Window opening and sidetrack drilling short-radius horizontal well and reverse circulation well cementing and water plugging method

A window sidetracking and short-radius technology, applied in directional drilling, wellbore/well components, earthwork drilling and production, etc., can solve problems such as high production costs, high risks, and water flooding accidents in production zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

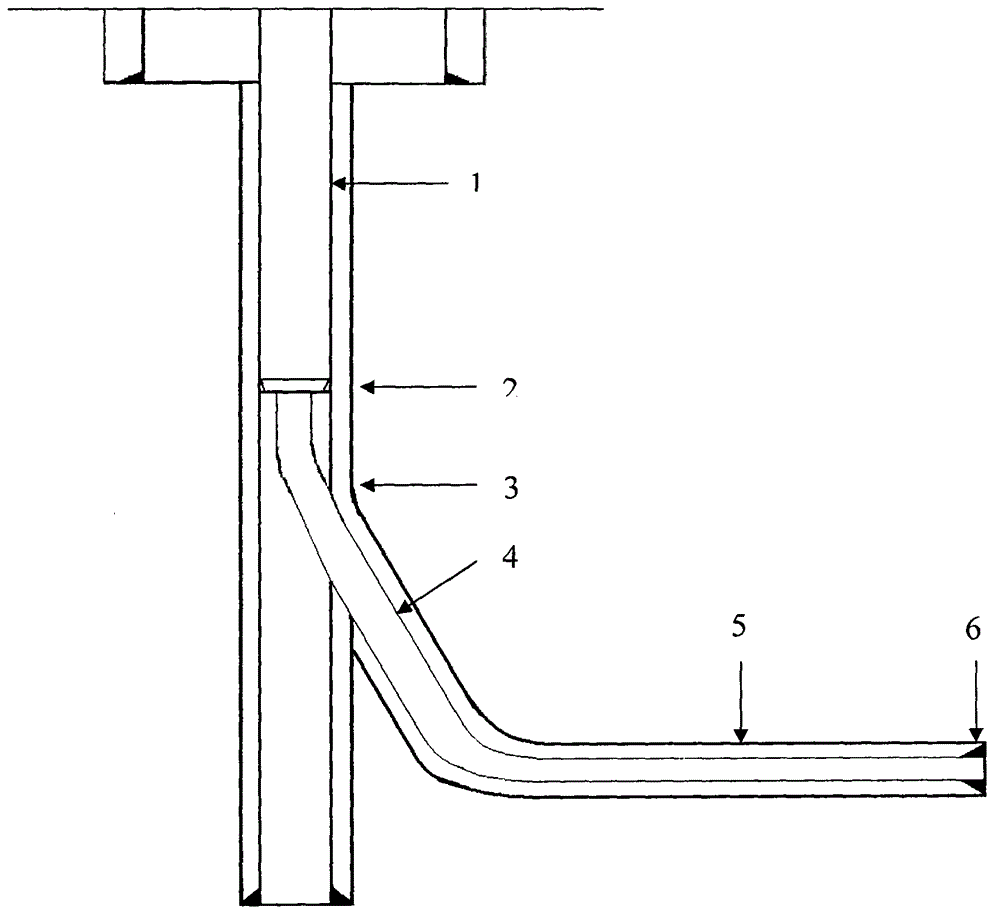

[0024] The following takes the K202S well as an example to specifically describe the construction flow of the process of the present invention.

[0025] 1. Selection of window opening point

[0026] Considering the geological conditions of the KAM oilfield block, the mining method, the window opening method, and the vertical distribution of oil and water, it is preferred that the forging-milling window position of Well K202S is 1154-1167m, and the window length is only 13m. During the on-site construction, the actual window opening point is located at 1160m.

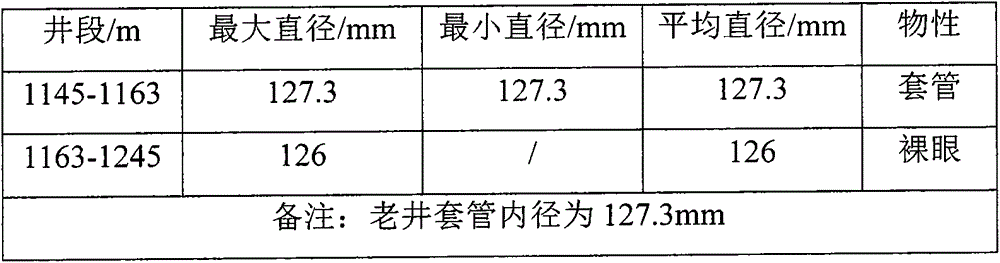

[0027] 2. Wellbore Trajectory Design

[0028] The basic data of wellbore trajectory design of Well K202S are shown in Table 1. The specific conditions are as follows: First, from the 1163m oblique depth at the opening point to the 1186m oblique depth, conventional drilling tools are used for compound drilling along the inclined plane of the oblique device, and the build rate is 0; 21.30° / 30m, which is mainly due to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com