Patents

Literature

57results about How to "Accurate volume measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

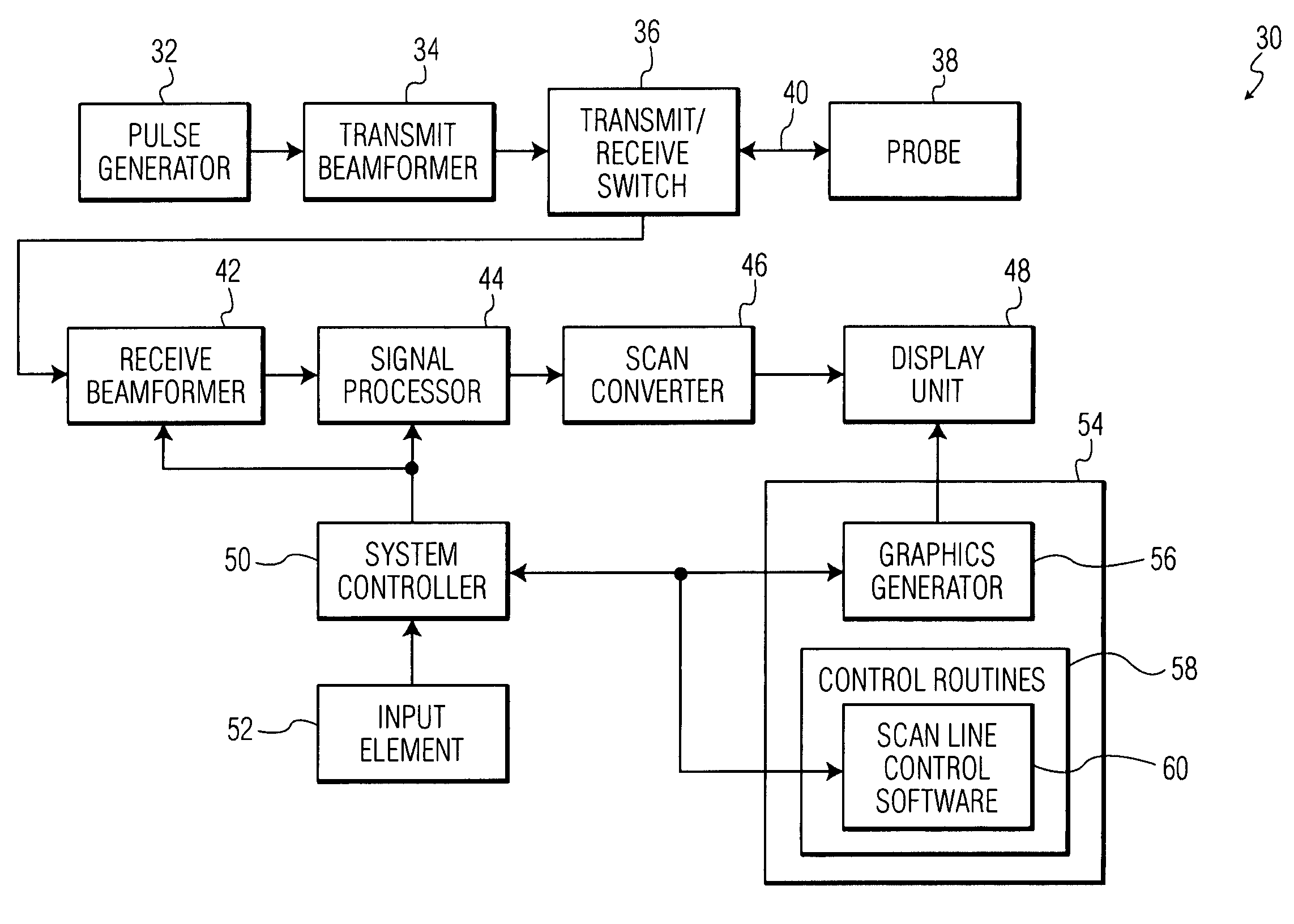

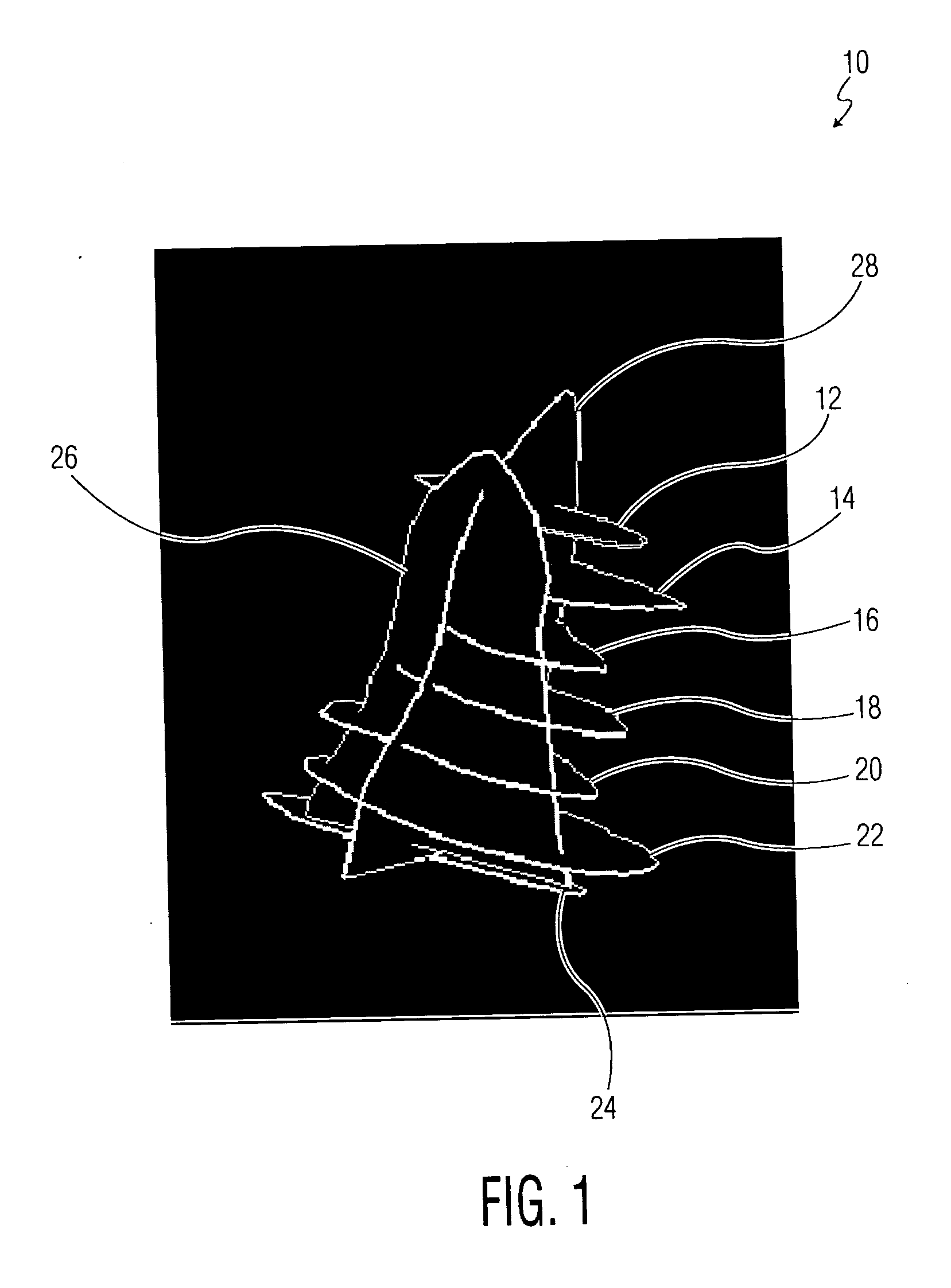

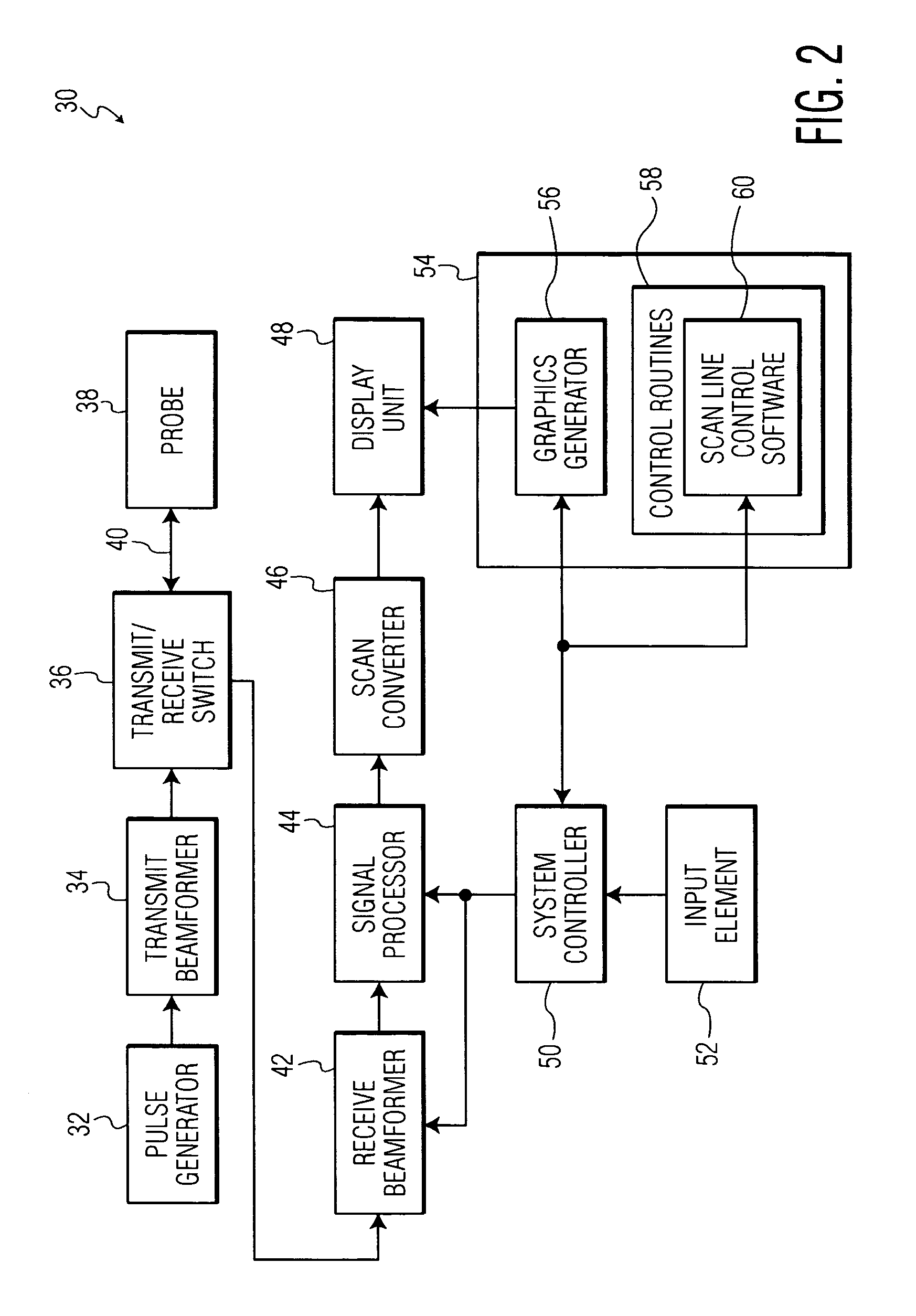

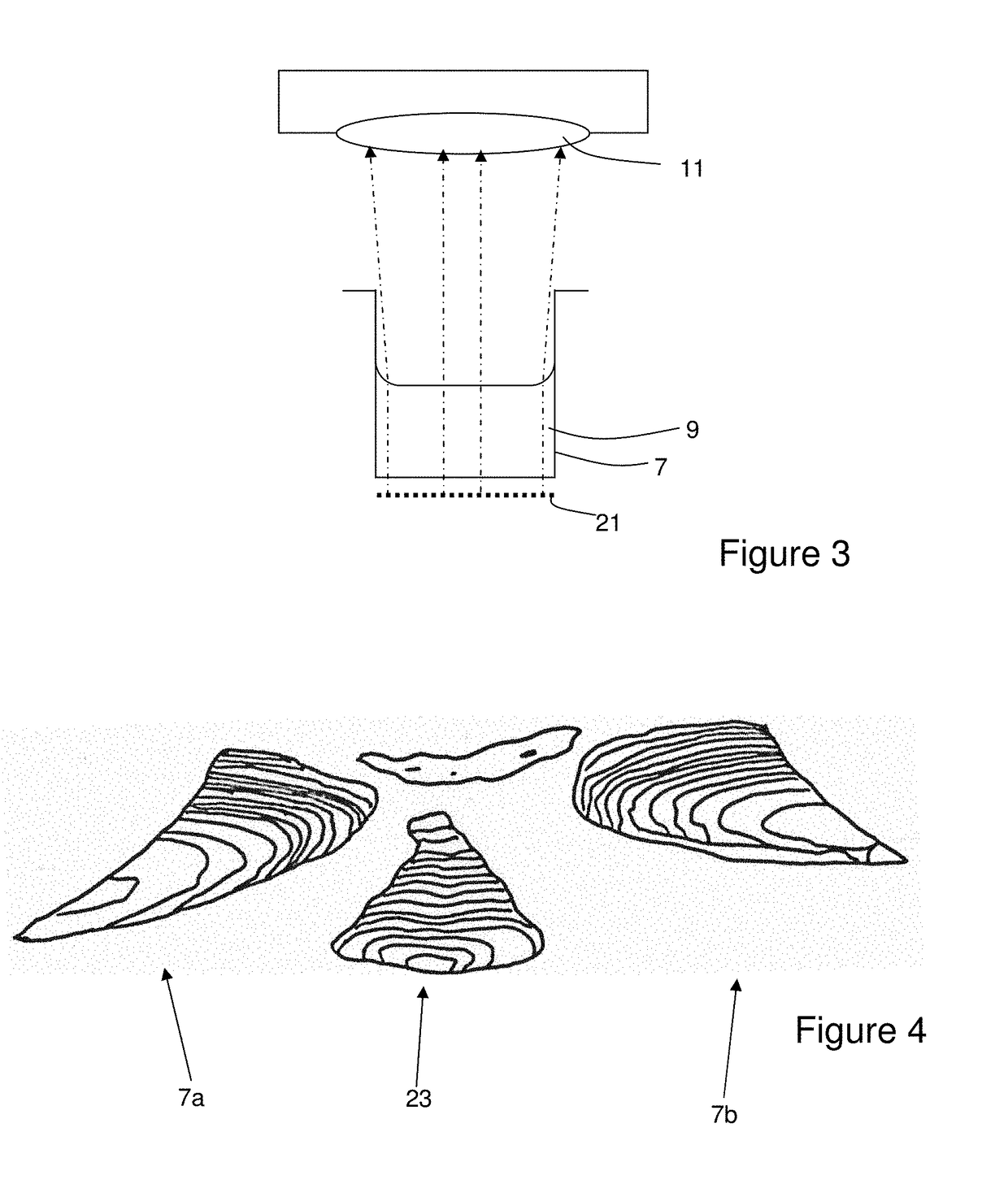

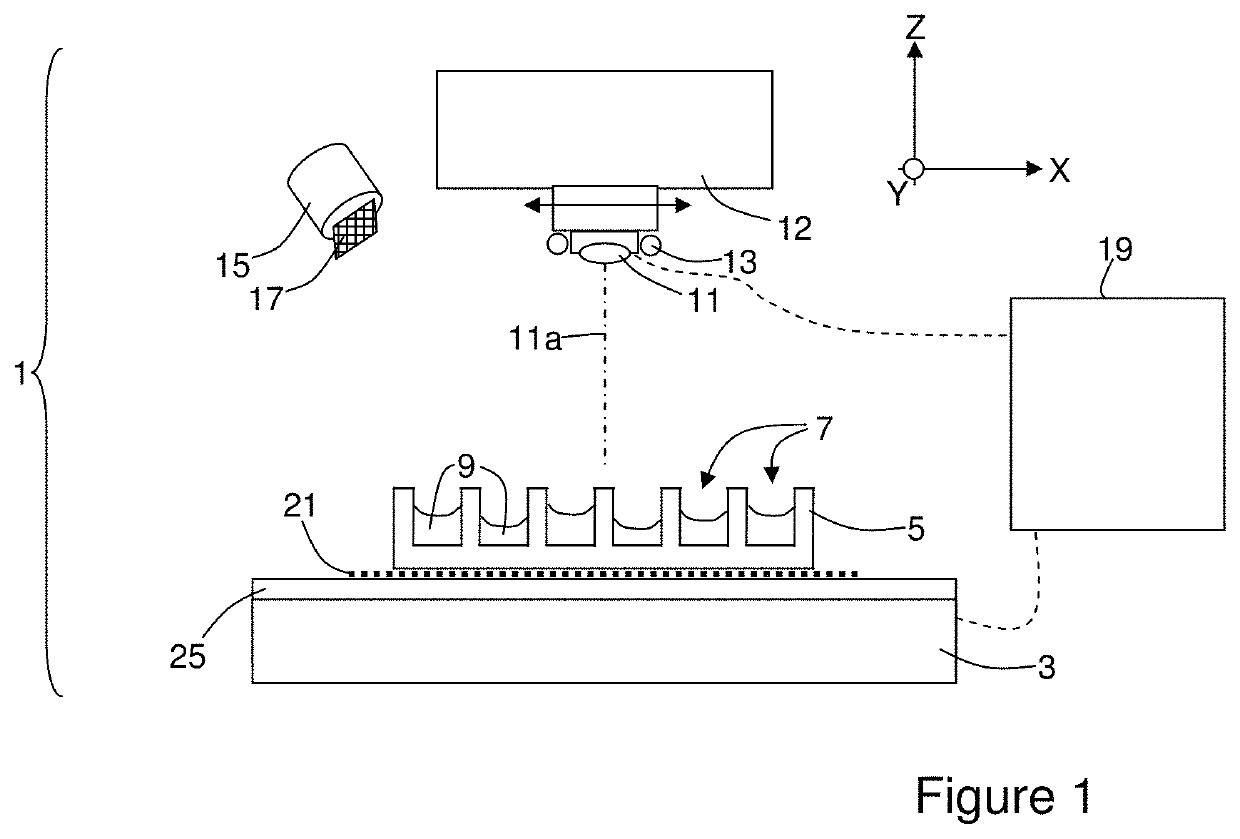

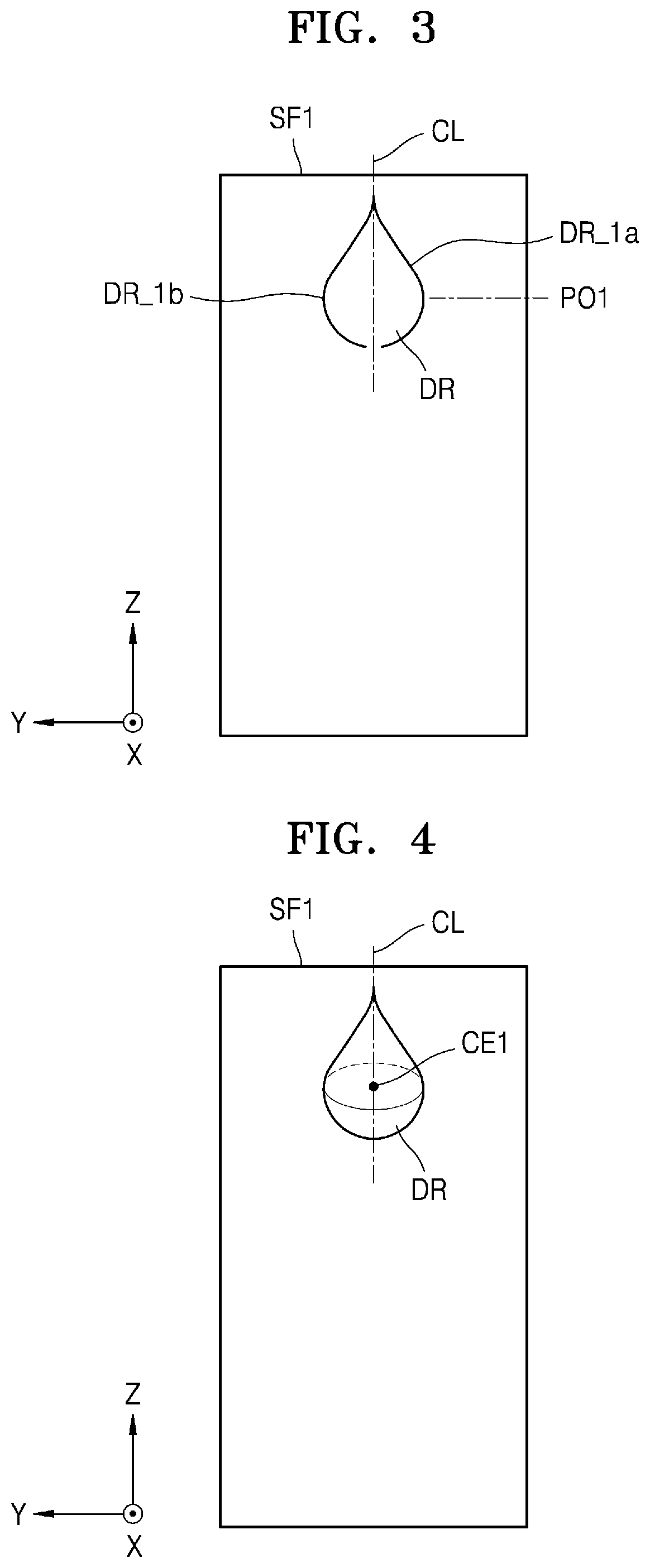

Ultrasound diagnostic imaging system and method for 3D qualitative display of 2D border tracings

InactiveUS20050101864A1Accurate volume measurementBlood flow measurement devicesOrgan movement/changes detectionData setComputer graphics (images)

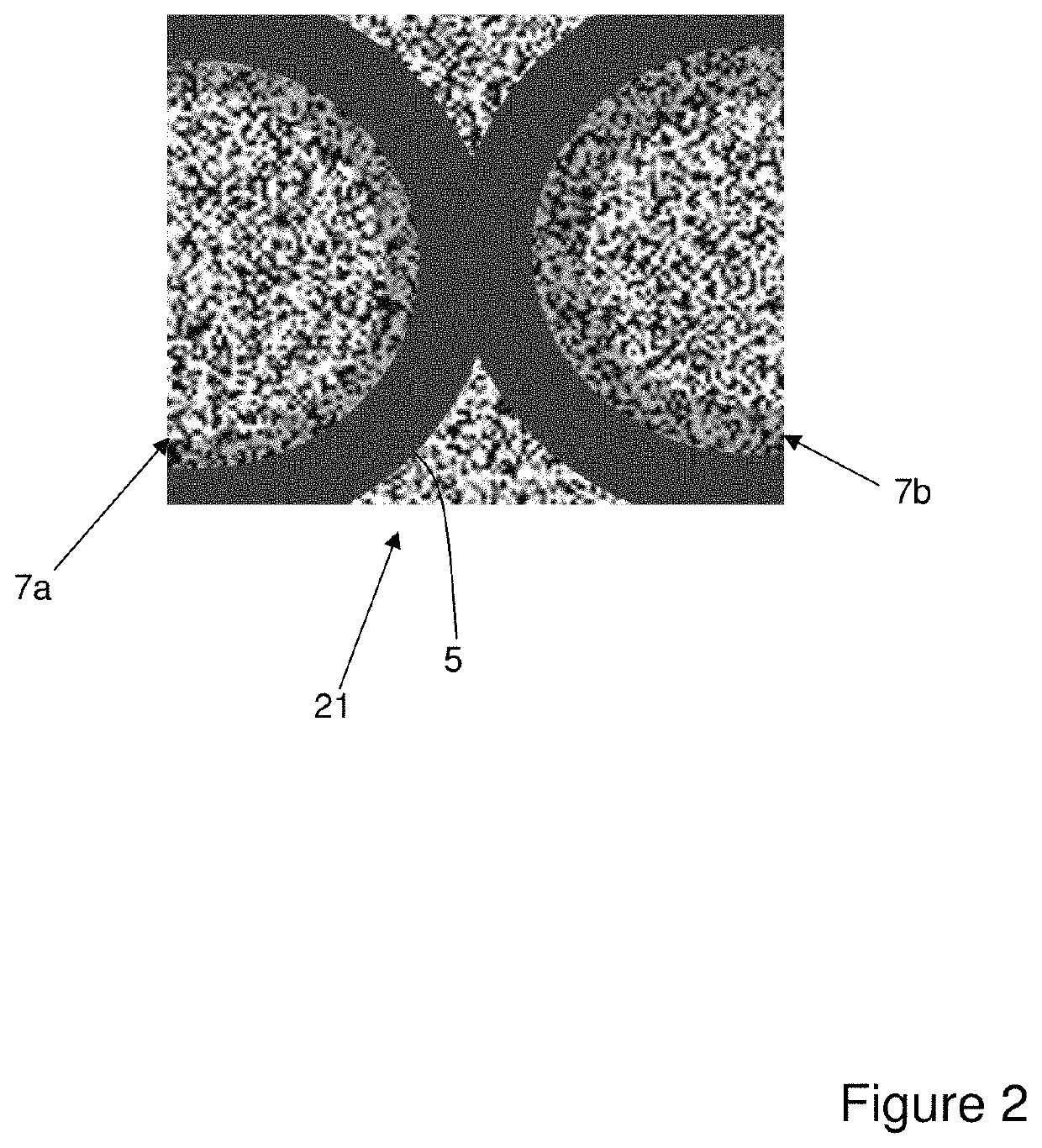

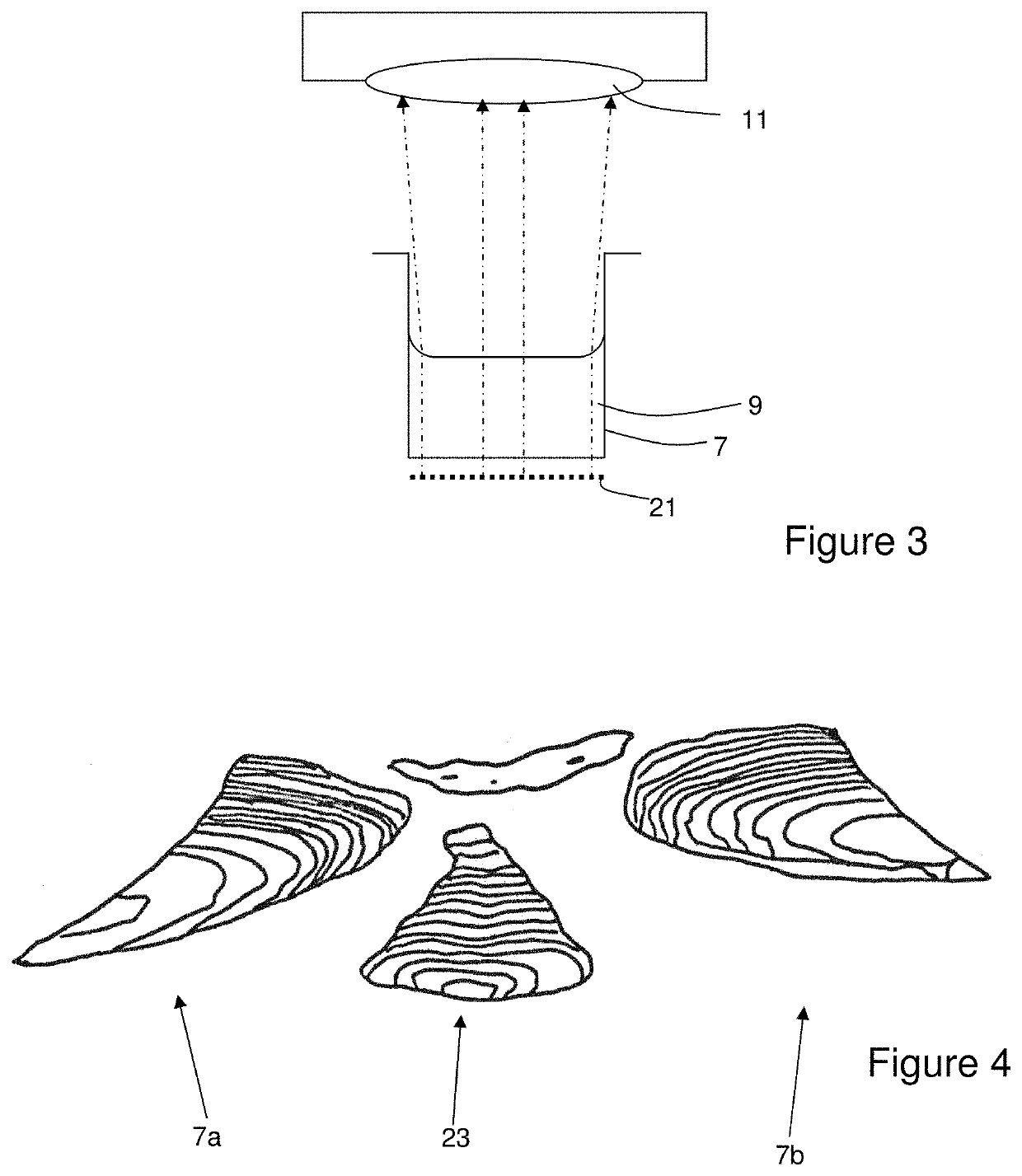

A method and system for generating a three-dimensional (3D) qualitative display (10,110,144) in an ultrasound system (30) include generating a first and a second two-dimensional (2D) slice (102,106,108) from a 3D data set of a 3D volume view of an ultrasound image. The first and second 2D slices (102,106,108) define a first and second plane of the 3D volume view along a first axis, wherein the second plane is orthogonal to the first plane. First and second border tracings (122,124) are generated around a portion of interest in the first and second 2D slices (102,106), respectively. A display (48) then displays (10,110) representations of the first and second border tracings within a single 3D view (10,128,130,146), wherein the 3D view provides an indication of alignment distortion of the first and second border tracings along the first axis. In one embodiment, at least one additional 2D slice defines an additional plane of the 3D volume view along a second axis, orthogonal to the first and second planes. Furthermore, at least one additional border tracing generated. The display (48) then further displays the at least one additional border tracing along the second axis within the single 3D view for providing an indication of alignment distortion of the first, second, and at least one additional border tracing along the first and second axes.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

