Patents

Literature

42results about How to "Reduce the row spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

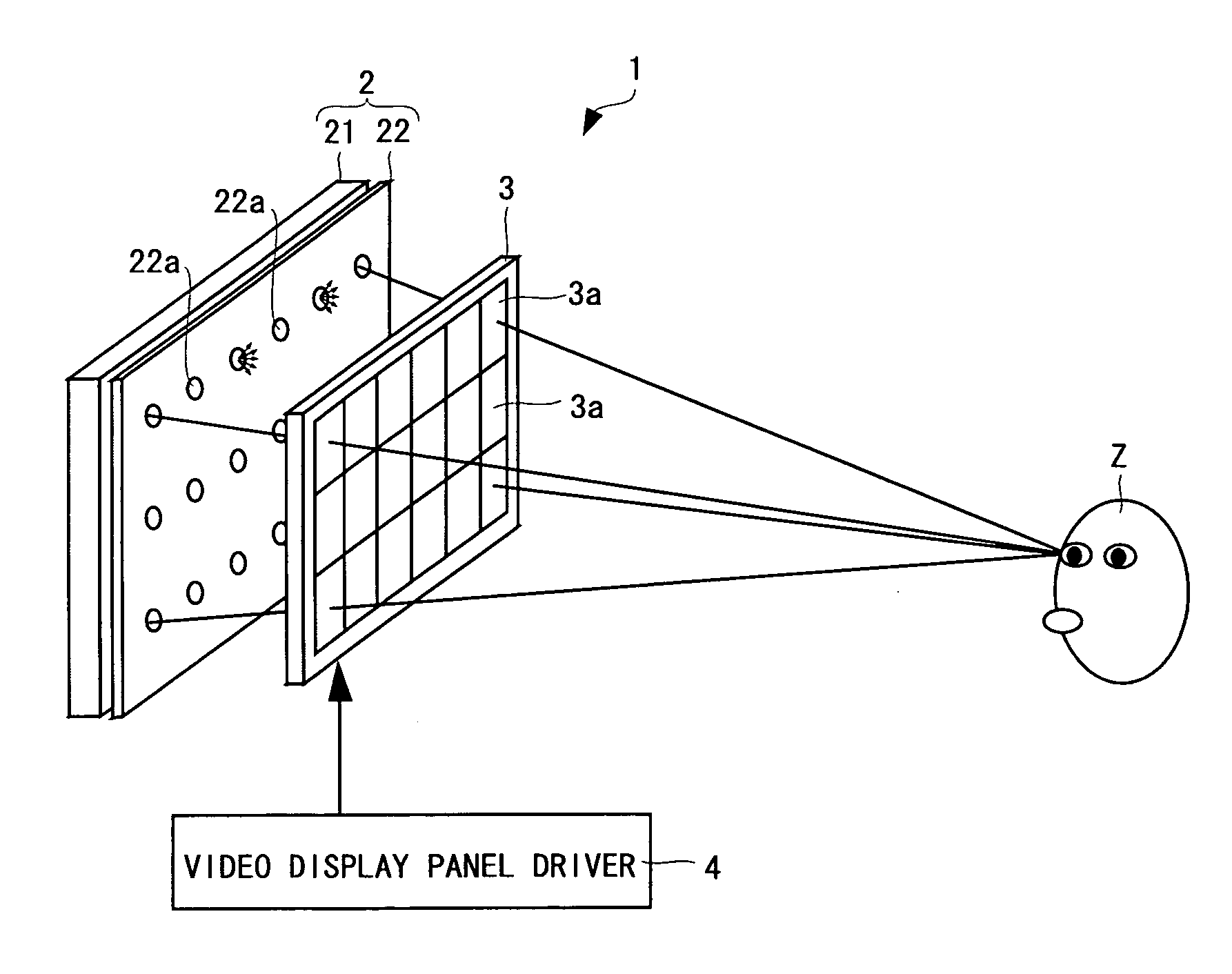

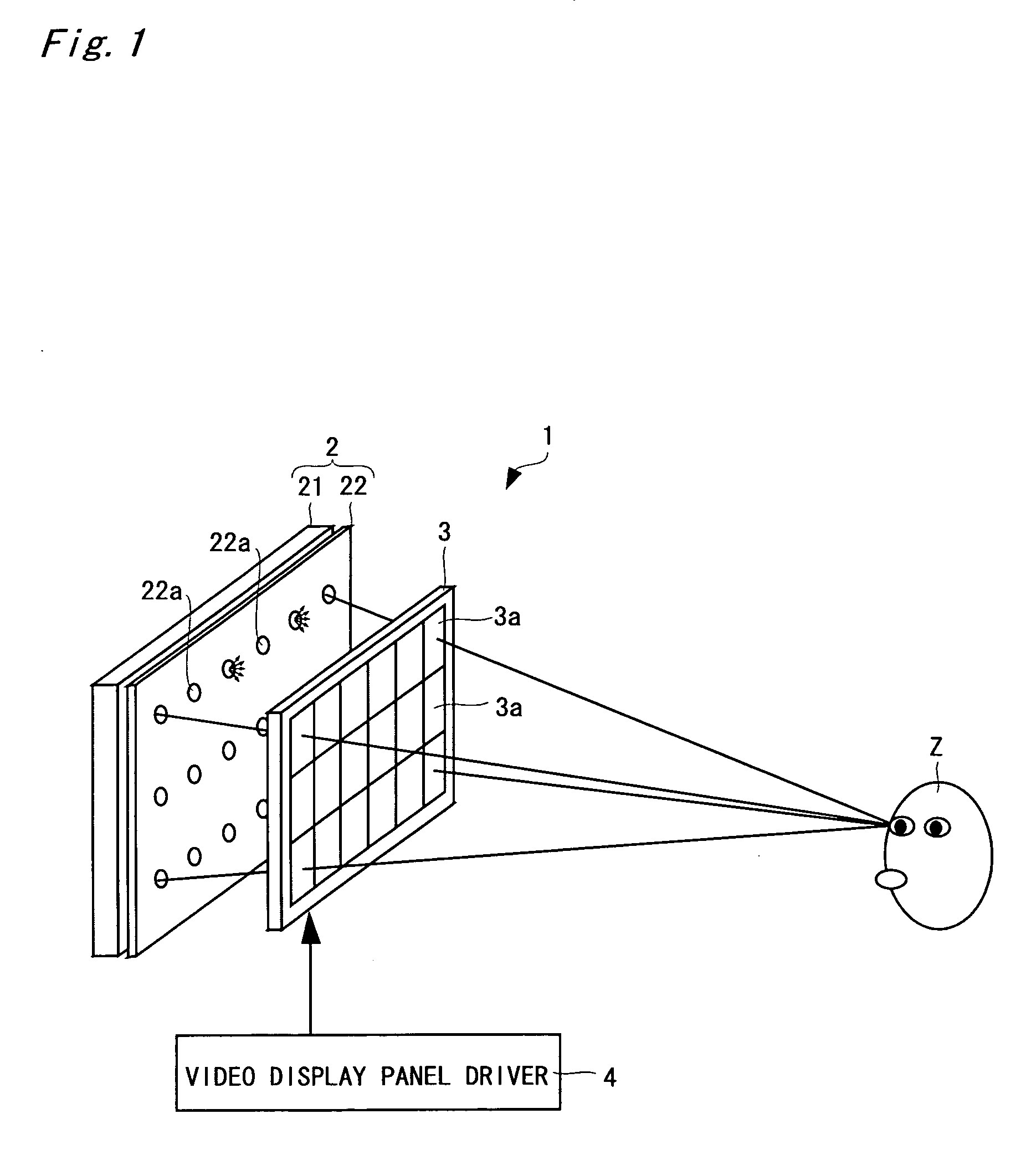

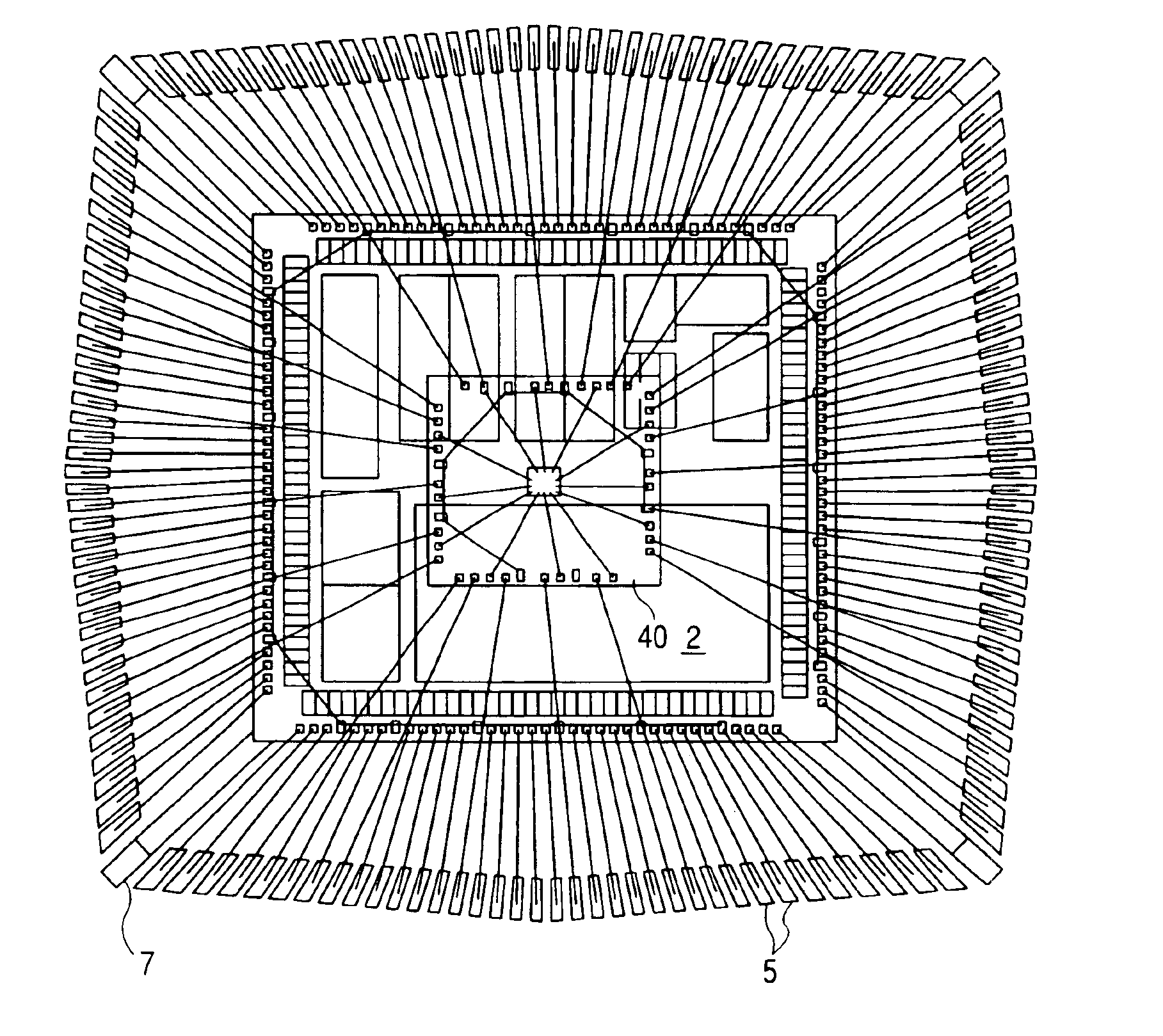

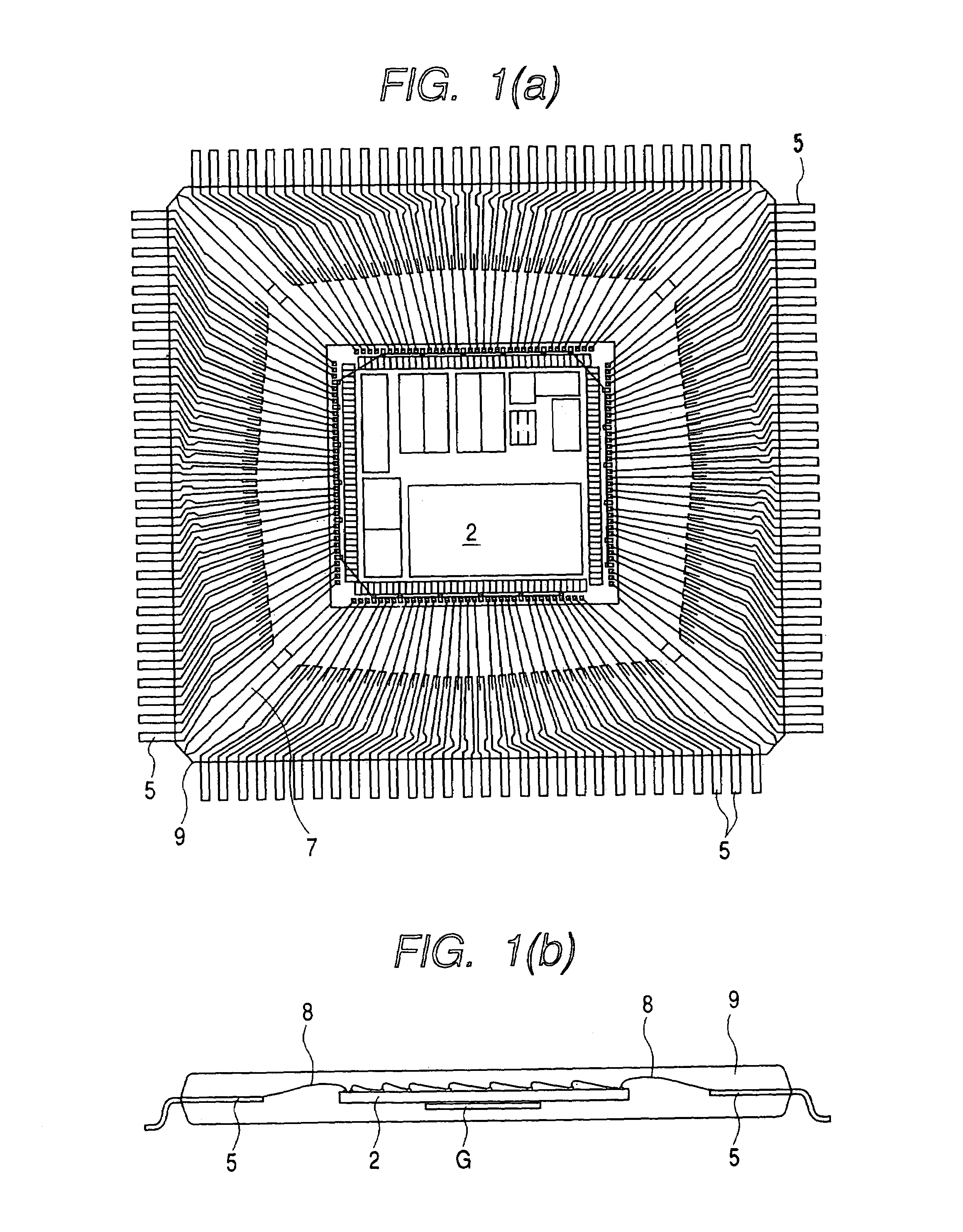

Three-dimensional video display and method for creating supply video supplied to three-demensional video display

InactiveUS20040130503A1Reduce the row spacingEfficient identificationCathode-ray tube indicatorsOptical light guidesStereoscopic videoLiquid-crystal display

