Movable mounting and dismounting device for mounting and dismounting bottom bolts of large equipment

A technology for bolt disassembly and assembly of large-scale equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of reducing work efficiency, noise, vibration, labor intensity, etc., to improve disassembly and assembly efficiency, accurate torque The effect of controlling and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

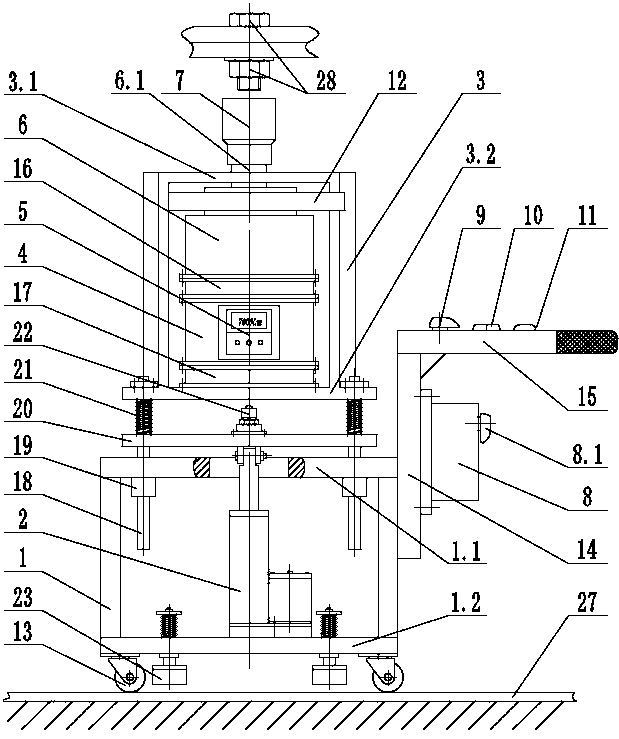

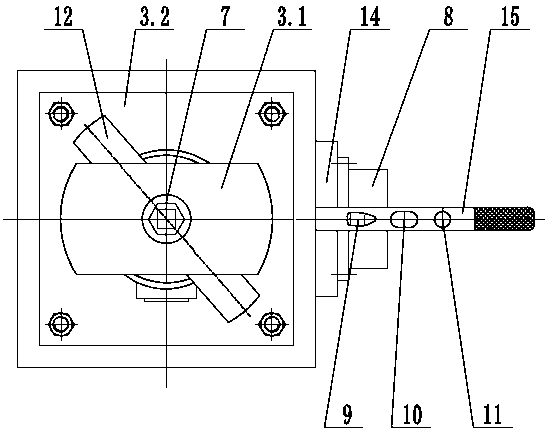

[0035] Such as Figures 1 to 3 , as shown in 6 to 8, a mobile disassembling device for disassembling bolts at the bottom of large-scale equipment, including a mobile frame 1, a jacking mechanism 2, a frame 3, a DC motor 4, a torque control display mechanism 5, and a reducer 6. Sleeve 7, lithium battery power supply 8 and control switch, mobile frame 1 includes mobile frame bottom plate 1.2, mobile frame top plate 1.1 and four columns fixedly connected between the two, frame 3 includes frame bottom plate 3.2, machine The frame top plate 3.1 and four columns fixedly connected between the two, the four corners of the bottom of the mobile frame 1 are equipped with universal wheels 13, so that the dismounting device can move in all directions; the torque control display mechanism 5 is connected with the motor 4, By inputting the torque value in the torque control display mechanism 5, the torque output by the motor 4 can be realized. Here, the torque of the motor 4 is related to its...

Embodiment 2

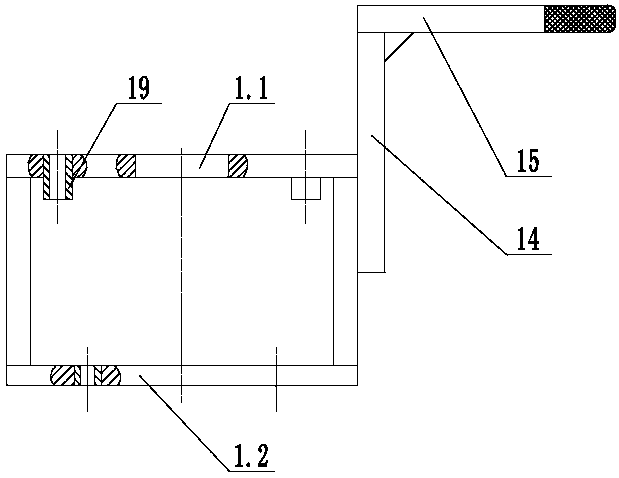

[0042] On the basis of Example 1, such as figure 1 , 3, 5, the jacking mechanism 2 is connected with the frame bottom plate 3.2 through the guide mechanism, the guide mechanism includes at least three guide columns 18 and guide sleeves 19 matched with each guide column 18, the top of the guide column 18 is connected with the frame bottom plate 3.2 Fixed connection, and the connection line between each guide column 18 and the bottom surface of the frame bottom plate 3.2 is not on the same straight line, the guide sleeve 19 is fixedly arranged on the top plate 1.1 of the mobile frame, and the top plate 1.1 of the mobile frame corresponds to each guide sleeve 19. Through holes, the guide sleeve 19 is fixedly installed in the corresponding through hole, and the guide column 18 passes through the corresponding guide sleeve 19 to guide the rise or fall of the frame 3; the jacking mechanism 2 is specifically an electric push rod, lithium The battery power supply 8 can provide power ...

Embodiment 3

[0044] On the basis of Example 2, such as figure 1 and 4 As shown, an adsorption positioning mechanism is fixedly arranged on the mobile frame base plate 1.2, and the adsorption positioning mechanism includes an electromagnetic chuck 23, a fixed rod 24, a return spring 25 and a baffle plate 26. The lithium battery power supply 8 can provide power for the electromagnetic chuck 23, and the mobile frame Bottom plate 1.2 is provided with through hole, and fixed rod 24 passes through this through hole, and the bottom end of fixed rod 24 is fixedly connected with electromagnetic sucker 23, and the top end is fixedly connected with baffle plate 26, and back-moving spring 25 is sleeved on the fixed rod 24, and its upper end withstands The bottom surface and the lower end of the baffle plate 26 withstand the top surface of the mobile frame base plate 1.2, when the electromagnetic chuck 23 is energized, it can absorb the ground steel plate 27 of the workshop, so that the dismounting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com