Patents

Literature

88results about How to "Accurate length measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

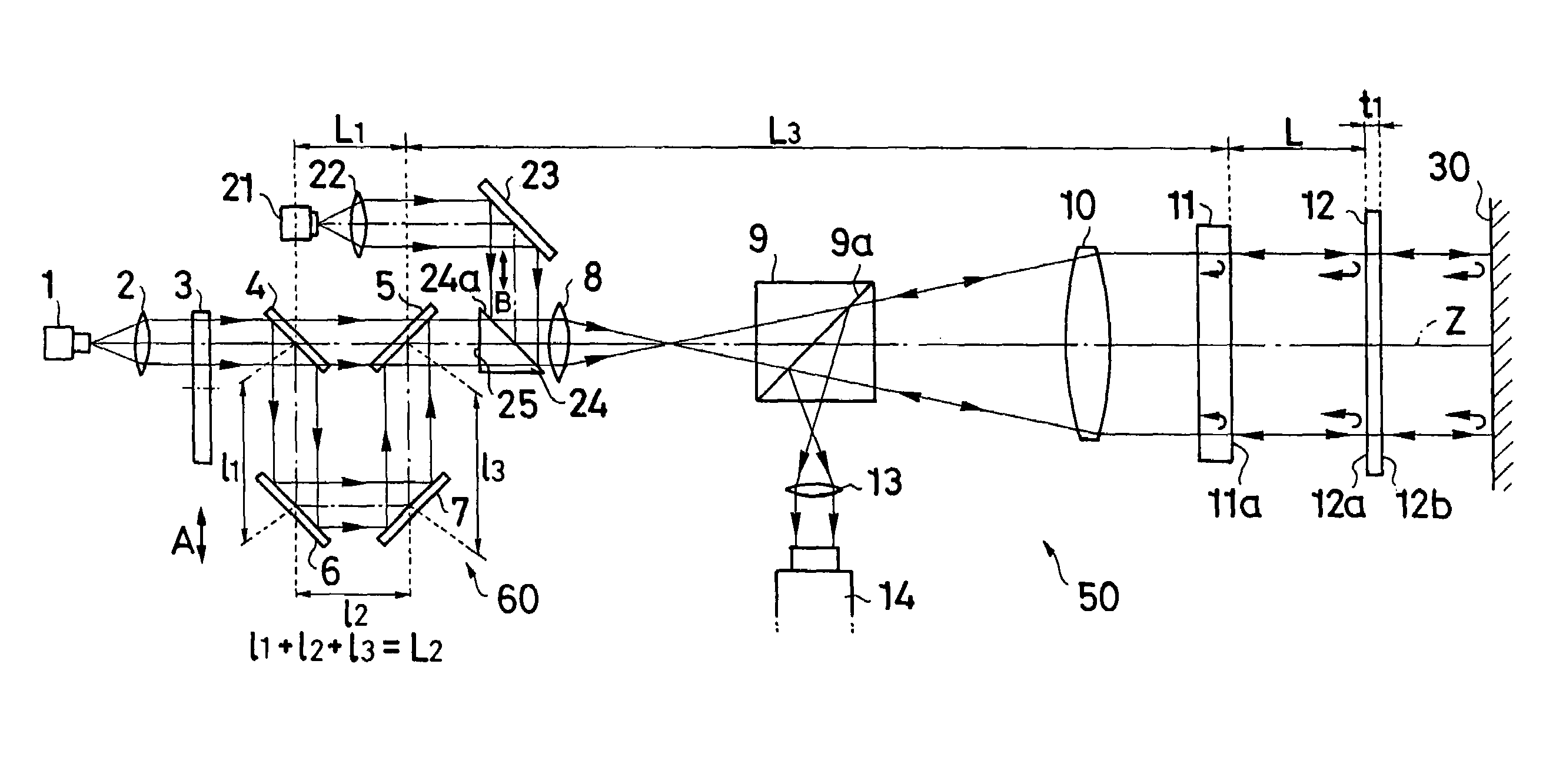

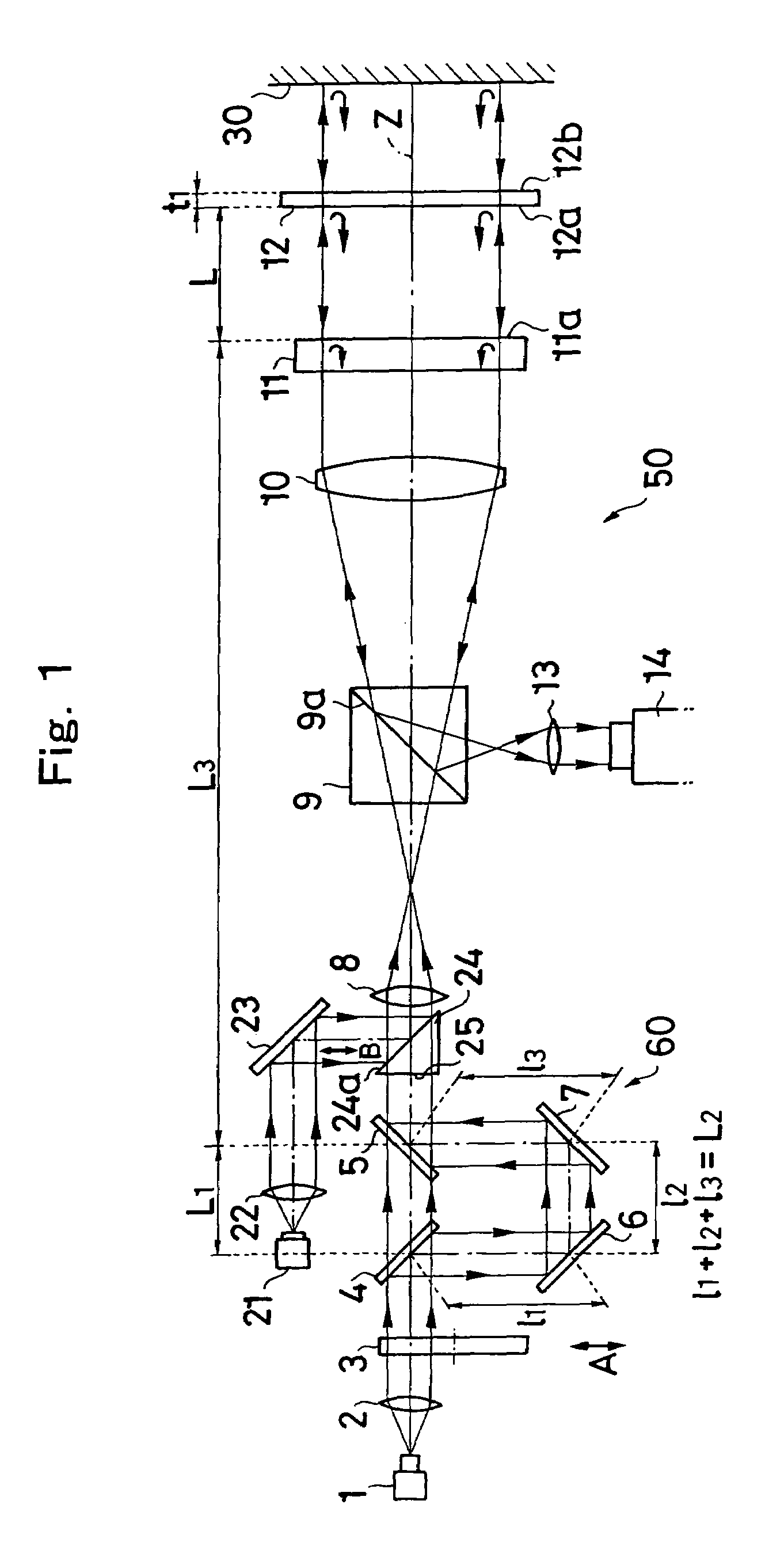

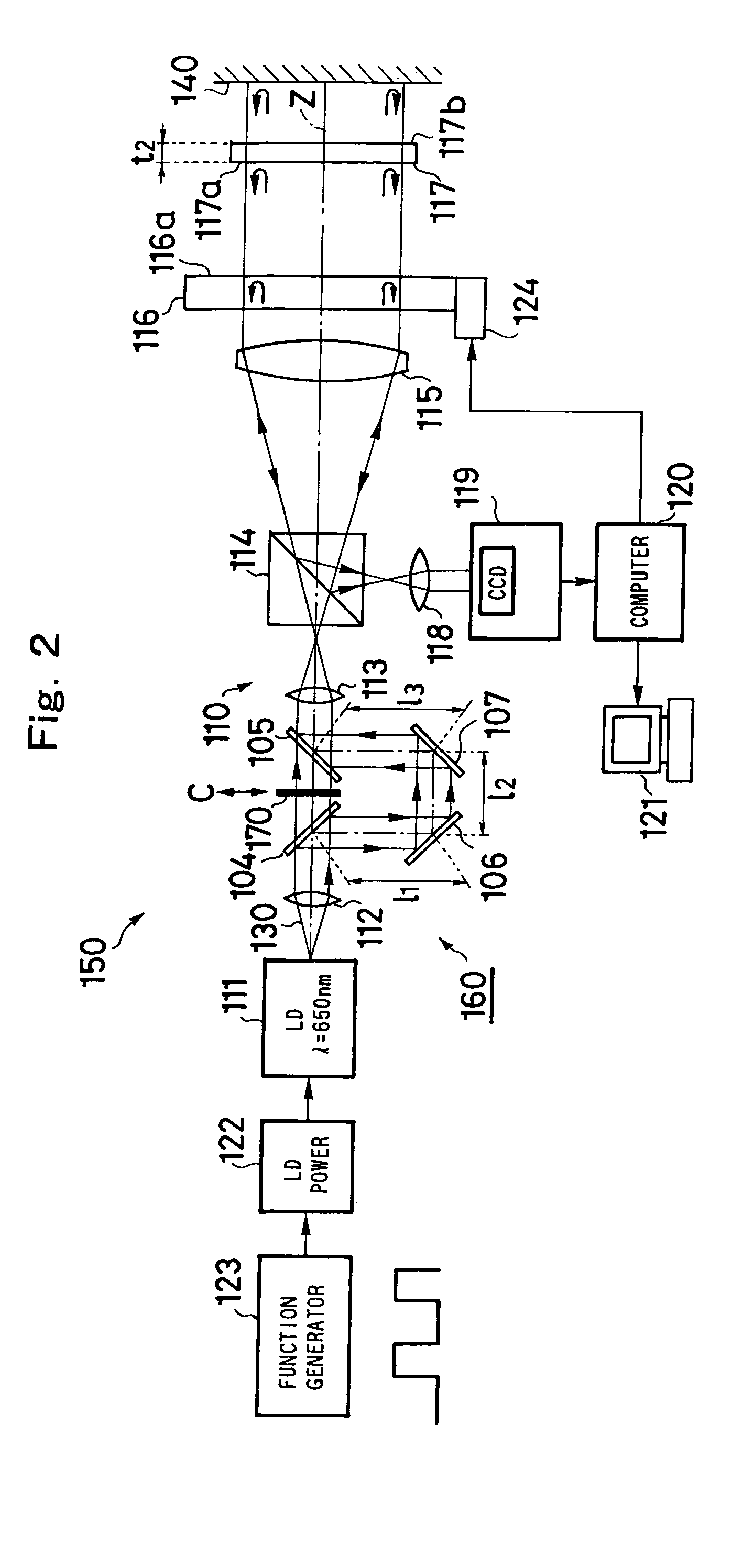

Interferometer apparatus for both low and high coherence measurement and method thereof

ActiveUS6992779B2Easy to measureImage interferenceOptical measurementsUsing optical meansOptoelectronicsLuminous flux

A Fizeau interferometer apparatus is used for both low and high interference measurement. When irradiating a reference surface and a sample with a low coherent luminous flux, a path-matching passage divides the low coherent luminous flux into first and second paths, while the optical path length difference between the respective luminous fluxes passed through the two paths equals twice the optical distance between the reference surface and the sample. When irradiating the reference surface and the sample with a high coherent luminous flux, the luminous flux is made incident on the sample side of the path-matching passage at a position coaxial with the low coherent luminous flux.

Owner:FUJI PHOTO OPTICAL CO LTD

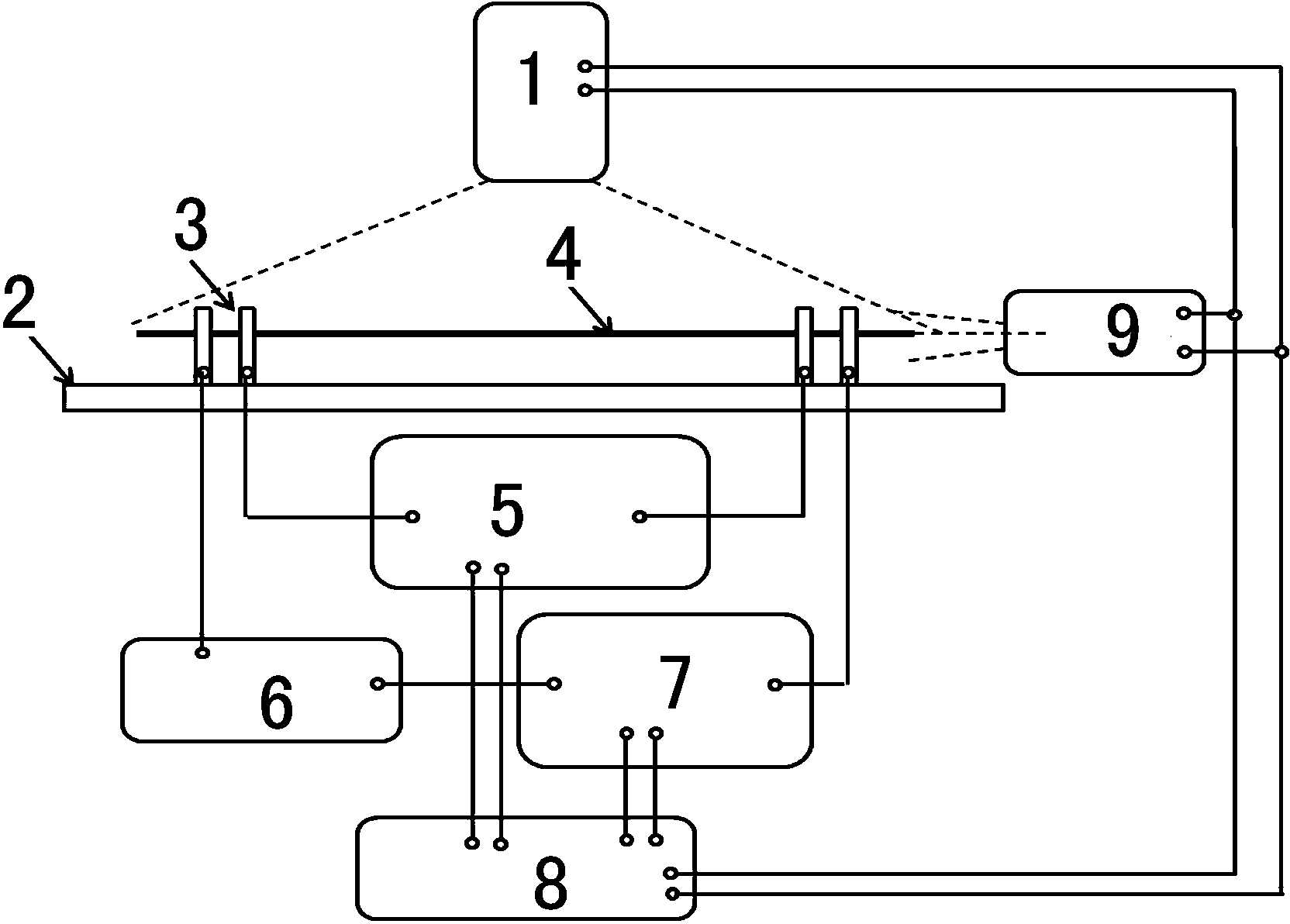

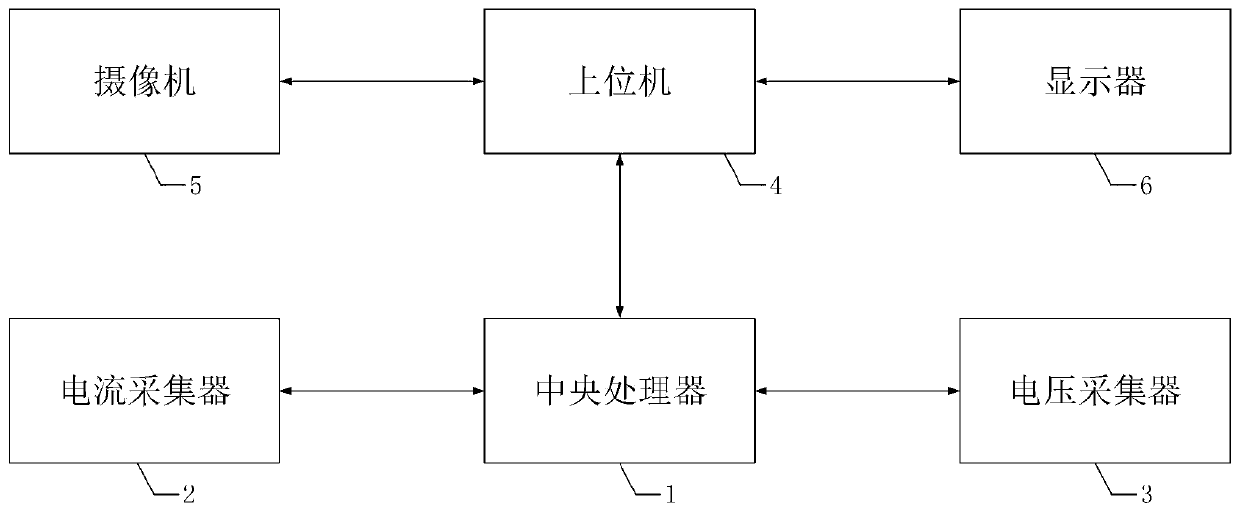

System and method for testing electric conductivity of metal wire

ActiveCN103513111AFilter impactEffect of Filtering Measured ValuesResistance/reactance/impedenceElectrical resistance and conductanceElectro conductivity

The invention relates to the technical field of electric power, in particular to a system and method for testing the electric conductivity of a metal wire. The system comprises a direct-current power supply, a wire clamping system and a test system. The output end of the direct-current power supply is in series connection with the metal wire to be tested through a fixture. The metal wire to be tested is connected to an optical platform through a fixture. A first camera and a second camera are respectively and electrically connected with a computer. A multiple-pass digital multimeter V is connected with the metal wire to be tested and is further electrically connected with the computer. A multiple-pass digital multimeter A is connected with the metal wire to be tested through the direct-current power supply. Due to the adoption of the system and method for testing the electric conductivity of the metal wire, the electric conductivity of a metal wire of any length and section shape can be tested without considering the effect of the temperature on the resistance of the wire to be tested, and experiments are easy and quick to operate. The system and method greatly improve working efficiency, obviously improve testing accuracy and are suitable for all kinds of novel energy-saving metal wires.