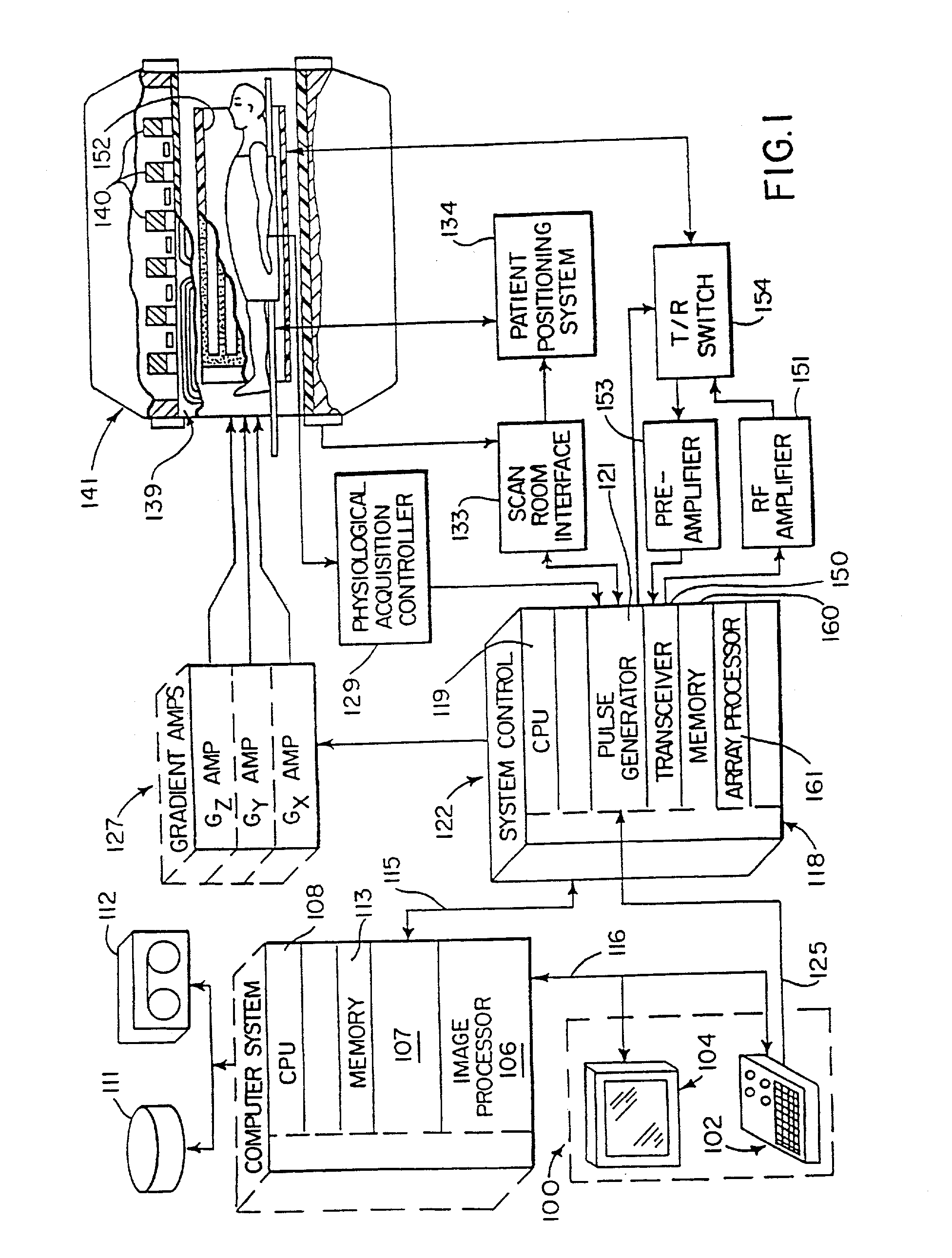

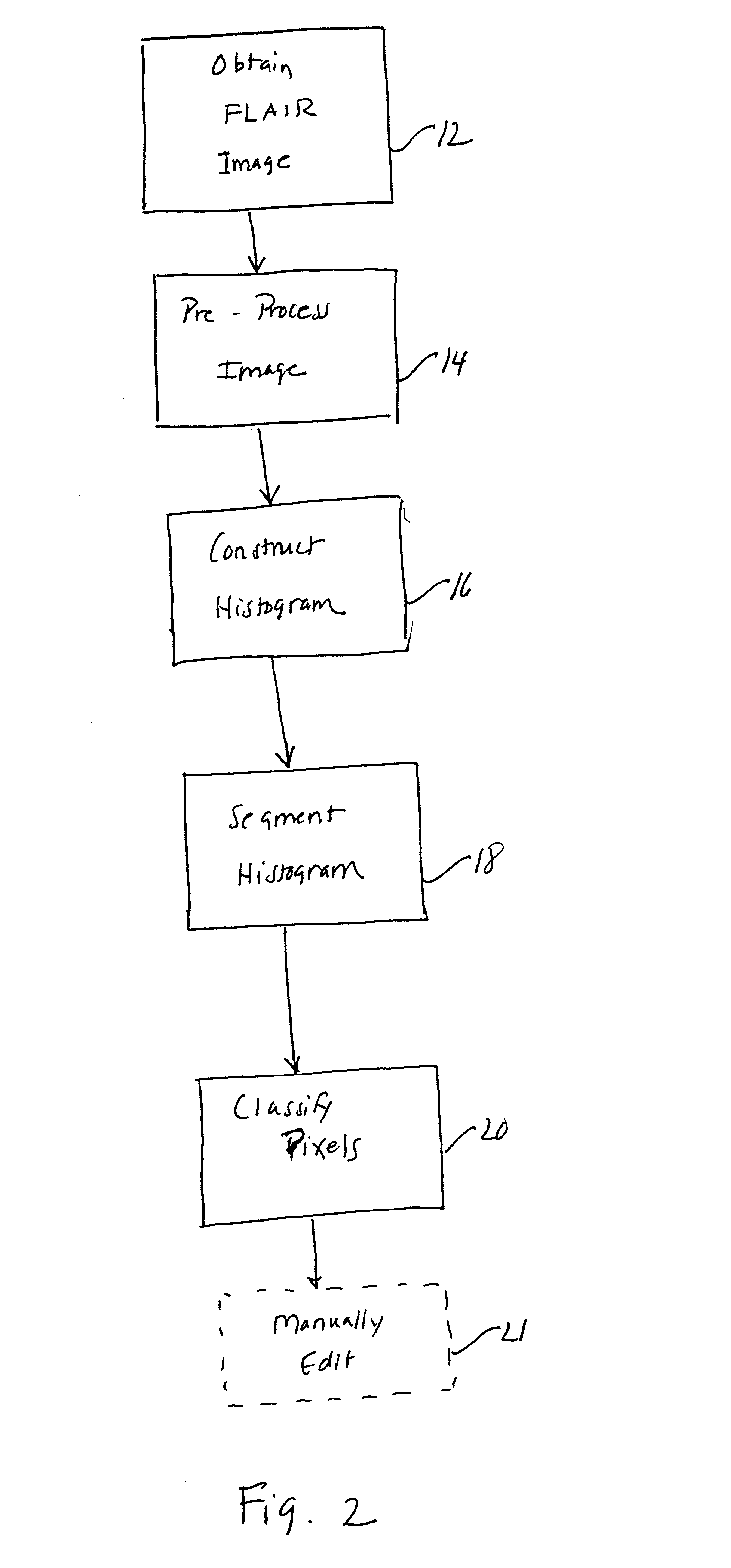

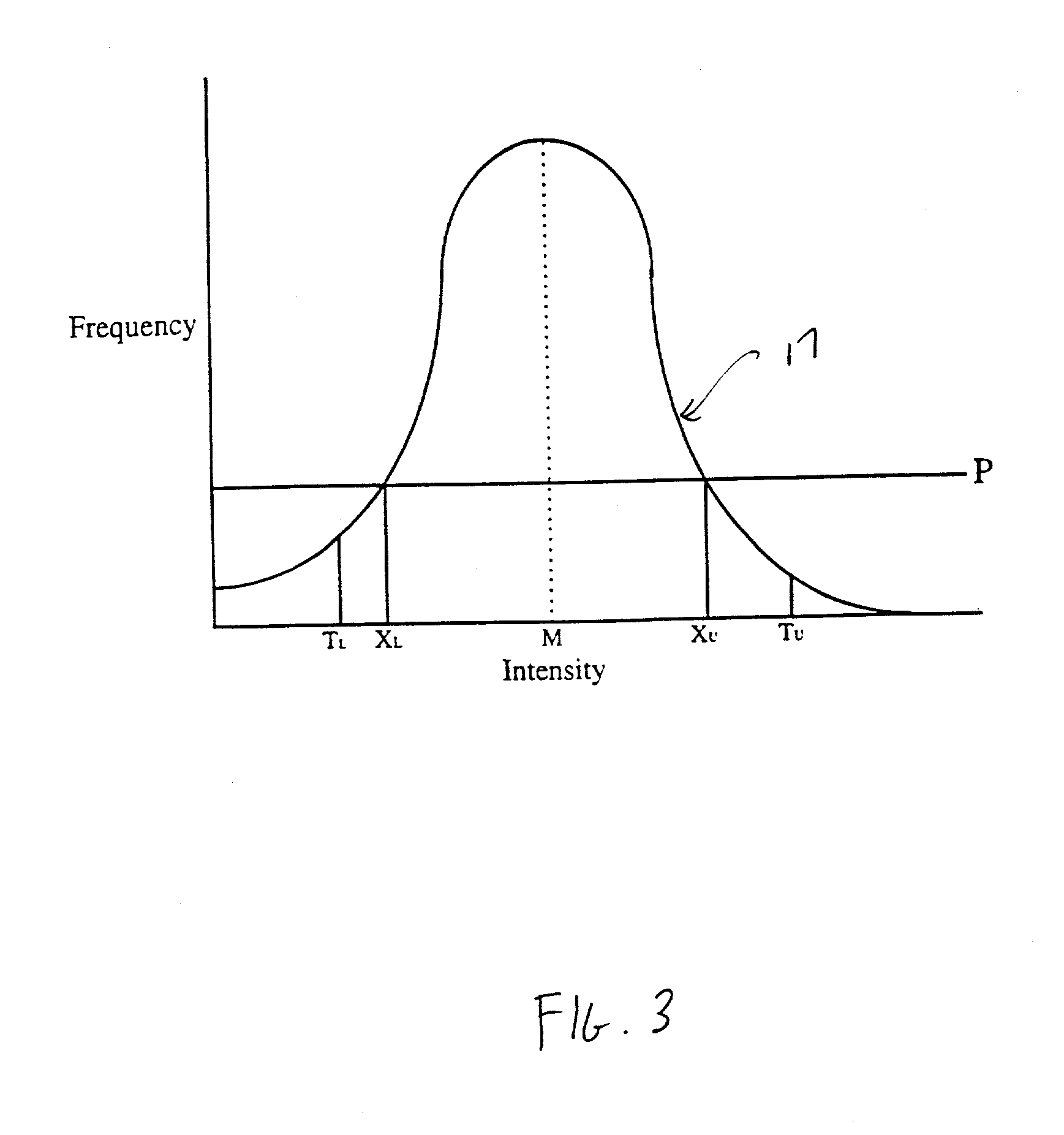

Histogram segmentation of FLAIR images

ActiveUS20030009098A1Automatically measuring the volume of tissueThe classification result is accurateImage enhancementImage analysisFluid-attenuated inversion recoveryLeukoaraiosis

A method for classifying tissue in a magnetic resonance image. and particularly for measuring a volume of pathological tissue such as white tissue hyperintensity (leukoaraiosis) in the brain based on the segmentation of the intensity histogram of fluid attenuated inversion recovery (FLAIR) images is described. A magnetic resonance image of the brain of a subject is acquired, and a pixel intensity histogram is constructed from the image. A statistically-based regression analysis is applied to the histogram to determine upper and lower threshold values, which define different types of brain tissue, particularly normal brain, cerebral spinal fluid (CSF), or lesion.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

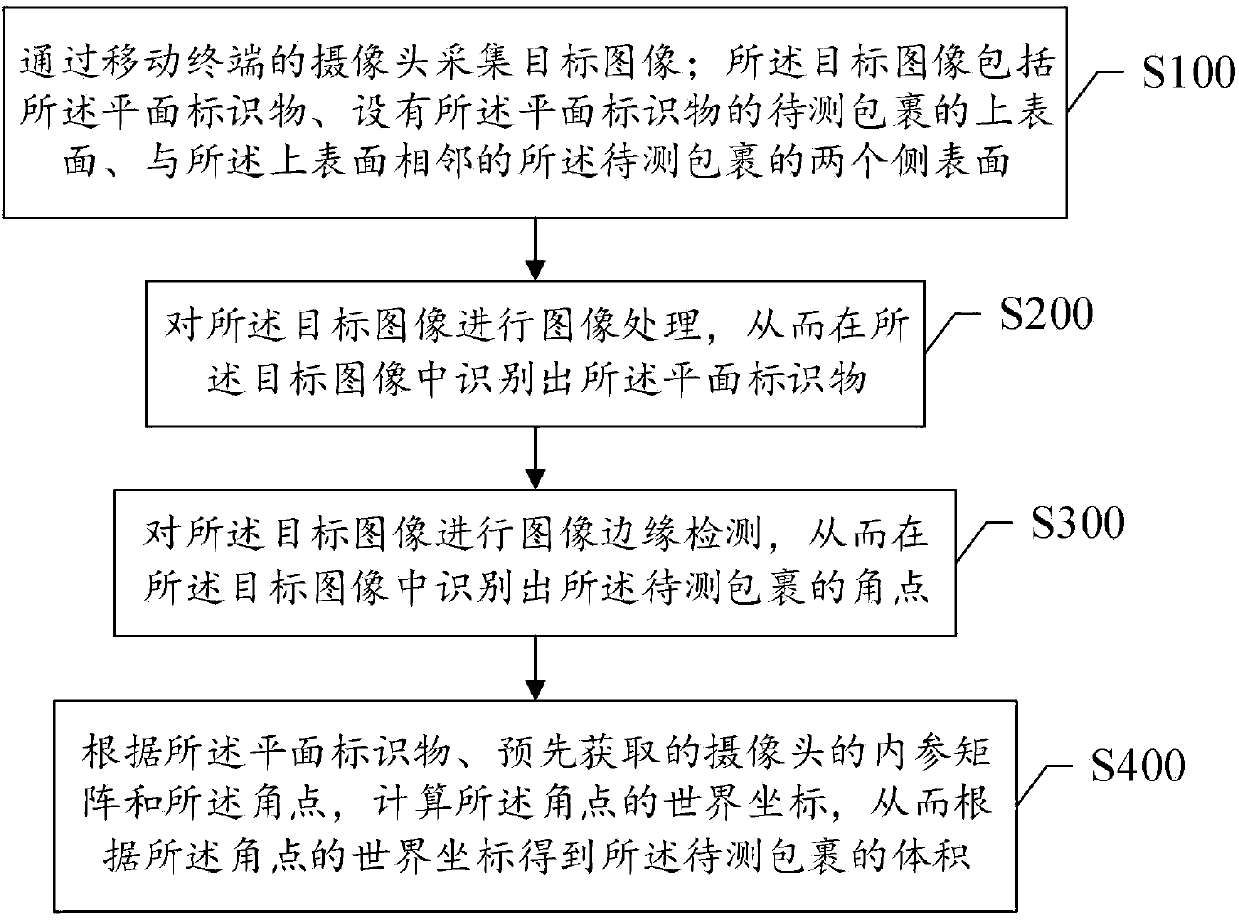

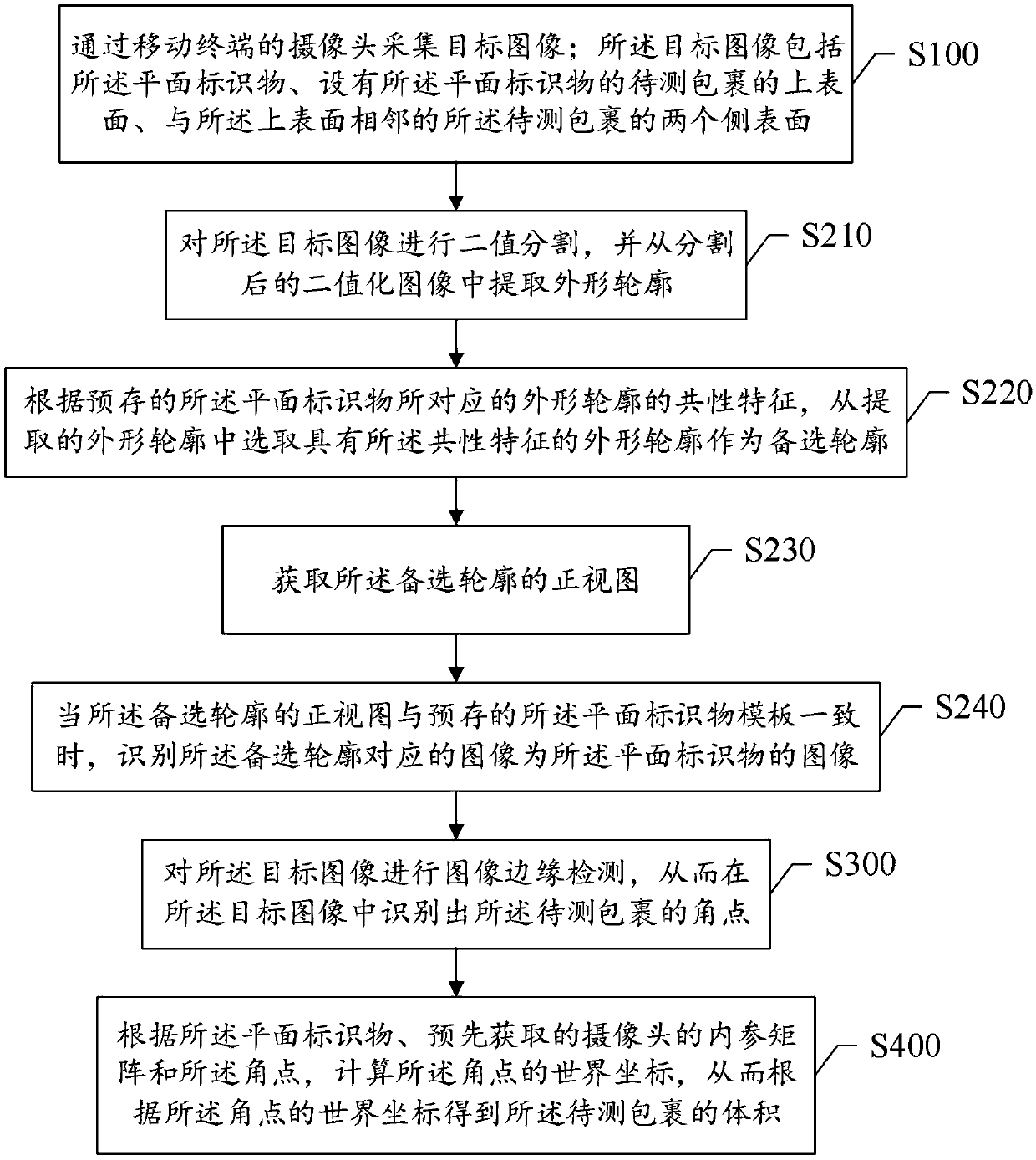

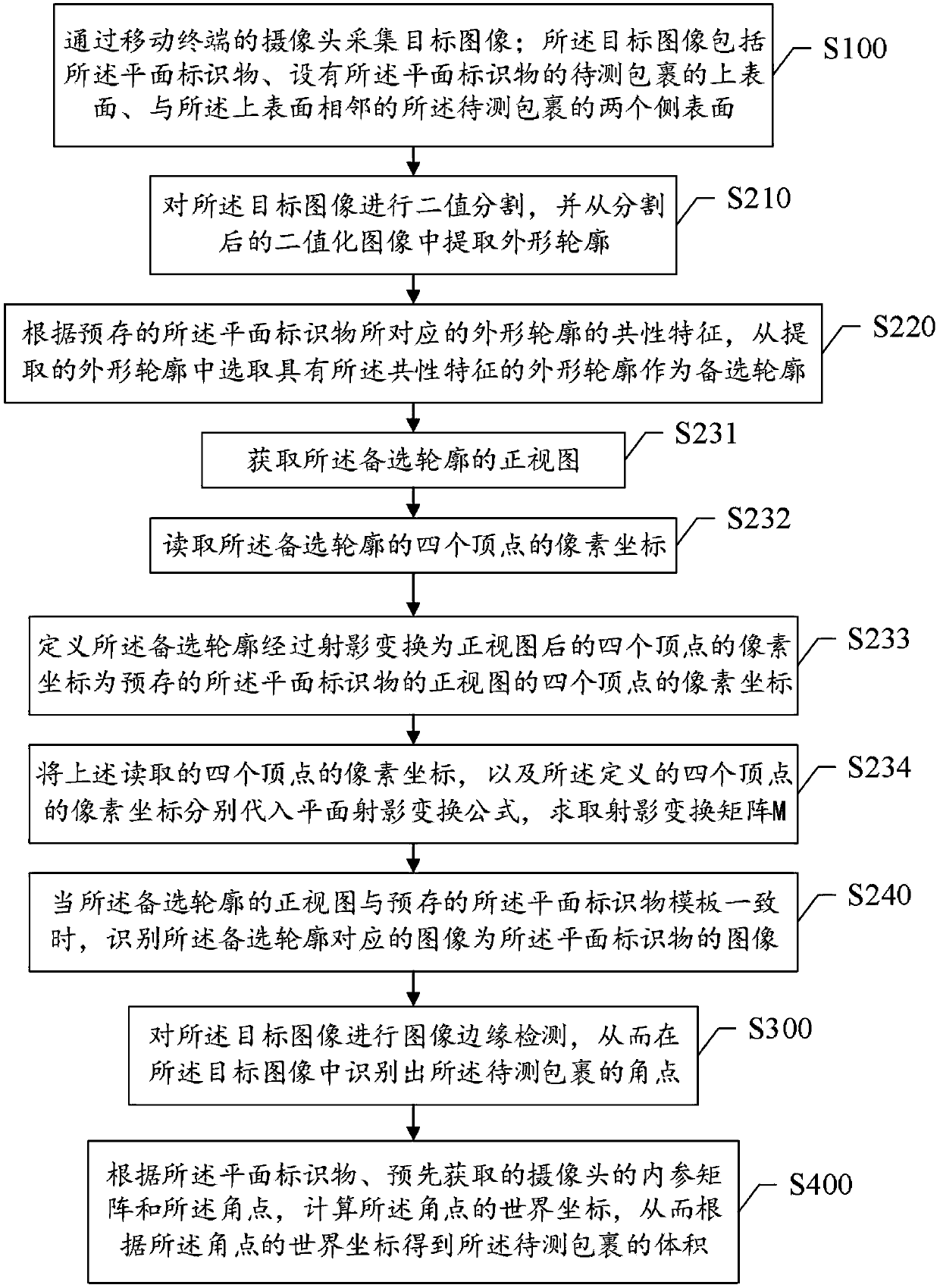

Parcel volume measuring method and system, storage medium and mobile terminal

InactiveCN108627092AAccurate volume measurementReal-time measurementImage analysisUsing optical meansImage edgeComputer graphics (images)

The invention provides a parcel volume measuring method and system, a storage medium and a mobile terminal. The method comprises the following steps that S100, a target image is obtained through a camera of the mobile terminal, wherein the target image comprises a plane marker, an upper surface of a to-be-measured parcel with the plane marker, and two side surfaces of the to-be-measured parcel adjacent to the upper surface; S200, image processing is conducted on the target image, so that the plane marker is recognized in the target image; S300, image edge detection is carried out on the targetimage, so that the angle points of the to-be-measured parcel are identified in the target image; S400, the world coordinates of the angular points are calculated based on the plane marker, the pre-obtained internal reference matrix and the angle points of the camera, so that the volume of the to-be-measured parcel is obtained according to the world coordinates of the angular points. According tothe invention, the volume of the parcel to be measured is accurately measured by using the camera built in the mobile terminal in a real-time manner; the use scene is enriched, additional hardware facilities do not need to be added, and the cost is saved.

Owner:NANJING AVATARMIND ROBOT TECH CO LTD

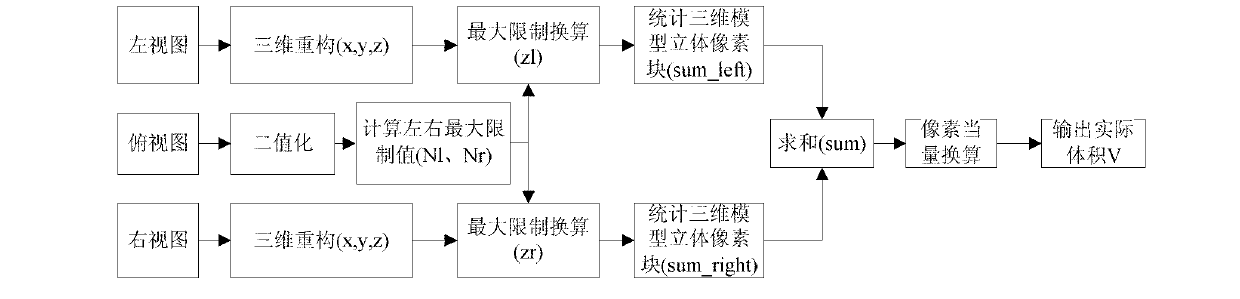

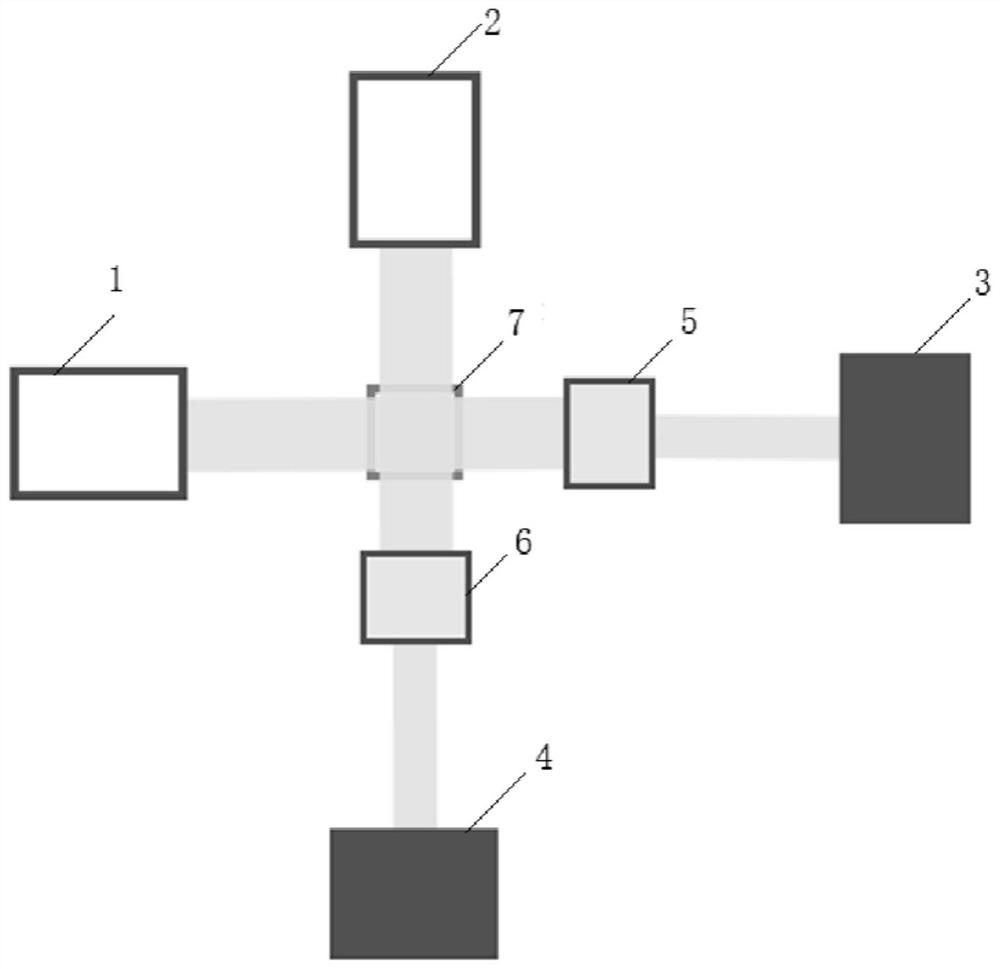

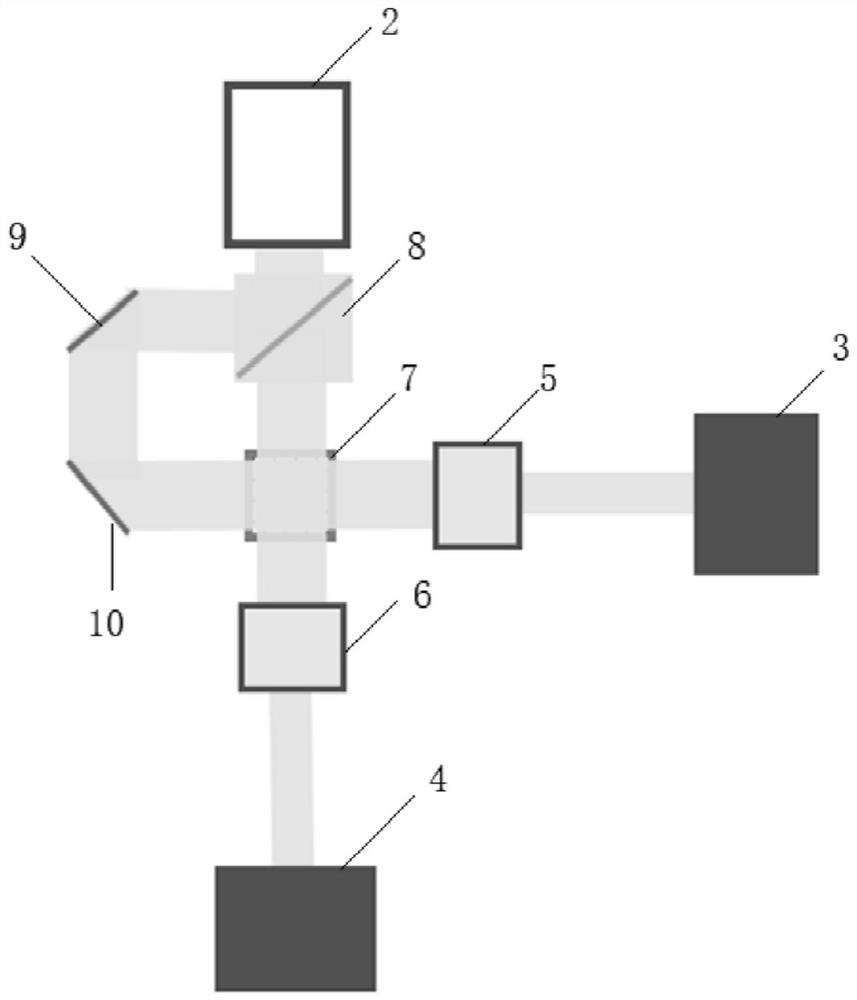

Visual measurement method for volume of irregular object

InactiveCN103278090AVolume measurement achievedAccurate volume measurementImage enhancementUsing optical meansGray levelComputer vision

The invention belongs to a visual measurement method for the volume of an irregular object. According to the method, firstly, a system is demarcated, and the pixel equivalent of the system is obtained; secondly, three cameras are utilized for respectively obtaining original images of an object to be measured in three directions of overlooking, left looking and right looking, and in addition, the maximal peripheral length image coordinate parameter of the object to be measured is obtained through a top view; then, a left view and a right view are subjected to three-dimensional reconstruction based on the gray level, and meanwhile, the maximal length pixel of the top view is used as the basis for cutting the reconstruction range corresponding to the left view and the right view; next, corresponding statistical algorithms are adopted for calculating the volume of a three-dimensional object in a three-dimensional model in an image coordinate; and finally, the practical volume of the object to be measured in a world coordinate system is calculated according to the pixel equivalent. The visual measurement method has the advantages that the image grey value is utilized for the three-dimensional reconstruction of the object in an image coordinate system, the volume of the object is calculated through the pixel value, only the pixel equivalent is demarcated in the method, the calculation speed is high, and the real-time requirement can be met in the precision range.

