Lithium battery tab length verifying device

A technology of length inspection and lithium battery, applied in the direction of measuring device, using mechanical device, mechanical measuring device, etc., can solve the problem of inability to analyze and obtain the specific value of the length of the pole ear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

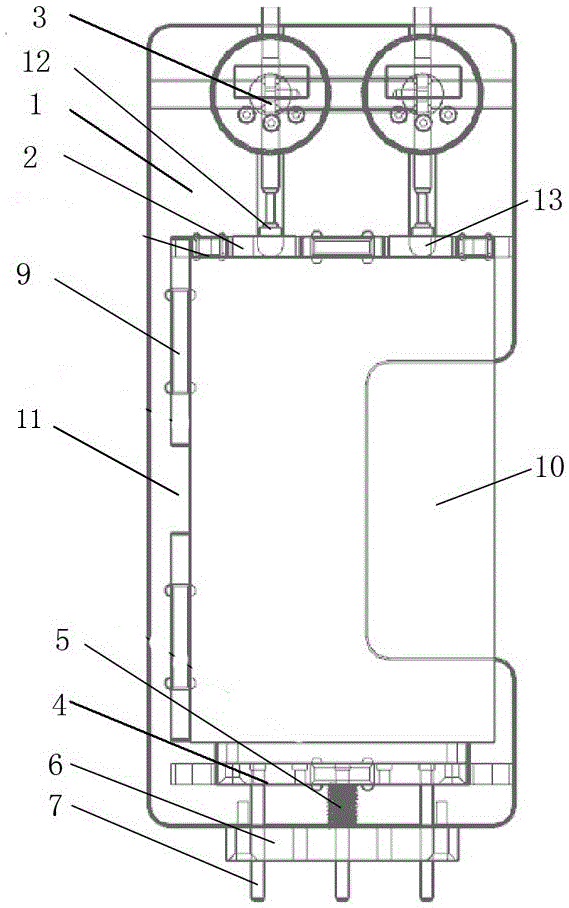

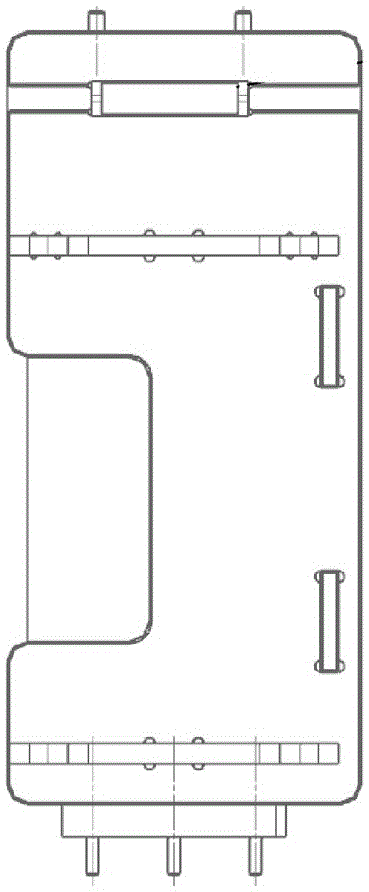

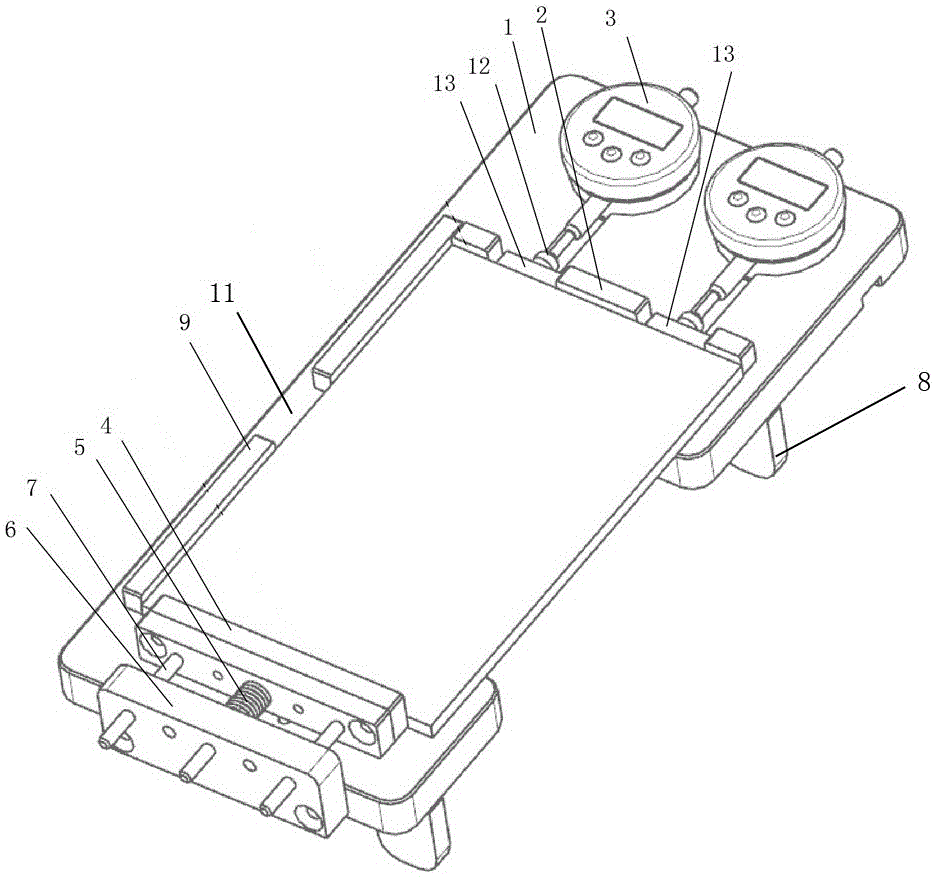

[0018] The embodiment of lithium battery lug length inspection device, as Figure 1-Figure 3 As shown, including the base 1, the top of the front side of the base 1 is provided with a first limiting boss 2 for limiting the displacement of one end of the lithium battery tab, and the first limiting boss 2 is provided with a tab for avoiding the lithium battery tab. Avoidance port 13, the tab of the lithium battery is put into the avoidance port 13 during detection, the avoidance port in this embodiment is a groove, and a second limiter for limiting the displacement of the end of the lithium battery without the tab is provided under the front side of the base Boss 4, the second limiting boss 4 in this embodiment is a movable boss, the underside of the second limiting boss 4 is provided with a fixed seat 6, between the second limiting boss 4 and the fixed seat 6 A spring is provided, and the spring in this embodiment is a helical spring 5 whose axis extends in the up and down dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com