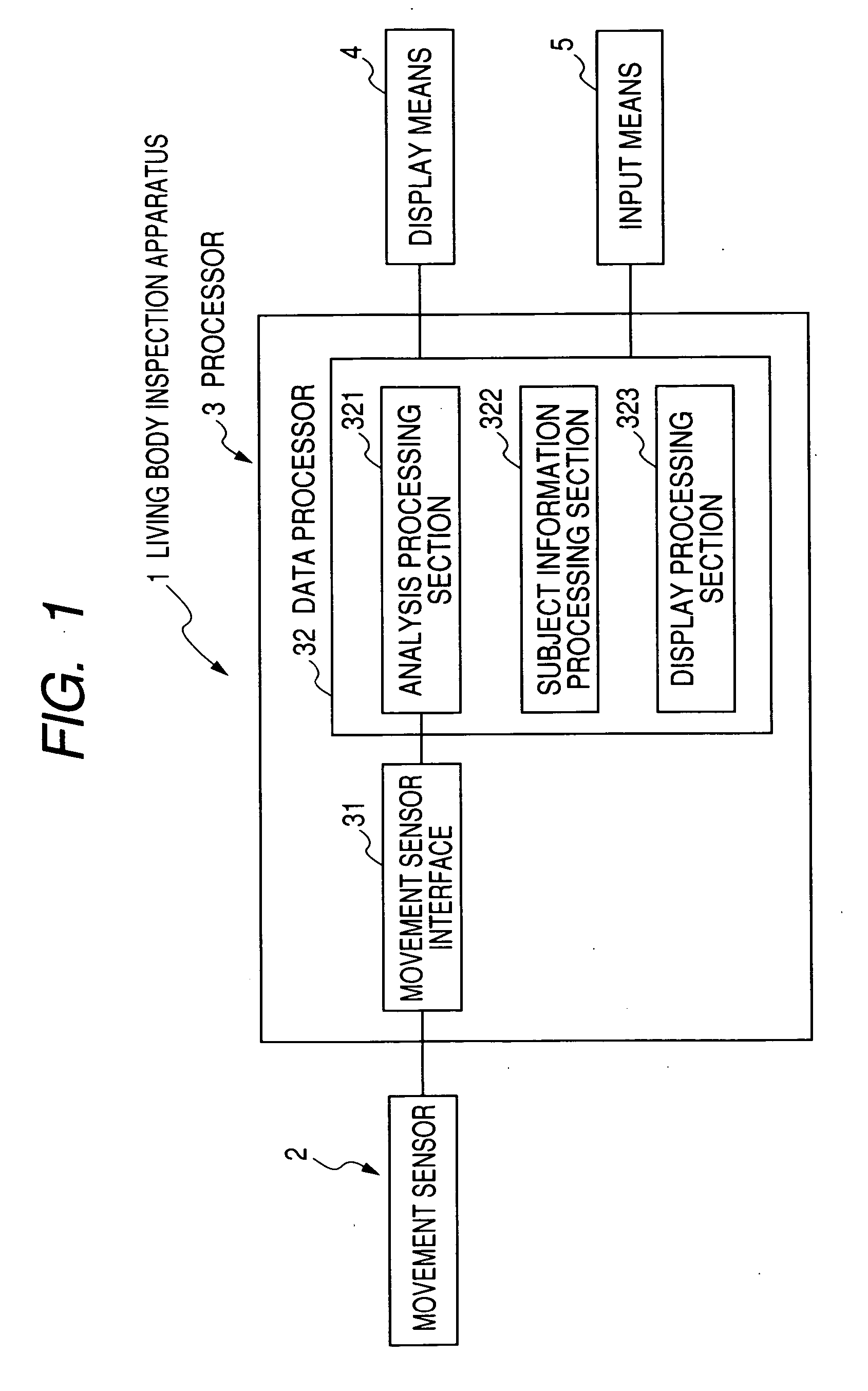

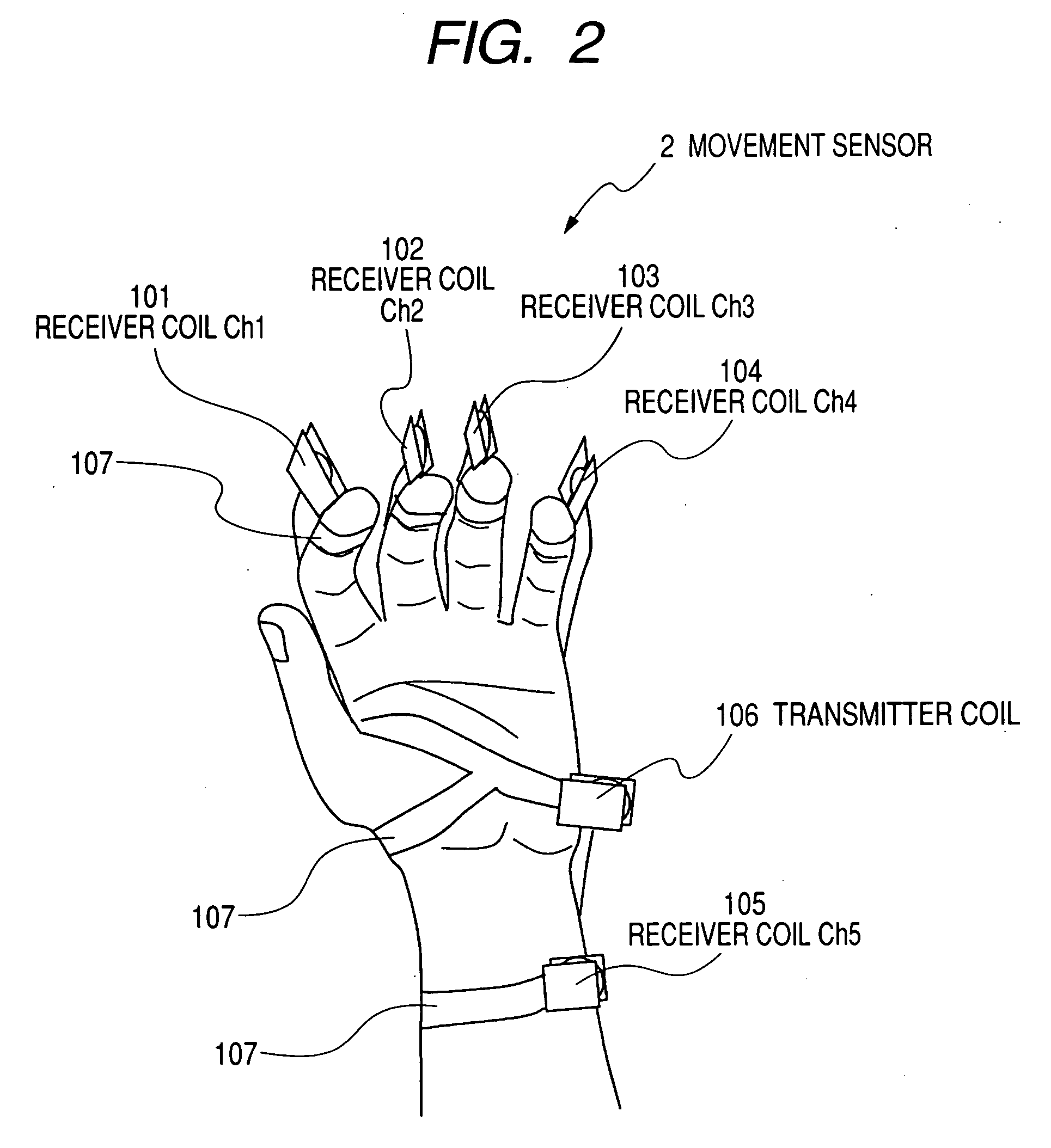

Living body inspection apparatus

A living body inspection apparatus which quantitatively evaluates timings of movements (bending and stretching) of fingers. The apparatus includes: a movement sensor including a transmitter coil for generating a magnetic field and a plurality of receiver coils for receiving the generated magnetic field from the transmitter coil; analyzing means which analyzes time-series waveform data acquired from the movement sensor; and display means which displays a result of analysis made by the analyzing means. For comparison of waveform data, the analyzing means includes distance waveform generating means for generating distance waveforms corresponding to the waveform data, and standard point generating means for generating standard points based on standard distances in the distance waveforms.