Owner:SHAANXI UNIV OF SCI & TECH

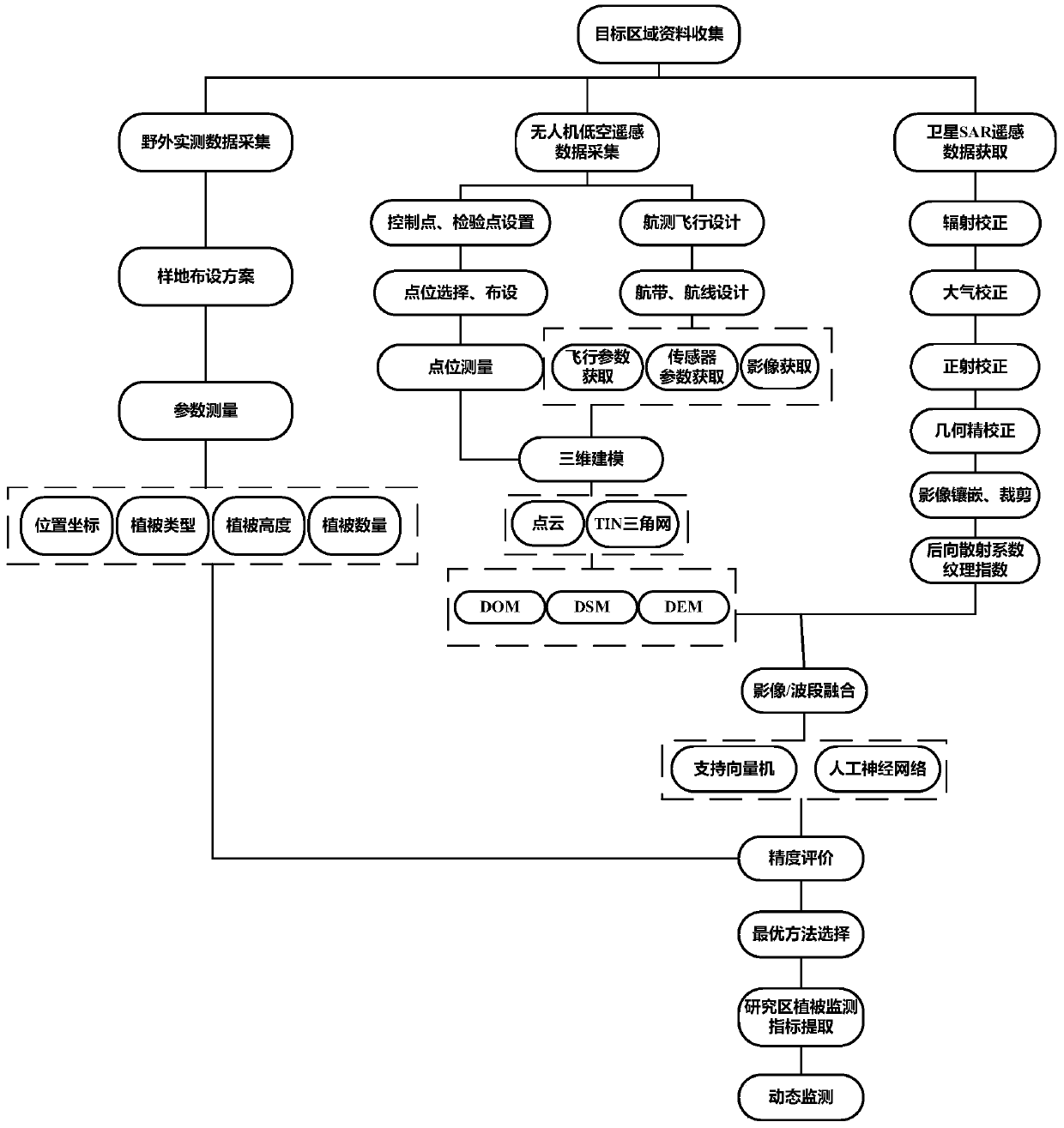

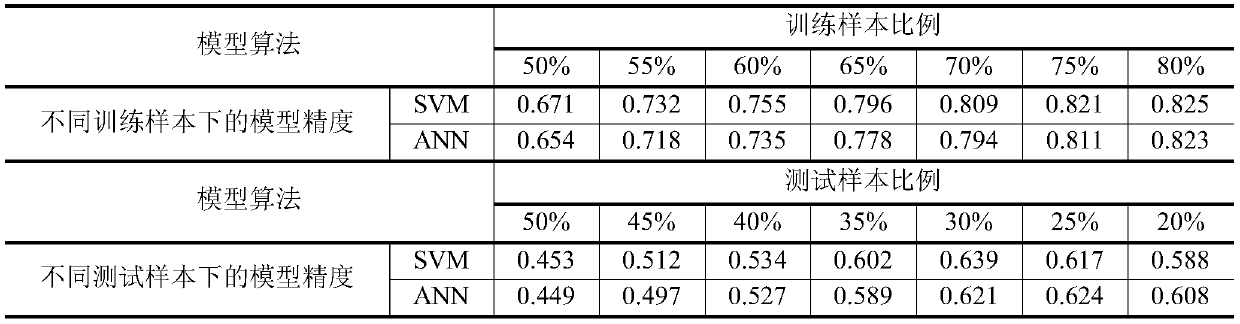

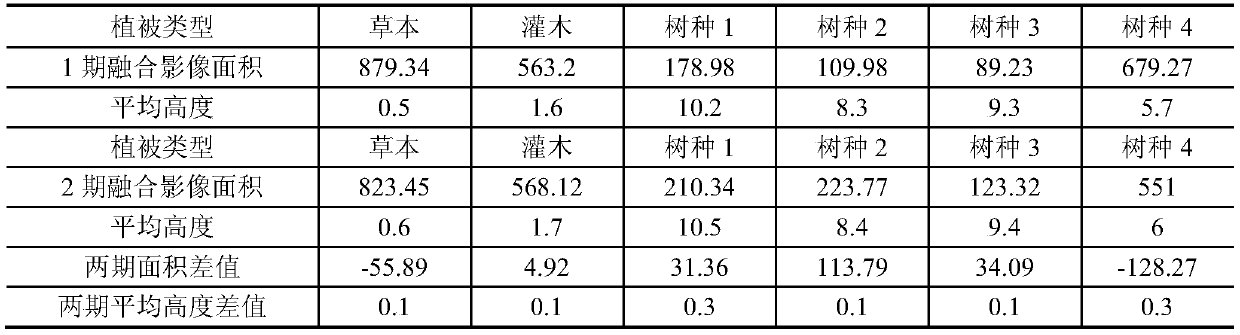

Vegetation classification method based on machine learning algorithm and multi-source remote sensing data fusion

PendingCN111553245AComprehensive and complete feature indicatorsLow costCharacter and pattern recognitionNeural architecturesEcological environmentVegetation classification

The invention relates to the field of ecological environment monitoring, and discloses a vegetation classification method based on a machine learning algorithm and multi-source remote sensing data fusion, which is used for efficiently realizing identification and classification of vegetation types in a target area. The method comprises the following steps: acquiring a low-altitude remote sensing image of terrestrial plants in a sample area by using an unmanned aerial vehicle, and acquiring a digital orthoimage and a digital surface model of the sample area based on the low-altitude remote sensing image; extracting elevation information of the digital surface model; acquiring an SAR image of a sample region corresponding to the aerial photography time of the unmanned aerial vehicle by utilizing satellite remote sensing; carrying out wave band and image fusion on the digital orthoimage, the elevation information and the SAR image; performing inversion model training and inversion model precision evaluation on the fused image through sample area actual measurement data and a machine learning algorithm to obtain an inversion model meeting requirements; and finally, classifying terrestrial plants in the target area based on the inversion model. The method is suitable for terrestrial plant ecological environment monitoring.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

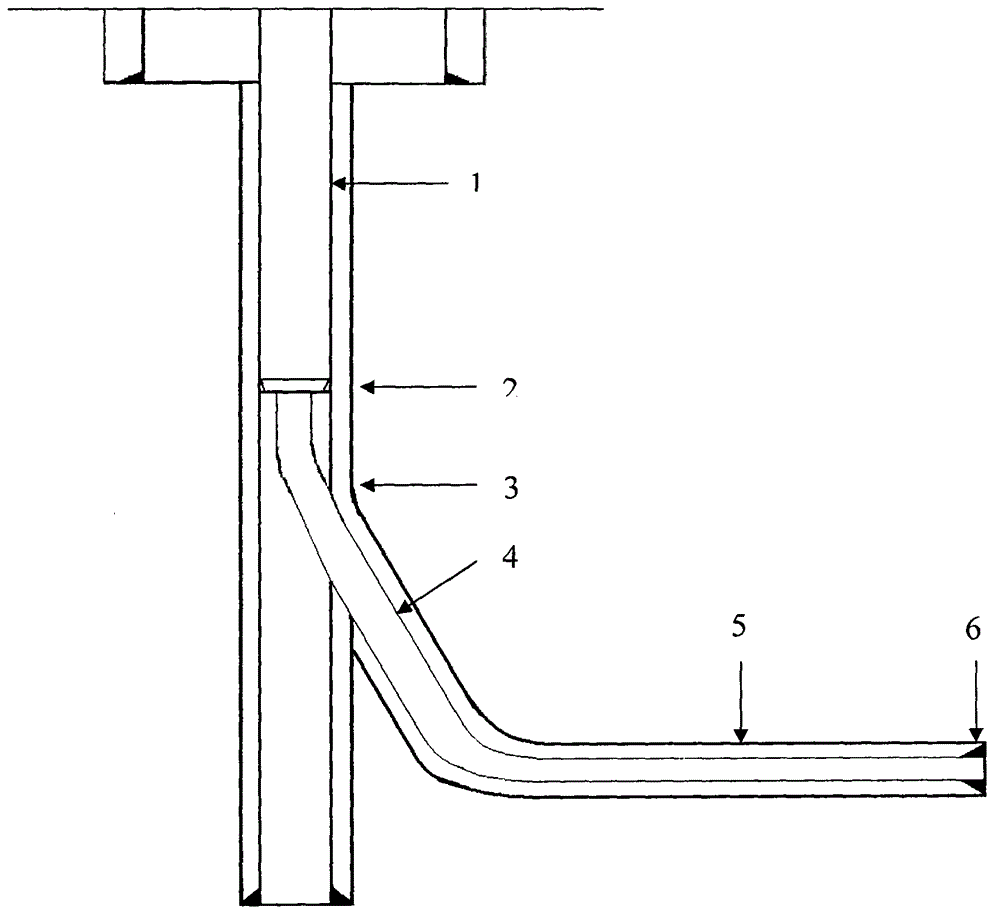

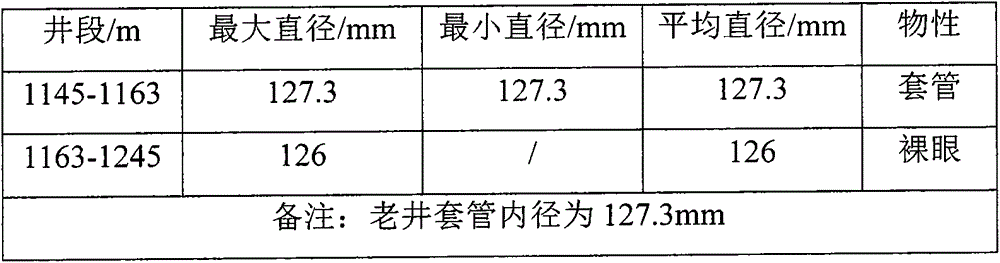

Window opening and sidetrack drilling short-radius horizontal well and reverse circulation well cementing and water plugging method

InactiveCN104832119APrevent movementAvoid cloggingDirectional drillingSealing/packingWindow openingWell cementing

The invention relates to secondary productivity development of old wells and shut-down wells in oil fields and provides a window opening and sidetrack drilling short-radius horizontal well and reverse circulation well cementing and water plugging method. The method mainly includes the following six steps that: 1) a window opening point is selected; 2) a well trajectory is designed; 3) a whipstock is positioned and set; 4) casing window cutting operation is performed; 5) well trajectory control is performed; and 6) well completion operation is performed. The method of the invention can be applied to the secondary development of a part of low-yield wells and scrapped shut-down wells, can effectively obtain stored oil and residual oil in dead corners in uncontrolled areas of old wells, and can restore and improve single well production and ultimate recovery efficiency.

Owner:BEIJING YILONG HENGYE PETROLEUM ENG TECH

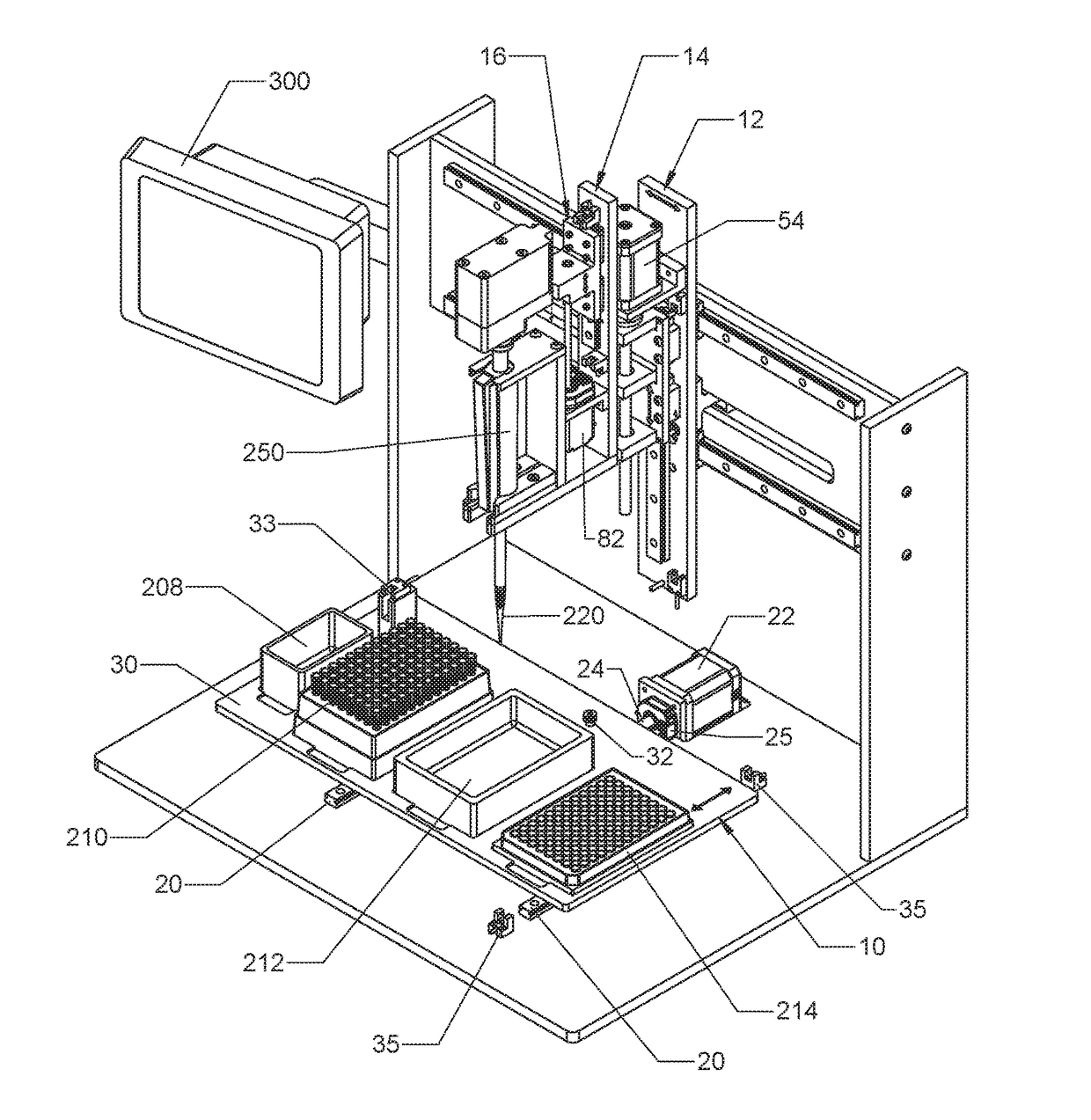

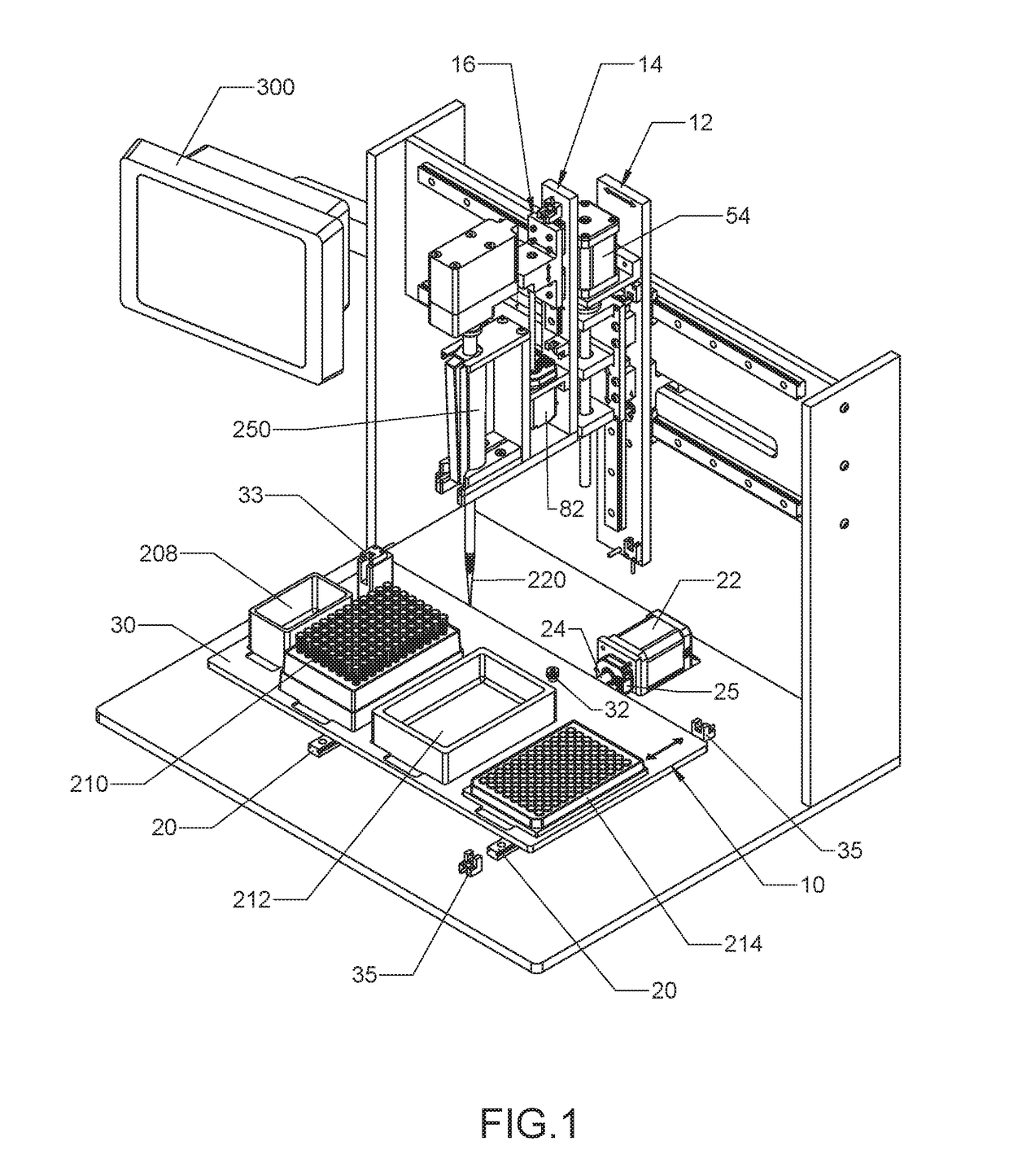

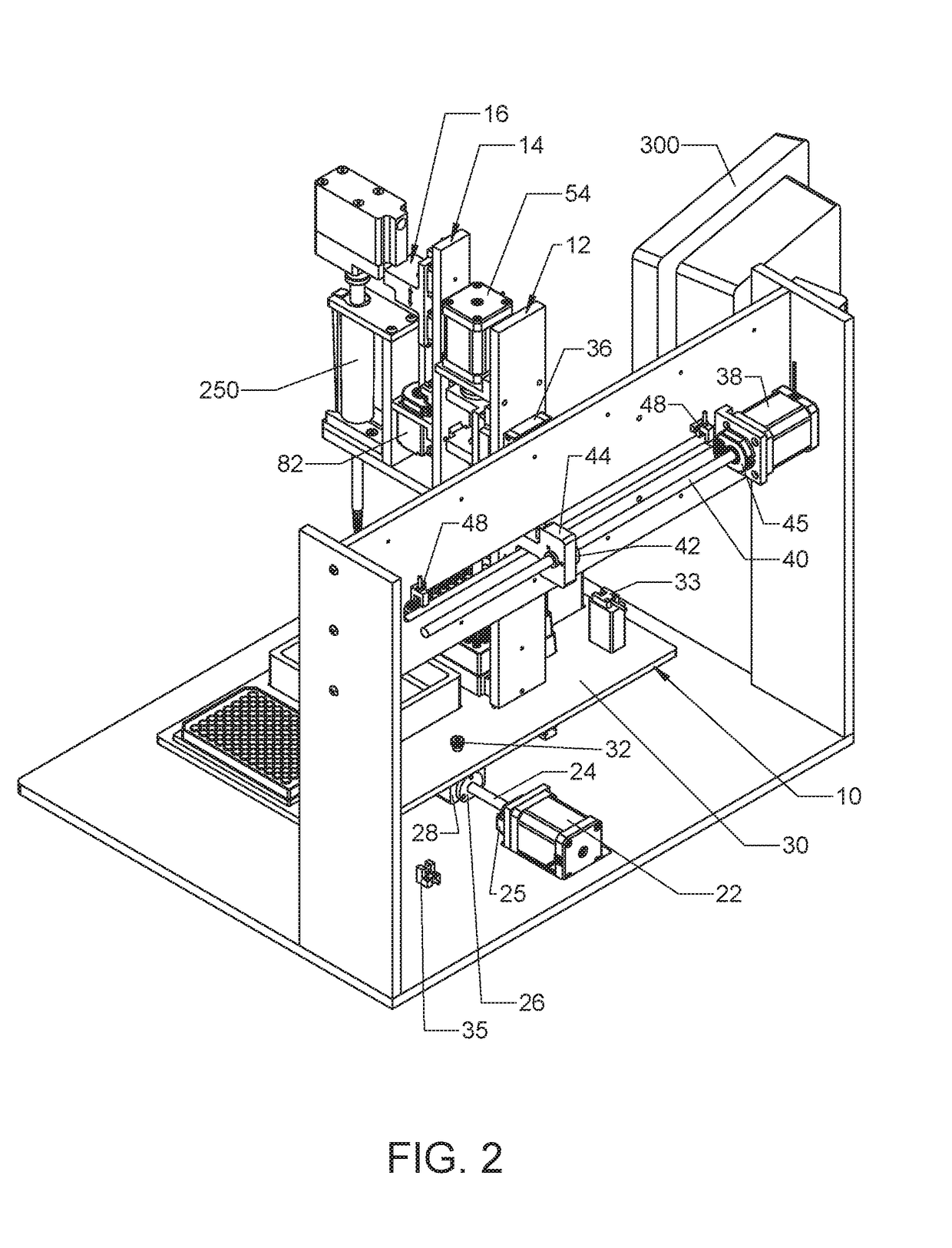

Automated pipette manipulation system

ActiveUS20180154349A1Accurate and robust and costAccurate volume measurementBurettes/pipettesMaterial analysisPipetteBiomedical engineering

The automated pipette manipulation system of the present invention allows for the automated manipulation of any pipette commercially available to aspire and dispense liquids in a chemical or biochemical laboratory setting. Measuring the amount of liquid aspired or dispensed by a pipette is conducted by a load sensor that records the starting point of the displacement of a pushbutton of said pipette and a motor that drives the displacement of said pushbutton a predetermined distance past the starting point that corresponds to a predetermined volume of liquid aspired or dispensed by said pipette. The automated pipette manipulation system of the present invention further detects whether a pipette tip is attached to said pipette and then automatically ejects said pipette tip at the end of a liquid handling process.

Owner:HABBAL WALID

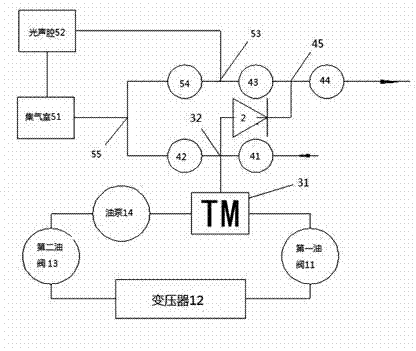

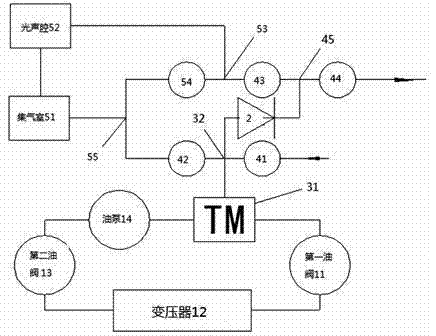

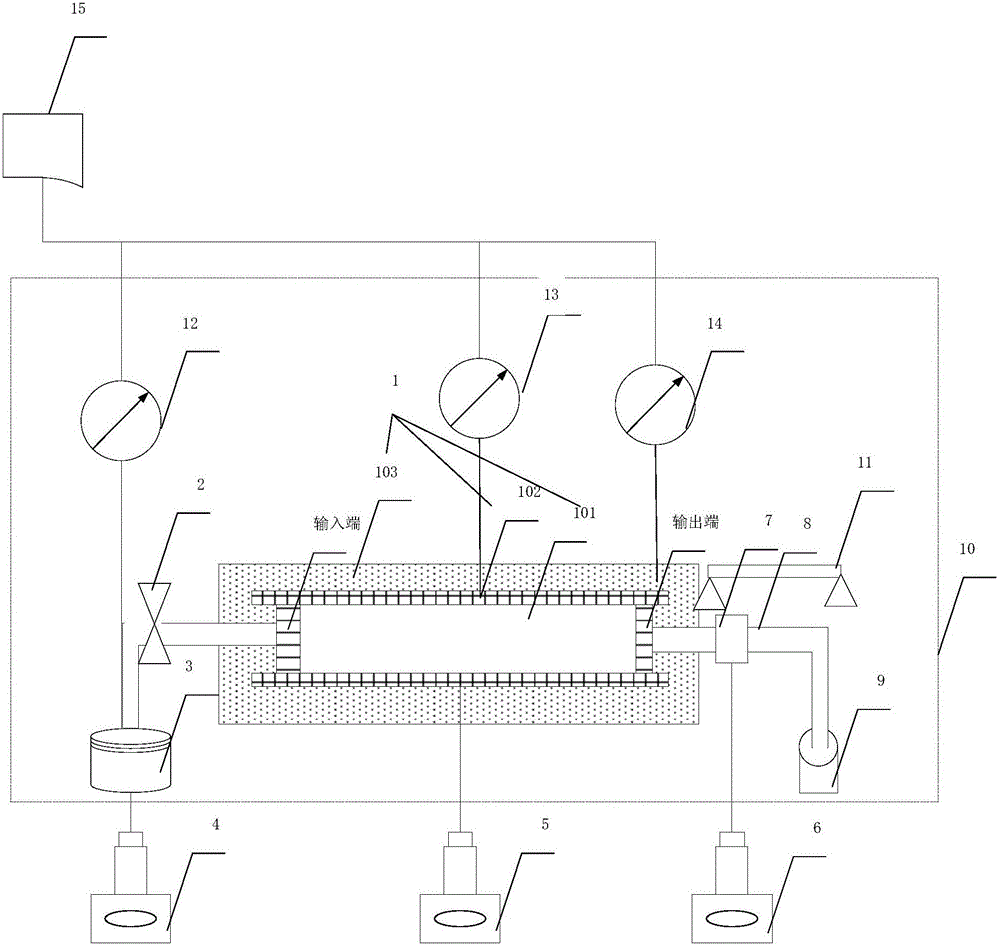

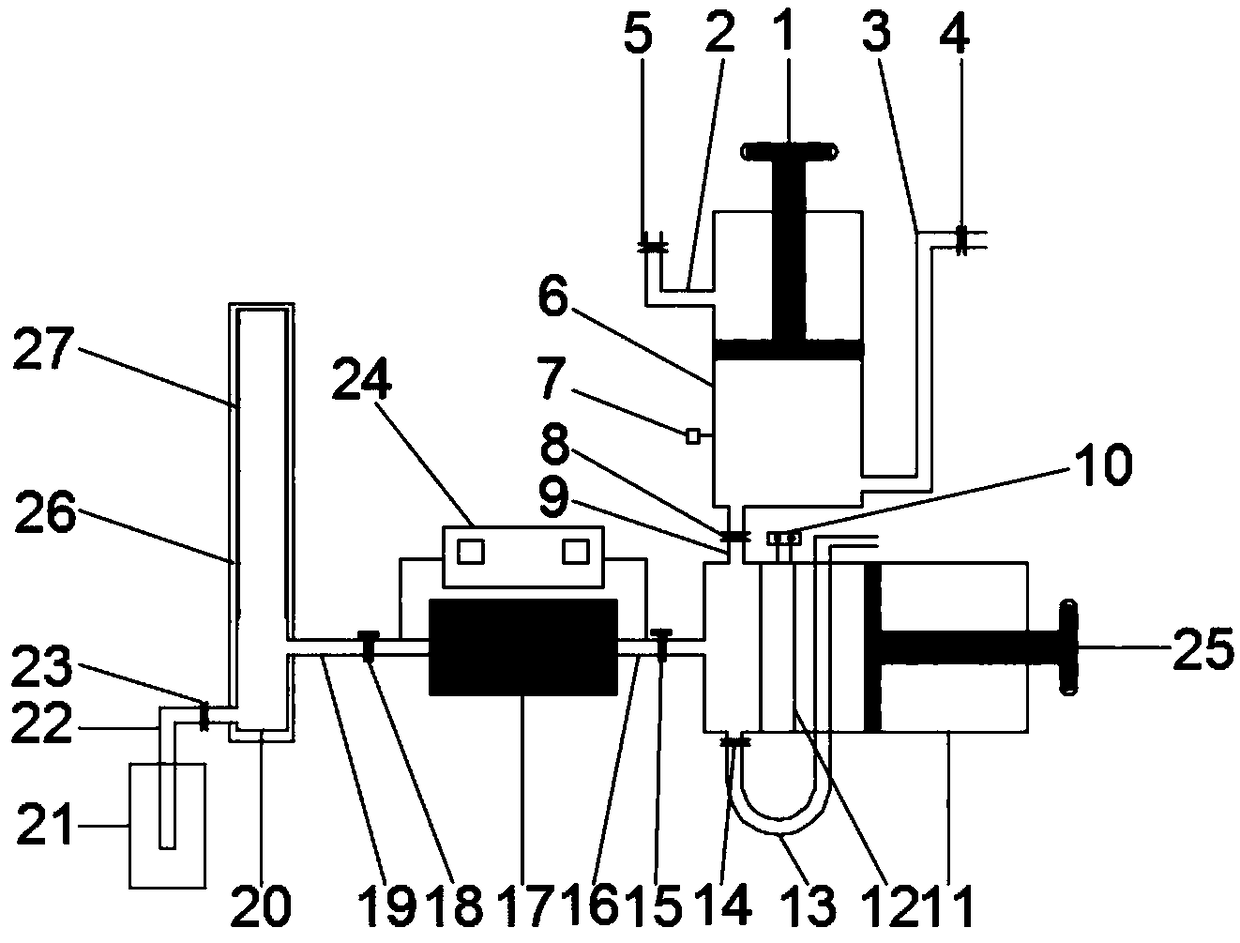

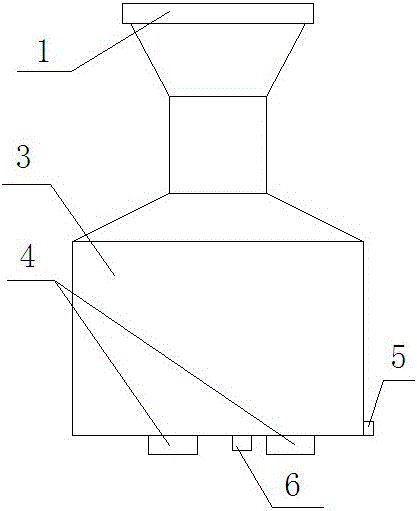

Oil-gas separation device for transformer insulation oil

ActiveCN102527094AEfficient separationAccurate volume measurementLiquid degasificationMaterial analysis by optical meansGas analysisAir pump

The invention discloses an oil-gas separation device for transformer insulation oil, which comprises an oil passing component, an air pump, a degassing module, an electromagnetic valve set component and a gas collection detection circulation component. The air pump, the degassing module, the electromagnetic valve set component and the gas collection detection circulation component are connected through gas pipes. The degassing module comprises a sealed cavity body and a macromolecule micropore capillary pipe arranged in the sealed cavity body, an oil inlet and an oil outlet of the sealed cavity body are respectively connected with the oil passing component, and a gas outlet of the sealed cavity body is connected with a gas inlet of the gas pump through two ports of a four-way pipe. The oil passing component comprises a first oil valve, a transformer, a second oil valve and an oil pump, wherein an inlet of the first oil valve is connected with the oil outlet of the sealed cavity body, and an outlet of the oil pump is connected with the oil inlet of the sealed cavity body. The oil-gas separation device prevents air or other gases from being mixed in the transformer oil, effectively avoids overflowing of oil vapor, and can protect analyzing equipment from being polluted by the oil vapor. Furthermore, gas analysis in online transformer oil cannot lead vacuum degree of a transformer to reduce.

