Coal tar multistage hydrogenation treatment technique

A technology for coal tar and pre-hydrogenation, which is used in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of furnace tube coking and affecting the operation cycle of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

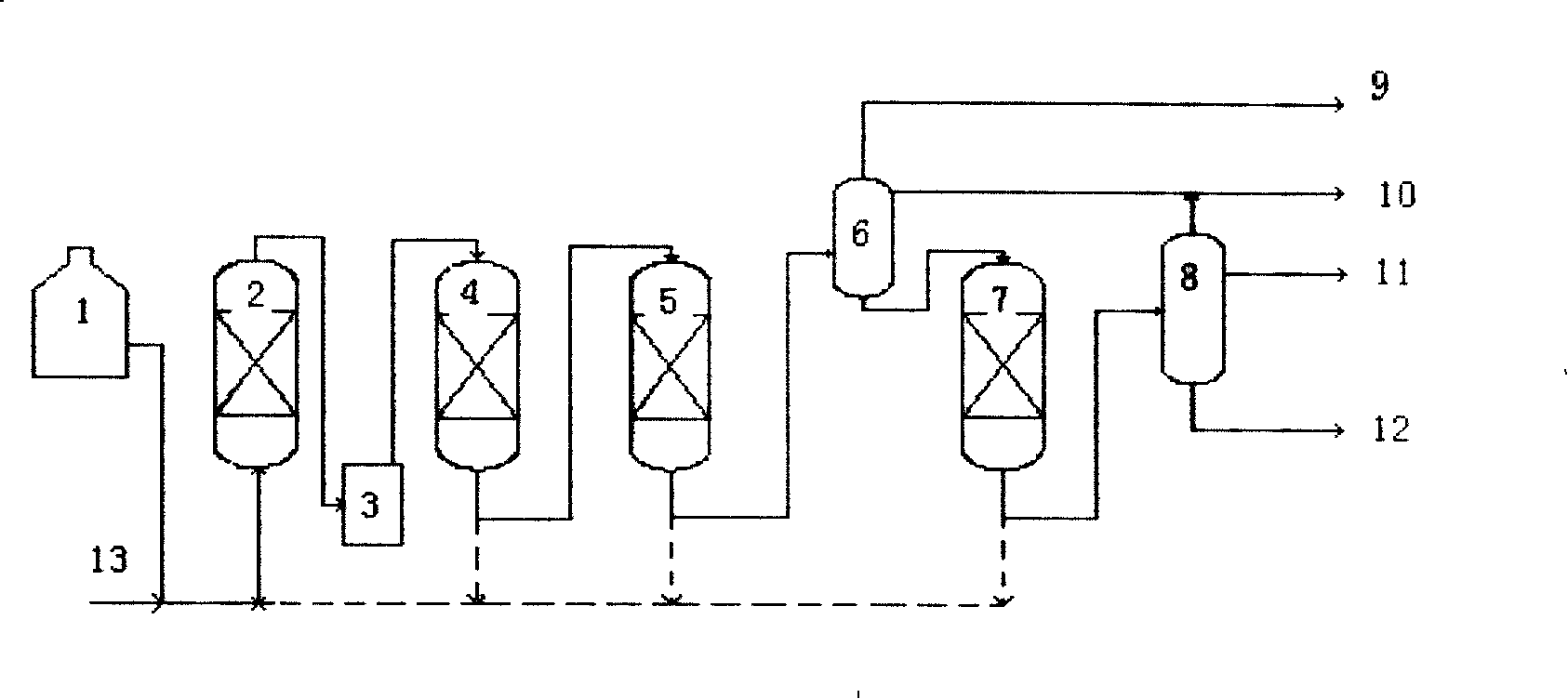

[0029] The serial number 1 is the raw material tank, 2 is the pre-hydrogenation reactor, 3 is the separation device, 4 is the hydrodemetallization reactor, 5 is the deep hydrofining reactor, 6 is the separation device, and 7 is the hydrocracking reactor , 8 is a distillation unit, 9 is water, 10 is gasoline, 11 is diesel oil, 12 is hydrocracking tail oil, 13 is hydrogen, and the rest are pipelines.

