Patents

Literature

36results about How to "Guaranteed Position Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

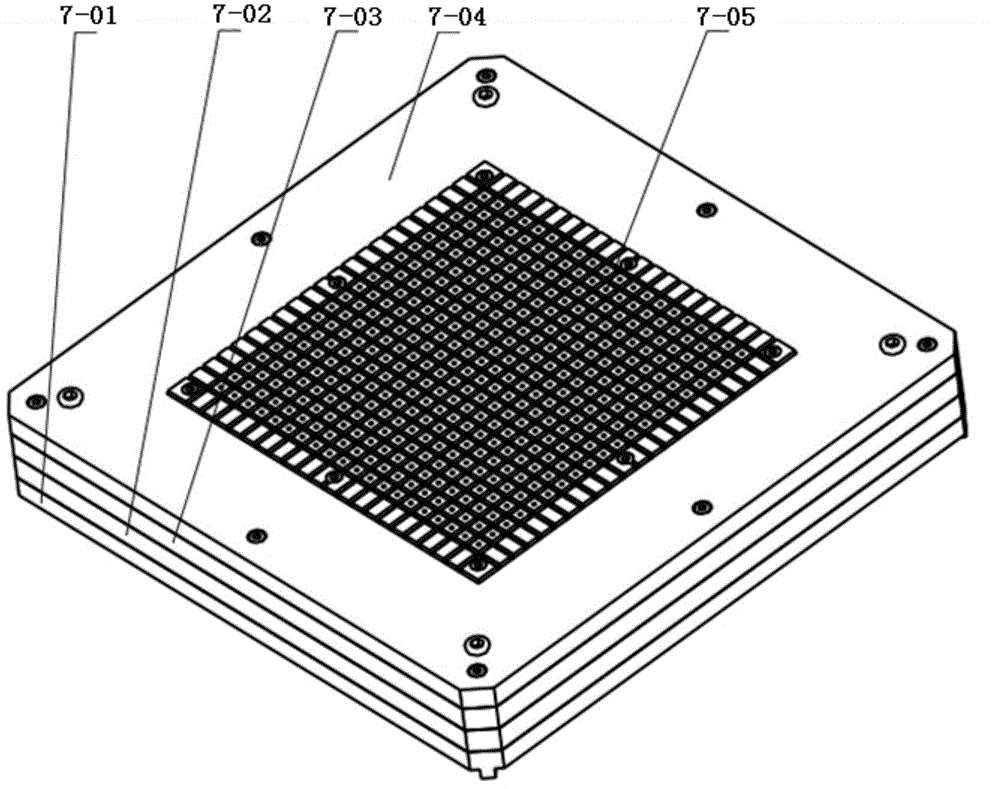

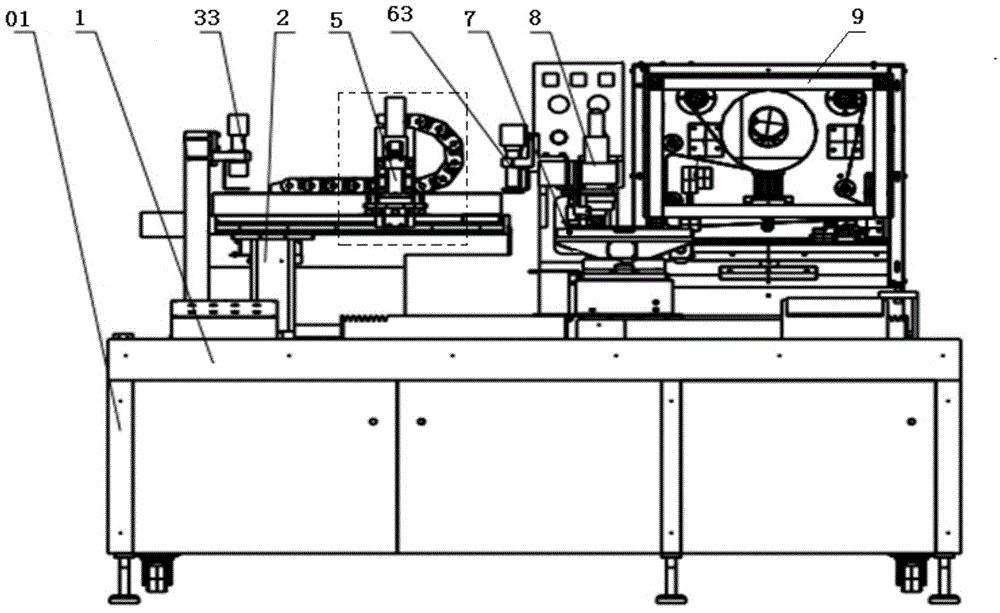

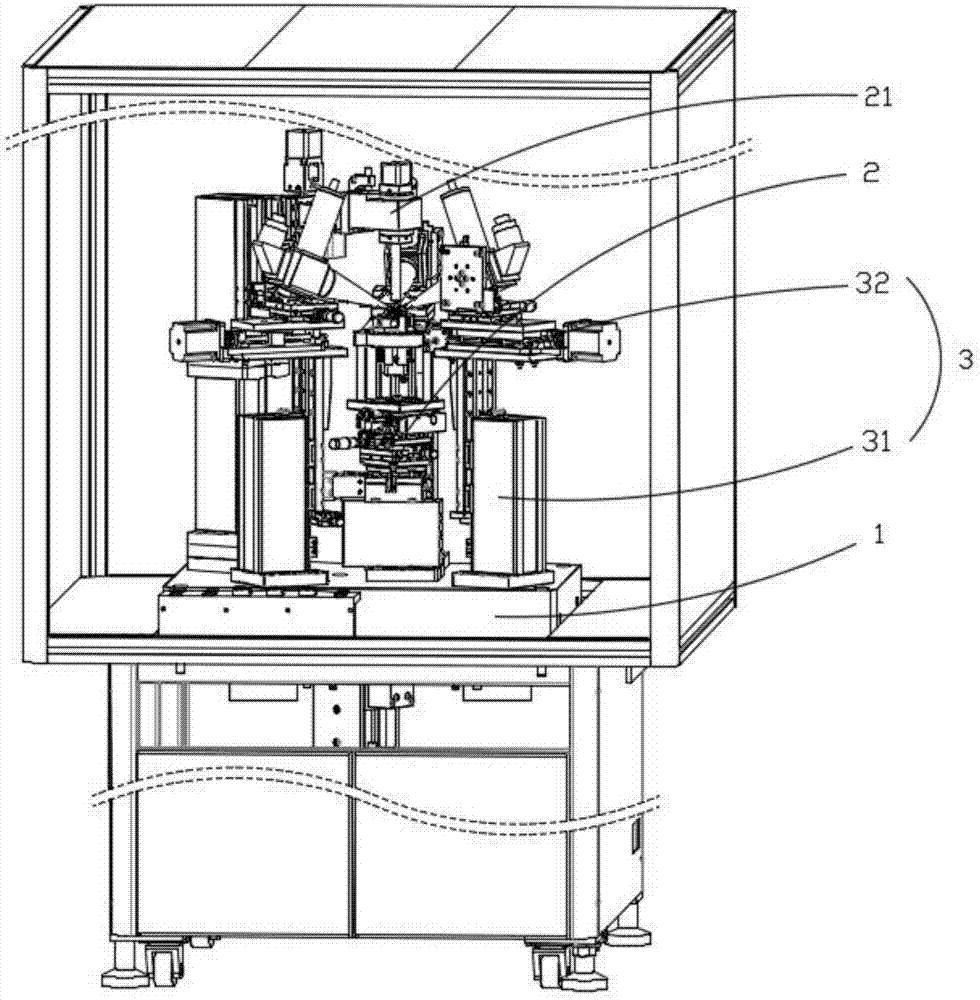

Laser cutting equipment for stainless steel chip

ActiveCN104084697AGuaranteed Position AccuracyPick up accuratelyMetal working apparatusLaser beam welding apparatusManipulatorLaser cutting

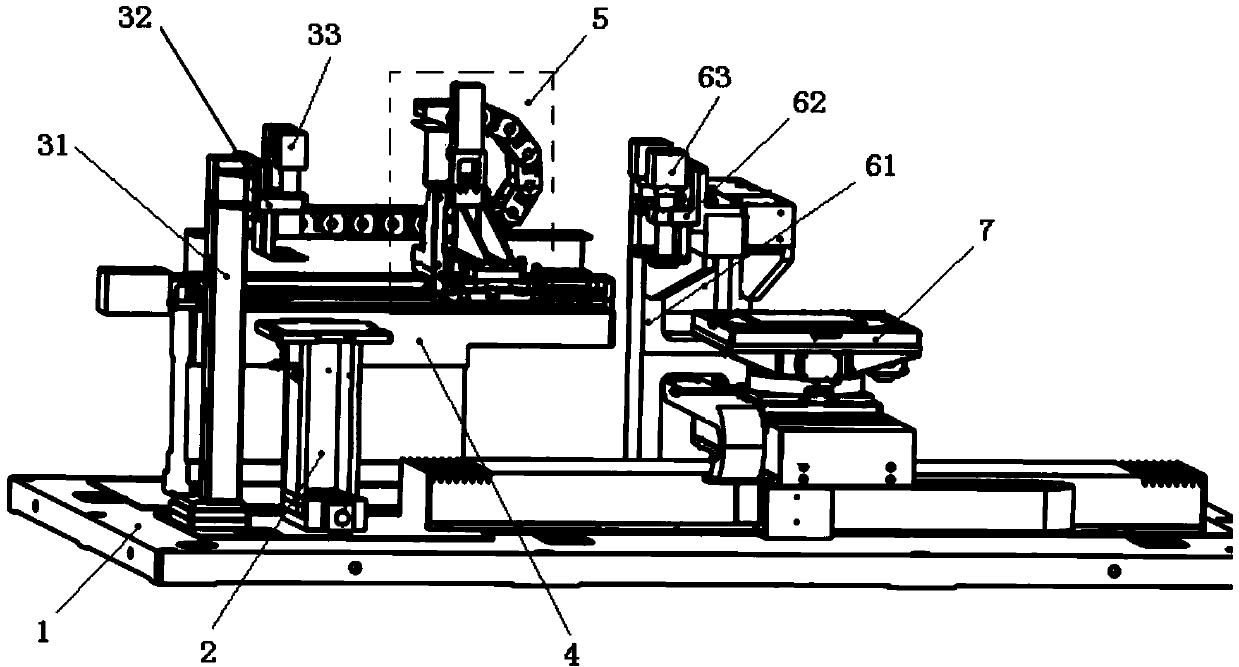

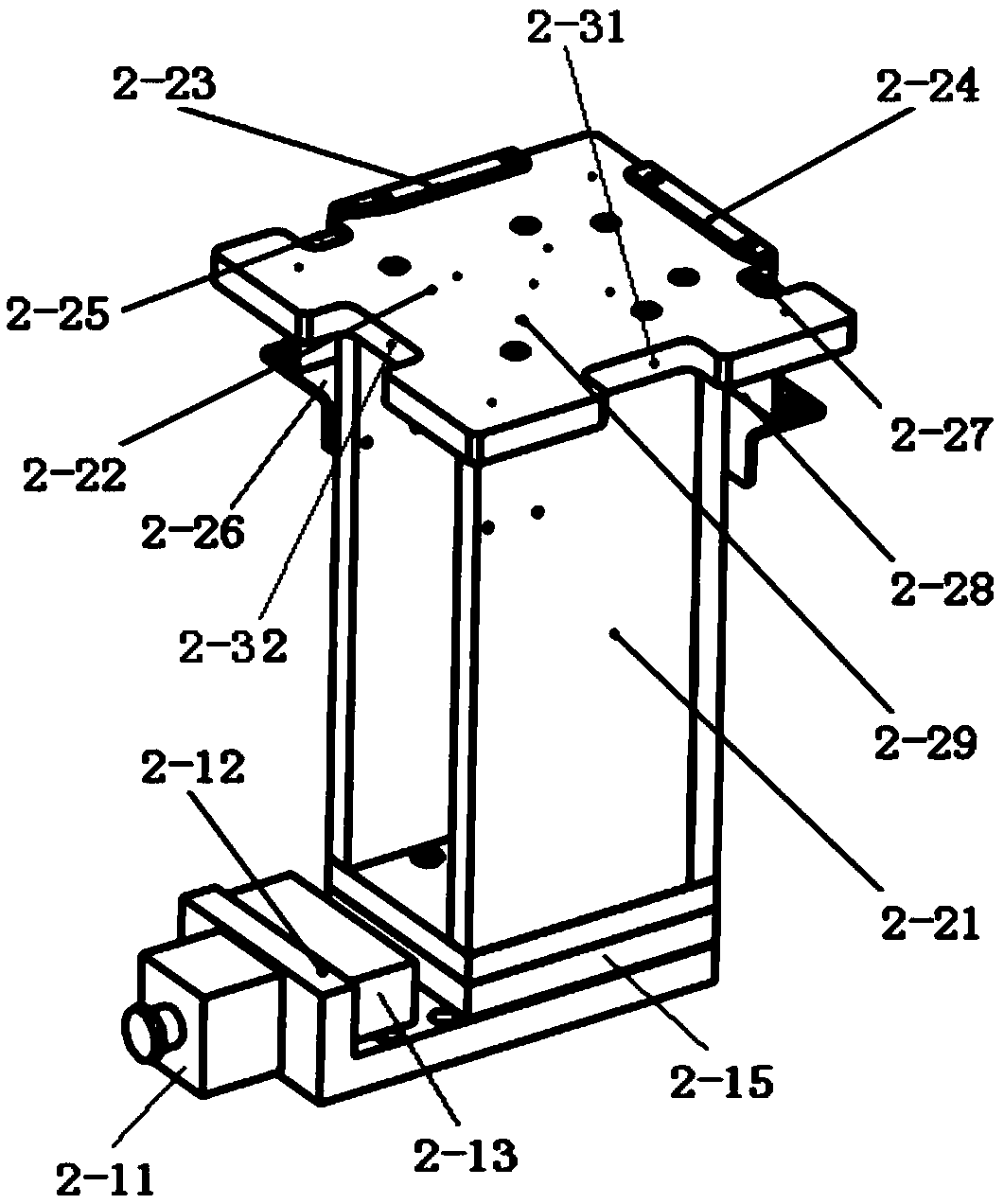

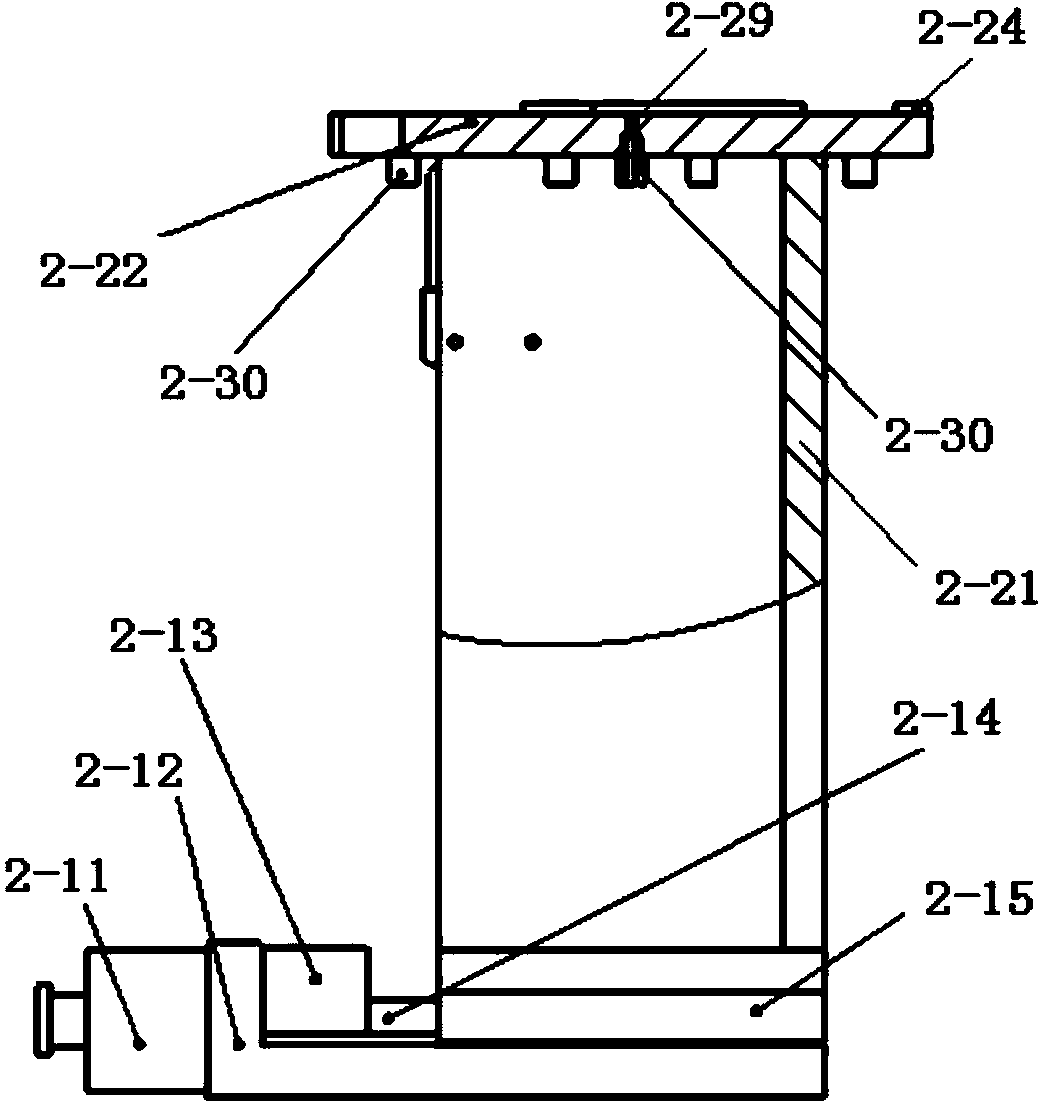

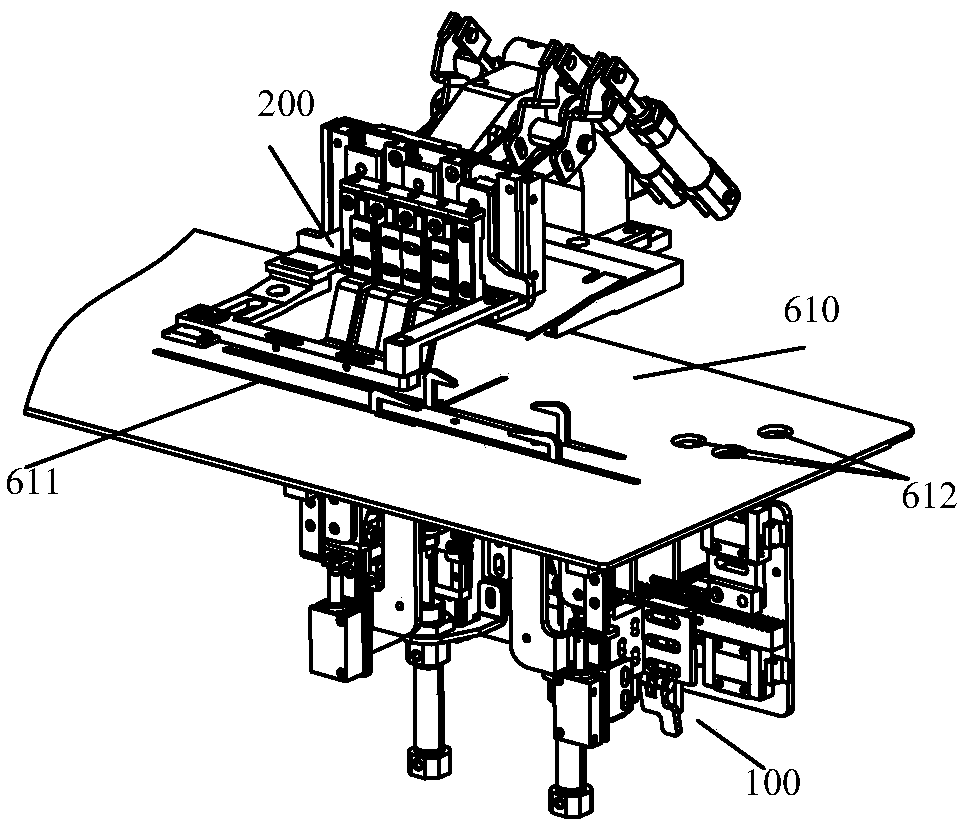

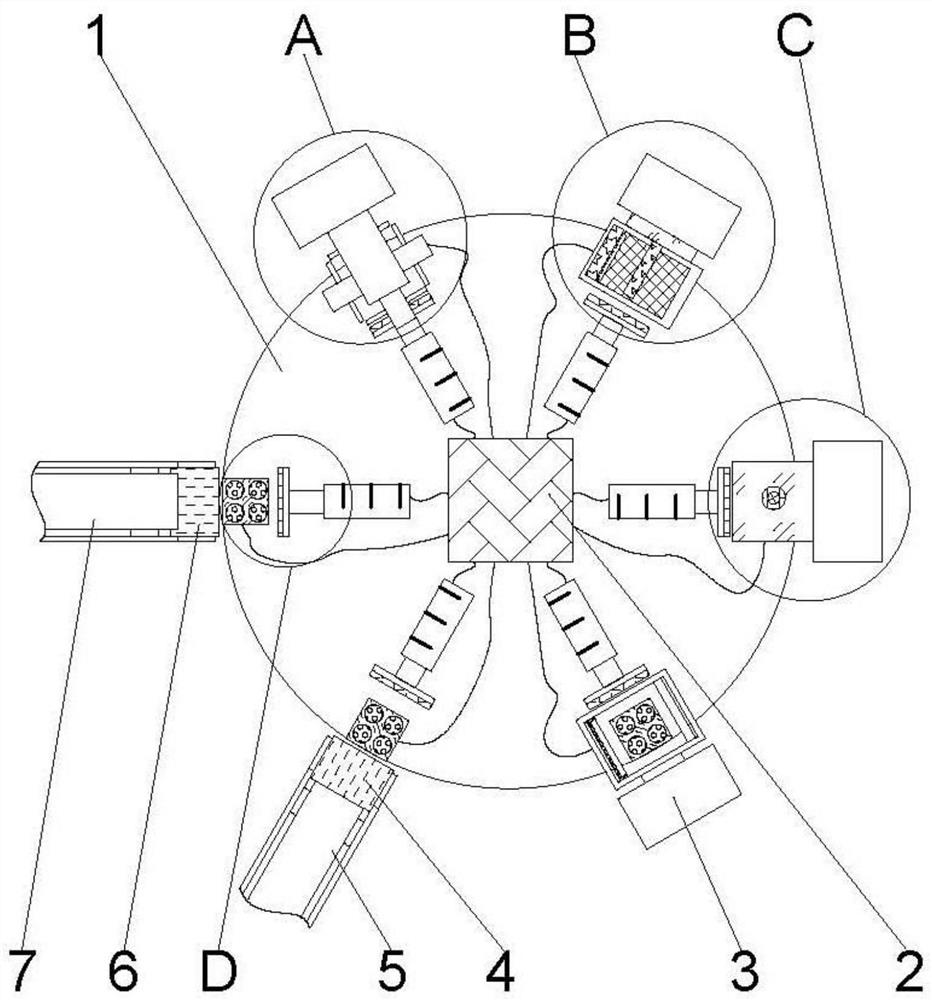

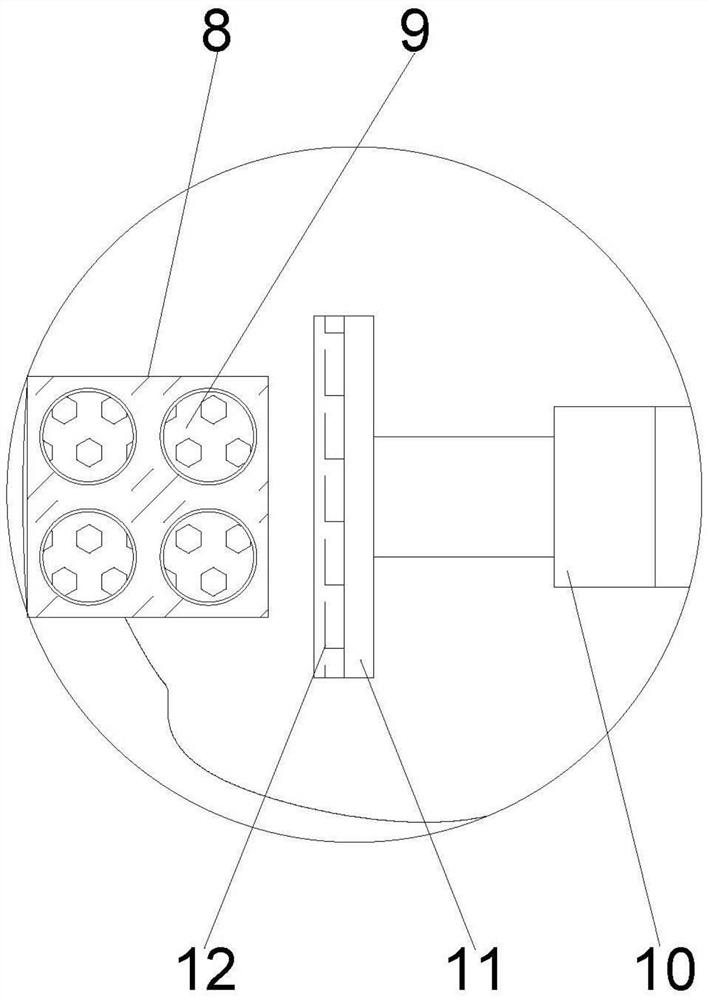

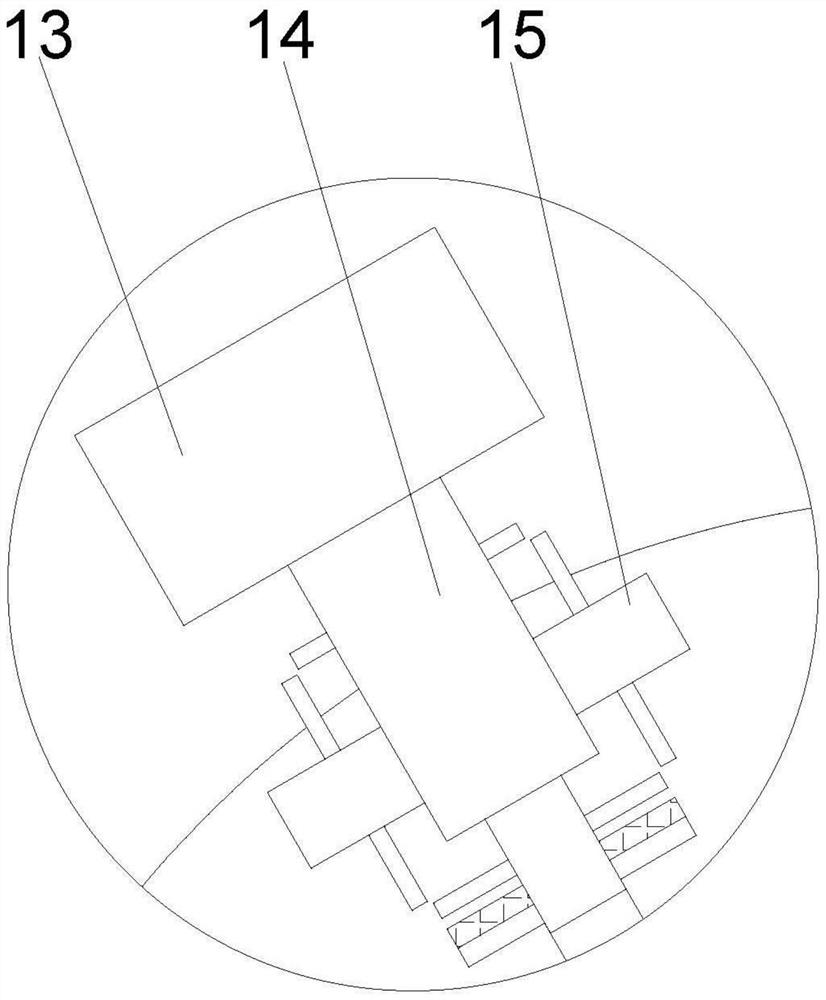

The invention relates to laser cutting equipment for a stainless steel chip. A loading platform device of the laser cutting equipment can carry out Y-direction straight-line motion on a platform base, and the stainless steel chip is placed on the loading platform device. A primary positioning camera is installed above the loading platform device, and used for primary positioning of the stainless steel chip. A loading mechanical hand can carry out X-direction straight-line motion and Y-direction straight-line motion on a loading base and is used for picking the stainless steel chip and placing the stainless steel chip to a suction platform. The suction platform can carry out X-direction straight-line motion, Z-direction straight-line motion and rotary motion on the platform base. A fine positioning camera is fixedly arranged above the suction platform on the platform base and used for adjusting the position of the suction platform to achieve fine positioning of the stainless steel chip. A laser cutting system and a film pasting device are fixed to the platform base and used for achieving cutting and film pasting of the stainless steel chip. The laser cutting equipment is high in integration degree, high in production efficiency, good in cutting quality and capable of well meeting the requirement for producing stainless steel chips on a large scale.