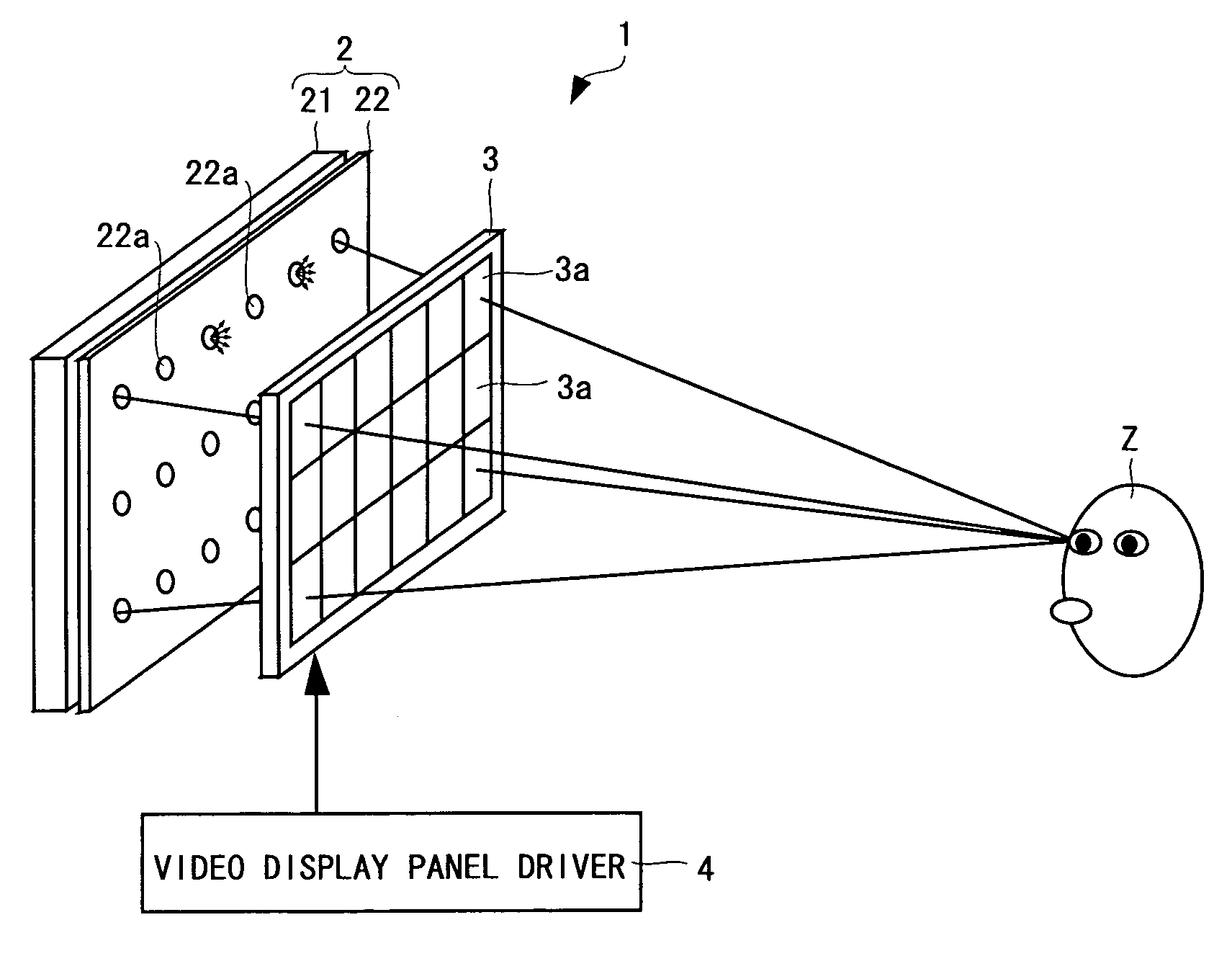

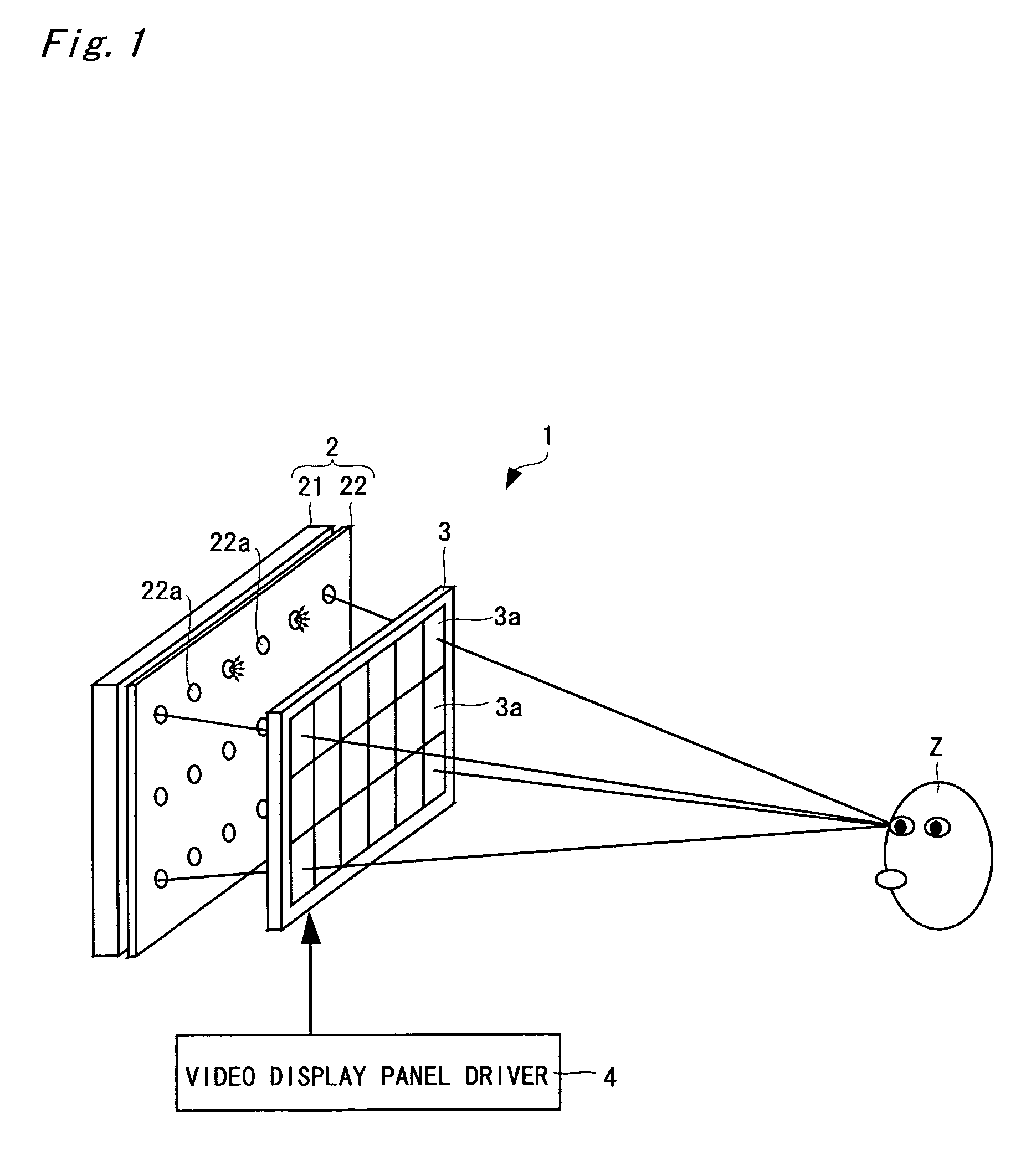

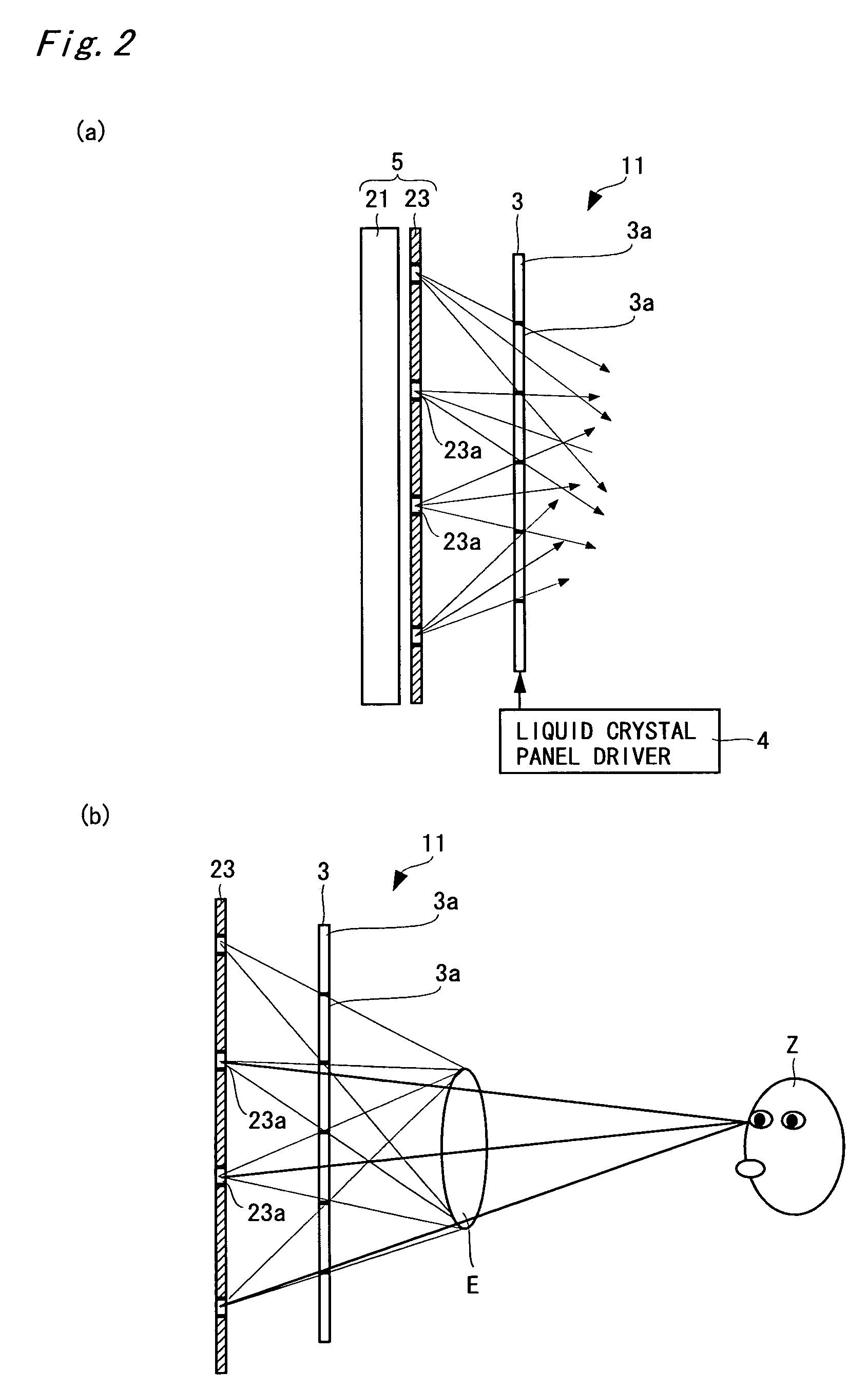

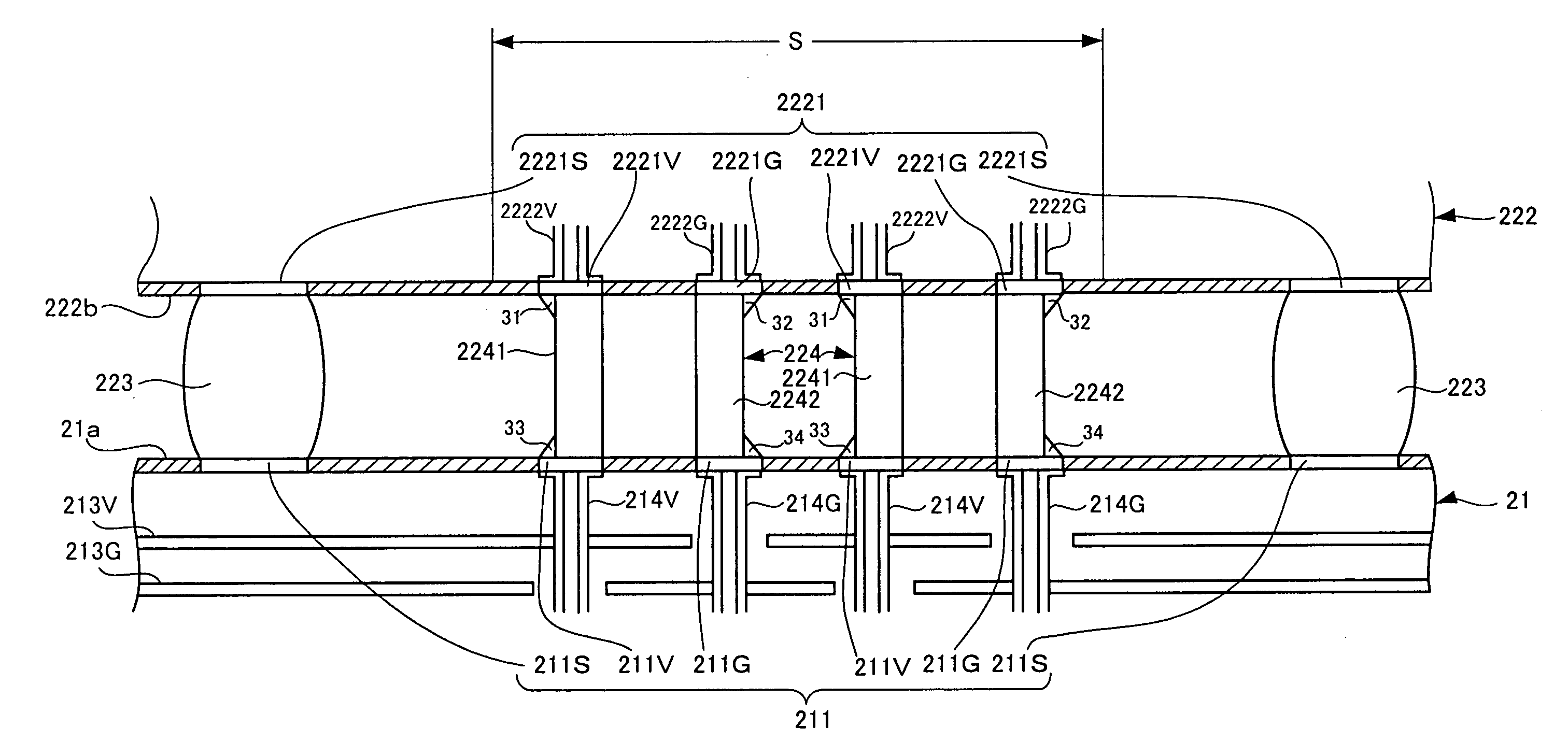

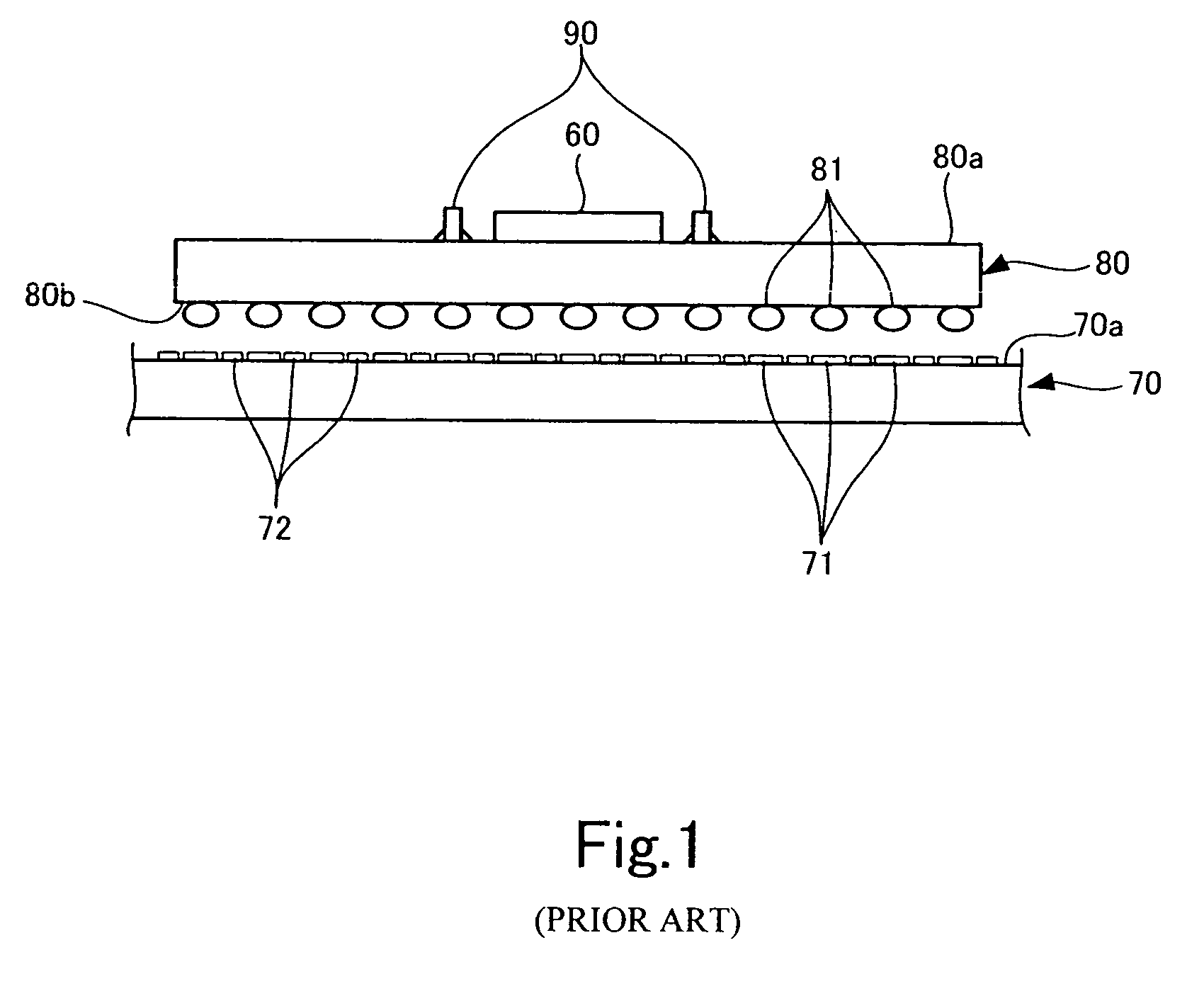

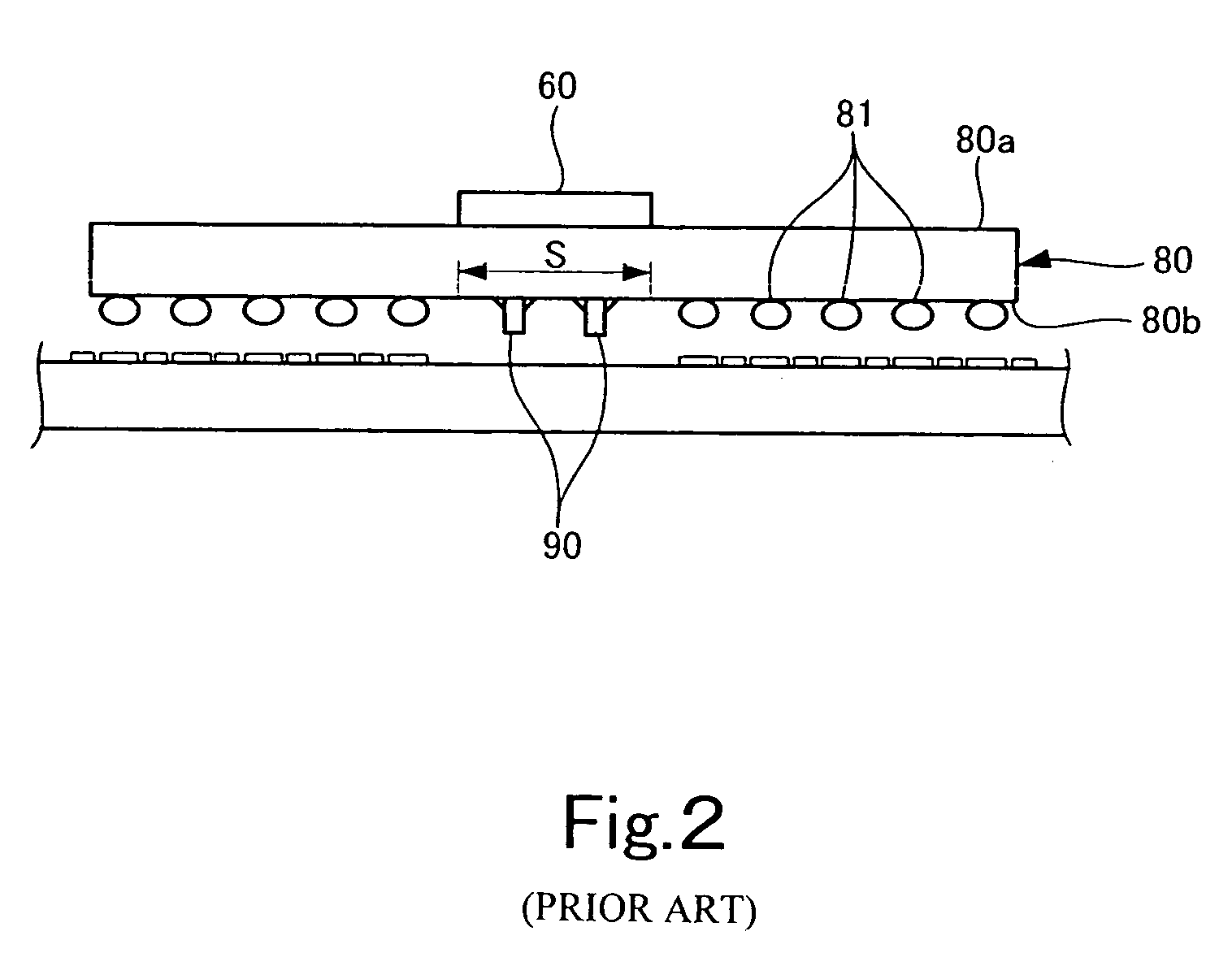

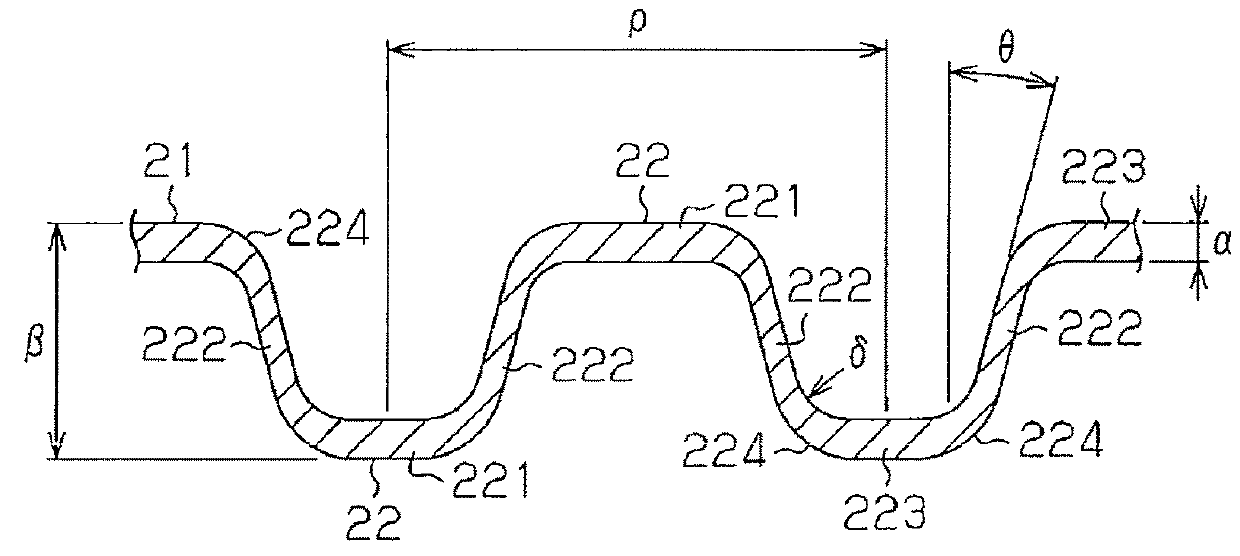

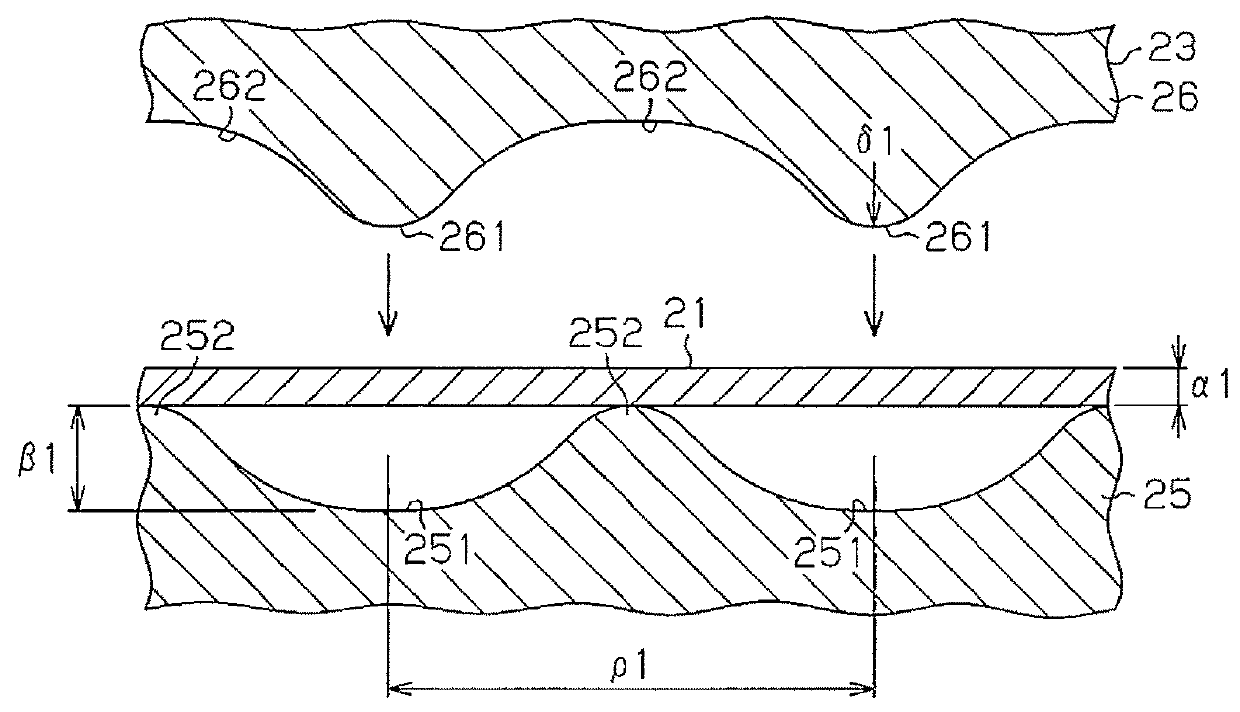

There is provided a stereoscopic video display that enables a viewer to recognize a more real stereoscopic video. A light source device 2 comprises a backlight 21 and a pinhole array plate 22. A liquid crystal display panel driver 5 feeds a pixel driving signal to a liquid crystal display panel 3, to form a pixel region 3a composed of a plurality of pixels respectively corresponding to pinholes 22a. Each of the pixels composing the pixel region 3a controls an amount of light transmission with respect to a light beam in each direction from the corresponding pinhole 22a. Consequently, the intensity of the light beam in each direction is reproduced. Lines respectively connecting the centers of the pinholes 22a and the centers of the pixel regions 3a are not parallel to one another, and are so set as to cross at one point of a position corresponding to the standard distance between the video display panel 3 and a viewer Z. Therefore, the light beams are efficiently concentrated at a standard viewing position, thereby making it possible to make the viewer Z recognize a more real stereoscopic video.

Owner:SANYO ELECTRIC CO LTD

Double-cropping sophora japonica cultivation and management method

InactiveCN103918486AReduced germination rateImprove germination rateSeed and root treatmentForestrySocial benefitsBud growth

The invention discloses a double-cropping sophora japonica cultivation and management method. The double-cropping sophora japonica cultivation and management method comprises the steps that after double-cropping sophora japonica seeds are selected and placed into a potassium permanganate solution with the mass concentration of 0.005 percent for soaking treatment, control over bed planting is conducted; then, nursery stock reproduction, garden construction, top grafting for breed changing, fertilizer application, shaping pruning, pest control and sophora japonica flower bud harvesting are managed. According to traditional sophora japonica, the flower bud growth period is long, and the yield is low; by the adoption of the double-cropping sophora japonica cultivation and management method, the flower buds grow in a double-cropping mode and are harvested in the double-cropping mode, so that the yield is increased, and remarkable economic benefit and social benefit are created.

Owner:GUILIN MINGXING BIOTECH

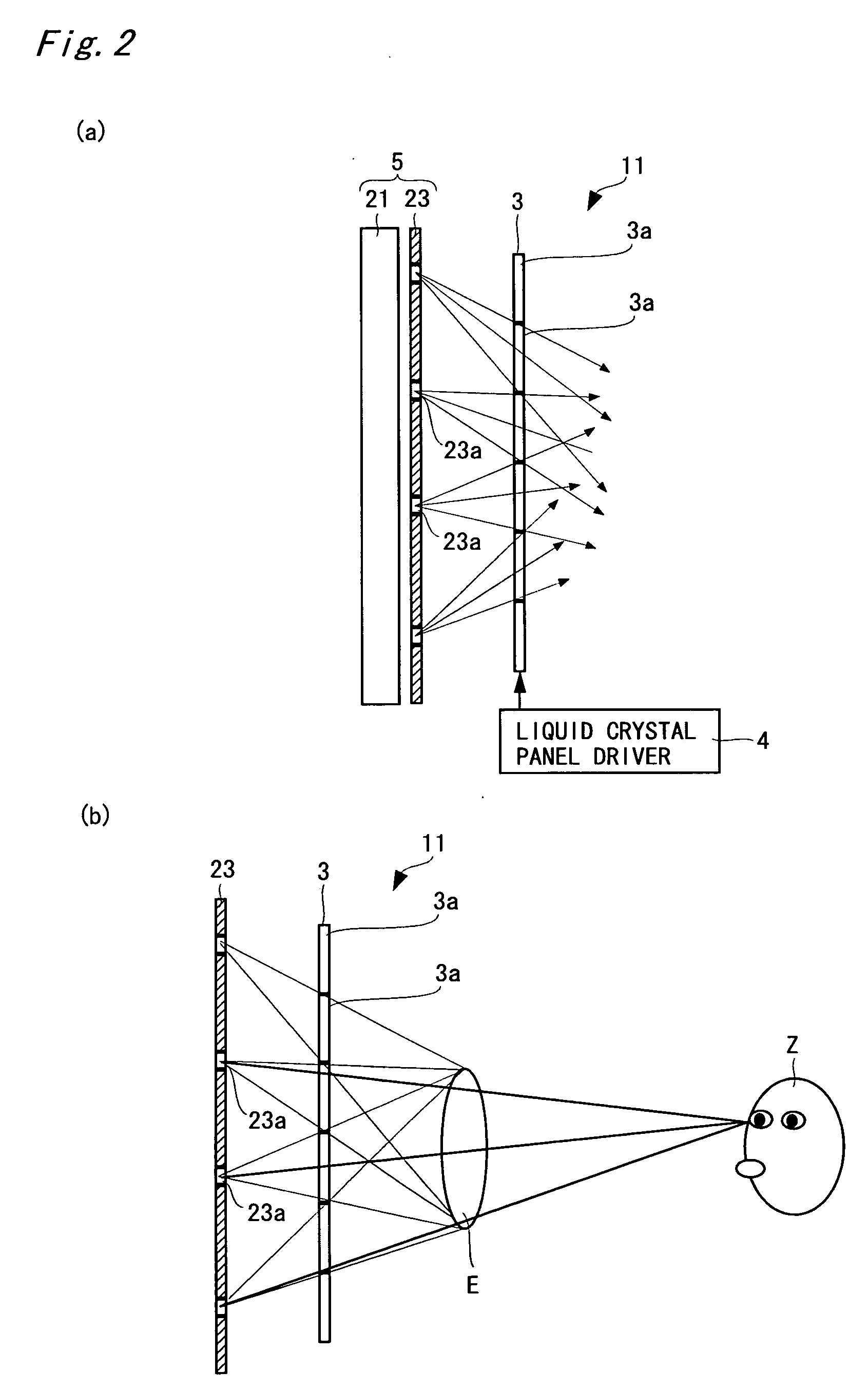

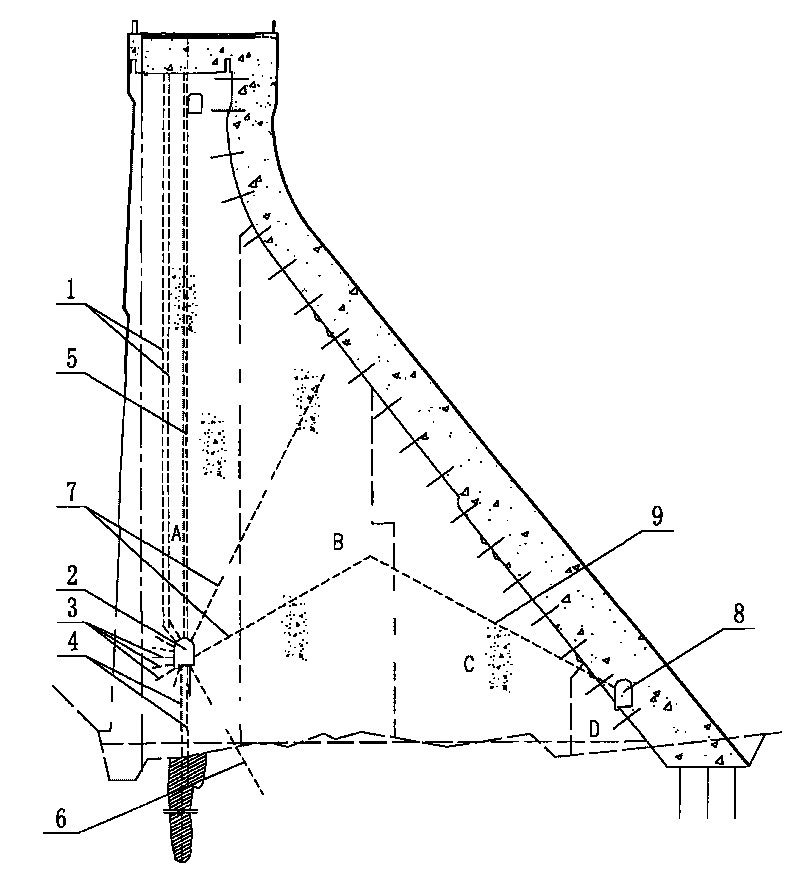

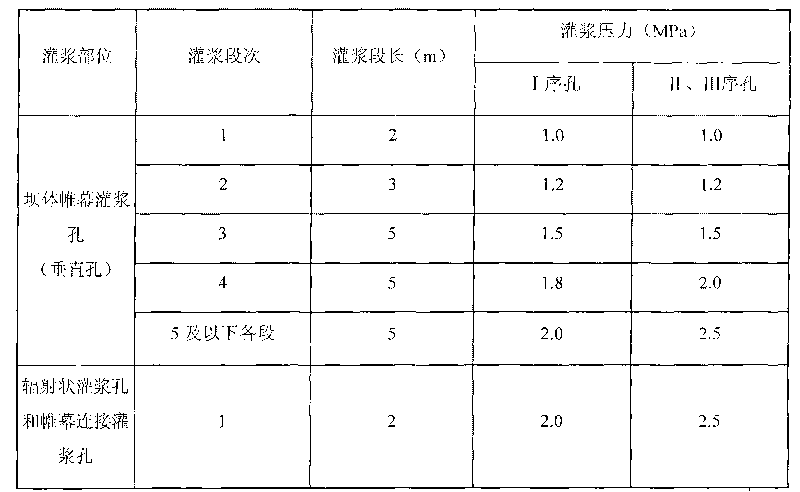

Construction method for dam body seepage preventing curtain grouting

ActiveCN101736719AIncreasing the thicknessIncreased durabilityMarine site engineeringWater dischargeSlurry

The invention relates to a construction method for dam body seepage preventing curtain grouting and provides a construction method for the dam body seepage preventing curtain grouting. The grouting is carried out by a technology of dense holes, high pressure, fine cement wet grinding and concentrated slurry, and the seepage preventing ability, the corrosion resistance and the durability of a dam body curtain are improved; the seepage is prevented in a way of front blockage and rear discharge, the downstream seepage escapement point elevation of a dam body and the uplifting pressure in a dam are reduced, and the problems of frozen thawing and frozen expansion of concrete are solved. The construction method for the dam body seepage preventing curtain grouting comprises the following steps of: a. downwards drilling a group of curtain grouting holes at the top of the dam; b. drilling radial grouting holes on the upstream surface in a basic gallery; c. downwards drilling curtain connection grouting holes extending into a dam foundation in the basic gallery; d. carrying out grouting by high pressure, fine cement wet grinding and concentrated slurry; and e. drilling a water discharge structure which is communicated with the basic gallery in the dam body. The invention is mainly used for the seepage prevention and discharge reinforcement processing of the concrete dam.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

