Patents

Literature

156results about How to "Guaranteed not to shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Positioning and navigation method for indoor robot

ActiveCN105737820ACorrect path deviationGuaranteed not to shiftNavigational calculation instrumentsPath deviationMarine navigation

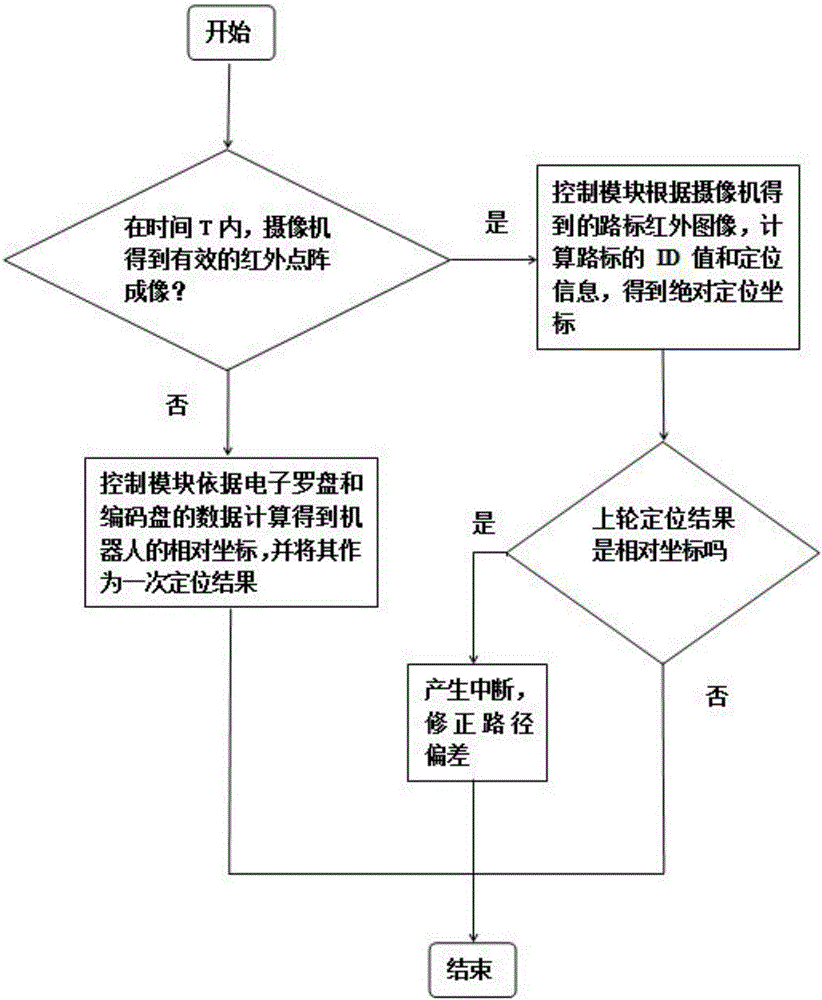

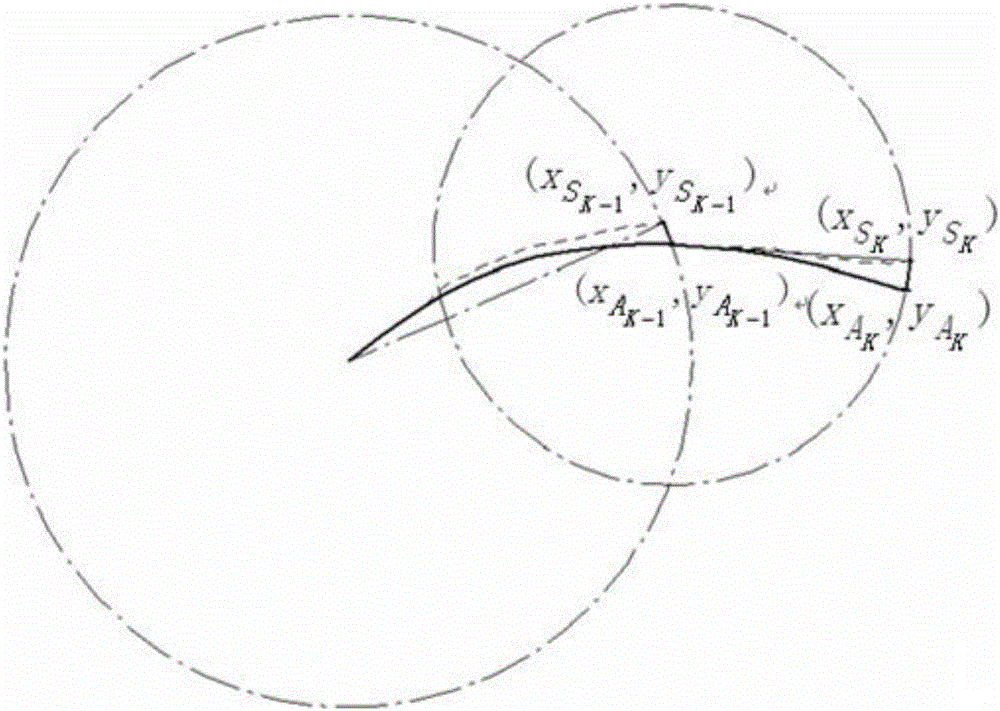

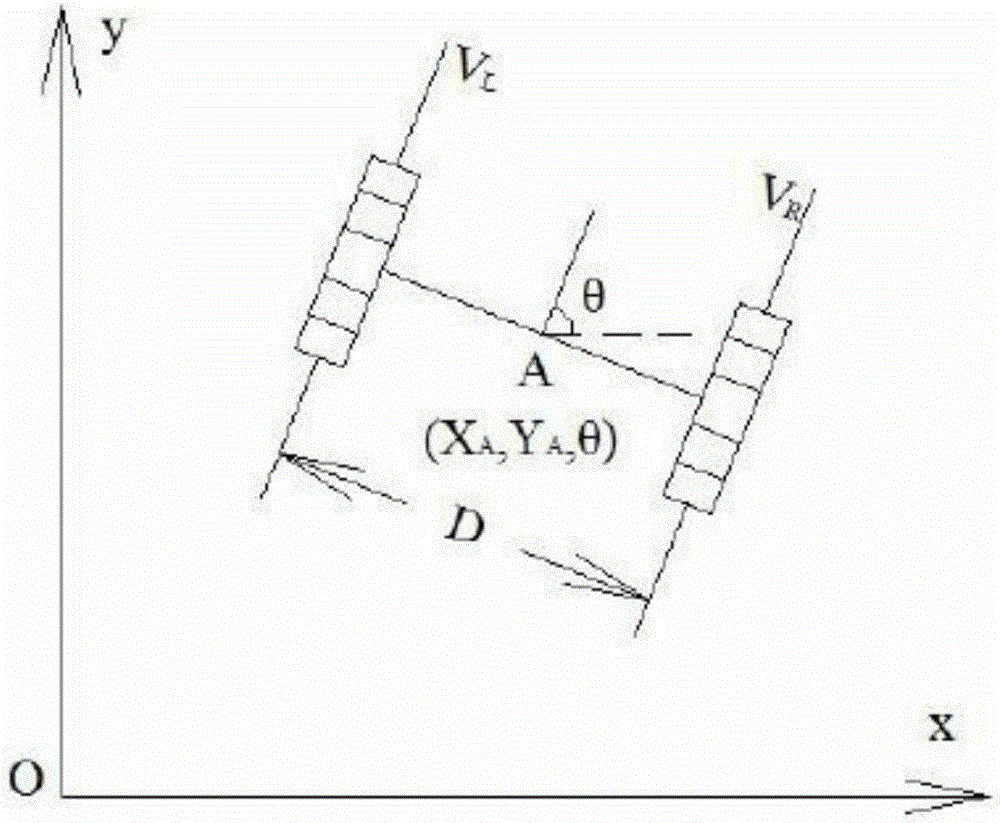

The invention relates to a positioning and navigation method for an indoor robot and belongs to the technical field of robot positioning and navigation.The positioning and navigation method for the indoor robot includes the steps that a position where a road sign is not detected is rapidly positioned through a dead reckoning relative positioning method; a position where the road sign is detected is calculated to obtain absolute coordinates, and therefore precise position coordinates are obtained; when the robot is moved to the position where the road sign is detected from the position where the road sign is not detected, the former displacement deviation caused by positioning error accumulation in a relative positioning region is corrected.The method is especially suitable for indoor environments where road signs are not conveniently arranged massively on ceilings and has the advantages that average treatment time is short, the number of sensors is small, and the path deviation can be corrected.

Owner:WUHU HIT ROBOT TECH RES INST

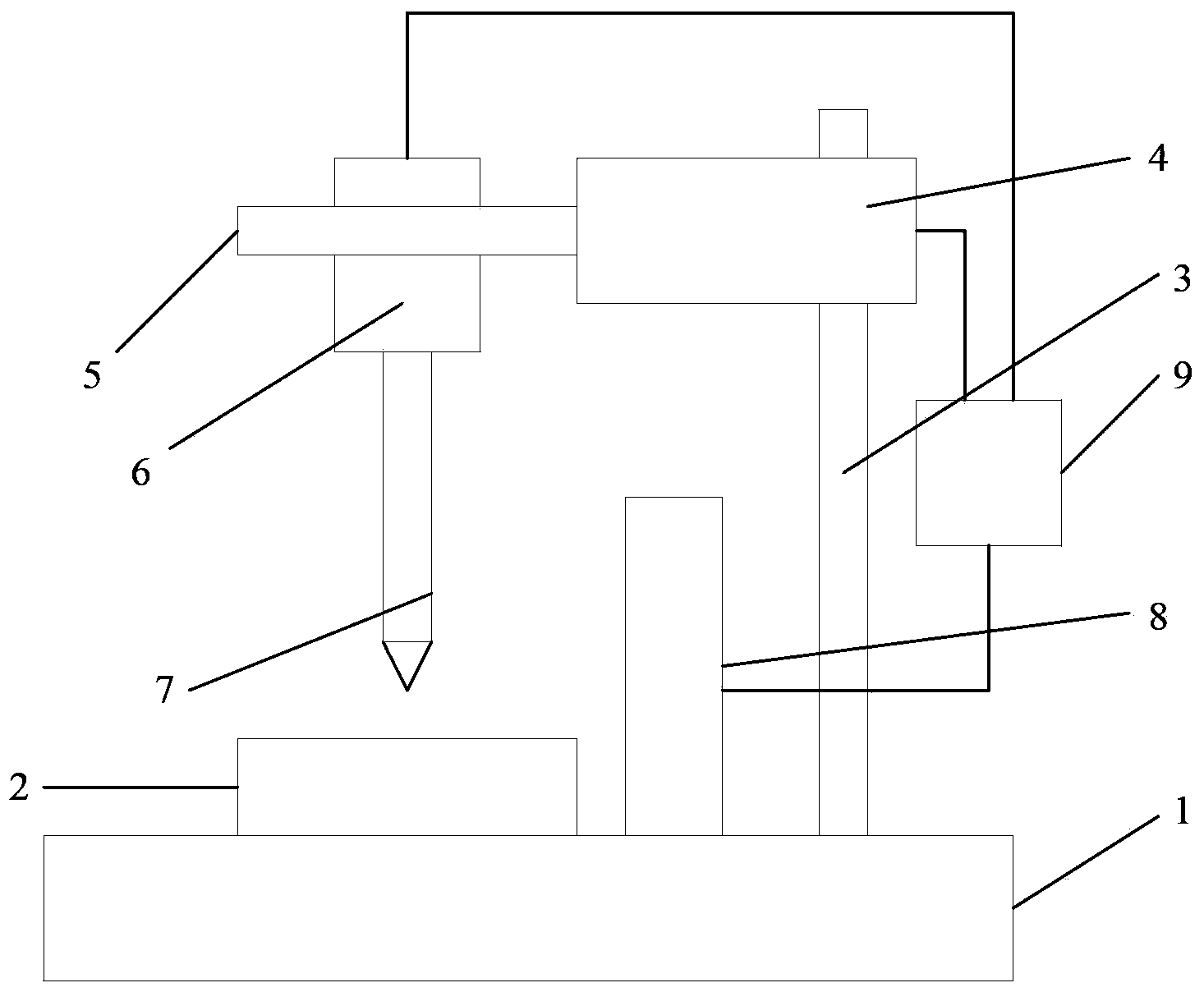

Drilling equipment capable of automatically controlling drilling depth

ActiveCN103506662AReduce speedGuaranteed not to shiftAutomatic control devicesDrilling/boring measurement devicesNumerical controlAutomatic control

The invention discloses drilling equipment capable of automatically controlling the drilling depth. A detection unit tests the inlet depth of a drill bit and automatically feeds the depth back to a numerical control unit. When the numerical control unit determines that the actual depth of the drill bit reaches a first preset position, the drill bit is notified of reducing the rotating speed of the drill bit to ensure that the drilling position is not shifted. When the numerical control unit determines that the actual depth of the drill bit reaches a second preset position, the rotating speed of the drill bit is increased and returned to a normal state. When the actual depth of the drill bit reaches a third preset position, the rotating speed of the drill bit is reduced. When the actual depth of the drill bit reaches a designated depth, the drill bit stops, then, the drilling depth can not be too large or too small, and the drilling depth is accurate.

Owner:ANHUI QIFENG MACHINERY & EQUIP

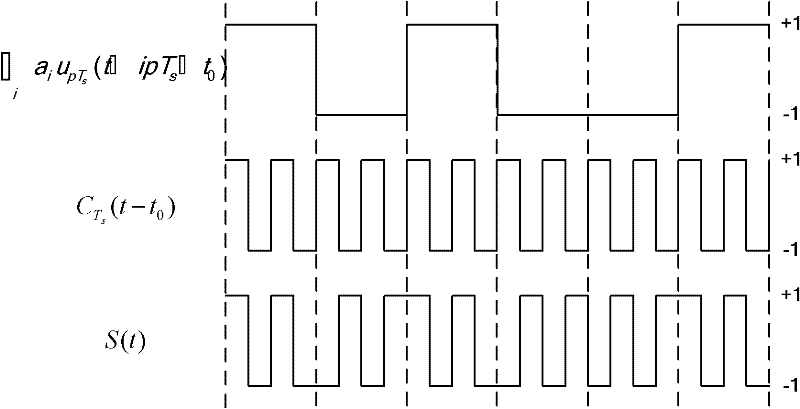

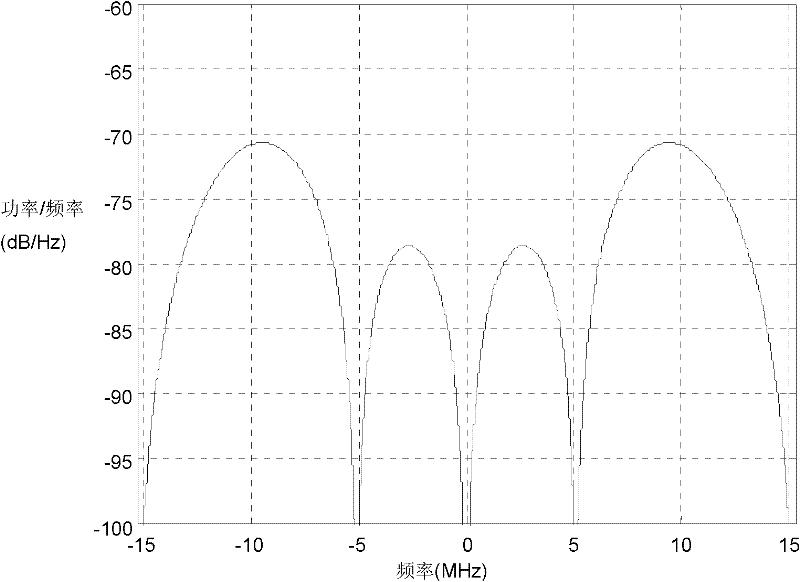

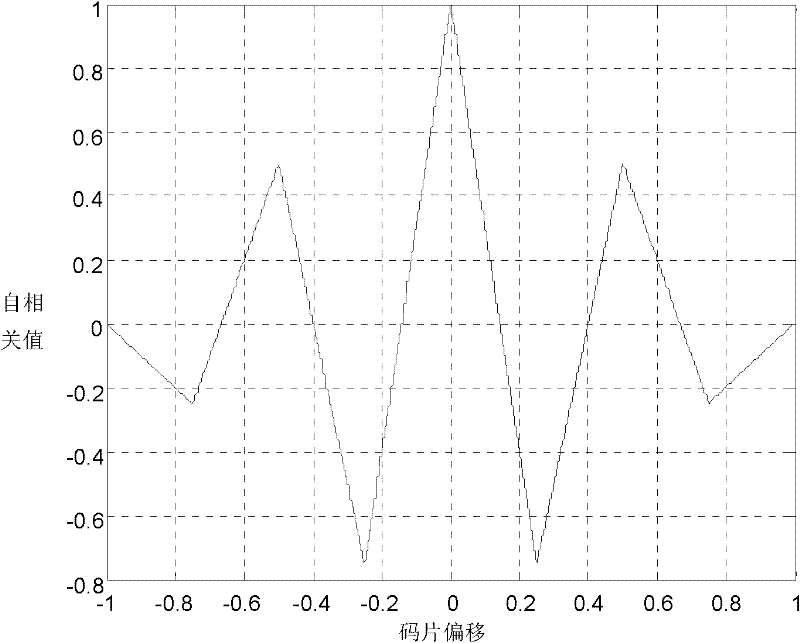

Novel multi-path inhibition BOC (Binary Offset Carrier) code tracking method and code tracking ring

The invention provides a pseudo-random code phase tracking method and a code tracking ring multi-path inhibition BOC (Binary Offset Carrier) code tracking method, which effectively inhibit multi-path effect according to structural characteristics of a BOC signal. A pseudo-random code generating step, a BOC code generating step, a reference waveform generating step, a relevant waveform constructing step, a mutual correlation step, a phase discrimination function generating step and a phase discrimination step are included. According to the invention, in the correlation waveform constructing step, the constructed forward correlation function and backward correlation function only have one peak value and good linearity is obtained; and a zero crossing point of a phase discrimination curve and a zero crossing point while no multi-path signal is available have no deviation when multi-path effect exists so that the offset of the tracking point is overcome to achieve the accurate distance measuring and positioning purpose.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

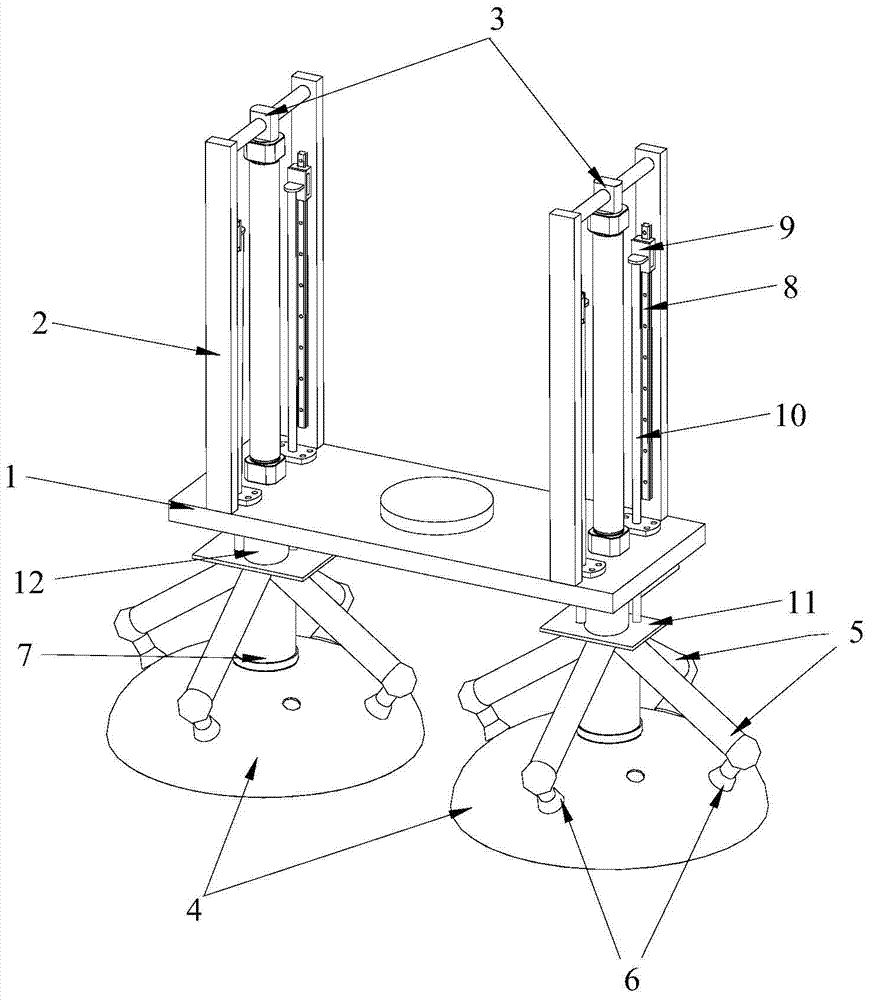

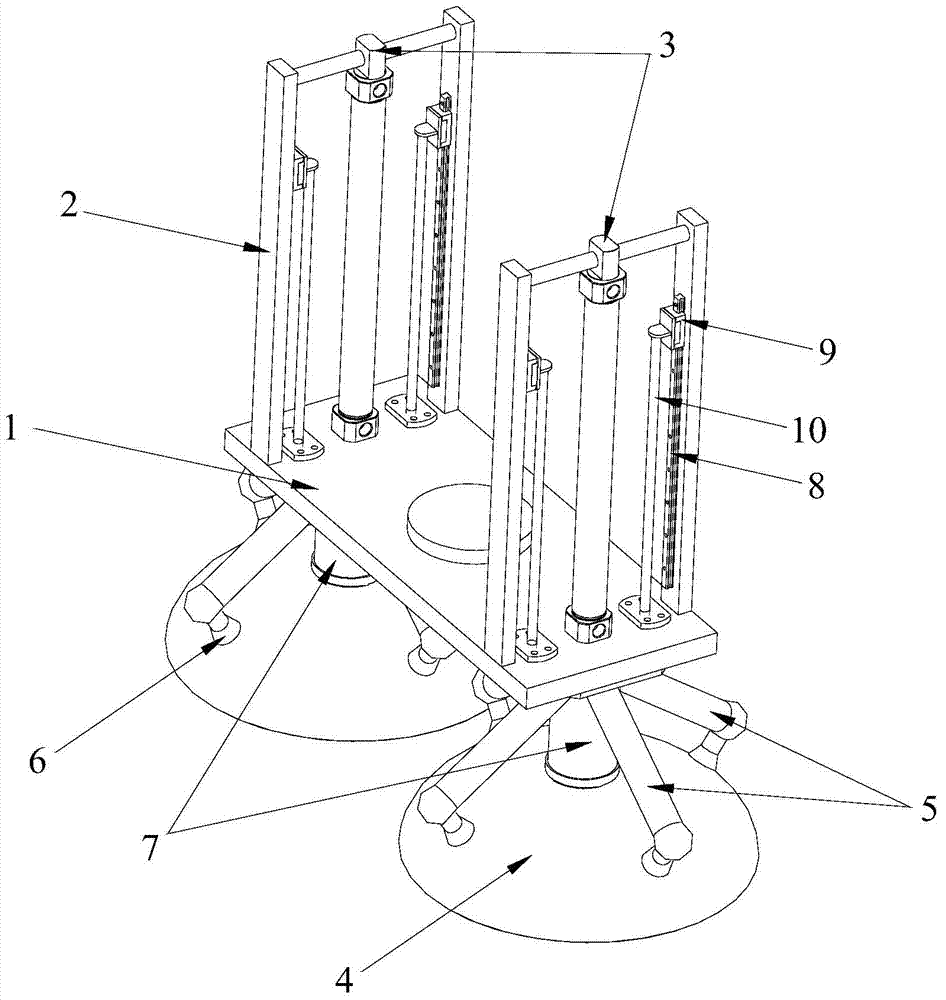

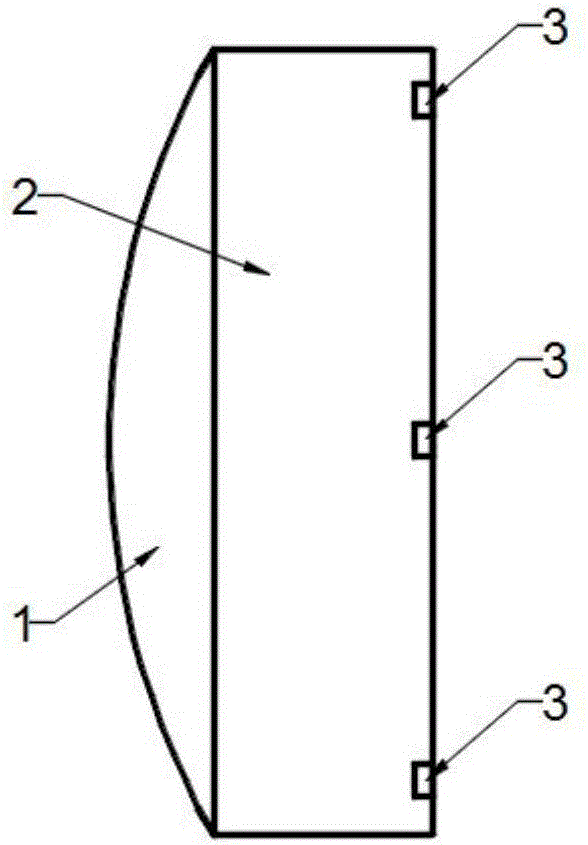

Ultrasonic cleaning drying method for deep curved glass reflector

InactiveCN102366750AGuaranteed not to shiftDrain fastCleaning using liquidsMegasonic cleaningPulp and paper industry