Owner:CHANGSHUN GUANGHUA MICRO ELECTRONICS EQUIP ENG CENT

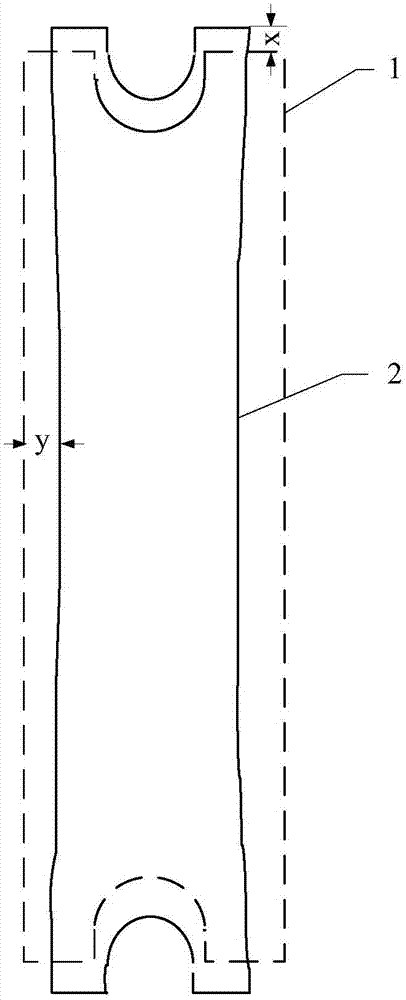

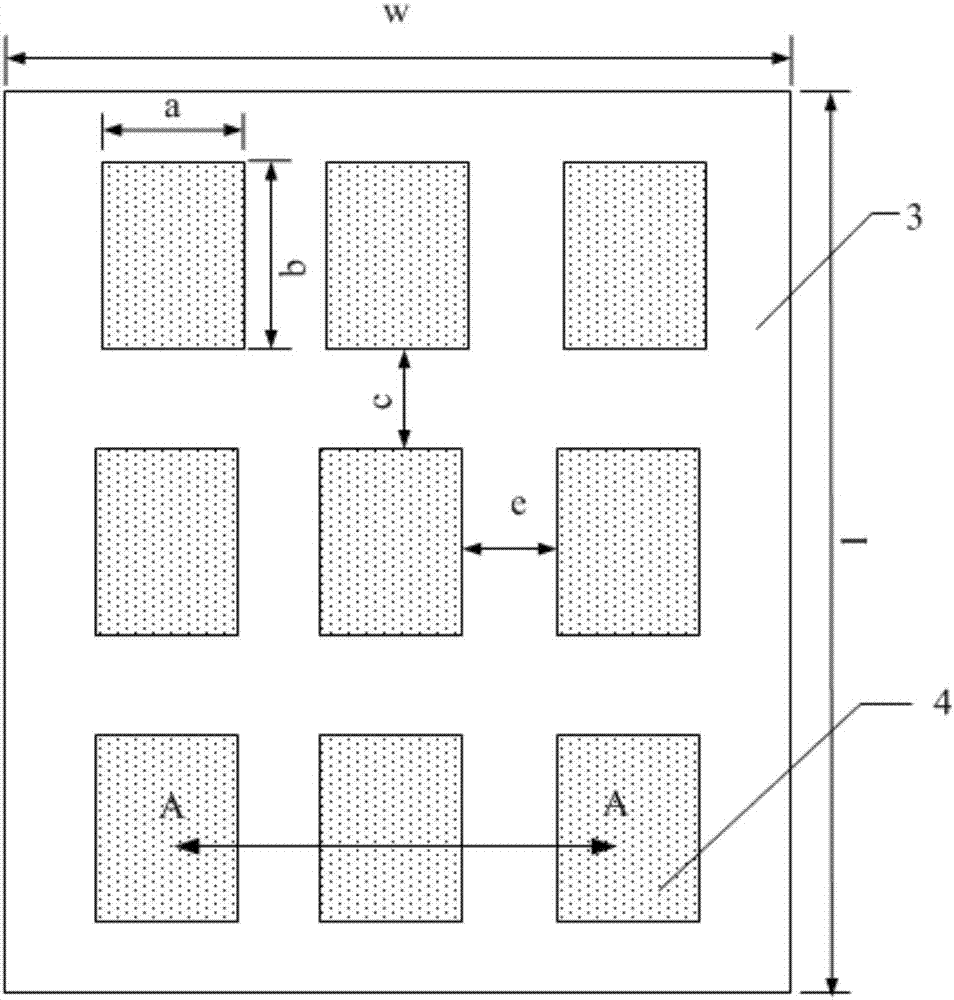

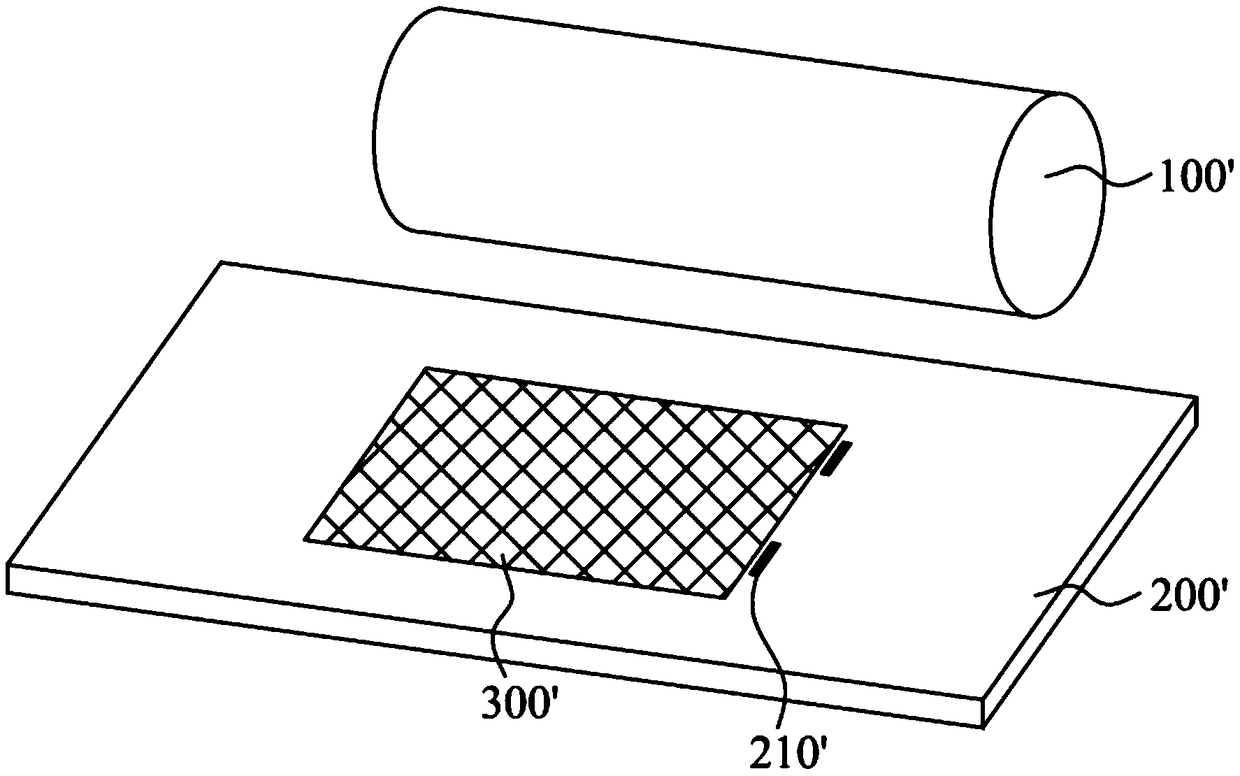

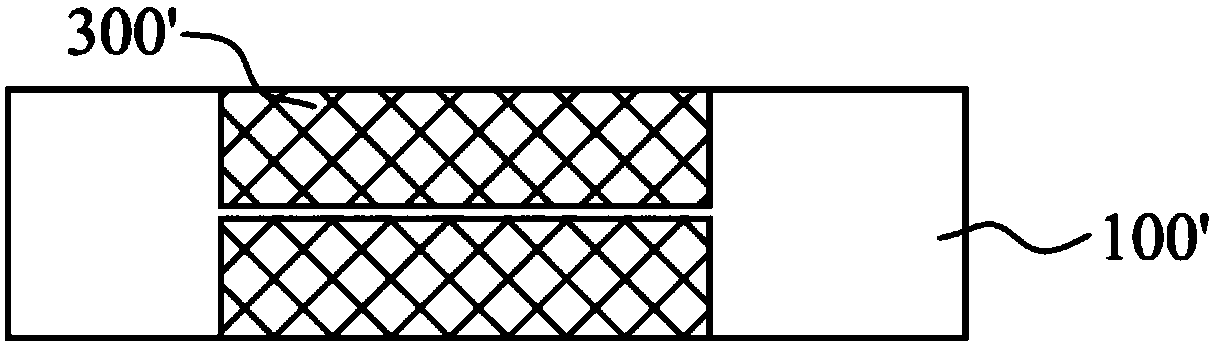

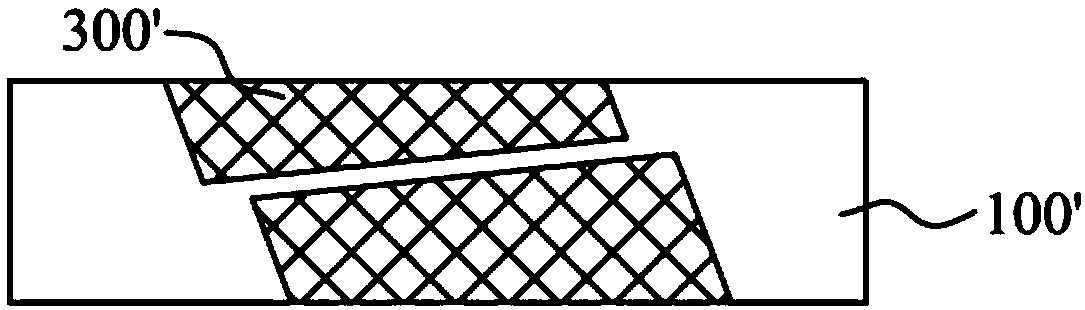

Design method of metal mask and preparation method of metal mask

ActiveCN107227438AGuaranteed Position AccuracyGuaranteed positioning accuracyGeometric CADSemiconductor/solid-state device testing/measurementDesign methodsPerpendicular direction

The invention belongs to the technical field of display, and particularly relates to a design method of a metal mask and a preparation method of the metal mask. The design method of the metal mask comprises the steps that the deformation quantities, in two perpendicular directions, of the metal mask are calculated correspondingly according to the tensile strength of the metal mask in use and the deformation attributes of the metal mask in the two perpendicular directions; and deformation, in the two perpendicular directions, of the metal mask is compensated by compensation quantities identical with the deformation quantities and with the opposite deformation tendency according to the deformation quantities, in the two perpendicular directions, of the metal mask. According to the methods, the compensation quantities required when the metal mask is manufactured are obtained by calculating the tensioning shrinkage of the metal mask, and then deformation is compensated when the metal mask is manufactured; and the deformation quantities of the metal mask are taken into consideration at the initial design stage of the metal mask, the metal mask with the compensation quantities being taken into consideration is designed, and the technological cost of the metal mask is reduced.

