Patents

Literature

302results about How to "Shorten the debugging cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

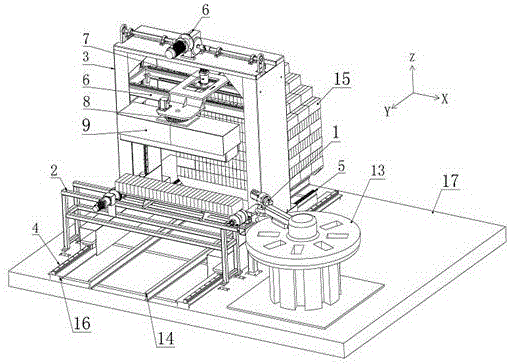

Automatic spraying system and automatic spraying method based on point cloud and image matching

ActiveCN106423656AReduce difficulty of useRealization of automatic sprayingSpraying apparatusVisual matchingPoint cloud

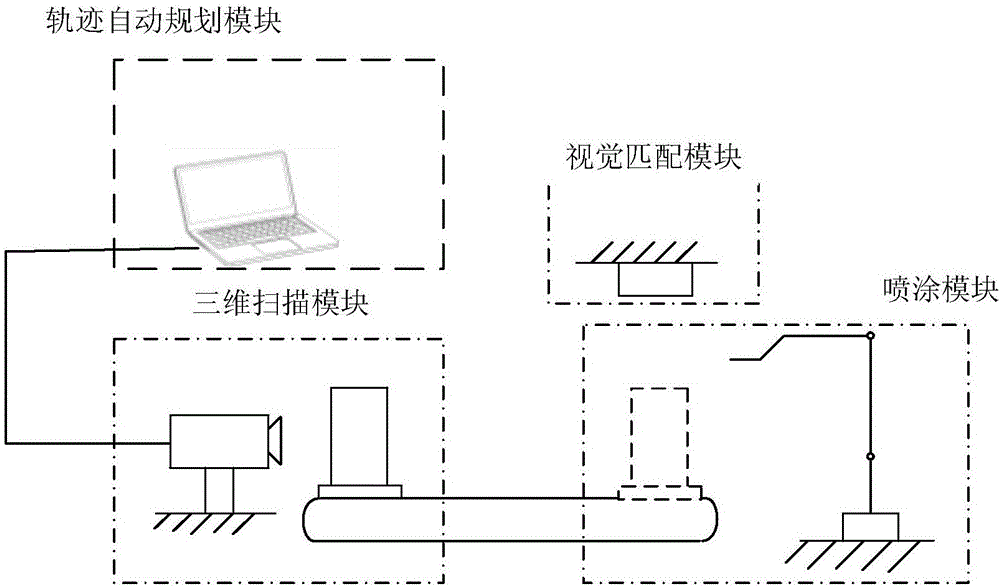

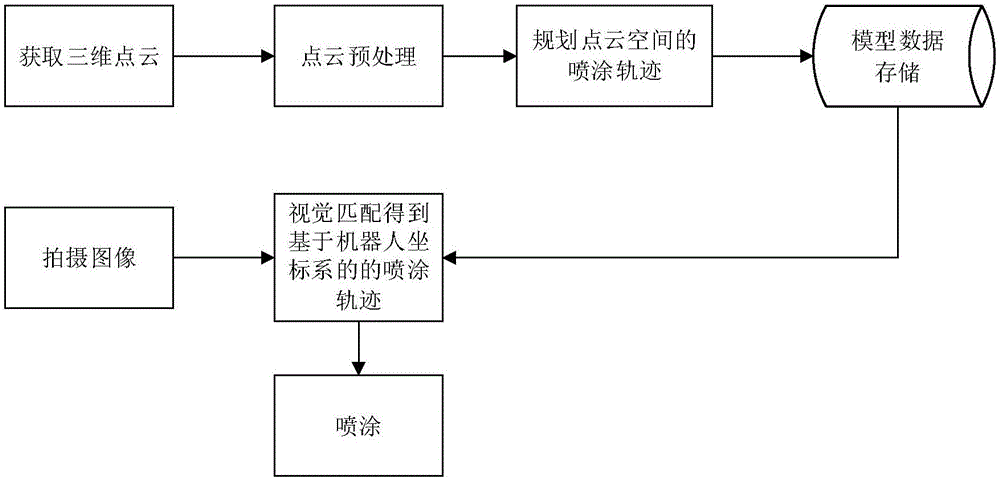

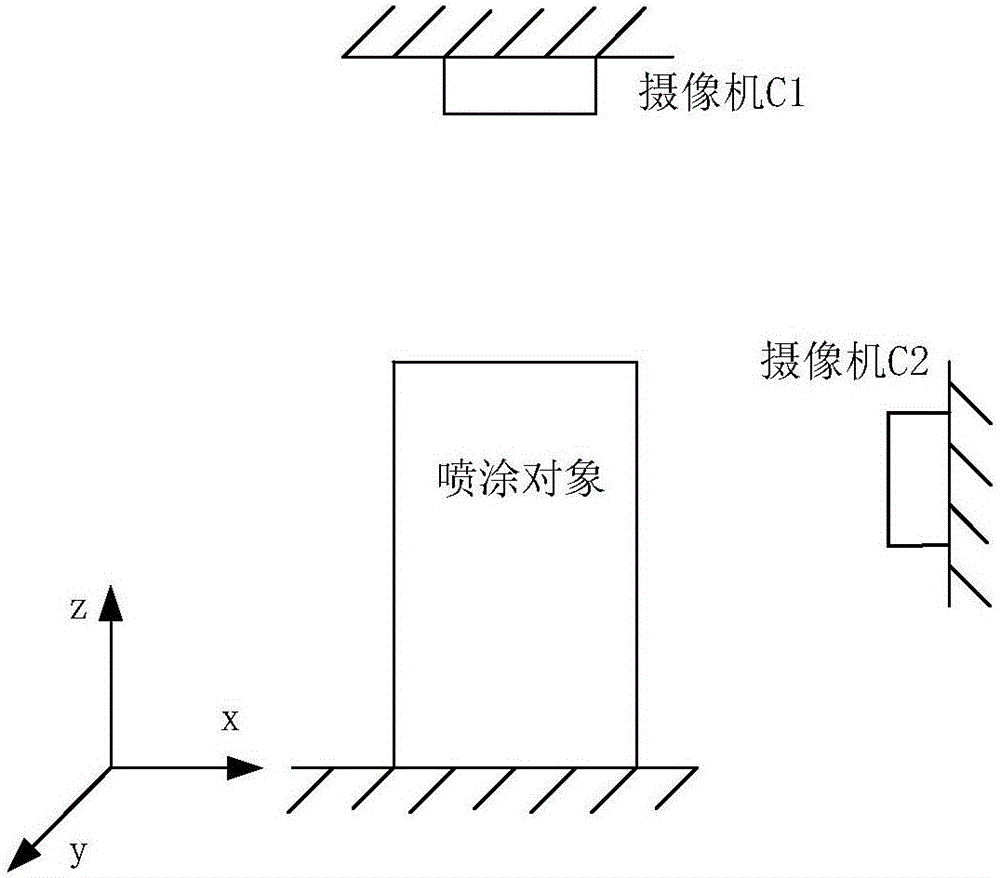

The invention provides an automatic spraying system based on point cloud and image matching. The automatic spraying system comprises a three-dimensional scanning module, an automatic trajectory planning module, a visual matching module and a spraying module. The three-dimensional scanning module is used for scanning a spraying object and acquiring a point cloud model according to scanned three-dimensional point cloud data; the automatic trajectory planning module is used for planning spraying trajectories in a point cloud space; the visual matching module is used for acquiring a transformational relation between a point cloud coordinate system and a spraying robot coordinate system; the spraying module is used for automatically spraying the spraying object. The automatic spraying system has the advantages that an algorithm is planned automatically according to a robot spraying path of the point cloud coordinate system, the point cloud coordinate system is correlated with the robot coordinate system according to the cloud point and image matching algorithm, and accordingly, automatic spraying of the spraying object is realized; on the basis of guaranteeing spraying efficiency, the spraying quality is improved greatly, calculation quantity for trajectory planning is reduced, and trajectory planning quality is improved.

Owner:CHONGQING UNIV

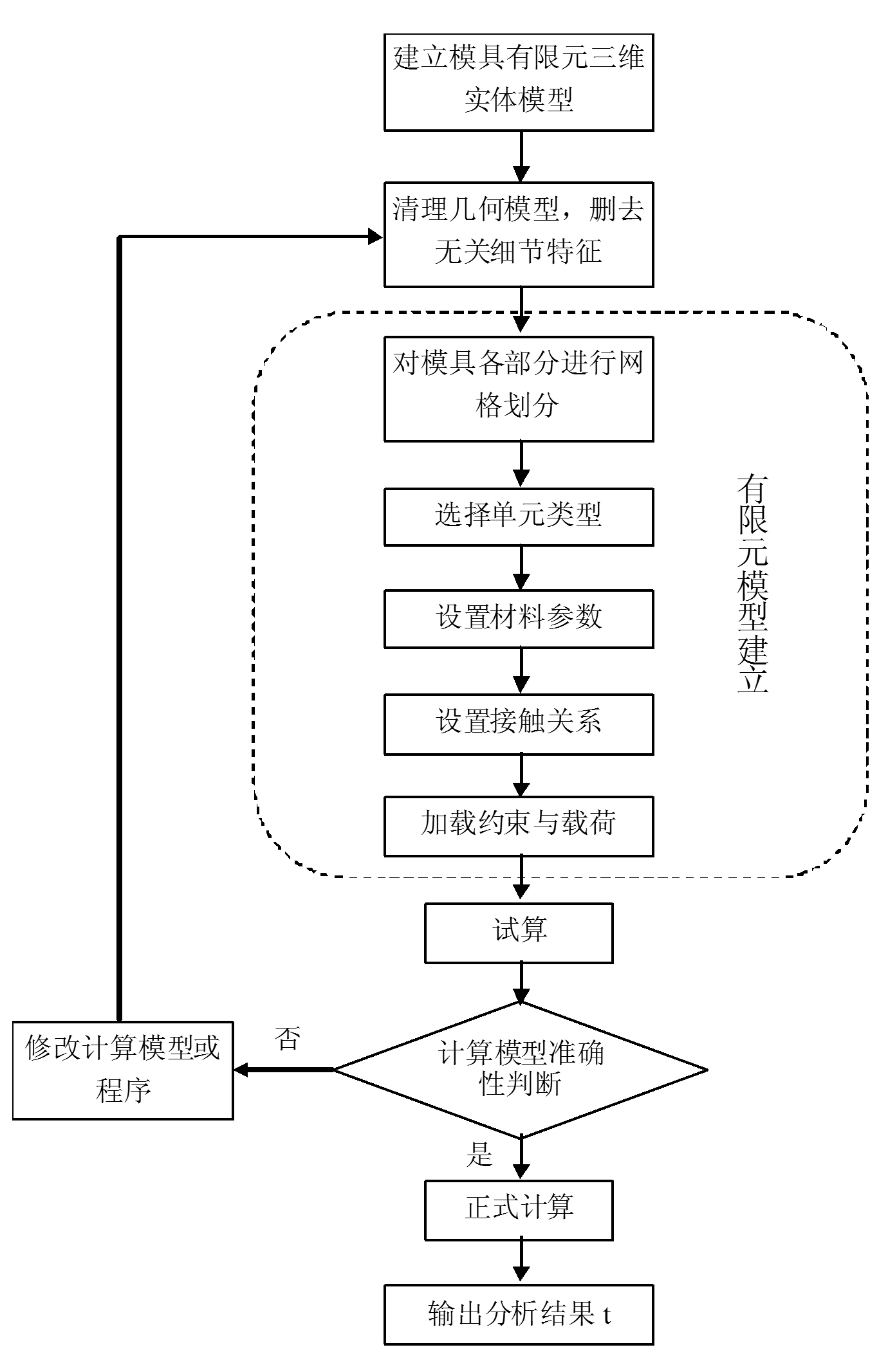

Automobile panel die design method

ActiveCN102024081AShorten the debugging cycleReduce manufacturing costSpecial data processing applicationsElement modelDesign stage

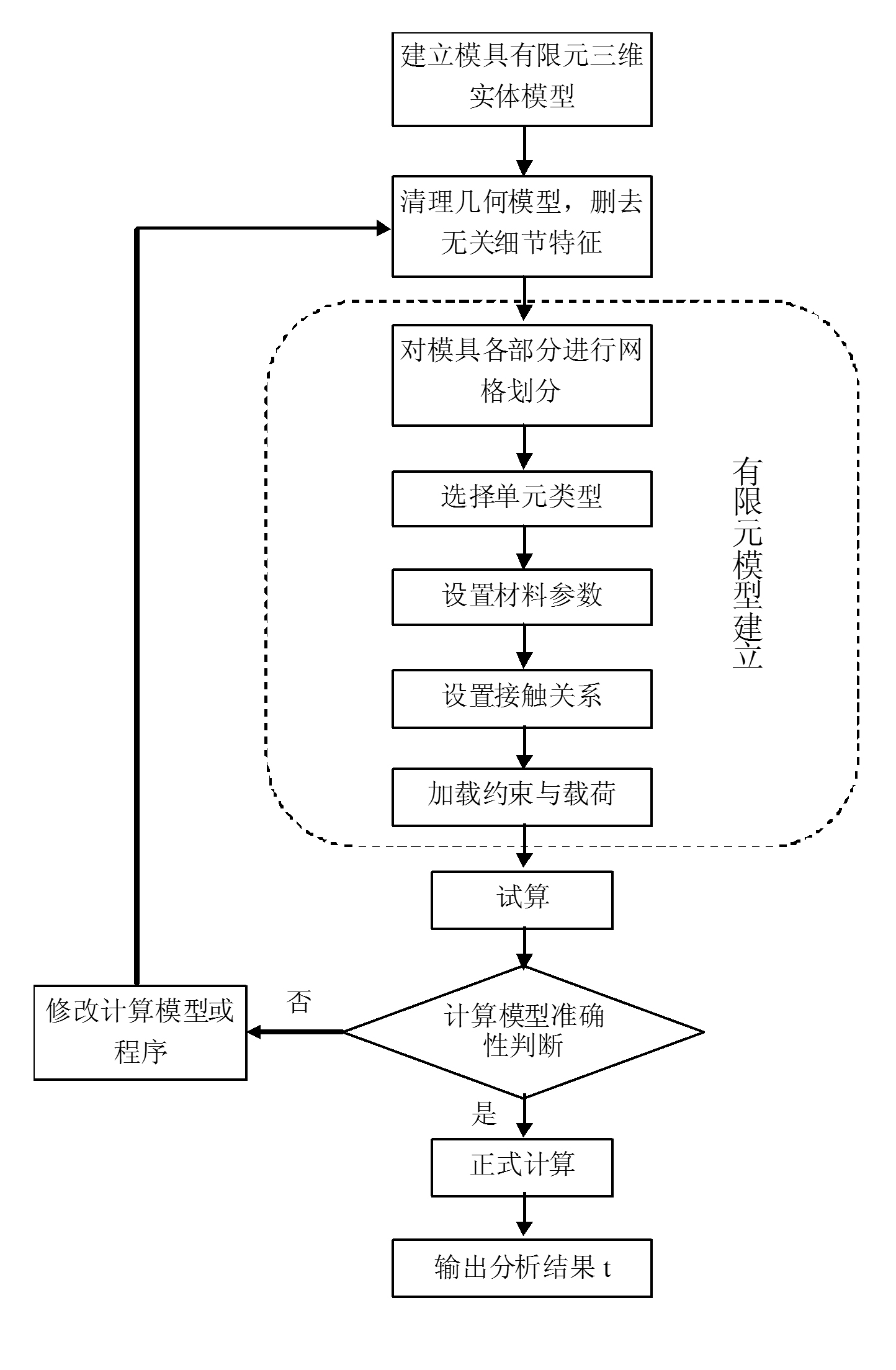

The invention discloses an automobile panel die design method, which comprises the following steps of: (1) establishing a corresponding theoretical model according to the geometrical structural characteristics of an automobile panel; (2) removing the structural characteristics unrelated to the deformation of a die cavity surface from the theoretical model; (3) establishing a finite element model according to the theoretical model simplified by the step (2), and simulating an automobile panel die molding process; (4) calculating the deformation of the die cavity surface after the simulation byusing a computer; (5) performing compensation design and amendment on the theoretical model obtained by the step (1) based on the deformation of the die cavity surface, thereby obtaining a model of an actual die to be machined; and (6) manufacturing the actual die according to the model obtained by the step (5). In the method, corresponding deformation compensation can be performed on the die cavity surface in a design stage so as to offset the influence of the deformation of the actual die, increase the joint degree of the die cavity surface, make the die can be designed and machined in place once, further shorten a die debugging period and reduce the manufacturing cost of the die.

Owner:成都普什汽车模具有限公司 +2

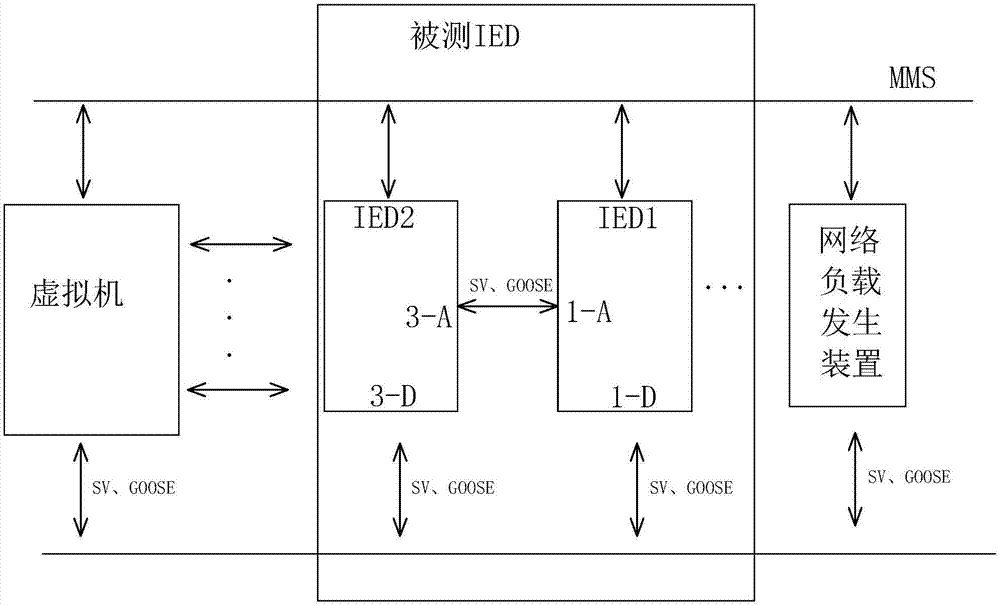

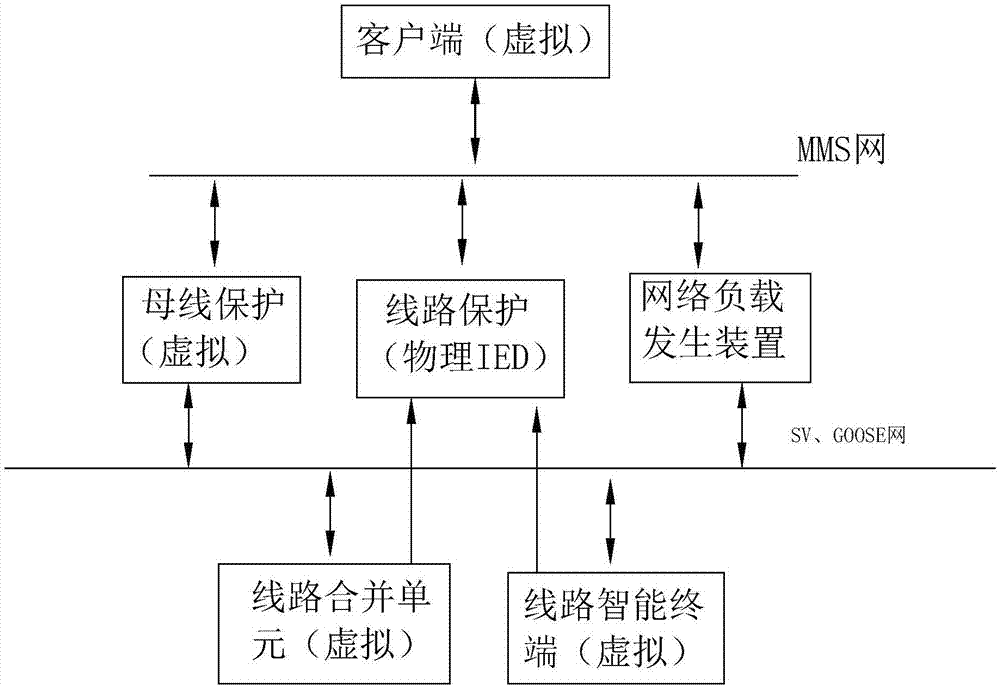

Secondary device integration and joint debugging method based on virtual machine

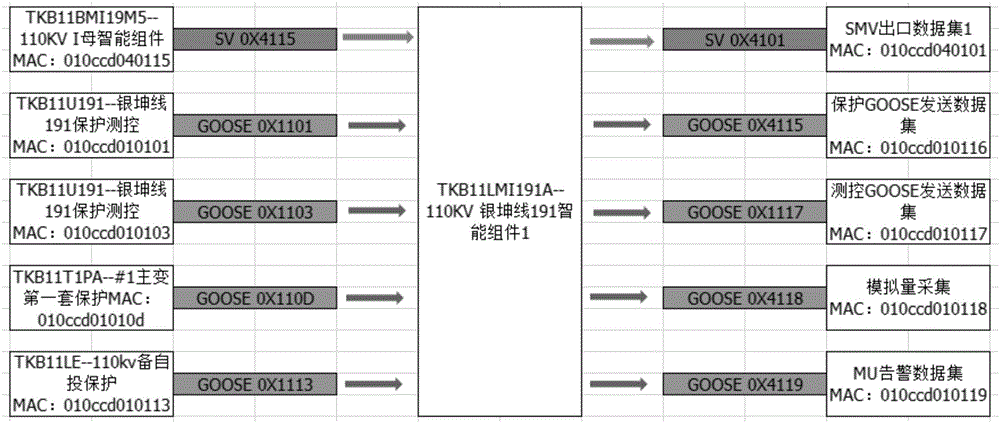

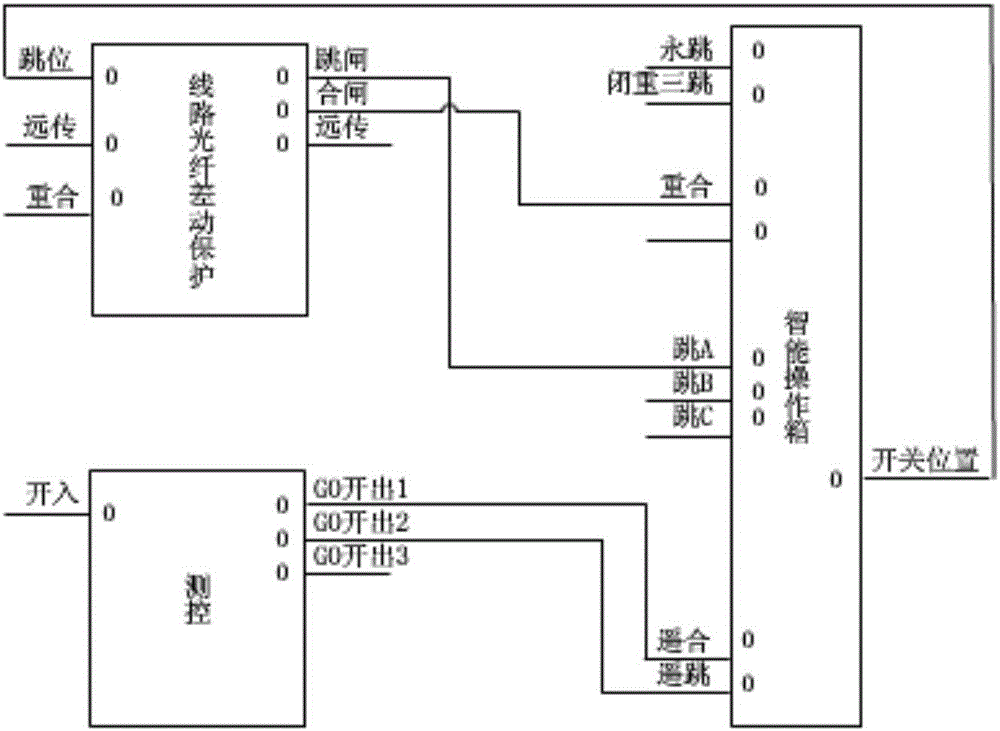

ActiveCN107346917AImprove comparison efficiencyStrong engineering practicabilityCircuit arrangementsInformation technology support systemSmart substationComputer science

The invention provides a secondary device integration and joint debugging method based on a virtual machine. The method comprises the steps that S1 the minimum test system of an intelligent substation is built according to the principle of guaranteeing the substation consistency; S2 the real test environment of the substation is built based on the minimum test system; by importing an SCD file, the configuration of the devices of the whole substation is acquired; data flows including SV flow and GOOSE flow in each device are acquired; the model of the whole substation is built through backstage, and the information of the devices of the whole substation is scanned; and S3 the minimum test system is used to integrate the device information and the definition and definite value of action behaviors to acquire a test item, a test program and a test result template. The factory-like joint debugging efficiency is improved. The joint debugging intelligent level is enhanced. The device debugging cycle is shortened, and the debugging environment is improved.