Owner:HITACHI LTD

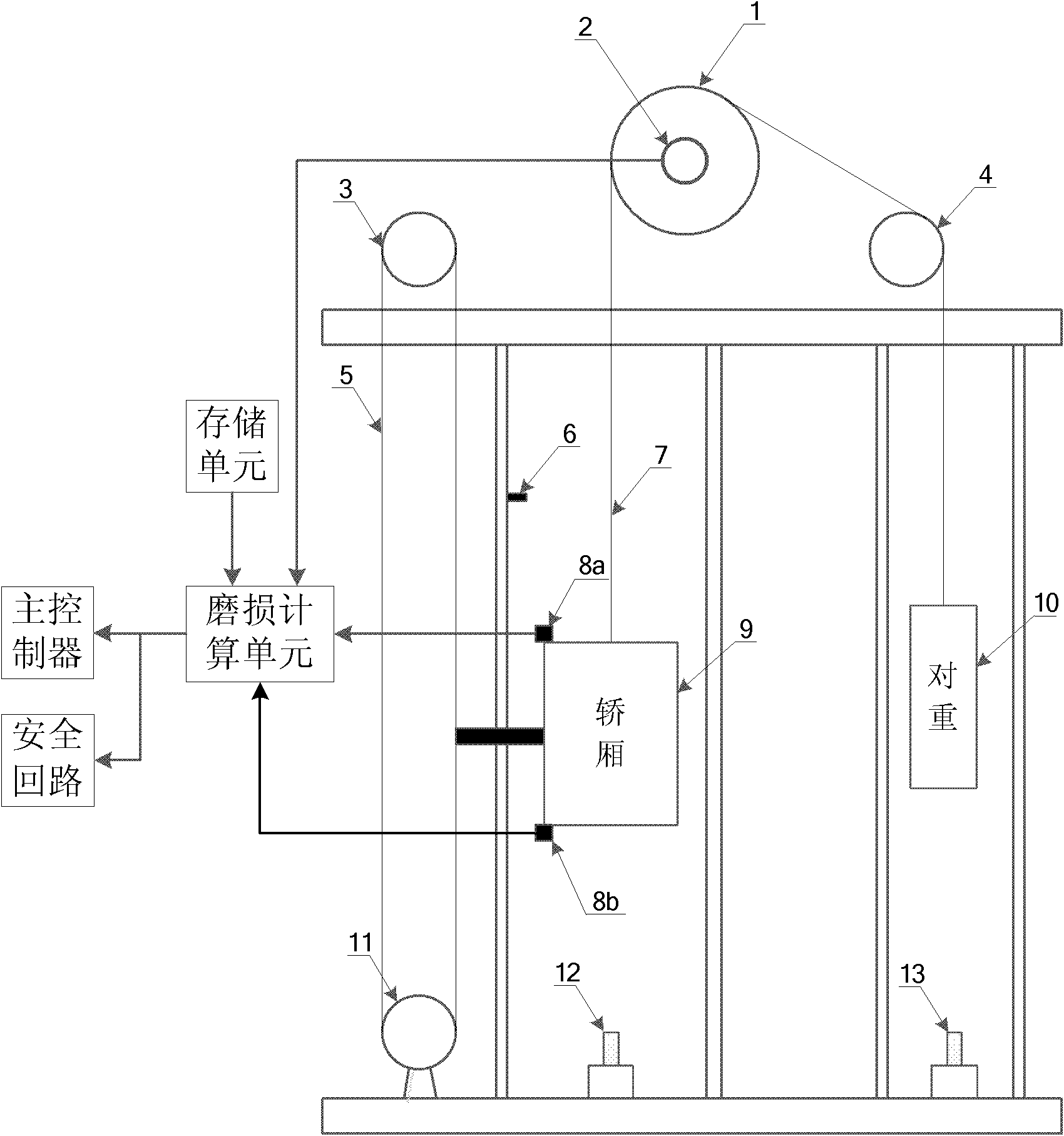

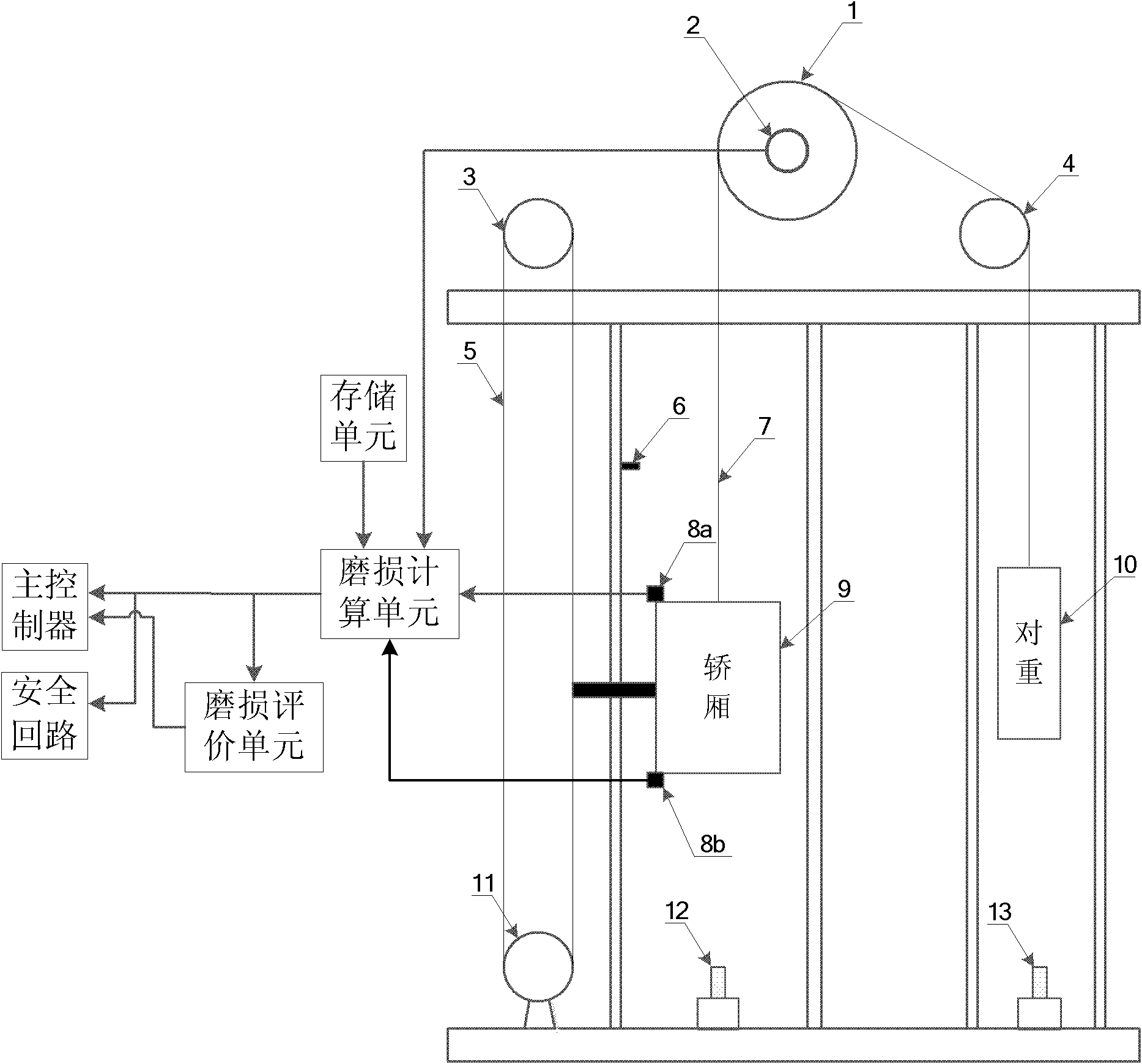

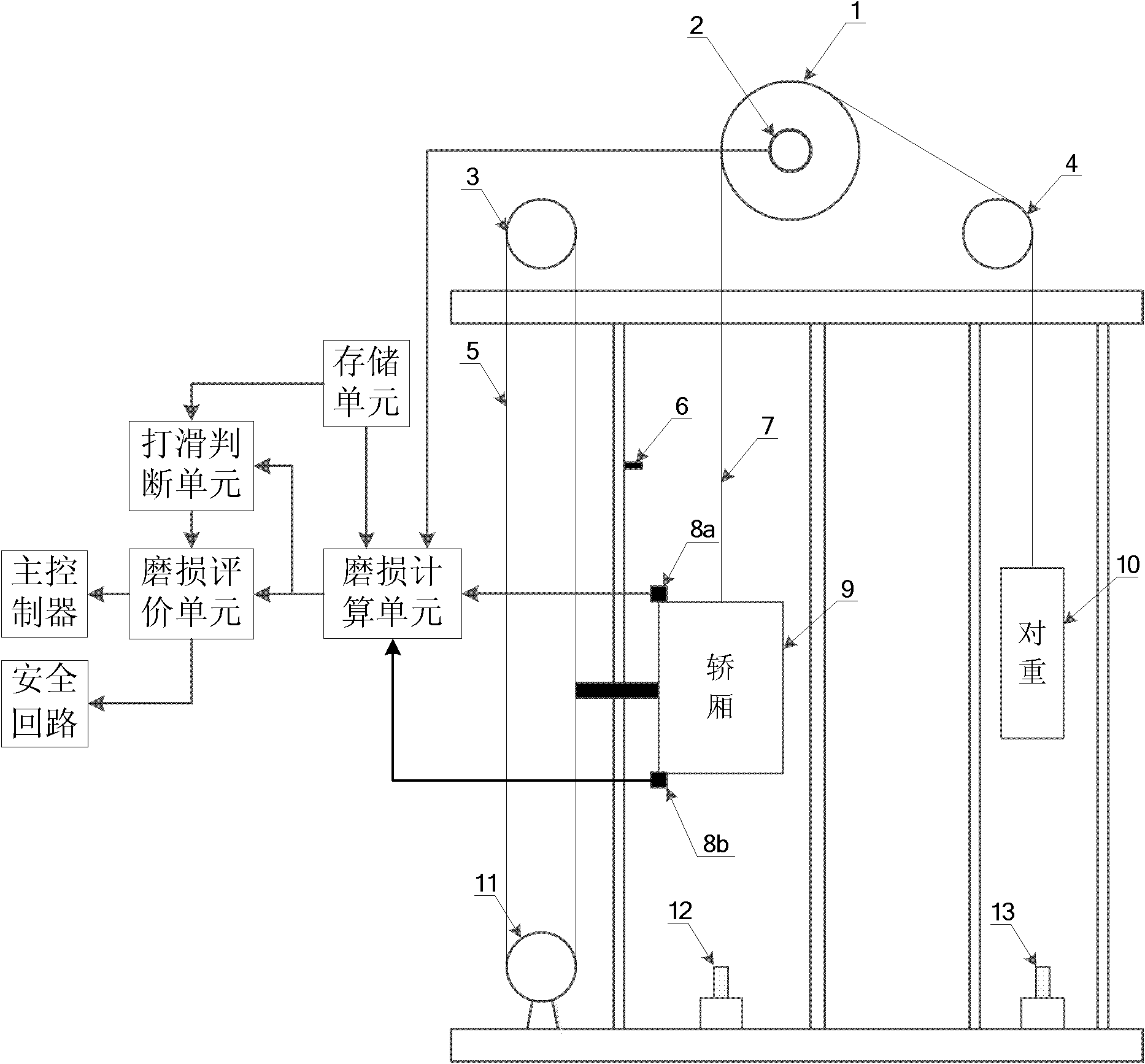

Wear detection device for elevator driving rope sheave

The invention discloses a wear detection device for an elevator driving rope sheave. The wear detection device comprises an angular displacement detection device, an angular displacement detection start-stop determining device, a storing unit, a wear calculating unit, a slippage judging unit and a wear evaluating unit, wherein the wear calculating unit is used for calculating the wear of the driving rope sheave according to the angular displacement of the driving rope sheave detected by using the angular displacement detection device in a time interval from the starting moment to the stopping moment of angular displacement detection determined by using the angular displacement detection start-stop determining device, and distances among standard intervals in the storing unit. According to the wear detection device for the elevator driving rope sheave disclosed by the invention, a uniform standard distance can be set for all elevators, the wear detection result accuracy of the driving rope sheave is high, the special situation of slippage existing between the elevator driving rope sheave and an elevator driving rope can be coped with, and corresponding evaluations can be made for a wear detection result.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

