Design method of metal mask and preparation method of metal mask

A metal mask, design method technology, applied in computer-aided design, metal material coating process, patterned surface photoengraving process, etc. The effect of ensuring positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

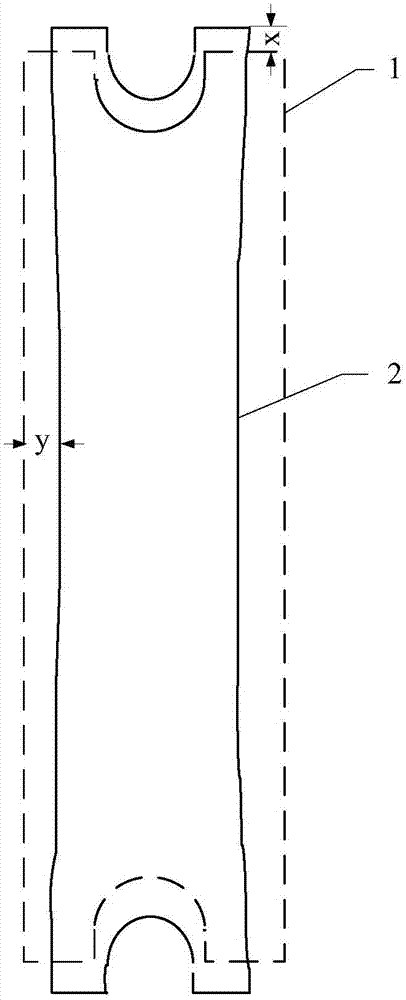

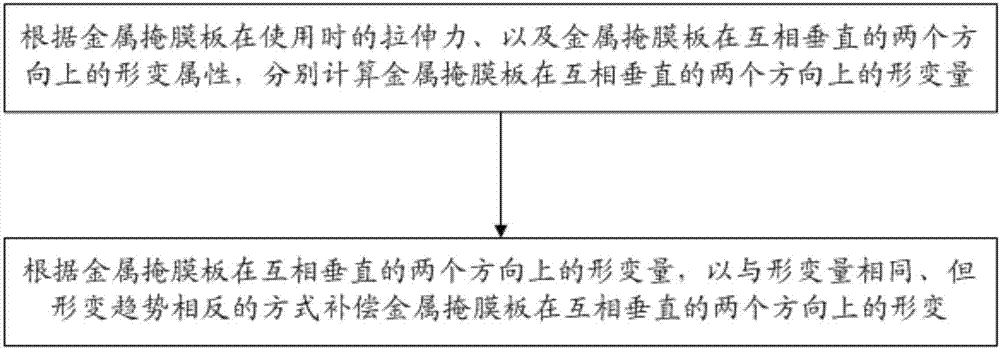

[0060] Aiming at the problem that the metal mask needs to be compensated in the length and width direction of the metal due to the stretching shrinkage, this embodiment provides a metal mask design method and a corresponding metal mask preparation method, using The design method of the metal mask and the corresponding metal mask preparation method do not need to prepare the sample mask in advance, and directly obtain the deformation compensation amount through calculation, so that the metal mask including the compensation amount can be designed at one time be realized.

[0061] Usually, it is known that the tensile force of the metal mask is F, the thickness is t, the width is w, the length is l, the Young's modulus is E, and Poisson's ratio is ν 0 ,but:

[0062] The cross-sectional normal stress σ of the metal mask in the stretching direction x for:

[0063] σ x =F / w×t Formula (1-1)

[0064] The cross-sectional elongation Δl of the metal mask in the stretching direction ...

Embodiment 2

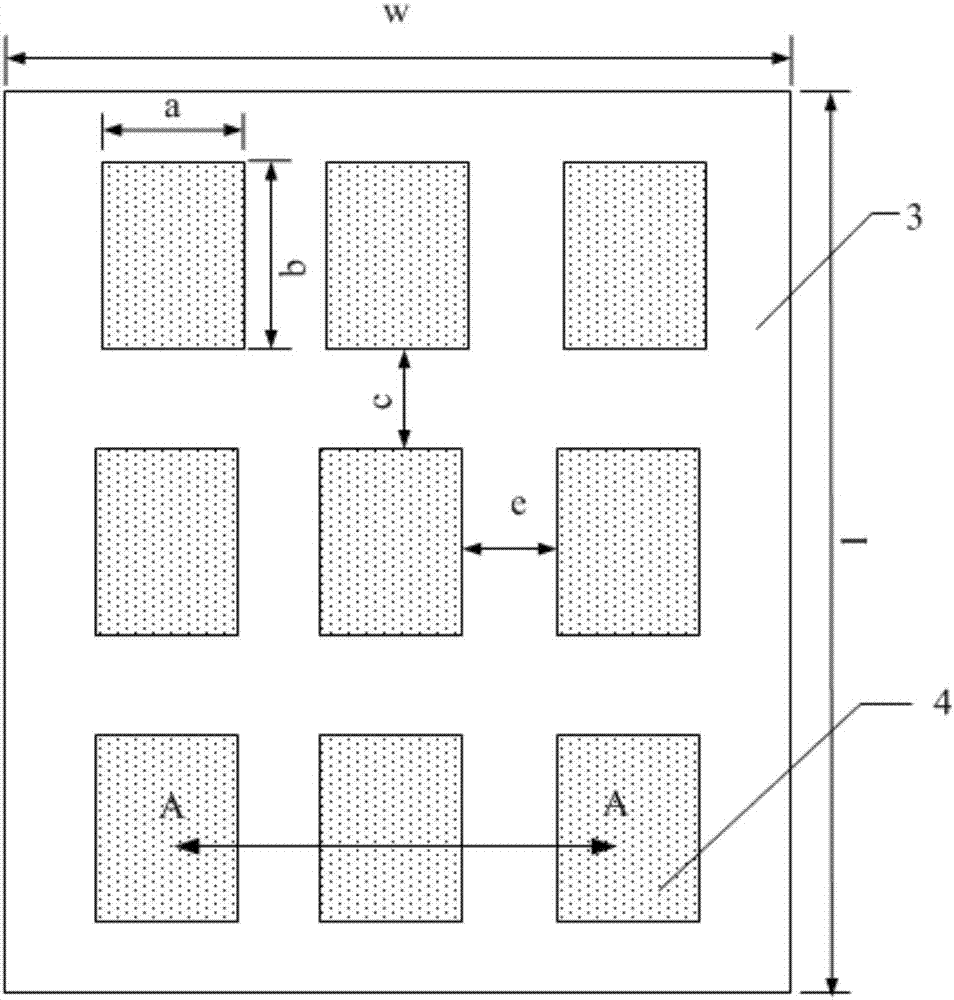

[0110] This embodiment provides a method for designing a metal mask and the corresponding method for preparing a metal mask. It is not necessary to prepare a sample mask in advance, and the amount of deformation compensation can be obtained directly through calculation, so that the one-time design includes compensation A large number of metal mask plates can be realized. The difference between this embodiment and Embodiment 1 is that, in the design method of the metal mask and the corresponding method of preparing the metal mask, corrections related to the thickness of the metal mask and the inclination of the opening are also provided. parameter, and set the correction parameter C according to the thickness of the metal mask and the inclination of the opening 1 .

[0111] On the basis of the design method of the metal mask plate of embodiment 1,

[0112] Axial Young's modulus E of the metal mask x for:

[0113] E. x =E×e / (a+e) Formula (2-1)

[0114] Transverse Young's m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile force | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com