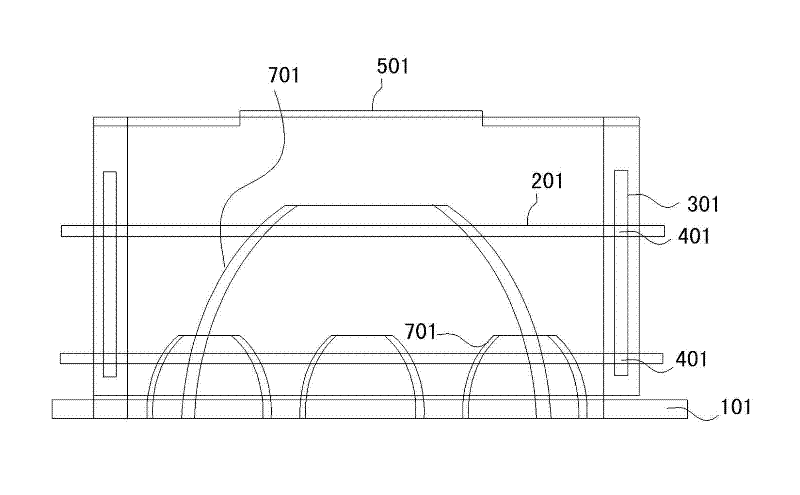

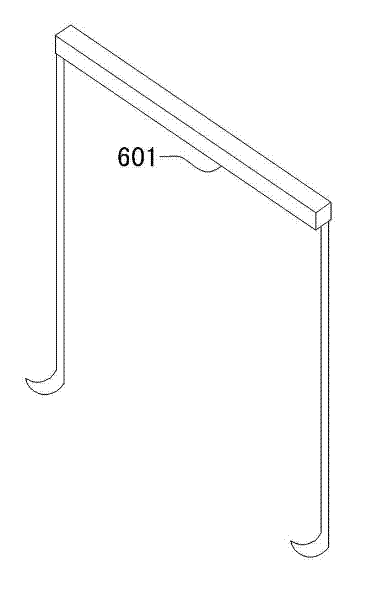

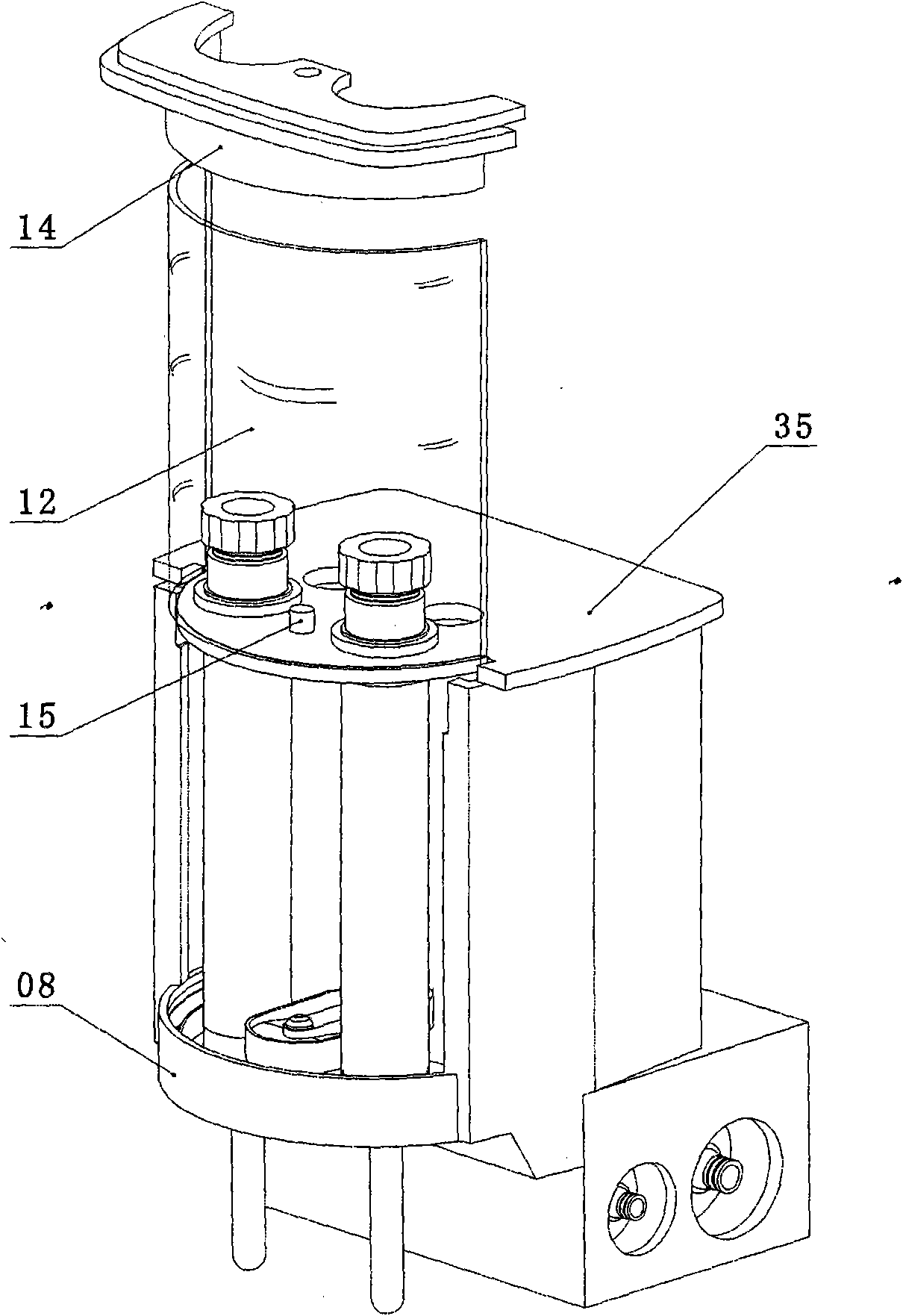

The invention belongs to the field of ultrasonic cleaning, and particularly relates to an ultrasonic cleaning drying method for a deep curved glass reflector. The method comprises the following steps of: (1) clamping the reflector; and (2) cleaning the reflector: a, washing with lotion; b, rinsing with pure water; c, slowly drawing for dehydration; and d, drying with hot wind. In the invention, the process of washing with lotion in the step (3) takes 3-8 minutes, wherein the ultrasonic power is 1,000-1,4000W, and the heating temperature is 30-50 DEG C; the process of rinsing with pure water takes 3-8 minutes, wherein the ultrasonic power is 1,000-1,400W; the process of slowly drawing for dehydration takes 3-8 minutes; and the process of drying with hot wind takes 8-15 minutes, wherein the heating temperature is 60-80 DEG C. A combined fixture comprises a reflector bracket (101), a pressure cover (201), a height adjusting slideway (301), a connecting rod (501) and a lifting mechanism (601). The method provided by the invention has the advantages of good stability, high cleanliness and ideal cleaning effect.

Owner:SHENYANG ACAD OF INSTR SCI

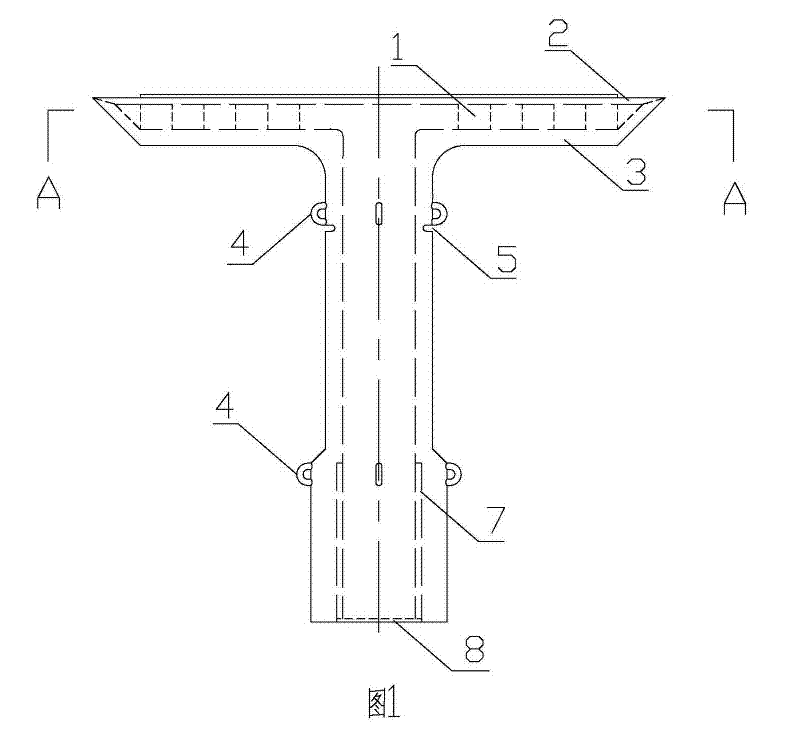

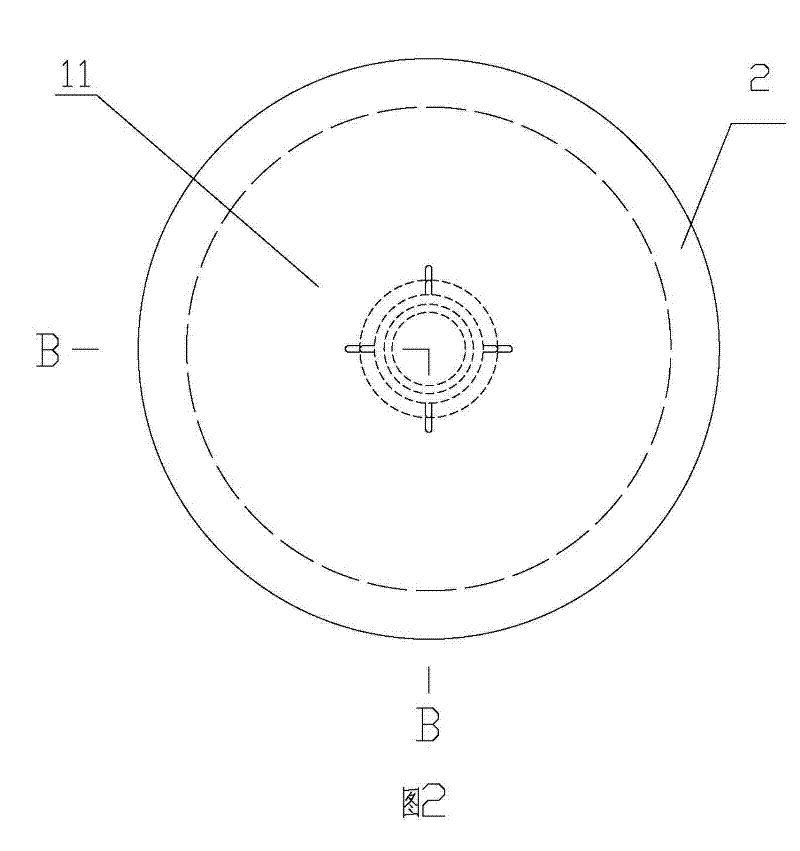

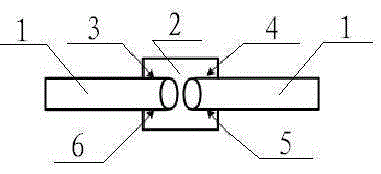

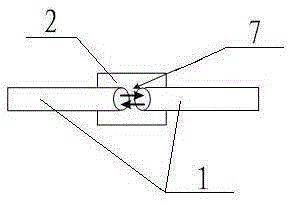

Tunnel two-lining structure back grouting device, and grouting method thereof

InactiveCN102251783AEasy to installAvoid cloggingUnderground chambersTunnel liningLine structureEnvironmental geology

The invention discloses a tunnel two-lining structure back grouting device and a grouting method thereof. The device consists of a tunnel two-lining structure back grouting valve and a quick joint. The upper surface of the tunnel two-lining structure back grouting valve is coated with a strong stamp gum. Through the strong stamp gum, the tunnel two-lining structure back grouting valve can be adhered to a waterproof layer and protects the waterproof layer from damage. The tunnel two-lining structure back grouting valve is connected with a grouting machine through the quick joint; and the grouting machine grouts the damage part of the gap between a one-lining structure and a two-lining structure of the tunnel through the tunnel two-lining structure back grouting valve. The grouting method for the tunnel two-lining structure back grouting device is reasonable in application, and the tunnel two-lining structure back grouting device is convenient to arrange. The tunnel two-lining structure back grouting device and the grouting method are a good method and a good device for grouting the gap between the one-lining structure and the two-lining structure of the tunnel.

Owner:BEIJING URBAN CONSTR YATAI GRP

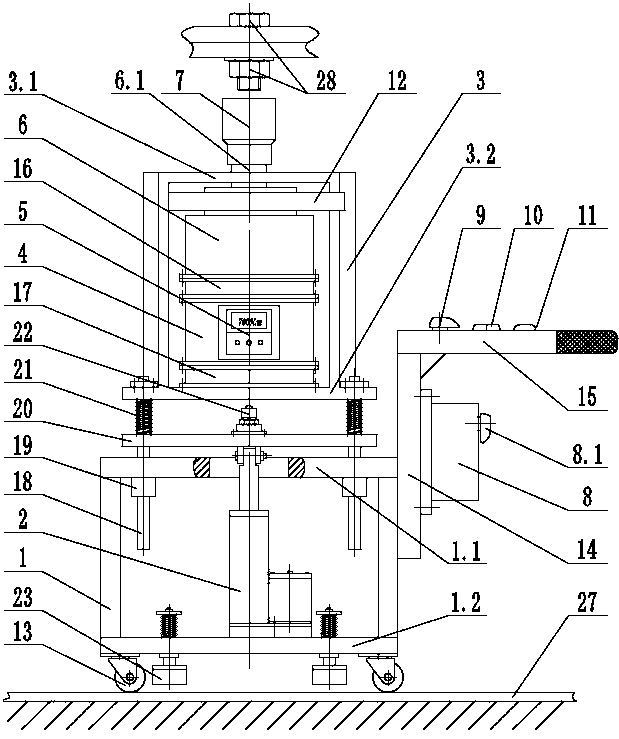

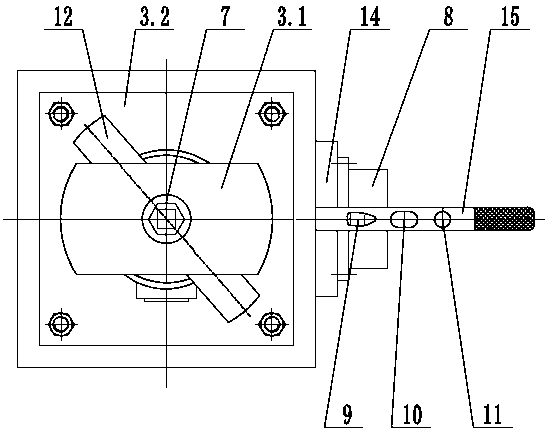

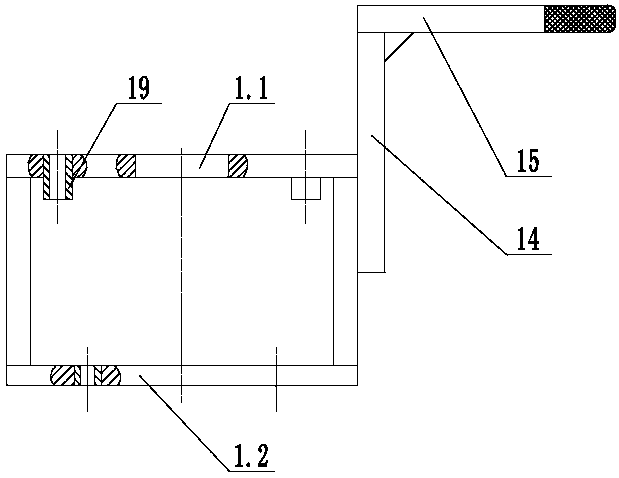

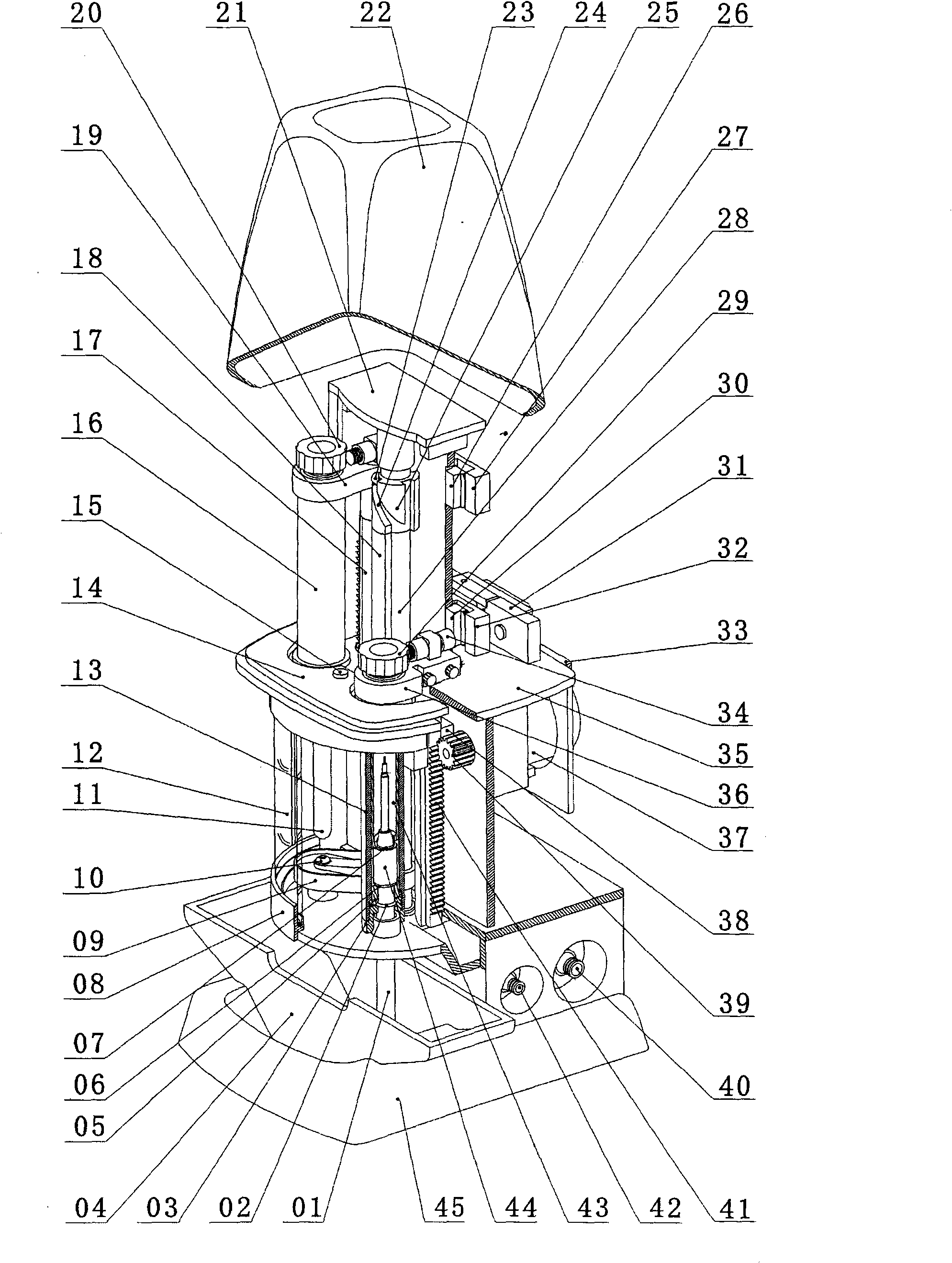

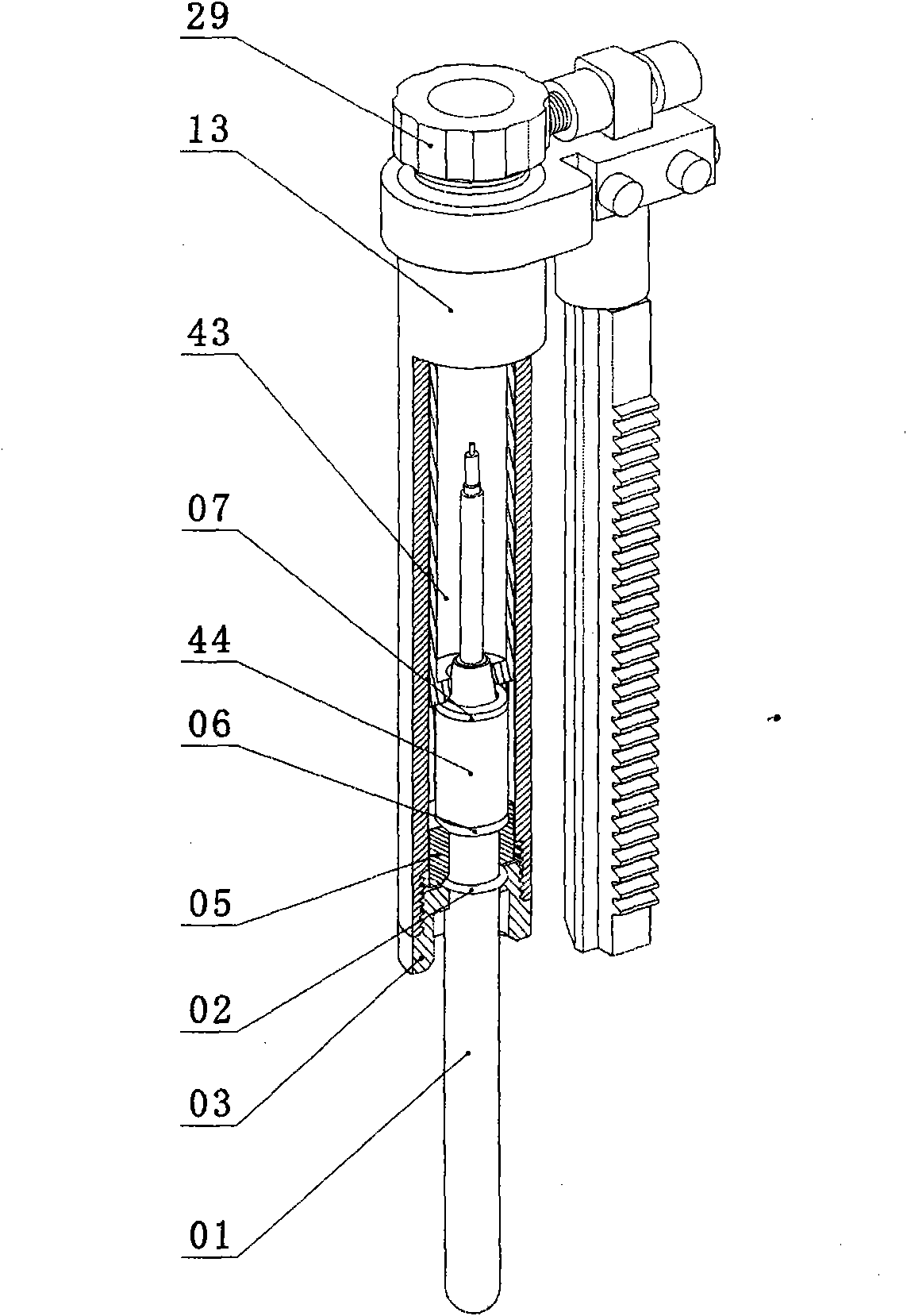

Movable mounting and dismounting device for mounting and dismounting bottom bolts of large equipment

ActiveCN108044341AStable supportPrecise positioningMetal working apparatusMotor driveReduction drive

The invention relates to the technical field of mounting and dismounting of mechanical equipment and discloses a movable mounting and dismounting device for mounting and dismounting bottom bolts of large equipment. The movable mounting and dismounting device comprises a moving frame, a jacking mechanism, a rack, a motor, a torque control display mechanism, a speed reducer, a sleeve, a lithium battery power supply and control switches; the torque control display mechanism is connected with the motor and controls the motor to output the torque; the jacking mechanism is fixedly arranged on a bottom plate of the moving frame; the rack is located above a top plate of the moving frame; the jacking mechanism is connected with the rack, supports the rack and controls the rack to rise or fall; themotor is arranged on a bottom plate of the rack; an output shaft of the motor is connected with the speed reducer; an output shaft of the speed reducer is connected with the sleeve; the motor drives the sleeve to rotate through the speed reducer; the lithium battery power supply supplies power to the motor and the jacking mechanism; and the control switches include a forward / reverse rotation switch, a rising / falling switch and a rotation switch. The device is moved under the large equipment conveniently by a worker, is safe and effort-saving to operate and is high in efficiency, a power inputline is not required to be dragged, passing of other equipment is not affected, and accurate control on the torque is realized.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