Owner:STATE GRID CORP OF CHINA +2

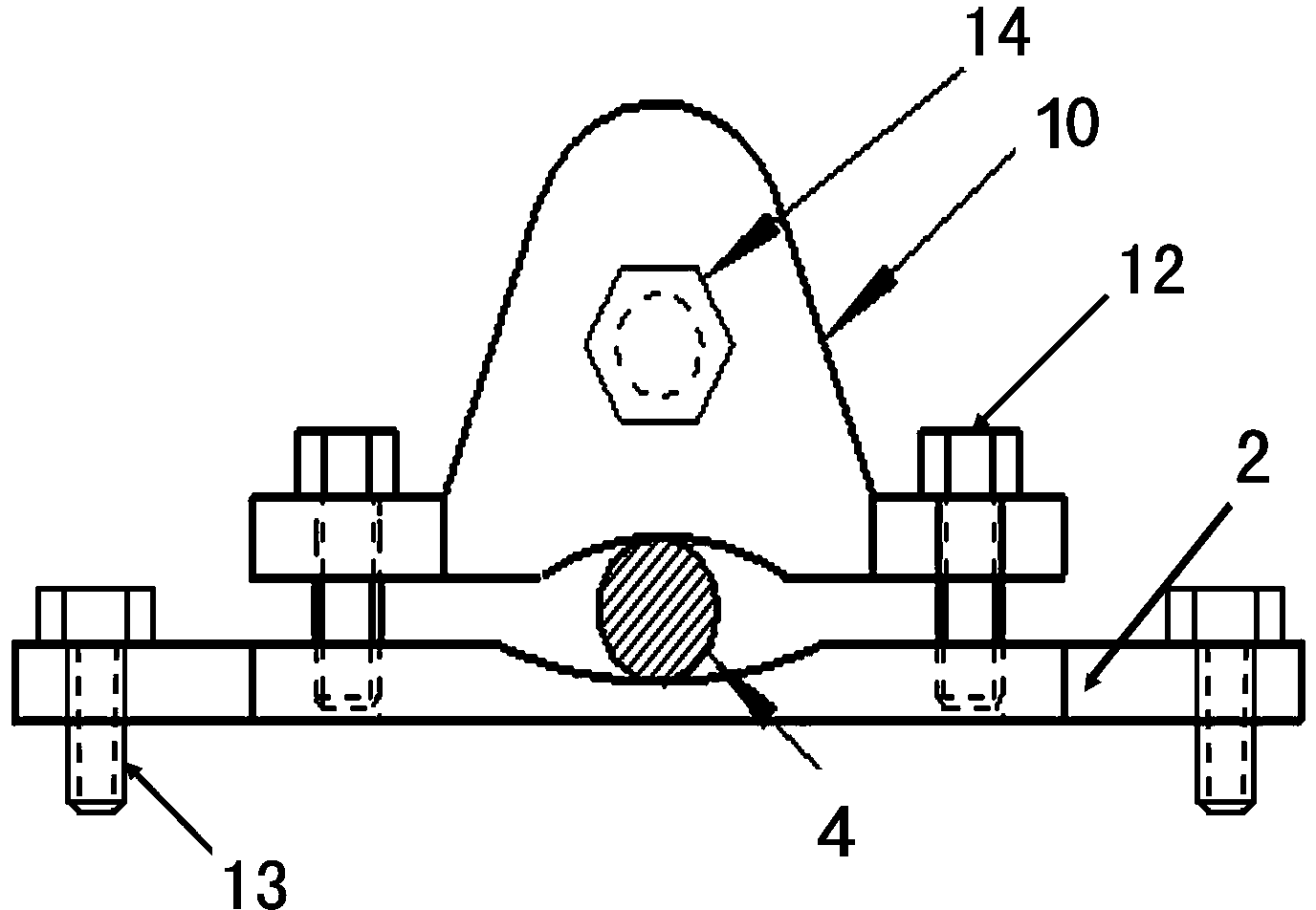

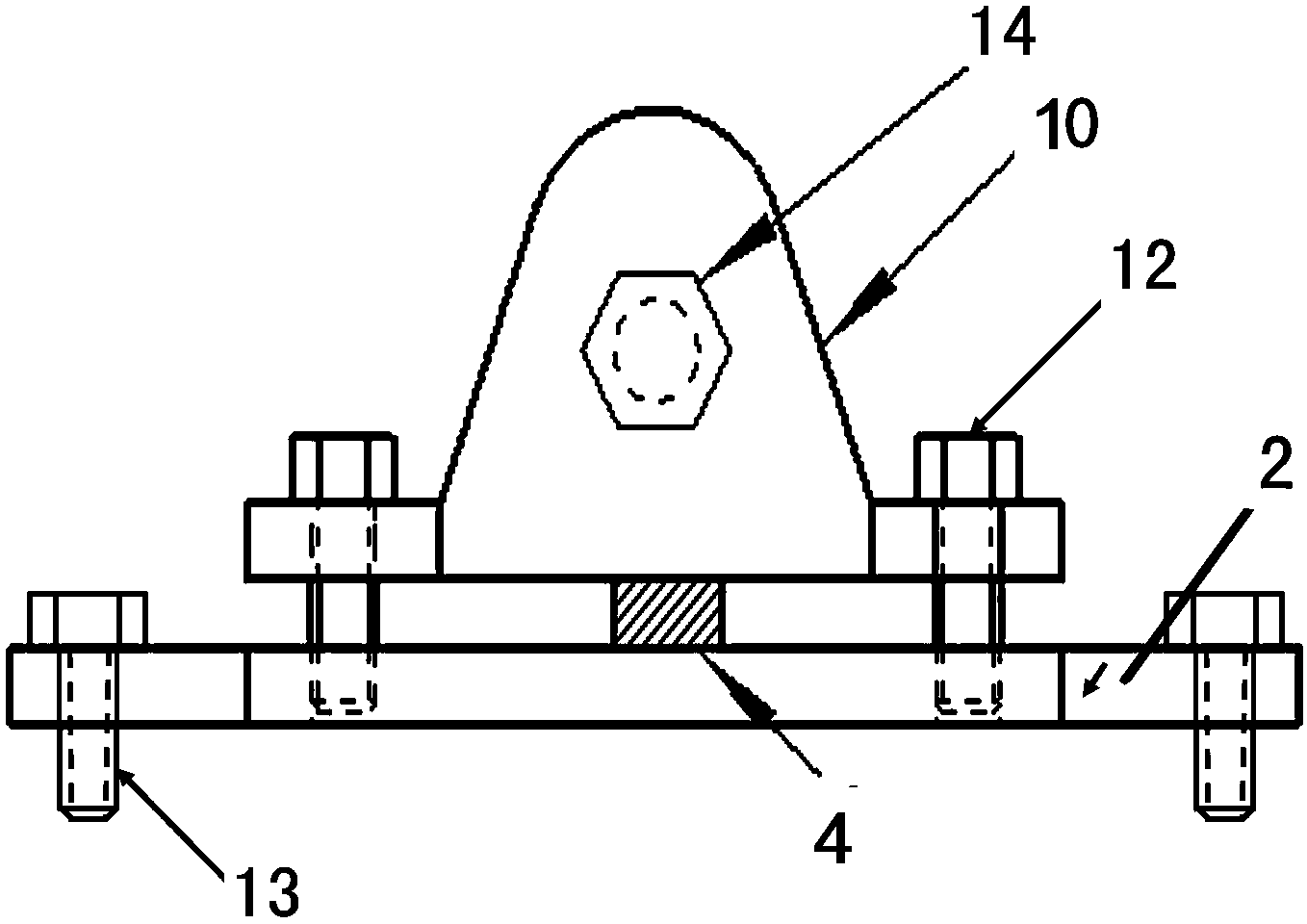

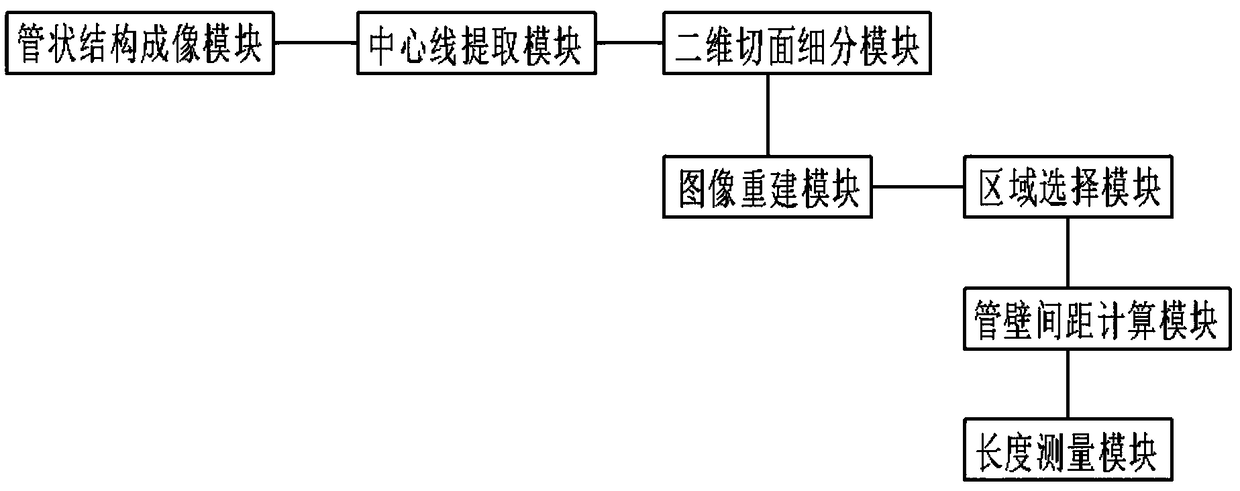

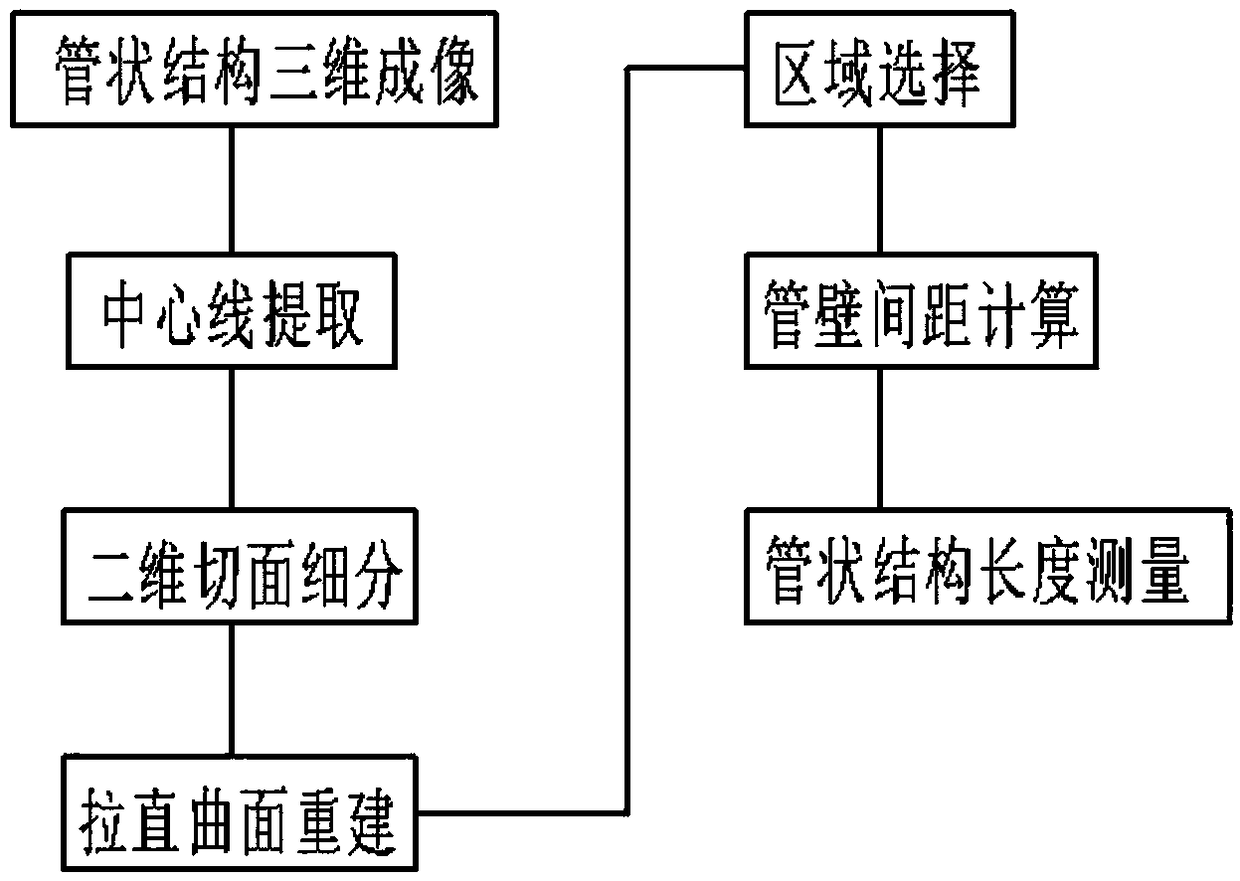

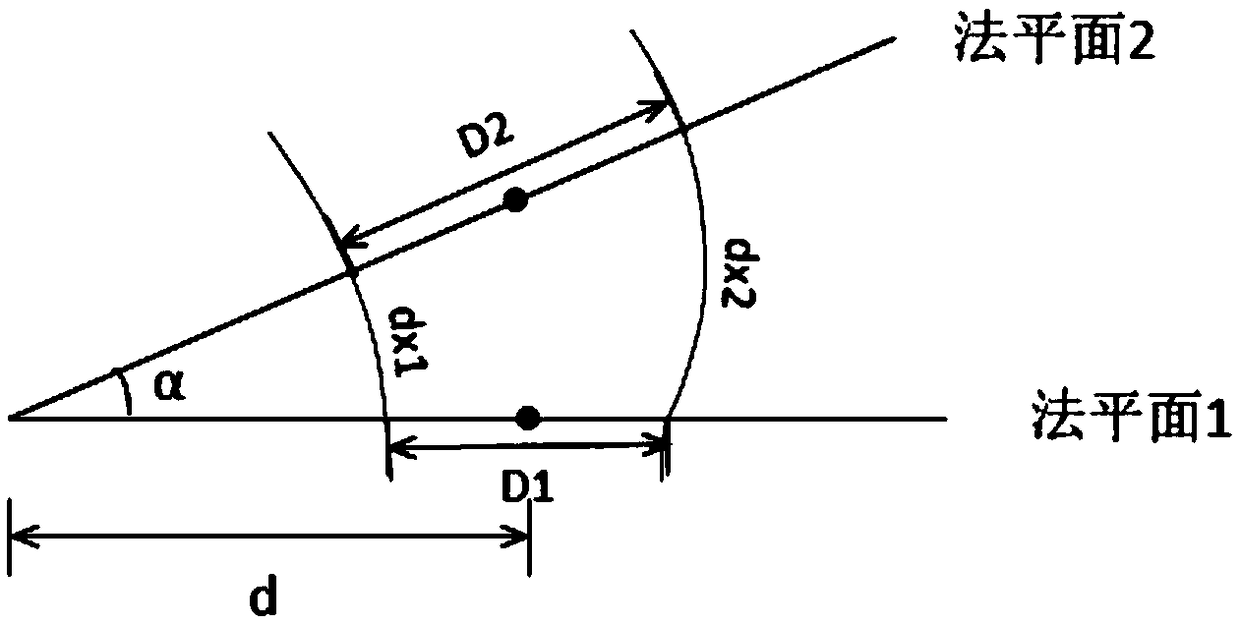

Tubular structure length measurement system and method based on three-dimensional medical image

The invention discloses a tubular structure length measurement system and method based on a three-dimensional medical image. According to the measurement system and method, by the adoption of the differential summation principle in mathematics, length value calculation of a tubular structure is converted into cumulative calculation of distances between a series of adjacent slices, wherein first, acenter line of the tubular structure is extracted; second, a normal plane is constructed based on the center line, the tubular structure is subdivided into a series of two-dimensional sections, and the range of a region-of-interest is determined on an image subjected to straightened surface reconstruction; and last, the sum of wall distances, between the adjacent sections contained in the region-of-interest, of the tubular structure is calculated, and a needed length value of the tubular structure is obtained. Therefore, precise measurement of the length of the tubular structure is realized,and the measurement system and method can be widely applied to the fields of intravascular stent preoperative planning, plaque length measurement, thrombus length measurement, angioma and interlayer measurement, intestinal polypus measurement, etc.

Owner:合肥融视信息科技有限公司

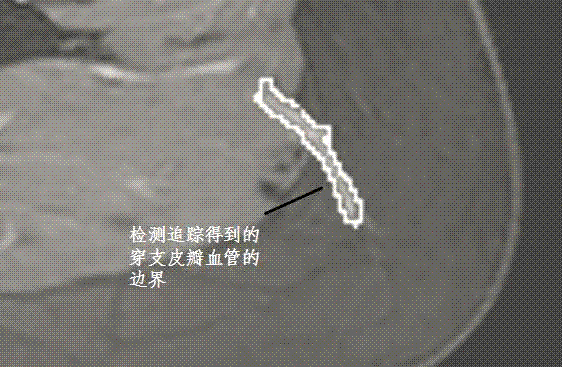

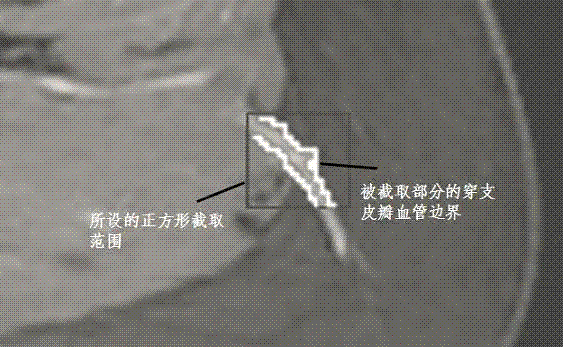

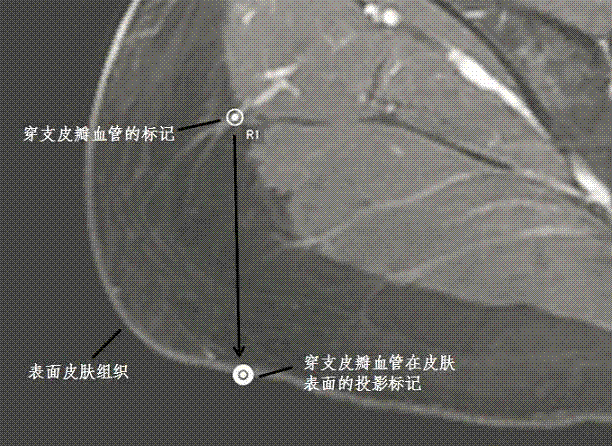

Magnetic resonance imaging-based perforator flap blood vessel positioning and measurement method

ActiveCN102764124AAccurate length measurementAccurate diameter measurementDiagnostic recording/measuringSensorsResonanceSkin surface

The invention discloses a magnetic resonance imaging-based perforator flap blood vessel positioning and measurement method, which comprises the following steps of: acquiring a magnetic resonance image of human subcutaneous tissues, and selecting a reference point from the image; searching for a position where a perforator flap blood vessel penetrates a muscle in the image, and setting mark points; reading imaging coordinates of the reference point and the mark points, and calculating displacement between the reference point and each mark point; tracking and segmenting the blood vessel, and calculating the length and diameter of the perforator flap blood vessel; and projecting all the mark points onto the surface of skin to obtain a perforator flap blood vessel mark image on the surface of the skin. The method can be used for accurately positioning the perforator flap blood vessel and accurately measuring the length and diameter of the perforator flap blood vessel, and is short in manual operation time and high in efficiency.

Owner:EAST CHINA NORMAL UNIV

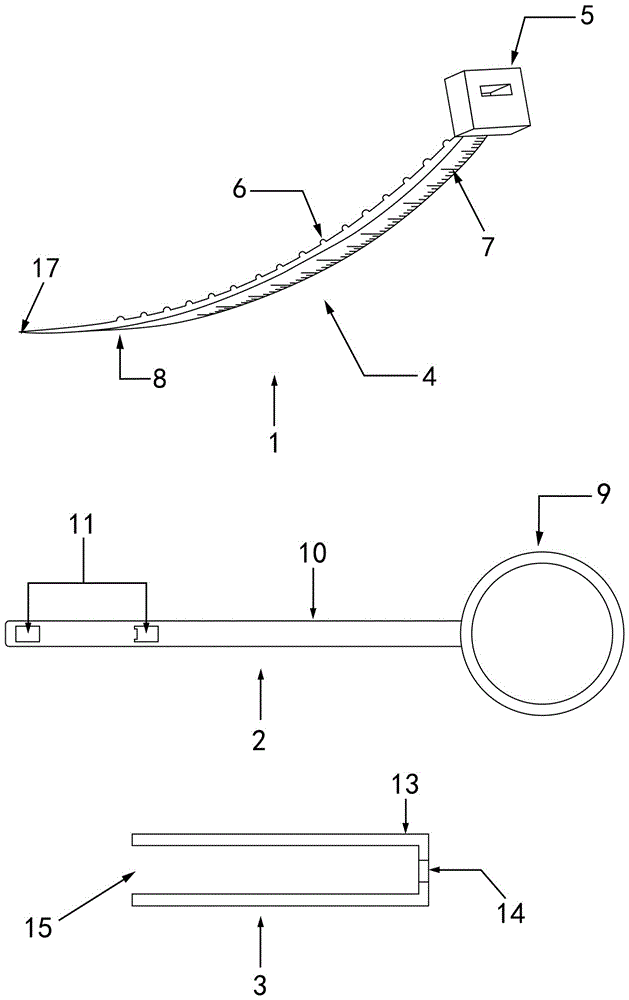

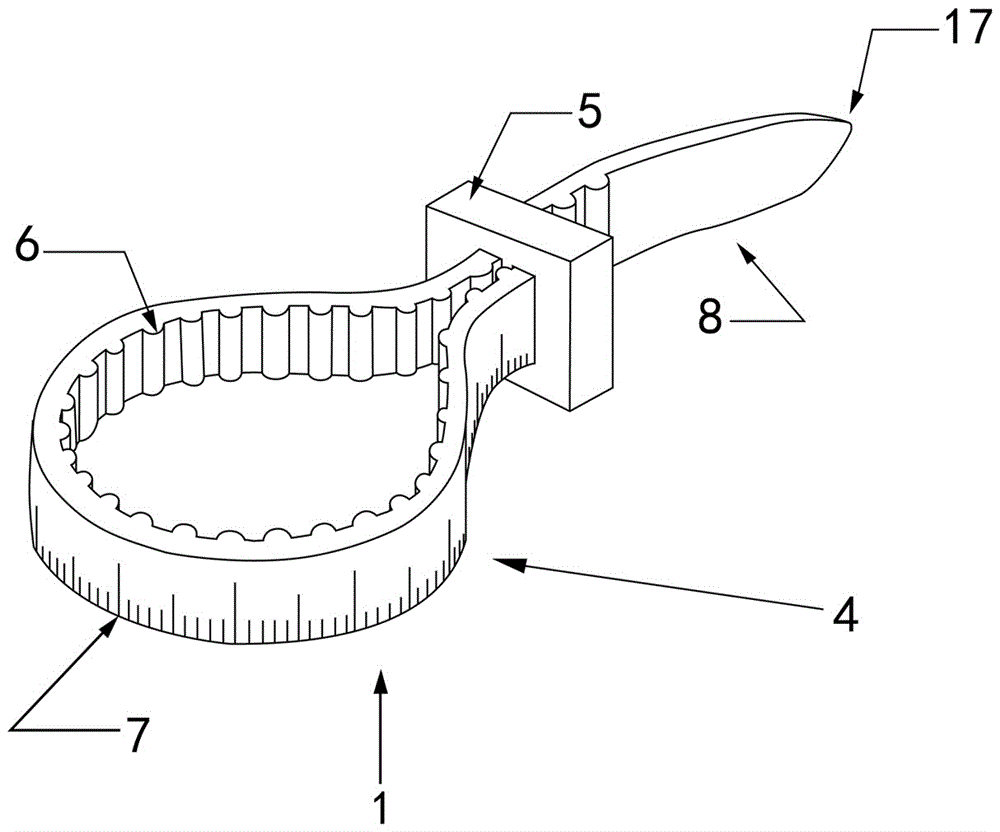

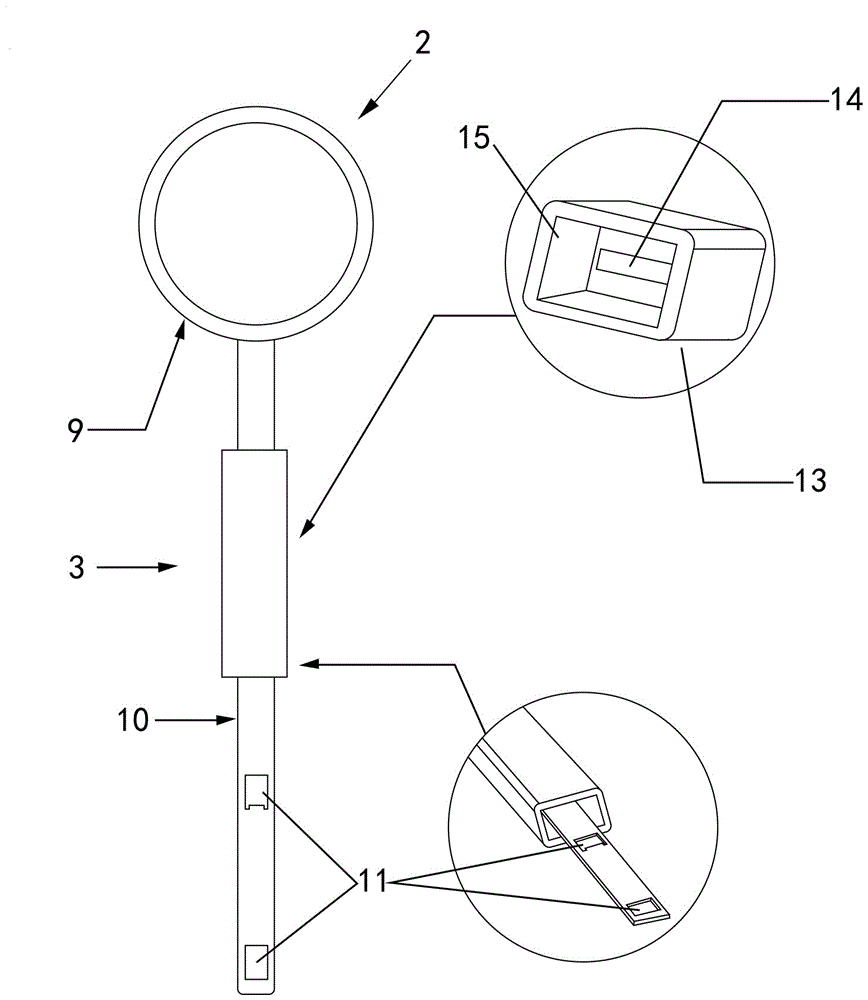

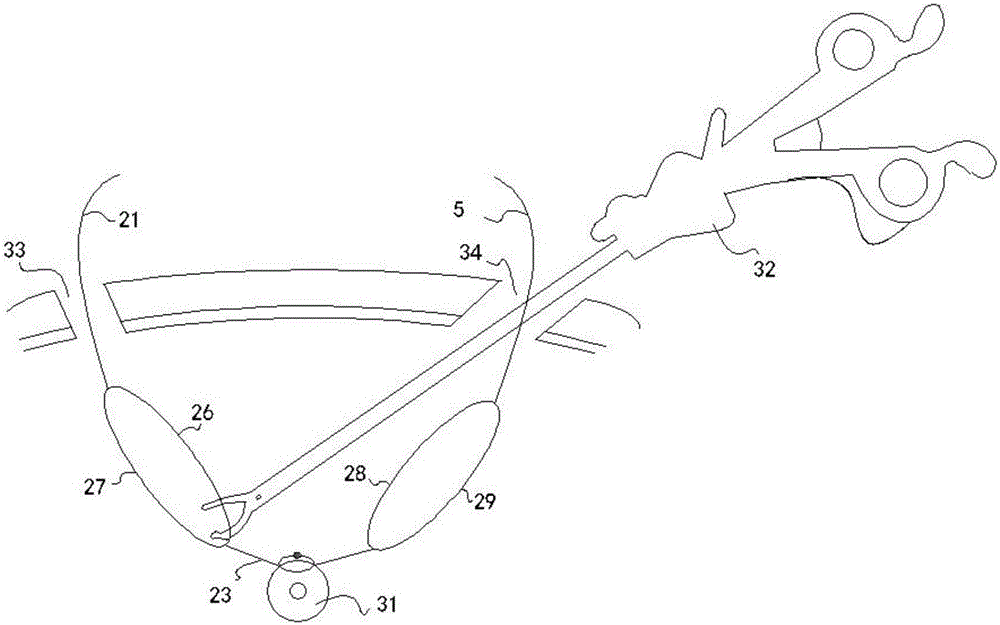

Disposable tubular viscera tying lift apparatus

ActiveCN105832370ASolve the problem that the knot is not easy to tighten, and it is easy to loosen after pullingEasy to loosenDiagnosticsSurgeryLength measurementEngineering

The invention relates to the field of medical apparatuses, and discloses a disposable tubular viscera tying lift apparatus. The lift apparatus comprises a lock fastener, a lift ring and a protective cover. The lock fastener is a key component composed of a tying strap and a locking unit, one side of the tying strap is provided with antislip convex teeth, the other side is provided with length scales, the tying strap surrounds the tubular viscera by a circle, the movable end penetrates the locking unit prior to being tightened, and then the tubular viscera such as the esophagus, intestine and stomach can be tied, blocked, lifted and subjected to length measurement. In laparoscopic surgery, the lock fastener can be used individually, and the lift ring and the protective cover are designed for use in combination for laparotomy operation. The disposable tubular viscera tying lift apparatus is compact, elastic and flexible, and is convenient to use in narrow operation space. Compared with the past common gauze and other instruments, the disposable tubular viscera tying lift apparatus has the advantages that the no-tumor procedure during tumor distal bowel resection in laparoscopic radical rectectomy for rectal cancer is well realized; difficulty in open rectal carcinoma radical operation is lowered greatly; the disposable tubular viscera tying lift apparatus is taken out with specimens to be discarded at the end of operation.

Owner:王劲

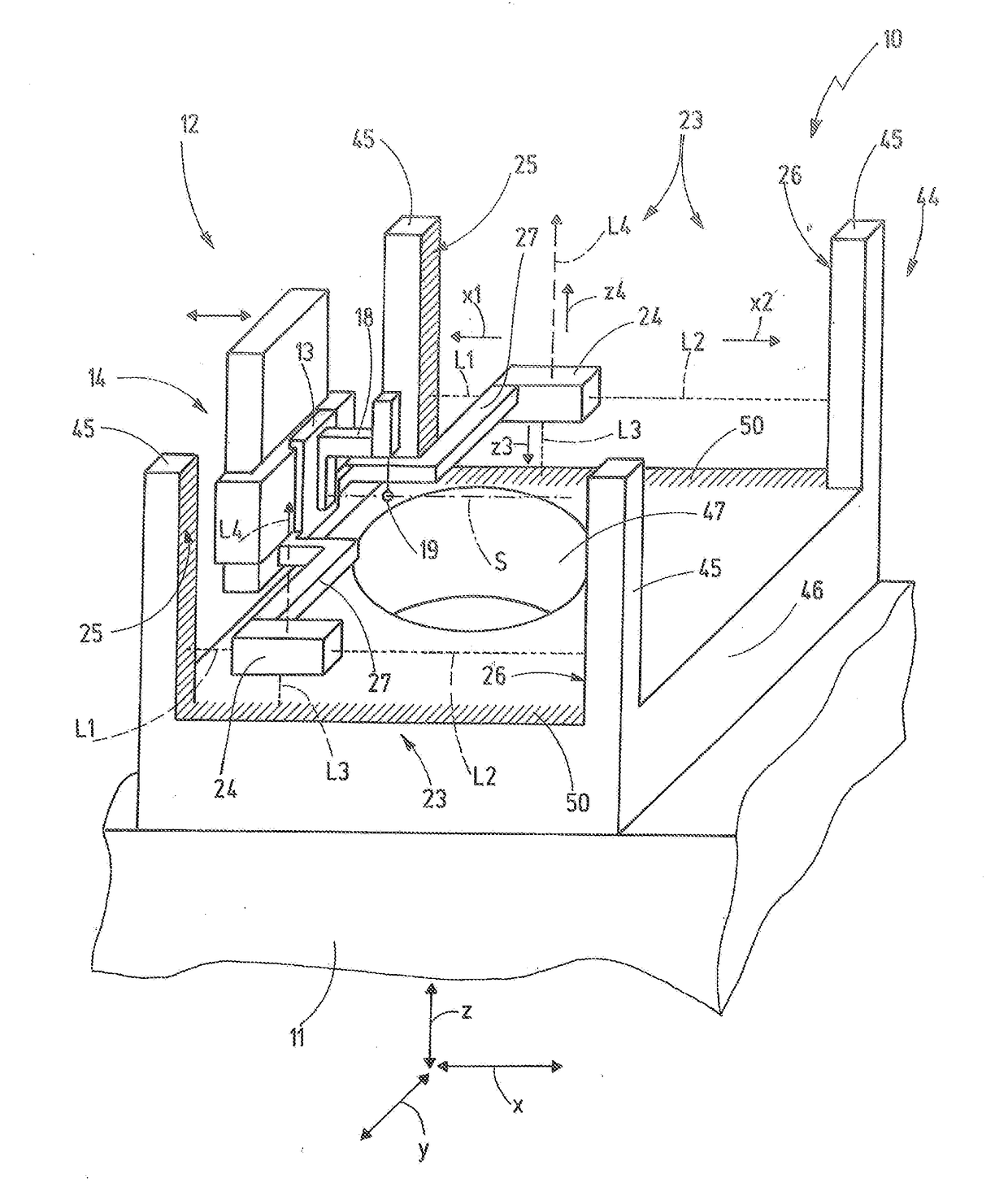

Measuring device and method for measuring at least one length measurand

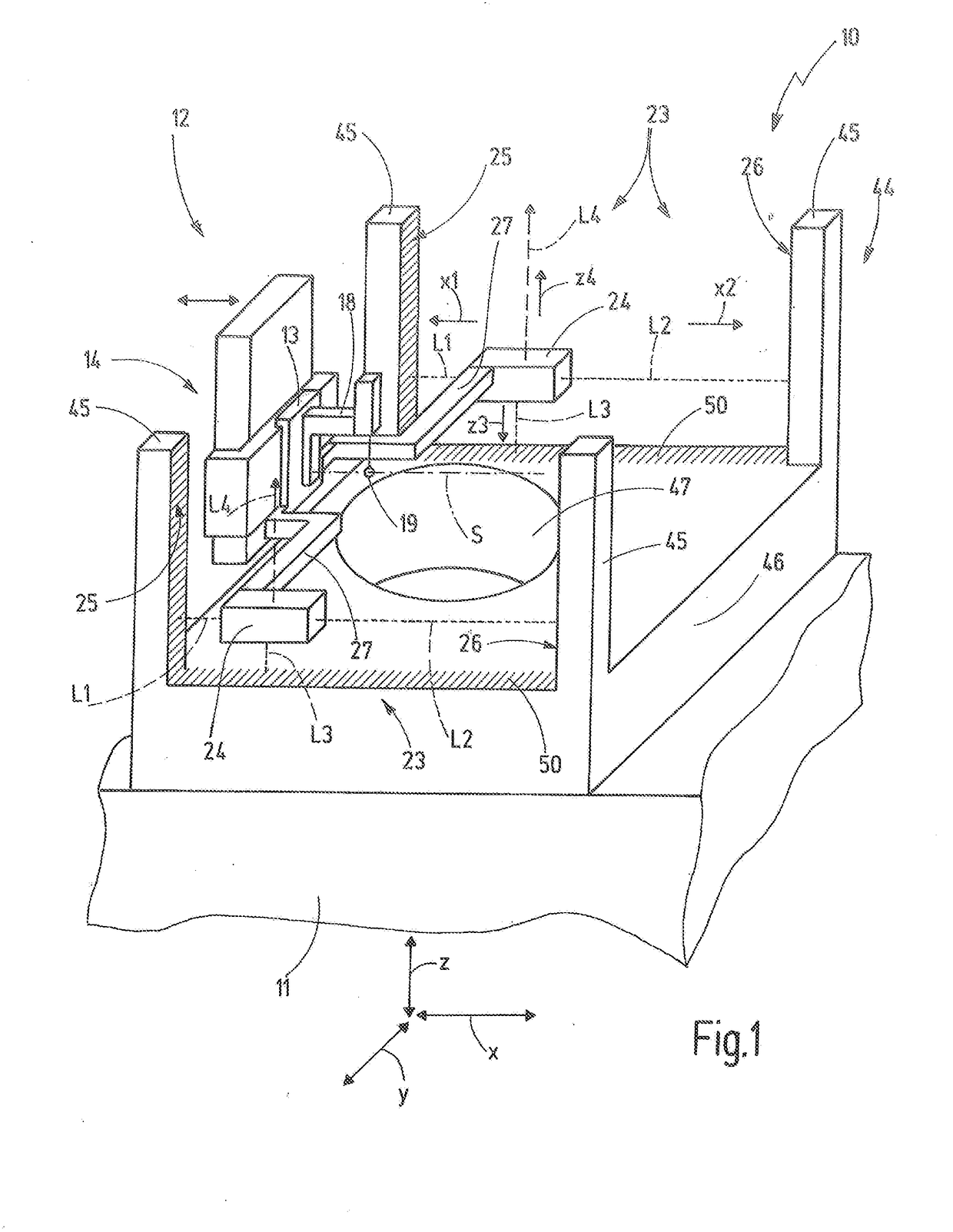

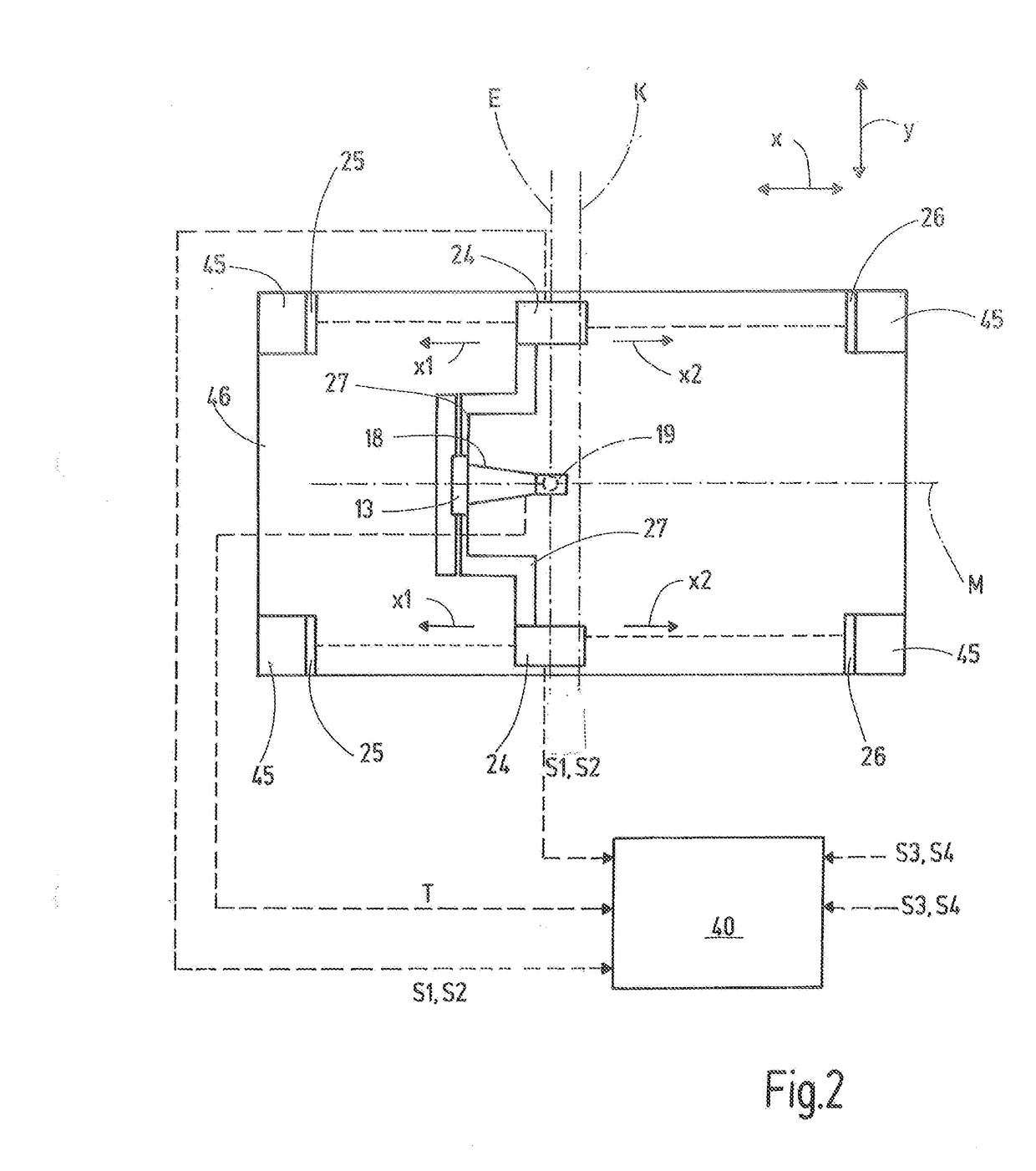

InactiveUS20180202796A1Easy to measureConvenient ArrangementUsing optical meansError compensation/eliminationMeasurement deviceLight beam

The invention relates to a measuring device (10) and a method for determining a length measurand of a workpiece. A carrier part (13), on which a probe unit (18) is arranged immovably in a first spatial direction (x), can be moved or positioned by means of a positioning arrangement (12). At least one laser interferometer (24) is connected to the carrier part (13) immovably in the first spatial direction (x). By means of a first laser measuring beam (L1) and a second laser measuring beam (L2), the laser interferometer (24) generates a first measurement signal (S1), which measurement signal describes the distance of the laser interferometer (24) from a first reflector (25) in the first spatial direction (x), and a second measurement signal (S2), which describes the distance of the laser interferometer (24) from a second reflector (26) in the first spatial direction (x). A probe system plane (E), which is immovable in the first spatial direction (x) relative to the carrier part (13) or the probe unit (18) and which extends at right angles to this first spatial direction (x), therefore has a position in the first spatial direction (x) that can be determined by means of the distances of the laser interferometer (24) from the first reflector (25) and the second reflector (26).