Owner:JIAXING HENGCHUANG ELECTRIC POWER DESIGN & RES INST CO LTD +1

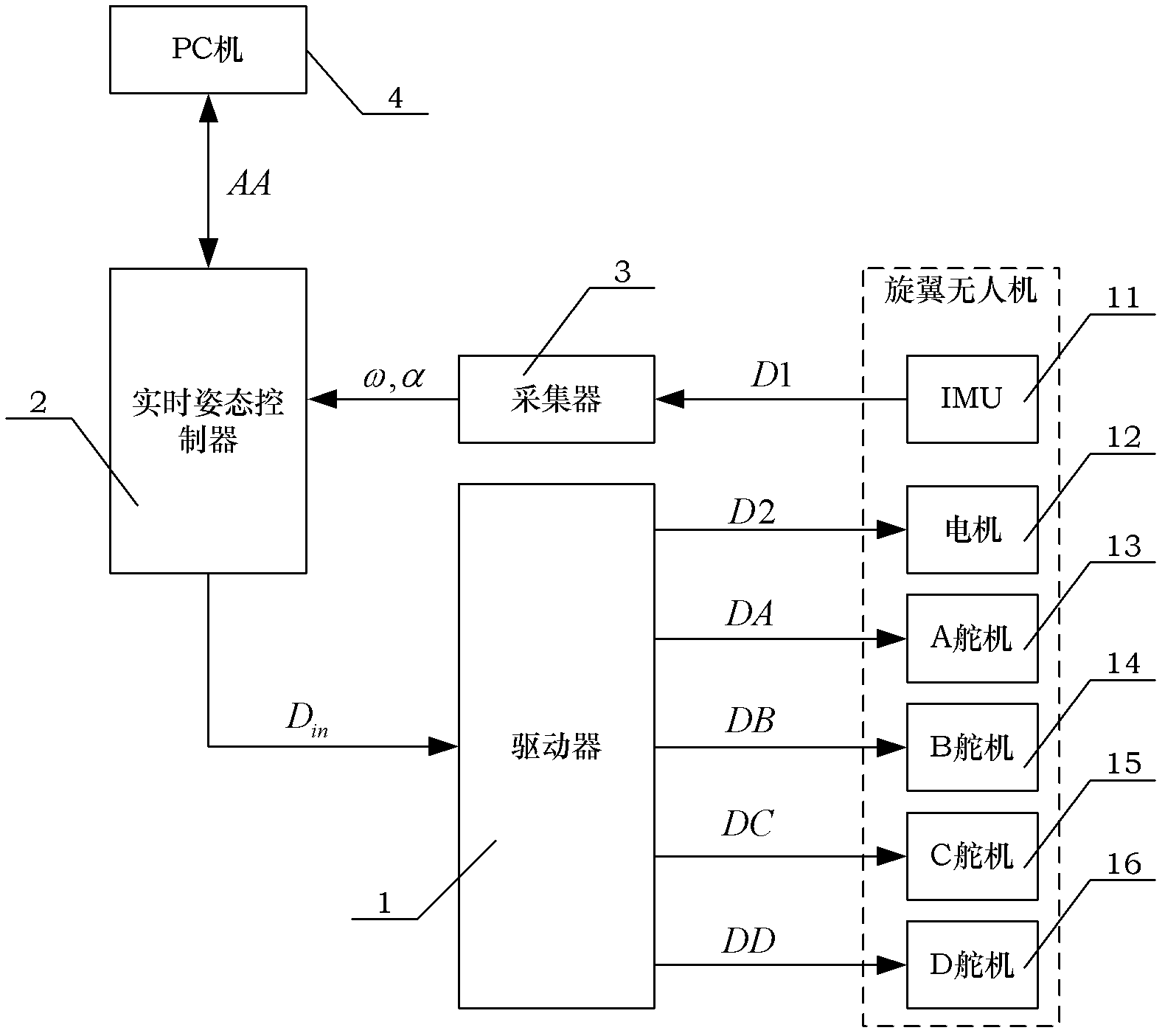

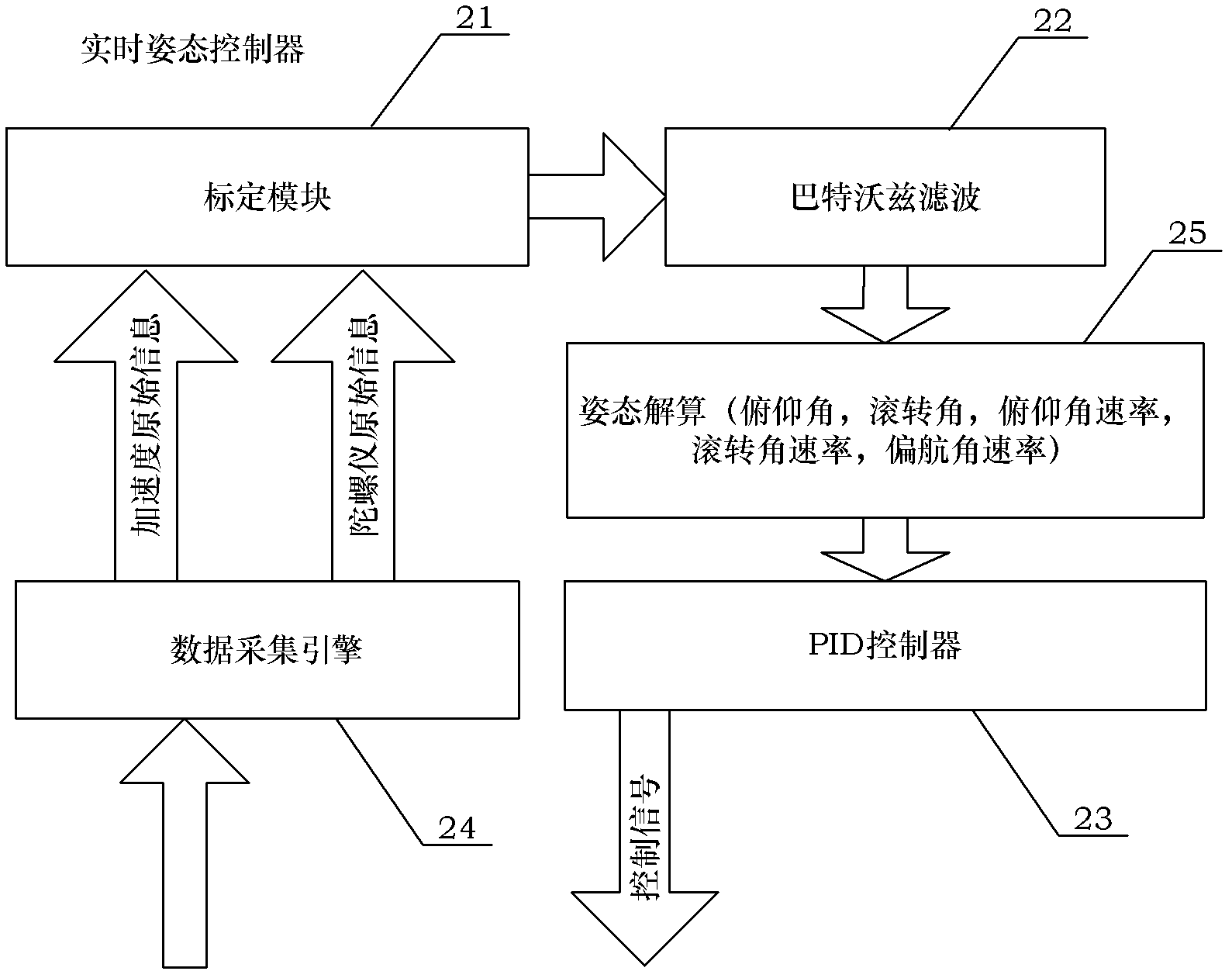

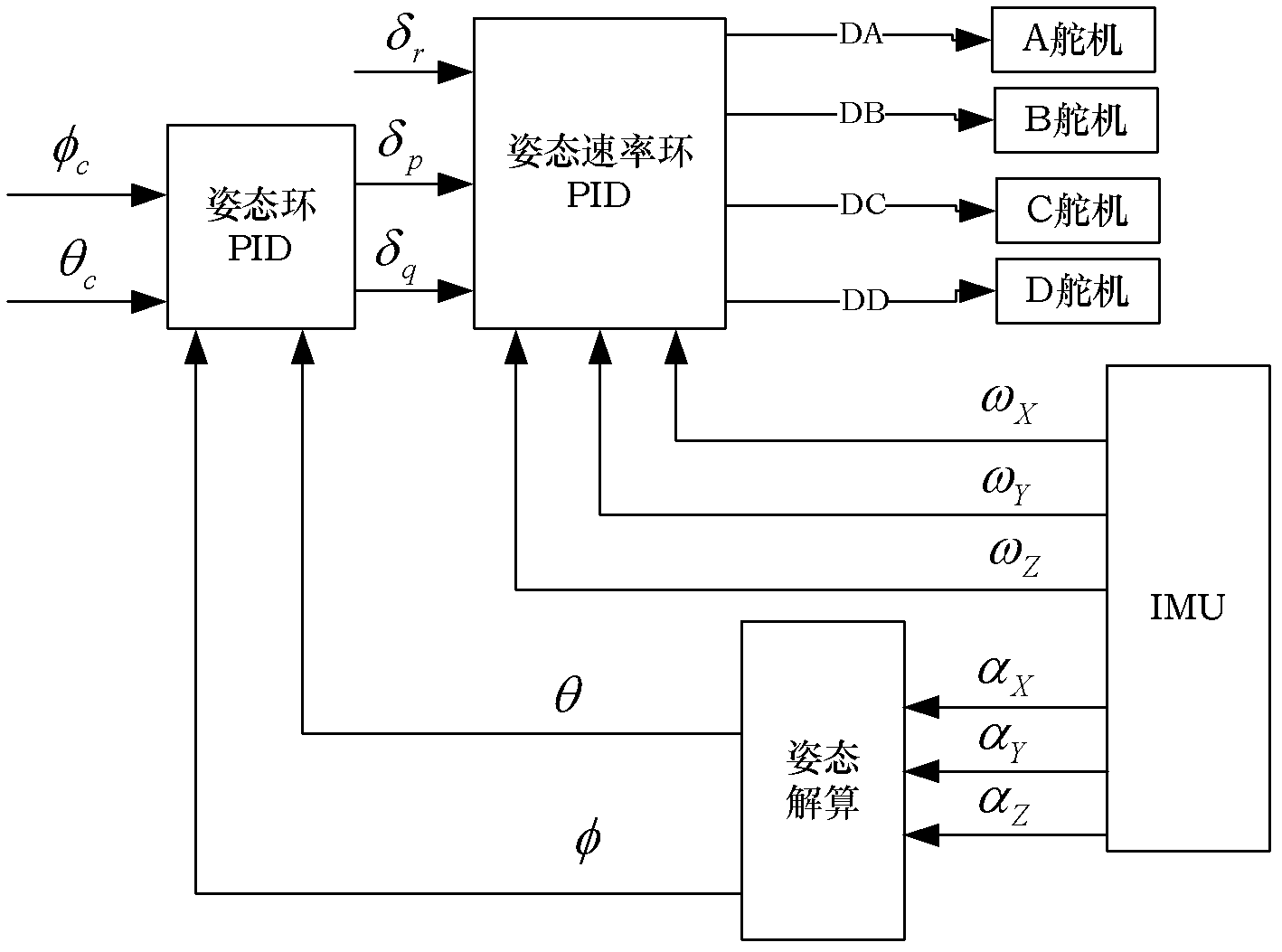

Ground control system applicable to rotor-wing unmanned aerial vehicle

InactiveCN102426458AAvoid unreliabilityLow costAttitude controlHuman–machine interfaceAttitude control

The invention discloses a ground control system applicable to a rotor-wing unmanned aerial vehicle. The ground control system comprises a personal computer (PC) (4), a real-time attitude controller (2), a serial peripheral interface (SPI) communication acquirer (3) and a driver (1), wherein the driver (1) receives a movement instruction Din which is output by the real-time attitude controller (2), and according to the movement instruction Din, the driver (1) outputs a motor control signal D2 to drive a motor (12) to move, outputs an A-th path of steering engine signal DA to drive an A steering engine (13) to move, outputs a B-th path of steering engine signal DB to drive a B steering engine (14) to move, outputs a C-th path of steering engine signal DC to drive a C steering engine (15) tomove and outputs a D-th path of steering engine signal DD to drive a D steering engine (16) to move; the SPI communication acquirer (3) acquires parameter information D1 which is measured by an inertia measurement unit (11) on the rotor-wing unmanned aerial vehicle and outputs linear acceleration signals alpha and angular speed signals omega of three degrees of freedom of the rotor-wing unmanned aerial vehicle to the real-time attitude controller (2); and the PC (4) communicates with the real-time attitude controller (2) through a transmission control protocol (TCP) / internet protocol (IP) and provides a friendly human-computer interface for an operator.

Owner:BEIHANG UNIV

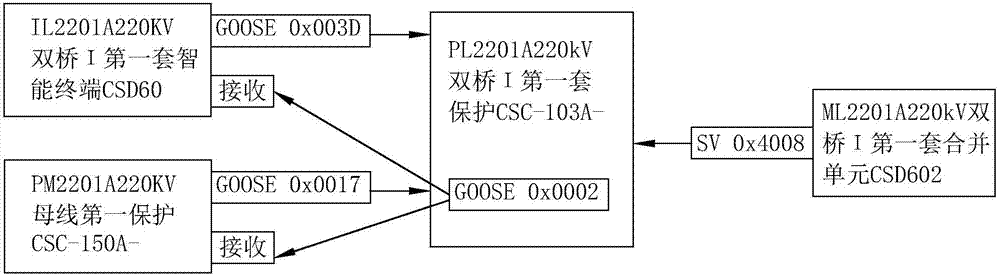

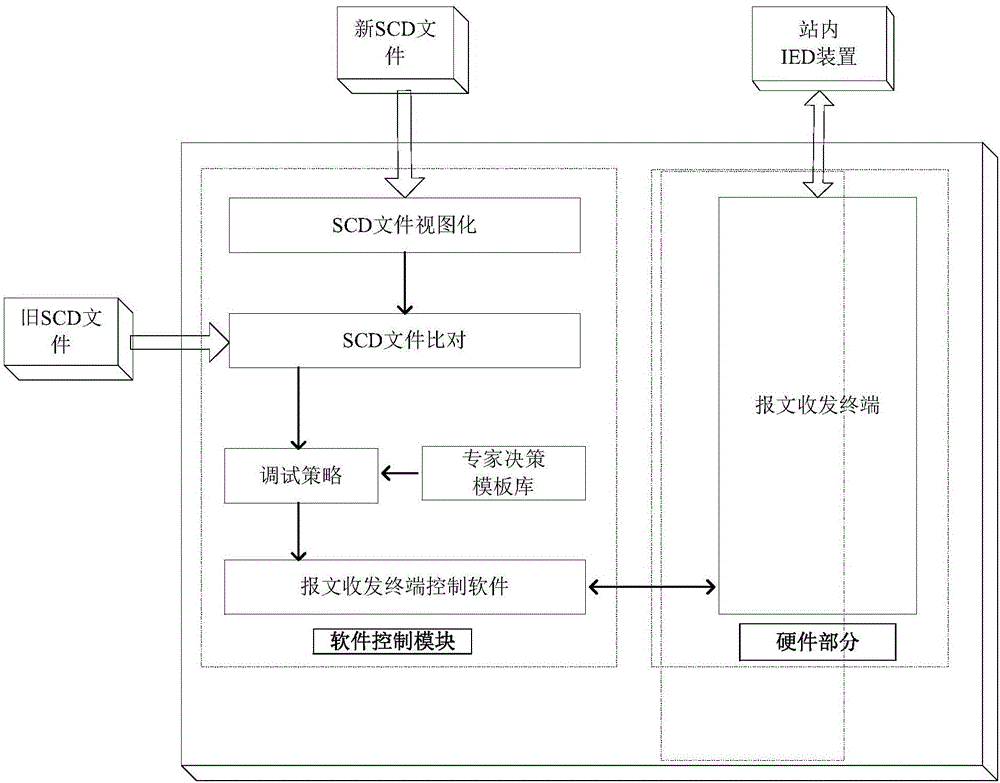

Method and system for detecting visualization and configuration consistency of configuration file of intelligent substation

InactiveCN106372301AImprove readabilityEasy to readGeometric CADDesign optimisation/simulationSmart substationTopological graph

The invention discloses a method for detecting visualization and configuration consistency of a configuration file of an intelligent substation. The method comprises the following steps: 1) viewing an SCD file; 2) comparing the SCD file: performing imaging comparison, primarily reporting an error in a topological graph when different versions of loops or inconsistent message parameters are detected, then reporting the error in details on a detailed virtual secondary loop diagram and displaying the loop or terminal change, and finally, listing the configuration change of the compared SCD file; 3) debugging strategy and verifying by the SCD file: a) generating a corresponding debugging strategy according to a comparison result, and b) verifying the related IED device according to the debugging strategy, thereby checking the correctness of the loop and maintaining the consistency of the practical information and SCD file description between the in-station intelligent devices of the intelligent substation. The reliability of information interconnection between the IED devices is guaranteed; the invisible hidden danger of the safe running of a power grid is eliminated; the systematic and targeted properties of the debugging work of the intelligent substation are increased; and the debugging period of the intelligent substation is effectively reduced.

Owner:西电通用电气自动化有限公司

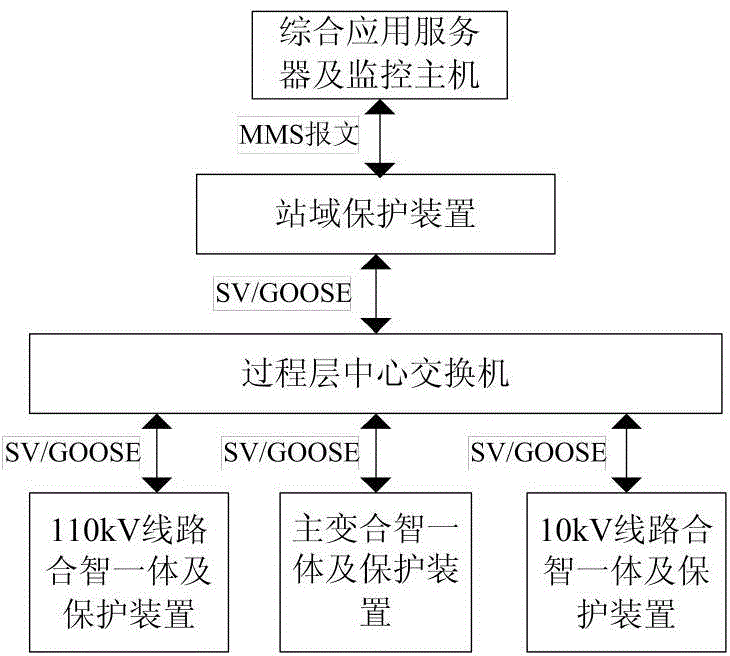

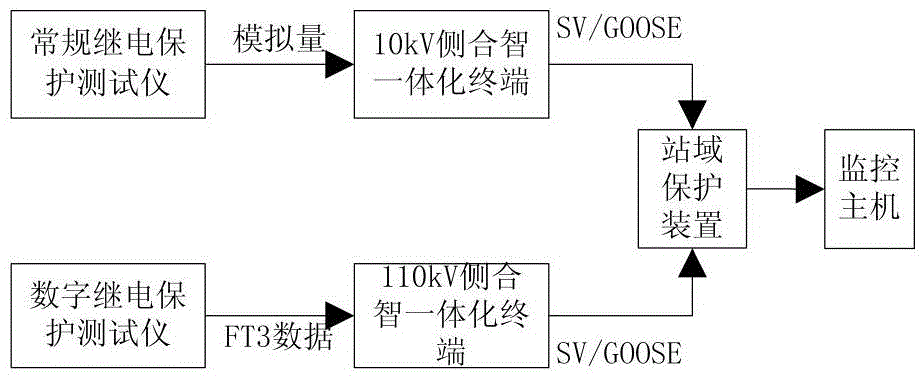

Station-domain protection system of intelligent transformer station and function debugging method of system

InactiveCN104935079AWork lessReduce layoutEmergency protective circuit arrangementsElectrical testingApplication serverSmart substation

The invention relates to a station-domain protection system of an intelligent transformer station and a function debugging method of the system. A station-domain protector is mounted between an integrated application server and monitor host and a central switch of a process layer, the station-domain protector is networked with the integrated application server and monitor host via MMS messages, and the integrated application server and monitor host is networked with the central switch of the process layer via GOOSE and SV messages. The debugging technology as well as single debugging, network debugging and group transmission methods of station-domain protection of the new generation of intelligent transformer station are included, the workload of equipment maintenance is reduced, wire arrangement is greatly reduced, wiring is simple and convenient, the installation efficiency is effectively improved, the whole construction period is shortened, and the operation stability of the system is improved.

Owner:TIANJIN ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG CORP +1

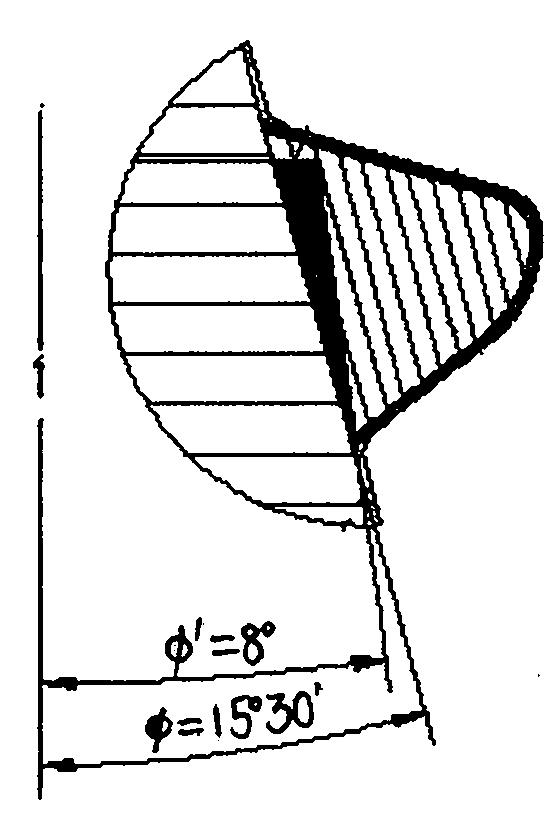

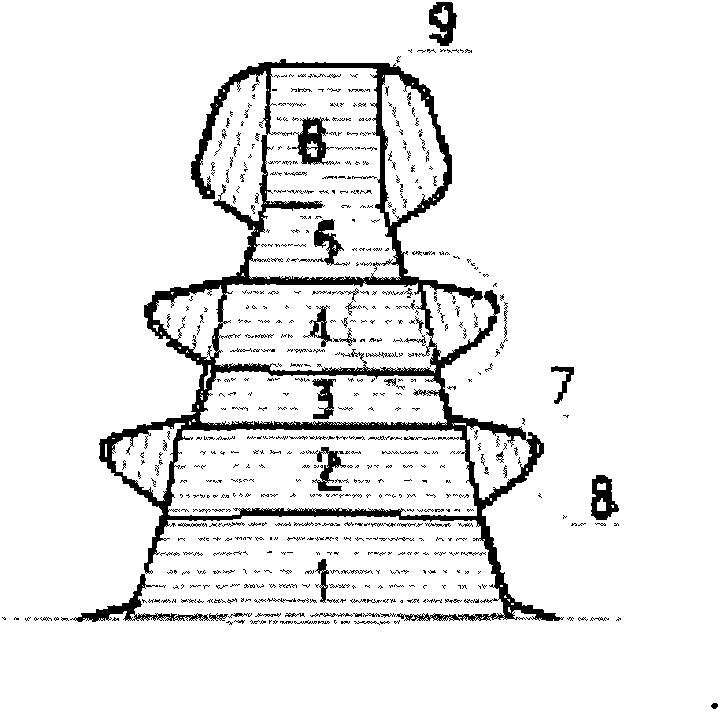

Turbine disk fir-shaped mortise broaching tool

InactiveCN101774045AShorten the lengthIncreased durabilityBroaching toolsPositioning apparatusEngineeringTurbine

The invention relates to a turbine disk fir-shaped mortise broaching tool, which is characterized in that a milled chamfer angle of 0.2x45 DEG is arranged on a sharp corner at two sides of the bladewidth of the turbine disk fir-shaped mortise broaching tool, parts 1 to 6 are slotted roughly, a seventh part is roughly broached with a mortise thread shape, an eighth part is precisely broached with a mortise thread-form sectional surface, and the top surface of a ninth part is precisely broached; the parts 1 to 6 adopt six slotting cutters, the seventh part adopts one rough-broaching thread-form cutter, the eighth part adopts one precise-broaching thread-form cutter, and the ninth part adopts one top-surface broach which is also named cap knife. The turbine disk fir-shaped mortise broaching tool has the advantages that the design structure of the broach is changed, the service life of the slotting broach is improved, and the manufacturing precision and the product complete qualification rate of the thread-form precise broach are broken through. The debugging period is successfully shortened, the trial broaching at one time is completely qualified, the production efficiency is improved by 30 percent, and the service life of the broach is prolonged. Compared with the combination-type broach and the powder metallurgy broach, the broaching tool with the above structure has simpler manufacturing process, good interchangeability, safe application and low cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

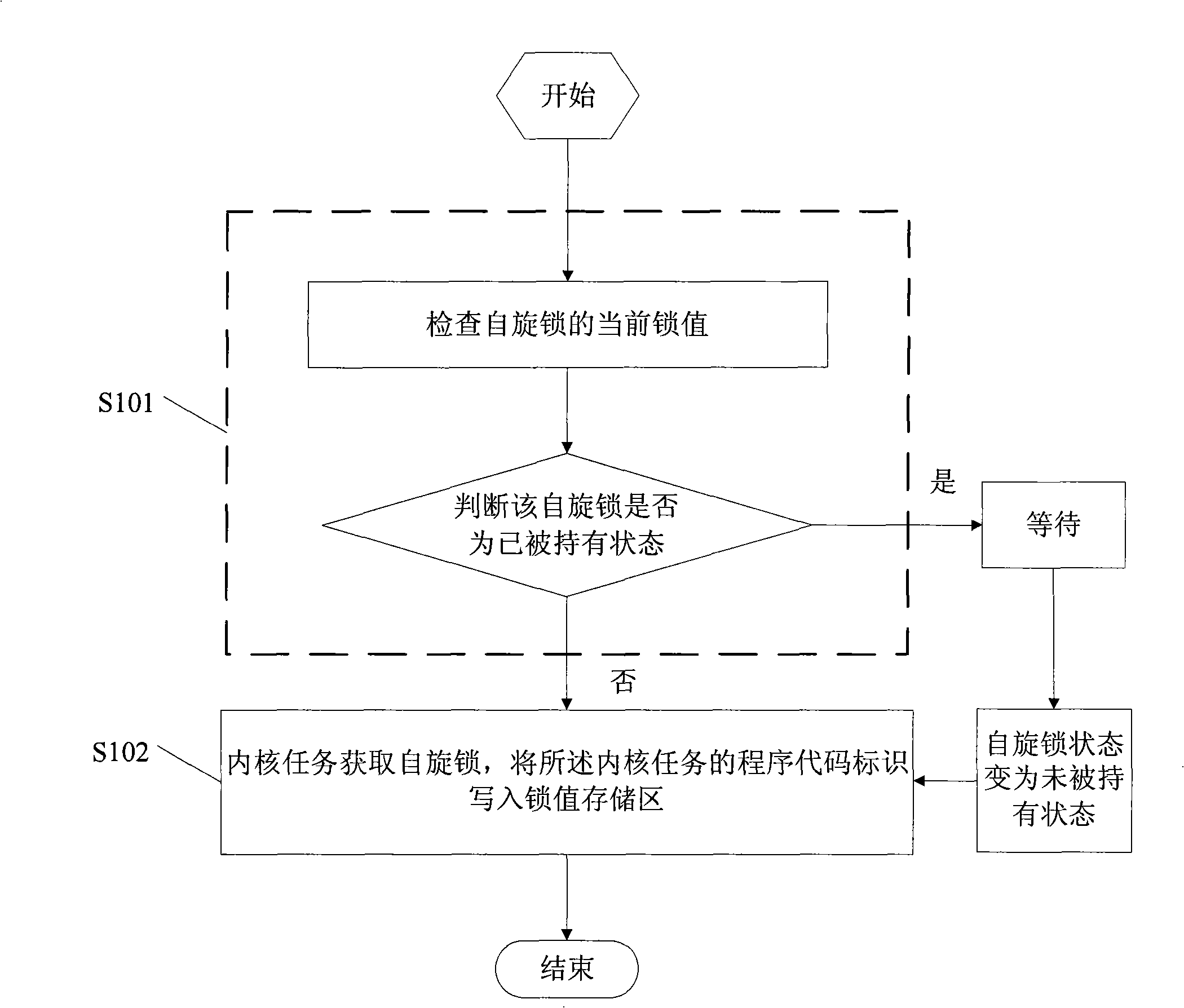

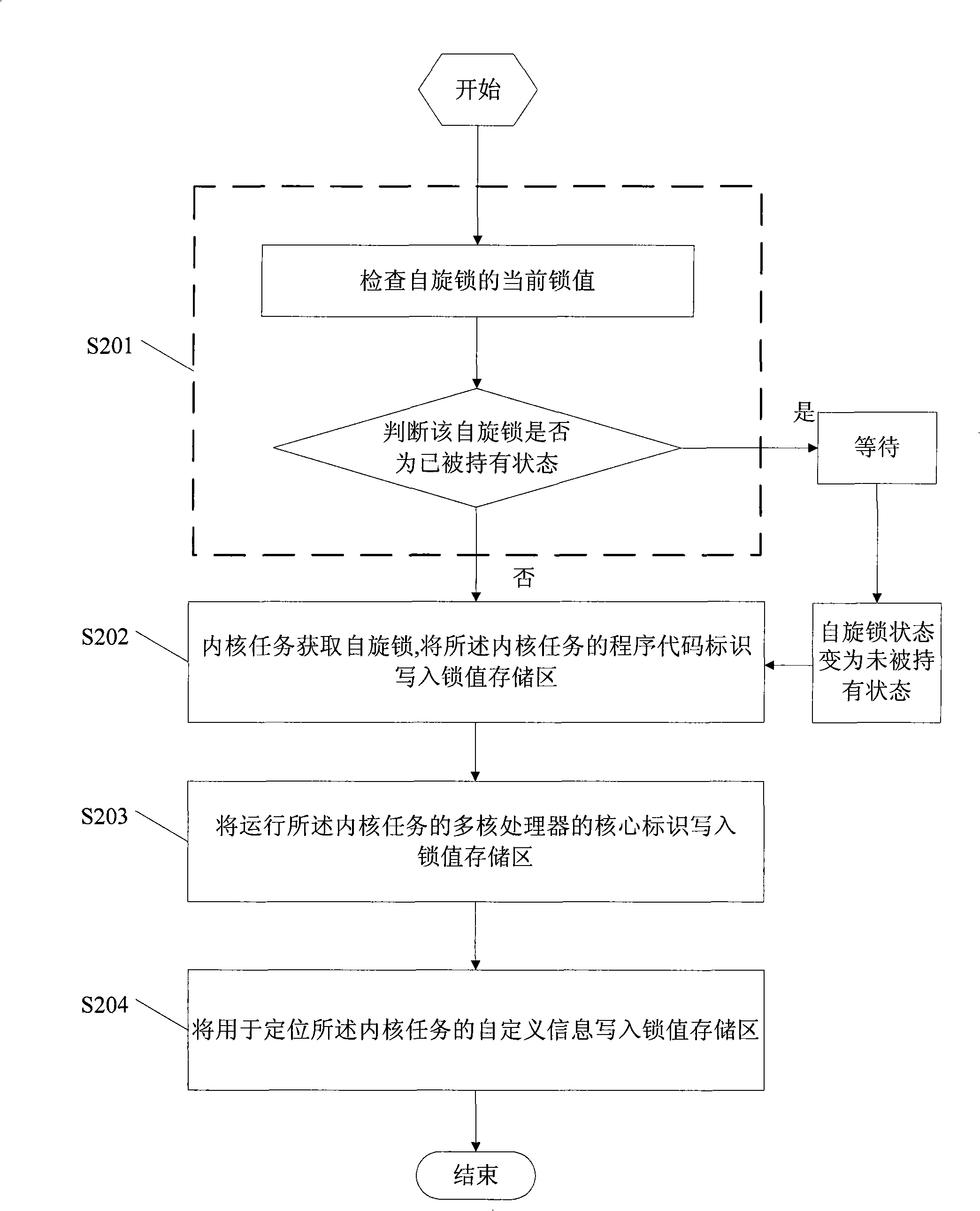

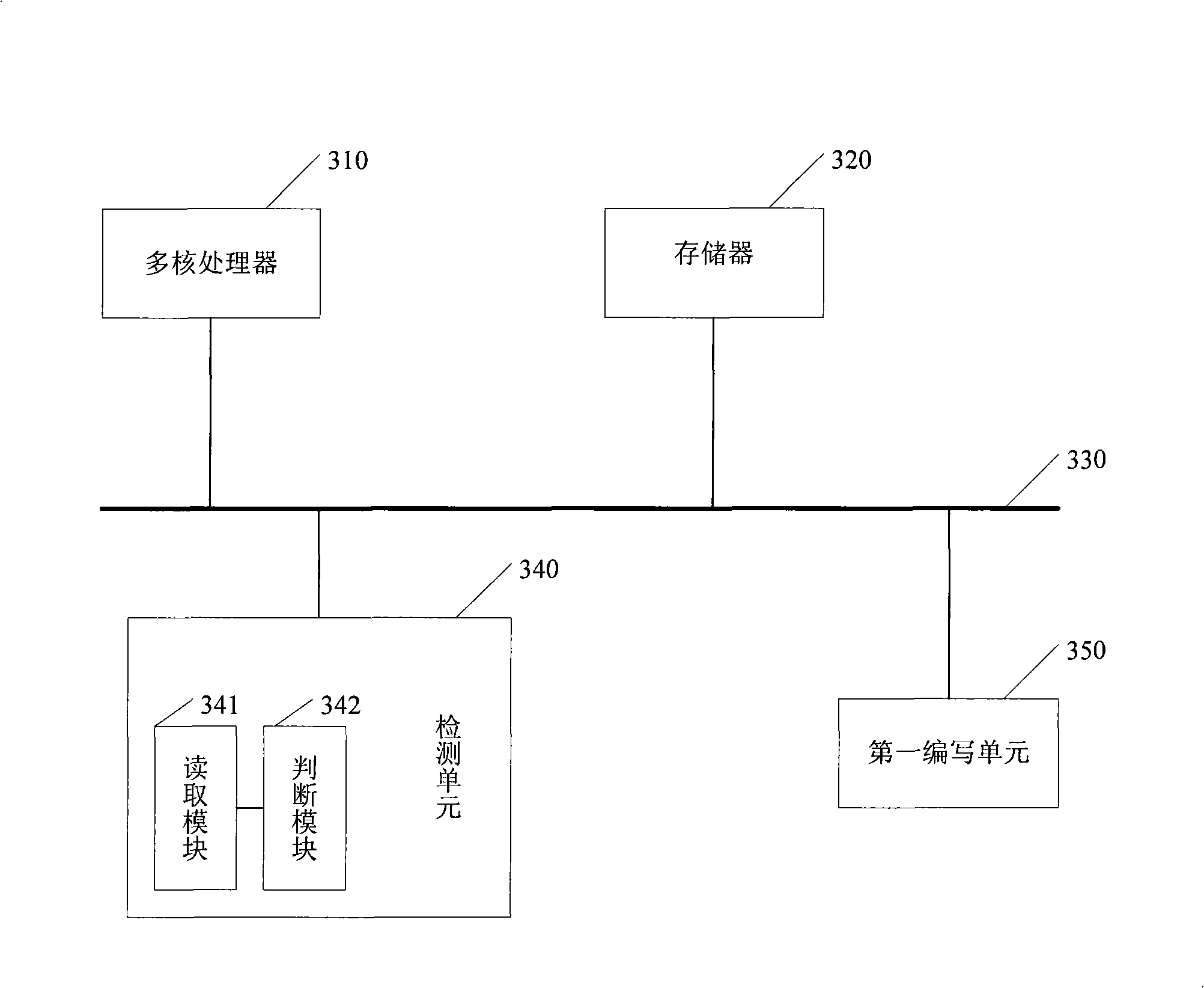

Locking method for self-spinning lock and computer system

InactiveCN101403979ARapid positioningShorten the debugging cycleMultiprogramming arrangementsComputerized systemSpin locks

The invention relates to a locking method of a spin lock, comprising the following steps: the spin lock is detected to be in an un-held state; an inner core task acquires the spin lock; a procedure code mark in the inner core task is written into a lock value storage area; the lock value storage areas is used for storing the lock values of the spin lock. Correspondingly, the embodiment of the invention also discloses a locking device and a computer system of the spin lock. By the procedure code mark written into the inner core task in the storage area which represents the lock value of the spin lock, the embodiment can quickly locate the position of an error according to the information in the storage area when the spin lock is dead locked, and shortens the adjustment cycle greatly while occupying a relatively small space of the system.