Owner:BOE TECH GRP CO LTD +1

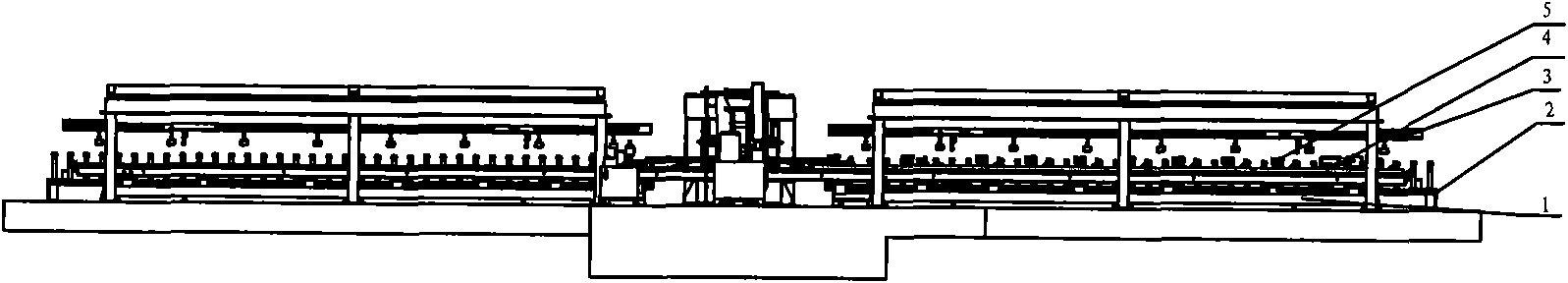

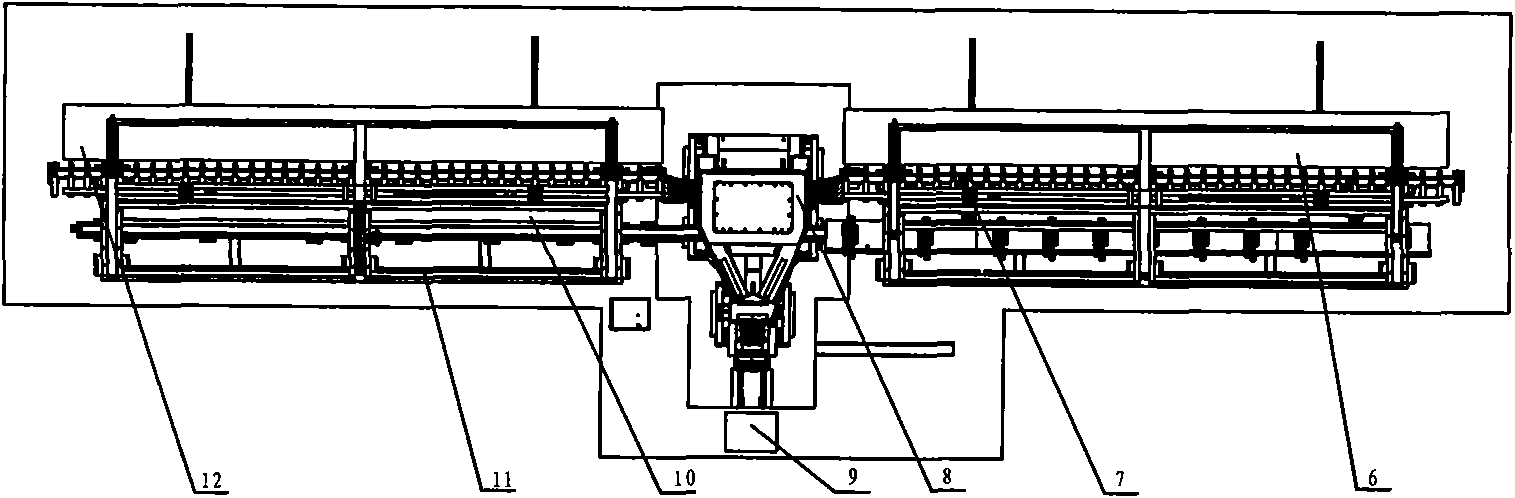

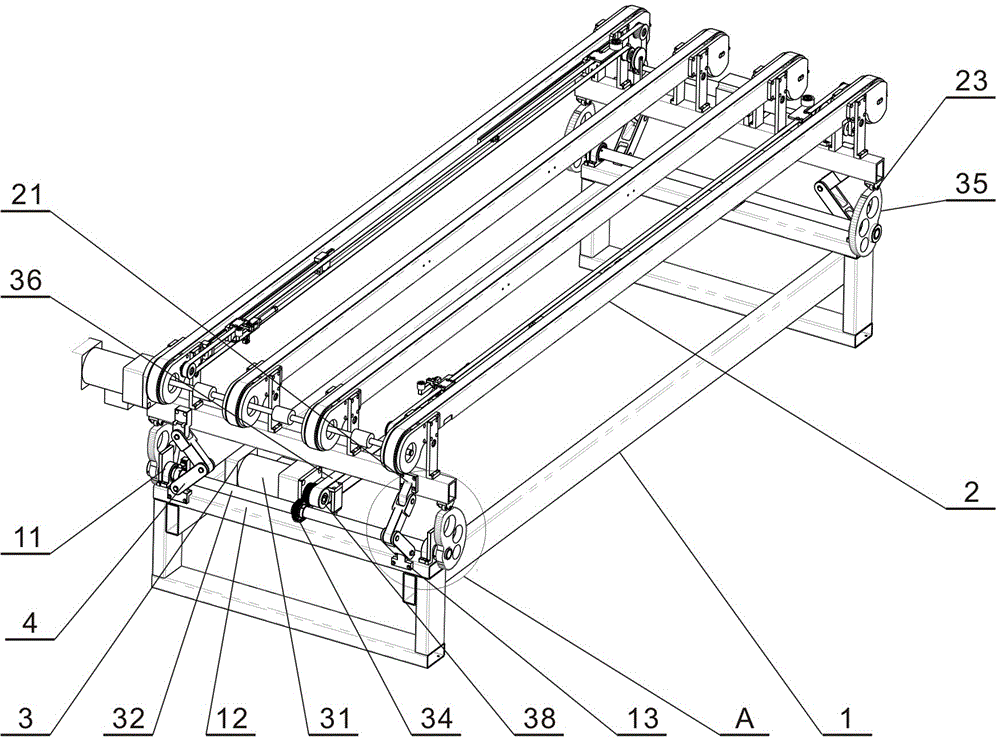

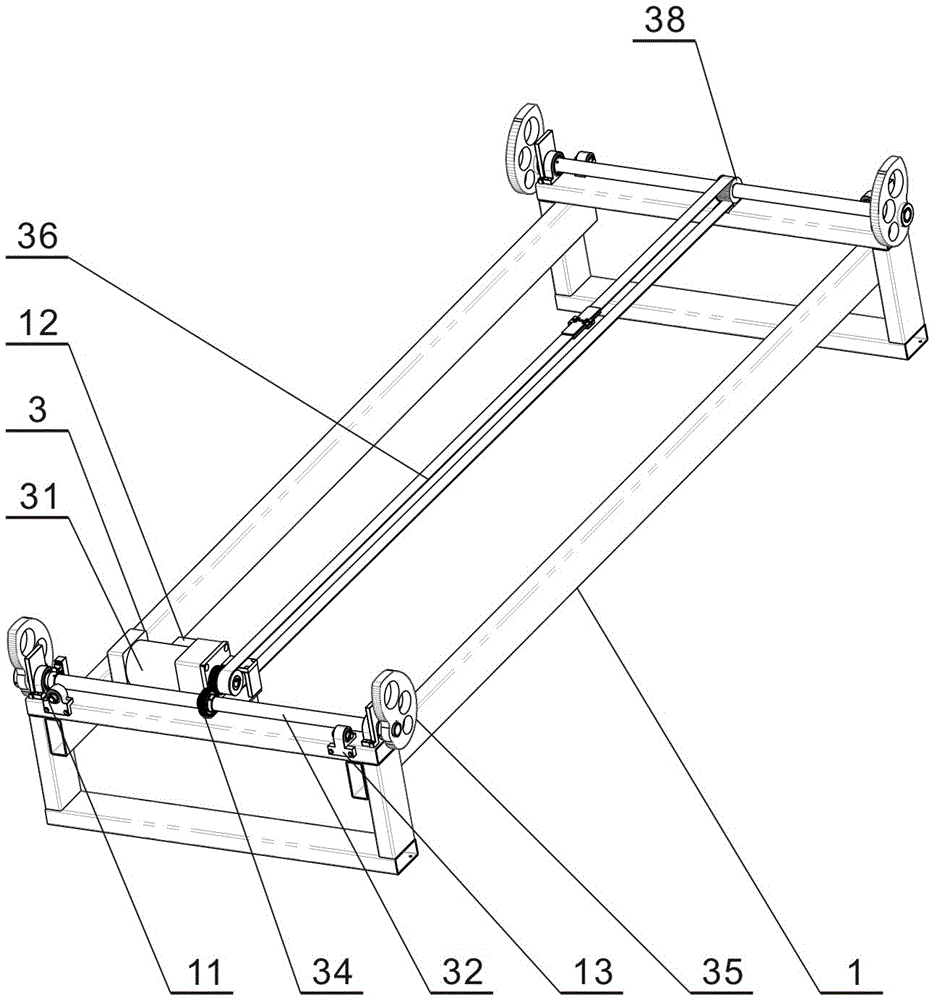

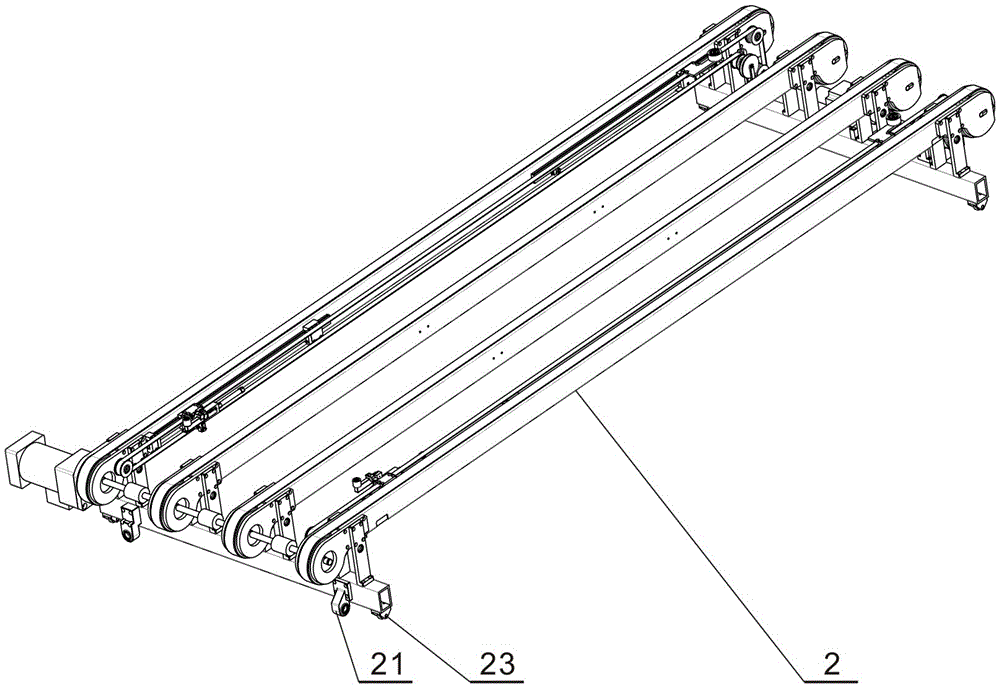

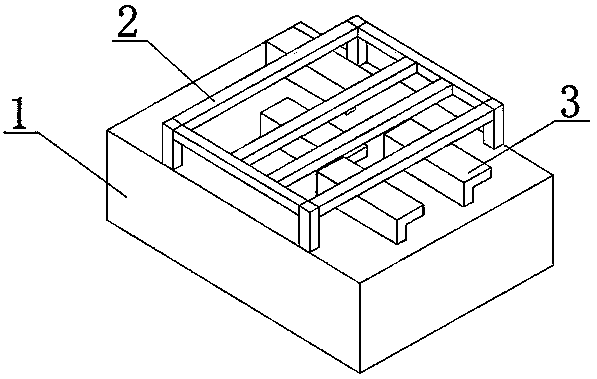

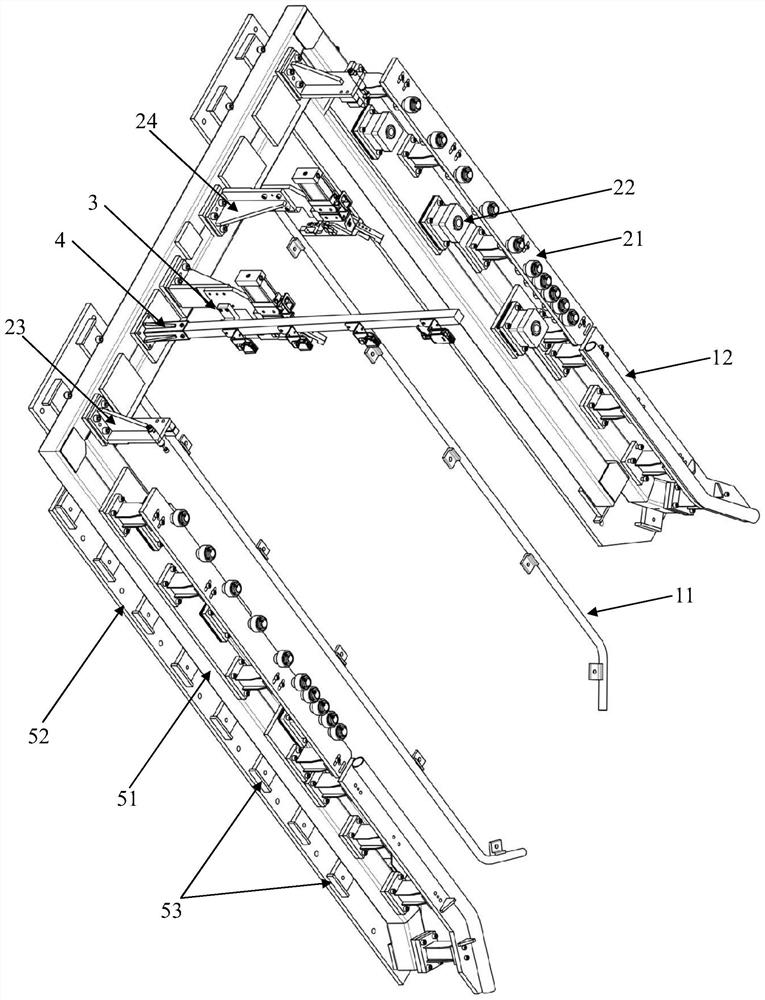

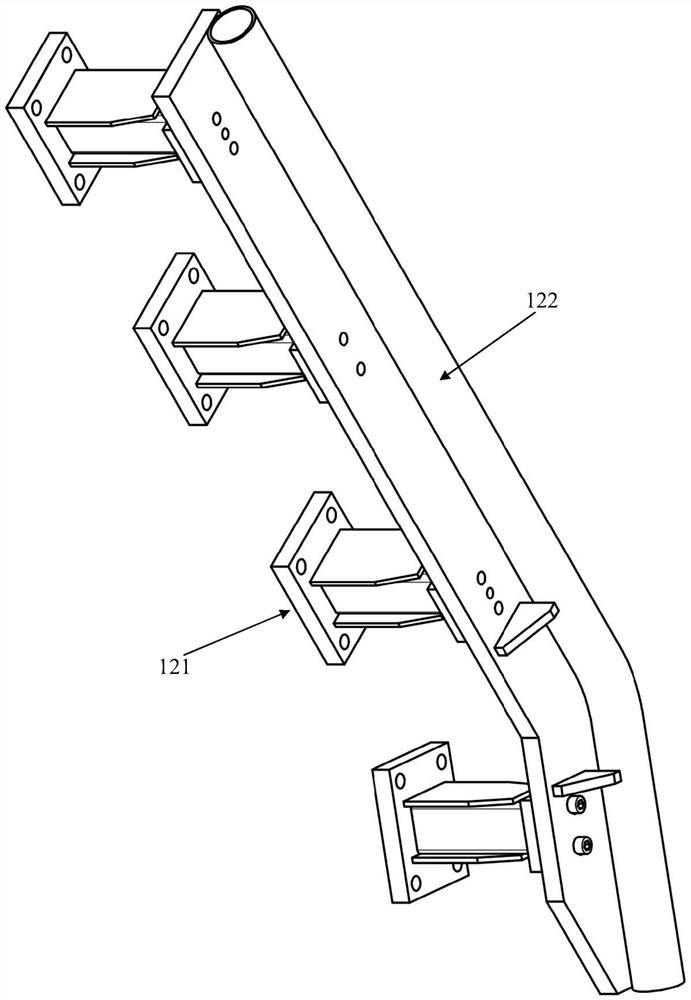

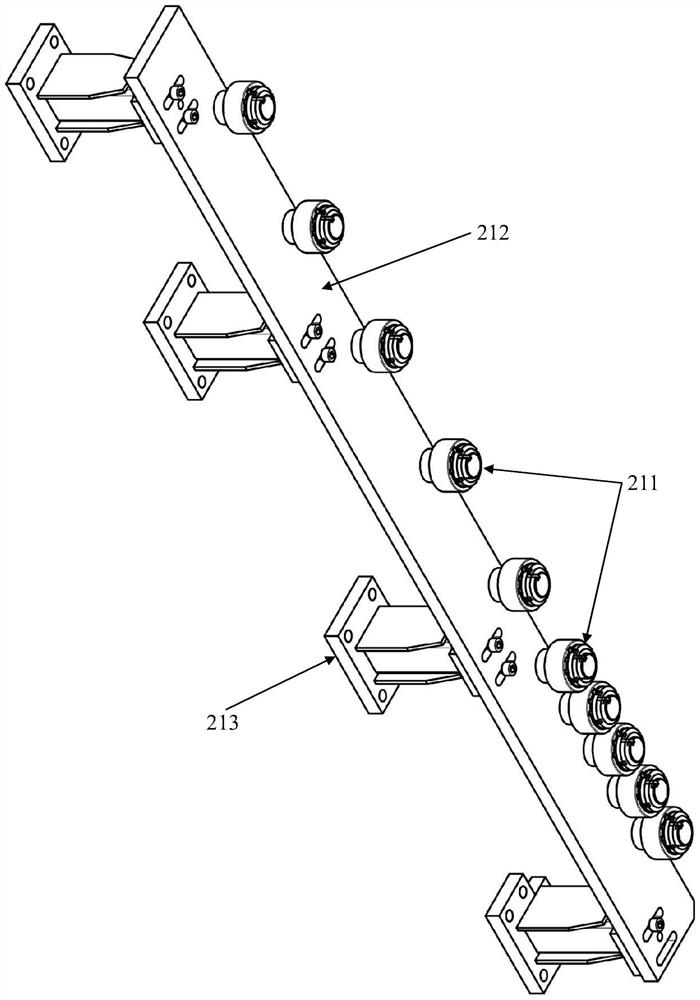

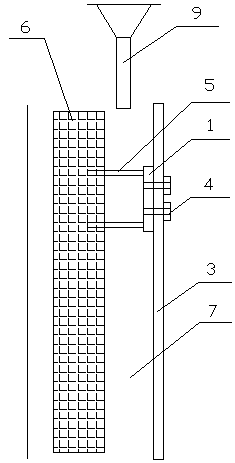

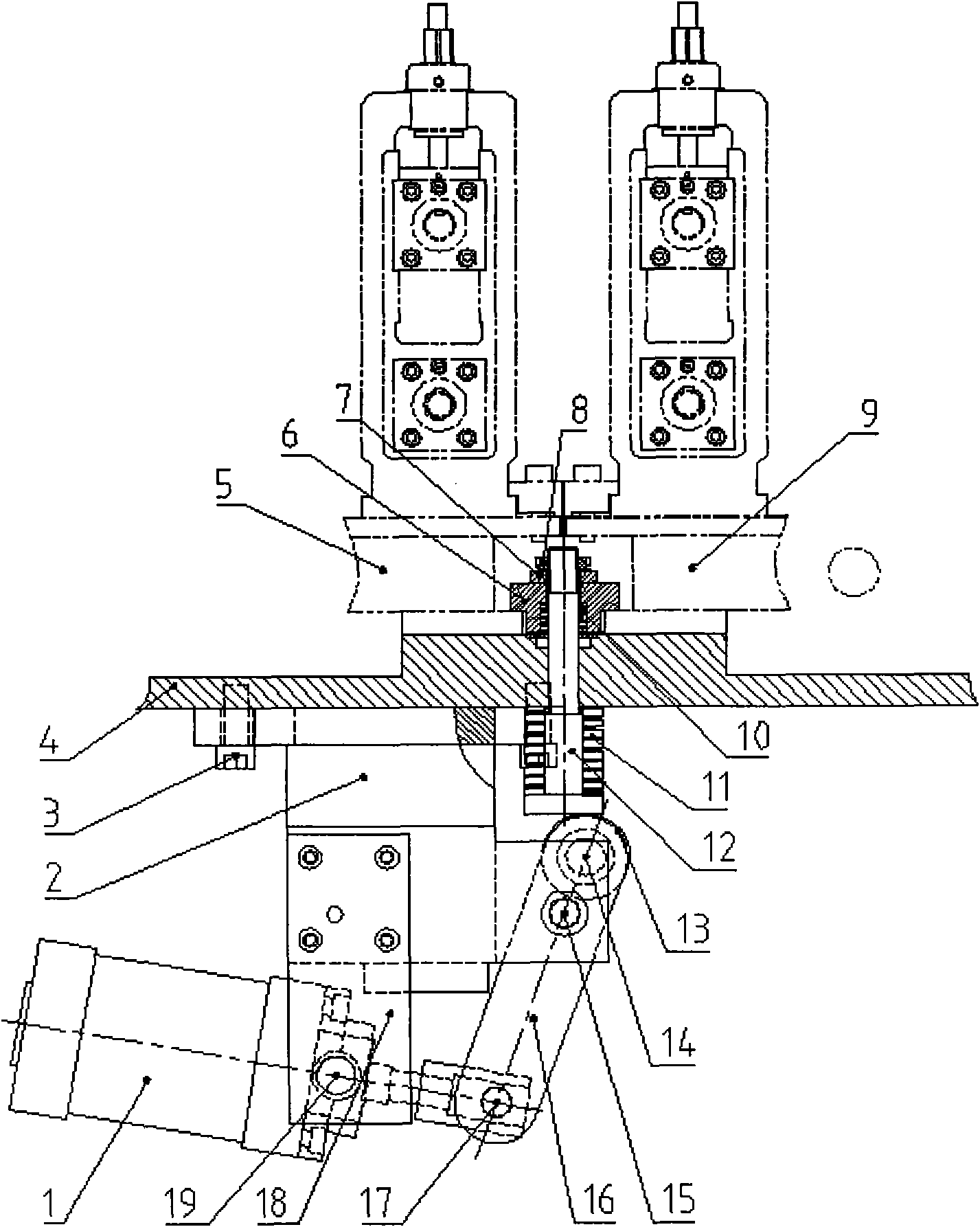

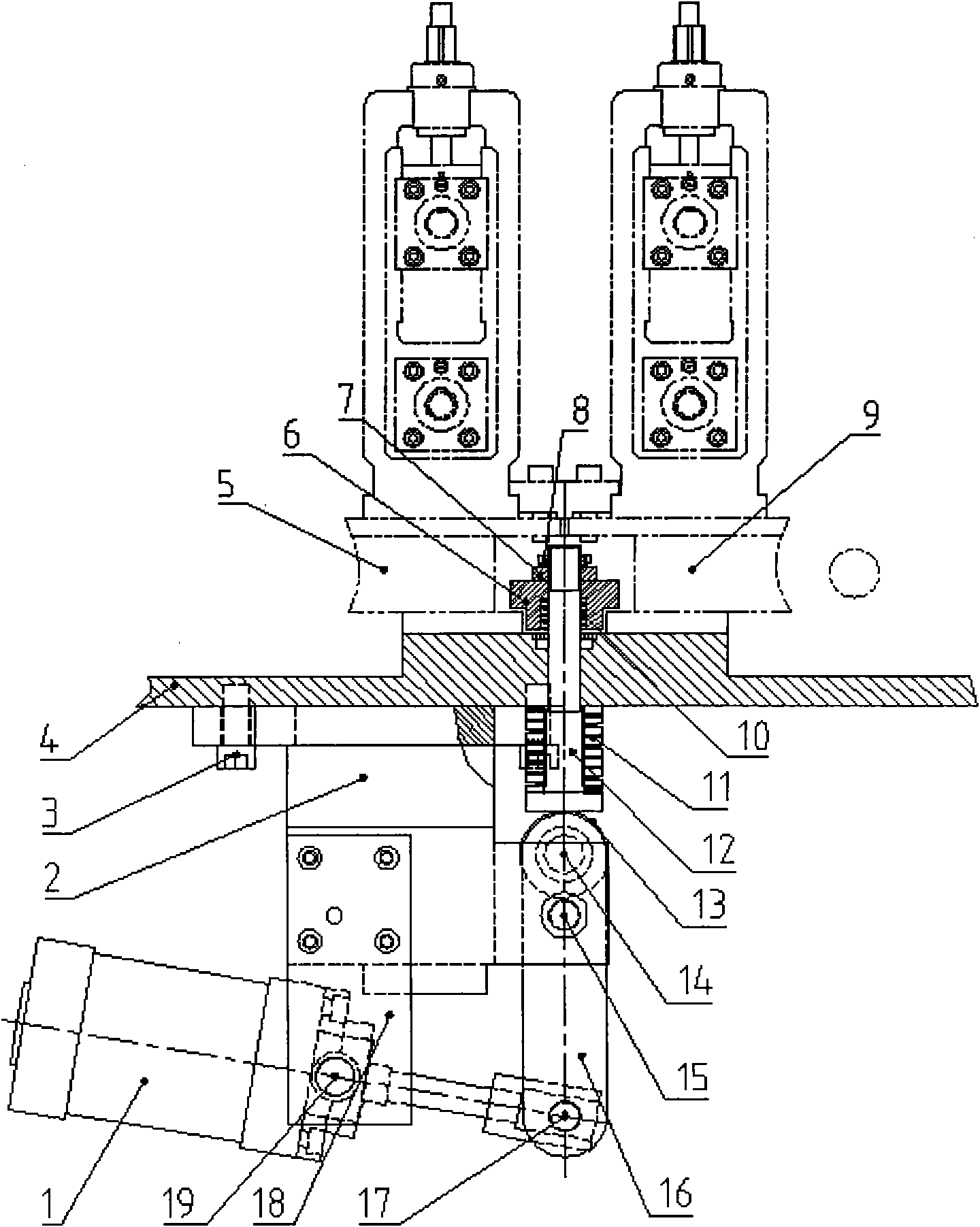

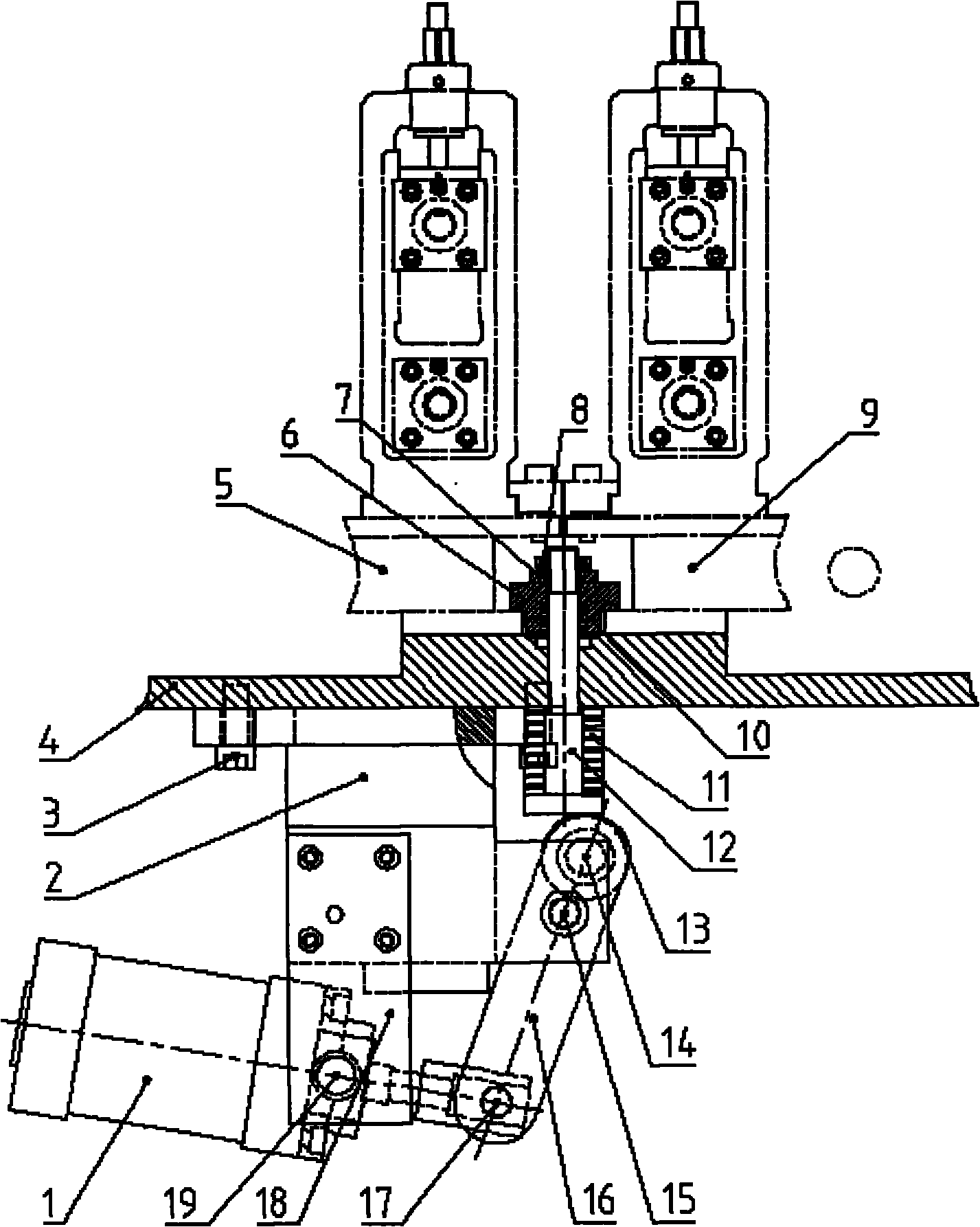

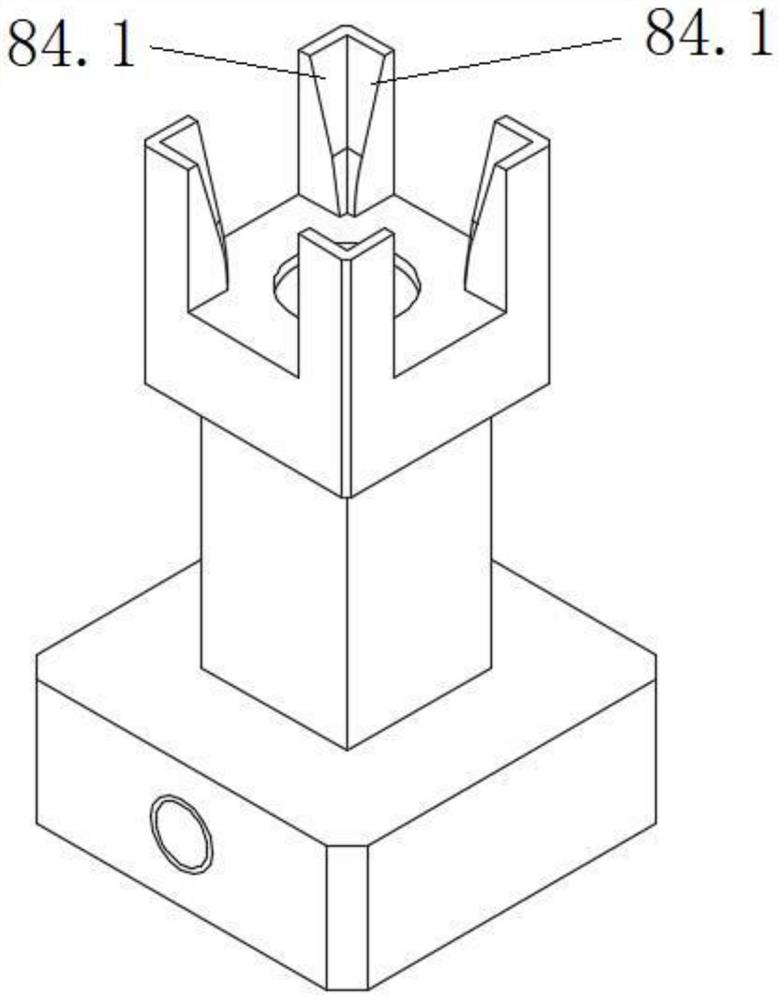

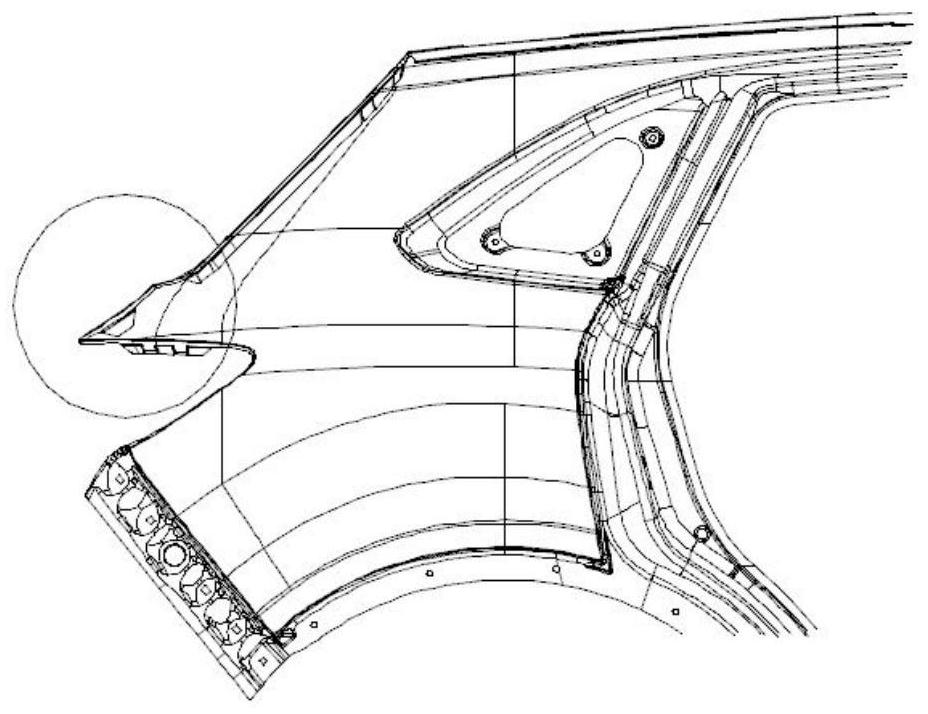

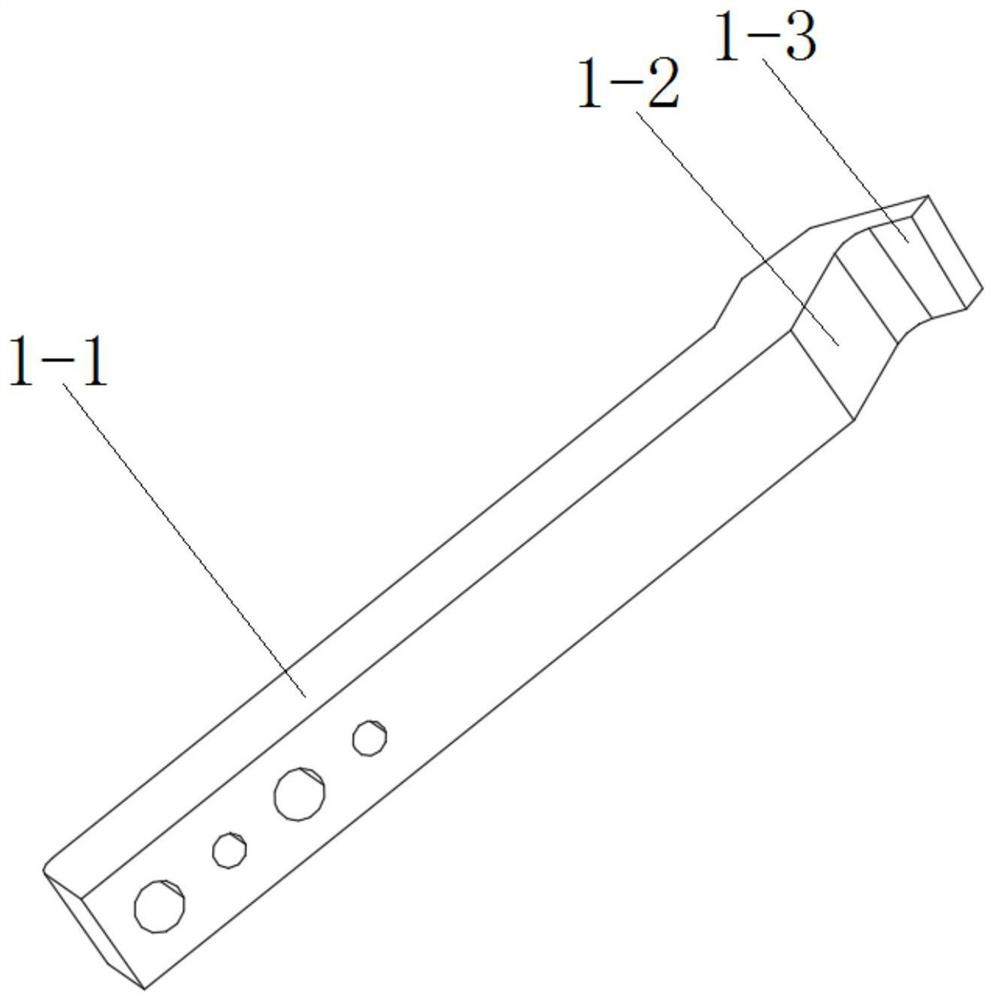

Numerical control punching machine for longitudinal beam of automobile

The invention discloses a numerical control punching machine for a longitudinal beam of an automobile, and relates to a molding machine special for large plates. A host machine comprises a three-column closed A-type body, a sliding block, a sliding block driving device and a workbench; the workbench is provided with a floating supporting device; the sliding block is provided with a pressing device; a discharging device comprises a discharging base, a blanking bracket and a blanking trolley; a feeding device comprises a feeding base, a beam moveably connected among the feeding base, the workbench and the discharging base, a loading trolley, a loading bracket, a lifting device, a gripping mechanism fixedly connected on two sides of the top surface of the beam, and a centering device arranged on the loading bracket; the loading bracket is provided with a roller set, the centering device is arranged on two sides of the roller set; the gripping mechanism is arranged on the two sides of the roller set and positioned between the centering device and the workbench in the feeding direction; and a jaw of the gripping mechanism is slightly higher than the top surface of the floating supporting device. The numerical control punching machine has the advantages of high automation degree, low manufacturing lost of corresponding mold, and high reliability and adaptability.