Owner:CARL MAHR HLDG

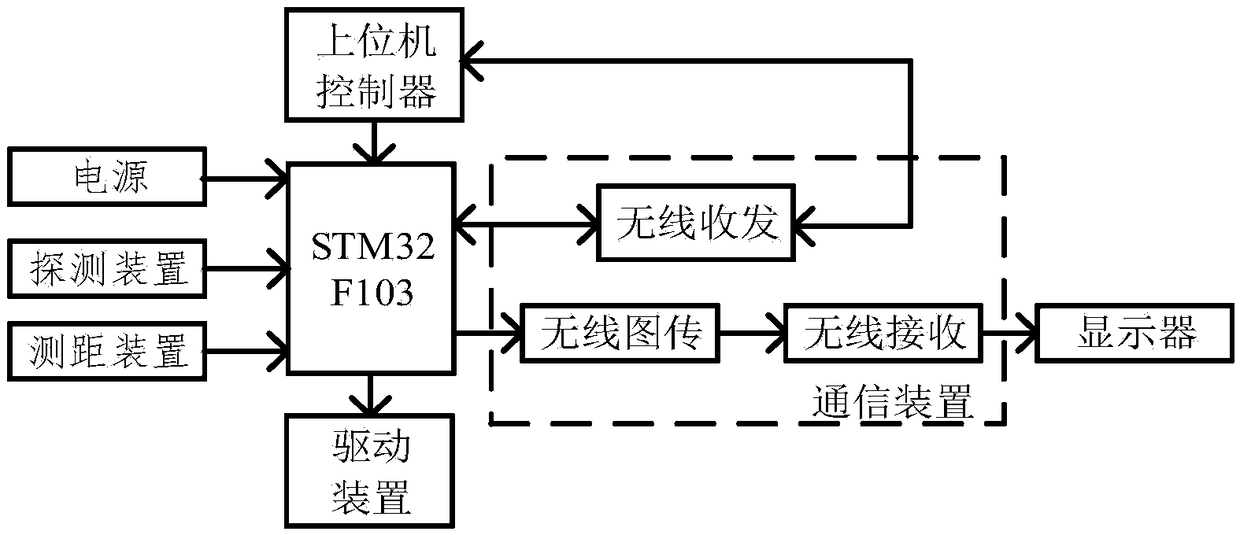

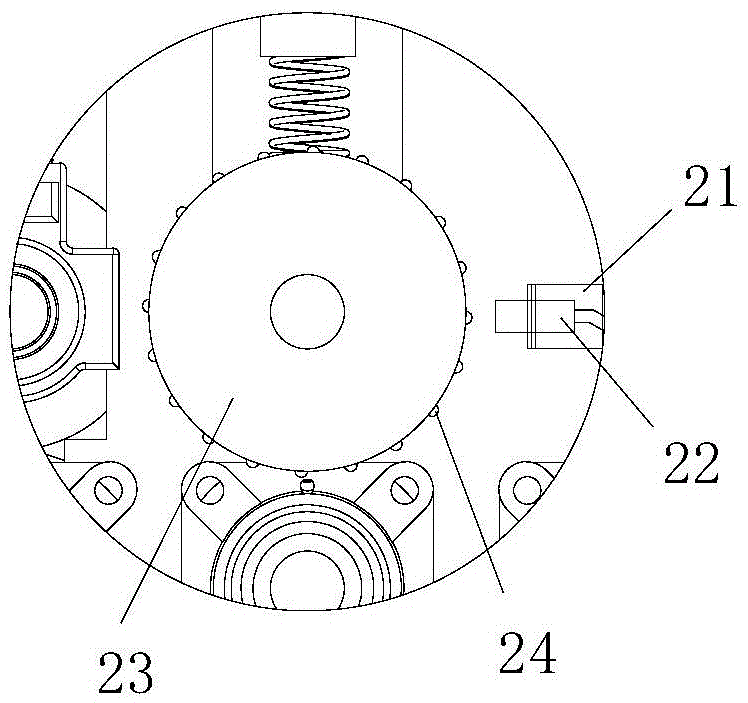

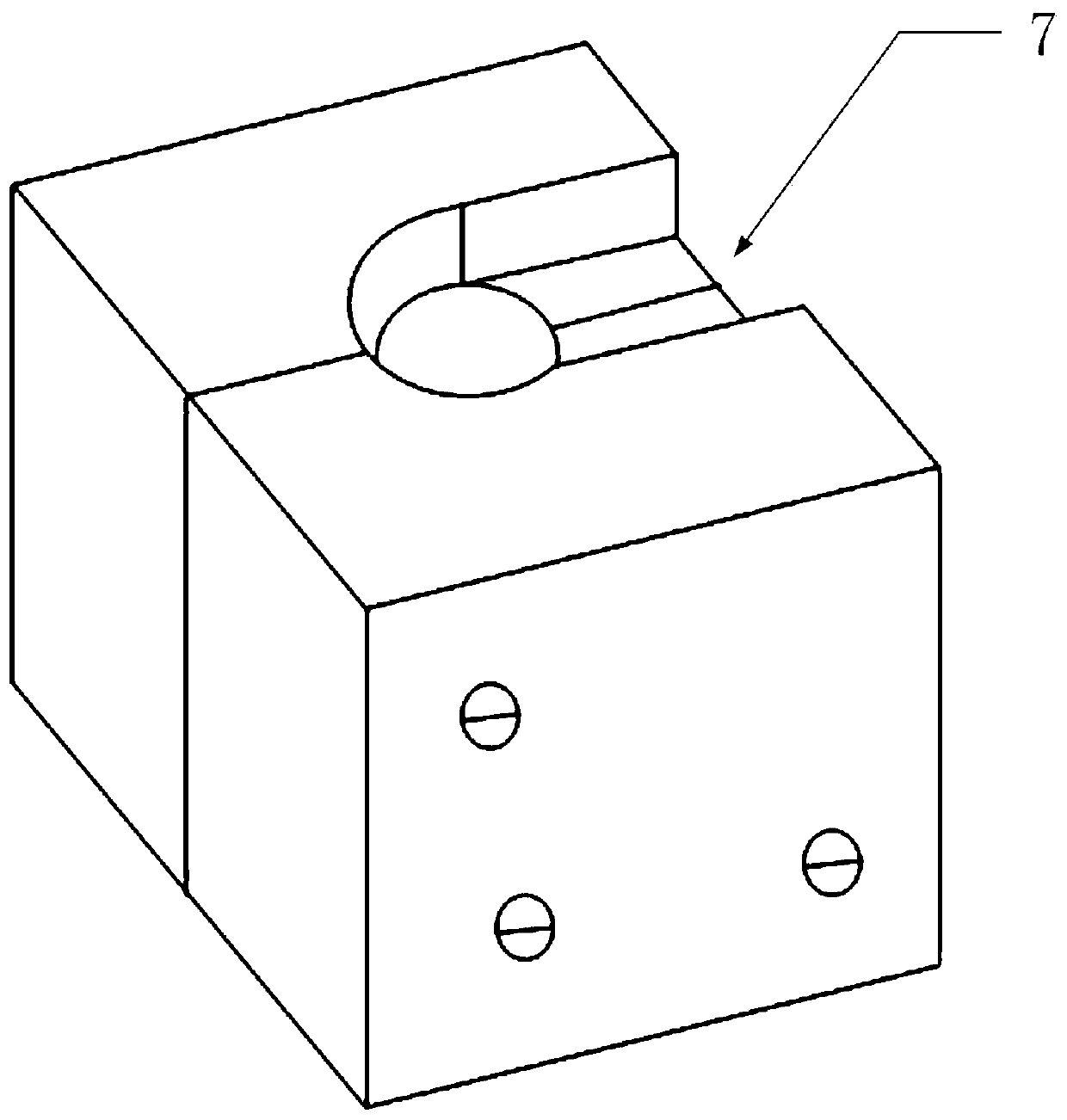

Robot used for electric power pipeline inspection

PendingCN109397306AHigh measurement accuracyAvoid sliding frictionProgramme-controlled manipulatorLine tubingMeasurement precision

The invention relates to a robot used for electric power pipeline inspection. The robot comprises a control device used for receiving and processing video and distance measurement signals, a detectiondevice, a distance measurement device used for carrying out inner wall distance measurement, a communication device and a drive device. The detection device is used for detecting whether cracks, obstacles and the blocking situation exist in electric power pipelines or not in real time. The communication device is used for transmitting the in-pipeline condition detected by the detection device andthe distance signals measured by the distance measurement device, and the robot can be controlled by an upper computer. The drive device is responsible for providing power for the robot. The robot ishigh in measurement precision, the blocking condition in the electric power pipelines can be remotely controlled and accurately measured, and the cost is relatively low.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +1

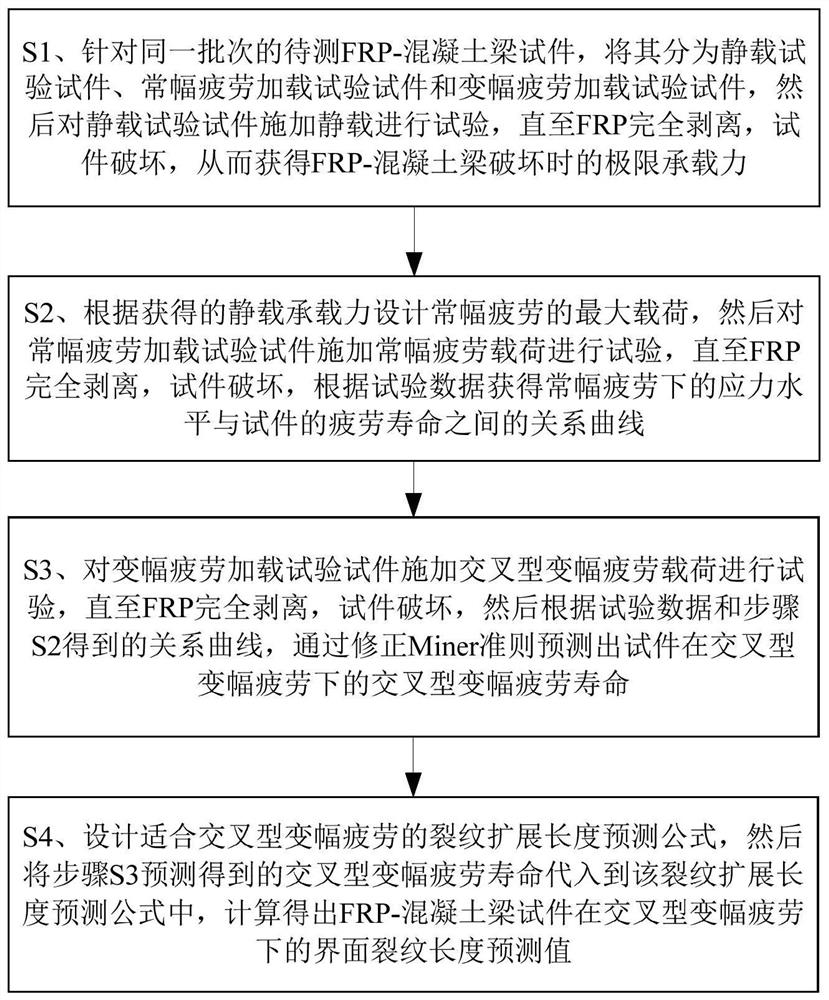

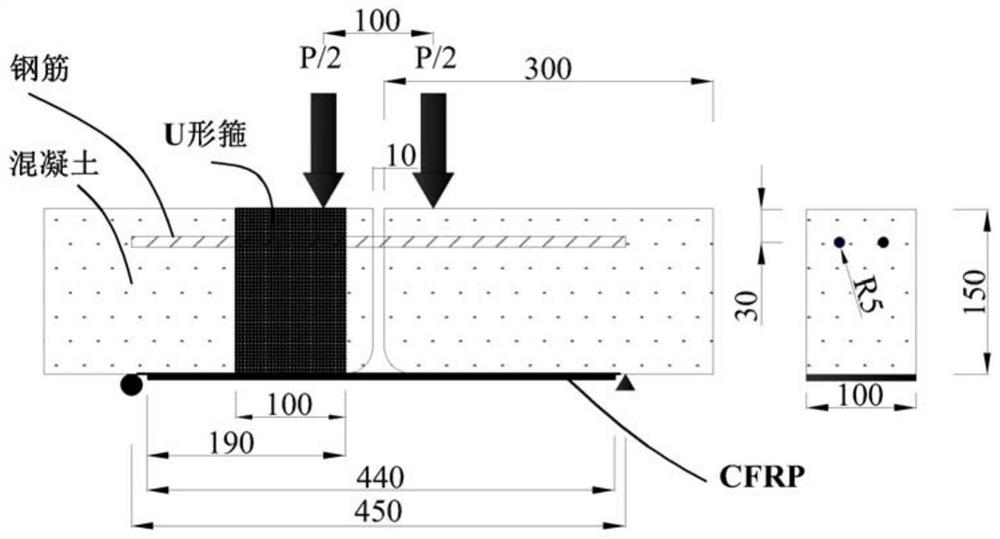

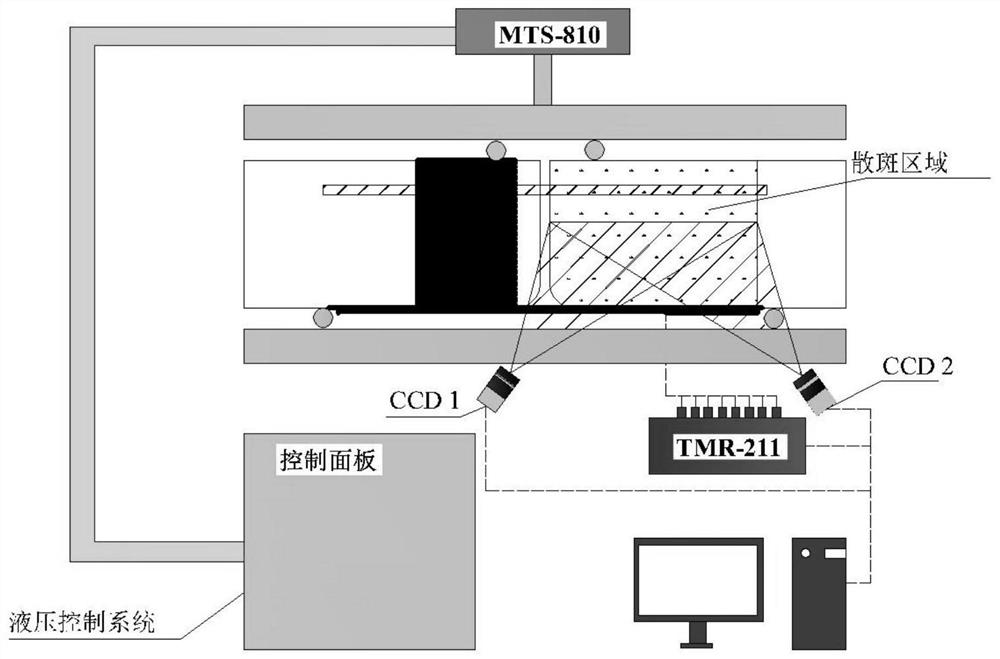

Method for predicting FRP-concrete beam interface crack length under variable amplitude fatigue

ActiveCN111855405AAccurate length measurementLength predictionSustainable transportationMaterial strength using tensile/compressive forcesFatigue loadingConcrete beams

The invention discloses a method for predicting an FRP-concrete beam interface crack length under a variable amplitude fatigue. The method comprises the steps of firstly applying a static load to a static load test piece, and obtaining the ultimate bearing capacity of the FRP-concrete beam during damage, designing the maximum load of constant-amplitude fatigue according to the static load bearingcapacity, applying a constant-amplitude fatigue load to the constant-amplitude fatigue test loading test piece, and obtaining a stress-fatigue life relation curve under constant-amplitude fatigue according to test data, then applying a crossed variable-amplitude fatigue load to the variable-amplitude fatigue test loading test piece for testing, and predicting the crossed variable-amplitude fatiguelife of the test piece by correcting a Miner criterion according to test data and the obtained stress-fatigue life relation curve, and finally, designing a crack propagation length prediction formula, and substituting the crossed variable-amplitude fatigue life into the formula to obtain an interface crack length prediction value of the test piece under crossed variable-amplitude fatigue. The FRP-concrete interface crack propagation length under the crossed variable-amplitude fatigue can be accurately measured.