Owner:HUAWEI DIGITAL TECH (CHENGDU) CO LTD

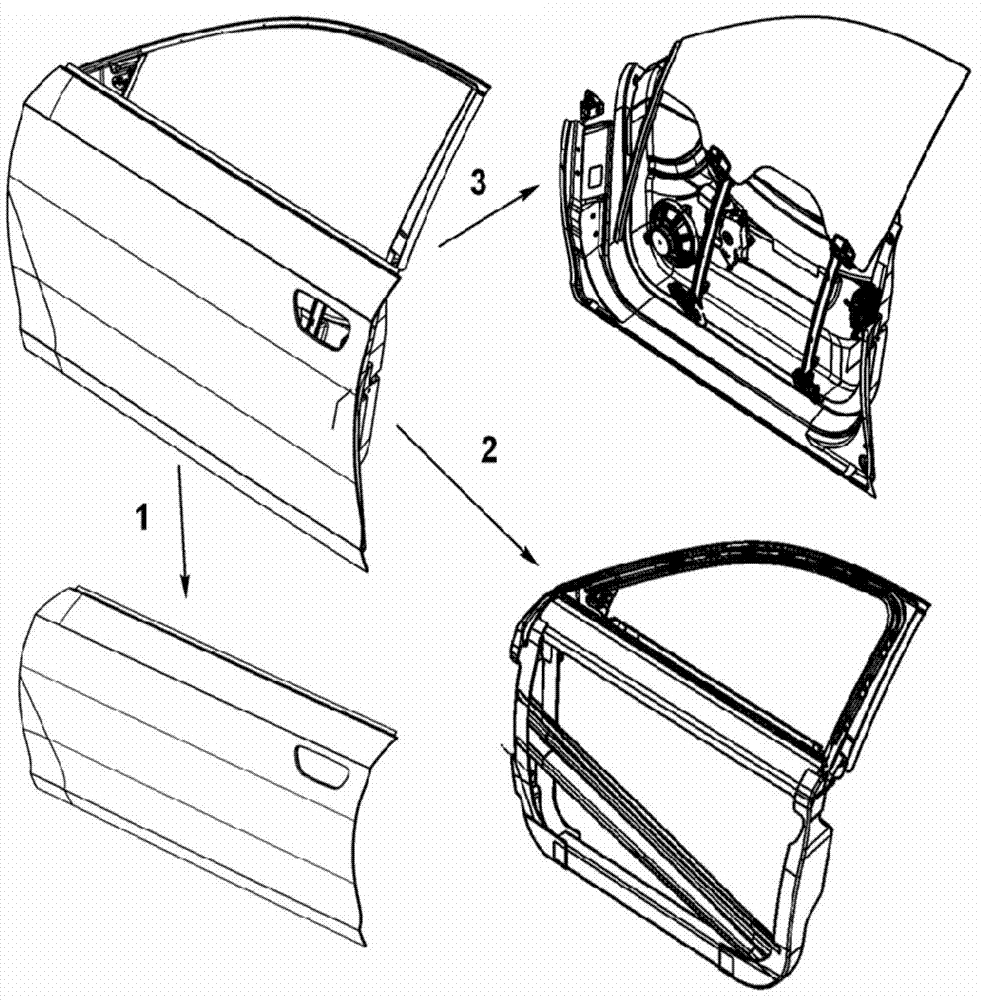

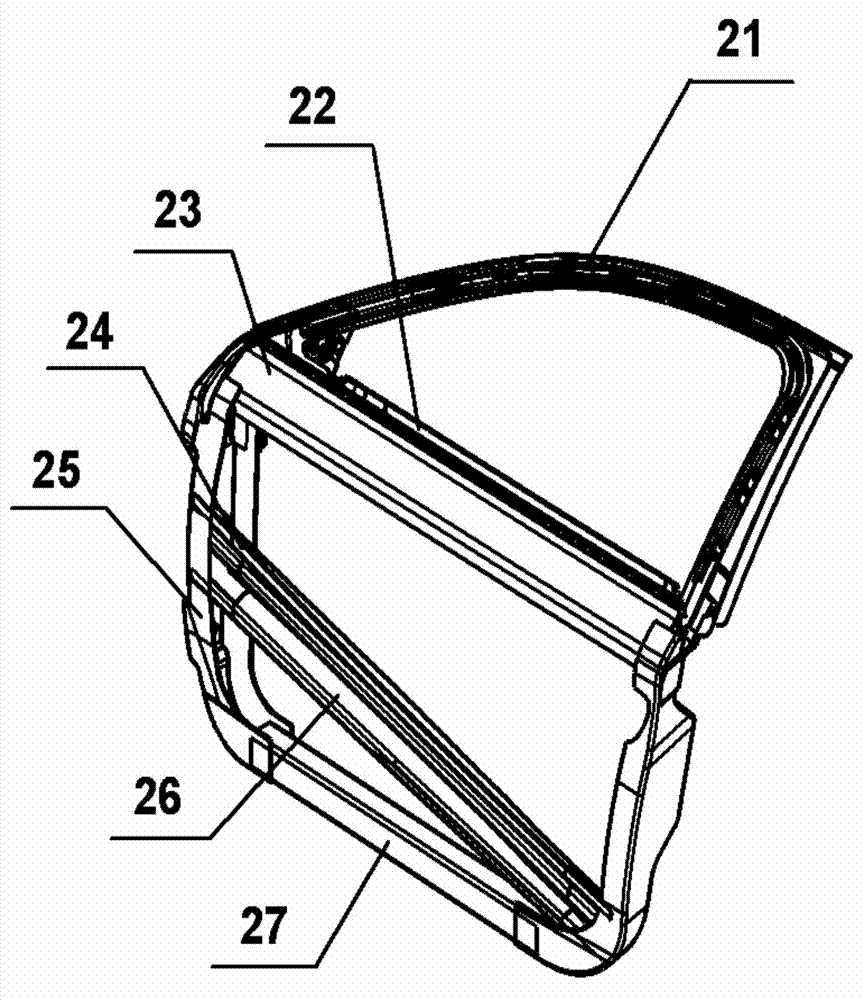

Modularized vehicle door with steel, aluminum and plastic mixed

The invention relates to a modularized vehicle door with steel, aluminum and plastic mixed. Compared with a total complex structure of a traditional vehicle door, according to the modularized vehicle door with steel, aluminum and plastic mixed, the original complex vehicle door structure is modularized, and the vehicle door structure is divided into three functional modules which include a vehicle door outer plate, a vehicle door frame, a vehicle door inner plate and an accessory module. According to the functionality of all parts of the vehicle door, traditional vehicle door modules are functionalized, and good vehicle door manufacturing and assembling manufacturability is achieved. The modularized vehicle door with steel, aluminum and plastic mixed is specifically characterized in that the vehicle door outer plate is not a main stressed part in the vehicle door structure, the strength and rigidity requirements are moderate, and the purpose generally lies in the effect that the functional requirements for meeting external shapes are improved; the vehicle door inner plate is not a main stressed part, either, and can be made of composite materials or plastic. According to the modularized vehicle door with steel, aluminum and plastic mixed, factors in all the aspects of strength, rigidity, appearance and weight are taken into comprehensive consideration, the vehicle door outer plate can be made of thinner metal material plates and aluminum alloy materials, and the aluminum alloy materials are light, small in specific gravity, high in strength, good in ductility, and high in corrosion resistance and meanwhile has good forming performance, machinability and the like.

Owner:HUNAN UNIV

Tread centering adjustment device and method

InactiveCN101966755AImprove lamination processing qualityAvoid disagreementRegistering devicesTyresMeasurement deviceBall screw

The invention relates to a tread centering adjustment device and a tread centering adjustment method. The device is applied to a fully-automatic tread gluing machine for retreading tires. The method comprises the following steps of: before gluing a tread, measuring positions of two side tire shoulders to determine a center line of a tire body; and adjusting the center line of transported tread rubber to be coincident with the center line of the tire body to ensure that the non-concentric or deflection phenomenon does not occur during tread gluing, and the processing quality of the tread gluing is improved. The device comprises a center measurement device, a left block roller assembly and a right block roller assembly, wherein a photoelectric switch and a reflection board of the center measurement device are arranged on the same inner side of a side panel respectively; two sets of bilaterally symmetric center measuring devices are arranged on an installation board; each set of center measuring device is provided with a transverse linear displacement sensor, a linear guideway and a driving cylinder; two side baffle plates of the left and right block roller assemblies are parallelly arranged above a conveying roller by supports; the supports are extended to the lower part of the conveying roller and are sleeved on a ball screw pair respectively; and the bottom ends of two side supports are connected with a displacement sensor respectively.

Owner:MESNAC

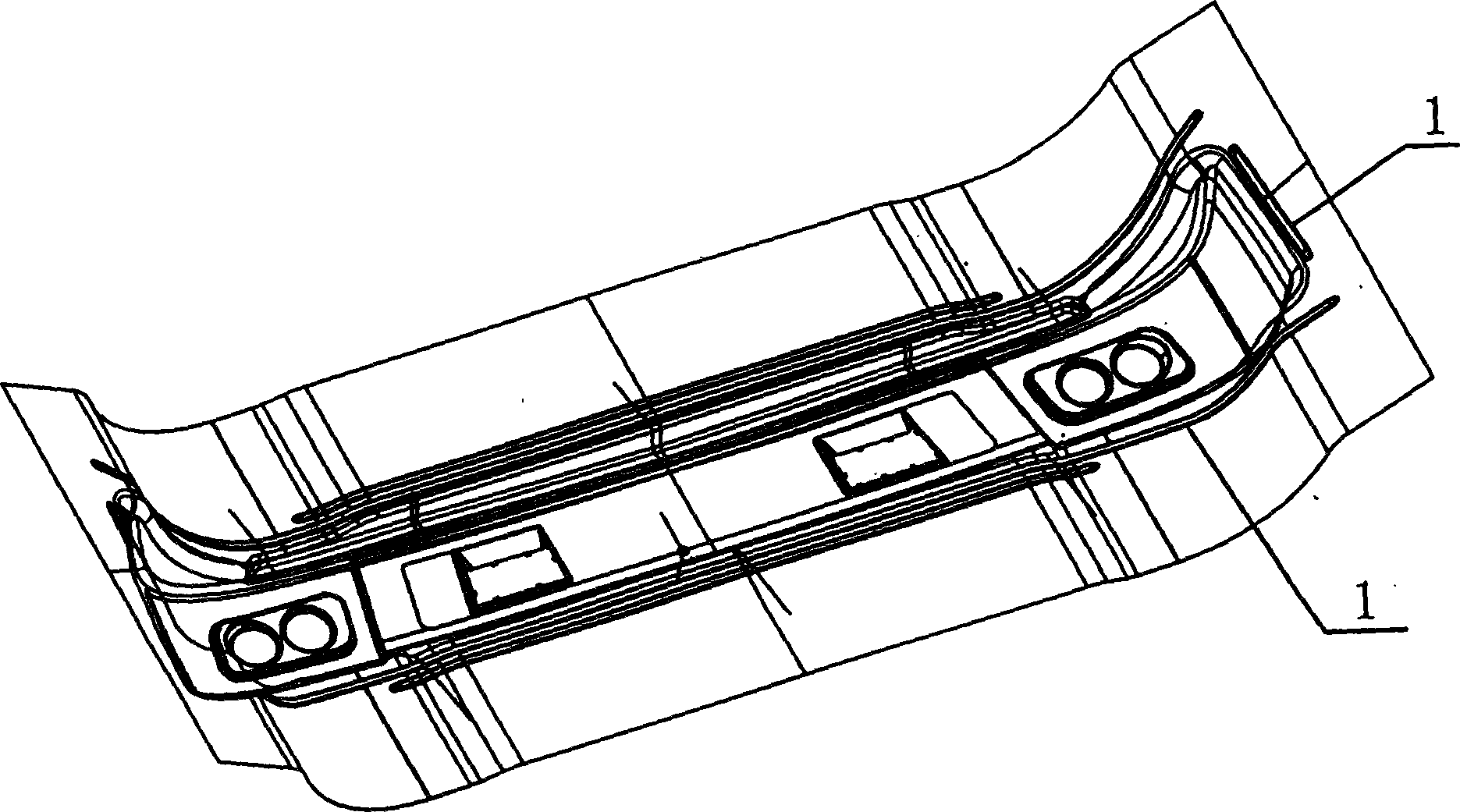

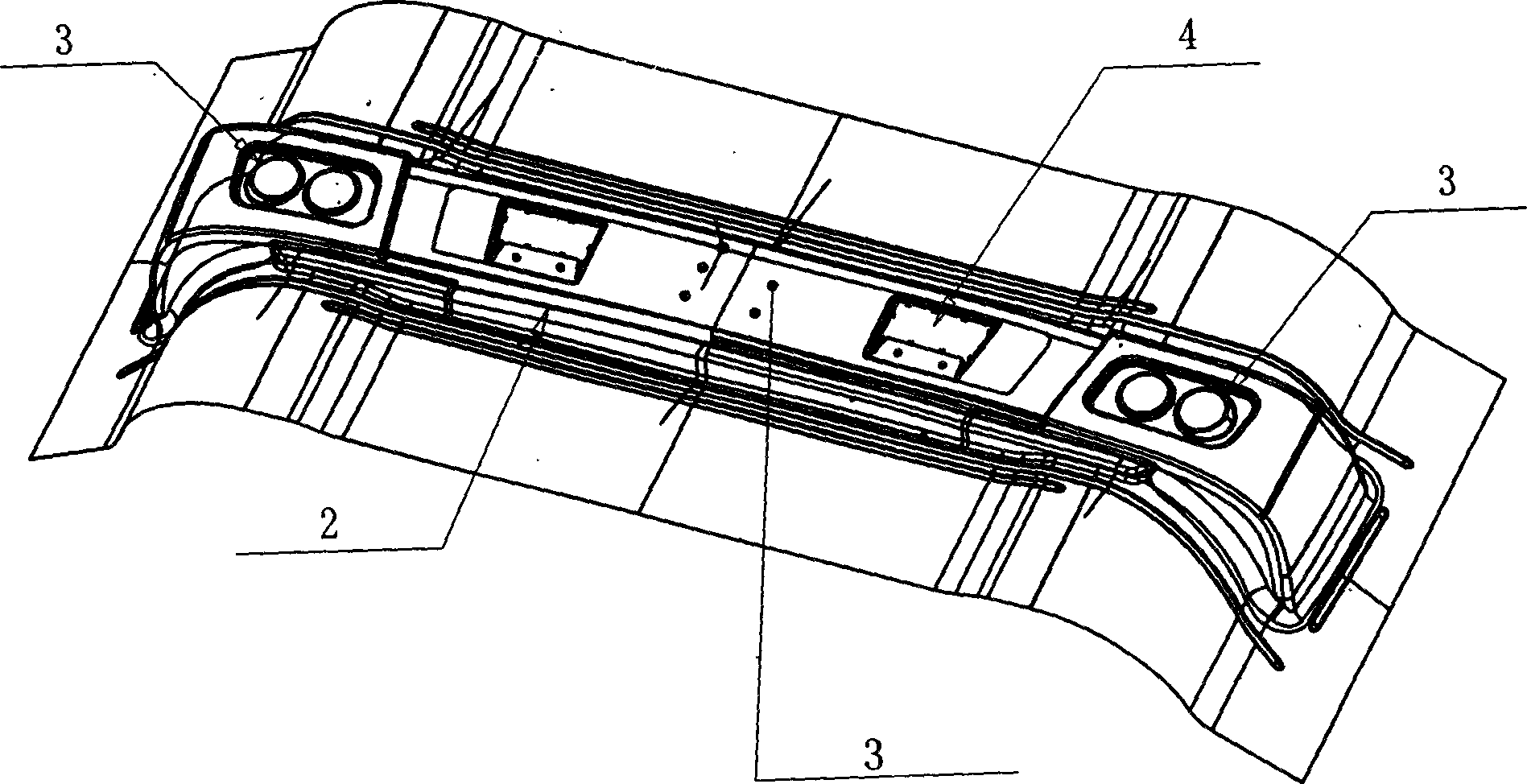

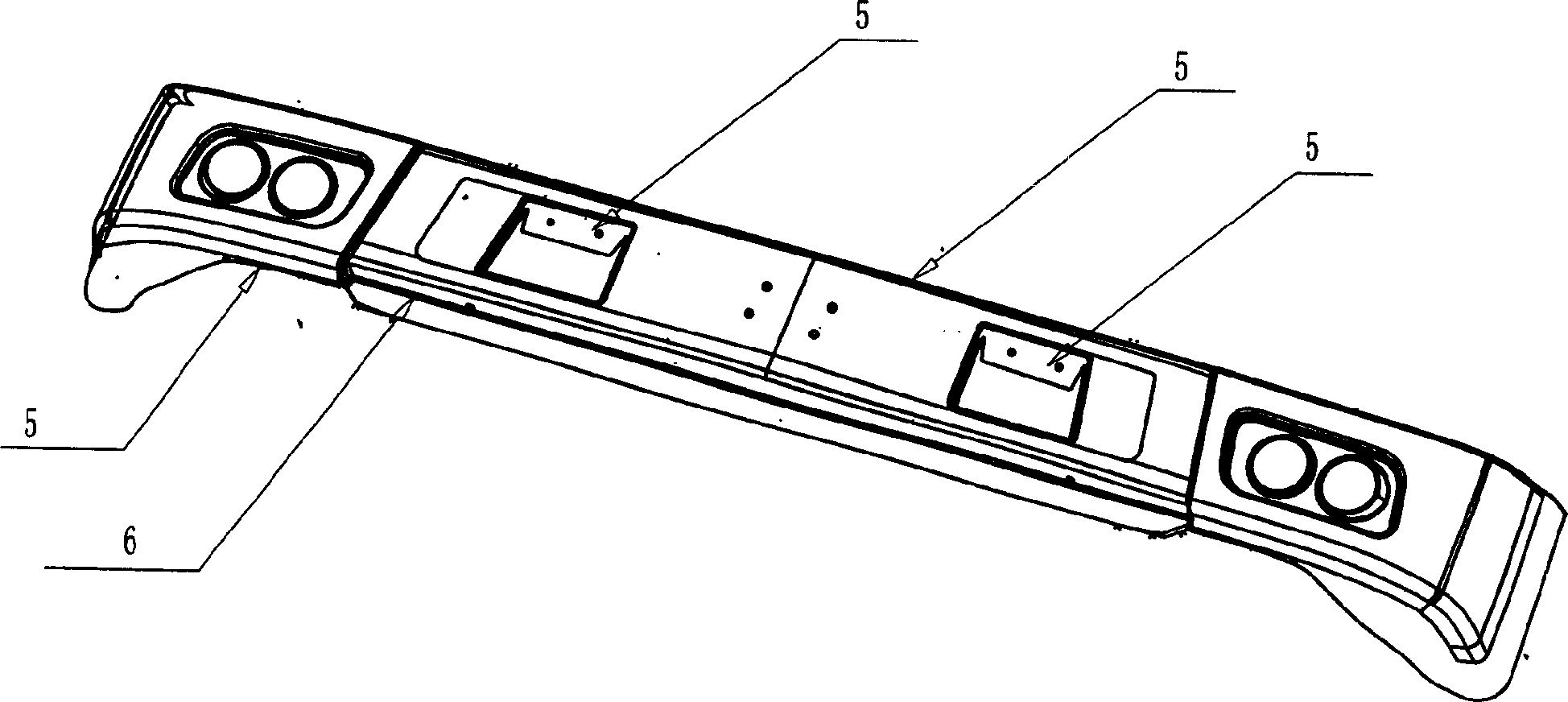

Punch process of integral automobile metal bumper

The present invention discloses the punch process of integral automobile metal bumper with the advantages of low cost for mold, short production period, high product surface quality, etc. The punch process includes the steps of once drawing to form drawn ribs on two ends of bumper; trimming edge and punching hole; shaping and flanging; punching hole, trimming bevel edge and cutting tongue; re-punching hole, trimming bevel edge and punching side hole.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

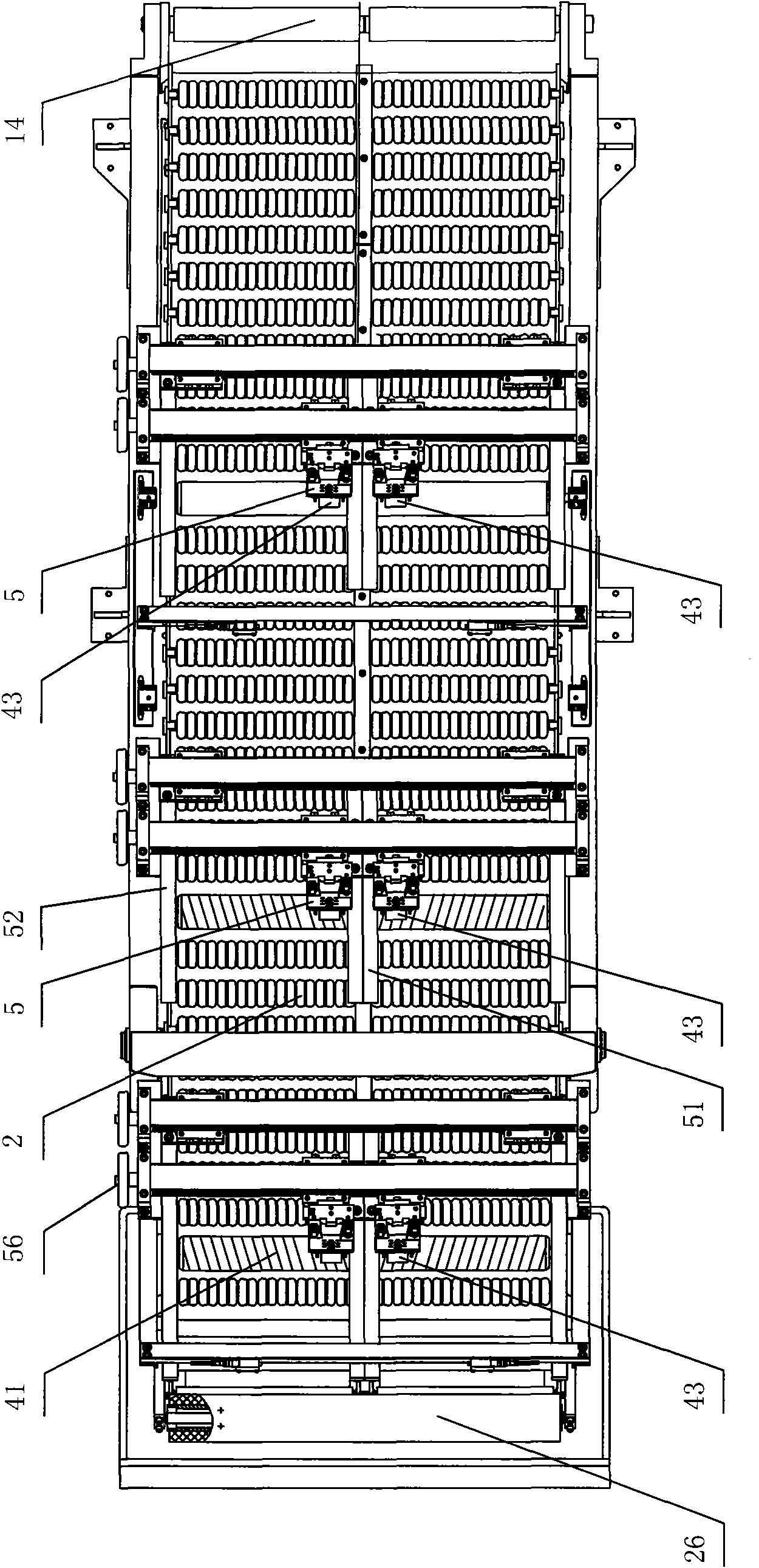

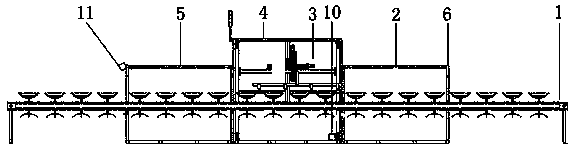

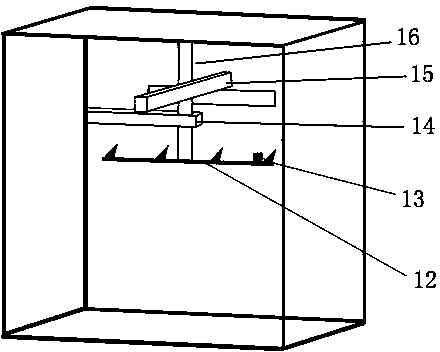

Adobe stacking machine and adobe stacking method

InactiveCN105836481AThe stacking method is criss-crossThe stacking method is criss-cross, without reducing the output of a single brick car.Stacking articlesDe-stacking articlesBrickControl system

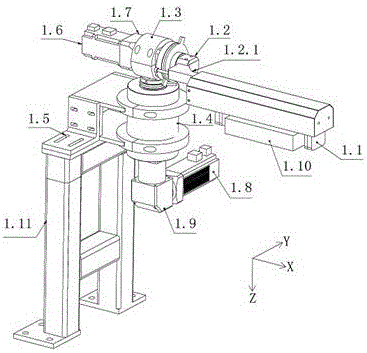

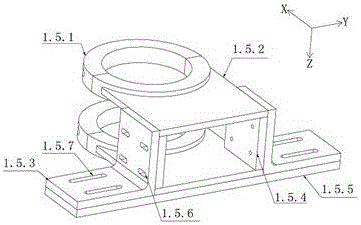

The invention discloses an adobe stacking machine and an adobe stacking method. The adobe stacking machine comprises a small mechanical arm, a conveying line, a large mechanical arm with a movable portal frame as a frame and a control system. The portal frame serves as the frame of the large mechanical arm. The large mechanical arm comprises a lifting mechanism, an X axial movement mechanism, a rotating mechanism and a clamping mechanism. The lifting mechanism is located in the portal frame to slide vertically, and therefore the height of the whole equipment is controllable. The X axial movement mechanism slides left and right in the portal frame, and the requirement for stacking adobes clamped by the clamping mechanism to the two sides of a brick vehicle after the adobes are rotated is met to the maximum degree. The rotating mechanism and the clamping mechanism are arranged so that a rotating function can be increased for the large mechanical arm, the stacking direction of the adobes is changed by changing the rotating angle of the clamping mechanism, and therefore the adobes are sacked in a criss-cross manner, and the brick collapsing accident is avoided on the basis of not reducing the yield of a single brick vehicle.