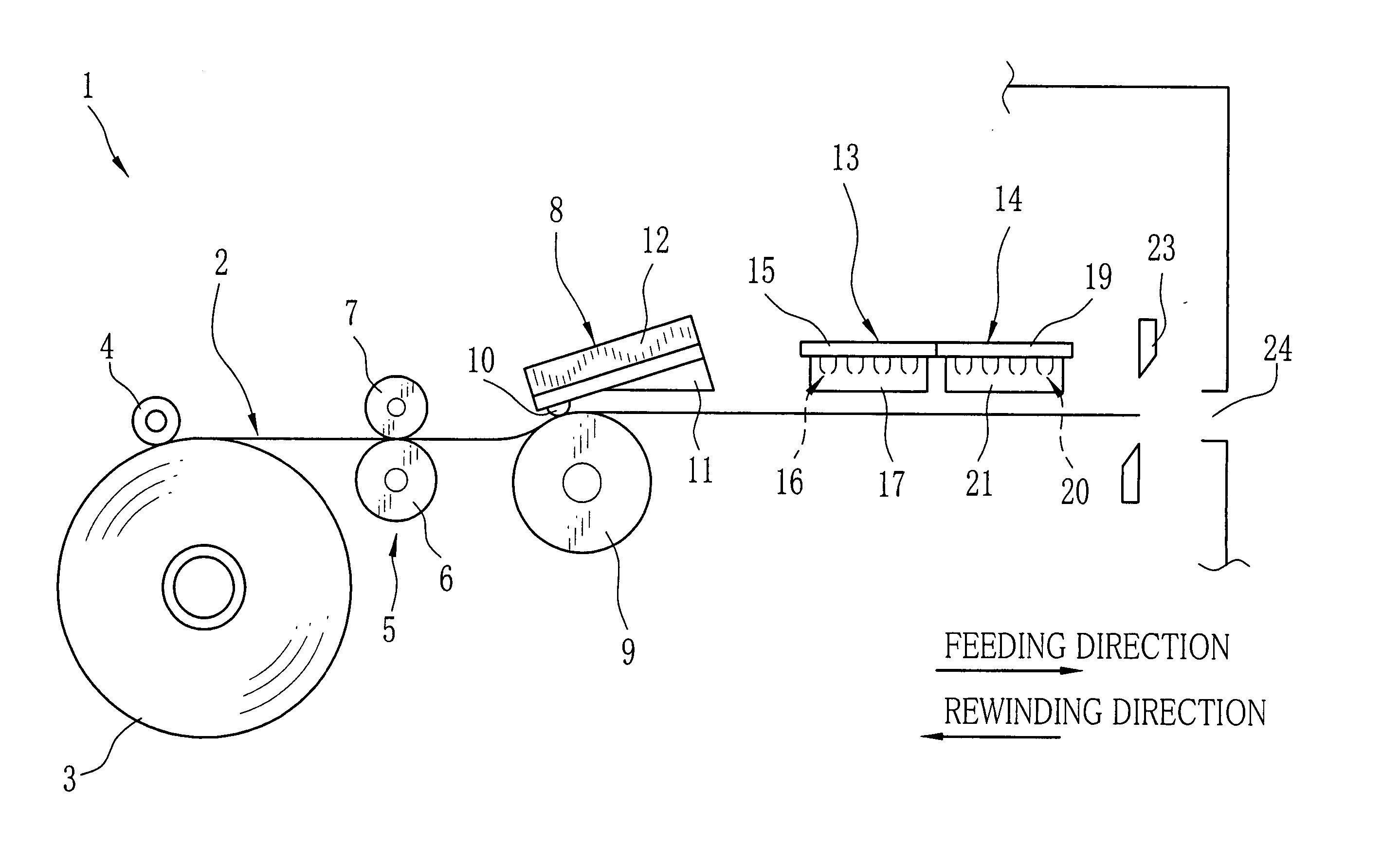

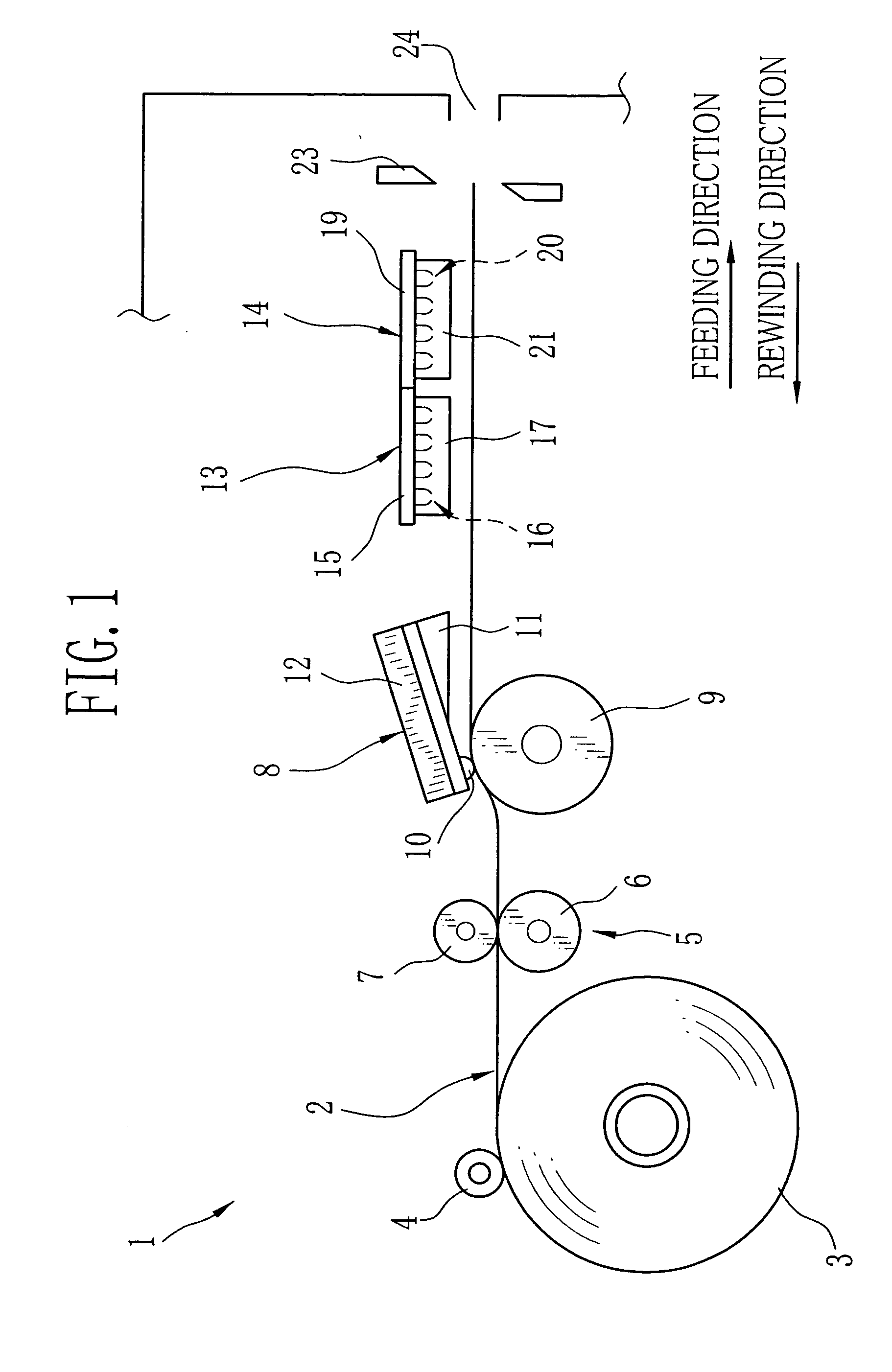

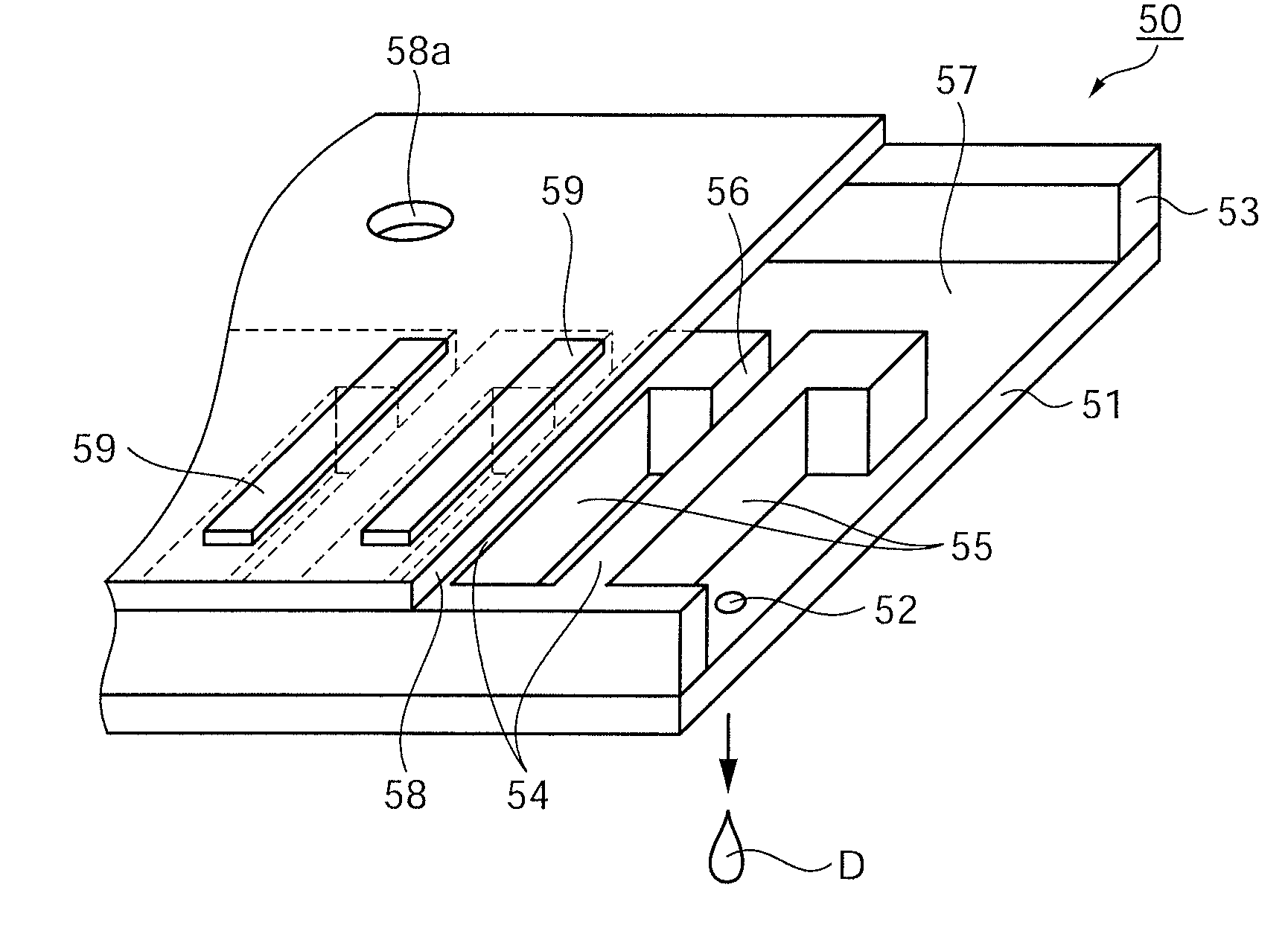

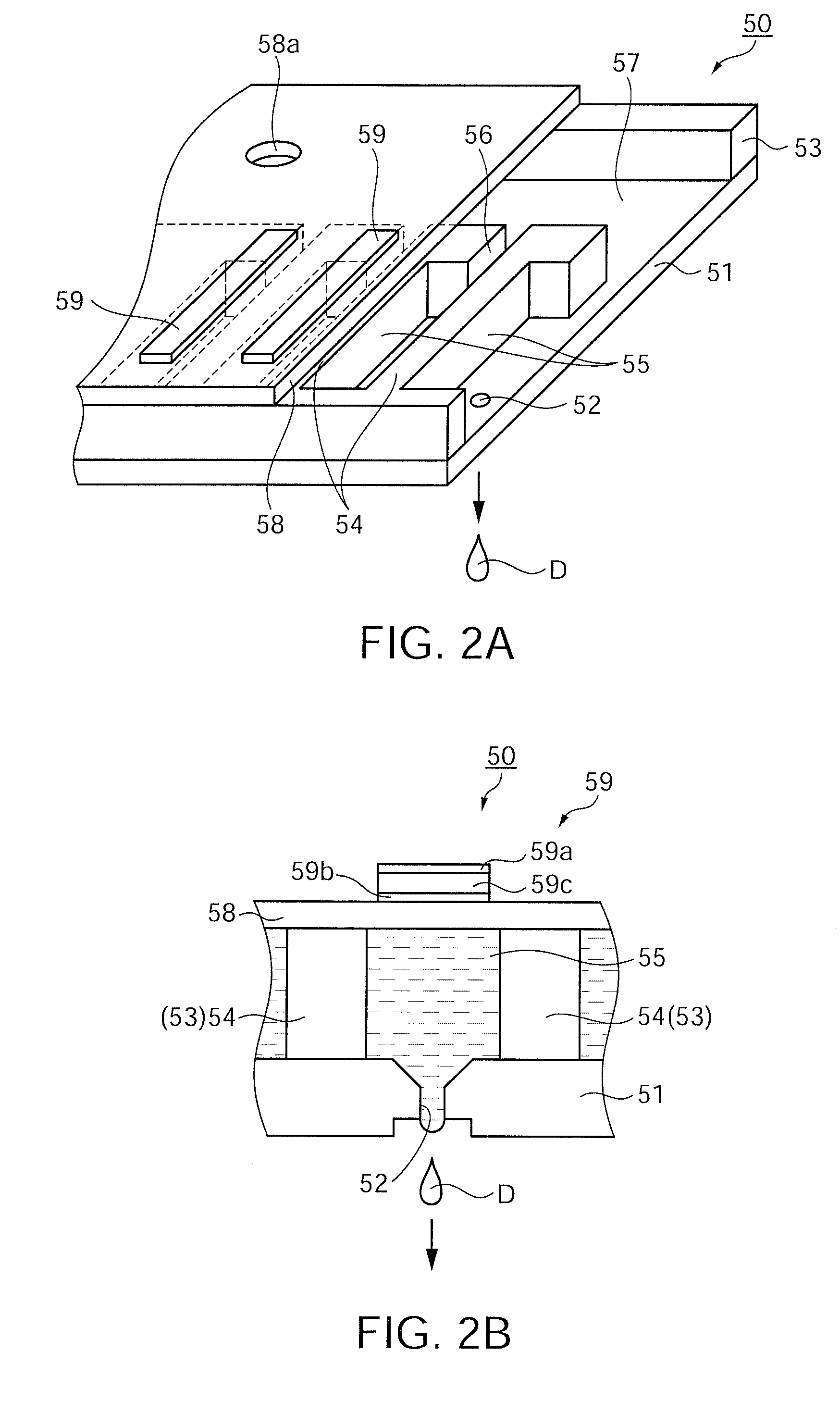

Light irradiating unit and optical fixing unit

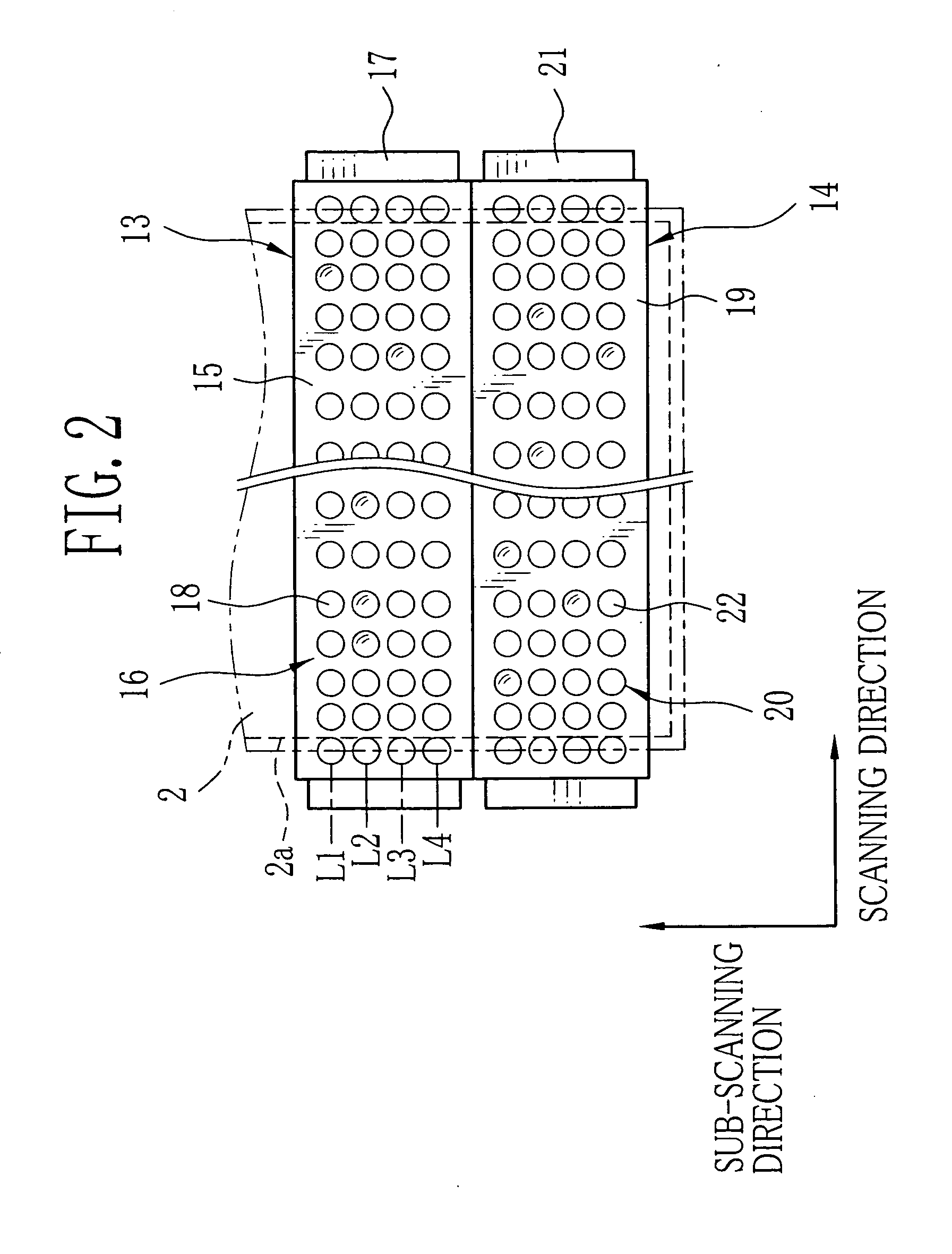

InactiveUS20050062830A1Suppress mutationAvoid unevennessElectrographic processes using charge patternOther printing apparatusLight irradiationLed array

A width of an LED array in a scanning direction is determined in accordance with a width of thermosensitive recording paper. A plurality of LEDs is arranged in the LED array in such a way that an arranging pitch between the LEDs are lessened from a center area toward side edge areas of the LED array. Thus, an arranging density of the LEDs increases from the center area toward the side edge areas of the LED array, so that radiated fixing light becomes uniform in a width direction of the thermosensitive recording paper. As a result, unevenness in fixing is prevented. Further, irradiation efficiency in the side edge areas of the LED array is improved by providing reflectors on both side edges of the LED array. Accordingly, the unevenness in fixing is prevented more efficiently.

Owner:FUJIFILM HLDG CORP

Three-dimensional video display and method for creating supply video supplied to three-dimensional video display

InactiveUS7180478B2Efficient workReduce the row spacingCathode-ray tube indicatorsOptical light guidesStereoscopic videoLiquid-crystal display

There is provided a stereoscopic video display that enables a viewer to recognize a more real stereoscopic video.A light source device 2 comprises a backlight 21 and a pinhole array plate 22. A liquid crystal display panel driver 5 feeds a pixel driving signal to a liquid crystal display panel 3, to form a pixel region 3a composed of a plurality of pixels respectively corresponding to pinholes 22a. Each of the pixels composing the pixel region 3a controls an amount of light transmission with respect to a light beam in each direction from the corresponding pinhole 22a. Consequently, the intensity of the light beam in each direction is reproduced. Lines respectively connecting the centers of the pinholes 22a and the centers of the pixel regions 3a are not parallel to one another, and are so set as to cross at one point of a position corresponding to the standard distance between the video display panel 3 and a viewer Z. Therefore, the light beams are efficiently concentrated at a standard viewing position, thereby making it possible to make the viewer Z recognize a more real stereoscopic video.