Owner:JINAN UNIVERSITY

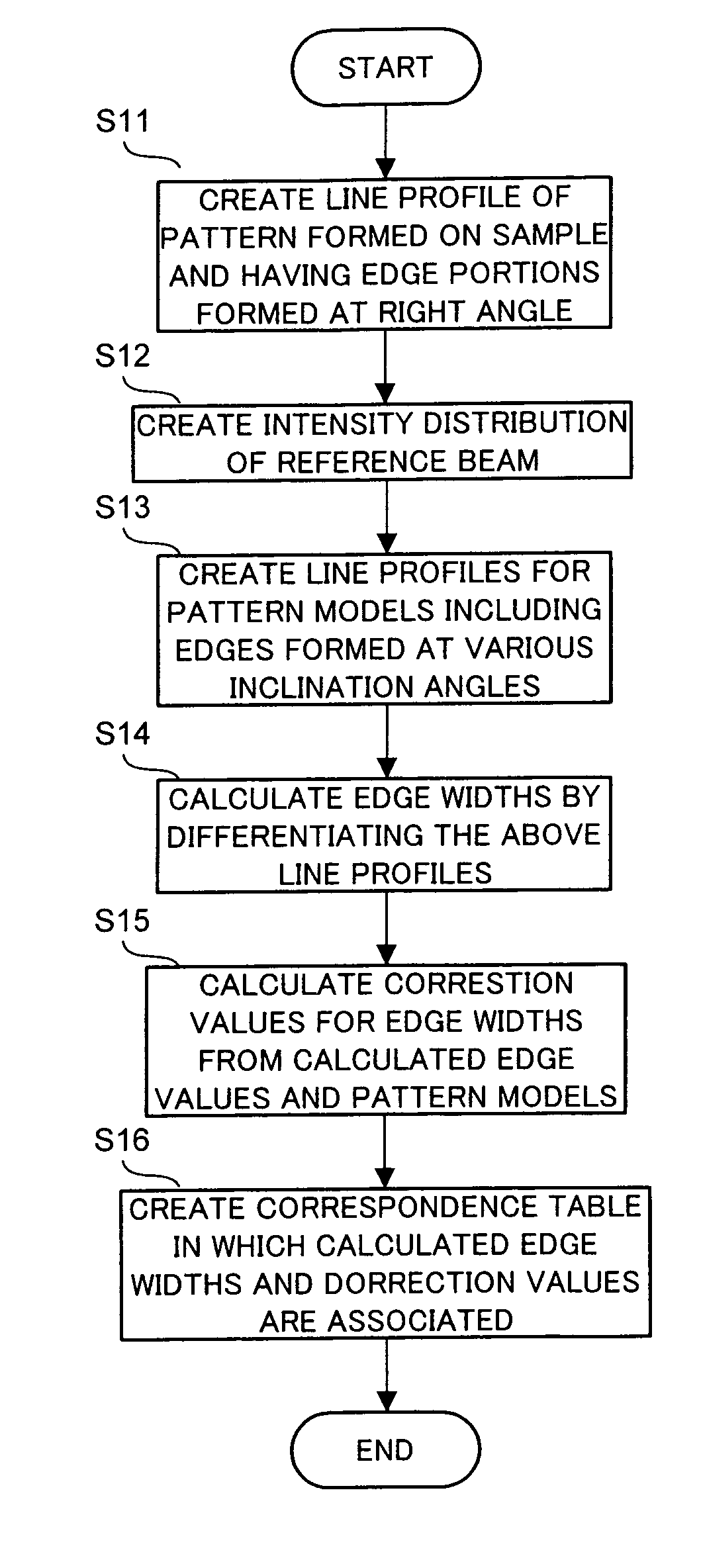

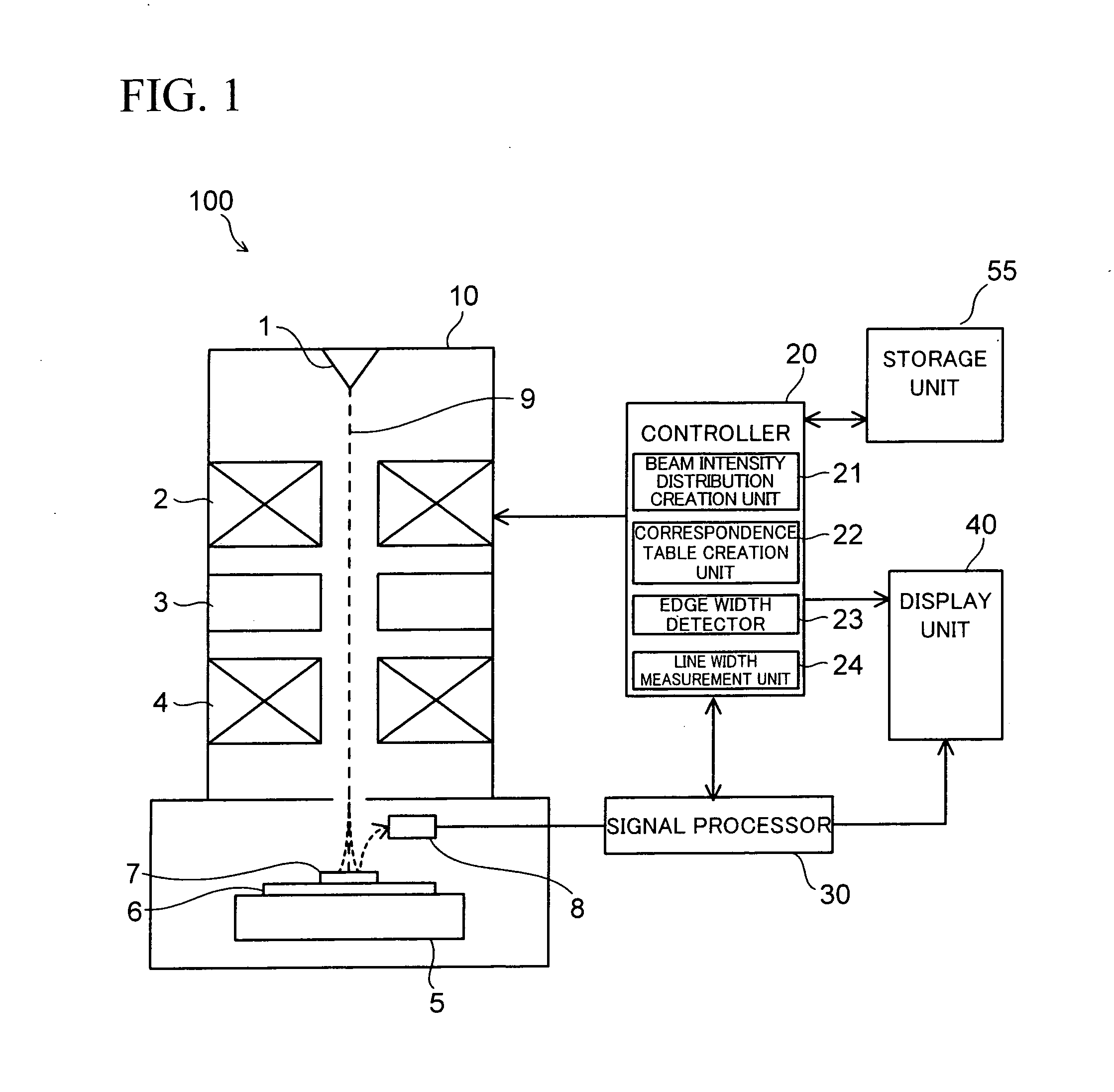

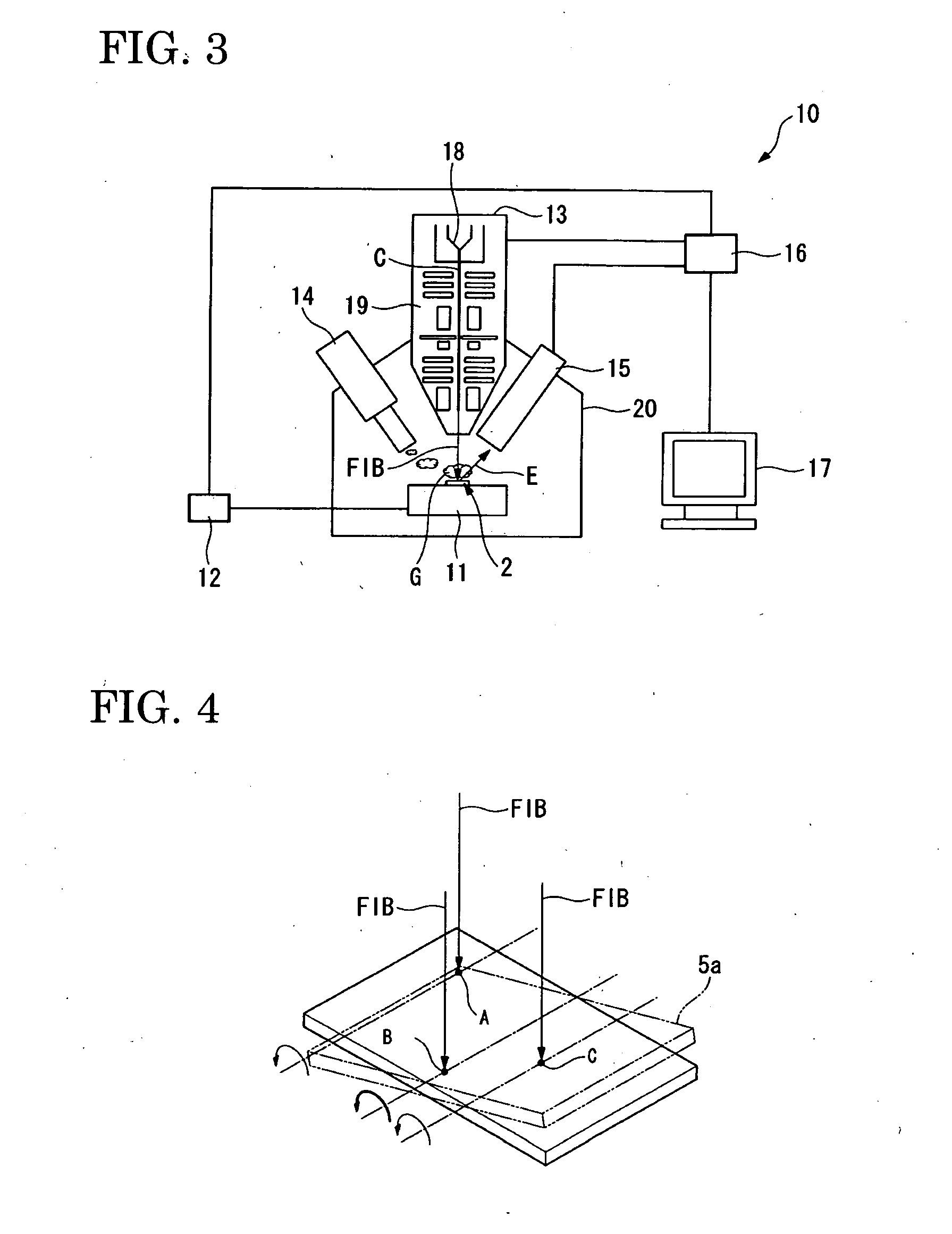

Pattern measurement apparatus and pattern measurement method

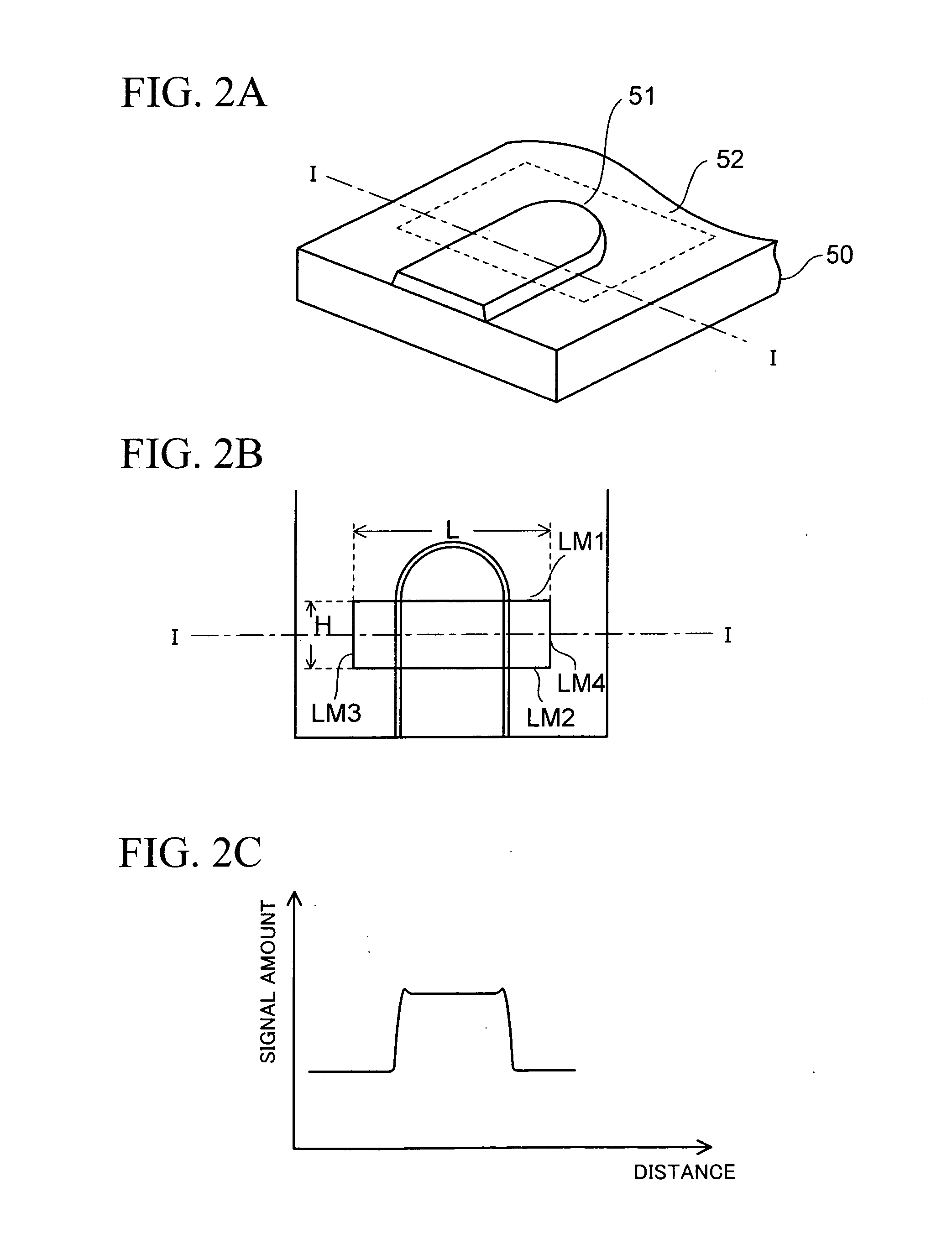

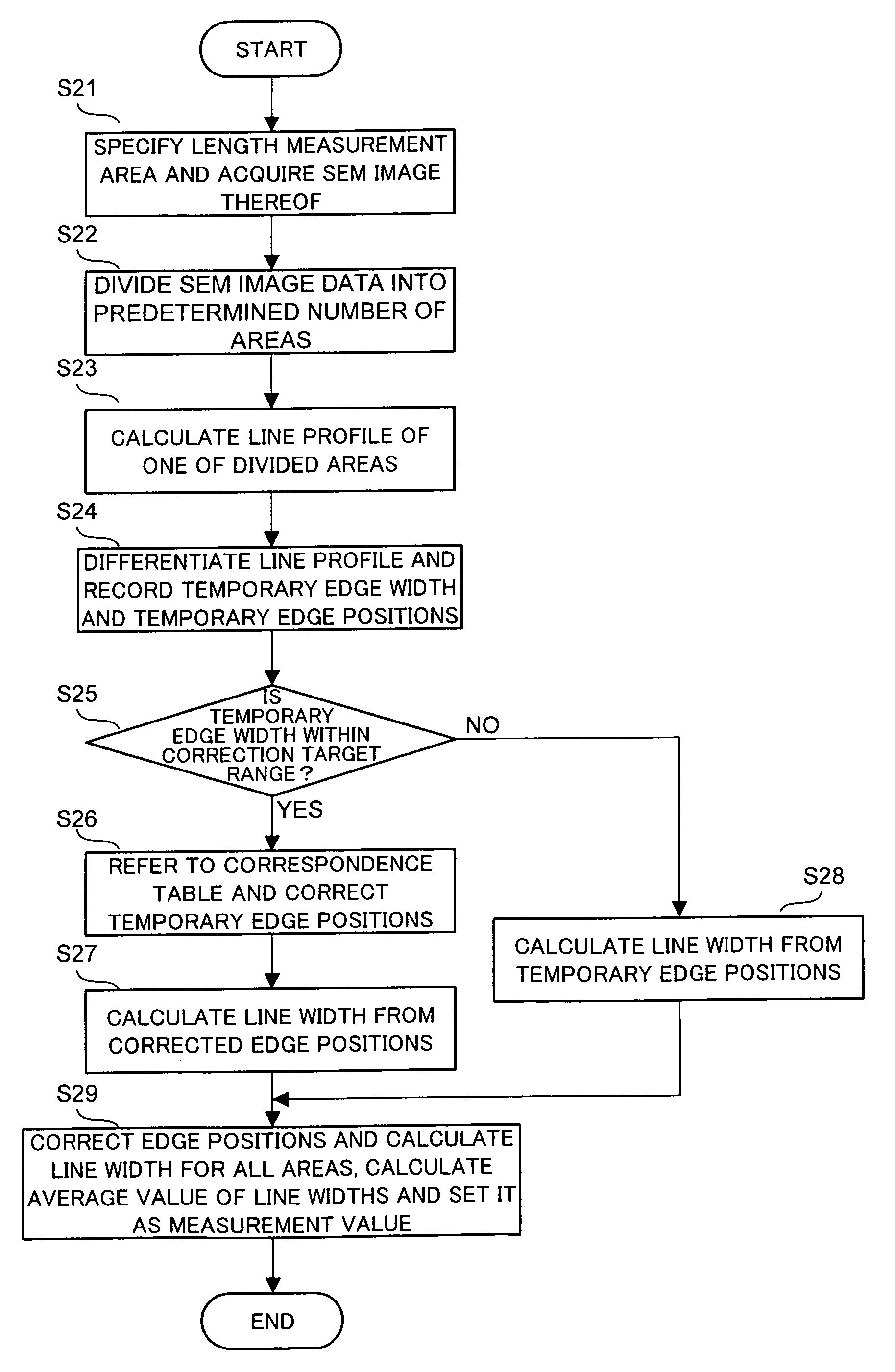

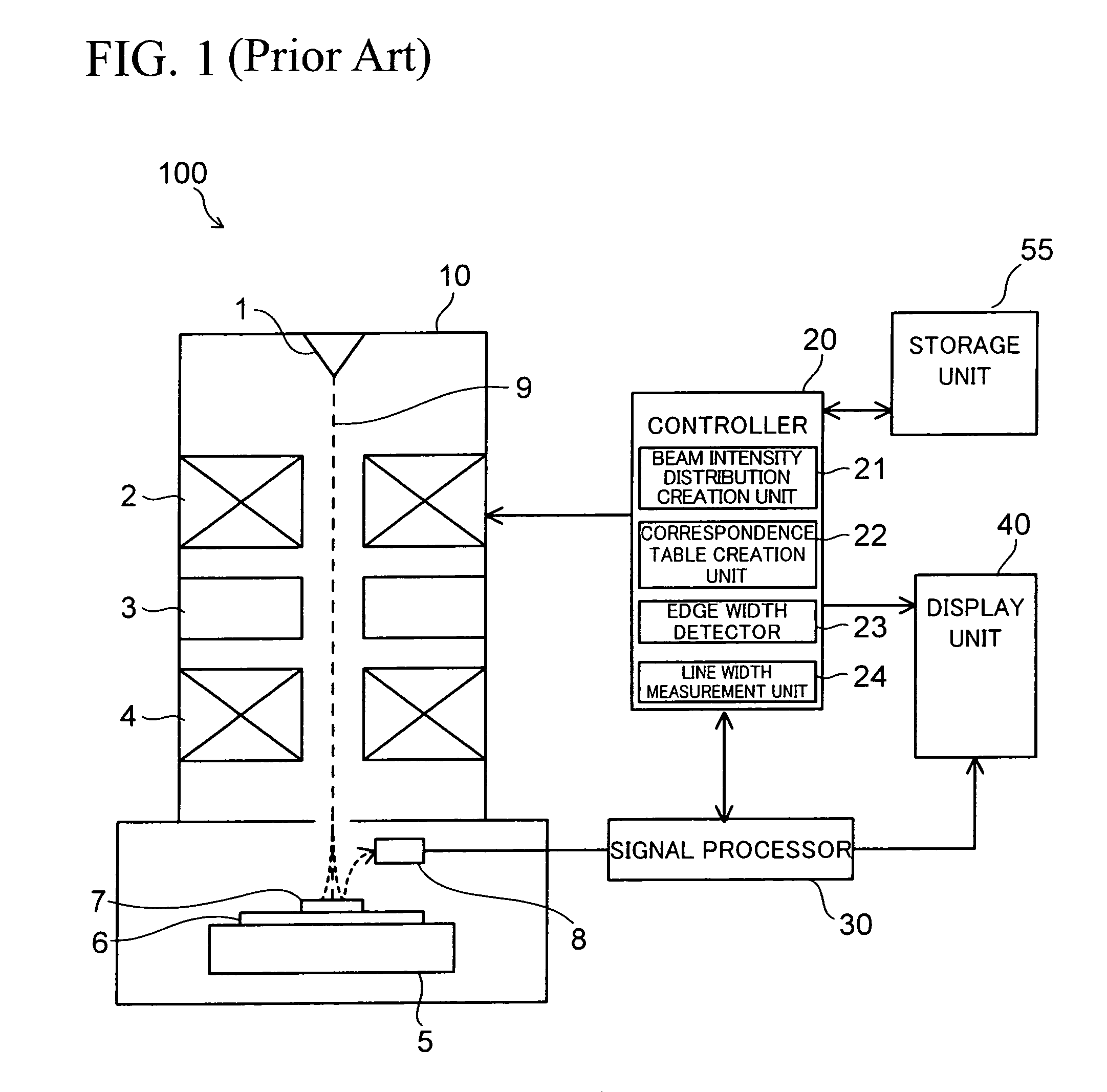

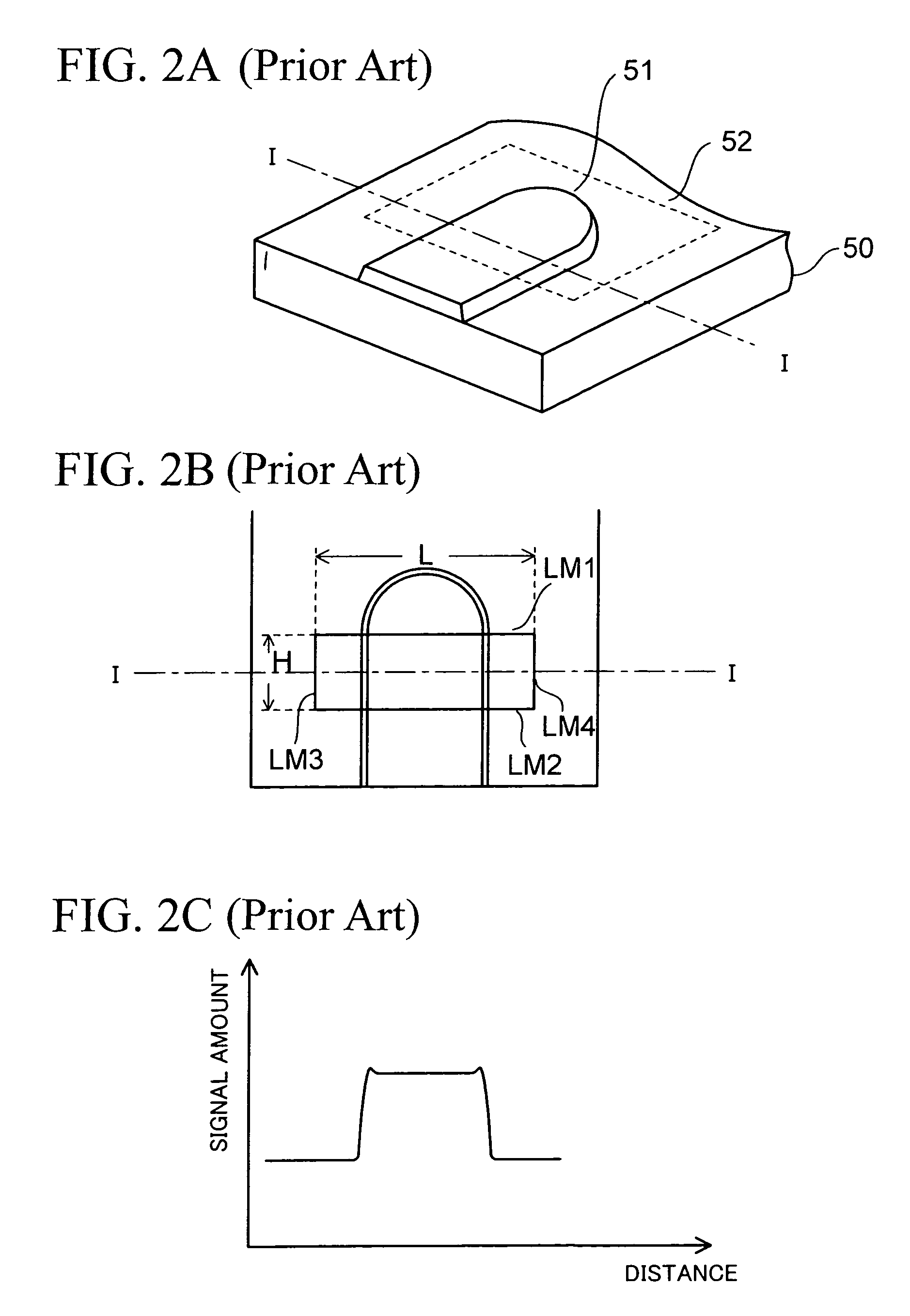

ActiveUS20110233400A1Accurate pattern lengthAccurate length measurementMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementLight beamReference patterns

A pattern measurement apparatus includes a beam intensity distribution creation unit to scan a charged particle beam over a reference pattern having edge portions formed at a right angle to create a line profile of the reference pattern and thus create a reference-beam intensity distribution, an edge width detection unit to determine line profiles for pattern models including edges formed at various inclination angles by use of the reference-beam intensity distribution and calculate edge widths reflecting an influence of a width of a reference beam, and a correspondence table creation unit to calculate correction values for edge positions from the calculated edge widths and the pattern models and create a correspondence table in which the edge widths and the correction values are associated with one another.

Owner:ADVANTEST CORP

Pattern measurement apparatus and pattern measurement method

ActiveUS8330104B2Accurate length measurementMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementReference patternsCharged particle beam

A pattern measurement apparatus includes a beam intensity distribution creation unit to scan a charged particle beam over a reference pattern having edge portions formed at a right angle to create a line profile of the reference pattern and thus create a reference-beam intensity distribution, an edge width detection unit to determine line profiles for pattern models including edges formed at various inclination angles by use of the reference-beam intensity distribution and calculate edge widths reflecting an influence of a width of a reference beam, and a correspondence table creation unit to calculate correction values for edge positions from the calculated edge widths and the pattern models and create a correspondence table in which the edge widths and the correction values are associated with one another.

Owner:ADVANTEST CORP

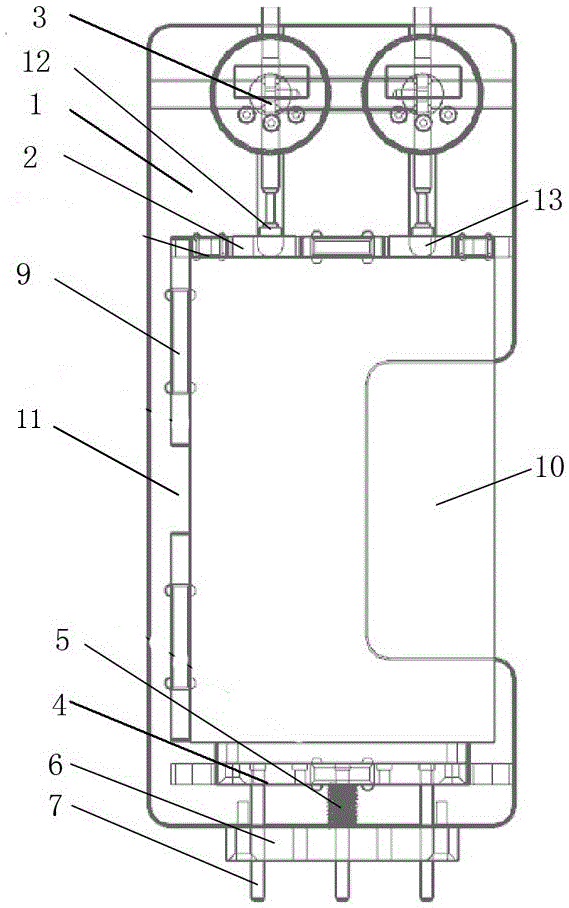

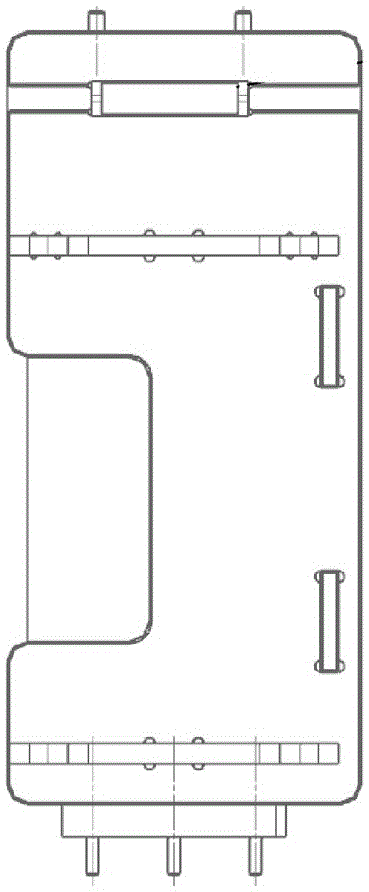

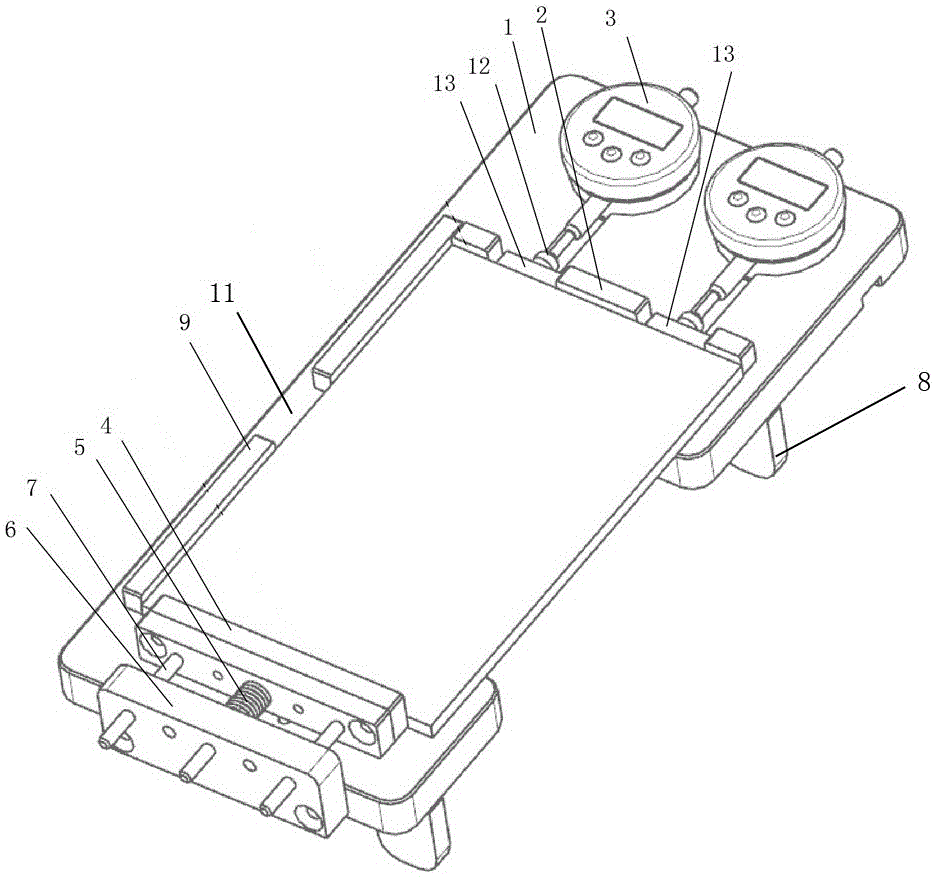

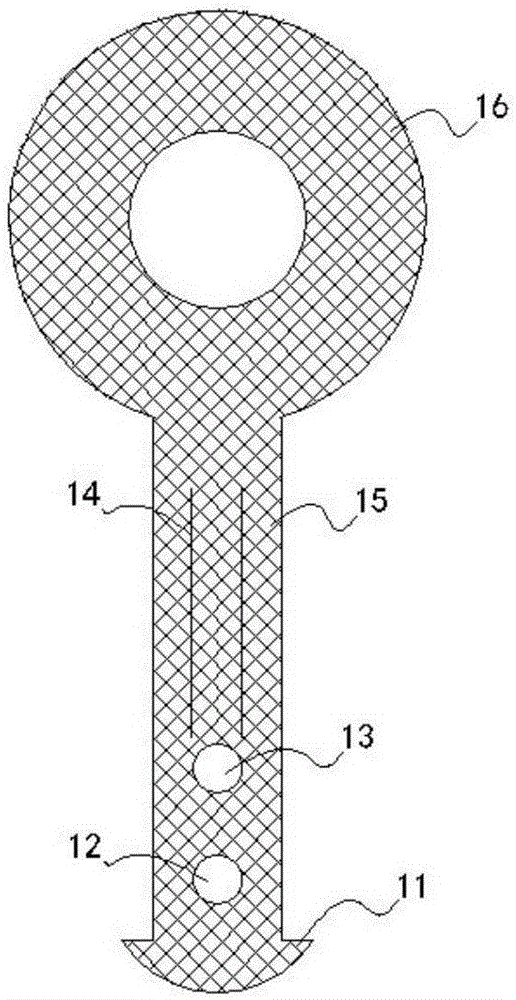

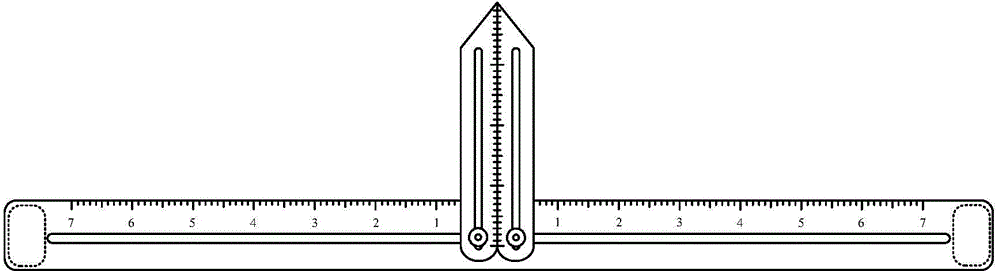

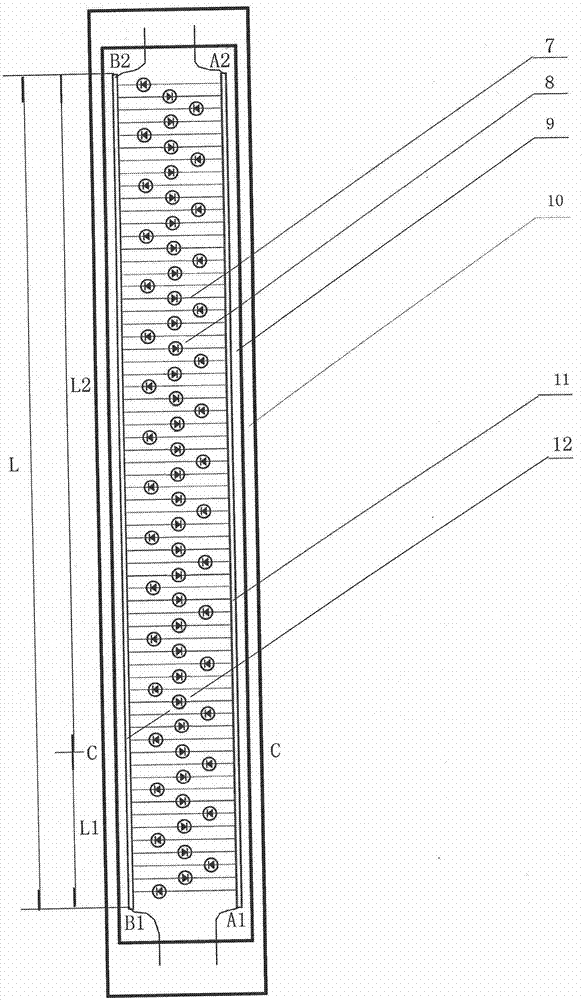

Lithium battery tab length verifying device

ActiveCN105004300AKeep the position fixedAccurate length measurementMechanical measuring arrangementsEngineeringFixed position