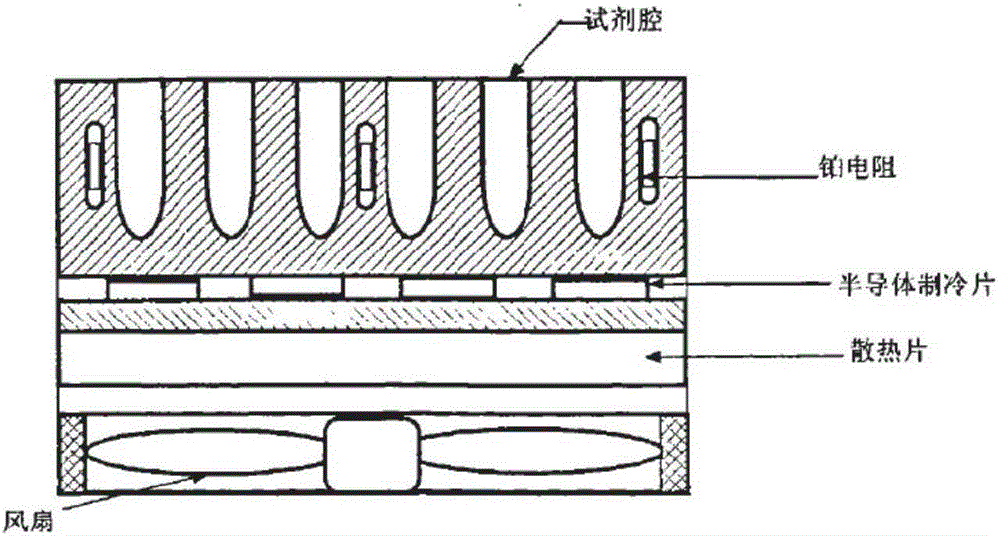

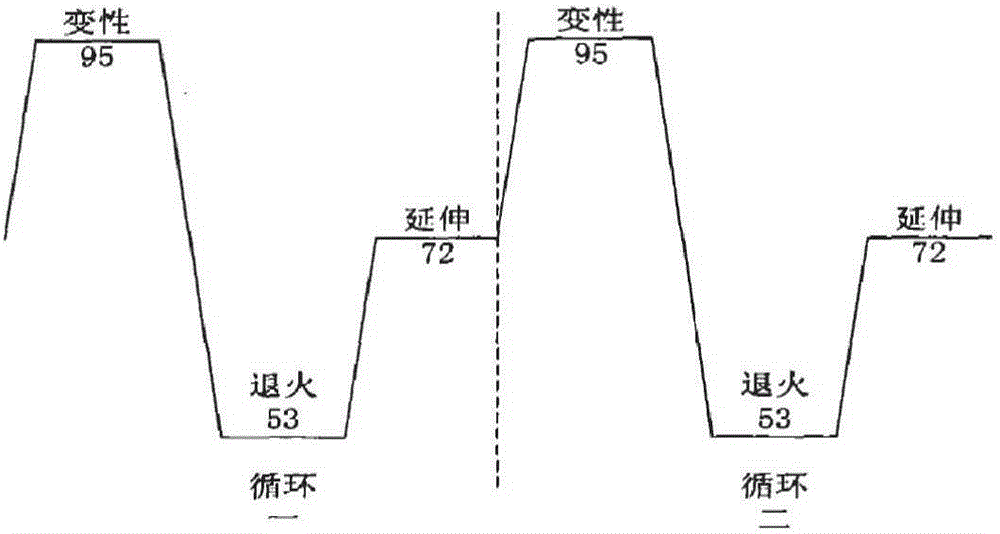

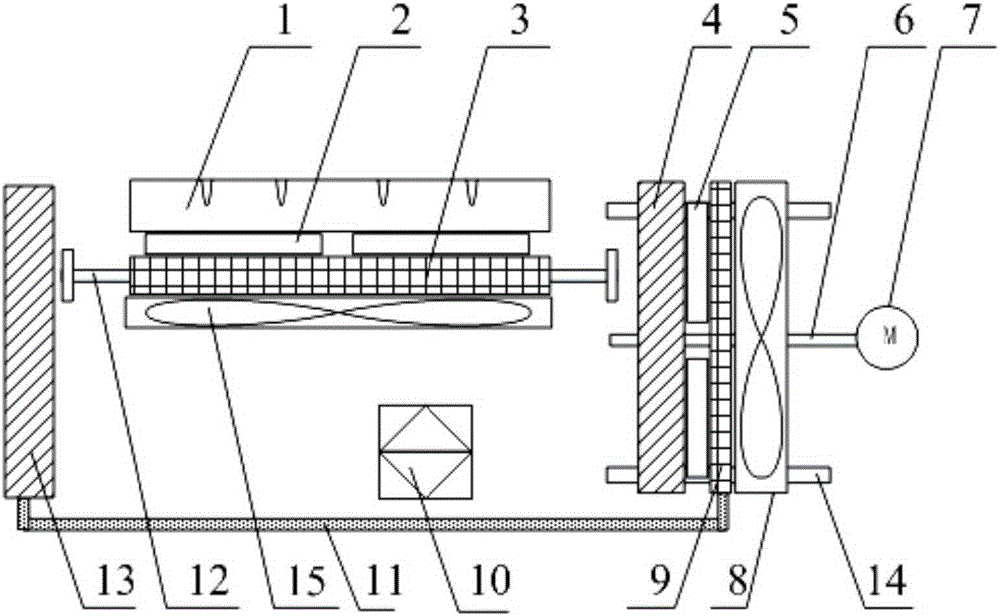

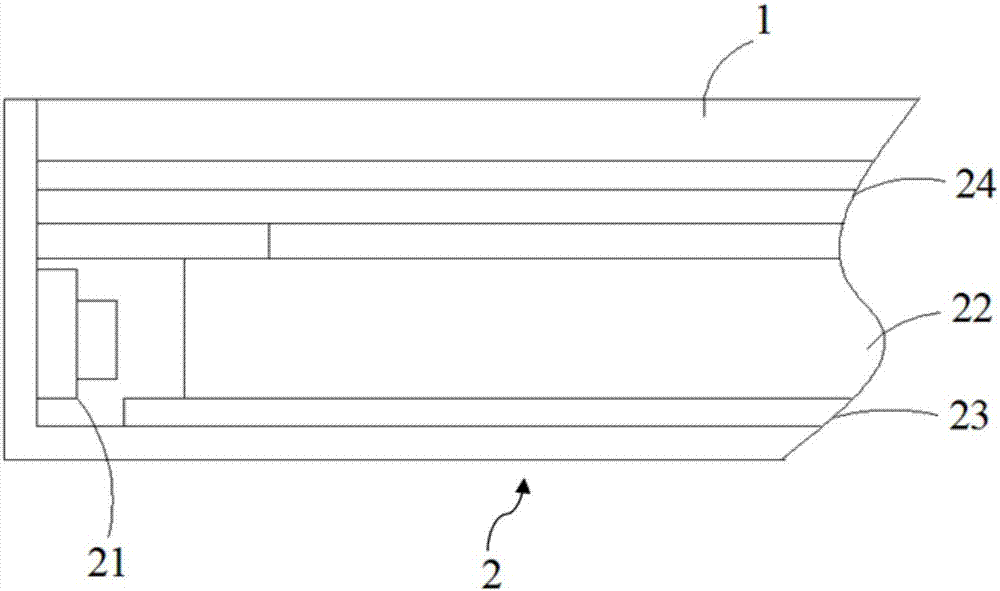

PCR (polymerase chain reaction) apparatus based on phase change thermal storage material and heat pipes

ActiveCN105219638AExport as soon as possibleImprove thermal conductivityBioreactor/fermenter combinationsBiological substance pretreatmentsHeat energyStorage material

The invention discloses a PCR (polymerase chain reaction) apparatus based on a phase change thermal storage material and heat pipes. The PCR apparatus comprises a reagent heating platform, a first semiconductor refrigerating sheet, a metal radiating plate, a first phase change thermal storage device, a second fan, a second semiconductor refrigerating sheet, a screw lever, a stepping motor, a first fan, a metal radiating fin, a controller, a first heat pipe, a second heat pipe, a second phase change thermal storage device, a sliding rail and a temperature sensor. According to the PCR apparatus disclosed by the invention, two heat switches are formed by the second phase change thermal storage device and one end of the second heat pipe as well as by the first phase change thermal storage device and the other end of the second heat pipe; with the design of the heat switches, a heat energy transmission direction is controlled, and with the use of the heat switches, heat conductivity is effectively improved; secondary utilization of waste heat is achieved by using the phase change material; and compared with original design schemes, the invention, mentioned above, can improve a heating rate by more than one time, improve a cooling rate by more than two times and meanwhile reduce total power consumption of equipment by a half; therefore, the invention is of great significance to updating and upgrading of the PCR apparatus.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