Owner:SANYO ELECTRIC CO LTD

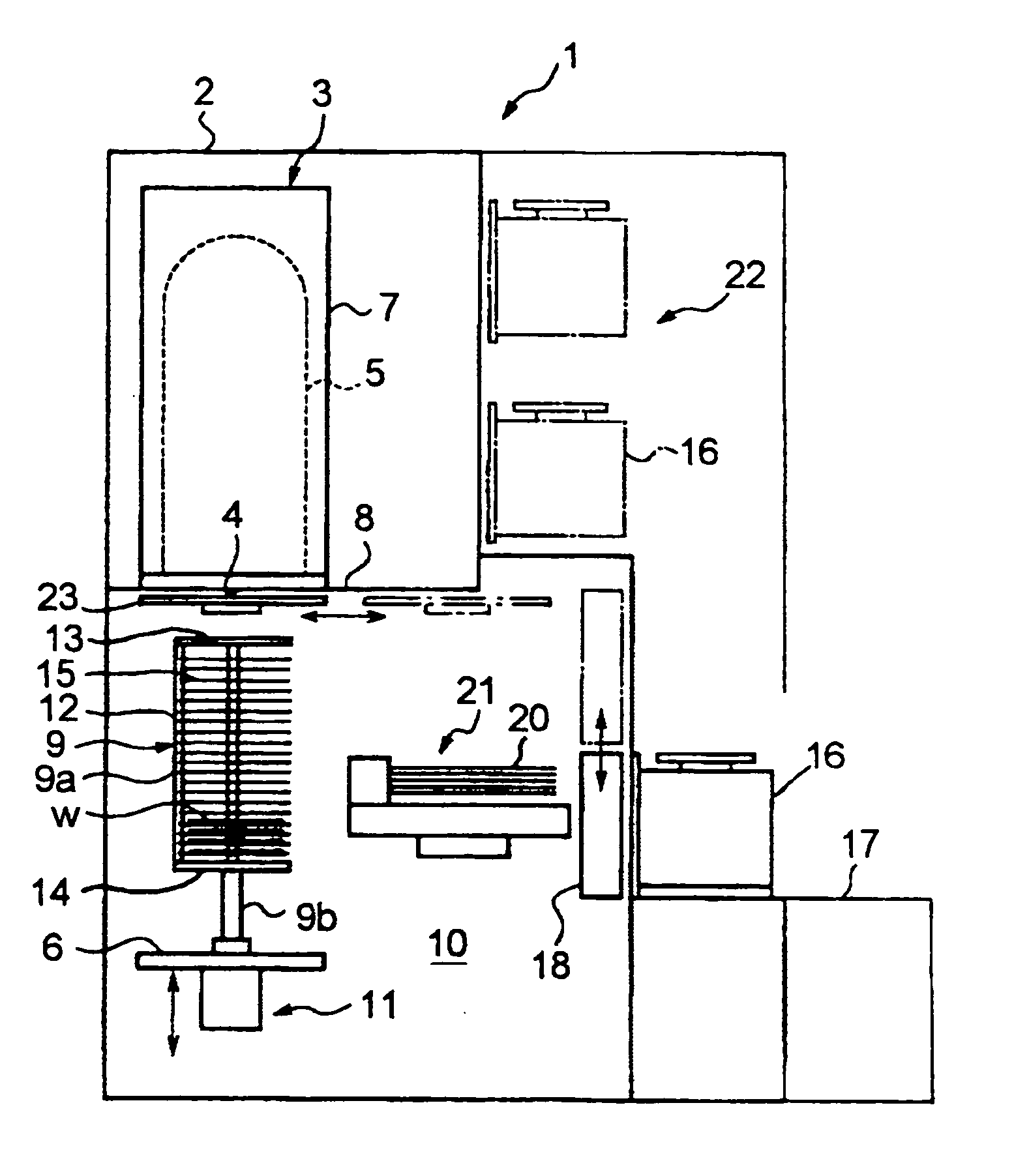

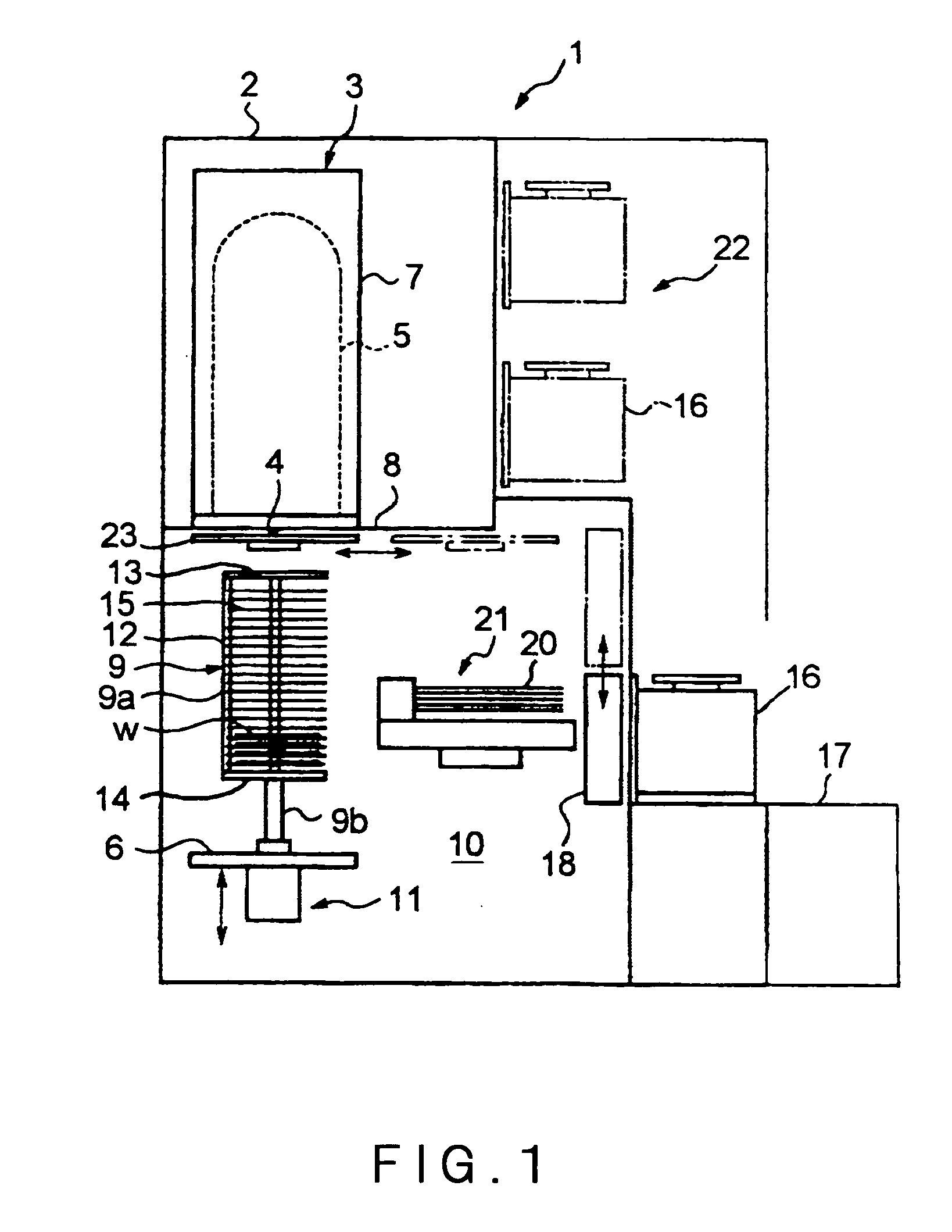

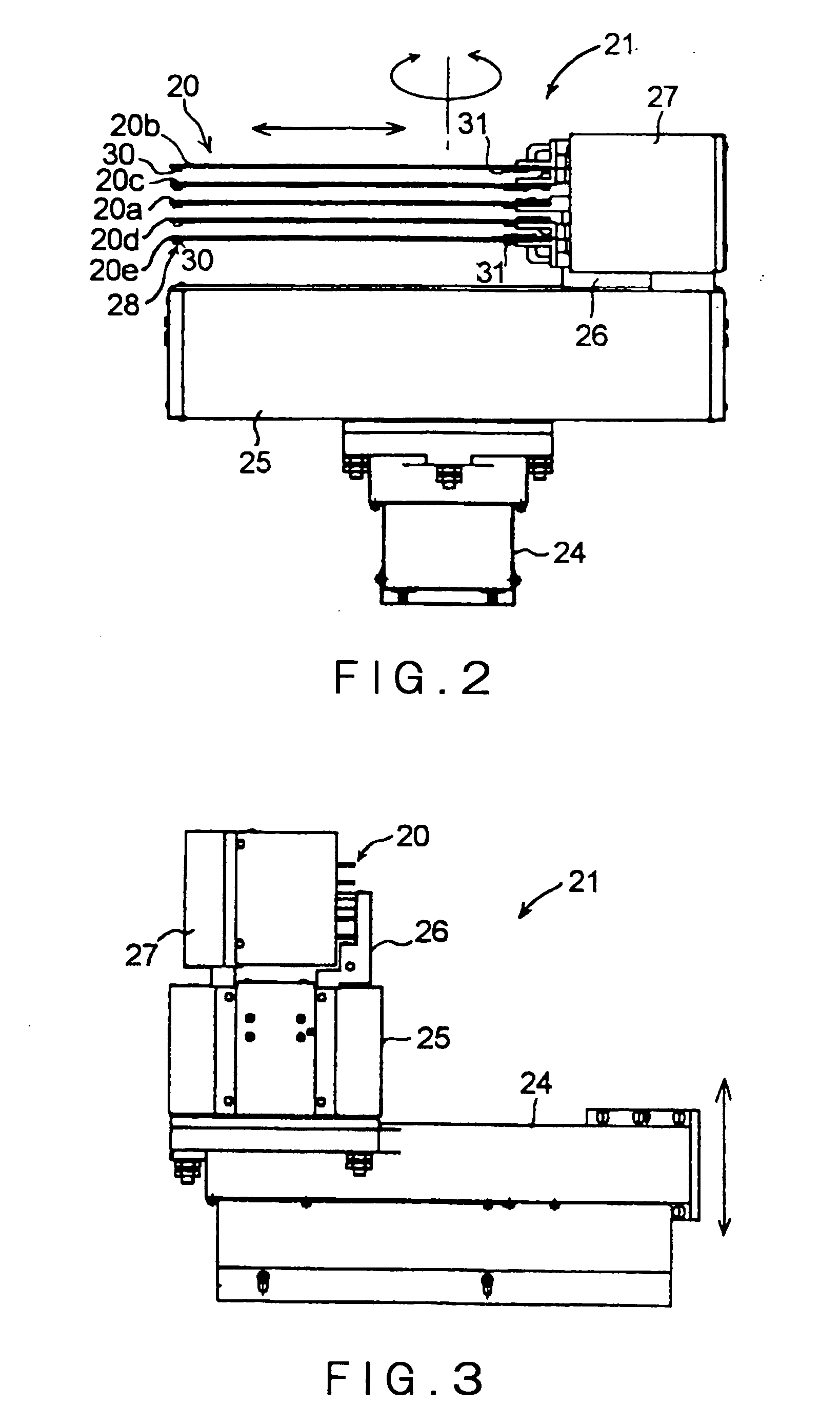

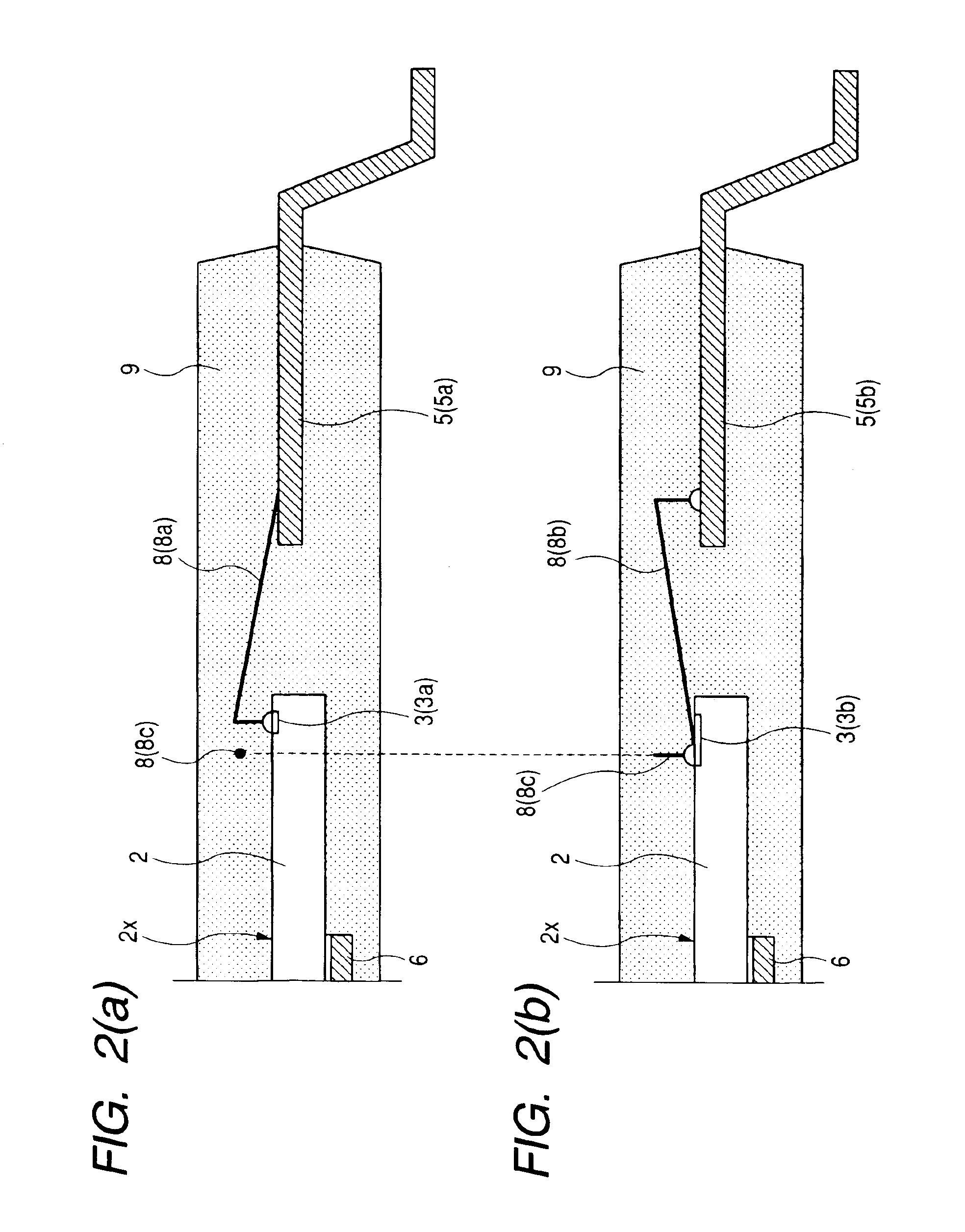

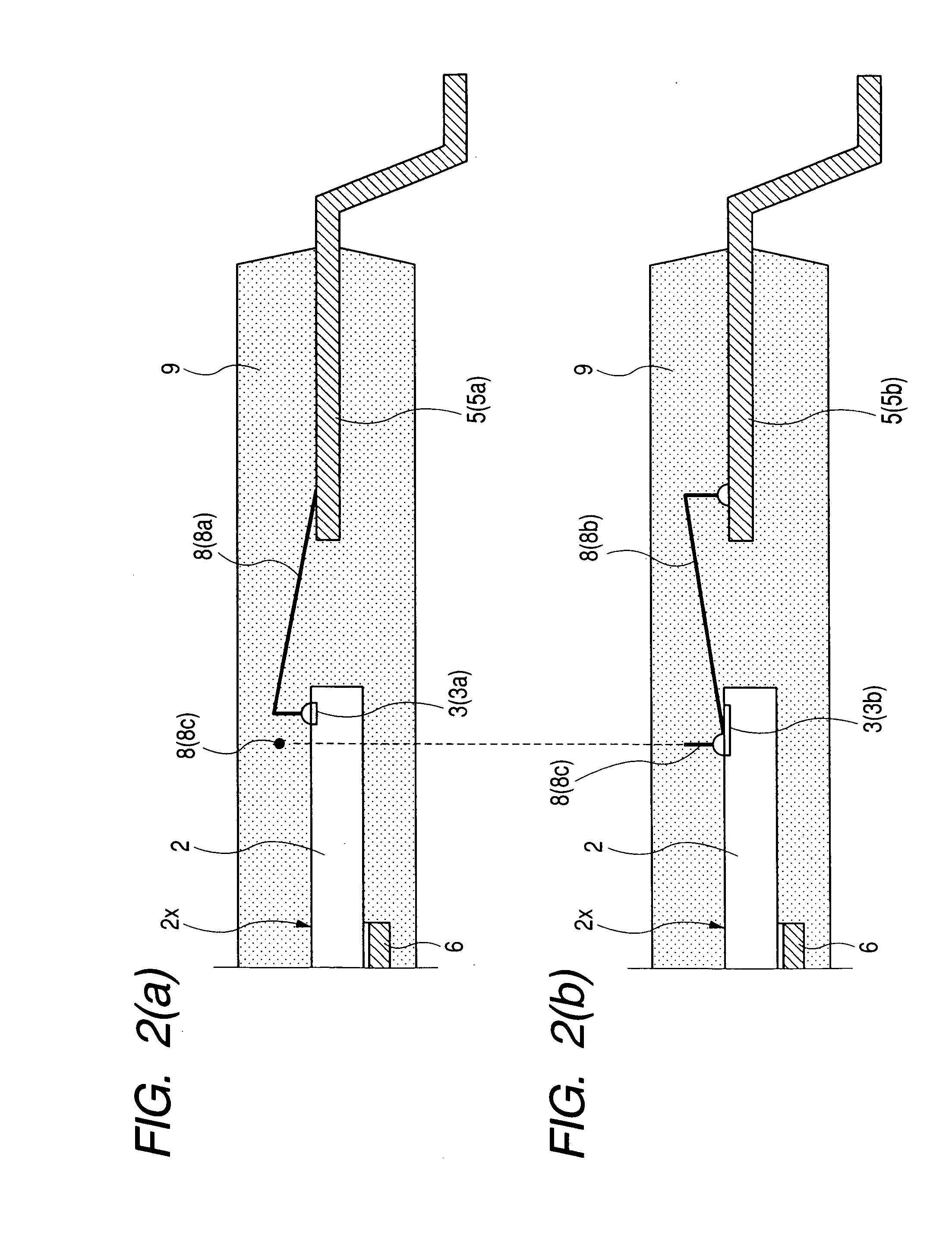

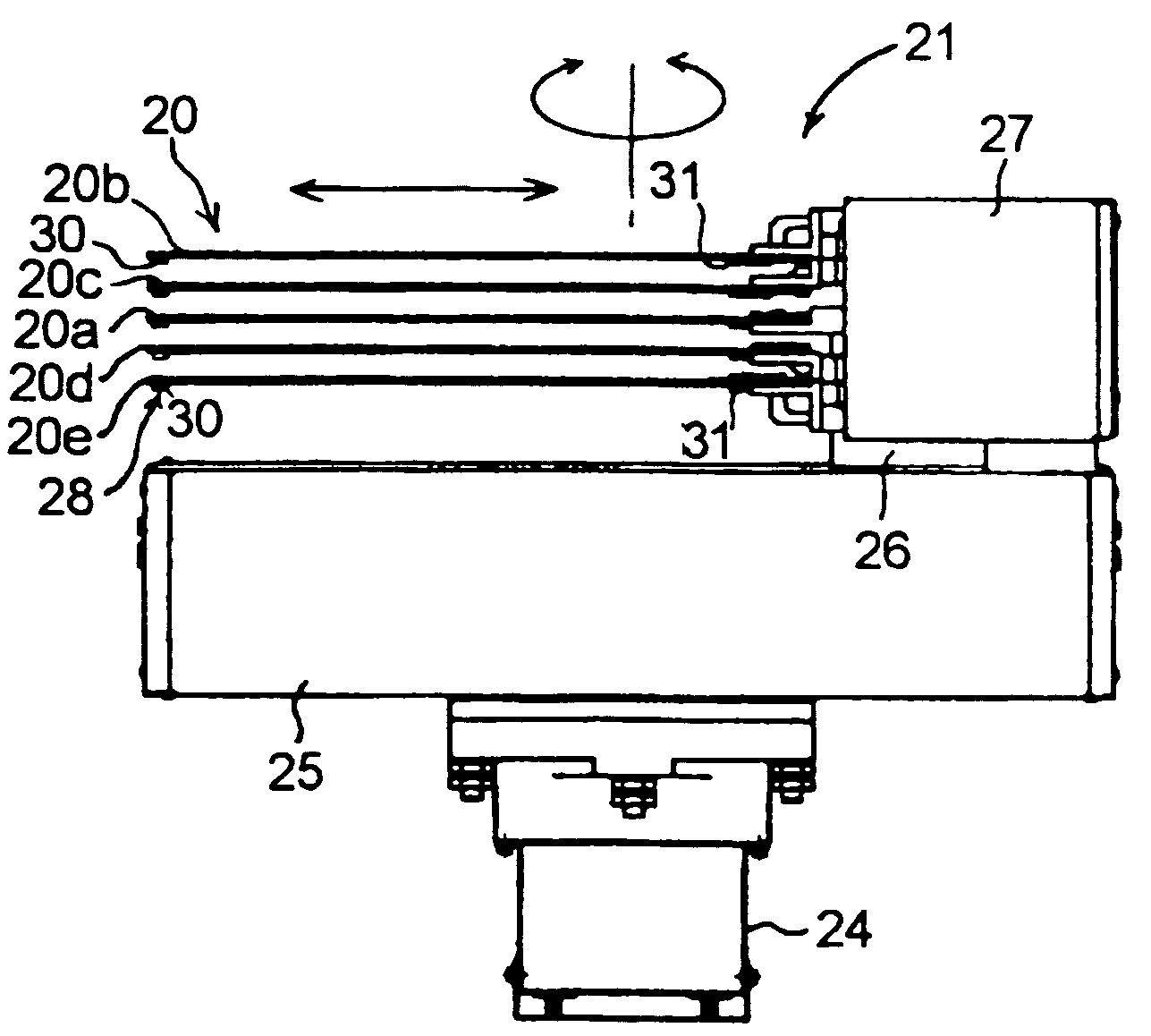

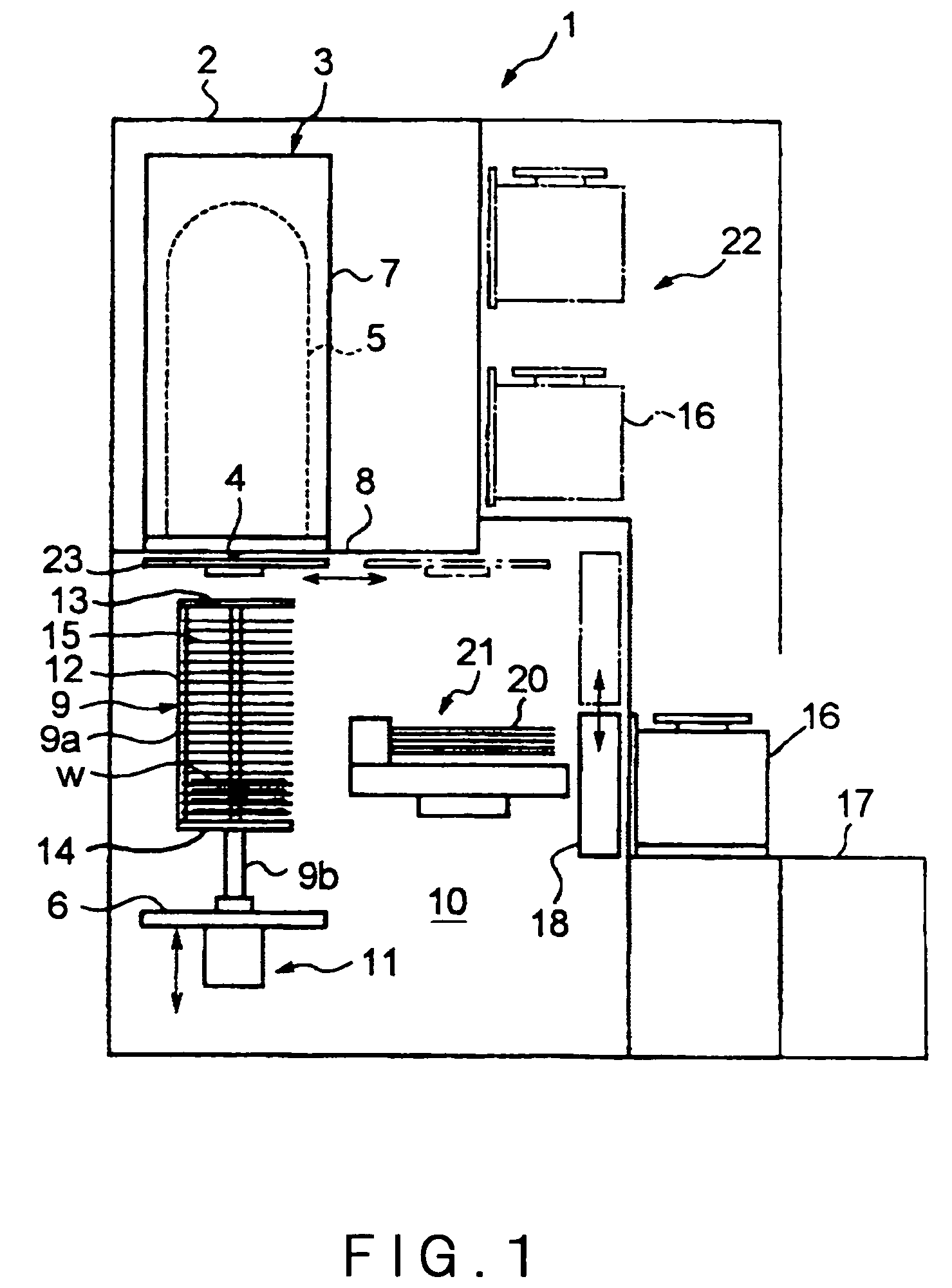

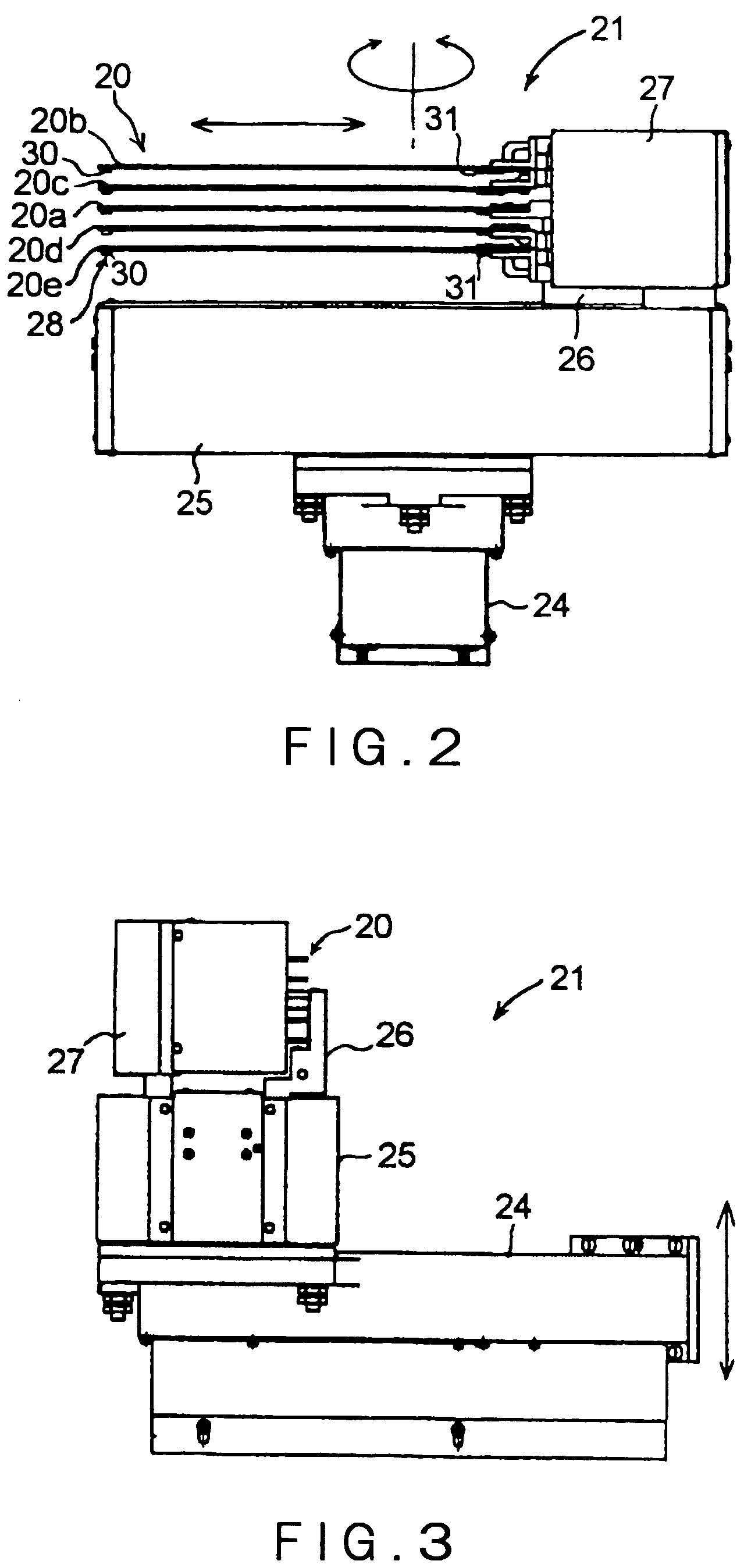

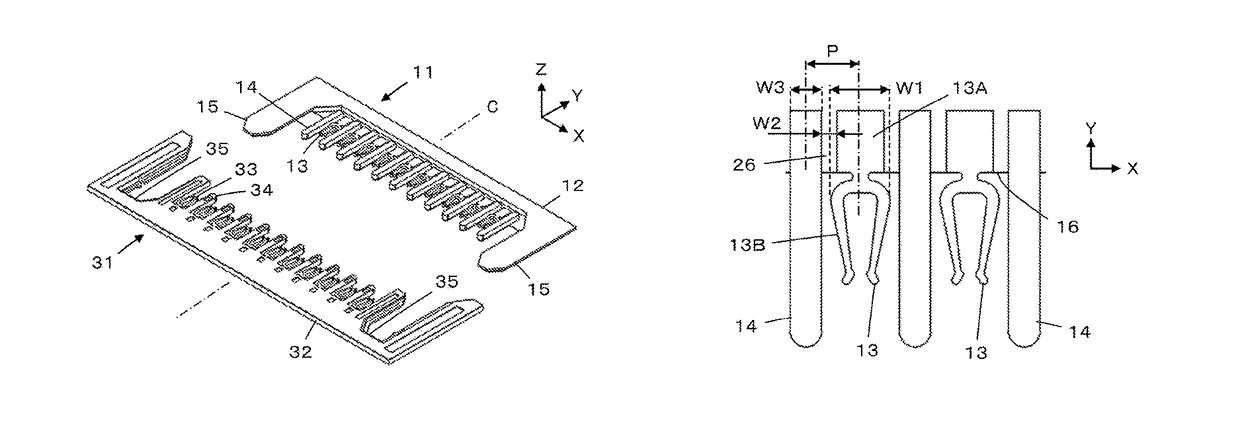

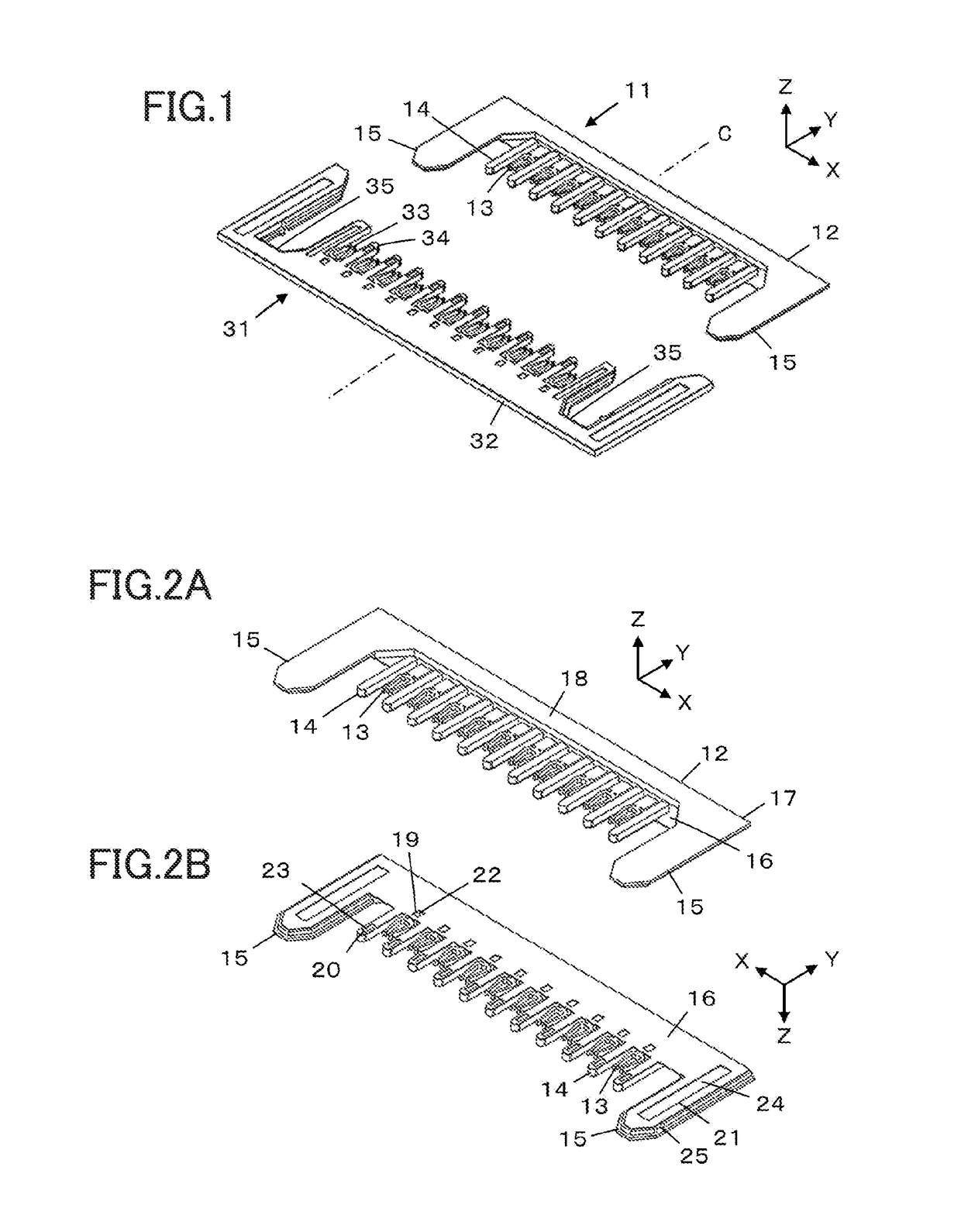

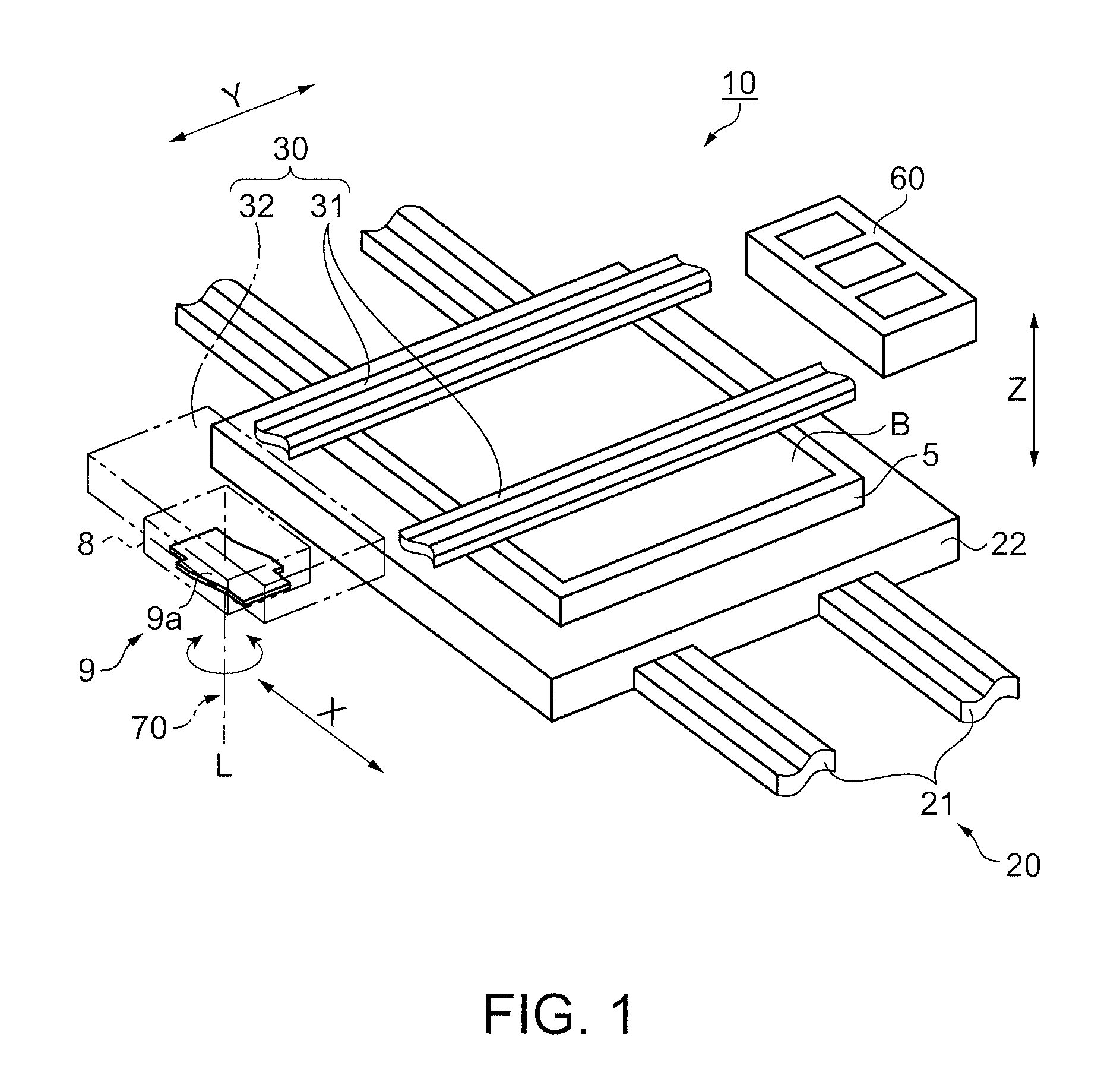

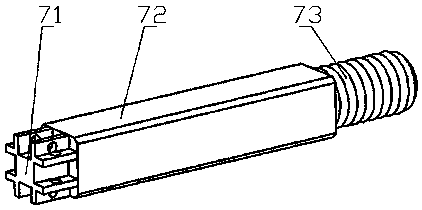

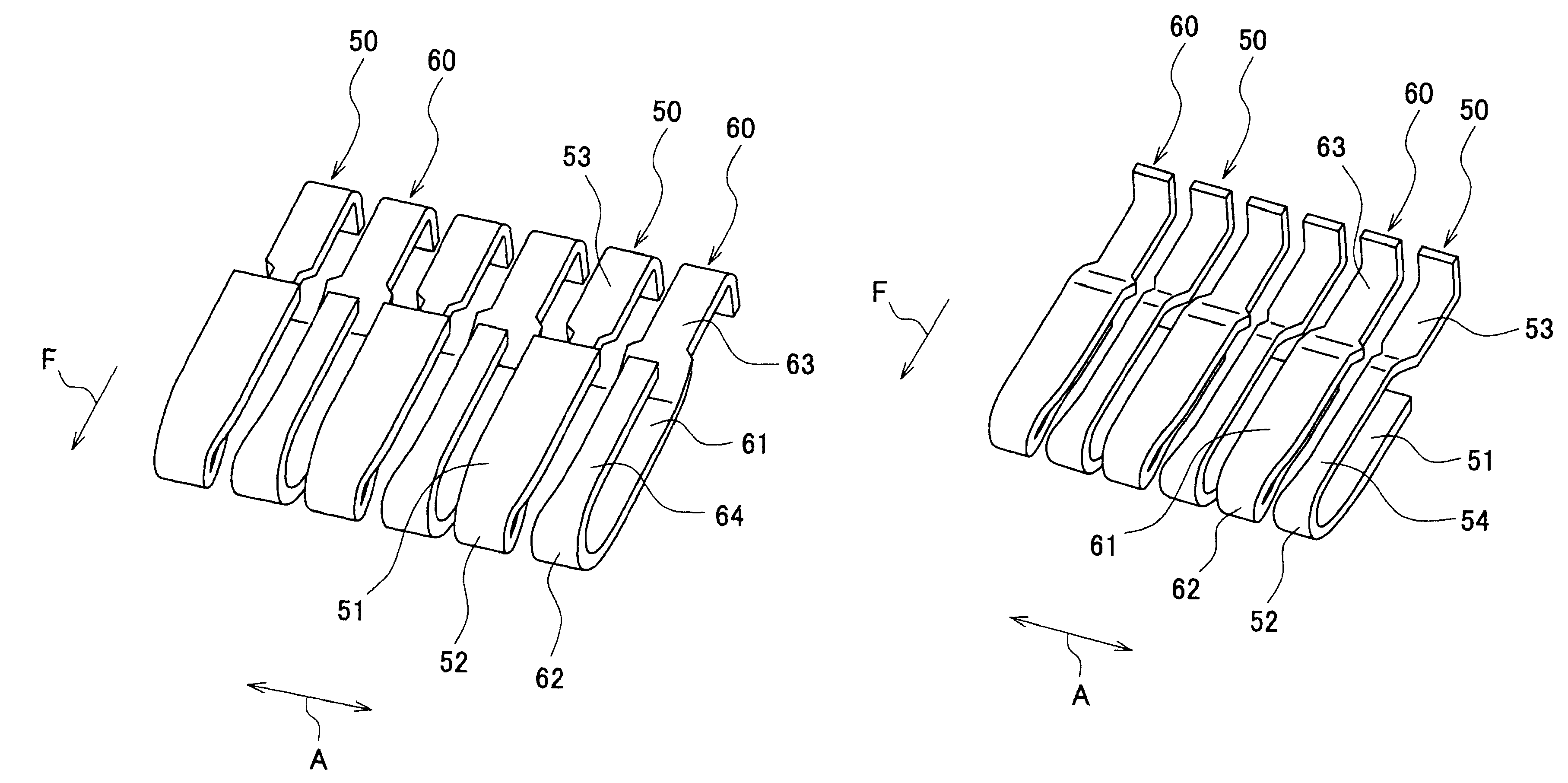

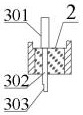

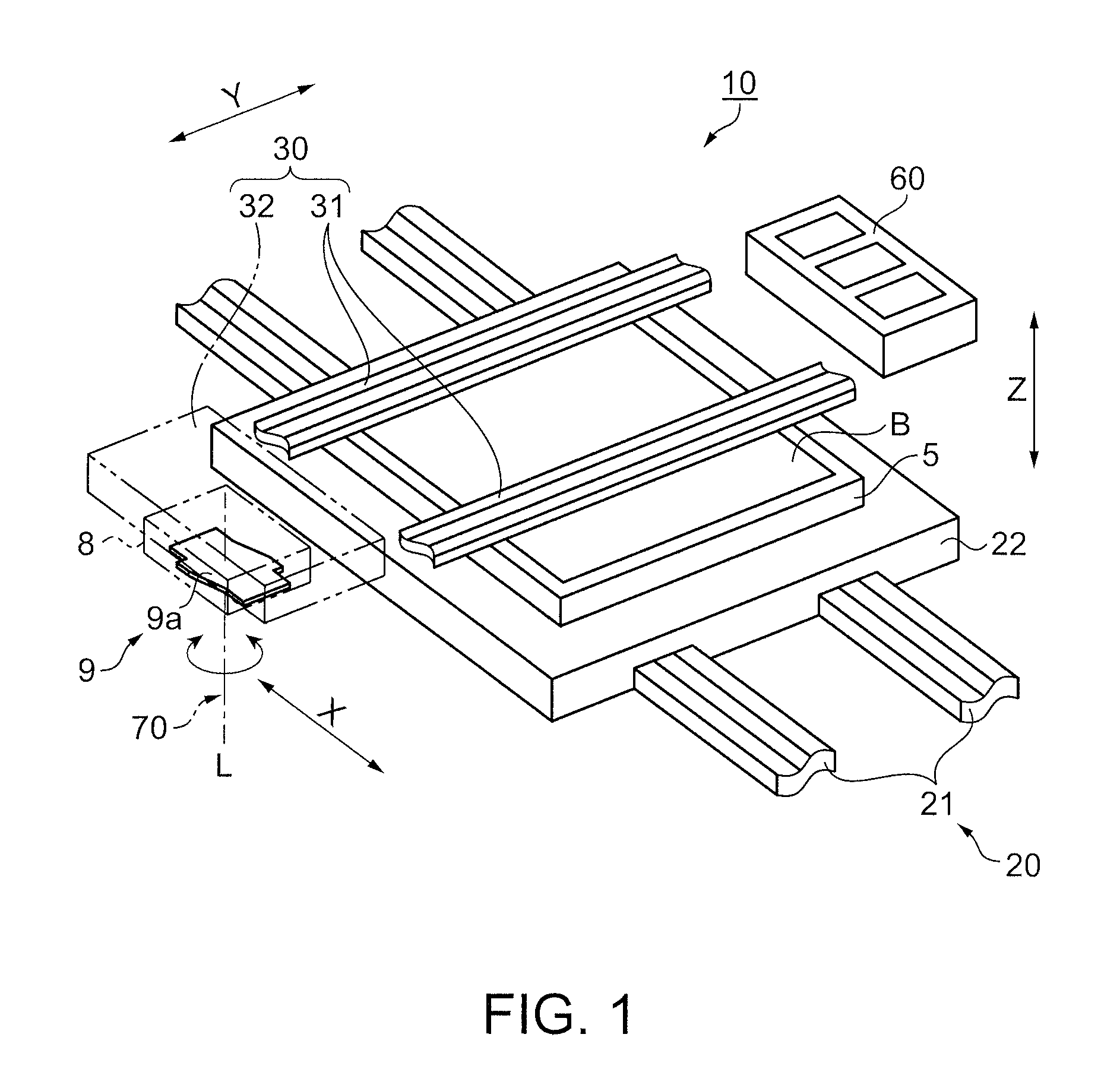

Vertical Heat Treatment System And Method Of Transferring Process Objects

InactiveUS20070199860A1Avoid collisionImprove gripConveyorsMuffle furnacesEngineeringTransfer mechanism

Disclosed is an improved transfer mechanism 21 that transfers, in a vertical heat treatment system, process objects W between a container (carrier) 16 for containing therein plural process objects, and a holder (boat) 9 for holding plural process objects at vertical intervals via ring-shaped support plates 15. The transfer mechanism 21 includes plural substrate support devices 21 spaced at intervals, and each of the substrate support devices 21 has a gripping mechanism 28 for gripping a process object W on the under side of the respective one of the substrate support devices 20. The gripping mechanism 28 includes a fixed engagement member 30 fixedly provided on a distal end of the substrate support device 20 to be engaged with a front edge of a process object W, and a movable engagement member 31 movably attached to a proximal end of the substrate support device 20 to be engaged with a rear edge of the process object W. Plural process objects W can be rapidly, securely transferred at the same time. A simple structure of the gripping mechanism 28 reduces the thickness of the substrate support device 21, so that the intervals of the ring-shaped support plates 15 can be reduced. Thus, the number of process objects to be simultaneously treated in a heat treatment furnace can be increased. As a result, improvement in throughput can be achieved.