The present invention relates to a lithium battery tab length verifying device. The lithium battery tab length verifying device comprises a pedestal on which a first limiting boss used for limiting the displacement of one end of a lithium battery possessing a tab is arranged, an avoiding port used for avoiding a lithium battery tab is arranged on the first limiting boss, and a second limiting boss used for limiting the displacement of one end of the lithium battery not having the tab and a measuring tool used for measuring the length of the tab are also arranged on the pedestal. According to the lithium battery tab length verifying device of the present invention, the lithium battery is placed between the first limiting boss and the second limiting boss, thereby guaranteeing the fixed position of the lithium battery. The tab of the lithium battery is placed in the avoiding port, the length of the tab can be measured accurately by the measuring tool, and the data is provided for the subsequent analysis.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

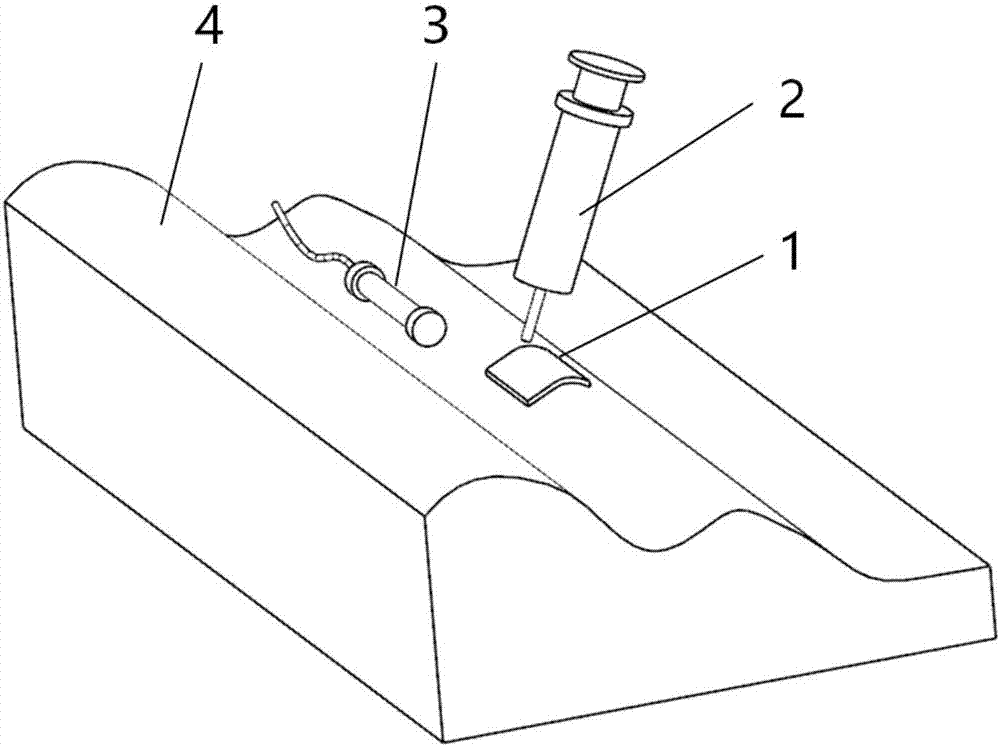

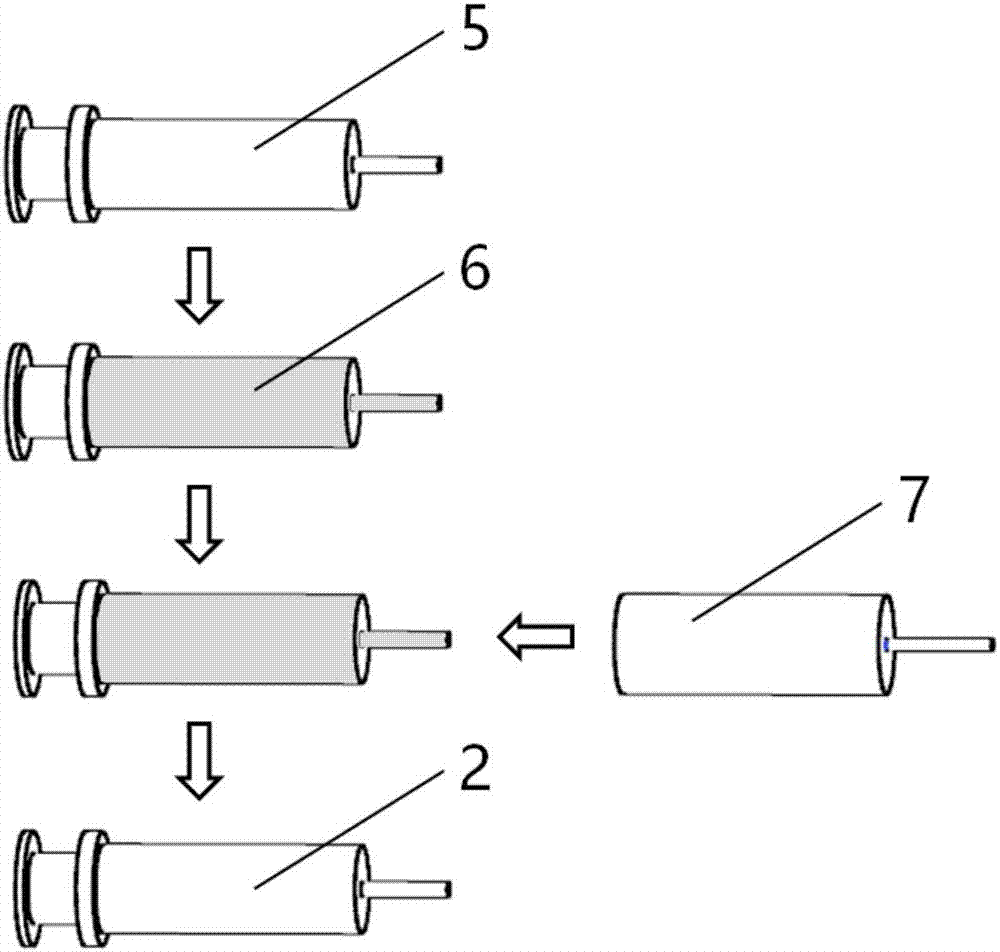

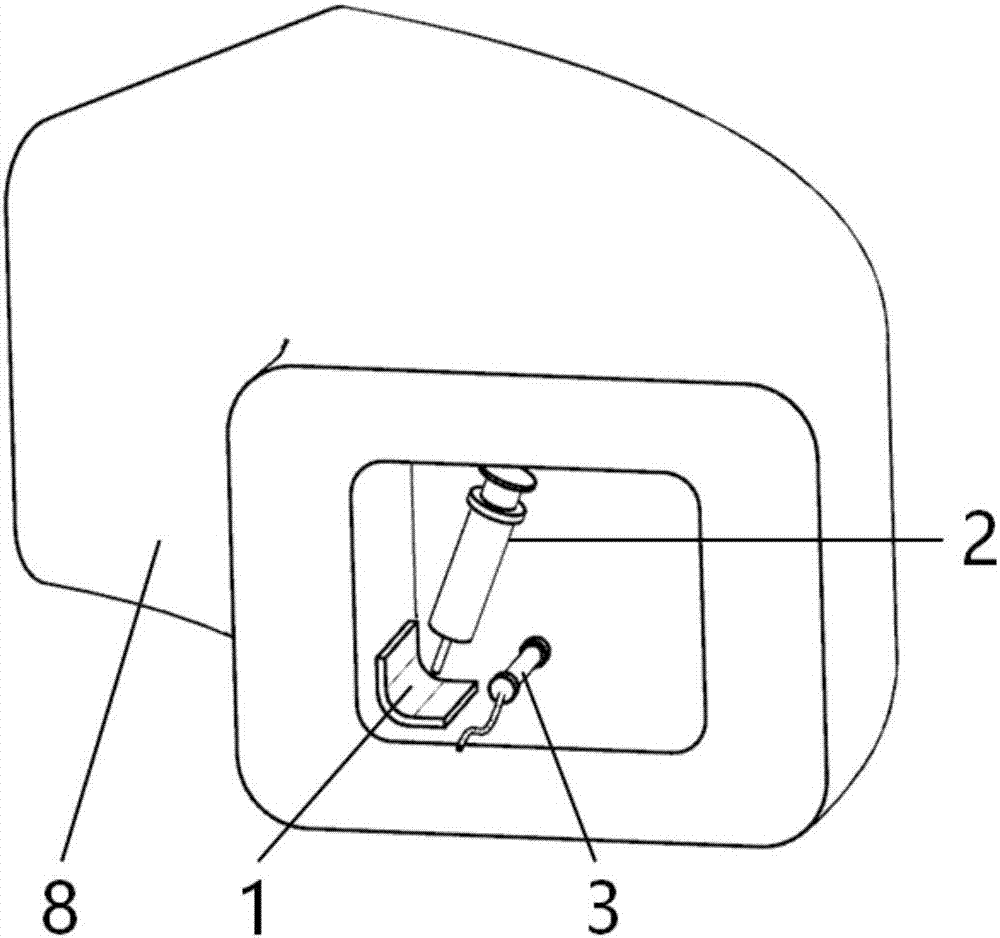

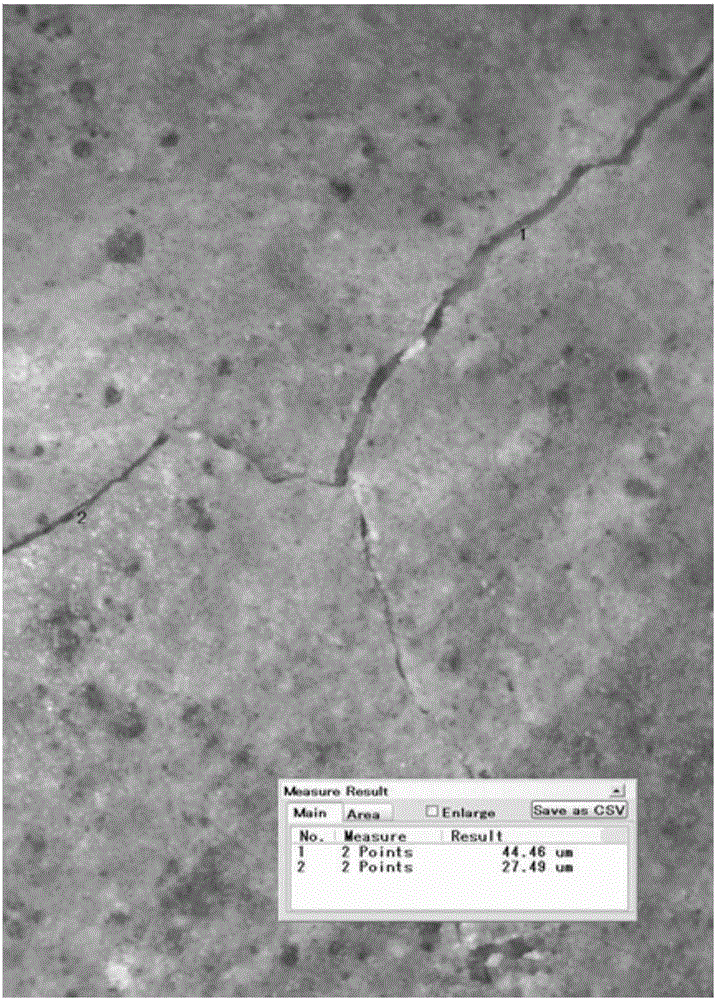

Photosensitive resin-based surface crack detecting method for complex structure

InactiveCN107219109AHigh precisionEasy to operatePreparing sample for investigationOptically investigating flaws/contaminationLiquid stateUltraviolet lights

The invention provides a photosensitive resin-based surface crack detecting method for a complex structure. The photosensitive resin-based surface crack detecting method is characterized in that a for the complex structure with surface cracks, a light-shading injector is utilized for spraying liquid-state photosensitive resin to the positions of the surface cracks; when spraying is performed, a hand-held type ultraviolet light source is used for irradiating the photosensitive resin, and the liquid-state photosensitive resin is gradually cured into solid; surface crack length, surface crack shape and the like of the complex structure are copied; the cured photosensitive resin is stripped off from the surface of the structure, is put under an optical microscope or a scanning electron microscope to precisely measure the crack length and observe the crack shape, so that a safety state of the structure is accessed. The surface crack detecting method is simple to operate, can be used for precisely and quickly detecting cracks on the surfaces of complex structures such as a gas turbine engine blade, a pressure container, a car housing and a building, and solves the problems that detection is not liable to perform on the production and working sites or detection cannot be performed on the production and working sites.

Owner:BEIHANG UNIV

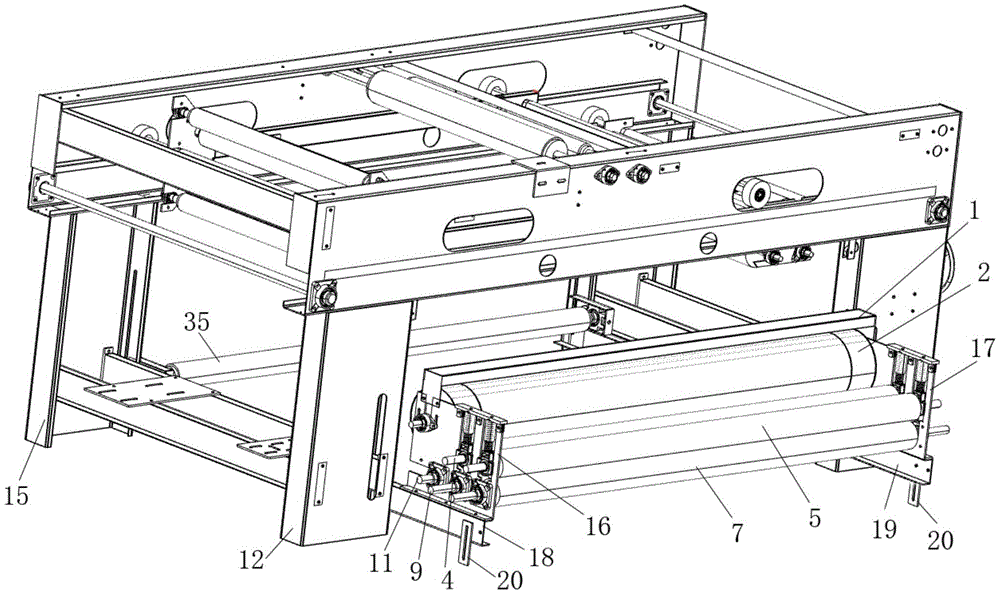

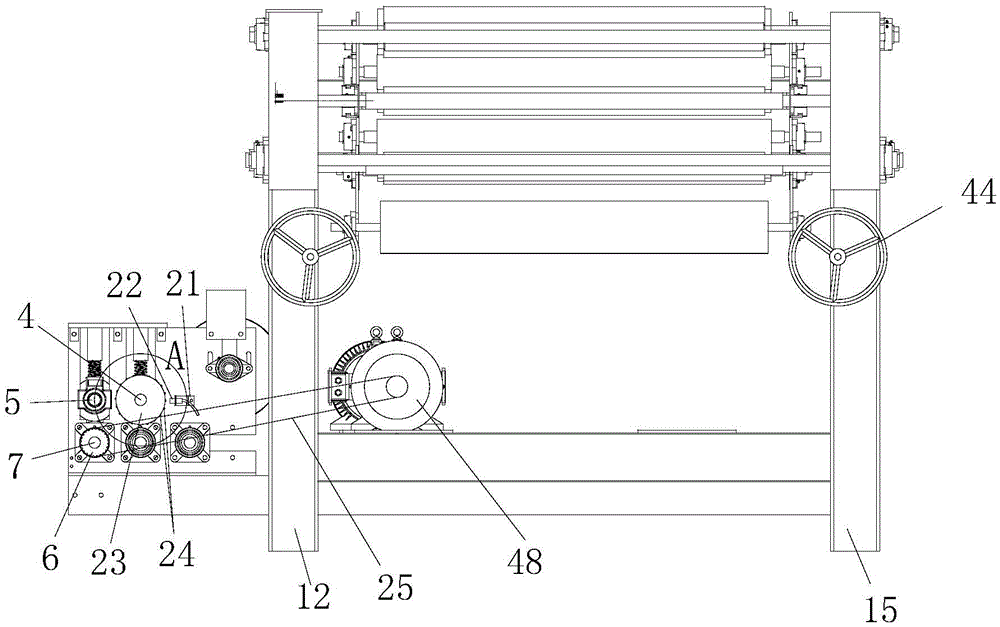

Lapping machine

ActiveCN105463706AAccurate length measurementImprove efficiencyNon-woven fabricsEngineeringMetal detectors

The invention discloses a lapping machine which comprises a rack. A lapping mechanism is arranged over the rack, a web forming curtain, a web forming curtain front transmission roll and a web forming curtain back transmission roll are arranged below the rack, the web forming curtain is wound on the web forming curtain front transmission roll and the web forming curtain back transmission roll, and a cotton web breaking mechanism and a cotton web length measuring mechanism are arranged in front of the rack; the cotton web breaking mechanism comprises a cotton web breaking support, the cotton web breaking support comprises a left breaking support body and a right breaking support body, and an upper conveying roll, a lower conveying roll, an upper speed-up roll and a lower speed-up roll are arranged between the left breaking support body and the right breaking support body; the cotton web length measuring mechanism comprises a length measuring disc and a metal detector, the length measuring disc is arranged at the roll shaft end of the upper conveying roll or the lower conveying roll in a sleeving mode, a plurality of metal convex points are evenly and circumferentially distributed on the length measuring disc, and the metal detector directly faces the length measuring disc. The lapping machine can break a cotton web according to the cotton web length detected by the metal detector and is high in automation degree.

Owner:青岛鑫鸿圣智能科技有限公司

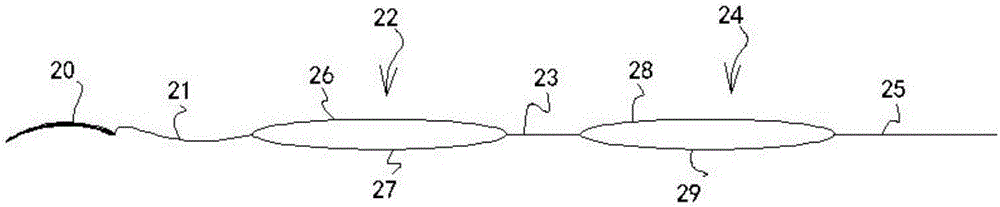

Medical material for treating uterine prolapse

The invention discloses a medical material for treating uterine prolapse. The medical material is characterized in that an anchor net is arranged to be a strip-like sheet, wherein clamping fins raised and extending from the two side edges are arranged at the bottom of the anchor net; cutting separation lines are arranged on an upper section of the anchor net on a body of the anchor net; when the anchor net is transversely sheared at the upper ends of the cutting separation lines, the anchor net at the positions of the cutting separation lines on a lower section can be separated into net pieces; a lead fixing hole and a bottom fixing hole are formed at an interval along the length direction of the anchor net in the lower section of the anchor net; the line end of a suspending line can sequentially penetrate through the bottom fixing hole and the lead fixing hole and form a contracted and fixed net knot around the lead fixing hole surrounding the anchor net. According to the medical material, the anchor net can be ensured to be accurately placed, the net pieces are conformally and loosely rooted to the abdominal wall to ensure and improve the anchor effect of the anchor net in the abdominal wall, and the middle part of the suspending line is accurate in positioning.

Owner:凌安东

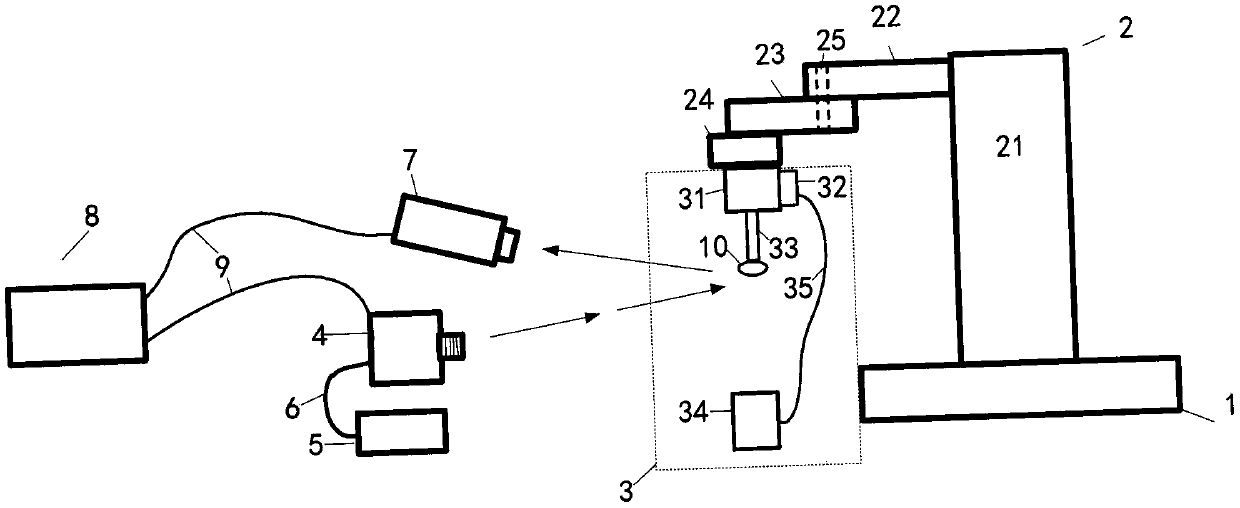

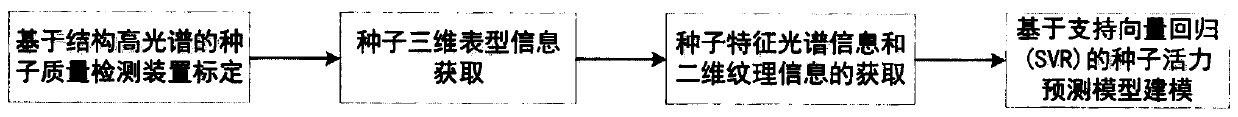

Seed quality detection method and device based on structure hyperspectrum

PendingCN111579511AAccurate length measurementAccurately measure widthImage enhancementImage analysisComputer scienceStructure based

The invention provides a seed quality detection method and device based on structure hyperspectrum. The device is composed of a mechanical arm base, a mechanical arm, a vacuum seed suction module, a structured light projection module, a white light source, an optical fiber, a hyperspectral camera, a computer, a signal line and seeds. The seed quality detection method based on structure hyperspectrum comprises the following steps: calibrating a seed quality detection device based on structure hyperspectrum, acquiring seed three-dimensional phenotypic information, acquiring seed characteristic spectrum information and two-dimensional texture information, and modeling a seed vigor prediction model based on support vector regression (SVR). A structured light three-dimensional imaging technology is adopted, three-dimensional size information such as the length, the width and the volume of the seeds can be accurately measured, hyperspectral information of the seeds at different depths can bedetected through a structured light modulation technology, the information dimension is expanded, and the detection precision of the seed vigor index is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

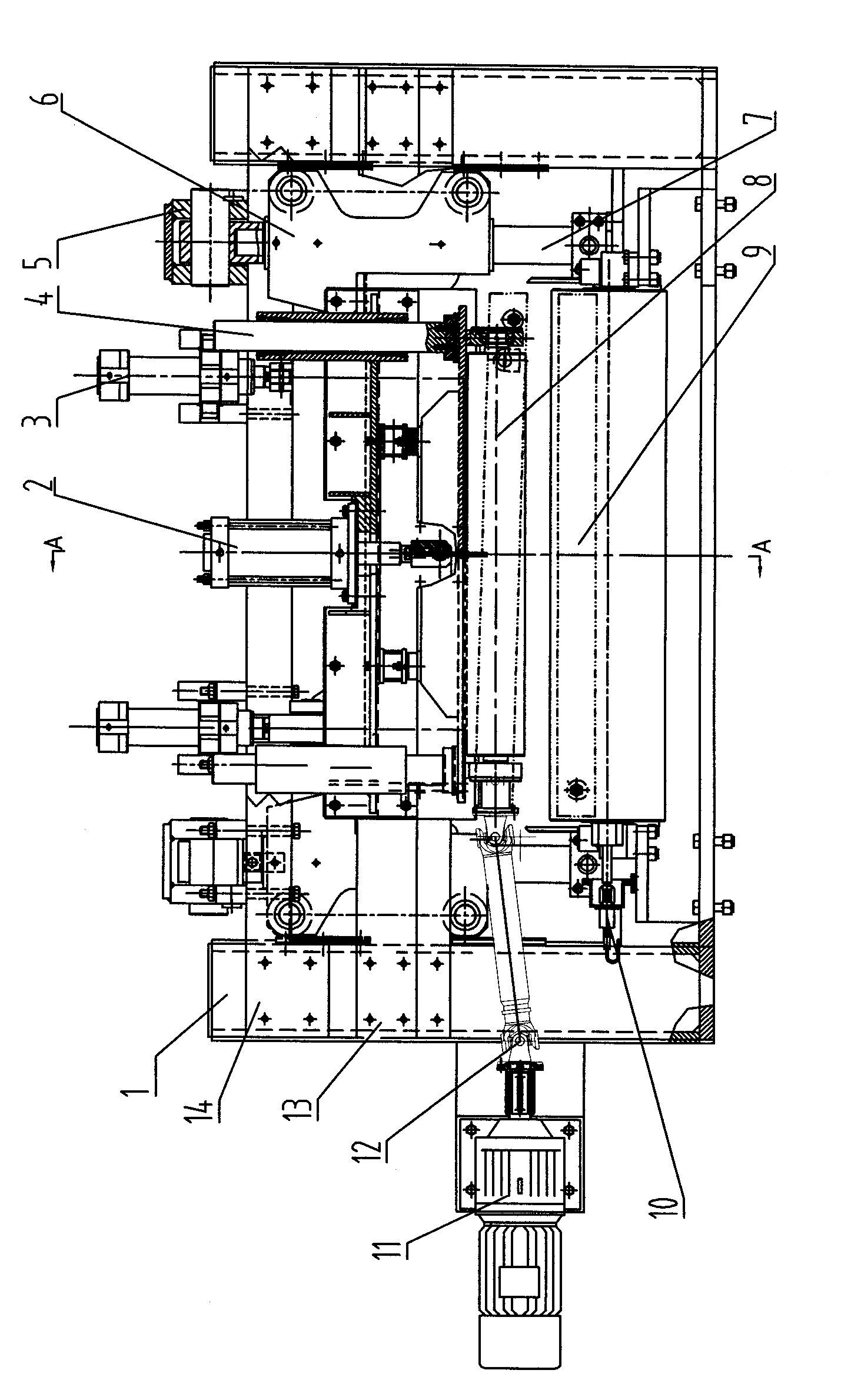

Dragging length-measuring thin plate hydraulic cutter

InactiveCN102366843AReduce gapSmall spaceMeasurement/indication equipmentsShearing machinesHinge angleEngineering

The invention discloses a dragging length-measuring thin plate hydraulic cutter. An upper cross beam is fixed on an open door frame, a hinge seat is arranged on the upper cross beam, the upper end of a guide post is hinged with the hinge seat, the lower end of the guide post is respectively connected on a baseframe, symmetric guide frames are fixedly connected on the two sides of an upper cutting blade, guide sleeves arranged on the guide frames are in movable fit with the guide post, idler wheels of the guide frames are matched with a lining plate of the open door frame, a suspension beam is fixedly connected onto the open door frame, a cylinder and the guide sleeves in fit with the guide post are all fixed on the suspension beam, the end part of a piston rod of the cylinder and the lower end of the guide post are connected with a movable base plate, a rubber roller is mounted on the back surface of the movable base plate, a motor drives the rubber roller to rotate, a built-in bearing and an encoder connecting rod structure are arranged, and a free roller matched with the rubber roller is arranged on the baseframe. The dragging length-measuring thin plate hydraulic cutter disclosed by the invention has multiple using functions and has the advantages of flattening strip steel, centring, dragging and auxiliary strip penetrating, cutting head, tail and middle part of the strip steel, cutting and shunt winding, accurately measuring length and speed of the rolled strip steel and the like, improving strip penetrating speed and cutting speed, ensuring production safety and improving production efficiency.