Owner:KUNSHAN HEZHI ELECTRICAL EQUIP

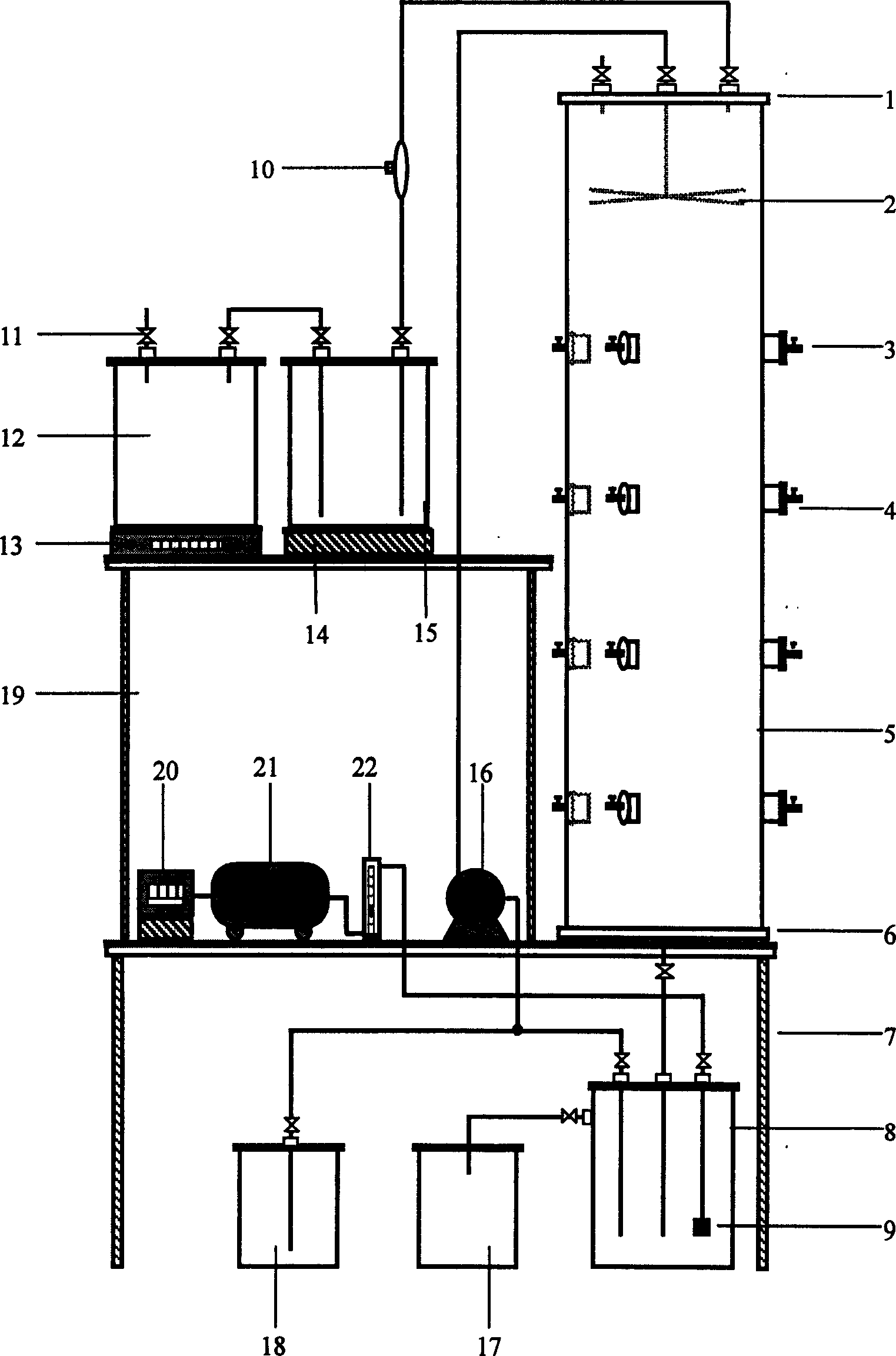

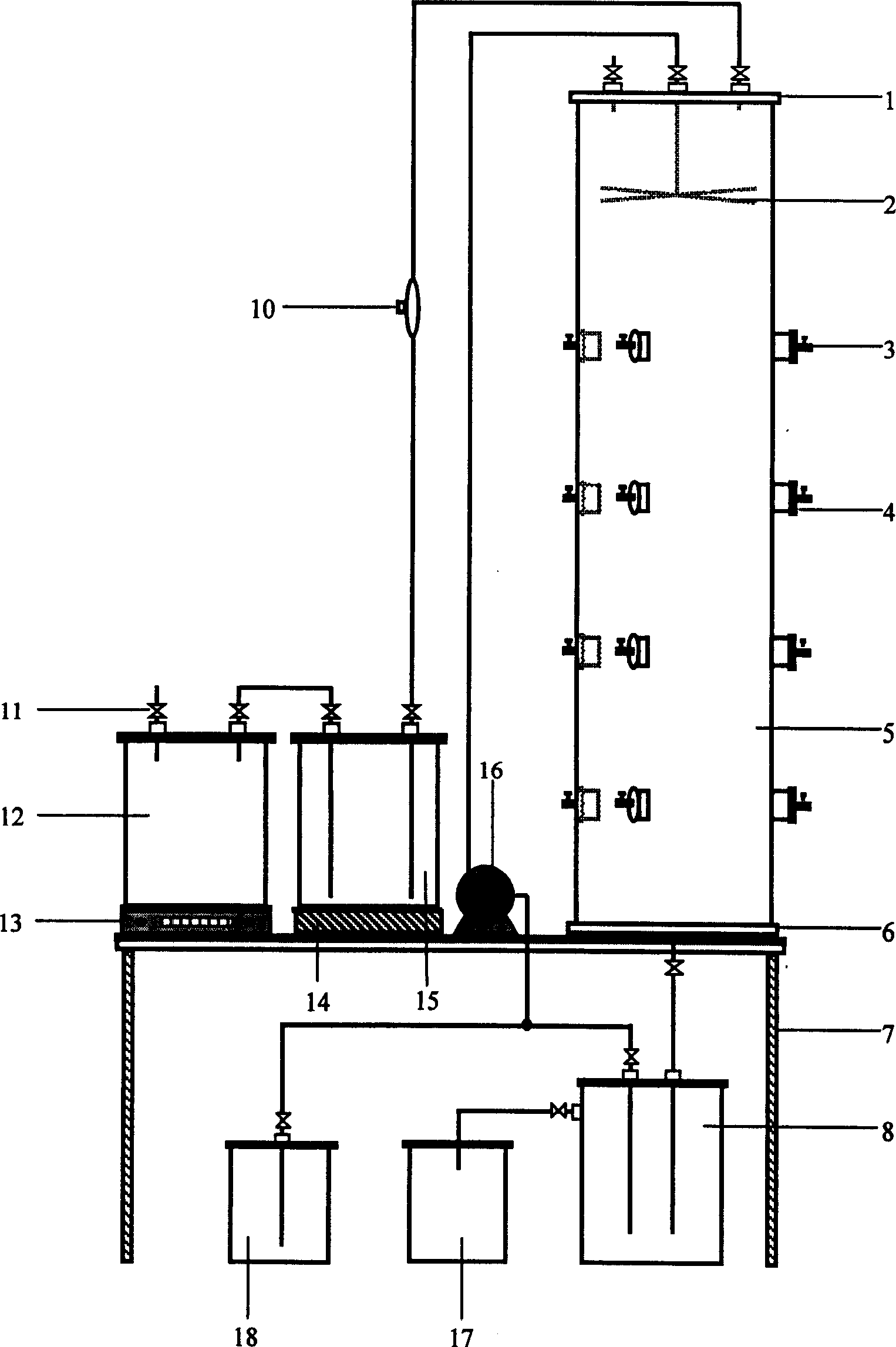

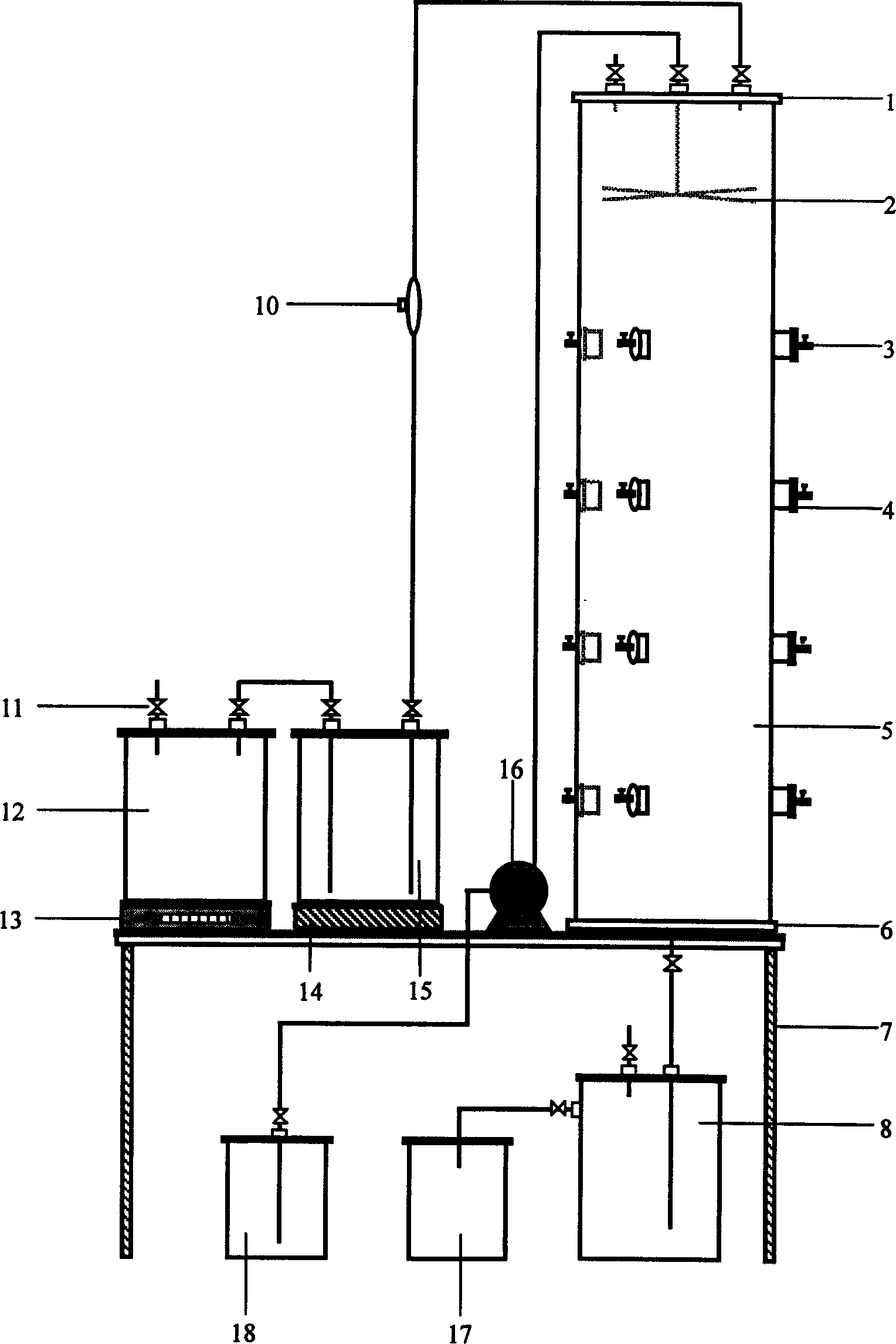

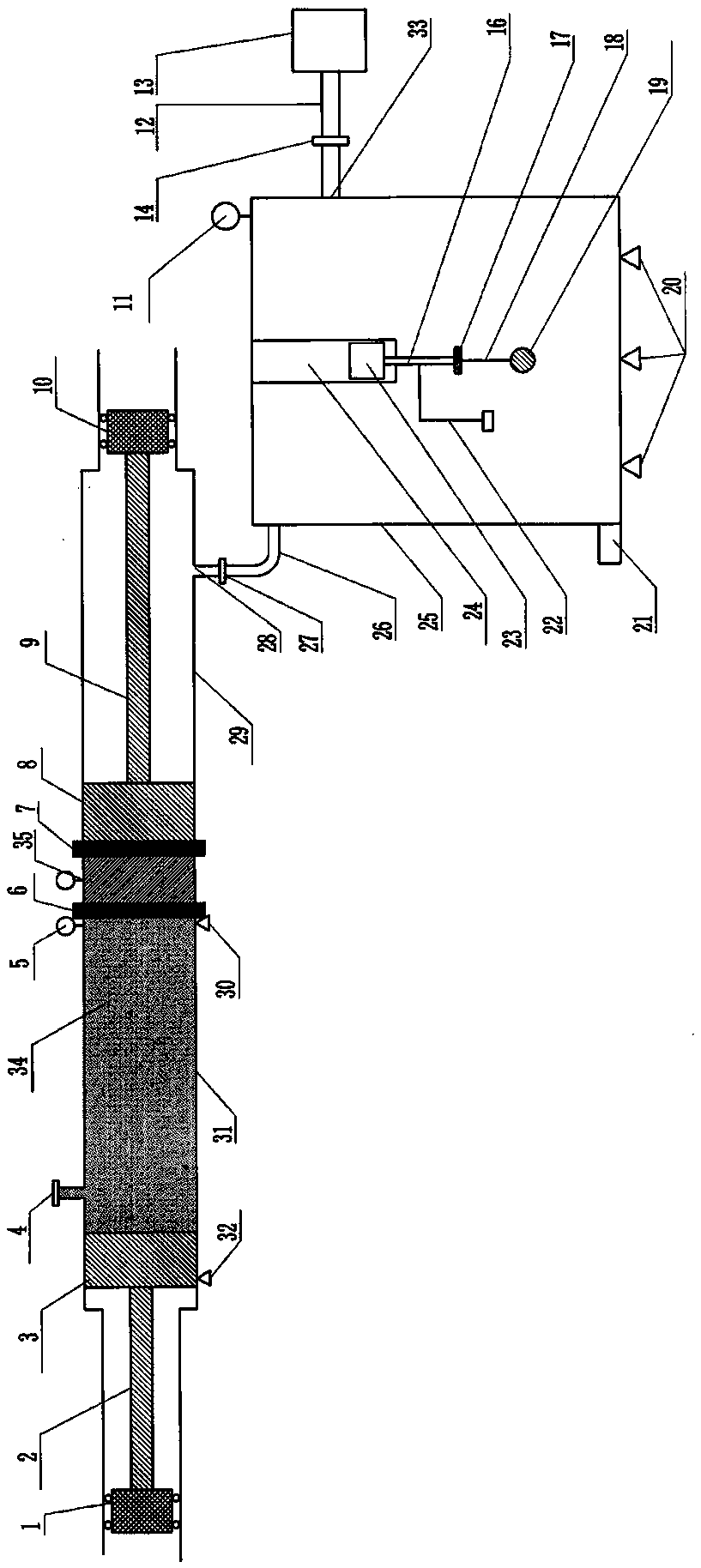

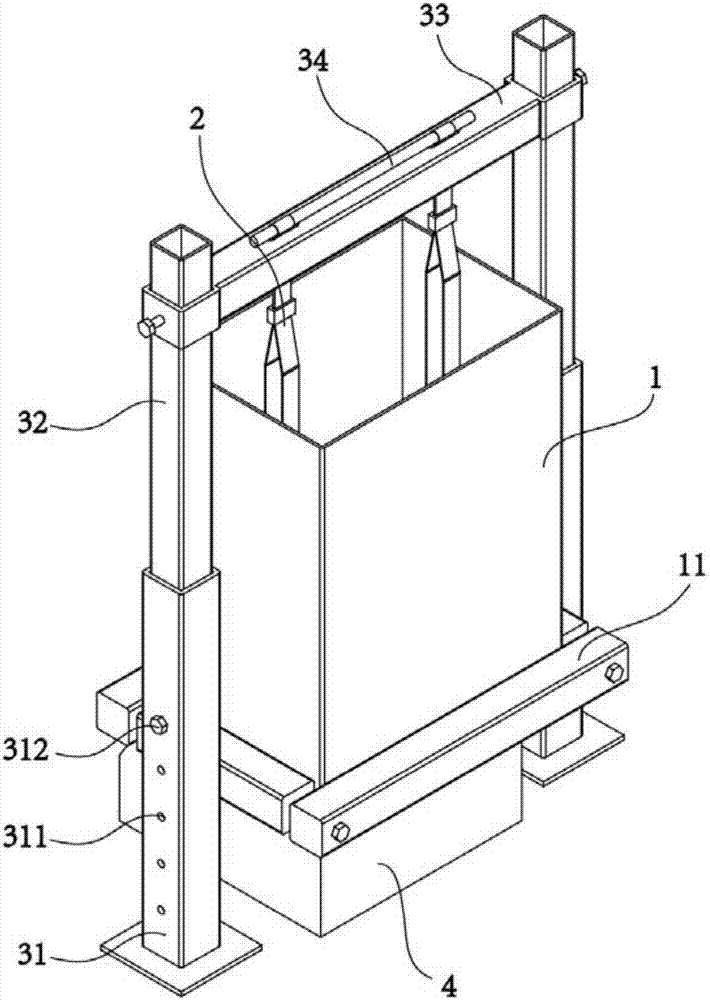

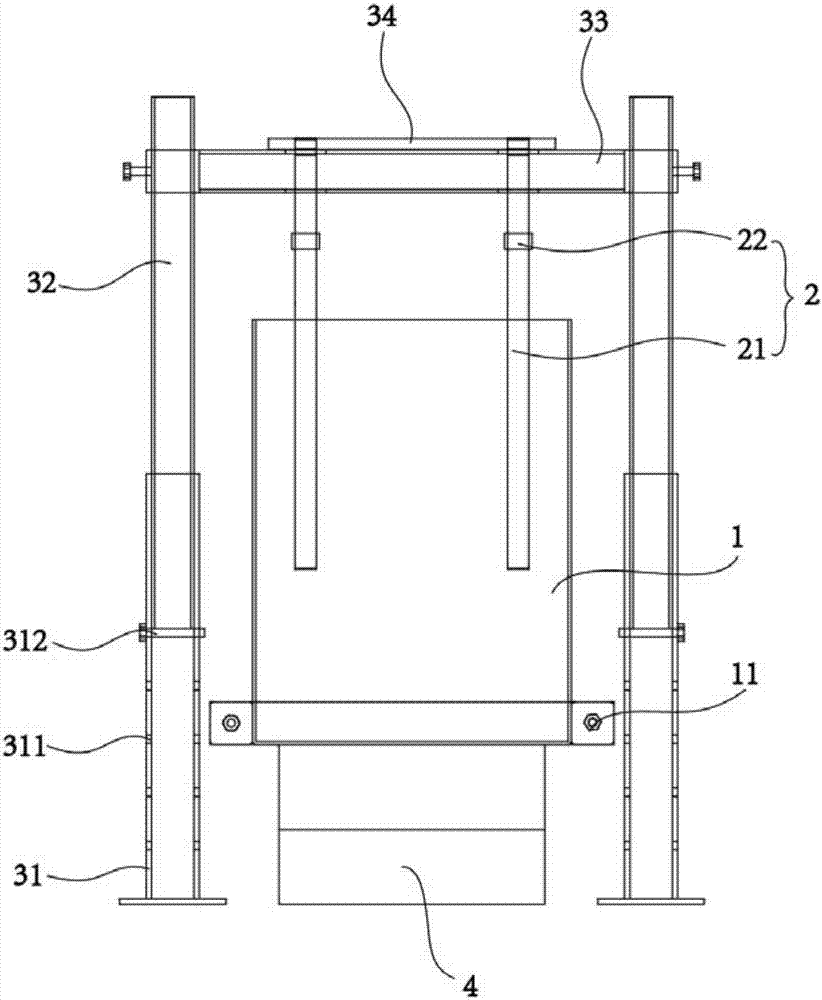

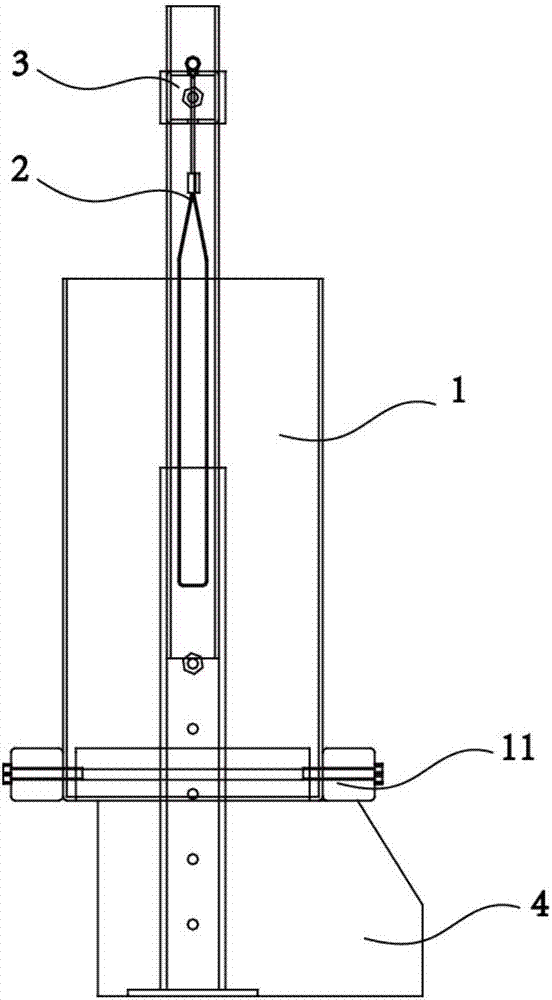

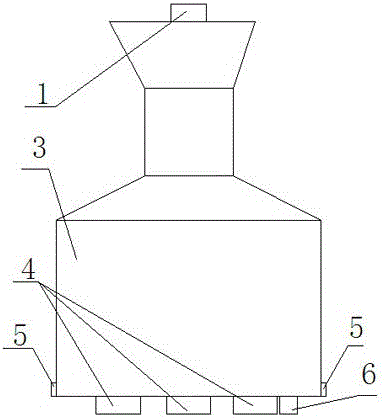

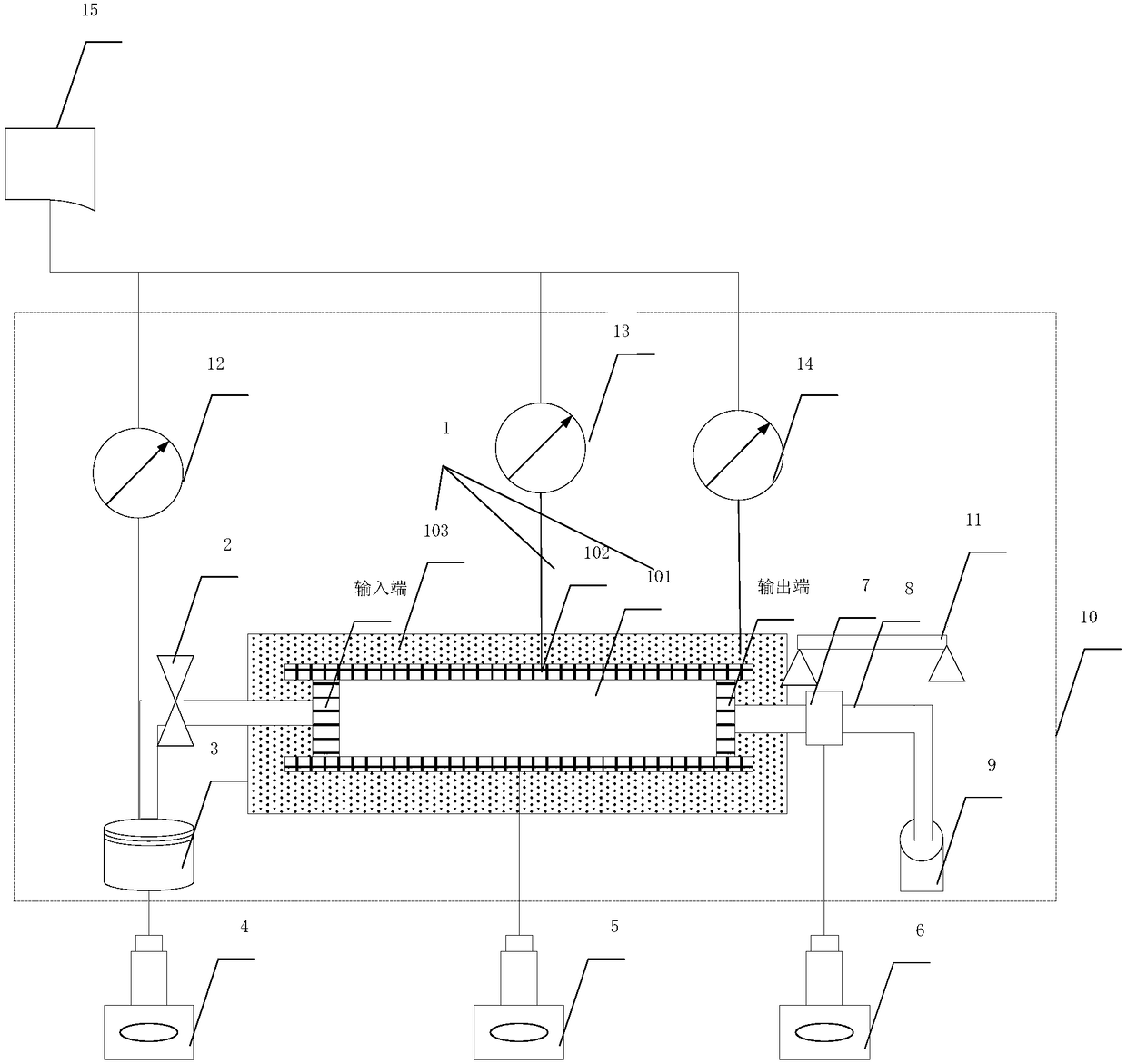

Multilayer sampling type life garbage ecological landfill reactor

InactiveCN1715860AAccurate volume measurementEasy to operateWithdrawing sample devicesPreparing sample for investigationPeristaltic pumpLitter

The ecological domestic garbage landfill reactor includes the first stainless steel frame with reactor, micro computerized time controller, aeration pump, glass rotor flow meter and precise peristaltic pump; the second stainless steel frame with exhaust liquid collecting bottle and gas collecting bottle; percolate regulating water tank, percolate collecting tank and simulating rainwater tank below the first frame. The micro computerized time controller is connected with the aeration pump, the glass rotor flow meter, the percolate regulating water tank, the precise peristaltic pump and the reactor; the percolate regulating water tank is connected to the reactor, percolate collecting tank and the imulating rainwater tank; and the reactor is connected to the sampling battle, the exhaust liquid collecting bottle, the gas collecting bottle and the control valve. The present invention can realize laminated sampling and instantaneous gas sampling in simple operation and high volumetric measurement precision.

Owner:吴伟祥 +2

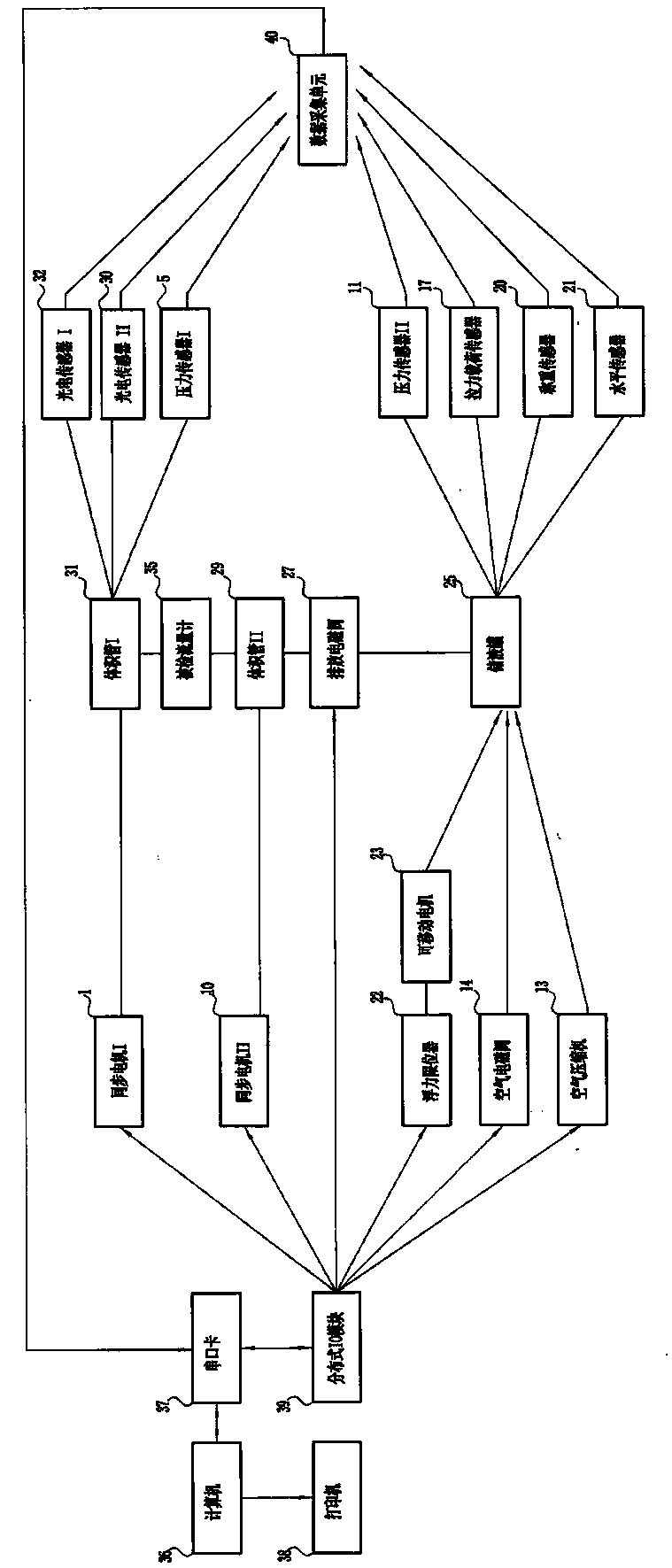

Flowmeter verification device and verification method thereof

InactiveCN107843315AChange won't happenTest results are not affected by temperatureTesting/calibration apparatusSynchronous motorLiquid storage tank

Provided are a flowmeter verification device and a verification method thereof. The device comprises a volume pipe I31, a volume pipe II29, a working piston I and a working piston II which are arranged in the volume pipe I and the volume pipe II, a synchronous motor I and a synchronous motor II which are connected with the working piston I and the working piston II, a photoelectric sensor I and aphotoelectric sensor II which are installed on the volume pipe I, a liquid storage tank 25 connected with the volume pipe II, a data collection unit 40, a computer and the like, a flowmeter to be verified is installed at the two ends of the volume pipe I and the volume pipe II, liquid which is the same as liquid flowing through the flowmeter actually is injected into the volume pipe I, the synchronous motor I and the synchronous motor II drive the working piston I and the working piston II to work to trigger the photoelectric sensor I and the photoelectric sensor II, time for the liquid to flow through the flowmeter to be verified is read, then the liquid is discharged into the liquid storage tank so that the volume of the liquid which flows through the flowmeter to be verified can be measured, the normal flow which flows through the flowmeter to be verified is calculated, according to readout data of the flowmeter to be verified, a readout error is calculated, and according to the error, whether or not the flowmeter is qualified is judged. According to the device and the method, measurement is convenient, and the data is accurate.