Owner:TOKYO ELECTRON LTD

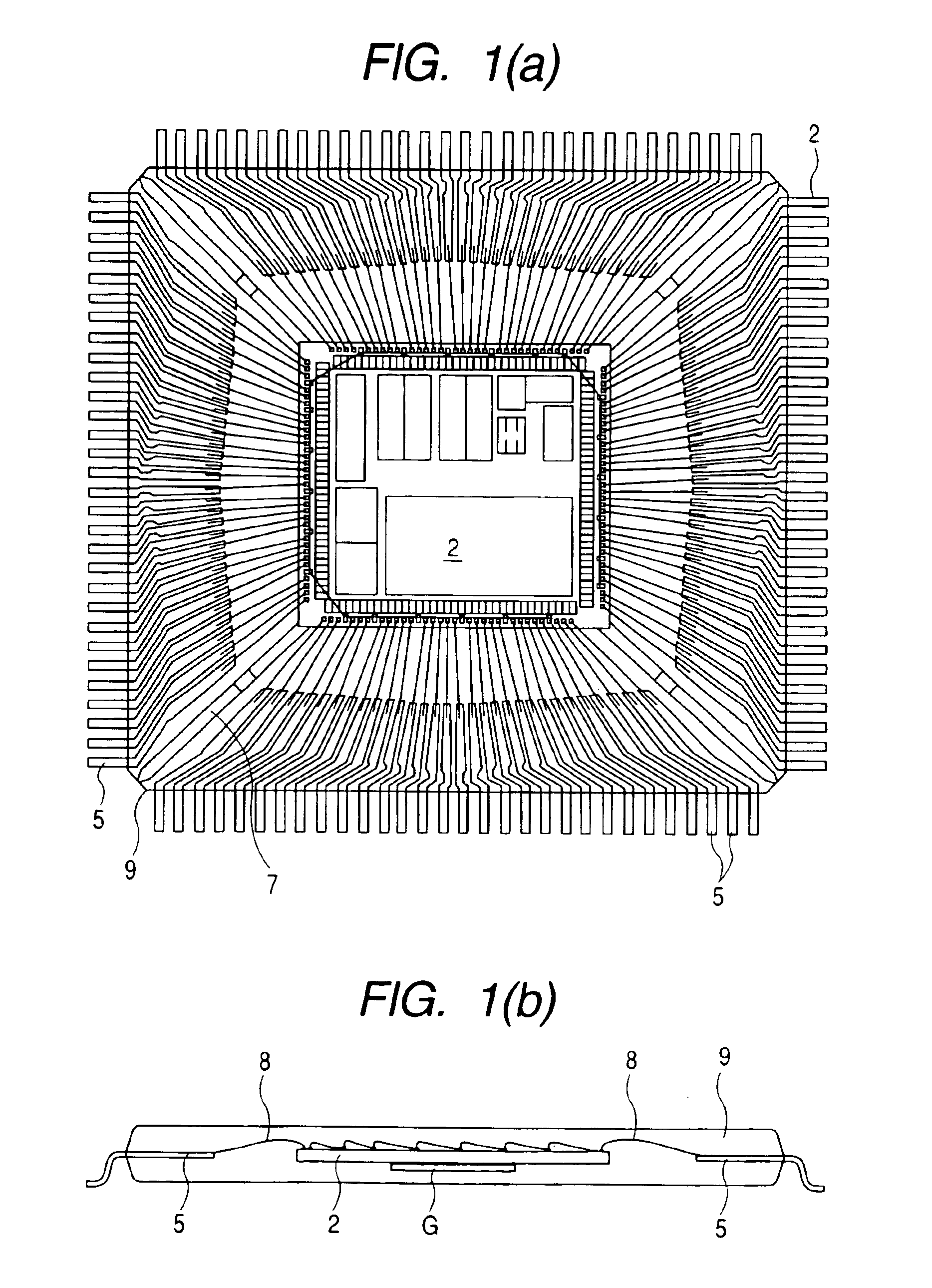

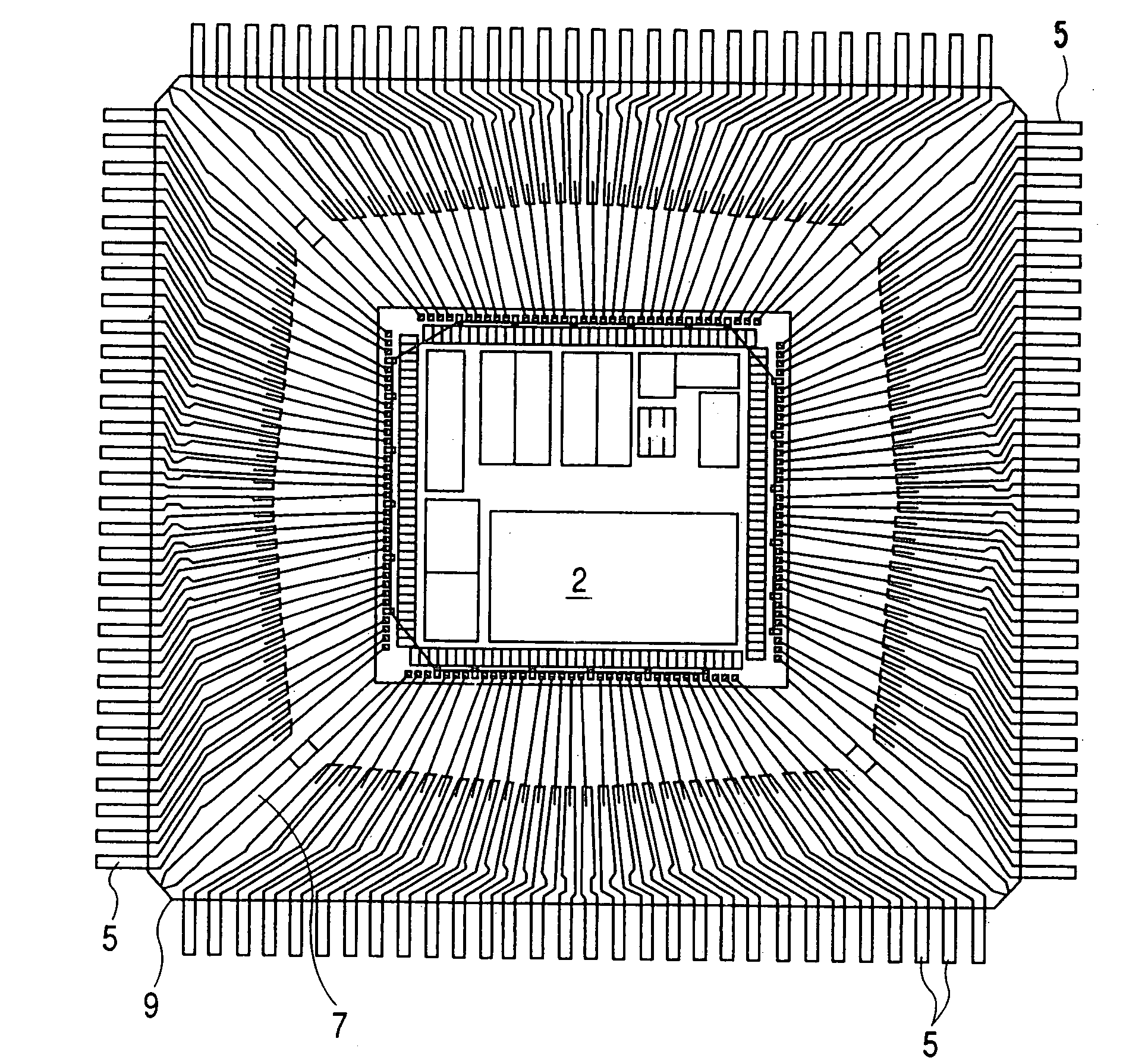

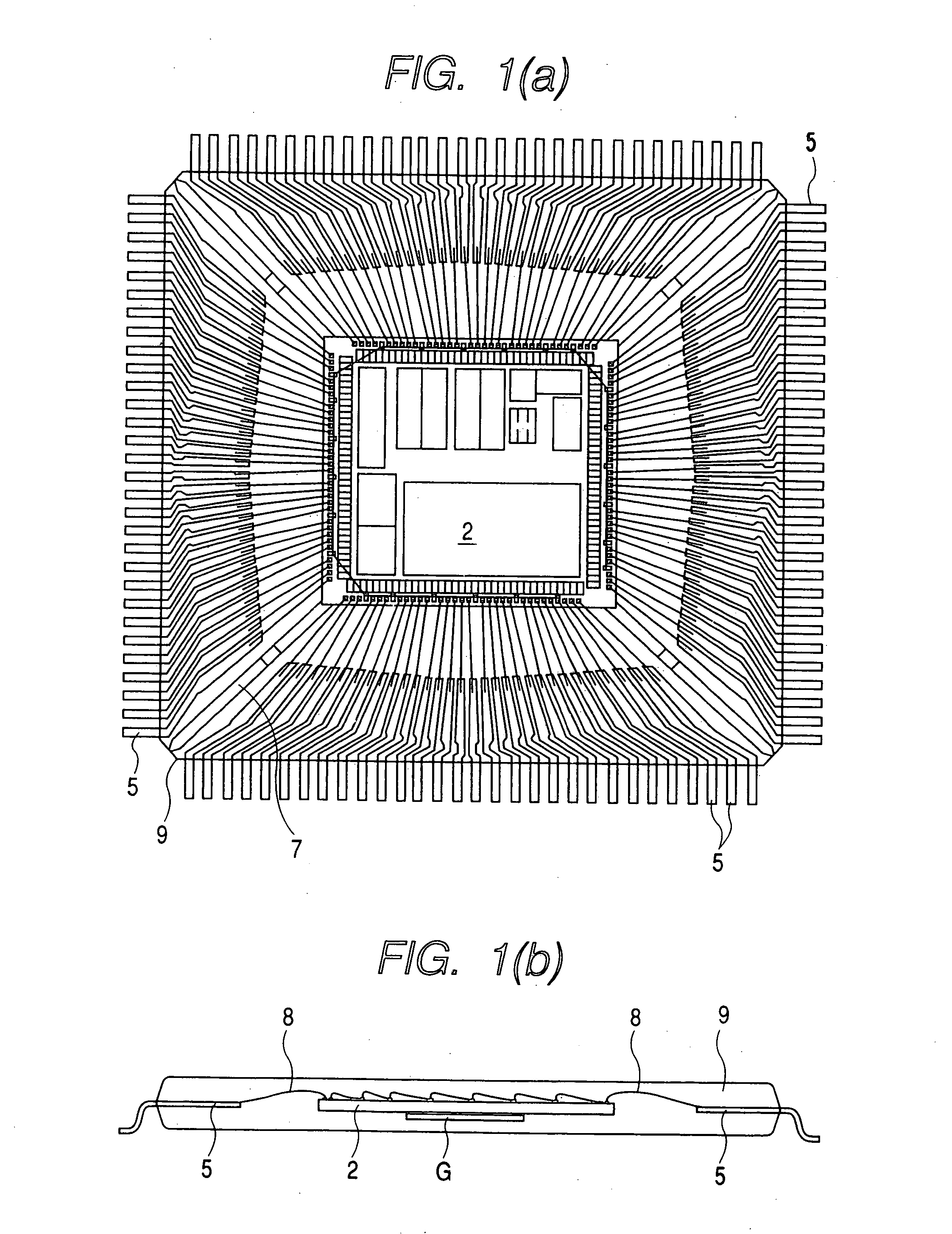

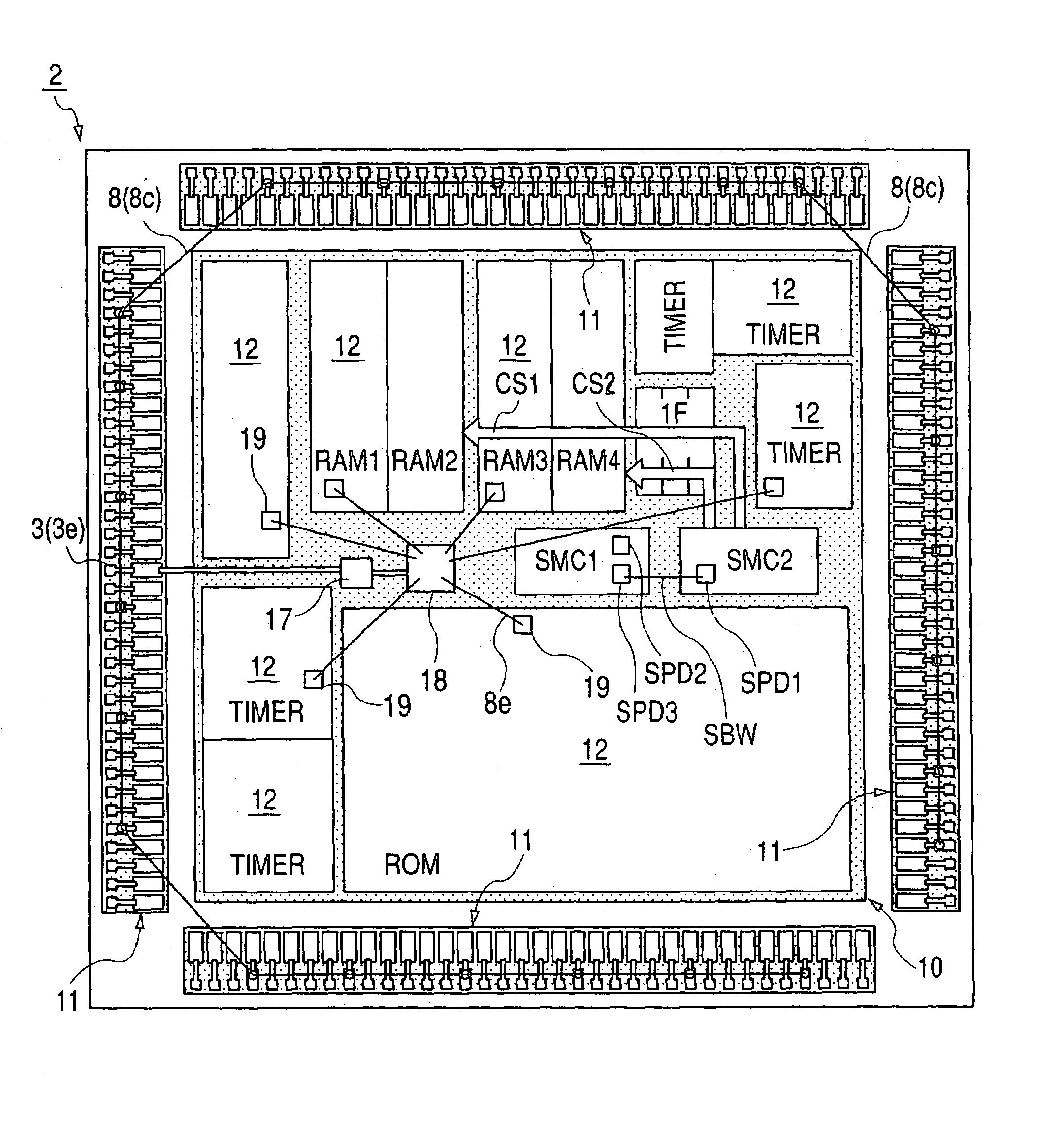

Semiconductor device

InactiveUS6930380B2Reduce in quantityCurb bendingTransistorSemiconductor/solid-state device detailsSemiconductor chipEngineering

A semiconductor device includes a semiconductor chip, a plurality of bonding pads which are formed on a main surface of the semiconductor chip and include first power source bonding pads, second power source bonding pads and a plurality of signal bonding pads, a plurality of leads which are arranged around the semiconductor chip and include first power source leads and a plurality of signal leads, a plurality of bonding wires which include first bonding wires for connecting the first power source bonding pads with the first power source leads, second bonding wires for connecting the first bonding pads with second bonding pads and third bonding wires for connecting the plurality of signal bonding pads with the plurality of signal leads, and a sealing body which seals the semiconductor chip, the plurality of bonding wires and some of the plurality of leads.

Owner:RENESAS ELECTRONICS CORP +1

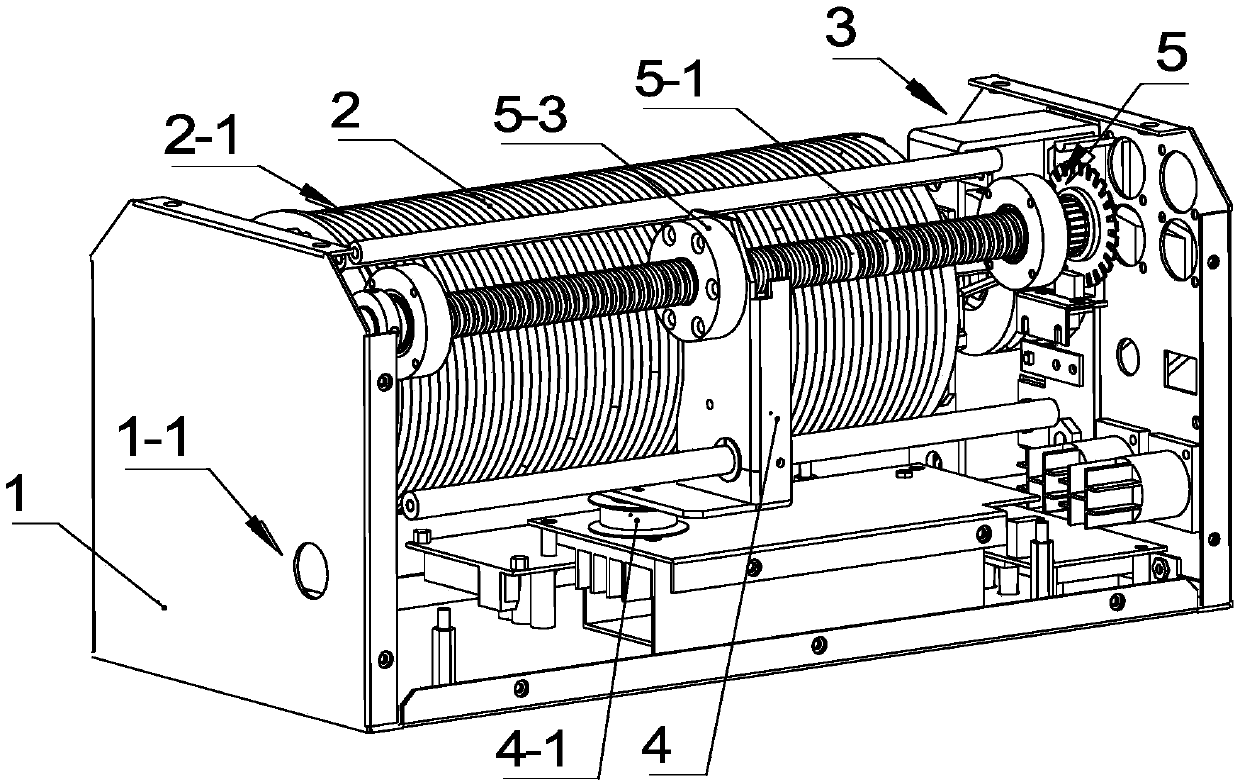

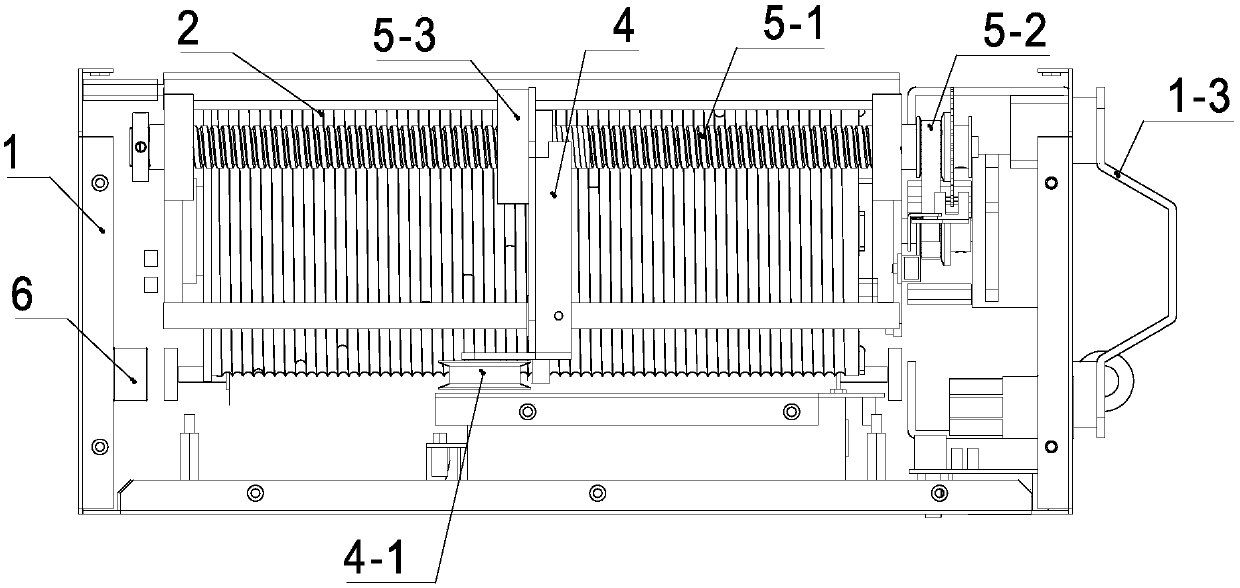

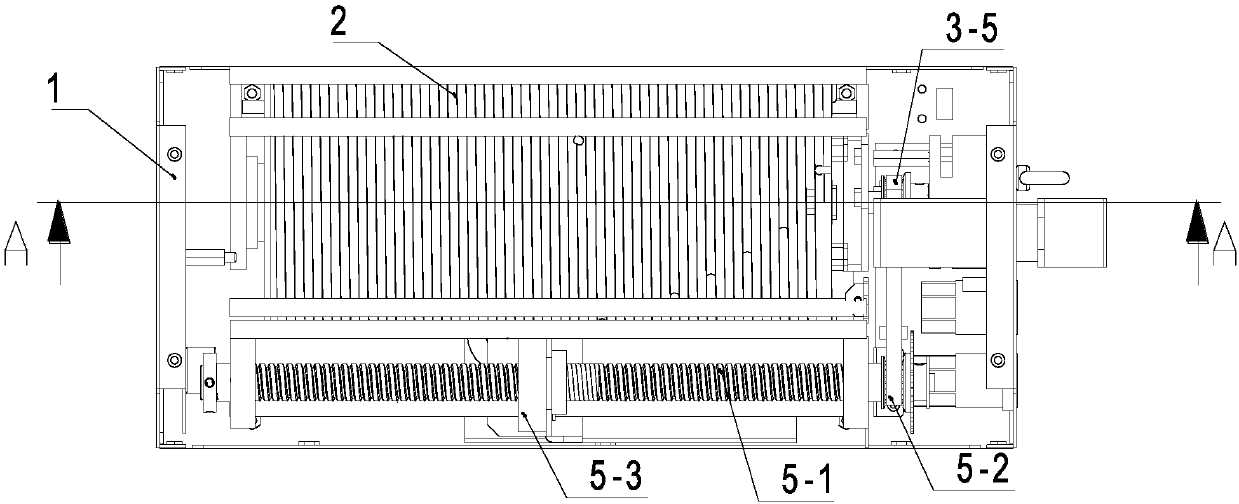

Compact type lifting device

PendingCN108017001AIncreased rewindable lengthLarge lifting strokeLighting support devicesWinding mechanismsEngineeringMechanical engineering

Owner:广东艺尚灯光科技有限公司

Semiconductor device having a switch circuit

InactiveUS20060060965A1Curb bendingIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A semiconductor device includes a semiconductor chip, a plurality of bonding pads which are formed on a main surface of the semiconductor chip and include first power source bonding pads, second power source bonding pads and a plurality of signal bonding pads, a plurality of leads which are arranged around the semiconductor chip and include first power source leads and a plurality of signal leads, a plurality of bonding wires which include first bonding wires for connecting the first power source bonding pads with the first power source leads, second bonding wires for connecting the first bonding pads with second bonding pads and third bonding wires for connecting the plurality of signal bonding pads with the plurality of signal leads, and a sealing body which seals the semiconductor chip, the plurality of bonding wires and some of the plurality of leads.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device having a switch circuit

InactiveUS7078824B2Curb bendingIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor device includes a semiconductor chip, a plurality of bonding pads which are formed on a main surface of the semiconductor chip and include first power source bonding pads, second power source bonding pads and a plurality of signal bonding pads, a plurality of leads which are arranged around the semiconductor chip and include first power source leads and a plurality of signal leads, a plurality of bonding wires which include first bonding wires for connecting the first power source bonding pads with the first power source leads, second bonding wires for connecting the first bonding pads with second bonding pads and third bonding wires for connecting the plurality of signal bonding pads with the plurality of signal leads, and a sealing body which seals the semiconductor chip, the plurality of bonding wires and some of the plurality of leads.

Owner:RENESAS ELECTRONICS CORP

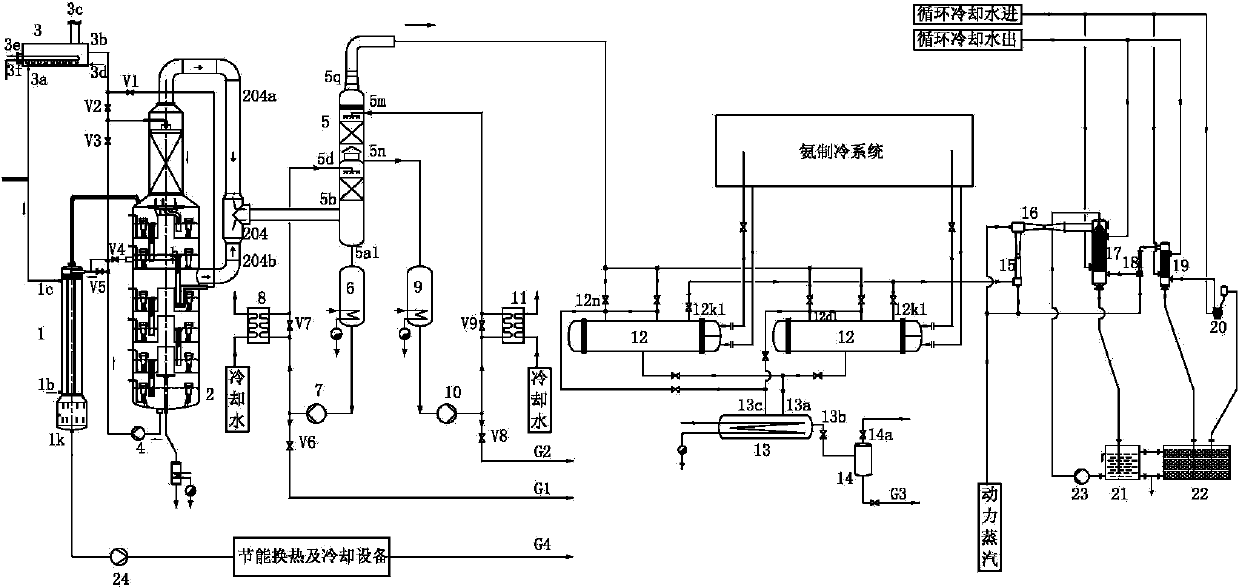

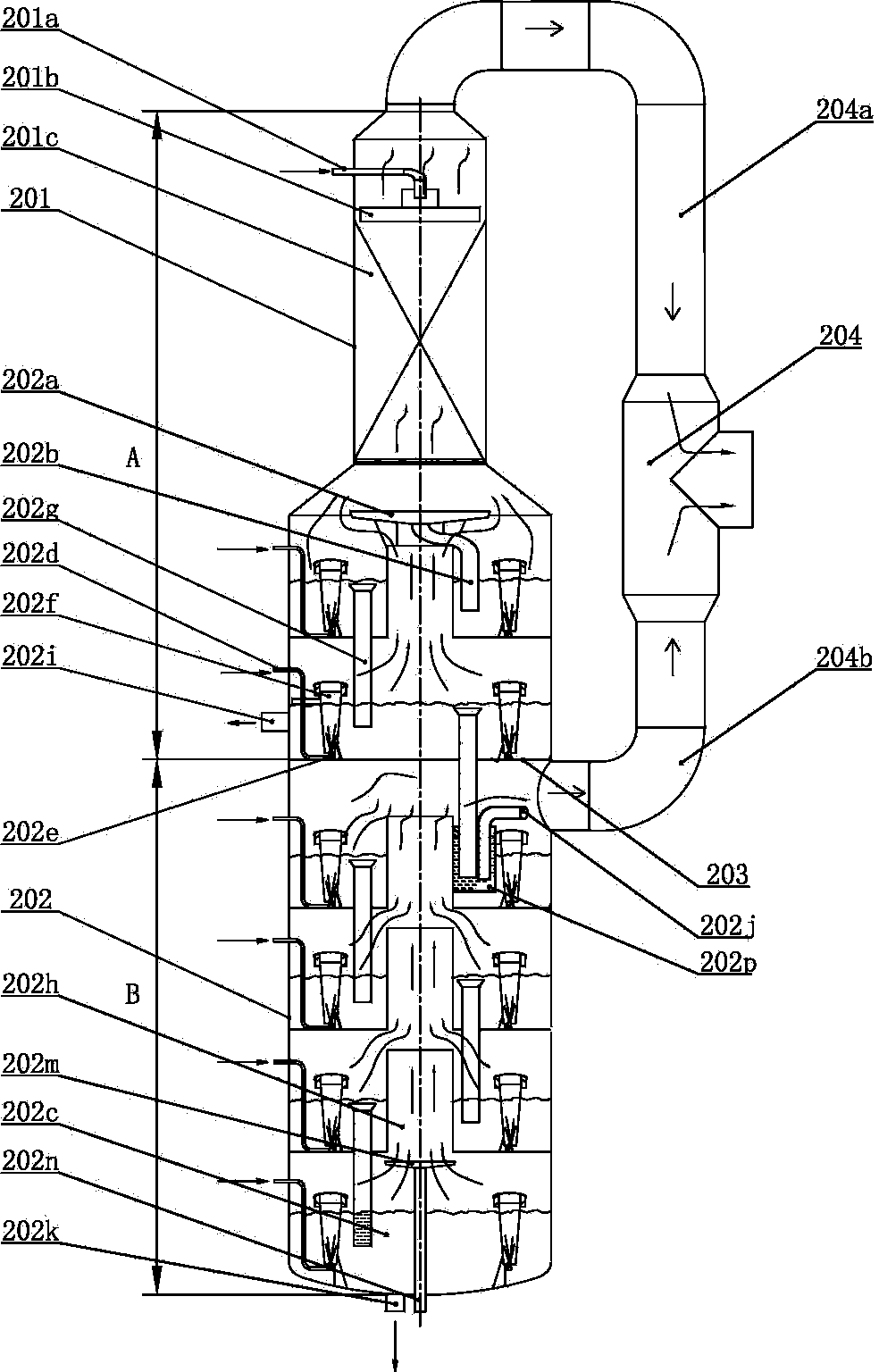

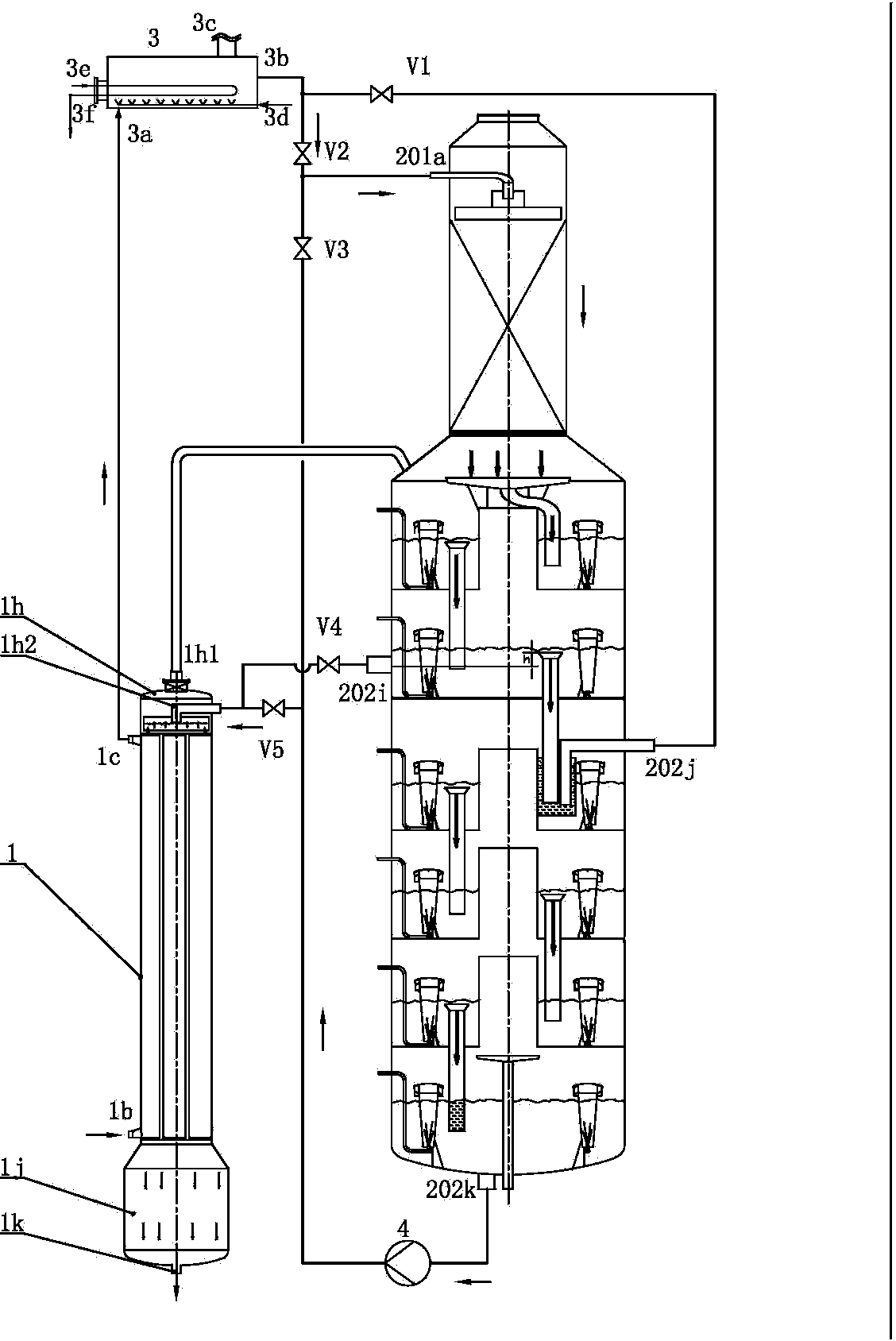

Vegetable oil deodorization system

ActiveCN104046512AGuaranteed unobstructedIncrease contentOrganic chemistryFatty acids production/refiningVacuum pumpingVegetable oil

The invention relates to a vegetable oil deodorization system. A packing segment is arranged at the upper part of a deodorization tower; a plate tower segment is arranged at the lower part of the deodorization tower; the top of an upper shell is connected with packing segment vacuum-pumping pipes; plate tower segment vacuum-pumping pipes connected to a lower shell of the deodorization tower at the upper part of the plate tower segment are respectively connected with an overall vacuum-pumping pipe; a plurality of oil distribution holes are distributed in a baseplates of oil distribution disks of vacuum oil heat exchangers; the projections of all the oil distribution holes are uniformly distributed at the peripheries of upper pipe openings of array pipes of the corresponding heat exchangers; a plurality of sawtooth grooves are uniformly distributed in the circumferences of the upper pipe openings of the array pipes of all the heat exchangers; a deodorization distillate capturing tower is divided into an upper segment and a lower segment, gas phases of which are communicated; a vitamin E capturing packing layer is arranged at the lower part of the deodorization distillate capturing tower; a fatty acid capturing packing layer is arranged above the deodorization distillate capturing tower; the vitamin E capturing packing layer and the fatty acid capturing packing layer are respectively used for capturing vitamin E and fatty acid; a dry-type freezing condenser is formed by a plurality of primary condensers which are connected in parallel and then connected in series with secondary condensers; the arrangement spacing of refrigerant array pipes is gradually reduced along an air feeding direction. The vegetable oil deodorization system has a good deodorization effect and realizes energy conservation and environmental friendliness.