Owner:XINJIANG BAYI IRON & STEEL

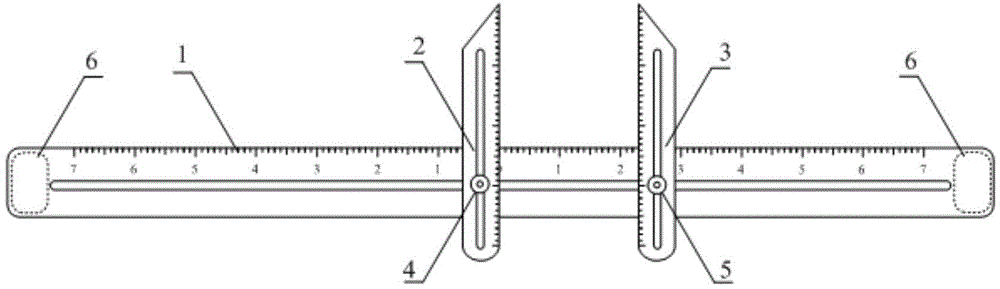

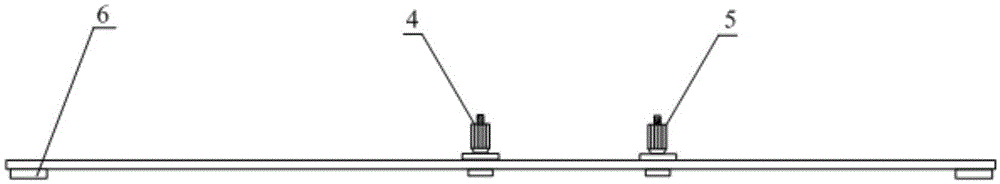

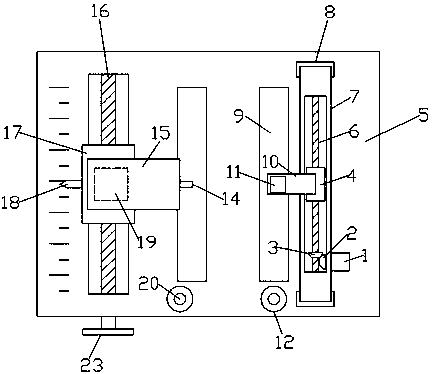

Ultrasonic flaw detection and defect positioning and measuring apparatus and use method thereof

ActiveCN105277613APrecise positioningAccurate length measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesLength measurementUltrasound

The invention relates to the technical field of nondestructive flaw detection, and concretely relates to an ultrasonic flaw detection and defect positioning and measuring apparatus and a use method thereof. The apparatus is used for onsite ultrasonic nondestructive flaw detection, auxiliary positioning of a hiding defect and measurement of the length of the defect, and the apparatus used to position and measure the length allows positioning and length measurement to be visually and accurately carried out, and is simple to operate.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER

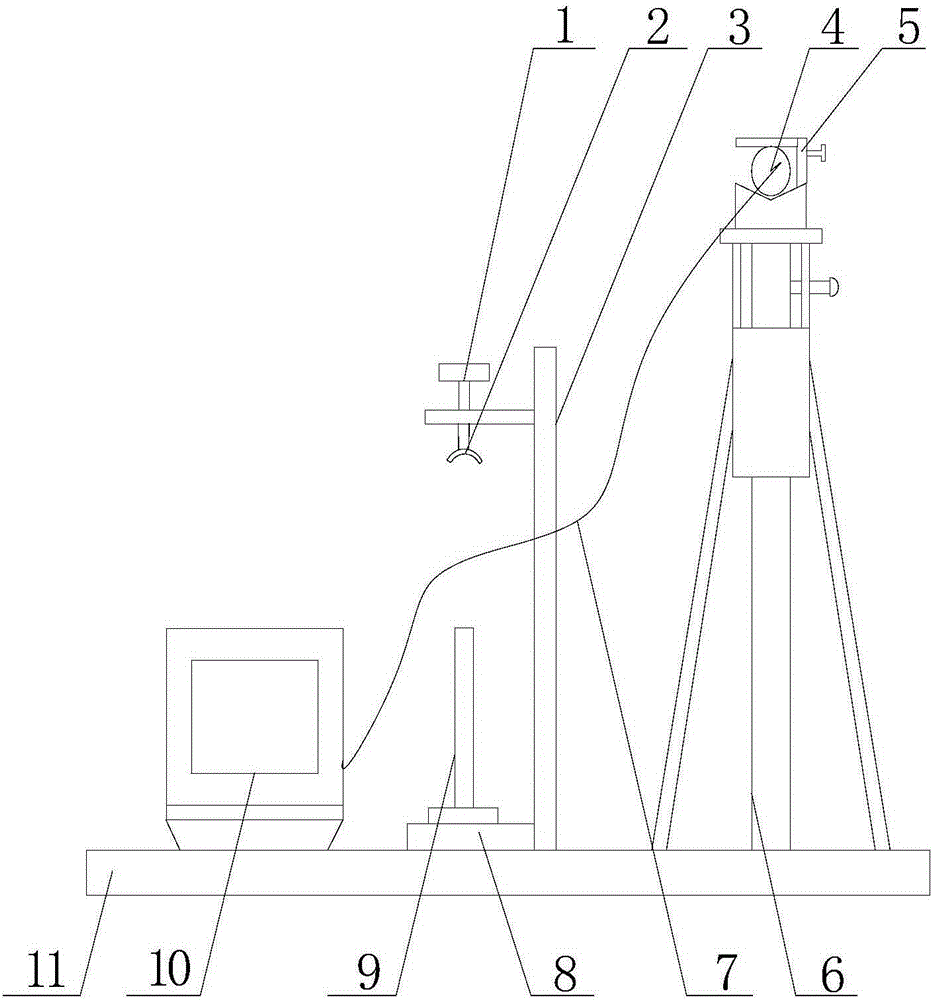

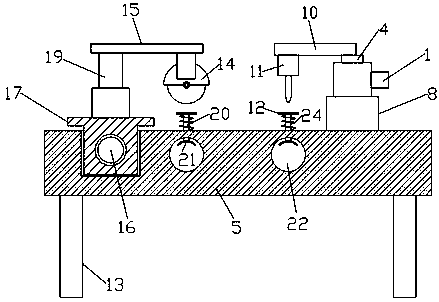

Microscopic dynamic monitoring device and repairing method for ceramic historical relic painting layer micron-scale crack

ActiveCN105199495AHigh fine resolutionPrecise positioningOptically investigating flaws/contaminationEpoxy resin coatingsMicron scaleDynamic monitoring

The invention discloses a microscopic dynamic monitoring device and a repairing method for a ceramic historical relic painting layer micron-scale crack. The device is formed by connecting a work bench, an ultra depth-of-field microscope, a repairing table, a tripod, a rotating shaft, an adjusting frame screw and a lens. When the ceramic historical relic painting layer micron-scale crack is repaired by the device, a cultural relic is arranged on the rotating shaft; a lens of the ultra depth-of-field microscope is adjusted to amplify a historical relic painting layer; the micron-scale crack is positioned through an image processor; the lens is adjusted by rotating the tripod, so that the image processor clearly displays the crack and then fixes the cultural relic; the crack is repaired with a reattachment repairing agent; and the whole repairing process is recorded and taken. According to the microscopic dynamic monitoring device disclosed by the invention, the painting layer micron-scale crack can be accurately positioned; the crack size can be accurately measured; multi-angle and multi-azimuth observation is achieved; an image and a video in the repairing process can be collected in real time; data and image collection is visual and accurate; and the repaired crack is completely closed and fitted.

Owner:SHAANXI NORMAL UNIV

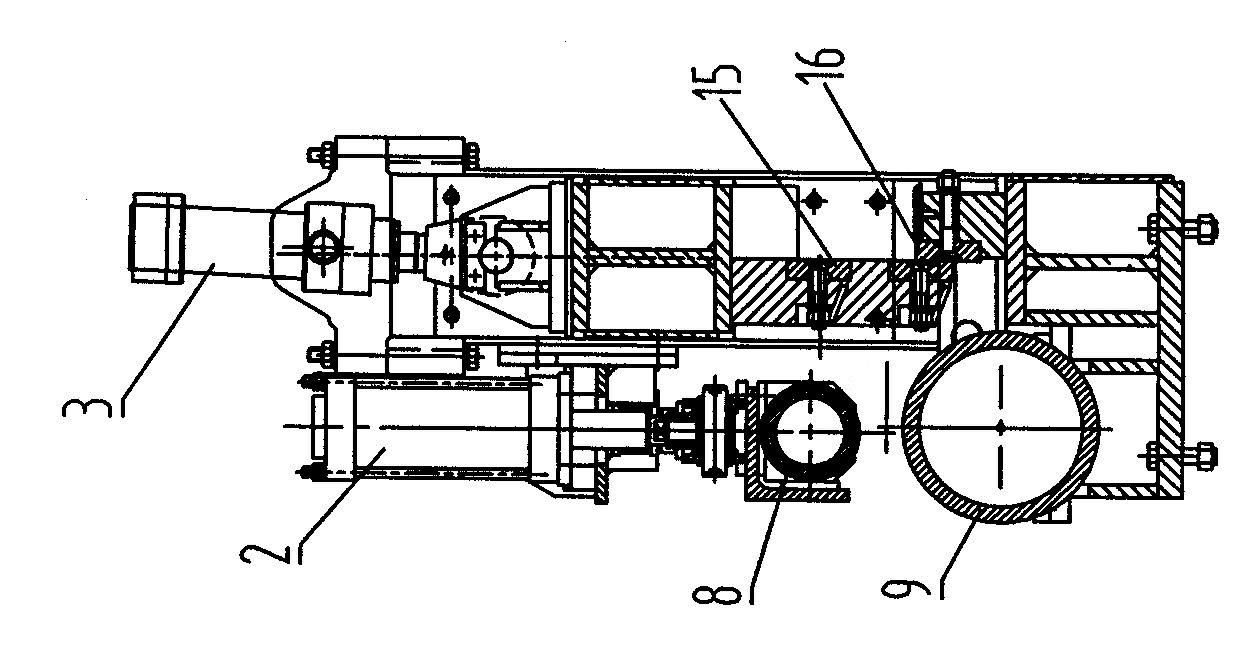

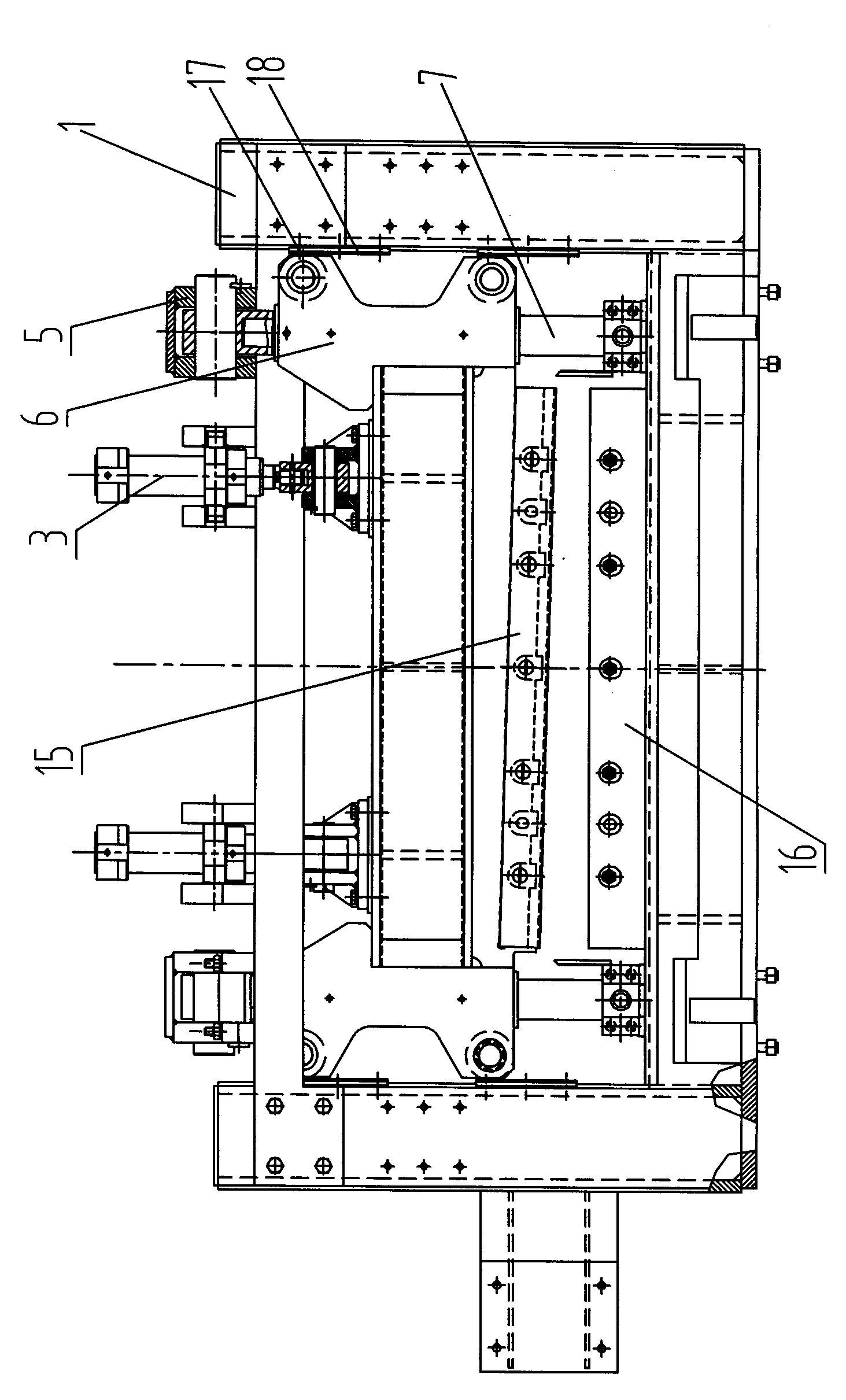

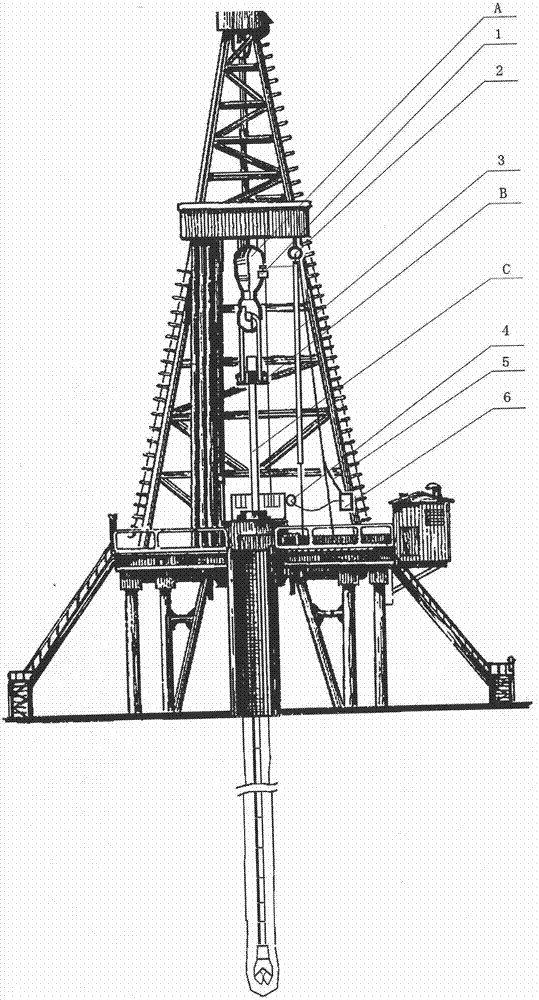

Petroleum tripping pipe column work automatic measurement system

InactiveCN107201895AAccurate length measurementOvercoming Manual MeasurementsSurveyQuality assuranceLength measurement

The invention relates to an automatic measurement system for oil pipe string operation, which is composed of a rotating laser, a pulley, a photosensitive scale detector, a suspension weight sensor, electric power and signal cables, and a reading display instrument, which solves the troublesome oil pipe string operation The problem of string length measurement for many years has overcome the disadvantages of manual measurement, low precision, cumbersome and error-prone, the instrument is easy to install and use, with less manual intervention during use and a high degree of automation. Accurate string length measurement is the follow-up Drilling and oil production operations provide technical quality assurance.

Owner:张洪新

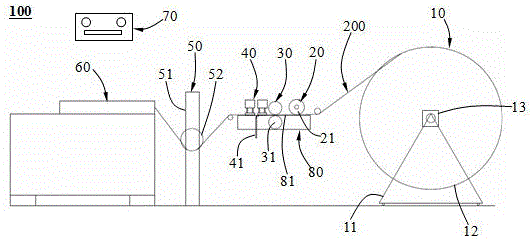

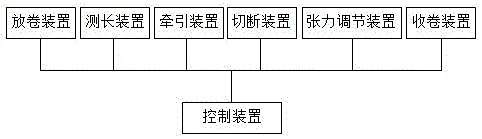

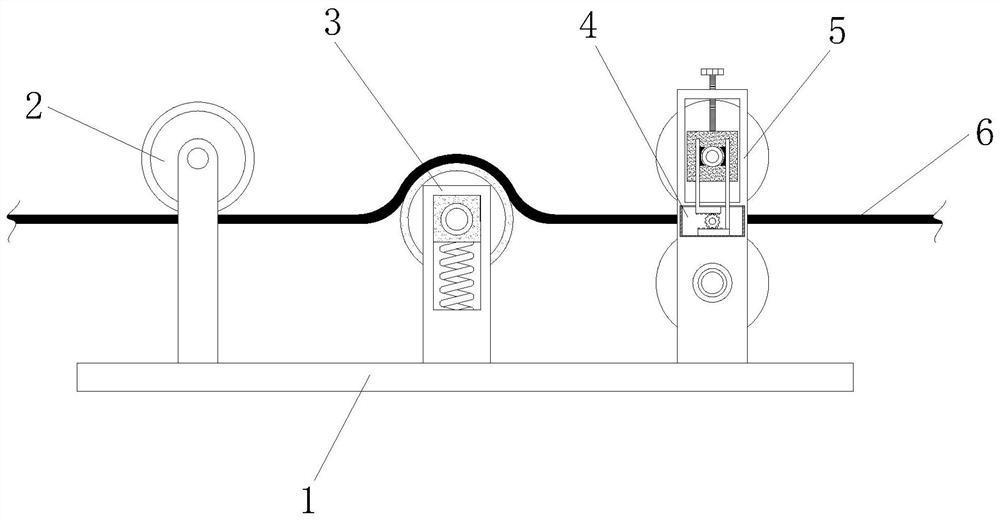

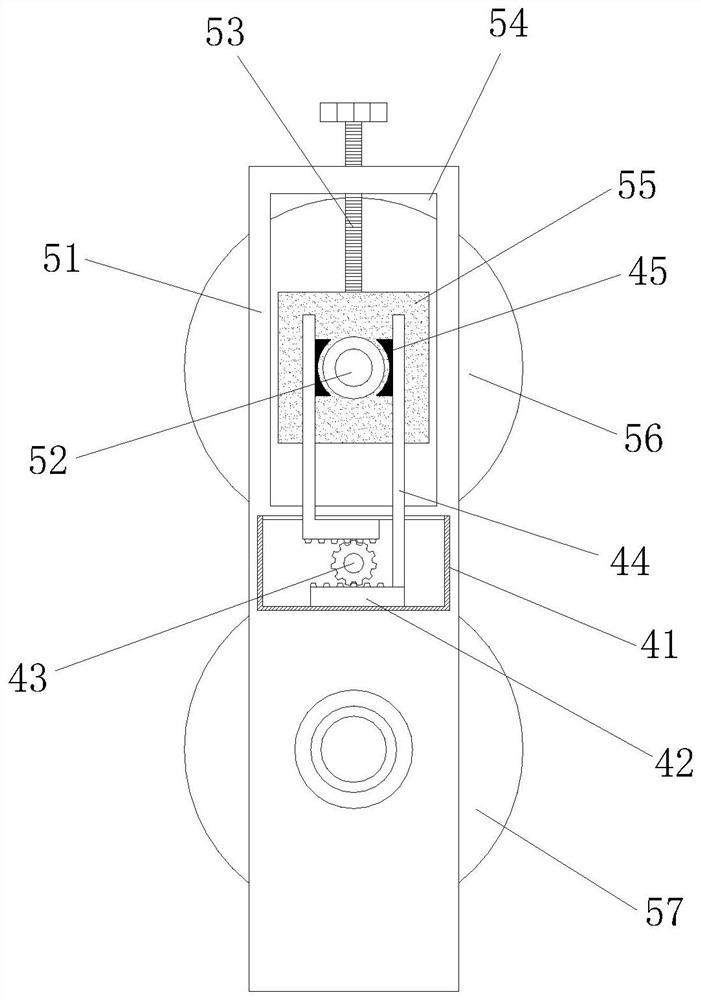

Fixed-length cutting facility for flat steel strip of elevator

ActiveCN106624141AAccurate length measurementIncrease the level of automationMetal sawing devicesMeasurement/indication equipmentsEngineeringSteel belt

The invention provides a fixed-length cutting facility for a flat steel strip of an elevator. The fixed-length cutting facility for the flat steel strip of the elevator comprises an unwinding device, a length measuring device, a traction device, a cutting device, a tension adjusting device, a winding device and a control device, wherein the control device is connected with the unwinding device, the length measuring device, the traction device, the cutting device, the tension adjusting device and the winding device. The length measuring device calculates the length of the conveyed steel strip according to the rotating cycle number of a rolling wheel. The traction device is used for driving the flat steel strip to be conveyed backwards. The cutting device comprises a disk cutting saw blade and a steel blade, wherein the disk cutting saw blade and the steel blade are arranged in an adjacent mode. The preset length is set in the control device, and when the length of the conveyed steel strip is equal to the preset length, the cutting device is started. Compared with the prior art, the fixed-length cutting facility for the flat steel strip of the elevator has the advantages that the length of the steel strip can be accurately measured by the length measuring device, the level of automation of the production process is improved, and the problems caused by manual measurement of the length are solved.

Owner:依合斯电梯配件(上海)有限公司

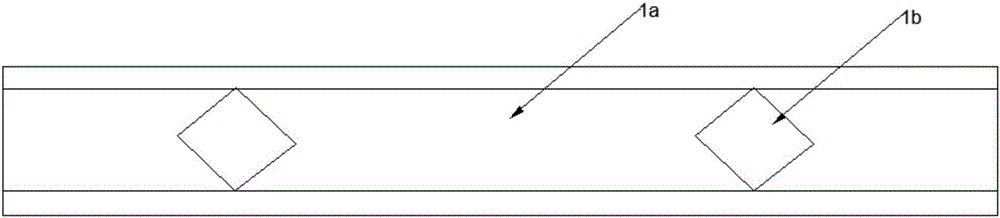

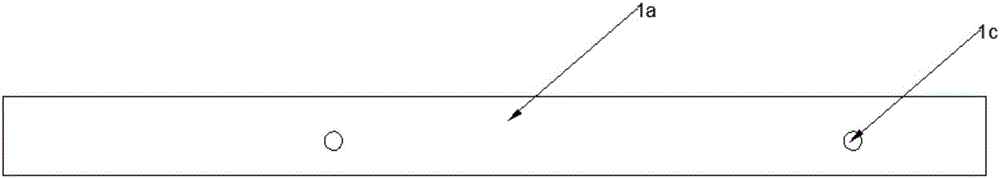

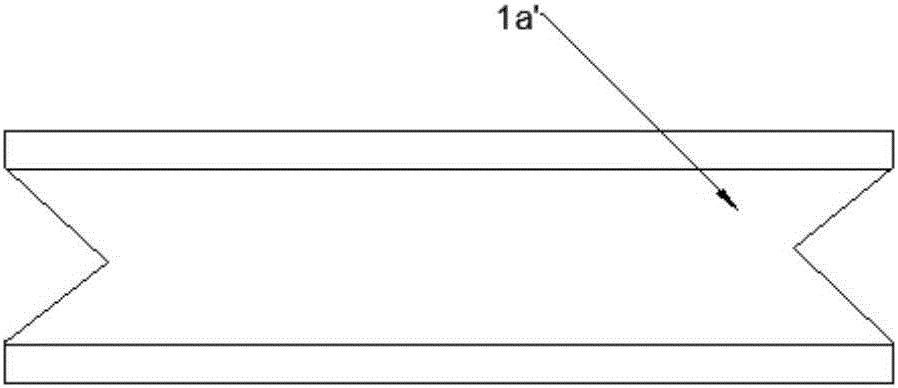

High-precision cut-out device and high-precision punching cut-out equipment thereof

InactiveCN106391825AGuaranteed accuracyLow costMetal-working feeding devicesMetal working apparatusPunchingElectrical and Electronics engineering

The invention relates to a high-precision cut-out device. The high-precision cut-out device comprises a length detection mechanism, a cut-out positioning mechanism and a cut-out mechanism. The length detection mechanism is arranged on one side of a to-be-conveyed panel strip and used for detecting the length of the panel strip. The cut-out positioning mechanism is inserted in an auxiliary hole of the panel strip and used for positioning the panel strip. The cut-out mechanism is arranged between the length detection mechanism and the cut-out positioning mechanism and used for cutting out the panel strip after the cut-out positioning mechanism is inserted in the auxiliary hole. Compared with the prior art, after the length of the panel strip is detected through the length detection mechanism and the panel strip is positioned through the cut-out positioning mechanism, the panel strip is cut out, the cut-out precision is ensured, the cost for manually cutting out the panel strip is greatly saved, and the cut-out efficiency is improved. Meanwhile, the invention relates to high-precision punching cut-out equipment.

Owner:TAISHAN AIDA ELECTRICAL FACTORY

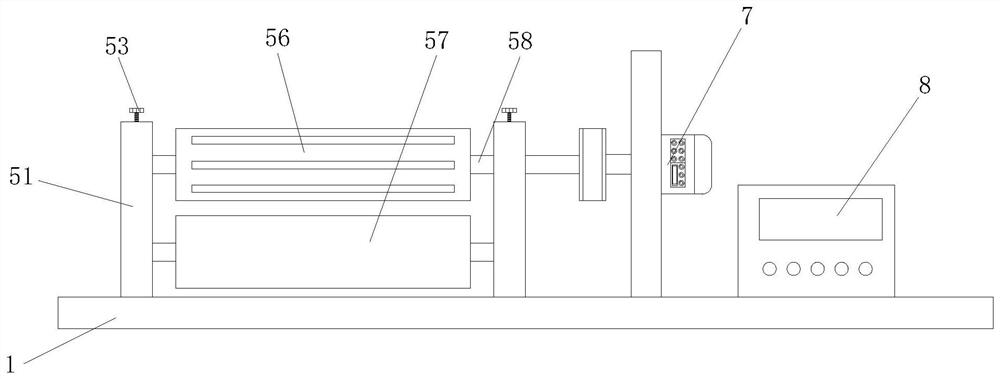

Device and method for automatically measuring quantity and length of cloth

PendingCN114353714AAccurate length measurementMeasurement devicesCounting mechanisms/objectsBrakeMicrocomputer control

According to the device for automatically measuring the number and the length of the cloth, the traction wheel, the tensioning mechanism and the measuring mechanism are sequentially arranged on the base from left to right, and the measuring mechanism comprises the first connecting frames which are oppositely arranged front and back and the first rolling roller and the second rolling roller which are rotationally installed between the first connecting frames. Cloth sequentially passes through the traction wheel, the tensioning mechanism and the measuring mechanism, the cloth enters a rolling gap between the first rolling roller and the second rolling roller, the rotating shaft drives the roller type meter counter to rotate in the rolling process, the roller type meter counter is used for recording the length of the cloth, and when the tail end of the cloth is separated from the first rolling roller, the cloth is taken out. When the monitoring plates on the first rolling roller do not make contact with the cloth any more, the first pressure sensor is used for monitoring the stress condition of the monitoring plates, when all the monitoring plates in the first rolling roller are in a non-stress state, the single-chip microcomputer controls the brake mechanism to enable the rotating shaft to stop rotating, and the roller type meter counter also stops metering; therefore, the length of the cloth is accurately measured.