Owner:李盛

Liquid level detection in receptacles

ActiveUS20190017857A1Accurate measurementAccurate volume measurementImage enhancementTelevision system detailsEngineeringTopography

Disclosed is a method of measuring a volume of a liquid provided in at least one receptacle, including the steps of: providing a receptacle having at least one cavity for holding a liquid; providing a plenoptic camera positioned so as to be able to image the surface of the liquid; positioning the receptacle such that the liquid surface faces an objective lens of the plenoptic camera; making at least one plenoptic image of the surface of the liquid by way of the plenoptic camera; determining a surface topography of the liquid on the basis of the at least one image; calculating the volume of liquid based on the measured surface topography and at least one known dimension and / or position of the cavity.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

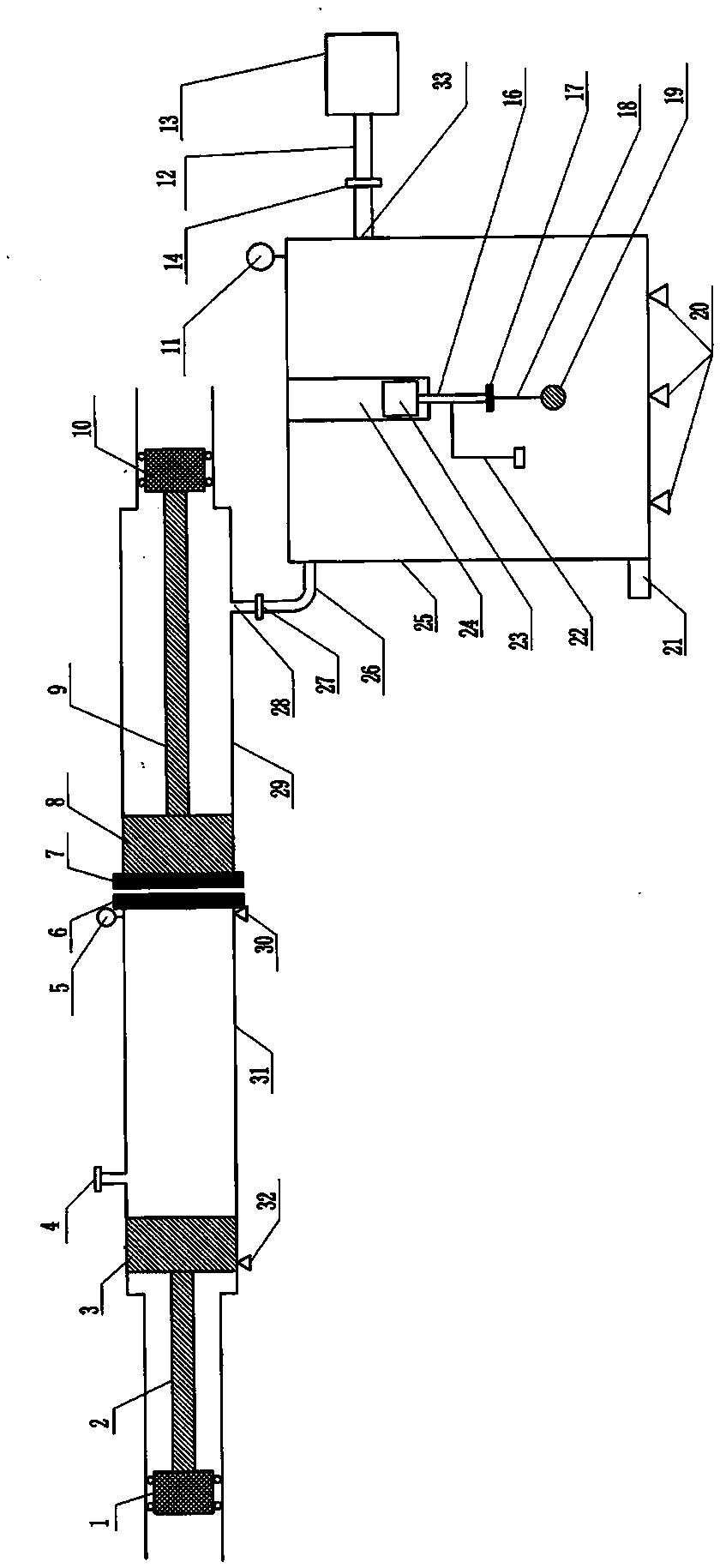

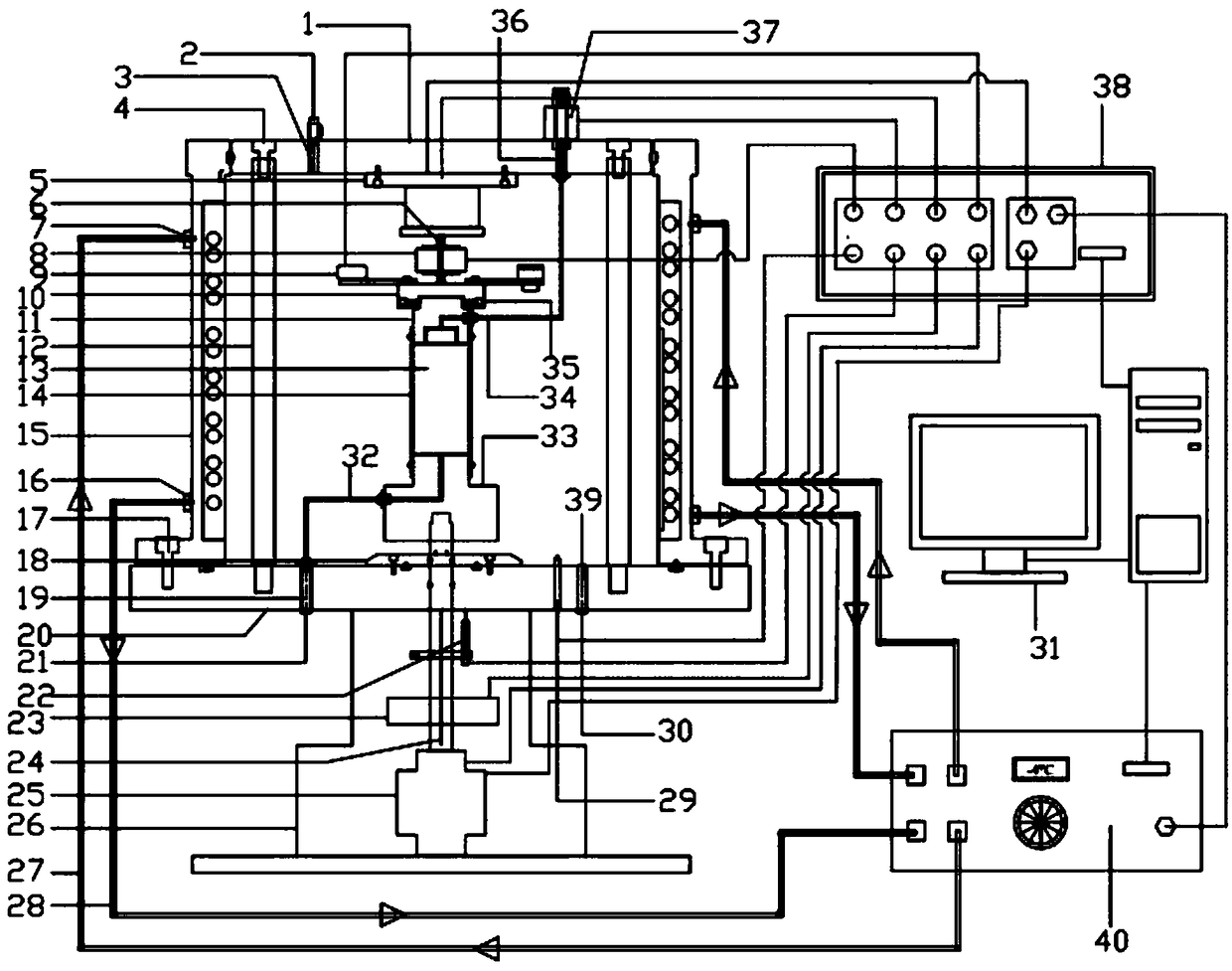

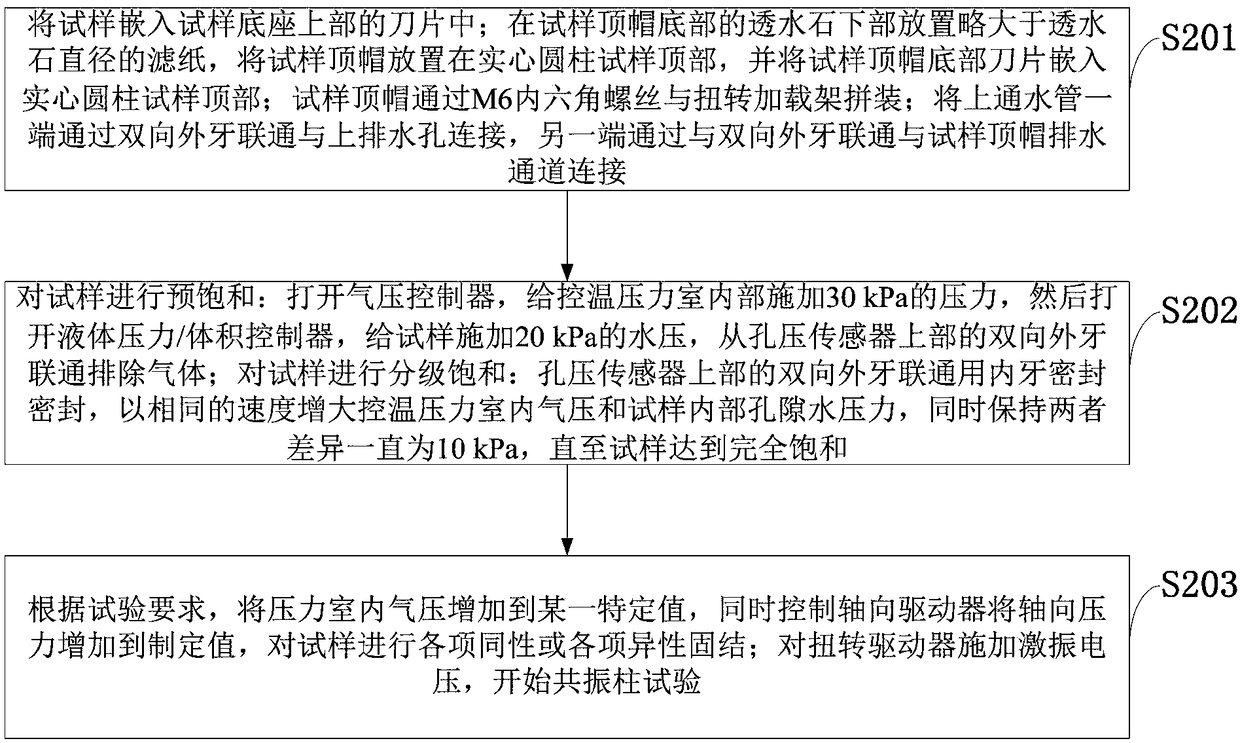

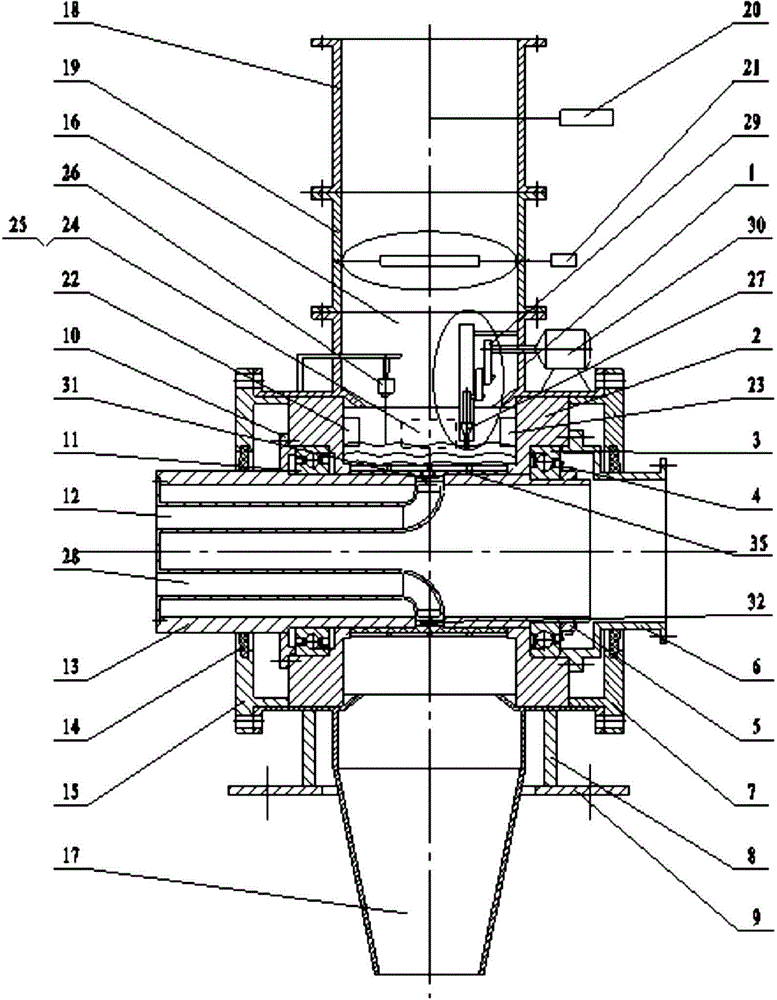

Anisotropism resonant column system and method in stable and accurate temperature control

PendingCN109187168AEvenly distributedAccurately measure axialSimultaneous control of multiple variablesStrength propertiesEngineeringSoftware

The invention belongs to the technical field for testing strength characteristic of a solid material by using mechanical stress, and discloses an anisotropism resonant column system and method in stable and accurate temperature control. The system comprises a temperature control pressure chamber part, a torsion excitation part, an axial loading part, a temperature and signal collection and controlpart, and an auxiliary equipment part. The system disclosed by the invention can prevent sample eccentric distance in torsion excitation, and perform back-pressure saturation on original soil or remolded soil, thereby enabling the same to achieve complete saturation; each sensor numerical value is digitally displayed by utilizing a software program, and an axial driver is accurately and effectively controller, and each of a torsion driver and a temperature automatic regulator can achieve a test target value; the device can work as normal at the environment temperature of -20 to 90 DEG C so asto accurately measure and control liquid pressure and liquid volume change and accurately measure and control gas pressure change.

Owner:NANJING UNIV OF TECH

Negative pressure pneumatic conveying type rotary feeder

The invention discloses a negative pressure pneumatic conveying type rotary feeder which comprises an air speed measurement and air volume regulation control device, a rotary feeder main body structure and a material volume precision measurement system. Double airflow channels are arranged in a rotary feeder main body, materials are carried by airflow and fall onto a filter net in an impeller hopper through an air inlet channel, and air is sucked away by a negative pressure air station through an upper air inlet and a ventilation pipeline III; the materials enter a shell discharge port along with airflow through an exhaust channel and are discharged. According to the negative pressure pneumatic conveying type rotary feeder, conveying of materials having the characteristics of being low in density, prone to suspend in air, difficult to collect, likely to be damaged and the like is achieved; meanwhile, the air speed measurement and air volume regulation control device can be used for monitoring the air speed and air volume in real time, the air volume is convenient to regulate and control, the crushing effect of strong air on the materials is reduced, the material volume precision measurement system can be used for precisely measuring the volume of the conveyed materials, and the compact degree of the conveyed materials is guaranteed on the premise that the materials are prevented from being crushed.

Owner:YANSHAN UNIV

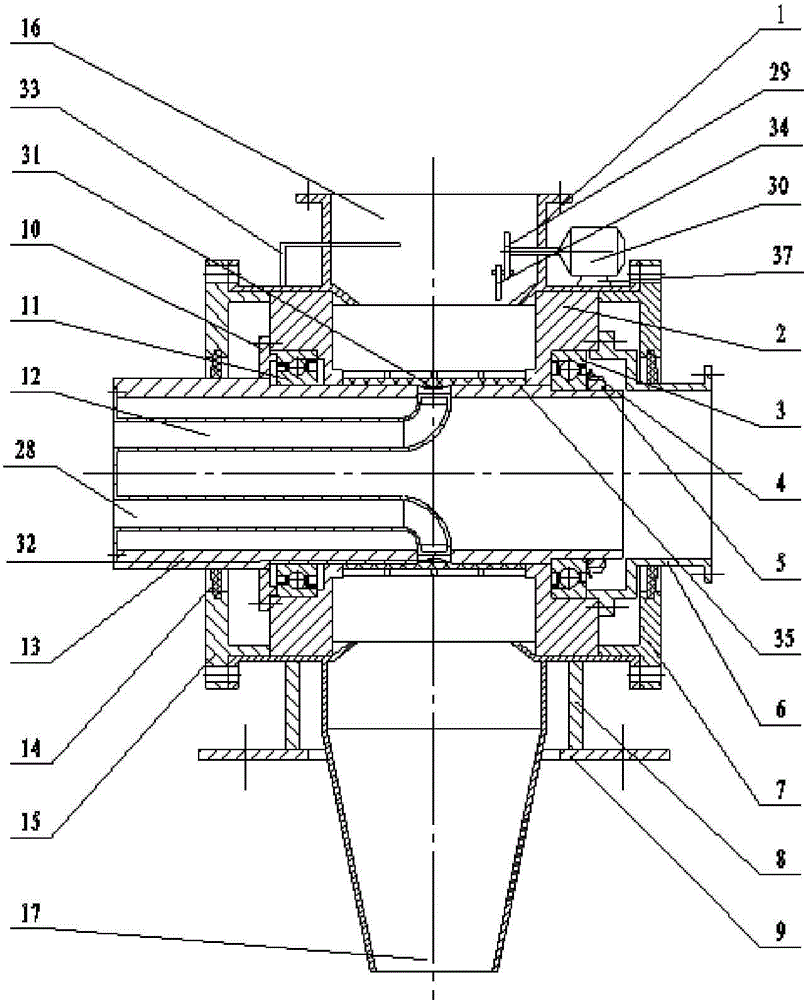

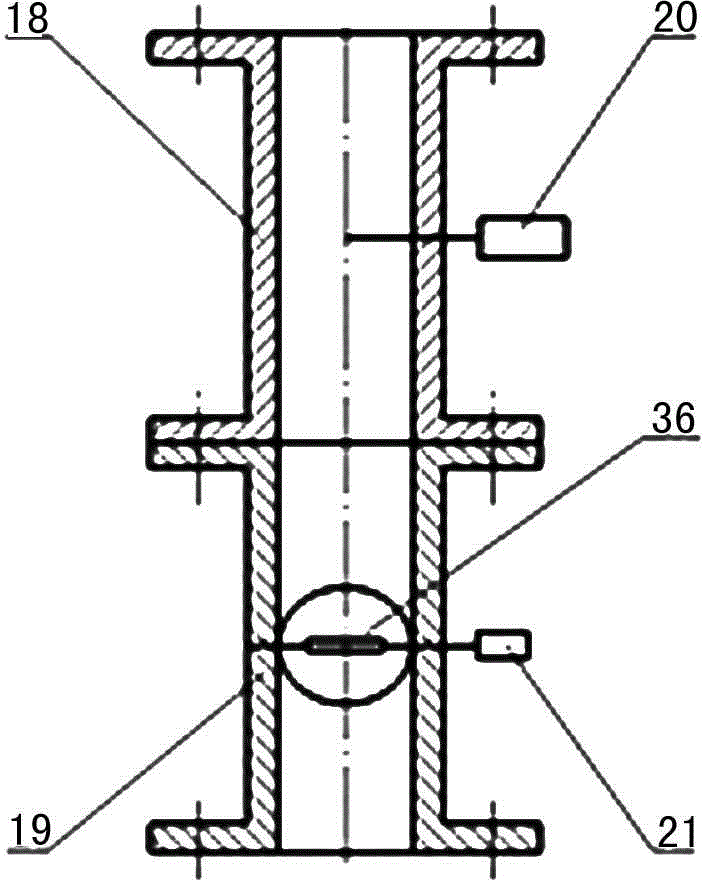

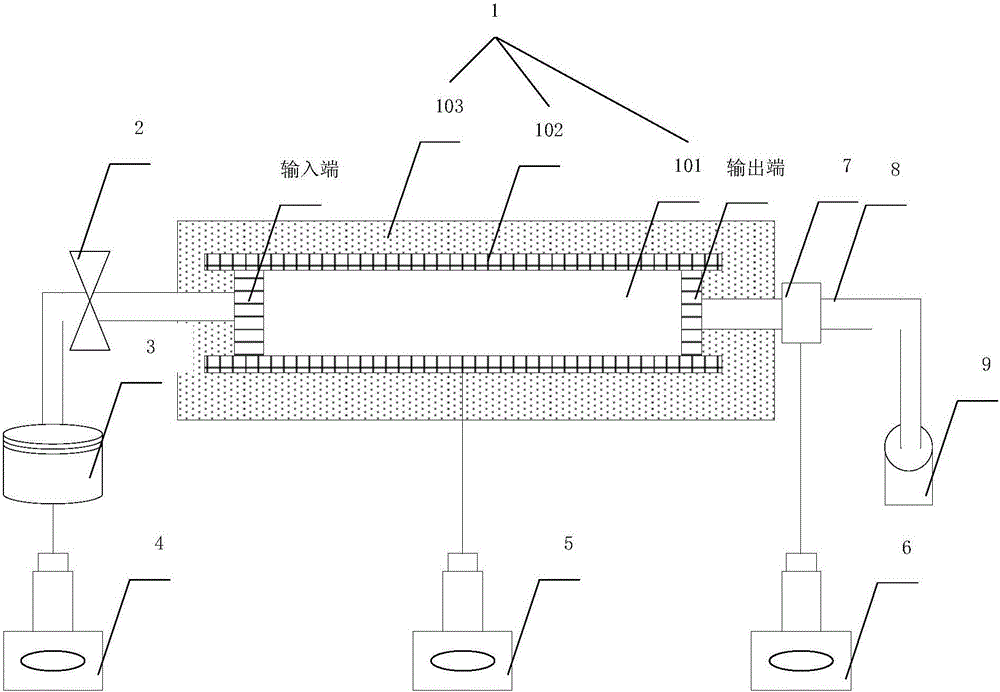

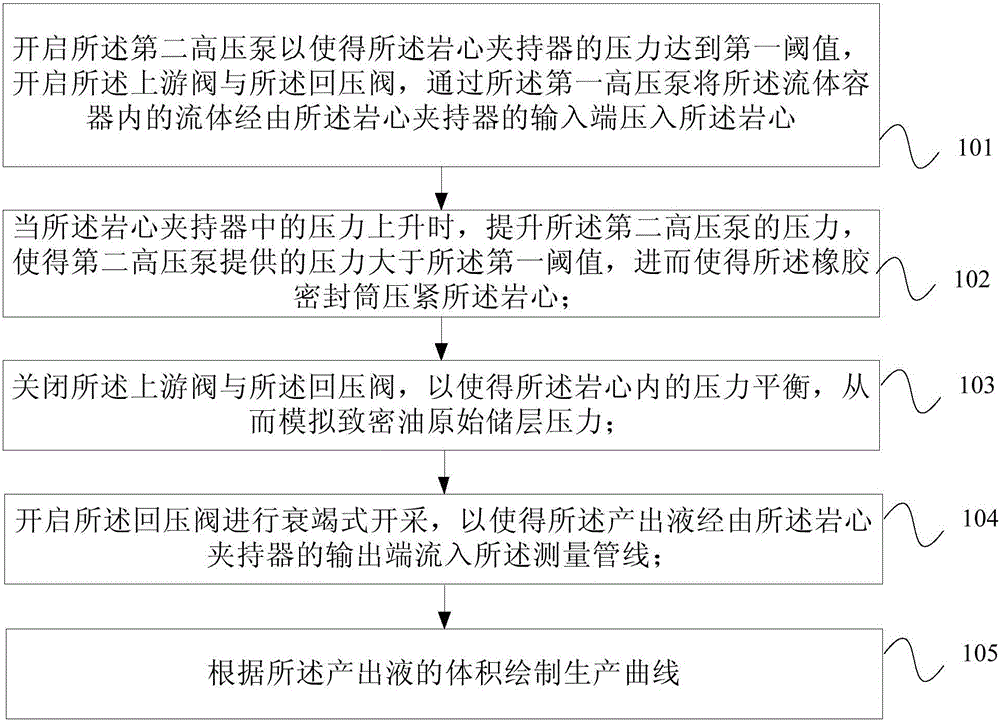

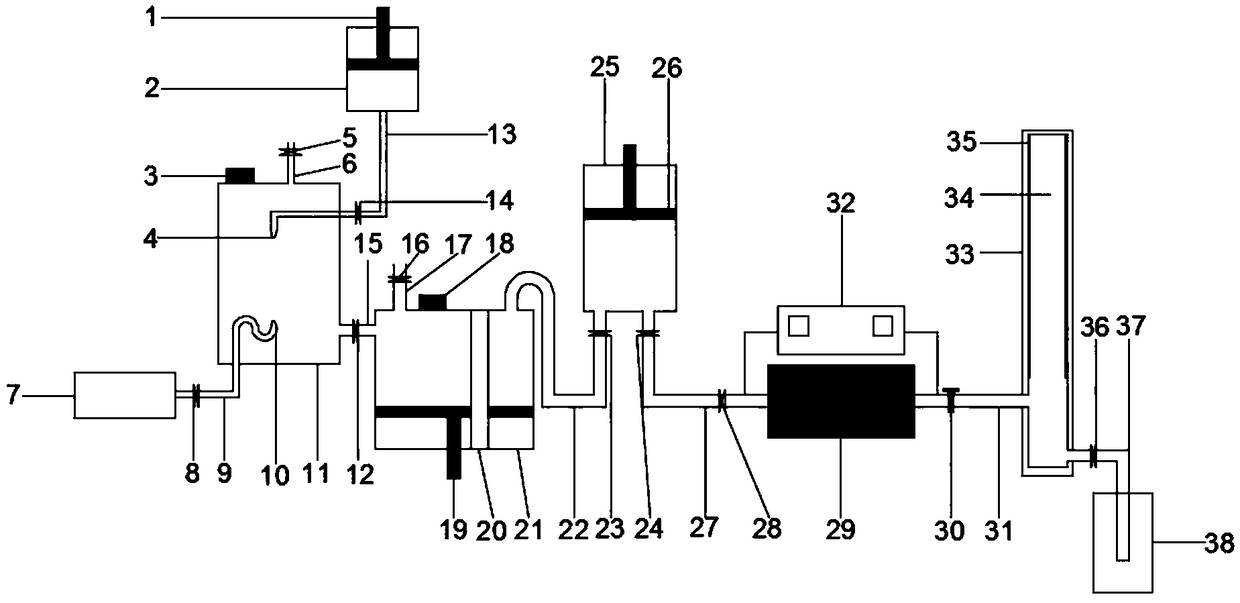

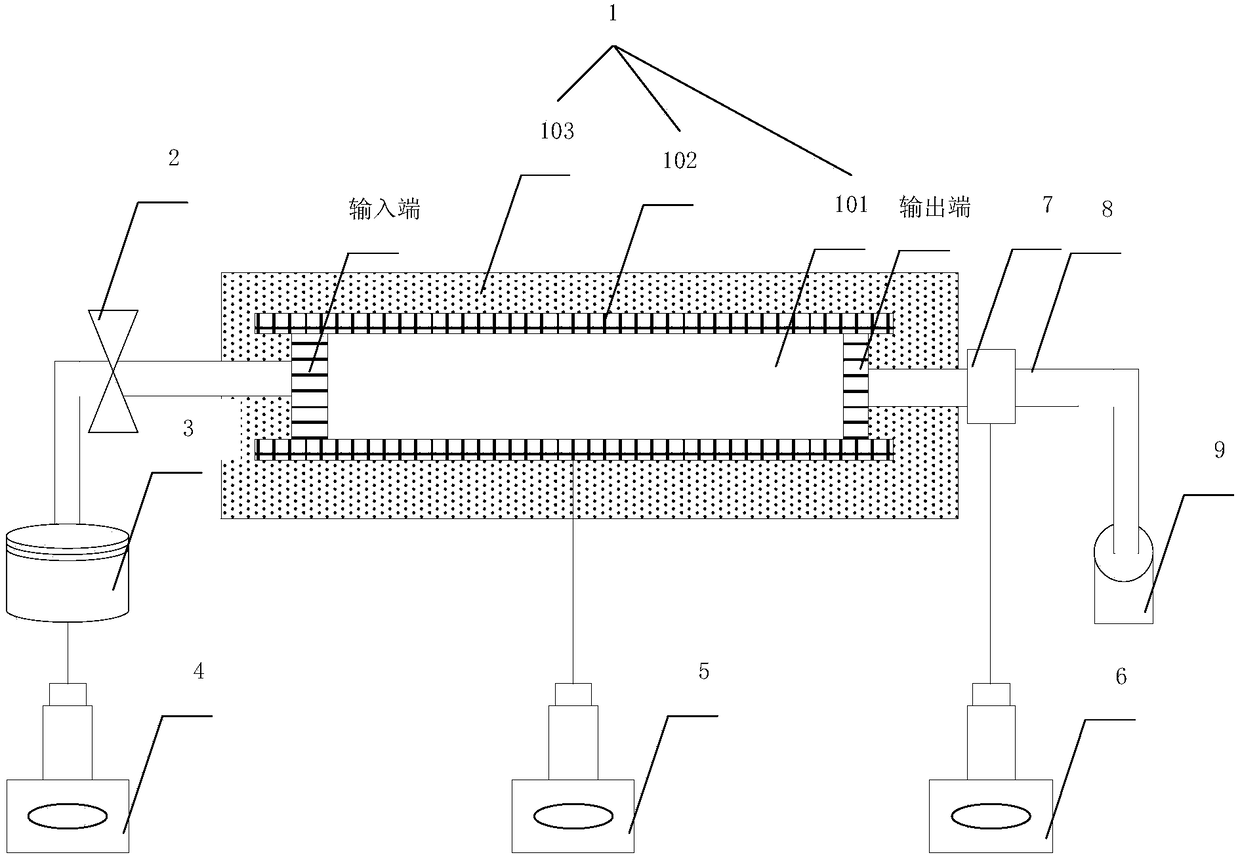

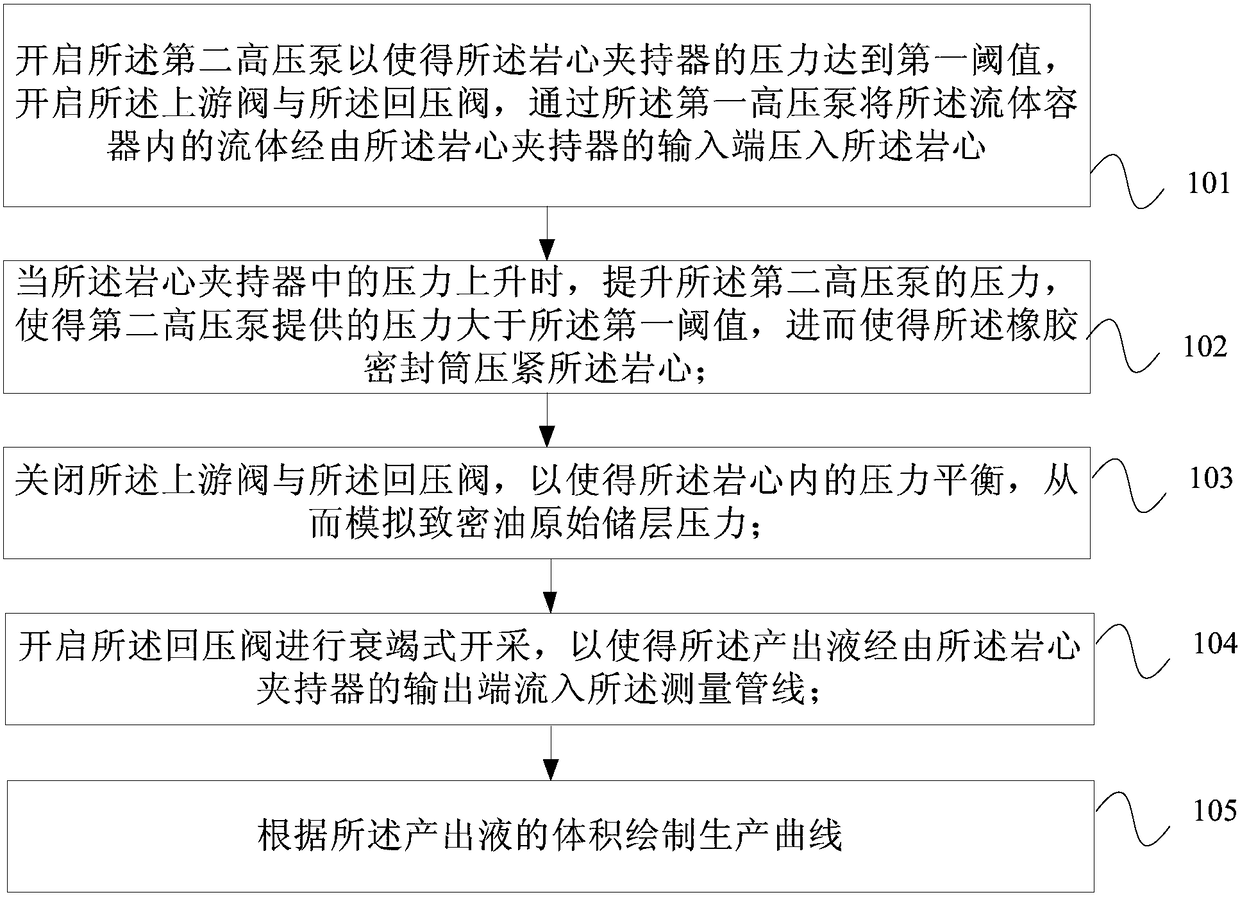

Dense oil reservoir exploitation simulation device and method

The present invention provides a dense oil reservoir exploitation simulation device and method. According to the present invention, a first high-pressure pump is connected with the input end of a core holding unit via a crude oil pipeline and an upstream valve after being connected with a fluid container, and the core holding unit comprises a core, a rubber sealing cylinder and a sealing steel cylinder. The rubber sealing cylinder sleeves the core and tightly presses on the core by the pressure provided by a second high-pressure pump, and the sealing steel cylinder wraps the rubber sealing cylinder. The output end of the core holding unit is connected with a back-pressure valve, and the back-pressure valve is connected with a gas flow meter via a measurement pipeline and is also connected with a back-pressure control pump. During the process of simulating the dense oil reservoir exploitation, by the first high-pressure pump, the fluid in the fluid container is pressed in the core via the input end of the core holding unit, the back-pressure control pump controls the back-pressure valve, and the pressure difference is generated at the upstream part and the downstream part of the core holding unit, so that an outputted liquid is outputted from the input end of the core holding unit and flows in the gas flow meter via the measurement pipeline. The measurement pipeline can measure the size of the output liquid accurately, so that the daily output, namely the production capability of a dense oil reservoir can be evaluated accurately.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