Owner:江苏扬力数控机床有限公司

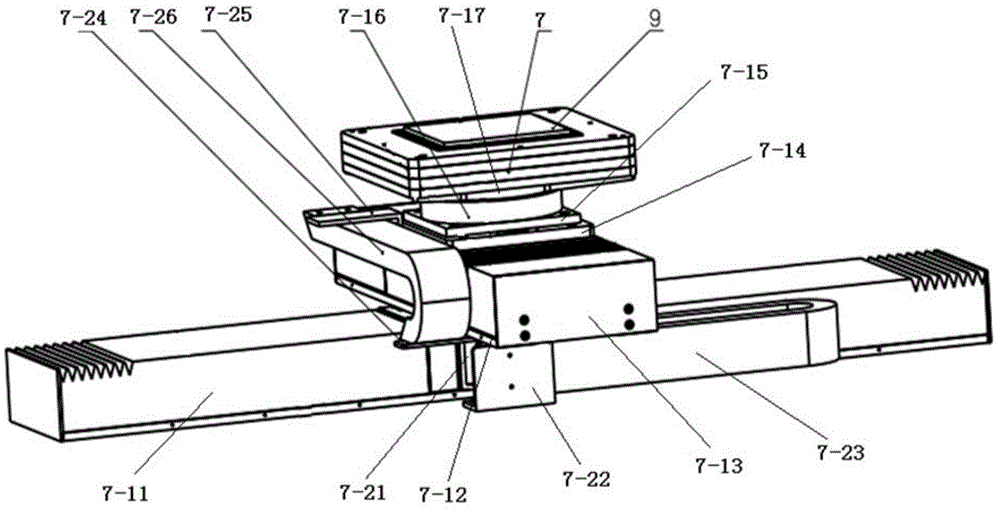

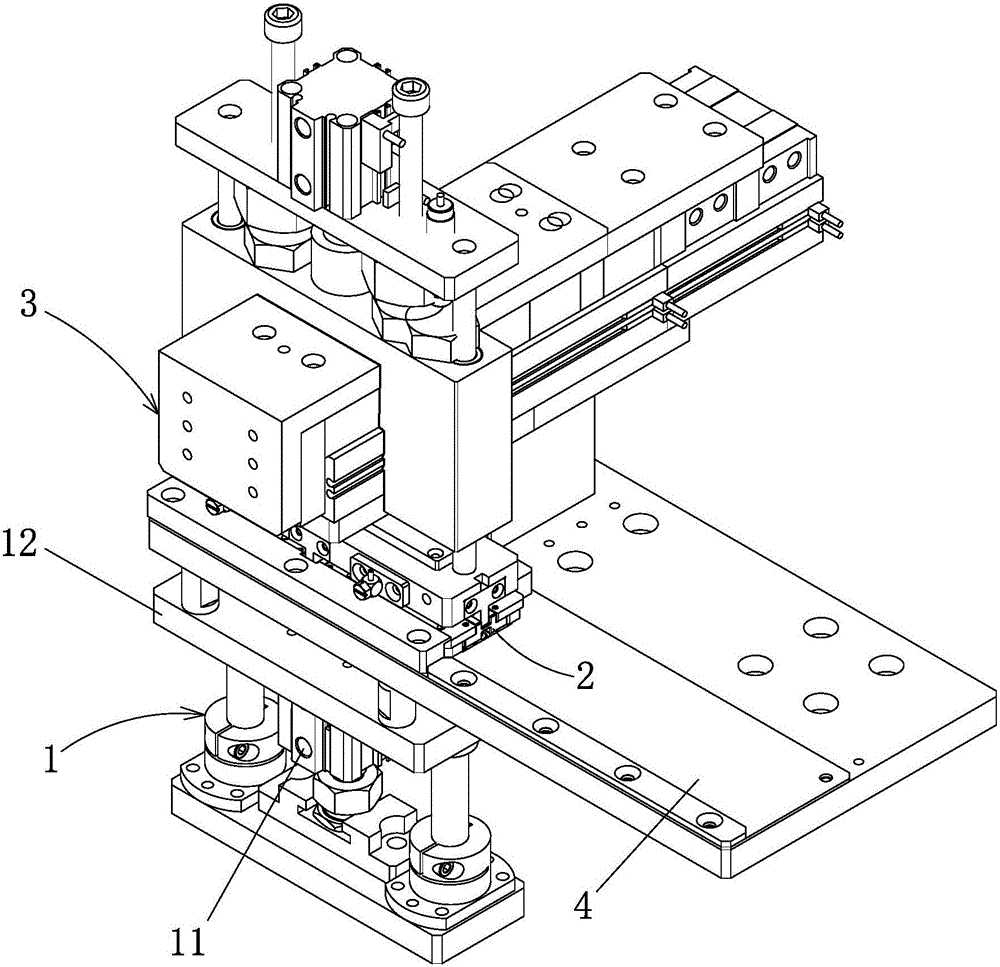

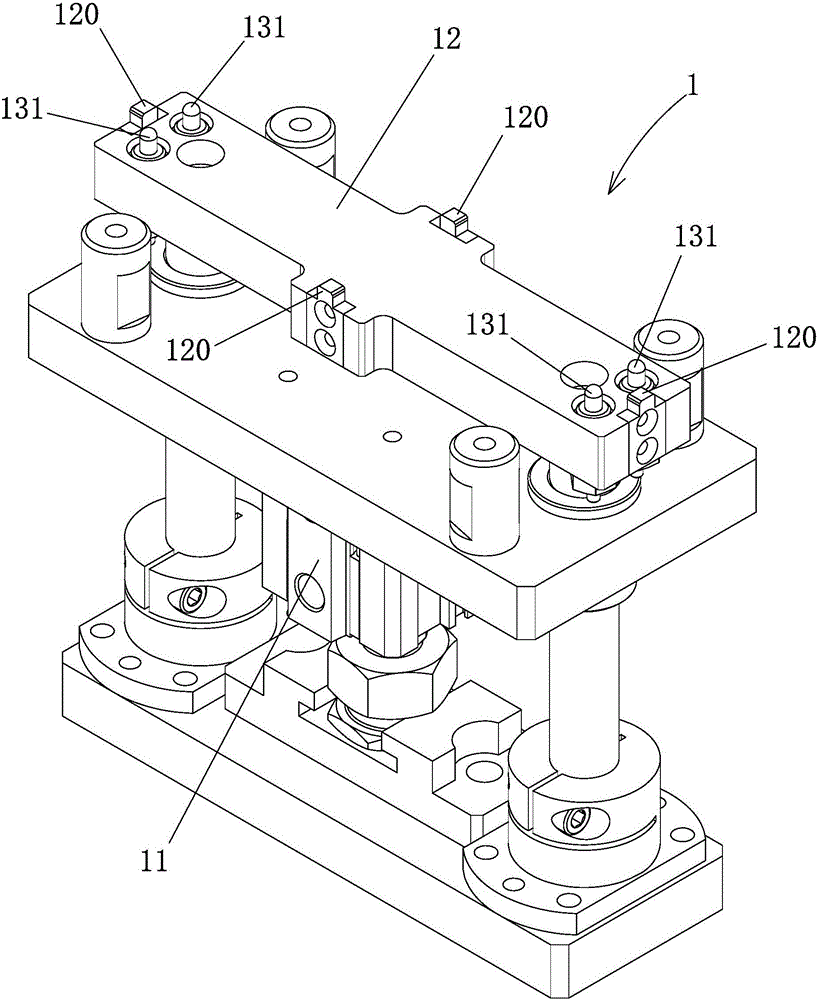

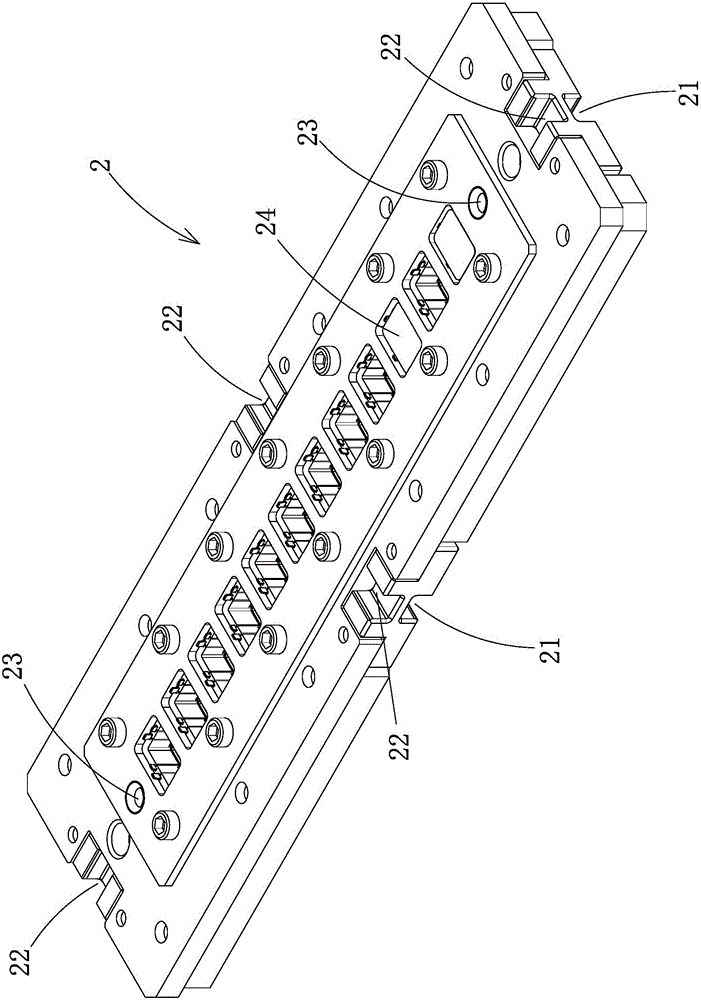

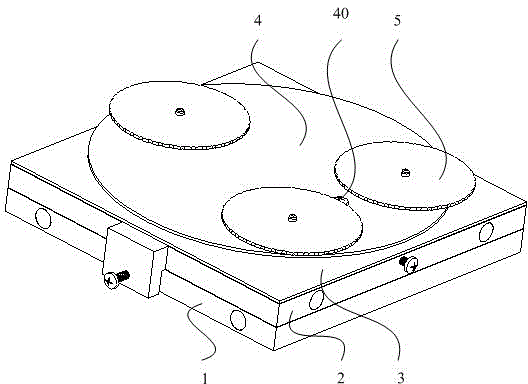

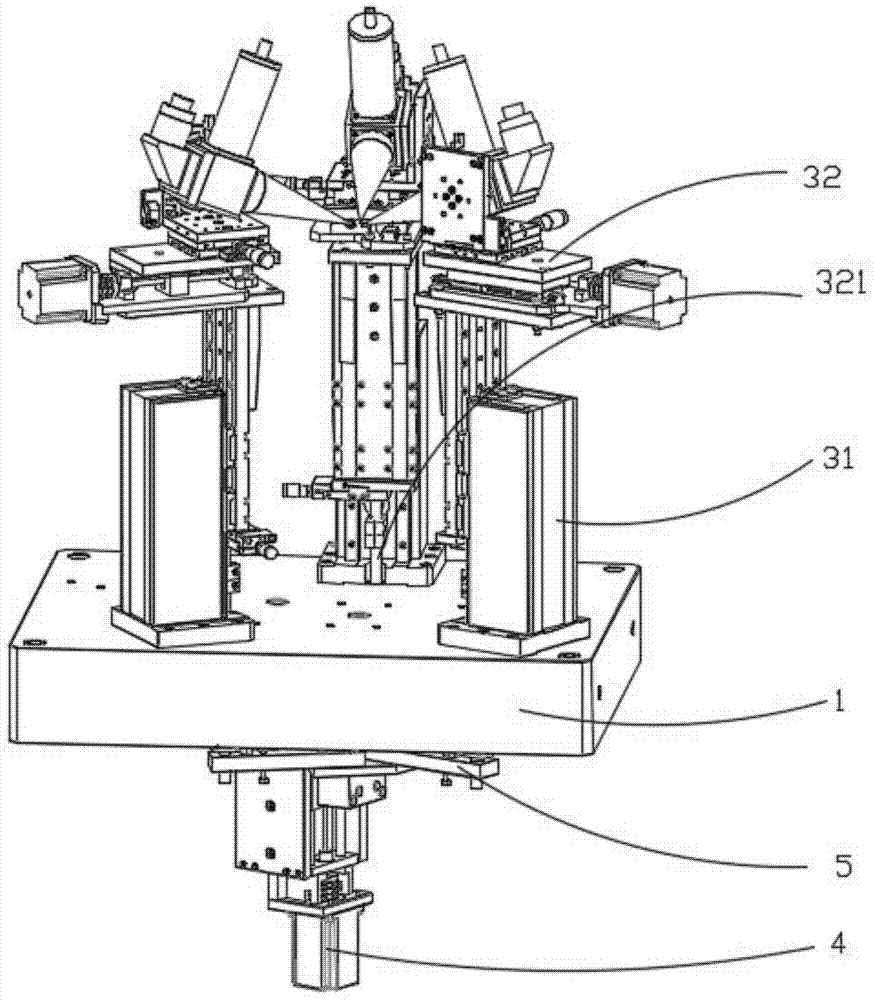

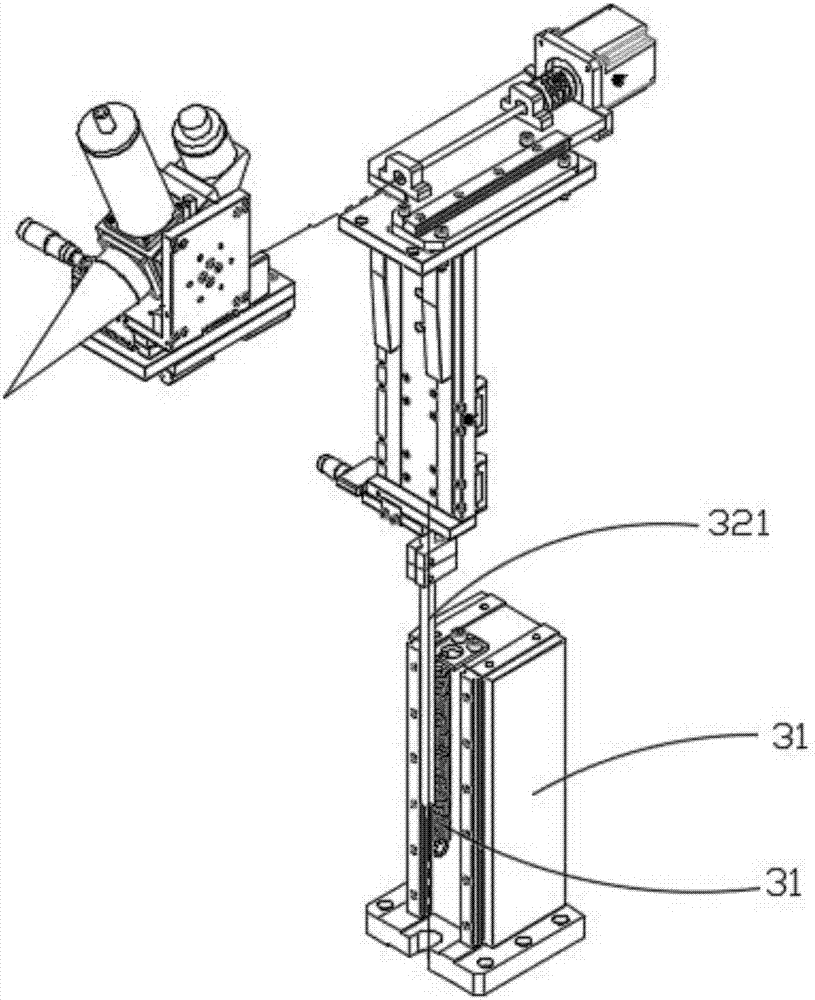

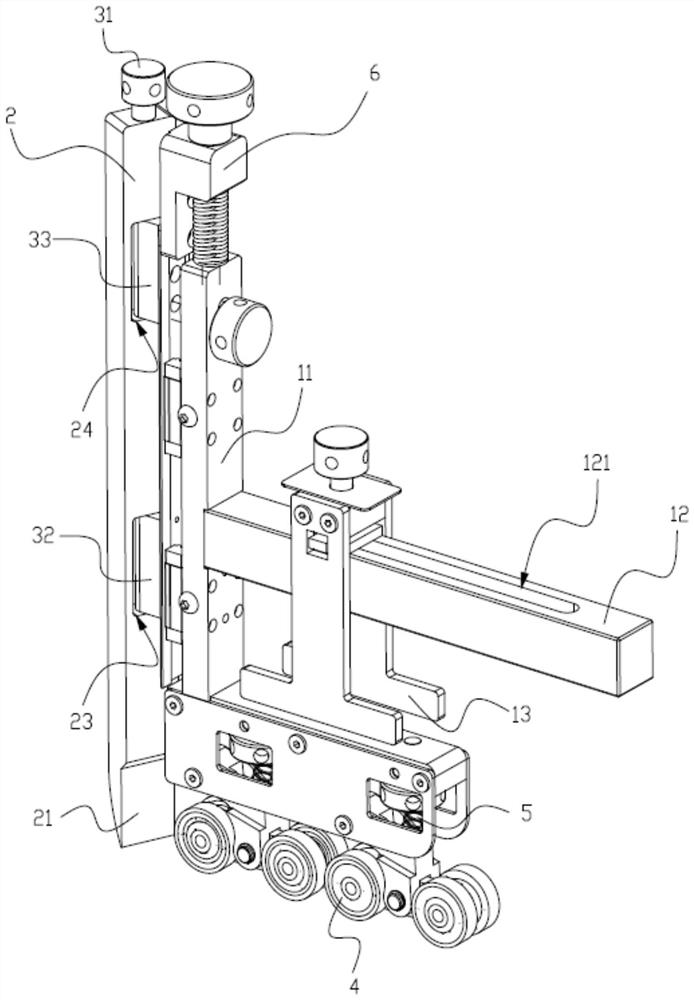

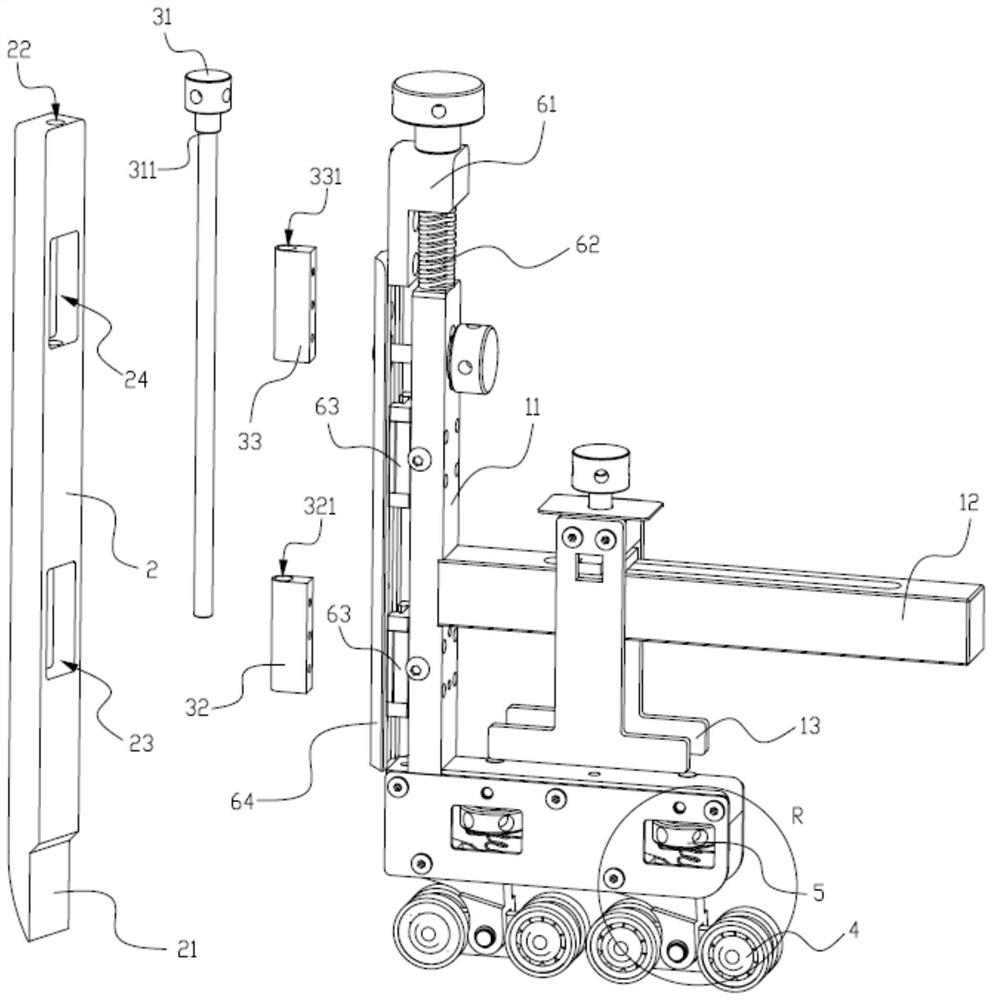

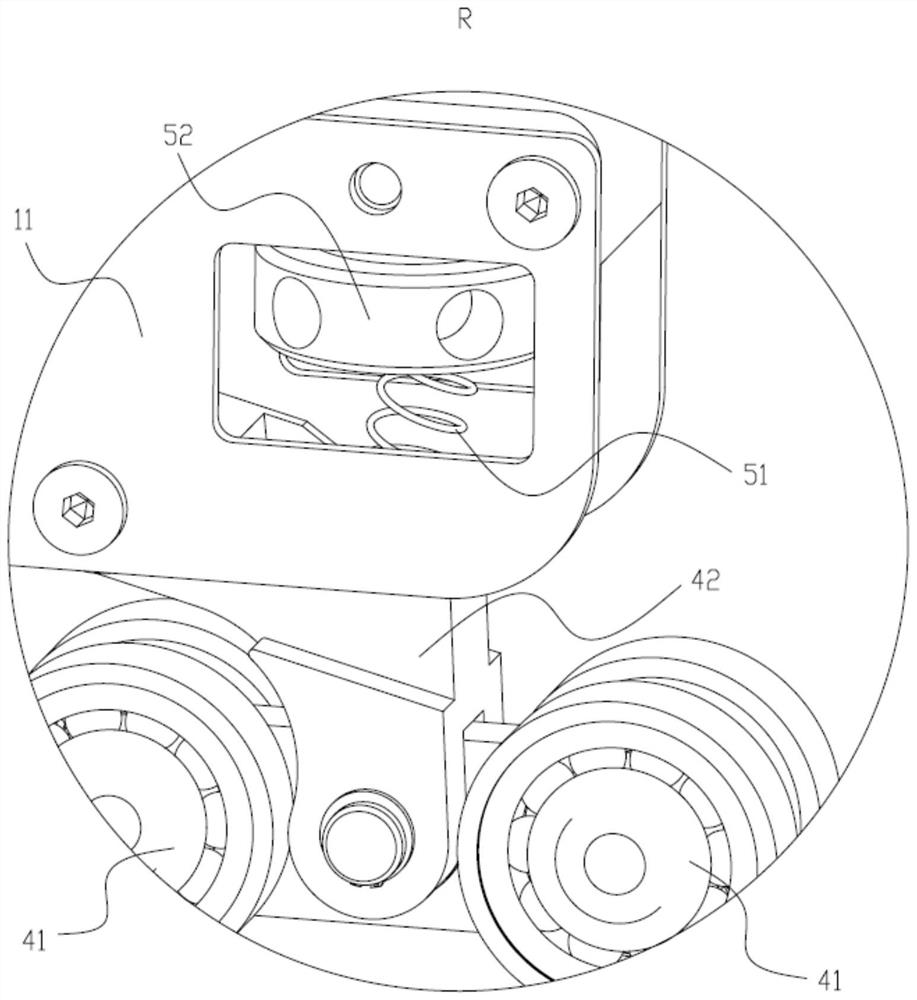

Automatic alignment device for stainless steel substrate loading

ActiveCN104084702AGuaranteed Position AccuracyAchieve adsorptionWelding/soldering/cutting articlesMetal working apparatusManipulatorEngineering

The invention relates to an automatic alignment device for stainless steel substrate loading. A loading platform device of the device is installed on a platform base through a Y-direction straight-line motion mechanism and can carry out Y-direction straight-line motion on the platform base. A primary positioning camera is installed above the loading platform device. A loading base is fixed to the platform base. A loading mechanical hand is installed on the loading base, and can carry out X-direction and Z-direction straight-line motion on the loading base. A fine positioning camera is fixedly arranged above a suction platform of the platform base and used for adjusting the position of the suction platform to achieve fine positioning of a stainless steel substrate. The suction platform is installed on the platform base through an X-direction straight-line motion mechanism, the Y-direction straight-line motion mechanism and a rotary motion mechanism. The fine positioning camera is located above the suction platform. According to the automatic alignment device for stainless steel substrate loading, automatic alignment for stainless steel substrate loading can be effectively achieved, and the cutting position precision of the stainless steel substrate is ensured.

Owner:中科长光精拓智能装备(苏州)有限公司

Lifting device for upper platform of automatic layout machine for photovoltaic cell strings

The invention discloses a lifting device for an upper platform of an automatic layout machine for photovoltaic cell strings. The lifting device comprises a rack, the upper platform, a lifting device and corner chains, wherein a bearing seat and a lower corner chain seat are arranged on four corners of the rack respectively; a guide wheel and an upper corner chain seat are arranged on four corners of the upper platform respectively; transmission shafts of the lifting device are arranged in the bearing seats of the rack respectively in parallel, and lifting cams are arranged on four end heads of the transmission shafts; and the upper platform is arranged above the rack and the guide wheels contact with the lifting cams. According to the invention, a lifting movement of the upper platform is driven by virtue of the lifting cams, thus a tail-end inertia force of the upper platform during an ascending movement is buffered; and longitudinal or transversal swinging of the upper platform during the ascending movement is restrained, and the position accuracy of glass on the platform is effectively ensured by virtue of corner chain mechanisms which are symmetrically arranged in pairs along the diagonal line of the rack, thus product quality is stabilized and improved.

Owner:上海豪力起重机械有限公司

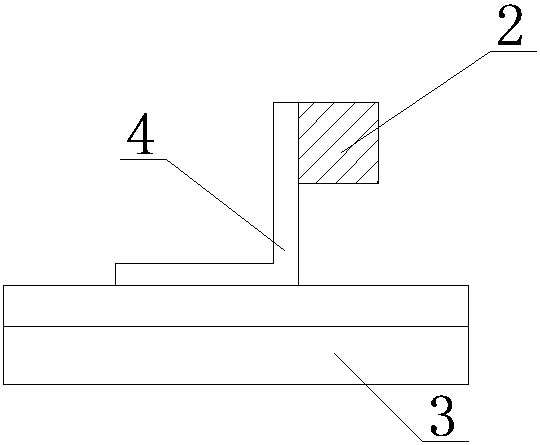

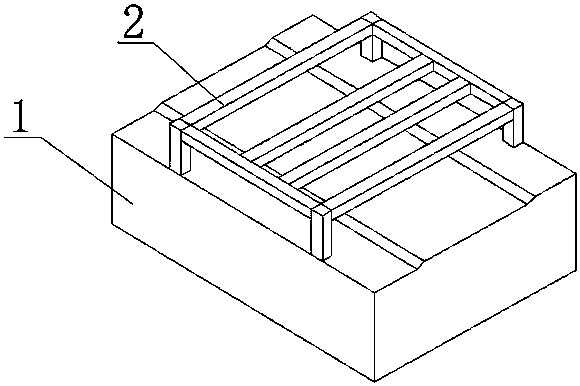

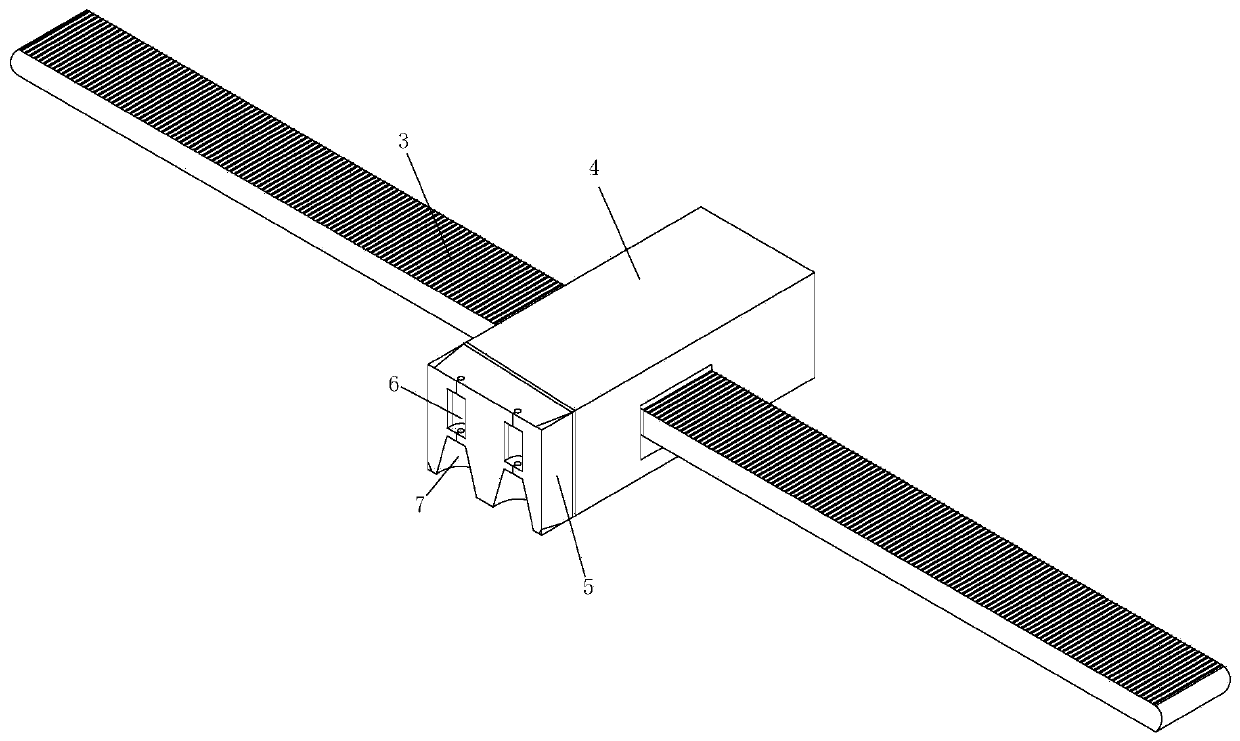

Multi-rib and skin co-curing mold combining positioning frame and multiple female mold bodies

The invention discloses a multi-rib and skin co-curing mold combining a positioning frame and multiple female mold bodies. The multi-rib and skin co-curing mold combining the positioning frame and themultiple female mold bodies comprises a supporting frame, the positioning frame and the multiple female mold bodies, wherein a working platform for holding a skin is formed on the upper surface of the supporting frame; a plurality of supporting feet are arranged on the bottom of the positioning frame, and the positioning frame is detachably installed on the working platform through the supportingfeet; and the female mold bodies are arranged on the positioning frame so as to position ribs. The multi-rib and skin co-curing mold combining the positioning frame and the multiple female mold bodies has the beneficial effects that a special fixture is provided for glue joint of the skin and the ribs, accurate positioning of the skin and the ribs can be achieved, and thus the glue joint qualityof the skin and the ribs is improved. In addition, the multi-rib and skin co-curing mold combining the positioning frame and the multiple female mold bodies is simple in structure, convenient to use,beneficial for one-time forming so as to simplify processing technologies, and beneficial for improving glue joint efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

