Range-finding calibration tool and range-finding calibration method and device

A jig and calibration parameter technology, which is applied in the field of ranging calibration jigs and ranging calibration methods and devices, can solve problems such as inaccuracy, influence, and inaccurate ranging of ultrasonic sensors, and achieve the effect of improving the accuracy of ranging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

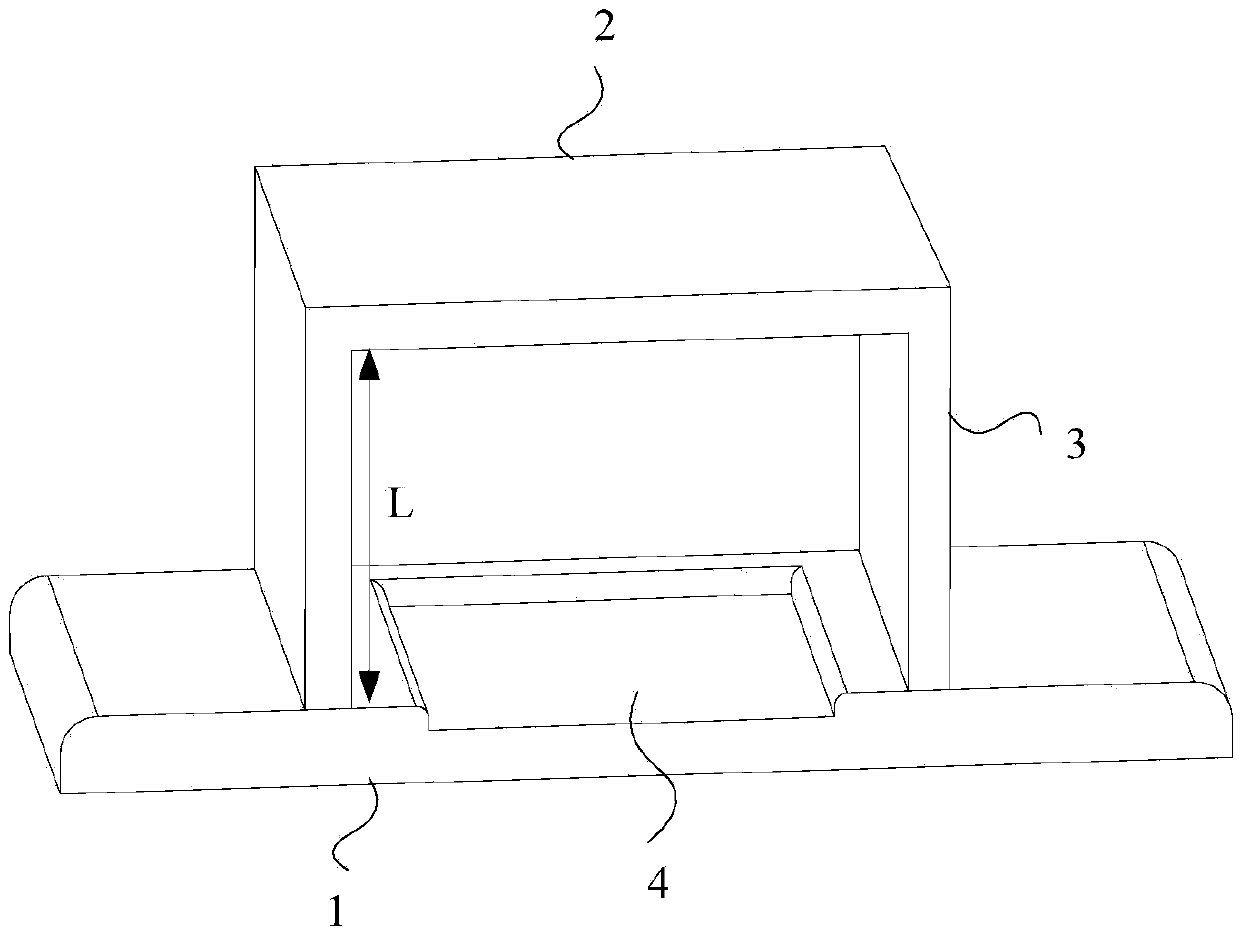

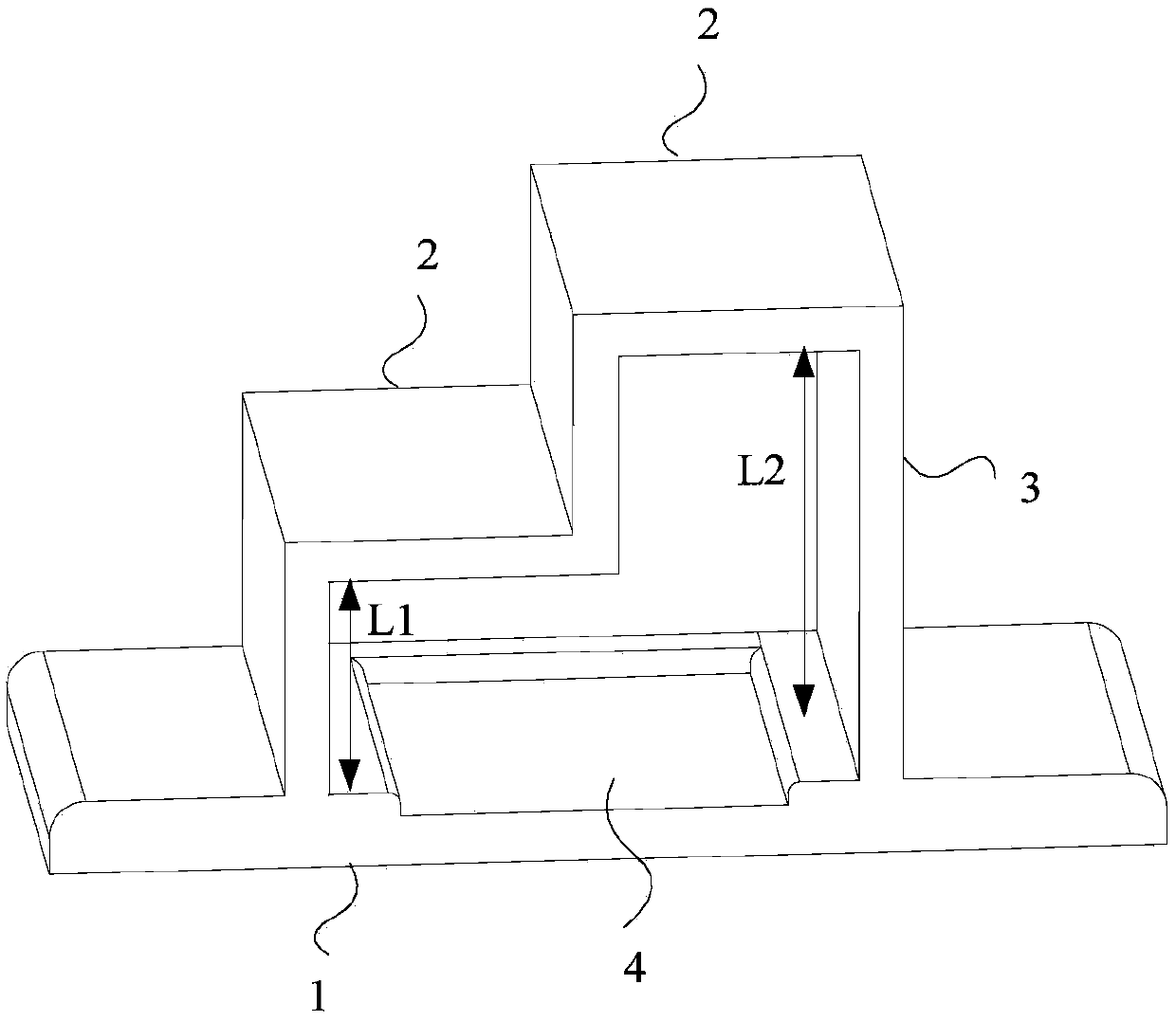

[0025] figure 1 A schematic structural diagram of the ranging calibration jig provided by Embodiment 1 of the present invention is given. Such as figure 1 As shown, the ranging calibration jig provided by Embodiment 1 of the present invention includes a placement platform 1 and a calibration substrate 2 located above the placement platform, and the placement platform 1 is parallel to the calibration substrate 2; the placement platform 1 is used for Place the mobile terminal to support the ultrasonic sensor of the mobile terminal to transmit ultrasonic waves to the calibration substrate 2; the calibration substrate 2 is used to reflect the received ultrasonic waves back to the ultrasonic sensor of the mobile terminal to support the The mobile terminal generates a test distance between the placement platform 1 and the calibration substrate 2, and generates distance measurement calibration parameters according to the test distance and a preset standard distance L.