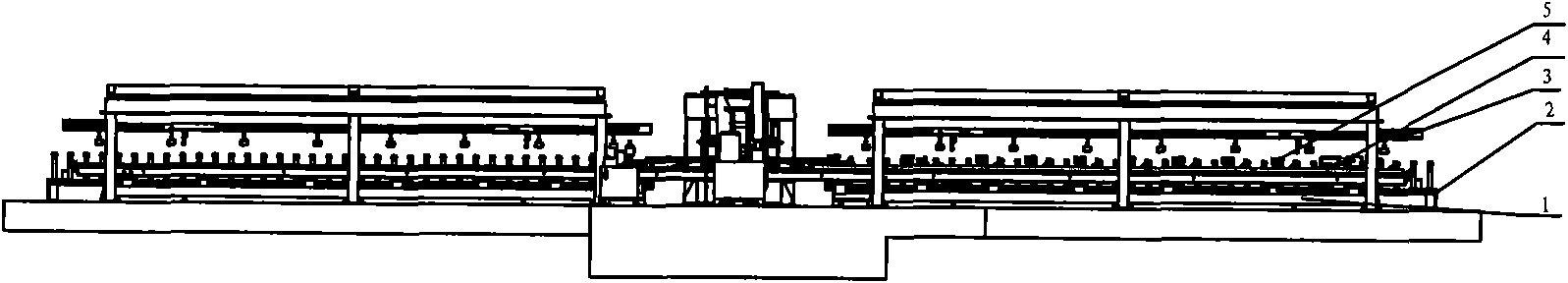

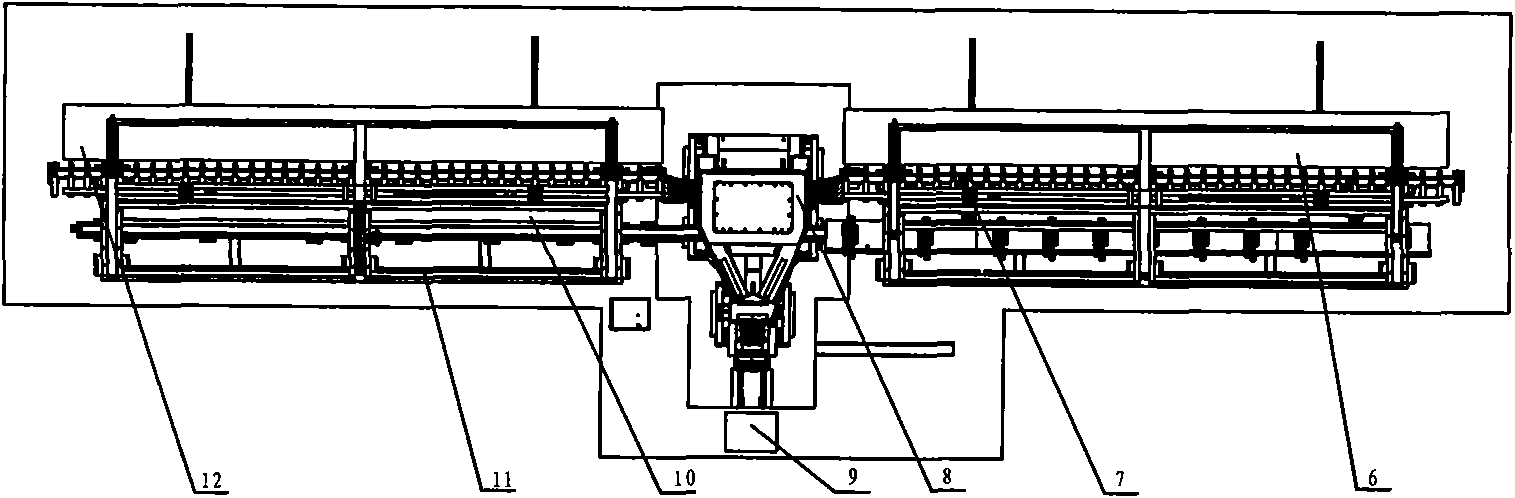

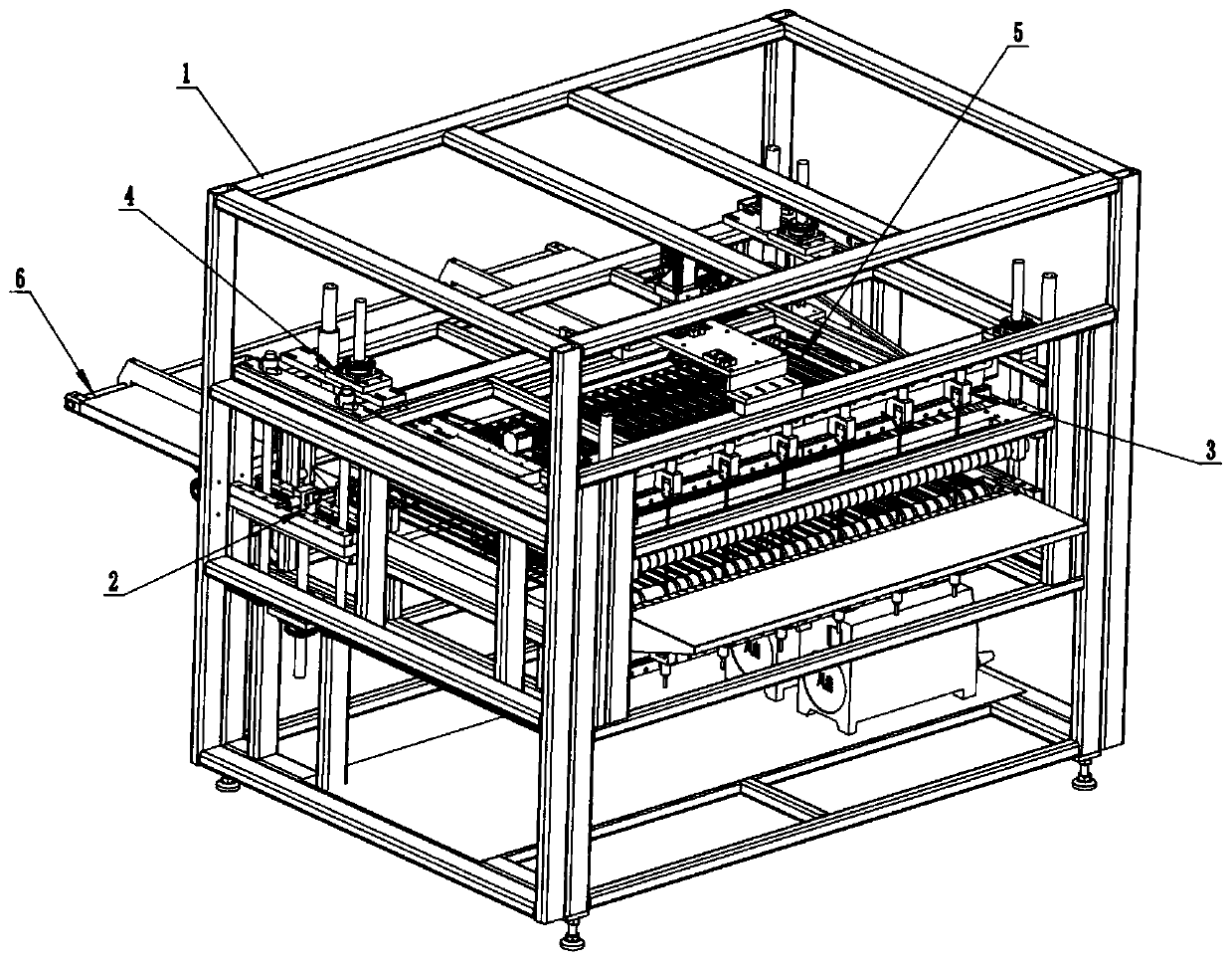

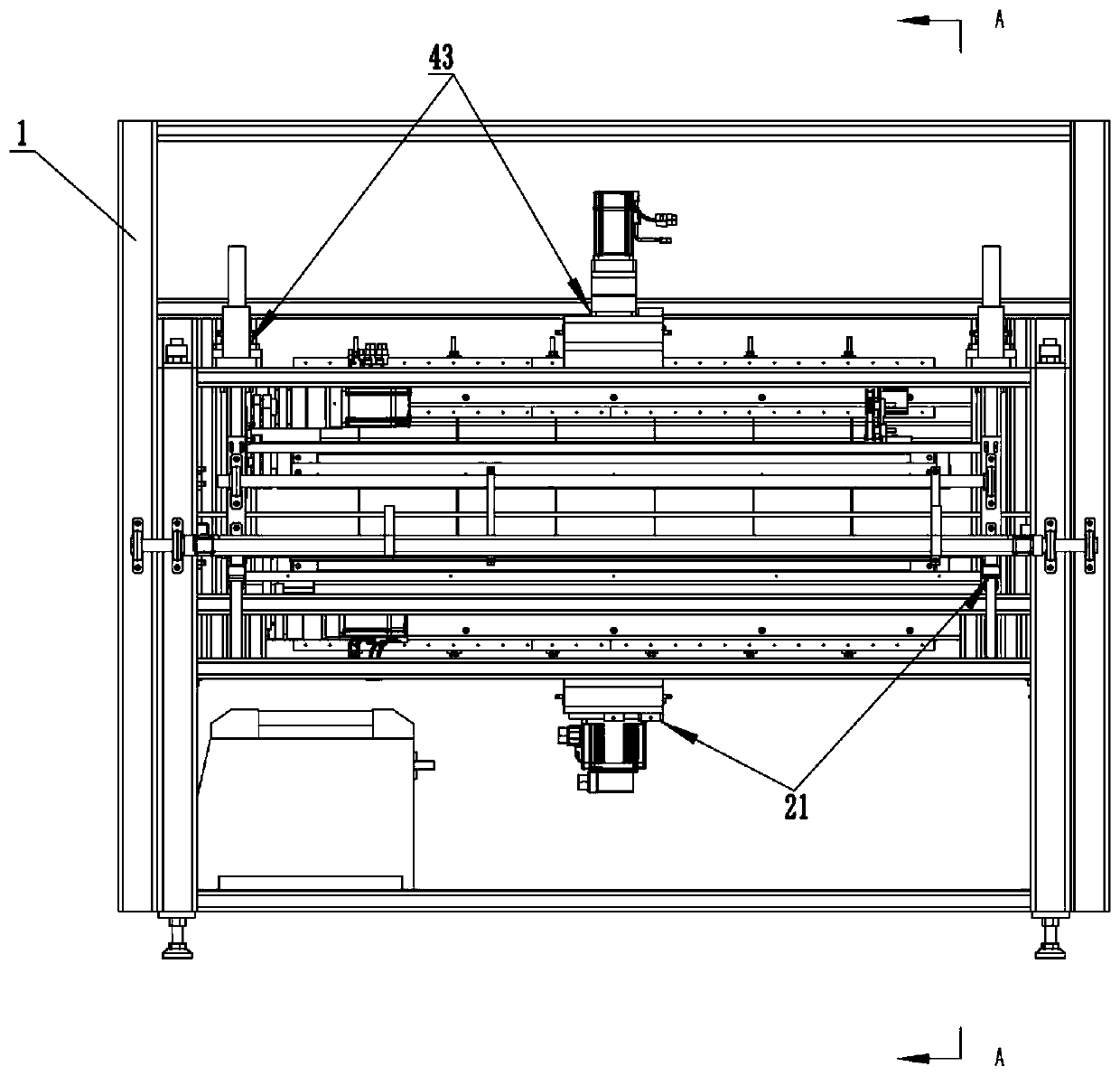

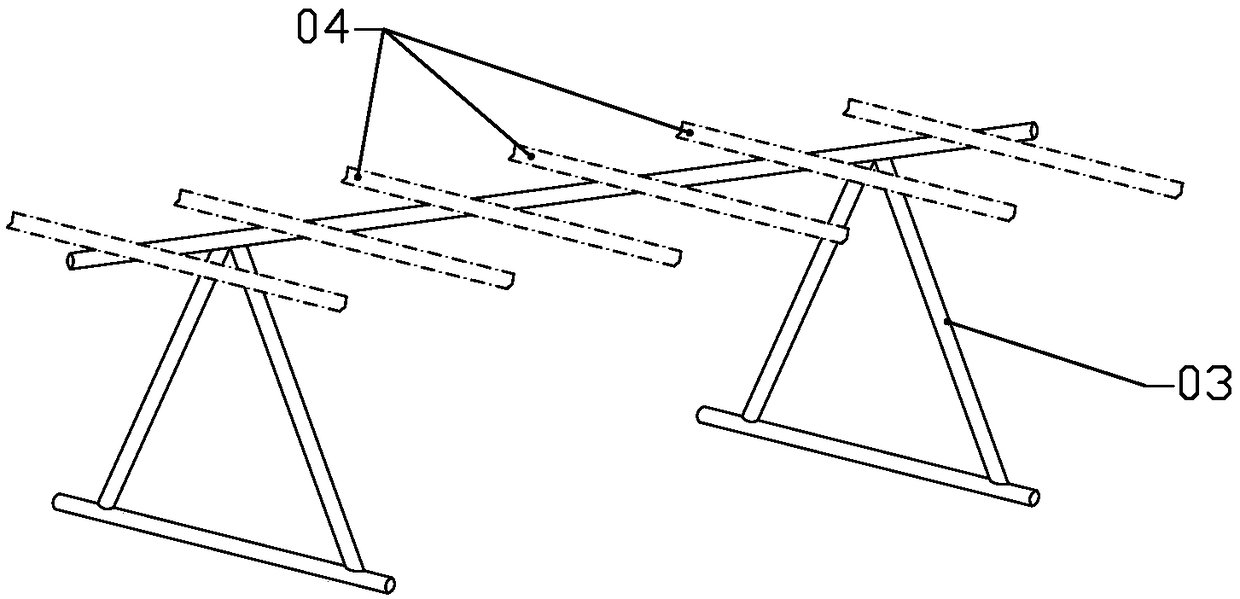

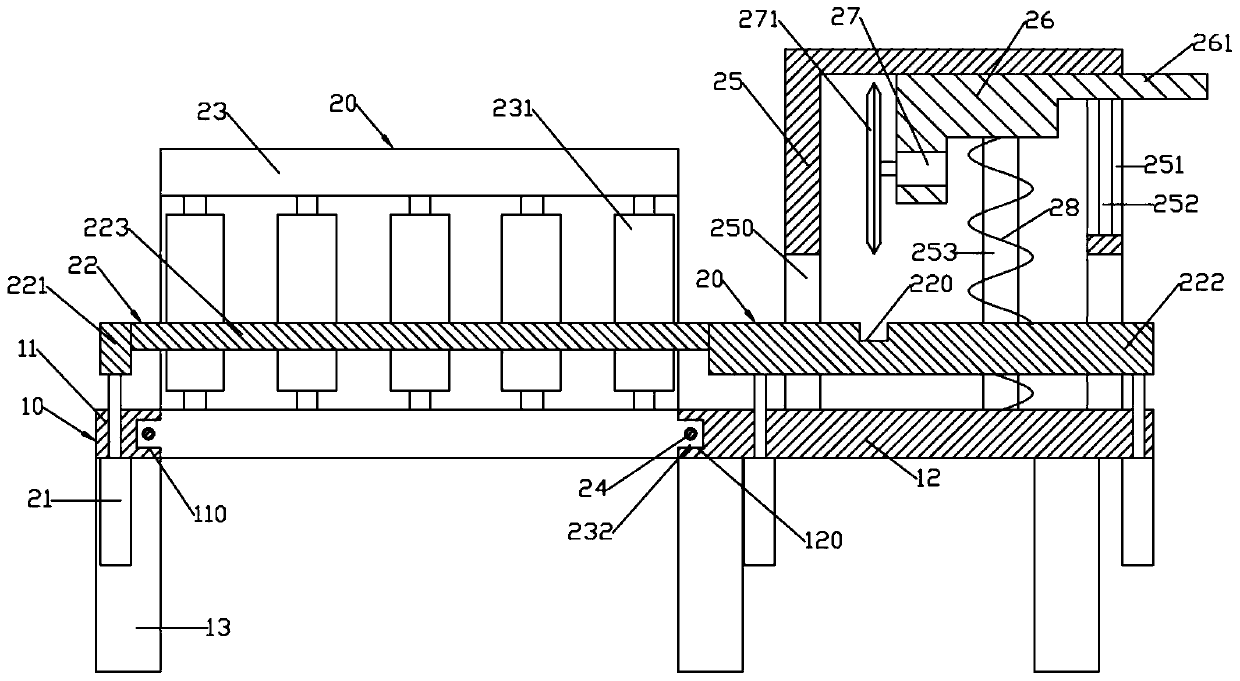

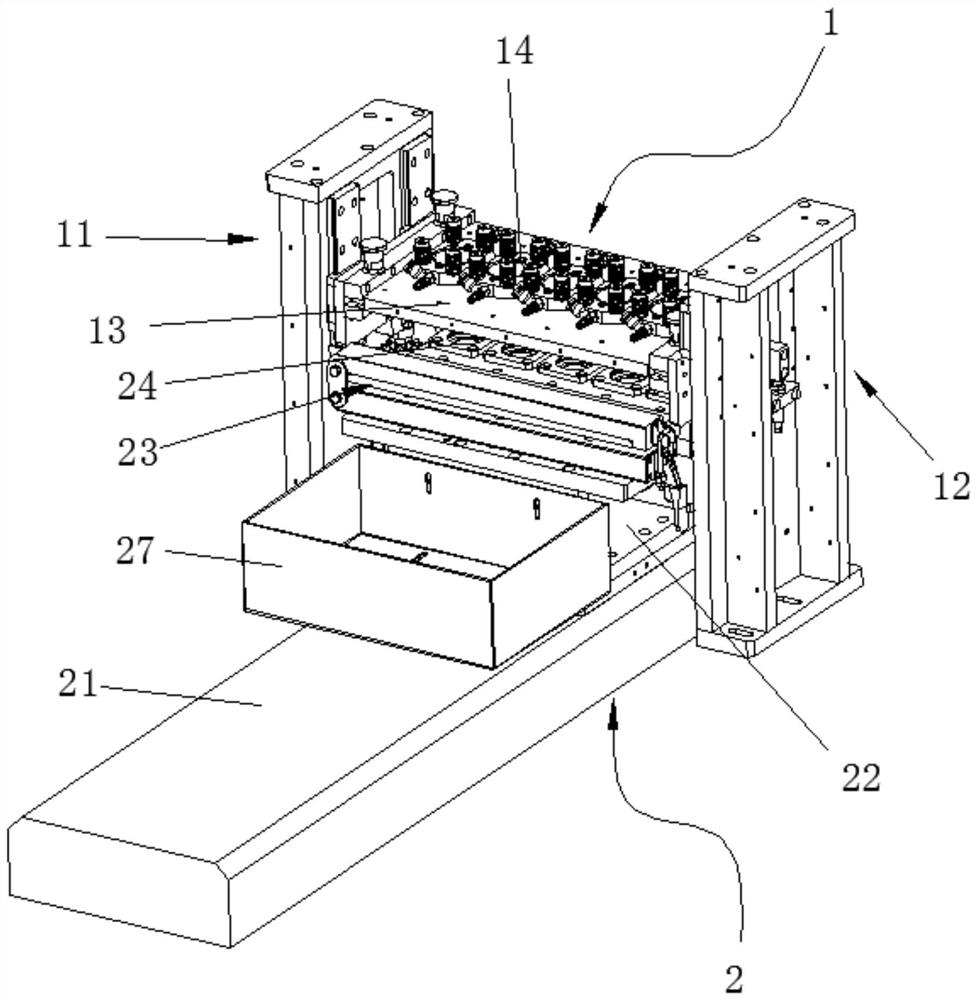

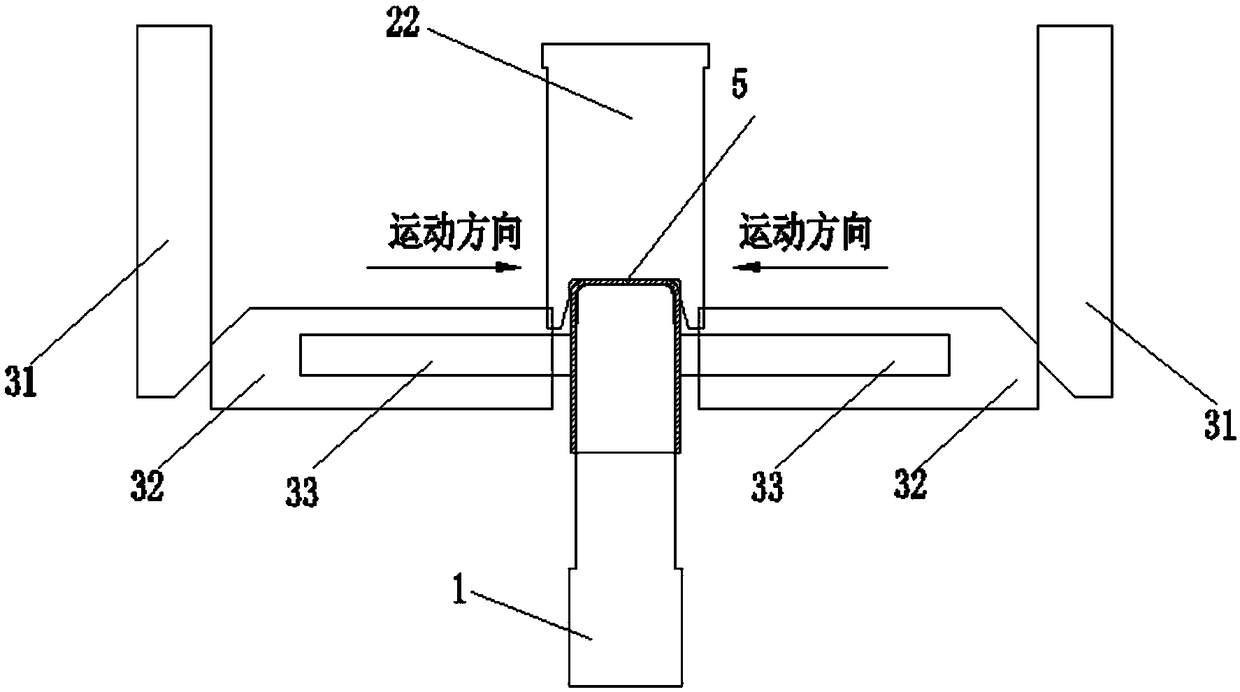

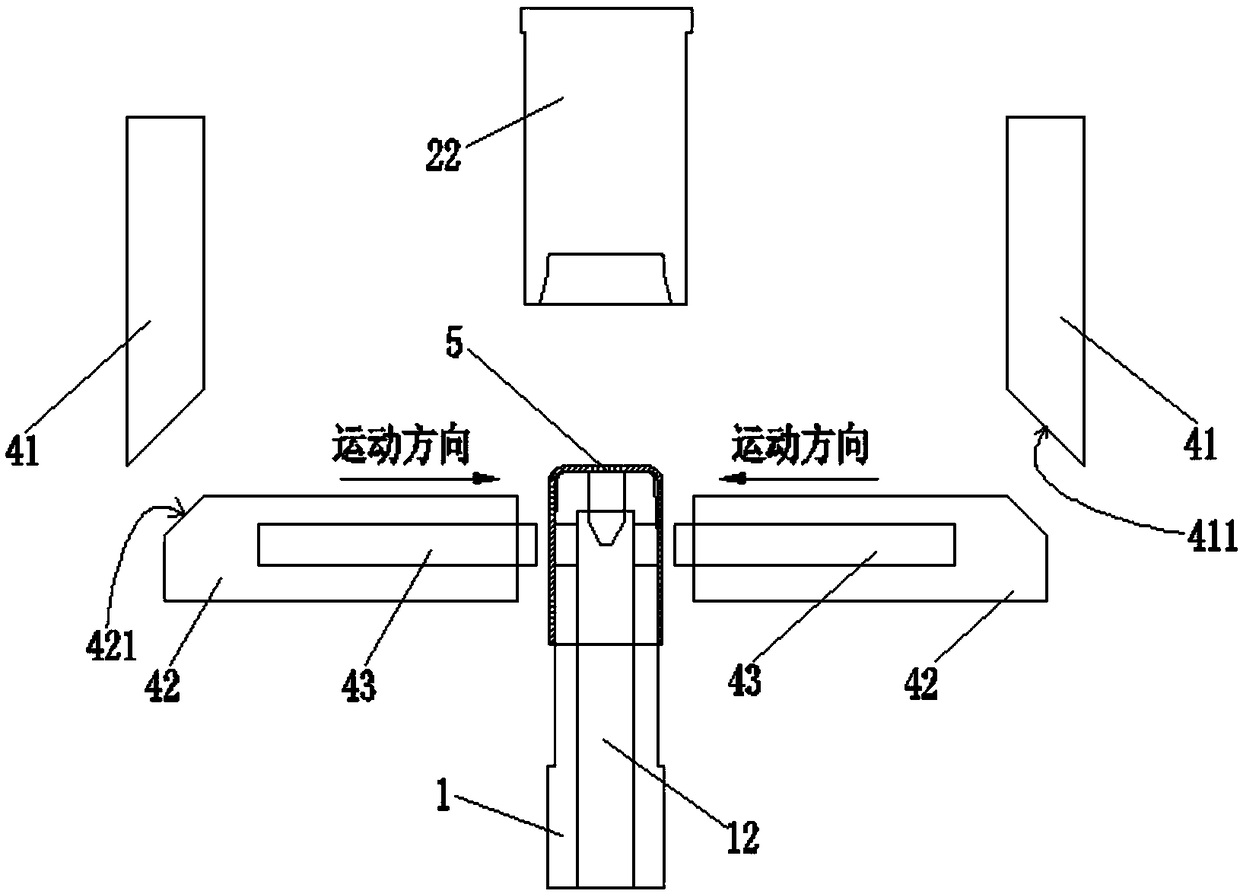

Numerical control punching machine for longitudinal beam of automobile

The invention discloses a numerical control punching machine for a longitudinal beam of an automobile, and relates to a molding machine special for large plates. A host machine comprises a three-column closed A-type body, a sliding block, a sliding block driving device and a workbench; the workbench is provided with a floating supporting device; the sliding block is provided with a pressing device; a discharging device comprises a discharging base, a blanking bracket and a blanking trolley; a feeding device comprises a feeding base, a beam moveably connected among the feeding base, the workbench and the discharging base, a loading trolley, a loading bracket, a lifting device, a gripping mechanism fixedly connected on two sides of the top surface of the beam, and a centering device arranged on the loading bracket; the loading bracket is provided with a roller set, the centering device is arranged on two sides of the roller set; the gripping mechanism is arranged on the two sides of the roller set and positioned between the centering device and the workbench in the feeding direction; and a jaw of the gripping mechanism is slightly higher than the top surface of the floating supporting device. The numerical control punching machine has the advantages of high automation degree, low manufacturing lost of corresponding mold, and high reliability and adaptability.

Owner:江苏扬力数控机床有限公司

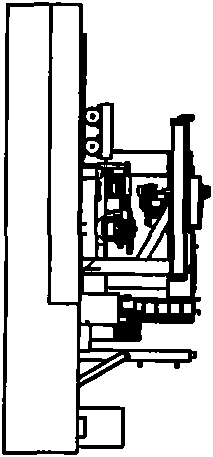

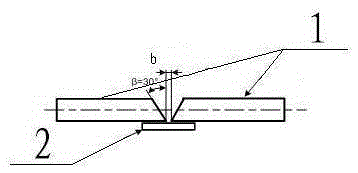

Rebar groove welding method

InactiveCN104117762ASolve the problem of easy air hole defectsImprove pass rateArc welding apparatusMetal working apparatusRebarSlag

The invention discloses a rebar groove welding method. The rebar groove welding method includes the following steps that first, preparation is made before welding, wherein two rebars needing to be welded are paired, and grooves of the rebars are correspondingly arranged horizontally; second, positioned welding is performed, wherein gas metal arc welding is performed with a flux-cored wire which can generate titania-calcium type slag after melting, and spot welding used for positioning is performed on the two sides of the rebars needing to be welded through electric arcs; third, gas metal arc welding is performed through the flux-cored wire which can generate titania-calcium type slag after melting, the welding time of the first layer ranges from 0.5 min to 1 min, and main weld beads of the rebars and reinforced weld beads of a base plate are welded layer by layer, wherein for the main weld beads, electric arcs make linear reciprocating motion along the main weld beads of the rebars, the welding current I ranges from 280 A to 300 A, the arc voltage U ranges from 24 V to 25 V, and the welding speed ranges from 35 cm / min to 50 cm / min; for the reinforced weld beads, electric arcs make linear motion along the reinforced weld beads of the base plate, the welding current I ranges from 260 A to 280 A, the arc voltage U ranges from 23 V to 24 V, and the welding speed ranges from 20 cm / min to 35 cm / min. The rebar groove welding method has the advantages of being easy and convenient to use, high in production efficiency, stable in welding quality, resistant to rust, less in included slag and free of pore defects.

Owner:STATE GRID CORP OF CHINA +1

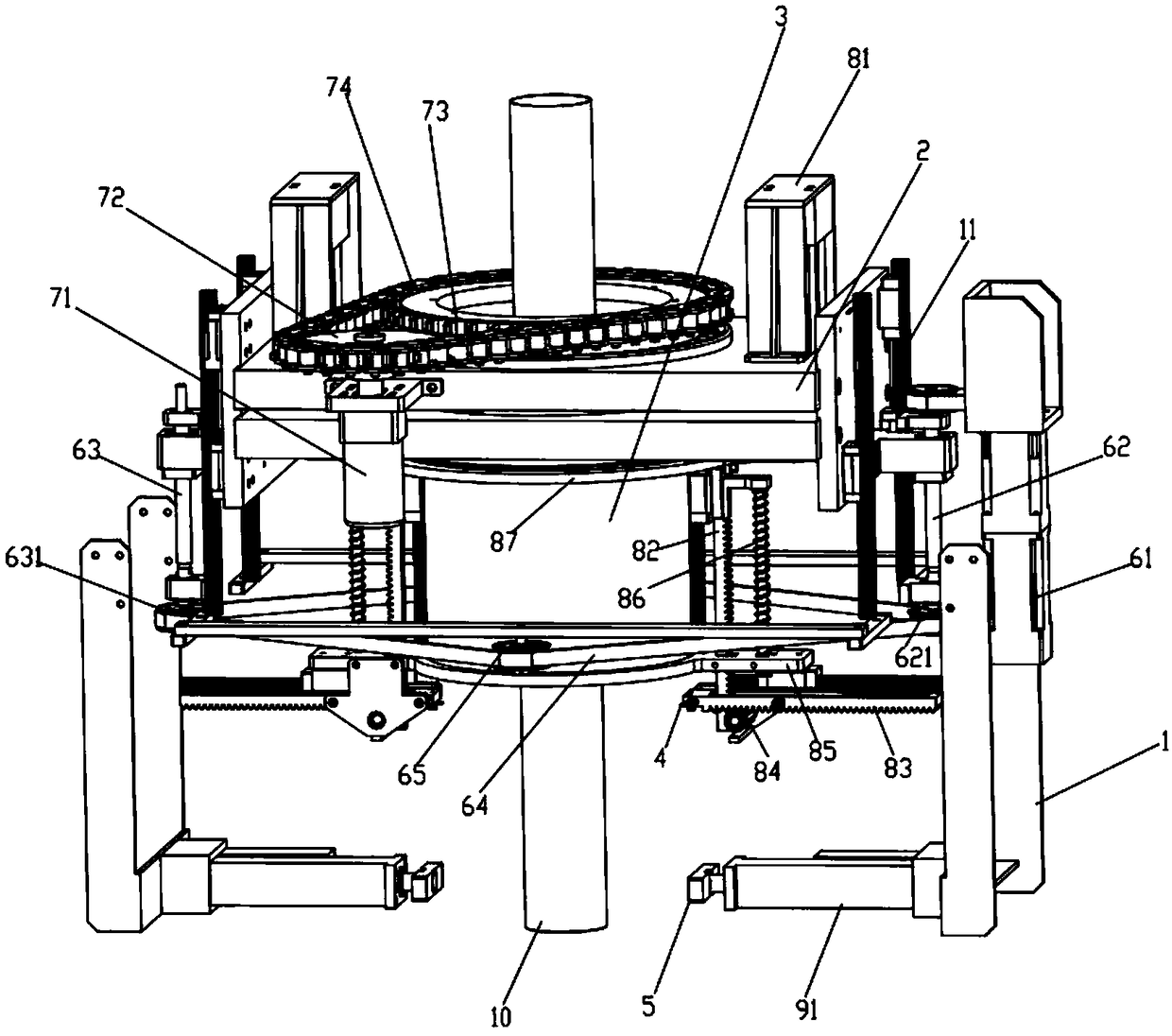

Suction type robot hand grab applied to circular arc surface workpieces

ActiveCN104772763AImprove gripIncrease absorptionGripping headsStacking articlesRobot handEngineering

The invention provides a suction type robot hand grab applied to circular arc surface workpieces. The suction type robot hand grab is arranged at the movable end of a robot, and is used for grabbing the circular arc surface workpieces. The hand grab comprises a connecting plate connected with the movable end of the robot and more than one bracket arranged on the connecting plate, wherein each bracket is provided with a driving device and a suction unit connected with the driving device; the driving devices are arranged on the brackets, and pushing parts of the driving devices are connected with the suction units; the suction units are arranged at the bottom of the connecting plate; suction points of the suction units and the workpieces are circumferentially distributed in a manner that the centers of the workpieces are centers of circles. The suction type robot hand grab applied to the circular arc surface workpieces is simple and compact in structure, high in universality and applicable to circular arc surface workpieces in different specifications; the workpieces can be stably grabbed in a rapid movement process of the robot, so that the problem about match between the hand grab and the workpieces is effectively solved, the grabbing balance and stability of the hand grab are improved, and production efficiency is improved.

Owner:广东泰格威机器人科技有限公司

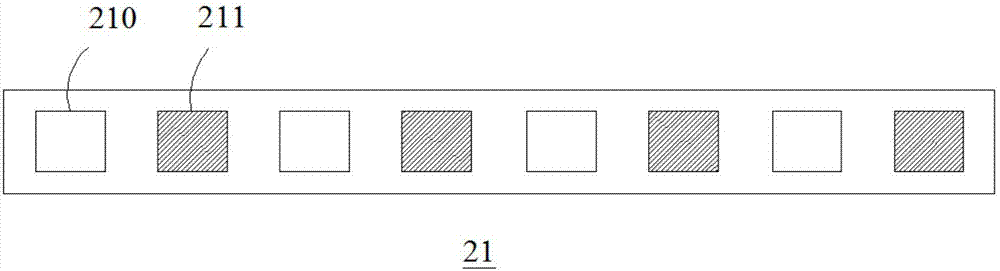

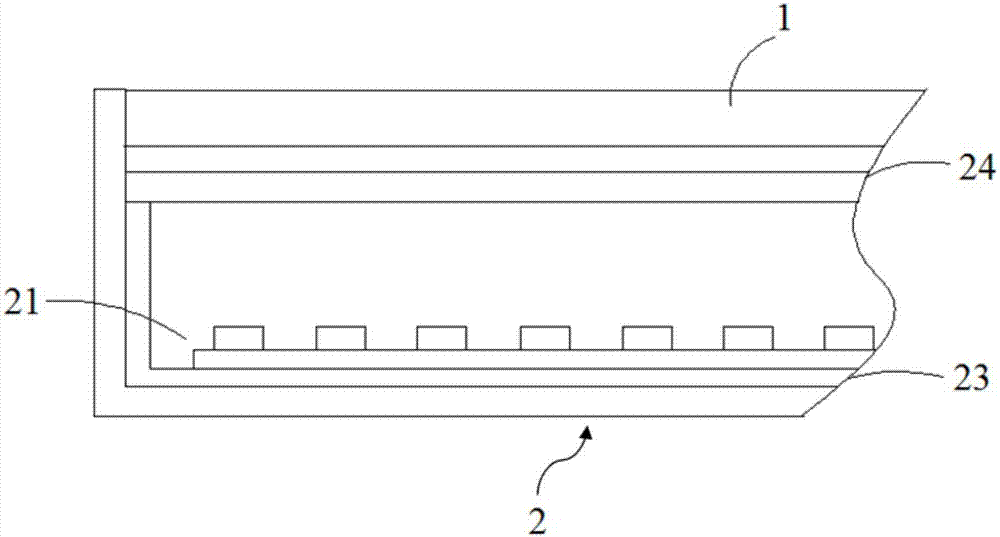

Liquid crystal display and low-blue-ray display control system and low-blue-ray display method thereof

ActiveCN107966859AGuaranteed not to shiftReduce shortwave blue light energyStatic indicating devicesOptical light guidesLiquid-crystal displayGamut

The invention provides a liquid crystal display and a low-blue-ray display control system and low-blue-ray display method thereof. The low-blue-ray display method of the liquid crystal display comprises partitioning a backlight source to obtain a plurality of backlight partitions which contain a first light emitting peak and a second light emitting peak, wherein the first light emitting peak is higher than the second light emitting peak; separately calculating the blue ray proportion of the display frame corresponding every backlight partition to acquire the blue ray proportion of every backlight partition; according to the blue ray proportion of every backlight partition, driving the first light emitting peak and / or the second light emitting peak. The low-blue-ray display method can ensure no offset of white dot coordinates and no reduction in display range when short-wave blue ray energy is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for fixing embedded part of large foundation side wall

InactiveCN101672038AGuaranteed not to shiftGuaranteed installation accuracyFoundation engineeringBuilding constructionsEngineeringEmbedded system

Owner:TIANJIN 20 CONSTR

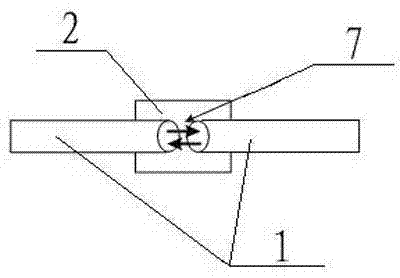

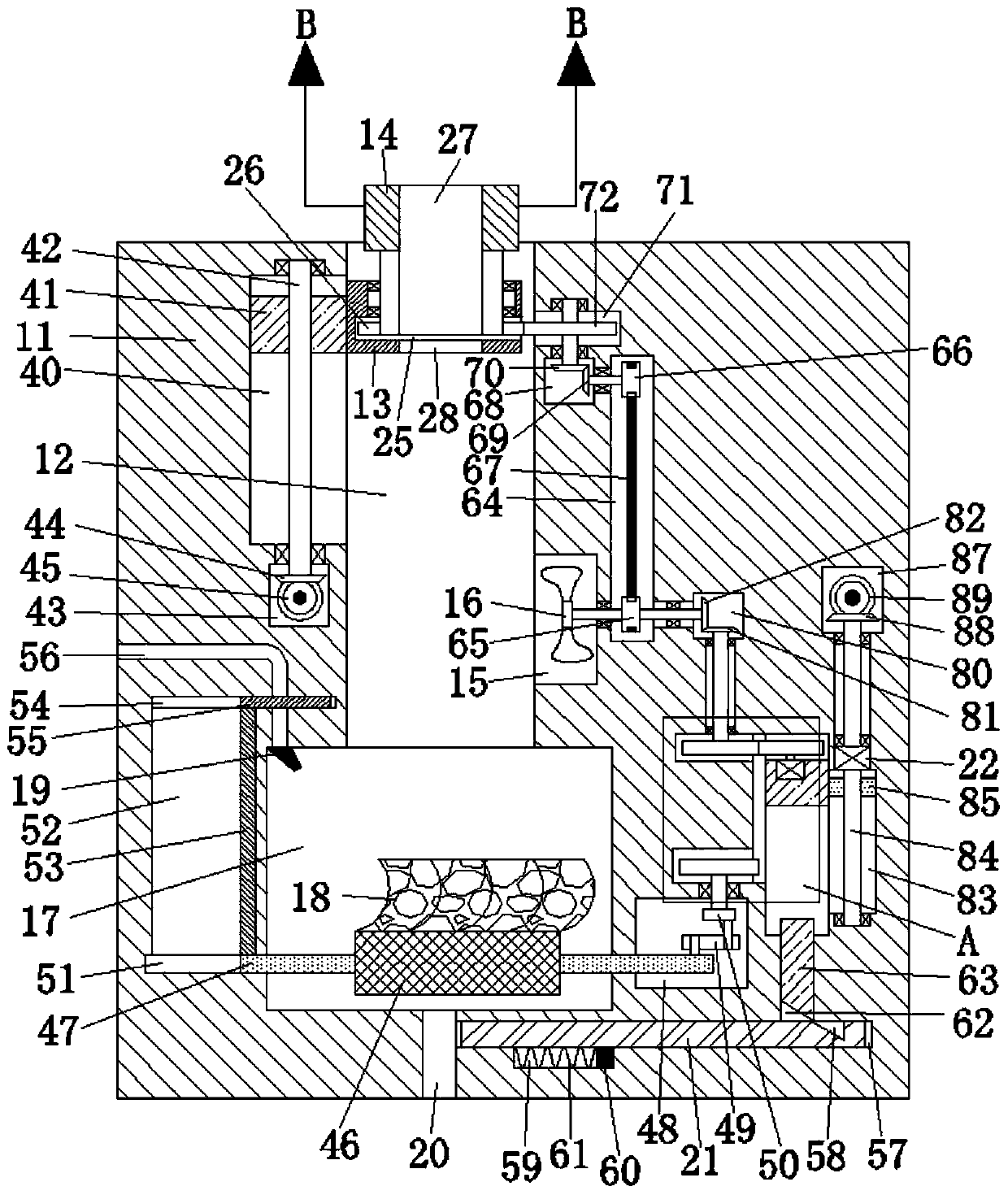

Brush head cleaning device for writing brush

ActiveCN110816118AEffective protectionEven by forceDrying gas arrangementsNib removersMechanical engineeringMaterials science

The invention discloses a brush head cleaning device for a writing brush. The brush head cleaning device comprises a device body, wherein a clamping lifting device is arranged in the device body; an air drying device is arranged on the right side of the clamping lifting device; a cleaning device is arranged on the lower side of the clamping lifting device; a control device is arranged on the rightside in the device body; the clamping lifting device comprises a lifting cavity; the lifting cavity is arranged in the device body and is provided with an upward opening; a lifting plate is slidablyarranged in the lifting cavity; and a clamping block is rotatably arranged at the upper side of the lifting plate. The clamping block clamps a brush holder, and then the lifting plate drives the writing brush to descend to dip the brush head into the cleaning device; and when the brush head cleaning device is used for cleaning the brush head, the writing brush is firstly washed while being brushed, and then air-dried while rotating, the writing brush head can be effectively protected in an air drying mode, and meanwhile, the writing brush head can be uniformly stressed by rotating, so that thenon-deviation and good uniformity are guaranteed.