Owner:CHANGDE GUIXIANG HYDRAULIC EQUIP CO LTD

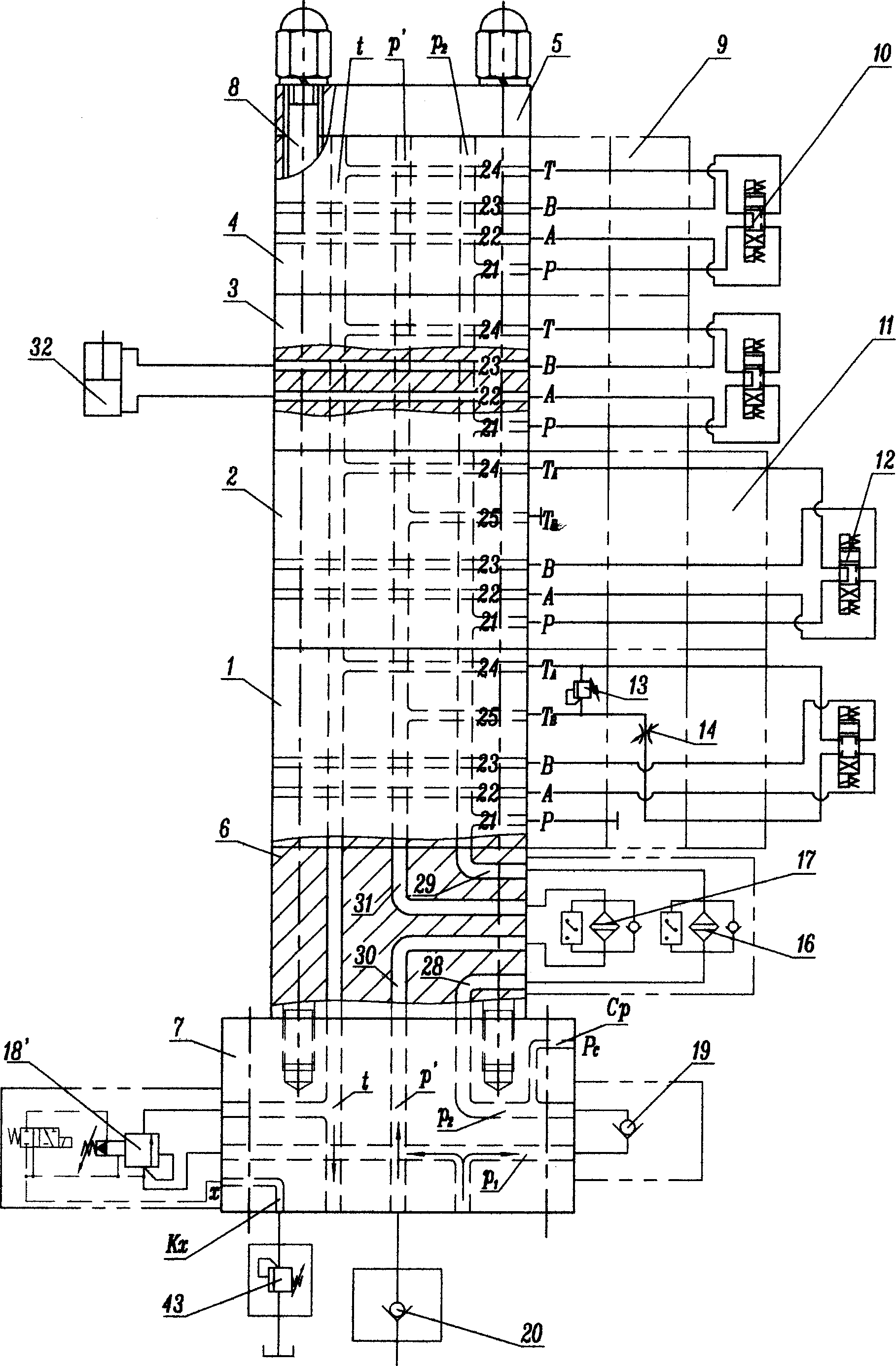

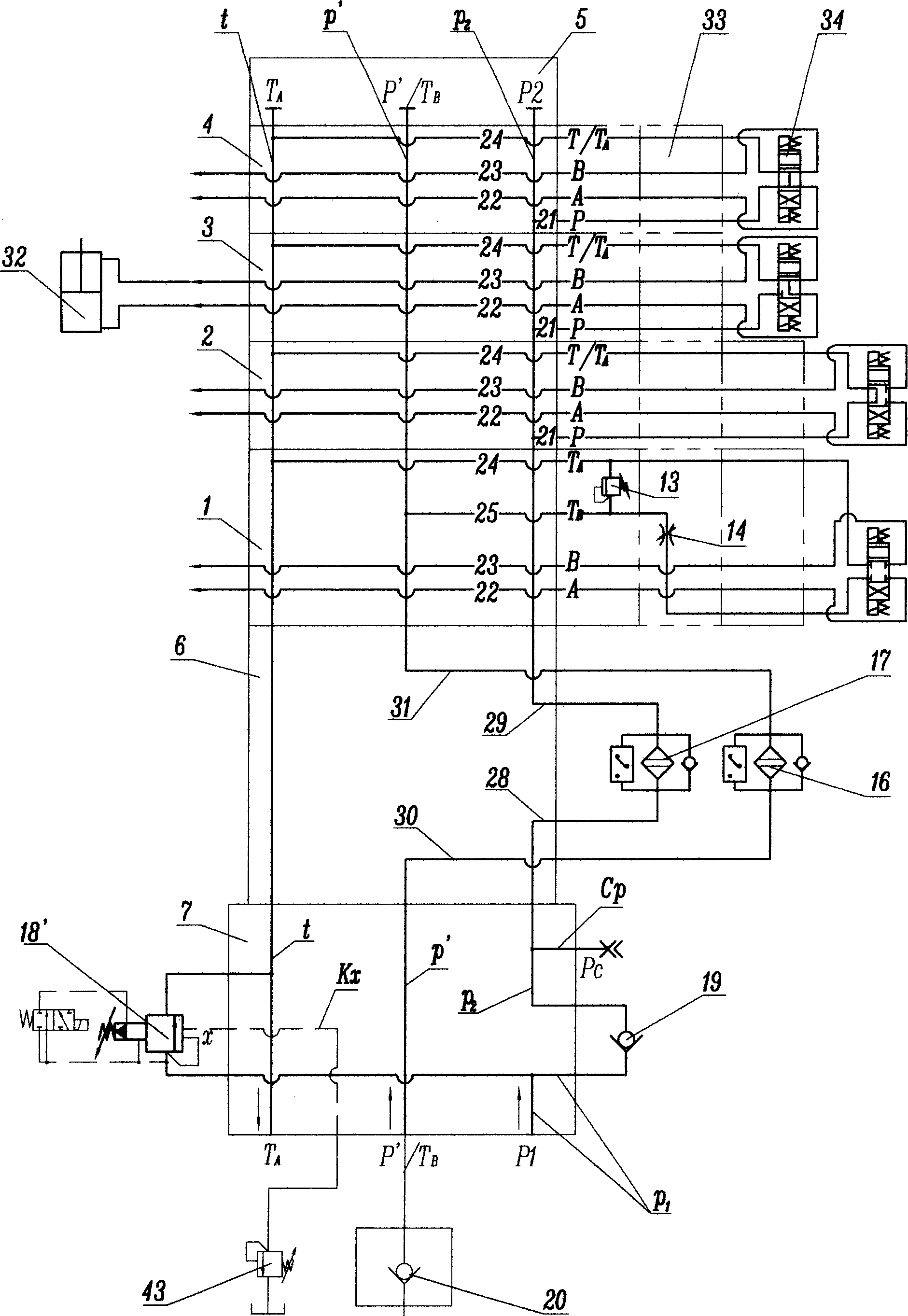

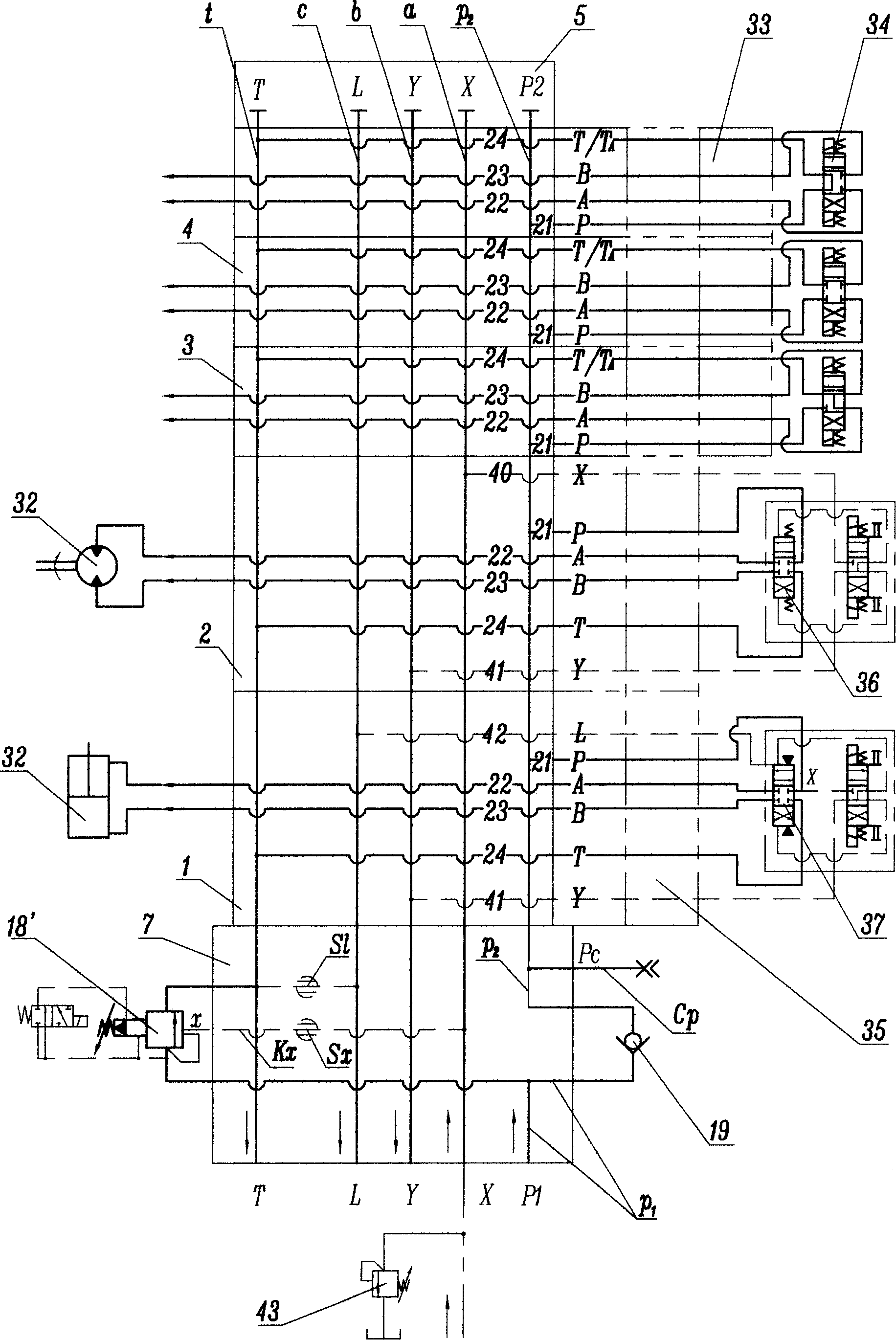

Hydraulic system integrated with hydranlic blocks

InactiveCN1514139AGood interchangeabilityShorten the debugging cycleServomotor componentsReturn channelEngineering

A hydraulic system integrated by hydraulic bolcks of top block, bottom block and base block consists of base block which has channel connecting oil inlet channel, oil returning channel, A, B, P, T or Ta opening of superposition or change valve to oil opening of executive element, another oil opening, oil inlet channel and returning oil channel of executive element separately in each of it as well as bottom block which is connected with at least one control valve on it and has oil inlet channel and oil returning channel Each base block having been superposed in sequence is connected to the bottom block as oil inlet channel and oil returning channel in the bottom block and the base block are connected to each other. The hydraulic blocks provided in the present invention for top, base, connection and bottom are interchangeable ones.

Owner:龚步才

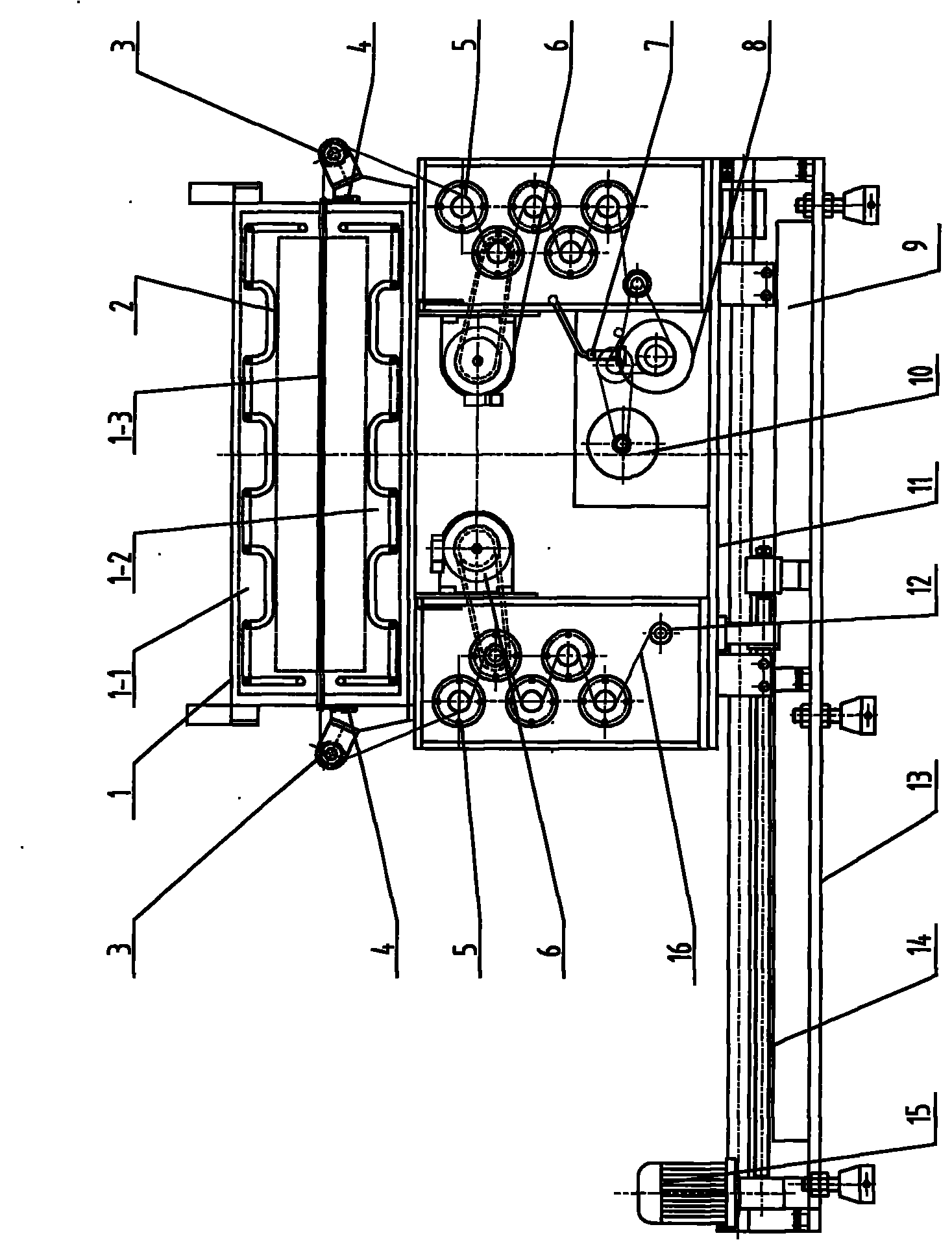

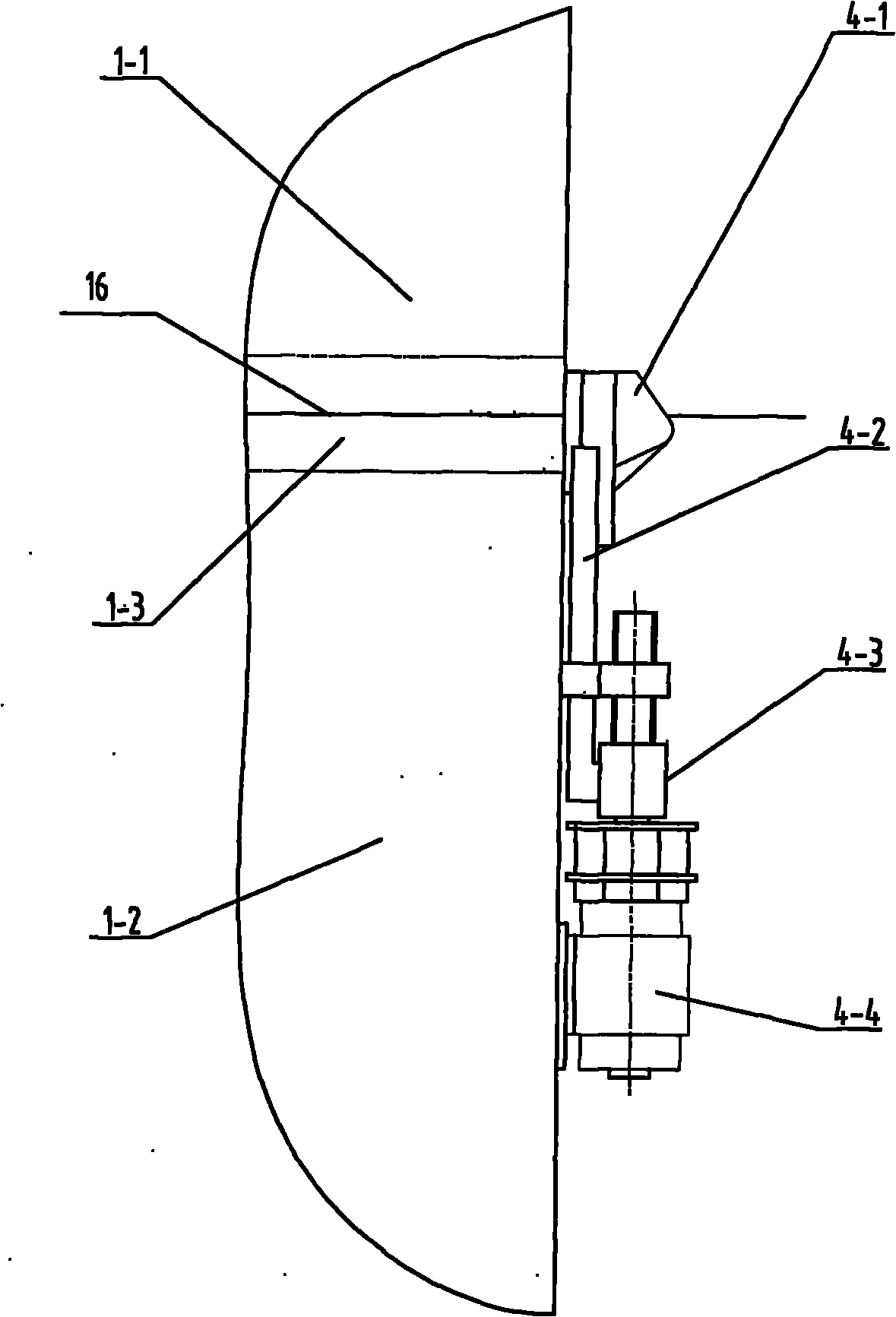

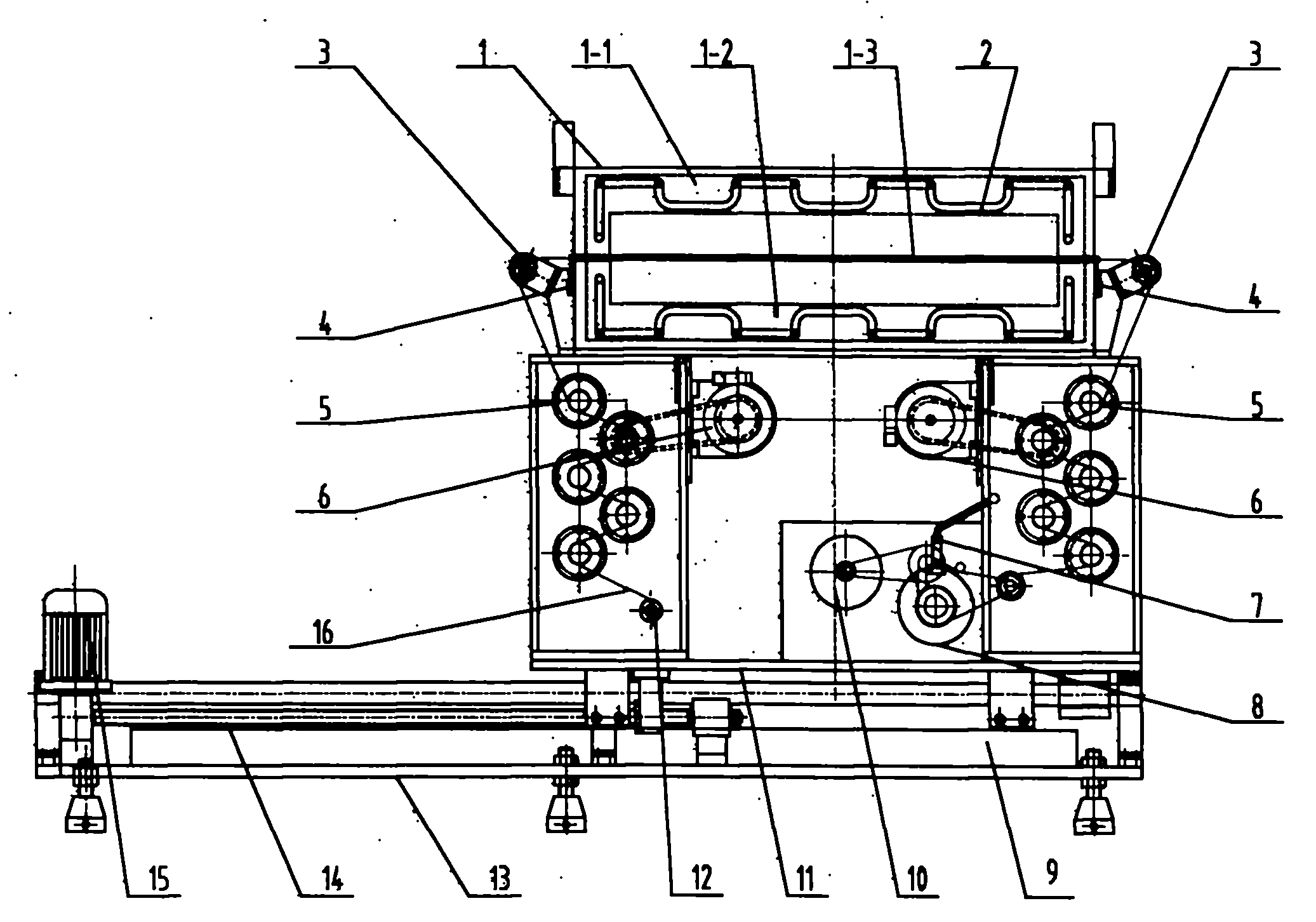

High-performance fiber synchrotron radiation in-situ testing machine

ActiveCN101831719AGuarantee product qualityReasonable structureInspecting textilesArtificial filament heat treatmentHot boxFiber

The invention provides a high-performance fiber synchrotron radiation in-situ testing machine. The testing machine comprises a base, a chassis, a drafting hot box, a front drafting mechanism, a back drafting mechanism, a winding mechanism and a translating mechanism, wherein the drafting hot box is used to heat fibre tows, one side of the box body opposite to the heat fibre tows is provided with a working gap; the front and back drafting mechanisms are used to provide drafting force for drafting the heated heat fibre tows; the winding mechanism is used to wind the heat fibre tows after hot stretching; and the translating mechanism is used to move the chassis horizontally and contains a translation motor, a turn-screw and a slideway. The testing machine has reasonable structure and convenient operation and is used commonly with the synchrotron radiation device so as to timely and accurately test the molecular changes of the high-strength and high-modulus polyethylene fibre tows under hot stretching, provide powerful technical support for the hyperploid hot stretching technology of the production of high-performance fiber, shorten debugging period and ensure the quality of fiber products.

Owner:JIANGSU SHENTAI SCI & TECH DEV

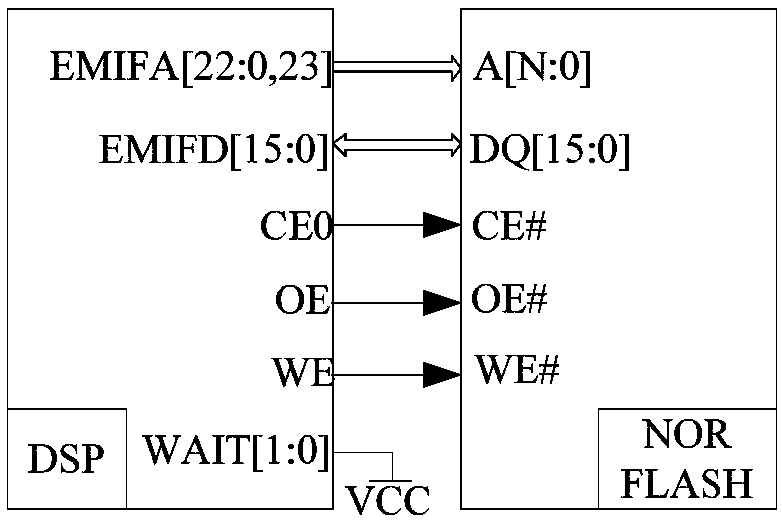

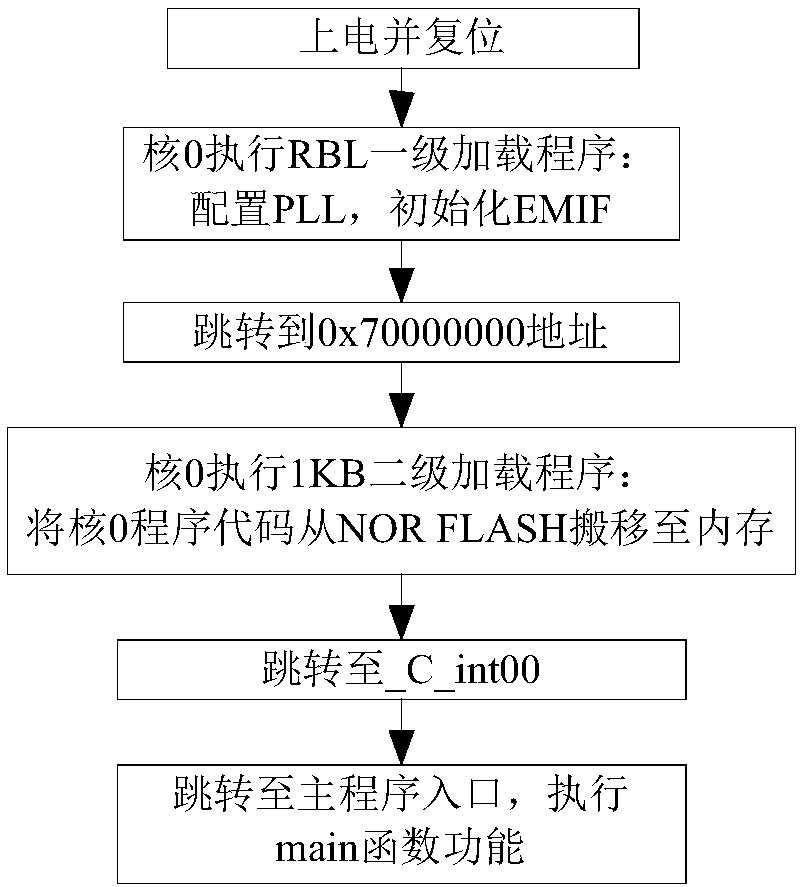

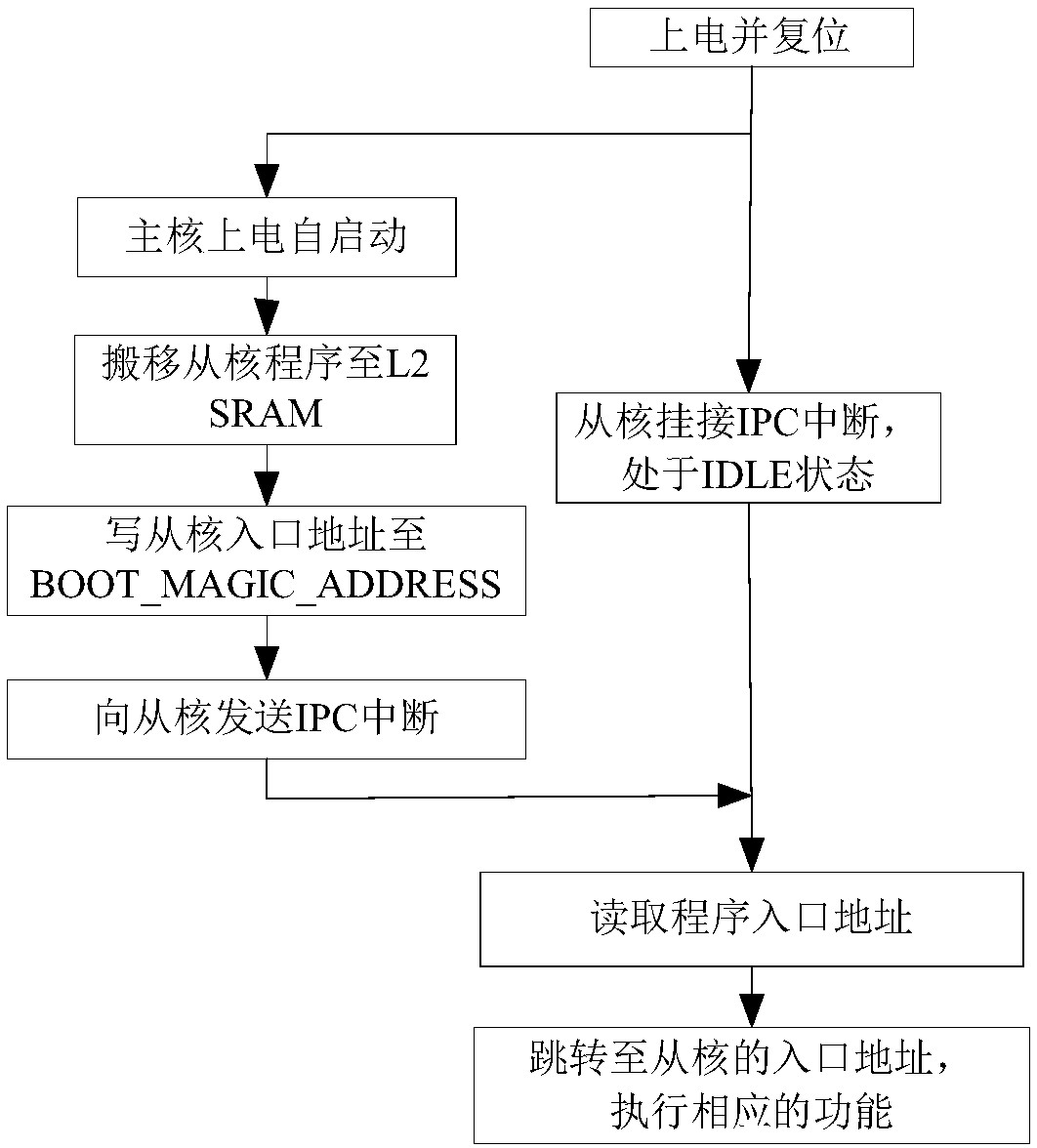

A simplified implementation of multi-core DSP power-on self-startup based on EMIF16

InactiveCN109213531AImprove loading efficiencyEasy to writeBootstrappingSoftware deploymentElectricitySoftware engineering

The invention relates to a simplified implementation method of multi-core DSP power-on self-start based on EMIF16, belonging to the field of embedded device power-on self-boot technology. Through thethree-stage loading process, the invention modifies the CMD file, stores the multi-core program in sections, and writes the program burning-writing function and the two-stage boot program, so that thecompiling and burning-writing process of the multi-core program can be completed under the same CCS project, and finally correctly realizes the power-on self-startup of the multi-core DSP program. The method disclosed by the invention discards the tedious processing process of the current multi-core DSP power-on self-startup, does not need to compile the multi-core programs separately, omits thestep of manually synthesizing a plurality of image files, and improves the loading efficiency of the multi-core programs. The method of writing burn-write function in engineering is adopted, which makes multi-core program burn-write convenient. The power-on loading process is simple, the program is more readable, the debugging cycle is greatly shortened, and the correct and reliable loading and running of multi-core DSP software can be realized.

