Vegetable oil deodorization system

A vegetable oil and deodorization technology, which is used in fat oil/fat refining, chemical industry, fatty acid production, etc., can solve problems such as affecting oil quality, polymerization of small molecular components in oil, and removal of unfavorable odor substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

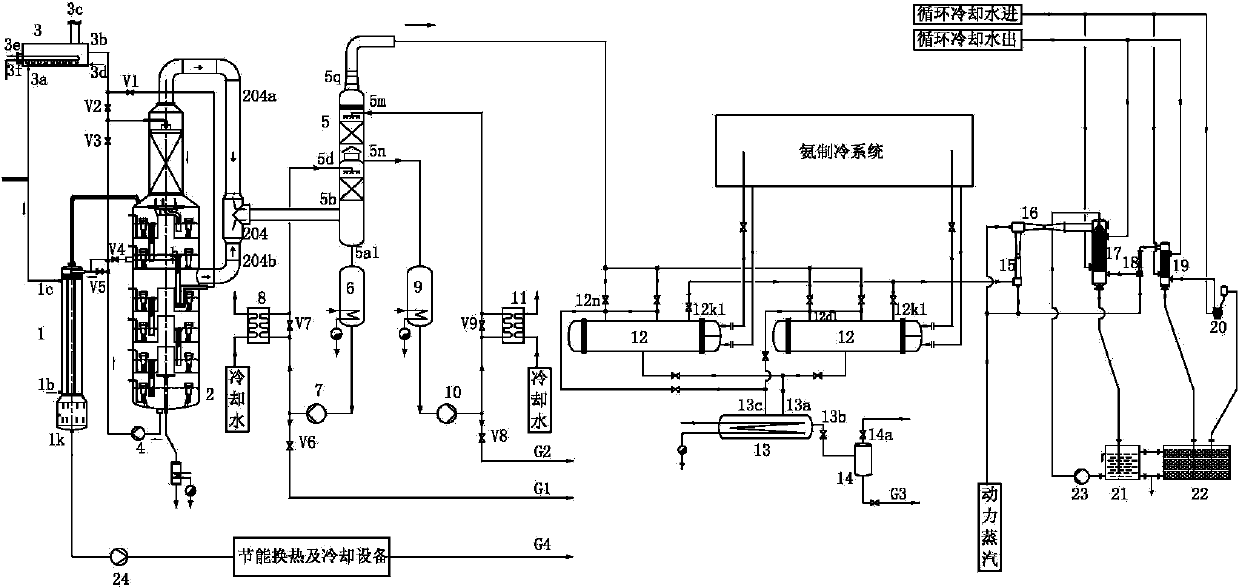

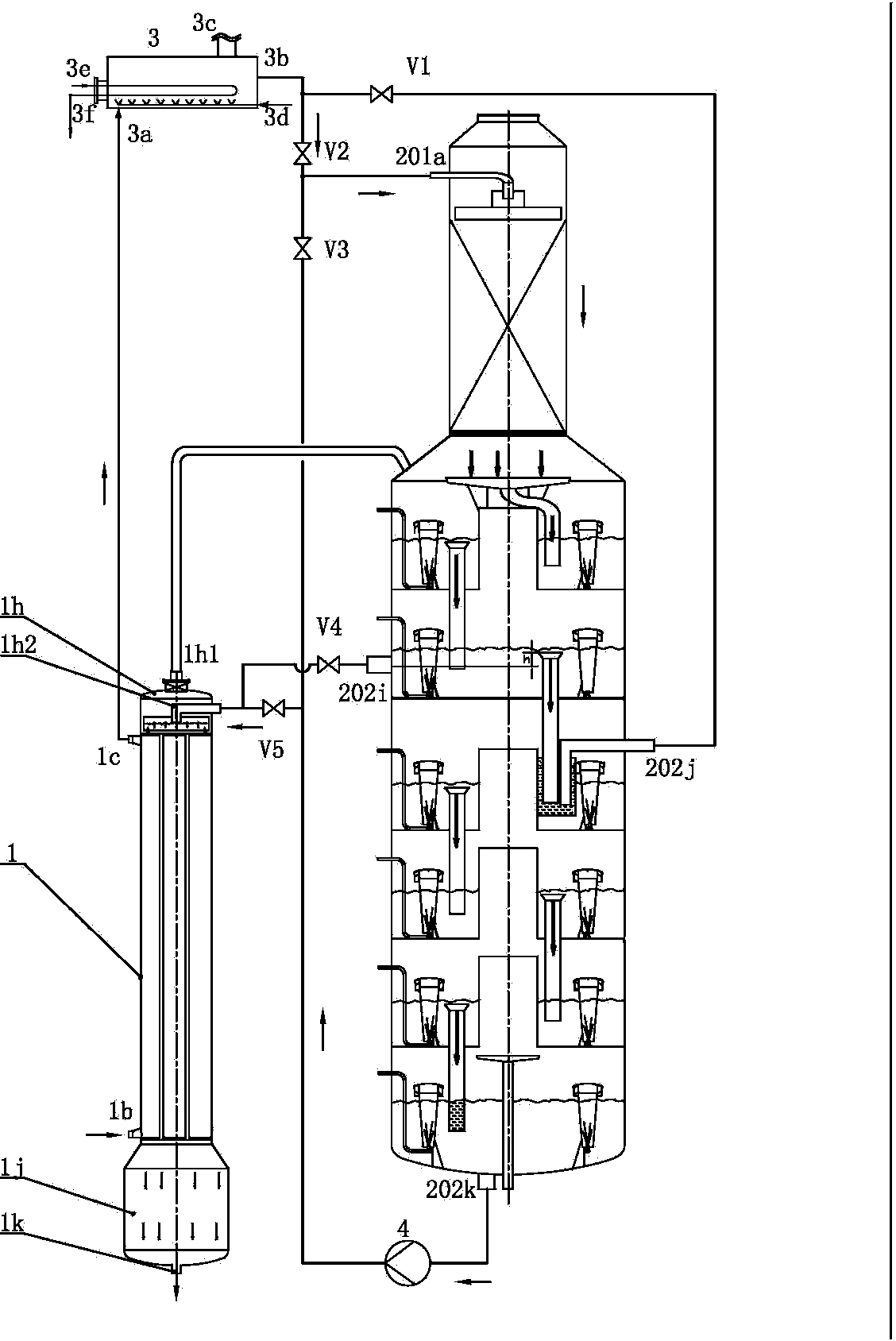

[0032] like figure 1 As shown, the vegetable oil deodorization system of the present invention includes a vacuum oil heat exchanger 1 , a deodorization tower 2 , a vacuum heater 3 , a deodorized oil transfer pump 4 , a deodorized fraction capture tower 5 and a freezing condenser 12 .

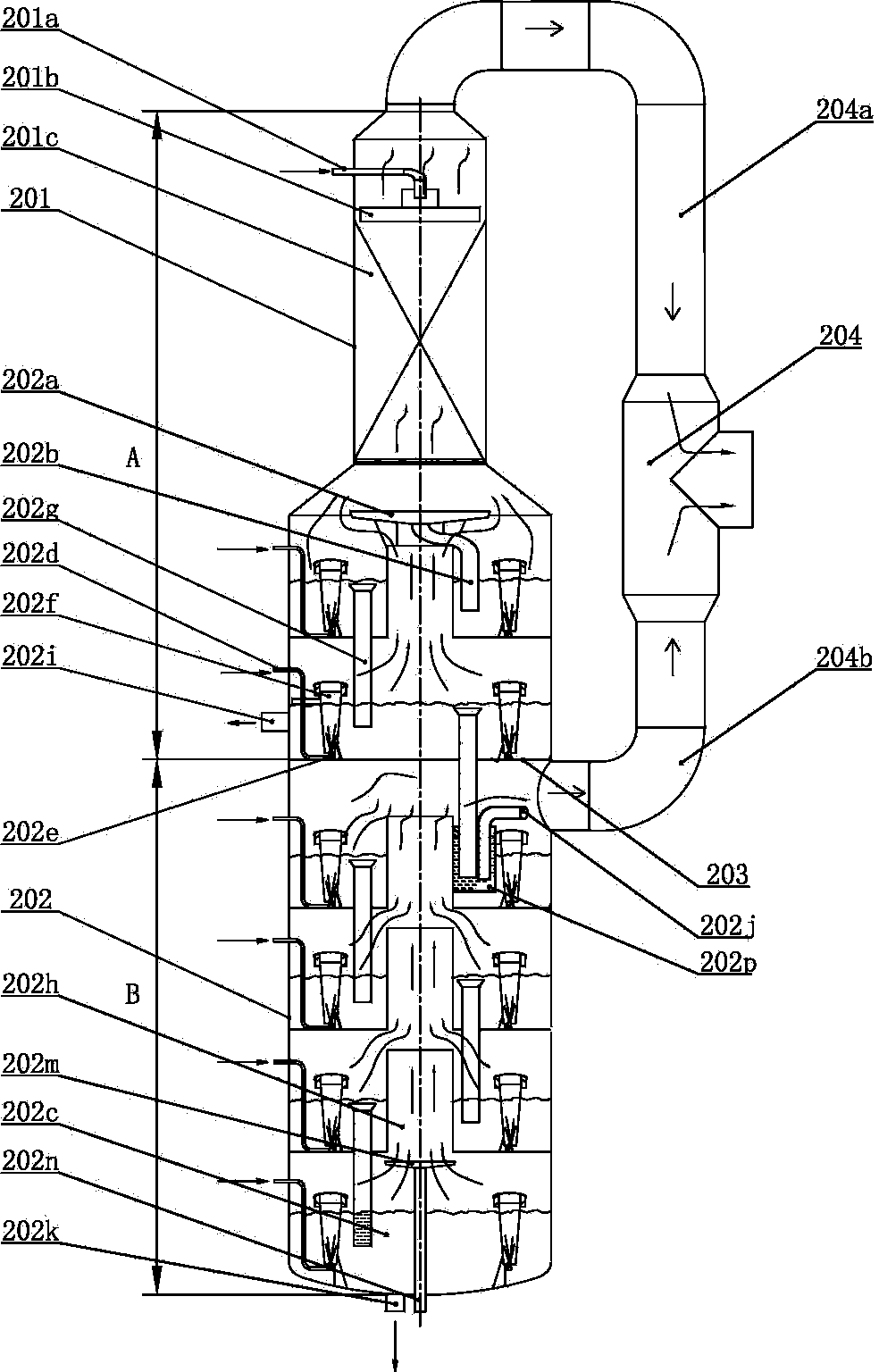

[0033] like figure 2 , image 3 As shown, the deodorization tower 2 includes an upper shell 201 of the deodorization tower and a lower shell 202 of the deodorization tower connected to each other. The upper part of the upper shell 201 of the deodorization tower is connected with an oil inlet pipe 201a of a packing section, and the outlet of the oil inlet pipe 201a of the packing section is aligned downward. The center of the oil distributor 201b, below the oil distributor 201b until the bottom of the upper shell 201 of the deodorization tower is filled with the deodorization tower packing 201c; the bottom of the lower shell 202 of the deodorization tower is provided with a plate column section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com