Owner:SUZHOU XINYAO HEALTH TECH CO LTD

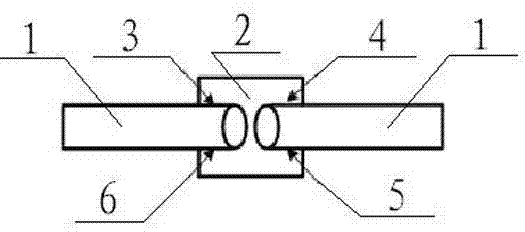

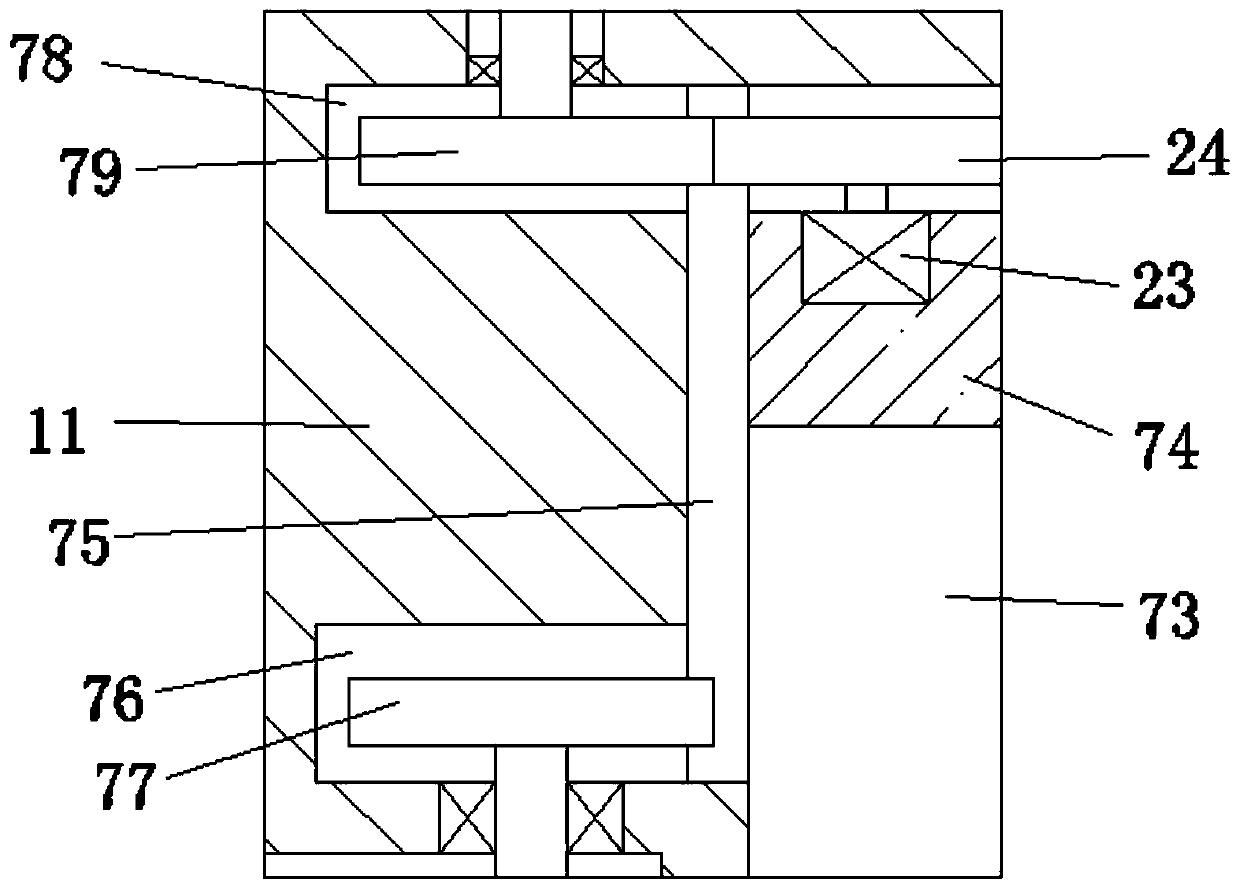

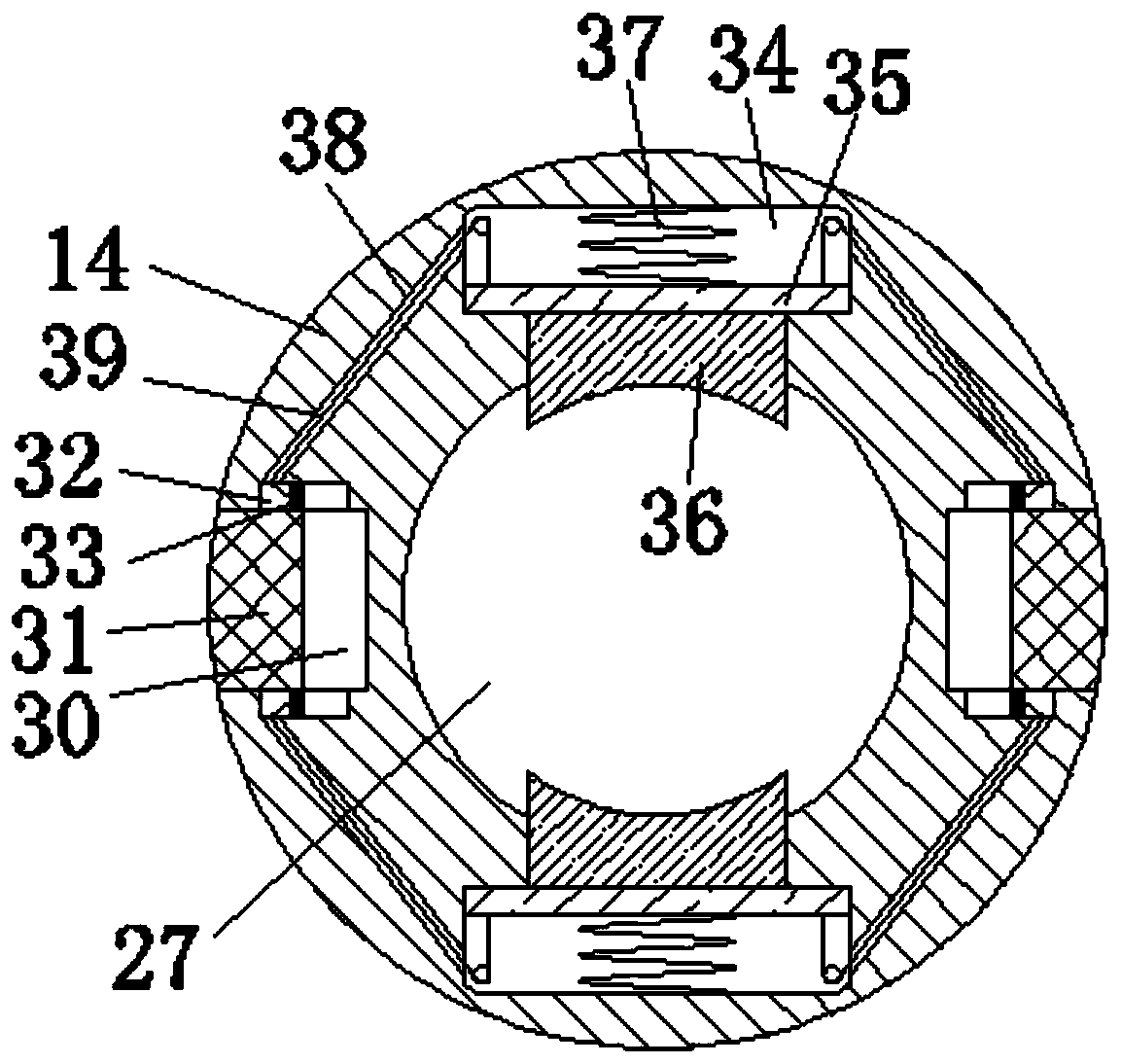

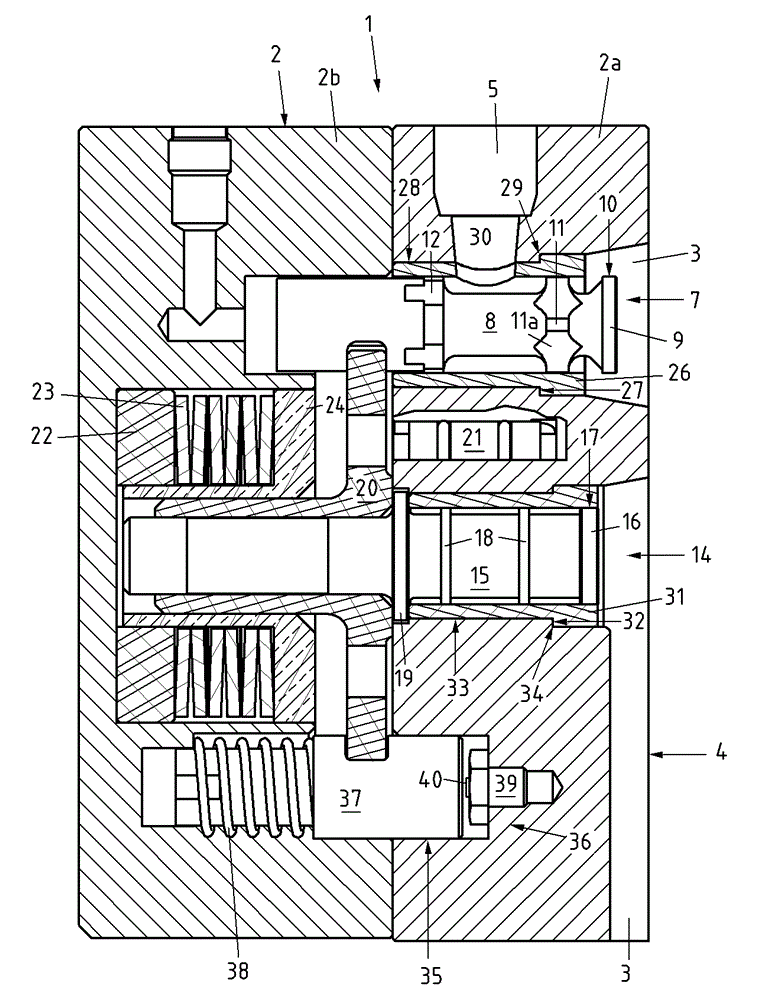

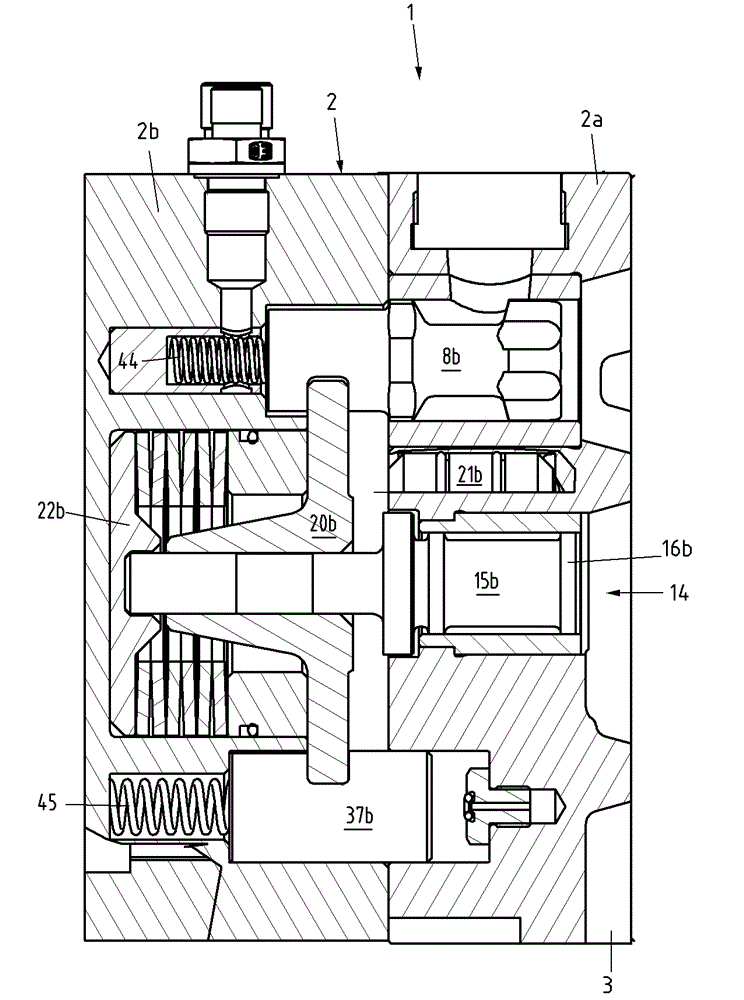

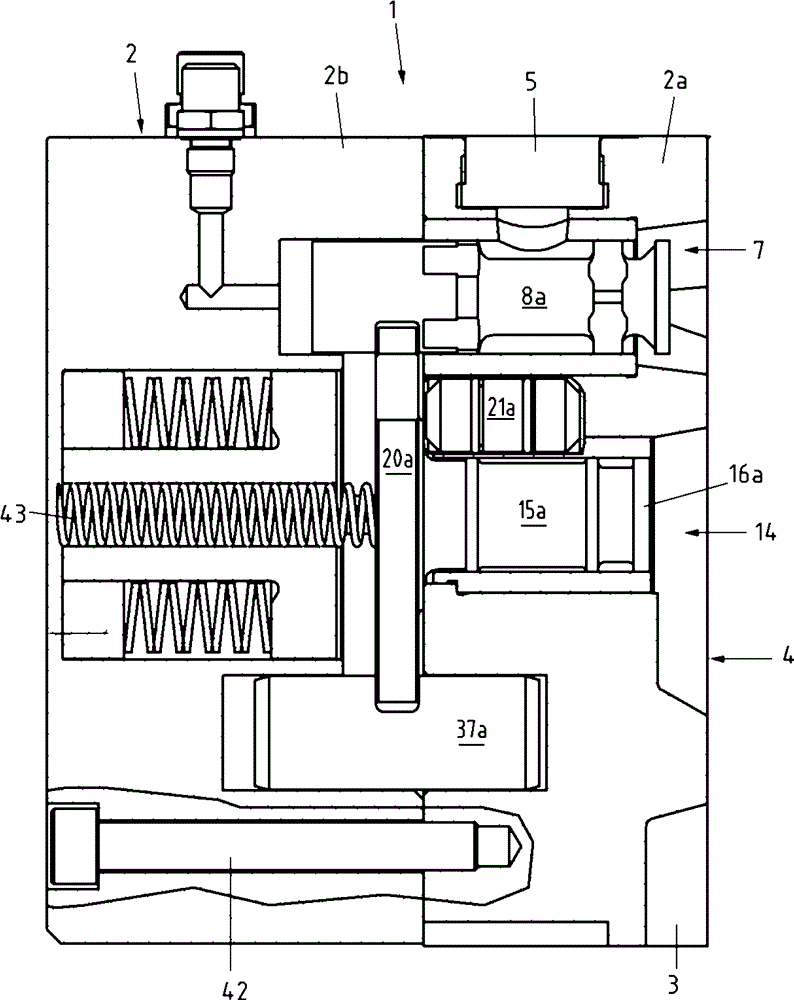

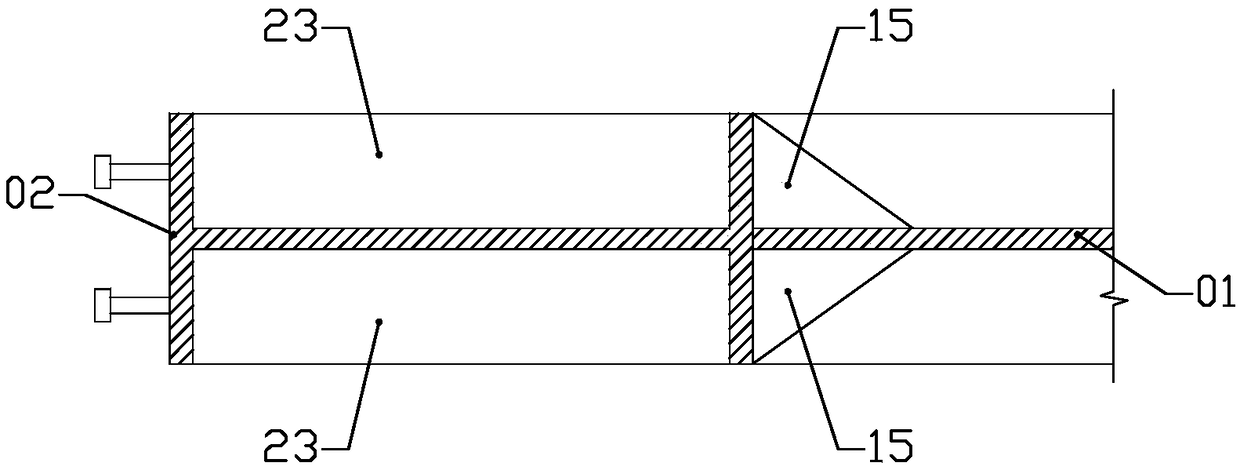

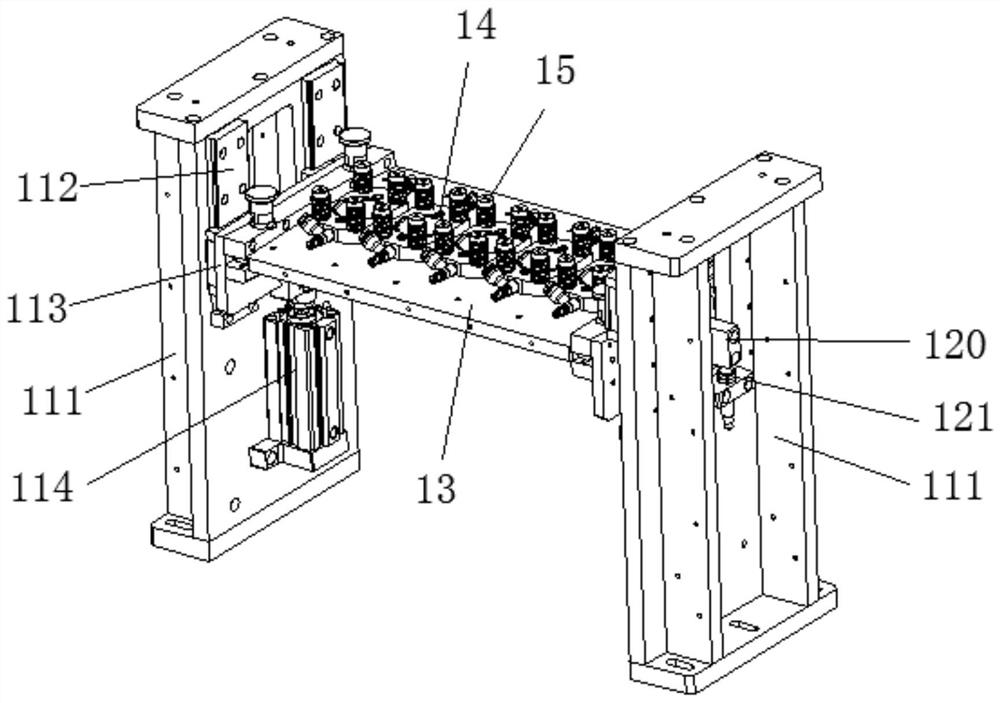

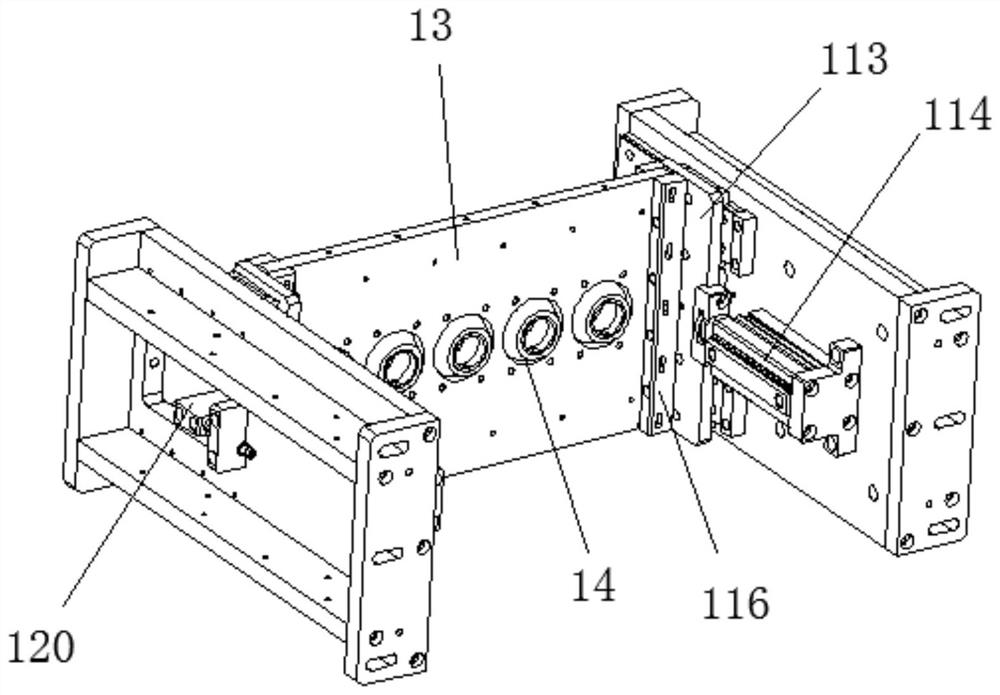

Exhaustion valve assembly in die-casting mold

InactiveCN106180630AGuaranteed not to shiftPrecise positioningOperating means/releasing devices for valvesFoundry mouldsExhaust valveEngineering

To provide an exhaustion valve assembly in a die-casting mold manufactured relatively inexpensively even while having abrasion resistance. The valve assembly 1 includes a valve housing 2 divided into two parts. Exhaust ducts 3 and 5 closable by an exhaust valve 7 are provided in the front housing part 2a, an actuator 14 for operating the valve piston 8 of the exhaust valve 7 is housed in the housing 2, and the actuator 14 includes a force converter 15 operated by a casting material, and a force transmission member 20 for transmitting the closing motion of the force converter 15 to the valve piston 8 of the exhaust valve 7, and further includes a laminate spring assembly 23 for returning the actuator 14 and / or discharging a riser.

Owner:FONDAREX

Transversal-vertical slitting machine for pearl wool

PendingCN110576474AGuaranteed to be straightHigh precisionMetal working apparatusEngineeringElectrical and Electronics engineering

The invention relates to the technical field of pearl wool processing, and particularly relates to a transversal-vertical slitting machine for pearl wool. The transversal-vertical slitting machine forthe pearl wool comprises a rack as well as a transversal slitting device, a vertical slitting device and a feeding guide roll device which are installed on the rack, wherein the transversal slittingdevice comprises a transversal slitting lifting mechanism and a transversal slitting heat knife group, the transversal slitting heat knife group is installed on the transversal slitting lifting mechanism and used for lifting movement, the vertical slitting device comprises a vertical slitting translation support and a plurality of groups of vertical slitting heat knife groups, and the plurality ofgroups of vertical slitting heat knife groups are movably installed on the vertical slitting translation support; and the feeding guide roll device comprises a first guide roll mechanism and a secondguide roll mechanism, and the first guide roll mechanism and the second guide roll mechanism are arranged at the upper side and the lower side of a charge direction. The transversal-vertical slittingmachine for the pearl wool further comprises a charge induction mechanism arranged on the rack. The transversal-vertical slitting machine for the pearl wool is conducive to increasing the cutting accuracy for the pearl wool, reducing the cutting deviation, ensuring more accurate dimensions of the cut pearl wool, and increasing the cutting efficiency.