Owner:HARBIN ENG UNIV

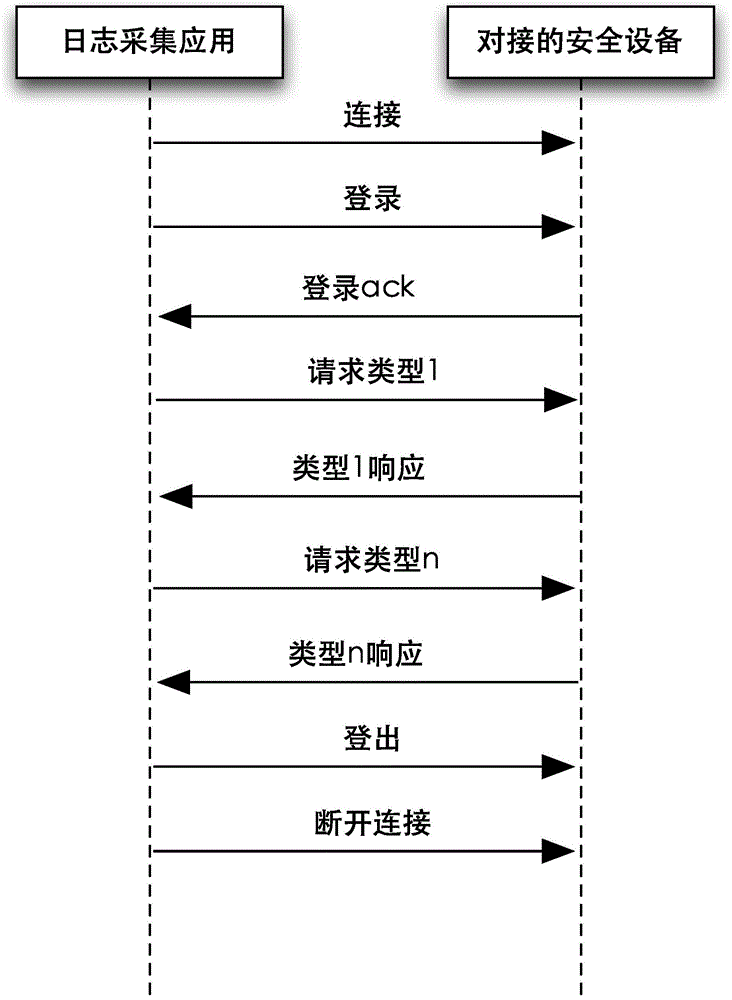

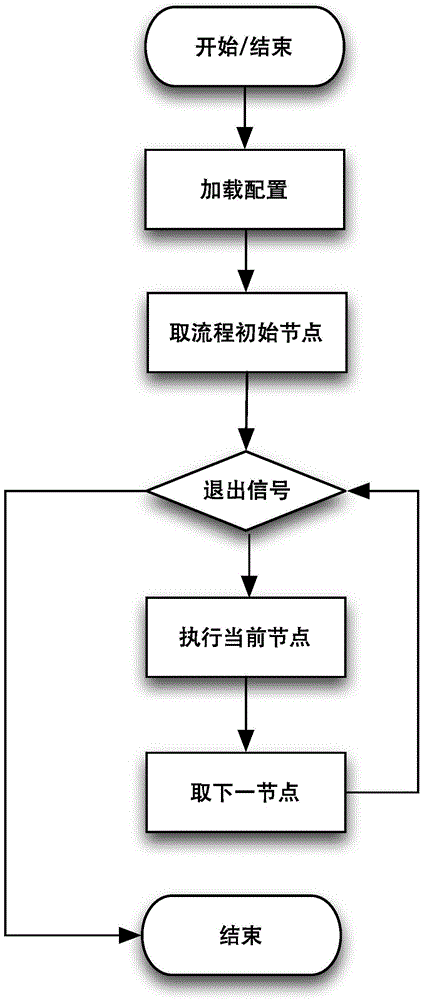

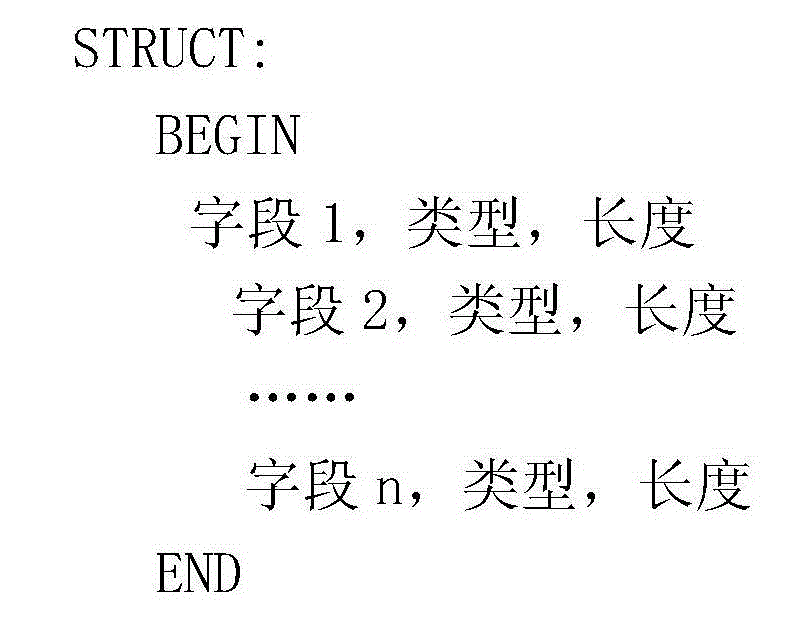

Method for universal adaptation for communication with safety device interfaces

ActiveCN103957204AShorten the development cycleShorten the debugging cycleTransmissionCommunication interfaceStructure of Management Information

The invention belongs to the field of network information safety, relates to a universal adaptation method, in particular to a method for universal adaptation for communication with safety device interfaces. A configuration generation tool, a configuration loading unit, a workflow engine unit, a node assembly and a universal adaptation system are involved in the method, wherein the configuration generation tool is used for generating a communication interface protocol structure configuration file and an interactive workflow configuration file, the configuration loading unit is used for loading a corresponding configuration file, the workflow engine unit is used for creating a workflow instance and starting the workflow instance according to workflow configuration information, the node assembly is obtained after interactive actions are abstracted, and the universal adaptation system is composed of a communication protocol assembly providing a support for the communication capacity and is in communication with the safety device interfaces. The method for universal adaptation for communication with the safety device interfaces can rapidly adapt to a communication interface protocol, when interfaces of different safety devices and assemblies are connected, nearly no coding development is needed, only configuration is needed, and the adaptation efficiency is effectively improved.

Owner:FUZHOU BOKE WANGAN INFORMATION TECH CO LTD

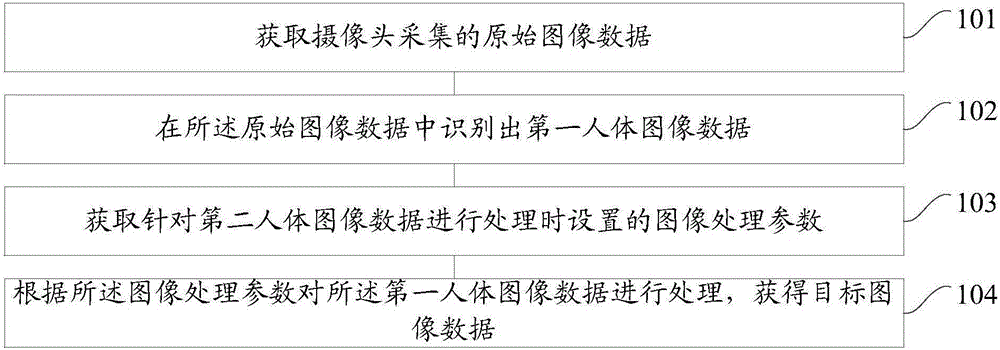

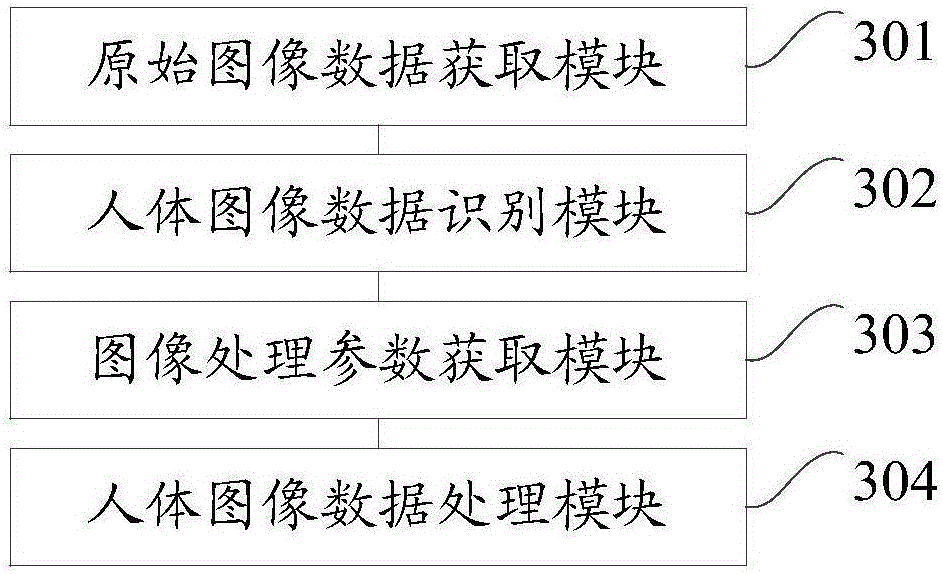

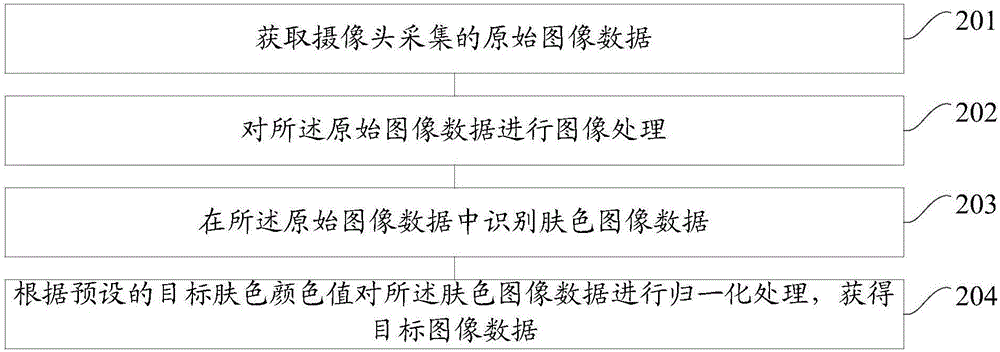

Image data processing method, device and mobile terminal

InactiveCN106210517ALower technical barriersQuality improvementTelevision system detailsColor television detailsComputer visionData processing

The embodiment of the invention provides an image data processing method, device and mobile terminal. The method comprises the following steps: acquiring an original image data collected by a camera; recognizing the first human body image data in the original image data; acquiring an image processing parameter which is set while processing the second human body image data; processing the first human body image data according to the image processing parameter so as to acquire the target image data. Through the adoption of the method provided by the embodiment of the invention, the image processing parameter is fast set to process through the learning of the experience of other users, the technical threshold for image processing is greatly reduced; the setting of a reasonable image processing parameter can be guaranteed under the condition that the user is unfamiliar with the image processing technology, and the quality of the processed image data is improved.

Owner:BEIJING QIHOO TECH CO LTD +1

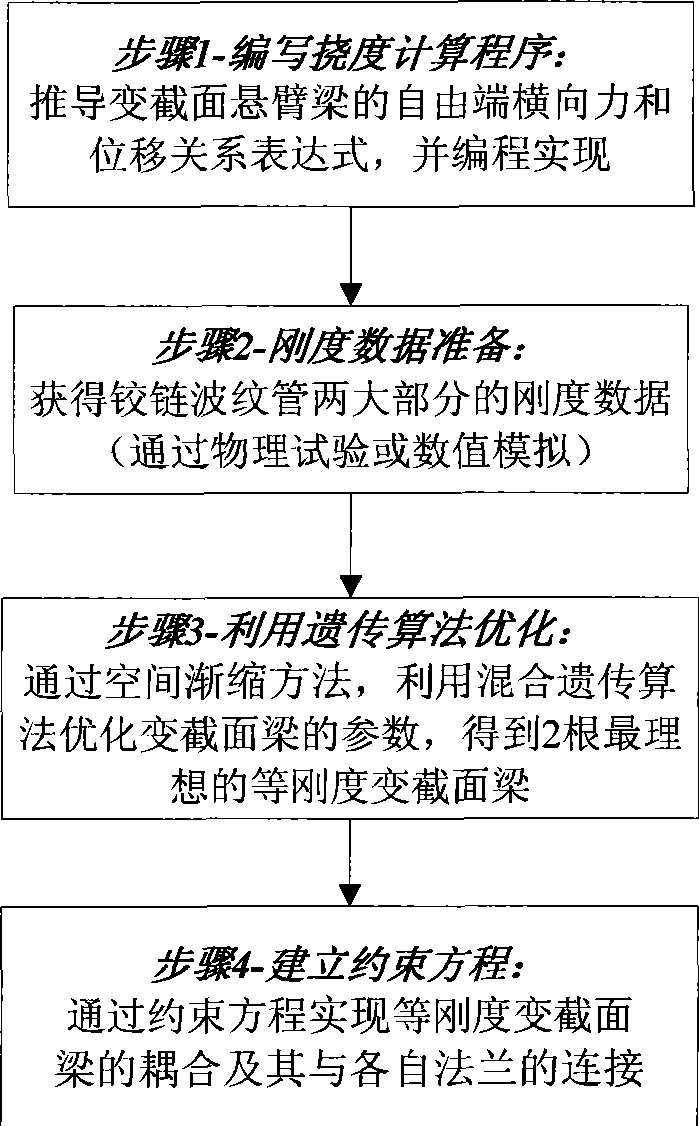

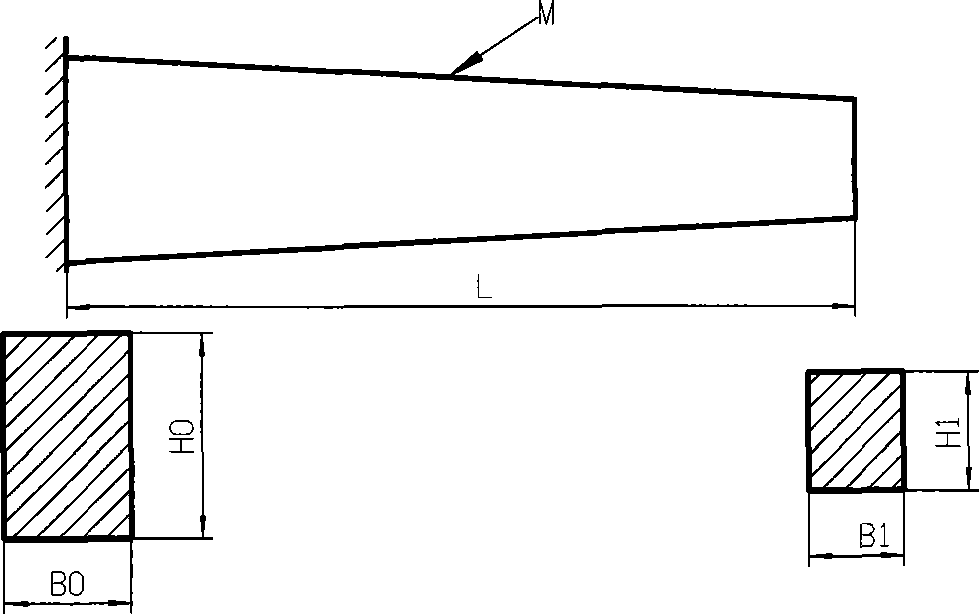

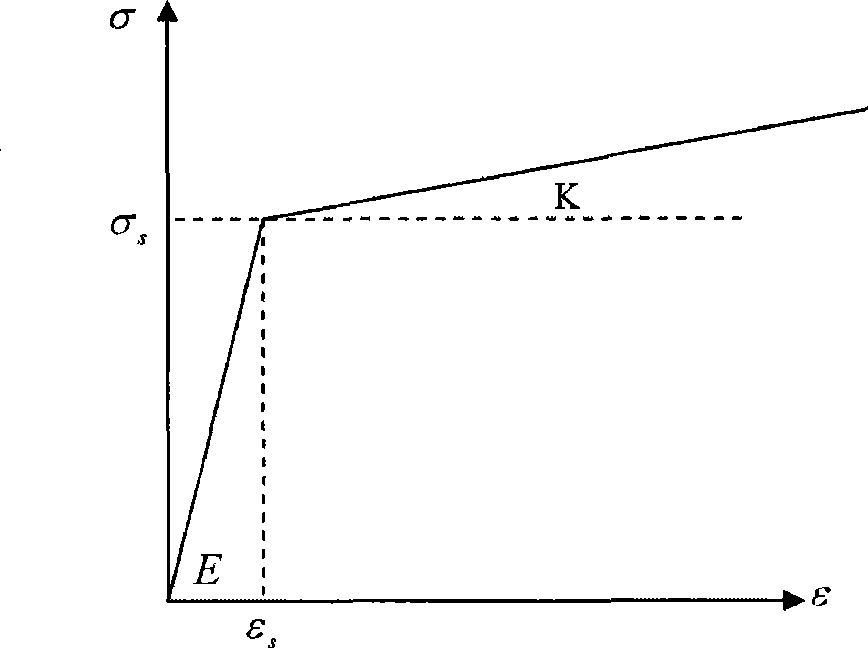

Method for equivalence hinged corrugated pipe by coupled variable cross-section beam

InactiveCN101520814ASolve the difficult problem of finite element calculation and debuggingSolve the problem of difficult calculation and debuggingSpecial data processing applicationsCircular discSystems design

The invention relates to a design method for the equivalence a hinged corrugated pipe by coupled variable cross-section beams in order to simplify the finite element analysis work for the complicated pipeline system design of the hinged corrugated pipe. Firstly, deducing the relation between force and displacement when transversal force is exerted on the free end of either variable cross-section beam of which any interface is rectangular based on the assumption that a cantilever beam has small deflection, and considering the elasticity and the elastic plastic deformation of either variable cross-section beam; secondly, proposing a method of simplifying a hinged corrugated pipe model and a method of utilizing finite element calculation to obtain the rigidity data of the fixed part of the simplified hinged corrugated pipe in two directions; thirdly, proposing a method of utilizing a mixing genetic algorithm to optimize parameters of the variable cross-section beams and proposing a special gradual shrinkage method aiming at the mixing genetic algorithm so as to further obtain geometric parameters and material parameters of the two variable cross-section beams; and finally, coupling the two variable cross-section beams at the free ends by constraint equations and connecting the roots of the variable cross-section beams with flanges by establishing auxiliary discs.

Owner:TSINGHUA UNIV

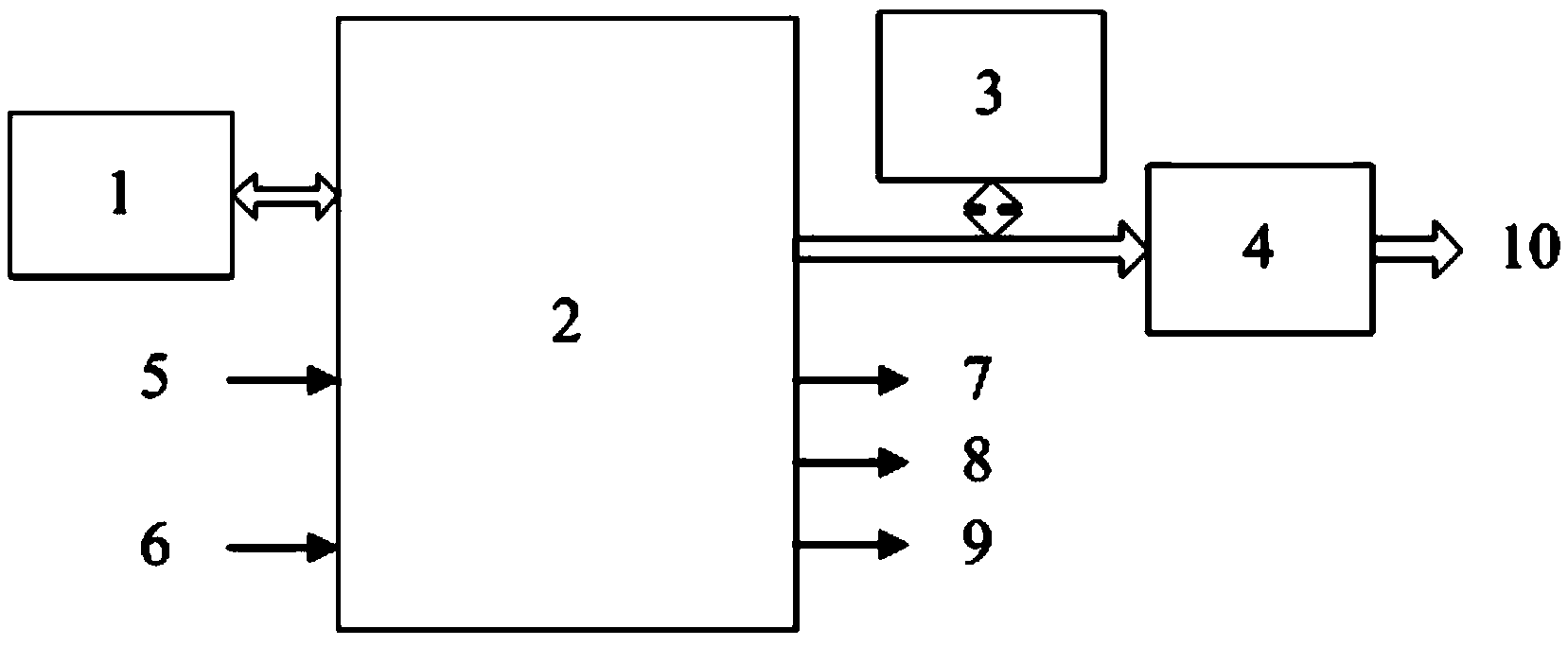

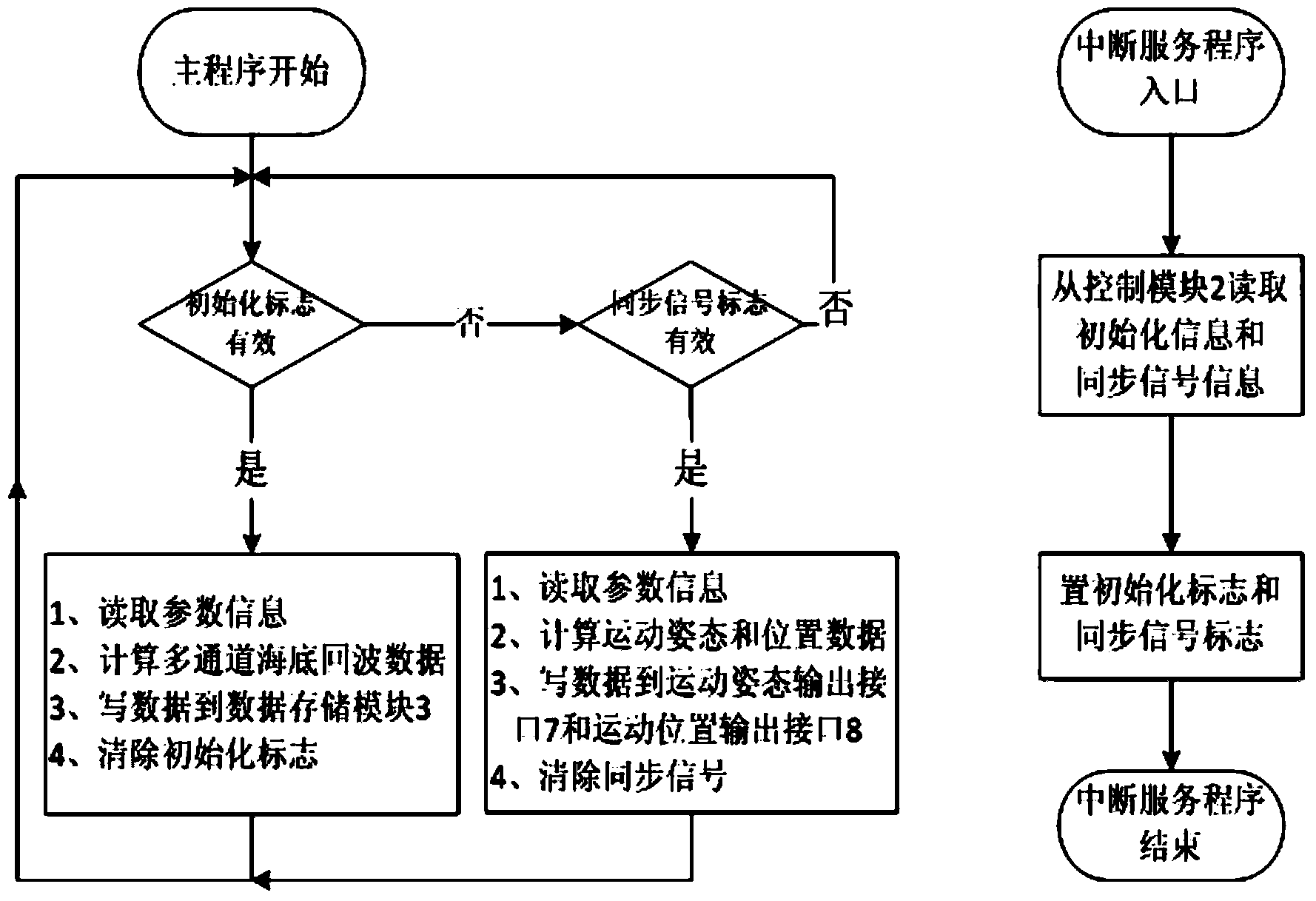

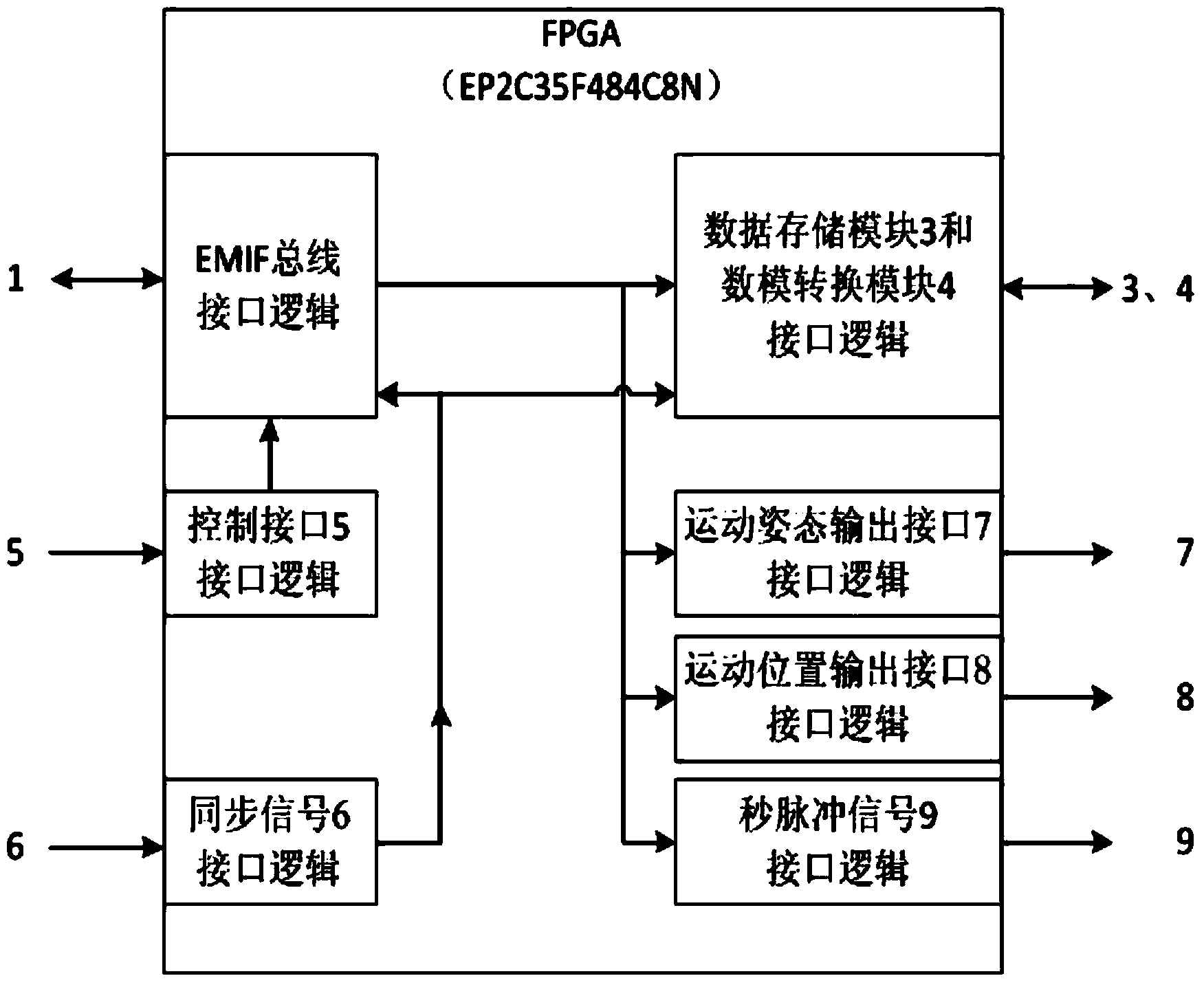

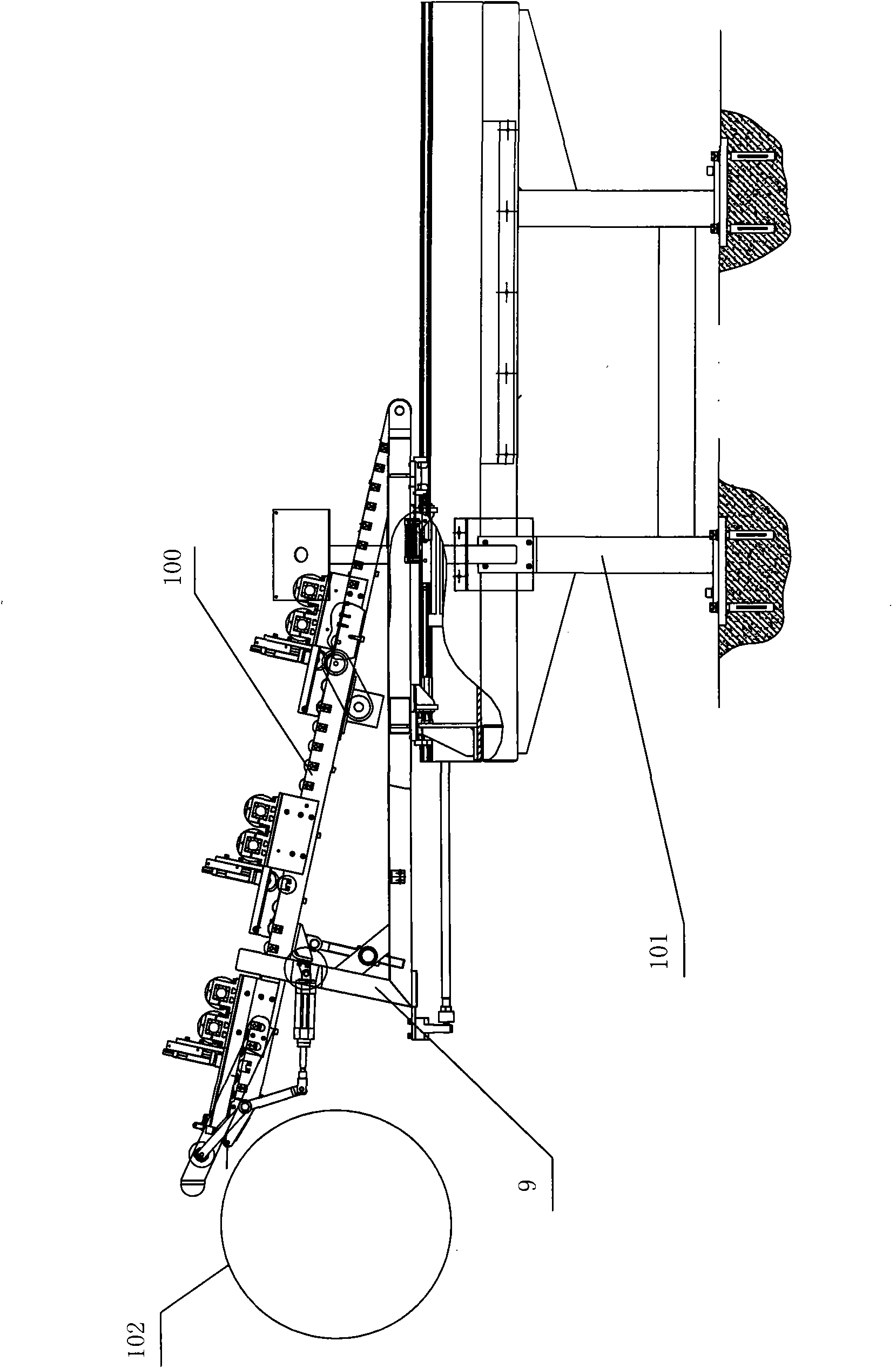

Multi-beam sonar multi-channel seabed echo and movement attitude and position simulator