Owner:MYANDE GRP CO LTD

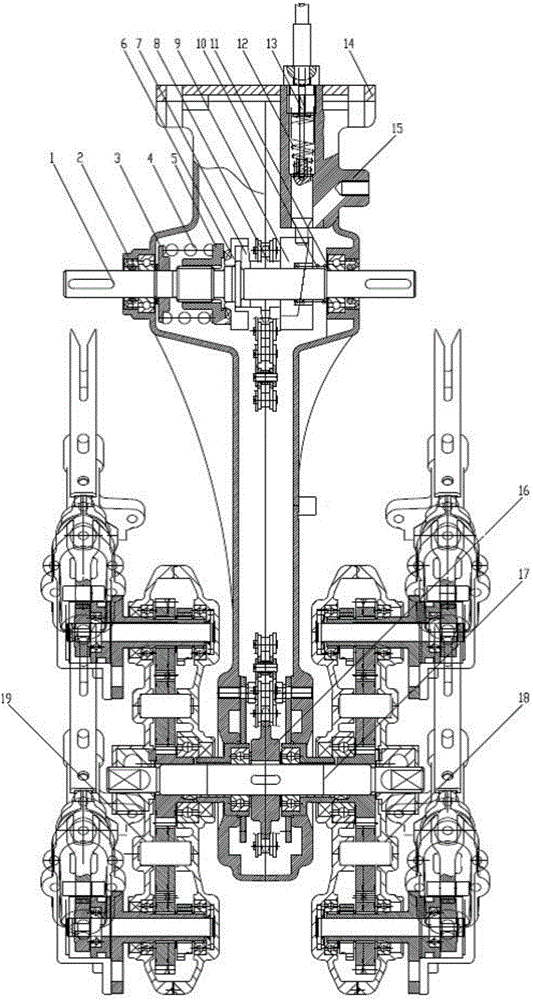

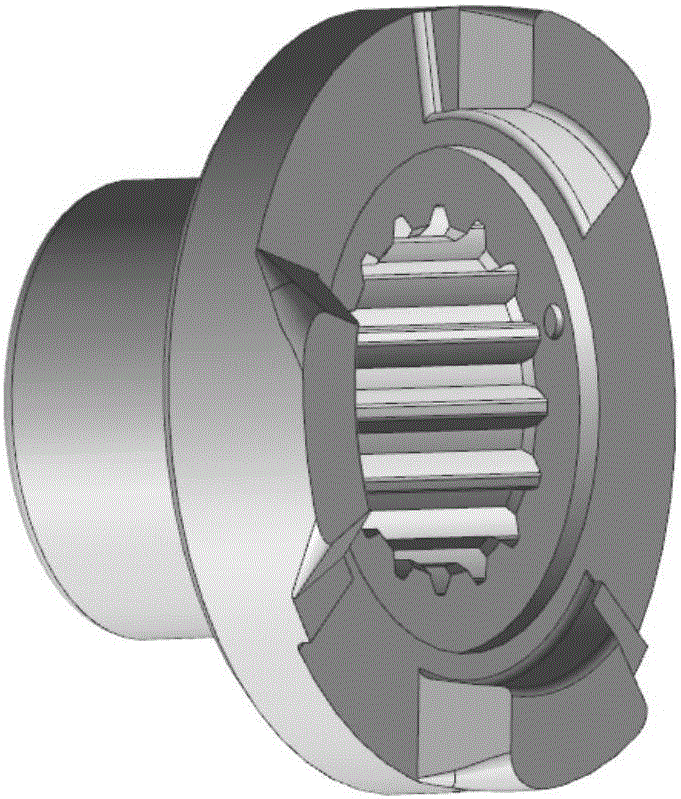

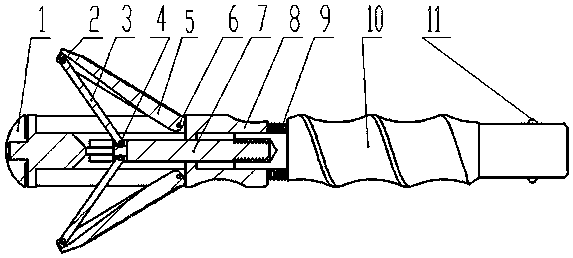

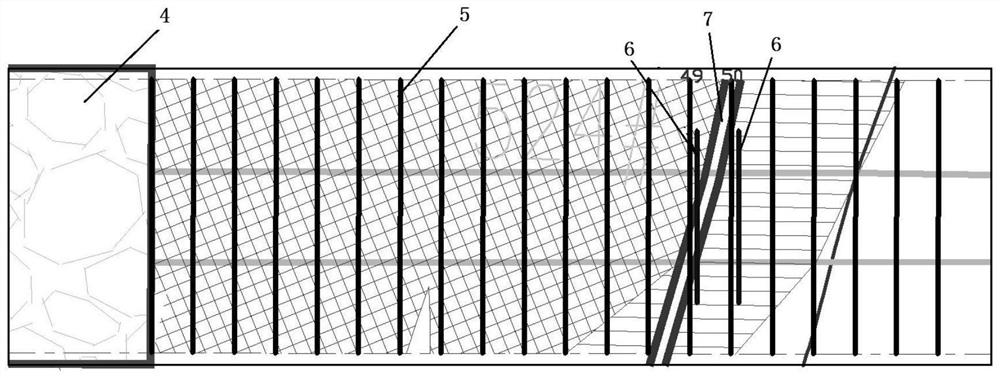

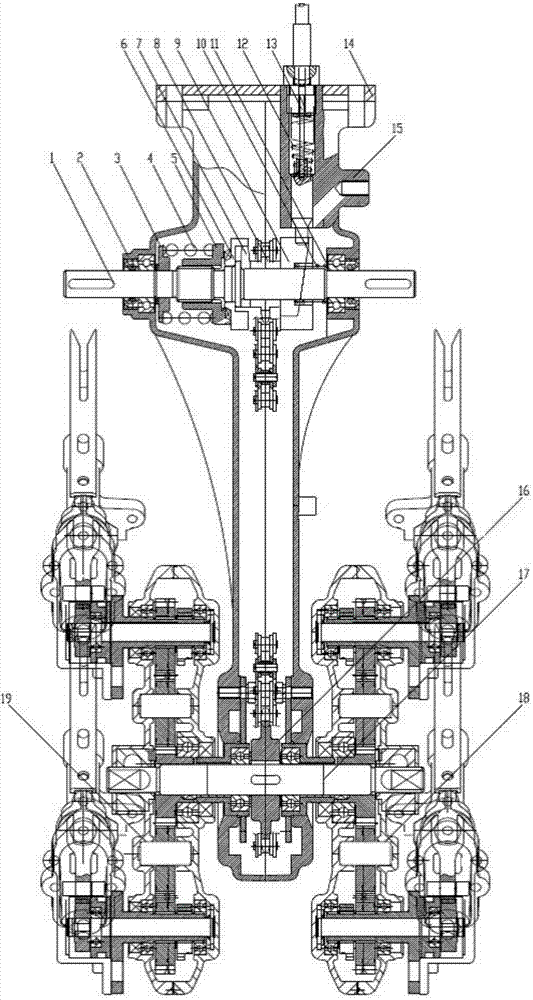

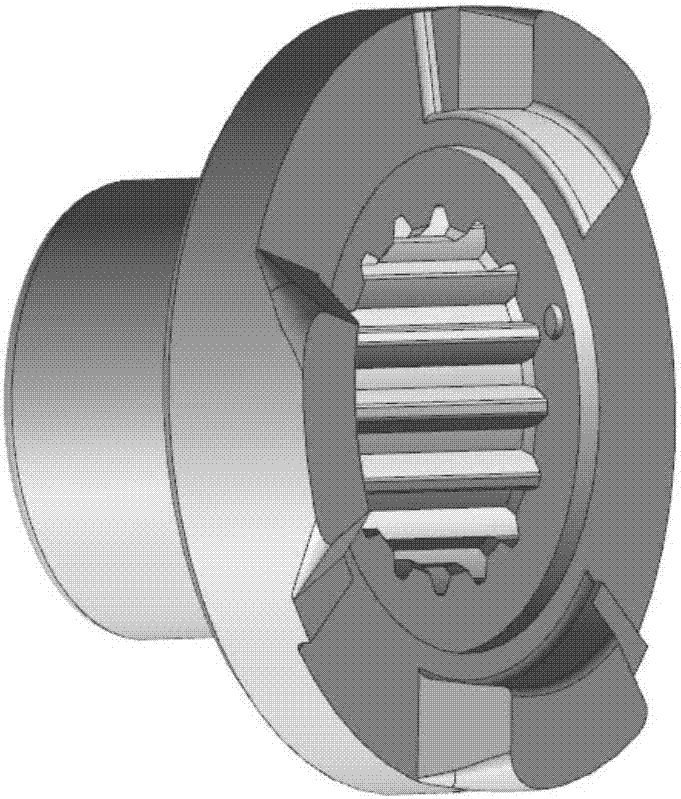

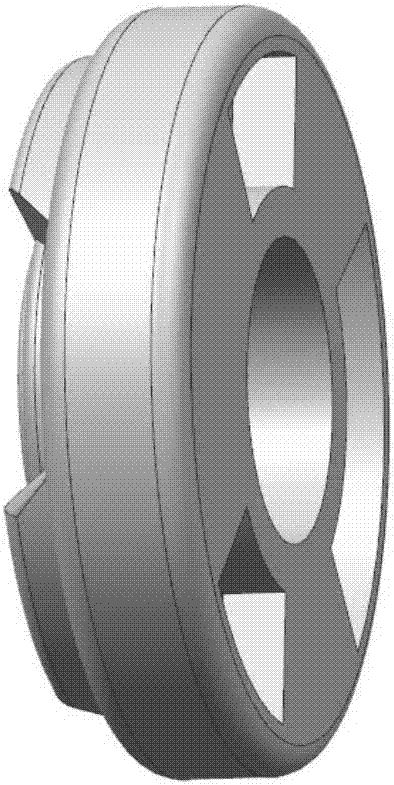

Narrow-spaced transplanting device and method for rice seedlings

The invention discloses a narrow-spaced transplanting device and method for rice seedlings. According to the device, a gear box comprises a left box body and a right box body; a safety spring seat, a safety spring, a safety pressure disc, a safety clutch disc, a claw disc, a drive sprocket, a clutch disc, a clutch spring and a clutch spring seat are mounted on a drive shaft sequentially and form an integrated structure of power transmission and safety protection as well as power interruption and connection, so that the safety of a transplanting mechanism and a power transmission system is effectively protected. The drive shaft is transversely mounted at the front part of the gear box, a driven shaft is mounted at the rear part of the gear box, and the drive shaft and the driven shaft transmit power through chain transmission, accordingly, the overall structure is compact, the structure size of a power transmission system is greatly reduced, the structure of transplanting arms is optimized at the same time, and spacing between the two transplanting arms meets the agronomic requirement of transplanting of rice.

Owner:浙江小精农机制造有限公司

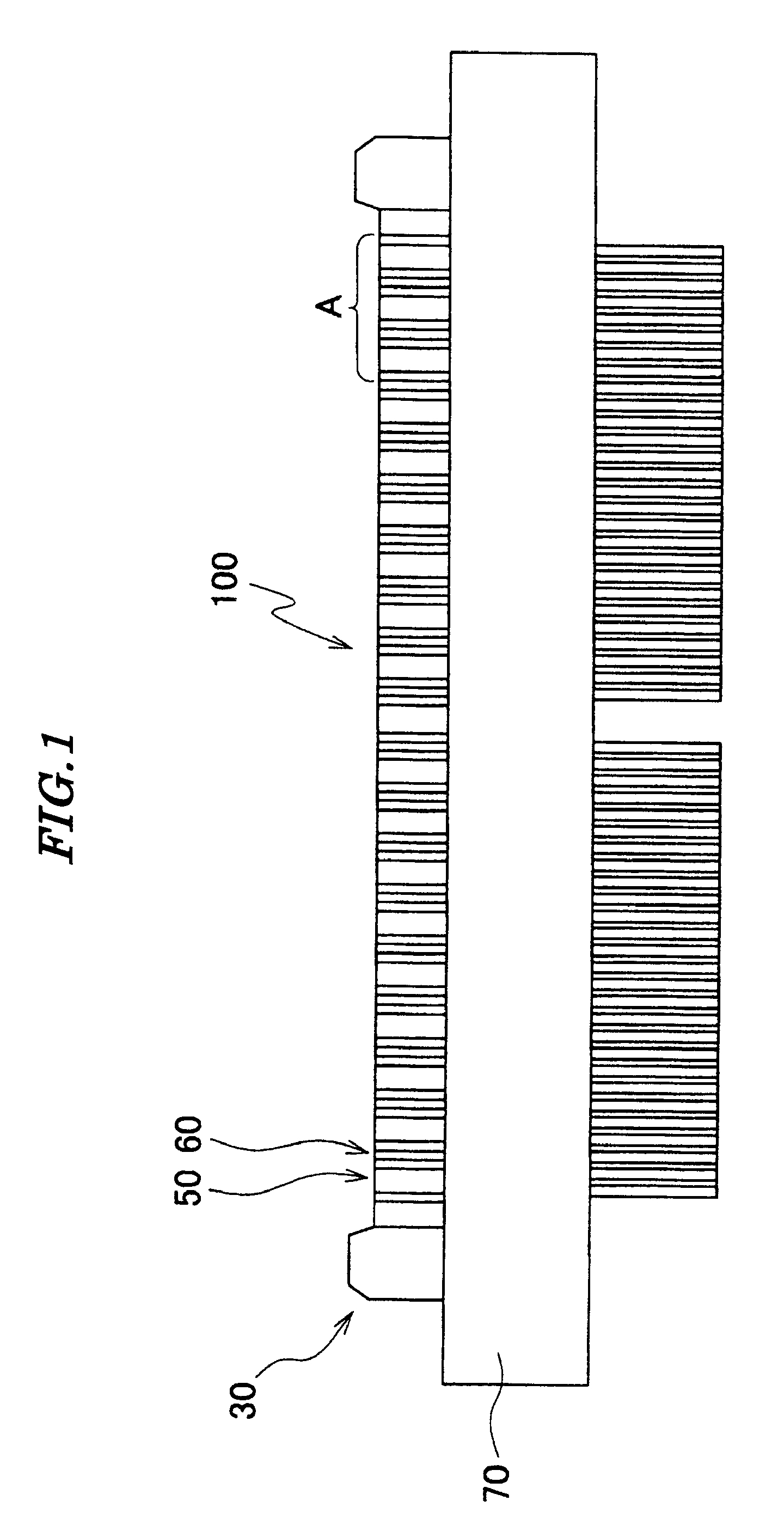

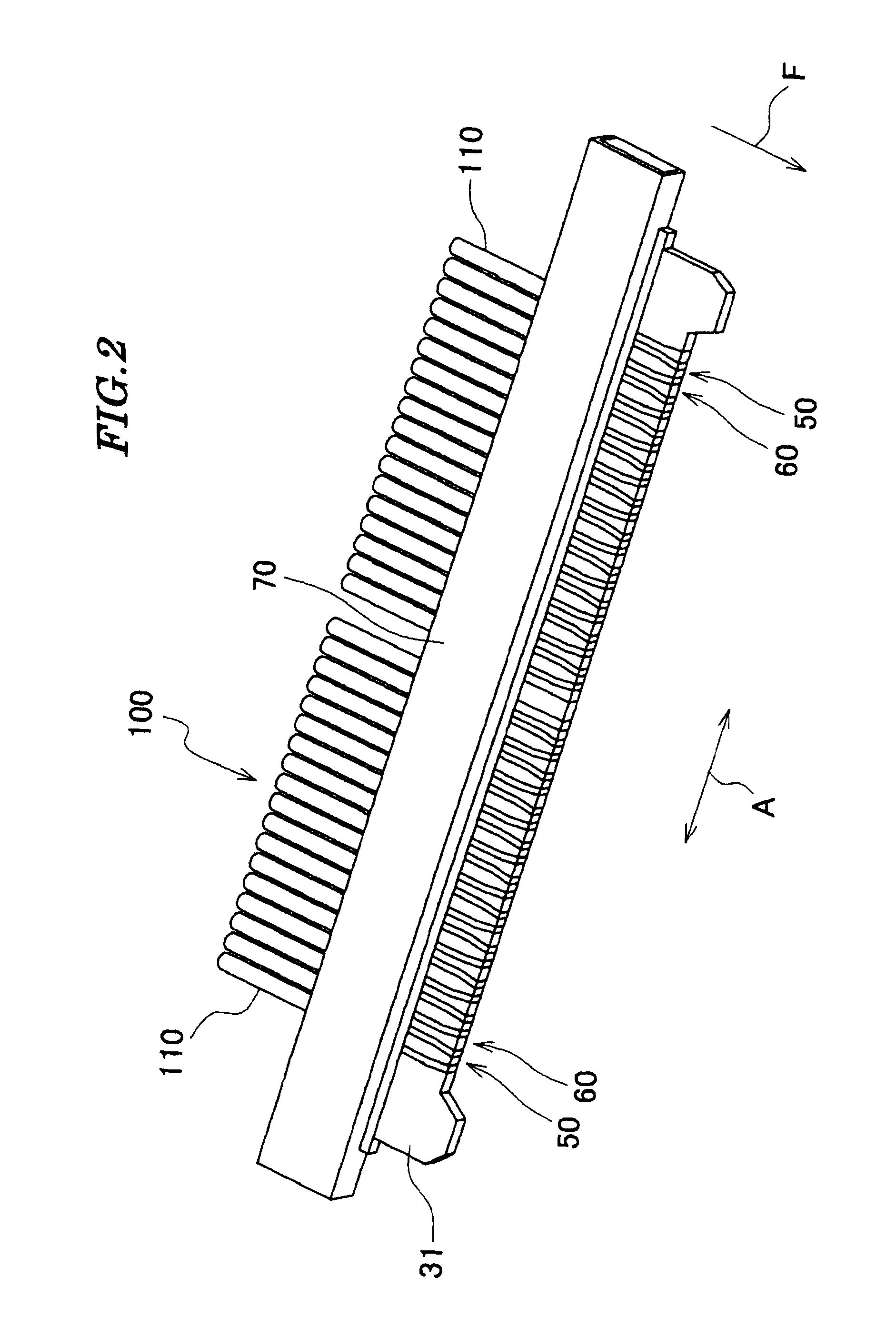

Vertical heat treatment system and method of transferring process objects

InactiveUS7677858B2Shorten the timeSimple structureConveyorsMuffle furnacesEngineeringTransfer mechanism

Disclosed is an improved transfer mechanism that transfers, in a vertical heat treatment system, process objects W between a container (carrier), and a holder (boat) holding plural process objects at vertical intervals. The transfer mechanism includes plural substrate support devices spaced at intervals, and each of the substrate support devices has a gripping mechanism for gripping a process object on the under side. The gripping mechanism includes a fixed engagement member on a distal end of the substrate support device, and a movable engagement member movably attached to a proximal end of the substrate support device.

Owner:TOKYO ELECTRON LTD

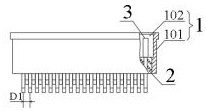

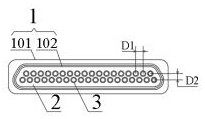

Connector

ActiveUS9601884B2Reduce the row spacingSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

Owner:JAPAN AVIATION ELECTRONICS IND LTD

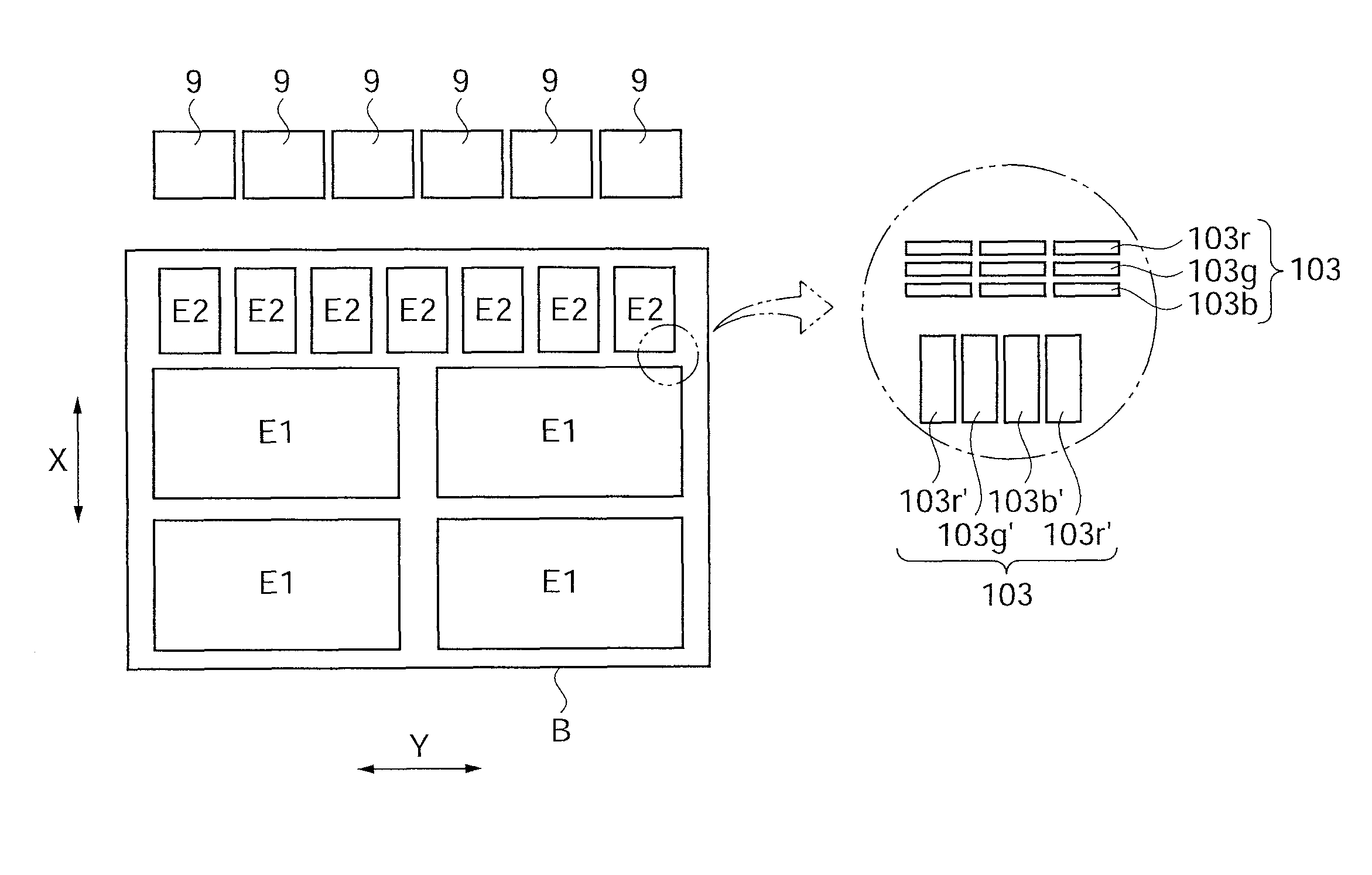

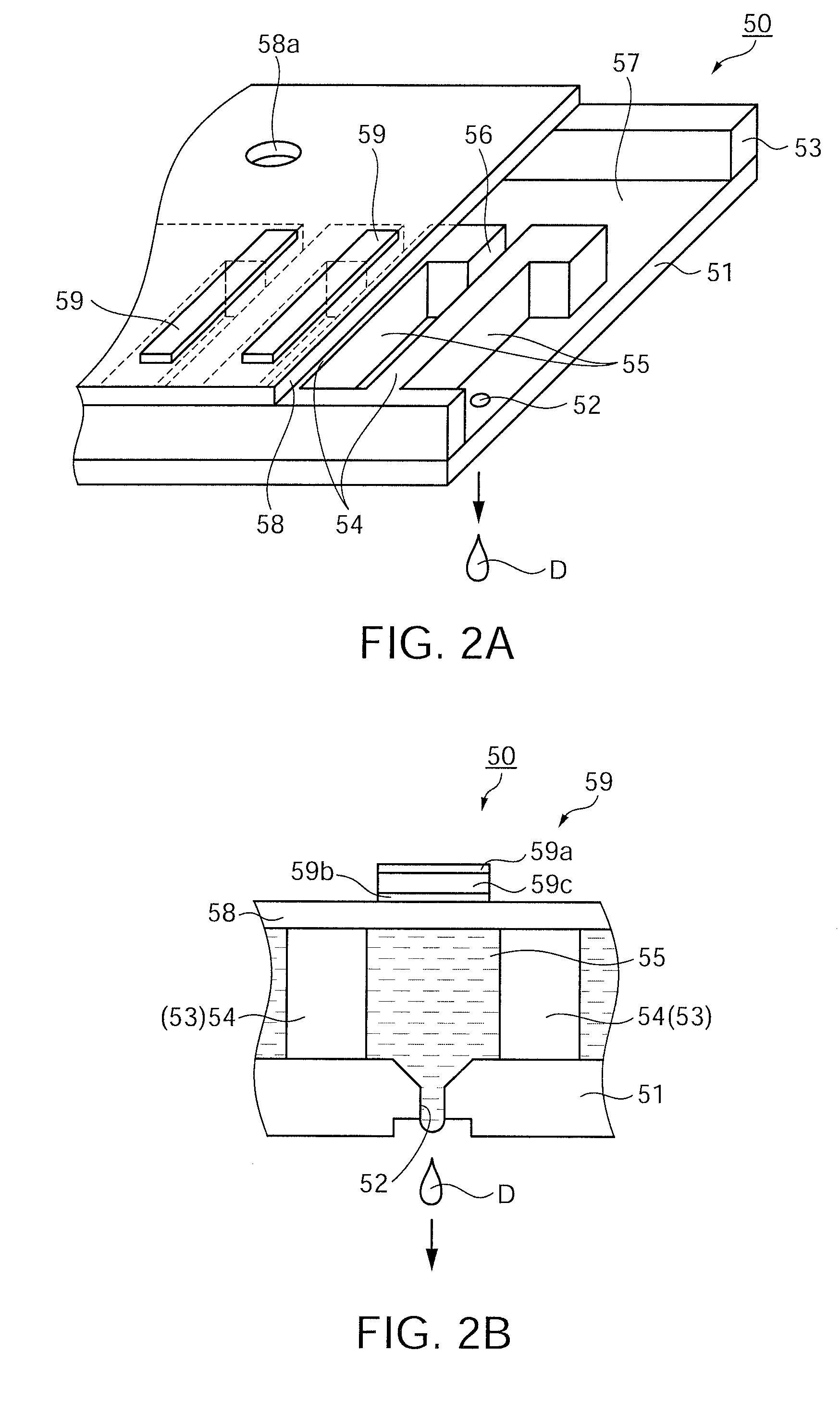

Method for discharging liquid body, method for manufacturing color filter, and method for manufacturing organic EL device

ActiveUS8580335B2Quality improvementImprove productivitySolid-state devicesBleaching apparatusEngineeringLiquid drop