Owner:广州千宝机械实业有限公司

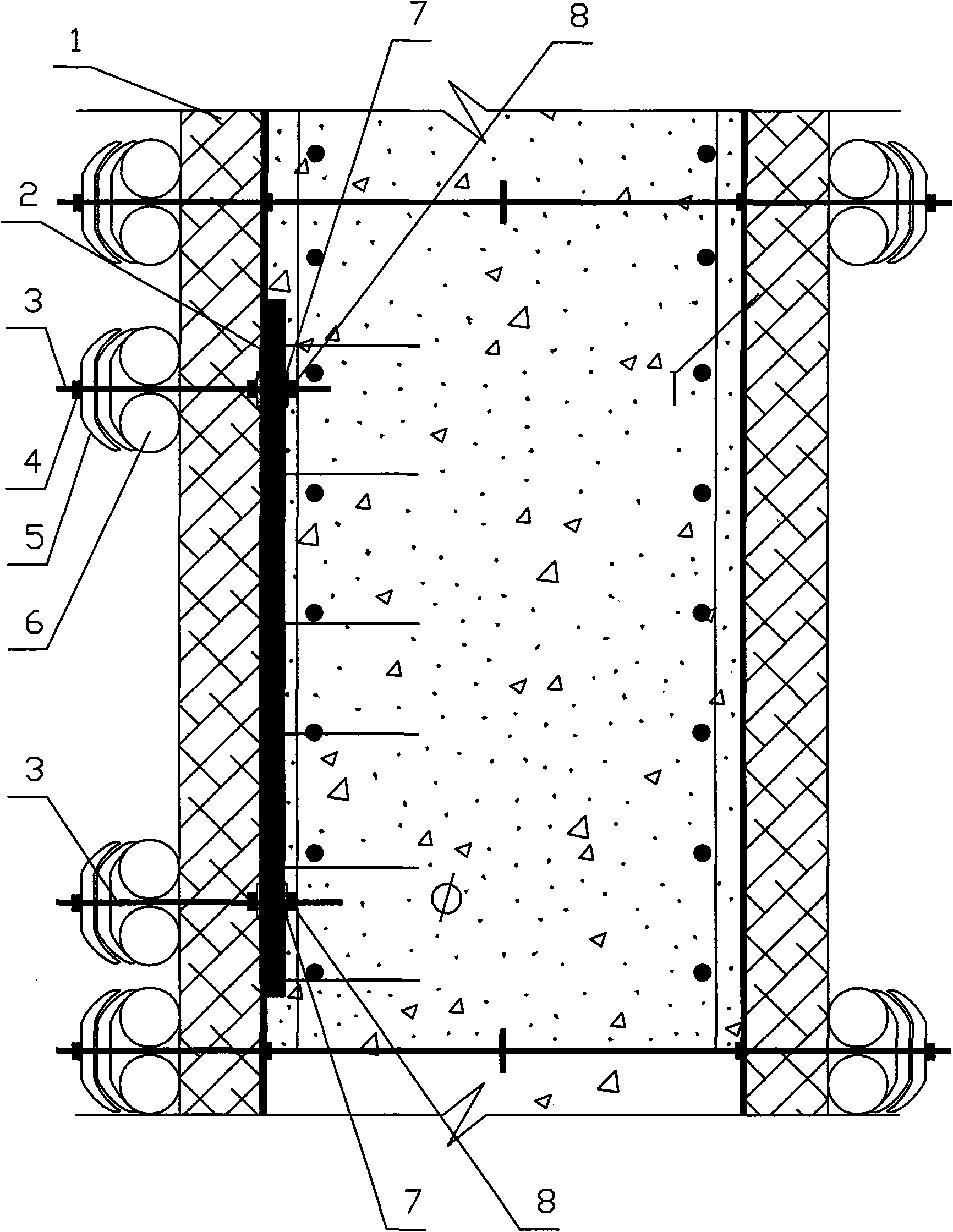

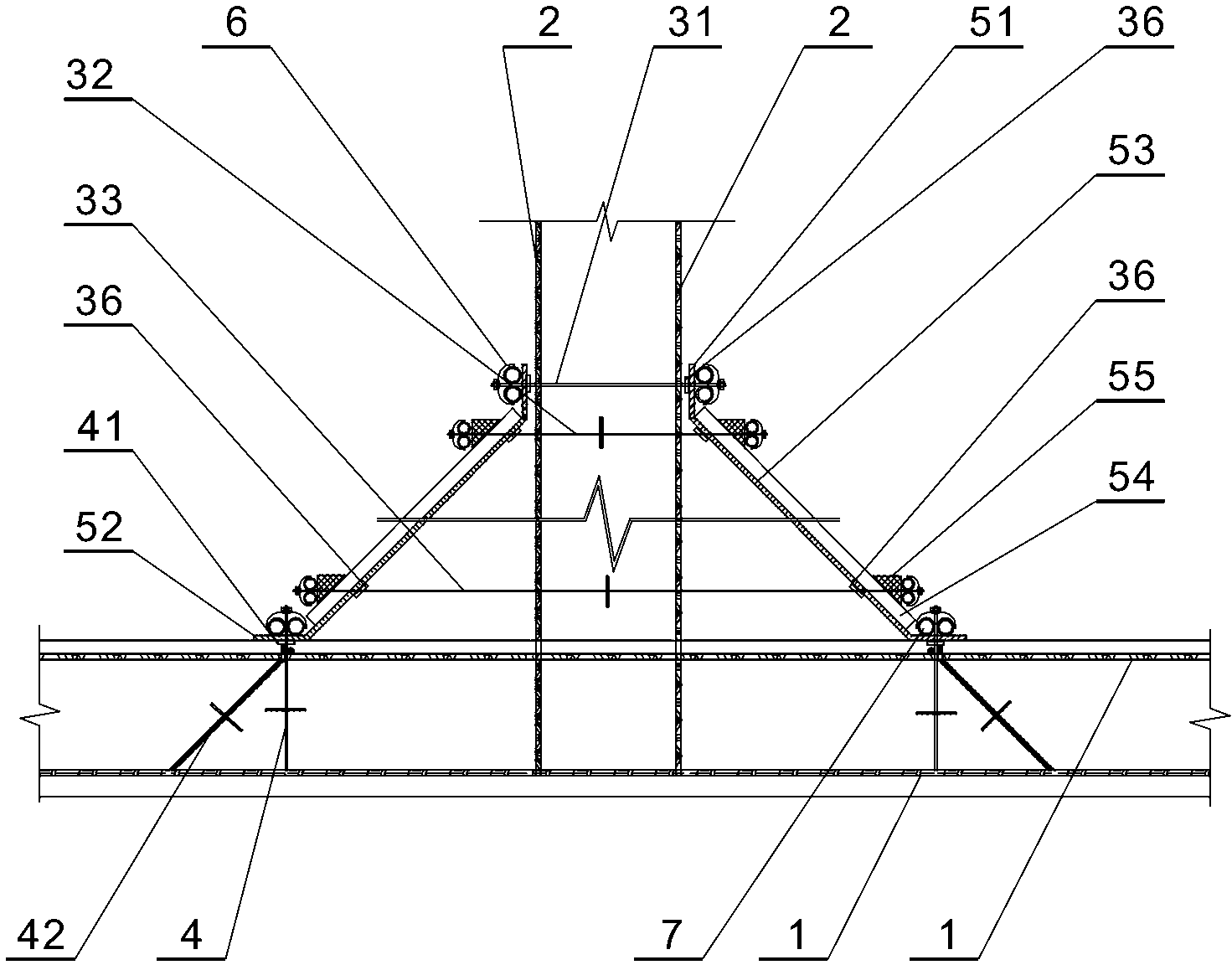

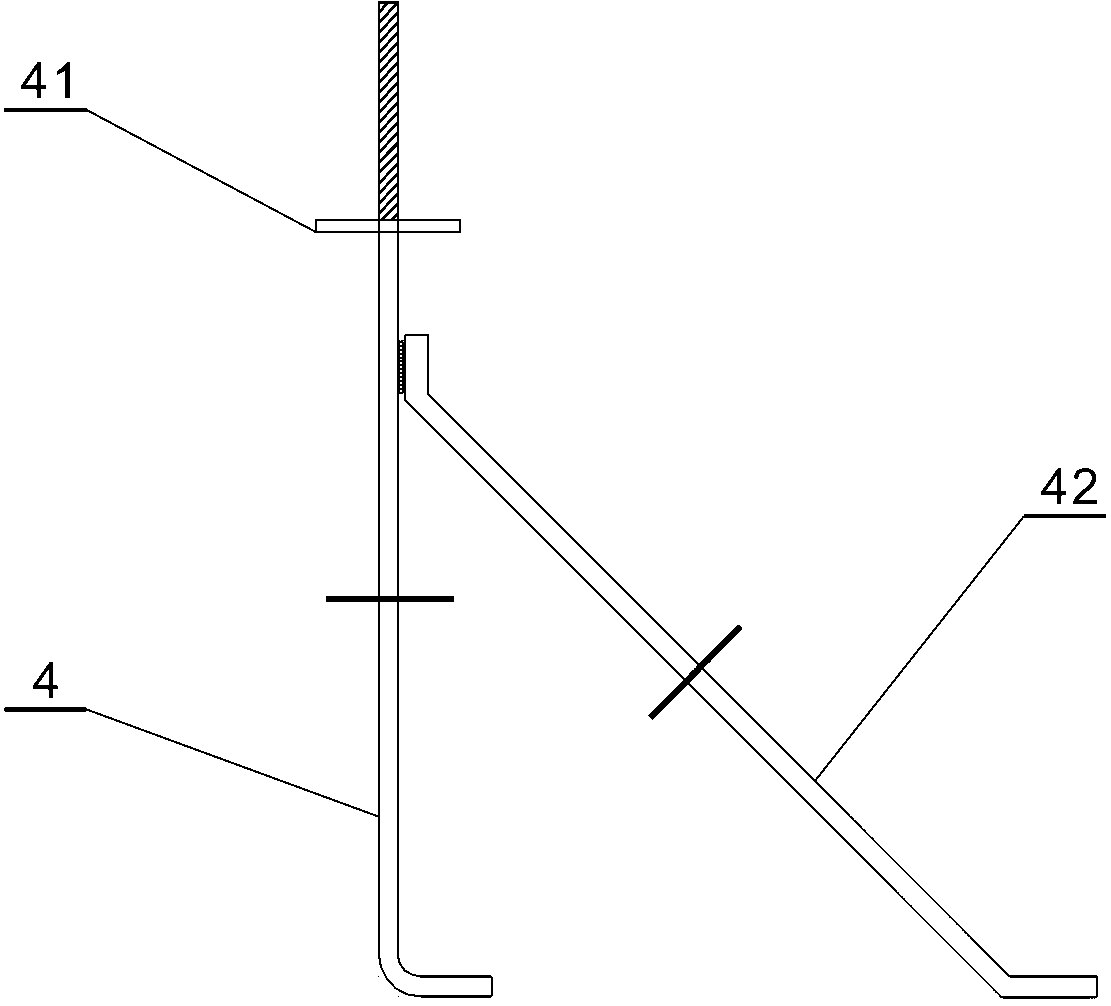

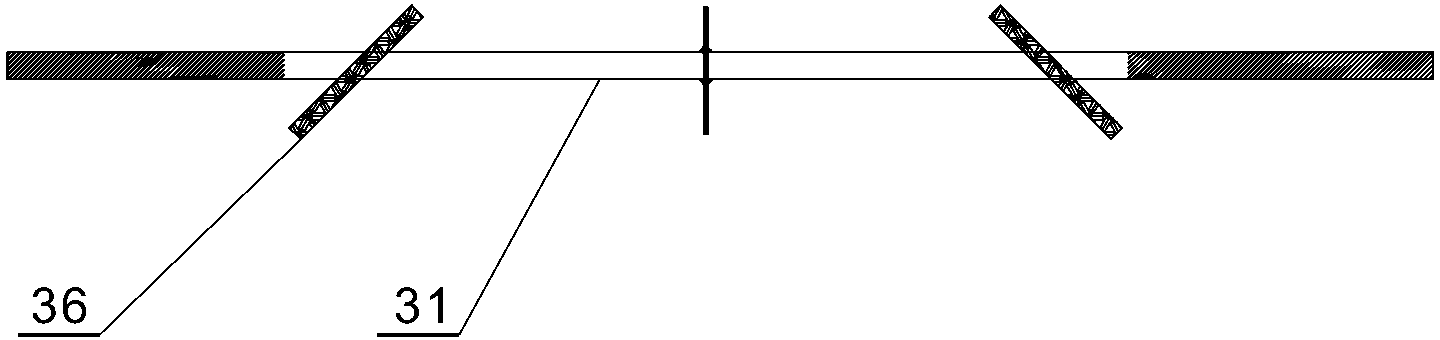

Mould supporting method for trapezoid cross section base of shear wall

InactiveCN103243731AGeometry ControlImproved ability to withstand lateral pressureFoundation engineeringEngineeringShort ribs

The invention discloses a mould supporting method for a trapezoid cross section base of a shear wall. The method adopts a mode that split bolts are fixed with wall plate ribs, support bolts are fixed with base plate ribs and limit short ribs are arranged on the split bolts and the support bolts to determine support mould points of two waist mould plates of the trapezoid cross section base and ensure that the geometrical size of the trapezoid section is controlled. Lateral pressure bearing capability of the waist mould plates is improved by means of reinforcing square columns to prevent deformation and mould expansion. Double-frame pipes, butterfly fasteners and wedge gaskets are adopted to fix the mould plates, the wall plate ribs and the base plate ribs to ensure that the axis of the trapezoid cross section base is not offset in the concrete pouring process.

Owner:CHINA CONSTR SEVENTH ENG DIV SHANGHAI CORP

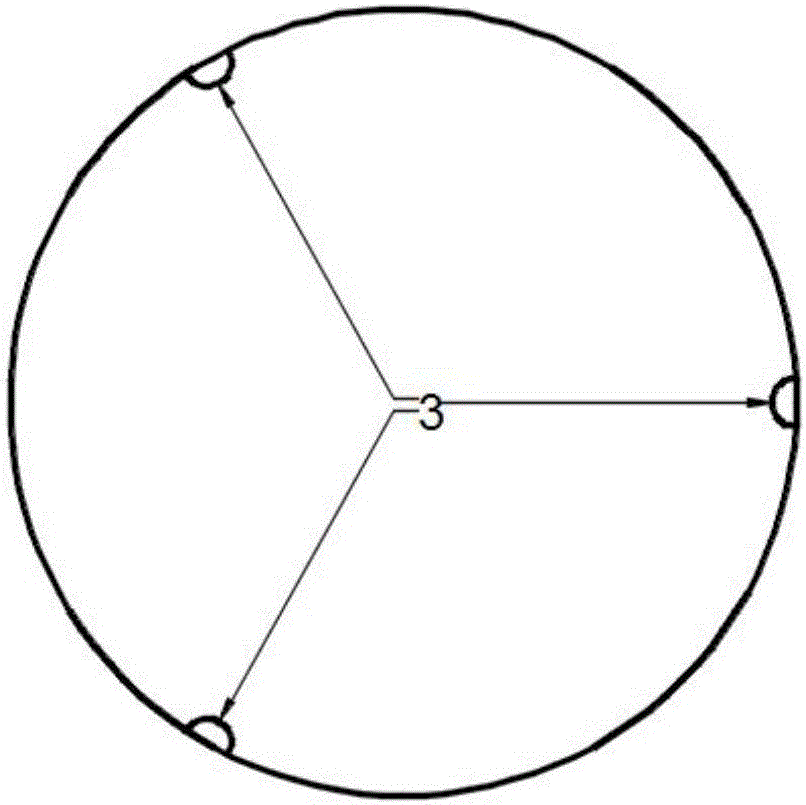

Path rectifying method for super long tunnel shield construction

The invention discloses a path correction method for ultra-long tunnel shield construction. Three GPS locators are placed in the working chamber of the shield machine; the coordinates of the three GPS locators are measured and uploaded to a server, and the server calculates the centroid of the section The position of the shield machine is drawn as a traveling trajectory map; the deviation correction route is obtained by comparing the obtained traveling trajectory diagram with the designed route; the travel angle of the shield machine is adjusted or provisionally determined according to the obtained deviation correction route. The deviation correction method in the present invention can effectively ensure that the shield construction path of the ultra-long-distance tunnel does not deviate, and is of great significance for ensuring the smooth progress of the project.

Owner:CHINA MCC17 GRP

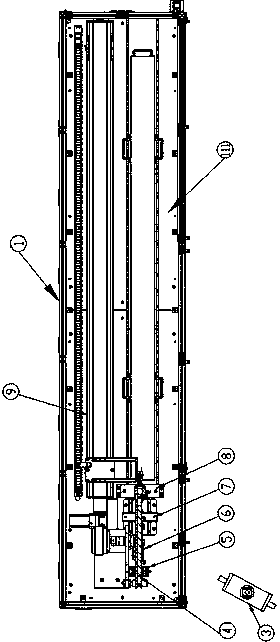

Cutting device of glass tube

PendingCN108298806ARealize cut-to-lengthGuaranteed not to shiftGlass severing apparatusReciprocating motionFixed length

The invention belongs to the technical field of glass tube cutting, and particularly relates to a cutting device of a glass tube. The cutting device of the glass tube comprises a fixed machine frame,a moveable machine frame, a cylinder, a cutting head and a clamping head. The moveable machine frame is connected with the fixed machine frame through a vertical guide rail. The cylinder is verticallyinstalled and is rotatably connected with the moveable machine frame. The cutting head is moveably connected with the cylinder. The clamping head is moveably connected with the fixed machine frame. The cutting device of the glass tube further comprises a lifting device for driving the moveable machine frame to do up-down reciprocating motion relative to the fixed machine frame, a rotation devicefor driving the cylinder to rotate relative to the moveable machine frame, a cutting head telescopic device for driving the cutting head to do reciprocating motion along the radial direction of the cylinder, and a fracture fixing device for driving the clamping head to do reciprocating motion along the radial direction of the cylinder so as to clamp or loosen the glass tube. The cutting device ofthe glass tube is capable of cutting the continuously discharged glass tube in a fixed length, the production efficiency is high, the product quality is stable, and the cutting device is suitable forthe glass tubes in different diameters.

Owner:HEYUAN PX WATER JET CUTTING MACHINERY

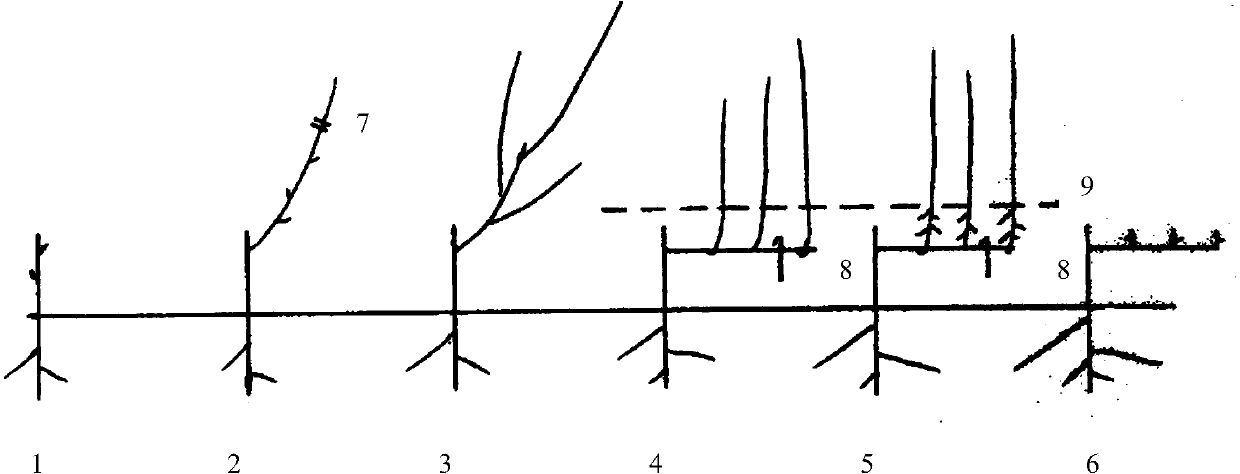

Five-step apple stock continuous layering propagation method

The invention discloses a five-step apple stock continuous layering propagation method. The five-step apple stock continuous layering propagation method includes the steps of carrying out piece-root grafting on stock root sections and self-rooted stock variety scions; then carrying out ditching deep planting on the piece-root-grafted seedlings; carrying out pinching branch promotion on the grafted seedlings, restraining the heights of the seedlings, and promoting sprouting of auxiliary buds on the lower portions of the seedlings to increase the propagation seedling number; taking roots multiple times in batches through cultivating media comprising, by weight, 1 part of garden soil and 1 part of river sand, and finally pushing ridged soil aside to carry out shearing to obtain stock seedlings; properly carrying out ridging every year from the second year, growing out young sprouts, and repeating the working process of the last year to obtain stock seedlings. Compared with the prior art, the propagation efficiency is greatly improved, and the five-step apple stock continuous layering propagation method has the advantages of being high in propagation efficiency and saving time and labor.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Full-automatic efficient cutting machine for bus bar

PendingCN108274241APrevent slippingAvoid offsetOther manufacturing equipments/toolsEngineeringMechanical engineering

A full-automatic efficient cutting machine for a bus bar is characterized in that the full-automatic efficient cutting machine comprises a square cutting machine shell; a controller support is arranged on the top of the cutting machine shell; one end of the controller support is fixed to the top of the cutting machine shell, and a controller is fixed to the bottom of the other end of the controller support and is a PLC; and an operation room is arranged on the upper portion of the cutting machine shell, and a discharging assembly, a deburring mechanism, a straightening mechanism, a compressionfeeding mechanism, a cutting mechanism and a traction mechanism are sequentially arranged on a bottom plate of the operation room from left to right. Using of manual work is avoided, labor force is liberated, the time and labor are saved in operation, and the requirement of enterprises for large-scale mechanical production is met conveniently.

Owner:苏州市中辰昊科技有限公司

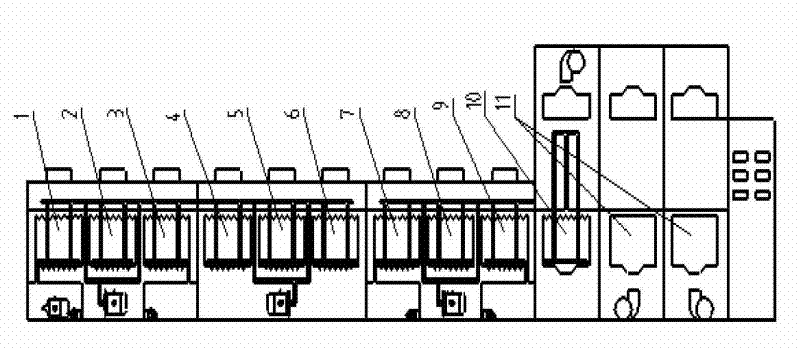

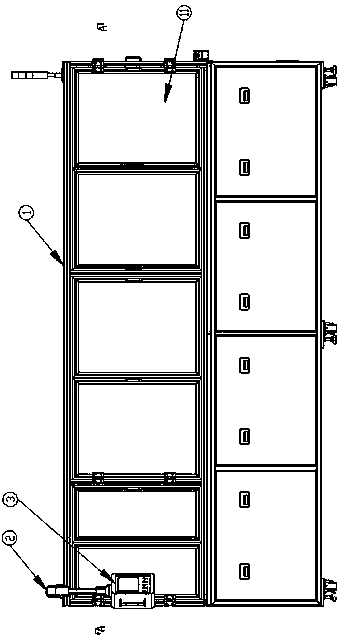

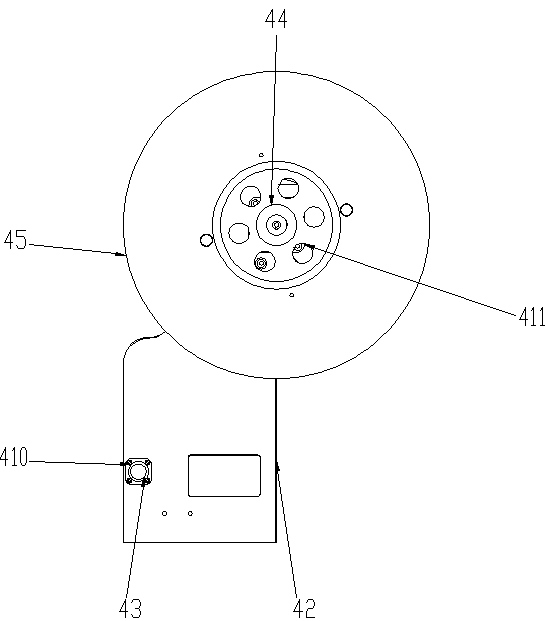

Improved double-glass pH electrode fully automatic detection device

ActiveCN102103120ASignificant progressAvoid damageMaterial electrochemical variablesLower limitControl system

The invention discloses a double-glass pH electrode fully automatic detection device. The device comprises a group A of glass electrodes, a group B of glass electrodes, a motor, an electrode lifting system, a measurement control system, an upper limit hall switch, a lower limit hall switch and an electrode cleaning system, wherein the electrodes are arranged at the lower end of an electrode container; the upper end of the electrode container is provided with an electrode lead which is connected to the measurement control system; the motor is connected with an electrode lifting mechanism through a transmission mechanism; the electrode lifting mechanism comprises a guide seat, a connecting arm, a rack shaft and a rack; and the guide seat is fixed on a body. The device is characterized in that: (1) a container pressing hand wheel for guaranteeing non-displacement of the electrodes and a wire is arranged above the electrode container; (2) a chute plate below a deflecting spiral chute bodyis modified, and the original single-chute structure is changed into a double-chute structure; (3) the electrode container is provided with an acid shielding cover, and the lower part of the electrode is provided with a positioning ring which prevents the electrodes from swinging left and right as well as up and down along with the movement of the electrode container, seals an electrode head and keeps the electrode head dry for a long time; and (4) the upper part of acid shielding glass is provided with a fixing plate which is fastened by a positioning pin.