[0030] Schematic diagram of the principle process for producing light fuel oil by multi-stage hydrotreating of coal tar ( figure 1 ): Firstly, the coal tar raw material in the raw material tank 1 is mixed with hydrogen, and then the mixture is contacted with part of the stream generated from hydrodemetallization, or deep hydrofinishing or hydrocracking reaction in the pre-hydrogenation reactor to carry out Hydrogenation of olefins, descaling and demetallization of raw materials, the reaction conditions are: pressure 1-10Mpa, temperature: 150-280°C, hydrogen-oil volume ratio 500-50...

specific Embodiment approach

[0031] In the present invention, a multi-stage combination process is used to carry out hydrocracking of coal tar raw material to produce light oil products.

[0032] For further illustrating various main points of the present invention, enumerate following embodiment. The percentages are percentages by weight.

[0033] Among them, the fixed bed hydrogenation and prehydrogenation catalyst is FZC-102 catalyst developed and produced by Fushun Petrochemical Research Institute, the hydrodemetallization catalyst is FZC-202 catalyst developed and produced by Fushun Petrochemical Research Institute, and the deep hydrorefining catalyst is Fushun Petroleum. The FF-16 catalyst developed and produced by the Research Institute of Chemical Industry, the hydrocracking catalyst is the FC-28 catalyst developed and produced by Fushun Petrochemical Research Institute, the fluidized bed hydrogenation and pre-hydrogenation catalyst is spherical, the particle diameter is 0.5mm, and the pore volume...