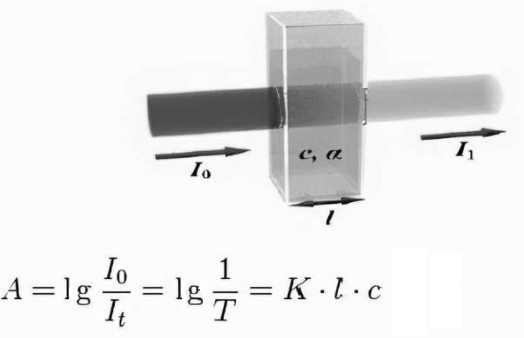

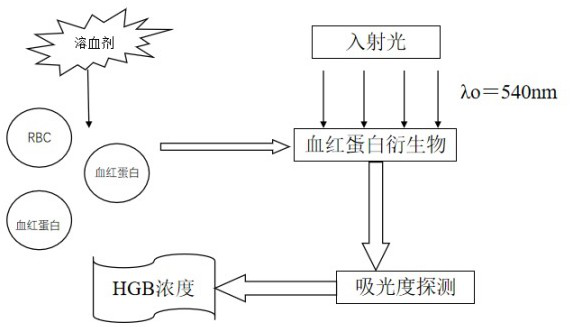

Hemoglobin analysis method and system based on microscopic amplification digital image

ActiveCN114778418AComplete formImprove accuracyImage enhancementImage analysisStatistical analysisCell layer

The invention discloses a hemoglobin analysis method based on a microscopic amplified digital image. The first absorbance alpha1 of the target cell is equal to 1g (the average gray value Gb of the blank area / the average gray value Gc of the target cell area); and obtaining the hemoglobin content CH = of the target cell. The hemoglobin content CH of the target cell is equal to the first absorbance alpha1 * the target cell area STC * the first hemoglobin content correction coefficient CHGB1. By combining the Beer-Lambert law and microscopic magnification digital images, the hemoglobin content of a single target cell can be accurately obtained, so that the visual angle of clinically observing the hemoglobin content goes deep from the total sample hemoglobin content to the hemoglobin content of a single cell level, and the statistical analysis of the single hemoglobin content can be developed. And a deeper layer of valuable information is obtained for clinic. And the whole measurement system is extremely simple, a light path and a liquid path are free from maintenance, the operation and control processes are also extremely simple, and the comprehensive efficiency of hemoglobin detection is greatly improved.

Owner:SHENZHEN ANLV MEDICAL TECH CO LTD

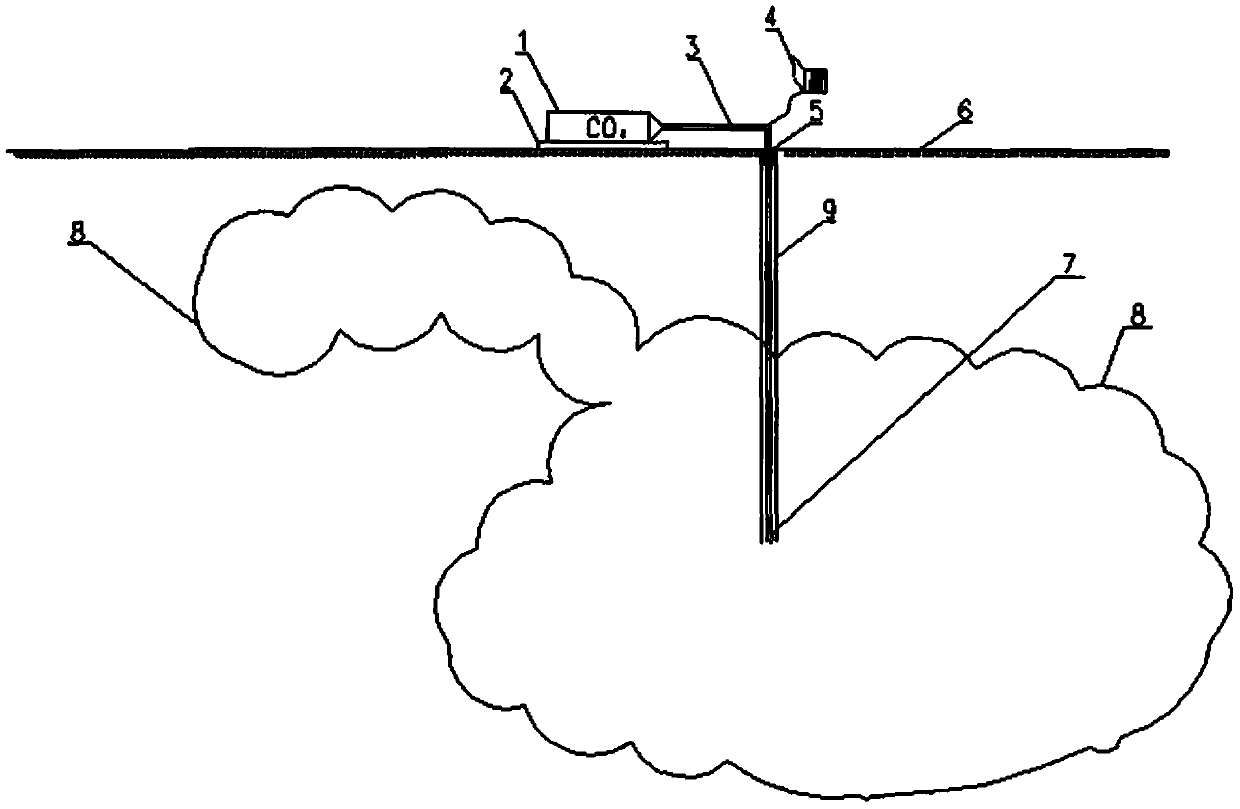

Method and apparatus for measuring volume of goaf by using gas concentration difference method

PendingCN110207780AThe principle is simpleMature equipmentContainer/cavity capacity measurementDrill holeEnvironmental geology

The disclosure provides a method and apparatus for measuring the volume of a goaf by using a gas concentration difference method. The method comprises: after determination of a goaf position, carryingout drilling to obtain a drill hole communicated with the goaf; carrying out measurement by using a concentration detecting sensor to obtain an originally preselected gas concentration value rho1; communicating a preselected gas storage device, injecting preselected gas into the goaf, and recording the mass deltam of the injected preselected gas and a concentration value pho2 of the preselected gas in the goaf at the time; and according to a formula, calculating the volume Vx of the goaf. The volume of the goaf is measured by using the gas concentration difference method; and the volume can be obtained accurately on the premise that the specific shape of the goaf is not considered, so that the accurate data are provided for backfilling of the goaf.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队

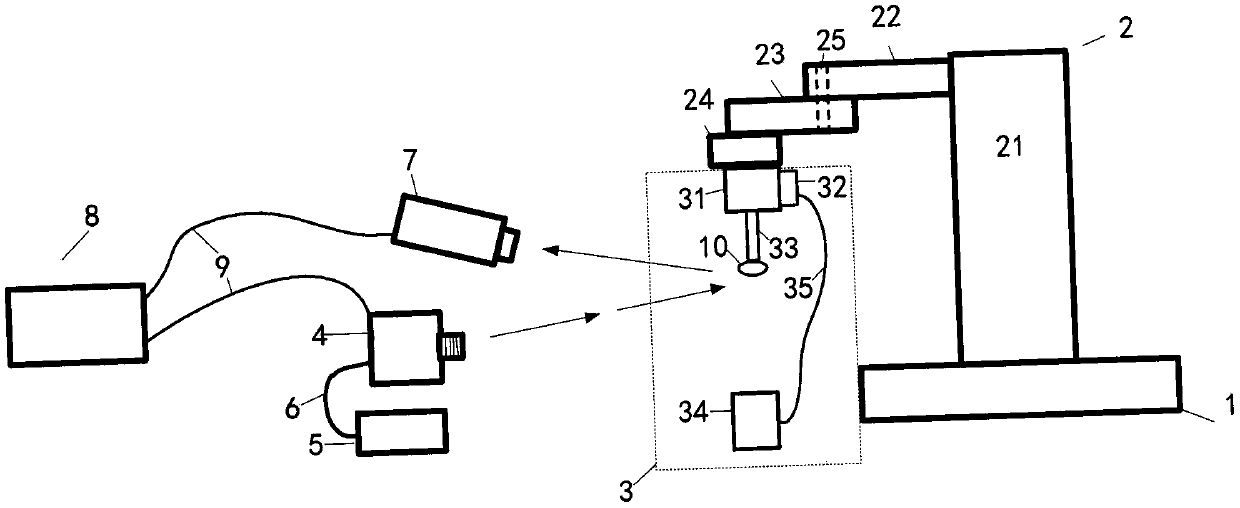

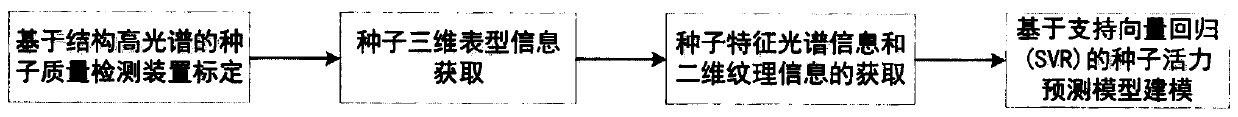

Seed quality detection method and device based on structure hyperspectrum

PendingCN111579511AAccurate length measurementAccurately measure widthImage enhancementImage analysisComputer scienceStructure based

The invention provides a seed quality detection method and device based on structure hyperspectrum. The device is composed of a mechanical arm base, a mechanical arm, a vacuum seed suction module, a structured light projection module, a white light source, an optical fiber, a hyperspectral camera, a computer, a signal line and seeds. The seed quality detection method based on structure hyperspectrum comprises the following steps: calibrating a seed quality detection device based on structure hyperspectrum, acquiring seed three-dimensional phenotypic information, acquiring seed characteristic spectrum information and two-dimensional texture information, and modeling a seed vigor prediction model based on support vector regression (SVR). A structured light three-dimensional imaging technology is adopted, three-dimensional size information such as the length, the width and the volume of the seeds can be accurately measured, hyperspectral information of the seeds at different depths can bedetected through a structured light modulation technology, the information dimension is expanded, and the detection precision of the seed vigor index is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

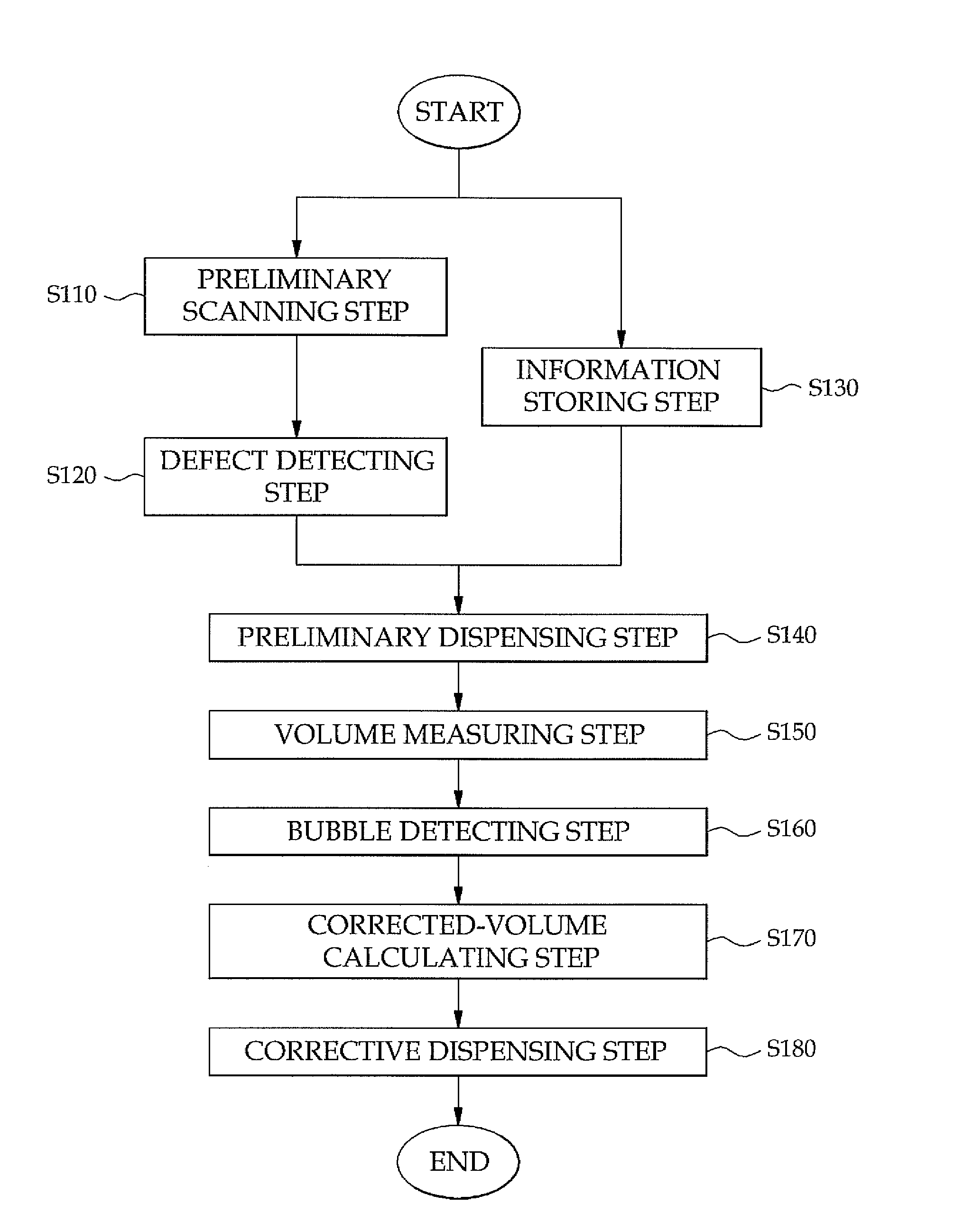

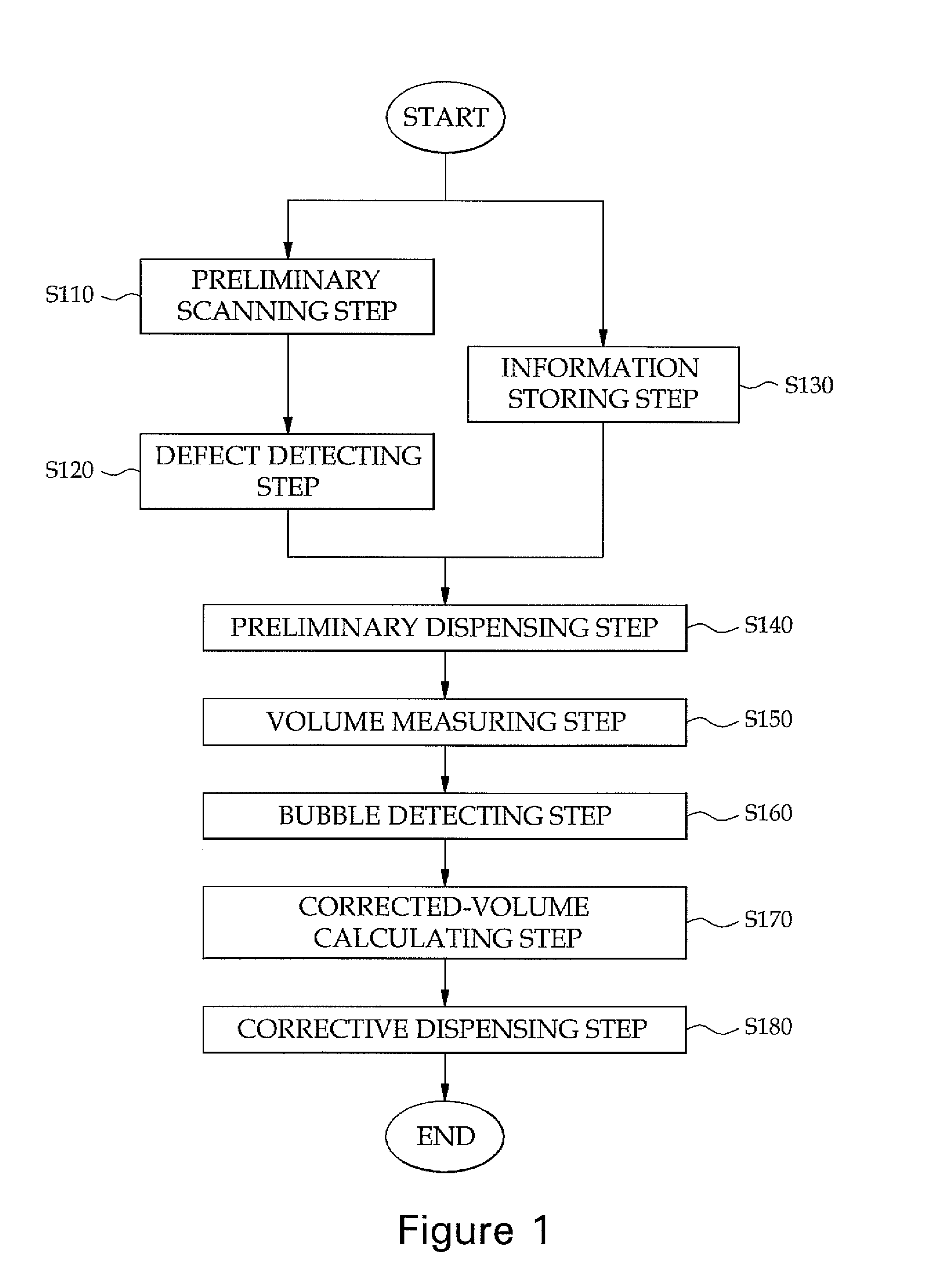

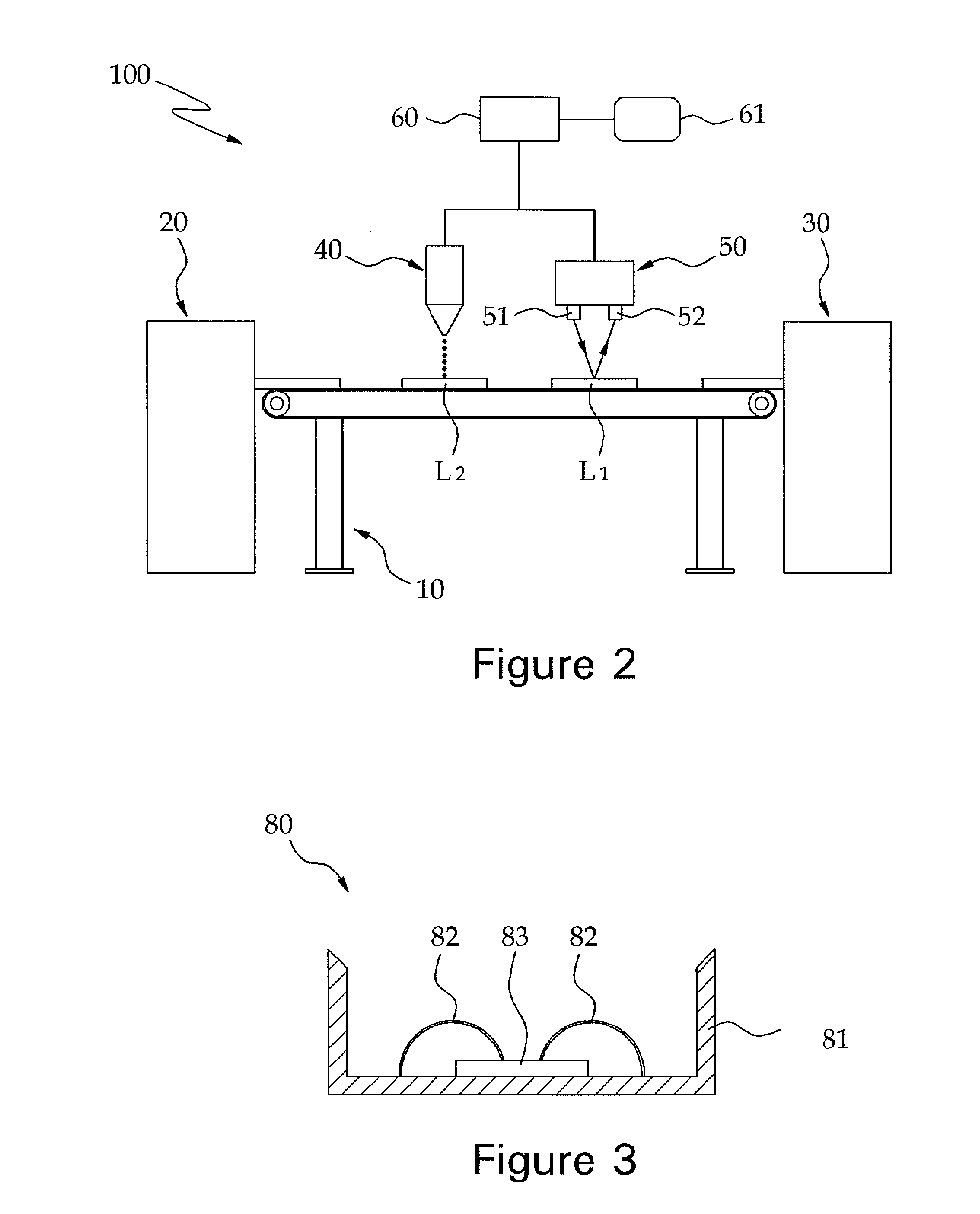

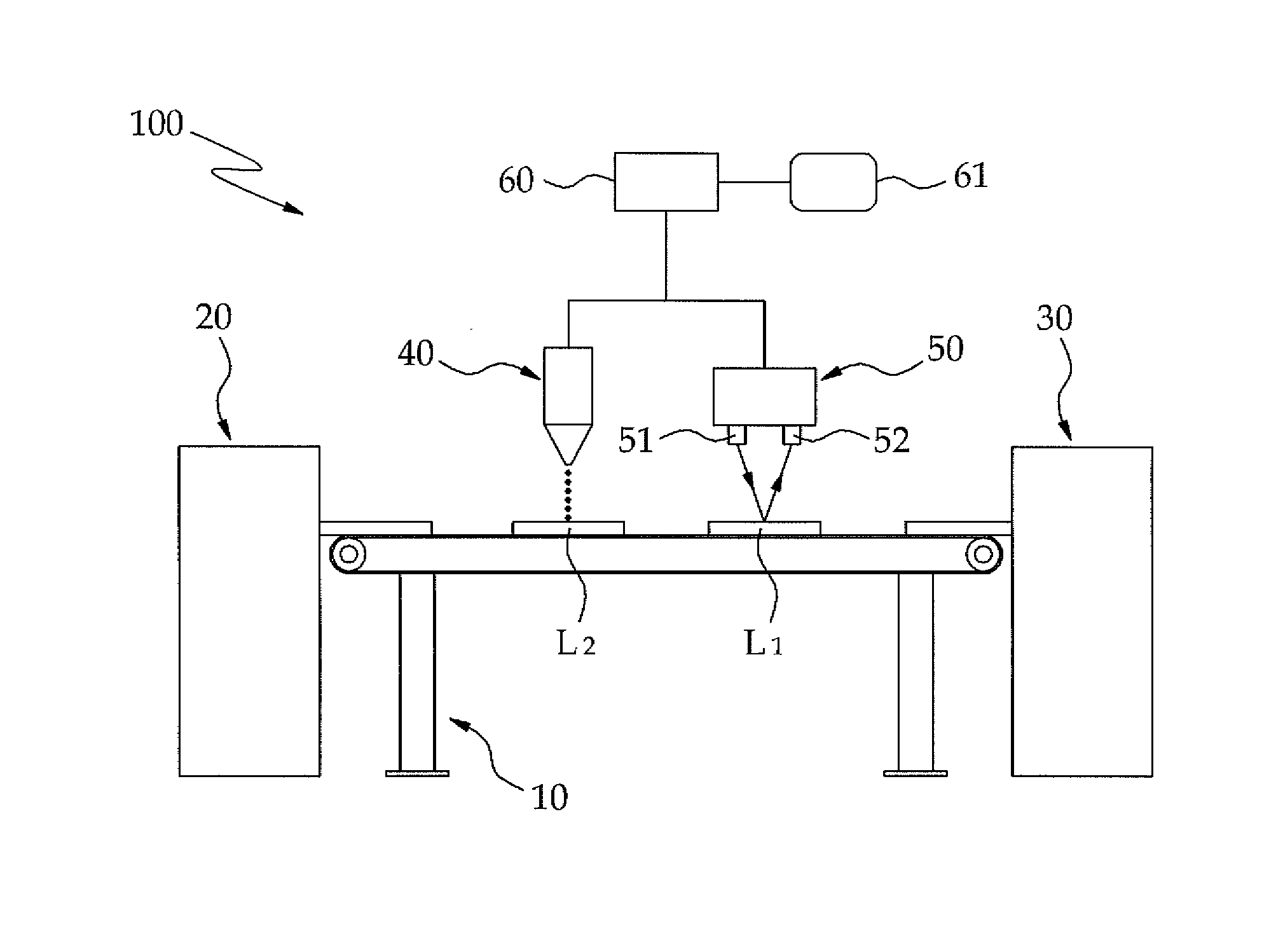

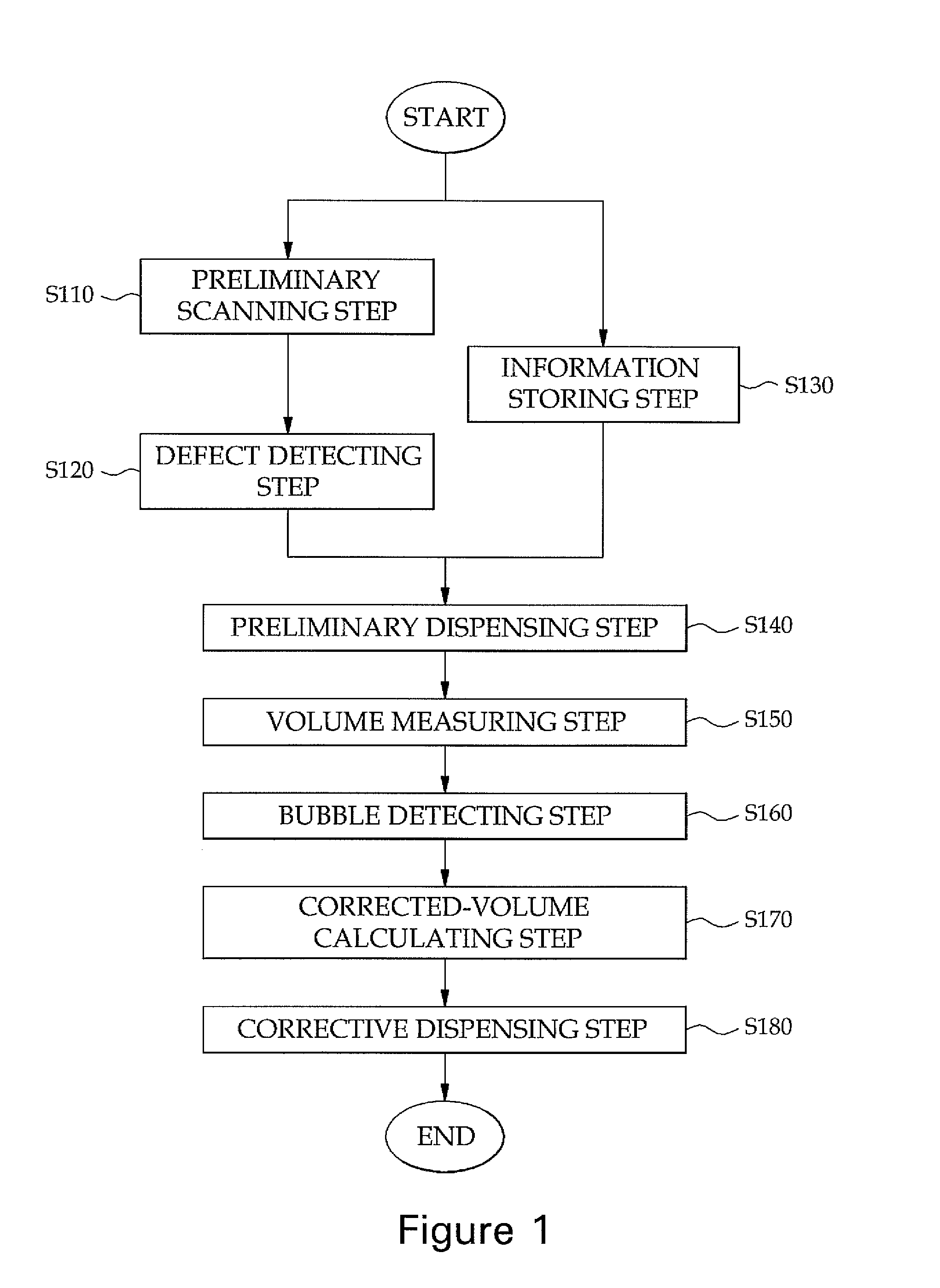

Volume-based dispensing control method

ActiveUS20100327468A1Easy to controlQuick measurementSemiconductor/solid-state device detailsSolid-state devicesResin dispensingDistribution control

A volume-based dispensing control method is capable of enabling a pump to dispense a resin with greatly increased accuracy. The method includes: a preliminary dispensing step in which a resin is dispensed on one or more workpieces with a pump; a volume measuring step in which the workpieces passed through the preliminary dispensing step is scanned by an optical scanner to measure a dispensed resin volume; a corrected-volume calculating step in which a corrected volume of the resin to be additionally dispensed is calculated by using a difference between the dispensed resin volume measured in the volume measuring step and a predetermined dispensing volume; and a corrective dispensing step in which the resin is dispensed on the workpieces in light of the corrected volume calculated in the corrected-volume calculating step.