Owner:SHOWMETEX KNITTING & DYEING

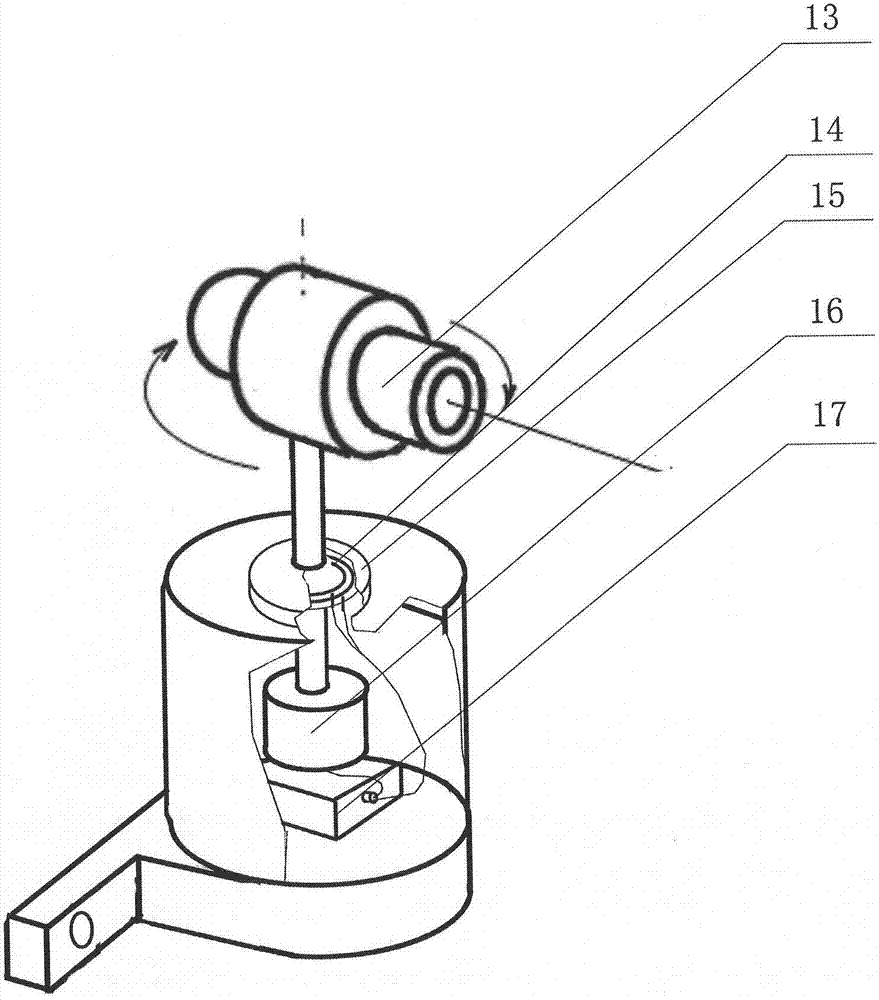

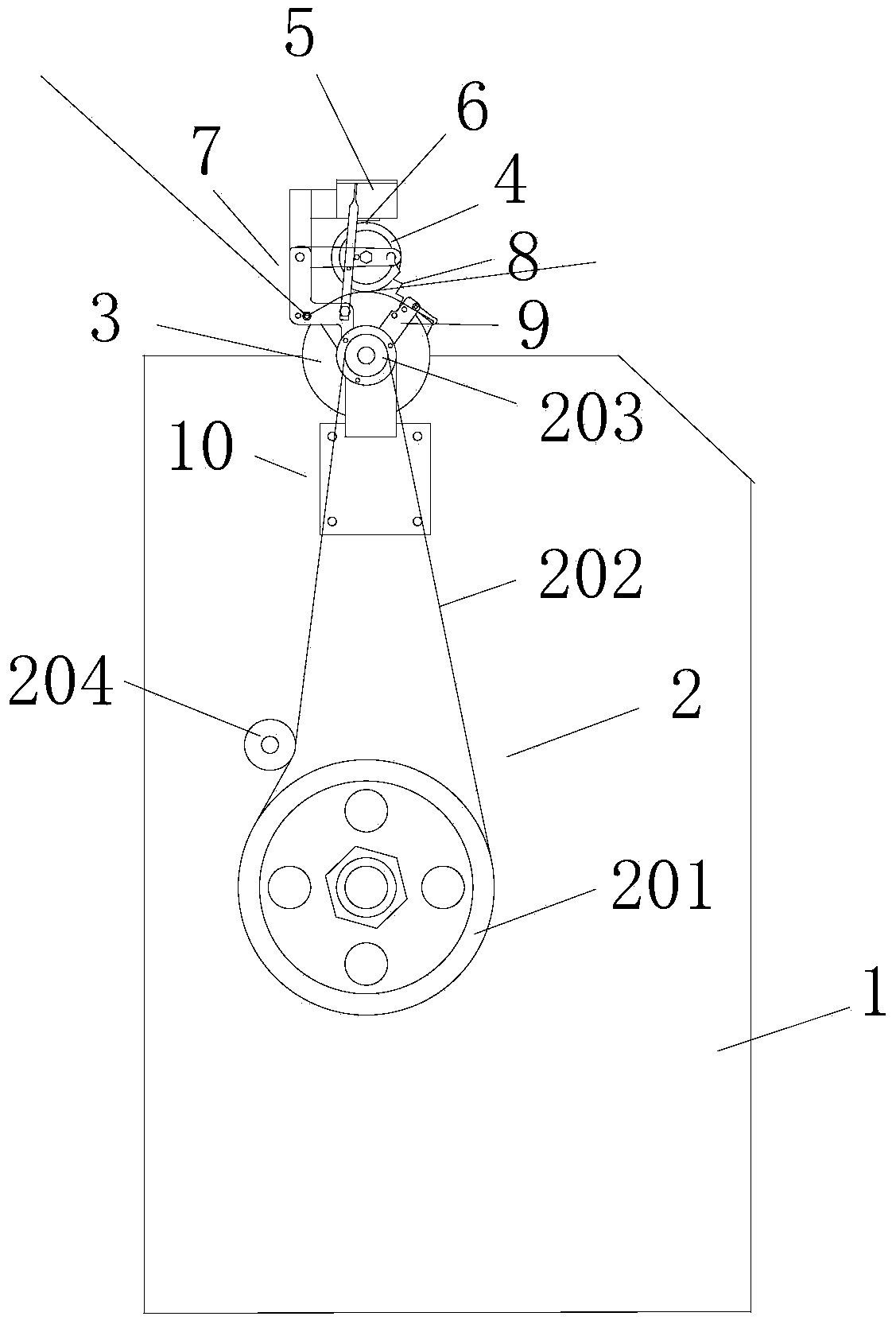

Arc length adjuster

PendingCN110788460AContinuous length adjustmentAccurate length measurementWelding accessoriesEngineeringMechanical engineering

The invention relates to the technical field of welding, in particular to an arc length adjuster. The arc length adjuster comprises a sliding mechanism, a welding gun fixing mechanism, a cooling mechanism and a signal collector. The sliding mechanism is provided with a movable sliding block guide groove matched with a fixed block guide rail. The welding gun fixing mechanism is installed on a movable sliding block. A welding gun is installed on the welding gun fixing mechanism. Electrodes, corresponding to the welding gun, of the cooling mechanism are immersed in cooling water. The signal collector is connected with a welding loop. By means of the arc length adjuster, a welding arc can be stably ignited, and meanwhile, the length of the arc can be continuously adjusted and accurately measured, data are collected through circuit control, and welding current and arc welding voltage can be collected at the same time.

Owner:HEFEI UNIV OF TECH

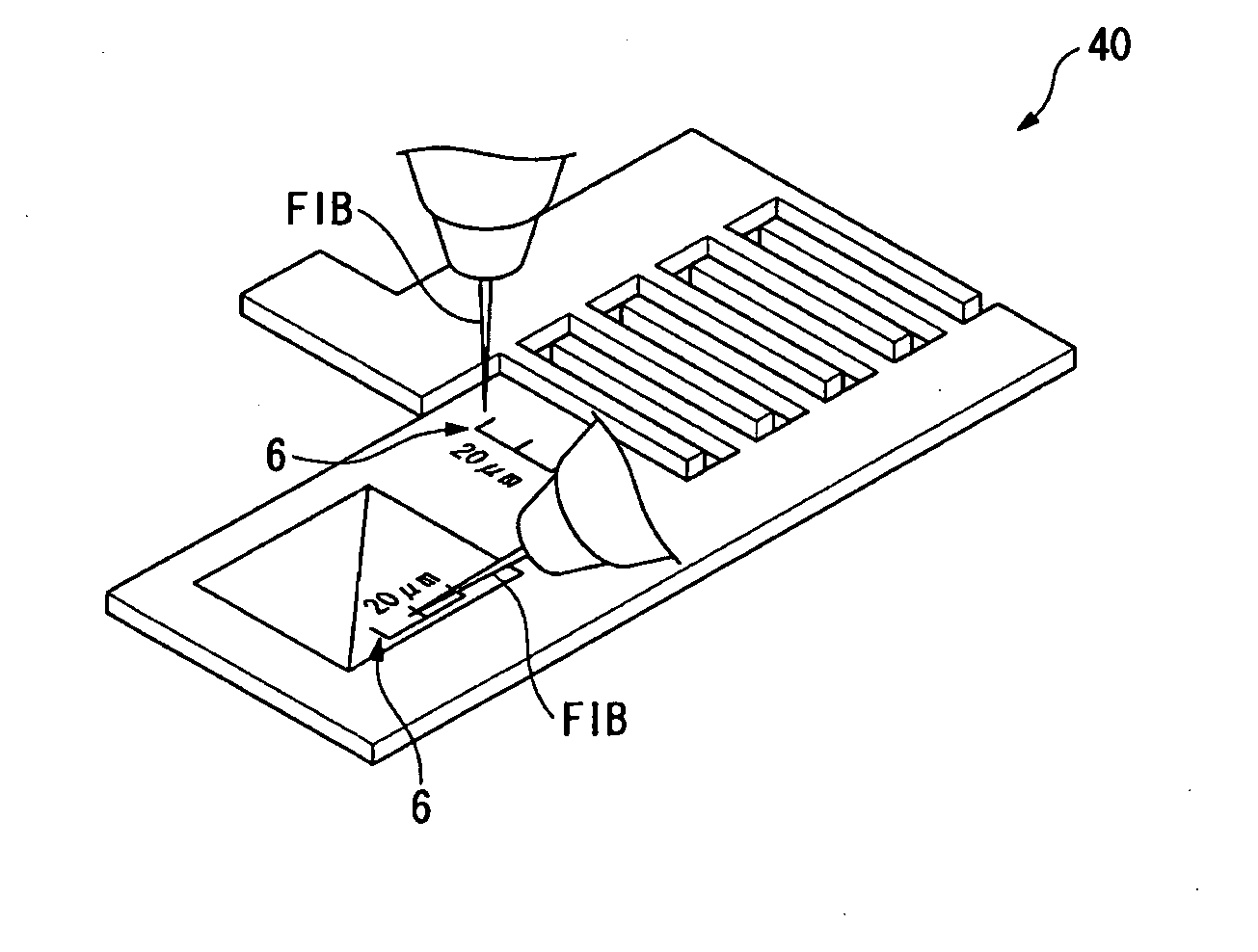

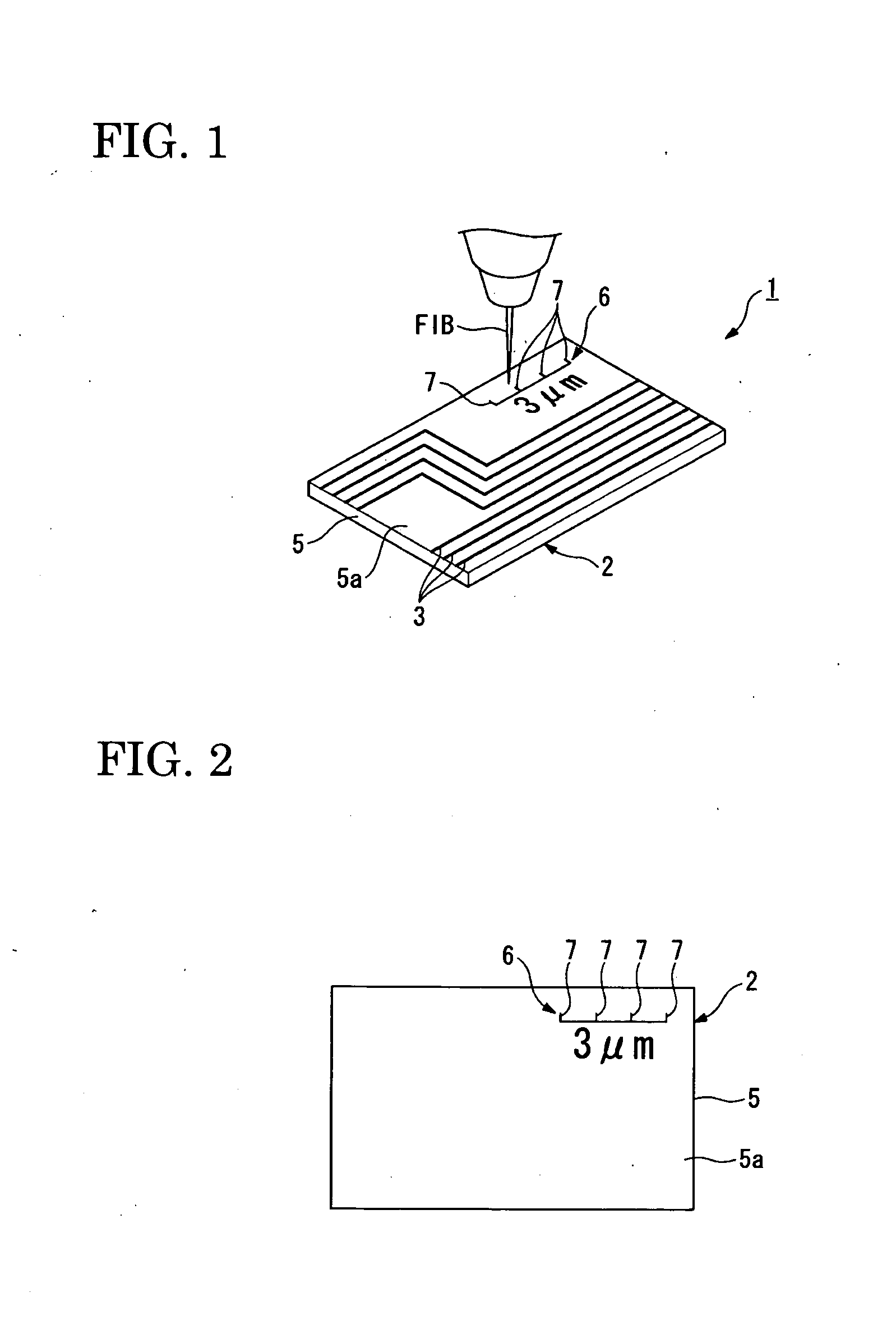

Substrate, micro structure, method of making reference scale, and method of measuring length of micro structure

InactiveUS20060216838A1Accurate length measurementAddressing slow performanceSemiconductor/solid-state device testing/measurementMaterial analysis by optical meansFocused ion beamOptics

There is provided a substrate possessing a substrate main body in whose surface there is formed a measurement object article, and a reference scale having been provided, on the surface of the substrate main body, in the vicinity of a region where the measurement object article is formed so as to extend in at least one direction, wherein the reference scale has plural graduations which have been formed by utilizing a focused ion beam FIB and adjacently disposed for every spacing having been previously determined.

Owner:SII NANOTECHNOLOGY INC

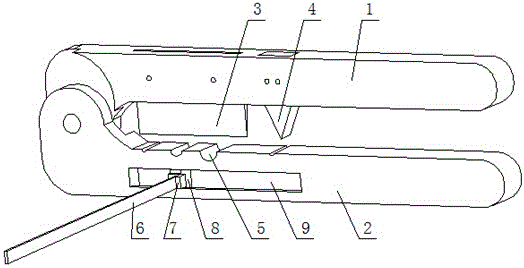

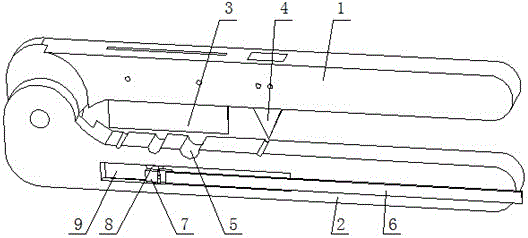

Cable Strippers

InactiveCN104795715BCircumcision is simple and fastMake up for the defect of splittingLine/current collector detailsApparatus for removing/armouring cablesElectric power systemEngineering

The invention discloses a cable wire stripper and belongs to the field of electric power systems. The cable wire stripper comprises a stripper handle I and a stripper handle II which are hinged through a pin shaft arranged on the end portion, wherein a horizontal knife and a vertical knife are fixed on the stripper handle I, the knife point of the horizontal knife is parallel to the length direction of the stripper handle I, the knife point of the vertical knife is perpendicular to the length direction of the stripper handle I, and the knife points of the horizontal knife and the vertical knife extend between the stripper I and the stripper II. At least two cable placing grooves are formed in the position of the stripper handle II corresponds to the knife point of the horizontal knife, and a cable placing groove is formed in the position of the stripper handle II corresponds to the knife point of the vertical knife. A sliding block which slides in the length direction of the stripper handle II is connected on the stripper handle II through a sliding way and hinged with a scale plate which is perpendicular to the stripper handle II when being unfolded. The cable wire stripper is applicable to stripping of the insulating wires of cables with various specifications, can accurately control the stripping lengths of the cable insulating wires, and is small in size and convenient to carry.

Owner:STATE GRID CORP OF CHINA +2

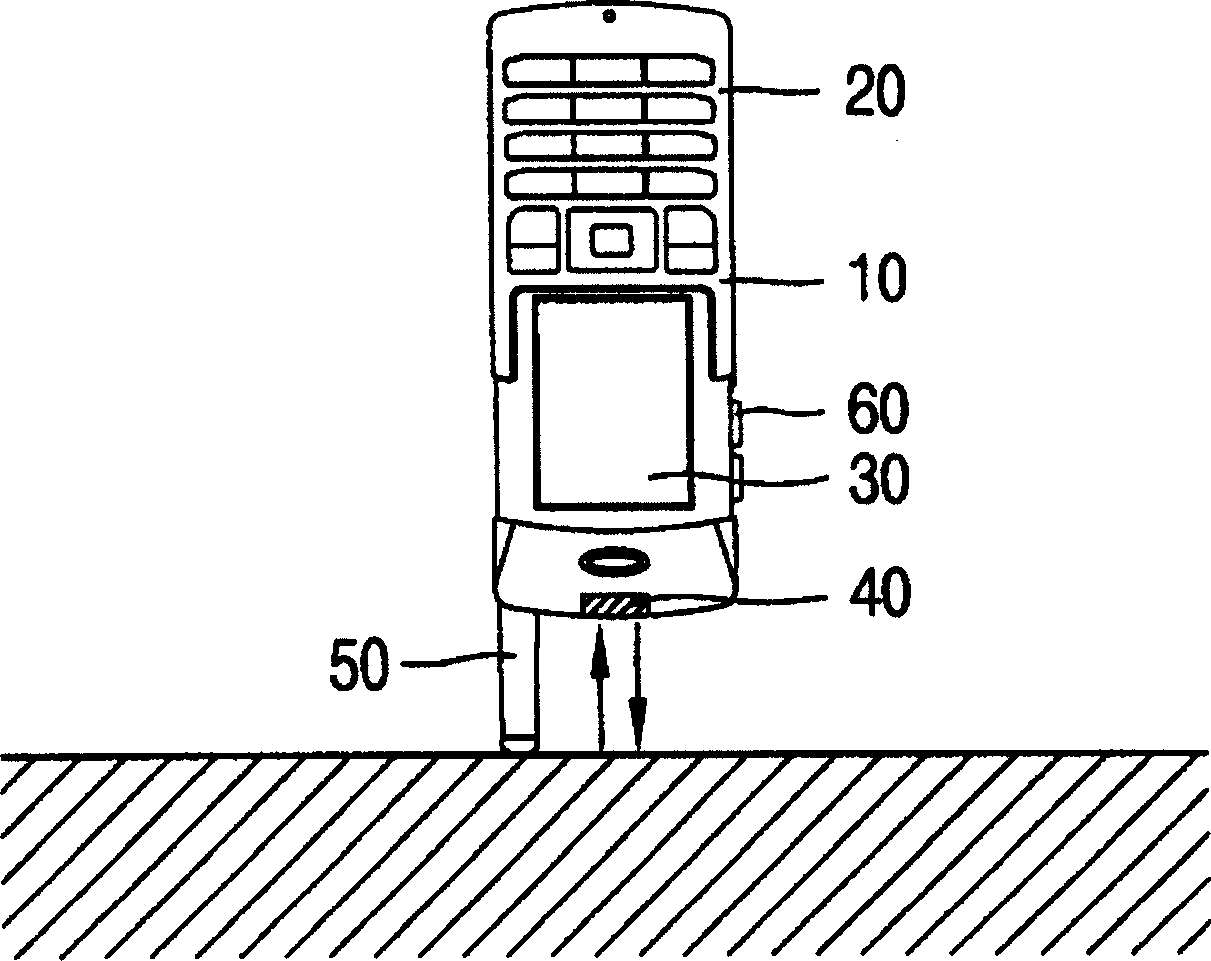

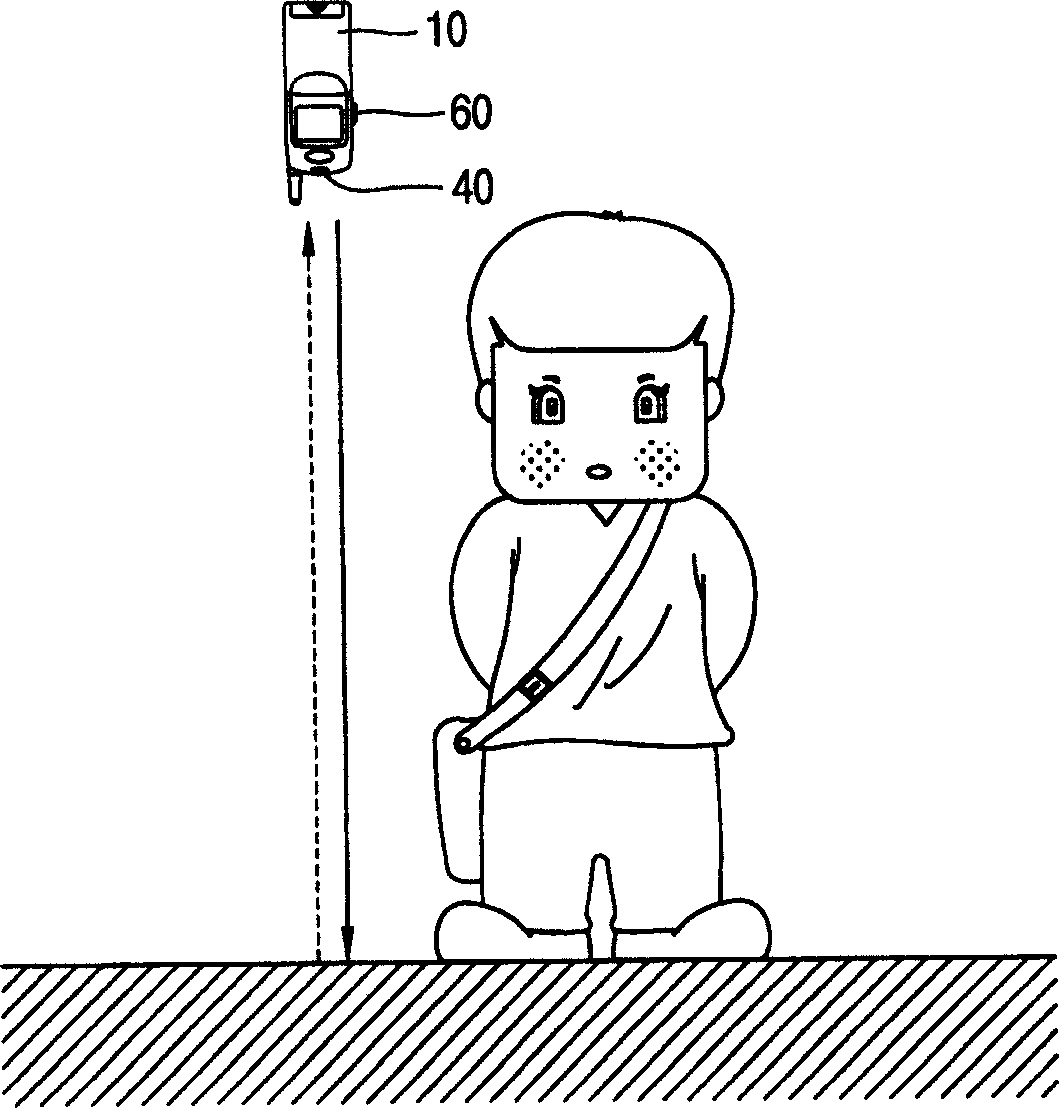

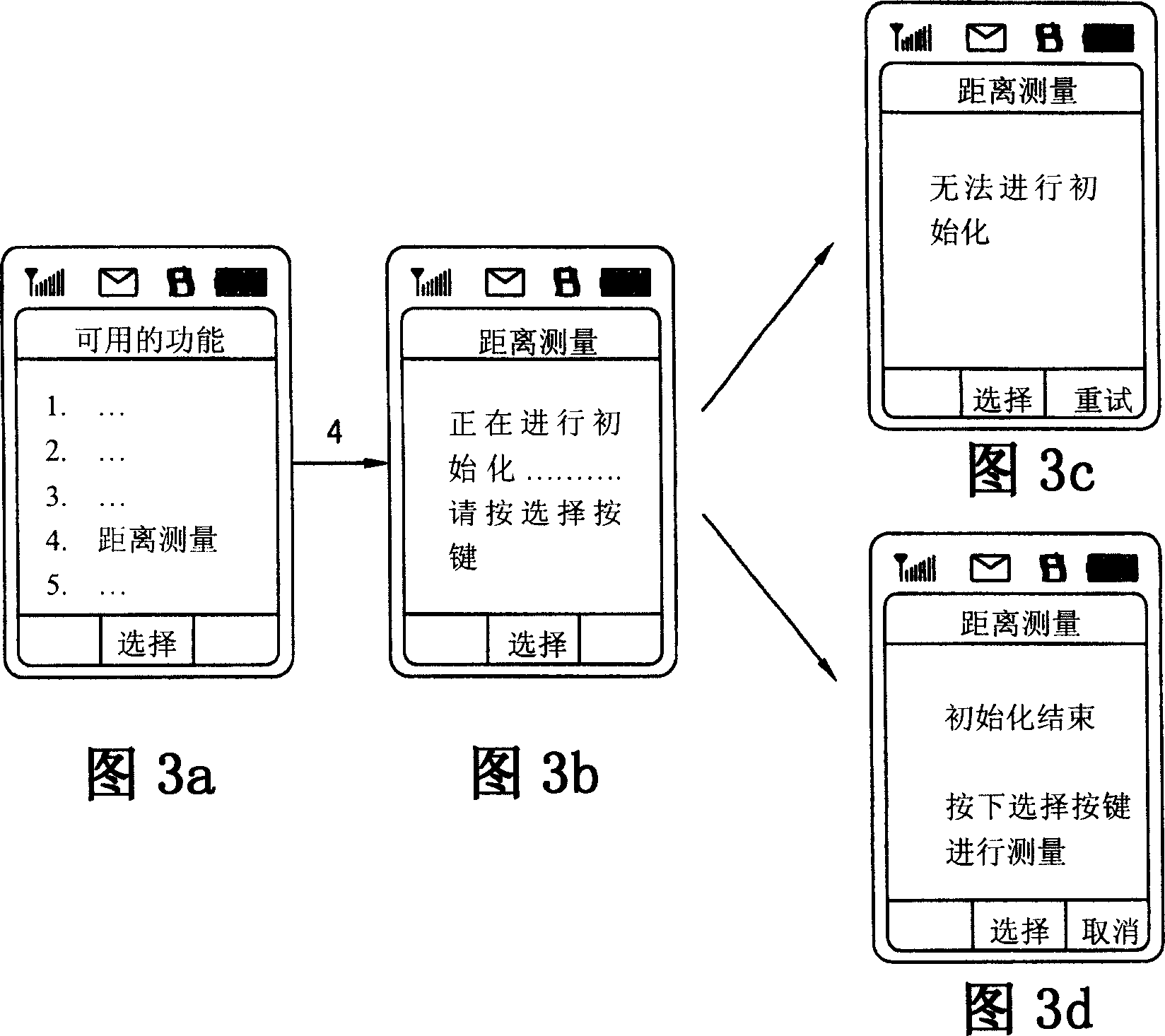

Mehtod for length measuring by mobile communication terminal

InactiveCN1725033AImprove convenienceAccurate length measurementOptical rangefindersDevices with bluetooth interfacesShortest distanceComputer terminal

The present invention discloses a mehtod for length measuring by mobile communication terminal, which is used for a built-in short distance communication equipment in the mobile communication terminal; which transmits a certain signal to a reflecting surface, and then grasps the characteristicof surface reflection according to the weakening extent of the received signal, and then measures the distance between the reflecting surface the mobile communication terminal. The present invention uses the short distance communication equipments which has been set up in the mobile communication terminals, using the weakening of signal strength generated by the transmitted reflection signals by the said communication equipments to measure the distance between the reflective object and the mobile communication terminal. Taking into account the reflective properties of the reflective object, the present invention takes the external structures of the mobile communication terminals from a fixed distence as a reference, to analyse the reflective properties of the specific reflective object, and takes it as the basic information of its length measurement. Therefore, regardless of whatever types of the reflective objects, regardless of the time and places, the present invention can achieve a more precise length measurement, accordingly achieving the effect of providing convenience for users.