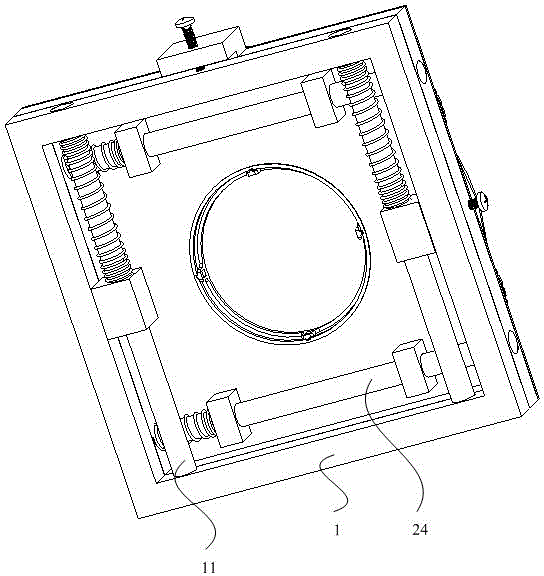

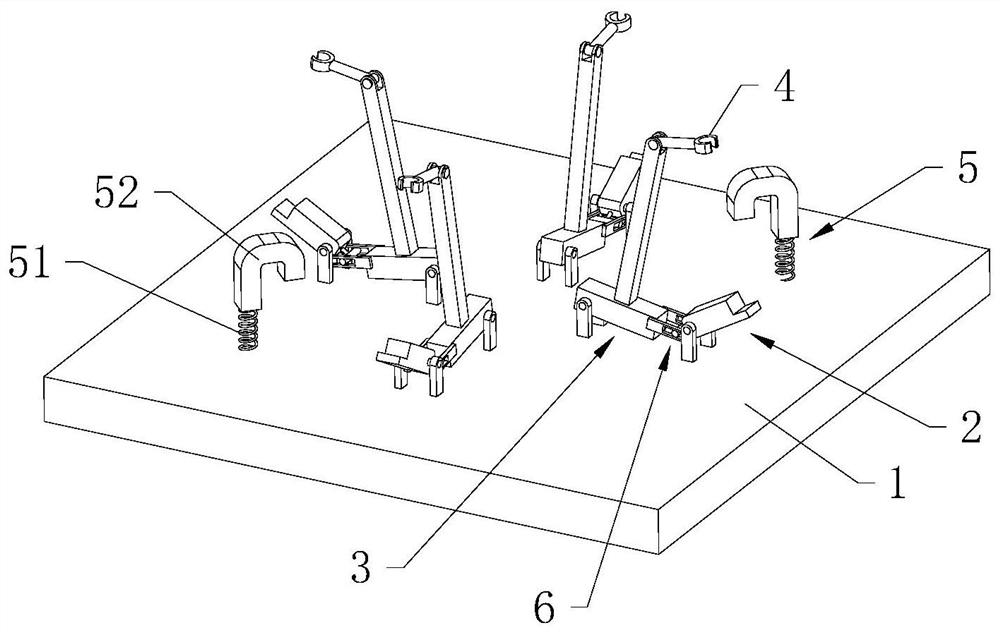

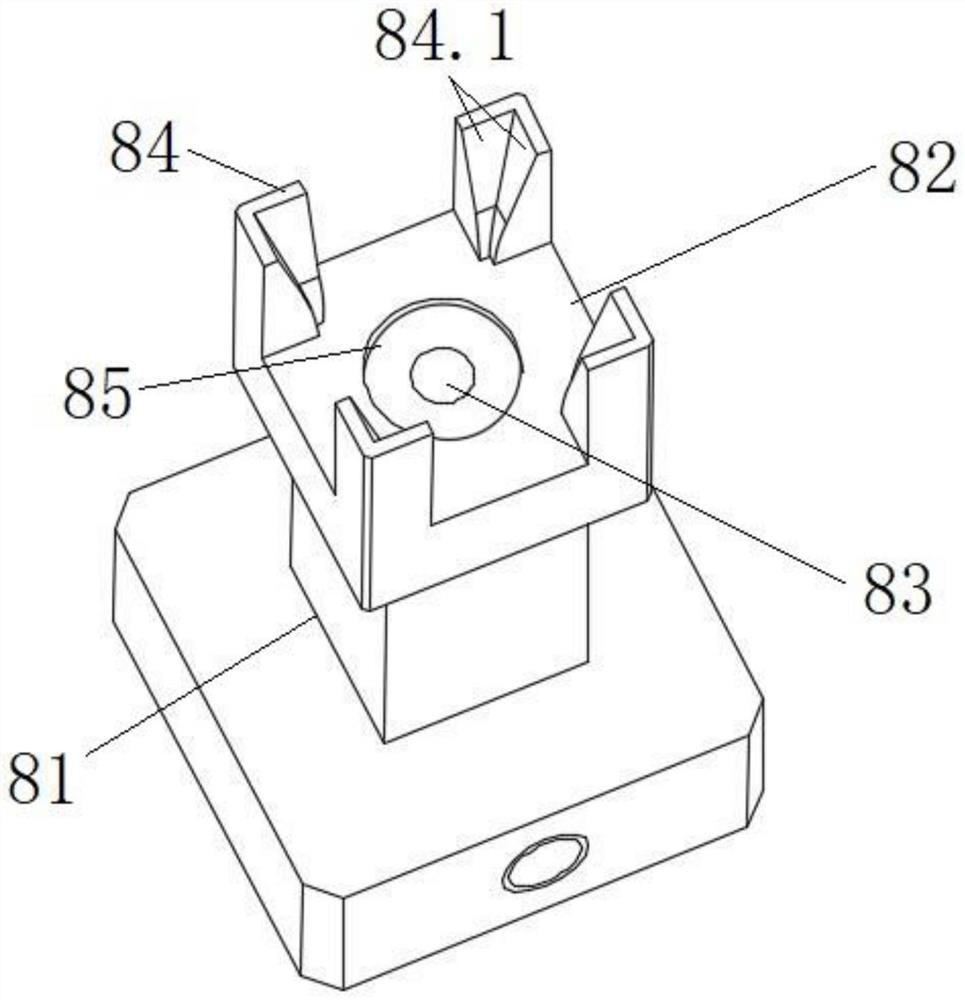

Automobile spoke clamp

InactiveCN105215710AGuaranteed Position AccuracyGuaranteed positioning accuracyPositioning apparatusMetal-working holdersEngineering

The invention belongs to the field of clamping devices or locating devices for workpieces and particularly discloses an automobile spoke clamp. The automobile spoke clamp comprises a clamp body base plate and further comprises a centering column. The centering column is arranged in the middle of the clamp body base plate, and a disc is arranged on the centering column. A floating locating pin assembly is further arranged on the clamp body base plate. The floating locating pin assembly comprises a locating column, a locating pin and a spring. The locating column is hollow and is arranged on the clamp body base plate. Both the spring and the locating pin are located inside the locating column. One end of the spring is connected with the clamp body base plate, and the other end of the spring is connected with the locating pin. By means of the automobile spoke clamp, the position accuracy during automobile spoke drilling can be guaranteed.

Owner:CHONGQING HONGQI JIEXUN WHEEL

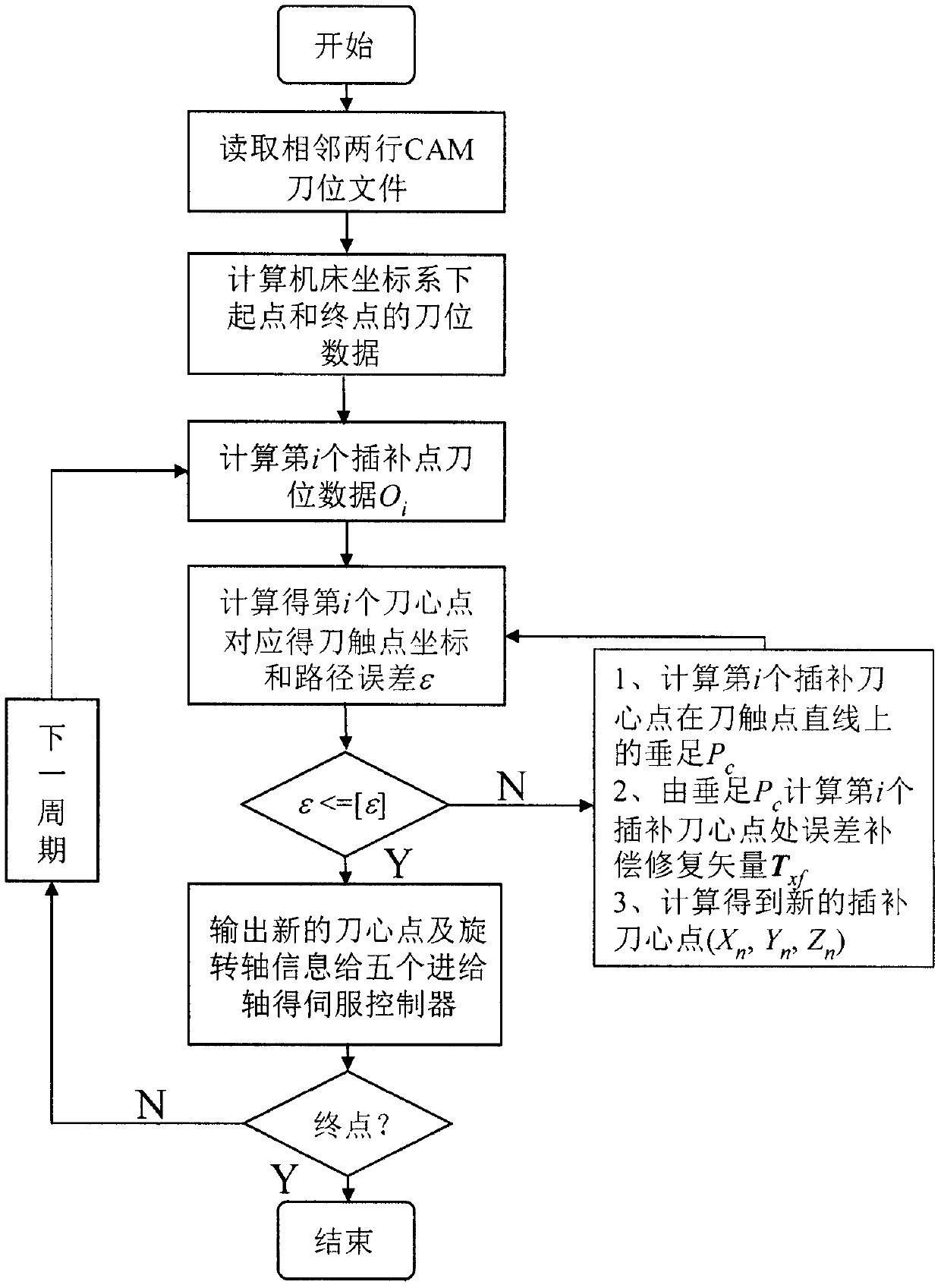

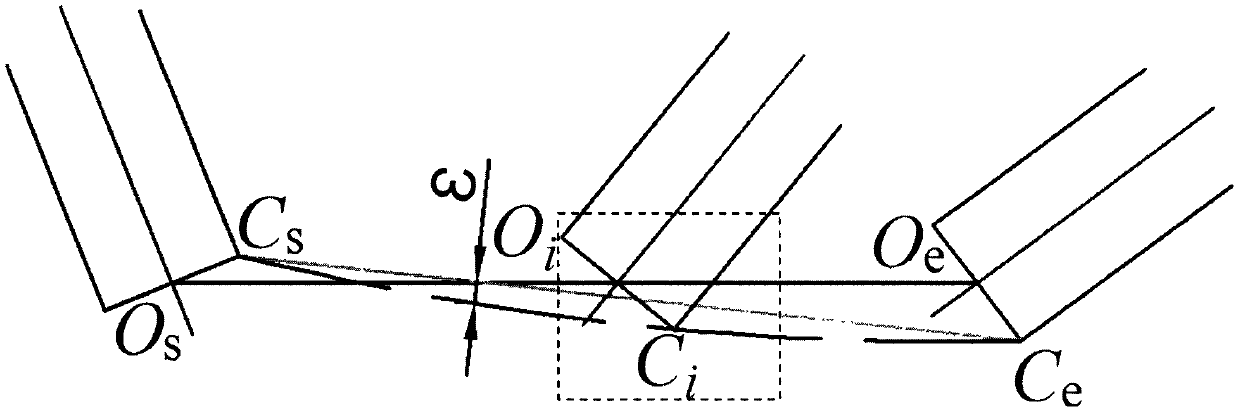

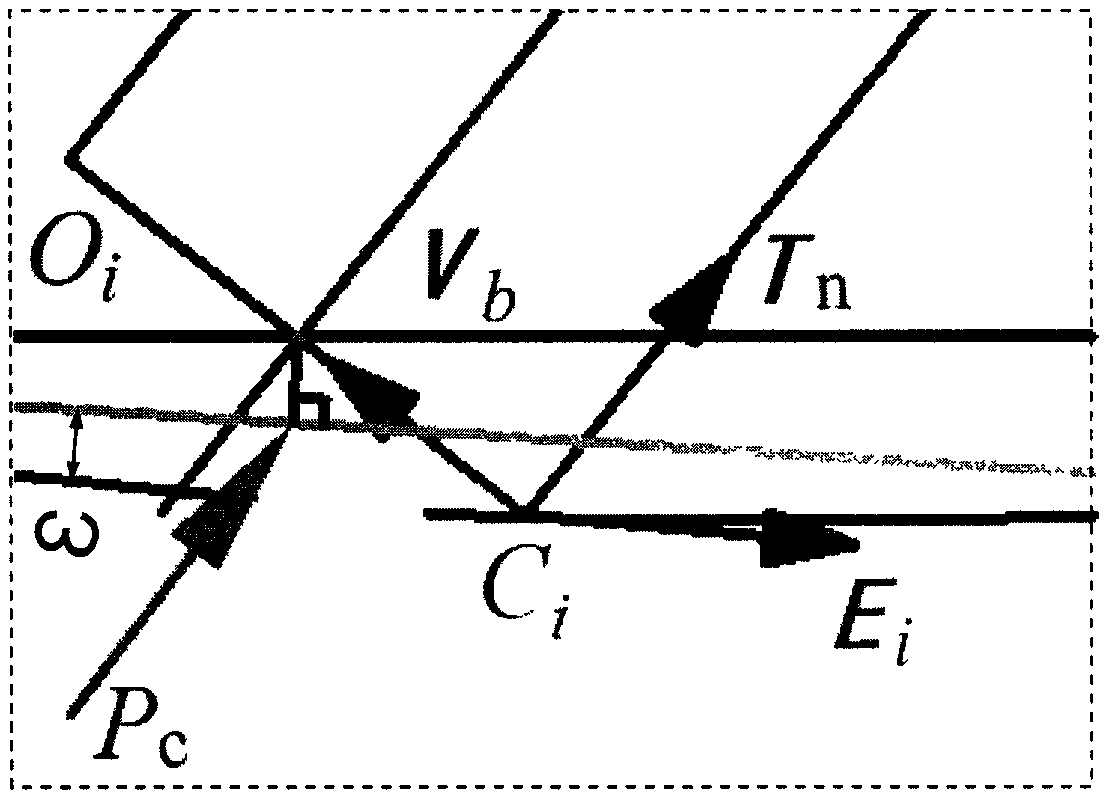

Non-linear error control method based on eight-parameter five-axis linear interpolation

InactiveCN110501974AGuaranteed Position AccuracyNonlinear error controlProgramme controlComputer controlPrinciple of orthogonal designMachine tool

The invention discloses a non-linear error control method based on eight-parameter five-axis linear interpolation, and is to solve the problem of control of non-linear error of a linear trajectory ofa tool contact point during five-axis linear interpolation. The method is characterized by establishing a mathematical model of the non-linear error of the linear trajectory of the tool contact pointaccording to a production mechanism of the non-linear error of the linear trajectory of the tool contact point caused by tool swing and the principle of motion coordinate transformation of a five-axismachine tool; when performing eight-parameter five-axis linear interpolation, calculating an interpolation tool center point and a corresponding interpolation tool contact point in the current interpolation period, and calculating a perpendicular foot position coordinate between the interpolation tool center point and the linear trajectory of the tool contact point and spatial distance between the interpolation tool center point and the linear trajectory of the tool contact point to determine a compensation and repair vector of the non-linear error; and finally calculating and outputting a new position coordinate of the interpolation tool center point to complete control of the non-linear error of the tool contact point in one interpolation period. The method has practical value in improving control accuracy of the linear trajectory of the five-axis linear interpolation tool contact point.

Owner:TIANJIN POLYTECHNIC UNIV

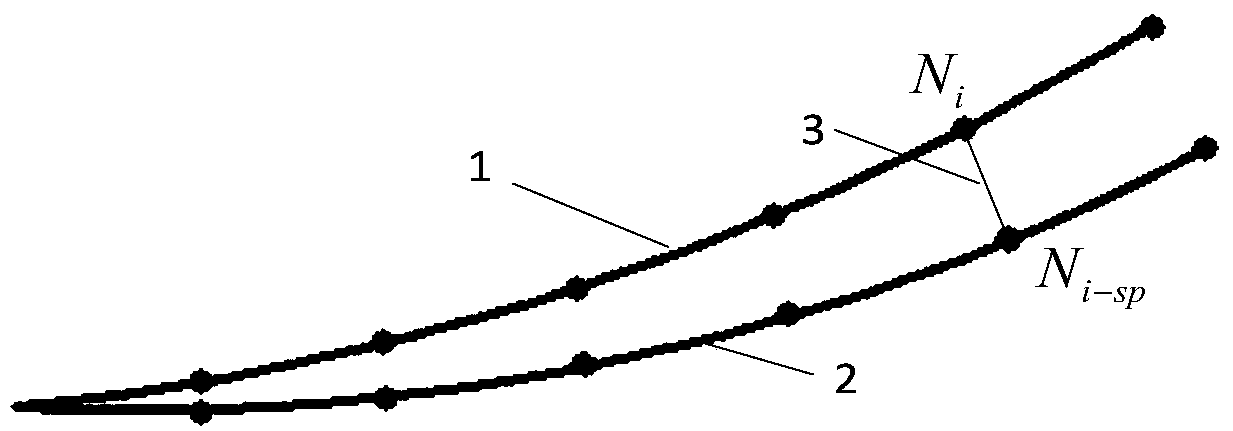

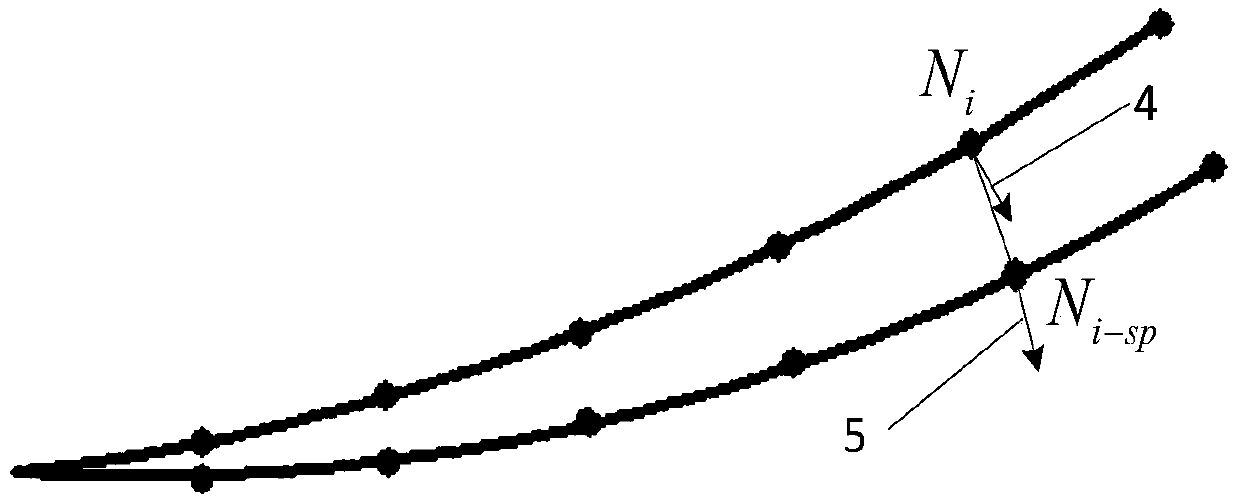

Construction method of springback compensation grid models

InactiveCN108595886AGood part shape accuracyGuaranteed position accuracyDesign optimisation/simulationSpecial data processing applicationsLine segmentElement analysis

The invention discloses a construction method of springback compensation grid models. Finite-element analysis is used as a means to obtain grid models before and after springback through springback simulation calculation, and springback path relationships of nodes are constructed through a manner of corresponding-node line connection; then normal vectors of each corresponding node on the grid models before and after springback are calculated, and normal vectors and line segments of a grid model after springback are translated onto corresponding nodes of a grid model before springback, and anincluded angle of two normal vectors and a constructed plane are calculated; and then translated the normal vectors and line segments are rotated until the same coincide with the normal vectors of thenodes on the grid model before springback, and currently endpoints of the line segments are compensation nodes of solving. According to the method, reverse compensation of the nodes is carried out by a method, of rotating springback paths according to the normal vectors of the nodes, according to the characteristics that feature forms of parts before and after springback are not changed, and only curvature of curved surfaces is changed, thus location precision of each node of springback compensation is effectively guaranteed, and precise construction of the springback compensation grid models is realized.

Owner:HUNAN UNIV

High-precision fixture positioning mechanism and method based on vertical and horizontal positioning error compensation

InactiveCN106216977AGuaranteed Position AccuracyTo compensate for the errorMetal working apparatusConveyor partsEngineeringMechanical engineering

Owner:DONGGUAN GONGYI ROBOT CO LTD

High-precision skip car positioning device for front and rear bottom plate assemblies of body in white

PendingCN112429483AGuaranteed Position AccuracyRealize automatic and precise graspingControl devices for conveyorsMechanical conveyorsAutomotive engineeringBody in white

The invention belongs to the technical field of automobile equipment manufacturing, and particularly relates to a skip car positioning device. A high-precision skip car positioning device for front and rear bottom plate assemblies of a body in white comprises a skip car guiding device, a six-degree-of-freedom positioning device, a skip car detection device, a part detection device, and a positioning mechanism frame, wherein the skip car guiding device is used for guiding a skip car to enter the six-degree-of-freedom positioning device; the six-degree-of-freedom positioning device is used for positioning six degrees of freedom including left, right, high, low, advancing and returning of the skip car; the skip car detection device is used for detecting whether the skip car is in place; the part detection device is used for detecting whether parts exist on the skip car; and the positioning mechanism frame is used for supporting and fixing each device. The high-precision skip car positioning device is suitable for an automatic feeding station with the relatively high automation degree; a robot can automatically grab materials from the skip car after the skip car receives the materials;the position precision of the skip car can be guaranteed; the automatic and accurate grabbing of the robot is achieved, the production efficiency is improved; and the fault rate is reduced.

Owner:SHANGHAI SINYLON AUTO EQUIPMENT MANUFACTURE CO LTD

Method for improving positioning qualification rate of pipe gallery embedded parts

InactiveCN110616737AGuaranteed Position AccuracyImprove positioning pass rateArtificial islandsBuilding constructionsRebarArchitectural engineering

The invention discloses a method for improving positioning qualification rate of pipe gallery embedded parts, and belongs to the technical field of utility tunnel production. According to the method,the defects of traditional embedment construction are overcome, the embedded parts are fully attached to a template to ensure the positioning accuracy of the components, and then the embedded components are welded on the pipe gallery engineering wall steel bars while the vertical dies are vertical, so that the position precision of the embedded parts is guaranteed, the positioning qualification rate of the embedded parts is improved, the prefabricated efficiency is improved, the construction cost is reduced, and the construction period is shortened.