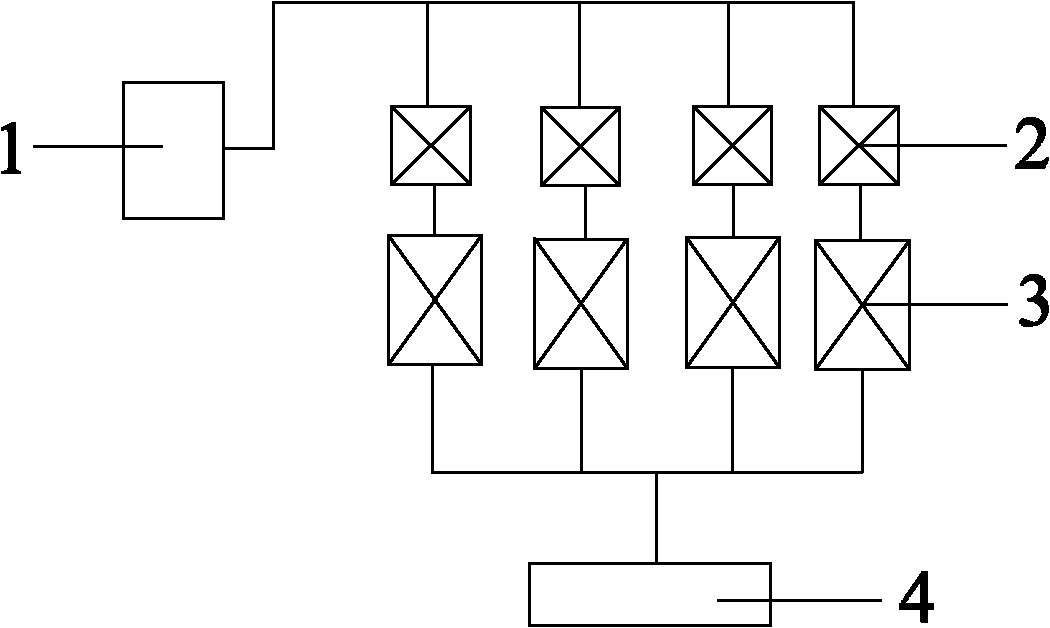

The invention discloses a multi-beam sonar multi-channel seabed echo and movement attitude and position simulator which comprises a data generating module, a control module, a data storage module, a digital-to-analog conversion module and multi-channel seabed echo signals. Multi-beam seabed data can be generated by the data generating module, the control module is connected with the data generating module, the data storage module and the digital-to-analog conversion module are respectively connected with the control module, and the multi-channel seabed echo signals are connected with the digital-to-analog conversion module; a control interface and synchronous signals on the control module are respectively connected with tested multi-beam sonar, and the multi-channel seabed echo signals can be outputted; movement attitude and movement position data can be generated by the data generating module in real time after the synchronous signals are received, and can be outputted to to-be-tested equipment via an output interface, and pulse-per-second signals are simultaneously outputted from a pulse-per-second signal interface on the control module. The multi-beam sonar multi-channel seabed echo and movement attitude and position simulator has the advantages that real measurement procedures can be simulated in laboratories, and accordingly problems of high cost and long cycle of debugging and testing modes due to the fact that multi-beam sonar devices and auxiliary equipment need to be transmitted to specific sea areas to be actually measured can be solved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

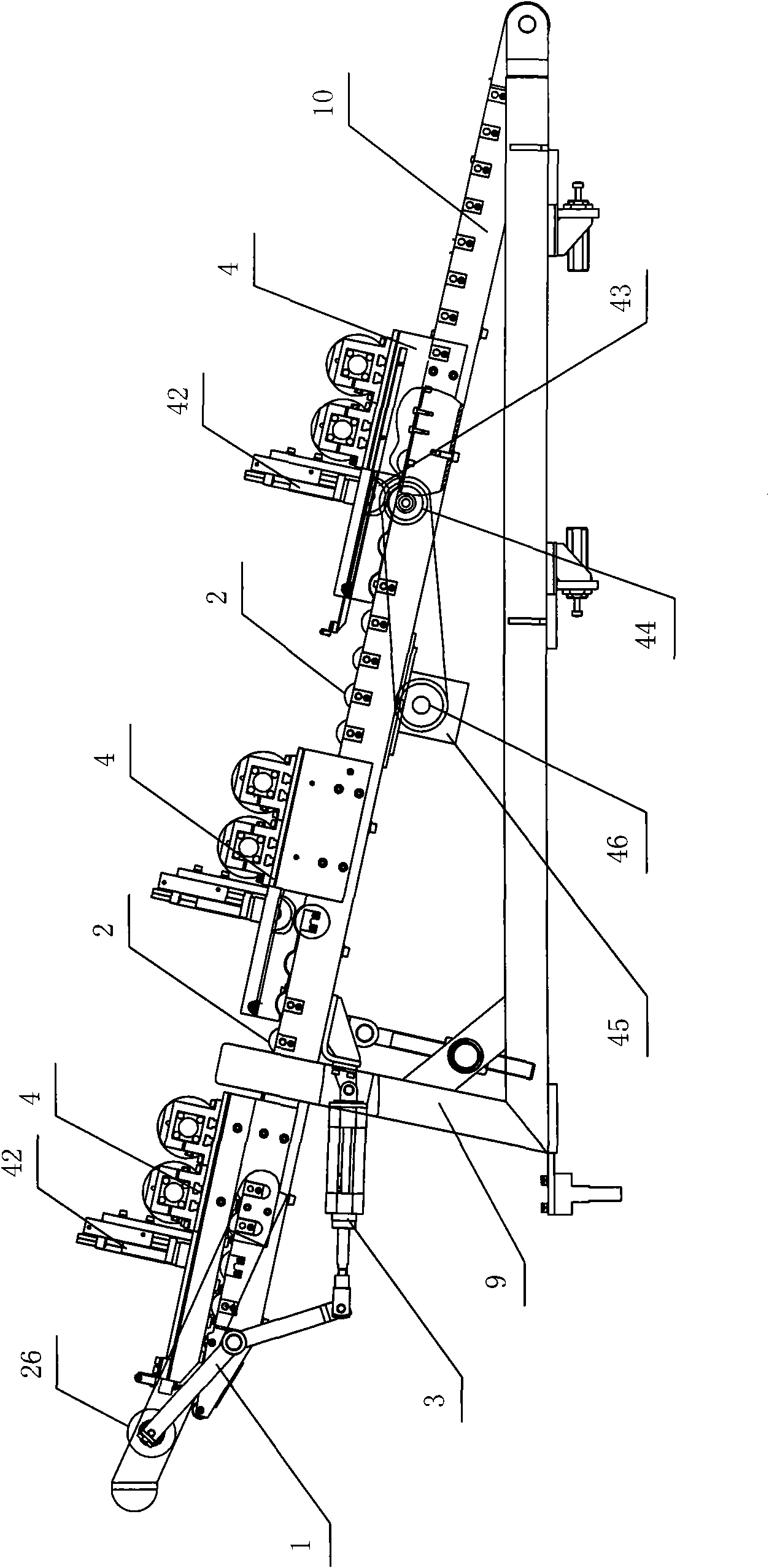

Shoulder wedge feeding frame and front guiding and positioning method thereof

ActiveCN101850628AOvercoming frictional resistancePrevent affecting the subsequent fit qualityTyresHelixSupport plane

The invention relates to a shoulder wedge feeding frame and a front guiding and positioning method thereof. A fixed edge guiding device and method capable of realizing the purpose of pressing downwards, rotating and pushing laterally simultaneously is used for realizing synchronous conveying of two shoulder wedges in limited conveying distance, thereby improving the conveying consistency of the two shoulder wedges to ensure that the two shoulder wedges can be accurately jointed on shoulder positions in parallel. The device is mainly provided with a conveying frame and a conveying template, wherein the conveying template is used for conveying shoulder wedges onto a forming drum and is installed on the conveying frame through a supporting frame. Different from the prior art, at least one group of fixed edge guiding mechanisms are arranged on brackets along the conveying direction of shoulder wedges. The fixed edge guiding mechanisms comprise at least one group of guiding rollers which are axially arranged between brackets at two sides and can axially rotate, and surface rollers of the guiding rollers are spirally arranged along the central line in the transverse direction and the brackets at two sides in the oblique direction. At least two groups of compression rollers which are driven by cylinders are arranged above the guiding rollers in the vertical direction, and the vertical central lines of the guiding rollers and the compression rollers are coincident.

Owner:MESNAC

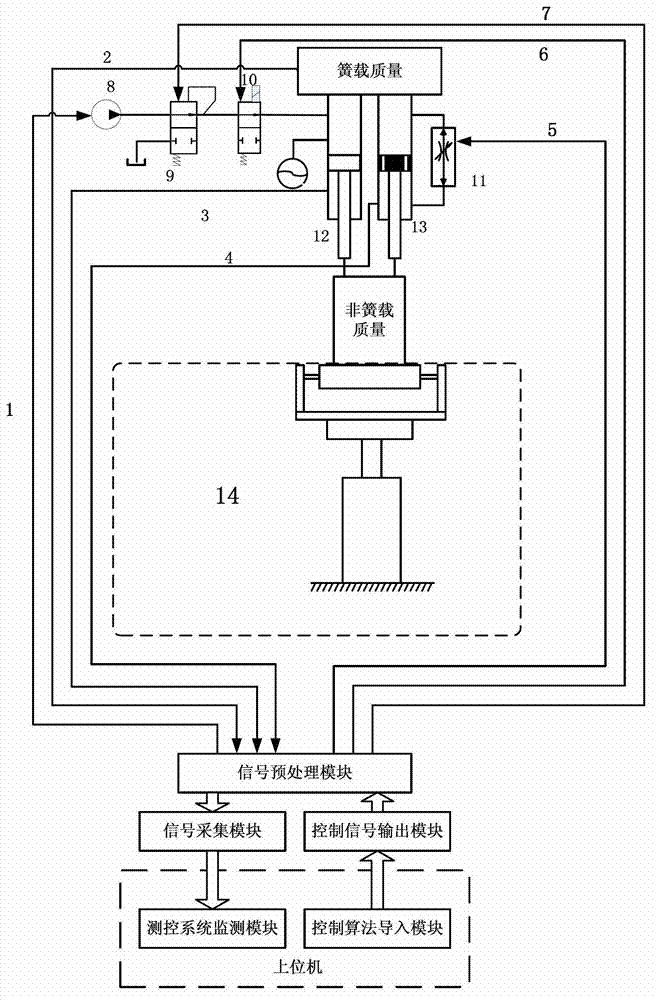

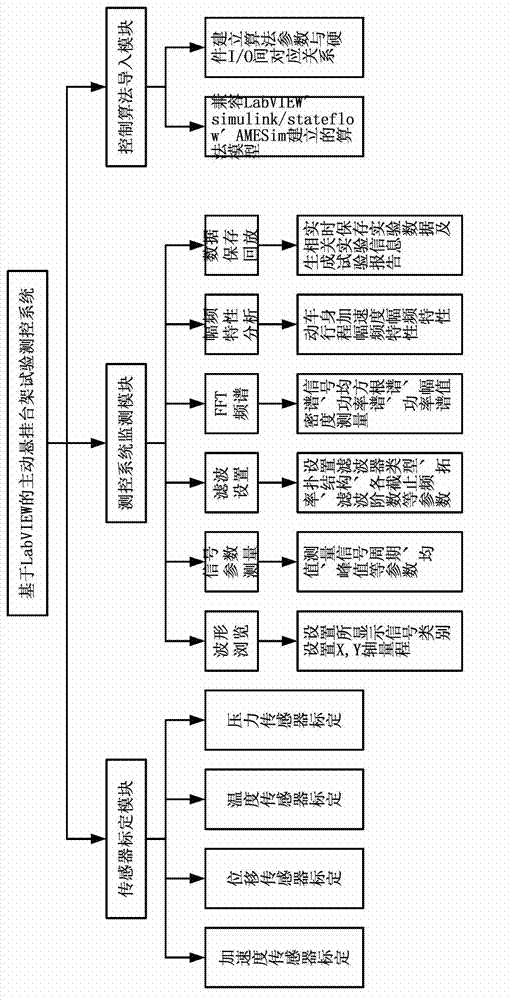

Active suspension bench test measurement and control system based on LabVIEW platform

InactiveCN103115784AEasy to debugShorten the debugging cycleVehicle suspension/damping testingEquipment under testControl signal

The invention relates to an active suspension bench test measurement and control system based on a LabVIEW platform. The active suspension bench test measurement and control system comprise a to-be-tested device, a sensor calibration module, a signal acquisition module, a control signal output module, a signal preprocessing module, a measurement and control system monitoring module, a control algorithm import module and an upper computer, wherein the sensor calibration module is used for calibrating sensors for tests, the signal acquisition module is used for acquiring signals, the control signal output module is used for outputting control signals, the signal preprocessing module is used for preprocessing the signals, the measurement and control system monitoring module is used for monitoring acquired data, and the control algorithm import module is used for importing control algorithm and building relation between hardware and software. An active suspension system actuator, sensors, a controller and control algorithm are built into the complete measurement and control system, so that algorithm debugging is facilitated greatly, algorithm debugging cycle is shortened, test cost is lowered, and high reliability is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

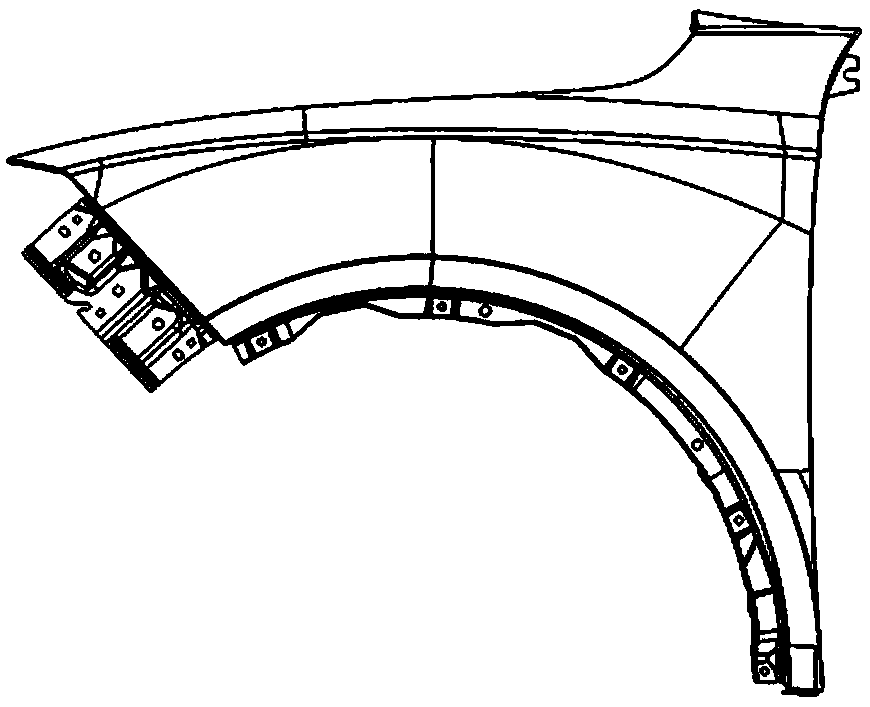

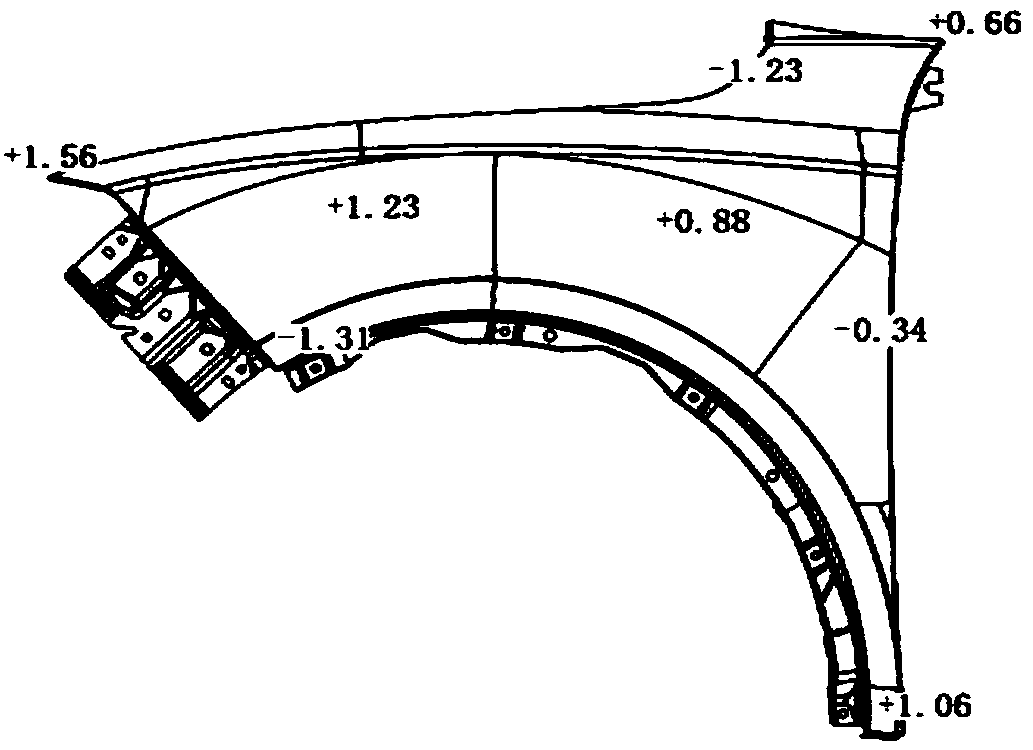

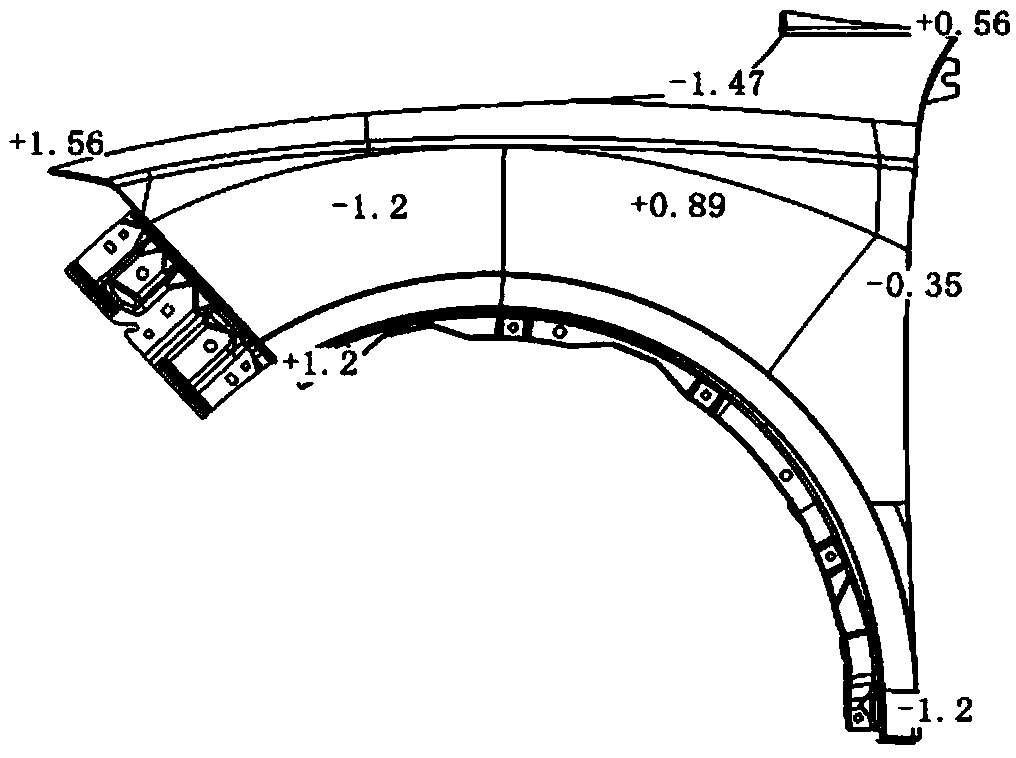

Spring-back analysis and full-profile compensation method for cold-stamping of automobile fender

InactiveCN107900255ASolve the accuracy problemSolve the workloadDesign optimisation/simulationVehicle componentsElement analysisFinite element analysis software

The invention relates to a spring-back analysis and full-profile compensation method for a cold-stamped part of an automobile fender and belongs to the field of manufacturing of stamping molds for automobile covering parts. The method comprises specific steps as follows: step 1: a spring-back result of the part of the fender is predicted as follows: analog simulation is performed on the forming process of the part of the fender by the aid of finite element analysis software AutoForm, and the spring-back result is predicted; step 2: a spring-back compensation scheme for the part of the fender is determined; step 3: full-profile spring-back compensation for the part of the fender is performed, and multiple rounds of iterative compensation is performed by the aid of the finite element analysis software AutoForm until the size requirements are met; step 4: product data of the part of the fender are reconstructed. The method has the positive effects that the defects of low fender size precision and high mold transformation workload in the past are overcome by the aid of fender spring-back analysis and spring-back compensation based on the finite element analysis technology, the qualityof a fender product is substantially improved, the mold debugging cost is reduced, and the mold debugging period is shortened.

Owner:CHINA FIRST AUTOMOBILE

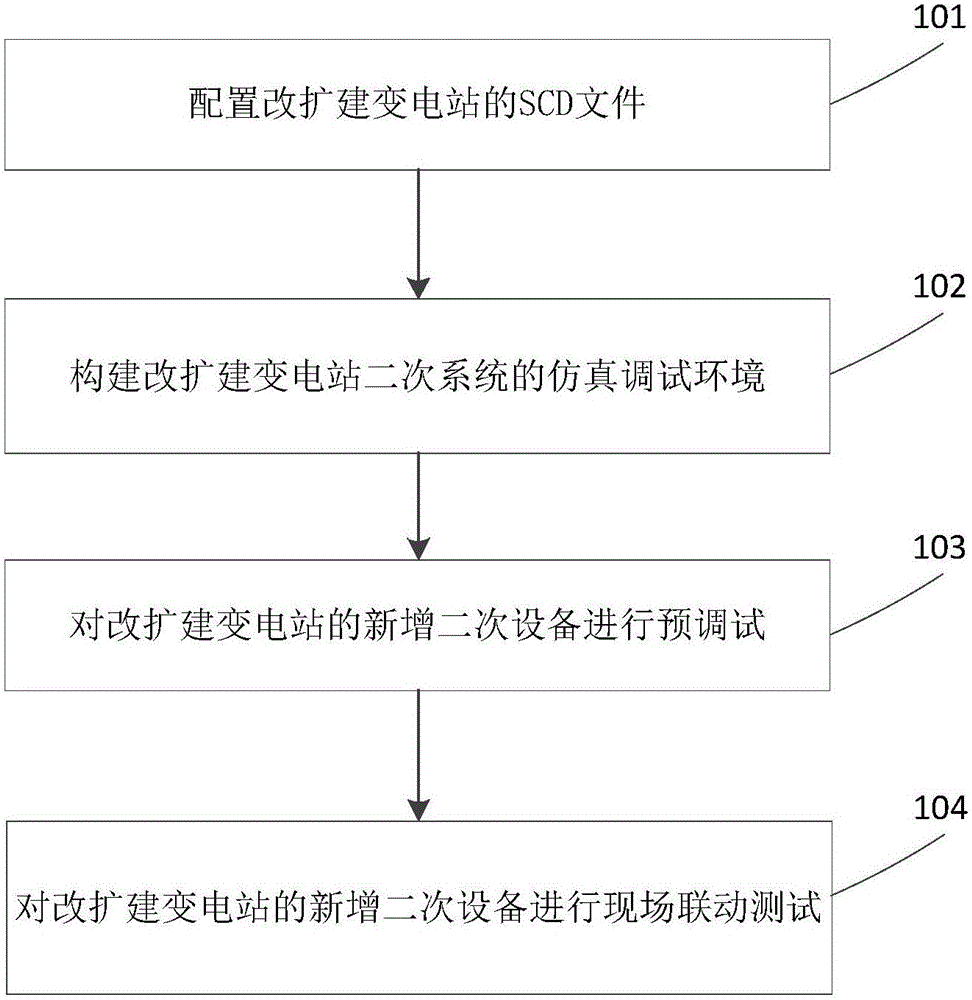

Detecting and debugging method for reconstruction and extension project secondary system for intelligent substation

ActiveCN106329720AOptimize the debugging processImprove debugging efficiencyPower network operation systems integrationCircuit arrangementsSmart substationSoftware engineering

The invention relates to a detecting and debugging method for a reconstruction and extension project secondary system for an intelligent substation. The detecting and debugging method comprises the steps of configuring an SCD file for a reconstruction and extension substation; establishing a simulation debugging environment for the secondary system of the reconstruction and extension substation; performing pre-debugging on newly-added secondary equipment of the reconstruction and extension substation; and performing onsite linkage test on the newly-added secondary equipment of the reconstruction and extension substation. By adoption of the detecting and debugging method, the debugging process of the reconstruction and extension project secondary system can be optimized; the debugging efficiency is improved; the debugging period of the reconstruction and extension project secondary system can be shortened; the construction cost is lowered; and meanwhile, the onsite debugging workload is effectively reduced while safety risk in debugging is lowered.