Owner:KATEEVA

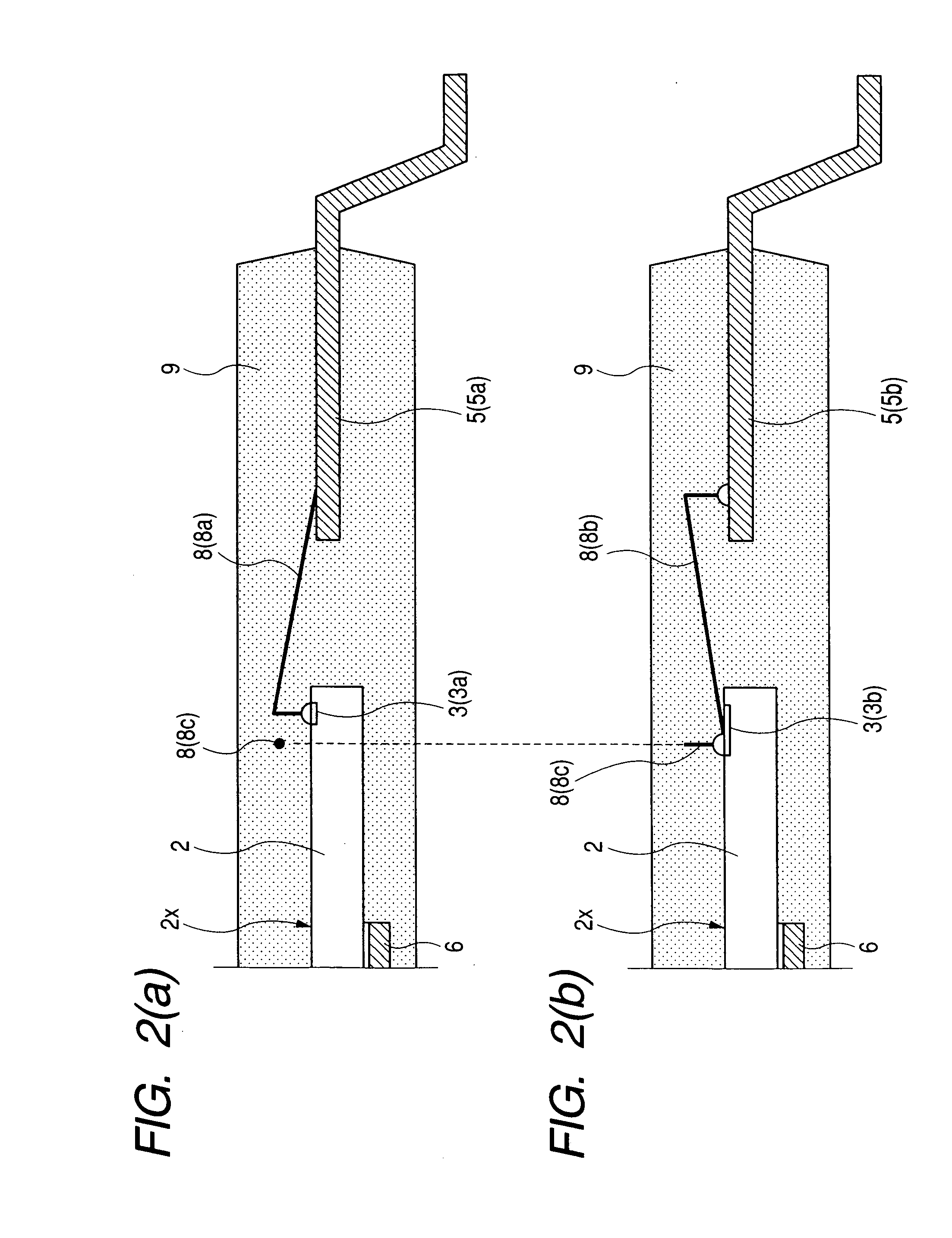

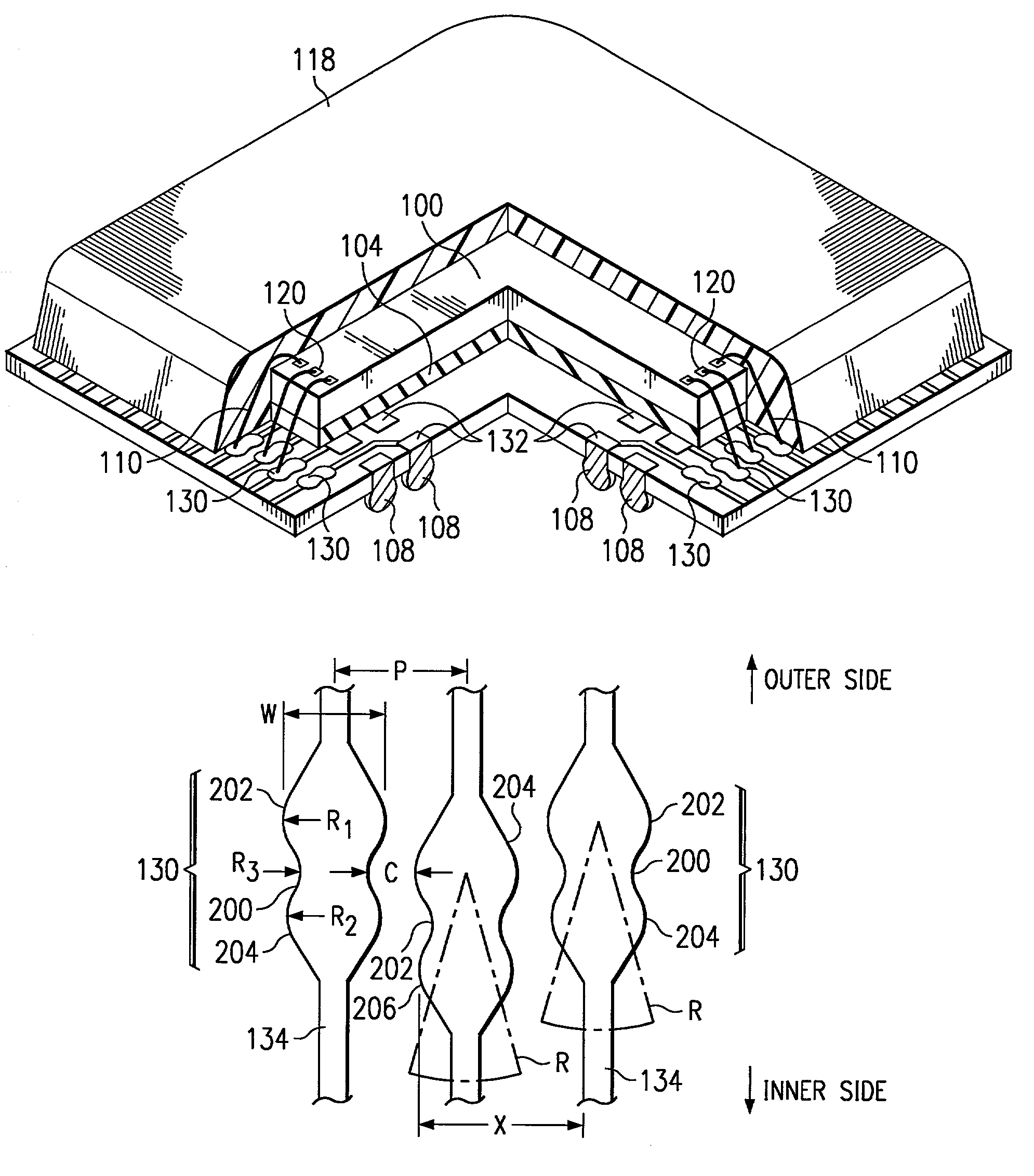

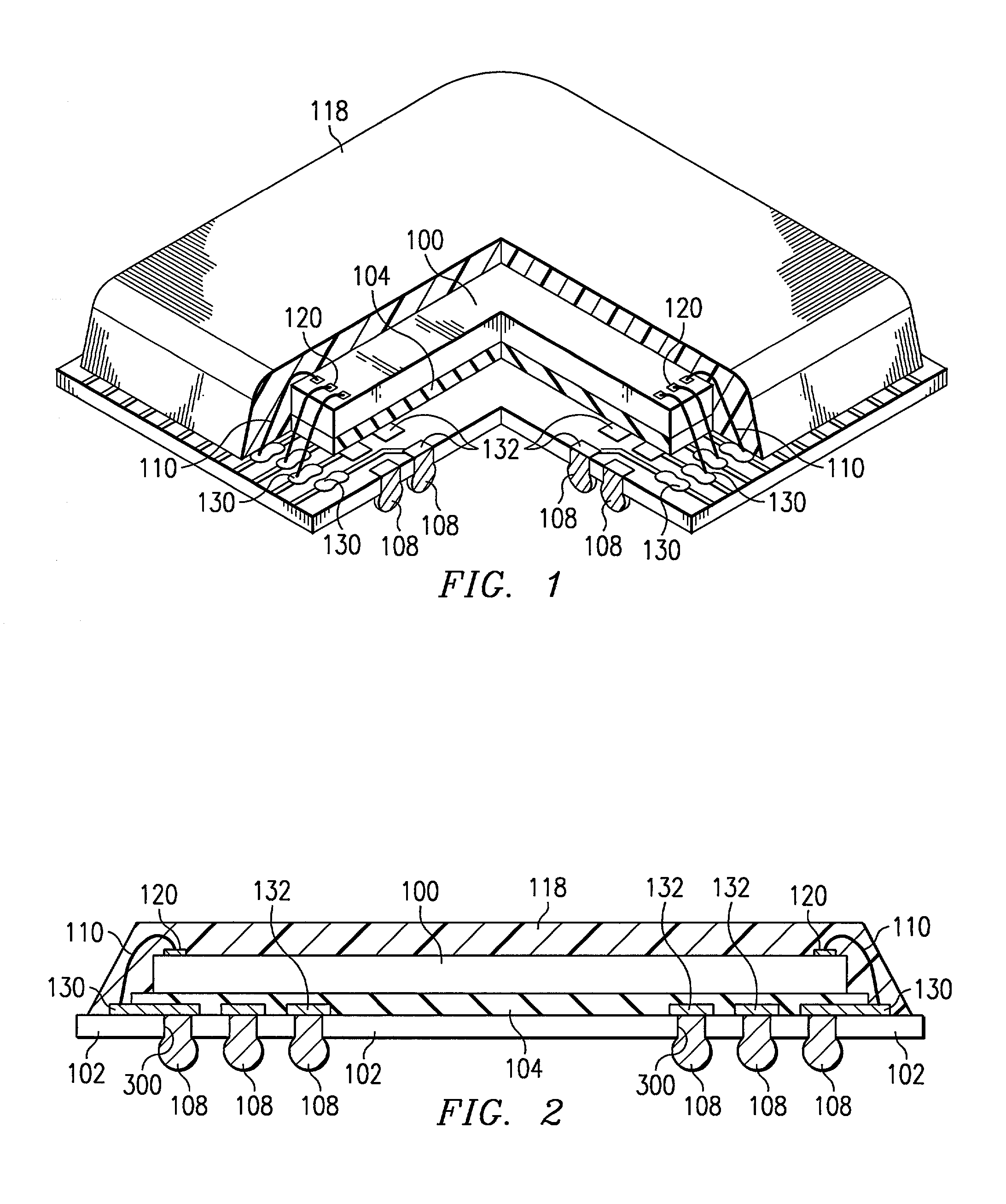

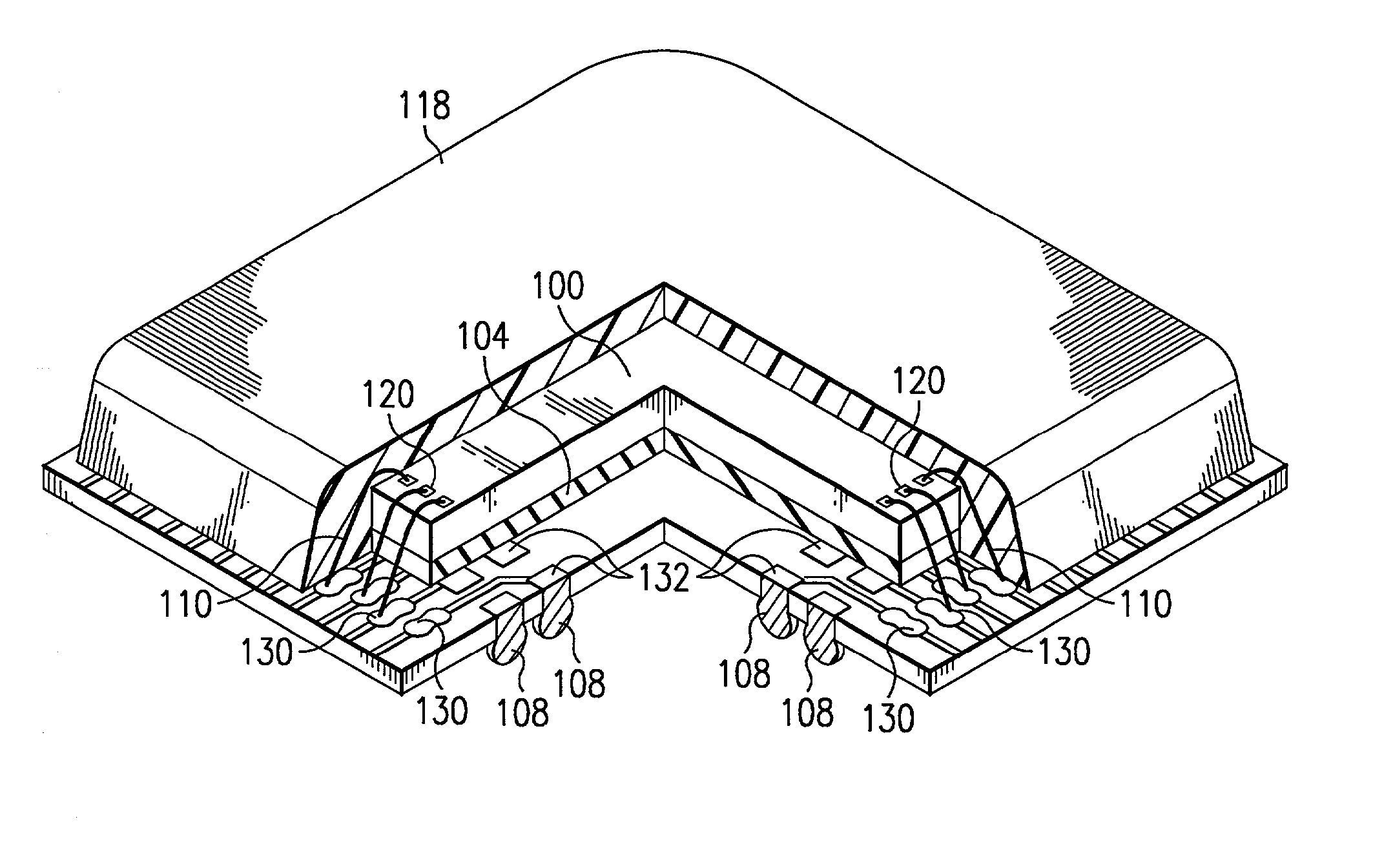

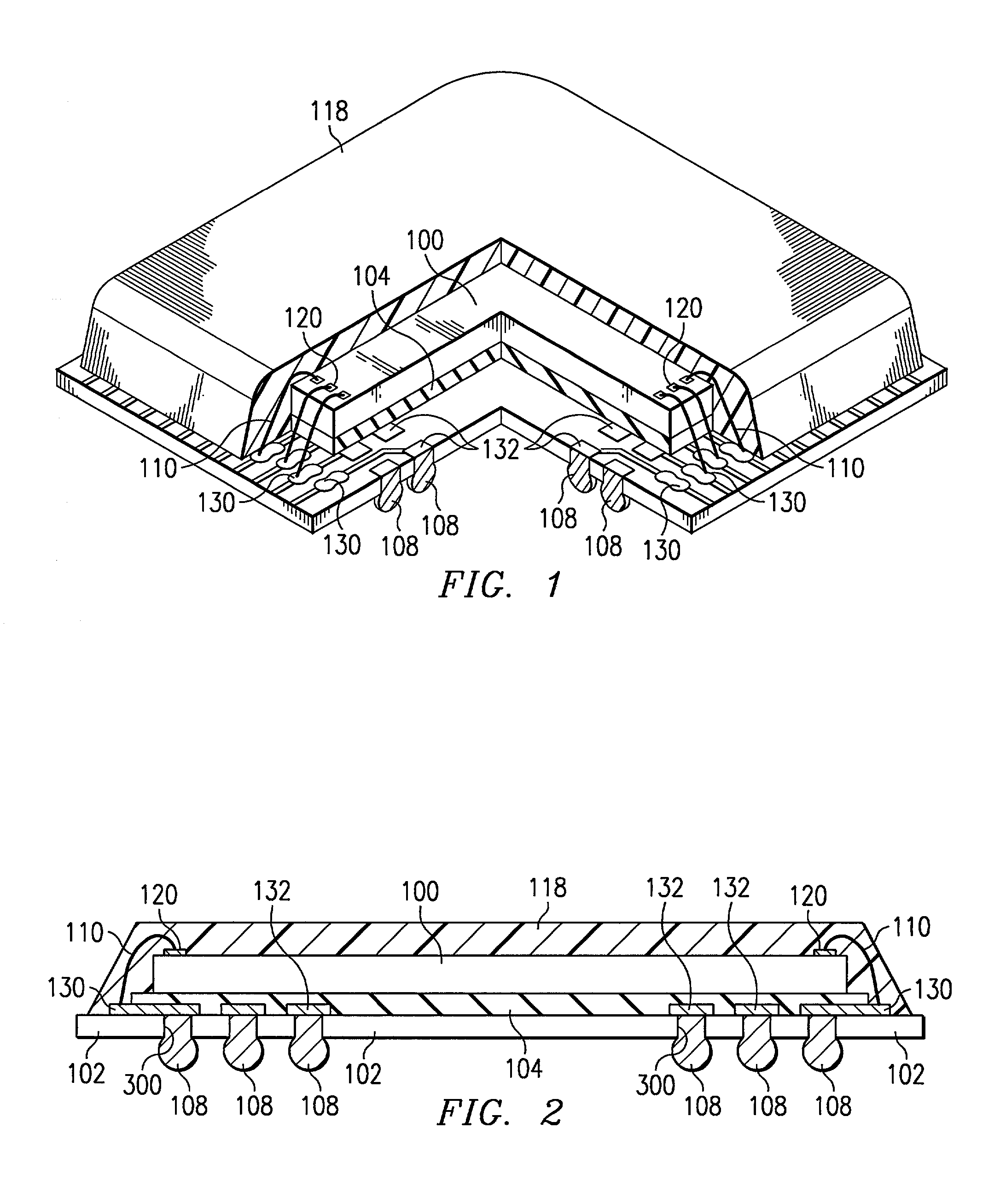

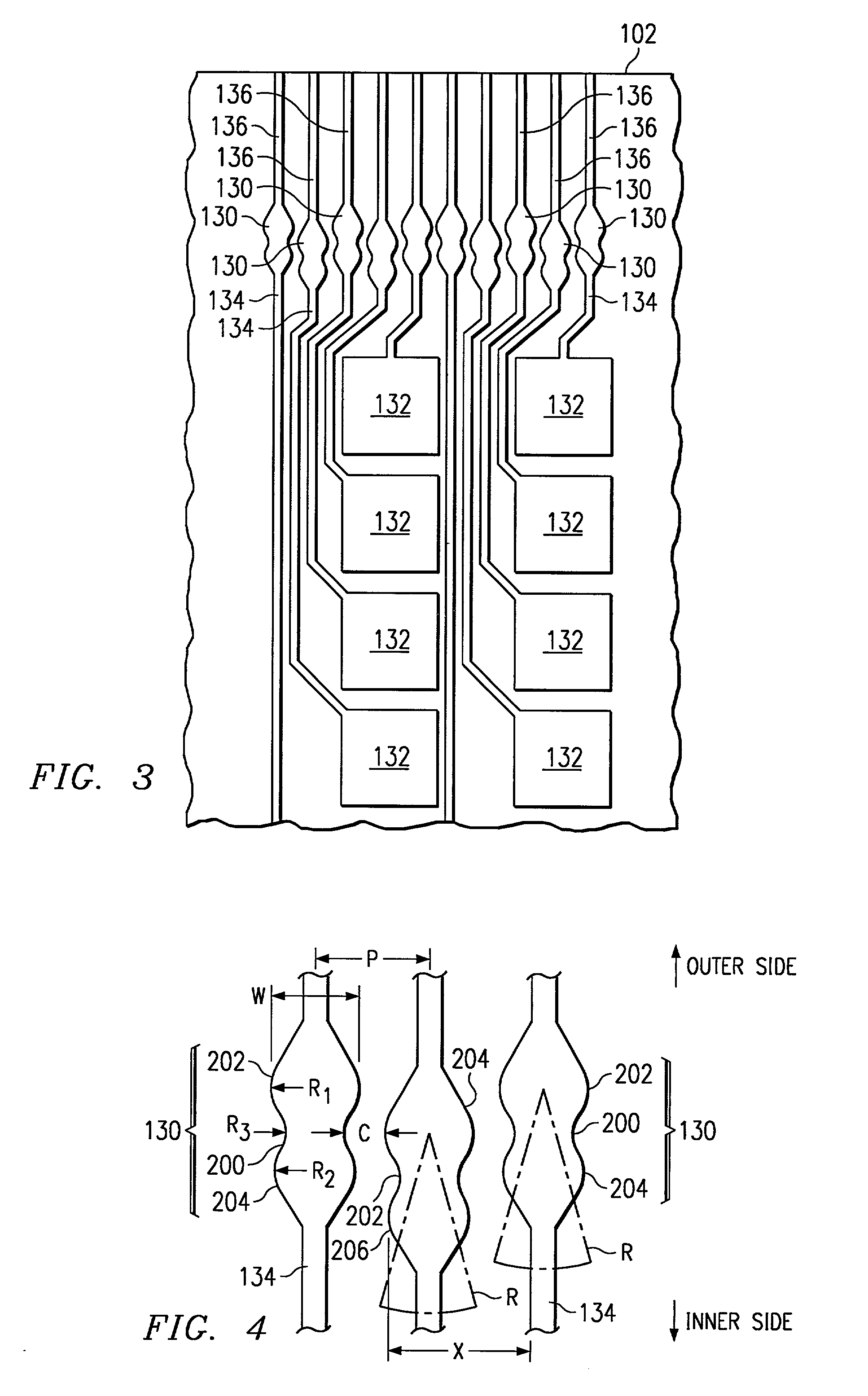

Substrate for carrying a semiconductor chip and semiconductor device using same

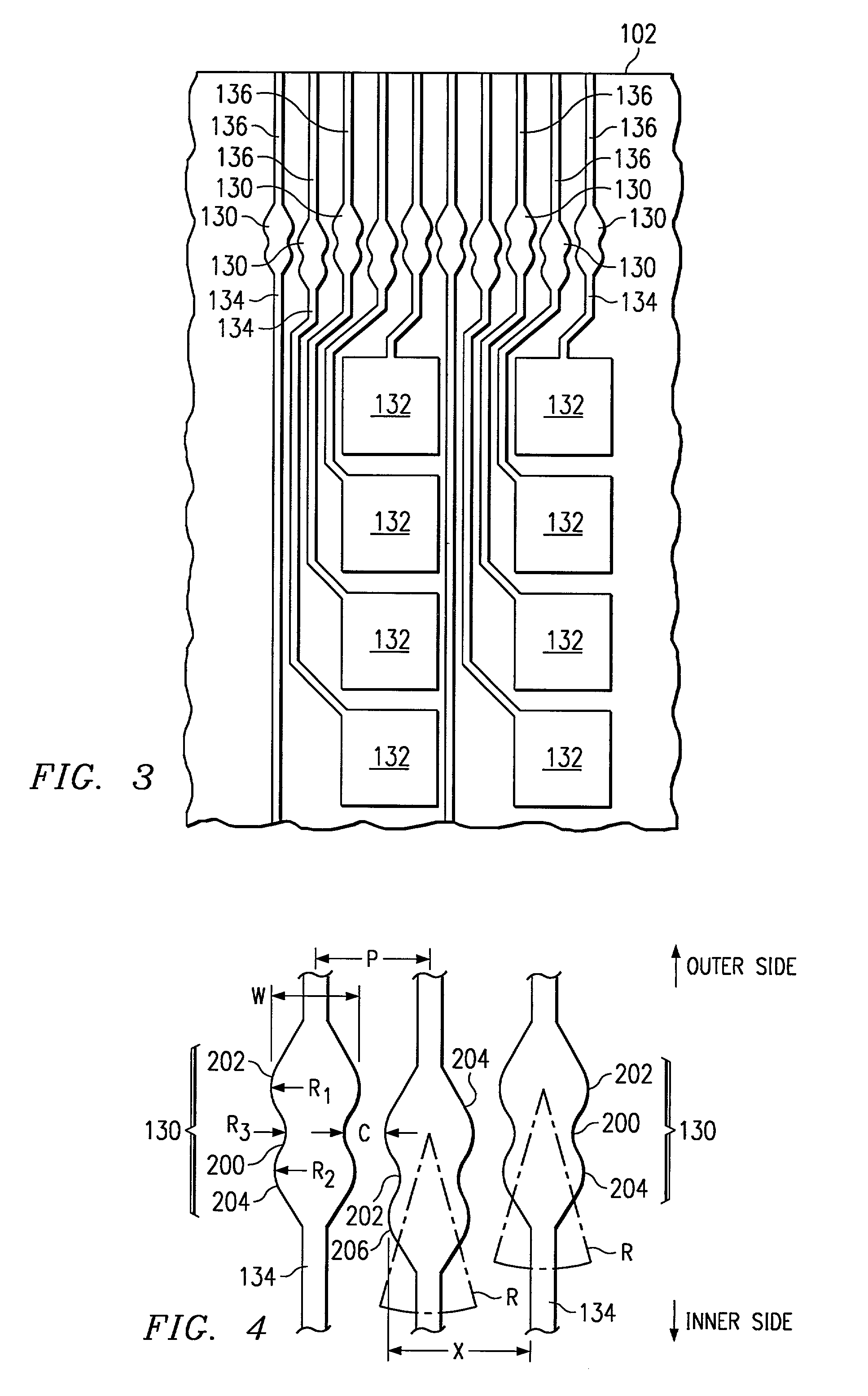

InactiveUS6977443B2Increase the arrangement densityReduce arrangementSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

The objective of this invention is to provide a type of substrate for carrying a semiconductor chip that can increase the arrangement density of lands, and a type of semiconductor device that makes use of said substrate for carrying a semiconductor chip. Constitution: The conductor pattern on insulating substrate 102 contains lands 130 that are respectively connected to electrode pads 120 of semiconductor chip 100 via conductor wires 110. Each land 130 of conductor pattern 110 as capillary tool contact portion 202 where the capillary tool makes contact during bonding, and wire contact portion 204 that allows contact of conductor wire 110. The portion of wire contact portion 204 on the side toward capillary tool contact portion 202 becomes constricted portion 200. Lands 130 are positioned such that constricted portion 200 and capillary tool contact portion 202 of adjacent lands 130 are arranged facing each other.

Owner:TEXAS INSTR INC

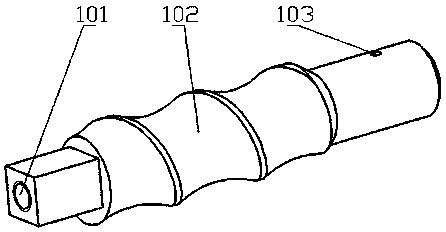

Bottom reaming device for roadway anchor hole

InactiveCN105401882BImprove stabilityFast constructionAnchoring boltsDrilling machines and methodsSystem stabilityEngineering

The invention belongs to the field of supports in coal mines, and discloses a roadway anchor hole hole-bottom reaming device, comprising a support connecting rod (3), rotating cutters (5), a cutter connecting spring pin (6), a push rod (7), a cutter support sleeve (8), and a drilling tool handle (10). The first end of the push rod (7) is provided with a plurality of rotating cutters (5). One end (5) of the rotating cutter (5) is connected with the push rod (7) through the support connecting rod (3), and the other end is connected with the drilling tool handle (10) which is on the second end of the support connecting rod (3) through the cutter support sleeve (8). The drilling tool handle (10) pushes the push rod (7) to move under the action of external forces, so as to apply external forces on the rotating cutters (5), so the rotating cutters (5) expand rotating radius outward. The device improves binding power of a roadway anchoring agent and drill hole surrounding rocks, improves anchoring system stability, and has significance on controlling occurrence of wall caving and roof collapse accidents in an anchor bolt support roadway.

Owner:XINJIANG INST OF ENG

Circuit substrate and electronic equipment

InactiveUS7167374B2Reduce noiseShorten the pathFinal product manufactureSemiconductor/solid-state device detailsNoise reductionElectrical and Electronics engineering

A circuit substrate comprises a first substrate on a first surface of which circuit elements are loaded, a second substrate on which the first substrate is loaded, and noise reduction elements. Each of the noise reduction elements is sandwiched between an area of a second surface of the first substrate over against the first surface of the first substrate and a surface of the second substrate facing the second surface of the first substrate. The noise reduction element is connected between a power source terminal of the second surface of the first substrate and a power source terminal of the surface of the second substrate, and / or between a ground terminal of the second surface of the first substrate and a ground terminal of the surface of the second substrate.

Owner:FUJITSU LTD

Processing method for copper bonding wire for encapsulation

ActiveCN108231600AImprove electrical conductivityPromote softeningSolid-state devicesSemiconductor/solid-state device manufacturingAlloy elementCopper wire

The invention discloses a processing method for a copper bonding wire for encapsulation. The method comprises the following steps: adding Cu and Li in percentage by weight into a smelting furnace under nitrogen protection to be smelted, adding La and Ce to be smelted continuously, and then adding Ag, Sr and Sn to be smelted continuously, and directionally condensing the mixture to obtain an oxygen-free copper rod; and adding the cooled oxygen-free copper rod into a stretcher, and roughly stretching, finely stretching and annealing the cooled oxygen-free copper rod to obtain the copper bondingwire for encapsulation. From the aspect of oxidization resistance, corrosion resistance and conductive property of the copper wire, the type and content of alloy elements of the copper wire are designed reasonably, and the copper bonding wire for encapsulation which is excellent in performance is prepared by combining a proper processing technology.