Owner:江苏永联精筑建设集团有限公司

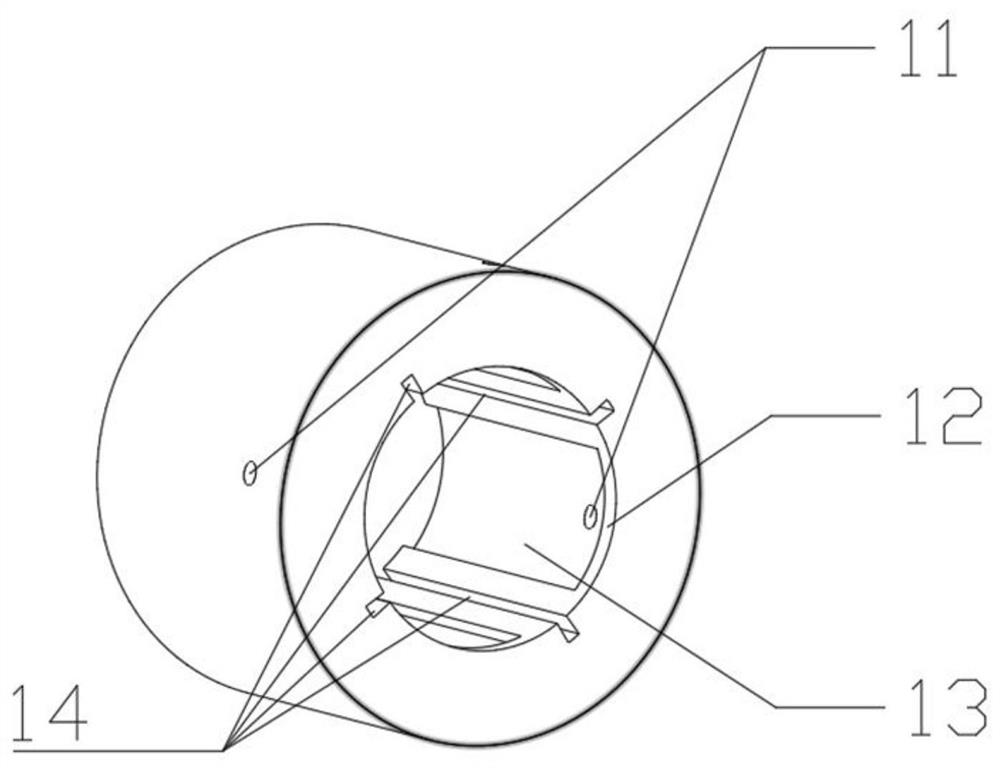

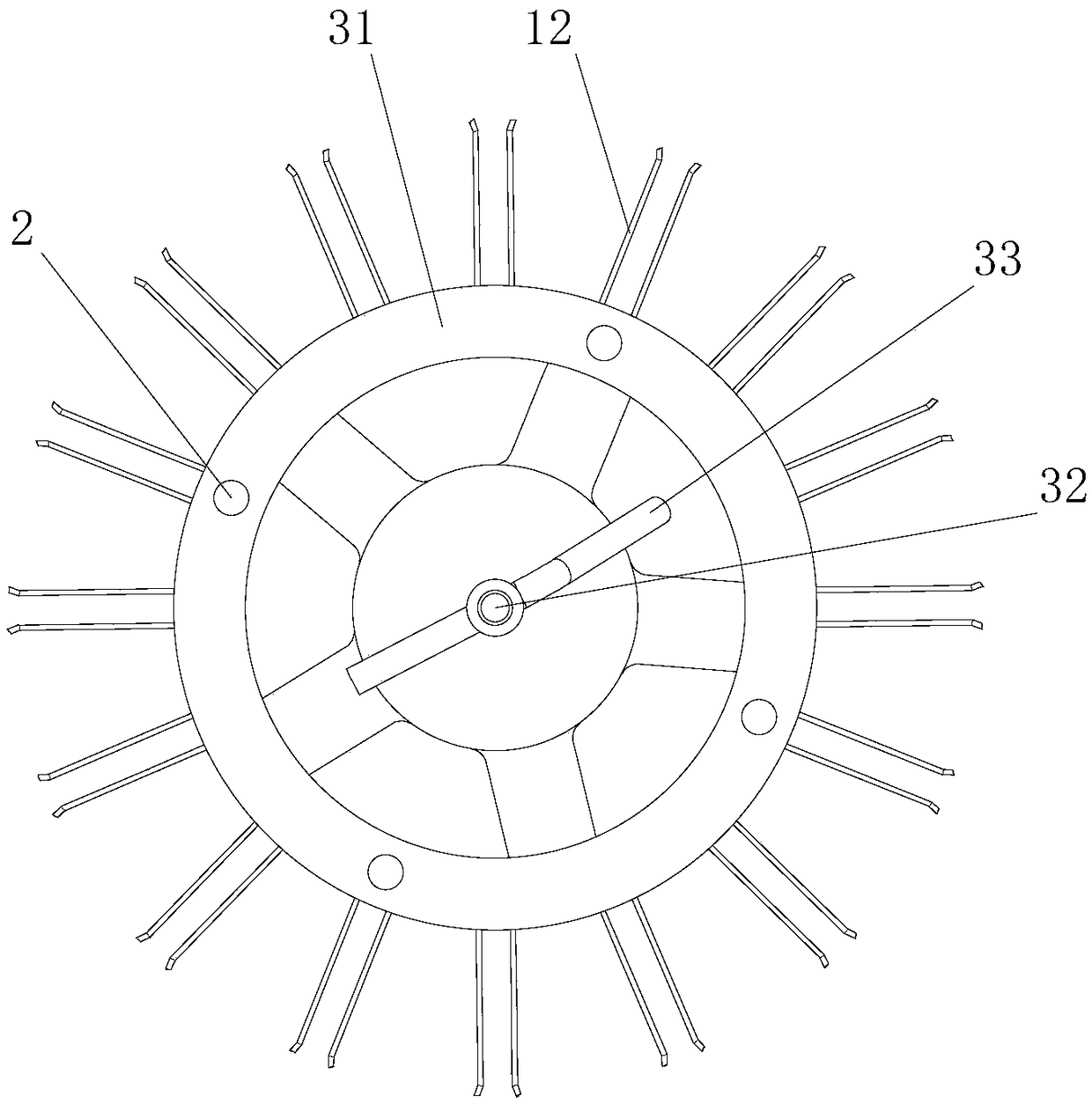

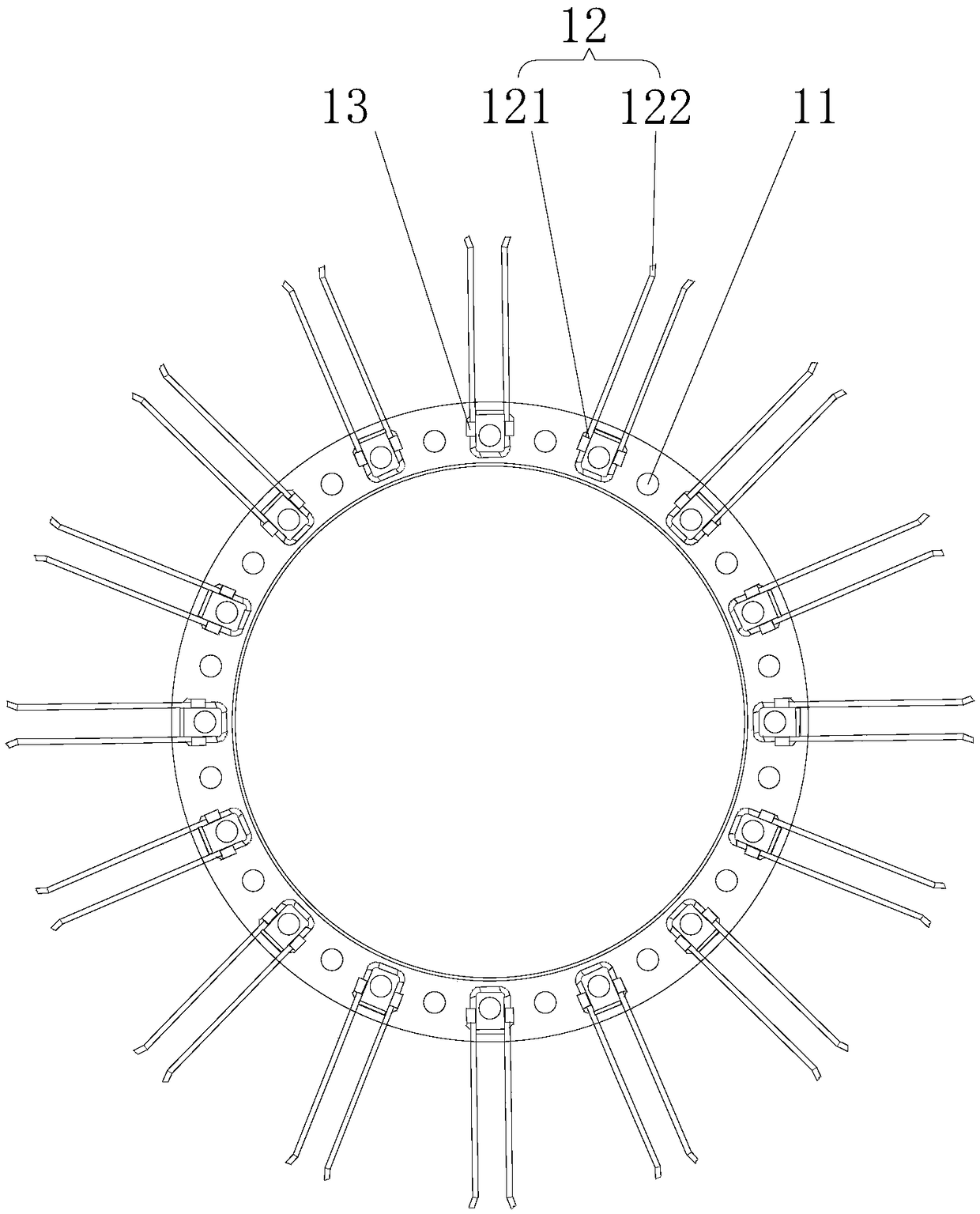

Hydrostatic bearing

The invention discloses a hydrostatic bearing. The hydrostatic bearing comprises several oil cavities, wherein the oil cavities are uniformly formed in the inner wall face of the hydrostatic bearing,each oil cavity comprises an oil cavity adjusting mechanism (3) which works independently, and the oil cavity adjusting mechanisms dynamically adjust the size of the corresponding oil cavities according to the pressure of the oil cavities. According to the hydrostatic bearing, when the loads of a main shaft change, resultant force opposite to the change direction of the loads can be actively produced to reduce the offset generated by the main shaft, and the position accuracy of the main shaft is guaranteed accordingly.

Owner:杭州中奥工业设计有限公司

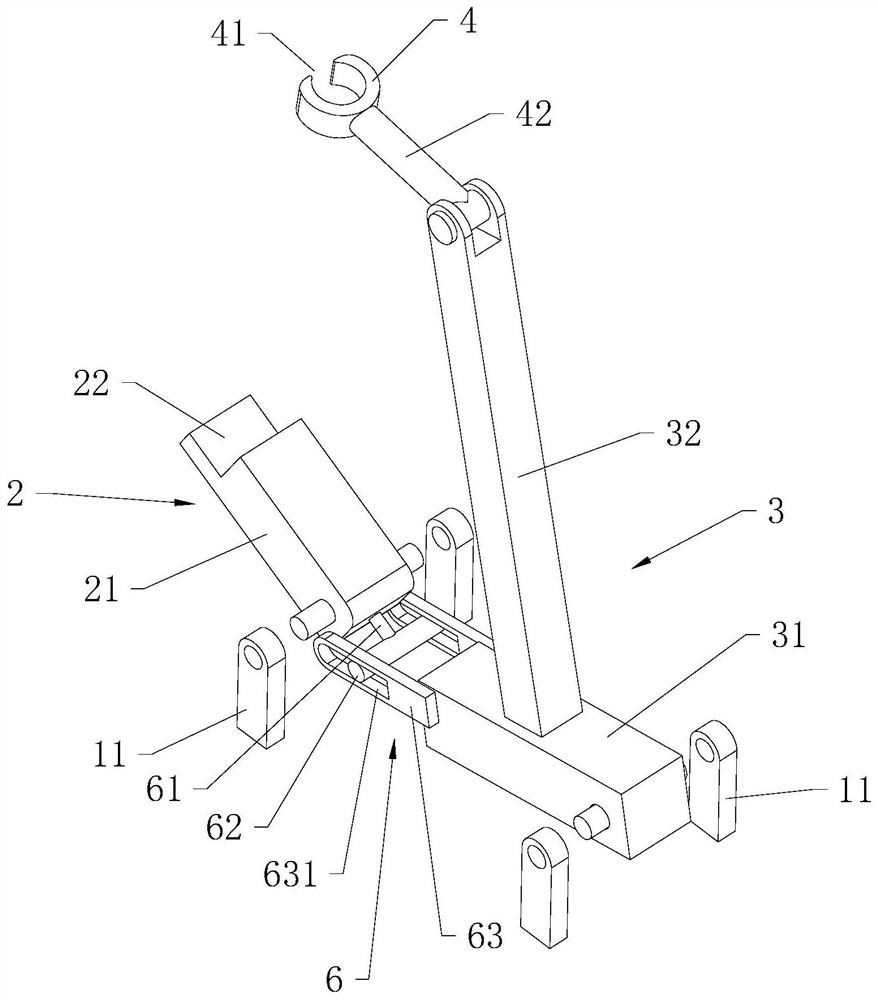

Adjusting support for projection equipment and laser projection TV

InactiveCN105527785AImprove operational convenienceGuaranteed Position AccuracyProjectorsStands/trestlesEngineeringMechanical engineering

The invention relates to an adjusting support for projection equipment and a laser projection TV. The adjusting support for the projection equipment comprises a foundation, an X-axis adjusting platform, a Y-axis adjusting platform, a rotary adjusting platform and an angle adjusting platform, wherein the X-axis adjusting platform is in sliding connection with the foundation, the Y-axis adjusting platform is in sliding connection with the X-axis adjusting platform, a sliding direction of the X-axis adjusting platform is perpendicular to a sliding direction of the Y-axis adjusting platform, the rotary adjusting platform is in rotatable connection with the Y-axis adjusting platform, the angle adjusting platform is provided with a stud, and the stud is perpendicular to the rotary adjusting platform and is in thread connection with the rotary adjusting platform. Through the adjusting support for the projection equipment, operation convenience and adjusting precision of the projection equipment are improved.

Owner:HISENSE

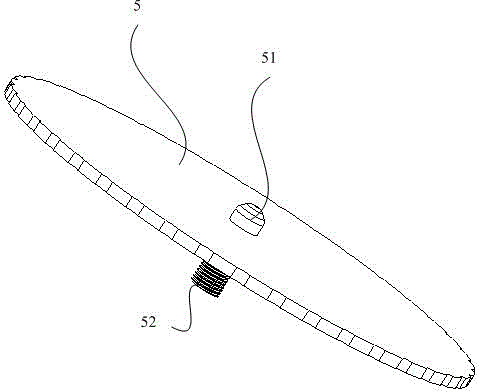

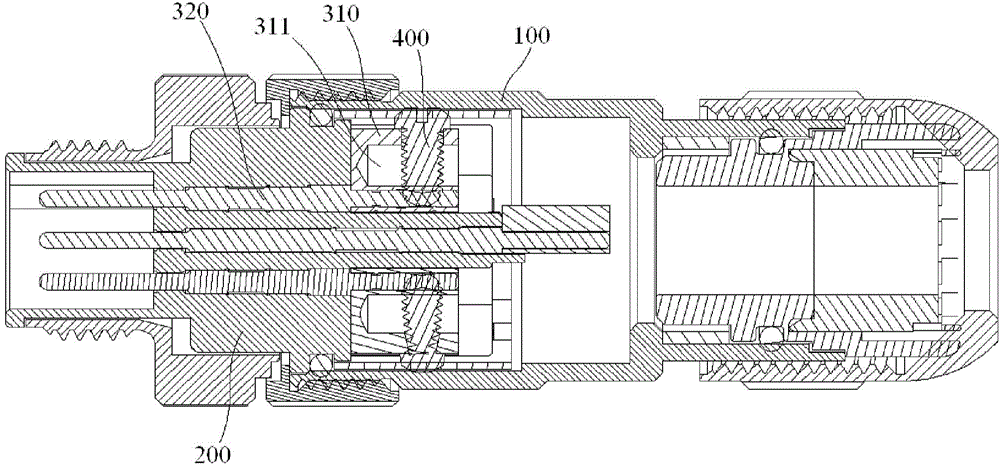

Coupling welding machine

PendingCN107398637AHighly consistentGuaranteed Position AccuracyLaser beam welding apparatusPhysicsLaser soldering

The invention is applicable to the field of optical devices and provides a coupling welding machine. The coupling welding machine comprises a supporting part, a coupling system and a plurality of welding devices. Each welding device comprises a base body part fixed to the supporting part and a laser welding part capable of moving up and down relative to the base body part. The coupling welding machine further comprises a motor. The motor can control a driving plate to move up and down through a lead screw. The laser welding parts are connected to the driving plate and can slide up and down along with motion of the driving plate. The laser welding parts are connected with elastic devices. Elastic force generated by the elastic devices can balance gravity borne by the laser welding parts. The coupling welding machine controls all the laser welding parts to slide up and down through the driving plate, and the effect of height consistence of the laser welding parts is achieved. Meanwhile, the elastic force generated by the elastic devices can balance the gravity borne by the laser welding parts. Thus, the high-precision lead screw can be adopted, and the up-down movement position precision of the laser welding parts is guaranteed.

Owner:深圳市大族锐波传感科技有限公司

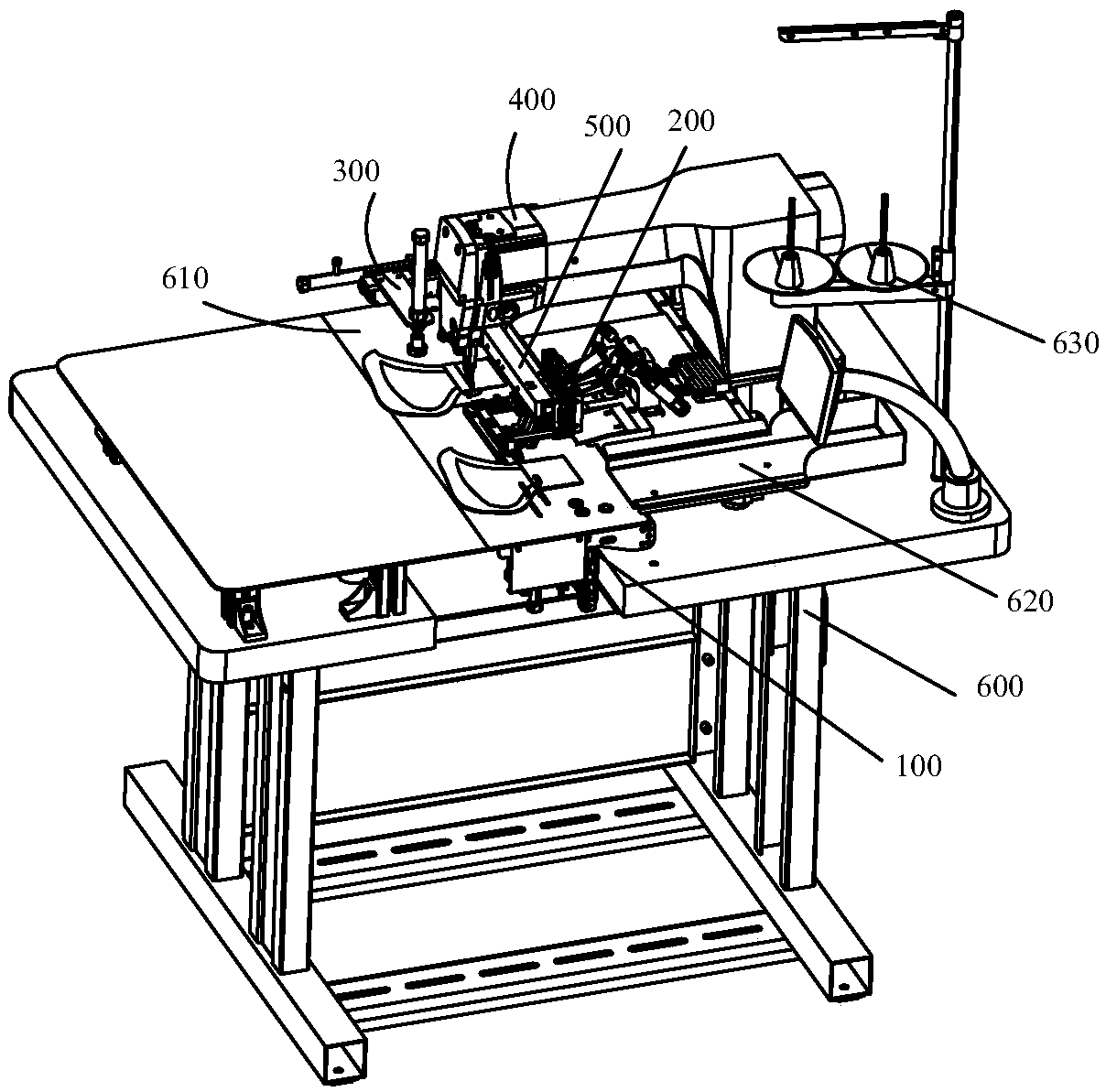

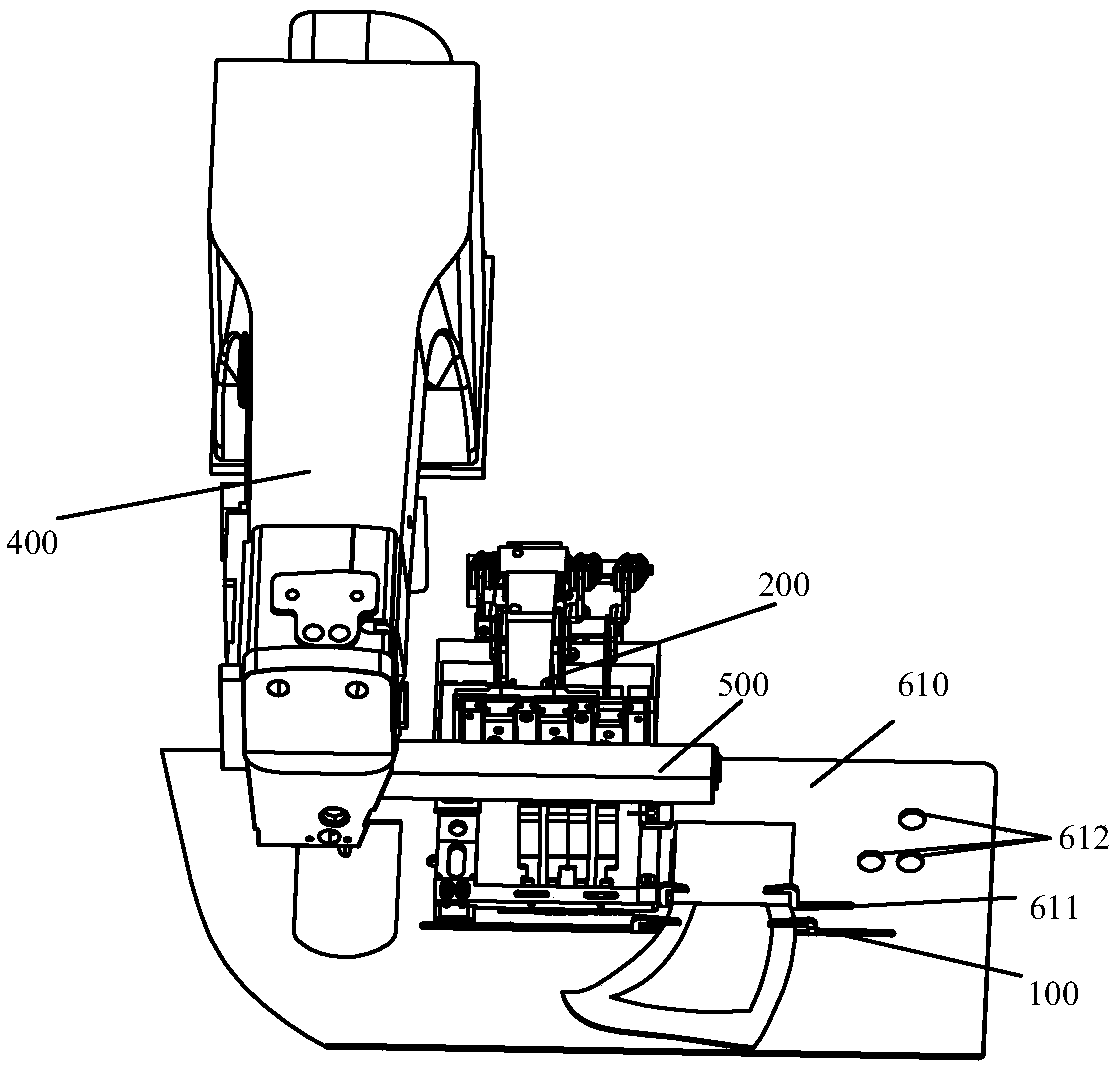

Sewing equipment

PendingCN108893874AGuaranteed Position AccuracyOptimize sewing effectWork-feeding meansPressersMachining processBiomedical engineering

The invention relates to sewing equipment. The sewing equipment is characterized by comprising a foot stand, a processing device, a pressing device and a feeding device, wherein the processing deviceis mounted on the foot stand; the processing device comprises a head capable of sewing materials; the pressing device can press the materials and convey the materials to the processing device; the feeding device can pick up the materials can convey the materials to the pressing device; an optical fiber detecting device is positioned between the pressing device and the feeding device; and the positions of the materials can be detected and corrected. The sewing equipment is adopted, the materials are positioned and conveyed through the pressing device and the feeding device, deviation rectification of positions can be carried out through the optical fiber detecting device, position accuracy of a material conveying process and a processing course is ensured, and the material sewing effect isoptimized.

Owner:SHENZHEN DEYE AUTOMATION TECH

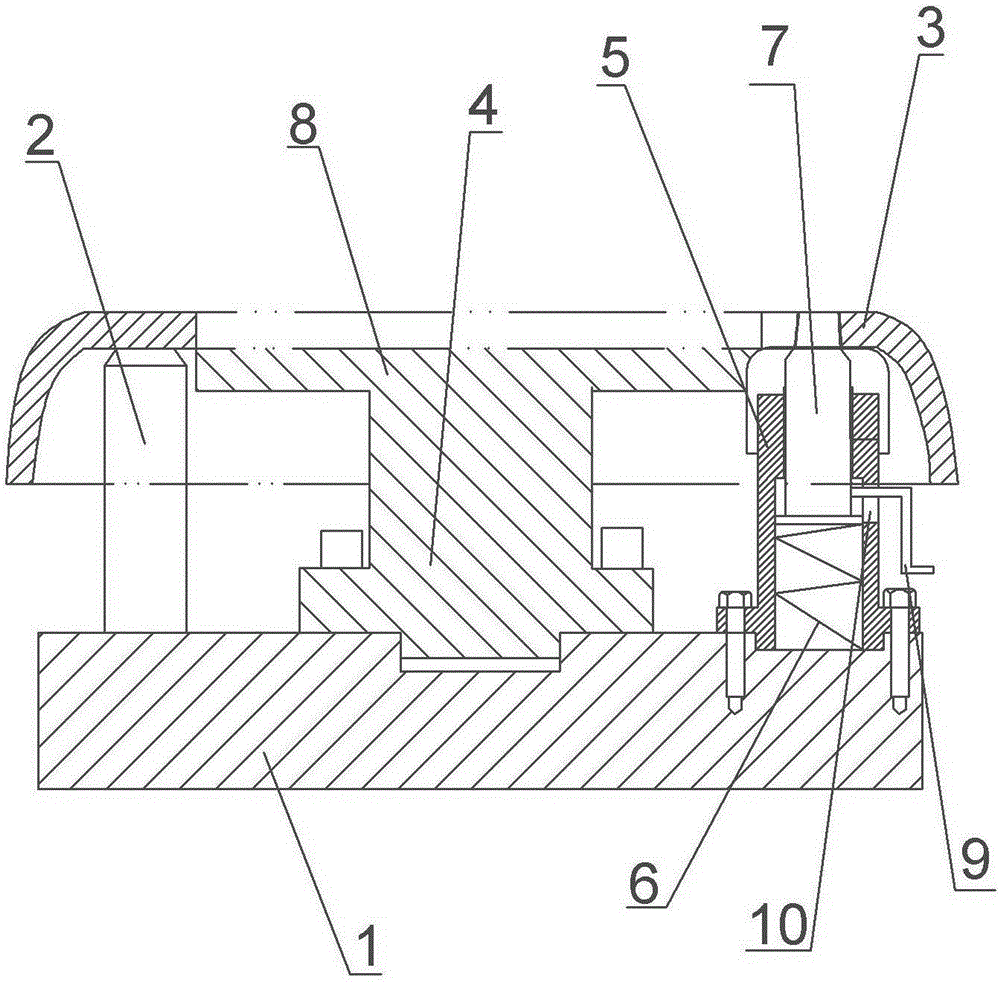

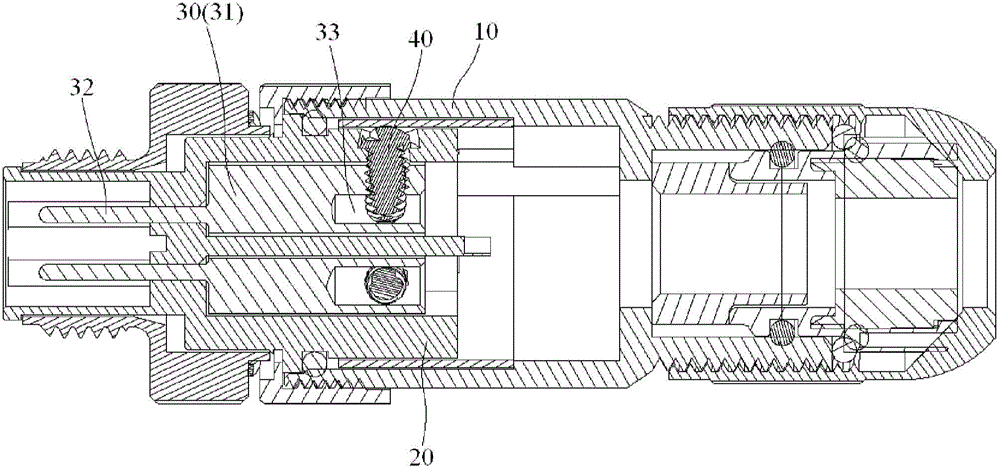

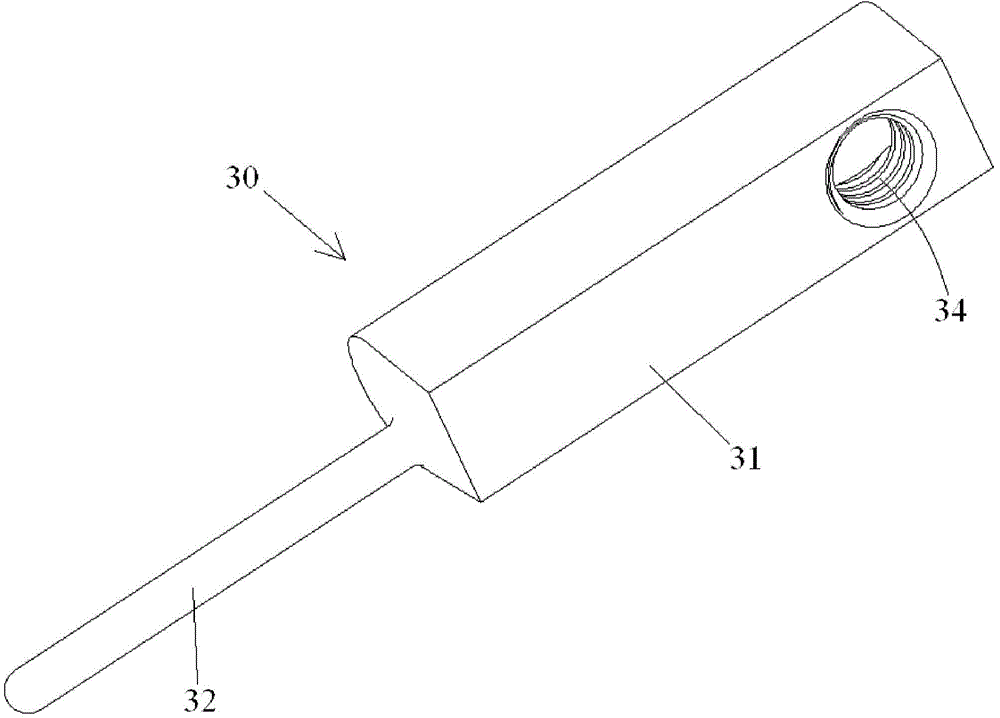

Electric connector

ActiveCN105762542AGuaranteed Position AccuracyLow manufacturing costSecuring/insulating coupling contact membersCoupling contact membersElectrical and Electronics engineeringInterference fit

The invention discloses an electric connector, and the connector comprises a housing; an insulating main body which is stored in the housing; and at least one conductive terminal which is kept in the insulating main body. The conductive terminal comprises a substrate which is kept in the insulating main body; and a pin which is inserted into the substrate, and extends in a longitudinal direction to pass through the insulating main body. The pin is assembled in the insulating main body in a manner of interference fit. According to the invention, the pin of the conductive terminal is assembled in the insulating main body in the manner of interference fit, so the pin can be prevented from moving relative to the insulating main body, thereby guaranteeing the position precision of the pin.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

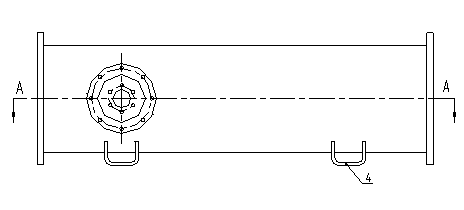

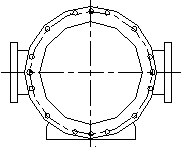

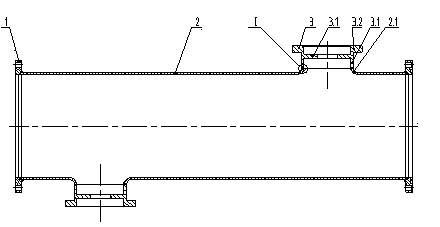

Reinforced bus drum shell

InactiveCN104037695AGuaranteed Position AccuracyEasy to makePartially enclosed bus-bar installationsWelding defectEngineering

The invention discloses a reinforced bus drum shell which comprises a main drum, main drum flanges, branch drum assemblies and bases. The main drum flanges are fixedly connected to two ends of the main drum by means of welding, the branch drum assemblies comprise branch drums, branch drum flanges and partition plates, the partition plates are fixedly connected onto the inner walls of the branch drums, each branch drum flange is connected to one end of the corresponding branch drum, and the other end of each branch drum is fixedly connected with a branch drum on a side surface of the main drum by means of welding; the bases are of U-shaped elongated structures and are fixedly connected to the bottom of the main drum by means of welding; the branch drum assemblies are of integral structures which comprise the branch drums, the branch drum flanges and the partition plates. The reinforced bus drum shell is characterized in that the bases are of the U-shaped integral structures, and plates are bent to form the U-shaped integral structures; outer grooves and inner grooves are formed in joints of the branch drums and the branch drums on the side surfaces of the main drum; the depths H1 of the outer grooves are smaller than the depths H2 of the inner grooves. The reinforced bus drum shell has the advantages that the reinforced bus drum shell is provided with the integral branch drum assemblies and the bases, is simple in manufacturing process, low in manufacturing cost and welding stress and high in structural strength and has few welding defects.