Owner:CHINA ELECTRIC POWER RES INST +1

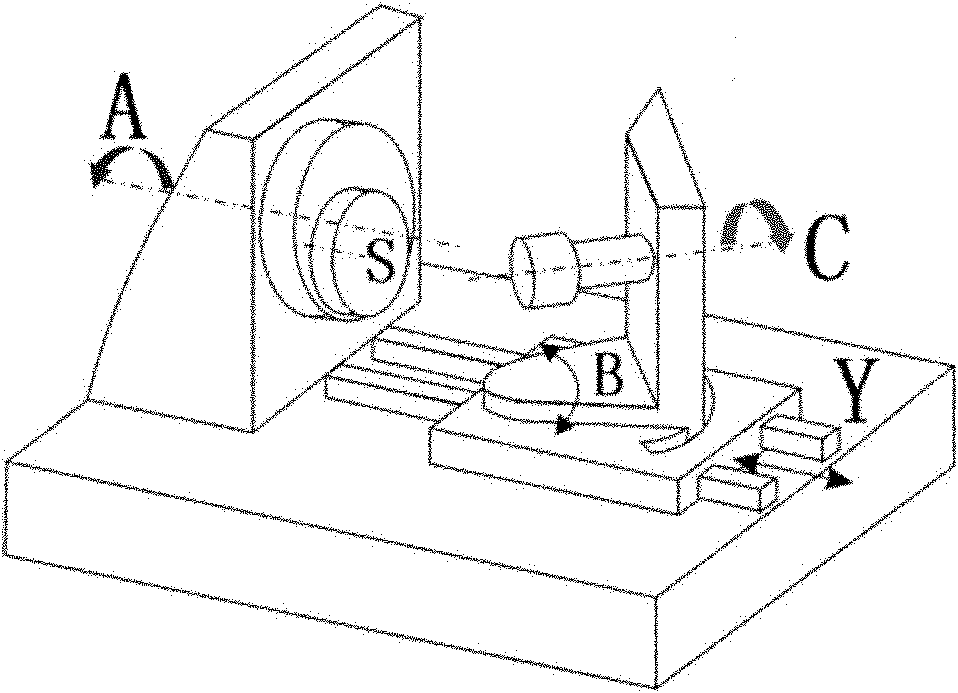

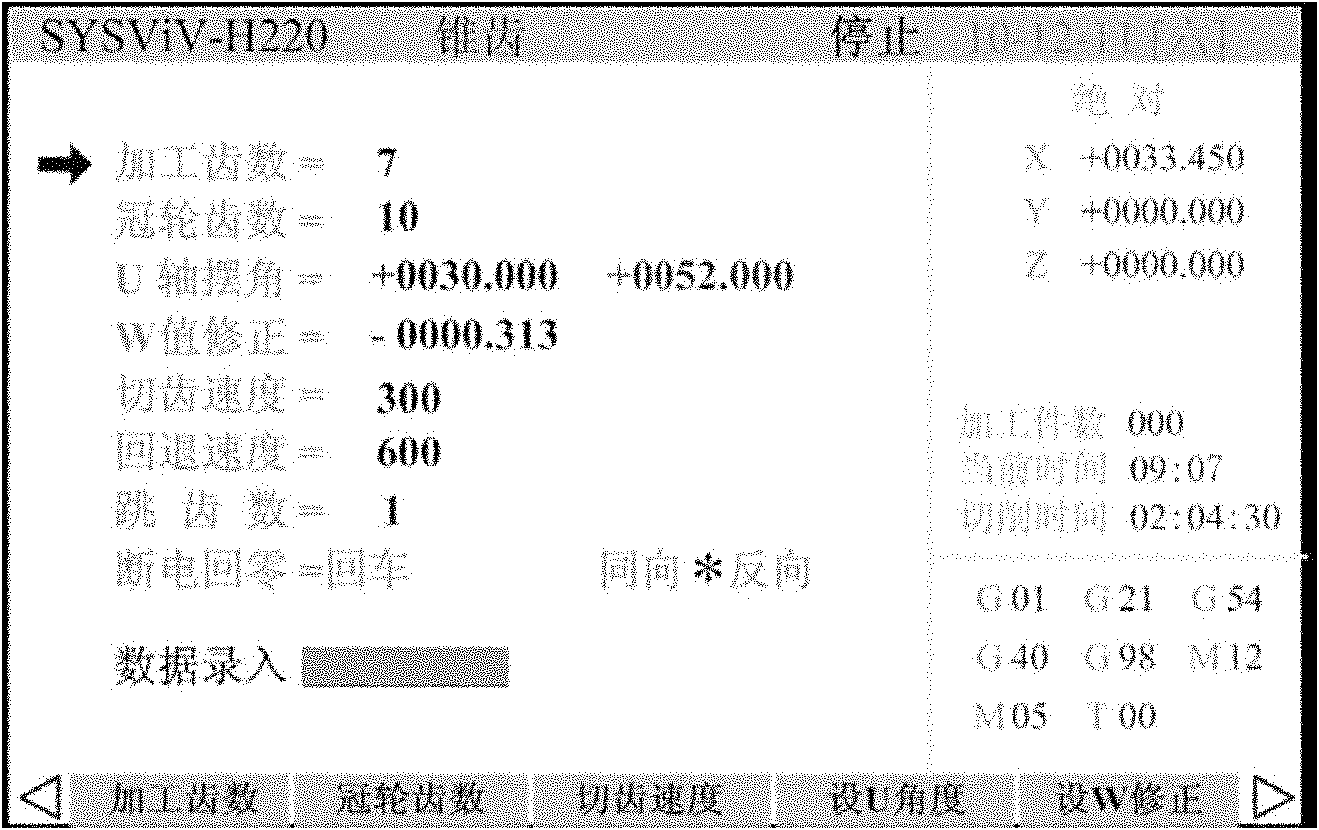

Spiral bevel gear machine tool numerical control system and control method thereof

InactiveCN102129231AEasy to adjustImprove processing efficiencyNumerical controlGear wheelMilling cutter

The invention discloses a spiral bevel gear machine tool numerical control system, by which the traditional mechanical transmission is simplified, exchange is unnecessary for a change wheel, adjustment time for the machine tool is shortened, a mechanical transmission chain is simplified, higher machining accuracy and steady machining quality can be obtained, and the machine tool can be conveniently adjusted, and parameters of generating cutting, dividing, gear feeding, revolving speed of a milling cutter, and reversing of a cradle can be set according to requirements of different cutting methods; and simultaneously, machining efficiency of the machine tool can be greatly improved. Additionally, in the control method of the spiral bevel gear machine tool numerical control system, programming is unnecessary, the adjustment period is shortened, numerical control improvement on normal gear cutting machine tools is facilitated, gear cutting parameters are set in one picture, a tooth surface curvature corrected value is introduced, and the adjustment is more accurate, quicker and more convenient, so that the method is suitable for small-scale production and large-scale production.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

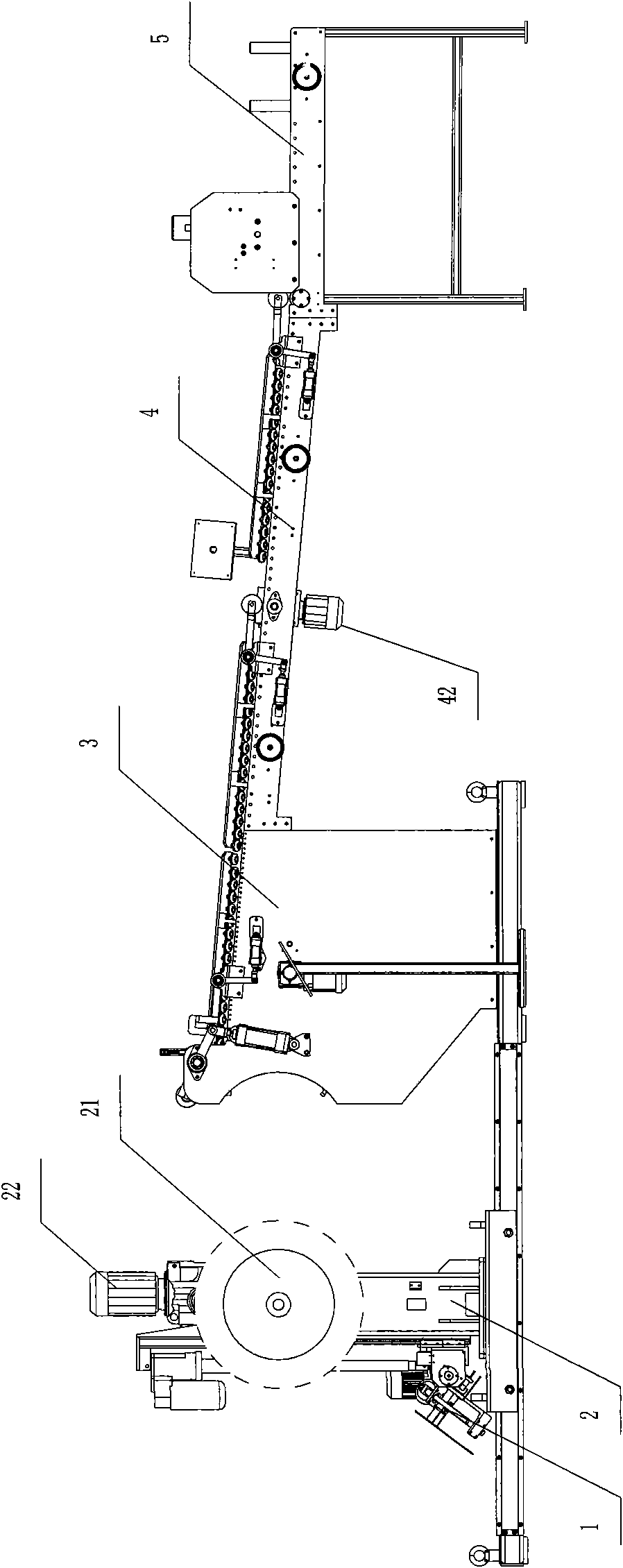

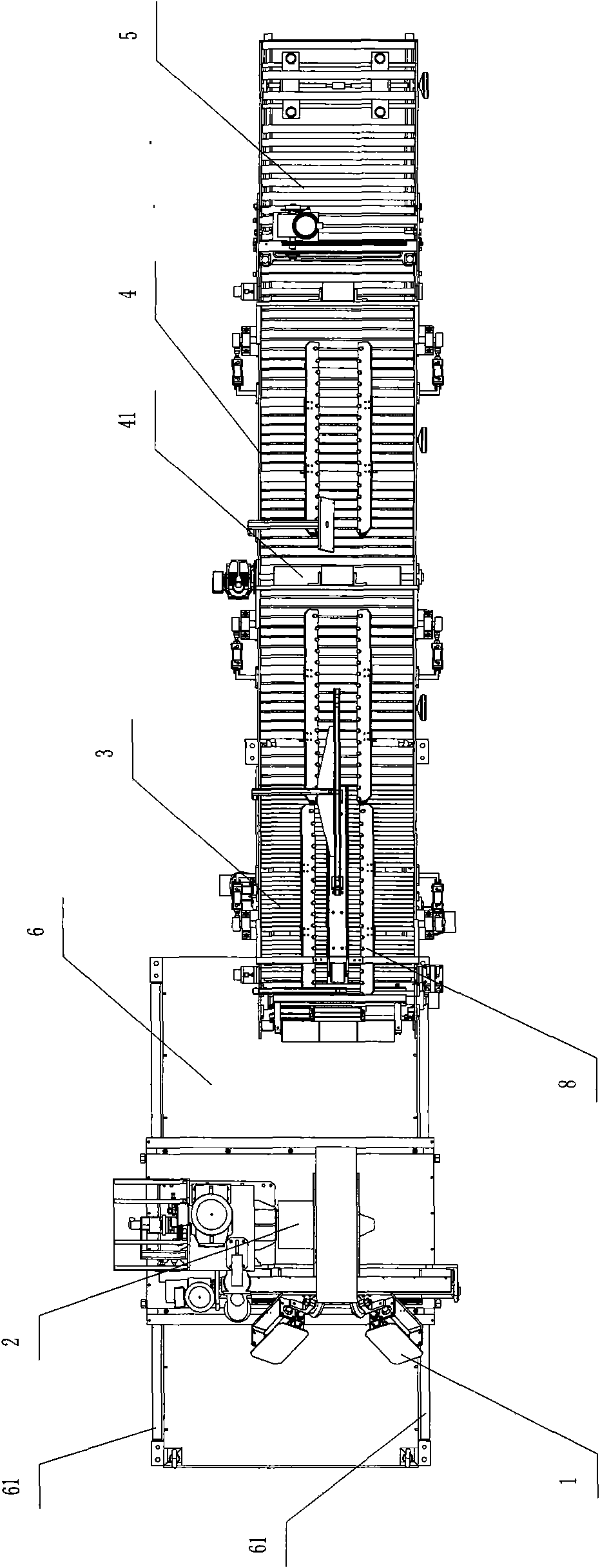

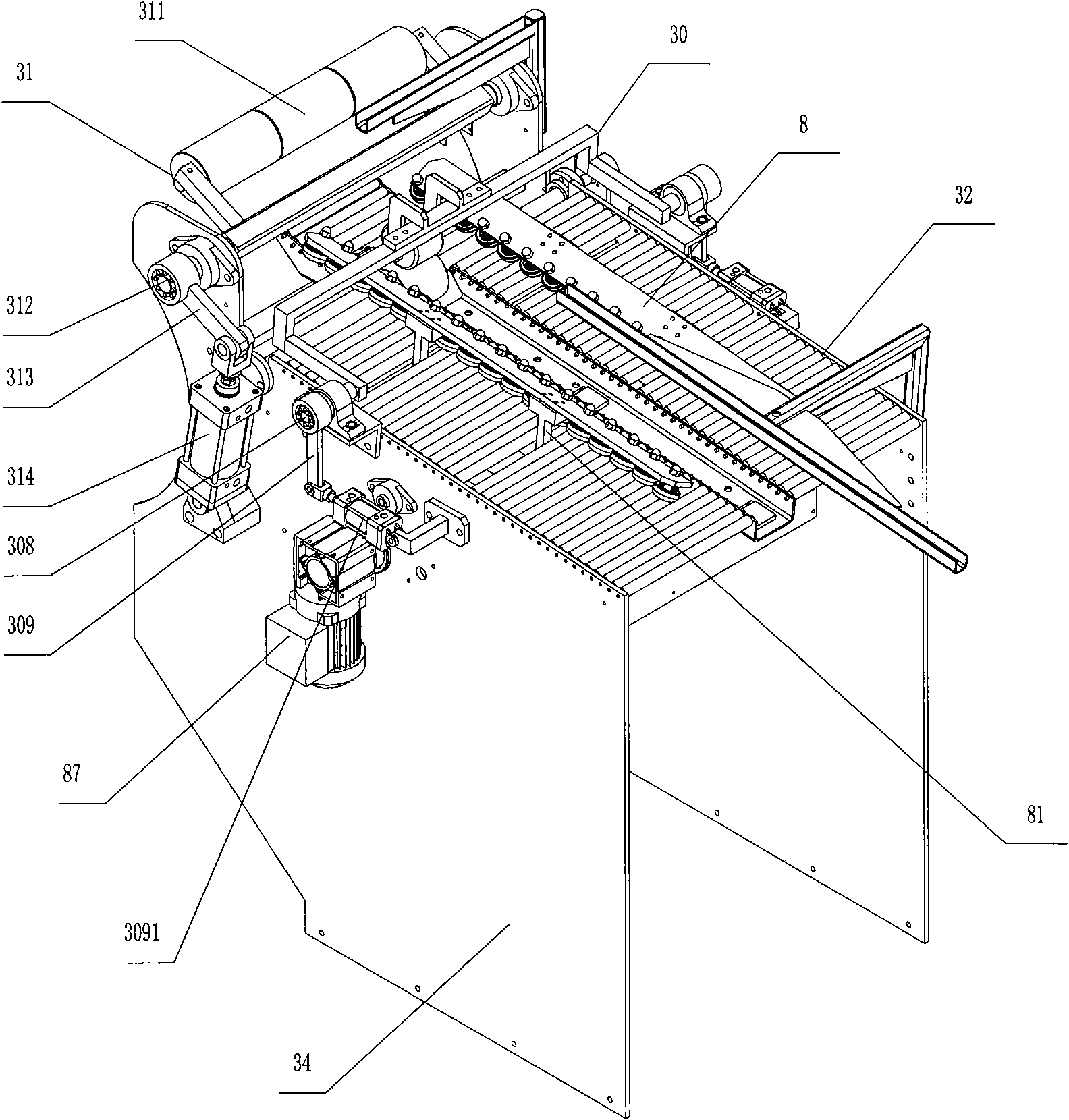

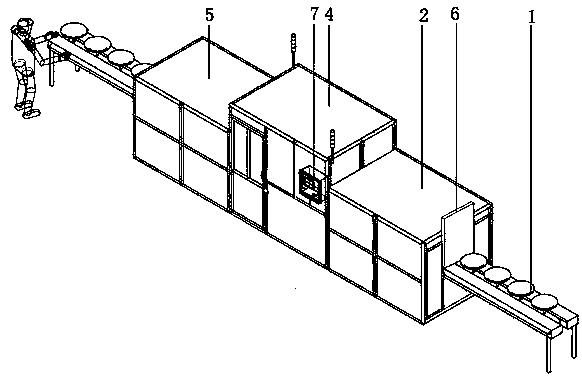

Precise glaze spraying and microwave heating drying method and equipment for ceramics

The invention relates to precise glaze spraying and microwave heating drying method and equipment for ceramics and belongs to the technical field of ceramics for daily use. According to the technical field, the equipment comprises four parts, including a product turning line (1), a front microwave heating part (2), an intermediate precise glaze spraying part (3) and a tail drying part (5); the control part adopts a programmable logic controller (PLC) system; a corresponding program is compiled by using time as an axis and a product as the basis; and a product to be sprayed is sequentially subjected to front microwave heating and intermediate precise glaze spraying, and the sprayed product is subjected to tail drying. The method and the equipment have the beneficial effects that energy is saved, procedures are reduced, and about 1 / 3 of energy consumption can be reduced in comparison with the energy consumption of traditional gas open fire heating or infrared heating; through online control, the thickness of a glaze layer is ensured, human intervention is reduced and rejects are reduced; the production efficiency is improved through flexible combination of spray guns; through automatic maintenance of the spray guns, the glaze spraying flow is ensured, and manual maintenance is reduced; and the adaptability is strong, the equipment debugging cycle in the chase of change of produces is reduced, and the efficiency is improved.

Owner:TANGSHAN RUIQI CERAMIC TECH DEV CO LTD

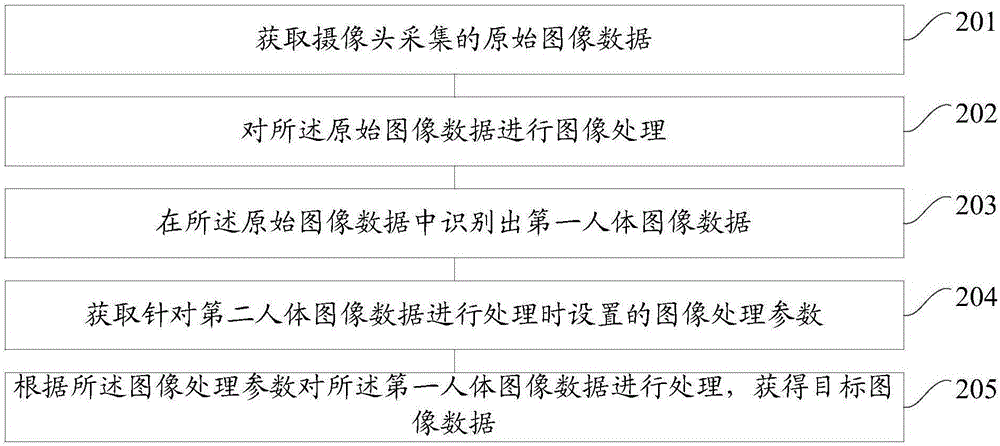

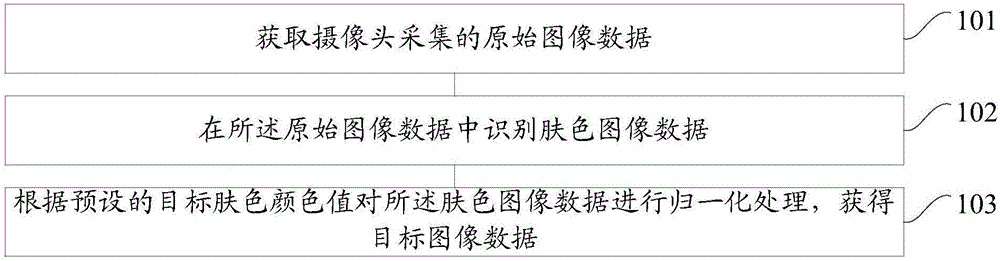

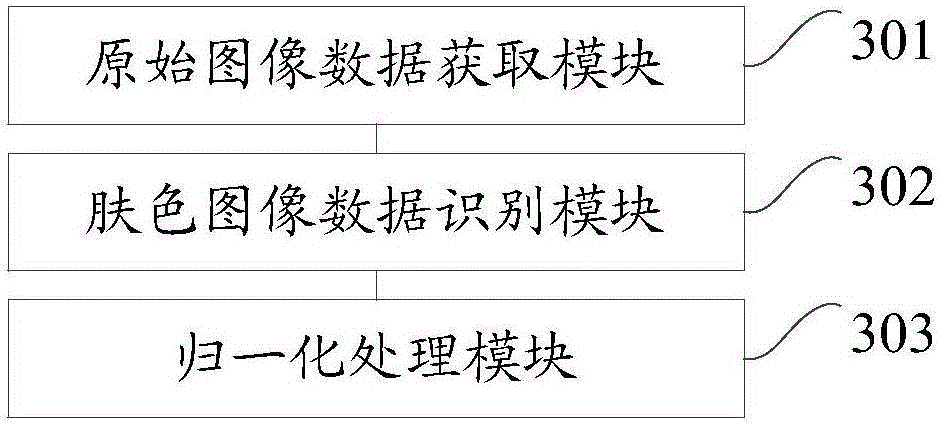

Image data processing method and device, and mobile terminal

InactiveCN106060402AShorten the debugging cycleInput stableTelevision system detailsImage analysisPattern recognitionImaging processing

The embodiment of the invention provides an image data processing method and device, and a mobile terminal. The method comprises the steps of obtaining original image data collected by a camera; identifying skin color image data in the original image data; and normalizing the skin color image data according to a preset target skin color value, thereby obtaining target image data. According to the embodiment of the method, the device and the mobile terminal, an input skin color is enabled to trend to or even reach the target skin color; the problem that the skin color is expressed differently in various environments due to the fact that the integrated stability of the skin color is low under the control of image processing is solved; the stable and consistent skin color is output; and moreover, the image processing debugging period is shortened.

Owner:BEIJING QIHOO TECH CO LTD +1

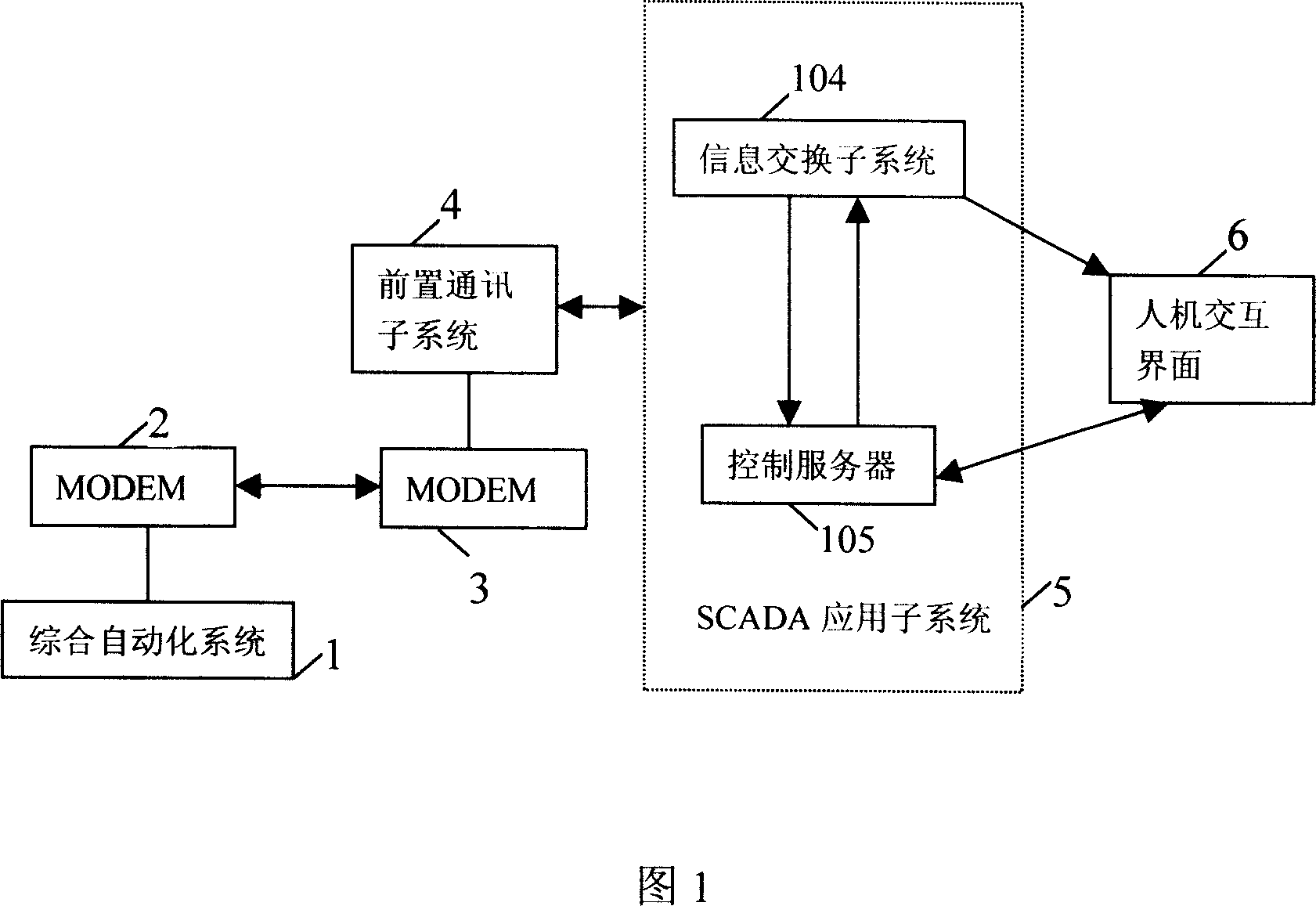

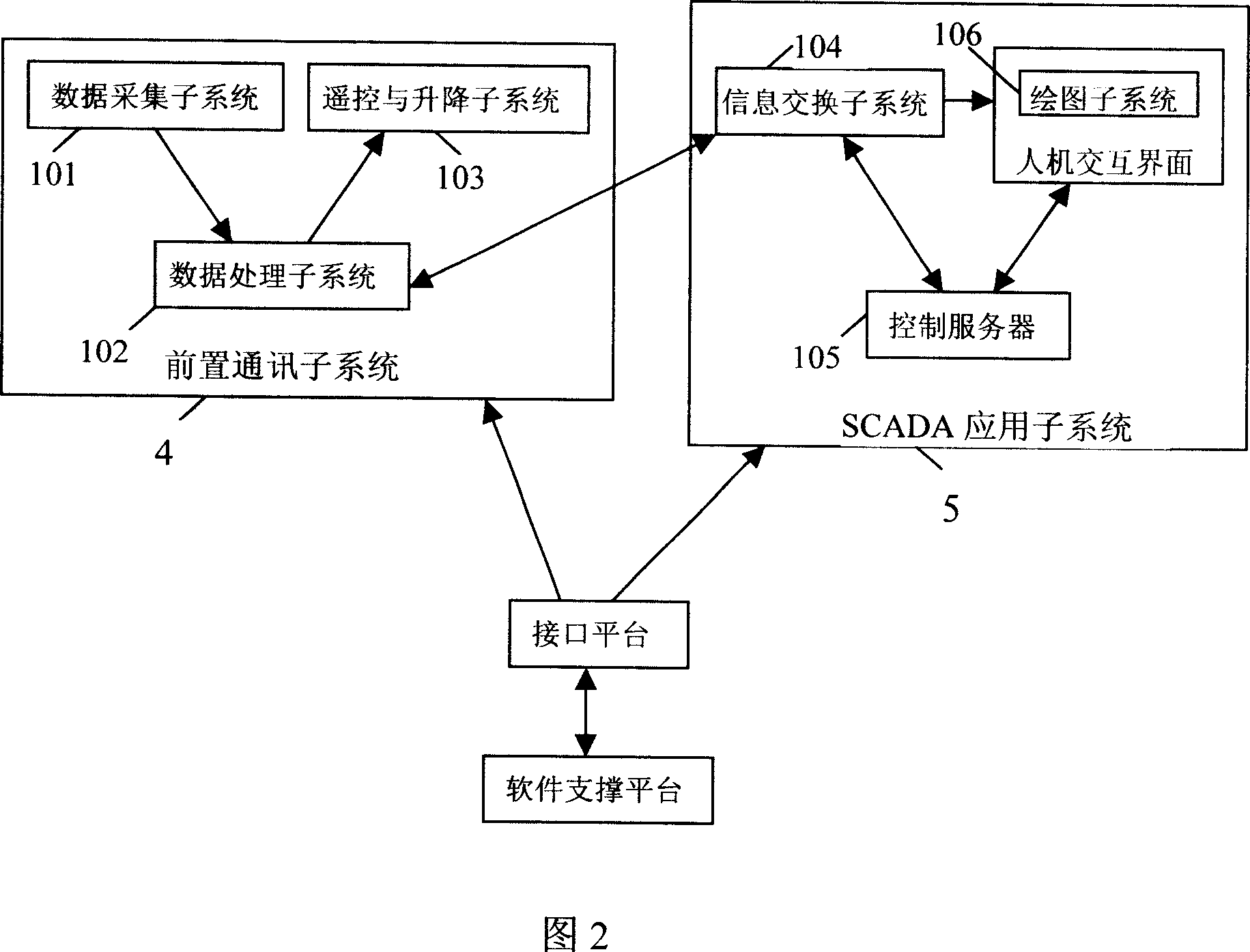

Integrated automation converting station debugging apparatus

InactiveCN1929223AEasy to operateShorten the debugging cycleSupervisory desks/panelsElectronic circuit testingProcess systemsData acquisition

This invention discloses one complex automatic substation adjusting device, which comprises portable machine and data line, wherein, the portable machine comprises one set of artificial software composed of front communication system and SCADA application system; the front communication system comprises data collection system, data process system and remote control lift system; the SCADA application sub system comprises information exchange system, control servo and drawing sub system.