Owner:PROTEC CO LTD

Device and method for monitoring bladder volume of a subject

ActiveUS20170000401A1Enhanced Ultrasound ImagingIncrease volumeOrgan movement/changes detectionInfrasonic diagnosticsControl signalAbdomen

The present invention provides a device and a method for monitoring the bladder volume of a subject. A device for monitoring the bladder volume of a subject comprises a sensor to be attached to a region on the exterior surface of the abdomen of the subject, the region corresponding to the bladder of the subject, the sensor being configured to obtain a sensor signal indicating the bladder volume of the subject; a controlling unit configured to generate a control action signal if it determines, based on the sensor signal, that the change of the bladder volume of the subject exceeds a predetermined amount; an ultrasound probe to be attached to the subject and configured to emit, in response to the control signal, an ultrasonic signal toward the bladder of the subject and receive echo signals from the bladder of the subject; a deriving unit configured to derive the bladder volume of the subject from the received echo signals. According to the device, long-time monitoring of the bladder volume of the subject may be achieved.

Owner:KONINKLJIJKE PHILIPS NV

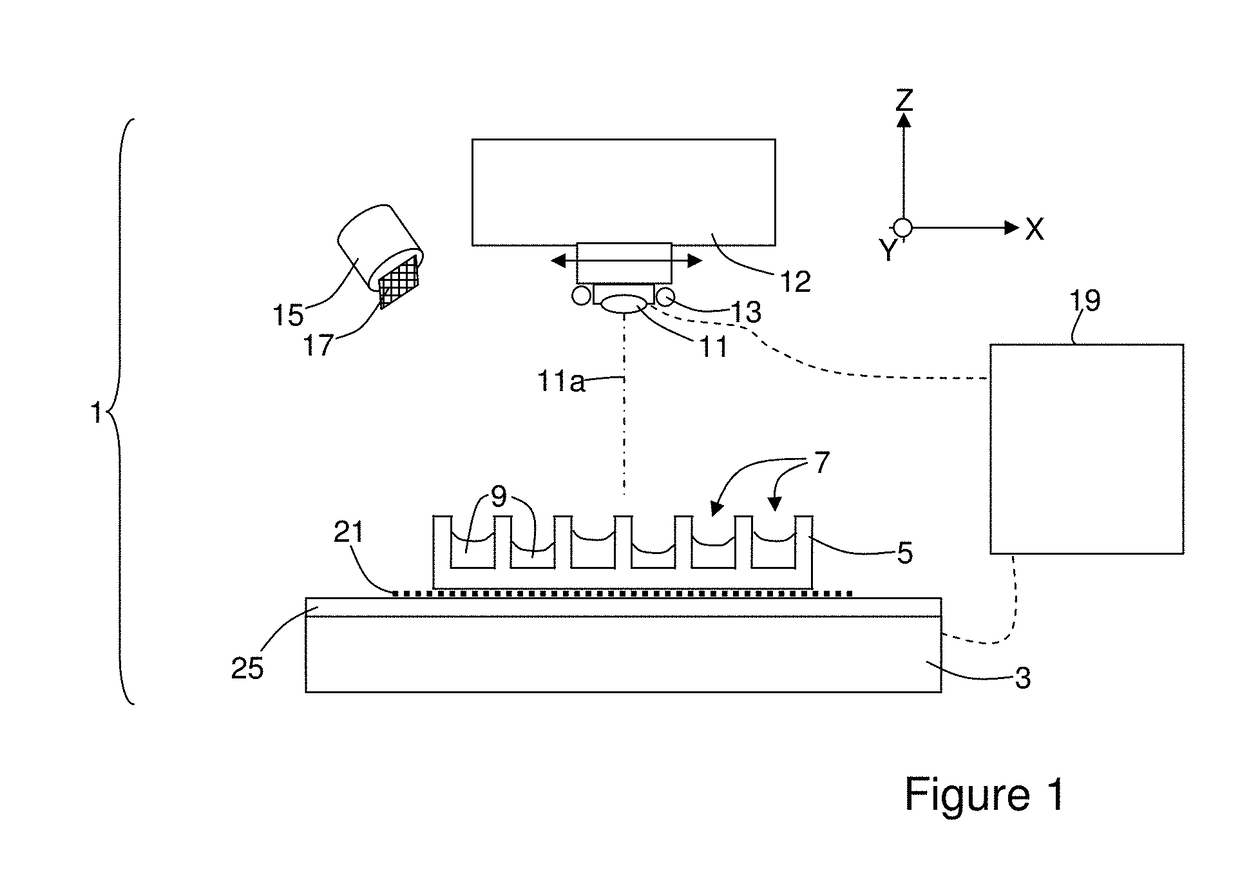

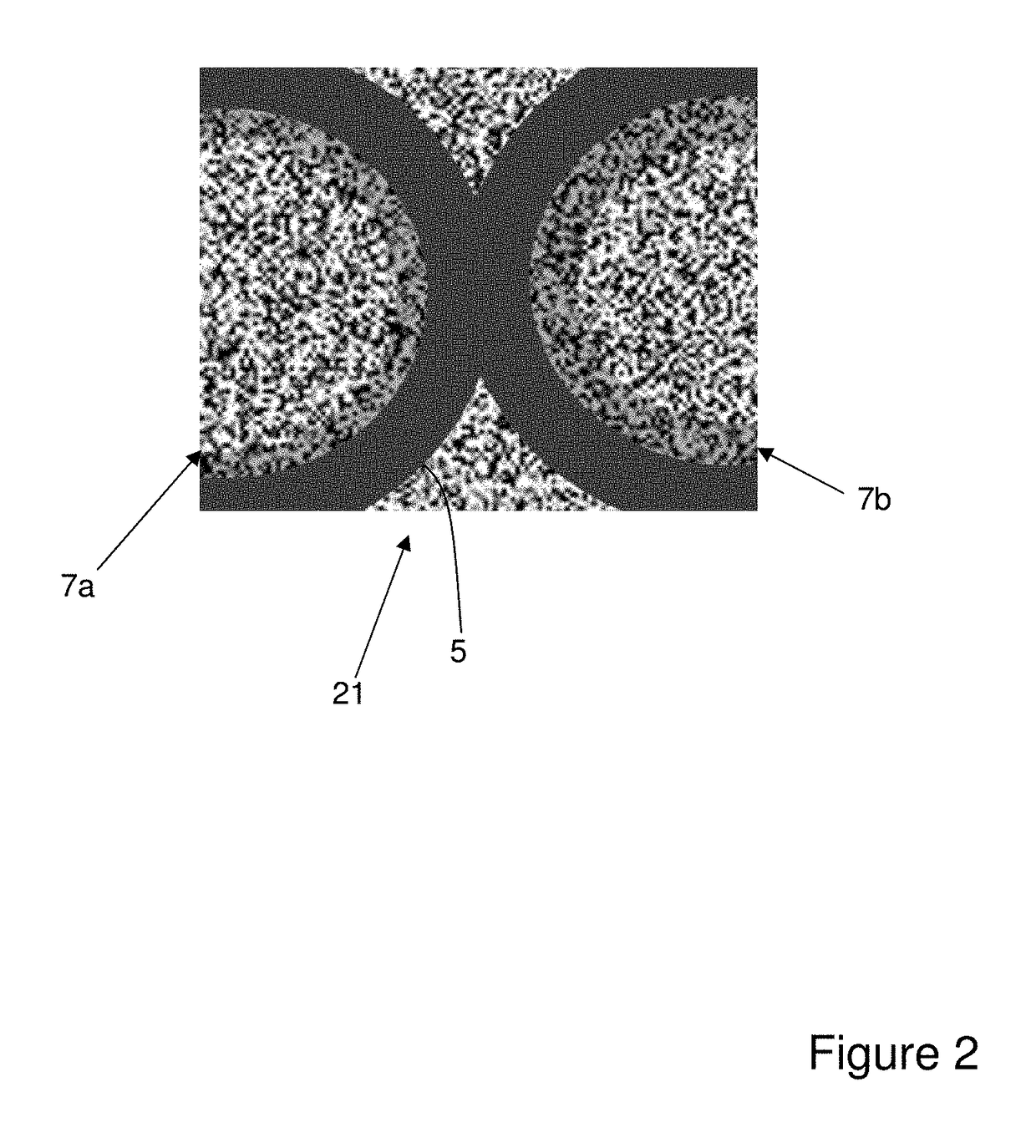

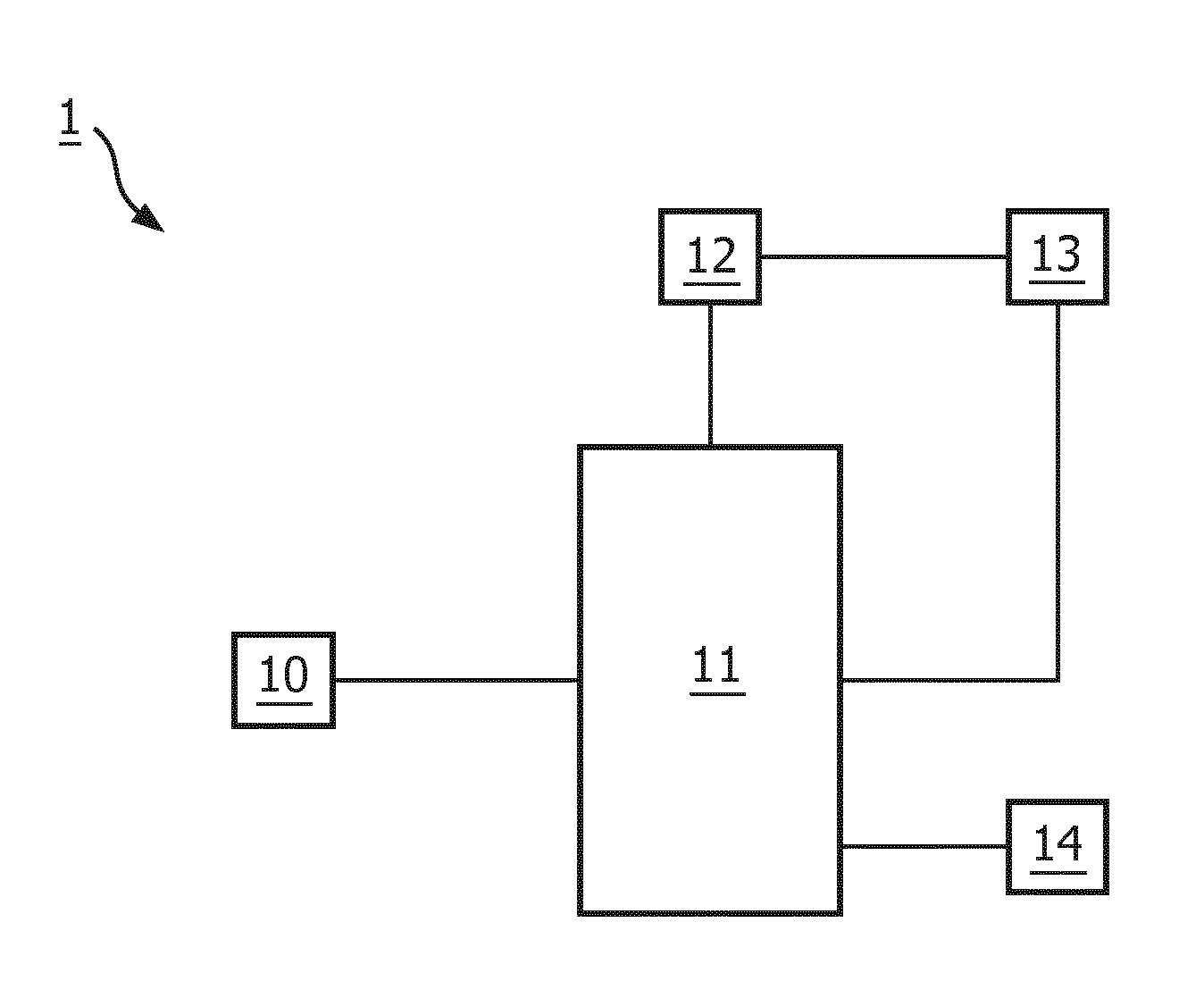

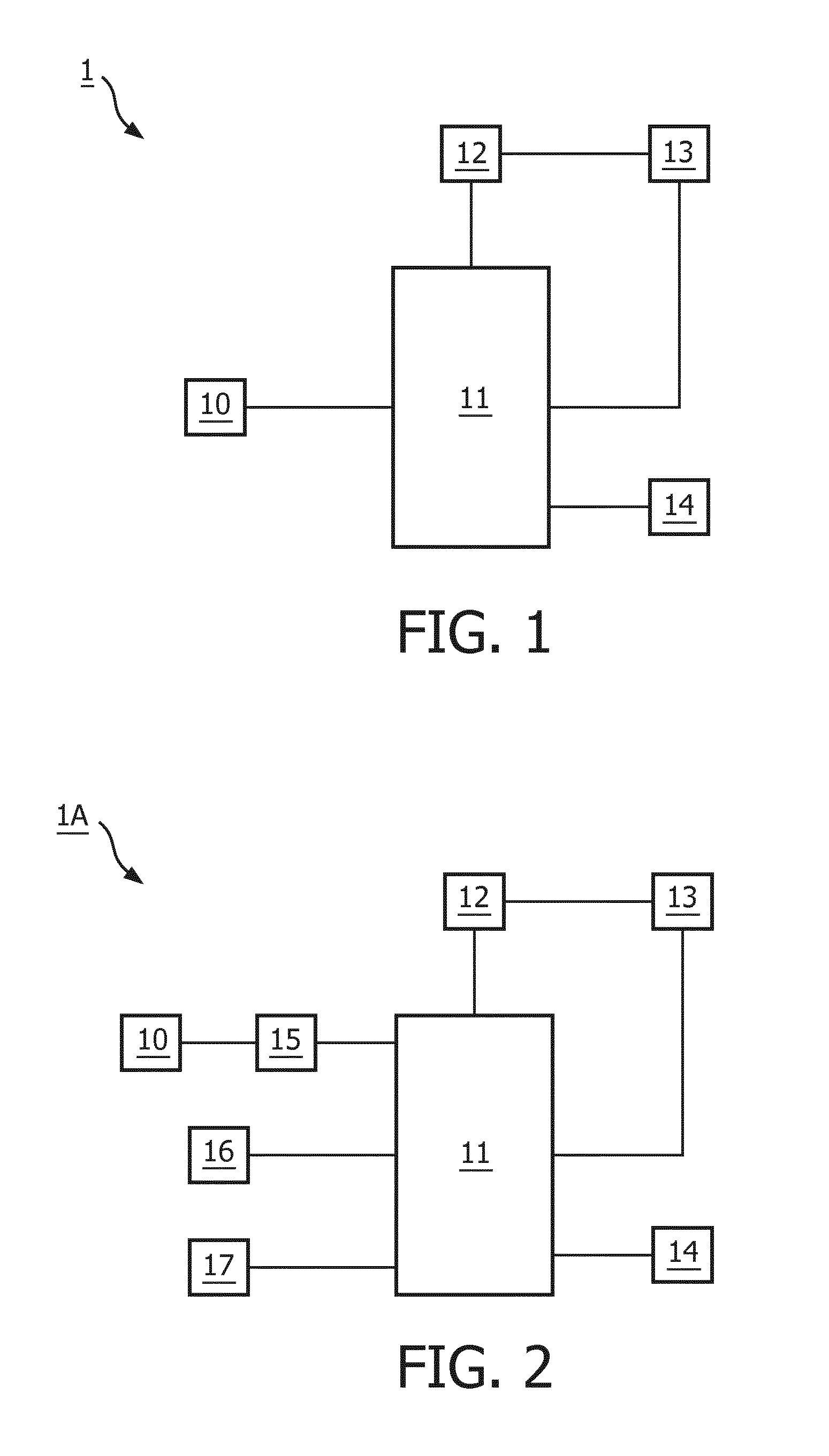

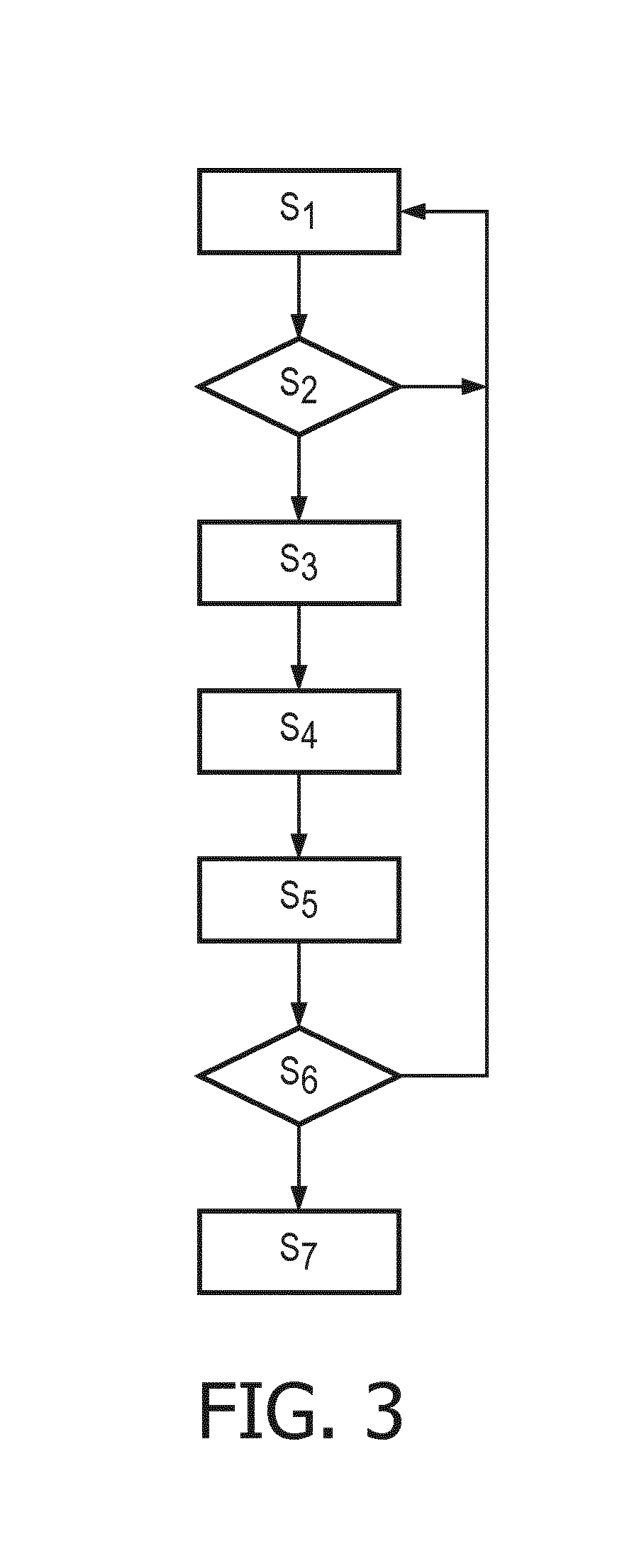

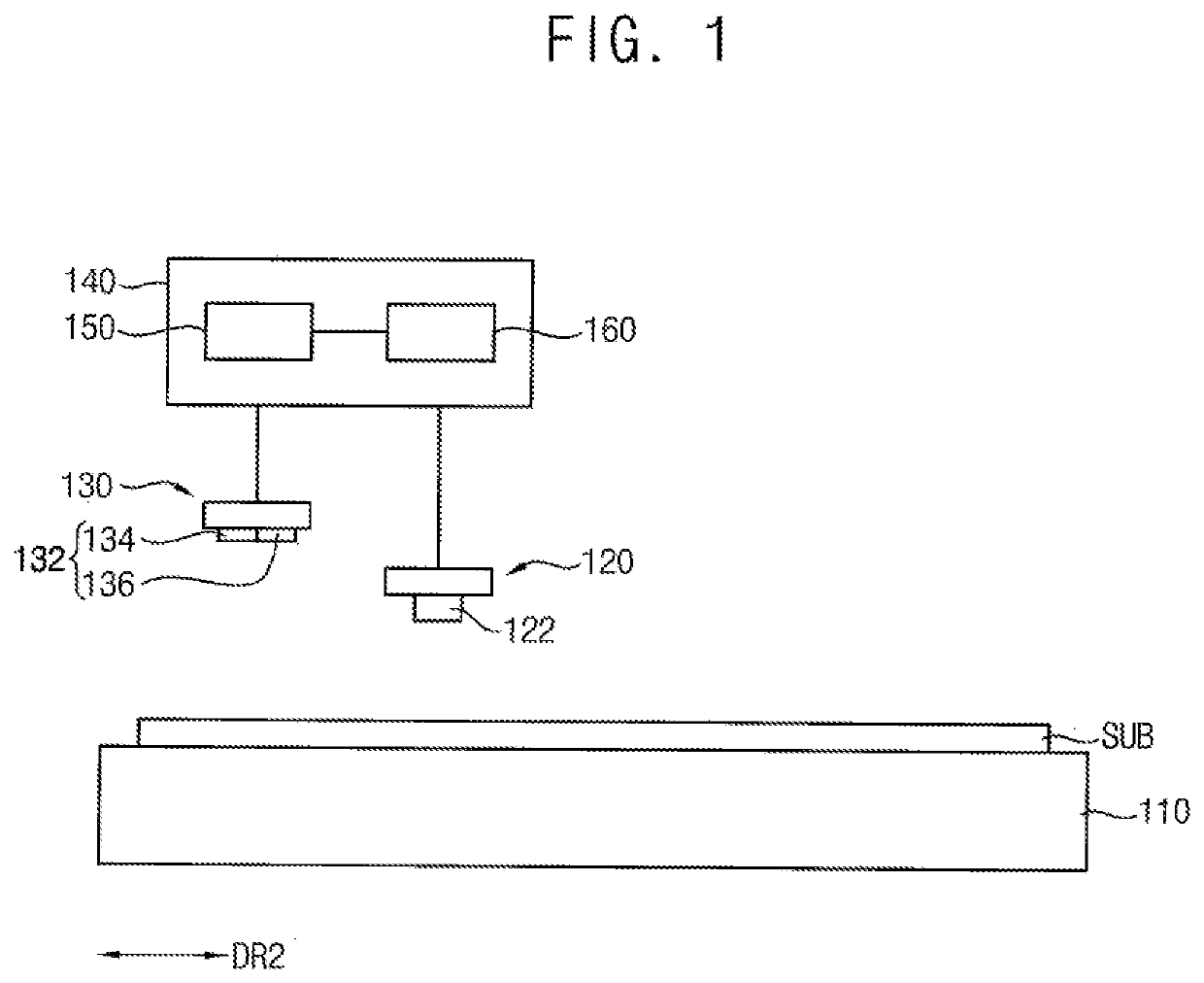

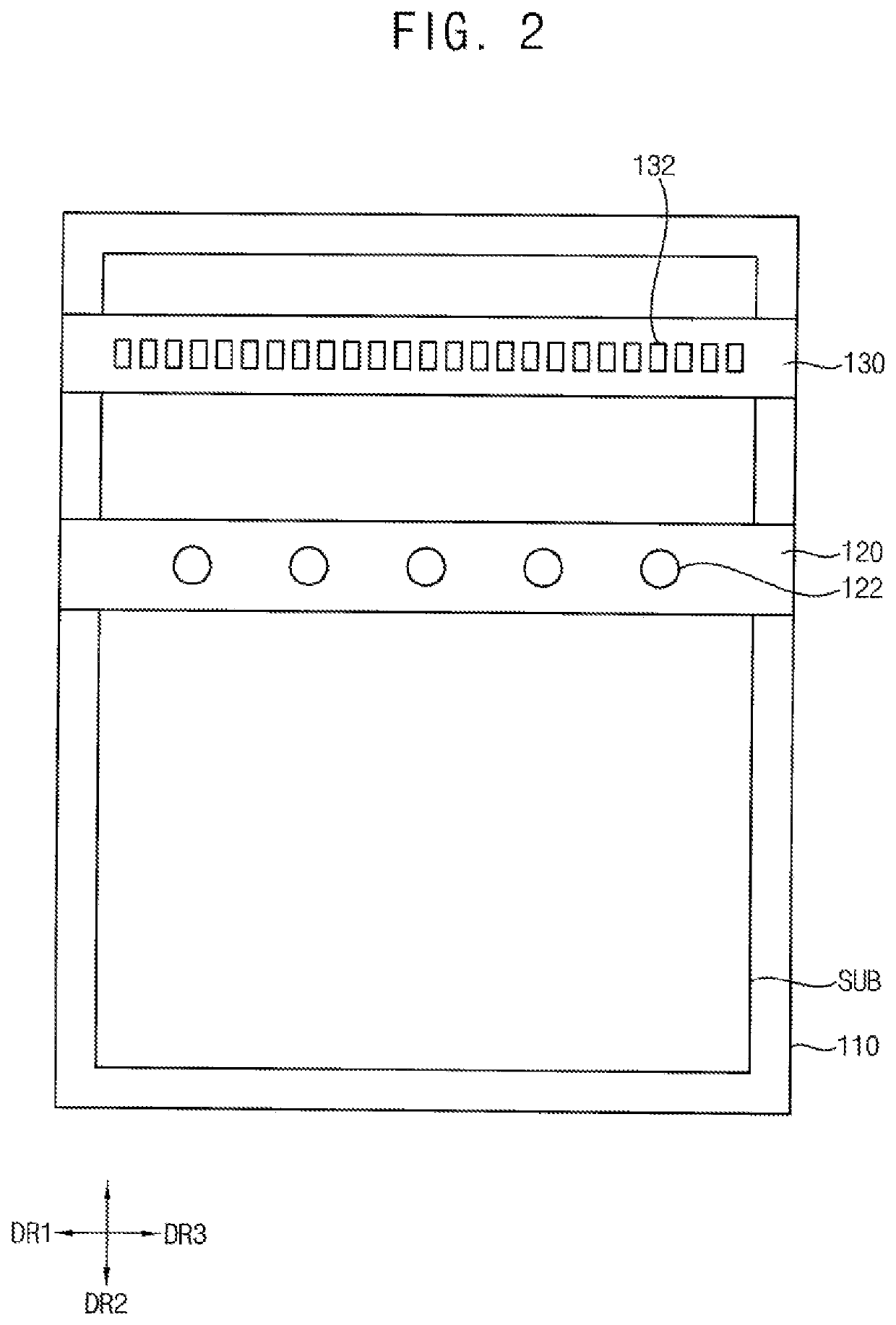

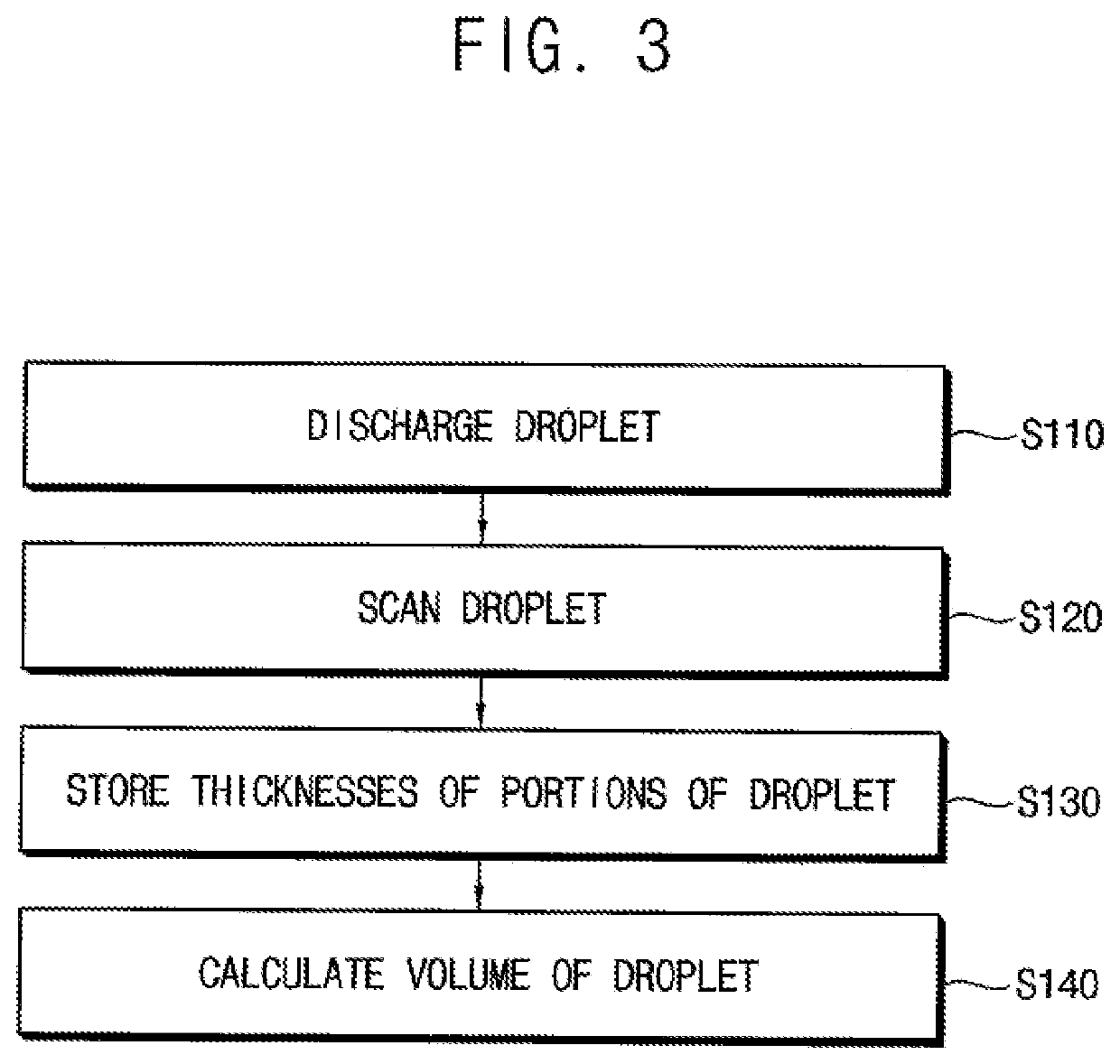

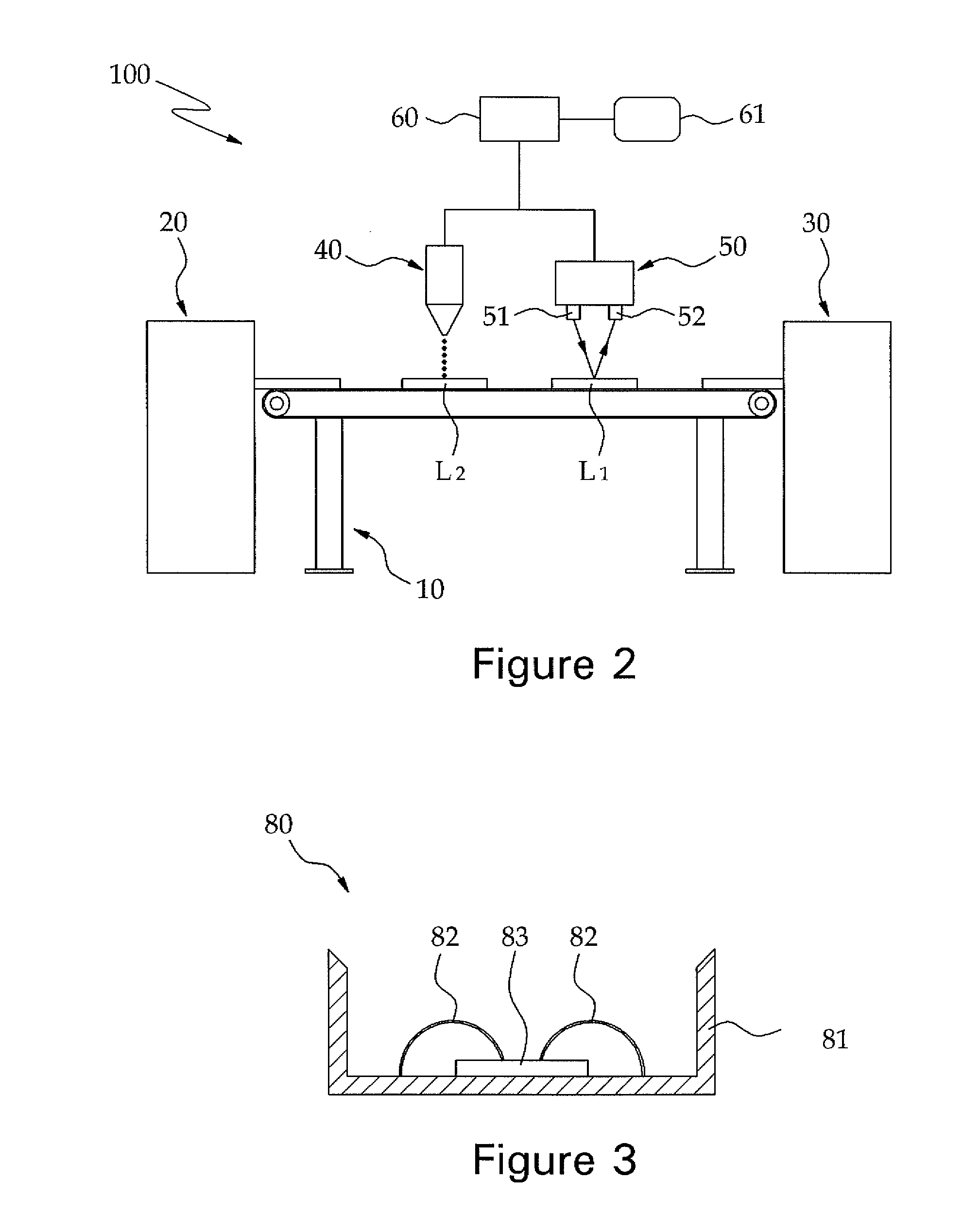

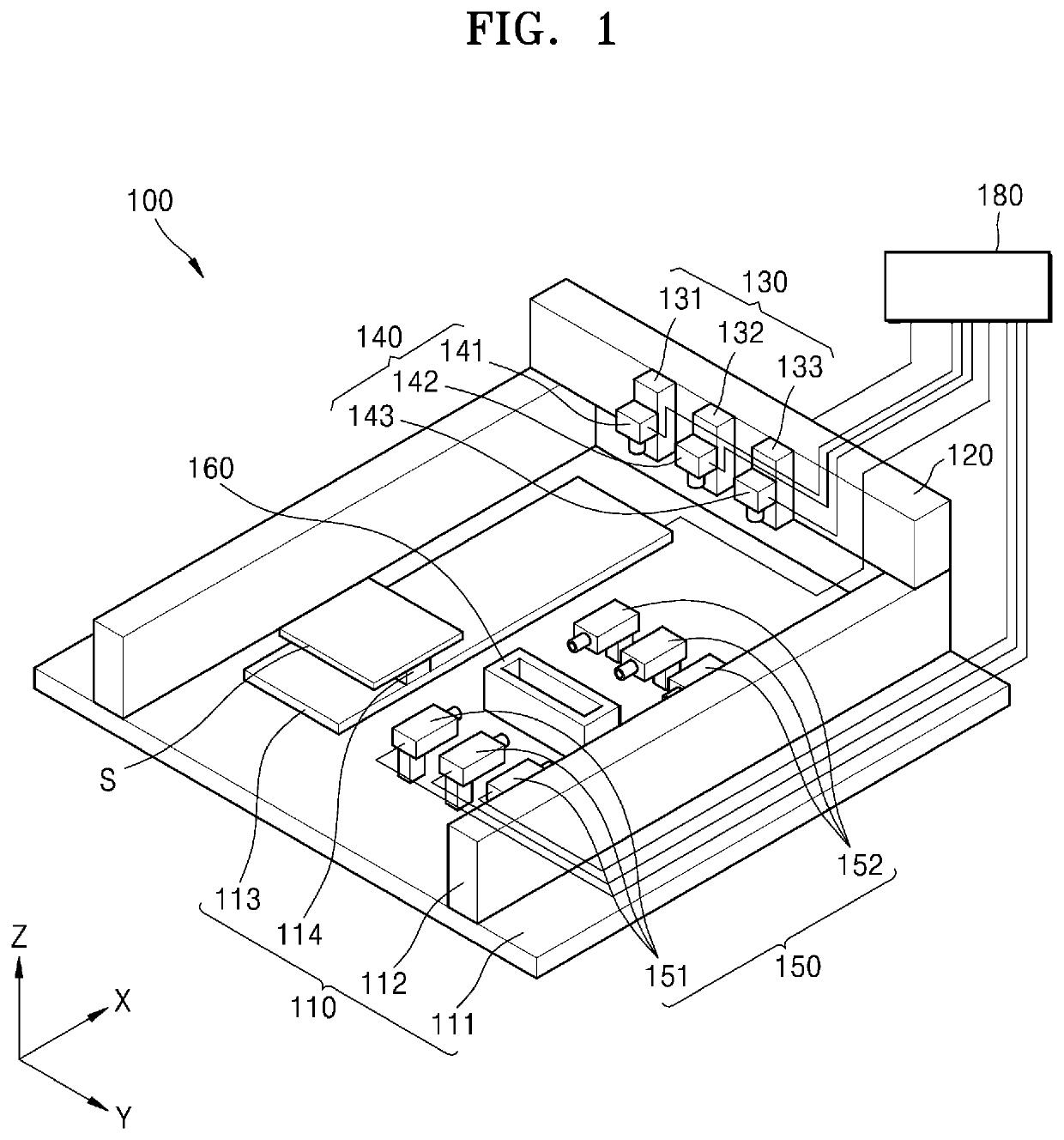

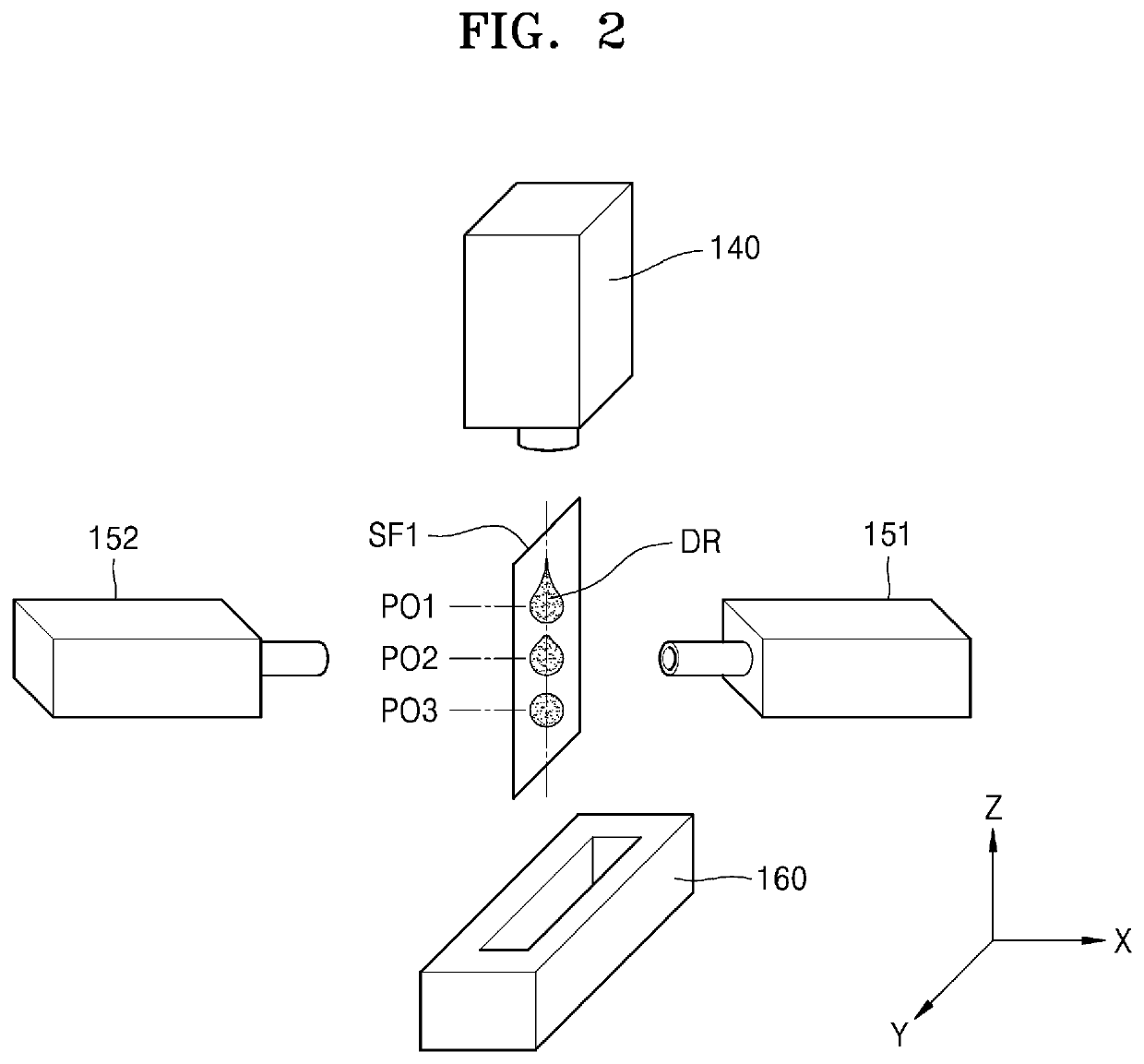

Droplet measurement method, droplet measurement apparatus, and method of manufacturing display device

ActiveUS20210050270A1Accurate measurementAccurate volume measurementImage analysisSemiconductor/solid-state device testing/measurementOptical scannersDisplay device

A droplet measurement method is described. The droplet measurement method may include discharging a droplet on a substrate, scanning the droplet by moving a scanning unit, and calculating a volume of the droplet by using the thicknesses of the portions of the droplet. The scanning unit may include optical scanners arranged in multiple directions, storing thicknesses of portions of the droplet scanned by the scanning unit.

Owner:SAMSUNG DISPLAY CO LTD

CO2 mixed-phase core displacement outer phase-mixing device and method

PendingCN109267976AAccurate volume measurementOther gas emission reduction technologiesFluid removalEngineeringHigh pressure

The invention relates to a CO2 mixed-phase core displacement outer phase-mixing device which comprises a CO2 filling device, a CO2 phase-mixing device and a multifunctional counting device. The CO2 filling device comprises a manual pressure pump, a CO2 storage, a first guide pipe, a second guide pipe and a third guide pipe, the CO2 phase-mixing device comprises an automatic pressure pump, a high-pressure and high-temperature-resistible phase mixer, a fourth guide pipe, a fifth guide pipe, a core clamping device, a sixth guide pipe and a differential pressure measuring device, and the multifunctional counting device comprises a multifunctional counter, a large measuring cylinder and a seventh guide pipe. According to a CO2 mixed-phase core displacement outer phase-mixing method, experimentsare performed by the CO2 mixed-phase core displacement outer phase-mixing device. CO2 mixed-phase core displacement outer phase-mixing effects are achieved, a whole oil displacing process can be completely simulated after CO2 phase-mixing, CO2 phase-mixed effects are really evaluated, and the volume of various phases of fluids after displacement can be accurately measured.

Owner:YANGTZE UNIVERSITY

Clamp and method for measuring size of battery cell

InactiveCN107389148AAccurate volume measurementSimple structureContainer/cavity capacity measurementIonSize change

The invention provides a clamp and method for measuring the size of a battery cell, and relates to the technical field of clamps. The clamp for measuring the size of the battery cell comprises a barrel containing deionized water, a locking device and a support assembly. The battery cell is fixed by one end of the locking device, the other end of the locking device is connected with the support assembly, the battery cell can be soaked with deionized water of the barrel through the locking device, the size of the battery cell is obtained through changes of weight reads obtained by a weighing device before and after the battery cell is placed into the deionized water, the clamp is simple in structure and convenient to operate, the size of the battery cell can be accurately measured, and the technical problems that the precision is poor and the efficiency is low due to the fact that the battery cell is measured by a traditional vernier caliper are solved. According to the method for measuring the size of the battery cell, the sizes of battery cells of various shapes can be accurately measured, whether expansion and other size changes occur or not after the battery cell is subjected to various performance tests can be visually measured, and the method is high in precision, simple and rapid.

Owner:NORTHERN ALTAIR NANOTECH CO LTD

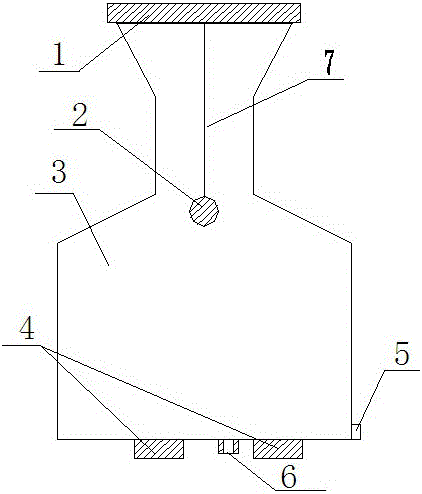

Calibrating device for fuel oil re-fuelling device and use method thereof

PendingCN106643995AEasy to use and flexibleDoes not affect check resultTesting/calibration for volume measurementEngineeringFuel oil

The invention discloses a calibrating device for a fuel oil re-fuelling device and a use method thereof. The calibrating device comprises a tank body (3), a tensile force load sensor (1), a known volume solid standard metal ball (2), a gravity load sensor (4), a level bubble (5) and a liquid draining hole (6), wherein the gravity load sensor and the liquid draining hole are arranged at the bottom of the tank body; the level bubble is formed on the side wall of the tank body; the tensile force load sensor is arranged on an upper cover of the tank body; the solid standard metal ball is located in an inner chamber of the tank body and is suspended on the tensile force load sensor. In a use process, to-be-measured liquid is injected into the tank body, the weight of the to-be-measured liquid is measured by the gravity load sensor, the tensile force is measured through the tensile force load sensor so that the density of the to-be-measured liquid can be calculated, the volume of the to-be-measured liquid is calculated according to a formula, and then a calculated result is compared with a numerical value of the re-fuelling device, so that a measuring result can be acquired. The calibrating device disclosed by the invention has the advantages of simple structure, convenience in use, accurate calibration, small error and high accuracy.

Owner:李盛

Liquid level detection in receptacles using a plenoptic camera to measure the surface topography of the liquid

ActiveUS10724889B2Accurate volume measurementHigh resolutionTelevision system detailsImage enhancementOphthalmologyMicroscope objective

Disclosed is a method of measuring a volume of a liquid provided in at least one receptacle, including the steps of: providing a receptacle having at least one cavity for holding a liquid; providing a plenoptic camera positioned so as to be able to image the surface of the liquid; positioning the receptacle such that the liquid surface faces an objective lens of the plenoptic camera; making at least one plenoptic image of the surface of the liquid by way of the plenoptic camera; determining a surface topography of the liquid on the basis of the at least one image; calculating the volume of liquid based on the measured surface topography and at least one known dimension and / or position of the cavity.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

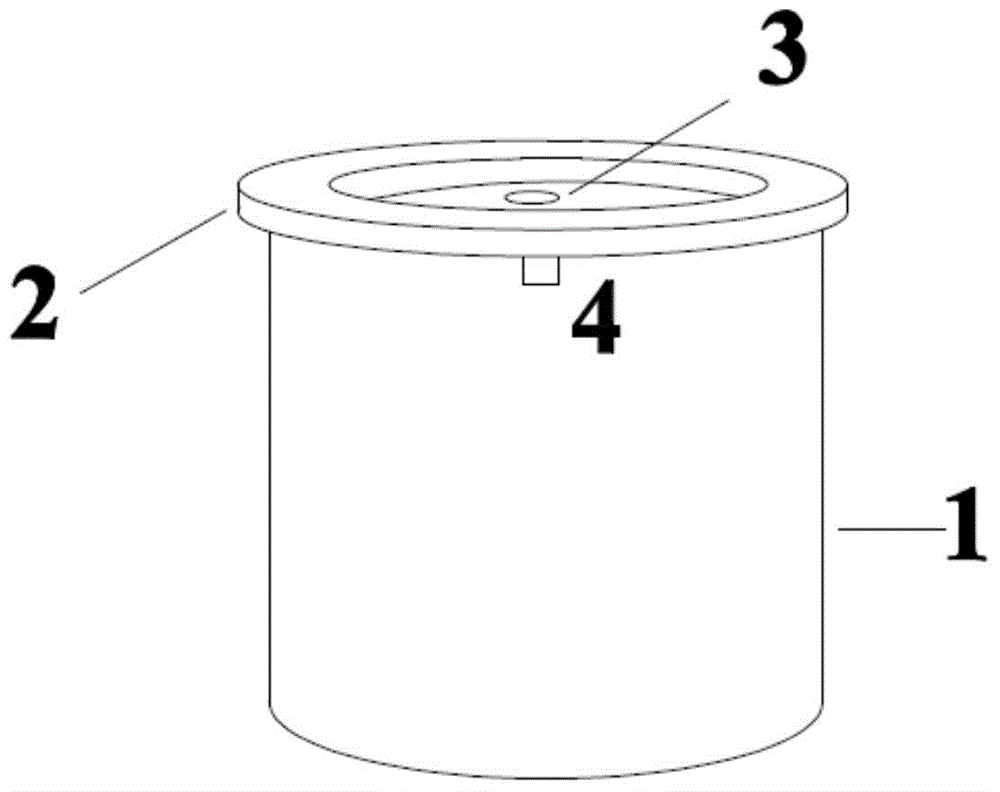

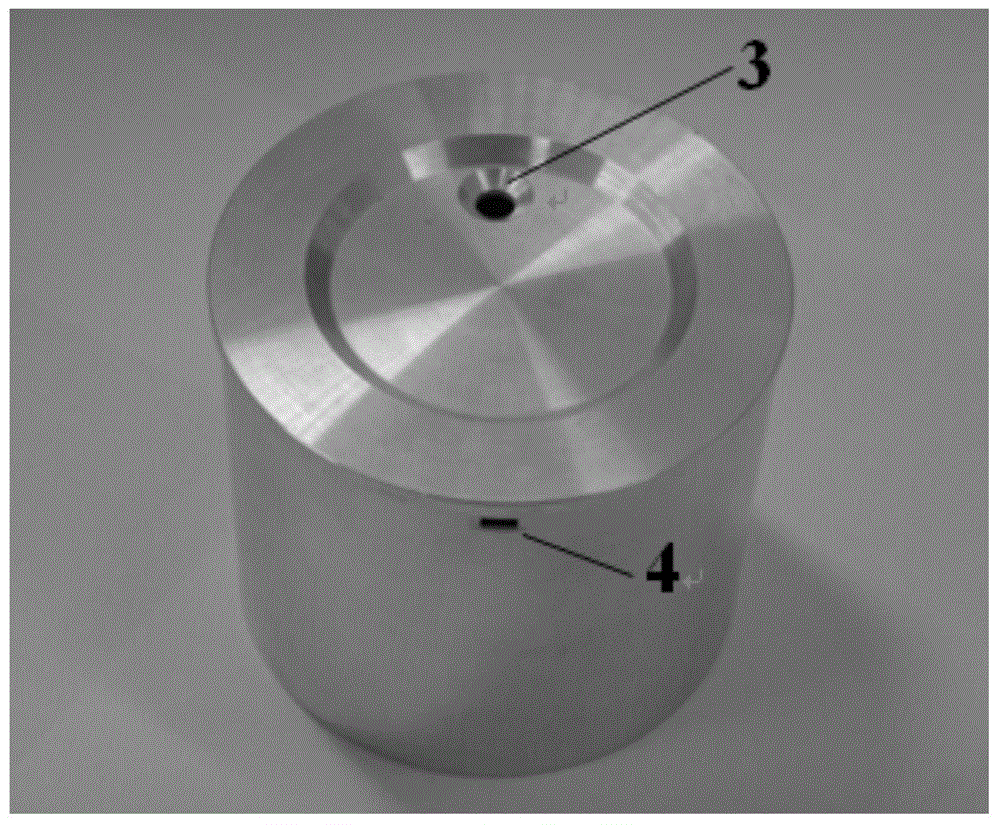

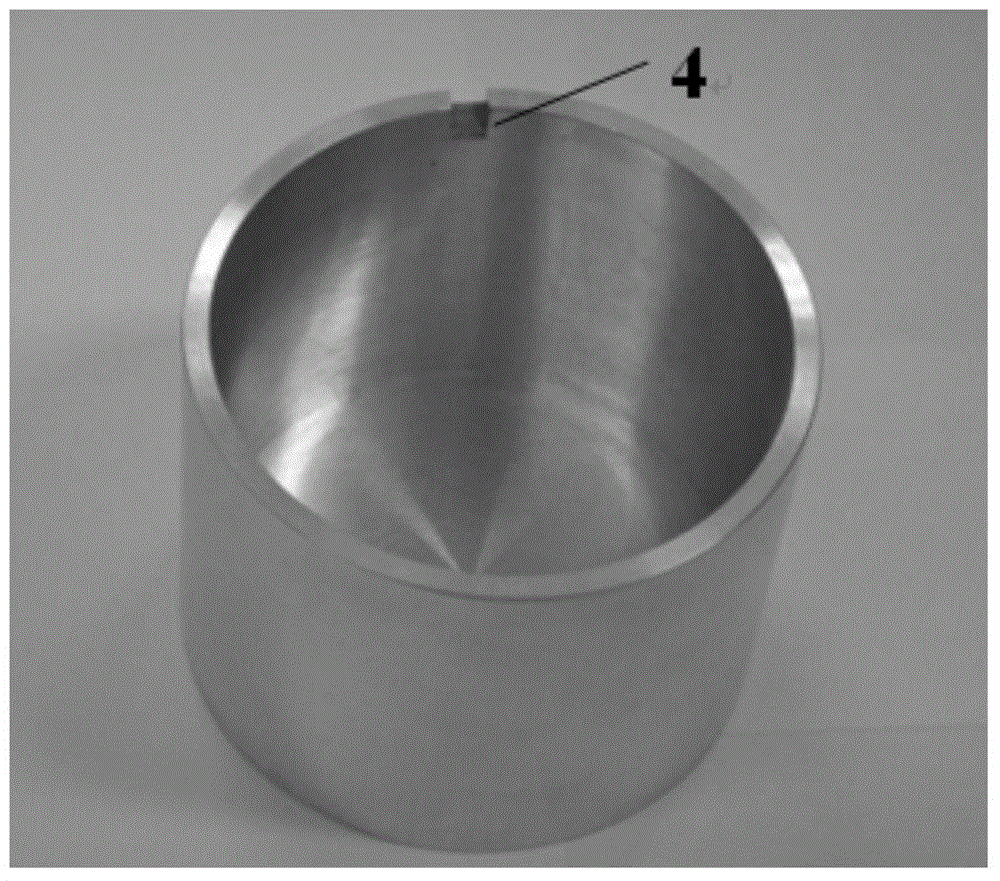

Constant-volume container and using method thereof

InactiveCN103604478AHigh precisionAccurate volume measurementCapacity measurement calibrationEngineeringMeasurement precision