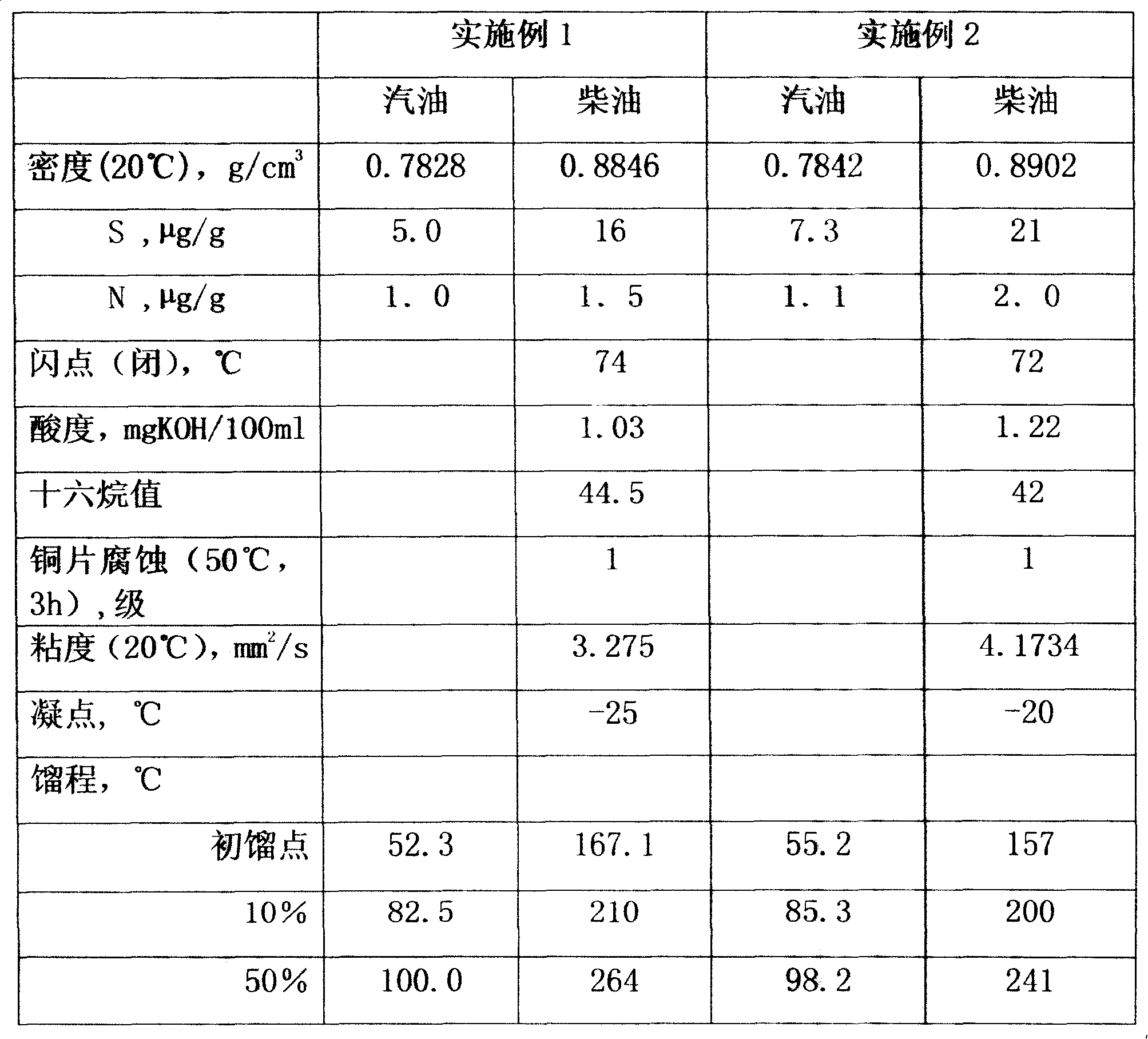

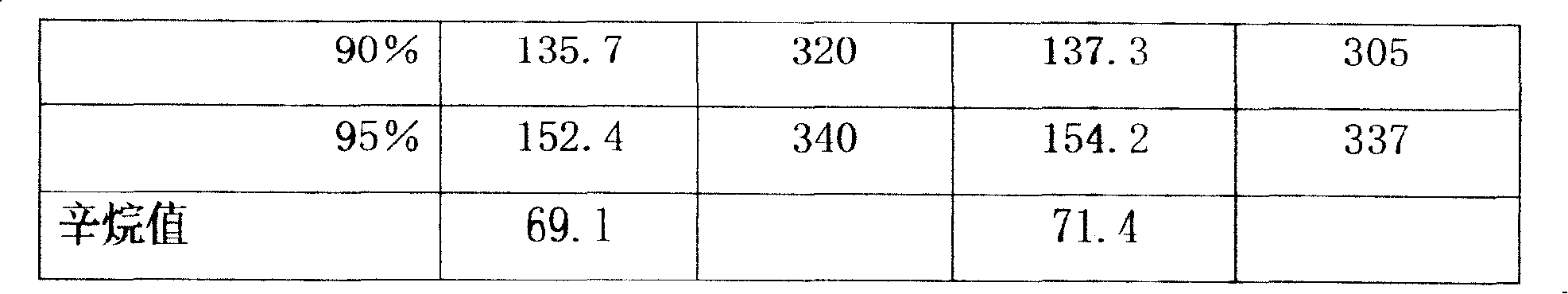

Embodiment 1

[0035] This example is a hydrogenation test of high-temperature coal tar distillates using a multi-stage combined process. Among them, the properties of coal tar raw materials are: Density (20°C): 1.1365g / cm 3 , carbon residue: 3.4%; sulfur: 6000μg / g, nitrogen: 10000μg / g, saturated content: 0%; aromatic component: 69.1%; colloid: 27.9%, asphaltenes: 3%; mechanical impurities 1.8%. First, the coal tar raw material in the raw material tank 1 is mixed with hydrogen, and then the mixture is contacted with the stream generated from the hydrodemetallization reaction in the fixed bed pre-hydrogenation reactor to carry out hydrogenation saturation of olefins and descaling and demetallization of the raw material ; The pre-hydrogenation stream is separated from the fine solid particles suspended in the product stream by a centrifugal separation device, and then enters the hydrodemetallization reactor to remove metal impurities; the stream from the bottom of the hydrodemetallization reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com