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

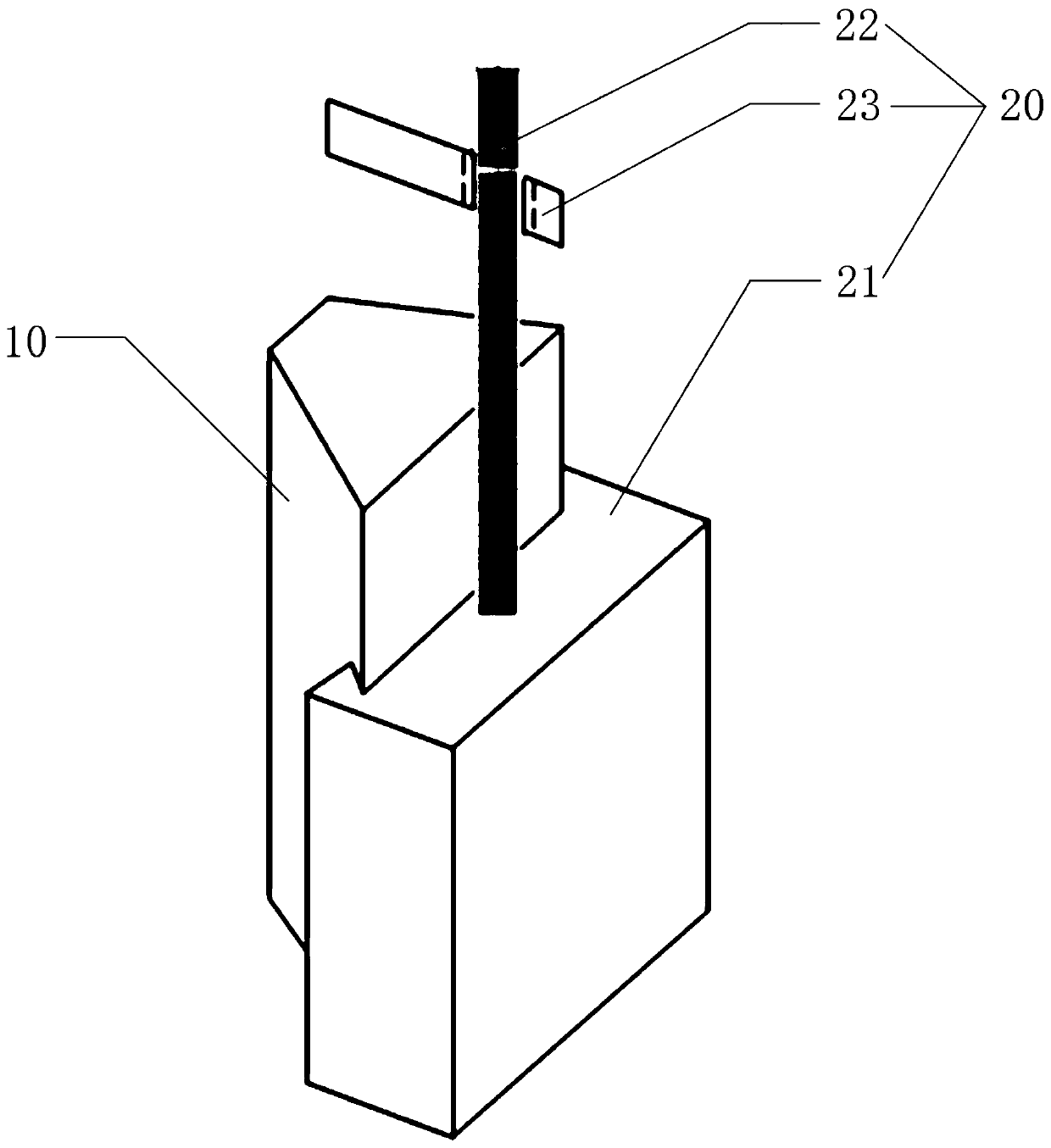

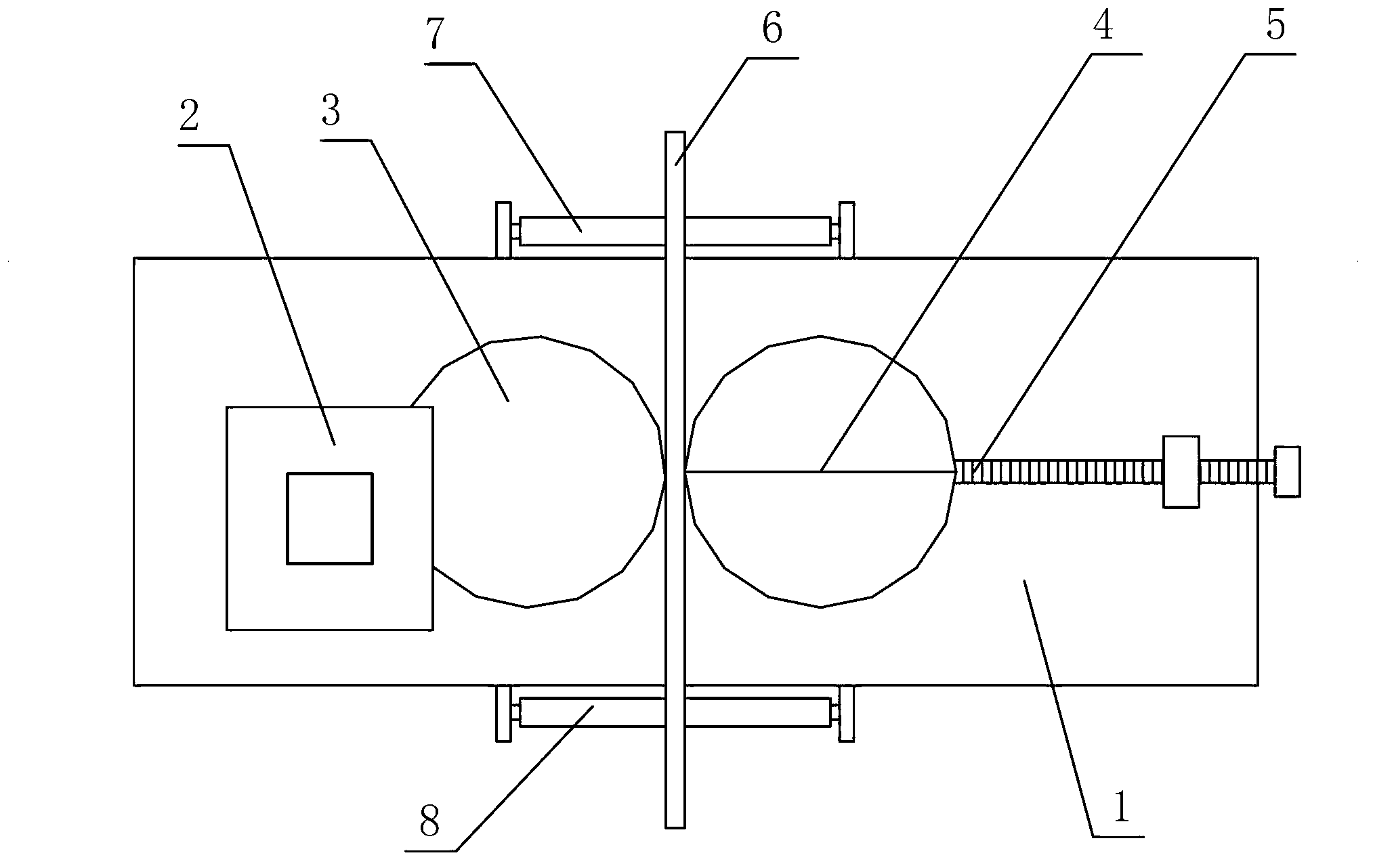

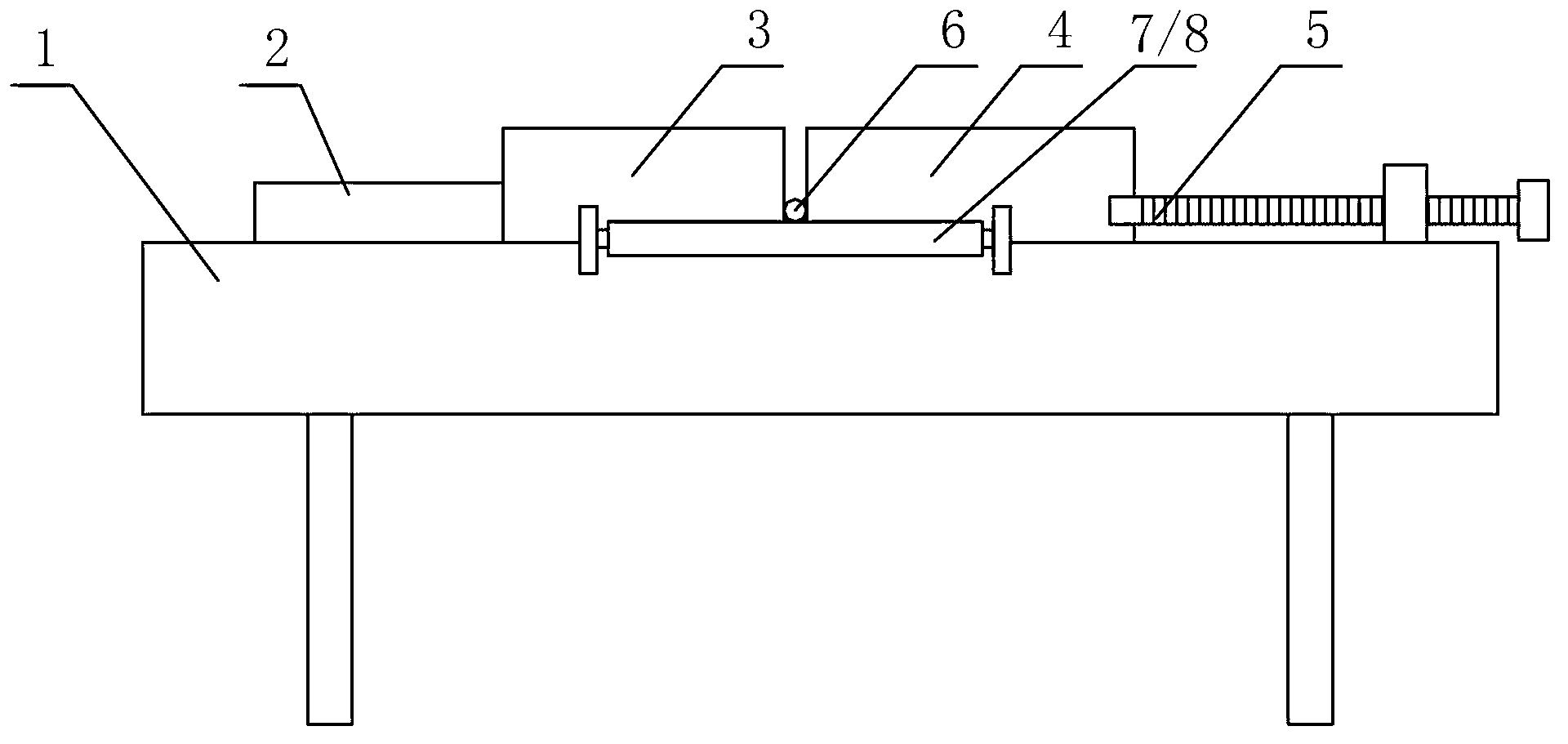

Table-type accurate cable length measuring instrument

InactiveCN103017710ASimple structureAccurate measurementMeasurement devicesLength measurementEngineering

The invention discloses a table-type accurate cable length measuring instrument. The table-type accurate cable length measuring instrument comprises a workbench, a plate which is movably supported by the workbench, a screw passing through a screw hole in the workbench, a rotary plate rotationally connected with the workbench, and a length measuring instrument, wherein a gap through which a cable can pass is reserved between the plate and the rotary plate; and the length measuring instrument comprises a display plate and is capable of measuring the rotation distance of the rotary plate. The table-type accurate cable length measuring instrument is simple in structure, can measure the cable length accurately and does not influence the normal traction of a cable.

Owner:JING FENG GRP

Aluminum alloy cutting and punching machining device

InactiveCN108772703AImprove processing efficiencyReduce usageOther manufacturing equipments/toolsPositioning apparatusPunchingGear wheel

The invention discloses an aluminum alloy cutting and punching machining device. The device comprises a workbench, wherein a first sliding groove is formed in the upper end of the workbench; a first threaded rod penetrates through the side wall of the workbench, one end of the first threaded rod is rotationally connected to the inner wall of the first sliding groove, the first threaded rod is in threaded connection with a first sliding block, and the upper end of the first sliding block is fixedly connected to a hydraulic oil cylinder. According to the aluminum alloy cutting and punching machining device, the structural design is reasonable, aluminum alloy cutting and aluminum alloy punching are integrated, the aluminum alloy machining efficiency can be effectively improved, and the use oflabor force is reduced; graduation is arranged on the workbench and a pointer is arranged on the side wall of the first sliding block, the length of the aluminum alloy can be accurately measured, anderrors generated during work can be effectively reduced; and a driving motor drives a second bevel gear to rotate, then a first bevel gear is driven to rotate, so that a second threaded rod drives asecond sliding block to move, and a drill bit can be driven to be punched at any position, and therefore the work convenience is improved.

Owner:NANJING TONGWANG ALMINIUM CO LTD

Length measuring device of loom

ActiveCN104141187ARealize length measurementSimple structureTextiles and paperYarnLength measurement

The invention discloses a length measuring device of a loom. The length measuring device comprises a rack, wherein the rack is provided with a loom main shaft, a mechanical length measuring mechanism and an electronic length measuring mechanism, the mechanical length measuring mechanism comprises a length measuring wheel, and the length measuring wheel is arranged on the rack through a length measuring wheel seat; the rack is also provided with a transmission mechanism which is used for transmitting the power of the loom main shaft to the length measuring wheel; the electronic length measuring mechanism comprises an electronic length measurer and a pressing wheel, the pressing wheel is positioned above the length measuring wheel, a yarn flying gap is formed by the match of the pressing wheel and the length measuring wheel, the electronic length measurer is positioned above the pressing wheel, the inner part of the electronic length measurer is provided with an encoder which rotates synchronously with the loom main shaft, and the bottom part of the electronic length measurer is provided with an electromagnetic needle directly facing the pressing wheel. According to the length measuring device disclosed by the invention, the structure is simple, the operation is easy, the length measurement of yarn is realized by adopting a matching mode of the electronic length measuring mechanism and the mechanical length measuring mechanism, and the length measuring can be more accurate.

Owner:QINGDAO KAISHUO MACHINERY TECH CO LTD

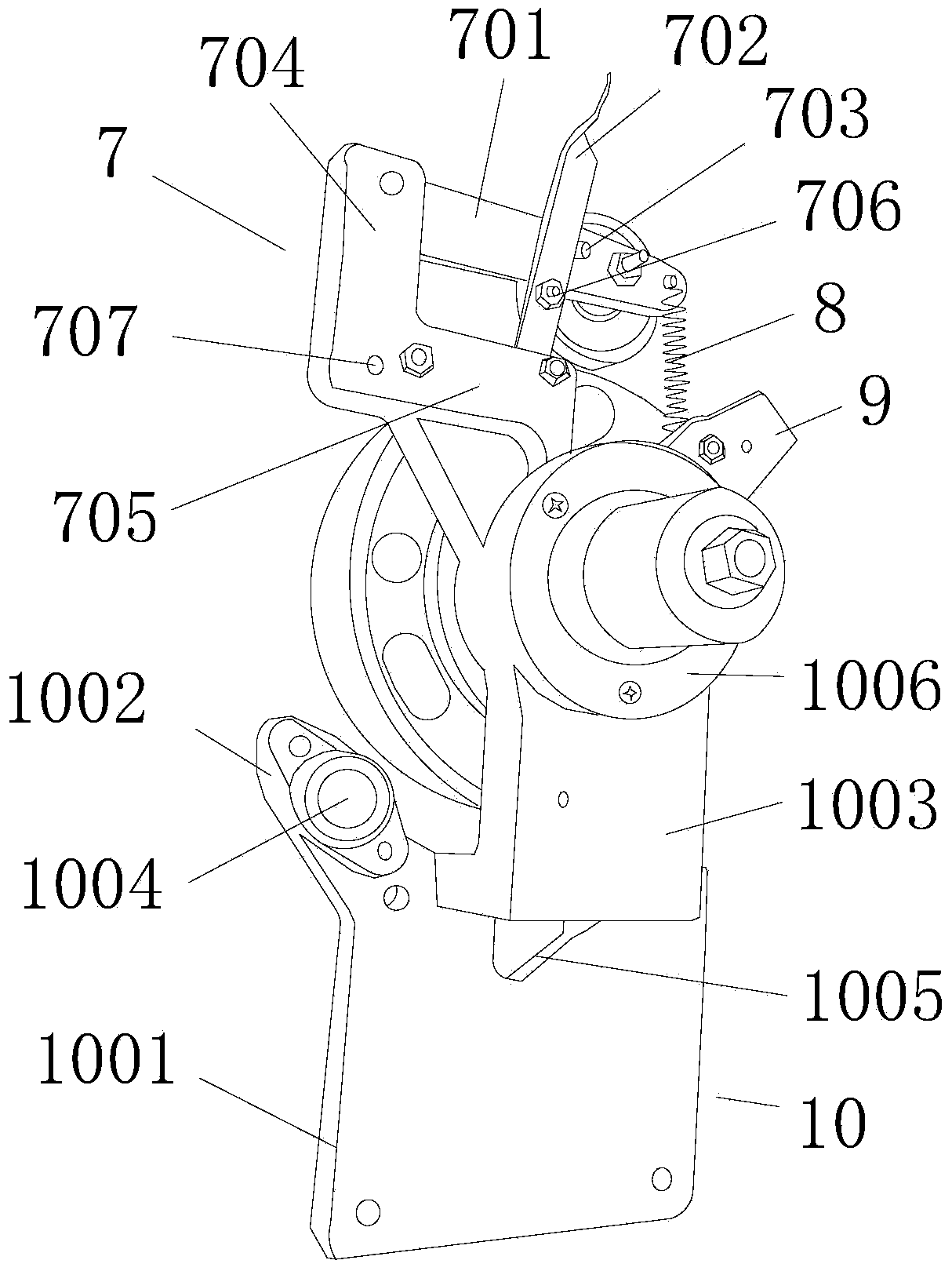

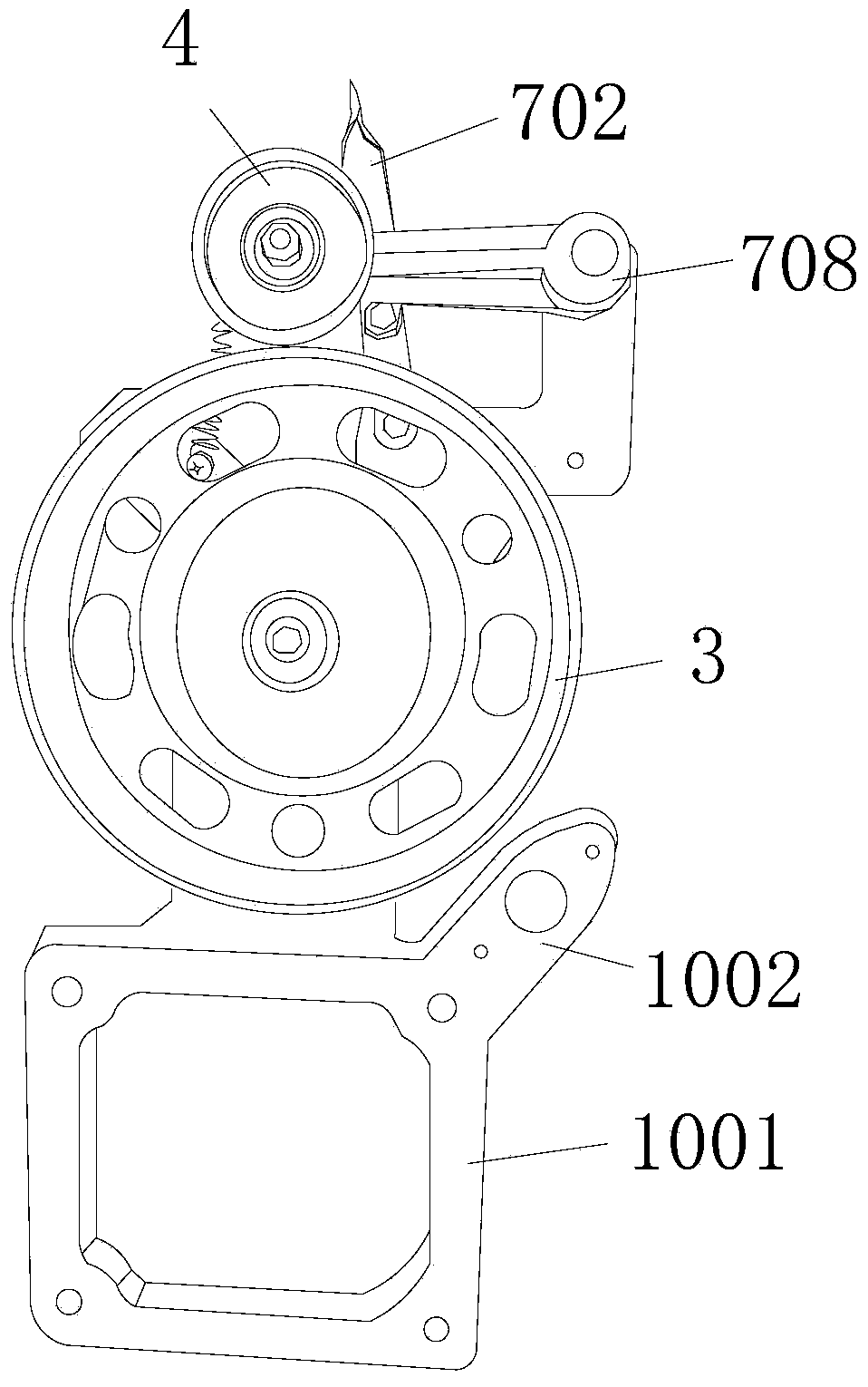

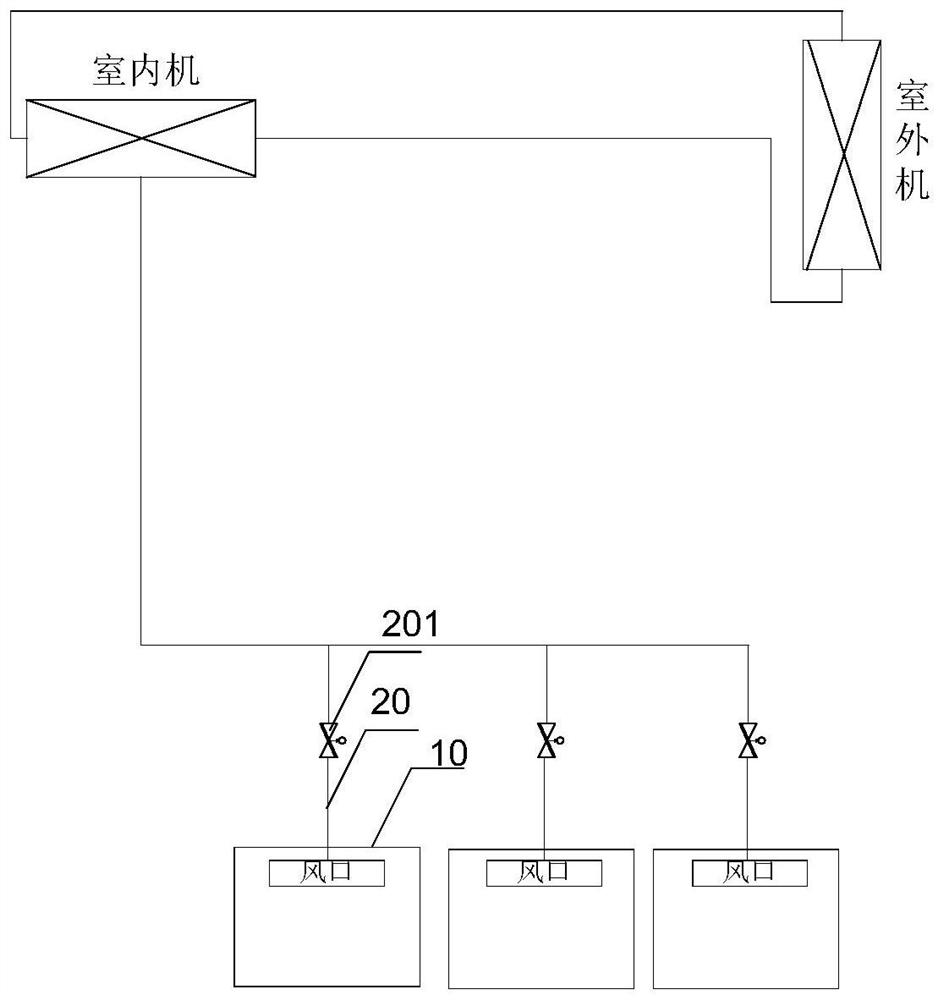

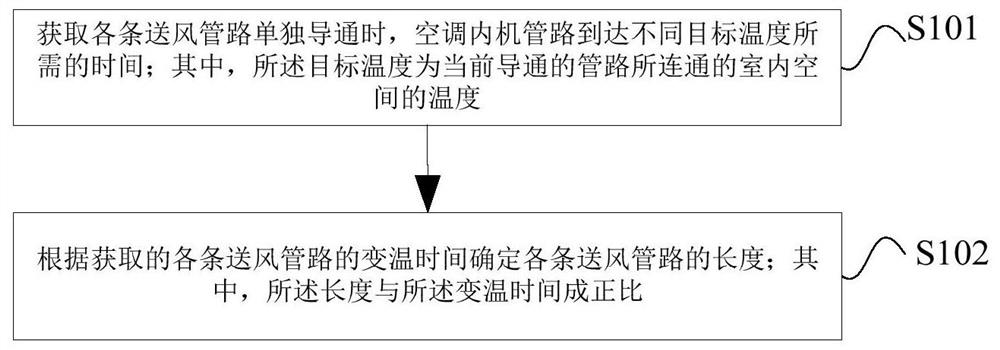

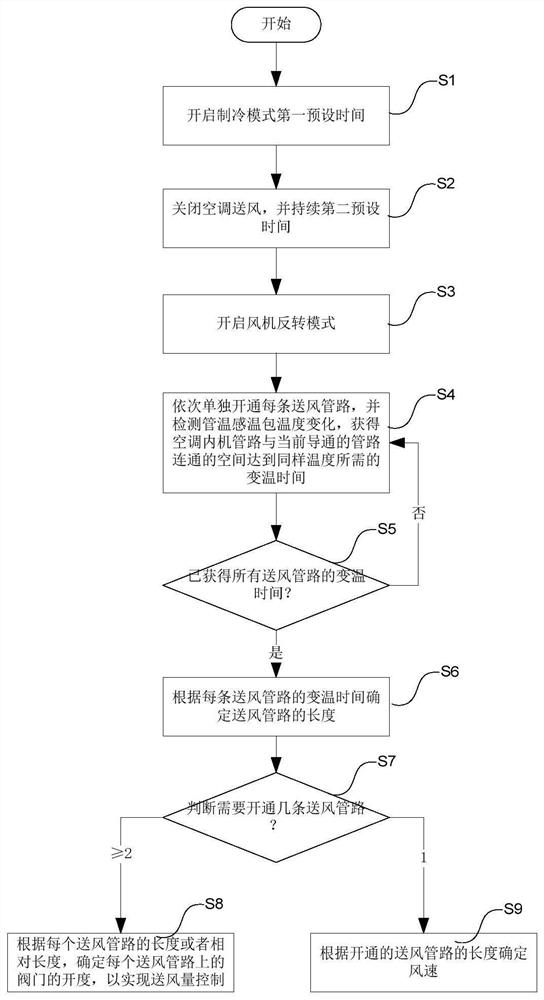

Air supply control method and device and air conditioning equipment

ActiveCN111780328AAccurate length measurementImprove comfortMechanical apparatusProcess engineeringAir conditioning

The invention discloses an air supply control method and device and air conditioning equipment. The method comprises the steps of acquiring the temperature change time required by an air conditioner indoor unit pipeline to reach the target temperature when each air supply pipeline is separately communicated, wherein the target temperature is the temperature of the indoor space communicated by thecurrent communicated pipeline; and determining the length of each air supply pipeline according to the acquired temperature change time of each air supply pipeline, wherein the length is proportionalto the temperature change time. Through the air supply control method and device and the air conditioning equipment, the length of the air supply pipelines can be accurately measured, the air supply parameters can be adaptively adjusted, and the comfort is improved.

Owner:格力电器(南京)有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com