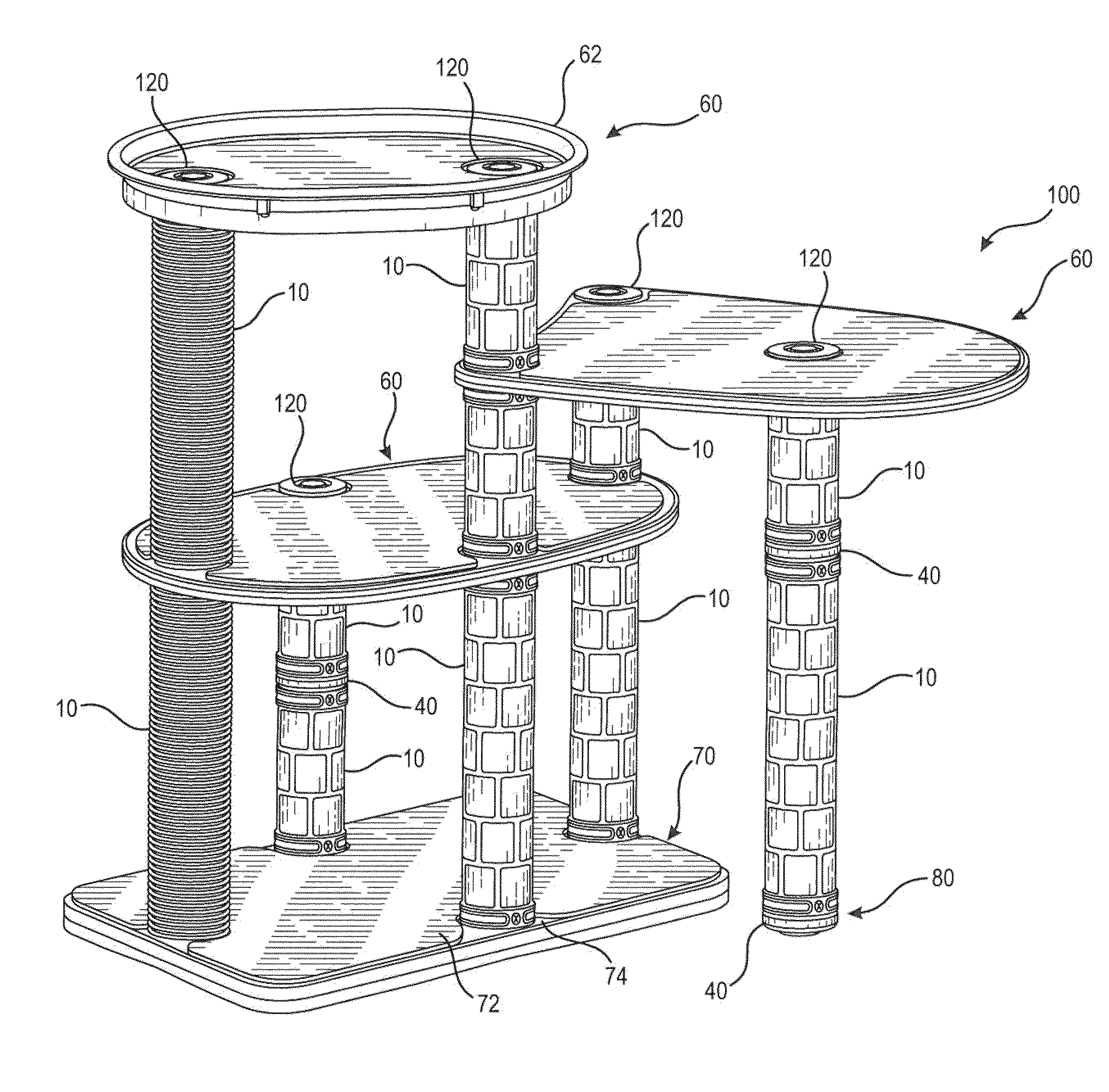

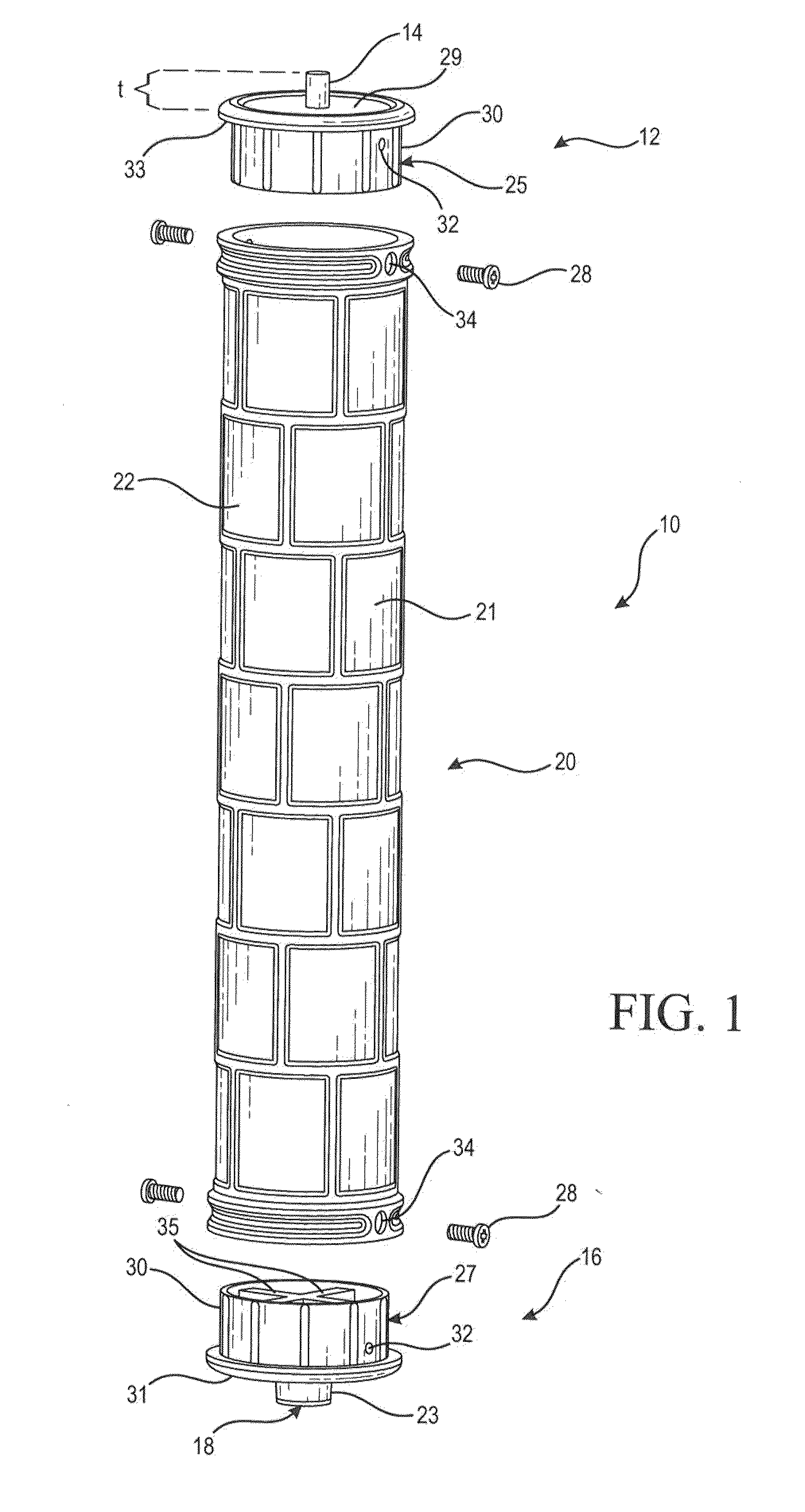

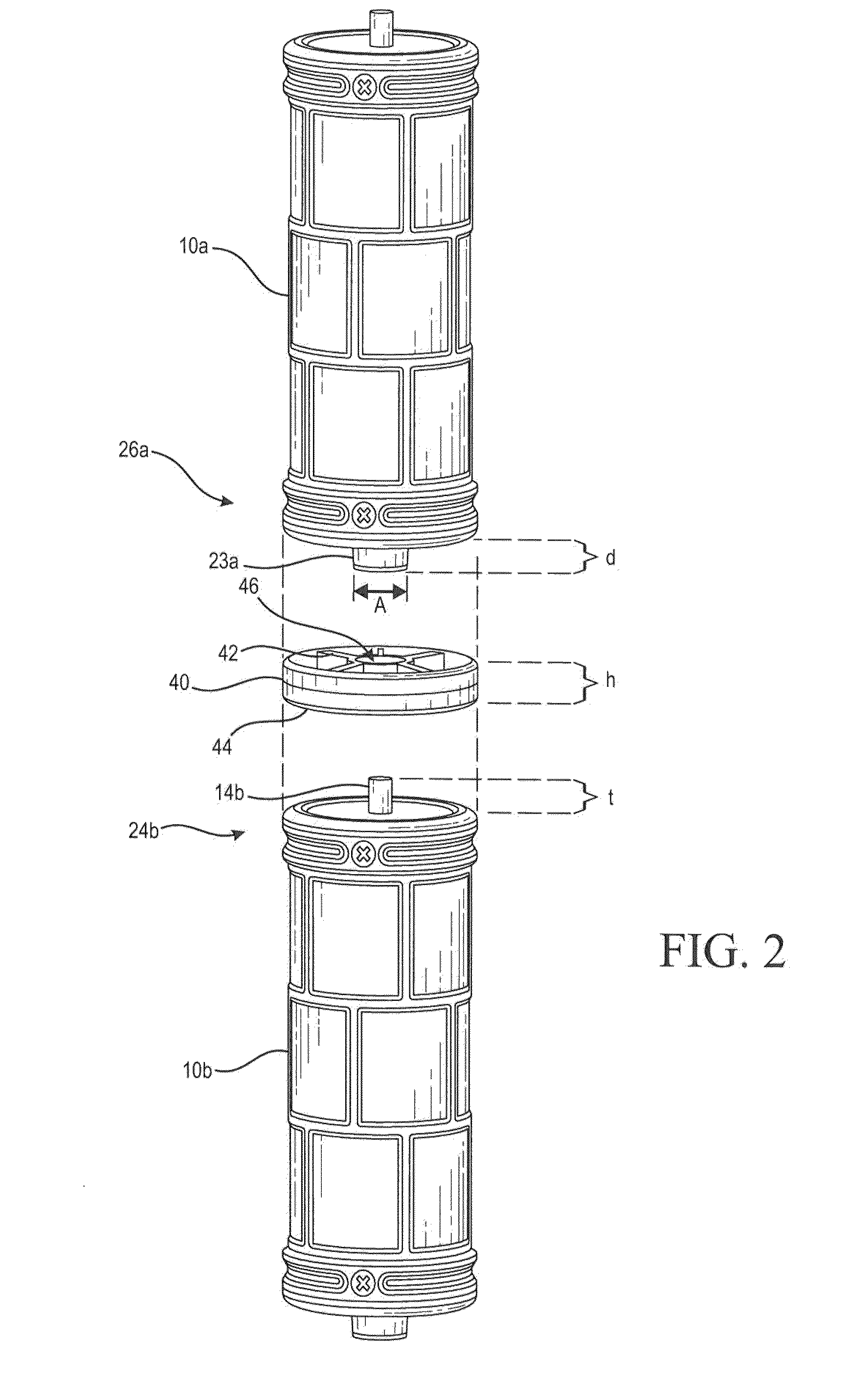

Modular animal exercise structure

A modular play structure for animals has base and platform pieces with connector mechanisms, such countersunk bores, spaced apart by a standard distance. Thus platforms and bases can be oriented in multiple directions and are interchangeable. Columns space the bases and platforms vertically. Columns may be of varying height, preferably with different heights described by a common factor. Stacked columns are connected end-to-end with a spacer of the same thickness as a platform interposed therebetween. Columns are oriented in the same direction with female and male ends connecting with platform, base, and adjacent columns.

Owner:SOLV IT PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com