Owner:安徽晋源铜业有限公司

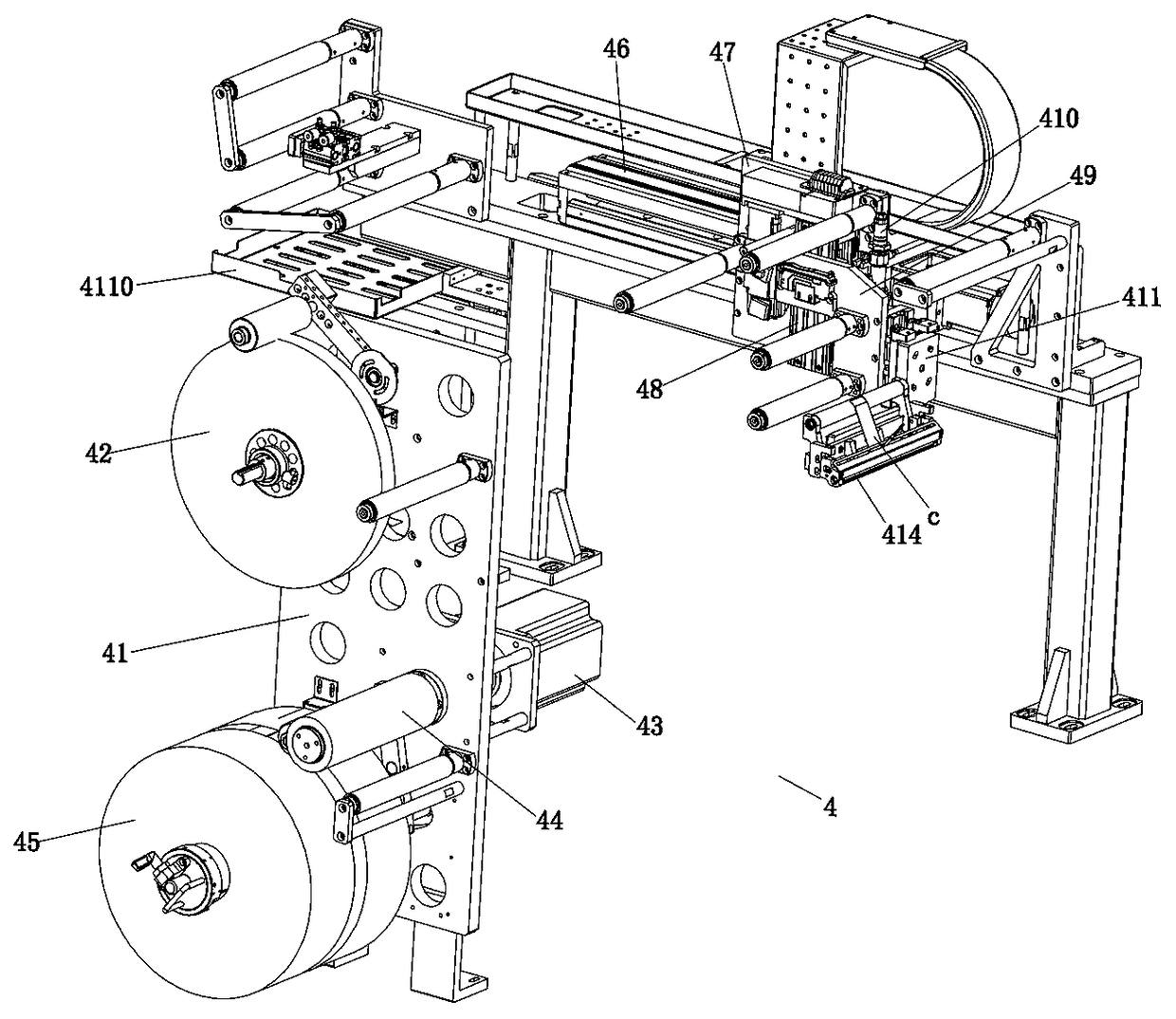

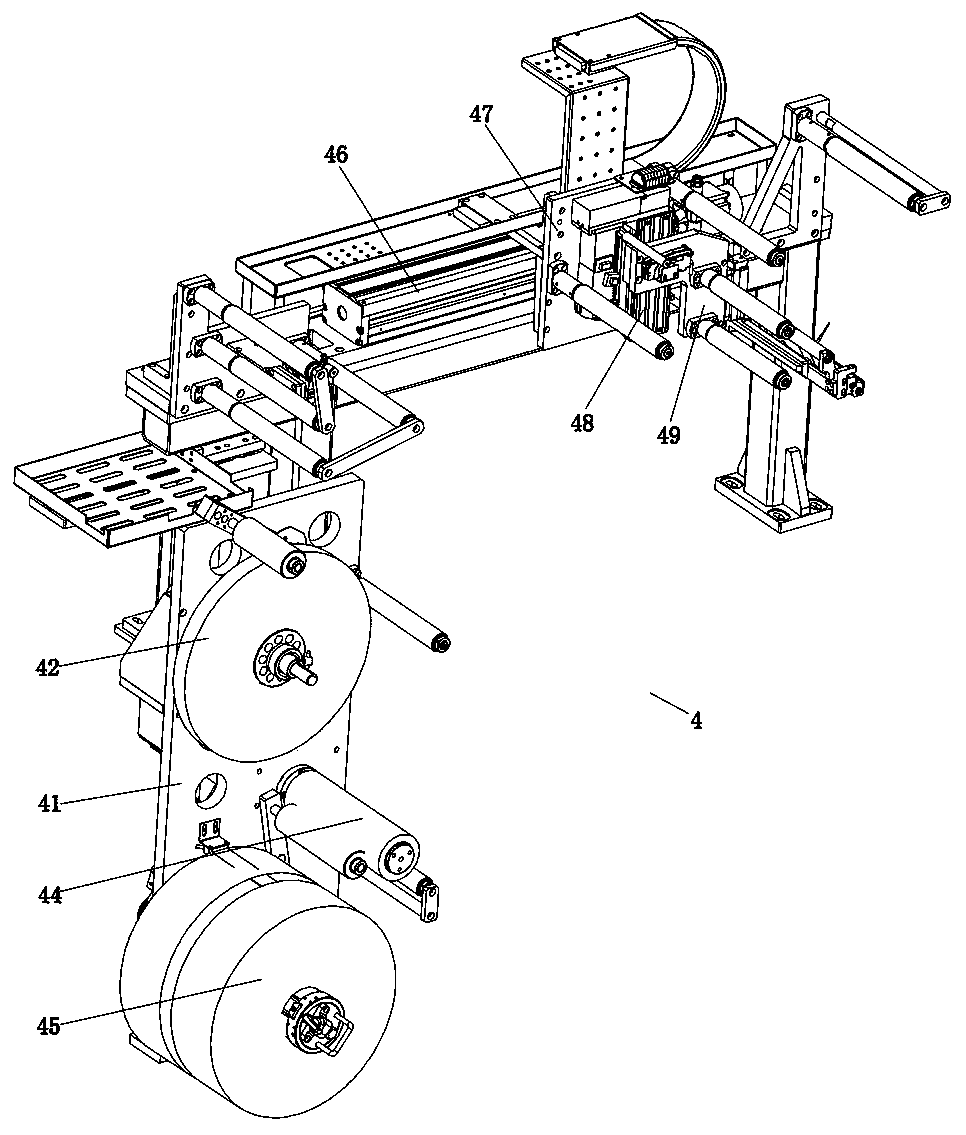

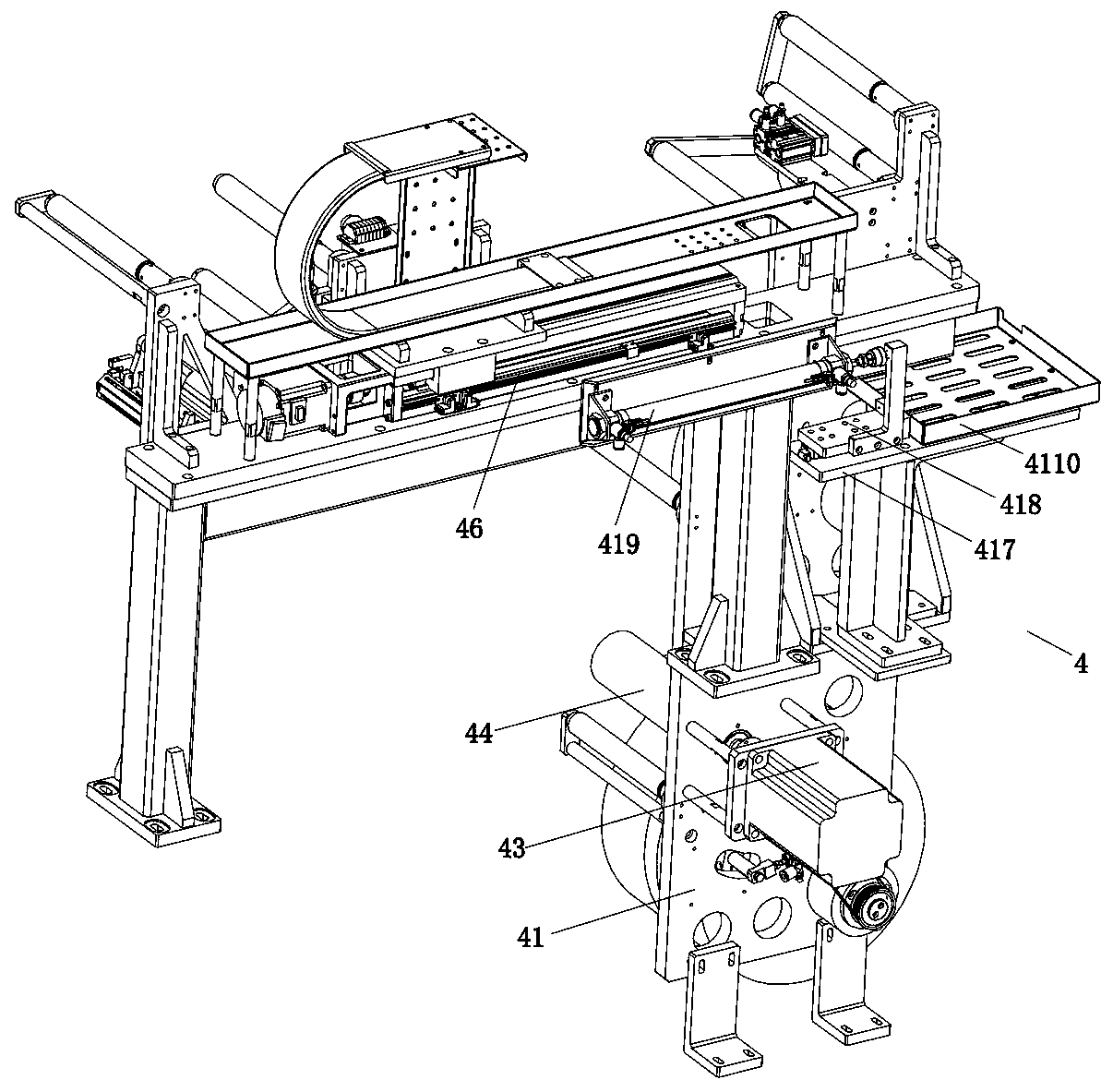

Automatic membrane tearing device of OLED membrane and membrane tearing process thereof

PendingCN109509846AControl tensionAvoid situations such as vacuum failureSolid-state devicesSemiconductor/solid-state device manufacturingMembrane bodiesEngineering

The invention discloses an automatic membrane tearing device of an OLED membrane and a membrane tearing process thereof. The automatic membrane tearing device comprises a first adhesive tape pull-outassembly, an OLED membrane tearing assembly and a waste membrane collecting assembly. The first adhesive tape pull-out assembly is arranged in mounting space at the front end of a rack and is used forpulling a coiled first membrane-tearing adhesive tape out. The OLED membrane tearing assembly is arranged above the first adhesive tape pull-out assembly in a linearly sliding manner and extends horizontally above an OLED adsorption and transfer platform. The first membrane-tearing adhesive tape passes through the OLED membrane tearing assembly and has the adhesive surface facing down, so that the first membrane-tearing adhesive tape is adhered to and fixed with the surface membrane body of the OLED membrane. The OLED membrane tearing assembly drives the first membrane-tearing adhesive tape to make linear movement, so that the first membrane-tearing adhesive tape is torn from the surface of the OLED membrane; and the angle of tearing of the first membrane-tearing adhesive tape from the membrane body is controlled by a first membrane-tearing plate. Therefore, problems of surface membrane tearing of the flexible membrane, adsorption stability of membrane tearing, membrane body angle change control in membrane tearing, and automatic separation of the membrane body after membrane tearing are solved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

Substrate for carrying a semiconductor chip and semiconductor device using same

InactiveUS20030042586A1Arrangement pitch can be reducedIncrease the arrangement densitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

The objective of this invention is to provide a type of substrate for carrying a semiconductor chip that can increase the arrangement density of lands, and a type of semiconductor device that makes use of said substrate for carrying a semiconductor chip. Constitution: The conductor pattern on insulating substrate 102 contains lands 130 that are respectively connected to electrode pads 120 of semiconductor chip 100 via conductor wires 110. Each land 130 of conductor pattern 110 as capillary tool contact portion 202 where the capillary tool makes contact during bonding, and wire contact portion 204 that allows contact of conductor wire 110. The portion of wire contact portion 204 on the side toward capillary tool contact portion 202 becomes constricted portion 200. Lands 130 are positioned such that constricted portion 200 and capillary tool contact portion 202 of adjacent lands 130 are arranged facing each other.

Owner:TEXAS INSTR INC

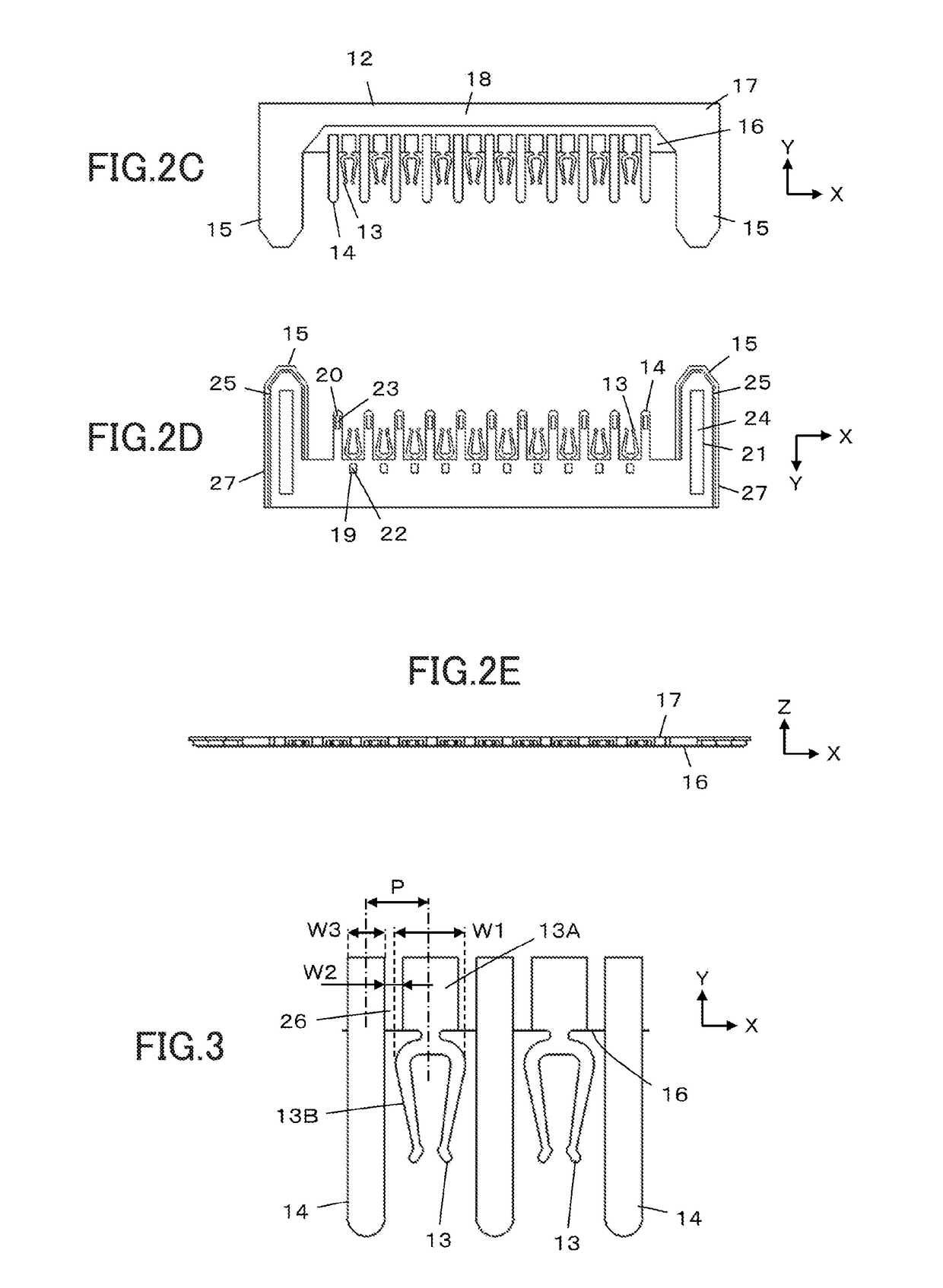

Connector having contacts with a linkage portion having a width smaller than that of the contact portion

InactiveUS7942698B2Maintain reliabilityReduce the row spacingElectric discharge tubesCoupling contact membersCoaxial cableEngineering

A connector capable of maintaining contact reliability even with reduced arrangement pitch of contacts. First and second contacts are alternately arranged on a housing along contact arrangement direction orthogonal to direction of fitting the housing to a receptacle connector. A first contact portion, first bending portion, and first connecting portion connected to a coaxial cable, of each first contact are disposed on an upper surface, front portion and rear portion of the arranging portion, respectively. A linkage portion connecting the first bending and connecting portions, and a second contact portion continuous with a second connecting portion of each second contact are disposed on a lower surface of the arranging portion. A second bending portion disposed on the front portion is continuous with the second contact portion. The linkage portion is smaller in width in the arrangement direction than the first and second contact portions.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

Ultramicro rectangular electric connector and manufacturing method thereof

PendingCN112563786AReduce volumeLiquidityContact member manufacturingContact member cases/bases manufactureEngineeringSlurry

The invention discloses an ultramicro rectangular electric connector and a manufacturing method thereof, and belongs to the technical field of communication, the ultramicro rectangular electric connector comprises a shell, a glass base and a plurality of jack contact pieces, the outer part of the shell is of a step rectangular structure, and the inner part of the shell is of a trapezoidal step hollow structure; wherein the plurality of jack contact pieces are arranged in two rows and installed on the glass base, and the glass base is formed by sintering glass slurry. Compared with an existingstructure, a glass slurry filling sintering process is adopted, the characteristics that glass slurry is high in fluidity and low in sintering temperature are fully utilized, the row distance of the connector can be remarkably reduced, the shell and the jack contact pieces are made of alloy materials and sintered with glass DM308 into a whole, and interface sealing with the leakage rate not largerthan 1.01*10<-3>Pa.cm<3> / S is formed.

Owner:SHAANXI HUADA SCI TECH

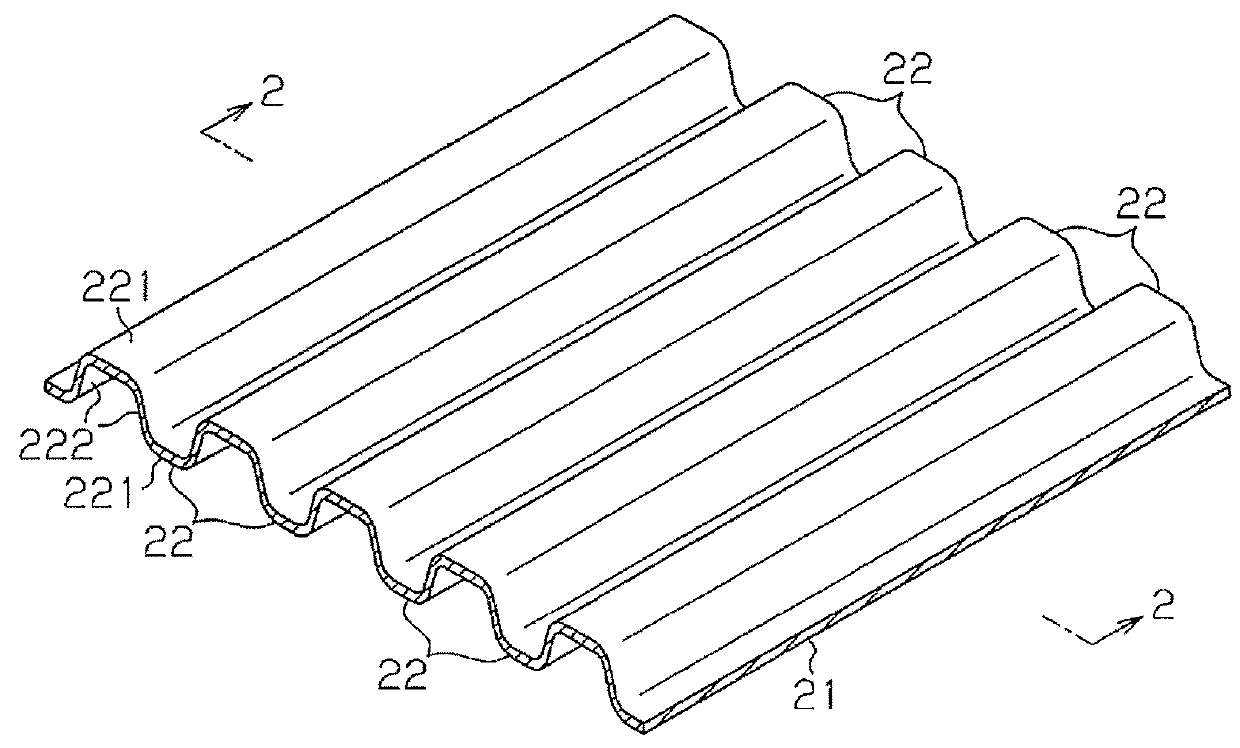

Metal plate forming method and forming device

ActiveUS9962751B2Reduce the row spacingRestrain and undulationDomestic articlesCollectors/separatorsPre treatmentMechanical engineering

Owner:TOYOTA BOSHOKU KK

Medium-deep hole construction and blocking treatment method in large fault section of sublevel caving method without bottom pillar

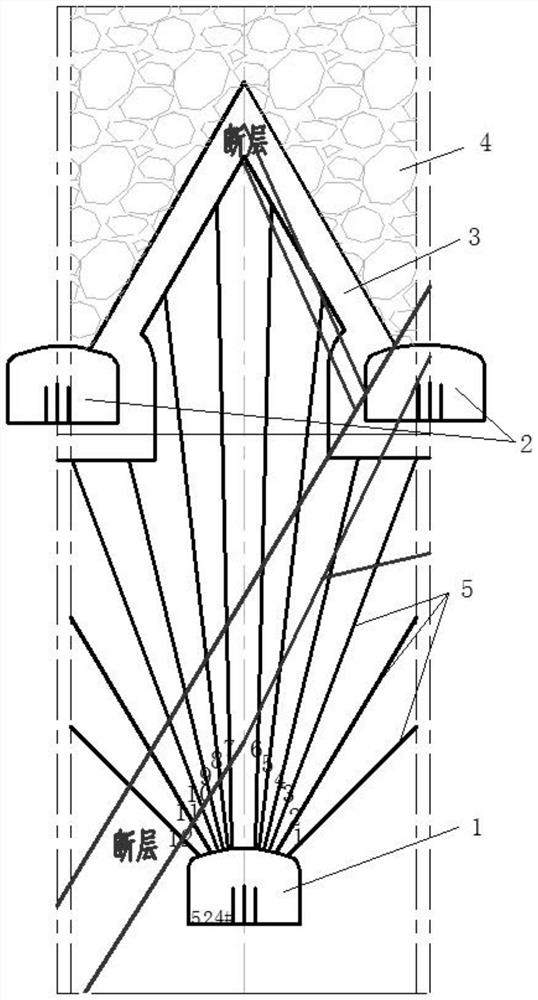

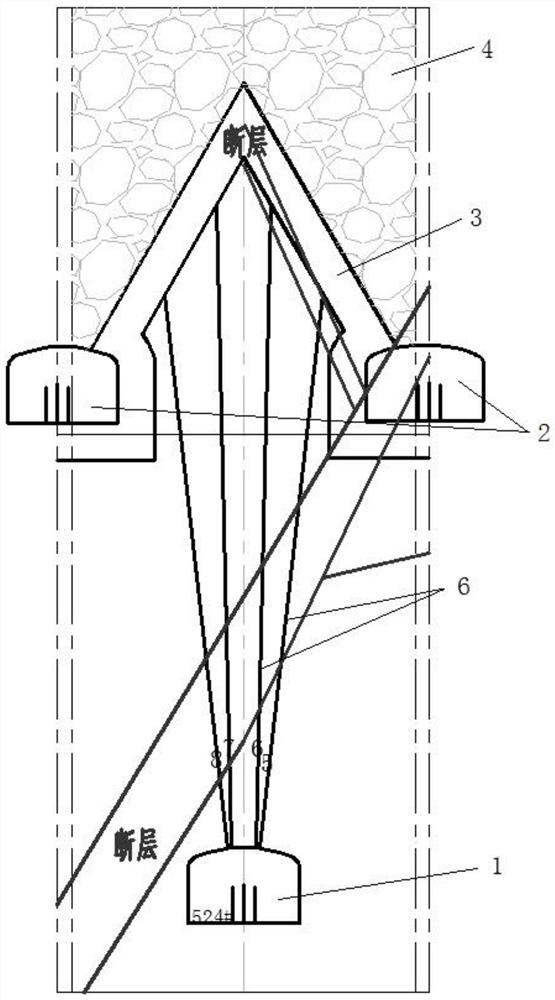

ActiveCN111749693AAvoid cloggingSmall apertureUnderground miningSurface miningDetonatorStructural engineering

The invention discloses a medium-deep hole construction and blocking treatment method in a large fault section of a sublevel caving method without a bottom pillar. According to the method, reserved medium-deep holes are constructed during blasting to the large fault section, according to a fault occurrence state and combing an actual situation of roof side walls of an on-site roadway, hole diameters of the medium-deep holes are reduced, the row distance between the medium-deep holes is reduced, the medium-deep holes are encrypted, the explosive payload of a single row is reduced, and 3-5 auxiliary deep holes are pre-supplemented at the positions of 10-30cm after withdrawing on the basis of the original arrangement of the medium-deep holes; and through the series of measures, the phenomenonof hole plugging caused by overlong laying time after medium-deep hole construction is avoided. According to the method, the hole blocking processing sequence of high-pressure air washing hole-detonator punching-sleeve hole- hole filling is adopted to solve the problem of middle-deep hole blocking, the method can be used for safely and efficiently processing the hole blocking from easy to difficult to advance step by step, so that the blasting effect is guaranteed, and the problems of suspended ceiling, vertical walls and extrusion of a stope are avoided.

Owner:YUXI DAHONGSHAN MINING

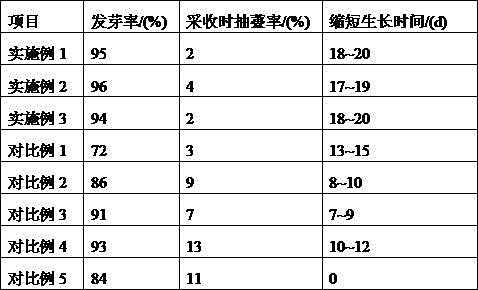

Method for avoiding early-stage bolting of celery

InactiveCN106561254AReduced activityPromote germinationFertilising methodsNitrogenous fertilisersSeed dormancySeed treatment

The invention mainly relates to the technical field of planting, and discloses a method for avoiding early bolting of celery. The method comprises steps of seed processing, seedling management, planting management and plantation management. The method is simple. Celery seeds are subjected to seed coat softening by Angel wine yeast, and acetic acid bacteria fermentation. The pH is adjusted, and seed coats are softened and damaged, so activity of seed dormancy substances is reduced, and seed germination is accelerated. The germination acceleration time is shortened to be 4-5 days, and the germination rate reaches 96%. During the seedling and planting periods, the concentration of carbon dioxide in a greenhouse is strictly adjusted, vegetative growth of celery seedlings is accelerated and bolting is inhibited. During planting, the seedlings are immersed in the planting agents, thereby accelerating rooting, so the survival rate reaches 100%, growth is accelerated and a new application approach of glucosamine and zeatin is provided. During planting, the distance between plants is reduced, and growth of celery bolts is inhibited. Plant ash solution is sprayed regularly, thereby accelerating the vegetative growth, so the harvest time is advanced by 18-20 days, and economic benefit is increased by 10.3%.

Owner:杨珊洪

Method for discharging liquid body, method for manufacturing color filter, and method for manufacturing organic el device

ActiveUS20100099325A1Reduce unevennessImprove productivitySolid-state devicesLuminescent coatings applicationNozzleProcess engineering

A method for discharging a liquid body includes: discharging the liquid body to a discharged region from a plurality of nozzles while a plurality of droplet discharge heads having a nozzle line having the plurality of nozzles that discharge the liquid body as droplets and are arranged in a linear manner, and a substrate including a plurality of discharged regions having a nearly rectangular shape are relatively moved in a main scan direction that is nearly orthogonal to an arrangement direction of the droplet discharge heads. In the method, the plurality of discharged regions are composed of a first discharged region and a second discharged region. The first discharged region is disposed on the substrate to set a long side thereof along a certain direction, and the second discharged region has a smaller area than the first discharged region and is disposed to set a long side thereof nearly orthogonal to the long side of the first discharged region. Further, the first discharged region is disposed to set the long side thereof along the main scan direction in the discharging.

Owner:KATEEVA

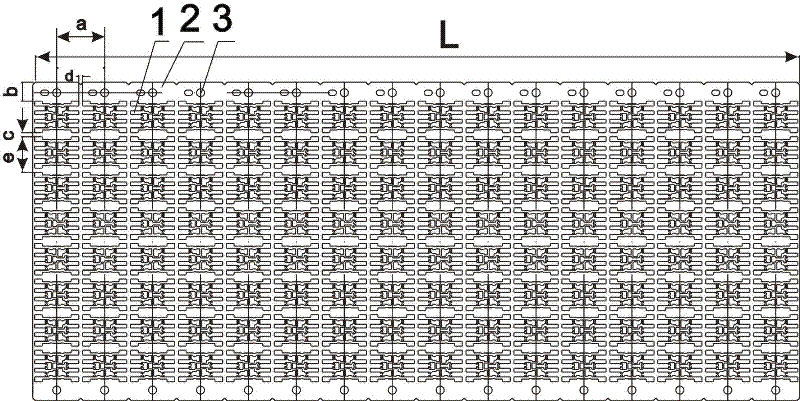

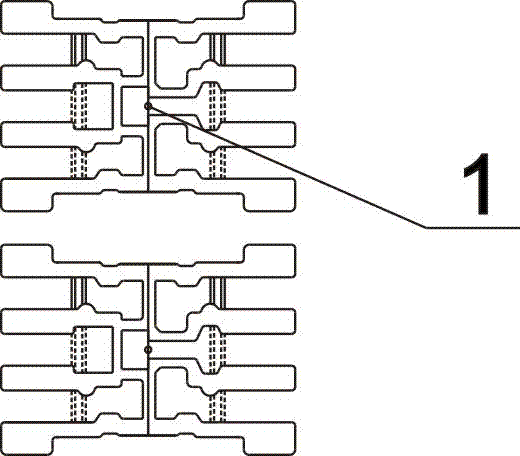

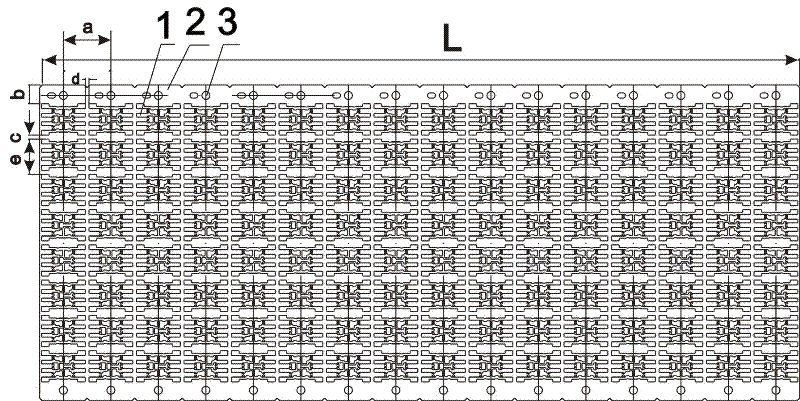

SMD(surface mount device) type LED short-pitch lead frame

InactiveCN102544339AReduce material consumptionReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesMaterial consumptionEngineering

An SMD (surface mount device) type LED short-pitch lead frame comprises a support, multiple process edge units and positioning holes, wherein the support consists of a plurality of lead frame units, the process edge units are arranged on two sides of the support, and the positioning holes are arranged on the process edge units. The distance a between two adjacent positioning holes is smaller than 12.0mm, and the array pitch e between the two adjacent lead frame units is smaller than 8.0mm. The pitch and the array pitch between two adjacent central lines on the single SMD type LED short-pitch lead frame are shortened, and more SMD type LED leads can be distributed on the conventional lead frame with each support with 72 LEDs, for example, the pitch of the SMD type LED lead frame is 9.00mm, the array pitch is 6.7mm, the material usage of the SMD type LED lead frame is saved by 35.71% as compared with that of the conventional lead frame with the pitch of 12.00mm and the array pitch of 8.00mm, material consumption and production cost are reduced, and meanwhile, production efficiency is improved greatly.

Owner:HUBEI KUANGTONG ELECTRONICS

Device and method for planting rice seedlings with narrow row spacing

The invention discloses a narrow-spaced transplanting device and method for rice seedlings. According to the device, a gear box comprises a left box body and a right box body; a safety spring seat, a safety spring, a safety pressure disc, a safety clutch disc, a claw disc, a drive sprocket, a clutch disc, a clutch spring and a clutch spring seat are mounted on a drive shaft sequentially and form an integrated structure of power transmission and safety protection as well as power interruption and connection, so that the safety of a transplanting mechanism and a power transmission system is effectively protected. The drive shaft is transversely mounted at the front part of the gear box, a driven shaft is mounted at the rear part of the gear box, and the drive shaft and the driven shaft transmit power through chain transmission, accordingly, the overall structure is compact, the structure size of a power transmission system is greatly reduced, the structure of transplanting arms is optimized at the same time, and spacing between the two transplanting arms meets the agronomic requirement of transplanting of rice.

Owner:浙江小精农机制造有限公司

A processing method of bonding copper wire for packaging

ActiveCN108231600BImprove conductivityImprove antioxidant capacitySolid-state devicesSemiconductor/solid-state device manufacturingCopper wireCopper-wiring

The invention discloses a method for processing bonding copper wires for packaging, which comprises the following steps: adding Cu and Li to a smelting furnace under nitrogen protection according to the weight percentage for melting, adding La and Ce to continue melting, and then adding Ag, Li Sr and Sn are continuously smelted, and the oxygen-free copper rod is obtained through directional solidification; the oxygen-free copper rod is added to the drawing machine after cooling treatment, rough drawing, fine drawing and annealing treatment to obtain the bonding copper wire for packaging. The invention starts from the anti-oxidation, corrosion resistance and electrical conductivity of the copper wire, rationally designs the type and content of the alloy elements of the copper wire, and combines a suitable processing technology to obtain a bonding copper wire with excellent performance for packaging.

Owner:安徽晋源铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com