Owner:钦州华成自控设备有限公司

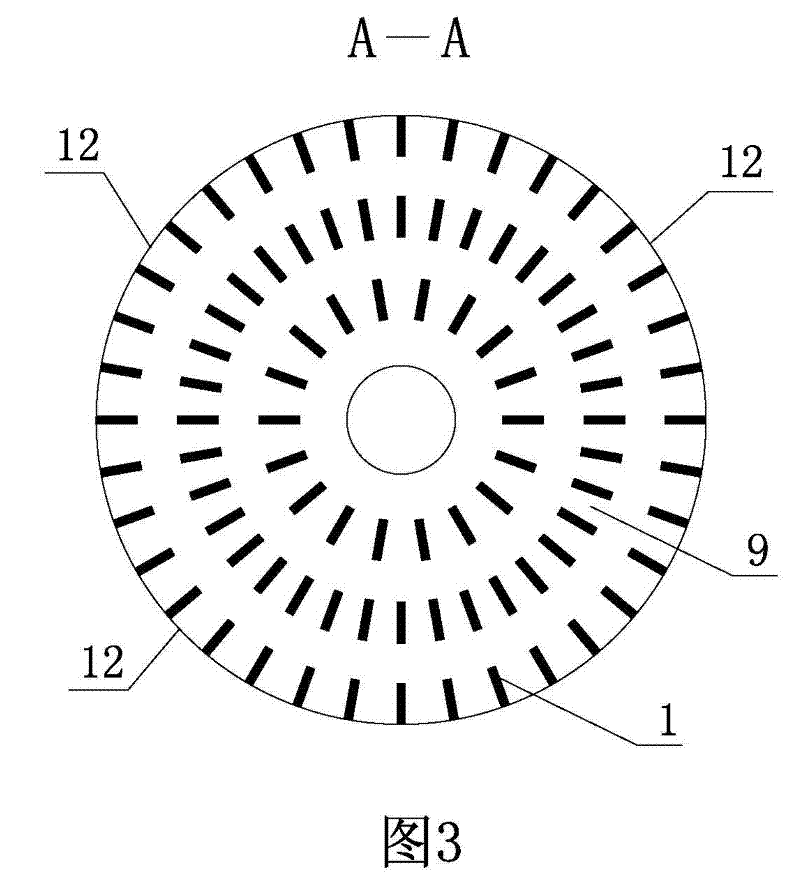

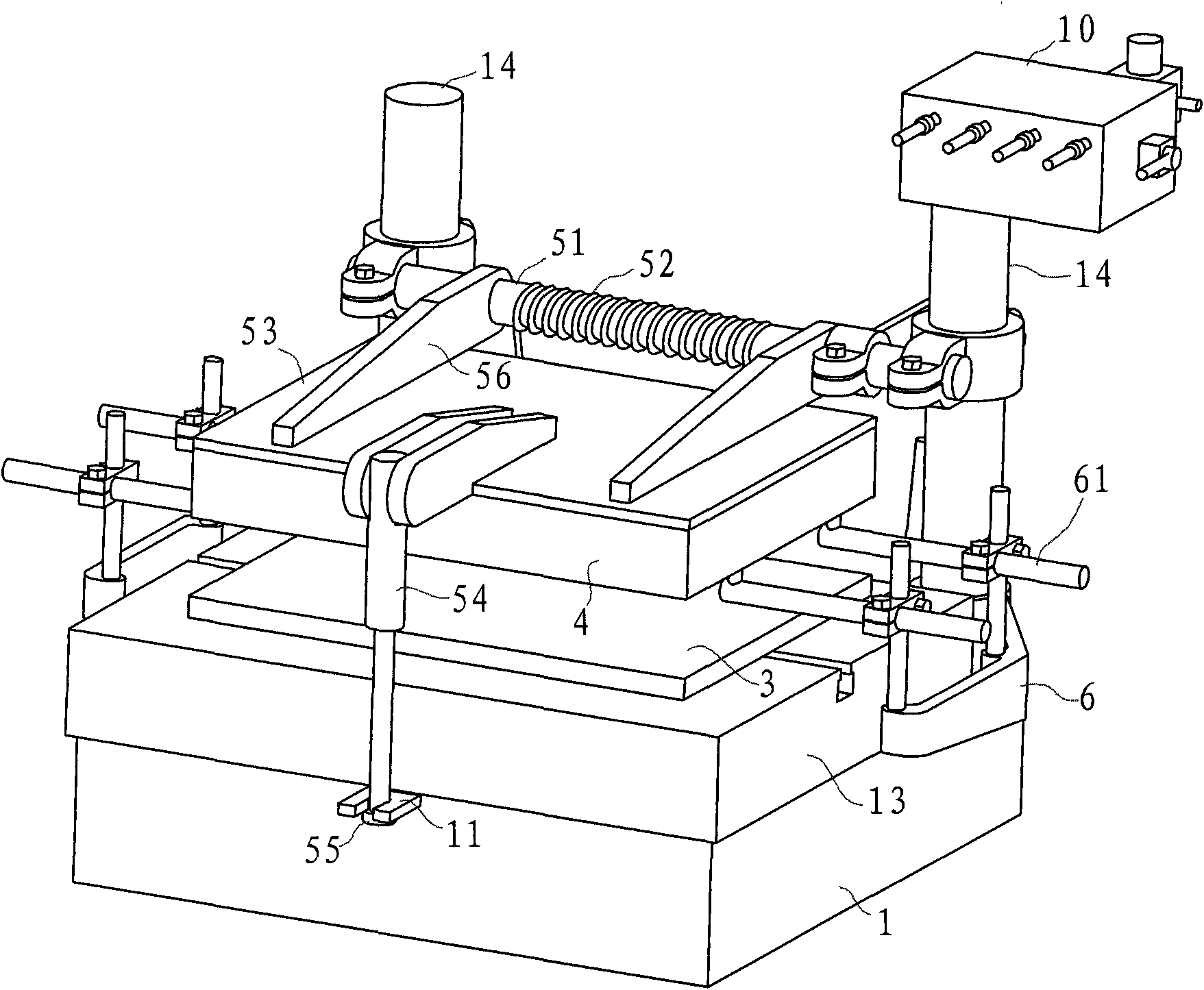

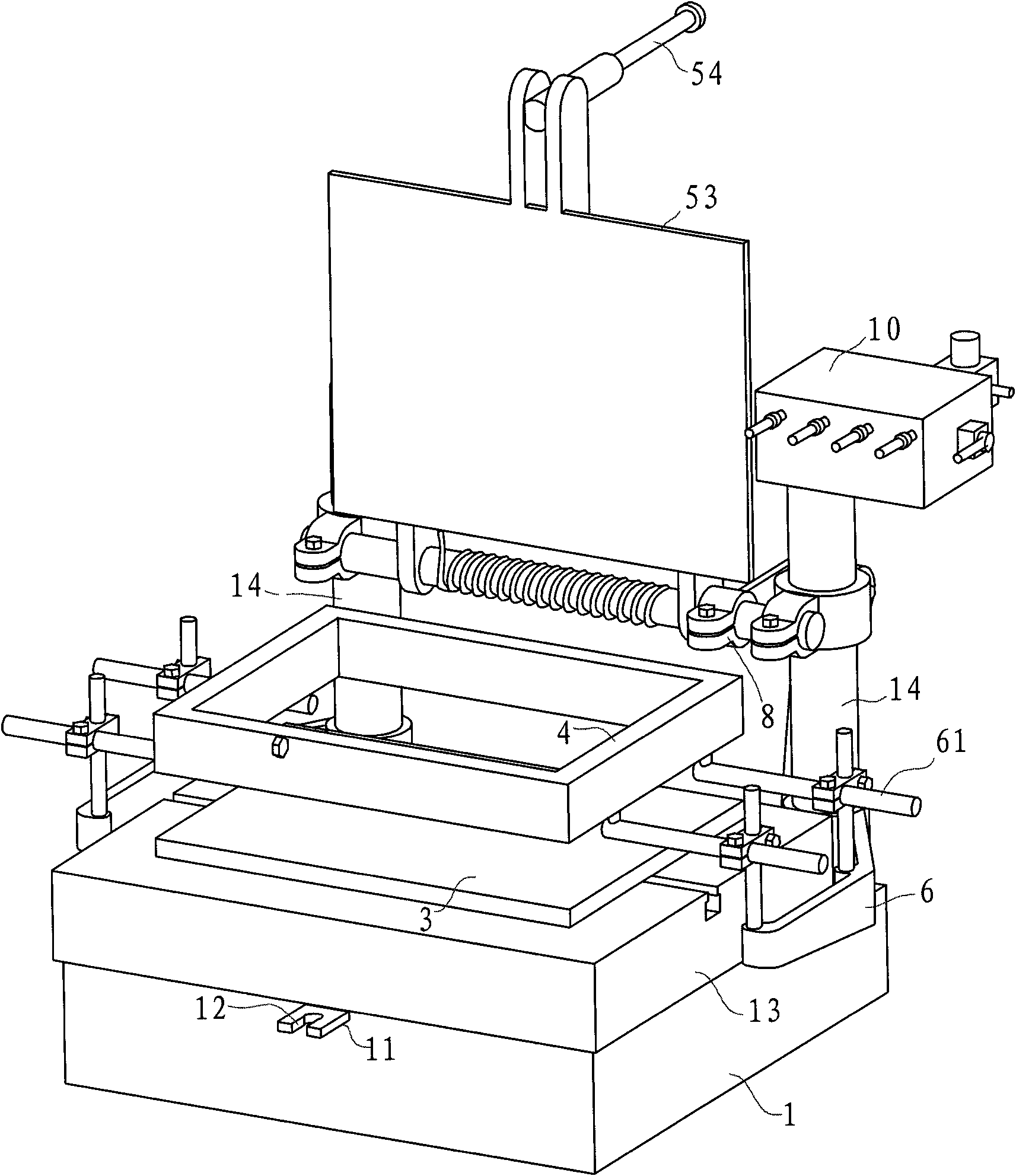

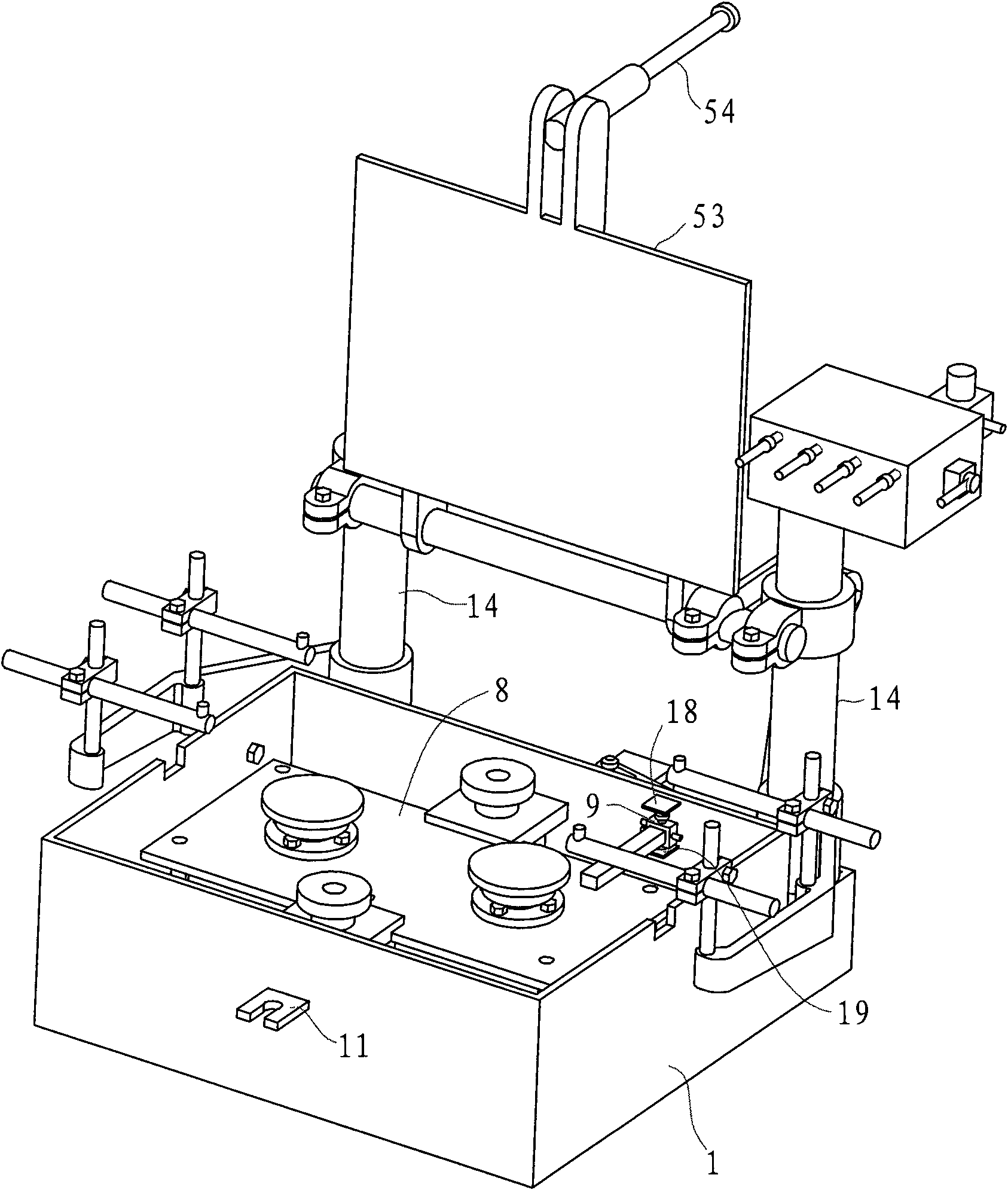

Pattern drawing mechanism for founding moulding and founding moulding machine using the pattern drawing mechanism

InactiveCN102205399AGuaranteed deformationReduce labor intensityMoulding machinesUltimate tensile strengthMechanical engineering

A pattern drawing mechanism for founding moulding is characterized in that the mechanism comprises a pedestal, columns, a sand mould, a sandbox, and a pattern drawing bracket; a workbench plate is disposed at the upper end of the pedestal, the two columns are disposed at the back side part of the pedestal vertically with an interval; the pattern drawing bracket comprises two branch brackets facing to each other; each branch bracket is bended, and a central part is connected to the respective column and is rotatable; both front end parts have a support bar respectively, and back end parts are connected to a sliding member together; correspondingly, a guiding member is transversely extended out from the back end part of the pedestal; and the sliding member is disposed on the guiding member and is capable to move back and forth. The invention also discloses a founding moulding machine using the pattern drawing mechanism. Compared with the prior art, the pattern drawing mechanism of the invention has the advantages of convenient and fast operation, reduced labor intensity, no displacement or deformation of the sand mould, and can guarantee the precision of subsequent casting products.

Owner:陆腾

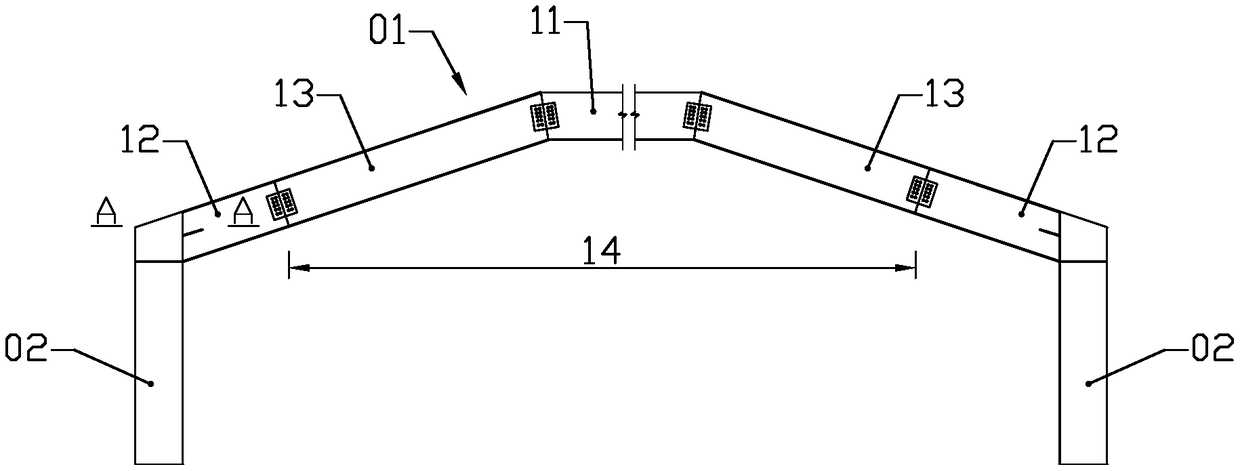

Formwork installation method for steel reinforced concrete composite structural beam

InactiveCN108999398AGuaranteed not to shiftQuality assuranceForms/shuttering/falseworksReinforced concreteBuilding construction

The invention discloses a formwork installation method for a steel reinforced concrete composite structural beam. The formwork installation method belongs to the architecture construction methods, andsolves the problem that the prior art is difficult to ensure that screws effectively pull and tie formworks. According to the formwork installation method, side surface formworks on two sides of a steel beam are pulled and tied by means of through-wall screws on upper and lower sides of the steel beam, a split bolt pulling and tying the side surface formworks of the steel beam is arranged at a midspan position of the steel beam, and the split bolt is divided into two sections which are welded to the two sides of the steel beam respectively, thus the split bolt pulls, ties and supports the formworks by taking the steel beam as a supporting basis, thereby ensuring that the formworks do not shift when concrete is poured, and guaranteeing the quality of the steel reinforced concrete compositestructural beam.

Owner:ZHEJIANG ZHANCHENG CONSTR GROUP +1

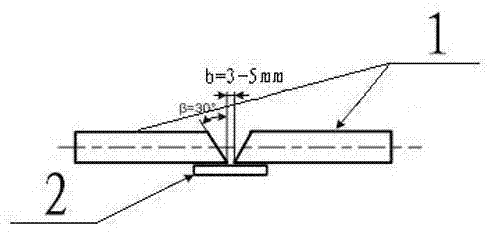

Steel bar fusion channel wall rod welding method

ActiveCN105382384AImprove pass rateSolve the problem of easy air hole defectsArc welding apparatusWelding/soldering/cutting articlesSlagSemi automatic

The invention discloses a steel bar fusion channel wall rod welding method. The method comprises the following steps: (1) preparation before welding, namely paring two segments of steel bars which are to be welded, and horizontally and correspondingly arranging the ends of the steel bars; (2) performing positioned welding, namely performing gas metal arc welding by adopting a flux-cored wire which is capable of generating titanium-calcium type slag after being fused; performing spot welding for location at an angle steel base plate and the two sides of the to-be-welded steel bar by electric arc; (3) welding a steel bar end butting welding pass and an angle steel base plate reinforcing welding pass. By adopting a flux-cored wire CO2 semi-automatic gas shielded welding method, the method disclosed by the invention is capable of solving the problem that defects of air holes are easy to cause when the steel bar is welded by adopting solid-cored wire CO2 semi-automatic gas shielded welding, and the one-time percent of pass of a site-welded welding line can be doubled.

Owner:STATE GRID CORP OF CHINA +1

Stainless steel pipe cutting device

ActiveCN110625180AGuaranteed not to shiftSimple structureTube shearing machinesMetal working apparatusMechanical engineering

The invention discloses a stainless steel pipe cutting device. The stainless steel pipe cutting device comprises a supporting workbench and a conveying and cutting device; the supporting workbench comprises a left supporting plate and a right supporting plate; the conveying and cutting device comprises a conveying device; the conveying device comprises a pair of U-shaped conveying support bases and a lifting support plate; openings of the pair of conveying support bases are opposite front and back; the pair of conveying support bases are arranged between the left supporting plate and the rightsupporting plate in a front-back moving manner and are synchronously far away from each other or close to each other; a plurality of conveying rollers which are evenly distributed left and right arerotatably arranged between a pair of vertically symmetrical horizontal portions of the conveying support bases; the lifting support plate is arranged over the supporting workbench in a lifting manner;the lifting support plate is composed of a left lifting support plate located at the left end, a middle supporting rod located in the middle and a right lifting support plate located at the right end; and a cutting device is arranged on the right supporting plate.