Owner:JIANGSU HAIDA ELECTRIC

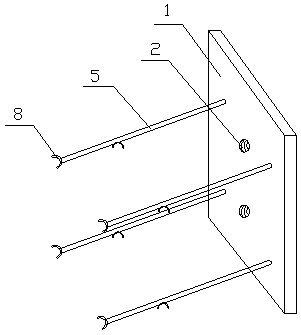

Positioning device and positioning method

PendingCN109434715AAvoid skewGuaranteed Position AccuracyWork holdersElectromagnetic wave reradiationEngineeringWorkbench

The invention discloses a positioning device and a positioning method, and relates to the technical field of positioning and measuring devices. The positioning device comprises a vertical reflecting plate, a supporting rod and a distance measuring mechanism; the vertical reflecting plate is arranged on a positioning reference part and is parallel to the positioning reference part; one end of the supporting rod is rotatably connected with a workbench, the other end of the supporting rod is provided with a positioning block, and the end face of the side, far away from the supporting rod, of thepositioning block is perpendicular to the length direction of the supporting rod; and the distance measuring mechanism is arranged on the supporting rod and arranged to be opposite to the vertical reflecting plate, and the distance measuring mechanism is configured to detect the distances between at least two points on the supporting rod and the vertical reflecting plate. According to the positioning device, when the distances between the at least two points on the supporting rod and the vertical reflecting plate are equal, the supporting rod is parallel to the positioning reference part; andthen the edge of a to-be-positioned workpiece is arranged along the end face of the side, far away from the supporting rod, of the positioning block, therefore, the edge of the to-be-positioned workpiece can be perpendicular to the positioning reference part, skewing of the to-be-positioned workpiece is avoided, and the position precision of the to-be-positioned workpiece is guaranteed.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

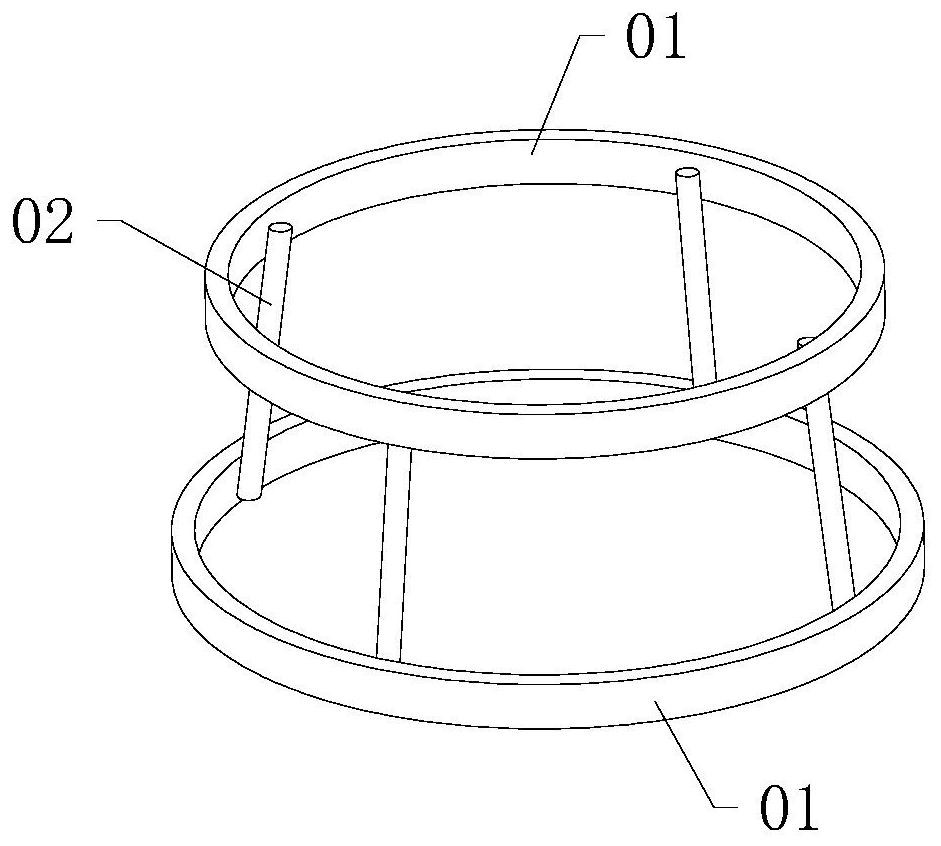

Welding table for producing cane chair framework

ActiveCN111889936AGuaranteed Position AccuracyReduce welding difficultyWelding/cutting auxillary devicesAuxillary welding devicesPhysicsElectrically conductive

The invention relates to a welding table for producing a cane chair framework. The welding table for producing the cane chair framework comprises a worktable, positioning pieces, fixing pieces, fixingrings and electric conduction pieces, wherein the positioning pieces are used for abutting against the lower ends and the inner peripheries of supporting rings, the fixing pieces extend upwards, thefixing rings are arranged at the upper ends of the fixing pieces and used for being connected to supporting rods in a sleeving mode, the fixing rings and the supporting rods are in one-to-one correspondence, openings are further formed in the fixing rings, and the ends at the openings are used for being attached to the inner peripheries of the supporting rings. According to the welding table for producing the cane chair framework, the fixing pieces and the fixing rings are used for achieving positioning to the upper ends of the supporting rods, shaking of the upper ends of the supporting rodsis avoided in the welding process, the position precision between the supporting rods and the supporting rings is effectively ensured, and thus the effect of ensuring the production quality of the framework is achieved.

Owner:临海市金源工艺品有限公司

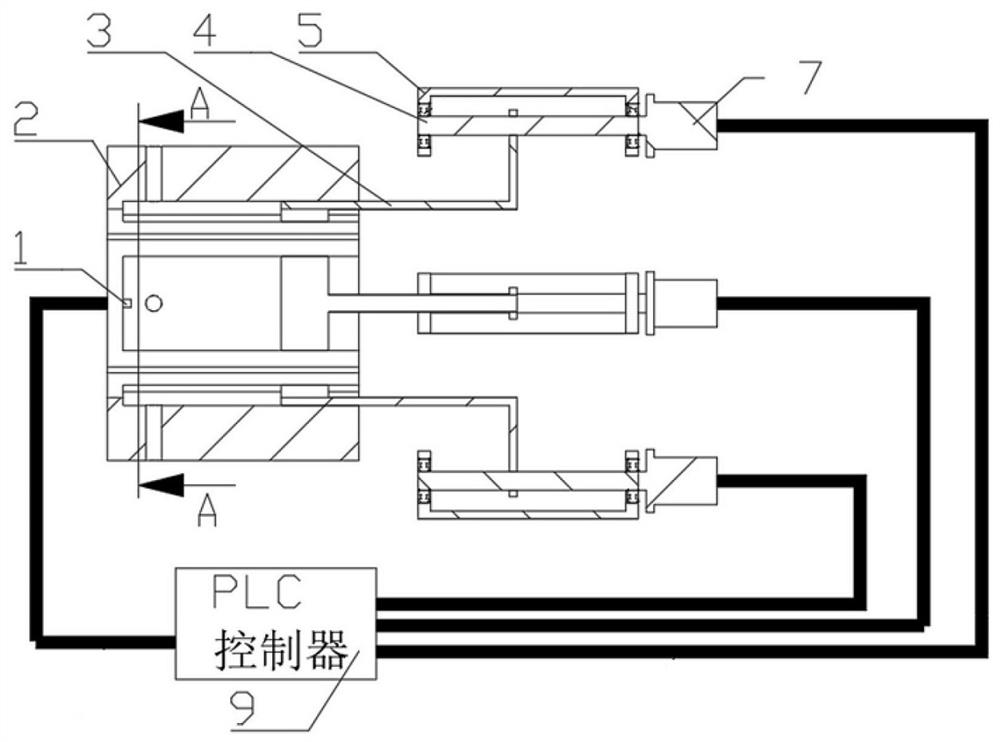

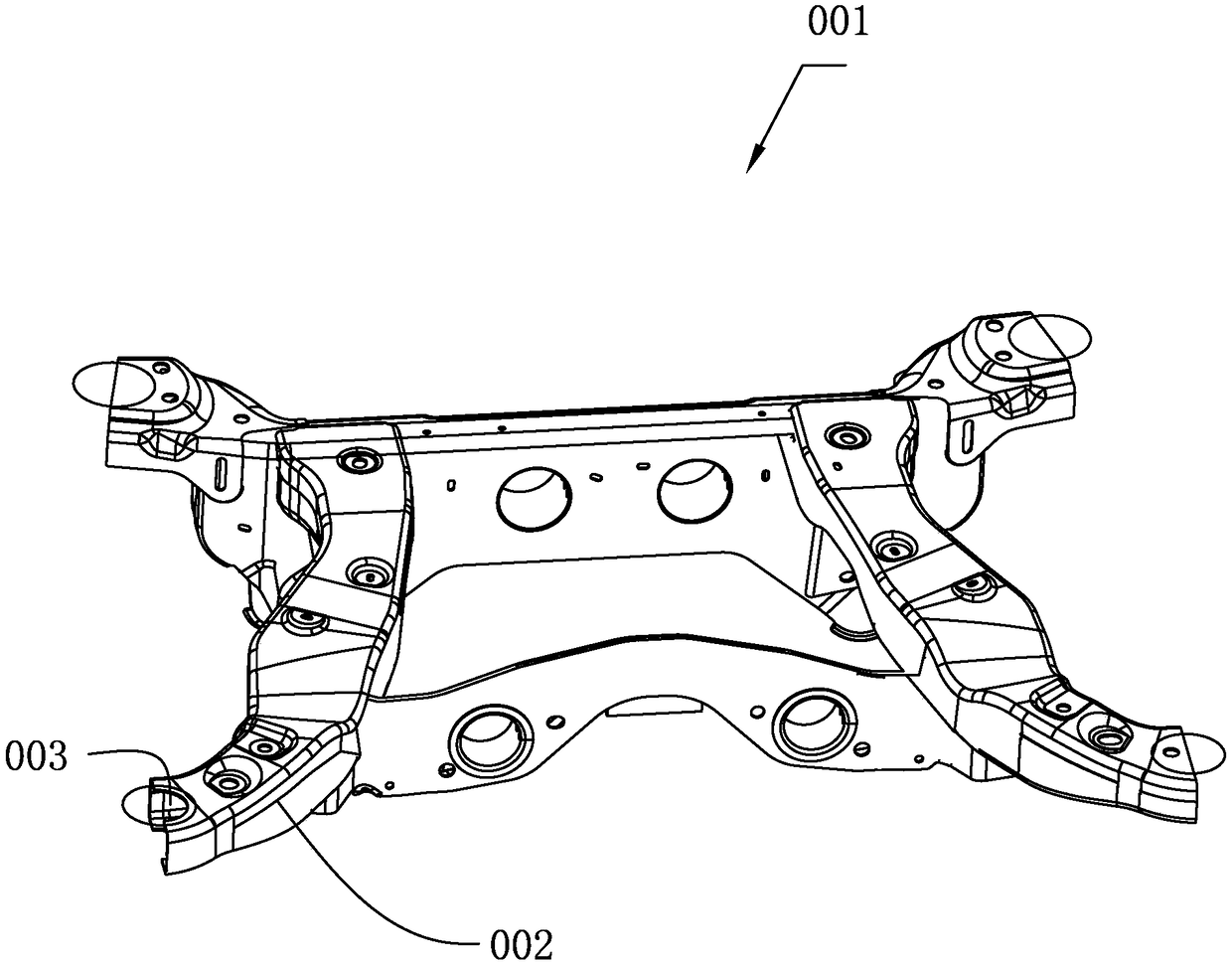

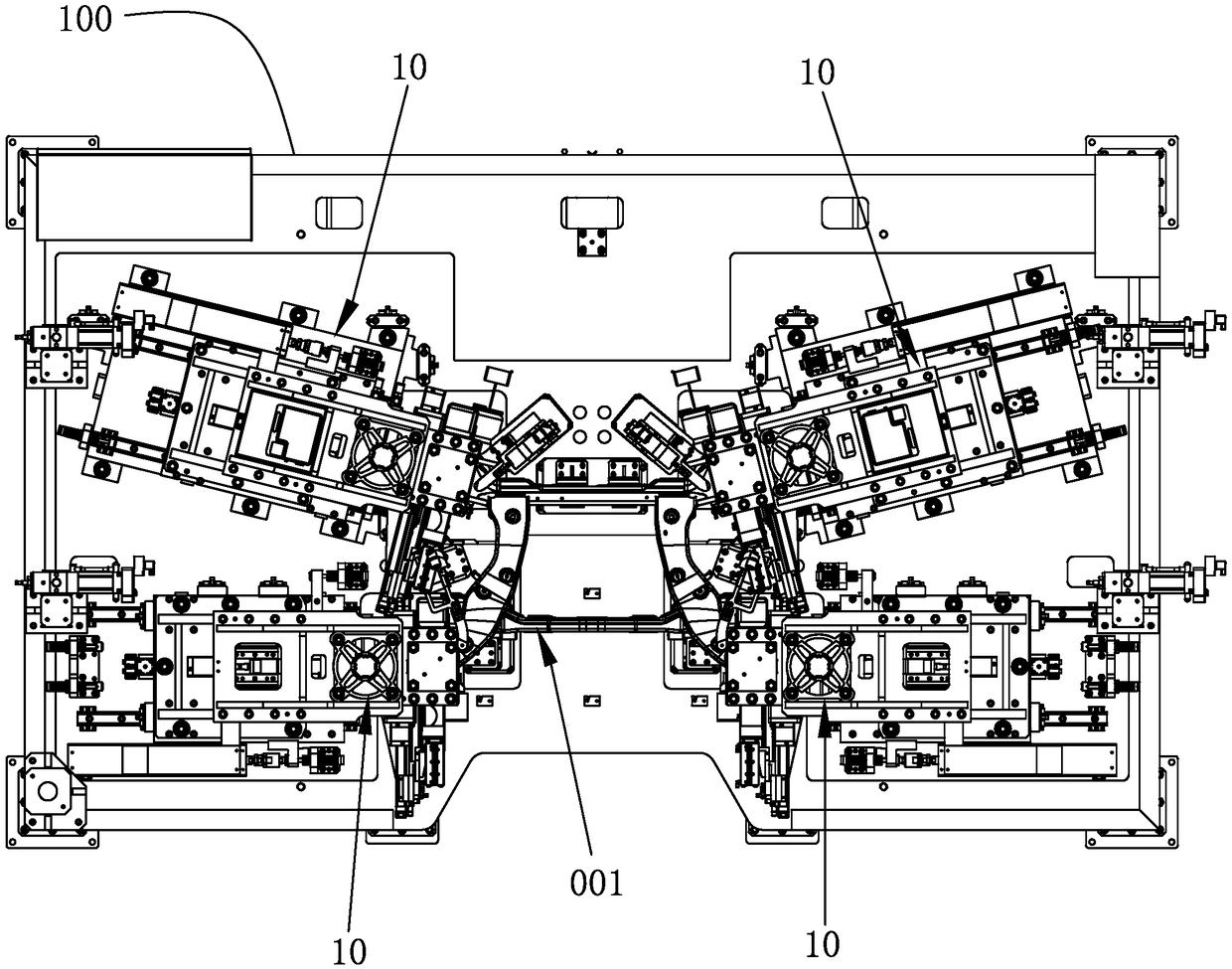

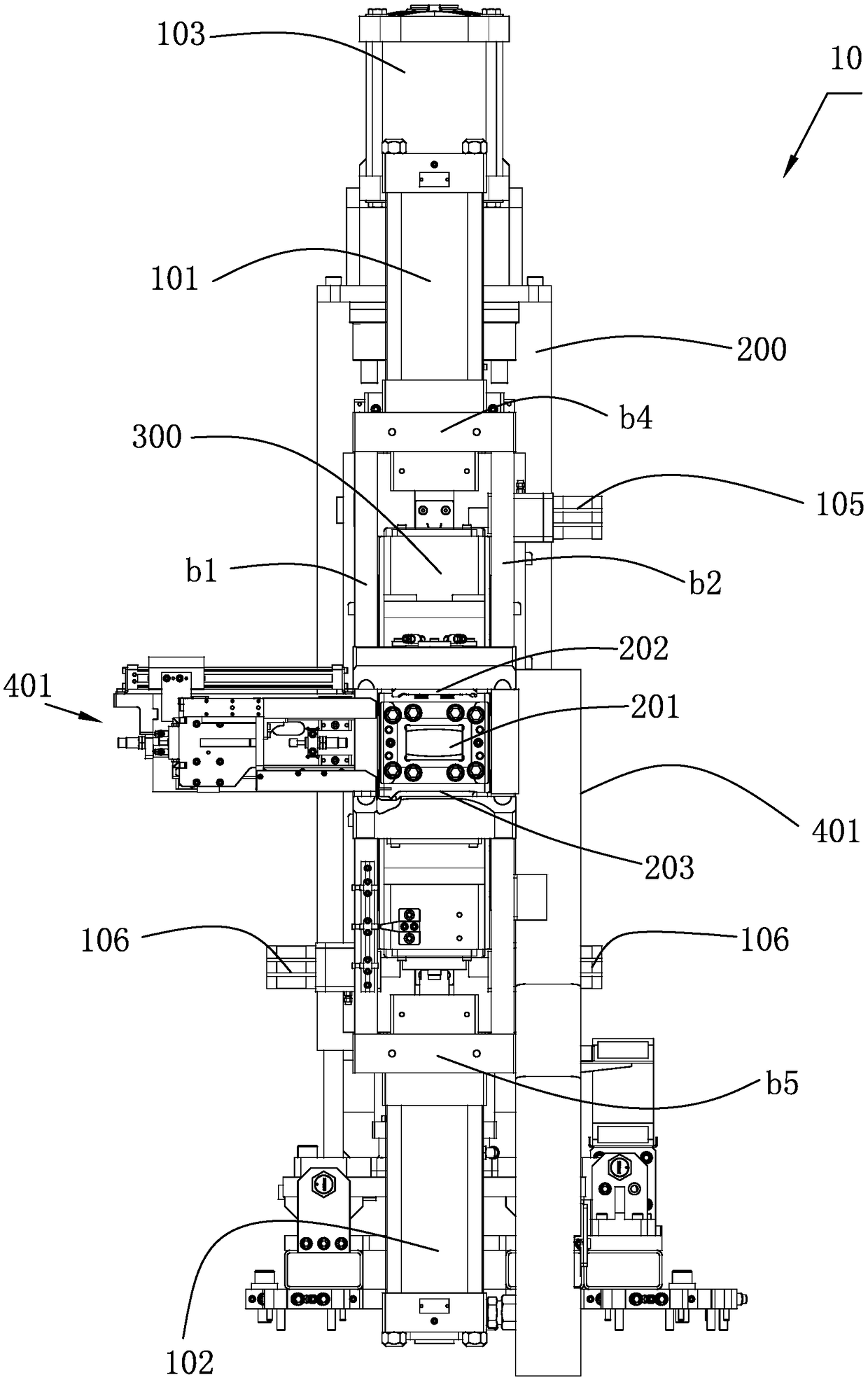

Auxiliary frame crescent hole forming equipment

PendingCN109365627AImprove processing efficiencyGuaranteed Position AccuracyPerforating toolsVehicle componentsVehicle frameEngineering

The invention relates to auxiliary frame crescent hole forming equipment. The forming equipment is used for conducting punching forming on crescent holes in the ends of multiple connection arms of anauxiliary frame synchronously; the forming equipment comprises an equipment frame, a plurality of punching units slidably arranged on the equipment frame, a positioning frame which is fixedly arrangedon the equipment frame, located between the multiple punching units and used for fixing the auxiliary frame, and a control system for controlling the punching units to work; the equipment frame is provided with a plurality of sets of slide rails; each punching unit comprises a supporting frame slidably arranged on the corresponding slide rail, and a punching module which is arranged on the supporting frame and used for crescent hole punching. The auxiliary frame crescent hole forming equipment can simultaneously conduct post-welding synchronous punching on the ends of the four connection armsof the auxiliary frame, the situation that the connection arms are subjected to punching machining in sequence is avoided, the machining efficiency is greatly improved, in addition, the position precision of the crescent holes on the auxiliary frame is ensured, and the product quality is improved.