The invention provides a constant-volume container which comprises a container body and a liquid surface positioning cover arranged at the upper end of the container body, wherein the container body has a regular shape and is unlikely to deform. A water filling port is arranged on the liquid surface positioning cover, and a water overflowing port is arranged on the opening of the container body. By arranging the liquid surface positioning cover at the upper end of the container body, the volume of the container body is controlled to be constant. Liquid is filled into the constant-volume container through the water filling port, and the water overflowing port is used for discharging liquid beyond the volume of the constant-volume container. The invention further provides a using method of the constant-volume container. The using method comprises steps of (1) accurately measuring liquid for a certain volume, or (2) measuring the volume of solid and / or liquid. The constant-volume container can accurately measure the liquid for a certain volume, accurately measure volume of any liquid, solid or solid-liquid mixtures, and provide basic conditions for actual application problems such as physical and chemical experiments, geotechnical survey and the like. Furthermore, the measurement operation process of the constant-volume container is simple and easy, and the constant-volume container is good in function stability, capable of saving time and labor and high in measurement precision.

Owner:CHINA AGRI UNIV

Volume-based dispensing control method

ActiveUS8080192B2Easy to controlAccurate volume measurementSemiconductor/solid-state device detailsSolid-state devicesResin dispensingDistribution control

A volume-based dispensing control method is capable of enabling a pump to dispense a resin with greatly increased accuracy. The method includes: a preliminary dispensing step in which a resin is dispensed on one or more workpieces with a pump; a volume measuring step in which the workpieces passed through the preliminary dispensing step is scanned by an optical scanner to measure a dispensed resin volume; a corrected-volume calculating step in which a corrected volume of the resin to be additionally dispensed is calculated by using a difference between the dispensed resin volume measured in the volume measuring step and a predetermined dispensing volume; and a corrective dispensing step in which the resin is dispensed on the workpieces in light of the corrected volume calculated in the corrected-volume calculating step.

Owner:PROTEC CO LTD

Optical measurement device and method for volume of suspended particles

PendingCN114166699AAccurate volume measurementAccurate measurementVolume measurement apparatus/methodsMaterial analysis by optical meansSuspended particlesProjection image

An optical measurement device and method of suspended particle volume, the measurement device comprising at least two illumination modules configured to illuminate suspended particles in a sample cell or a natural body of water from different angles simultaneously, at least two image acquisition modules, and a processing module, the at least two illumination modules being configured to illuminate the suspended particles in the sample cell or natural body of water from different angles simultaneously, the at least two image acquisition modules are configured to simultaneously perform image acquisition on suspended particles in a water body from different angles to obtain projection images of the suspended particles at at least two angles, and the processing module is connected with the at least two image acquisition modules, and the processing module reconstructs a three-dimensional structure model of the suspended particles according to the projection images of the suspended particles at the at least two angles, and calculates the volume of the suspended particles according to the three-dimensional structure model of the suspended particles. Compared with other optical measurement methods, the method has the advantages that the three-dimensional form information of the suspended particles is acquired by using the multi-angle projection images, and more accurate volume measurement of the suspended particles, especially biological debris, is realized.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Apparatus for manufacturing a display device

PendingUS20210336141A1Accurate volume measurementSignificant costLiquid surface applicatorsVolume measurement apparatus/methodsDisplay deviceMechanics

An apparatus for manufacturing a display device, the apparatus comprising: a droplet discharger comprising a nozzle configured to discharge a droplet; a first detector on a falling path of the droplet that falls from the droplet discharger and configured to detect a shape of the droplet; a second detector spaced apart from the first detector and configured to detect the shape of the droplet that falls from the droplet discharger; and a controller configured to calculate at least one of a volume of the droplet, a falling speed of the droplet, the falling path of the droplet, or a discharge angle, at which the droplet is discharged from the nozzle, based on results detected by the first detector and the second detector.

Owner:SAMSUNG DISPLAY CO LTD

Physical evaluation equipment and evaluation method of oxygen assisted microbial oil displacement

PendingCN109281666AAvoid influenceAccurate volume measurementFluid removalPlunger pumpProcess engineering

The invention relates to physical evaluation equipment of oxygen assisted microbial oil displacement. The physical evaluation equipment comprises a gas liquid mixing device, a solution gas injecting device and a multifunctional displacement metering device. The gas liquid mixing device comprises a first plunger pump, an intermediate container with scales, a gas liquid mixing container, a gas injecting pump, a storage, and a second plunger pump. The solution gas injecting device comprises an intermediate container, a third plunger pump, a sixth conduit and a seventy conduit. The multifunctionaldisplacement metering device comprises a rock core clamp, a differential pressure measuring device, a multifunctional meter, a measuring cup, an eighth conduit and a ninth conduit. According to the physical evaluation method of oxygen assisted microbial oil displacement, testing is conducted by adopting the physical evaluation equipment of oxygen assisted microbial oil displacement. The utilization of dissolved oxygen in water by microorganisms in the process of microbial oil displacement can be reasonably simulated, the whole process of microbial oil displacement can be completely simulated,and the volume of fluid in each phase after displacement can be accurately measured.

Owner:YANGTZE UNIVERSITY

Tight oil reservoir production simulation device and method

The present invention provides a dense oil reservoir exploitation simulation device and method. According to the present invention, a first high-pressure pump is connected with the input end of a core holding unit via a crude oil pipeline and an upstream valve after being connected with a fluid container, and the core holding unit comprises a core, a rubber sealing cylinder and a sealing steel cylinder. The rubber sealing cylinder sleeves the core and tightly presses on the core by the pressure provided by a second high-pressure pump, and the sealing steel cylinder wraps the rubber sealing cylinder. The output end of the core holding unit is connected with a back-pressure valve, and the back-pressure valve is connected with a gas flow meter via a measurement pipeline and is also connected with a back-pressure control pump. During the process of simulating the dense oil reservoir exploitation, by the first high-pressure pump, the fluid in the fluid container is pressed in the core via the input end of the core holding unit, the back-pressure control pump controls the back-pressure valve, and the pressure difference is generated at the upstream part and the downstream part of the core holding unit, so that an outputted liquid is outputted from the input end of the core holding unit and flows in the gas flow meter via the measurement pipeline. The measurement pipeline can measure the size of the output liquid accurately, so that the daily output, namely the production capability of a dense oil reservoir can be evaluated accurately.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com