Treatment agent for concrete waste slurry water and method for preparing premixed concrete from waste slurry water

A technology for ready-mixed concrete and concrete, applied in the field of building materials, can solve the problems of difficulty in direct utilization of waste water and waste slurry, and achieve the effects of simple and feasible preparation process, inhibition of agglomeration, and promotion of particle dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

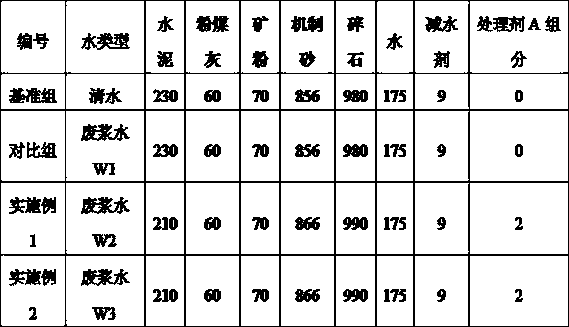

Embodiment 1

[0038] A concrete waste slurry water treatment agent is composed of a hydration inducing composition A and a waste slurry water dispersion composition B and used together.

[0039] The hydration-inducing composition A is made of the following raw materials in parts by mass: 8 parts of inorganic salt (5 parts of calcium formate, 3 parts of sodium silicate), 6 parts of nanocrystalline nucleus early strengthening agent, polycarboxylate superplasticizer 1 part, 0.5 parts of retarder (sodium citrate), 3 parts of polyethylene glycol (molecular weight 400), 1.2 parts of diethylene glycol, 0.02 parts of sodium glutamate, 0.03 parts of cetyltrimethylammonium bromide, 0.02 parts of thickener (polyvinyl alcohol), 3 parts of complex alcohol amines (0.6 parts of triethanolamine, 2.4 parts of diethanol monoisopropanolamine) and 77.23 parts of water; the preparation method is as follows: mix inorganic salt, sodium glutamate and Add 70% water into the mixing tank, stir for 20~30min; add thick...

Embodiment 2

[0042] A concrete waste slurry water treatment agent is composed of a hydration inducing composition A and a waste slurry water dispersion composition B and used together.

[0043] The hydration-inducing composition A is made of the following raw materials by mass: 4 parts of inorganic salt (4 parts of calcium formate), 10 parts of nano-crystal nucleus early strength agent, 0.5 part of polycarboxylate superplasticizer, retarder (sodium tripolyphosphate) 0.3 parts, polyethylene glycol (molecular weight 200) 3 parts, diethylene glycol 1 part, sodium glutamate 0.03 parts, cetyltrimethylammonium bromide 0.04 parts, thickener ( 0.03 parts of hydroxypropyl methylcellulose), 4 parts of complex alcohol amines (0.8 parts of triethanolamine, 0.8 parts of triisopropanolamine, 2.4 parts of diethanol monoisopropanolamine) and 77.1 parts of water; the preparation method is as follows: Add inorganic salt, sodium glutamate and 70% water into the mixing tank, stir for 20~30min; add thickener, ...

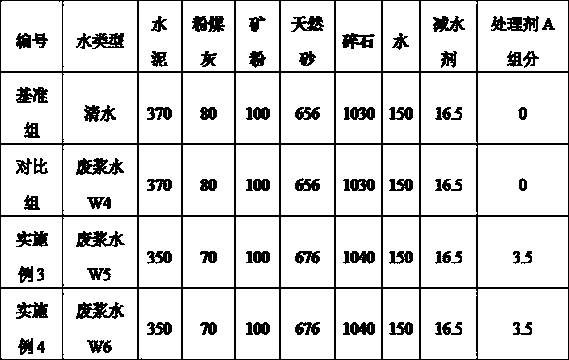

Embodiment 3

[0046] A concrete waste slurry water treatment agent is composed of a hydration inducing composition A and a waste slurry water dispersion composition B and used together.

[0047] The hydration-inducing composition A is made of the following raw materials in parts by mass: 5 parts of inorganic salt (3 parts of calcium hydroxide, 2 parts of sodium silicate powder), 8 parts of nanocrystalline nucleus early strength agent, polycarboxylic acid water-reducing agent 1 part of preservative, 1 part of retarder (sodium citrate), 2 parts of polyethylene glycol (molecular weight 400), 1 part of diethylene glycol, 0.04 part of sodium glutamate, 0.04 part of cetyltrimethylammonium bromide 0.02 parts of thickener (maltodextrin), 5 parts of complex alcohol amines (1 part of triethanolamine, 1 part of triisopropanolamine, 3 parts of diethanol monoisopropanolamine) and 76.9 parts of water; the preparation method is as follows : Add inorganic salt, sodium glutamate and 70% water into the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com