Owner:苏州托克斯冲压设备有限公司

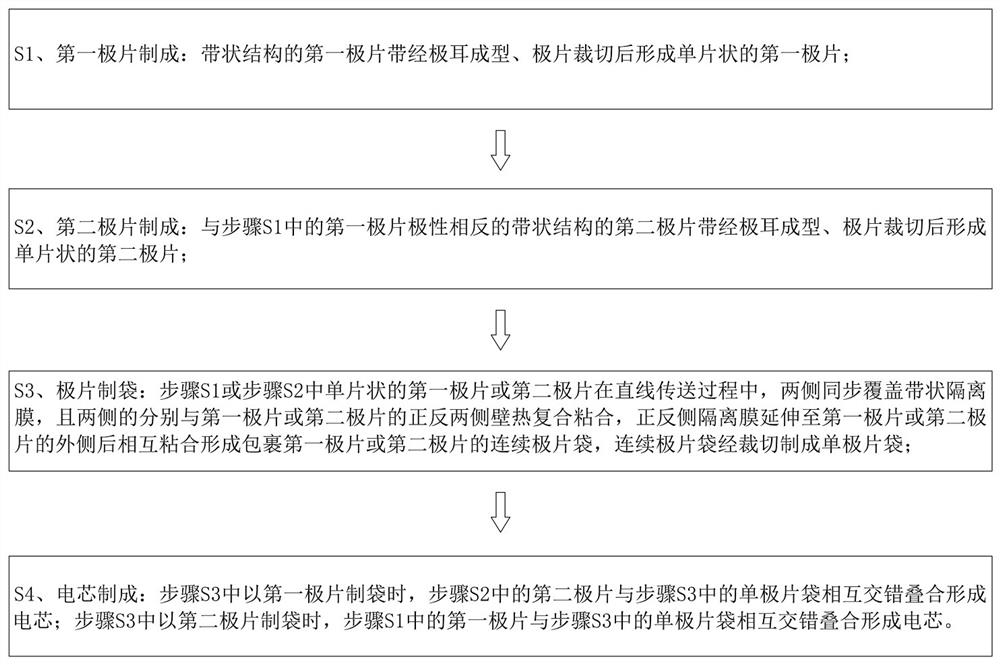

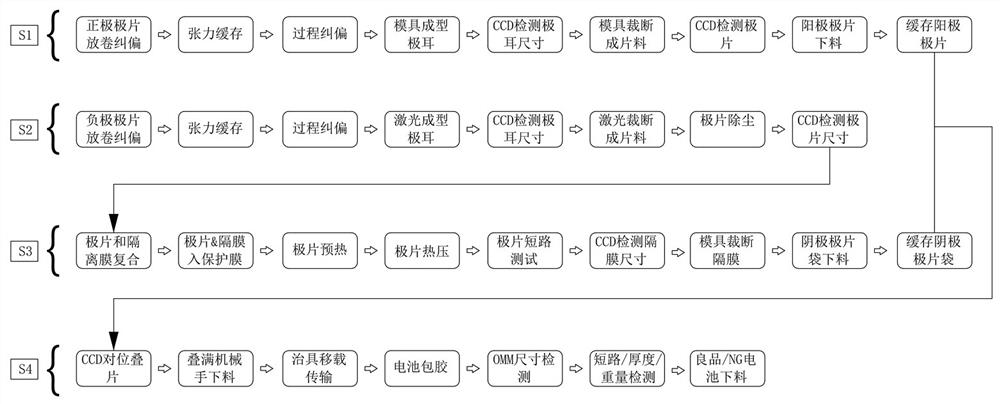

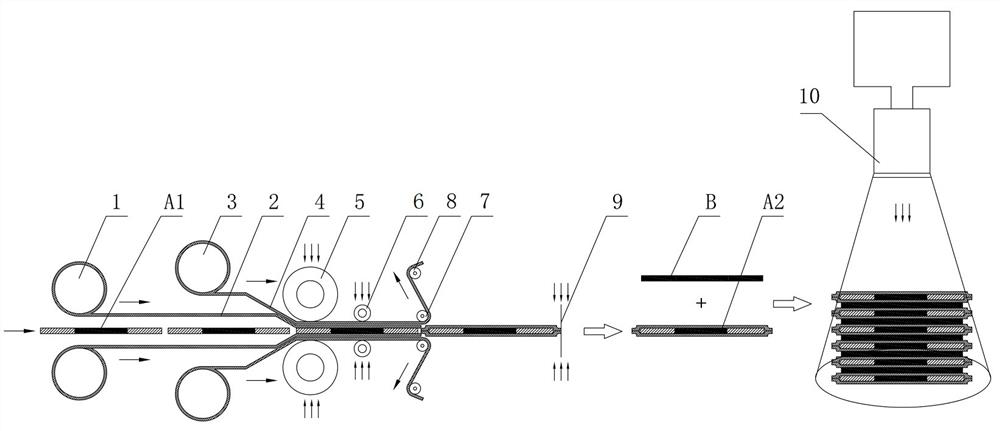

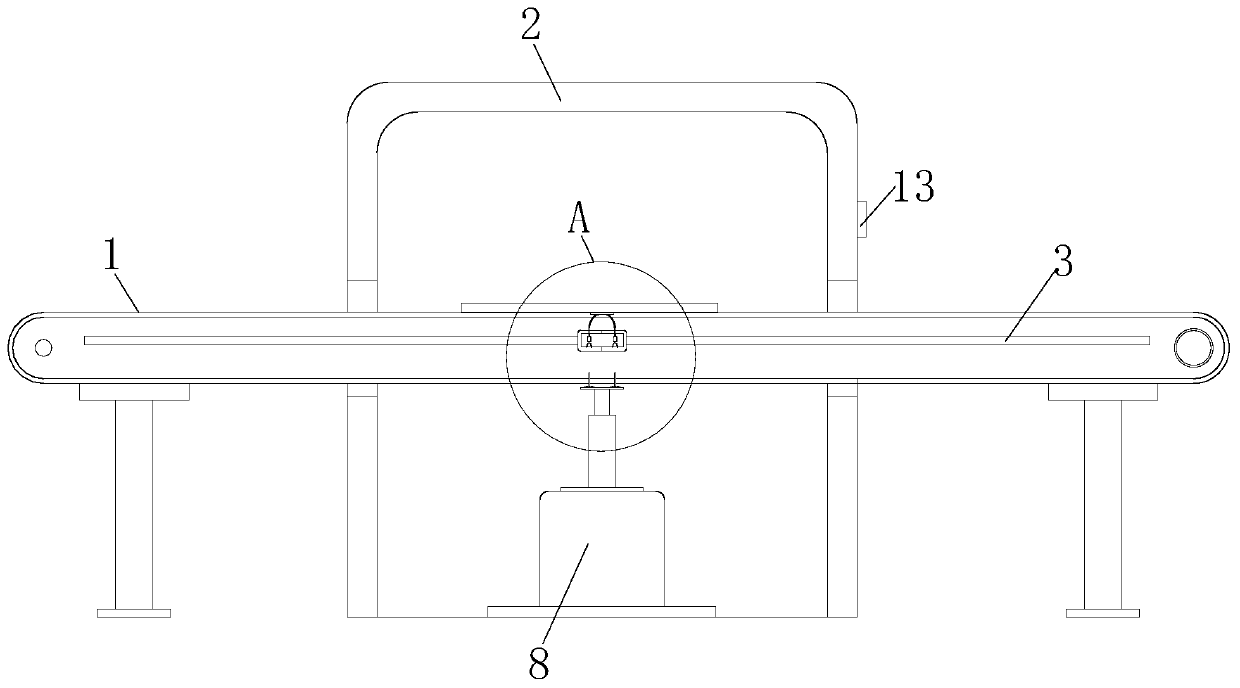

Thermal compounding manufacturing process of battery cell

ActiveCN113782838AGuaranteed Position AccuracyImprove lamination efficiencyFinal product manufactureCell component detailsManufacturing engineeringPole piece

The invention discloses a thermal compounding manufacturing process of a battery cell. The thermal compounding manufacturing process comprises the following process steps that: a pole piece is manufactured, namely, single pole pieces are formed after a pole piece belt with a belt-shaped structure is subjected to pole lug forming and pole piece cutting; pole piece bags are manufactured, namely, a single-sheet-shaped first pole piece or a single-sheet-shaped second pole piece is bonded to the front side wall and the back side wall through diaphragms on the two sides in a thermal compounding mode respectively, diaphragms on the front side and the back side extend to the outer side of the first pole piece or the outer side of the second pole piece and then are bonded to form a continuous pole piece bag, and the continuous pole piece bag is cut into single pole piece bags; and a battery cell is formed, namely, the single pole pieces and the single pole piece bags are mutually staggered and overlapped to form a battery cell. According to the invention, the problem of wrinkling of the diaphragms is solved, the position precision between the positive and negative pole pieces is ensured, the single diaphragm alignment process of the traditional lamination is simplified by adopting diaphragms larger than the pole pieces, the lamination efficiency is effectively improved, combustion caused by short circuit is reduced, and the safety coefficient of the battery is improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

IV automatic test assembly line

PendingCN110324002AGuaranteed position accuracyGuarantee the stability of coordinationPhotovoltaic monitoringPhotovoltaic energy generationDark roomMC4 connector

The invention relates to the related technical field of photovoltaic module test, and discloses an IV automatic test assembly line. The IV automatic test assembly line comprises an assembly line and an IV tester dark room, wherein the assembly line and the IV tester dark room both are fixedly arranged in a workshop, the assembly line is arranged at an inner side of the IV tester dark room in a penetrating way, a linear sliding rail is fixedly arranged at a front surface of the assembly line, a linear servo motor is movably arranged on the linear sliding rail, a locking block is fixedly arranged at a front surface of the linear servo motor, two end clamping grooves are formed in a part above a front surface of the locking block, two reserved plug grooves corresponding to the end clamping grooves are formed in a part below the front surface of the locking block, the reserved plug grooves communicate with the corresponding end clamping grooves, and an air cylinder is fixedly arranged at the bottom of an inner side of the IV tester dark room. By the IV automatic test assembly line, an MC4 connector is enabled to be plugged into the reserved plug groove and is abutted with leading-out line ends in the end clamping groove for test, a test error caused by manual operation is prevented, and the matching stability among mechanisms of equipment is guaranteed.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

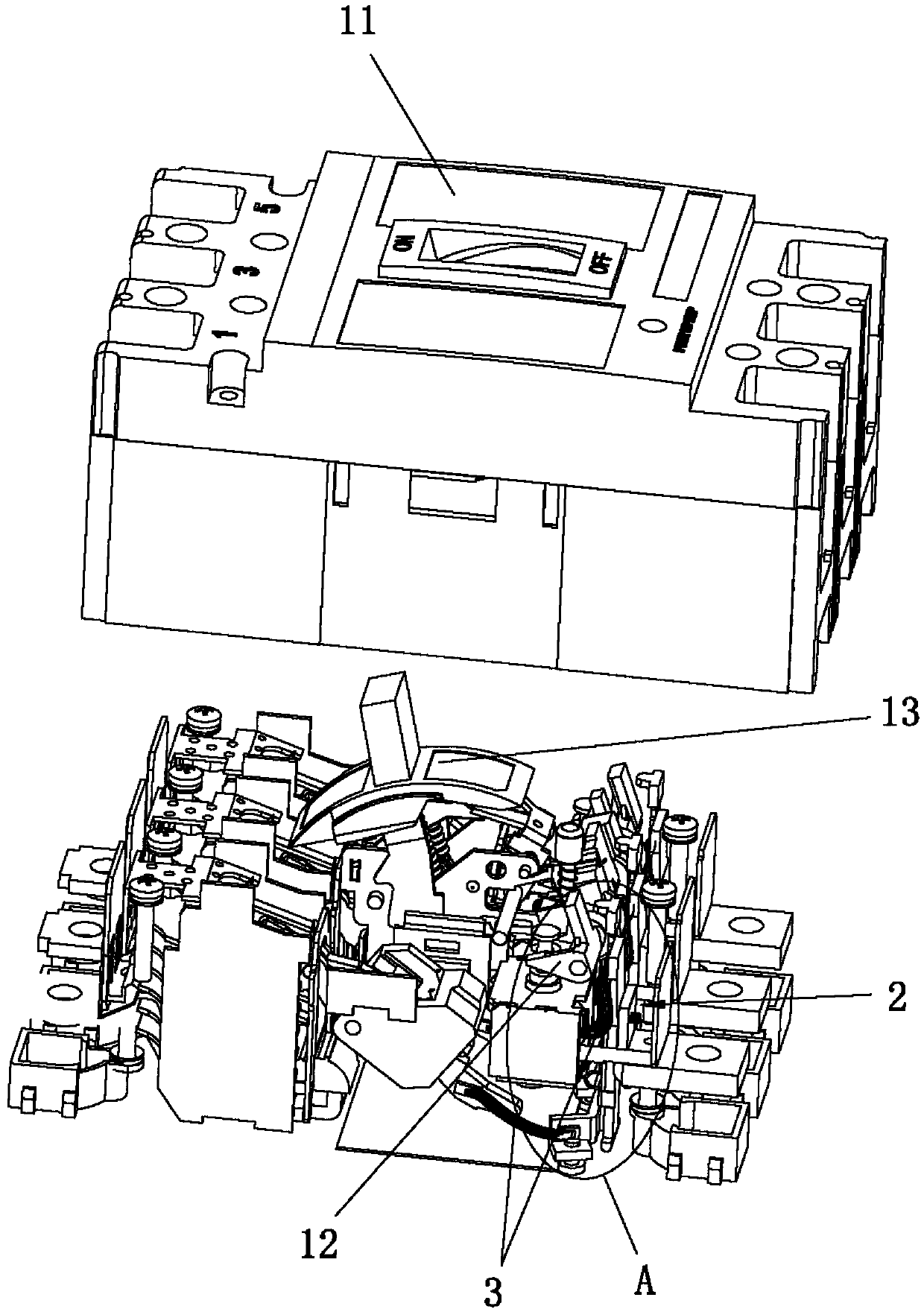

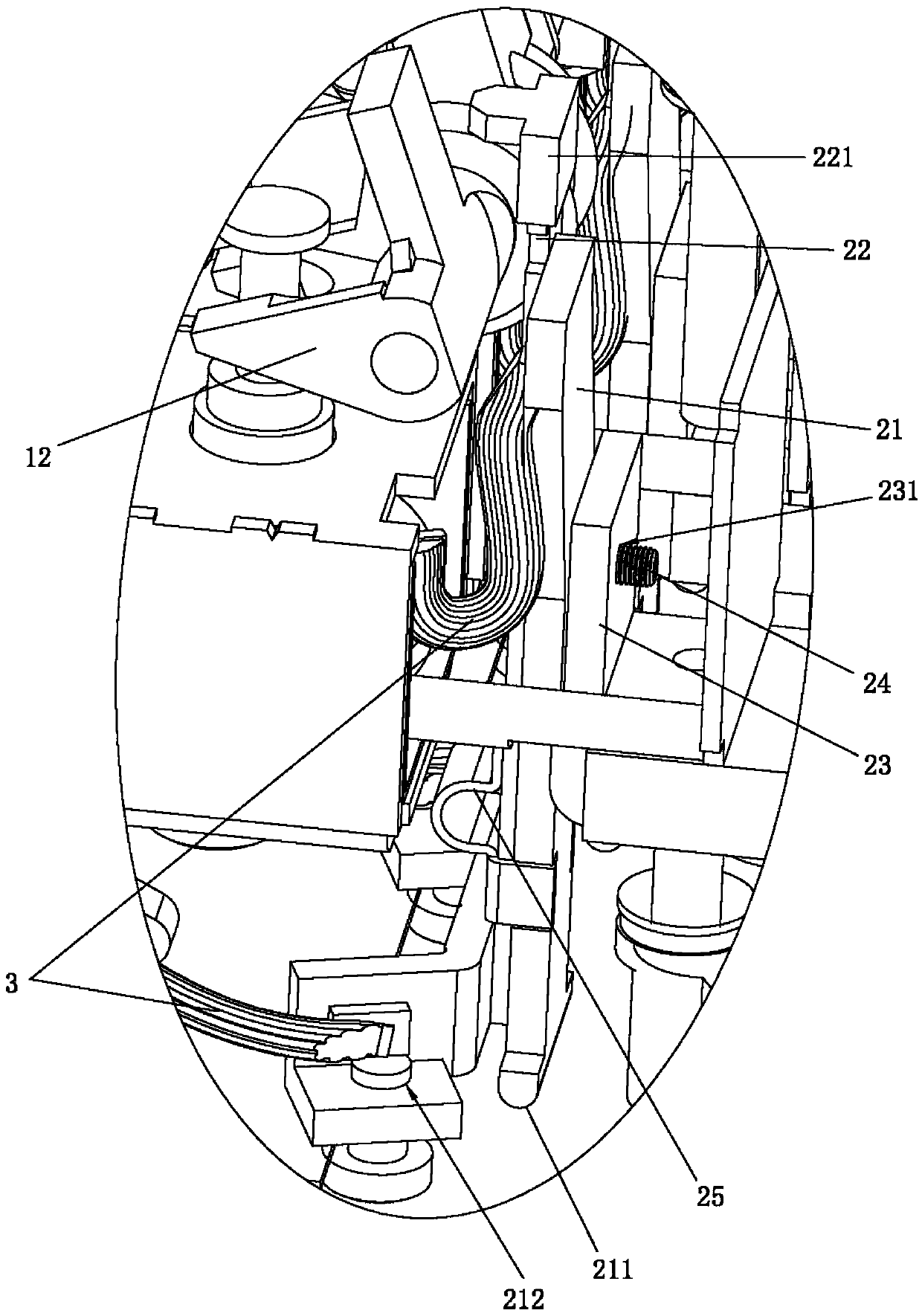

Circuit breaker suitable for debugging delay tripping

ActiveCN109599305AGuaranteed Position AccuracyGuaranteed positioning accuracyProtective switch operating/release mechanismsHeating elementBimetallic strip

The invention relates to the technical field of circuit breakers, in particular to a circuit breaker suitable for debugging delay tripping, comprising a circuit breaker main body and a delay trippingassembly; the circuit breaker main body comprises a shell, a traction assembly rotationally arranged in the shell and an opening mechanism arranged in the shell; the delay tripping assembly comprisesa heating element, a bimetallic strip arranged on the heating element, a debugging fixed plate arranged in parallel with the heating element, a debugging piece movably arranged on the debugging fixedplate for being abutted against the heating element to swing, and a reset piece for driving the heating element to reset; a gap is formed between the debugging fixed plate and the heating element, andthe bimetallic strip is heated, bent and is abutted against the traction assembly to rotate so as to enable the rotating traction assembly to trigger the opening mechanism to be switched off. The position of the debugging piece in the invention on the debugging fixed plate is unchanged, thereby guaranteeing the position precision of the debugging piece, facilitating automatic debugging equipmentto be aligned with a debugging part; and the delay tripping assembly of the structure is suitable for automatic debugging of the circuit breaker.

Owner:DONGGUAN JIYE ELECTRICAL EQUIP CO LTD

Card issuing mechanism and radian positioning device

PendingCN114314077AGuaranteed Position AccuracyAvoid skewArticle feedersMechanical engineeringEngineering

The invention belongs to the technical field of paper piece conveying, and discloses a card issuing mechanism which comprises a card issuing knife used for positioning a paper piece, a base, a rotating shaft, a connecting part and an adjusting part, the rotating shaft is connected to the base and embedded in the card issuing knife, the card issuing knife is connected to the base through the connecting part, and the adjusting part is connected to the base through the rotating shaft. The connecting part can enable the knife face, used for positioning a paper piece, of the card issuing knife to rotate around a rotating shaft, and the adjusting part is arranged on the connecting part and connected to the card issuing knife. And the adjusting part has a locking state in which the card issuing knife is locked on the base and an adjusting state in which the knife surface of the card issuing knife can be adjusted to rotate around the rotating shaft. On the other hand, the invention discloses a radian positioning device. The radian positioning device comprises a pair of card issuing mechanisms which are arranged at intervals. The angle of the knife face of the card issuing knife can be adjusted, the position precision of paper pieces is guaranteed, the paper pieces are prevented from inclining, and the production efficiency is guaranteed.

Owner:苏州凌云光工业智能技术有限公司 +2

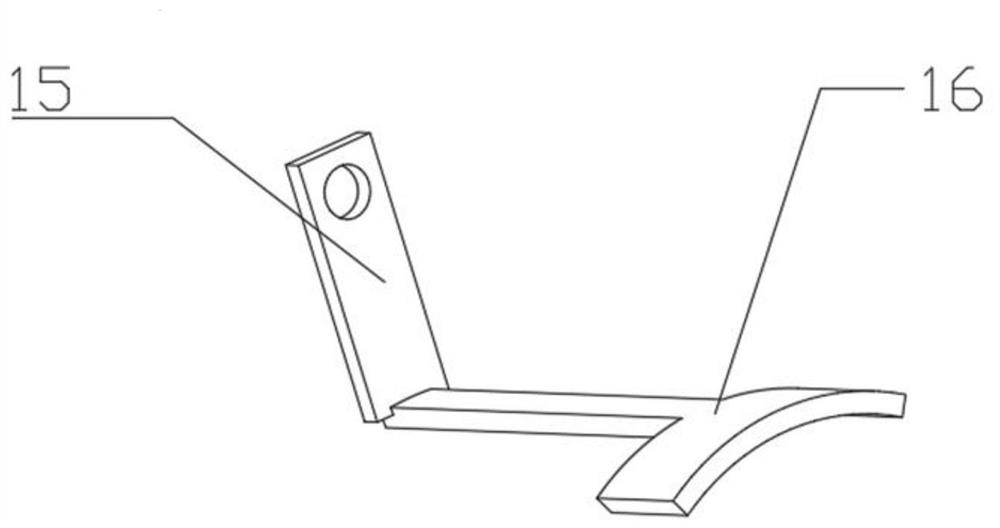

Automatic fixing device for rolling fixture

The invention discloses an automatic fixing device for a rolling fixture. The device is characterized in that: a fixing seat (2) is provided with a cylinder bracket (18), and a cylinder (1) is mounted on the cylinder bracket (18) through a fourth rotary shaft (19). A compaction block (6) and a cushion block (7) are sleeved on a pull rod (12); a lock nut (8) on the upper part of the pull rod (12) compacts the compaction block (6) and the cushion block (7); and the pull rod (12) passes through a rolling work platform (4), and a compaction spring (11) is sleeved on the lower part of the pull rod(12). One end of a rotary arm (16) is connected with a piston rod of the cylinder (1) through a third rotary shaft (17); and a roller (13) is arranged at the other end of the rotary arm (16) through a first rotary shaft (14), and resists against the lower surface of a flange at the lower end of the pull rod (16). Through the invention, quick replacement and automatic fixation of the rolling fixture are realized, the position precision and stability of the rolling fixture on the work platform are ensured, the size precision of the rolling section is guaranteed, the fixture replacing time is shortened, the production efficiency is improved, and the labor intensity of workers is reduced. Compaction is realized by use of spring force, the cost is lowered, and energy is saved.

Owner:QINHUANGDAO FANGHUA SECM MACHINERY

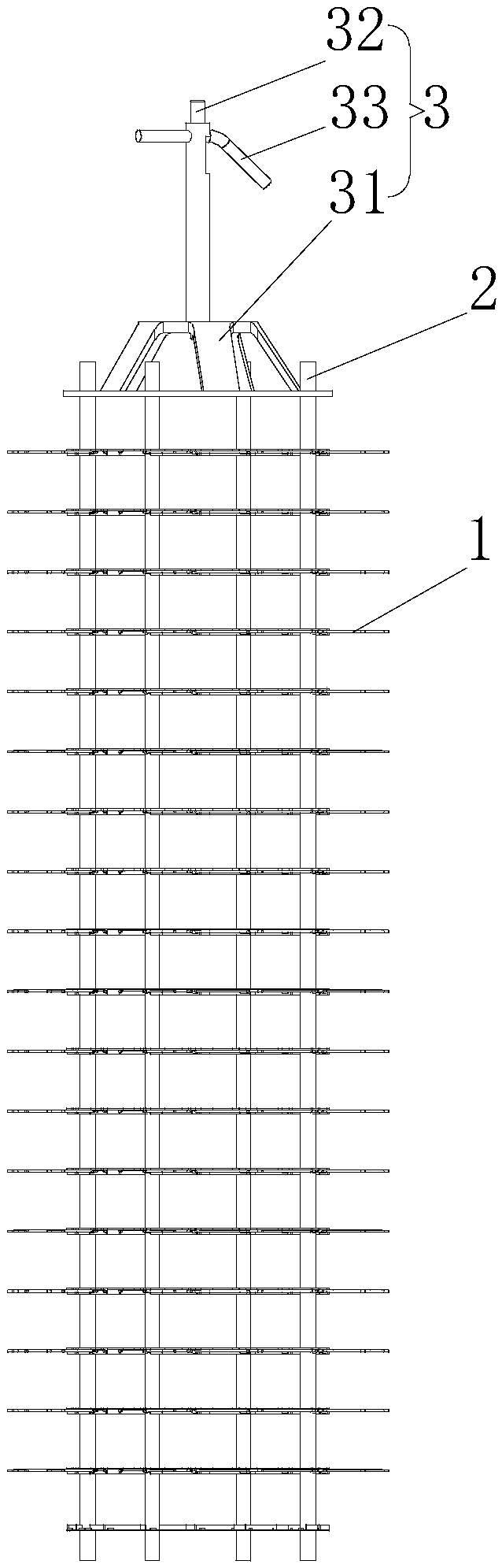

Zipper head plating hanger and manufacturing method thereof

PendingCN109023492AGuaranteed Position AccuracyImprove manufacturing precisionElectrolysis componentsSlide fastenersEngineeringElectroplating

The invention relates to the technical field of zipper head hangers, in particular to a zipper head plating hanger and a manufacturing method thereof. The zipper head electroplating hanger comprises aplurality of hanging loops, a plurality of hanging needles for hanging zipper heads are fixed to the hanging loops, a plurality of connecting rods are further included, the hanging loops are providedwith a plurality of through holes, the connecting rods sequentially pass through the through holes of the multiple hanging loops to be fixedly connected with the hanging loops, and the multiple connecting rods are evenly fixed on the multiple hanging loops arranged at intervals to form a round cage structure. According to the zipper head plating hanger, the hanging loops are provided with the multiple evenly-distributed through holes, the through holes are used for positioning after the hanging loops and the connecting rods are connected, and the positional accuracy of the hanging loops is guaranteed; and the hanging needles are pressed and fixed by pressing pieces, the pressing pieces are also positioned through the through holes, and the positional accuracy of the hanging needles is guaranteed. According to the zipper head plating hanger and the manufacturing method, a stamping forming method is used for manufacturing the hanging loops, and the manufacturing precision of the hangingloops is improved.

Owner:石狮市八九机械设备有限公司

Multi-station circuit board printing machine and printing method

PendingCN112172317AImprove printing efficiencyGuaranteed Position AccuracyScreen printersConductive pattern formationManufacturing engineeringElectrical and Electronics engineering

The invention discloses a multi-station circuit board printing machine and a printing method. The machine comprises a rotating disc; a plurality of fixed bases and limiting assemblies matched with thefixed bases are fixed to the edge of the upper end face of the rotating disc; the limiting assemblies are arranged on the inner sides of the fixed bases; a feeding belt, a position adjusting assembly, a printing assembly, a drying assembly, a overturning assembly and a discharging belt are sequentially and annularly distributed on the side face of the rotating disc; and the position adjusting assembly, the printing assembly, the drying assembly and the overturning assembly are all installed above the edge of the rotating disc and are connected with the rotating disc in a sliding mode. The printing machine and the printing method have the beneficial effects that the printing quality is guaranteed, and the printing efficiency is greatly improved.

Owner:杭州九州环保科技有限公司

Self-centering positioning component, attaching mechanism and attaching system for cubic prism

The invention discloses a self-centering positioning component, an attaching mechanism and an attaching system for a cubic prism, and the self-centering positioning component comprises at least one supporting surface which is used for bearing a cubic three-color light combination prism; the at least one adsorption unit is used for adsorbing and fixing the cubic three-color light combination prism positioned on the supporting surface; the at least four flexible joints are used for guiding the cubic three-color light combination prism to slide to the supporting surface, and the flexible joints are rotationally and symmetrically arranged relative to the first shaft; and the central axis of the cubic three-color light combination prism which slides to the supporting surface through the guiding of the flexible joint is collinear with the first axis. The device is simple in structure, the positioning precision of the cubic three-color light combination prism can be effectively guaranteed, and the fitting precision of the cubic three-color light combination prism and the three single-color Panel units is improved.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

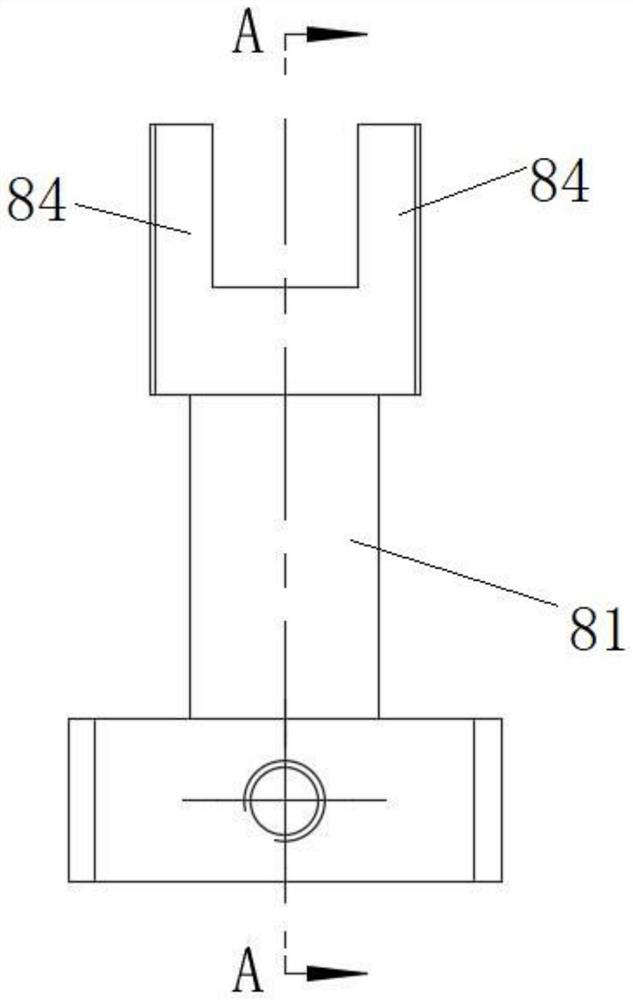

Side enclosure outer plate tail springback control structure

PendingCN112536565AGuaranteed Position AccuracyShorten the debugging cycleWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention belongs to the technical field of automobiles, and particularly relates to a side enclosure outer plate tail springback control structure. The structure comprises a first positioning block, a second positioning block, a third positioning block, a rotating block, a supporting block, a connecting block, an air cylinder and a clamp base. The first positioning block is fixed to the supporting block; the second positioning block is fixed to the supporting block through the connecting block; the third positioning block is fixed to the lower end of the rotating block; the rotating blockis connected with a movable end of the air cylinder; the air cylinder is fixed to the supporting block; the supporting block is fixed to the clamp base through a connecting plate; and the positioningblock attracts a side enclosure outer plate part. With the side enclosure outer plate tail springback control structure, the dimensional accuracy of the side enclosure outer plate part can be effectively controlled in the welding process, and the debugging period can be remarkably shortened.

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com