[0026] The ...

Embodiment 2

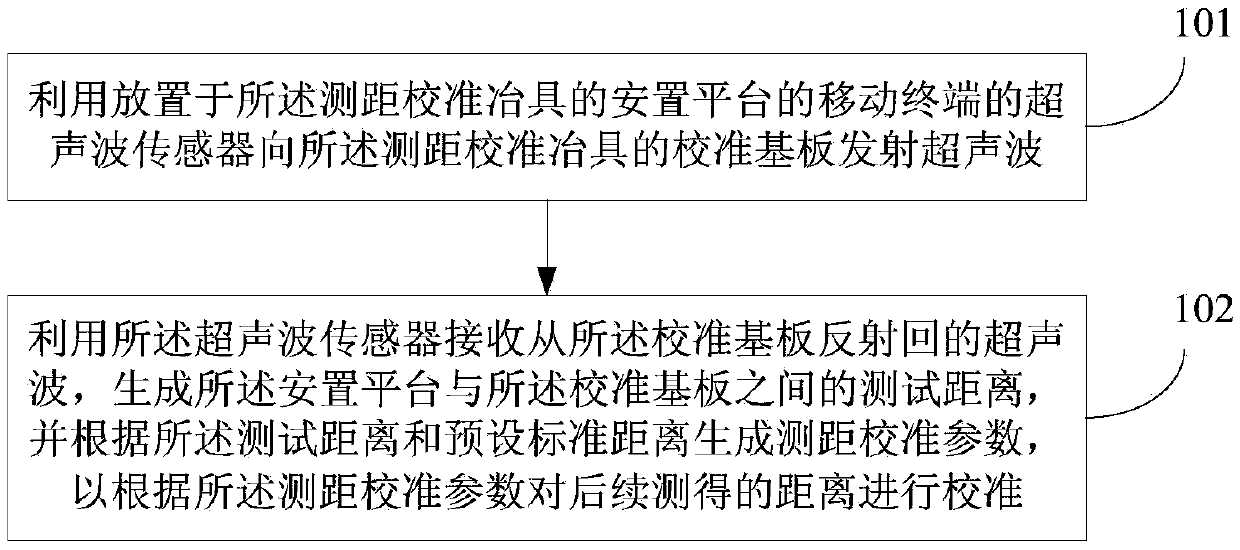

[0034] image 3 A flow chart of the distance measurement calibration method provided by Embodiment 2 of the present invention is given, and the method can be executed by a distance measurement calibration device. The device can be realized by software and / or hardware, and can be built in the mobile terminal as a part of the mobile terminal. The mobile terminal is placed on the installation platform of the calibration jig provided in Embodiment 1, and the ultrasonic sensor of the mobile terminal emits ultrasonic waves to the calibration substrate of the calibration jig, and receives the ultrasonic waves reflected back from the calibration substrate to generate The test distance is used to generate ranging calibration parameters according to the test distance and a preset standard distance. Such as image 3 As shown, the ranging calibration method provided in this embodiment specifically includes the following steps:

[0035] Step 101: Utilize the ultrasonic sensor of the mob...

Embodiment 3

[0049] Figure 5 A flow chart of the ranging calibration method provided by Embodiment 3 of the present invention is given. This embodiment is optimized on the basis of the second embodiment above. In this embodiment, when the calibration substrate is a planar calibration substrate, step 102 in Embodiment 2 is specifically optimized as: using the ultrasonic sensor to receive the ultrasonic wave reflected from the planar calibration substrate to generate the arrangement The test distance between the platform and the calibration substrate; the ratio of the preset standard distance to the test distance is used as the distance measurement calibration coefficient, so as to calibrate the subsequently measured distance according to the distance measurement calibration coefficient.

[0050] Correspondingly, such as Figure 5 As shown, the ranging calibration method provided in this embodiment specifically includes the following steps:

[0051] Step 201: Utilize the ultrasonic senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com