Owner:佛山力肇金属制品有限公司

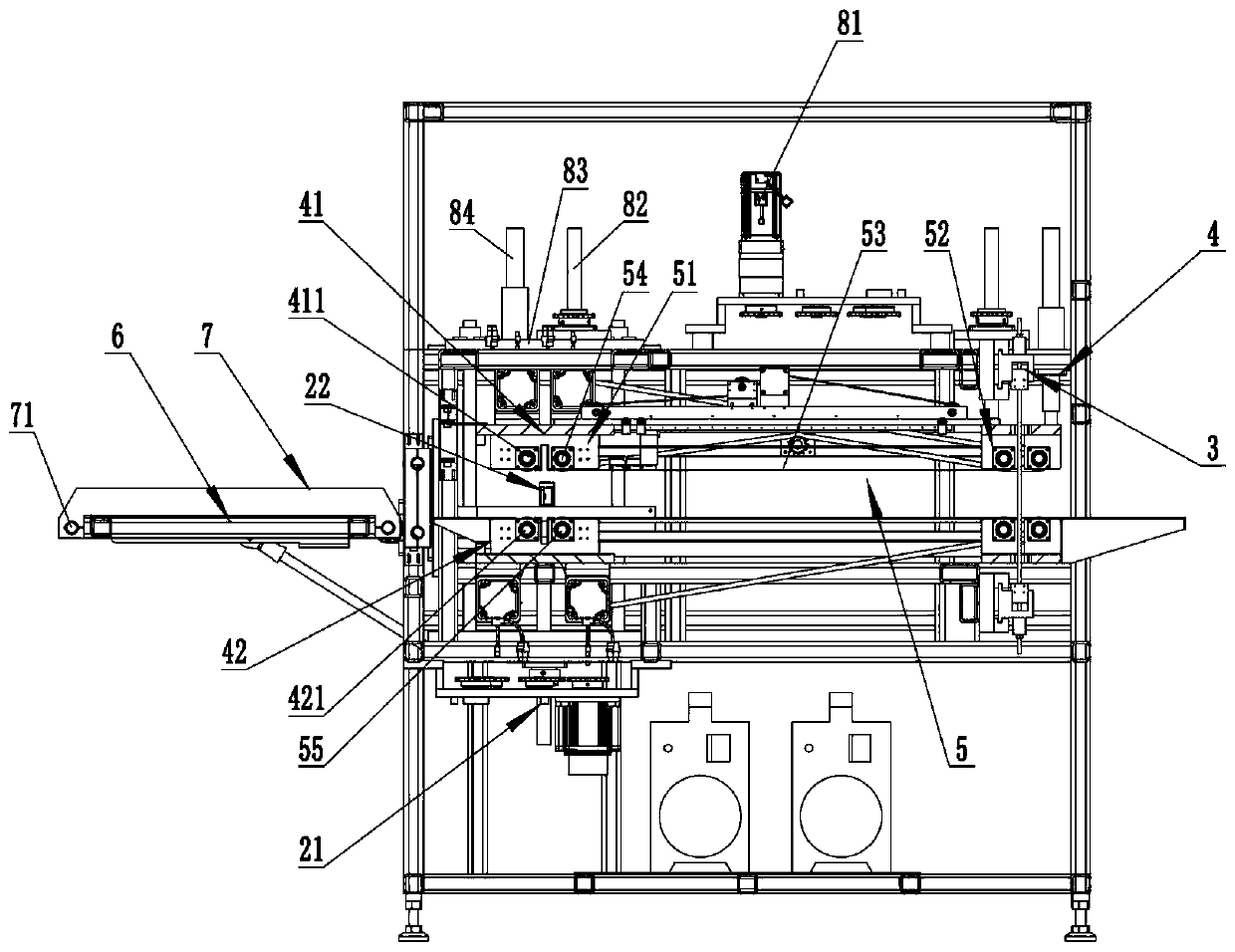

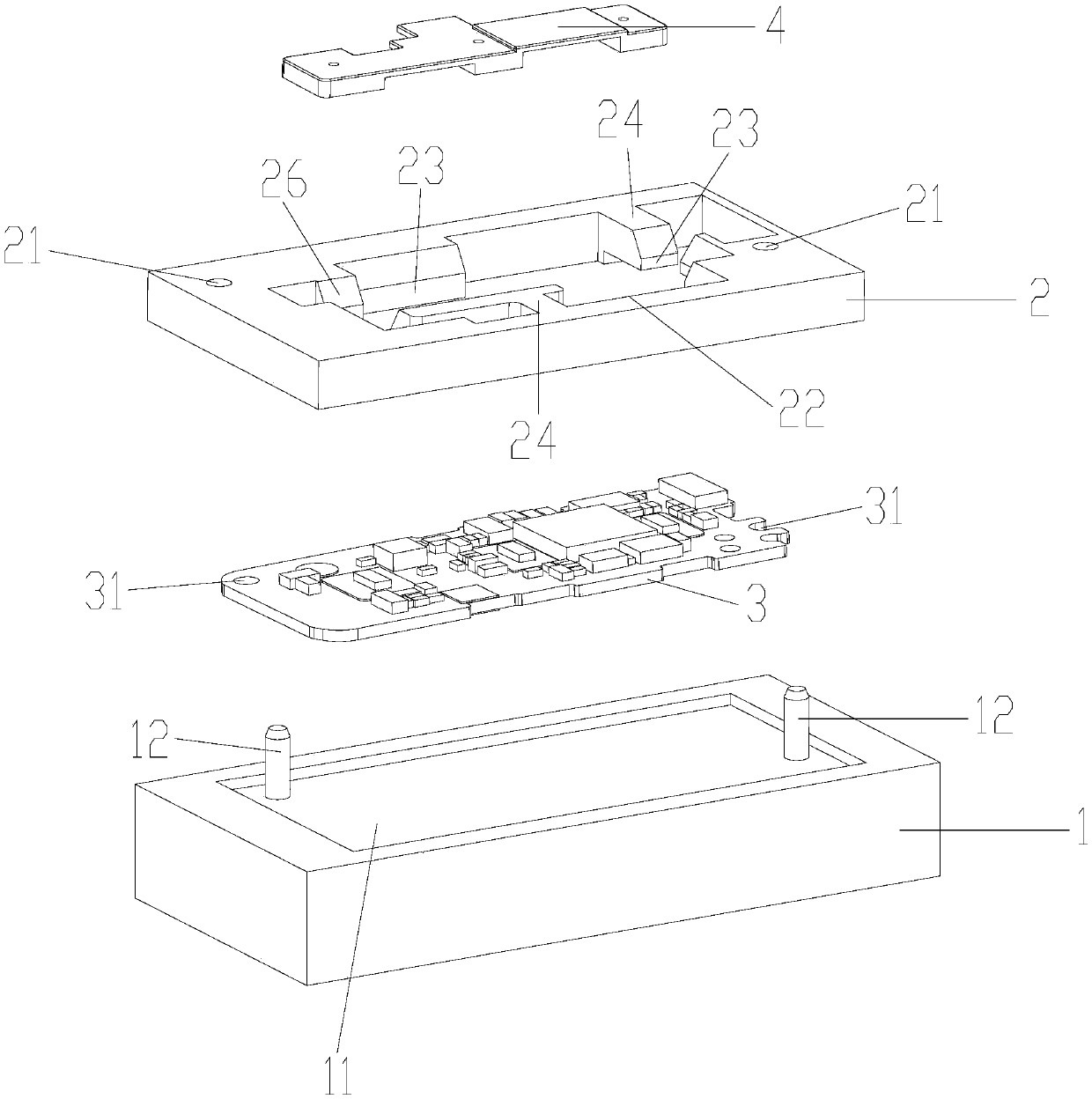

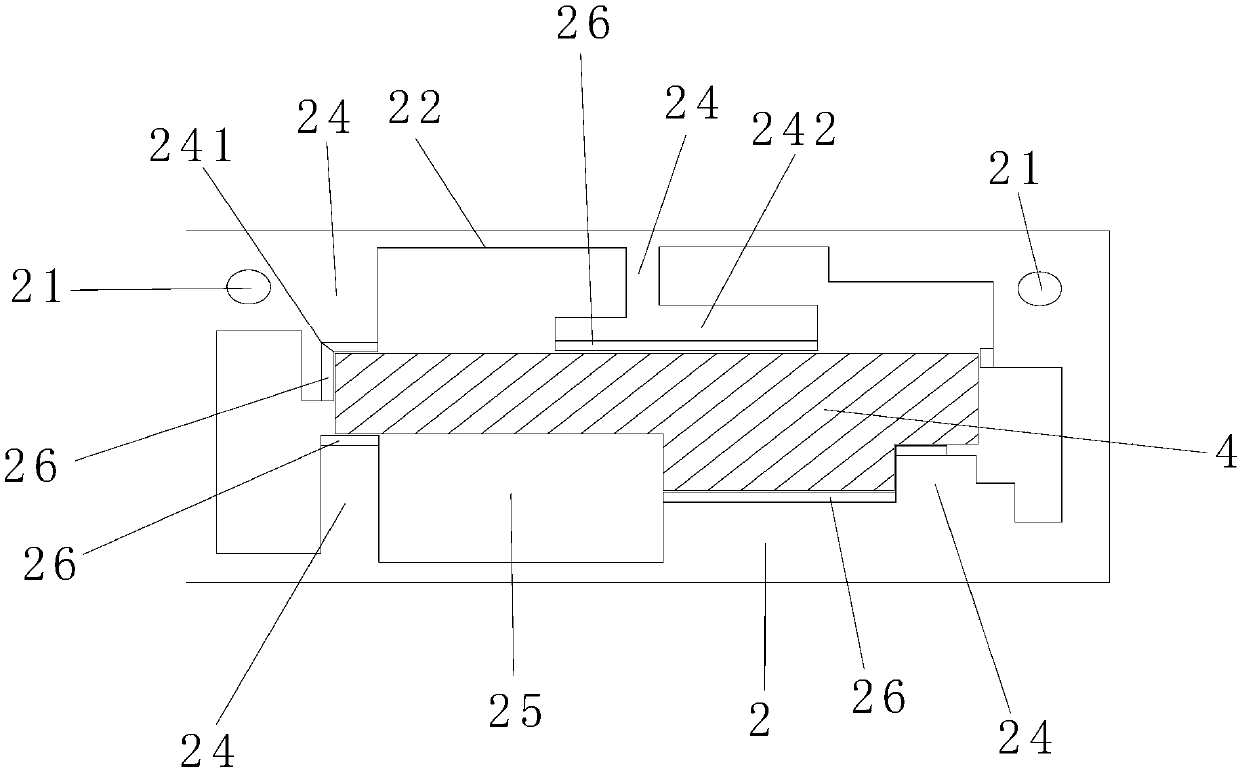

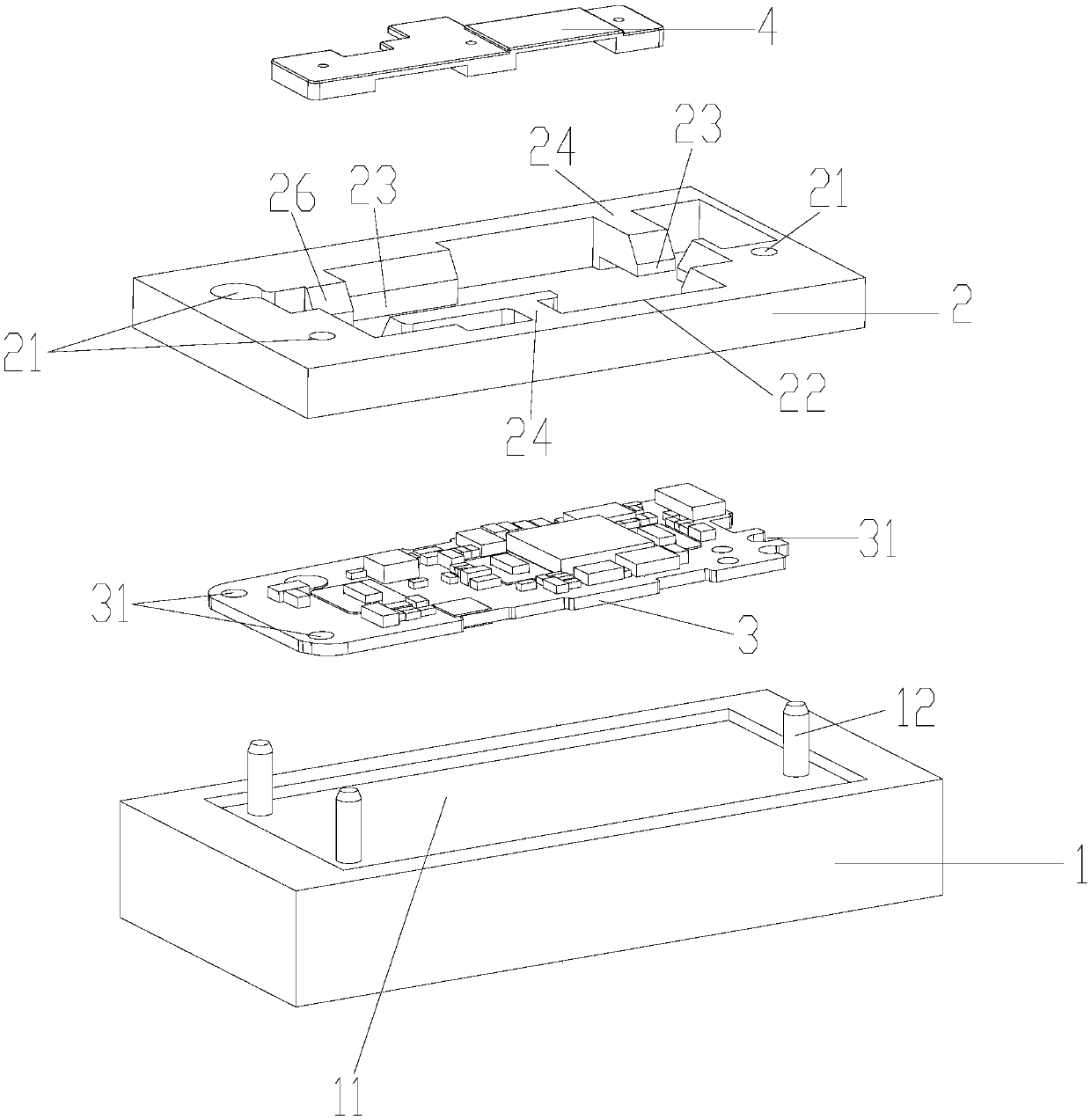

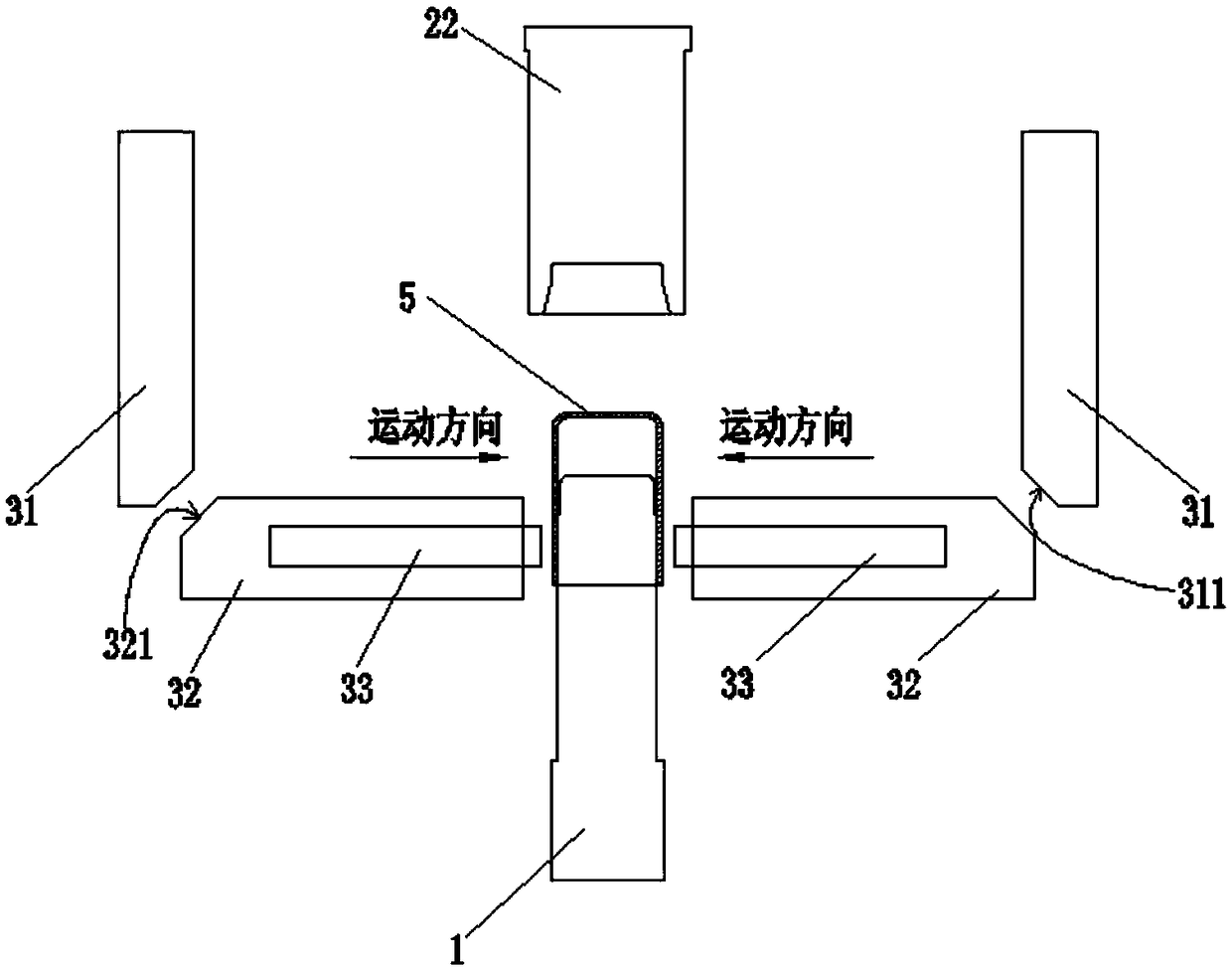

Laser welding clamp for copper bar connecting piece of battery module

ActiveCN113523567AGuaranteed not to shiftReasonable structural designLaser beam welding apparatusShielding gasEngineering

The invention discloses a laser welding clamp for a copper bar connecting piece of a battery module. The laser welding clamp comprises a flexible material pressing and positioning mechanism and a product positioning and feeding mechanism, wherein the flexible material pressing and positioning mechanism comprises a first lifting driving device, a second lifting driving device, a pressing head mounting plate and pressing heads, and the pressing heads are movably arranged on the pressing head mounting plate through elastic connecting pieces; the product positioning and feeding mechanism comprises a feeding translation device, a clamp base, a product fixing clamp and positioning sleeves; and the feeding translation device can drive all the positioning sleeves to move to the positions under the corresponding pressing heads. The positions of a copper bar and a PIN can be ensured not to deviate, the mounting precision of the copper bar and the PIN can be ensured, so that the laser welding clamp assists a laser generating mechanism to carry out laser welding on the copper bar and the PIN. The pressing heads are flexibly arranged and cannot crush the copper bar. The clamp can be compatible with different products, the corresponding positioning sleeve and the corresponding pressing head can be replaced according to the size and the length of the PIN, and replacement is convenient. In addition, a protective gas runner can be arranged in each pressing head.

Owner:东莞市万连实业有限公司

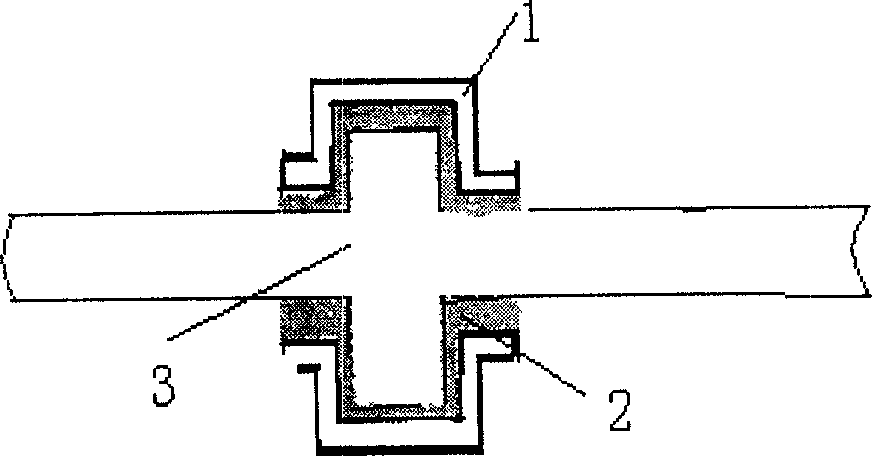

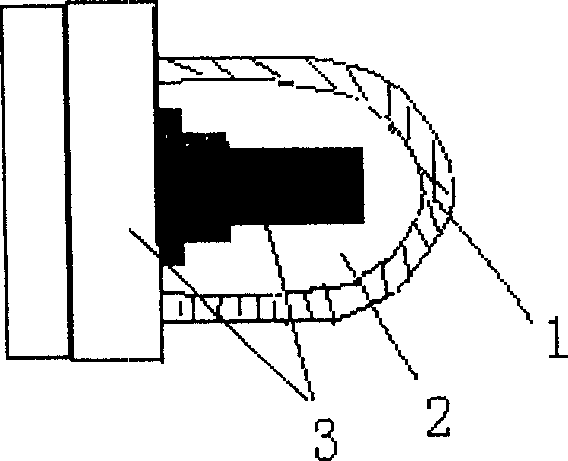

Long-acting preserving and sealing protection method

InactiveCN1811234AGuaranteed not to shiftIncrease contact areaEngine sealsPinsGas cylinderEngineering

The long-acting preserving and sealing protection method has double-layer preserving and sealing structure adopted including an outer layer of rubber jacket and an inner layer of preserving and sealing glue to adhere the rubber jacket and the protected part integrally. The present invention is especially suitable for use in preserving and sealing protection of gas cylinder joint, pipeline, flange joint, nut and screw bolt in ships.

Owner:NANJING UNIV

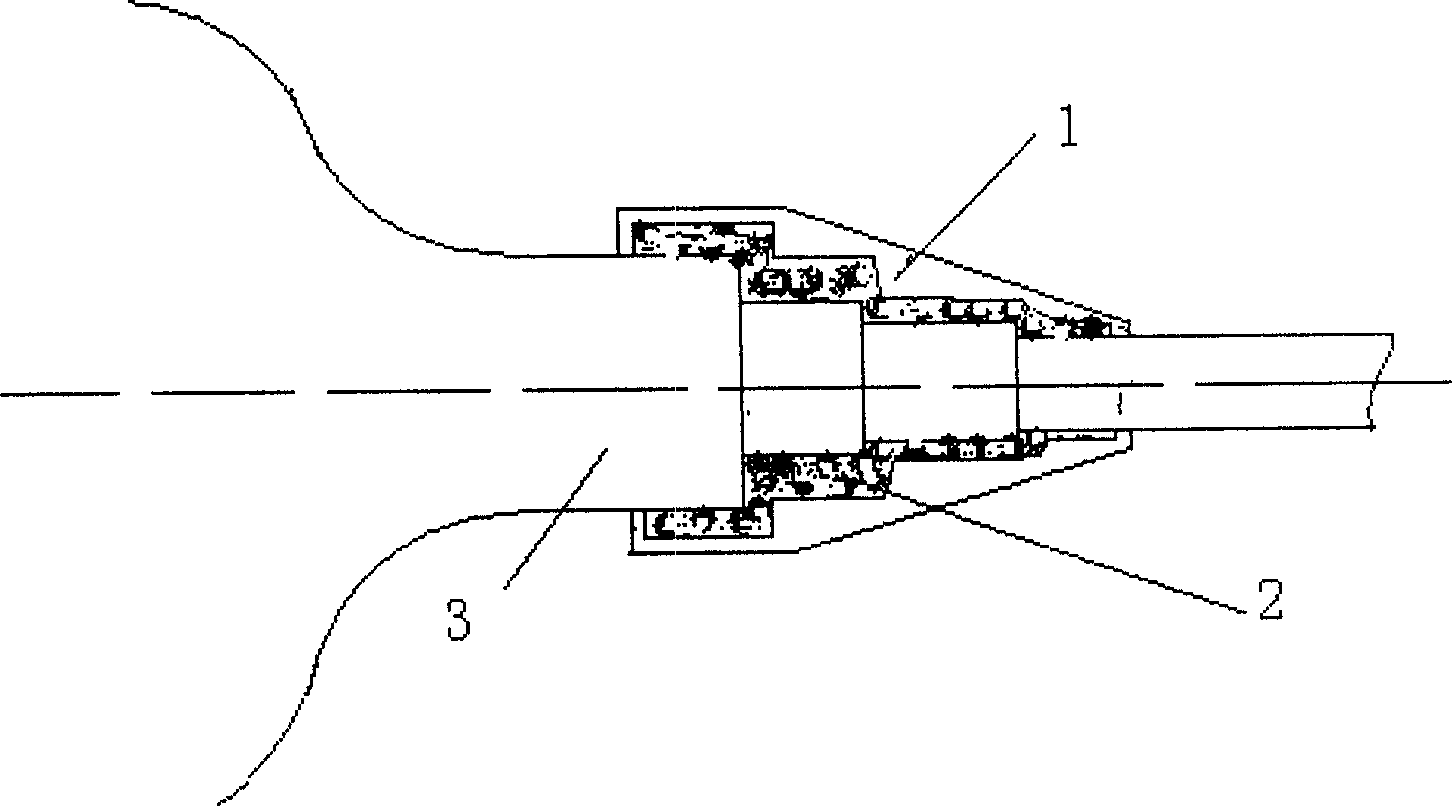

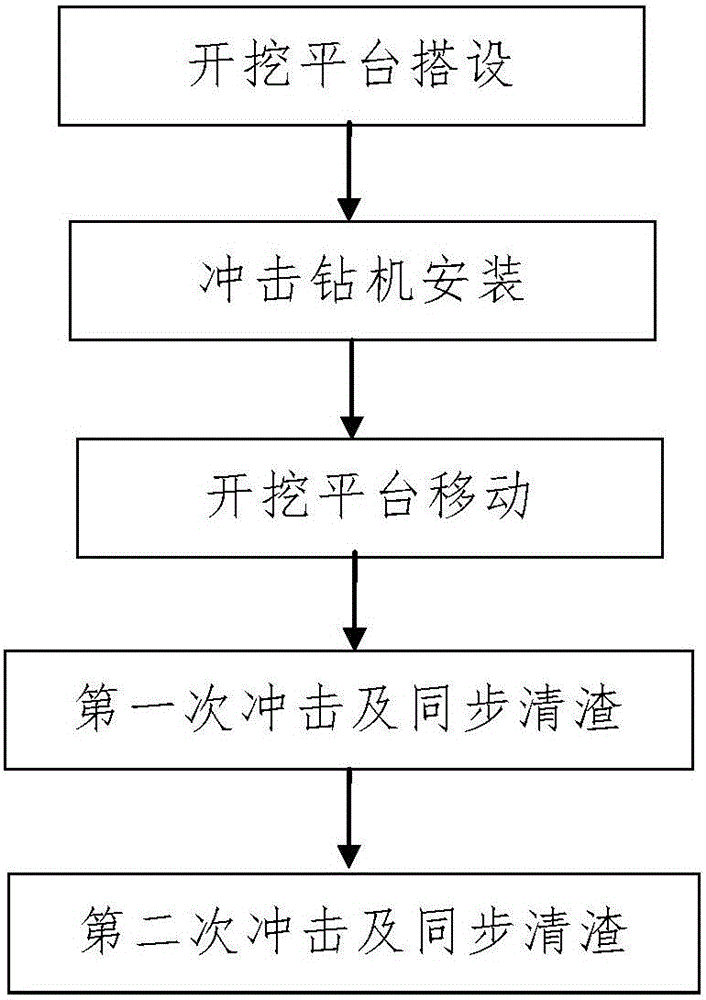

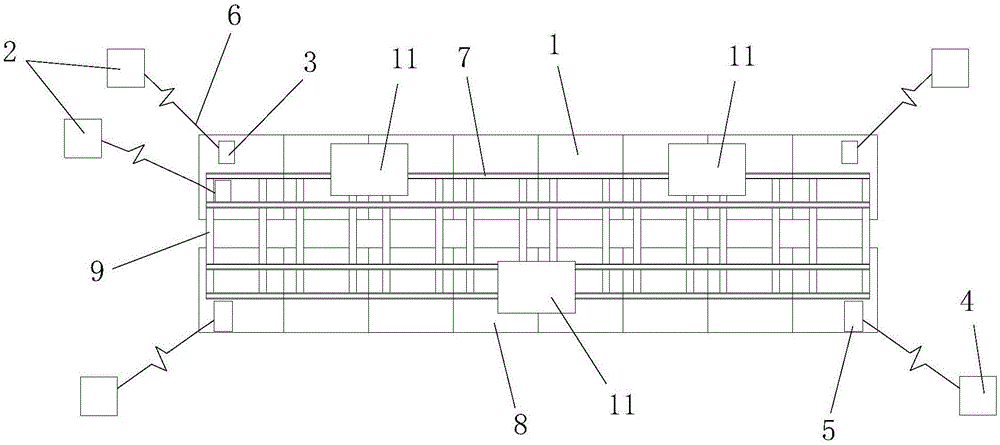

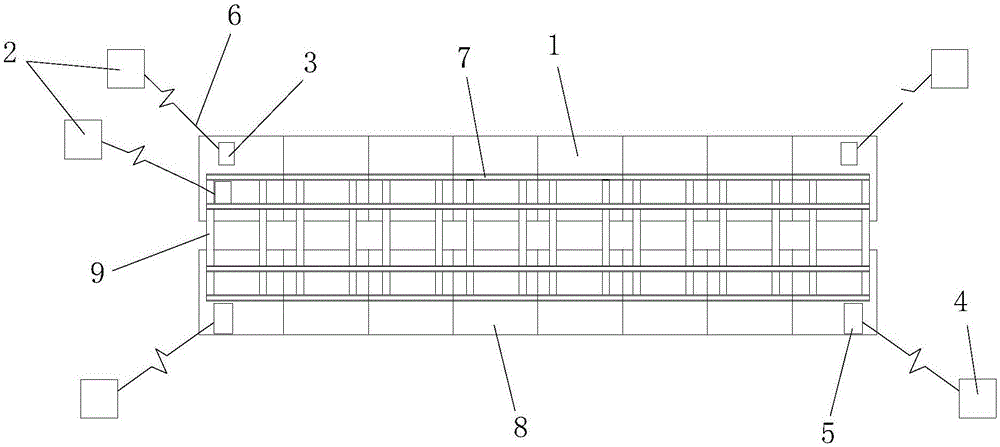

Excavation construction method for underwater foundation pits of deep water foundation adjacent to existing line large-span continuous beam

InactiveCN106120802AThe method steps are simpleReasonable designBridge erection/assemblyExcavationsSlagUnderwater

The invention discloses an excavation construction method for underwater foundation pits of a deep water foundation adjacent to an existing line large-span continuous beam. The excavation construction method comprises the following steps: I, erecting an excavation platform which comprises an assembly type floating body and a floating body position regulating device; II, mounting impact drilling machines: mounting the plurality of impact drilling machines on the excavation platform, wherein the plurality of the impact drilling machines form impact crushing equipment; III, moving the excavation platform; IV, impacting for a first time and synchronously removing slag: carrying out impact crushing on integral underwater base rocks in a construction area where an underwater abutment lies and moving away rock blocks by adopting a long-arm excavator; and V, impacting for a second time and synchronously removing slag: carrying out impact crushing on underwater rocks at bottom mounting positions of a cofferdam, and moving away rock blocks by adopting the long-arm excavator. The excavation construction method disclosed by the invention is simple in step, is reasonable in design, is simple and convenient to construct, is good in using effect, and can simply, quickly and quickly complete an excavation construction process for the underwater foundation pits of the deep water foundation; and the excavation construction process is safe and reliable, and has relatively small influences on the outside world.

Owner:NO 1 ENG LIMITED OF CR20G

Fixing fixture

ActiveCN107624037AImprove assembly accuracyHigh positioning accuracyElectrical componentsEngineering

The invention provides a fixing fixture, which comprises a base for fixing a PCB and an upper cover for limiting movement of an assembly unit, wherein the base is provided with at least two positioning columns; the PCB is provided with first positioning holes with positions corresponding to the positioning columns; the upper cover comprises second positioning holes corresponding to the positioningcolumns and a processing through groove for limiting movement of the assembly unit; and the opposite side walls between the processing through groove and the assembly unit are provided with positioning surfaces contacted with the assembly unit. In comparison with the prior art, through the match between the positioning columns on the fixture base and the positioning holes on the upper cover of the fixture, the positioning accuracy is improved; and when the assembly unit is assembled, the assembly area on the PCB is determined through the positioning surface of the upper cover, non offset in the case of assembly of the assembly unit is thus ensured, and the production yield is improved.

Owner:JRD COMM

Side punching and balancing mechanism and side punching method for automobile vehicle-mounted power source shell type parts

ActiveCN109290427AGuaranteed not to shiftGuaranteed accuracyPerforating toolsEjection devicesPunchingLocking mechanism

The invention discloses a side punching and balancing mechanism and a side punching method for automobile vehicle-mounted power supply shell type parts. The mechanism comprises a lower mold base, a lower mold base balance locking mechanism and a side punching mechanism, wherein the shell type parts are arranged on the lower mold base in a sleeve mode, and the side surface of the lower mold base isprovided with a punching concave portion; the lower mold base balance locking mechanism is used for fixing the lower mold base; and the side punching mechanism is used for carrying out side punchingon the shell parts pressed on the lower mold base. According to the mechanism, the side punching and balancing mechanism is additionally provided with the lower mold base balance locking mechanism, and the lower mold base is fixed through the lower mold base balance locking mechanism, when the side punching mechanism is used for carrying out side punching on the shell type parts, the lower mold base can be ensured not deviated, shaken and inclined after being stressed, and the vertical direction is kept; the roundness of the side punching circular holes is guaranteed, and the precision of thespecial-shaped holes is guaranteed; and the the lower mold base is stably arranged, the service lives of the lower mold base and a male mold can be guaranteed, the punching smoothness is guaranteed, the production efficiency is improved, punching burrs of products are reduced, and the product quality is improved.

Owner:CHANGZHOU GONGLI SEIKI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com