High-performance fiber synchrotron radiation in-situ testing machine

A high-performance fiber, in-situ detection technology, used in the inspection of textile materials, material analysis using radiation, textiles and papermaking, etc., can solve the lack of real-time tracking and detection of the internal structure of the fiber, the quality of the fiber cannot be guaranteed, and the debugging Long cycle and other problems, to achieve the effect of shortening the debugging cycle, convenient operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

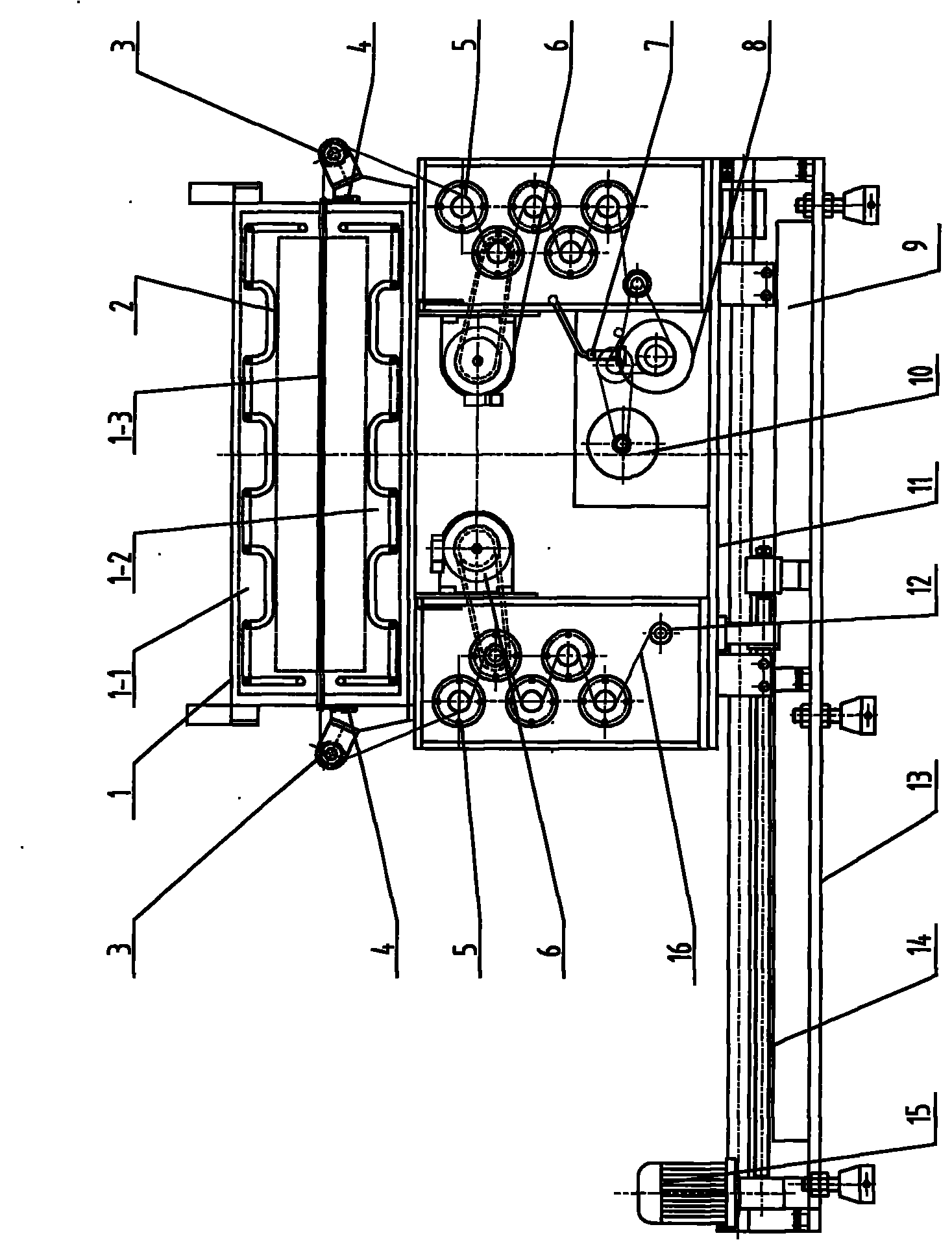

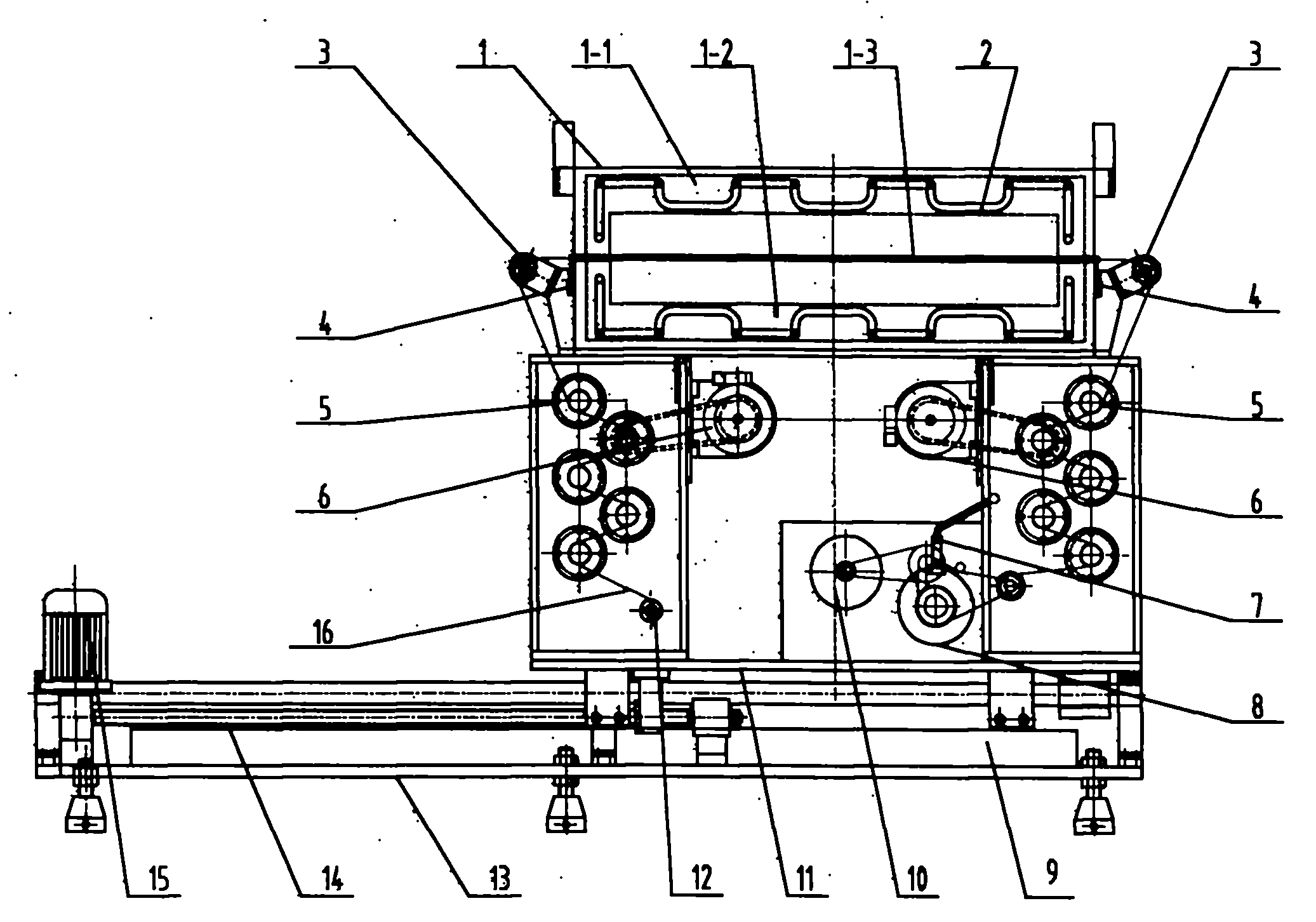

[0019] The high-strength and high-modulus polyethylene fiber hot-drawing testing machine of the present invention includes a machine base 13, a frame 11, a drafting heating box, a front drafting mechanism, a rear drafting mechanism, a winding mechanism and a translation mechanism.