Owner:SHANGHAI DONGJIE CONSTR GROUP

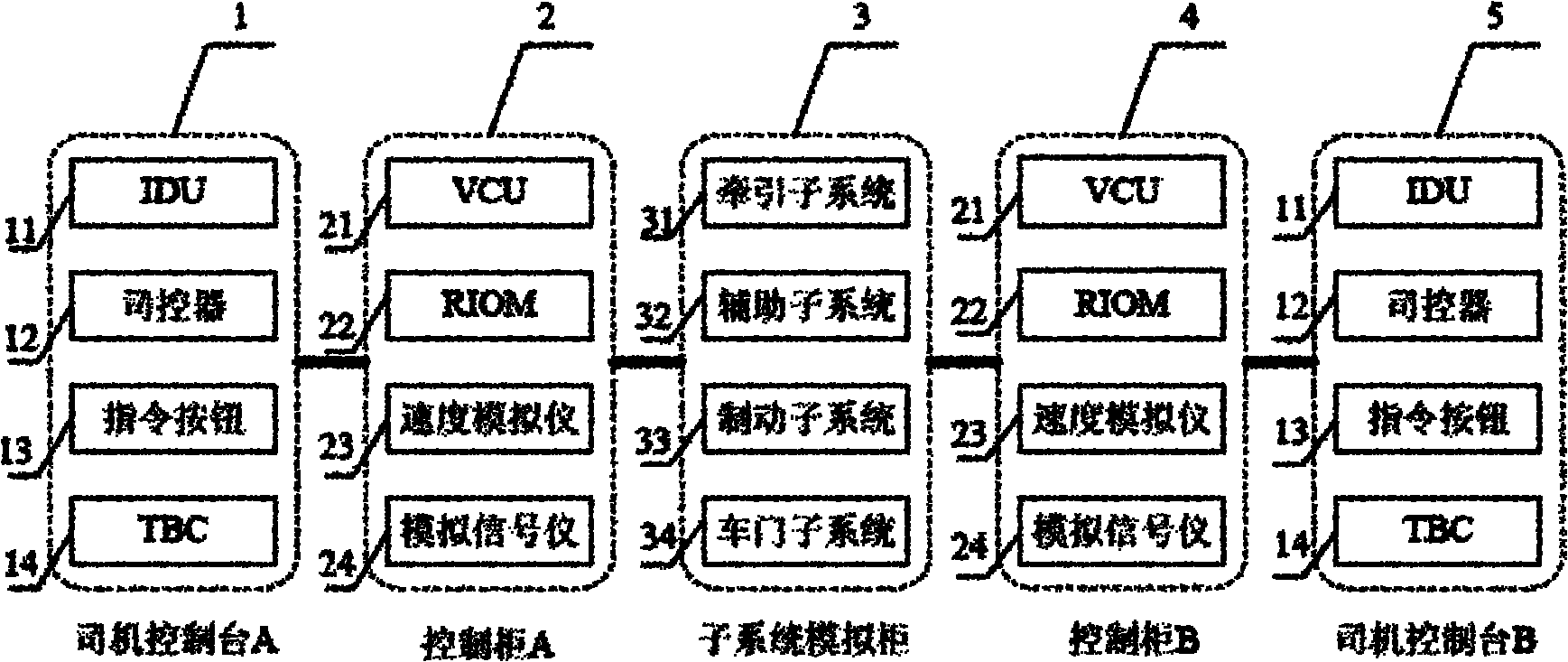

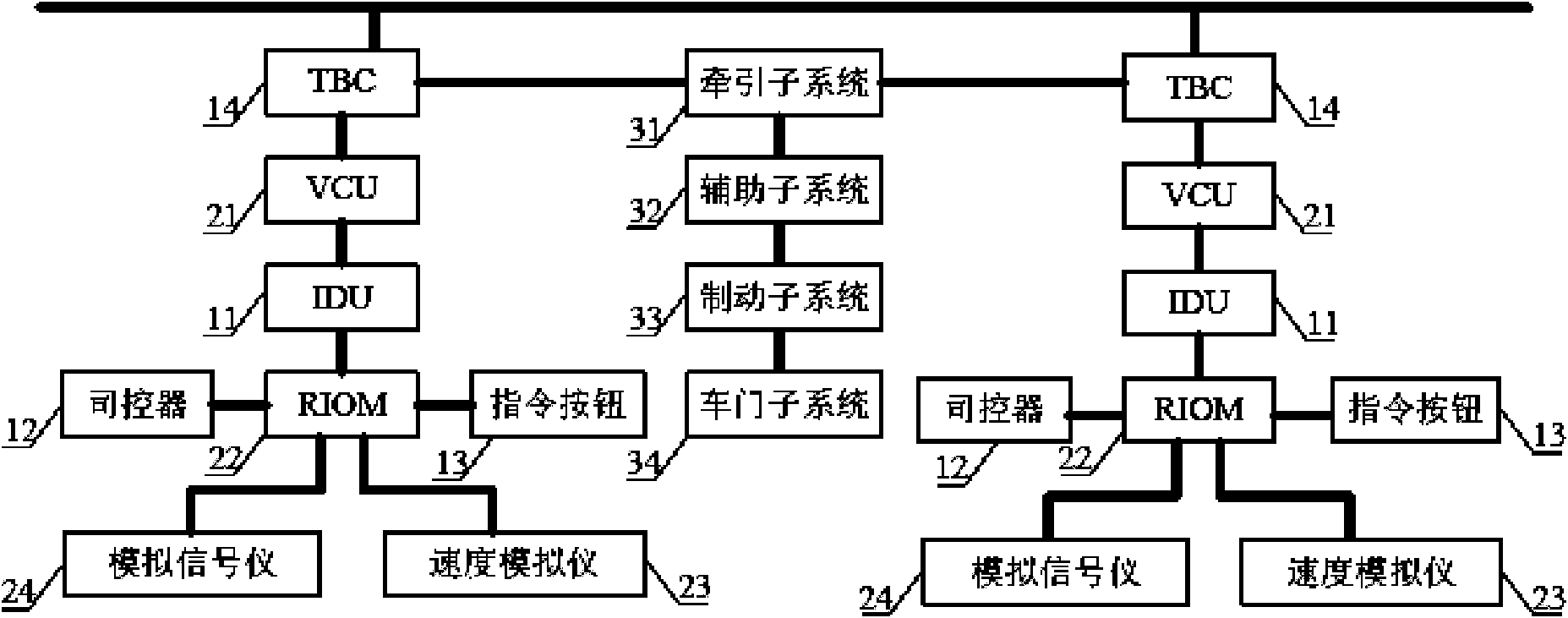

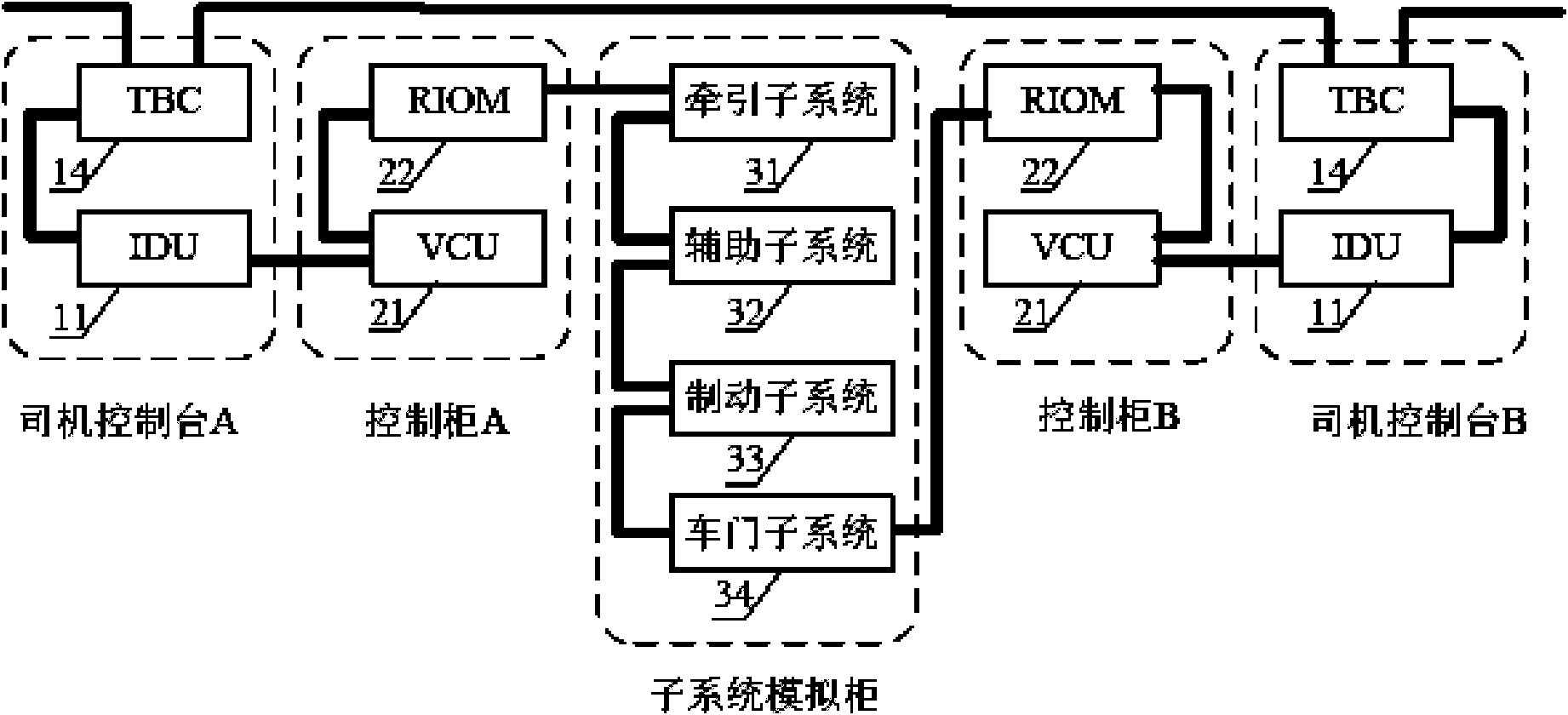

Test platform of controller area network (CAN)-based light rail vehicle network control system

InactiveCN102023637AGuaranteed normal operationDebug impactElectric testing/monitoringArea networkControl system

The invention discloses a test platform of a controller area network (CAN)-based light rail vehicle network control system, which comprises a driver console A, a driver console B, a control cabinet A, a control cabinet B and a subsystem simulation cabinet, wherein the driver consoles A and B have the same structure; the control cabinets A and B have the same structure; and the driver console A, the control cabinet A, the subsystem simulation cabinet, the control cabinet B and the driver console B are connected by a CAN. The test platform can greatly shorten the debugging time of the vehicle network control system so as to shorten the time of delivering vehicles to users by original equipment manufacturers and finally realize the advanced delivery or operation of the vehicles. The test platform and a research platform are provided for the CAN technology-based control system, are favorable for the popularization and application of a CAN system in China and further promote the diversified development of the light rail vehicle network control system in China.

Owner:CHINA CNR CORPORATION

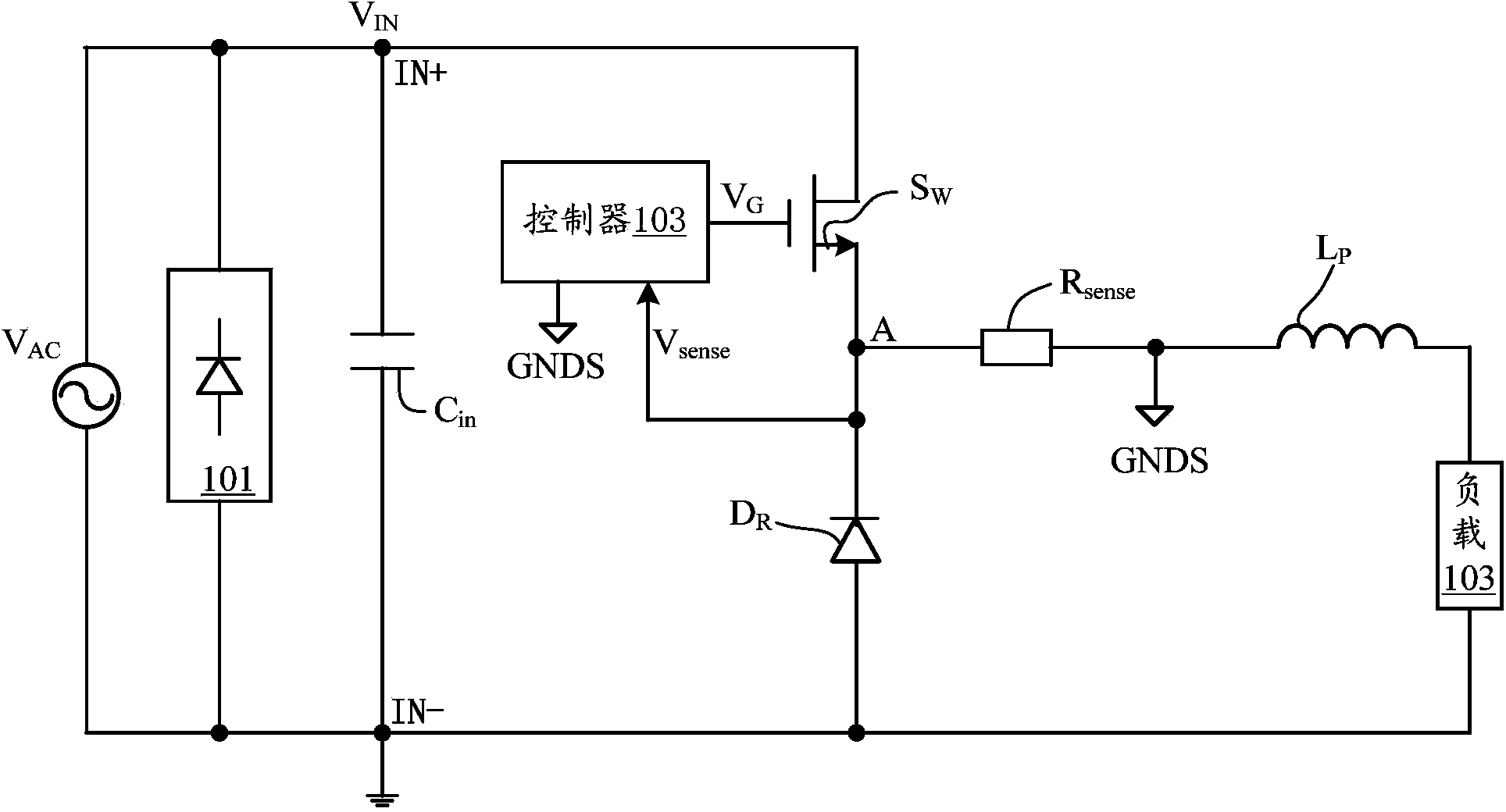

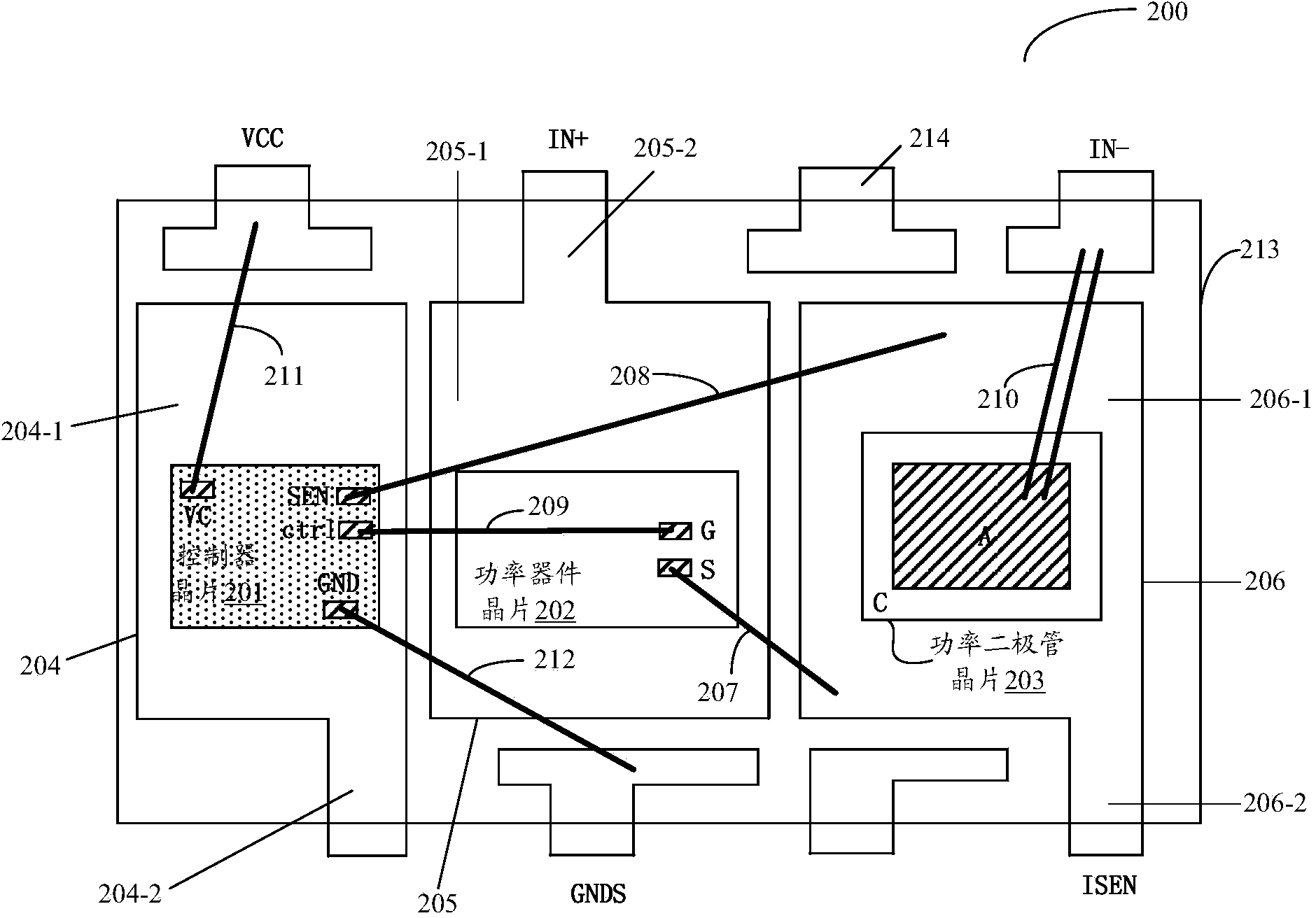

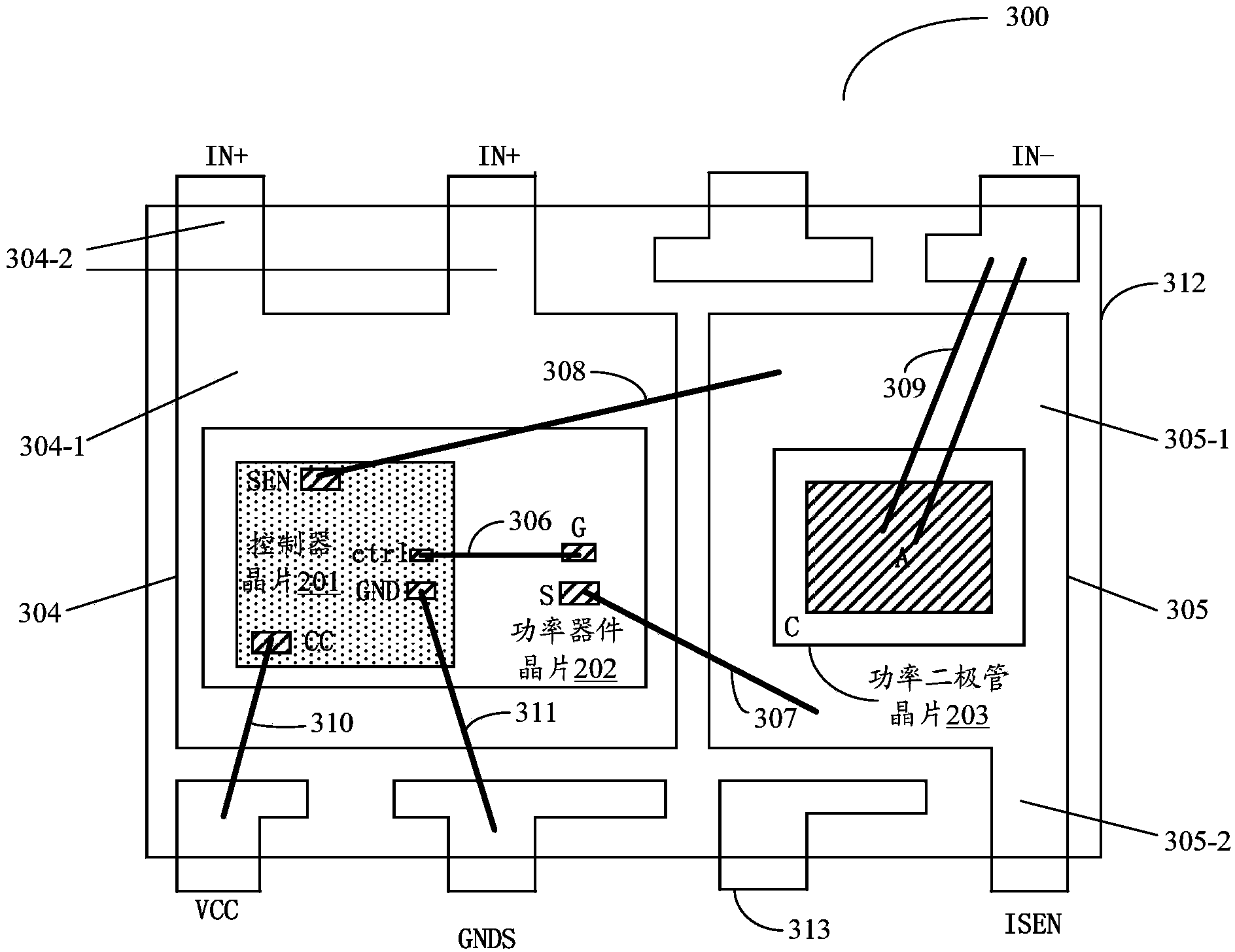

Chip packaging structure used for power converter

InactiveCN104167401AImprove cooling effectImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPower diodeLead frame

The invention discloses a chip packaging structure used for a power converter, comprising a lead frame constituted by first type lead feet and second type lead feet, a power member wafer and a power diode wafer. In a multi-chip-packaging structure, better heat radiation performance can be obtained through directly placing a power member wafer and the power diode wafer on a big-area middle bonding pad between the first type lead foots and forming direct electric connection. Furthermore, wafers can form specific electric connection among the wafers in the packaging structure not outside the packaging structure, so that the capability of resisting interference is strong and the reliability and stability of the system are improved.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

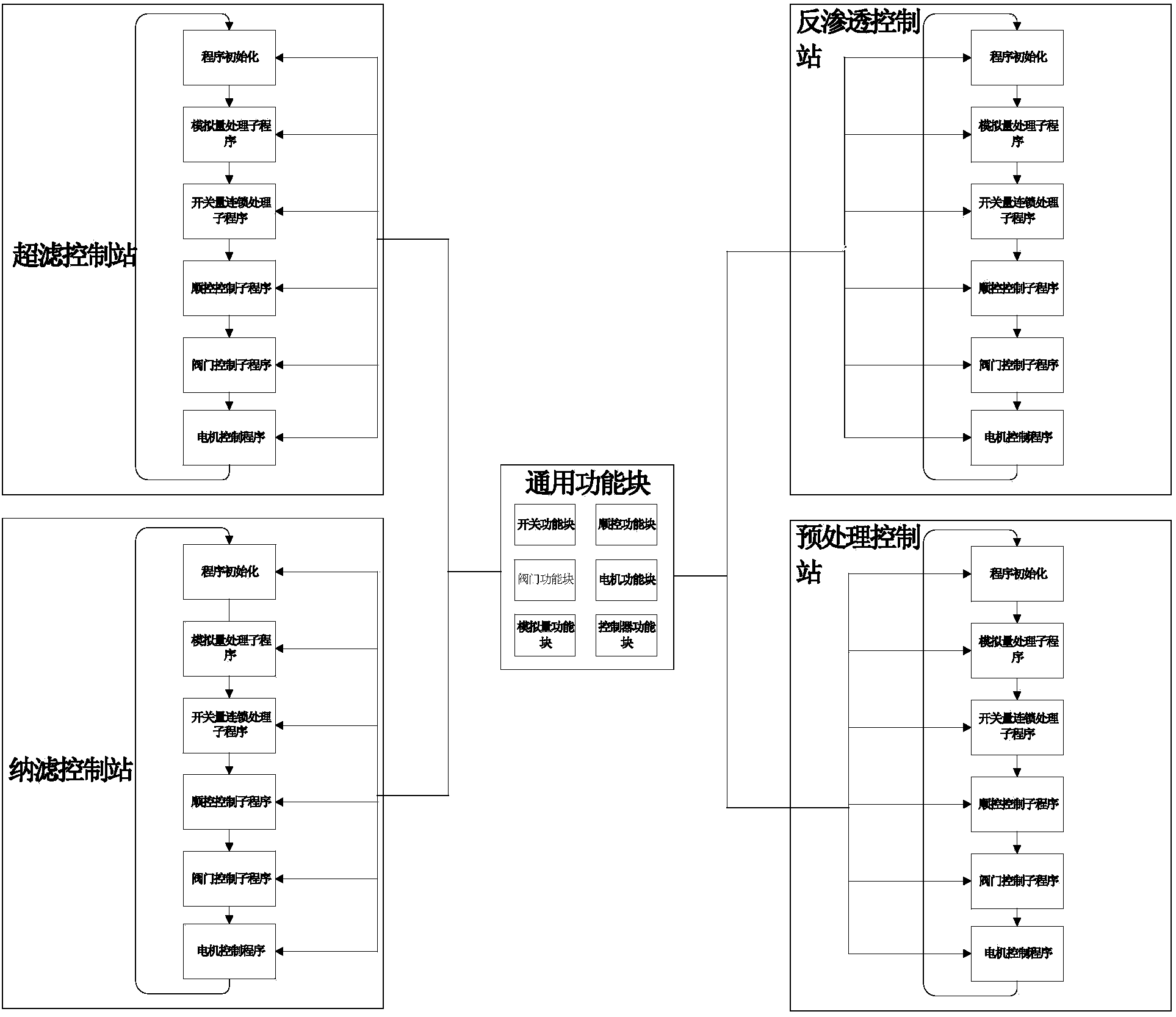

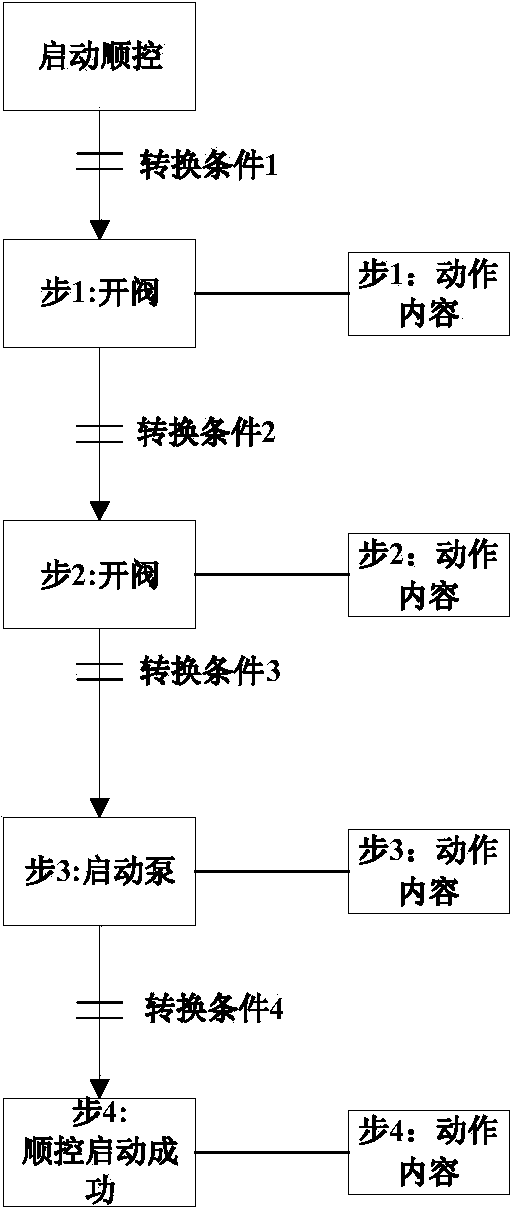

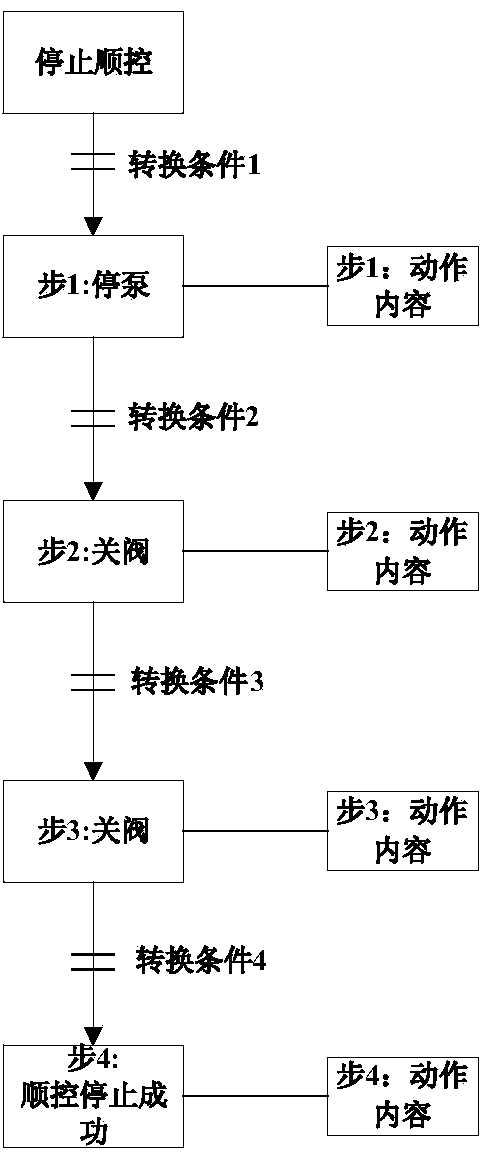

Refuse leachate membrane treatment control system and method

ActiveCN103663625AImprove reliabilityImprove anti-interference abilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationClosed loop

The invention relates to a refuse leachate membrane treatment control system and method. The refuse leachate membrane treatment control system comprises an ultrafiltration membrane set unit, a nanofiltration membrane set unit and a reverse osmosis membrane treatment unit, wherein each unit comprises a switch function module, a motor function module, a valve function module, a analog quantity function module, a controller function module and a sequential control function module; the switch function module is used for processing alarm signals of hardware and software; the motor function module is used for controlling equipment such as motors, blowers and pumps; the valve function module is used for controlling switch valve equipment; the analog quantity function module is used for performing analog quantity data processing; the controller function module is used for controlling equipment required for closed-loop control; and the sequential control function module is used for controlling equipment such as motors, blowers and pumps. According to the invention, the software developing and debugging period is greatly shortened, and the reliability and anti-interference performance of a control system are increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com