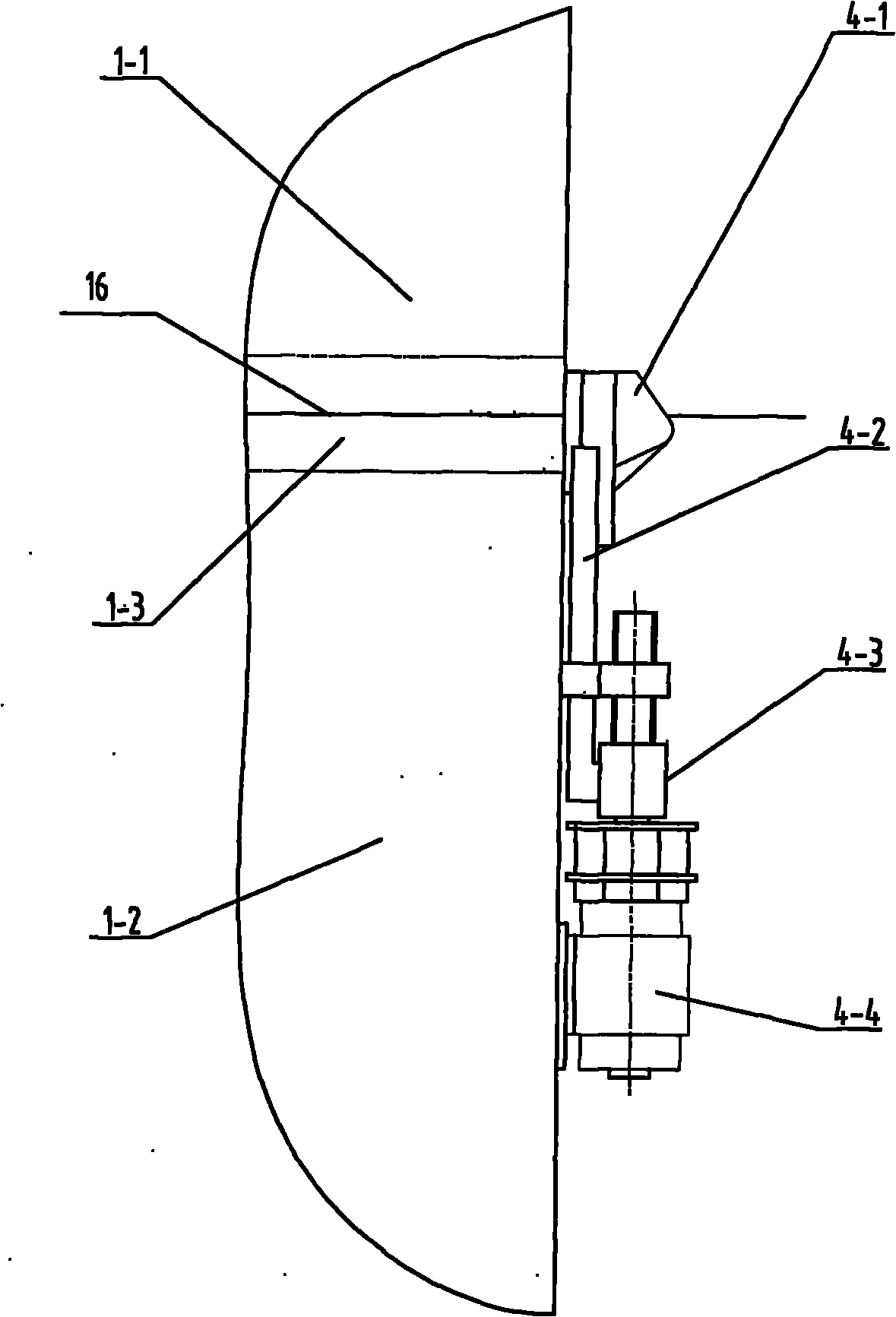

[0020] The drafting hot box is used for heating the fiber tow, including a box body 1 and a heating element 2 placed in the box body 1; the box body 1 is installed on the frame 11, and the two ends of the box body 1 are respectively equipped with The fiber tow inlet and the fiber tow outlet, and a support roller 3 is provided at the fiber tow inlet and the fiber tow outlet; a working area 1-3 is provided on one side of the box body 1 corresponding to the fiber tow ; Described casing 1 is divided into loam cake 1-1 and lower casing 1-2 along working area 1-3, and loam cake 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com